Patents

Literature

92results about How to "Improve welding success rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

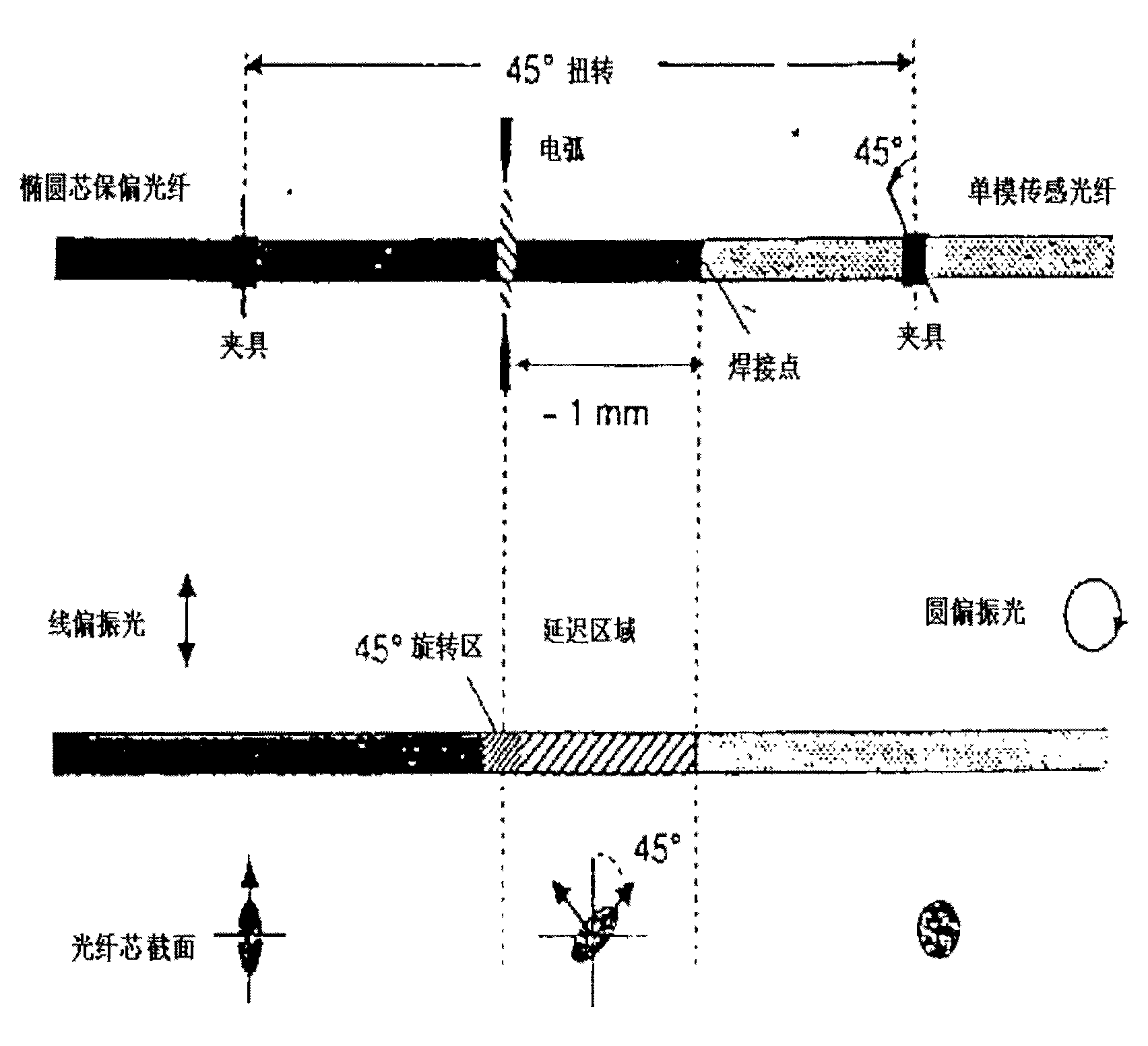

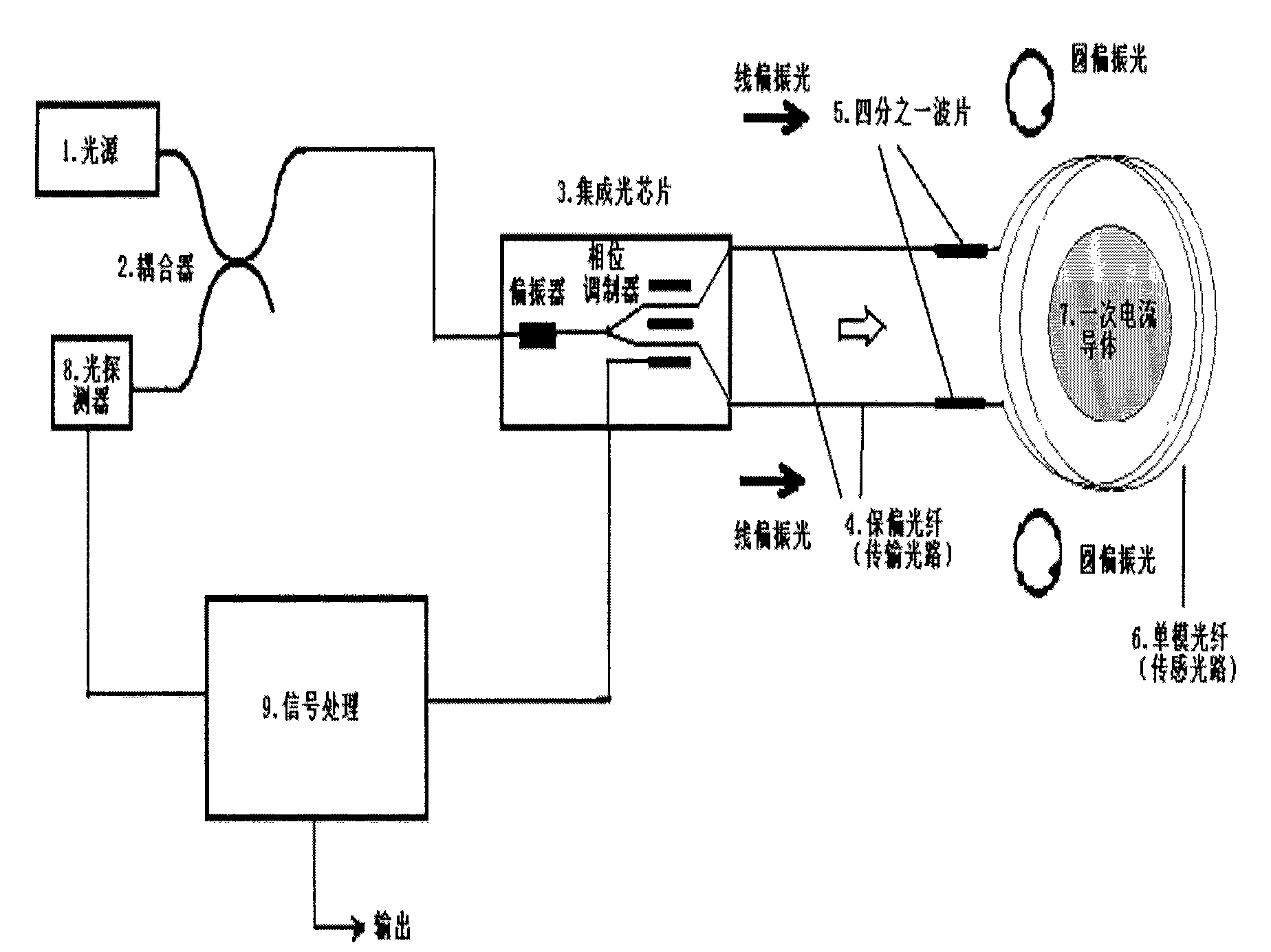

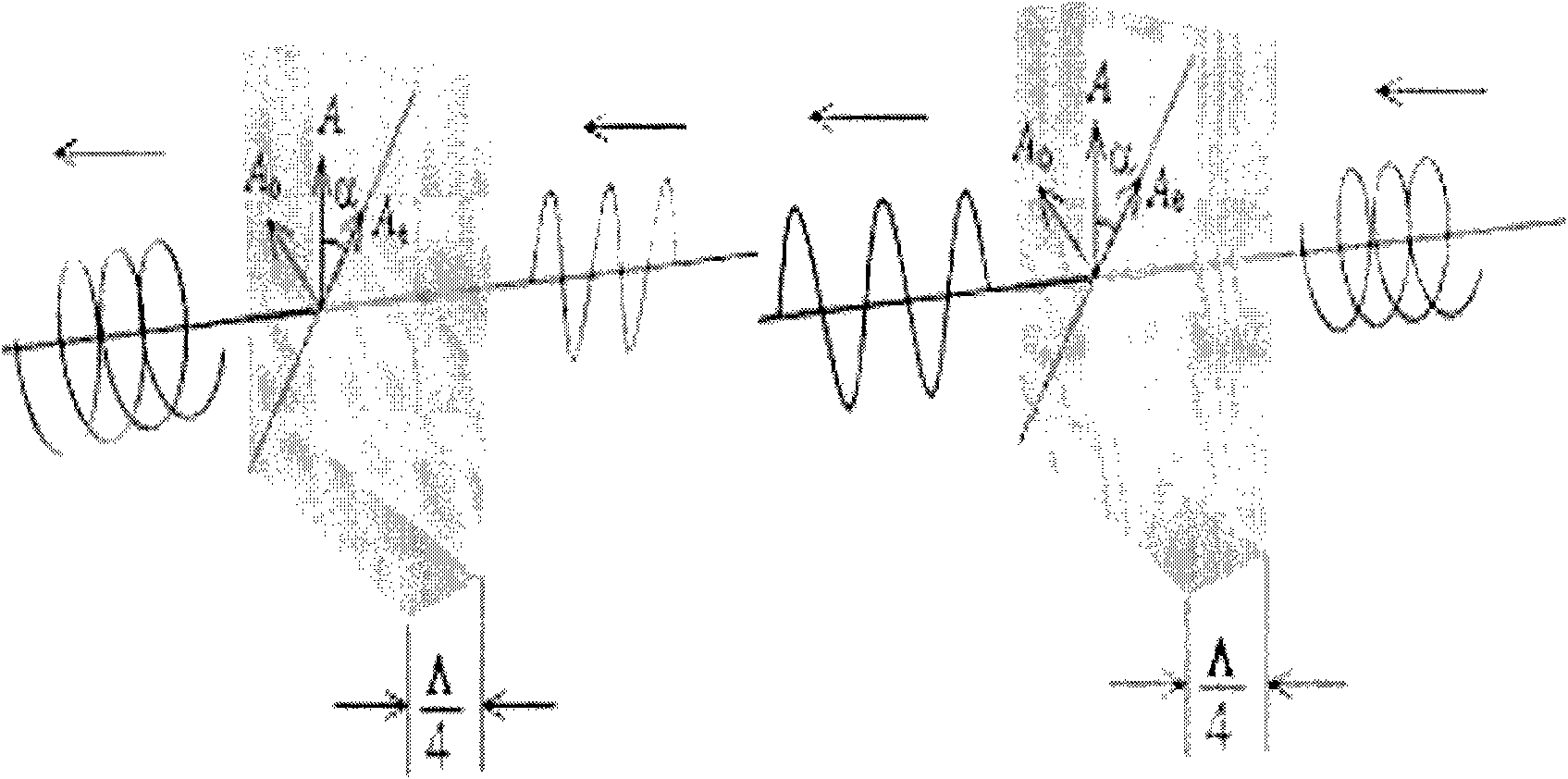

Method for manufacturing full-fiber quarter wave plate

InactiveCN101620287ASimple preparation processImprove welding success ratePolarising elementsVoltage/current isolationCurrent sensorEngineering

The invention discloses a method for manufacturing a full-fiber quarter wave plate. A Sagnac interferometer type full-fiber current transformer comprises modules such as a sensing light path, a transmission fiber from a high-voltage part of 110kV to 550kV to 1,000kV to a control room of a power station, a signal processing electronic circuit, an interface circuit of a merging unit and the like, accords with the standard of IEC 60044-8, and is applicable to the industry of electric transmission and transformation and other situations for measuring high current. A full-fiber current sensor realizes current sensing by changing a phase of circularly polarized light of a (gauge outfit) in a sensitive coil through the current. The method for manufacturing the quarter wave plate, namely a key component for realizing mutual conversion of linearly polarized light and circularly polarized light in the full-fiber current transformer comprises the steps of selecting a wave plate, welding the wave plate, a transmission light path and the sensing light path, and protecting welding spots.

Owner:SHANGHAI XINYUE METER FACTORY

Dynamic welding method of laser welding machine

ActiveCN104722922AReduce labor intensityImprove equipment efficiencyWelding/soldering/cutting articlesMetal working apparatusThree-dimensional spaceEngineering

The invention discloses a dynamic welding method of a laser welding machine. Through the dynamic welding method of the laser welding machine, it can be well guaranteed that welding joints are linear. The head edge and the tail edge of a front stainless steel roll and the head edge and the tail edge of a rear stainless steel roll are fed to a welding machine, it is guaranteed that the edges to be welded to are located in the actual welding area of the welding machine, shears of the welding machine shear the edges of strip steel, the width of the strip steel is measured through an external sensor, and the adjustment process of a center line is achieved; accurate welding parameters are called according to actual material specifications, and a laser head moves from the driving side to the operating side so that the welding process of the strip steel can be completed. First, data of the actual welding joints are acquired; second, the data are analyzed and screened, and calculation of deviation points is performed; third, displacement adjustment reference data are generated according to data deviation. The dynamic welding method of the laser welding machine has the advantages that it is guaranteed that the welding joints are linear, a longitudinal traction track of a welding gun vertically coincides with the welding joints in a three-dimensional space, the labor intensity of production and operation staff is relieved, efficiency and stability of equipment are improved, the welding success rate is increased, and the automation degree is improved.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

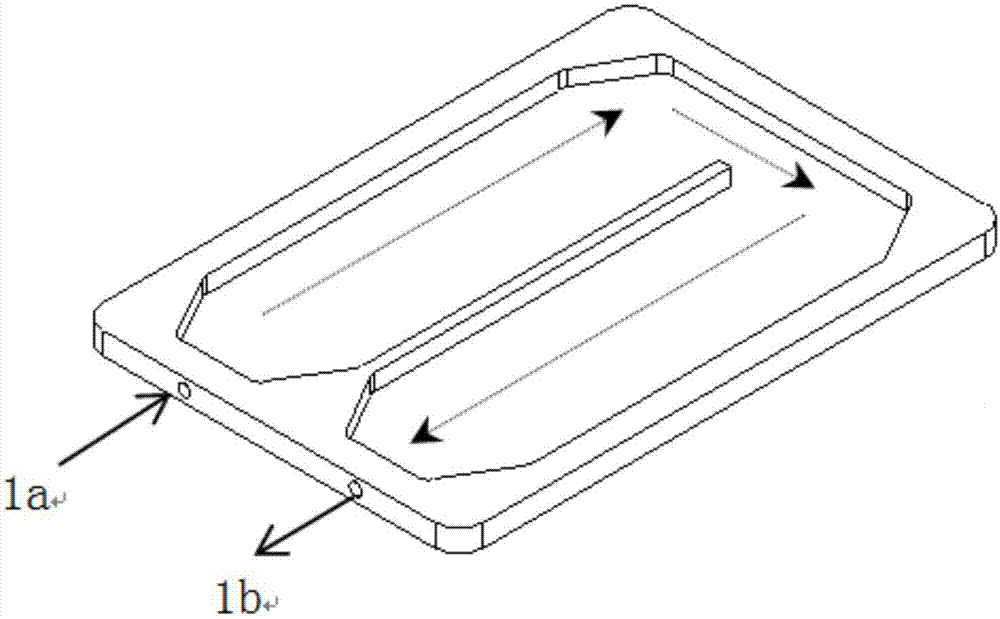

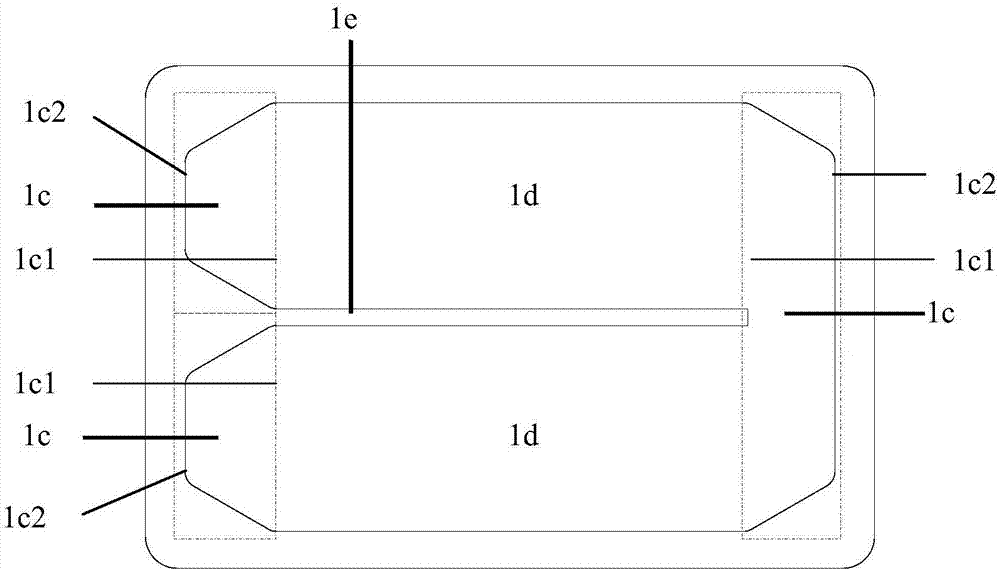

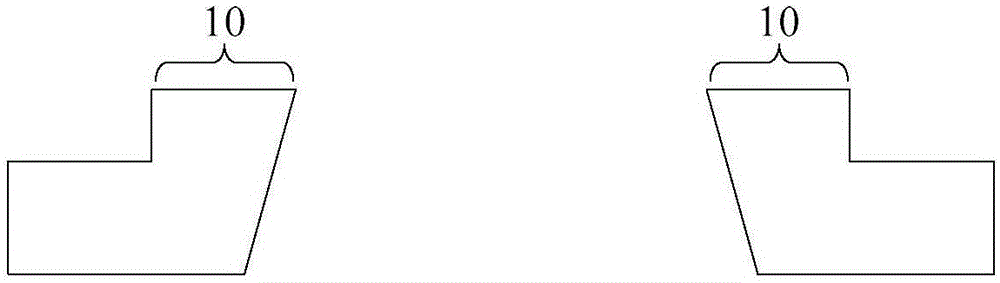

Micro-channel integrated cold plate based on a micro-channel porous flat tube and making method thereof

InactiveCN107464793AExpansion coefficient matchingReduce thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringCold plate

The invention relates to the field of an equipment heat dissipation technology, in particular to a micro-channel integrated cold plate based on a micro-channel porous flat tube and a making method thereof. The micro-channel integrated cold plate comprises a cavity area used for accommodating the micro-channel porous flat tube, a liquid-cooled cavity substrate used for accommodating the cavity area and a cover plate used for covering the liquid-cooled cavity substrate to form a closed structure; the cavity area is formed by two confluence cavities with a gradual change in shape and a flow channel cavity; the confluence cavity in the head part of the cavity area, the flow channel cavity and the confluence cavity in the tail part of the cavity area are sequentially connected; the end part of the flow channel cavity formed close to a cold plate liquid inlet and a cold plate liquid outlet is matched with the size of the flaring end of each of the confluence cavities; cooling liquid sequentially passes through the cold plate liquid inlet and outlet, the confluence cavity converging end, the confluence cavity flaring end, the flow channel cavity, the confluence cavity flaring end, the confluence cavity converging end and the cooling liquid outlet; the micro-channel porous flat tube is hermetically welded in the flow channel cavity of the liquid-cooled cavity substrate, and the cold plate liquid inlet and the cold plate liquid outlet are formed in the front end or the rear end of the liquid-cooled cavity substrate.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

Method for producing extra-thick steel plates by vacuum electron beam horizontal hybrid welding

InactiveCN105855685AImproving the Yield of Composite RollingGuaranteed sealing performanceElectron beam welding apparatusVacuum pumpingThick plate

The invention relates to a method for producing extra-thick steel plates by vacuum electron beam horizontal hybrid welding. The method comprises the steps that cleaned plate blanks are horizontally combined and aligned and are integrally and horizontally hoisted and conveyed to a service wagon; the service wagon is moved into a vacuum chamber of an electron beam welding machine, and the contact faces of electron beams and the combined blanks are placed in the same horizontal plane having the included angle of 2-4 degrees with respect to the perpendicular direction of the plate blanks; a welding starting point is located in the position 10 mm away from the side portion of the adjacent side of a to-be-welded side; the vacuum chamber is subjected to deep vacuum pumping until the pressure is smaller than or equal to 3*10<-3> Pa; a workbench is rotated by 90 degrees or 180 degrees to sequentially weld the periphery of the contact faces of the combined blanks at a time, and the effects that weld joints are even and the fusion depth is larger than 50 mm are guaranteed; the compound interface between the combined blanks is made to be in a deep vacuum state; and the welded combined plate blanks are subjected to heating, rolling, flaw detection and thermal treatment and finally the extra-thick steel plates are produced. The method achieves deep vacuum electron beam horizontal hybrid welding production of the combined plate blanks, improves the welding efficiency and welding success rate and greatly improves the clad rolling yield of the combined blanks.

