Patents

Literature

366results about How to "Reduce compressive stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

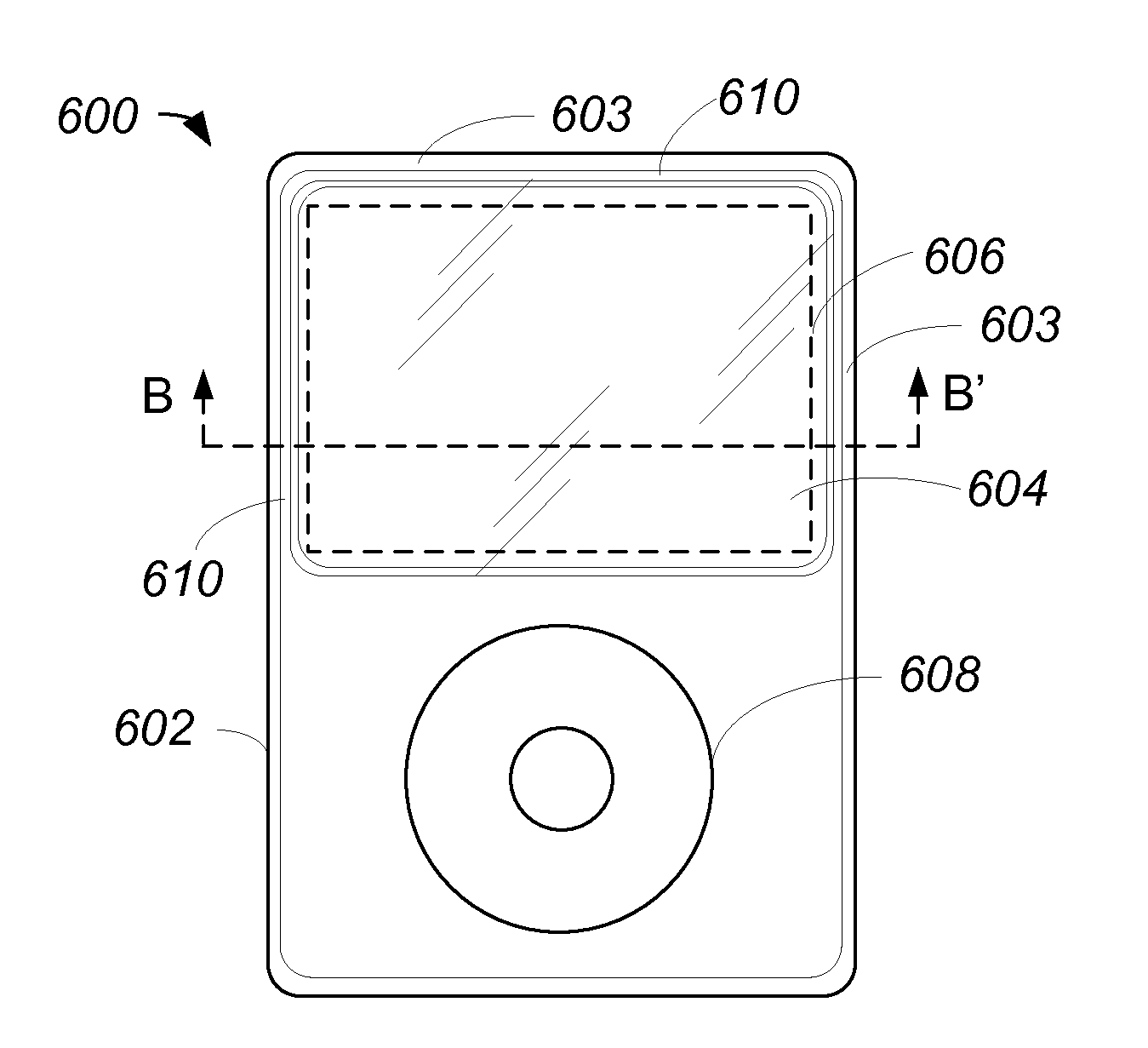

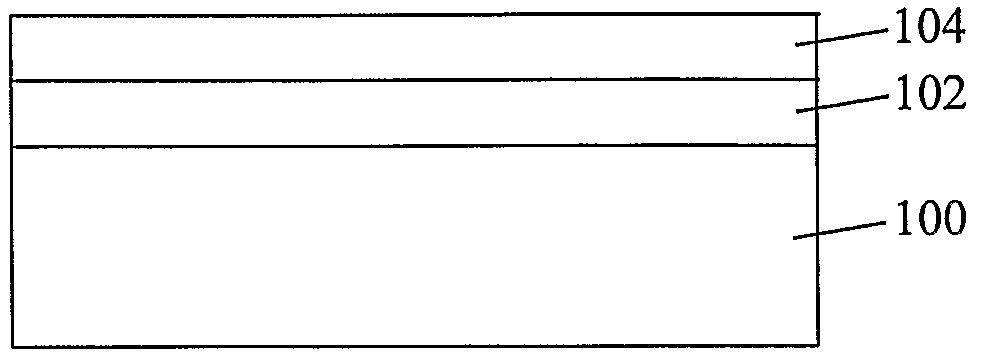

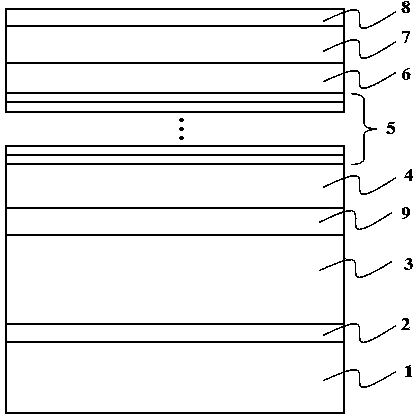

Enhanced chemical strengthening glass for portable electronic devices

InactiveUS20120194974A1Reduce compressive stressDigital data processing detailsGlass/slag layered productsIonIon exchange

Apparatus, systems and methods for improving strength of a thin glass member for an electronic device are disclosed. In one embodiment, the glass member can have improved strength characteristics in accordance with a predetermined stress profile. The predetermined stress profile can be formed through multiple stages of chemical strengthening. The stages can, for example, have a first ion exchange stage where larger ions are exchanged into the glass member, and a second ion exchange stage where some of the larger ions are exchanged out from the glass member. In one embodiment, the glass member can pertain to a glass cover for a housing for an electronic device. The glass cover can be provided over or integrated with a display.

Owner:APPLE INC

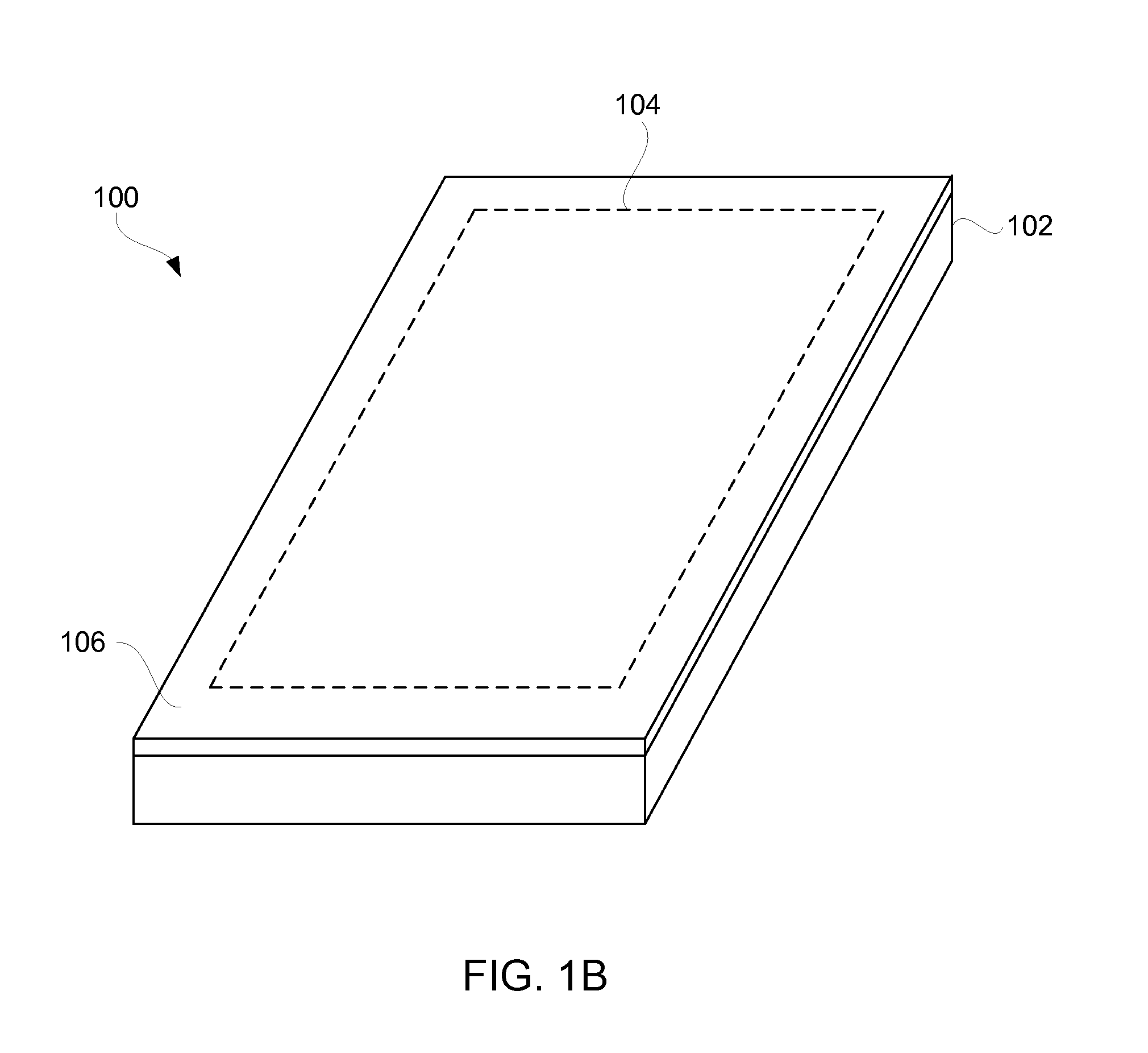

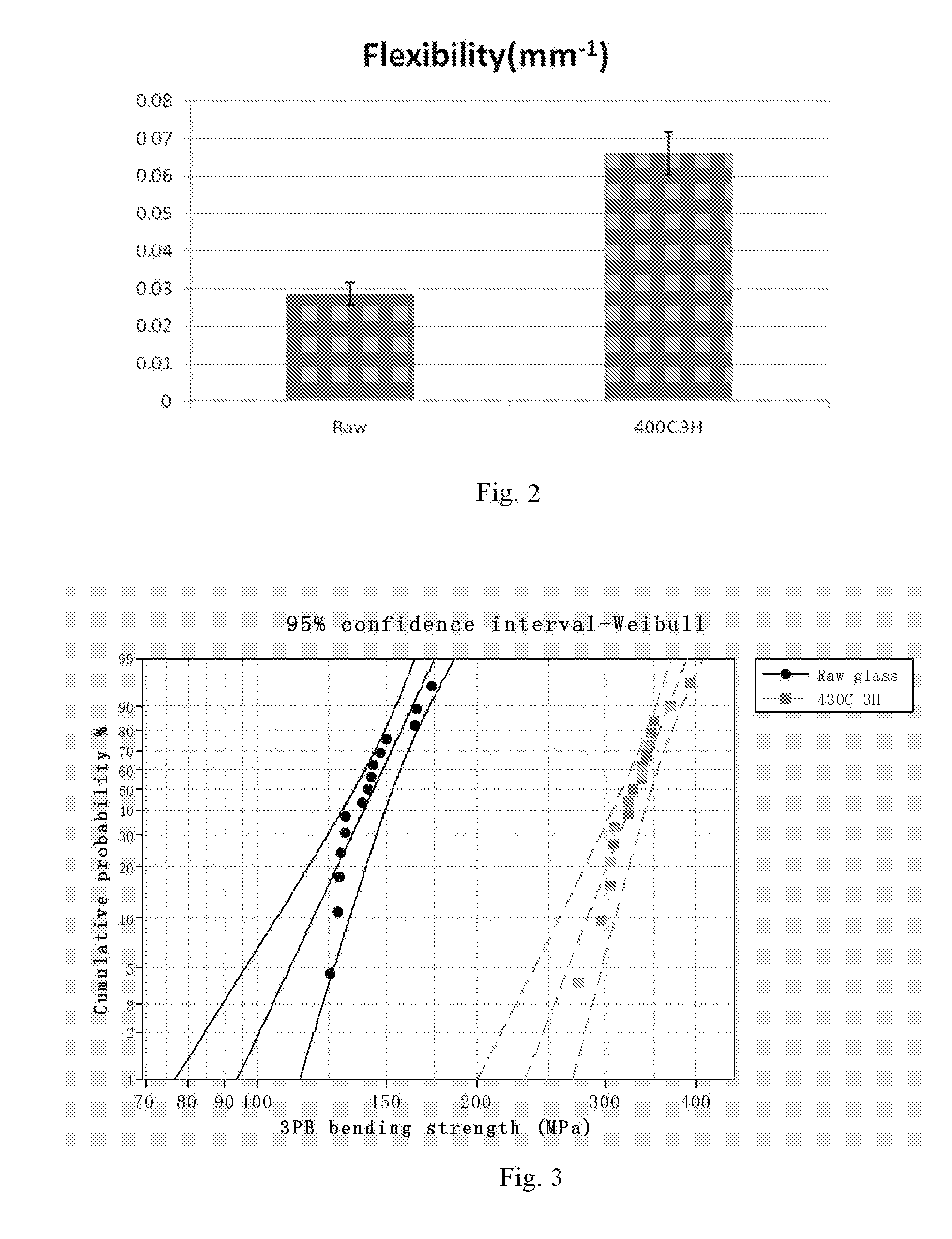

Chemically Toughened Flexible Ultrathin Glass

ActiveUS20160002103A1Reduce compressive stressIncrease flexibilityFilm/foil adhesivesSynthetic resin layered productsGlass sheetThermal shock

A chemically toughened ultrathin glass is provided. The glass has a thickness less than 500 μm and a surface compressive layer having a depth of at most 30 μm. The toughened ultrathin glass sheet is more flexible and has extraordinary thermal shock resistance with the glass being easier to handle for processing.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

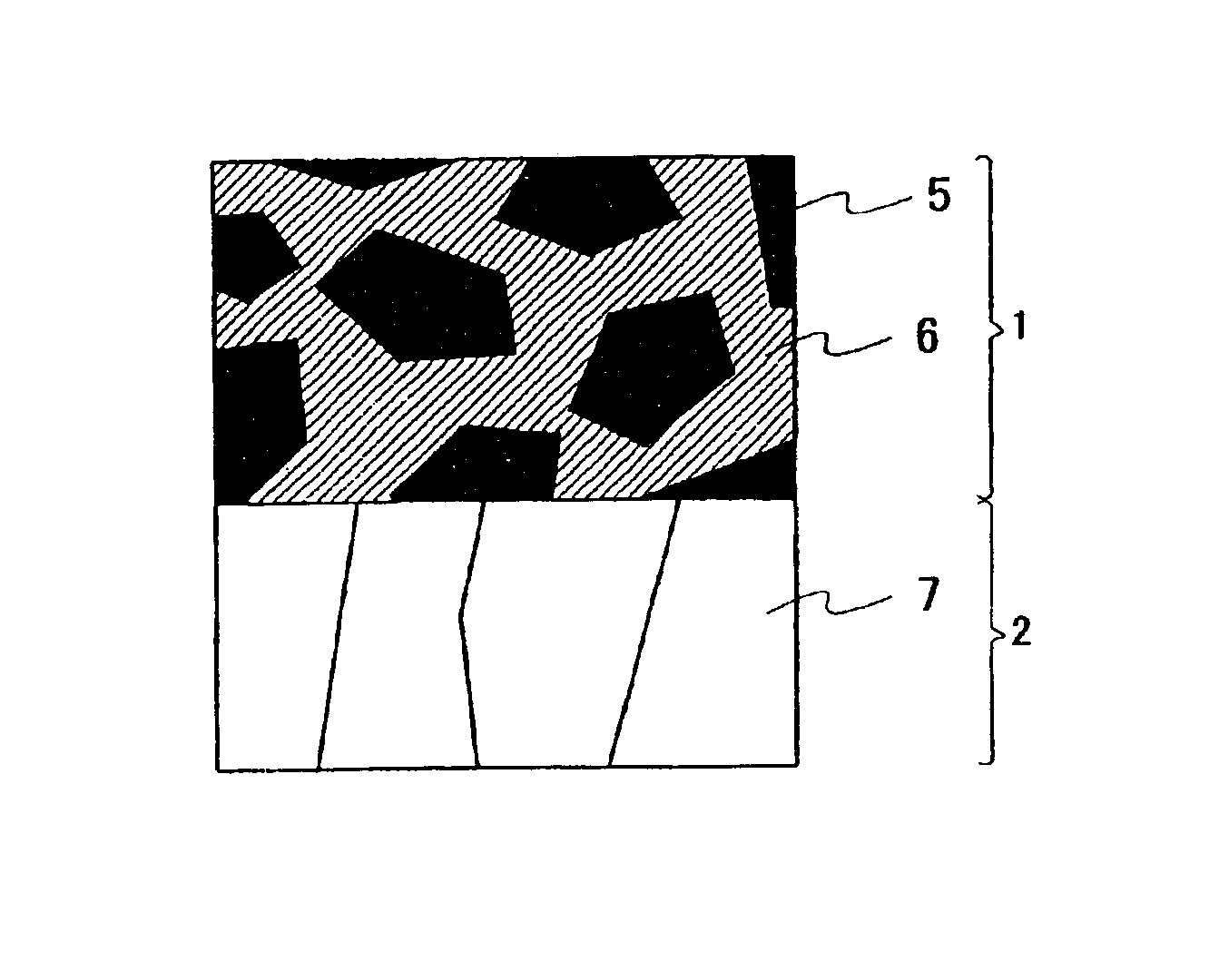

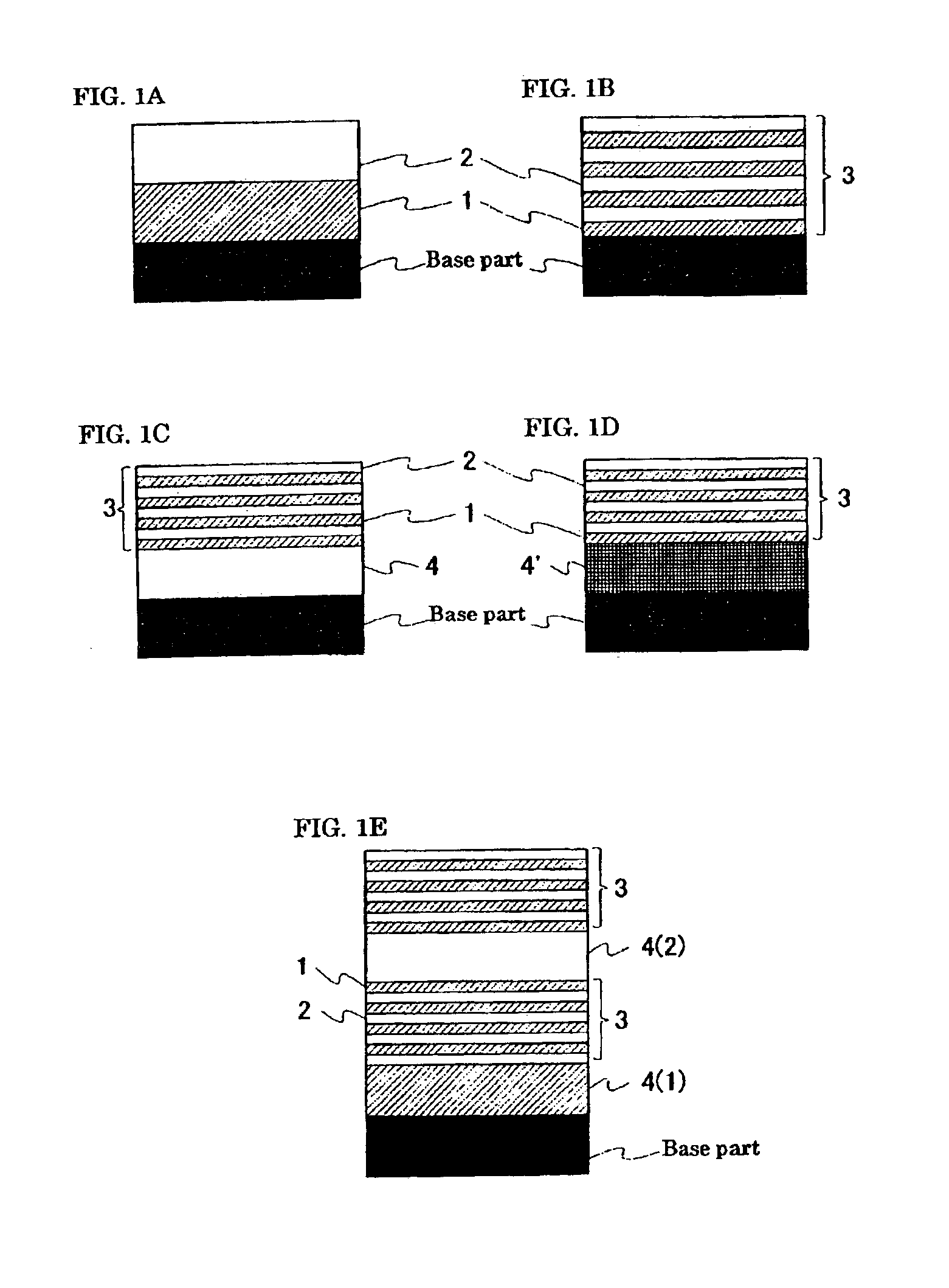

Coated tool

ActiveUS7060345B2High hardnessImprove wear resistancePigmenting treatmentMilling cuttersCarbideNitrogen oxide

Coating-film furnished coated tools that are lubricative while maintaining resistance to wear are realized by coated tools in which a plurality of coating films is furnished on a base part. Furnished as the coating are one or more layers of, respectively: a first film composed of one compound selected from nitrides, carbides, carbonitrides, oxynitrides and carboxynitrides of TiSi; and a second film composed of one compound selected from nitrides, carbides, carbonitrides, oxynitrides and carboxynitrides of one metal M selected from Ti, Cr, and TiCr. The first film and the second film are laminated in alternation.

Owner:SUMITOMO ELECTRIC IND LTD

Glass with compressive surface for consumer applications

ActiveCN102131740AIncrease the surface compressive stressReduce compressive stressIon exchangeContact force

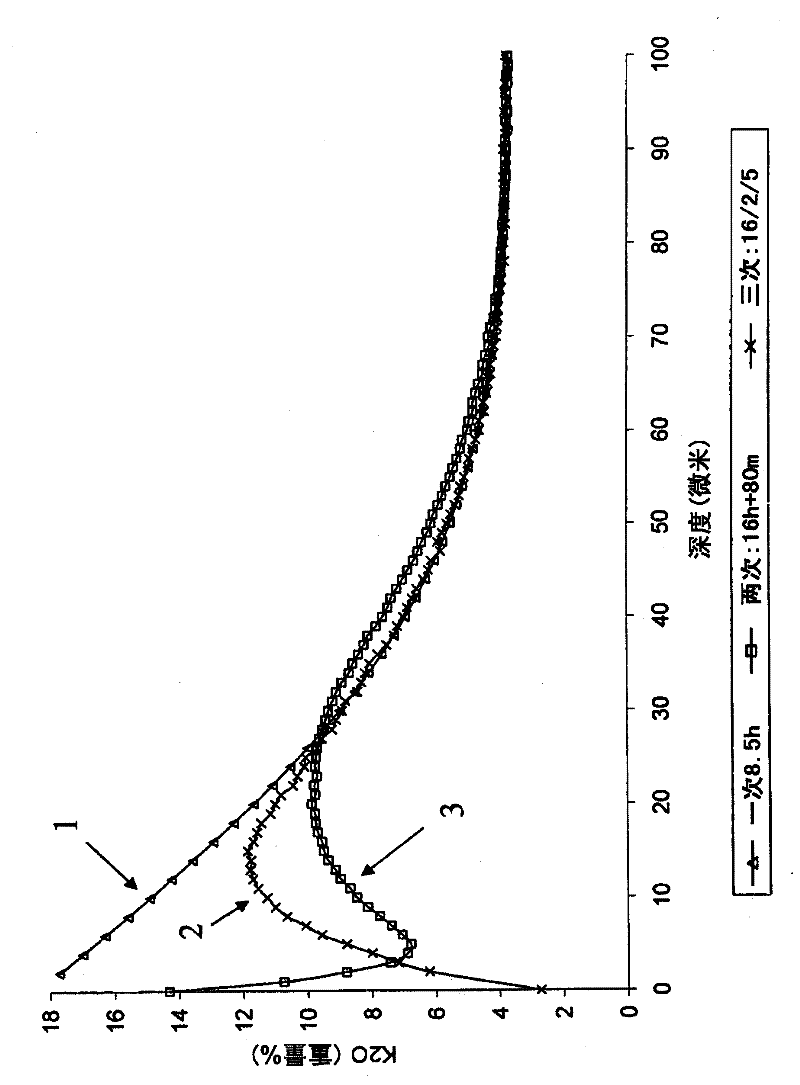

The present invention provides a strengthened glass that does not exhibit frangible behavior when subjected to impact or contact forces, and a method of strengthening a glass. The glass may be strengthened by subjecting it to multiple, successive, ion exchange treatments. The multiple ion exchange treatments provide a local compressive stress maximum at a depth of the strengthened layer and a second local maximum at or near the surface of the glass.

