Washing apparatus

a technology of washing machine and wash water, which is applied in the direction of other washing machines, cleaning using liquids, textiles and paper, etc., can solve the problems of inability to accurately sense the leakage of wash water, troublesome water leakage sensors, and malfunction of constituent elements, so as to reduce processing costs and material costs, the effect of simplifying the structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

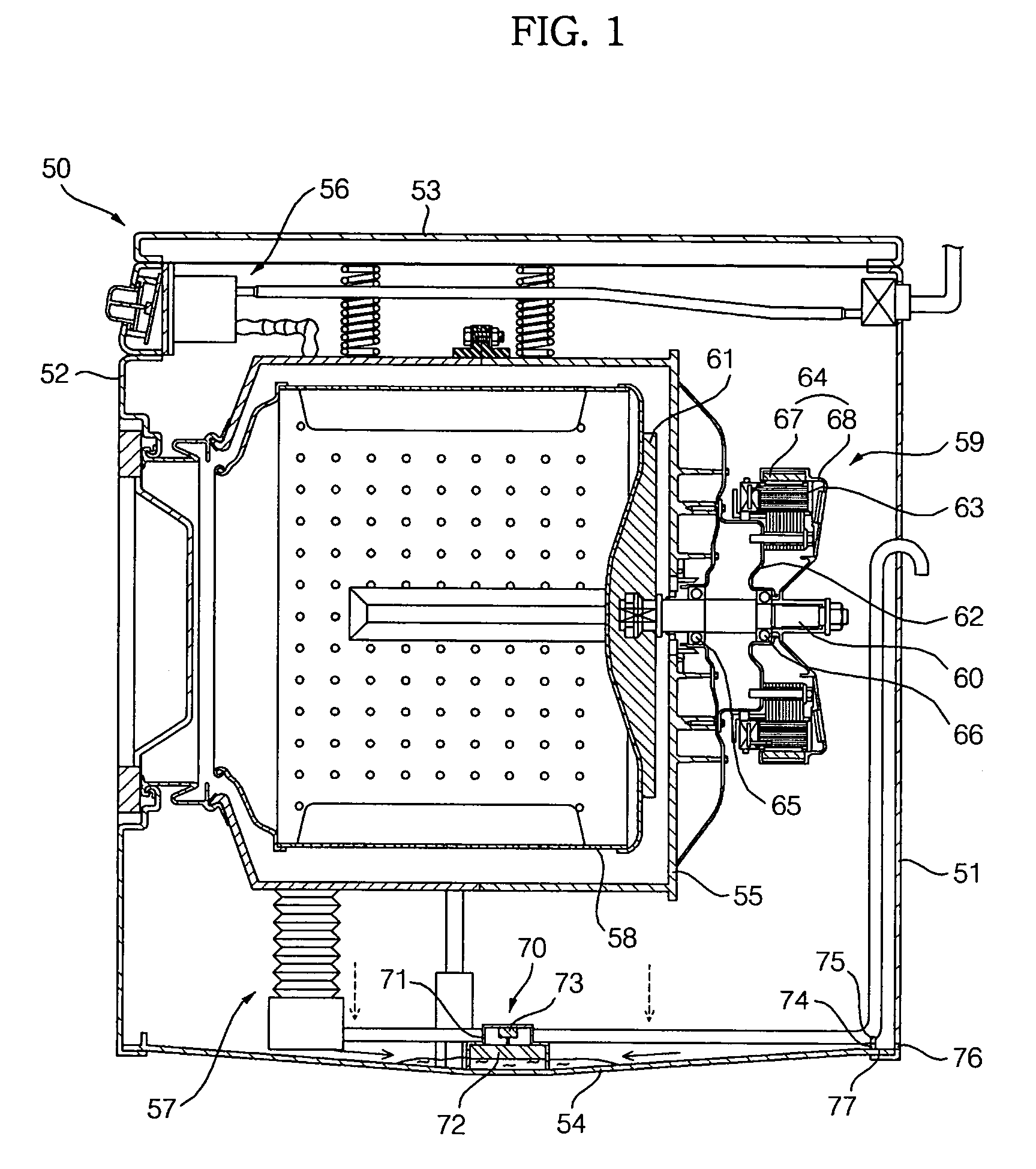

[0054] As shown in FIGS. 1 and 2, the washing apparatus according to the present invention is a washing machine for washing laundry using detergent and water. The washing machine comprises: a casing 50 forming the outer appearance of the washing machine and having a laundry entrance / exit opening formed at a front side thereof; a tub 55 supported in the casing 50 in a shock-absorbing manner; a water supply device 56 to supply detergent or wash water into the tub 55; a water drainage device 57 to drain the wash water in the tub 55 to the outside of the casing 50; a drum 58 rotatably disposed in the tub 55 to receive laundry therein; and a motor 59 to rotate the drum 58.

