Patents

Literature

204 results about "Defect size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The size of the defect is usually described as small, moderate, or large. Precise measurement of defect size in millimeters can be provided by an echocardiogram. ASDs are further categorized by location of the defect within the atrial septum. Terms used to describe defect location include secundum,...

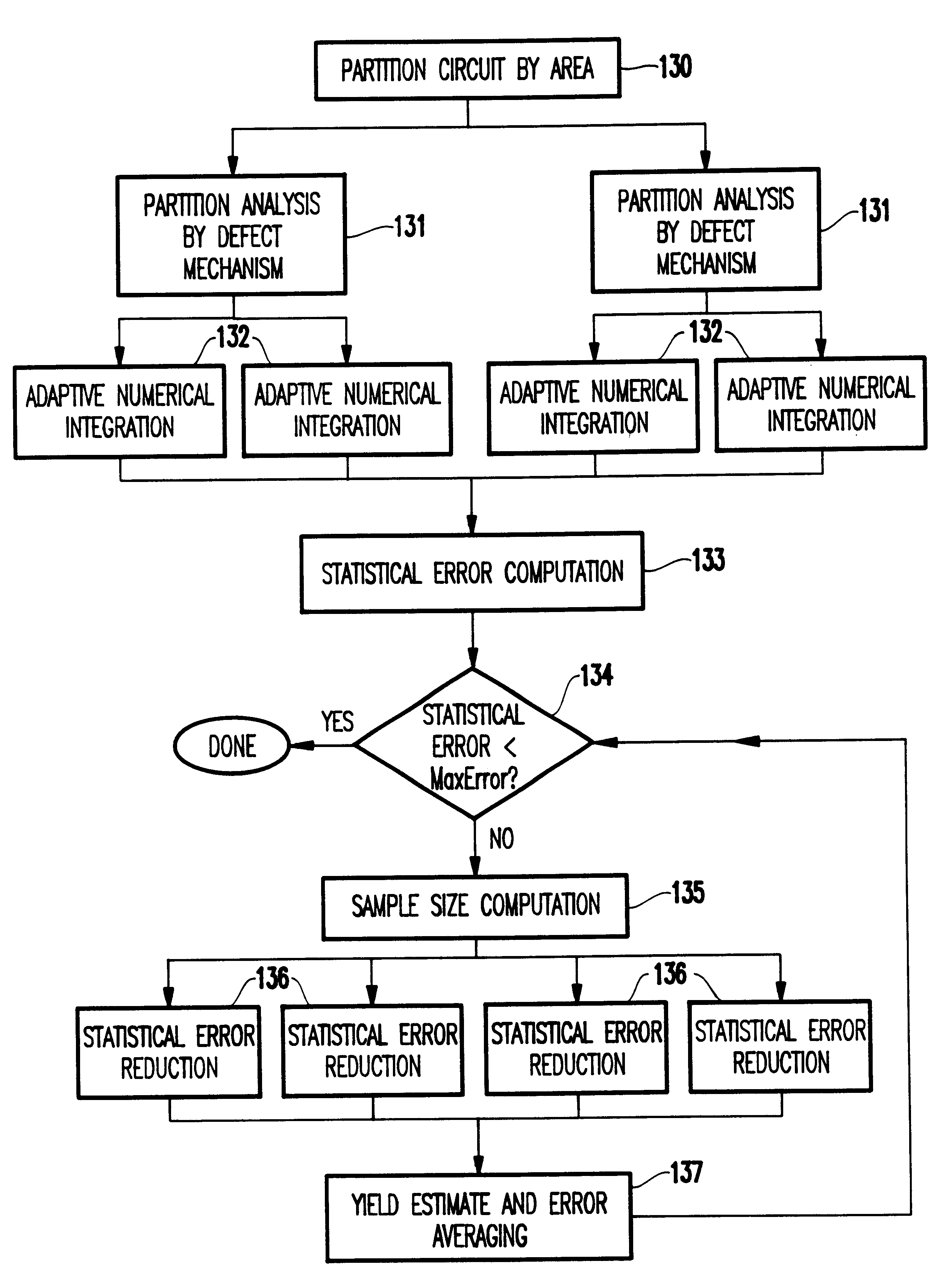

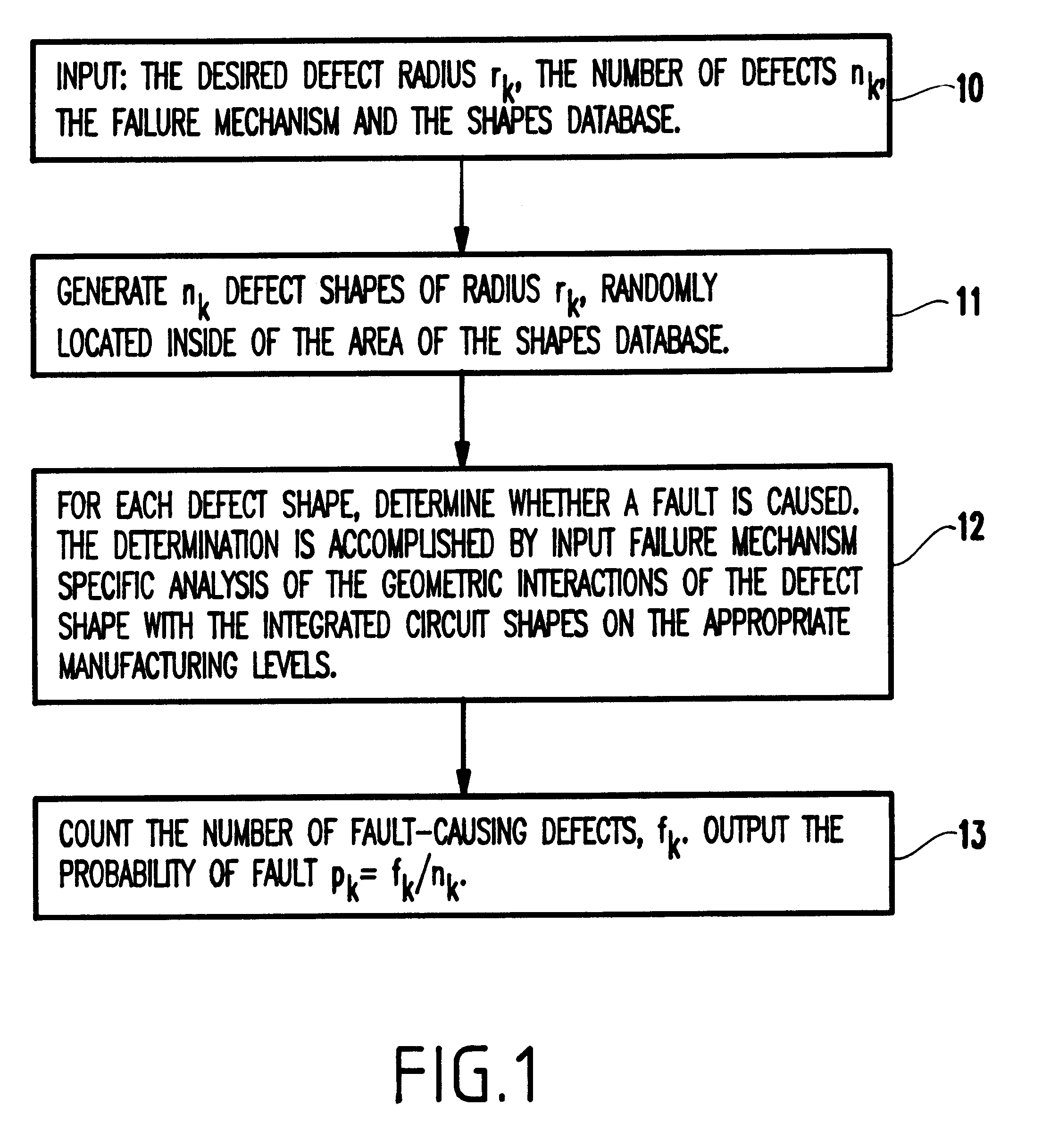

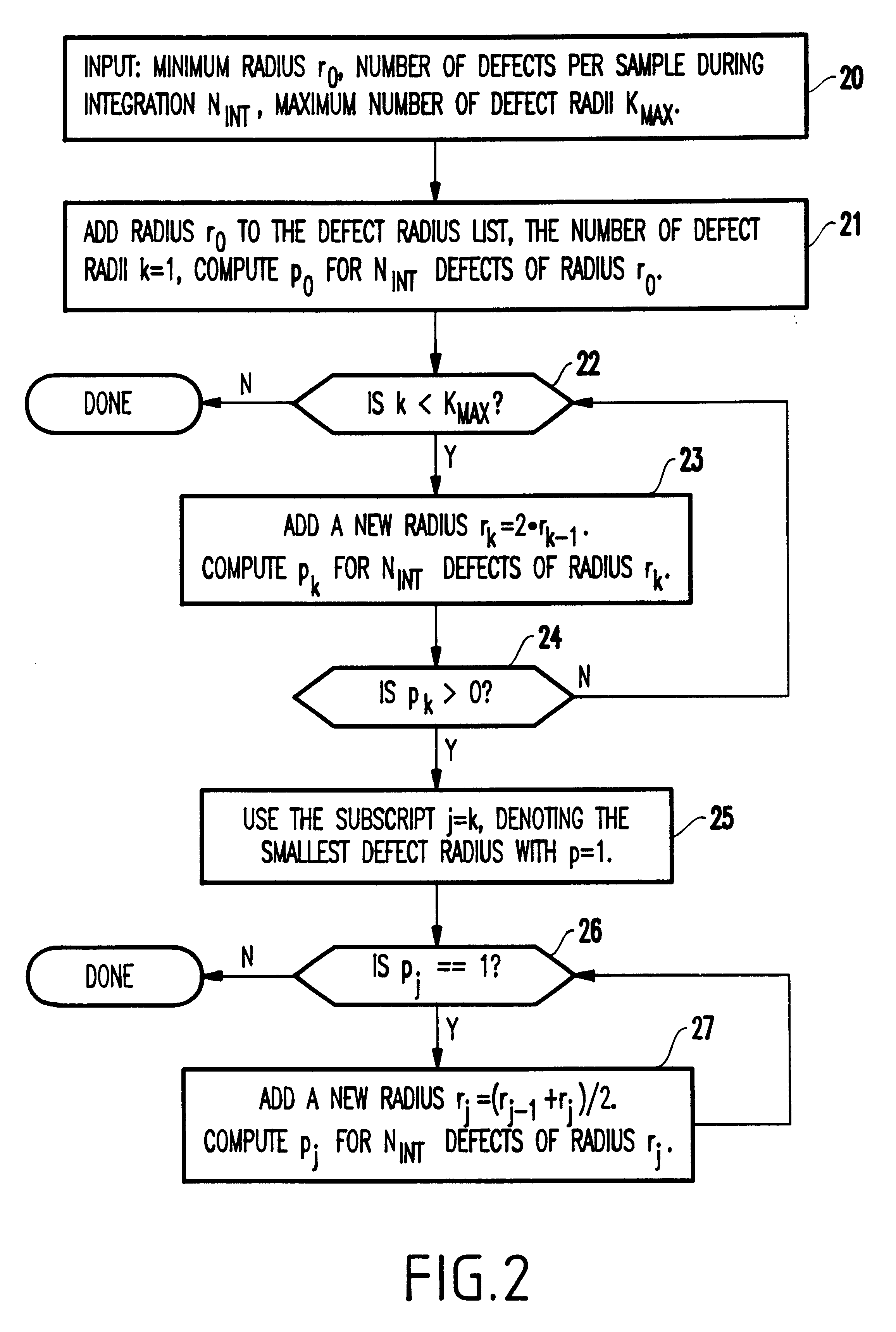

Method for prediction random defect yields of integrated circuits with accuracy and computation time controls

InactiveUS6738954B1Reduce the amount of calculationReduce errorsDigital circuit testingSemiconductor/solid-state device testing/measurementDefect sizeIntegrated circuit layout

A method of computing a manufacturing yield of an integrated circuit having device shapes includes sub-dividing the integrated circuit into failure mechanism subdivisions (each of the failure mechanism subdivisions includes one or more failure mechanism and each of the failure mechanisms includes one or more defect mechanisms), partitioning the failure mechanism subdivisions by area into partitions, pre-processing the device shapes in each partition, computing an initial average number of faults for each of the failure mechanisms and for each partition by numerical integration of an average probability of failure of each failure mechanism, (the numerical integration produces a list of defect sizes for each defect mechanism, and the computing of the initial average includes setting a maximum integration error limit, a maximum sample size for a population of each defect size, and a maximum number of allowable faults for each failure mechansim), and computing a final average number of faults for the integrated circuit by iterativelly reducing a statistical error of the initial average number of faults for each of the failure mechanisms until the statistical error is below an error limit.

Owner:GOOGLE LLC

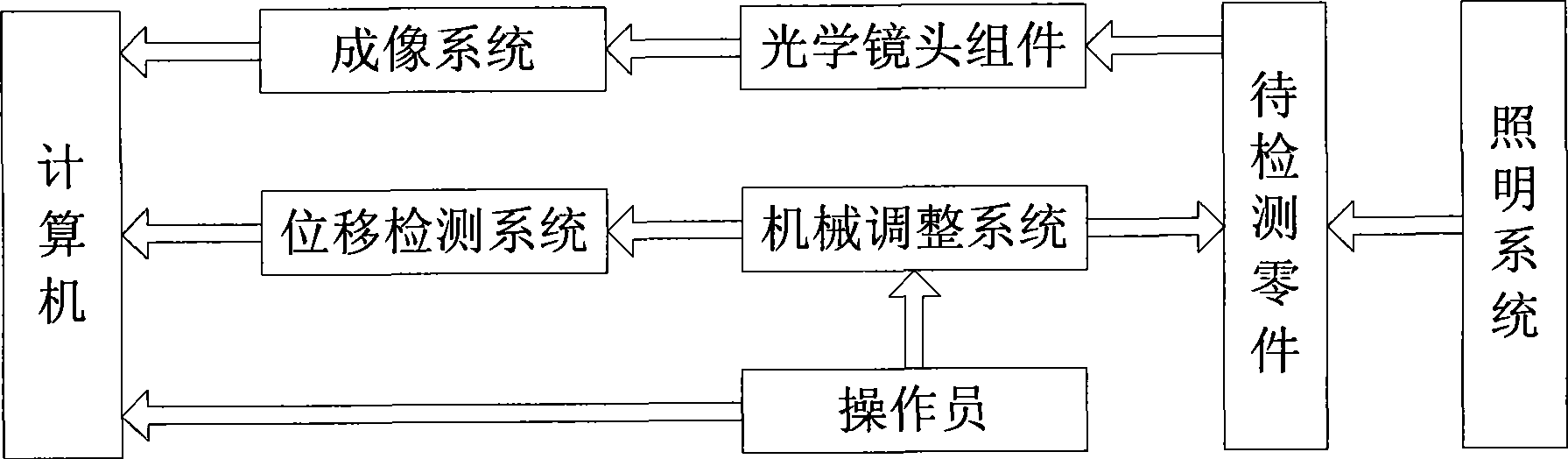

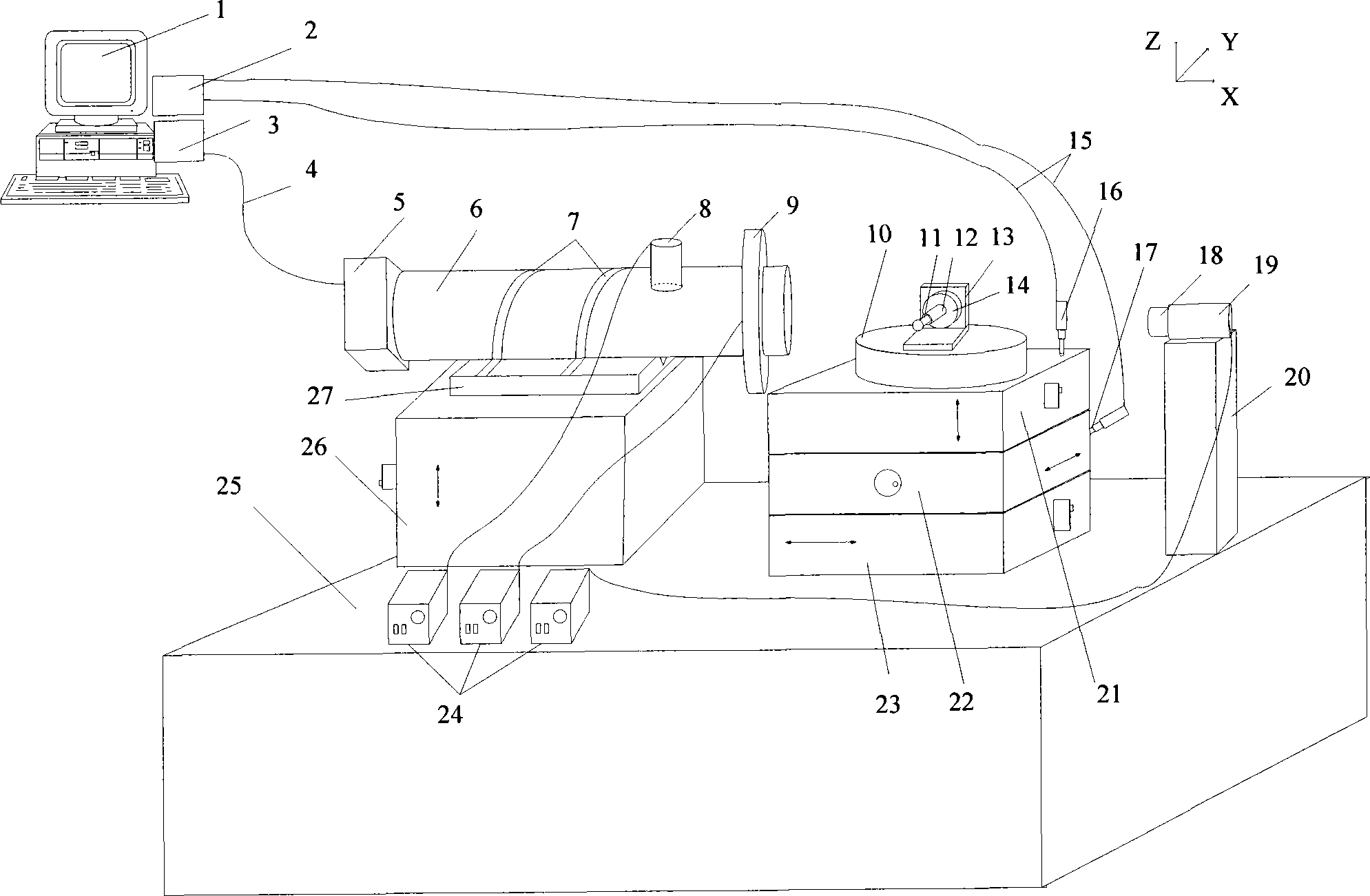

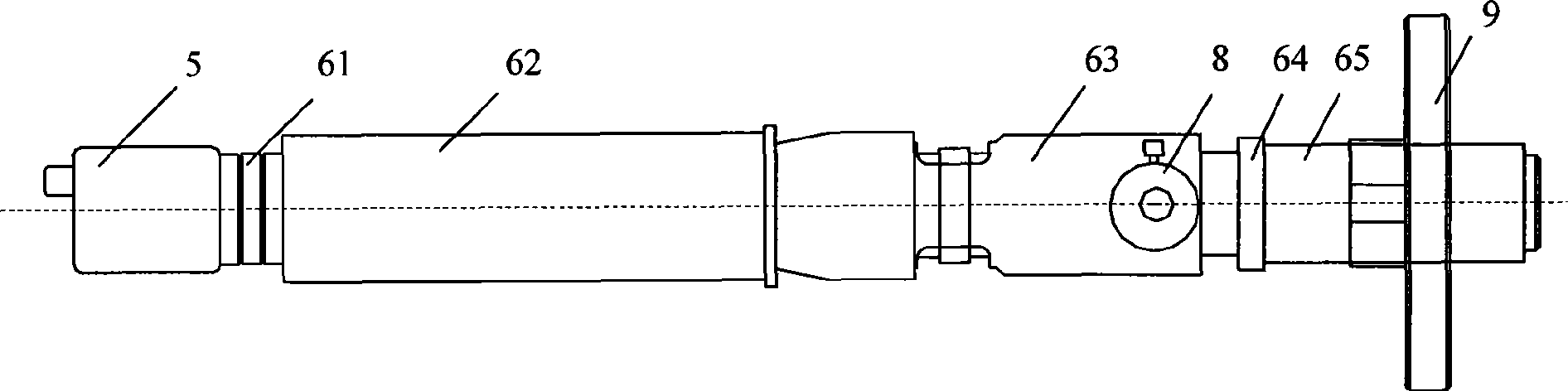

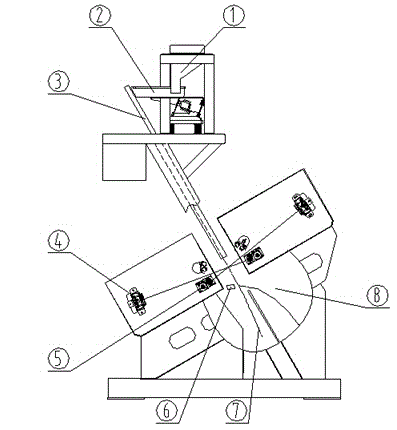

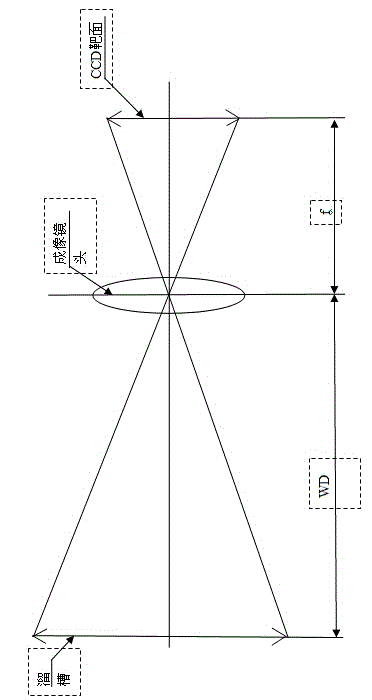

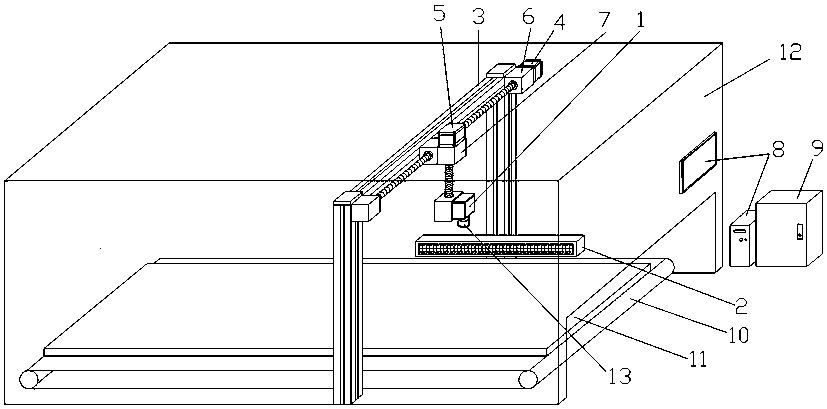

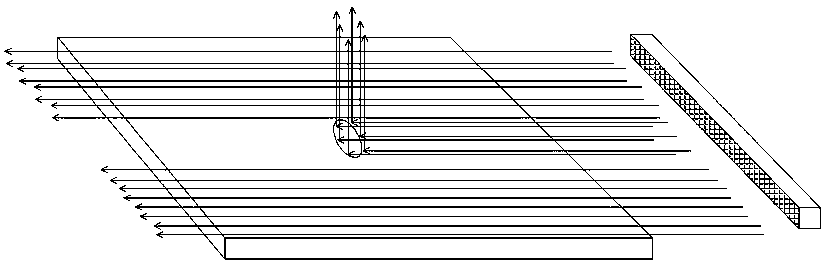

Part vision detection device

InactiveCN101509878AAvoid fatigueAvoid subjectivityMaterial analysis by optical meansUsing optical meansCamera lensDefect size

A visual detection device for parts mainly comprises an imaging system, an optical lens component, a lighting system, a mechanical adjusting system, a displacement detection system and a computer, wherein the imaging system consists of a CCD camera and an image acquisition card; the optical lens component consists of a lens body, an amplifying objective lens, and the like; the lighting system is respectively used for detecting surface defects and measuring topographic sizes; the mechanical adjusting system consists of displacement platforms used for adjusting the positions of the parts; the displacement detection system is used for recording the displacement distance of the displacement platforms; and the computer is used for recording and processing images. By shooting edge images of theparts through the imaging system and recording the displacement distance of the displacement platforms through the displacement detection system, the detection device calculates the topographic sizessuch as diameter, and the like, detects the surface defects of the whole spherical surface by the combined rotation of rotary tables, measures the defect sizes accurately, records the number of the defects and meets the two detection requirements of topography measurement and surface detection. By utilizing the visual microscopic detection technology, the device has high system resolution, good integrated performance and simple measurement process.

Owner:BEIHANG UNIV

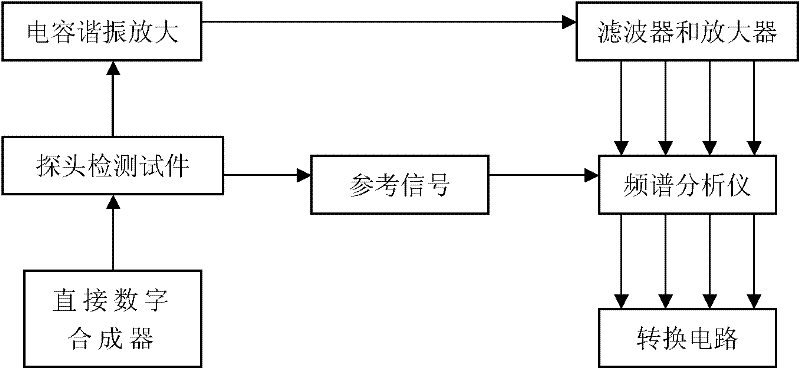

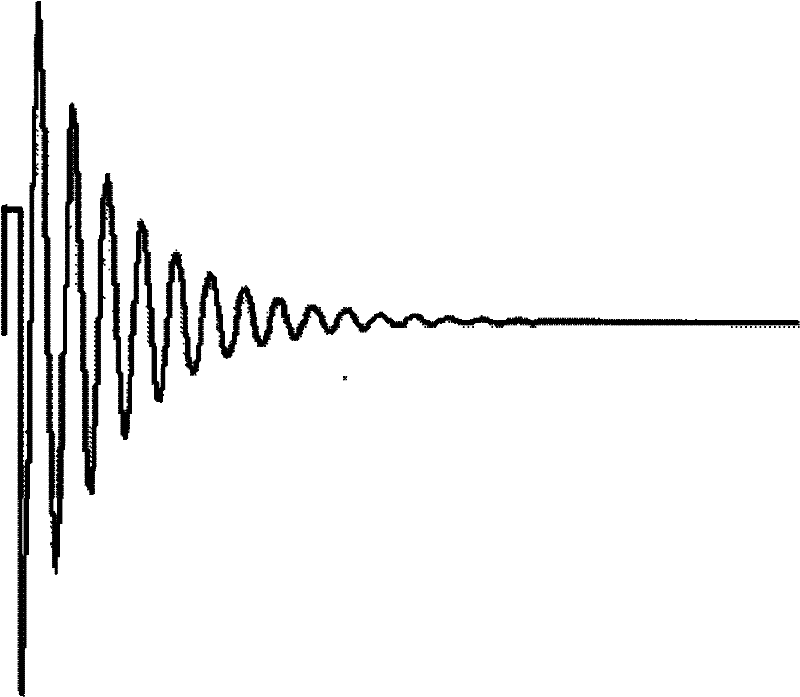

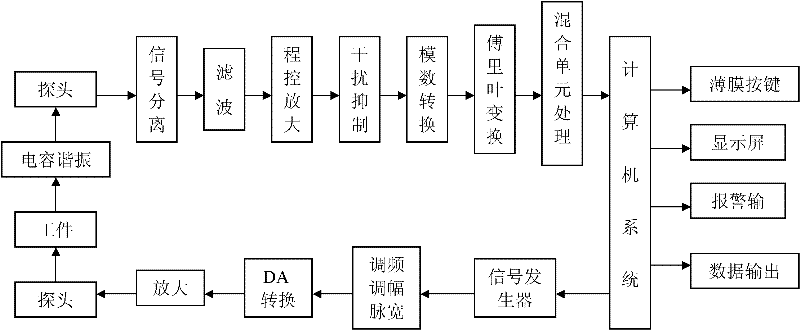

Electromagnetic resonance-based nondestructive testing method for metal material

InactiveCN102230914AFacilitates non-destructive testingRealize detectionMaterial magnetic variablesCapacitanceMetallic materials

The invention discloses an electromagnetic resonance-based nondestructive testing method for metal materials. According to the method, responding resonance signals of eddy current testing are obtained through multipled resonant capacitors in testing coils, comparative analysis of the responding resonance signals is carried out, and the relationships between a defect size and a signal amplitude and between defect depth and a signal phase are calibrated in advance, thereby enabling convenient nondestructive testing of metal materials. The electromagnetic resonance-based nondestructive testing method not only can produce same defect detection effects as a plurality of conventional electromagnetic testing methods like single-frequency eddy current and pulsed eddy current do, but also can effectively detect internal defects in a workpiece and detect workpieces with complicated surface conditions such as a casting surface, an unsmooth surface, a surface with oil stains, a rust-resisting paint, a corrosion layer or other pollutants, etc., without contact under the condition of a high liftoff value; according to the method, no cleaning is needed for test pieces, and particularly, no cumbersome processes like magnetization and demagnetization of magnetic metal materials are needed.

Owner:XIAMEN ANRUI JIE ELECTRONICS TECH

Biocompatible medical implant element

The object of the invention is to make available implant elements or other medical products made of biological material with optimum mechanical and biological properties for a wide group of materials by introduction of a specially designed surface layer onto a strong core, where the surface layer is densified by means of hot isostatic pressing and dimensioned according to the basic fracture mechanics equation so that the thickness of the surface layer is less than c in the equation KIC=Ysigma c½, where Klc is the fracture toughness, Y a position and shape factor, c the critical defect size, and sigma the permitted stress for the actual material and the chosen design stress.

