Patents

Literature

35results about How to "Improve impregnation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

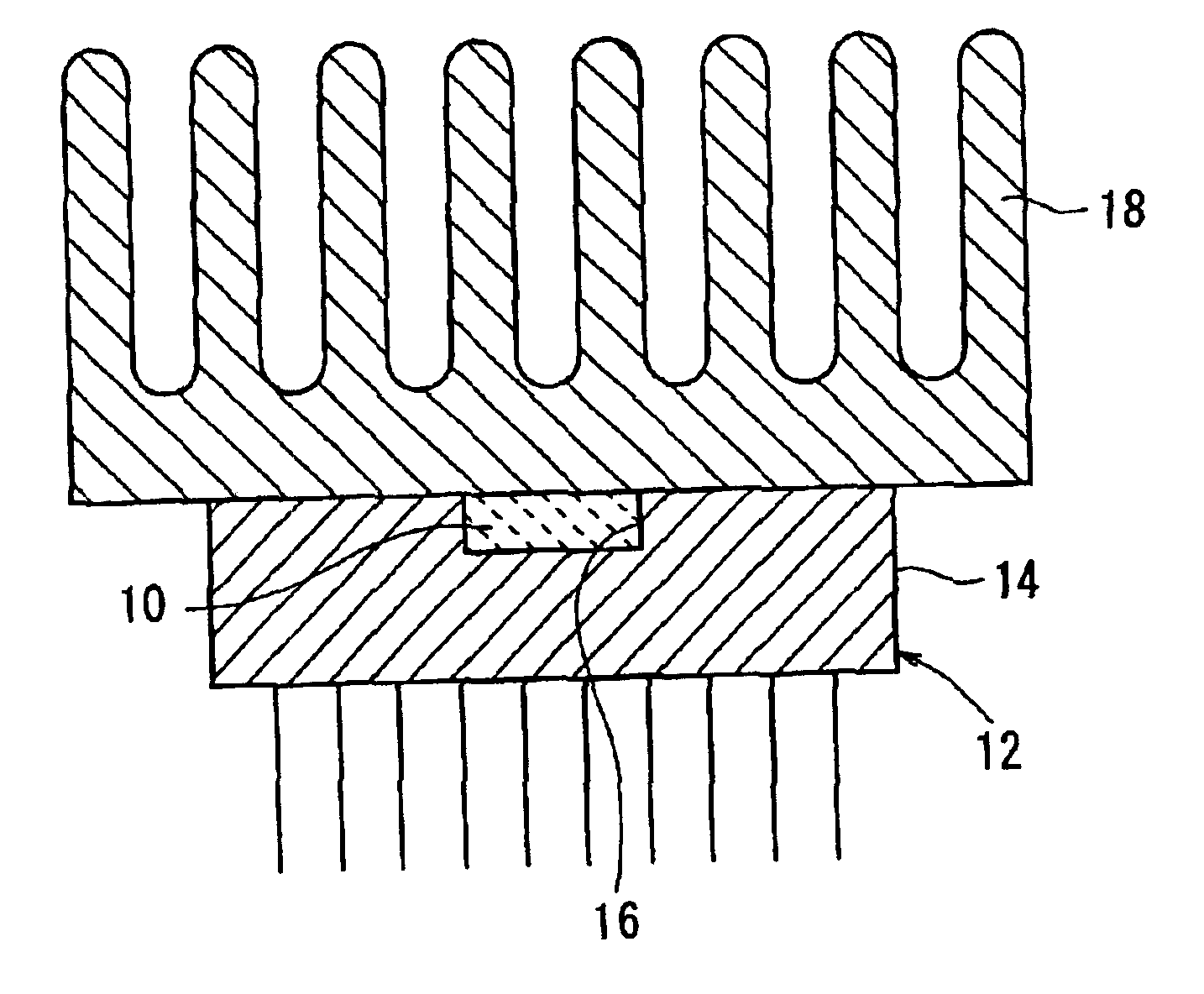

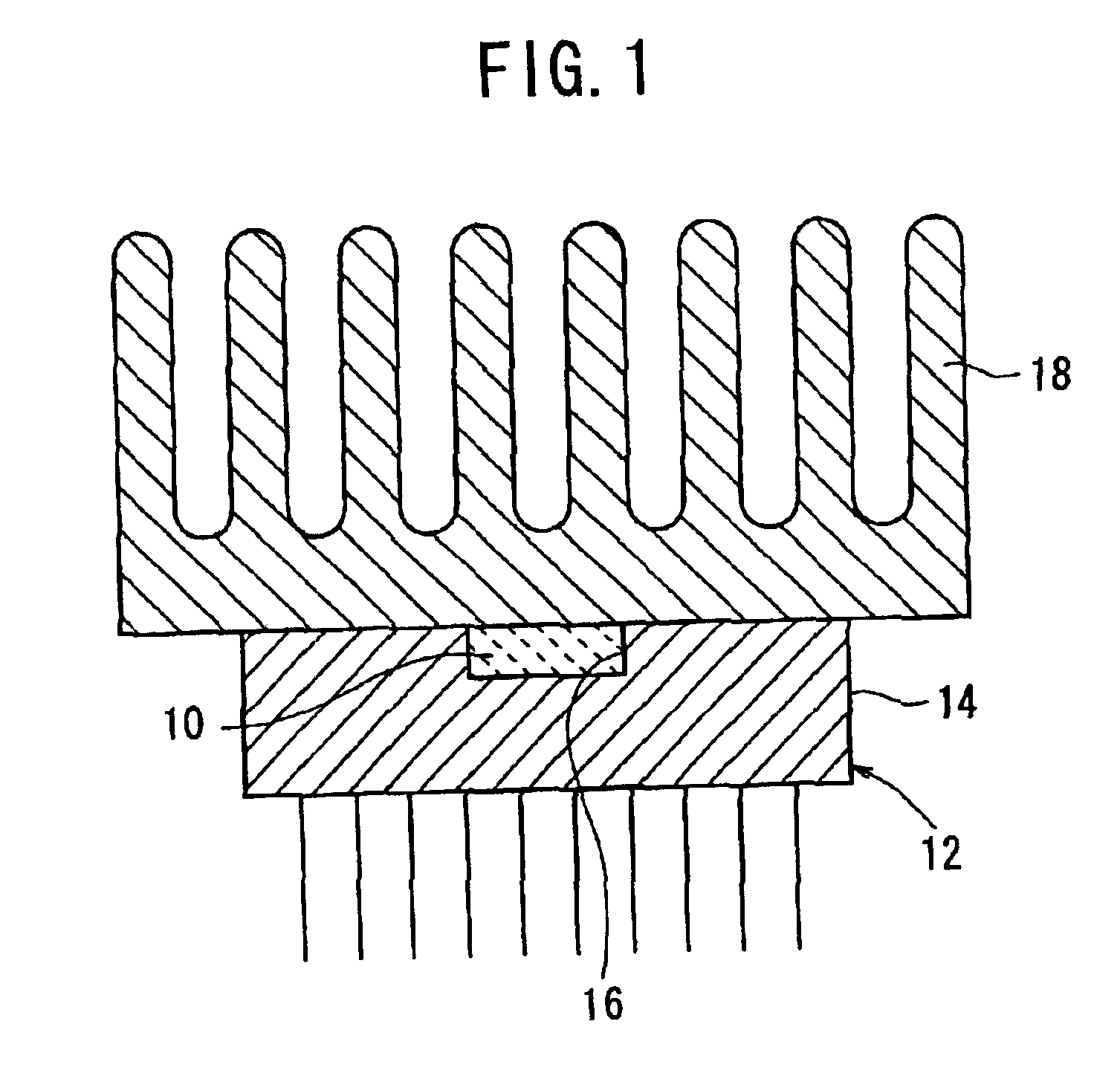

High density electrode and battery using the electrode

InactiveUS20060188784A1Impairment of electrolytic solution permeability can be preventedHigh theoretical capacityActive material electrodesLi-accumulatorsElectrolytic agentFiber

The invention relates to a high-density electrode, comprising an electrode active substance and carbon fiber having a filament diameter of 1 to 1,000 nm, wherein the porosity of the electrode is 25% or less. According to the invention, electrolytic solution permeability and electrolytic solution retainability, which are matters of importance in realizing a high-density electrode for achieving a battery having a high energy density, can be improved.

Owner:SHOWA DENKO KK

High density electrode and battery using the electrode

ActiveUS20070111101A1Permeability impairmentHigh theoretical capacityNon-metal conductorsSolid electrolytesHigh energyElectrolyte

The invention relates to a high-density electrode, obtained by impregnating a high-density electrode which comprises an electrode active substance and carbon fiber having a fiber filament diameter of 1 to 1,000 nm and has a porosity of 25% or less, with a solid polymer electrolyte; and to a battery including the resultant (high-density) electrode. According to the invention, electrolytic solution permeability and electrolytic solution retainability, which are matters of importance in realizing a high-density electrode for achieving a battery having a high energy density, can be improved.

Owner:SHOWA DENKO KK

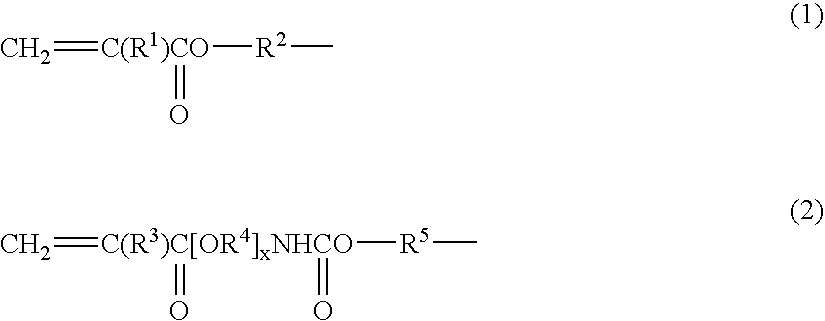

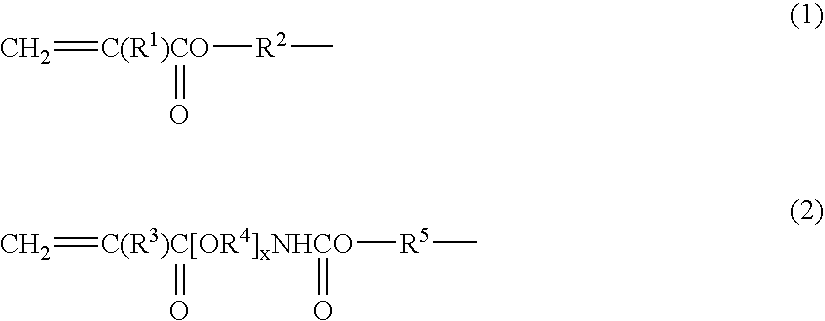

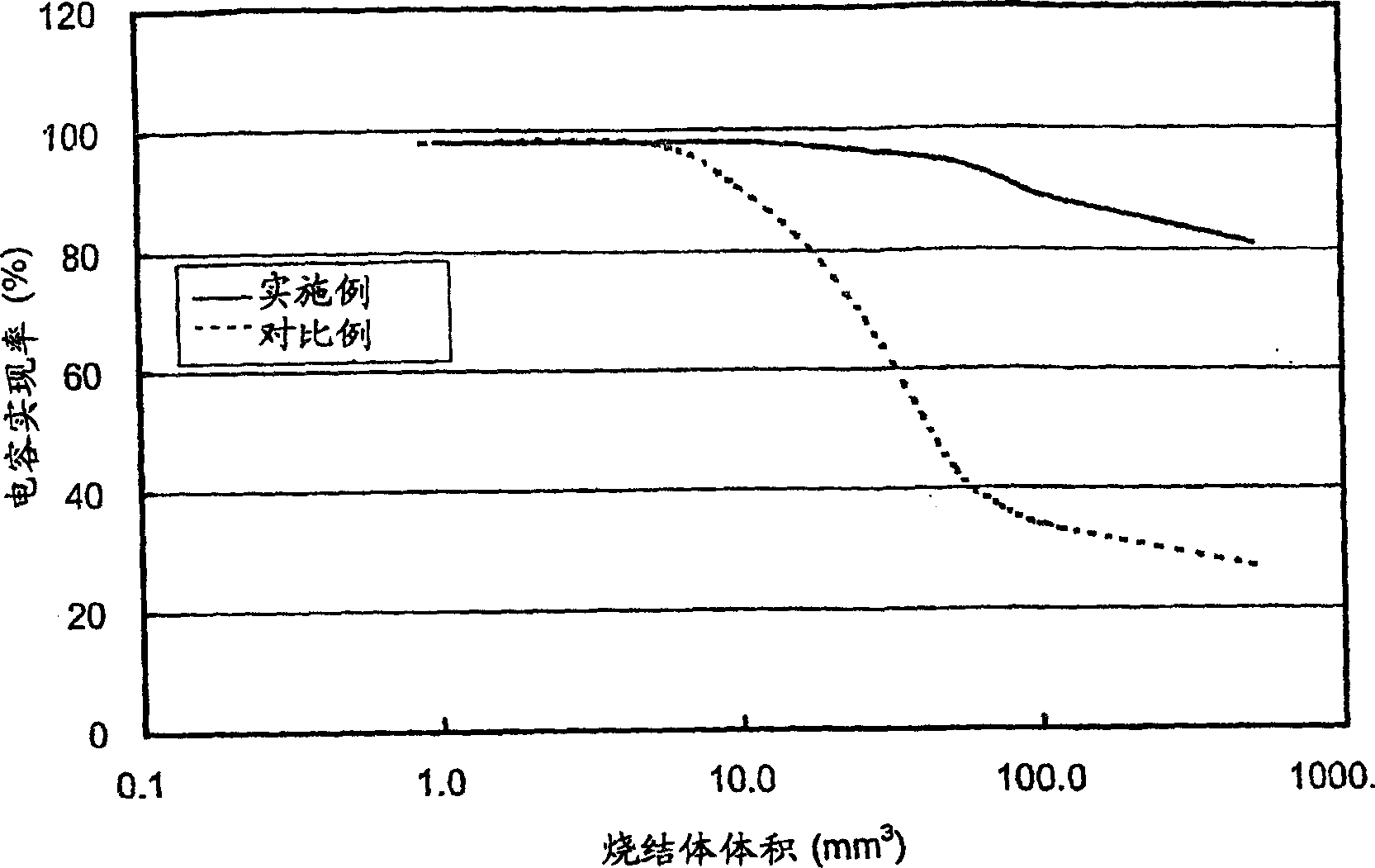

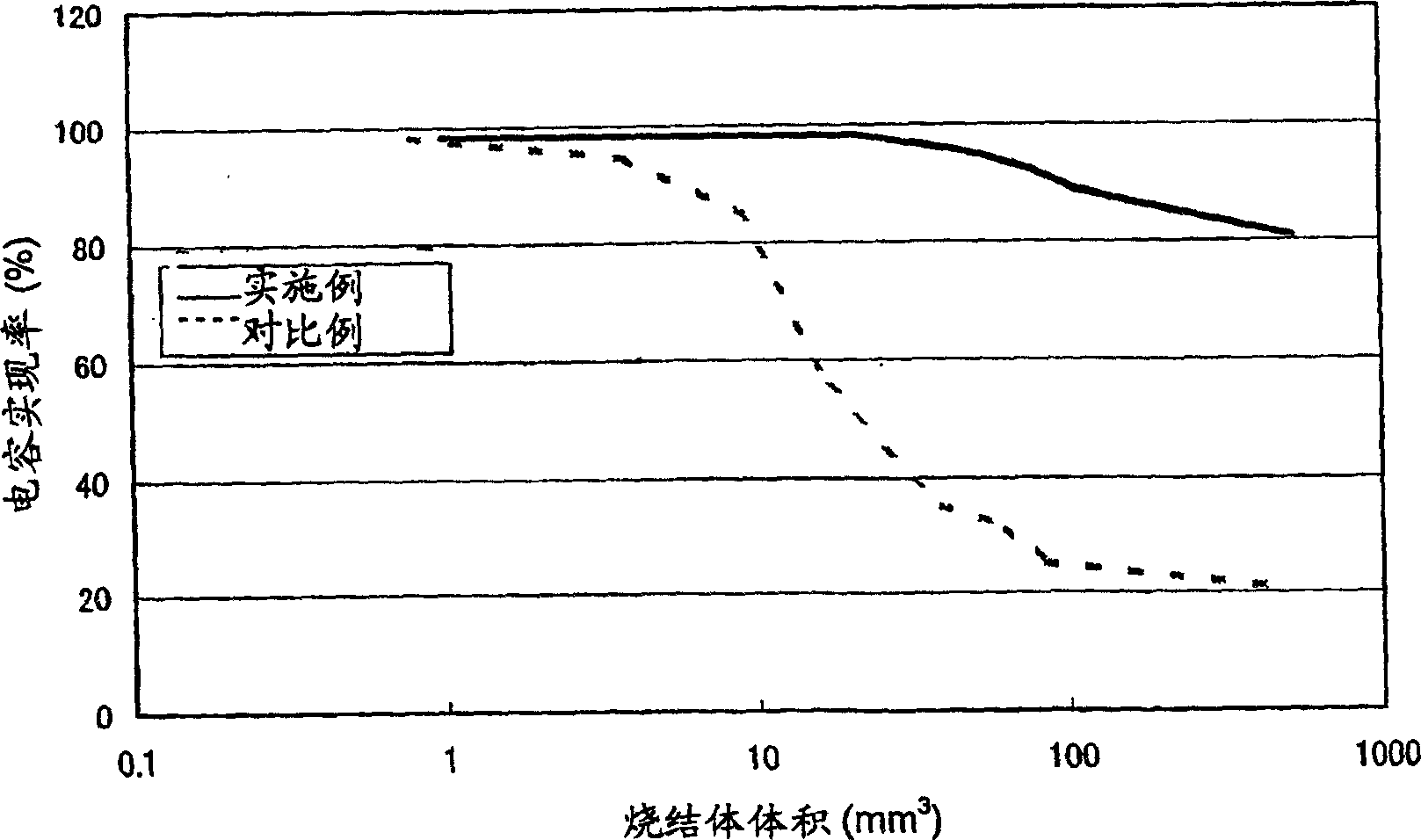

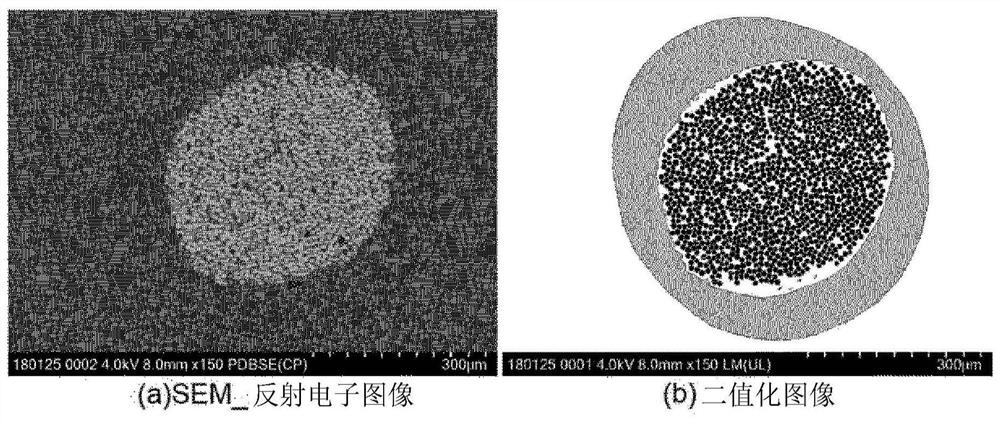

Valve acting metal sintered body, production method therefor and solid electrolytic capacitor

InactiveCN1813323AIncrease capacitanceImprove impregnation rateSolid electrolytic capacitorsCapacitor electrolytes/absorbentsCapacitanceElectrolysis

The invention provides a valve-acting metal sintered body for anode of a solid electrolytic capacitor, having a high capacitance, well impregnated with cathode material, and exhibiting excellent properties particularly when having a large volume, a capacitor having a low ESR, an excellent tan delta value and good long-term reliability such as moisture resistance and heat resistance by using the sintered body, and a production method therefor comprising the following steps: coating / printing / shaping a granulated product of a mixed dispersion containing a pore-forming agent, an organic binder and a primary powder or secondary aggregated powder of at least one member selected from valve-acting metal, a valve-acting metal compound and a valve-acting metal alloy or a granulated powder thereof, and a solvent, or compressing and shaping the granulated product of a mixture obtained by removing the solvent from the dispersion; sintering the shaped article containing a pore-forming agent; and removing the pore-forming agent from the sintered body.