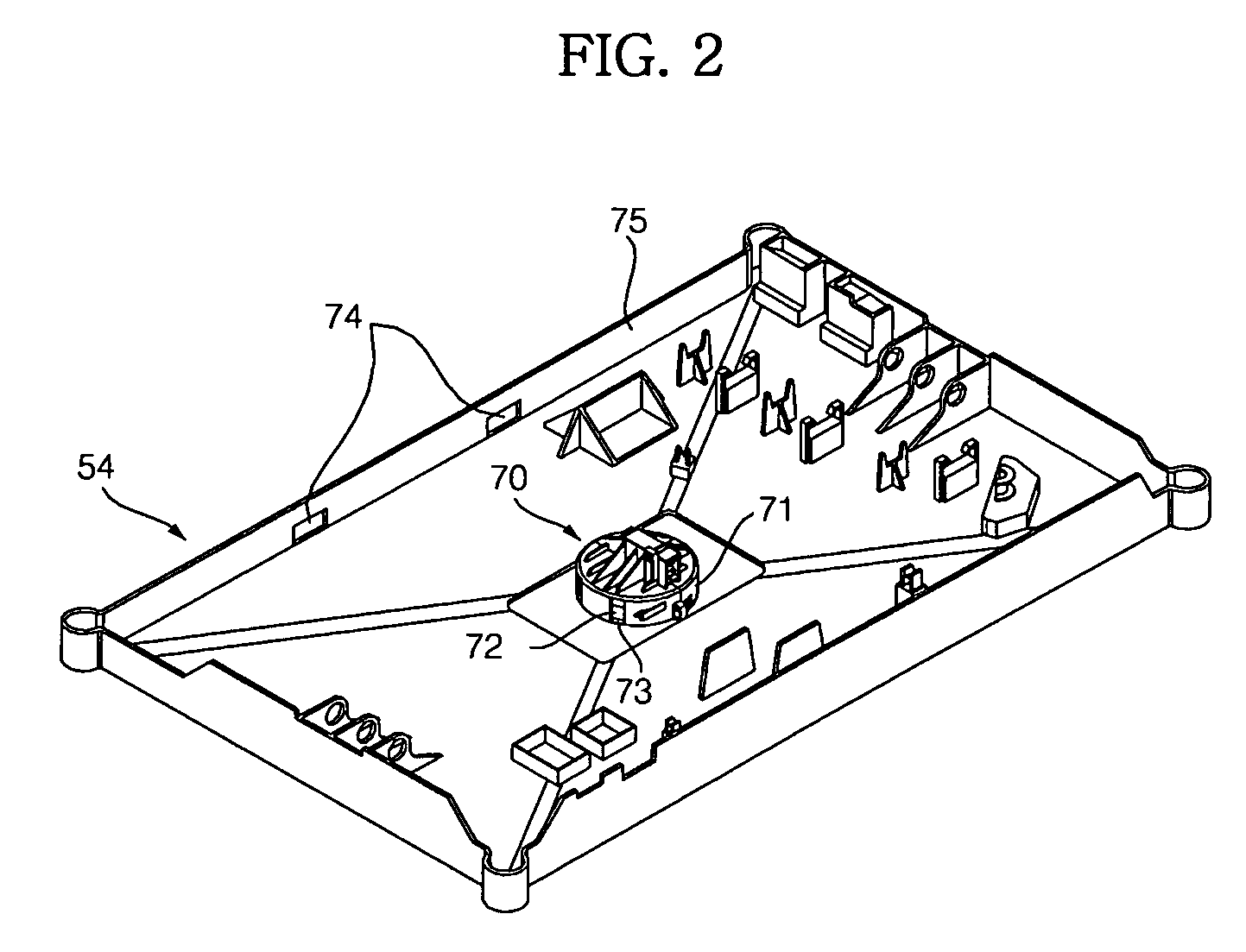

[0055] The casing 50 includes: a cabinet body 51 having open front and upper sides; a cabinet cover 52 mounted to the open front side of the cabinet body 51; a top cover 53 mounted to the open upper side of the cabinet body 51; and a base pan 54 mounted to a lower end of the casing 50 to form the bottom of the casing 50...

second embodiment

[0079]FIG. 3 is a side sectional view illustrating a washing apparatus according to the present invention.

[0080] The washing apparatus according to the second embodiment of the present invention is a drying machine for blowing dry hot air into a certain space that accommodates wet laundry to dry the laundry. As shown in FIG. 4, the drying machine comprises: a casing 80 forming the outer appearance of the drying machine; a drum 81 rotatably disposed in the casing 80 and having open front and rear sides to put or take the laundry into or out of the drum 81, a plurality of lifters being provided at an inner peripheral surface of the drum 81 to raise and drop the laundry; and a heater assembly 82 mounted to the casing 80 to heat outside air introduced into the casing 80.