Owner:康宁陶瓷材料(上海)有限公司 +1

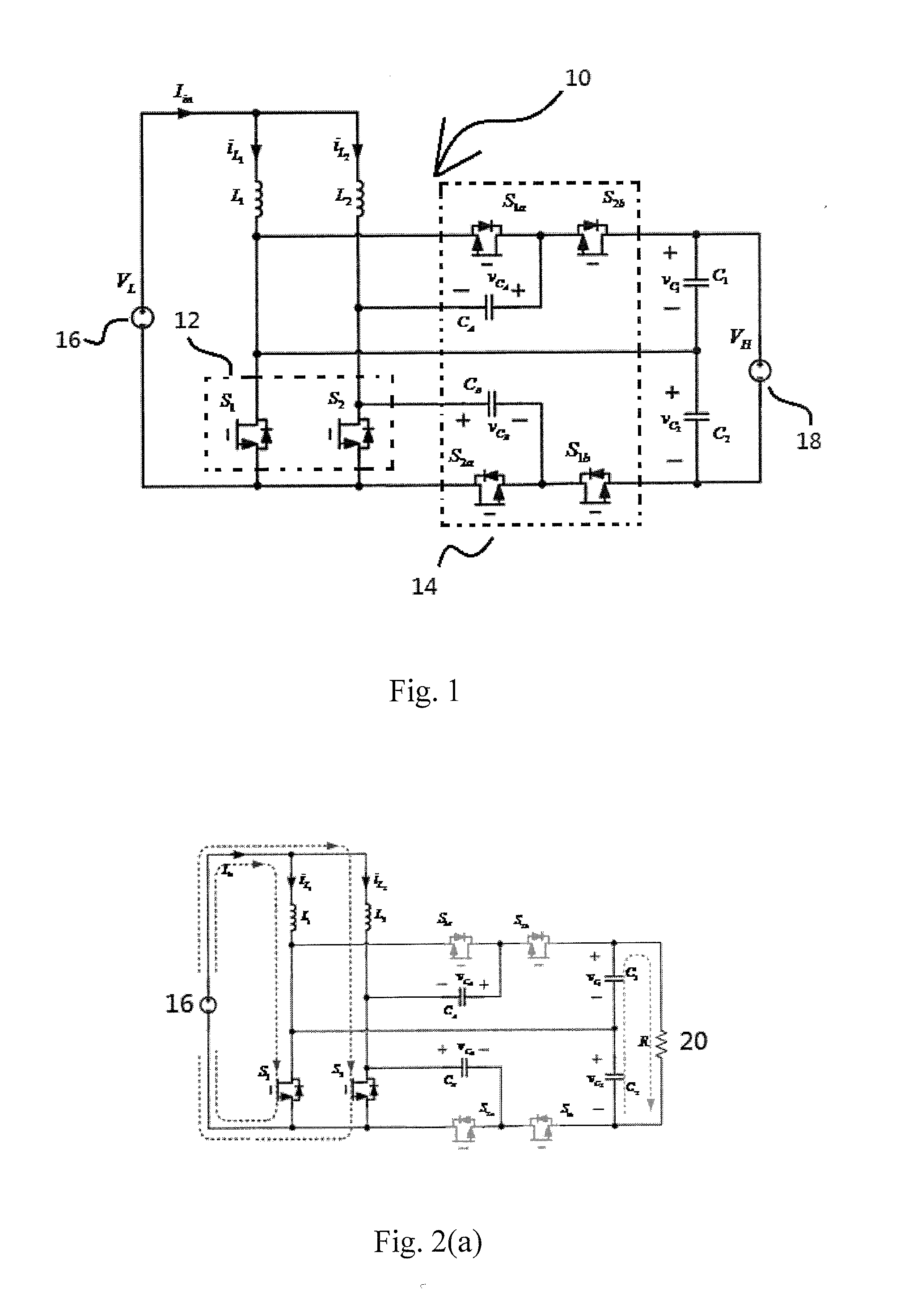

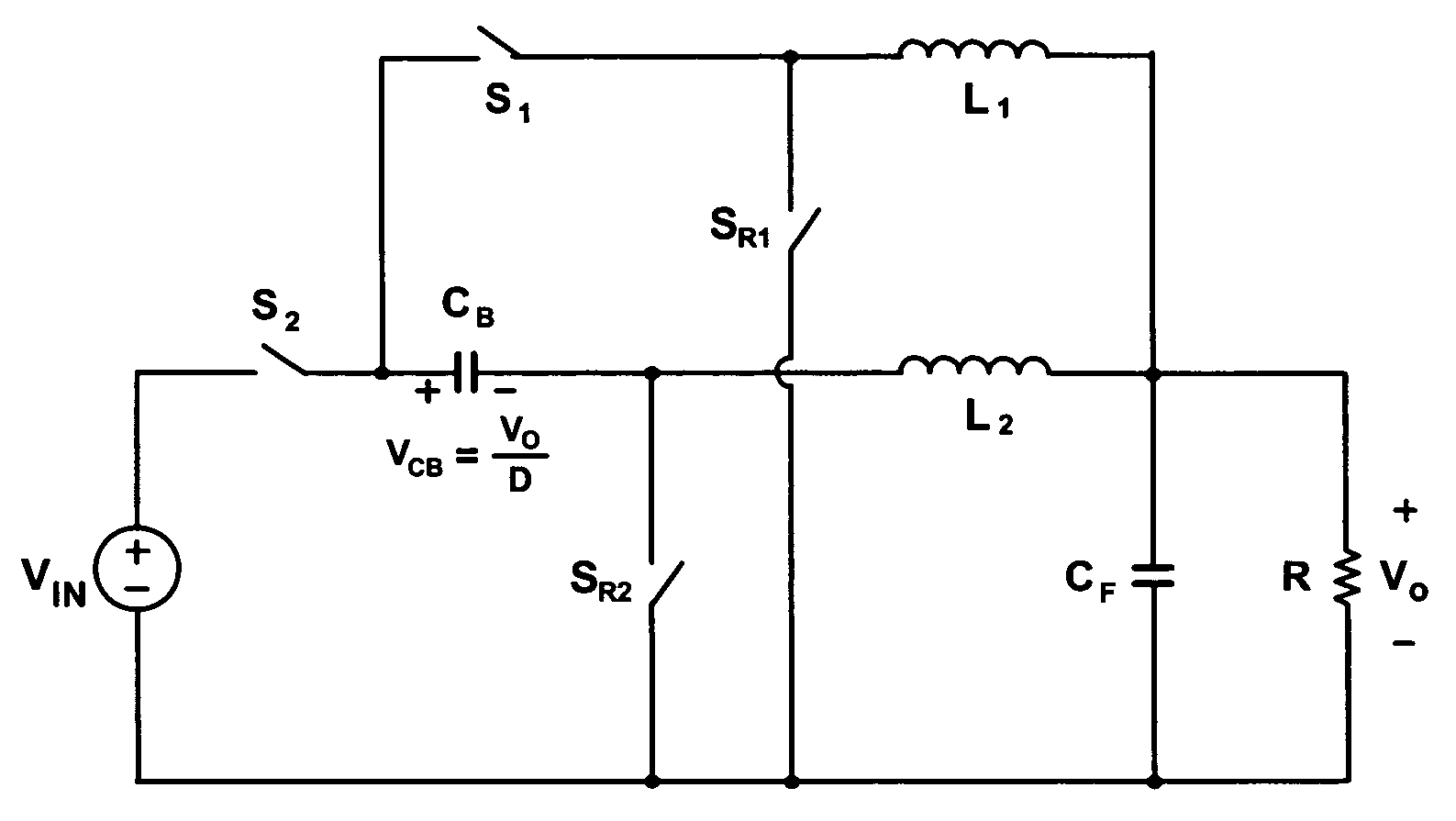

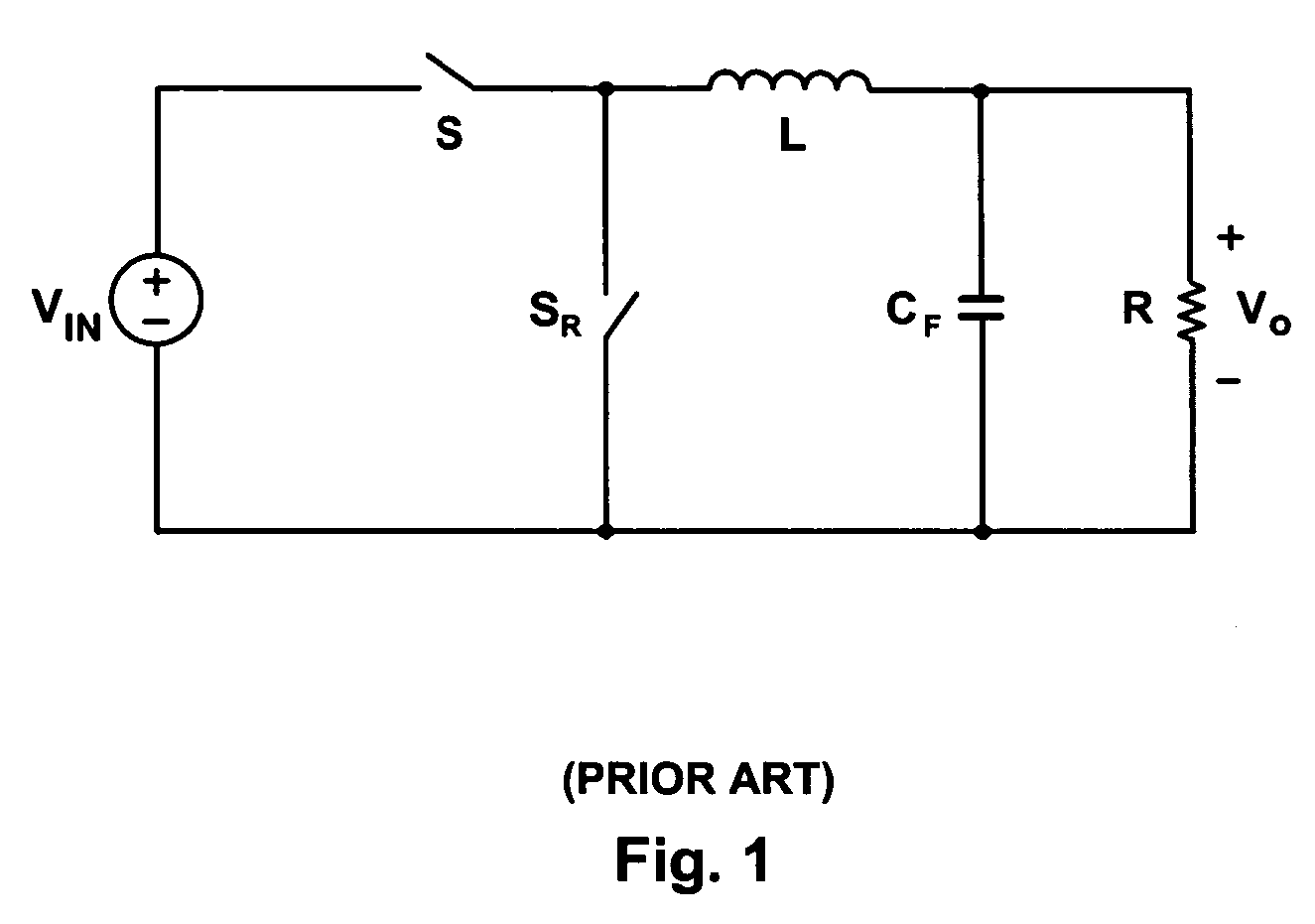

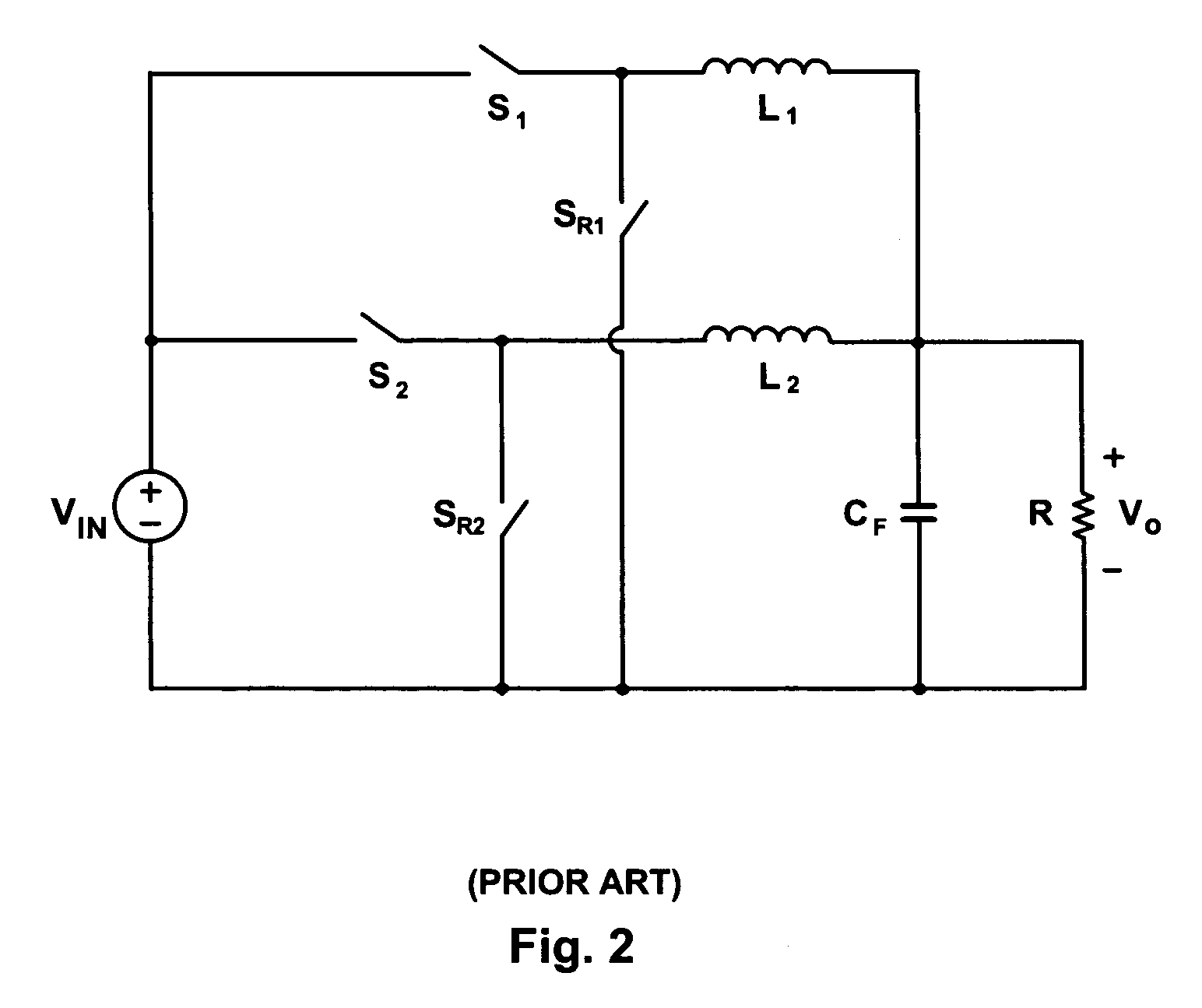

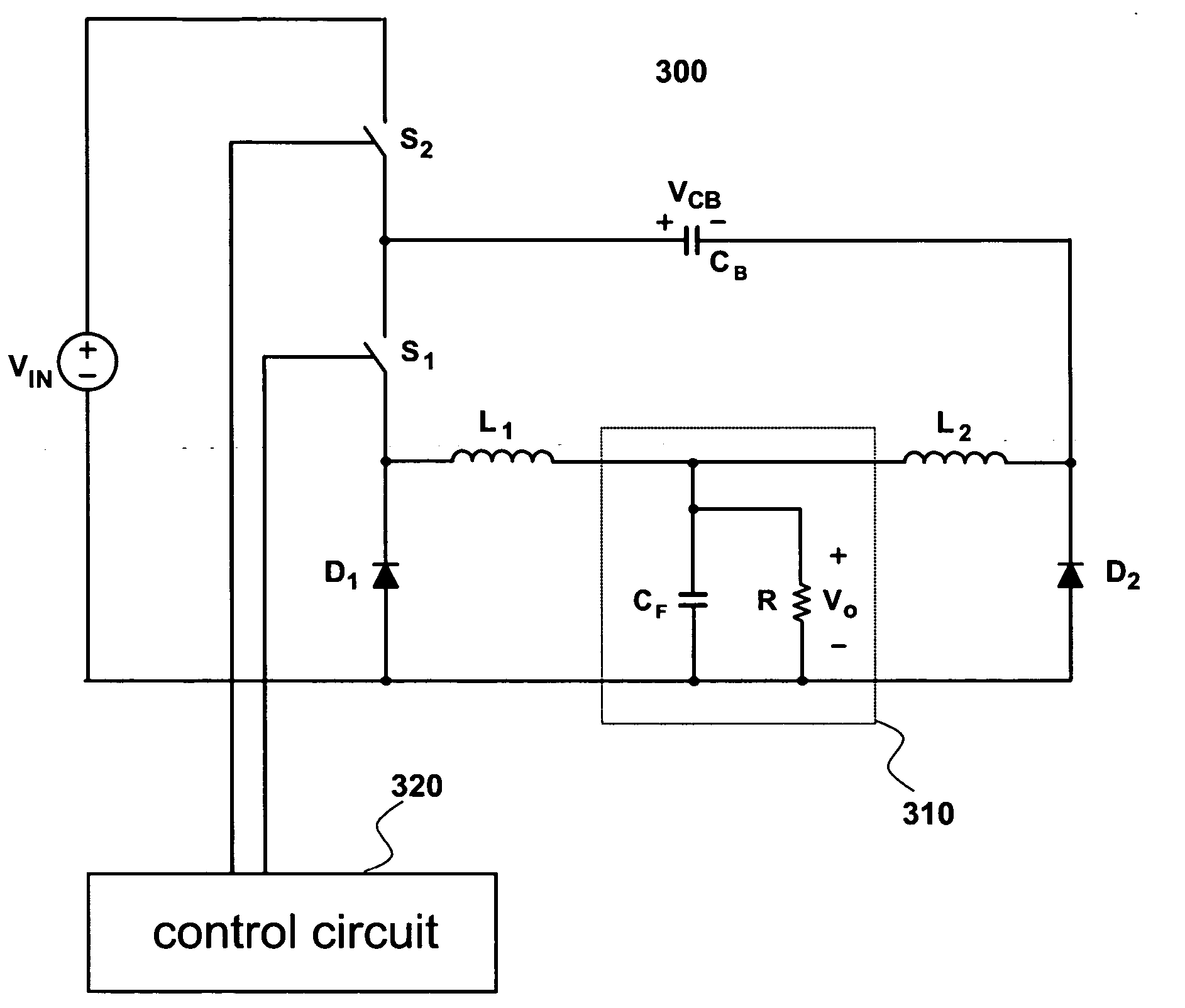

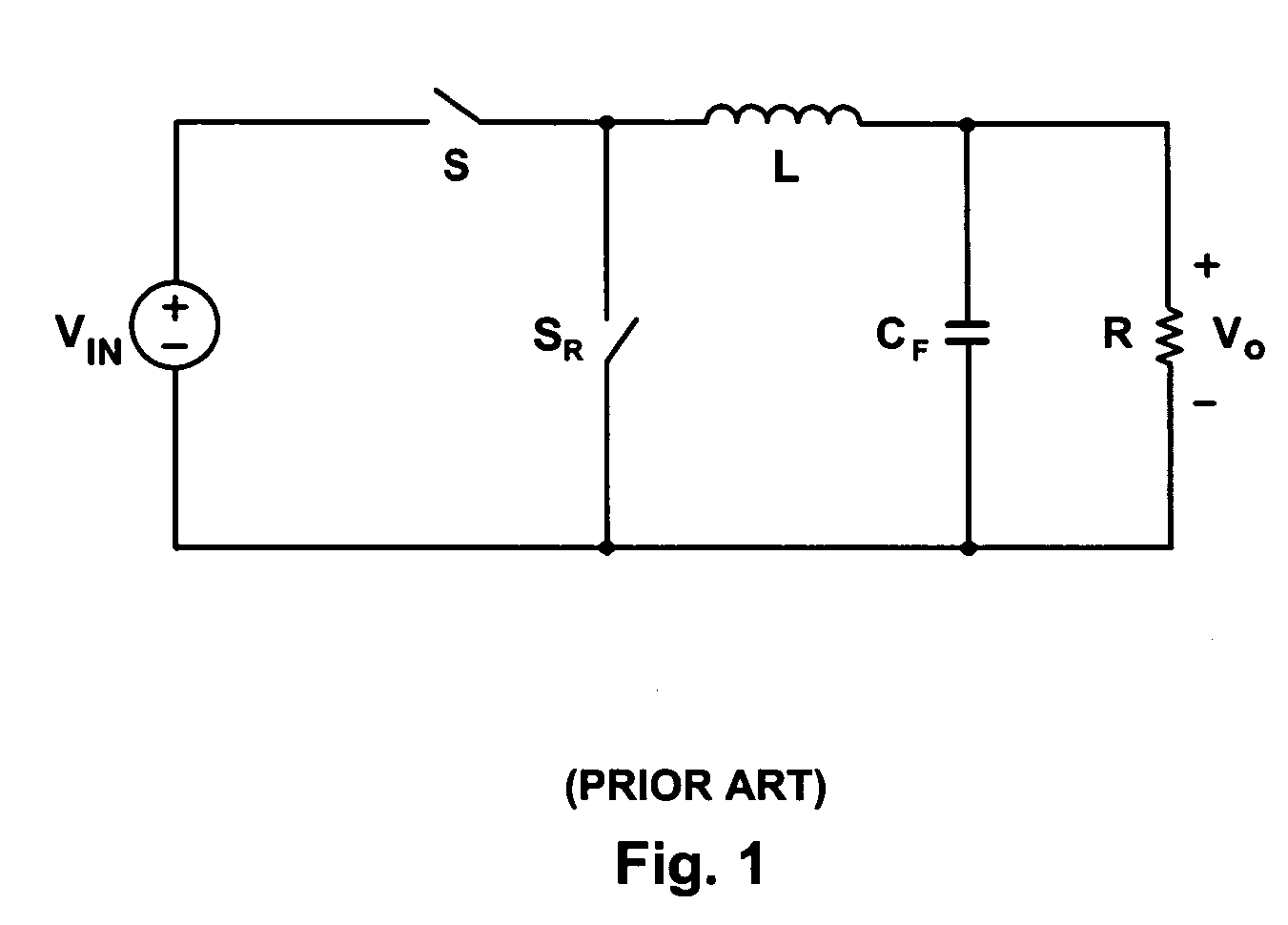

Bidirectional dc-dc converter

InactiveUS20150097546A1Improve conversion rateLow switching voltageEfficient power electronics conversionDc-dc conversionDc dc converterVoltage source

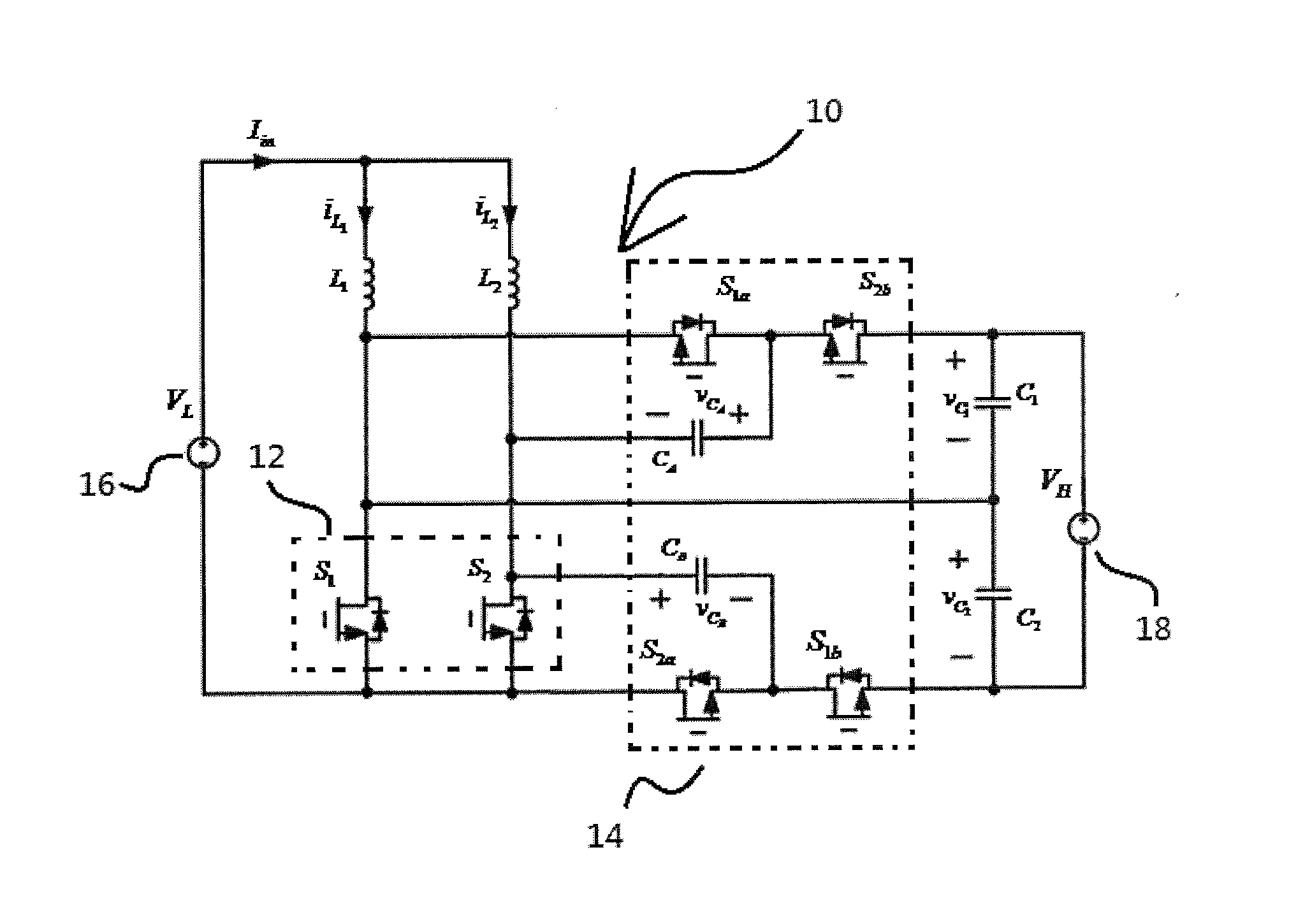

A bidirectional converter circuit includes a voltage source which provides an input voltage, an energy storage set connected to the voltage source and receives the input voltage, a switch set connected to the energy storage set, wherein the switch set includes a first switch and a second switch; an operating switch set connected to the switch set, wherein the operating switch set includes a first operating switch, a second operating switch, a third operating switch and a fourth operating switch. The bidirectional converter further includes a blocking capacitor set and a (input / output) capacitor set. Wherein, the blocking capacitor set is connected to the switch set and the operating switch set. The first operating switch and the second operating switch are driven complementarily with the first switch, and the third operating switch and the fourth operating switch are driven complementarily with the second switch.

Owner:NATIONAL TSING HUA UNIVERSITY

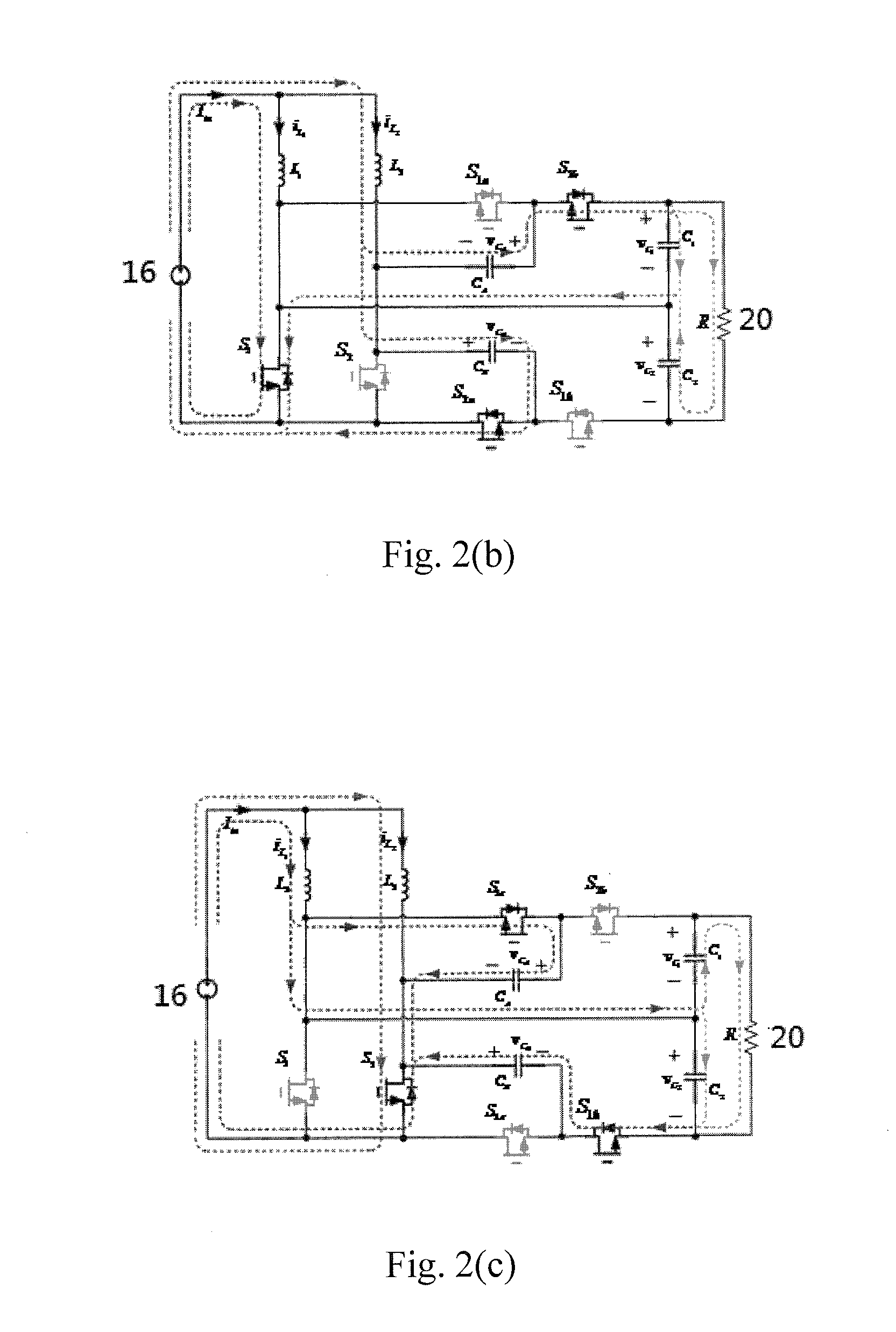

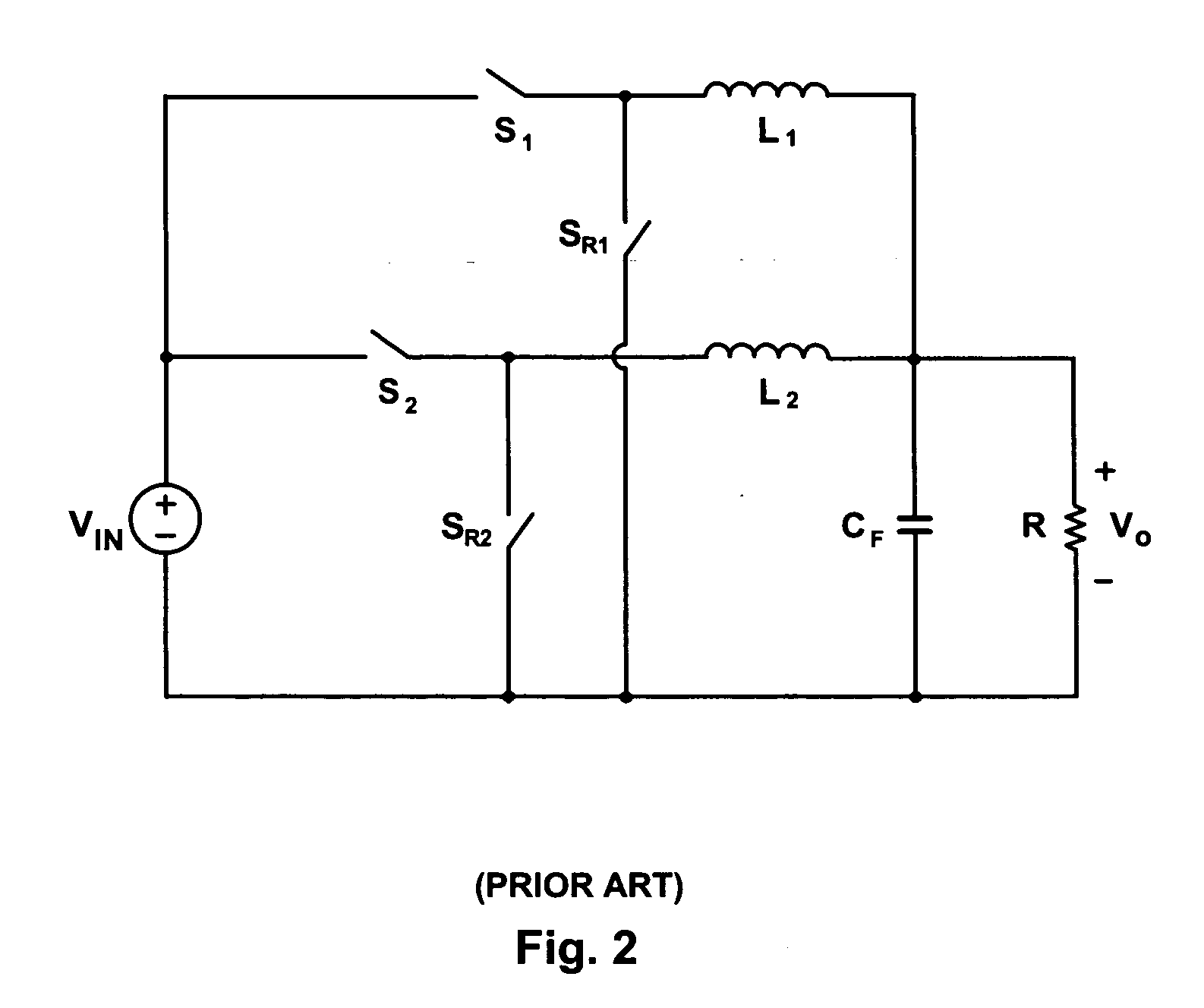

Non-isolated power conversion system having multiple switching power converters

ActiveUS7230405B2Raise the ratioReduce compressive stressDc network circuit arrangementsIgnition automatic controlSwitching cycleEngineering

Owner:DELTA ELECTRONICS INC

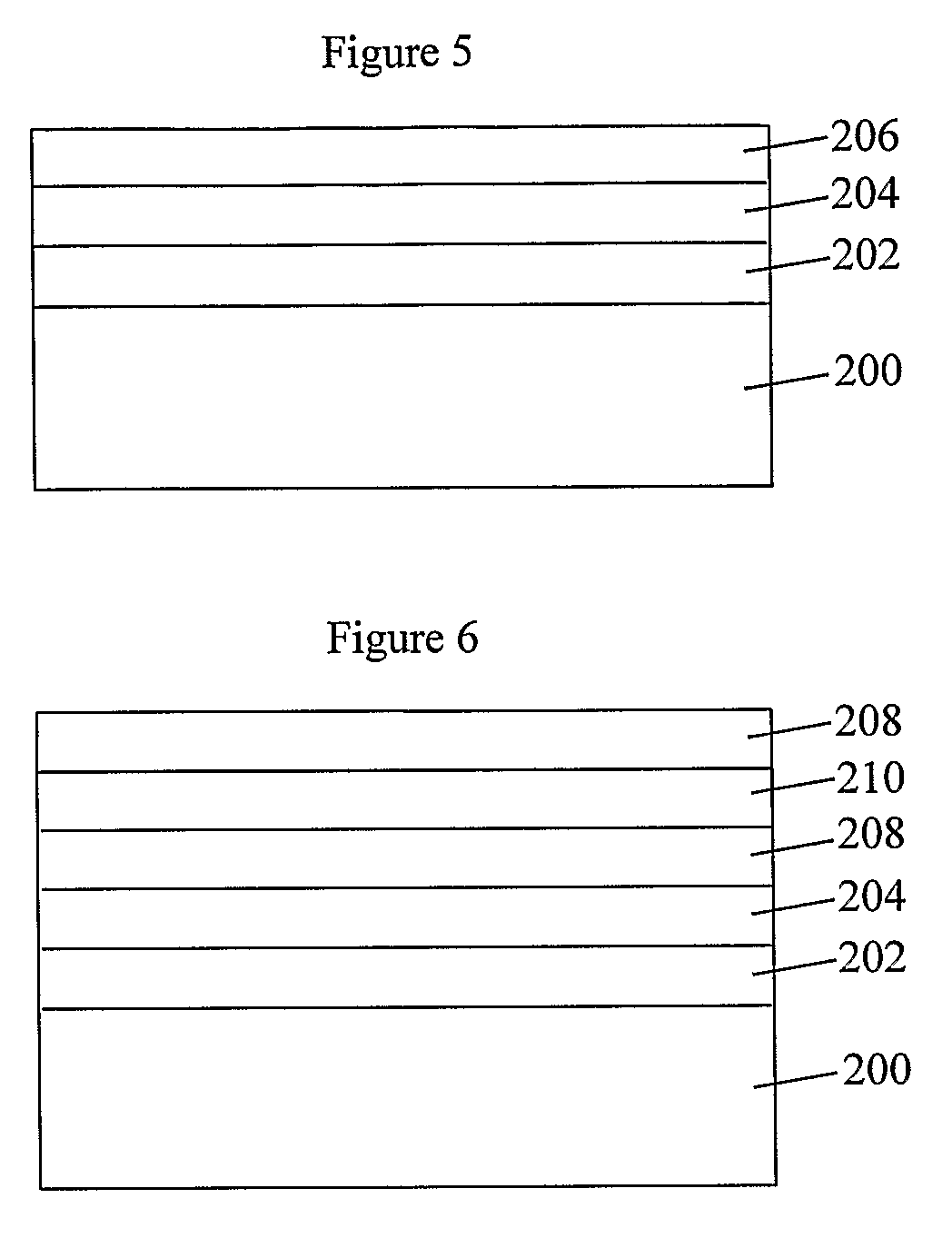

Coated chemically strengthened flexible thin glass

InactiveUS20170183255A1Improve antifouling performanceEasy to cleanGlass forming apparatusPriming paintsNiobiumCerium

A coated chemically strengthened flexible thin glass includes a coating of an adhesive layer in the form of a silicon mixed oxide layer, which contains or consists of a silicon oxide layer in combination with at least one oxide of aluminum, tin, magnesium, phosphorus, cerium, zirconium, titanium, cesium, barium, strontium, niobium, zinc, or boron, and magnesium fluoride, such as at least aluminum oxide.

