MEMS (Micro Electro Mechanical System) inertial measurement unit-based pipeline surveying and mapping and defect positioning device and pipeline surveying and mapping and defect positioning method thereof

A technology of inertial measurement unit and measurement unit, which is applied in the field of pipeline surveying and mapping, and can solve the problems of pipeline surveying and mapping defect positioning, no fixed-point magnetic mark, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in more detail below in conjunction with the drawings:

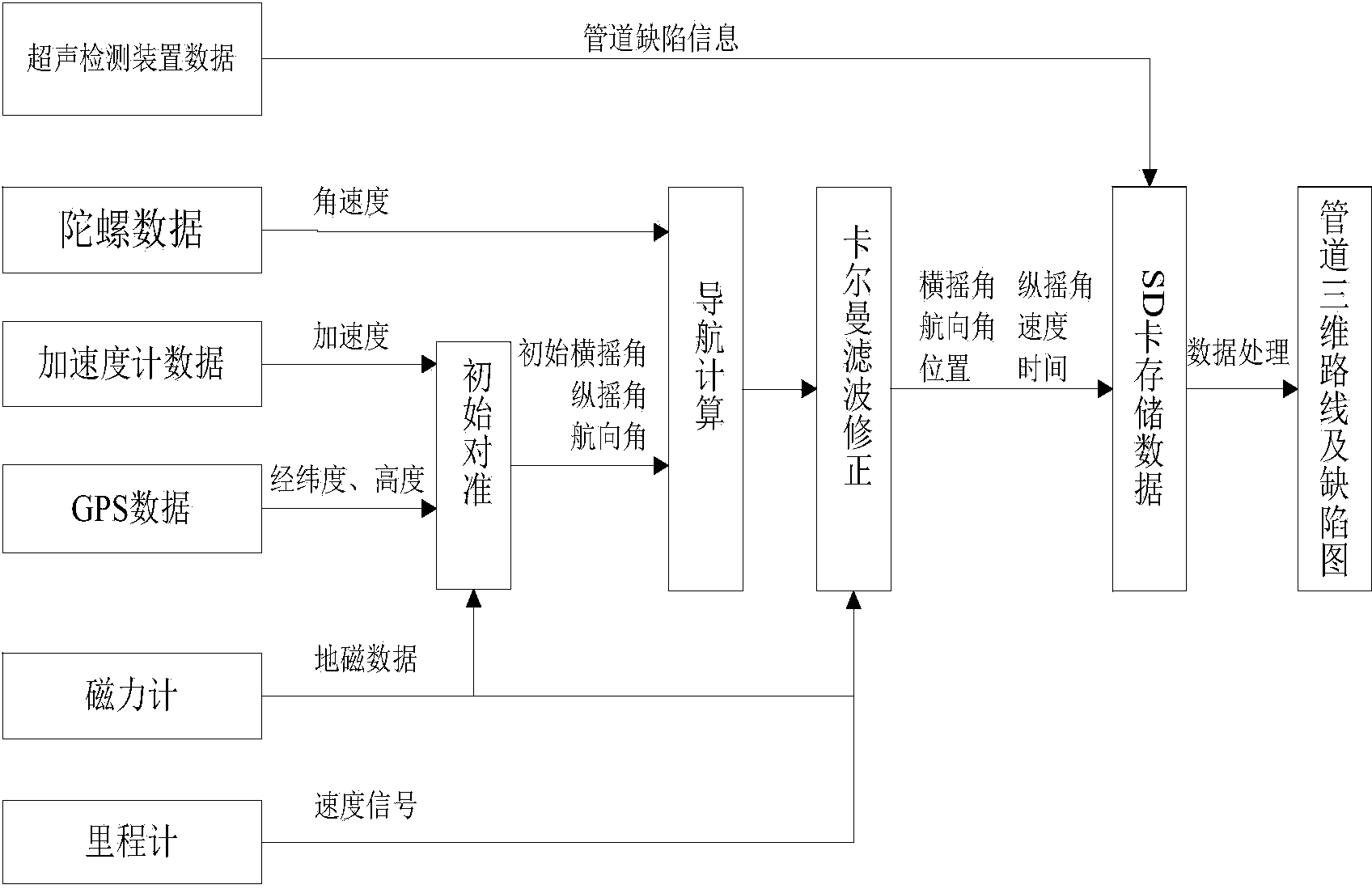

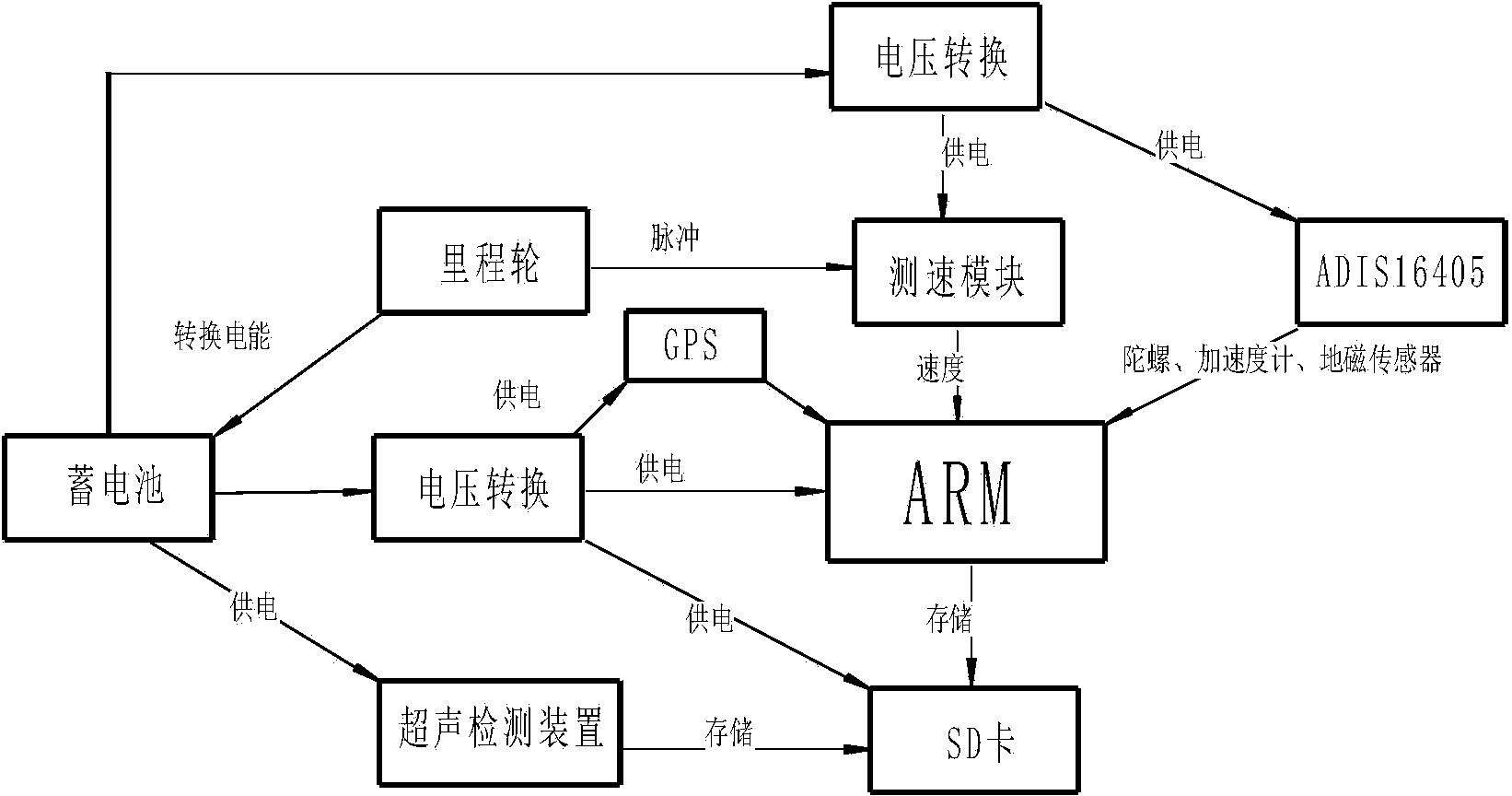

[0054] The invention is a technique for surveying and mapping and defect location in pipelines, specifically based on a multifunctional self-powered underground detection device composed of MEMS inertial measurement unit, odometer, magnetometer, ultrasonic detection device, etc. This invention has the advantages of autonomous measurement, wide range of pipe diameters, unlimited pipe depth, and high accuracy. In today’s pipeline inspections mostly rely on fixed-point magnetic marks, it is especially suitable for early laying of unset Point the magnetically marked pipelines with long years.

[0055] The invention detects the internal defects of the pipeline at the same time in combination with the ultrasonic detection device, stores the data in real time and can use the stored data after the operation is completed, and draws the three-dimensional direction coordinate map of the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com