Coated substrates and methods for their preparation

A substrate and coating technology, applied in coatings, semiconductor/solid-state device manufacturing, transportation and packaging, etc., can solve problems such as reducing the effectiveness of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

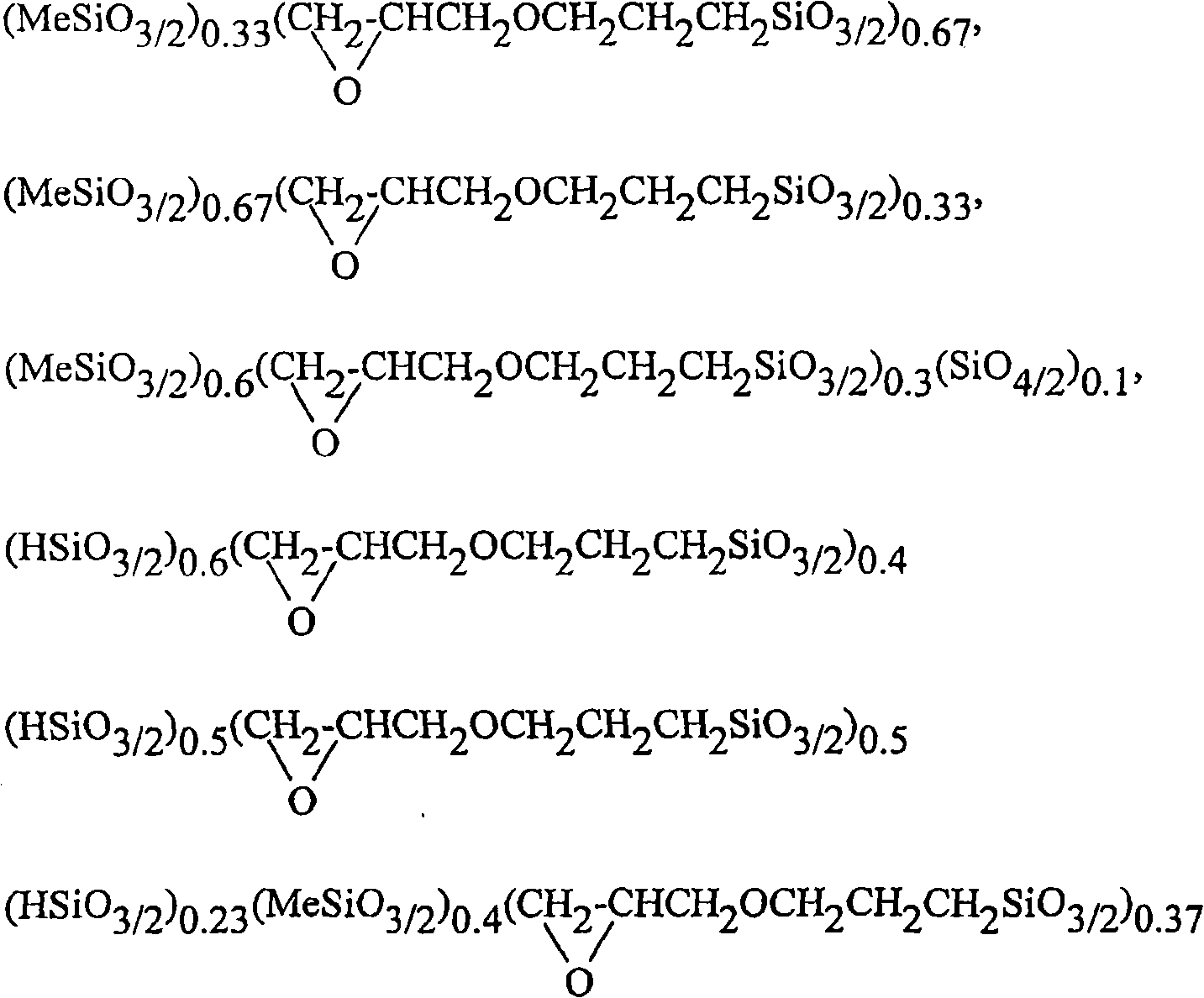

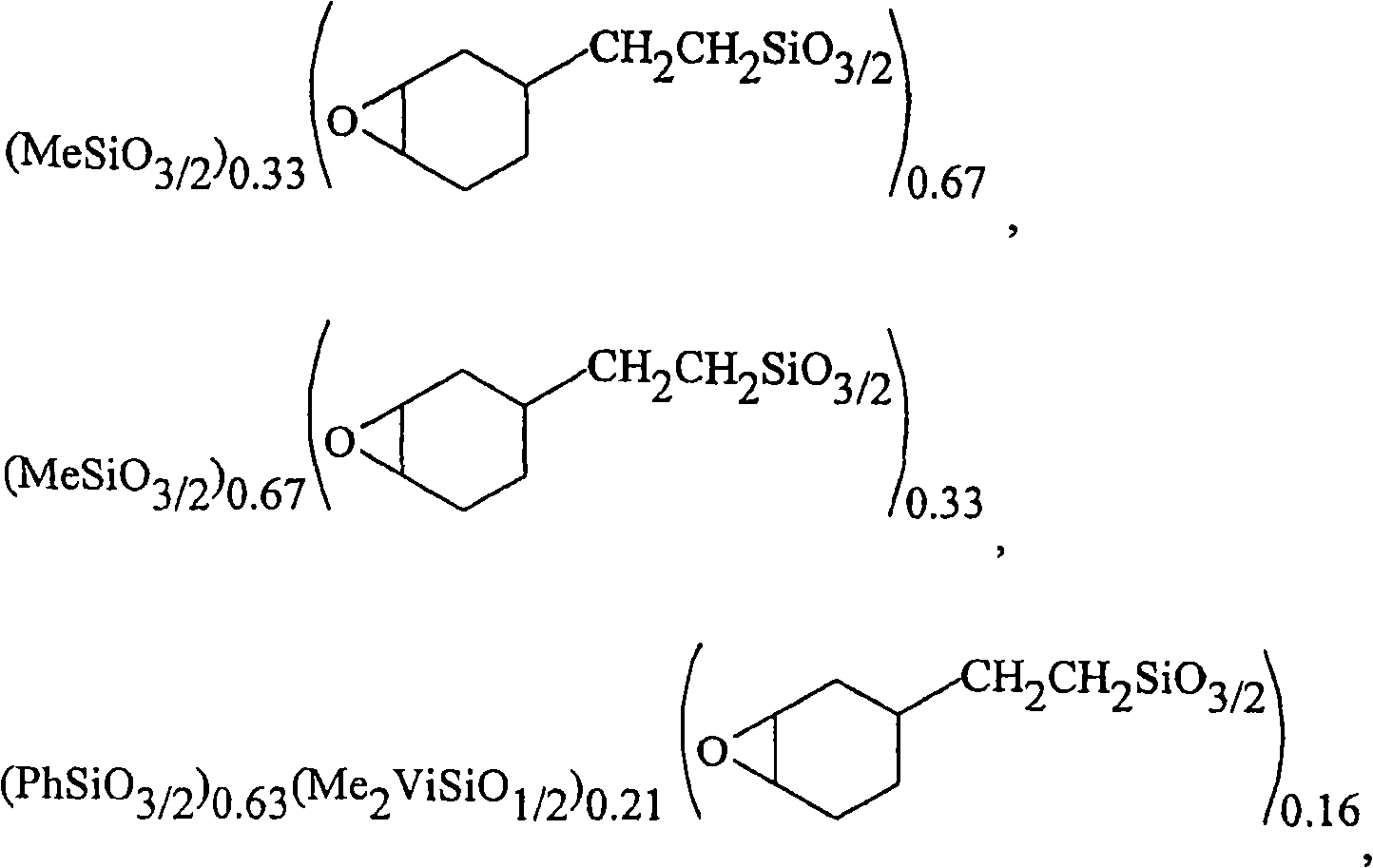

Method used

Image

Examples

Embodiment 1

Embodiment 2

[0114] In a flask combine concentrated hydrochloric acid (37%, 600 g), 1020 g of toluene, and 3.0 g of sodium octanesulfonate monohydrate. A solution consisting of 90.75 g (0.67 mol) of trichlorosilane, 100.15 g (0.67 mol) of methyltrichlorosilane and 6.14 g (0.038 mol) of trichlorovinylsilane was added dropwise to the in the mixture. The mixture was stirred at room temperature for 4 hours, after which time the aqueous layer was removed. The resulting organic layer was washed with 100 ml of 45% sulfonic acid (2 times) and with 250 ml of deionized water (10 times). The solution was dried over magnesium sulfate and passed through a sintered glass filter. Toluene was removed under reduced pressure at 30 °C using a rotary evaporator. The residue was placed under vacuum (1 Pa) at room temperature overnight to give a silicone resin having the following formula (as determined by 29SiNMR and 13CNMR) and a weight average molecular weight of 11,600:

Embodiment 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com