Half-chip assembly

A component and solar cell technology, applied in semiconductor devices, electrical components, sustainable buildings, etc., can solve the problems of increased stress concentration at openings, reduced reliability of half-chip components, and reduced mechanical load-bearing capacity, so as to improve the mechanical load-bearing capacity , Improve conversion efficiency and reduce area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand and illustrate the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

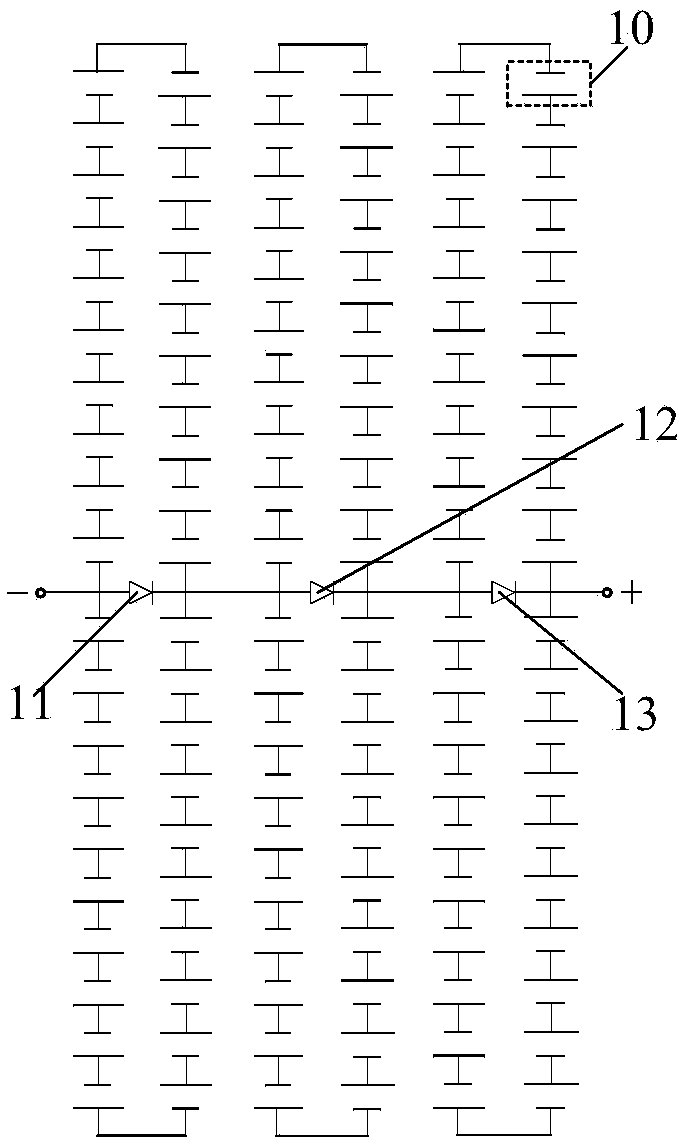

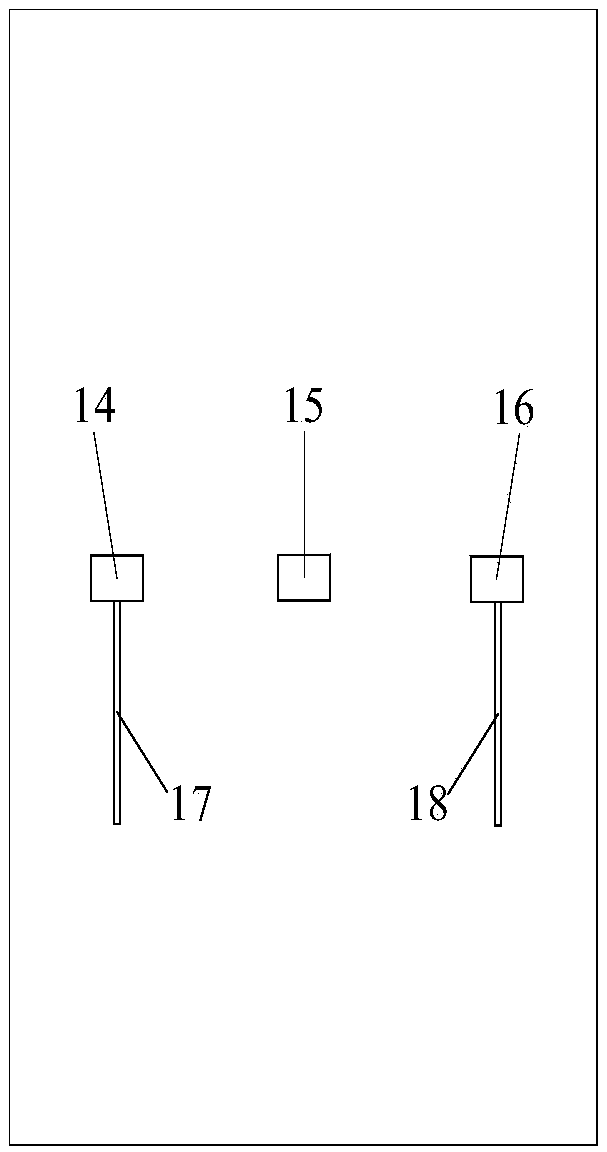

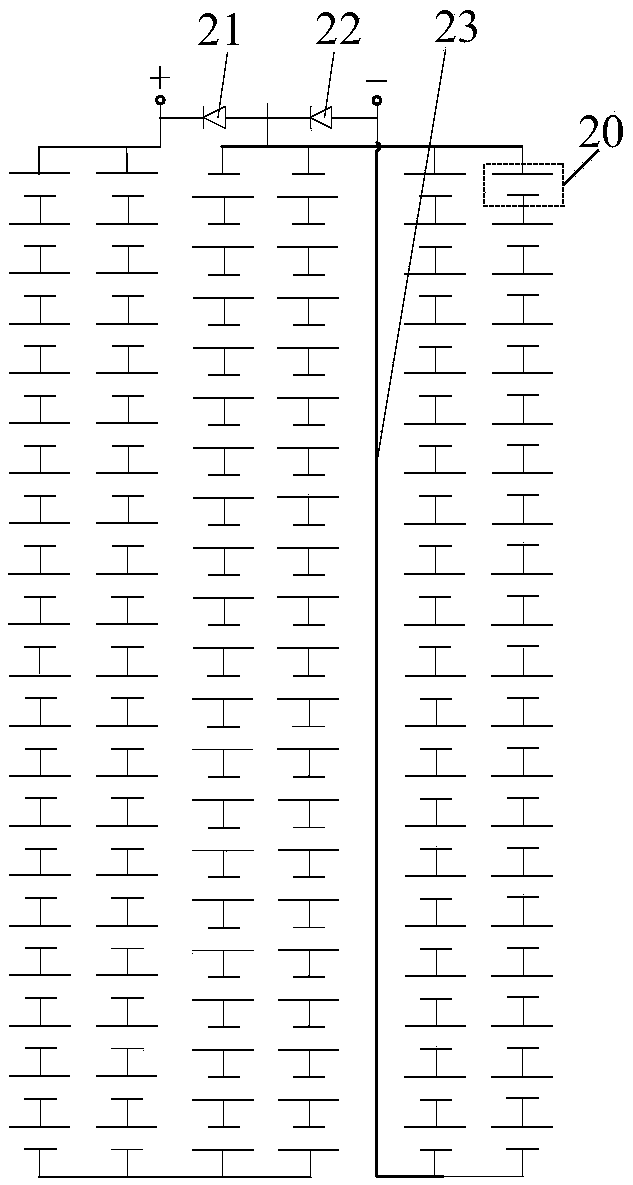

[0034] The invention provides a half-chip assembly, which includes a transparent cover plate, a back plate, a plurality of solar battery strings arranged between the transparent cover plate and the bottom plate, and wiring arranged on the back plate box, of which:

[0035] The plurality of solar battery strings are arranged side by side, wherein each of the solar battery strings includes a plurality of half-cell batteries, and the plurality of half-cell batteries are connected in series and arranged along the direction of the short side of the half-cell battery;

[0036] The number of the solar battery strings is an integer multiple of 4, wherein the solar battery strings are in groups of two, and the positive and negative poles of the solar battery strings in each group are arranged in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com