Owner:SCHOTT AG

Non-isolated power conversion system having multiple switching power converters

ActiveUS20060087295A1Raise the ratioReduce compressive stressDc network circuit arrangementsIgnition automatic controlSwitching cycleEngineering

A non-isolated power conversion system has an input stage and an output stage. A plurality of cascaded switching power converter stages are coupled between the input stage and the output stage. Each of the plurality of switching power converter stages has at least one switch that is activated in accordance with a duty cycle associated with a switching cycle. At least one energy storage device temporarily stores energy that is proportional to the duty cycle during the switching cycle for delivery to the output stage.

Owner:DELTA ELECTRONICS INC

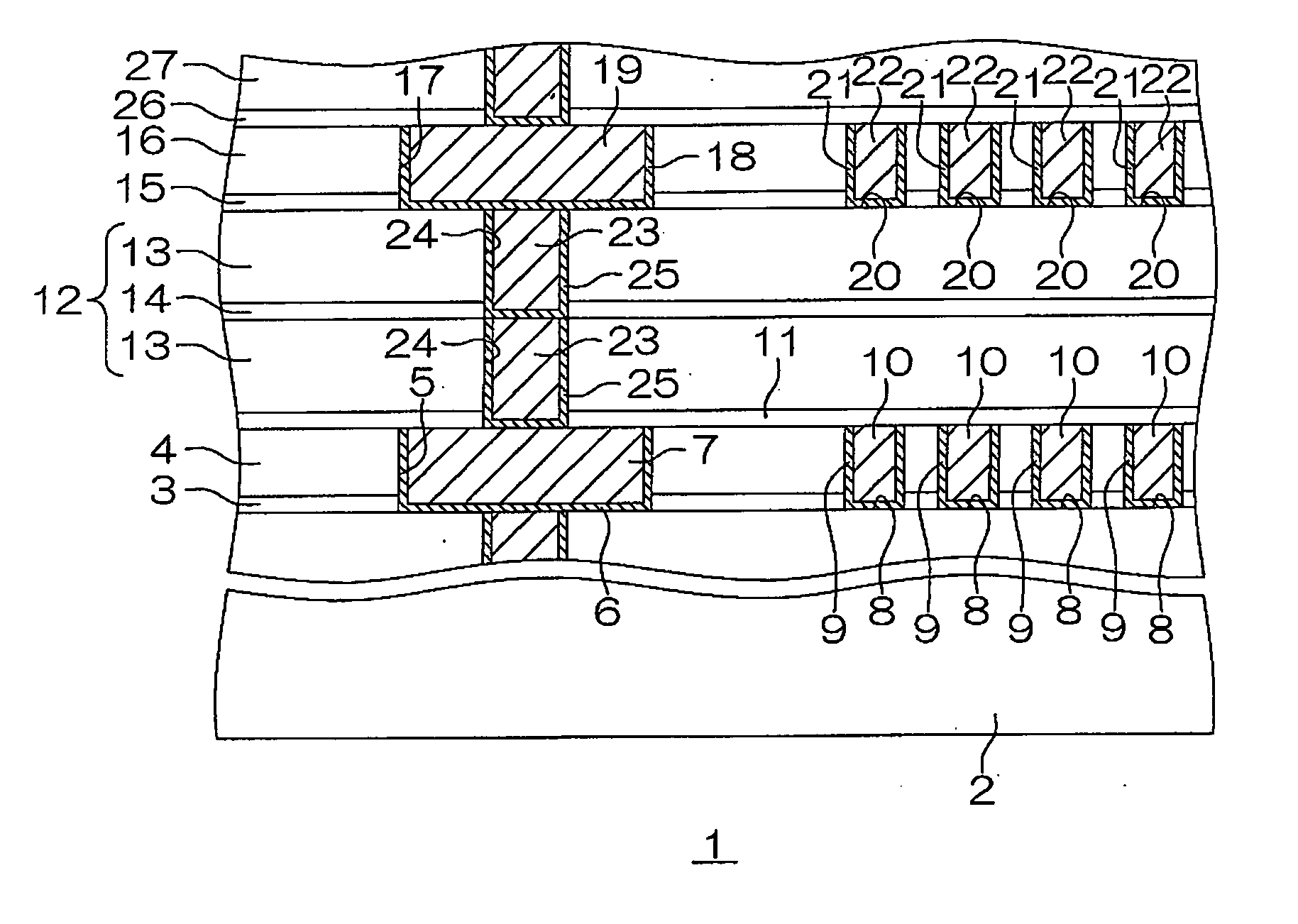

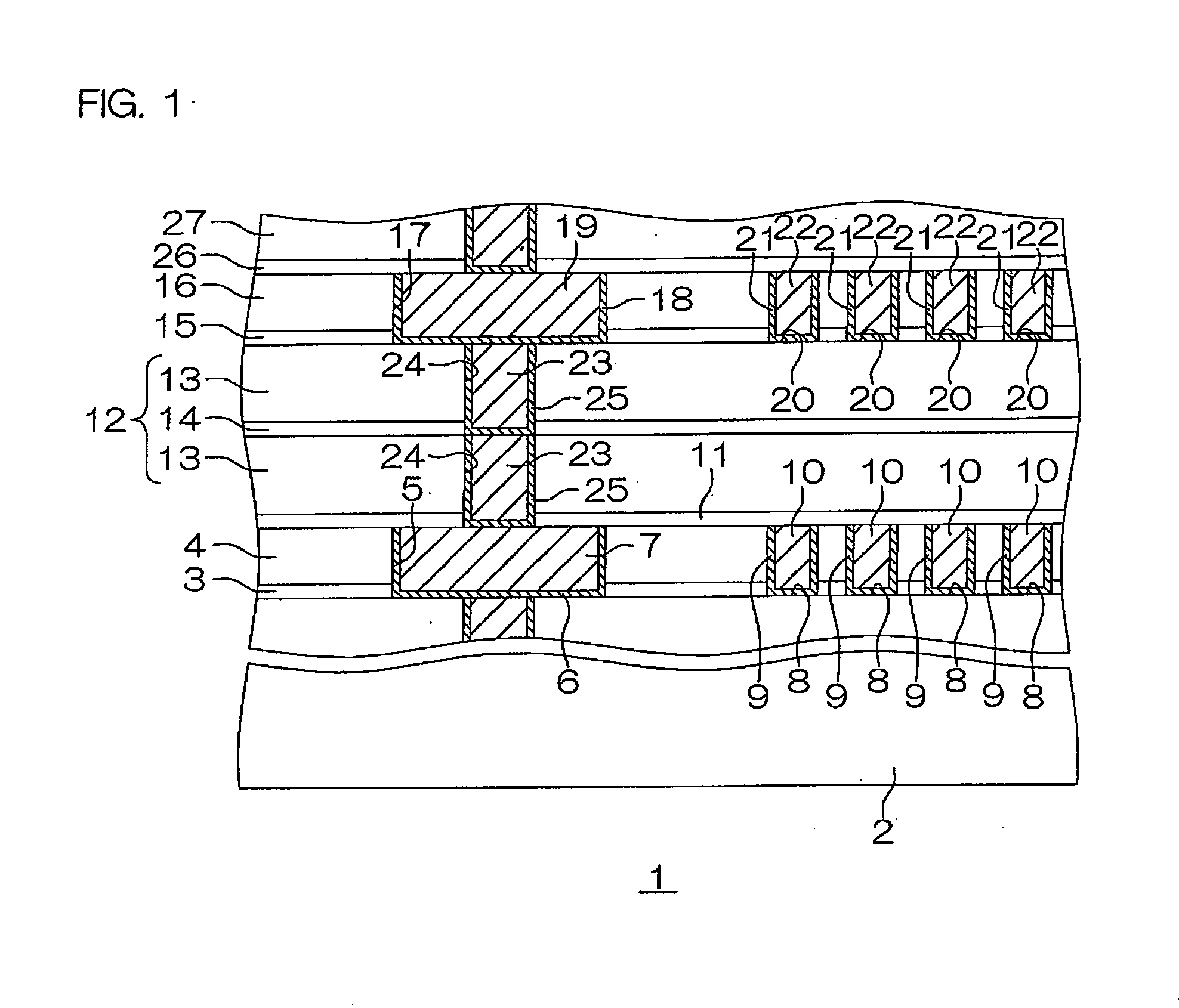

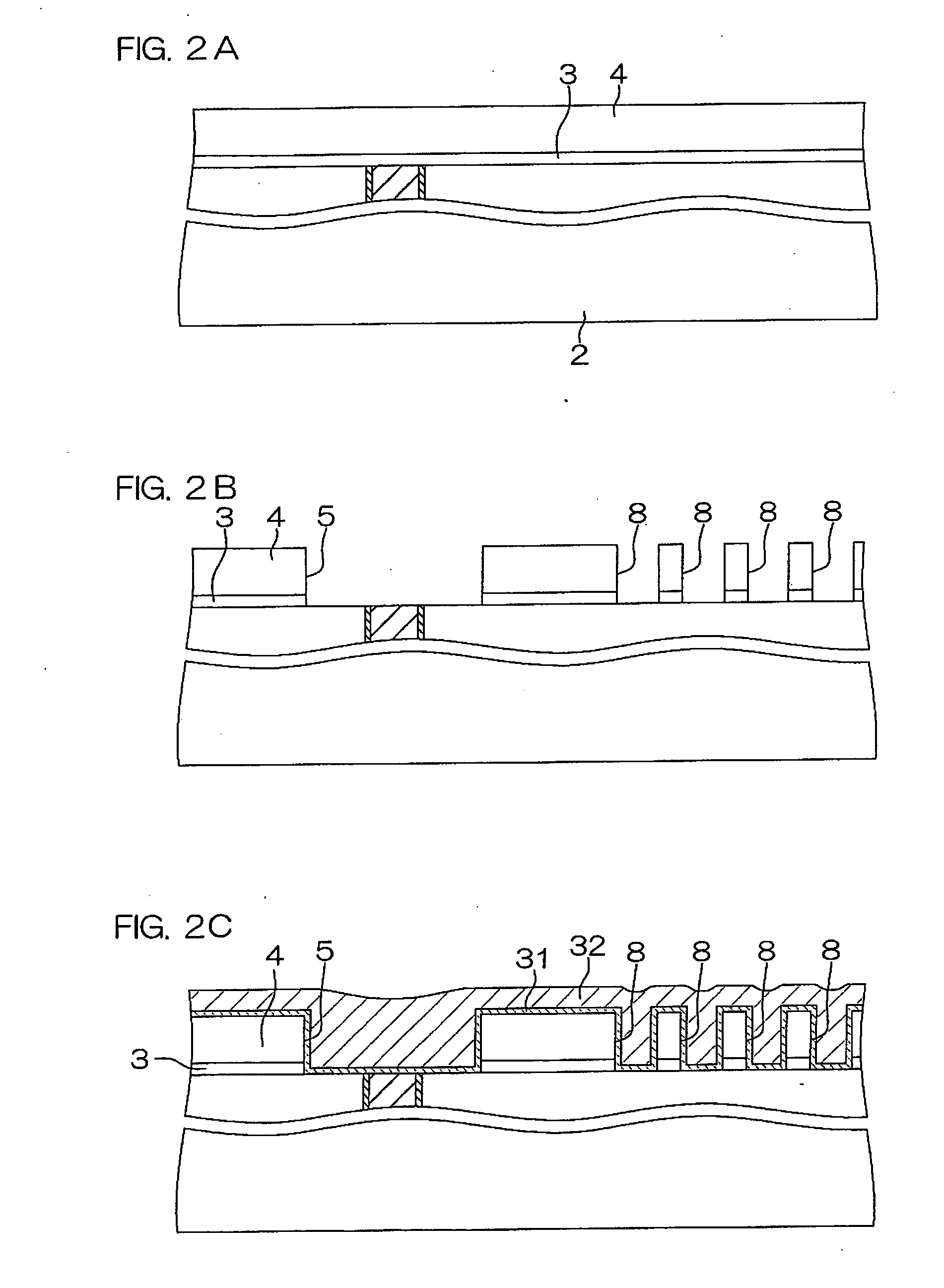

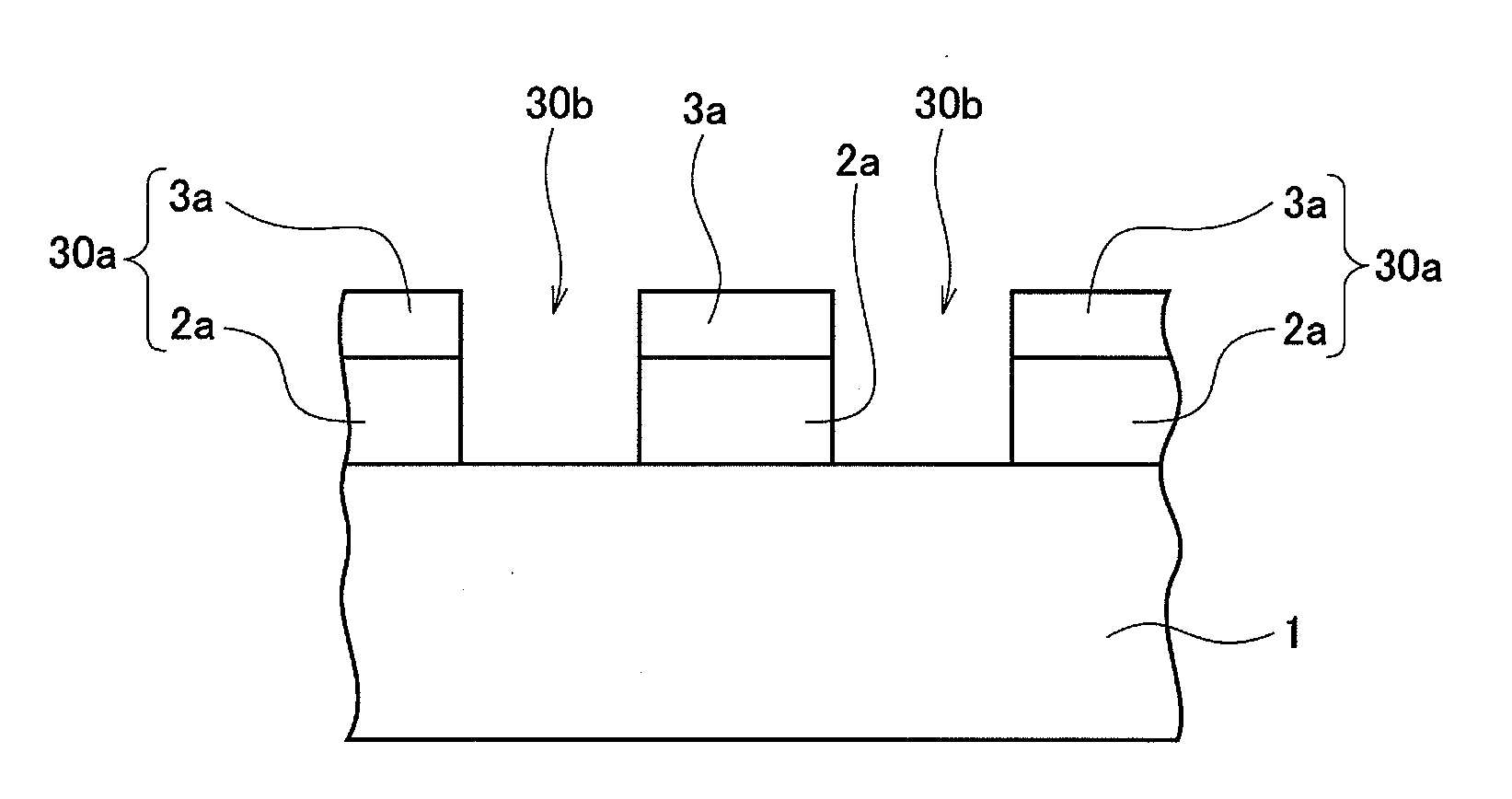

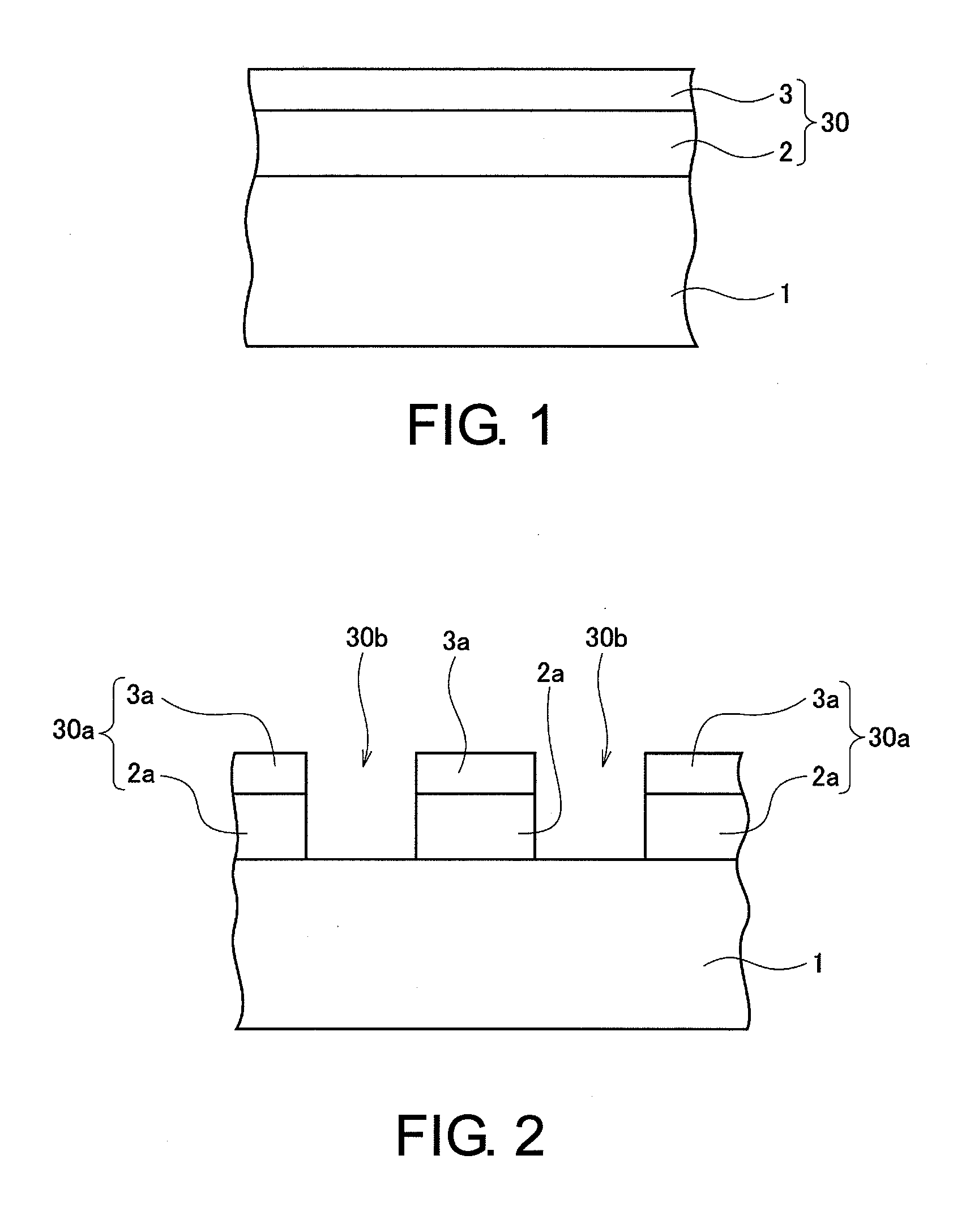

Semiconductor device and semiconductor device manufacturing method

ActiveUS20110175193A1Inhibited DiffusionInhibition is effectiveSemiconductor/solid-state device detailsSolid-state devicesDielectricSemiconductor

A semiconductor device according to the present invention includes a semiconductor substrate, and an interlayer dielectric film, formed on the semiconductor substrate, having a multilayer structure of a compressive stress film and a tensile stress film.

Owner:ROHM CO LTD

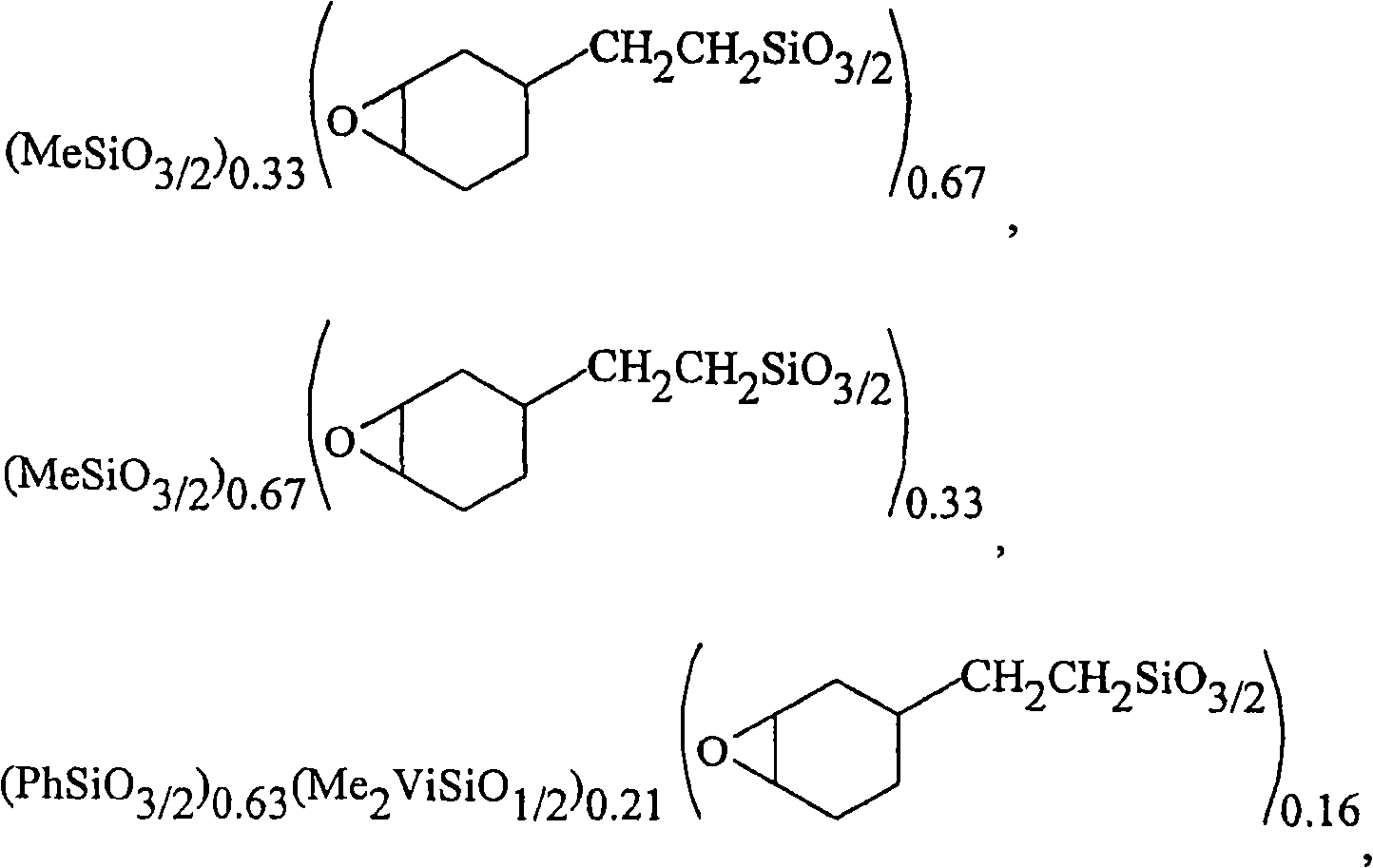

Coated Substrates and Methods for their Preparation

InactiveUS20090130463A1Low water vapor transmission rateReduce penetrationLiquid surface applicatorsSynthetic resin layered productsSiliconChemistry