Owner:ANGANG STEEL CO LTD

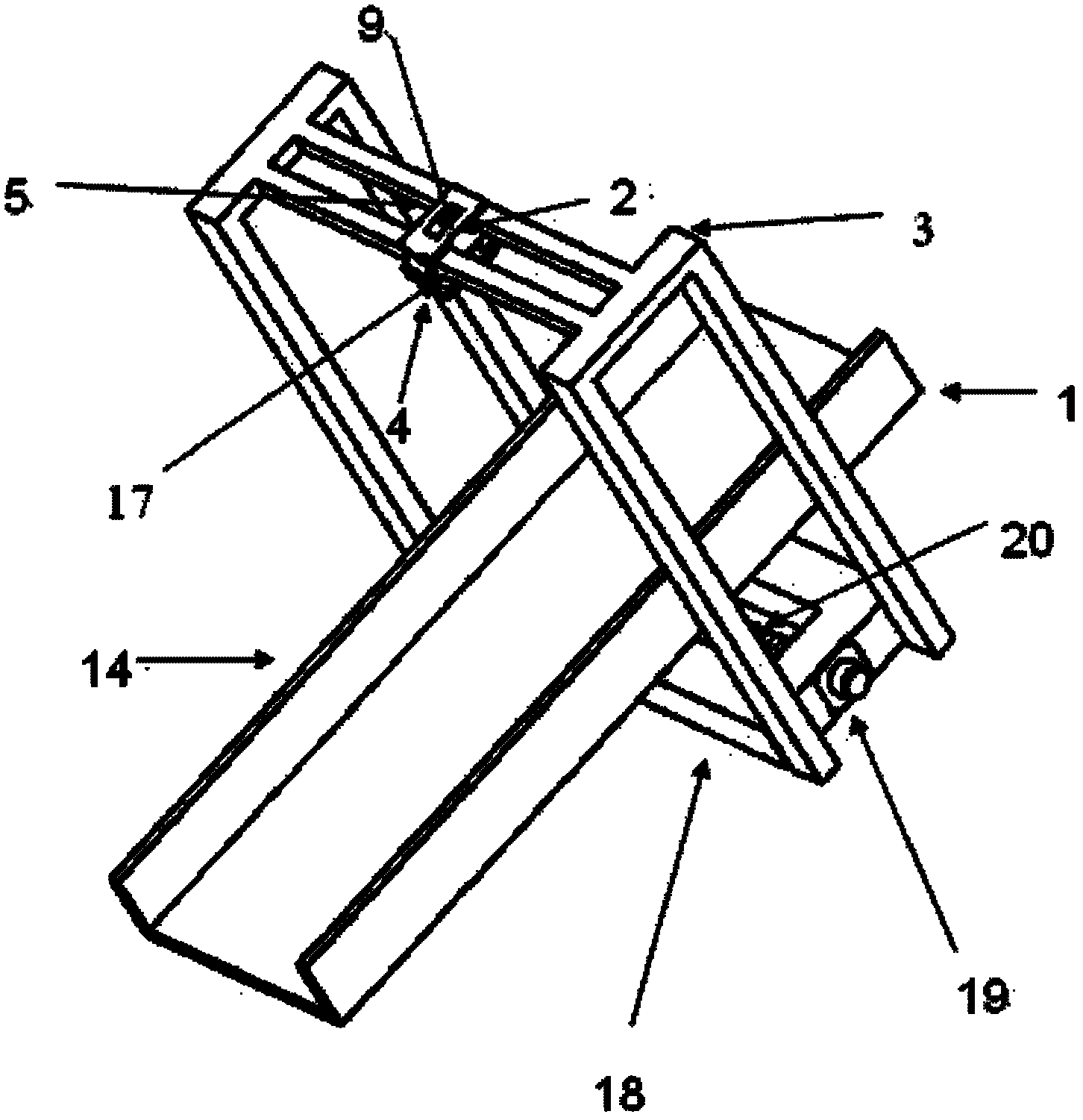

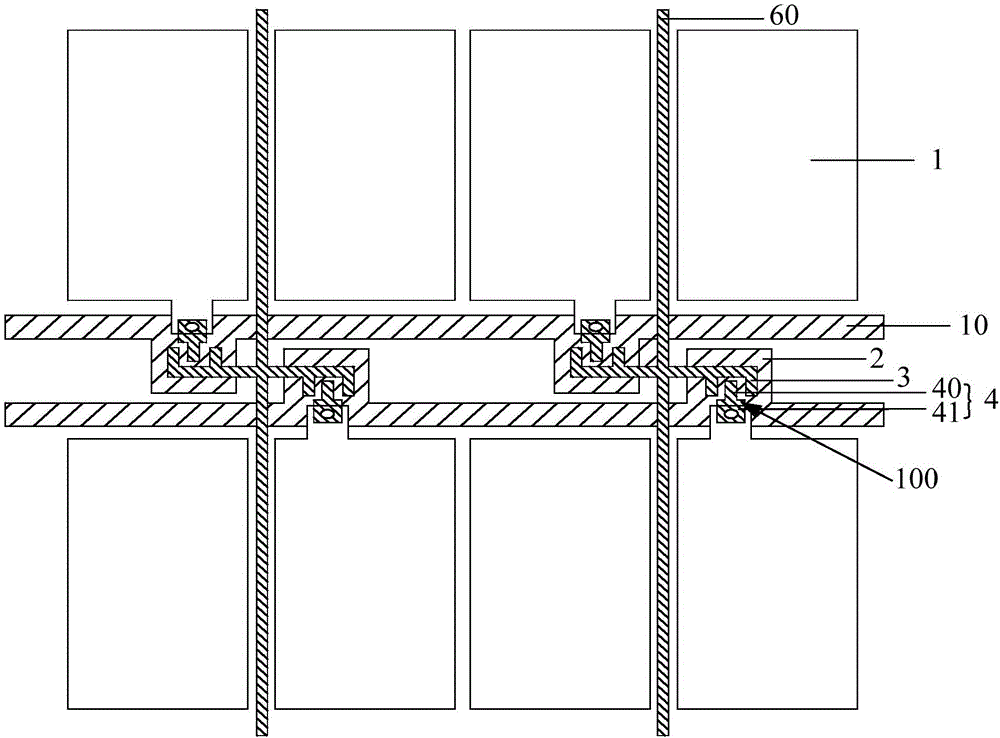

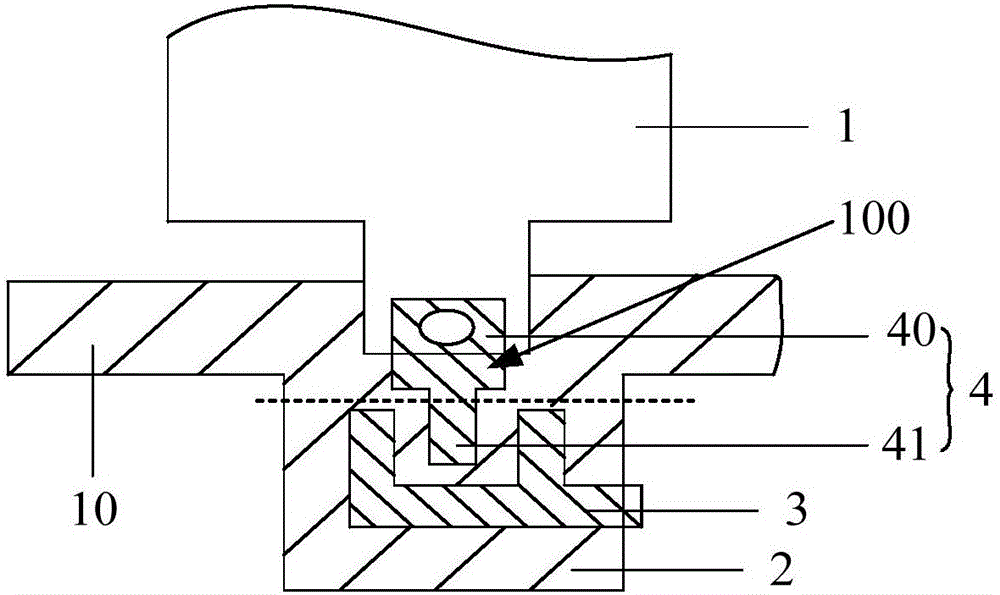

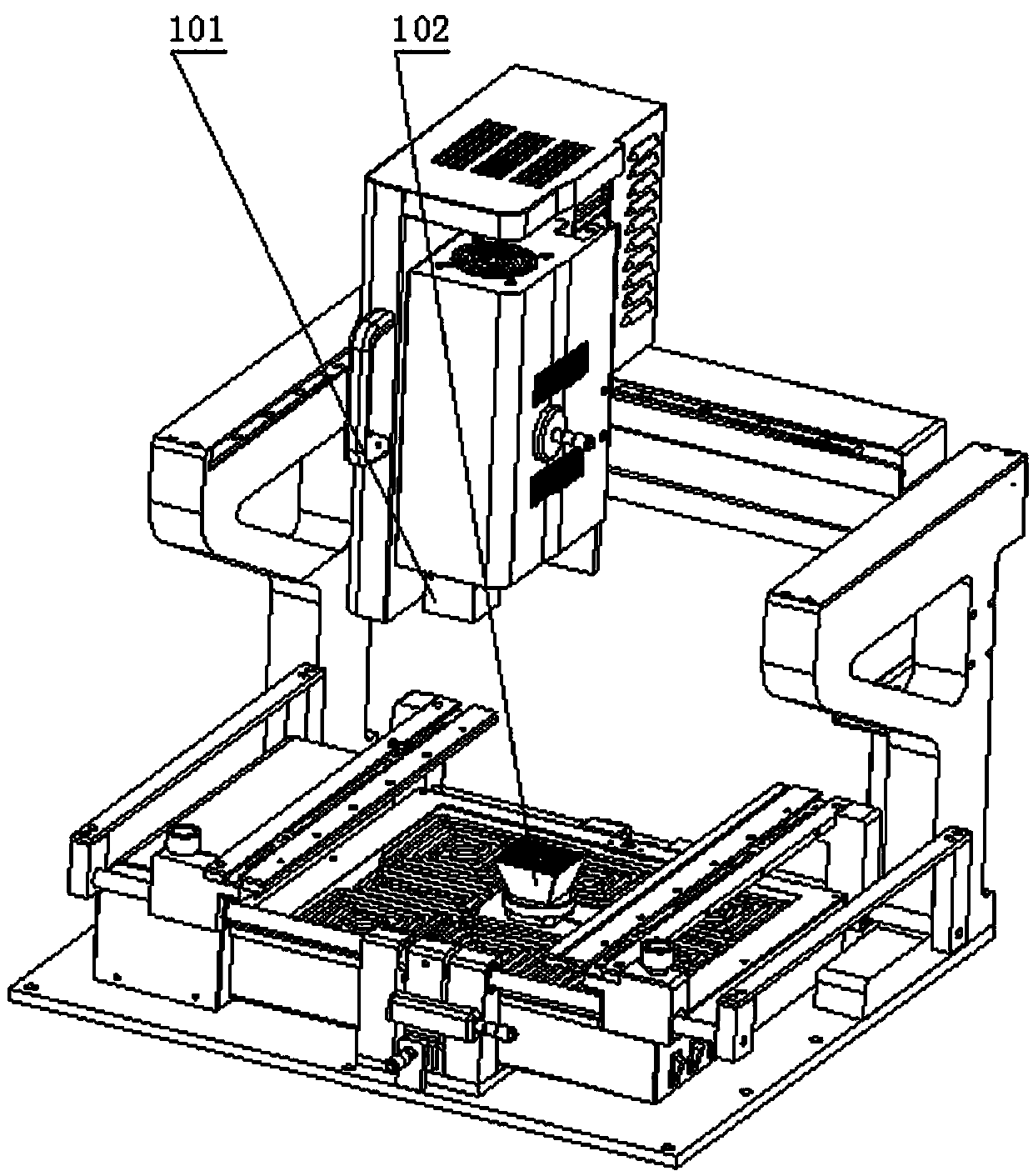

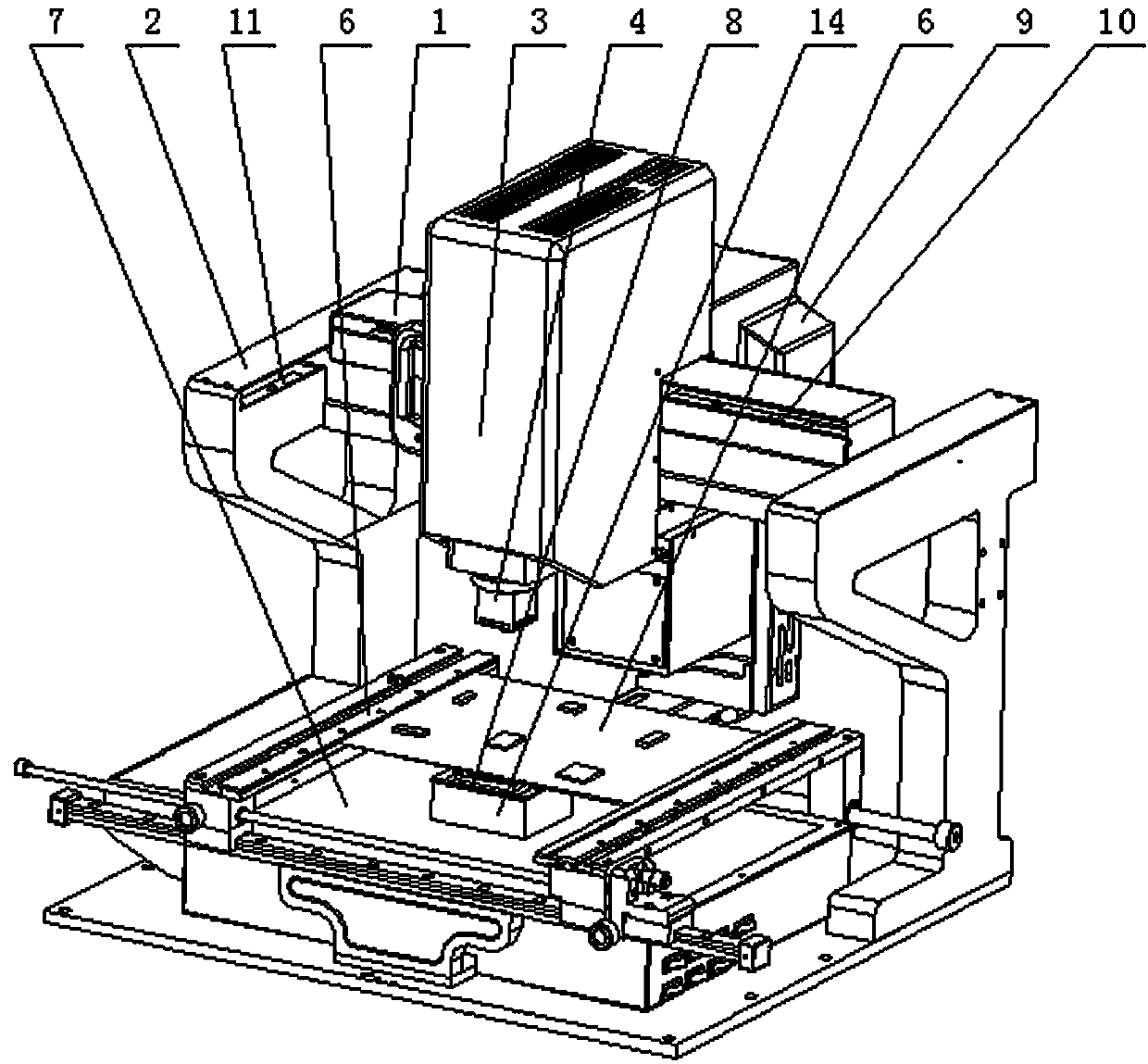

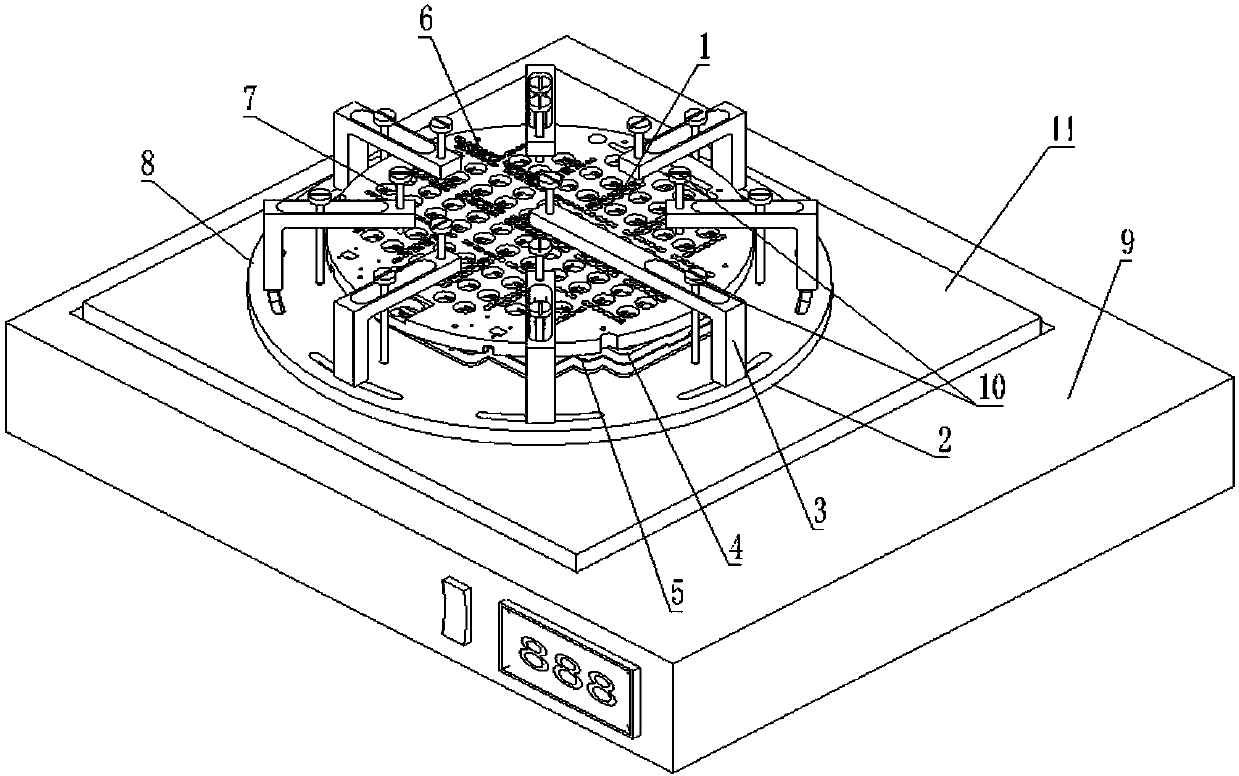

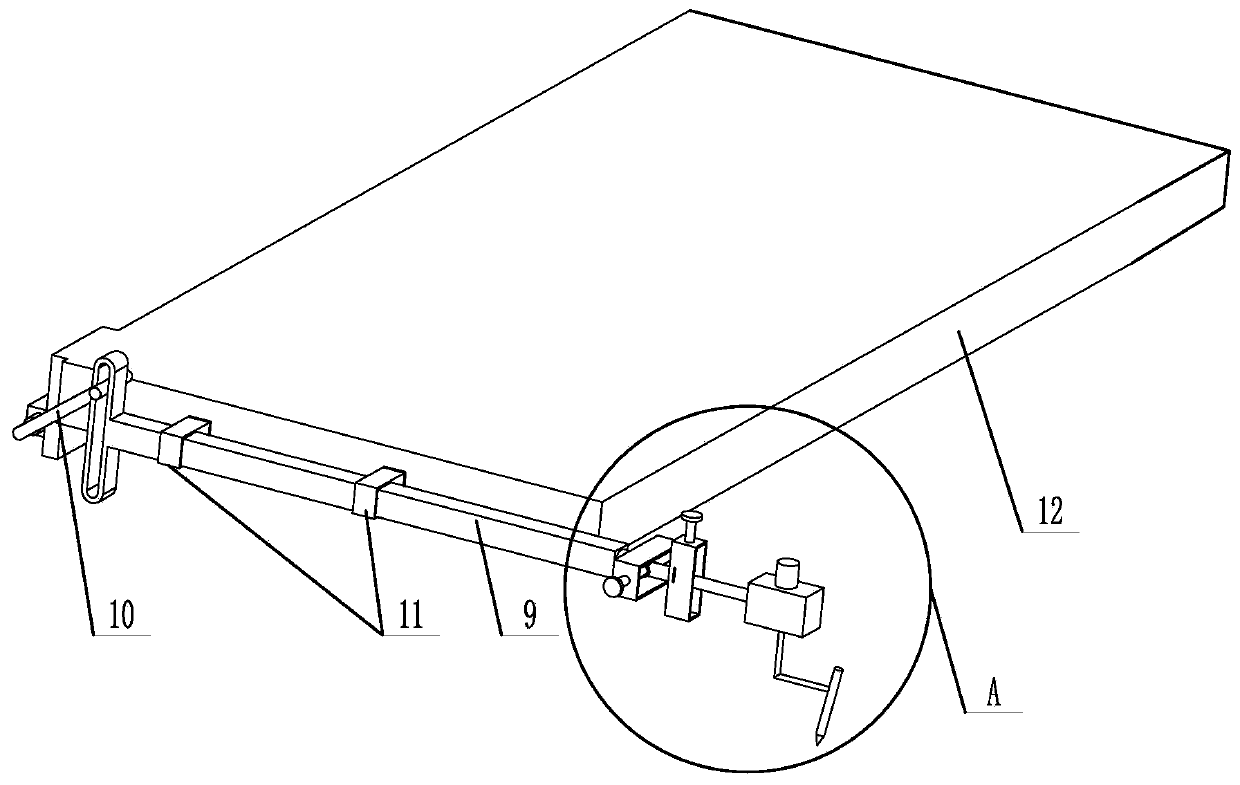

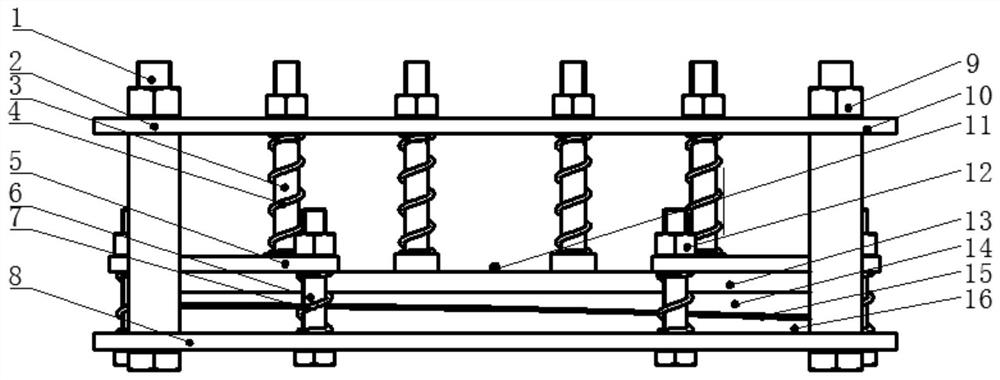

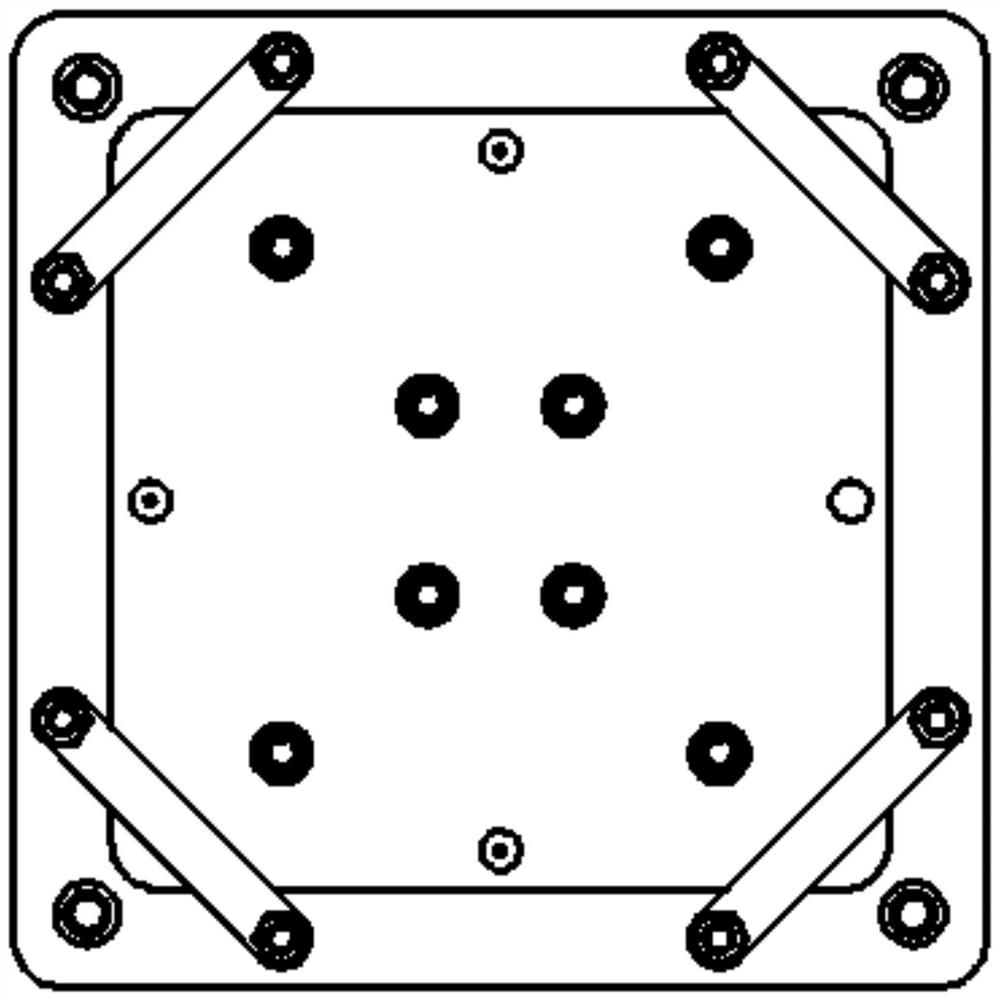

Laser welding fixture for square battery module

ActiveCN102328175AImprove welding success rateEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringBattery cell

The invention relates to a laser welding fixture for a square battery module. The laser welding fixture comprises a worktable, a pressing mechanism and a supporting mechanism, wherein, the pressing mechanism is fixed on an 'H'-shaped gantry support structure and comprises a pressing frame and a cylinder drive unit; the 'H'-shaped gantry support structure is fixed at two sides of the worktable and comprises an 'H'-shaped gantry support frame and a laser head drive unit; and the worktable comprises an X-Y axis drive unit and a supporting platform. By adopting the structure, the laser welding fixture has the beneficial effects that a connection piece can be tightly contacted with a battery cover plate during the welding process, thus achieving high welding success rate; and in addition, by means of movable arrangement of the worktable, the whole battery module can be completely welded only by one-time setup, thus being simple, convenient and fast in operation.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

