Patents

Literature

78results about How to "High mechanical load capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

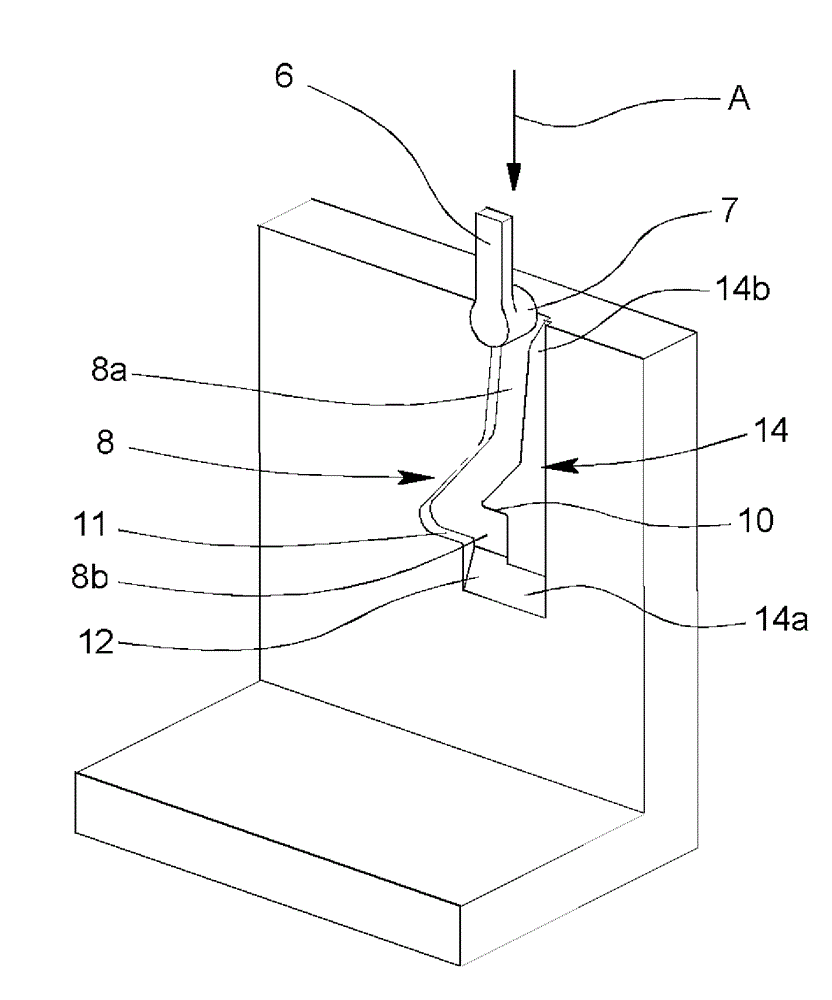

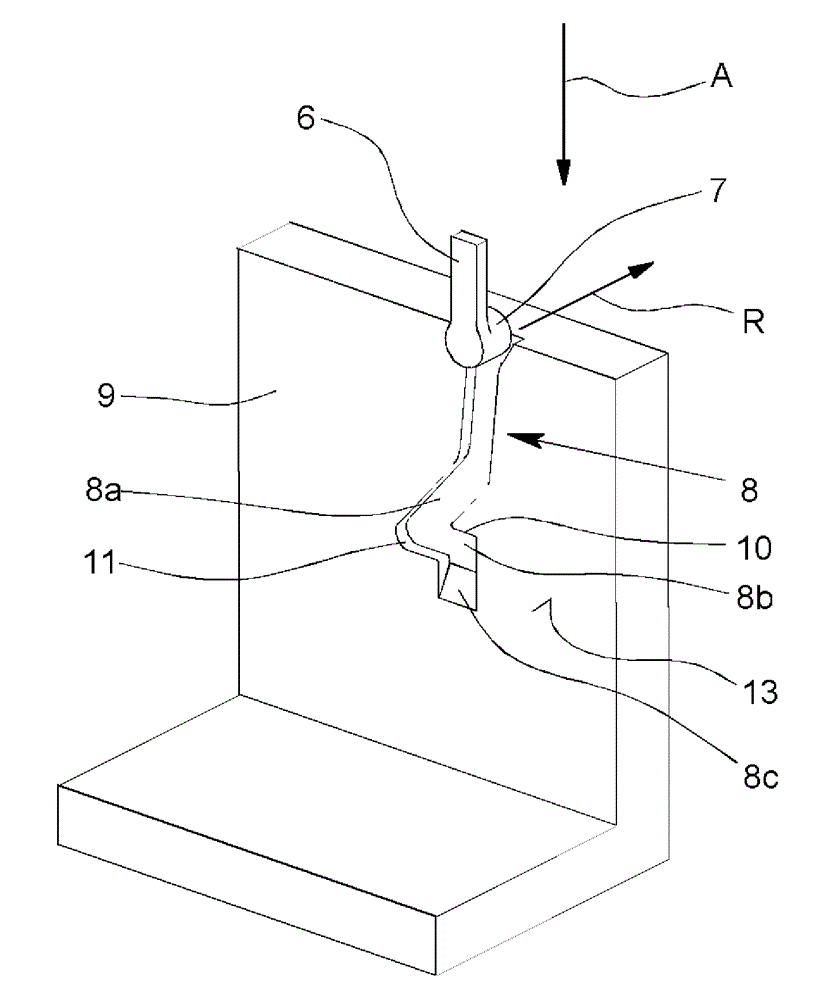

Integral joining

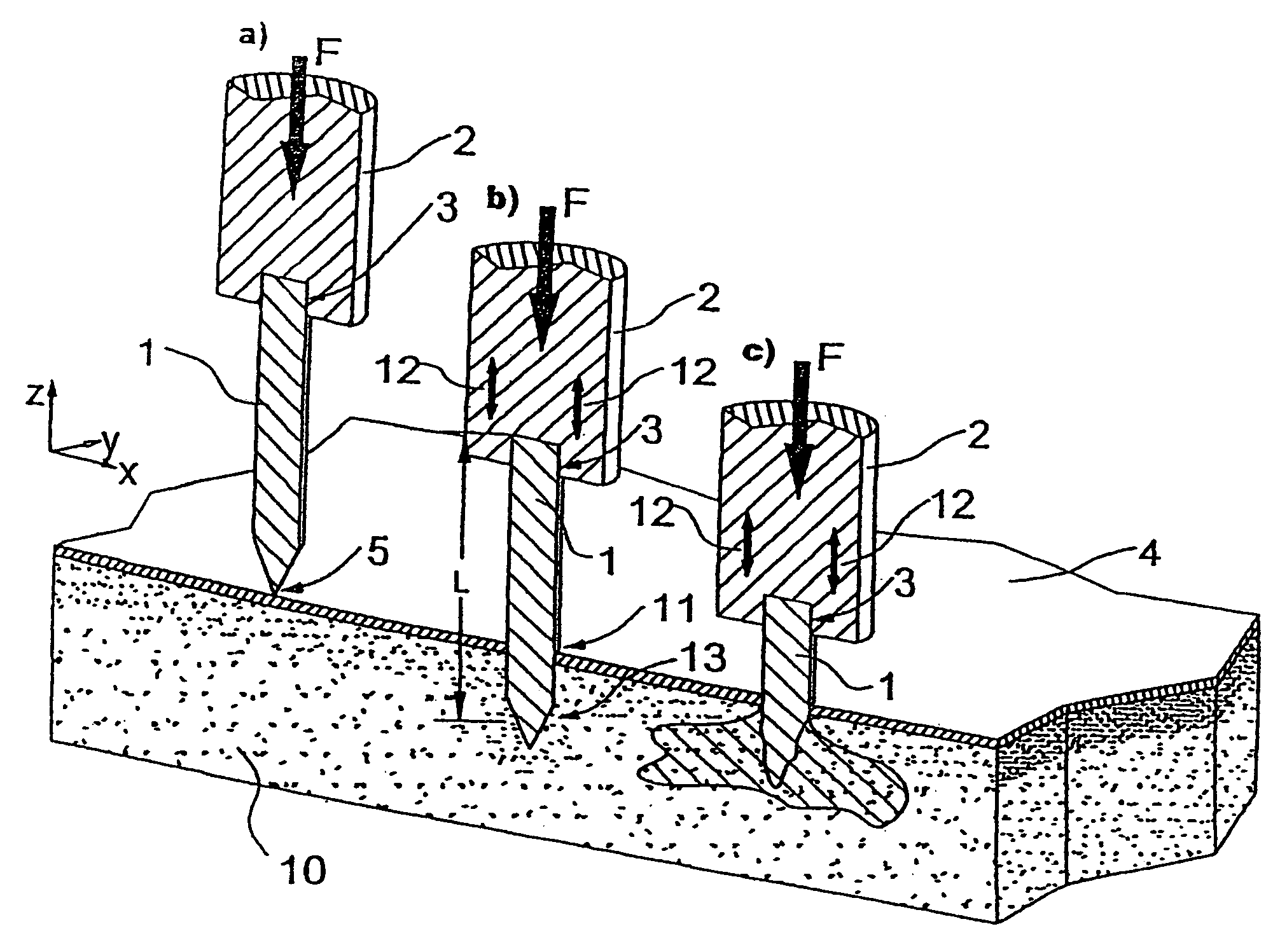

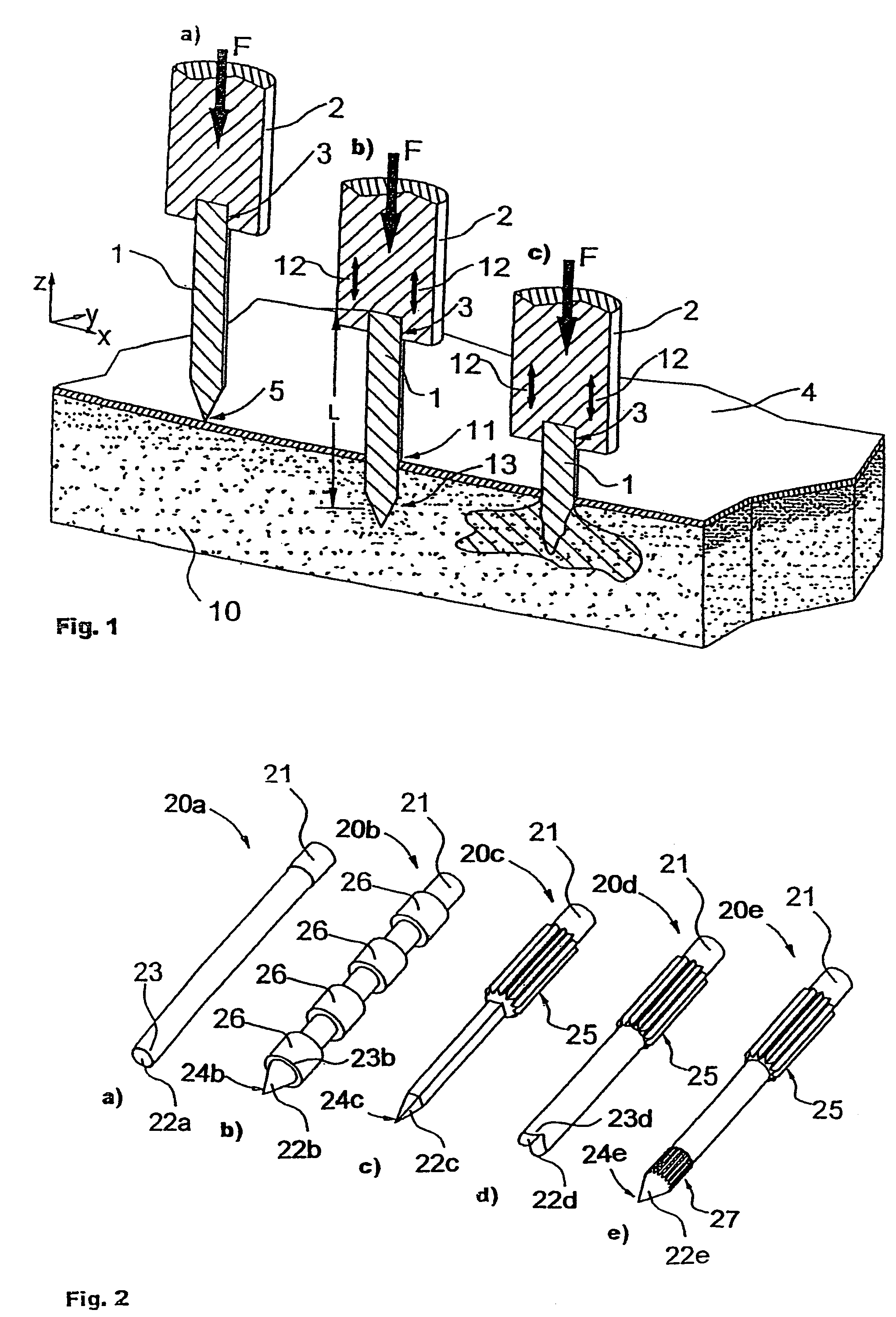

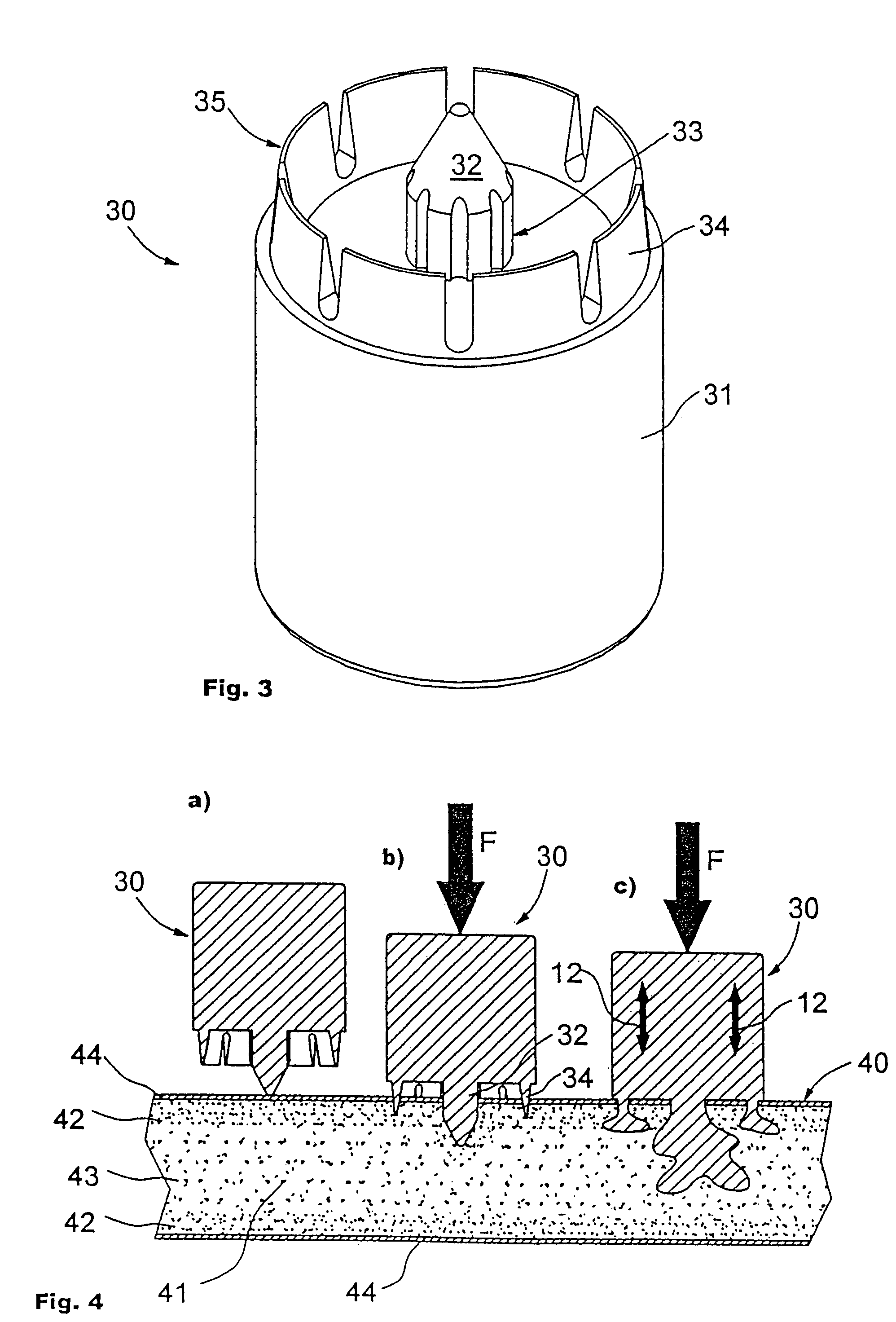

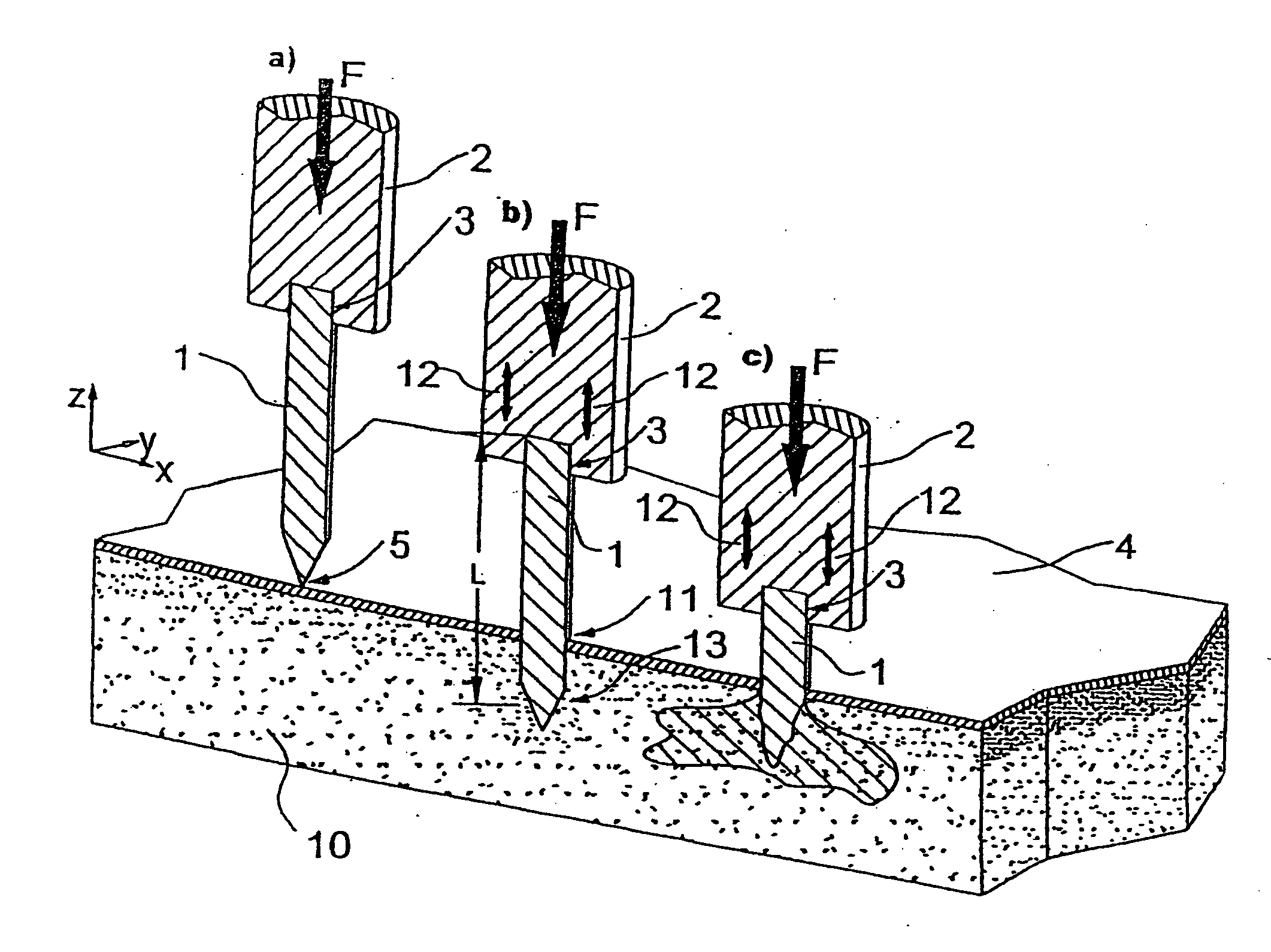

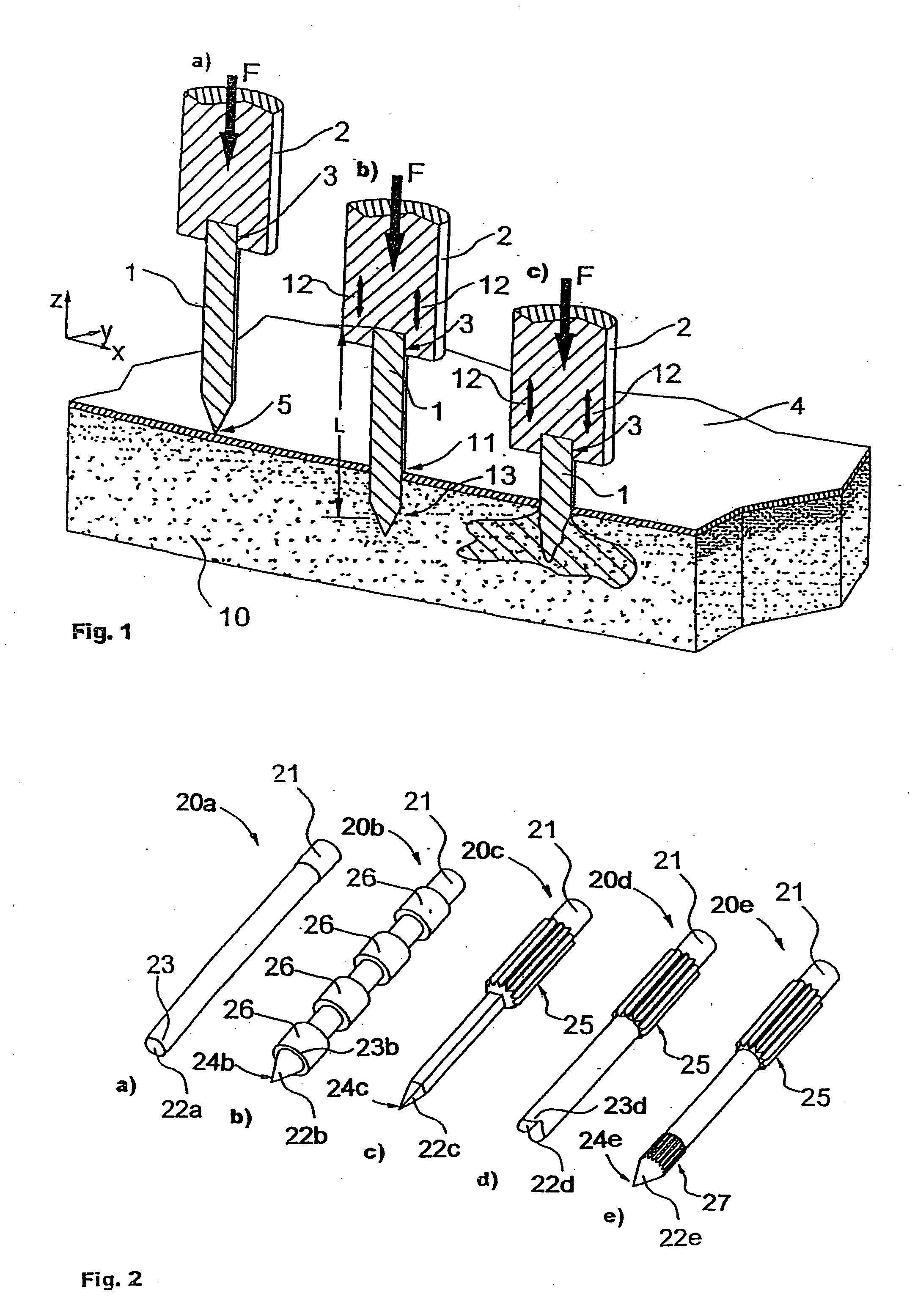

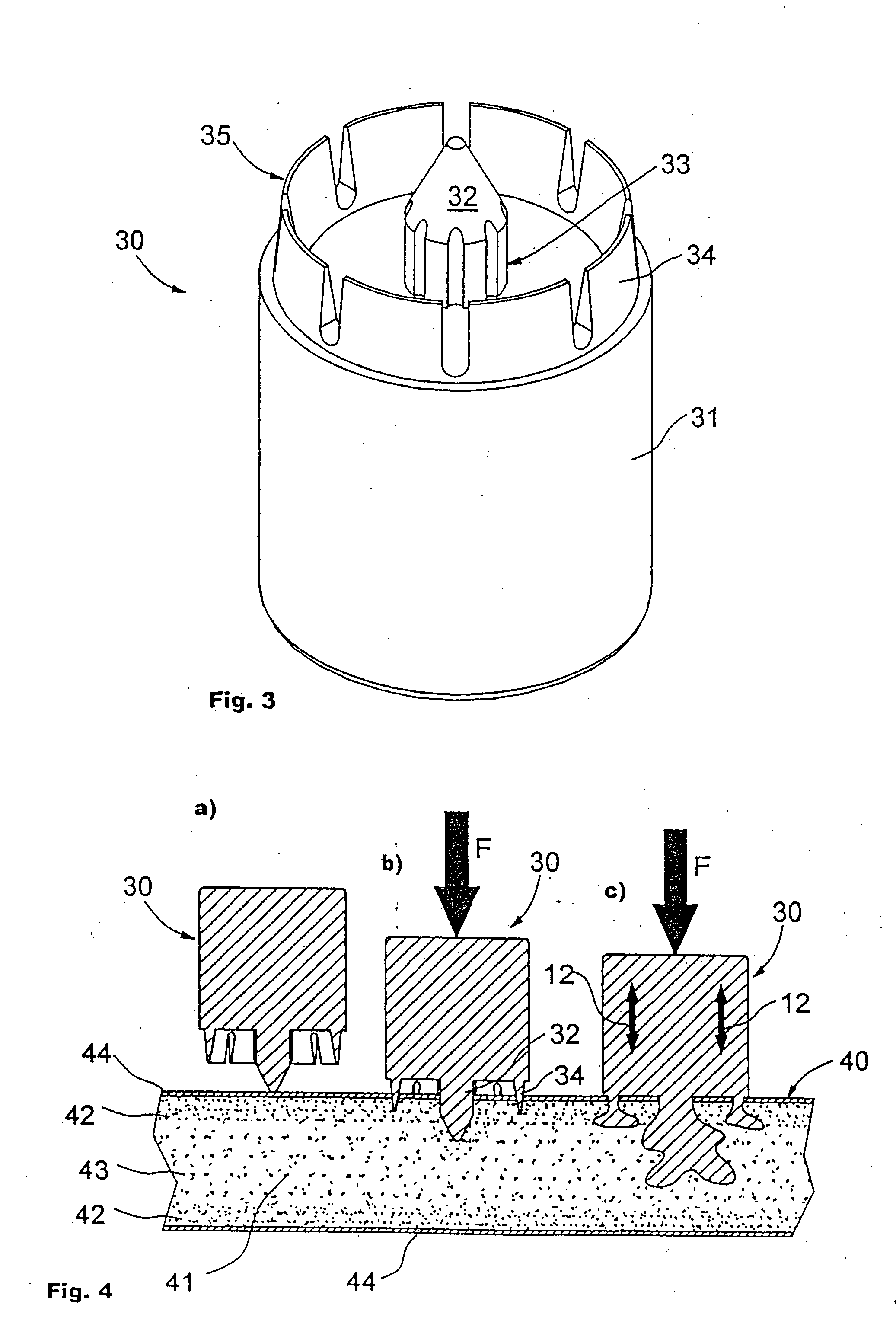

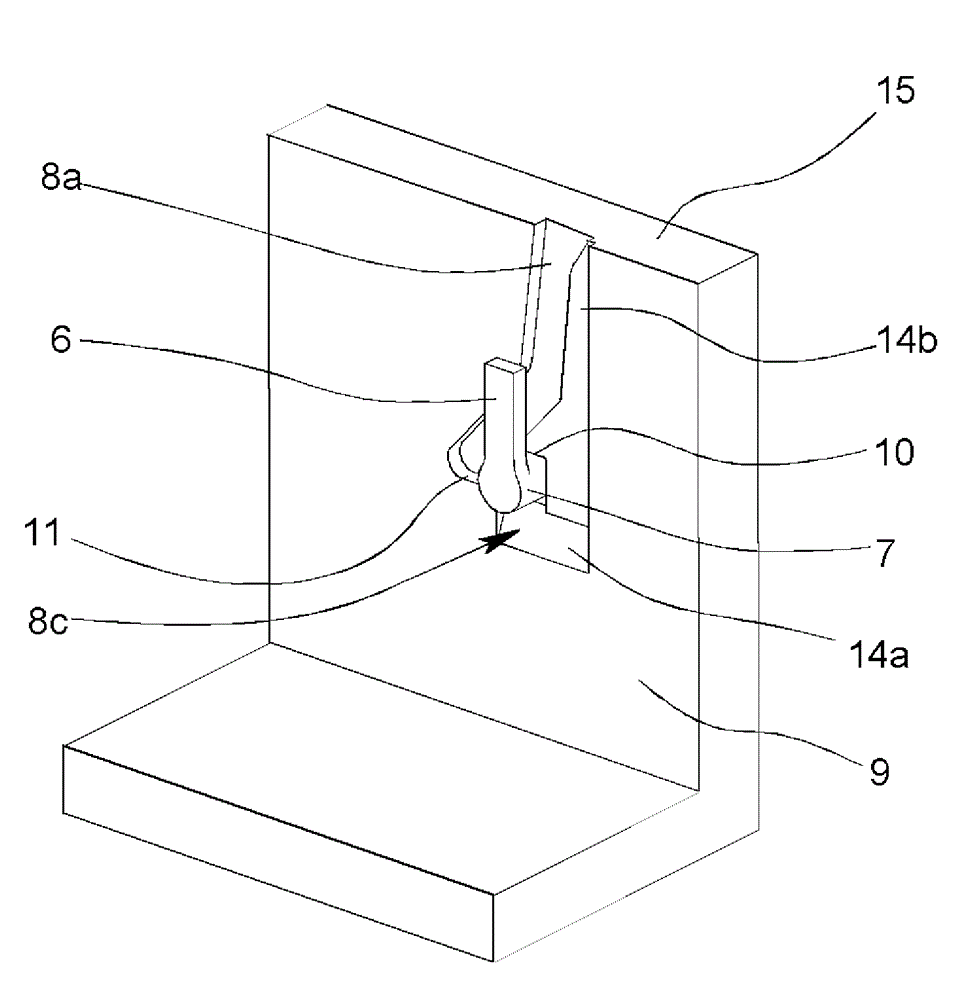

InactiveUS7160405B2Optimum introduction of loadHarmful stress concentrationLaminationLamination apparatusMaterials science

Owner:WOODWELDING

Integral joining

InactiveUS20050126680A1Optimum introduction of loadHarmful stress concentrationLaminationLamination apparatusMaterials science

Owner:WOODWELDING

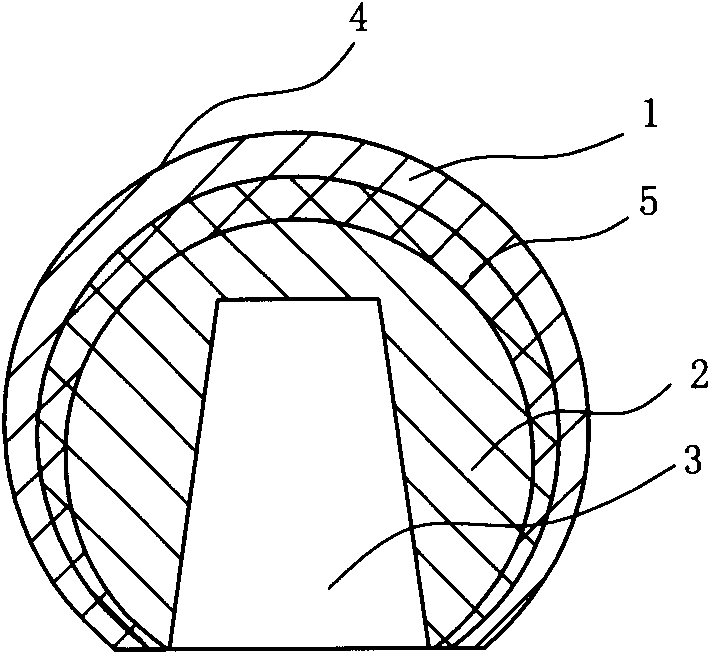

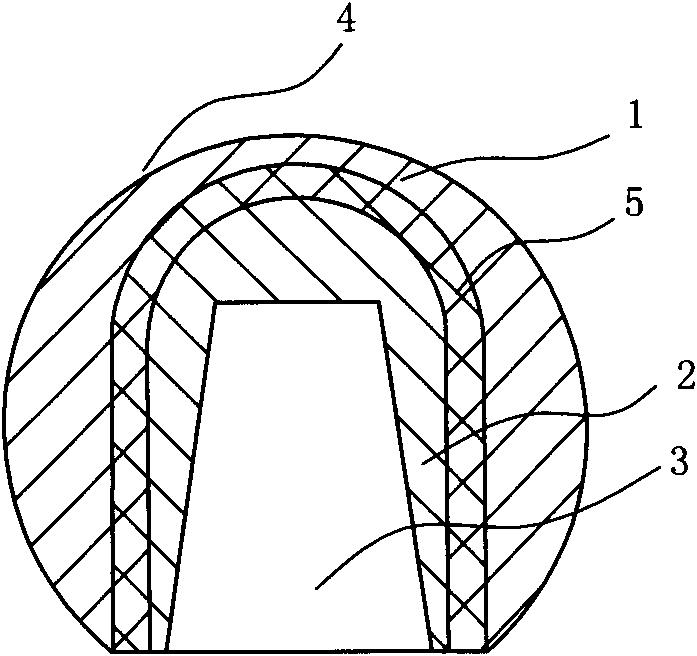

Manufacturing method of multilayer shell-core composite structural part

ActiveCN102009175AShell surface hardness is highHigh surface finishJoint implantsCeramic layered productsComposite constructionHigh surface

The invention discloses a manufacturing method of a multilayer shell-core composite structural part, which comprises the following steps of: (1) respectively preparing feed for injection forming of a core layer, a transition layer and a shell layer, wherein powder in the feed of the core layer and the powder in the feed of the shell layer are selected from one or a mixture of some of metal powder, ceramic powder, or toughened ceramic powder and are different from each other, and the powder in the feed of the transition layer is gradient composite powder; (2) respectively manufacturing blanks of the multilayer shell-core composite structural part layer by layer with a powder injection forming method; (3) degreasing the blanks; and (4) sintering the blanks to obtain the multilayer shell-core composite structural part. The multilayer shell-core composite structural part is manufactured with the powder injection forming method, and has the advantages of high surface hardness, abrasion resistance, uniform thickness of the shell layer, stable and persistent performance, strong binding force between the shell layer and the core layer due to the transition layer, good integral bending strength and good impact toughness and is difficult to crack.

