Patents

Literature

40results about How to "Increased ion exchange rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic-inorganic improvement fertilizer for saline-alkali soil and preparation method thereof

InactiveCN105906442AStrong cation exchange capacityImprove soil physical and chemical propertiesCalcareous fertilisersExcrement fertilisersIon exchangeHumic acid

The invention discloses an organic-inorganic improvement fertilizer for saline-alkali soil and a preparation method thereof. The organic-inorganic improvement fertilizer is prepared from, 20-30 parts of bentonite, 20-30 parts of zeolite, 20-30 parts of flue gas desulfurization gypsum, 10-20 parts of dehydrated sludge, 20-30 parts of humic acid, 10-20 parts of coal ash, 20-30 parts of ardealite, 10-20 parts of peat, 10-20 parts of straw meal, 10-20 parts of animal waste, 2-8 parts of microbial inoculation bacteria and 2-5 parts of emulsified asphalt. The invention further provides a preparation method of the organic-inorganic improvement fertilizer for saline-alkali soil. According to the organic-inorganic improvement fertilizer, the physicochemical character of soil can be improved, soil permeability and moisture and fertilizer preservation can be improved, the soil ion exchange rate can be improved, the PH value can be buffered, the chemical fertilizer consumption can be reduced, the crop yield can be improved, the product quality can be improved, the soil improvement effect can be improved, and the soil improvement cycle can be shortened.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Lithium aluminum silicon glass, lithium aluminum silicon chemically strengthened glass and preparation method and application thereof

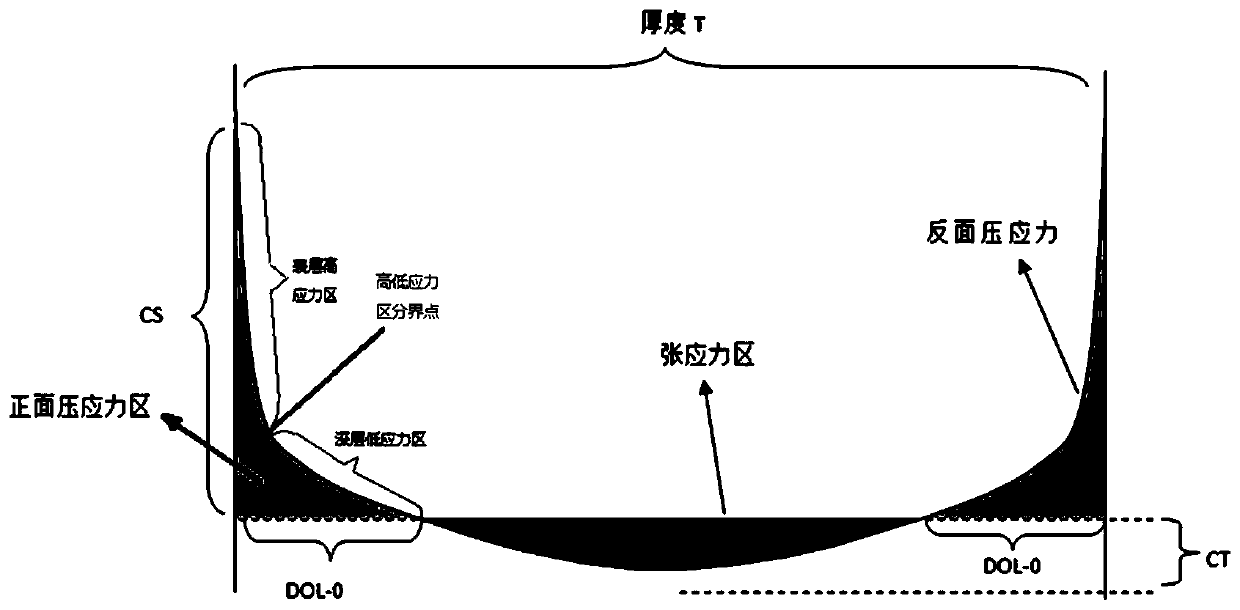

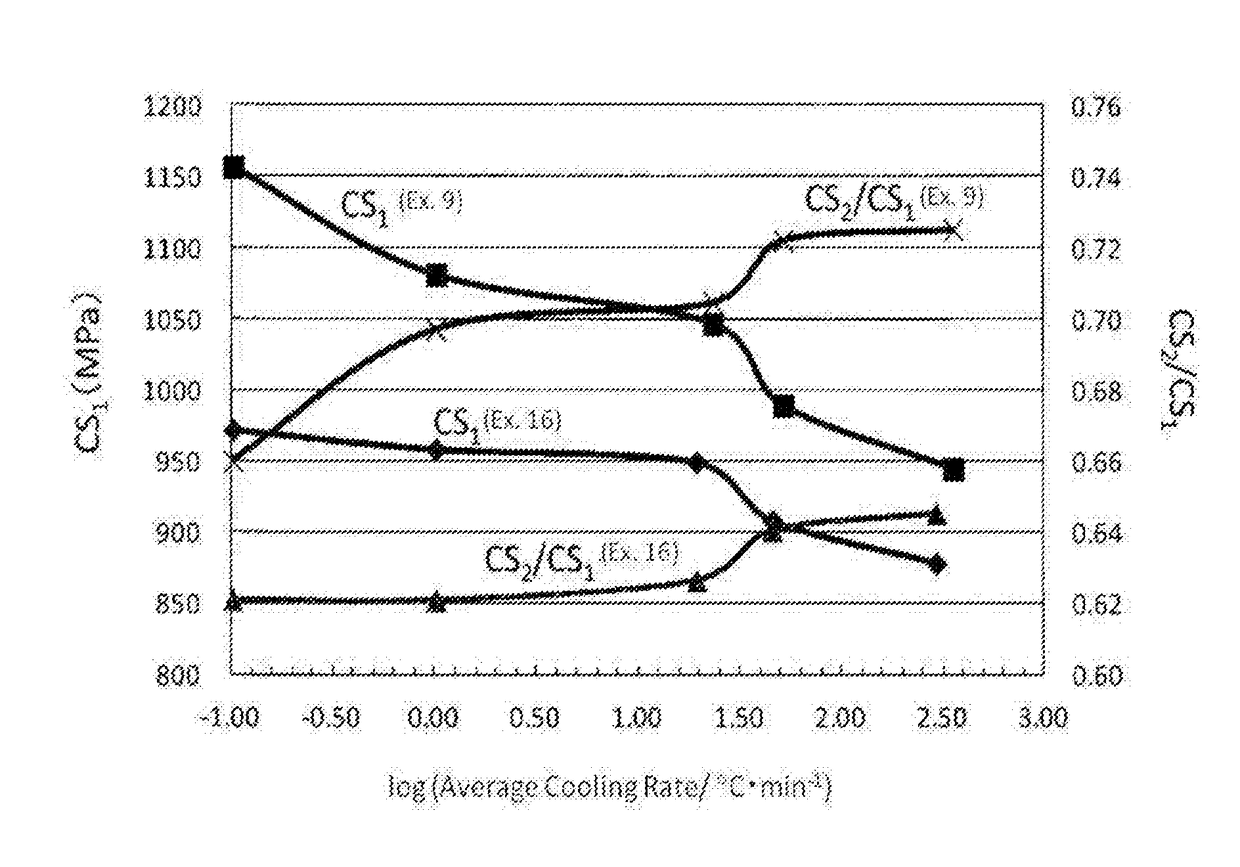

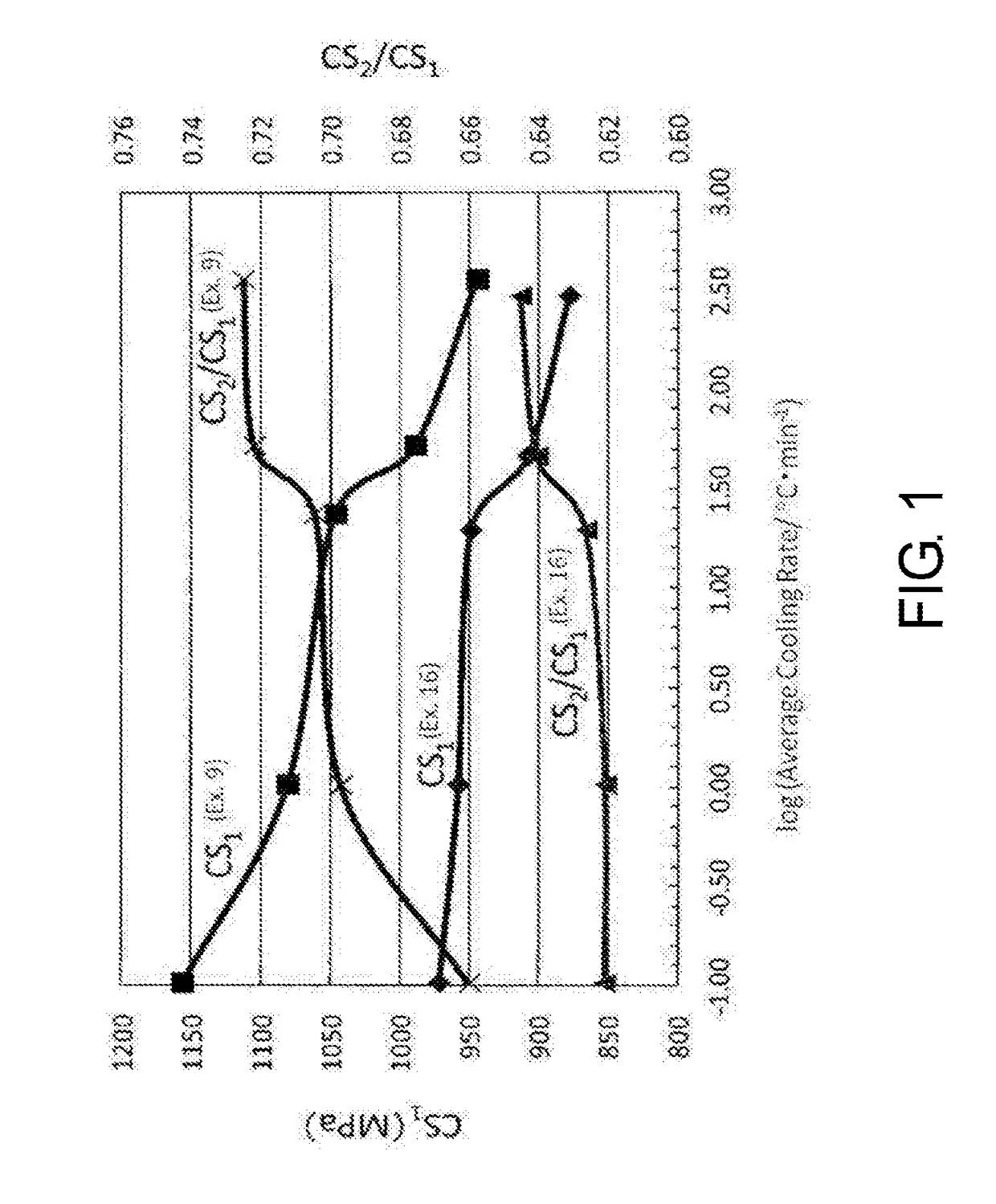

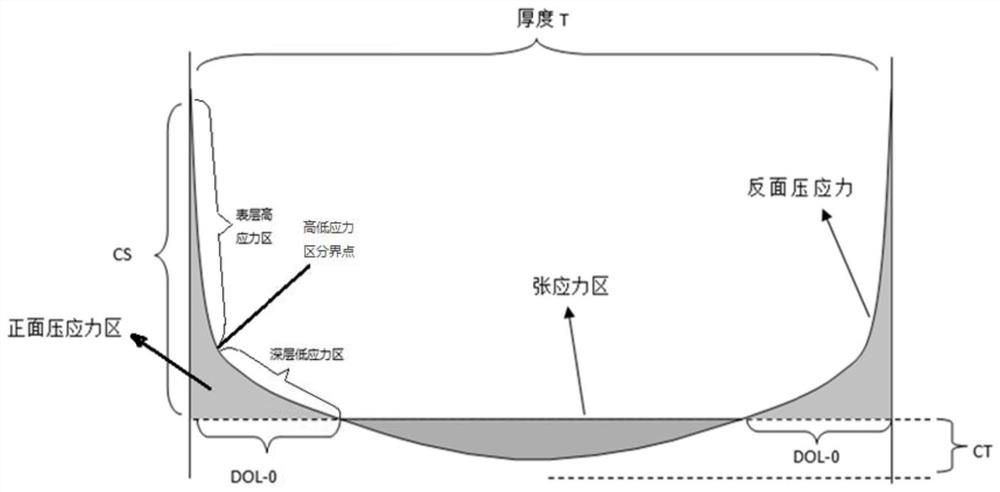

The invention discloses lithium aluminum silicon glass, lithium aluminum silicon chemically strengthened glass and a preparation method and application thereof. The molar content of oxide components contained in the lithium aluminum silicon glass satisfies the following relationship: the SiO2 content is at least 66.5 mol%, and the total amount of an alkali metal oxide usable for ion exchange is not more than 14 mol%; (Na2O+Li2O) / (SiO2+Al2O3) is 0.09-0.22; Na2O / Li2O is 0.4-1.2; MgO / SiO2 is 6%-18%; (Na2O+Li2O+0.3*MgO) / Al2O3 is 0.7-1.4; and 0.5%<P2O5+ZnO+SnO2+K2O+ZrO2+TiO2<7%. The lithium aluminum silicon chemically strengthened glass is formed by chemically strengthening the lithium aluminum silicon glass as basic glass.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

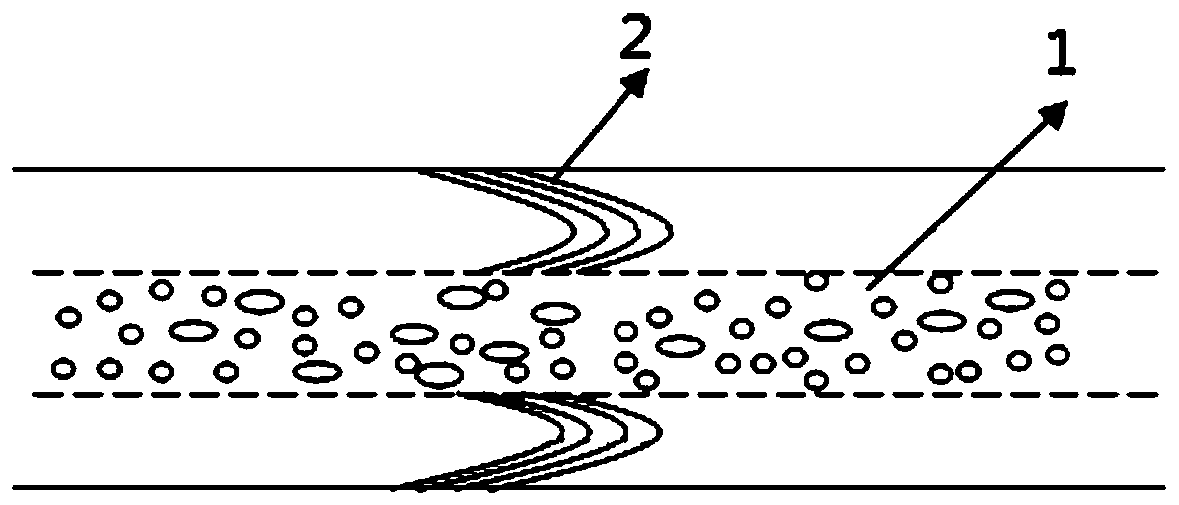

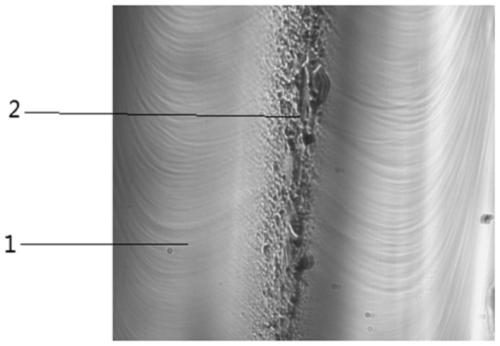

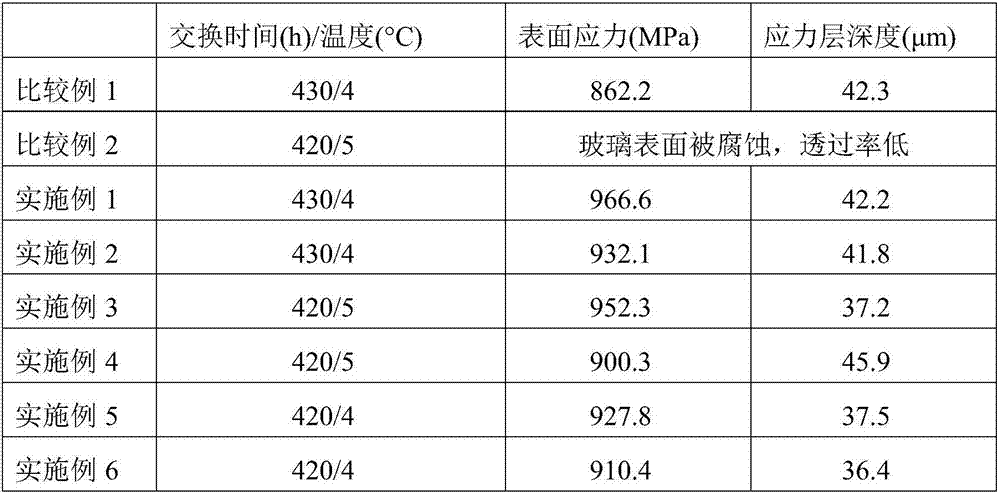

Fused salt for chemically enhancing medium-aluminum and high-aluminum silicate glass and method for performing chemically-toughened enhancement by using fused salt

The invention provides a fused salt for chemically enhancing medium-aluminum and high-aluminum silicate glass. The fused salt comprises the following compositions: KNO3, KOH, KCl and K2CO3, wherein a mass ratio of KOH to K2CO3 in the fused salt is 0.05-0.4; a mass ratio of KCl to K2CO3 is 0.075-1.0; and a mass ratio of KNO3 to K2CO3 is 100:(1.0-4.0). The invention further provides a method for performing chemically toughened enhancement by using the fused salt for chemical enhancing of medium-aluminum and high-aluminum silicate glass. The fused salt formula disclosed by the invention indicates a formula composition range suitable for chemical enhancing of the medium-aluminum and high-aluminum glass. According to the formula, corrosion on the glass surface can be avoided, and the chemically enhanced glass has high transmittance; and meanwhile, due to the formula disclosed by the invention, the surface stress and stress layer depth of the chemically enhanced glass can be greatly improved.

