Fabrication method of mask, mask and evaporation system

A mask and mask pattern technology is applied in the field of mask, evaporation system, and mask preparation to achieve the effect of improving welding success rate, improving flatness and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for preparing a mask, which can effectively alleviate the flatness of the frame and the mask pattern in the welding area during the process of preparing the mask, and improve the quality of the mask.

[0036] A method for preparing a mask. The mask includes a mask including a frame with an opening in the middle region and a mask pattern arranged above the frame. The preparation method includes the steps of:

[0037] During the forming process of the frame, a first resistance force is applied to the frame;

[0038] Welding the mask pattern to the frame at least partially in the area covering its internal opening, applying a second resisting force to the frame during the welding process;

[0039] Wherein: the first resistance force and the second resistance force have the same direction and are equal in magnitude.

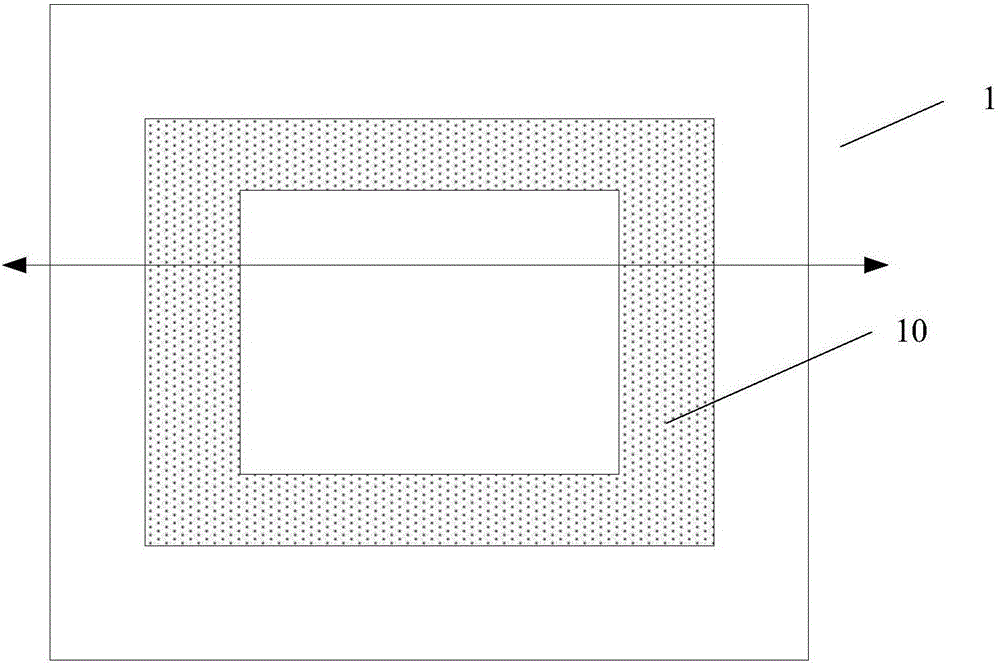

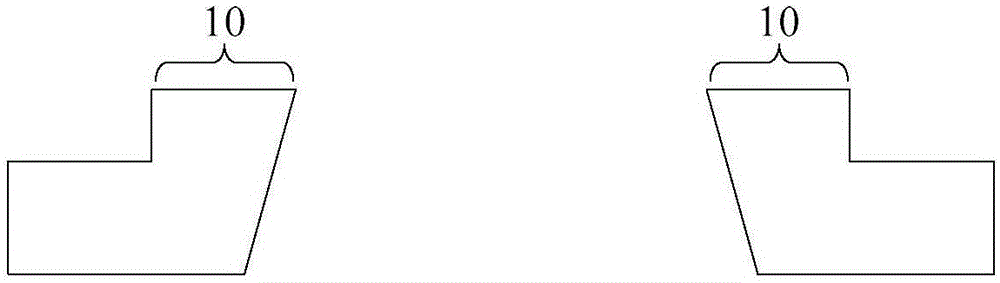

[0040] Among them, the structure of frame 1 is as follows Figure 1A and Figure 1B As shown, the cross section of the fra...

