Patents

Literature

1983 results about "Surveyor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surveying or land surveying is the technique, profession, art and science of determining the terrestrial or three-dimensional positions of points and the distances and angles between them. A land surveying professional is called a land surveyor. These points are usually on the surface of the Earth, and they are often used to establish maps and boundaries for ownership, locations, such as building corners or the surface location of subsurface features, or other purposes required by government or civil law, such as property sales.

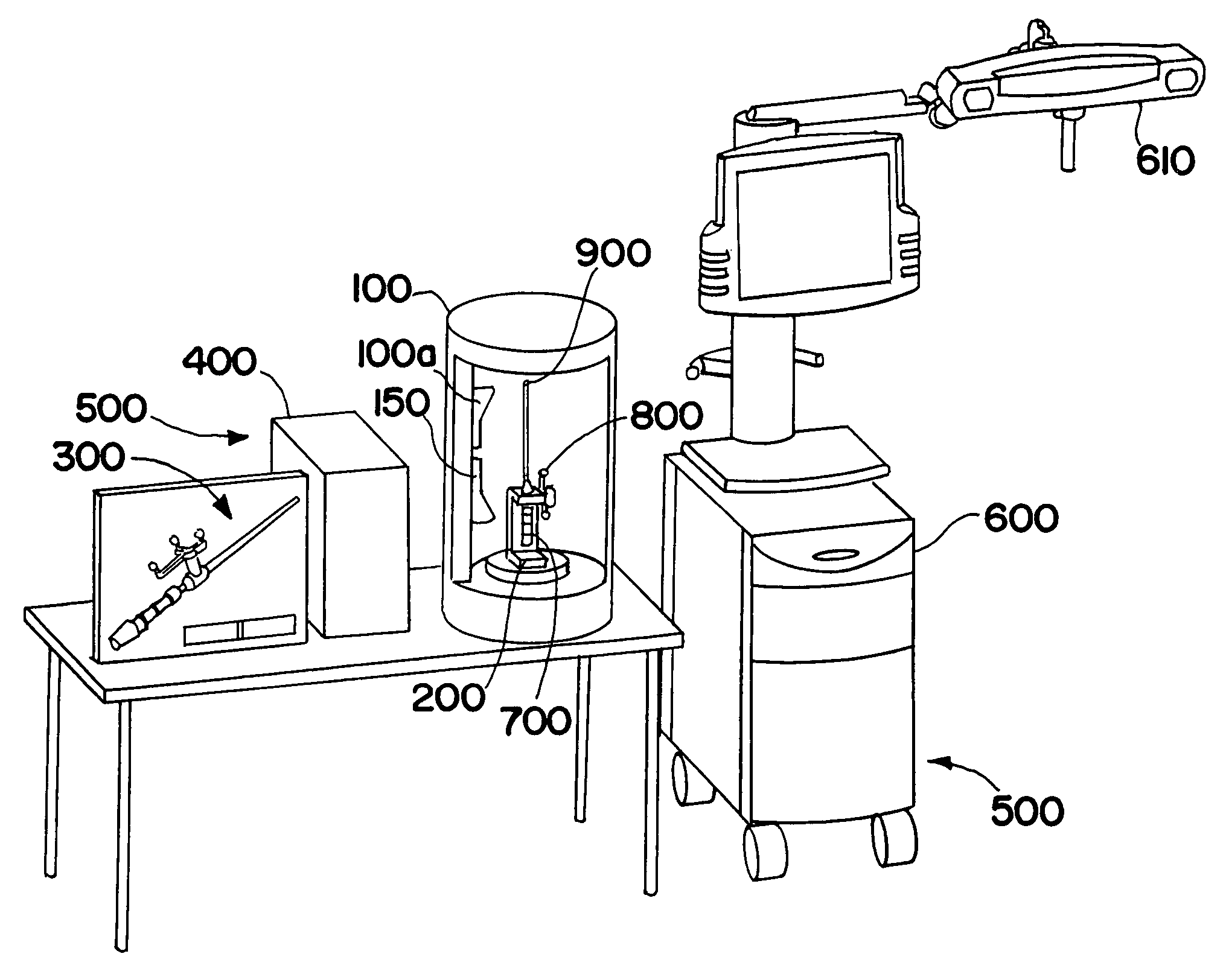

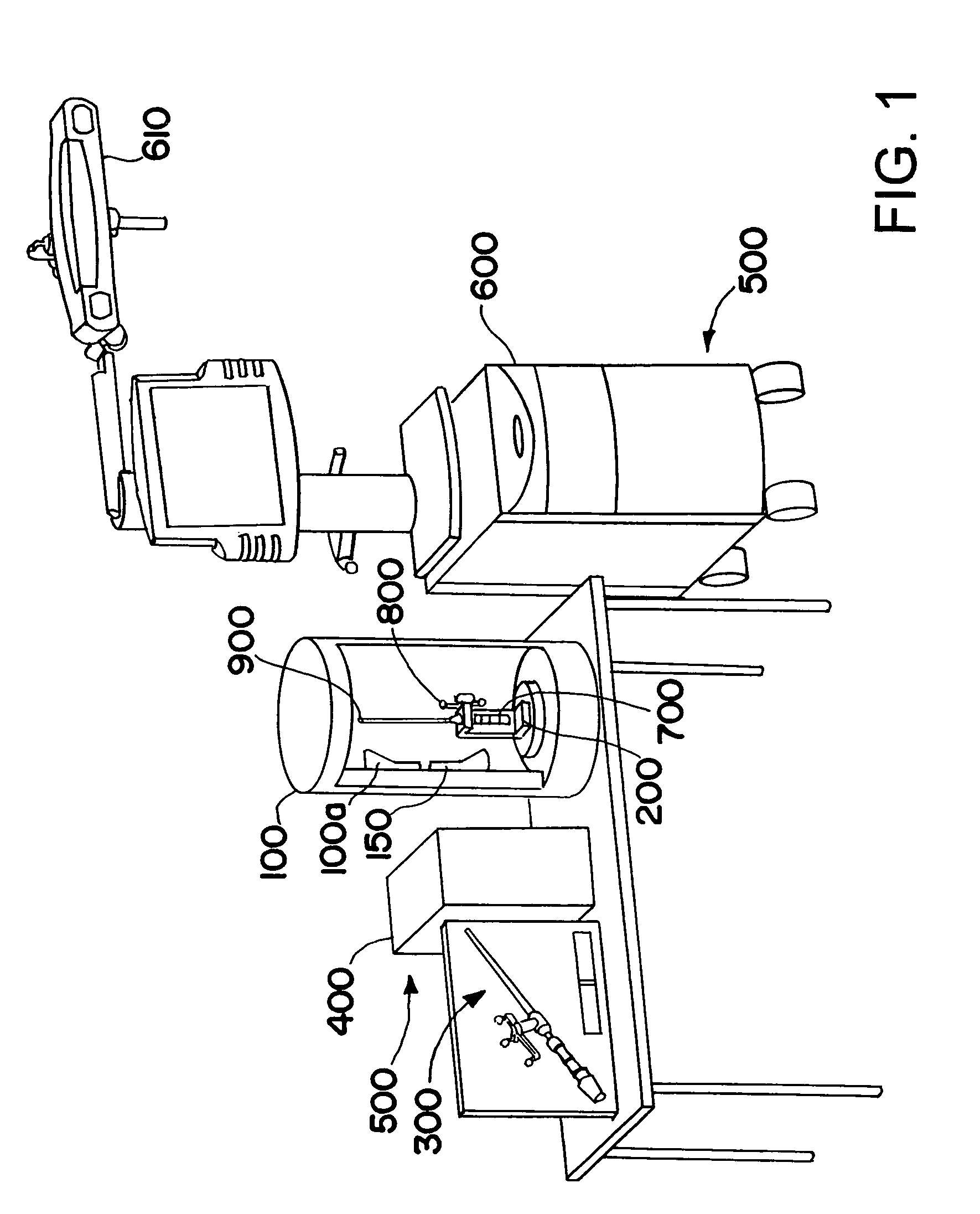

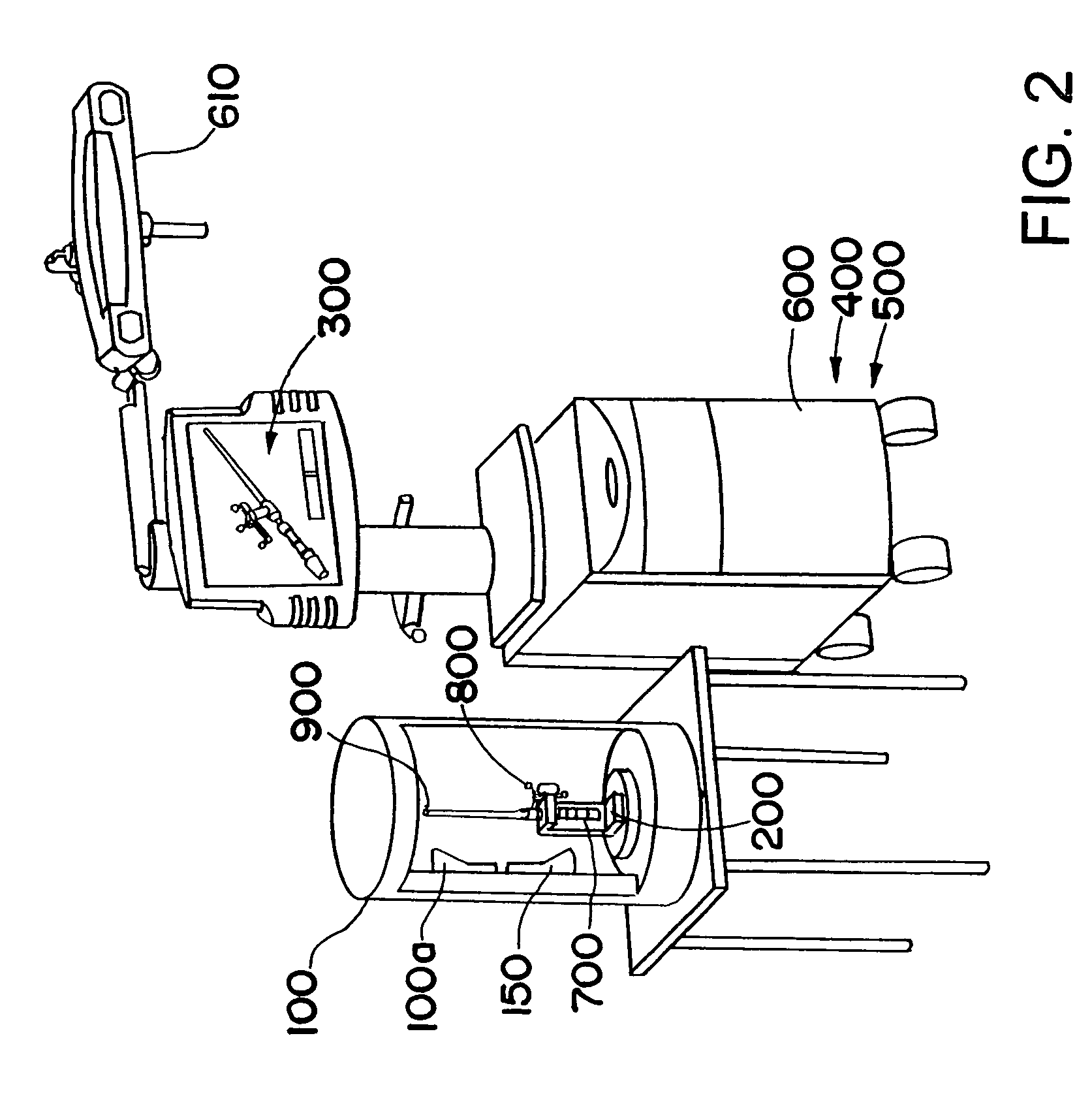

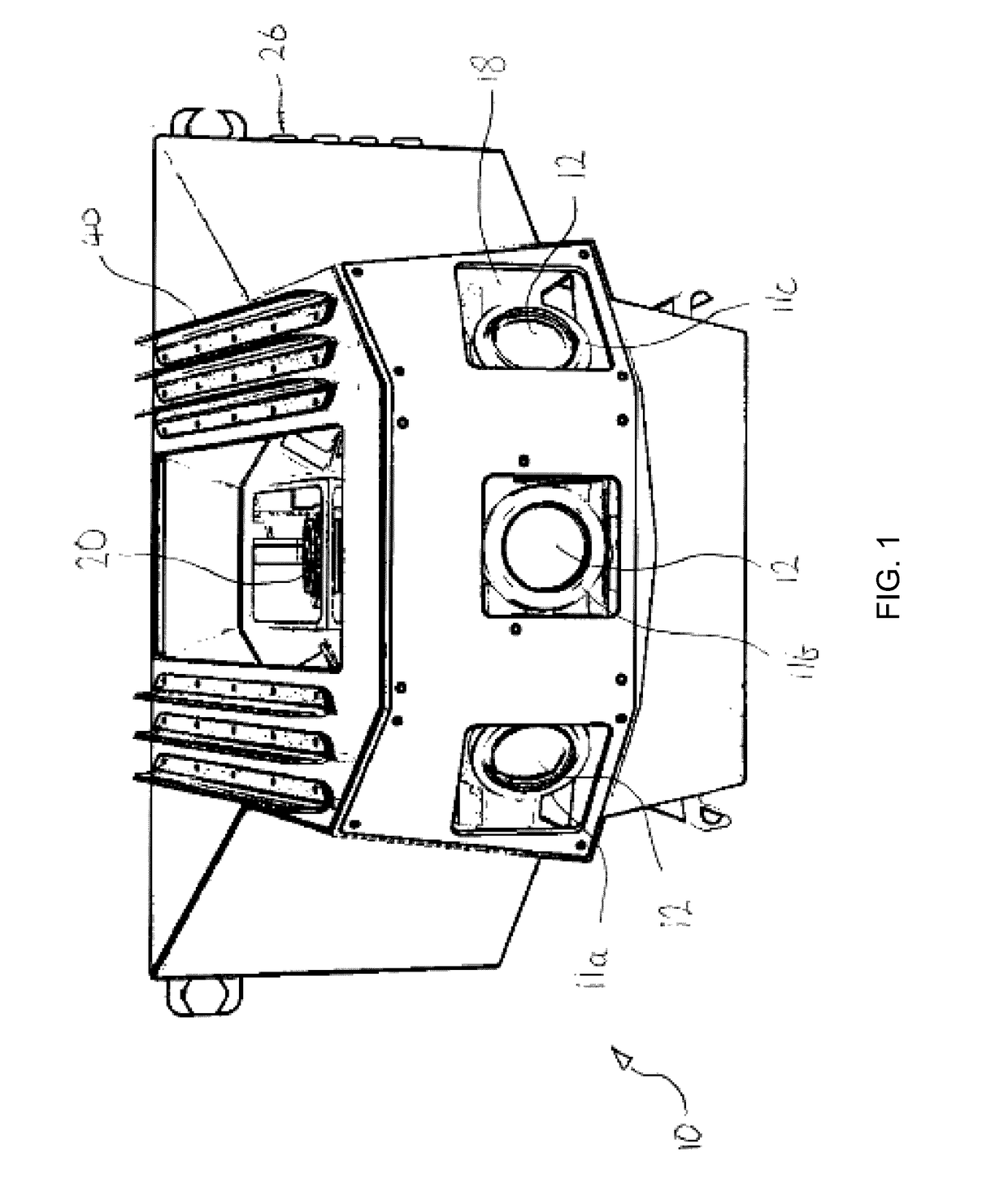

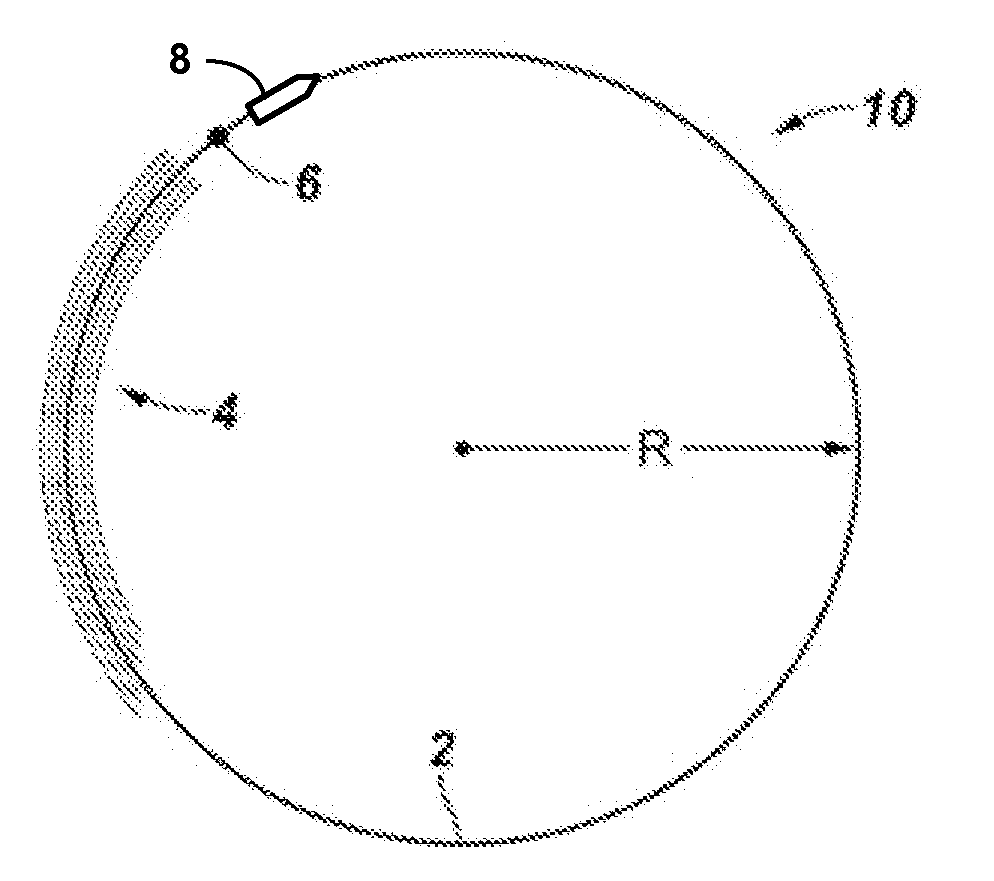

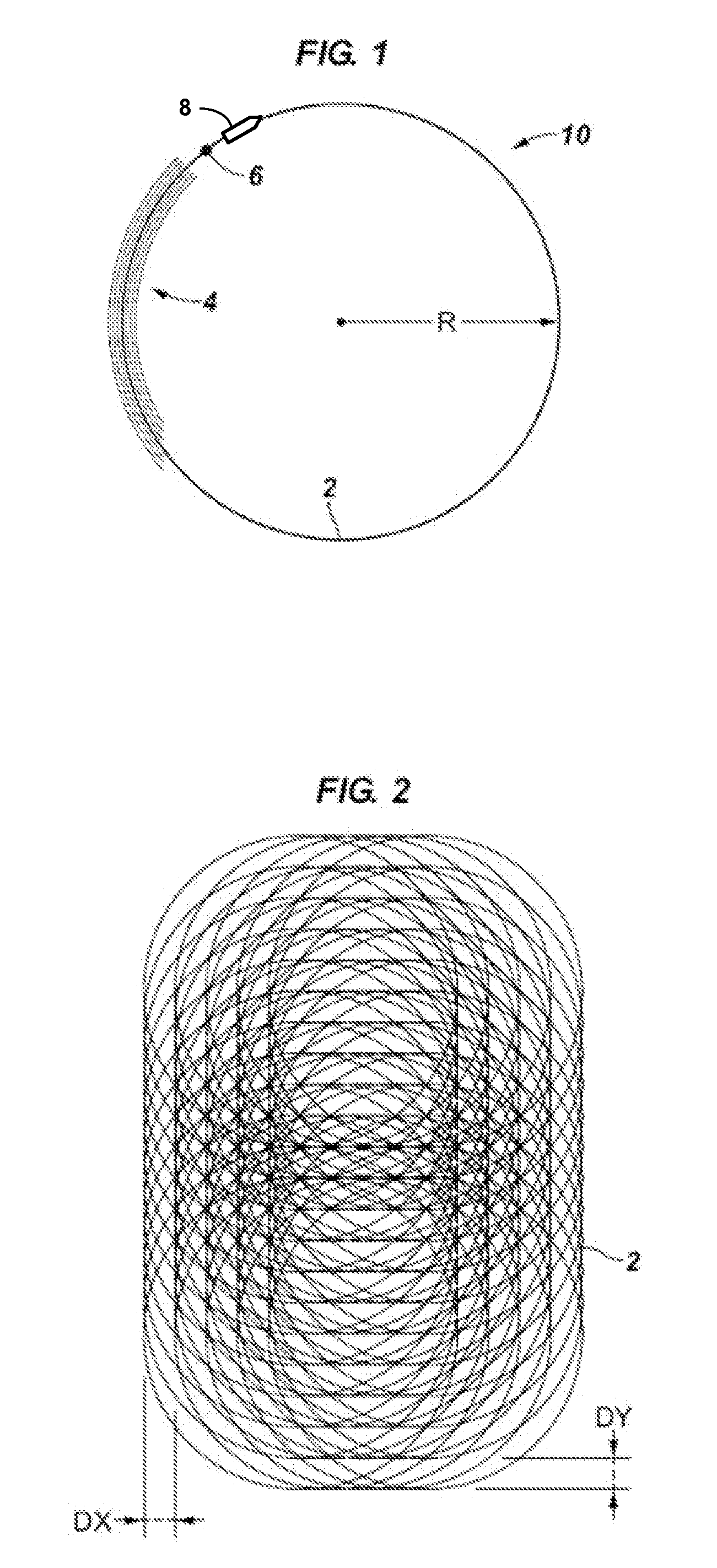

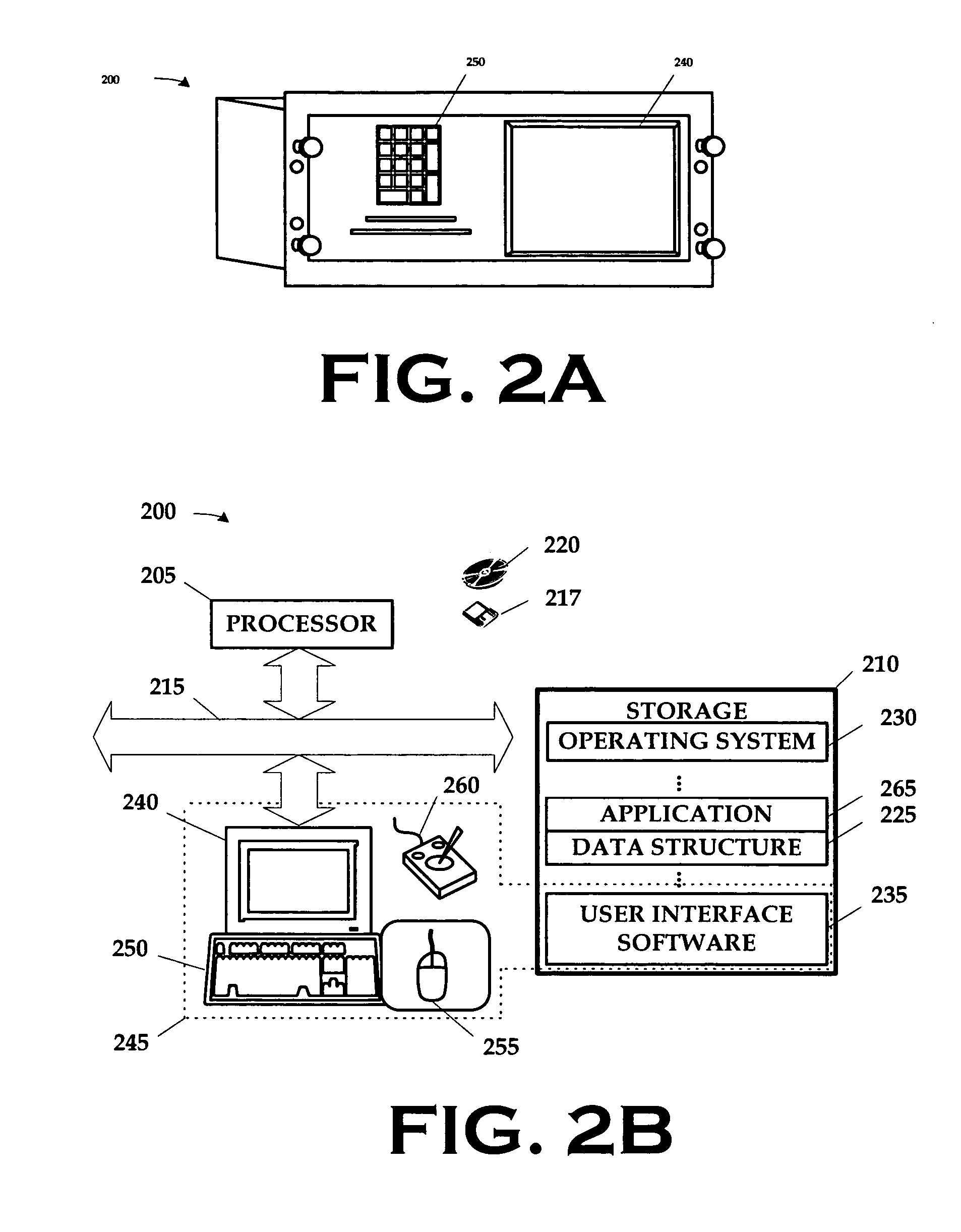

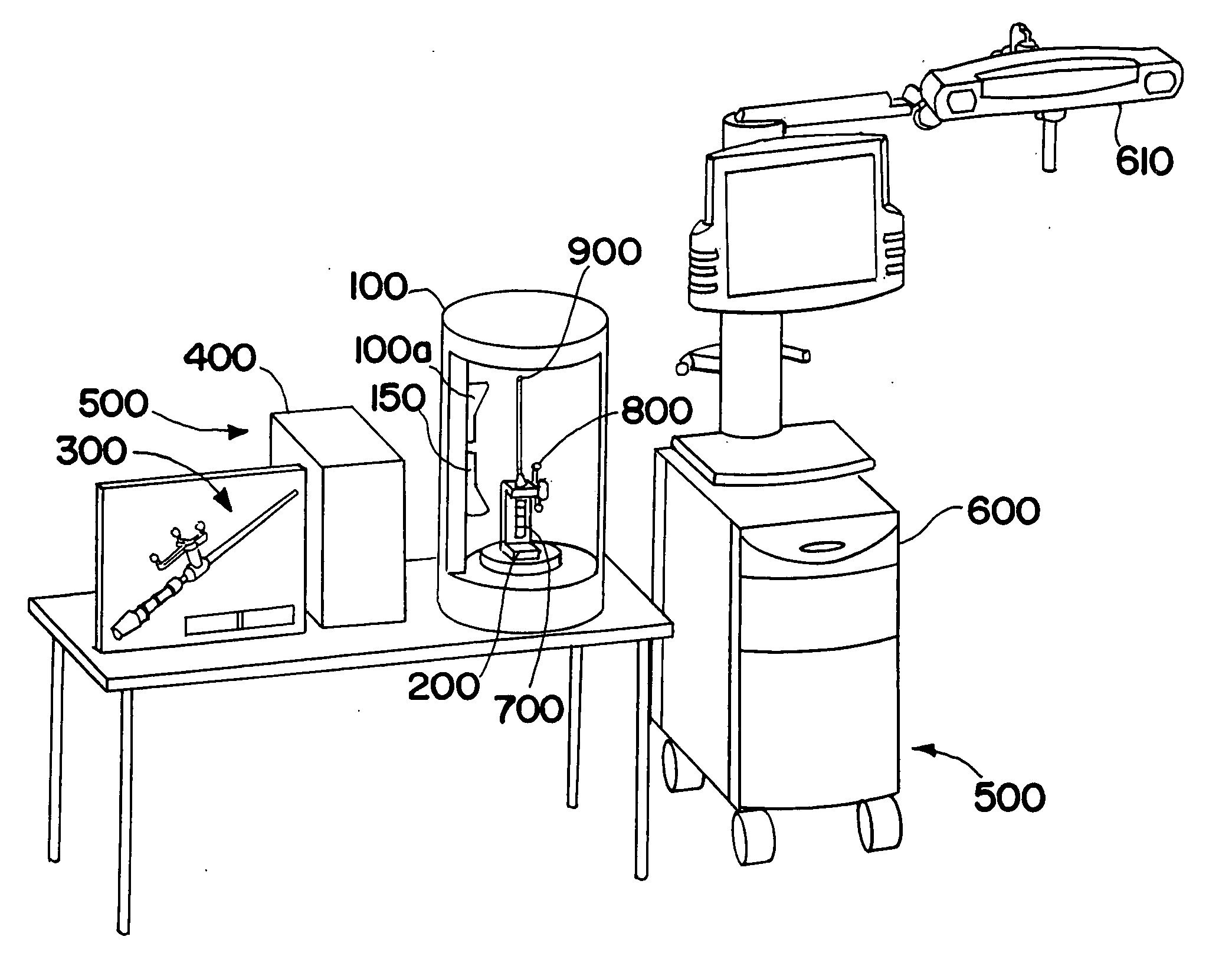

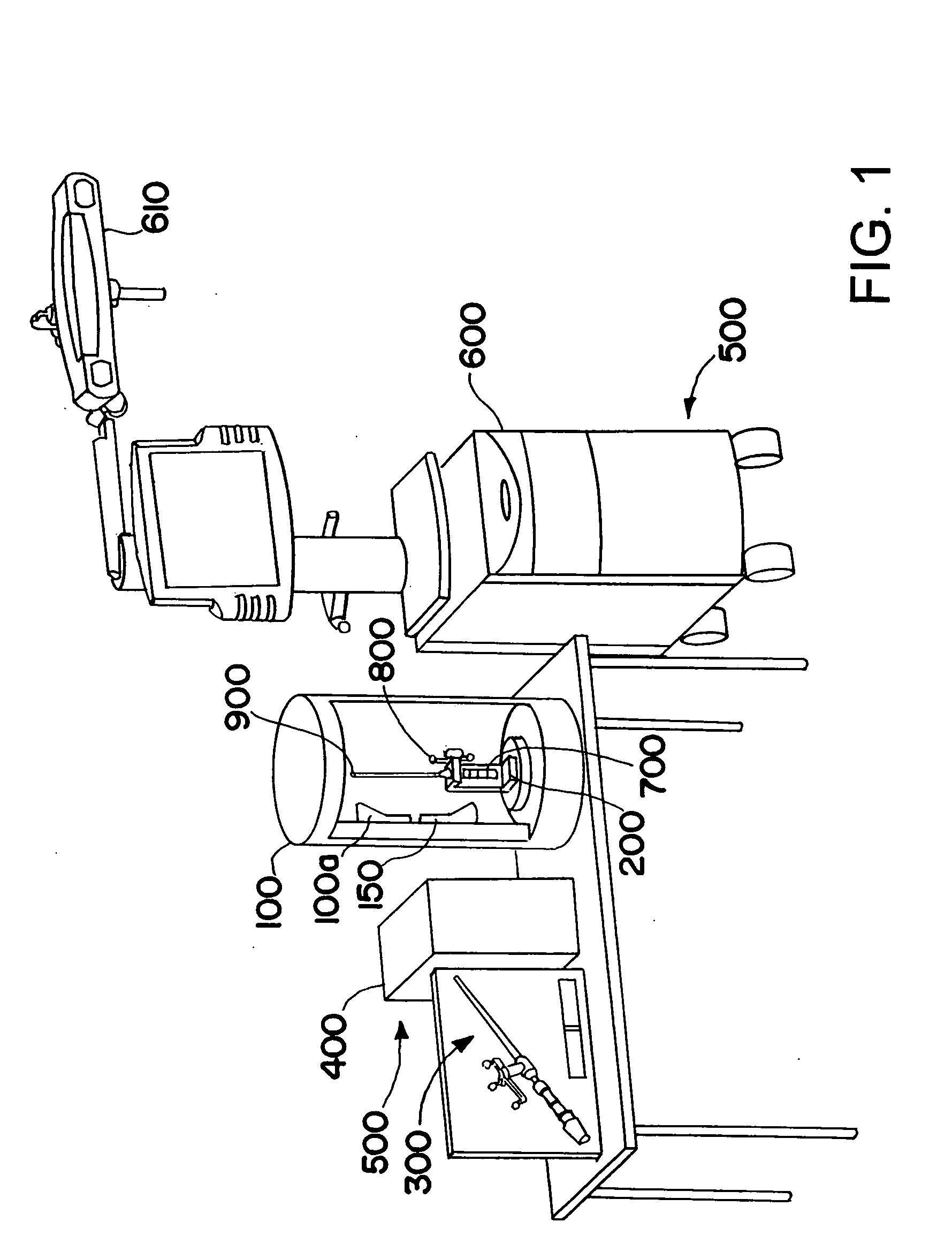

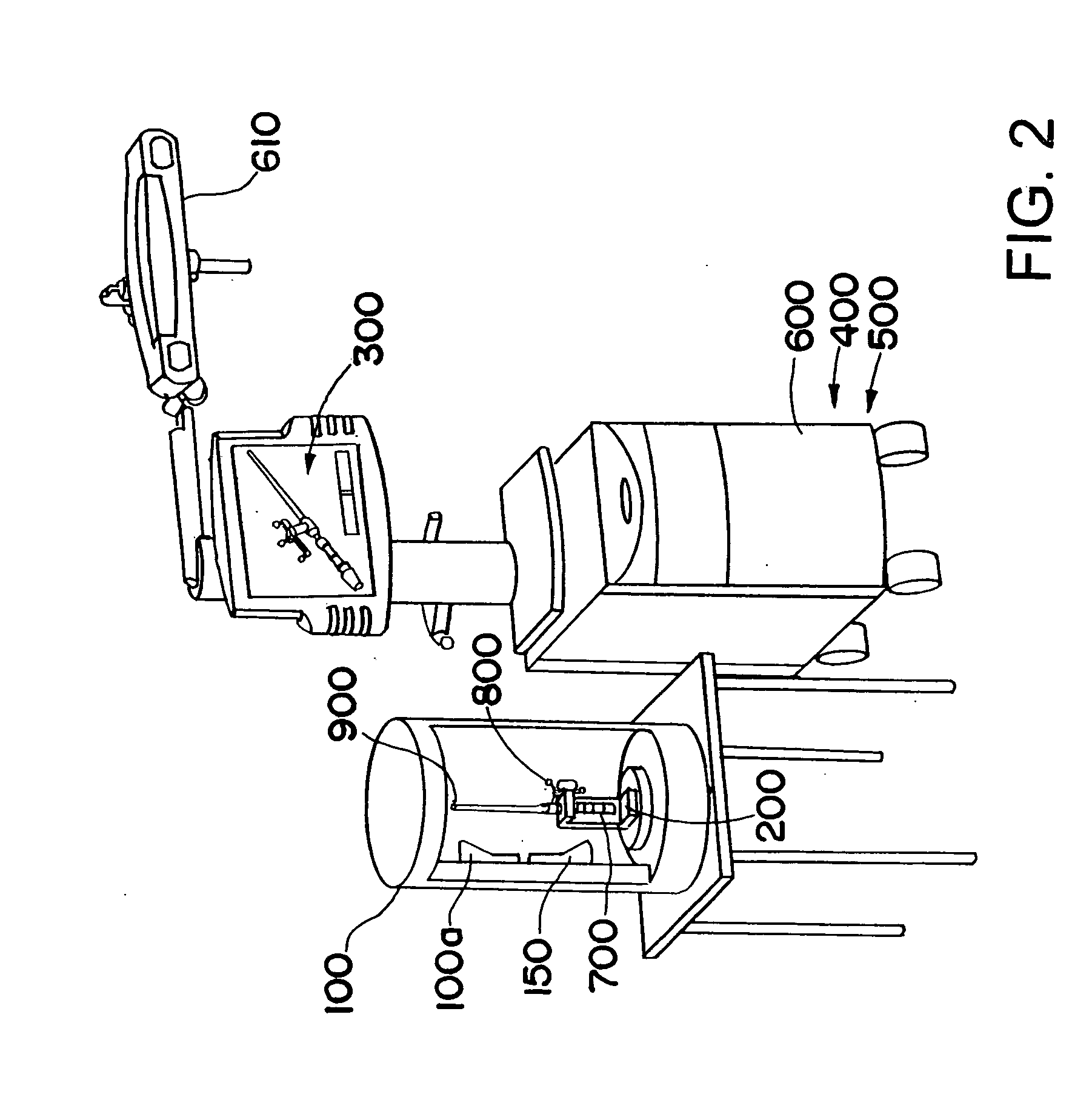

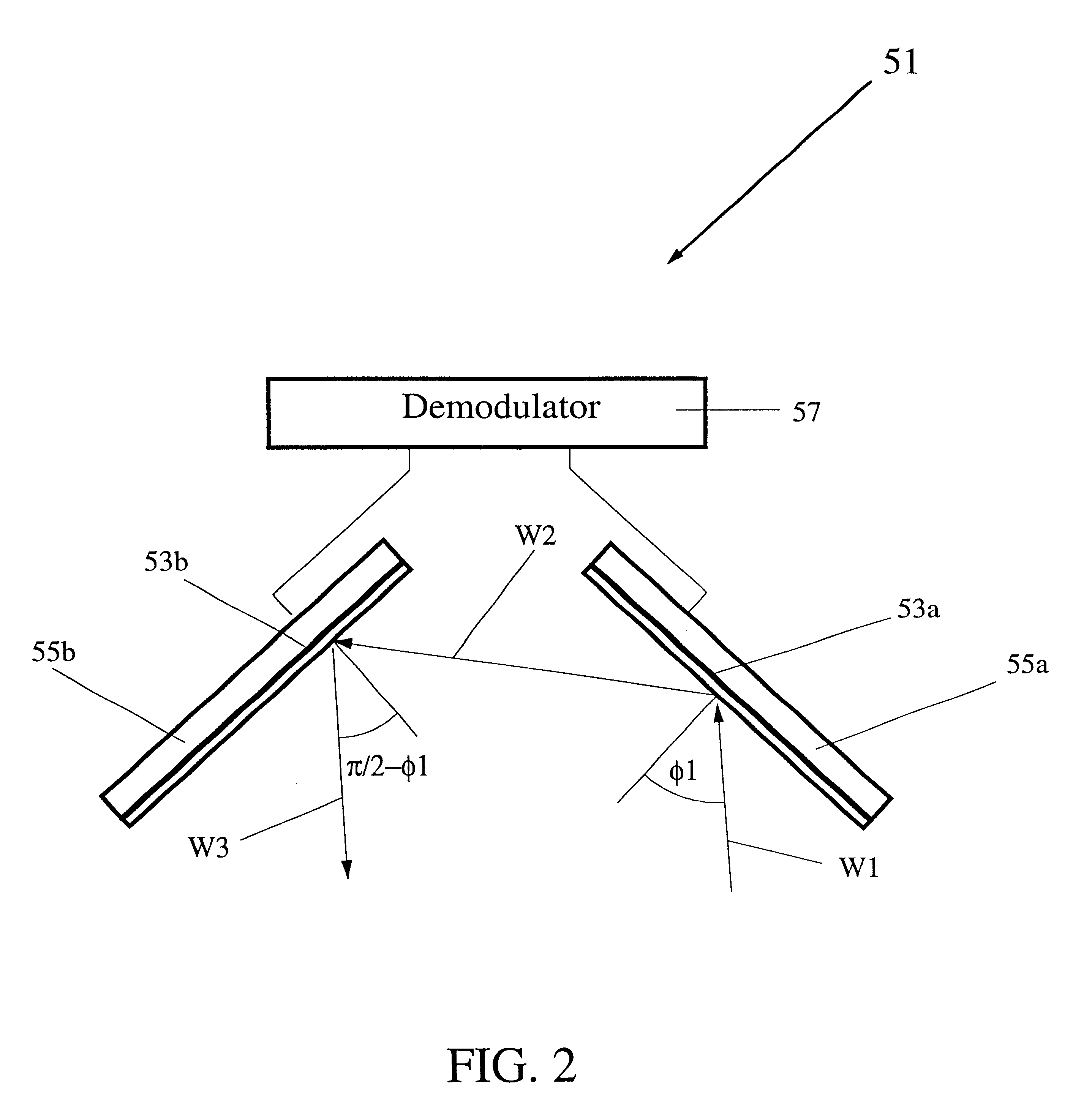

Devices and methods for automatically verifying, calibrating and surveying instruments for computer-assisted surgery

ActiveUS7809184B2Improve reliabilitySurgical navigation systemsCharacter and pattern recognitionComputer-assisted surgerySurvey instrument

A device and method for automatically verifying, calibrating and surveying a navigable surgical instrument, wherein by means of a scanning device, the geometry of the instrument, in particular the shape of the functional elements (e.g., tips) and their spatial position with respect to an attachable reference system, are detected. By means of a data processing unit, a three-dimensional model of the instrument is calculated from the detected information concerning the geometry of the instrument including the reference system, wherein verification, calibration or surveying is performed with the aid of the ascertained information concerning the geometry of the instrument.