Owner:WUHAN UNIV OF TECH

Glass and chemically strengthened glass

InactiveUS20170305789A1Increase the surface compressive stressReduce frequencyPhotochemistryChemically strengthened glass

Owner:ASAHI GLASS CO LTD

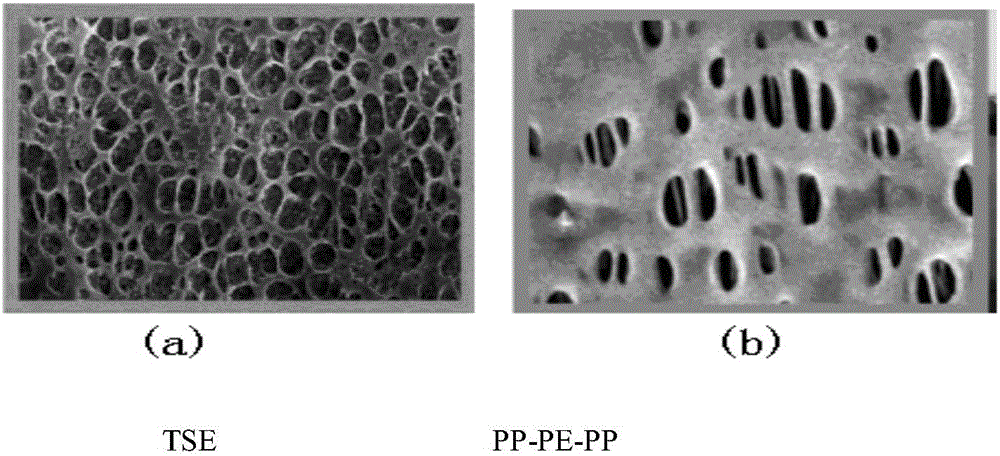

Composite isolation membrane for lithium-ion battery and preparation method of composite isolation membrane

InactiveCN106611828AImprove thermal stabilitySmall thermal expansionCell seperators/membranes/diaphragms/spacersSecondary cellsPower batteryPorosity

The invention provides a composite isolation membrane for a lithium-ion battery. The composite isolation membrane is characterized in that various component materials required by the isolation membrane are stirred in a ketone or carboxylate organic solvent in vacuum to prepare isolation membrane paste, and a membrane layer of which the thickness is 20-100 microns is directly prepared on a mylar film carrier or a positive plate or a negative plate of the battery by adopting a wet roller scraping and continuous coating method. The isolation membrane provided by the invention has unique combination of high porosity and high distortion; a resistance value of the prepared lithium battery is lower than those of other batteries in the industry, generated heat is low when the battery works at high power and the performance of the power battery is expected to be improved to that of a new generation.

Owner:浙江长兴中俄新能源材料技术研究院有限公司 +1

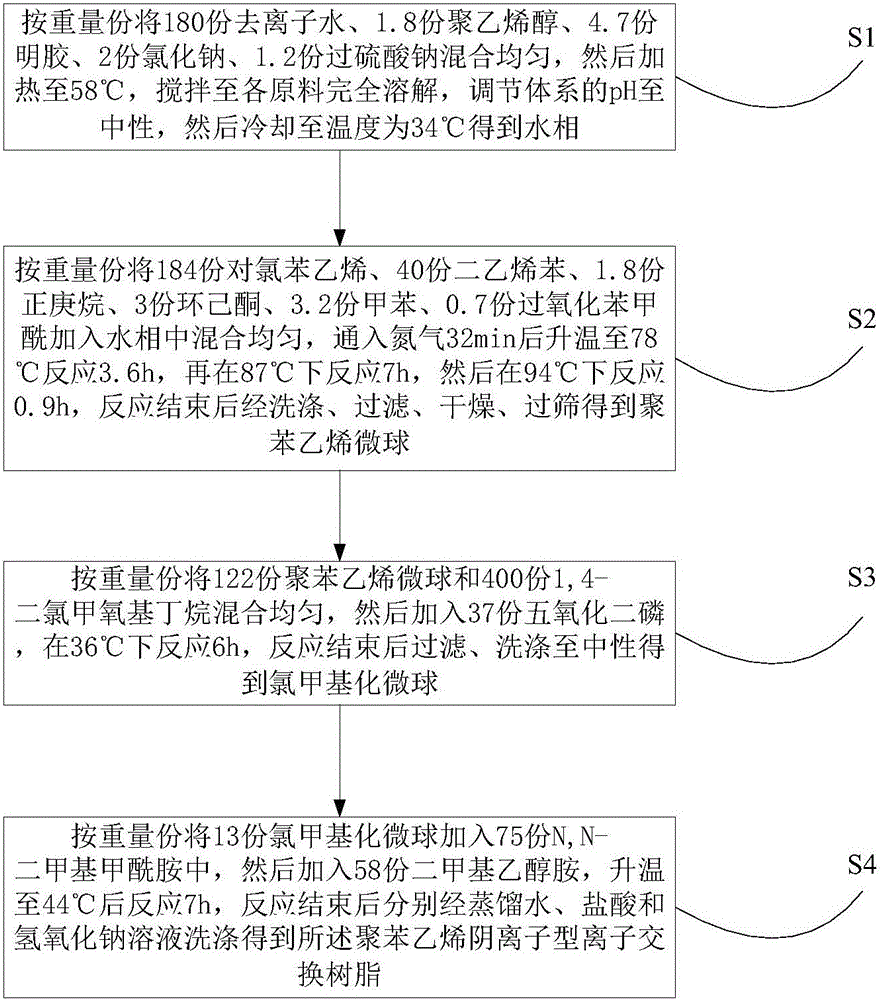

Preparation method of polystyrene anion-type ion exchange resin

InactiveCN105017464AImprove heat resistanceImprove completenessAnion exchangersBenzoyl peroxideN dimethylformamide

The invention discloses a preparation method of polystyrene anion-type ion exchange resin. The method comprises the following steps: deionized water, polyvinyl alcohol, gelatin, sodium chloride and sodium persulfate are well mixed, such that an aqueous phase is obtained; p-chlorostyrene, divinyl benzene, a pore-foaming agent and benzoyl peroxide are added, and the mixture is well mixed; the temperature is increased to 70-80 DEG C, and a reaction is carried out for 3-5h; a reaction is carried out for 4-8h under a temperature of 85-90 DEG C; a reaction is carried out for 0.3-1h under a temperature of 92-98 DEG C; washing, filtering, drying and sieving are carried out, such that polystyrene microspheres are obtained; the polystyrene microspheres are well mixed with 1,4-dichloromethoxybutane; phosphorus pentoxide is added, and a reaction is carried out for 5-10h under a temperature of 30-40 DEG C; filtering and washing are carried out, such that chloromethylated microspheres are obtained; the chloromethylated microspheres added into N,N-dimethylformamide; dimethylethanolamine is added; the temperature is increased to 40-45 DEG C and a reaction is carried out for 6-9h; and washing is carried out, such that the polystyrene anion-type ion exchange resin is obtained.

Owner:ANHUI WANDONG CHEM

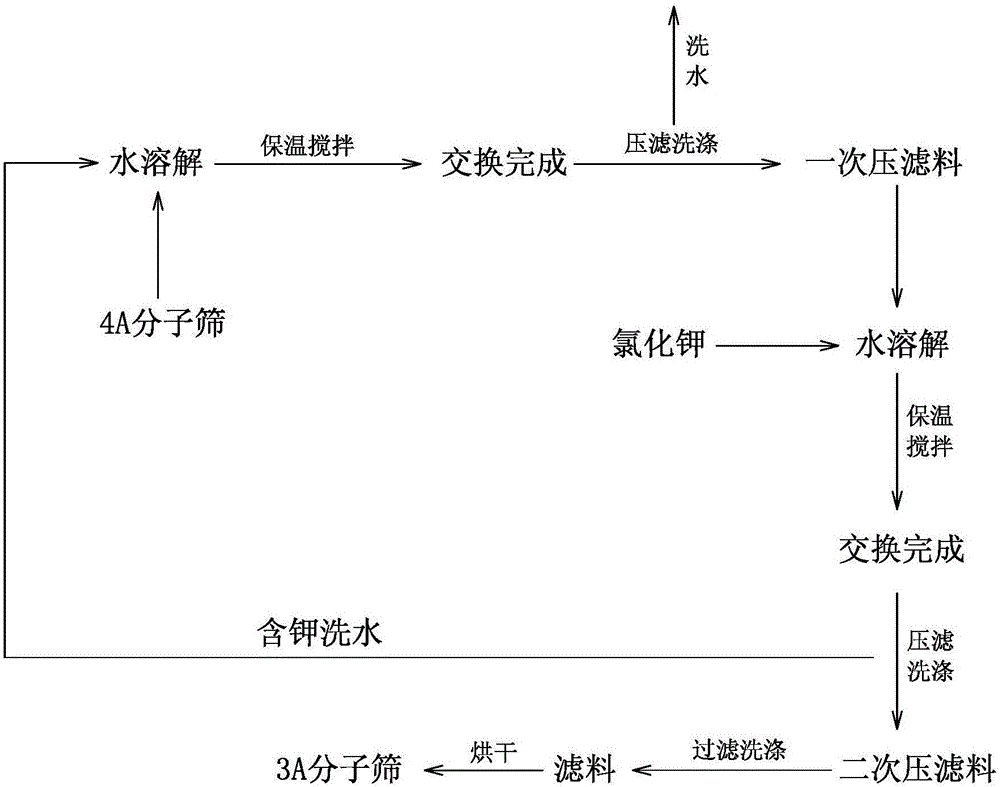

Preparation method of 3A molecular sieve

InactiveCN106365176AShorten the dissolution timeReduce contentOther chemical processesAluminosilicate zeolite type-AMolecular sievePotassium

The invention provides a preparation method of a 3A molecular sieve. The preparation method includes the steps of primary exchange and secondary exchange. Primary exchange includes the following steps that a 4A molecular sieve and potassium-containing washing water recycled through secondary exchange are mixed and stirred in a primary exchange tank for exchange, filter-press washing is carried out after exchange is completed, and a primary filter-press material is obtained. Secondary exchange includes the following steps that the primary filter-press material, water and potassium chloride are mixed and stirred in a secondary exchange tank for exchange, press-filter washing is carried out after exchange is completed, and a secondary press-filter material and potassium-containing washing water are obtained, the potassium-containing washing water is recycled into primary exchange to participate in exchange, and after the secondary press-filter material is subjected to press-filter washing with water, the 3A molecular sieve is prepared through drying.