Embodiment 2

[0064] This embodiment provides a method for preparing a mask, which can effectively alleviate the flatness of the frame and the mask pattern in the welding area during the process of preparing the mask, and improve the quality of the mask.

[0065] The difference between the preparation method of the mask plate of this embodiment and the embodiment 1 is that the mask pattern 2 welded above the welding area 10 of the frame 1 is different, and in the molding process of the frame 1 (also taking the grinding process as an example) The amount, magnitude and direction of the resisting force exerted by frame 1 are different.

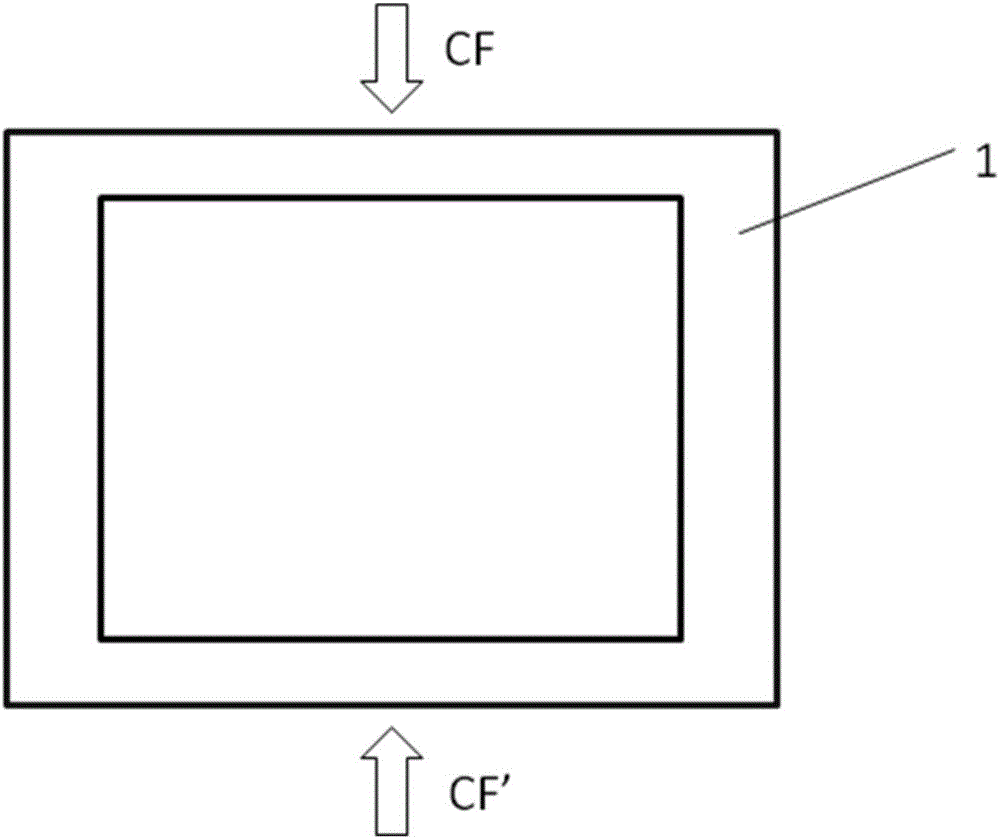

[0066] For pure frame 1, Figure 7A A schematic diagram showing the resistance force exerted on the frame 1 during the polishing process in the preparation method of the mask plate: when the surface flatness of the frame 1 is polished, the frame 1 is improved from the non-resistance force of the prior art to the first When the welding mask pattern 2 is applie...

Embodiment 3

[0075] This embodiment provides an evaporation system, which includes the mask plate prepared in Embodiment 1 or Embodiment 2, and the evaporation system can obtain a higher pattern precision for mask preparation.

[0076] In this evaporation system, the evaporation source comes from the bottom, and the mask pattern is fixed on the frame and applied to the evaporation system. The mask plate blocks or allows the evaporation material molecules below, so that the substrate above it Prepare to form a predetermined pattern.

[0077] Due to the high flatness of the mask plate used, the pattern precision of the substrate prepared and formed by the evaporation system is high, showing a high yield rate of finished products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com