Owner:SUZHOU DINGAN ELECTRONICS TECH

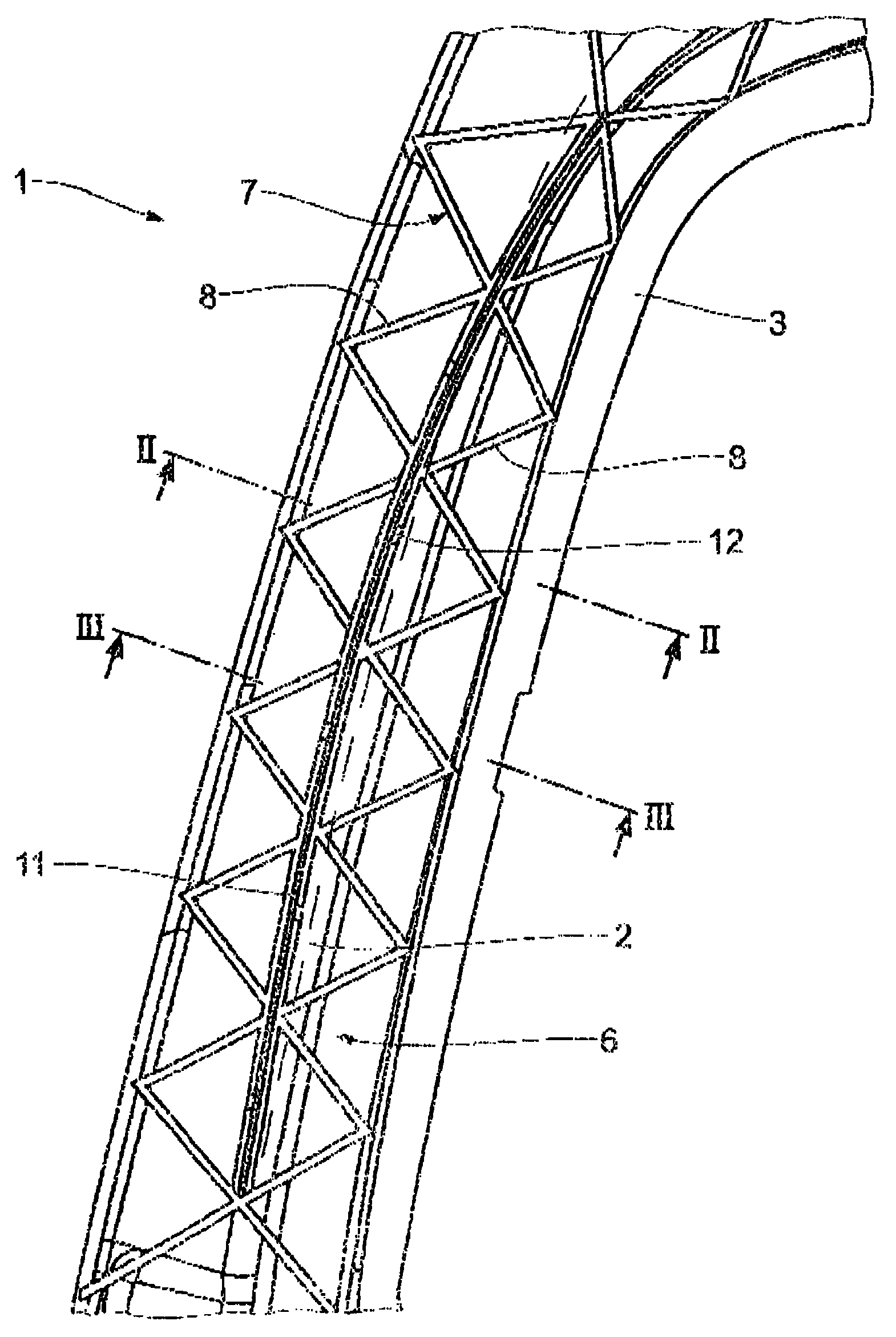

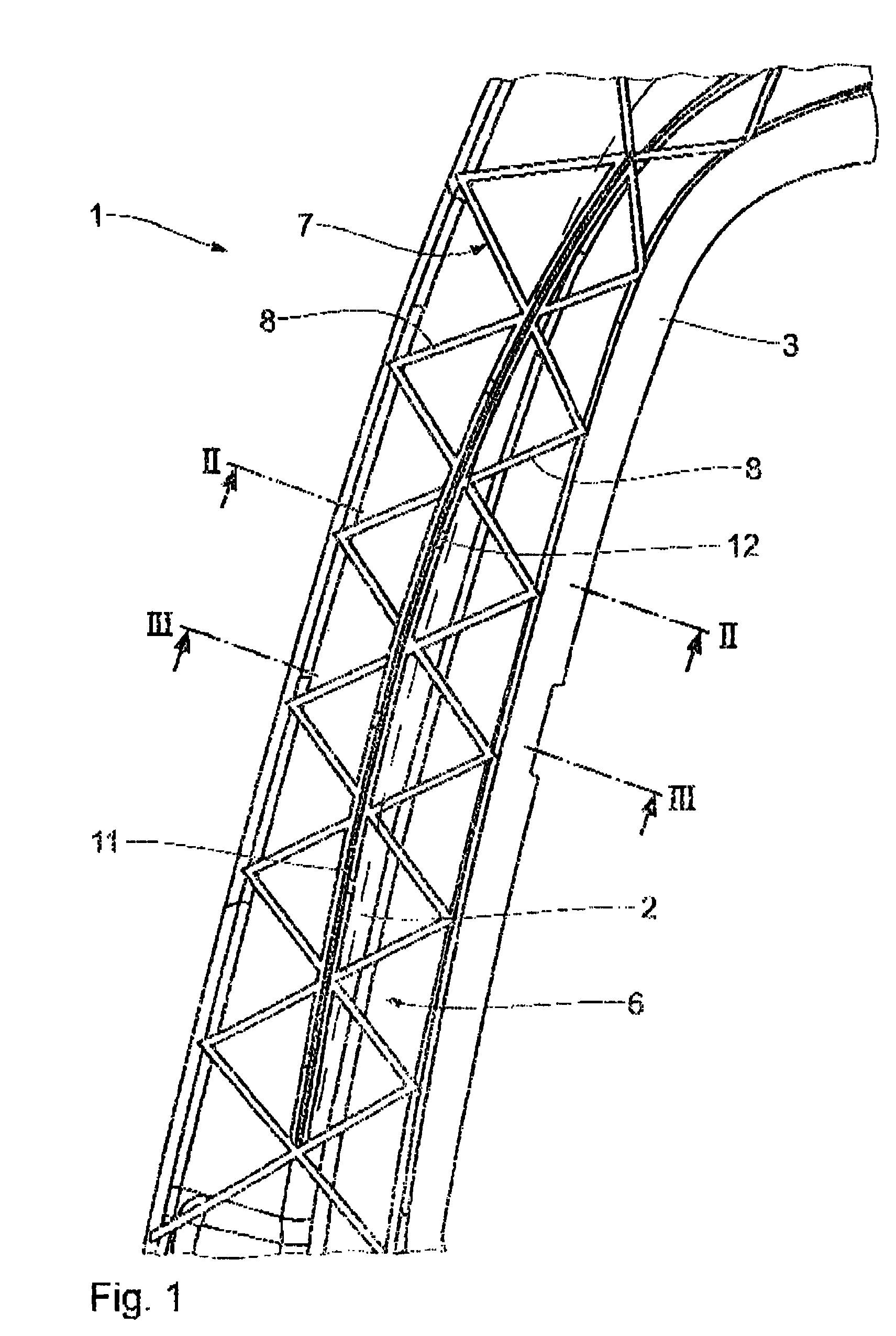

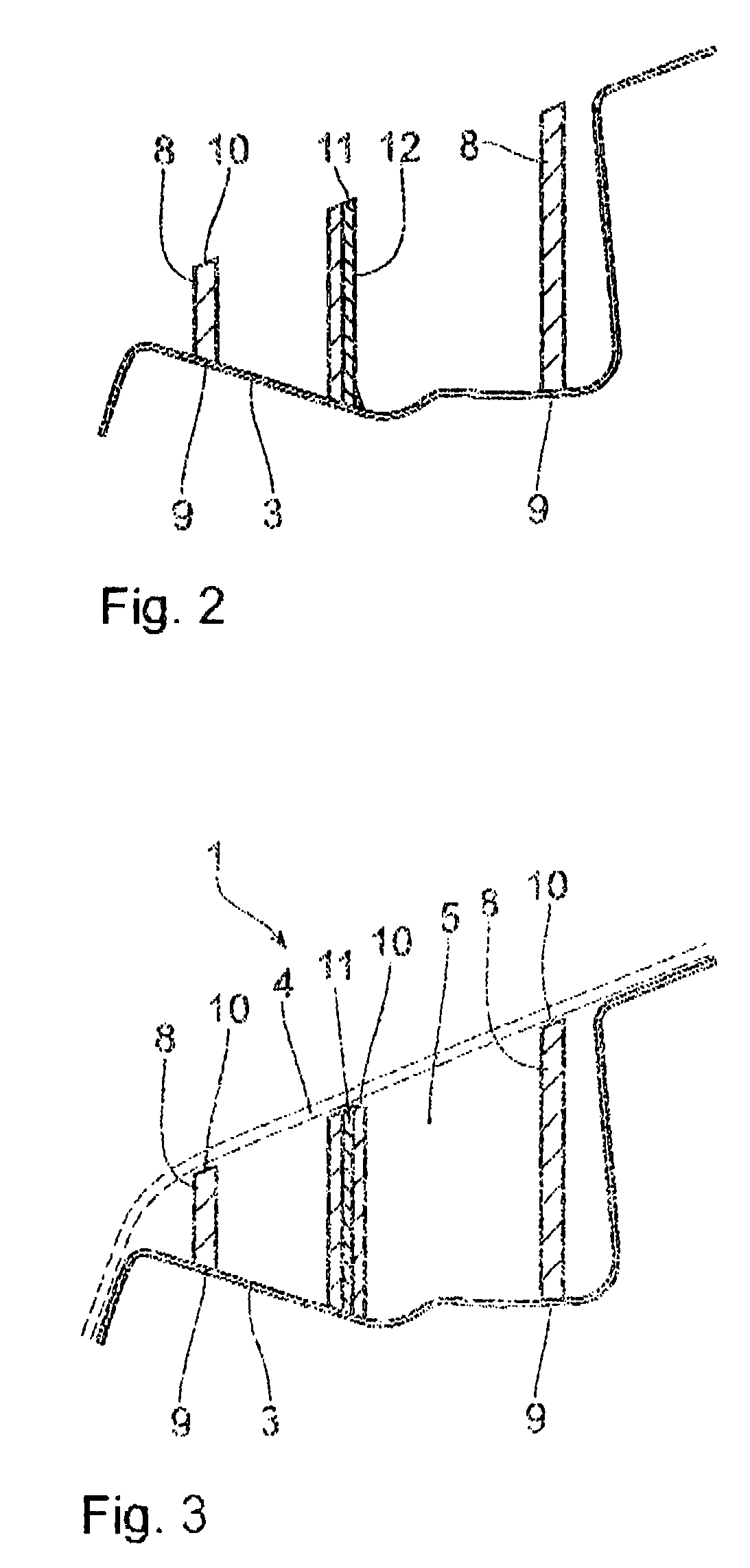

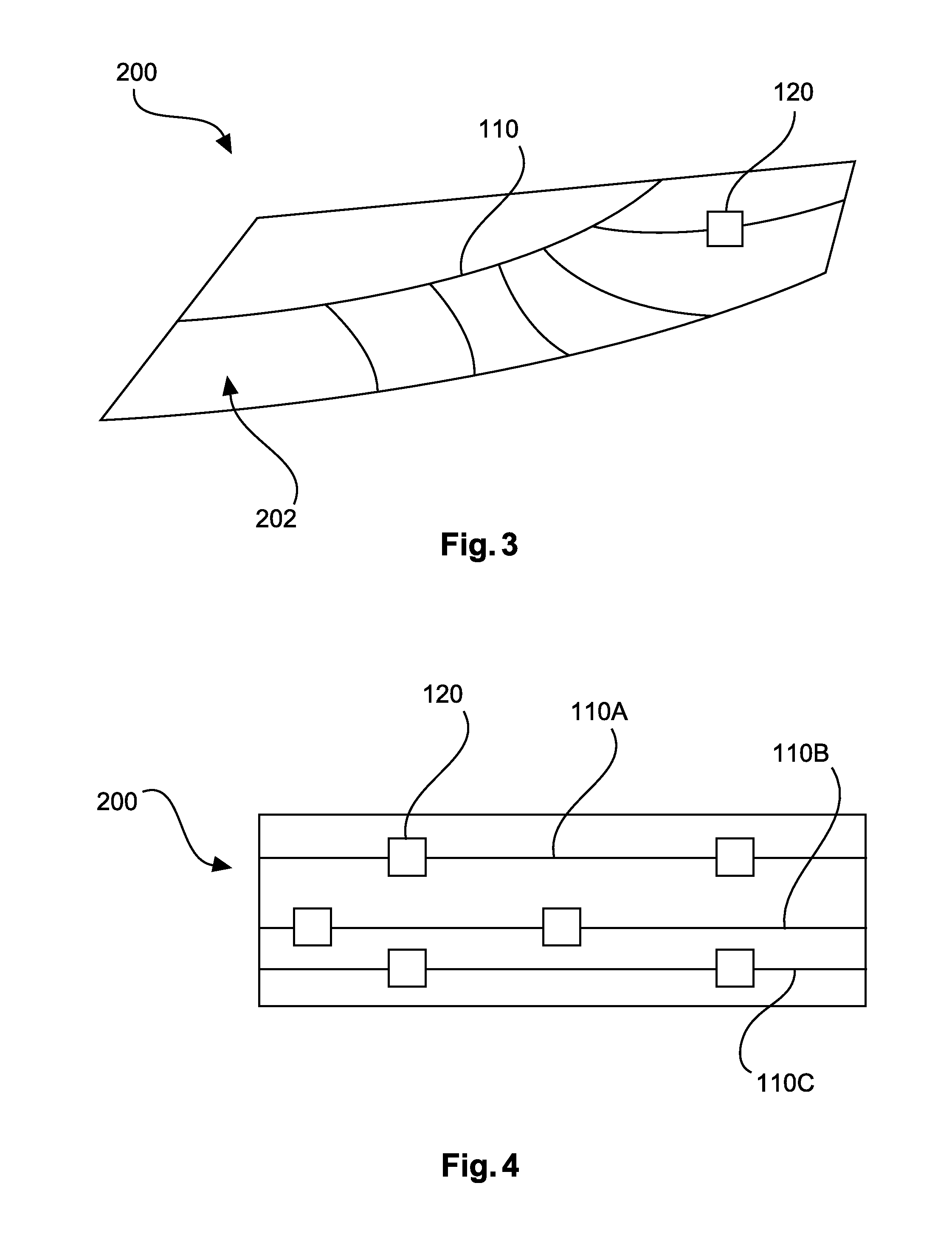

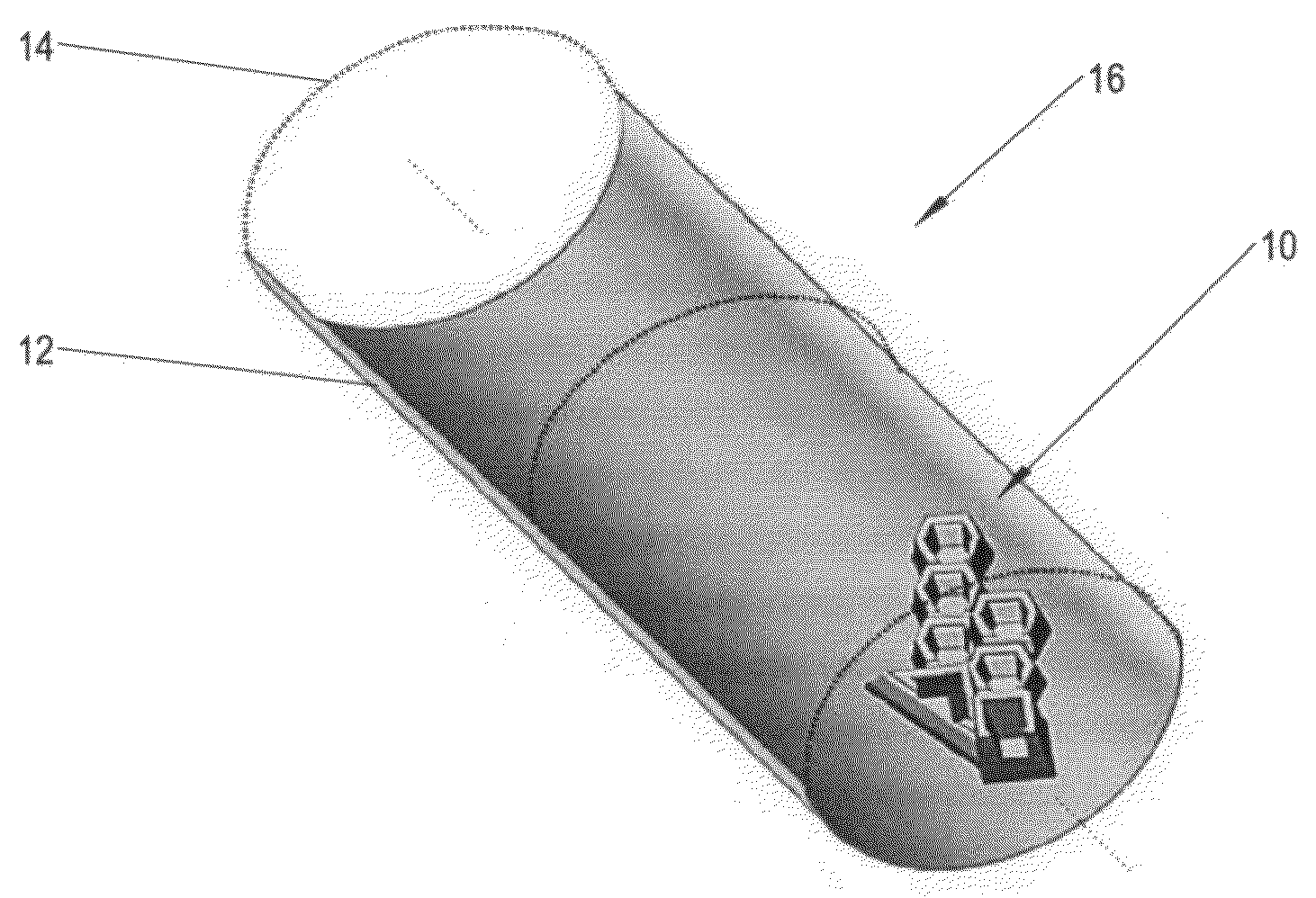

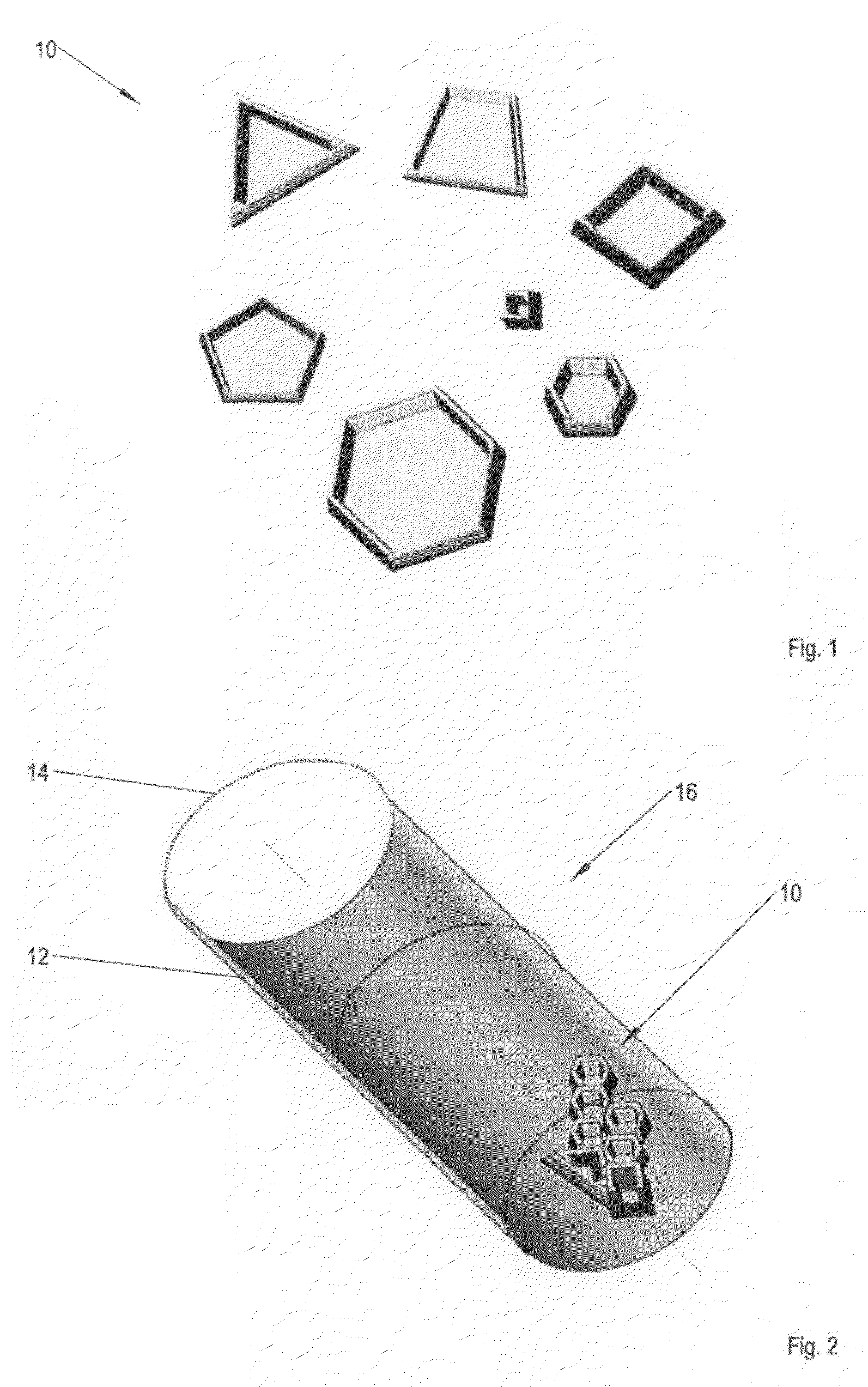

Lightweight structure, particularly primary aircraft structure or subassembly, as well as method for the manufacture thereof

