Patents

Literature

798results about How to "Control Uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of controlling the film properties of a CVD-deposited silicon nitride film

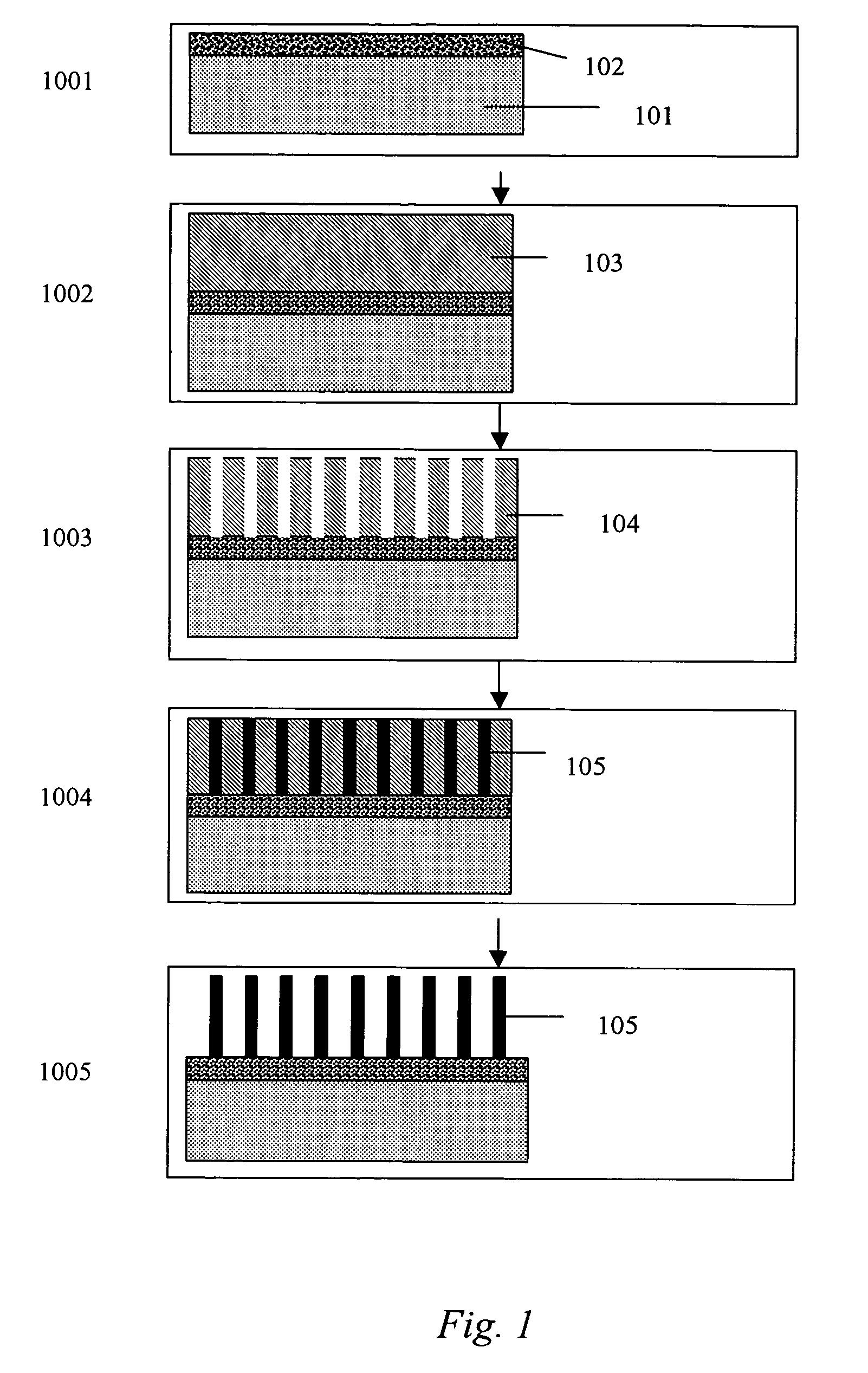

InactiveUS20060019502A1Increase wet etch rateEasy to controlSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGate dielectricGas composition

We have discovered that adding H2 to a precursor gas composition including SiH4, NH3, and N2 is effective at improving the wet etch rate and the wet etch rate uniformity across the substrate surface of a-SiNx:H films which are deposited on a substrate by PECVD. Wet etch rate is an indication of film density. Typically, the lower the wet etch rate, the denser the film. The addition of H2 to the SiH4 / NH3 / N2 precursor gas composition did not significantly increase the variation in deposited film thickness across the surface of the substrate. The a-SiNx:H films described herein are particularly useful as TFT gate dielectrics in the production of flat panel displays. The uniformity of the film across the substrate enables the production of flat panel displays having surface areas of 25,000 cm2 and larger.

Owner:APPLIED MATERIALS INC

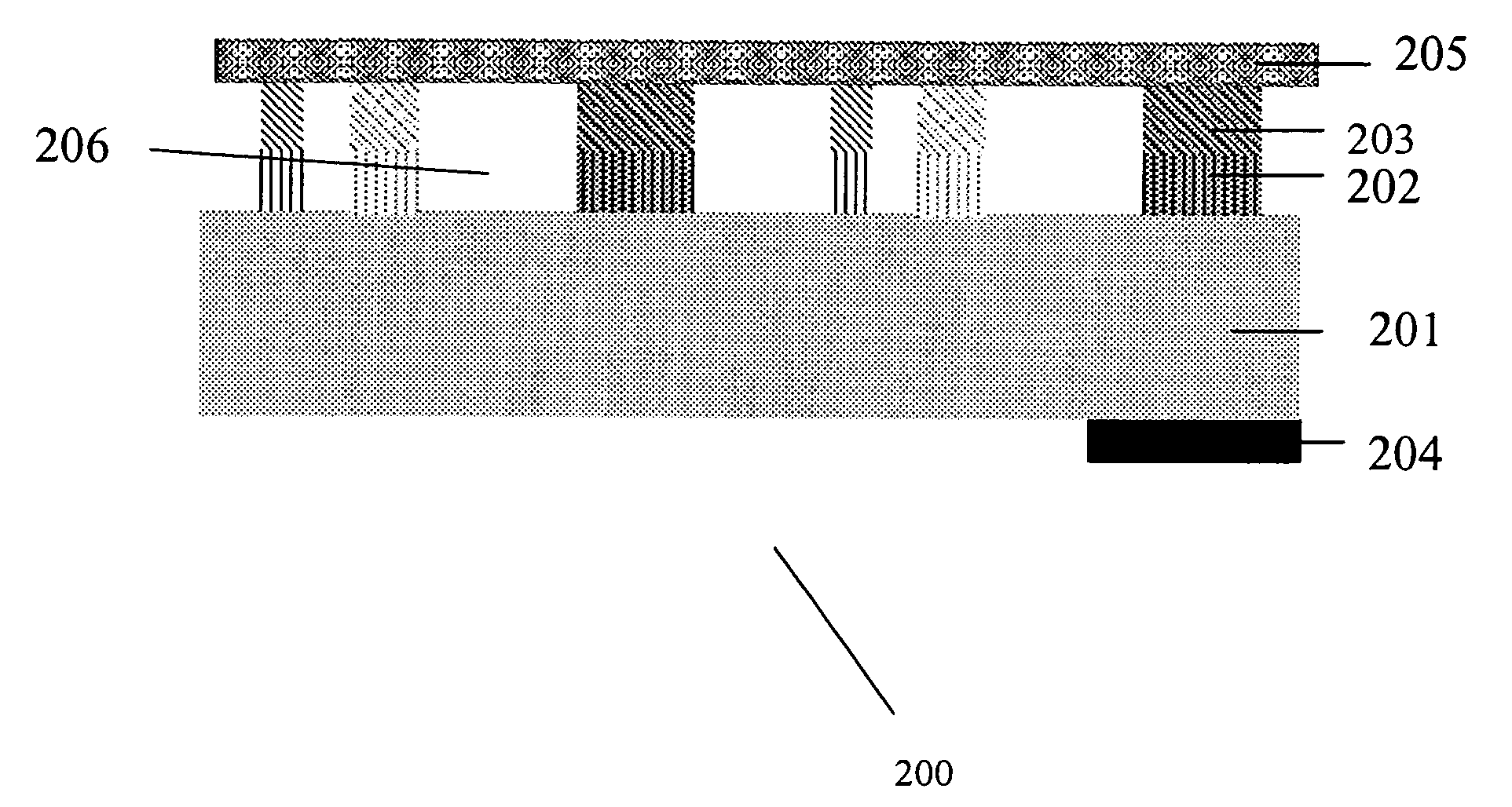

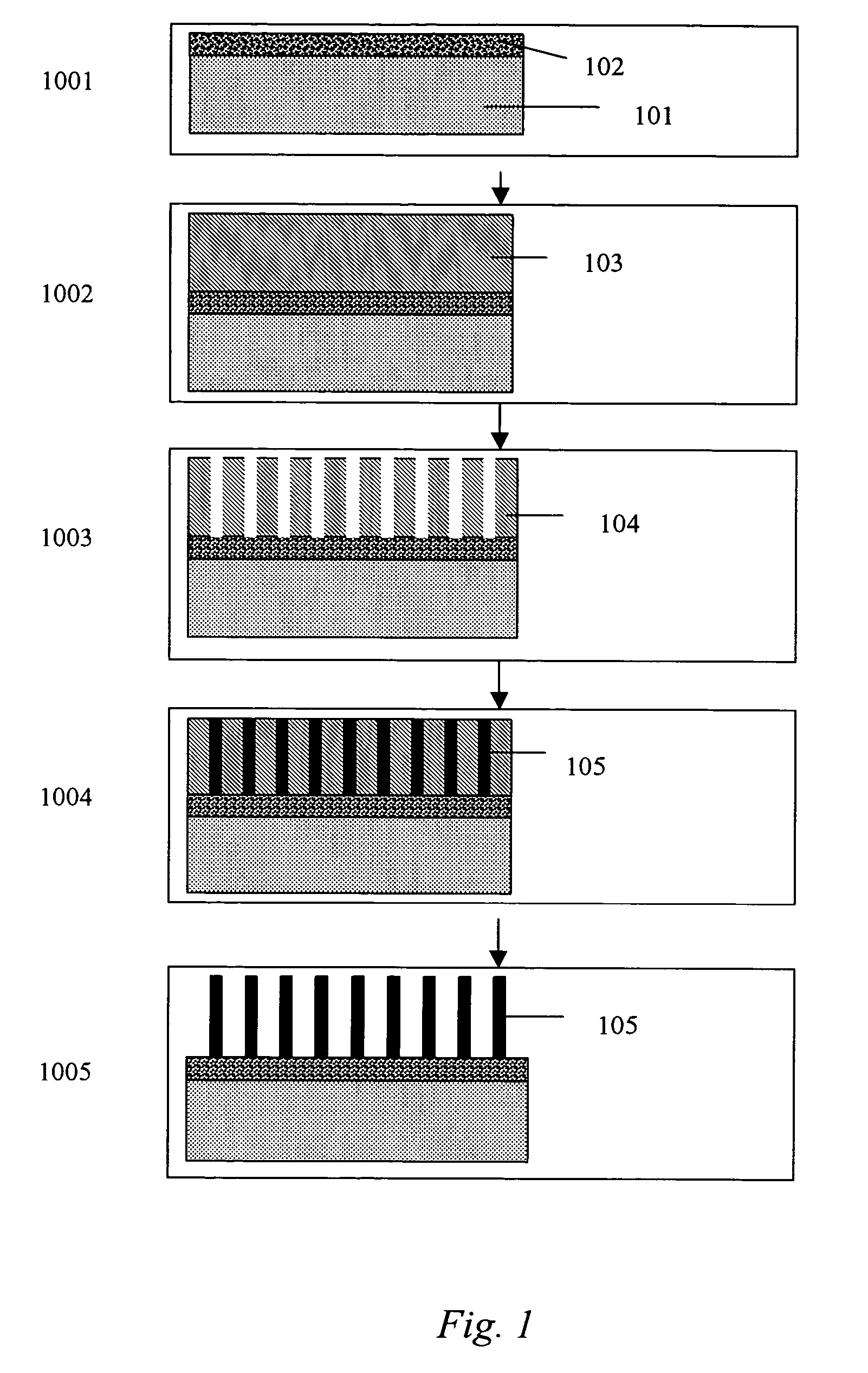

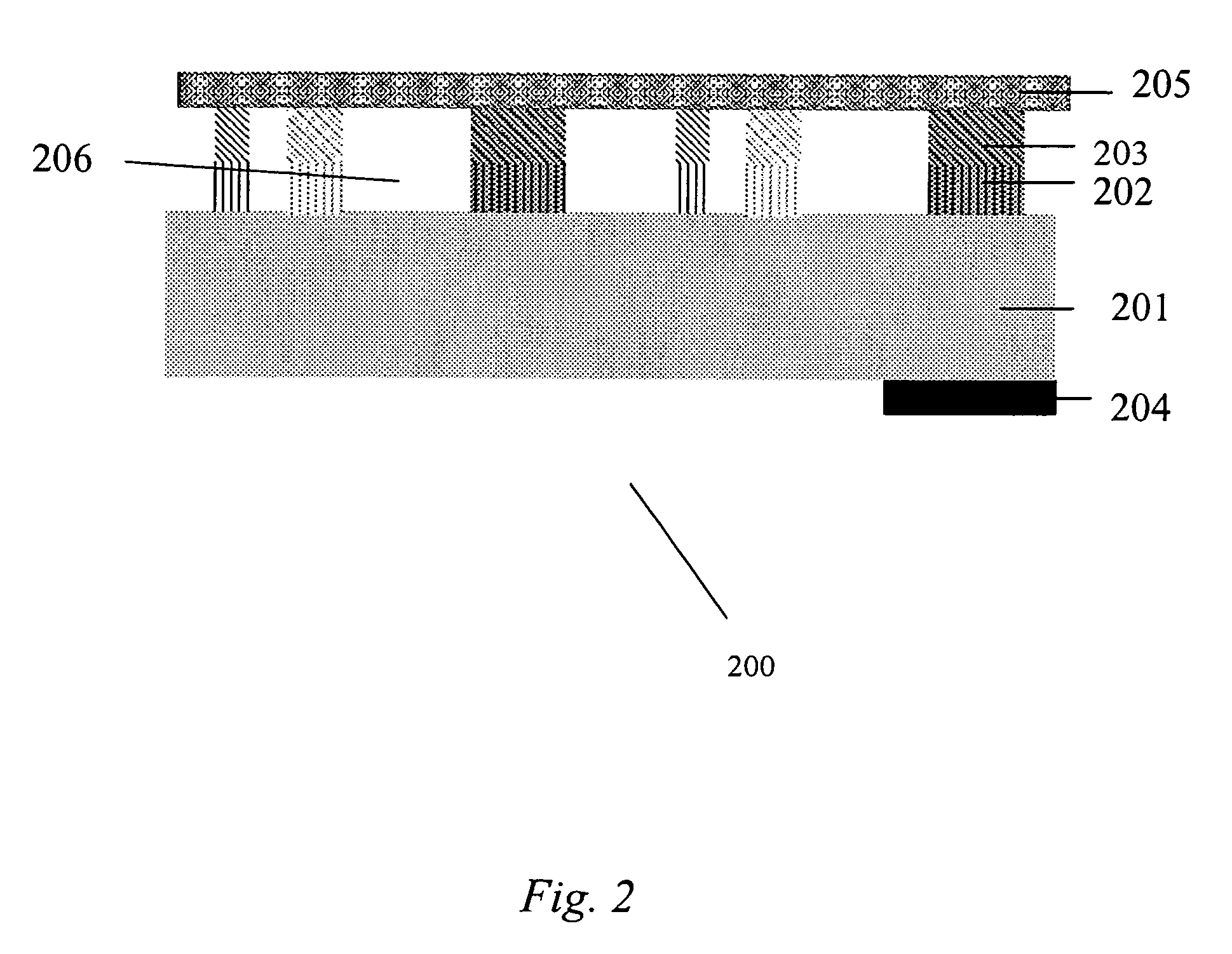

Monolithic light emitting devices based on wide bandgap semiconductor nanostructures and methods for making same

InactiveUS20050082543A1Reduce defectsSmall sizeLaser detailsLaser active region structureNanolithographyPhosphor

The present invention is directed toward a method for fabricating low-defect nanostructures of wide bandgap materials and to optoelectronic devices, such as light emitting sources and lasers, based on them. The invention utilizes nanolithographically-defined templates to form nanostructures of wide bandgap materials that are energetically unfavorable for dislocation formation. In particular, this invention provides a method for the fabrication of phosphor-less monolithic white light emitting diodes and laser diodes that can be used for general illumination and other applications.