Owner:ALBAUGH JOHN DEAN +5

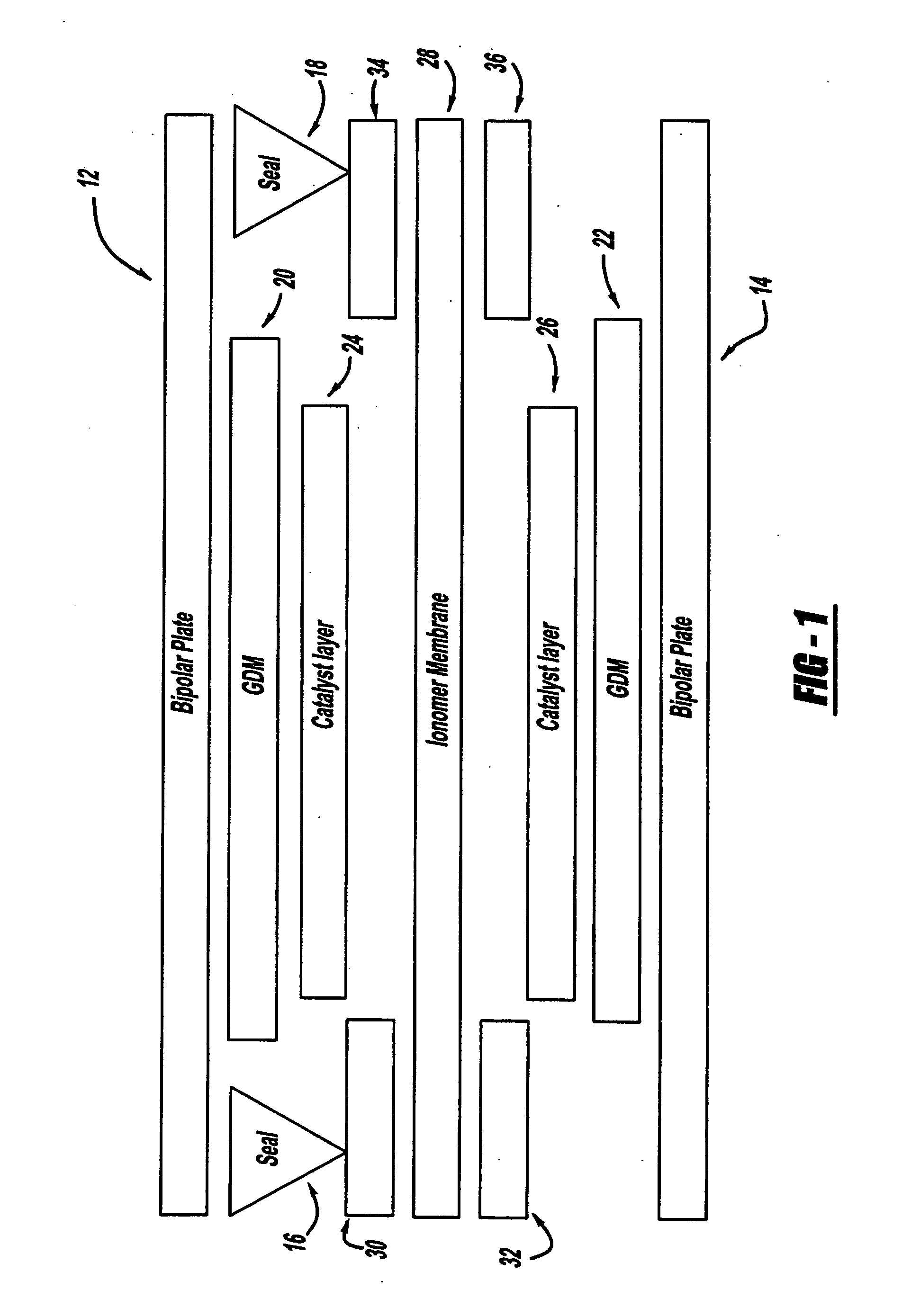

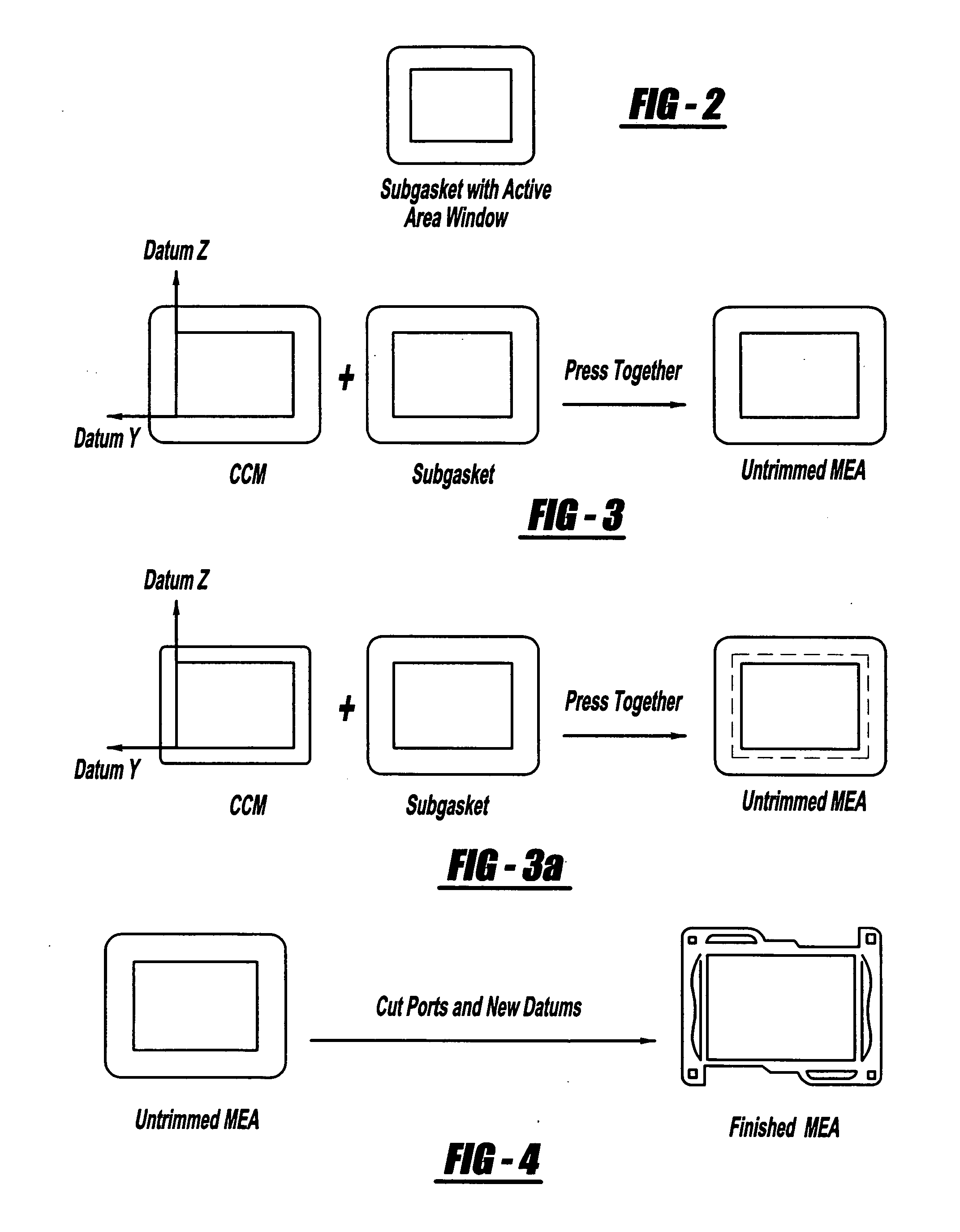

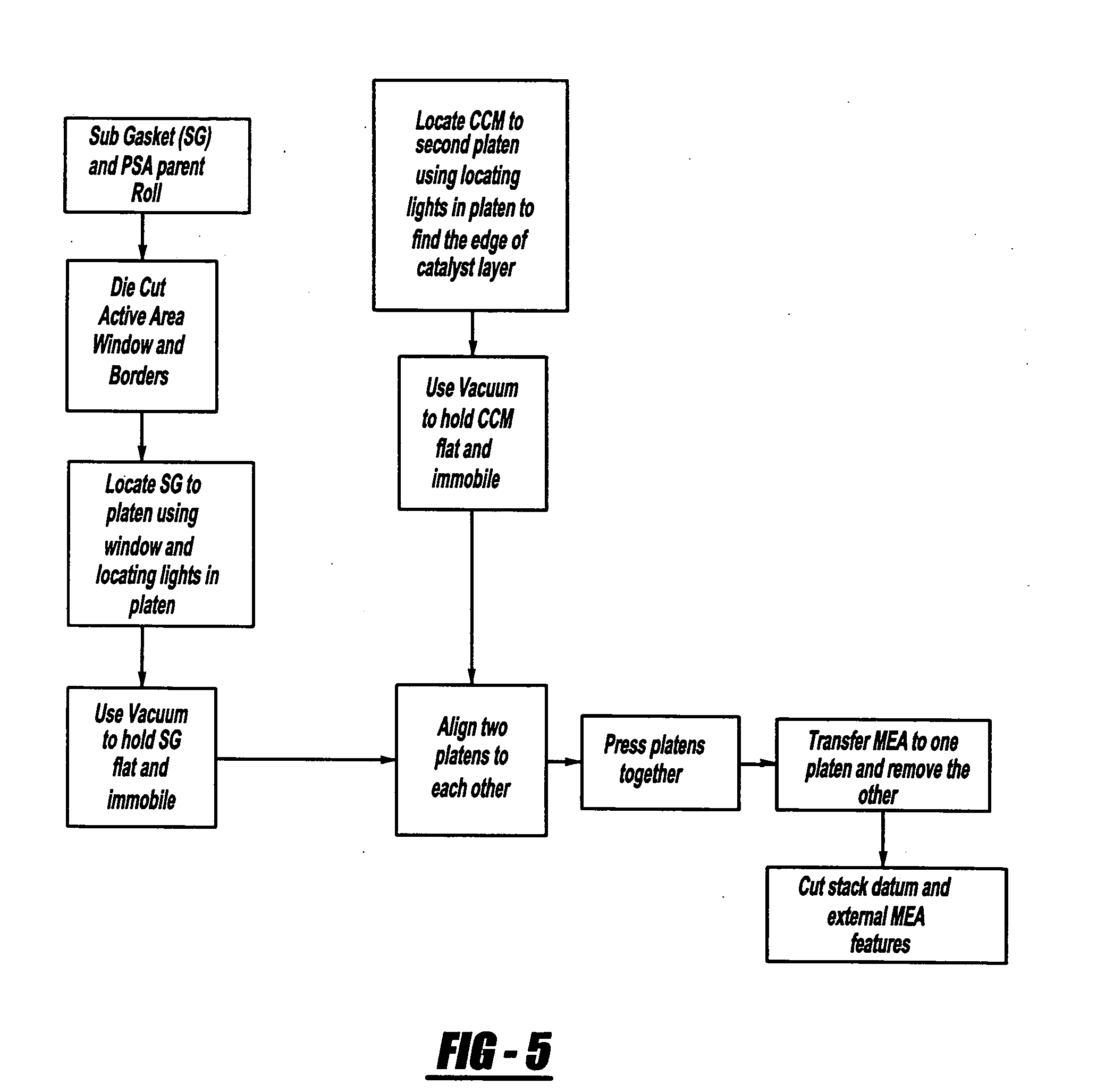

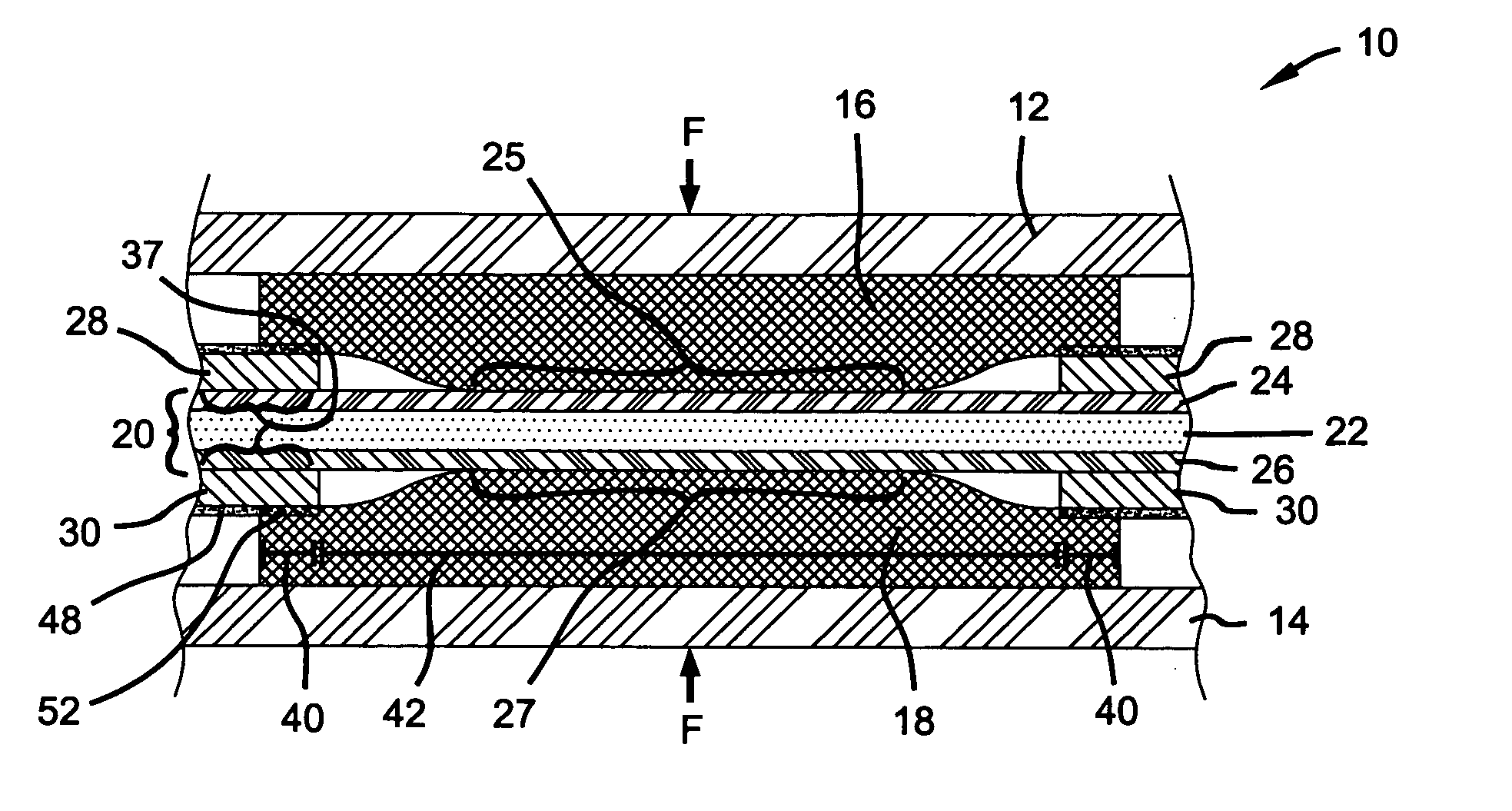

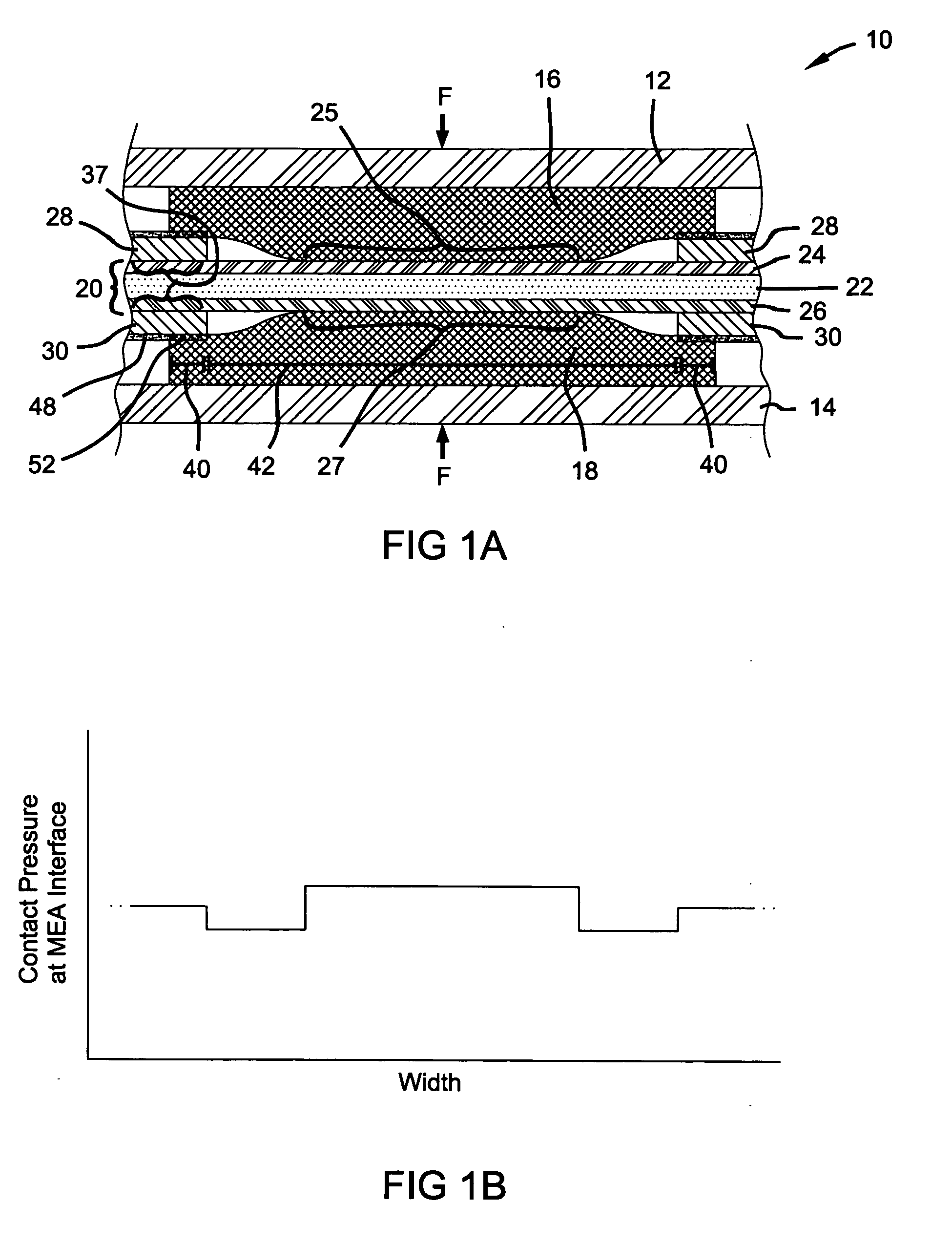

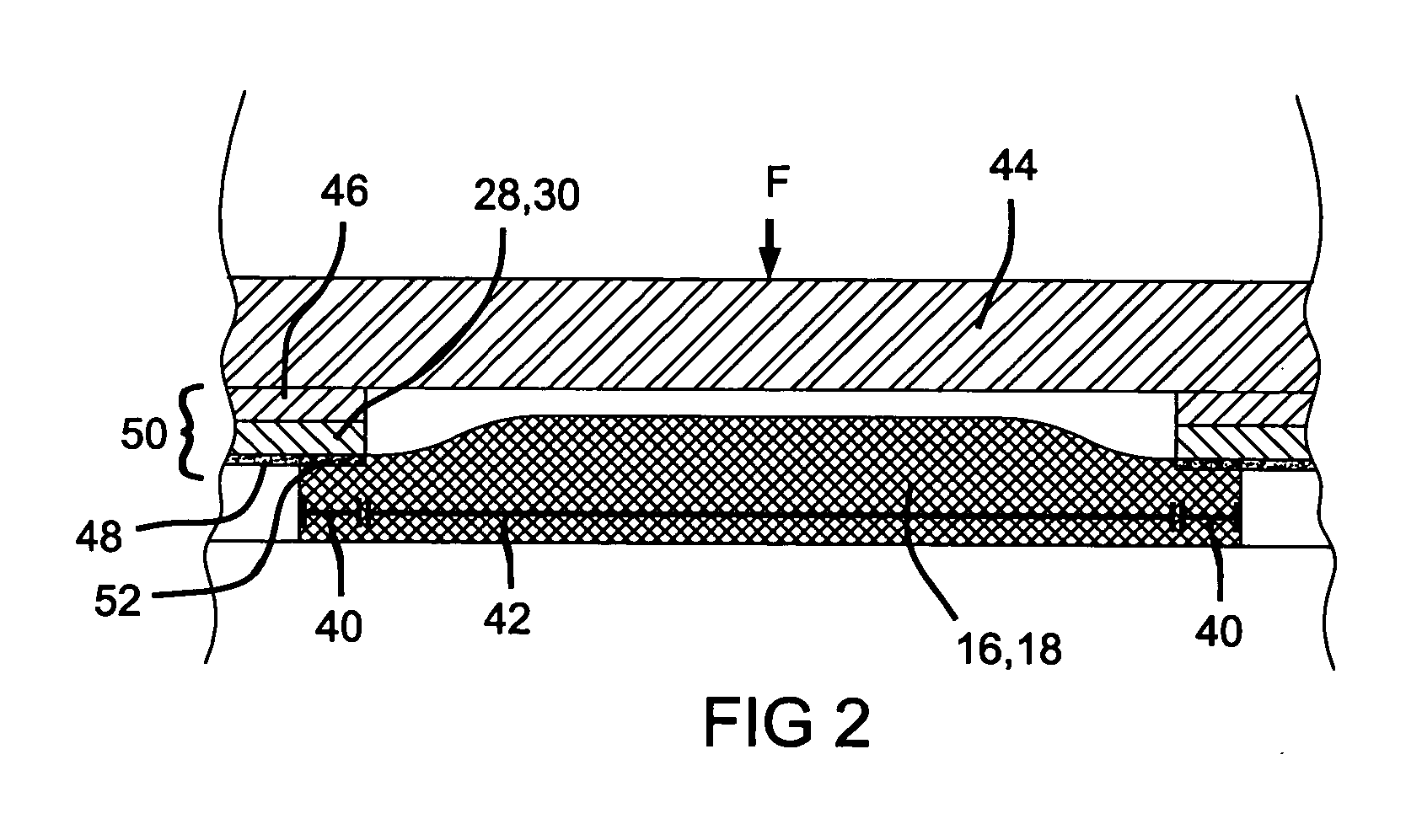

Manufacture or membrane electrode assembly with edge protection for PEM fuel cells

InactiveUS20080105354A1Easy part handlingIncreased durabilityFinal product manufactureLaminationIonomerFuel cells

Methods for attaching a subgasket to an ionomer membrane, wherein the methods provide for the precise location of the subgasket relative to the other component edges of the fuel cell, such as the catalyst layers, so as provide the functionality required to extend the ionomer membrane life and prevent damage to the ionomer membrane during the assembly process.

Owner:GM GLOBAL TECH OPERATIONS LLC

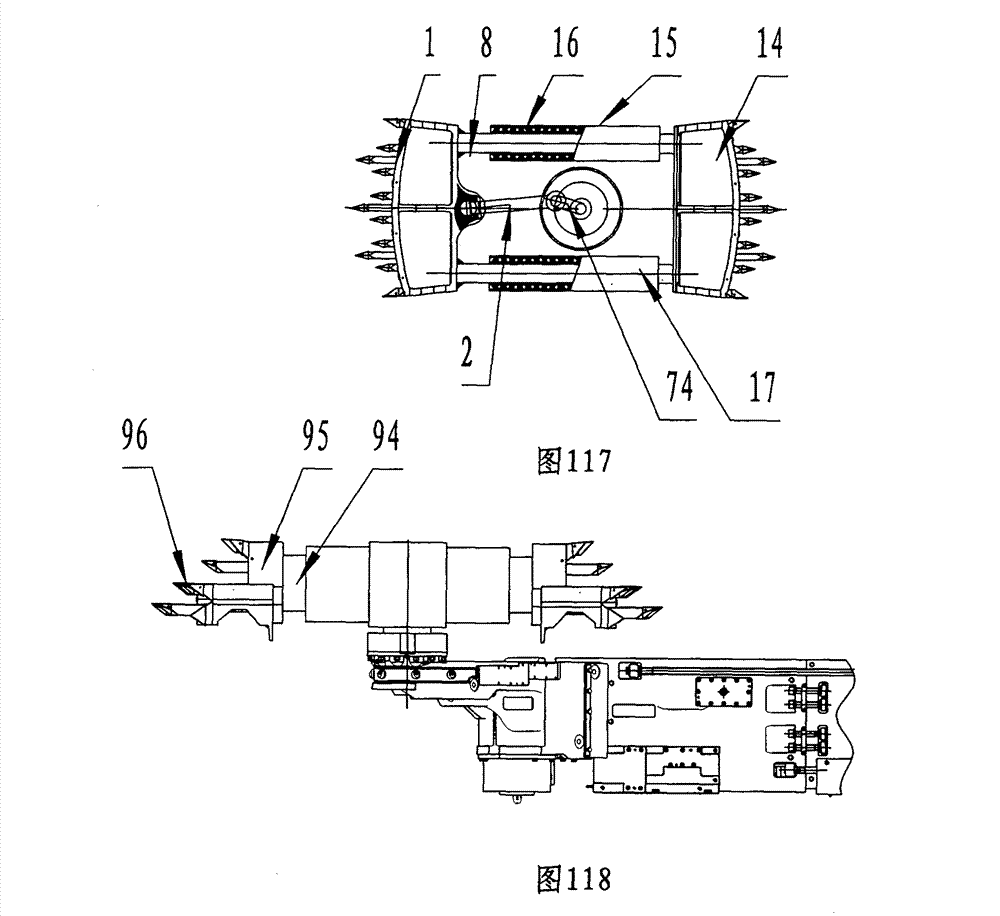

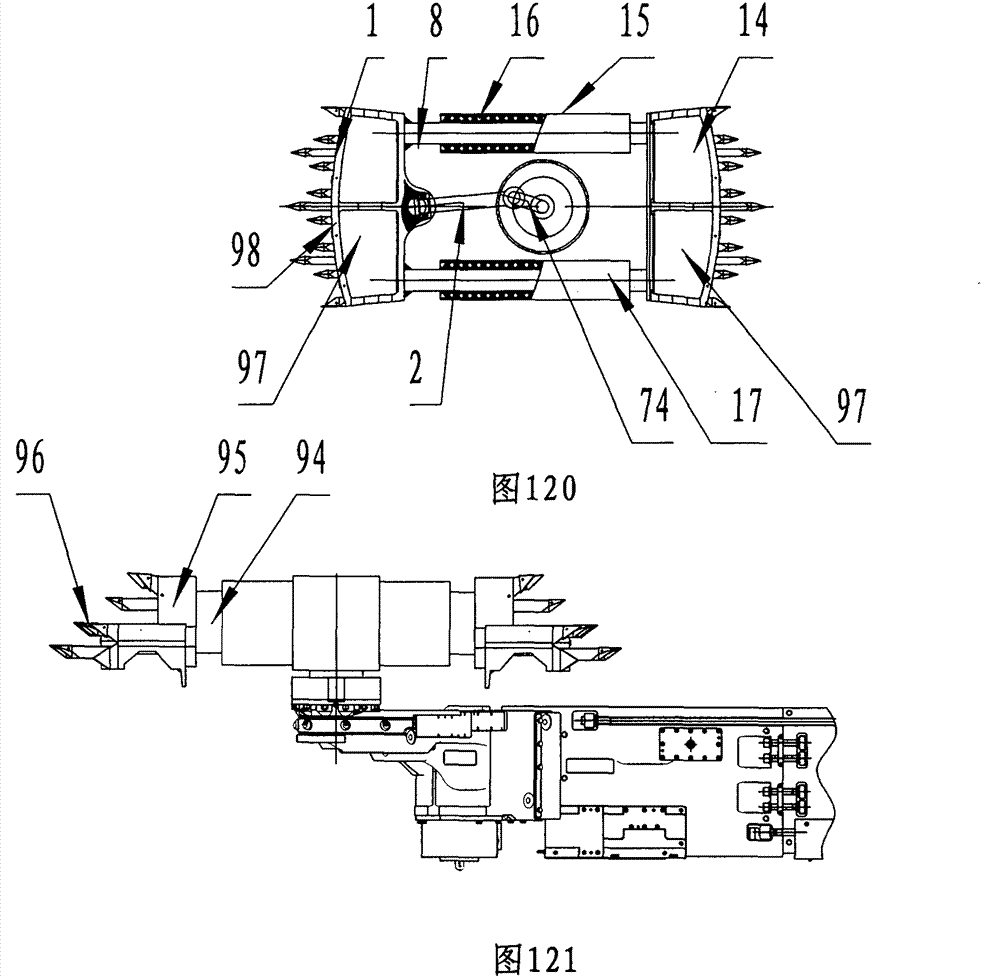

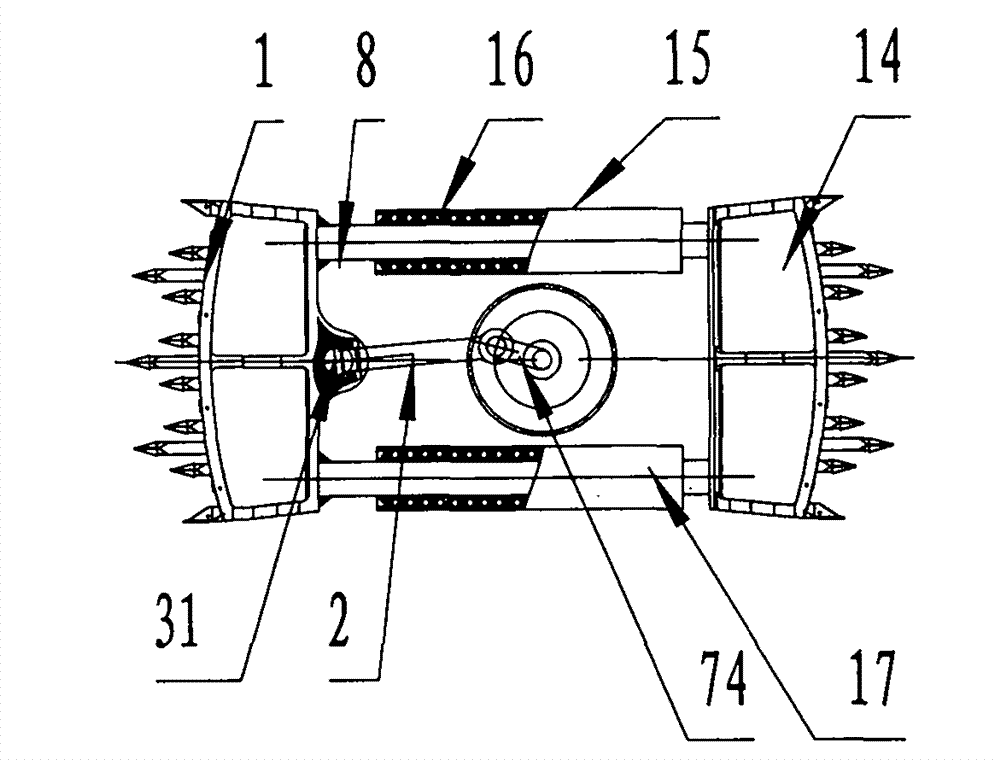

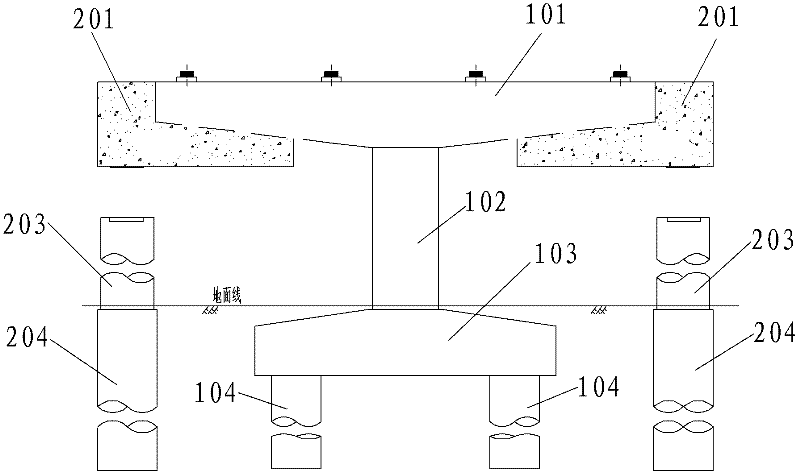

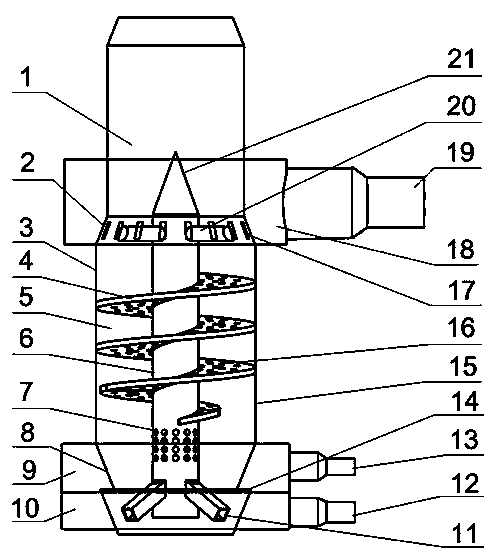

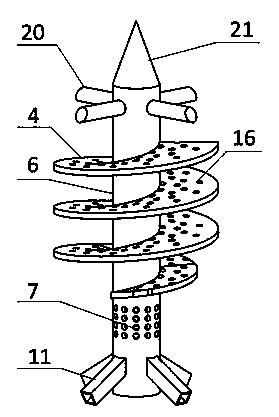

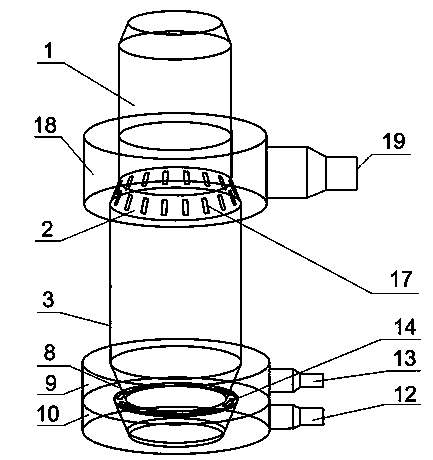

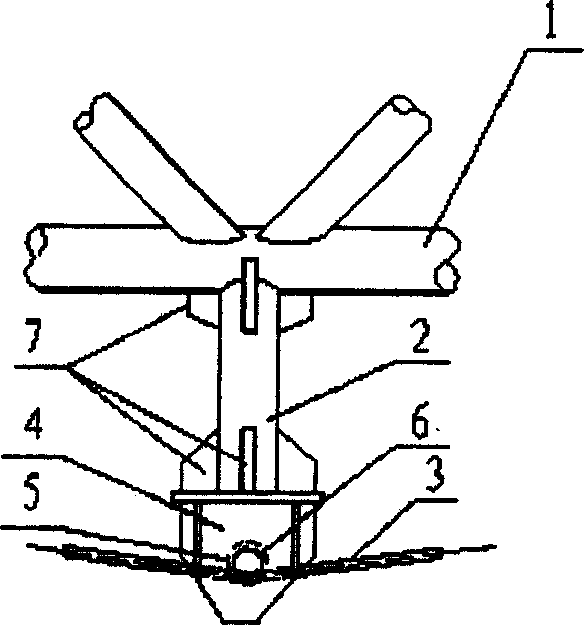

Bidirectional pounding and cutting excavating method and bidirectional pounding and cutting excavator for implementing same

ActiveCN103089259AReduce the number of adjustmentsExtend your lifeDriving meansReciprocating motionEngineering

The method provided by the invention comprises the following steps: a machine body, a walking part, a lifting part, a reciprocating pounding part and the like are arranged; a pounding guide element and the like are arranged on a pounding guide device; pounding heads are arranged at two ends of the pounding guide element, so that a power pounding element drives the pounding guide element; the reciprocating pounding part is arranged on the lifting part; the lifting part is arranged on the machine body; and the walking part drives the machine body to move ahead and retreats so as not to turn the machine body to excavate and drop materials forward and backward. Equipment provided by the invention comprises the machine body, the walking part, the lifting part, the reciprocating pounding part and the like; the reciprocating pounding part comprises the pounding guide device, the pounding driving device and the like; the pounding heads are both arranged at two ends of the pounding guide element; the pounding driving device comprises the power pounding element and the like; the power pounding element drives the pounding guide element to move in a reciprocating mode; the pounding guide element drives the pounding heads to pound; the reciprocating pounding part is arranged on the lifting part; the lifting part is arranged on the machine body; the walking part drives the machine body to move ahead and retreat so as not to turn the machine body to excavate and drop materials forward and backward.