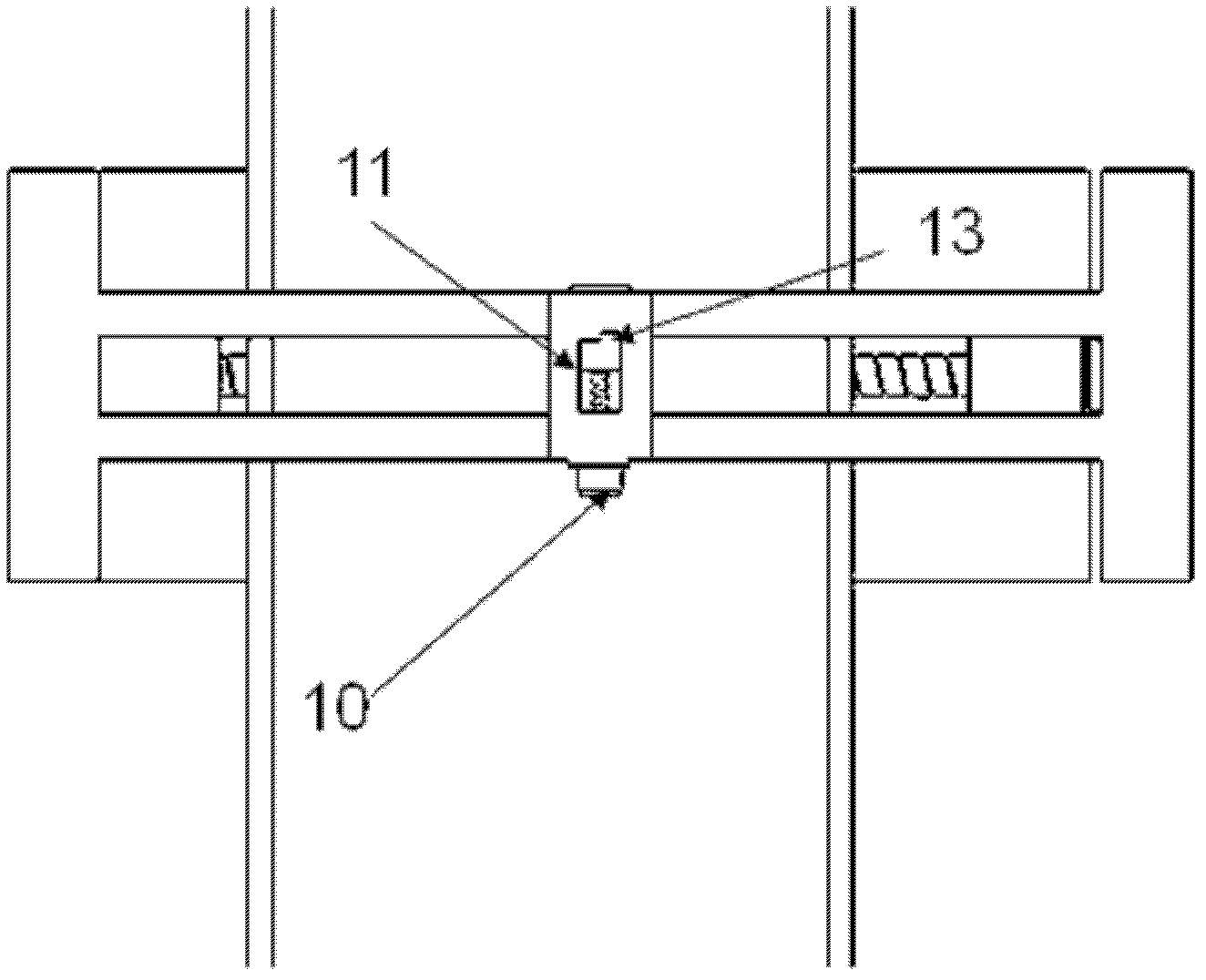

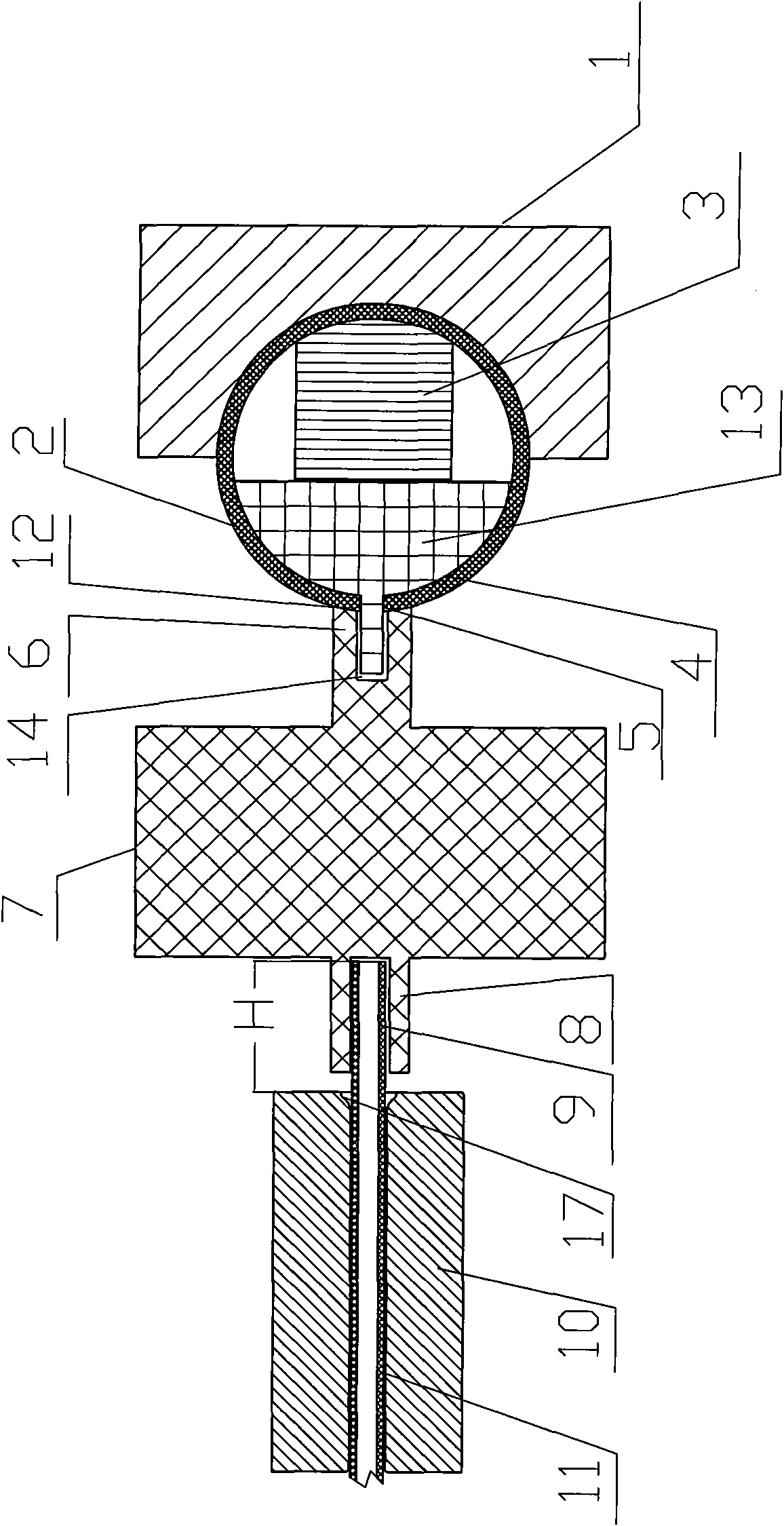

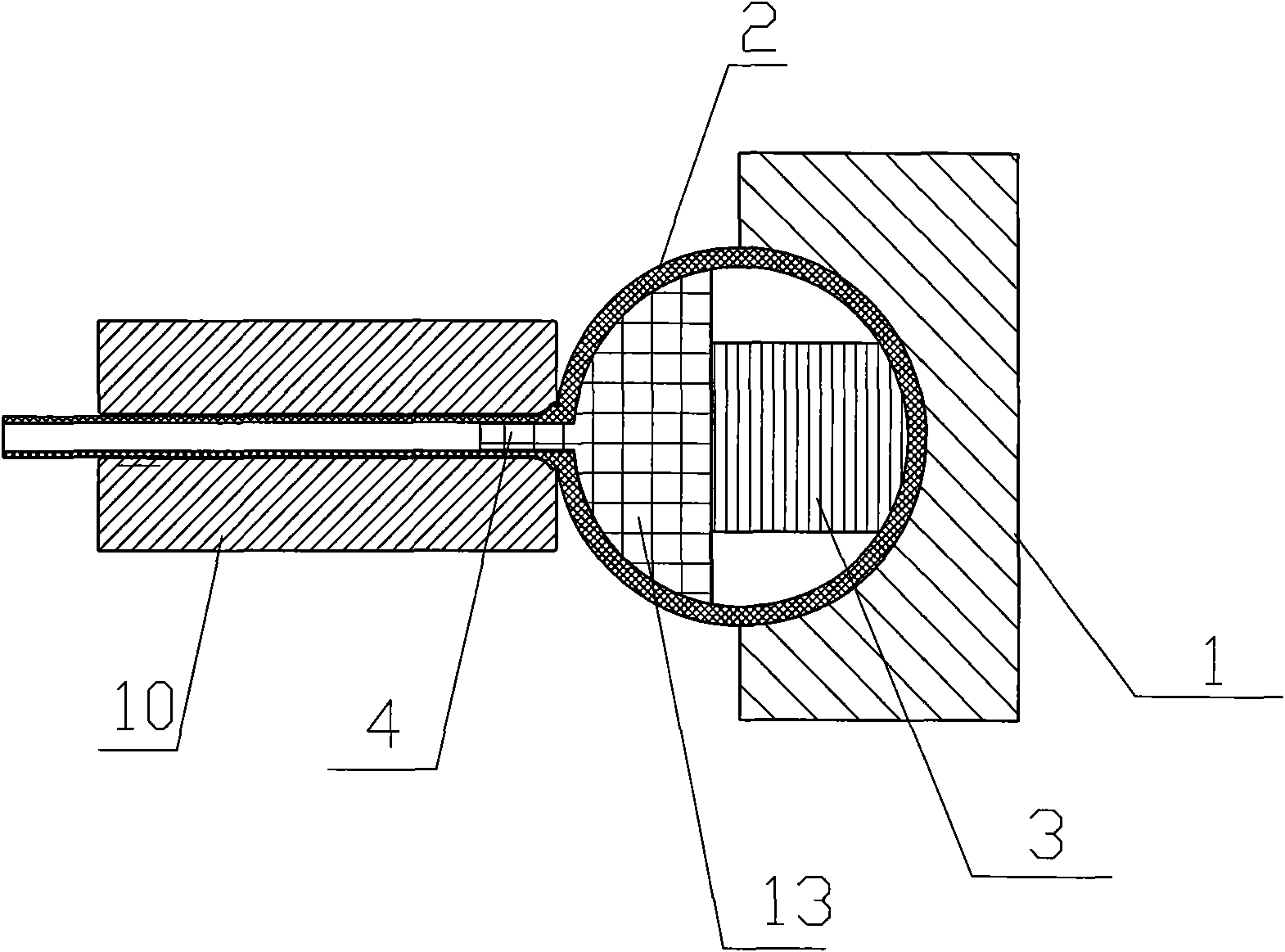

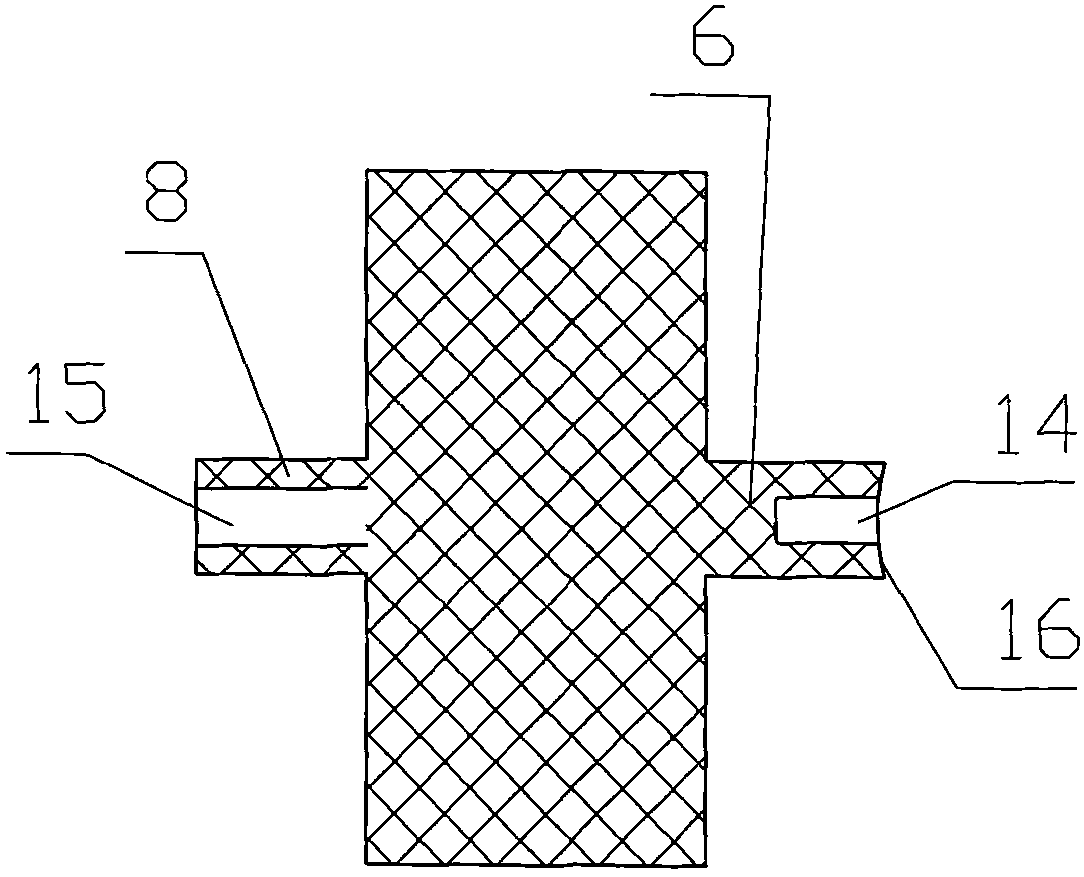

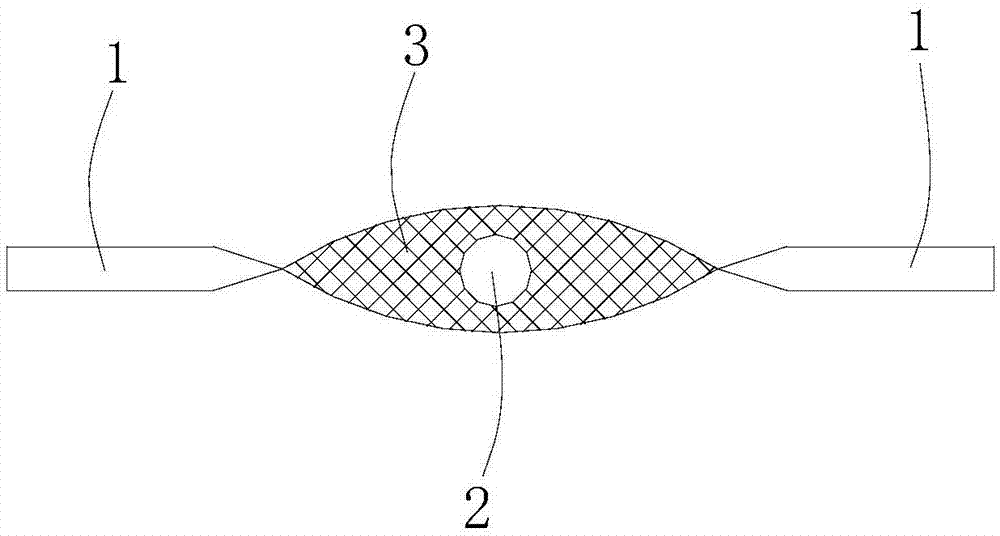

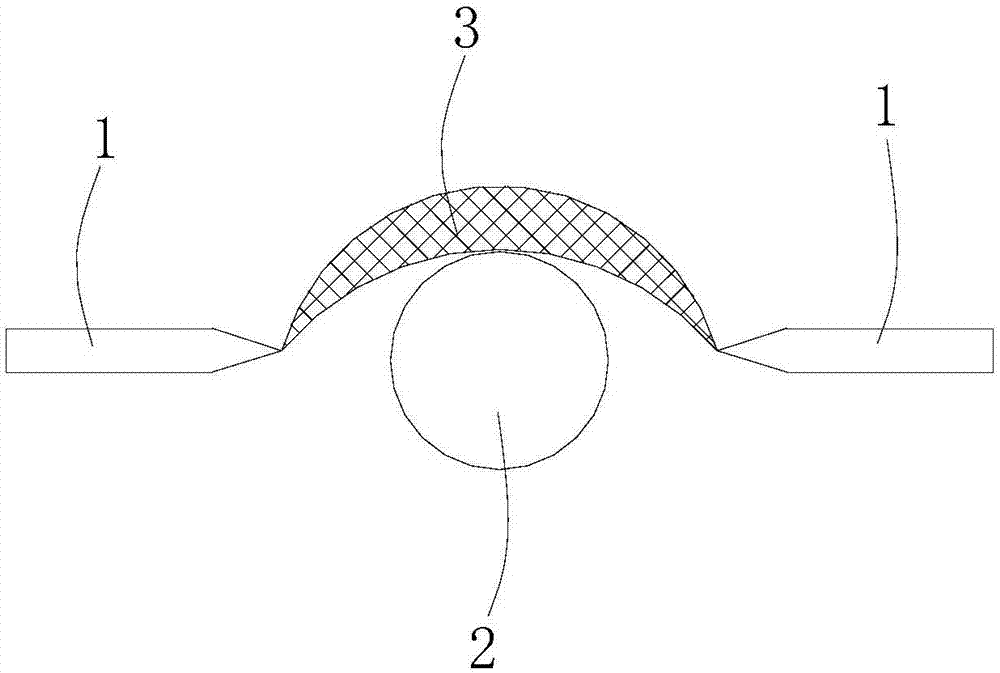

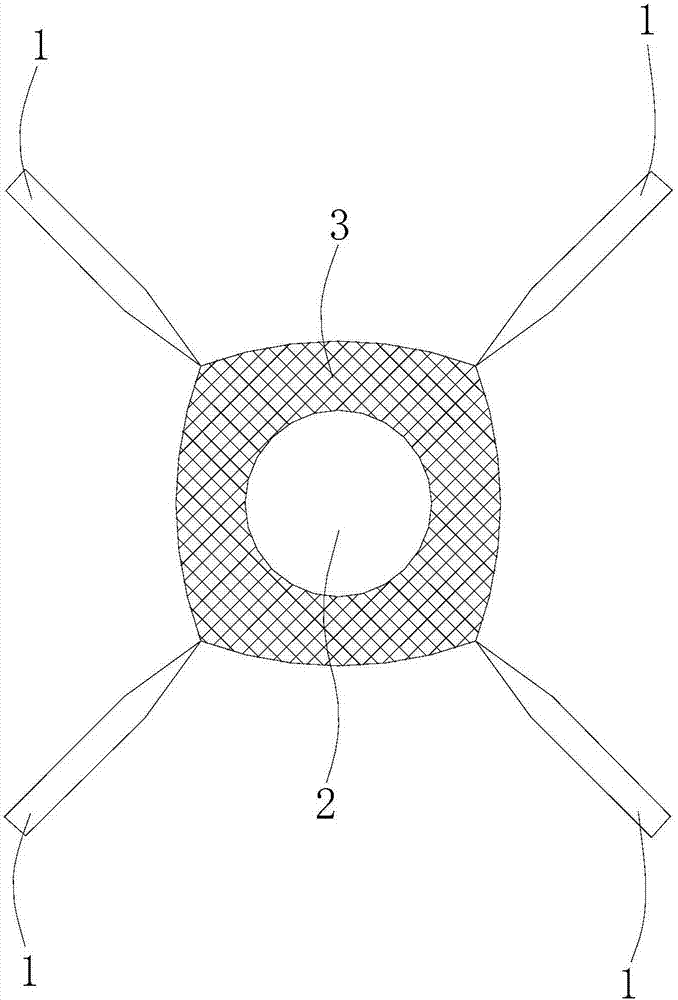

Method and equipment for welding plastic tube network

The invention relates to a method and equipment for welding a plastic tube network. The device comprises a heating device integrating a first heating element, a second heating element and a pore-forming positioning device comprised of a pore-forming ejector liner for forming a branched pore and a positioning liner for fixing the pore-forming ejector liner in the branched pore, wherein in a welding process, the needle protrusion of the pore-forming ejector is placed in the branched pore of a manifold and the pore-forming ejector liner is positioned by the positioning liner; and meanwhile, the end part of a thin tube and an annular welding area around the branched pore are heated so as to weld the end part of the thin tube with the annular welding area of the manifold together along the radial direction of the manifold through extrusion, and a preset profile is molded by an extrusion mold. When the equipment and the method are used, the bending of the manifold can be corrected and prevented, the success rate of primary welding can be improved, the welding efficiency is improved, the connecting force is improved and the mechanical loading capacity of the plastic tube network can be improved.

Owner:芶珍

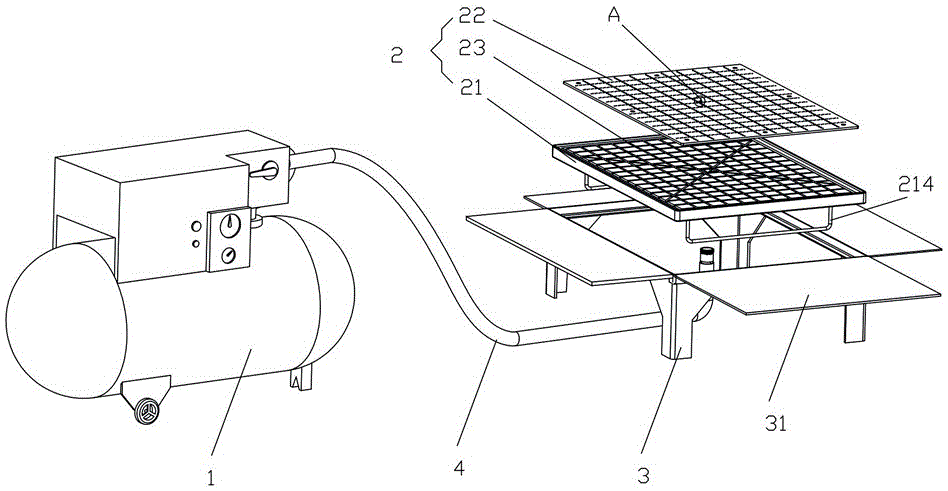

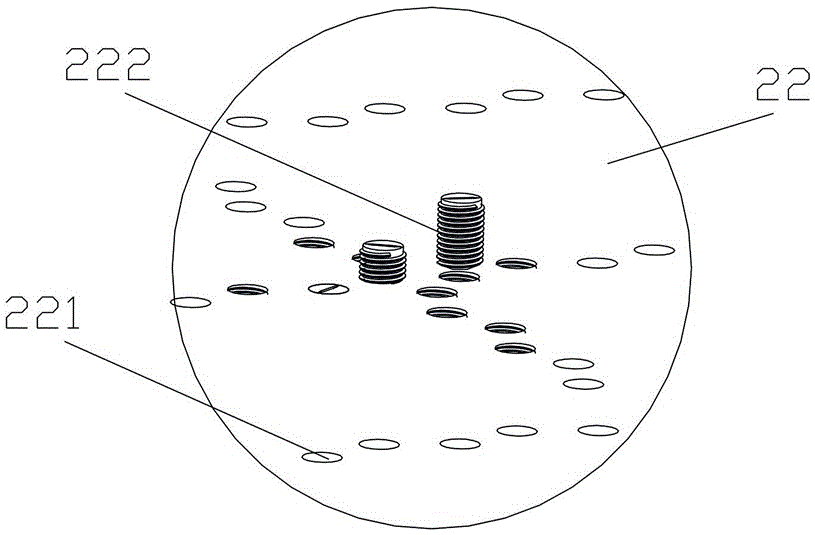

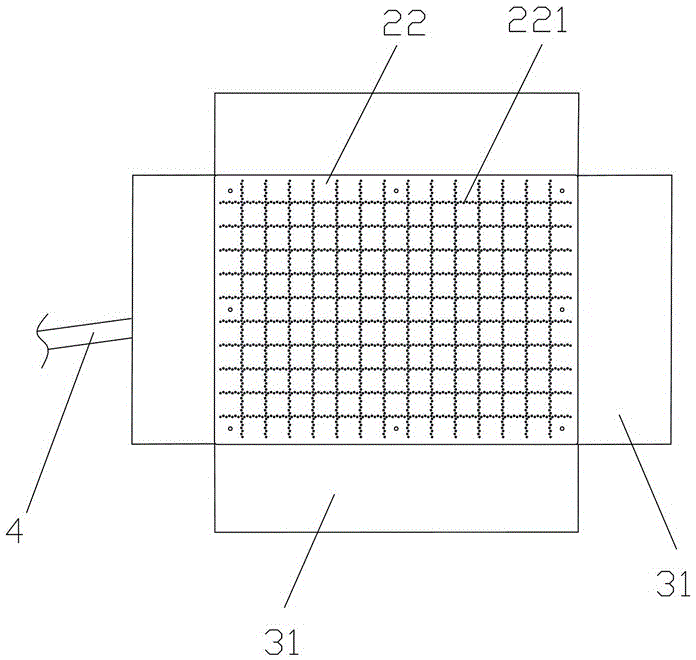

Negative-pressure adsorption welding device and negative-pressure adsorption welding method

InactiveCN106141519ANot prone to distortionImprove flatnessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding deformation

The invention discloses a negative-pressure adsorption welding device which comprises a negative-pressure producing assembly and negative-pressure adsorption plate assemblies; the negative-pressure adsorption plate assemblies comprise a bottom negative-pressure adsorption plate assembly and a top negative-pressure adsorption plate assembly; negative-pressure adsorption chambers are formed between the negative-pressure plate assemblies and the adsorption plate assemblies; the negative-pressure production assembly communicates with the negative-pressure adsorption chambers for extracting air in the negative-pressure adsorption chambers to form vacuum negative pressure; a plurality of negative-pressure adsorption holes are formed in the adsorption plate assemblies for fixing to-be-welded parts onto the adsorption plate assemblies in a negative-pressure adsorption manner to carry out welding operation when vacuum negative pressure is formed in the negative-pressure adsorption chambers. The invention further discloses a negative-pressure adsorption welding method. The negative-pressure adsorption welding device is reasonable in design, is convenient and quick to operate, is small in welding deformation and is capable of reducing working cost and improving working efficiency.