Owner:GENERAL ELECTRIC CO

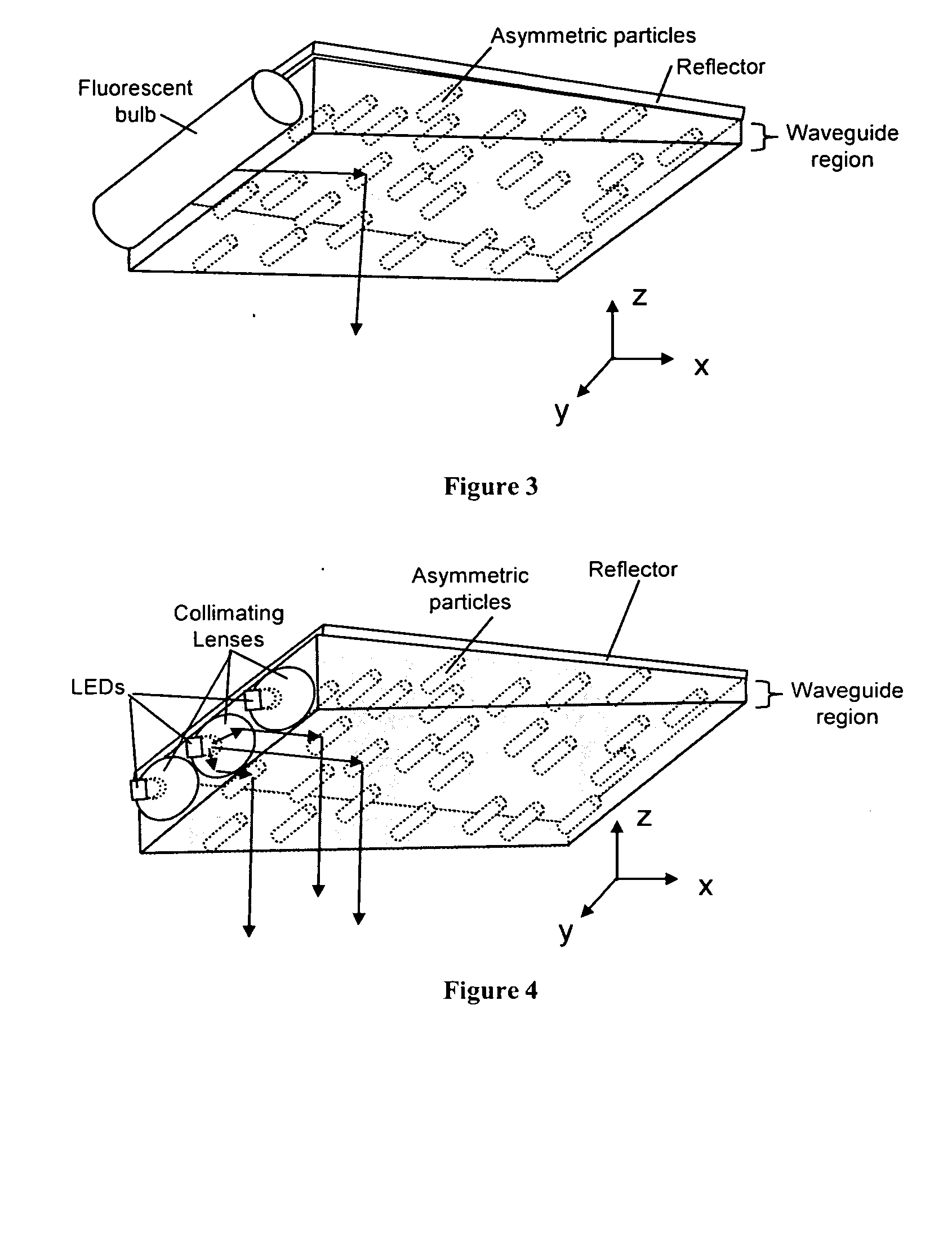

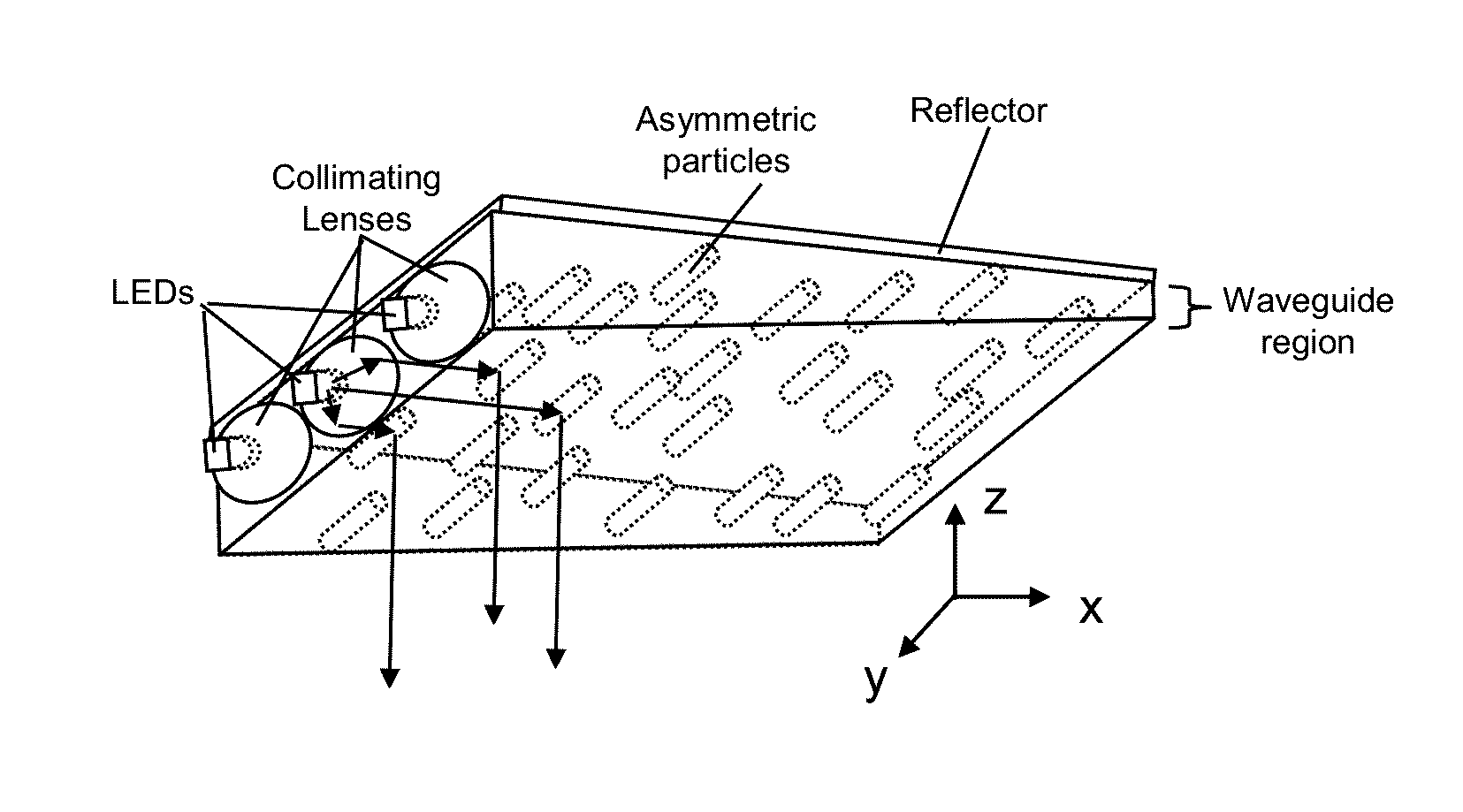

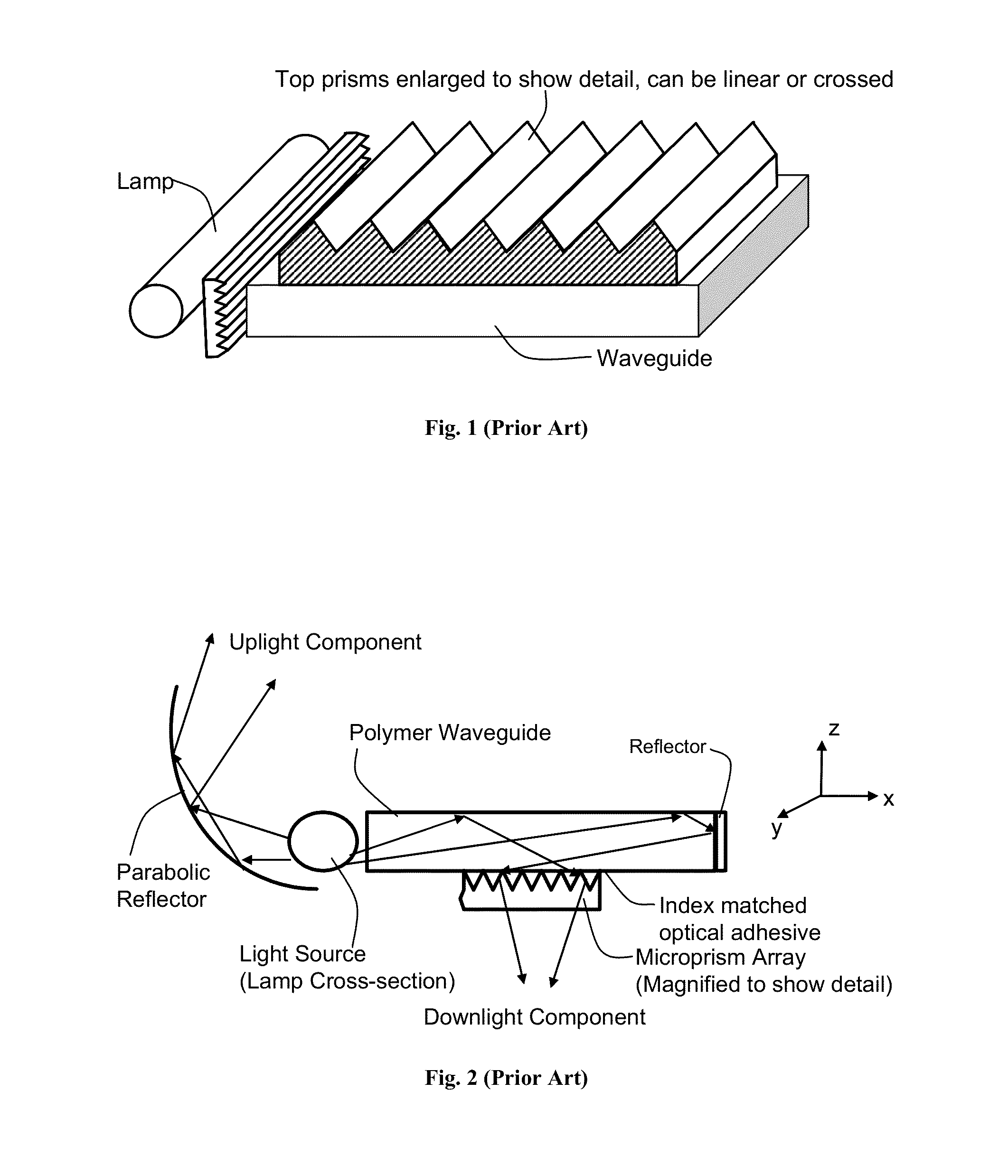

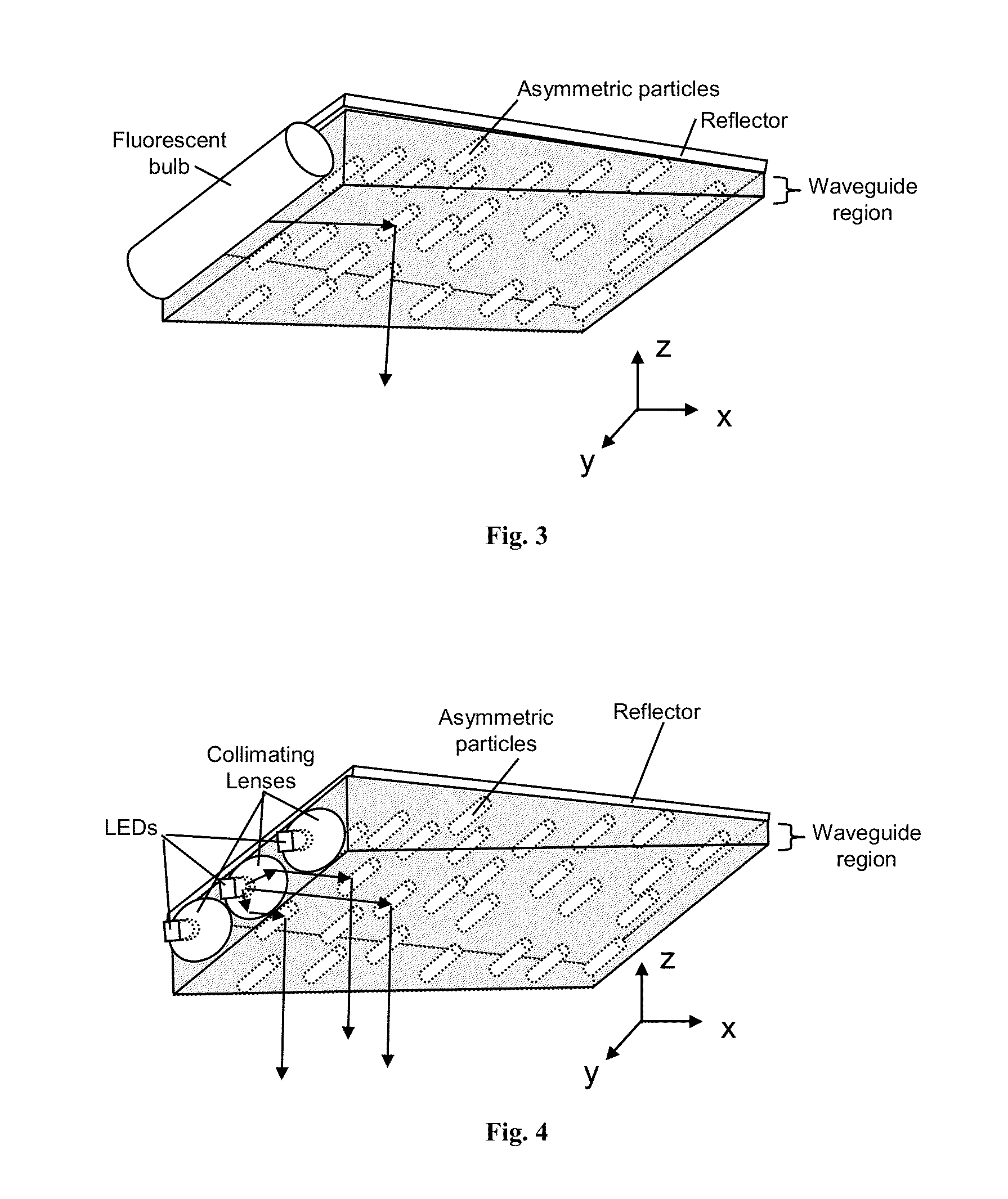

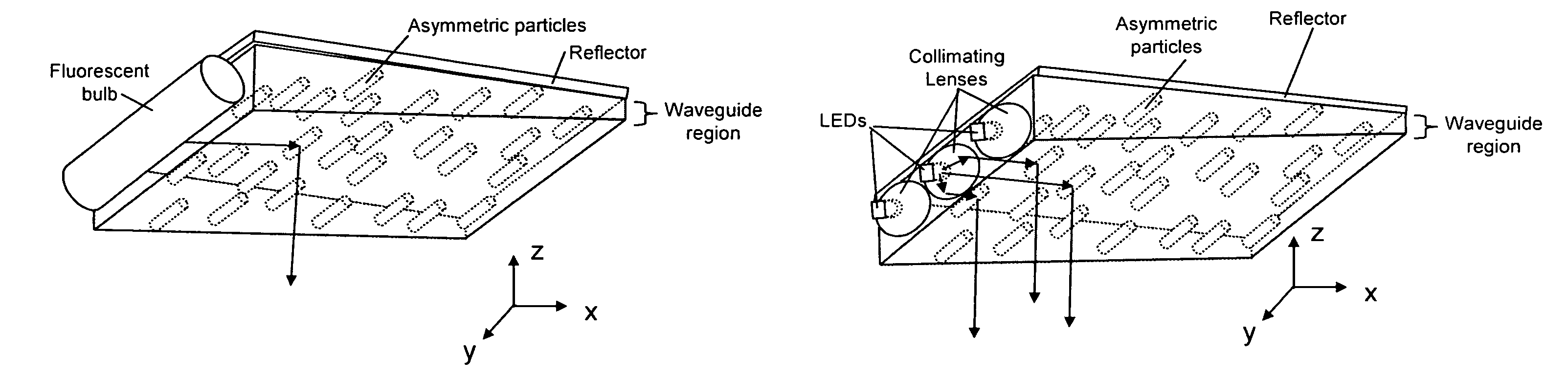

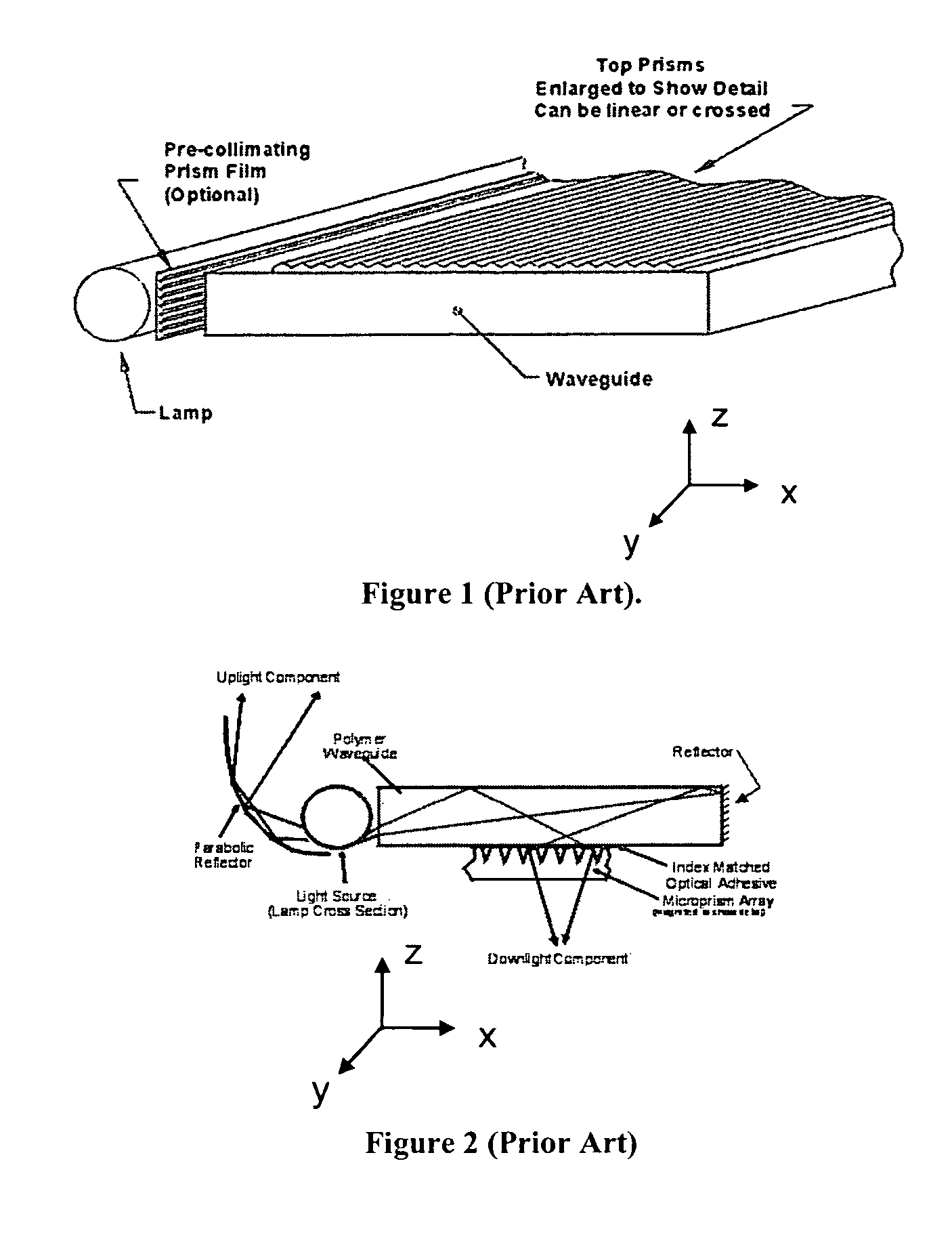

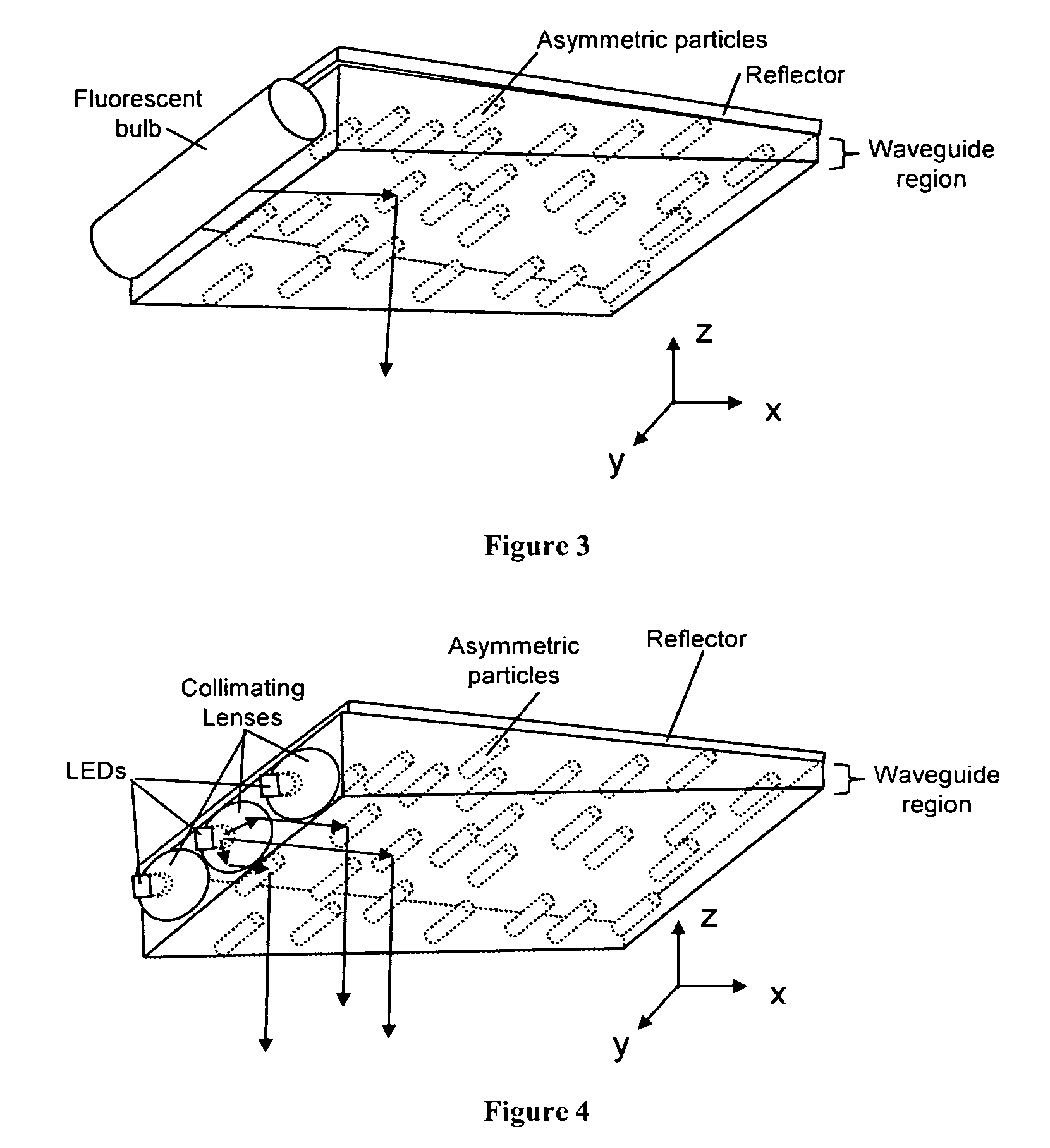

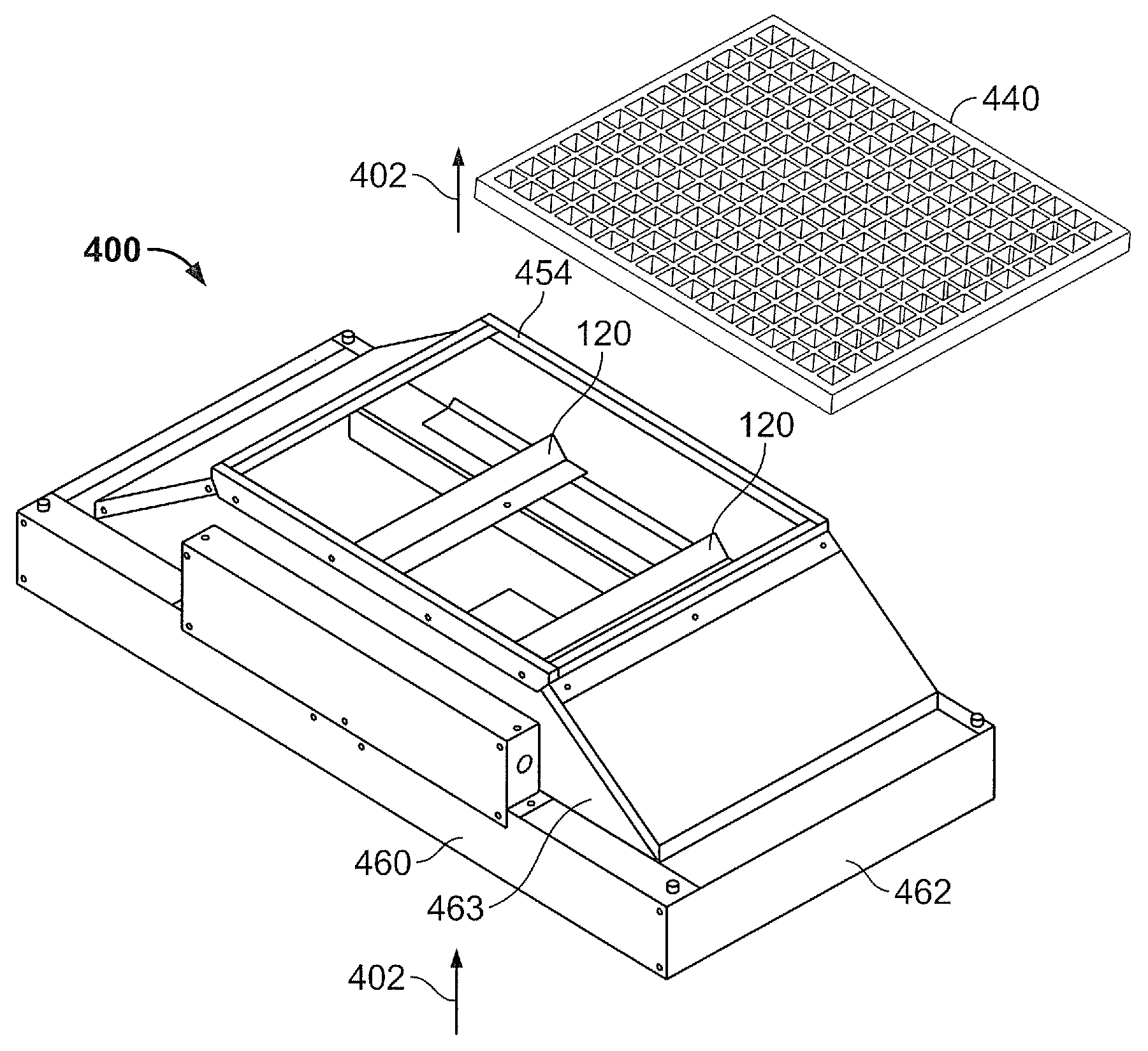

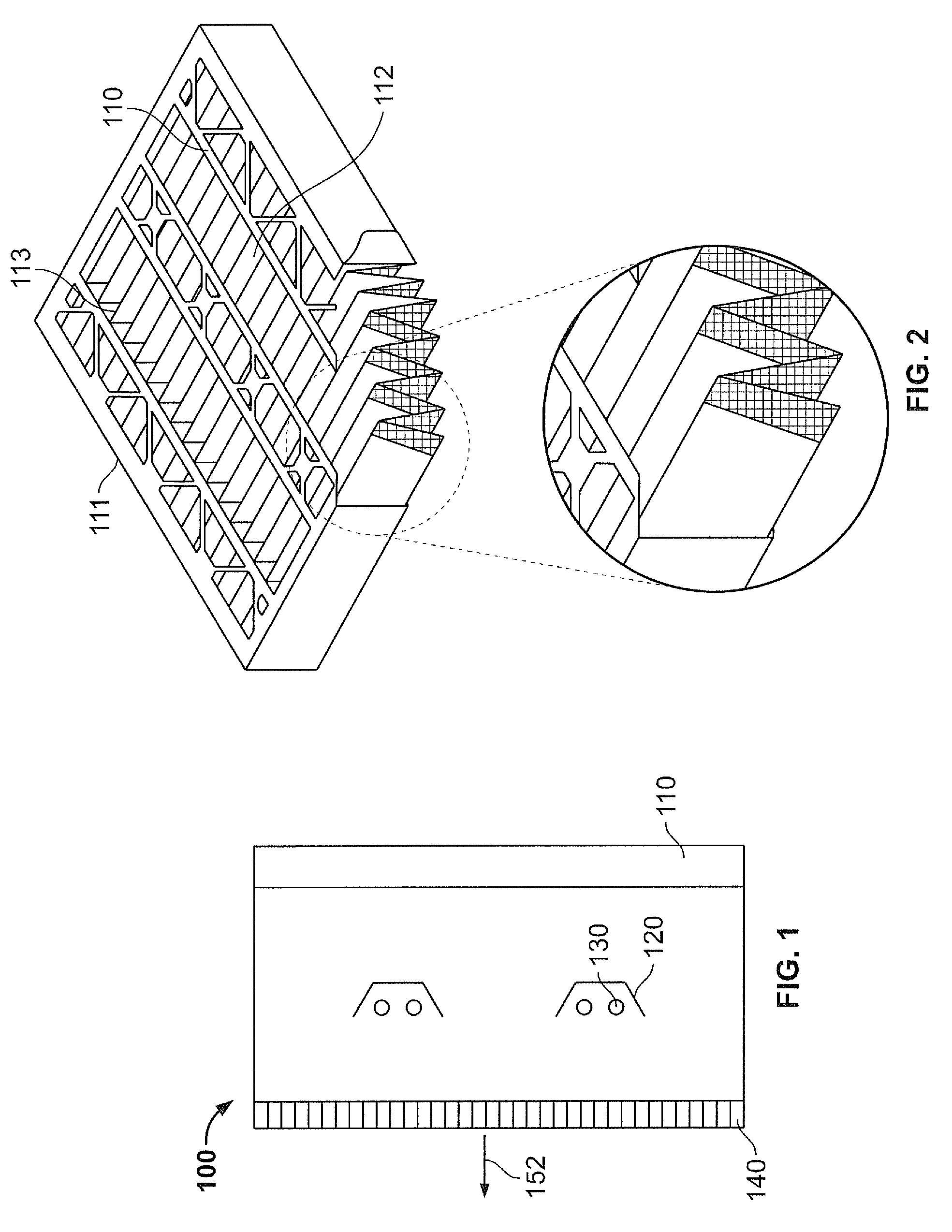

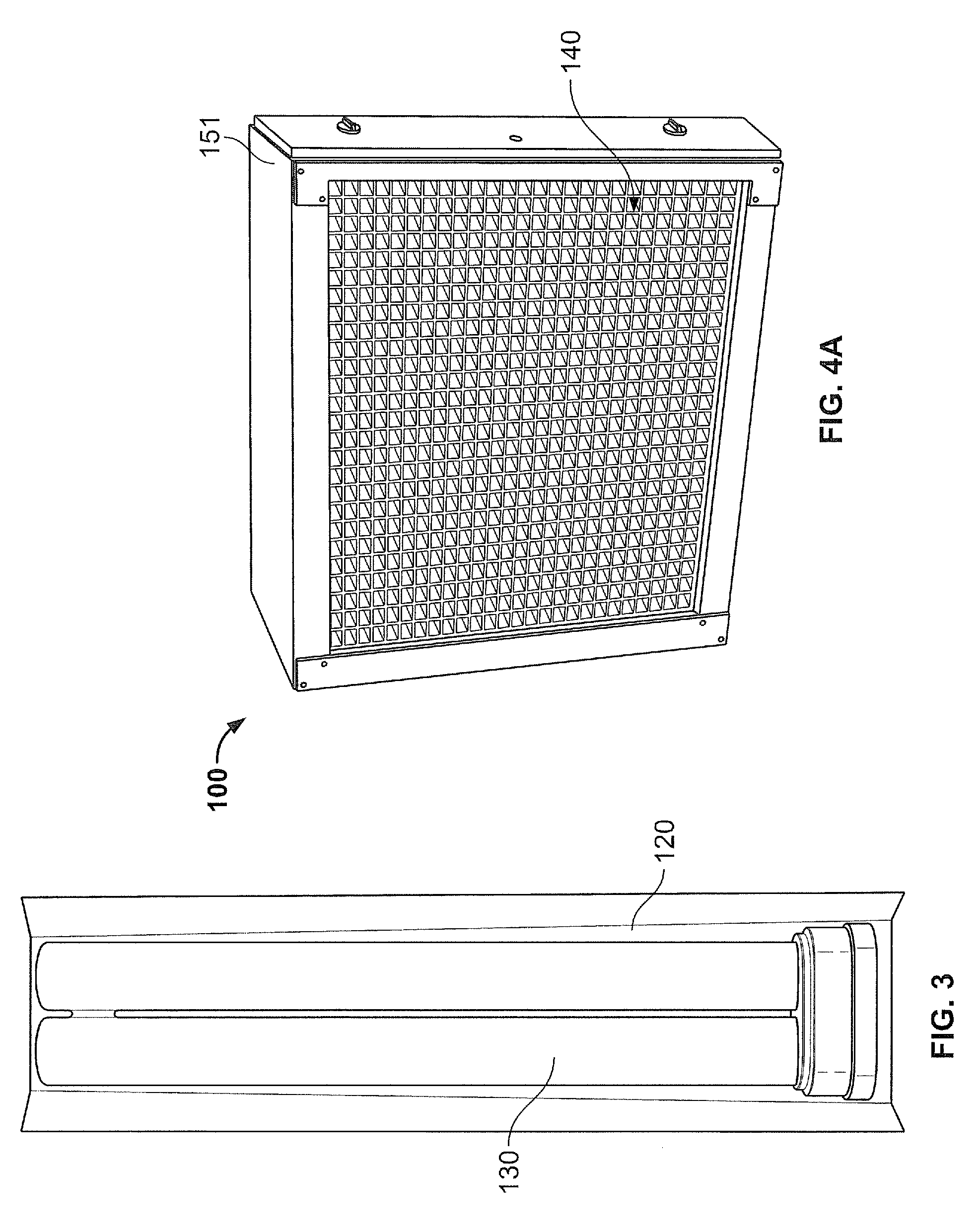

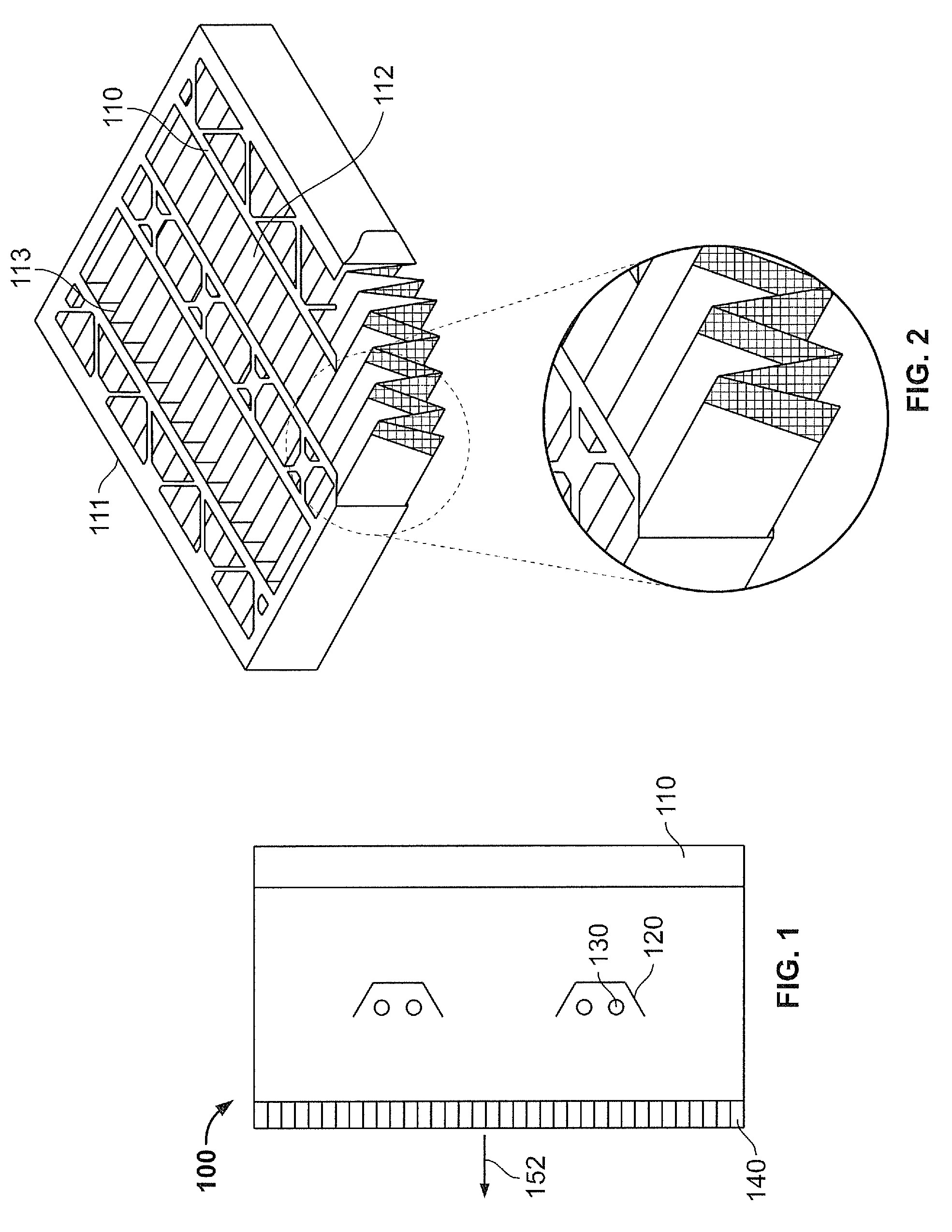

Enhanced light fixture

ActiveUS20060227546A1Effective controlEasy to cleanPlanar light sourcesMechanical apparatusIlluminanceReduced size

