Sample preparation method and device for testing high temperature strength retention rate of fiber bundles

A technology of high-temperature strength and fiber bundles, which is applied in the field of material testing, can solve the problems of high-temperature strength retention without silicon carbide fiber bundles, large dispersion of test results, and distortion of test results, so as to avoid discrete test results and improve test accuracy. And the efficiency of sample preparation and the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0058] The present embodiment provides a sample preparation method for high temperature strength retention rate testing of fiber bundles, comprising the following steps:

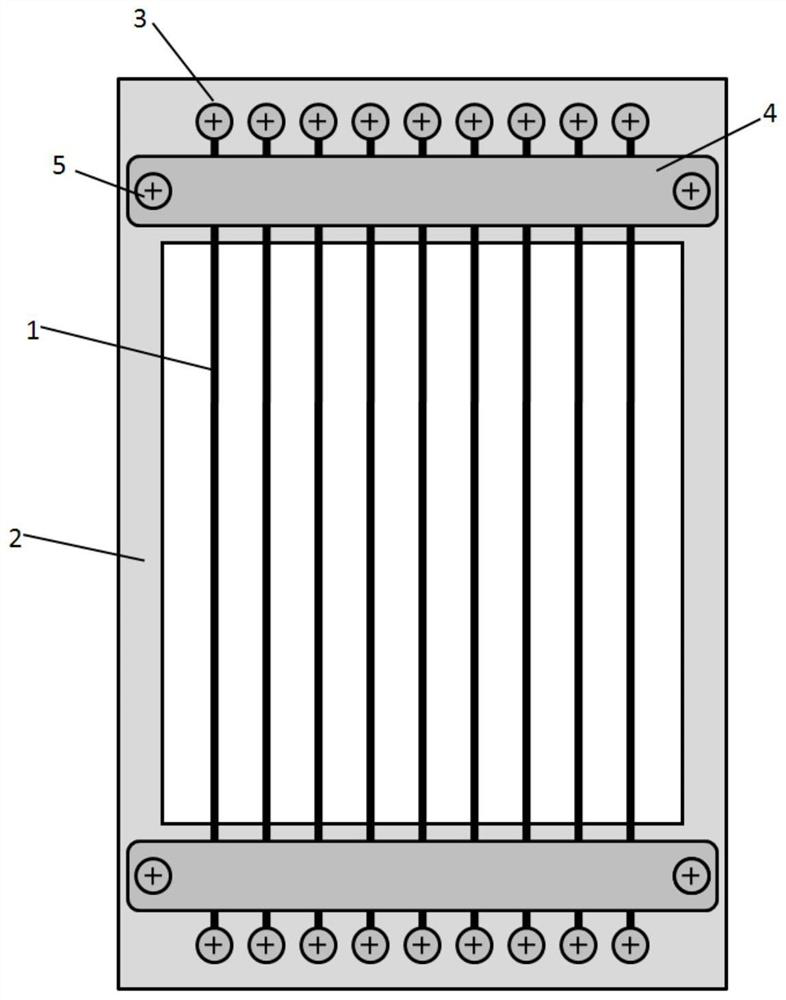

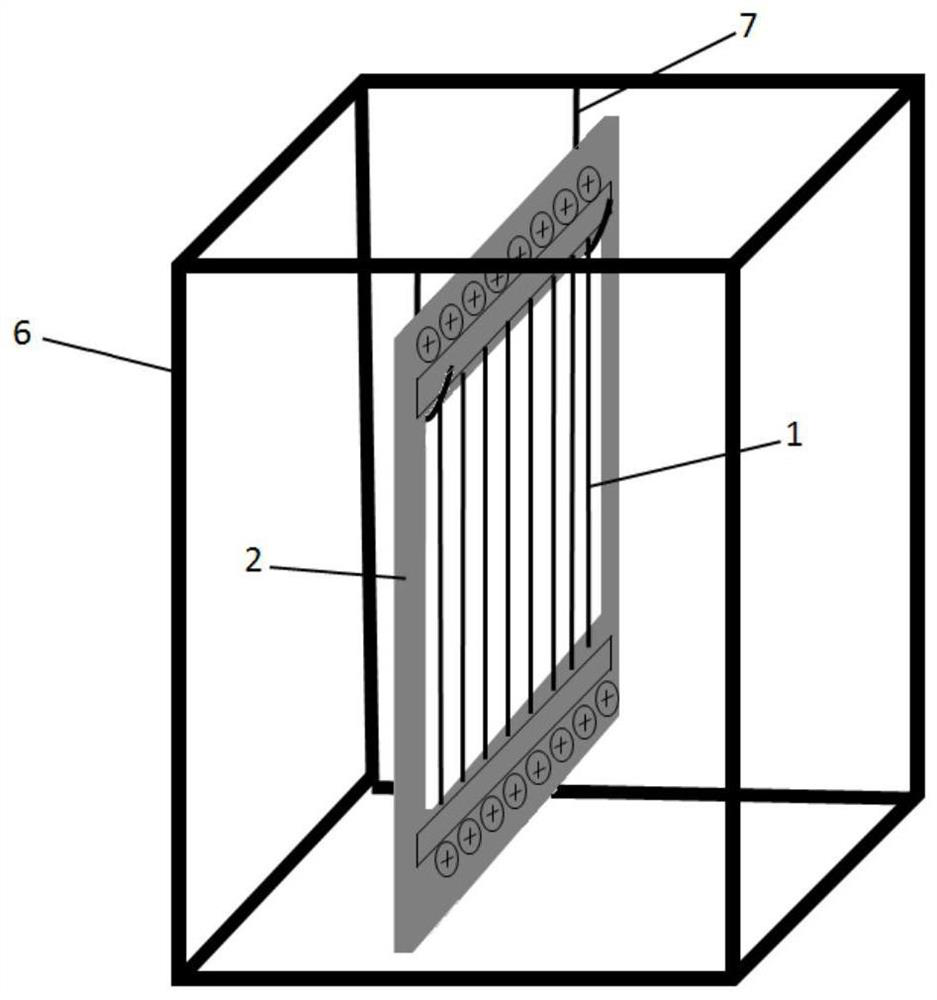

[0059] 1) Wind the silicon carbide fiber bundle to be tested on the sample preparation device, which includes a frame 2, 18 fiber fastening bolts, 4 tablet fastening bolts, and a suspension bracket 6, and two fastened tablet 4 ,like figure 1 shown. Gently rotate the fiber fastening bolts to fix on the frame 2, and leave a margin for further tightening. Wind the silicon carbide fiber bundle to be tested on the screw of the fiber fastening bolt for more than 4 turns, and apply tension to the fiber bundle by rotating the fiber fastening bolt to ensure that the silicon carbide fiber bundle to be tested is tight. After winding the nine silicon carbide fiber bundles to be tested on the fiber fastening bolts in turn and tightening, press the two fastening sheets 4 on both ends of the fiber bundles and tighten the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com