Owner:汇盈化学品实业(泉州)有限公司

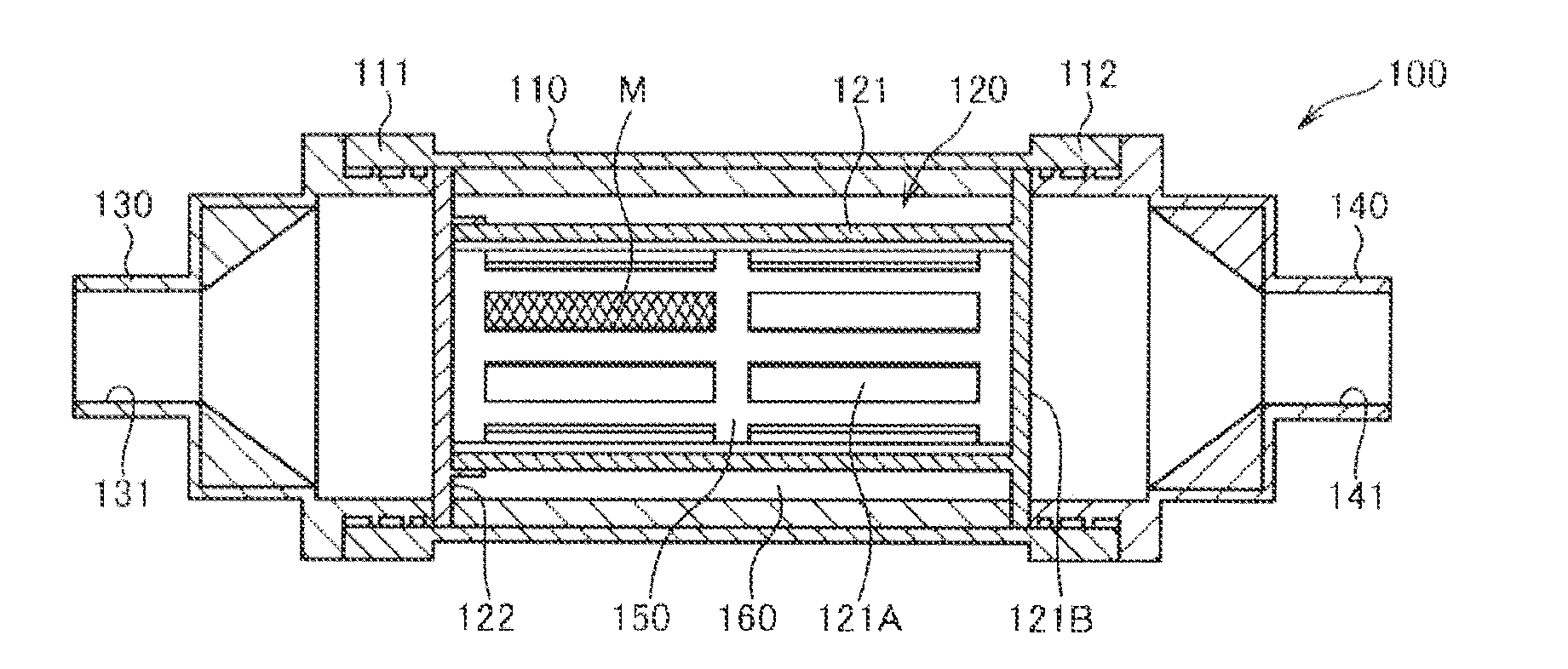

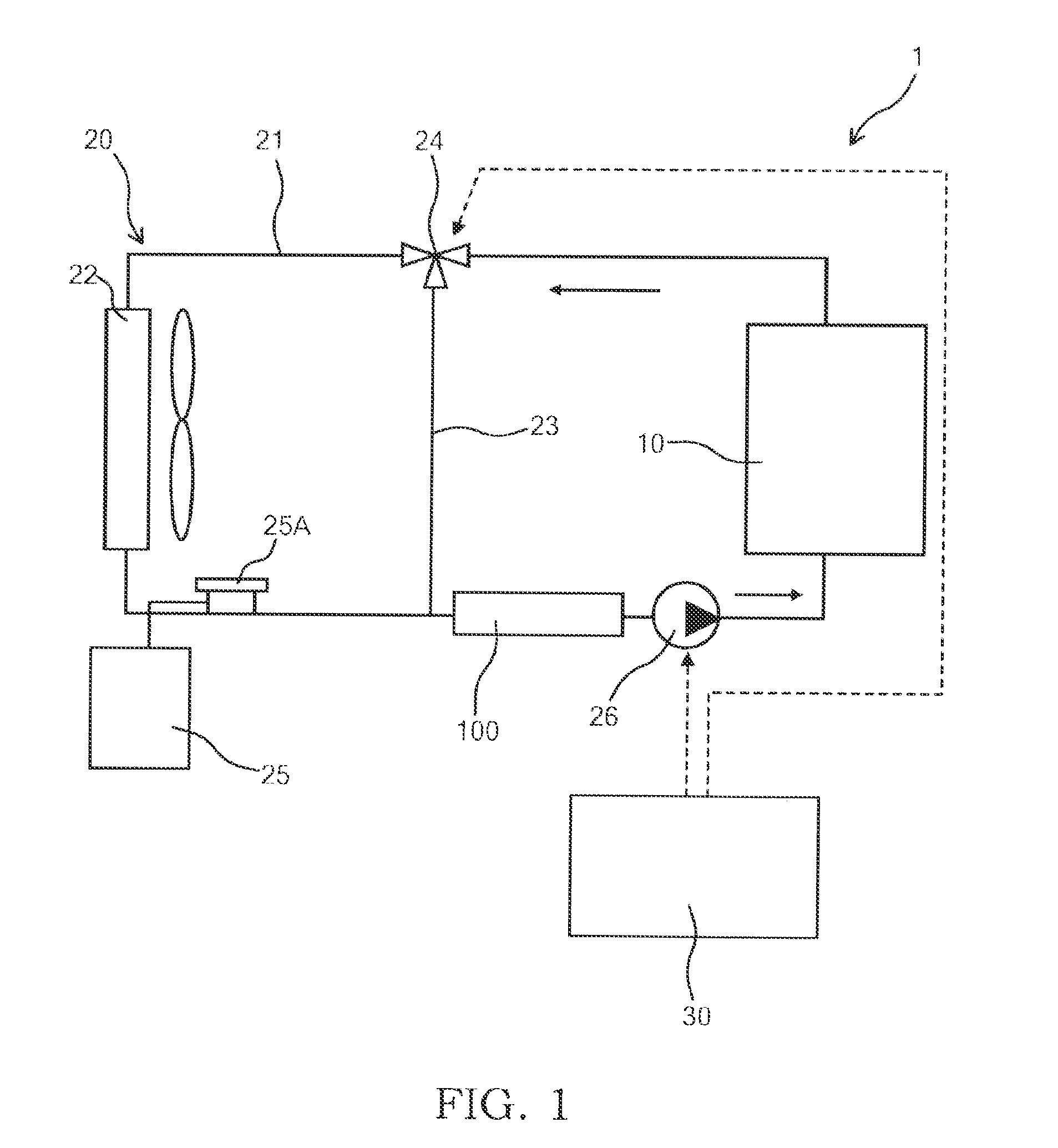

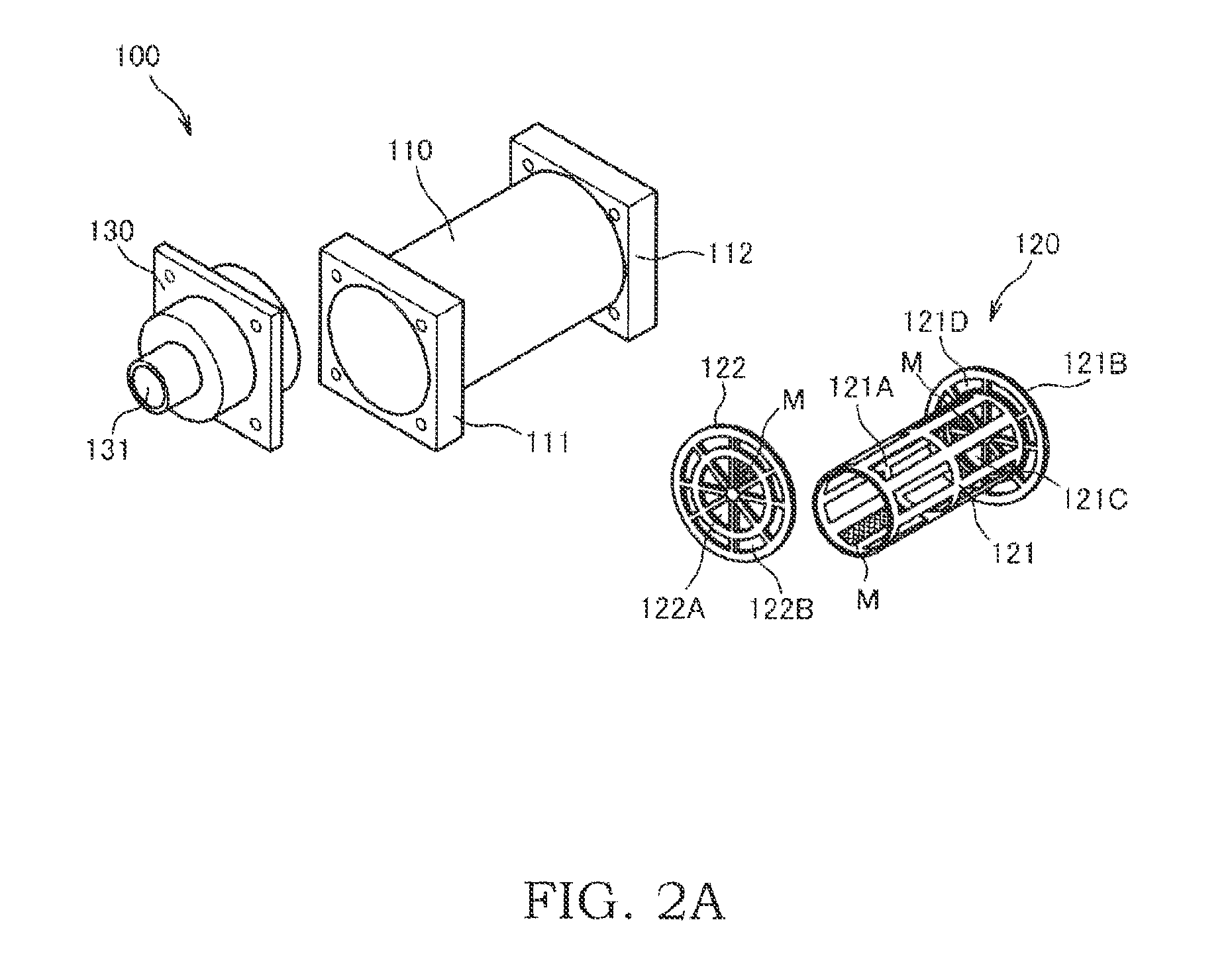

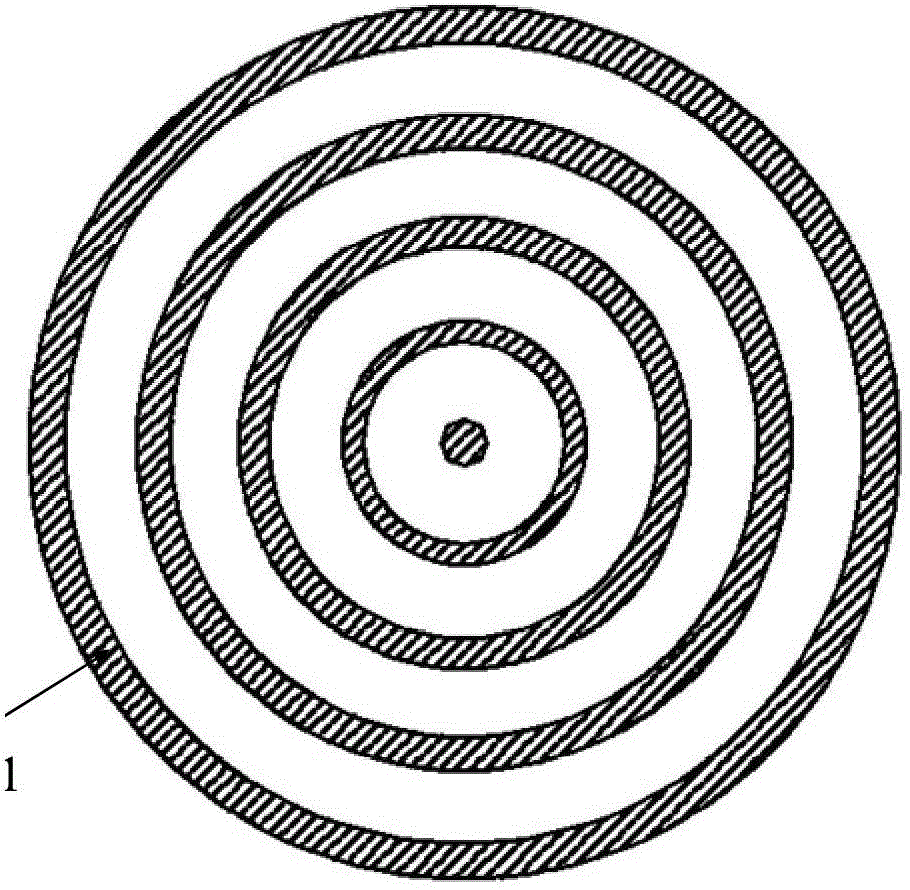

Ion exchanger and cooler having ion exchanger

ActiveUS20140248550A1Growth inhibitionIncreased ion exchange rateIon-exchange process apparatusFuel cell auxillariesFuel cellsIon exchange

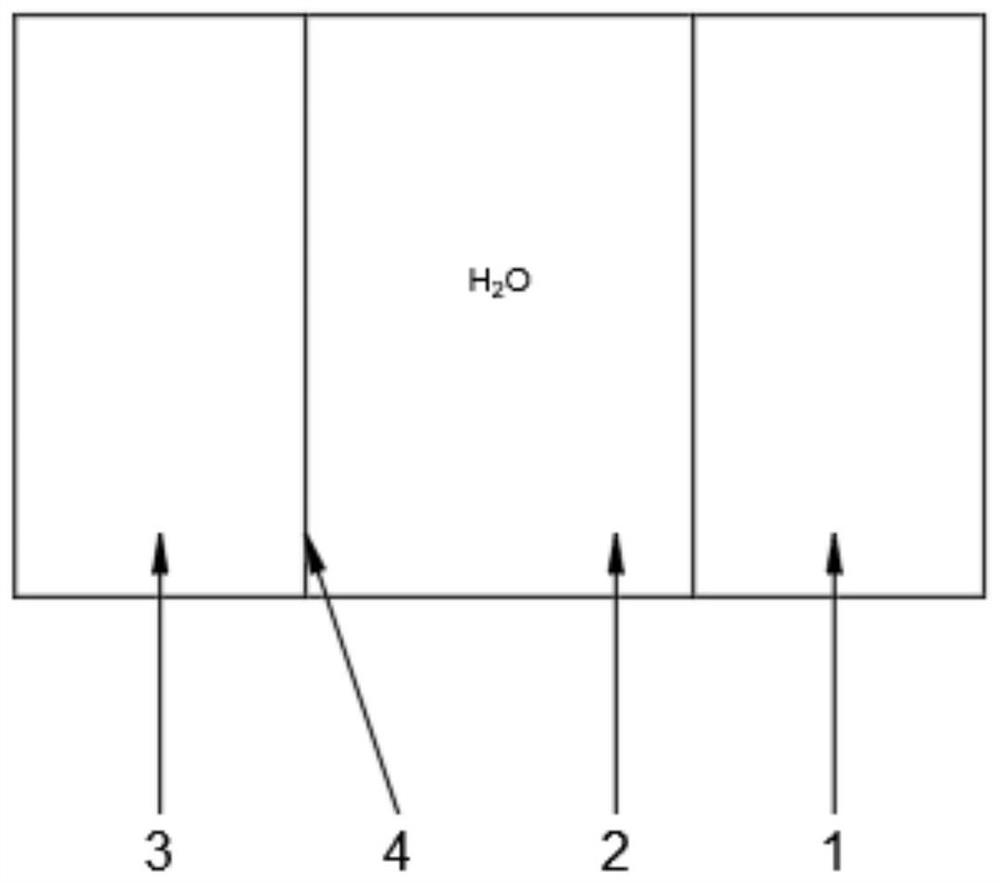

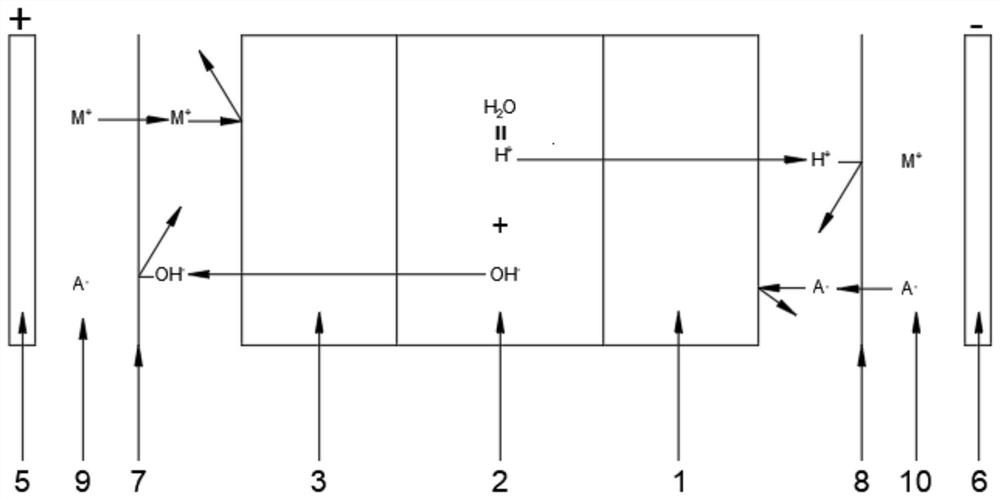

An ion exchanger configured to remove an impurity ion of a coolant for cooling a fuel cell, the ion exchanger includes an inflow portion having an inflow path where the coolant enters, a discharge portion having a discharge path for discharging the coolant, an outer casing having an upstream end where the inflow portion is provided and a downstream end where the discharge portion is provided, an inner casing housed inside the outer casing, an outer path formed between the inner casing and the outer casing to cause the inflow path and the discharge path to communicate with each other, and an inner path that is formed inside the inner casing to cause the inflow path and the discharge path to communicate with each other and is configured to enclose an ion exchange resin capable of removing an impurity ion of the coolant. The inner casing has a through-hole that causes the inner path end the outer path to communicate with each other.