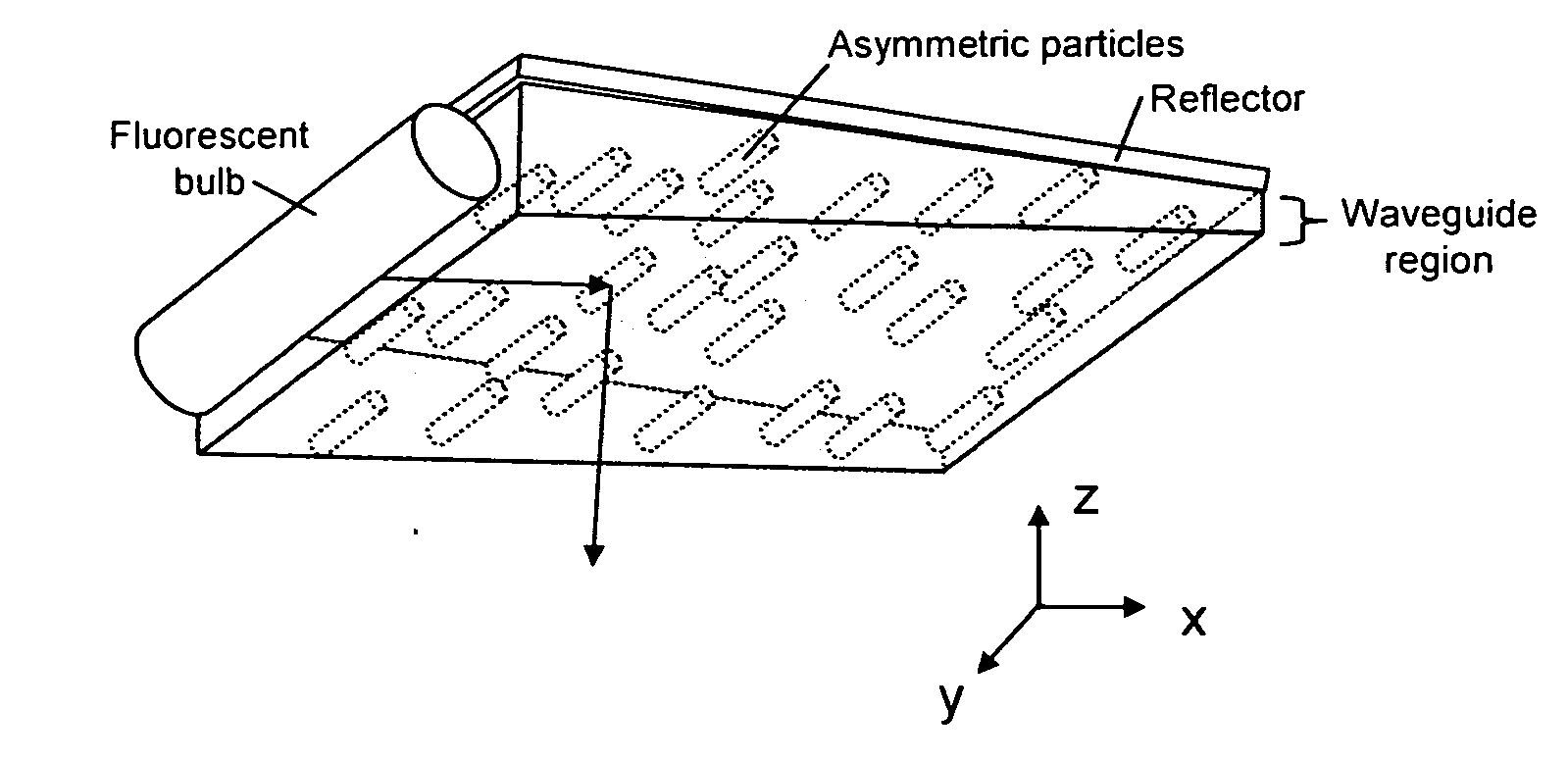

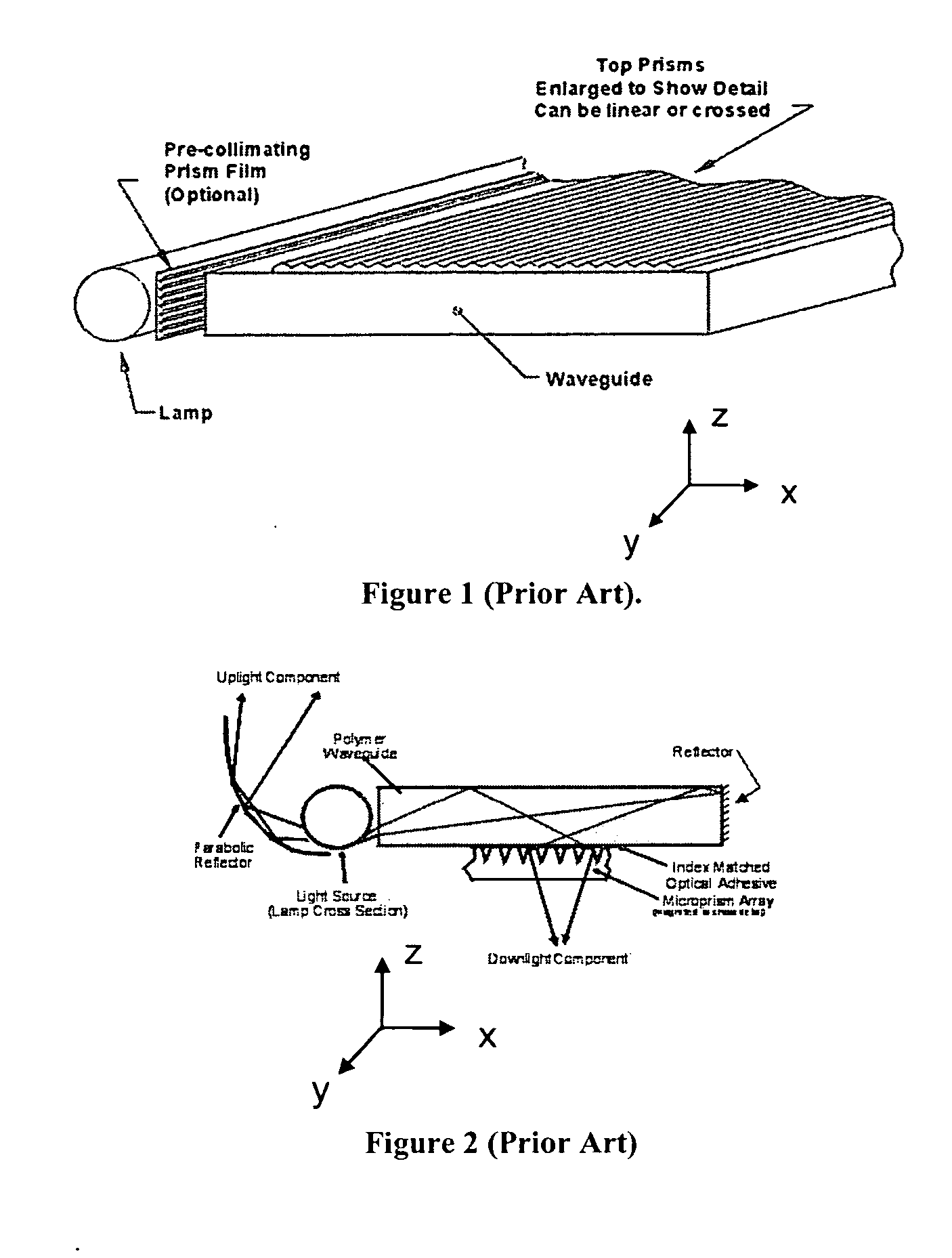

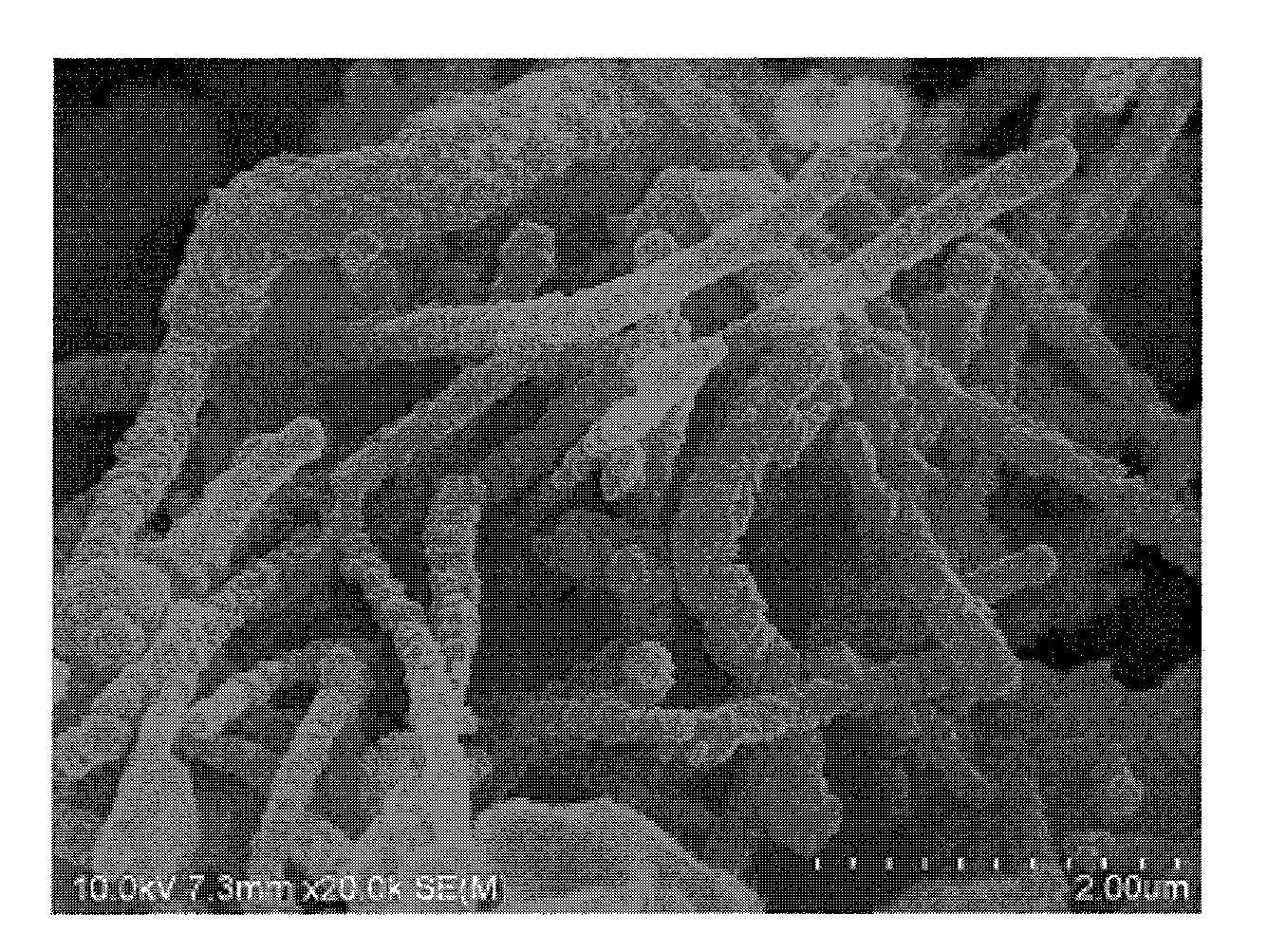

An enhanced light fixture containing a volumetric, anisotropic diffuser to control the spatial luminance uniformity and angular spread of light from the light fixture is disclosed. The anisotropic diffuser provides increased spatial luminance uniformity and efficient control over the illuminance such that power reductions, reduced cost or reduced size may be achieved. The anisotropic diffuser contains one or more regions of asymmetrically shaped light scattering particles. The spread of illumination of light from a light emitting source can be efficiently controlled by using a thin, low cost, volumetric, asymmetric diffuser to direct the light in the desired direction. This allows the reduction in number of light sources, a reduction in power requirements, or a more tailored illumination. When the anisotropic diffuser is used in combination with a waveguide to extract light, the light is efficiently coupled out of the waveguide in a thin, planar surface. This transmissive diffuser can be coupled to a reflecting element such that the resulting combination is a light reflecting element with a desired asymmetric light scattering profile.

Owner:MASSACHUSETTS DEV FINANCE AGENCY

Enhanced light fixture with volumetric light scattering

ActiveUS8430548B1Effective controlProvide spatial luminance uniformityPlanar light sourcesMechanical apparatusIlluminanceReduced size

An enhanced light fixture containing a volumetric diffuser to control the spatial luminance uniformity and angular spread of light from the light fixture is disclosed. The volumetric diffuser provides increased spatial luminance uniformity and efficient control over the illuminance such that power reductions, reduced cost or reduced size may be achieved. The volumetric diffuser contains one or more regions of volumetric light scattering particles. The spread of illumination of light from a light emitting source can be efficiently controlled by using a thin, low cost, volumetric, diffuser to direct the light in the desired direction. This allows the reduction in number of light sources, a reduction in power requirements, or a more tailored illumination. When the volumetric diffuser is used in combination with a waveguide to extract light, the light is efficiently coupled out of the waveguide in a thin, planar surface. This transmissive diffuser can be coupled to a reflecting element such that the resulting combination is a light reflecting element with a desired light scattering profile.

Owner:MASSACHUSETTS DEV FINANCE AGENCY +1

Enhanced light fixture

ActiveUS7431489B2Effective controlEasy to cleanPlanar light sourcesMechanical apparatusIlluminanceReduced size

An enhanced light fixture containing a volumetric, anisotropic diffuser to control the spatial luminance uniformity and angular spread of light from the light fixture is disclosed. The anisotropic diffuser provides increased spatial luminance uniformity and efficient control over the illuminance such that power reductions, reduced cost or reduced size may be achieved. The anisotropic diffuser contains one or more regions of asymmetrically shaped light scattering particles. The spread of illumination of light from a light emitting source can be efficiently controlled by using a thin, low cost, volumetric, asymmetric diffuser to direct the light in the desired direction. This allows the reduction in number of light sources, a reduction in power requirements, or a more tailored illumination. When the anisotropic diffuser is used in combination with a waveguide to extract light, the light is efficiently coupled out of the waveguide in a thin, planar surface. This transmissive diffuser can be coupled to a reflecting element such that the resulting combination is a light reflecting element with a desired asymmetric light scattering profile.

Owner:MASSACHUSETTS DEV FINANCE AGENCY

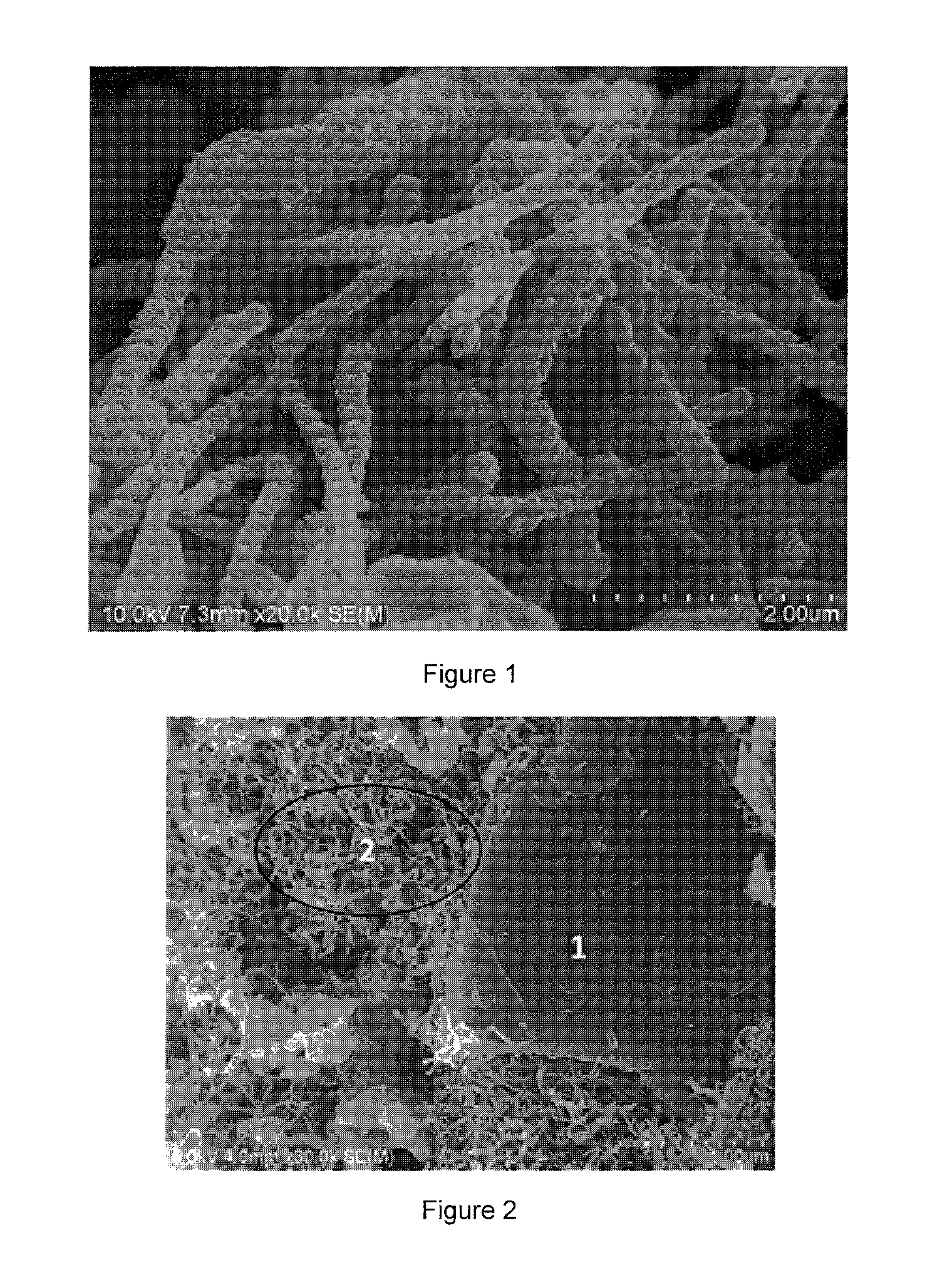

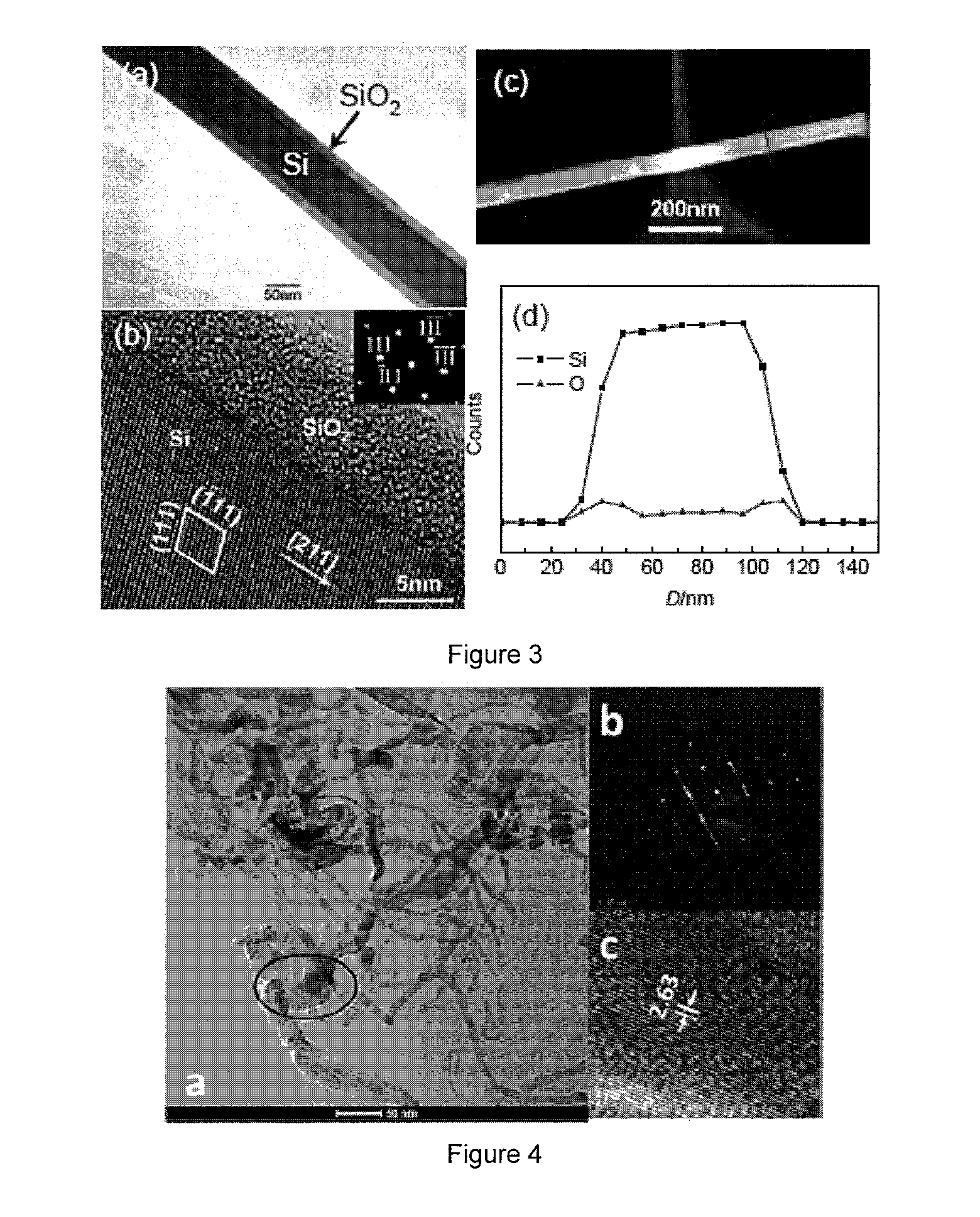

NANO silicon-carbon composite material and preparation method thereof

ActiveUS20140302396A1Improve cycle stabilityShort production processMaterial nanotechnologyElectrolysis componentsCarbon compositesSilicon dioxide

The invention relates to a nano silicon-carbon composite negative material for lithium ion batteries and a preparation method thereof. A porous electrode composed of silica and carbon is taken as a raw material, and a nano silicon-carbon composite material of carbon-loaded nano silicon is formed by a molten salt electrolysis method in a manner of silica in-situ electrochemical reduction. Silicon and carbon of the material are connected by nano silicon carbide, and are metallurgical-grade combination, so that the electrochemical cycle stability of the nano silicon-carbon composite material is improved. The preparation method of the nano silicon-carbon composite material provided by the invention comprises the following steps: compounding a porous block composed of carbon and silica powder with a conductive cathode collector as a cathode; using graphite or an inert anode as an anode, and putting the cathode and anode into CaCl2 electrolyte or mixed salt melt electrolyte containing CaCl2 to form an electrolytic cell; applying voltage between the cathode and the anode; controlling the electrolytic voltage, the electrolytic current density and the electrolytic quantity, so that silica in the porous block is deoxidized into nano silicon by electrolytic reduction, and the nano silicon-carbon composite material for lithium ion batteries is prepared at the cathode.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

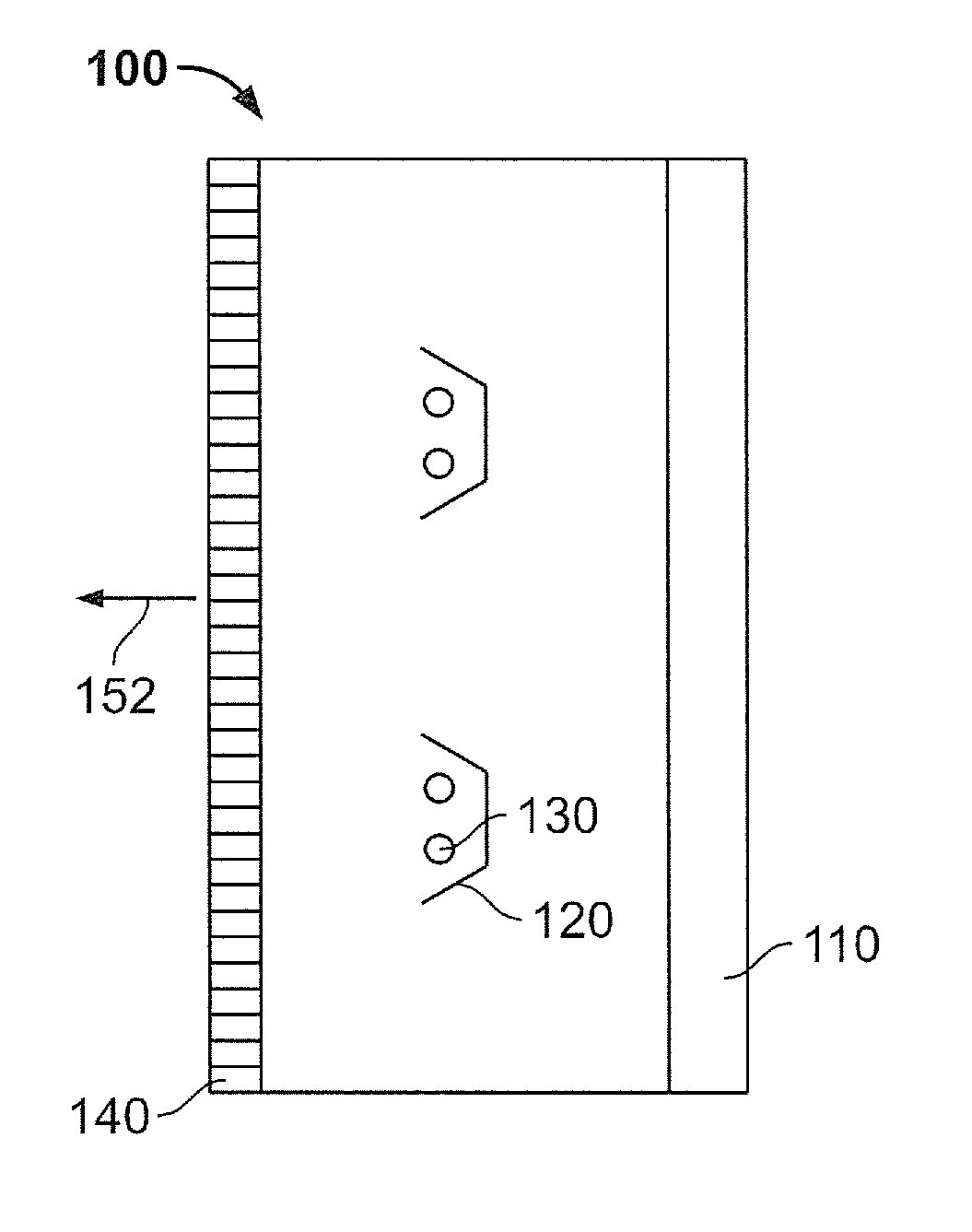

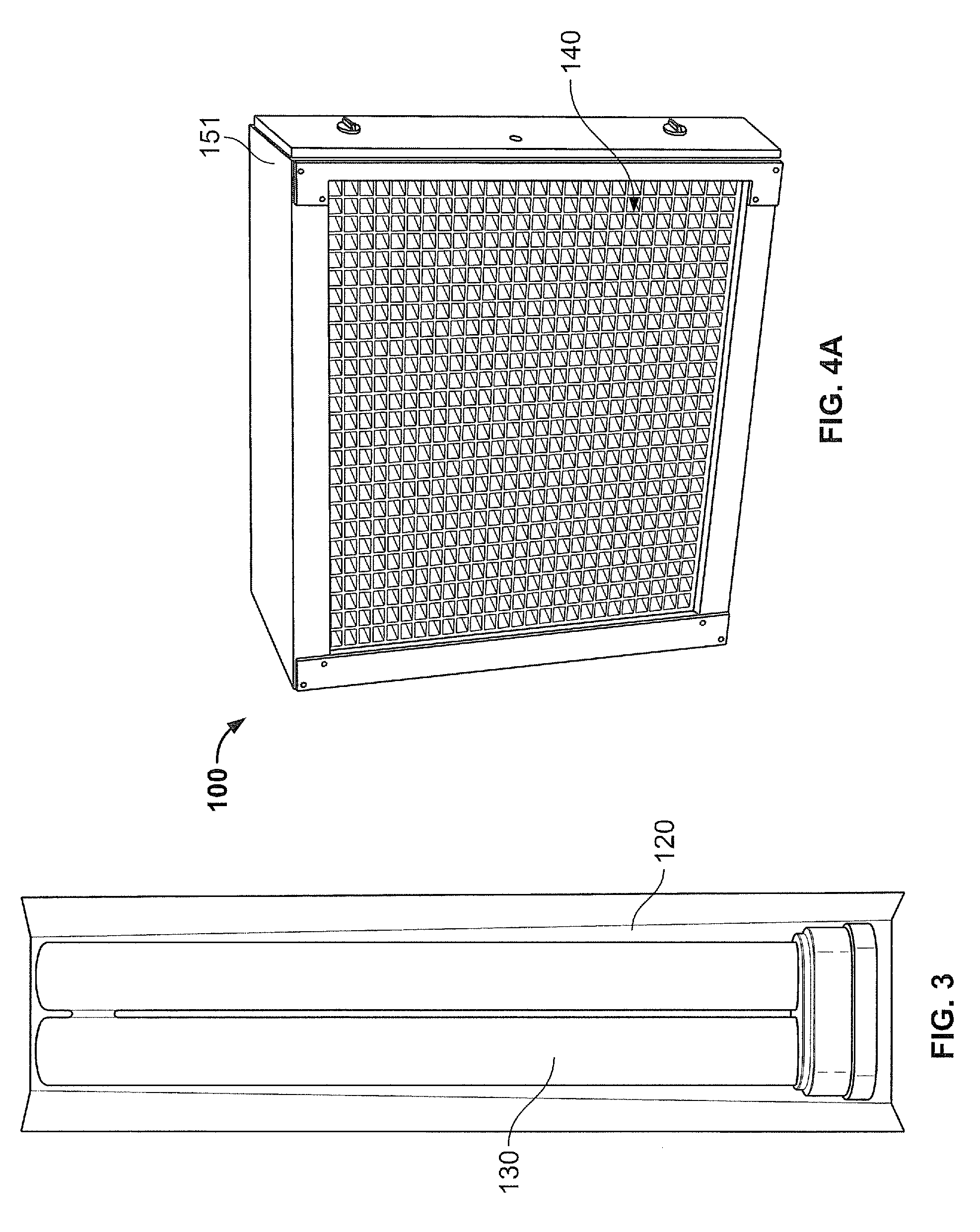

System and method for photocatalytic oxidation air filtration using a substrate with photocatalyst particles power coated thereon

ActiveUS20080286163A1Control thicknessControl UniformityPump componentsLighting and heating apparatusAir filtrationPhysical chemistry

The present invention relates to an air filtration system and a method for making a photocatalytic oxidation substrate by powder coating a photocatalyst onto a metal substrate.

