Vertical-type spiral particle waste heat recycling device and method for sintering waste heat power generation system

A technology of waste heat recovery device and waste heat power generation, which is applied in steam engine devices, waste heat treatment, machines/engines, etc. It can solve the problems of excessive resistance of the bottom air cap and cross air duct, gas-solid flow and temperature segregation, and low tank strength. , to achieve the effects of strong controllability of blanking, reduced operation difficulty, and improved heat transfer uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

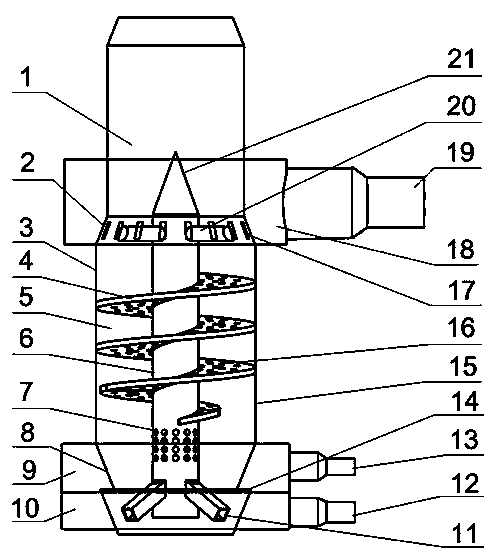

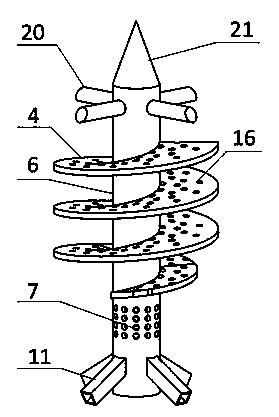

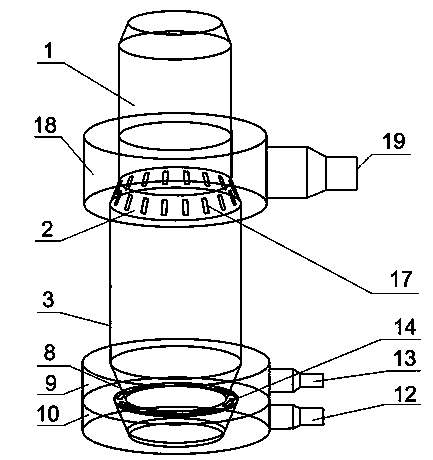

[0031] Such as figure 1 , 2 , 3, the vertical spiral particle waste heat recovery device for sintering waste heat power generation: including pre-storage section 1, chute section 2, cooling section 3, spiral feeding channel 4, heat exchange chamber 5, air supply body 6, central Air hole 7, lower cone section 8, upper air inlet chamber 9, lower air inlet chamber 10, cross air duct 11, lower air inlet pipe 12, upper air inlet pipe 13, annular air inlet 14, cooling section tank 15, blanking Road air hole 16, ramp section air hole 17, annular air outlet chamber 18, air outlet pipe 19, support rod 20, sharp cone 21;

[0032] The device body is sequentially provided with a pre-storage section 1, a chute section 2, a cooling section 3, and a lower cone section 8 from top to bottom; The body 6 is a cylinder with a hollow interior. The top of the air supply body 6 is provided with a sharp cone 21, and the upper part of the air supply body is provided with four support rods 20 in a cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com