Owner:刘素华

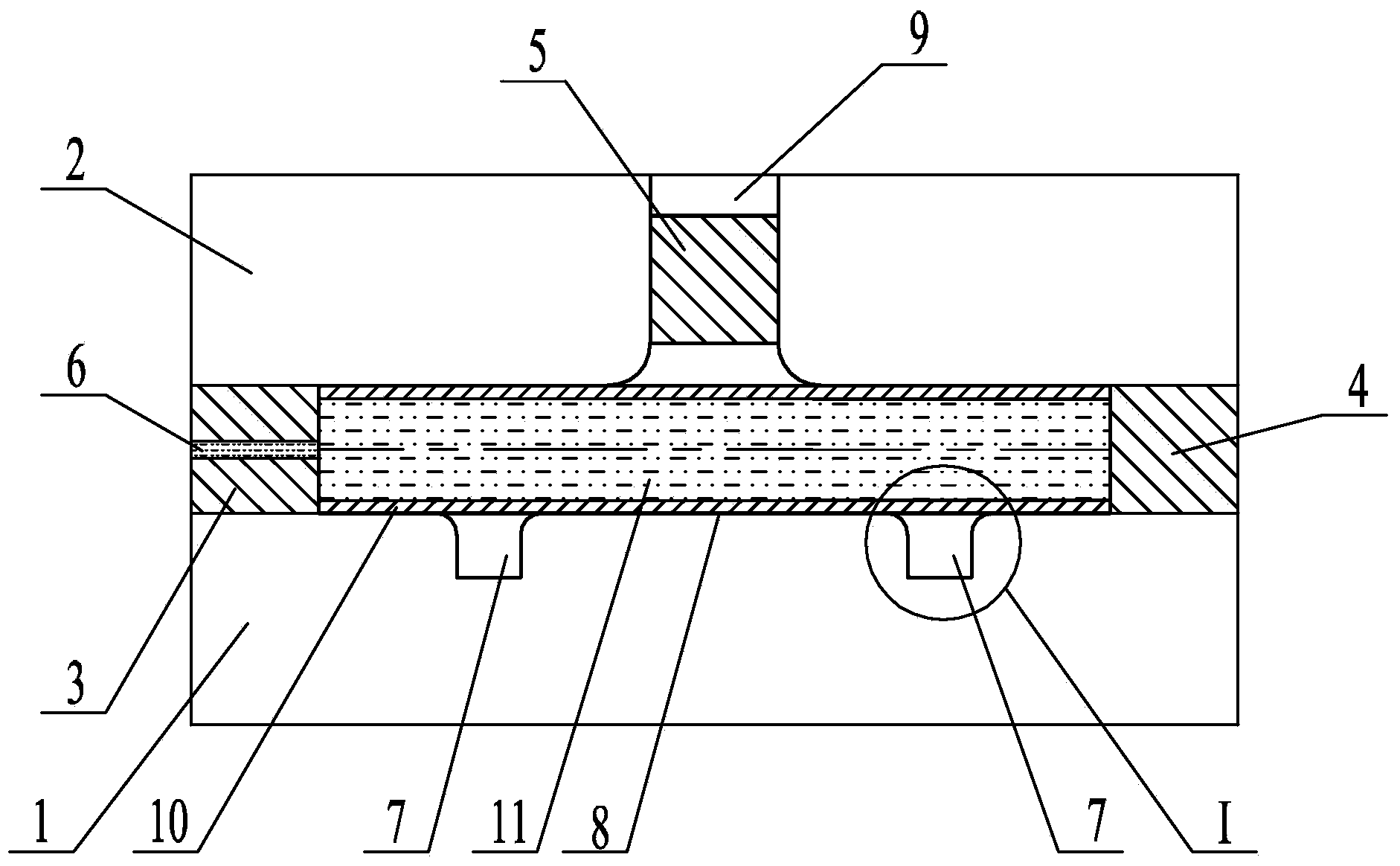

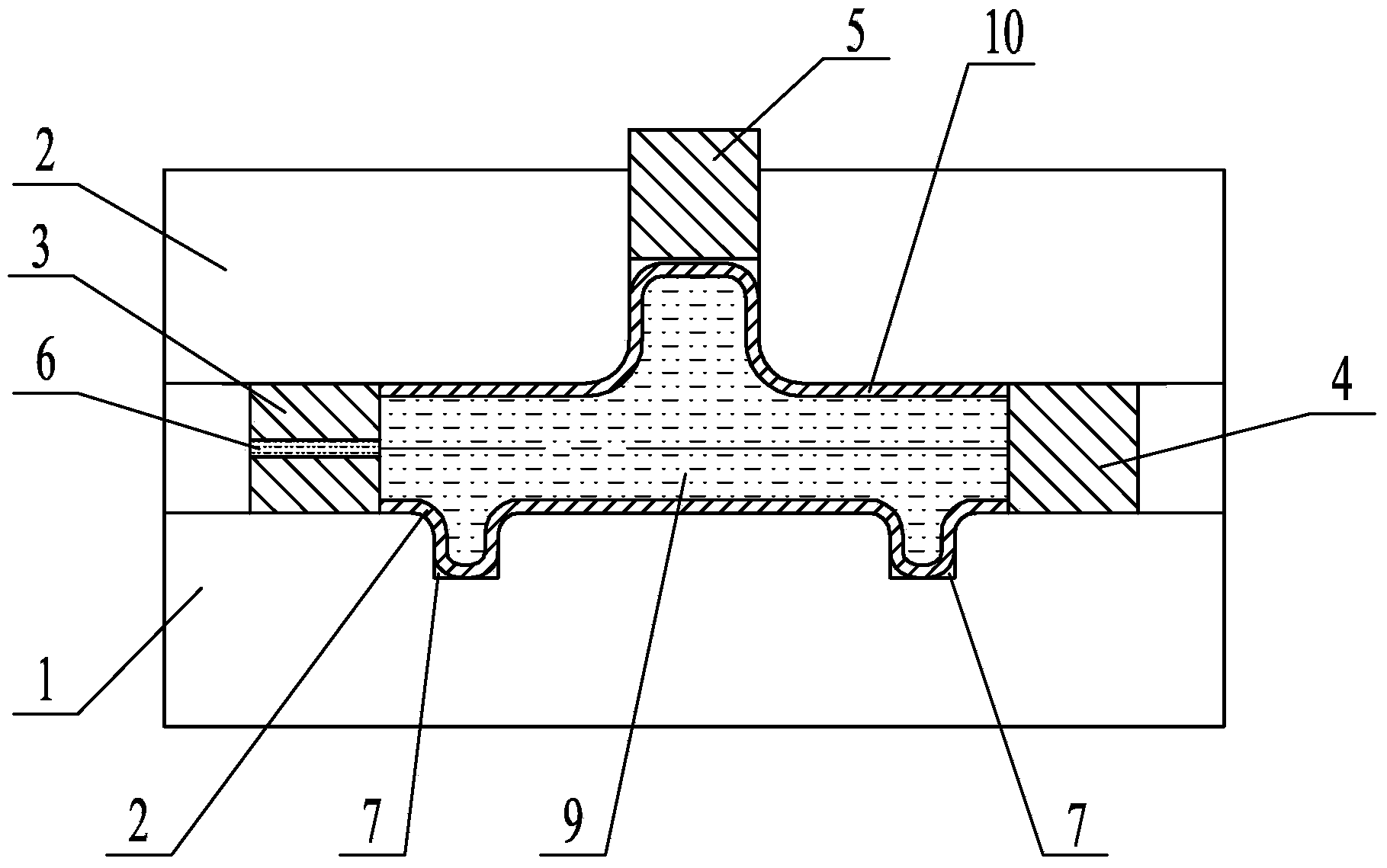

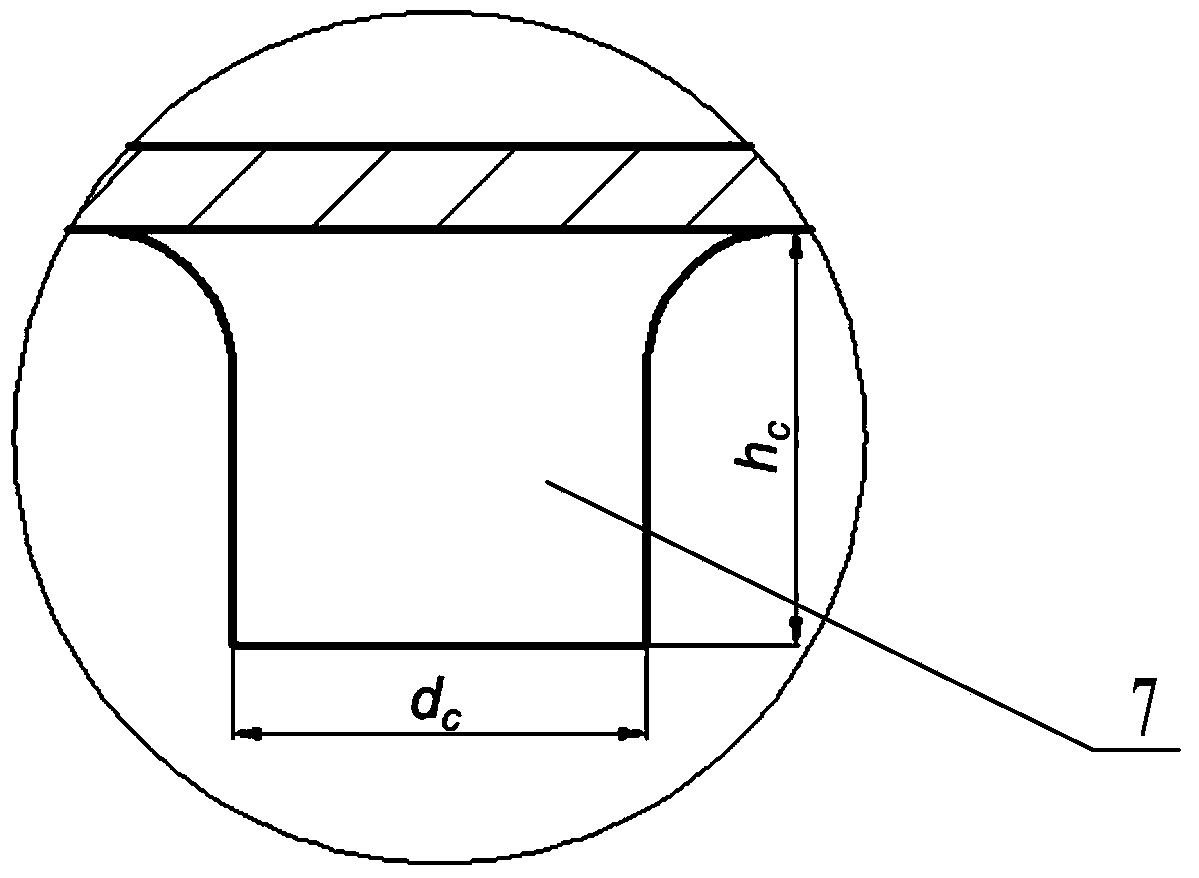

Internal high pressure forming die and method of elbow T-branch pipe

The invention discloses an internal high pressure forming die and method of an elbow T-branch pipe, relates to an internal high pressure forming die and method of a T-branch pipe, and aims to solve the problems that the bottom of a main cavity of an existing internal high pressure forming die is not provided with storage bins, and therefore the bottom of the formed T-branch pipe is compressed, deformed, and then seriously thickened. The die is characterized in that a branch pipe cavity communicated with a main cavity is formed in the top of the main cavity, and two storage bins are arranged at the bottom of the main cavity. The method includes the steps that firstly, the diameter D of the main cavity is determined; secondly, the diameter and the depth of the storage bins are determined; thirdly, a pipe blank is placed in a cavity of a lower die; fourthly, the two ends of the pipe blank are sealed through a first punch and a second punch; fifthly, internal pressure is injected; sixthly, the first punch and the second punch move towards the middle through external force for feed supplement, and extruded materials flow into the storage bins and the branch pipe cavity after the pipe fitting blank bulges; seventhly, the die is opened, and a part is taken out; eighthly, the process section of the part is cut off, and then bent and formed elbow T-branch pipe is obtained. The internal high pressure forming die and method are used for forming of the T-branch pipe.

Owner:HARBIN INST OF TECH

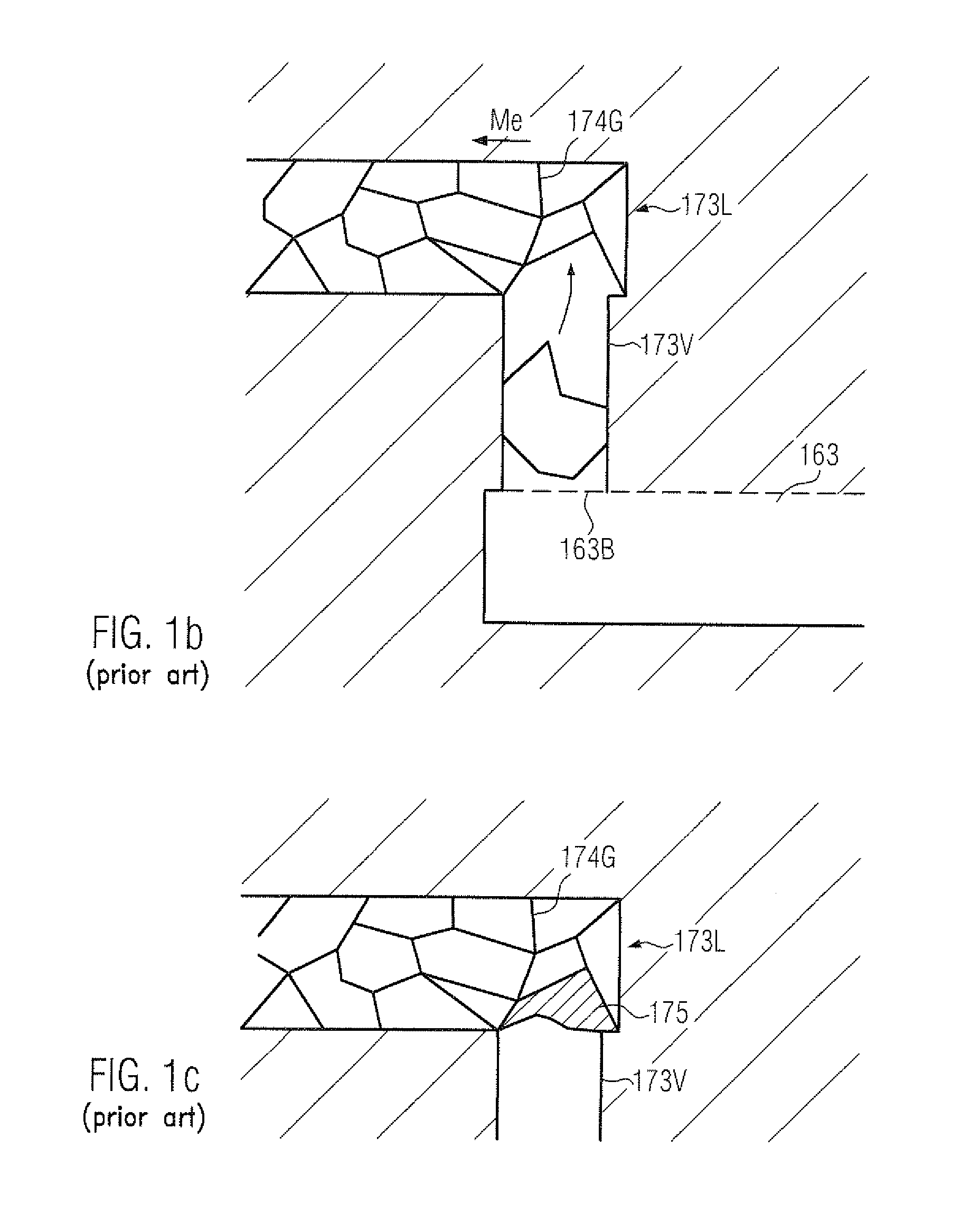

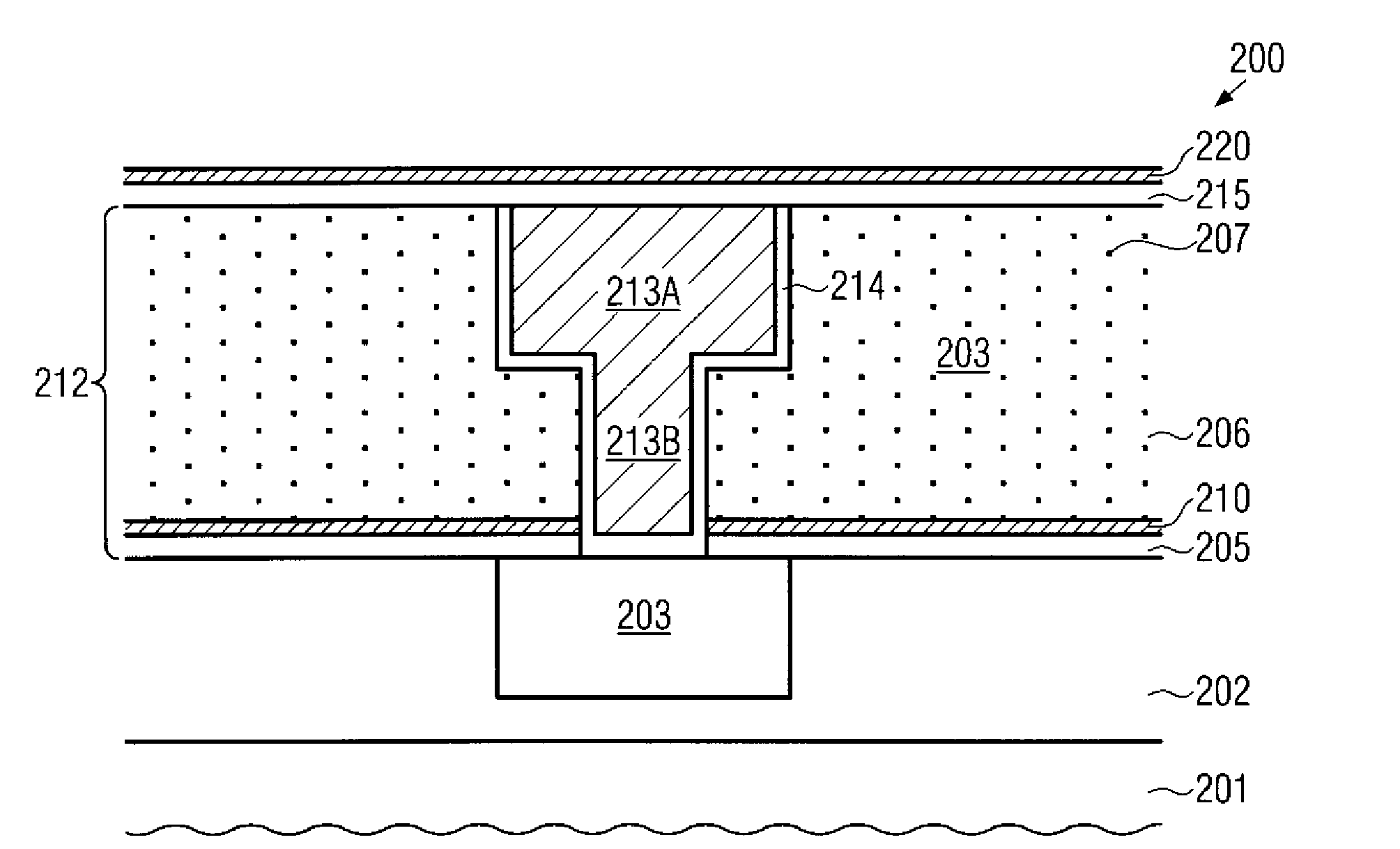

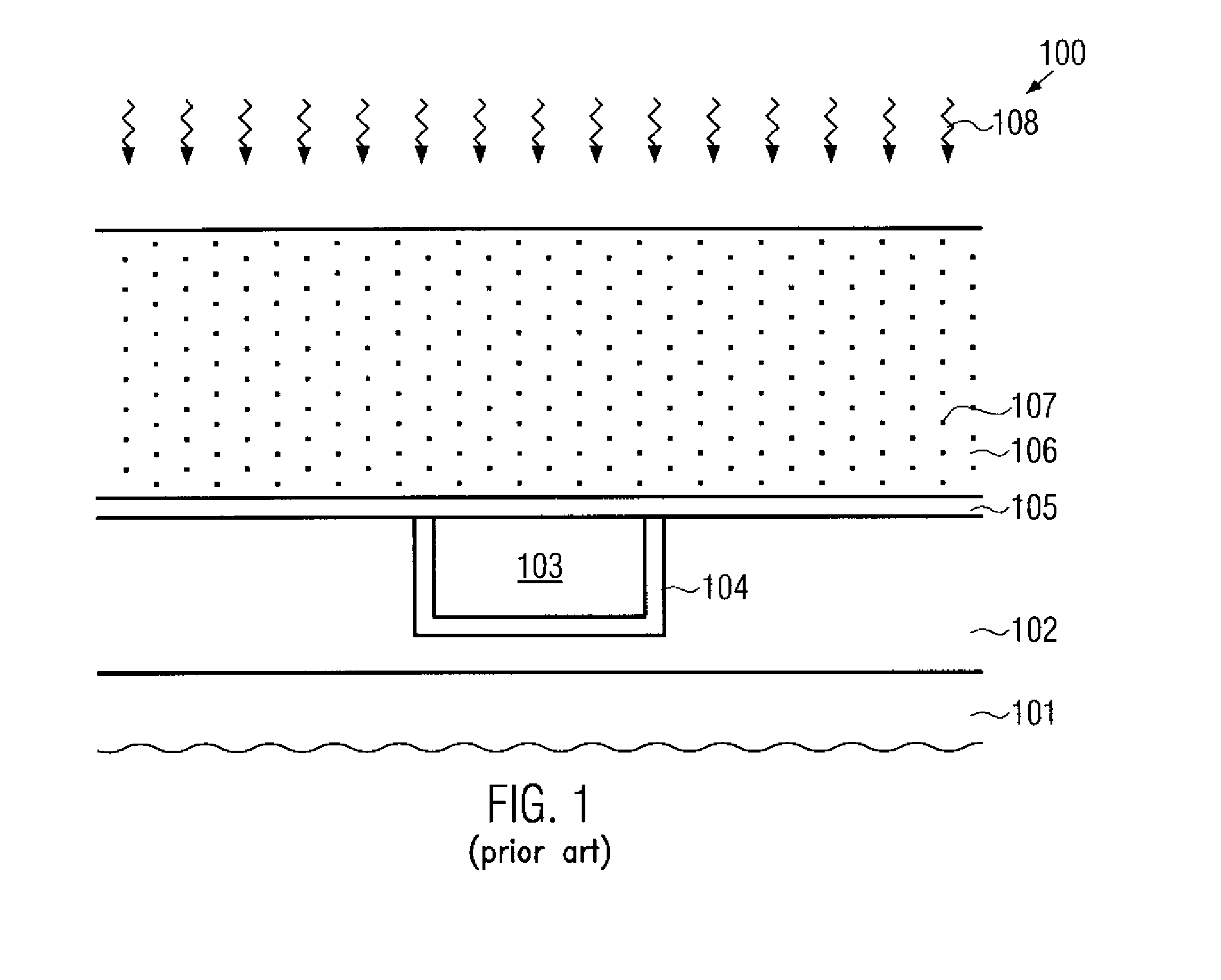

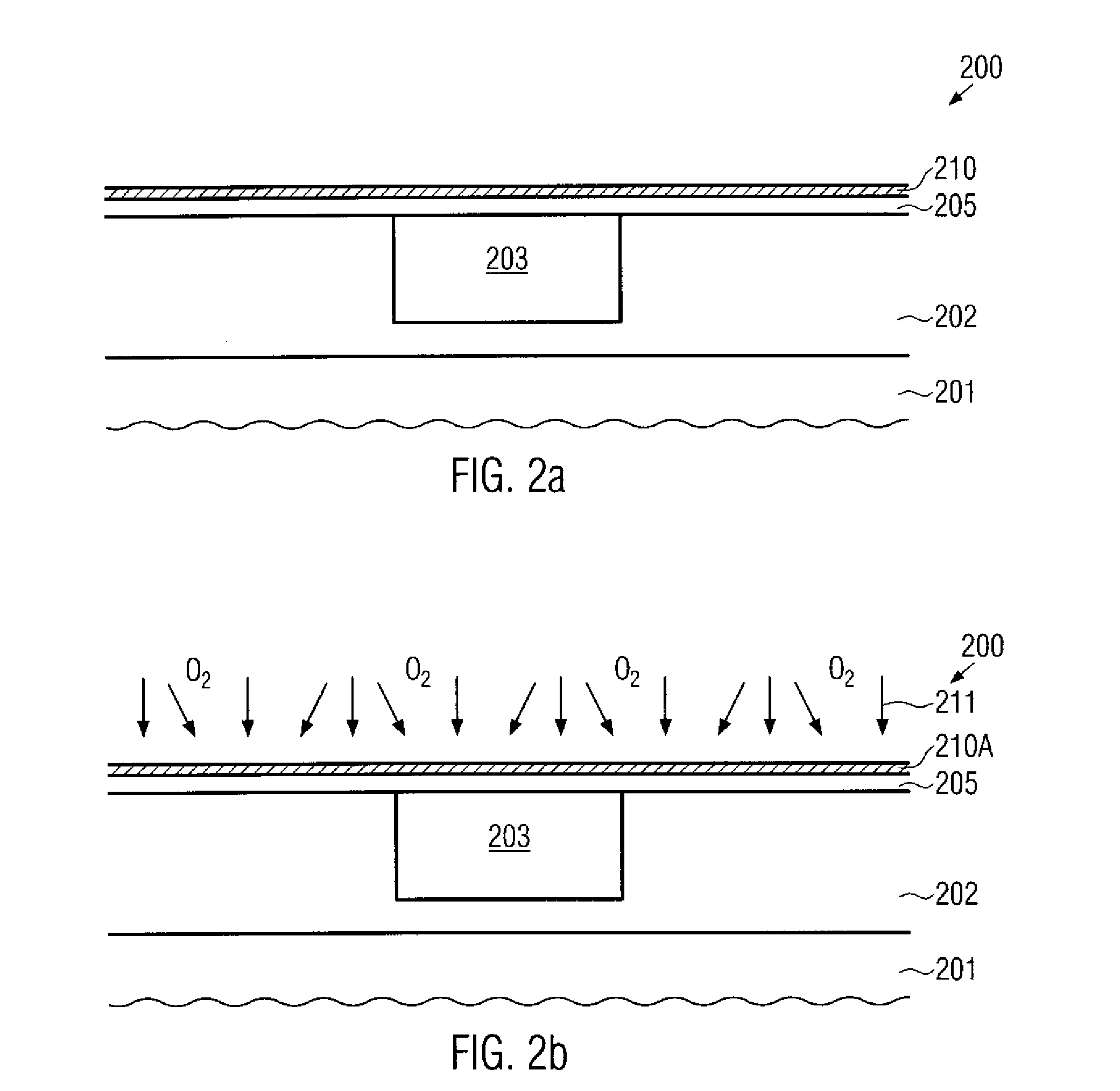

SEMICONDUCTOR DEVICE COMPRISING METAL-BASED eFUSES OF ENHANCED PROGRAMMING EFFICIENCY BY ENHANCING METAL AGGLOMERATION AND/OR VOIDING

InactiveUS20110156858A1Reduce compressive stressCompact configurationSemiconductor/solid-state device detailsSolid-state devicesMetallurgySemiconductor

Metal fuses in semiconductor devices may be formed on the basis of additional mechanisms for obtaining superior electromigration in the fuse bodies. To this end, the compressive stress caused by the current-induced metal diffusion may be restricted or reduced in the fuse body, for instance, by providing a stress buffer region and / or by providing a dedicated metal agglomeration region. The concept may be applied to the metallization system and may also be used in the device level, when fabricating the metal fuse in combination with high-k metal gate electrode structures.

