Equipment and method for producing fabric-enhanced composite board

A composite board, fabric reinforcement technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of easy warpage, small adjustment range of fiber content, uneven gram weight, etc., to improve warpage , cost saving and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

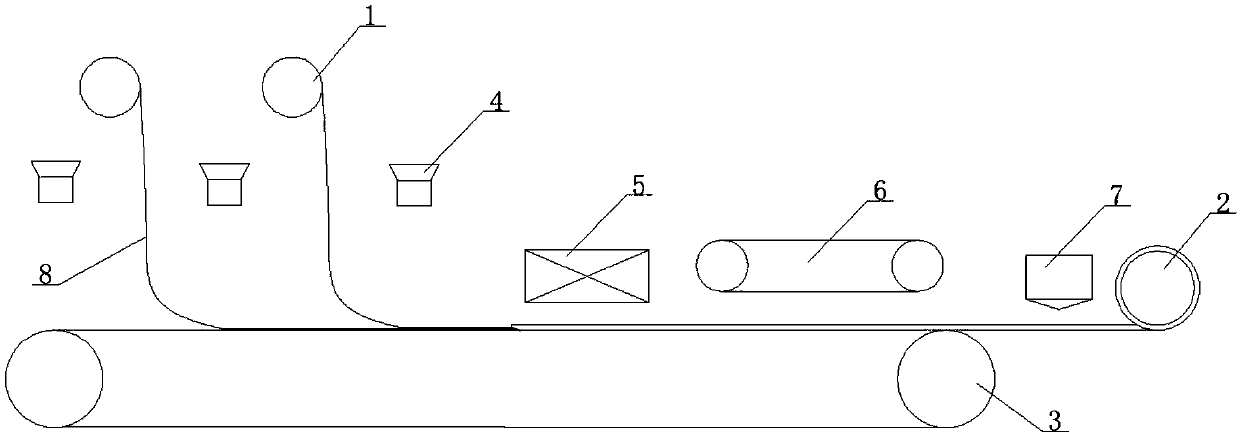

[0028] Such as figure 1 as shown, figure 1 It is a structural view of this embodiment of the fabric-reinforced thermoplastic composite plate production equipment of the present invention; the fabric-reinforced thermoplastic composite plate production equipment of the present invention includes a powder spreading device 4, a preheating device 5, a pressing device 6, and a cutting device 7 ,Braking device.

[0029] The braking device includes several unwinding parts 1, winding parts 2 and support rollers 3, and the supporting rollers 3 are arranged between the unwinding part 1 and the rolling part 2, and the continuous fiber fabric 8 The two ends of the unwinding part 1 and the rolling part 2 are arranged respectively, and the continuous fiber fabric 8 part between the unwinding part 1 and the rolling part 2 is set on the support On the roller table 3, to realize the movement of the continuous fiber fabric 8. The supporting roller table 3 is provided with a working belt, and ...

Embodiment 2

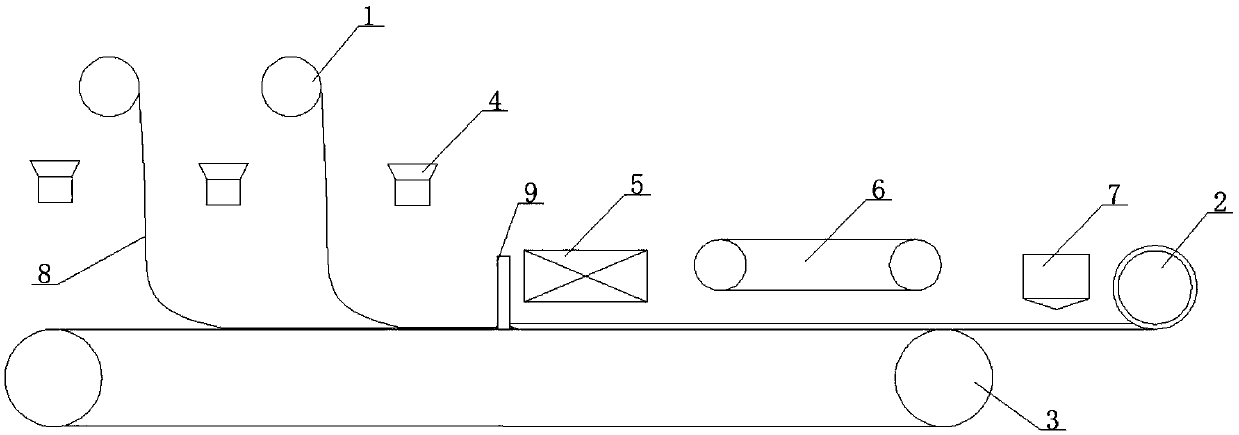

[0043] Such as figure 2 as shown, figure 2 It is a structural view of this embodiment of the fabric-reinforced thermoplastic composite plate production equipment of the present invention. Preferably, the fabric-reinforced thermoplastic composite sheet production equipment further includes a pretension device 9, the pretension device 9 is arranged between the preheating device 5 and the powder spreading device 4, and the prestressing device Preferably, a positioning device with an elastic structure is provided to realize the pressing and positioning effect on the continuous fiber fabric 8 .