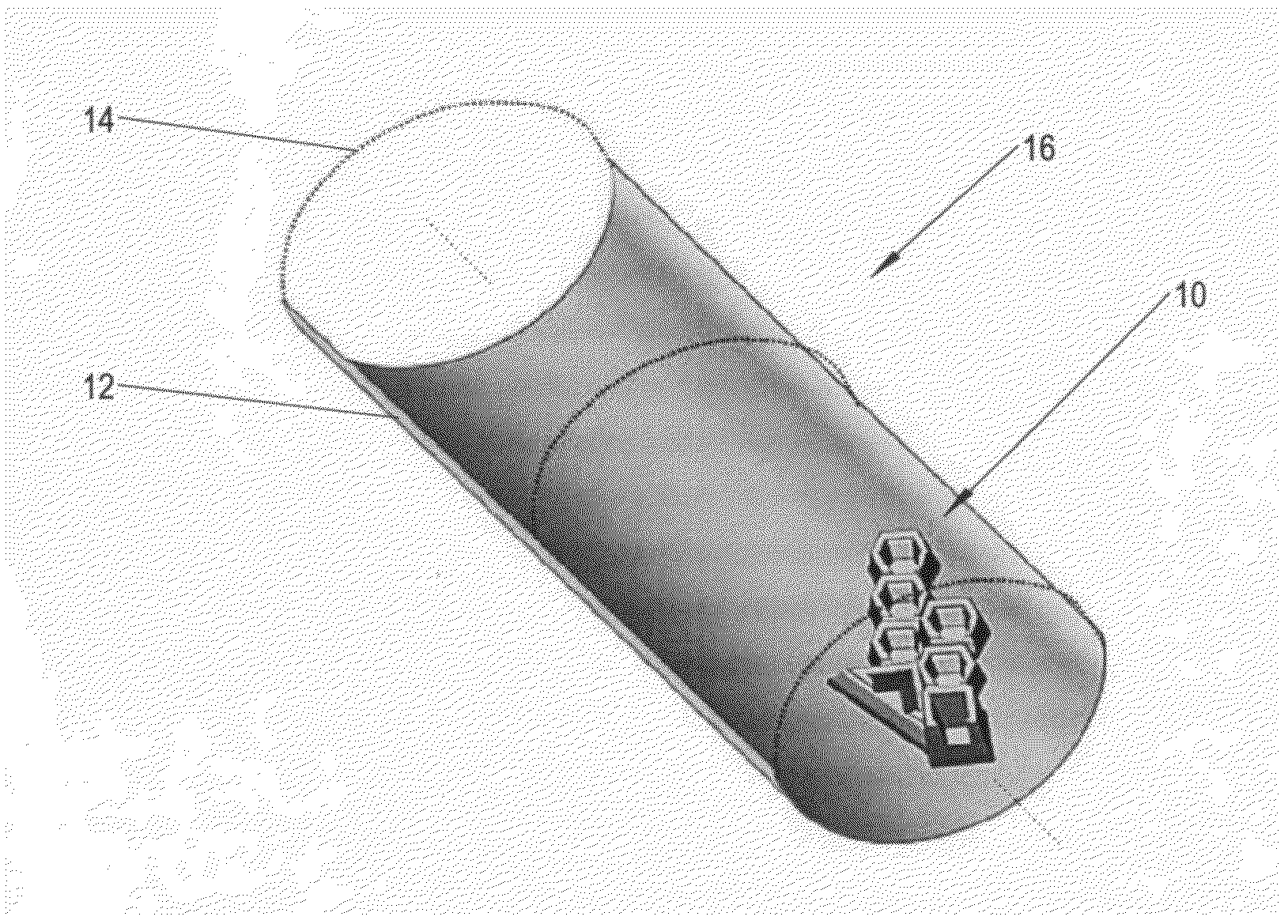

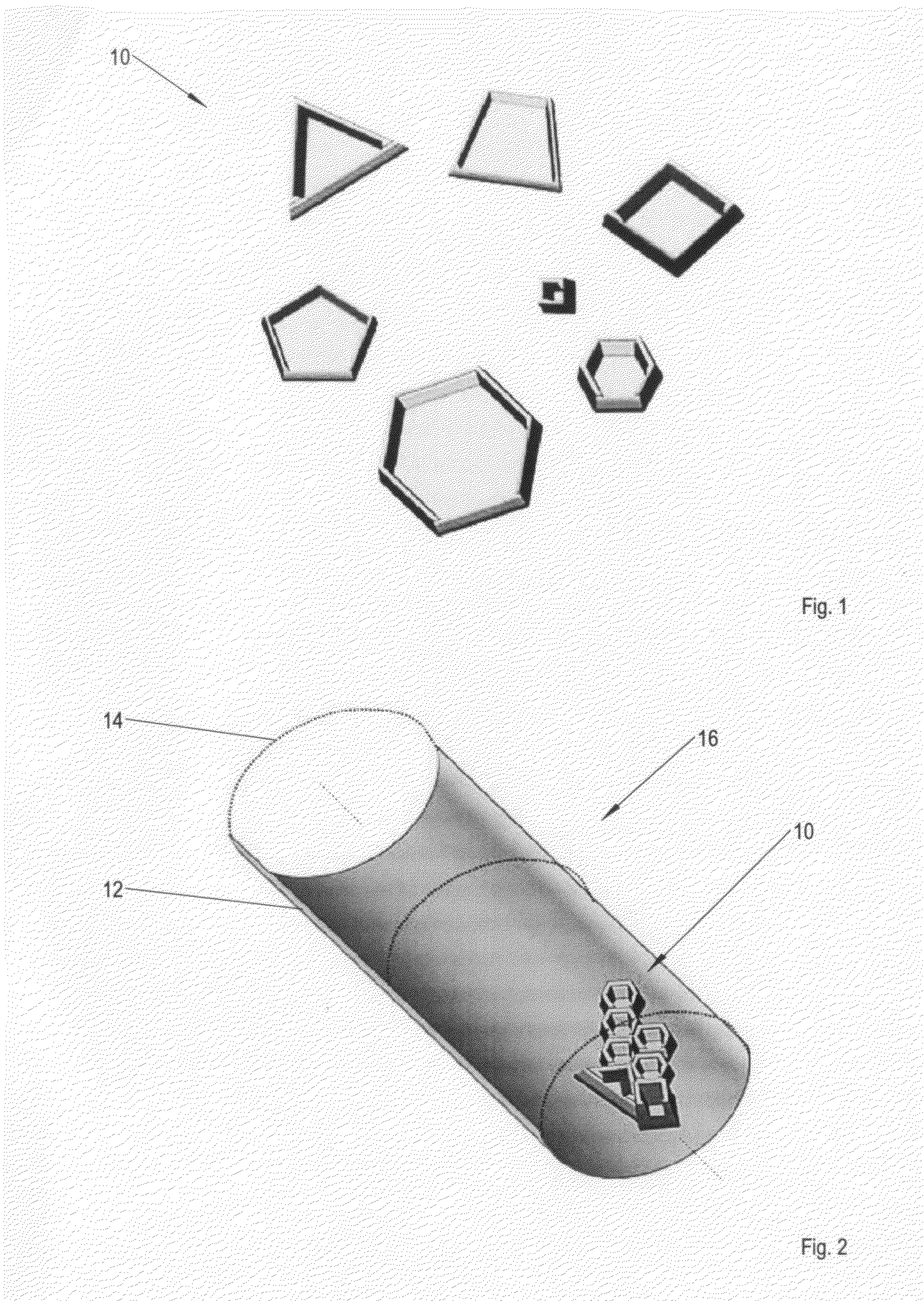

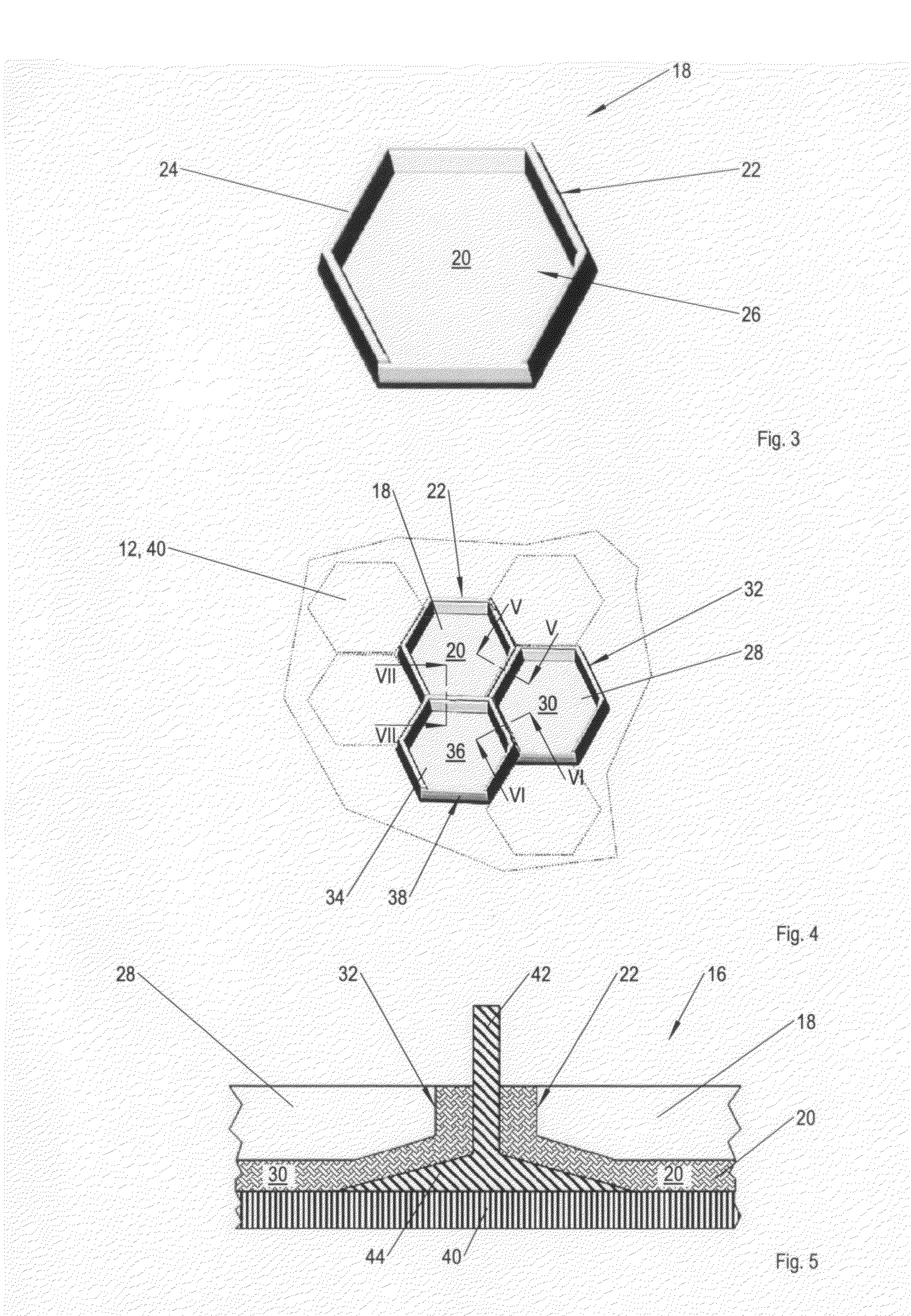

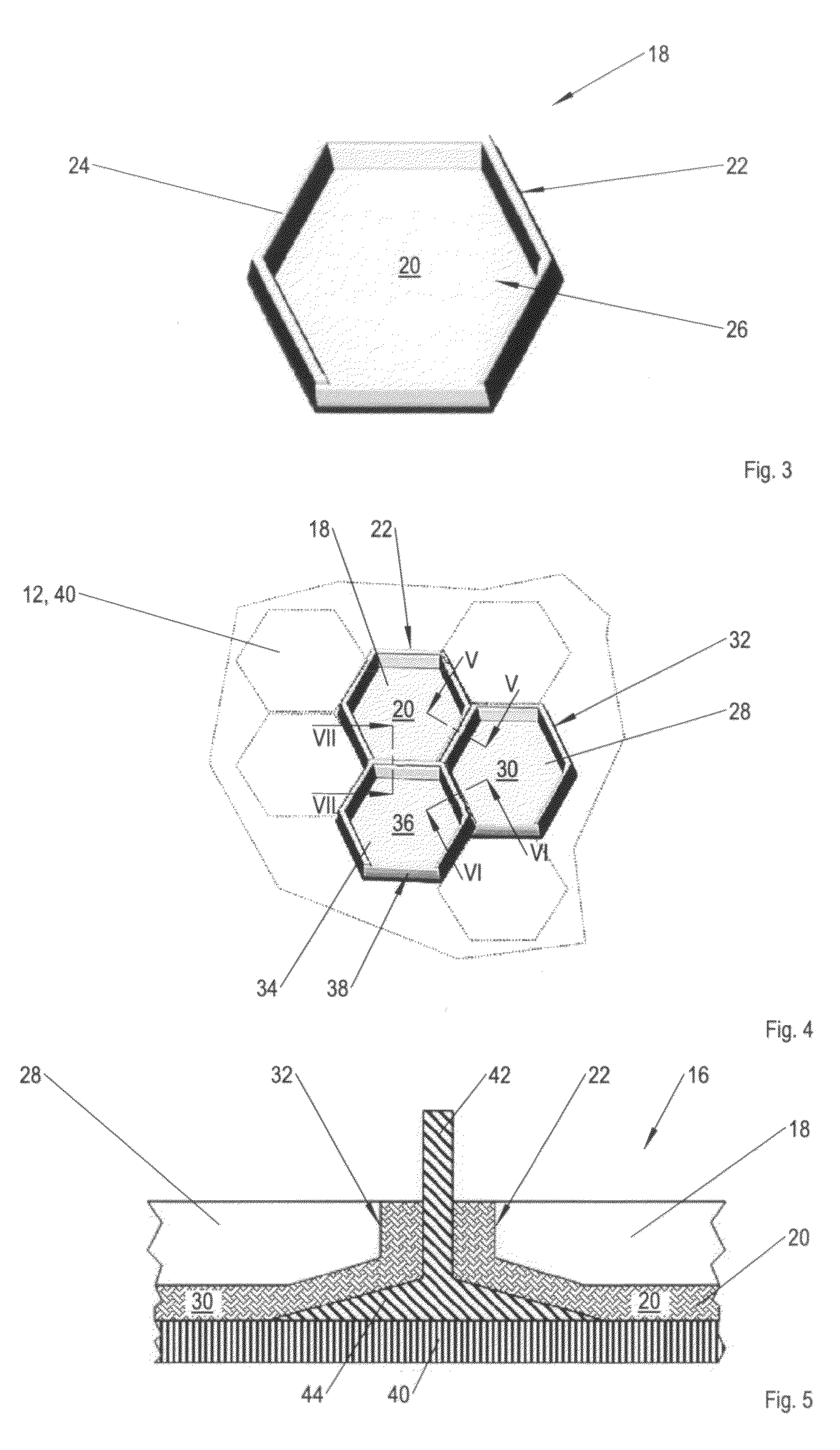

InactiveUS20130115404A1High mechanical load-bearing capacityLow weightLayered productsOrnamental structuresAirplaneSatellite

A lightweight structure at least sectionally composed of a plurality of connected mosaic elements and / or skin mosaic elements. The lightweight structure allows an essentially load-appropriate arrangement of the mosaic elements and / or the skin mosaic elements including the optional skin. The lightweight structure requires a significantly reduced number of connecting elements, such that the assembly effort can be reduced and an additional weight reduction can be achieved. Also, two variations of a method for manufacturing a lightweight structure are provided. Large-format lightweight structures such as, for example, an aircraft fuselage cell or partial shells thereof can also be manufactured in a reliable and dimensionally accurate fashion because only mosaic elements and skin mosaic elements, with relatively small dimensions, need to be handled. Other applications of the lightweight structure include launch vehicles, rocket stages, space stations, space station modules, satellites and masts or towers of wind power plants.

Owner:AIRBUS OPERATIONS GMBH

Mg2SiO4 dielectric constant microwave ceramic medium and its producing process

The invention discloses an Mg2SiO4 microwave dielectric ceramic with low dielectric constant and a method for preparing the same. The invention obtains a single phase high purity Mg2SiO4 ceramic through controlling the nonstoichiometric ratio of Mg to Si. The method overcomes the defect that the ceramic is easy to generate a second phase after the prior sintering according to the molar ratio of a chemical formula 2MgO.SiO2. The Mg2SiO4 ceramic obtained by the method has a low dielectric constant between 6 and 8, the dielectric loss thereof is less than 10<-5>, and the Qf thereof is more than 160, 000 GHz. The high-quality microwave dielectric ceramic with low dielectric constant is used as a material for manufacturing electronic circuit substrates, dielectric resonators, filters, microwave substrates and microstrip lines, and has important application prospect and great economic value in the fields of electronic circuit, microwave mobile communication, satellite communication and radar system.

Owner:HANGZHOU DIANZI UNIV

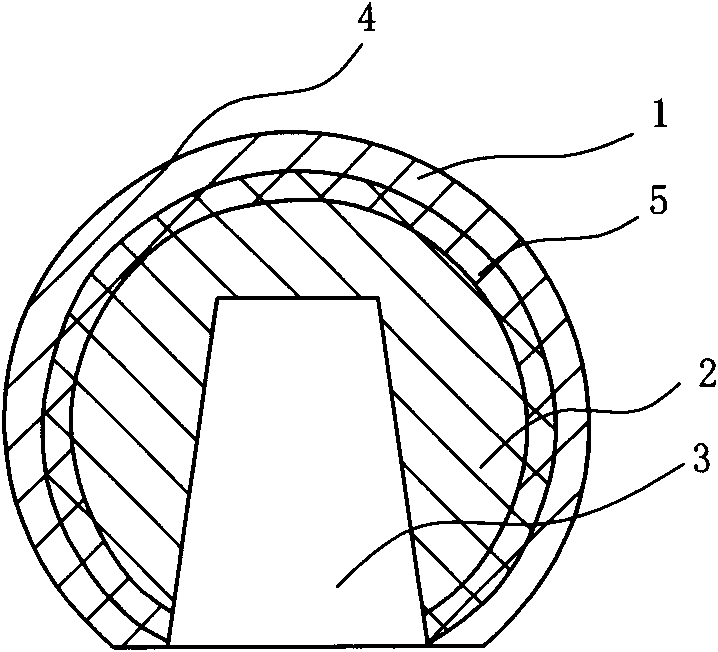

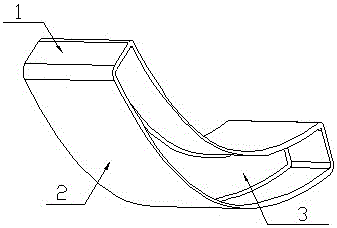

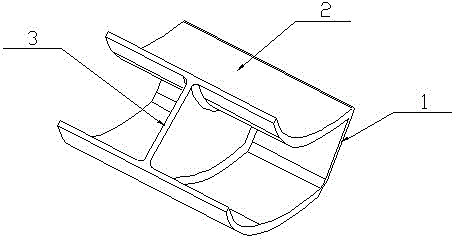

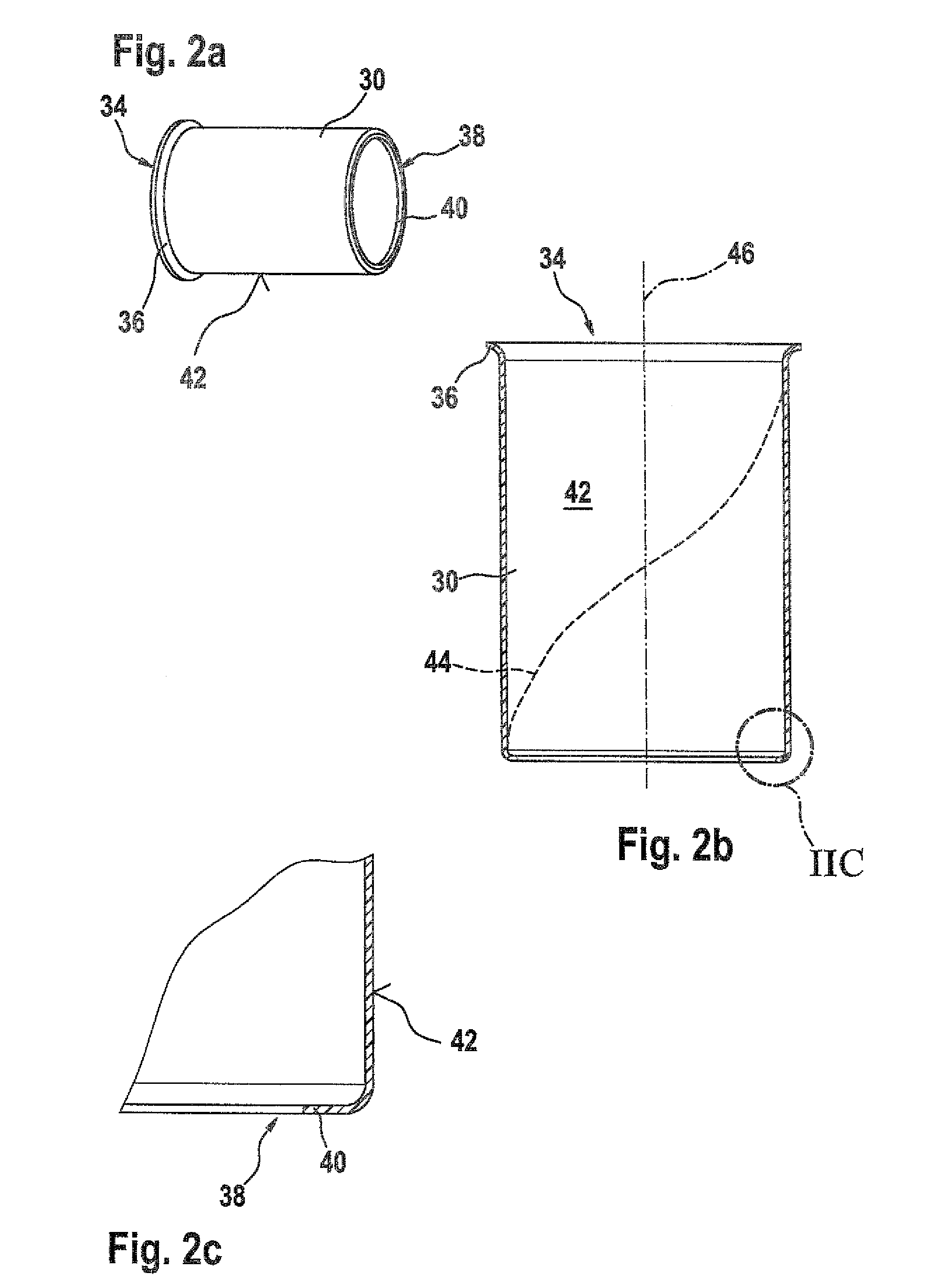

Hollow chamber structural component and method for producing same

InactiveUS7879435B2High mechanical load capacityImprove carrying capacityVehicle seatsEnvelopes/bags making machineryAdhesiveMechanical engineering

Owner:REHAU AG & CO

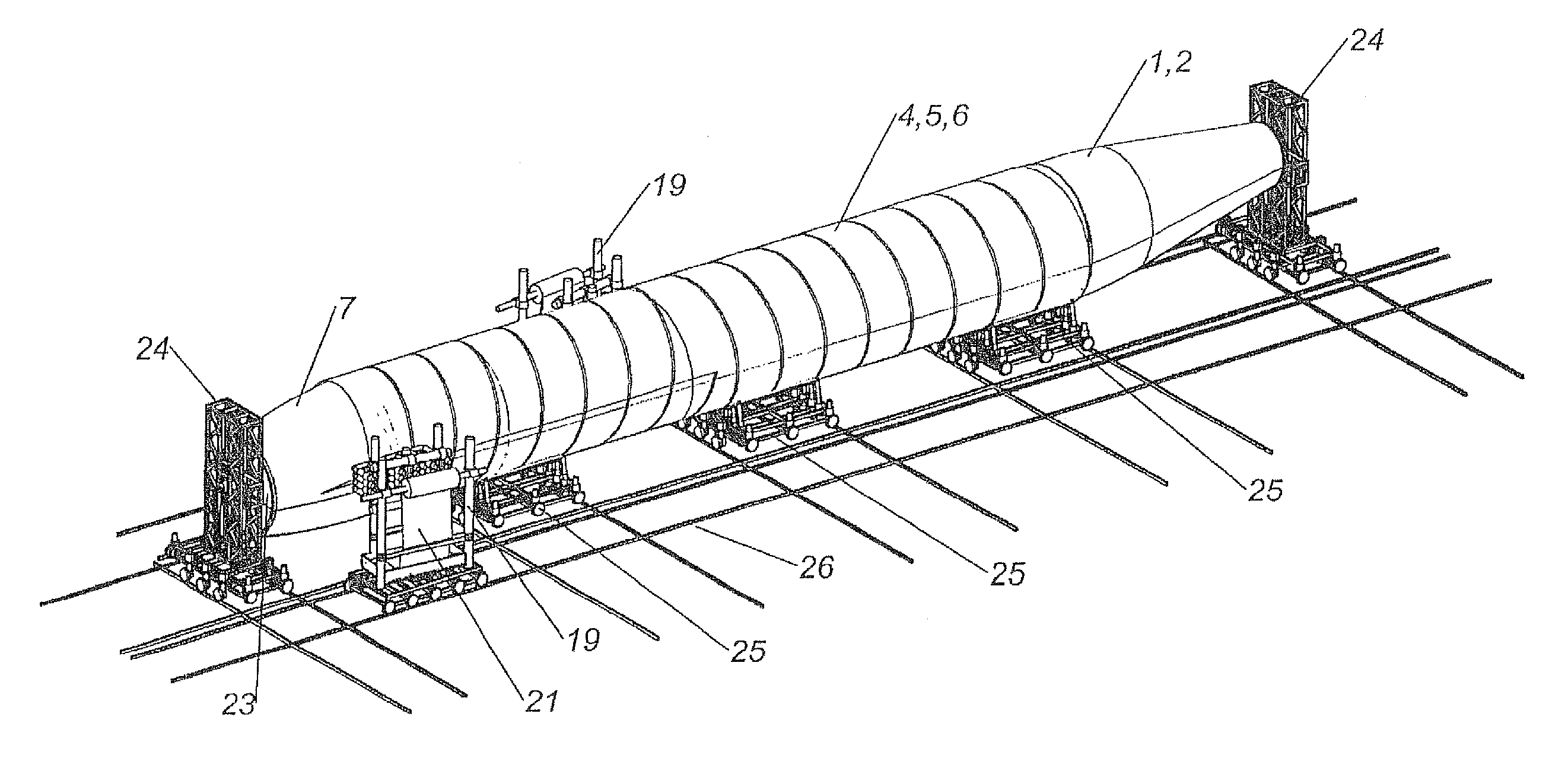

Method for producing a hollow body

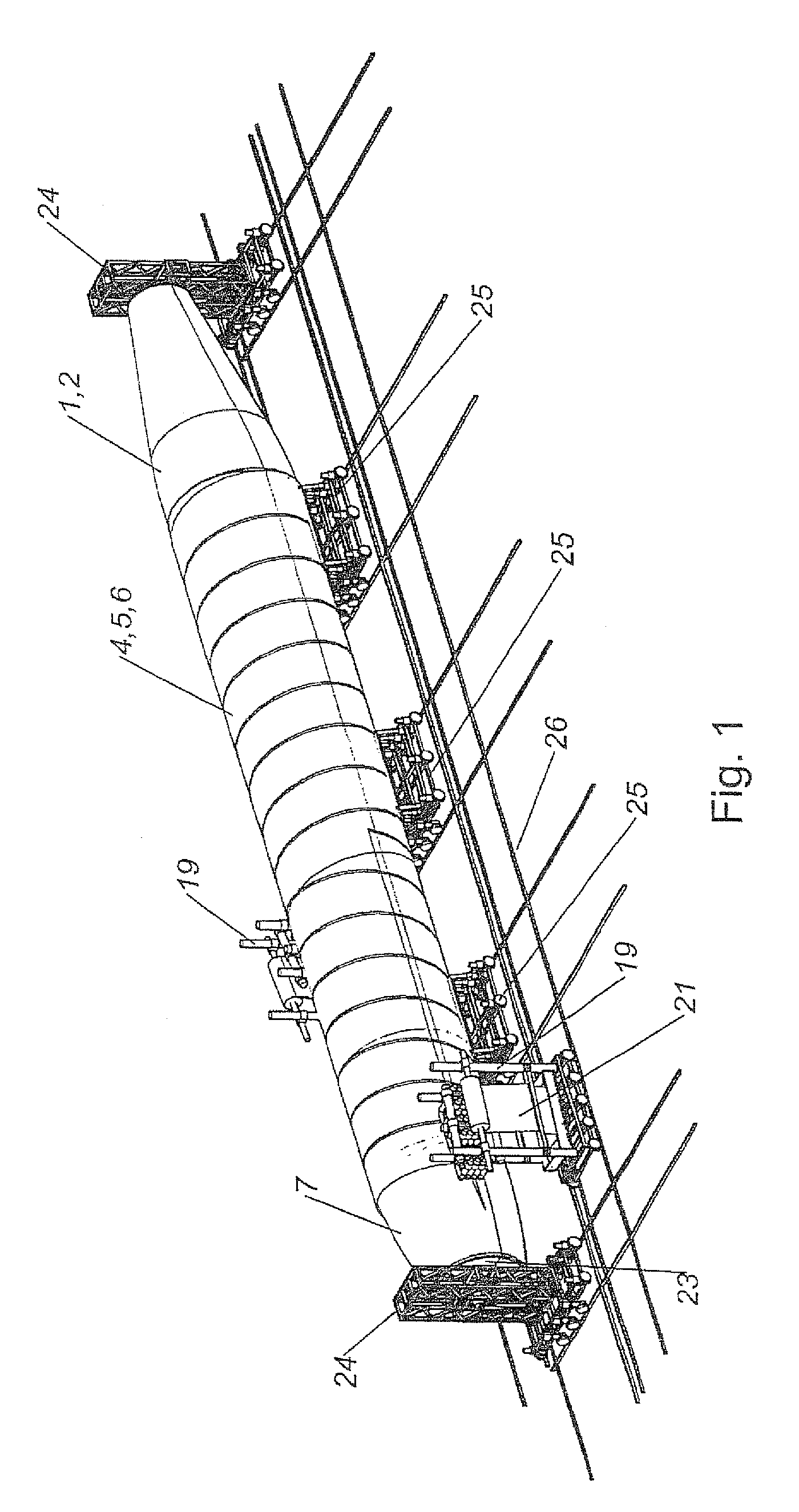

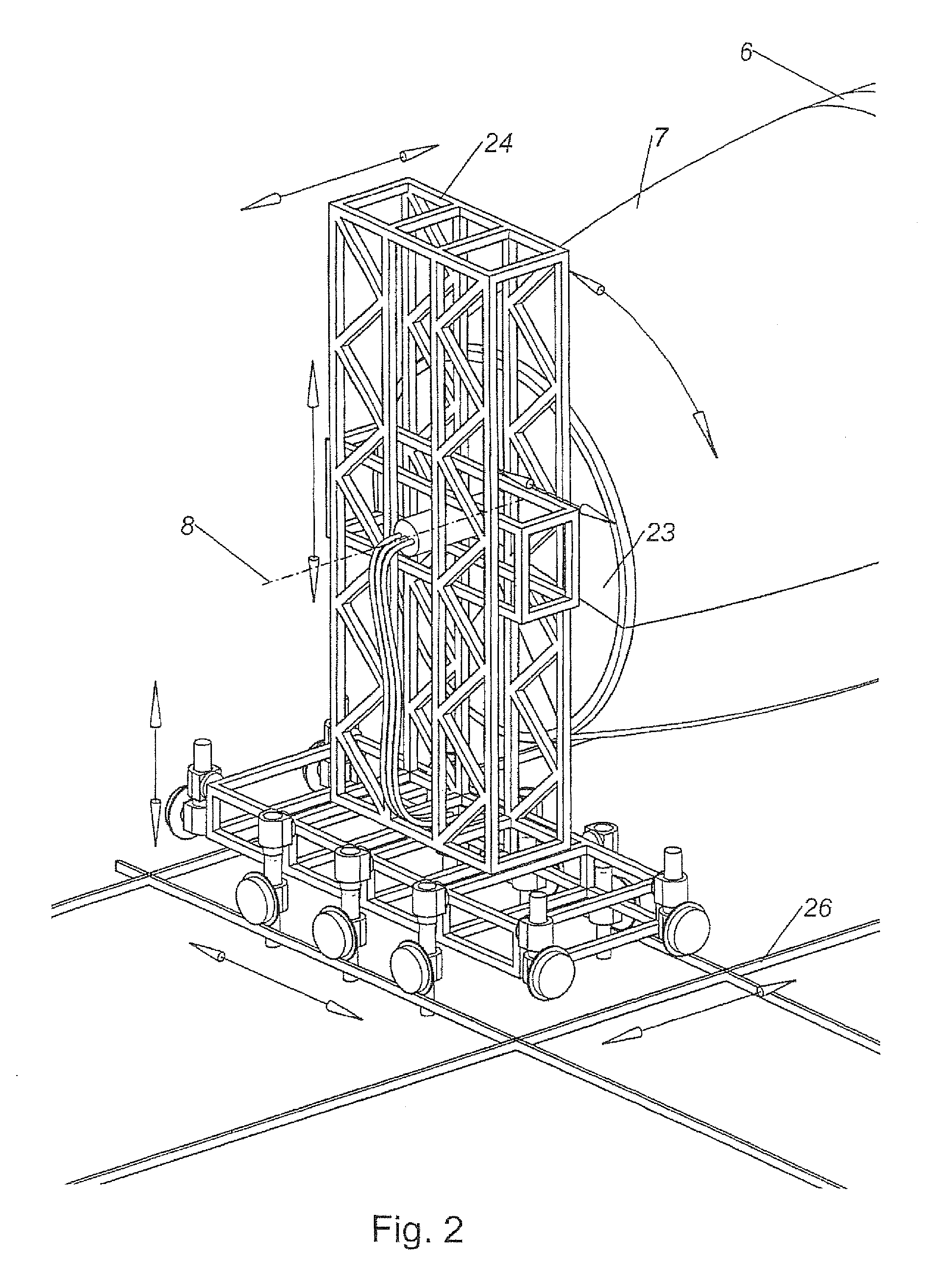

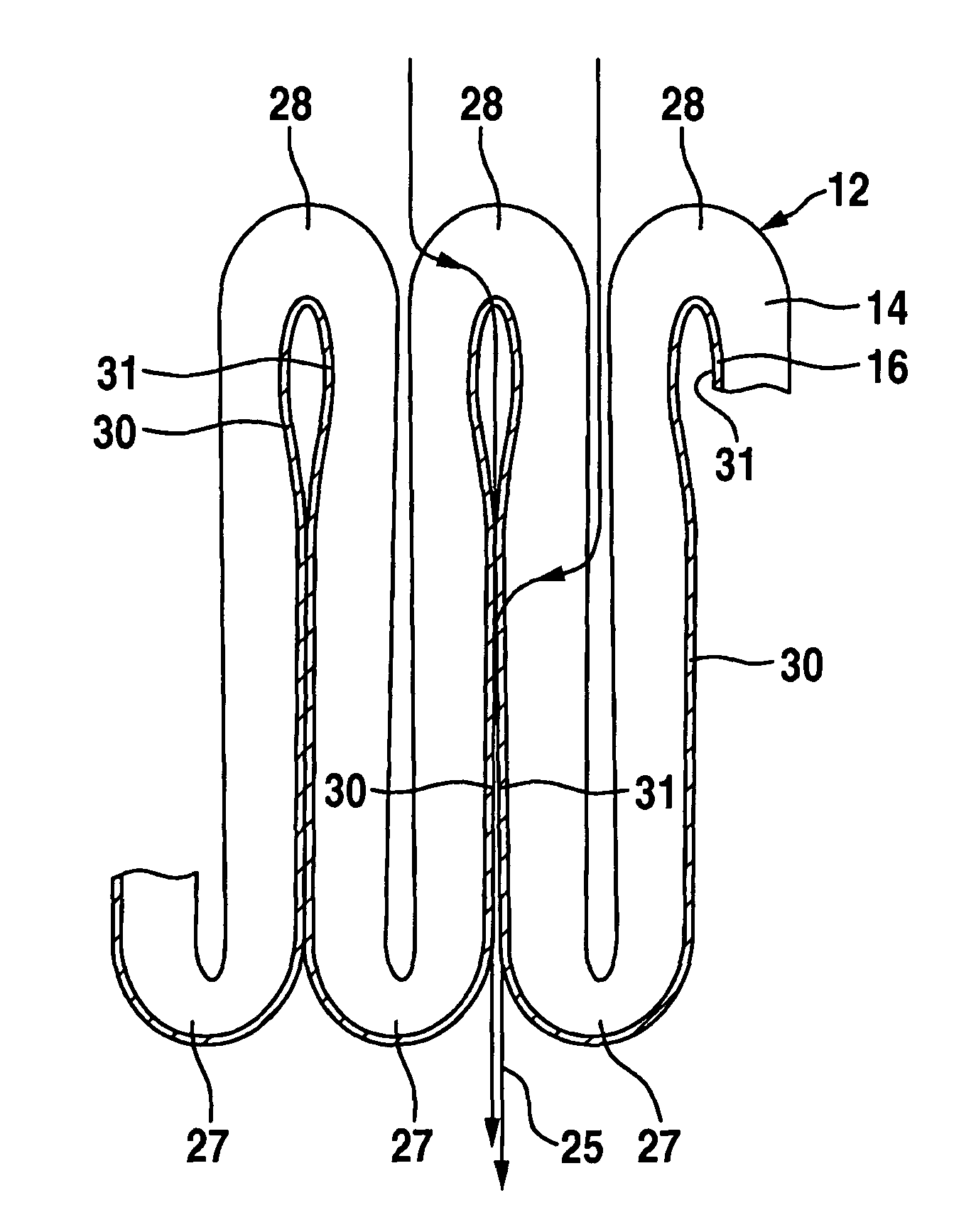

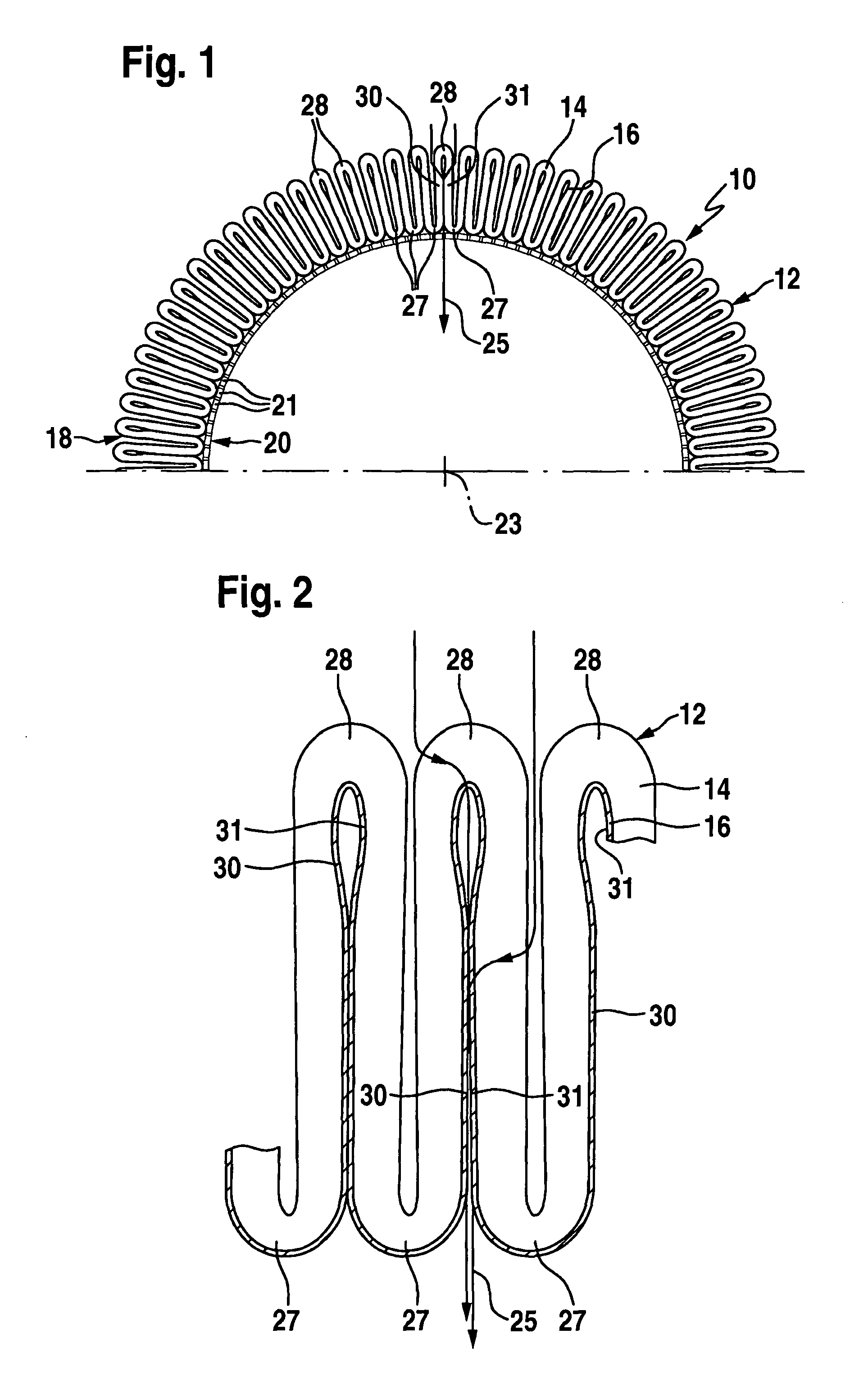

InactiveUS20110052845A1Reduce weightHigh mechanical load capacityEnvelopes/bags making machineryLiquid surface applicatorsFiberCarrying capacity

In a method for producing a hollow body—implemented as a sandwich construction—in particular an aircraft fuselage, an inner layer is formed from a specifiable number of plies of a specifiable at least resin-wetted fiber material, for simple, rapid, and cost-effective formation of a large-volume cavity, which has a low weight and a high mechanical carrying capacity in relation to its size. At least a first ply of the inner layer has a helical configuration and is configured without interruption essentially over an entire length of the hollow body.

