Transparent plate defect detection device based on machine vision and detection method thereof

A transparent plate and defect detection technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of missed detection efficiency, false detection of defects on the surface of transparent plates, etc., to improve efficiency, improve detection accuracy, and save labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

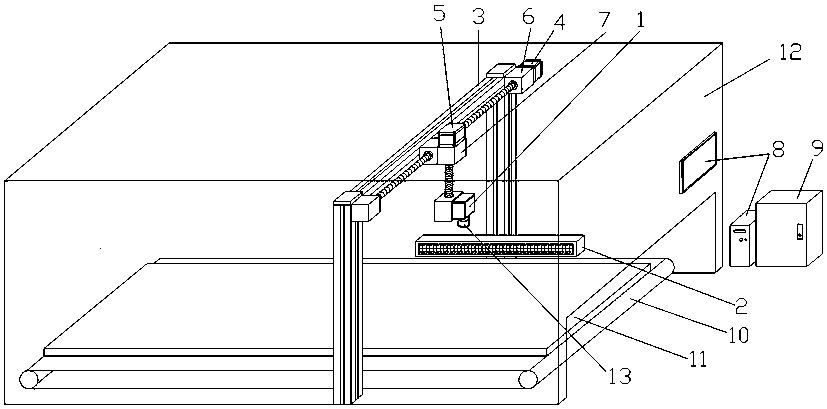

[0037] Such as figure 1 with figure 2 A machine vision-based transparent plate defect detection device shown includes an industrial camera 1, an industrial lens 13, an industrial light source 2, a stepping motor and a dark box 12, wherein:

[0038] The bottom of the dark box 12 is respectively provided with a feed port and a discharge port according to the conveying direction of the conveyor belt 10. The conveyor belt 10 runs through the feed port and the discharge port of the dark box 12 and extends to the outside of the dark box 12. The transparent plate to be tested 11 placed on the conveyor belt 10;

[0039] In said obscura 12:

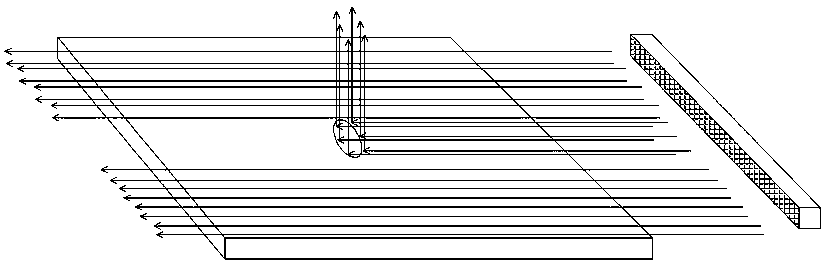

[0040] A door-shaped hanger 3 is arranged across the top of the conveyor belt 10, the industrial light source 2 is arranged at the root of the column of the door-shaped hanger 3, the industrial light source 2 is set as a line light source, and the beam direction is parallel to the surface of the transparent plate 11 to be tested , the light be...

Embodiment 2

[0057] The structure of a machine vision-based transparent plate defect detection device in Embodiment 2 is the same as that in Embodiment 1, and will not be repeated here.

[0058] In Example 2, the device and detection method provided by the present invention are applied to the detection of surface scratches, internal cracks, gravel and air bubbles on a transparent PEO plastic plate with a thickness of 4mm. Industrial lens, the object distance is 241.55mm, the field of view is 379.27mm*200mm, the exposure time is 4.6ms, and the captured image resolution is 4096×2160.

[0059] The selection range of the binarization noise reduction threshold is 46, the low-pass Gaussian filter uses a filter template of 15×15, and the selection range of the binarization enhancement threshold is 49.

[0060] The measured scratch width is 6.5mm, with a relative error of 3.2%; the scratch length is 42.7mm, with a relative error of 4.1%; the bubble width is 3.5mm, with a relative error of 3.3%; th...

Embodiment 3

[0062] The structure of a machine vision-based transparent plate defect detection device in Embodiment 3 is the same as that in Embodiment 1, and will not be repeated here.

[0063] In this embodiment 3, the device and detection method provided by the present invention are applied to the detection of air holes, surface scratches, internal cracks, gravel and air bubbles on a 1mm thick transparent PYREX glass plate, and a black and white industrial camera with 8.9 million pixels is used, and the focal length is selected It is a 25mm industrial lens, the object distance is 268.38mm, the field of view is 151.7mm*80mm, the exposure time is 4.2ms, and the resolution of the collected image is 4096×2160. The selection range of the binarization noise reduction threshold is 47, the low-pass Gaussian filter uses a filter template of 15×15, and the selection range of the binarization enhancement threshold is 51.

[0064] The measured air hole width is 6.0mm, with a relative error of 2.4%;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com