Owner:NISSAN MOTOR CO LTD +1

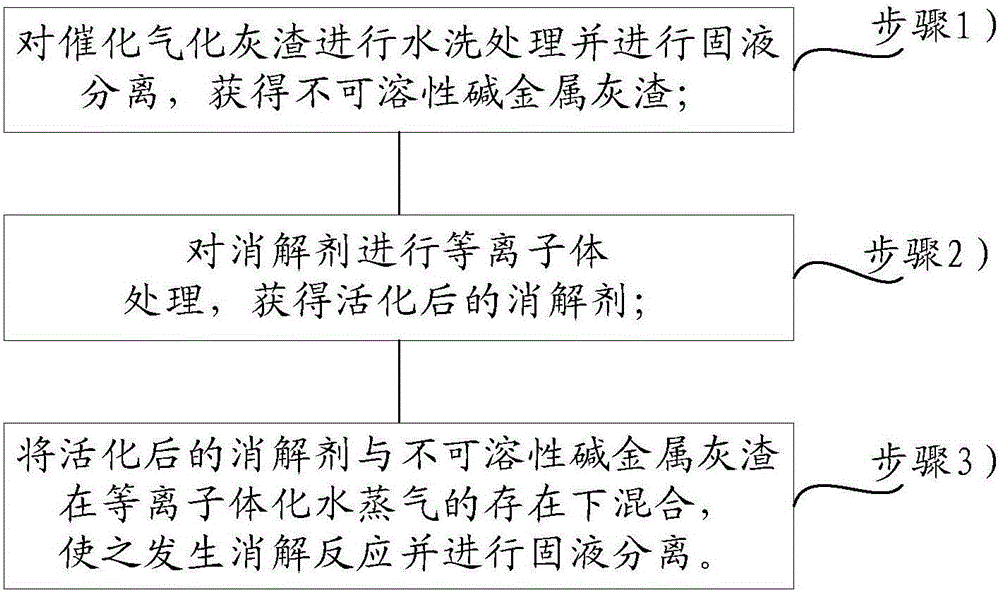

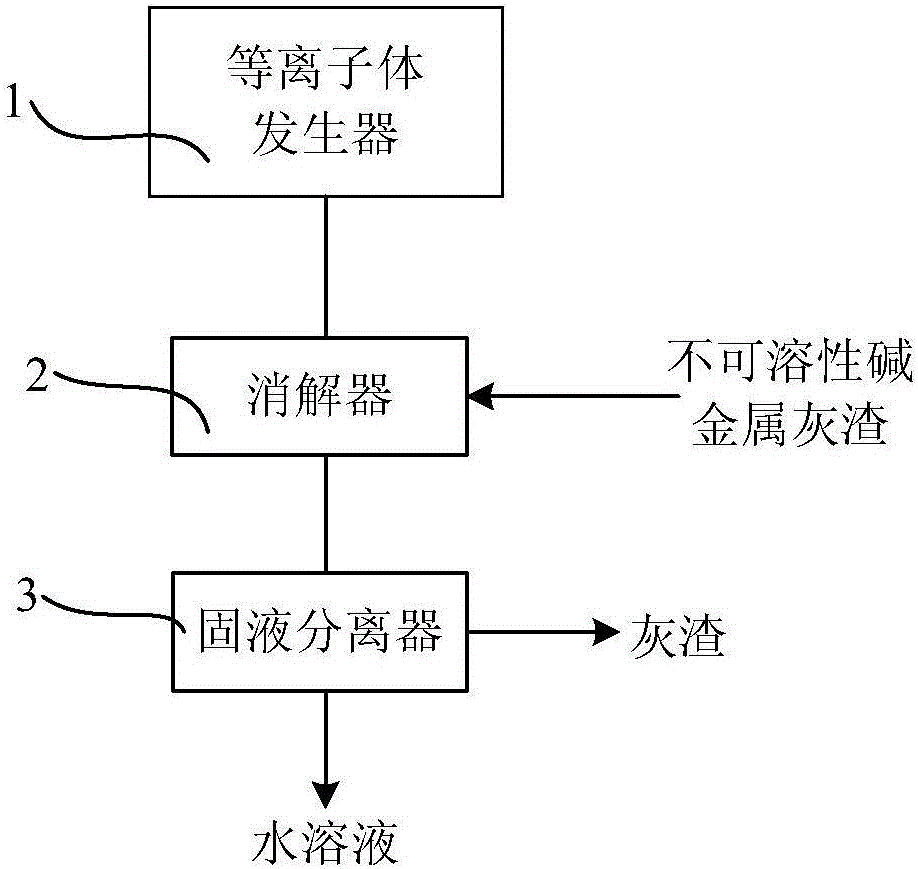

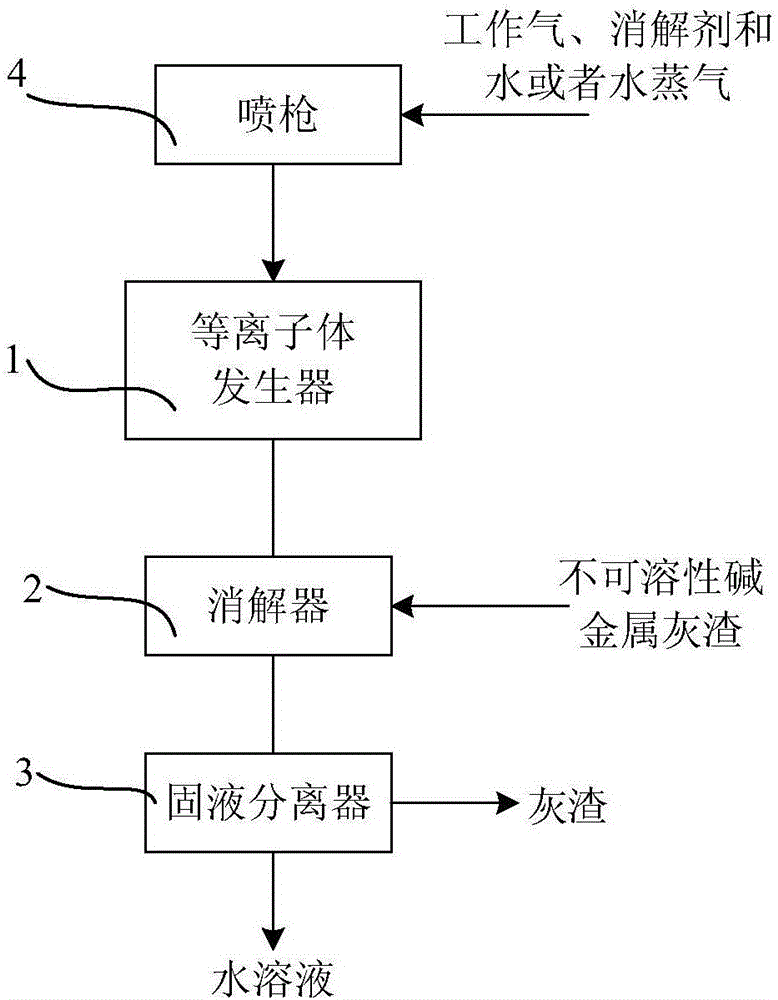

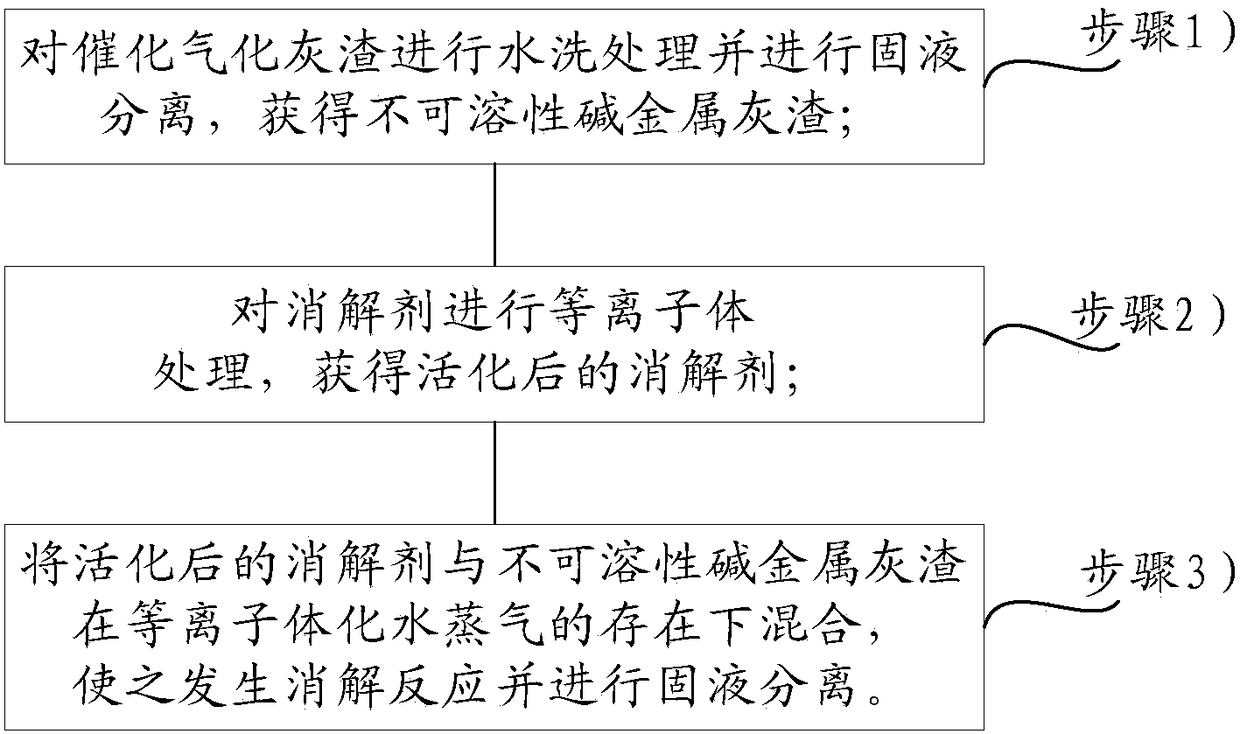

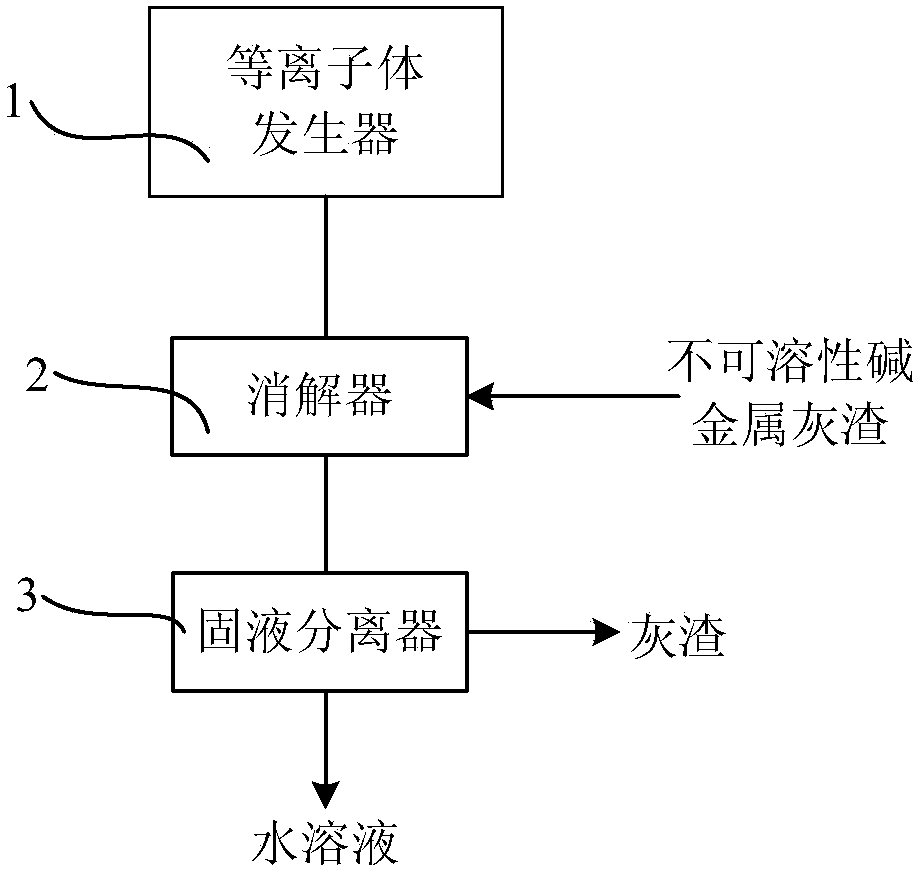

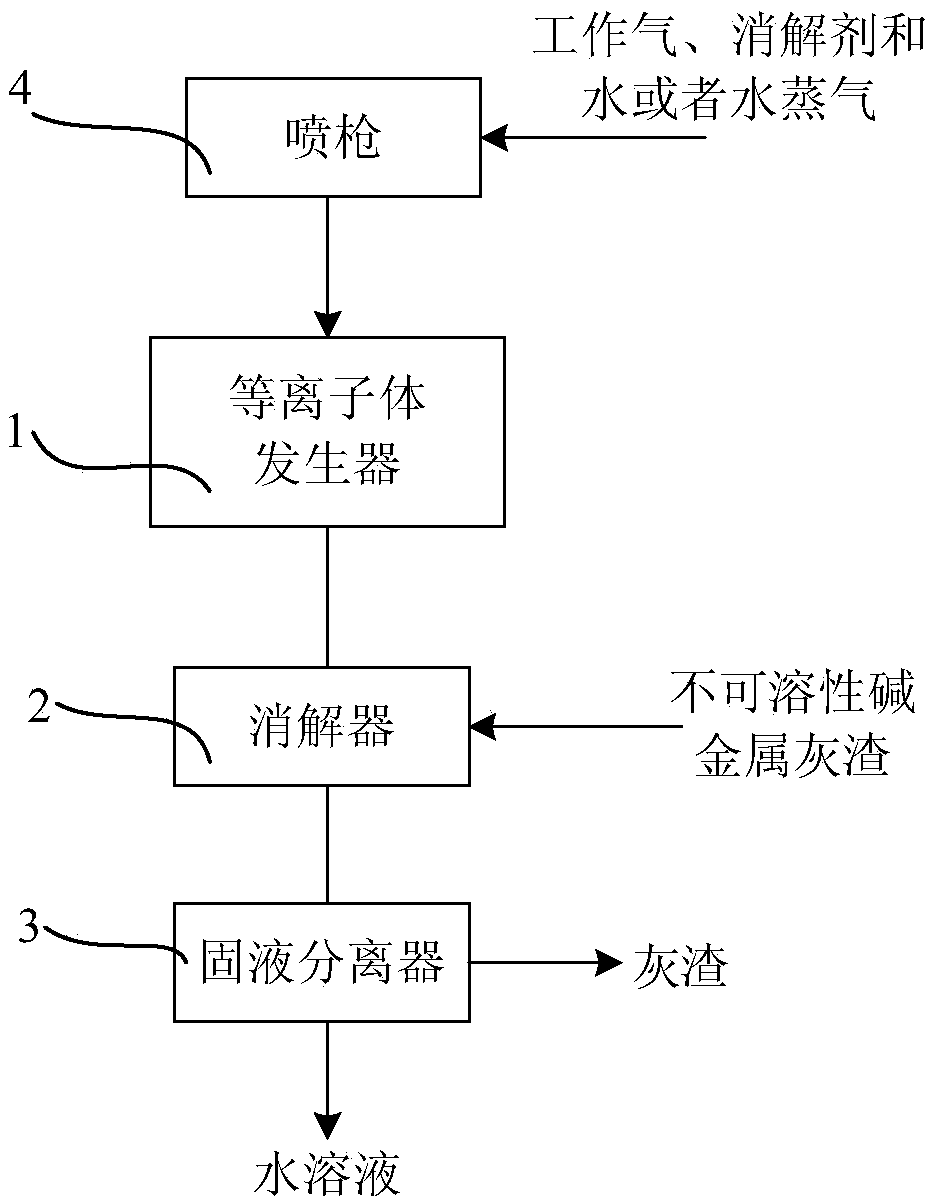

Method and system for recovery of insoluble alkali metal catalyst from catalytic gasification ash

ActiveCN106238069AImprove recycling efficiencyWell formedCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsSolubilityRecovery method

The invention relates to the technical field of catalyst recovery, particularly to a method and system for recovery of an insoluble alkali metal catalyst from catalytic gasification ash. The method has the advantages of simple process and low cost, also can improve the recovery efficiency of the insoluble alkali metal catalyst, and overcomes the defects of harsh process conditions, high cost and low recovery efficiency of insoluble alkali metal catalyst due to poor solubility of a digestion agent in water in the prior art. The method for recovery of the insoluble alkali metal catalyst from catalytic gasification ash consists of: step 1) performing washing treatment on the catalytic gasification ash and conducting solid-liquid separation to obtain insoluble alkali metal ash; step 2) carrying out plasma treatment on a digestion agent to obtain an activated digestion agent; and step 3) mixing the activated digestion agent with insoluble alkali metal ash in the presence of plasma water vapor to carry out digestion reaction and solid-liquid separation.

Owner:ENN SCI & TECH DEV

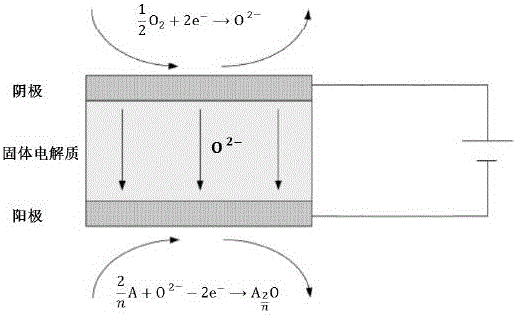

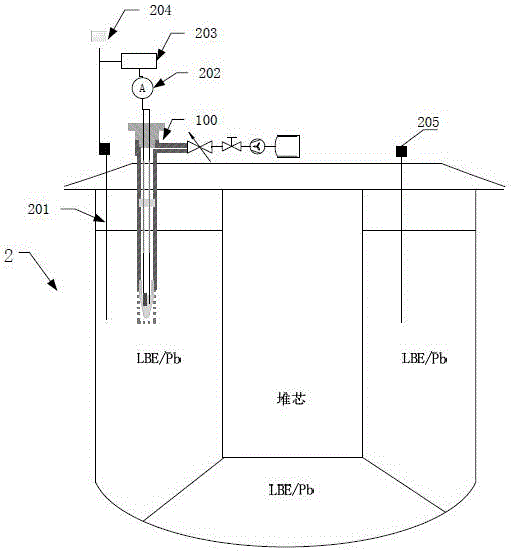

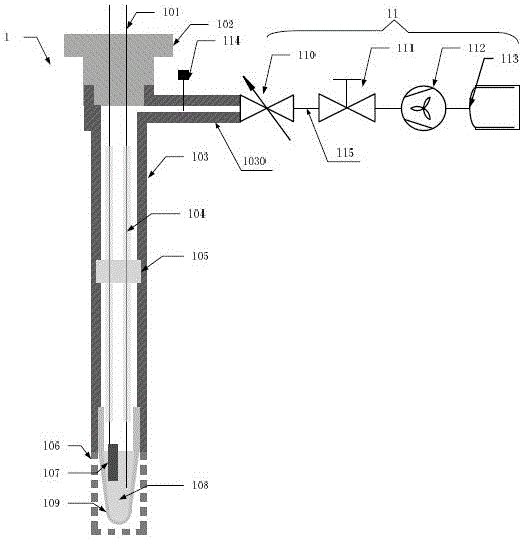

An apparatus and system for controlling the oxygen concentration in a liquid LBE/Pb coolant

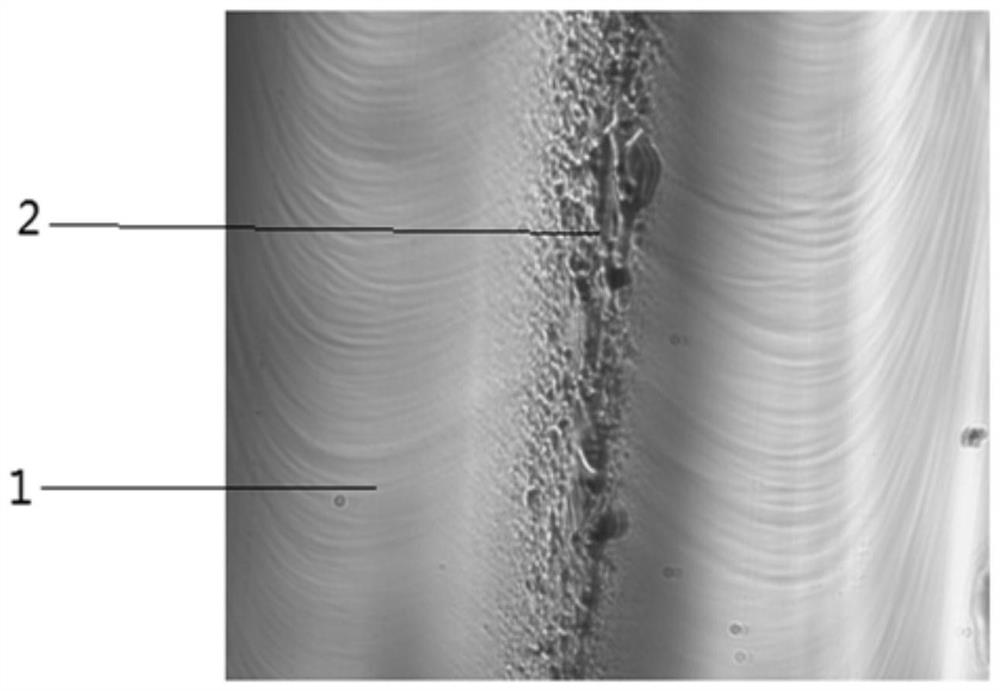

PendingCN106774481AIncreased ion exchange rateShort response timeControlling ratio of multiple fluid flowsMaterial analysis by electric/magnetic meansEngineeringAlloy

The invention discloses an apparatus and system for controlling the oxygen concentration in a liquid LBE / Pb coolant. Through the use of a novel electrochemical oxygen pump device, the oxygen concentration in the coolant can be precisely controlled to form a layer of dense oxide film on the steel surface to prevent further penetration of lead-based alloy into the steel and achieve a preservative effect; and key technical difficulties in lead-based fast reactors and ADS systems are solved to ensure long-term and safe operation of experimental loops and the lead-based fast reactors.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

Preparation method of composite molecular sieve defluorinating agent

InactiveCN107837785AHigh solid contentImprove adsorption capacityOther chemical processesWater contaminantsProtonationSorbent

The invention discloses a preparation method of a composite molecular sieve defluorinating agent. The composite molecular sieve defluorinating agent is prepared from raw materials including aluminum chloride, an ethoxypropoxy three-block polymer F127, calcium nitrate, sodium metaaluminate, sodium silicate, silver nitrate and the like. According to the preparation method disclosed by the invention,a calcium and aluminum oxide compound is prepared through immersion and high-temperature calcination; semi-dry gel is prepared through suction filtering to produce a molecular sieve; the solid content in a reaction kettle is improved and the production energy consumption of molecular sieve with the unit mass is reduced; after being combined, the calcium and aluminum oxide compound and the molecular sieve have ultra-strong affinity on fluorine ions; protonation and deprotonation on hydroxyl on the surface also have a promotion effect on adsorption of the fluorine ions; under a high-temperaturecondition, part of the defluorinating agent is thermally decomposed so that a lot of active sites and hydroxyl groups are generated on the surface of an adsorbent; the defluorinating agent can be subjected to ion exchange with the fluorine ions so that the fluorine ions are enriched on the surface of the adsorbent and the aim of removing the fluorine ions is realized.