Owner:BRAINLAB

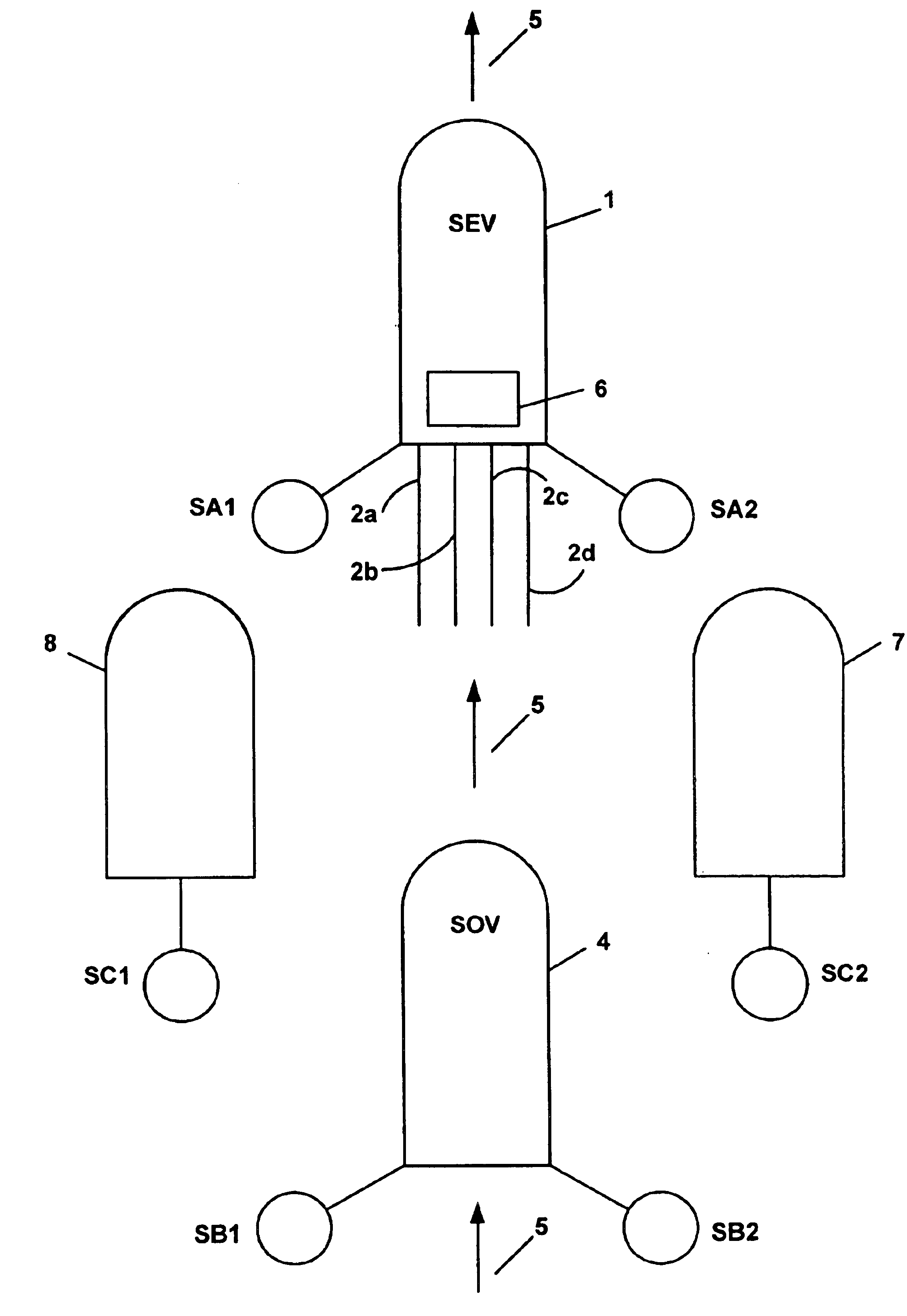

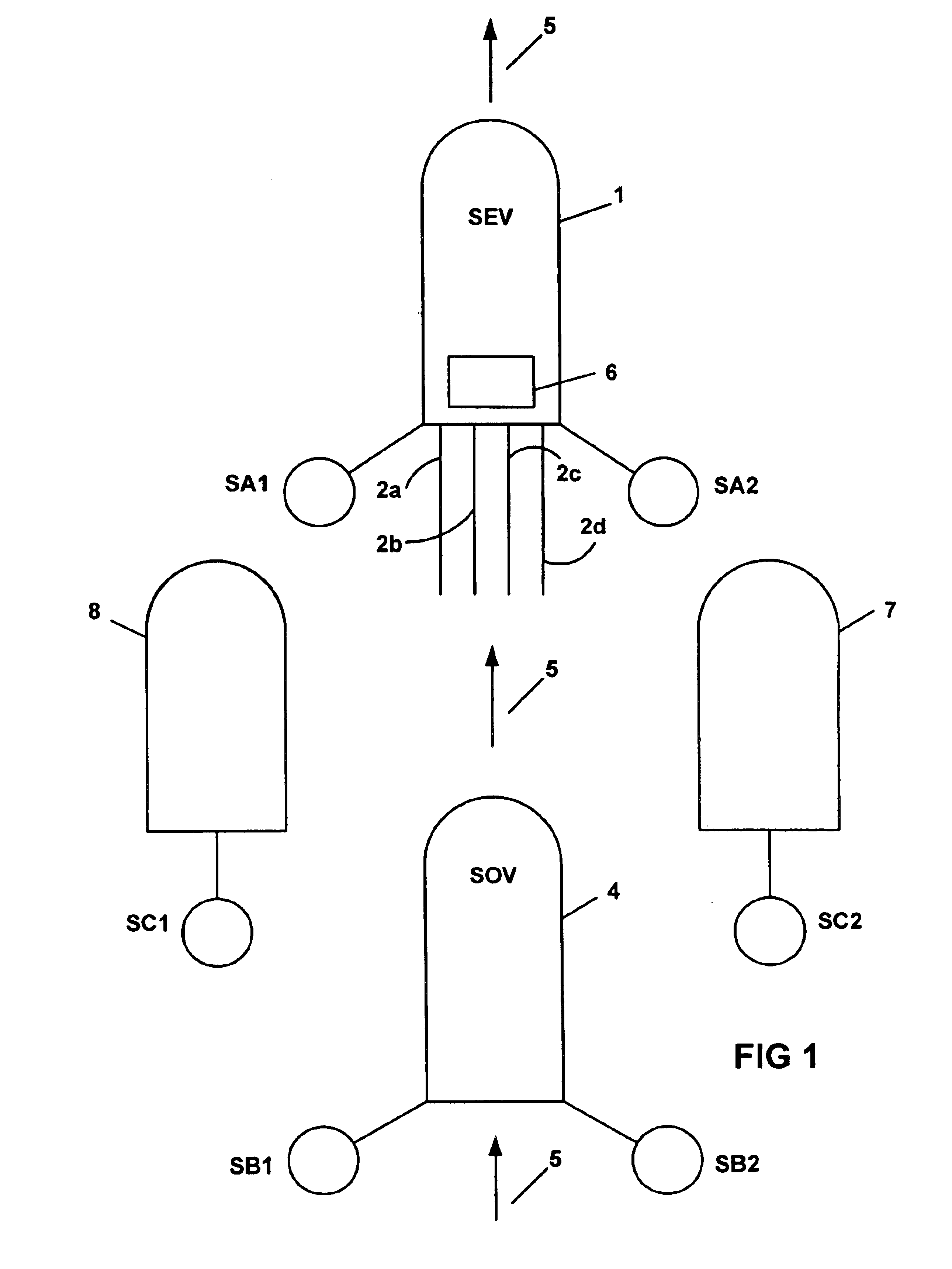

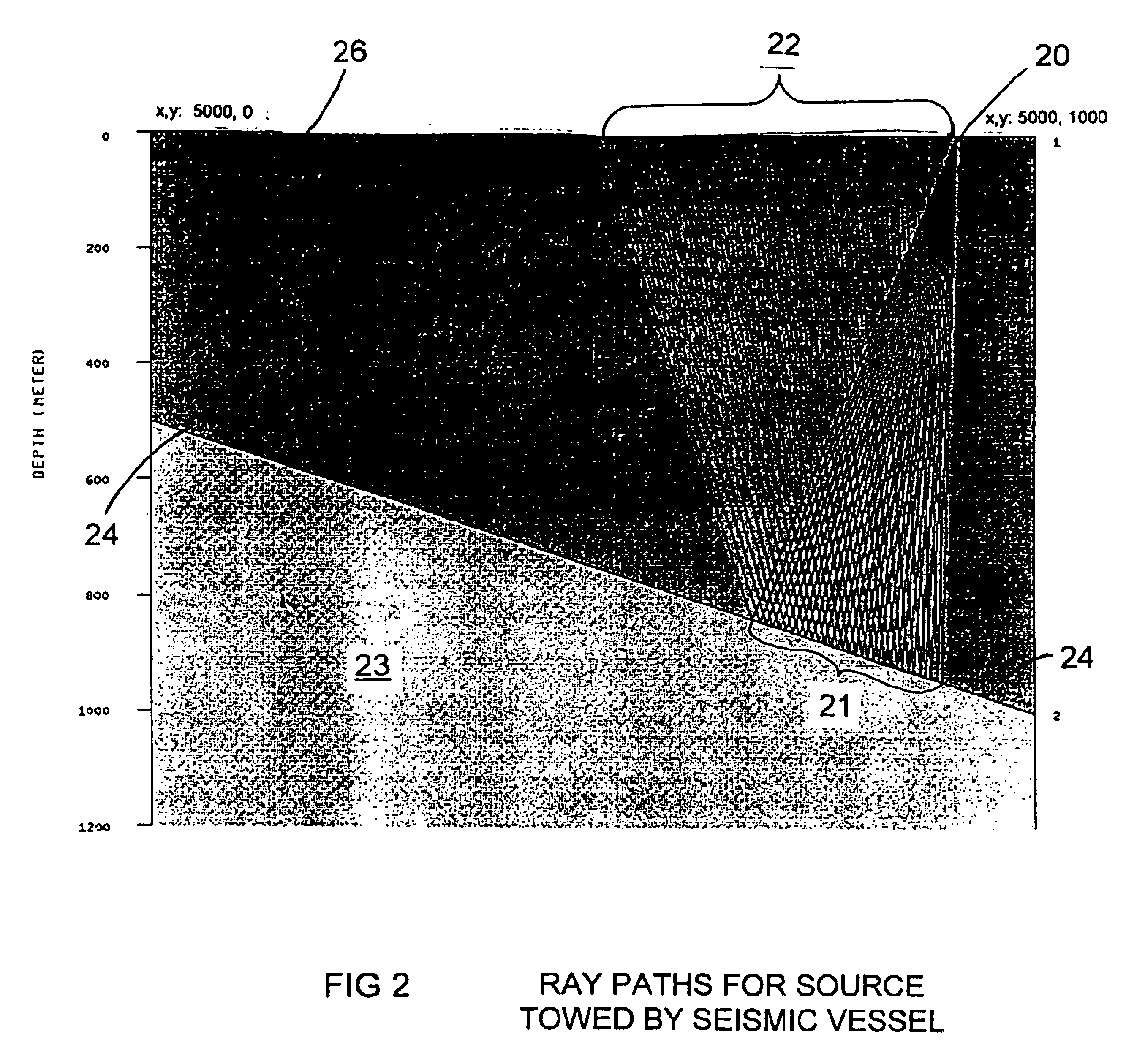

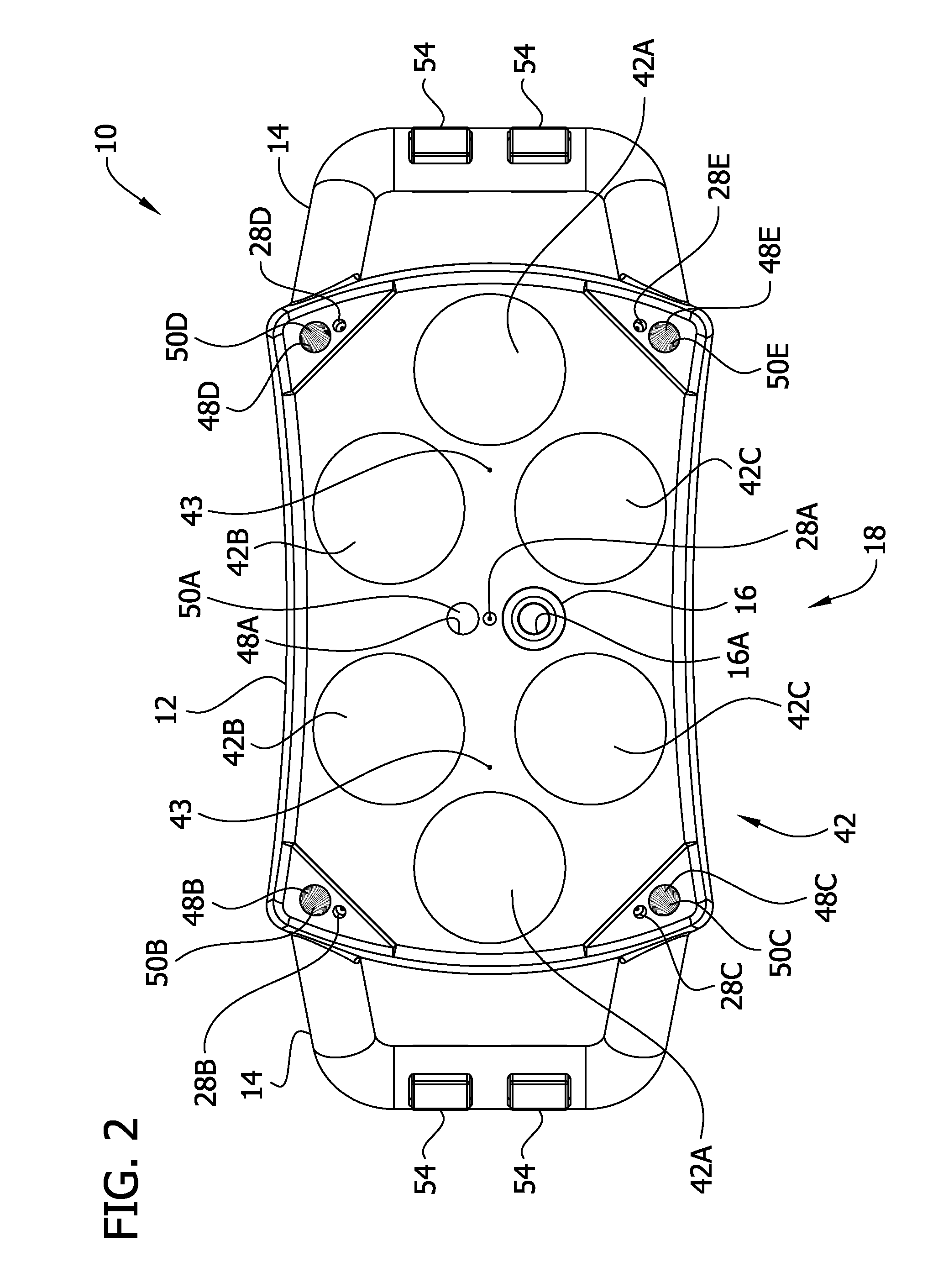

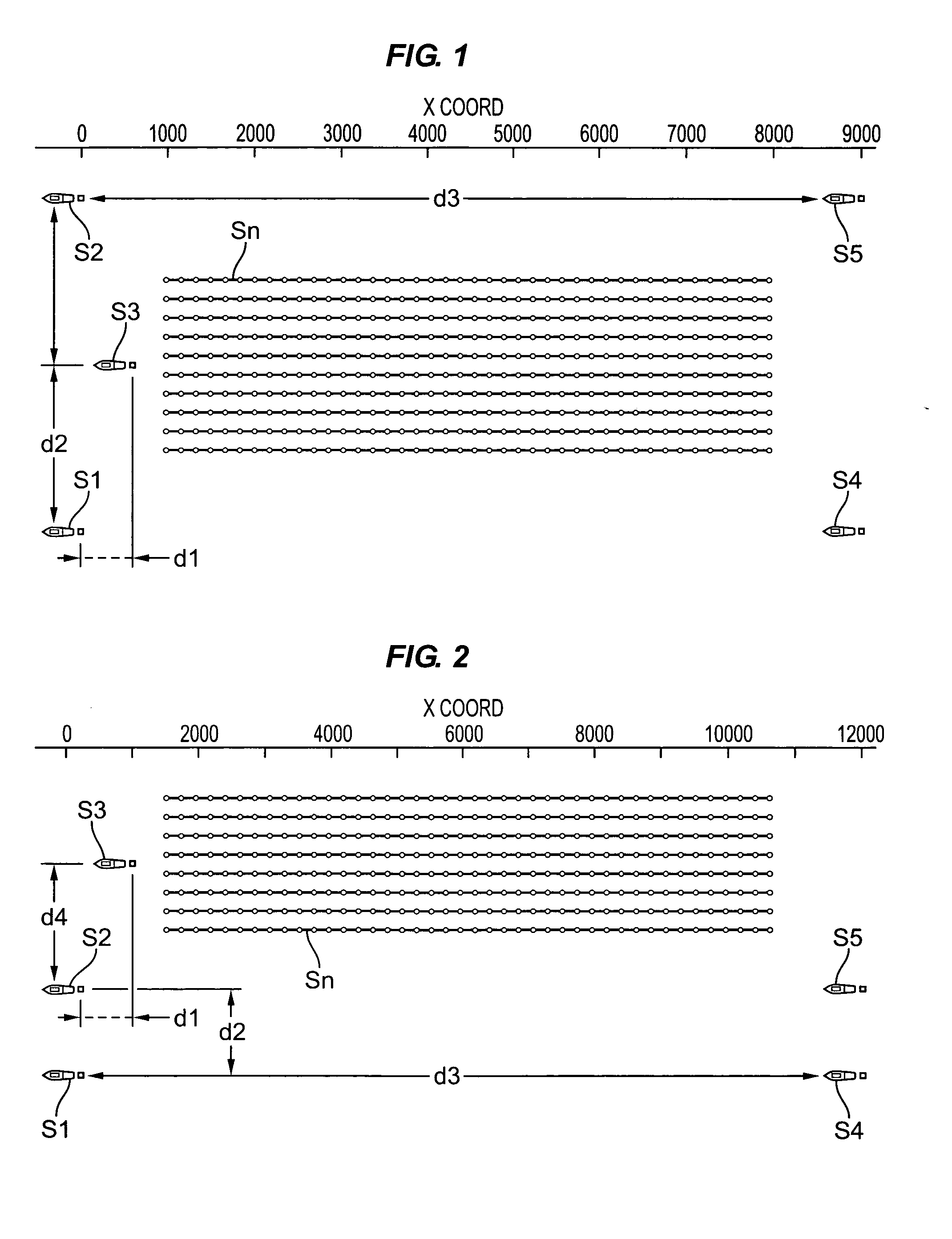

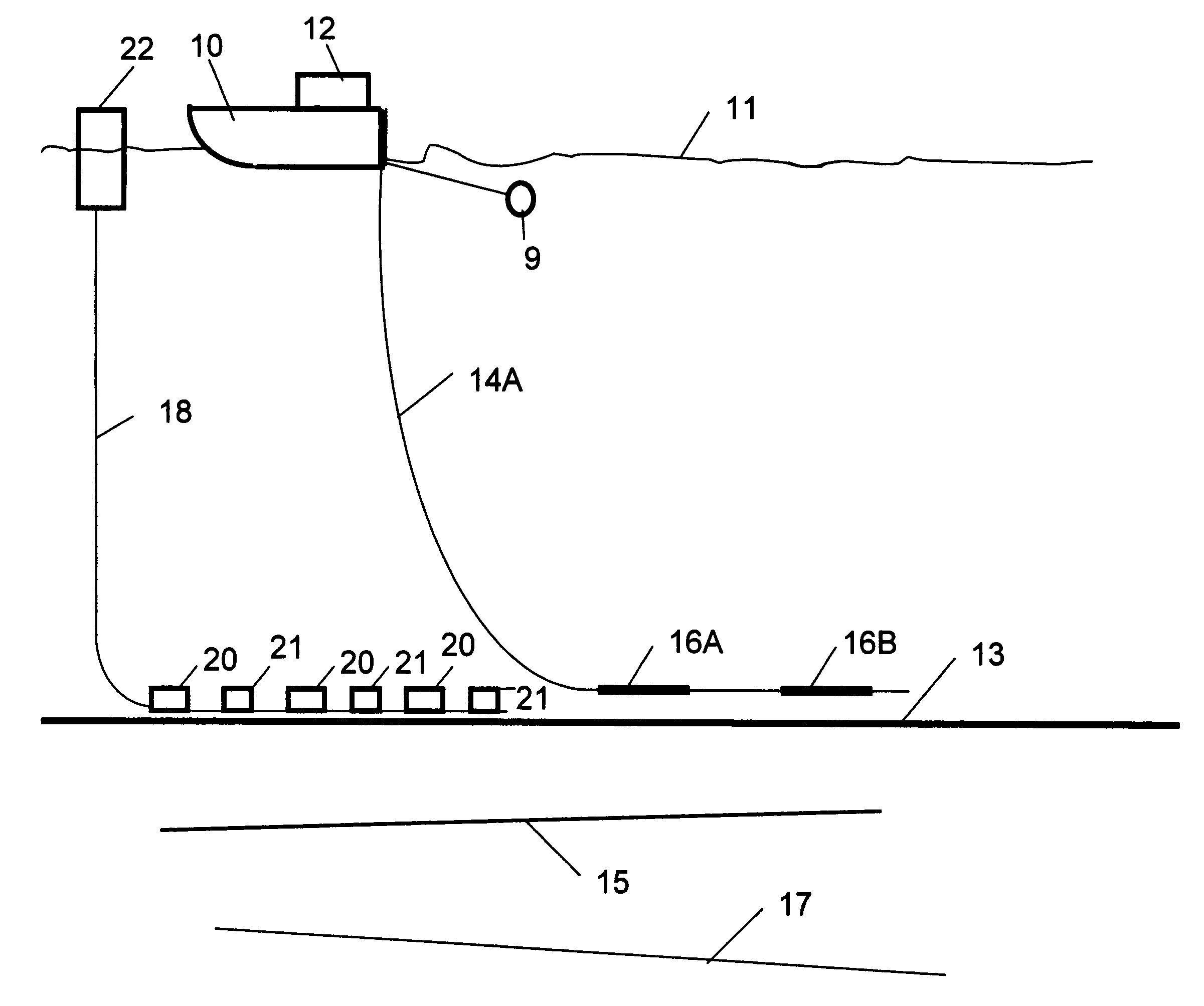

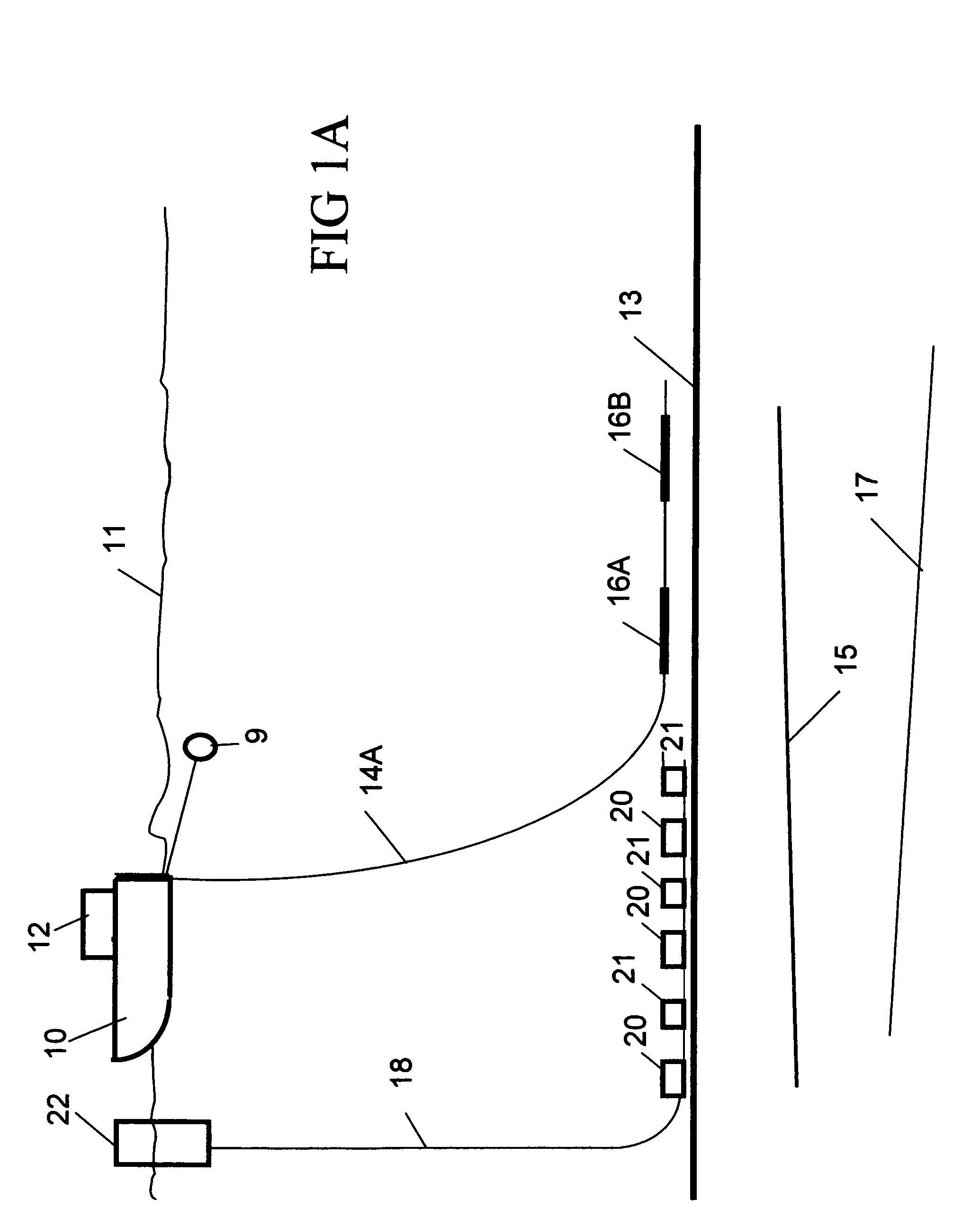

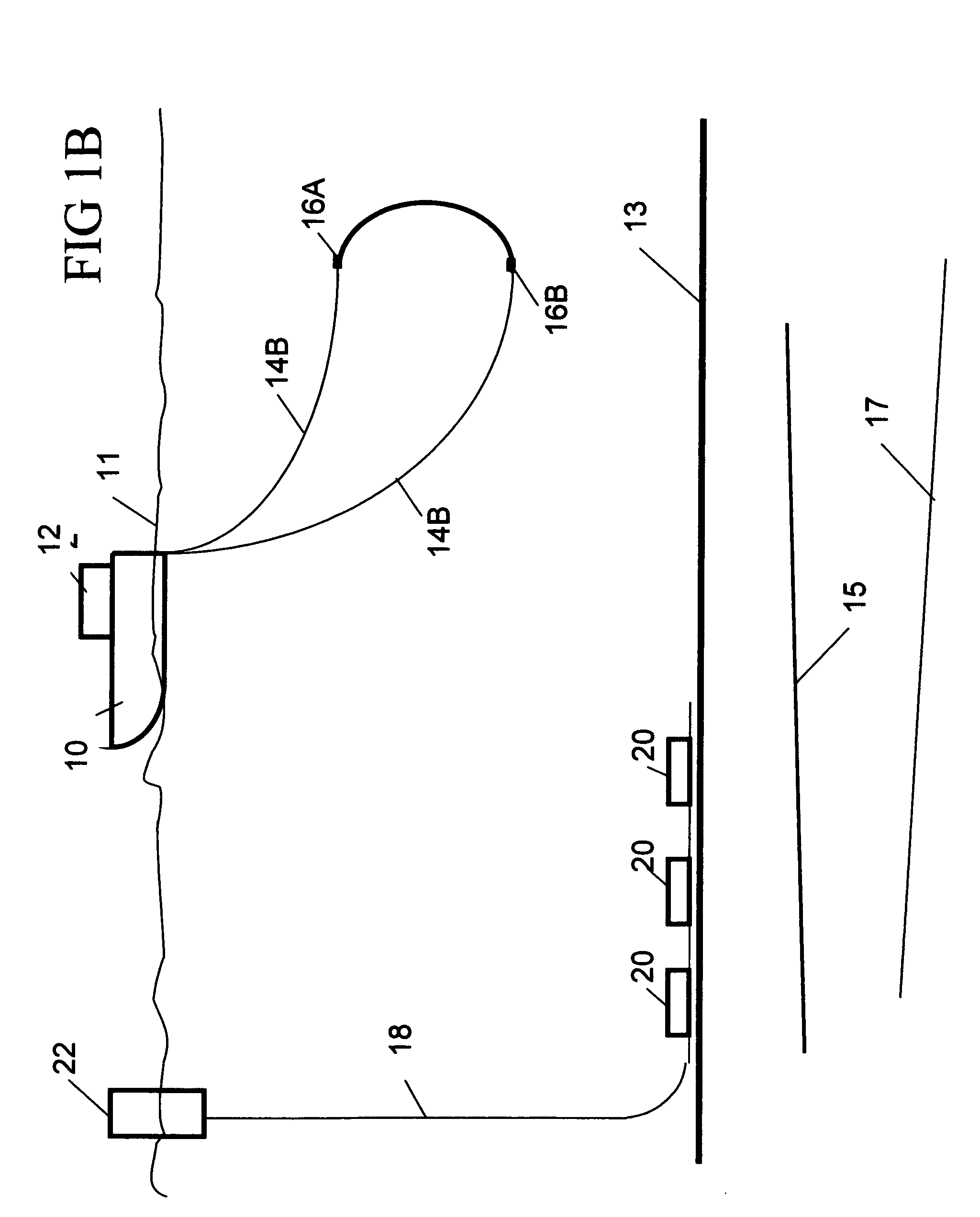

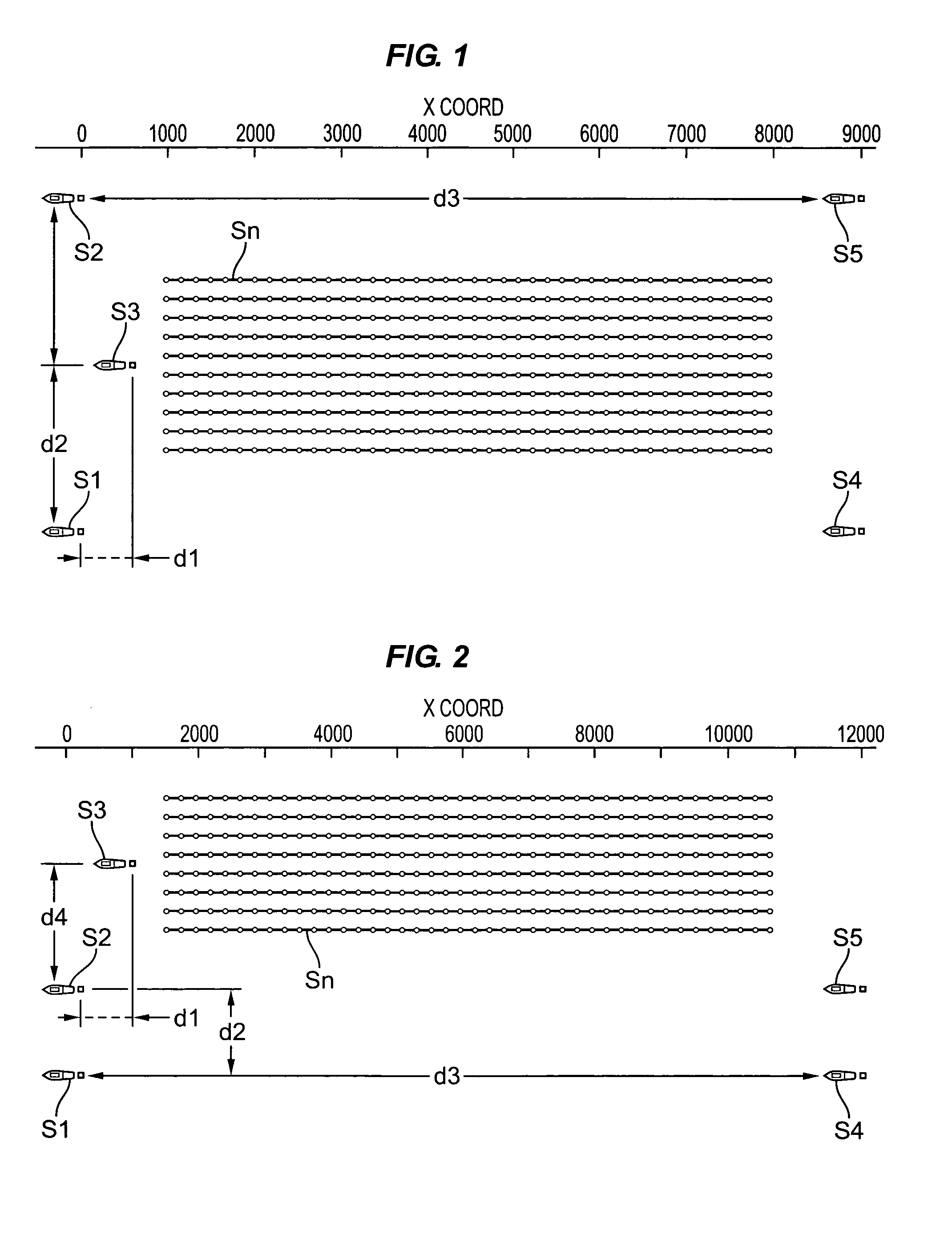

Method and system for acquiring marine seismic data using multiple seismic sources

InactiveUS6906981B2Easy to foldIncrease the lengthSeismic data acquisitionSeismic energy generationSeismic surveySurveyor

A method for seismic surveying is disclosed which includes towing a first seismic energy source and at least one seismic sensor system. A second seismic energy source is towed at a selected distance from the first source. The first seismic energy source and the second seismic energy source are actuated in a plurality of firing sequences. Each of the firing sequences includes firing of the first source, waiting a selected time firing the second source and recording signals generated by the seismic sensor system. The selected time between firing the first source and the second source is varied between successive ones of the firing sequences. The firing times of the first and second source are indexed so as to enable separate identification of seismic events originating from the first source and seismic events originating from the second source in detected seismic signals.

Owner:PGS GEOPHYSICAL AS

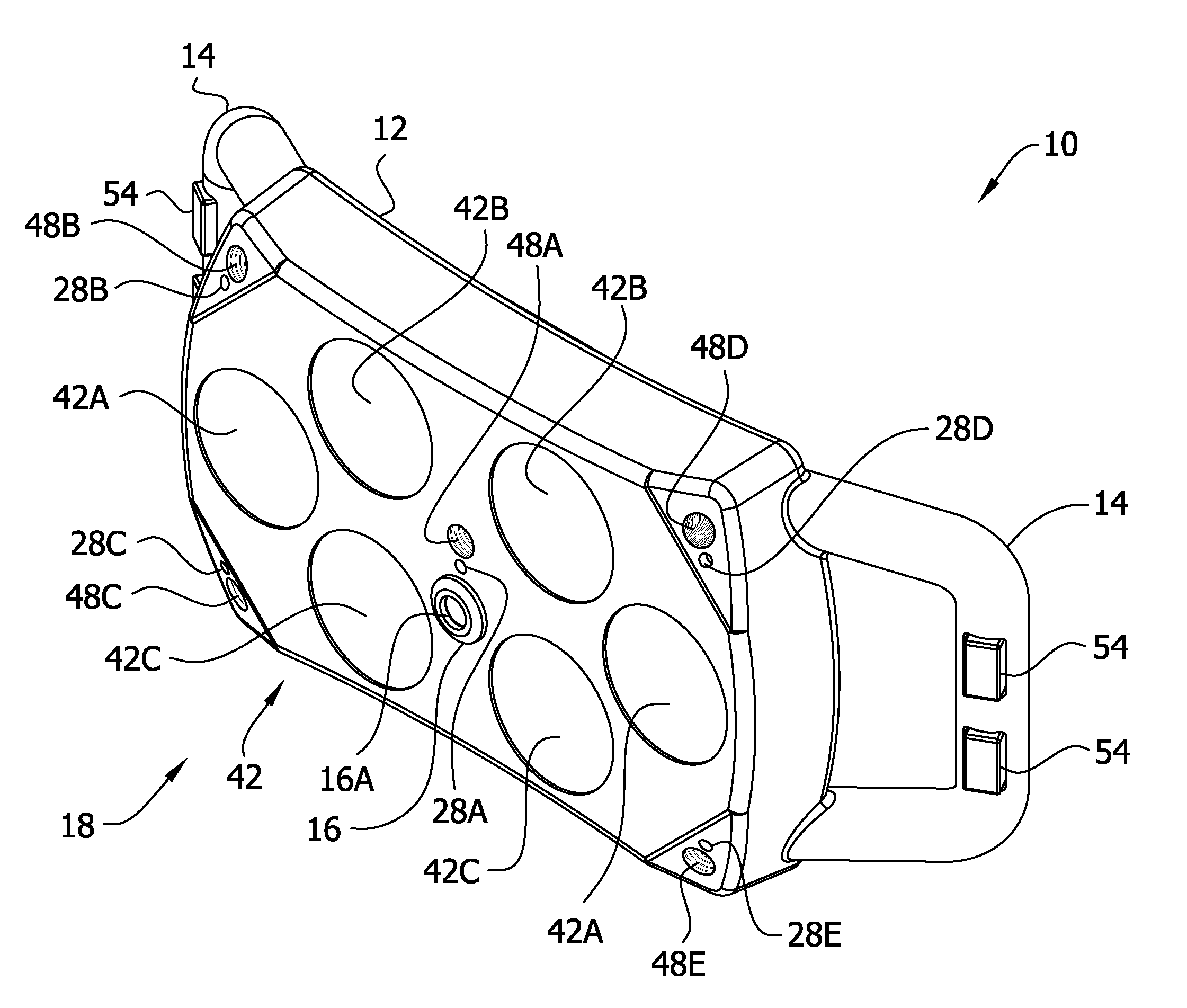

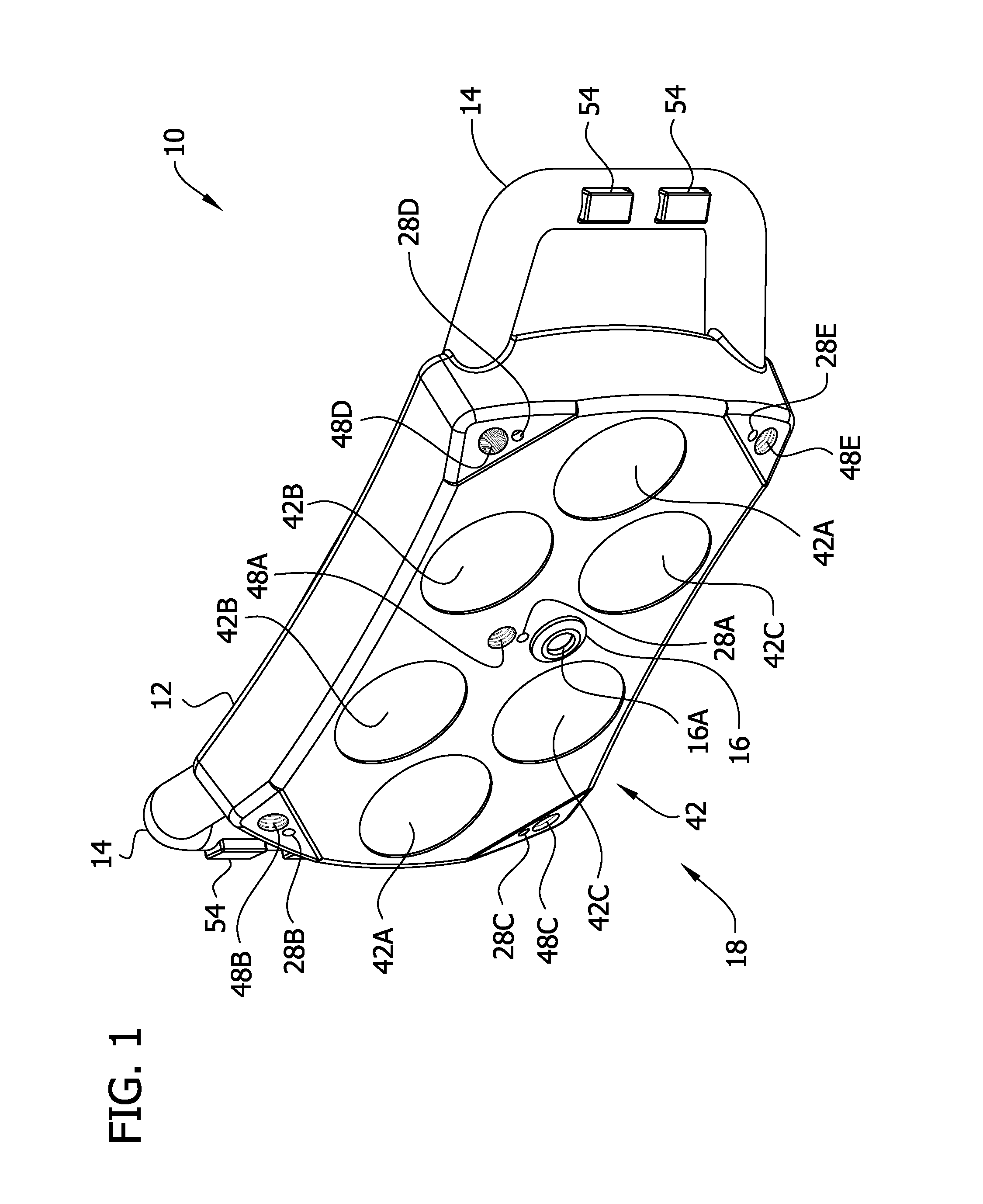

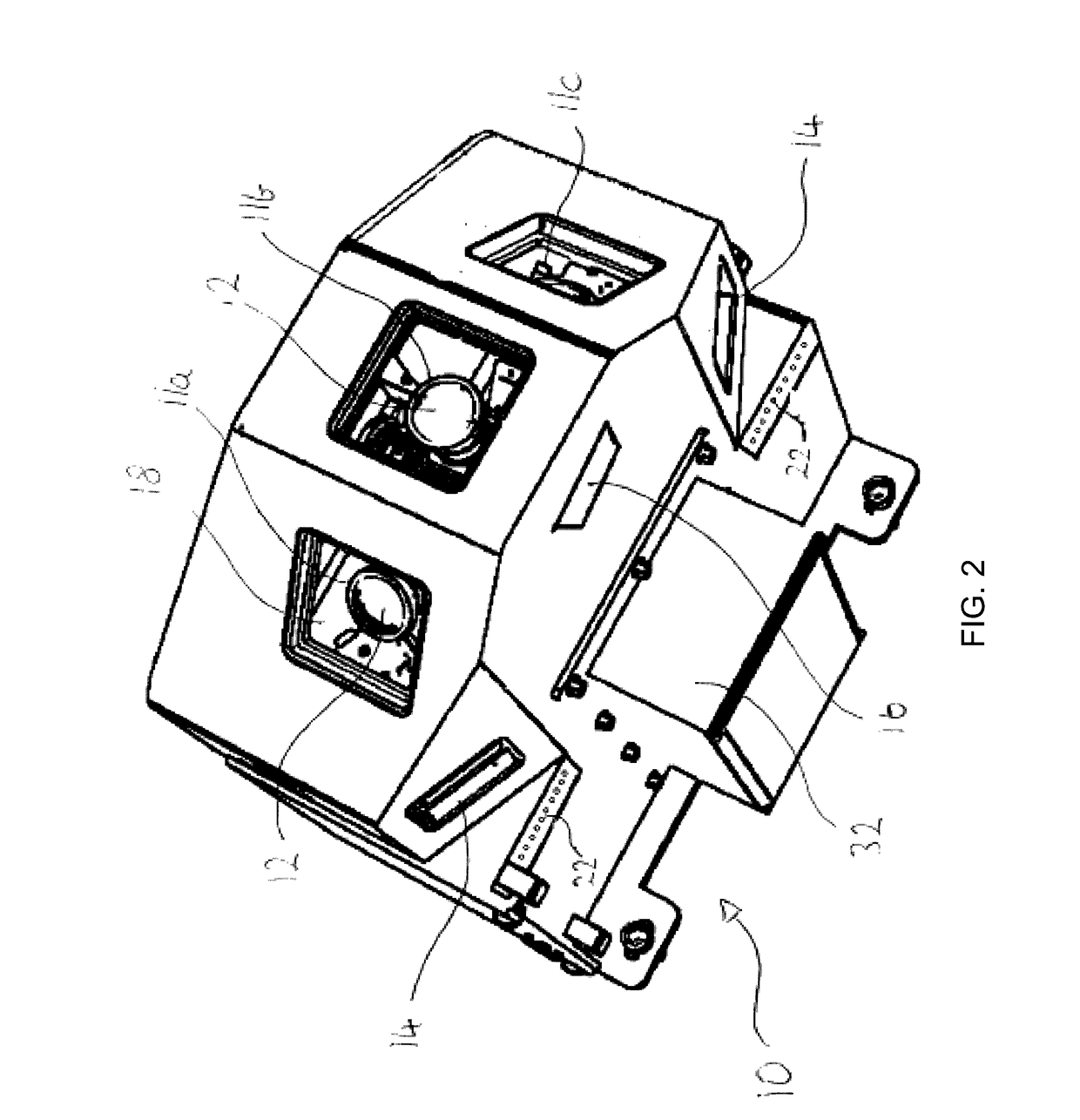

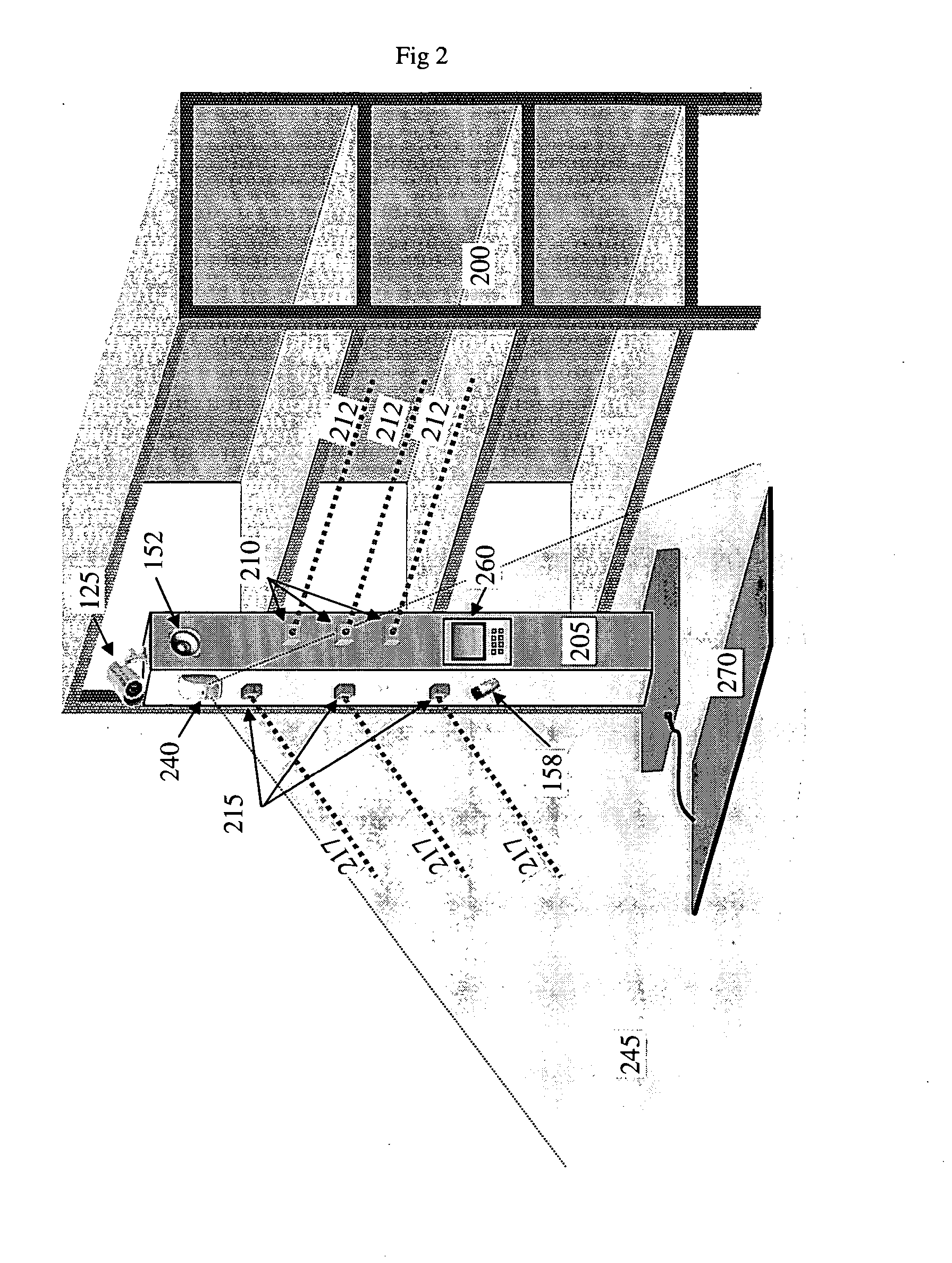

Scanners, targets, and methods for surveying

InactiveUS20140368373A1Indoor communication adaptationIndependent non-interacting antenna combinationsRich modelComputer graphics (images)

Apparatus and methods useful in surveying to provide information rich models. In particular, information not readily or possibly provided by conventional survey techniques can be provided. In some versions targets provide reference for baseline positioning or improving position information otherwise acquired. Scanning may be carried out in multiple locations and merged to form a single image. Machine mounted and hand mounted scanning apparatus is disclosed.