Owner:SCI HEALTH DEV LTD

Monolithic light emitting devices based on wide bandgap semiconductor nanostructures and methods for making same

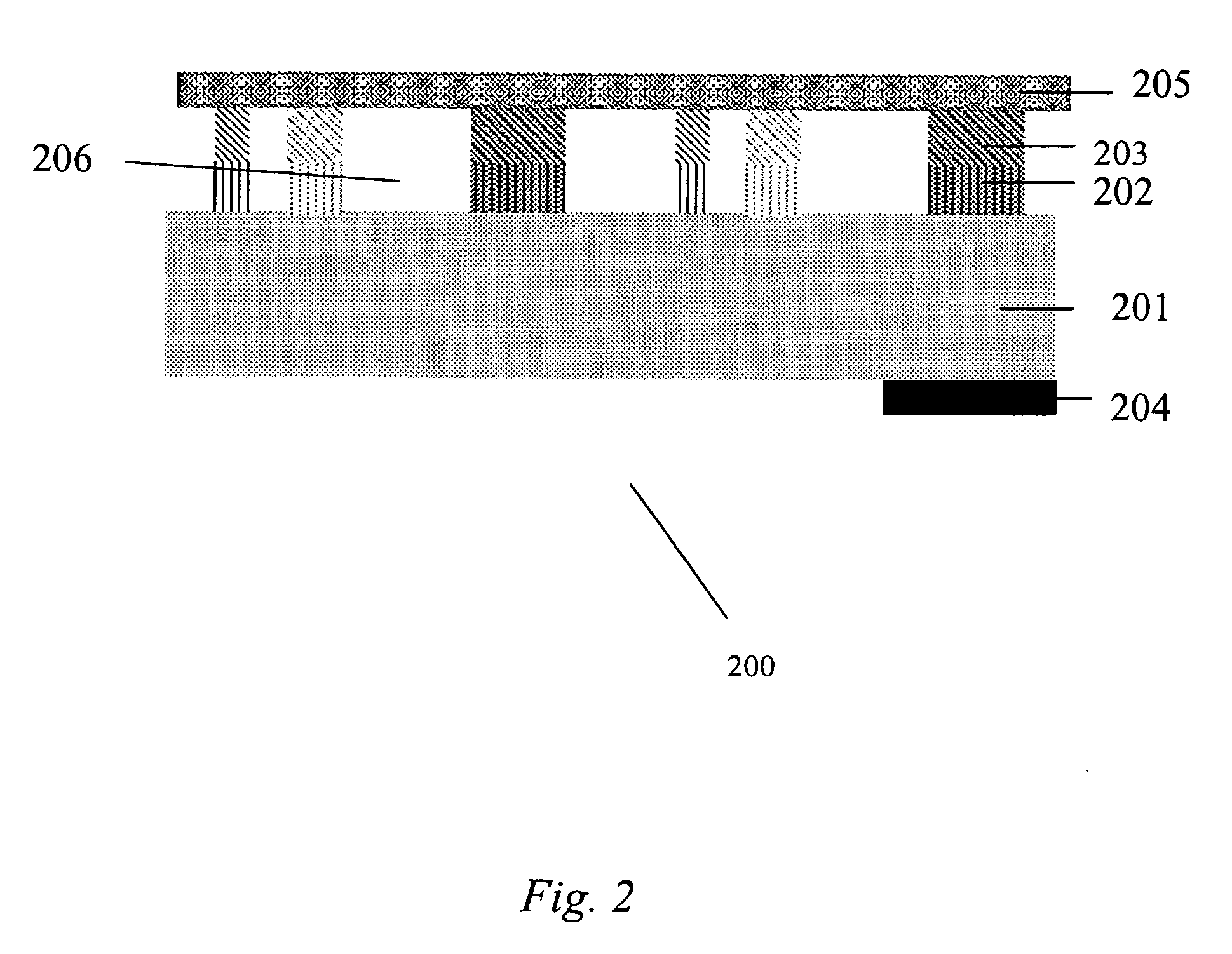

InactiveUS7122827B2Reduce defectsSmall sizeLaser detailsLaser active region structureNanolithographyNanostructure

The present invention is directed toward a method for fabricating low-defect nanostructures of wide bandgap materials and to optoelectronic devices, such as light emitting sources and lasers, based on them. The invention utilizes nanolithographically-defined templates to form nanostructures of wide bandgap materials that are energetically unfavorable for dislocation formation. In particular, this invention provides a method for the fabrication of phosphor-less monolithic white light emitting diodes and laser diodes that can be used for general illumination and other applications.

Owner:GENERAL ELECTRIC CO

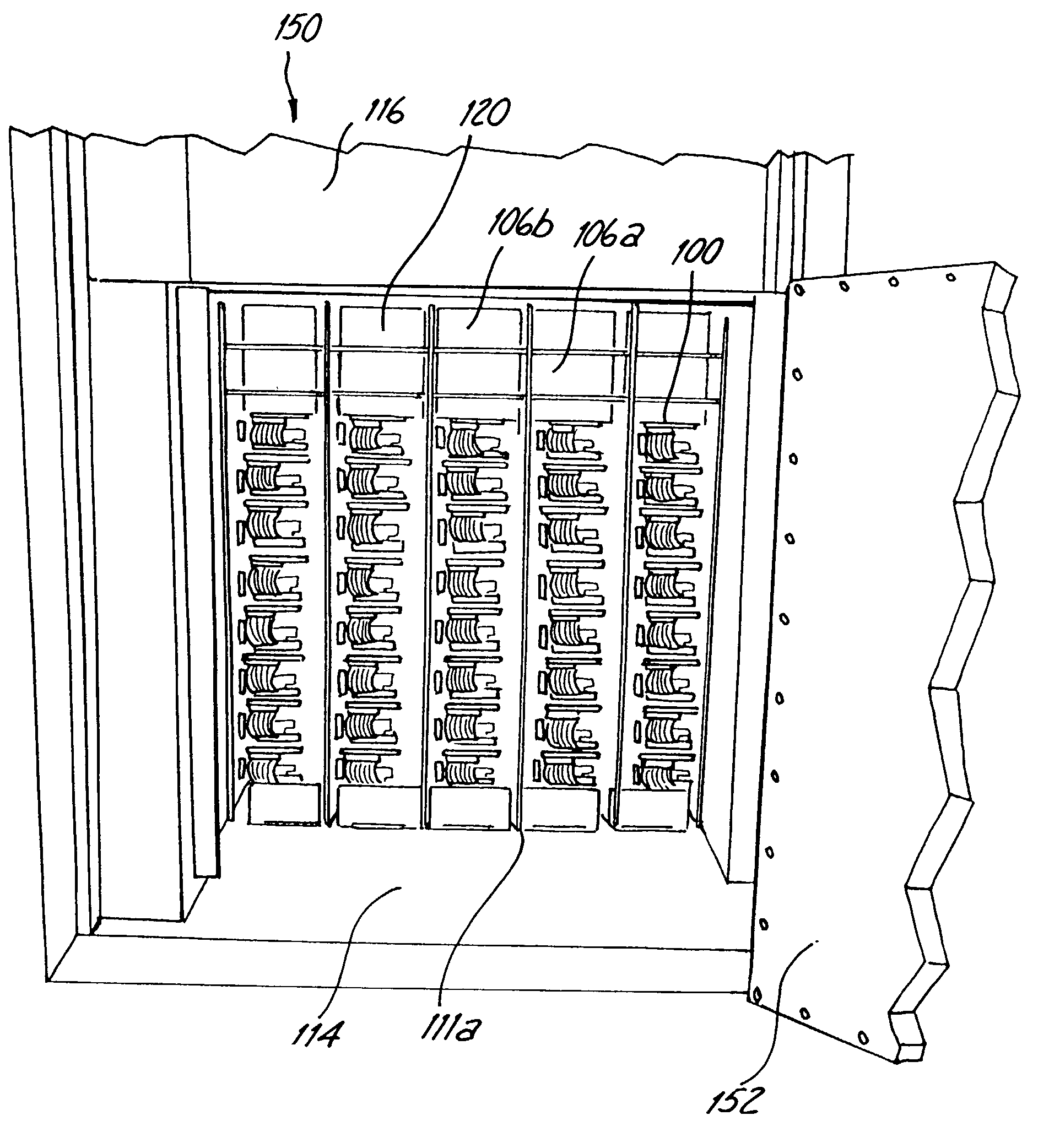

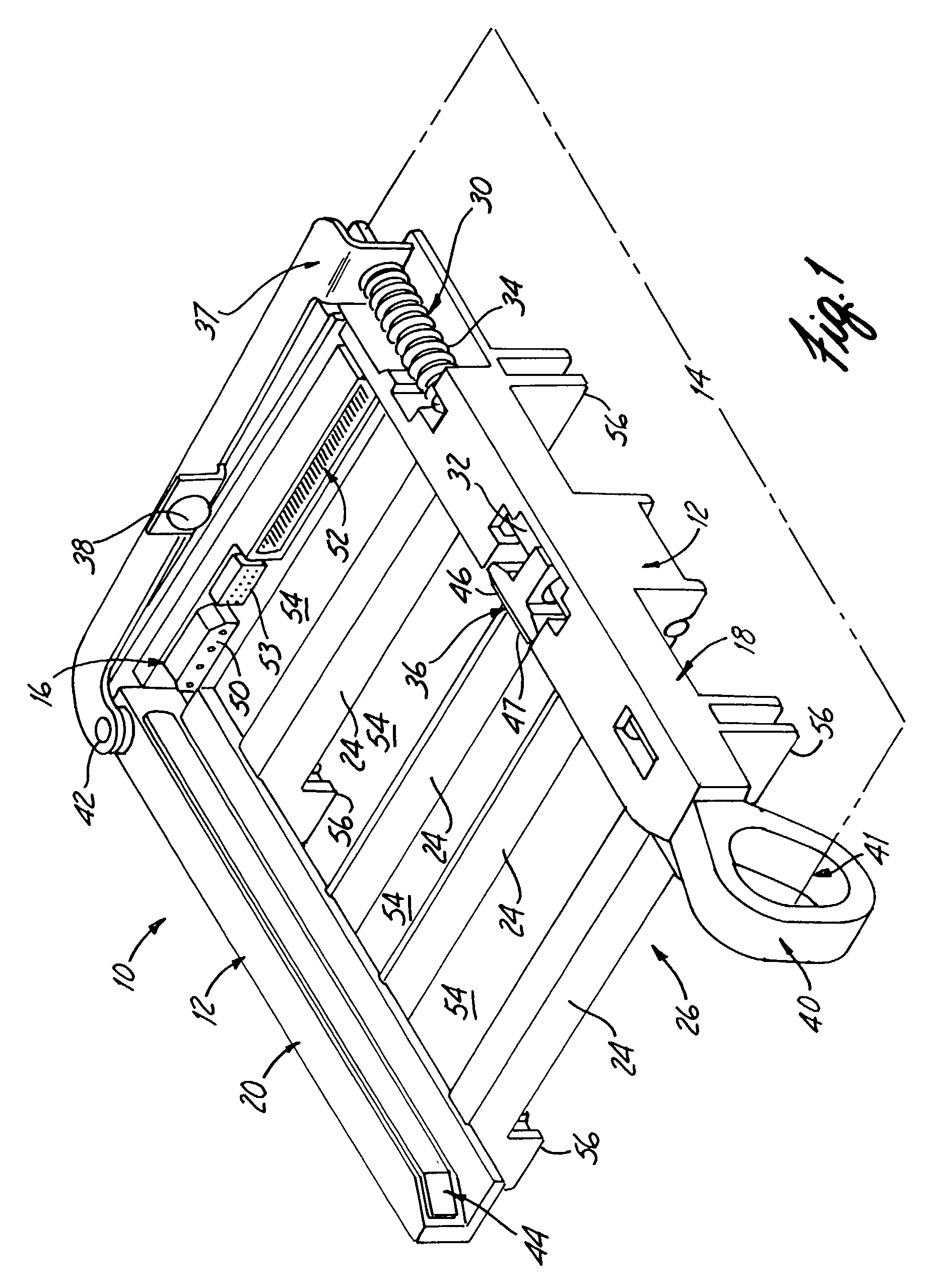

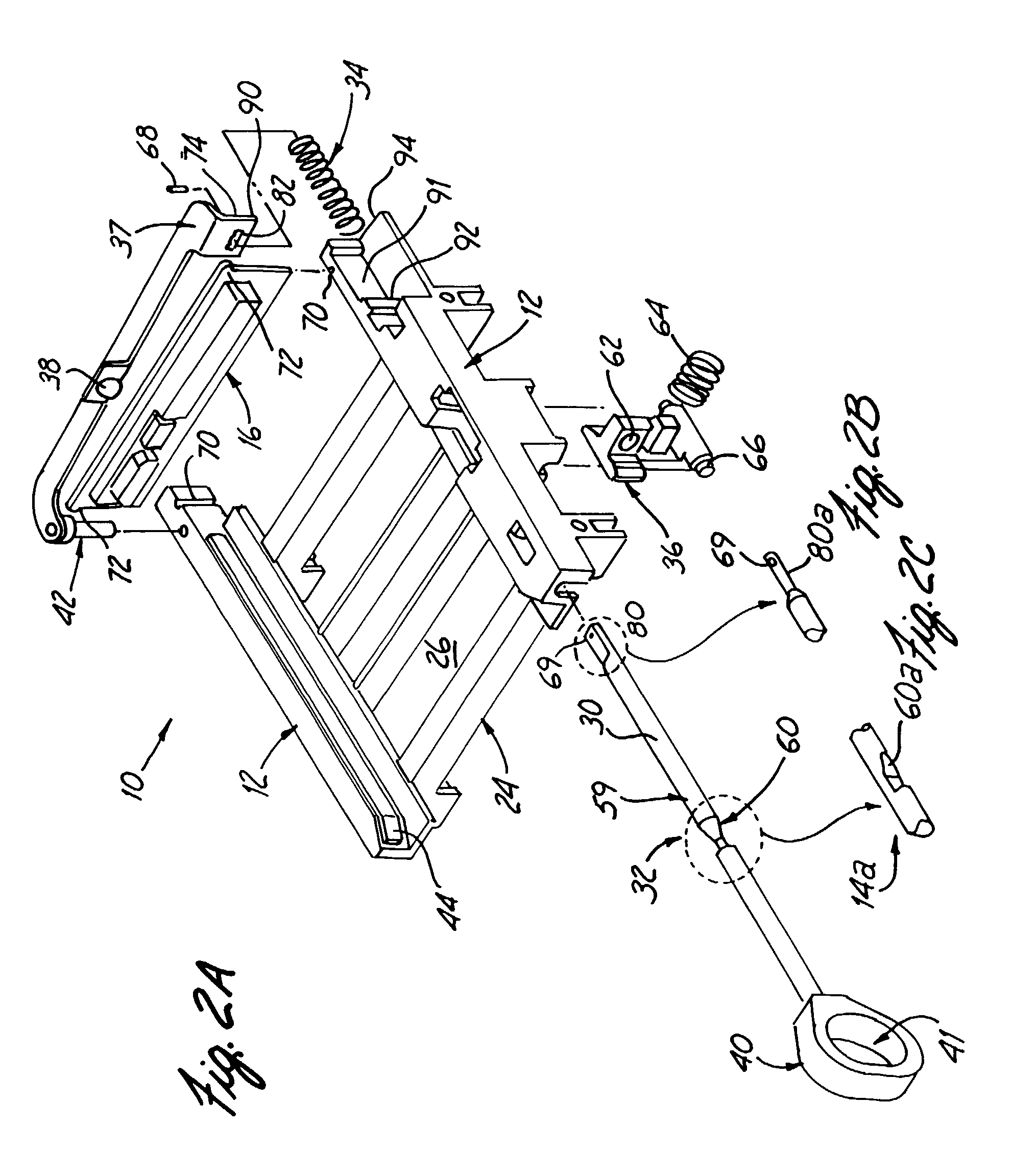

Environmental test chamber and a carrier for use therein

InactiveUS7070323B2Easy to adaptReduce the total massWeather/light/corrosion resistanceElectronic circuit testingBrickEngineering

One aspect of the present invention is a system of fabricating a barrier wall between the testing and tester volumes of an environmental test chamber. This aspect may use a plurality of pallets adapted to receive a device under test and a testing apparatus, a framework adapted to receive a plurality of pallets, and a plurality of insulation bricks associated with the plurality of pallets. The insulation bricks may be adapted such that they can cooperate to form an insulating barrier between the device under test and the testing apparatus.

Owner:BENCHMARK ELECTRONICS SUZHOU

Preparation method of electrostatic spinning hydrophobic nanofiber porous membrane for membrane distillation

The invention relates to a preparation method of an electrostatic spinning hydrophobic nanofiber porous membrane for membrane distillation. The method comprises the following steps of: dissolving a hydrophobic functional polymer material in the solvent to get a 1-35wt% polymer spinning solution, performing electrostatic spinning to get a hydrophobic nanofiber porous membrane, and further performing thermal treatment, thereby obtaining the electrostatic spinning hydrophobic nanofiber porous membrane for membrane distillation. The preparation method provided by the invention is simple and practicable, and can be used for conveniently and accurately controlling the thickness and uniformity of the nanofiber membrane and realizing operations of mass production more easily; the high-hydrophobicity nanofiber porous membrane prepared by the preparation method can be used for signally improving the defects of the conventional membrane for membrane distillation that the water flux is low and the membrane pores get wet easily, so that the membrane distillation technology can compete with a reverse osmosis technology in the seawater desalination field.

Owner:DONGHUA UNIV

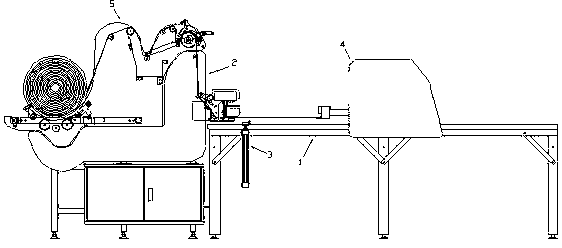

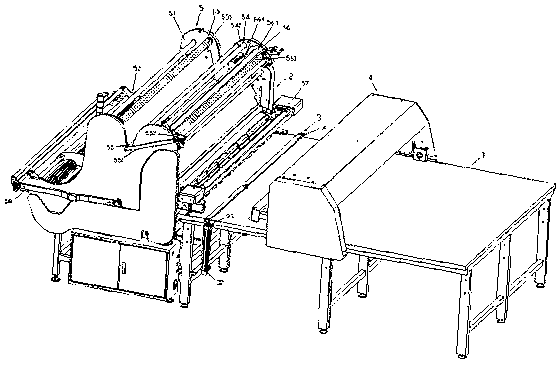

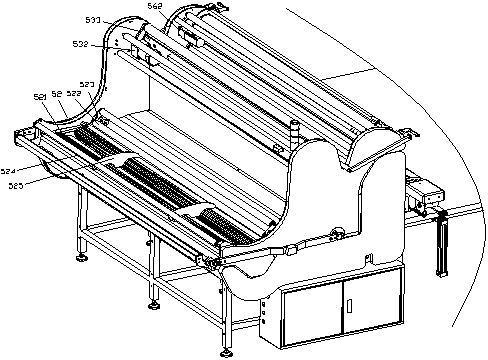

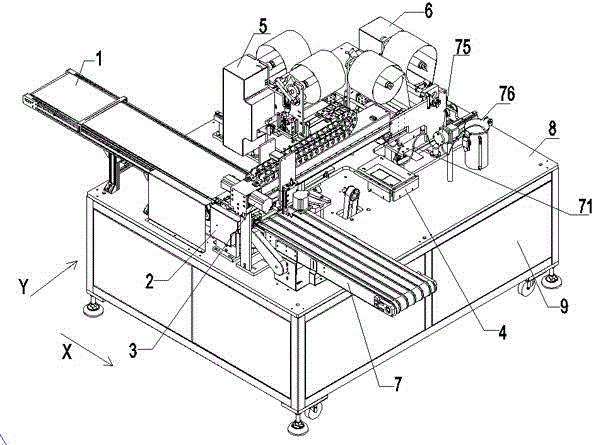

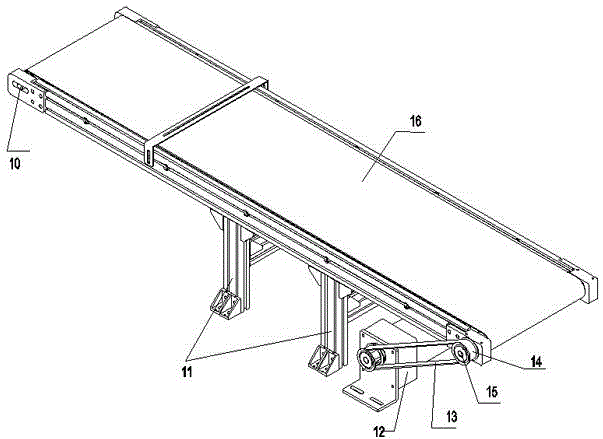

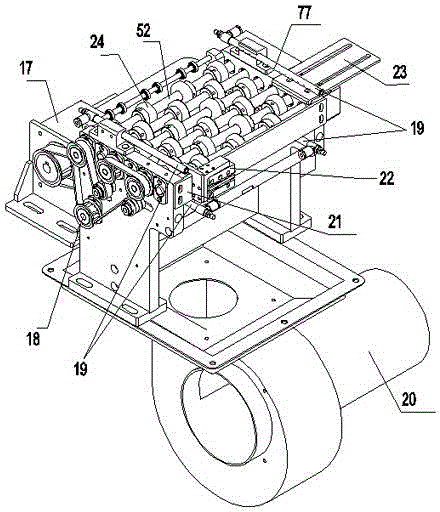

Cloth spreading machine with manipulator cloth clamping mechanism

ActiveCN103342251ARun smoothlyPrecise positioningUnfolding thin materialsArticle deliveryManipulatorTextile

The invention provides a cloth spreading machine with a manipulator cloth clamping mechanism. The cloth spreading machine comprises a making bed, a main machine, a cloth pressing mechanism above the making bed, and the manipulator cloth clamping mechanism arranged on the making bed in a sliding mode. The main machine is provided with a cloth making mechanism, a cloth releasing mechanism is arranged on one side of the cloth making mechanism, a cloth spreading mechanism is arranged on the other side of the cloth making mechanism, a front-positioning cloth spreading mechanism is arranged in front of the cloth spreading mechanism, a cloth feeding mechanism is arranged in front of the front-positioning cloth spreading mechanism, and a cloth cutting device is arranged below the cloth feeding mechanism; cloth materials enter from the cloth releasing mechanism to the cloth cutting device through the cloth spreading mechanism, the front-positioning cloth spreading mechanism and the cloth feeding mechanism, and the manipulator cloth clamping mechanism arranged on the making bed in the sliding mode is matched with the cloth cutting device to cut off cloth materials with setting lengths. The cloth spreading machine has the advantages that the manipulator cloth clamping mechanism is adopted to carry out single-pulling cloth folding, positioning is accurate, precision is high, the cloth is tidily folded, neatness of the two ends of the cloth can be effectively controlled, accuracy of cloth cutting is improved, and working efficiency is high.