Owner:MAANSHAN TUORUI METAL SURFACE TECH

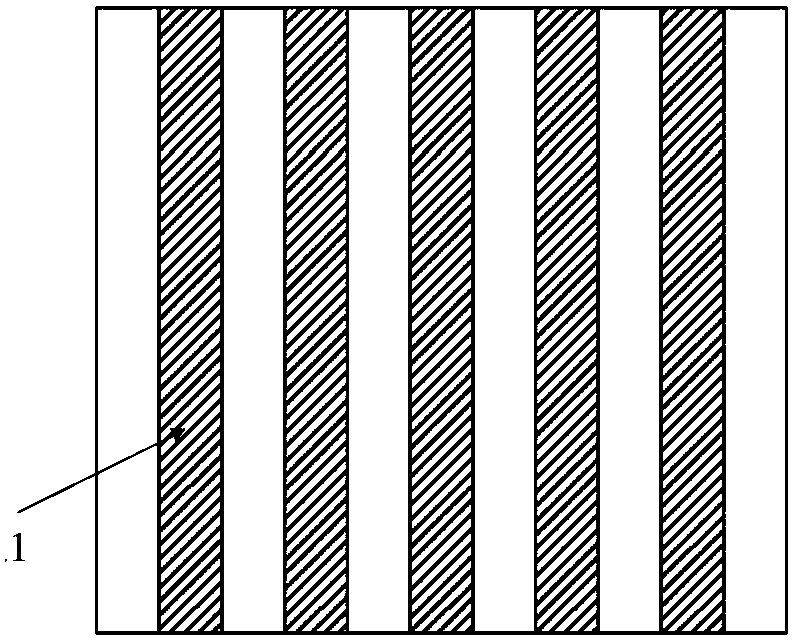

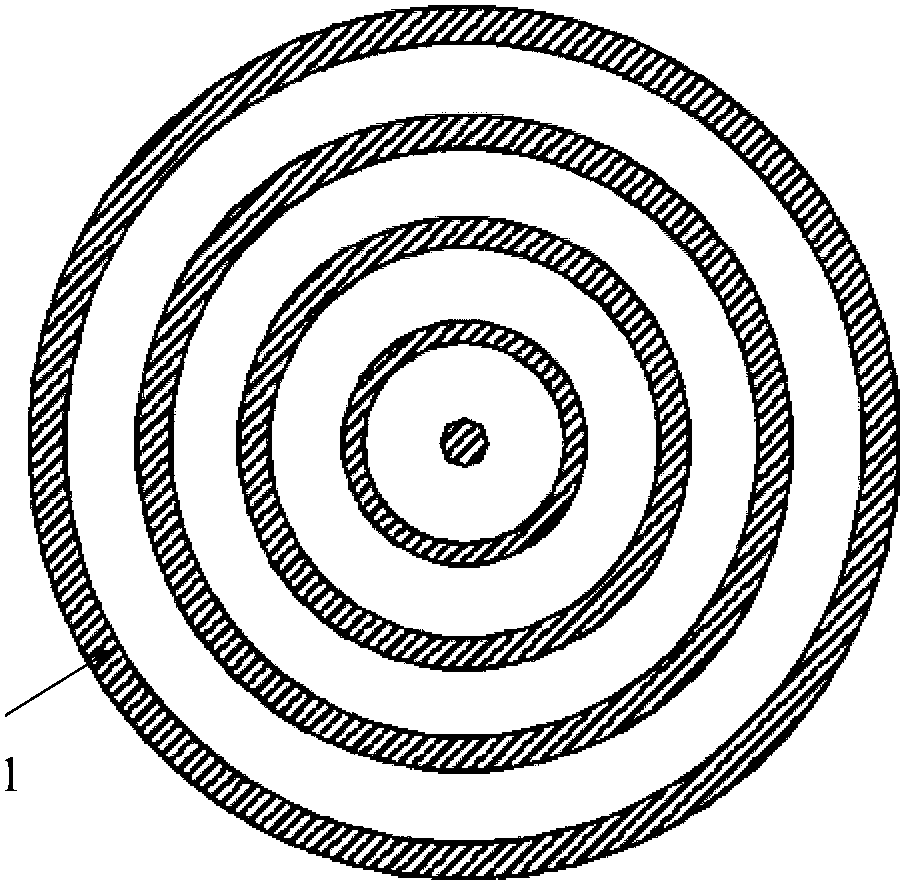

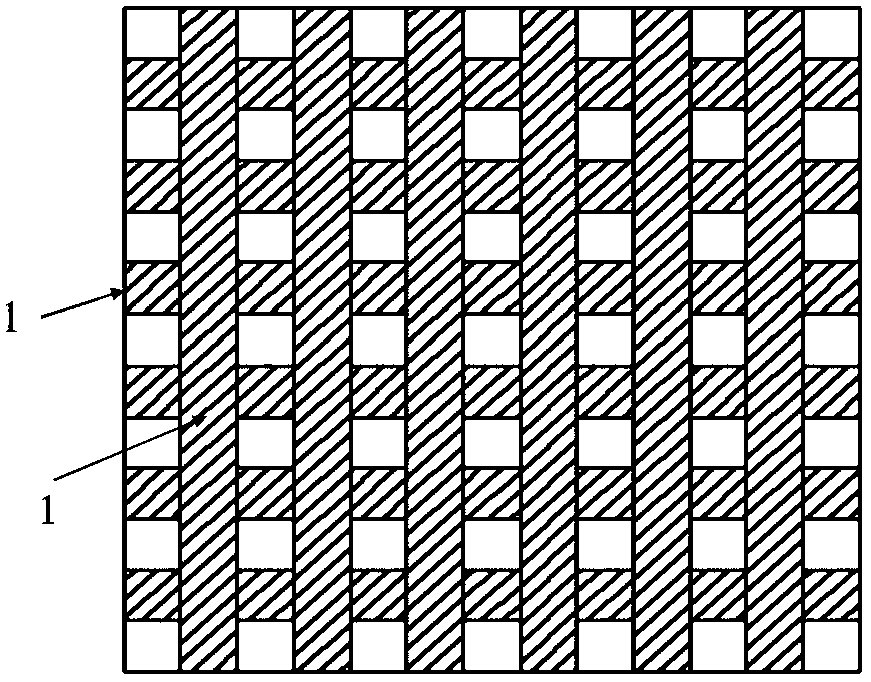

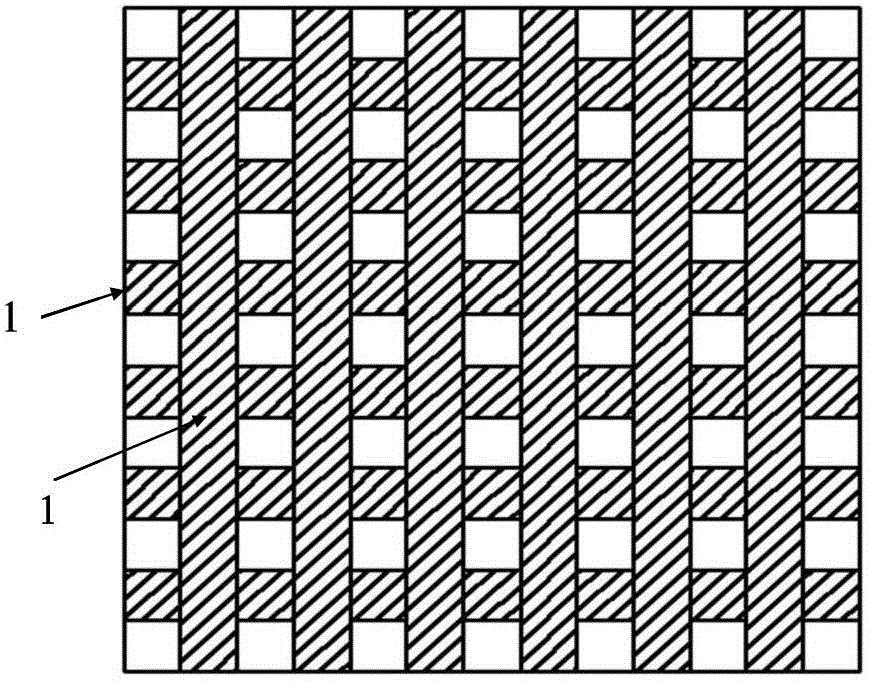

Mosaic-type nano film

InactiveCN103015036APrevent overloadSimple production processFilament/thread formingConjugated synthetic polymer artificial filamentsCross-linkPorosity

The invention discloses a mosaic-type nano film which consists of nano film layers, wherein each nano film layer consists of mutually parallel nano film units; a gap exits between the adjacent nano film units; each nano film unit is formed by alternately arranging at least three first nano fibers and at least three second nano fibers; each first nano fiber is formed by mixing a styrene-series cation exchange resin, an adhesive and a cross-linking agent at a mass ratio of 1:(4-9):(1-10); each second nano fiber is formed by mixing a vinylpyridine-series anion exchange resin, the adhesive and the cross-linking agent at a mass ratio of 1:(4-9):(1-10). The nano film has the favorable performances of high porosity, low bore diameter, favorable wettability, strong ionic conductivity and high mechanical strength.

Owner:SOUTHEAST UNIV

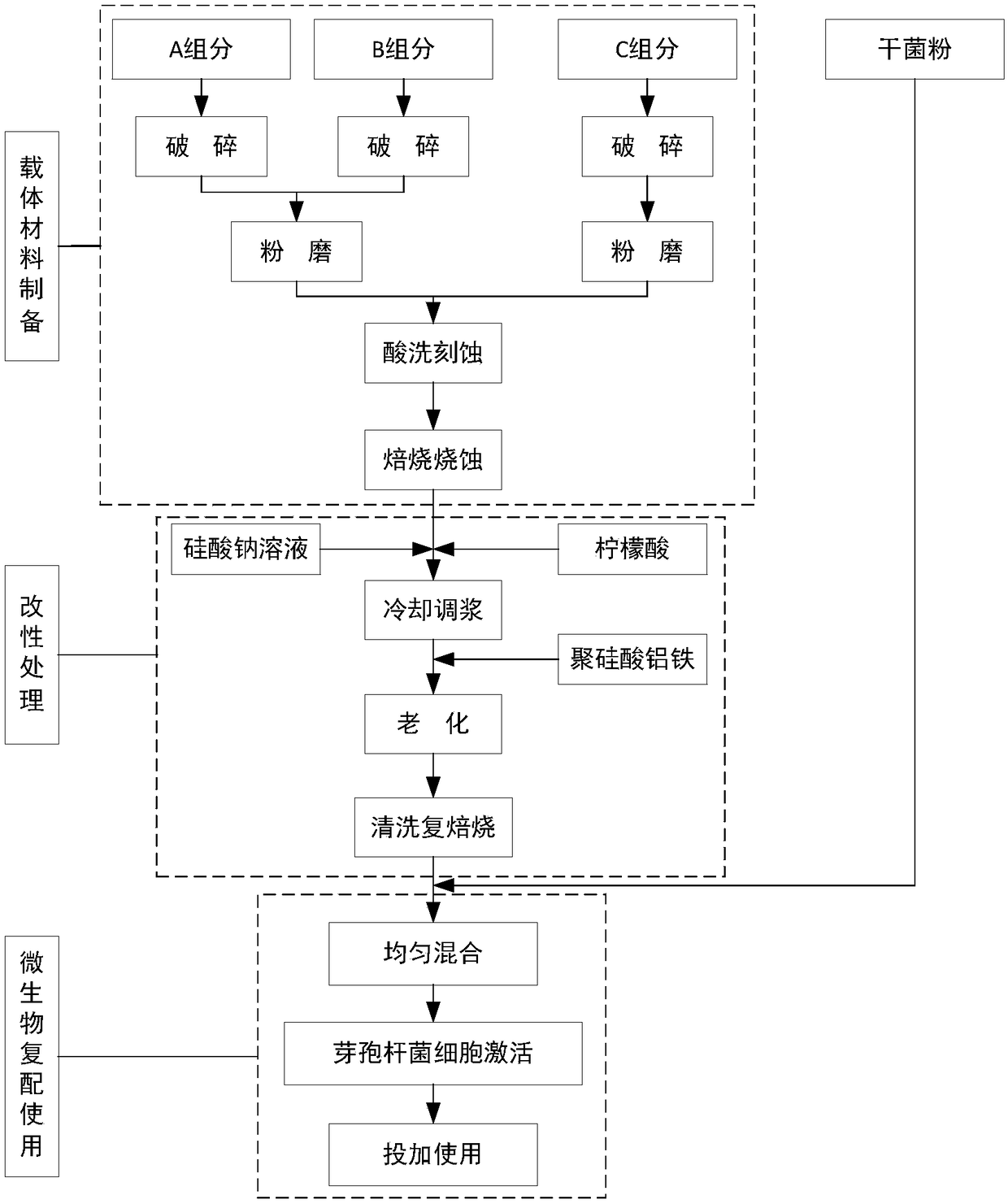

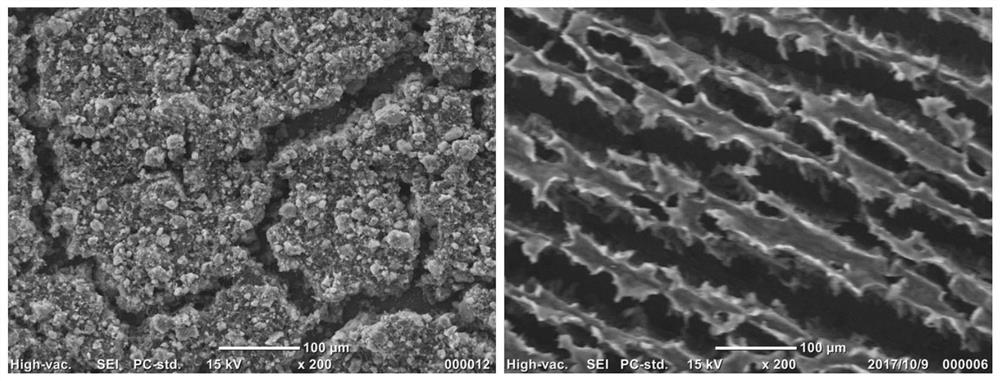

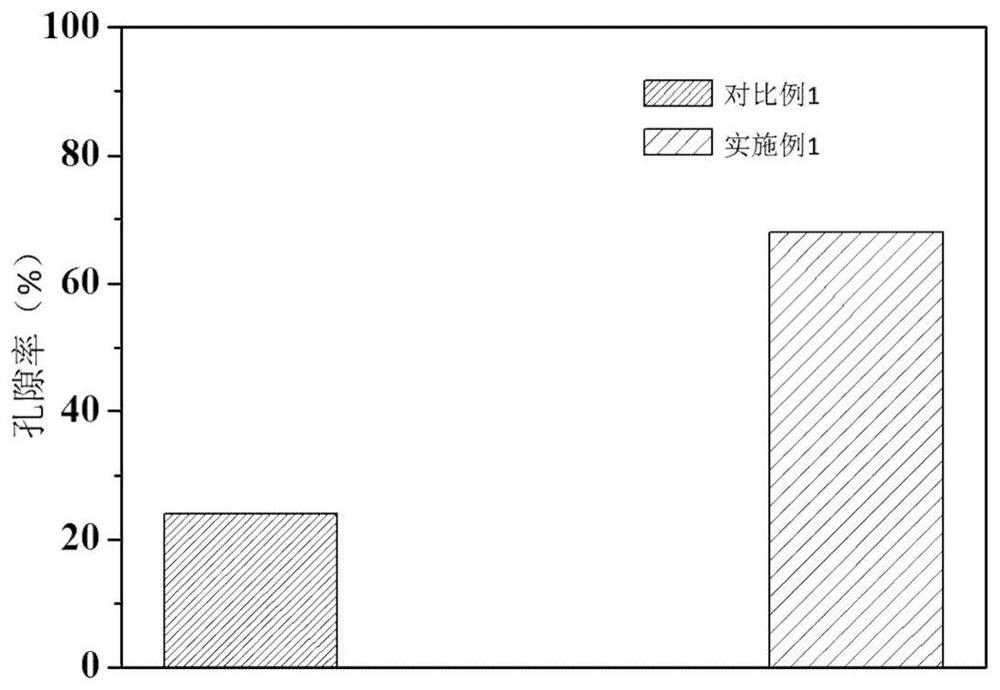

Modified mineral-microorganism coupled water purifying material and preparation method thereof

ActiveCN109354209AEasy to cleanIncreased ion exchange rateBacteriaMicroorganism based processesOrganic matterSuspended matter

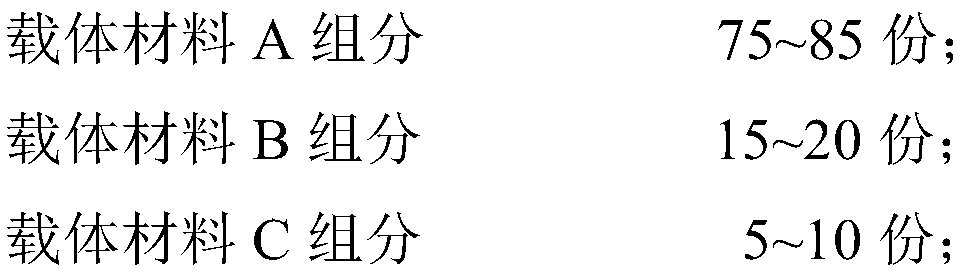

The invention discloses a modified mineral-microorganism coupled water purifying material and a preparation method thereof. The water purifying material is prepared from the following raw materials inparts by mass: 75-85 parts of a carrier material component A, 15-20 parts of a carrier material component B, 5-10 parts of a carrier material component C, 1-3 parts of a modifying agent and 0.1-0.3 part of a microbial preparation. Effects of minerals and effects of microorganisms are coupled into the water purifying material, by Fe3+ and Al3+ which are loaded on the modified carrier body, the surfaces of particles of the carrier material have positive charge, suspended matters with negative charges in polluted water can be adsorbed effectively, and after precipitates are adsorbed, organic pollutants in the precipitates can provide energy for growth of the microorganisms in the early stage; and after organic matters are dispelled completely, under the effect of the microorganisms, the valence state of loaded high-price cations is reduced, along with generation of H+, H+ can be used as biological energy for the microorganisms, therefore, a bottom mud mineralization process is promoted,and finally, a steady-state foundation bed is formed.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

Preparation method of molecular sieve type soil repairing agent

InactiveCN107892918AIncrease adsorption sitesHigh solid contentAgriculture tools and machinesOrganic fertilisersParticulatesUnit mass

The invention discloses a preparation method of a molecular sieve type soil repairing agent. The molecular sieve type soil repairing agent is prepared from diatomite, rice straw, sodium metaaluminate,water glass, silver nitrate and other raw materials. The diatomite and the straw are mixed and subjected to alkali treatment, then the surfaces of particles become concave-convex non-smooth structures, and adsorption sites are greatly increased; semi-dried gel is prepared through suction filtration to produce a molecular sieve, the solid content in a reaction kettle is increased, the unit mass molecular sieve production energy consumption is reduced, a finally obtained composite material is subjected to steam ageing and high-temperature activation, the size of internal pores of the particlesis increased, heavy metal ions and organic macromolecules can be adsorbed and immobilized, the adsorption capacity is improved, the purpose of low-cost pollution restoration of the soil by people canbe achieved, and the method has good economic and environmental benefits.