Owner:GLOBALFOUNDRIES INC

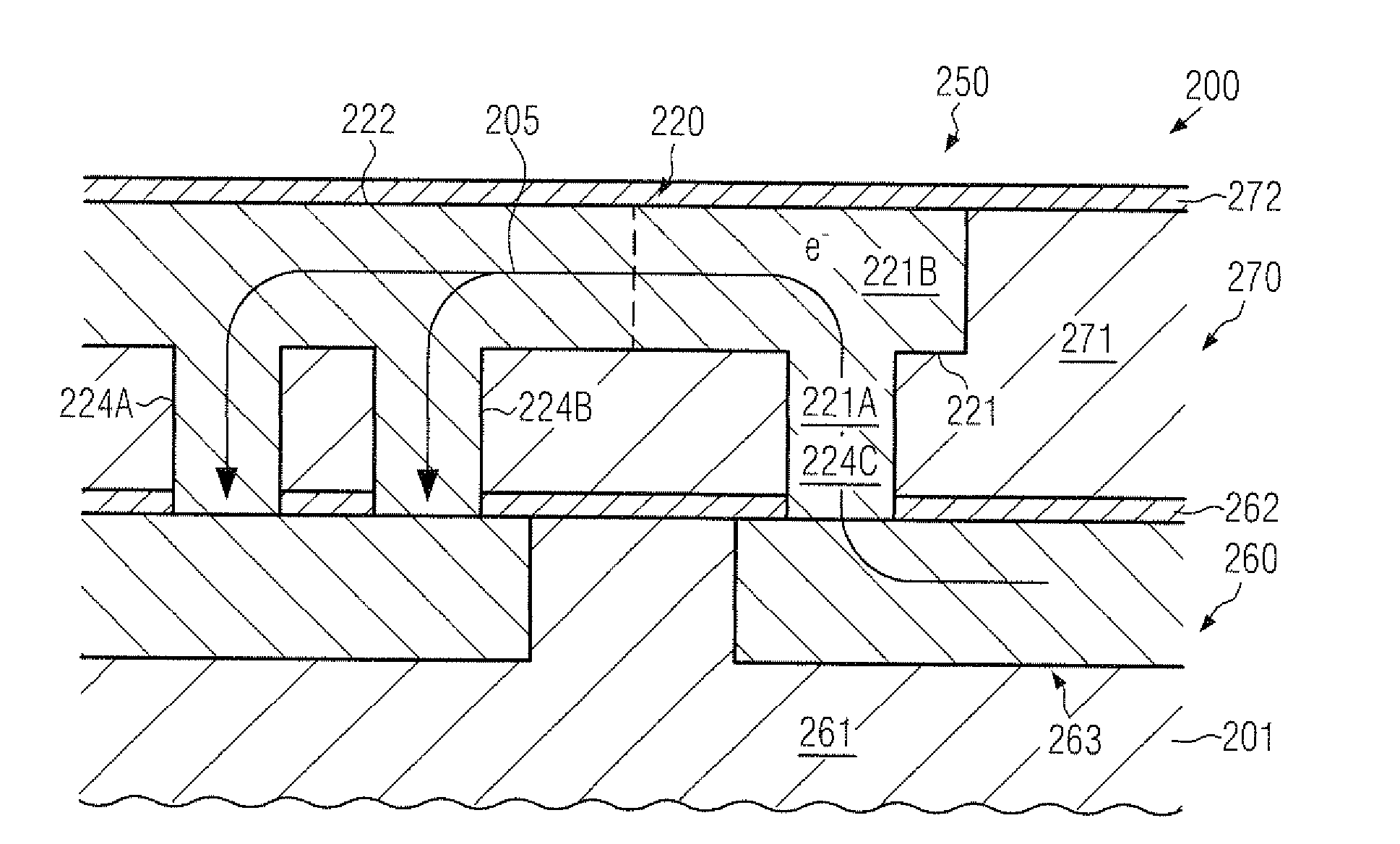

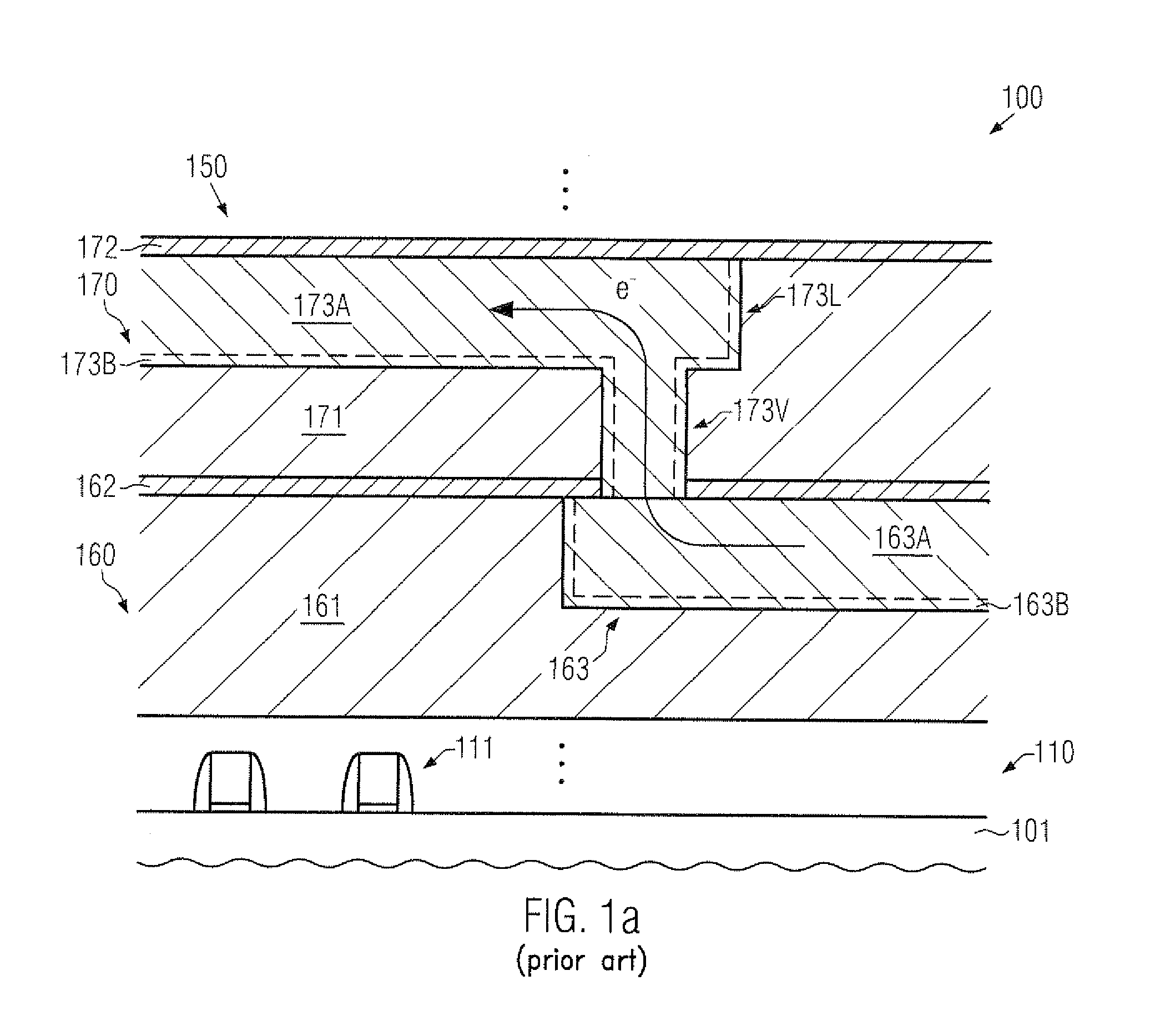

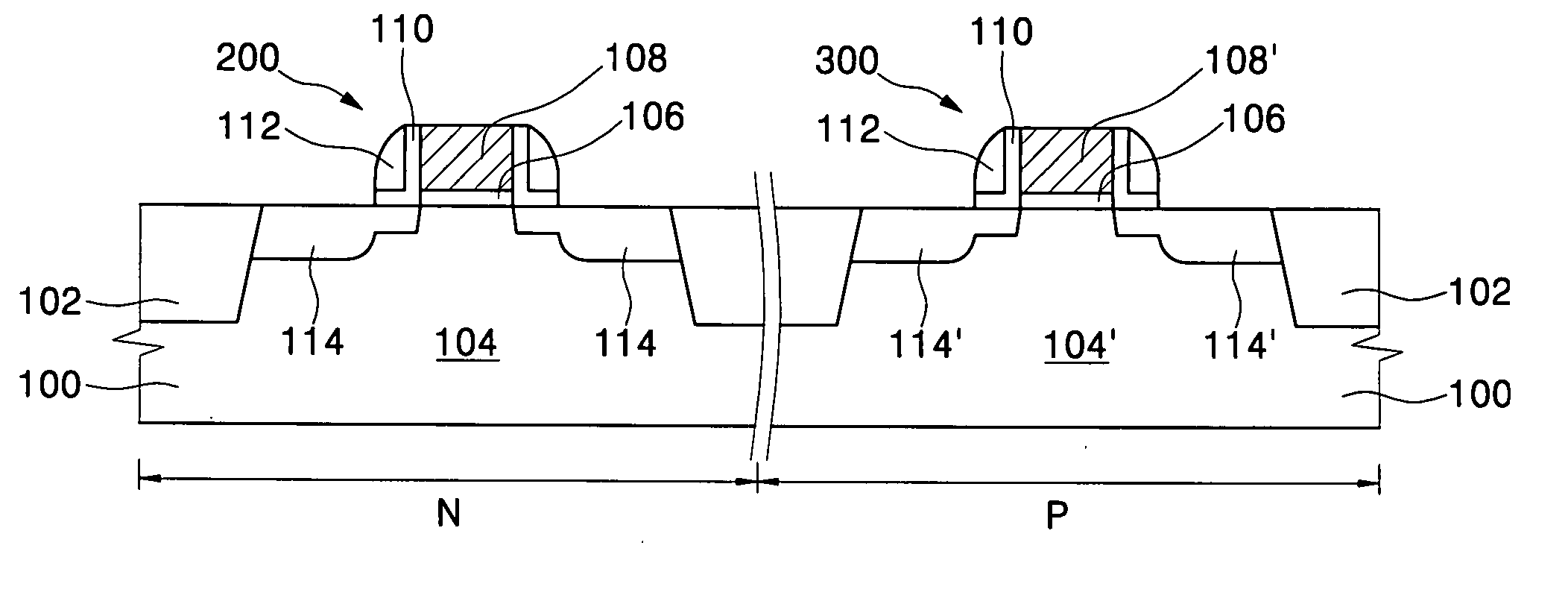

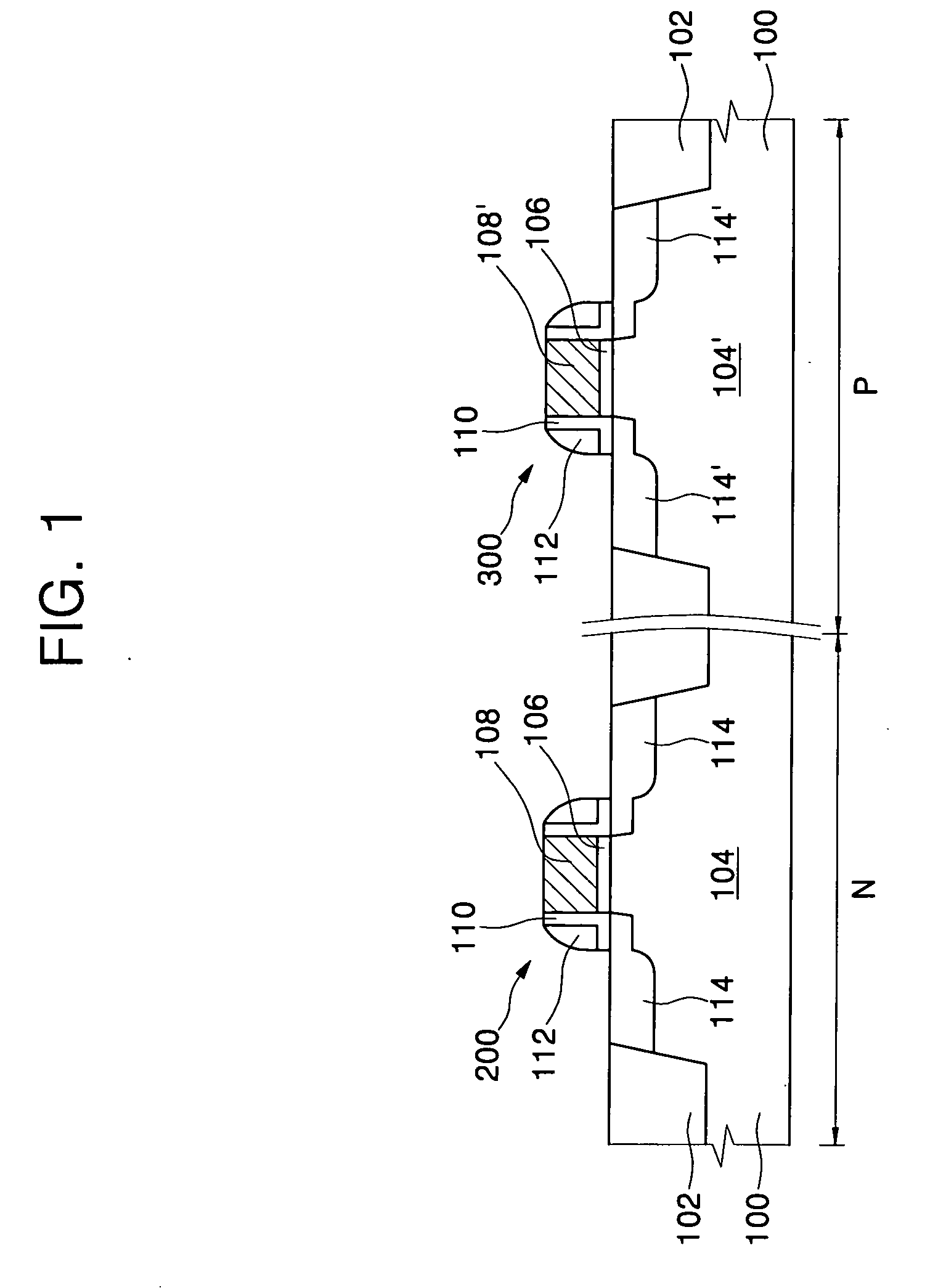

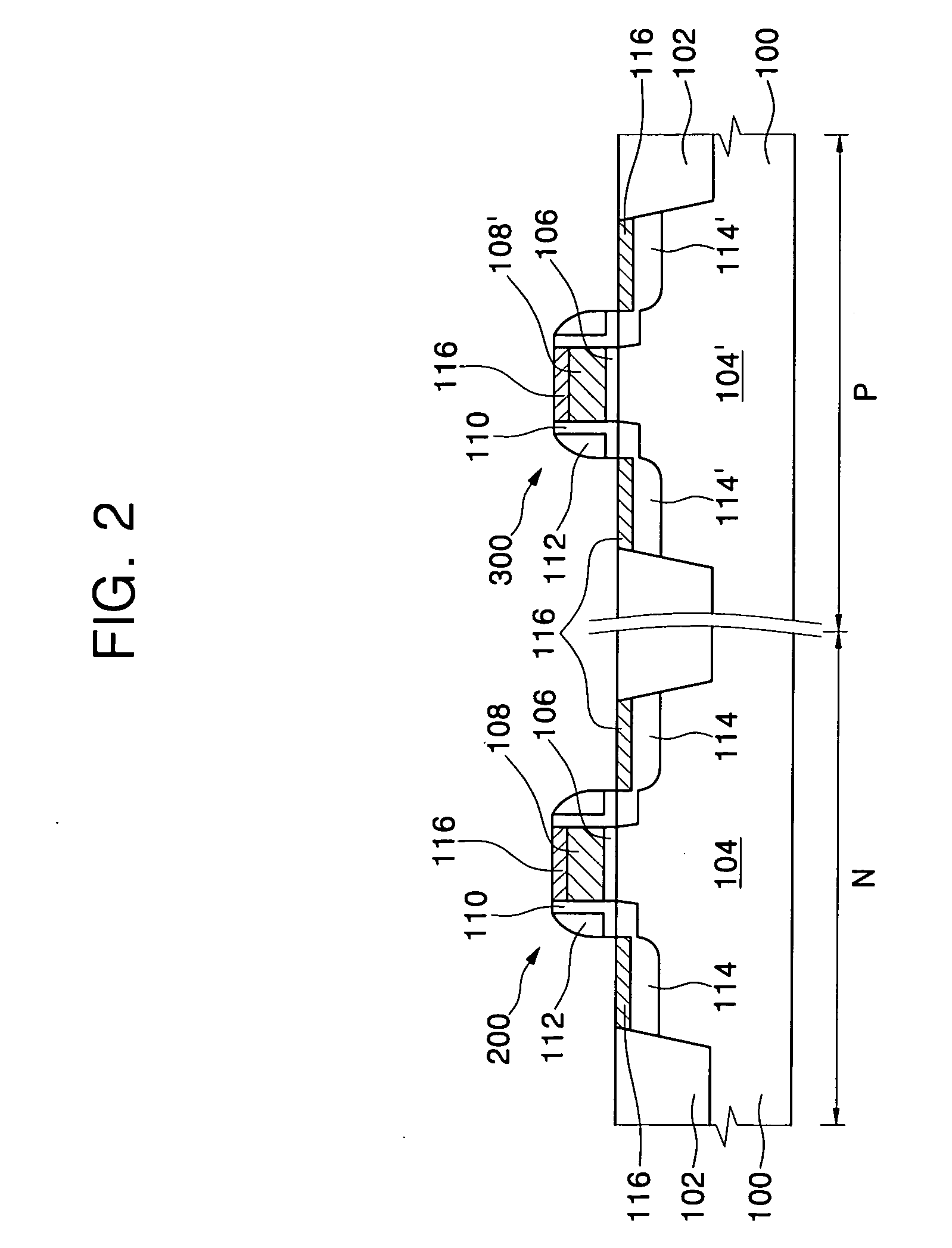

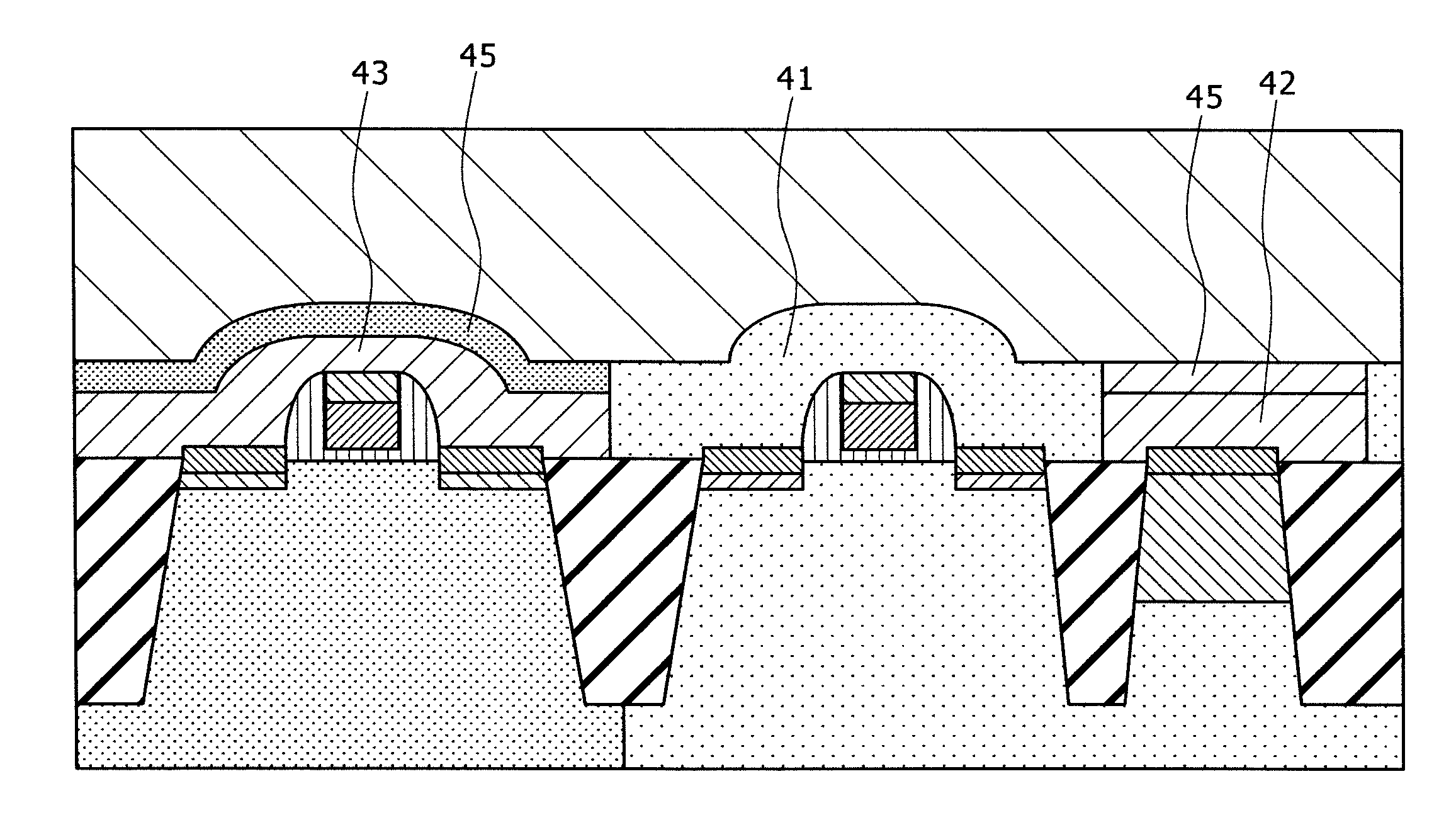

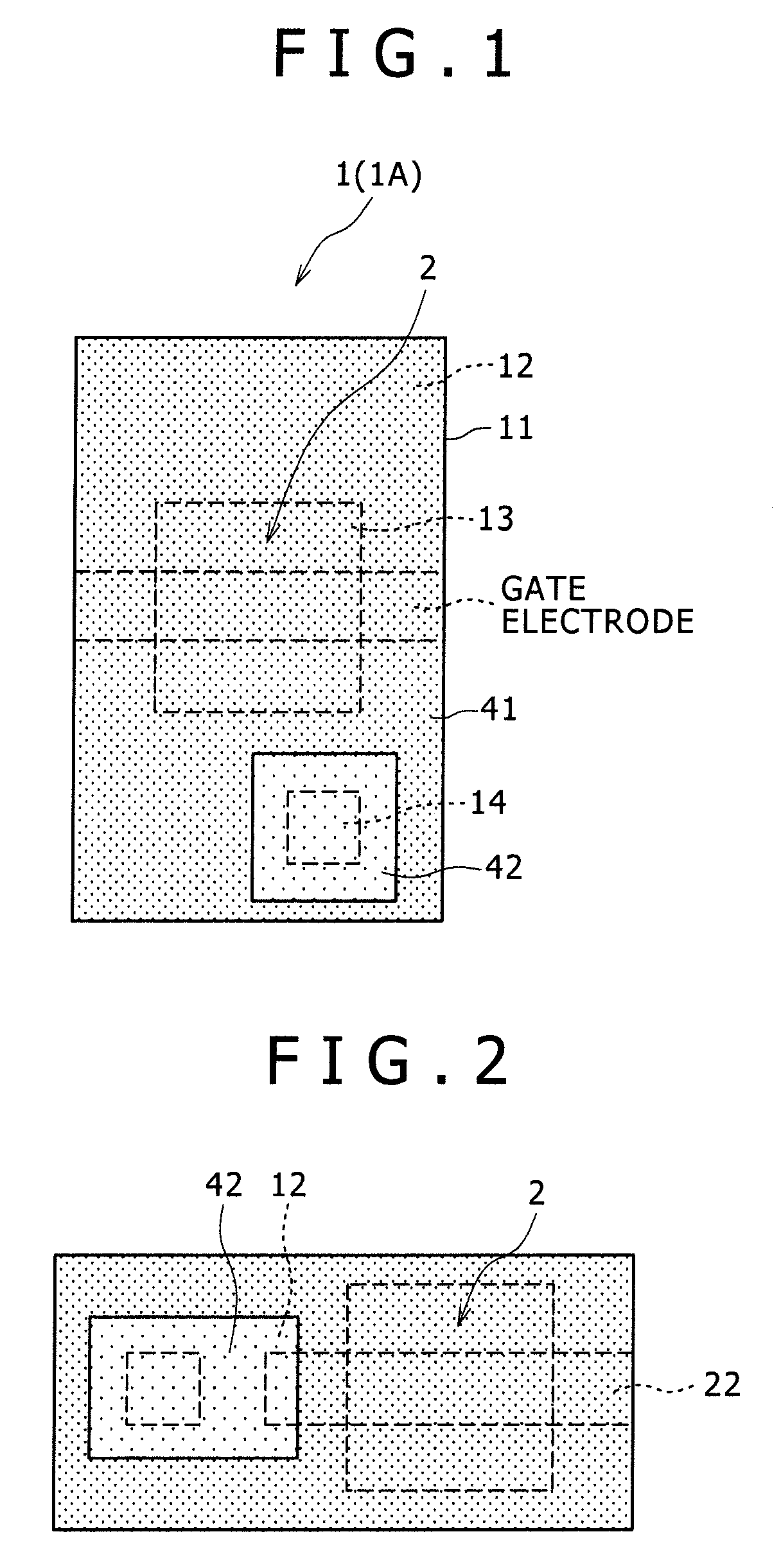

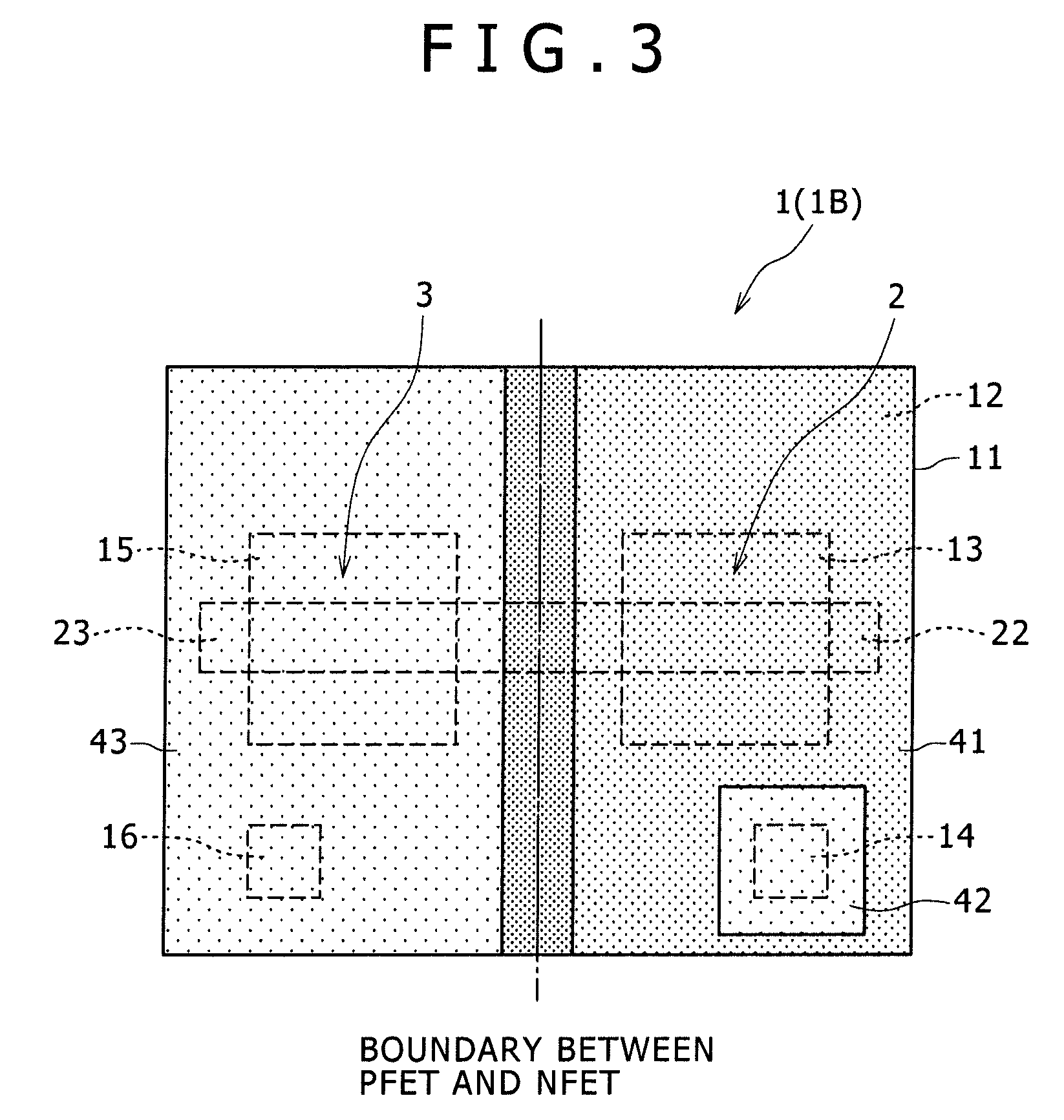

Methods of fabricating semiconductor devices having insulating layers with differing compressive stresses and related devices

ActiveUS20060148153A1Raise the ratioReduce compressive stressTransistorSemiconductor/solid-state device manufacturingDevice materialThermal treatment

Methods of fabricating semiconductor devices are provided. An NMOS transistor and a PMOS transistor are provided on a substrate. The NMOS transistor is positioned on an NMOS region of the substrate and the PMOS transistor is positioned on a PMOS region of the substrate. A first insulating layer is provided on the NMOS transistor. The first insulating layer has a first compressive stress. A second insulating layer is provided on the PMOS transistor. The second insulating layer has a second compressive stress and a stress relief ratio higher than a stress relief ratio of the first insulating layer. A thermal treatment process is performed on the first insulating layer and the second insulating layer such that the second compressive stress of the second insulating layer is lower than the first compressive stress of the first insulating layer. Related devices are also provided.

Owner:SAMSUNG ELECTRONICS CO LTD

Semiconductor device including a porous low-k material layer stack with reduced UV sensitivity

InactiveUS20080099918A1High porosityImprove mechanical stabilitySemiconductor/solid-state device detailsSolid-state devicesLayer thicknessVanadium oxide

By forming a cap layer on a dielectric barrier layer of a low-k dielectric material stack, the interaction of UV radiation during the generation of pores in the low-k dielectric material may be significantly reduced. In some illustrative embodiments, the cap layer may comprise titanium oxide and / or vanadium oxide which may provide a high degree of reflectivity and absorption, respectively. The layer thickness of the cap layer may be 10 nm or significantly less, thereby reducing any adverse influence on the overall performance of the resulting layer stack.

Owner:GLOBALFOUNDRIES INC

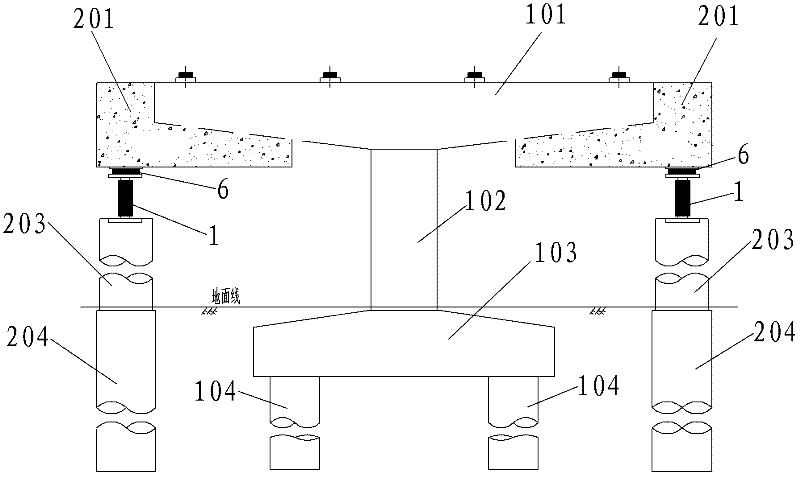

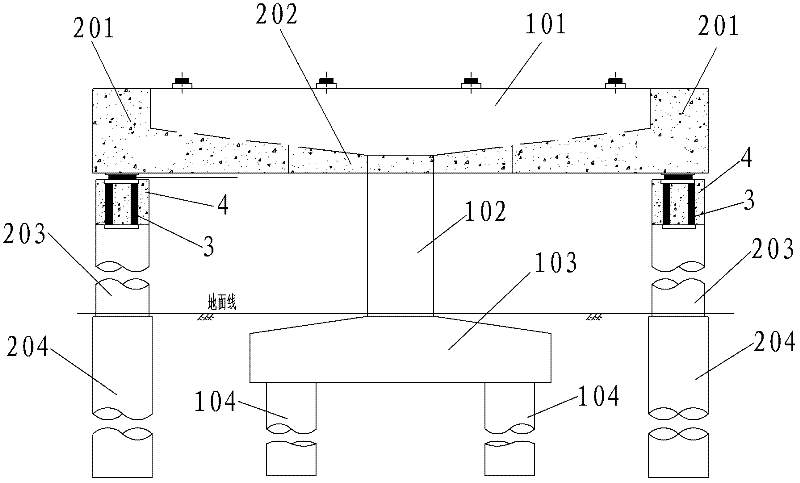

Process for reinforcing adjustable and controllable capping beam of piers

ActiveCN102383379AReduce negative bending momentReduce compressive stressBridge erection/assemblyBridge strengtheningFiberPre stress

The invention discloses a process for reinforcing adjustable and controllable capping beam of piers, comprising the following steps: (1) engraving shearing force grooves on the surface of the original capping beam concrete according to the design, embedding reinforcing steel bars and chiseling; (2) mixing plant fiber and steel fiber with the newly poured capping beam concrete, wherein the plant fiber is mixed in order to prevent the early shrinkage and crack of the concrete, and the steel fiber is mixed in order to prevent the later-stage stressed crack of the concrete; (3) leaving a certain area for secondary pouring in the middle in advance, wherein the area is 1 / 3 the length of the capping beam; (4) jacking capping beams by using two ends of a jack, and adjusting the reasonable load born by the new capping beam and the old capping beam according to a certain proportion by controlling the force and the jacking height of the jack to adjust the internal force of structures according to the design; (5) transferring the internal force of the basic part of the old structure to the basic part of the newly added structure by jacking; and (6) transferring partial or whole load born by the capping beam of the old biers to the new piers and the combined new and old capping beam structure by controlling the number and the position of prestressed steel strands to adjust the proportion of the whole load born by the combined new and old capping beam structure.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

Multi-quantum-well structure and light-emitting diode with multi-quantum-well structure

ActiveCN103872198ALower resistanceEliminates additional resistanceSemiconductor devicesQuantum wellParticle physics

The invention provides a multi-quantum-well structure and a light-emitting diode with the multi-quantum-well structure. The light-emitting area of the light-emitting diode is provided with at least one quantum well structure comprising a first protection layer, a first transitional layer on the first protection layer, a quantum well layer on the first transitional layer, a second transitional layer on the quantum well layer, a second protection layer on the second transitional layer and a quantum base layer on the second protection layer.