Owner:YYC IND CO LTD CHINA

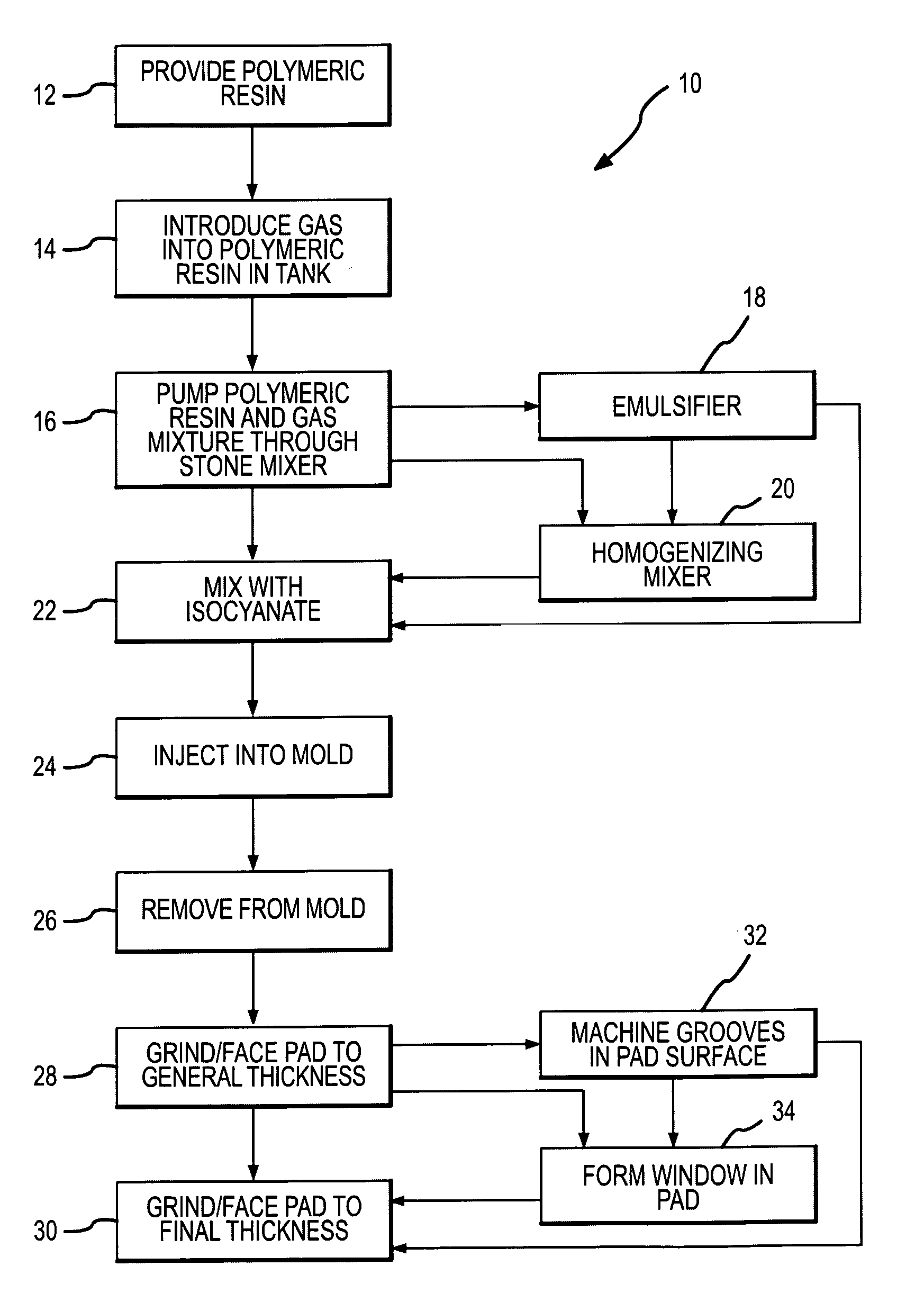

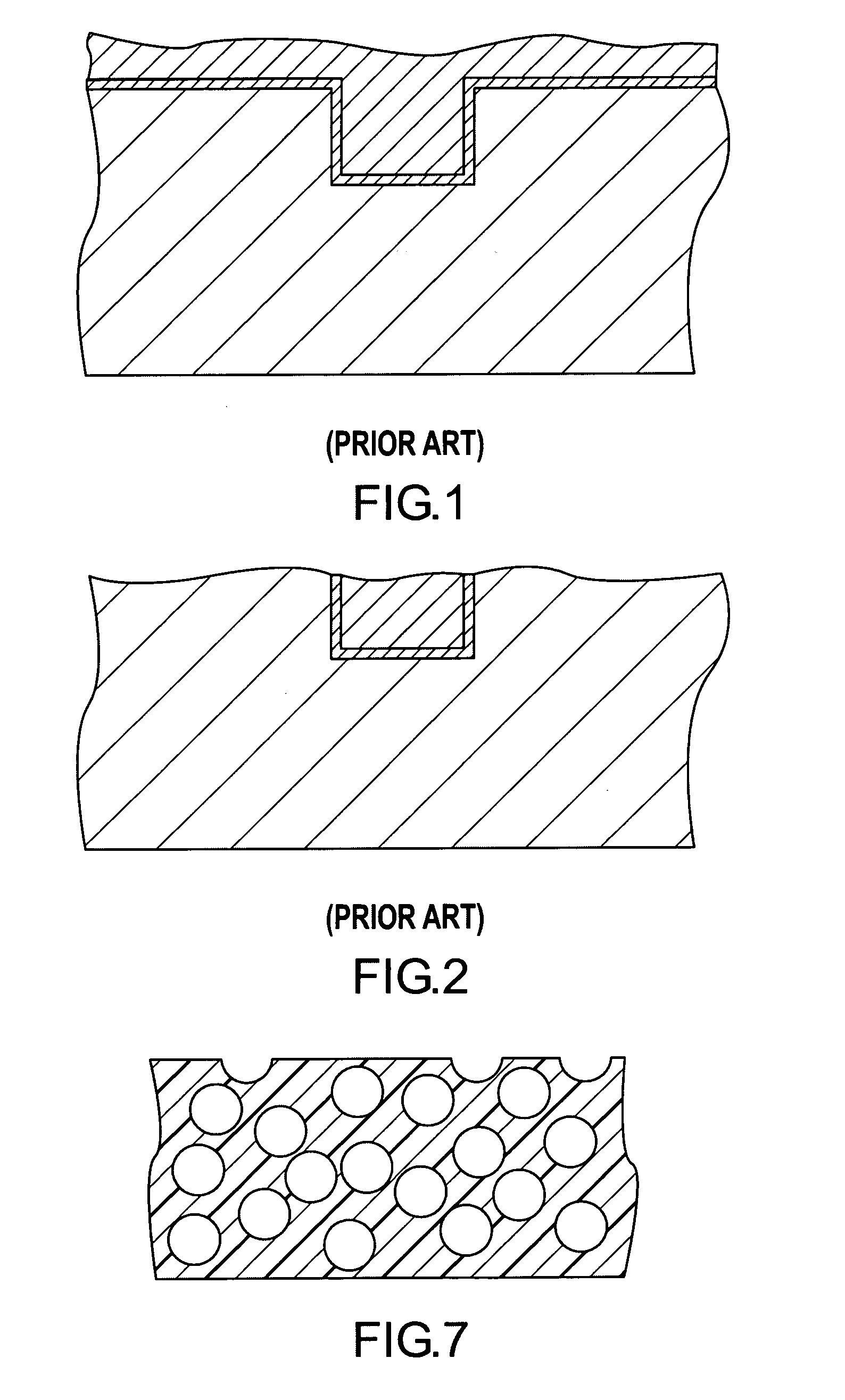

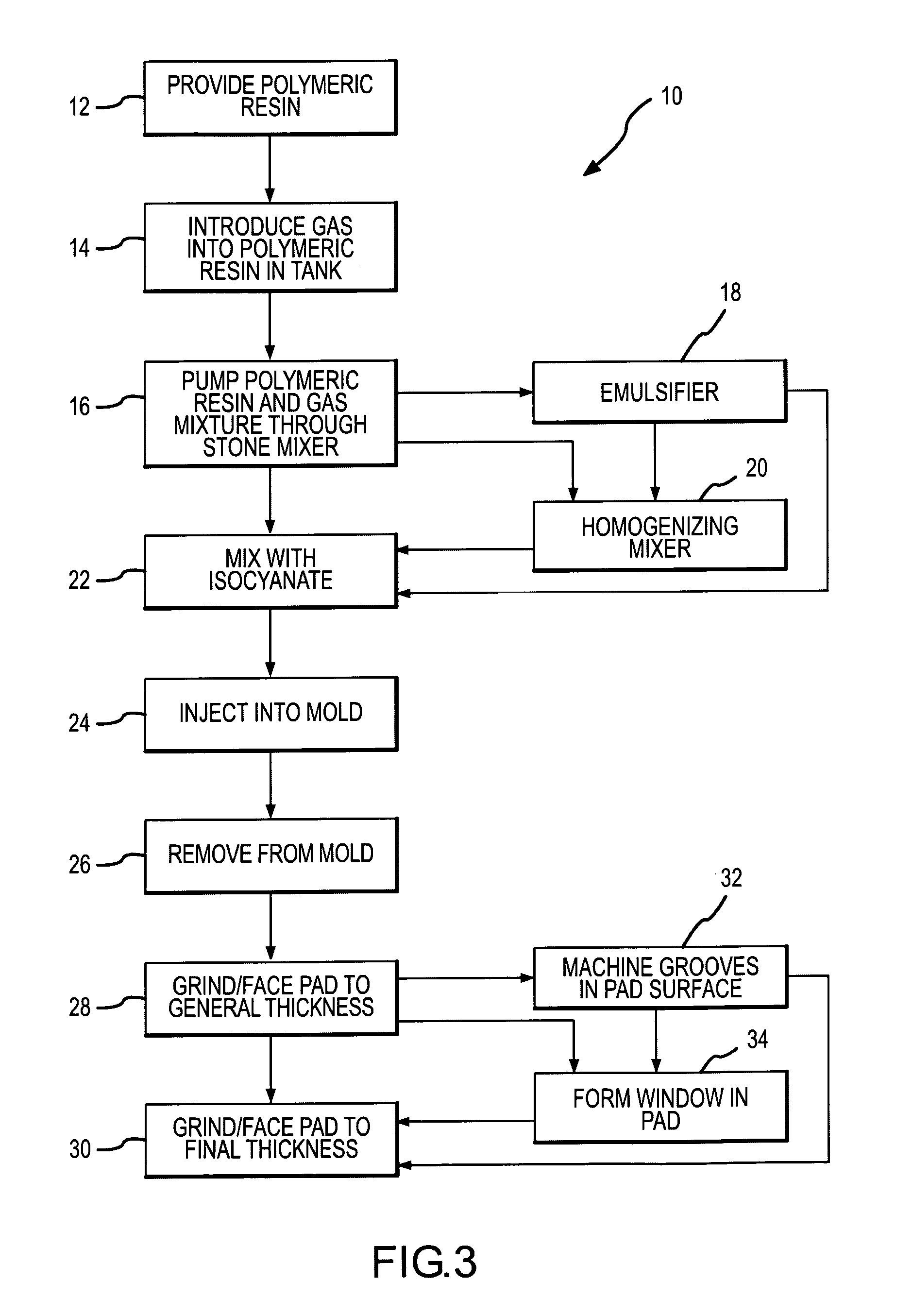

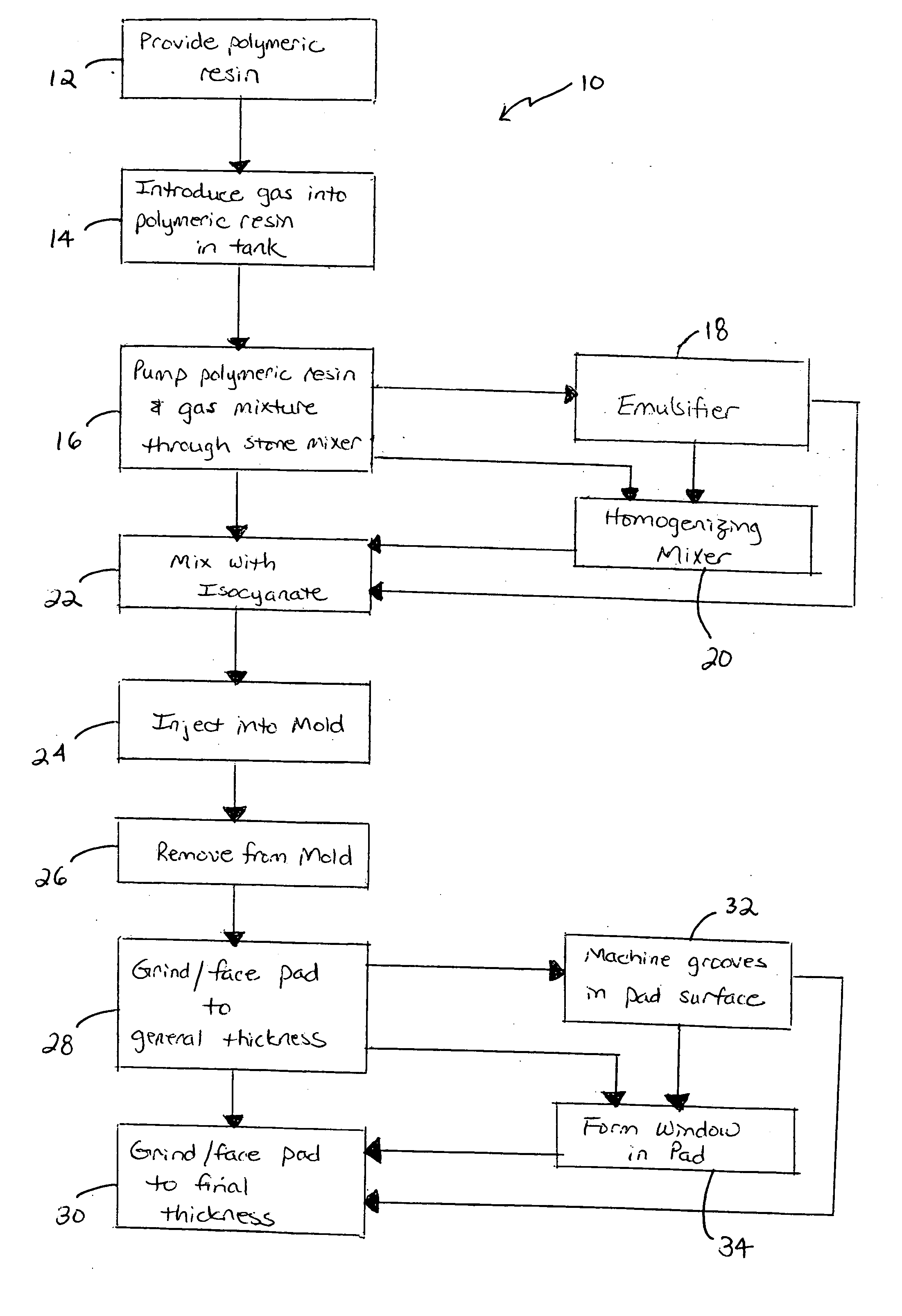

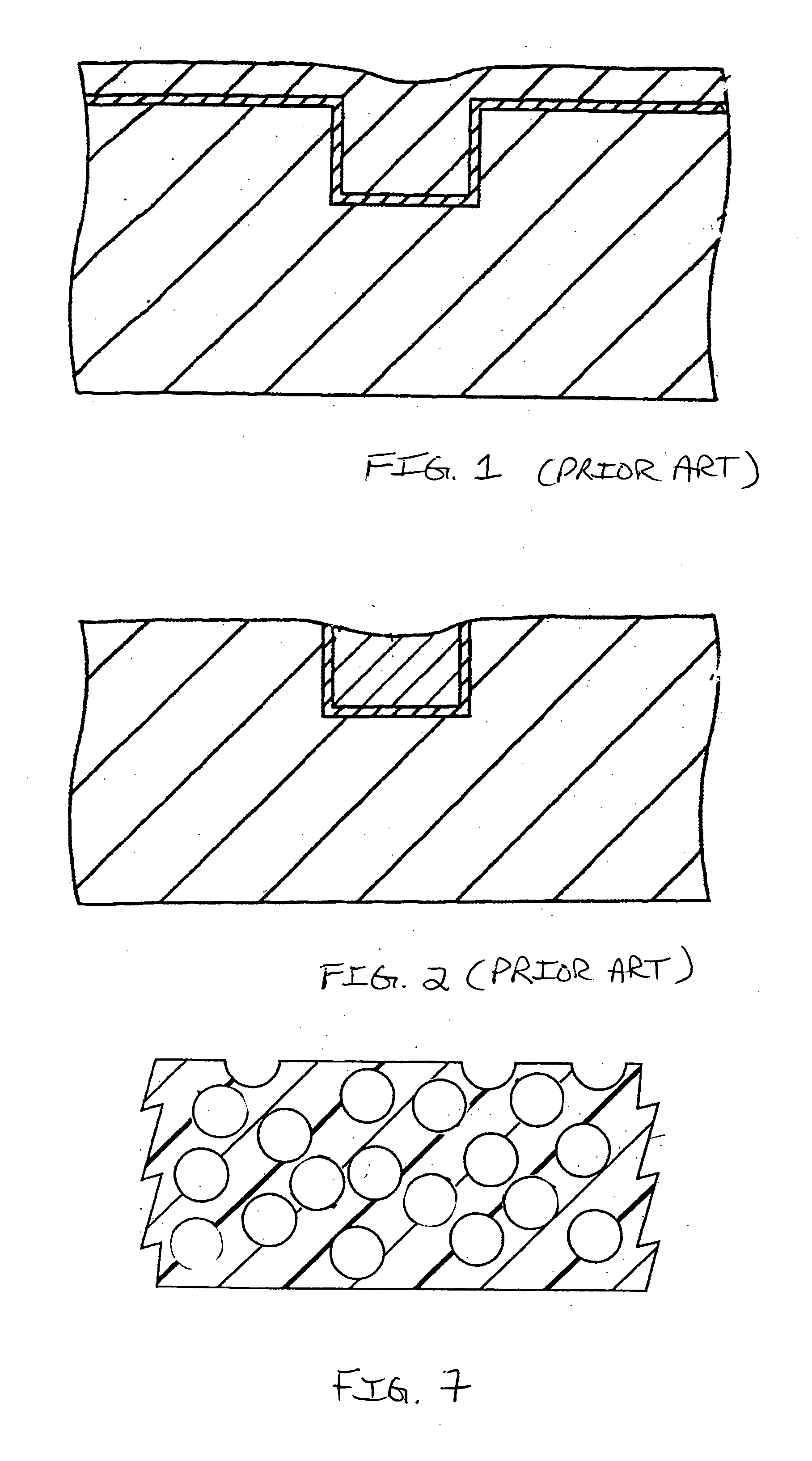

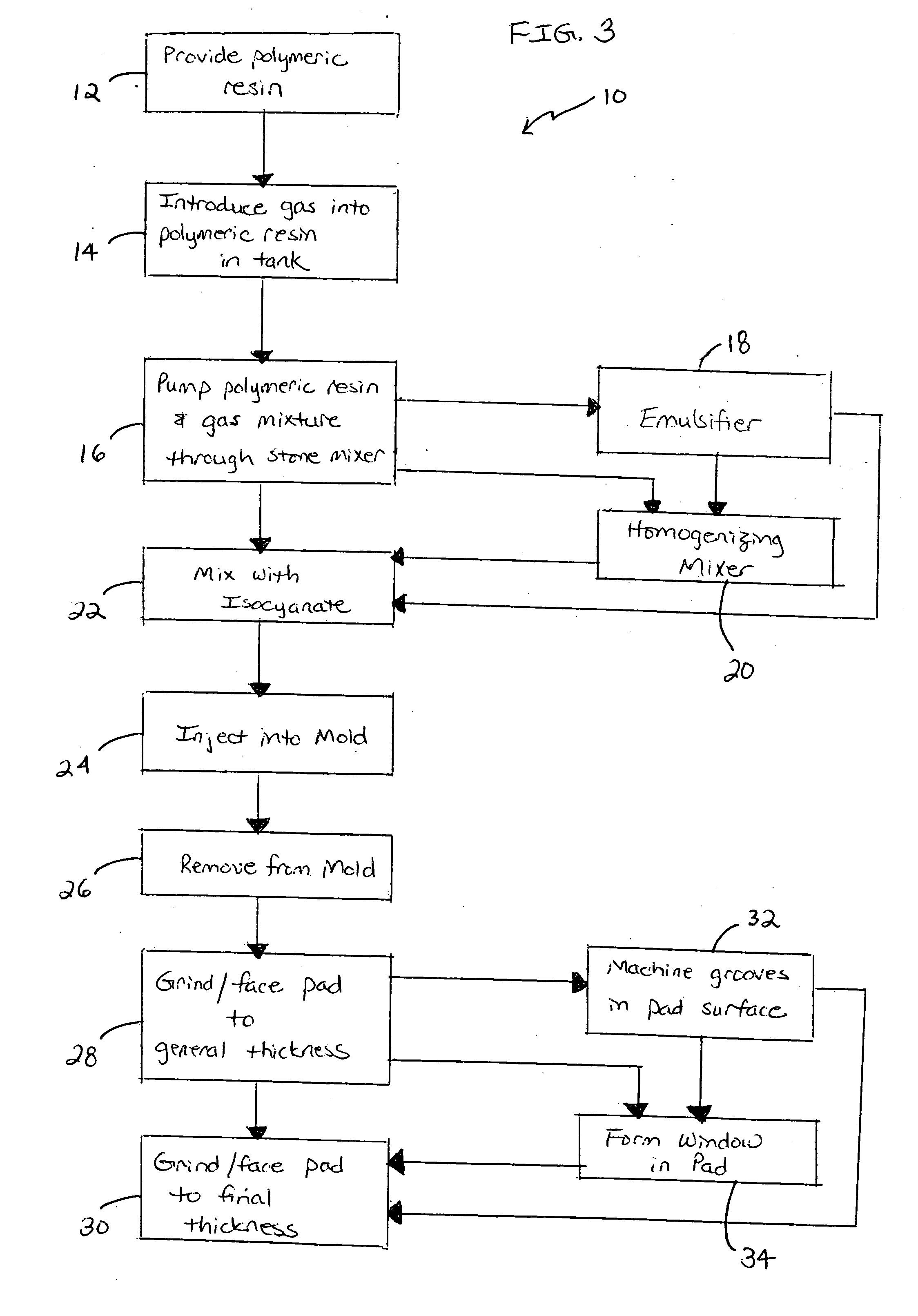

Polishing pad and method of making same

InactiveUS6986705B2Control UniformityUniform sizeSemiconductor/solid-state device manufacturingFlexible-parts wheelsShell moldingMaterials science

Owner:RIMPAD TECH

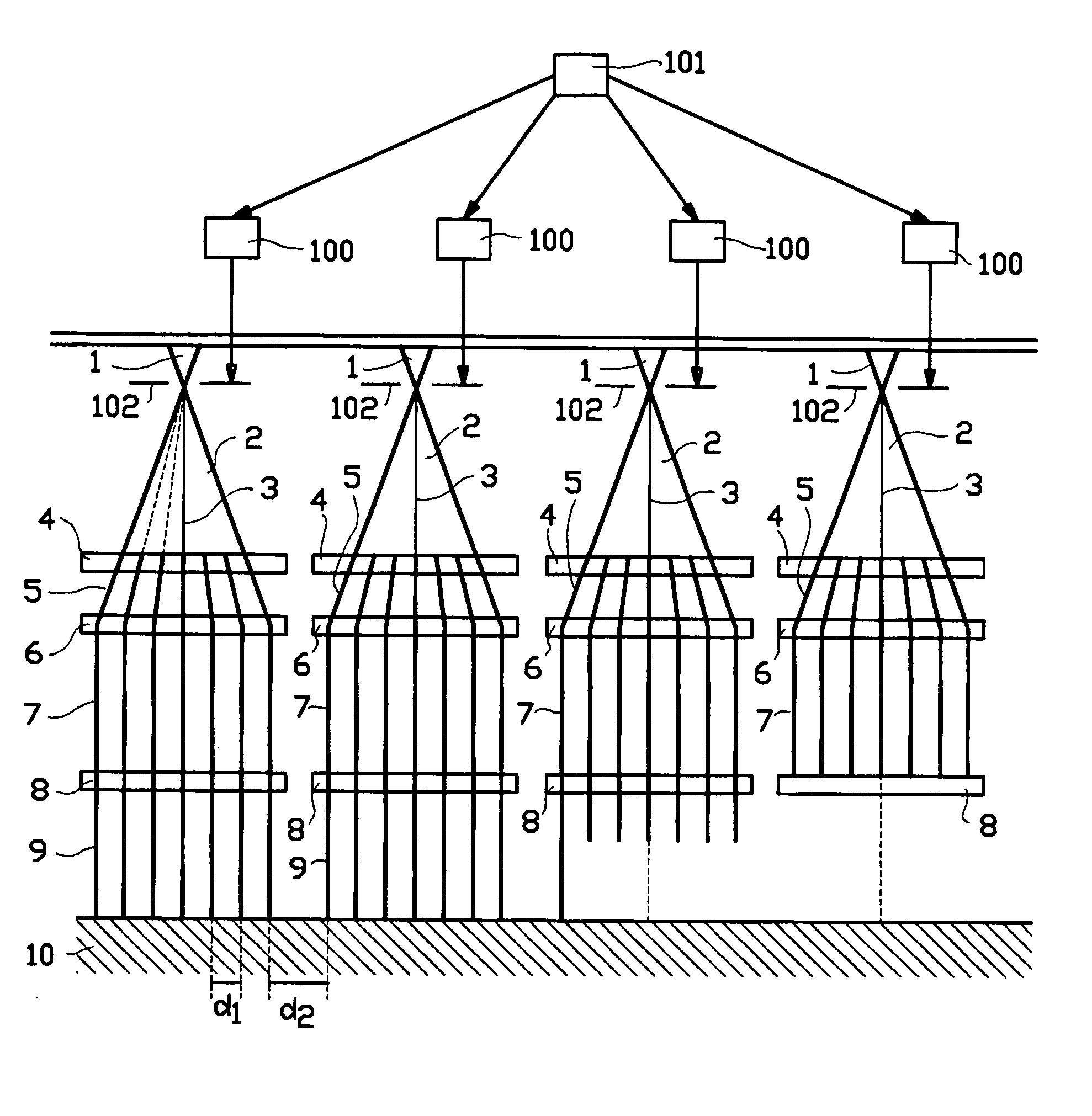

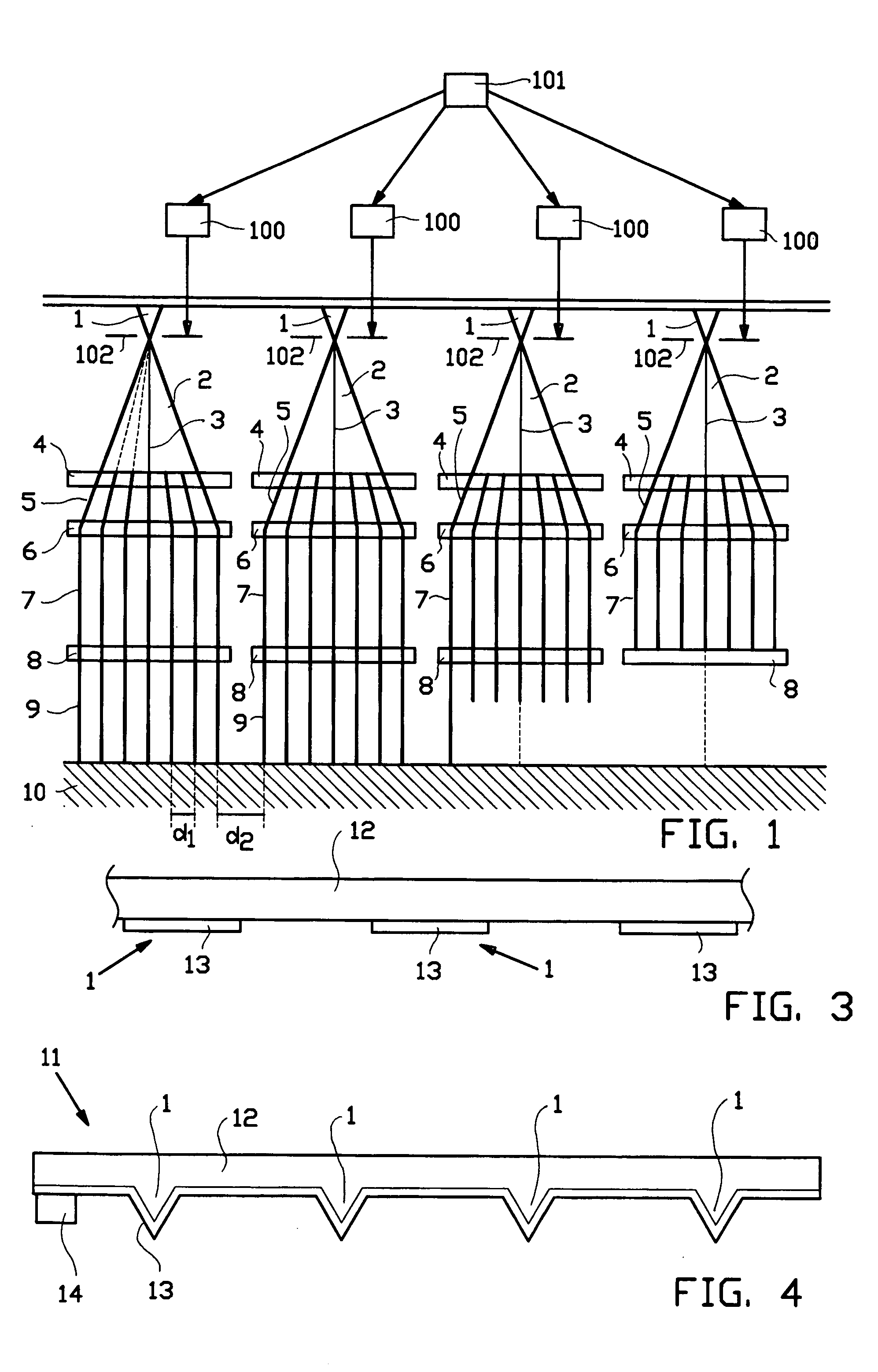

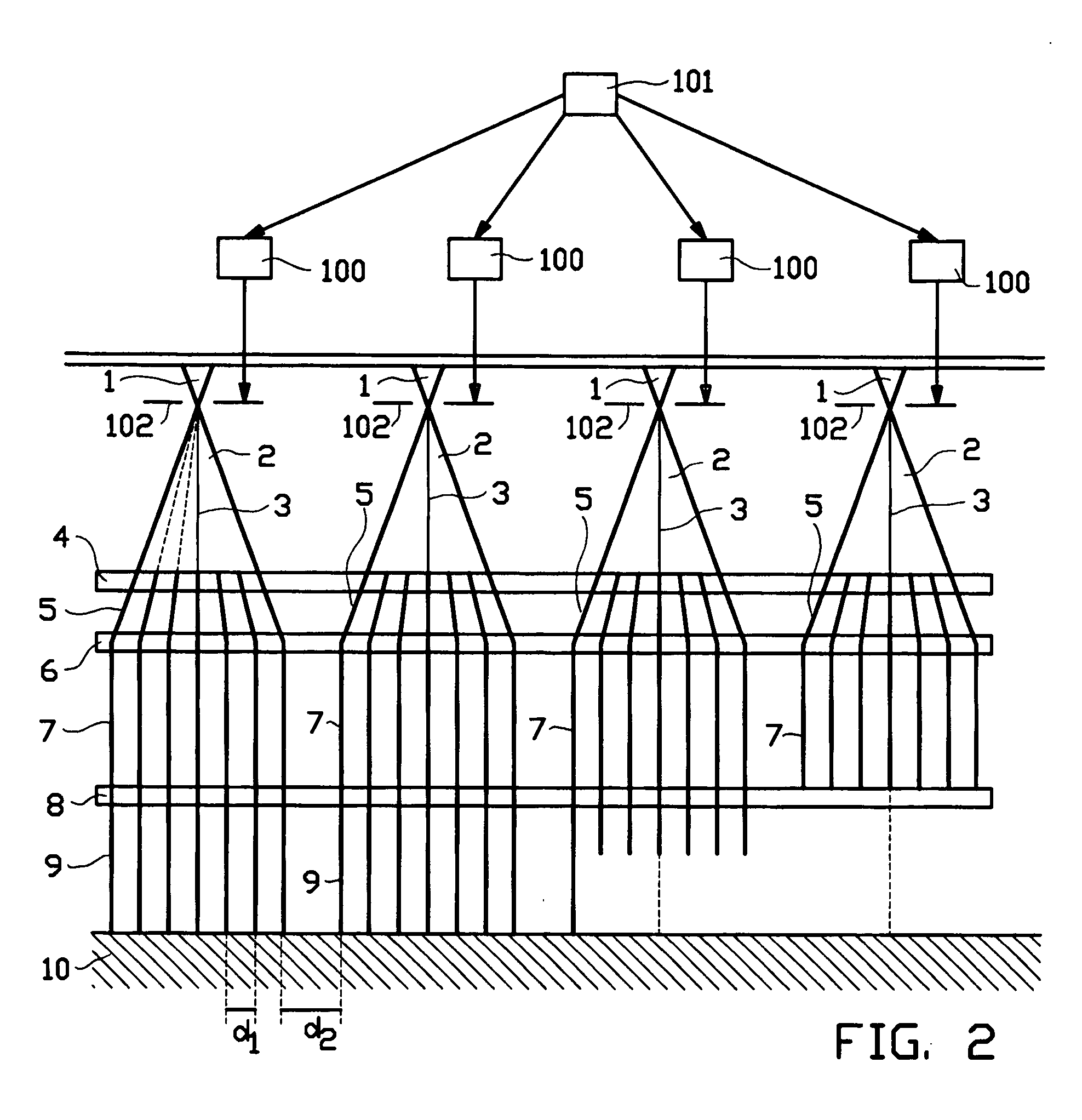

Charged particle beam exposure system

ActiveUS20050269528A1Improve performanceHigh resolutionElectric discharge tubesNanoinformaticsTarget surfaceLight beam

A charged particle beam exposure apparatus for transferring a pattern onto a surface of a target, comprising a beam generator comprising a plurality of n changed particle sources, substantially in one plane, each source adapted for generating a charged particle beam, a first aperture array, comprising a plurality of groups of apertures, each group of apertures aligned with one source, for splitting each beam up into a plurality of beamlets m, thus resulting in a total of nxm beamlets, and a deflector array, comprising a plurality of groups of deflectors, each group of deflectors aligned with one source and one group of apertures, each deflector in a group aligned with an aperture of the corresponding group, and each group of deflectors operable for asserting a collimating influence on its corresponding beam.

