Method for preparing room-temperature chlorine gas sensitive material with porous hierarchical structure

A technology of hierarchical structure and sensitive materials, applied in the field of sensing materials, can solve the problems of limiting gas sensitivity, increasing manufacturing costs, uneven powder distribution, etc., to improve long-term work stability, reduce manufacturing costs, and improve impregnation rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

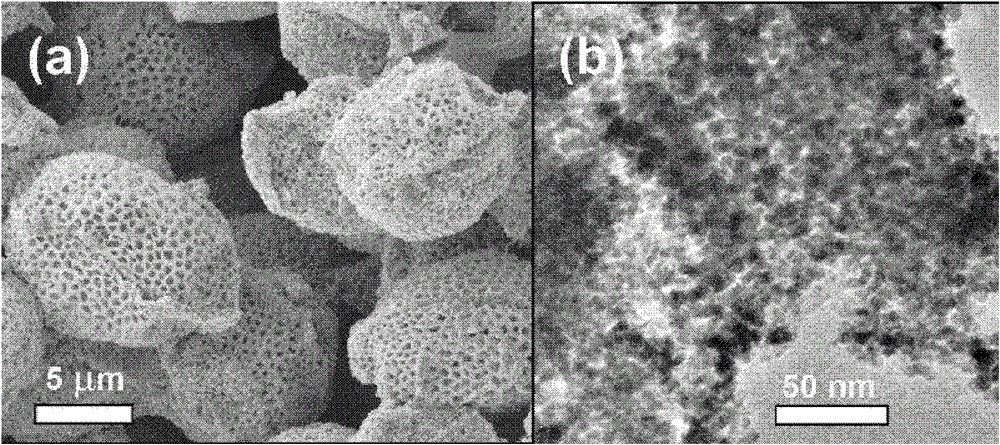

Embodiment 1

[0028] Rape pollen is selected as raw material for pretreatment. Rinse the pollen in absolute alcohol and dry. The treated dry pollen was placed in 1M SnCl 4 After immersion in alcohol solution for 14 hours, the pollen was separated by filtration and washed with alcohol for 3 times, then placed in water for washing, after filtration and separation, placed in a drying oven to dry, and then placed in an oxidation furnace to heat up at a heating rate of 2 °C / min. 600 ℃ and hold for 1.5 hours for burning treatment, then stop heating, and take out the burning product white powder after the furnace cavity is naturally cooled to room temperature, that is, a three-dimensional porous hierarchical structure composed of small grains with a size of 3.8 nm is obtained. Tin nanomaterials. Its microstructure is shown in figure 1 As shown, the porosity is 0.26 and the average pore size is 6.3 nm. After grinding the obtained tin oxide material, use an appropriate amount of deionized water ...

Embodiment 2

[0033] Rape pollen is selected as raw material for pretreatment. Rinse the pollen in anhydrous alcohol solution, air dry, and place the treated dry pollen in 1M SnCl 4 After immersion in alcohol solution for 14 hours, the pollen obtained by filtration and separation was washed with alcohol for 3 times, placed in water for cleaning and adjusted to pH=8 with ammonia water, filtered and separated again and put into a drying oven to dry, and then placed in an oxidation furnace with 2 The heating rate of ℃ / min was raised to 700 ℃ and kept for 1.5 hours for burning treatment, and the heating was stopped. After the furnace cavity was naturally cooled to room temperature, the white powder of the burning product was taken out, that is, small grains with a size of 4.2 nm were obtained. Three-dimensional porous hierarchical structure of tin oxide nanomaterials. Compared with Example 1, its microstructure is shrunk, the pore walls are thin and smooth, the porosity is 0.20, the average po...

Embodiment 3

[0035] Rape pollen is selected as raw material for pretreatment. Rinse pollen repeatedly in alcohol and dry. Place the treated dry pollen in 1M SnCl 4+CTAB in alcohol solution, immersion pretreatment for 14 hours. The pollen was separated by filtration and washed with alcohol for 3 times, then placed in water for washing, filtered and separated again and put into a drying oven to dry. The pollen obtained above was put into an oxidation furnace and heated to 800°C at a heating rate of 2°C / min and kept for 1.5 hours for burning treatment, and the heating was stopped. After the furnace cavity was naturally cooled to room temperature, the burning product white powder was taken out, That is, the tin oxide nanomaterial with a three-dimensional porous hierarchical structure composed of small crystal grains with a size of 4.9 nm is obtained and a tin dioxide gas sensing material with a porous hierarchical structure is obtained. Its microstructure is further shrunk compared to Examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com