Owner:TIANJIN SANAN OPTOELECTRONICS

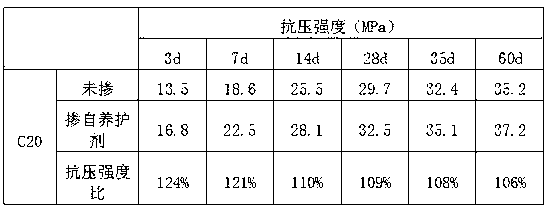

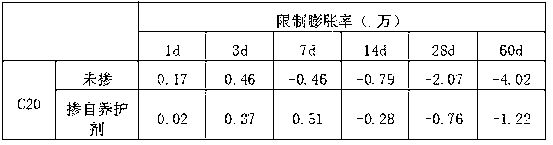

Autogenous curing agent for cement-based material and preparation method thereof

The invention provides an autogenous curing agent for a cement-based material and a preparation method thereof. The cement-based material just needs to be simply covered without later watering conservation after being poured. The autogenous curing agent for the cement-based material comprises the components in weight percent of 5-50% of super absorbent resin, and 50-95% of inorganic admixture, wherein the inorganic admixture is one or more of coal ash, slag powder, silicon ash, metakaolin, rice hull ash, steel slag powder, zeolite powder, bentonite and attapulgite. The preparation method of the autogenous curing agent comprises the steps of 1) weighing materials according to the formula ratio; 2) baking each material of the inorganic admixture and then cooling; 3) adding to a blender, firstly, slowly stirring, rapidly stirring, stagnating, then rapidly stirring and slowly stirring orderly; 4) heating the inorganic admixture, and 5) starting the blender, and slowly adding the super absorbent resin and mixed inorganic admixture when slowly stirring, rapidly stirring, stagnating, rapidly stirring, and then slowing stirring orderly, taking out the mixture and placing in a dry sealed container.

Owner:逄鲁锋

Vertical-type spiral particle waste heat recycling device and method for sintering waste heat power generation system

InactiveCN104048516AAvoid increased resistanceReduce compressive stressEnergy industryIncreasing energy efficiencyControllabilityFlat panel

The invention discloses a vertical-type spiral particle waste heat recycling device and method for sintering waste heat generation. A device body is sequentially provided with a prestoring segment, a chute segment, a cooling segment and a lower conical segment from top to bottom. The device body is internally provided with an air supply body. The air supply body is a cylinder and is hollow. The top of the air supply body is provided with a pointed cone. The upper portion of the air supply body is provided with four cross-shaped supporting rods. The outer ends of the four supporting rods are fixedly connected with the chute segment. A heat exchange cavity is formed between the air supply body and a tank body of the cooling segment. The outer side of the middle of the air supply body is provided with a spiral discharging channel. The periphery of the upper portion of the spiral discharging channel is connected with the cooling segment. The lower portion of the air supply body is provided with an upward-inclined cross-shaped air channel. The cross-shaped air channel is connected with the lower portion of the lower conical segment. The bottom of the lower conical segment is provided with a bulkhead gate. A closed-type vibrating feeder is arranged below the bulkhead gate. The vertical-type spiral particle waste heat recycling device meets the specific requirement of sintering ore for a cooling device and is high in controllability, the service life of the vertical-type spiral particle waste heat recycling device is prolonged, gas resistance is reduced, flow and temperature uniformity are improved, and the waste heat utilization rate is improved.

Owner:ZHEJIANG UNIV

Photomask blank, photomask, and methods of manufacturing the same

ActiveUS20090214961A1Good shading effectConsumption amount can be reducedVacuum evaporation coatingSputtering coatingTantalum nitrideOptoelectronics

A photomask blank has a light-shielding film composed of at least two layers on a transparent substrate. The light-shielding film includes a light-shielding layer made of a material mainly containing tantalum nitride and further containing xenon and a front-surface antireflection layer formed on the light-shielding layer and made of a material mainly containing tantalum oxide and further containing argon.

Owner:HOYA CORP

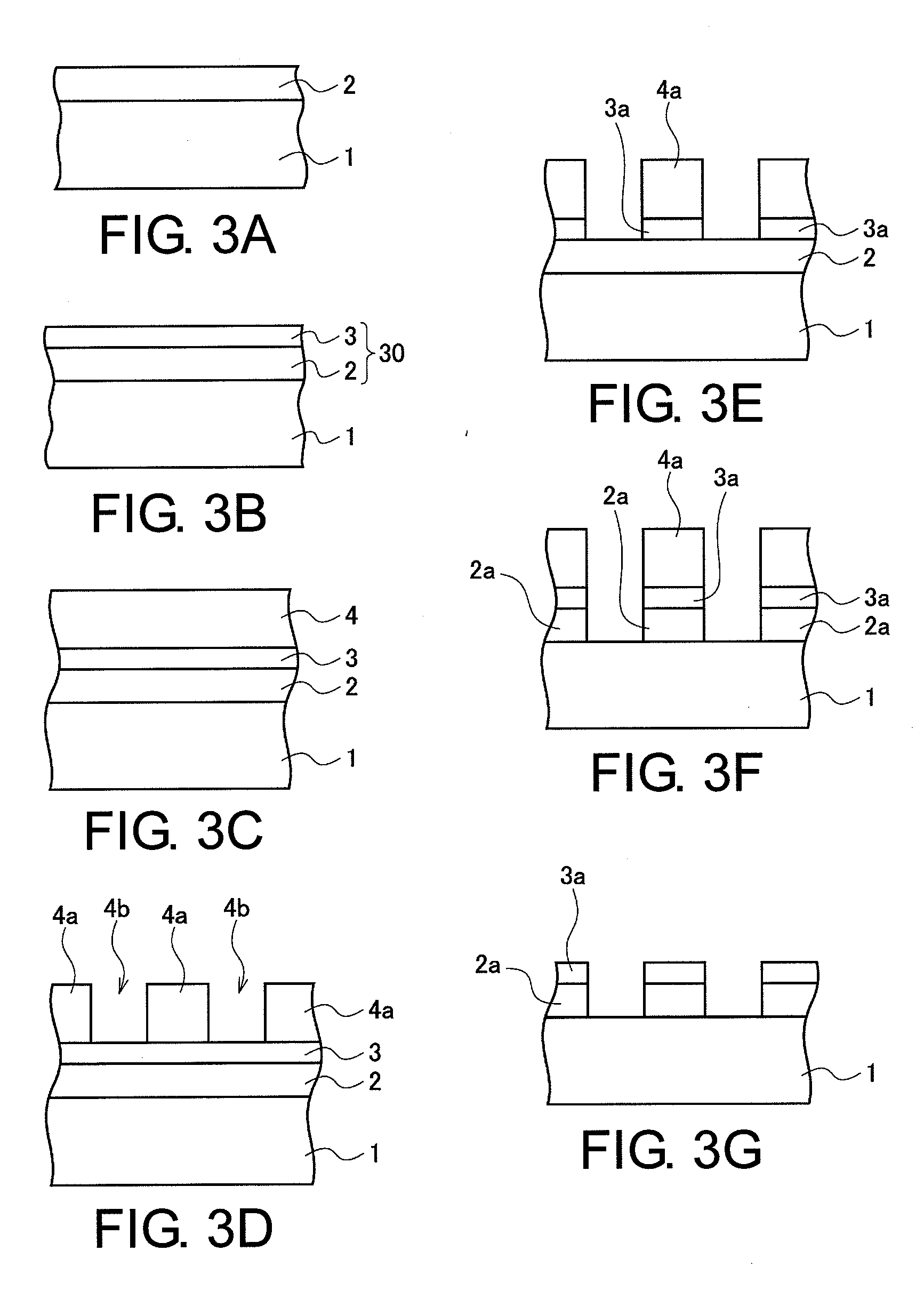

Short-brace rod type expanding-chord truss and producing method thereof

InactiveCN1609362AStrong pullReduce compressive stressBuilding constructionsStructural engineeringShort stay

The present invention is one new kind of short stay rod type tension string truss. The shuttle-shaped truss has serial short stay rods connected rigidly to the nodes in the lower string; shaft bracket with bearing and shaft fixed to the lower ends of the short stay rods, steel cable pressed on the shaft and with two ends fixed to the end seat nodes separately of the shuttle-shaped truss while in its tensile state. There are arced notch in center of the shaft for the steel cable to contact with, and reinforcing boards between the short stay rods and the shuttle-shaped truss and between the short stay rods and the shaft bracket. The short stay rods are 0.3-2.0 m long. The present invention has the advantages of less steel consumption, simple structure, low cost, high performance, easy construction, etc.

Owner:GUIZHOU UNIV

Edge stress relief in diffusion media

InactiveUS20060046124A1Reduce compressive stressUniform compressionFuel cells groupingFuel cell auxillariesFuel cellsEngineering

A diffusion media for use in a PEM fuel cell which includes a relieved edge region relative to the interior region of the diffusion media. The outer perimeter or portion of the diffusion media that will interface with a sealing gasket is pre-compressed. The pre-compressed diffusion media lowers the compression stress on the MEA at the gasket interfaces, enabling a more uniform compression on the entirety of the MEA surfaces during the build, compression, and later operation of a fuel cell stack.

Owner:GM GLOBAL TECH OPERATIONS LLC

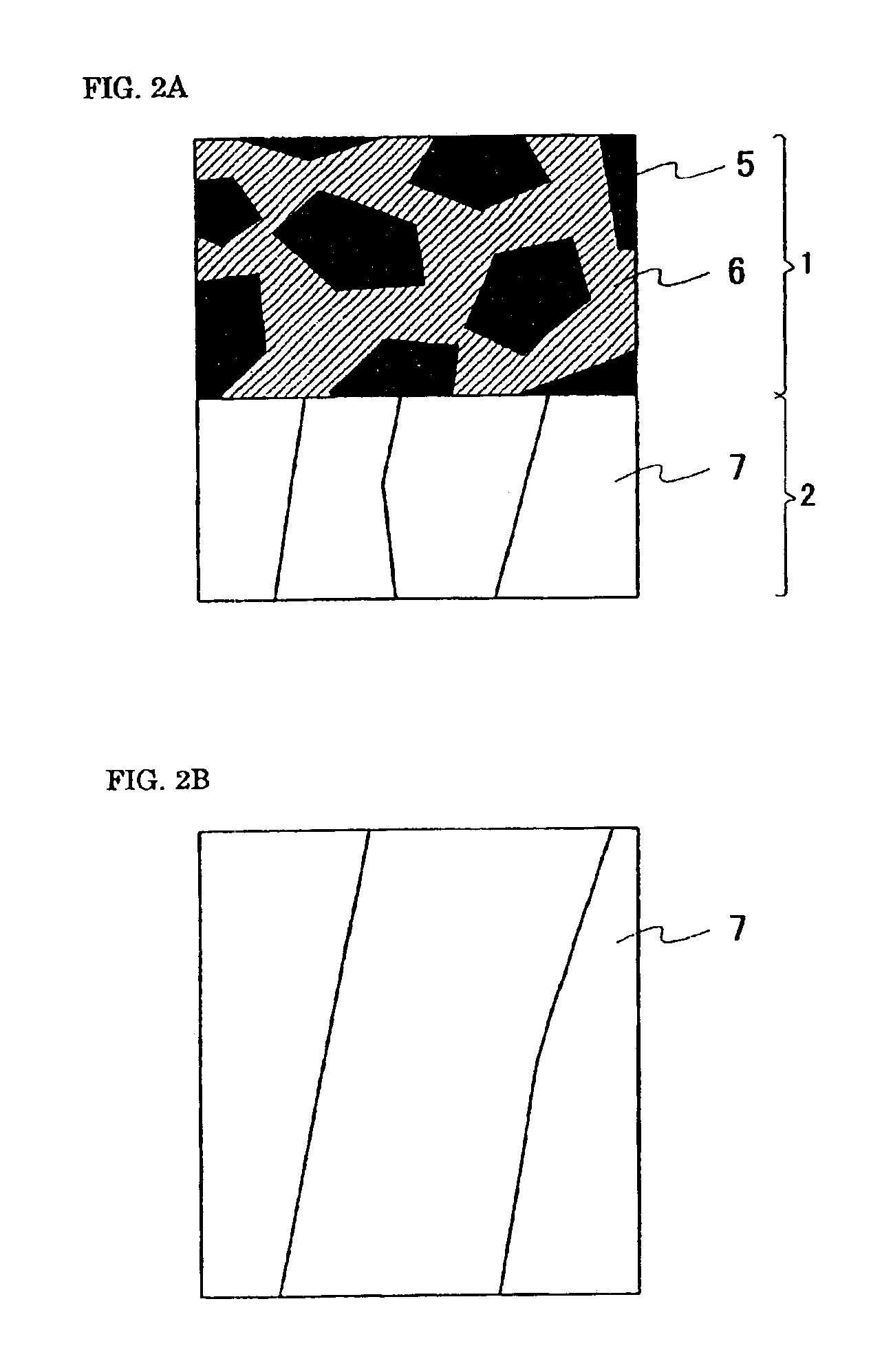

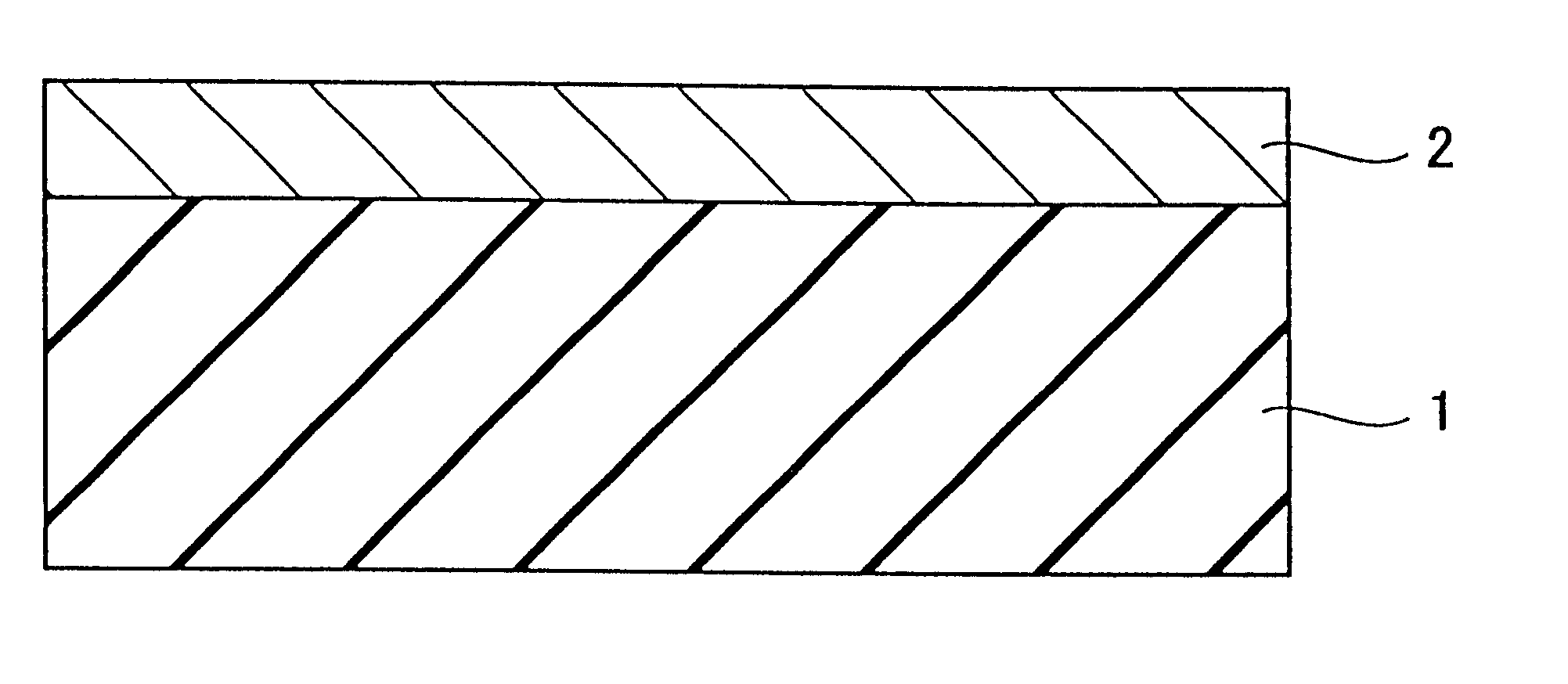

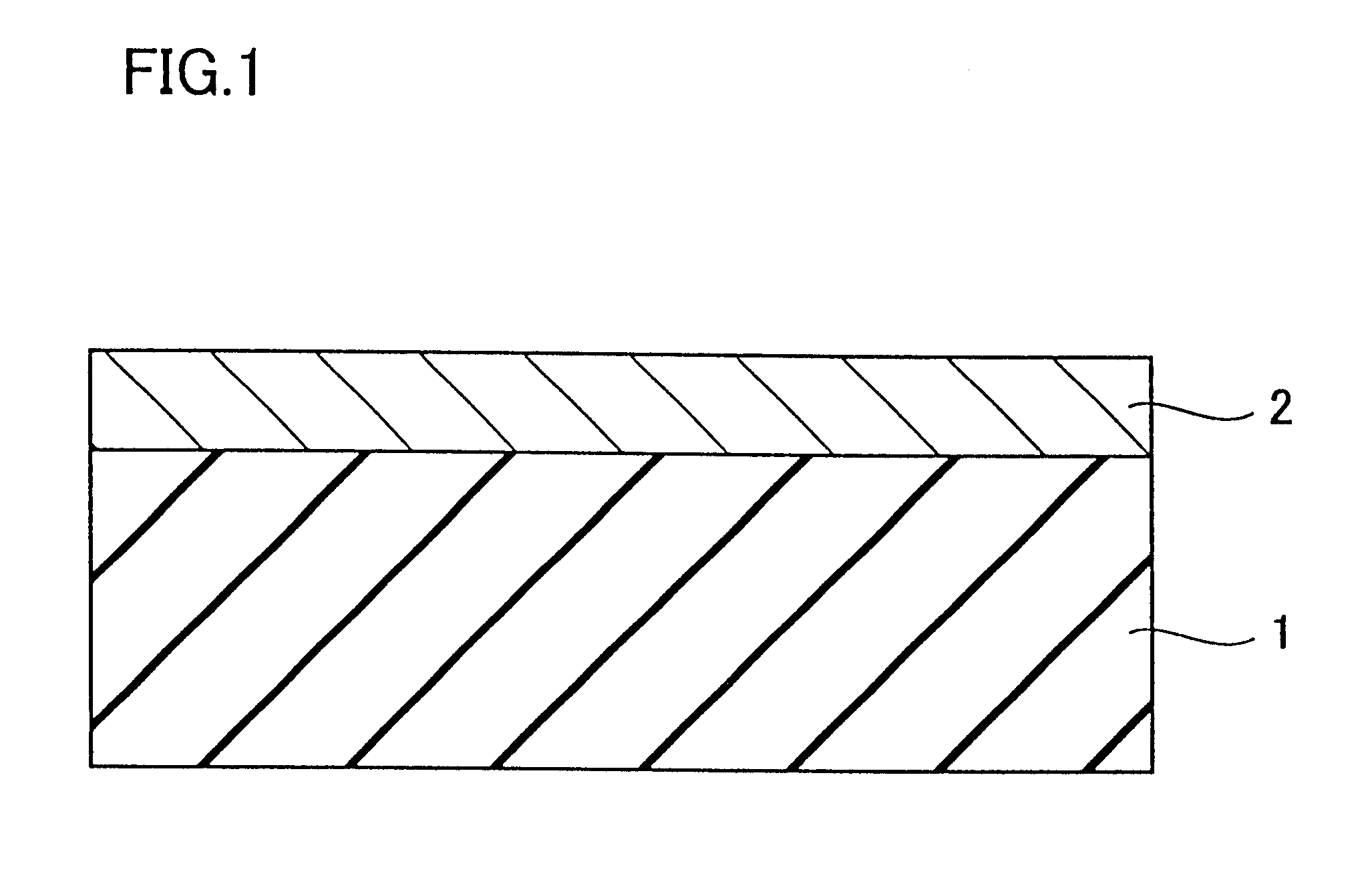

Hydrogen-permeable structure and method of manufacturing the same

InactiveUS6641647B2Reduce the amount of dissolutionDeterioration of crackingSemi-permeable membranesMembranesHydrogenGas phase

A hydrogen permeable structure includes a base material (1) including porous ceramic, and a hydrogen permeable film (2) formed on the base material (1), including palladium (Pd) and at least one element other than palladium and having an amount of hydrogen dissolution at a prescribed temperature smaller than that of palladium alone. The hydrogen permeable film (2) is formed on the surface of the porous ceramic base by a physical vapor deposition technique after any pin holes in the surface of the base have been filled with a porous oxide material.

Owner:SUMITOMO ELECTRIC IND LTD

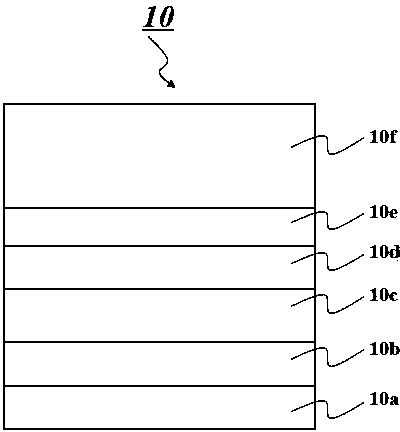

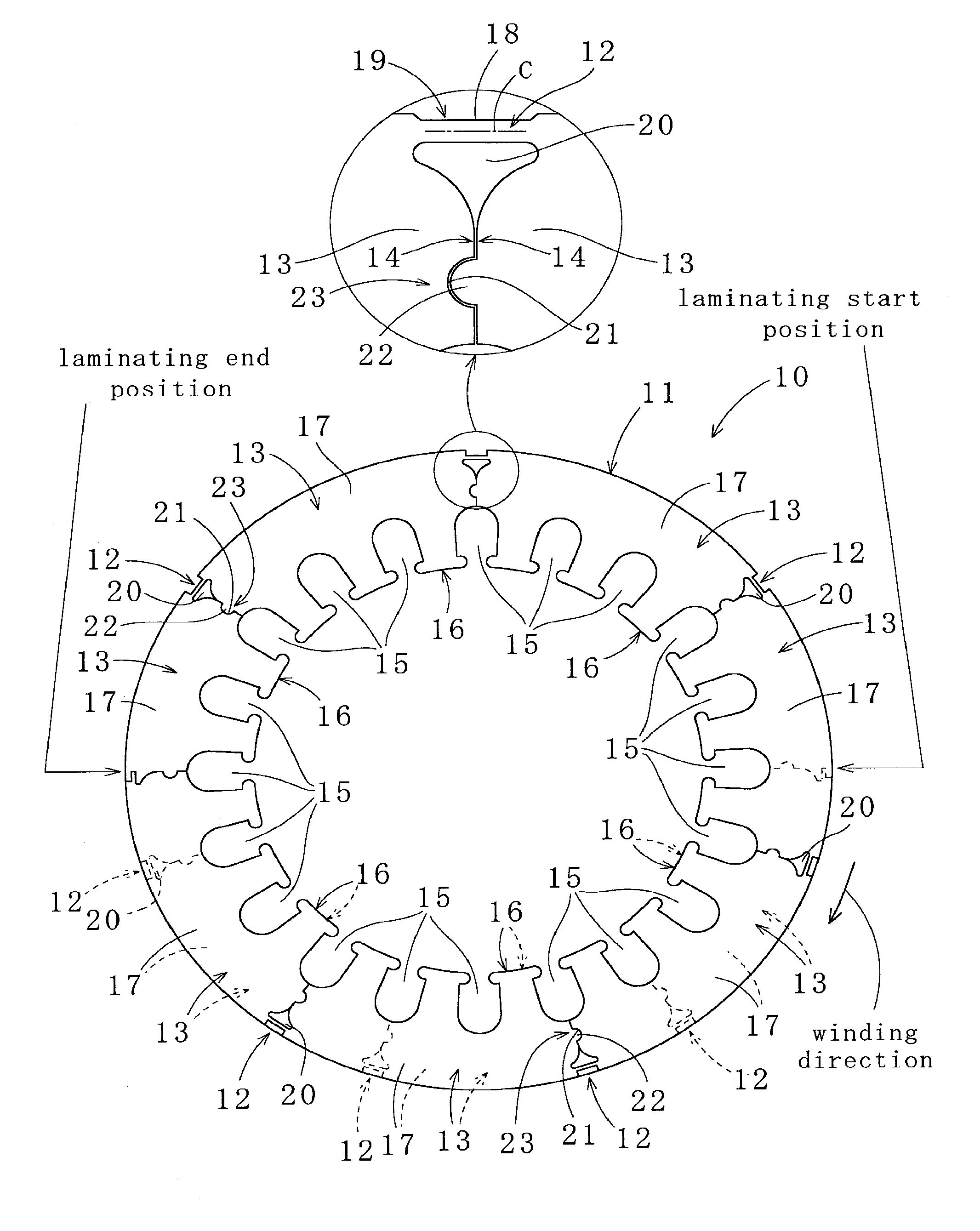

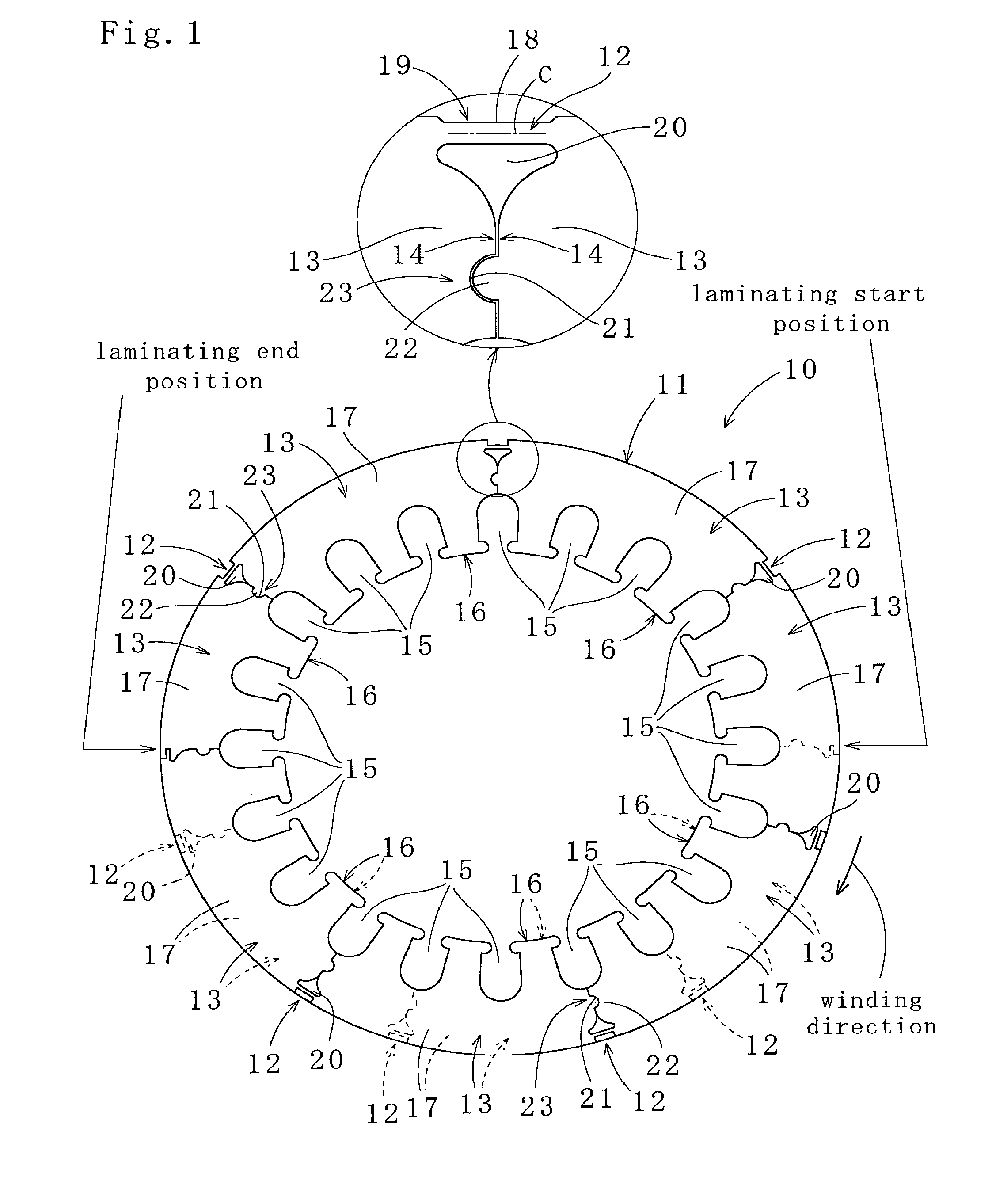

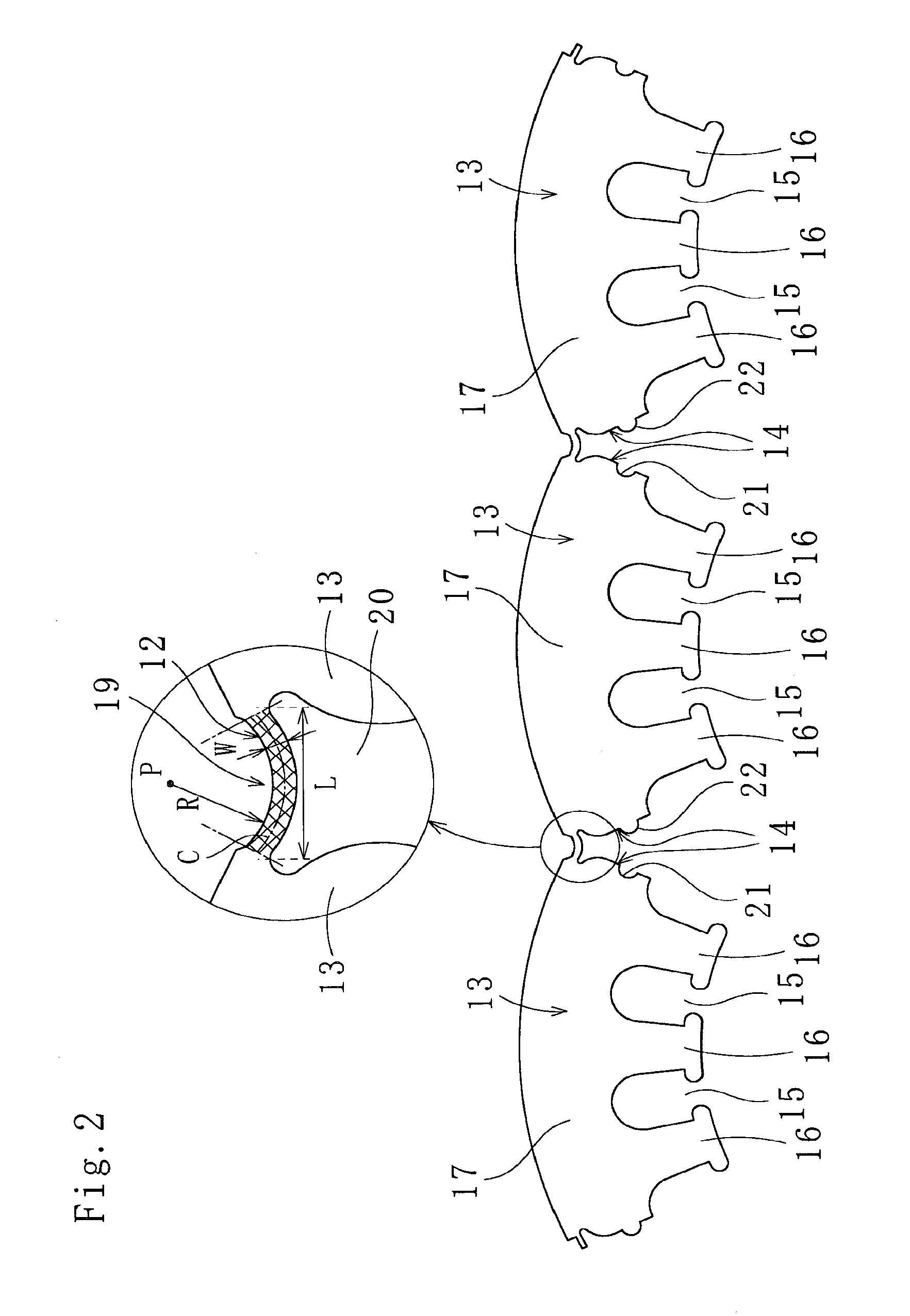

Laminated core and method for manufacturing the same

InactiveUS7847466B2Improve motor efficiencyImprove quality controlMagnetic circuit shape/form/constructionEngineeringMechanical engineering

A laminated core (10) and a method for manufacturing the same, the laminated core (10) formed with a plurality of continuous segment core sheets (13) wound and laminated in a spiral form while connecting portions (12) mutually connecting the adjacent segment core sheets (13) are bent and side edges of the adjacent segment core sheets (13) are fitted with each other, the connecting portions (12) being located in an outer peripheral portion (11) of the laminated core (10), the laminated core (10) comprising:a concave cutout (19) provided at a radially outward side of the connecting portion (12), the concave cutout (19) allowing a radial bulge (18) to be accommodated within an outer circle of the laminated core (19), the radial bulge (18) formed at a radially outward side of the connecting portion (12) by bending the connecting portion (12); andan inward cutout (20) provided at a radially inward side of the connecting portion (12), the inward cutout (20) defining a bending position of the connecting portion (12), wherein the connecting portion (12) has a narrow radial width and, before being bent, has a radial width in the range of 0.5 to 5 times a thickness of the segment core sheet (13).The laminated core (10) and the method for manufacturing the same are capable of producing a highly-efficient and high-quality product that is free from effects of the swell in the thickness direction of the connecting portion (12).