Owner:RESONAC HOLDINGS CORPORATION

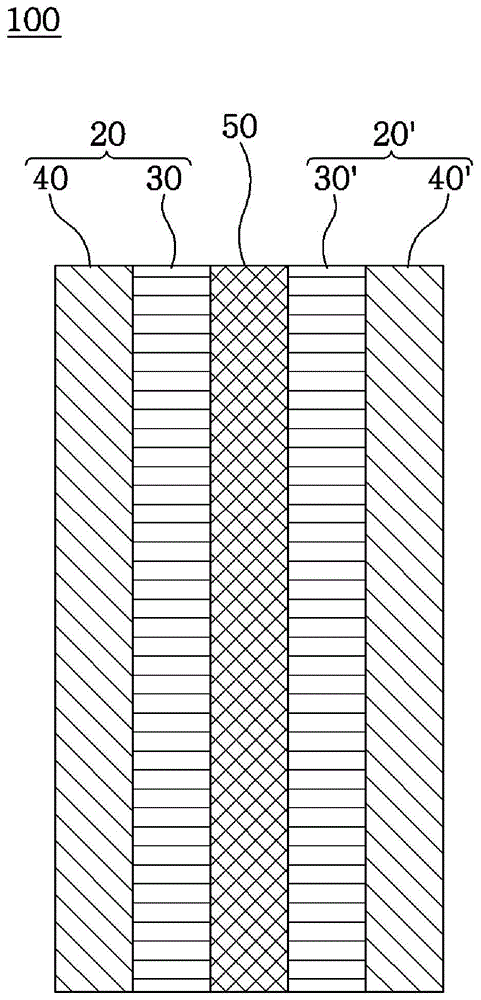

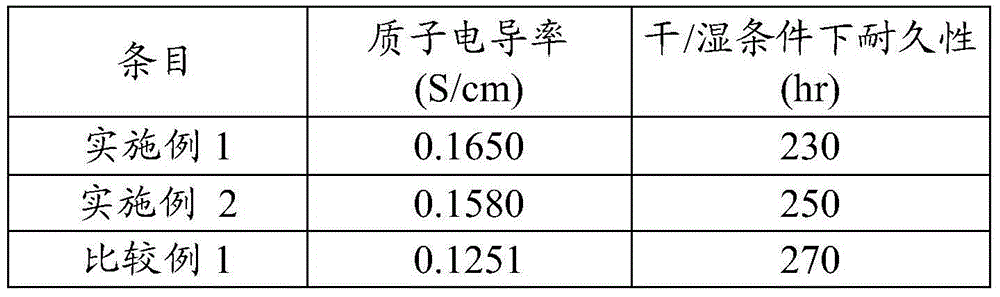

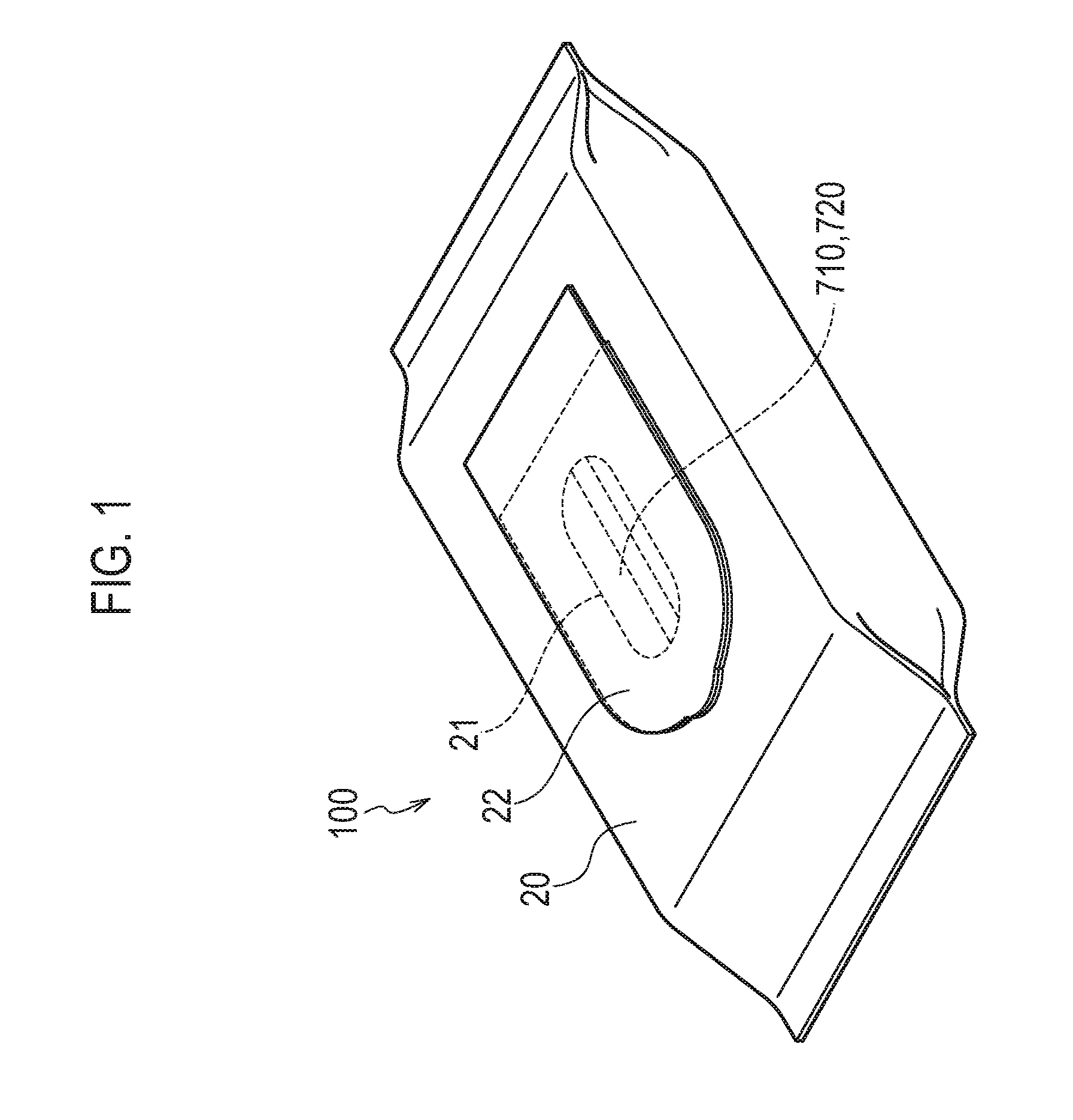

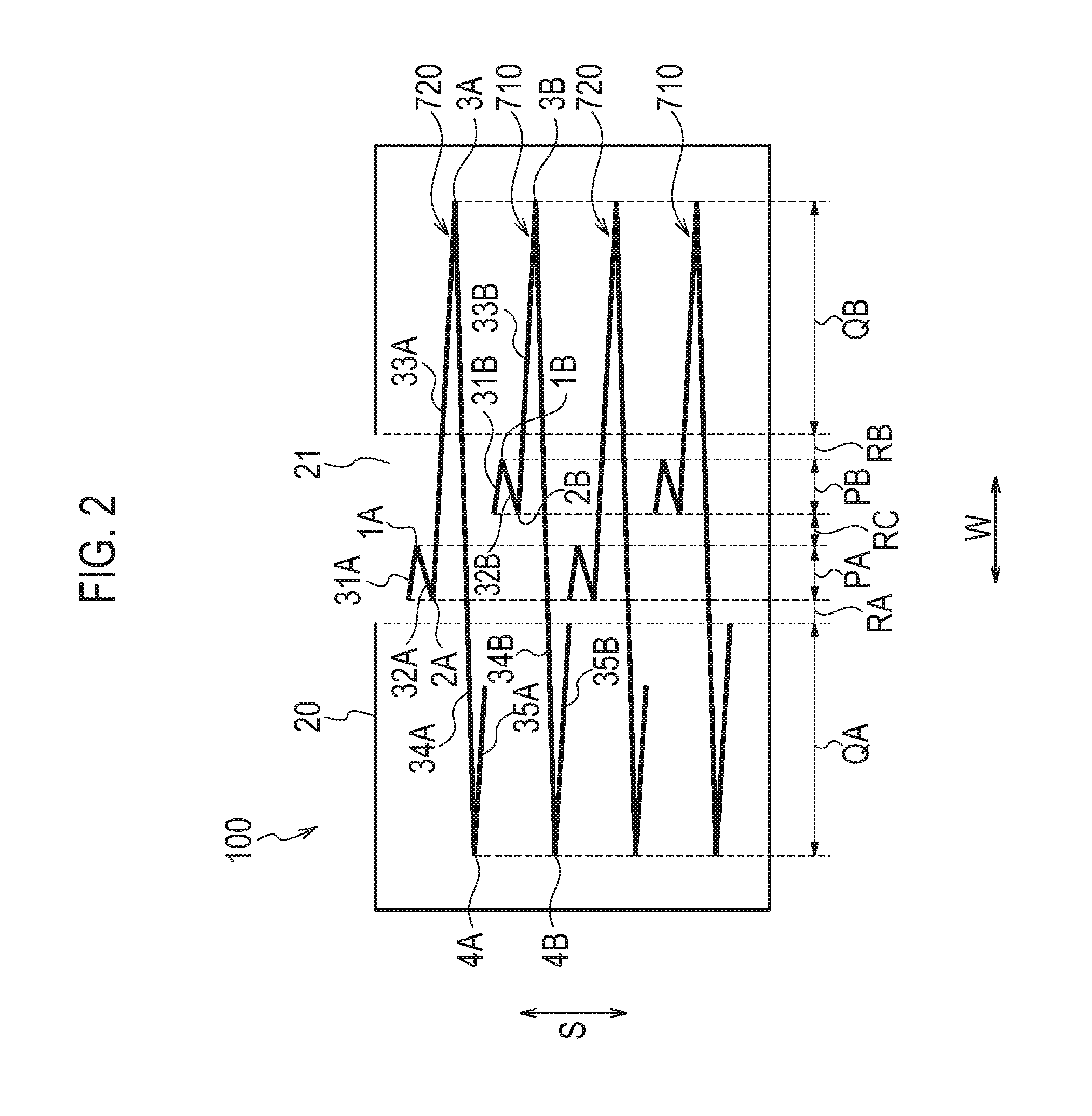

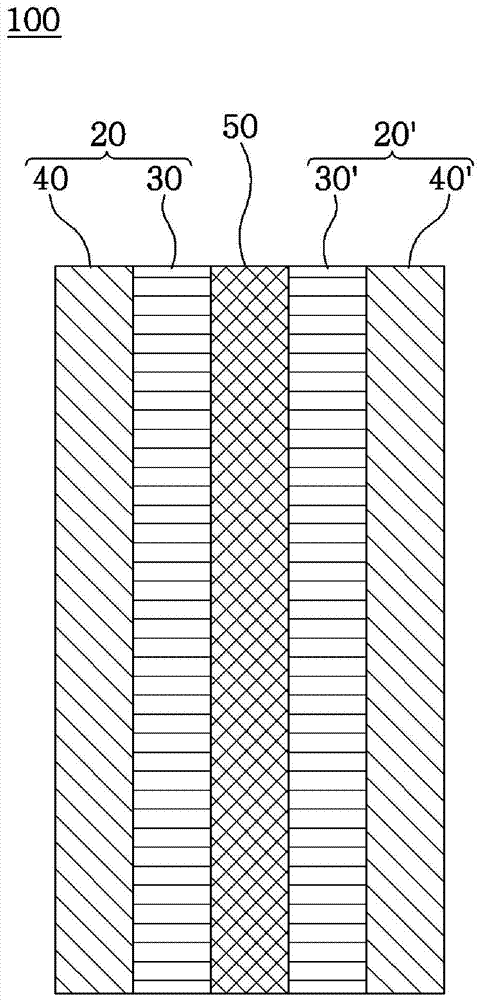

Reinforced composite membrane for fuel cell and membrane-electrode assembly for fuel cell comprising the same

ActiveCN104871354AImprove proton conductivityExcellent impregnationSolid electrolytesCell electrodesElectrical conductorFuel cells

Disclosed are a reinforced composite membrane for fuel cells including a porous support comprising three-dimensionally irregularly and discontinuously arranged nanofibers of a polymer and a first ionic conductor, and a second ionic conductor filling pores of the porous support, wherein the first ionic conductor is present as nanofibers in the porous support or is present in the nanofibers of the polymer to form the nanofibers together with the polymer, and a membrane-electrode assembly for fuel cells including the same. As a result, impregnation uniformity and impregnation rate of the ionic conductors are improved and proton (hydrogen ion) conductivity is thus enhanced.

Owner:KOLON IND INC

High density electrode and battery using the electrode

ActiveUS7572553B2Improve featuresIncrease energy densityNon-metal conductorsSolid electrolytesPorosityPolymer electrolytes

Owner:RESONAC CORPORATION

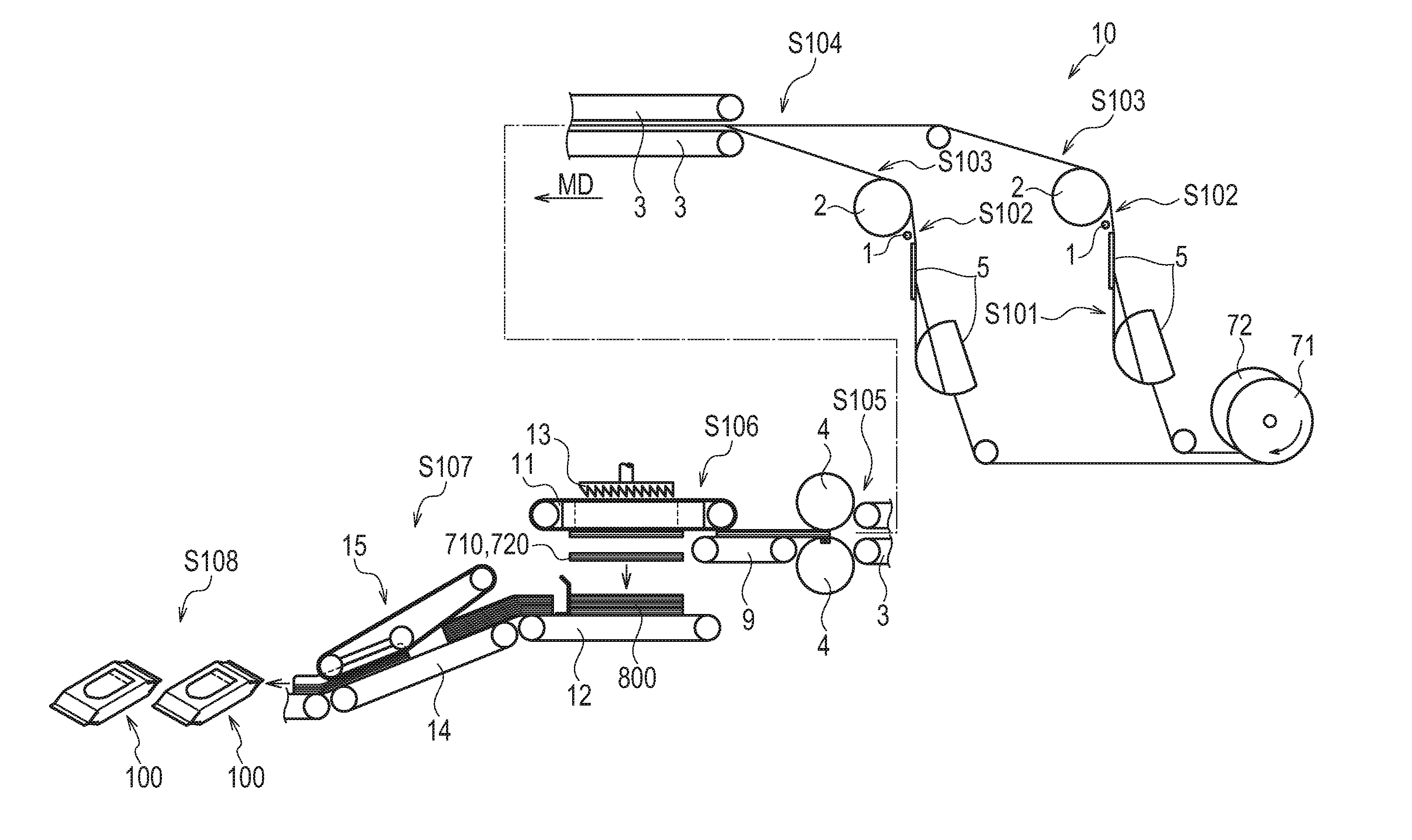

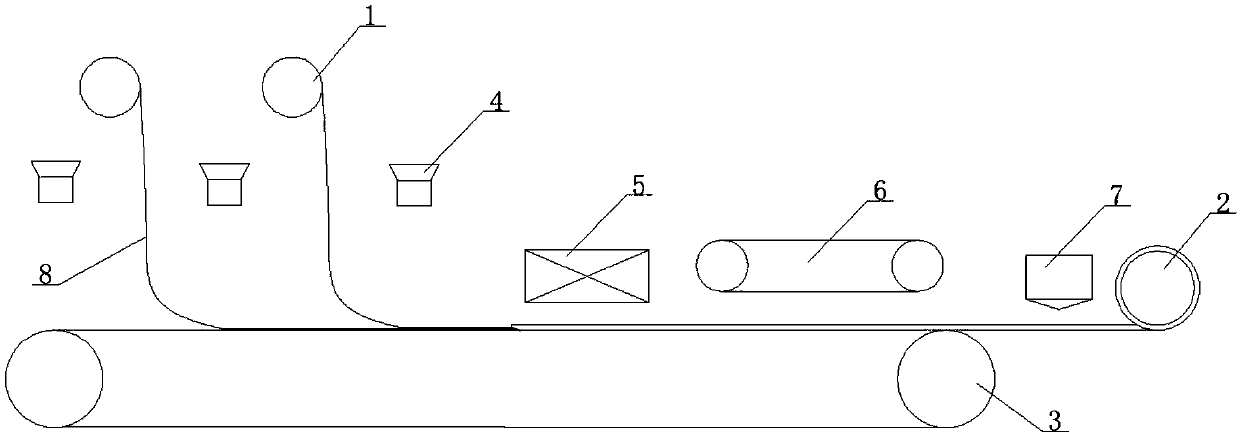

Alternating pressure melt impregnation device and melt impregnation method using the same

ActiveUS10744726B2Simple structureExcellent impregnationLiquid surface applicatorsCoatingsPolymer scienceFiber bundle

An alternating pressure melt impregnation device and a melt impregnation method, including having a resin melt squirted from each resin melt runner on an upper die and a lower die of a melt injection area, and thus the squirted resin melt is enable to be squirted directly on an upper surface and a lower surface of a continuous fiber bundle which is entering into an impregnation chamber. Impregnation and infiltration for both surfaces of the continuous fiber bundle are primarily completed by a squirted pressure. The resin melt inside the impregnation chamber flows to a decompression chambers at both sides of the impregnation chamber. When the resin melt flows to a throttle plate, a re-impregnation for the continuous fiber bundle is realized. Then the pressure is decreased and a section of the resin melt is enlarged and a radial flow is generated due to the Barus effect.

Owner:KINGFA SCI & TECH CO LTD

Method and apparatus for manufacturing wet wipes

InactiveUS20130298738A1Low variabilityEasy to carryDispensing apparatusDomestic applicationsWet wipeCompound (substance)

This method for producing wet wipes includes the following steps: a step for vertically folding non-woven cloth sheets; a step for impregnating the sheets with a chemical; a step for stacking the sheets; a step for cutting the sheets at predetermined lengths; a step for pulling the cut sheets away from a transporting conveyer provided with a suction mechanism by means of a pusher, and stacking the cut sheets; a step for pressing a bundle comprising the sheets; and a step for packaging the bundle. The pusher is disposed between the transporting conveyers. The blades of the pusher have a plurality of tooth sections. The pusher drops the sheets suctioned to the transporting conveyer downwards by means of moving vertically downwards.

Owner:UNI CHARM CORP

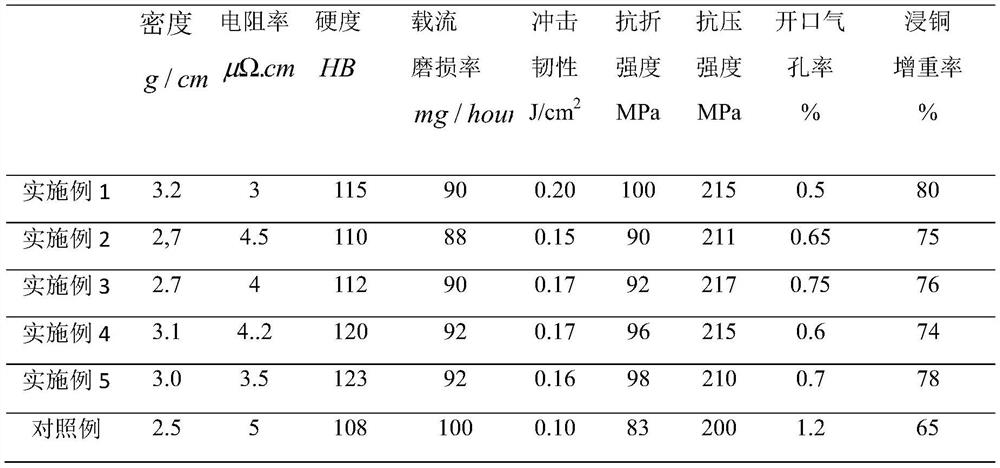

Method for preparing ramie-form SiC ceramic/Al-based composite material

InactiveCN102212763AImprove impregnation uniformityImprove impregnation rateThermal expansionWear resistance

The invention discloses a method for preparing a ramie-form SiC ceramic / Al-based composite material, comprising the following steps of: firstly, pre-treating ramie fibers; then performing vacuum and pressure impregnation of SiO2 sol on the pre-treated ramie fibers so as to obtain a ramie / SiO2 precursor; then performing anoxic and aerobic compound calcination on the ramie / SiO2 precursor so as to obtain ramie-form porous SiC ceramic precast body; and finally, performing vacuum and pressure impregnation on the ramie-form porous SiC ceramic precast body so as to obtain the ramie-form SiC ceramic / Al-based composite material. The ramie-form SiC ceramic / Al-based composite material prepared with the method in the invention has the advantages of light weight, shock absorbability, sound absorbability and good antifriction wear resistance and can be used for reducing thermal expansion coefficient and density, thereby having a wider application prospect.

Owner:XI'AN POLYTECHNIC UNIVERSITY

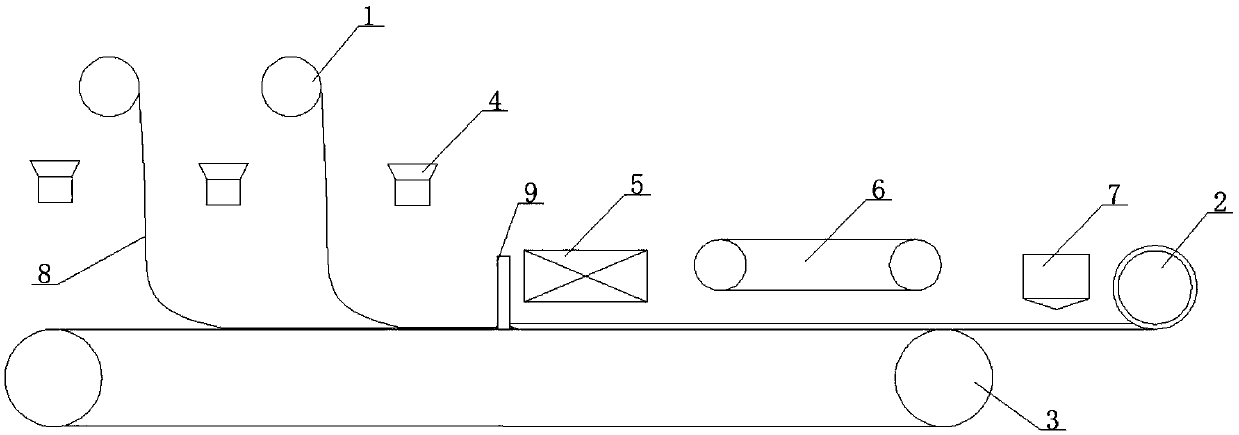

Equipment and method for producing fabric-enhanced composite board

PendingCN108673996AImprove impregnation rateHigh strengthLamination plant layoutLamination ancillary operationsFiberOperability

The invention discloses equipment and a method for producing a fabric-enhanced composite board. The equipment comprises a powder spraying device, a preheating device, a laminating device, a cutting device and a brake device, wherein the brake device comprises a plurality of uncoiling parts, a coiling part and a supporting roller; the supporting roller is arranged between the uncoiling parts and the coiling part; the powder spraying device comprises a plurality of powder spraying heads, the powder spraying heads are arranged between the uncoiling parts and the supporting roller, the number of the powder spraying heads is greater than the number of the uncoiling parts, and the powder spraying heads are respectively arranged between the adjacent uncoiling parts and at both sides of each uncoiling part. The equipment has the advantages that by arranging the powder spraying device, both surfaces of each layer of continuous fiber fabric are sprayed with resin powder, so that the impregnatinguniformity and operability of both sides can be well controlled, and the warp is effectively improved.