Owner:NOBEL BIOCARE SERVICES AG

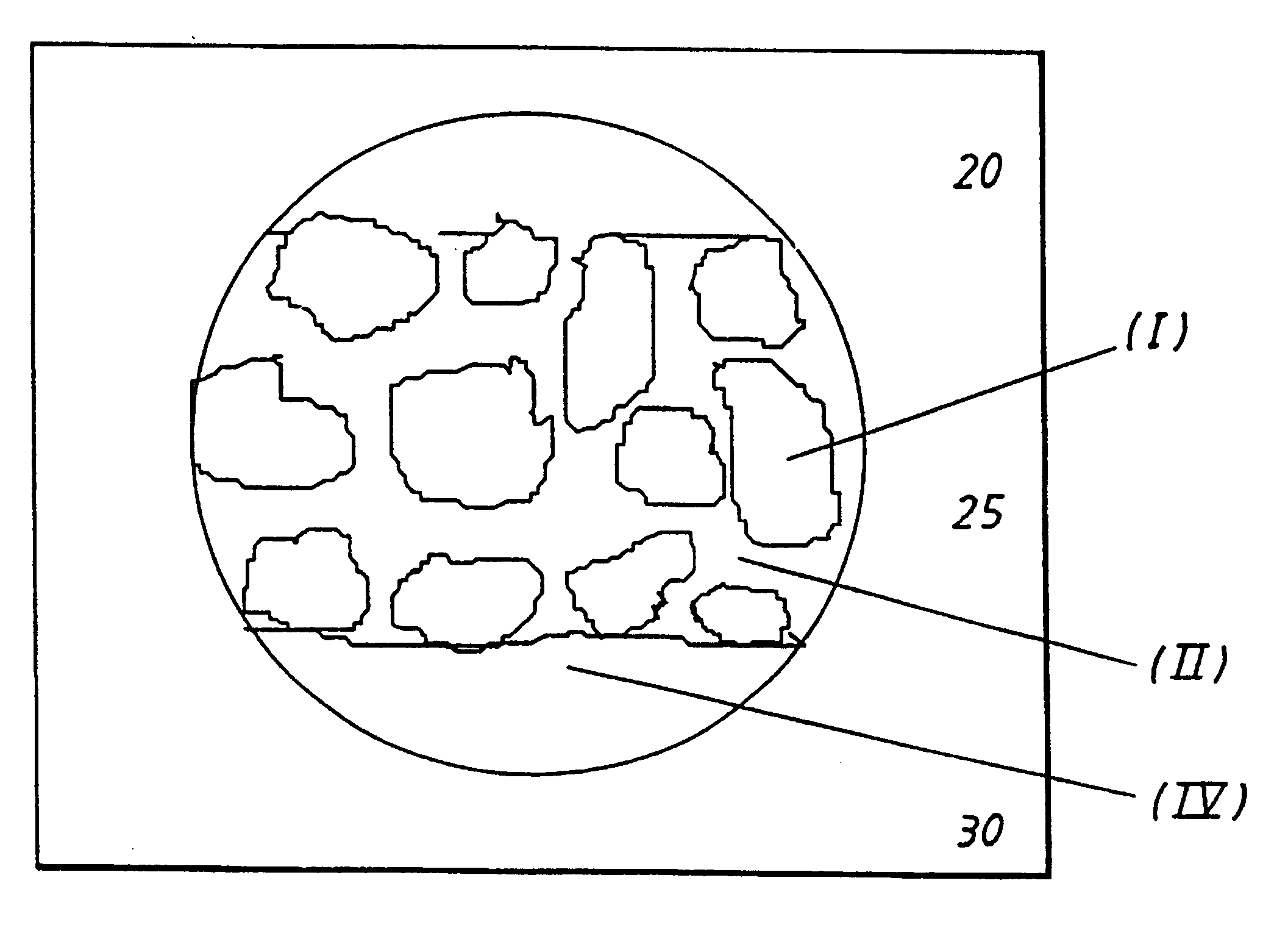

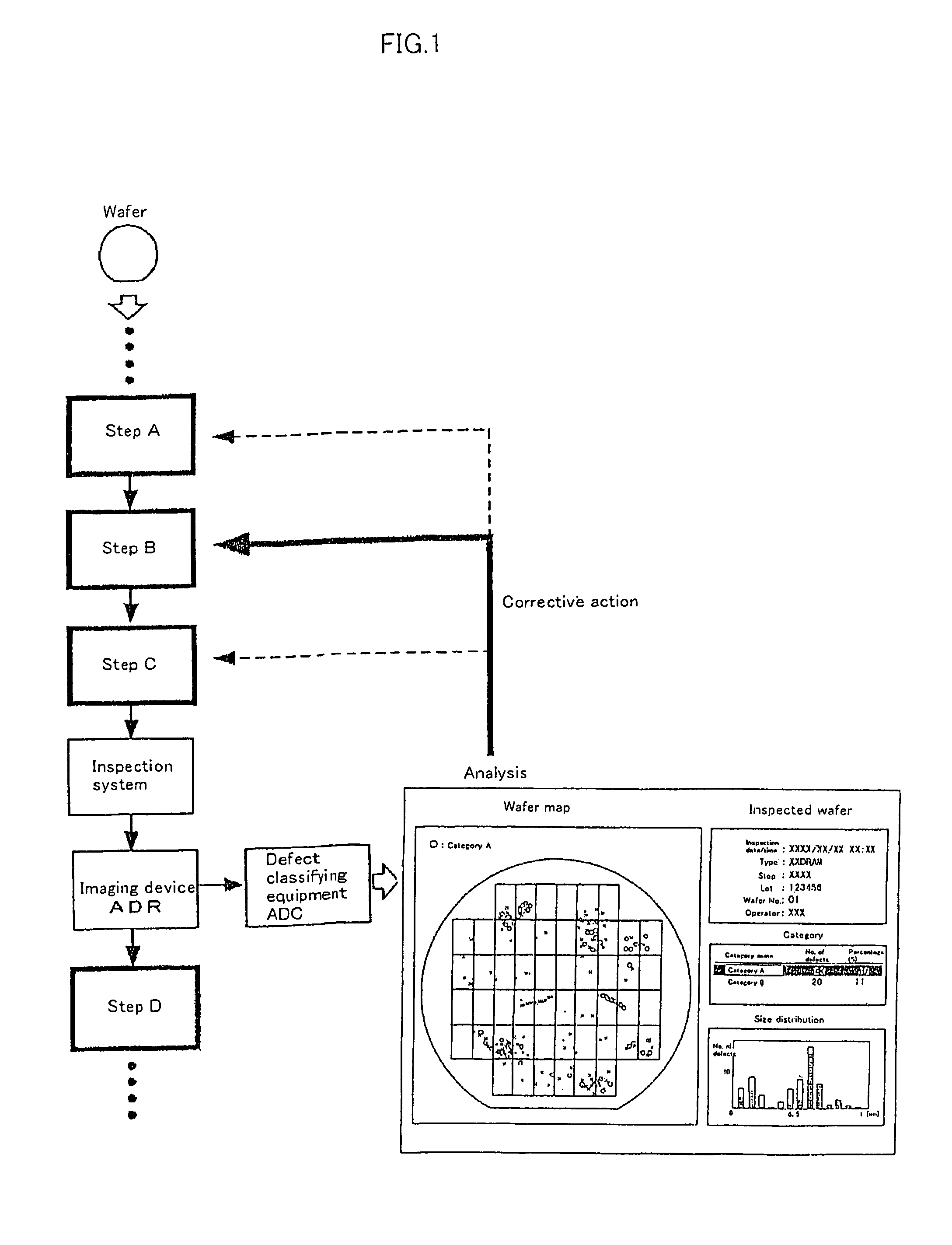

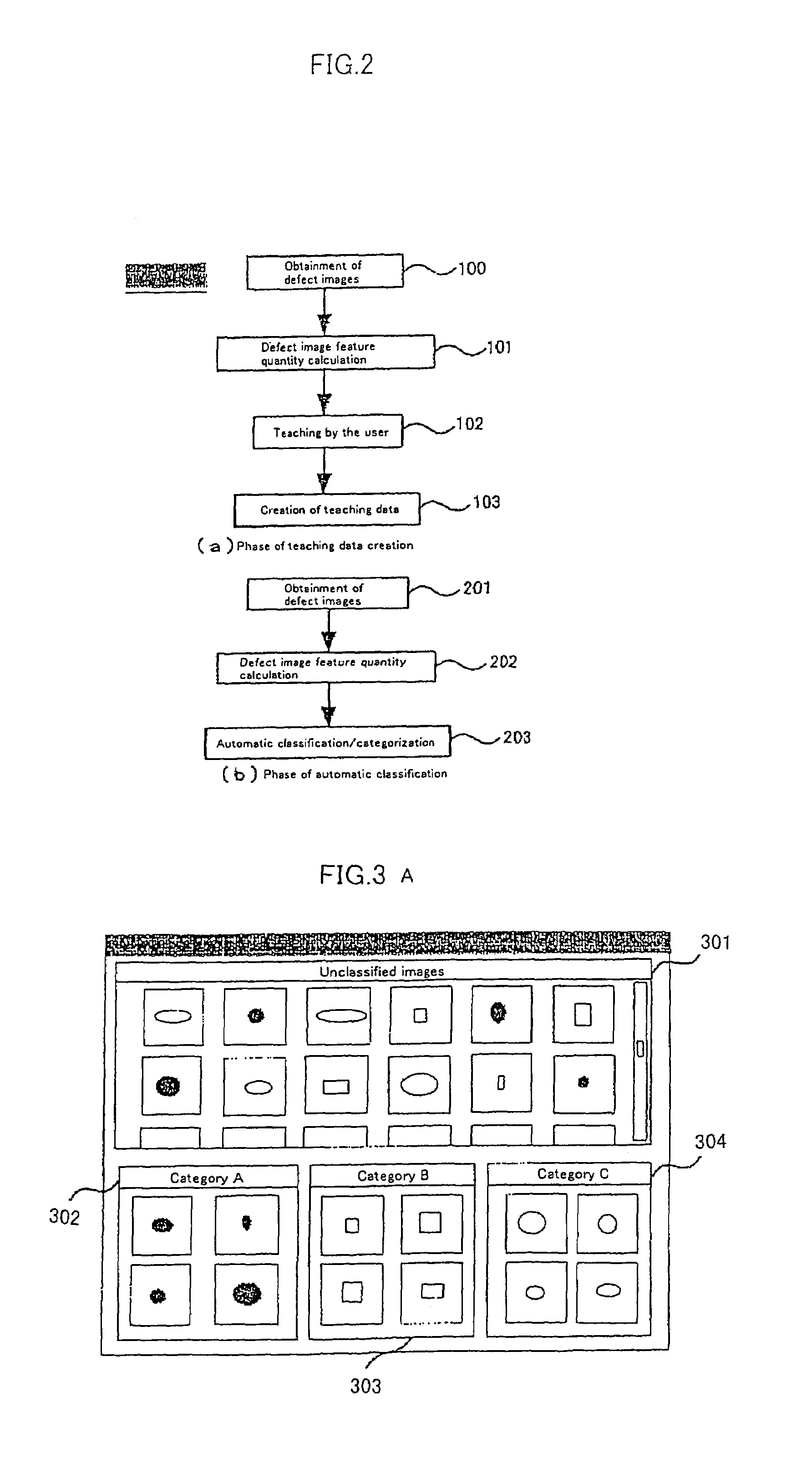

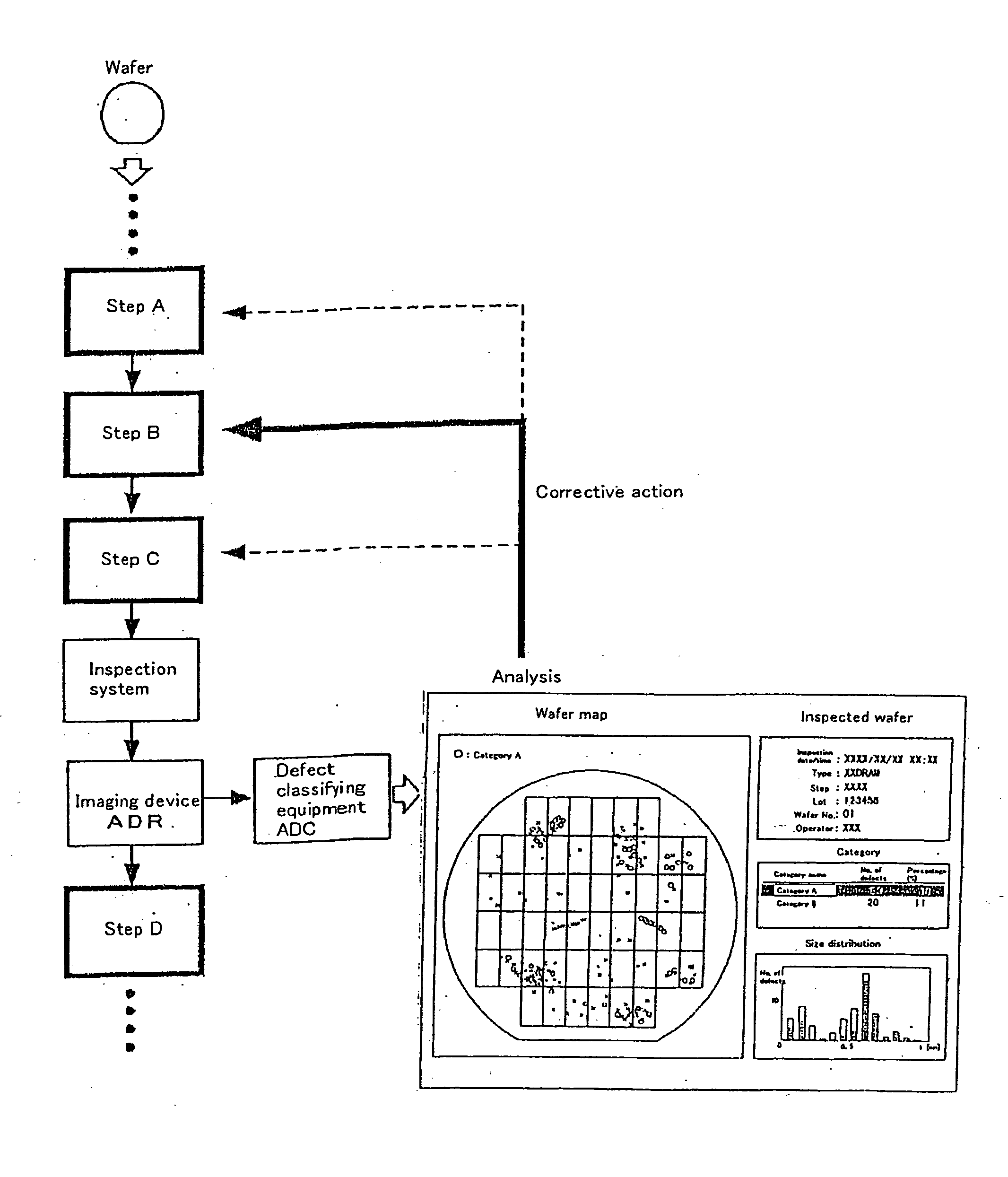

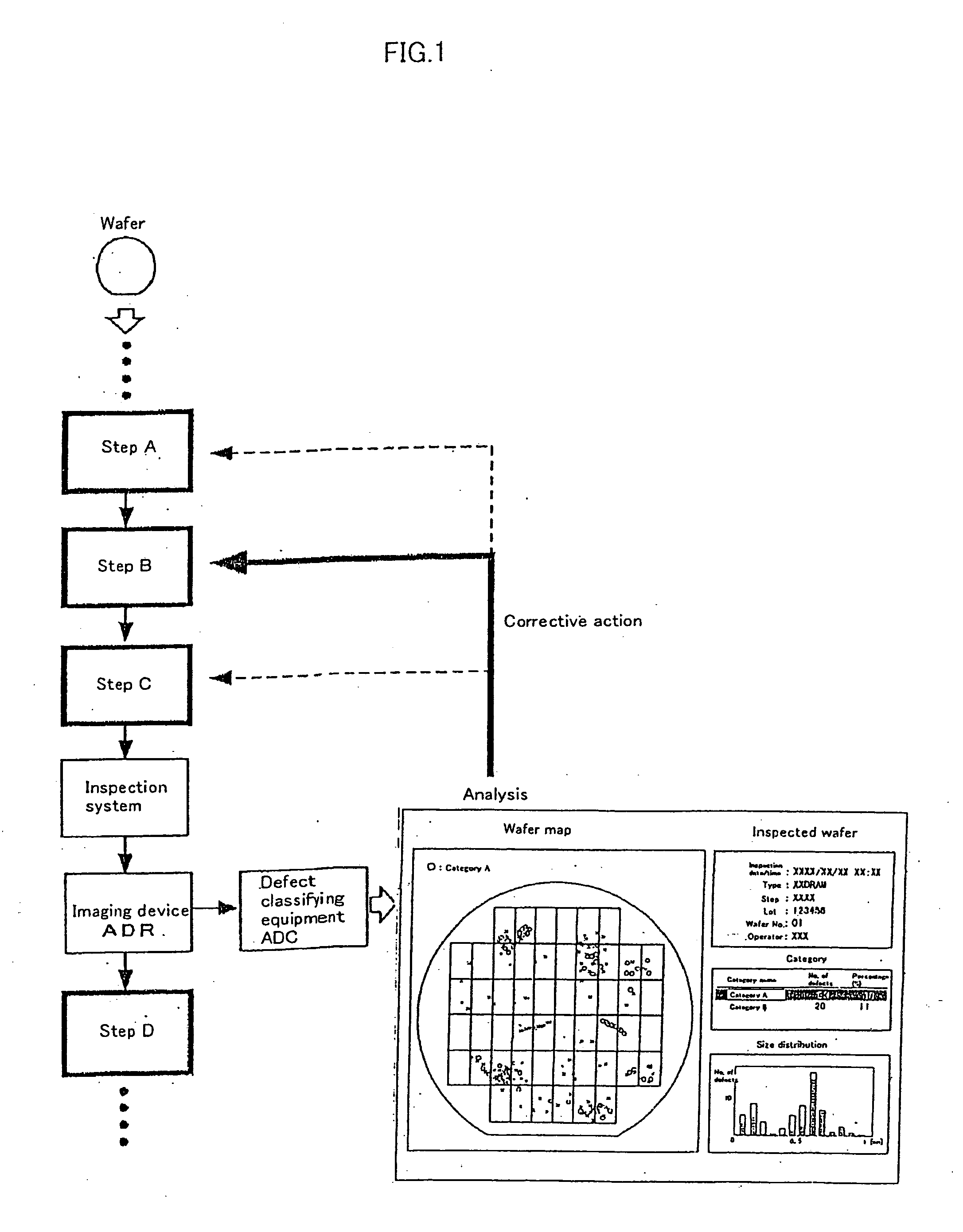

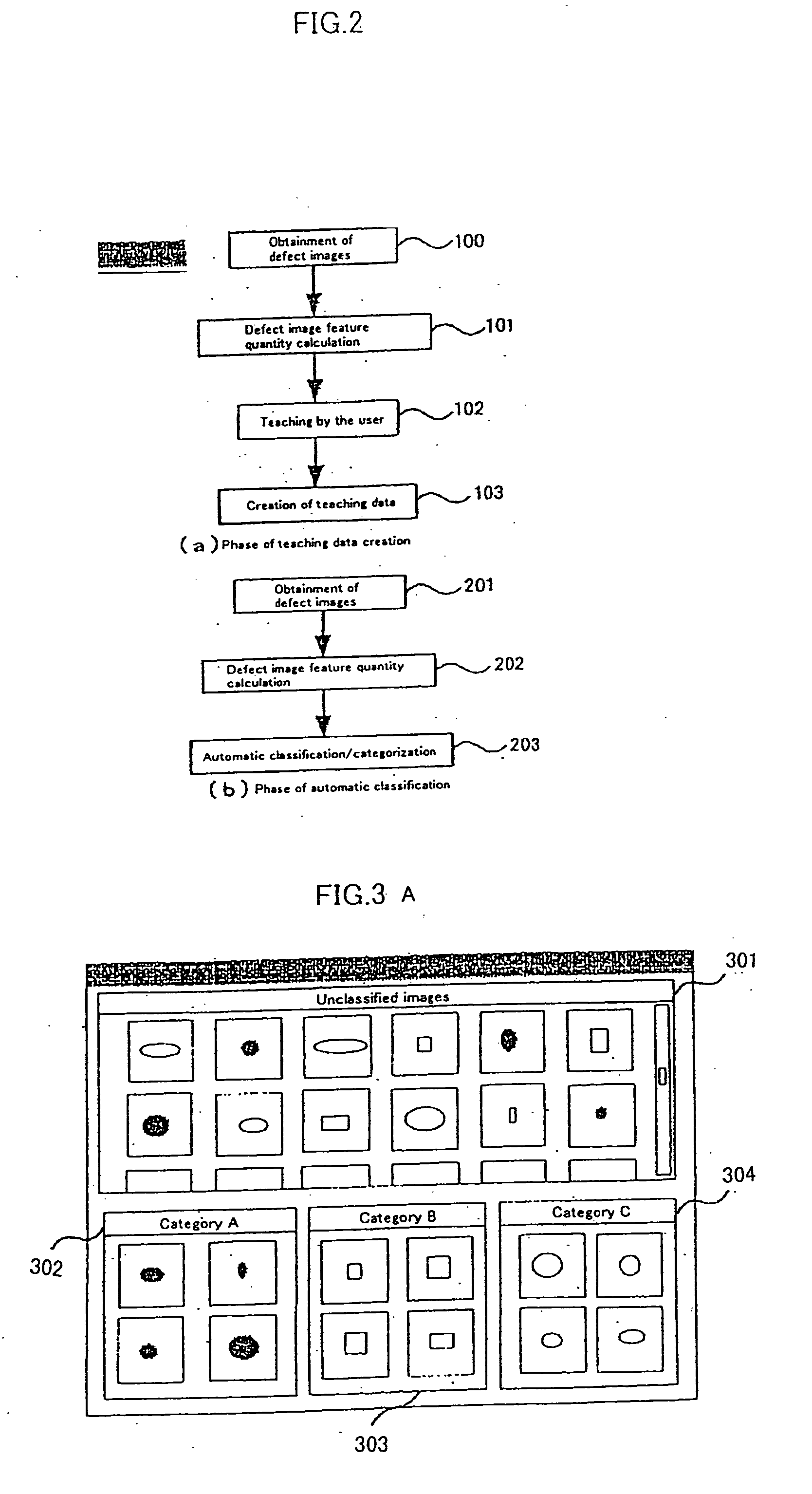

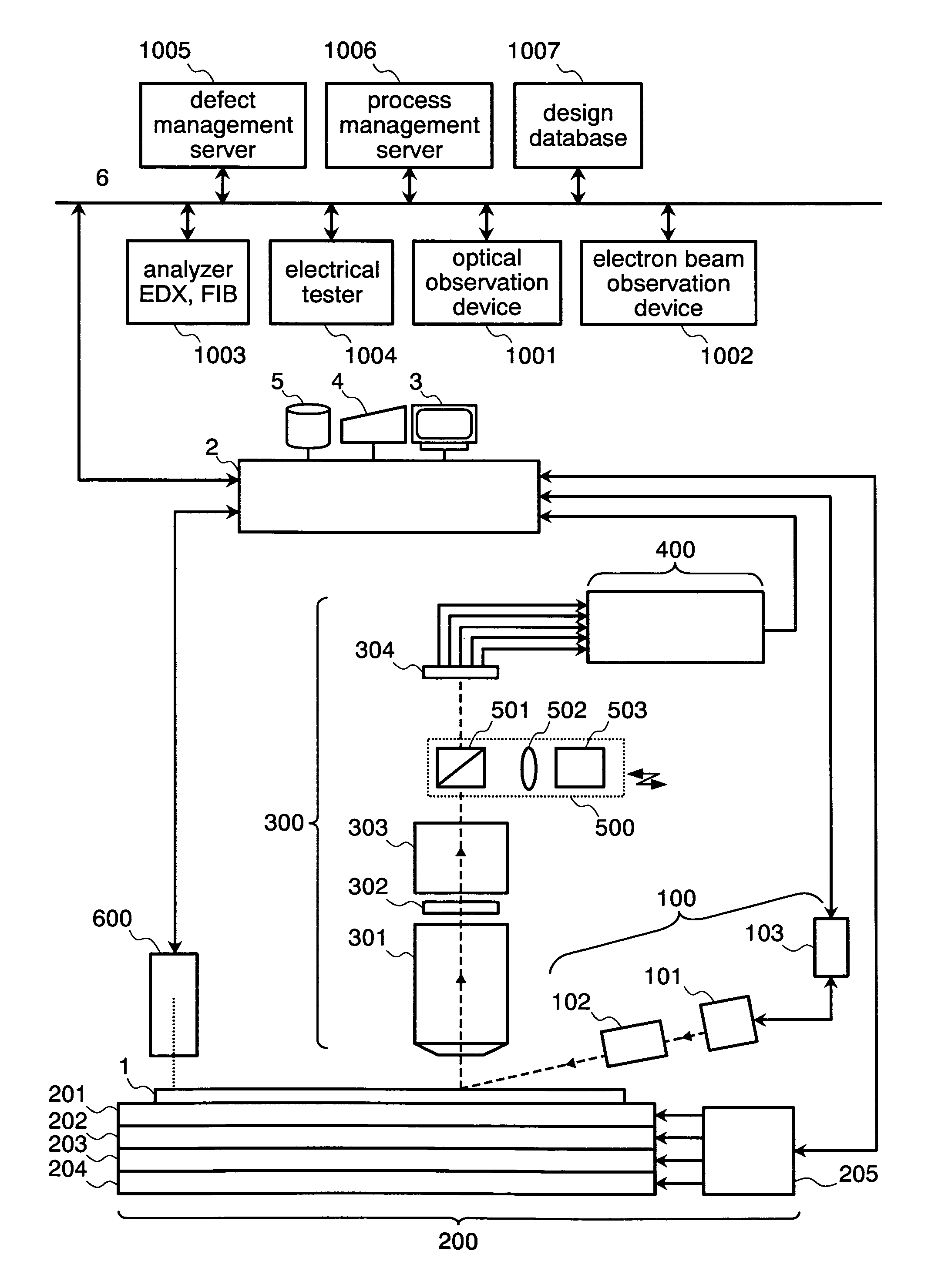

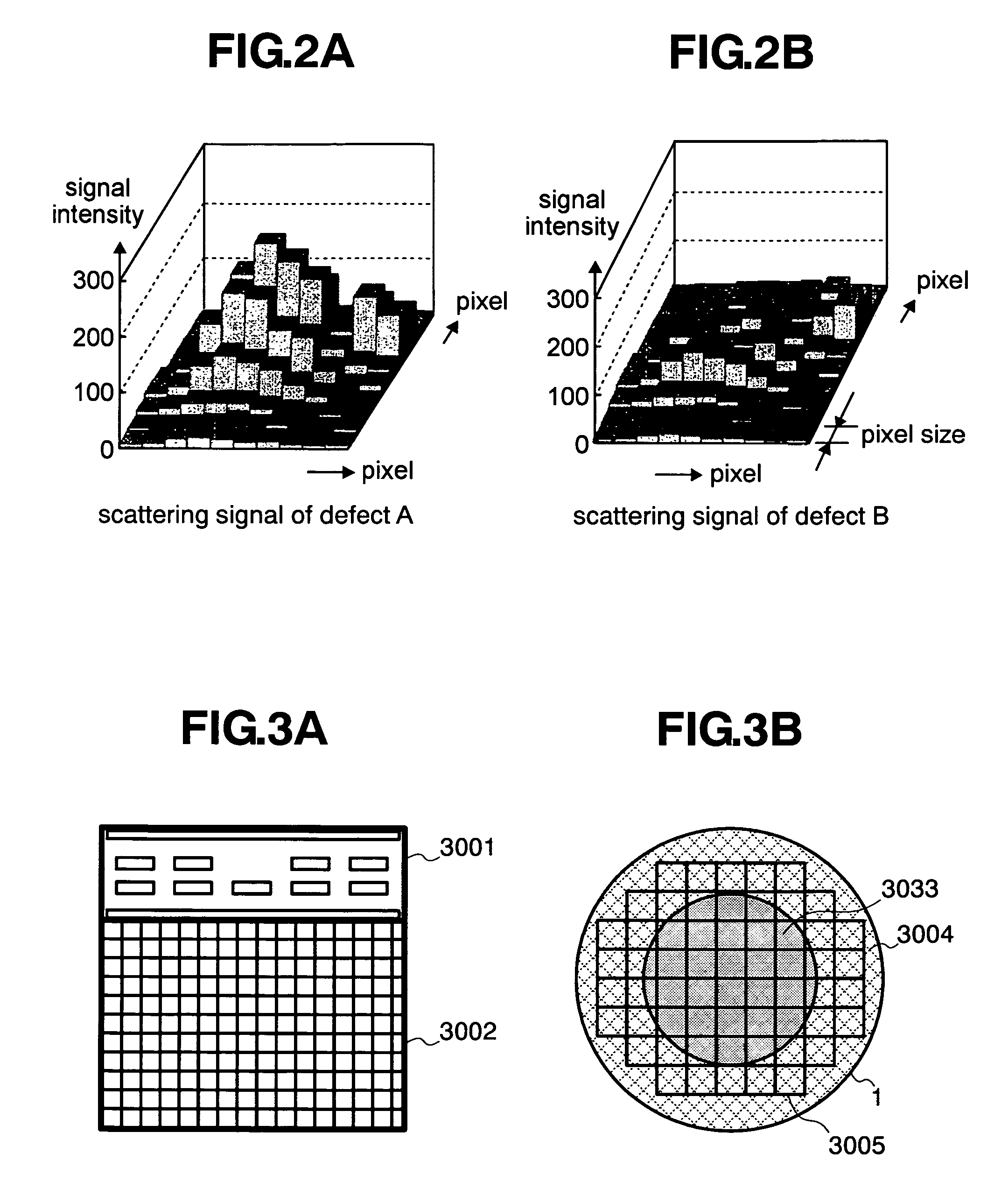

Defect image classifying method and apparatus and a semiconductor device manufacturing process based on the method and apparatus

InactiveUS7113628B1Improve teaching efficiencyLabor savingImage enhancementImage analysisDefect sizeClassification methods

According to the present invention, techniques including a method and apparatus for classifying and displaying images are provided. In an embodiment of the present invention a defect image classification method using inspected objects is provided. The method includes defect images obtained from at least one inspected object. Next a set of defect images is classified into a specified category, which has a feature. The defect images are arranged for display according to the feature and then displayed. The arranging of the defect images may also be based on an evaluation value for each defect image. Another embodiment provides a defect image classification method using inspected objects. Defect images are obtained from at least one inspected object. Next the defect images are classified into a plurality of categories and at least two information items for example, a defect distribution diagram showing locations of defects in the inspected object, information associated with a category of the plurality of categories, and a defect size distribution, are displayed.