Owner:MAANSHAN TUORUI METAL SURFACE TECH

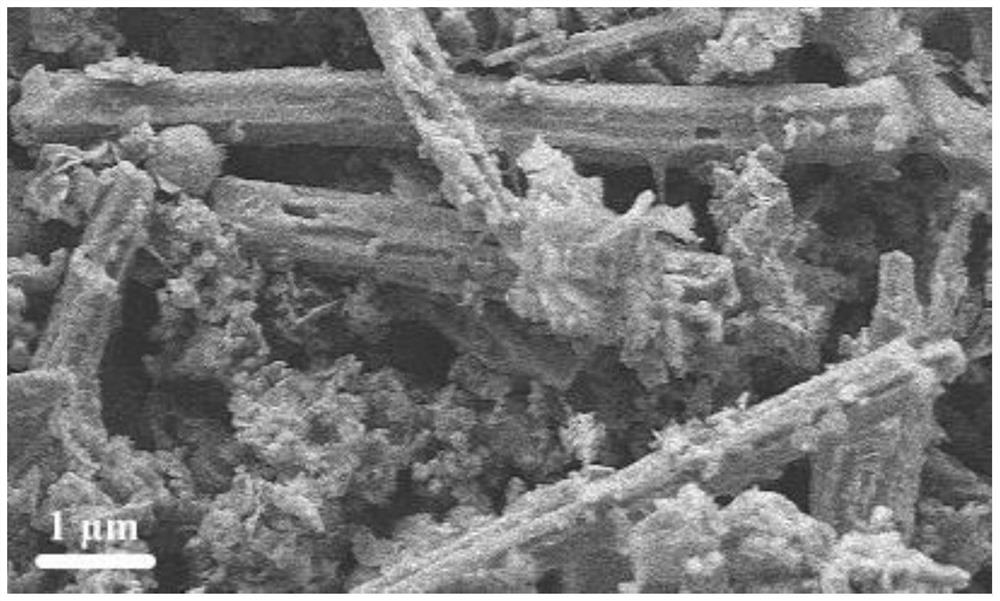

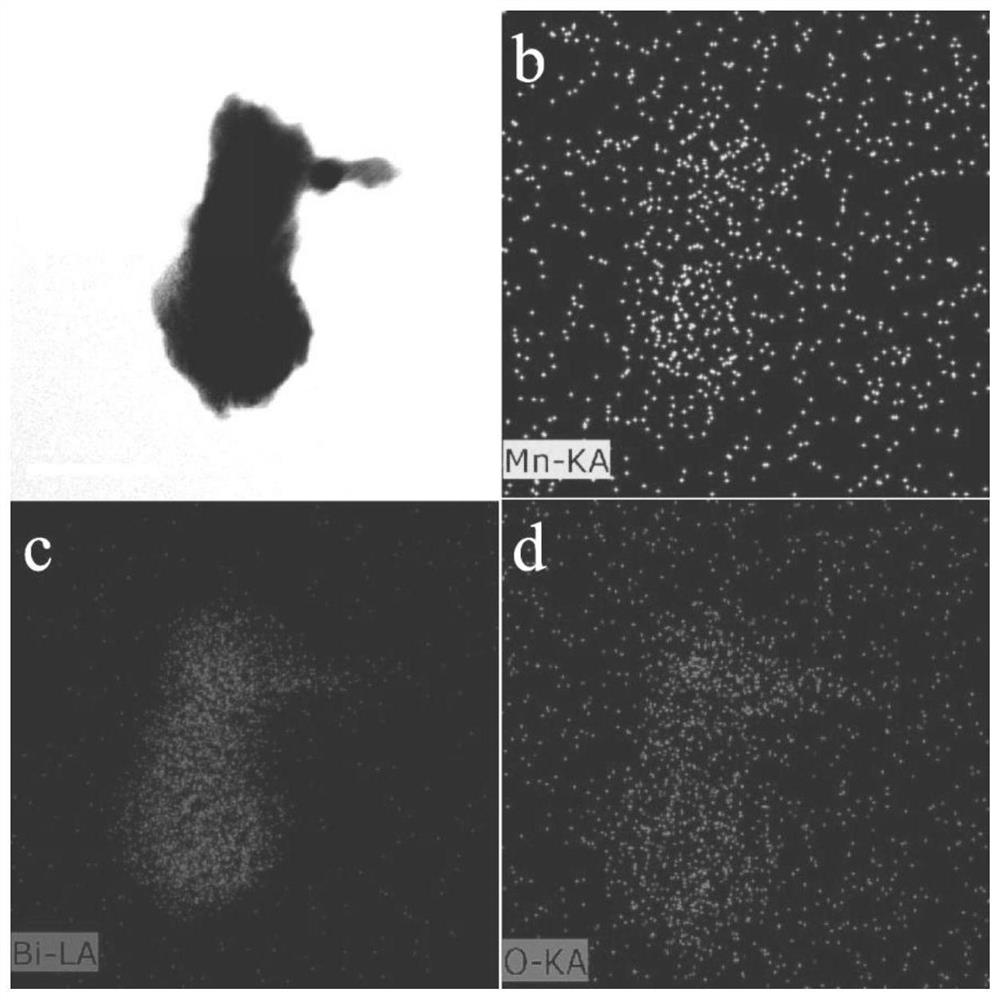

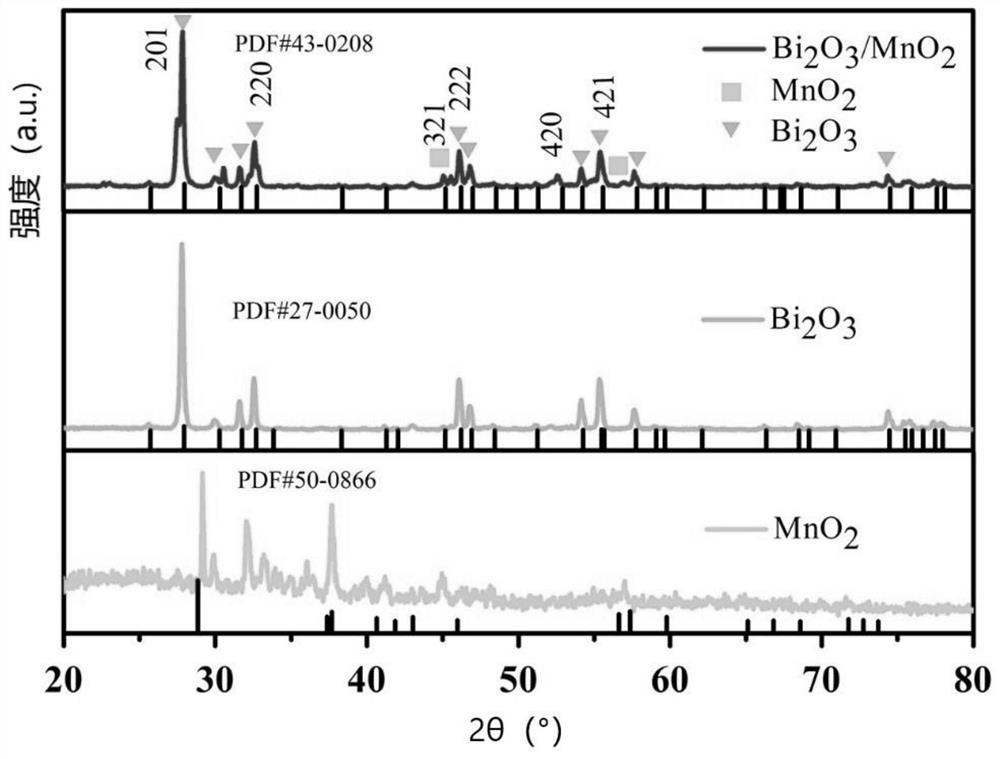

Bismuth oxide/manganese oxide composite supercapacitor and preparation method thereof

ActiveCN112420401AOvercome the defect of poor performance controllabilityIncrease active areaHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceSupercapacitor

The invention provides a bismuth oxide / manganese oxide composite supercapacitor and a preparation method thereof, and belongs to the technical field of material preparation. According to the invention, mesoporous silica is selected as a template, and bismuth oxide with high ionic conductivity and manganese oxide with high specific capacitance are combined to form the composite supercapacitor withmore excellent electrochemical performance; the prepared supercapacitor has relatively high specific capacitance and energy density on the premise of ensuring the stability of an electrode material; and the preparation method is cheap in required raw materials, simple in process and mild in reaction, and the prepared supercapacitor can be recycled in industry.

Owner:JIANGSU UNIV

Lead-acid accumulator material and a forming method thereof

InactiveUS20130015390A1Increase charging rateImprove conversion rateElectrochemical processing of electrodesElectrode thermal treatmentResonanceIon exchange

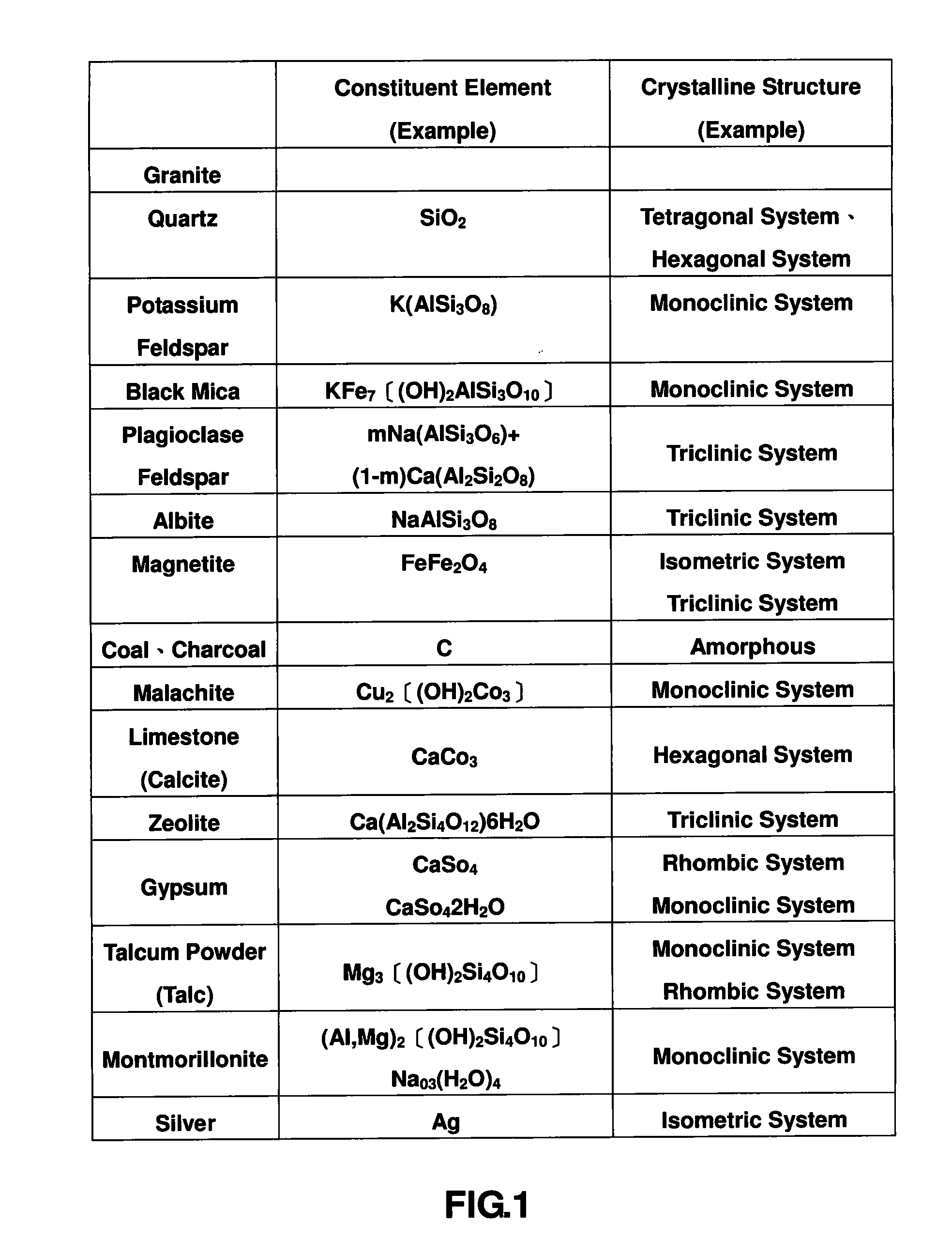

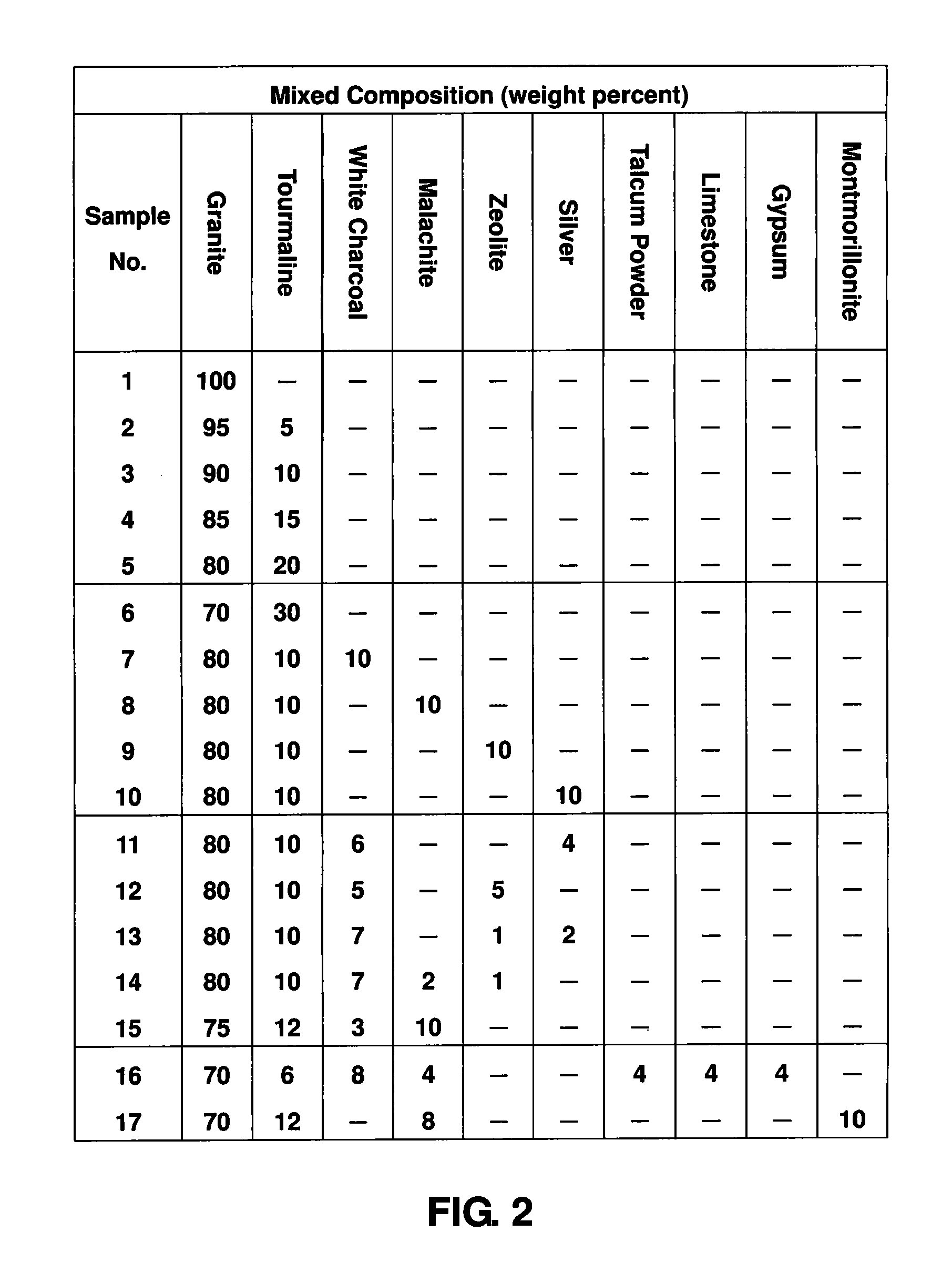

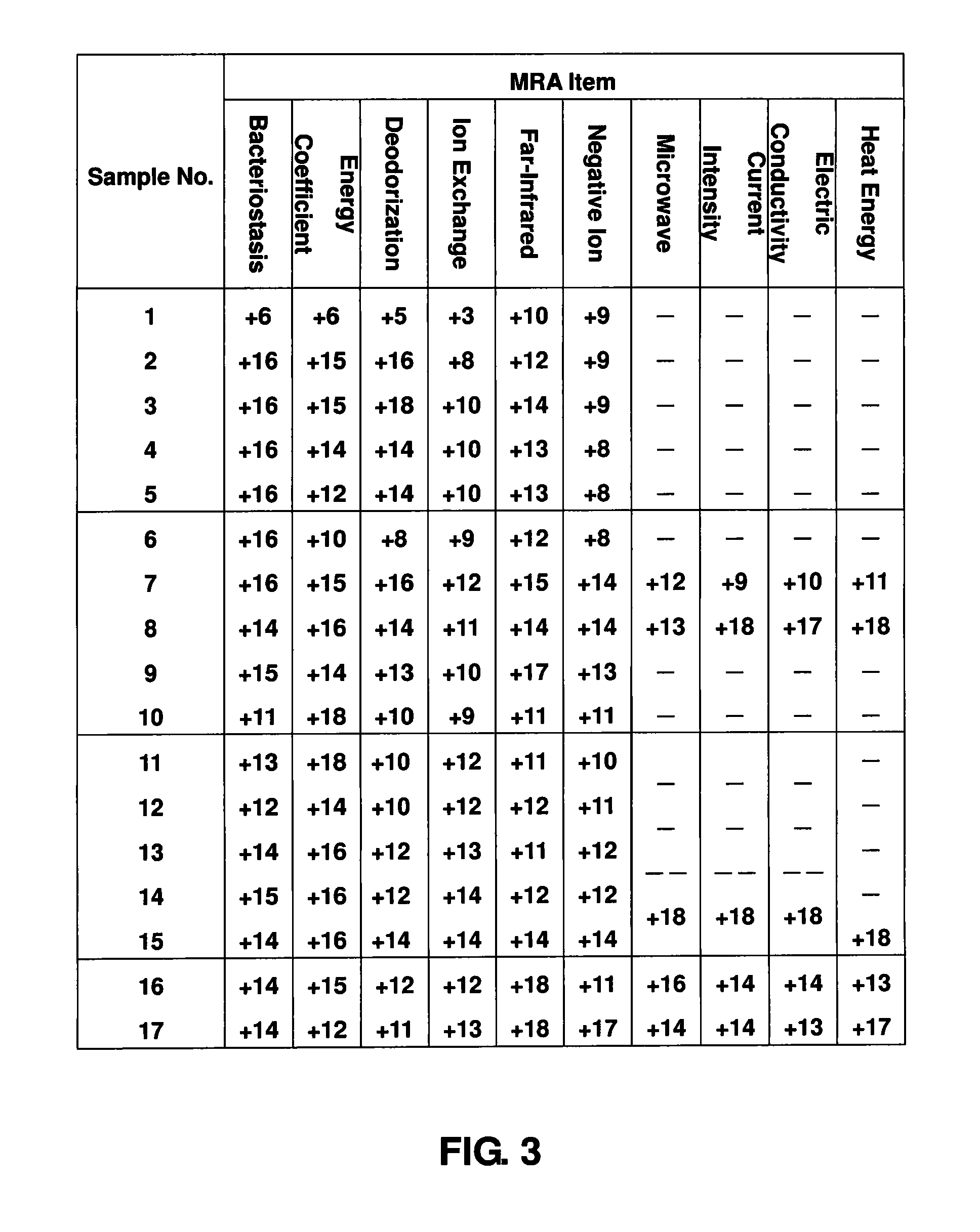

In the present invention, characteristics specific to all kinds of natural mineral and metal are analyzed by a magnetic resonance analyzer. The natural mineral and metal are combined and ground into powder and made into a lead plate, ceramic and a separator of a lead-acid accumulator to produce an undulation frequency and change a molecule structure of an electrolyte, thereby accelerating an ion exchange rate, speeding up a charging rate, increasing a conversion rate, decreasing stacking of lead sulfate crystalloids, reducing a corrosion rate of a positive electrode lattice body and extending a lifetime of use of the lead-acid accumulator.