Owner:宁波福瑞科新材料有限公司

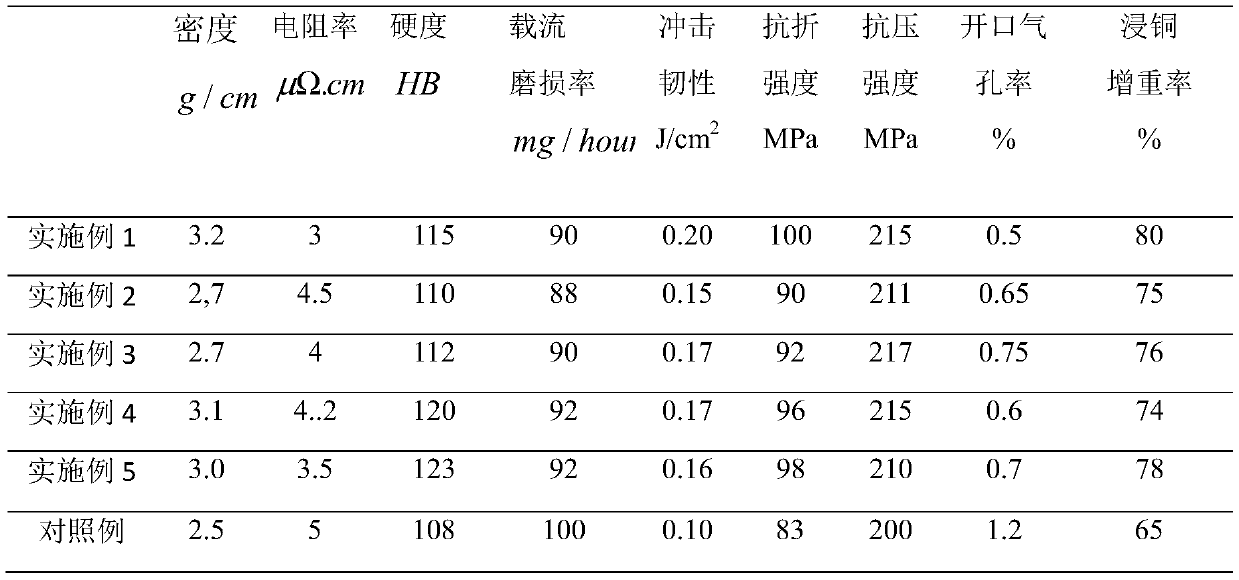

Copper-impregnated carbon contact strip material and preparation method of copper-impregnated contact strip

ActiveCN110156482AImprove liquidityImprove impregnation rateRailway vehiclesPower current collectorsHigh pressureCopper

The invention discloses a copper-impregnated carbon contact strip material and a preparation method of a copper-impregnated carbon contact strip, and belongs to the technical field of carbon contact strip preparation. The preparation method of the copper-impregnated carbon contact strip comprises the following steps: performing stirring on a carbon contact strip material, performing kneading, placing the kneaded material in a three-dimensional net structure pressing mold constructed by metal wires, performing pre-pressing treatment, performing solidification treatment and performing roasting treatment to obtain a carbon contact strip; and performing pickling treatment on the carbon contact strip, and performing immersion treatment in a copper solution to obtain the copper-impregnated carbon contact strip. The copper-impregnated carbon contact strip material comprises the following raw materials: 30-45 parts of petroleum coke powder, 26-32 parts of pitch coke powder, 5-10 parts of natural graphite powder and 6-9 parts of artificial graphite powder. The method for preparing the copper-impregnated carbon contact strip provided by the invention can easily realize impregnation in the copper solution without adding high temperature and high pressure, the impregnation rate of the copper solution is high, and the copper-impregnated carbon contact strip prepared by the method has high electrical conductivity, mechanical properties and wear resistance.

Owner:SOUTHWEST JIAOTONG UNIV

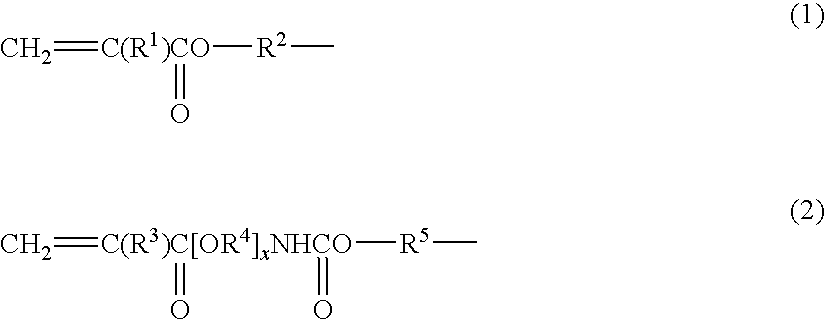

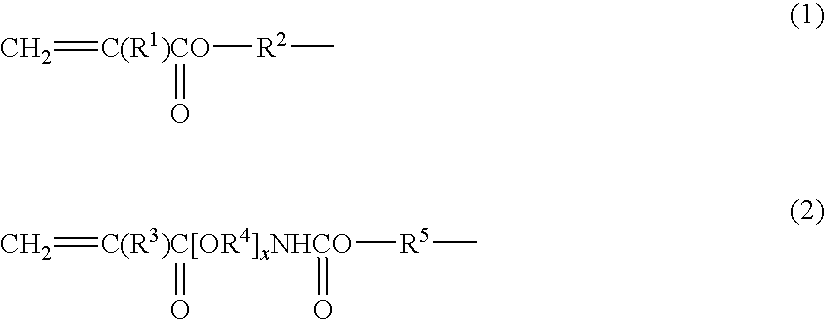

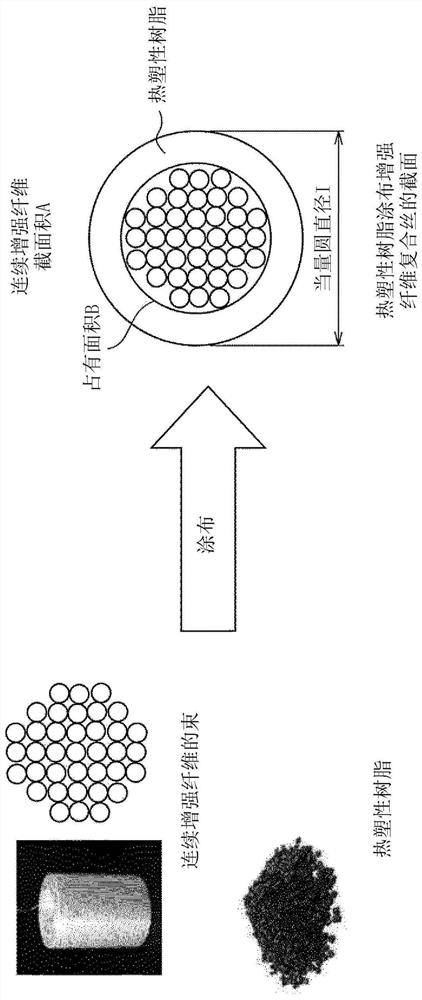

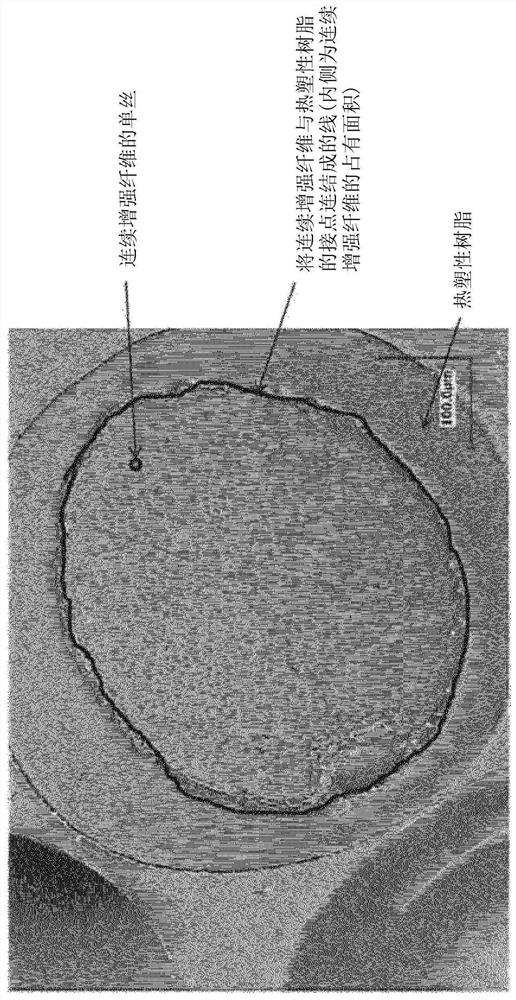

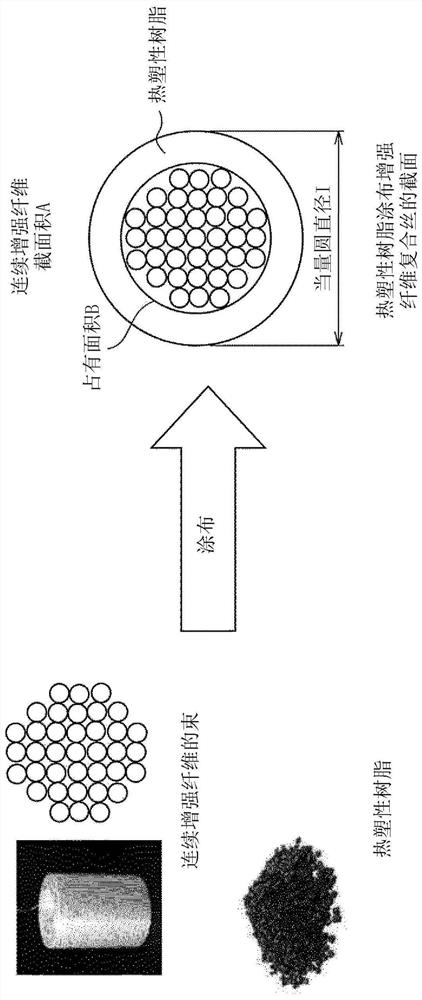

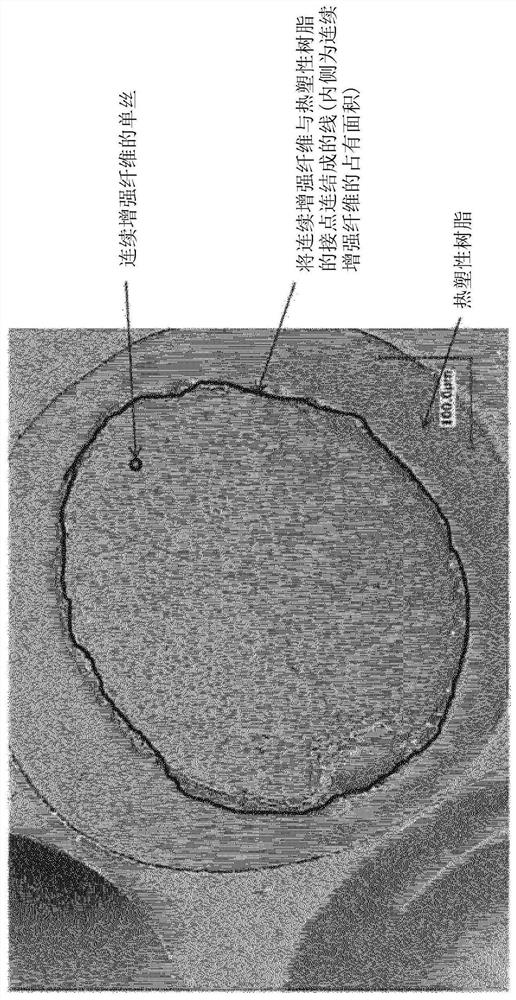

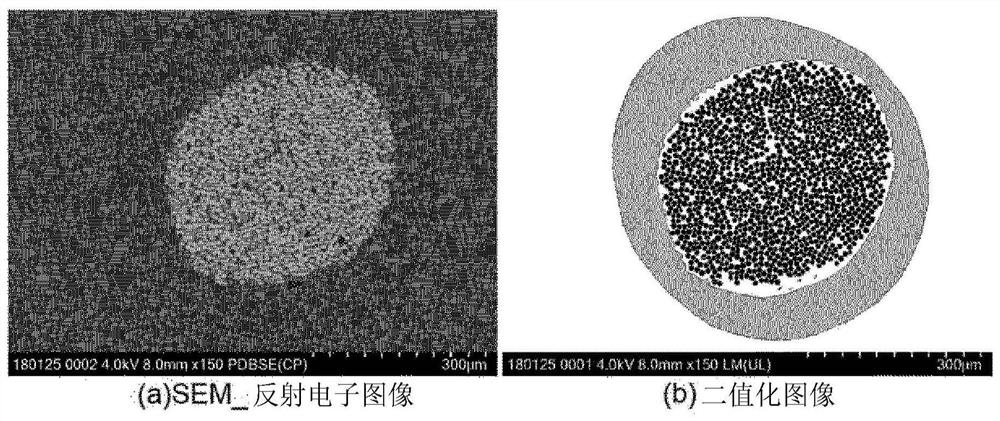

Thermoplastic resin-coated reinforcing fiber composite yarn, production method for said composite yarn, continuous fiber reinforced resin molding, and production method for composite material molding

Provided are: a thermoplastic resin-coated reinforcing fiber composite yarn, which has excellent resin-impregnation properties during molding, with which moldings of excellent properties can be produced even in short-time molding, and which, as a yarn, has excellent softness and excellent handling in weaving and knitting; a production method for said composite yarn; a continuous fiber-reinforced resin molding; and a production method for a composite material molding.

Owner:ASAHI KASEI KK

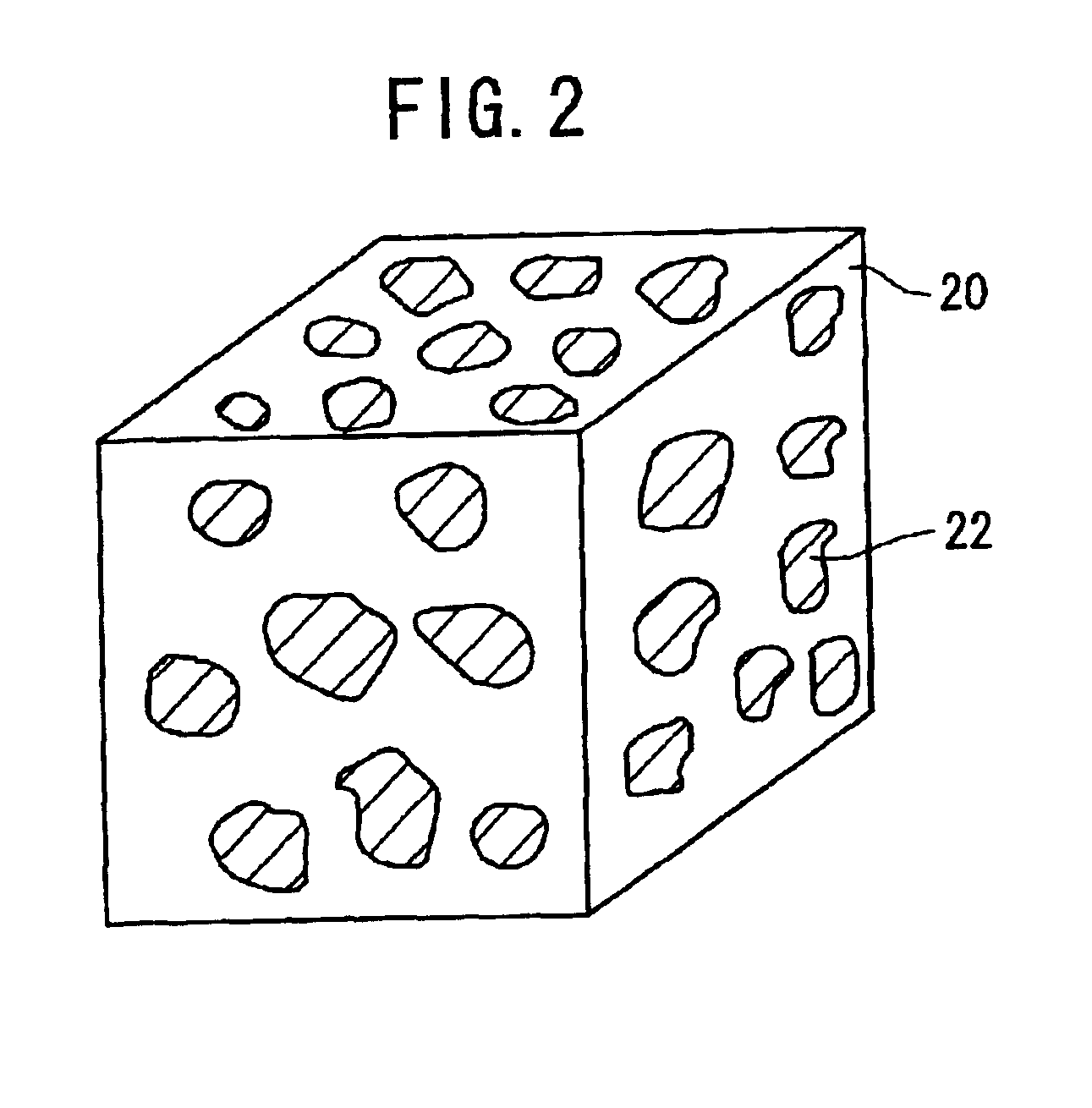

Composite material

InactiveUS6953539B2Inhibit interface reactionPromote generationNitrogen compoundsSemiconductor/solid-state device detailsCeramic sinteringThermal expansion

A composite material includes an SiC porous ceramic sintered body, which is formed by preliminarily sintering a porous body, having a coefficient of thermal expansion lower than the coefficient of thermal expansion of copper to construct a network therein. A copper alloy impregnating the porous ceramic sintered body includes copper and one or more additive elements which are prepared to impart a coefficient of thermal conductivity of 160 W / mK or higher to the composite material. The additive elements include up to 5% of at least one element selected from Be, Al, Si, Mg, Ti, Ni, Bi, Te, Zn, Pb, Sn, and mish metal, and also contain unavoidable impurities and gas components.

Owner:NGK INSULATORS LTD

Pure-plane solid wood floor and production process thereof

PendingCN111962806AEasy to cleanImprove hygienePretreatment apparatusPressure impregnationSolid woodAgricultural engineering

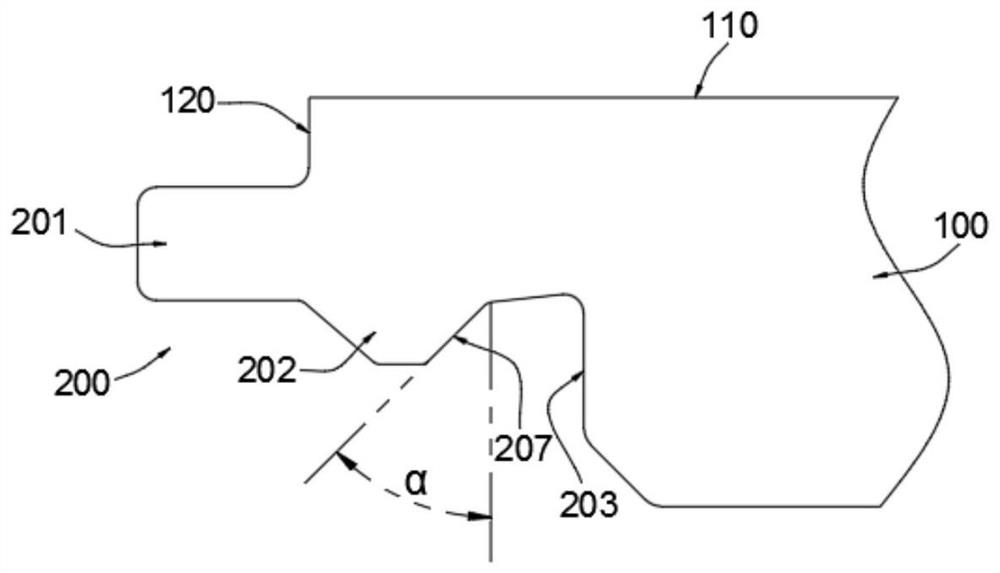

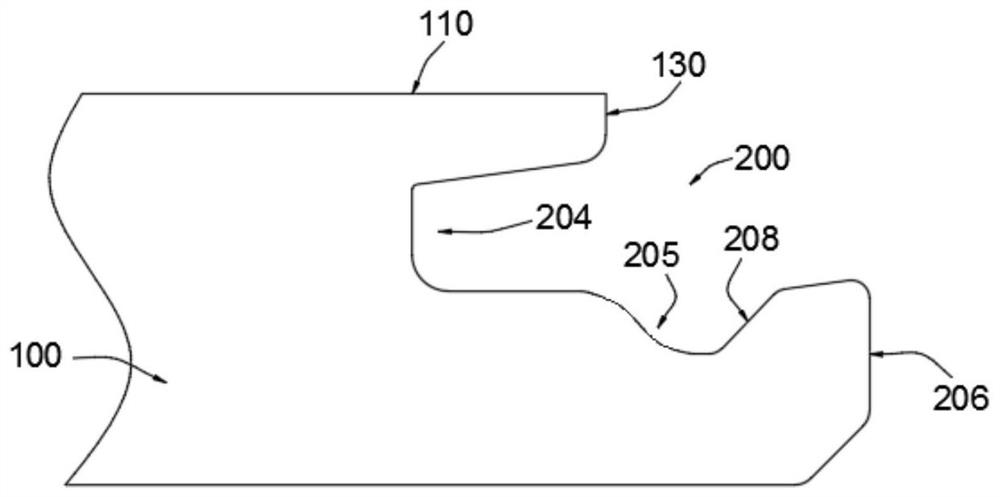

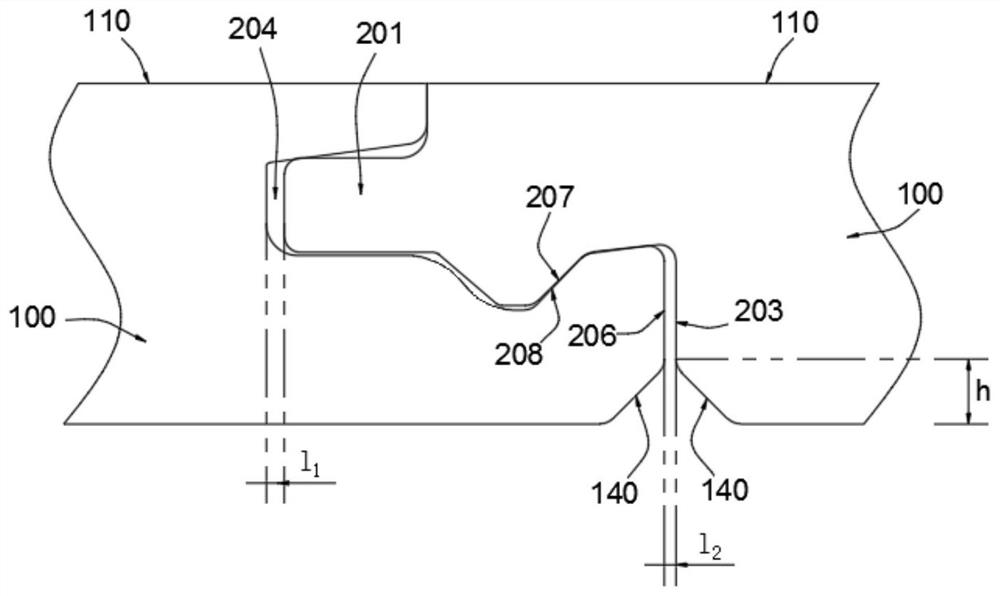

The embodiment of the invention discloses a pure-plane solid wood floor and a production process thereof. The pure-plane solid wood floor comprises a floor block body and lock catch structures arranged on the peripheral sides of the floor block body. The lock catch structure comprises a male tenon component and a female tenon component, the male tenon component is located on the side face of a male tenon, the female tenon component is located on the side face of a female tenon, the surface of the floor block body is directly connected with the side face of the male tenon and the side face of the female tenon, and after assembly, the upper edge of the side face of the male tenon abuts against the upper edge of the side face of the female tenon. The floor has the advantages that the floor isconvenient to clean and sanitary, and the integrity and attractiveness of a pavement surface are facilitated.