Owner:SADAR 3D

Rail track asset survey system

The present application involves a railroad track asset surveying system comprising an image capture sensor, a location determining system, and an image processor. The image capture sensor is mounted to a railroad vehicle. The location determining system holds images captured by the image capture sensor. The image processor includes an asset classifier and an asset status analyser. The asset classifier detects an asset in one or more captured images and classifies the detected asset by assigning an asset type to the detected asset from a predetermined list of asset types according to one or more features in the captured image. The asset status analyser identifies an asset status characteristic and compares the identified status characteristic to a predetermined asset characteristic so as to evaluate a deviation therefrom.

Owner:SINGH SAMEER

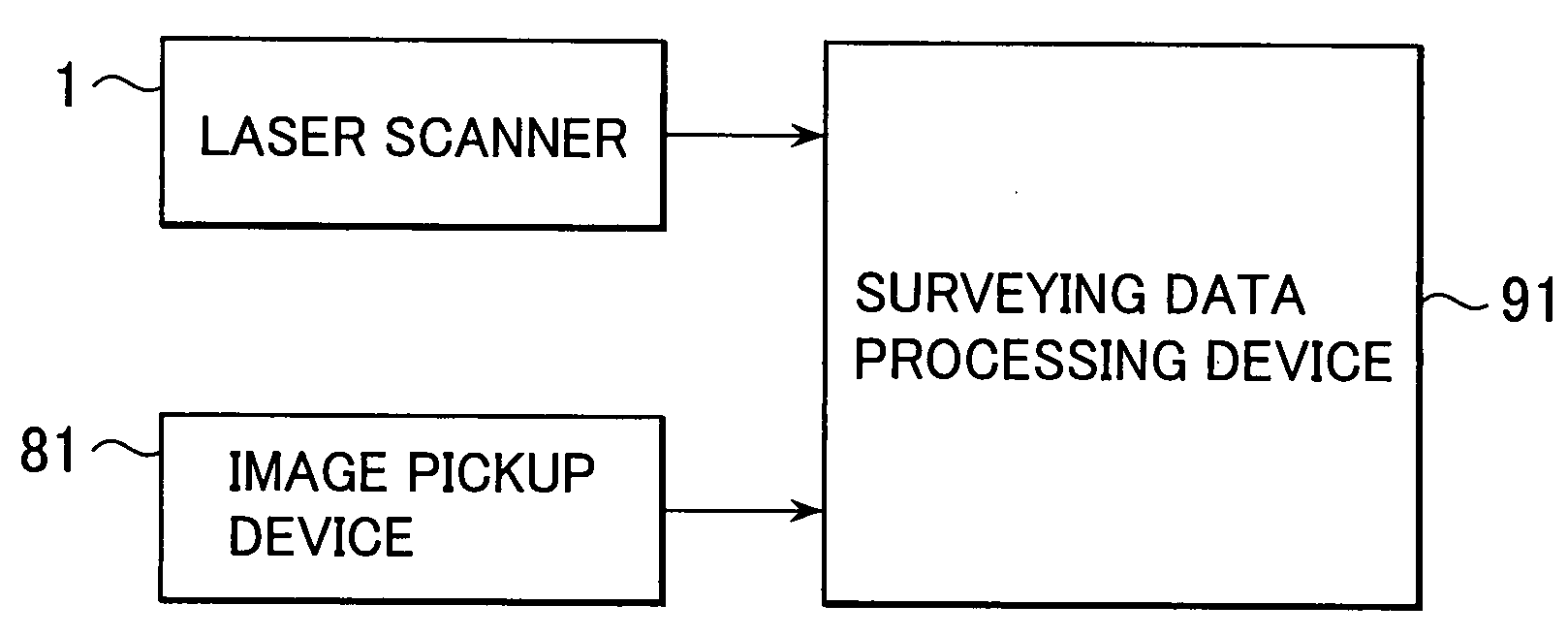

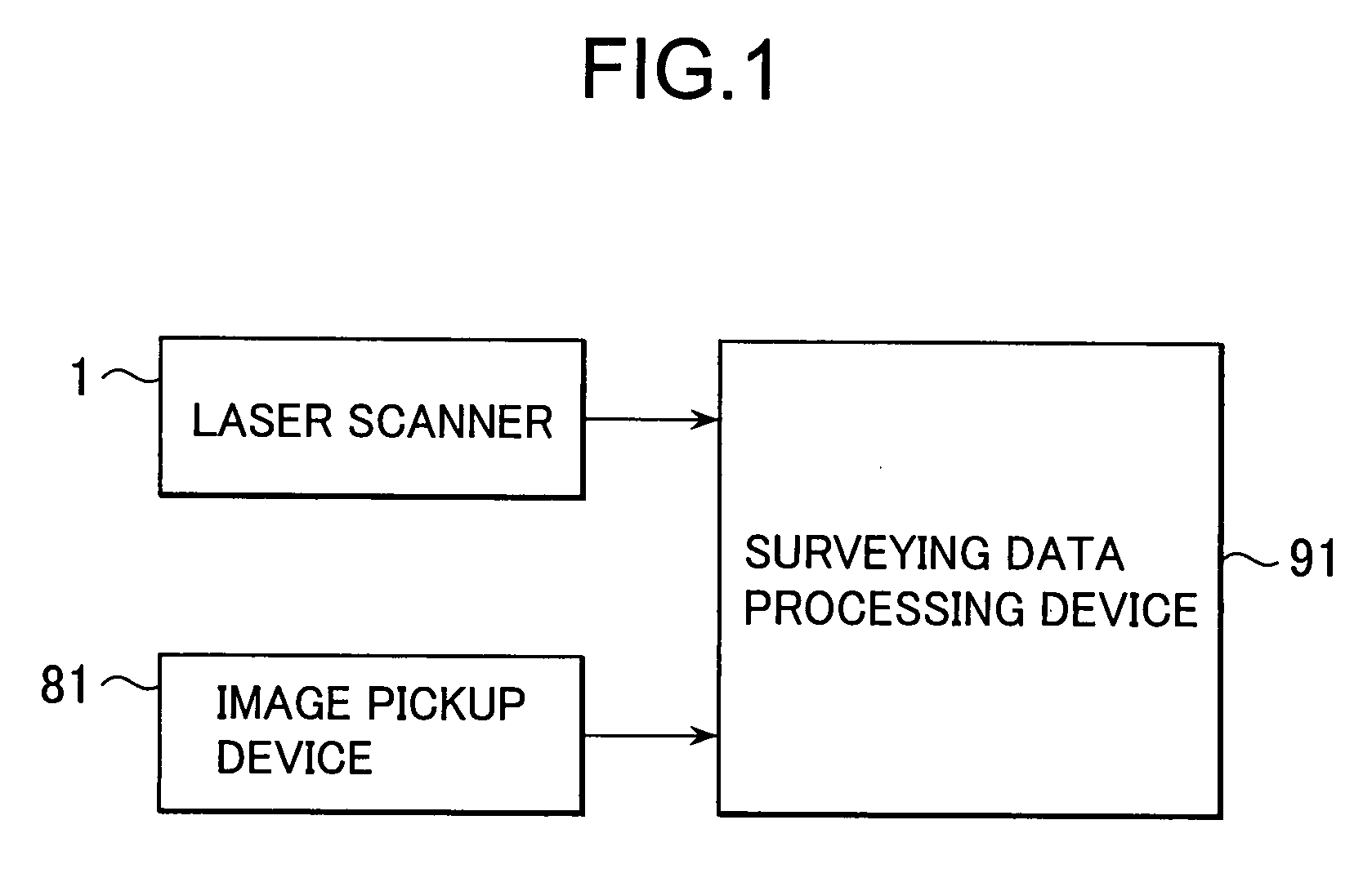

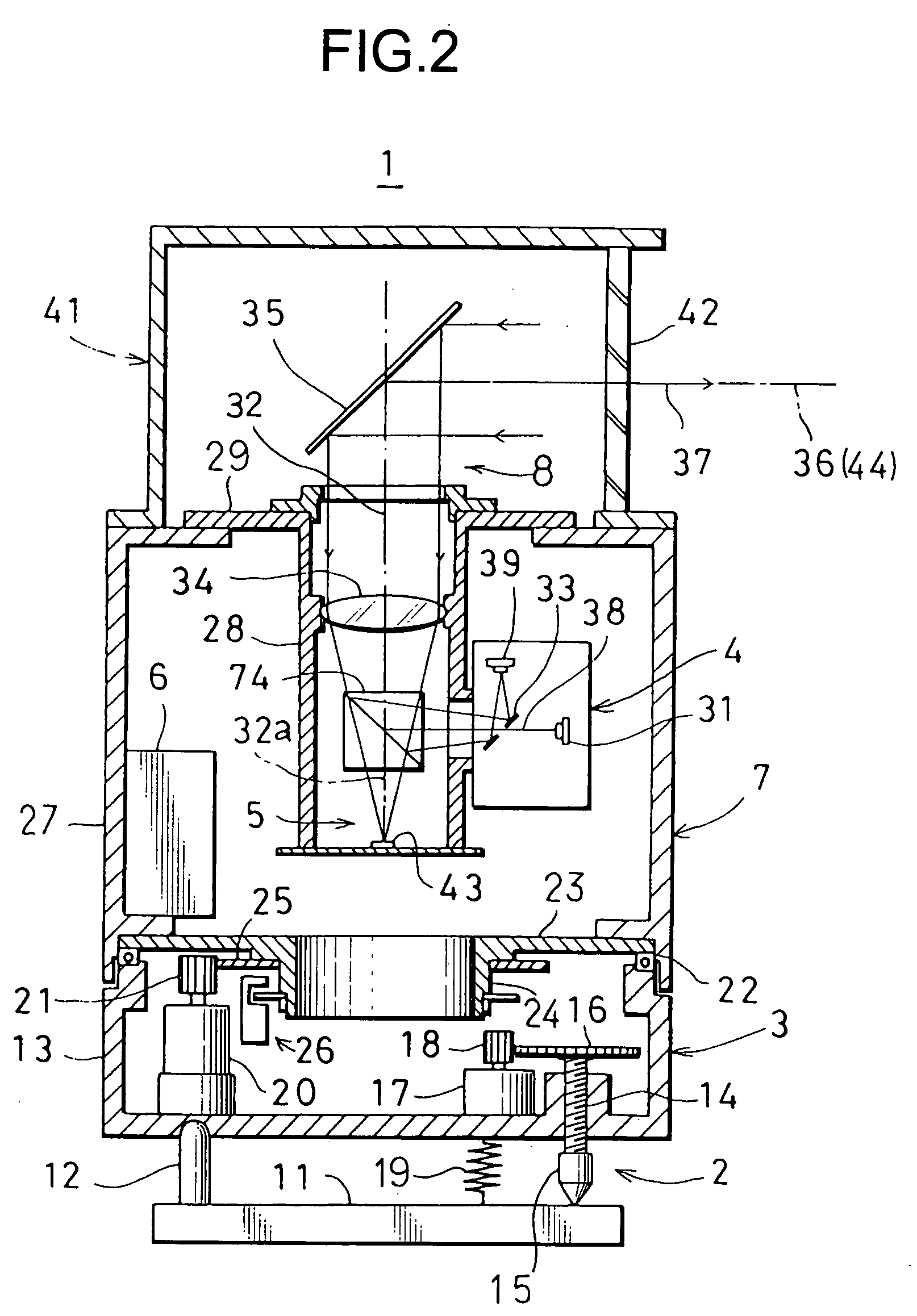

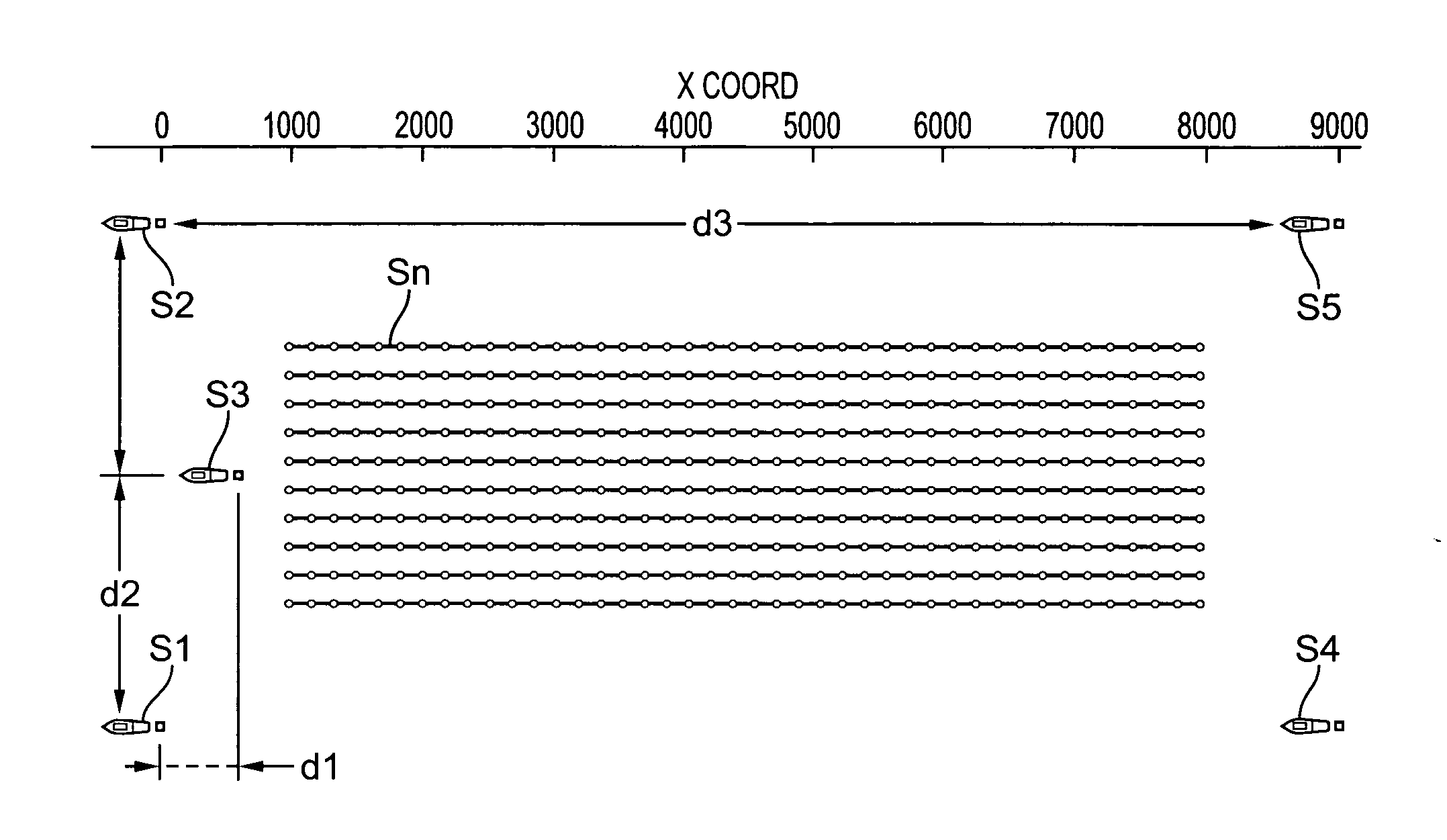

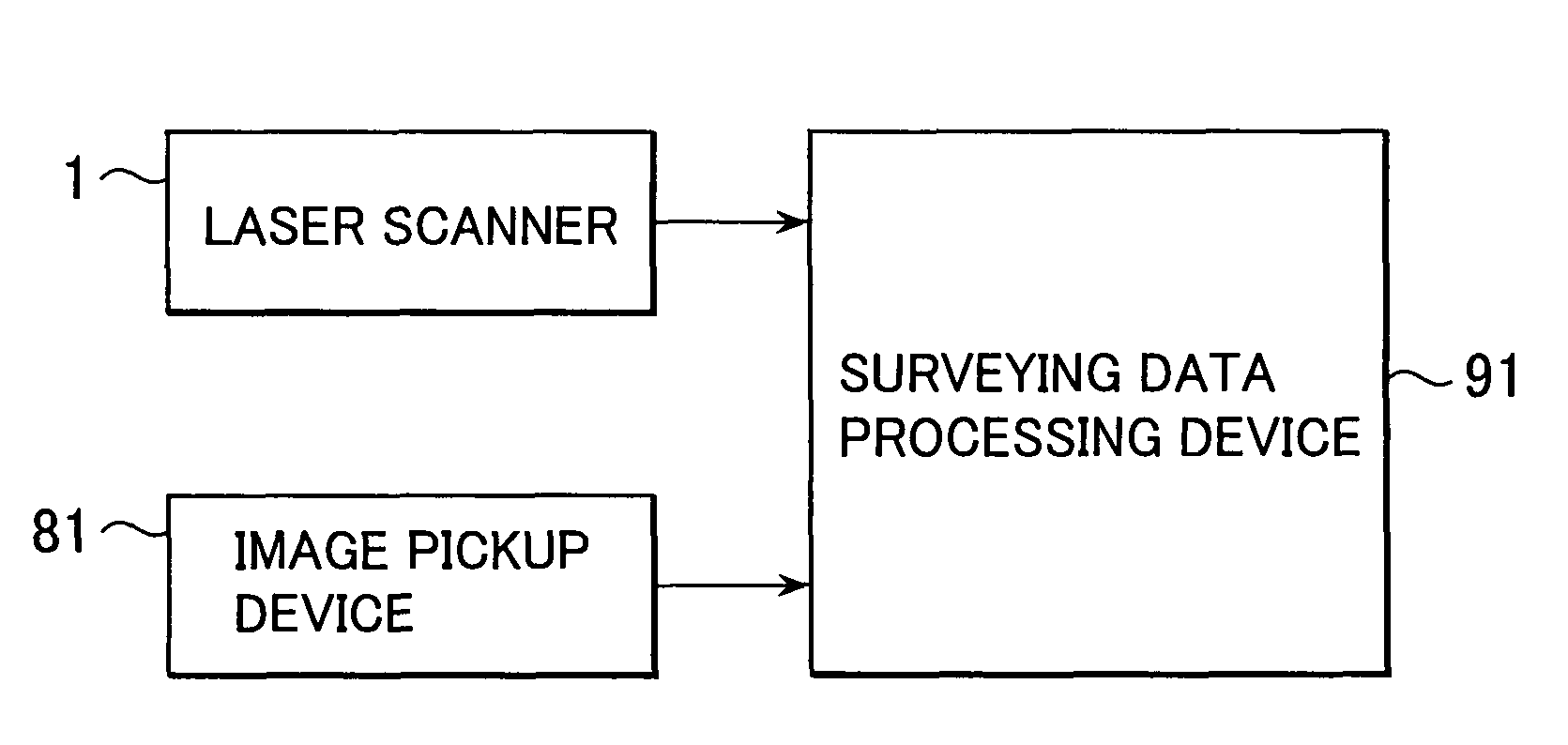

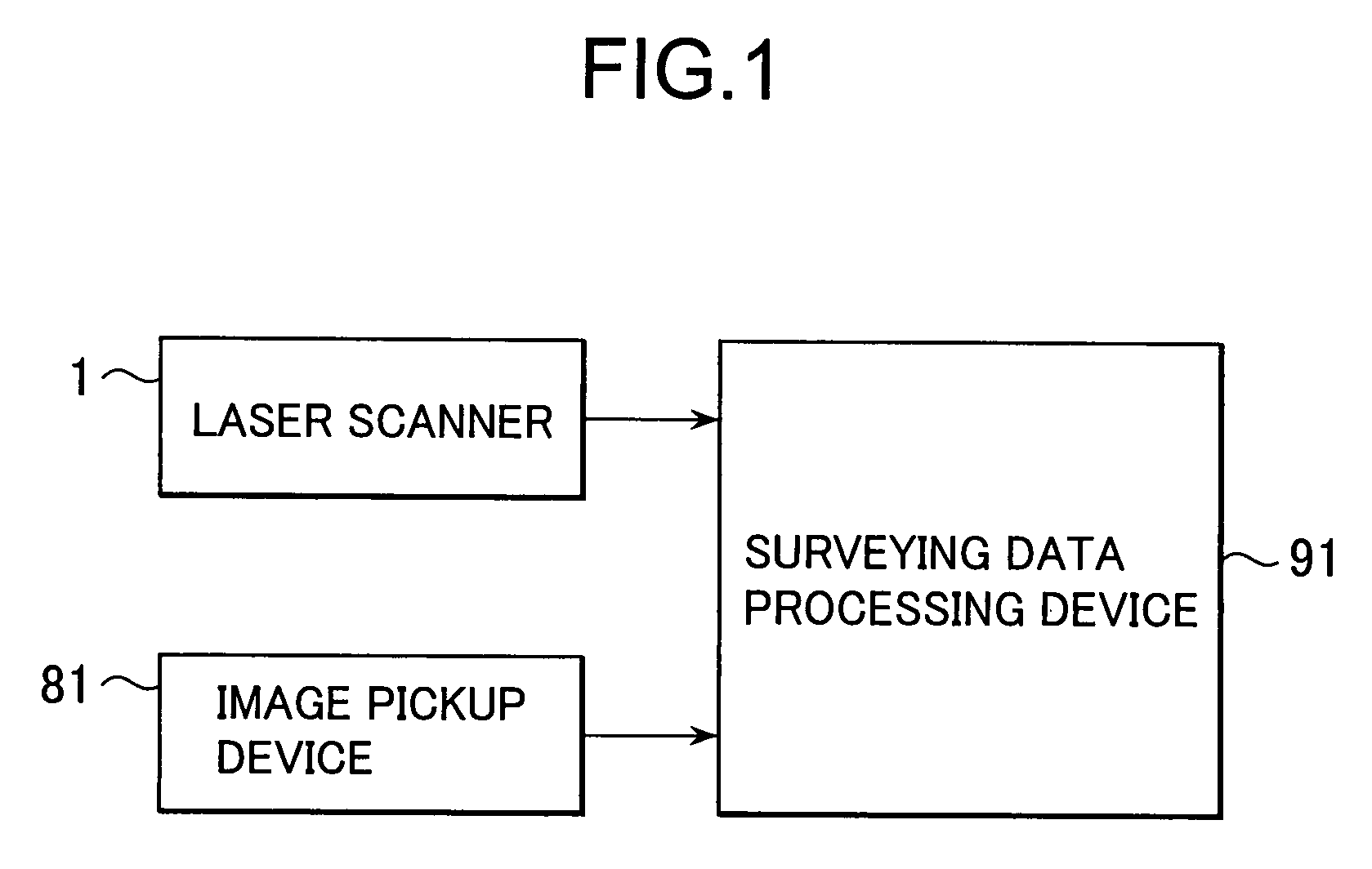

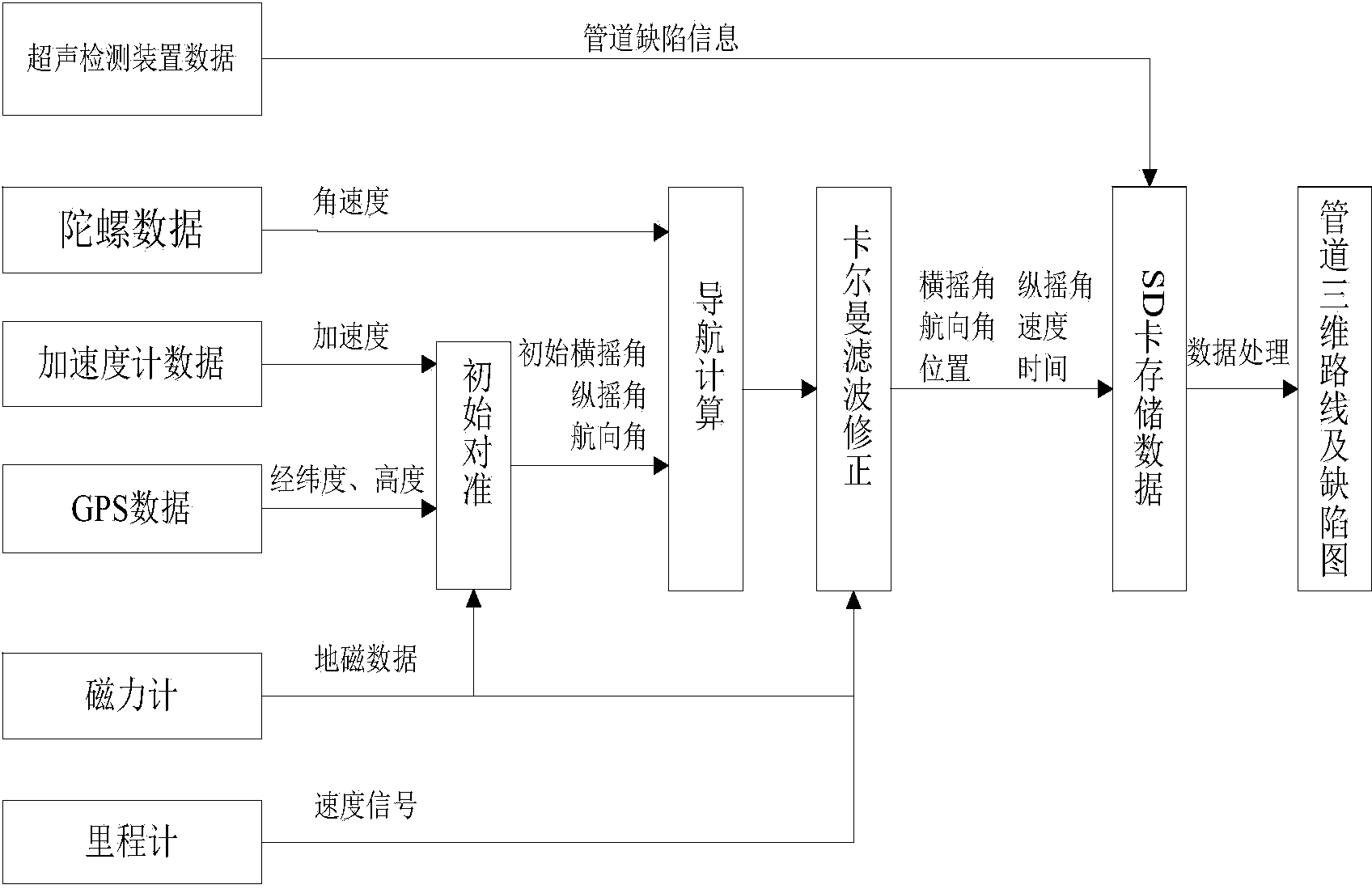

Surveying method, surveying system and surveying data processing program

There are provided a step of acquiring a main point cloud data on a predetermined measurement range by a laser scanner, a step of detecting a range with no data acquired, a step of acquiring a supplementary image data of the range with no data acquired by an auxiliary image pickup device, a step of preparing a stereoscopic image based on the supplementary image data obtained by the auxiliary image pickup device, a step of acquiring supplementary point cloud data from the stereoscopic image, and a step of supplementing the range with no data acquired of the main point cloud data by matching of the main point cloud data and the supplementary point cloud data.

Owner:KK TOPCON

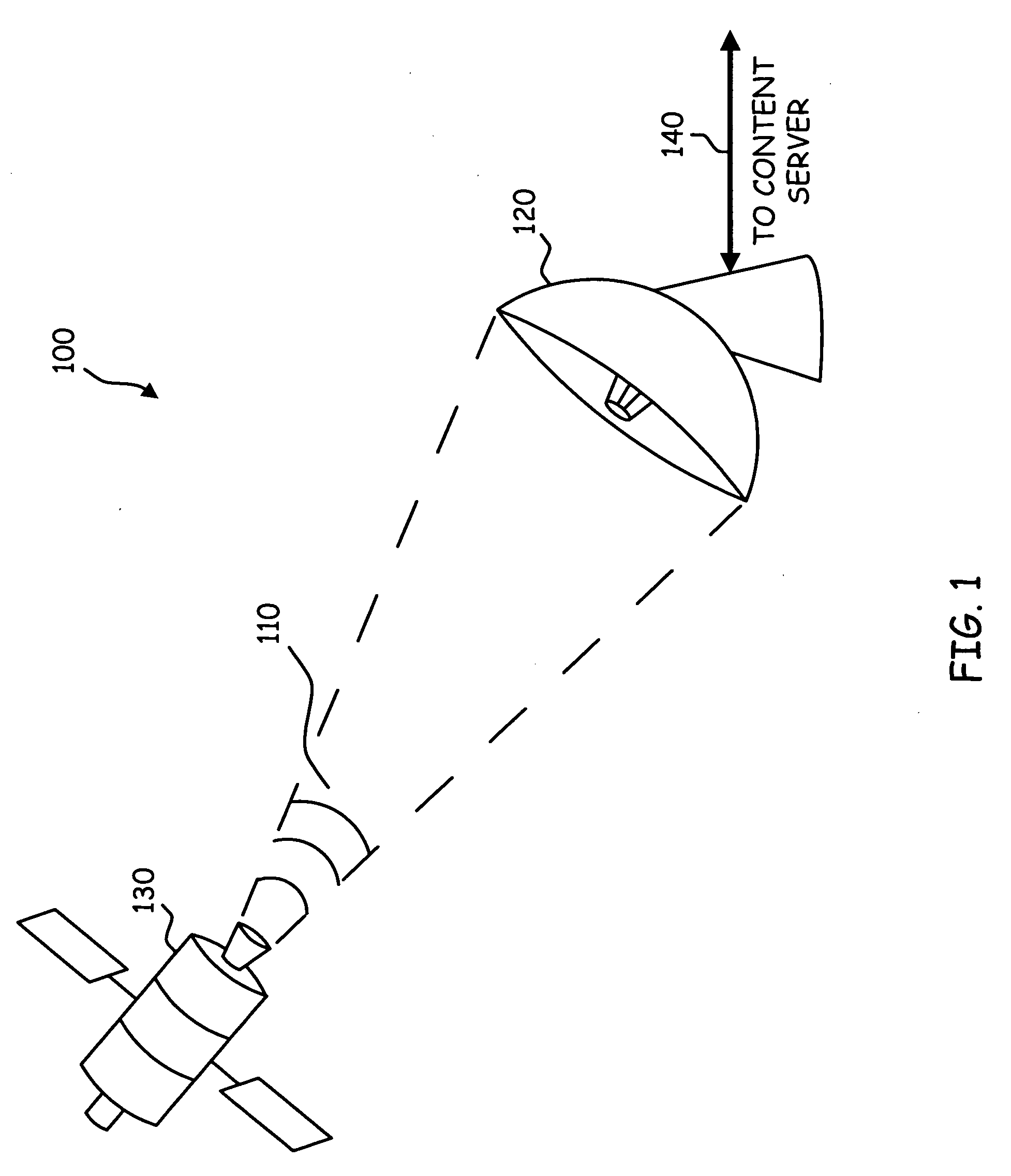

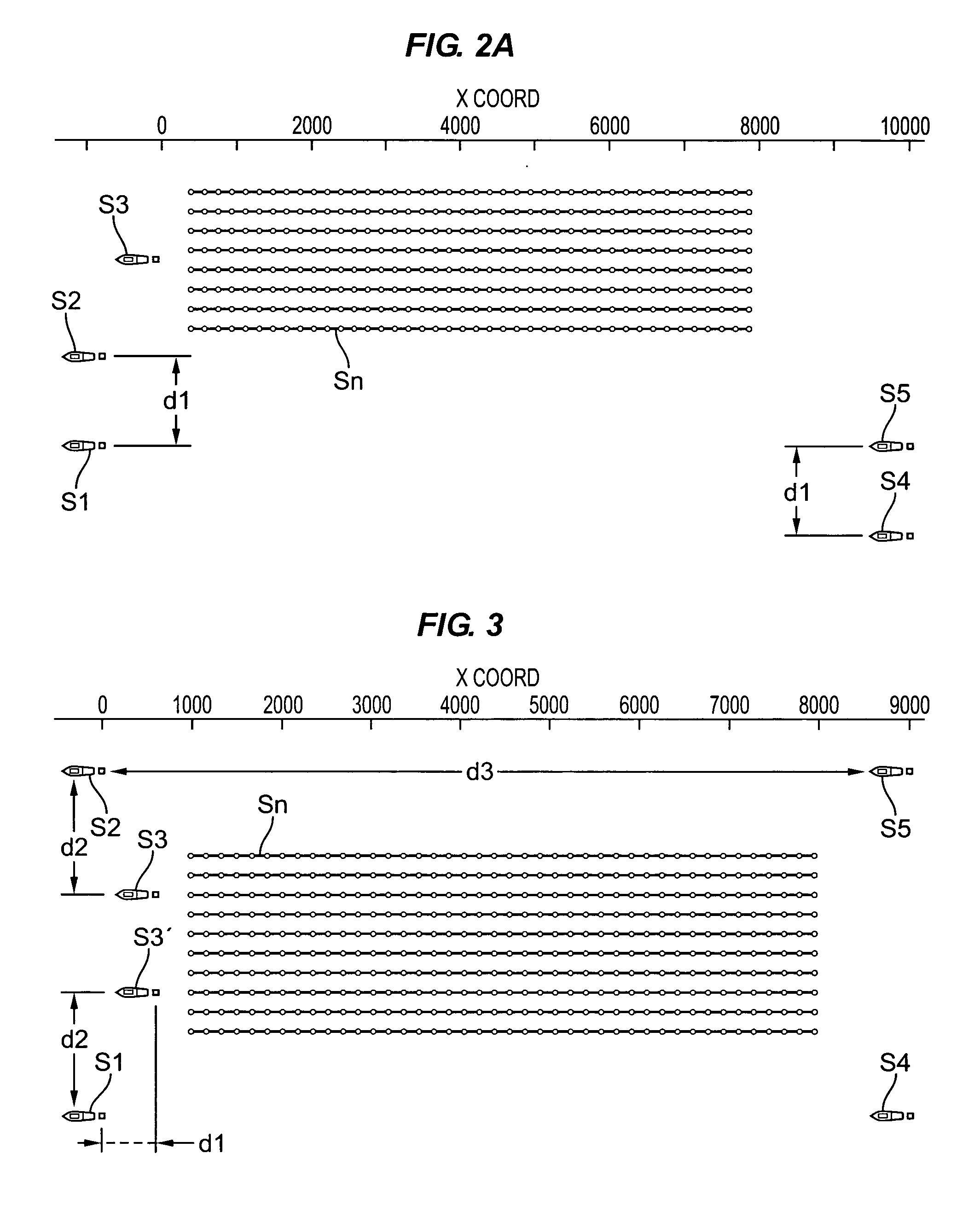

Methods and systems for efficiently acquiring towed streamer seismic surveys

ActiveUS20070165486A1Improved seismic imagingLess timeSeismic signal processingSeismology for water-covered areasSurveyorSeismic survey

Methods and systems for efficiently acquiring towed streamer marine seismic data are described. One method and system comprises positioning a plurality of source-only tow vessels and one or more source-streamer tow vessels to acquire a wide- and / or full-azimuth seismic survey without need for the spread to repeat a path once traversed. Another method and system allows surveying a sub-sea geologic feature using a marine seismic spread, the spread smartly negotiating at least one turn during the surveying, and shooting and recording during the turn. This abstract is provided to comply with the rules requiring an abstract, allowing a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the