Owner:DERMOND FORSTNER & SREBOTH OG

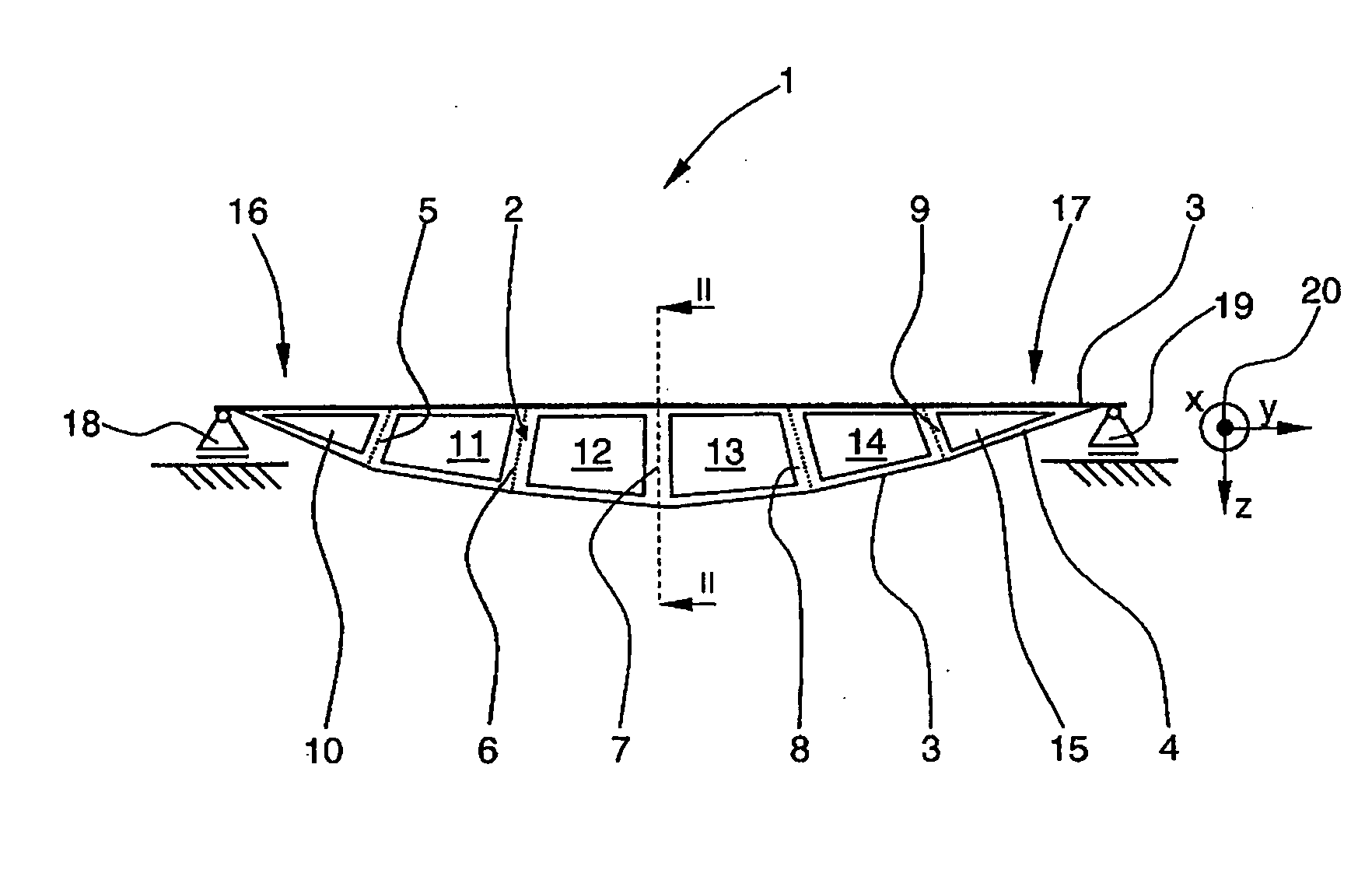

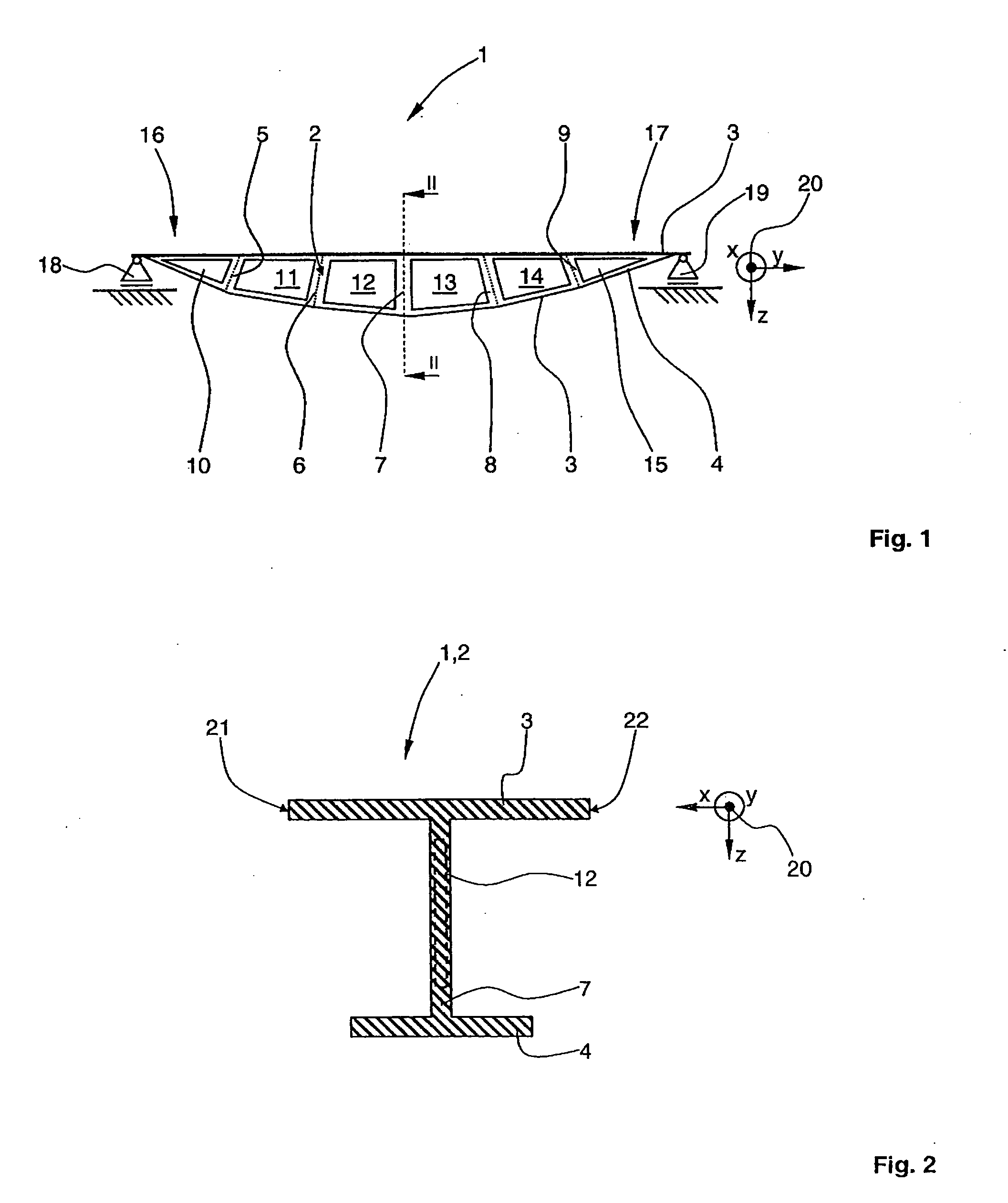

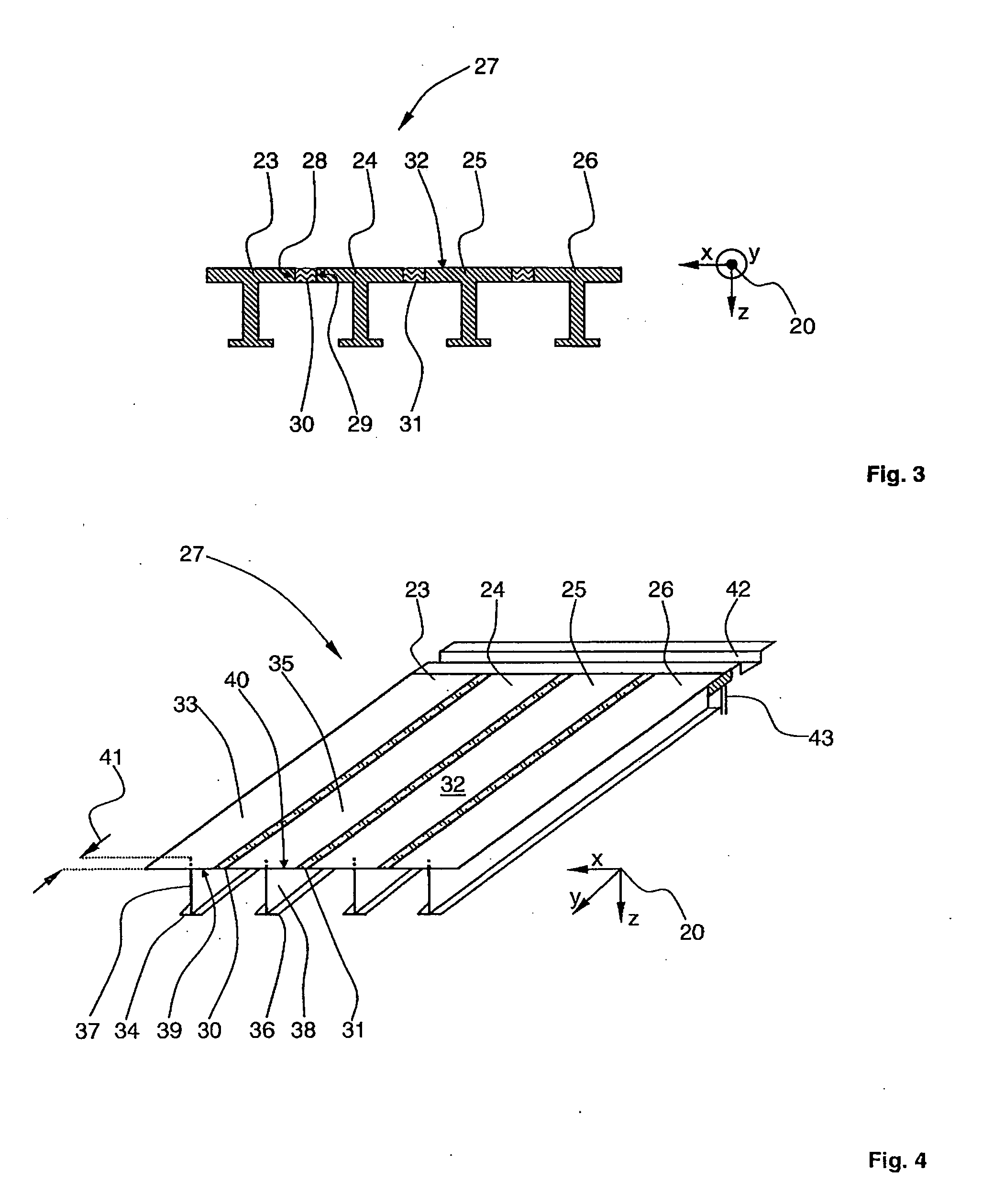

Floor panel for forming a loading area in a cargo hold of an aircraft

Disclosed is a floor panel, in particular for covering floors of cargo holds of aircraft. The floor panel is formed by a plurality of milled profiles, which are friction stir welded in each case along their longitudinal edges, with preference continuously to form longitudinal (butt) seams. The milled profiles each form a beam “of equal stress”, with an upper flange and a lower flange which are spaced apart from one another along their extent. The milled profiles have in each case a double-T-shaped cross-sectional profile, the upper flanges and the lower flanges being respectively connected by webs. With preference, the milled profiles are milled out in one piece from solid material of a sufficiently tough aluminium alloy. The joining together of the floor panel including a plurality of milled profiles that are arranged in parallel and friction stir welded allows a high mechanical load-bearing capacity of the floor panel in comparison with conventional sandwich floor panels along with a comparatively low weight.

Owner:AIRBUS OPERATIONS GMBH

Hollow chamber structural component and method for producing same

InactiveUS20080014388A1Increased intrinsic stabilityHigh mechanical load capacityEnvelopes/bags making machineryVehicle seatsAdhesiveEngineering

A hollow chamber structural component includes a shell component which extends along a main extension direction. A cover component is attached to the shell component, wherein a hollow chamber is disposed between the shell component and the cover component and extends in the main extension direction. A reinforcing structure is arranged in the hollow chamber and comprises: a synthetic support structure, which follows at least in some sections the main extension direction and rests with at least some sections against an inside of the shell component; and at least one reinforcing element that follows at least in some sections the main extension direction and is joined to the synthetic support structure with the aid of a layer of adhesive.

Owner:REHAU AG CO

Low-dielectric constant high-quality microwave ceramic medium and production process thereof

The invention discloses a microwave dielectric ceramic with low dielectric constant and high quality and a method for preparing the same. The chemical composition constitution formula of the microwave dielectric ceramic with low dielectric constant and high quality is Mg2(Si, Al )O4, which consists of MgO, SiO2 and Al2O3, wherein the mol percentage of the MgO to the SiO2 to the Al2O3 is equal to 60-70 to 15-35 to 0-15. The microwave dielectric ceramic with low dielectric constant and high quality is used as a core material for electronic circuit substrates, syntonizers, filters, microwave substrates and microstrip lines, and has important application prospect and economic benefit on electronic circuit, microwave communication, satellite communication and radar system.

Owner:HANGZHOU DIANZI UNIV

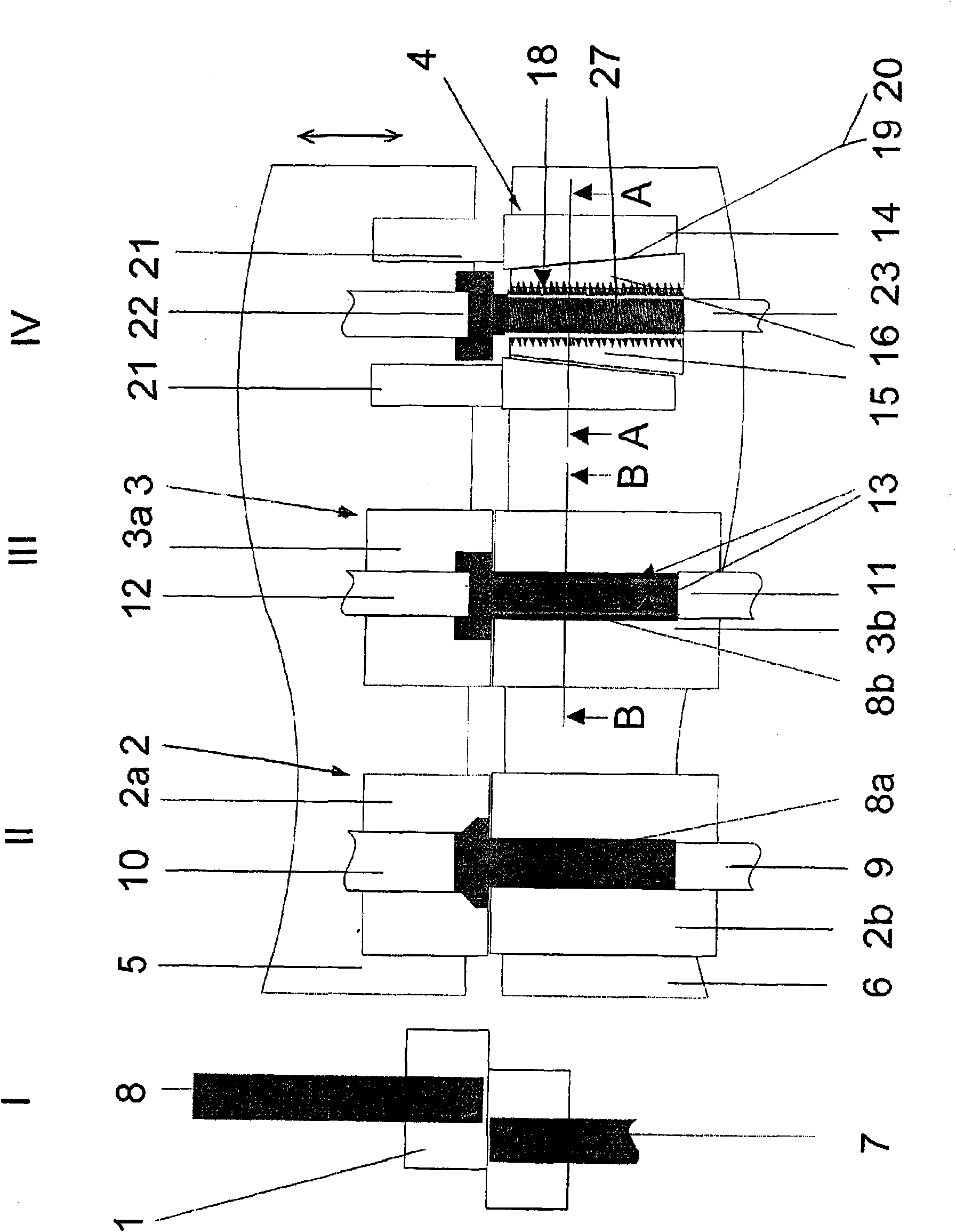

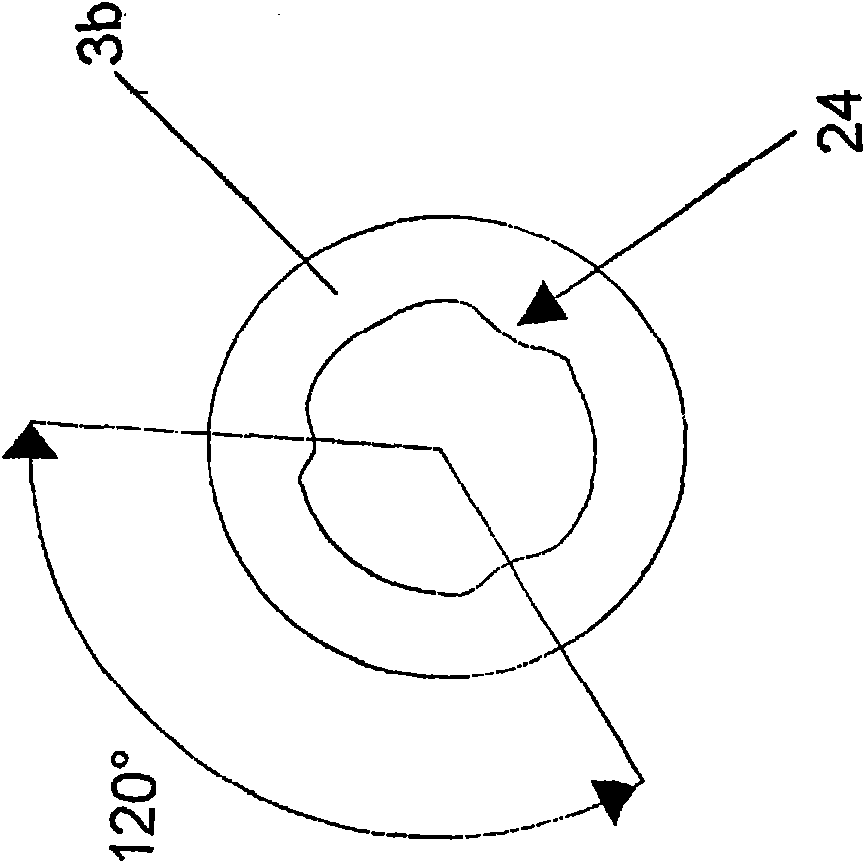

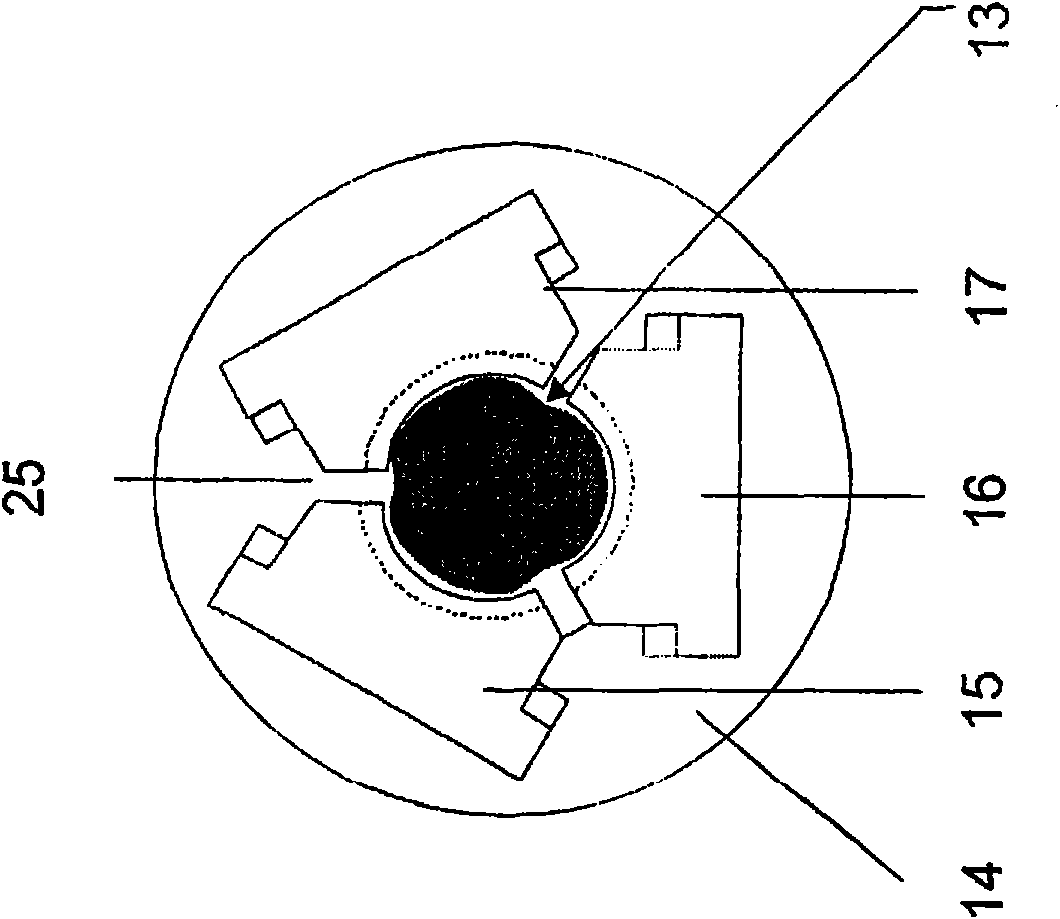

Method and device for producing fixing or connection components with radial outer contours, in particular screws or threaded bolts

InactiveCN101658894AHigh mechanical load capacityBoltsUpsetting pressesEngineeringMechanical engineering

A method of manufacturing fastenings or fasteners with radial outer contours, especially screws or threaded bolts, made of solid metal is performed by a device. The method manufactures the fasteningsor fasteners preferably on a multi-stage press. Several recesses running in an axial direction at a fixed radial distance are formed in the shank-shaped section of a blank. The prefabricated blank with the recesses is inserted into a multi-part split mold within a multi-stage press, whose die stocks have an inner profiling forming the outer contour, and are opened in the starting position, that atthe places where the die stocks are opened, there are the recesses. During the closing movement of the die stocks, at least one radial outer contour is pressed on the shank-shaped section of the blank by radial action of forces, with the recesses preventing material from getting between the die stocks during the pressing process.