Owner:ZHEJIANG LINGGE WOOD

Method and apparatus for manufacturing wet wipes

InactiveUS20130267401A1Easy to cutImprove impregnation rateCarpet cleanersFloor cleanersCompound (substance)Wet wipe

Owner:UNI CHARM CORP

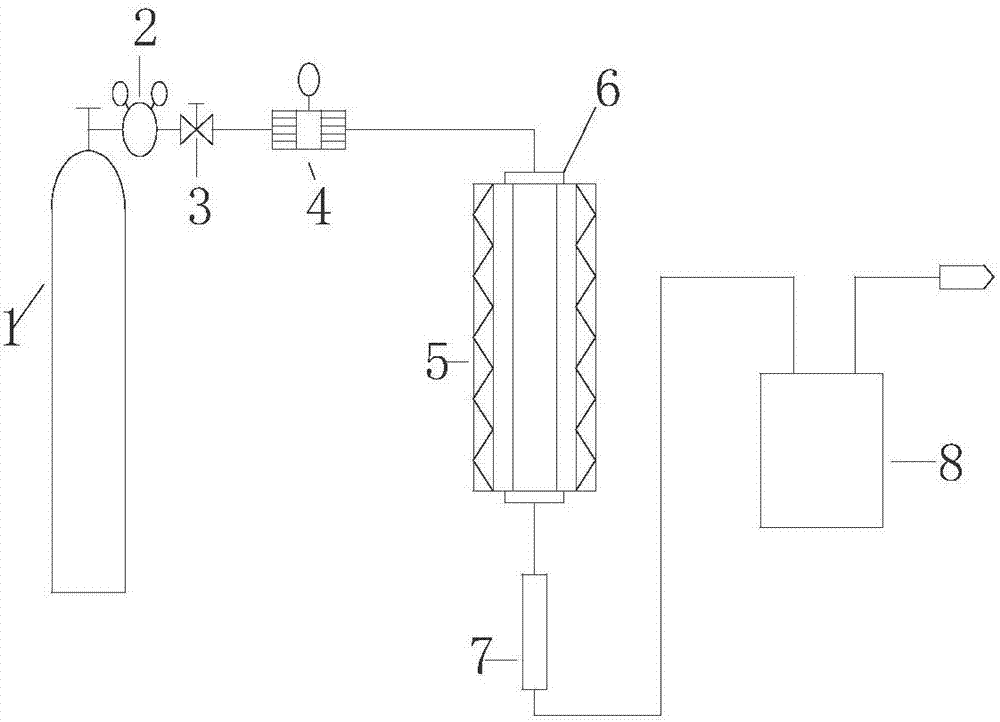

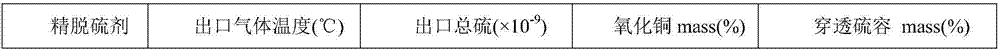

Low-temperature ultra-fine desulfurizing agent and preparation method thereof

InactiveCN107096359AReduce production processEasy to shapeGas treatmentGaseous fuelsCopper oxideUltra fine

The invention provides a low-temperature ultra-fine desulfurizing agent, and belongs to the technical field of desulfurizing agents. The desulfurizing agent comprises 50-90 parts by mass of a carrier, and 10-50 parts by mass of an active component, wherein the carrier is a porous composite comprising aluminum oxide and silicon oxide; the active component comprises one or a plurality of copper oxide, manganese oxide and zinc oxide. The desulfurizing agent is prepared by ultrasonically soaking the carrier in a saline solution of the active component after the carrier is treated by soaking and pickling through acid liquid and drying, and then drying and decomposing at high temperature. According to the low-temperature ultra-fine desulfurizing agent, the silicon-aluminum composite carrier is low in manufacturing cost, easy to form, high in stability, high in resistance to acid corrosion, developed in pore channel structure, and high in one-time soaking rate; the carrier is pickled, so that the specific surface area of the carrier can be further increased, and as a result, the dispersing performance of the active component on the carrier can be improved, the quantity of the active component loaded on the carrier is increased, and the desulfurizing effect of the desulfurizing agent is effectively improved.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Colorless phenolic impregnated resin, preparation method and application thereof

InactiveCN101659738AReduce free aldehyde contentSimple preparation processWood impregnation detailsAdhesivePhenol

The invention discloses a colorless phenolic impregnated resin, a preparation method and application thereof, which belong to the technical field of chemical adhesives. The colorless phenolic impregnated resin is prepared from phenol, water solution of sodium hydroxide, formaldehyde solution and water solution of strong reducing agent. The preparation method comprises the following steps: stirringthe formaldehyde solution; the phenol and the water solution of sodium hydroxide; heating the temperature of the mixture to be 85-90 DEG C; cooling the mixture; slowly dropping the water solution ofstrong reducing agent; and discharging. The preparation process is simple, easy to operate, increases the production efficiency and low raw material cost and obvious industrial economic benefit. The colorless phenolic impregnated resin is applied to impregnation of fast growing wood of artificial forest; on one hand, natural grains and color and luster of wood are preserved; and on the other hand,the physical and mechanical properties of densified wood by impregnation and hot press are obviously improved.

Owner:UNIV OF JINAN

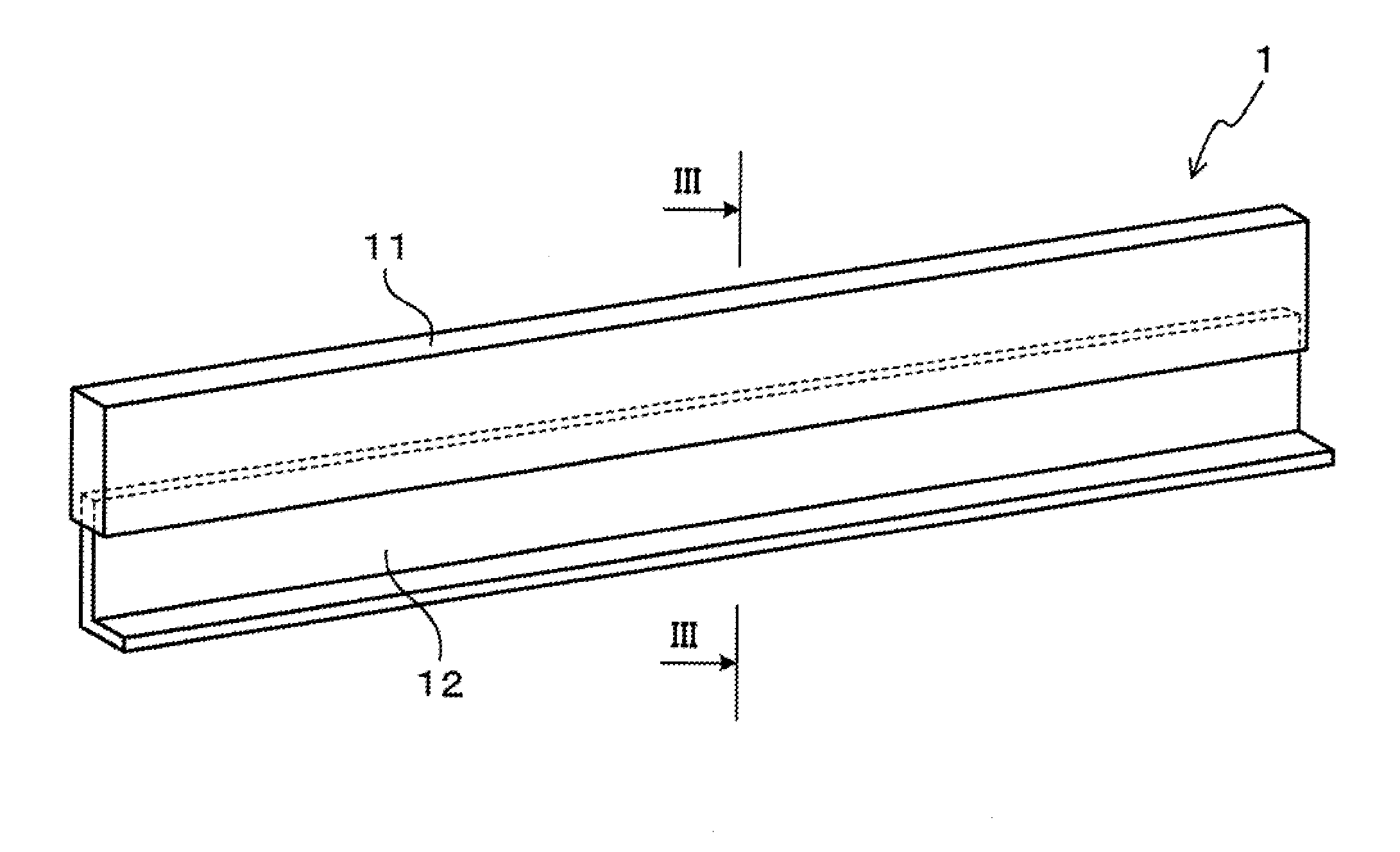

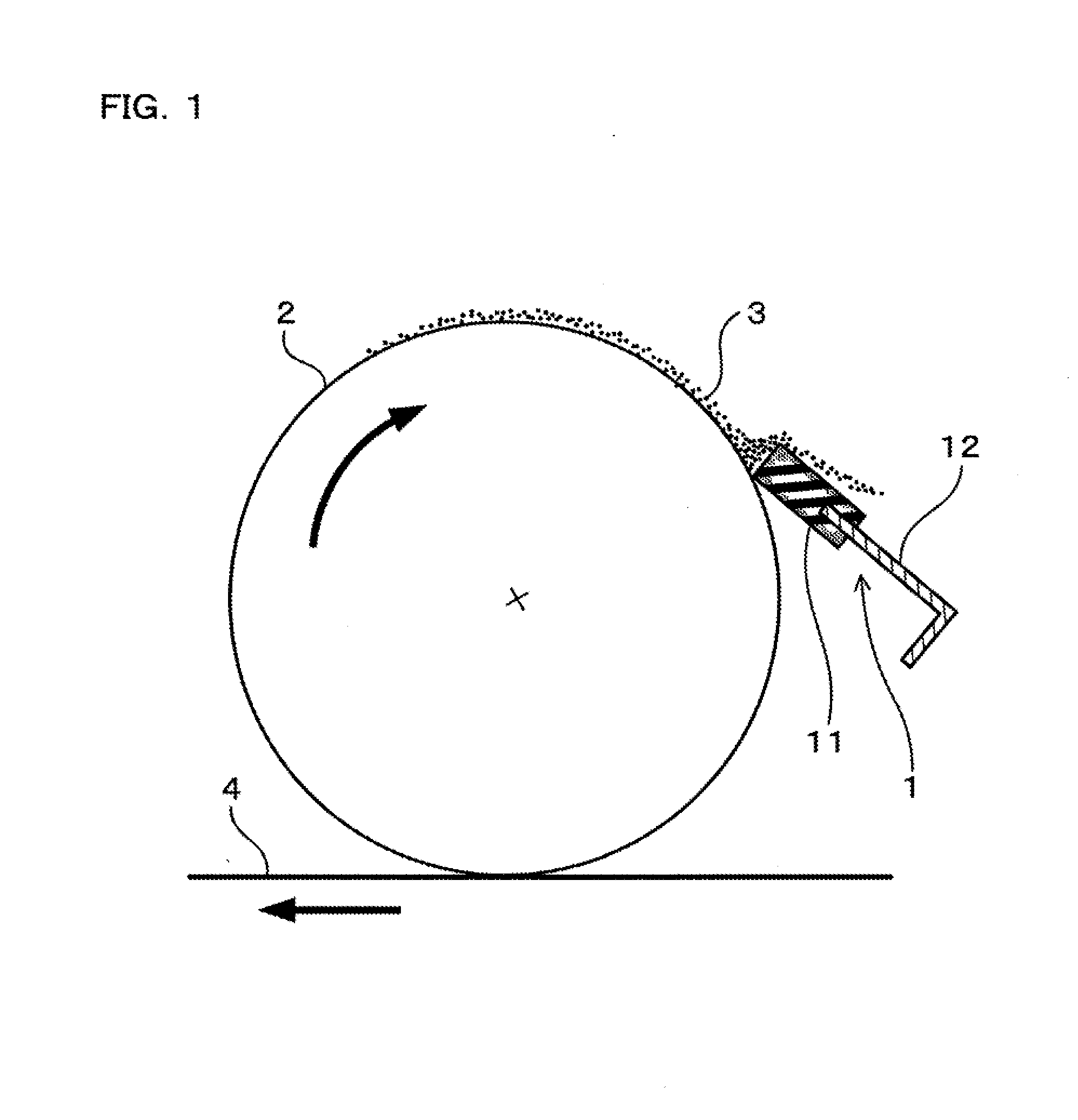

Method for producing blade member

ActiveUS20160297989A1Avoid PolymerizationEasy to usePolyurea/polyurethane coatingsElectrography/magnetographyChemistryIsocyanate compound

A method for producing a blade member 1 includes an impregnation step of impregnating at least a portion of a surface of a blade portion 11 made of a polyurethane rubber with a surface treatment liquid that includes a salt of diazabicycloundecene and a carbodiimide-modified polyvalent isocyanate compound including a carbodiimide-modified polyvalent isocyanate dimer and a carbodiimide-modified polyvalent isocyanate trimer or higher multimer, in which a content of the trimer or higher multimer is 50% by mass or less, and a cured layer formation step of heating and curing the carbodiimide-modified polyvalent isocyanate compound which is impregnated into the blade portion 11, to form a cured layer 110.