Owner:株洲天瑞精密钣金有限公司

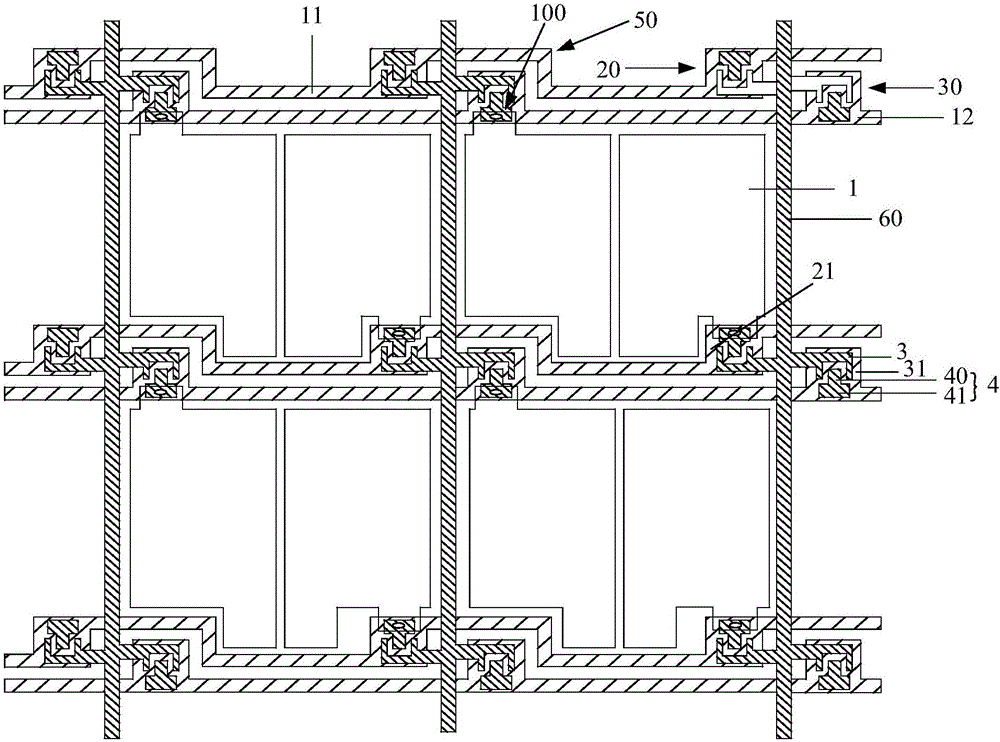

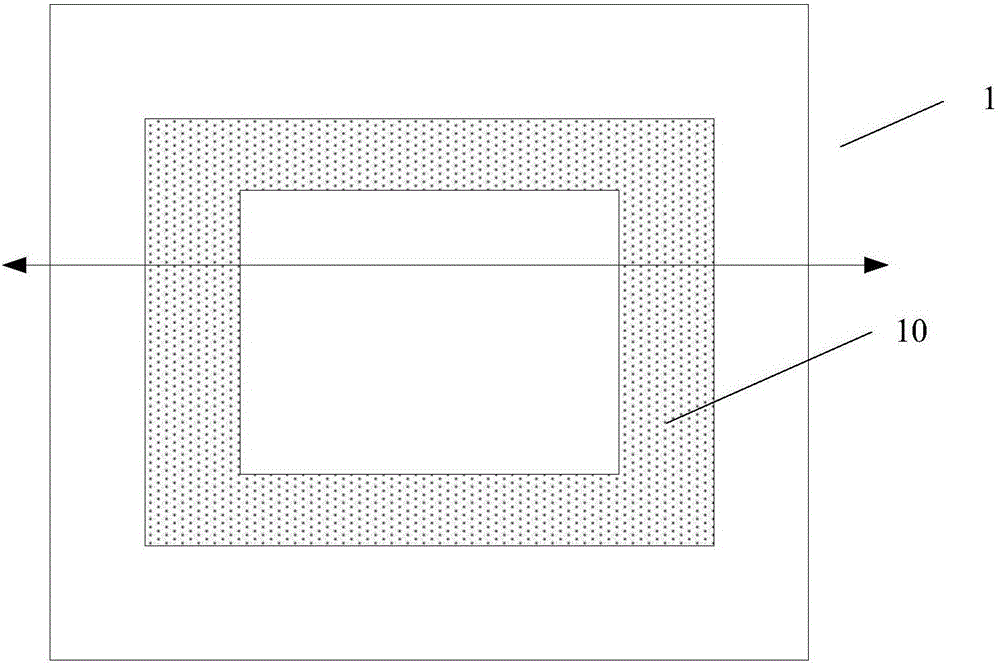

Display substrate and manufacturing method thereof and display device and maintenance method thereof

PendingCN106405951AImprove welding success rateConducive to maintenance success rateNon-linear opticsSignal onMetallic materials

The invention relates to the technical field of display and discloses a display substrate and a manufacturing method thereof and a display device and a maintenance method thereof. The display substrate comprises grid lines and data lines for defining a plurality of pixel regions. The display substrate comprises a plurality of display units. Each display unit comprises a pixel electrode and a thin film transistor arranged inside the corresponding pixel region to correspond to one pixel, wherein the orthographic projection of the plane, where a drain electrode of the thin film transistor is located, of the display substrate and the orthographic projection of the plane, where the grid lines are located, of the display substrate are overlapped partially to form overlapping regions, so that welding can be performed on the overlapping regions so as to short-circuit the pixel electrodes and the grid lines, the drain electrodes are cut, testing signals on the grid lines are transmitted to the pixel electrodes, and poor pixels of the display device are maintained. In order to achieve the purpose of short-circuiting the pixel electrodes and the grid lines, the drain electrodes and the grid lines are welded actually; due to the fact that the drain electrodes and the grid lines are made of metal materials, the welding success rate is increased, and the maintenance success rate is increased.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

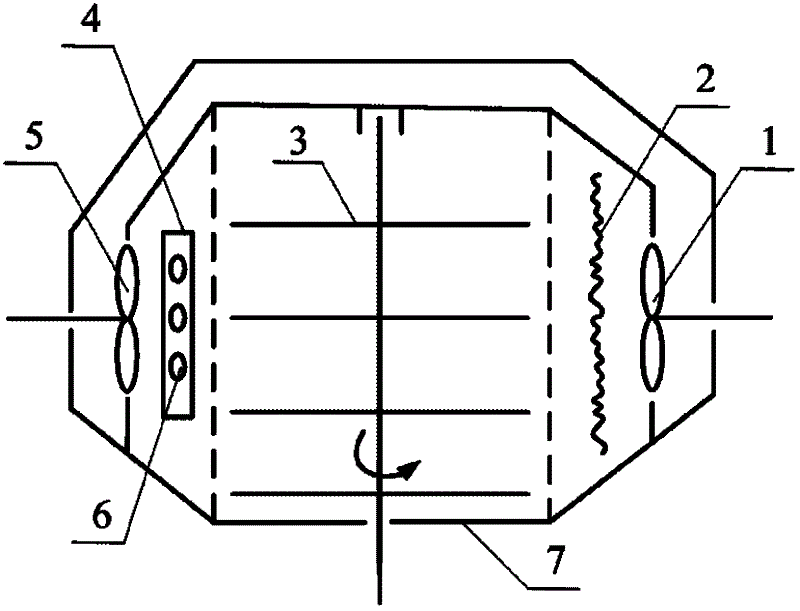

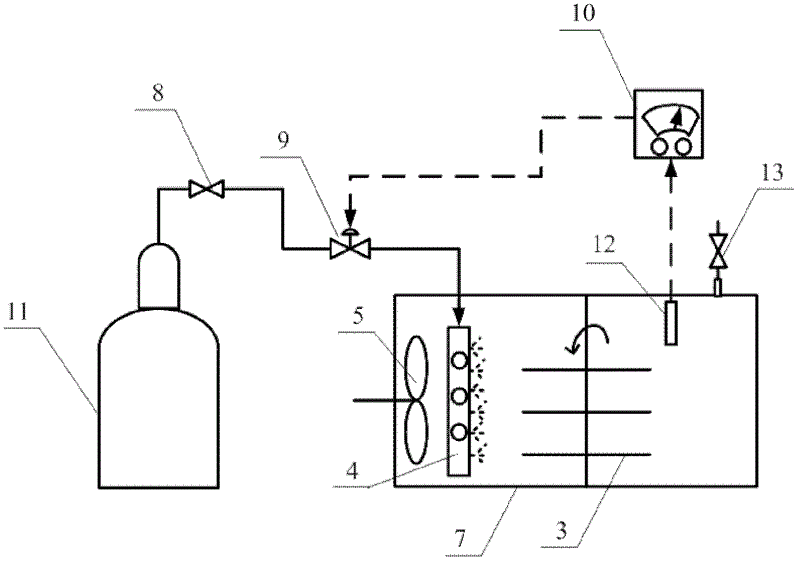

Reflow soldering system by aid of liquid nitrogen cooling and soldering method thereof

ActiveCN102615370AImprove temperature uniformityRapid coolingHeating appliancesMetal working apparatusLiquid nitrogen containerElectricity

The invention discloses a reflow soldering system and a corresponding soldering method thereof. The reflow soldering system comprises a sealed test box with the interior filled with nitrogen, a working turntable arranged in the test box, an electric heating device and a liquid nitrogen cooling device, wherein the working turntable is formed by a rotating shaft and a turntable and used for placing electronic components to be soldered and soldering fluxes, the electric heating device comprises a power supply, an electric heating element and a corresponding fan, and the liquid nitrogen cooling device comprises a self-pressurization liquid nitrogen container, a liquid nitrogen distributor, a low-temperature valve and a corresponding fan. The reflow soldering system by aid of liquid nitrogen cooling and the soldering method thereof can use nitrogen as protection gas to perform electric heating, simultaneously use liquid nitrogen to achieve cooling, and therefore technical effects including uniform soldering flux heating, soldering flux cooling and one-time massive soldering in mionectic environment are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

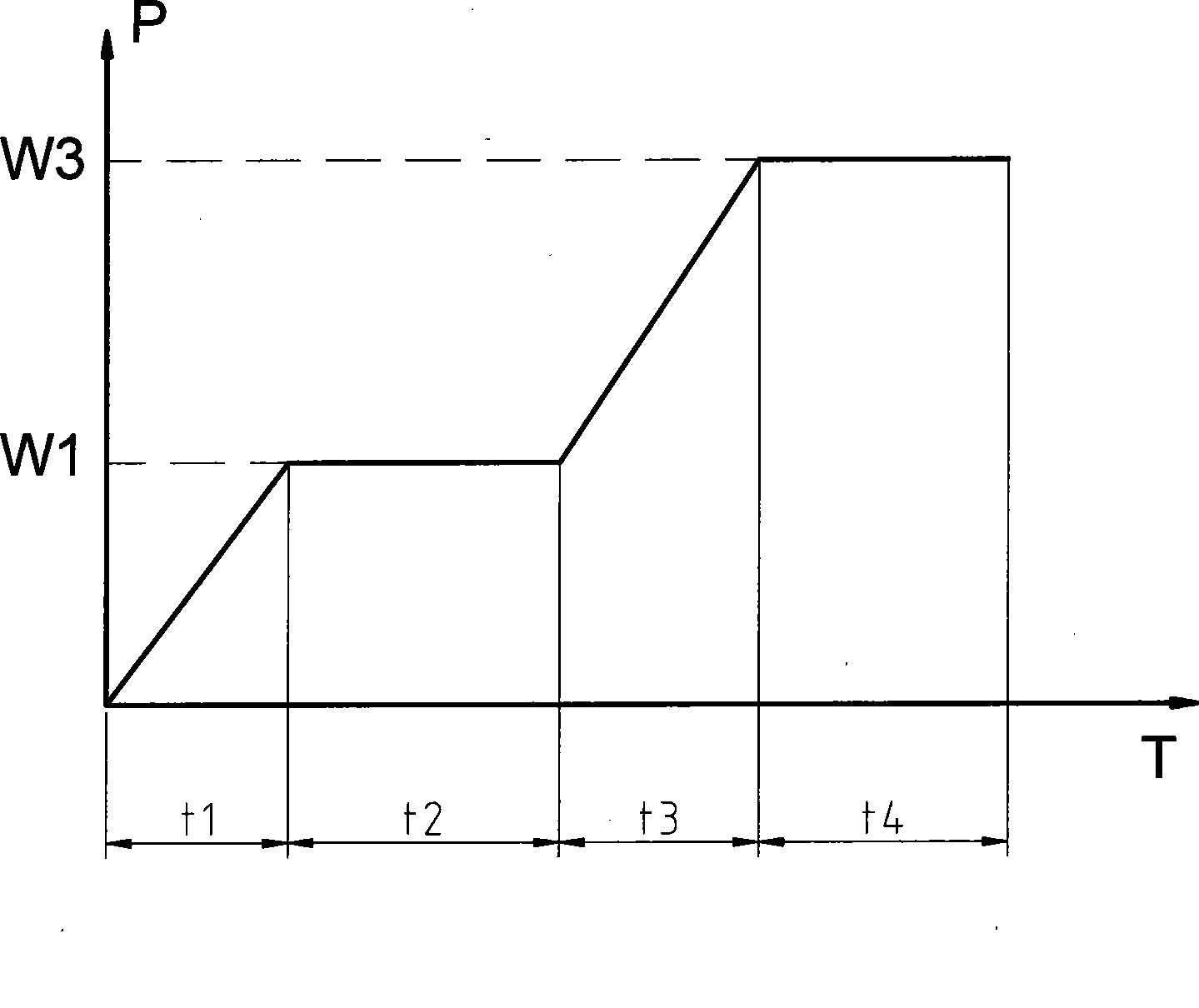

Semiconductor laser welding method

ActiveCN101428372AReduce welding defectsImprove solder joint adhesion and soldering success rateLaser beam welding apparatusPlastic weldingSoldering

The invention discloses a semiconductor laser welding method, the welding method includes the following four stages: the temperature rising stage, in which the laser power gradually rises from zero and the temperature of the welding flux rises the melting point or the approximate melting point from the room temperature; the maintaining stage, in which the laser power maintains invariable or slightly rises upon the laser power W1 at the later stage of rising the temperature; melting stage, in which the laser power continuously rises based on the later maintaining stage so that the welding flux is fully melted or close to the full melting; and the subsequent stage, in which the laser power maintains invariable upon the laser power W3 at the later melting stage so as to achieve welding. The invention has the advantages that work pieces can be optimized by processing parameters, the adhesive force of the samples to the welding point is greatly enhanced, wherein, the welding success rate for the tin soldering at one time reaches 100%, the situations such as false welding, lack welding, unsoldering and the like are not generated, and the oxidation phenomenon of the welded work pieces can be effectively avoided. Therefore, the continuous welding of the plastic welding can be realized to avoid the phenomenon for the initial point, the end point and the focal point, and the intensity of the welding point can surpass that of the original materials.

Owner:深圳市大族微加工软件技术有限公司

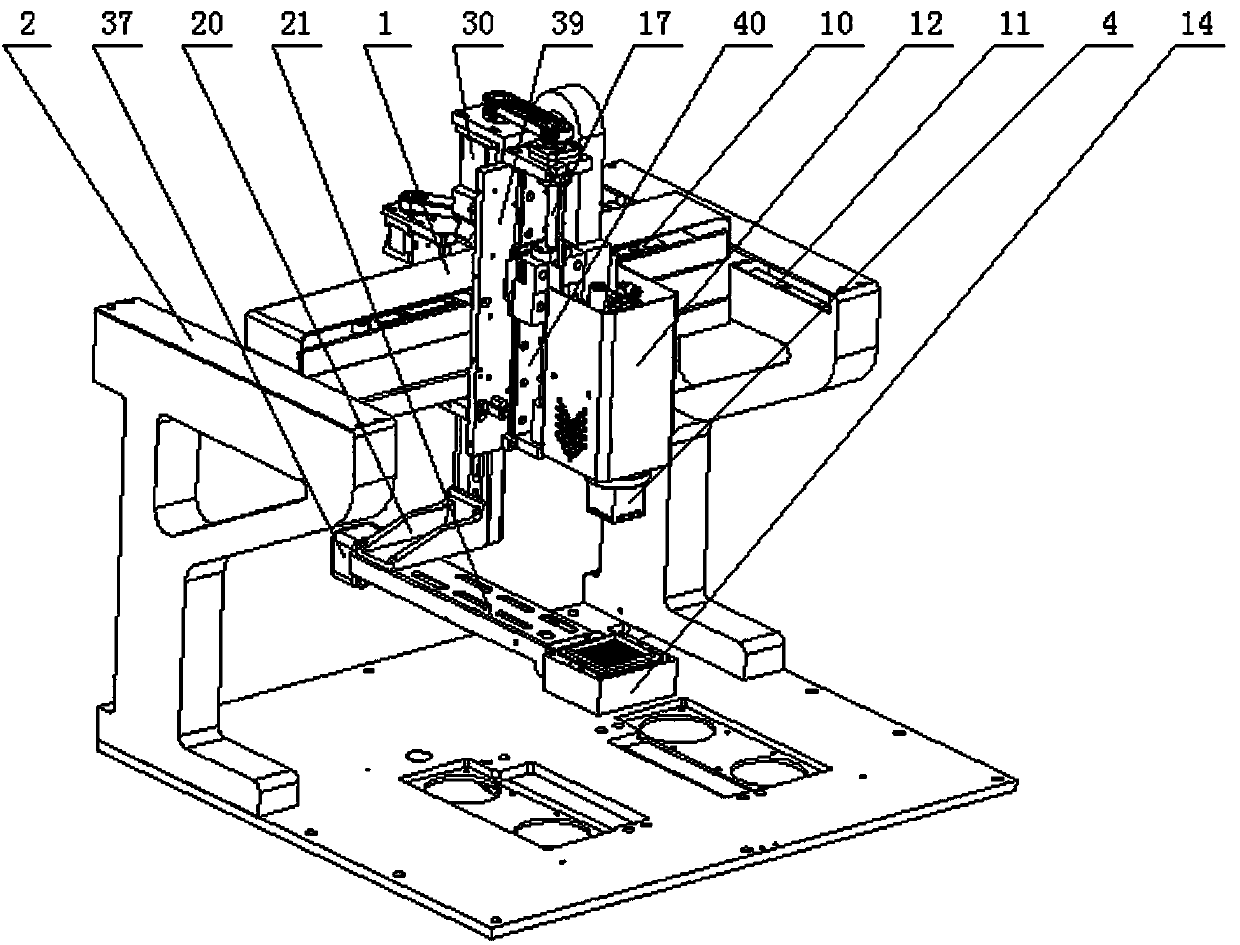

Integrated desoldering system conducting upper hot air heating and lower hot air heating synchronously

ActiveCN103752974ASimple structurePrevent deformation, sinking and bendingHeating appliancesMetal working apparatusSurface mountingBall screw

Provided is an integrated desoldering system conducting upper hot air heating and lower hot air heating synchronously. The integrated desoldering system comprises an upper heating device, a lower heating device and a synchronization mechanism. The upper heating device is composed of an upper heating group, an X-axis cross beam, a Y-axis cross beam, an upper heating cover, an upper heating tuyere, an X-direction guide rail, a Y-direction guide rail, a Z-direction guide rail, a ball screw and an upper synchronous wheel. The lower heating device is composed of a lower heating group and a heater through-connection body. The synchronization mechanism is composed of a manipulator front fixing plate, a manipulator upper arm, an arm connecting part, a manipulator front arm, an upper inductor, a lifting induction sheet, a lower inductor, a manipulator rear fixing plate, manipulator side fixing plates, a manipulator upper fixing plate, a ball screw, a lead screw nut, an arm braking component and a manipulator lower fixing plate. According to the integrated desoldering system conducting upper hot air heating and lower hot air heating synchronously, the upper heating group and the lower heating group move synchronously and move freely in the X direction, the Y direction and the Z direction; the desoldering and surface mount precision is effectively guaranteed; the automation is high, and the working efficiency is improved.

Owner:SHENZHEN ZHUO MAO TECH

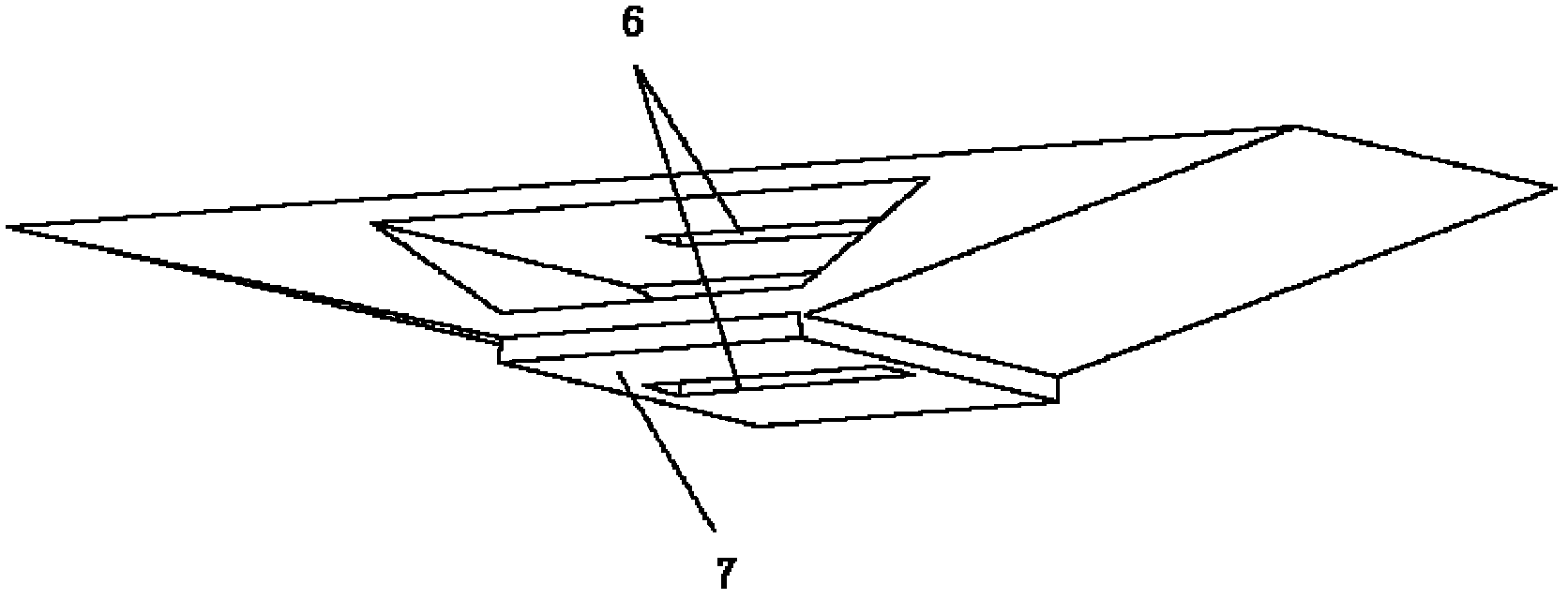

Fabrication method of mask, mask and evaporation system

InactiveCN106681100AImprove flatnessImprove surface flatnessSolid-state devicesVacuum evaporation coatingEvaporationEngineering

The invention belongs to the technical field of display, in particular to a fabrication method of a mask, the mask and an evaporation system. The mask comprises a frame and an open mask, wherein an opening is formed in an intermediate region of the frame, and the open mask is arranged above the frame. The fabrication method of the mask comprises the steps of applying a first counter force onto the frame during the frame formation process; and welding the open mask in a region at least covering the opening of the frame, and applying a second counter force onto the frame during the welding process, wherein the first counter force and the second counter force are same in direction and are equal in size. According to the fabrication method of the mask, the counter forces are applied onto the frame during the frame formation process, the counter forces are applied after the open mask is welded above the frame during the welding process, thus, an upper surface of the frame is better in flatness, the welding success rate can be effectively improved, and the flat state of the mask is improved.