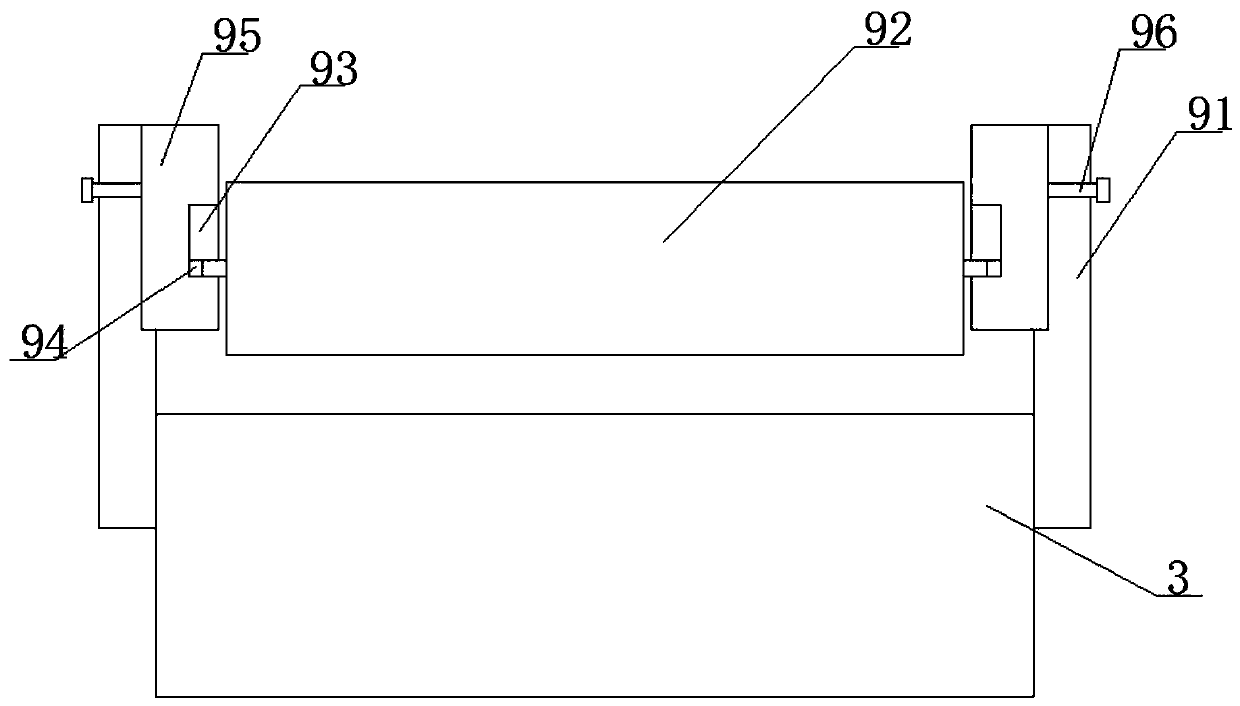

[0044] Such as image 3 as shown, image 3 It is a structural view of the pretensioning device 9; the pretensioning device 9 includes an adjusting part 91, an extruding part 92 and an elastic part 93, the extruding part 92 is connected with the adjusting part 91, and the adjusting part 91 Fixedly connected with the supporting roller table 3 , the adjustment part 91 can adjust the hei...

Embodiment 3

[0053] The production method of the fabric-reinforced composite sheet of the present invention comprises steps:

[0054] S1, fixing the continuous fiber fabric 8 on the braking device, and driving the continuous fiber fabric 8 to move through the braking device;

[0055] S2, the powder spreading device 4 is turned on and evenly spreads resin powder on the surface of the continuous fiber fabric 8 moved out of the unwinding part 1;

[0056] S3, the continuous fiber fabric 8 is preheated and dipped;

[0057] S4, the impregnated continuous fiber fabric 8 is preliminarily shaped by the pressing device 6, and then cut and wound by the cutting device 7.

[0058] Step S1 specifically includes: placing the continuous fiber fabric 8 on the unwinding part 1 and spreading it out. The unwinding roller of the unwinding section 1 is preferably set as an air shaft, which can be adjusted in size, thereby improving the unwinding stability of the continuous fiber fabric 8 . One end of the unw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com