Owner:ASML NETHERLANDS BV

Special high-performance carbon paper for gas diffusion layer of fuel cell and preparation method of carbon paper

InactiveCN103556543ASimple processProduct quality is easy to controlSpecial paperCell electrodesThermal bondingPapermaking

The invention relates to carbon paper and a preparation method thereof and particularly relates to special high-performance carbon paper for a gas diffusion layer of a fuel cell and a preparation method of the carbon paper. By taking short carbon fibers, plant fibers, heat bonding fibers and carbon black as raw materials, the carbon paper is prepared by the following steps: defibering, pulping and proportioning; then carrying out papermaking by adopting a wet-method papermaking process; and carrying out waterproof pigment coating treatment. The ratios of all the raw materials are as follows in parts by weight: 65-75 parts of the short carbon fibers, 10-15 parts of the plant fibers, 10-15 parts of the heat bonding fibers and 0-10 parts of the carbon black. According to the special high-performance carbon paper for the gas diffusion layer of the fuel cell and the preparation method of the carbon paper, a production process combining wet-method formation, hot pressing and coating is adopted and has the characteristics of simple process flow, easiness for controlling product quality, environment-friendly production process and the like; the material ratio of each raw material can be accurately controlled in the production so as to be good for controlling the product quality.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

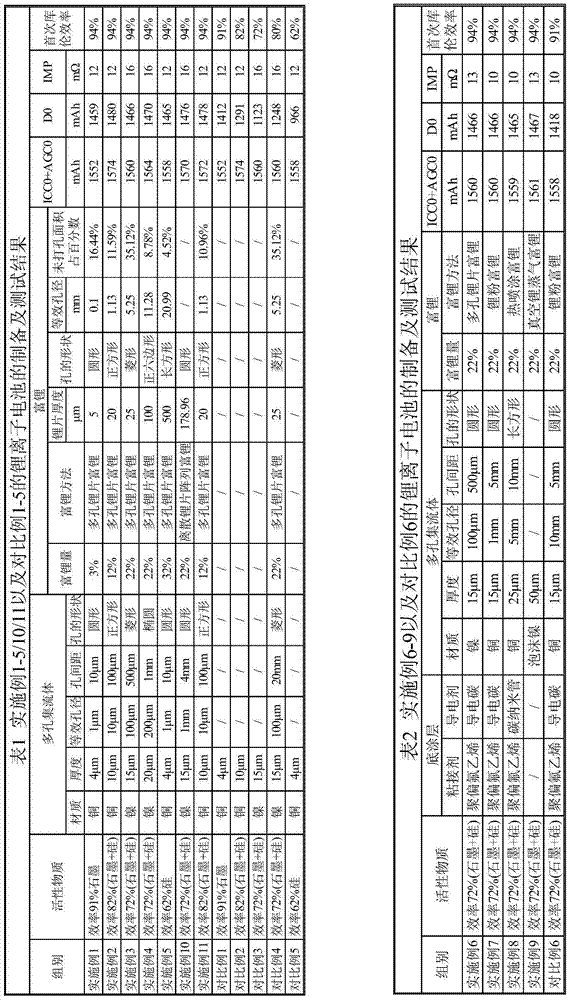

Lithium ion battery and lithium-rich anode sheet

ActiveCN103490041AImprove the first Coulombic efficiencyIncrease energy densityElectrode carriers/collectorsSecondary cellsPhysicsCurrent collector

The invention provides a lithium ion battery and a lithium-rich anode sheet. The lithium-rich anode sheet comprises: a current collector; and a diaphragm, which contains an active substance and is formed on the current collector, wherein the diaphragm and the current collector form an initial anode sheet. The current collector in the initial anode sheet is a porous current collector. The initial anode sheet is rich in lithium on one side, and the lithium rich amount matches the lithium supplement capacity needed by the initial anode sheet. The lithium ion battery includes: a cathode sheet; an anode sheet; an isolation membrane disposed between the cathode sheet and the anode sheet; and an electrolyte solution. The anode sheet is a lithium-rich anode sheet. The lithium-rich anode sheet of the lithium ion battery provided by the invention not only overcomes the excess lithium supplement problem in traditional lithium-rich anode sheets, and also can effectively control the lithium supplement amount of the anode so as to realize uniform lithium supplement and enhance the first coulombic efficiency of the lithium ion battery adopting the lithium-rich anode sheet. Thus, the energy density of the lithium ion battery is greatly improved, and the lithium ion battery can be ensured with better electrochemical properties.

Owner:DONGGUAN AMPEREX TECH

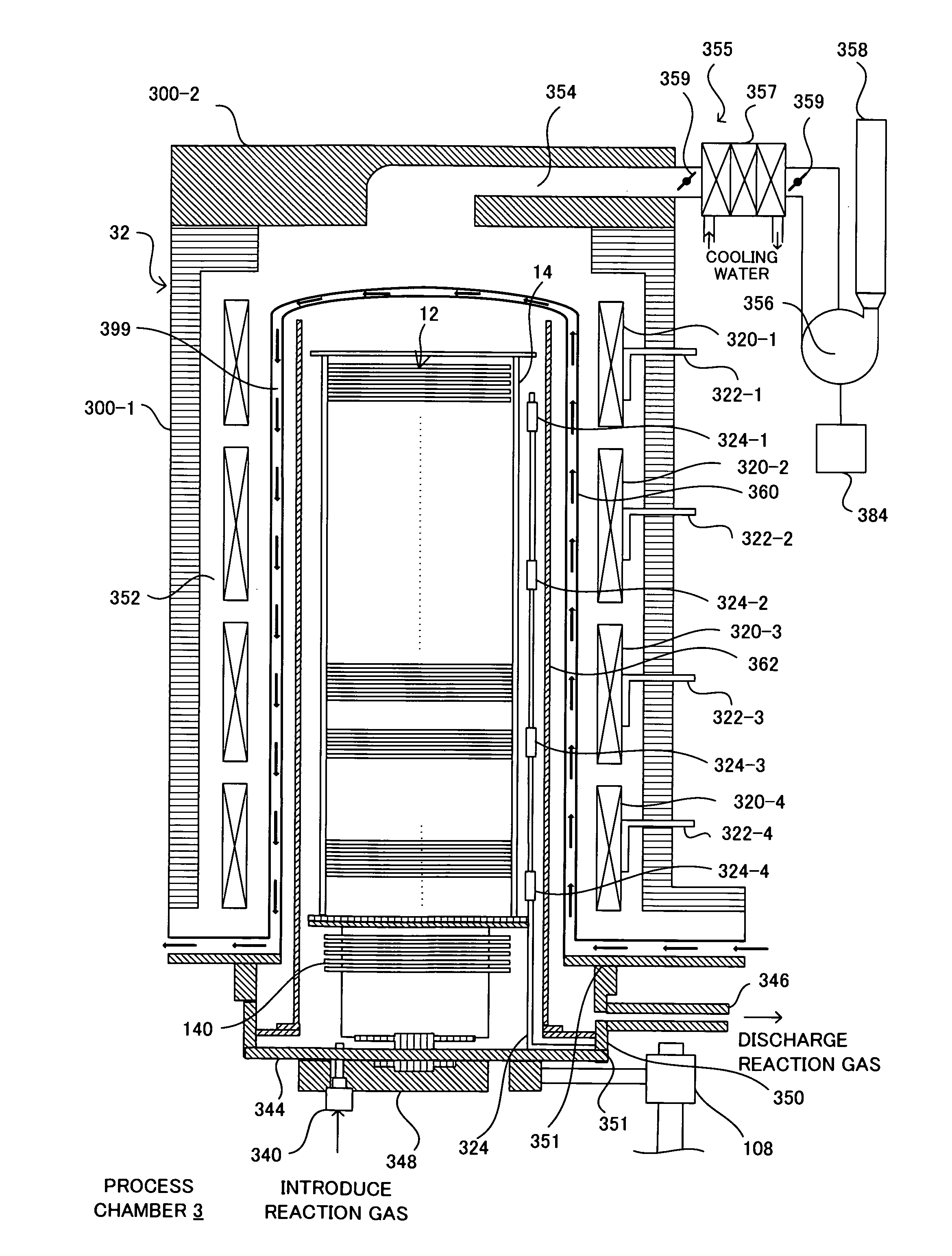

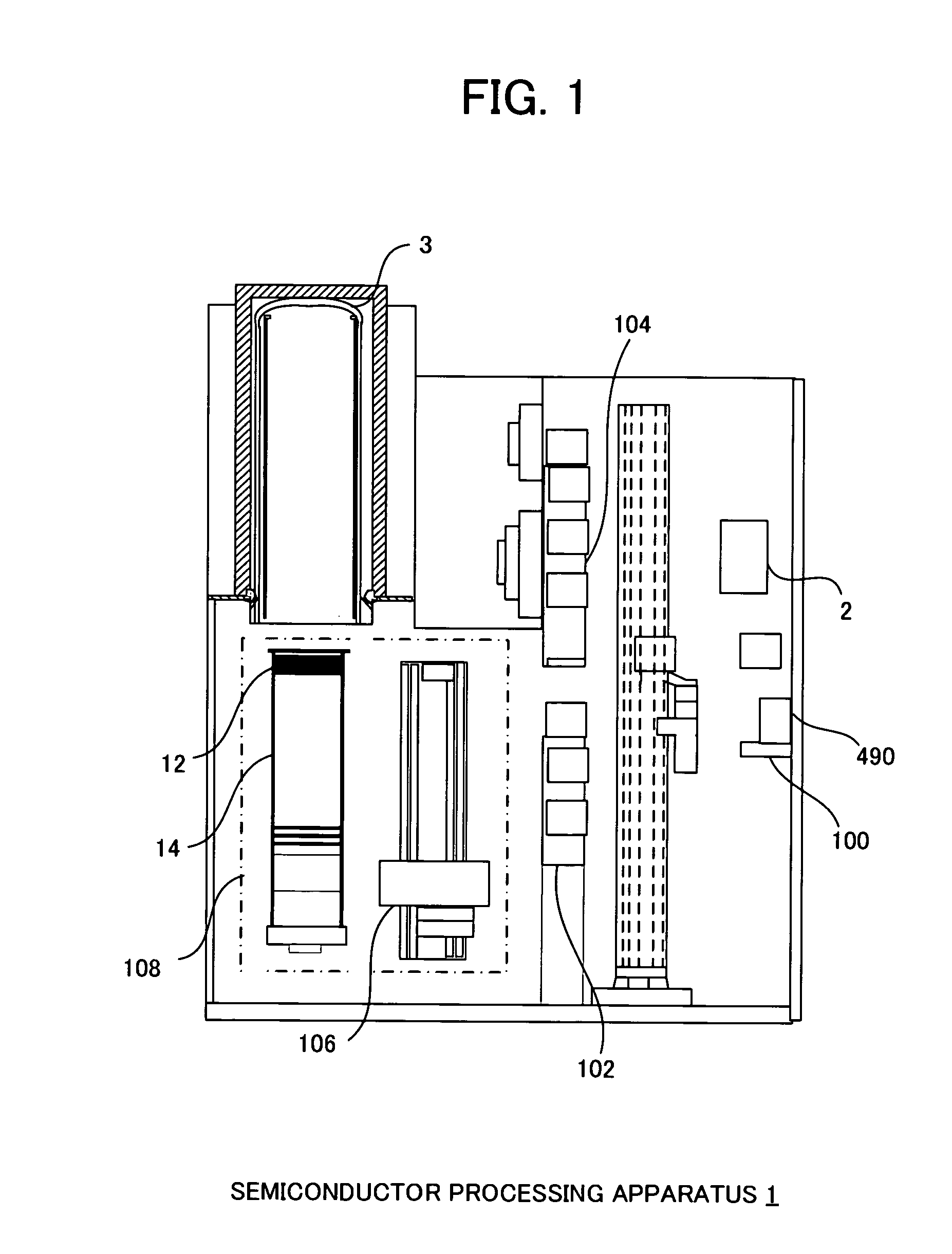

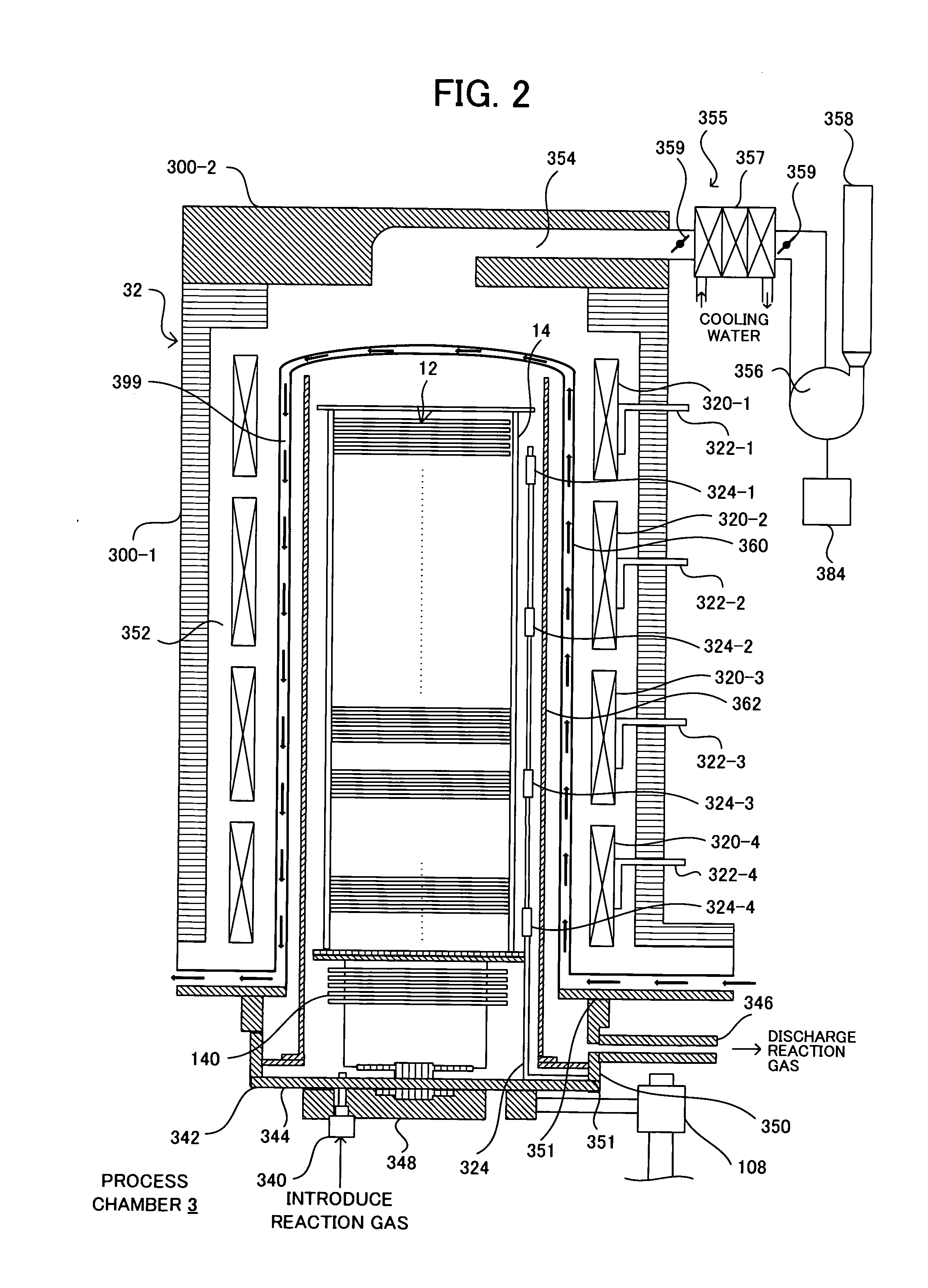

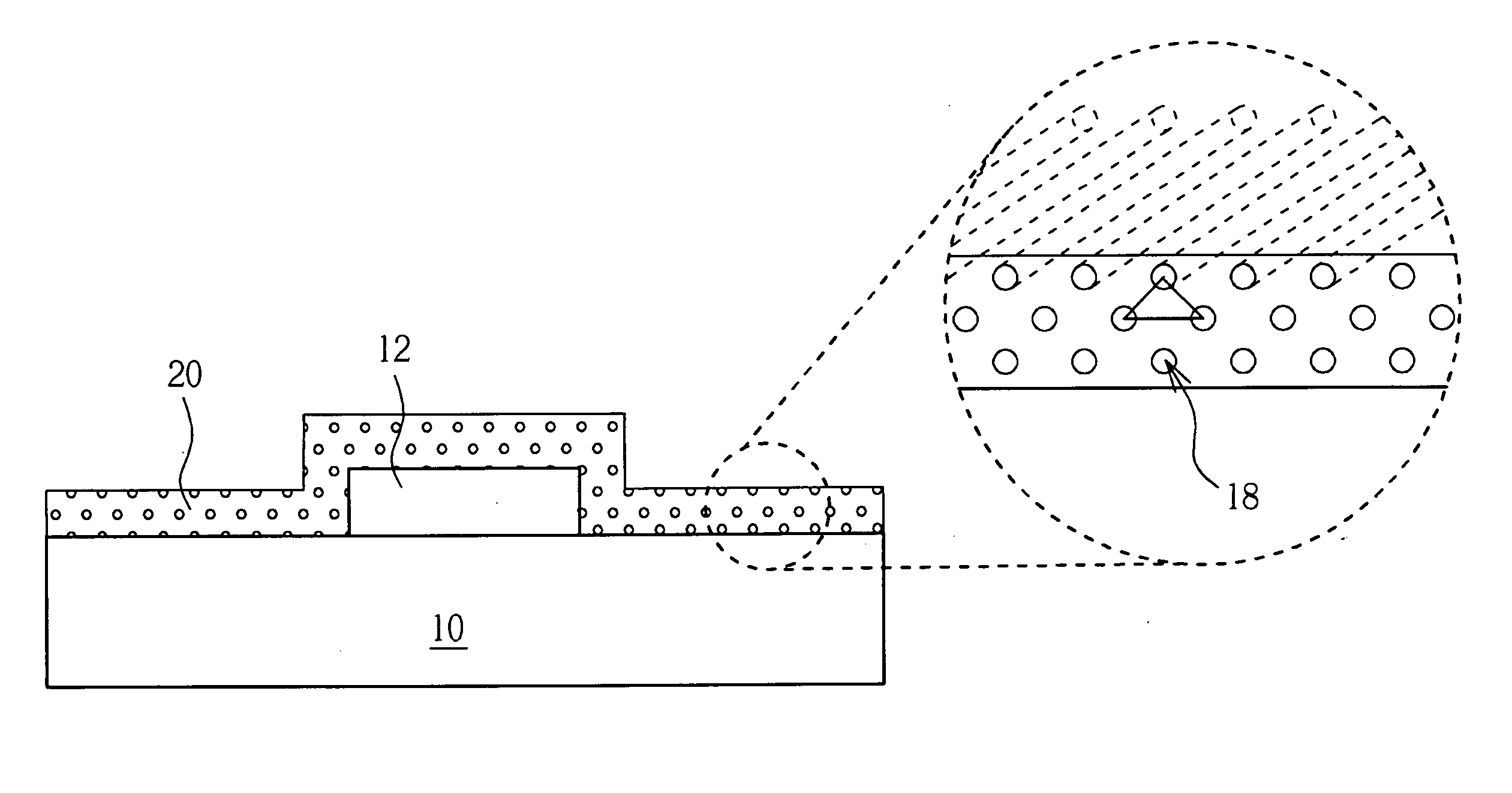

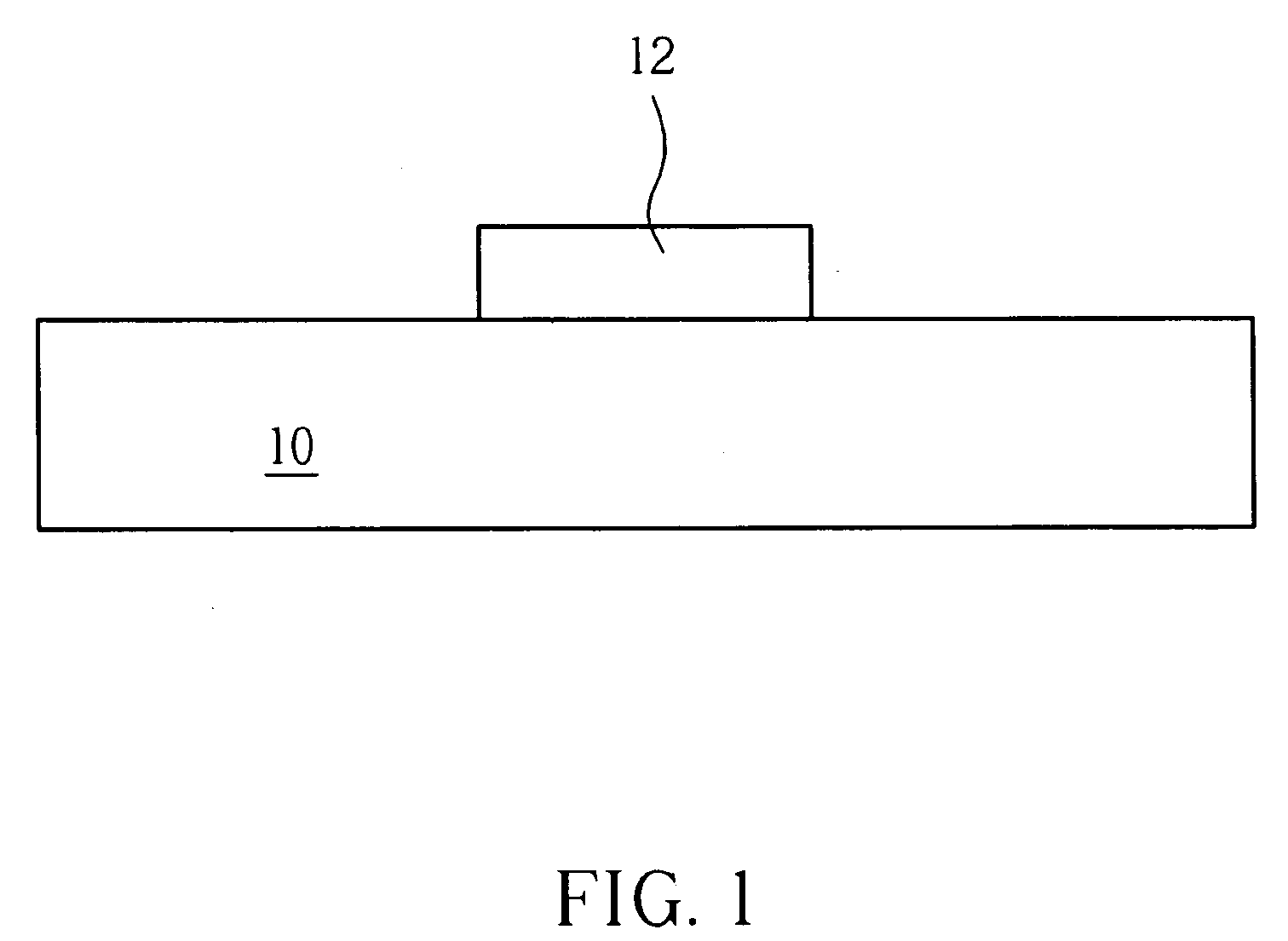

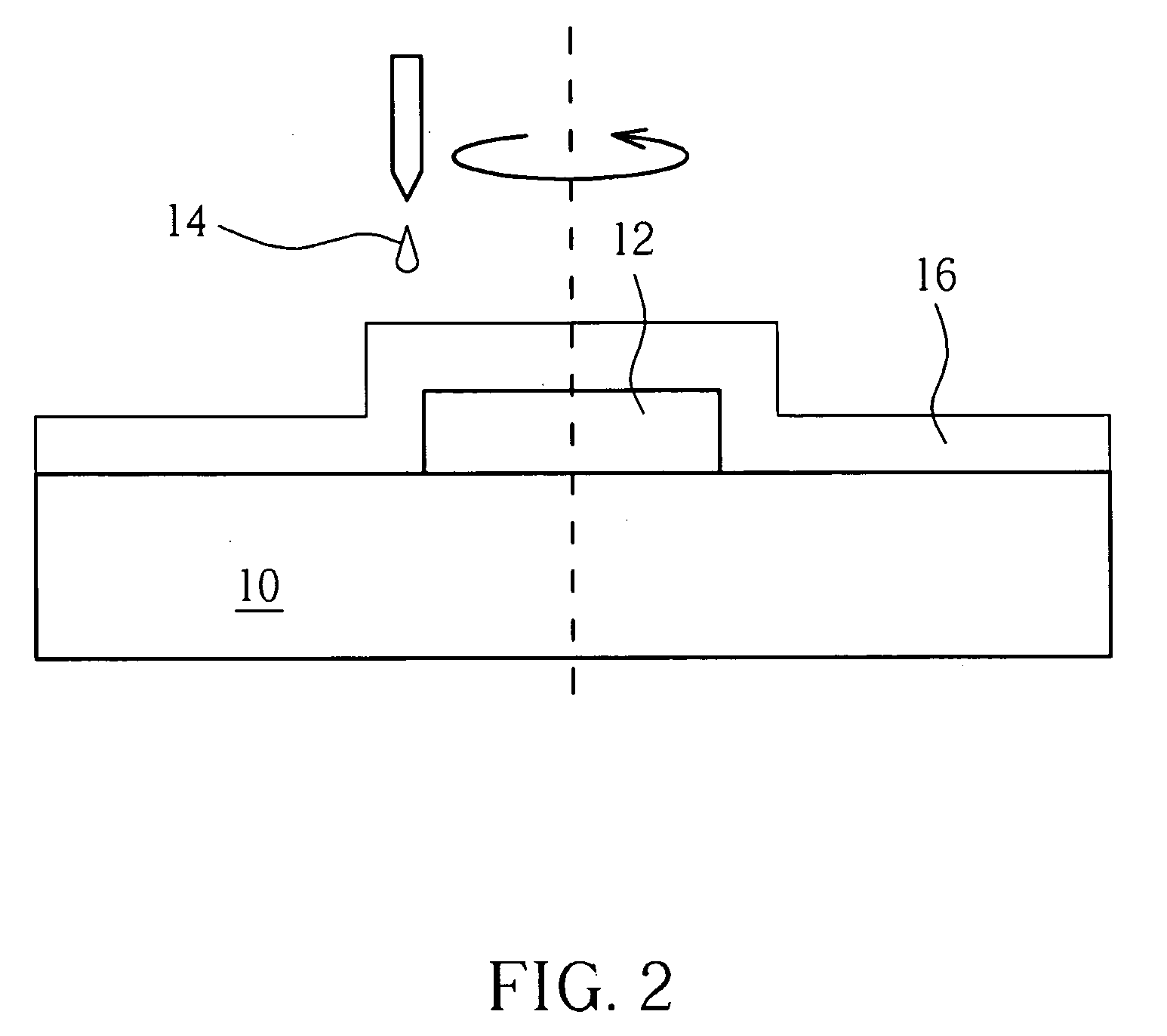

Substrate Processing Apparatus and Substrate Processing Method

ActiveUS20090029486A1Control UniformityLiquid surface applicatorsSemiconductor/solid-state device testing/measurementEngineeringTemperature difference

A substrate processing apparatus has: a process chamber in which a substrate is processed; a heating device that optically heats the substrate accommodated in the process chamber from an outer periphery side of the substrate; a cooling device that cools the outer periphery side of the substrate by flowing a fluid in a vicinity of an outer periphery of the substrate optically heated by the heating device; a temperature detection portion that detects a temperature inside the process chamber; and a heating control portion that controls the heating device and the cooling device in such a manner so as to provide a temperature difference between a center portion of the substrate and an end portion of the substrate while maintaining a temperature at the center portion at a pre-determined temperature according to the temperature detected by the temperature detection portion.