Owner:BOE TECH GRP CO LTD +1

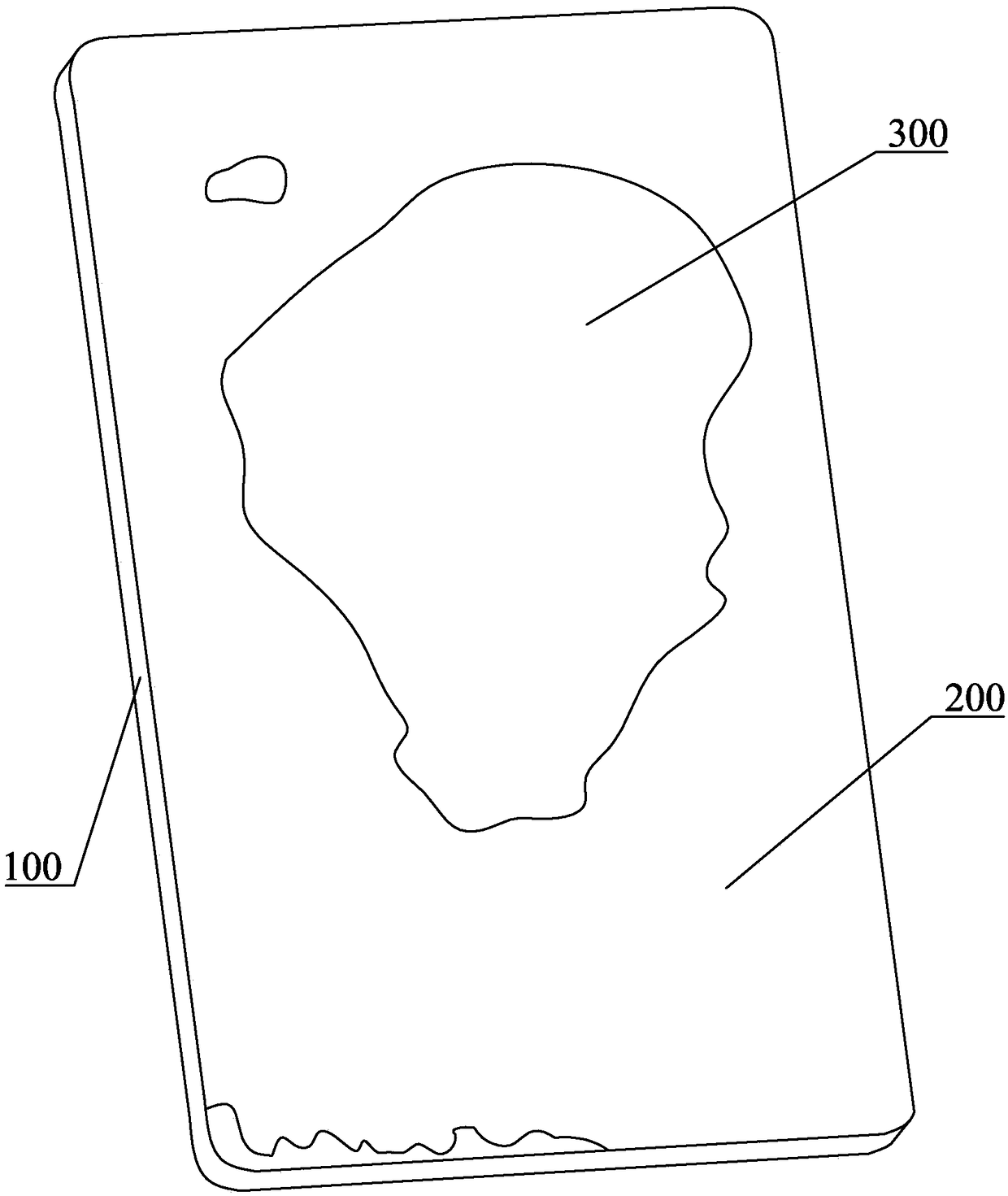

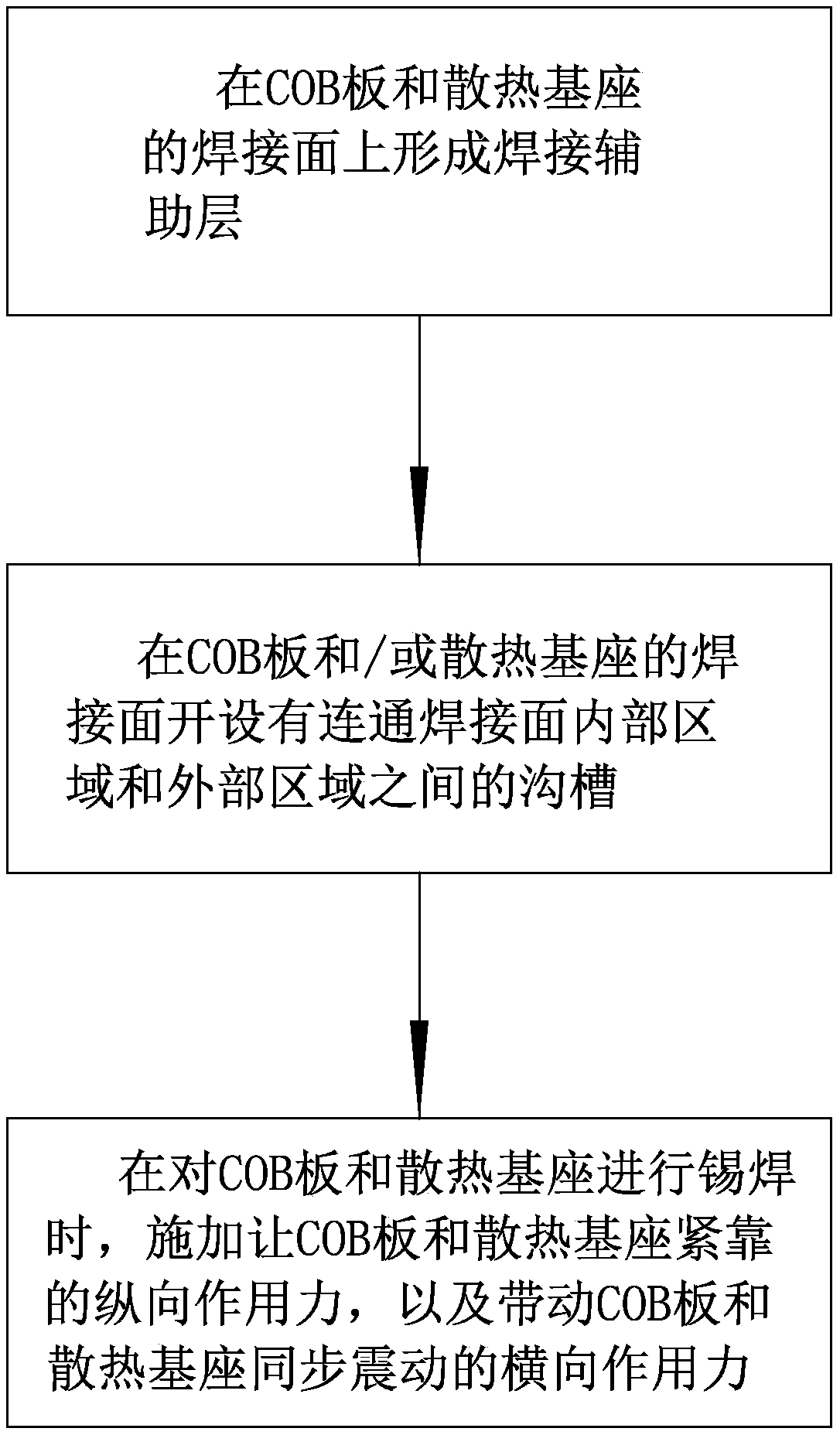

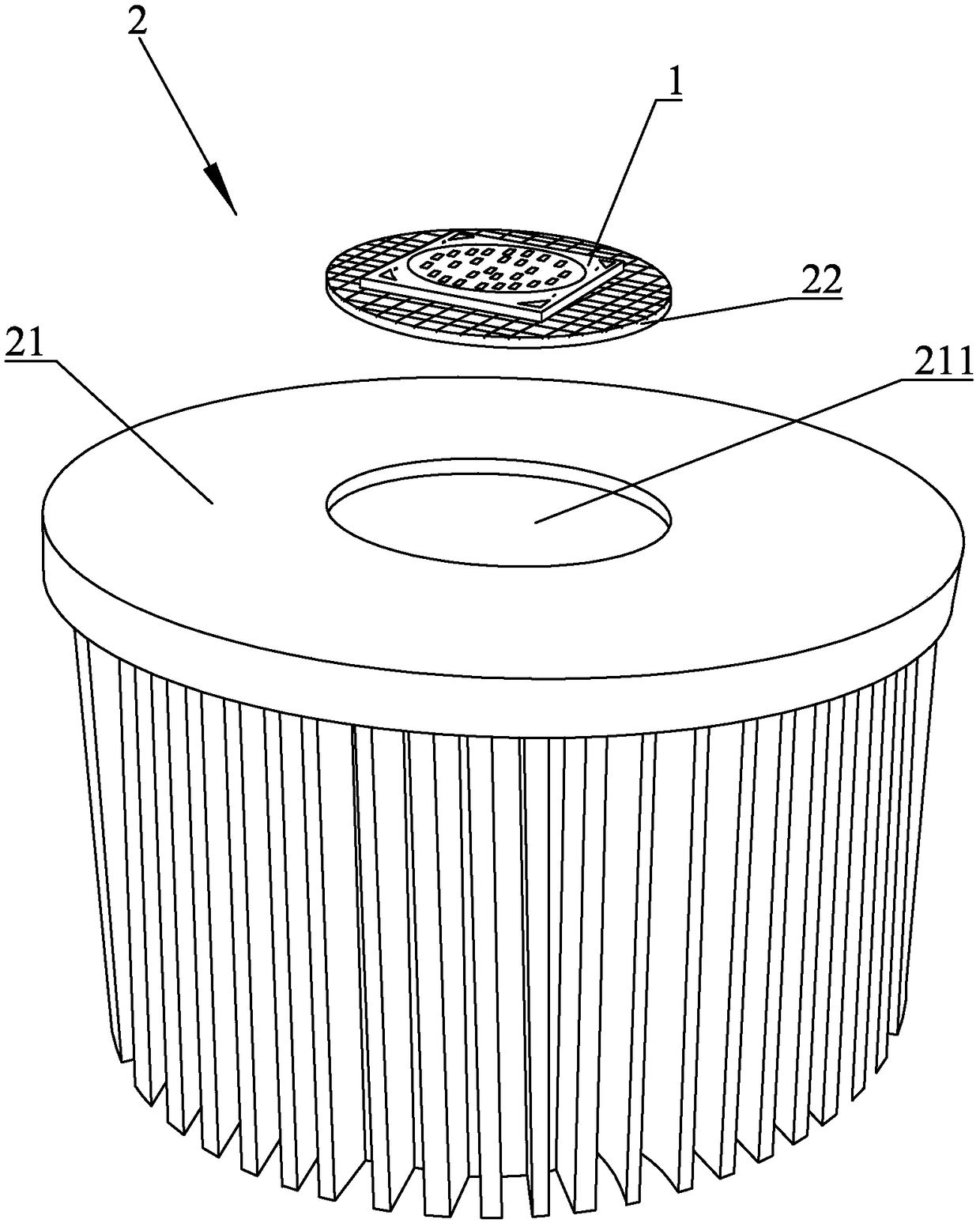

Method of reducing tin soldering voidage between COB (chip on board) and heat-dissipation base

InactiveCN109079274AIncrease success rateEnsure the promotion of industrializationSolder feeding devicesSoldering auxillary devicesSolderingHigher Power

The invention discloses a method of reducing tin soldering voidage between a COB (chip on board) and a heat-dissipation base. The method comprises the following steps of: (1) forming a soldering assistance layer on a soldering face of the heat-dissipation base, (2) forming a groove communicating an internal area and an external area of the soldering face in the COB or the soldering face of the heat-dissipation base, (3) applying a longitudinal acting force to allow the COB to close to the heat-dissipation base and a transverse acting force to drive the COB to rock during tin soldering of the COB and the heat-dissipation base, wherein the depth of the groove is greater than or equal to the thickness of the soldering assistance layer and less than the thickness sum of the soldering assistance layer and the COB or the heat-dissipation base. The method can greatly increase an actual soldering success rate; high efficiency of a heat conduction bridge between the COB and the heat-dissipationbase is guaranteed; and actual industrial popularization of the high-power COB is guaranteed.

Owner:厦门吉来特光电有限公司

Electrical engineer electrical appliance connection detection workbench

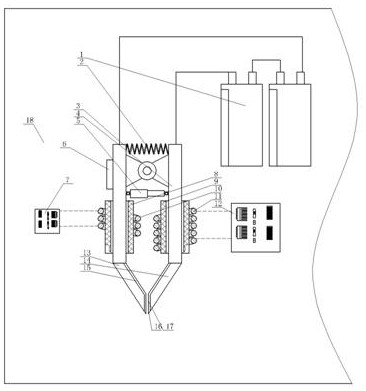

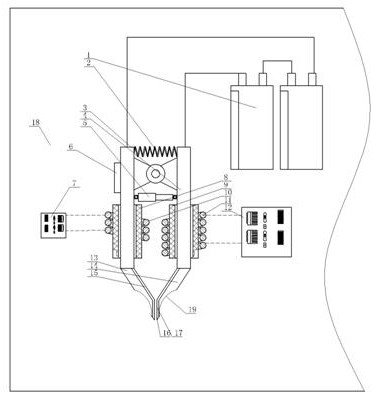

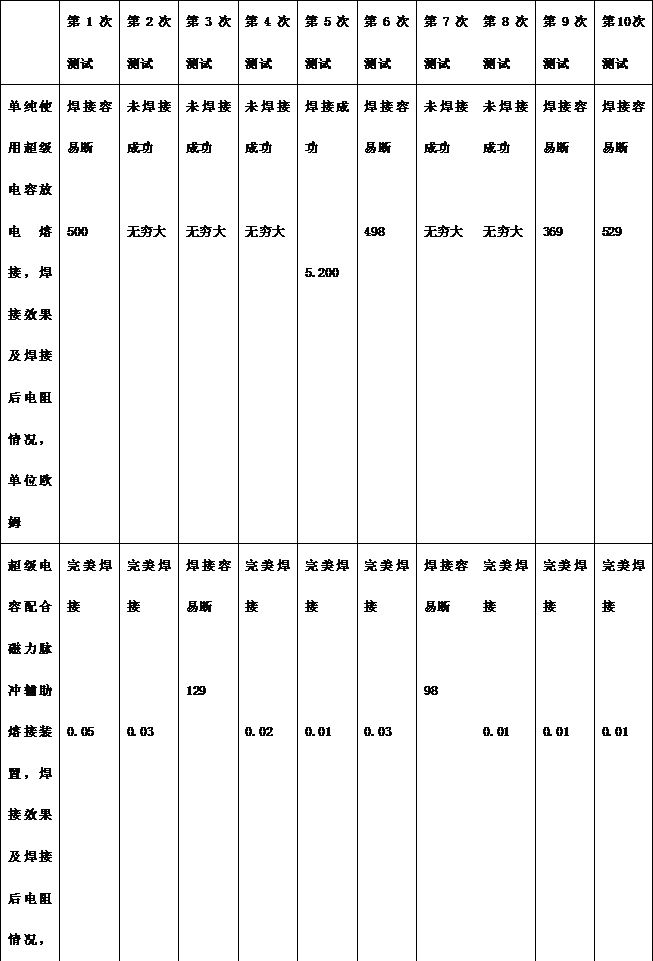

ActiveCN111999529AReduce contact resistanceIncrease success rateWelding/cutting auxillary devicesAuxillary welding devicesCapacitanceElectrical resistance and conductance

Provided is an electrical engineer electrical appliance connection detection workbench comprising a platform plate, a first pulse generator and a second pulse generator. A magnetic pulse auxiliary welding device is mounted at the upper part of the platform plate; the magnetic pulse auxiliary welding device comprises a fixing support. According to the invention, the magnetic pulse auxiliary weldingdevice is additionally arranged on the basis of a workbench; according to the magnetic pulse auxiliary welding device, the characteristic that a super capacitor can generate large-current discharge is utilized; a first clamping plate and a second clamping plate are matched to clamp two pins to be welded; therefore, the large current flows through the two pin contact areas, the two pin contact areas are heated by high temperature, but although the two pin contact areas are singly heated to realize direct welding of individual pins, the two pins are disconnected by slight external force after fusion welding is completed in most cases, and the contact resistance is still not reduced.