Owner:HITACHI LTD

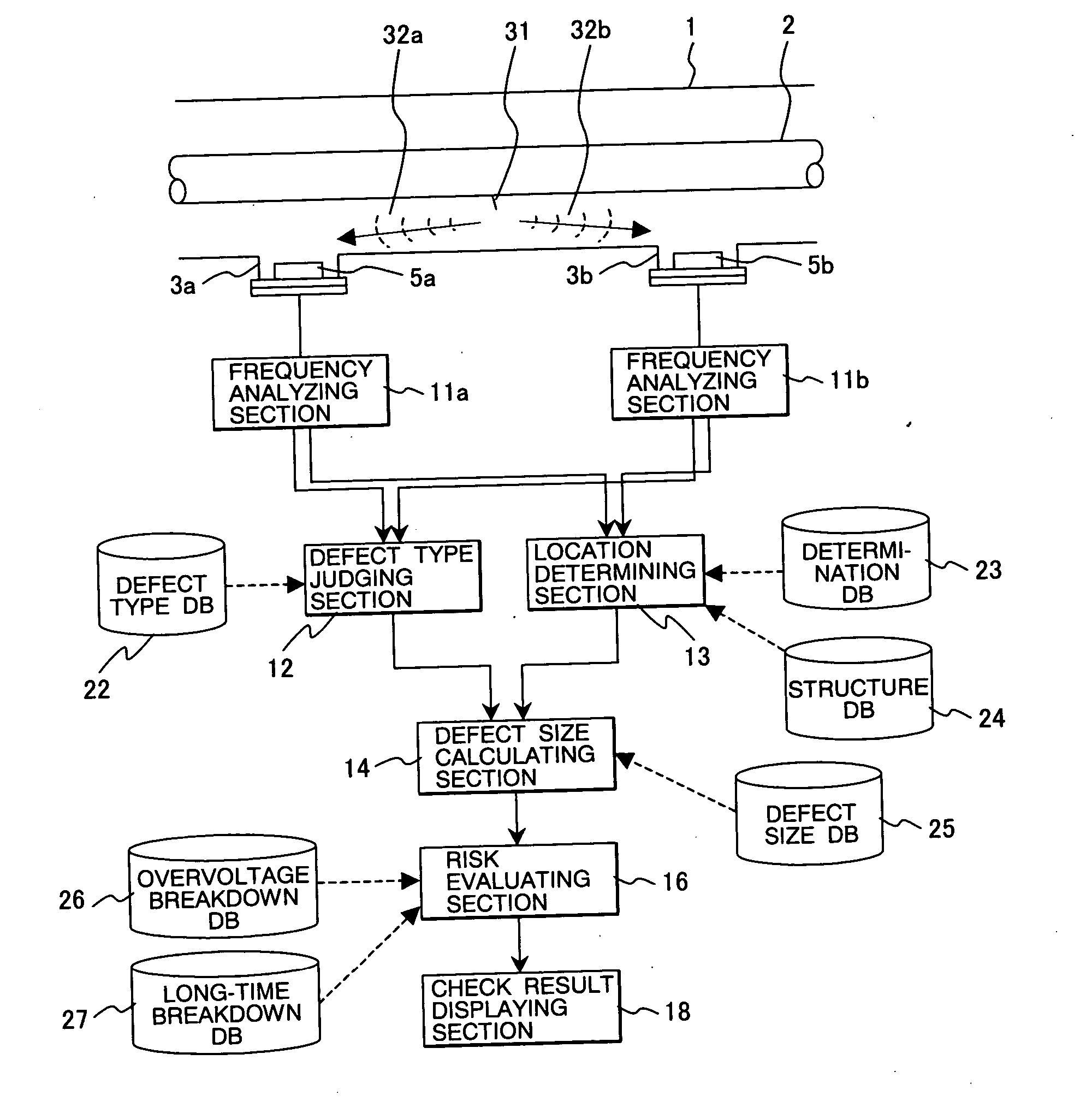

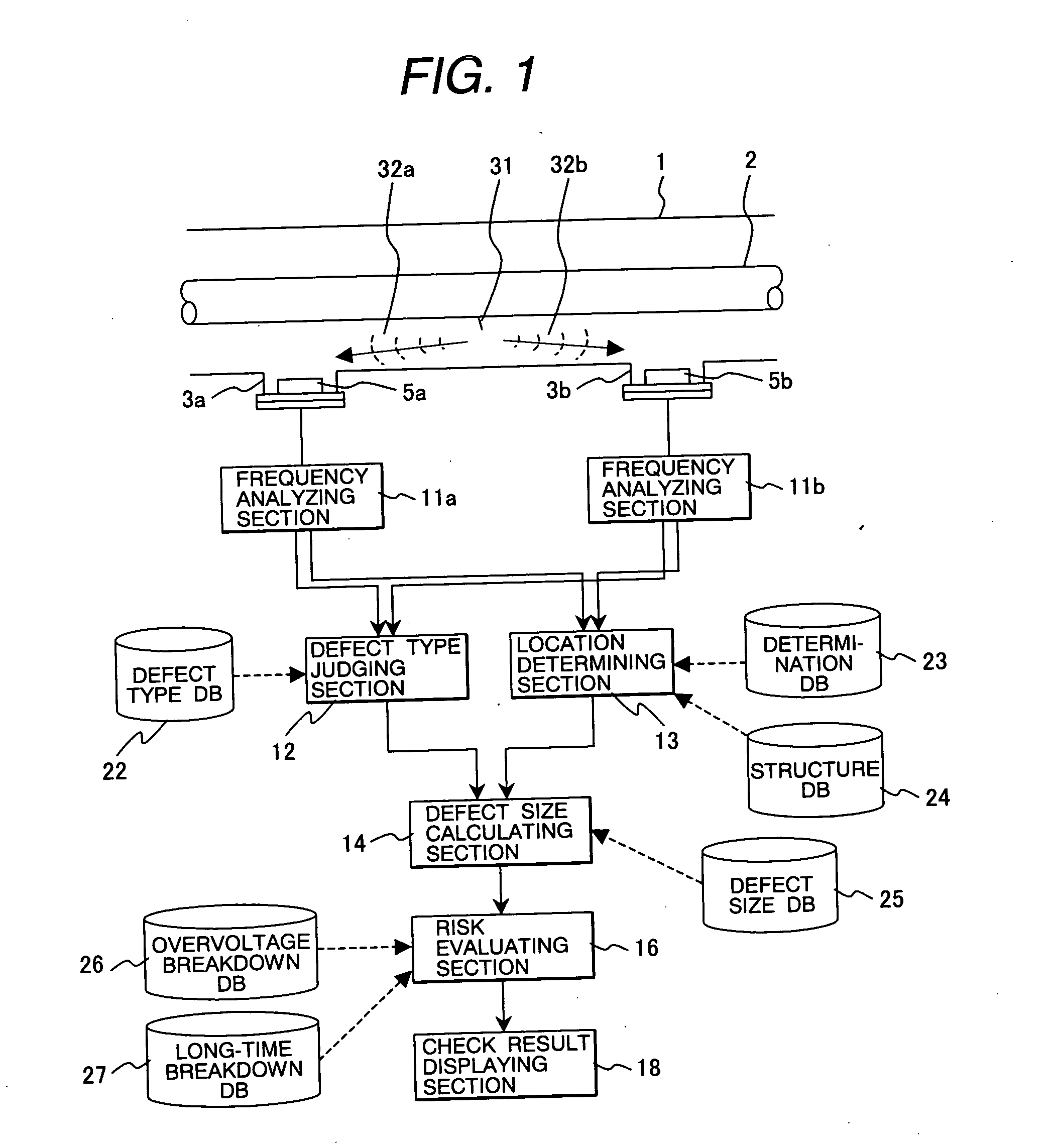

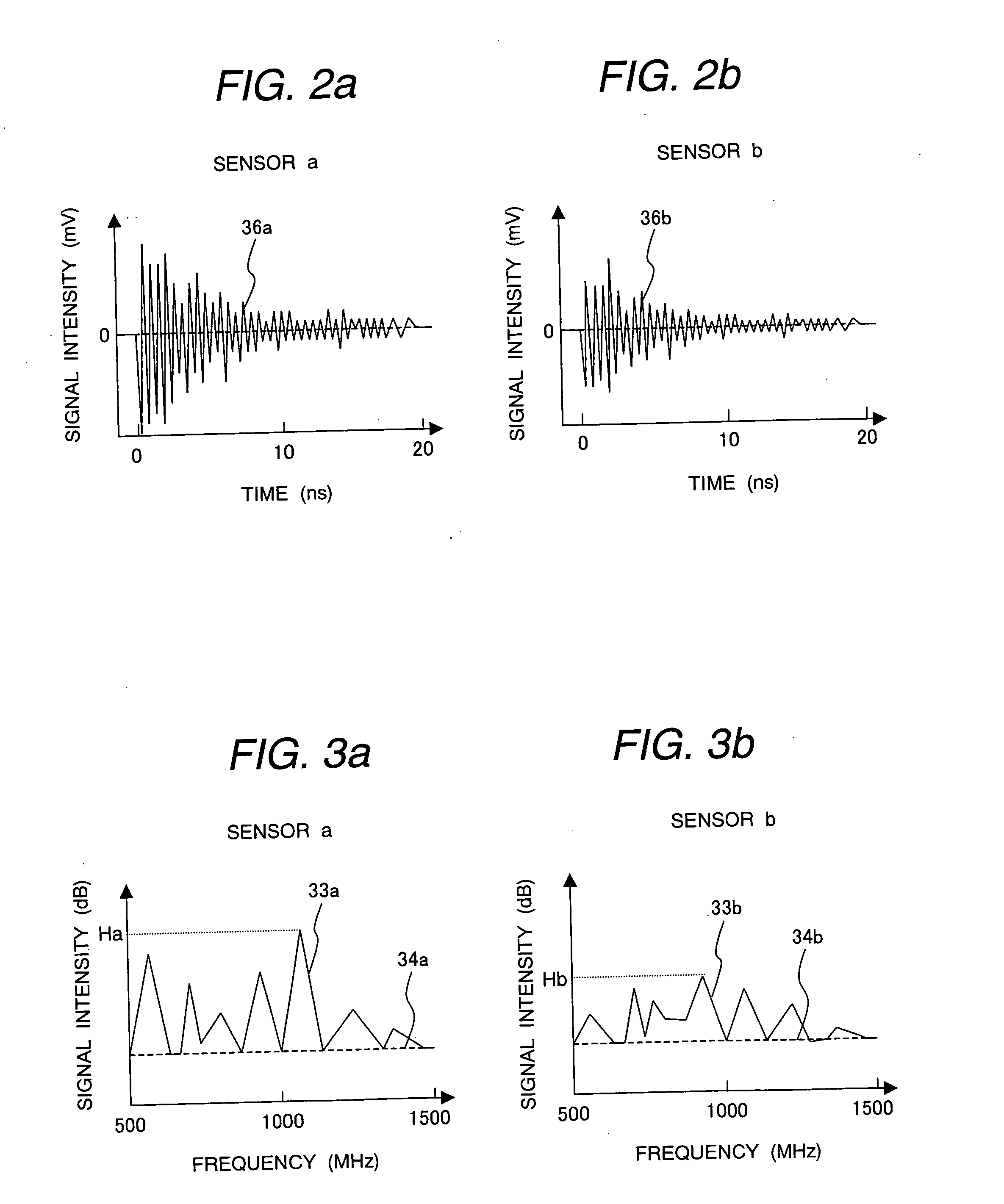

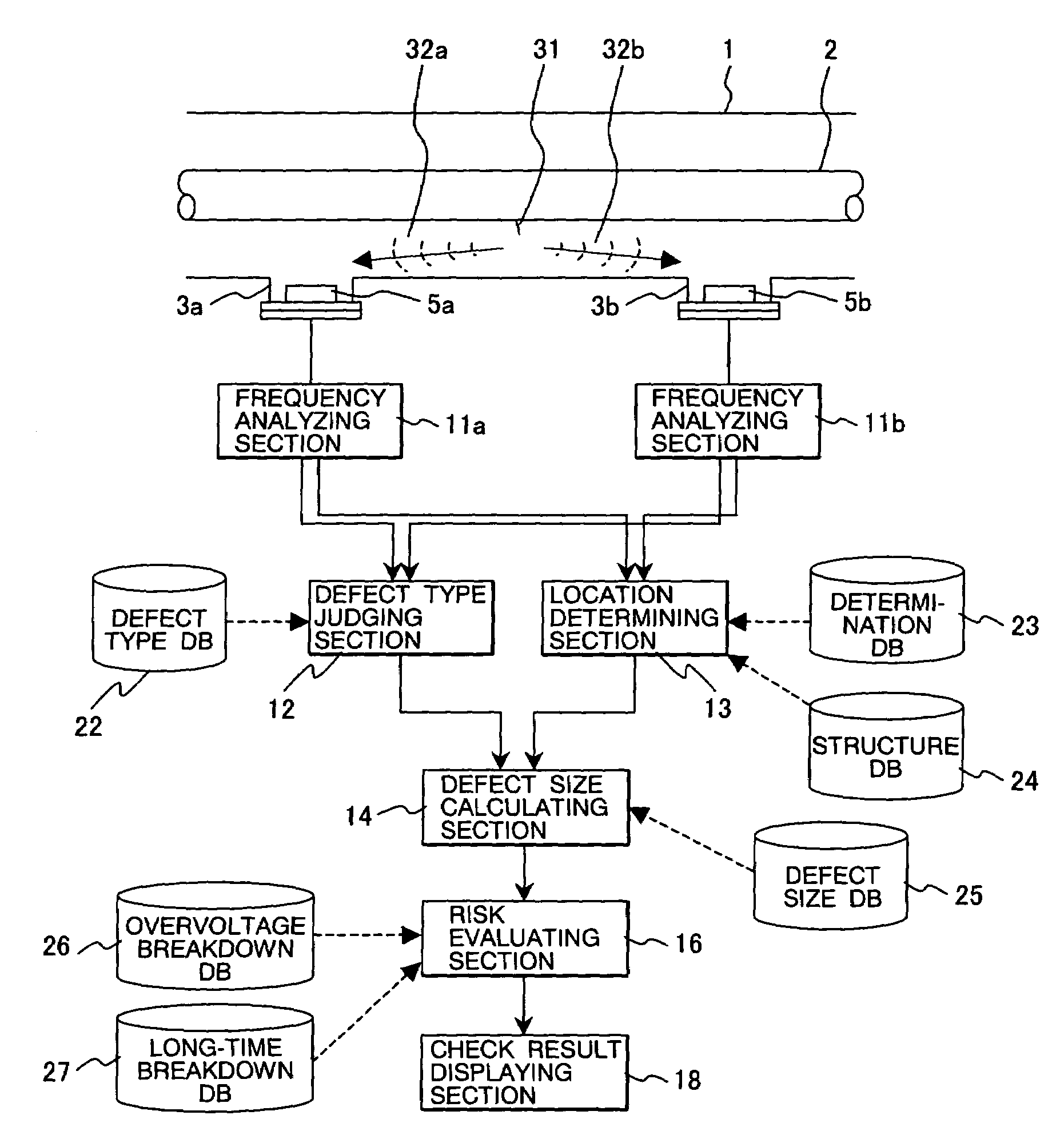

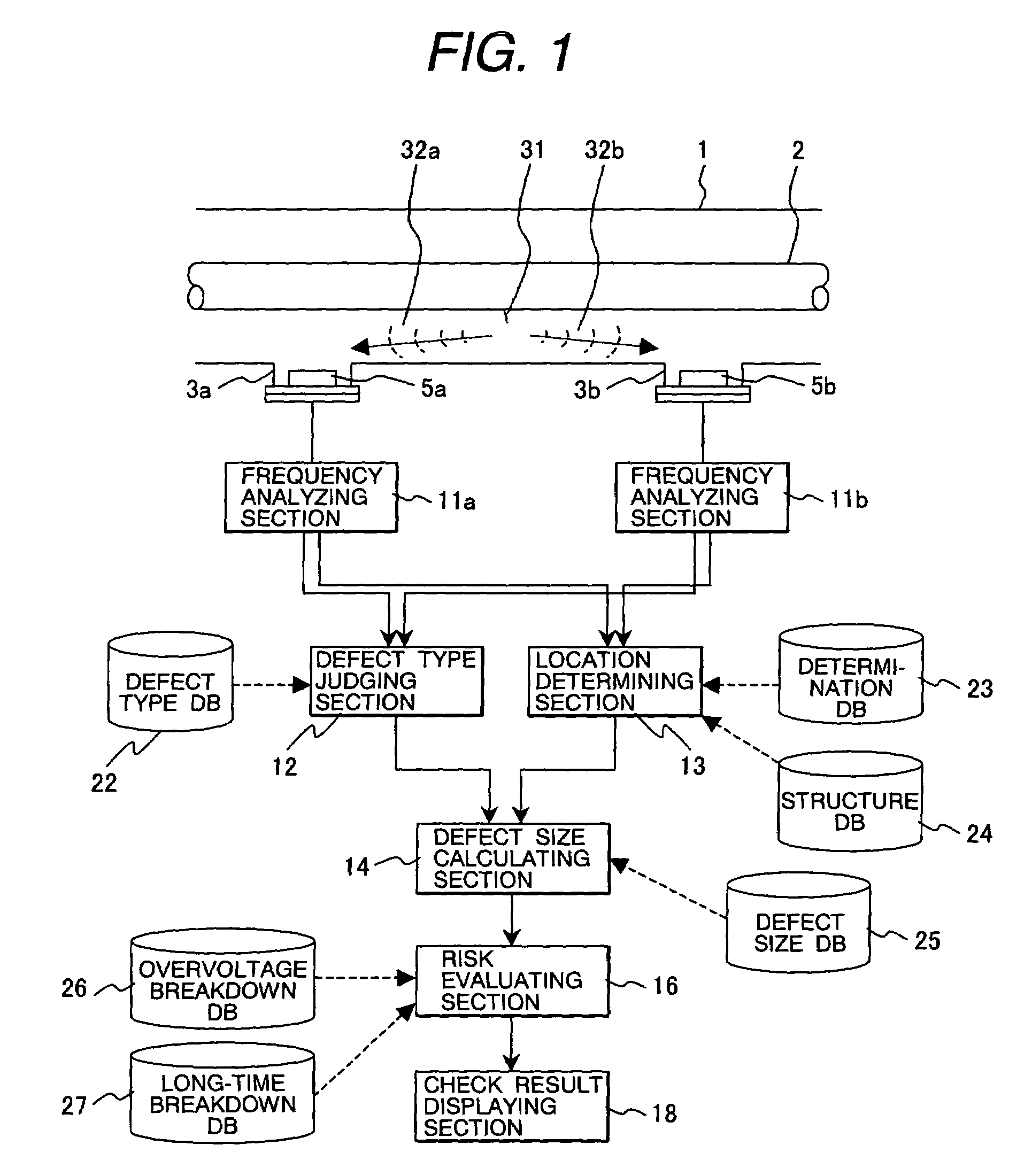

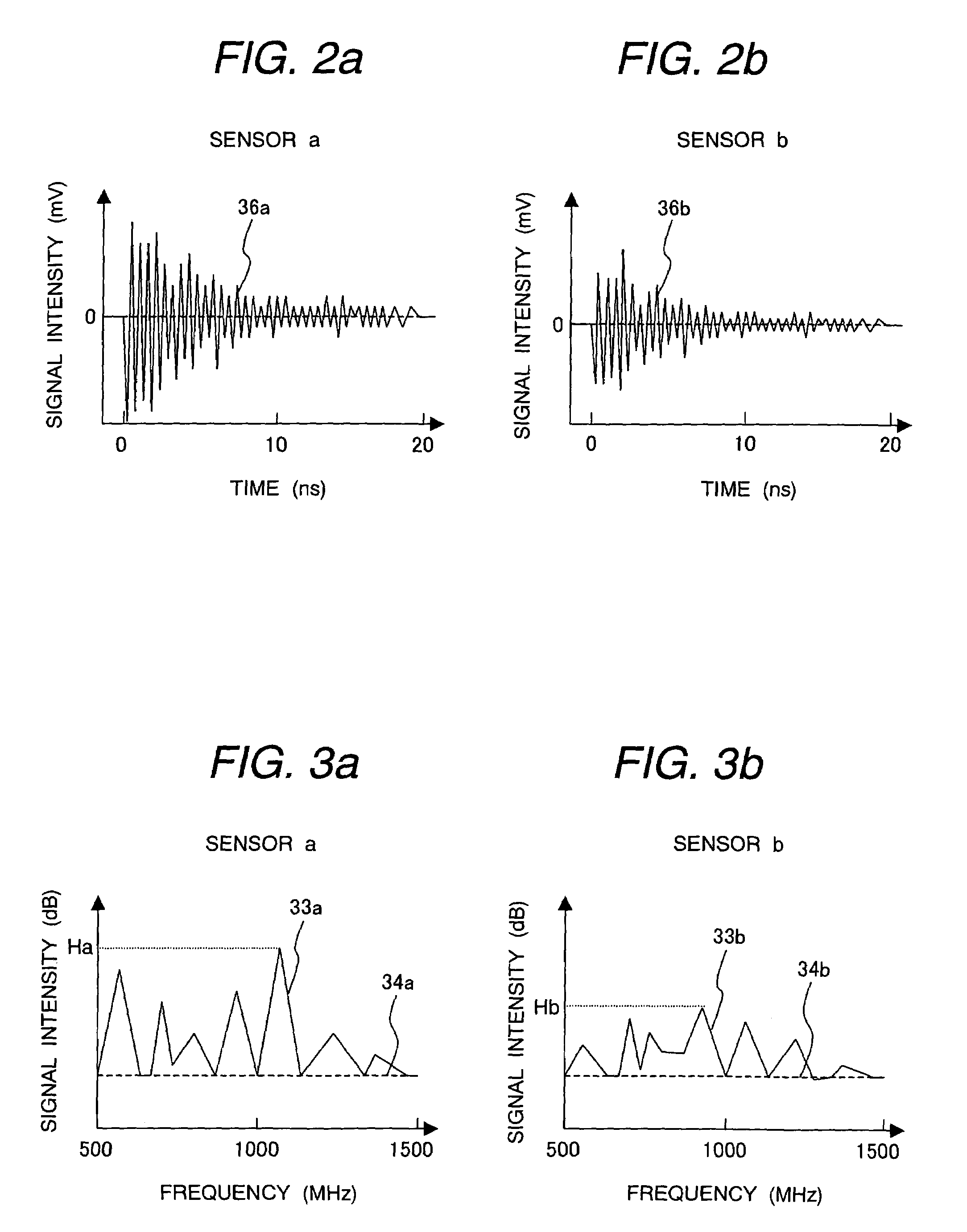

Method and system for monitoring partial discharge in gas-insulated apparatus

ActiveUS20060132144A1Reduce maintenance costsFailure conditionTesting dielectric strengthElectric switchesForeign matterDefect size

A gas-insulated apparatus is equipped inside with multiple sensors for sensing a partial discharge signal caused by a foreign substance, and a frequency analyzing section for analyzing the frequency of the sensed partial discharge signal. A defect type judging section estimates the defect type of the foreign substance from the signal obtained through the frequency analysis or from the voltage phase distribution of partial discharge synchronized with the frequency of the voltage applied to the gas-insulated apparatus, and a location determining section estimates the defect location and signal intensity from the multiple partial discharge signals. A defect size calculating section estimates the defect size for each defect type from the signal intensity and field distribution at the defect location. Dielectric breakdown risk evaluation is performed based on the defect size and type, and the insulation failure risk is diagnosed from the partial discharge.

Owner:JAPAN AE POWER SYST

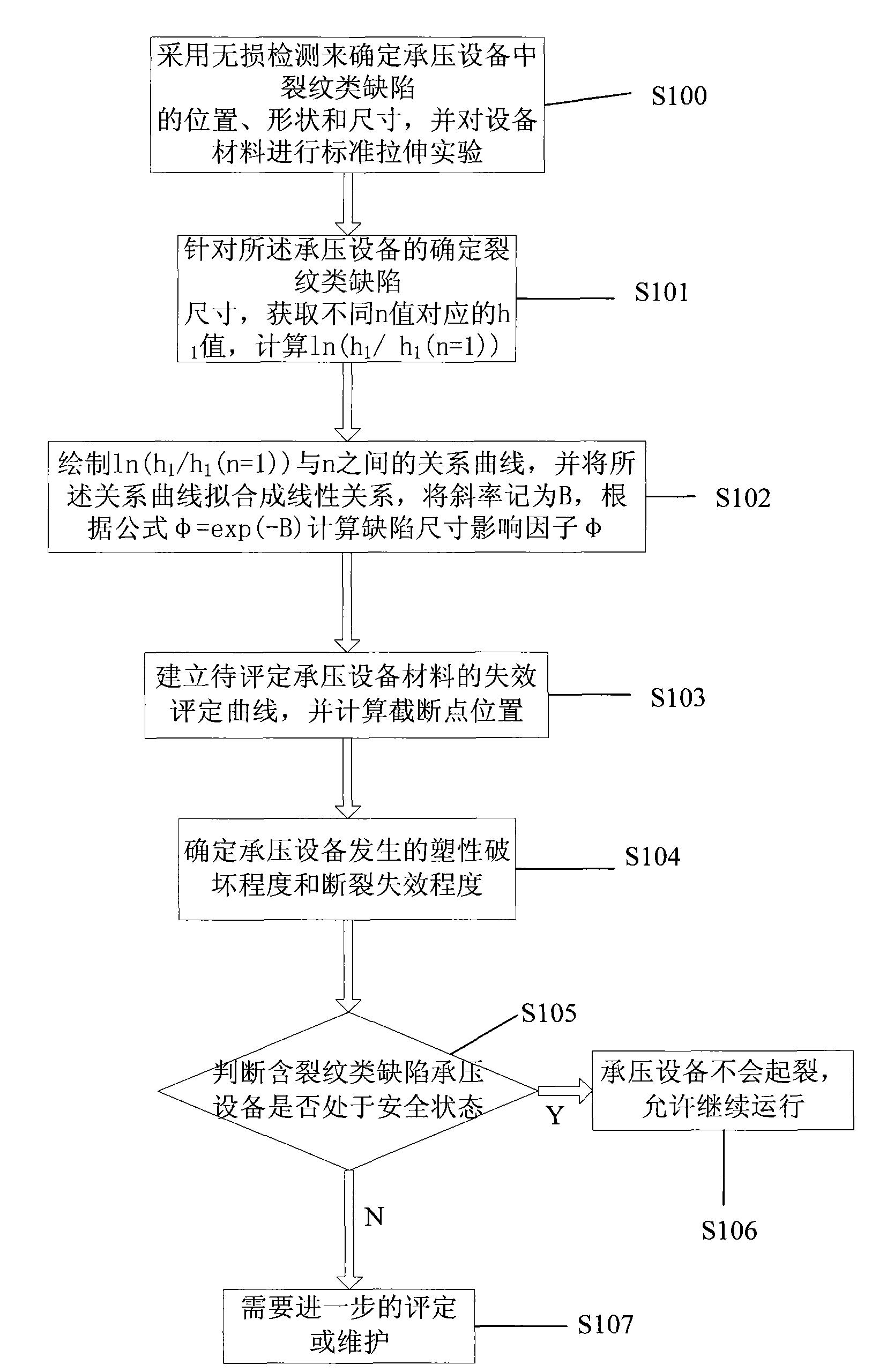

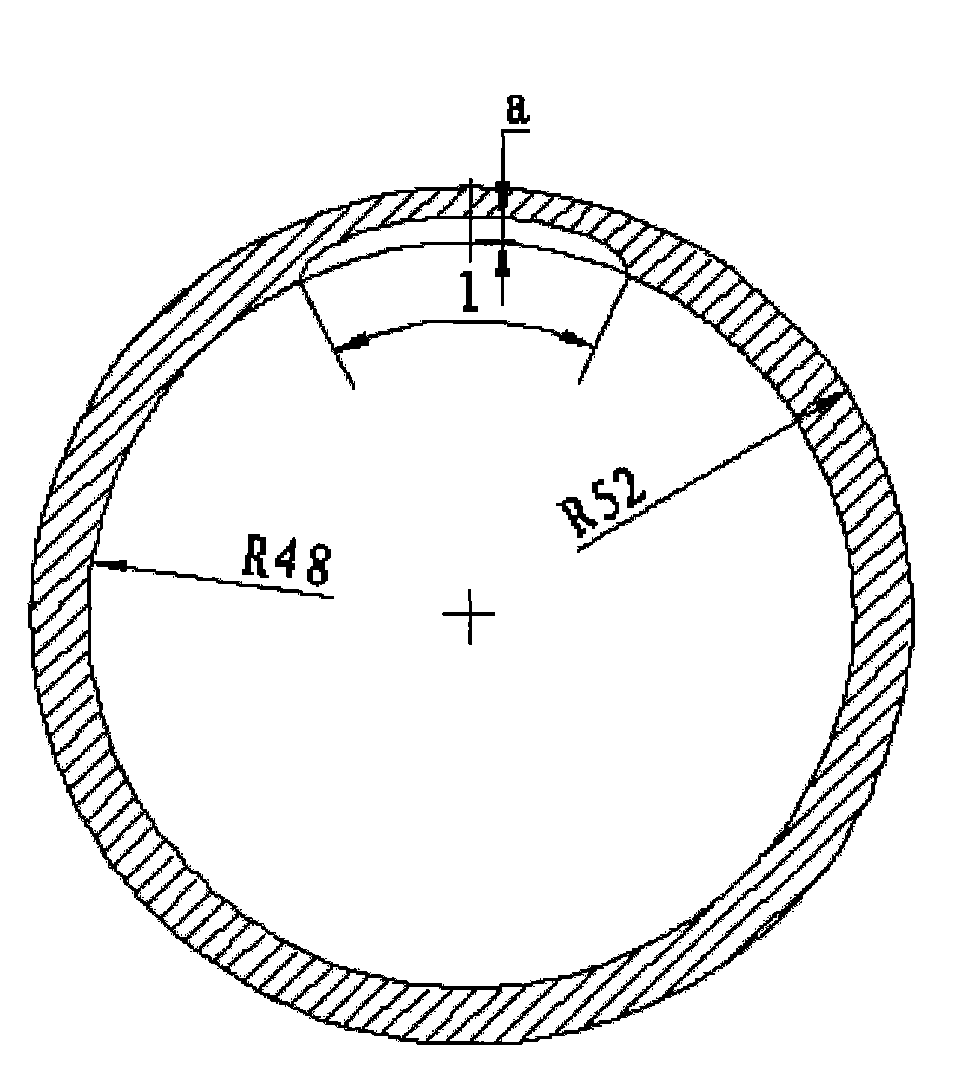

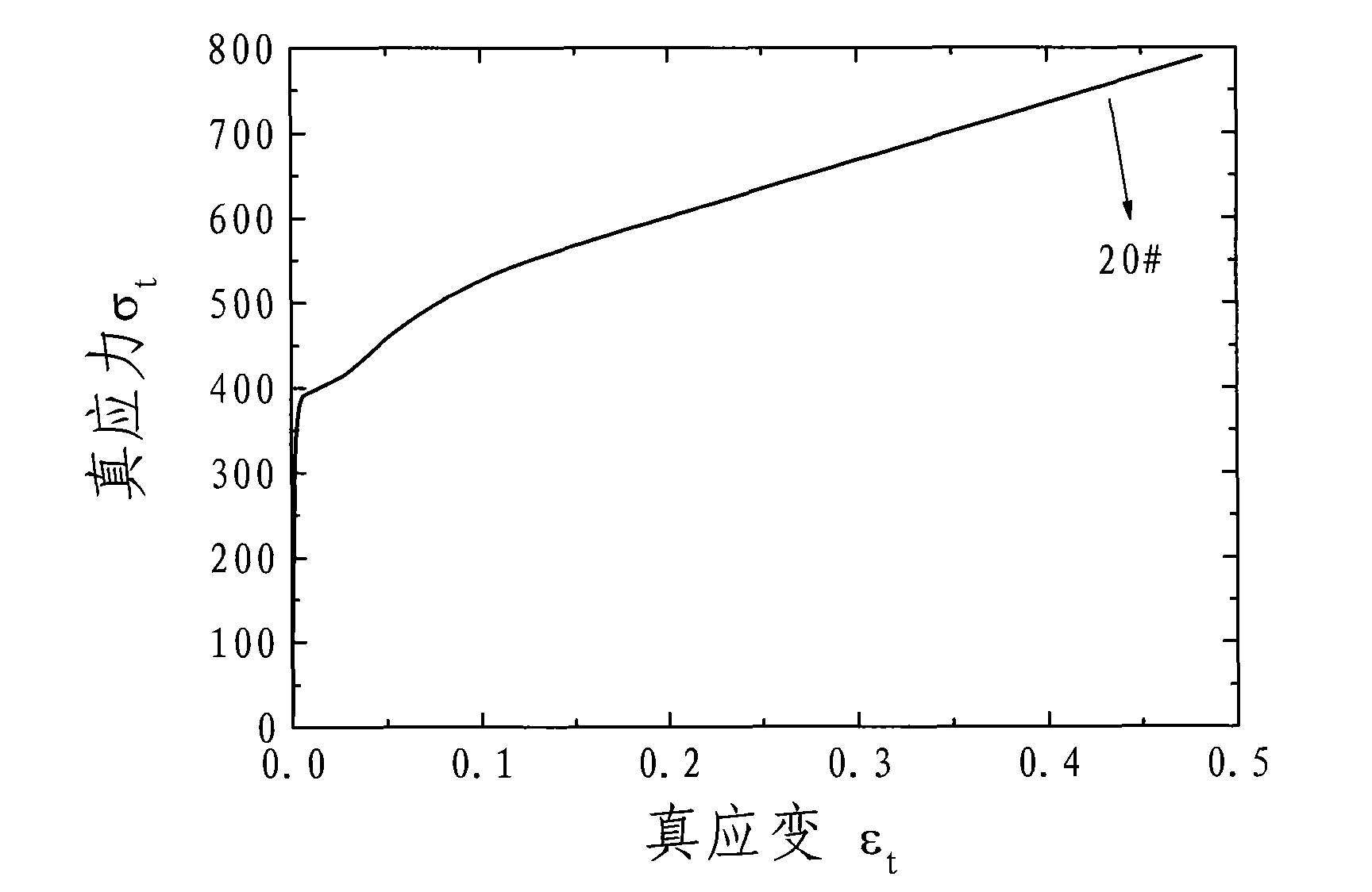

Safety evaluating method of pressure equipment containing crack defects

InactiveCN101975695AAccurately reflectAvoid mockingMaterial strength using tensile/compressive forcesDefect sizeLinear relationship

Owner:EAST CHINA UNIV OF SCI & TECH

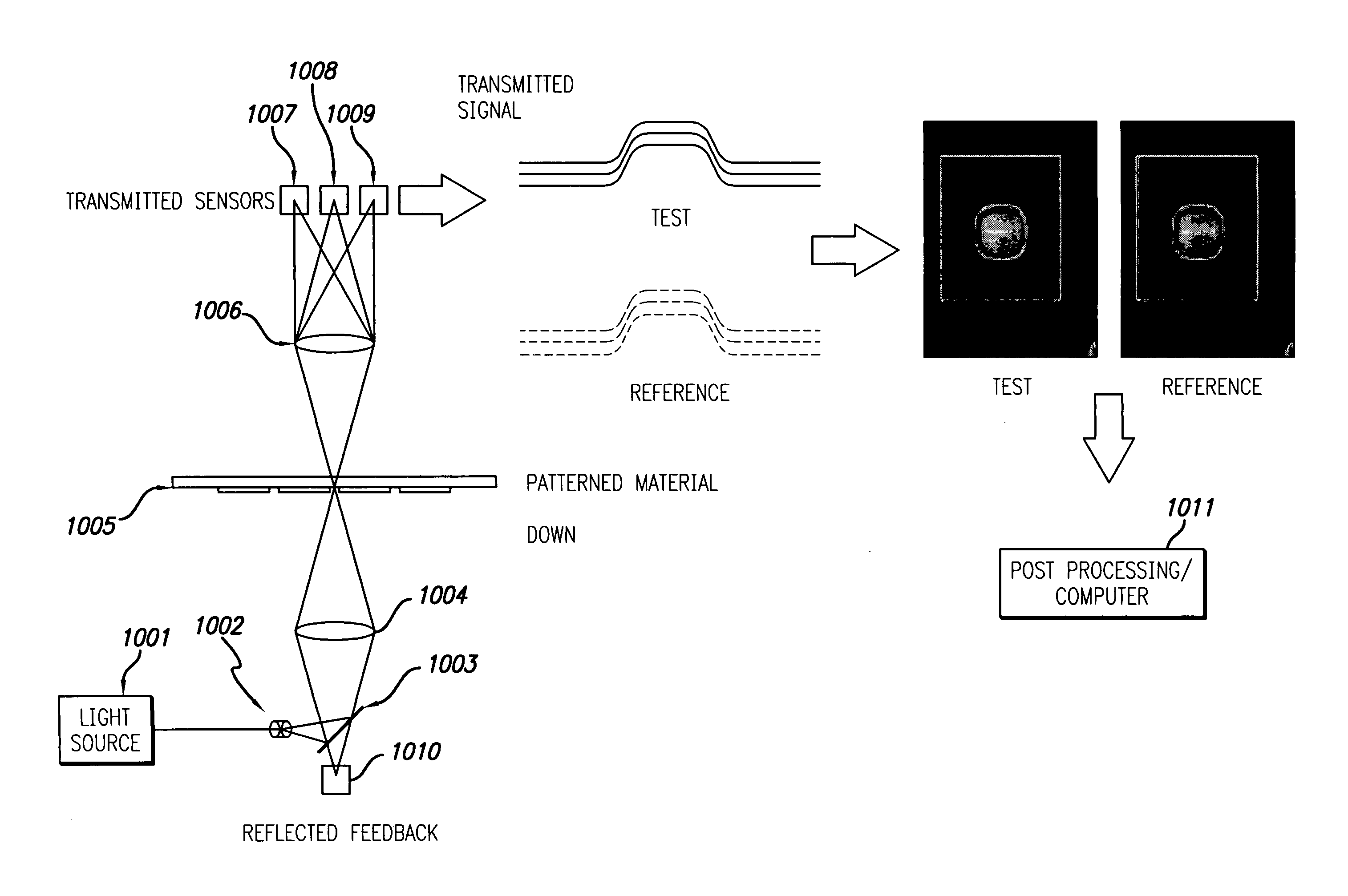

Closed region defect detection system

A method and apparatus for inspecting specimens or patterned transmissive substrates, such as photomasks, for unwanted particles and features, particularly those associated with contacts, including irregularly shaped contacts. A specimen is illuminated by a laser through an optical system comprised of a laser scanning system, individual transmitted and / or reflected light collection optics and detectors collect and generate signals representative of the light transmitted by the substrate. The defect identification of the substrate is performed using those transmitted light signals. Defect identification is performed using an inspection algorithm by comparing image feature representations of a test specimen with a reference specimen, and using a boundary computer and flux comparison device to establish tight boundaries around contacts and compute flux differences between the test and reference specimen contacts. Defect sizes are reported as ratio of flux difference, and entire contacts are highlighted for review.

Owner:KLA TENCOR TECH CORP

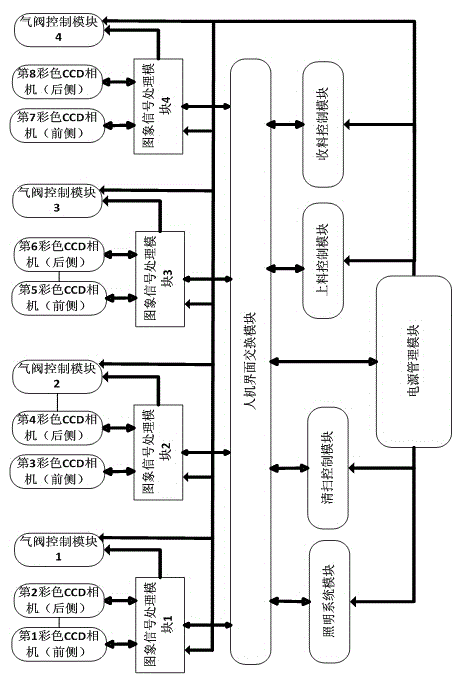

Colored double-CCD (Charge Coupled Device) color-sorting system for delinting cotton seeds and implementation method

InactiveCN104438135AImprove germination rateStable illuminationColor/spectral properties measurementsUsing optical meansInteraction systemsDefect size

The invention relates to a colored double-CCD (Charge Coupled Device) color-sorting system for delinting cotton seeds. The colored double-CCD color-sorting system comprises a vibratory feeding system, an optical detection system, a defective-product separation system, a human-computer interaction system and a sweeping system. The colored double-CCD color-sorting system is characterized in that the optical detection system comprises an LED RGB light-source system, a reference background unit and a colored CCD camera unit; a sorting interface processing unit is provided with two synchronously-arranged sensitivity thresholds and a defect-size customization control function. The colored double-CCD color-sorting system has the advantages that a colored double-CCD intelligent recognition algorithm is utilized to determine the feature information such as colors and shapes of the cotton seeds and screening on defective products such as red seeds, white seeds, seeds with cracks, damaged seeds and empty seeds in the processed cotton seeds is carried out, so that the germination rate and the commodification of the seeds are increased and the competitiveness of domestic color-sorting products is improved.