Owner:SUMITOMO RIKO CO LTD

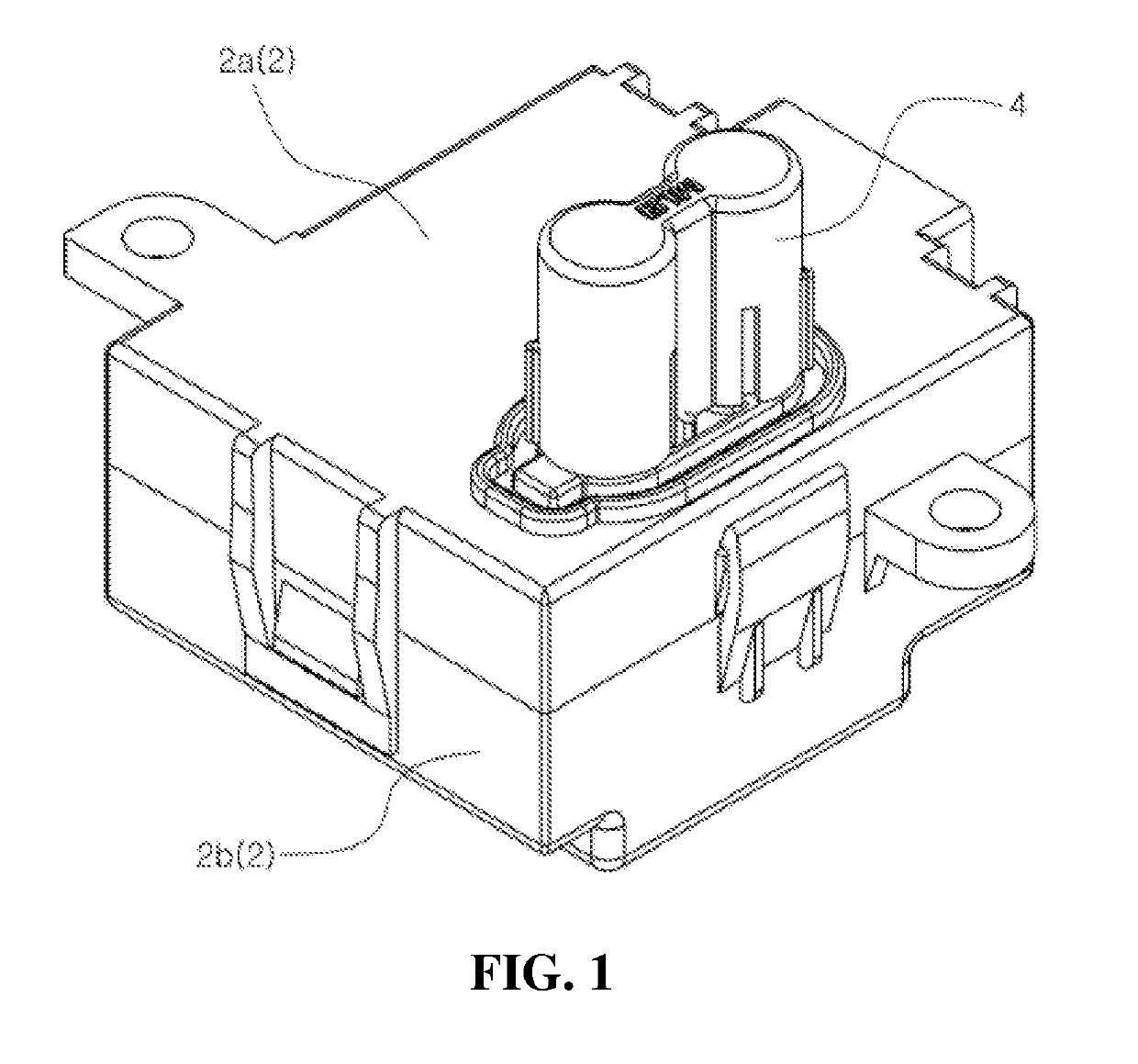

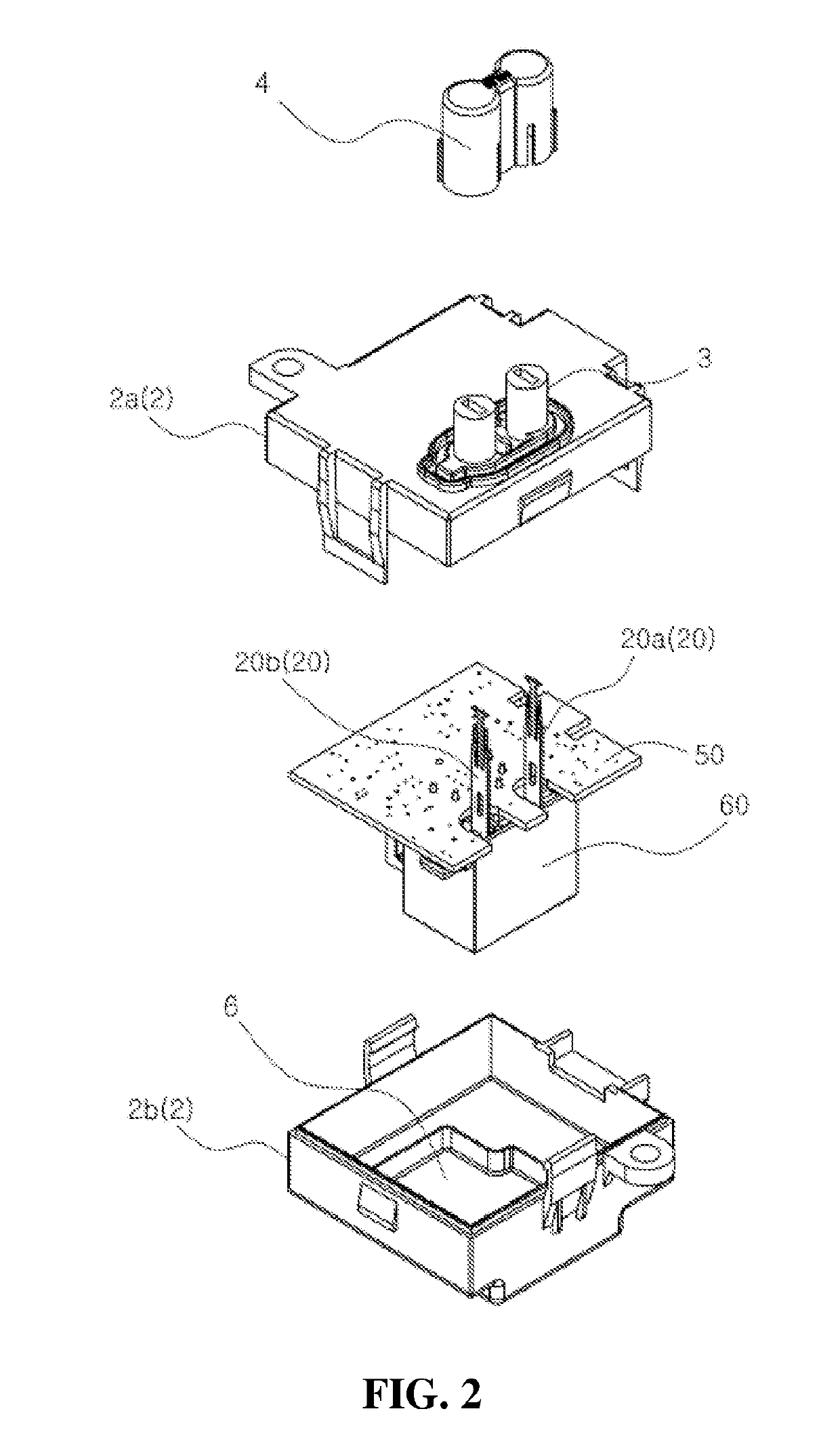

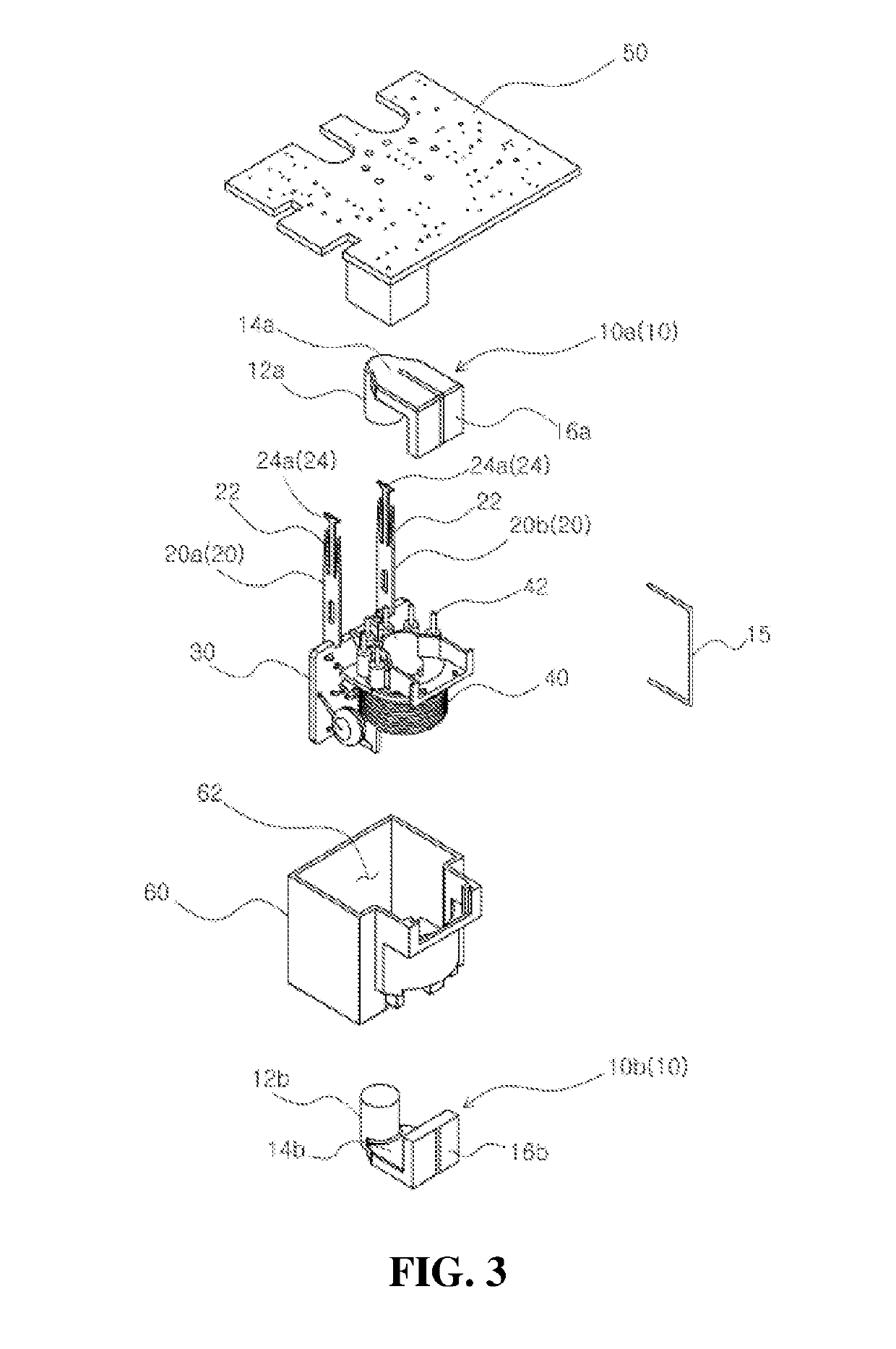

Cluster ionizer for vehicle utilizing needle electrodes

InactiveUS20190193527A1Avoid damageImprove impregnation rateAir-treating devicesMechanical apparatusNeedle ShapeVoltage

Provided is a cluster ionizer for a vehicle. The cluster ionizer uses a needle electrode and includes a case, and a housing disposed in the interior of the case. An ion generating element for generating positive ions and negative ions by applying a driving voltage, and a winding coil and a circuit board for generating the driving voltage that is applied to the ion generating element are mounted in the interior of the housing having a hollow housing part that is communicated with the outside of the housing and is blocked from the interior of the housing. A needle electrode that has sharp part, opposite ends of which are formed sharply to have two needle shapes as the ion generating elements, and a substantially T-shaped protection part extends between the sharp parts so that a direction physical contact with the sharp parts is interrupted.

Owner:ELIM ELECTRONICS CORP

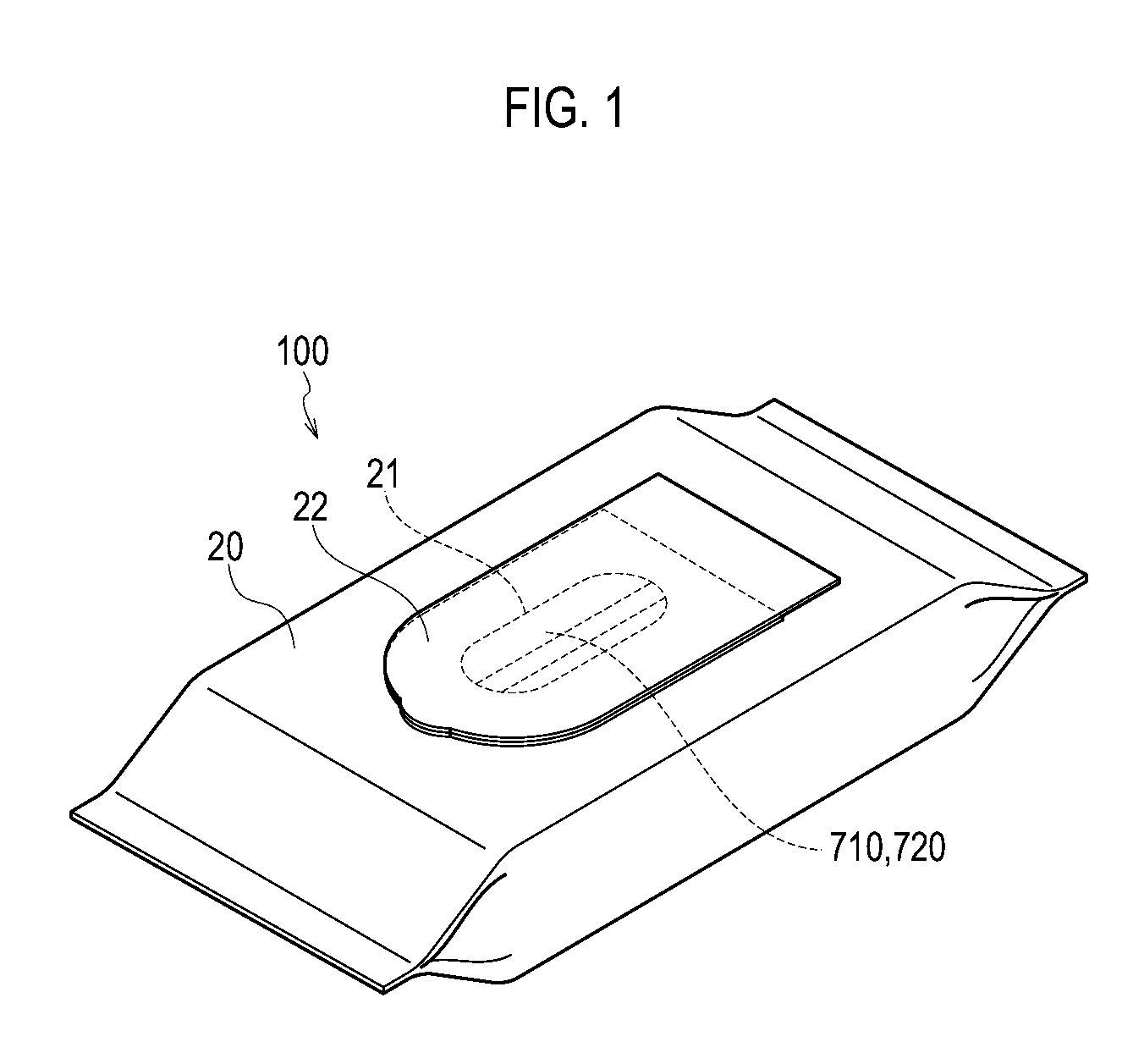

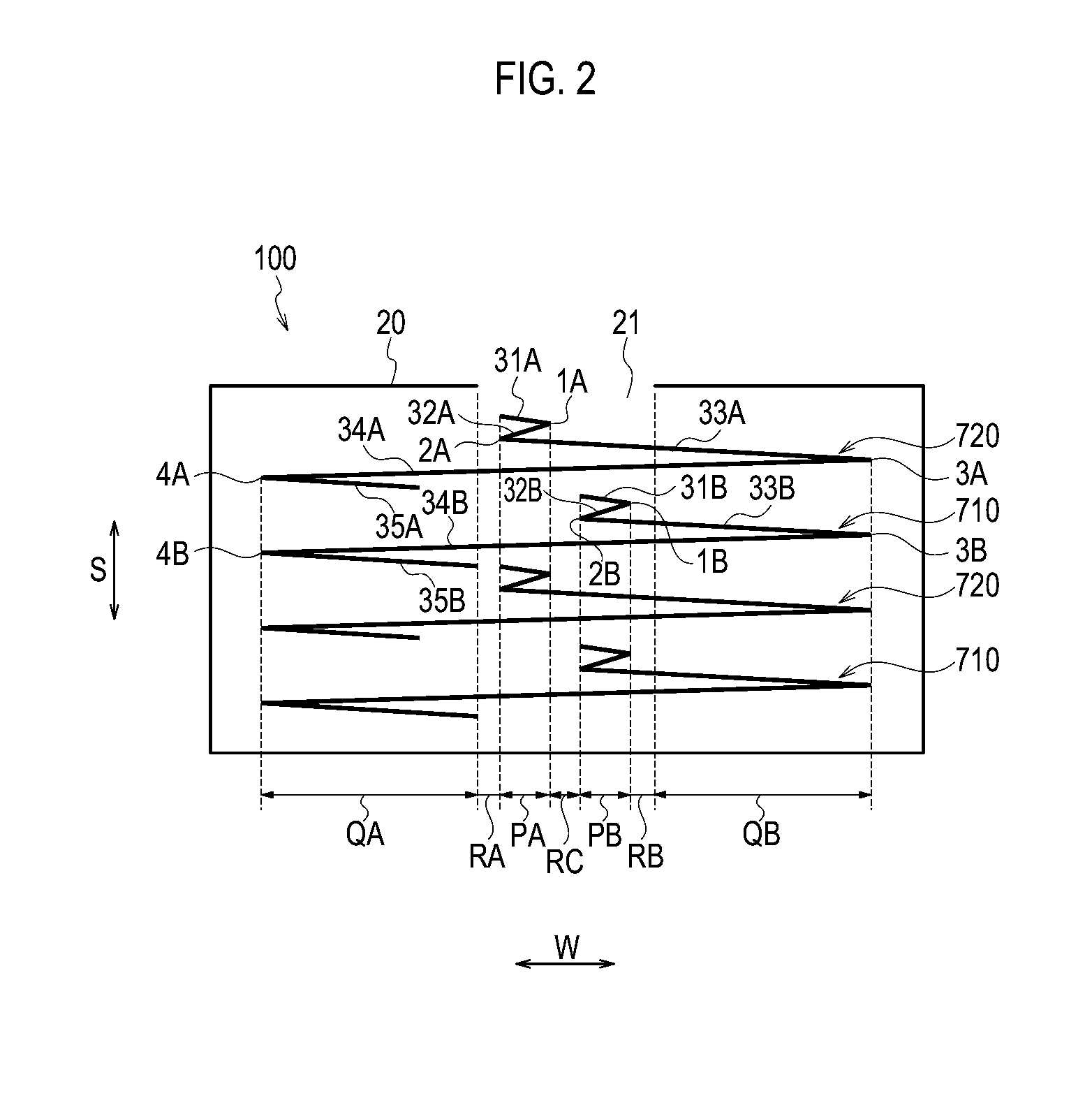

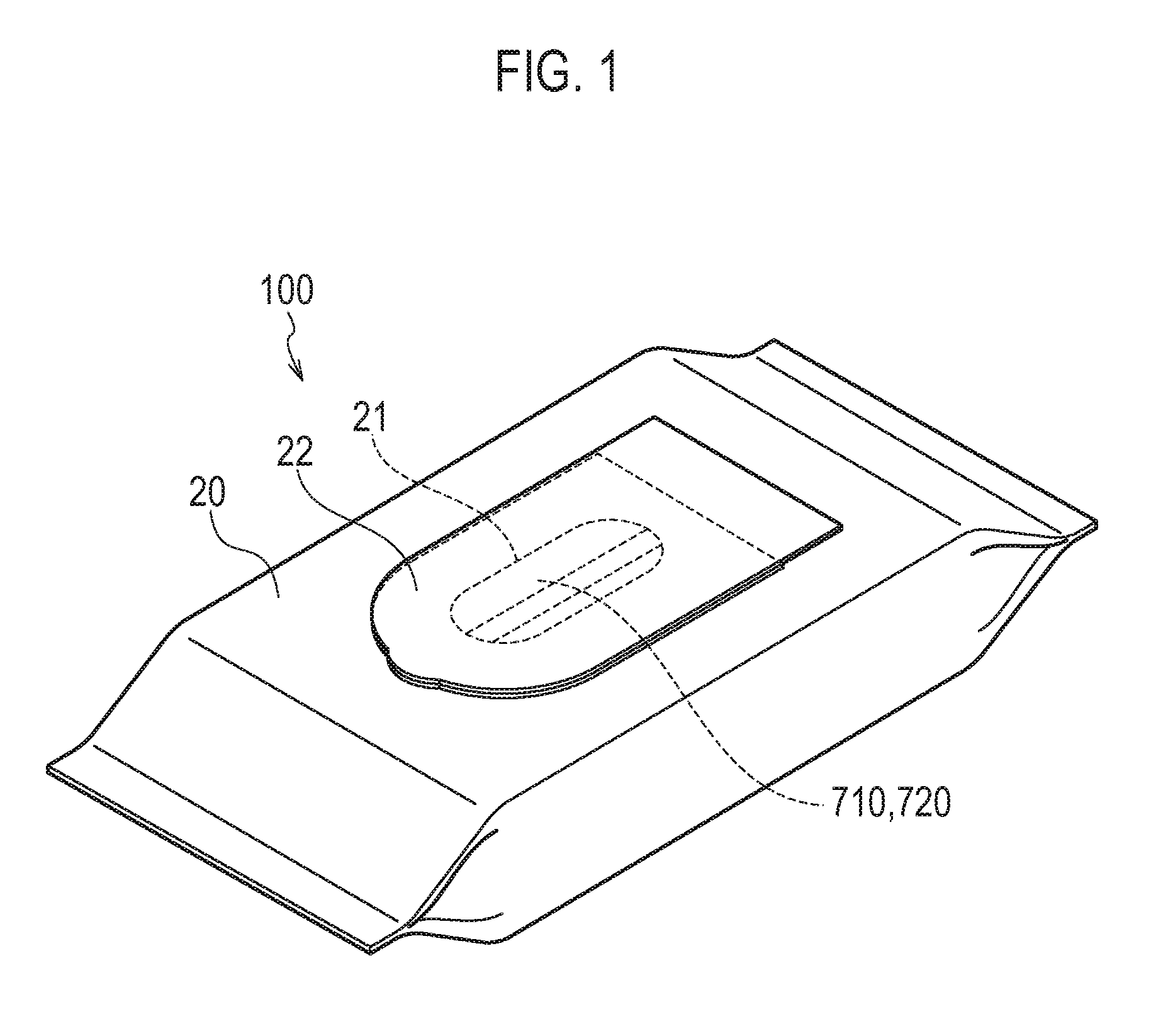

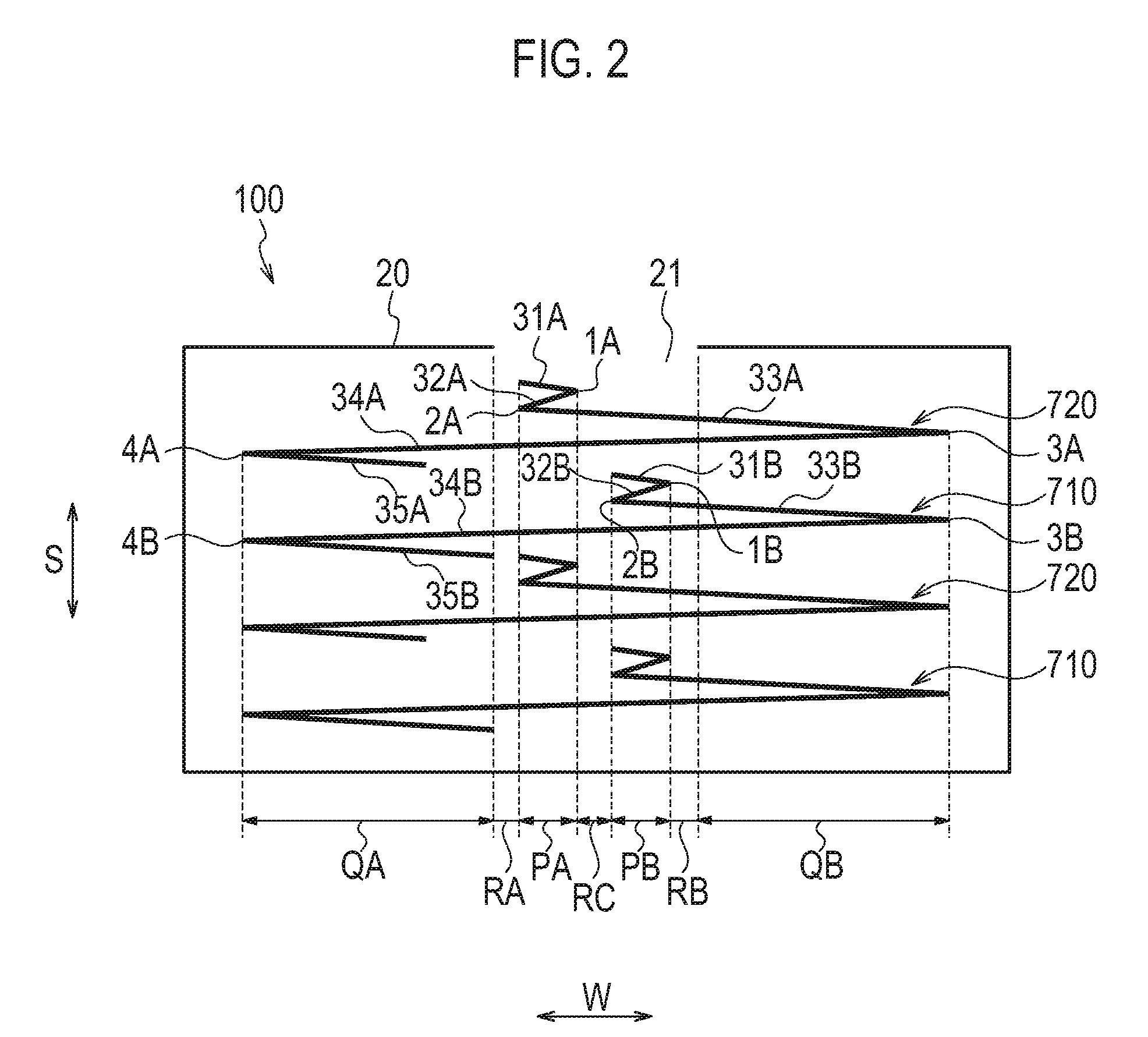

Package structure

InactiveUS9232876B2Improve impregnation rateEasy to takePaper article packagingDiagnosticsWet wipeEngineering