Owner:SHANDONG INST FOR PROD QUALITY INSPECTION

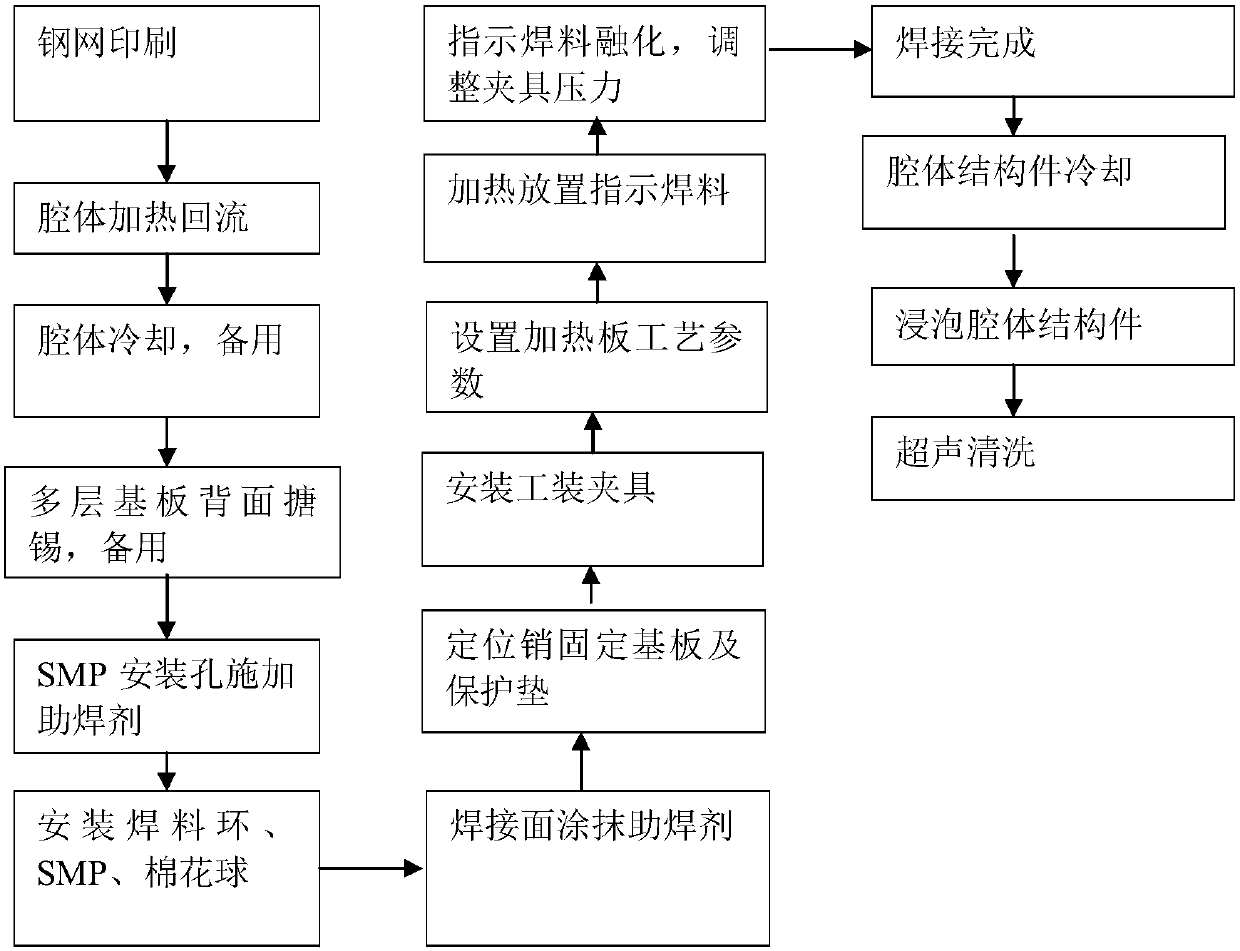

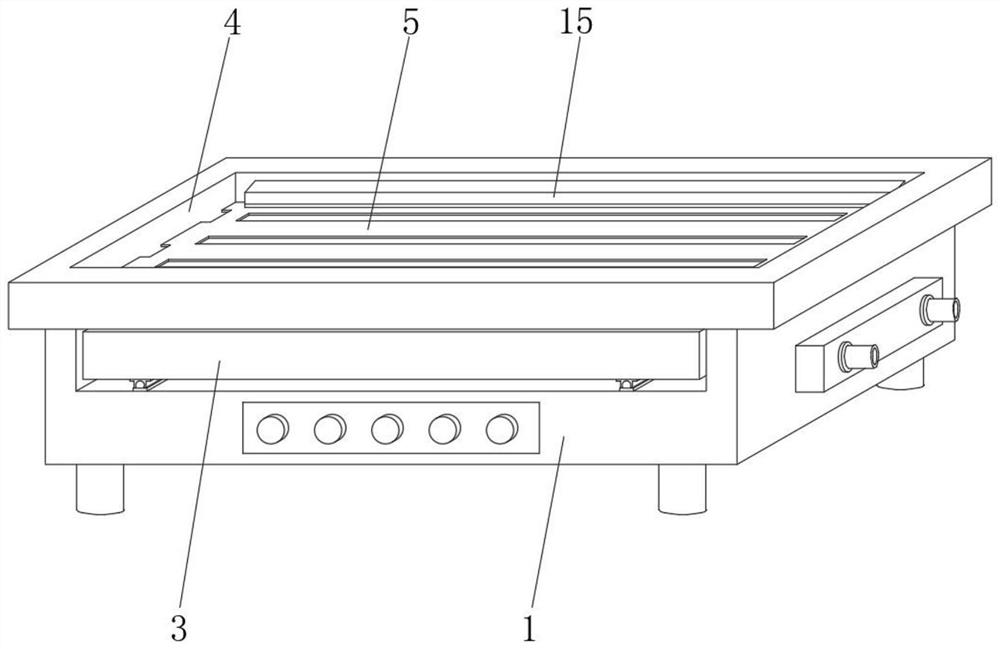

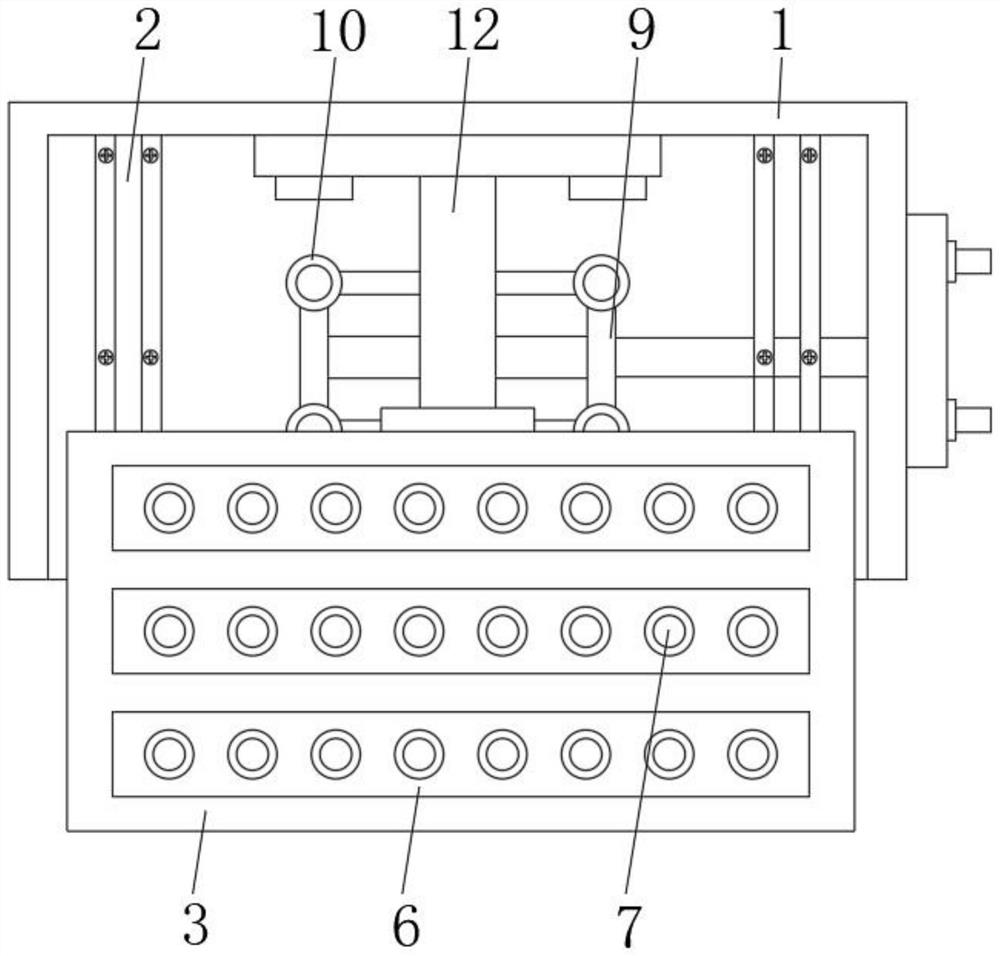

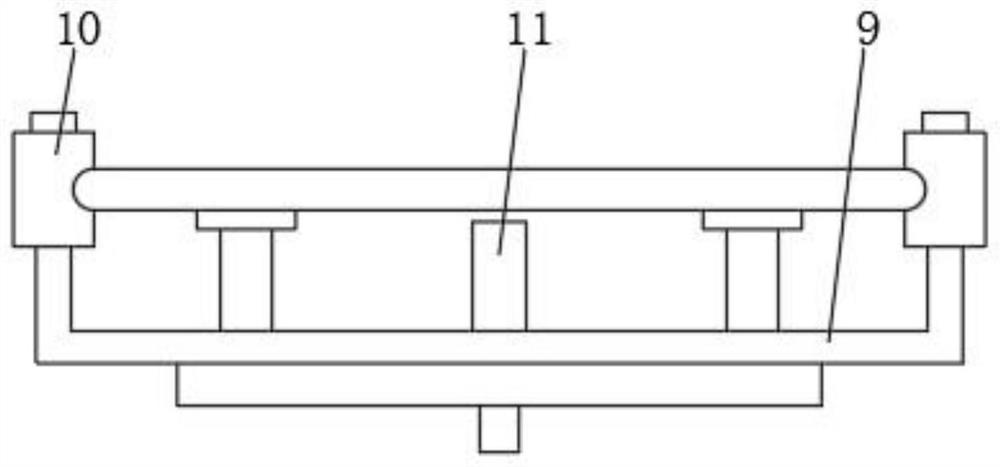

Welding method of multilayer copper-clad substrate of phased array active antenna array

ActiveCN107745166AGood welding performancePromote infiltrationWelding/cutting auxillary devicesAuxillary welding devicesRefluxEngineering

The present invention provides a welding method of a multilayer copper-clad substrate of a phased array active antenna array, and aims at providing a welding method capable of effectively preventing unstable welding quality of the multilayer copper-clad substrate. The welding method is implemented by the following technical scheme that a tool having the same shape with the multilayer copper-clad substrate and L-shaped clamps, an circular array of which is distributed on a tool pedestal, are prepared; steel mesh printing solder is applied to a front surface welding area of a cavity structural member and disposed on a reflux heating plate of a heater; the tool having the same shape with the multilayer copper-clad substrate and L-shaped clamps, the circular array of which is distributed on the tool pedestal, are prepared; the surface of the multilayer copper-clad substrate equipped with an SMP solder side is upward, the multilayer copper-clad substrate is fixed on a projection surface ofthe tool pedestal, solder rings and SMP radio frequency connectors are disposed in SMP installing holes in the reverse side of the cavity structural member, and soldering flux is applied; the back side of the multilayer copper-clad substrate is tinned, and the multilayer copper-clad substrate is fixed on the solder side of the cavity structural member coated with the soldering flux through pins and disposed on the reflux heating plate of the heater; and front surface welding of the multilayer copper-clad substrate and the cavity structural member is performed by hot reflux, and cavity back surface welding of the SMP radio frequency connectors to the cavity structural member is performed.

Owner:10TH RES INST OF CETC

Welding and positioning device for lamp strips and lamp beads

PendingCN113084422AEasy to weldImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMaterials science

The invention discloses a welding and positioning device for lamp strips and lamp beads. The welding and positioning device comprises a device main body, a sliding rail is arranged in the interior of the device main body, a lamp bead fixing seat is slidably mounted on the sliding rail, a lamp bead adsorption device used for limiting the positions of the lamp beads is arranged at a position, close to the bottom end, in the interior of the device main body, and a placement opening is formed in the outer surface of the upper end of the device main body. According to the welding and positioning device for the lamp strips and the lamp beads, welding can be directly carried out, people do not need to manually maintain the positions of the lamp beads and the lamp strips during welding, and therefore people can conveniently weld the lamp beads to the lamp strips, the welding efficiency and the success rate are improved, the plurality of sets of lamp beads are welded at a time, the welding speed is high, the stability of the lamp beads can be kept, the lamp beads are prevented from shaking in the welding process, the yield can be improved, the position of the lamp strip fixing plate can be limited, the positions of the lamp strips can be further limited, people can conveniently complete welding of the lamp strips and the lamp beads, and better use prospects are brought.

Owner:江苏运鸿辉电子科技有限公司

Gun-pressed elastic ground wire

PendingCN108493633AIncrease contact areaIncrease contactClamped/spring connectionsConnection contact member materialContact pressureEngineering

The invention discloses a gun-pressed elastic ground wire, which comprises a welding unit and a grounding unit, wherein the welding unit comprises a conductive transfer part and a welding part; the conductive transfer part is connected with a welding gun and can be pressed; the welding part is connected with sheet metal in a welding manner; a concave cavity and an opening groove are formed in thetransfer part; the welding part is arranged in the grounding unit in a penetrating manner; an elastic element is arranged between the welding part and the grounding unit; the grounding unit comprisesan insulating component and a ground wire base; the insulating component movably sleeves the outside of the welding part; and the ground wire base is in contact with the sheet metal. By adopting the transfer part with the concave cavity and the opening groove, the gun-pressed elastic ground wire can be matched with various welding drawing tools, and is convenient to operate; the distance between awelding head and the ground wire base is short, so that the resistance during welding is effectively reduced and the welding success rate is improved; the contact area of the ground wire base and thesheet metal of a car body is large, so that output impedance is effectively reduced and the conductivity is improved; and the condition that the ground wire base has sufficient contact pressure on the car body is ensured through the elastic element to ensure that a welding point is not easily loosened.

Owner:JIANGMEN BOSJOB

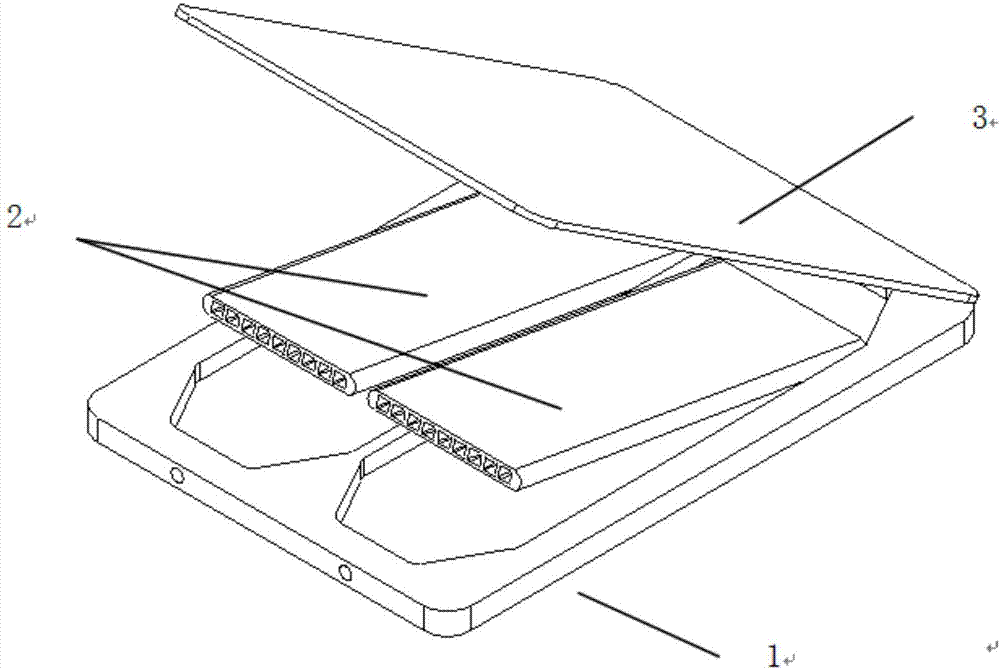

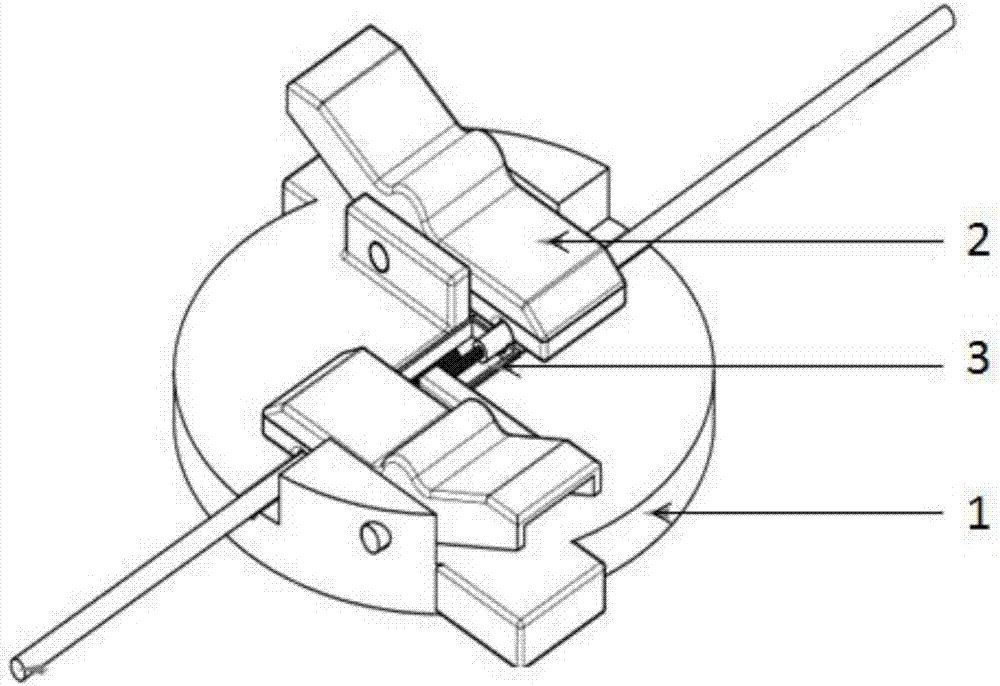

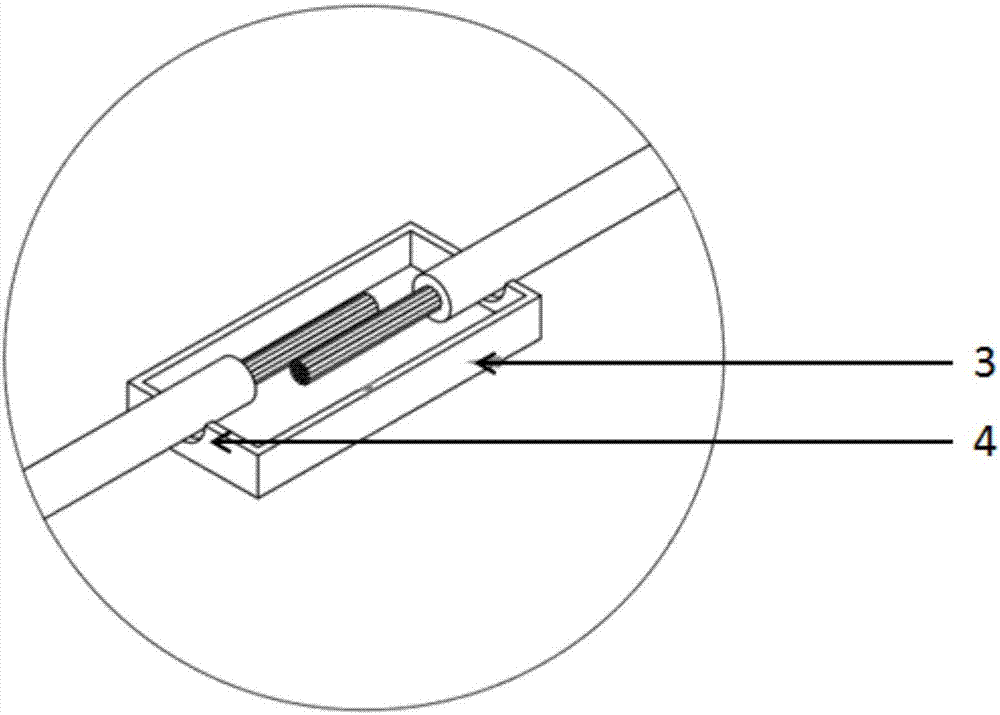

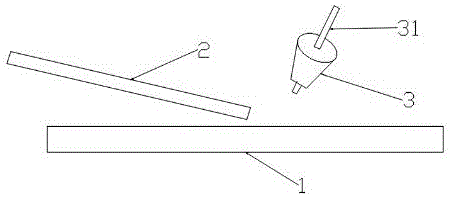

Wire harness welding tool

InactiveCN107008991AReduced risk of burnsReduce labor costsSoldering auxillary devicesEngineeringCable harness

The invention relates to the field of wire harness welding, and discloses a wire harness welding tool. The wire harness welding tool comprises a base (1), one or more pairs of wire harness clamps (2) which can be fixed on the base (1), and a welding box (3) which can be fixed on the base (1) and located between the wire harness clamps (2). Through the adoption of the wire harness welding tool disclosed by the invention, wire harness welding operation can be performed by one person, so that labor cost is reduced, and the risk that the operating staff is scalded is effectively reduced.

