Double-side double-arc welding process for root layer of pipeline

A double-sided, double-arc, pipeline technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of welding quality welding defects, incomplete penetration, undercut, etc., to ensure welding quality, reduce welding costs, The effect of reducing welding distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: A double-sided double-arc welding process for the root layer of a pipeline, comprising the following steps:

[0031] (1) Preparation before welding

[0032] a) Make a V-shaped groove at the corresponding part of the weld seam of the pipeline 1 to be welded, and clean the oil, paint, scale, rust, burr and galvanized layer on the groove and its inner and outer surfaces within a range of not less than 20mm clean;

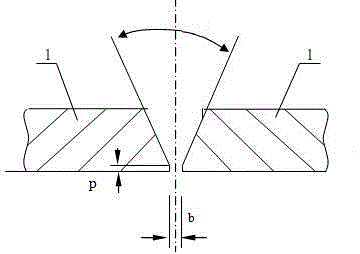

[0033] b) Assemble the pipe 1 with a V-shaped butt joint groove, and the welding position is all positions, such as figure 2 As shown, the groove angle of the V-shaped groove formed at the weld of the pipeline is 55-70°, the gap b is 2-3 mm, and the blunt edge p is 0.5-1 mm;

[0034] c) Tungsten argon arc welding is used for spot welding, the length of the spot welding is 30cm, the number of spot welding is 8 points and the current of the welding machine is 105A evenly distributed;

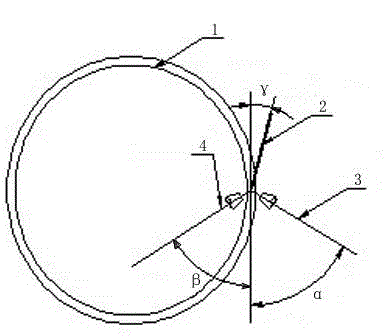

[0035] d) Set the main gun 3 on the outside of the pipe weld,...

Embodiment 2

[0048] Embodiment 2: A stainless steel pipe whose material is 00Cr19Ni10 and whose specification is φ1117×5 is welded at the root layer by double-sided double-arc welding, and the welding process is the same as that of Embodiment 1. Perform visual inspection, PT inspection, X-ray inspection on the weld, 100% qualified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com