Owner:REFLECTION MARINE NORGE AS

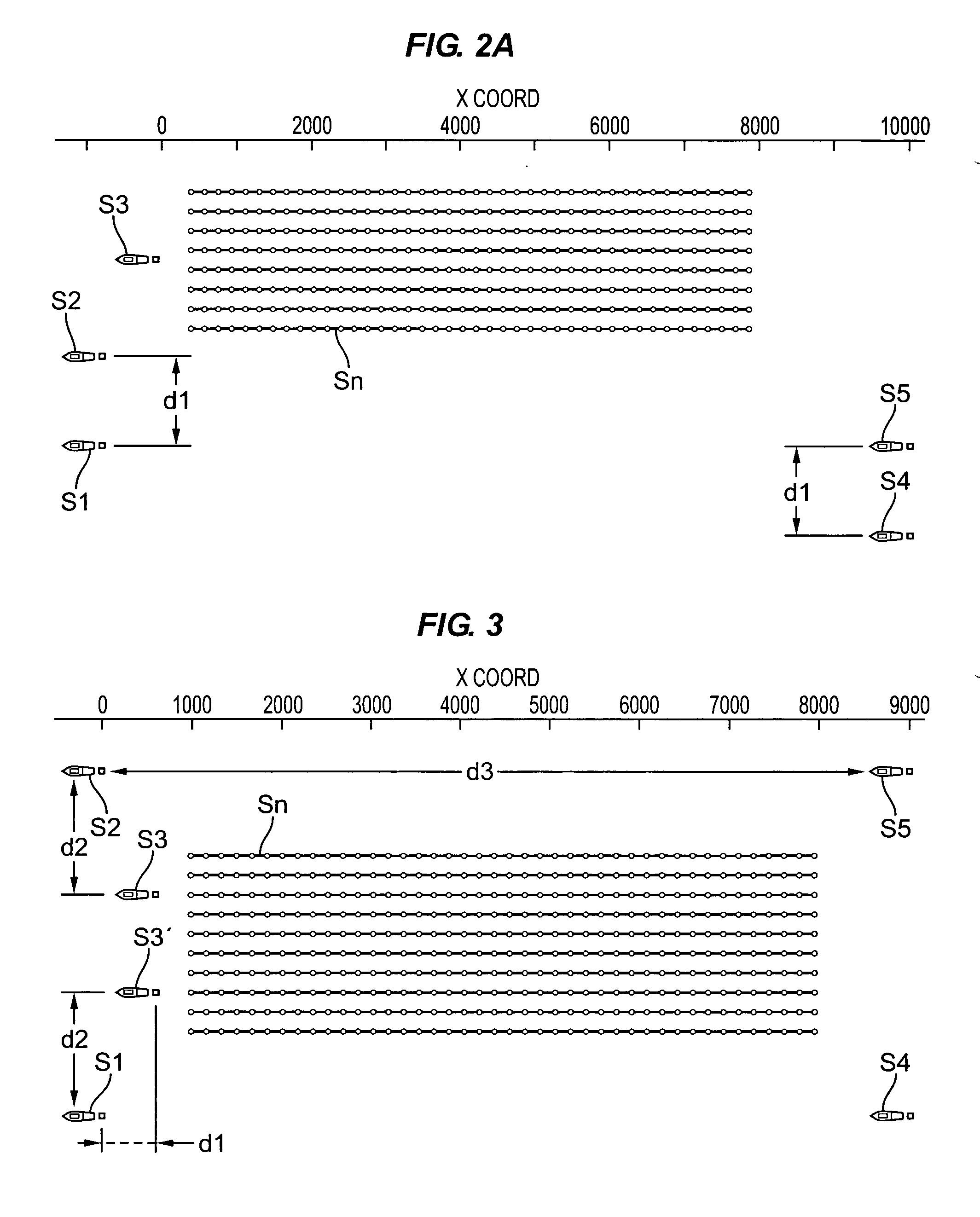

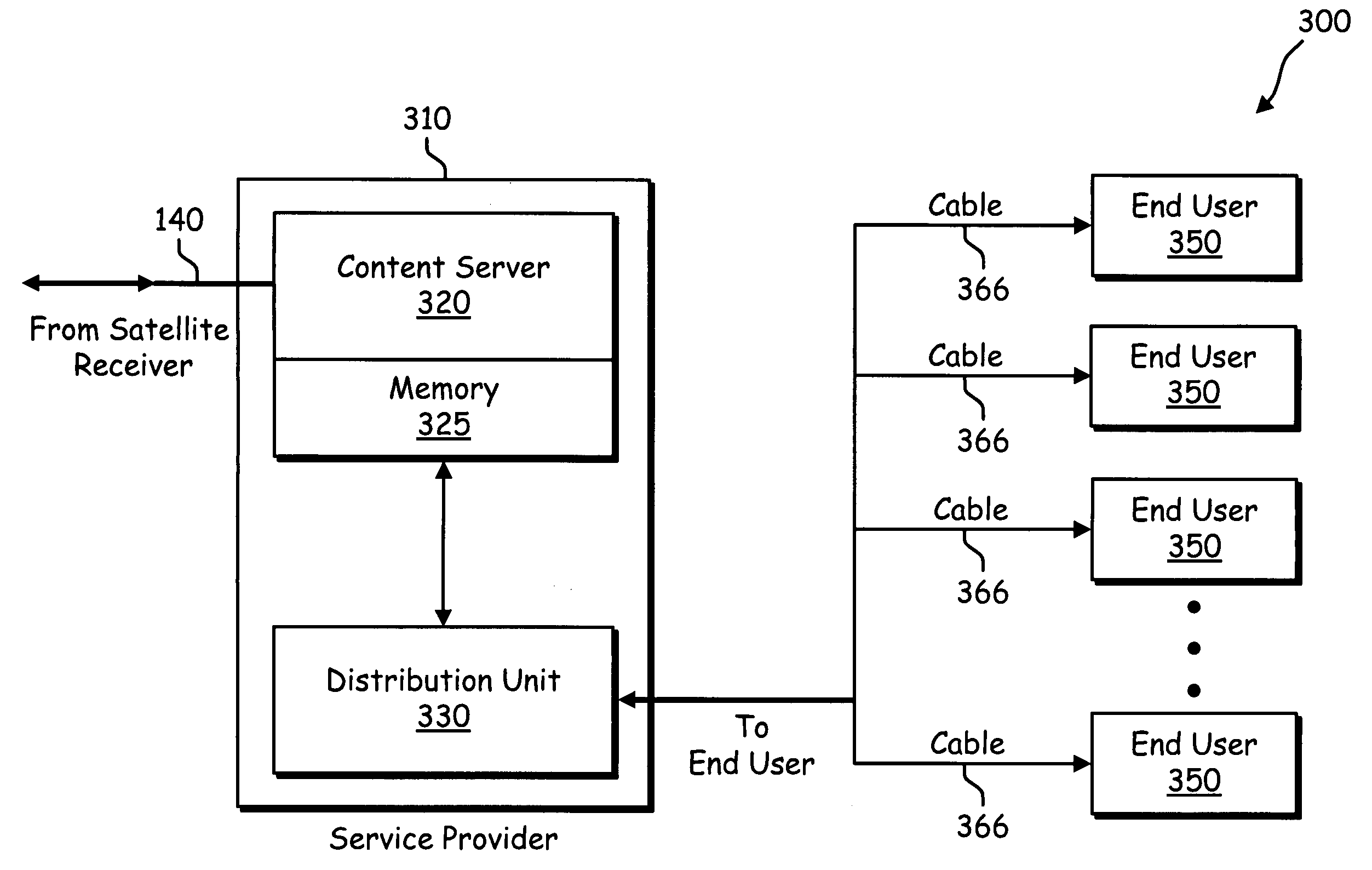

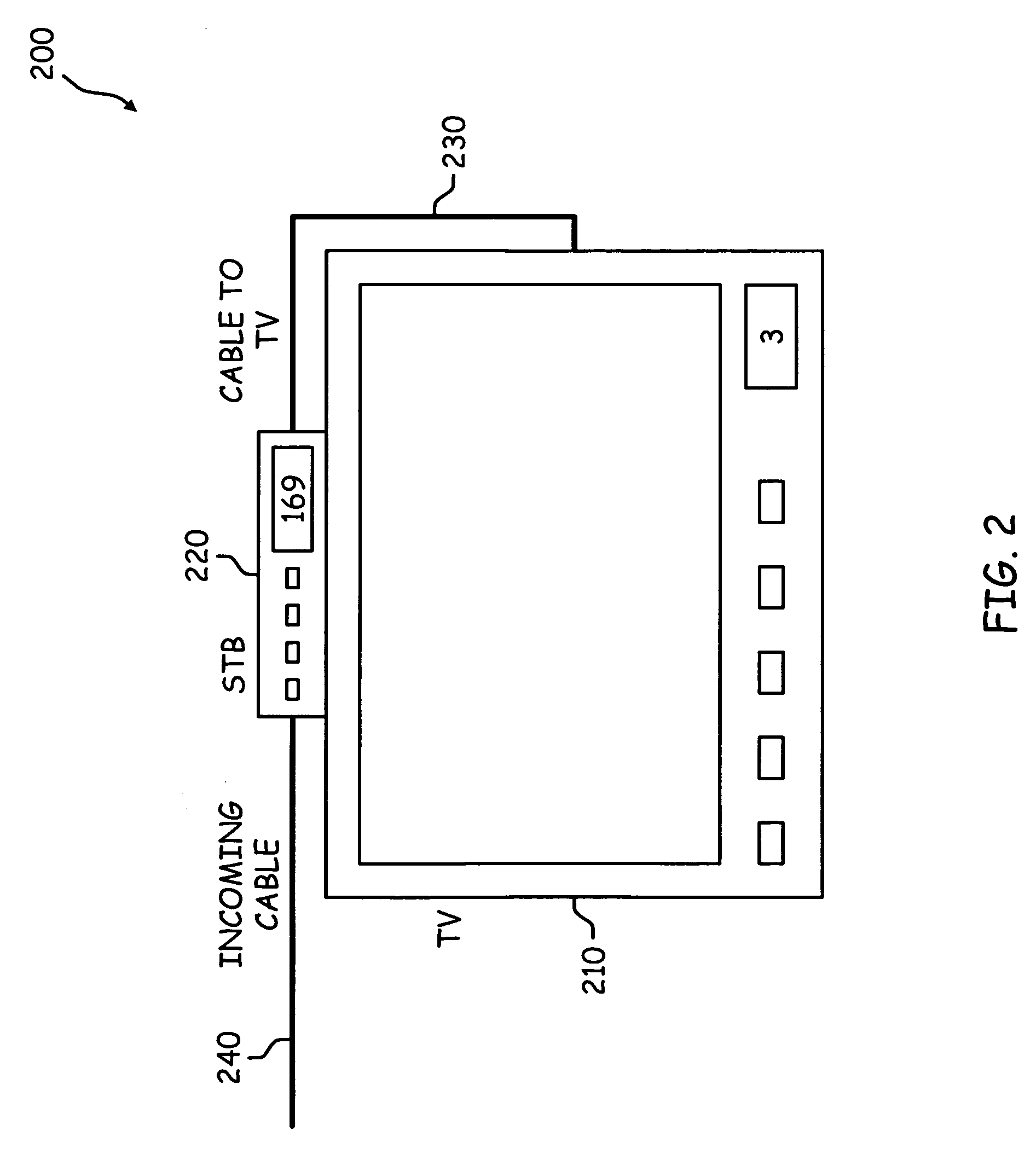

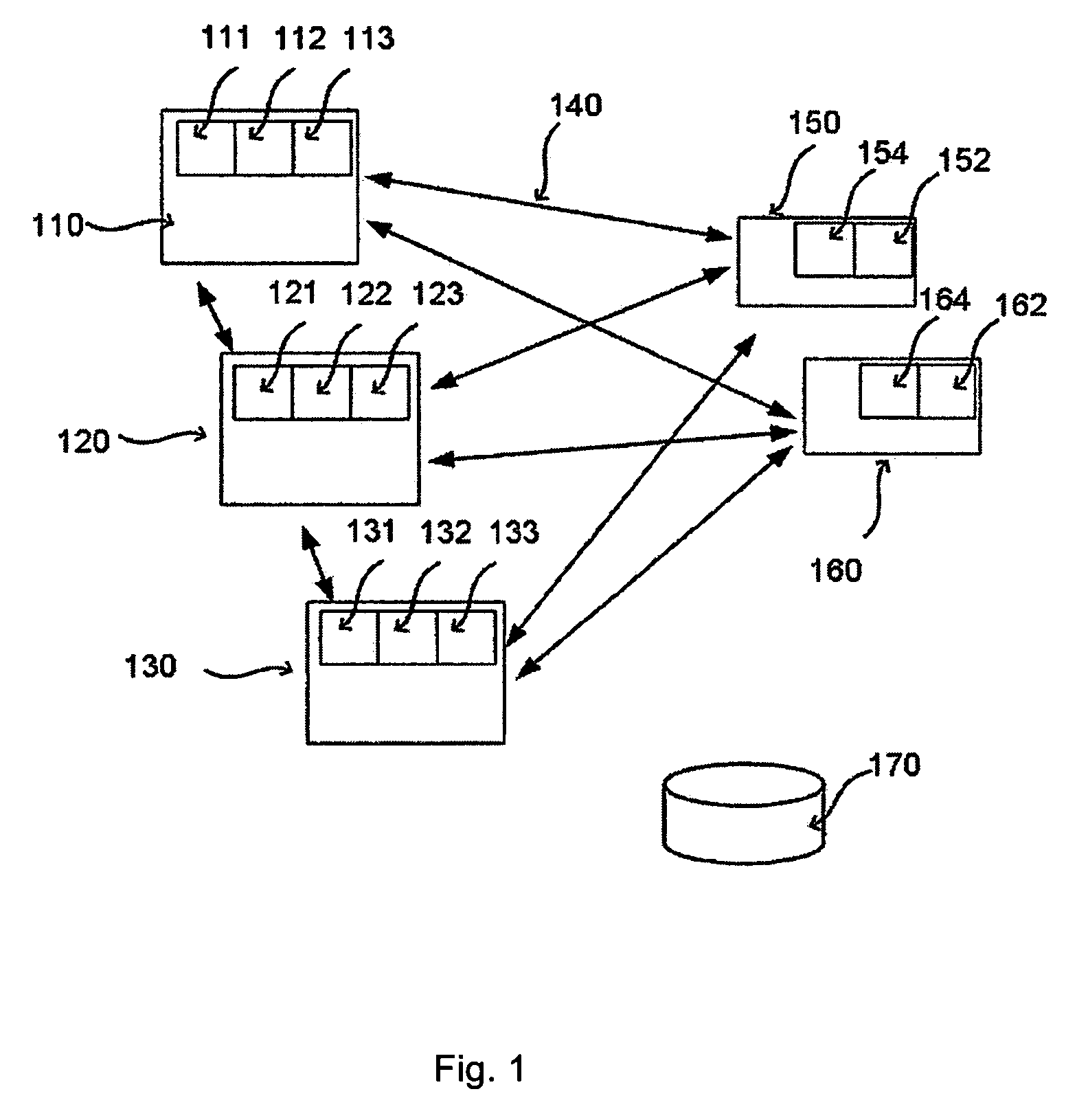

System and method for multimedia viewership surveying

ActiveUS20050235307A1Reduce bandwidth for transmittingGood channel qualityTelevision system detailsAnalogue secracy/subscription systemsSurveyorEnd user

Disclosed herein is a method and system for multimedia viewership surveying of an end-user's set-top-box (STB) The multimedia information may be received from at least one satellite via a satellite receiver. The satellite receiver may convey the multimedia information to a service provider location. At the service provider location, a content server may receive a request for transmission of multimedia information. The request may be validated to determine whether the request is authorized. The method may also include monitoring channel requests, and channel viewing times. The method may also include recording and / or logging the channel requests and information associated with the requested program in a user log. The user log may be evaluated to facilitate targeted marketing of end-user subscribers based upon demonstrated television viewing habits.

Owner:AVAGO TECH INT SALES PTE LTD

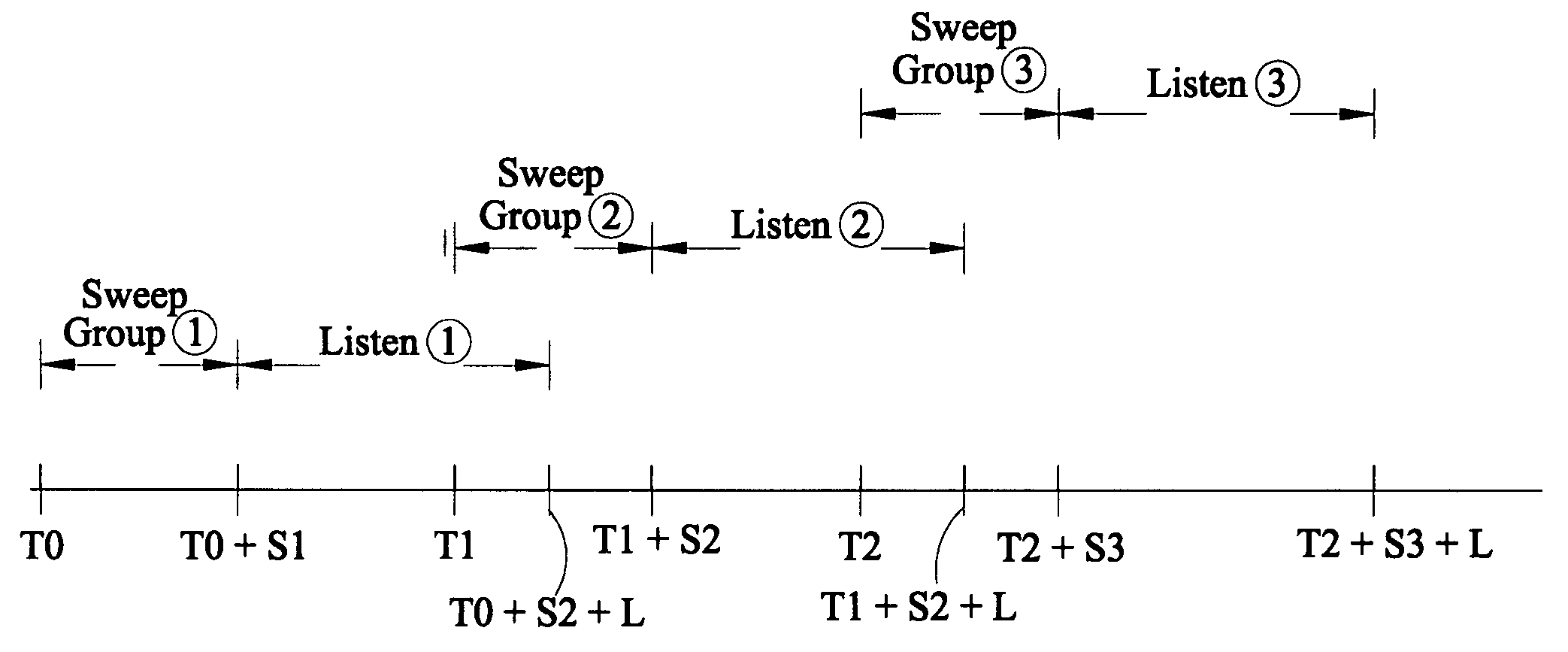

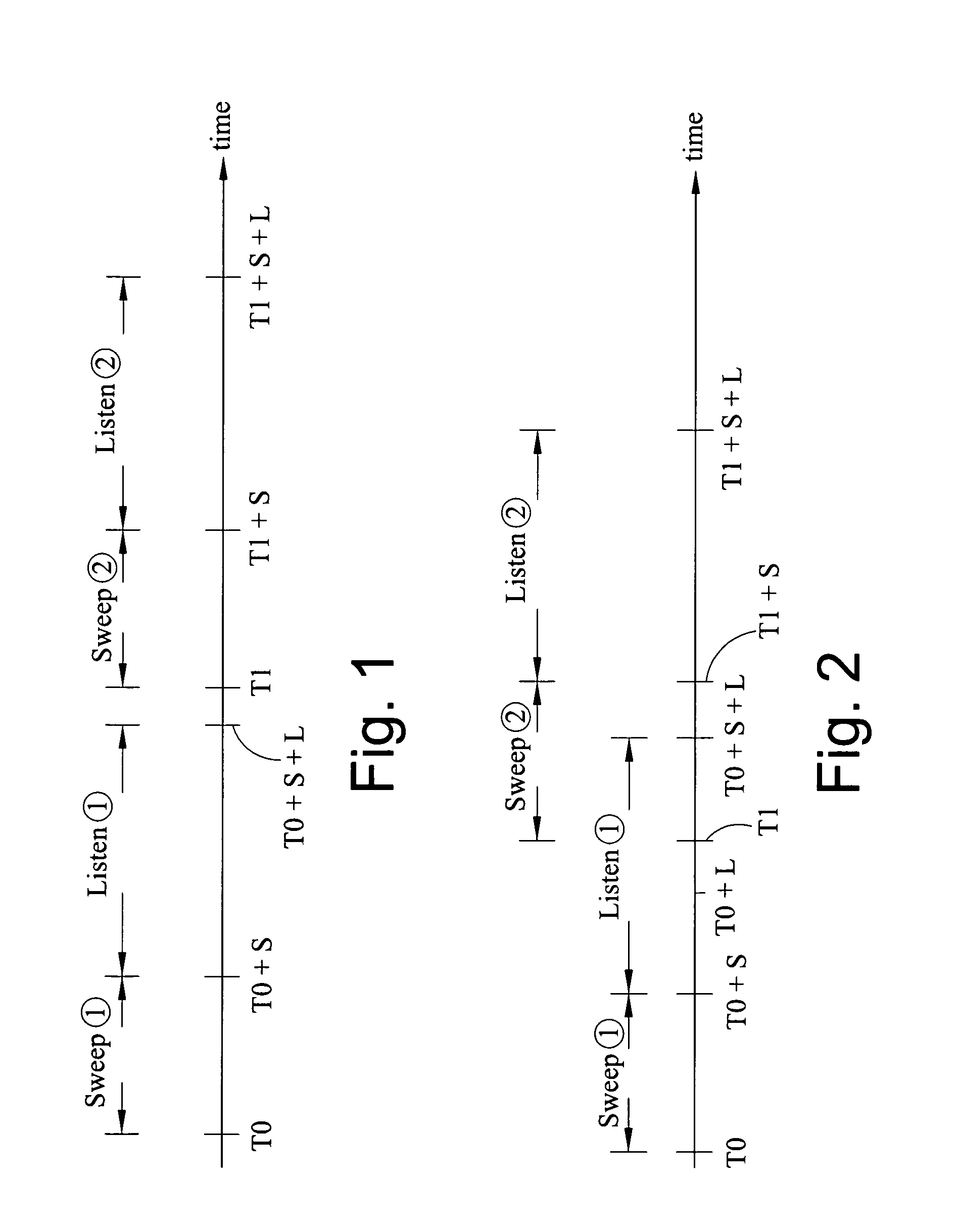

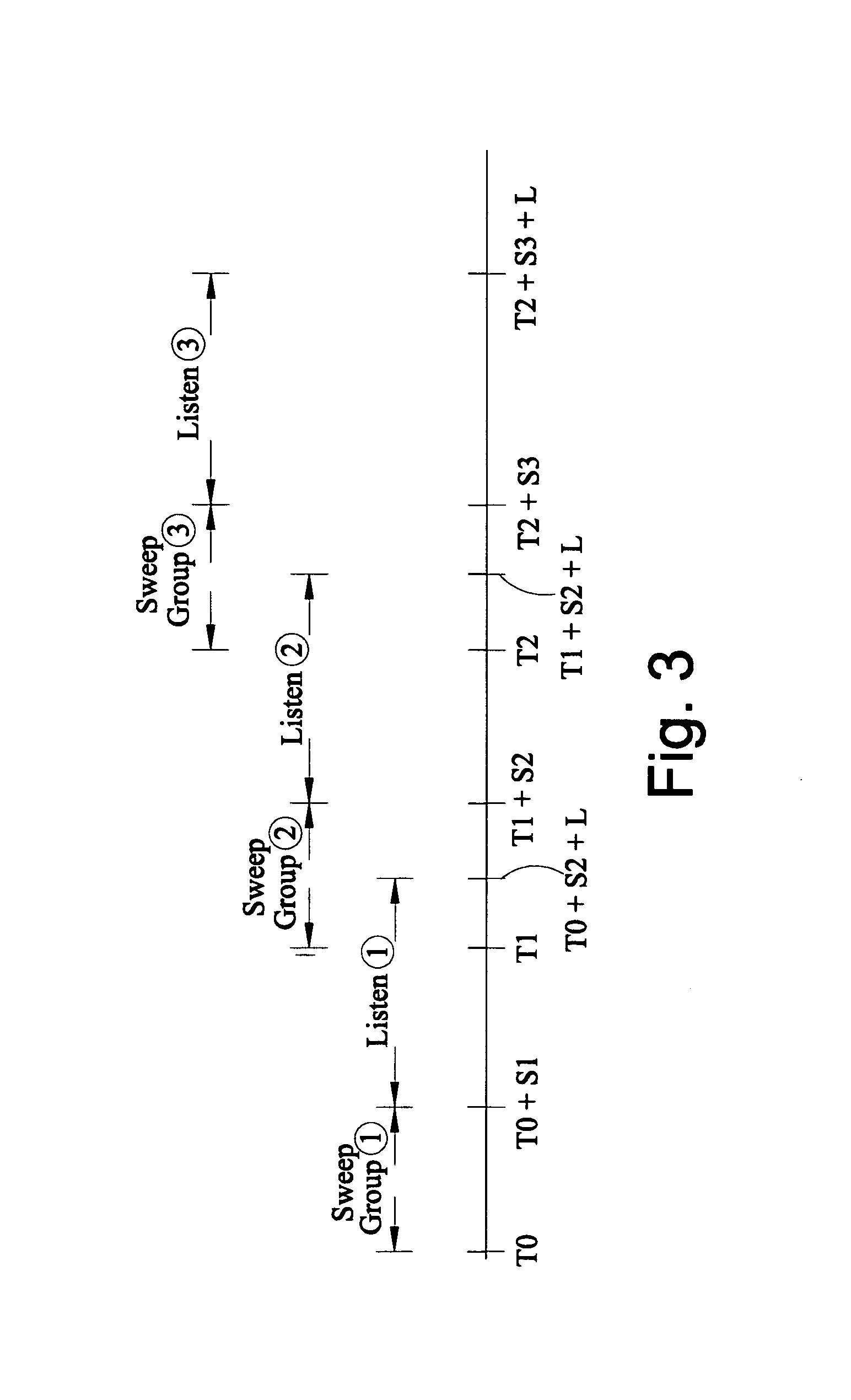

Method of seismic surveying

A method of seismic surveying comprising the steps of actuating the or each vibrator in a first vibrator group at time T0, and subsequently actuating the or each vibrator in a second vibrator group at time T1 that satisfies T0<T1<T0+S1+L where S1 is the sweep time of the first vibrator group and L is the listening time. At least one of the first vibrator group and the second vibrator group comprises at least two vibrators. The first group and the second group of vibrators may be the same group, or they may be different groups. This method enables the time required to complete a seismic survey to be reduced compared to the prior art “simultaneous shooting” and “slip-sweep shooting” techniques.In a case where the first group and the second group of vibrators are different, the method may further comprise actuating the or each vibrator in the first vibrator group at time T2, where T1<T2<T1+S2+L and S2 is the sweep time of the first vibrator group, and then actuating the or each vibrator in the second vibrator group at time T3 where T2<T3<T2+S1+L and where T3−T2≠T1−T0. The varying time delay between a shot of the first vibrator group and the corresponding shot of the second vibrator group means that harmonic noise will occur at different times in the shot records so that the noise may be eliminated by appropriately combining the shot records.

Owner:WESTERNGECO LLC

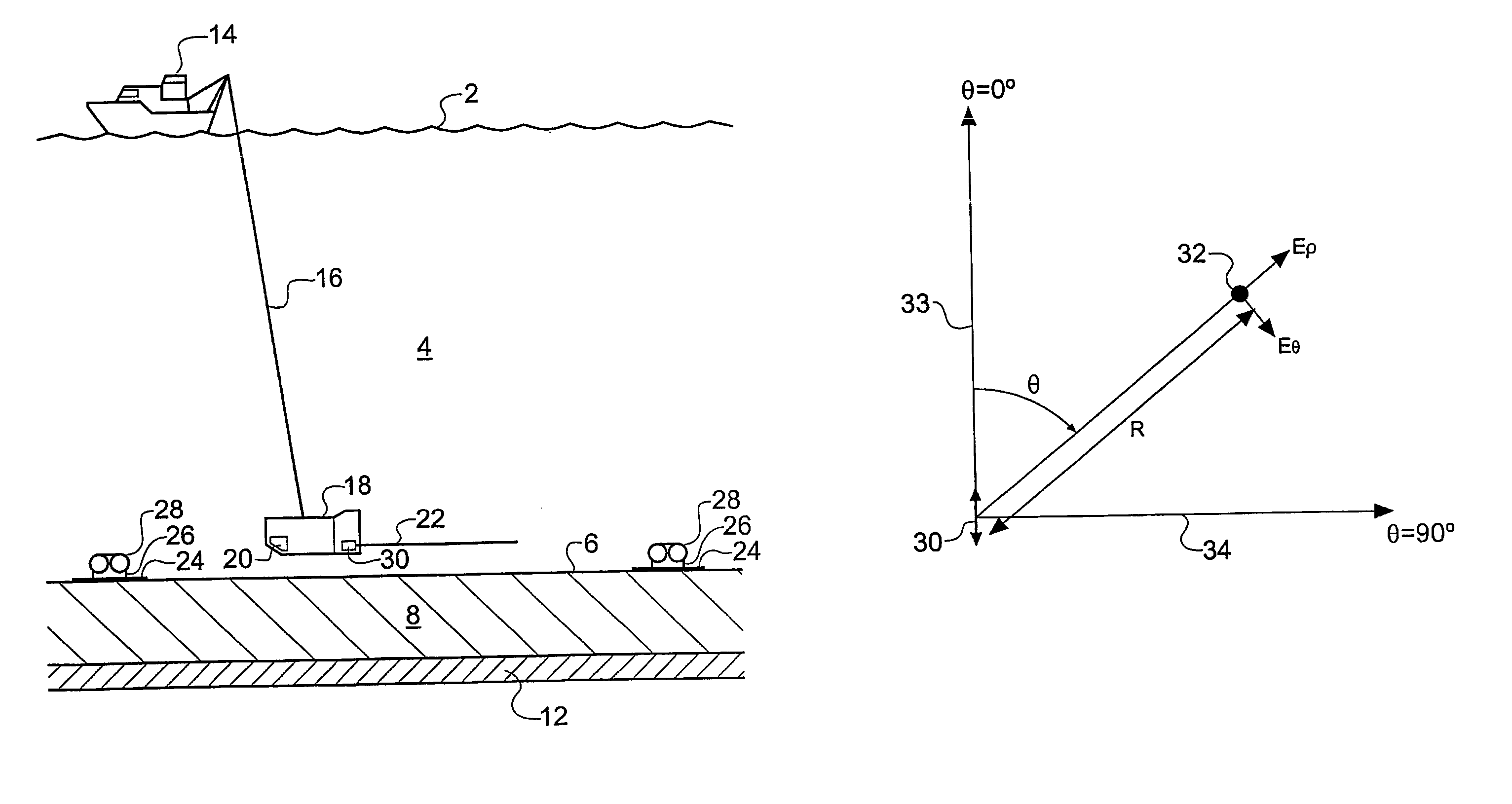

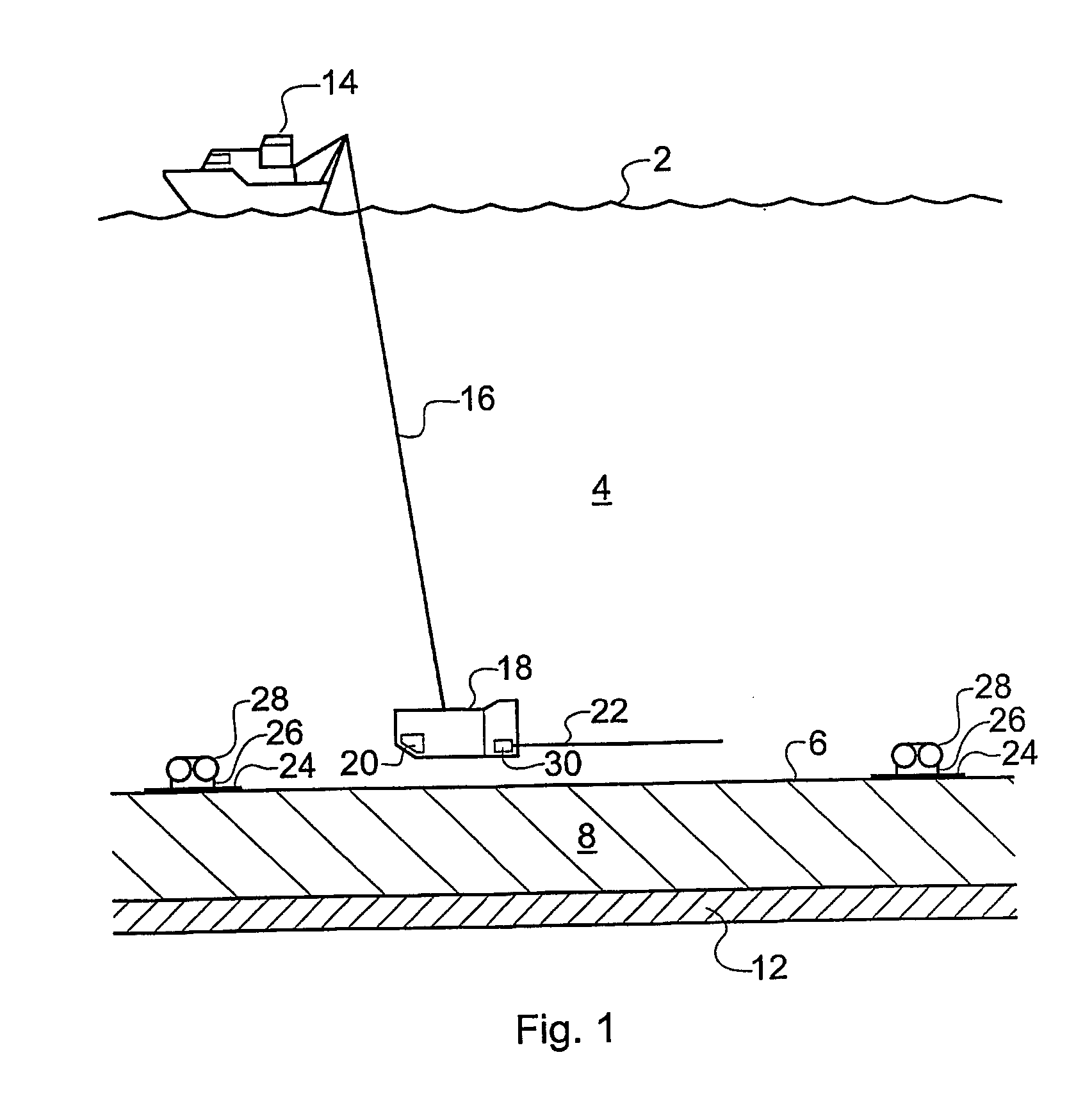

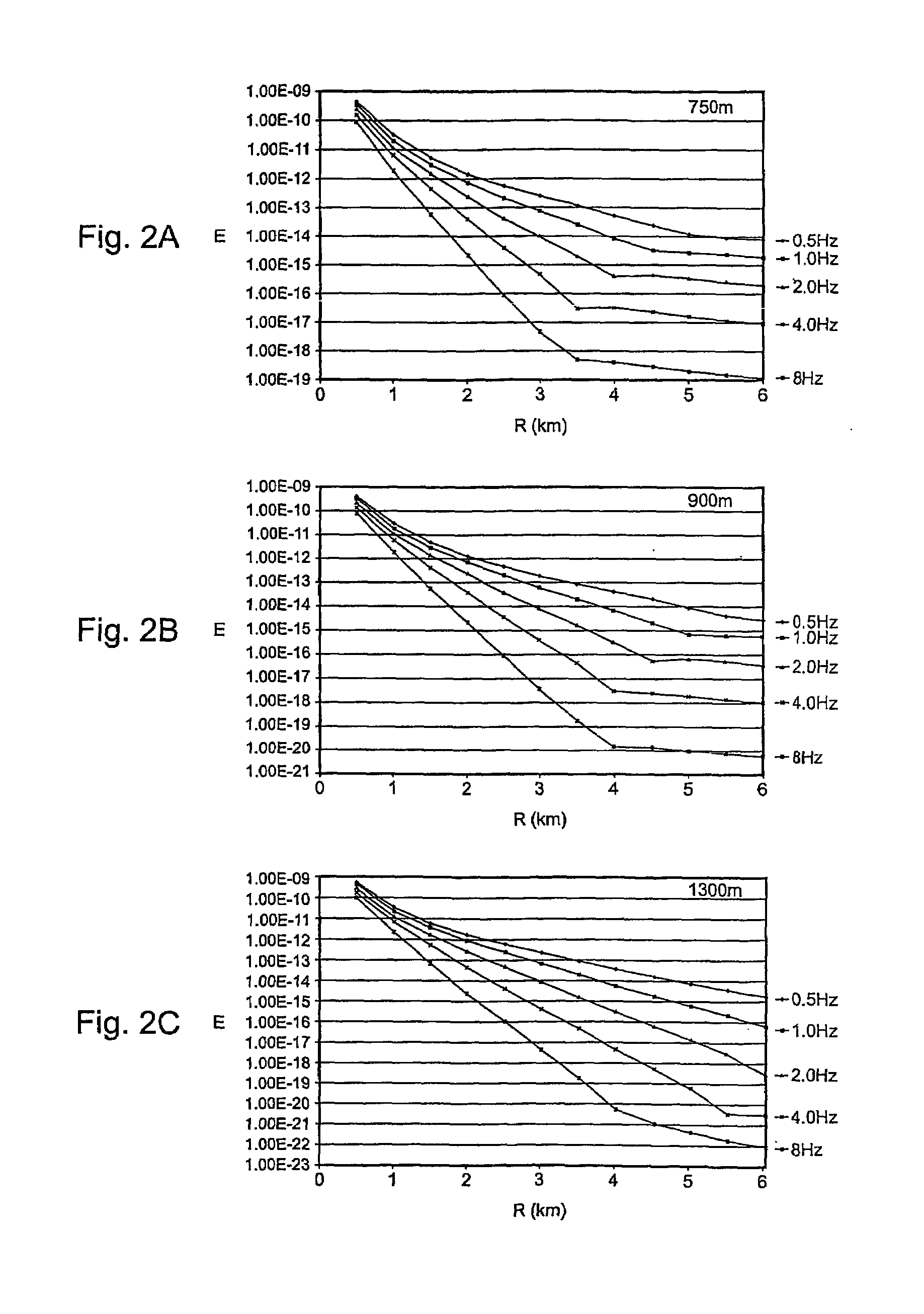

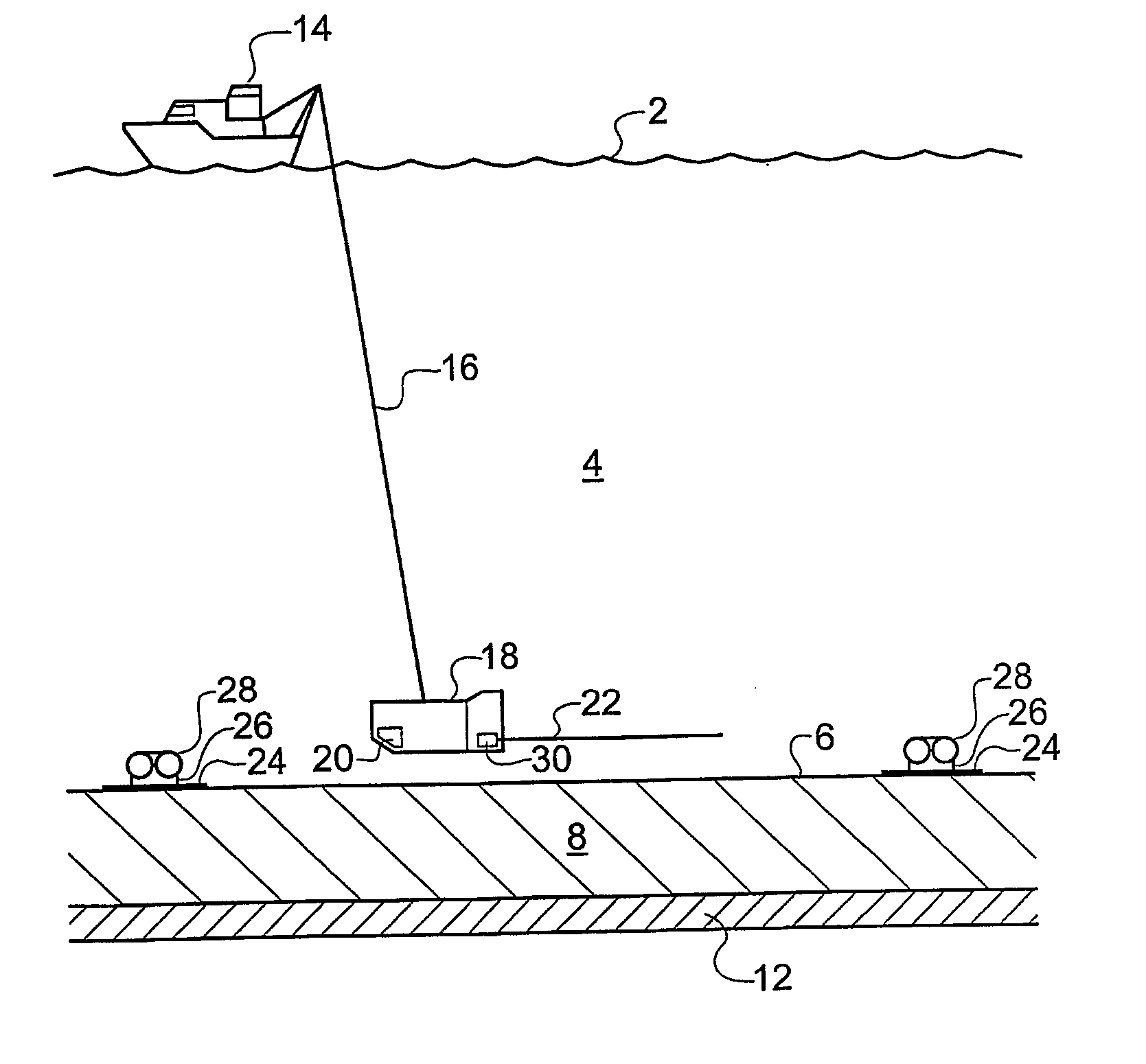

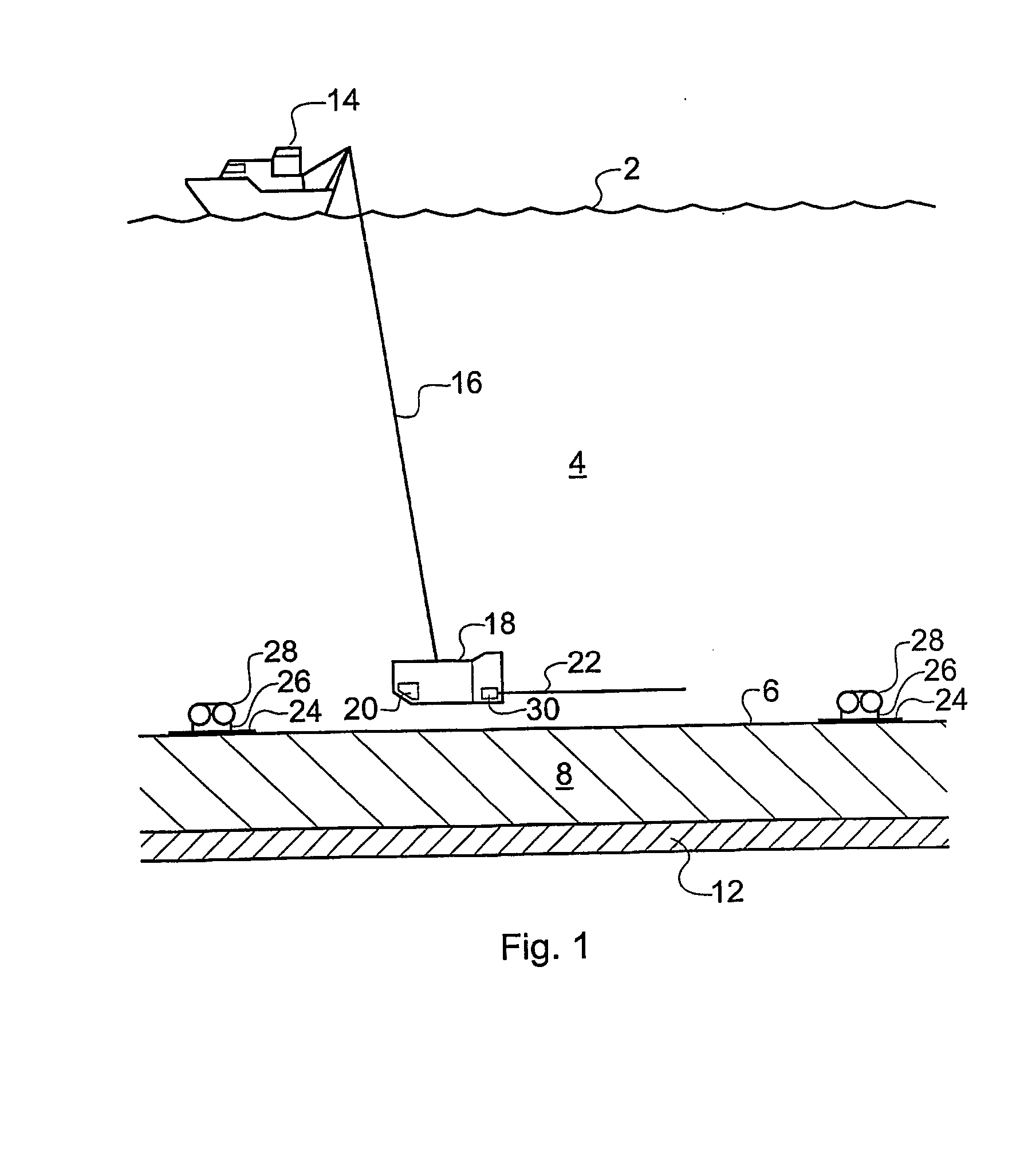

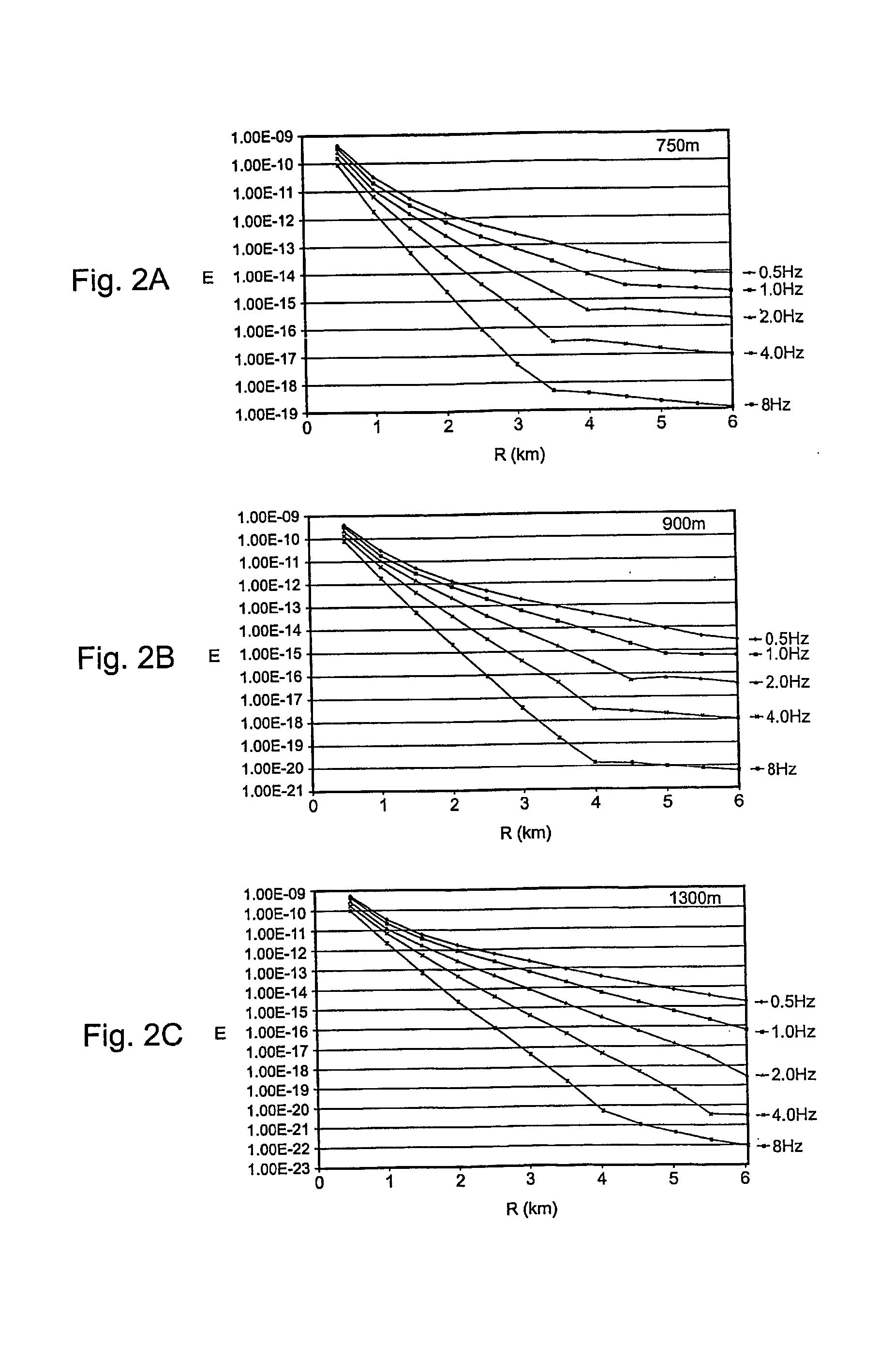

Electromagnetic surveying for hydrocarbon reservoirs

InactiveUS7126338B2Water resource assessmentDetection using electromagnetic wavesOcean bottomUltrasound attenuation

An electromagnetic survey method for surveying an area previously identified as potentially containing a subsea hydrocarbon reservoir, comprising obtaining first and second survey data sets with an electromagnetic source aligned end-on and broadside relative to the same or different receivers. The invention also relates to planning a survey using this method, and to analysis of survey data taken in combination allow the galvanic contribution to the signals collected at the receiver to be contrasted with the inductive effects, and the effects of signal attenuation, which are highly dependent on local properties of the rock formation, overlying water and air at the survey area. This is very important to the success of using electromagnetic surveying for identifying hydrocarbon reserves and distinguishing them from other classes of structure.