Owner:天津市环新光学精密机械研究有限公司

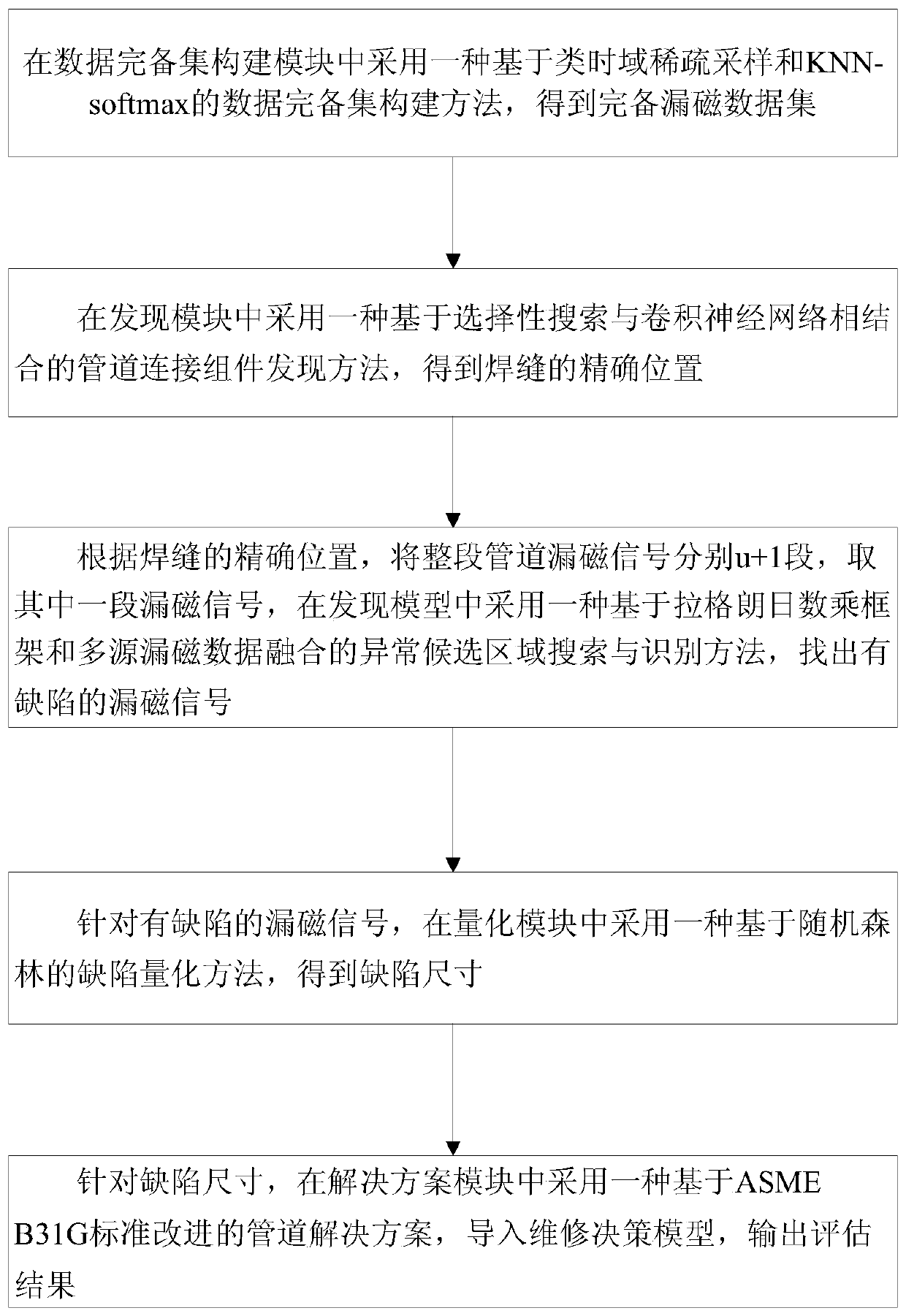

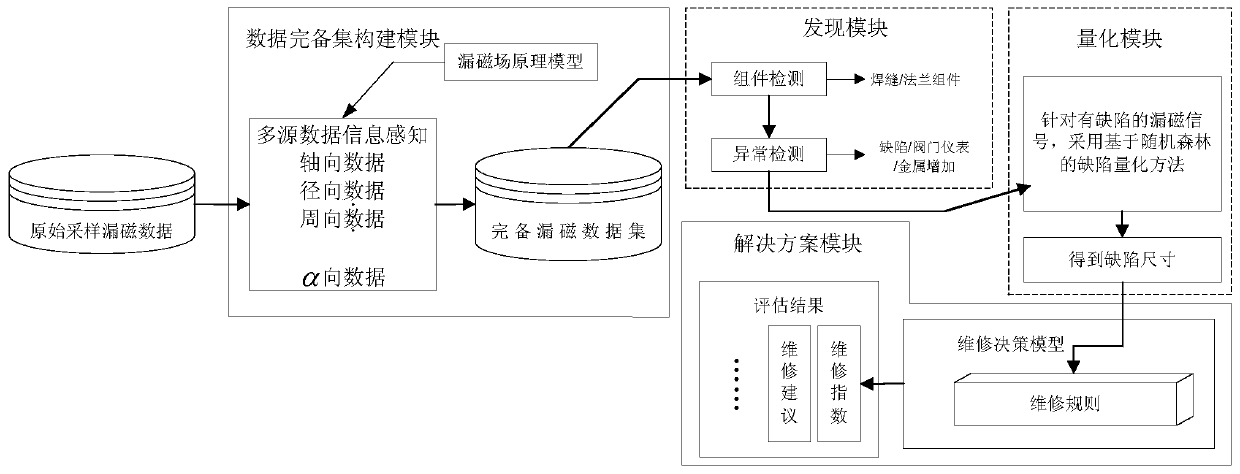

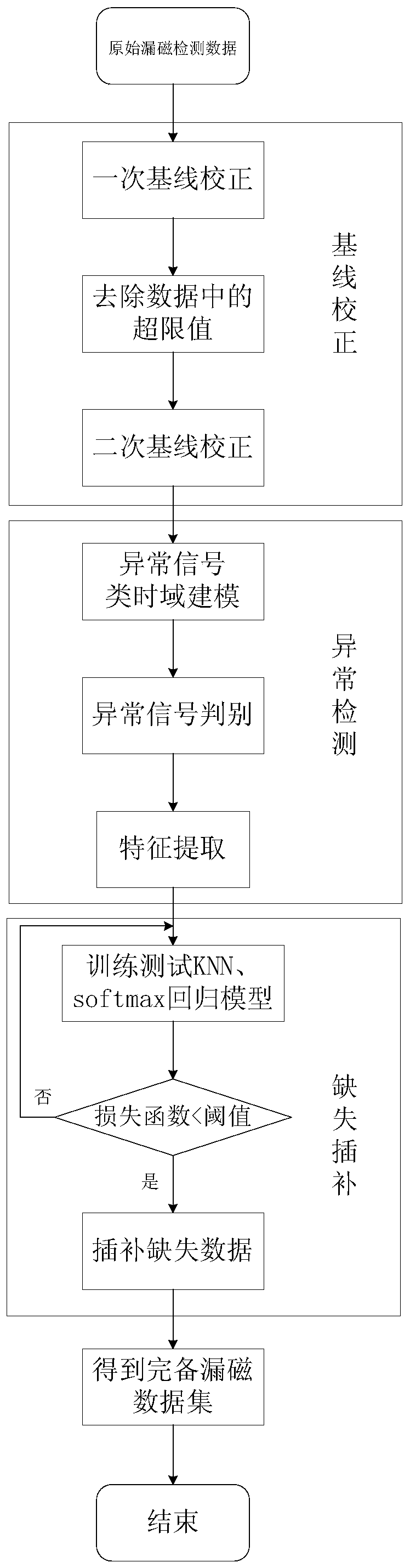

Intelligent analysis system and method for magnetic flux leakage detection data in pipeline

ActiveCN109783906AImprove accuracyImprove anti-interference abilityPipeline systemsNeural architecturesTime domainData set

The invention provides an intelligent analysis system and method for magnetic flux leakage detection data in a pipeline. The process comprises the following steps: adopting time domain-based sparse sampling and KNN-softmax data complete set construction module, obtaining a complete magnetic flux leakage data set; a pipeline connection assembly discovery method based on combination of selective search and a convolutional neural network is adopted in the discovery module to obtain the accurate position of the weld joint; adopting an abnormal candidate region searching and identifying method based on a Lagrangian multiplication frame and multi-source magnetic flux leakage data fusion in the discovery model to find out defective magnetic flux leakage signals; Adopting a defect quantification method based on a random forest in a quantification module to obtain a defect size; a pipeline solution improved based on the ASME B31G standard is adopted in the solution module, and an evaluation result is output. An analysis method is provided from the overall perspective, and pretreatment, connection assembly detection and abnormity detection, defect size inversion and final maintenance decision are achieved.

Owner:NORTHEASTERN UNIV

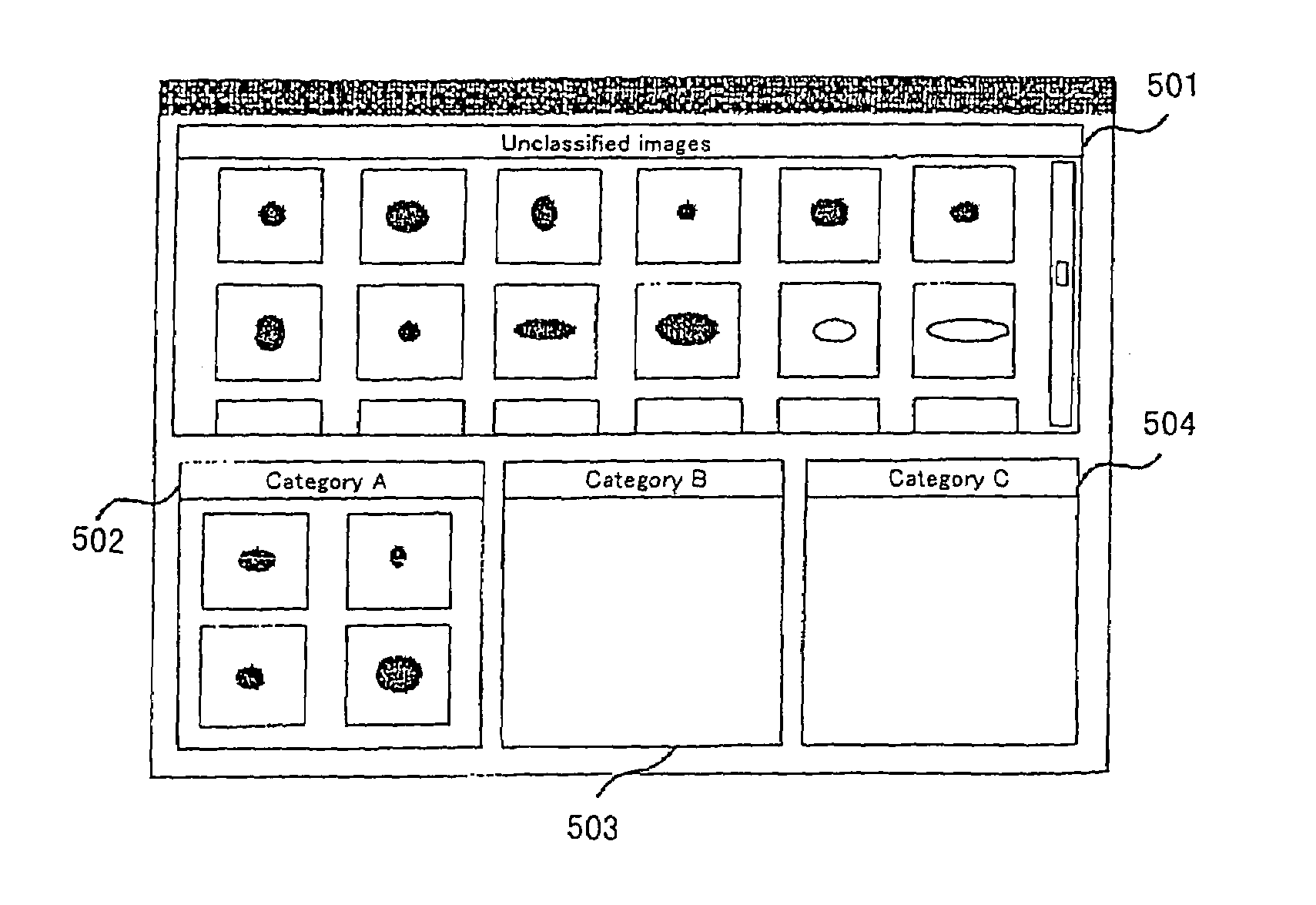

Defect image classifying method and apparatus and a semiconductor device manufacturing process based on the method and apparatus

InactiveUS20060274933A1Improve teaching efficiencyLabor savingImage enhancementImage analysisDefect sizeDevice material

According to the present invention, techniques including a method and apparatus for classifying and displaying images are provided. In an embodiment of the present invention a defect image classification method using inspected objects is provided. The method includes defect images obtained from at least one inspected object. Next a set of defect images is classified into a specified category, which has a feature. The defect images are arranged for display according to the feature and then displayed. The arranging of the defect images may also be based on an evaluation value for each defect image. Another embodiment provides a defect image classification method using inspected objects. Defect images are obtained from at least one inspected object. Next the defect images are classified into a plurality of categories and at least two information items for example, a defect distribution diagram showing locations of defects in the inspected object, information associated with a category of the plurality of categories, and a defect size distribution, are displayed.

Owner:HITACHI LTD

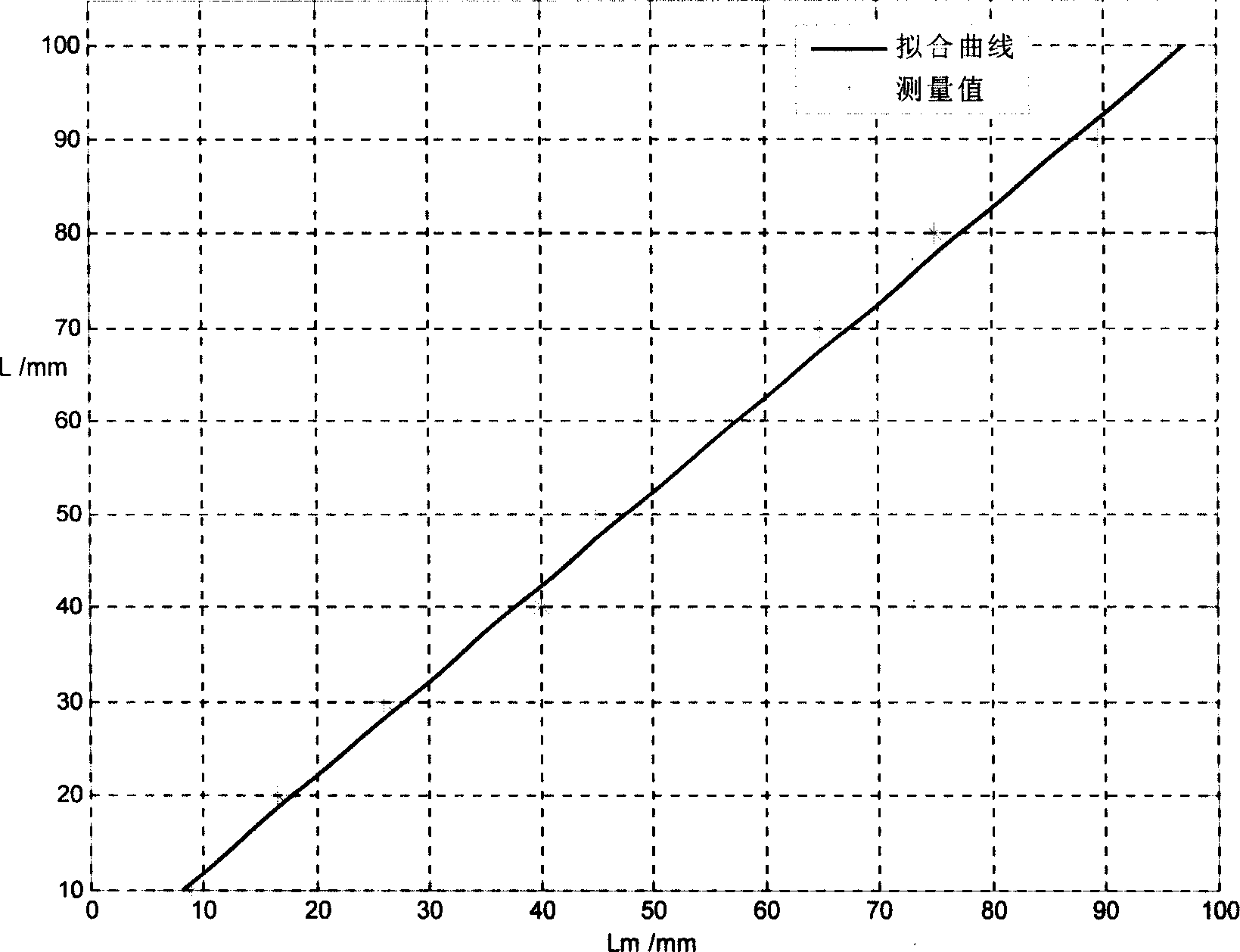

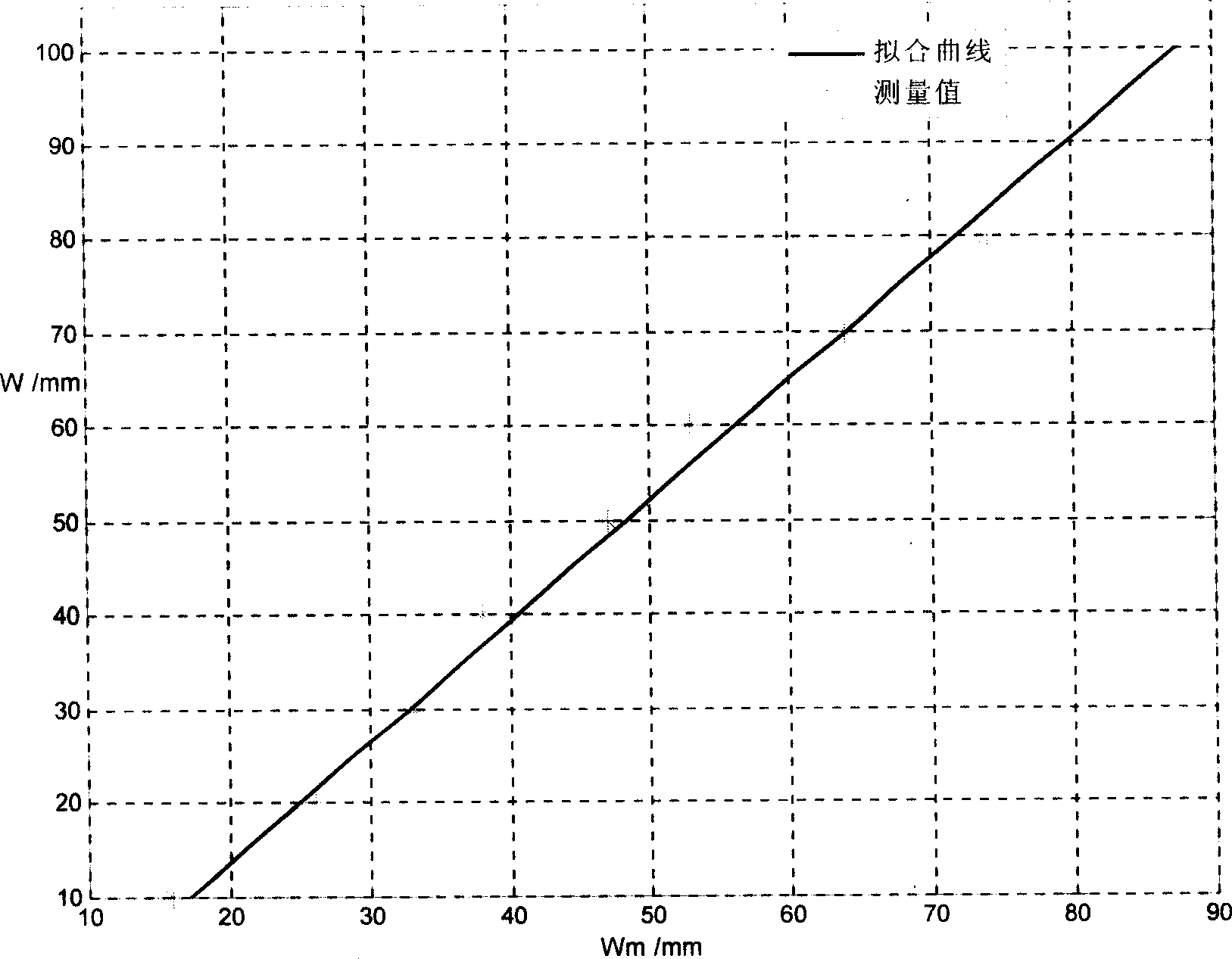

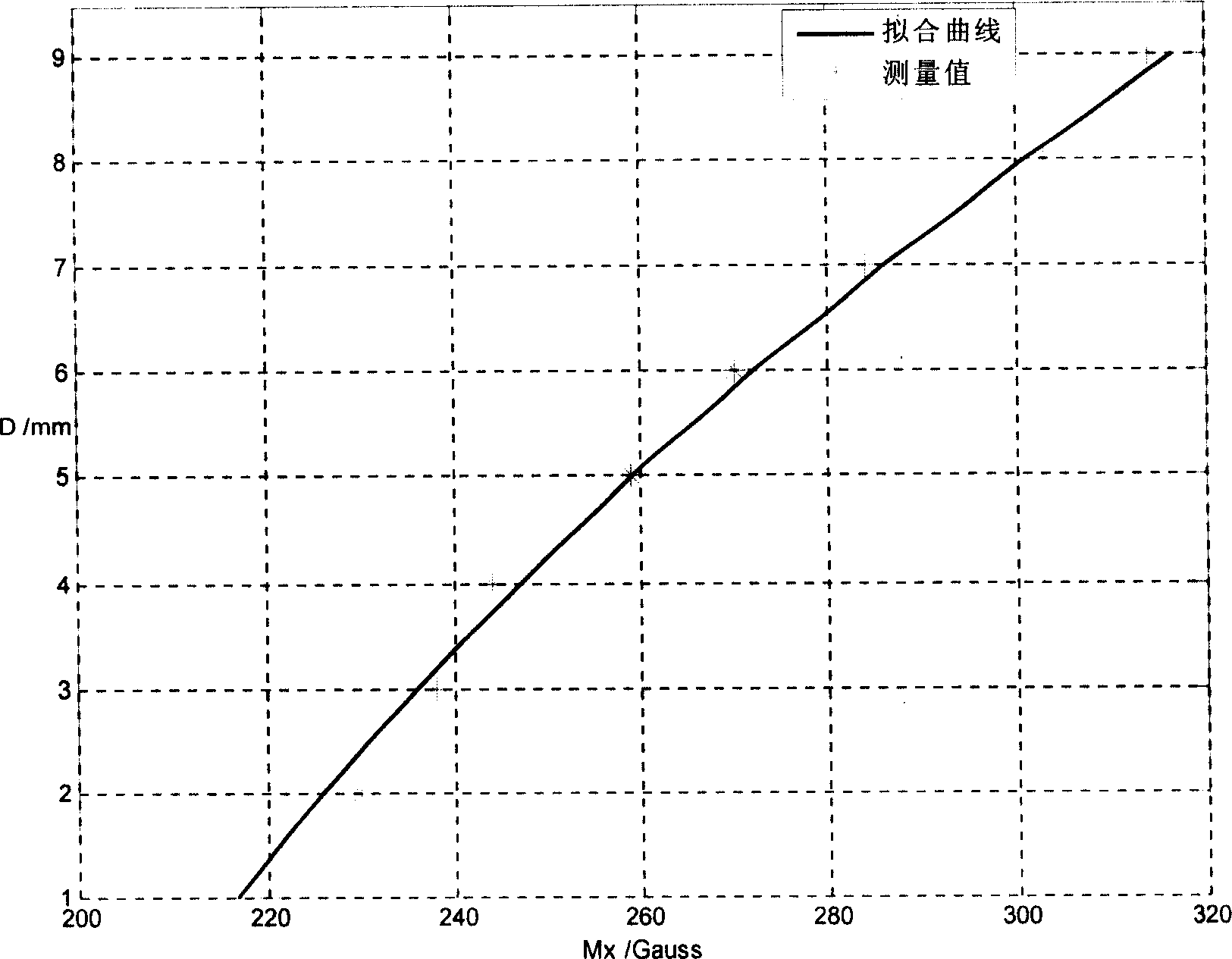

Quantizing method for detecting corrosion defect by magnetic leakage

InactiveCN1641347ACorrosion defects overcomeOvercome the shortcoming that the defect depth is difficult to quantifyUsing electrical meansFluid-tightness measurementDefect sizeMagnetic leakage

The invention is a quantizing method for detecting corrosive defect by using magnetic leakage. The invention uses the distribution property of the detected leakage magnetic field to implement quantizing corrosive defect size according to a specified algorithm. The concretely implementing method: firstly making a sample with three series of standard defects, according to the leakage magnetic detected data, determining the length, width and coefficient in deep quantizing method, thus obtaining a corrosive defect quantizing method and providing a basis for evaluating using state of equipment and equipment maintenance. The invention effectively overcomes the disadvantage of being difficult to quantize corrosive defect and defect depth in existing techniques, and the method of the invention is simple and easy to apply and able to be implemented, manually and by computer, high-efficiency and having a wider application prospect.

Owner:TSINGHUA UNIV

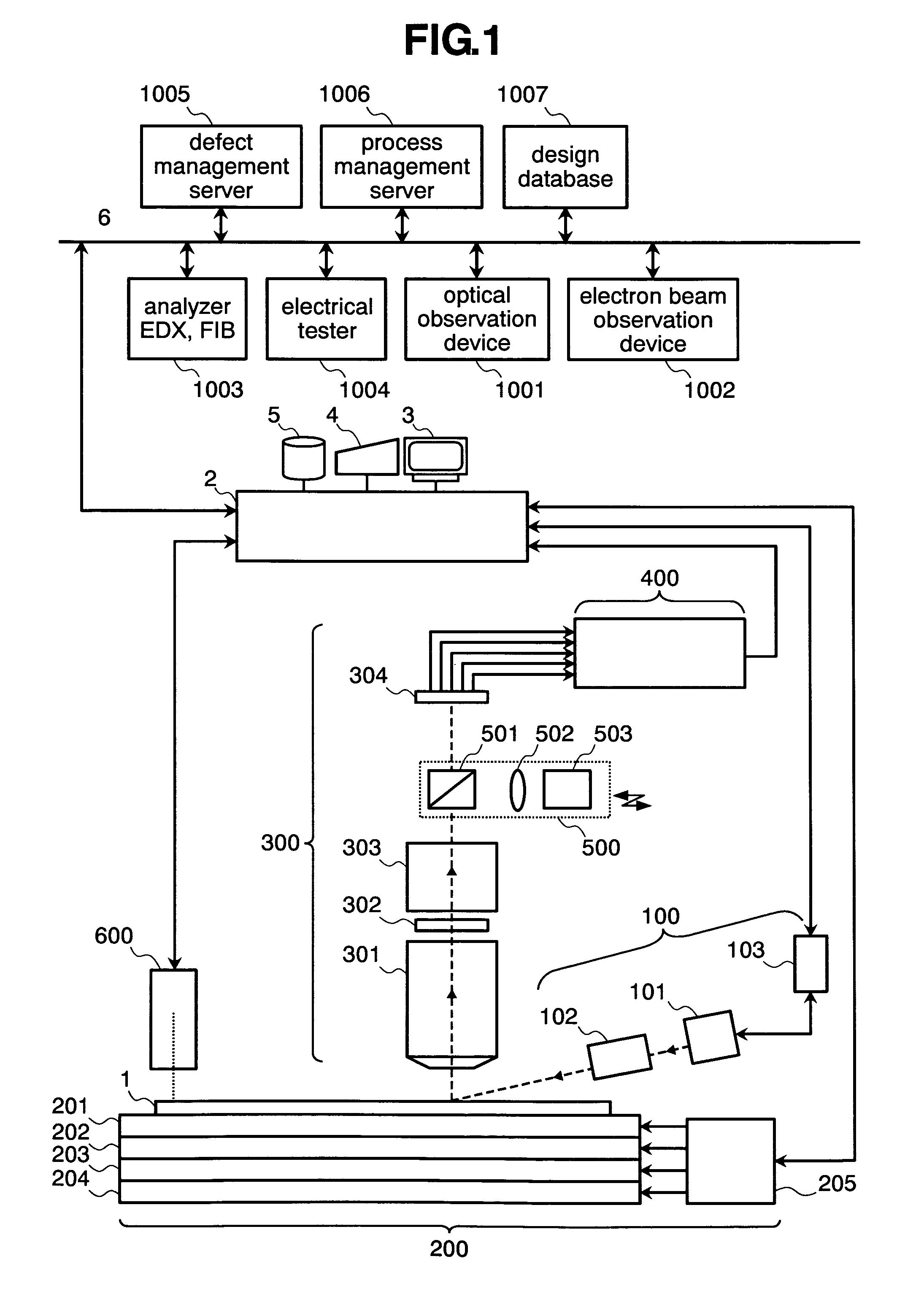

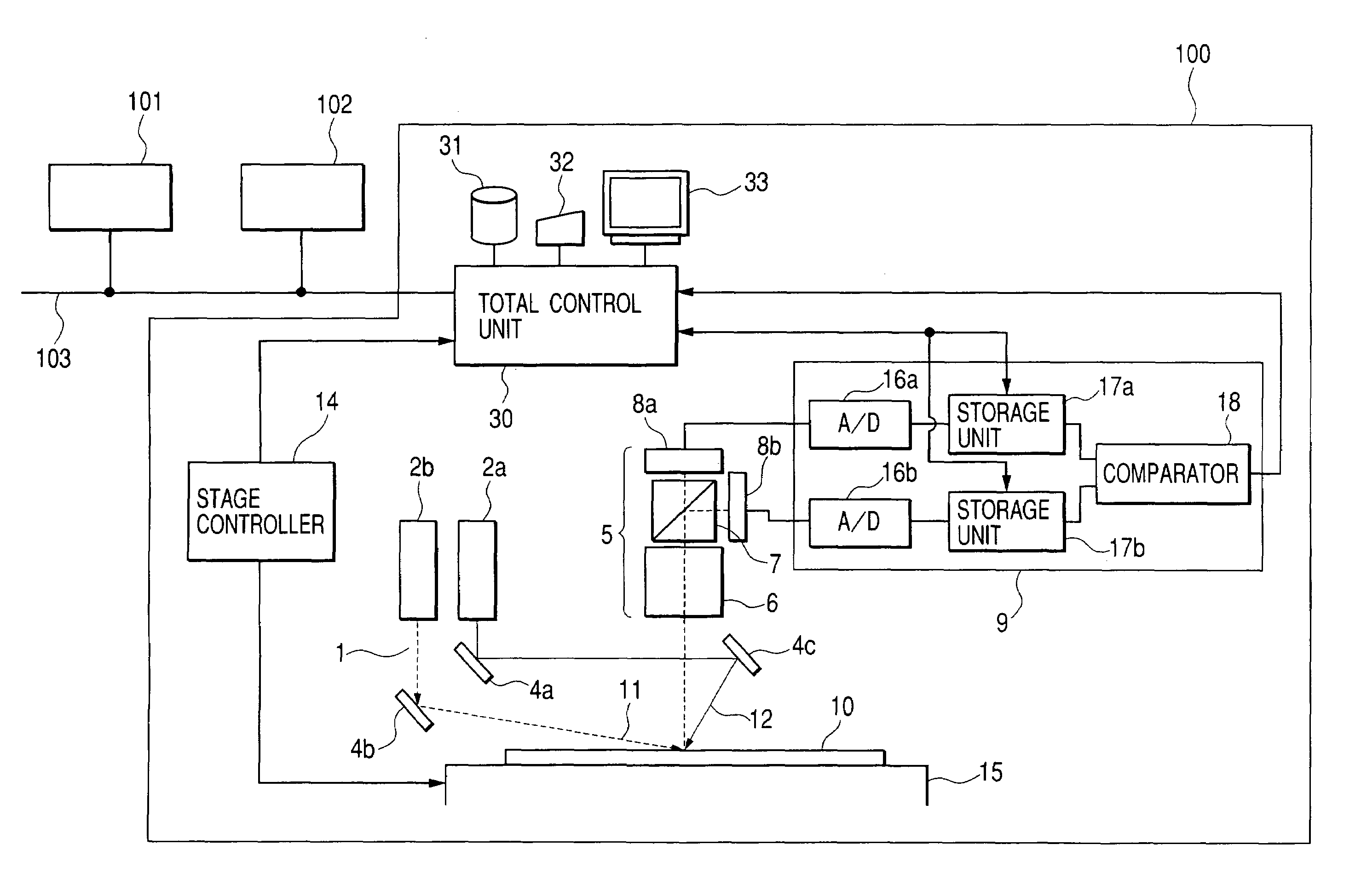

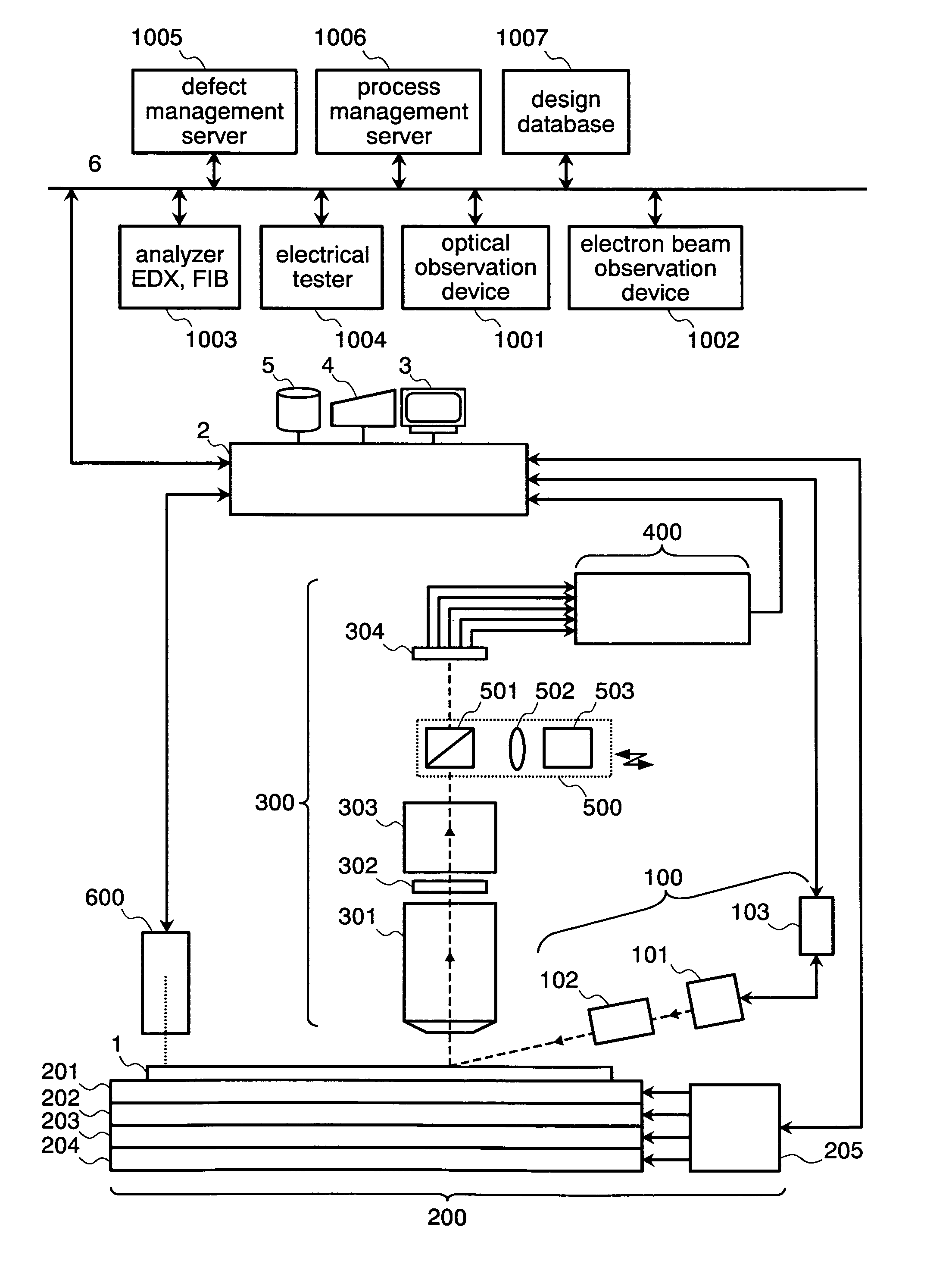

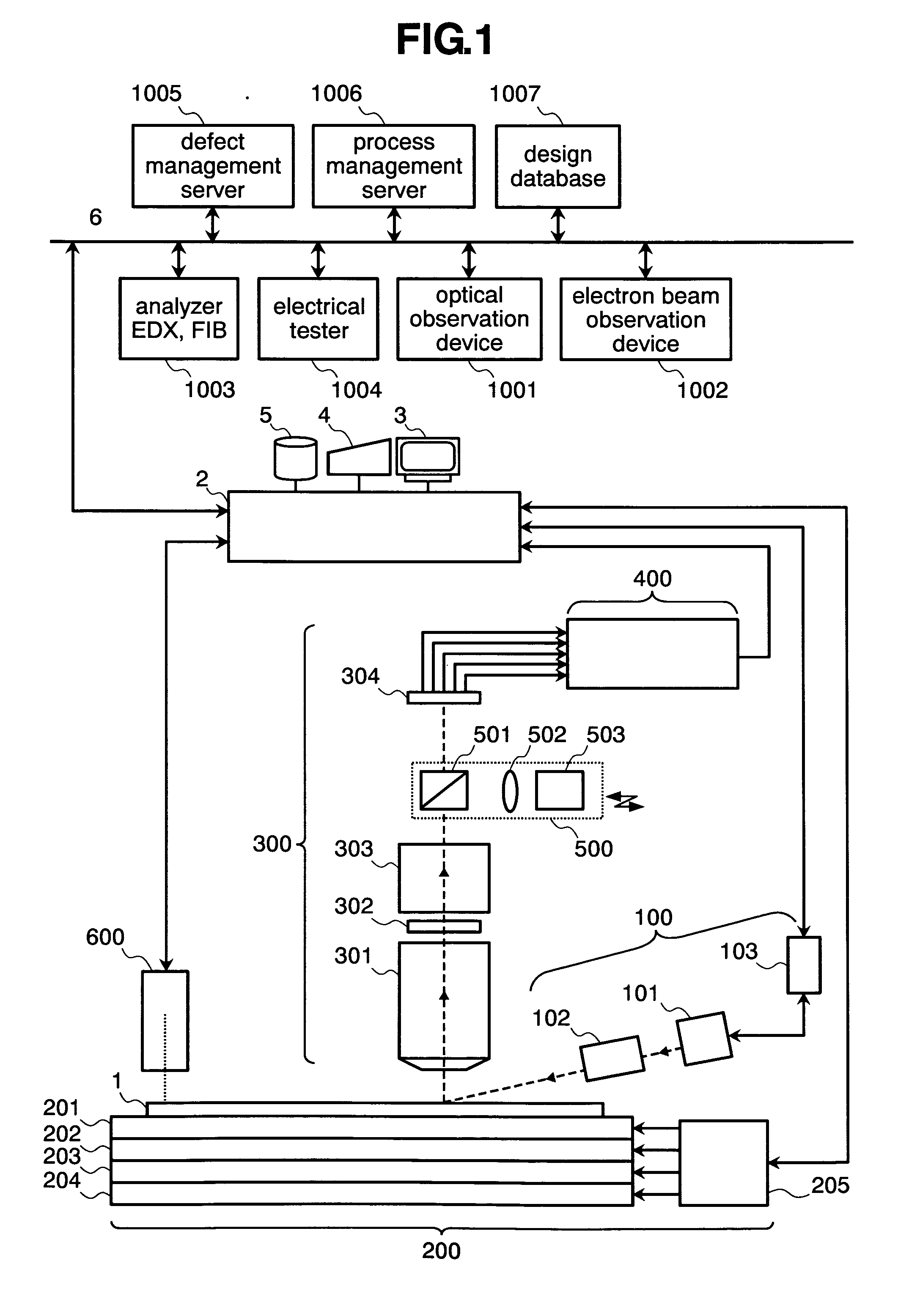

Apparatus of inspecting defect in semiconductor and method of the same

ActiveUS7474394B2Small sizeImprove productivitySemiconductor/solid-state device testing/measurementInvestigating moving sheetsDefect sizeMiniaturization

When size of a defect on an increasingly miniaturized pattern is obtained by defect inspection apparatus in the related art, a value is inconveniently given, which is different from a measured value of the same defect by SEM. Thus, a dimension value of a defect detected by defect inspection apparatus needs to be accurately calculated to be approximated to a value measured by SEM. To this end, size of the defect detected by the defect inspection apparatus is corrected depending on feature quantity or type of the defect, thereby defect size can be accurately calculated.