Owner:UNI CHARM CORP

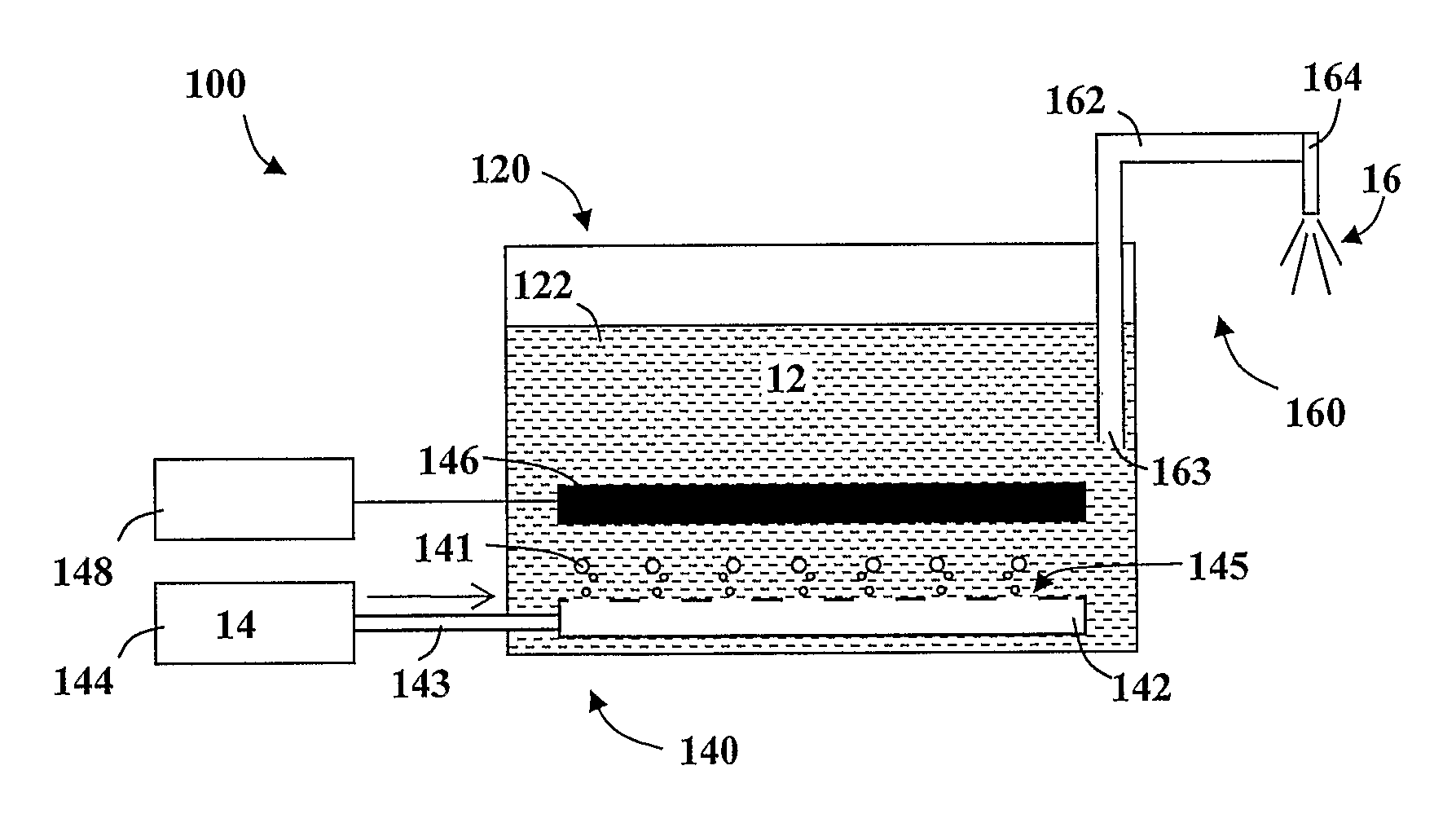

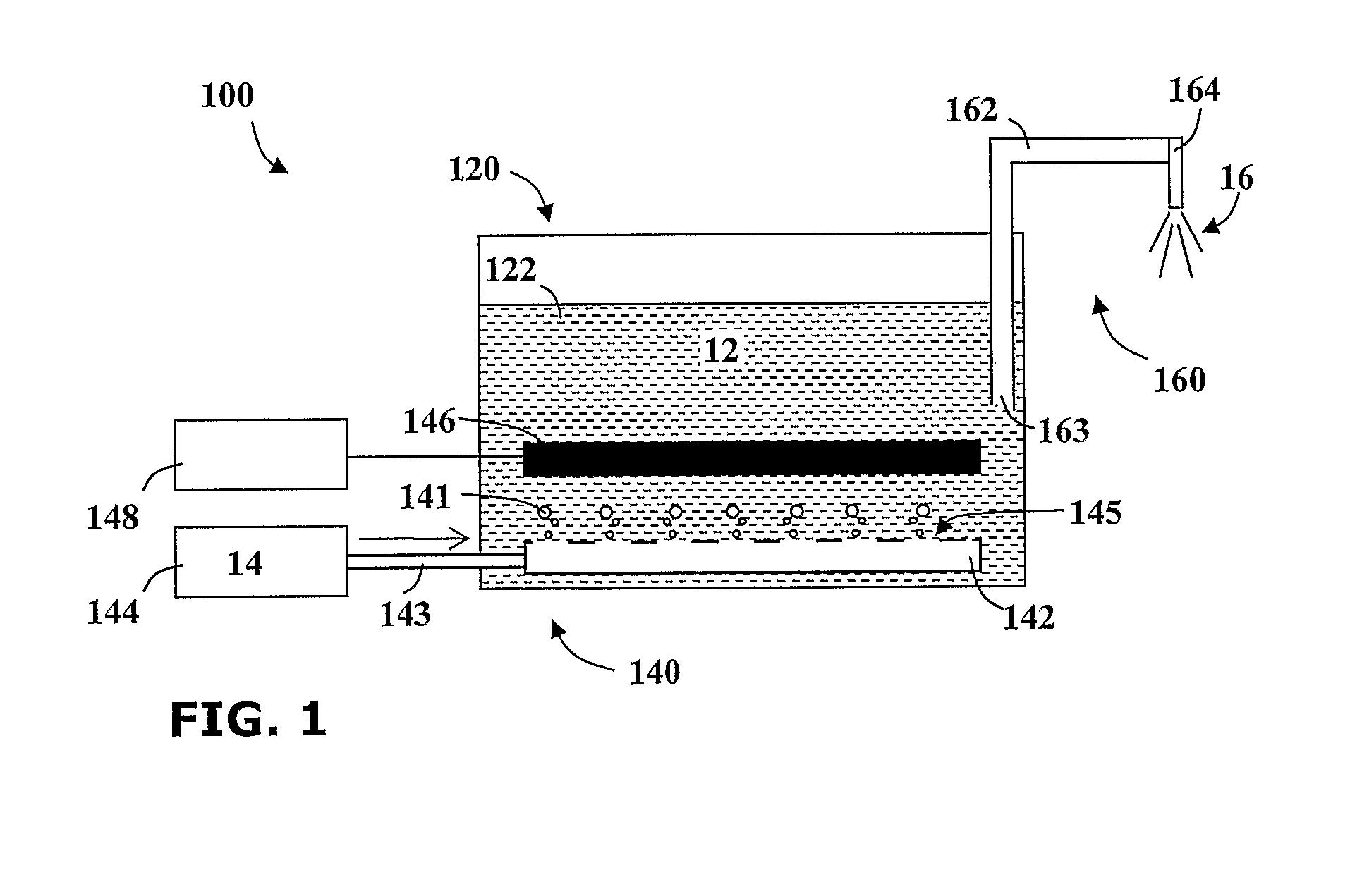

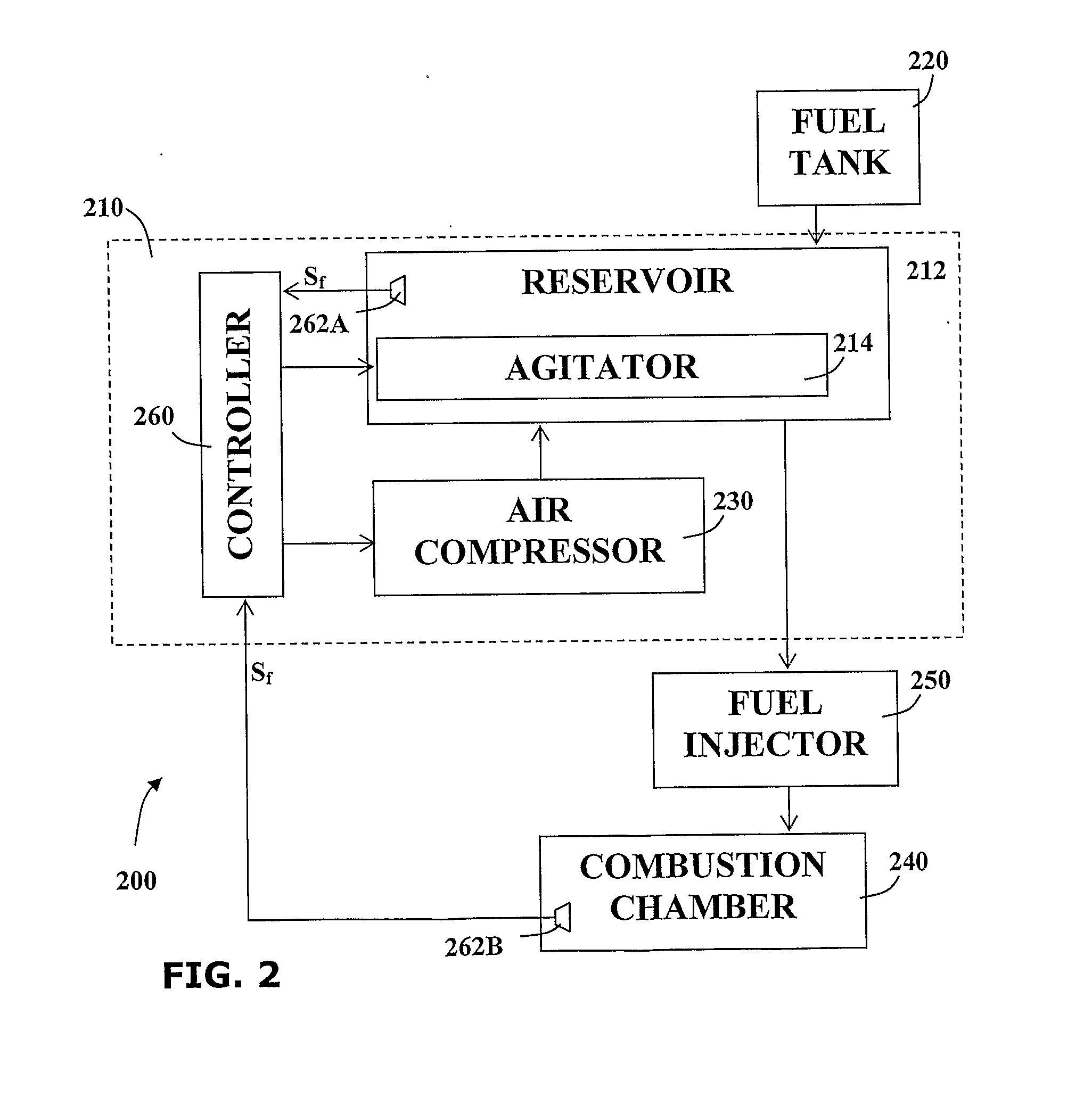

Sonic system and method for producing liquid-gas mixtures

InactiveUS20110209684A1Improve impregnation rateShaking/oscillating/vibrating mixersFlow mixersGas compressorProcess engineering

A sonic saturation system is provided that comprises at least one tank for containing a reservoir of liquid solvent; at least one gas-inlet in fluid communication with a gas compressor, for introducing gaseous solute into the reservoir, and at least one sonic agitator (146) for agitating the liquid reservoir thereby increasing the rate of impregnation of the solute into the solvent.

Owner:TECHNION RES & DEV FOUND LTD

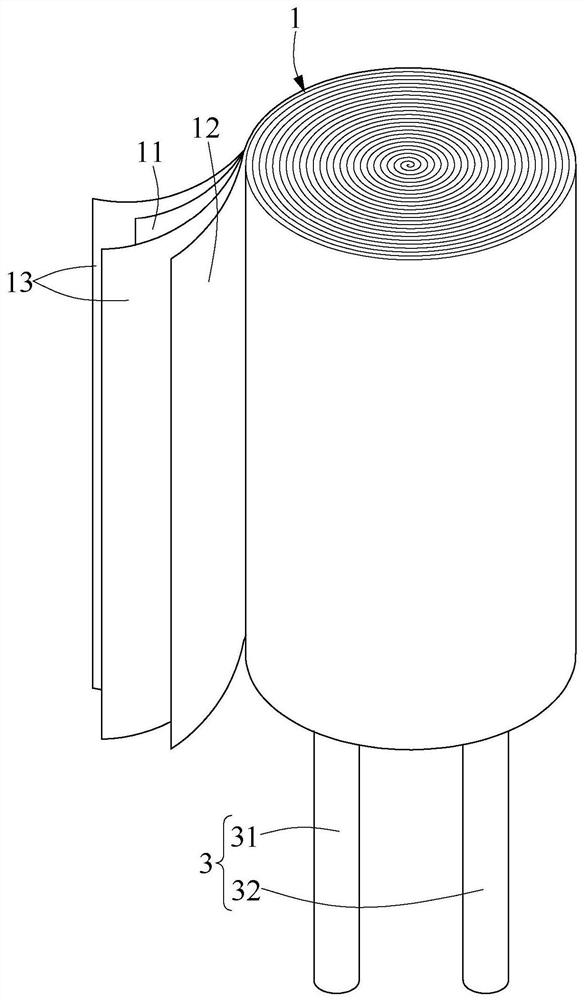

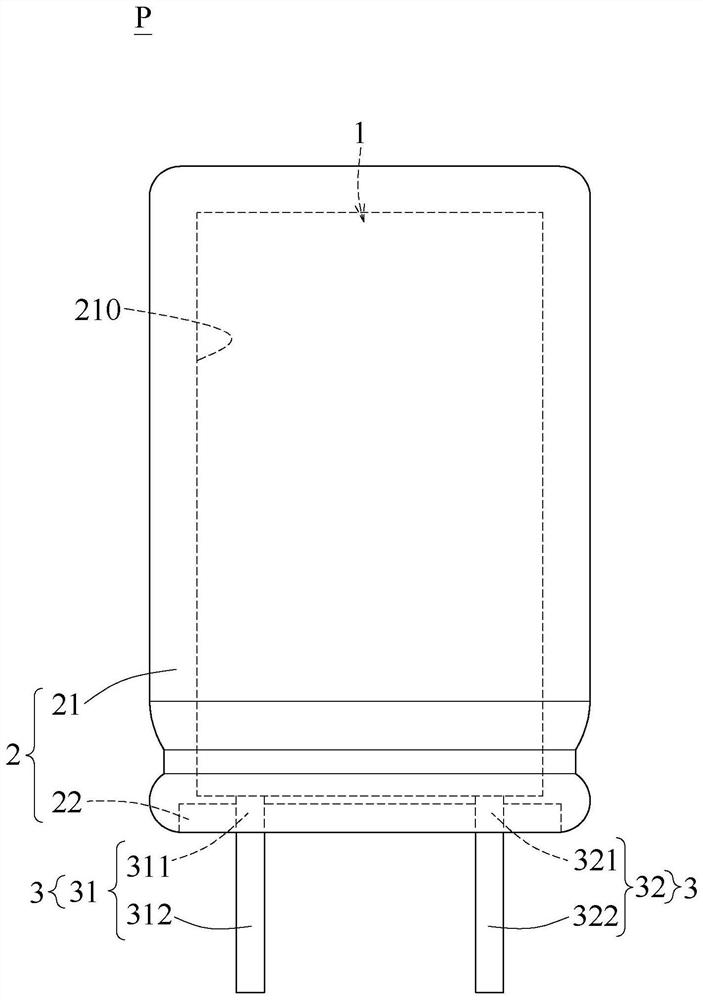

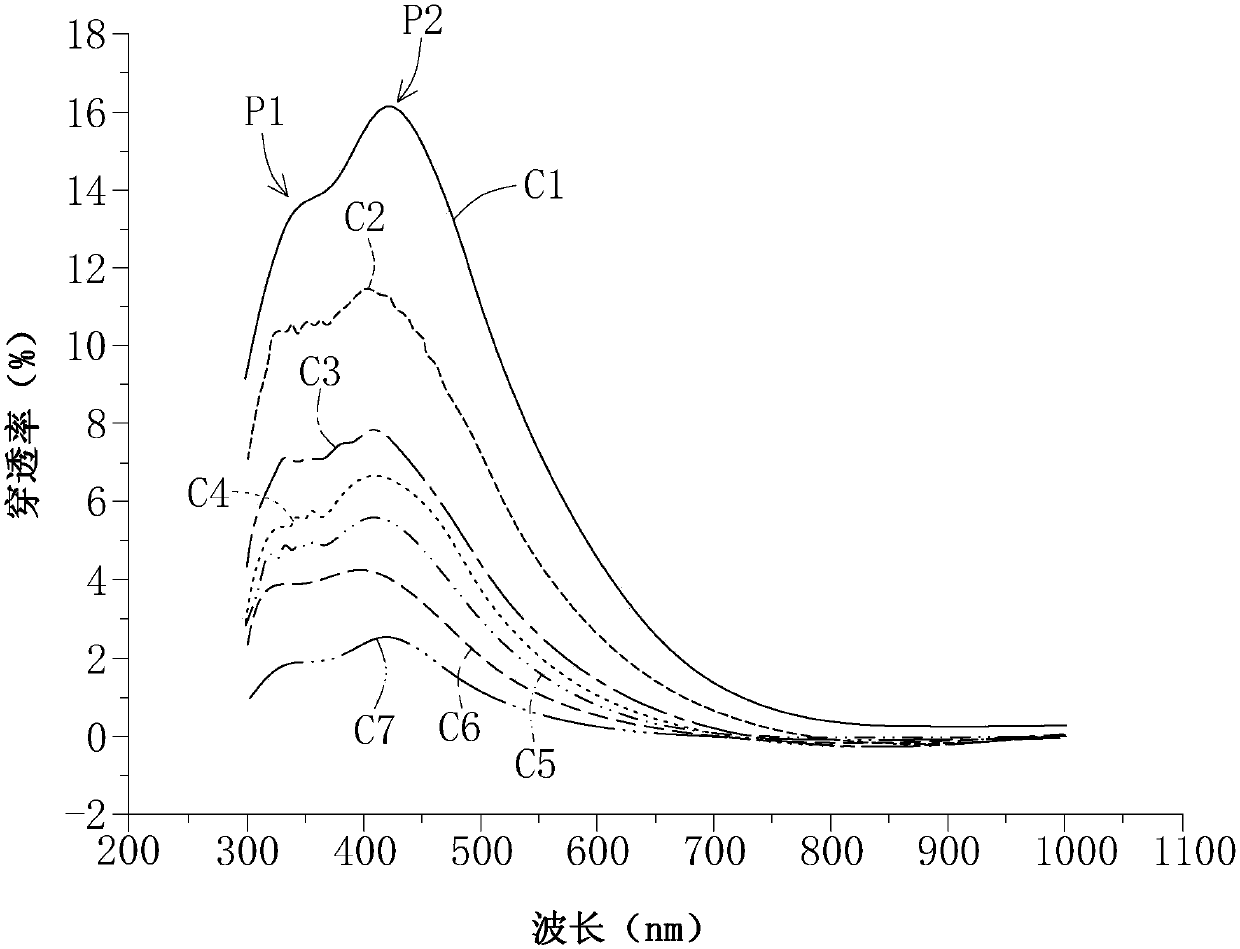

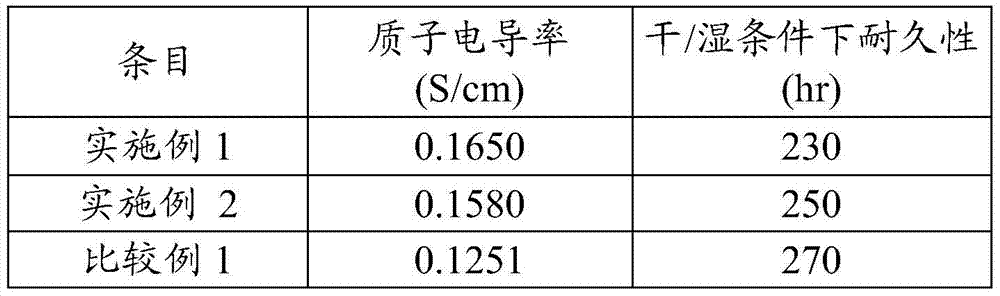

Conductive polymer dispersion for capacitors and capacitor packaging structure

ActiveCN109961954BImprove electrical characteristicsImprove conductivitySolid electrolytic capacitorsCapacitor housing/encapsulationConductive polymerOptical spectrometer

Owner:APAQ TECH

A kind of copper-impregnated carbon sliding plate material and its preparation method for impregnated copper-carbon sliding plate

ActiveCN110156482BAutomatic immersionEasy to achieve immersionRailway vehiclesPower current collectorsMetal filamentPhysical chemistry

The invention discloses a copper-impregnated carbon sliding plate material and a preparation method of the copper-impregnated carbon sliding plate, belonging to the technical field of carbon sliding plate preparation. The preparation method of the copper-impregnated carbon slide plate comprises: stirring and kneading the carbon slide plate material, placing it in a pressing mold with a three-dimensional network structure constructed of metal wires, and undergoing pre-pressing treatment, curing treatment and roasting treatment respectively. A carbon sliding plate was obtained; the carbon sliding plate was firstly treated with pickling acid and copper, and then the copper-impregnated carbon sliding plate was obtained. The copper-impregnated carbon sliding plate material includes: 30-45 parts of petroleum coke powder, 26-32 parts of pitch coke powder, 5-10 parts of natural graphite powder and 6-9 parts of artificial graphite powder. The method for preparing the copper-impregnated carbon sliding plate of the present invention can easily realize the impregnation of the copper solution without additional high temperature and high pressure, and the impregnation rate of the copper solution is high, and the prepared copper-impregnated carbon sliding plate has high conductivity, mechanical properties and wear resistance .

Owner:SOUTHWEST JIAOTONG UNIV

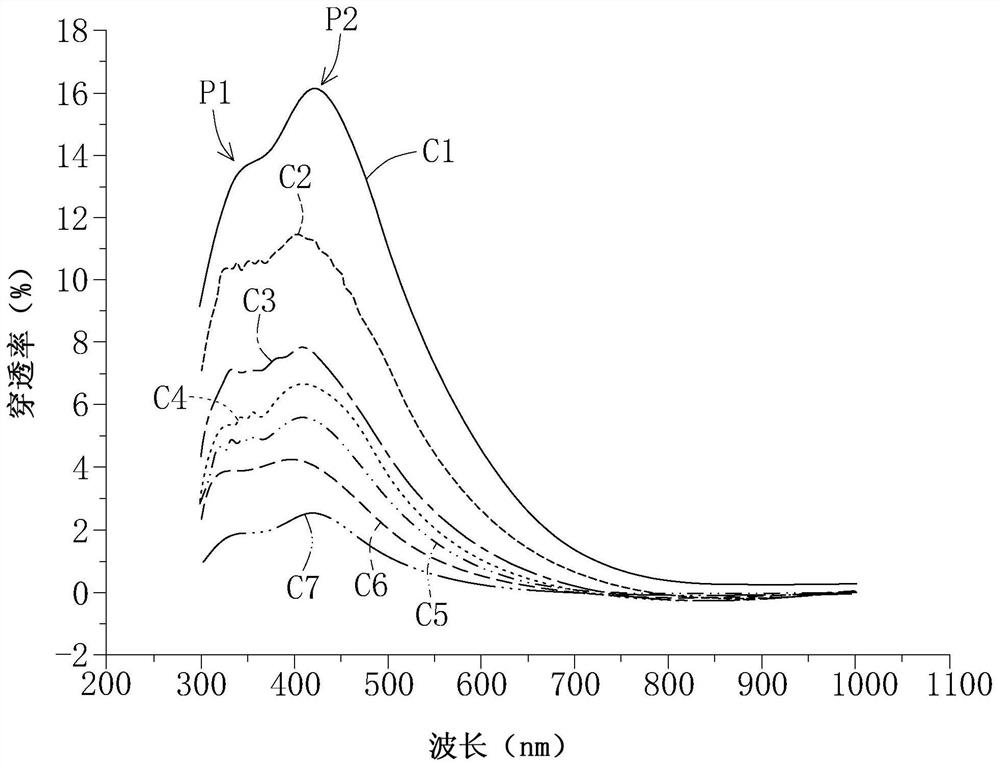

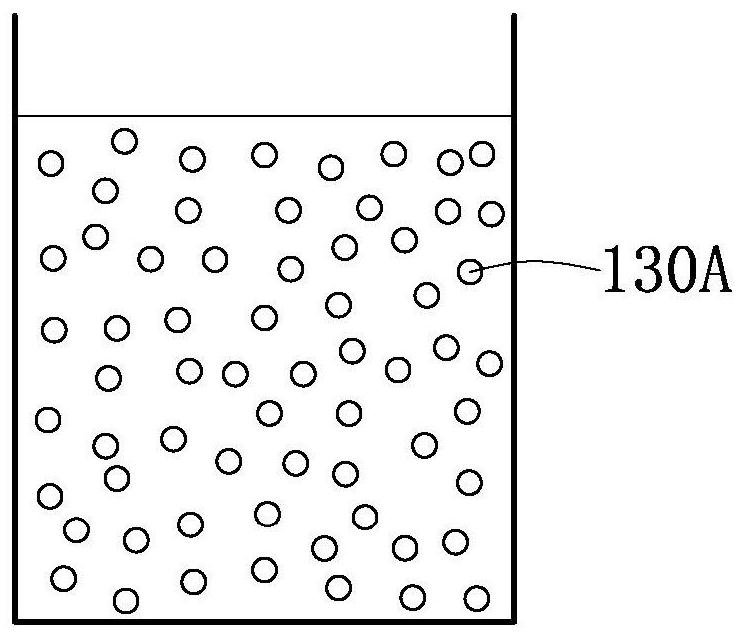

Conductive polymer dispersion for capacitor and capacitor packaging structure

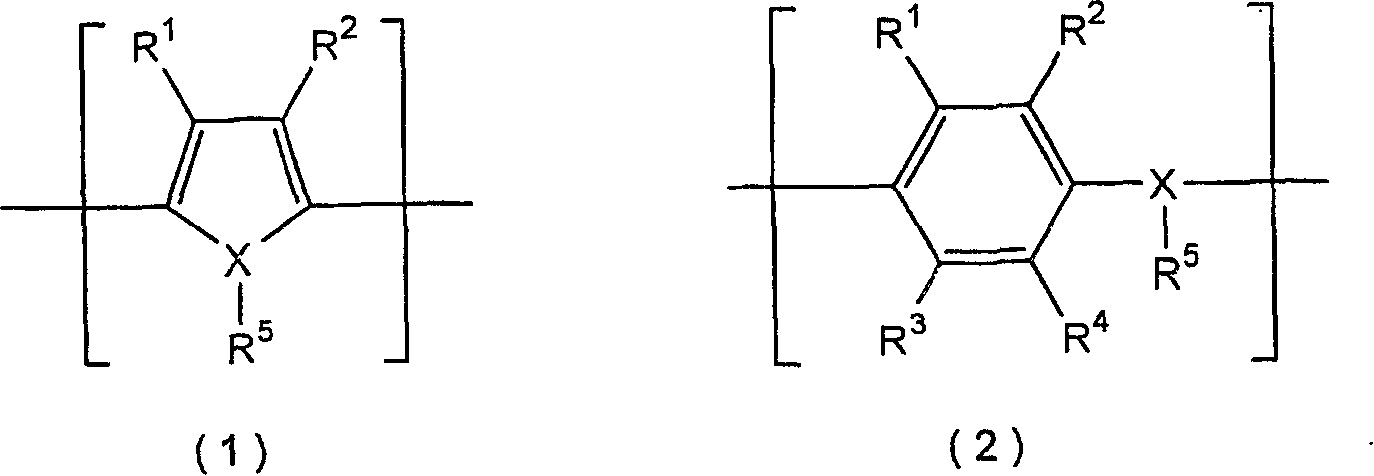

ActiveCN109961954AImprove electrical characteristicsImprove conductivitySolid electrolytic capacitorsCapacitor housing/encapsulationConductive polymerOptoelectronics

The invention provides a conductive polymer dispersion for a capacitor and a capacitor packaging structure. The invention discloses the conductive polymer dispersion for the capacitor. The conductivepolymer dispersion comprises a conductive polymer, a dispersant and an additive, wherein the conductive polymer dispersion is tested by an ultraviolet-visible spectrometer to obtain a transmission spectrum which has a first characteristic peak between 350 nm and 450 nm and a second characteristic peak between 300 nm and 400 nm. The conductive polymer dispersion can be effectively applied to the electrode body of the capacitor so that the electrical characteristics of the capacitor packaging structure can be improved.