Owner:STATOIL ASA PETRO SA (NO)

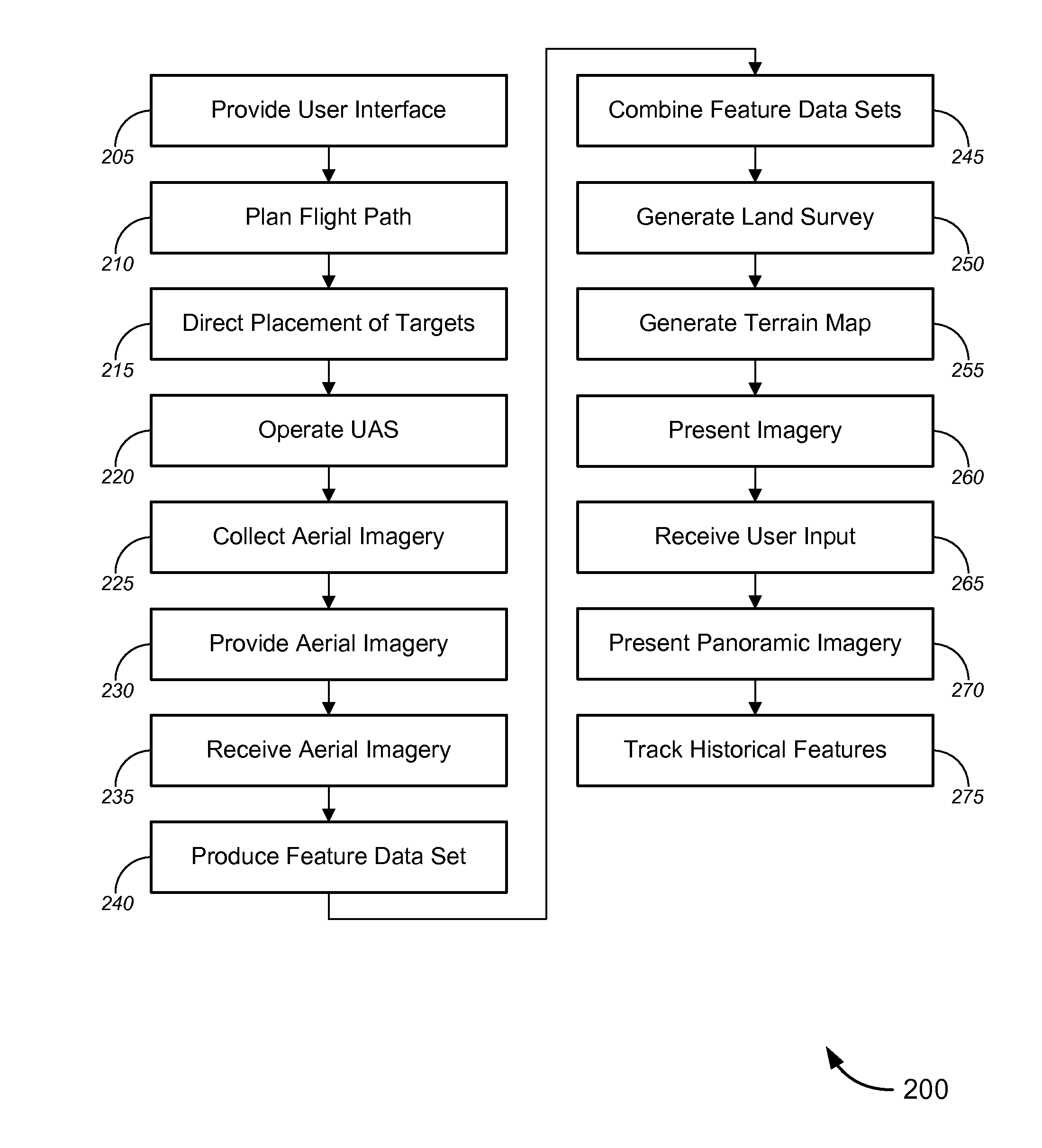

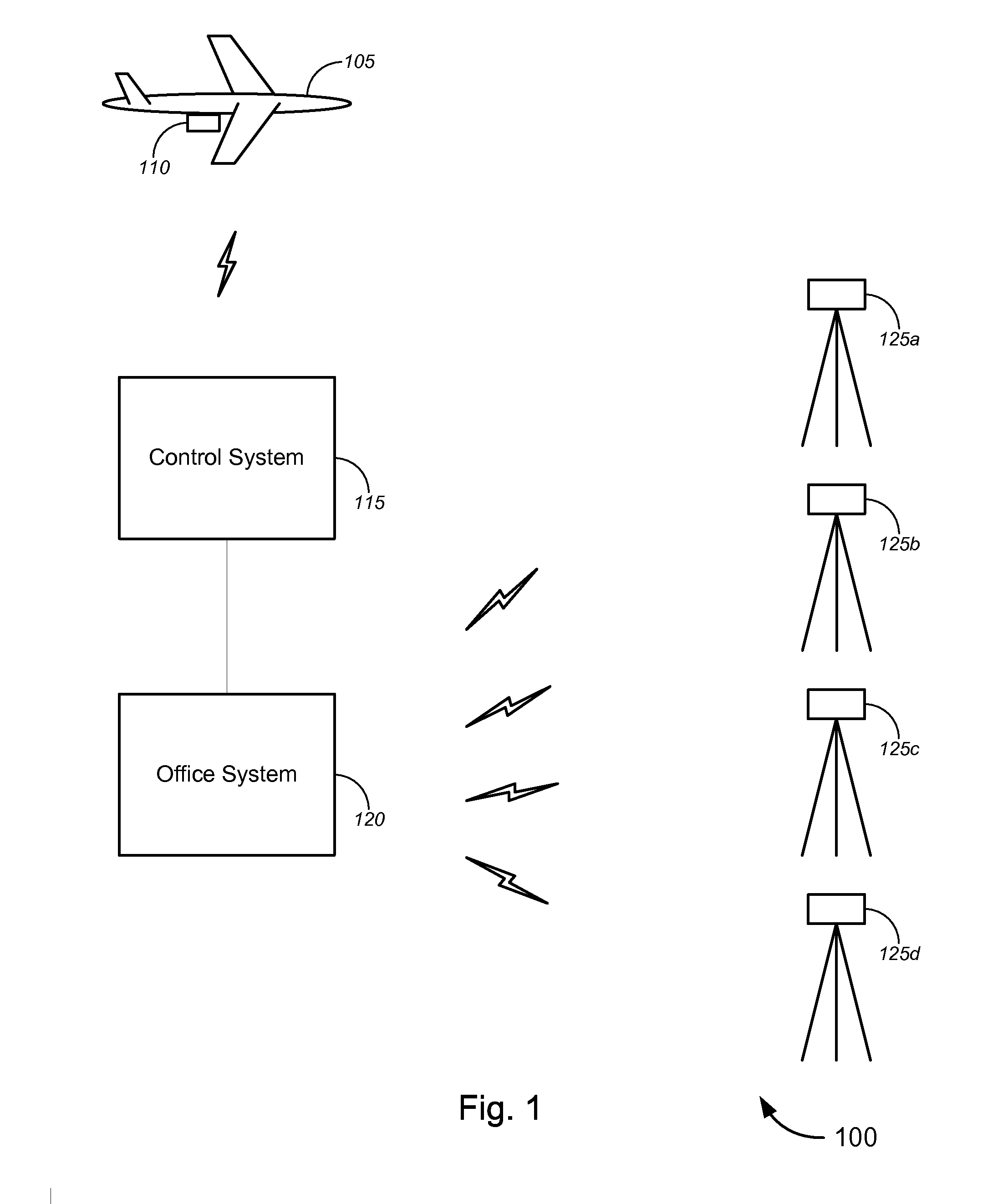

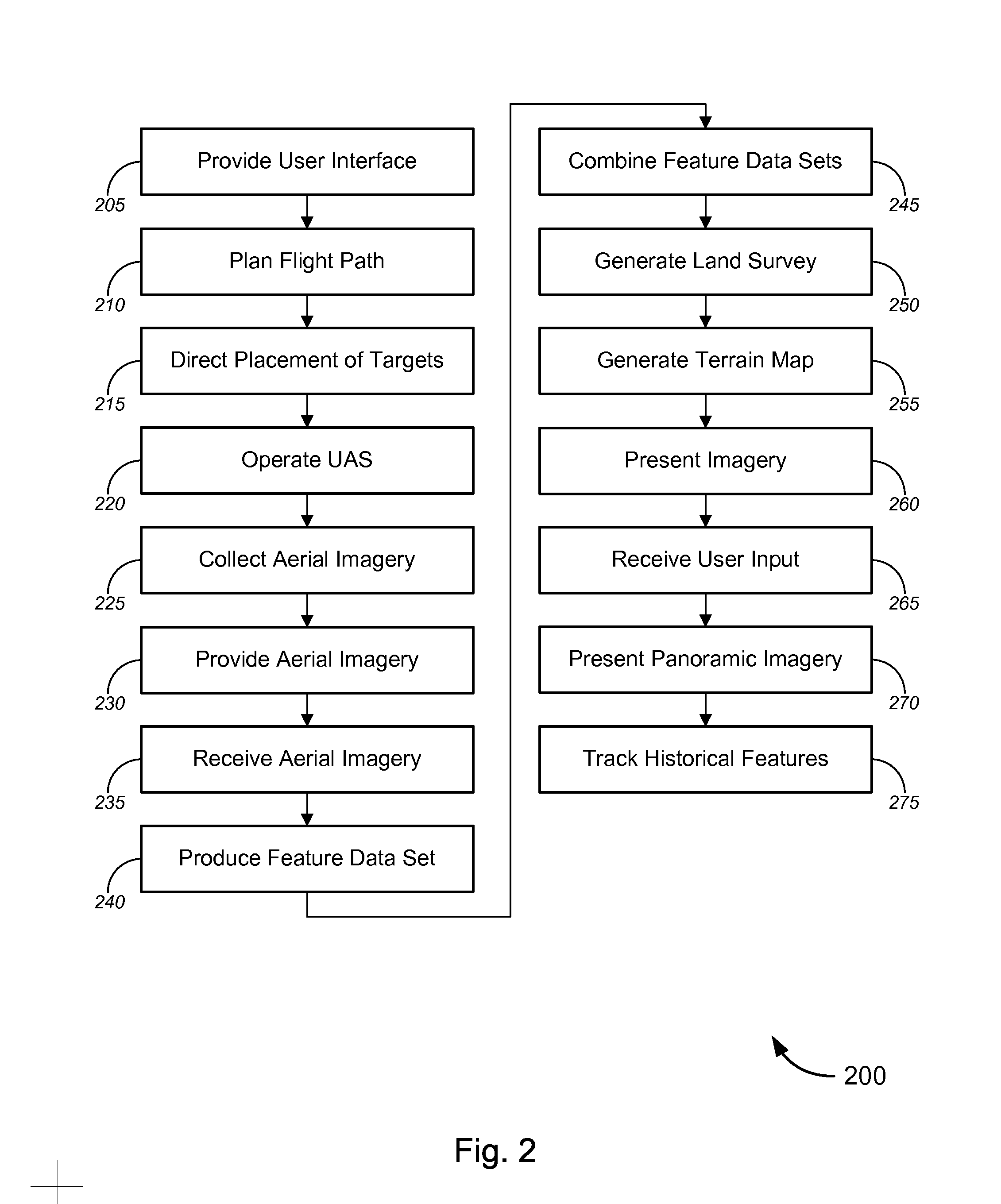

Integrated aerial photogrammetry surveys

ActiveUS9235763B2Low costSufficient resolutionSurveying instrumentsScene recognitionAviationEngineering

Novel tools and techniques for generating survey data about a survey site. Aerial photography of at least part of the survey site can be analyzed using photogrammetric techniques. In some cases, an unmanned aerial system can be used to collect site imagery. The use of a UAS can reduce the fiscal and chronological cost of a survey, compared to the use of other types aerial imagery and / or conventional terrestrial surveying techniques used alone.

Owner:TRIMBLE INC

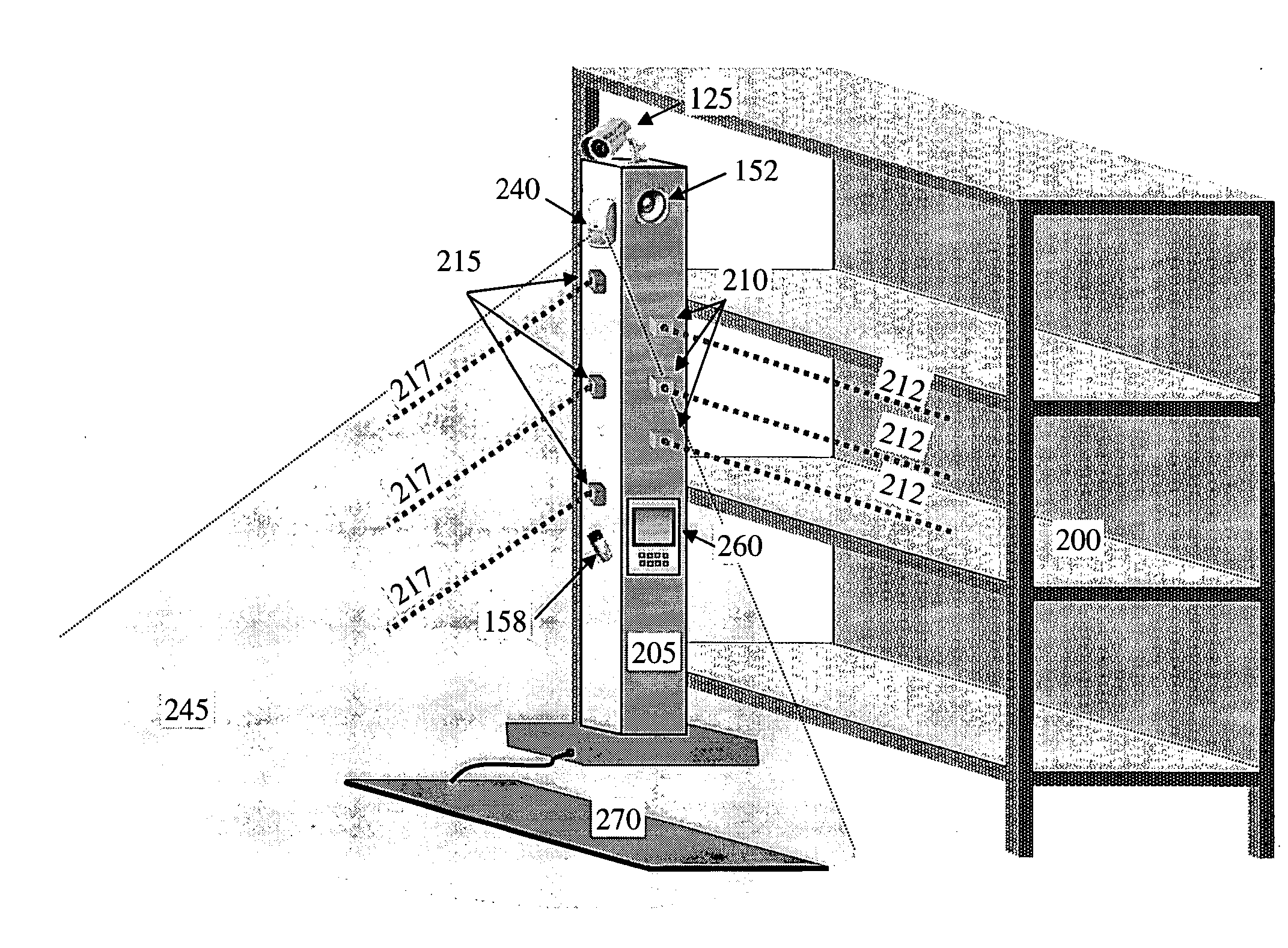

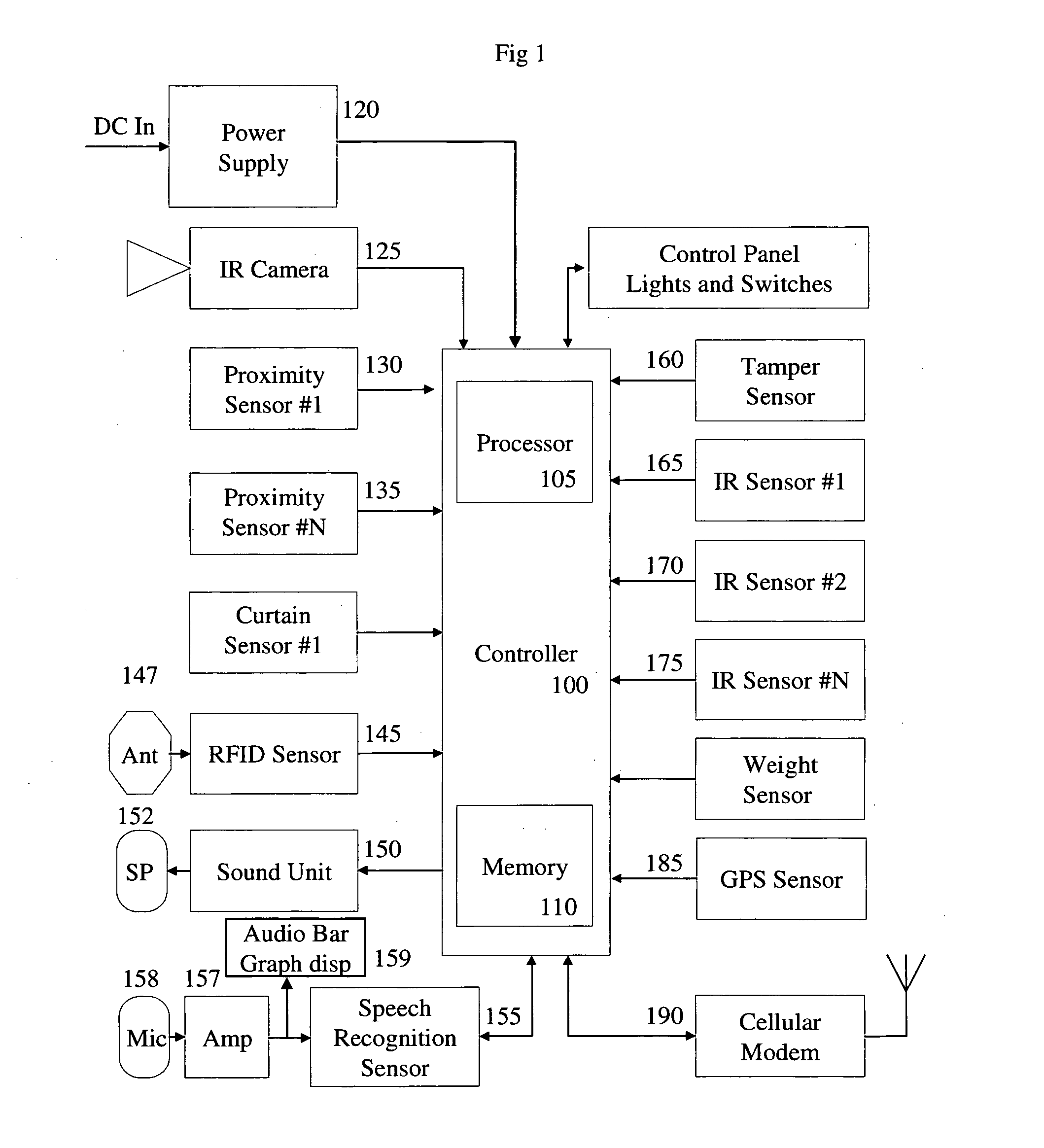

System for data collection from a point of sale

InactiveUS20070067203A1Market predictionsSpecial data processing applicationsInfraredProximity sensor

Disclosed is a system for data collection from a point of sale, product display area, or point of service area, that includes a data receiving and processing center. The system is stand-alone and portable, and collects real-time data about the customers. Such data includes tracking the number of customers passing by a specific product, the average time that customers remain in front of the product, comparisons between the periods of time that customers remain in front of different products, and tracking the height and weight of potential customers in order to determine their demographic characteristics. The system utilizes different sensors, including infrared and proximity. A speech recognition application helps to recognize and analyze customers' reactions on certain products and converts speech to text. This speech recognition system is programmable to capture pre-defined key words rather than recording entire conversations. The system further allows on-line inventory tracking and market surveying.

Owner:GIL SUKENIK +1

Method for acquiring transient electromagnetic survey data

ActiveUS7203599B1Character and pattern recognitionMaps/plans/chartsMagnetic field amplitudeControlled source electro-magnetic

A method for controlled source electromagnetic Earth surveying includes deploying a plurality of electromagnetic sensors in a selected pattern at the top of an area of the Earth's subsurface to be surveyed. At least one of a transient electric field and a transient magnetic field is applied to the Earth in the vicinity of the sensors at a plurality of different positions. At least one of electric field amplitude and magnetic field amplitude at each of the sensors is recorded each time the transient electric field and / or magnetic field is applied. Each recording is adjusted for acquisition geometry. An image is generated corresponding to at least one sensor position using at least two stacked, adjusted recordings.

Owner:KJT ENTPR

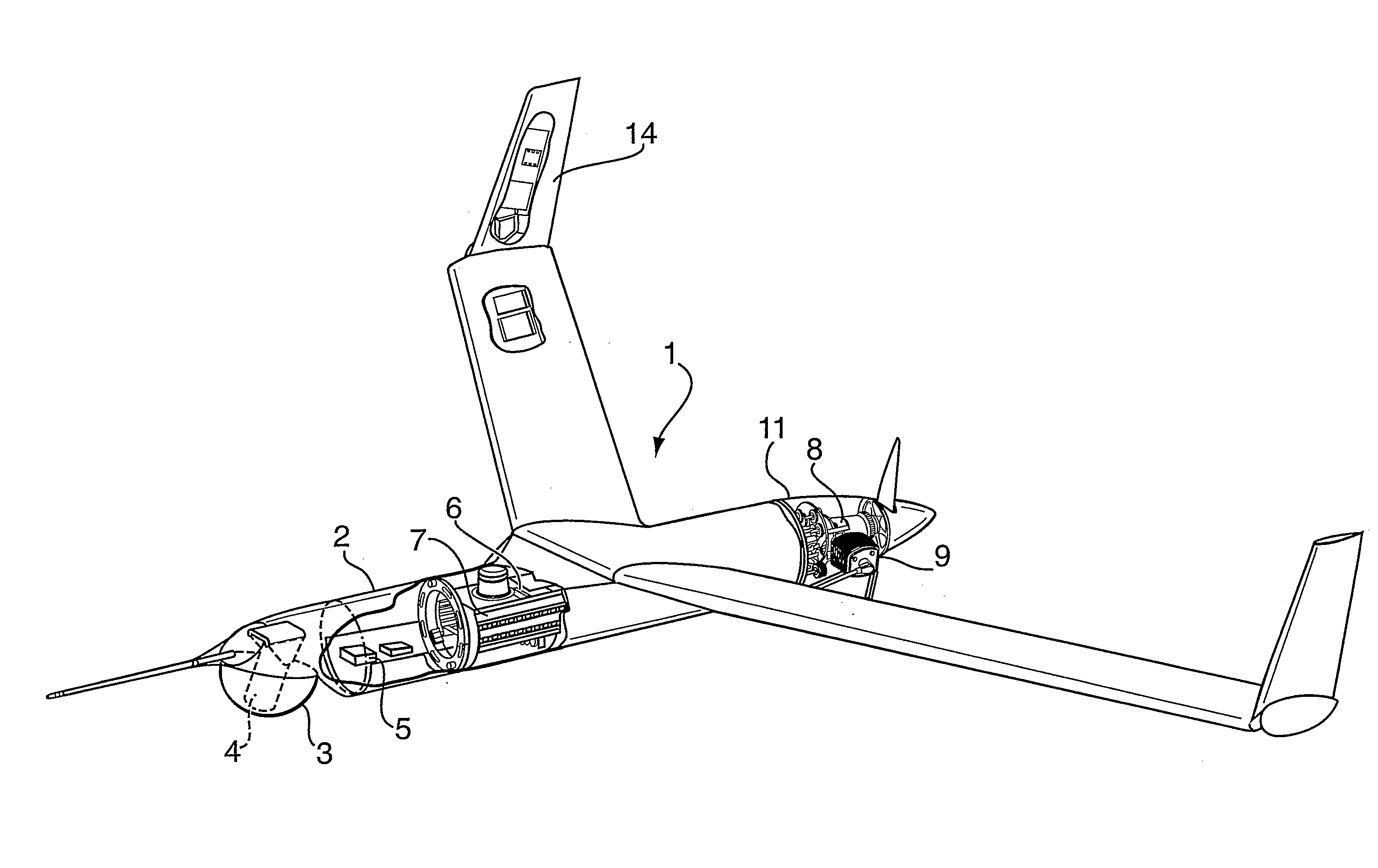

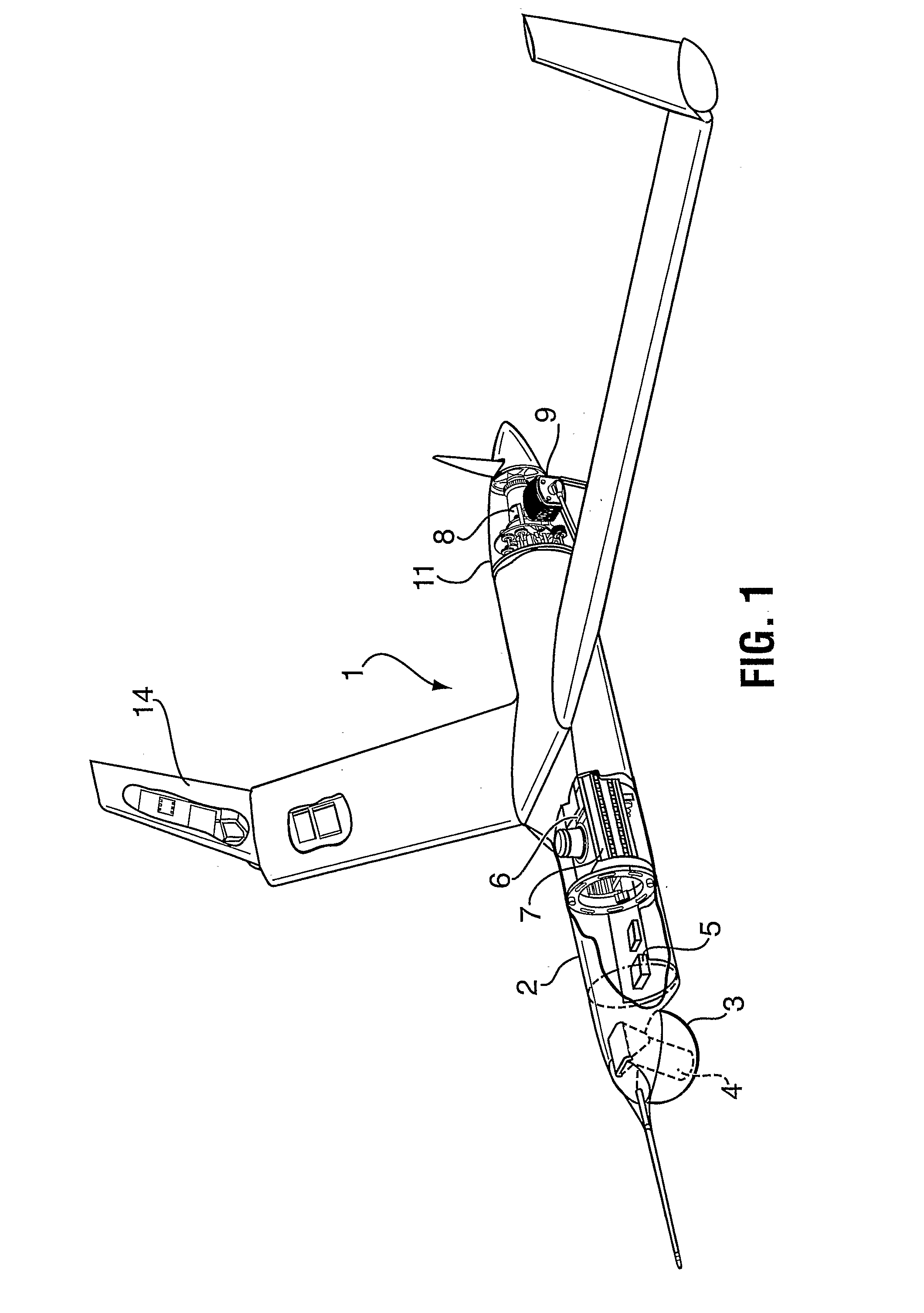

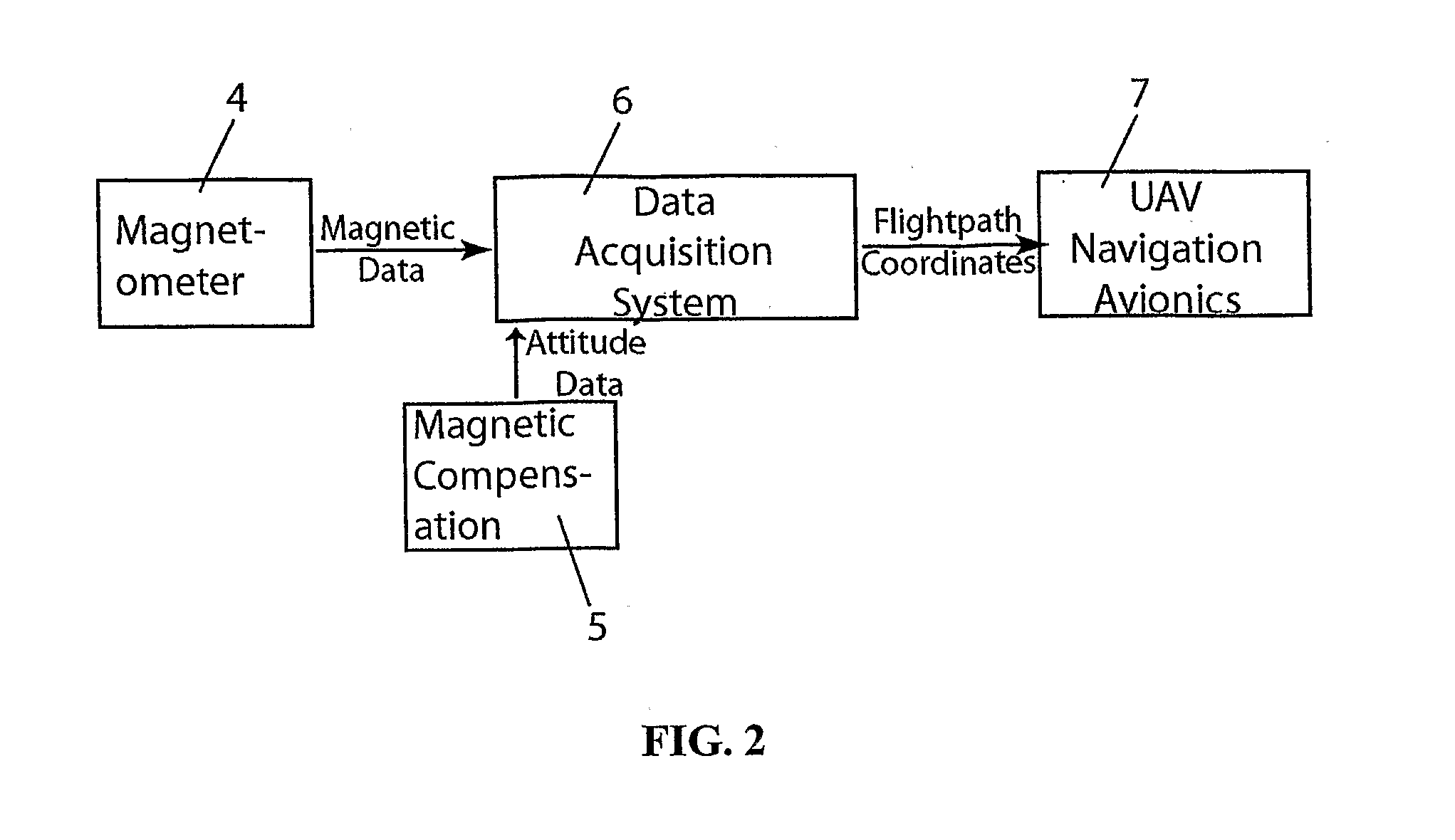

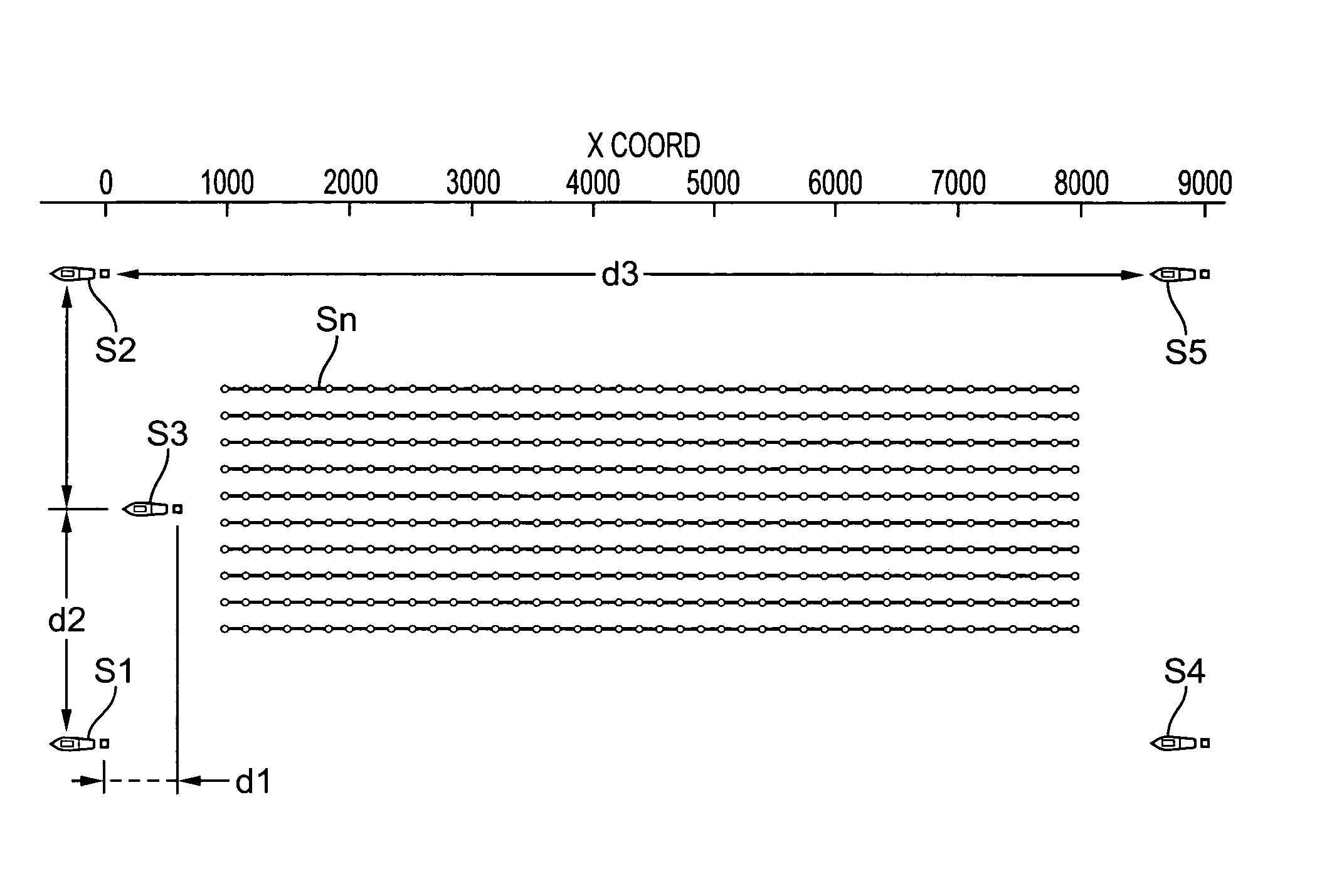

Unmanned Airborne Vehicle For Geophysical Surveying

InactiveUS20080125920A1Low costEasy mappingAircraft componentsAnalogue computers for vehiclesAviationData acquisition

An un-manned airborne vehicle (UAV), for acquiring aeromagnetic data for geophysical surveying at low altitude on land or over water, comprising an extended fuselage that is adapted to hold and maintain magnetometer and a magnetic compensation magnetometer at a minimum distance from the avionics and propulsion systems of the UAV. The magnetometer measures magnetic anomalies and the magnetic compensation magnetometer measures magnetic responses corresponding to the pitch, yaw and roll of the UAV. A data acquisition system stores and removes the magnetic response measurements from the magnetic anomaly measurements. The data acquisition system also stores a survey flight plan and transmits the same to the avionics system. The generator of the UAV is shielded and the propulsion system is stabilized to reduce magnetic and vibrational noises that can interfere with the operation of the magnetometer.

Owner:FUGRO AIRBORNE SURVEYS

Methods and systems for efficiently acquiring towed streamer seismic surveys

ActiveUS7400552B2Seismic signal processingSeismology for water-covered areasOcean bottomSeismic survey

Methods and systems for efficiently acquiring towed streamer marine seismic data are described. One method and system comprises positioning a plurality of source-only tow vessels and one or more source-streamer tow vessels to acquire a wide- and / or full-azimuth seismic survey without need for the spread to repeat a path once traversed. Another method and system allows surveying a sub-sea geologic feature using a marine seismic spread, the spread smartly negotiating at least one turn during the surveying, and shooting and recording during the turn. This abstract is provided to comply with the rules requiring an abstract, allowing a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:REFLECTION MARINE NORGE AS

Methods for Efficiently Acquiring Wide-Azimuth Towed Streamer Seismic Data

A technique for use in marine seismic surveying includes a method and an apparatus. In one aspect, the method includes towing a seismic spread including a source multiple streamers on a generally curved advancing path, the streamers being actively steered. The source is fired and data is acquired on the curve. In other aspects, the method is performed with only a single vessel or the generally curved advancing path is a sincurve advancing path. The method may include a dual circular shoot in another aspect. And, in yet another aspect, the invention includes an apparatus comprised of a computing apparatus on board a tow vessel receiving positioning data from the marine seismic streamers. It is also programmed to: sail the tow vessel in a generally curved advancing path and actively steer the marine seismic streamers through the generally curved advancing path.

Owner:REFLECTION MARINE NORGE AS

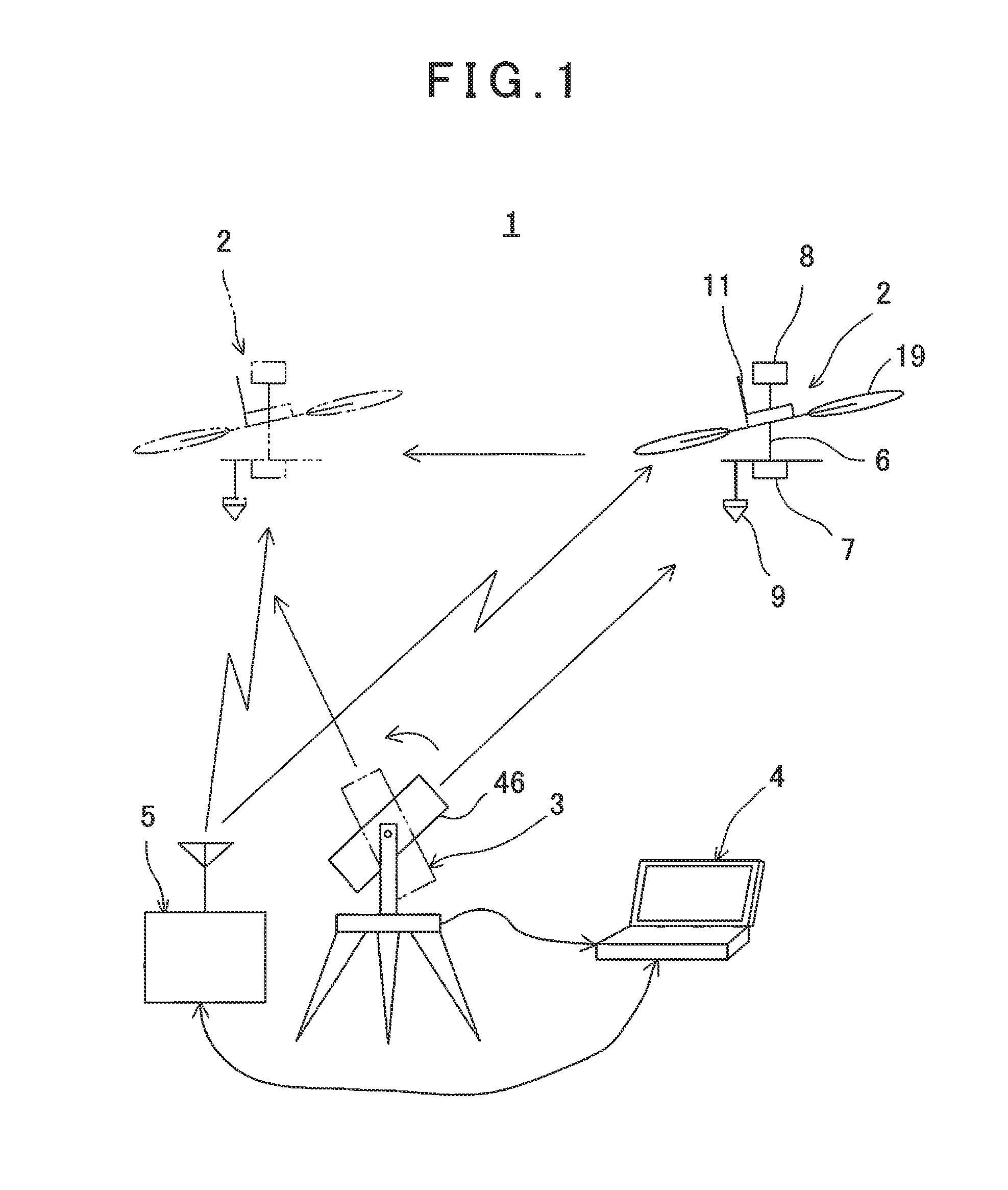

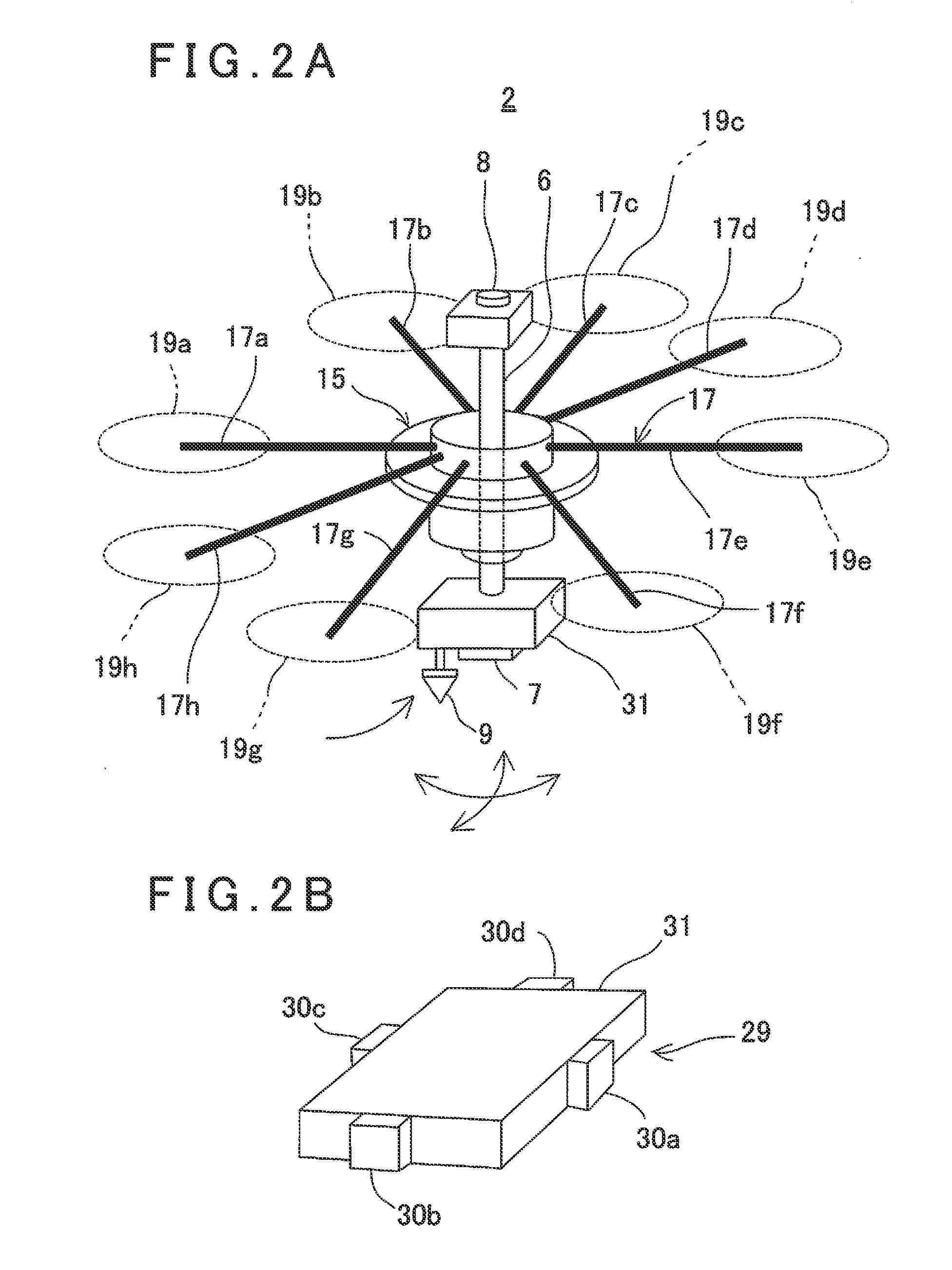

Flying Vehicle Guiding System And Flying Vehicle Guiding Method

ActiveUS20140371952A1Improve image processing capabilitiesOperational securityDigital data processing detailsPhotogrammetry/videogrammetrySurvey instrumentFlight vehicle

A flying vehicle guiding system, which comprises a remotely controllable flying vehicle system, a surveying instrument being able to measure distance, angle, and track, and a ground base station for controlling a flight of the flying vehicle system based on measuring results by the surveying instrument, wherein the flying vehicle system has a retro-reflector as an object to be measured, wherein the surveying instrument has a non-prism surveying function for performing distance measurement and angle measurement without a retro-reflector, a prism surveying function for performing distance measurement and angle measurement with respect to the retro-reflector, and a tracking function for tracking the retro-reflector and for performing distance measurement and angle measurement, wherein the surveying instrument performs non-prism measurement on a scheduled flight area, the ground base station sets a safe flight area based on the results of the non-prism measurement, and controls so that the flying vehicle system flies in the safe flight area based on the results of tracking measurement by de surveying instrument.