Owner:MITSUI HIGH TEC INC

Semiconductor device and method for manufacturing same

InactiveUS20090108367A1Reduce compressive stressLow densitySolid-state devicesSemiconductor/solid-state device manufacturingField-effect transistorSemiconductor

The present invention provides a semiconductor device includes: an element isolation region configured to be formed in a semiconductor substrate; a P-type field effect transistor configured to be formed in a first element formation region of the semiconductor substrate for which isolation by the element isolation region is carried out; an N-type substrate region configured to be formed in the semiconductor substrate for which isolation by the element isolation region is carried out, arsenic being ion-implanted into the N-type substrate region; a nickel silicide layer configured to be formed on the N-type substrate region; a first insulating film configured to cover the P-type field effect transistor and have compressive stress; and a second insulating film configured to cover the N-type substrate region and have tensile stress or compressive stress lower than the compressive stress of the first insulating film.

Owner:SONY CORP

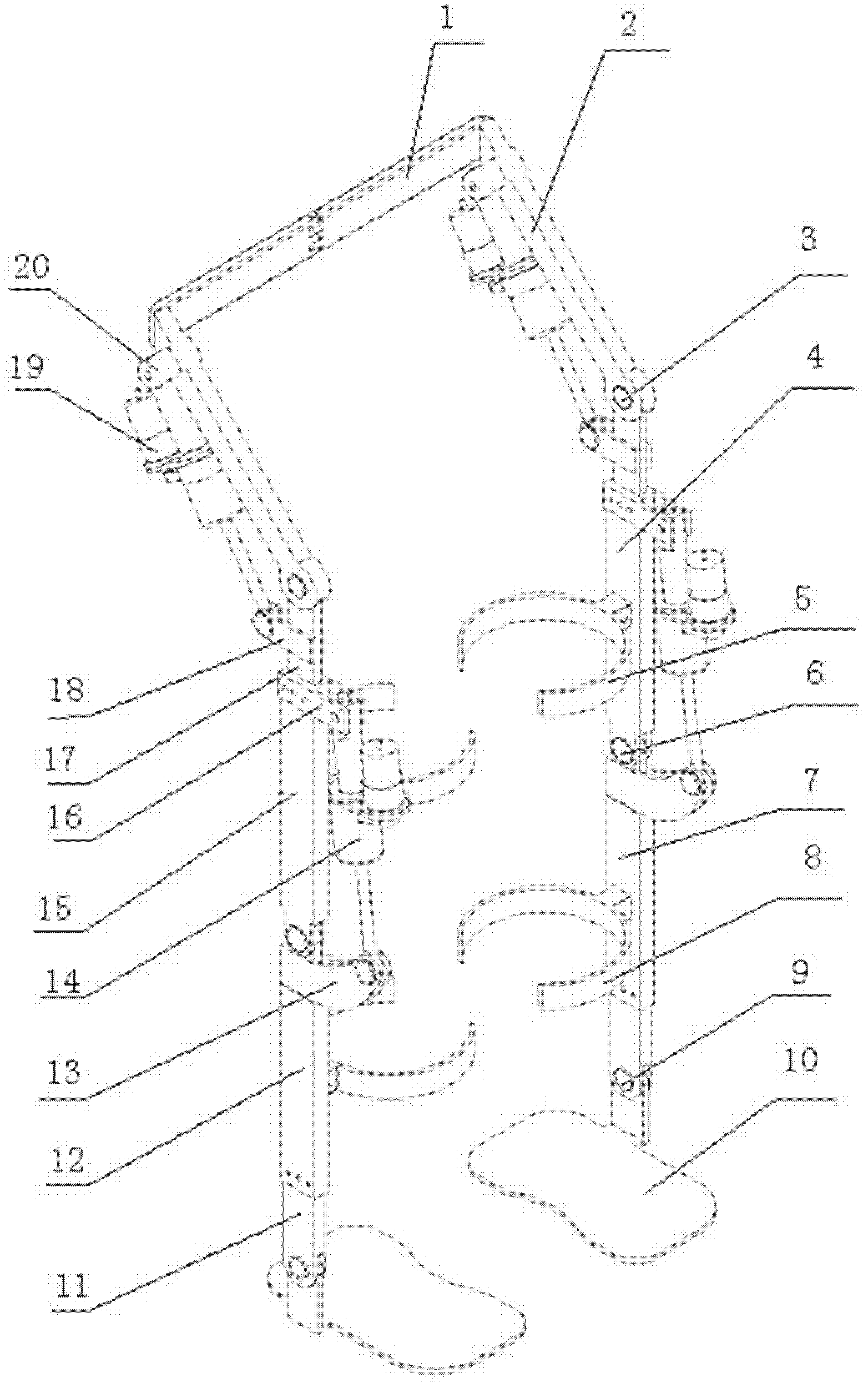

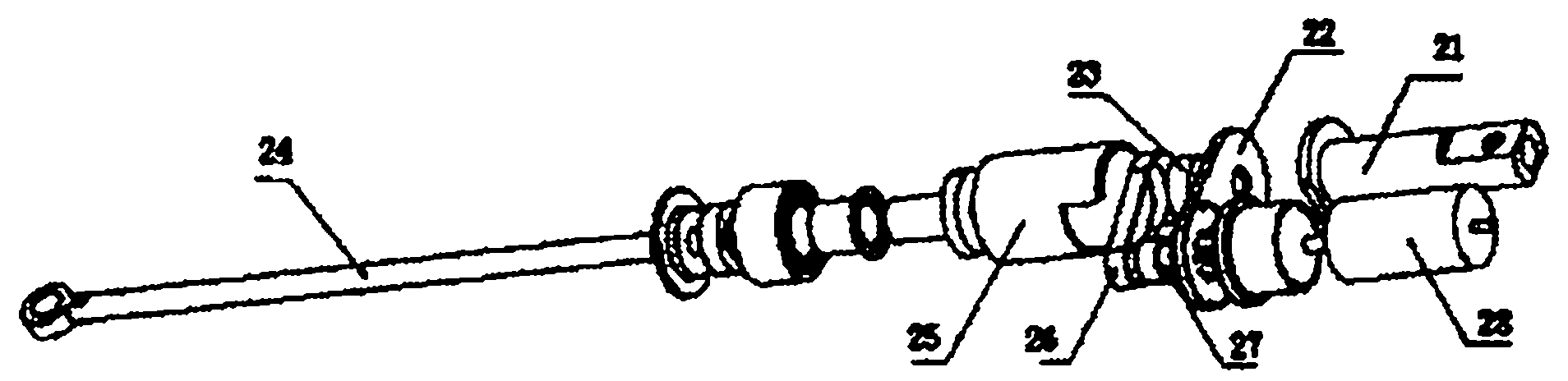

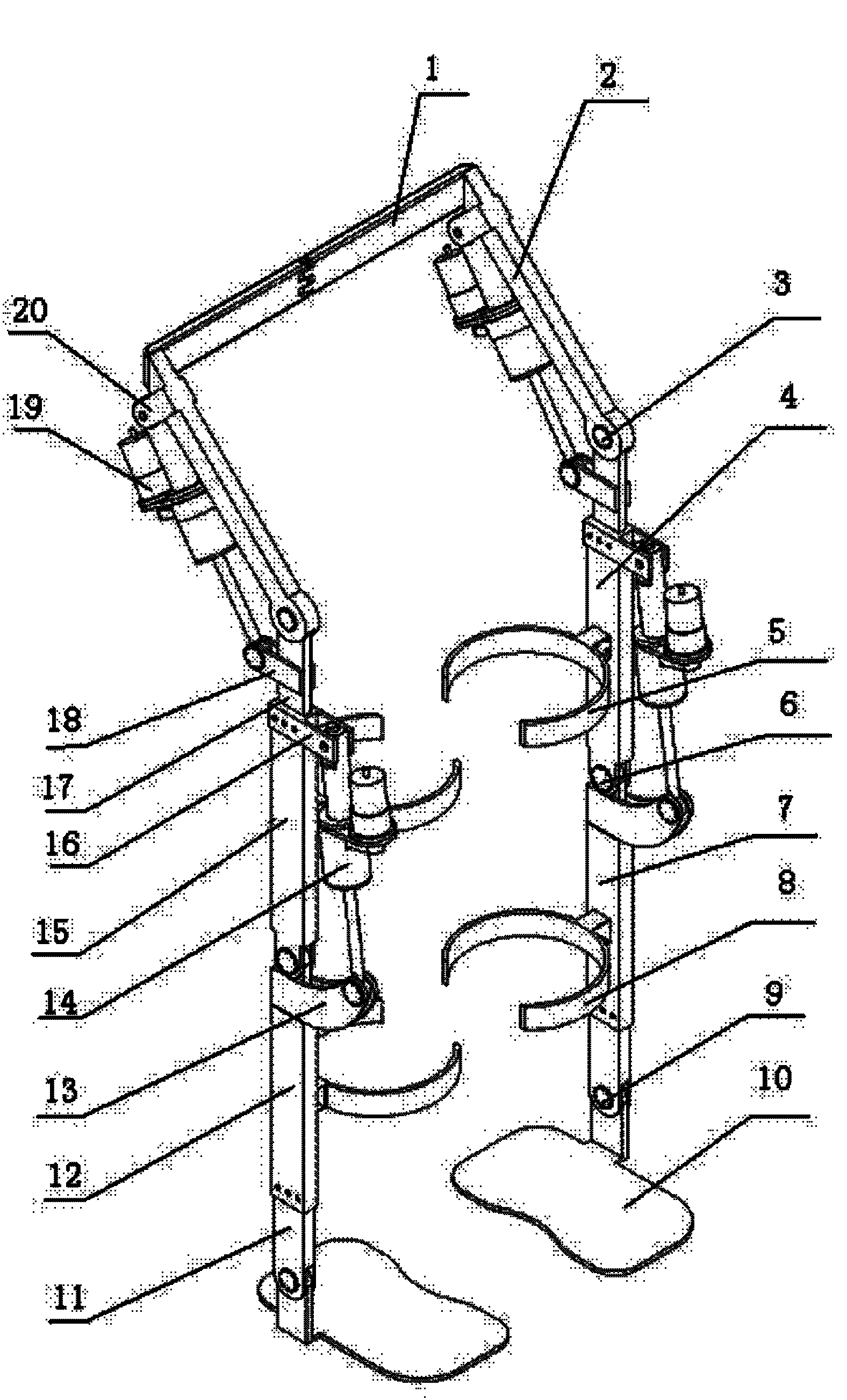

Self-contained lower limb walking aid

The invention relates to a self-contained lower limb walking aid, which consists of waist support frames, thigh support rods, calf support rods, foot support plates, hip joint rotating pairs, knee joint rotating pairs, ankle joint rotating pairs, hip joint driving mechanisms, knee joint driving mechanisms, thigh fastening belts, and calf fastening belts, which are arranged symmetrically left and right. The invention has the advantages that: the self-contained lower limb walking aid has a scientific and reasonable structural design, can assist crural paralysis patients in standing and walking, is stable in operation, reliable in support, easy to manufacture and low in cost, is a walking aid with higher innovativeness, and has wide market prospect.

Owner:TIANJIN UNIV OF SCI & TECH

Coated substrates and methods for their preparation

InactiveCN101313392AReduce penetrationImprove crack resistanceSolid-state devicesSemiconductor/solid-state device manufacturingSiliconChemistry

Owner:DOW CORNING CORP +1

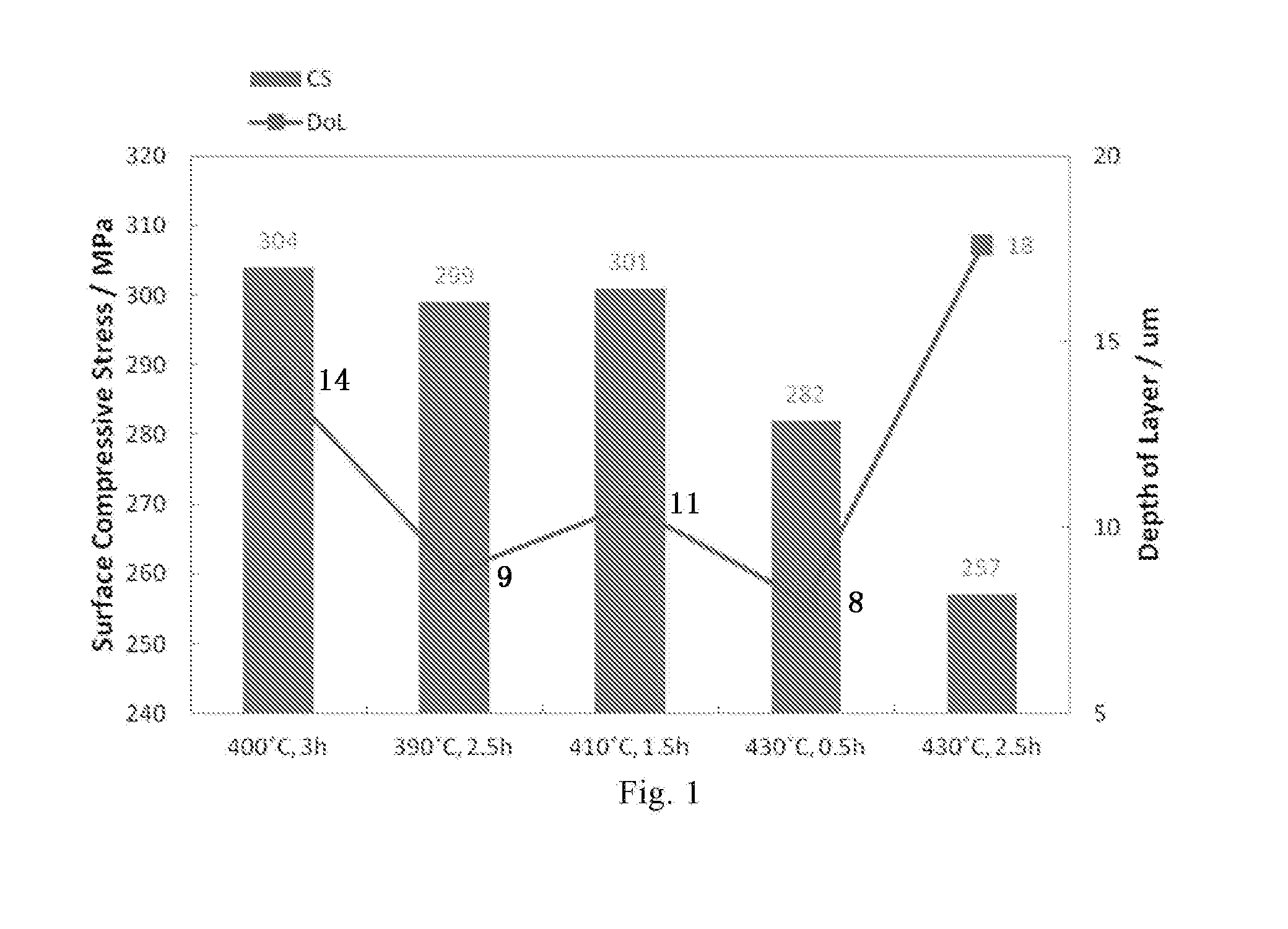

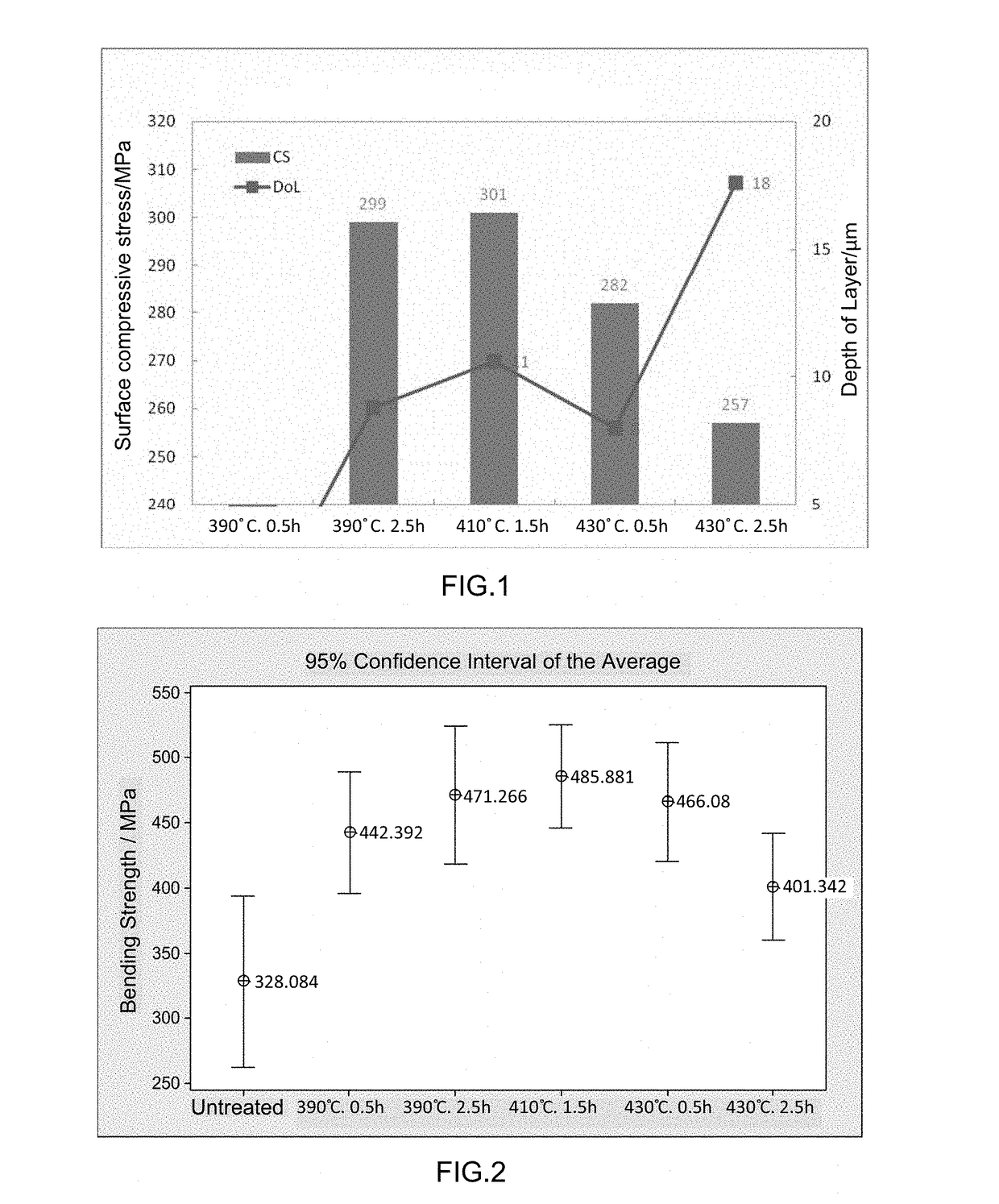

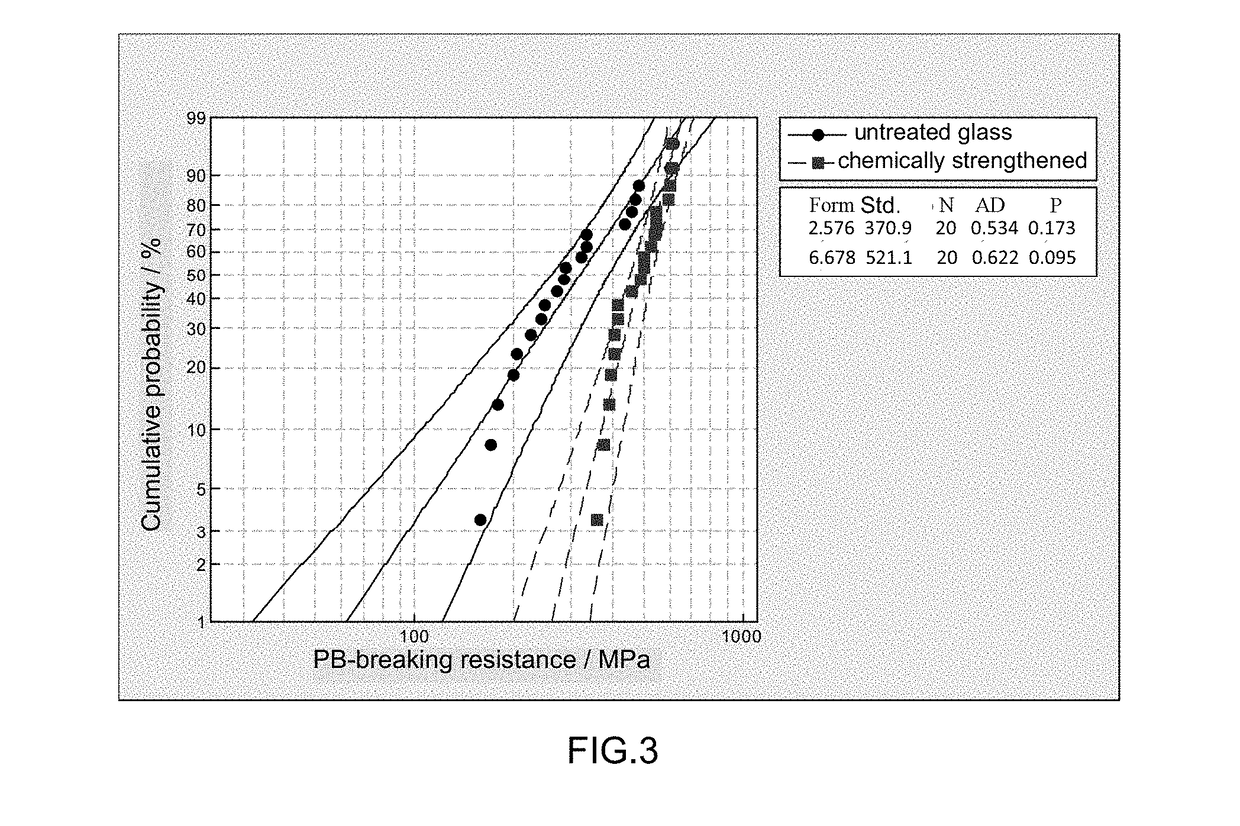

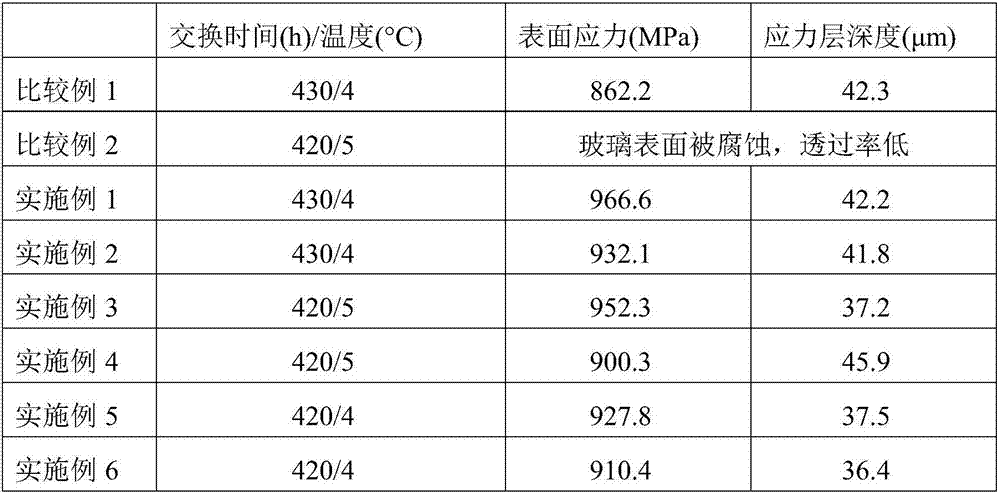

Fused salt for chemically enhancing medium-aluminum and high-aluminum silicate glass and method for performing chemically-toughened enhancement by using fused salt

The invention provides a fused salt for chemically enhancing medium-aluminum and high-aluminum silicate glass. The fused salt comprises the following compositions: KNO3, KOH, KCl and K2CO3, wherein a mass ratio of KOH to K2CO3 in the fused salt is 0.05-0.4; a mass ratio of KCl to K2CO3 is 0.075-1.0; and a mass ratio of KNO3 to K2CO3 is 100:(1.0-4.0). The invention further provides a method for performing chemically toughened enhancement by using the fused salt for chemical enhancing of medium-aluminum and high-aluminum silicate glass. The fused salt formula disclosed by the invention indicates a formula composition range suitable for chemical enhancing of the medium-aluminum and high-aluminum glass. According to the formula, corrosion on the glass surface can be avoided, and the chemically enhanced glass has high transmittance; and meanwhile, due to the formula disclosed by the invention, the surface stress and stress layer depth of the chemically enhanced glass can be greatly improved.

Owner:WUHAN UNIV OF TECH

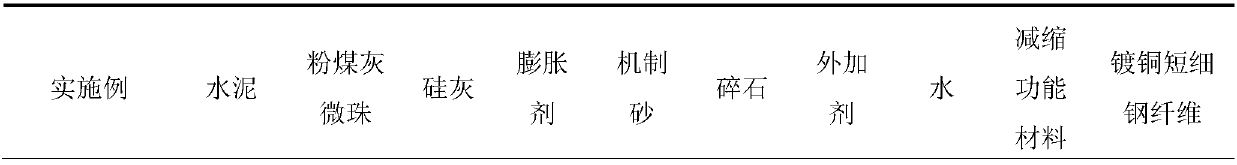

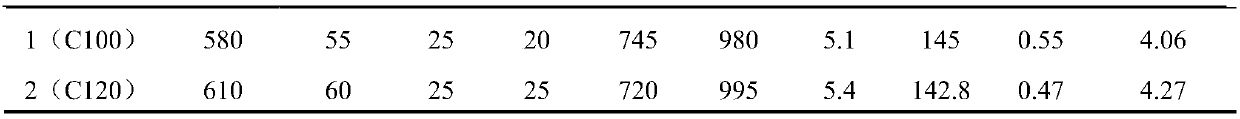

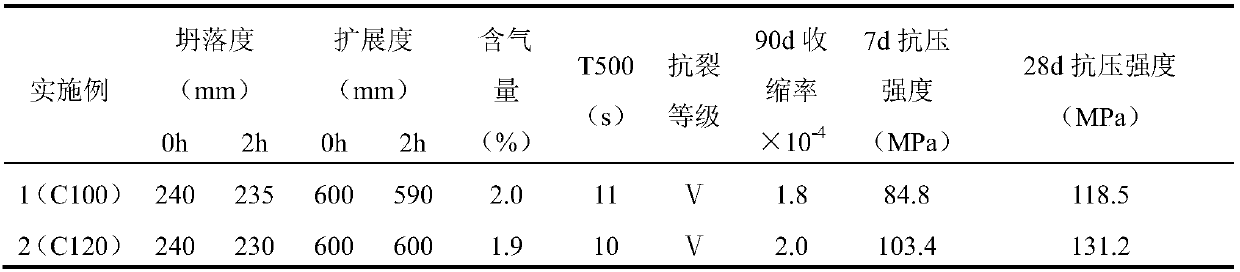

Ultrahigh-strength self-compaction micro-expansion steel pipe-encased concrete and preparation method thereof

The invention discloses ultrahigh-strength self-compaction micro-expansion steel pipe-encased concrete and a preparation method of the ultrahigh-strength self-compaction micro-expansion steel pipe-encased concrete. The steel pipe-encased concrete comprises the following raw materials in parts by weight: 580-680 parts of cement, 30-60 parts of pulverized fuel ash microbeads, 25-50 parts of silica fume, 20-35 parts of an expanding agent, 700-750 parts of manufactured sand, 800-1050 parts of macadam, 0.4-1.2 parts of a shrinkage reducing functional material, 3.5-7 parts of an additive, 120-160 parts of water and 4-5.5 parts of copper plated short and fine steel fibers. The manufactured sand with a high stone powder content is used for replacing natural river sand; the stone powder serves as an inert admixture; the high activity pulverized fuel ash microbeads and silica fume are adopted; and workability, compactness, and homogeneity of the concrete are improved by using a ball effect and amicro-aggregate effect of the high activity pulverized fuel ash microbeads and the silica fume. A novel expanding agent is prepared from the pulverized fuel ash and phosphogypsum; the strength is improved; moreover, an air content is further reduced by using the additive to improve the compactness. The obtained manufactured sand concrete with the high stone powder content is excellent in serviceability, mechanical property, volume stability and crack resistance.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com