Solid electrolytic capacitor element, its manufacturing method and its manufacturing tool

A technology of solid electrolysis and manufacturing method, applied in the direction of electrolytic capacitor manufacturing, solid electrolytic capacitor, capacitor manufacturing, etc., can solve the problems of rising, corrosion and deterioration of the dielectric layer, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

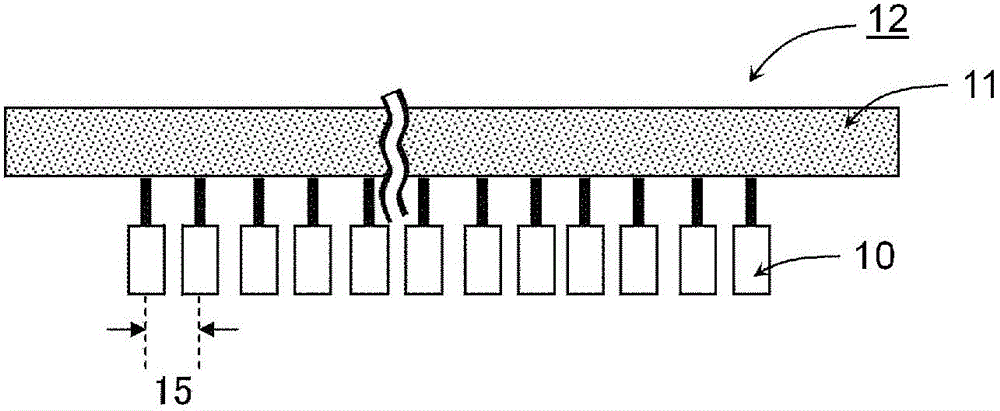

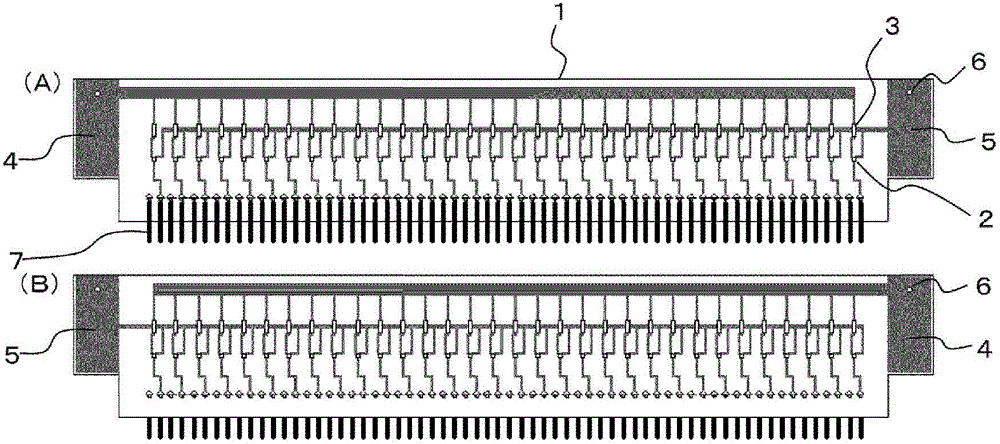

Method used

Image

Examples

Embodiment 1~3 and comparative example 1~4

[0091] After the niobium ingot was stored hydrogen, it was pulverized, dehydrogenated, nitrided, and then granulated to obtain niobium powder with a CV of 150,000 μF·V / g and a nitrogen content of 8,600 ppm. The niobium powder is molded together with a niobium lead wire of 0.29 mmФ, and vacuum sintered at 1280 ° C for 30 minutes to obtain a size of 1.5 × 3.0 × 4.5 mm (volume is 20.25 mm) 3 ), the density is 3.3g / cm 3 There are 640 niobium sintered bodies, and these niobium sintered bodies are used as anode bodies. In addition, the niobium lead was implanted in the center of the 1.5×3.0 mm surface so that 3.7 mm was buried inside the sintered body and 4.3 mm was exposed on the outer surface.

[0092] A separately prepared spacer made of tetrafluoroethylene polymer having an outer diameter of 2 mm, an inner diameter of 0.26 mm, and a thickness of 0.2 mm was inserted into the lead wire at a position 0.2 mm from the surface of the sintered body.

[0093] Next, connect the front e...

Embodiment 4~5 and comparative example 5~6

[0108] In the same manner as in Example 1, niobium powder with a CV value of 220,000 μF·V / g and a nitrogen content of 15,000 ppm was prepared by adjusting the pulverization time and nitriding treatment time to obtain a sintered body. About this niobium sintered body (1.0×2.4×3.4mm (volume 8.16mm 3 ) except that the electrolytic polymerization conditions were set to the values shown in Table 2, a capacitor element was produced in the same manner as in Example 1, and the capacity of the obtained capacitor element was measured to obtain the impregnation rate. The results are shown in Table 2. In addition, Table 5 shows the average capacity of the capacitors produced in the same manner as in Example 1 and the range of the upper and lower limit values of the capacity.

[0109] Table 2

[0110]

Embodiment 6~7 and comparative example 7~8

[0112] In Example 1, commercially available tantalum powder CV 70,000 μF·V / g was used instead of niobium powder. The tantalum powder was vacuum sintered at 1400°C for 30 minutes to obtain a density of 6.5g / cm 3 , size 2.5×3.8×7.2mm (volume 68.4mm 3 ) of the sintered body. Furthermore, on the sintered body, a tantalum lead with a diameter of 0.40 mmФ was planted on the 2.5×3.8 mm surface of the sintered body.

[0113] Capacitor elements were produced in the same manner as in Example 1 except that the conditions of electrolytic polymerization were set to the values shown in Table 3, and the capacitance of the obtained capacitor elements was measured to obtain the impregnation rate. The results are shown in Table 3. In addition, Table 5 shows the average capacity of the capacitors produced in the same manner as in Example 1 and the range of the upper and lower limit values of the capacity.

[0114] table 3

[0115]

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| apparent porosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com