Evaluation Method for Welding Defects of Steam Turbine Rotor

A steam turbine rotor and welding defect technology, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids and process detection response signals, can solve the problems of difficulty in accurate acquisition, limitation of defect detection capabilities, and lack of technical support for process condition selection Achieve the effect of optimizing the welding process, clear thinking of the method, and simple and fast calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation of the steam turbine rotor welding defect assessment method of the present invention will be described in detail below in conjunction with the accompanying drawings.

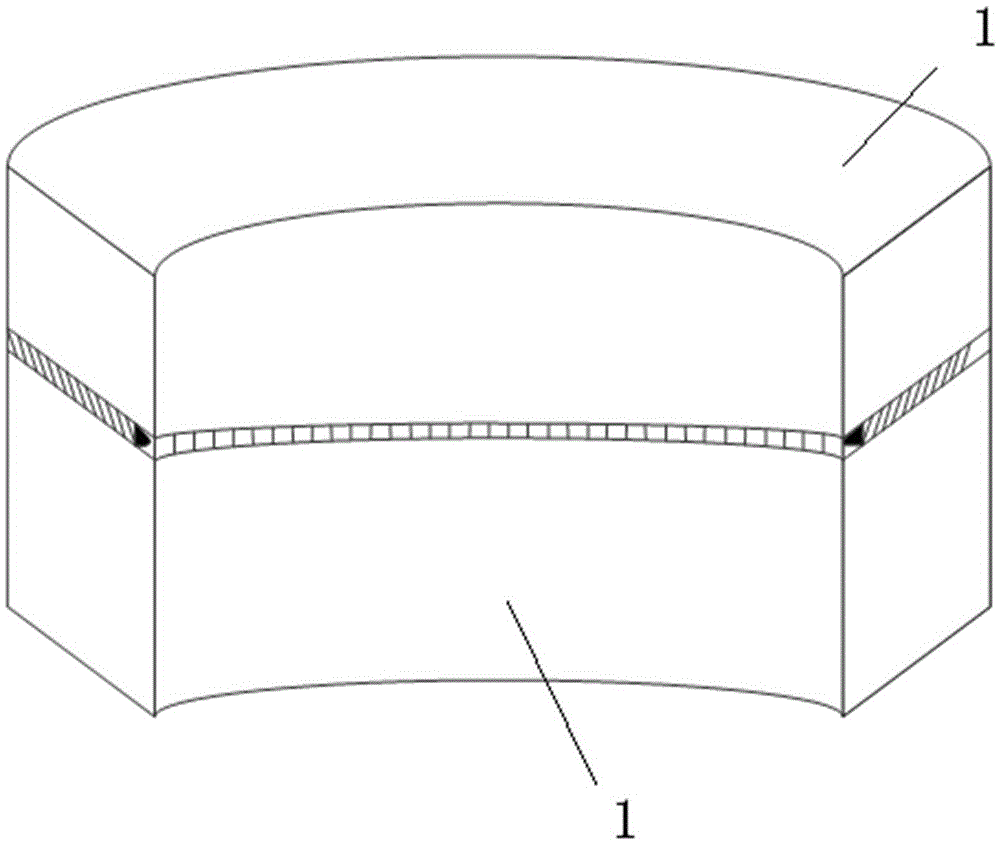

[0030] See attached figure 1 , the two steam turbine rotor parts 1 are connected together by welding, and the welding quality depends on the welding process, and the quality of the same batch of weldments with the same welding process is relatively close.

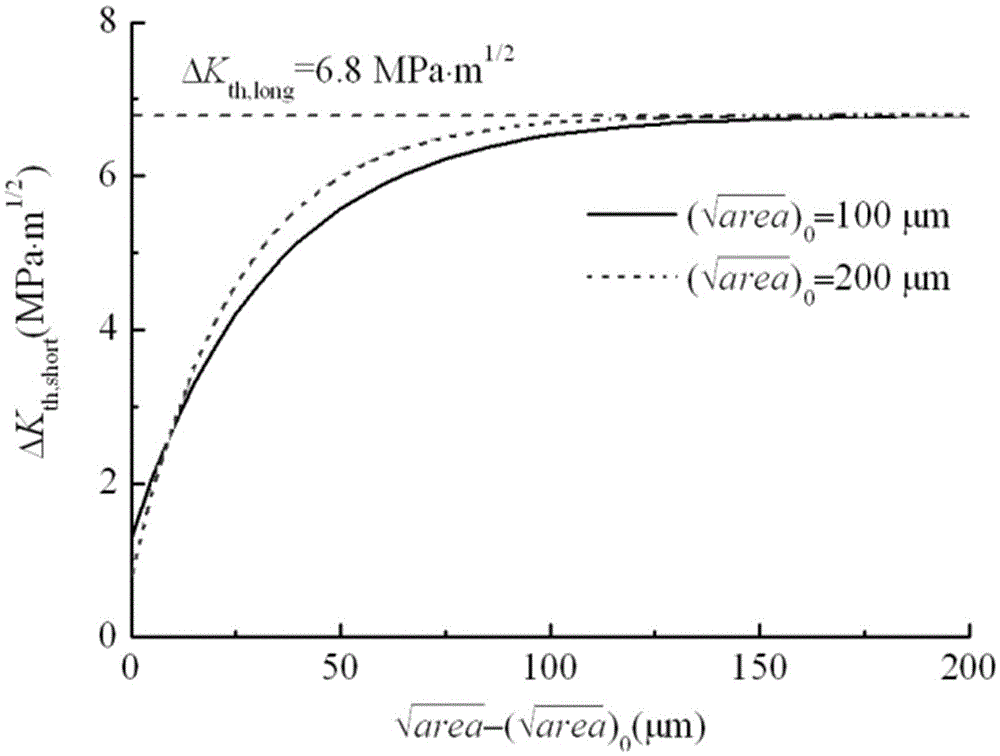

[0031] See attached Figure 4 , the following is an example to evaluate the optimization process of steam turbine rotor welding defects.

[0032] Taking a certain nuclear power low-voltage welded rotor as an example, the material of the rotor is 25Cr2Ni2MoV steel, and the yield strength σ 0.2 700MPa, tensile strength σ b It is 750MPa, and the elastic modulus E is 200GPa. The specific steps of its welding defect assessment method are as follows.

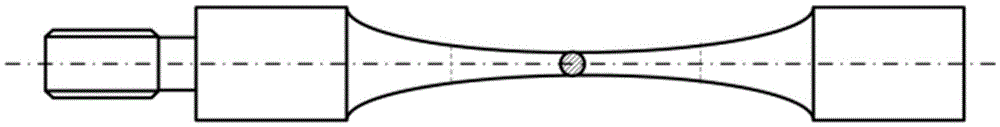

[0033] Step 1: Ultrasonic accelerated fatigue tests are used for different...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com