Owner:HITACHI HIGH-TECH CORP

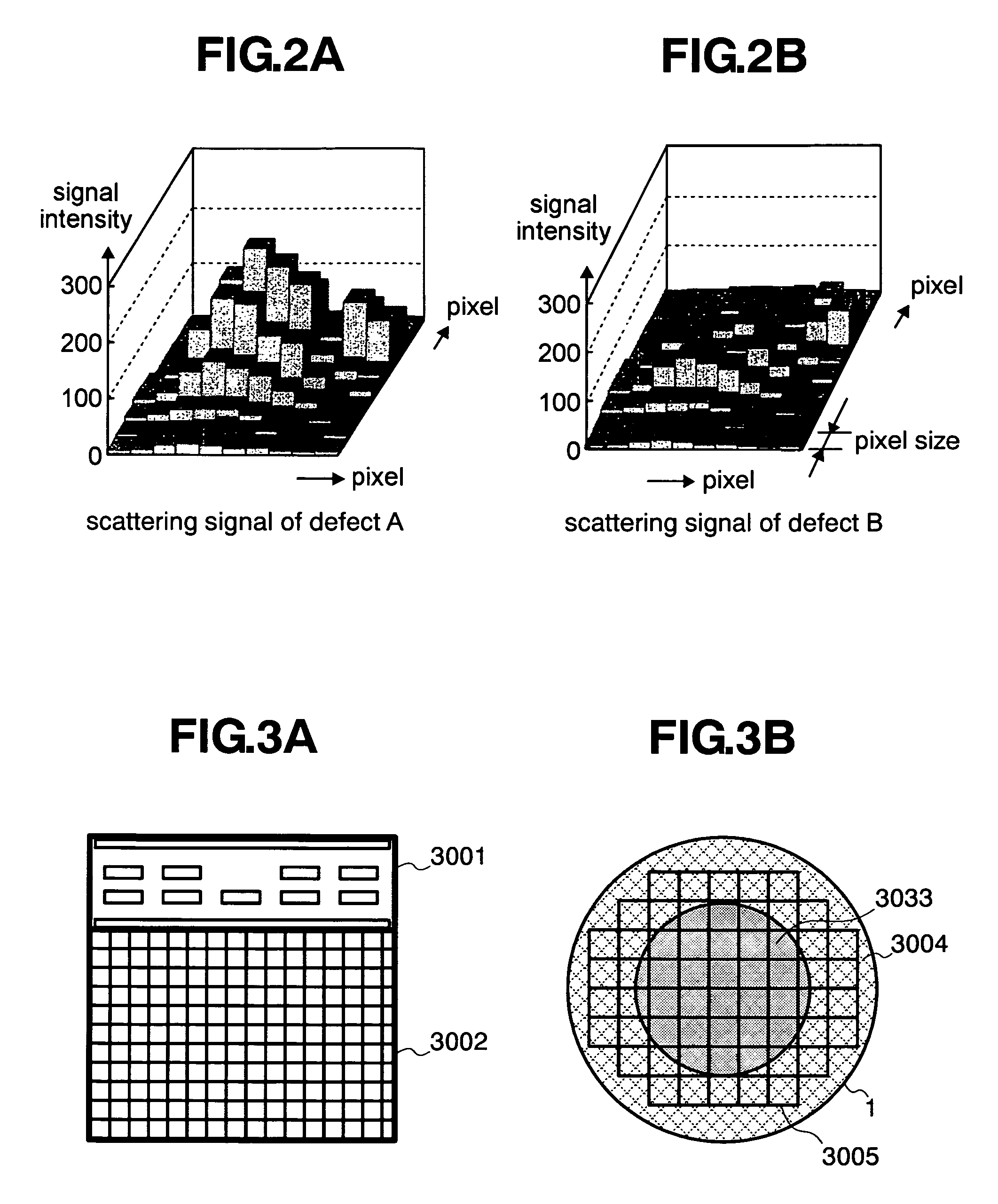

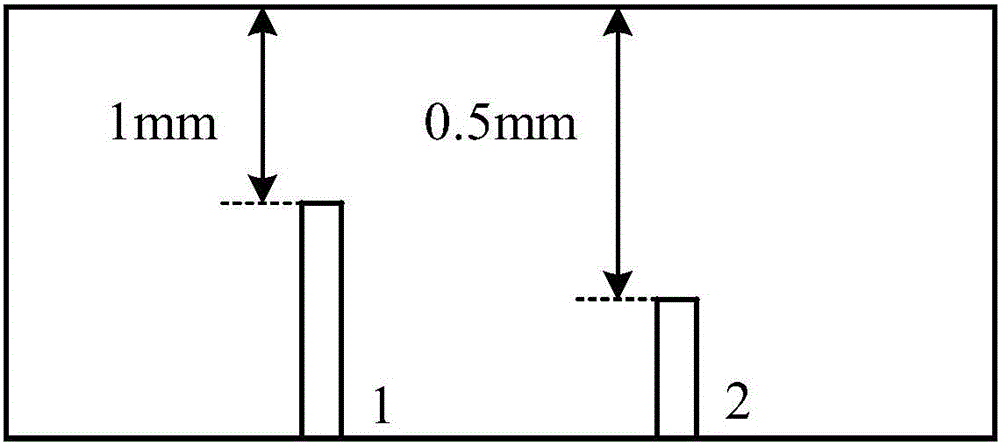

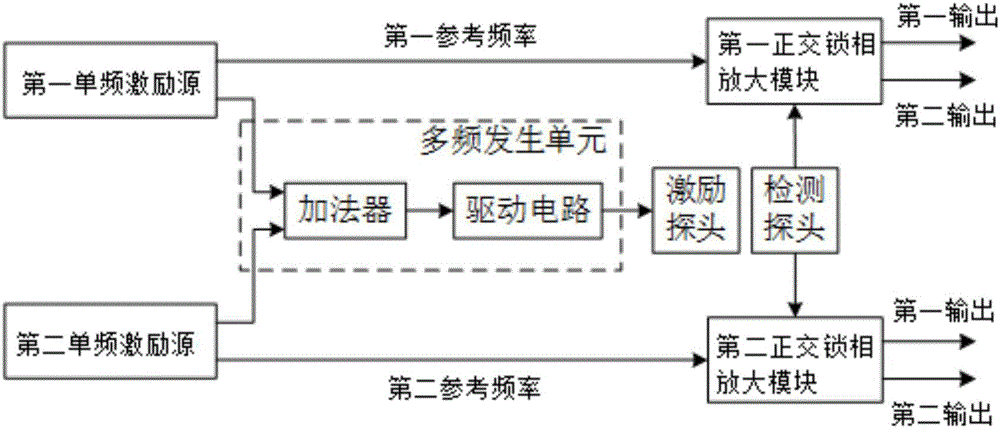

Multi-frequency eddy current testing system and method for evaluating carbon fiber plate defect depth

InactiveCN106645391AReduce noise disturbanceReduce transmission lossMaterial magnetic variablesFiberEngineering

The invention discloses a multi-frequency eddy current testing system and method for evaluating carbon fiber plate defect depth. The system comprises a composite-material to-be-tested part, a multi-frequency sine excitation signal generating module, an eddy current sensing unit, a signal processing and separating module, a signal collecting module and a depth inversion module, wherein the eddy current sensing unit comprises a transmission cable, a probe control mechanism, an eddy current excitation coil and an eddy current detecting coil; the signal processing and separating module comprises a pre-amplifier and a multi-frequency detecting signal separating module. The multi-frequency eddy current testing system and method for evaluating the carbon fiber plate defect depth has the advantage that defect size information is obtained by measuring the peak sensing voltage and peak frequency of different-depth defects, and accordingly the defect depth of composite plates can be evaluated.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for repairing main bearing hole of body

The invention relates to the technical field of maintenance of bearing holes and in particular relates to a method for repairing a main bearing hole of a body. The main bearing hole refers to the design, assembly and processing reference of the body, the central position is not allowed to deflect, the pore diameter is not allowed to be enlarged, and a brushing electroplating process cannot be used due to the reasons that the coating is small and easy to strip and cannot be machined and the like. However, thermal deformation of a welding part is increased by a common surfacing method, and the generated welding stress cannot be effectively eliminated; and meanwhile, the crack influence is large, the welding period is long, and the repair welding success rate is low. Aiming at the problems, a repair method for performing main bearing hole laser cladding surfacing and restoring the original precision of a drawing by virtue of machining is adopted, the repair processes of the main bearing hole of the body include four parts, namely cladding surfacing, surfacing part cover replacement and machining, detection of the repaired body and body cleaning and rust removal, wherein laser cladding surfacing is the key point of the whole repair process, and global surfacing and local surfacing of the pore diameter can be adopted aiming at the defect size and severity. The invention discloses an improved method for repairing the main bearing hole of the body.

Owner:CRRC QISHUYAN CO LTD

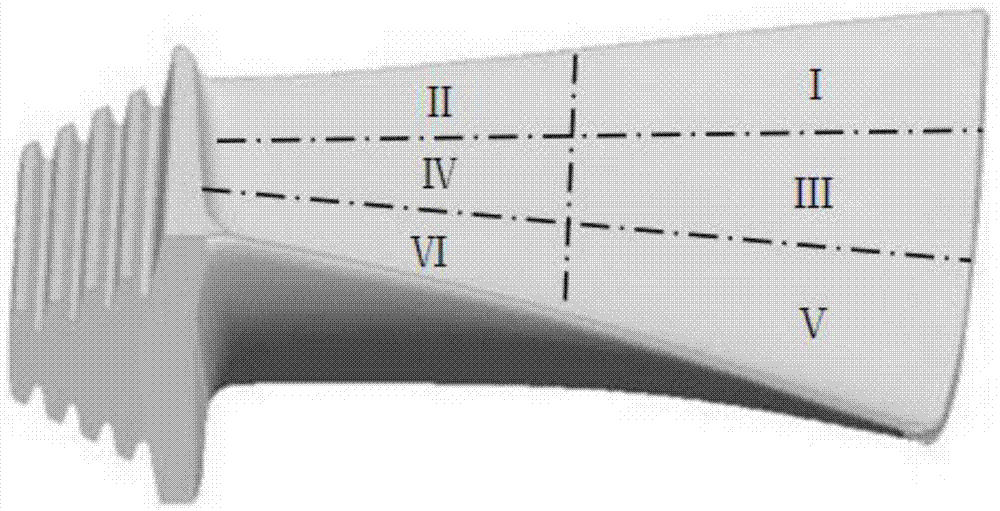

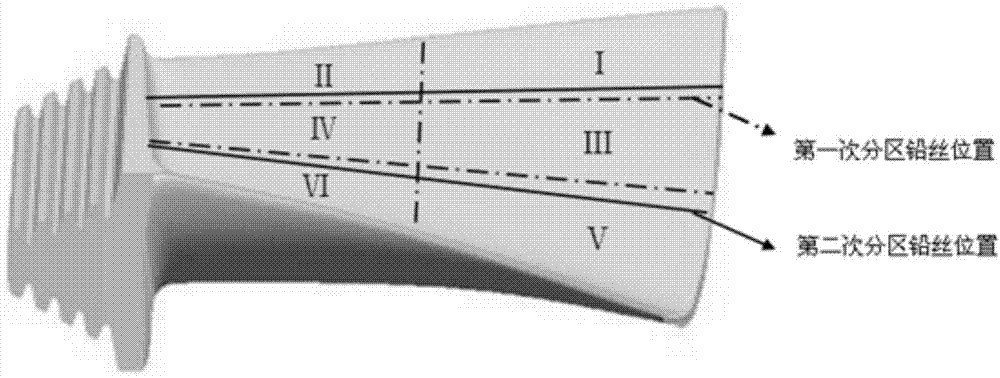

Gas turbine blade defects extraction and analysis method based on region segmenting detection

The invention discloses a gas turbine blade defects extraction and analysis method based on region segmenting detection, comprising the following steps: firstly segmenting a gas turbine blade into several regions by a lead wire, and carrying out defect detection on the segmented regions through a DR (Digital Radiography) device to obtain a blade whole gray level image A; then, moving the lead wire for certain distance to carry out defect detection inside each region, and thus obtaining a blade whole gray level image B; fusing the images A and B together to obtain a whole X-ray gray level original image without a lead wire; preprocessing the whole X-ray gray level original image and thus obtaining an X-ray detection image of the blade; further processing the X-ray detection image to obtain a binary image with outstanding defects, and building a two-dimensional coordinate system on the binary image, and carrying out location analysis on the existing internal defects; and finally, calculating amount of perimeter pixels and amount of area pixels of the defects in the binary image, thus obtaining actual defect size through conversion, and carrying out qualitative and quantitative analysis on the existing internal defects. The method provided by the invention realizes rapid and automatic extraction and analysis on internal defects of the blade.

Owner:XI AN JIAOTONG UNIV

Perambulated inspection system and method

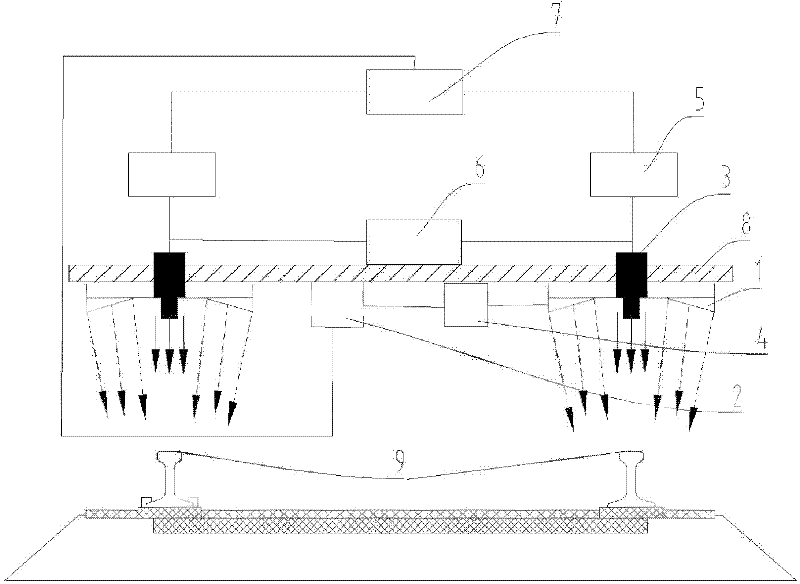

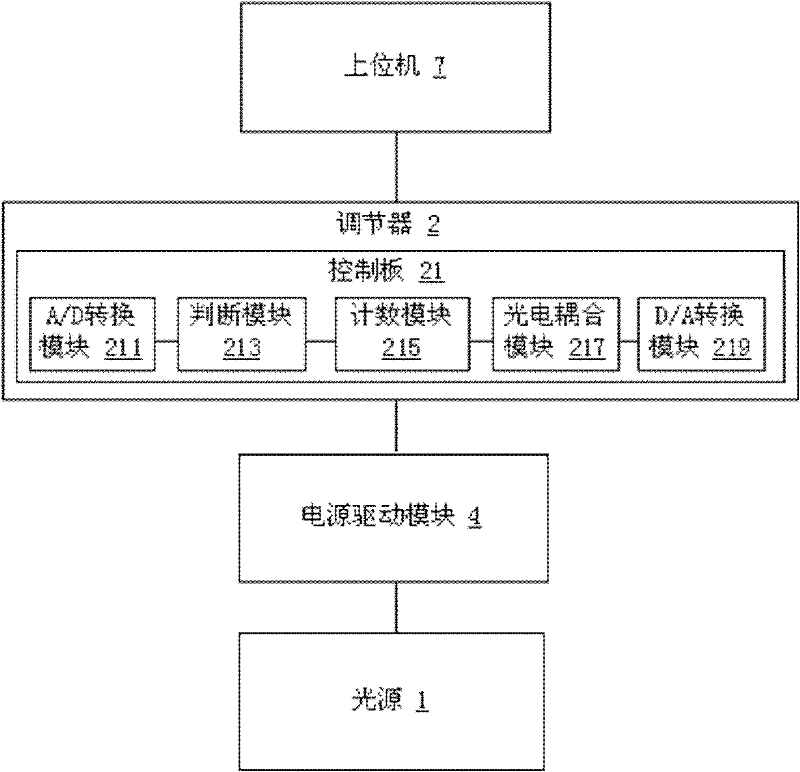

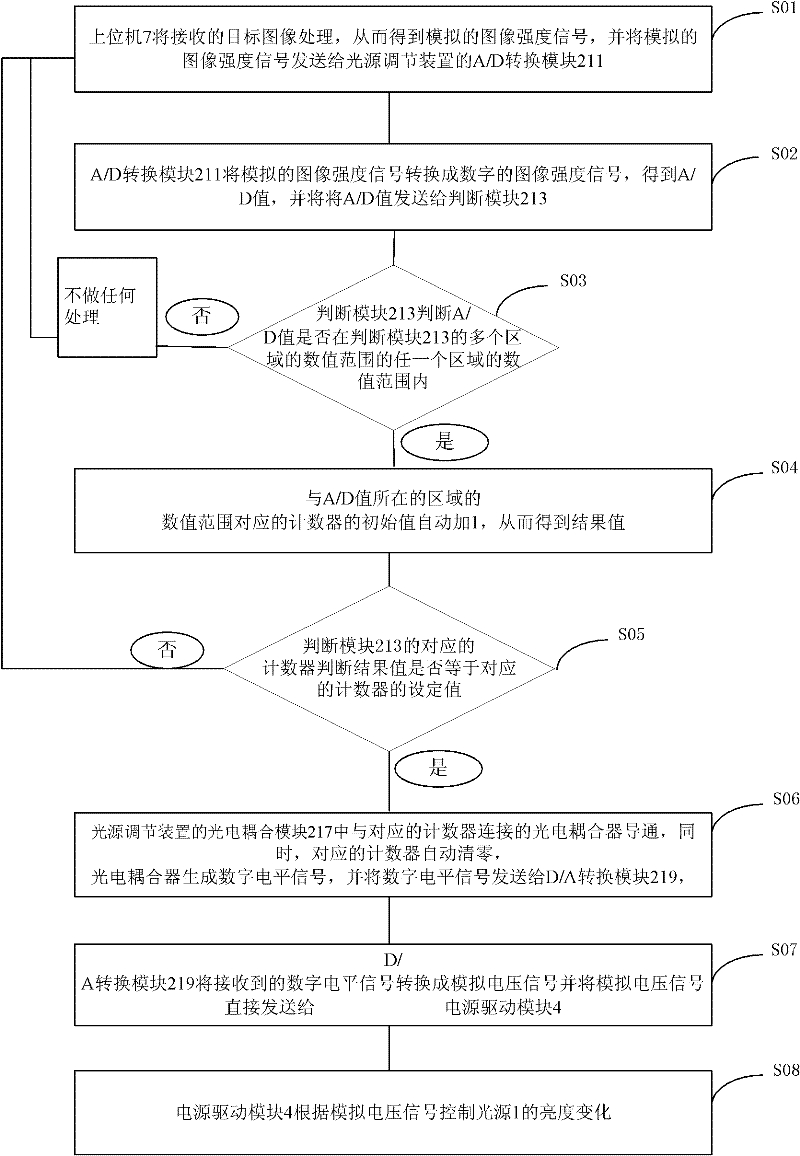

ActiveCN102507587AHigh inspection efficiencyHigh defect size detection accuracyOptically investigating flaws/contaminationUsing optical meansDefect sizeComputer graphics (images)

The invention provides a perambulated inspection system and method, wherein the perambulated inspection system comprises an installation frame, an upper computer, a plurality of cameras and a plurality of light sources; the cameras and the light sources are arranged on the installation frame; the installation frame is arranged above a target object and can move relative to the target object; the light sources are used for irradiating the target object; the cameras are used for shooting target object images so as to obtain target images; the cameras are used for sending the target images to the upper computer; and the upper computer is used for analyzing and processing the target images. According to the perambulated inspection system and method, disclosed by the invention, the effects of high efficiency on track perambulated inspection, accurate track defect positioning and high accuracy on defect size inspection can be achieved.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +1