Owner:HUANG HSUEH HUNG

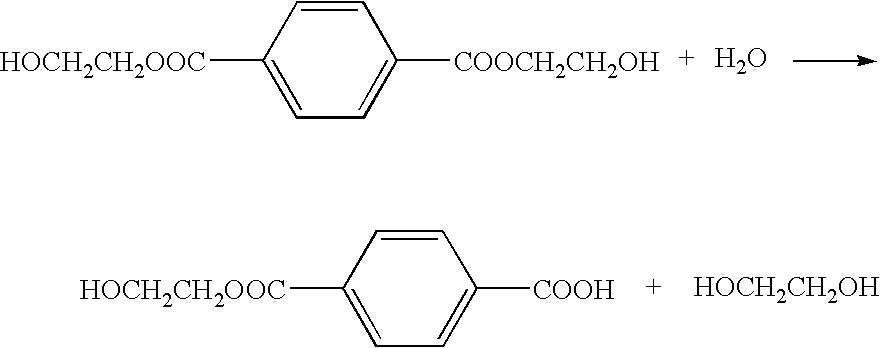

Method of deionizing solution yielded by polyester decomposition with ethylene glycol

InactiveUS7306738B2Low purityReduce yieldPreparation by ester-hydroxy reactionOrganic compound preparationPolyesterDecomposition

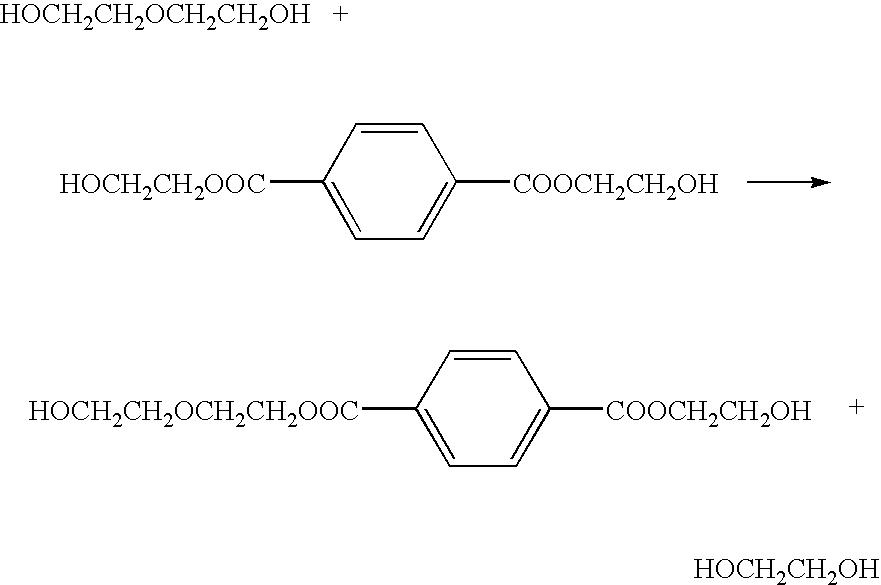

There is provided a method for deionizing a decomposition produced solution resulting from decomposition of a polyester by ethylene glycol. The ester interchange reaction and hydrolysis reaction along with cation removing treatment of a decomposition product resulting from decomposition of a polyester by ethylene glycol are suppressed. Thereby, a method for deionizing the decomposition produced solution with small reductions in yield and purity can be provided.

Owner:PET REBIRTH CO LTD

Method for preparing photocatalytic composite modified molecular sieve

InactiveCN107899604AHigh solid contentImprove catalytic performanceMolecular sieve catalystsAnhydrous ethanolMolecular sieve

The invention discloses a method for preparing a photocatalytic composite modified molecular sieve. The photocatalytic composite modified molecular sieve is prepared from tetrabutyl titanate, anhydrous ethanol, an alkaline solution, sodium metaaluminate, water glass and silver nitrate. Suction filtration is carried out to prepare semi-dry gel, and the semi-dry gel is used to produce the molecularsieve, so the solid content of a reaction kettle is improved, and the energy consumption in the production of per unit mass of the molecular sieve is reduced; the molecular sieve is modified with alkali, and the abundant meso-porous structures are introduced to the molecular sieve mainly based on micro-pores, so the load capacity of titanium dioxide is greatly improved; and a rich adsorption surface is used to increase the contact area of the titanium dioxide and pollutants, so the photocatalysis effect is efficiently completed, and the photocatalytic degradation of the pollutants is realized.

Owner:MAANSHAN TUORUI METAL SURFACE TECH

Method for preparing molecular sieve type heavy metal curing agent

InactiveCN107792862AHigh solid contentImprove catalytic performanceSolid waste disposalCrystalline aluminosilicate zeolitesFiltrationUnit mass

The invention discloses a method for preparing a molecular sieve type heavy metal curing agent. The molecular sieve type heavy metal curing agent is prepared from raw materials such as ferrochrome slag, monopotassium phosphate, tetramethyl-disilazane, sodium metaaluminate, sodium silicate and silver nitrate. According to the method, a molecular sieve is produced from half-dry gel through suction filtration, the solid content of a reaction kettle is increased, the production energy consumption of a unit mass molecular sieve is reduced, on the basis, silanization modification is implemented on the molecular sieve, and a calcium series phosphate chemical bonding material is introduced, so that on one hand, the static and dynamic water adsorption amount of the molecular sieve is reduced, the hydrophobicity of the molecular sieve is improved, and the situation that the heavy metal curing sites are reduced due to water adsorption is reduced, on the other hand, heavy metal ions are adsorbed through hydroxyapatite, ion exchange is implemented under the catalysis action of the molecular sieve, corresponding heavy metal phosphate is formed, and heavy metals are immobilized in an immobilizingagent efficiently for a long time.

Owner:MAANSHAN TUORUI METAL SURFACE TECH

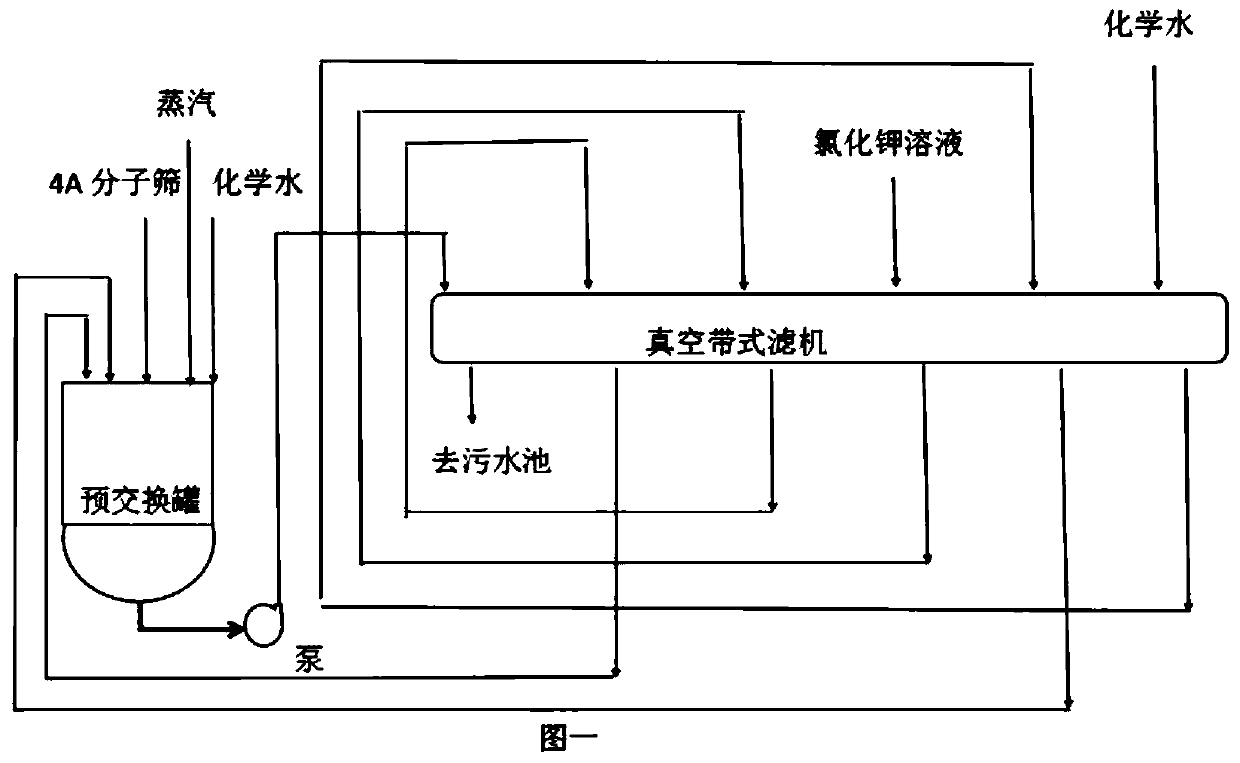

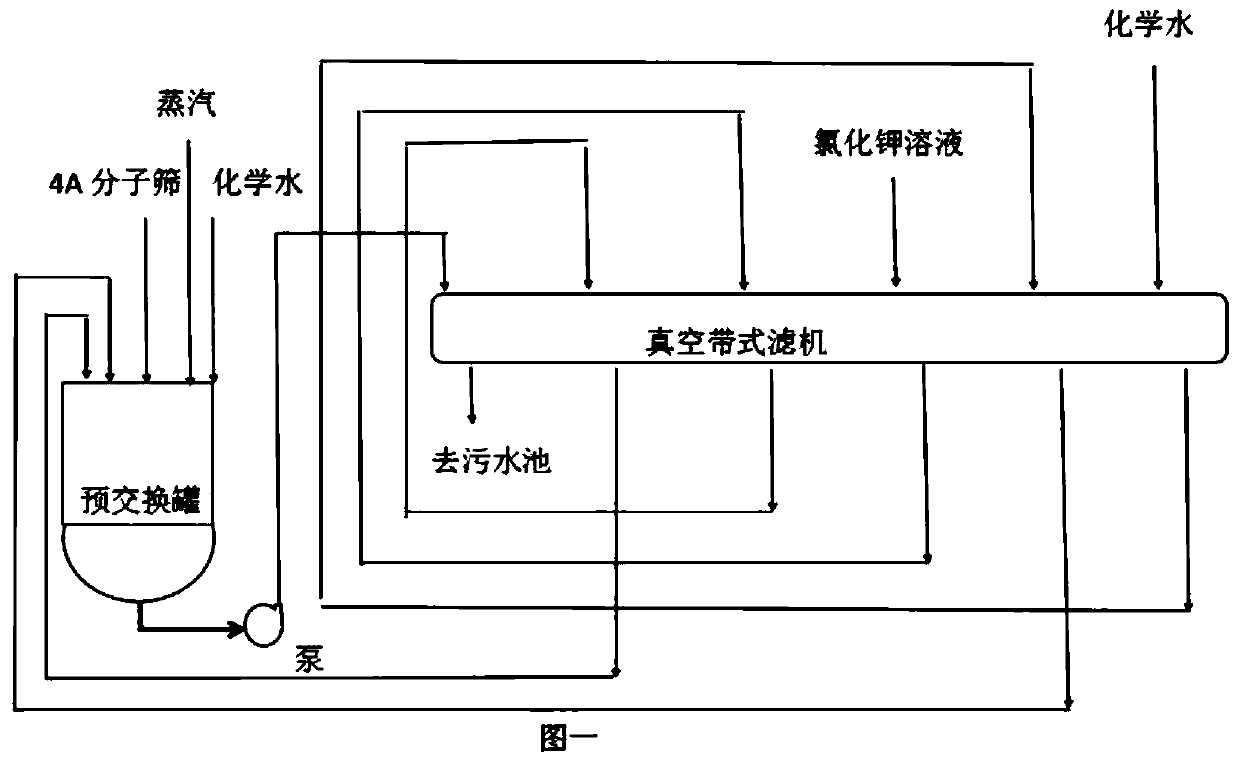

Preparation method of improved 3A molecular sieve raw powder

PendingCN111135787AReduce dosageImprove ion exchange rateOther chemical processesIon exchangeMolecular sieve

The invention discloses a preparation method of improved 3A molecular sieve raw powder. The preparation method comprises the following steps: subjecting potassium-containing exchange liquid recoveredby countercurrent exchange of a vacuum belt filter and a 4A molecular sieve to mixing and stirring in a pre-exchange tank for exchange, and pumping the potassium-containing exchange liquid and the 4Amolecular sieve to the vacuum belt filter for tertiary countercurrent exchange and secondary countercurrent washing after exchange is completed; and carrying out flash evaporation and drying to obtainthe improved 3A molecular sieve raw powder. The improved 3A molecular sieve raw powder prepared by the method is high in ion exchange rate and has better water adsorbability.

Owner:润和科华催化剂上海有限公司

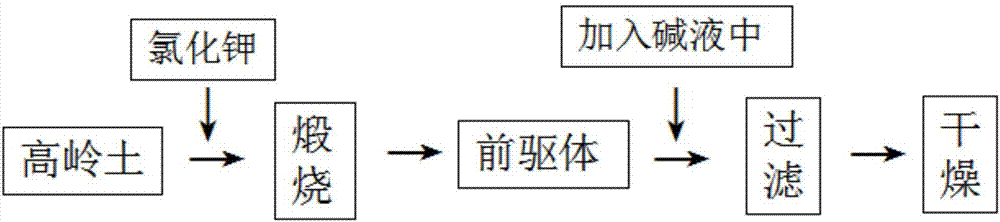

3A molecular sieve and processing technology thereof

InactiveCN107055566AAvoid complex processesIncrease concentrationAluminosilicate zeolite type-AMolecular sieveSynthesis methods

The invention discloses a 3A molecular sieve and a processing technology thereof. The 3A molecular sieve is prepared by using kaolin as a raw material and directly reacting with lye after being calcined with salt, and specifically includes the following steps: mixing and calcining KC1 and kaolin to obtain an active Precursor mixture, then react the prepared mixture in lye, make K during the formation of 4A molecular sieve + directly with Na + The exchange effect occurs, and the 3A molecular sieve is directly obtained in one step. The present invention explores a simple method for directly synthesizing molecular sieves from cheap raw materials, and at the same time avoids the complex process of preparing 4A molecular sieves first and then preparing them by ion exchange in the traditional synthesis method.

Owner:MINGGUANG FEIZHOU NEW MATERIAL

Method for preparing molecular sieve-type dehydrating agent of coal tar

InactiveCN107937018AImprove adsorption capacityIncrease spaceOther chemical processesHydrocarbon oil dewatering/demulsificationFiltrationPhosphoric acid

The invention discloses a method for preparing a molecular sieve-type dehydrating agent of coal tar. The molecular sieve-type dehydrating agent of the coal tar is prepared from sodium carboxymethyl starch, attapulgite, alkyl phenolic resin polyoxyethylene ether, sodium metaaluminate, sodium silicate, silver nitrate and other raw materials. According to the method for preparing the molecular sieve-type dehydrating agent of the coal tar, the phosphoric acid-modified attapulgite is adopted so as to increase adsorption sites and water storage space of the product, and a molecular sieve is producedby optimizing preparation of the molecular sieve and preparing semidry gel by using extraction filtration, so that the solid content in a reaction vessel is improved, the production energy consumption of each unit mass of the molecular sieve is reduced, and the overall hydrophilicity of the material is improved; the usage amount is small when the molecular sieve-type dehydrating agent is in use,the preparation cost is low, and the water content of a coal tar finished product is met; compared with an existing dehydrating method, the molecular sieve-type dehydrating agent has the advantages ofa high dehydrating speed, low cost and small pollution to the environment.