Owner:SIEBER FORMING SOLUTIONS

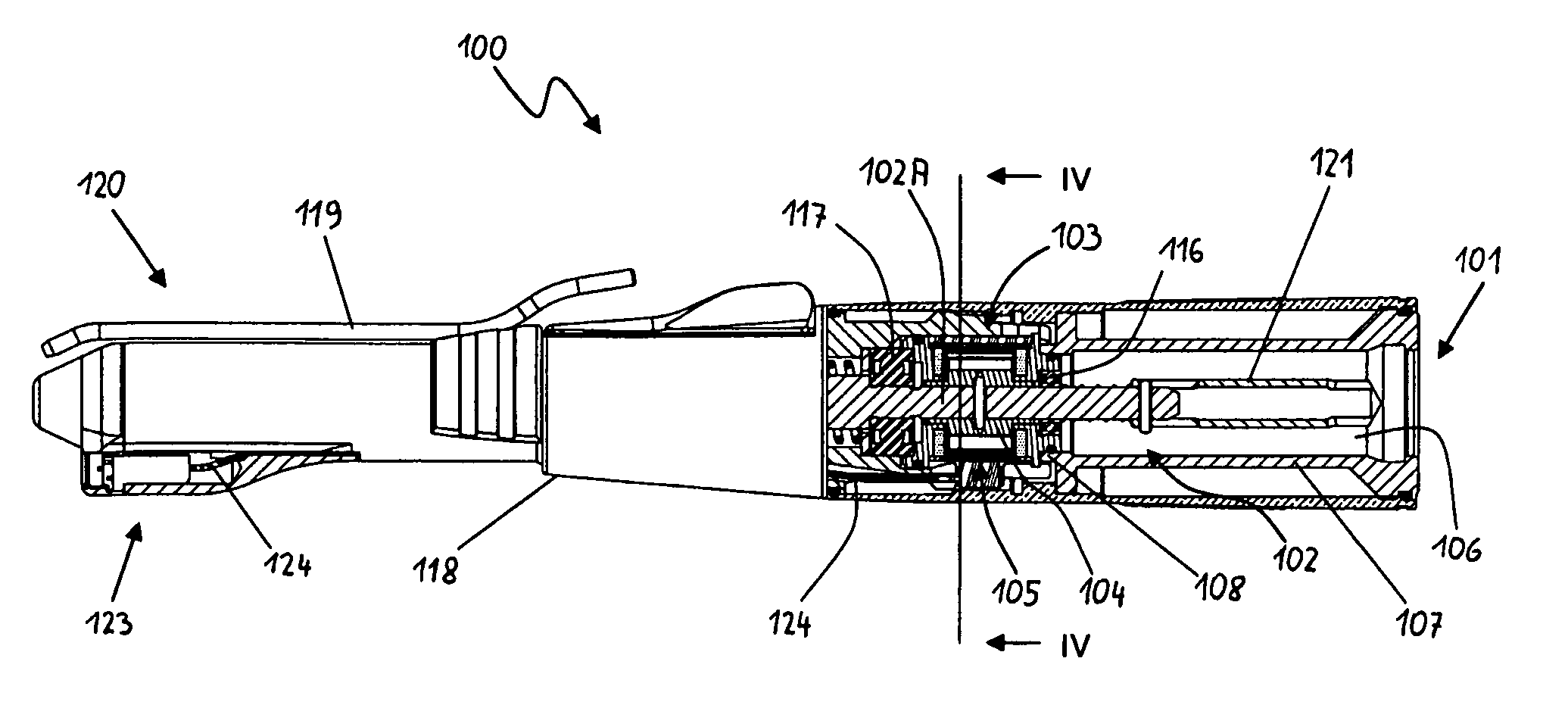

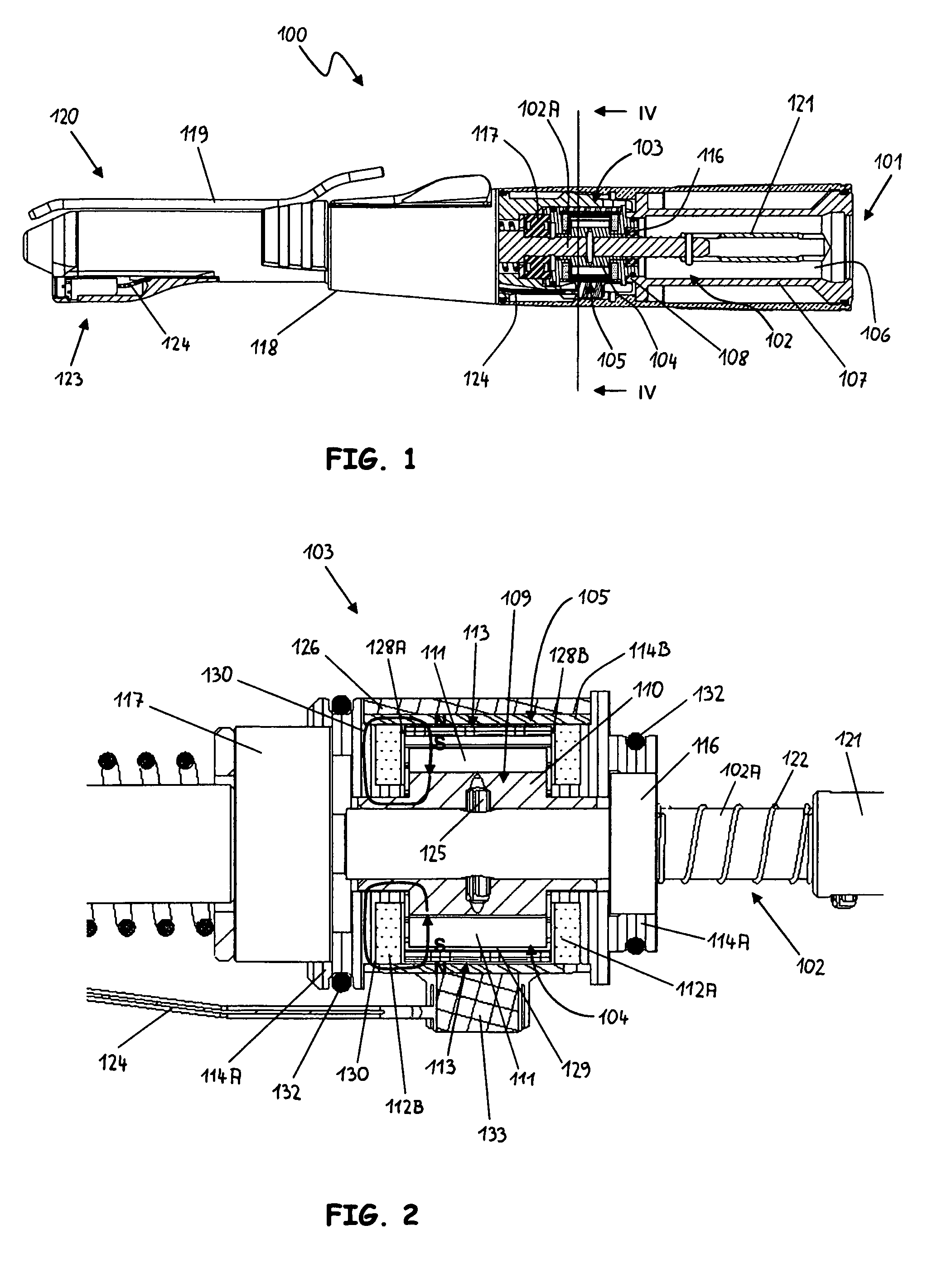

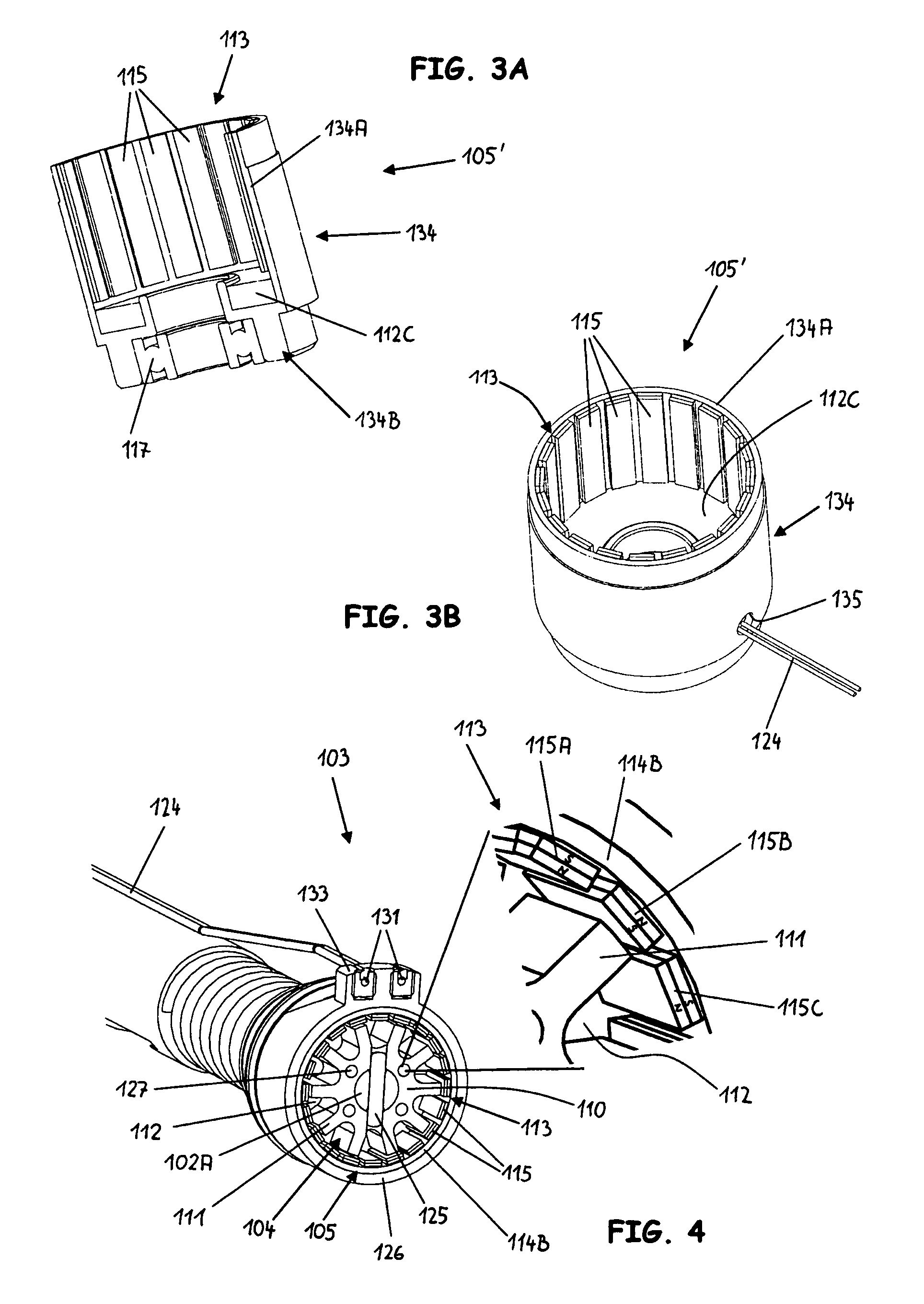

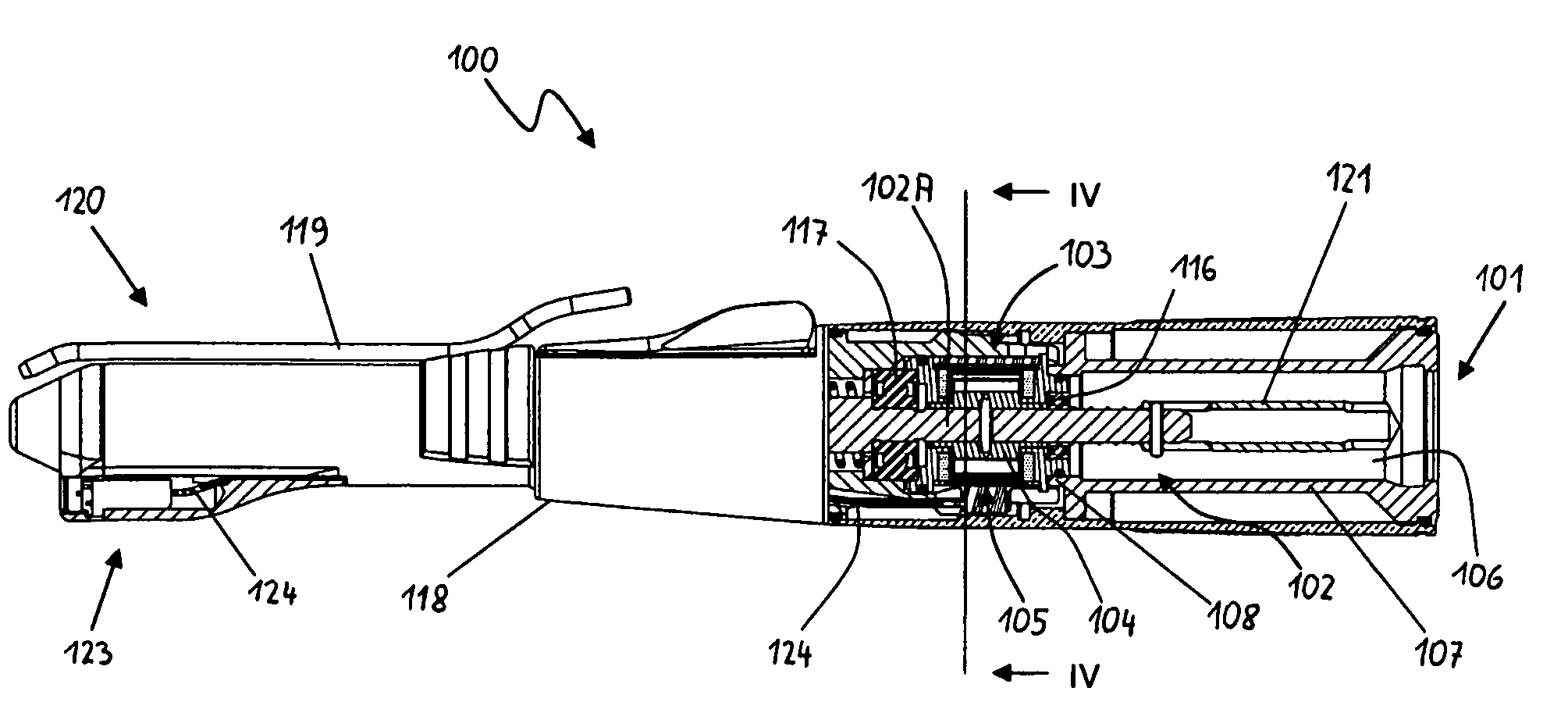

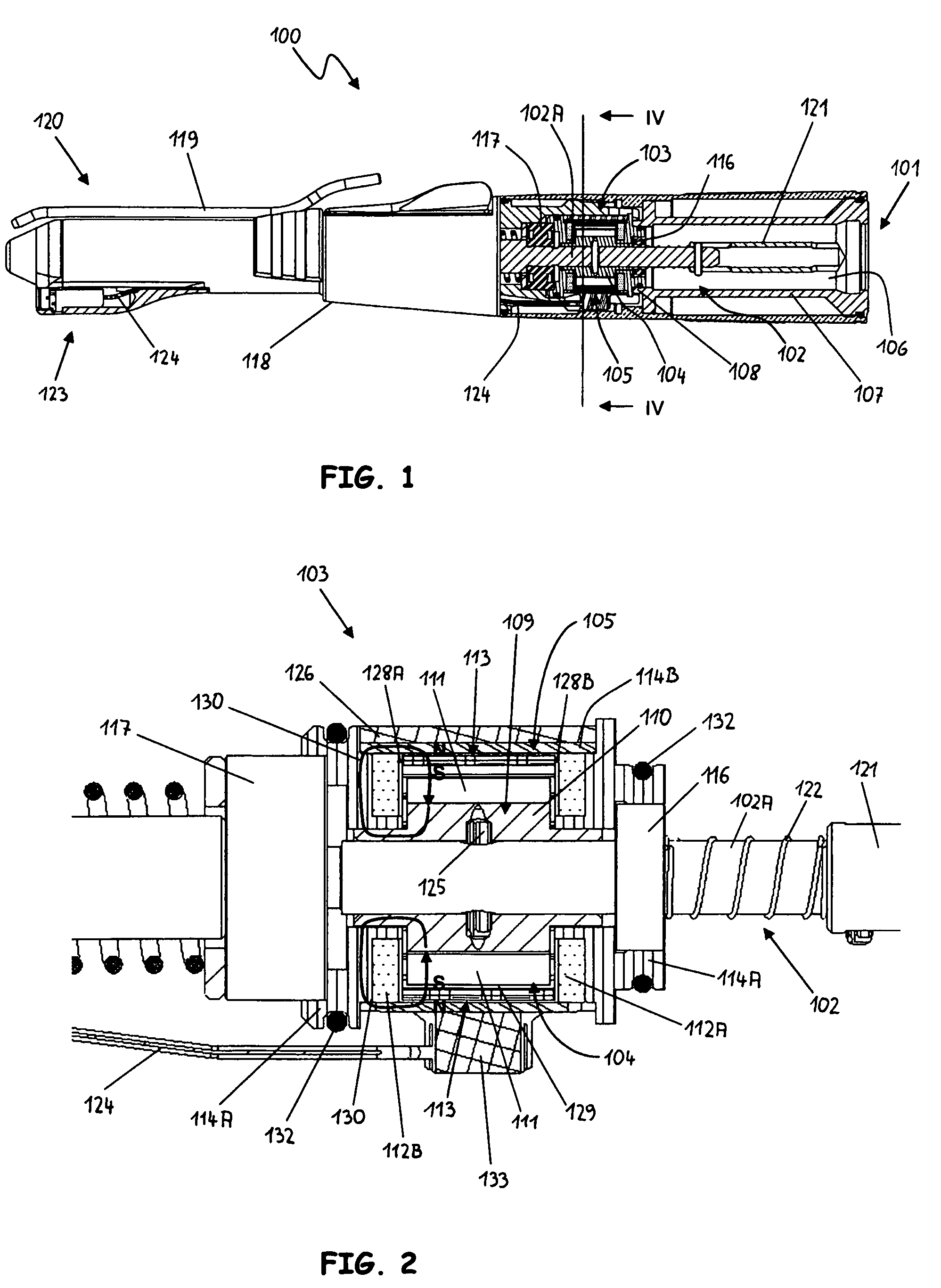

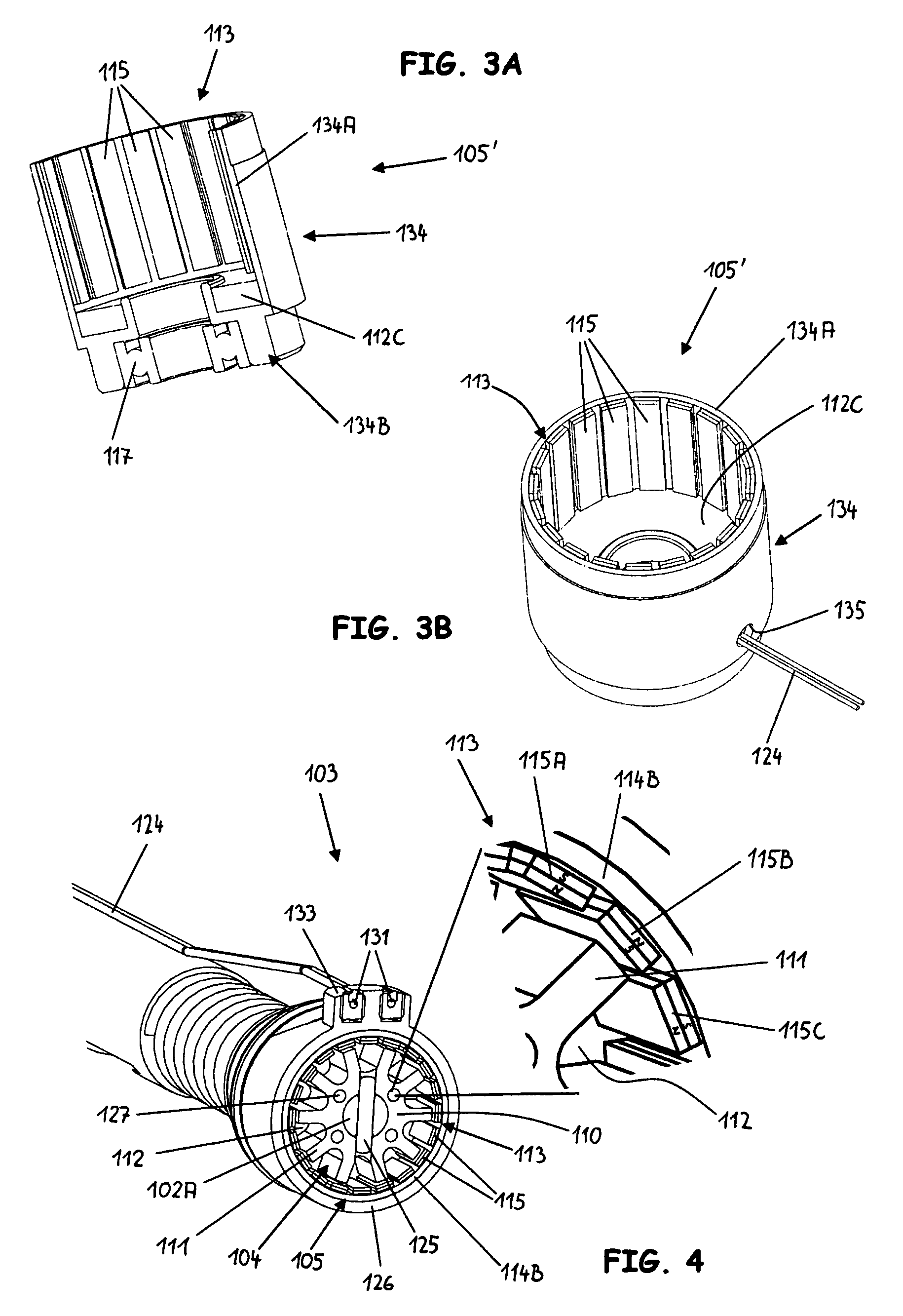

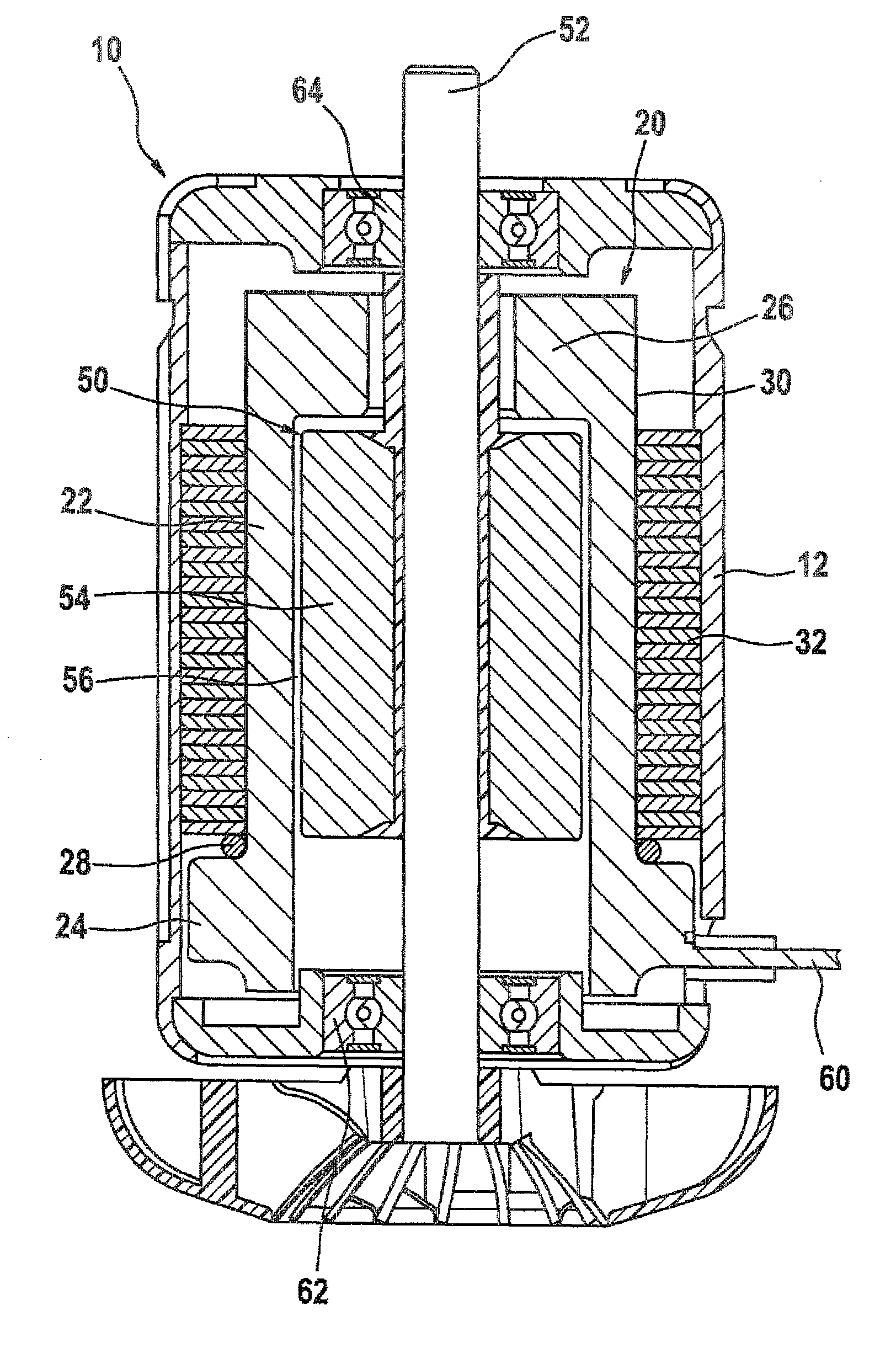

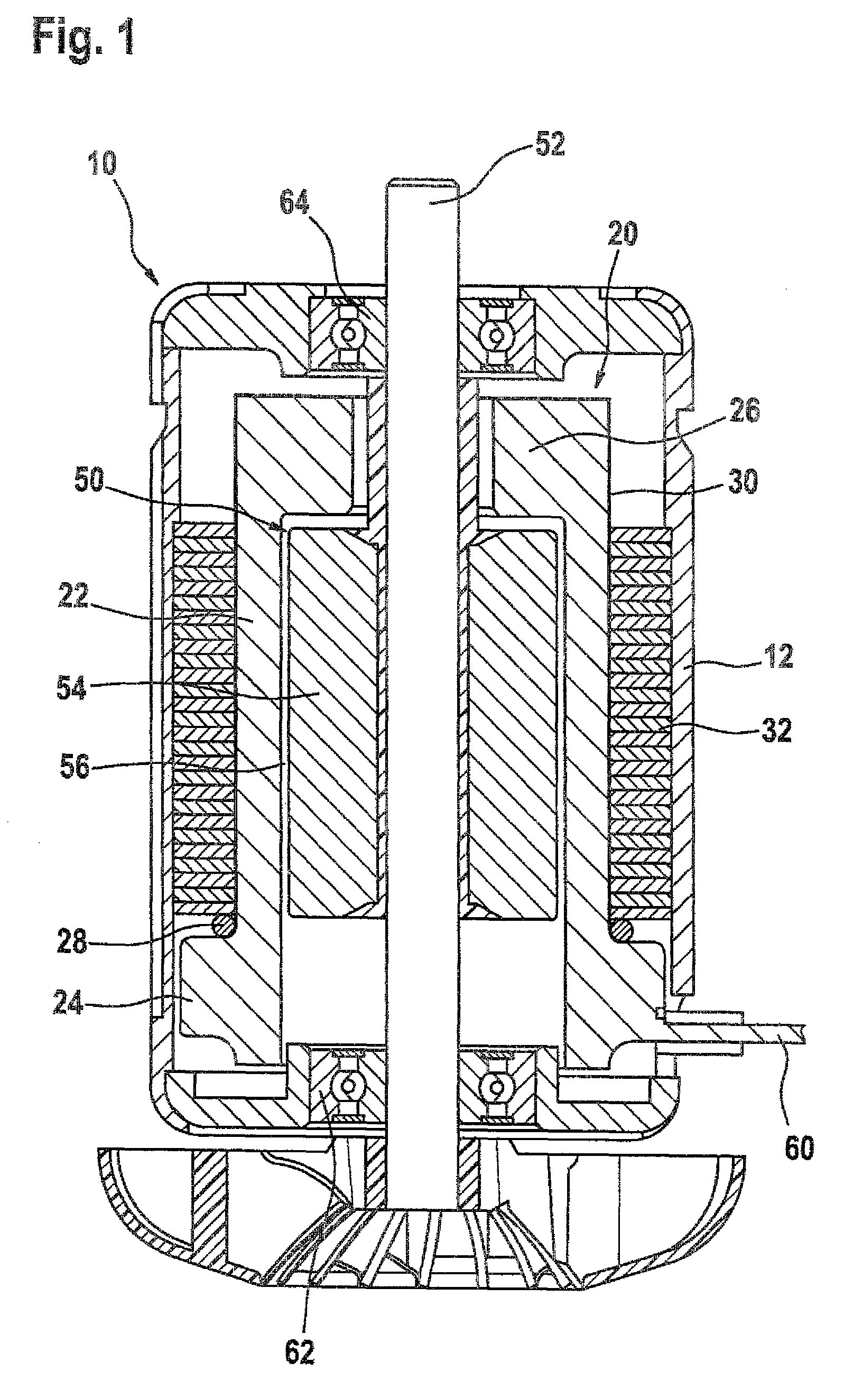

Medical or dental hand-piece element

ActiveUS20080176181A1Power Loss MinimizationSimple and inexpensive productionDental toolsDynamo-electric machinesMechanical energyEngineering

There is disclosed a medical or dental hand-piece element comprising a coupling mechanism for a detachable connection of the hand-piece element to a drive unit, a tool receptacle that is or can be connected to the hand-piece element, and a drive element for transmitting a driving movement from the drive unit to the tool receptacle so that the tool receptacle can be set into a working movement, wherein the drive element comprises at least one rotatable shaft, and a generator for converting mechanical energy into electric energy, wherein the generator can be driven by the at least one rotatable shaft of the drive element.

Owner:W&H DENTALWERK

Medical or dental hand-piece element

ActiveUS8333588B2Reduce in quantityEasy to handleDental toolsDynamo-electric machinesMechanical energyDriven element

There is disclosed a medical or dental hand-piece element comprising a coupling mechanism for a detachable connection of the hand-piece element to a drive unit, a tool receptacle that is or can be connected to the hand-piece element, and a drive element for transmitting a driving movement from the drive unit to the tool receptacle so that the tool receptacle can be set into a working movement, wherein the drive element comprises at least one rotatable shaft, and a generator for converting mechanical energy into electric energy, wherein the generator can be driven by the at least one rotatable shaft of the drive element.

Owner:W&H DENTALWERK

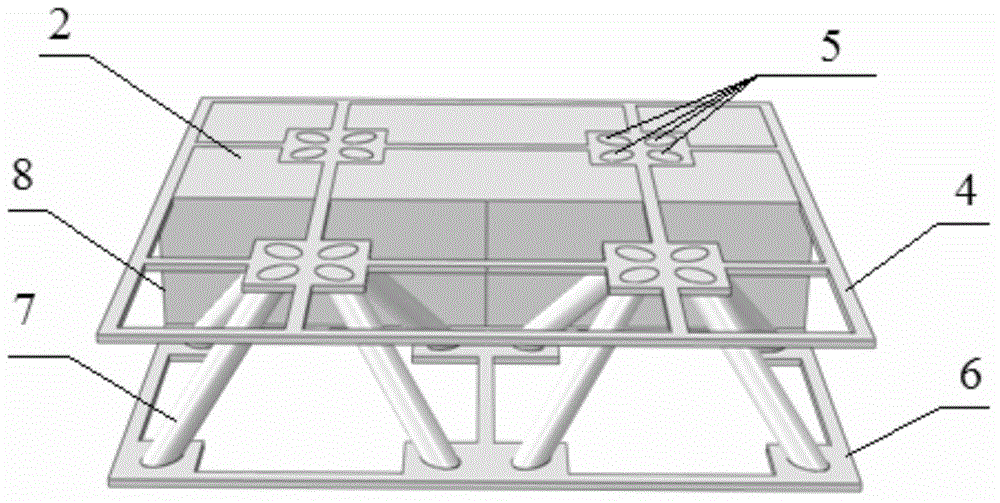

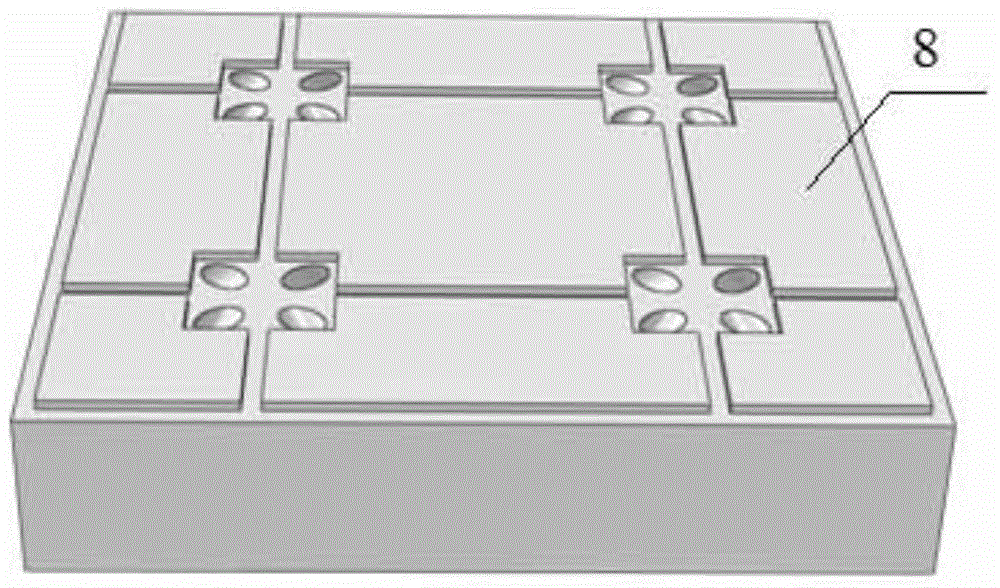

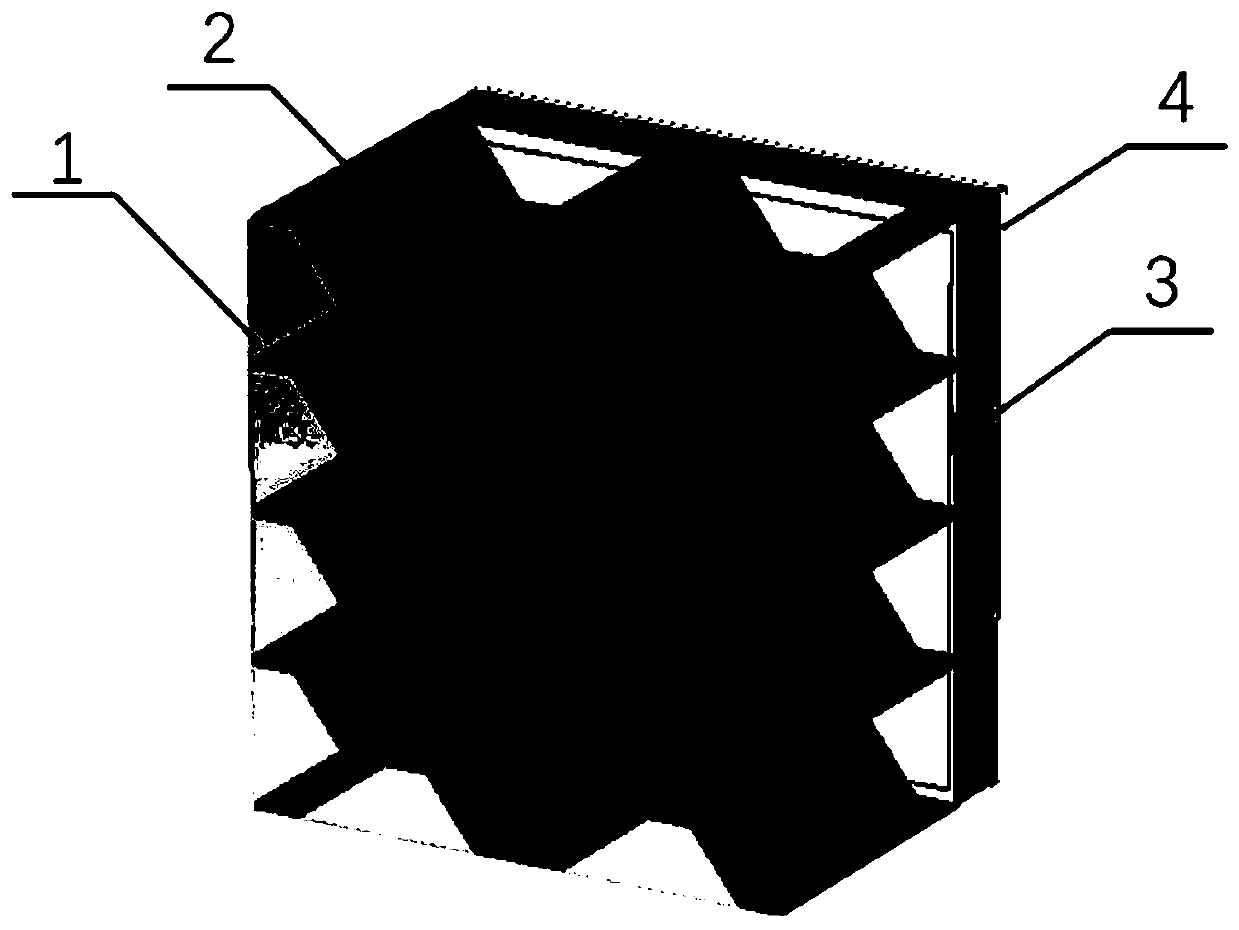

Heat conduction and load bearing integrated light sandwiched panel with lattice structure and preparation method thereof

InactiveCN104553090AImprove thermal conductivityHigh mechanical load capacityLaminationLamination apparatusHeat conductingEngineering

The invention relates to a heat conduction and load bearing integrated light sandwiched panel with a lattice structure and a preparation method of the heat conduction and bearing integrated light sandwiched panel, aiming at solving the problems that the existing sandwiched panel with the lattice structure has poor heat conducting property and single structure performance. The heat conduction and load bearing integrated light sandwiched panel is composed of an upper panel, a sandwiched layer with a lattice structure and a lower panel, and the sandwiched layer with the lattice structure is composed of an upper reinforcing mesh, multiple pyramid lattice structure unit cells, a lower reinforcing mesh and a carbon foam sandwiched panel. The preparation method comprises the following steps: I. preparing a cylindrical rod; II. preparing the foam sandwich panel; III. preparing the upper reinforcing mesh and the lower reinforcing mesh; IIIV. preparing the sandwiched layer with the lattice structure; and V. preparing the sandwiched panel with the lattice structure. The heat conduction and load bearing integrated light sandwiched panel with the lattice structure can be used for solving the problems that the existing sandwiched panel with the lattice structure has poor heat conducting property and single structure performance, and when the light multi-functional sandwiched panel is subjected to action of thermal loading, the panel with high heat conducting property and the carbon foams with high heat conducting property form a heat conducting passageway, so that the heat conducting property of the light multi-functional sandwiched structural panel is improved.

Owner:HARBIN INST OF TECH

Preparation method of special-shaped carbon fiber composite I-beam and special-shaped I-beam prepared through method

The invention provides a preparation method of a special-shaped carbon fiber composite I-beam and the special-shaped I-beam prepared through the method. The preparation method of the special-shaped carbon fiber composite I-beam comprises the steps that a setting agent is scattered on carbon fiber fabric according to the mass of 3-8 g / m<2>, heat setting is conducted, the fabric is cut into the required shape through a cutting machine after setting of the carbon fiber fabric is completed, the fabric cut into the specific shape is laid on a mold prepared in advance in an attached mode, so that a prefabricated body is obtained, and the prefabricated body is placed in a vacuum bag to be stored in an airtight mode after laying is completed; composite liquor is formed, so that a crude special-shaped carbon fiber composite I-beam is obtained; and the finished special-shaped carbon fiber composite I-beam is obtained by treating the crude special-shaped carbon fiber composite I-beam. The special-shaped carbon fiber composite I-beam is high in bearing capacity, good in rigidity, low in self weight and high in surface smoothness, the porosity of a product is low, and the outer surface dimension and the resin content can be controlled accurately.