Owner:KK TOPCON

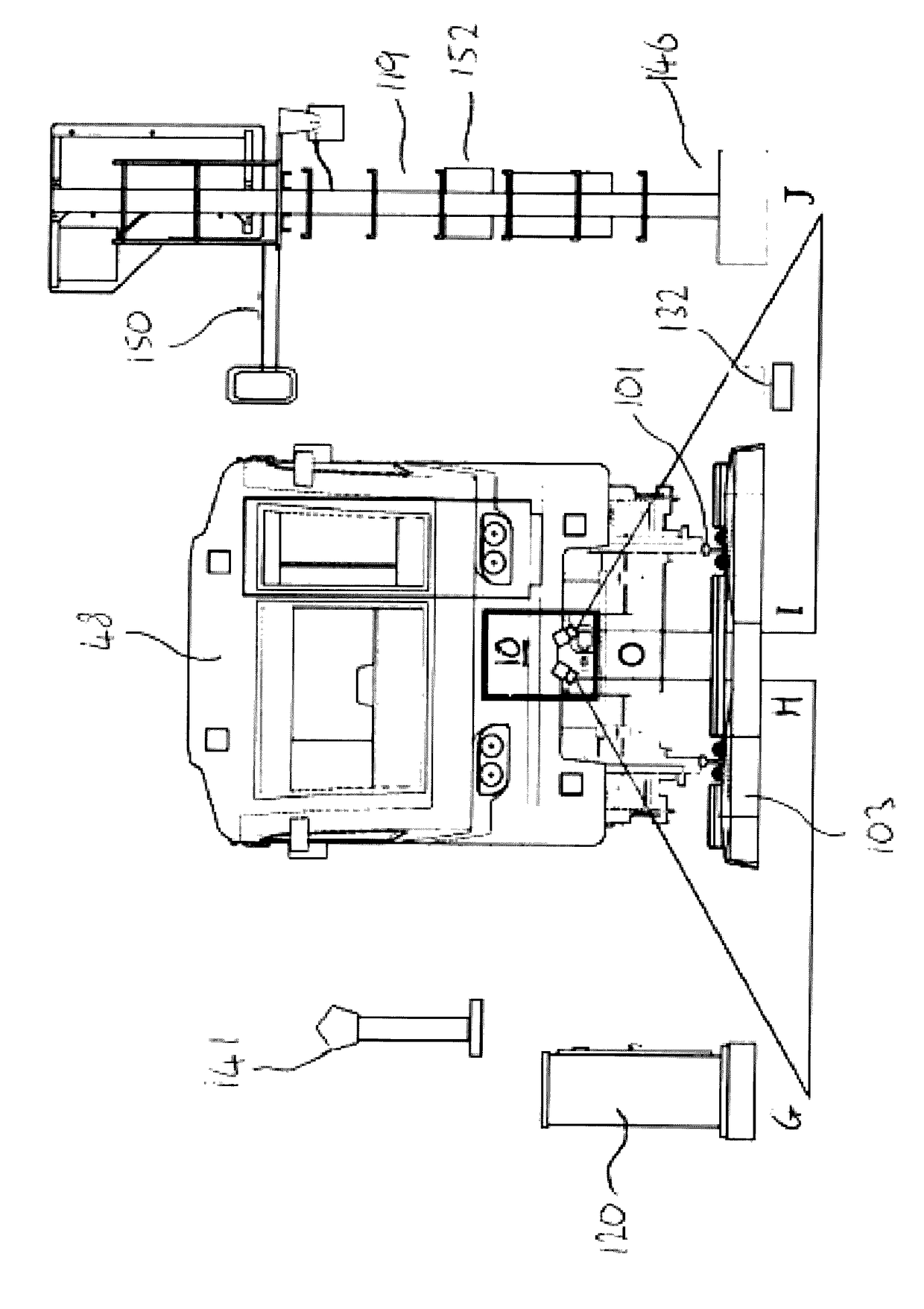

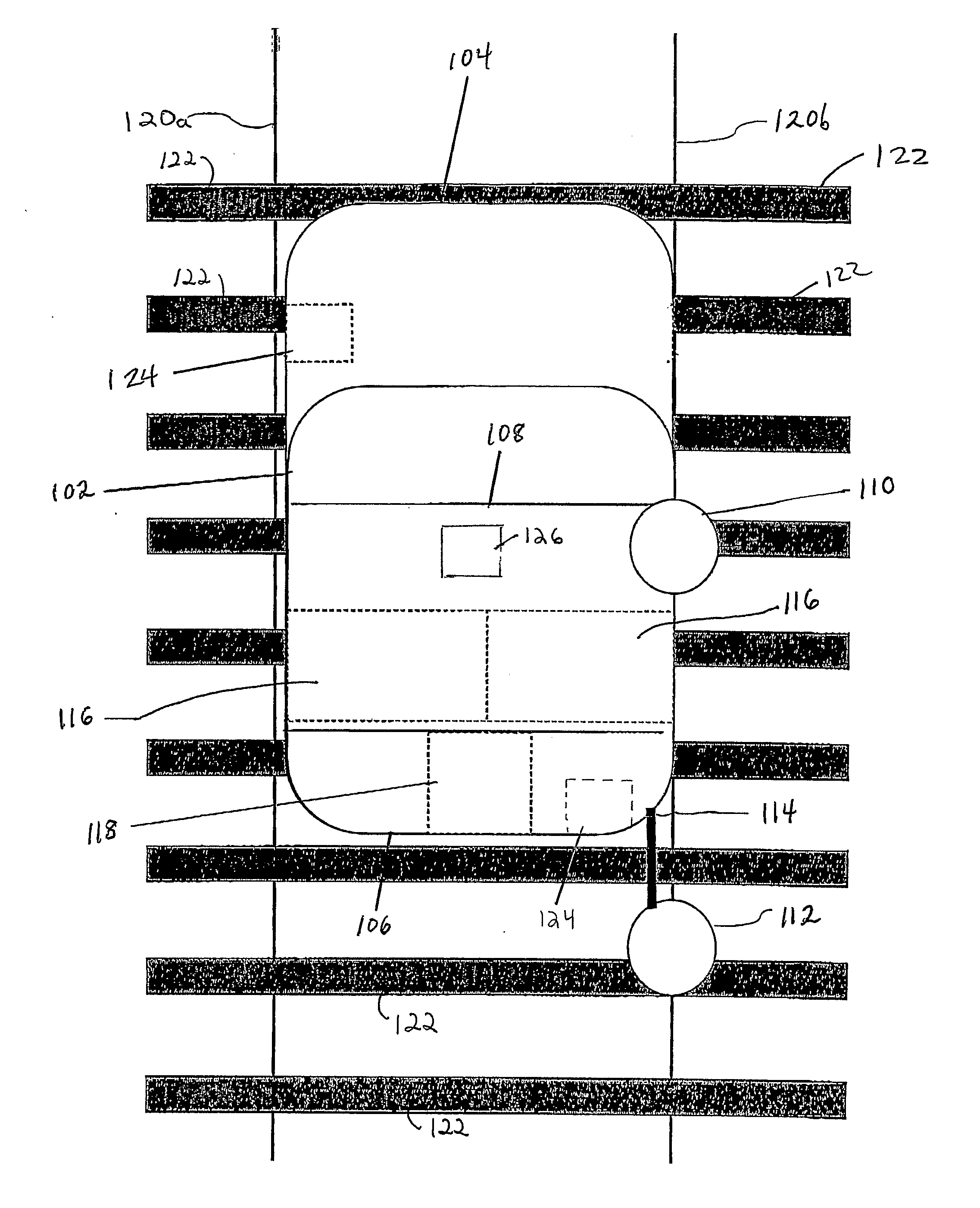

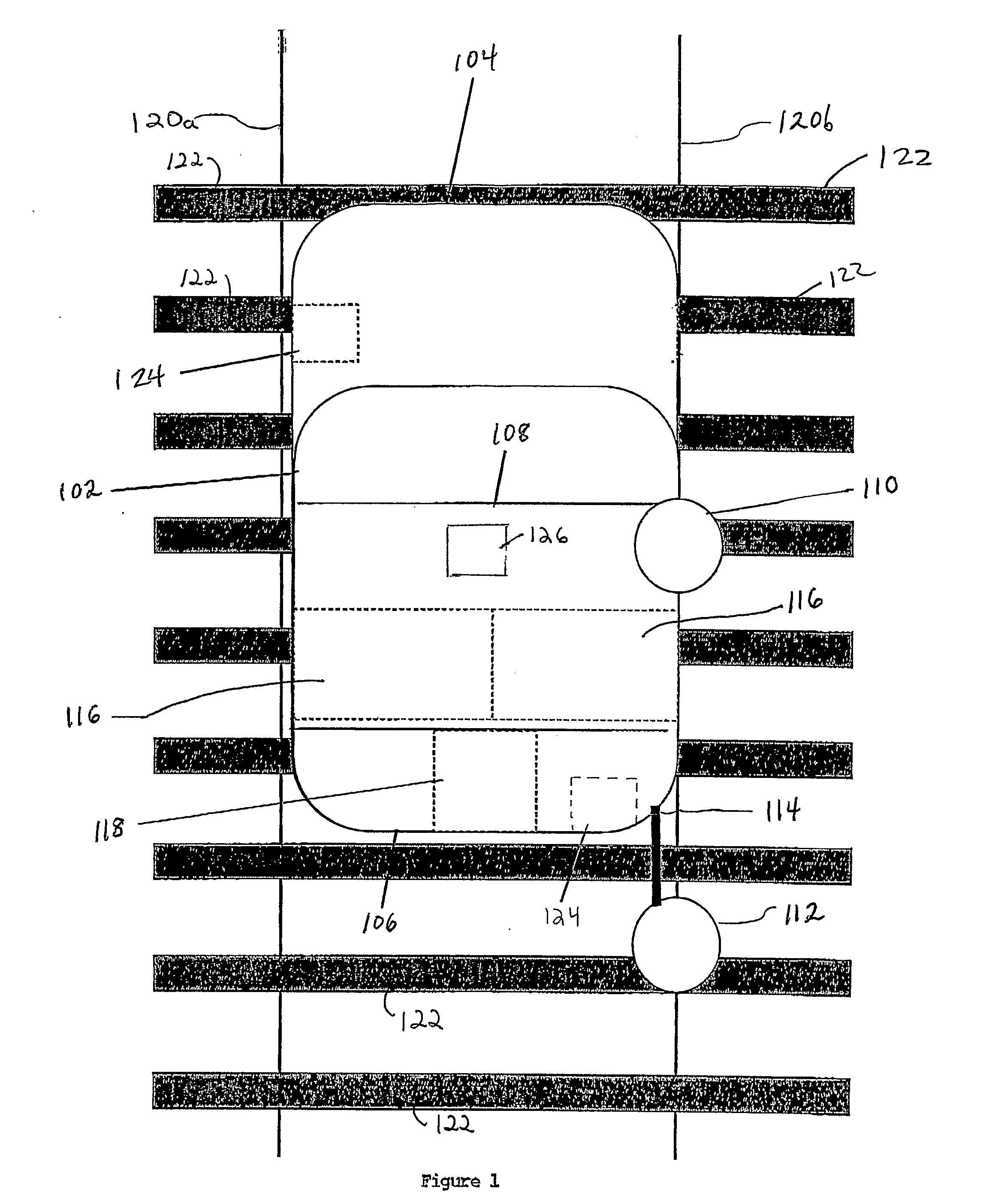

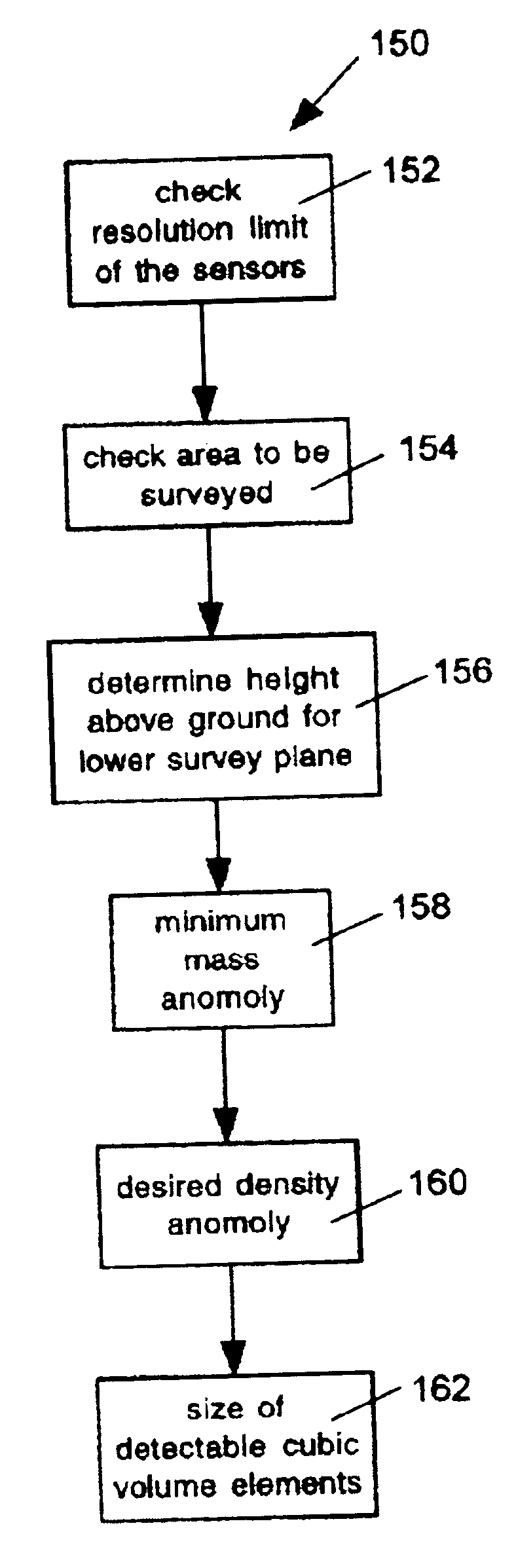

Railroad surveying and monitoring system

InactiveUS20100026551A1Easy to adaptOptimizationPosition fixationTesting/calibration of speed/acceleration/shock measurement devicesTerrainLandform

A Railroad Surveying and Monitoring System configured on a mobile platform for surveying, monitoring, and analyzing rail position and superstructure and terrain substructure of railroad tracks (20a,b) or other structures. The system employs two or more High Accuracy Differential Global Positioning System devices (110,112), ground penetrating radar devices (116), terrain conductivity instruments (118), optical cameras (124), and data receivers and processors (126), which in turn process, display, and store the data in a usable database. Precise coordinate data generated from a High Accuracy Global Positioning System provides both location data for subsurface sensors and surface sensors and rail position coordinates to monitor track displacements during track inspection in real time.

Owner:MARSHALL UNIV RES

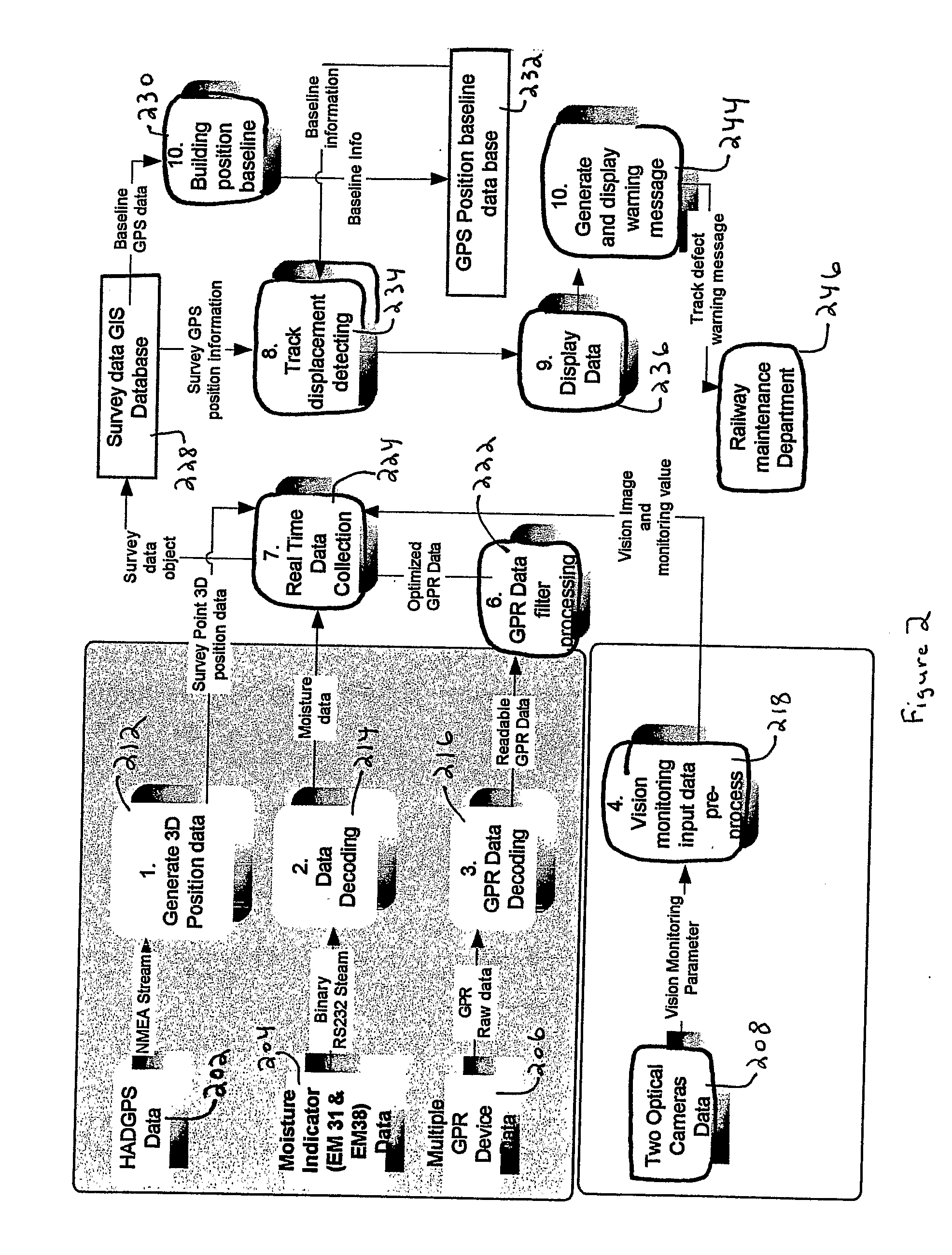

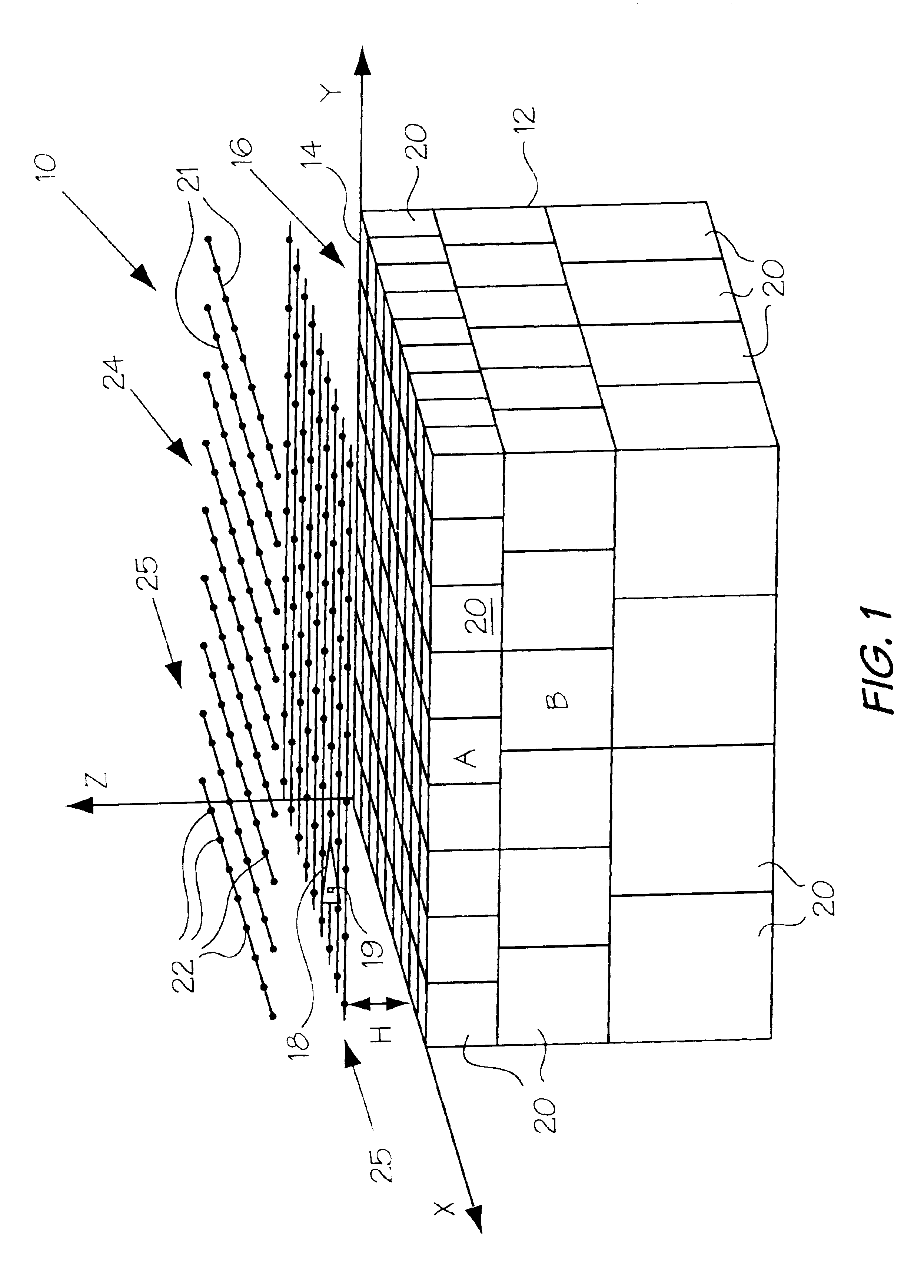

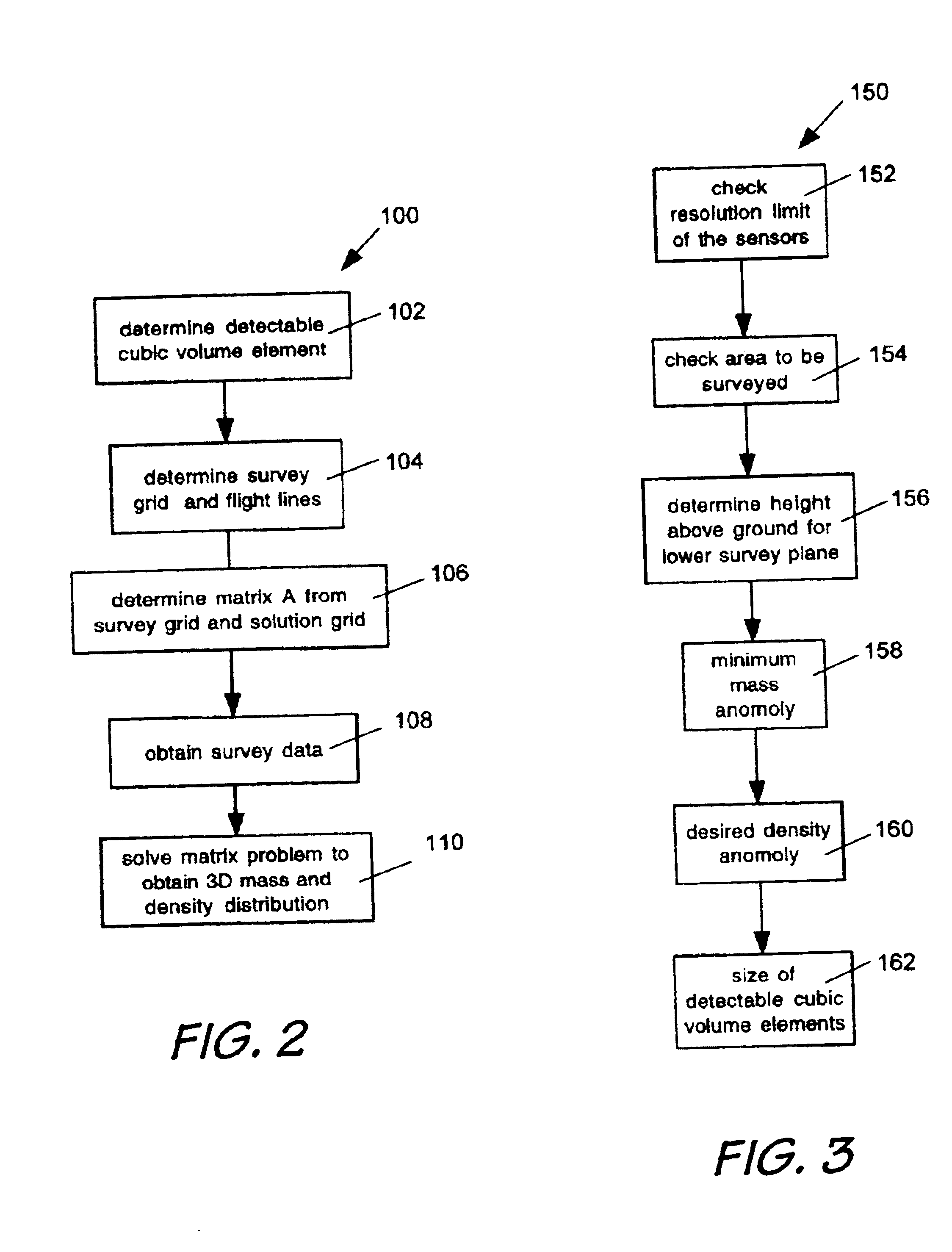

System and method for surveying underground density distributions

ActiveUS6954698B2Special data processing applicationsGravitational wave measurementMassive gravityMagnetic susceptibility

Owner:GEDEX

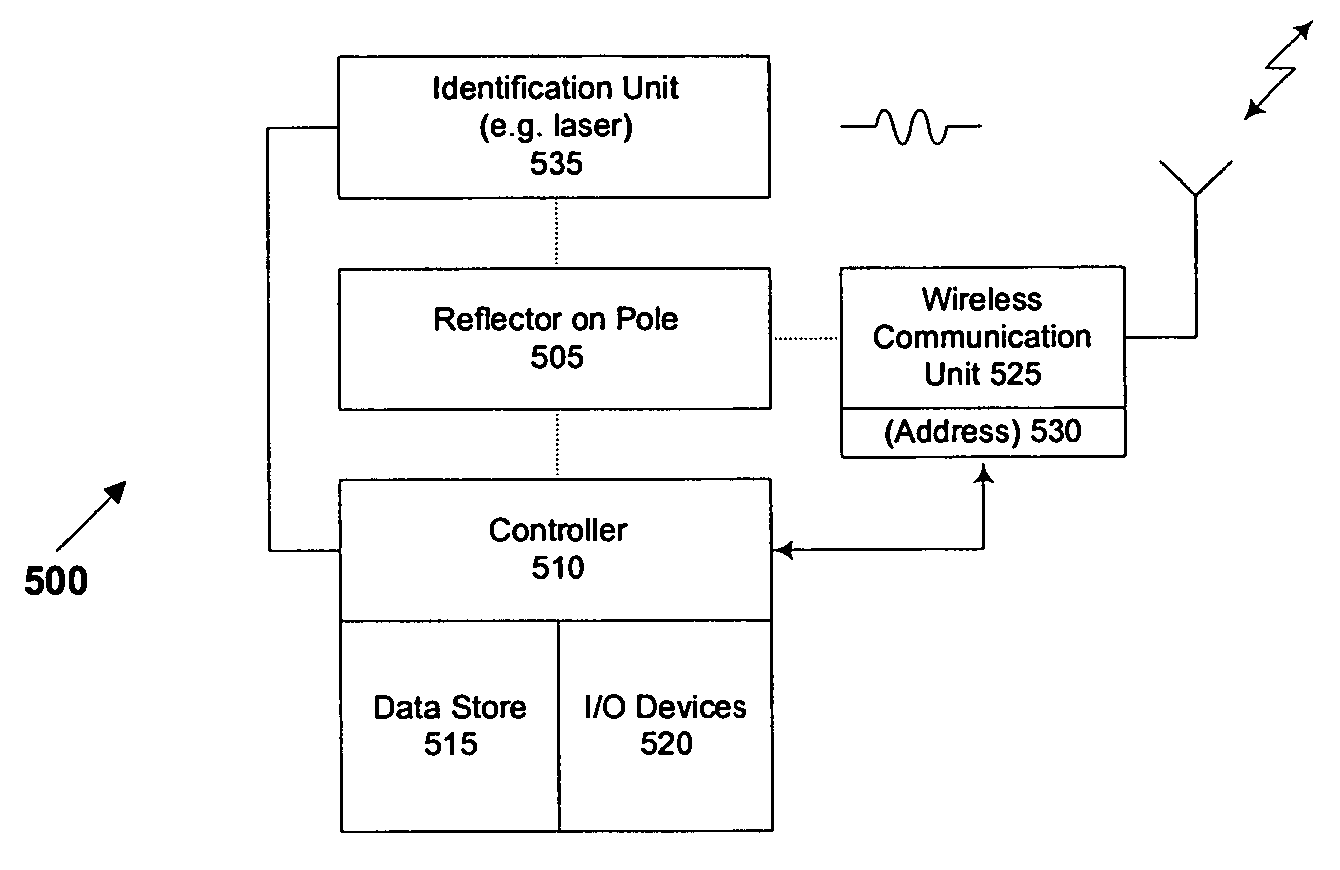

Surveying systems and methods

ActiveUS20070019212A1Good choiceIncrease rangeAngle measurementPosition fixationIdentification deviceTotal station

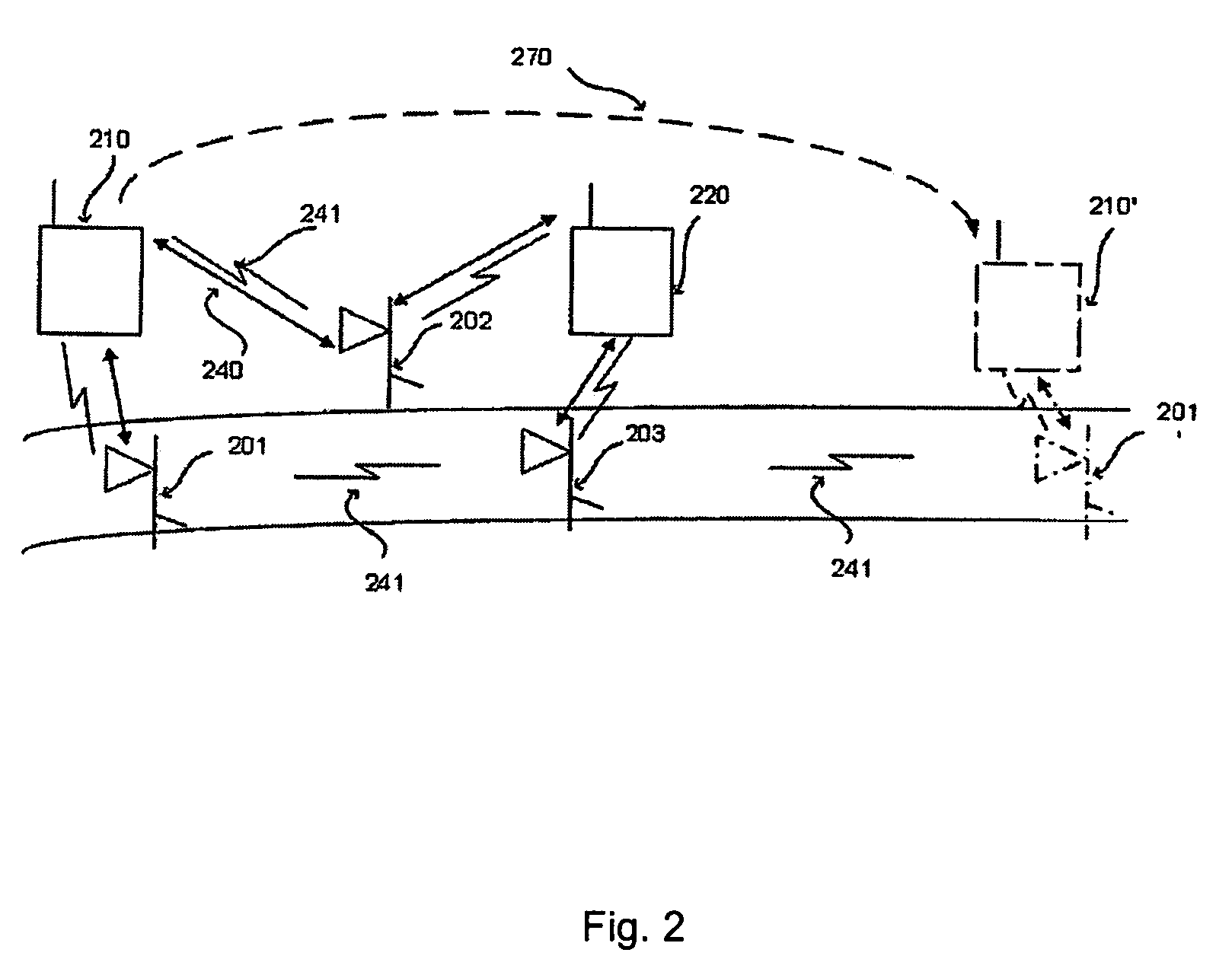

The invention relates to a surveying system, comprising at least one total station unit (210,220), and at least one target (201,203), said targets having wireless communication means, each unit provided with a unique wireless communication address for wireless communication, the wireless communication to be used to activate a selected total station (210,220) to identify and measure the location of a chosen target (201,203) in relation to a relative reference system, each target having identification means to be used by the total station for identification of the chosen target, each total station having identifying means used for identification of the chosen target to be measured. The invention also relates to a target and a method for surveying using the total stations and the targets according to the system.

Owner:TRIMBLE A B A CORP OF SWEDEN

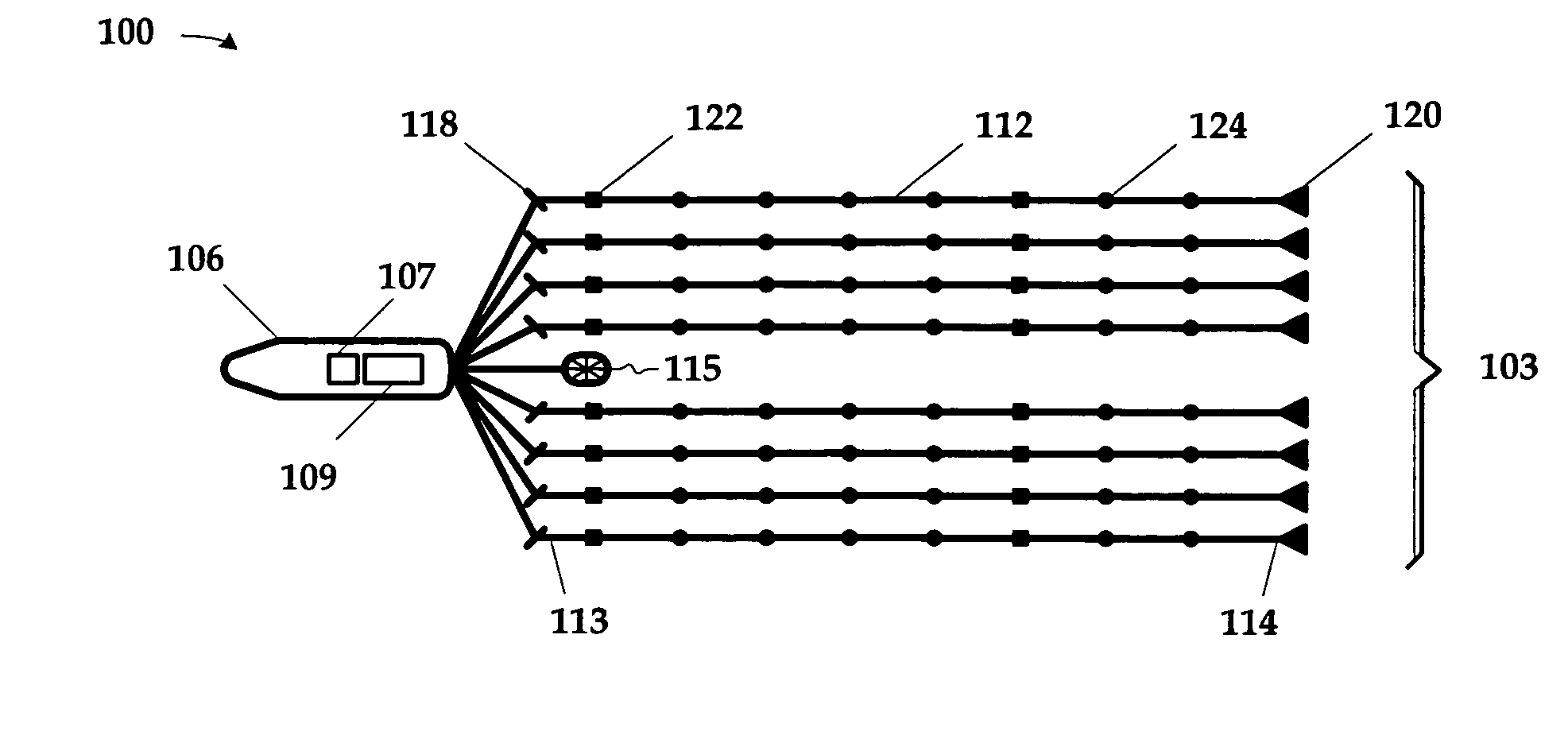

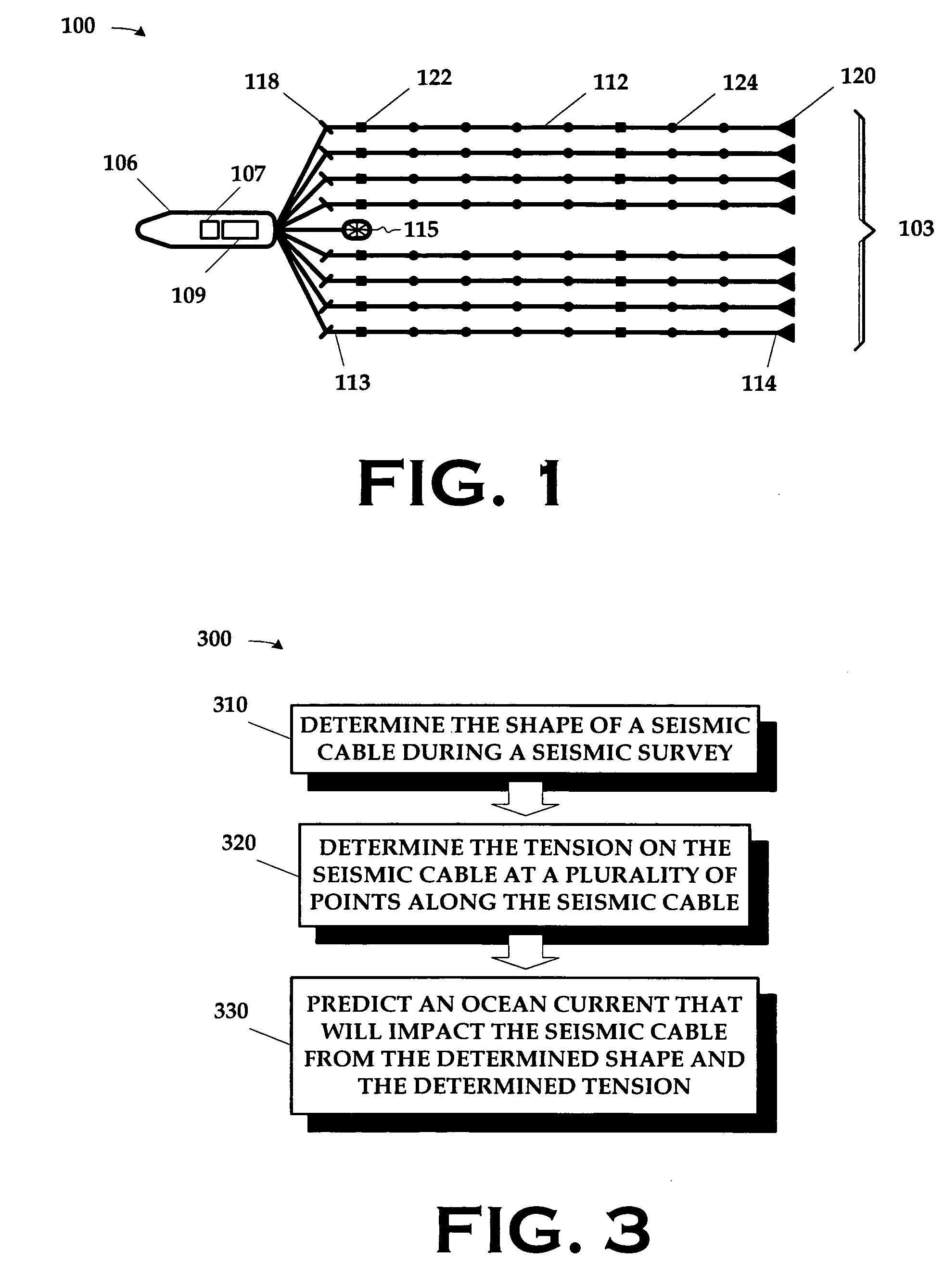

Current prediction in seismic surveys

ActiveUS20070127312A1Measuring open water movementSeismic signal processingOcean bottomSeismic survey

A method for use in seismic surveying includes determining the shape of a seismic cable during a seismic survey; determining the tension on the seismic cable at a plurality of points along the seismic cable; and predicting a current that will impact the seismic cable from the determined shape and the determined tension. The method may be practiced two-dimensionally in the context of a marine survey employing a towed streamer array or three-dimensionally in the context of laying an array of ocean bottom cables on the seabed. The predicted currents can, in some embodiments; be used to make steering corrections for the seismic cables.