Owner:MAANSHAN TUORUI METAL SURFACE TECH

Glazed tile surface treatment method and application

The invention relates to the technical field of ceramic processes, and particularly discloses a glazed tile surface treatment method and application. The glazed tile surface treatment method comprises the following steps of mixing potassium salt, an adsorbent and an activating agent, and heating to a molten state to obtain a molten salt mixture, immersing the glazed tile in the molten salt mixed solution for surface treatment and then taking out, and acquiring the glazed tile with the surface treated. The glazed tile is immersed in the low-temperature molten salt mixture, alkali metal ions in the glaze layer and alkali metal ions in the molten salt mixture are subjected to ion exchange due to mutual diffusion, and pressure stress is generated on the surface of the glaze layer, so that the wear resistance of the glaze surface is enhanced. The adsorbent can adsorb impurity ions in the glaze layer, the activator is used for eliminating passivation of the potassium salt in the ion exchange process, so that the ion exchange rate is further improved, the wear resistance of the glazed tile is jointly enhanced through the synergistic interaction of the potassium salt, the adsorbent and the activator, and the glazed tile is suitable for surface treatment of glazed ceramic.

Owner:FOSHAN OCEANO CERAMICS

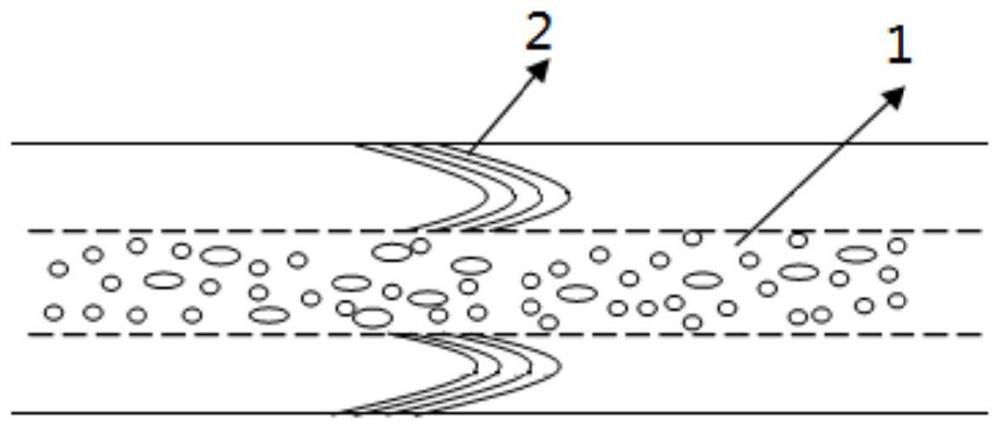

Preparation method of bipolar membrane

InactiveCN112295413AHigh ion exchange capacityImprove impregnation rateMembranesSemi-permeable membranesPtru catalystChloromethyl Ether

The invention belongs to the technical field of bipolar membranes, and discloses a preparation method of a bipolar membrane. The method comprises the following steps: blending at least one of an ethylene-propylene copolymer, an ethylene-butylene copolymer and an ethylene-octene copolymer with polypropylene, heating, mixing, granulating, drying, and casting to obtain a raw material membrane; immersing the raw material membrane into an irradiation solution formed by mixing absolute ethyl alcohol, a styrene monomer and a divinylbenzene monomer, and carrying out constant-temperature irradiation grafting by using 60Co gamma rays at -5-15 DEG C to obtain a base membrane; introducing anion / cation exchange groups into two sides of the base membrane respectively, soaking the base membrane into sulfuric acid for heating sulfonation at 75 DEG C by taking silver sulfate as a catalyst on one side through a covering protection method, and hydrolyzing to form a cation membrane layer after reaction ina reaction kettle; and adding chloromethyl ether into the other side of the bipolar membrane at 45 DEG C by taking stannic chloride as a catalyst, carrying out chloromethylation, and then immersing the bipolar membrane into a mixed aqueous solution of trimethylamine and polyethylene glycol at 40 DEG C to carry out quaternization reaction to form a negative membrane layer so as to obtain the bipolar membrane.

Owner:ZHEJIANG BLUE POLAR MEMBRANE TECH

Lithium-aluminosilicate glass, lithium-aluminosilicate chemically strengthened glass and preparation method and application thereof

The invention discloses a lithium aluminum silicon glass, a lithium aluminum silicon chemically strengthened glass, a preparation method and an application thereof. The molar content of the oxide component contained in the lithium aluminum silicate glass satisfies the following relationship: the SiO 2 The content is at least 66.5mol%, and the total amount of alkali metal oxides that can be used for ion exchange is not more than 14mol%; (Na 2 O+Li 2 O) / (SiO 2 +Al 2 o 3 ) is 0.09‑0.22; Na 2 O / Li 2 O is 0.4‑1.2; MgO / SiO 2 6%‑18%; (Na 2 O+Li 2 O+0.3×MgO) / Al 2 o 3 0.7‑1.4; 0.5%<P 2 o 5 +ZnO+SnO 2 +K 2 O+ZrO 2 +TiO 2 <7%. The lithium aluminum silicon chemically strengthened glass is formed by chemically strengthening the lithium aluminum silicon glass as plain glass.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

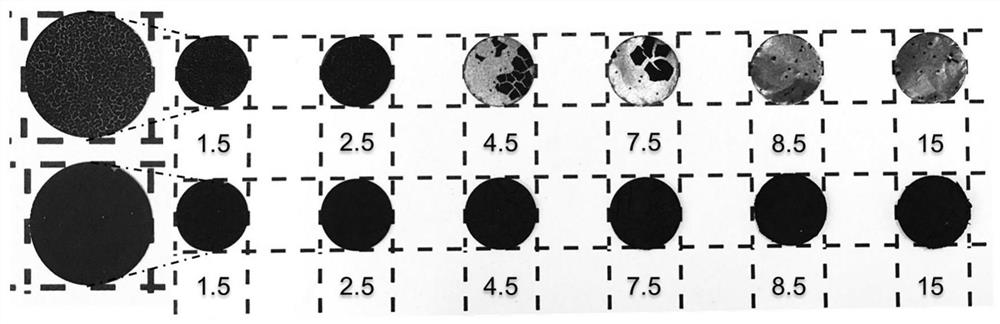

A kind of drying method for preparing electrode based on blade coating method and its electrode and application

ActiveCN109873119BGuaranteed bonding performanceTight bondDrying solid materials without heatNon-aqueous electrolyte accumulator electrodesFreeze-dryingElectrical battery

The invention relates to a drying method for preparing an electrode based on a scraping coating method, the electrode and its application. In the process of preparing an electrode by the scraping coating method, the electrode slurry scraped on the substrate is pretreated by a freeze-drying method, and then dried get electrodes. The freeze-drying method is simple, the process is environmentally friendly, the prepared electrode has a stable structure and high cohesiveness, and can effectively improve the cracking of the oven-dried electrode, the falling off of active materials and the like. The prepared electrode is usually a porous electrode, and this porous electrode structure effectively improves the specific surface area of the electrode reaction. This electrode drying method can be applied in the field of lithium-sulfur battery, lithium-ion battery, sodium-ion battery or carbon dioxide reduction.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A method and system for recovering insoluble alkali metal catalyst in catalytic gasification ash

ActiveCN106238069BImprove recycling efficiencyWell formedCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsSolubilityRecovery method

Owner:ENN SCI & TECH DEV

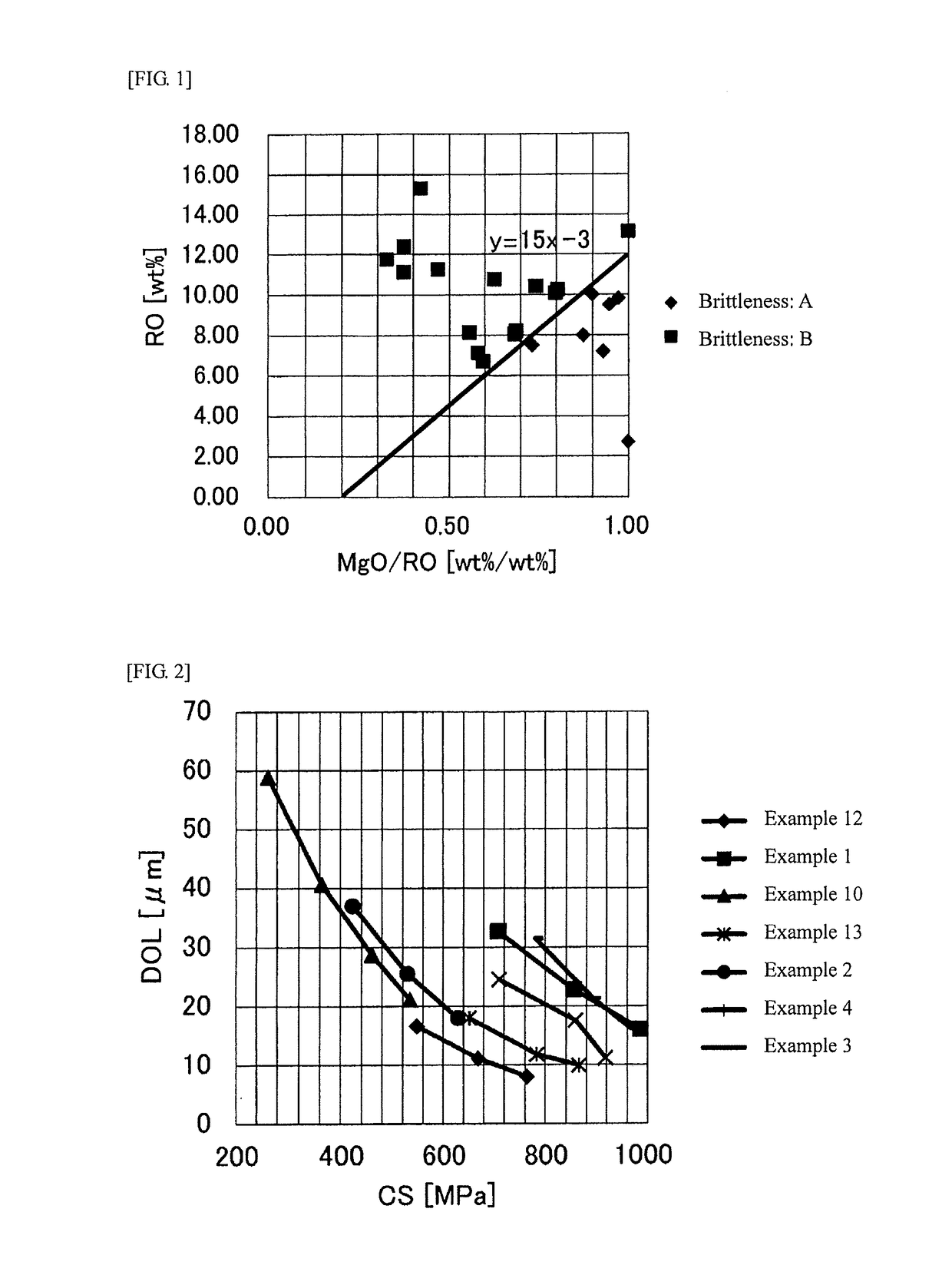

Glass and chemically toughened glass using same

An object is to provide a glass for chemical toughening treatment satisfying low brittleness, low melt viscosity and high chemical toughening characteristics, and a chemically toughened glass using the same. Provided is a glass for chemical toughening treatment containing, in mass % in terms of oxides, SiO2 63 to 76, B2O3 0 to 2, Al2O3 2 to 10, MgO 2 to 12, CaO 0.1 to 8, Na2O 14.5 to 19, K2O 0 to 3, and Fe2O3 0 to 0.5, satisfying a total content of alkali earth metal oxides (RO) being from 5 to 15, satisfying 15×MgO / RO−RO≥3, and having a temperature T2 at which a glass viscosity reaches 102 dPa·s being 1,600° C. or lower.

Owner:ASAHI GLASS CO LTD

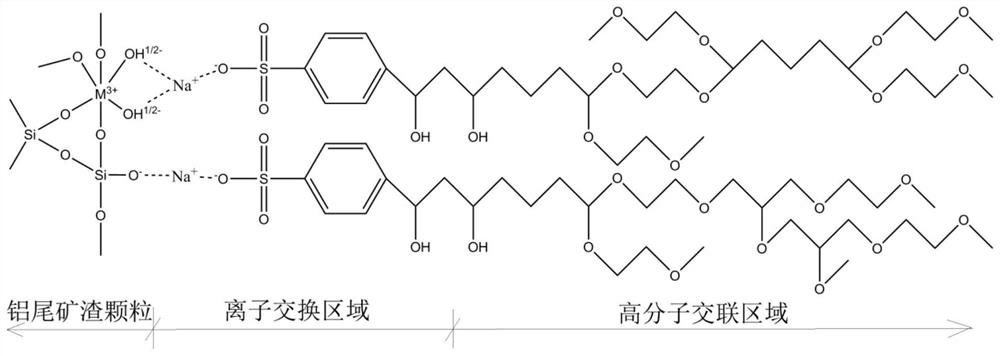

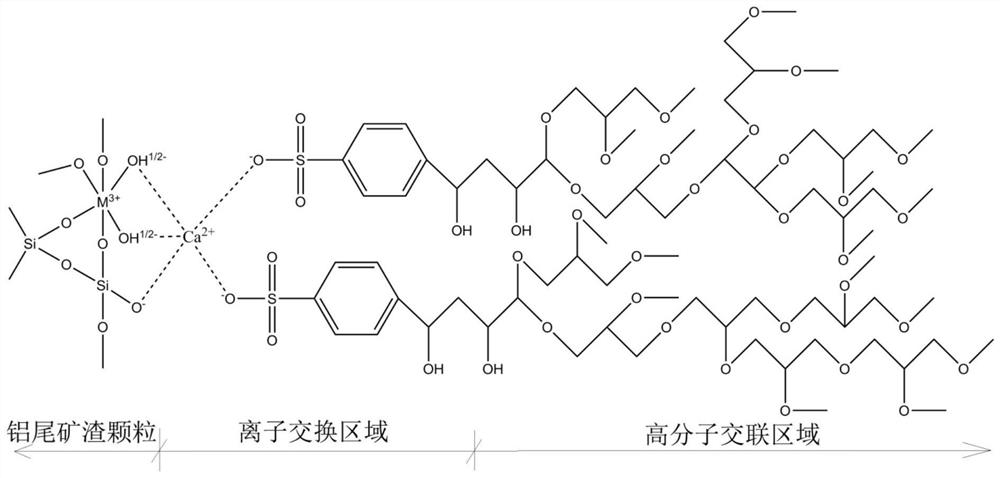

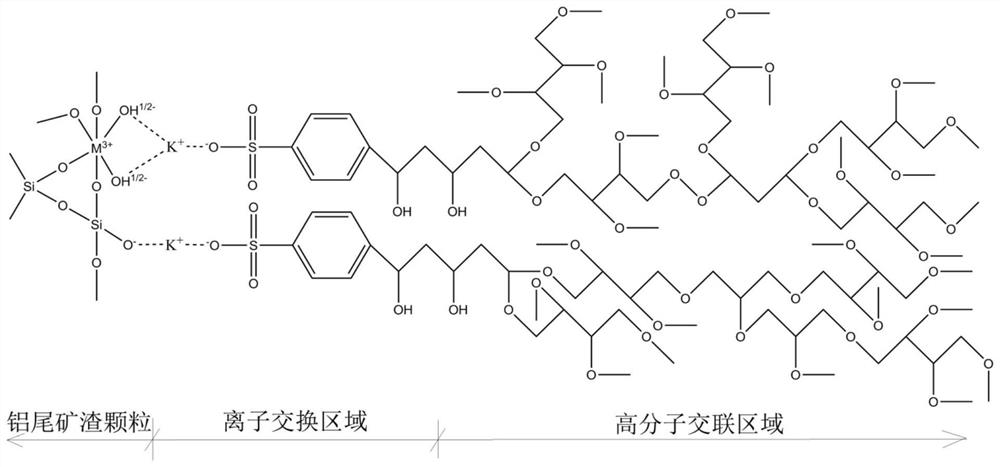

Aluminum tailing slag improvement method based on ion exchange and cross-linking reaction

The invention discloses an aluminum tailing slag improvement method based on ion exchange and cross-linking reaction, and belongs to the field of soil regulating materials or soil stabilizing materials. Aiming at the technical problems of insufficient strength and serious alkali pollution of the aluminum tailing slag, the invention provides a aluminum tailing slag modifier and aluminum tailing slag modifying steps. The aluminum tailing slag modifier comprises an alkali reduction curing agent, an ion exchange stabilizer and a particle linkage curing agent. The aluminum tailing slag modifying steps are the steps of of how to quantitatively use the aluminum tailing slag modifier. According to the aluminum tailing slag improvement method based on ion exchange and cross-linking reaction, the solidification of the aluminum tailing slag is promoted, the compactness of the aluminum tailing slag is improved, the aluminum tailing slag becomes a stable and continuous solid, and the strength of the aluminum tailing slag is obviously improved. And moreover, the alkalinity of the aluminum tailing slag is reduced, and the pollution to the environment is reduced.

Owner:南宁市建筑规划设计集团有限公司 +1

Mosaic-type nano film

InactiveCN103015036BPrevent overloadSimple production processFilament/thread formingConjugated synthetic polymer artificial filamentsFiberPorosity

The invention discloses a mosaic-type nano film which consists of nano film layers, wherein each nano film layer consists of mutually parallel nano film units; a gap exits between the adjacent nano film units; each nano film unit is formed by alternately arranging at least three first nano fibers and at least three second nano fibers; each first nano fiber is formed by mixing a styrene-series cation exchange resin, an adhesive and a cross-linking agent at a mass ratio of 1:(4-9):(1-10); each second nano fiber is formed by mixing a vinylpyridine-series anion exchange resin, the adhesive and the cross-linking agent at a mass ratio of 1:(4-9):(1-10). The nano film has the favorable performances of high porosity, low bore diameter, favorable wettability, strong ionic conductivity and high mechanical strength.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com