Method and equipment for welding plastic tube network

A welding method and welding equipment technology are applied to the welding method of plastic pipe network and the field of special equipment thereof, which can solve the problem of low mechanical load capacity of plastic pipe network, weak connection at the welding point of thin pipe and collecting pipe, easy deformation of plastic pipe network, etc. problems, to achieve the effect of improving the success rate of welding, improving welding efficiency, and improving mechanical bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

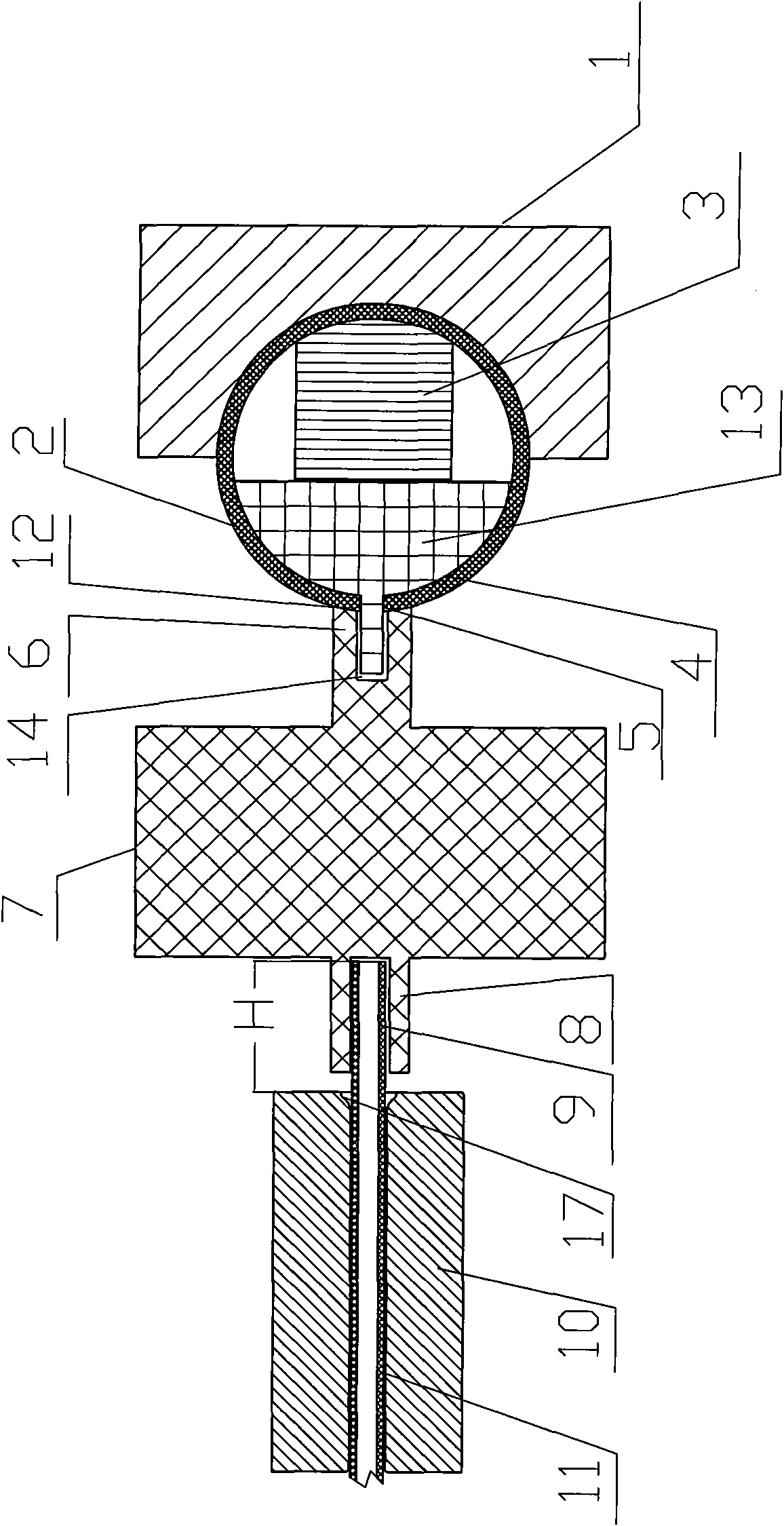

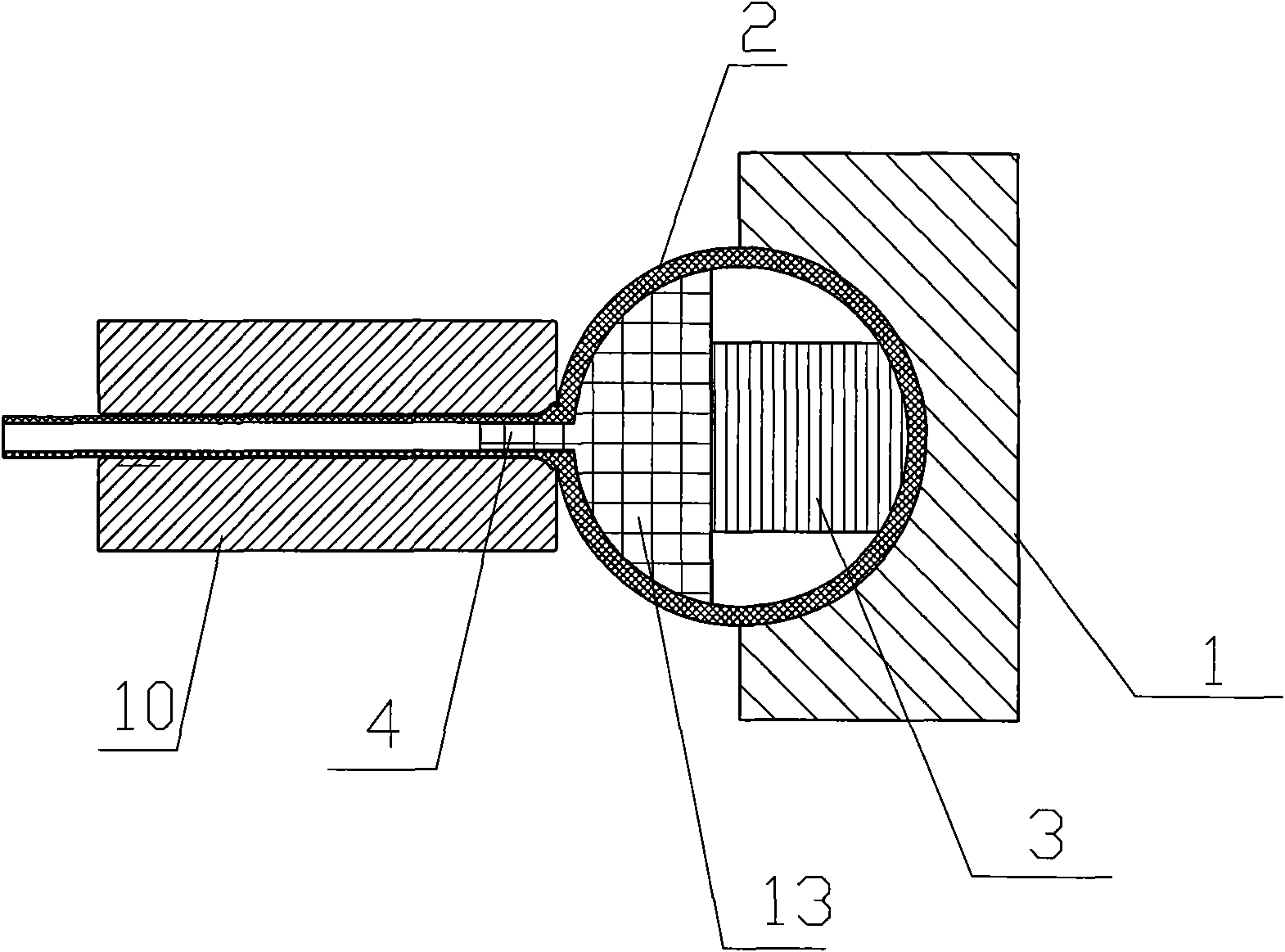

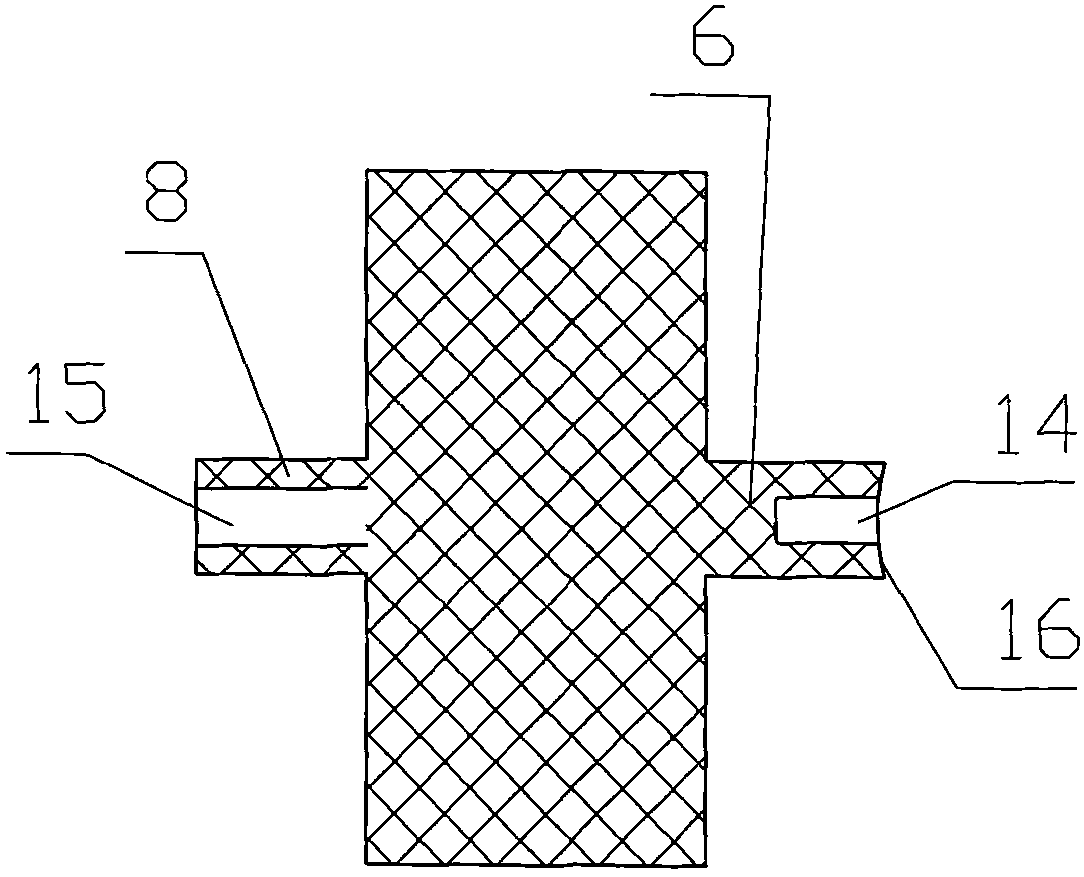

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0027] Such as figure 1 As shown in -5, when manufacturing the plastic pipe network, use special welding equipment to weld the collecting pipe 2 and the thin pipe 11. The welding equipment is at least composed of the following parts: hole forming positioning device, conveying device and heating device. The hole positioning device consists of two parts, one part is the hole-forming thimble liner 4, and the hole-forming thimble liner 4 is provided with needle-shaped protrusions 18 on the strip plate 13 that match the number, shape and position of the bifurcated holes 5. The other part is the positioning strip 3, the length of the positioning strip 3 and the hole-forming thimble strip 4 is equal to or slightly longer than the length of the manifold 2, and its shape is to extend into the bifurcation when the hole-forming thimble strip 4 After the hole 5, the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com