Owner:REFLECTION MARINE NORGE AS

Indoor surveying apparatus

An indoor surveying apparatus comprises a 2D range finder, means for automatically aligning 2D range finder data and computing a 2D map of the environment, a calibrated optical imaging system for capturing images of environment, and means for establishing positions and extents of walls, doors, and windows and for drawing floor plans using the computed 2D map and calibrated images where 2D range finder data is missing. It is further contemplated that the imaging system can also be part of the range finder, that the range finder can be a scanning laser range finder, that the imaging system can include a panoramic lens with 180 degree field of view, that the apparatus can further include an IMU, an electronic compass, a panoramic rotator, and means for measuring positions of points on the floor using the image data.

Owner:PLANITAR INC

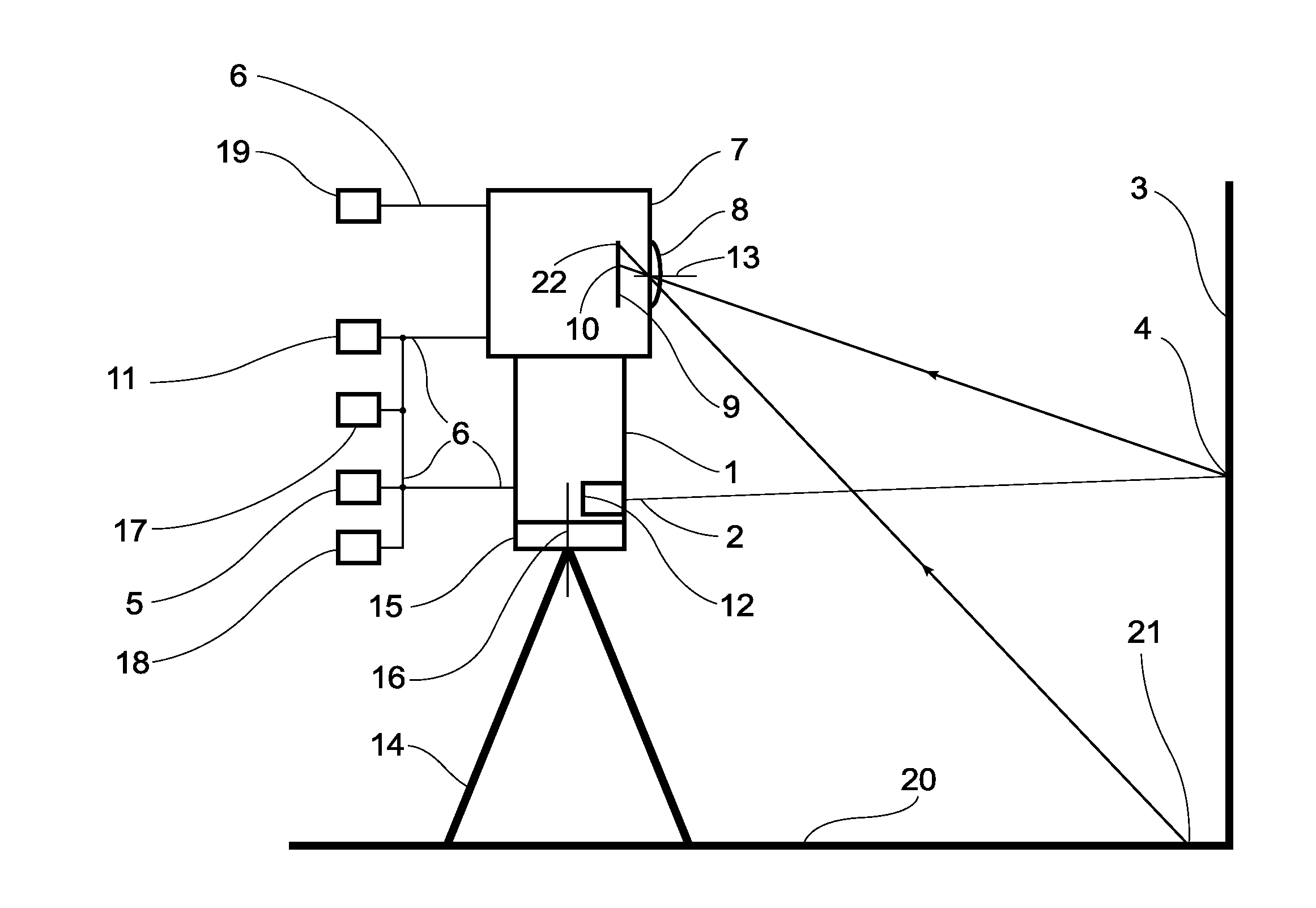

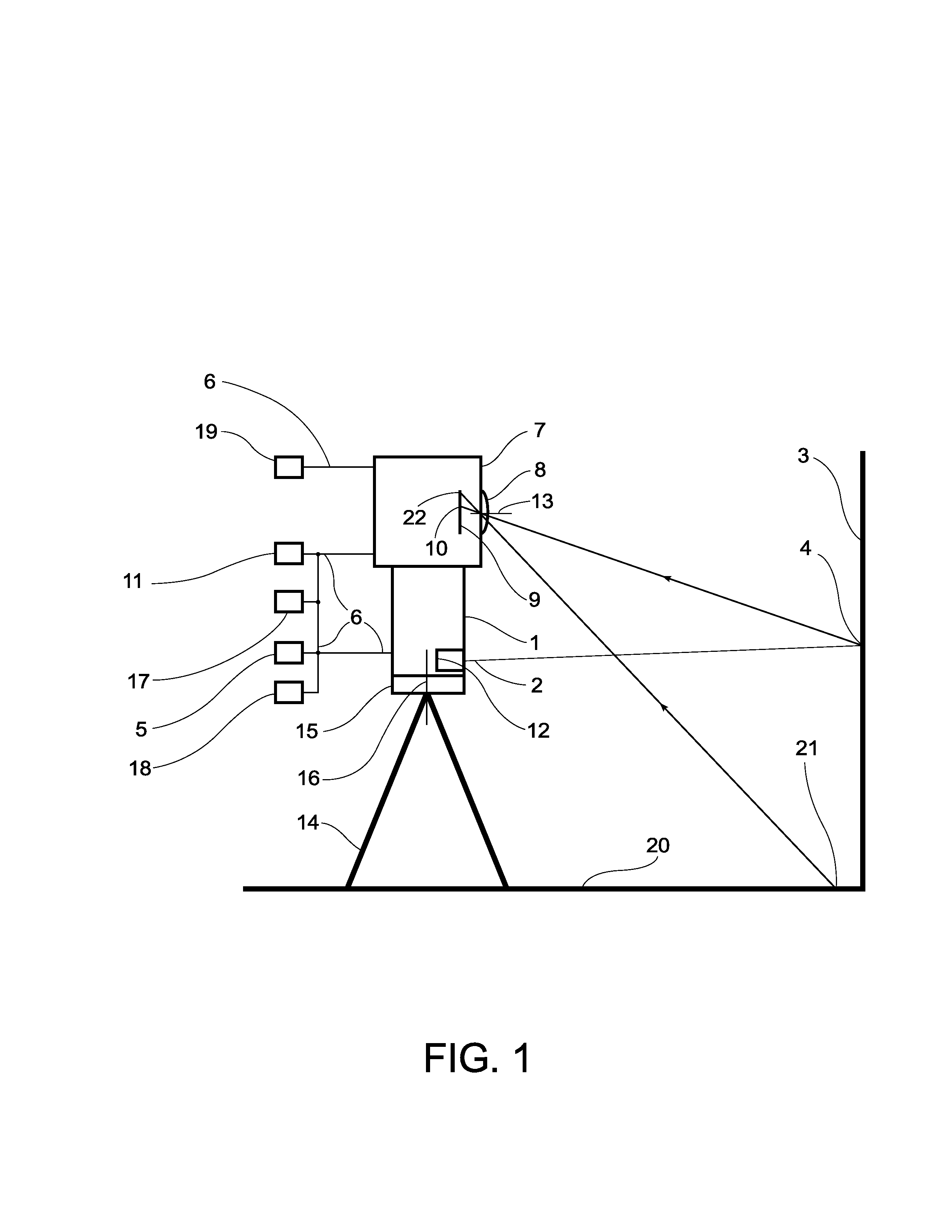

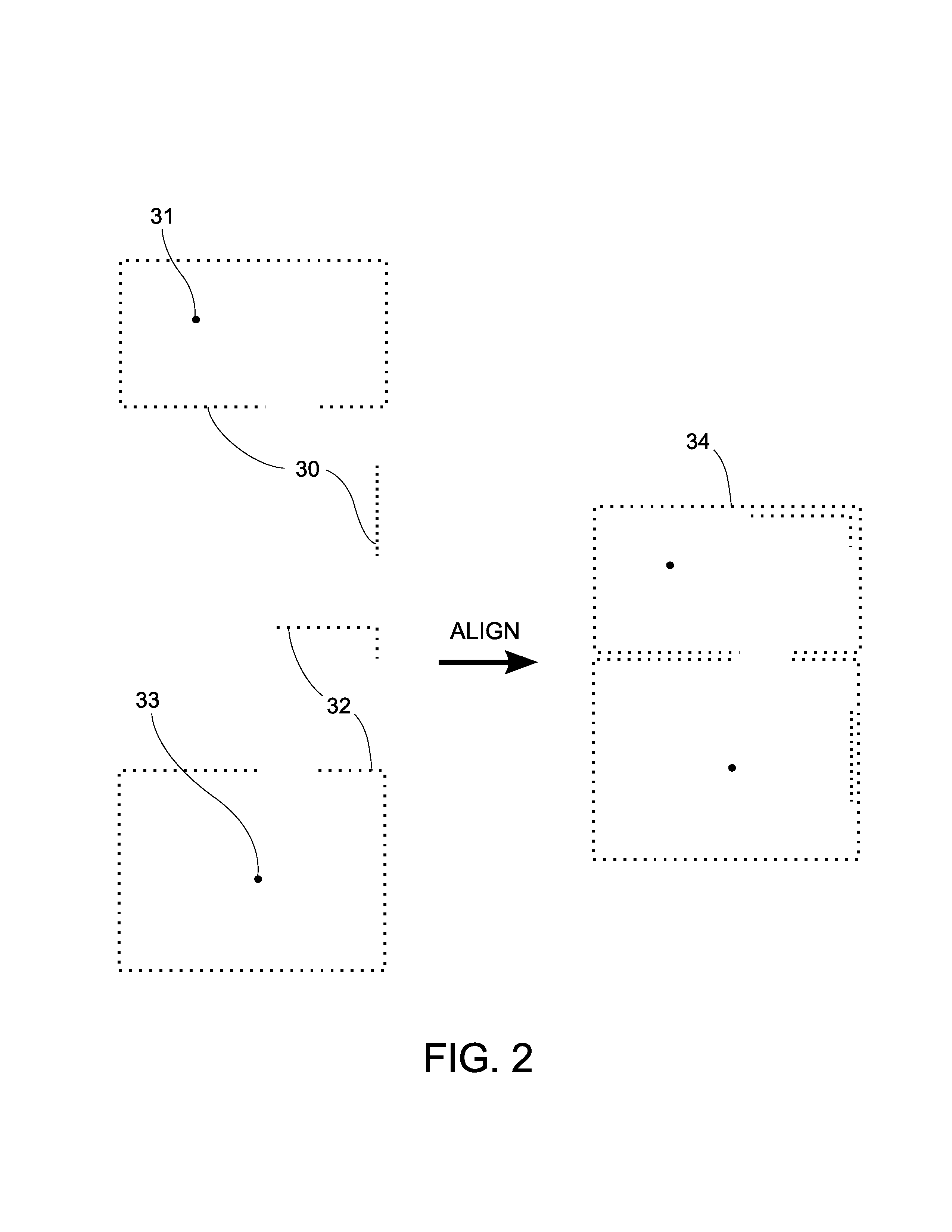

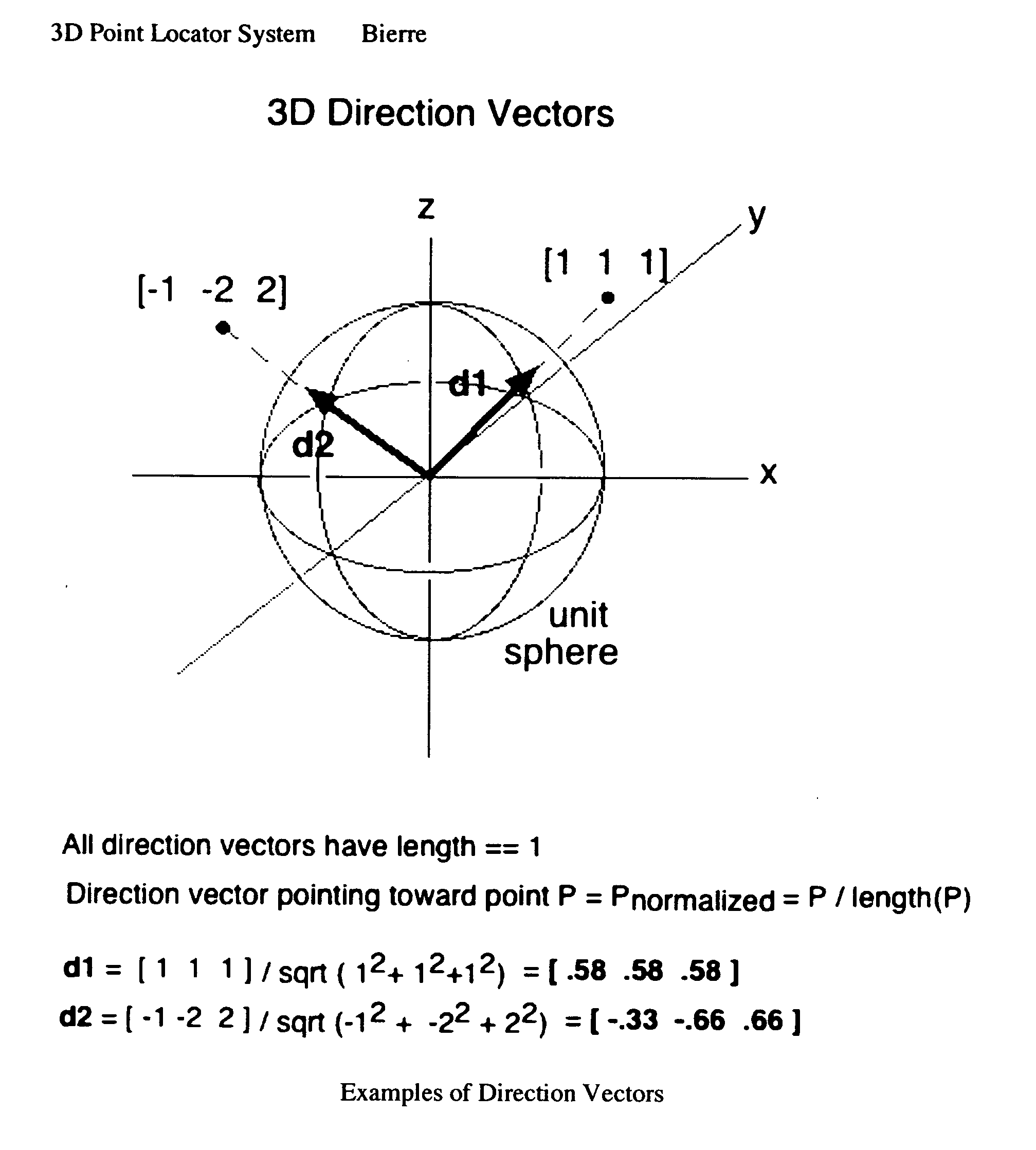

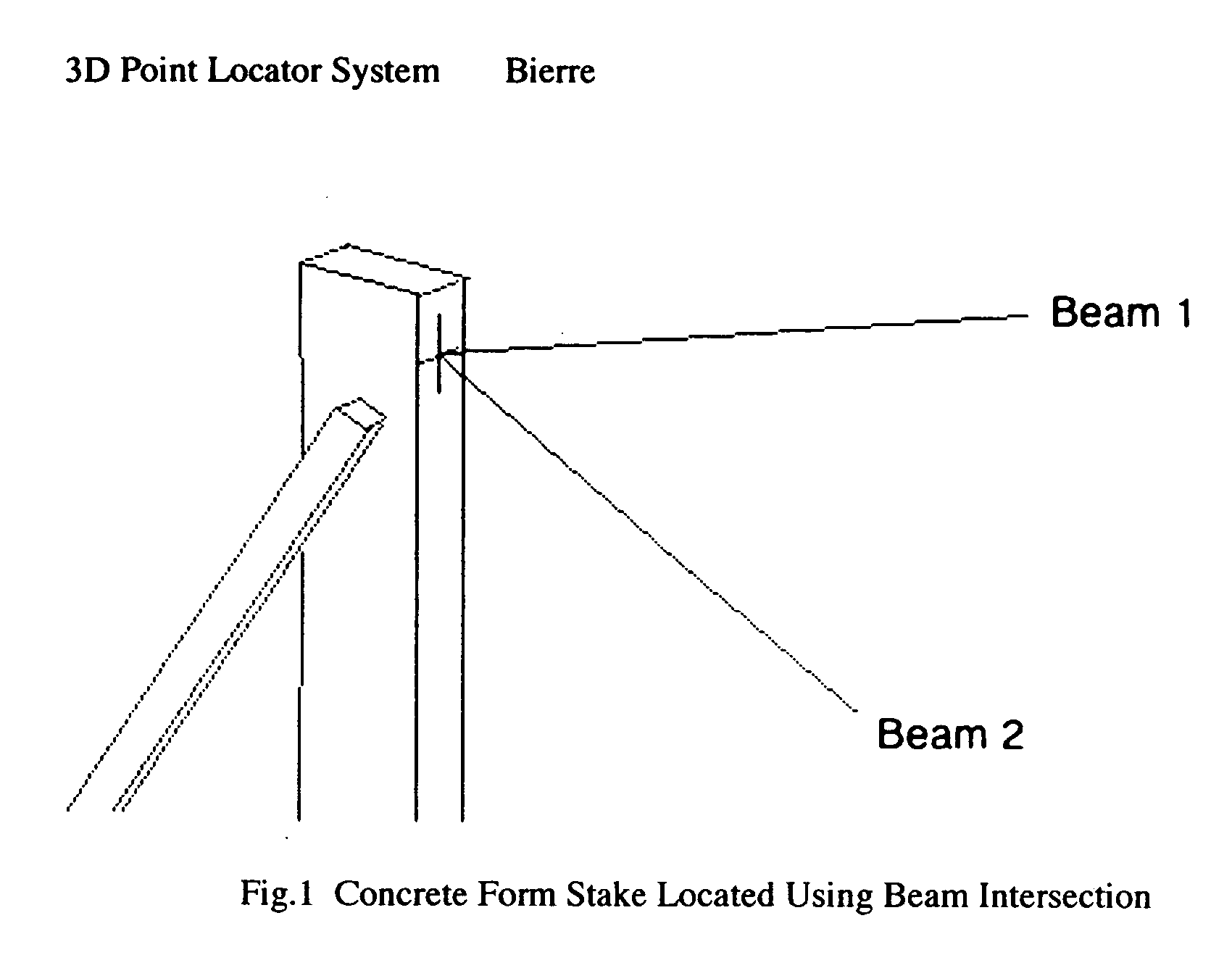

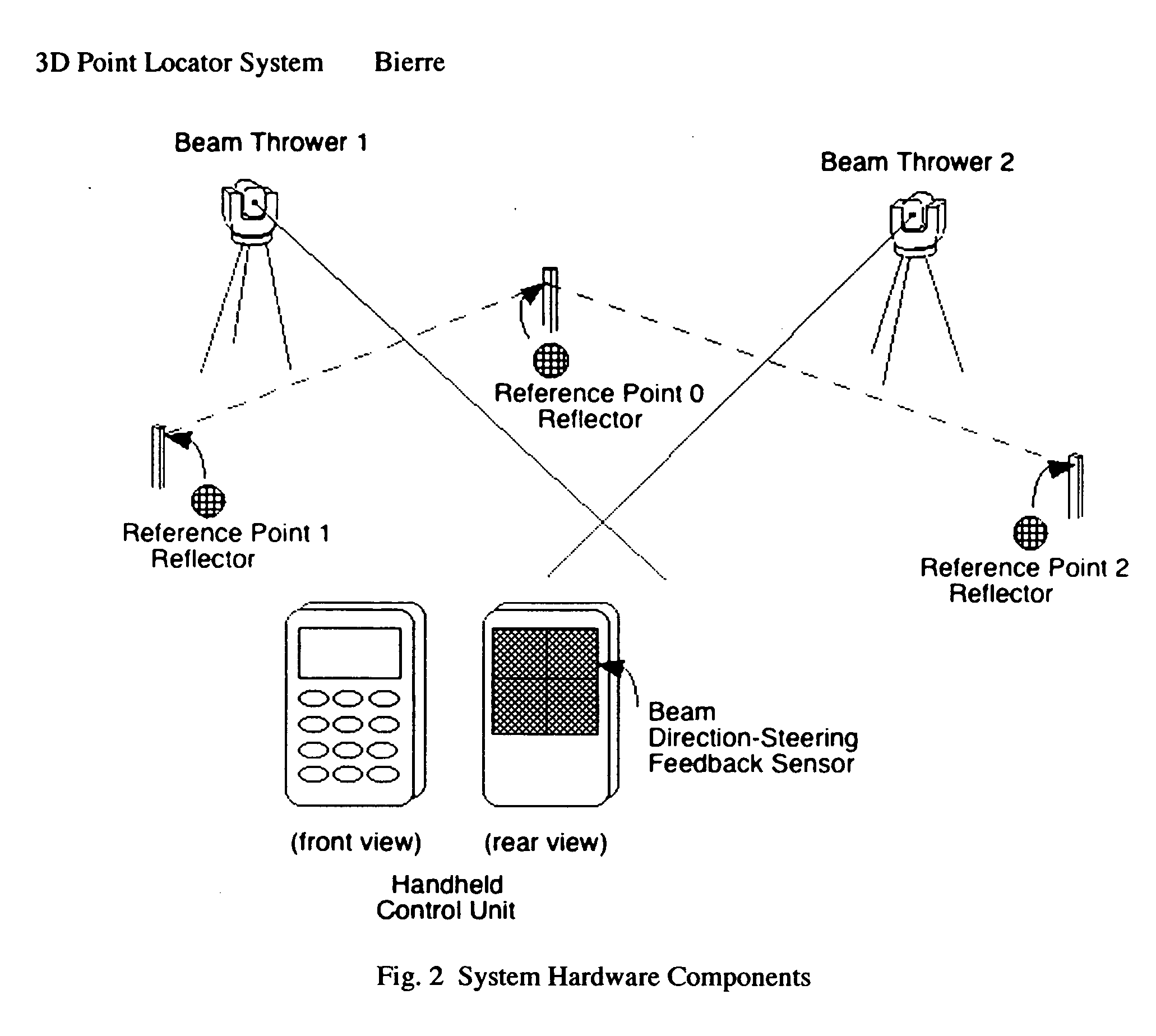

3D point locator system

InactiveUS20050102063A1DistanceReduce distanceComputer controlSimulator controlOperational systemSurvey instrument

An automated system and method of geometric 3D point location. The invention teaches a system design for translating a CAD model into real spatial locations at a construction site, interior environment, or other workspace. Specified points are materialized by intersecting two visible pencil light beams there, each beam under the control of its own robotic ray-steering beam source. Practicability requires each beam source to know its precise location and rotational orientation in the CAD-based coordinate system. As an enabling sub-invention, therefore, an automated system and method for self-location and self-orientation of a polar-angle-sensing device is specified, based on its observation of three (3) known reference points. Two such devices, under the control of a handheld unit downloaded with the CAD model or pointlist, are sufficient to orchestrate the arbitrary point location of the invention, by the following method: Three CAD-specified reference points are optically defined by emplacing a spot retroreflector at each. The user then situates the two beam source devices at unspecified locations and orientations. The user then trains each beam source on each reference point, enabling the beam source to compute its location and orientation, using the algorithm of the sub-invention. The user then may select a CAD-specified design point using the handheld controller, and in response, the handheld instructs the two beam sources to radiate toward the currently selected point P. Each beam source independently transforms P into a direction vector from self, applies a 3×3 matrix rotator that corrects for its arbitrary rotational orientation, and instructs its robotics to assume the resultant beam direction. In consummation of the inventive thread, the pair of light beams form an intersection at the specified point P, giving the worker visual cues to precisely position materials there. This design posits significant ease-of-use advantages over construction point location using a single-beam total station. The invention locates the point effortlessly and with dispatch compared to the total station method of iterative manual search maneuvering a prism into place. Speed enables building features on top of point location, such as metered plumb and edge traversal, and graphical point selection. The invention eliminates the need for a receiving device to occupy space at the specified point, leaving it free to be occupied by building materials. The invention's beam intersection creates a pattern of instantaneous visual feedback signifying correct emplacement of such building materials. Unlike surveying instruments, the invention's freedom to situate its two ray-steering devices at arbitrary locations and orientations, and its reliance instead on the staking of 3 reference points, eliminates the need for specialized surveying skill to set up and operate the system, widening access to builders, engineers, and craftspeople.

Owner:BIERRE PIERRE

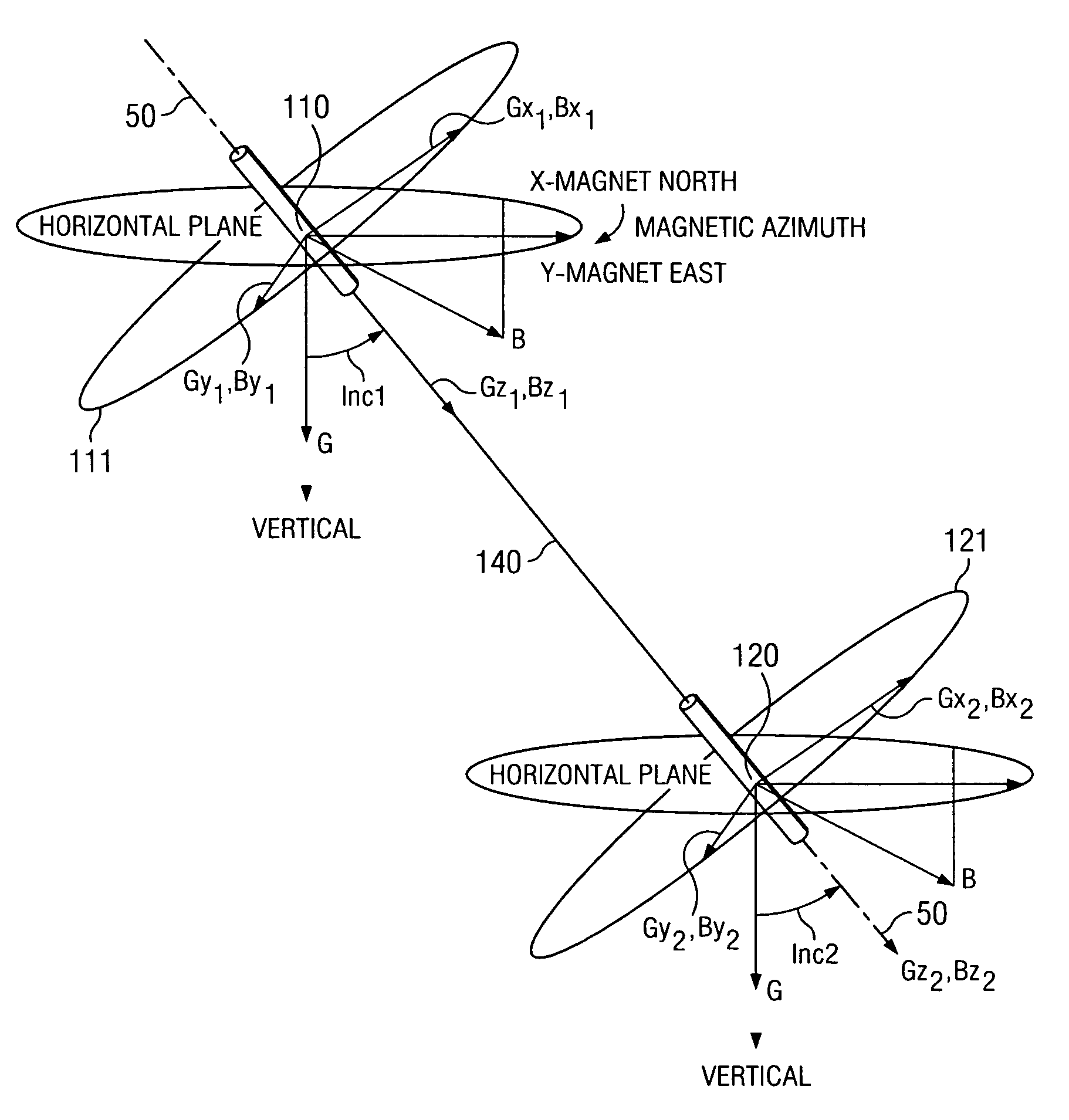

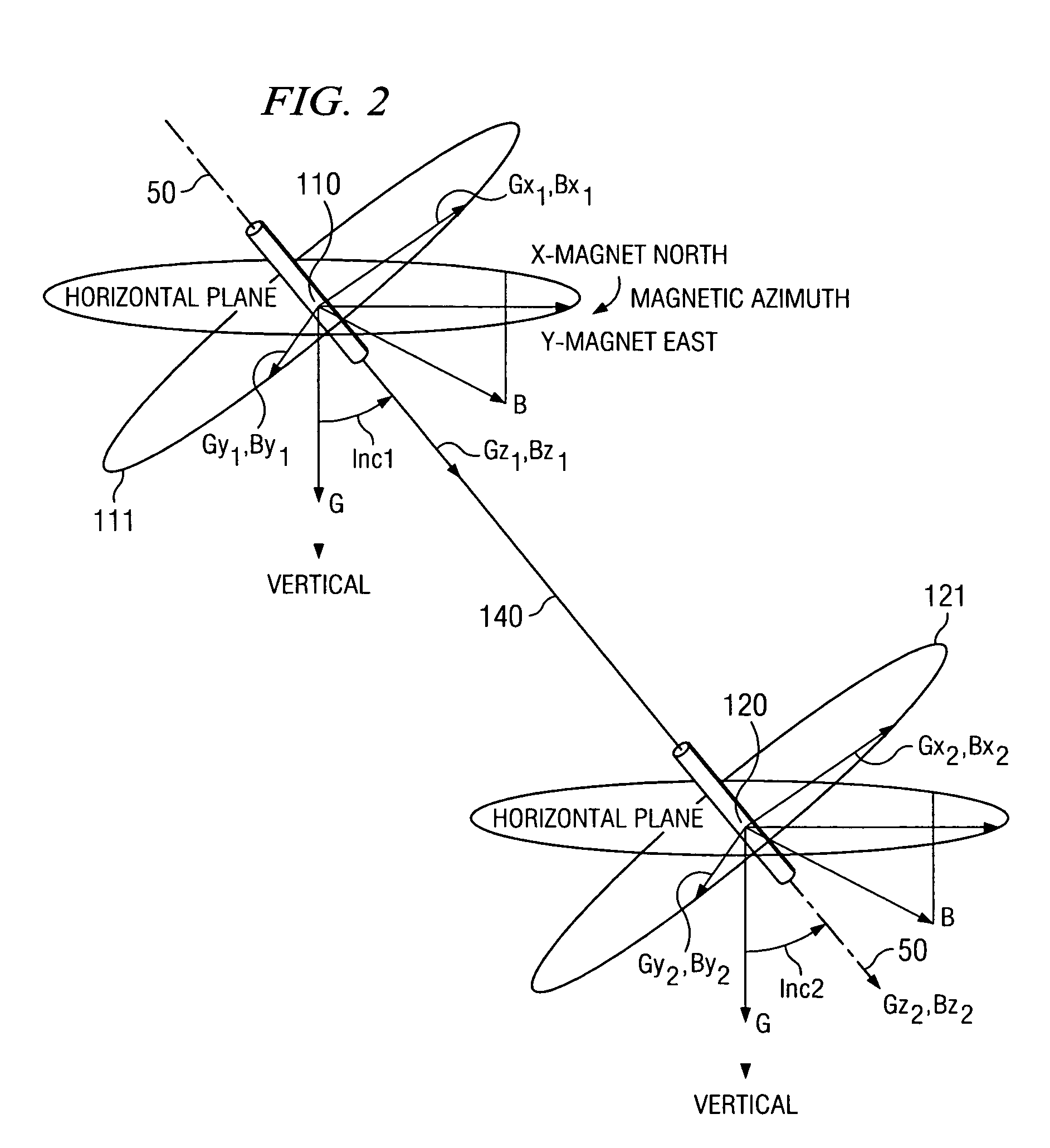

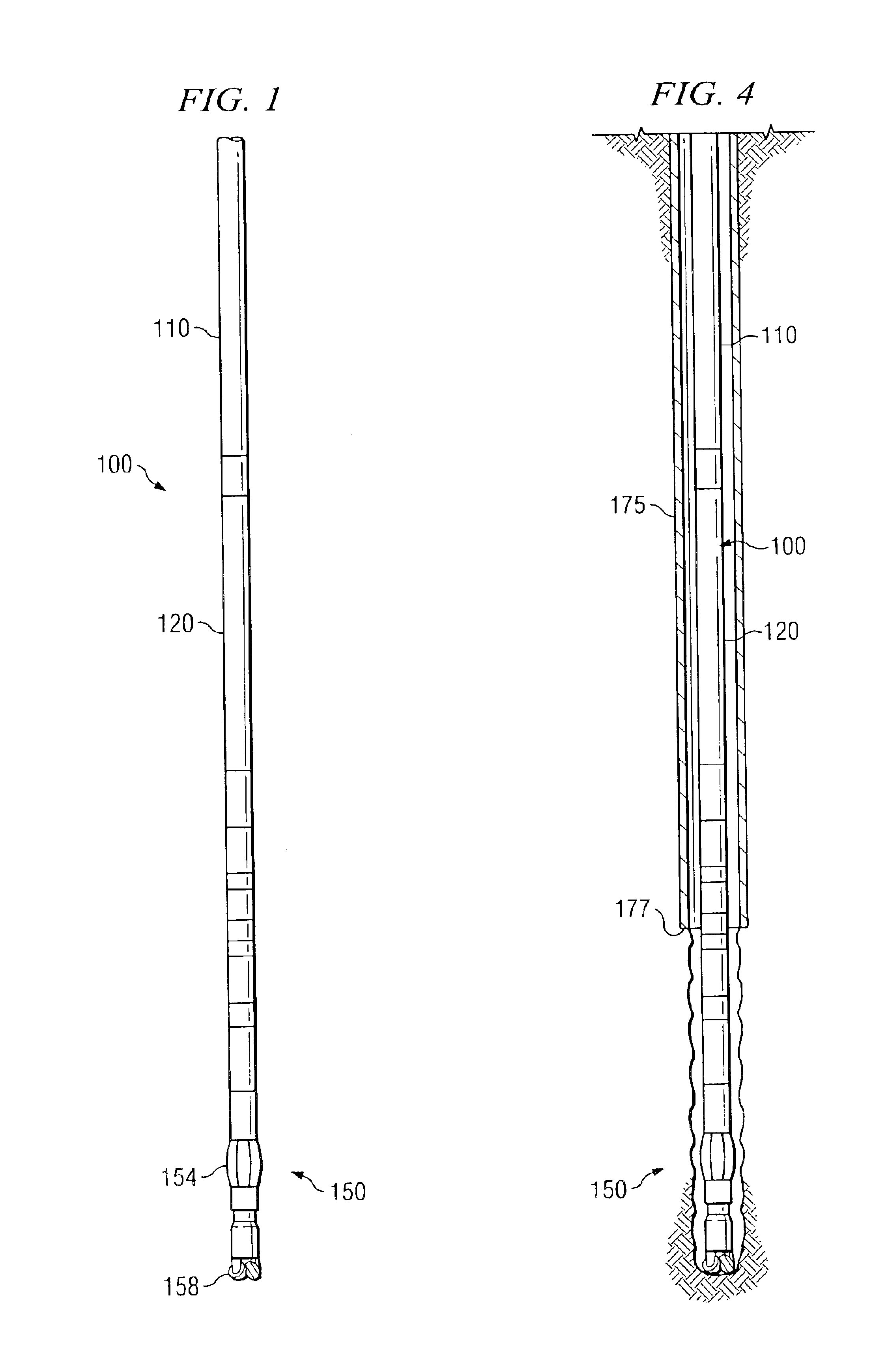

Well twinning techniques in borehole surveying

ActiveUS6985814B2Easy to determineElectric/magnetic detection for well-loggingSurveyMeasurement deviceSurvey methodology

A method for surveying a borehole is provided. The method includes providing a tool having a magnetic field measurement device disposed thereon and positioning the tool in a borehole. Magnetic interference vectors are determined at at least two positions in the borehole by comparing the measured magnetic fields at those positions with a known magnetic field of the earth. The magnetic interference vectors indicate a direction to a target subterranean structure. Various embodiments of the invention compare the directions to the target subterranean structure with a historical survey thereof, so as to determine a distance between the borehole and the subterranean structure and an azimuth of the borehole. The surveying methodology of this invention may advantageously improve borehole surveying data obtained, for example, in relief well and / or well twinning drilling applications.

