Semiconductor laser welding method

A laser welding and semiconductor technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inability to weld, the welding effect cannot meet the ideal requirements, and the bending of tin wires, so as to improve the welding quality and improve the solder joints. Adhesion and welding success rate, the effect of reducing welding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

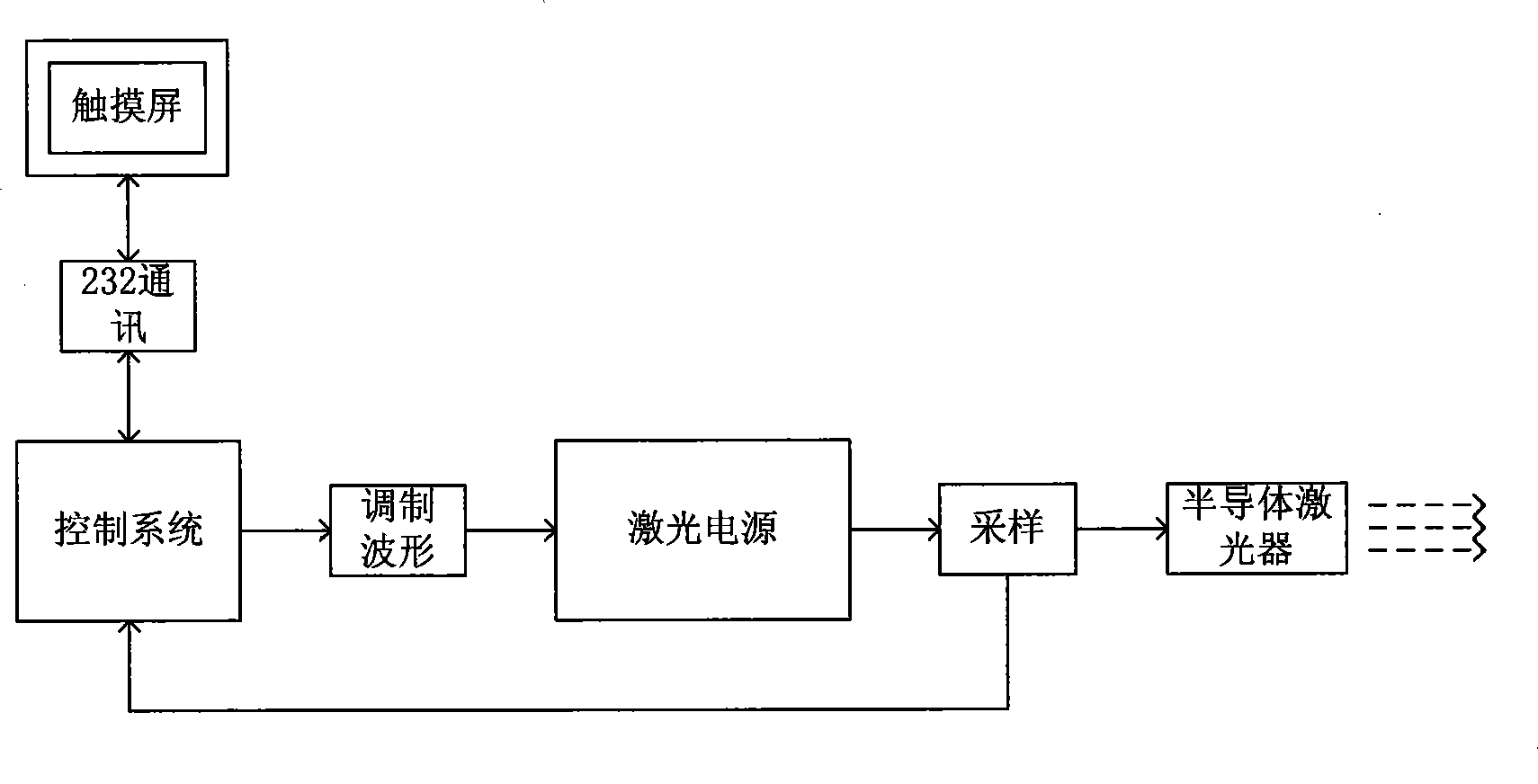

[0026] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0027] The core idea of the method for improving the welding process of a semiconductor laser machine in the embodiment of the present invention is: based on the material characteristics of the sample itself, the melting point curve and the welding point curve of the material to be welded are established, and the maximum welding point adhesion is the goal. The welding process has been improved.