[0081] The drying machine further comprises: a supply duct (not shown) to supply dry hot air, having passed through the heater assembly 82, into the drum 81; an exhaust duct 83 to discharge the used air, which became hi...

third embodiment

[0093]FIG. 4 is a side sectional view illustrating a washing apparatus according to the present invention.

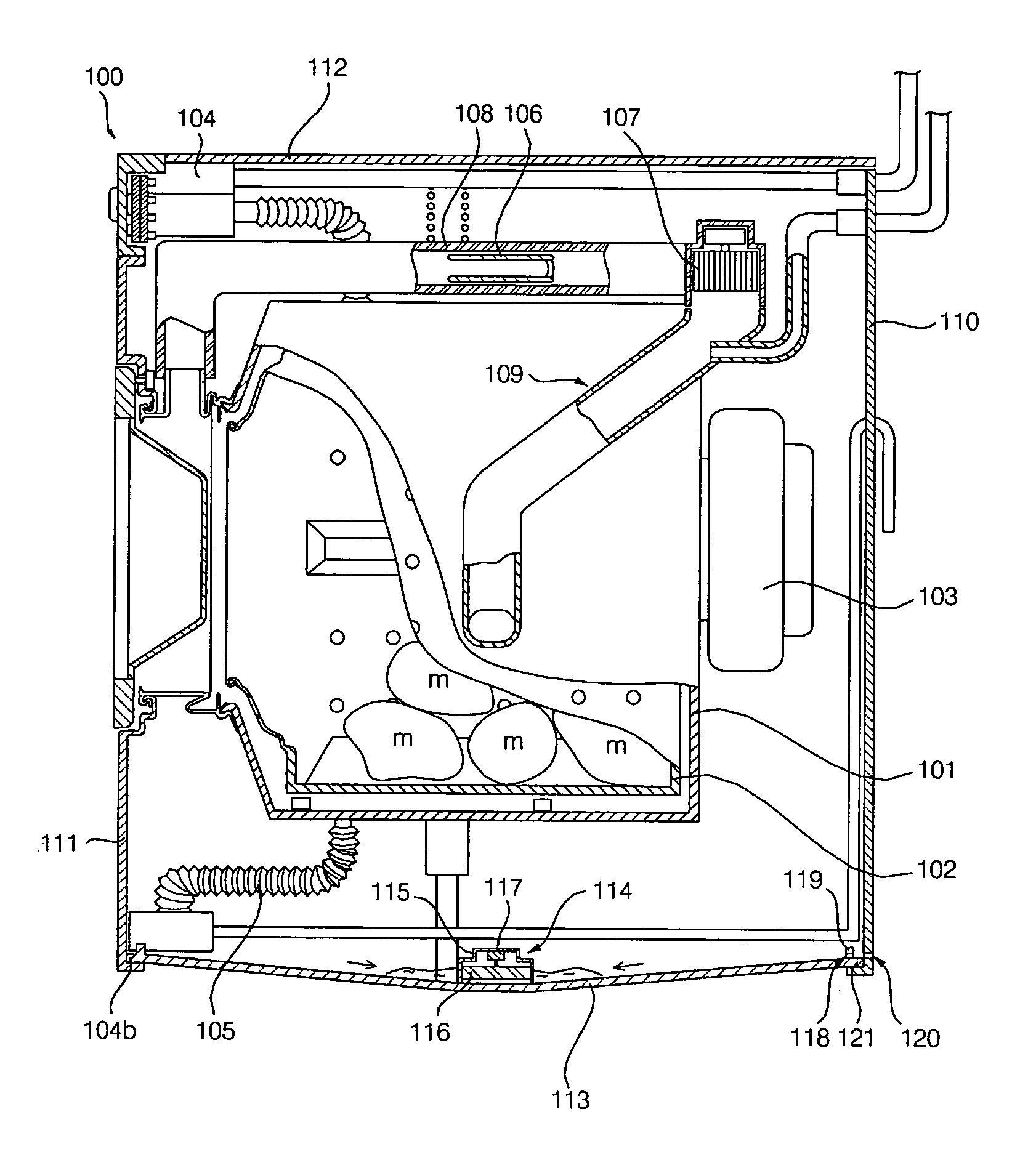

[0094] The washing apparatus according to the third embodiment of the present invention is a combined washing and drying machine for washing laundry using appropriate detergent and water while applying mechanical force and, successively, drying the washed laundry. As shown in FIG. 4, the combined washing and drying machine comprises: a casing 100 forming the outer appearance of the machine; a tub 101 horizontally mounted in the casing 100; a drum 102 mounted in the tub 101 to receive laundry therein; a motor 103 to rotate the drum 102; a water supply device 104 to supply detergent or wash water into the tub 101; a water drainage device 105 to drain the wash water received in the tub 101 to the outside of the casing 100; a drying duct located above the tub 101 and configured to accommodate a heater 106 and a blowing fan 107, which serve to discharge hot air into the tub 101; and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com