Owner:SCHLUMBERGER TECH CORP

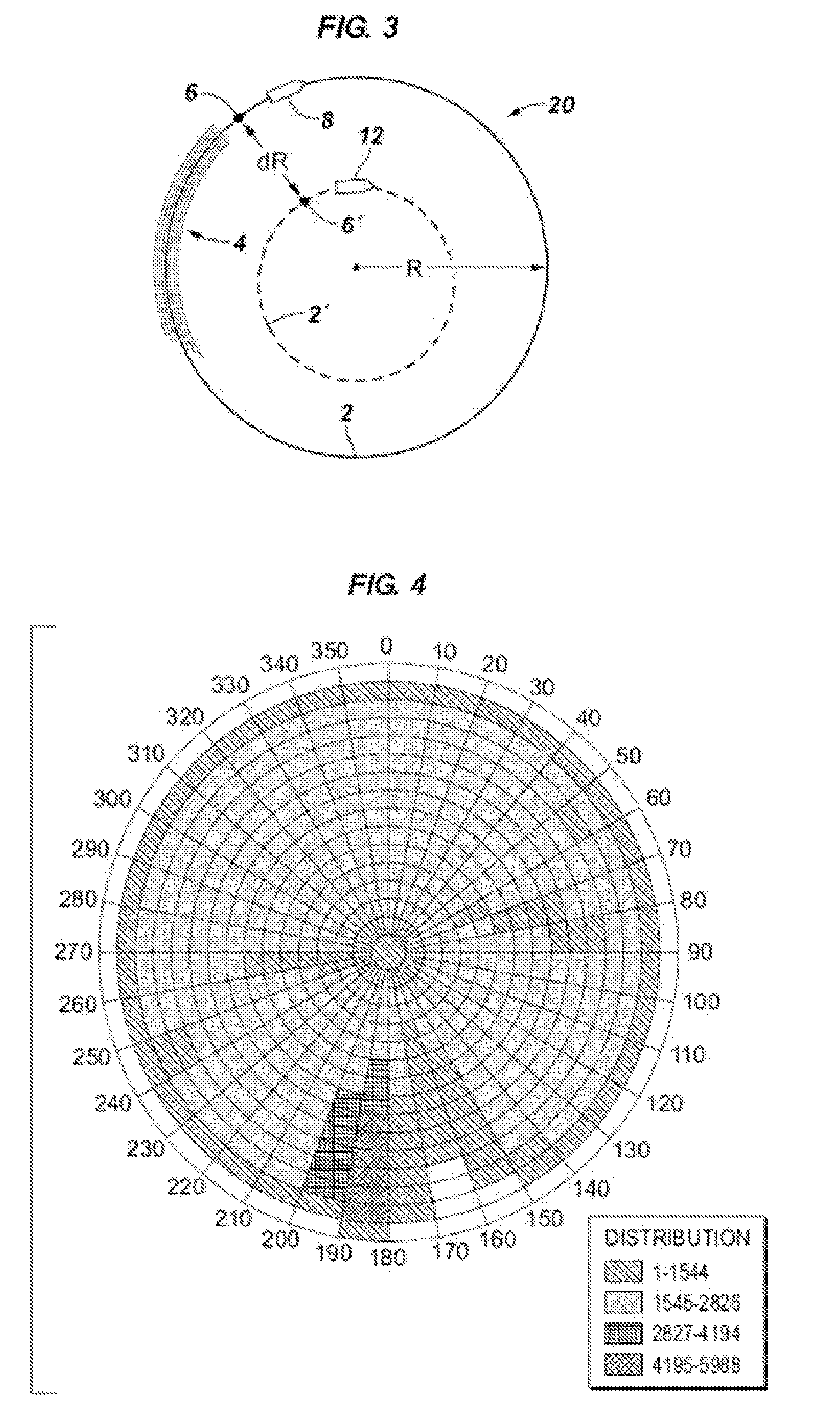

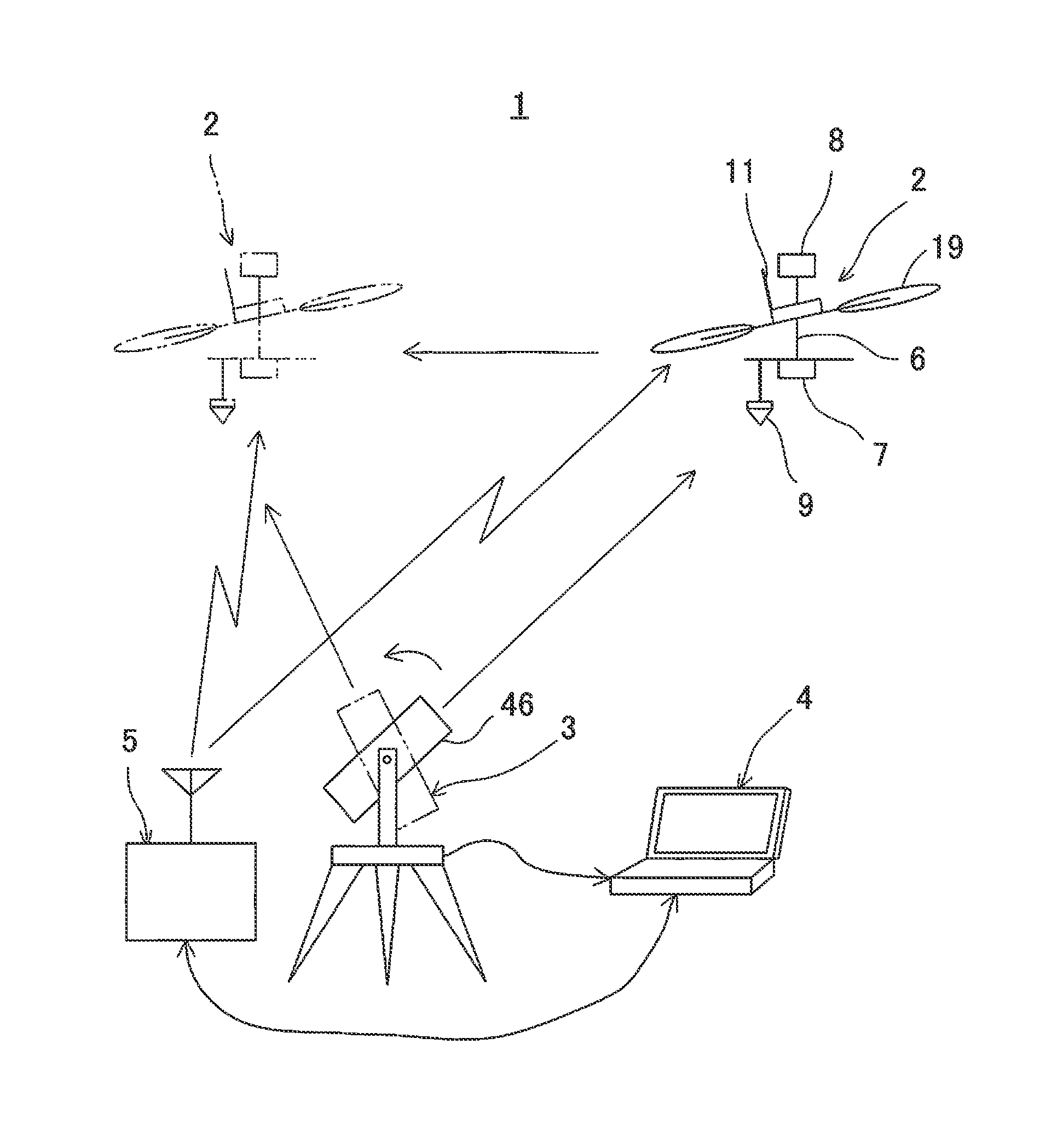

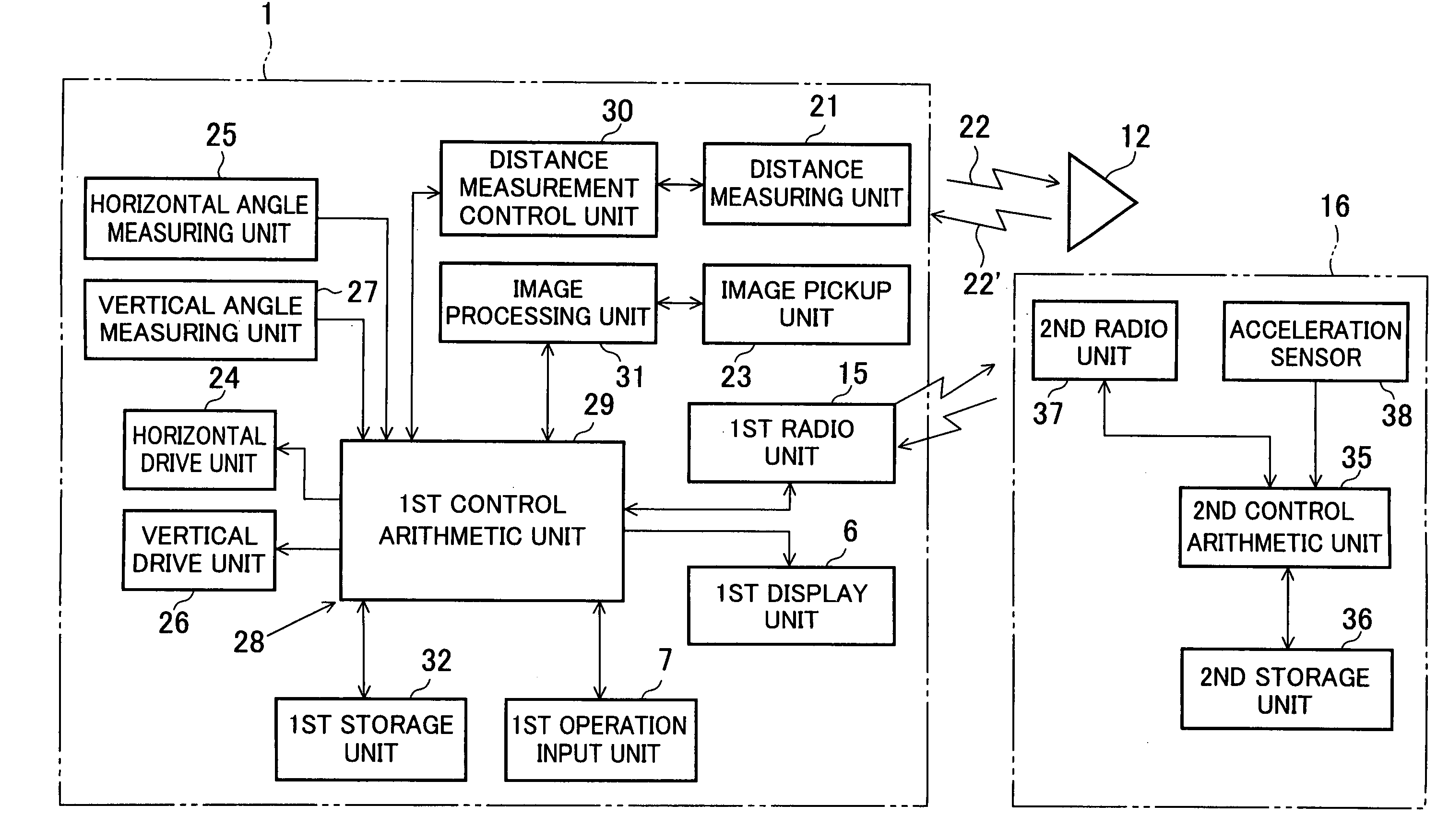

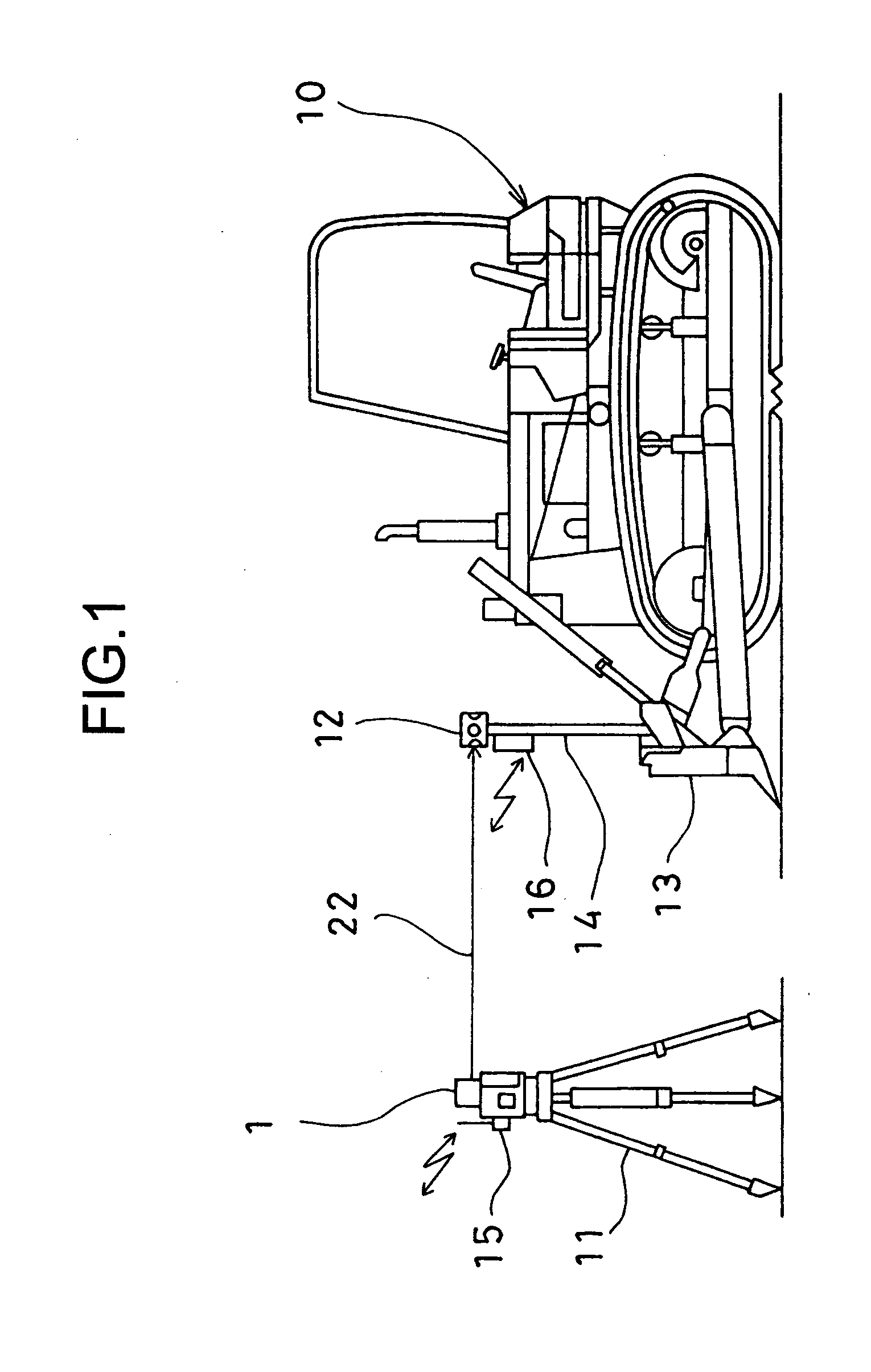

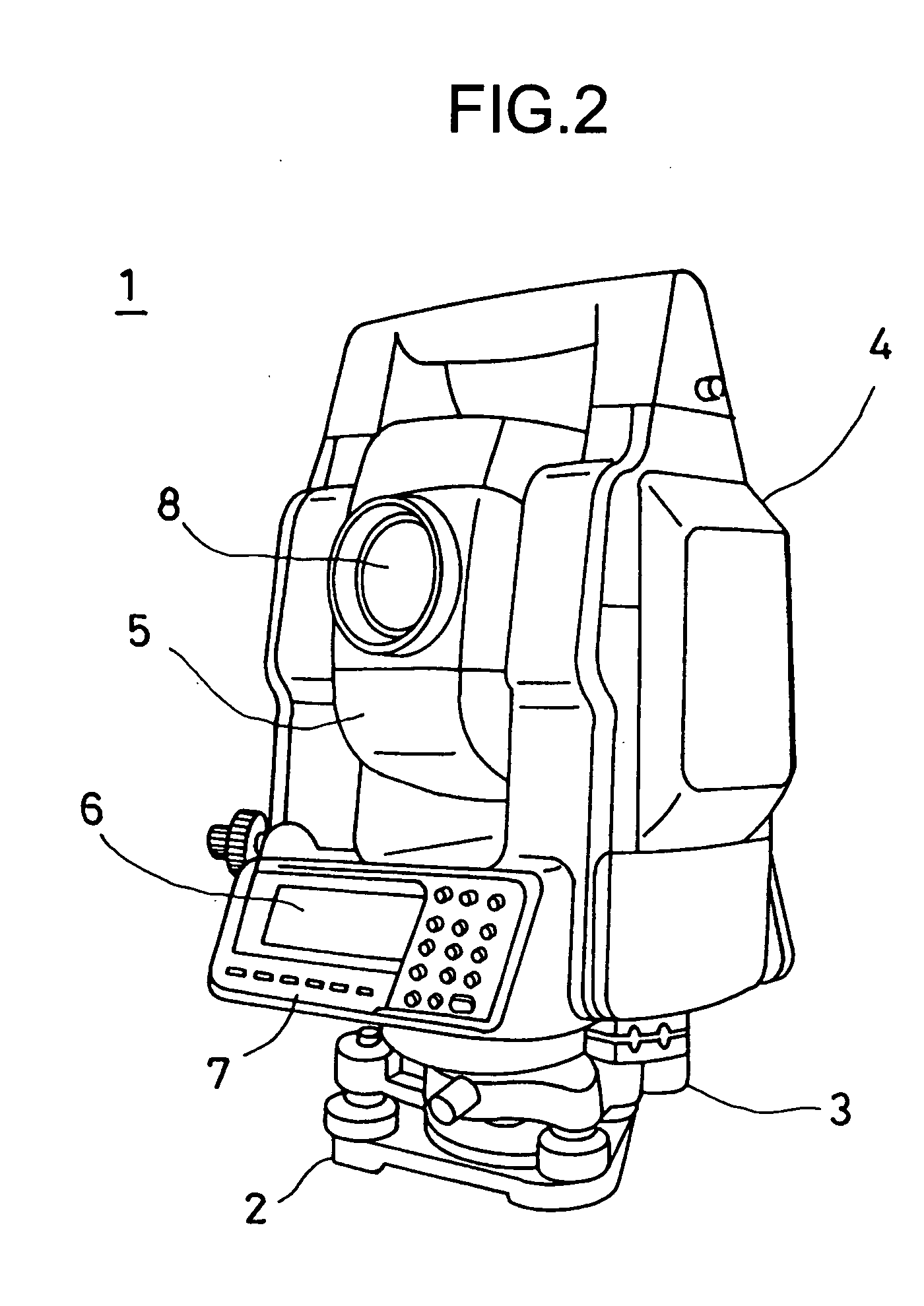

Surveying system

ActiveUS20090171618A1Easy to startLow-cost detectorAngle measurementOptical rangefindersSurvey instrumentMeasuring instrument

The present invention provides a surveying system, which comprises a surveying instrument 1 which measures a distance and an angle by projecting a distance measuring light toward a target 12 and can measure a three-dimensional position data of said target and has a function to track the target, and a movable side control device 12 provided on the target side, wherein said surveying instrument has a communication means 15 capable to transmit the three-dimensional position data of the target measured by the surveying instrument to said movable side control device and a first control arithmetic unit 29 for controlling the search of the target by the surveying instrument, wherein said movable side control device has a displacement amount detecting means 38 of the target and a second control arithmetic unit 35 for calculating the displacement amount of the target based on a target detection signal from the displacement amount detecting means and for calculating a target position based on the displacement amount of the target and based on the three-dimensional position data, and in case the surveying instrument cannot track the target, the target position transmitted from the movable side control device is acquired, and the first control arithmetic unit starts searching of the target with the target position as a starting point.

Owner:KK TOPCON

Electromagnetic surveying for hydrocarbon reservoirs

ActiveUS20050077902A1Water resource assessmentDetection using electromagnetic wavesOcean bottomUltrasound attenuation

An electro-magnetic survey method for surveying an area previously identified as potentially containing a subsea hydrocarbon reservoir, comprising obtaining first and second survey data sets with an electromagnetic source aligned end-on and broadside relative to the same or different receivers. The invention also relates to planning a survey using this method, and to analysis of survey data taken in combination allow the galvanic contribution to the signals collected at the receiver to be contrasted with the inductive effects, and the effects of signal attenuation, which are highly dependent on local properties of the rock formation, overlying water and air at the survey area. This is very important to the success of using electromagnetic surveying for identifying hydrocarbon reserves and distinguishing them from other classes of structure.

Owner:STATOIL ASA PETRO SA (NO)

Devices and methods for automatically verifying, calibrating and surveying instruments for computer-assisted surgery

ActiveUS20060264742A1Improve reliabilityShorten the timeSurgical navigation systemsCharacter and pattern recognitionComputer-assisted surgeryMeasuring instrument

A device and method for automatically verifying, calibrating and surveying a navigable surgical instrument, wherein by means of a scanning device, the geometry of the instrument, in particular the shape of the functional elements (e.g., tips) and their spatial position with respect to an attachable reference system, are detected. By means of a data processing unit, a three-dimensional model of the instrument is calculated from the detected information concerning the geometry of the instrument including the reference system, wherein verification, calibration or surveying is performed with the aid of the ascertained information concerning the geometry of the instrument.

Owner:BRAINLAB

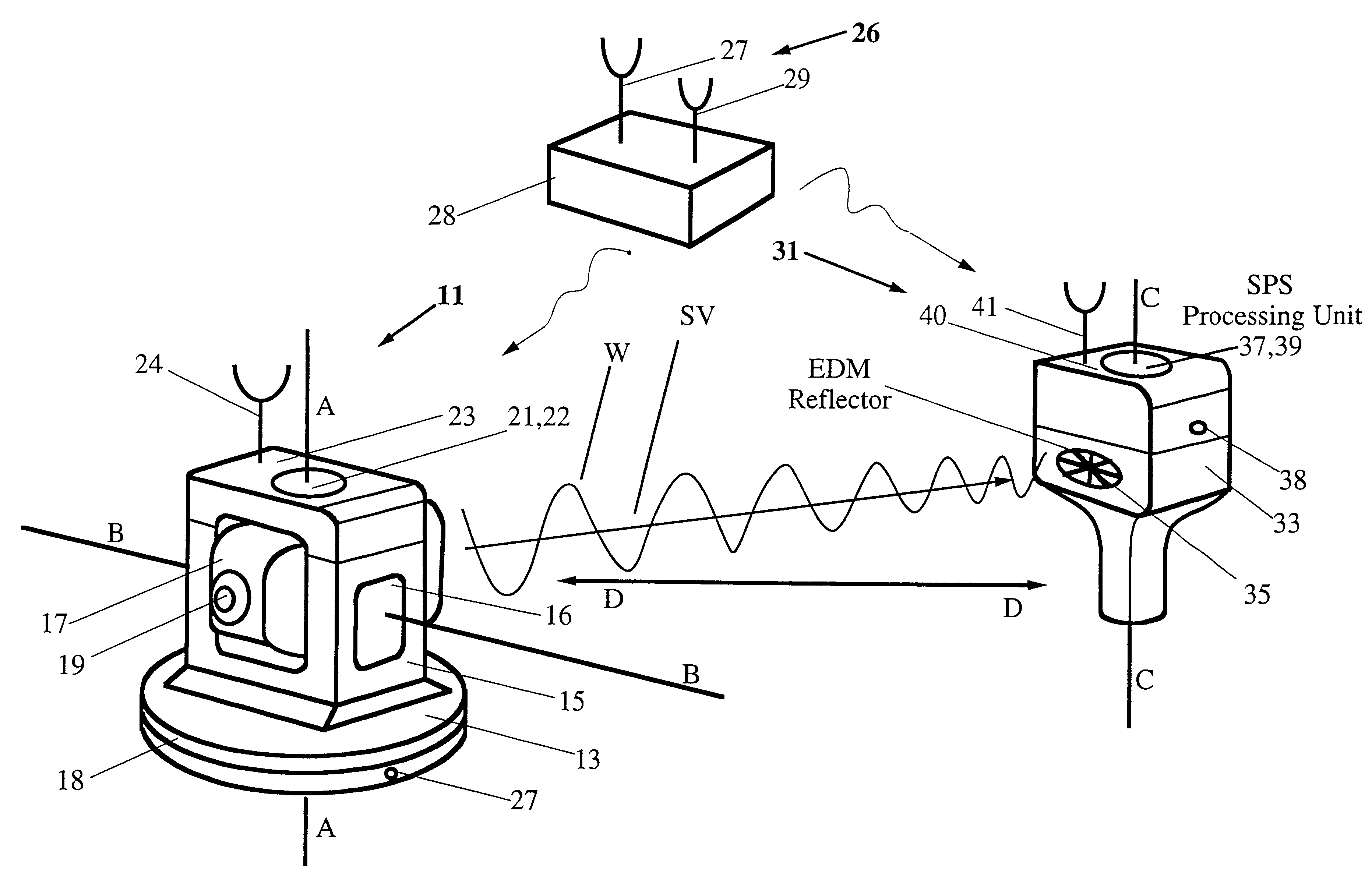

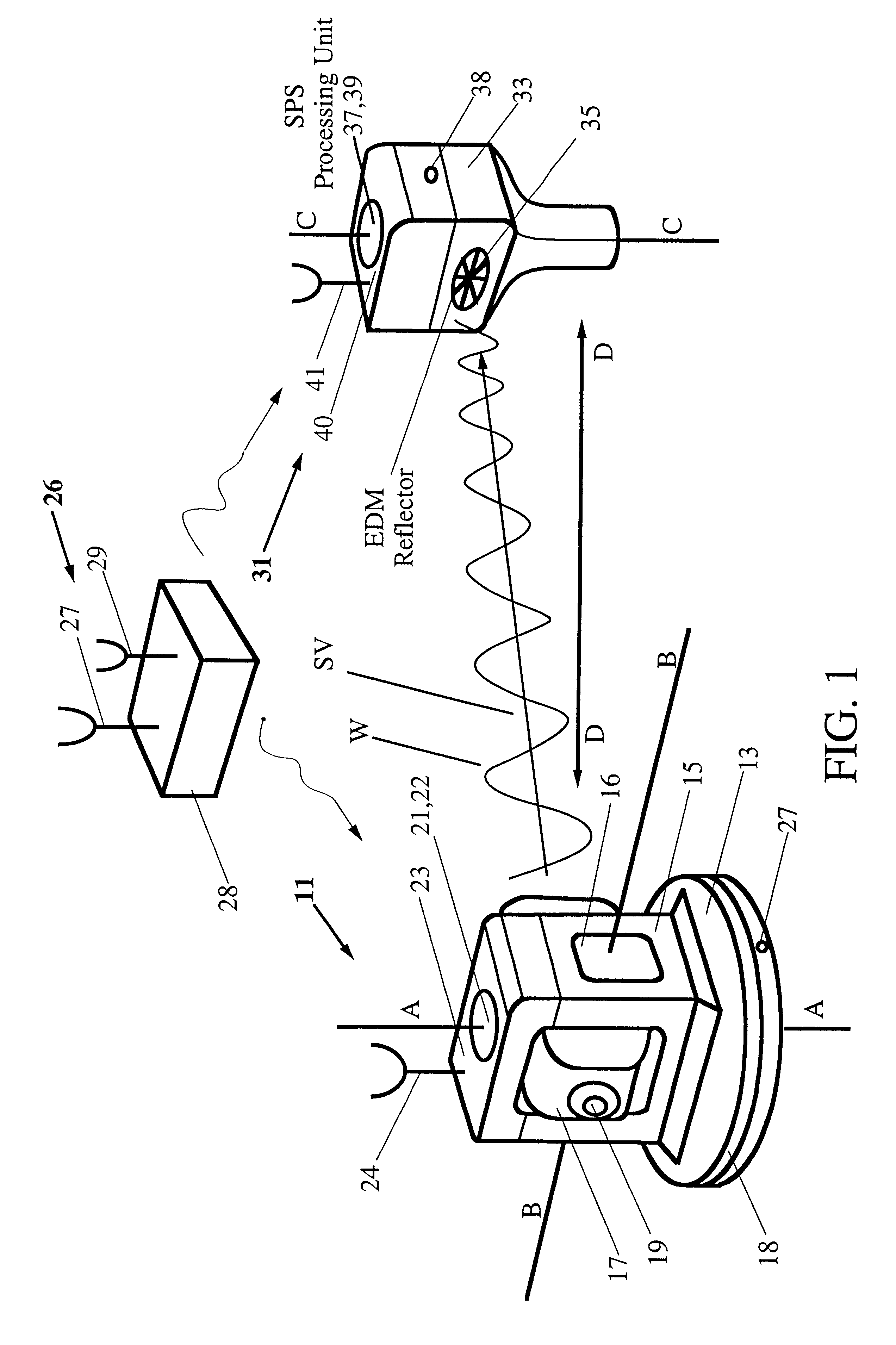

Integrated SATPS total survey station

Apparatus for measuring surveying parameters, such as distances and angular displacements between an instrument survey station and a mobile survey station, with improved accuracy. The invention combines a differential satellite positioning system (DSATPS), available with positioning systems such as GPS and GLONASS, with electromagnetic measurements of distances and optically encoded angles by a conventional electro-optical survey instrument to provide survey measurements that can be accurate to within a few millimeters in favorable situations. The DSATPS relies upon pseudorange measurements or upon carrier phase measurements, after removal of certain phase integer ambiguities associated with carrier phase SATPS signals. The SATPS may be retrofitted within the housing of the conventional electro-optical instrument. In a first approach, a remote station provides DSATPS corrections for the mobile station and / or for the instrument station. In a second approach, the mobile station provides DSATPS corrections for itself and for the instrument station. In a third approach, the instrument station provides DSATPS corrections for itself and for the mobile station.

Owner:TRIMBLE NAVIGATION LTD

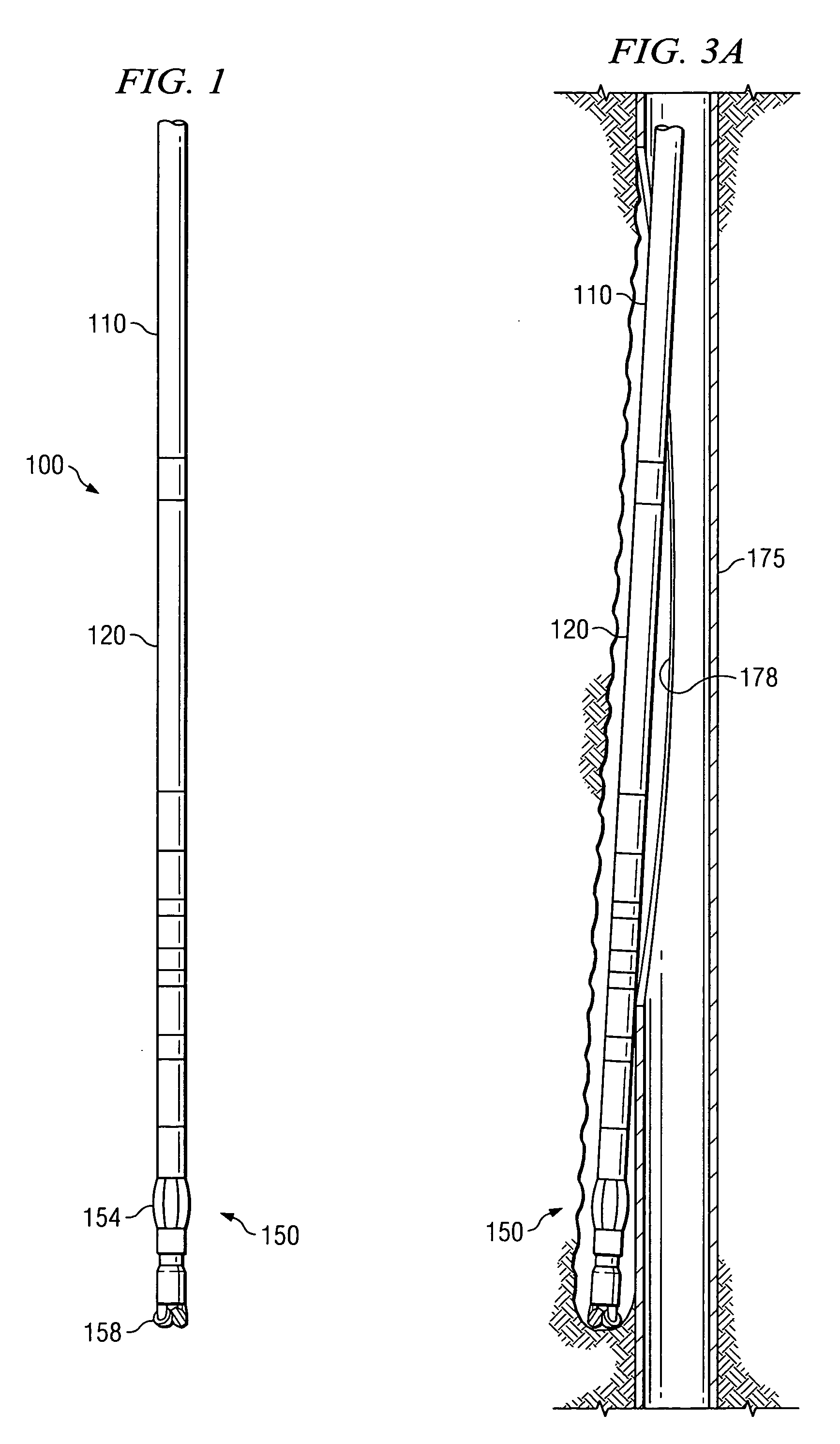

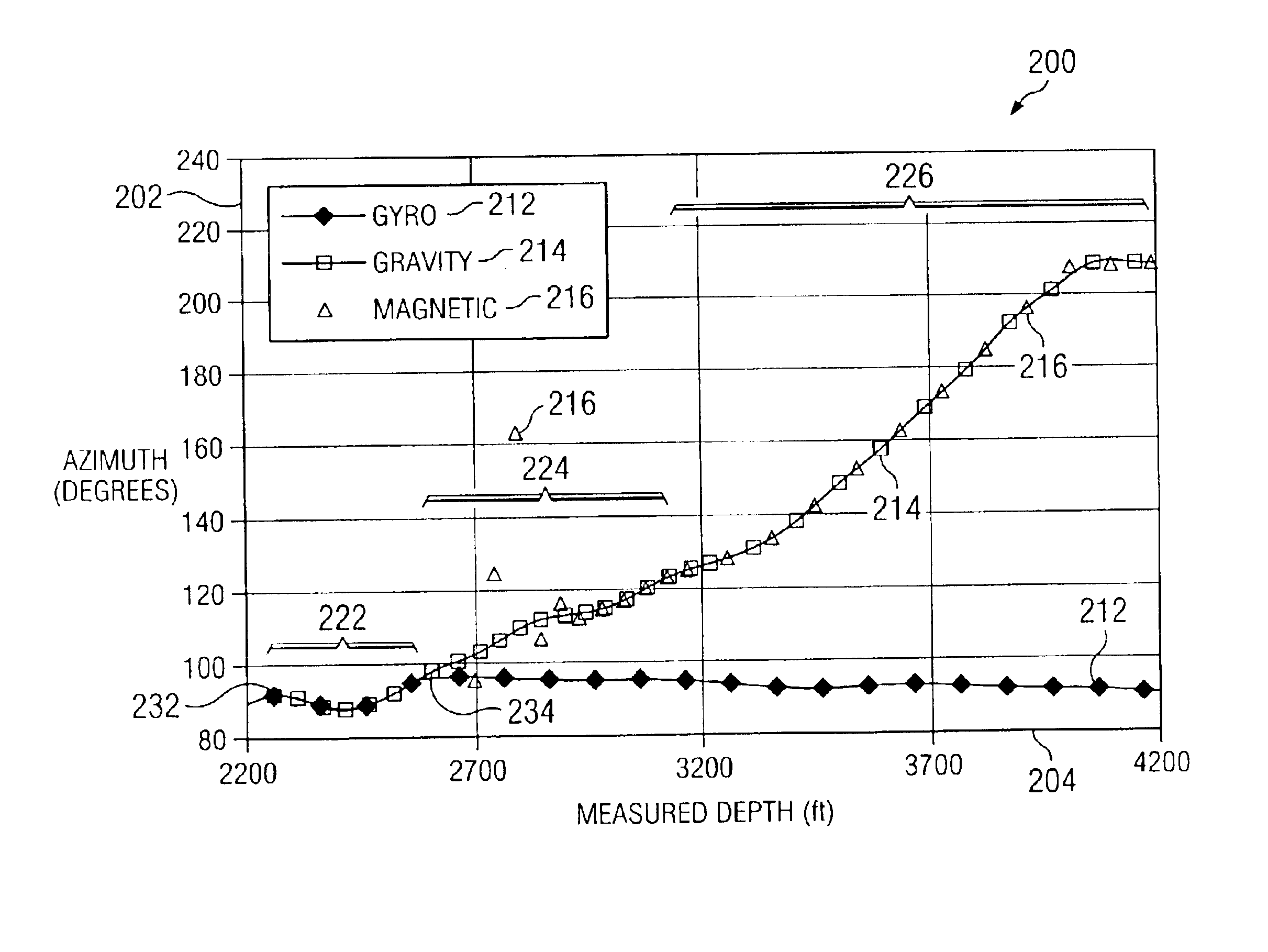

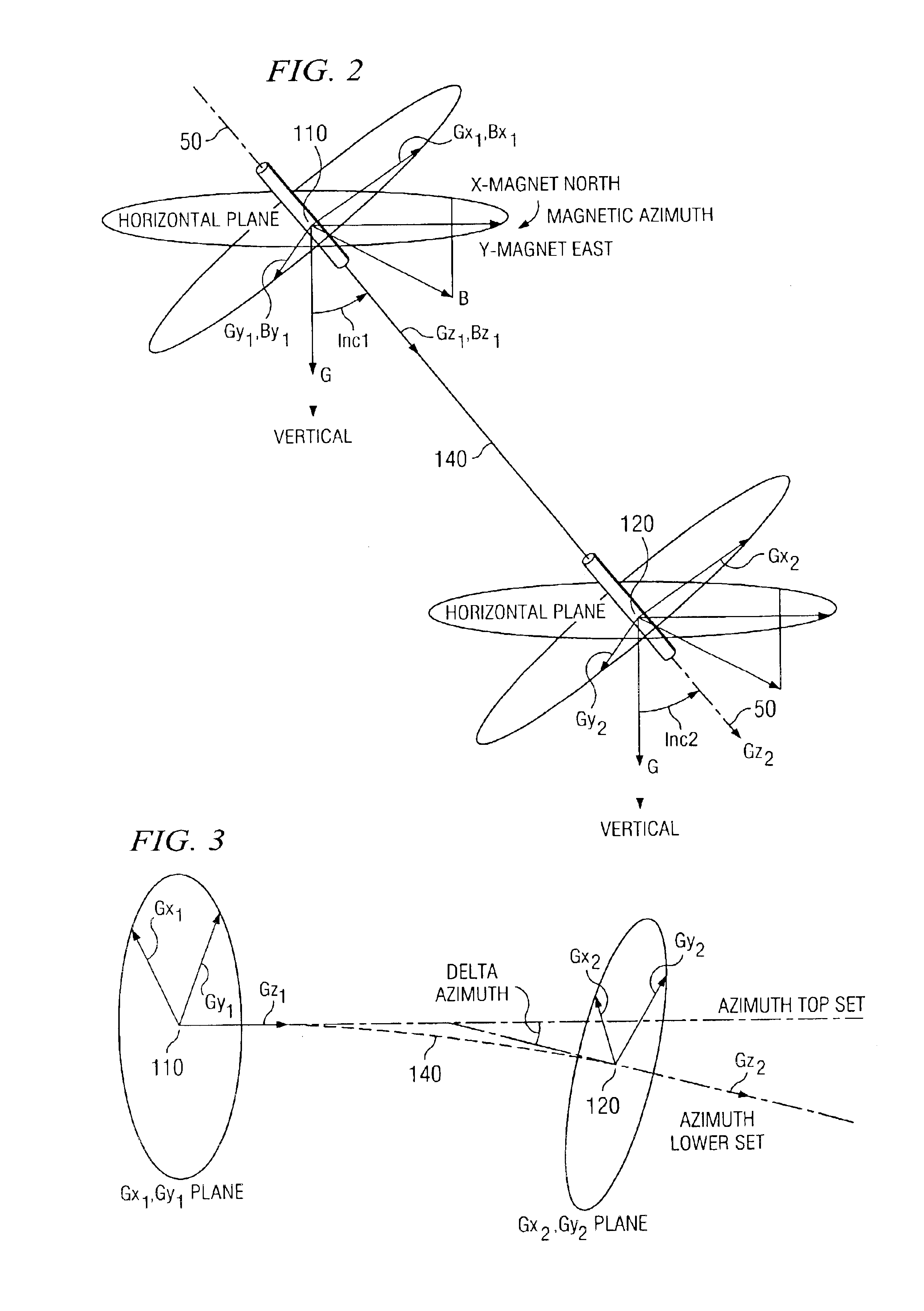

Downhole referencing techniques in borehole surveying

InactiveUS6882937B2Reduce riskMany timesElectric/magnetic detection for well-loggingSurveyMeasurement deviceComputerized system

A method for determining rotational offset between first and second gravity measurement devices deployed on a downhole tool is disclosed. The method includes positioning the tool in a previously surveyed section of a borehole that provides a historical survey including at least three previously surveyed azimuthal reference points and utilizing the gravity measurement devices to determine local azimuths at three or more sites in the previously surveyed section of the borehole. The method further includes comparing local azimuths with the historical survey and determining a rotational offset between the measurement devices that gives a best fit between local azimuths and the historical survey. A system adapted to execute the disclosed method and a computer system including computer-readable logic configured to instruct a processor to execute the disclosed method are also provided.

Owner:SCHLUMBERGER TECH CORP

Surveying method, surveying system and surveying data processing program

There are provided a step of acquiring a main point cloud data on a predetermined measurement range by a laser scanner, a step of detecting a range with no data acquired, a step of acquiring a supplementary image data of the range with no data acquired by an auxiliary image pickup device, a step of preparing a stereoscopic image based on the supplementary image data obtained by the auxiliary image pickup device, a step of acquiring supplementary point cloud data from the stereoscopic image, and a step of supplementing the range with no data acquired of the main point cloud data by matching of the main point cloud data and the supplementary point cloud data.

Owner:KK TOPCON

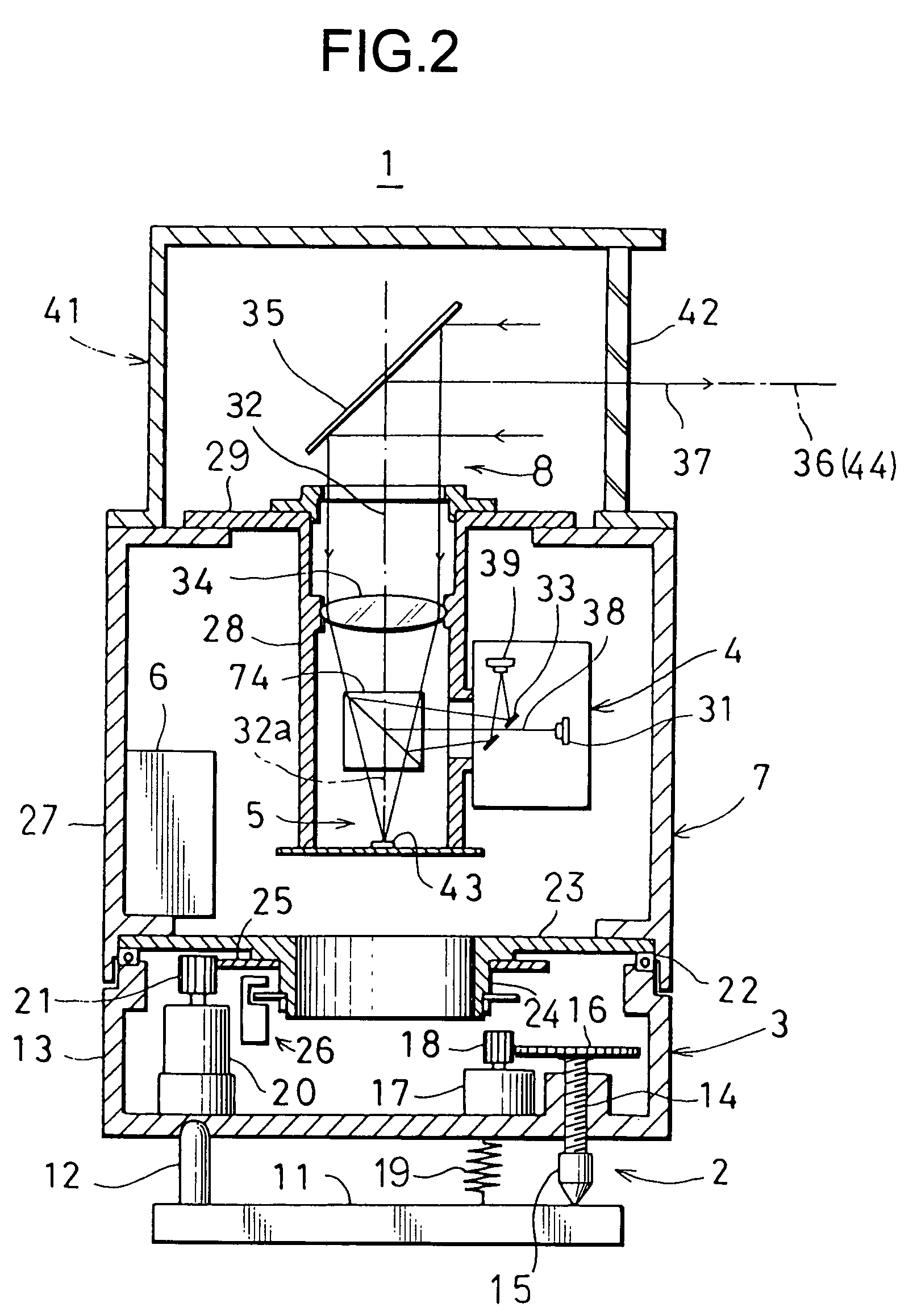

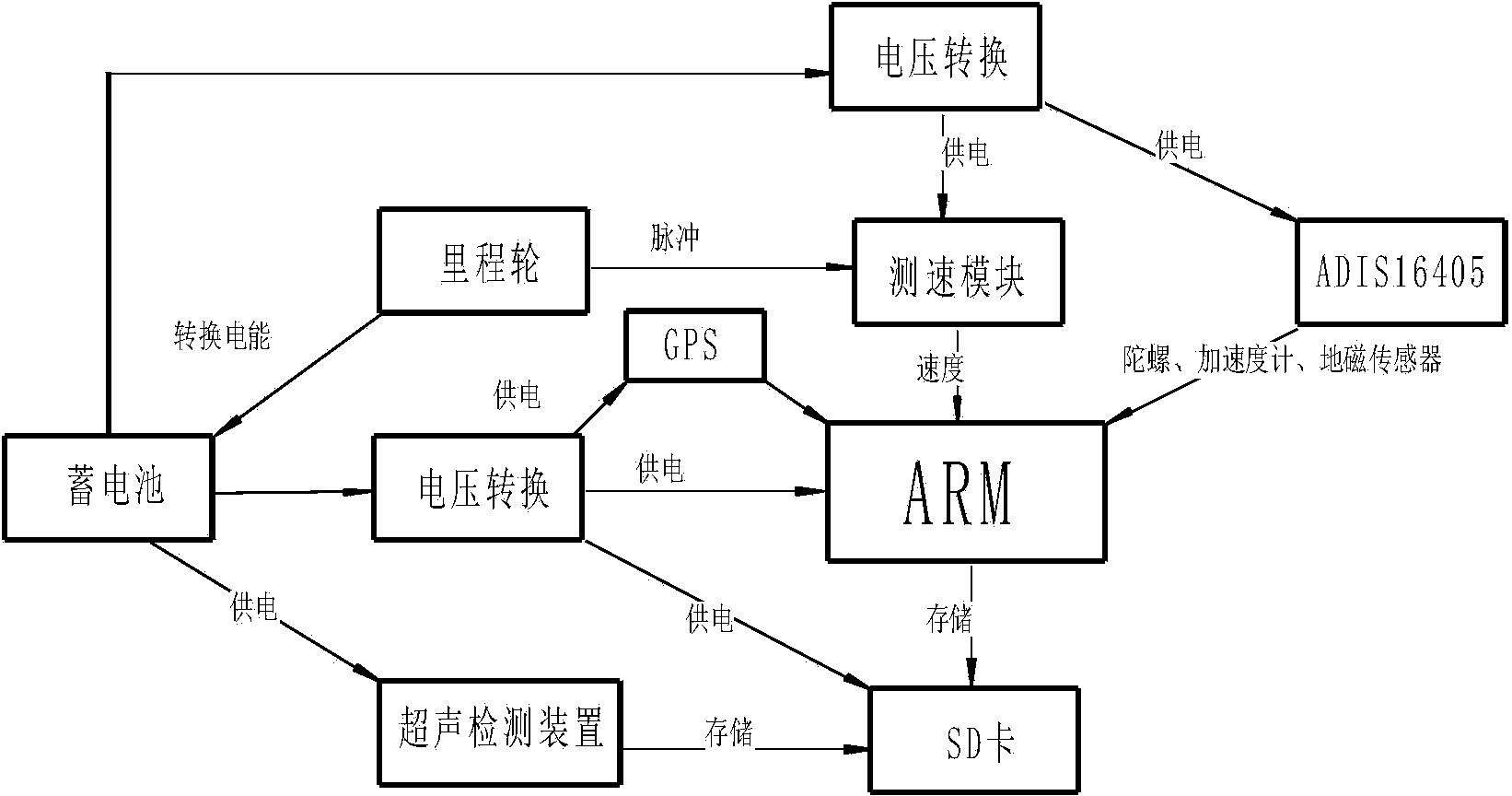

MEMS (Micro Electro Mechanical System) inertial measurement unit-based pipeline surveying and mapping and defect positioning device and pipeline surveying and mapping and defect positioning method thereof

The invention belongs to the technical field of pipeline surveying and mapping, and in particular relates to an MEMS (Micro Electro Mechanical System) inertial measurement unit-based pipeline surveying and mapping and defect positioning device and a pipeline surveying and mapping and defect positioning method thereof. The MEMS inertial measurement unit-based pipeline surveying and mapping and defect positioning device comprises a measurement unit, a correction unit, a defect detection unit, a power supply unit and a data processing and memory unit. Compared with the conventional inventions and papers and the like, the MEMS inertial measurement unit is lower in cost, and has a wider pipe diameter application range of being 60 mm at minimum besides the autonomy. The MEMS inertial measurement unit is combined with an odometer, a flux-gate magnetometer and an ultrasonic detection device. The pipeline surveying and mapping problem without laying a fixed-point magnetic scale is solved, meanwhile, the information on a defect position is detected and marked, and convenience is provided for the maintenance and strengthening of pipeline defects. An odometer wheel is also connected with a power generation device, so that the problems caused by external power supply are solved.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com