Owner:KOKUSA ELECTRIC CO LTD

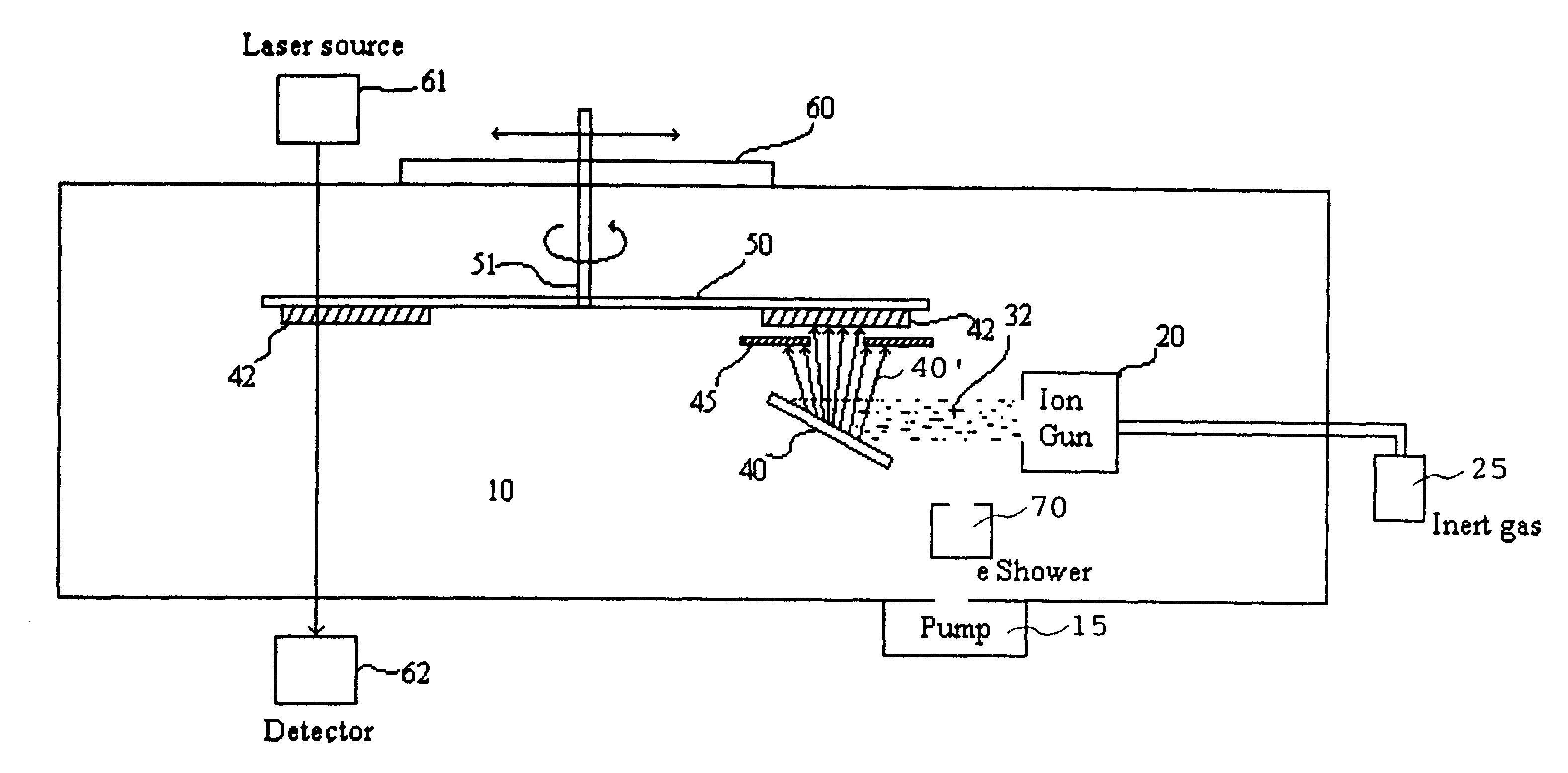

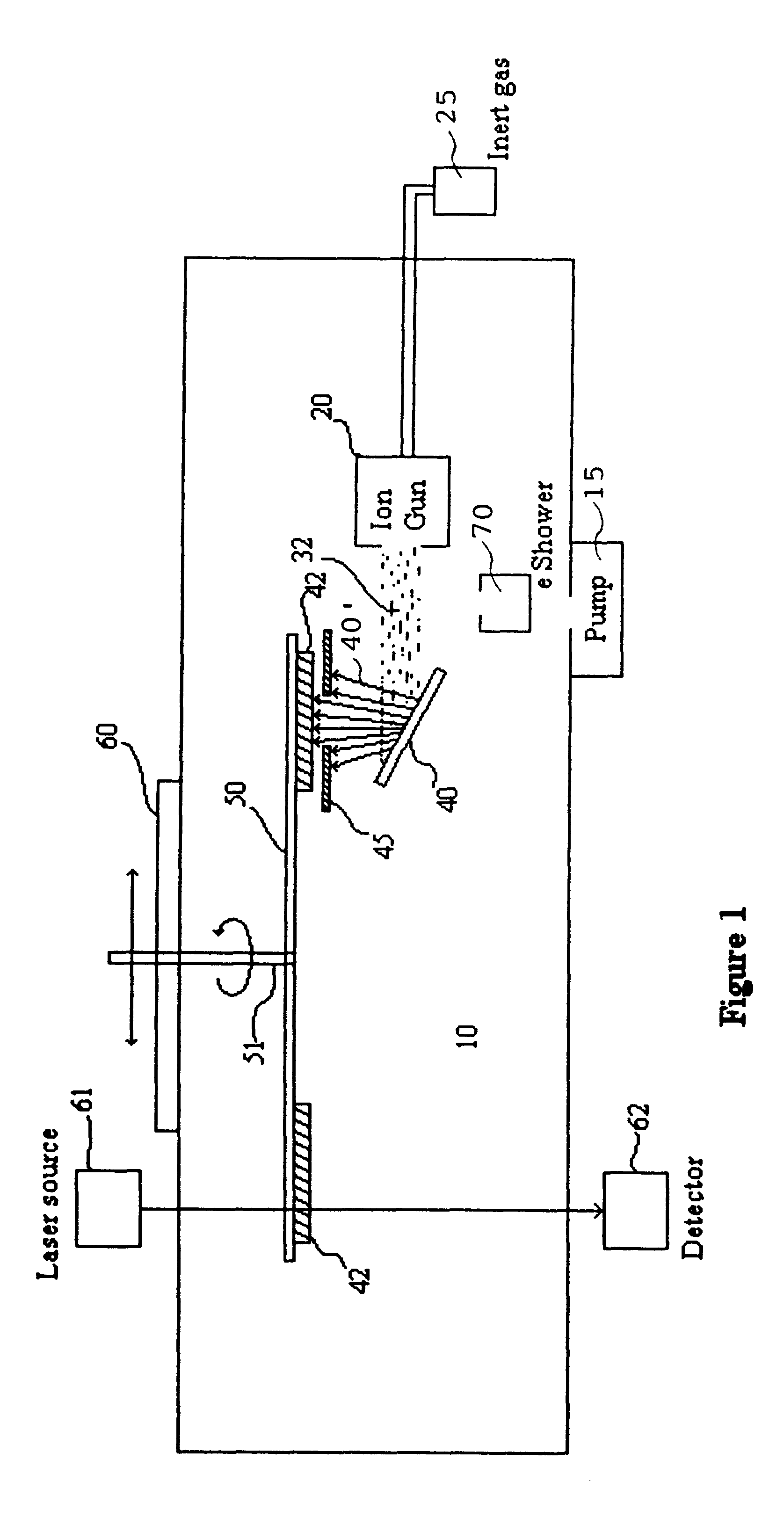

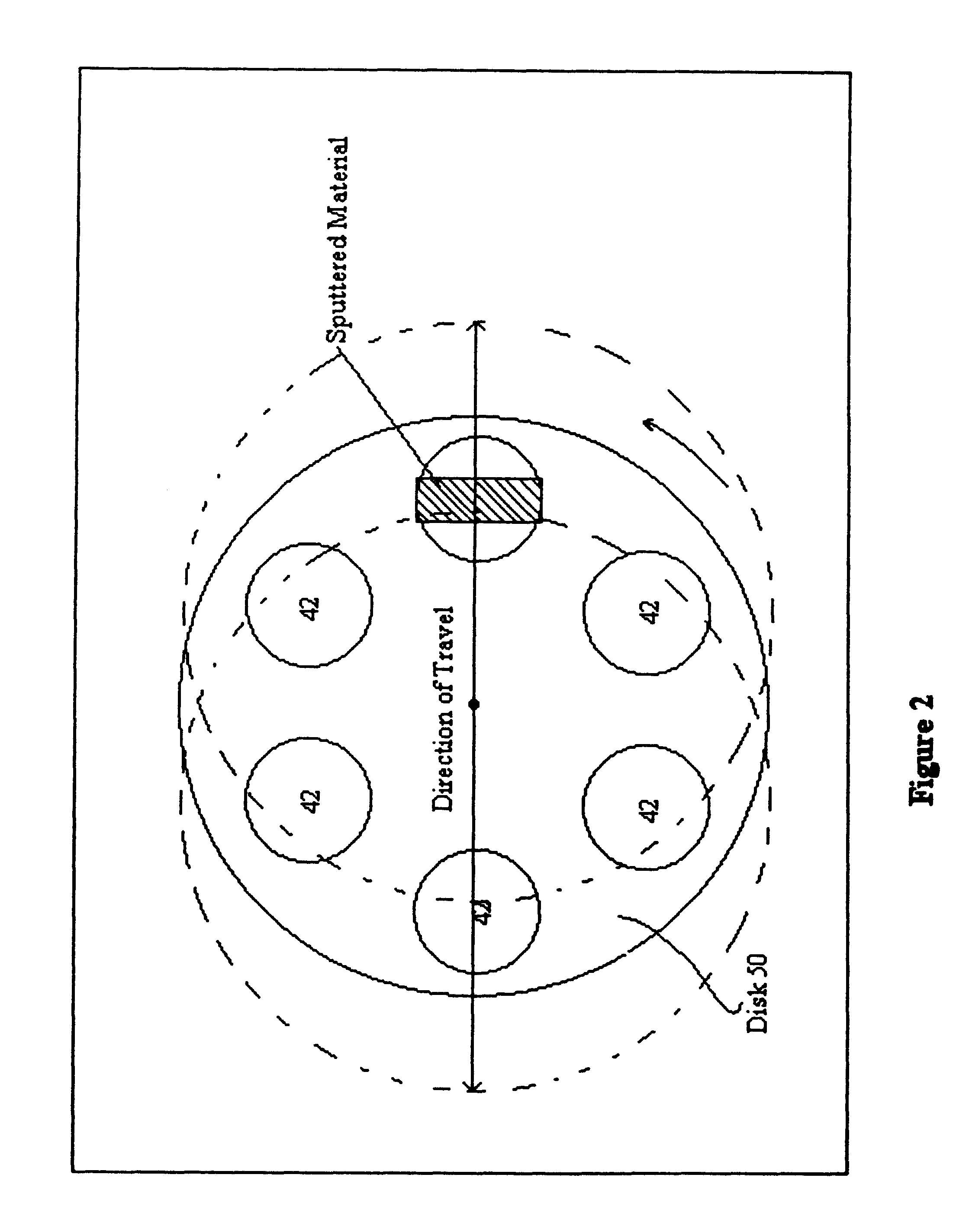

Apparatus and method for uniformly depositing thin films over substrates

A thin film deposition apparatus and method are disclosed in this invention. The method includes a step of providing a vacuum chamber for containing a thin-film particle source for generating thin-film particles to deposit a thin-film on the substrates. The method further includes a step of containing a substrate holder in the vacuum chamber for holding a plurality of substrates having a thin-film deposition surface facing the thin-film particle source. The method further includes a step of providing a rotational means for rotating the substrate holder to rotate each of the substrates exposed to the thin-film particles for depositing a thin film thereon. And, the method further includes a step of providing a lateral moving means for laterally moving and controlling a duration of exposure time across a radial direction for each of the substrates for controlling thickness uniformity of the thin-film deposited on each of the substrates.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

System and method for photocatalytic oxidation air filtration using a substrate with photocatalyst particles powder coated thereon

ActiveUS7820100B2Control thicknessControl UniformityCombination devicesAuxillary pretreatmentAir filtrationPhysical chemistry

The present invention relates to an air filtration system and a method for making a photocatalytic oxidation substrate by powder coating a photocatalyst onto a metal substrate.

Owner:SCI HEALTH DEV LTD

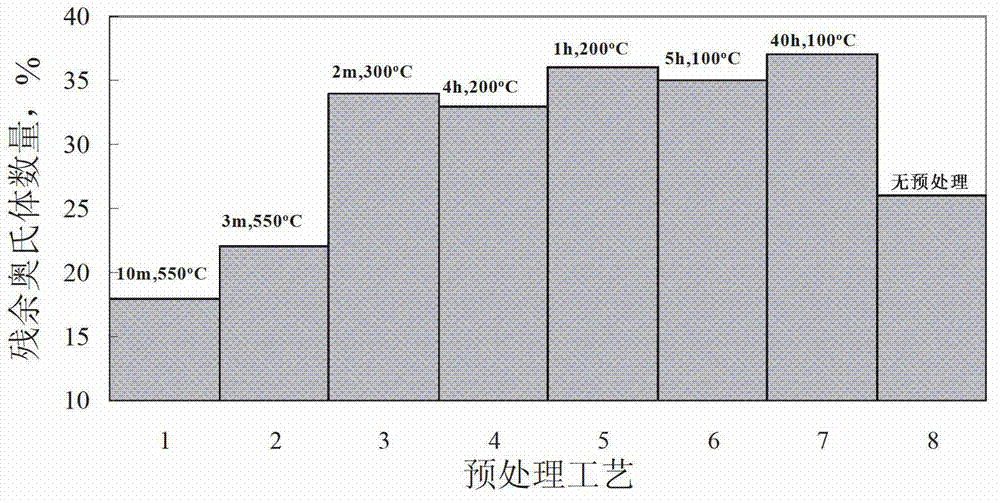

Method for producing high-strength and elongation product automobile steel plate by continuous annealing technology

The invention provides a method for producing a high-strength and elongation product automobile steel plate by a continuous annealing technology, belonging to the technical field of an automobile steel plate. The method comprises the following steps: based on the reasonable chemical component design and the alloy element partition, firstly, obtaining transition carbide with fine dispersion distribution by a cold rolled plate coil importantly, and promoting austenite inverse phase transformation through the solid solution of the fine carbide through two-phase region annealing, to obtain more and stable austenite phases to be remained. According to the method, the strict technological conditions for forming the finely-dispersed carbide and the strict interval for carrying out the technological parameters of the two-phase region annealing are given, so that the method has the advantages that the continuous annealing plate coil which is even in performance and good in surface quality can be obtained due to the short-time annealing of the existing continuous annealing production line of a steel factory, wherein the strength of the steel plate is 0.6-1.2GPa, the percentage elongation of the steel plate is 45-20%, and the product of strength and elongation is 25-40GPa%.

Owner:CENT IRON & STEEL RES INST

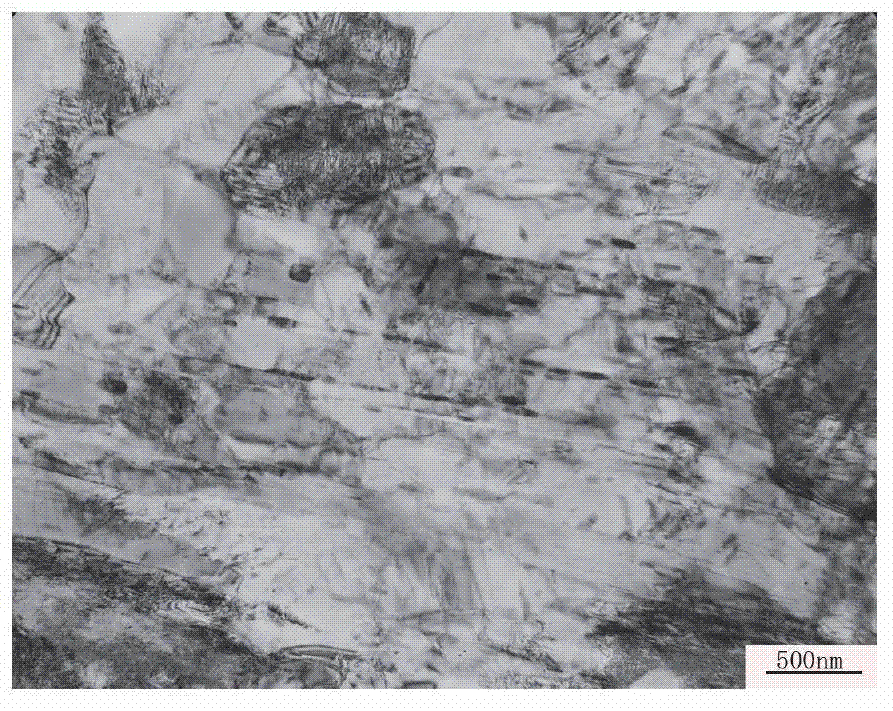

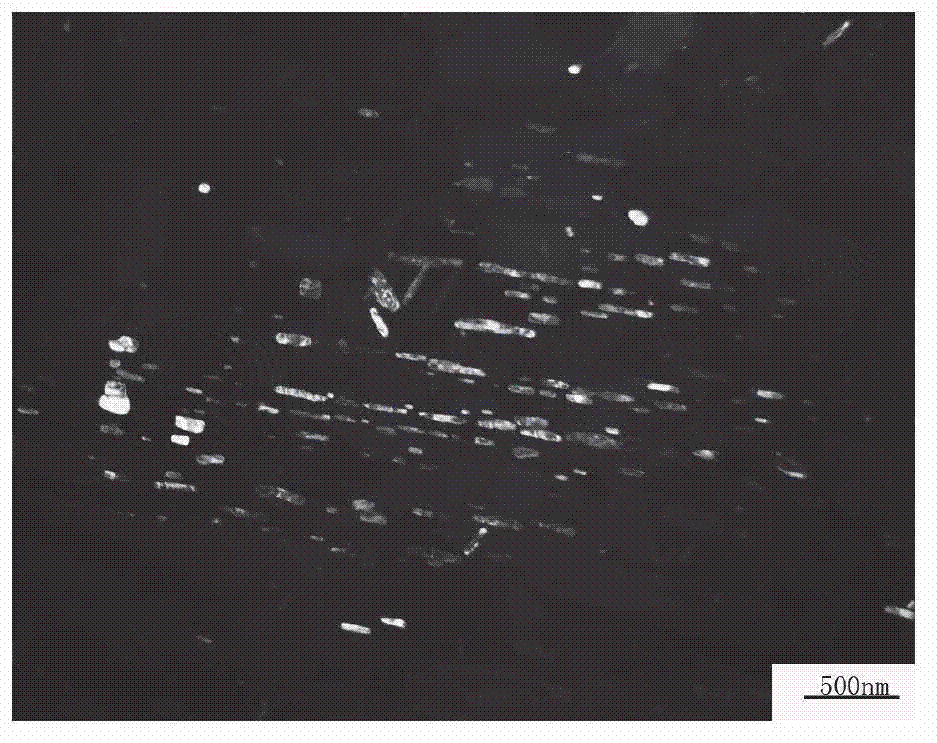

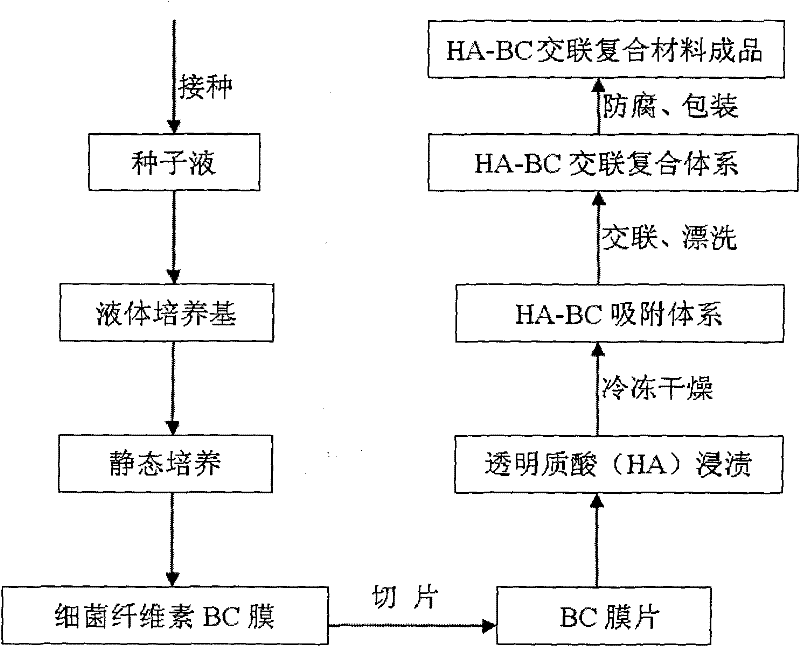

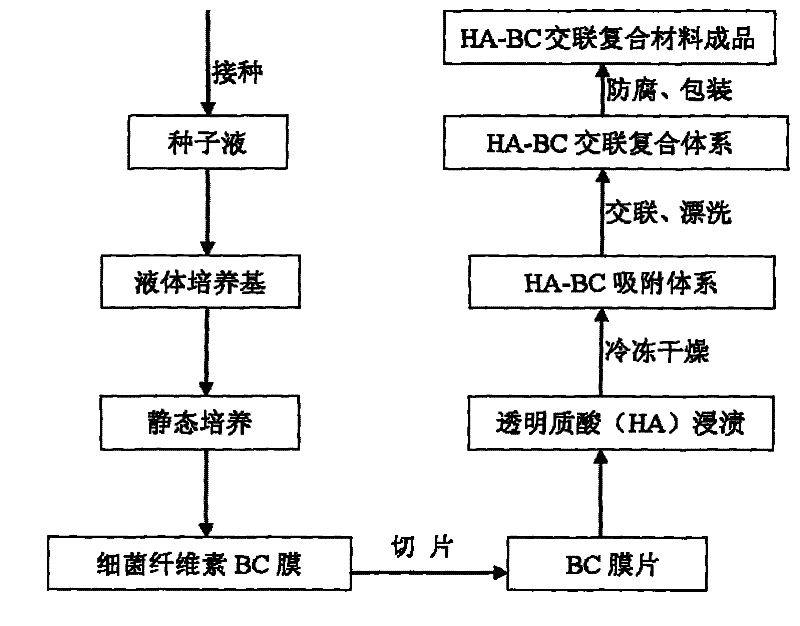

Preparation method of bacteria cellulose/hyaluronic acid composite

ActiveCN102212208AControl thicknessControl UniformityMicroorganism based processesAbsorbent padsChemistryPre treatment

The invention discloses a preparation method of a bacteria cellulose / hyaluronic acid composite. The functional material is prepared according to the following steps of: pre-treating a bacteria cellulose wet film, impregnating slices of the bacteria cellulose wet film in a hyaluronic acid solution, and then freezing at low temperature and drying the hyaluronic acid-adsorbing bacteria cellulose slice to remove a certain moisture. The bacteria cellulose / hyaluronic acid composite is formed by means of crosslinking cellulose molecules and the hyaluronic acid under the action of carbodiimide. Through the crosslinking, not only is the stability of the hyaluronic acid improved, but also the wetting property, the air permeability and the biocompatibility of the bacteria cellulose are enhanced. According to the preparation method disclosed by the invention, a certain amount of the hyaluronic acid is crosslinked in the bacteria cellulose film, so that high flexibility and adhesion of the bacteria cellulose as well as the moisturizing, nourishing and skin moistening effects of the hyaluronic acid can be exerted, and the prepared bacteria cellulose / hyaluronic acid composite can be used in the fields, such as healing promoting dressings, self-nutrition type whitening masks, and the like.

Owner:NANJING UNIV OF SCI & TECH

Polycrystalline silicon surface wool manufacturing method

InactiveCN101805929AReduce surface reflectivityEfficient collectionAfter-treatment detailsFinal product manufactureSolar batteryUltrasonic atomization

The invention relates to the manufacturing field of solar batteries, in particular to a polycrystalline silicon surface wool manufacturing method for solar batteries. The invention has the technical scheme that the polycrystalline silicon surface wool manufacturing method is characterized by successively adopting the following steps: 1) pre-cleaning a silicon wafer and removing an affected layer;2) adopting the ultrasonic atomization process or electrostatic spraying process to coat one layer of discontinuous plastic particle film on the surface of the silicon wafer to serve as a masking film; 3) putting the silicon wafer in acid solution and aqueous alkali for corrosion and wool manufacturing; and 4) cleaning the silicon wafer obtained in step 3) with acetone to remove plastic particle films, then cleaning with deionized water, and drying the silicon wafer. By adopting the scheme, the invention overcomes the defects and deficiencies in the prior art, and provides the polycrystallinesilicon surface wool manufacturing method. The method can be used for manufacturing high-performance polycrystalline silicon surface texture, has industrialization prospect and effectively lowers thesurface reflectivity of the silicon wafer.

Owner:SUN POWER PHOTOVOLTAIC SCI & TECH

Automatic surface wiping and cleaning device and automatic cleaning machine

ActiveCN104624590AEliminate health hazardsIncrease frictionFlexible article cleaningEngineeringTouchscreen

The invention relates to an automatic surface wiping and cleaning device and an automatic cleaning machine which are used for cleaning the surface of a touch screen of a mobile phone. A platform rotating mechanism is arranged at the center of a bottom plate of a power distribution cabinet, a feeding conveying line is arranged at the starting end of the cleaning machine, the feeding conveying line, a blowing conveying line, a feeding and discharging mechanical arm and a discharging conveying line are sequentially connected in a front-back mode and fixed to the front end of the bottom plate of the power distribution cabinet, the far end of the feeding and discharging mechanical arm is connected with the platform rotating mechanism, a first cleaning head mechanism and a second cleaning head mechanism are arranged beside the platform rotating mechanism, the cleaning head mechanisms are provided with cleaning press plates used for cleaning materials according to sine wave tracks, and the cleaning press plates are connected with ethyl alcohol spraying mechanisms. The automatic surface wiping and cleaning device and the automatic cleaning machine have the advantages of eliminating health hazards of manual operation and greatly improving cleaning work efficiency and cleaning quality.