Owner:ANHUI RNTEC TECH CO LTD

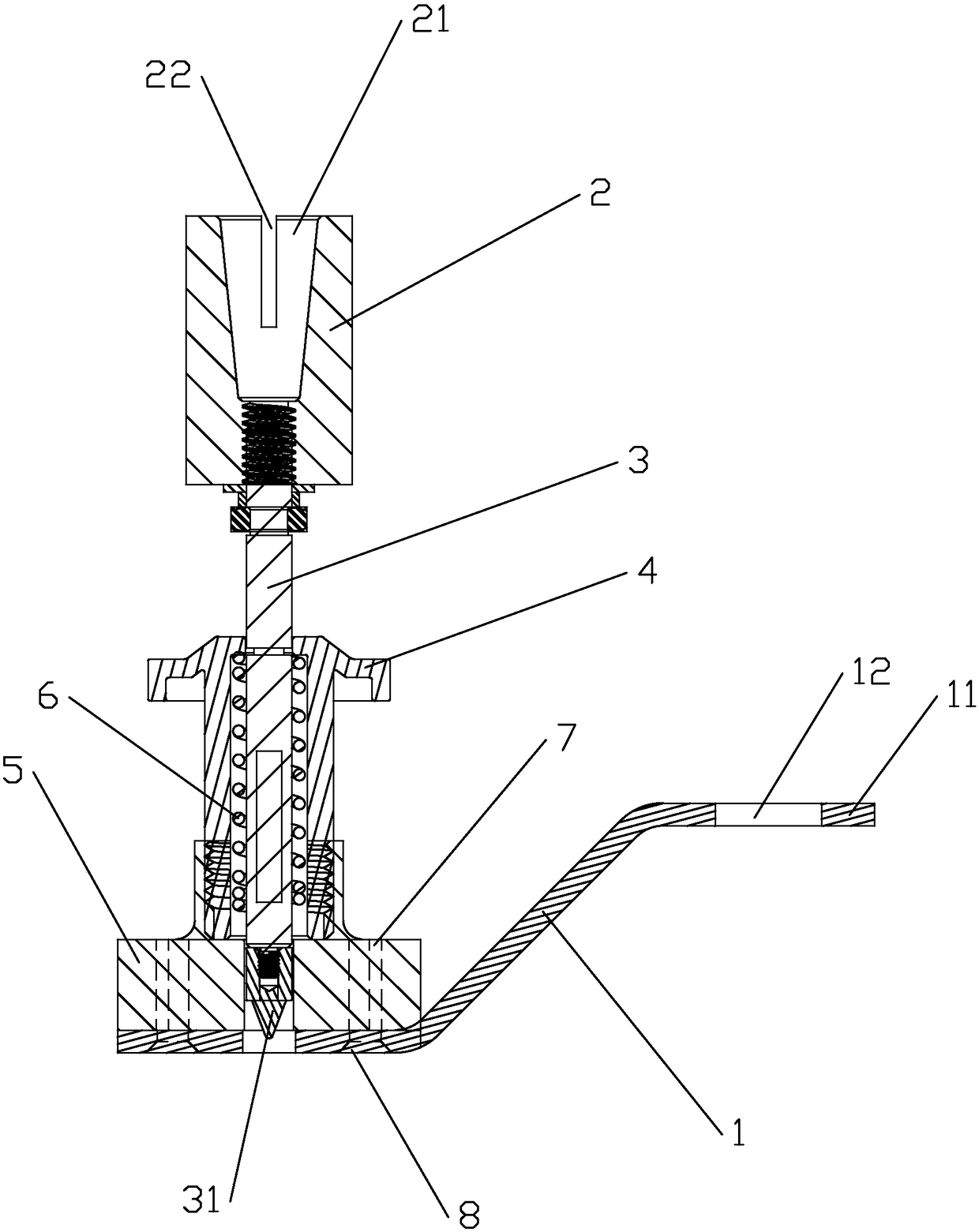

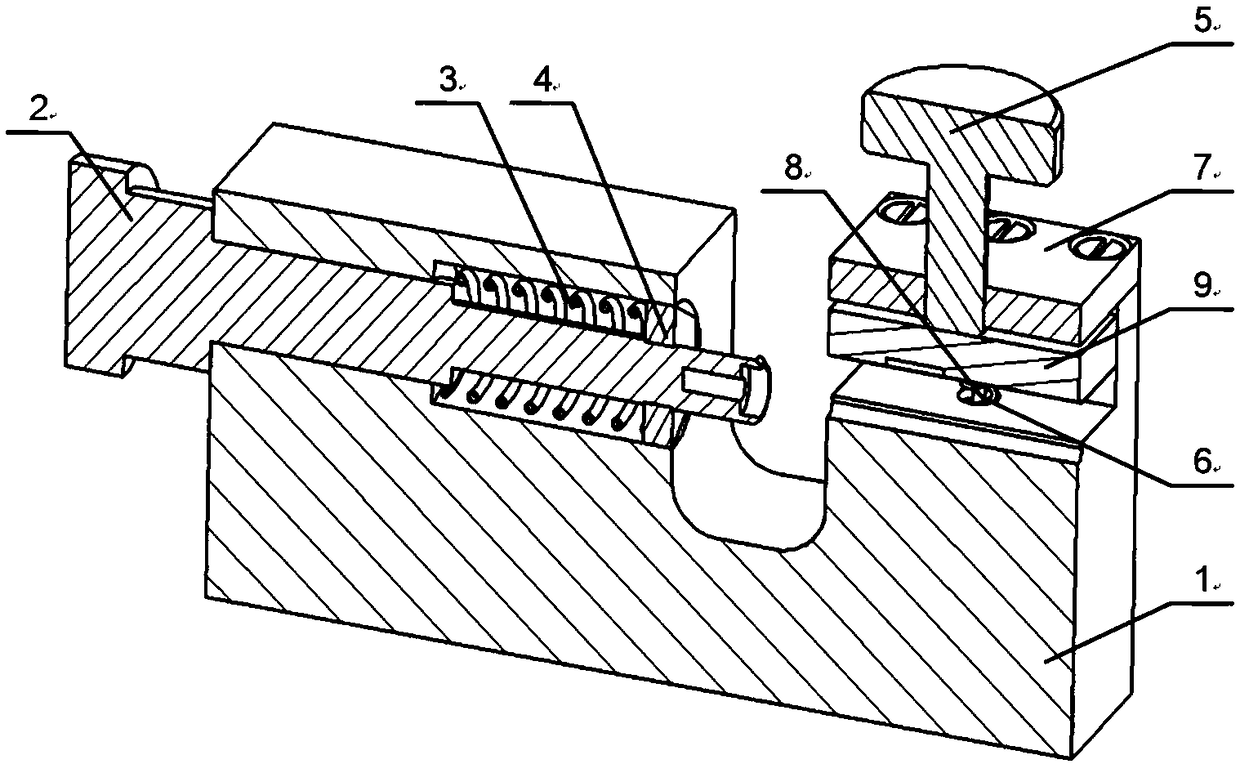

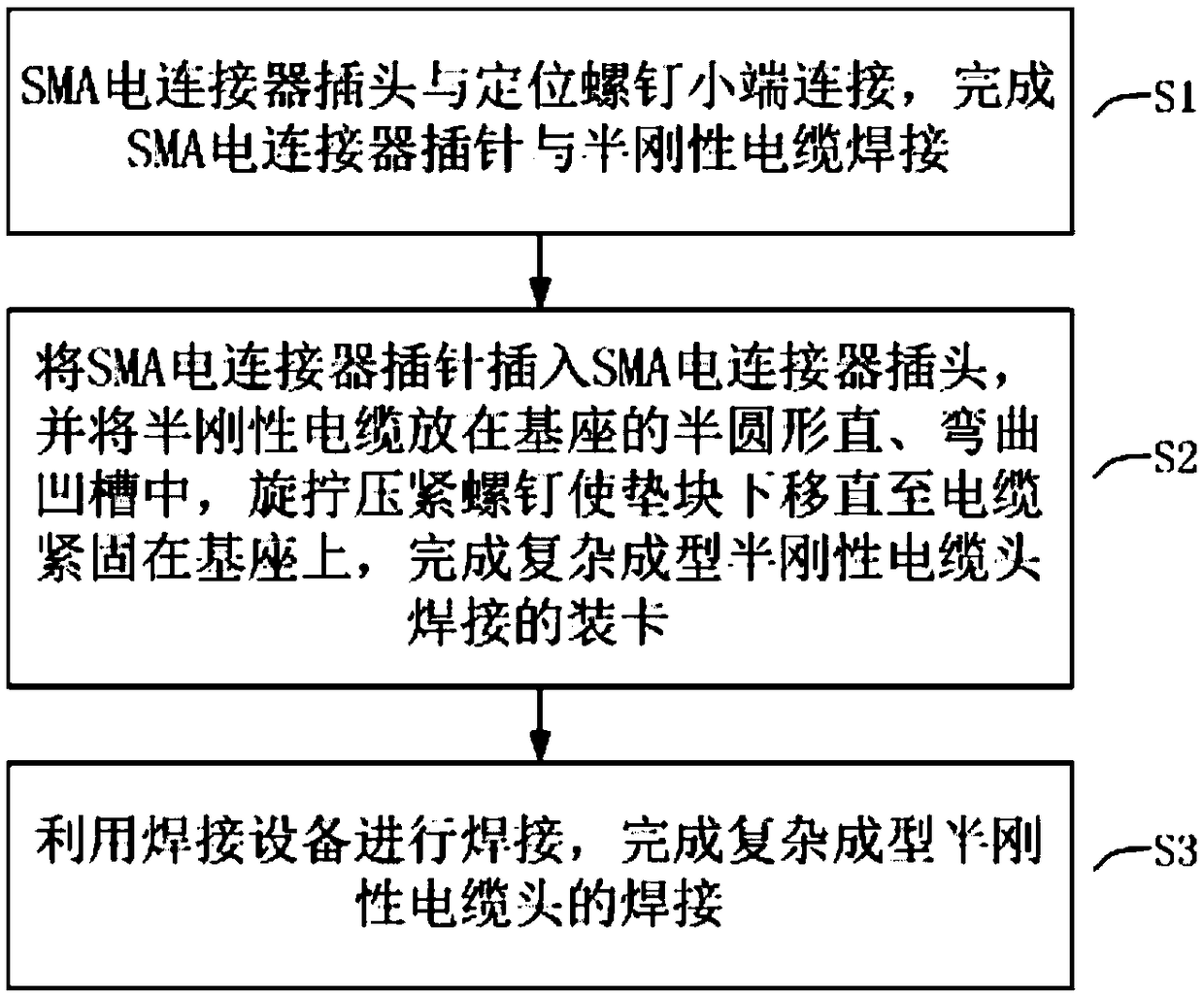

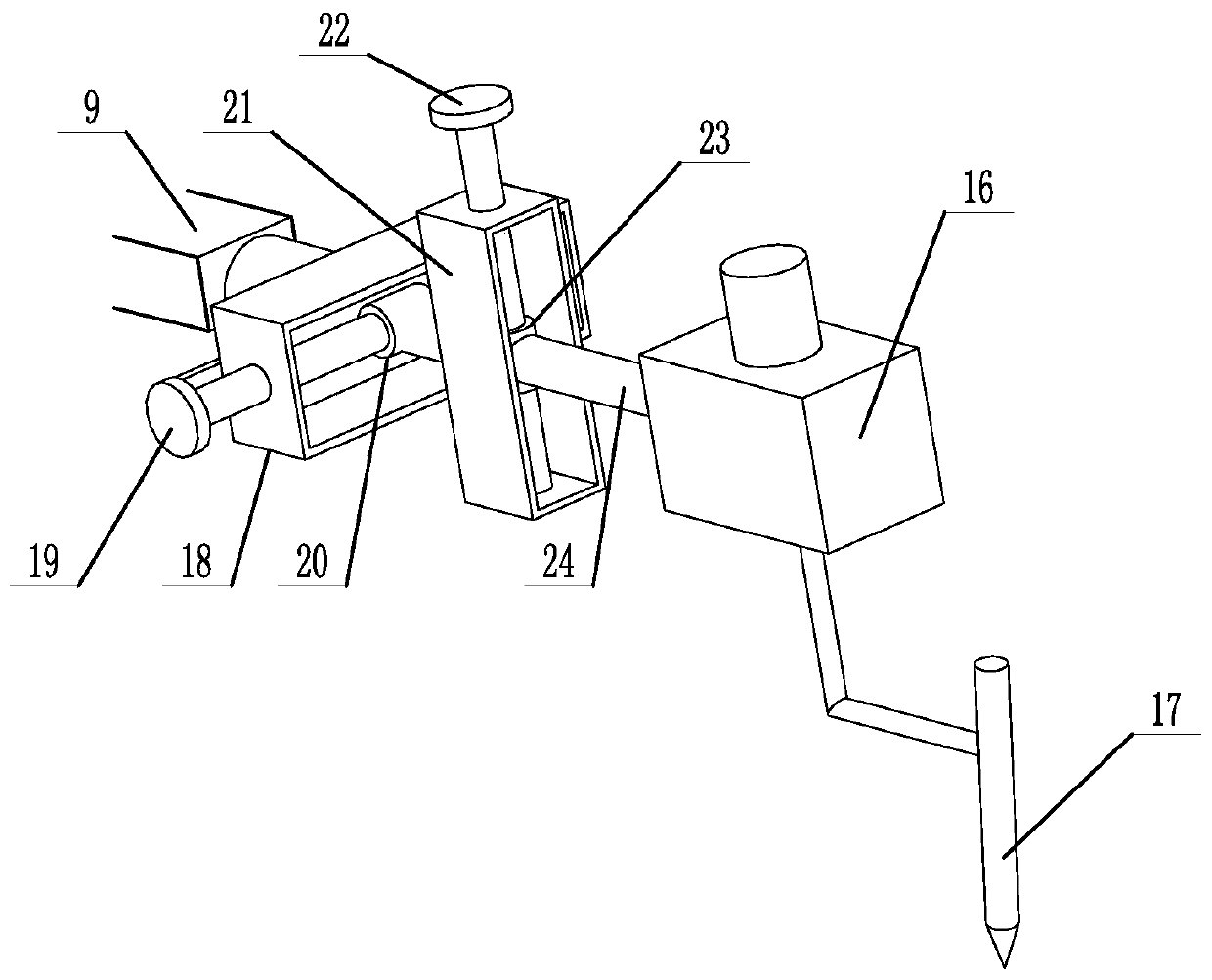

Complex formed semi-rigid cable head welding clamping device and application method thereof

InactiveCN109317888ASolve the accuracy problemSolution rangeWelding/cutting auxillary devicesAuxillary welding devicesElectricityEngineering

The invention discloses a complex formed semi-rigid cable head welding clamping device. The complex formed semi-rigid cable head welding clamping device comprises a pedestal, a positioning screw, a first spring, a nut, a compression screw, a second spring, a cover plate, a pin and a pressing block. An aligning mechanism is formed by the positioning screw, the first spring and the nut. A hold-downmechanism is formed by the compression screw, the cover plate, the pressing block, the pin and the second spring. The aligning mechanism and the hold-down mechanism are fixed to the pedestal, and thecomplex formed semi-rigid cable head welding clamping device is formed. According to the complex formed semi-rigid cable head welding clamping device, the problems that when a complex formed semi-rigid cable is welded, due to the clamping difficulty, the alignment precision of an electric connector plug is bad, and the scattering range of a standing-wave ratio after welding is large are solved, itis ensured that after the cable is welded, the standing-wave ratio meets the design requirement, and the one-time welding success rate is increased.

Owner:BEIJING INST OF REMOTE SENSING EQUIP

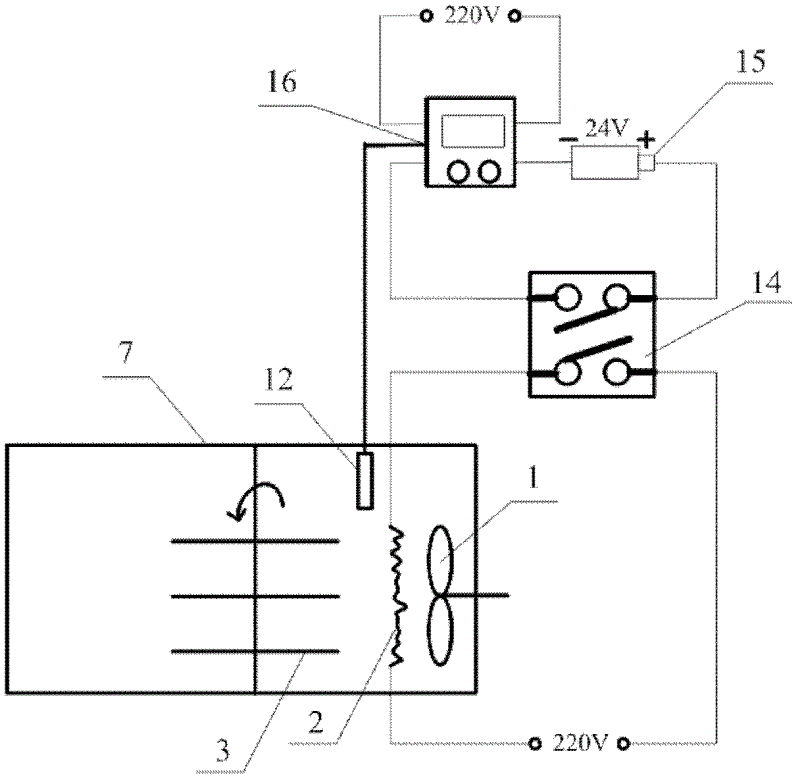

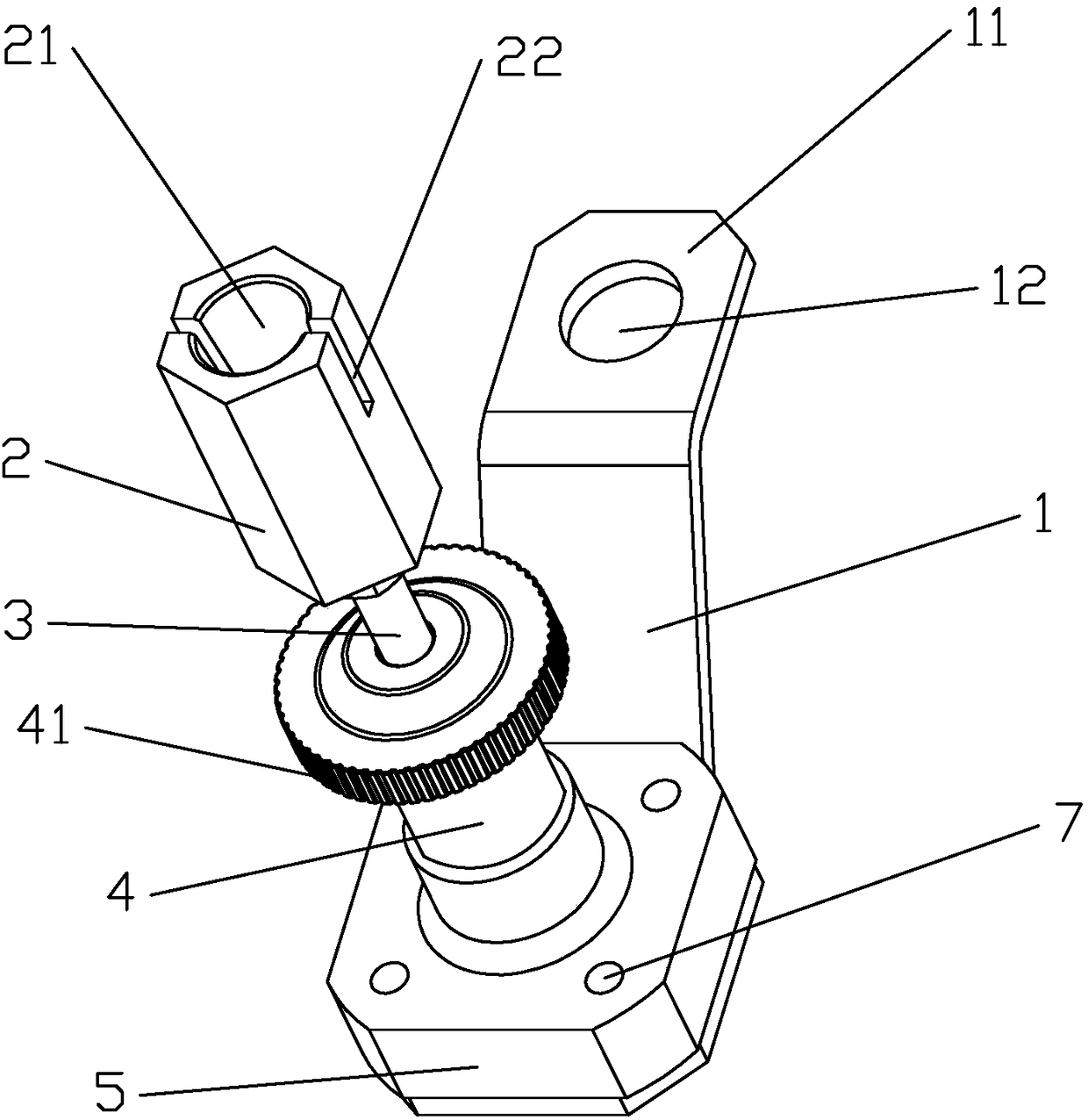

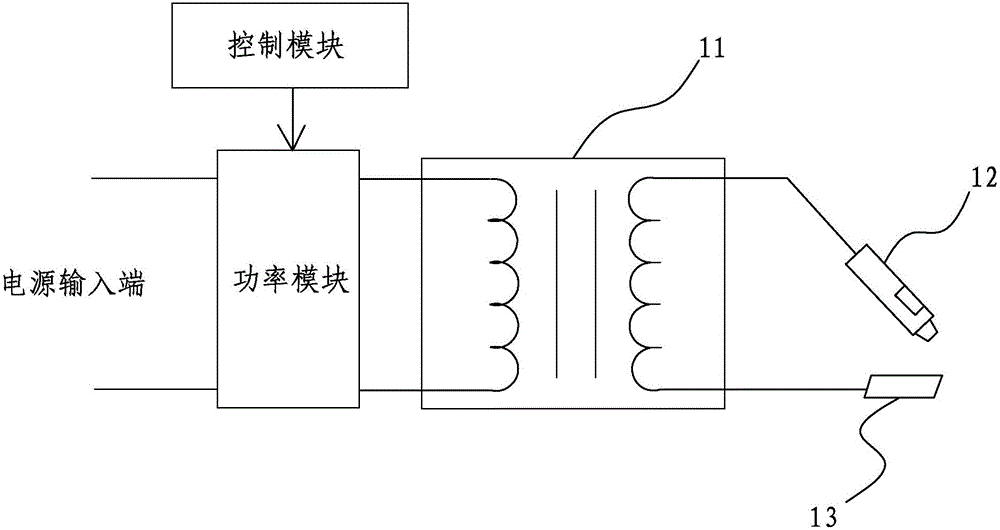

Handheld active control type spot welder for planting nails

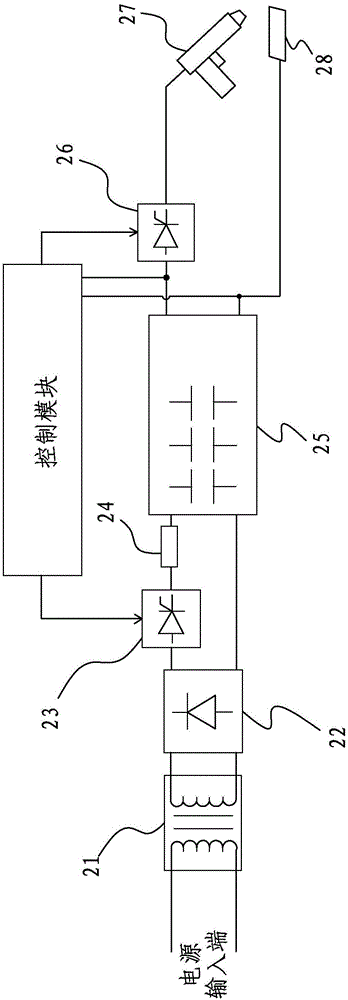

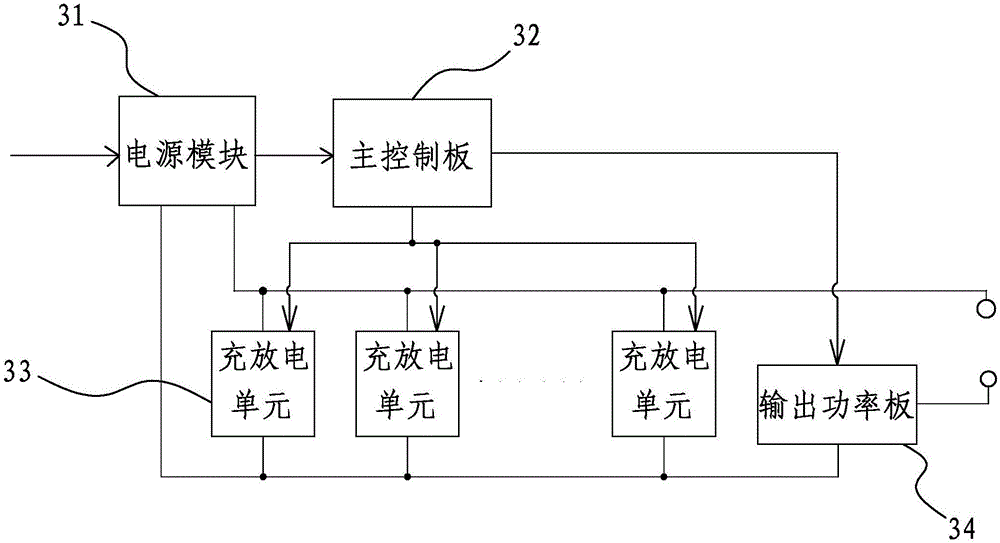

ActiveCN105057868AHighly integratedReduce volumeResistance electrode holdersVehicle componentsMOSFETPower flow

The invention discloses a handheld active control type electric welder. The electric welder comprises a power module and an operation handle, wherein a main control panel, a charging / discharging circuit, a power output board and a welding head are fixedly arranged on the operation handle; the charging / discharging circuit comprises a charging switch and a plurality of charging / discharging units arranged in parallel; each charging / discharging unit comprises an electrolytic condenser and a discharging switch; each of the charging switch and the discharging switch is an MOSFET tube. The handheld active control type electric welder disclosed by the invention has the advantages of high integration degree, small size, low cost and the like, and can realize the active control of the output time of welding current, so that the success rate of welding is increased; the electric welder adopts the confluence of the parallel charging / discharging units, so that each MOSFET tube is guaranteed to normally work; besides, the large current for welding is satisfied, so that the MOSDET tubes can be used for controlling large current.

Owner:JIANGMEN BOSJOB

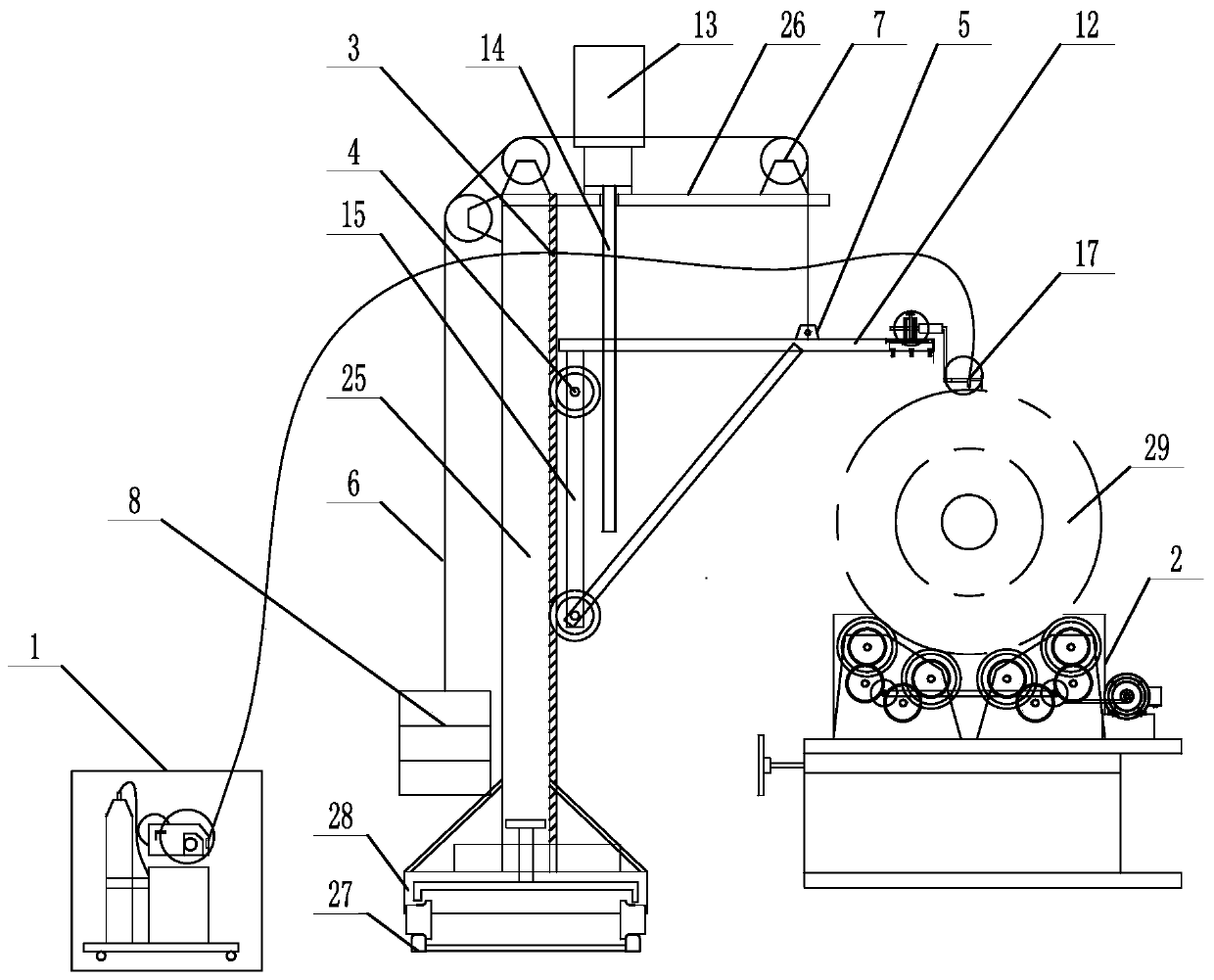

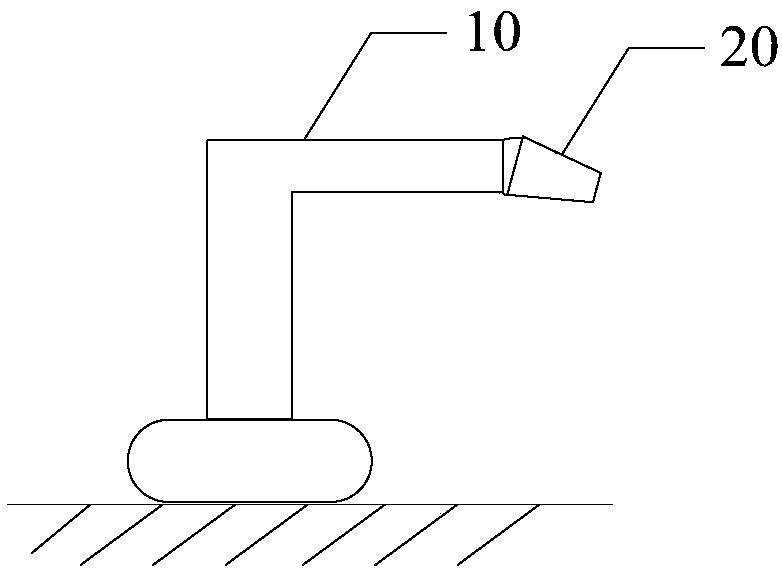

Longitudinal and circumferential seam welding device for large pressure container barrel

InactiveCN110614468AImprove welding success rateReduce lifting resistanceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSeam welding

The invention relates to a longitudinal and circumferential seam welding device for a large pressure container barrel, and belongs to the technical field of welding. The stability of a cantilever is improved, the starting resistance of a lifting platform is reduced, and fine adjustment of a welding gun is facilitated, so that the welding positioning is accurate. An automatic wire feeding welding machine comprises a wire feeding mechanism and a welding gun fixing mechanism; a sliding lifting platform comprises a sliding platform, a cantilever support frame, the lifting platform and a transversedriving mechanism, wherein the sliding platform is fixedly connected to the cantilever support frame, one side of the cantilever support frame is connected to the lifting platform, the transverse driving mechanism is fixed on the lifting platform, and the transverse driving mechanism is fixedly connected to the welding gun fixing mechanism; a roller frame is fixed below the lifting platform; anda first guide mechanism is arranged between the cantilever support frame and the lifting platform, the first guide mechanism comprises guide rods and guide wheels, the guide wheels are fixed on the two sides of the lifting platform, and the guide rods matching the guide wheels are fixed on the cantilever support frame.