Owner:HENGSHEN

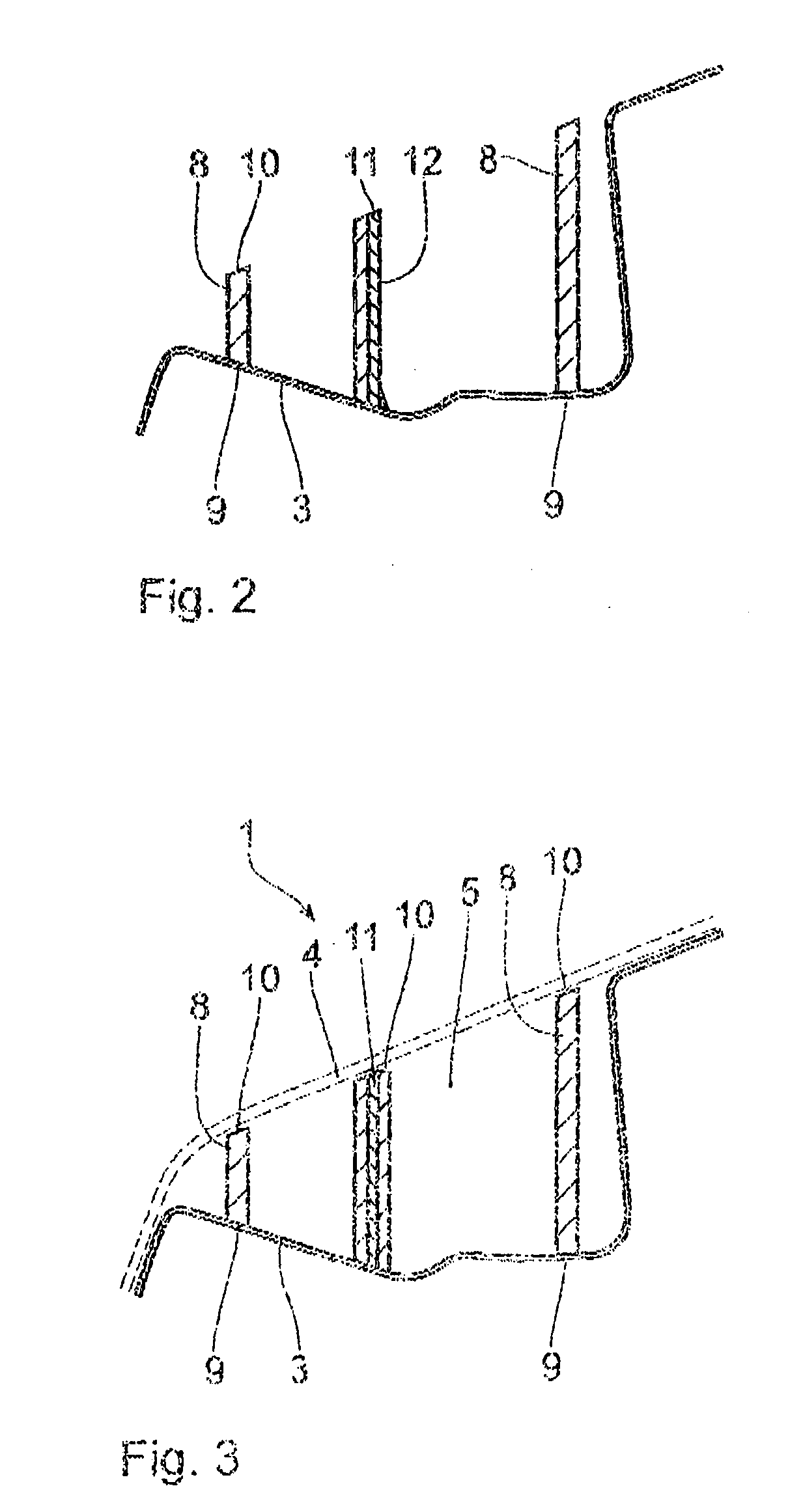

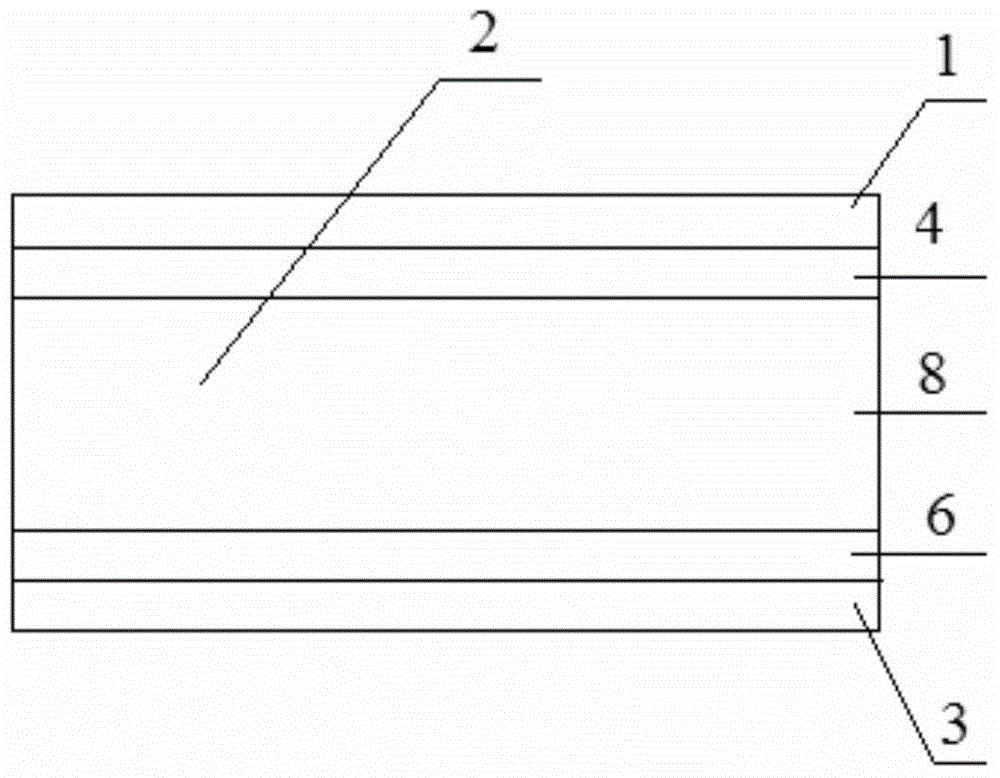

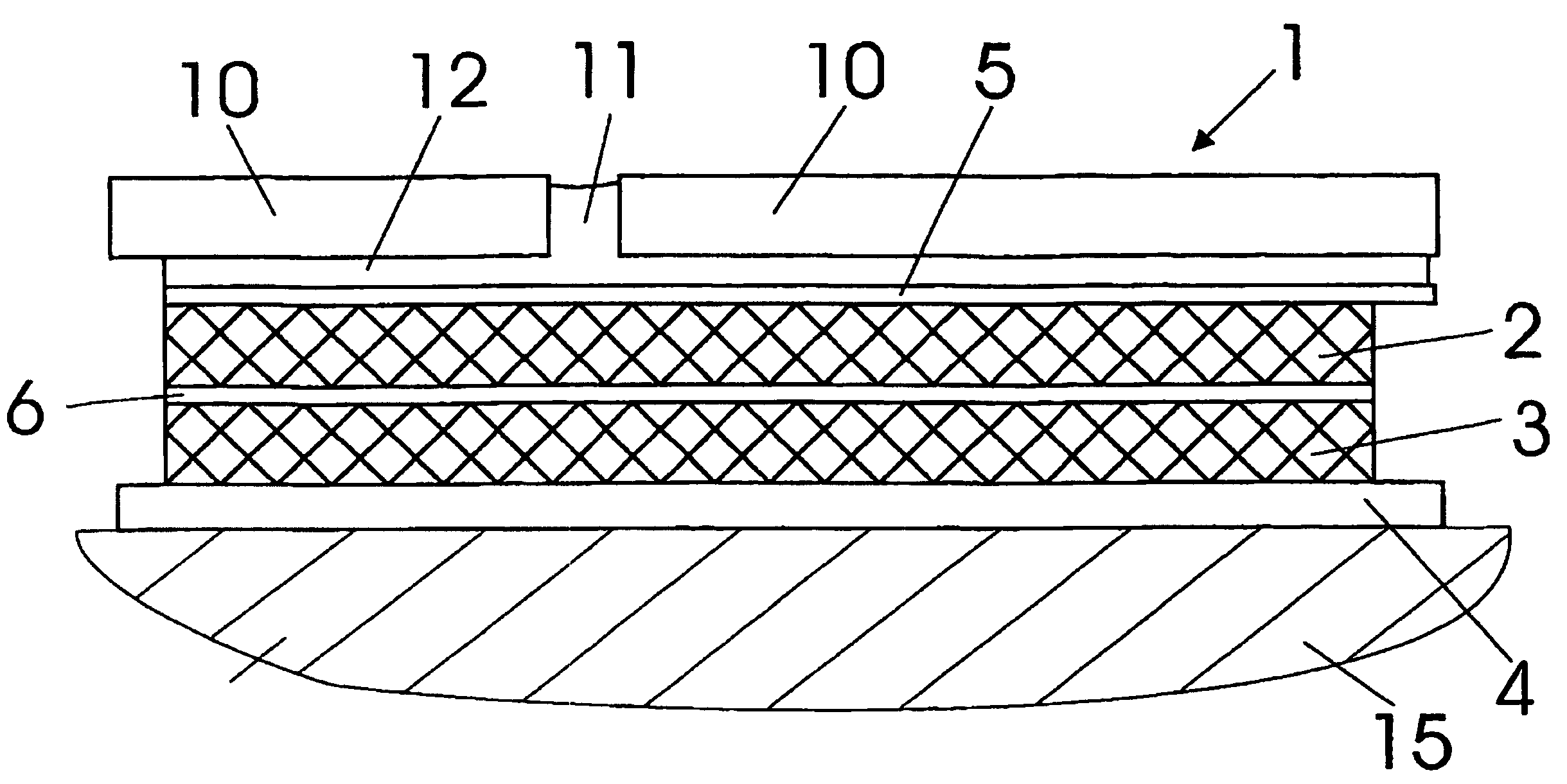

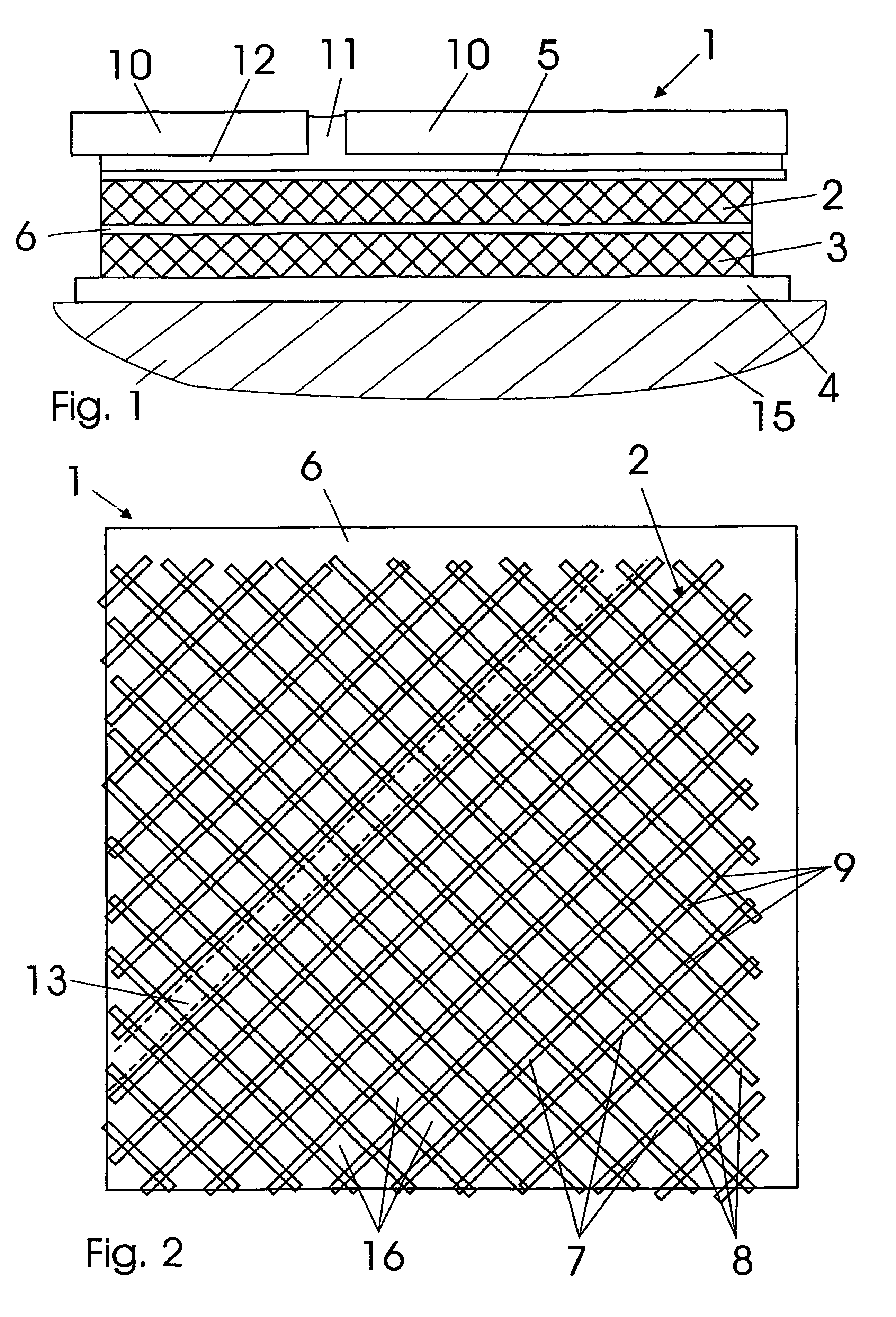

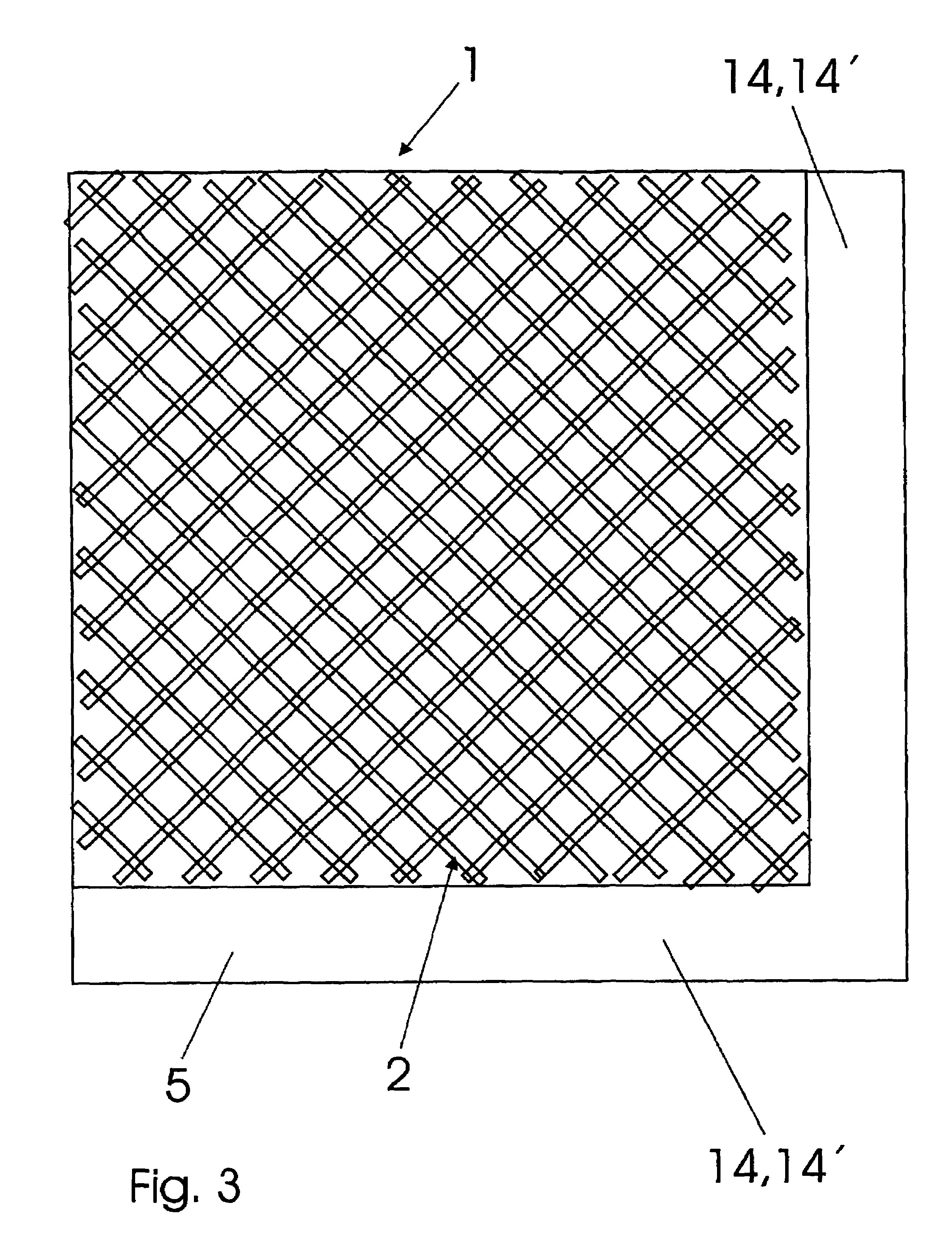

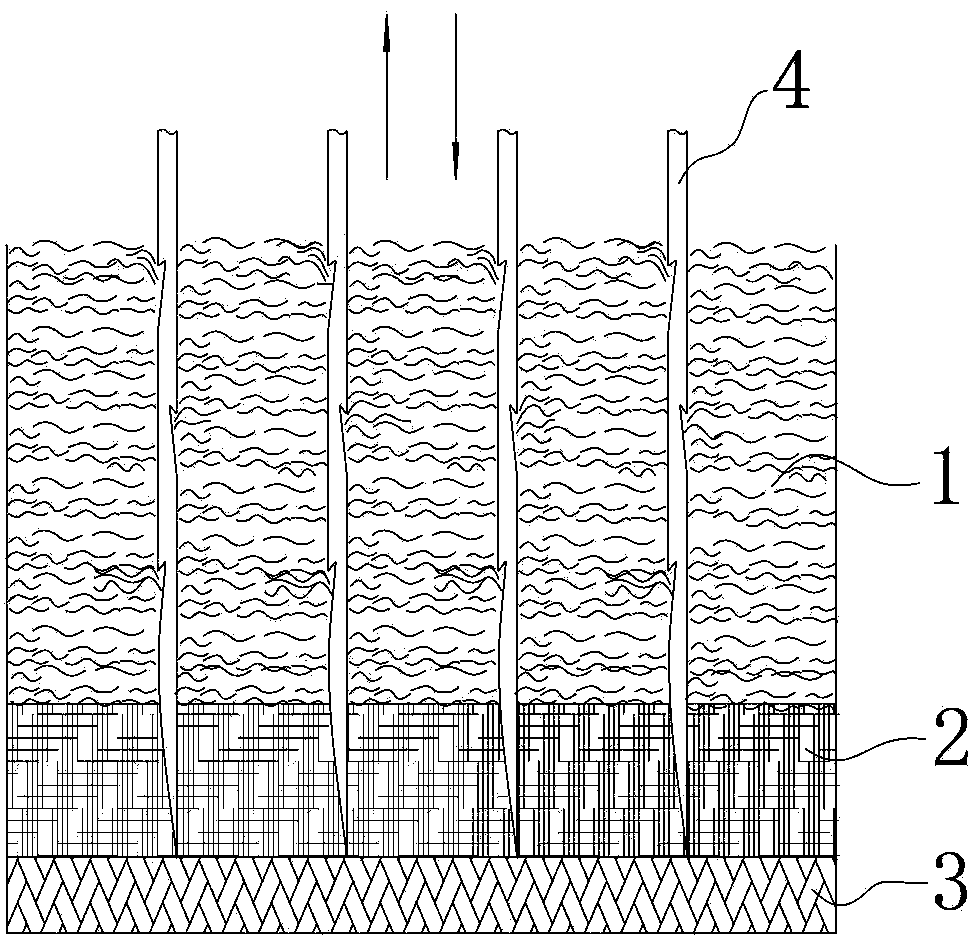

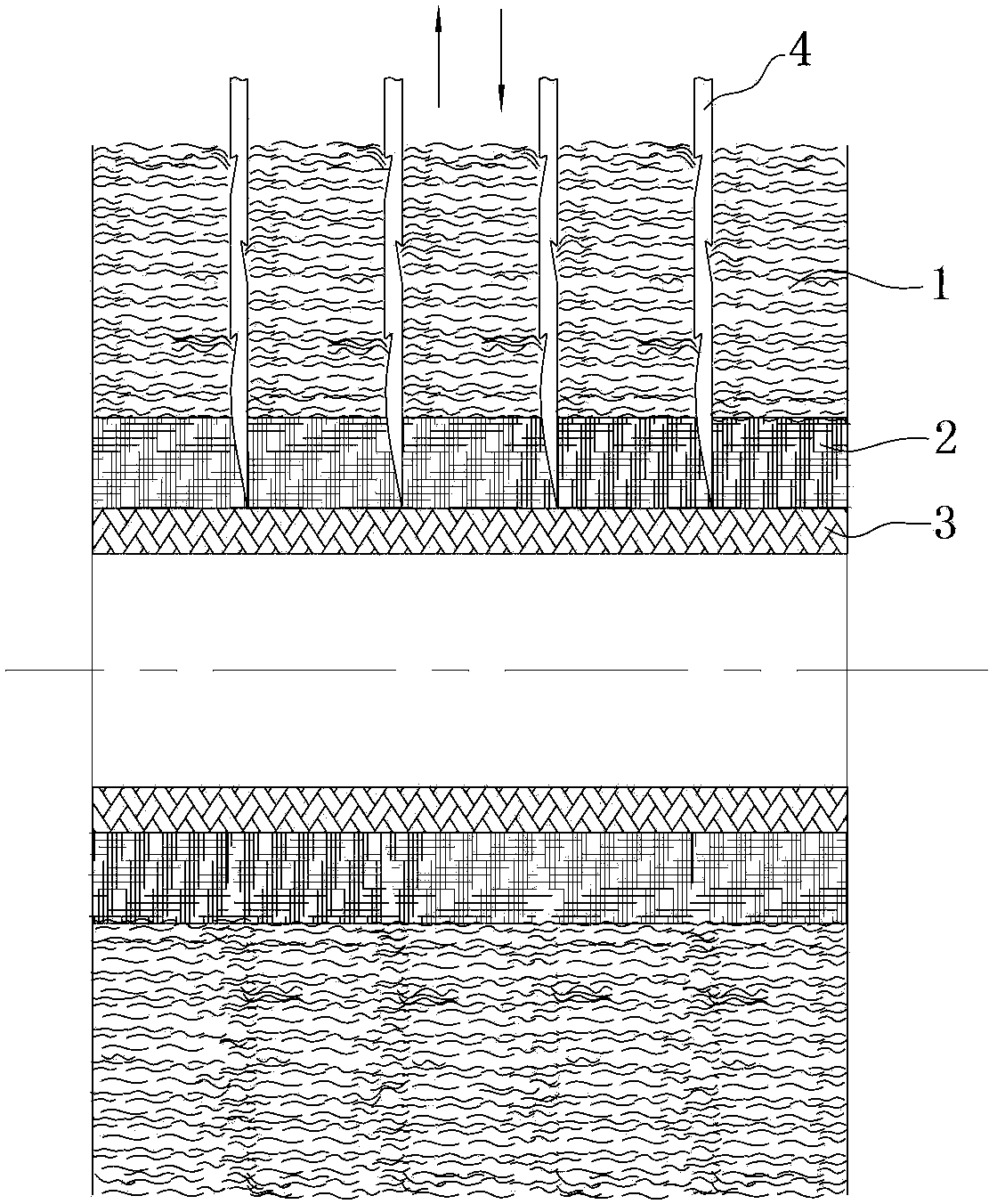

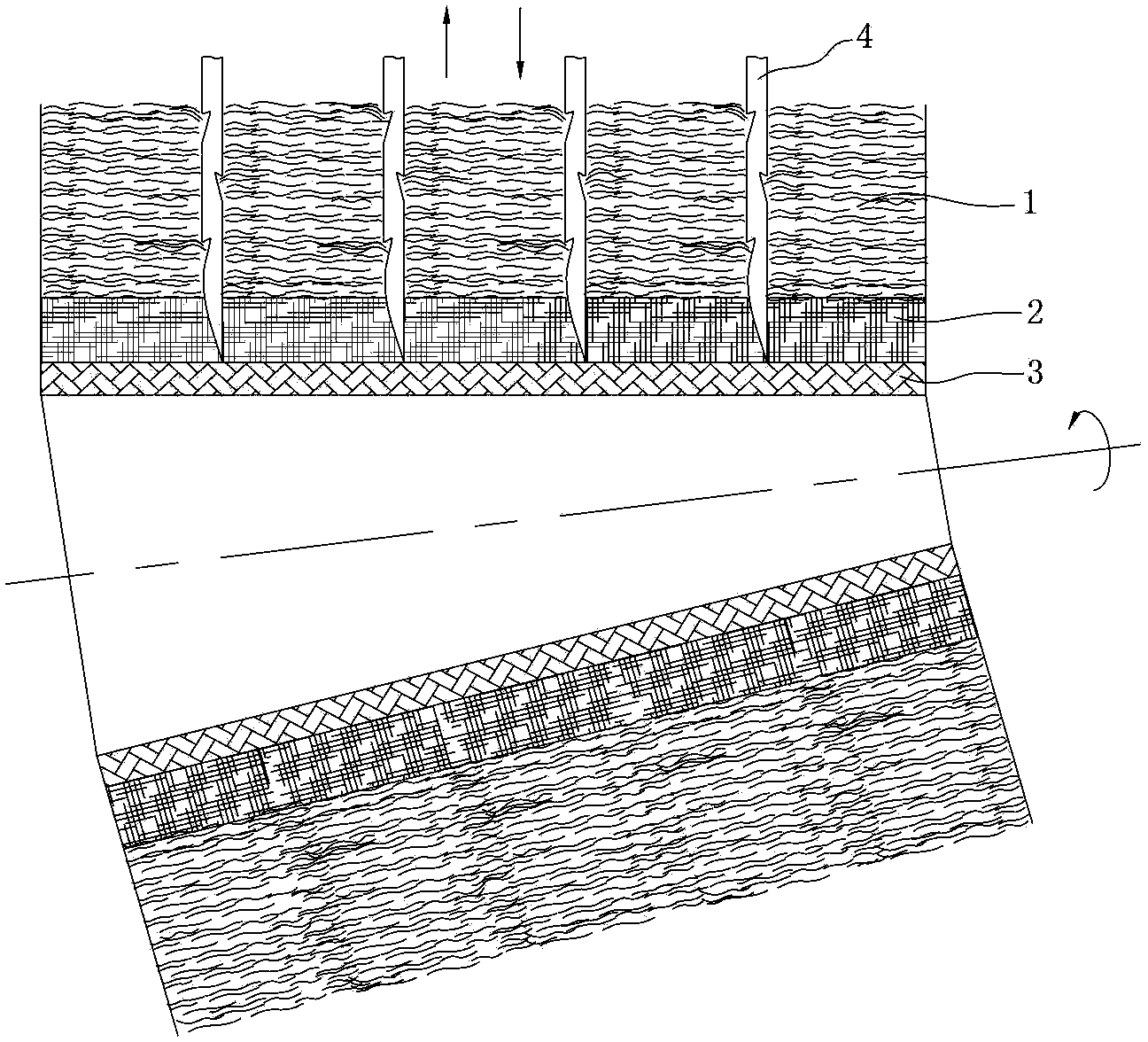

Multi-layer decoupling, sealing and drainage system

ActiveUS7624551B2Improve drainageHigh mechanical load capacityCovering/liningsLayered productsFilling materialsEngineering

The invention relates to a multi-layer sealing and drainage system (1), in particular for the laying of ceramic paving (10) according to a thin-bed method (12). Said system comprises a layered construction containing, from the base upwards, a drainage layer (3) that is configured from a first lattice-type structural element and comprises drainage regions (13) that are formed between the lattice structures of said element, a liquid-permeable nonwoven layer (6), an anchorage layer (2) that is configured from a second lattice-type structural element and that is used to hold a filler material (12), which is to be incorporated into the upper face of the sealing and drainage system (1) and which is plastic during processing and subsequently cures, in addition to a reinforcement layer (5), which is fixed, at least in some sections, to the anchorage layer (2). The system can also comprise a sealing layer below the drainage layer.

Owner:BLANKE

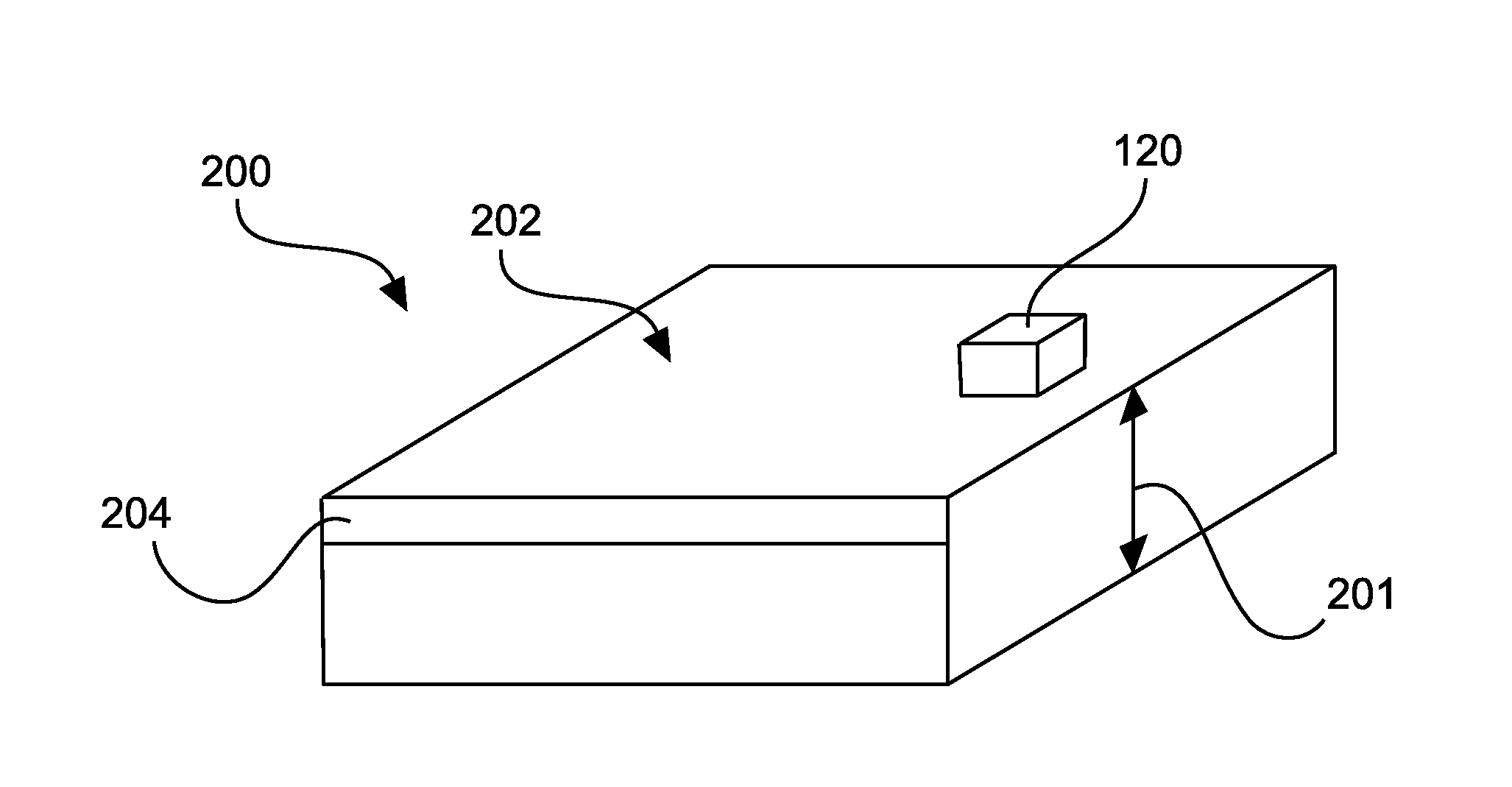

Structural Health Monitoring System for a Material and Production Method

ActiveUS20150071324A1Enable detectionReduce weightVolume/mass flow by thermal effectsAerodynamic testingCarbon nanotubeEngineering

A structural health monitoring system includes a signal transmission element and a sensor unit. The sensor unit is designed to feed a first signal into the signal transmission element and to read out a second signal from the signal transmission element. The signal transmission element has carbon nanotubes.