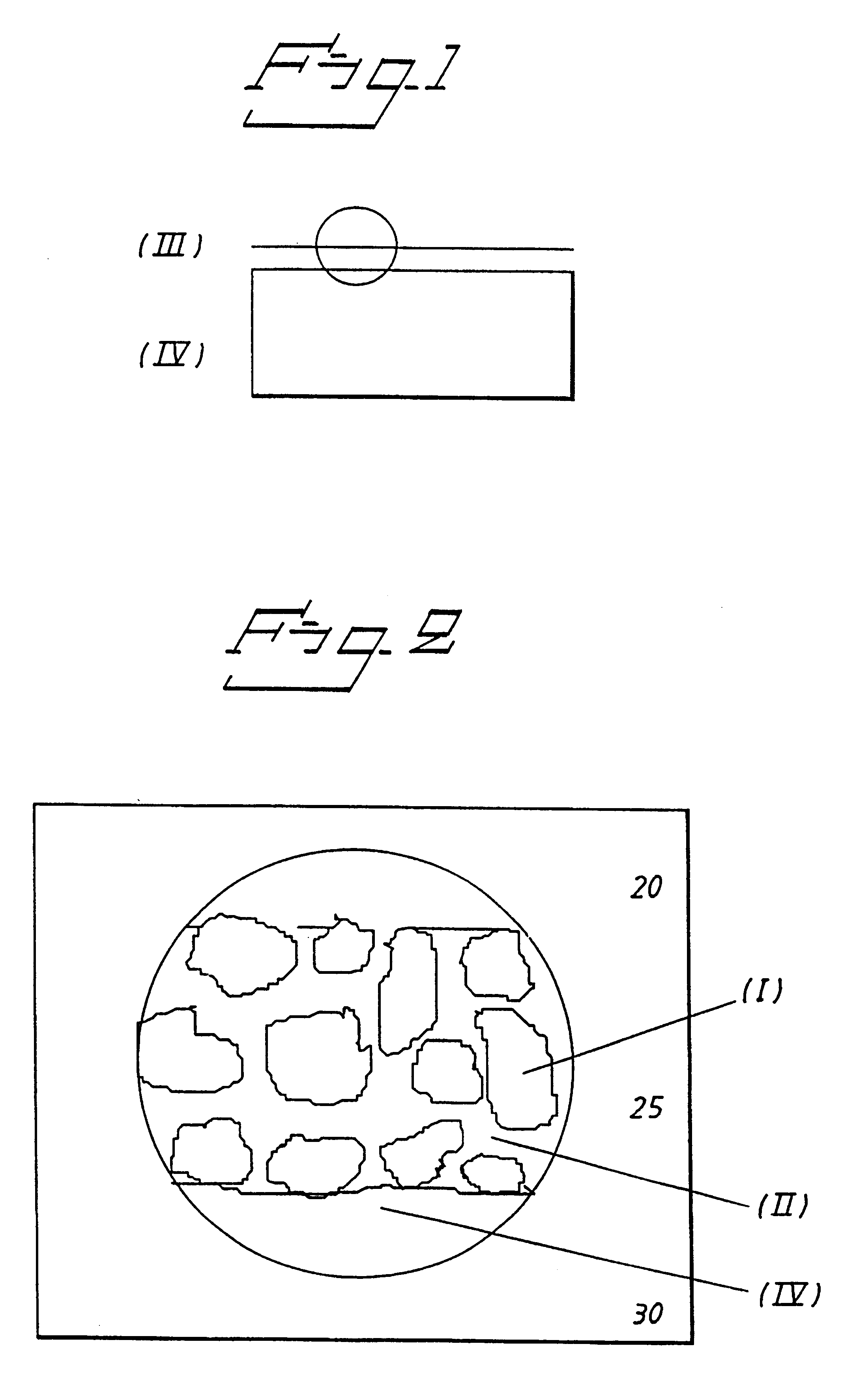

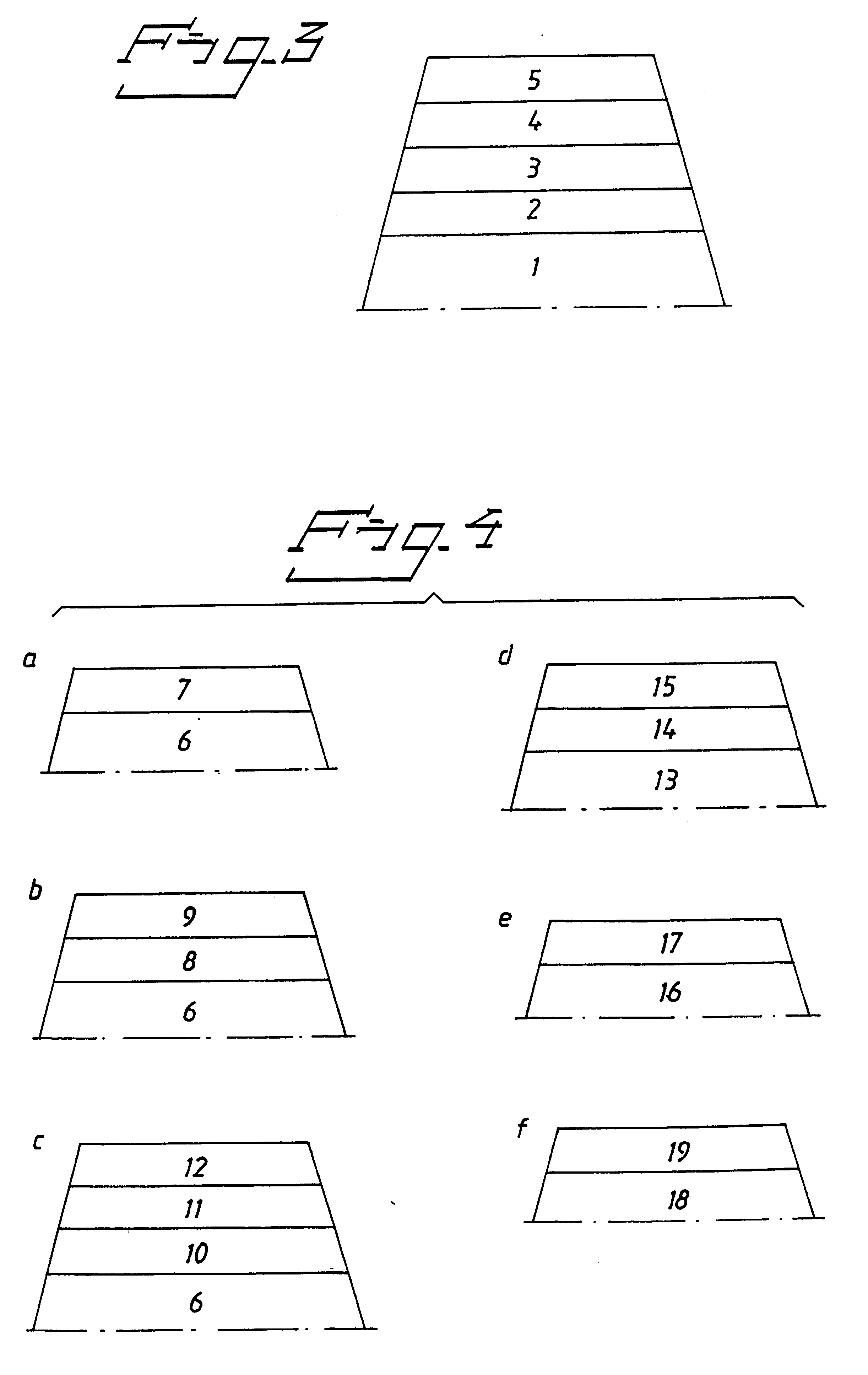

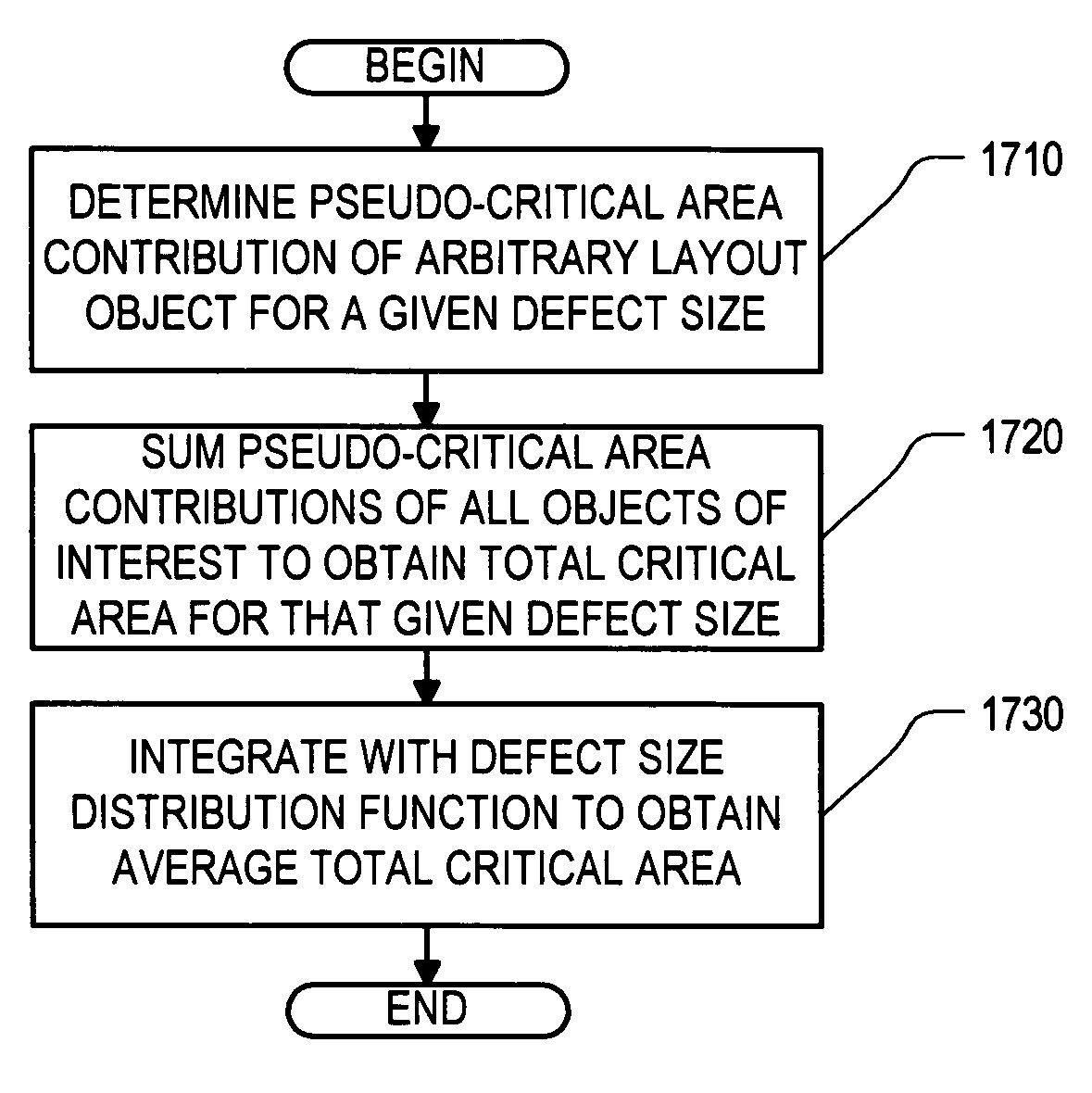

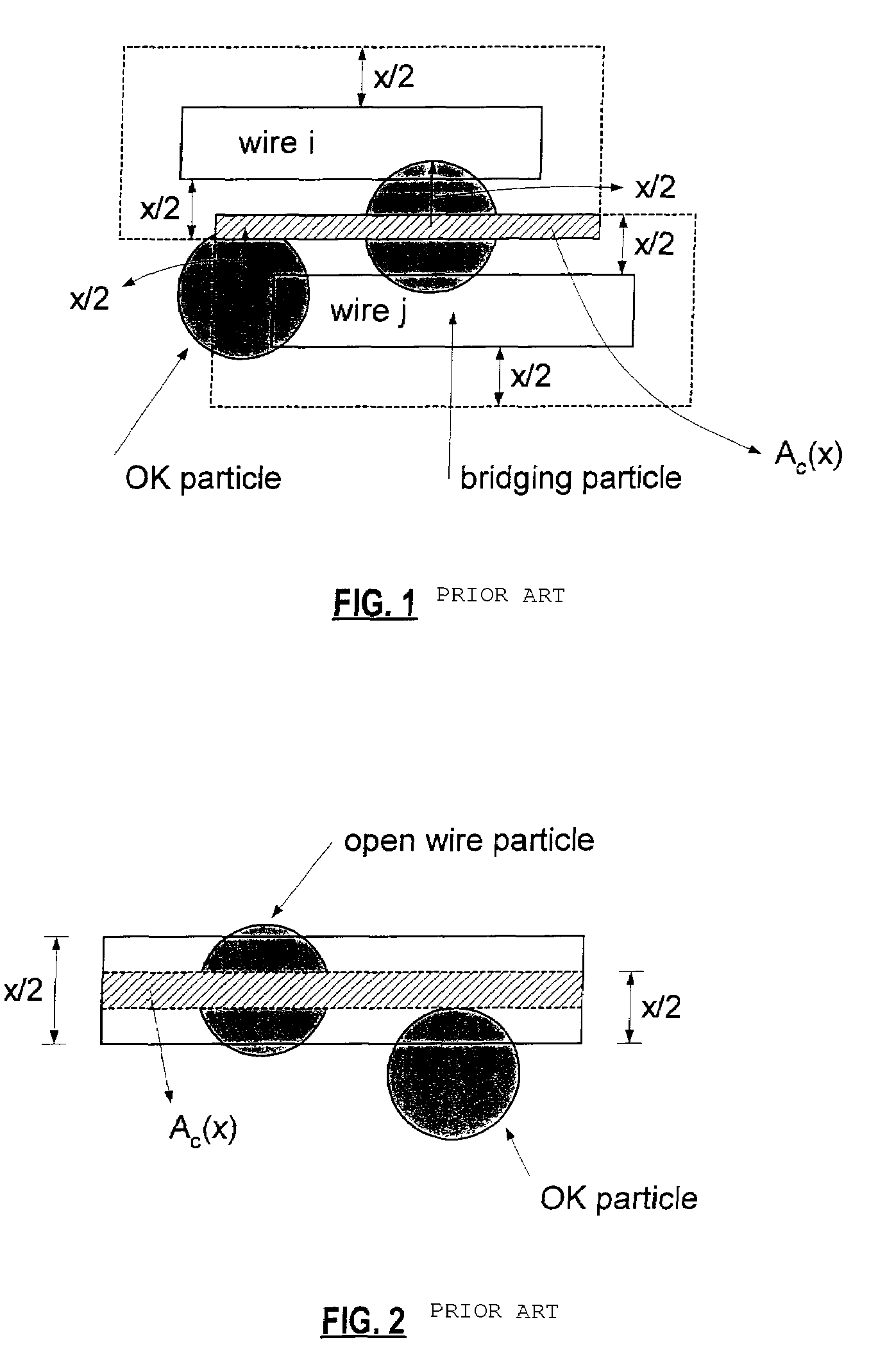

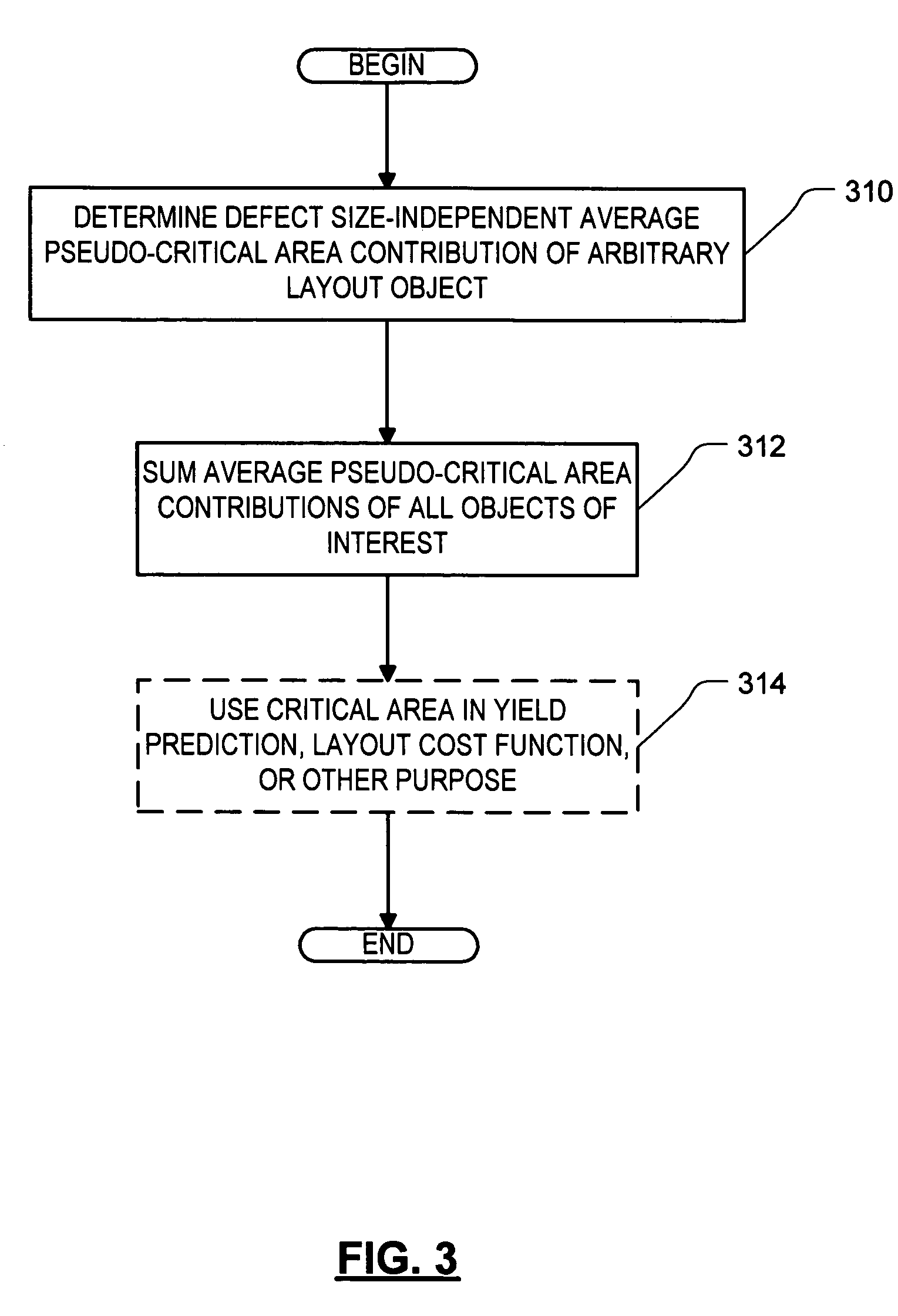

Fast evaluation of average critical area for IC layouts

ActiveUS7346865B2Computation using non-denominational number representationCAD circuit designDefect sizeEngineering

Method and apparatus for approximating the average critical area of a layout or layout region, involving summing, over all the object segments of interest, respective critical area contribution values that are dependent upon particular layout parameters of the objects, each of the contribution values being representative of a plurality of defect sizes, and being defined such that for each defect size in the plurality of defect sizes, and for a particular defect type, the contribution values collectively count all critical areas arising due to the object segments of interest only once.

Owner:SYNOPSYS INC

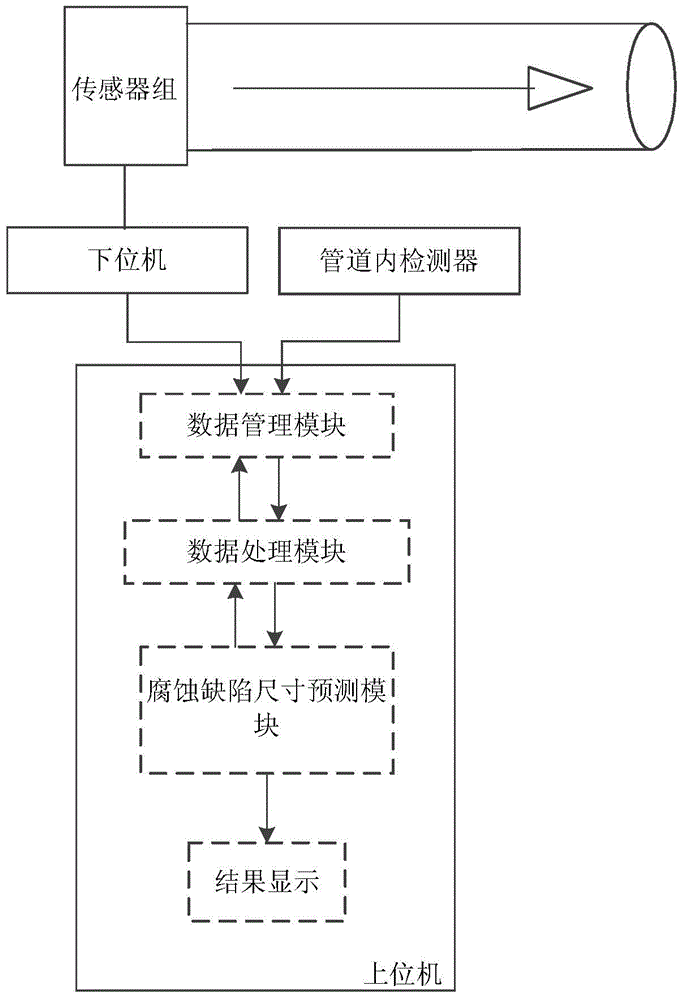

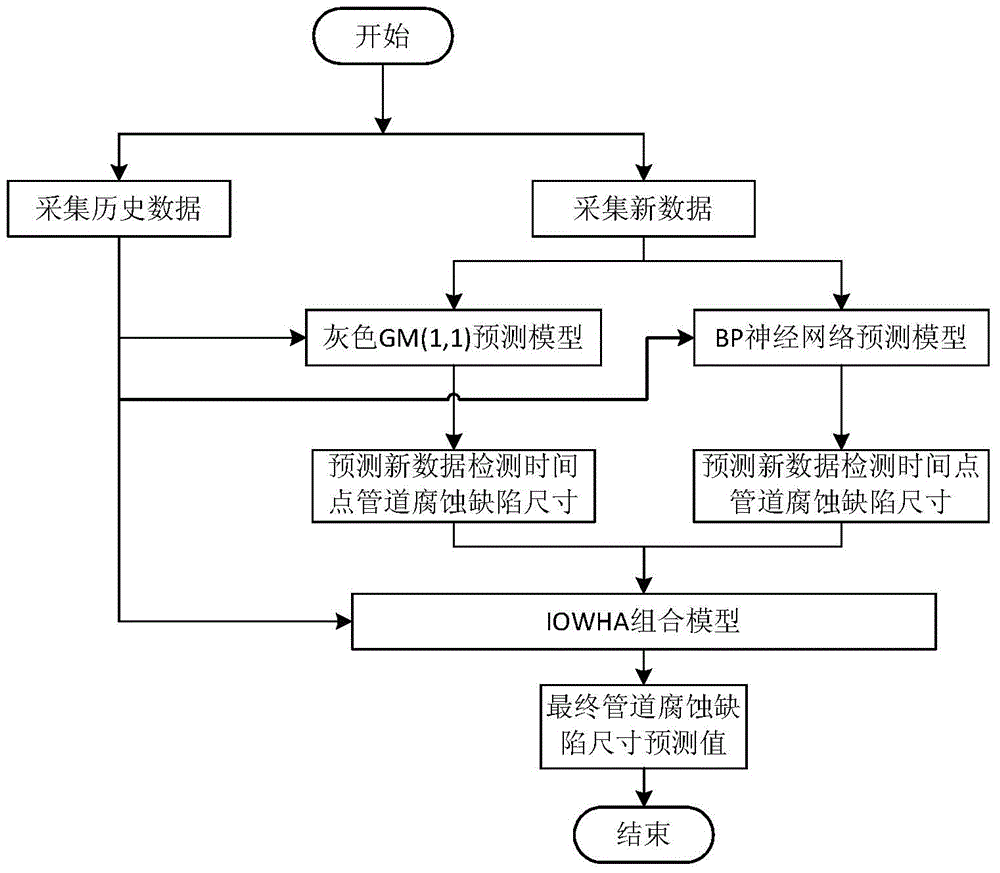

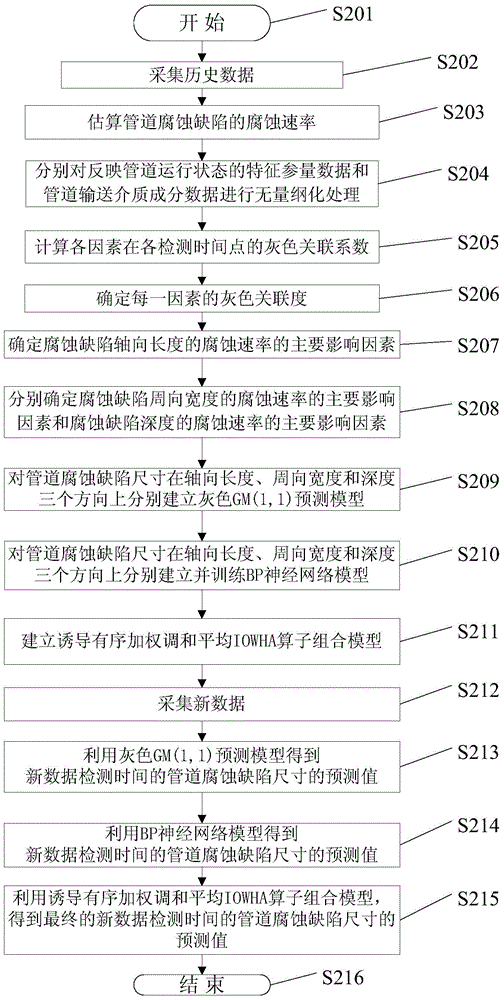

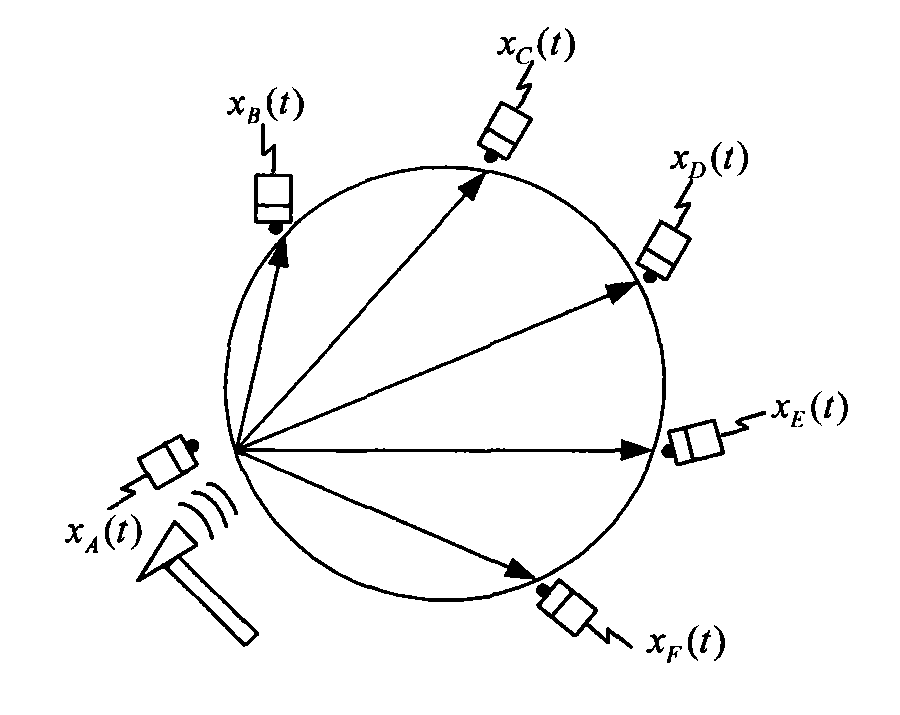

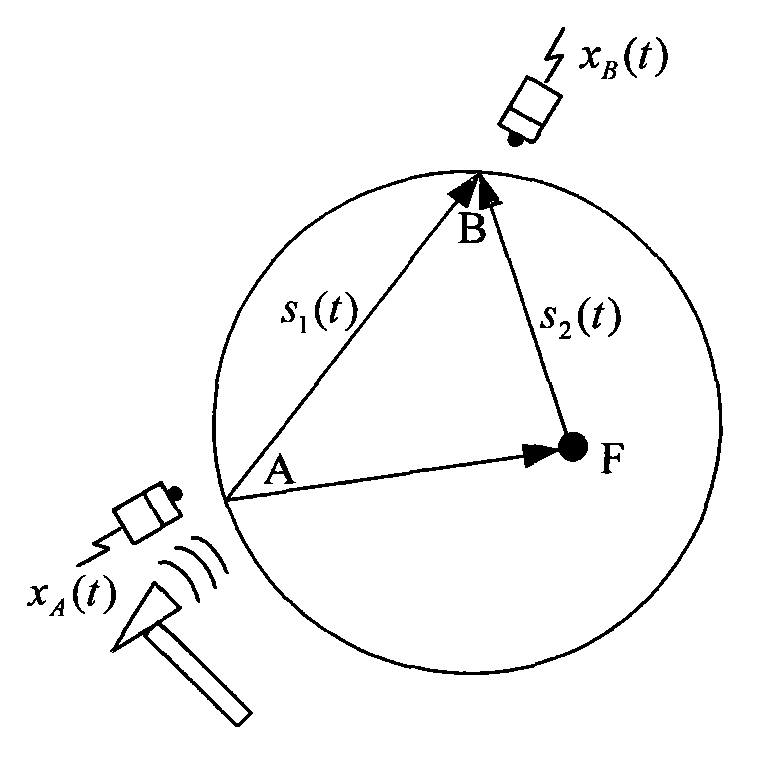

Multi-source data fusion-based system and method for predicting pipeline corrosion defect size

ActiveCN104063588AImprove accuracyAvoid direct detectionSpecial data processing applicationsDefect sizeAlgorithm

The invention discloses a multi-source data fusion-based system and method for predicting pipeline corrosion defect size. The system comprises a sensor group, a lower computer and an upper computer, wherein the sensor group is arranged at the head end or the tail end of a pipeline and is in contact with a transmission medium; the sensor group is connected with the lower computer connected with the upper computer. The method comprises the steps of firstly building a gray GM (1,1) prediction model and a BP neural network model by using historical data; then using the two models to obtain a prediction value; next building an inducted orderly weighted harmonic average (IOWHA) operator combination model according to the historical data and the prediction value of the two models; for new data, using the three models in sequence to predict the corrosion defect size in three directions of axial direction, circumference and depth respectively, so that a corrosion defect size prediction value of the pipeline is finally acquired. By adopting the system and the method, the prediction accuracy is higher, and the input of data is reduced.

Owner:NORTHEASTERN UNIV

Frequency characteristic-based nondestructive detection method of stress waves of wood

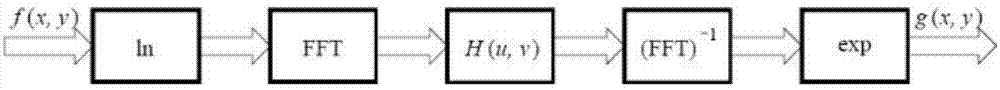

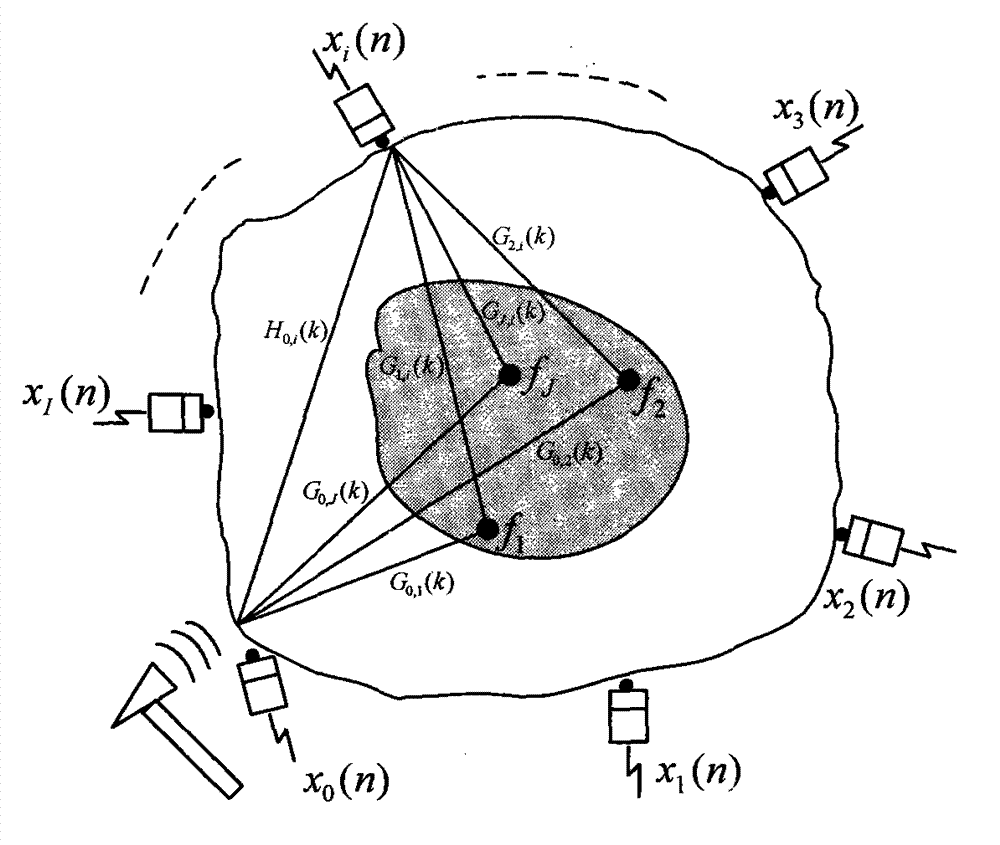

InactiveCN102928514AThe test result is accurateEasy to detectAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalFourier transform on finite groupsData acquisition

The invention discloses a frequency characteristic-based nondestructive detection method of stress waves of wood. The frequency characteristic-based nondestructive detection method comprises the following steps of: mounting piezoelectric type acceleration sensors around raw wood uniformly, knocking the No. 0 sensor by using a pulse hammer, and acquiring and storing output signals of the sensors by using a data acquisition card; carrying out K-point fast Fourier transform on the acquired signals and then solving an actual measurement frequency response function; establishing an observation matrix according to the actual measurement frequency response function and a frequency response function of healthy wood; carrying out blind source separation on the basis of second order statistic and establishing a frequency response function between a defect point and an observation point; and finally, judging whether the interior of the wood has defects as well as defect quantity and defect sizes according to a clustering result. The nondestructive detection method of the stress waves based on the frequency response function of the wood is not subject to interference from reflected wave and refracted wave signals and is more accurate in detection result, capable of automatically detecting information, such as whether the interior of the wood has defects as well as the defect sizes, and simple and convenient in detection process and strong in practicability.

Owner:ZHEJIANG FORESTRY UNIVERSITY

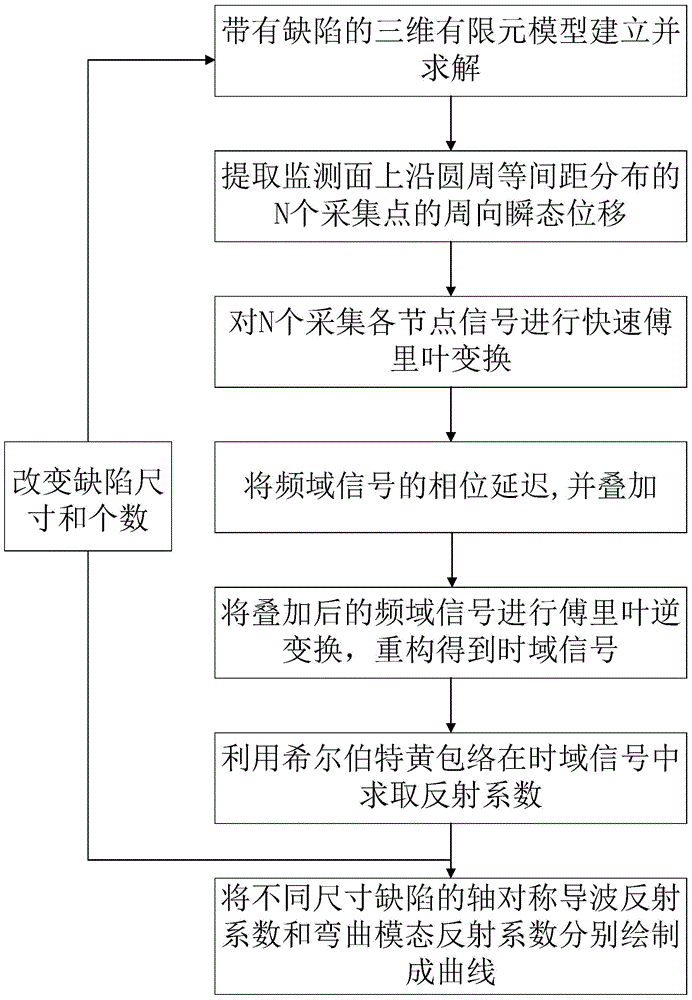

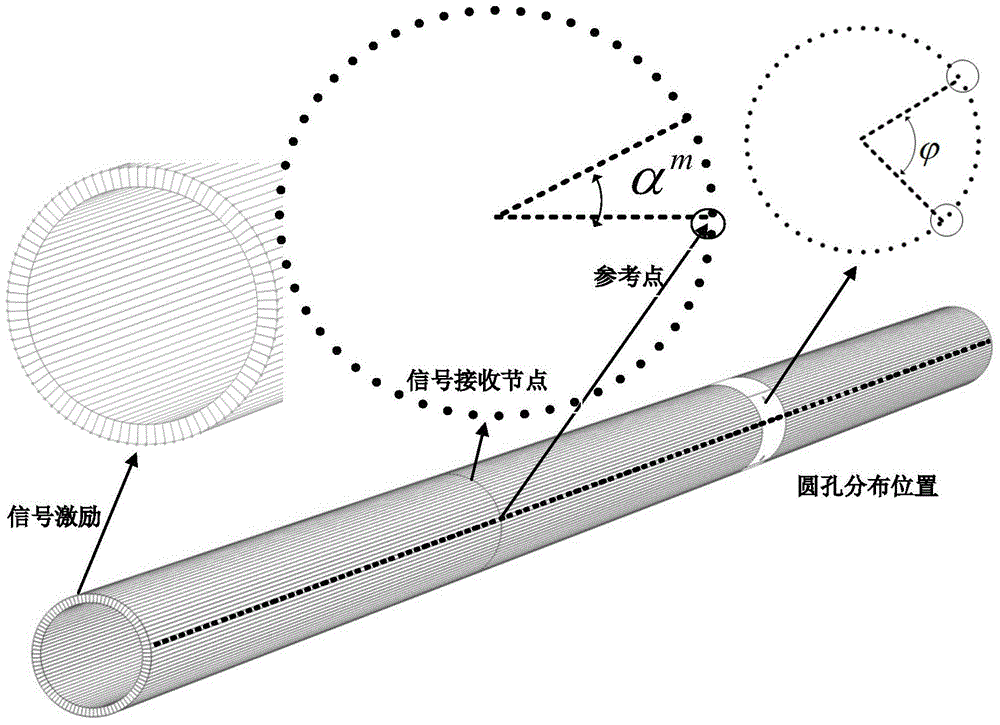

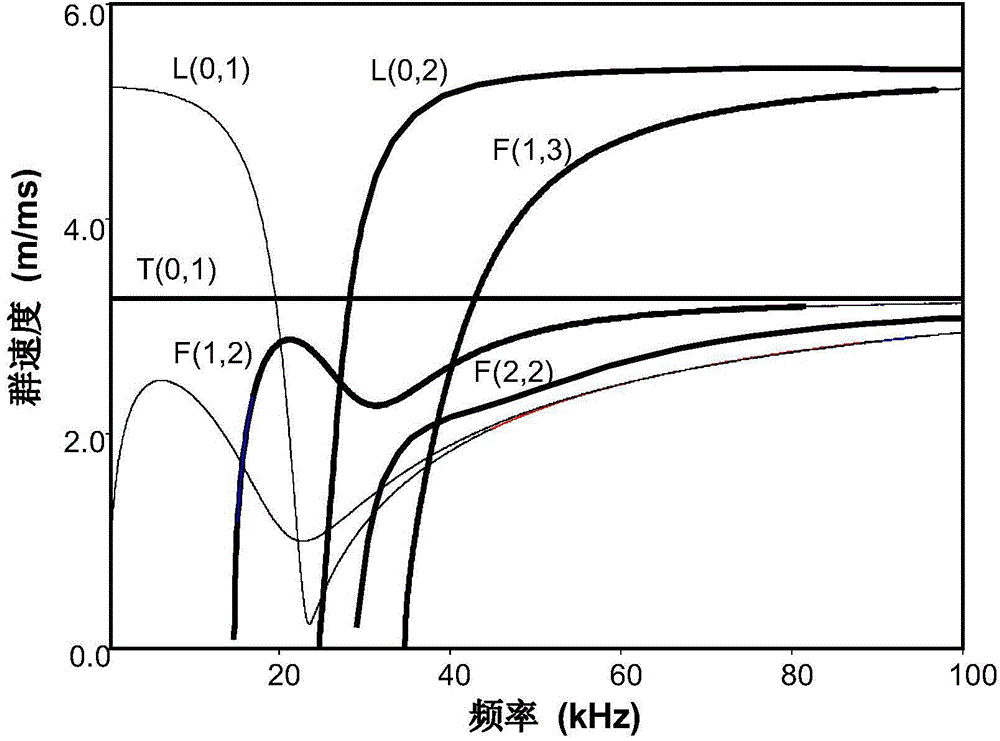

Ultrasonic guided-wave based calculation method for separating flexural mode reflected signal

ActiveCN104833729AGet reflection coefficientSave human effortProcessing detected response signalWave structureSonification

The present invention discloses a calculation method for separating symmetric and flexural mode wave packet and extracting weak signal of the bending mode. Based on the wave structure characteristic theory of axisymmetric mode and bending mode, the method uses finite element software to establish correlative model, extracts transient displacement signal of signal acquisition nodes of a guided-wave monitoring surface, and conducts delay superimposing on the collected signals on the frequency domain in accordance with relative formula; then the superimposed frequency domain signal is subjected to the inverse Fourier transform to obtain guided-wave mode wave packet of each order after separation; and Hilbert-Huang envelope is employed to calculate reflection coefficient for each mode. The method uses secondary development function of finite element software to compile the secondary development program, quantitatively analyze the influence degree of the parameters such as characteristics of defect size, location distribution, the number of defects and the center excitation frequency on the amplitude value of the flexural mode reflection echo generated from the defect locations through modal conversion, thereby integrally utilize reflection coefficients of axisymmetric mode and bending mode to evaluate the distribution of defect locations.

