Production technology for trim cover of automobile exhaust pipe

A production process and automobile exhaust technology, which is applied in the direction of exhaust devices, noise reduction devices, vehicle parts, etc., can solve the problems of difficult welding, reduced life, high labor costs, etc., to improve the success rate of welding, increase the service life, reduce the Worker Burden Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

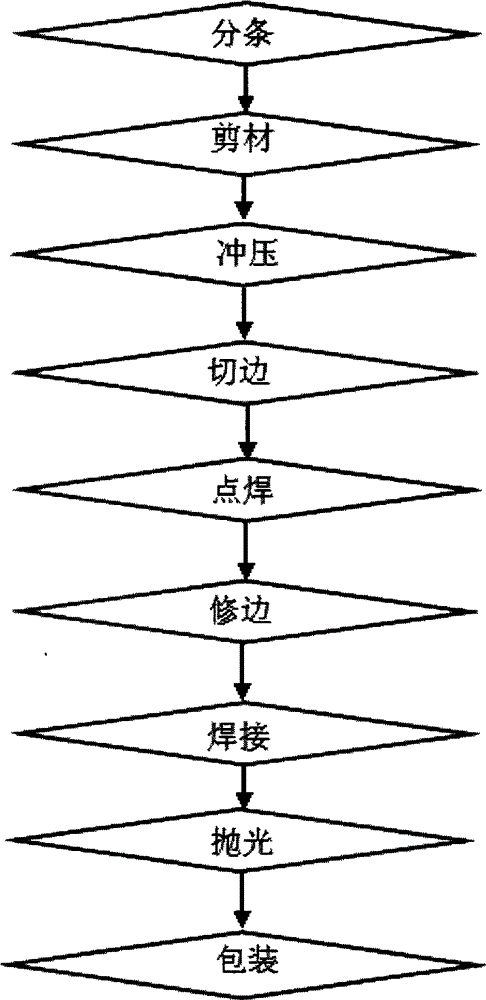

[0016] A kind of production process of automobile exhaust pipe decorative cover of the present invention, described process comprises the following steps:

[0017] a. Slitting: Slitting the 304 plate with a thickness of 0.7 mm on the slitting machine;

[0018] b. Cutting material: cutting the 304 plate after step a;

[0019] c. Stamping: Stamping the 304 plate that has passed step b with a punching machine, so that the 304 plate is plastically deformed to form blank parts, wherein the punching machine is controlled by a computer, which realizes automation and effectively improves production efficiency and product quality;

[0020] d. Edge trimming: Trimming the blank parts after step c, trimming the edges of the blank parts neatly or cutting them into required shapes;

[0021] e. Spot welding: Fix the datum surface of the rough parts after step d with a special fixture, and then use bolts for three-hole positioning and fixing. After fixing, perform spot welding on the welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com