Owner:AIRBUS DEFENCE & SPACE

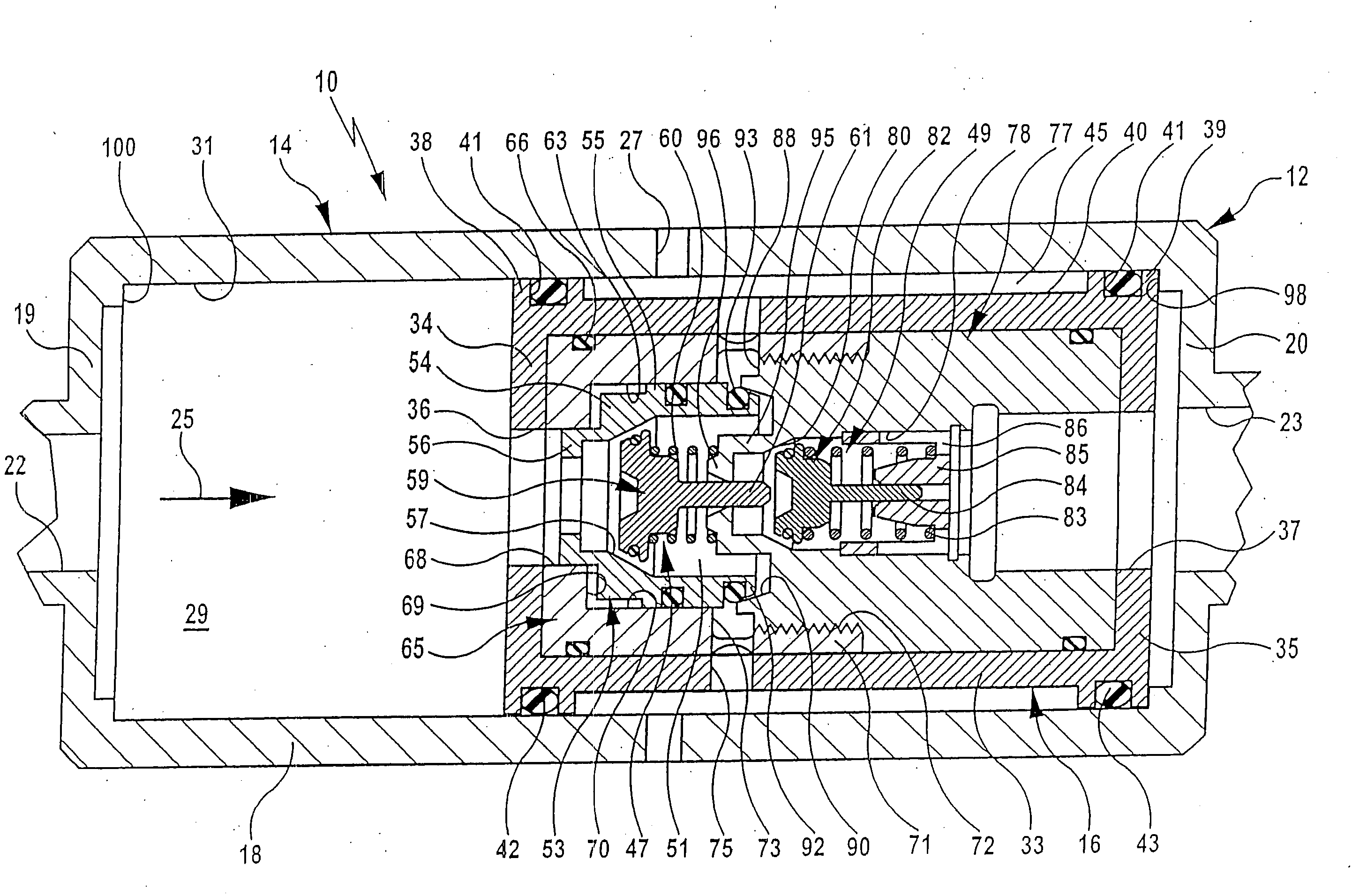

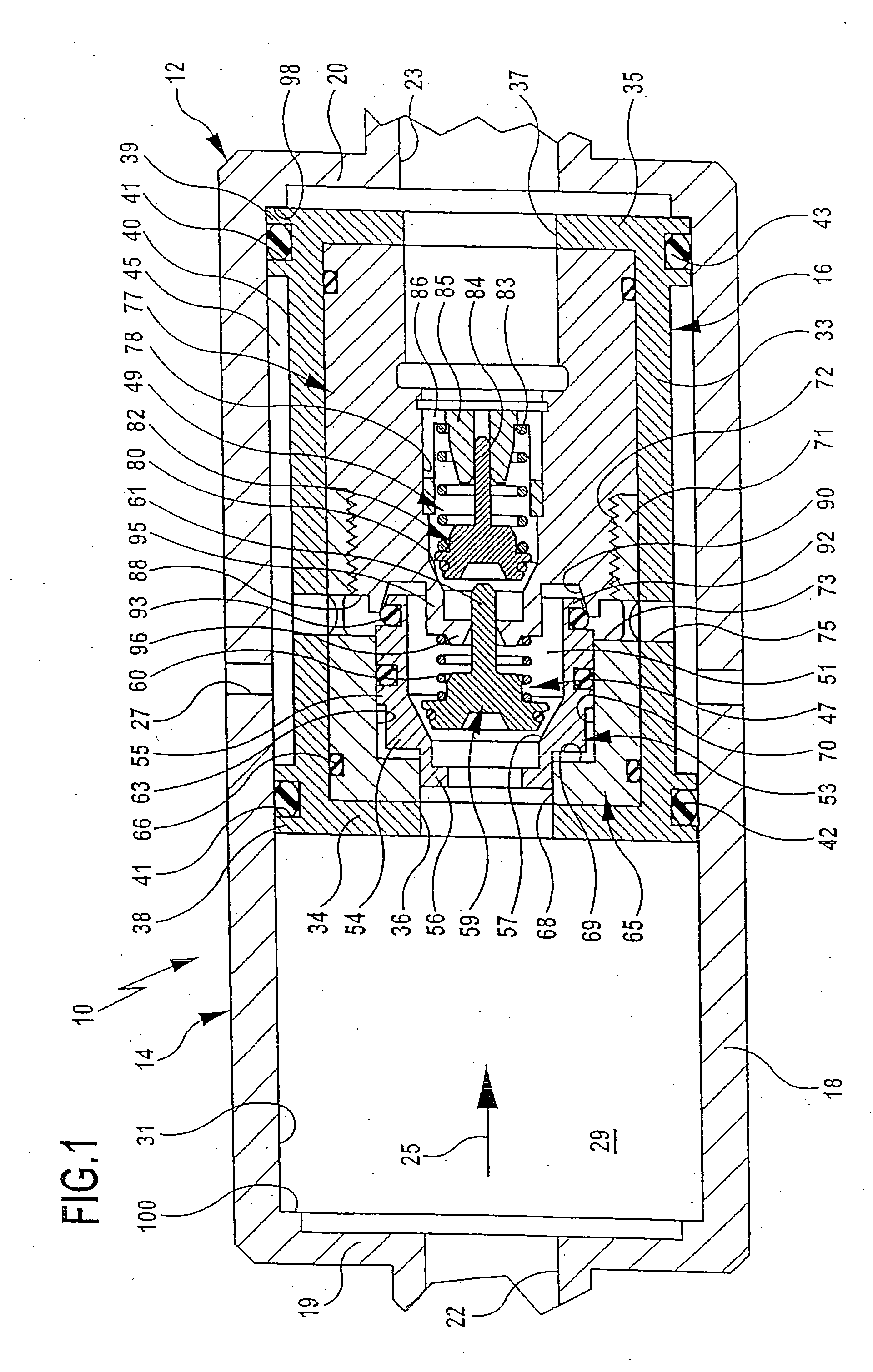

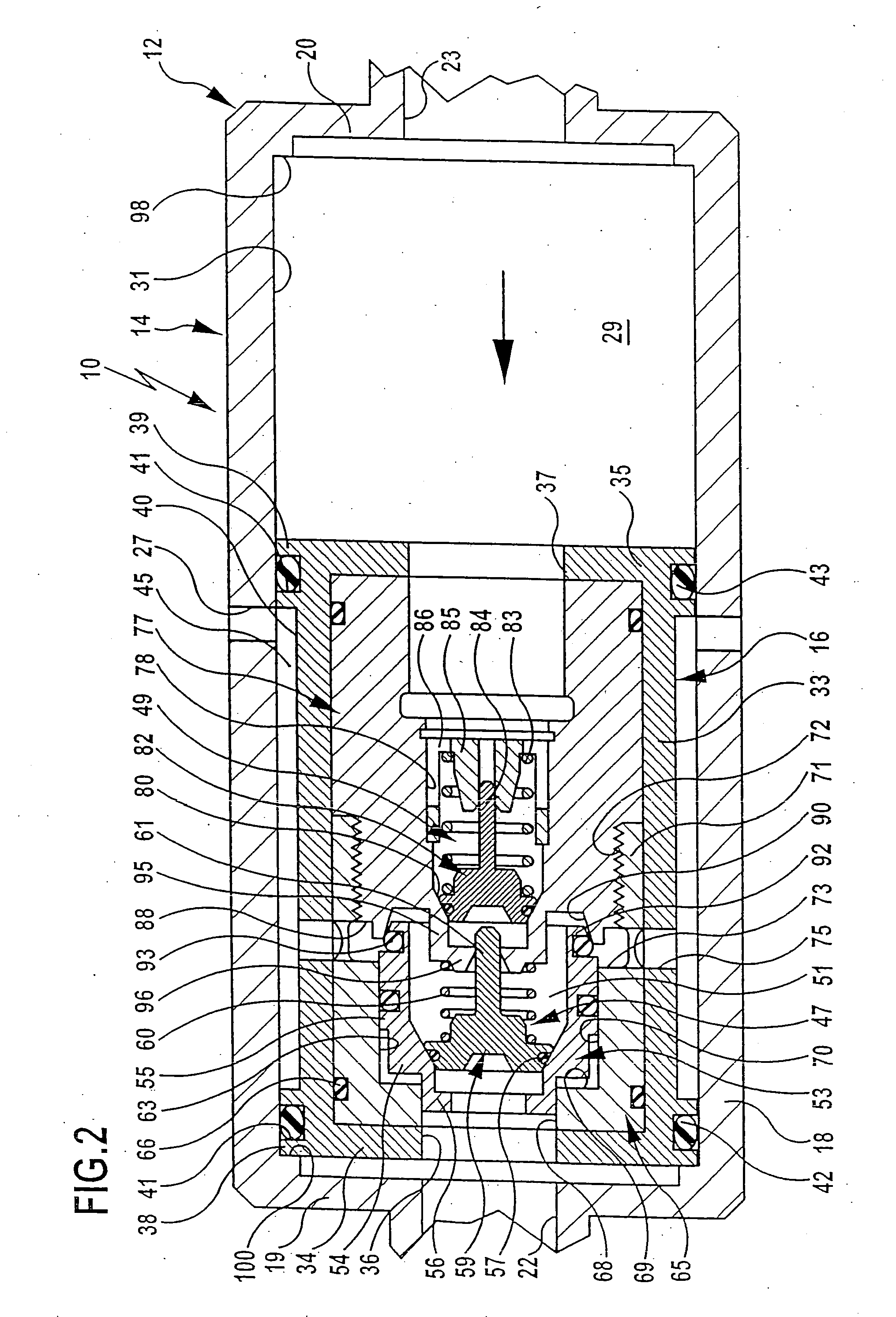

Backflow preventer

InactiveUS20060157111A1Easy to assembleHigh mechanical load capacityOperating means/releasing devices for valvesCheck valvesIntermediate spaceEngineering

The invention relates to a backflow preventer having a housing, which has an inlet opening, an outlet opening and at least one leakage opening disposed between these openings and accommodates first and second nonreturn valves disposed in series, the first nonreturn valve being held displaceably in order to open up and close a flow connection between an intermediate space of the housing and the leakage opening. To develop the backflow preventer in such a manner that an inadmissible increase in pressure in the region of the outlet opening can be avoided in a structurally simple way, according to the invention it is proposed that the housing comprises an inner housing and an outer housing, the outer housing having the at least one leakage opening and the inner housing accommodating the two nonreturn valves and being held such that it can be displaced to and fro in the direction of through-flow within the outer housing, and the inner housing having an outlet opening, via which the flow connection between the intermediate space and the leakage opening can be produced independently of the position of the inner housing, by displacement of the first nonreturn valve relative to the second nonreturn valve.

Owner:ALFRED KARCHER GMBH & CO KG

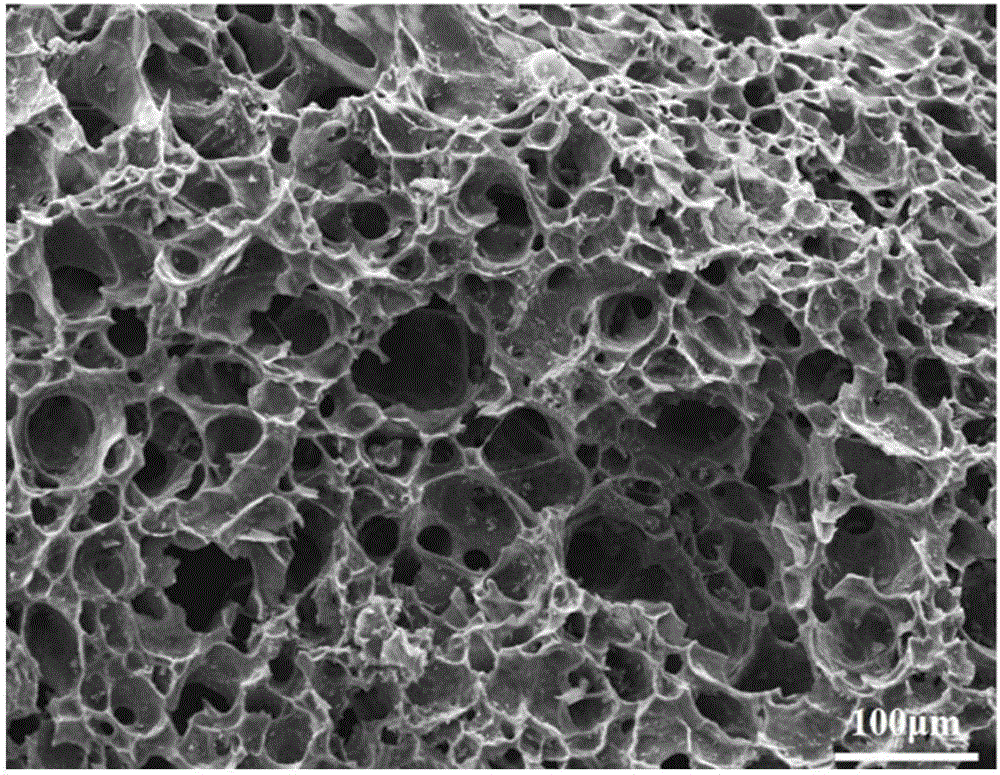

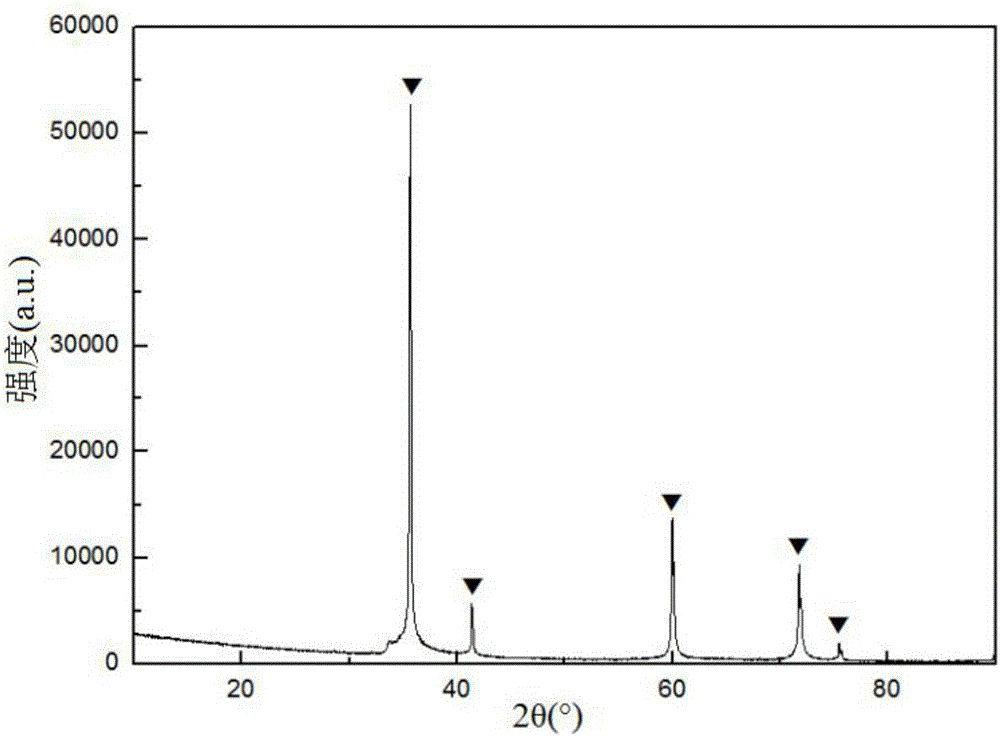

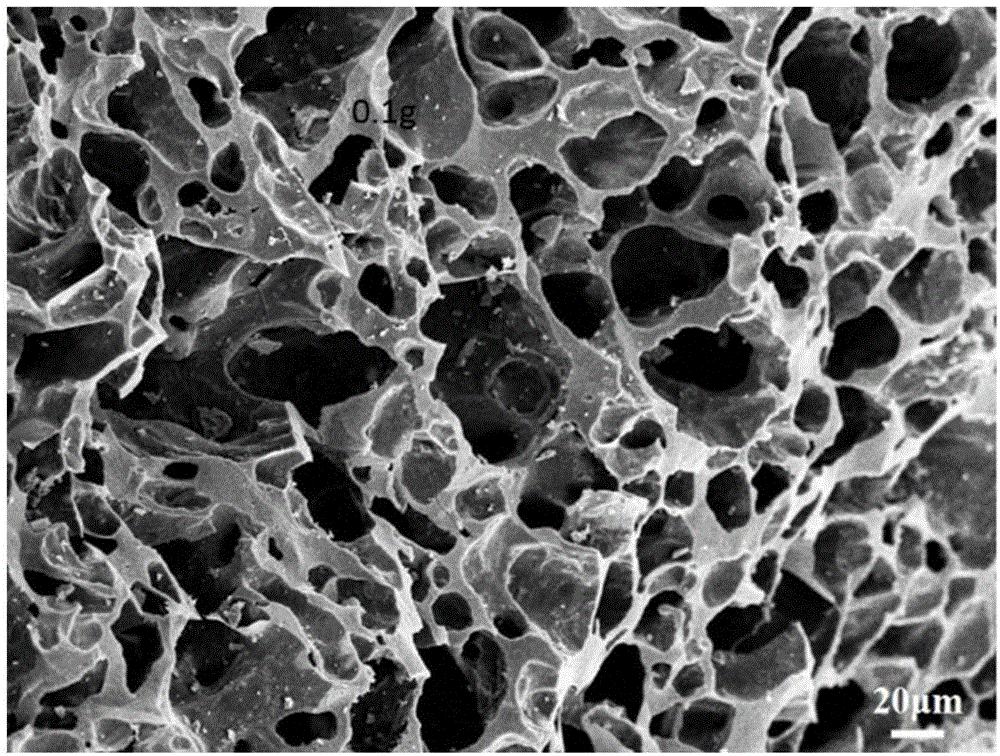

Method for preparing high-temperature-resistant structural SiC porous ceramics

ActiveCN106588085AAperture adjustableHigh mechanical load capacityCeramicwareSemiconductor materialsMicrowave

The invention provides a method for preparing high-temperature-resistant structural SiC porous ceramics, belongs to the field of preparation of microwave-absorbing, environment-firendly, catalytic and biosensing semiconductor materials and energy sources and nuclear protective materials, and specifically relates to a method for preparing the SiC porous ceramics. The method aims to solve the problems that in an existing method for preparing the SiC porous ceramics, the pore size distribution and size of the porous ceramics are generally difficult to control, the specific surface area is small, and the mechanical strength of the high-porosity ceramics is low. The method includes the following steps: 1, kneading dough; 2, conducting fermentation and freeze drying to obtain porous dough; 3, conducting carbonization to obtain a porous carbon skeleton; 4, conducting sintering to obtain the high-temperature-resistant structural SiC porous ceramics. The method is mainly used for preparing the high-temperature-resistant structural SiC porous ceramics.

Owner:HARBIN INST OF TECH

Fabric punched felt complex and preparation method thereof

ActiveCN103879076AEquivalent mechanical propertiesImprove mechanical propertiesGlass/slag layered productsNatural mineral layered productsIntensity changeEngineering

The invention provides a fabric punched felt complex and a preparation method thereof. The preparation method comprises the following steps: compounding a continuous functional fiber fabric layer and a continuous functional fiber bulked yarn crude fabric layer together so as to obtain integrated fabric; then compounding a chopped functional fiber punched felt layer with the continuous functional fiber bulked yarn crude fabric layer of the integrated fabric through needling so as to obtain the fabric punched felt complex. The fabric punched felt complex has a light and high strength structure with stepped intensity changes. The weight of the fabric punched felt complex is 30% lighter than that of complete fabric with a same volume, while the mechanical performance of the fabric punched felt complex is equal to that of complete fabric with a same volume, and is better than that of complete chopped fiber punched felt. At the same time the fiber raw material is saved by 30% or more, moreover the preparation technology is simple, and the production period is short.

Owner:HUNAN JIUHUA CARBON HI TECH

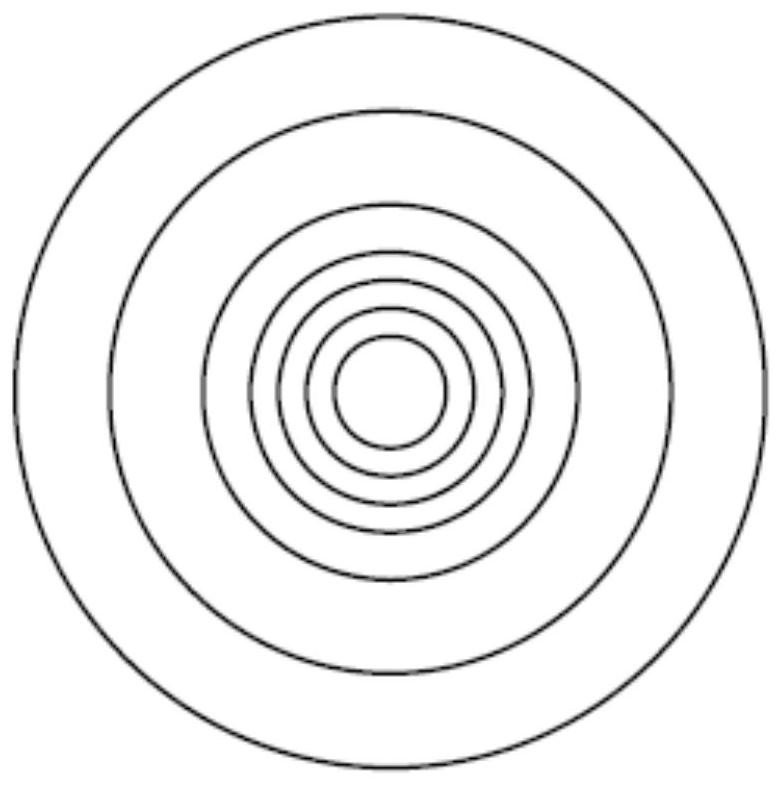

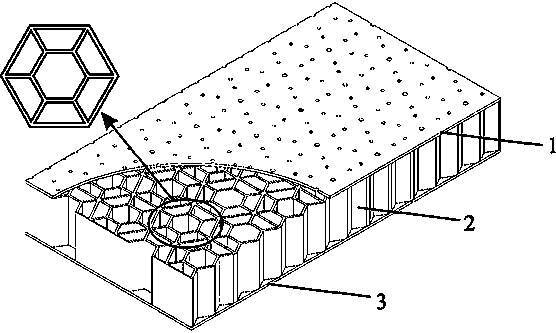

Super-structure honeycomb composite wave-absorbing material

InactiveCN111086301AAbsorbing frequency band is wideHave selective absorptionSynthetic resin layered productsLaminationEpoxyFrequency wave

The invention discloses a super-structure honeycomb composite wave-absorbing material, belonging to the technical field of wave-absorbing materials. The invention particularly relates to a honeycomb structure-metamaterial composite wave-absorbing material, which is mainly composed of an upper wave-transmitting skin layer, a middle sandwiched aramid fiber wave-absorbing honeycomb wave-absorbing layer and a bottom metamaterial wave-absorbing layer, wherein the three layers of materials are bonded through an epoxy resin adhesive. The metamaterial wave-absorbing layer is formed by manufacturing ametamaterial array on a printed circuit board, and the metamaterial array is an array formed by diamond-shaped, square, hollow-square-shaped or cross-shaped metal units. A metamaterial wave-absorbingbody and the honeycomb wave-absorbing material are creatively combined, and the broadband wave absorbing performance and the low-frequency wave absorbing function of the super-structure honeycomb composite wave-absorbing material are achieved through the selective wave absorbing function of the metamaterial wave-absorbing body.

Owner:ZHEJIANG UNIV OF TECH

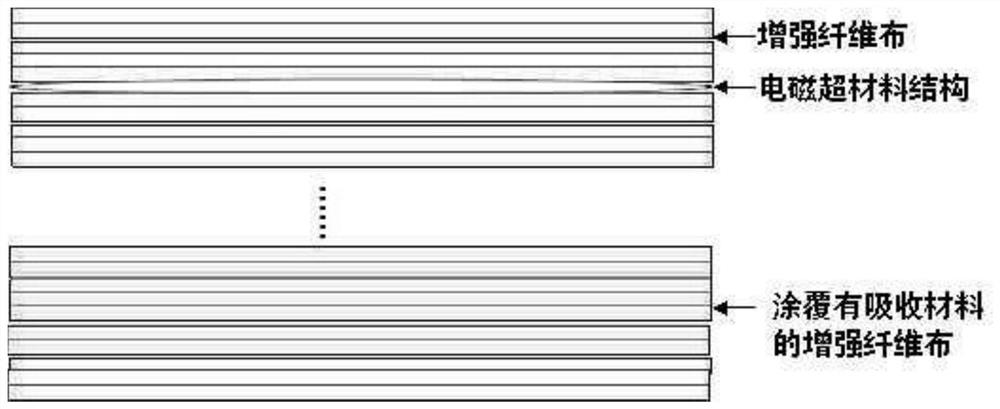

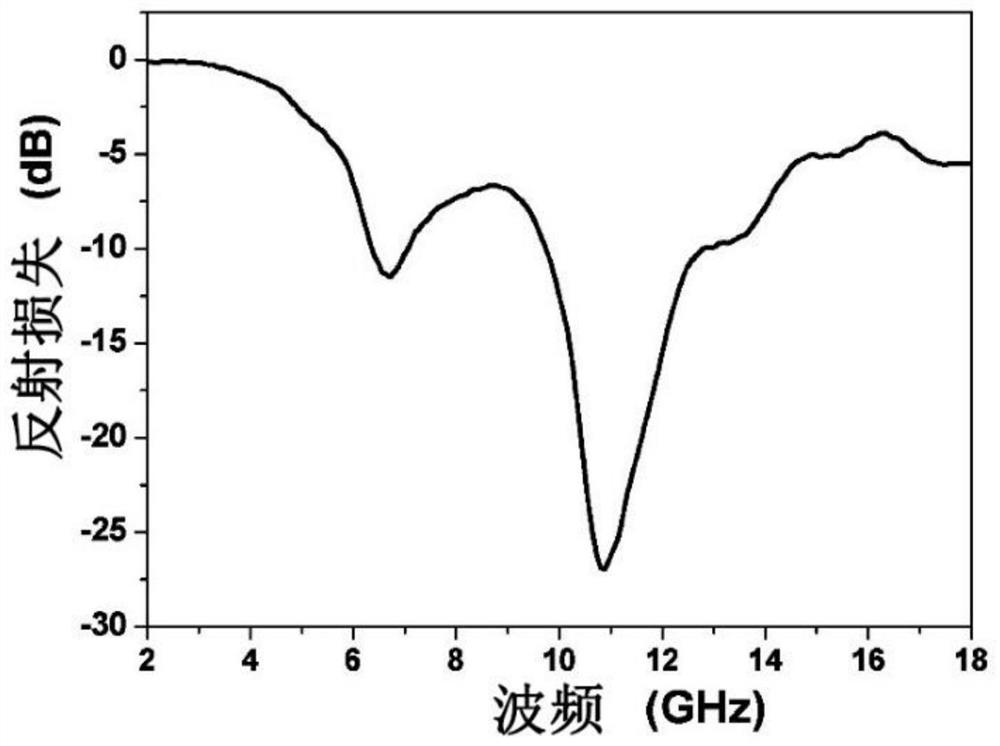

Structural composite wave-absorbing material and preparation method thereof

PendingCN112312754AGood level interface compatibilityWide absorption bandwidthShielding materialsFrequency bandFibre reinforcement

The invention discloses a structural composite wave-absorbing material and a preparation method thereof, which belong to the technical field of materials. The structural composite wave-absorbing material is composed of a fiber-reinforced resin-based composite material, an absorbent and a metamaterial wave-absorbing structure. Different layers of fiber cloth are uniformly coated with resin and a mixture of resin and absorbent and are combined with the metamaterial wave-absorbing structure to form a laminated structure to obtain the wave-absorbing material. According to the composite wave-absorbing material with the structure, the bearing mechanical property of the composite material structure is maintained, meanwhile, the material absorption bandwidth is effectively widened, and strong absorption of key frequency bands is realized.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

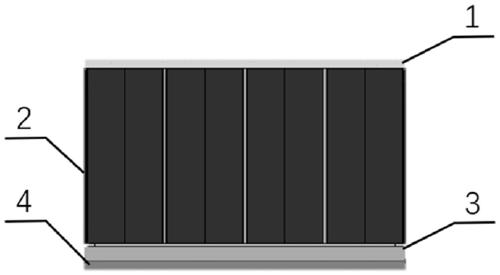

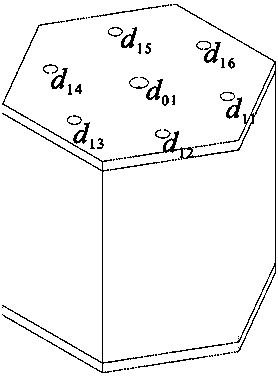

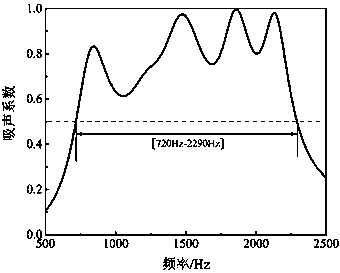

Micro-perforated plate cobweb honeycomb sandwich sound absorption bearing composite structure

PendingCN111048059AHigh mechanical load capacityImprove carrying capacitySound producing devicesMicro perforated plateHelmholtz resonator

The invention provides a micro-perforated plate cobweb honeycomb sandwich sound absorption bearing composite structure, which comprises an upper panel, a cobweb honeycomb core body and a lower panel.All the components are welded or bonded to form an integral structure. The upper panel is provided with micro-perforations, and the micro-perforations and the inner cavity of the cobweb honeycomb forma Helmholtz resonator to absorb noise. Under the condition of equal quality, the cobweb honeycomb is more excellent in bearing performance than a traditional honeycomb, and the cobweb honeycomb corebody can effectively support the panel to resist external loads. During use, the upper panel is installed towards a noise source, and the lower panel is back to the noise source. The structure of theinvention is simple, convenient to manufacture and light in weight, achieves the effects of sound absorption and bearing, can be used as a noise reduction component for high-speed trains and civil aircrafts, and improves the riding comfort.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