Owner:APAQ TECH

Reinforced composite membrane for fuel cell and membrane electrode assembly including the same

ActiveCN104871354BImprove proton conductivityExcellent impregnationSolid electrolytesCell electrodesElectrical conductorFuel cells

The present invention provides a reinforced composite membrane for a fuel cell and a membrane electrode assembly comprising the reinforced composite membrane, wherein the reinforced composite membrane includes a porous support having three-dimensionally irregular and discontinuously arranged polymer nanofibers and a first ion conductor body, and a second ion conductor that fills the pores of the porous support, the first ion conductor exists in the porous support in the form of nanofibers, or exists in the polymer nanofibers to form nanofibers together with the polymer The fiber, thereby, improves the impregnation uniformity and impregnation rate of the ion conductor to increase the proton (hydrogen ion) conductivity.

Owner:KOLON IND INC

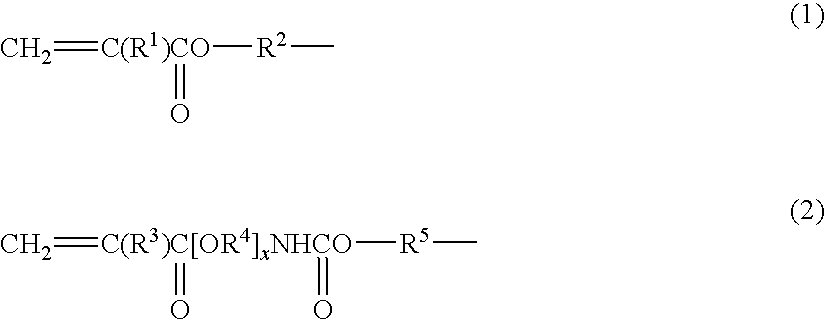

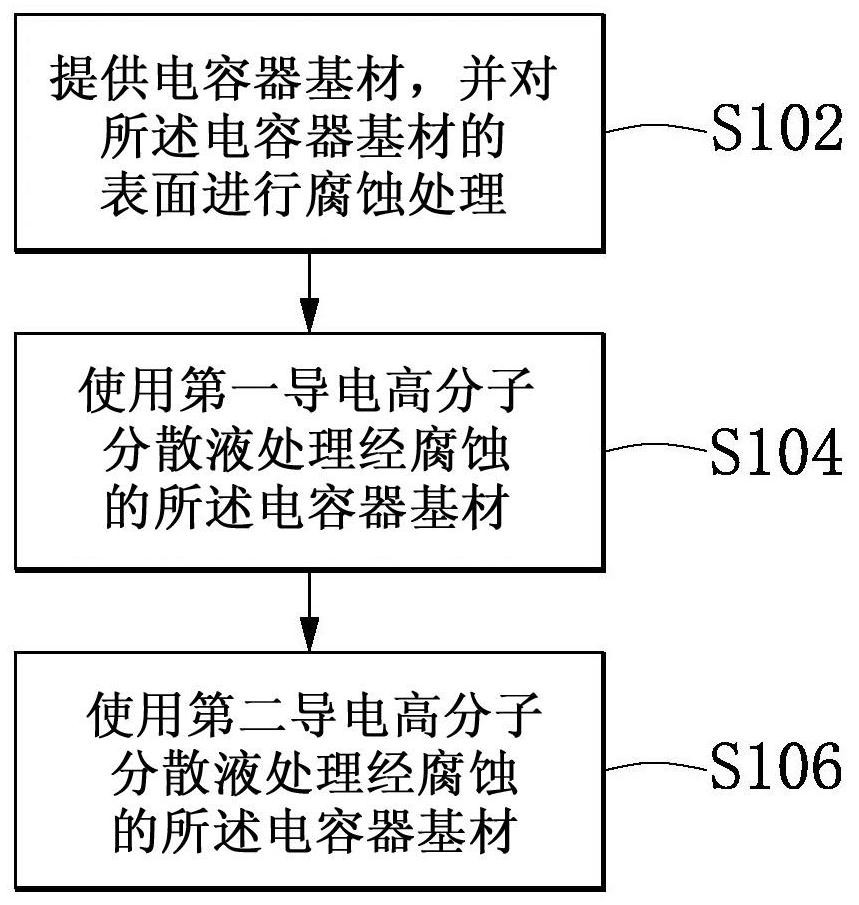

Anti-surge capacitor and manufacturing method thereof

ActiveCN111048314BImprove permeabilityImprove impregnation rateSolid electrolytic capacitorsCapacitor electrolytes/absorbentsShunt capacitorsConductive polymer

The invention discloses an anti-surge capacitor and a manufacturing method thereof. The manufacturing method of the anti-surge capacitor comprises the following steps: (a) providing a capacitor substrate, and performing corrosion treatment on the surface of the capacitor substrate to form a corroded surface; (b) using the first conductive polymer dispersion to process the corrosion surface; (c) using the second conductive polymer dispersion to treat the corroded surface; wherein, step (b) and step (c) are to process the corroded capacitor substrate according to a predetermined sequence, so as to form a conductive high Molecular layer; wherein, the concentration of the first conductive polymer dispersion is different from the concentration of the second conductive polymer dispersion. The anti-surge capacitor of the invention has the electrical characteristics of anti-surge and reduced capacity failure rate. The invention also discloses an anti-surge capacitor.