Owner:BEIJING UNIV OF TECH

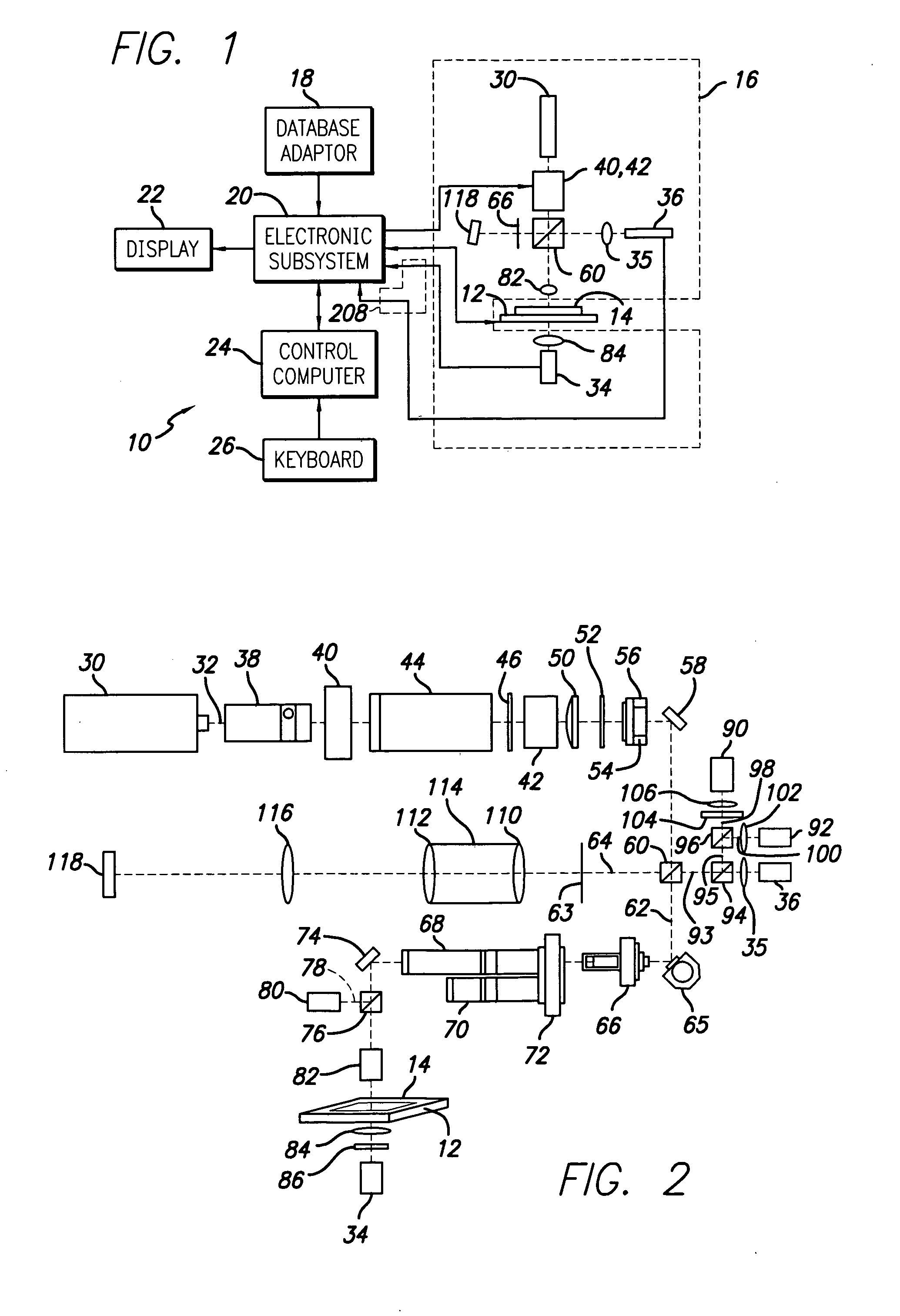

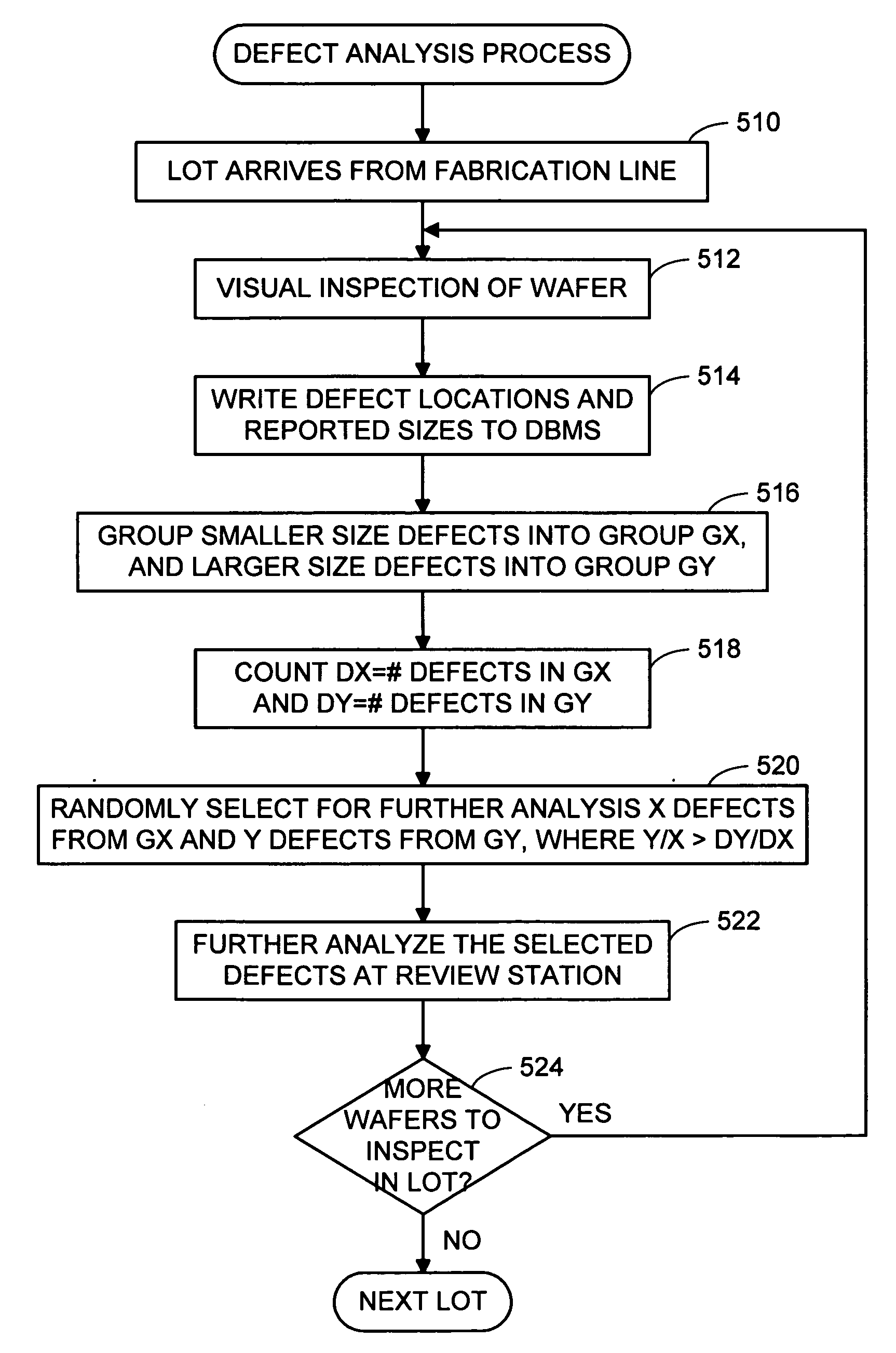

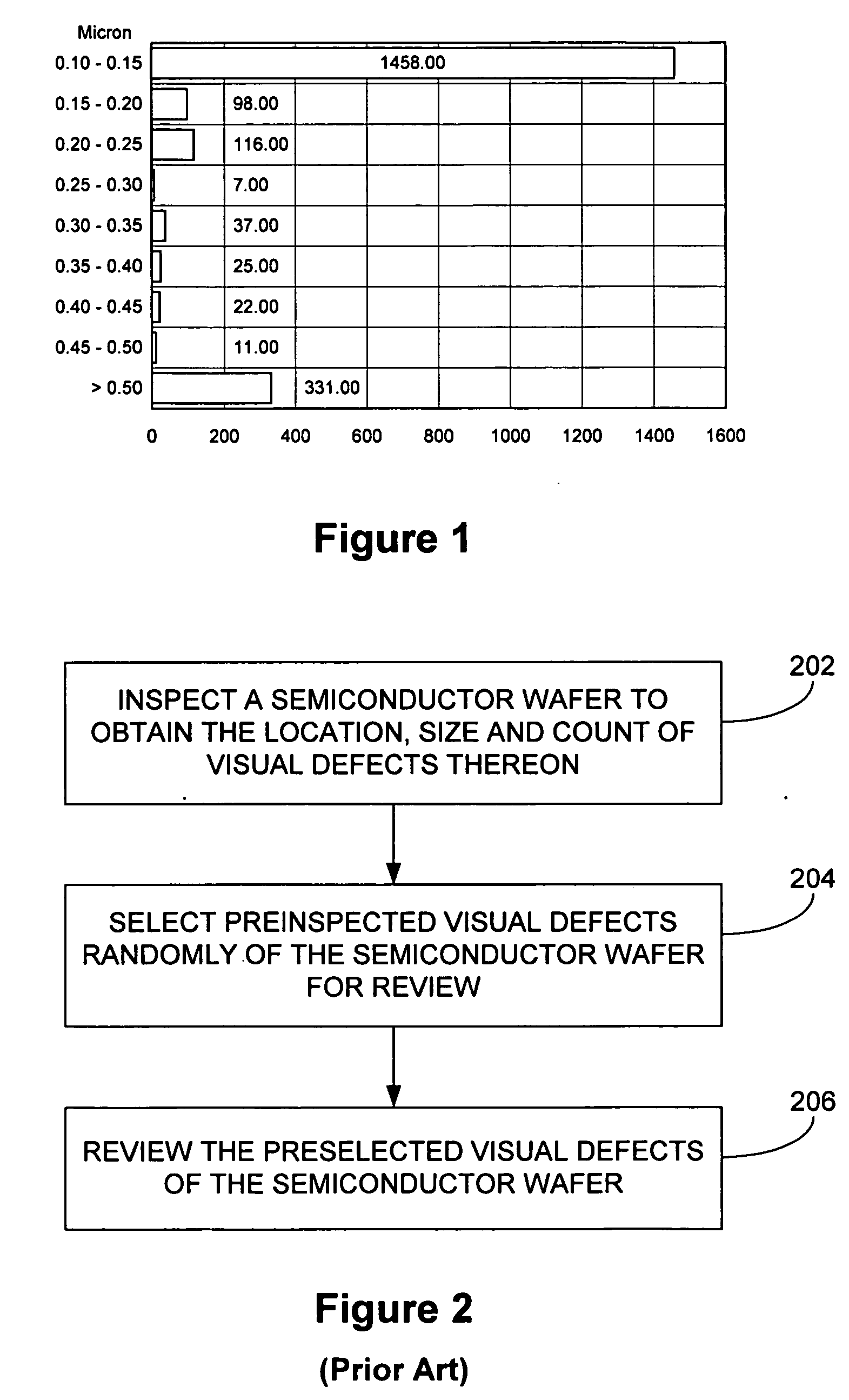

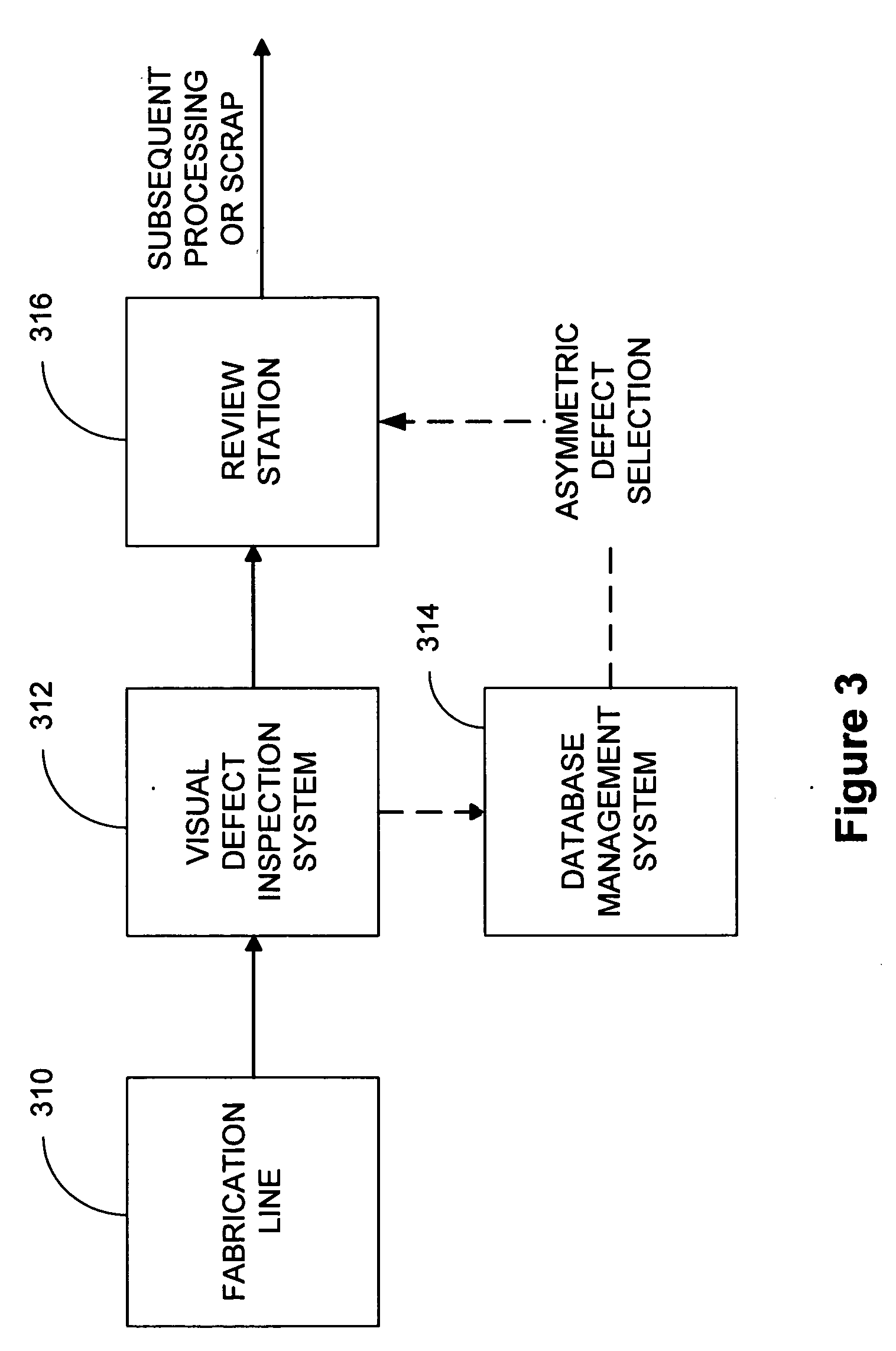

Method and system for analyzing defects of an integrated circuit wafer

ActiveUS20050210423A1Efficient analysisHigh yield-killing defectsSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingDefect sizeEngineering

Method and apparatus for efficiently analyzing visual defects of an integrated circuit wafer in the manufacturing process thereof by utilizing an asymmetric visual defect review methodology that can effectively extract high yield-killing defects out of numerous reported defects within the limited capacity and manpower available for review. Roughly described, the method comprises inspecting the semiconductor wafer, thereby obtaining the defect location and defect size, sampling the defects asymmetrically by determining asymmetrical defect review ratios, and thereby reviewing the defects asymmetrically. Also described is a method of asymmetrically sampling visual defects that can effectively extract out high yield-killing defects from a mass of defects by determining asymmetric defect review ratios, and a system for use in sampling visual defects asymmetrically.

Owner:MACRONIX INT CO LTD

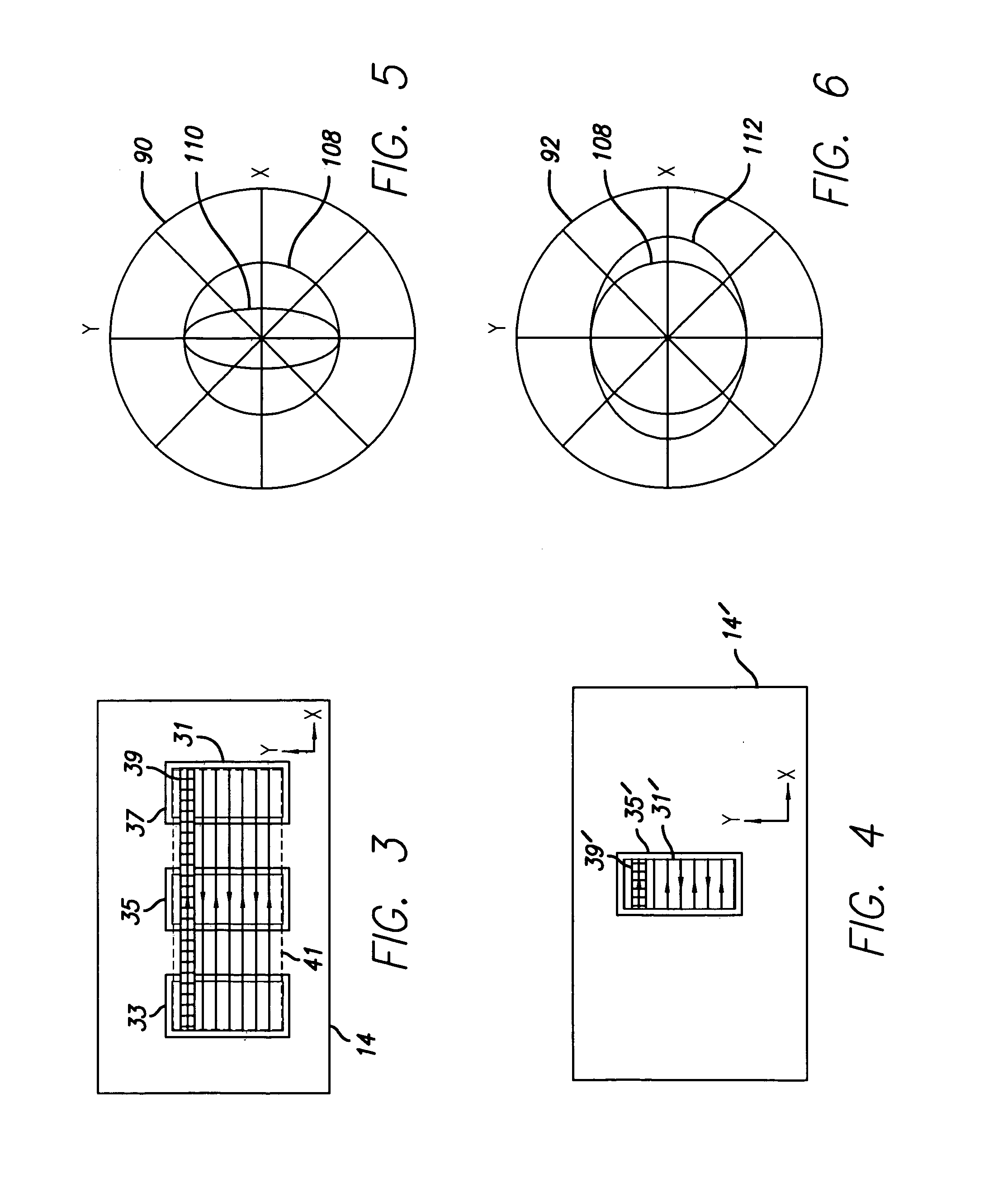

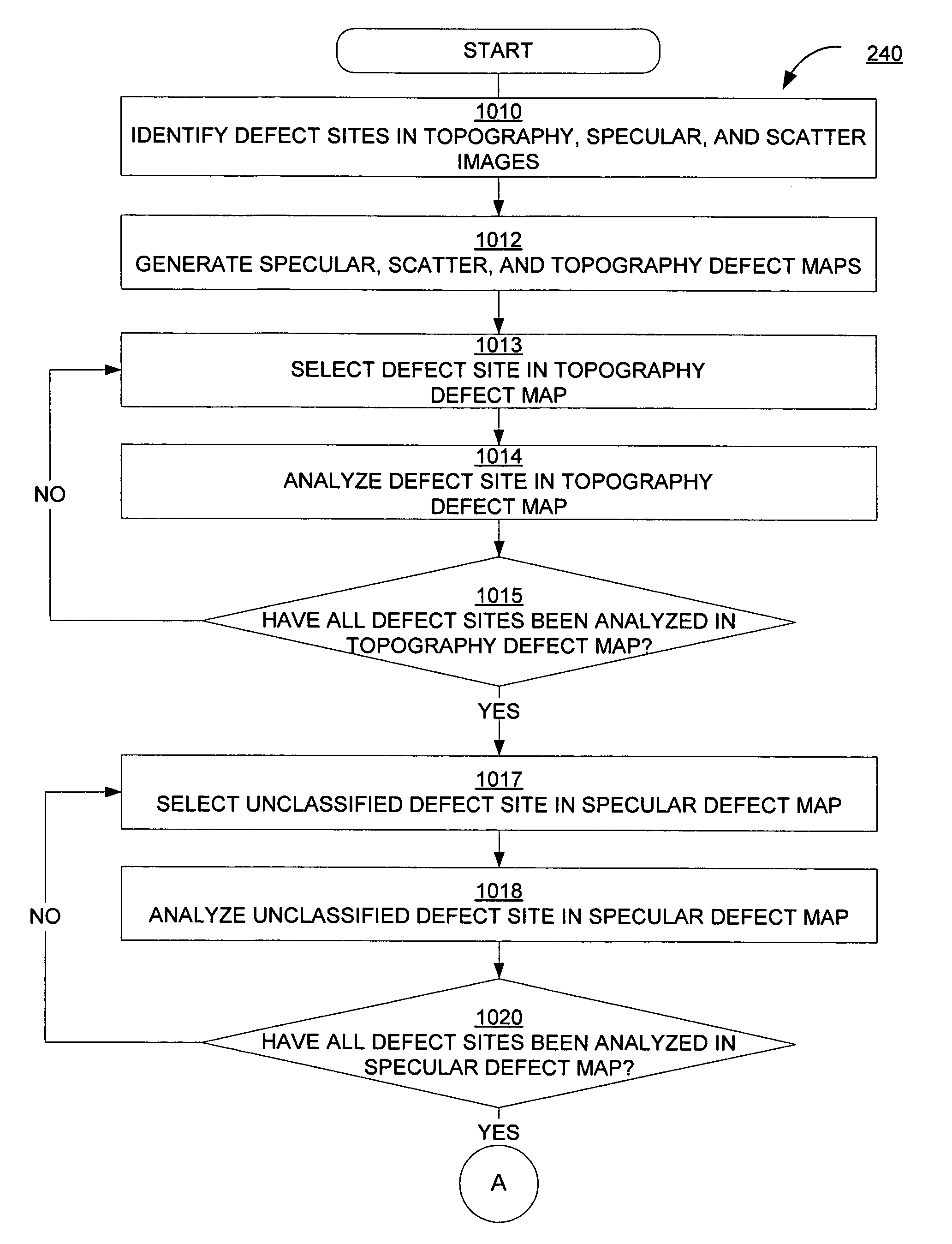

System and method for classifying, detecting, and counting micropipes

ActiveUS7201799B1Accurate measurementOvercome limitationsPolycrystalline material growthAfter-treatment detailsDefect sizeNon invasive

An automated, non-invasive method for classifying, detecting, and counting micropipes contained within silicon wafers, and generally any assortment of transparent wafers. Classifying, detecting, and counting micropipes takes place through the use of a data processing algorithm that incorporates information regarding: defect size; pit signature; area of pit signature when comparing a topography, specular, or scatter images; and detecting a tail within the standard pit signature. The method of the present invention teaches the development of a topography defect map, specular defect map, and scatter defect map for a complete analysis of the surface of a particular transparent wafer. Conventional detection, classification, and counting of micropipes involve characterization of micropipes in a manual fashion and rely upon an extremely invasive form of sample preparation. The method disclosed in the present invention is completely automated and non-invasive with regards to the treatment of the transparent wafer to be analyzed.

Owner:KLA TENCOR TECH CORP

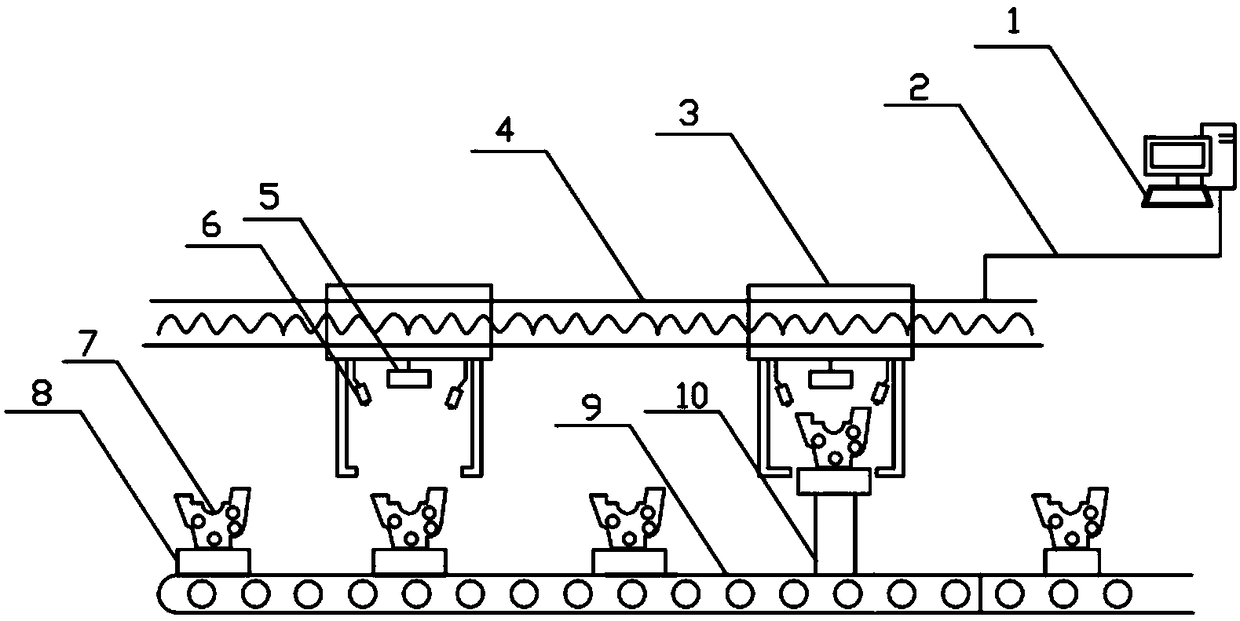

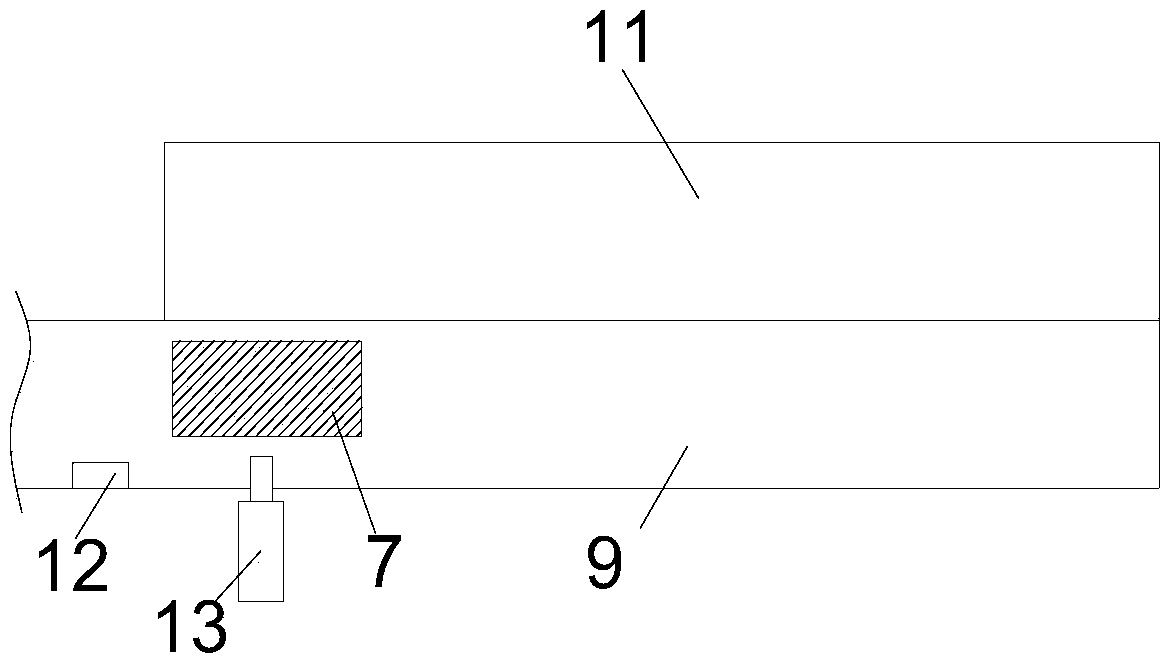

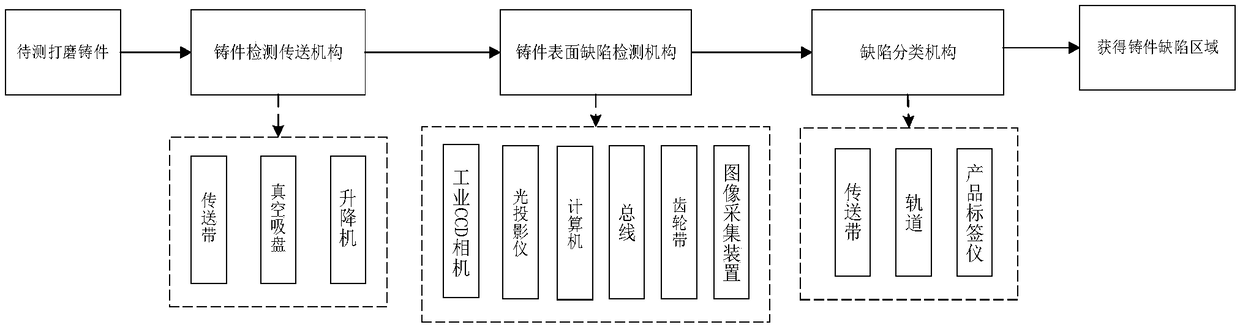

Casting polishing quality test method and device and application method of device

ActiveCN109115785AOvercome the problem of low quality inspection efficiencySolve the low detection efficiencyOptically investigating flaws/contaminationDefect sizeCcd camera

The invention discloses a casting quality test method and device and an application method of the device. The casting quality test device comprises three parts including a casting test conveying mechanism, a casting surface defect test device and a defect identification and classification mechanism, wherein the casting test conveying mechanism can be used for fixing a polished casting to be testedon a vacuum suction disc; the polished casting to be tested is conveyed into the casting surface defect test device through a conveyor belt; the device mainly applies a digital image processing technology, and a mounted industrial CCD (Charge Coupled Device) camera is used for acquiring an image; and a digital image processing algorithm designed on a background is used for carrying out defect identification on a casting surface polishing image. In an identification process, surface defect positions of the casting need to be obtained, and defect size and area also need to be calculated, so that defect grades are judged and classification of defect types is realized. A parameter report is generated according to a final identification result and a tested casting body is marked; and castingswith qualified polishing and castings with unqualified polishing are classified and output through the defect identification and classification mechanism.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Method and system for monitoring partial discharge in gas-insulated apparatus

ActiveUS7388384B2Reduce maintenance costsFailure conditionTesting dielectric strengthFault location by conductor typesForeign matterDefect size

A gas-insulated apparatus is equipped with multiple sensors for sensing a partial discharge signal caused by a foreign substance, and a frequency analyzing section for analyzing the frequency of the sensed partial discharge signal. A defect type judging section estimates the defect type of the foreign substance from the signal obtained through the frequency analysis or from the voltage phase distribution of partial discharge synchronized with the frequency of the voltage applied to the gas-insulated apparatus, and a location determining section estimates the defect location and signal intensity from the multiple partial discharge signals. A defect size calculating section estimates the defect size for each defect type from the signal intensity and field distribution at the defect location. Dielectric breakdown risk evaluation is performed based on the defect size and type, and the insulation failure risk is diagnosed from the partial discharge.