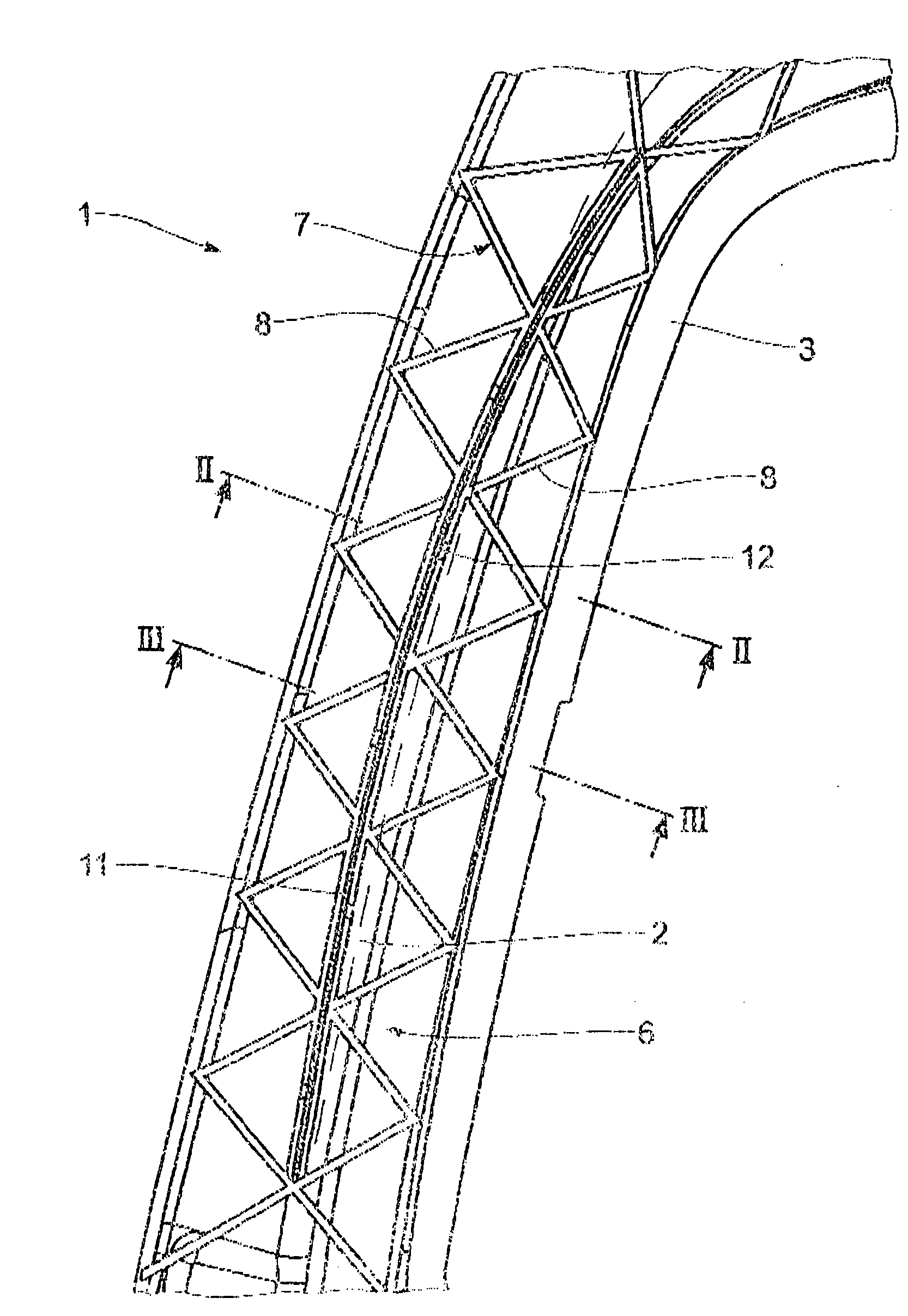

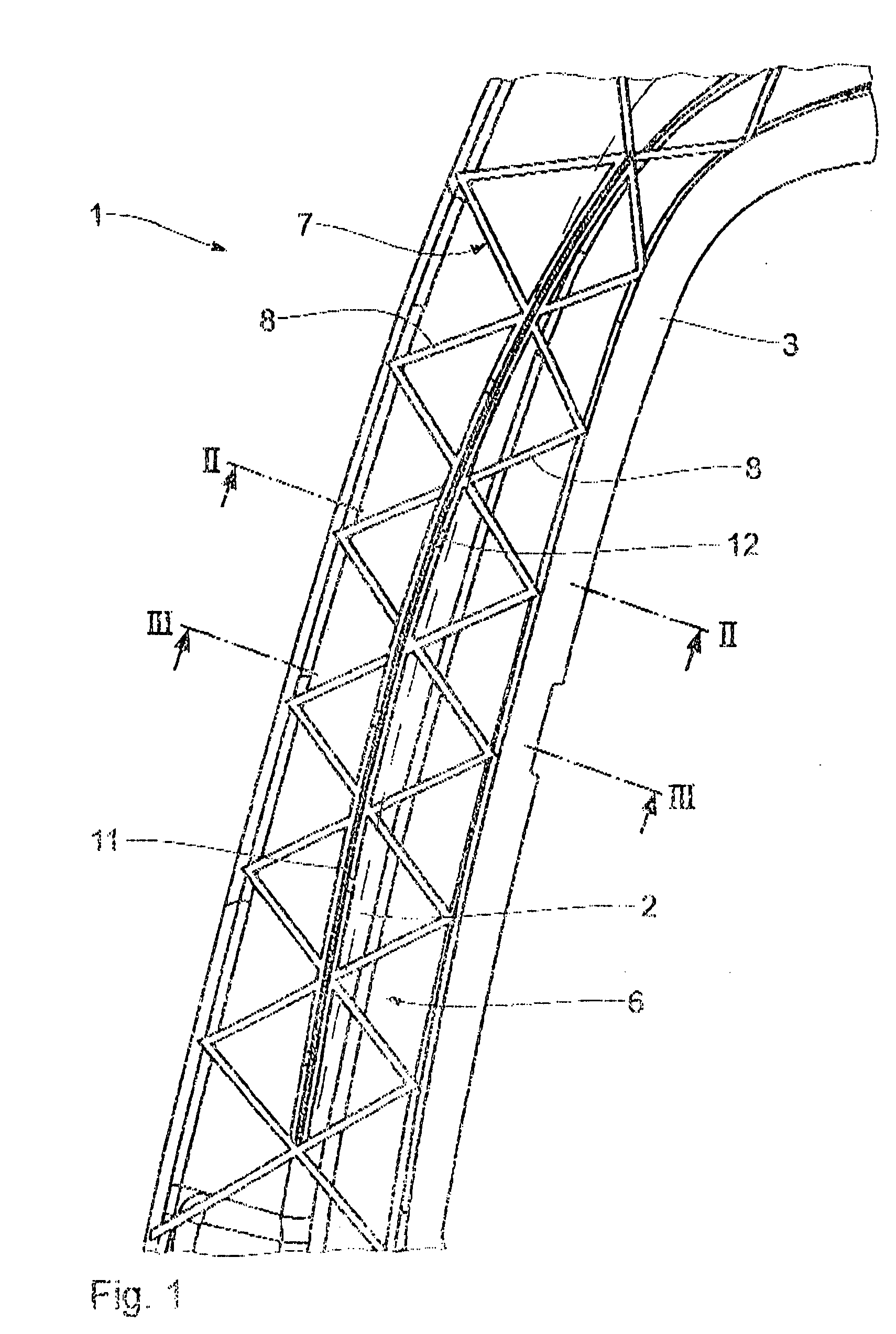

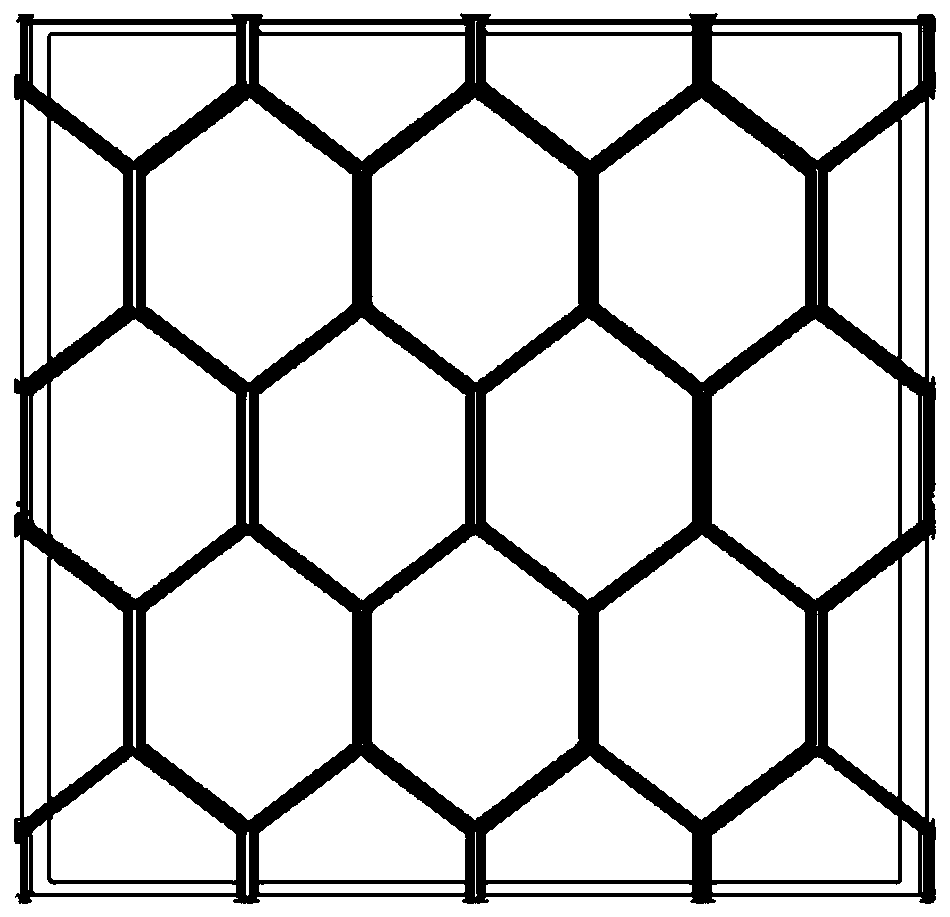

Lightweight structure, particularly primary aircraft structure or subassembly, as well as method for the manufacture thereof

InactiveUS9138958B2High mechanical load capacityReduce weightFuselage framesLayered productsPower stationComputer module

A lightweight structure at least sectionally composed of a plurality of connected mosaic elements and / or skin mosaic elements. The lightweight structure allows an essentially load-appropriate arrangement of the mosaic elements and / or the skin mosaic elements including the optional skin. The lightweight structure requires a significantly reduced number of connecting elements, such that the assembly effort can be reduced and an additional weight reduction can be achieved. Also, two variations of a method for manufacturing a lightweight structure are provided. Large-format lightweight structures such as, for example, an aircraft fuselage cell or partial shells thereof can also be manufactured in a reliable and dimensionally accurate fashion because only mosaic elements and skin mosaic elements, with relatively small dimensions, need to be handled. Other applications of the lightweight structure include launch vehicles, rocket stages, space stations, space station modules, satellites and masts or towers of wind power plants.

Owner:AIRBUS OPERATIONS GMBH

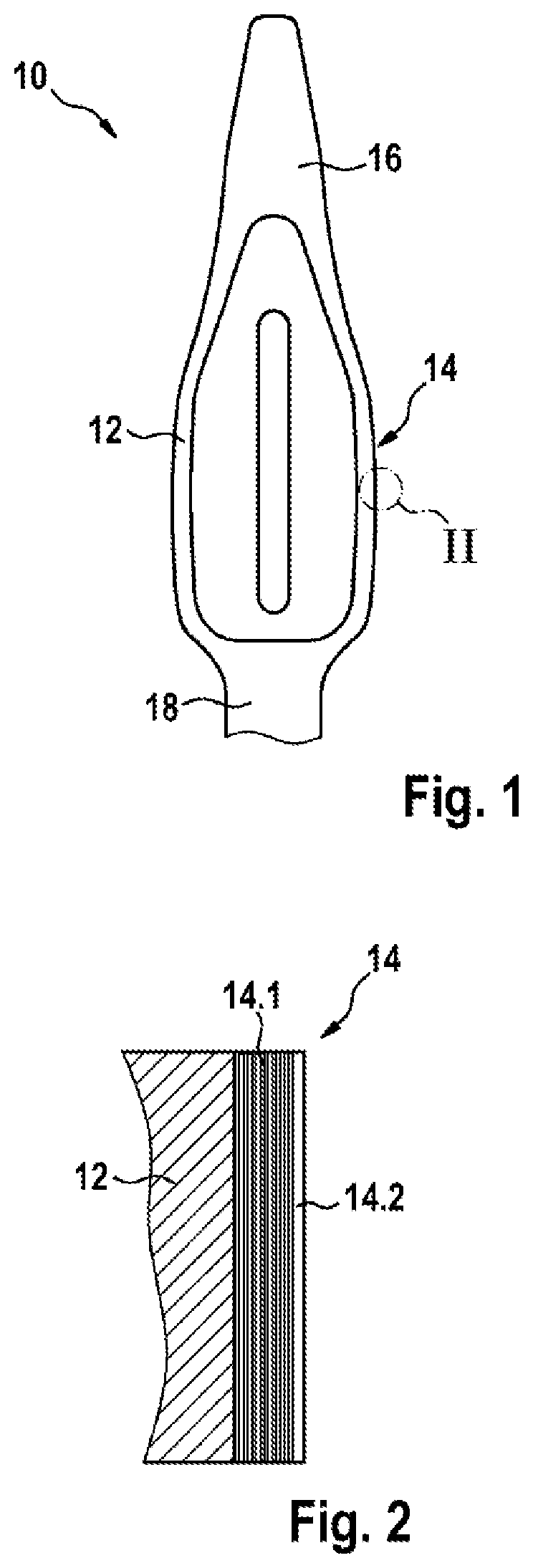

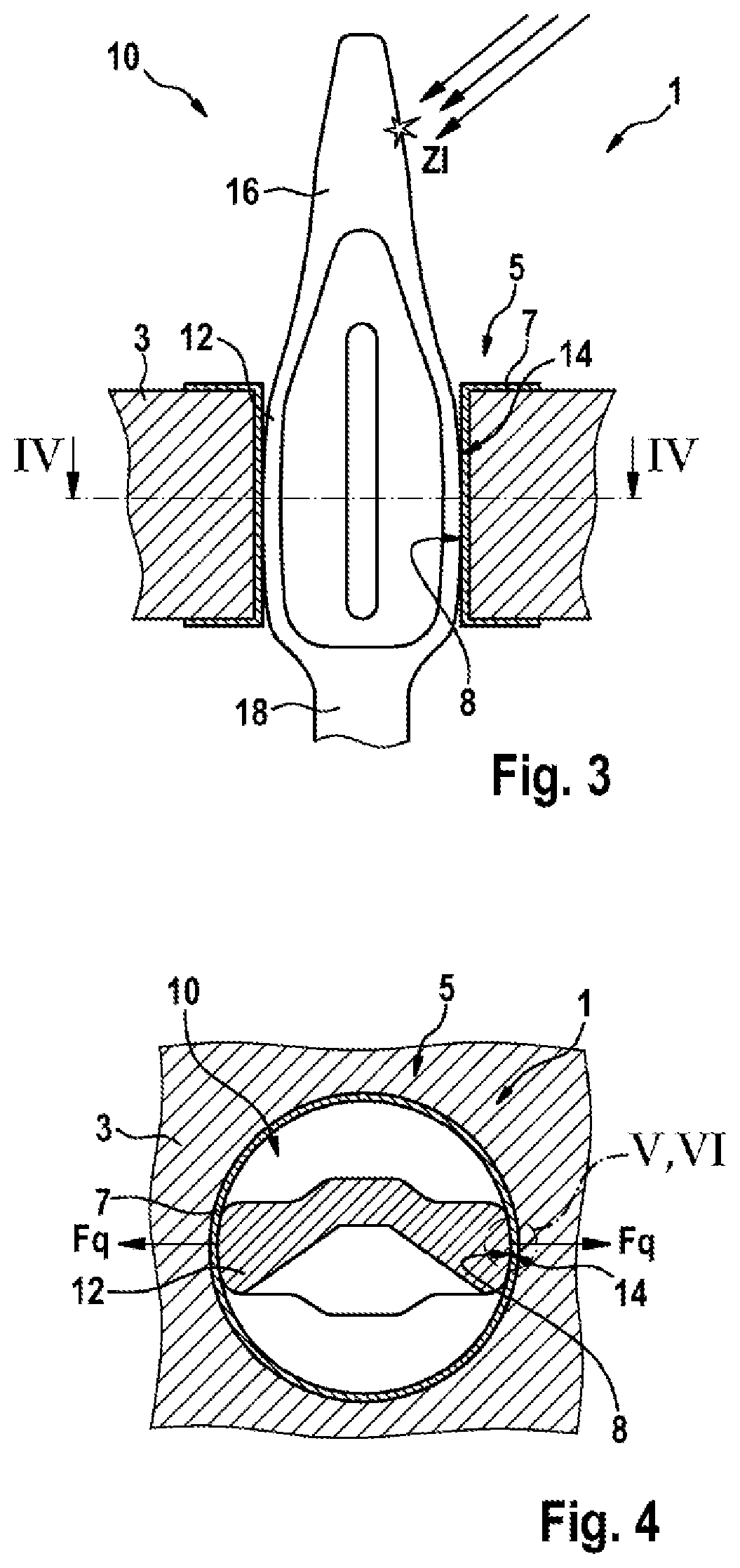

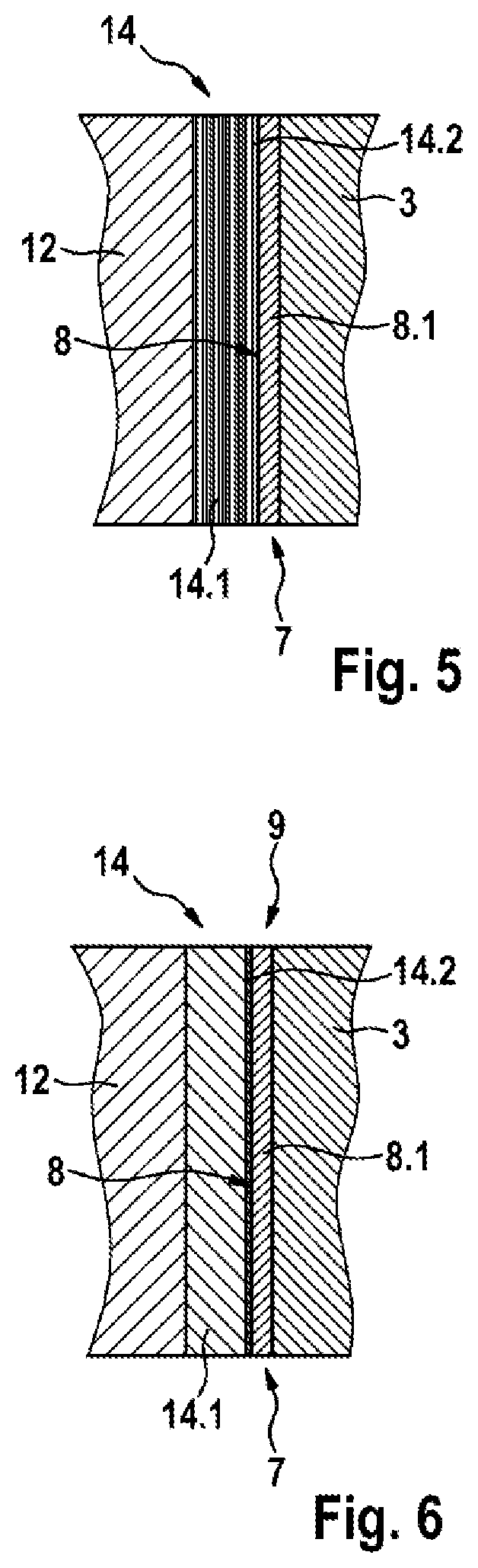

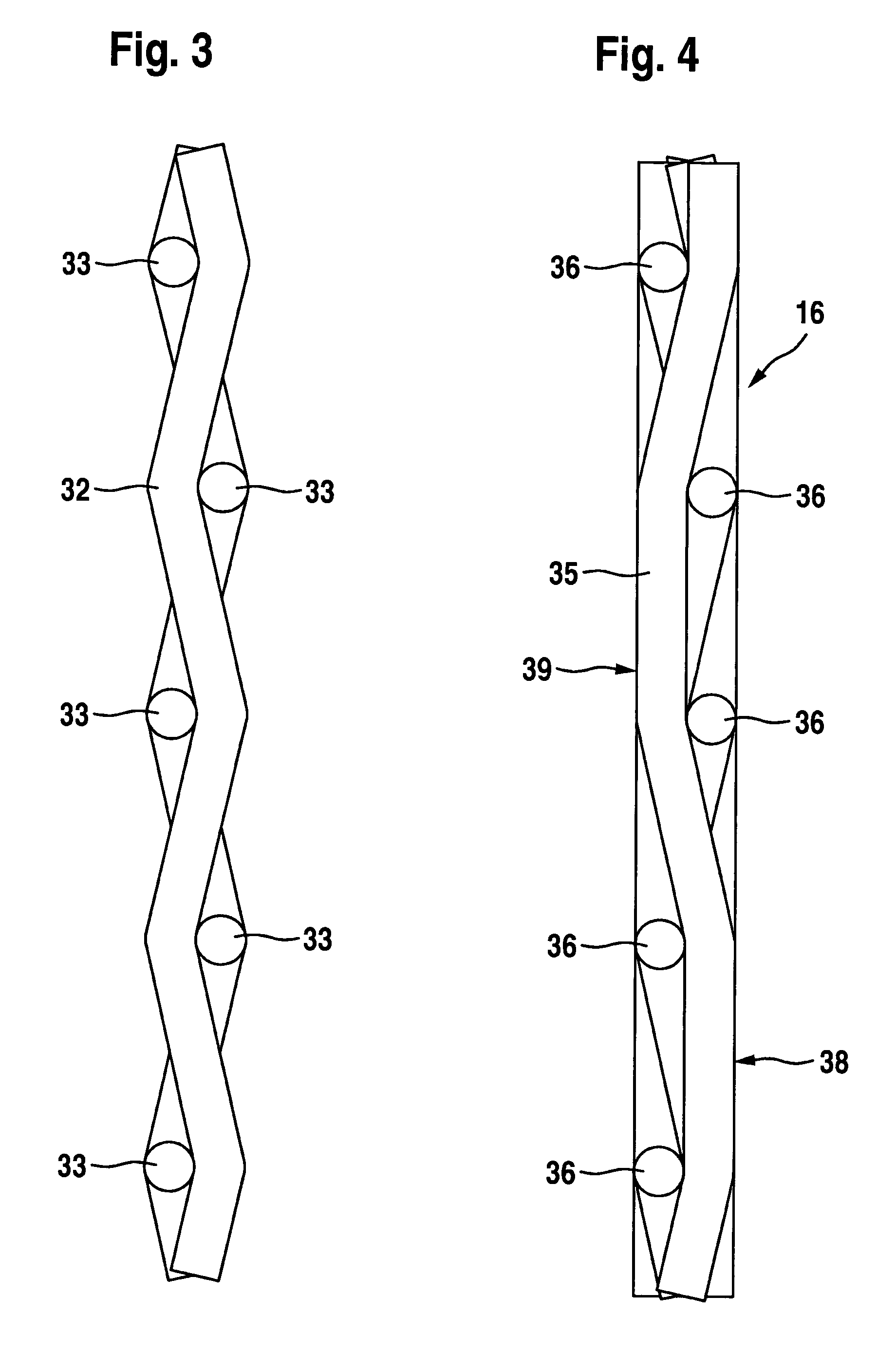

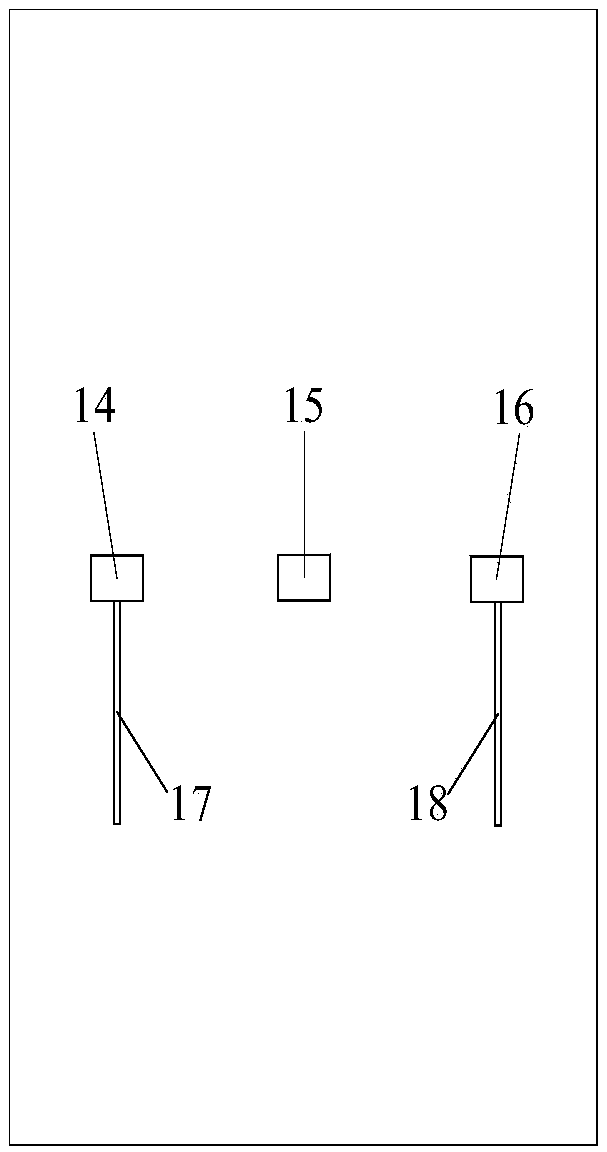

Press-in pin for an electrical contacting assembly

ActiveUS20200343655A1Improve carrying capacityReduce compressive stressLine/current collector detailsPrinted circuit aspectsConductive coatingEngineering

The invention relates to a press-in pin (10) for an electrical contacting assembly (1), having an elastic press-in region (12) and an electrically conductive coating (14). The invention further relates to a corresponding contacting assembly (1), and to a method for joining a press-in pin (10) and a metallized via (7). The coating (14) comprises a reactive multi-layer applied to the press-in pin (10) and a first contact layer applied to the reactive multi-layer.

Owner:ROBERT BOSCH GMBH

Corrugated or pleated flat material

ActiveUS8251231B2Throughflow resistanceReduce risk of damageDispersed particle filtrationLayered productsEngineeringForeign substance

The invention relates to a corrugated or pleated flat material with a plurality of pleats or corrugations that run parallel to one another and successively define a pleat or corrugation peak and a pleat or corrugation valley, the peak and valley being connected to one another by way of a pleat or corrugation flank, wherein a fluid can flow through the flat material and the flat material has at least one deformable functional layer which rests on a supporting layer in the direction of throughflow of the fluid, said supporting layer comprising a supporting fabric, the functional layer allowing foreign substances to be removed from or delivered to the fluid. In order to develop the flat material in such a way that it has greater mechanical load-bearing capacity and lower resistance to throughflow, it is proposed according to the invention that the supporting fabric is deformable and comprises a twill weave. Furthermore, the use of a supporting fabric of this kind for providing support on the outflow side for a pleated or corrugated functional layer is proposed.

Owner:ARGO HYTOS GRP AG

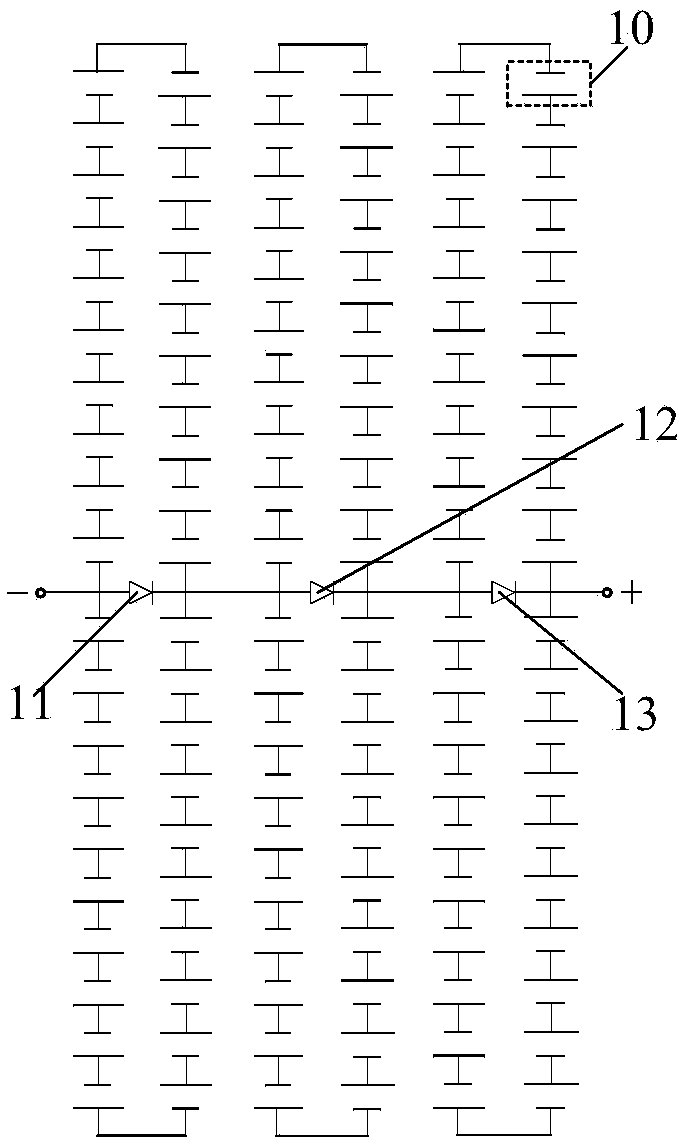

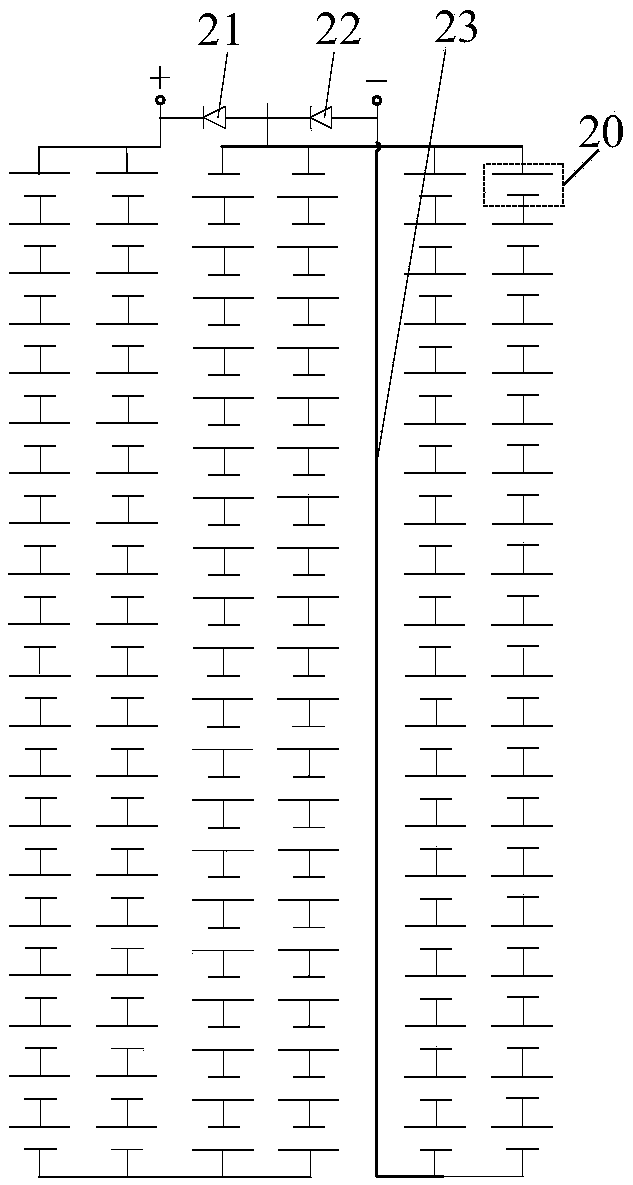

Half-chip assembly

PendingCN109244147AHigh mechanical load capacityReduce areaPhotovoltaic energy generationSemiconductor devicesString groupEngineering

The invention provides a half-chip assembly, comprising a plurality of solar cell strings and a junction box, wherein, a plurality of solar cell strings are arranged in parallel, and each solar cell string comprises a plurality of half-chip cells connected in series; The number of solar cell strings is an integer multiple of 4. The positive and negative electrodes of the solar cell strings in eachgroup are arranged in the same direction, and the positive and negative electrodes of the solar cell strings in the two adjacent groups are arranged in the opposite direction. The solar cell string in each group is connected in parallel to form a solar cell string group through a bus bar, and the adjacent solar cell string groups are connected in series to form a battery loop through the bus bar,and the positive and negative electrodes of the battery loop are located on the same side of the half-chip module. The junction box is arranged on the same side as the positive and negative electrodes of the battery circuit, and the bus bar on the same side as the positive and negative electrodes of the battery circuit is connected into the junction box, and the positive and negative electrodes of the half-piece assembly are led out from the junction box. The half-chip assembly provided by the invention has high reliability and high conversion efficiency.

Owner:CHINT NEW ENERGY TECH (HAINING) CO LTD

Plug-in combination of devices

InactiveCN104916979AHigh mechanical load capacityEasy to manufactureCoupling device detailsOvervoltage arrestors using spark gapsPower gridEngineering

The present invention relates to a plug-in apparatus combination with an apparatus base and a plug-in module, wherein, the plug-in module can be plugged into the apparatus base. The apparatus base has a base housing with a recess for receiving the plug-in module, a linkage terminal for a conductor of a power grid to be protected, and a plug-in contact linked with the linkage terminal. The plug-in module has a plug housing, a protective element arranged in the plug-in housing, and a linkage plug-in contact corresponding to the plug-in contact. In the apparaut combination, locking and replacement of the plug-in module are executed thereby, namely, a latching linkage portion acting between the apparatus base and the plug-in module has a latching arm with a latching mechanism and a groove, the latching linkage portion is arranged on the wall opposite to the latching arm, a latching hook of the latching arm is used for guding when the plug-in module is plugged into the apparatus base. The groove has a first region, a second region, and a third region, and the deepth of the groove is too small in the end of the third region so that the latching hook does not guide in the groove.

Owner:PHOENIX CONTACT GMBH & CO KG

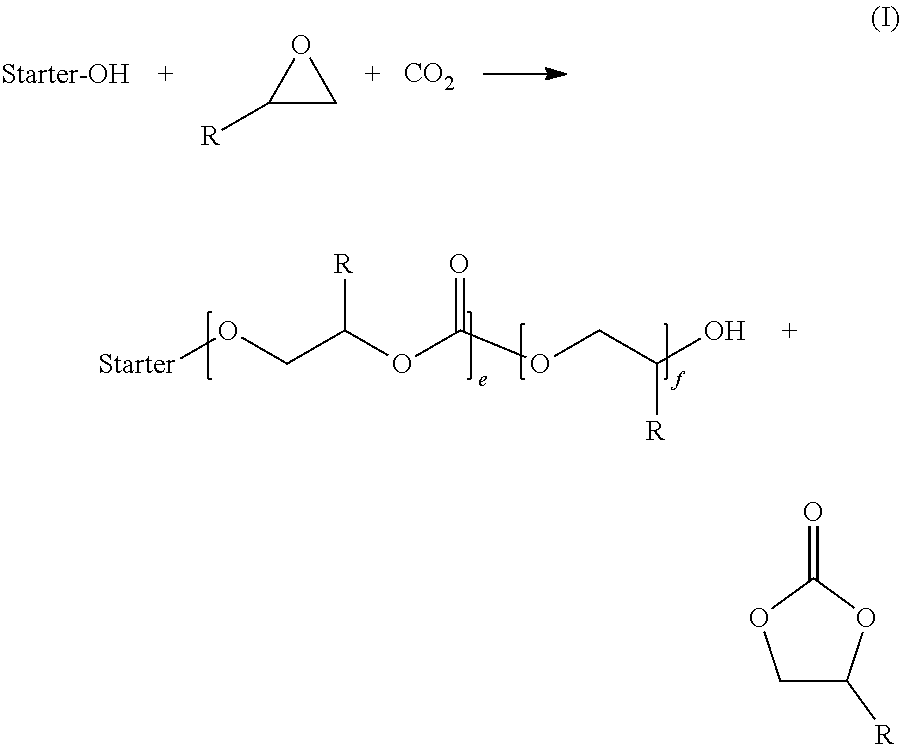

Process for the preparation of polyether polyols

The invention relates to a method for producing polyether carbonate polyols, wherein (i) in a first step a polyether carbonate polyol is produced from one or more H-functional starter substances, one or more alkylene oxides, and carbon dioxide in the presence of at least one DMC catalyst, and (ii) in a second step the polyether carbonate polyol is chain-extended with a mixture of at least two different alkylene oxides in the presence of at least one DMC catalyst. The invention further relates to polyether carbonate polyols that contain a terminal mixed block of at least two alkylene oxides and to a method for producing soft polyurethane foams, wherein a polyol component containing a polyether carbonate polyol according to the invention is used.

Owner:COVESTRO DEUTSCHLAND AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com