Owner:ANDAQ TECH CO LTD

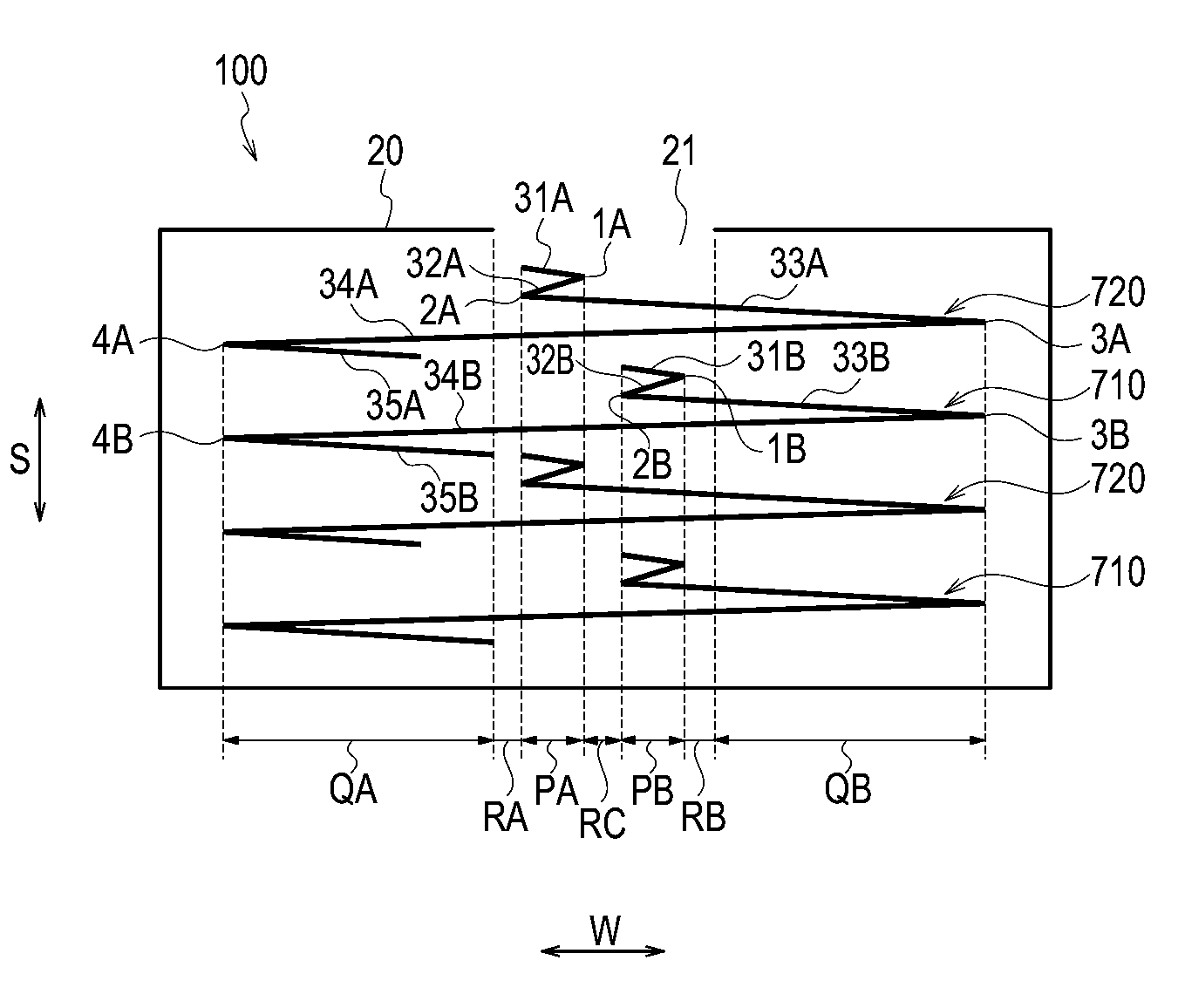

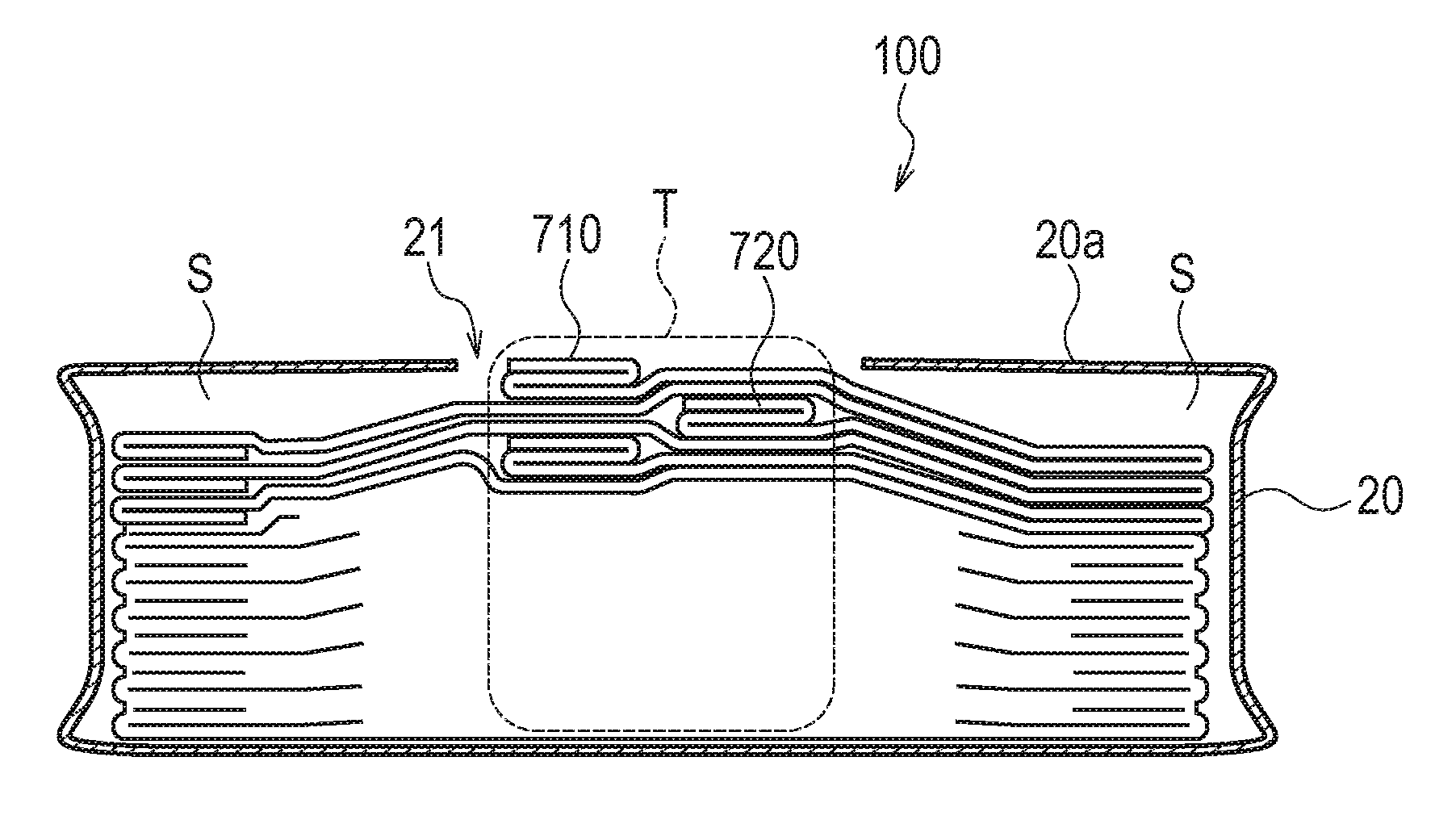

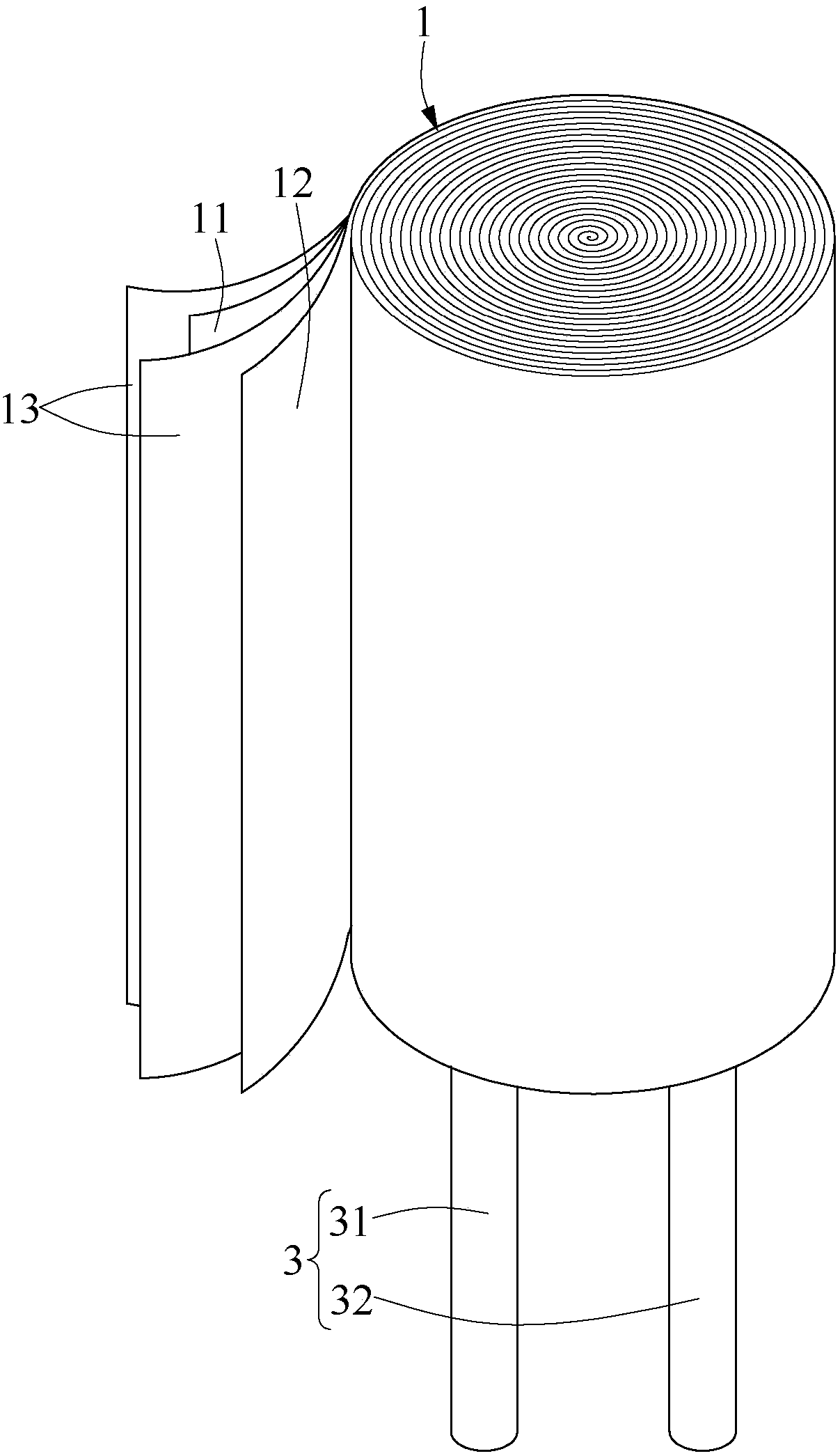

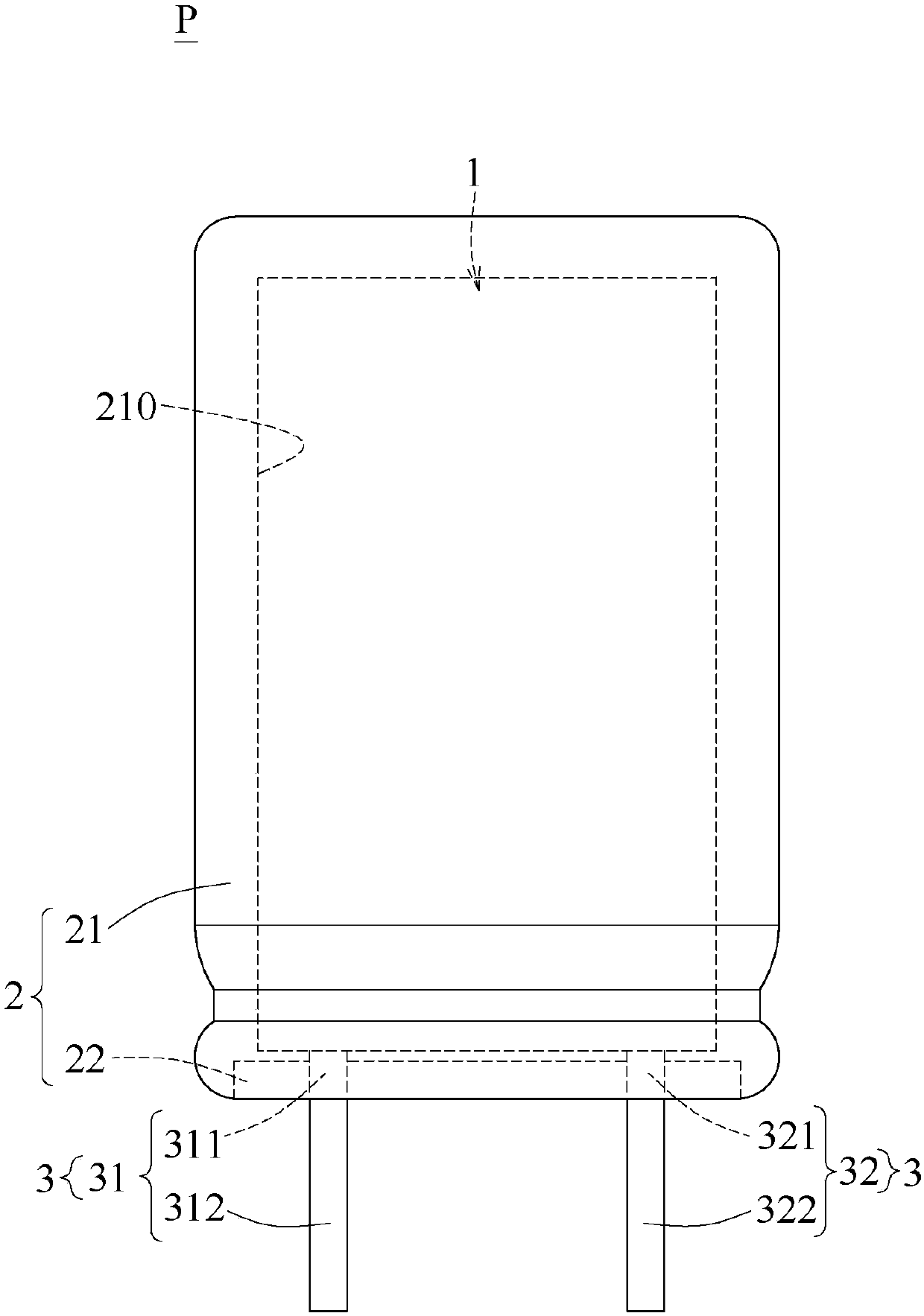

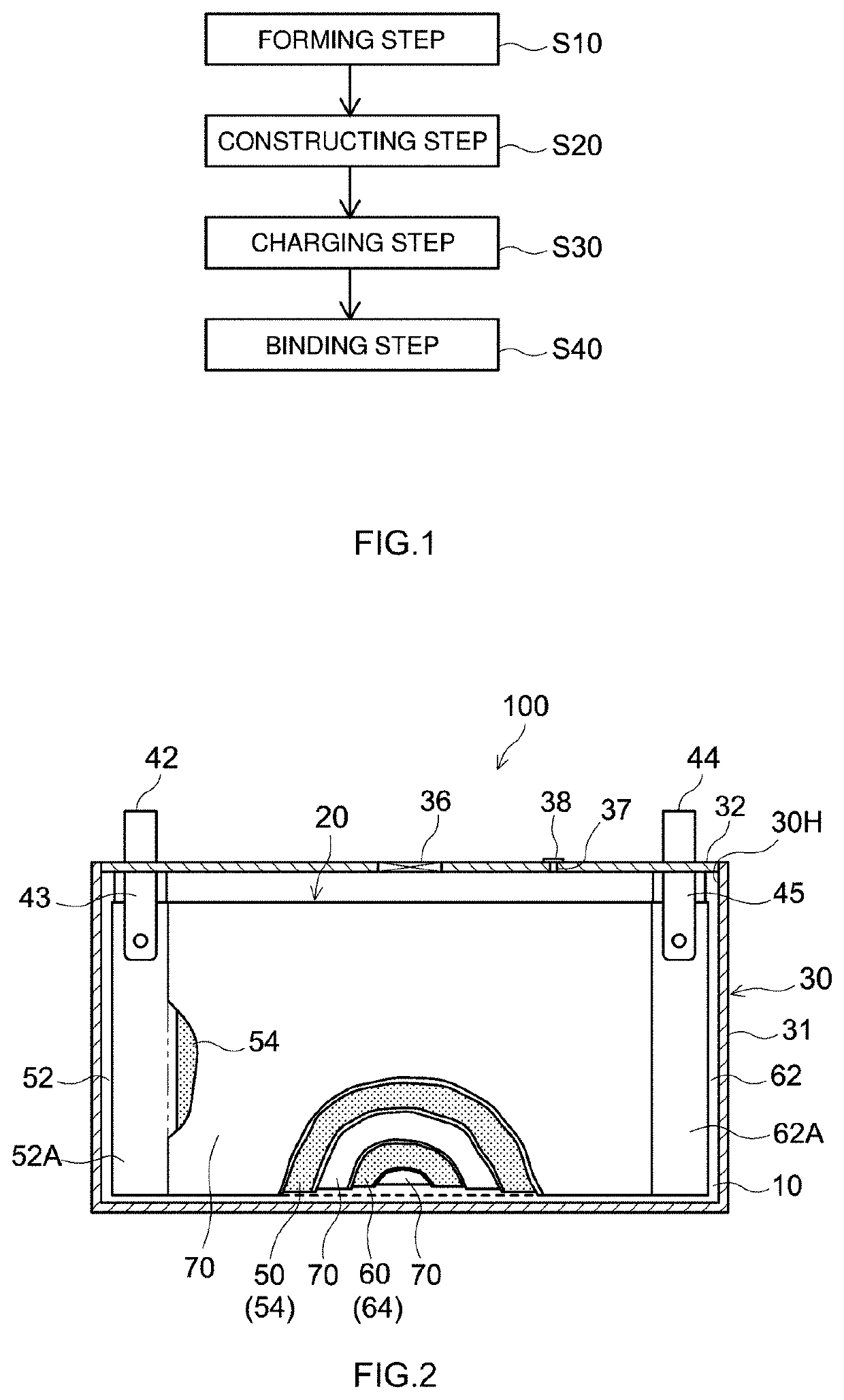

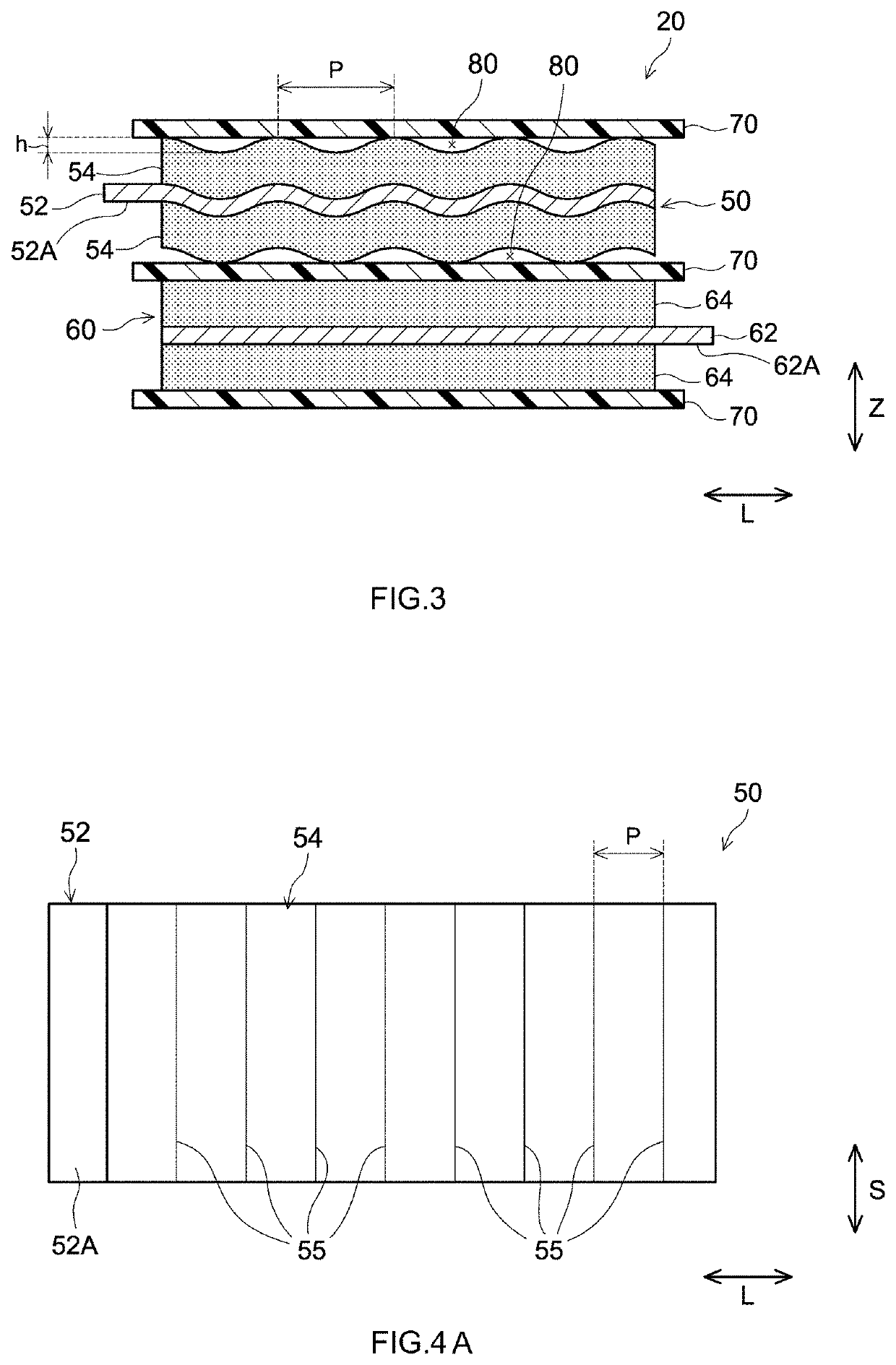

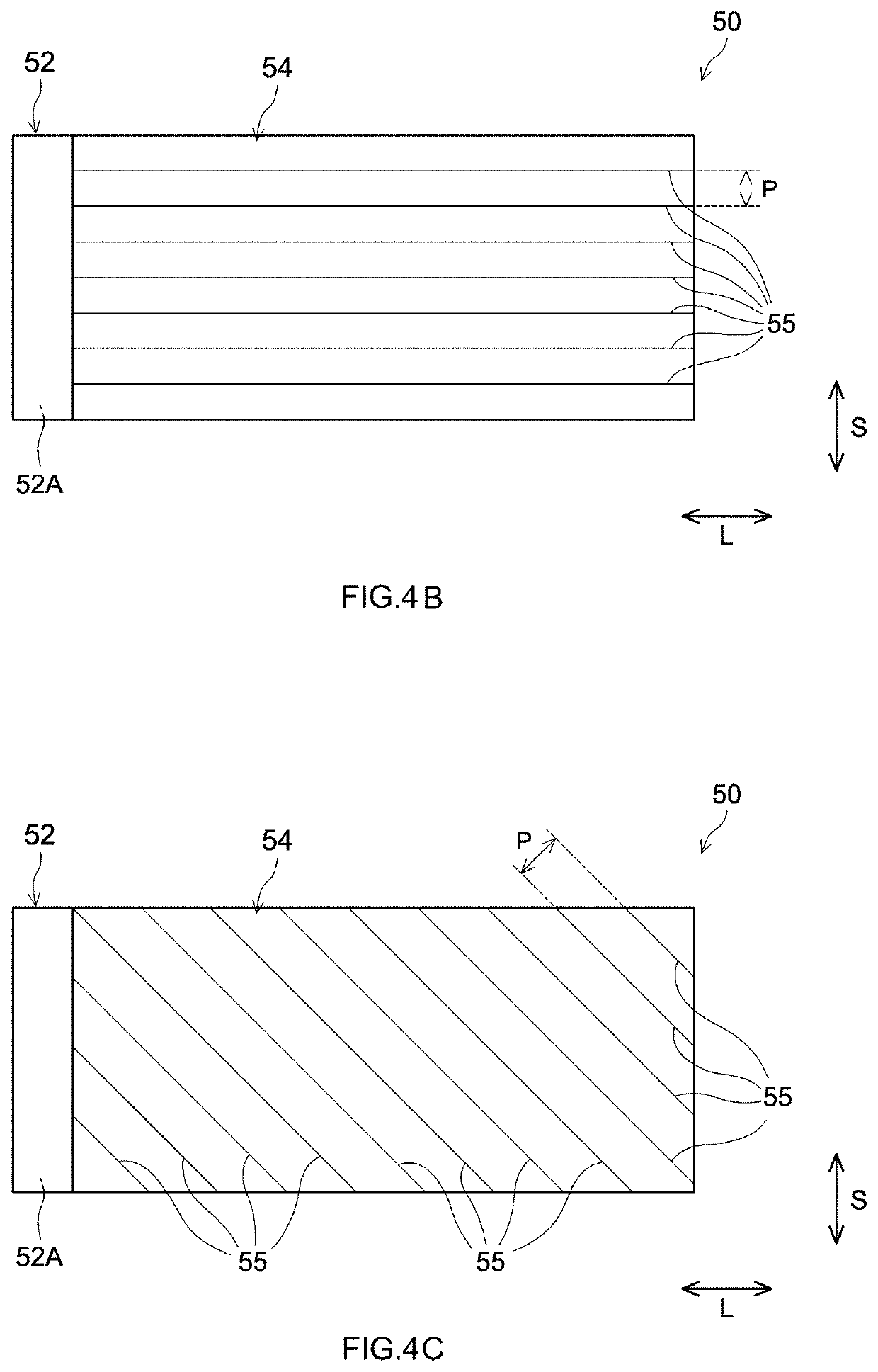

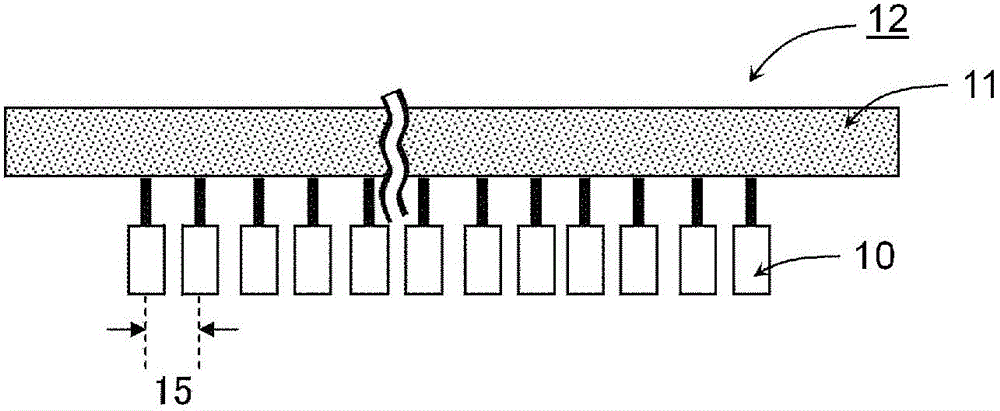

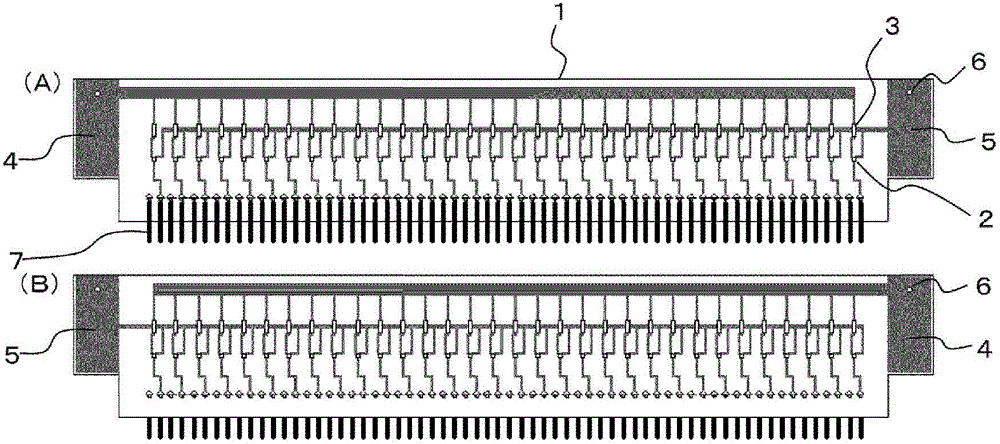

Method for manufacturing secondary battery

PendingUS20220263139A1Reduce the ratioReduced strengthCell electrodesFinal product manufactureElectrolytic agentElectrical battery

The manufacturing method herein disclosed includes a forming step of stacking a positive electrode sheet including a positive electrode active material layer on a positive electrode collector, a negative electrode sheet including a negative electrode active material layer on a negative electrode collector, and a separator sheet, thereby forming an electrode body; a constructing step of accommodating the electrode body in a battery case, and pouring an electrolyte into the battery case, thereby constructing a battery assembly; and a charging step of charging the battery assembly. At least any one of the positive electrode active material layer and the negative electrode active material layer has an undulating shape in a stacking direction, and a pit depth of the undulation is 10 μm or more.

Owner:PRIME PLANET ENERGY & SOLUTIONS INC

Composite yarn and method for producing the same, continuous fiber-reinforced resin molded product, and method for producing composite molded product

The present invention provides a thermoplastic resin-coated reinforced fiber composite yarn, a method for producing the composite yarn, a continuous fiber-reinforced resin molded body, and a method for producing a composite molded body, which are excellent in resin impregnation during molding, even in short A molded article with high physical properties can be produced even during molding over time, and it is also excellent in flexibility as a thread and excellent in handleability during weaving and weaving.

Owner:ASAHI KASEI KK

Colorless phenolic impregnated resin, preparation method and application thereof

InactiveCN101659738BReduce free aldehyde contentSimple preparation processWood impregnation detailsAdhesivePhenol

Owner:UNIV OF JINAN

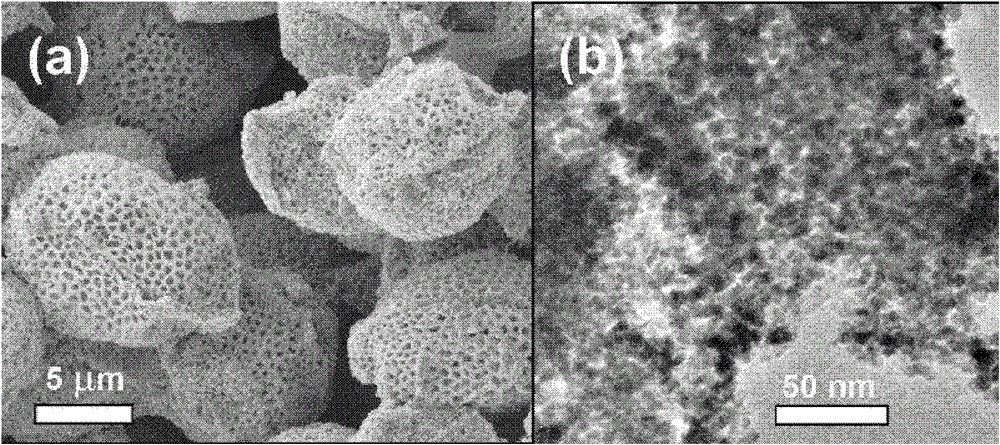

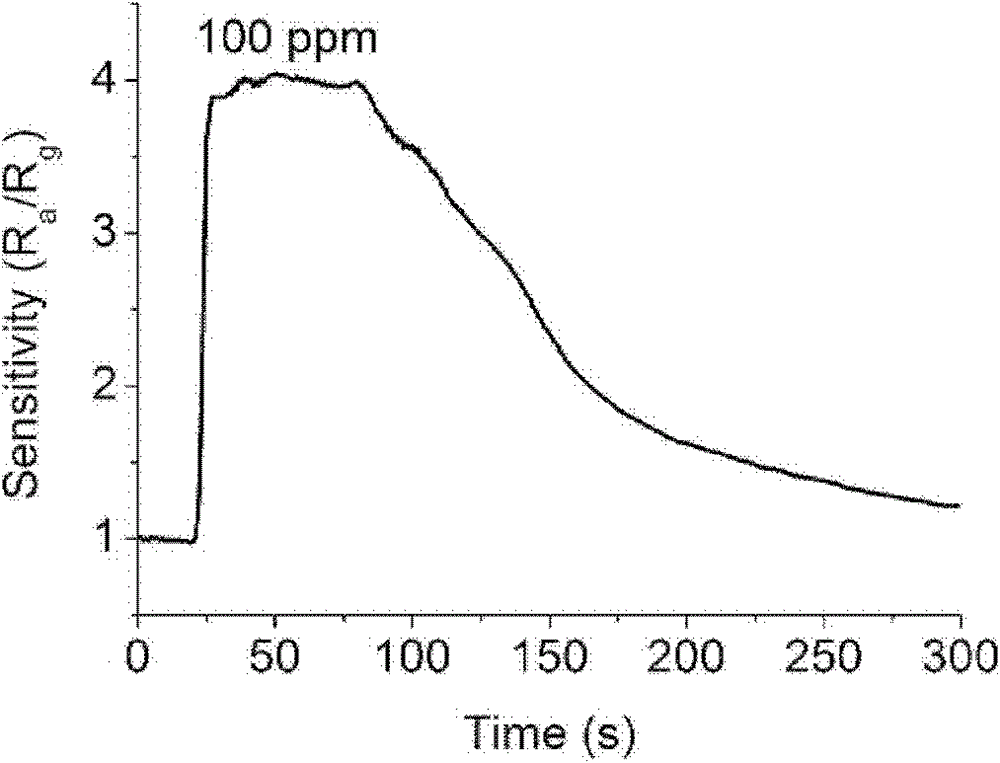

Method for preparing room-temperature chlorine gas sensitive material with porous hierarchical structure

InactiveCN101825593BImprove impregnation rateLarge specific surface areaMaterial analysis by electric/magnetic meansRoom temperaturePre treatment

The invention relates to a method for preparing a room-temperature chlorine gas sensitive material with a porous hierarchical structure, which belongs to the technical field of sensitive materials. The method comprises the following steps of: pre-treating rape pollen as raw materials, and then dipping into precursor liquid of pink salt; hydrolyzing, drying, oxidizing and burning the rape pollen to obtain a tin oxide gas sensitive material; coating the tin oxide gas sensitive material onto a substrate surface, ageing and then making into the room-temperature chlorine gas sensitive material with a porous hierarchical structure. The invention has the advantages that the process is easy and flexible and the cost is low; the gas sensitive material with good properties can be obtained by controlling the grain size and the porous hierarchical structure of metal oxides effectively, and the prepared gas sensitive material with a porous hierarchical structure can detect low-density C12 selectively and quickly at room temperature.

Owner:SHANGHAI JIAO TONG UNIV

Solid electrolytic capacitor element, its manufacturing method and its manufacturing tool

InactiveCN103109334BImprove moisture resistanceSmall rate of change in capacitySolid electrolytic capacitorsCapacitor electrolytes/absorbentsElectricityLower limit

The present invention relates to a method of manufacturing a solid electrolytic capacitor element comprising the steps of forming a semiconductor layer on the dielectric layer formed on surfaces of a plurality of anode bodies at one time, wherein a step of forming a semiconductor layer comprises repeating an electrolytic polymerization operation several times by applying a current from a power-feeding terminal that comes into contact with each anode body, and at least one of the electrolytic polymerization operations continuously applies a current while changing the amount of current between the range of 5 to 200 µA per power-feeding terminal; and a jig for electrolytic polymerization for forming a semiconductor layer on the dielectric layer formed on a surface of an anode body, comprising a plurality of power supply circuits (i) provided on an insulating substrate and capable of continuously changing the amount of current between a lower limit and an upper limit; and a power-feeding terminals (ii) electrically connected to the output of each of the plurality of power supply circuits to be placed in contact with anode bodies. According to the present invention, a group of capacitor elements having high humidity resistance can be obtained by forming a semiconductor layer at one time on the dielectric layer formed on a plurality of anode bodies by electrolytic polymerization with a high impregnation rate.

Owner:RESONAC HOLDINGS CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com