Owner:SHANDONG SPECIAL INDUSTRY GROUP CO LTD

SA-213TP347HFG steel small diameter tube welding method

InactiveCN105750709AImprove performanceGood welding performanceWelding accessoriesAusteniteRelative humidity

The invention relates to the field of austenitic stainless steel material welding, in particular to an SA-213TP347HFG steel small diameter tube welding method.The method comprises the following steps: 1, conducting treatment before welding, wherein a V-shaped groove is machined out of an SA-213TP347HFG steel small diameter tube to be welded, the single-side groove angle is 33-38 degrees, and grinding treatment is conducted on the groove; 2, controlling the welding environment, wherein the temperature is higher than or equal to 0 DEG C, the air speed is less than or equal to 2 m / s, and the relative humidity is less than or equal to 75%; 3, welding the tube to be welded through manual tungsten inert gas arc welding (TIG), wherein an TIG welding machine with high frequency arc striking and current attenuation is selected, the electric arm length in the welding process is 1-2.5 mm, an ERNiCr-3 welding wire is selected, the welding root is filled with argon and coated with an anti-oxidation protective agent for protection, the argon purity is 99.99%,and the flow rate is 8-15 L / min, narrow weld bead and short bead intermittent welding is adopted, tracking is conducted from time to time for temperature measurement so that the welding interlayer temperature cannot be higher than 70 DEG C, weld lines on each layer are covered with cloth dipped in purified water for cooling, and in the welding process, a slope with length being 7-9 mm is formed through grinding at a joint between each weld line and the previous weld line.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

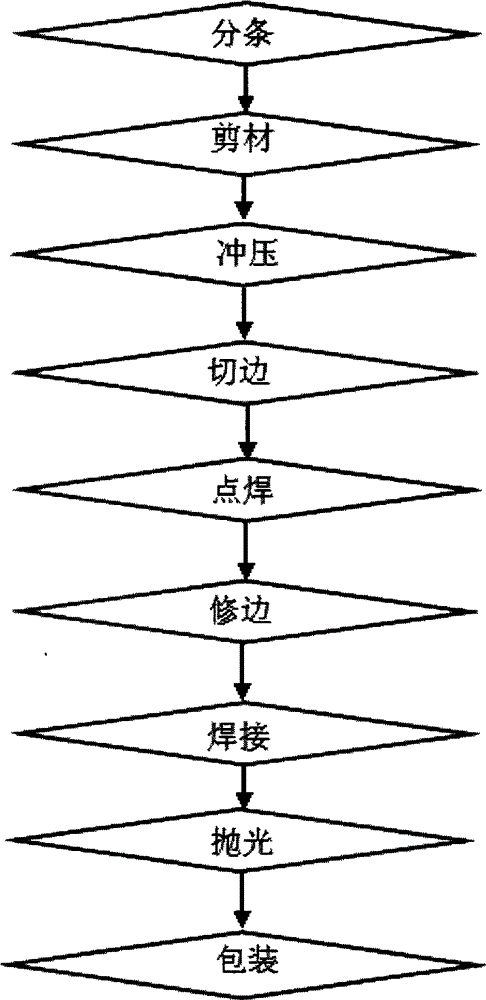

Production technology for trim cover of automobile exhaust pipe

InactiveCN105081684APrevent floatingExtended service lifeExhaust apparatusSilencing apparatusEngineeringSpot welding

The invention relates to a production technology for a trim cover of an automobile exhaust pipe. The technology includes the following steps of splitting, cutting, stamping, edge cutting, electric welding, trimming, welding, polishing and packaging. According to the production technology for the trim cover of the automobile exhaust pipe; fixing and assembly are conducted in a welding manner, and floating of a spare part is avoided; the trim cover is firmly fixed; and the service life of the trim cover of the exhaust pipe is prolonged. Three-hole datum plane positioning is adopted; spot welding is conducted firstly, and then welding is conducted; the welding successful rate is increased; it is ensured that the qualification rate of products is 100%; the burden of workers is relieved; the production efficiency is improved; materials are saved; and cost is reduced. The production technology for the trim cover of the automobile exhaust pipe is suitable for large-scale popularization.

Owner:宁海县健腾模塑厂

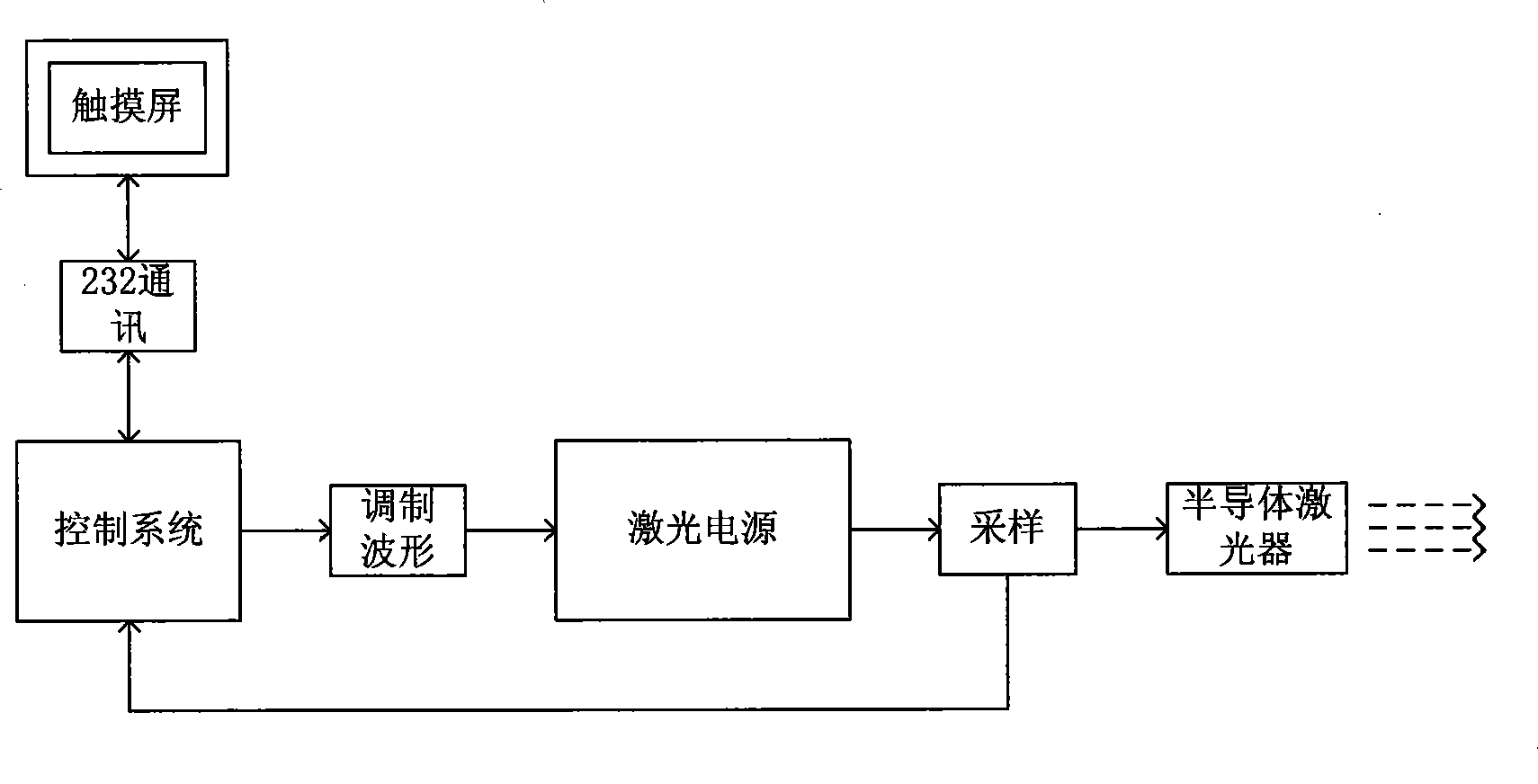

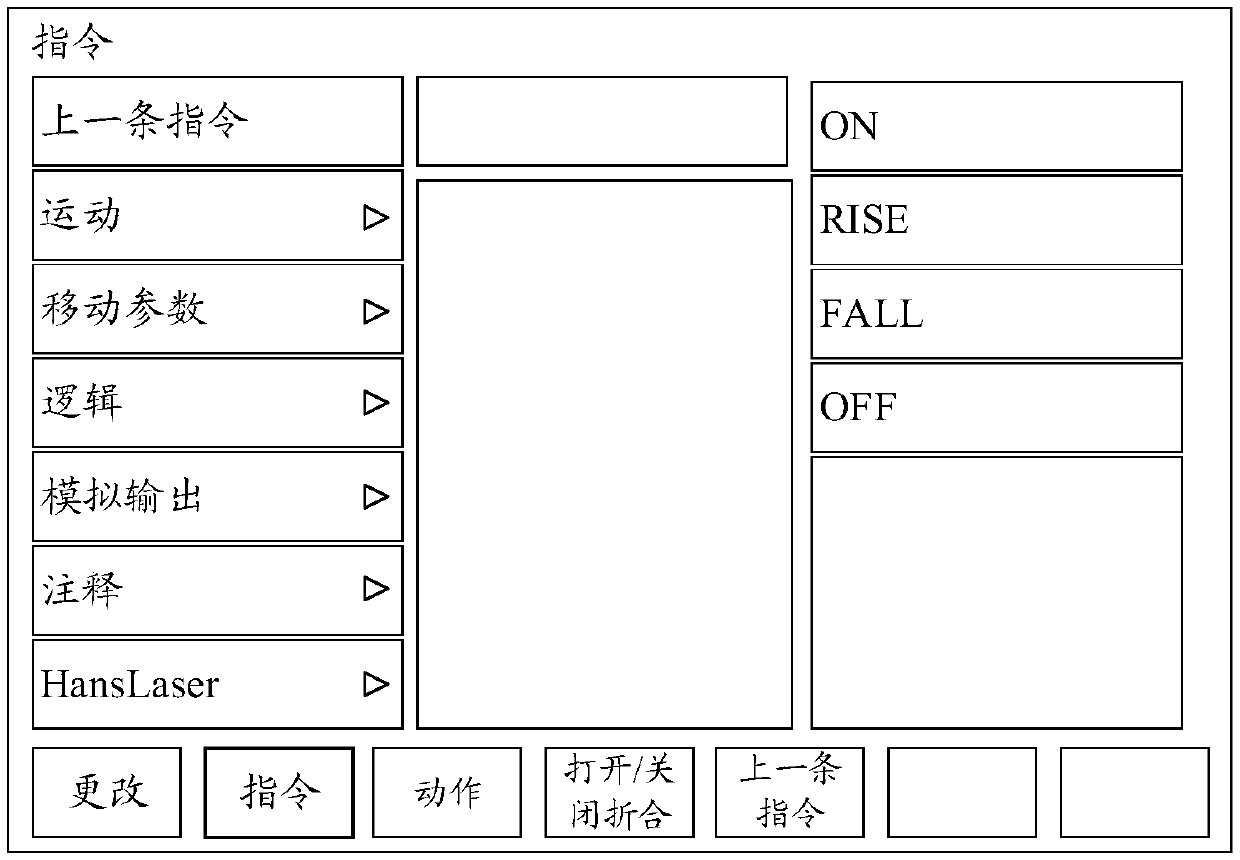

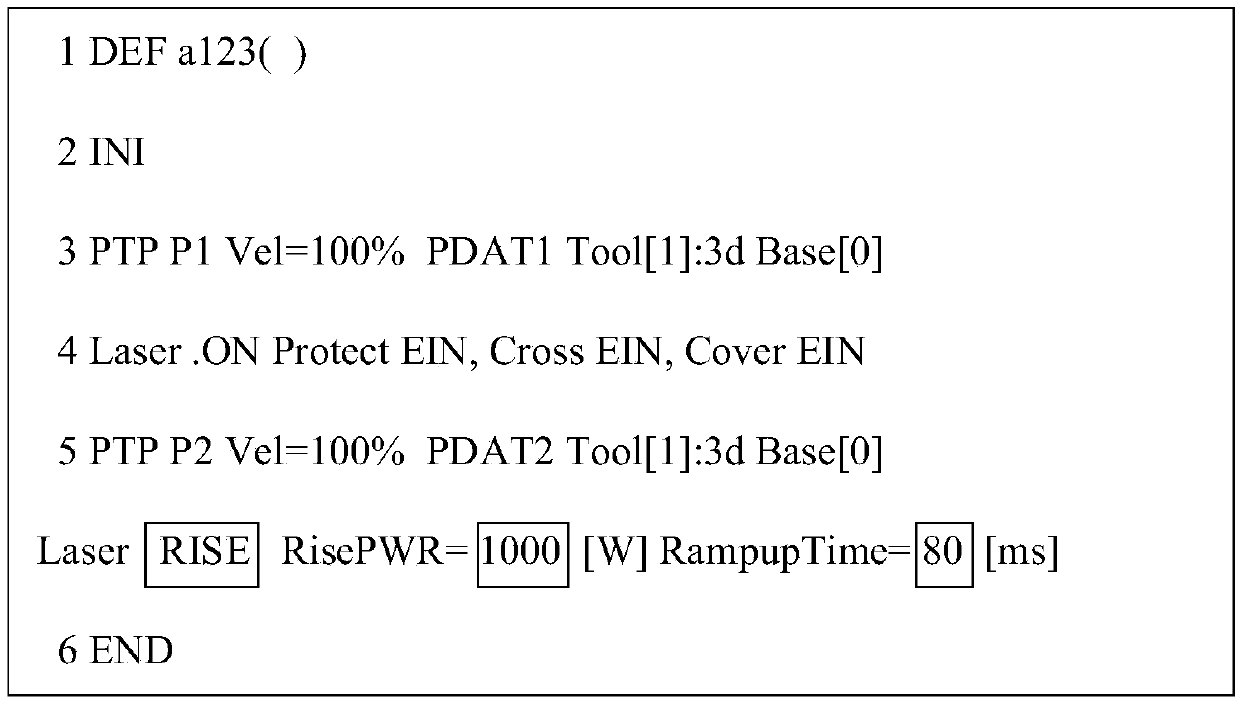

Welding control method, device and system and welding robot

ActiveCN109531576ASimplify the interaction processFast communication speedProgramme-controlled manipulatorLaser beam welding apparatusNumerical controlEngineering

The invention provides a welding control method, device and system and a welding robot, and relates to the technical field of numerical control. The welding control method comprises the following steps: the welding robot receives calling instructions through an operation interface of input and output equipment; laser parameter setting lists corresponding to the calling instructions in welding tasks are called out; each laser parameter setting list corresponds to a welding control instruction in the welding tasks; according to input set instructions, laser control parameters in the laser parameter setting lists are set; when the laser parameter setting lists of the welding tasks are finished, the set laser parameter setting lists are stored; and according to the laser control parameters inthe laser parameter setting lists corresponding to the welding tasks, a laser is controlled to finish the welding tasks. The welding efficiency and the welding success rate can be improved.

Owner:HANS LASER TECH IND GRP CO LTD +1

Welding method of vacuum tube central fulcrum bar component

The present invention relates to a welding method of vacuum-tube fulcrum bar component. Said welding method includes the following steps: 1), on the molybdenum cap cutting a sink hole; (2), adding silicon-molybdenum welding flux piece into the sink hole; 3), inserting molybdenum bar into the sink hole; 4), in the sink hole adopting high-frequency welding method to weld molybdenum bar and molybdenum cap; and 5), in molybdenum cap opening adopting resistance welding to make molybdenum cap and molybdenum bar be fusion-welded together.

Owner:MIDEA GRP CO LTD

Welding method for sputtering target material

PendingCN108994444AGuaranteed success rateImprove welding effectNon-electric welding apparatusFriction weldingEngineering

The invention discloses a welding method for a sputtering target material. The welding method for the sputtering target material comprises the following steps: (1) a welding gap between a sputtering target material main material and an auxiliary material is adjusted to be smaller than or equal to 0.3 mm; and (2) a stirring friction welding machine is used to conduct welding; the depth of a rotational cutting tool of the stirring friction welding machine inserted into the welding gap is 10.5-11 mm; welding is conducted rotatably by the rotational cutting tool; and when welding is conducted rotatably by the rotational cutting tool, the auxiliary material rotates with the main material. The welding method for the sputtering target material has the advantages that the cost of raw materials formanufacturing the sputtering target material is saved; moreover, high welding rate is guaranteed; by adopting the welding method, the cost is also lowered when large-scale production is conducted; thus the low-cost sputtering target material can be produced in a large scale; and when the target material is used for manufacturing chips again, the manufacturing cost of the chips is lowered greatly.

Owner:宁波顺奥精密机电有限公司

Four-electrode welding device for fiber splicer

PendingCN107390322ASimple structureImprove welding success rateCoupling light guidesFiberEngineering

The invention provides a four-electrode welding device for a fiber splicer; the four-electrode welding device comprises four electrode rods arranged in a rectangular form, center lines of the four electrode rods are coplanar, extension lines of the center lines of the four electrode rods intersect at a point, and the tips of all the electrode rods point to the point; after the four electrode rods are electrified, an arc discharge zone is formed among the tips of the four electrode rods. The arc discharge zone generated by the four-electrode welding device can splice a thick fiber or multiple fibers, and can withhold slight fluctuations from outside; the four-electrode welding device is disposed in partial or complete vacuum; compared with the prior art, the four-electrode welding device, with convection eliminated (or diminished) and an enhanced plasma field isothermal range provided, has the advantages that slight upward fluctuations are generated at the premise of rising of heat from plasm (under atmospheric pressure) and may destroy ionic paths among the electrodes, and the destroying may sway or extinguish plasma in air.

Owner:NANJING JILONG OPTICAL COMM

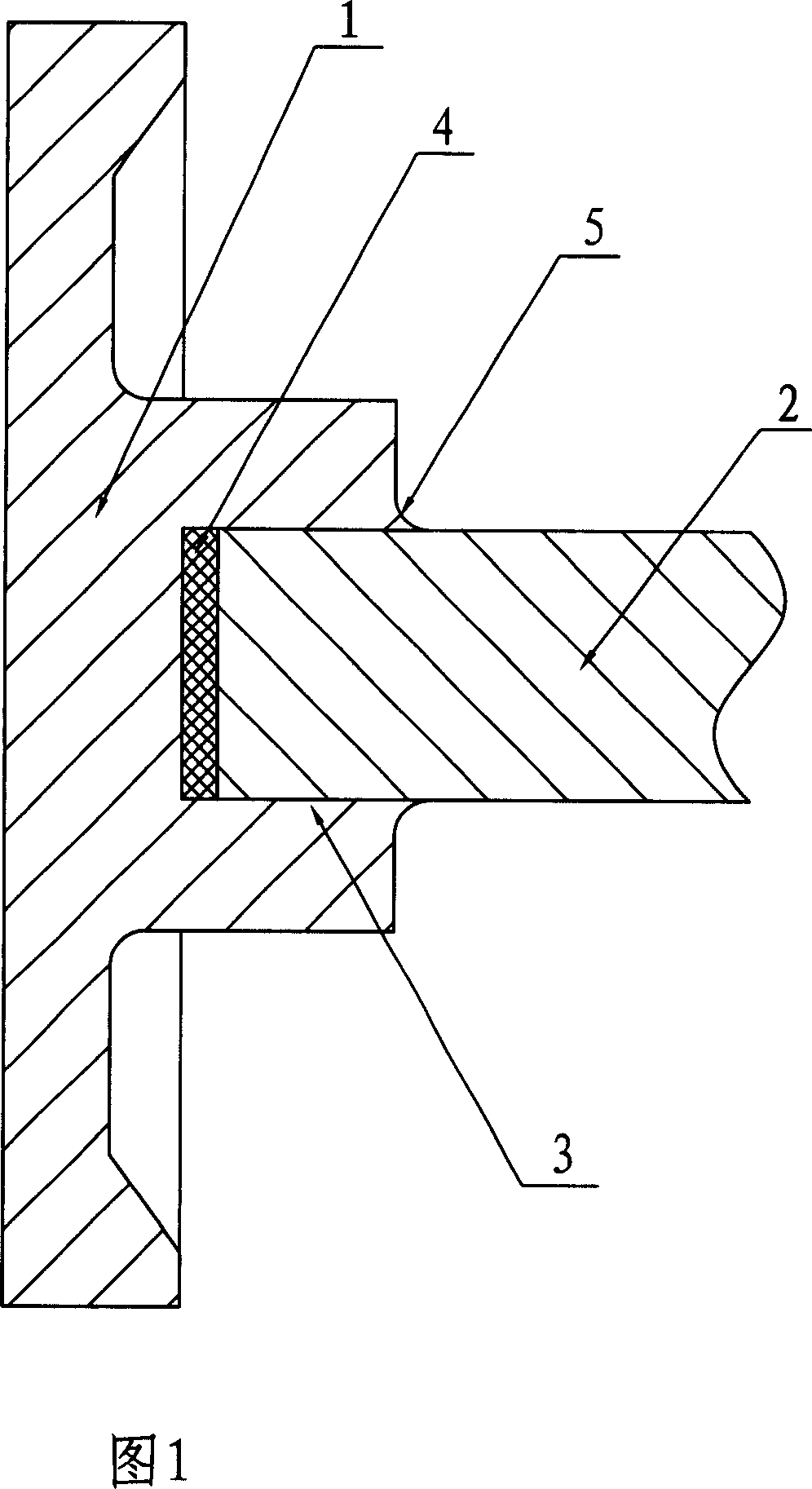

Low-carbon steel heating wire PE electric melting pipe fittings

InactiveCN101033820AReduce manufacturing costLow costPipe connection arrangementsElectricityCopper plating

The invention discloses a kind of low carbon steel heater PE electric melting pipe fittings which includes a PE pipe fittings and a heater compounding in the wall of PE pipe sittings which are two parallel low carbon steel heaters. The heater described above after over-plastic directly circles homogeneously and compounds in the wall of PE pipe sittings by annealing soften, surface burnish, multiple layers coppering corrosion protection, oxidation resistant treatment, and over-plastic treatment and the over-plastic adopts the way of making the two heaters paralleled over-plastic. When using the PE electric melting pipe sittings to connect the PE pipe implant the PE pipe into the PE electric melting pipe sittings and then use the electric melting pipe soldering machine to cut-in electricity for the two-pole of heater winding and make the low carbon steel heater generated heat by the current and then melt the PE pipe and the contact surface plastic of PE electric melting pipe sittings then solvate and solder the PE pipe and the PE electric melting sittings. The invention using in soldering the PE pipe has the low cost and high soldering mission success rate merits and saves the electrical power.

Owner:钟世全

Welding method of curved-surface microstrip antenna

InactiveCN111958079AMeet welding requirementsStrong welding adaptabilityAntenna adaptation in movable bodiesWelding apparatusStructural engineeringClose contact

The invention provides a welding method of a curved-surface microstrip antenna, and aims to provide the welding method of the curved-surface microstrip antenna, which is high in welding success rate and high in welding quality so as to meet the reliability requirement of the curved-surface microstrip antenna in long-term use. The method comprises the following steps that a clamping tool for supporting an upper pressing plate and a lower pressing plate through a fixed stand column is prepared, a pressure stand column is sleeved with a main pressure spring, and penetrates through the upper pressing plate to be connected with a main pressure nut; a layer of welding flux is printed at the bottom of the micro-strip in a steel mesh printing mode, and the micro-strip is fixed to a base, a flexible voltage-sharing plate and a rigid voltage-sharing plate through pins; auxiliary pressing plates are arranged at the four corners of the rigid voltage-sharing plate, and the auxiliary pressing plates, auxiliary stand columns and auxiliary pressure springs are fixed to the lower pressing plate through auxiliary pressure nuts to compress main pressure springs and the auxiliary pressure springs, sothat the micro-strip makes close contact with the base; and after assembly is completed, the whole clamping tool is put into a vacuum gas phase furnace to be heated, and after cooling, the tool is disassembled to complete welding of the micro-strip and the base.

Owner:10TH RES INST OF CETC

Repair method of main bearing hole of body

The invention relates to the technical field of maintenance of bearing holes and in particular relates to a method for repairing a main bearing hole of a body. The main bearing hole refers to the design, assembly and processing reference of the body, the central position is not allowed to deflect, the pore diameter is not allowed to be enlarged, and a brushing electroplating process cannot be used due to the reasons that the coating is small and easy to strip and cannot be machined and the like. However, thermal deformation of a welding part is increased by a common surfacing method, and the generated welding stress cannot be effectively eliminated; and meanwhile, the crack influence is large, the welding period is long, and the repair welding success rate is low. Aiming at the problems, a repair method for performing main bearing hole laser cladding surfacing and restoring the original precision of a drawing by virtue of machining is adopted, the repair processes of the main bearing hole of the body include four parts, namely cladding surfacing, surfacing part cover replacement and machining, detection of the repaired body and body cleaning and rust removal, wherein laser cladding surfacing is the key point of the whole repair process, and global surfacing and local surfacing of the pore diameter can be adopted aiming at the defect size and severity. The invention discloses an improved method for repairing the main bearing hole of the body.

Owner:CRRC QISHUYAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com