Owner:JAPAN AE POWER SYST

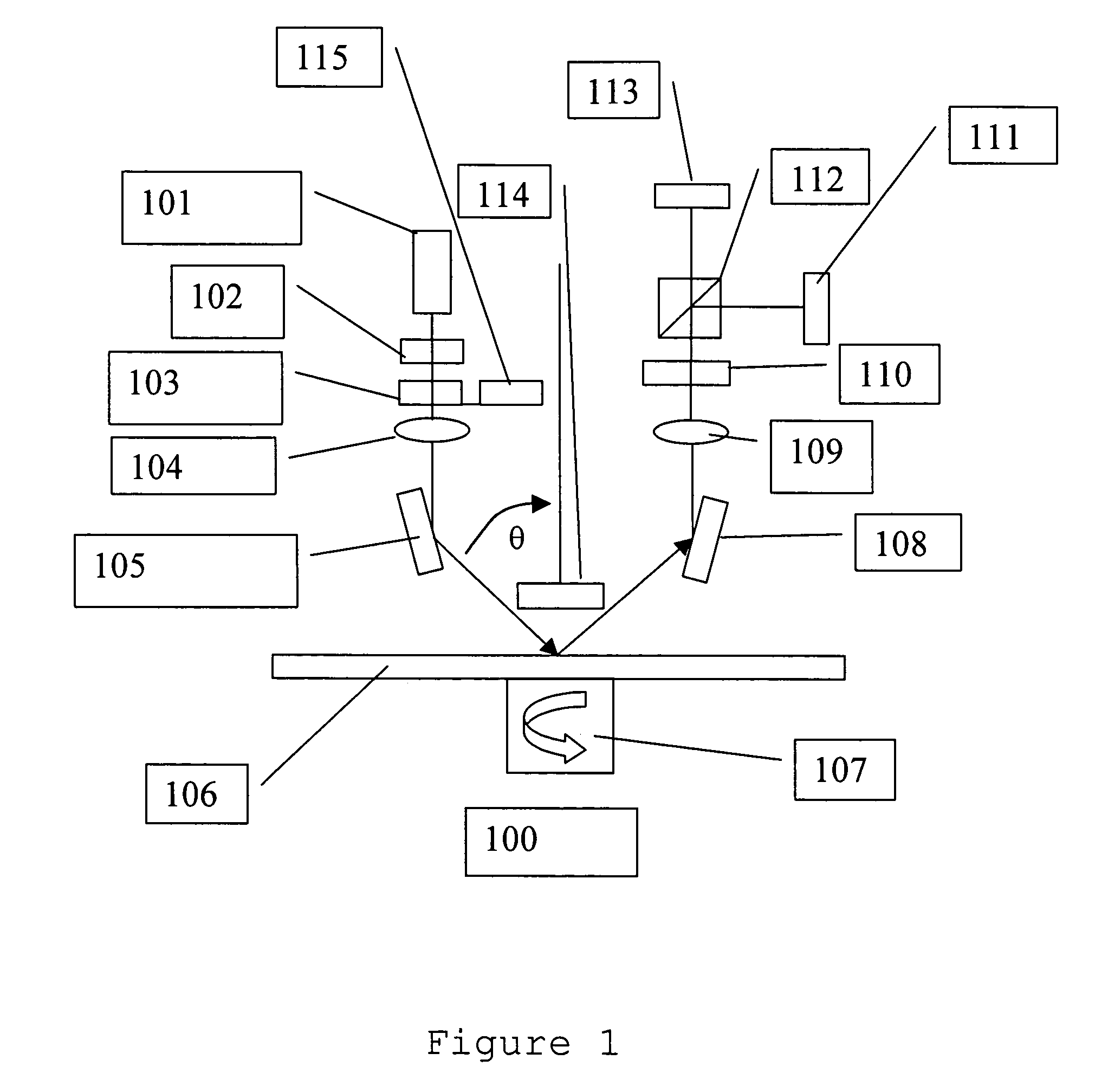

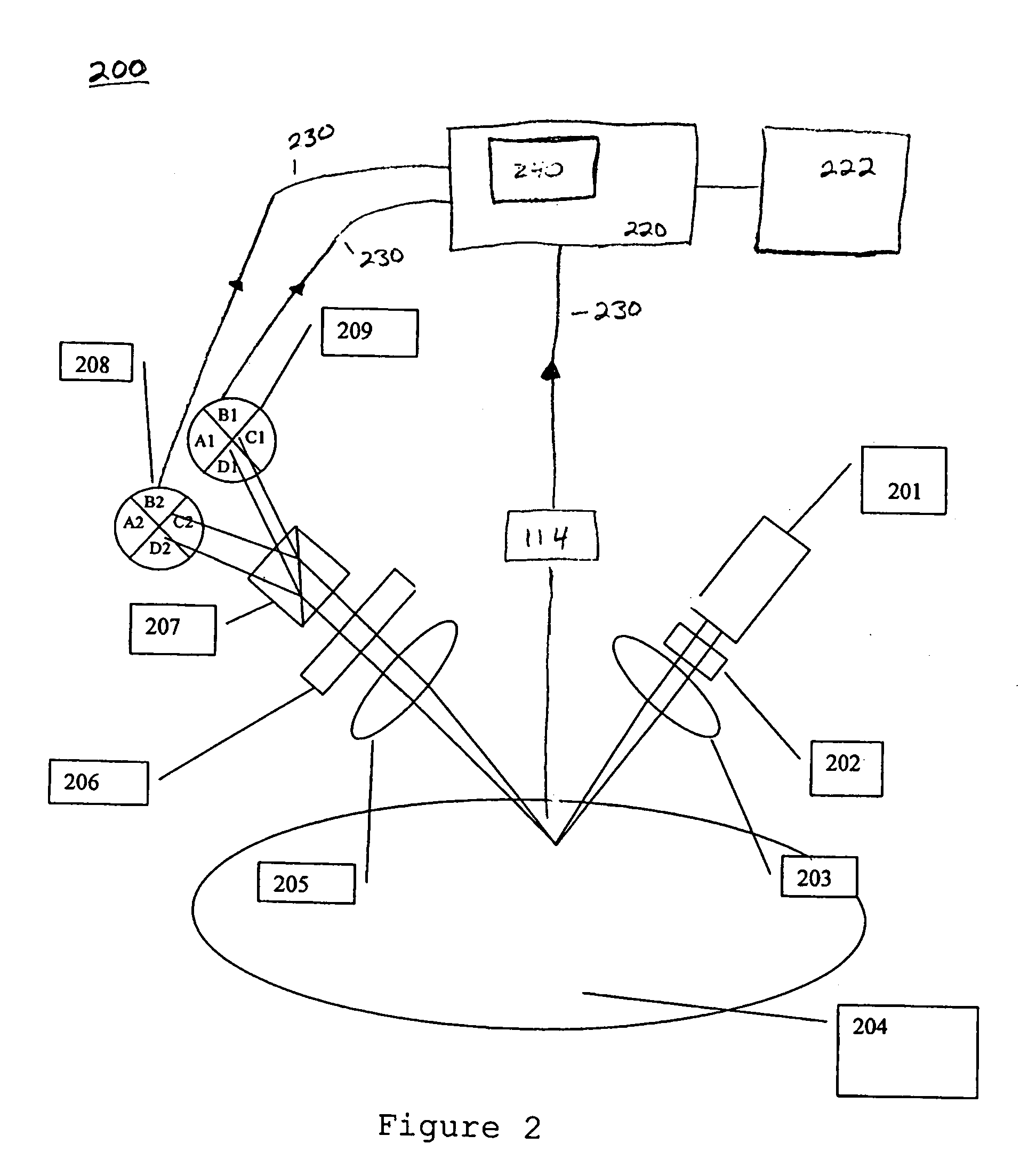

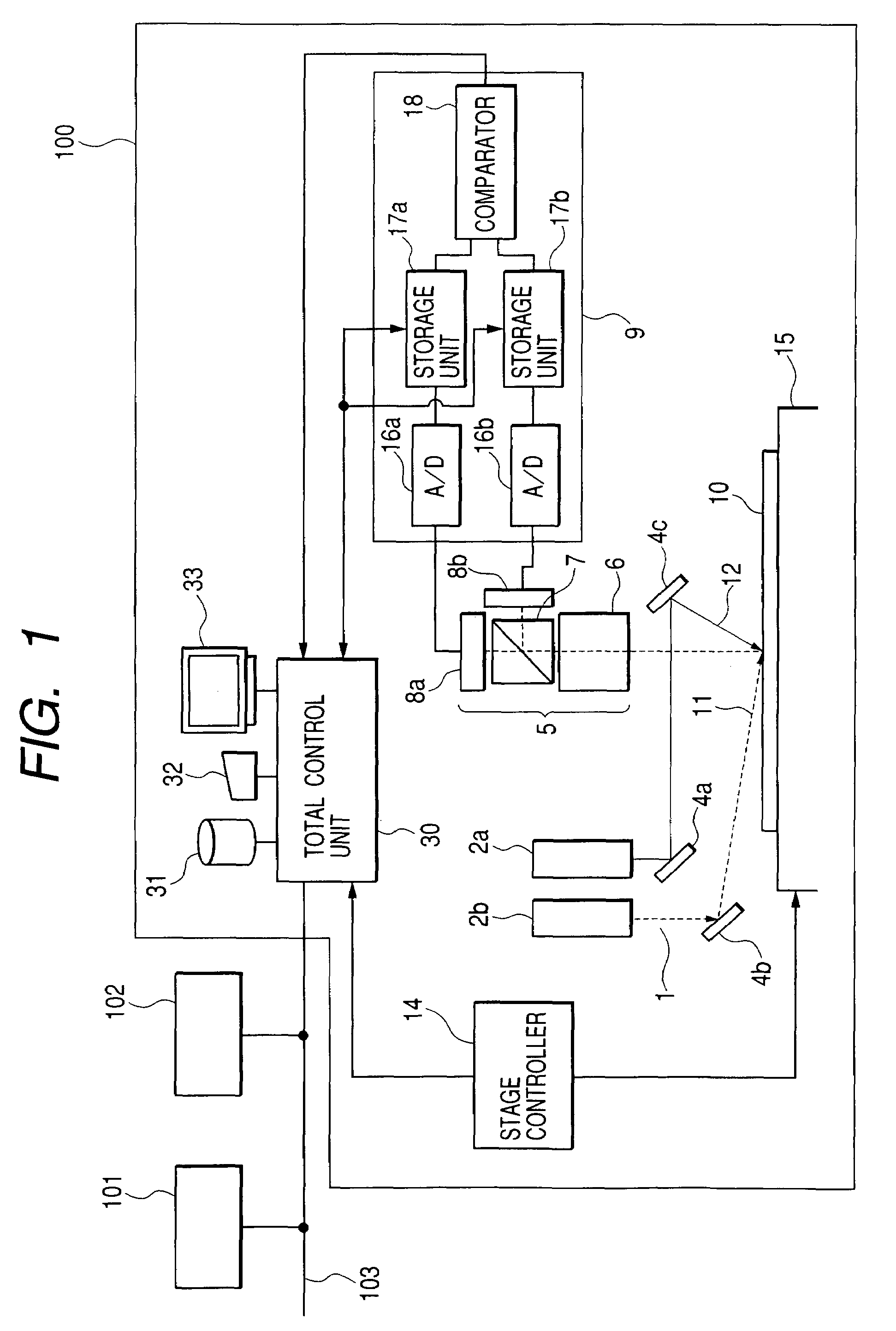

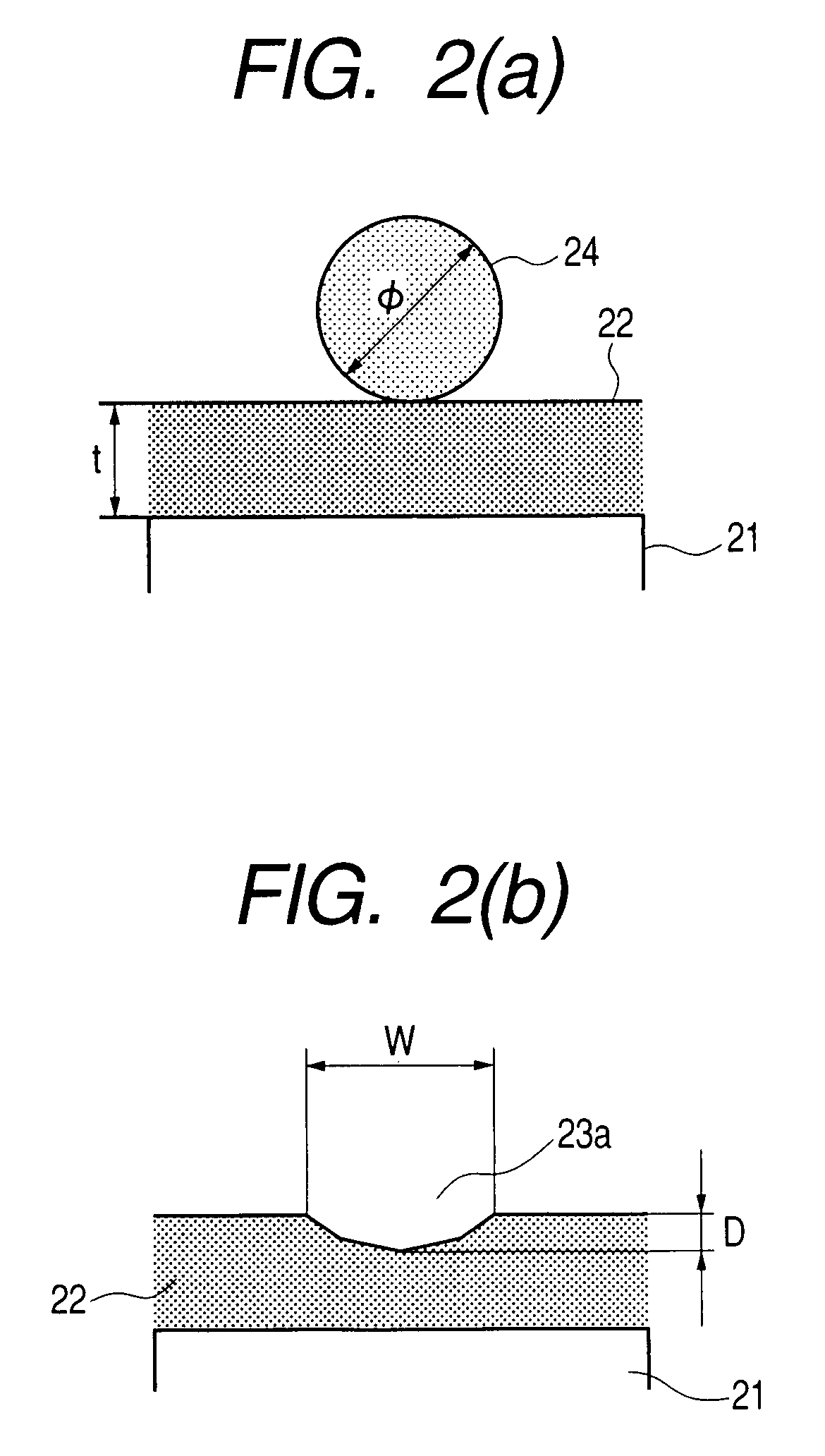

Apparatus and method for inspecting defects

InactiveUS7315366B2Improve reliabilityImprove efficiencyImage analysisSemiconductor/solid-state device testing/measurementDefect sizeHigh angle

A defect-inspecting apparatus including an arrangement to convert detected light into a first signal corresponding to light illuminated by a high-angle illumination optical system and / or a second signal corresponding to light illuminated by a low-angle illumination optical system; and a classification unit which utilizes the first and second signal and classifies defects on the object to be inspected, wherein a defect size is estimated by changing a correction coefficient of the defect size on a basis of a concave-convex level (b / a), where the concavo-convex level (b / a) of a defect is indicated by a ratio of a size b of a first direction of the defect to a size a of a second direction of the defect, where the second direction is lateral to the first direction.

Owner:HITACHI HIGH-TECH CORP

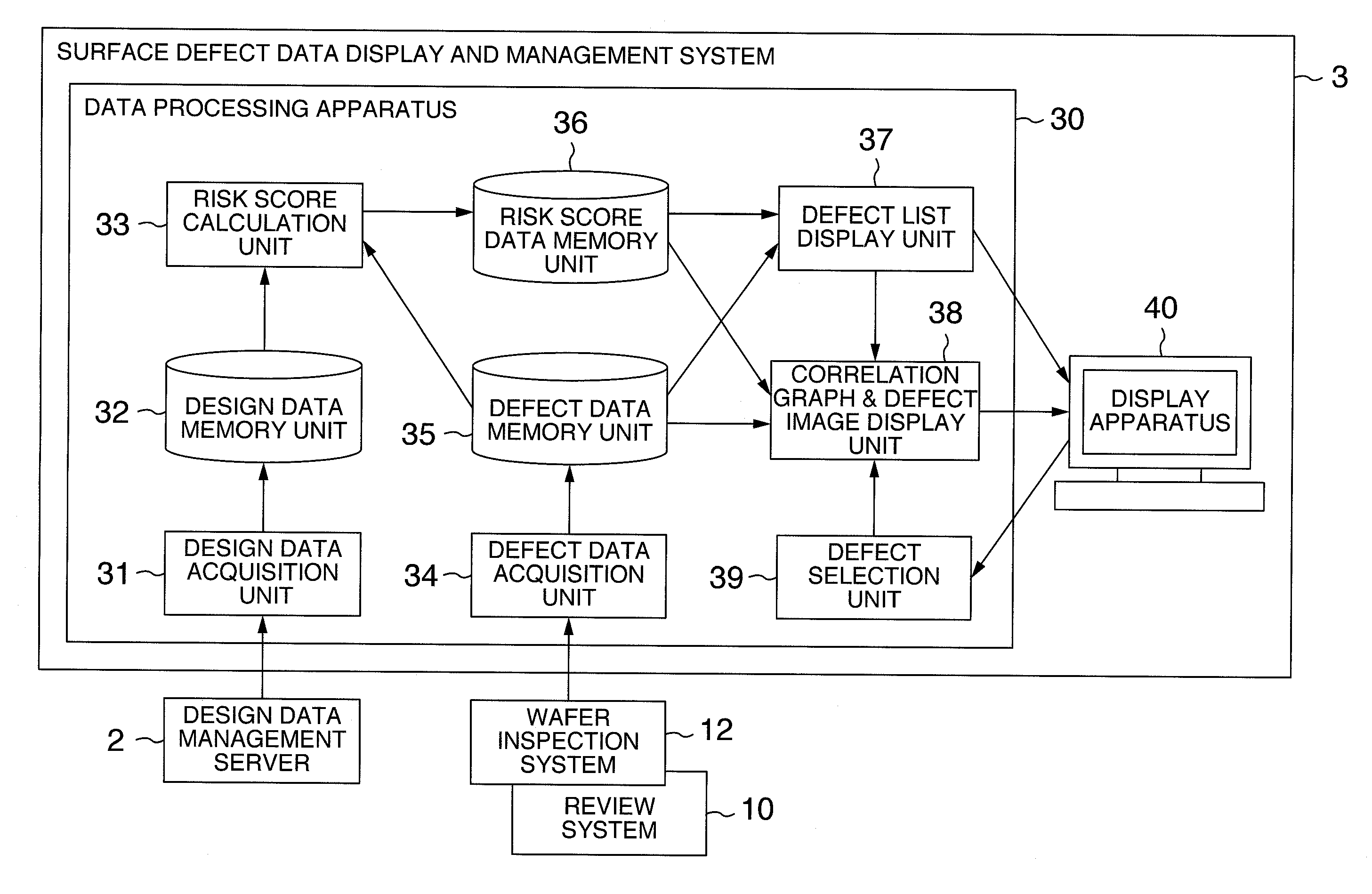

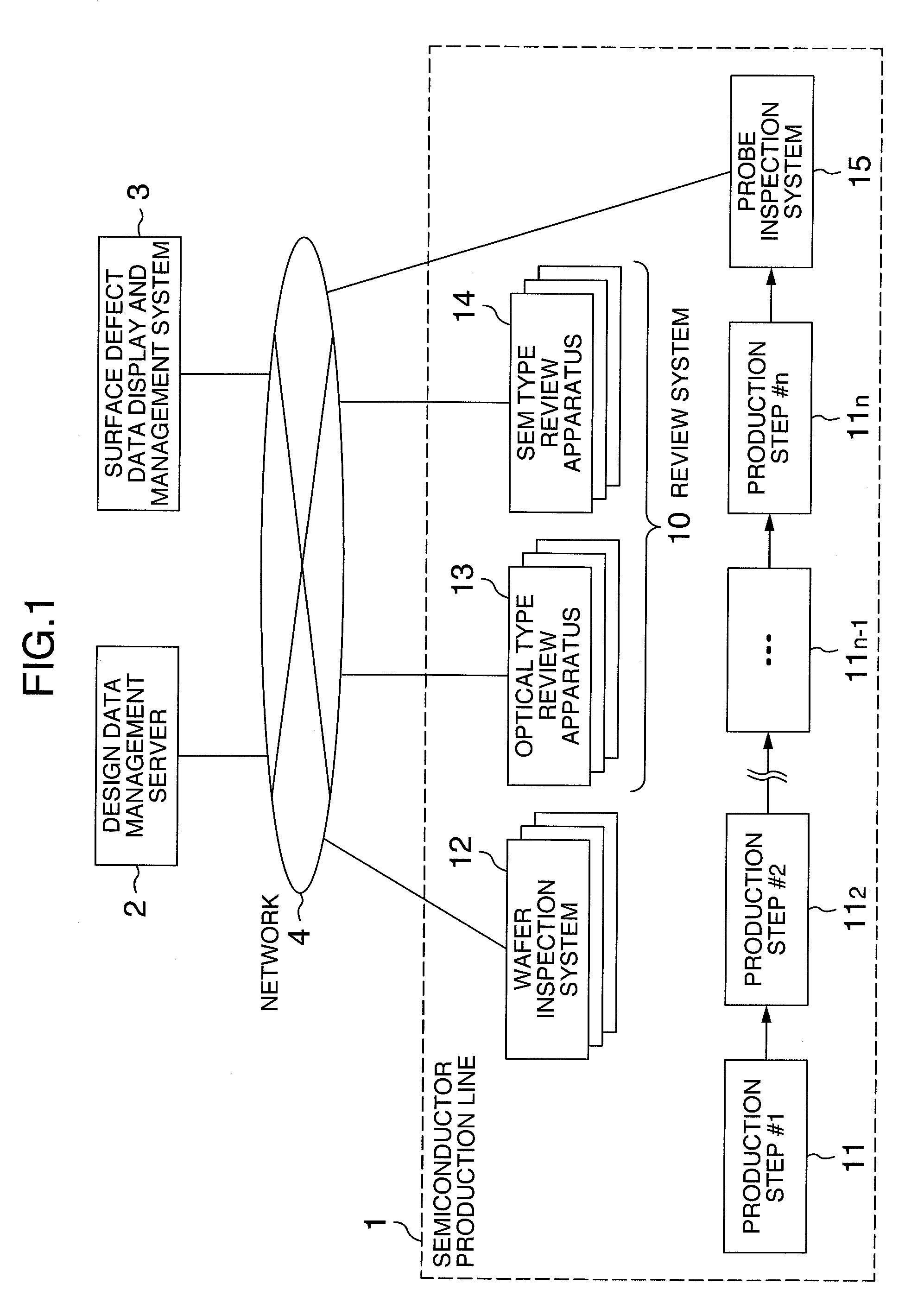

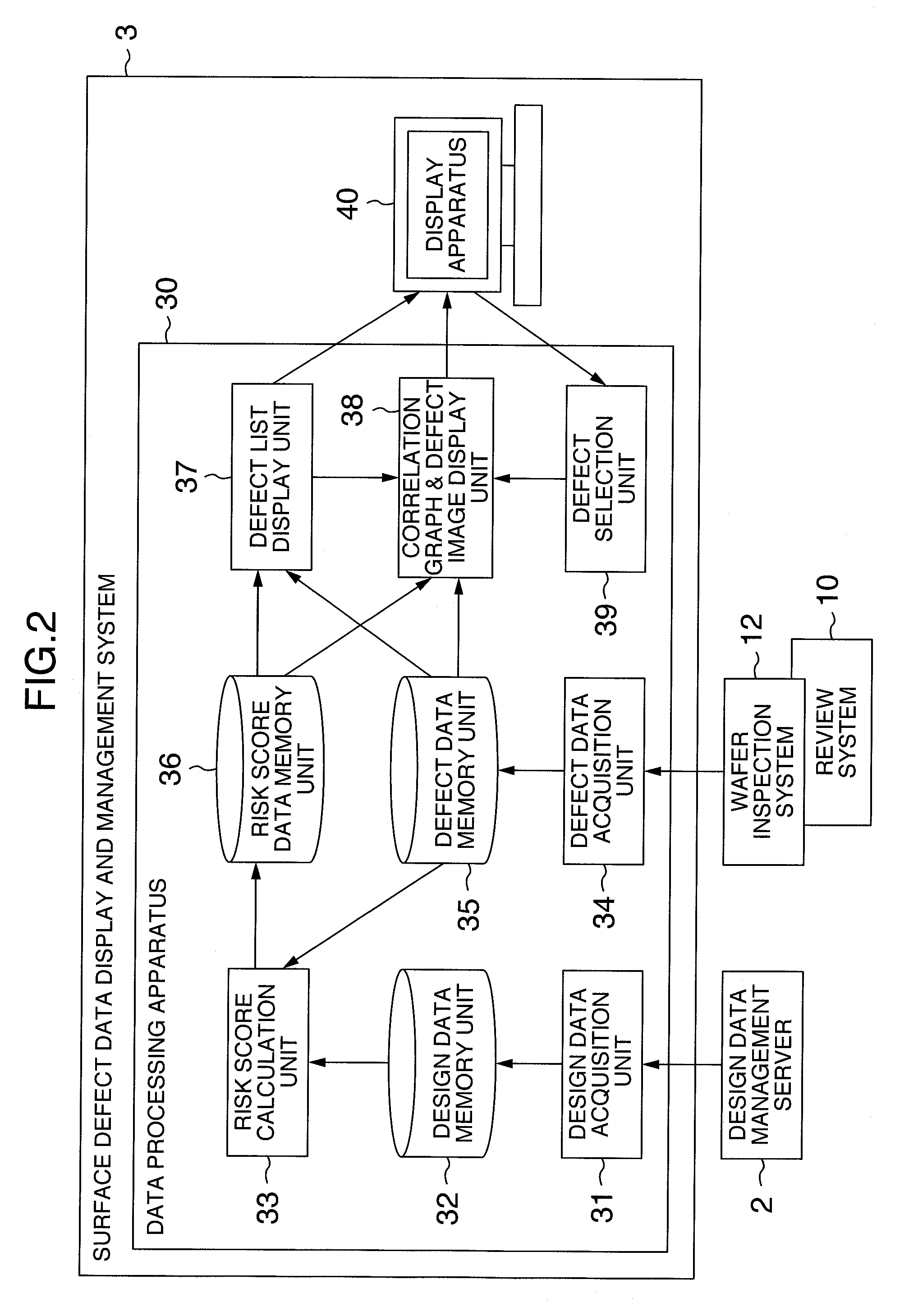

Surface defect data display and management system and a method of displaying and managing a surface defect data

ActiveUS20090292387A1High risk scoreGood choiceSemiconductor/solid-state device testing/measurementBuilding locksData displayDefect size

A surface defect data display and management system comprises a risk score calculation unit for calculating the magnitude of an influence a surface defect on a wafer detected by a wafer inspection system or review system has upon a reduction in the yield of a final product as a risk score of the surface defect based on a defect size of the surface defect on the wafer and a pattern concentration obtained from design data of a pattern figure nearby a location corresponding to the position of the surface defect, and a correlation graph and defect image display unit for preparing a correlation graph showing the correlation between the defect size and the risk score of each defect, displaying the prepared correlation graph on the display apparatus and displaying additionally a defect image list of one or more defects selected by using the correlation graph.

Owner:HITACHI HIGH-TECH CORP

Apparatus of inspecting defect in semiconductor and method of the same

ActiveUS20070019185A1Small sizeImprove productivitySemiconductor/solid-state device testing/measurementInvestigating moving sheetsDefect sizeSoftware engineering

When size of a defect on an increasingly miniaturized pattern is obtained by defect inspection apparatus in the related art, a value is inconveniently given, which is different from a measured value of the same defect by SEM. Thus, a dimension value of a defect detected by defect inspection apparatus needs to be accurately calculated to be approximated to a value measured by SEM. To this end, size of the defect detected by the defect inspection apparatus is corrected depending on feature quantity or type of the defect, thereby defect size can be accurately calculated.

Owner:HITACHI HIGH-TECH CORP

Transparent plate defect detection device based on machine vision and detection method thereof

The invention discloses a transparent plate defect detection device based on machine vision and a detection method thereof, belongs to the technical field of intelligent defect detection of transparent materials, and solves the technical problems of false detection, missing detection and low efficiency in detection of internal defects and surface defects of transparent plates. According to the technical scheme, the device comprises a detection system composed of an industrial camera, an industrial lens, an industrial light source and a stepping motor, the detection system is placed in a cameraobscura, the light source is installed on the side surfaces of a conveying belt and a detected material, and the industrial camera is installed at a vertical position above the detected material forshooting. The detection system adopts a computer to realize Ethernet communication with the industrial camera to obtain an image, and processes the image by adopting a method of first binarization noise reduction, then Gaussian filtering and binarization enhancement to obtain contour information. The defect size information and the defect area are calculated in a mode of comparing by adopting a shooting graduated scale. According to the invention, the labor can be saved, the cost is reduced, the detection accuracy is improved, and the size detection error range is 0.5-5.0%.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Rolling bearing outer ring defect full-size quantitative diagnosis method

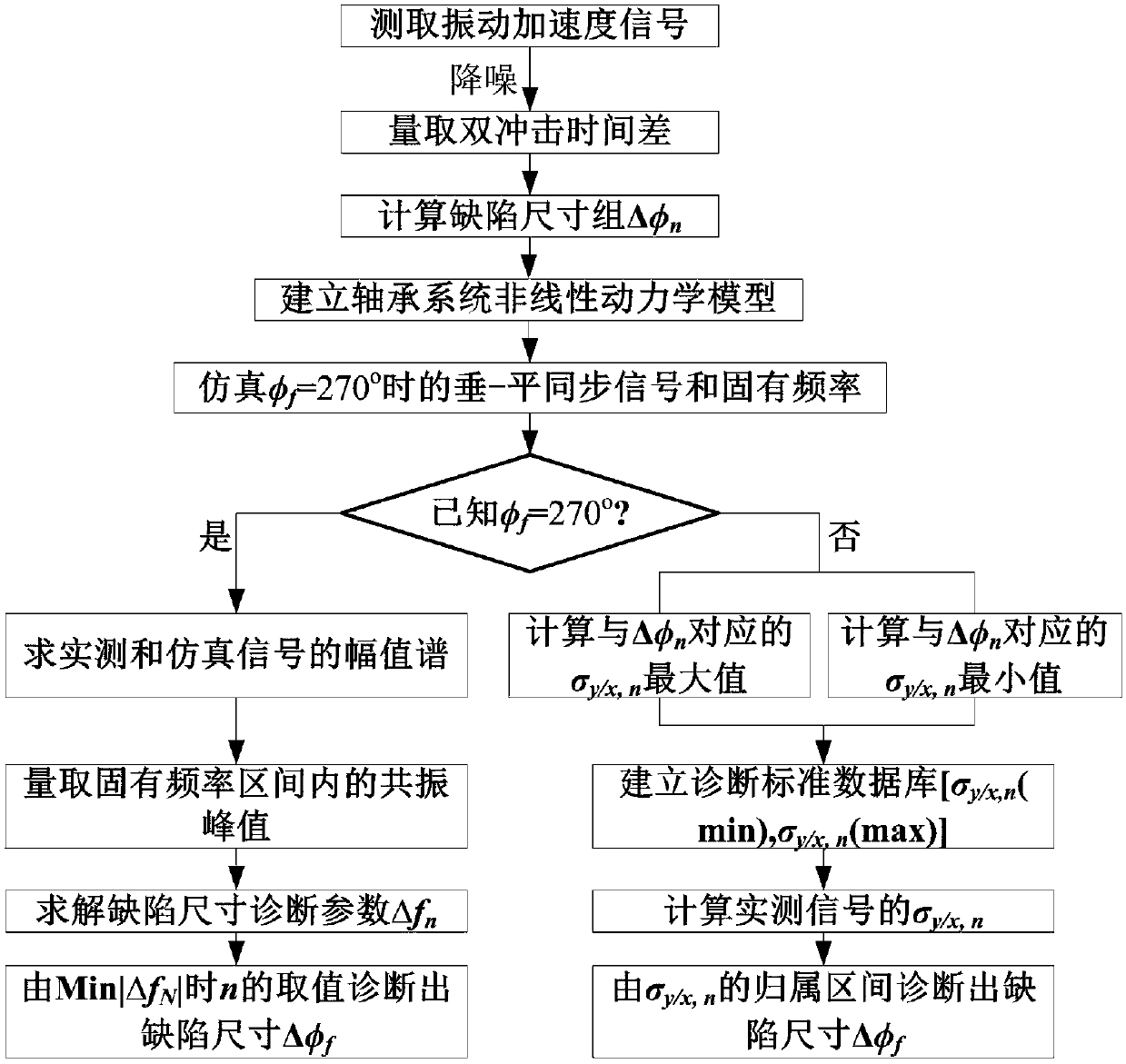

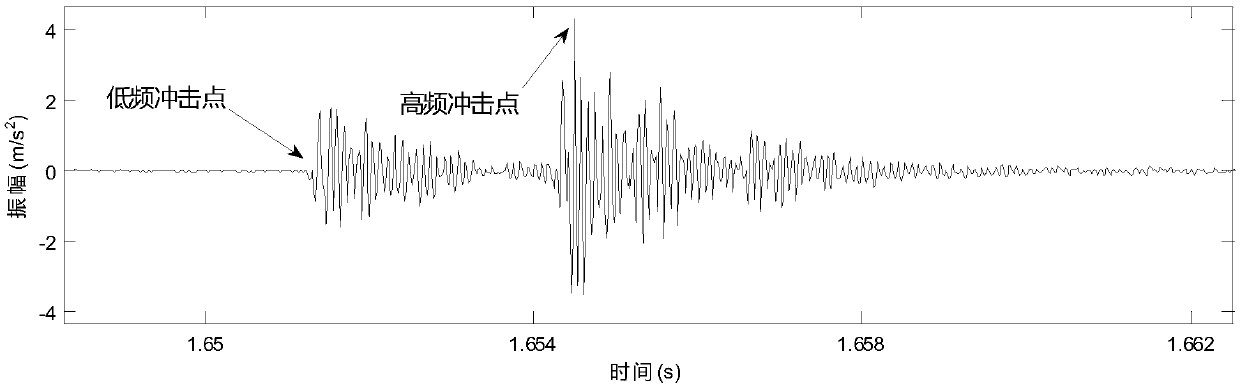

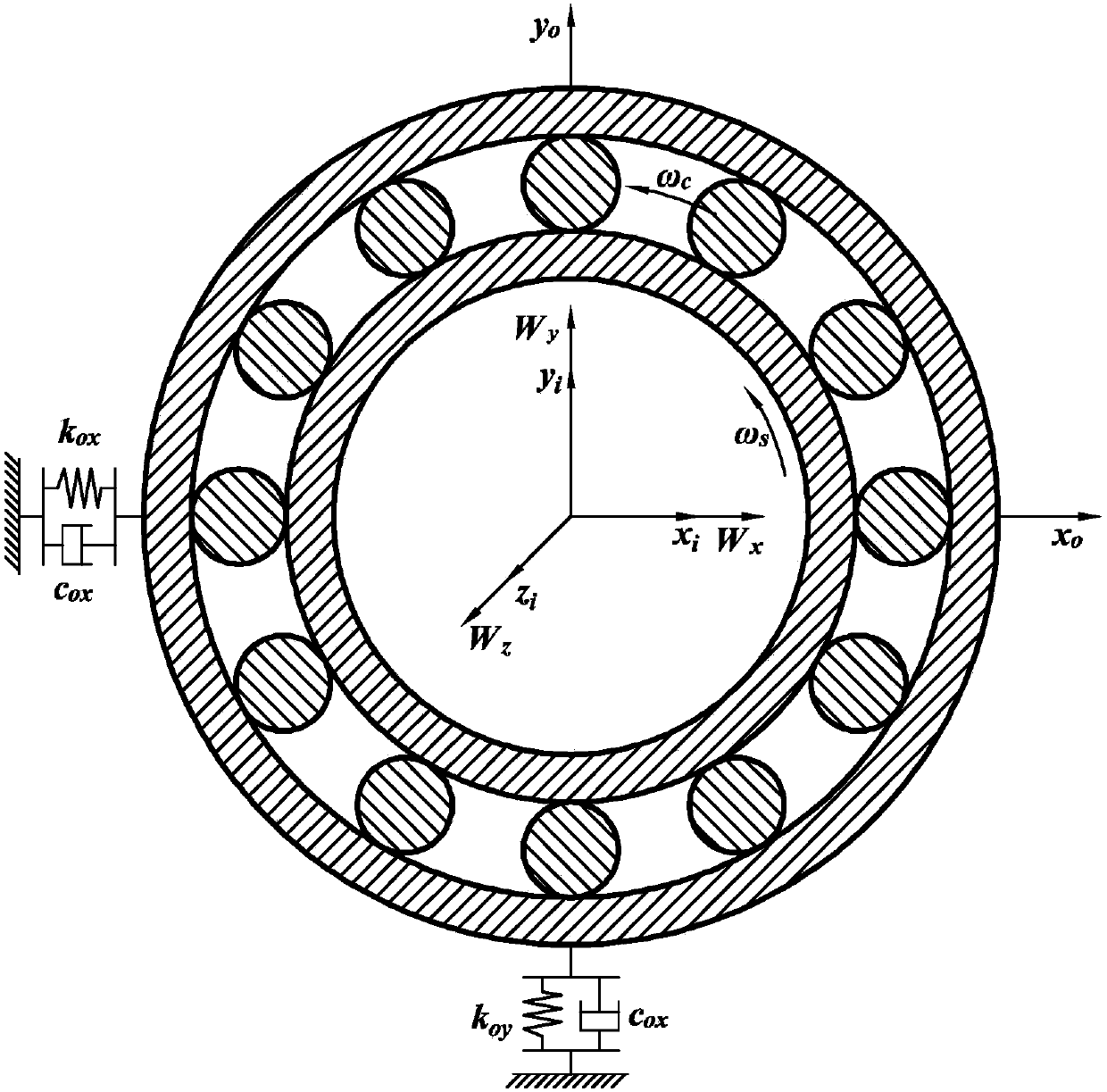

ActiveCN107704695AAvoid misdiagnosisMeet the urgent needs of economic developmentGeometric CADMachine bearings testingDiagnosis standardsDefect size

The invention discloses a rolling bearing outer ring defect full-size quantitative diagnosis method. Firstly primary diagnosis is performed on an actual measurement signal based on an impact time difference to obtain a basic size and selectable sizes of an outer ring defect. Secondly a nonlinear dynamics model of a bearing system is built, and through numerical solving, a vertical-horizontal synchronous simulation vibration signal corresponding to each defect size is obtained. For the situation that a defect angle is 270 degrees, Fourier transform is performed on the actual measurement signaland a simulation signal of each selectable defect size to obtain corresponding amplitude spectrums, a minimum diagnosis parameter Min / delta fN / of the actual measurement signal is solved, and an outerring defect size is diagnosed out. For the situation that the defect angle is 250-290 degrees, an outer ring defect full-size quantitative diagnosis standard database is established based on a vertical-horizontal synchronous standard deviation, and by determining an attribution interval of the vertical-horizontal synchronous standard deviation of the actual measurement signal, the outer ring defect size is diagnosed out.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com