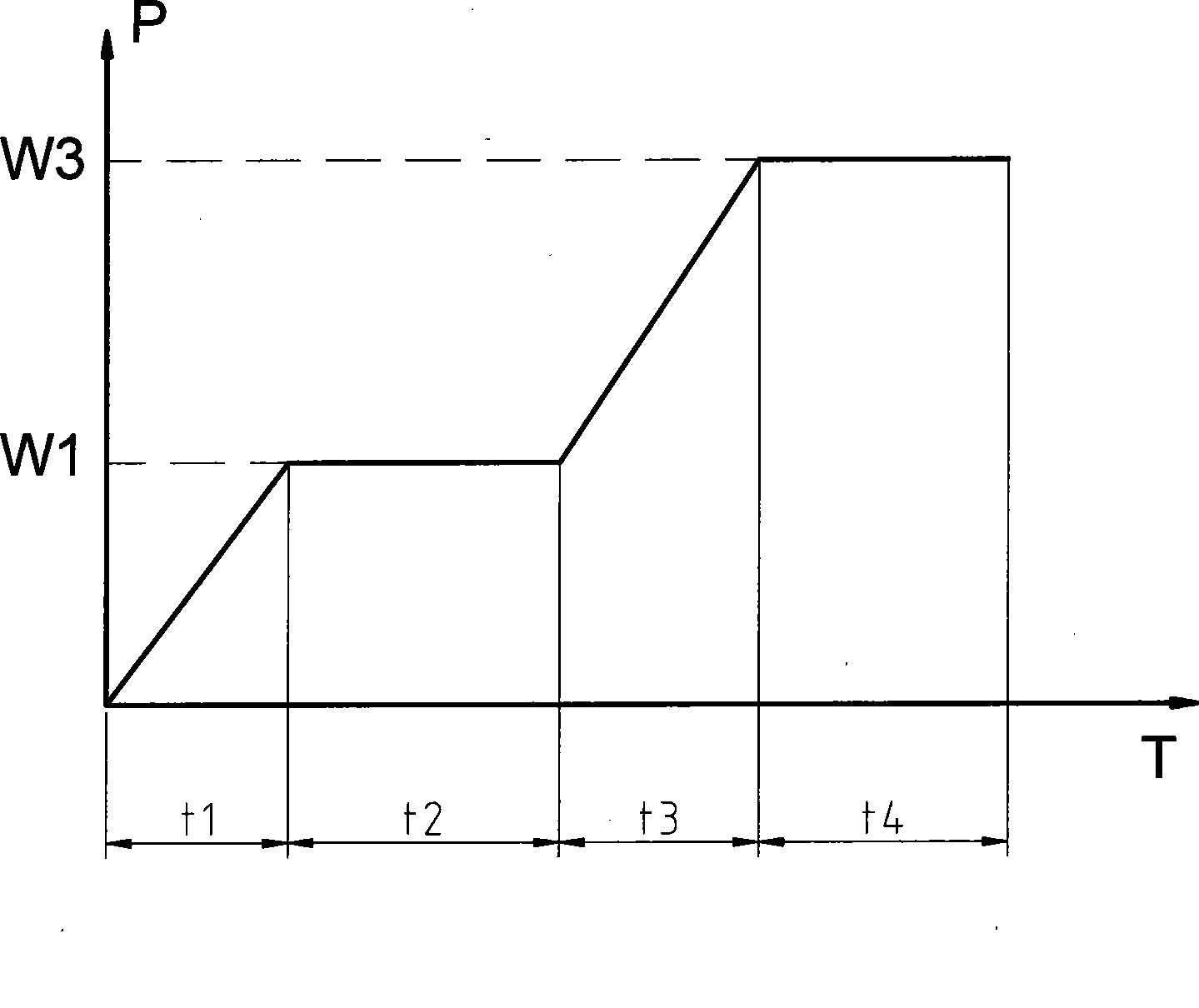

[0028] Such as figure 1 As shown, the welding process of the embodiment of the present invention is formulated according to the following steps:

[0029] Step A. Establish melting point characteris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com