Owner:GUANGZHOU LINKCORE AUTOMATIC EQUIP CO LTD

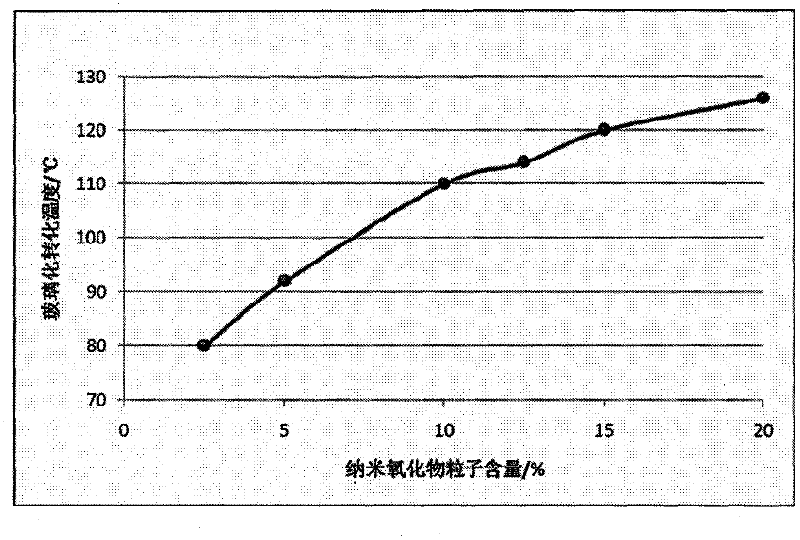

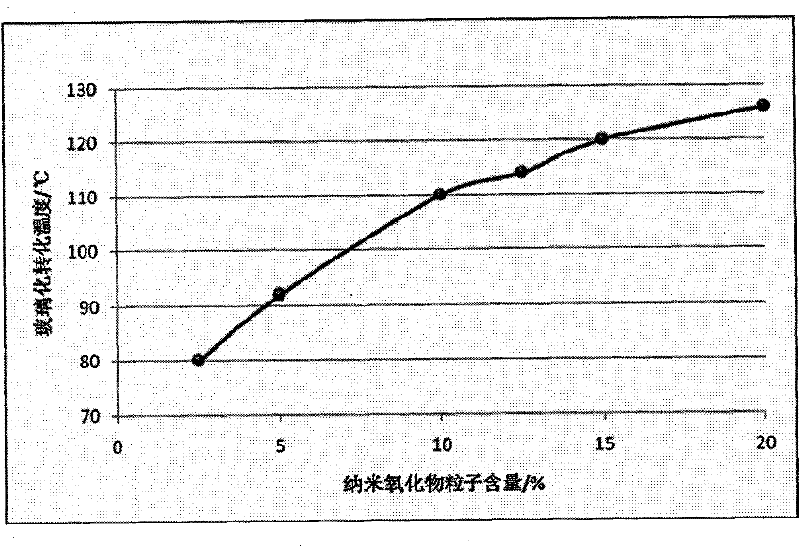

High molecule and inorganic nano-particle hybrid film and preparation method thereof

The invention relates to a high molecule and inorganic nano-particle hybrid film and a preparation method thereof, and particularly relates to a high molecule and inorganic nano-particle hybrid film for doping inorganic particles into a high molecule material by using a sol-gel method and a preparation method thereof. In the high molecule and inorganic nano-particle hybrid film, inorganic nano-particles are uniformly dispersed in the high molecular polymer film and account for 30-50 percent by weight of the total weight of the polymer film. The method comprises the following steps of: (1) preparing an inorganic oxide particular solution; (2) preparing a polymer solution; (3) preparing a high molecule-inorganic nano-particle mixed solution by using a low-temperature sol-gel method; and (4) injecting and drying the mixed solution to form a film. Compared with the prior art, the preparation method provided by the invention is easy and practical, can be used for conveniently and accurately controlling the thickness and the uniformity of the high molecular film, and is easy for production in scale. The inorganic nano-particle doped high molecular film can be widely applied to automobiles, construction and building materials and other fields.

Owner:DONGHUA UNIV

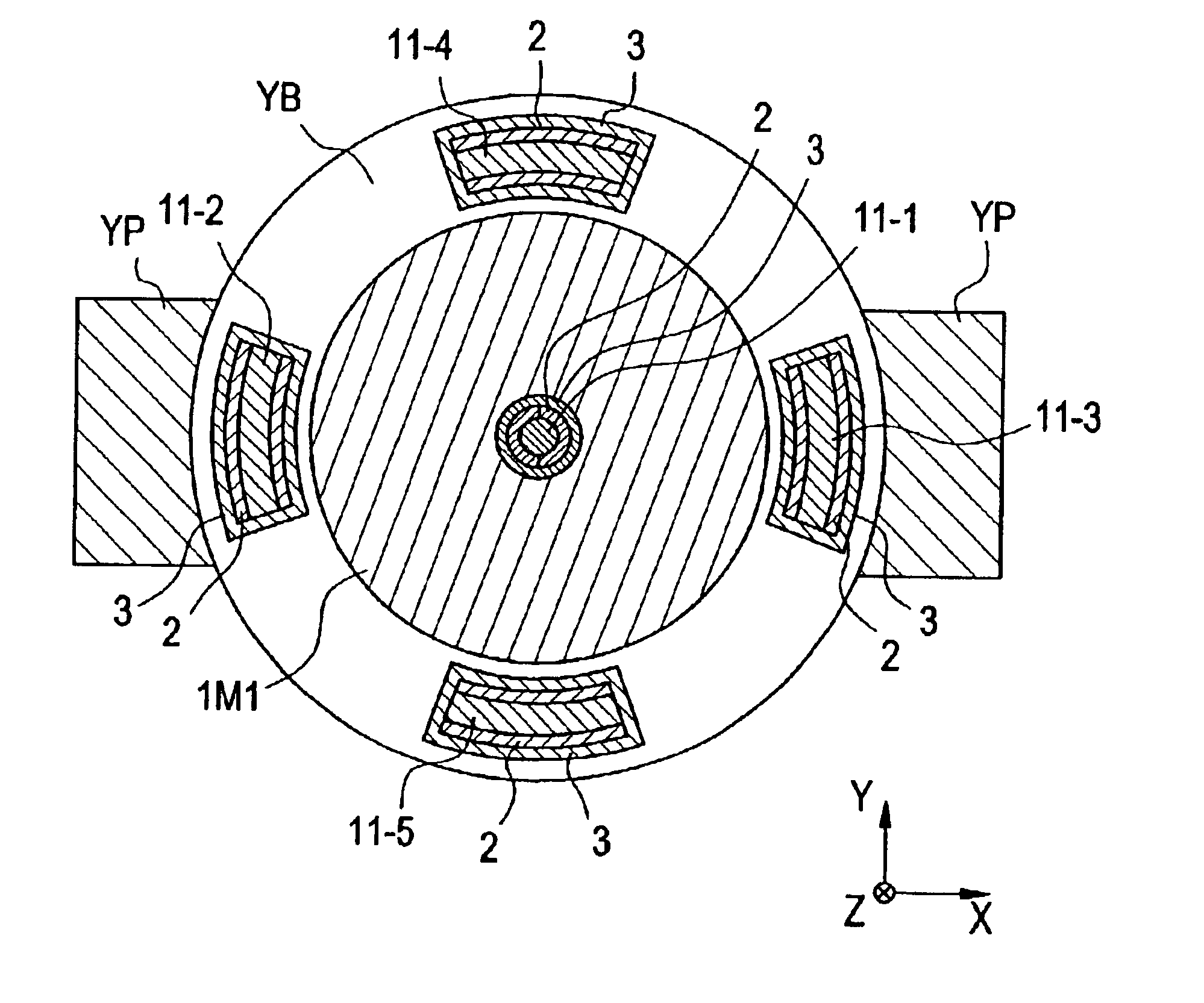

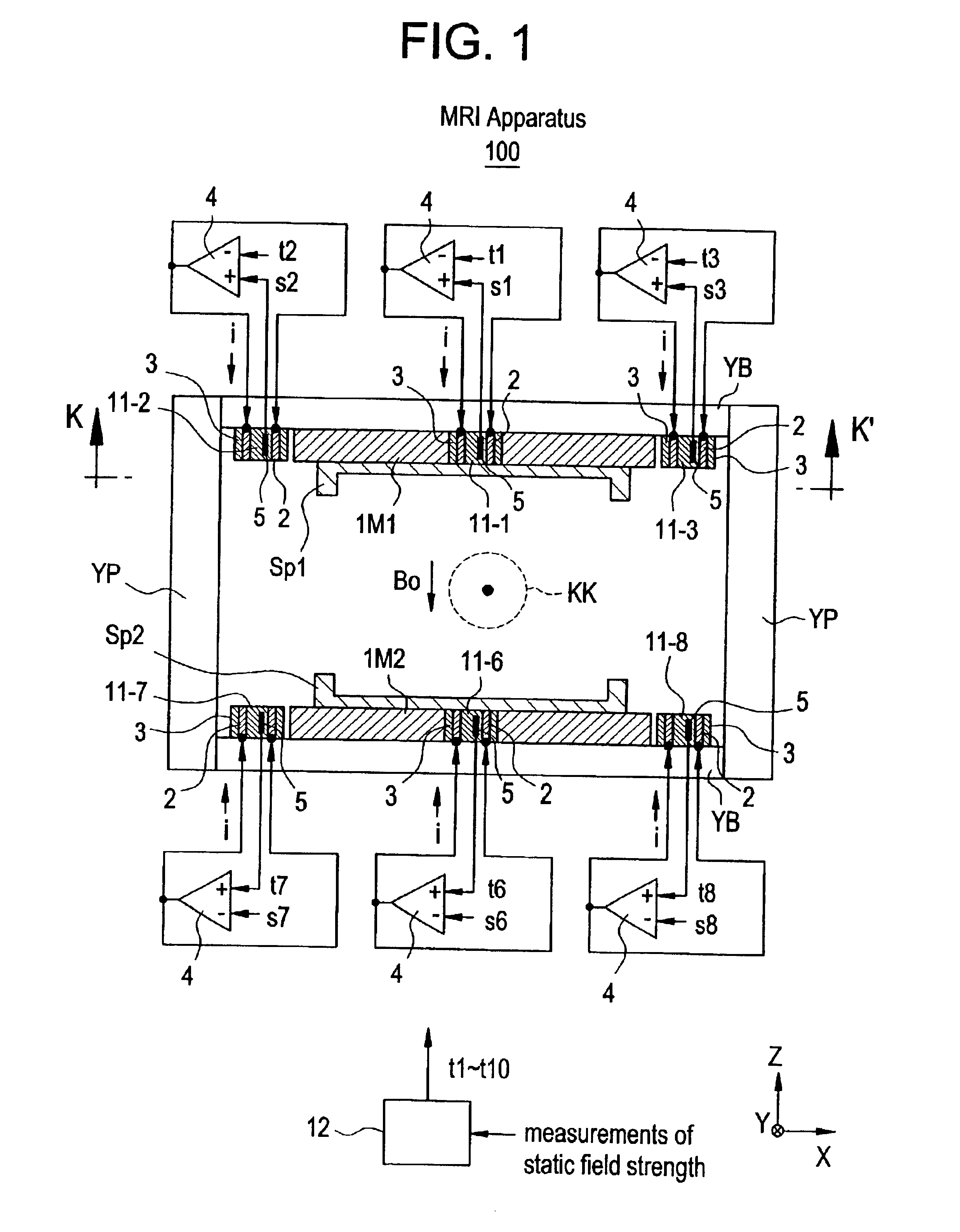

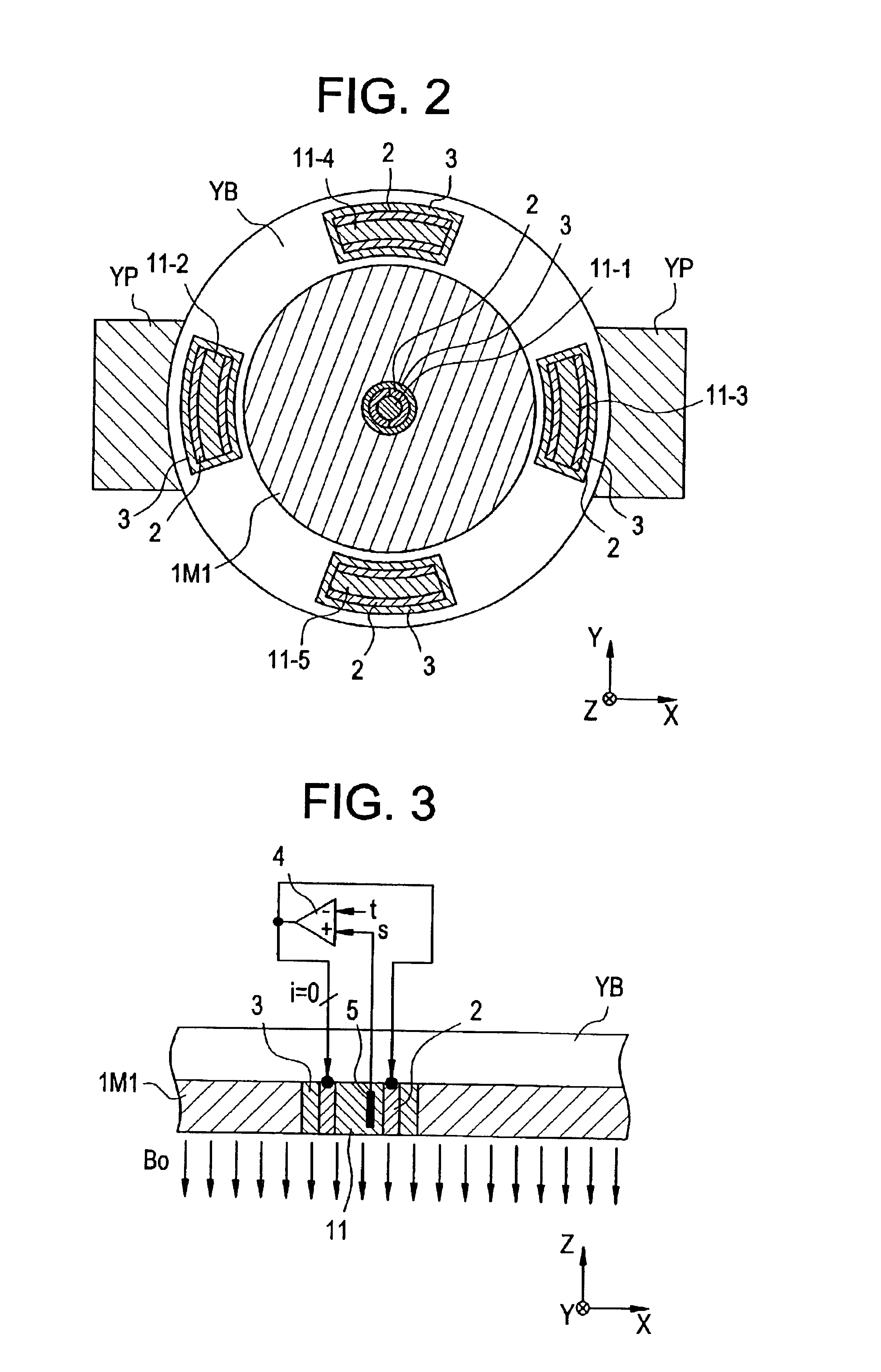

Static field controlling method and MRI apparatus

InactiveUS6891375B2Avoid interferenceControl UniformityDiagnostic recording/measuringSensorsStatic fieldMagnet

The temperature of permanent magnet blocks embedded in several positions in permanent magnets and base yokes will be adjusted by device of a heater to improve the static field uniformity.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

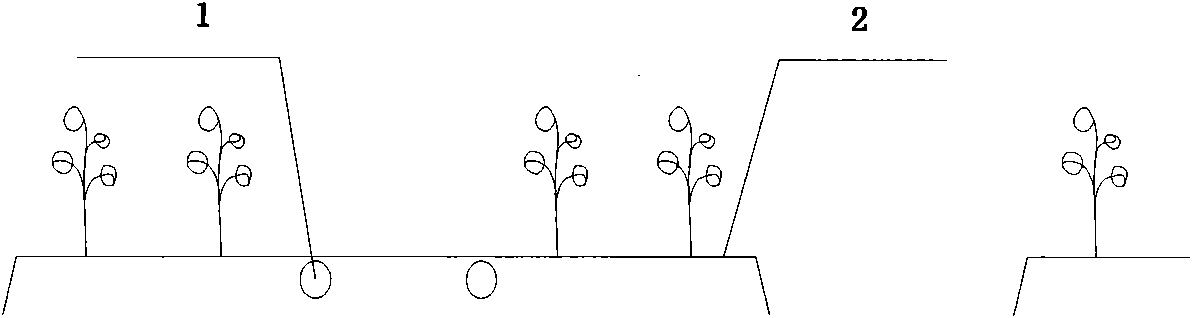

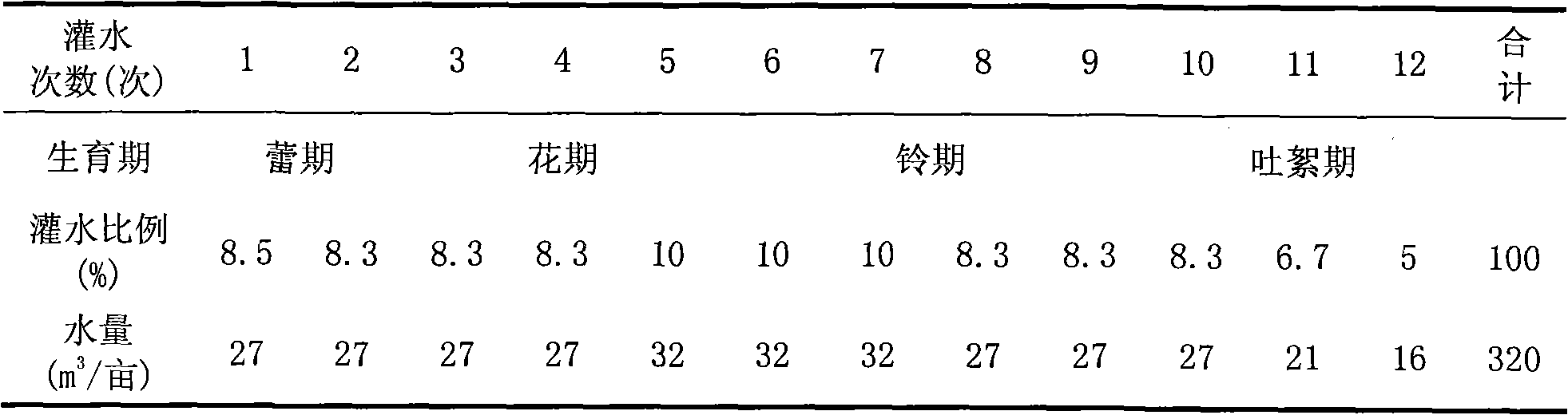

Drip Irrigation Method for Planting Cotton in Severe Saline Alkaline Land

InactiveCN102257946AReduce irrigated areaGood wetting range and wetting uniformityClimate change adaptationWatering devicesGrowth controlAgricultural science

The invention relates to a drip irrigation method for planting cotton in severe saline-alkali land. The method adopts the steps of pre-sowing preparation, capillary laying, drip irrigation, and salt control during growth period. This method does not carry out traditional submerged irrigation in autumn and winter after cotton is harvested. Before cotton is sown, pipes are laid and covered with film to drip water, and drip irrigation under film is used during the cotton growth period. It is aimed at the current situation of decreasing agricultural water consumption. A new water-saving and salt-controlling technology developed is an important supplement to the traditional method of flooding salt irrigation with large water. It has the advantages of less water consumption, good salt washing effect, and high crop emergence rate. The severely salinized areas have great potential for popularization and application.

Owner:XINJIANG AGRI UNIV

Light emitting diode device and manufacturing method thereof

ActiveUS20100079061A1Reduce light scattering effectImprove efficiencyDischarge tube luminescnet screensLamp detailsPhosphorNanocrystal

A manufacturing method of an LED device includes the following steps. First, a substrate and at least one LED disposed on the substrate are provided. Next, a porous material layer having a plurality of pores is formed on a surface of the LED. Finally, a plurality of nanocrystals are formed in the pores to construct a phosphor layer on the surface of the LED.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

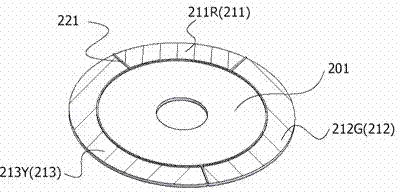

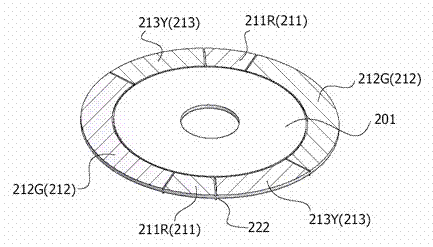

Fluorescent powder color wheel base plate with demarcation structures and manufacturing method thereof

InactiveCN103900035APrecisely control relative positionControl relative positionProjectorsSpectral modifiersCrystallographyAdhesive

The invention relates to a fluorescent powder color wheel base plate with demarcation structures and a manufacturing method of the fluorescent powder color wheel base plate. The manufacturing method comprises the steps that firstly, the base plate is machined, the base plate generates certain deformation, demarcation is conducted, and the demarcation structures which are convex or concave relative to a datum plane are formed at the demarcation positions; meanwhile, protrusion layers which are in a required shape and have a certain height and width are formed in advance in required color section areas on the base plate through adhesives, and accurate demarcation and accurate control are conducted in the process of follow-up manufacturing of fluorescent powder color sections; then, multiple fluorescent powder color sections are manufactured through printing, adhesive dispensing, spaying and the like, and finally a needed multi-color-section fluorescent powder color wheel is manufactured. The fluorescent powder color wheel base plate with the demarcation structures has the advantages that the important parameters such as the relative positions, the required shape (the width, the thickness, the flatness, the angle, the gap and the like), and evenness of fluorescent powder sheet layers on the fluorescence powder color wheel base plate can be more accurately controlled, control over the demarcation of the fluorescent powder sheet layers is guaranteed, the requirement for the performance of the fluorescent powder sheet layers is met, and therefore the accuracy, the efficiency and the quality of the fluorescence powder sheet layers in the forming process are greatly improved.

Owner:YANGZHOU G-NOVA OPTOELECTRONIC CO LTD

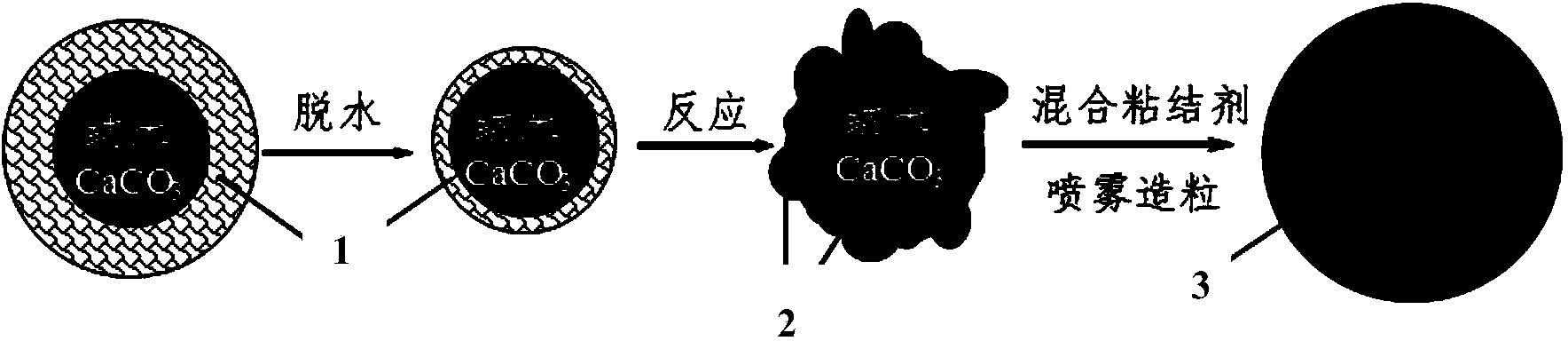

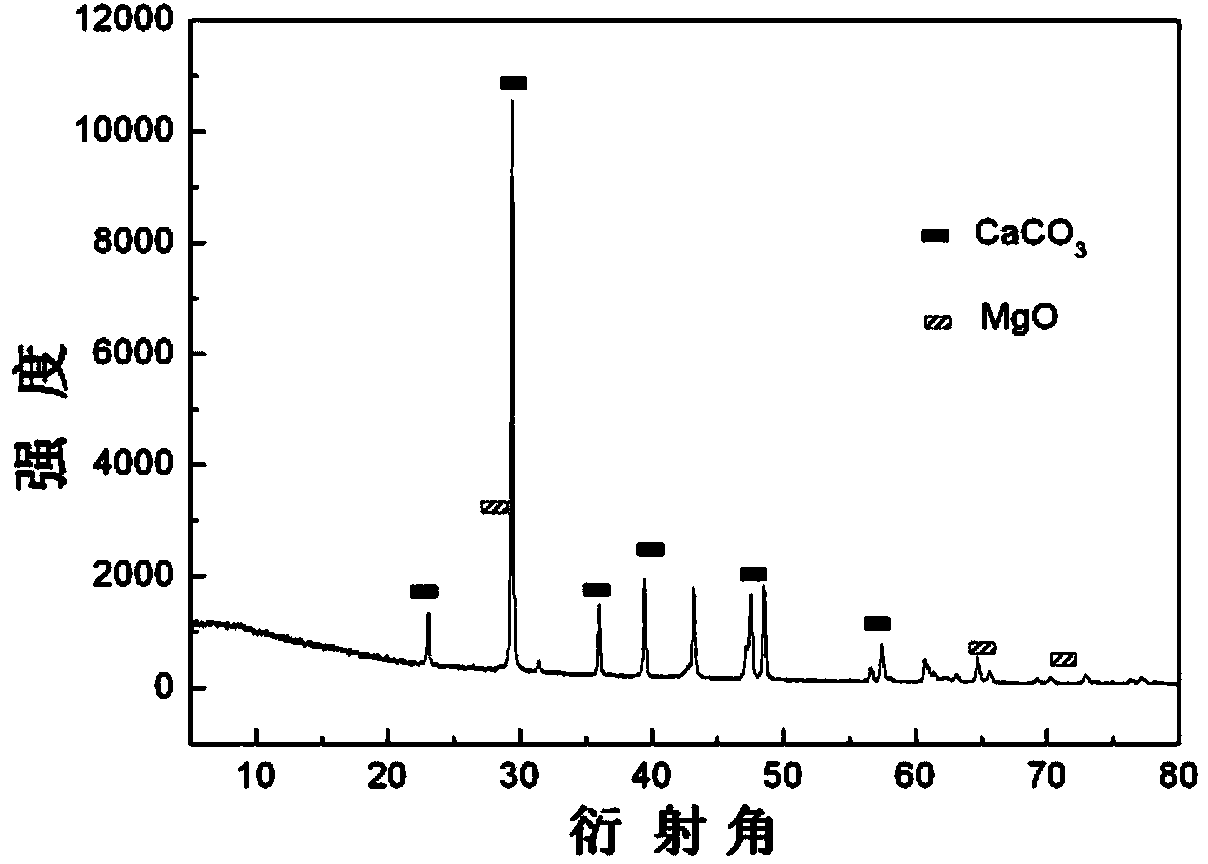

Surface coating modified nano calcium oxide based CO2 adsorbing agent and preparation method thereof

ActiveCN103962087AControl UniformitySimple methodOther chemical processesDispersed particle separationReaction fieldSorbent

The invention discloses a surface coating modified nano calcium oxide based CO2 adsorbing agent which is composed of internal nano calcium oxide and an external surface coating layer; the surface coating layer is prepared from at least one of Al2O3, Ca12Al14O33 and MgO. The invention further discloses a preparation method of the surface coating modified nano calcium oxide based CO2 adsorbing agent. An adsorption phase reaction method is utilized, and thickness and uniformity of the surface coating layer are controlled by controlling a reaction field, the method is simple and regulation and control are facilitated; according to the invention, the prepared surface coating modified nano calcium oxide based CO2 adsorbing agent has high CO2 adsorption capacity and obvious stability in adsorption ability in manifold cycles, can be in long-term recycling, and is an ideal adsorption agent in the adsorption process of high-temperature CO2.

Owner:ZHEJIANG UNIV

Polishing pad and method of making same

InactiveUS20050218548A1Control microcellular sizeControl UniformitySemiconductor/solid-state device manufacturingLapping machinesGas bubbleReaction injection molding

An article or polishing pad for altering a surface of a work piece includes a polymer matrix created by reaction injection molding of size controlled gas bubbles within a polyurethane matrix. The proposed liquid urethane precursor is first injected into an actuated mold and cured. The molded product is then removed from the mold and double side faced or ground to form a single thin polishing pad comprising a single layer of homogeneous material.

Owner:RIMPAD TECH

Iron-based soft magnetic composite magnetic powder core and preparation method thereof

ActiveCN104078182AThickness controllable and adjustableGuaranteed uniformityInorganic material magnetismAlcoholHeat stability

The invention relates to an iron-based soft magnetic composite magnetic powder core and a preparation method thereof. The invention adopts the technical scheme as follows: sequentially adding iron-based alloy powder, absolute ethyl alcohol, a silane coupling agent and distilled water into a reaction vessel according to the mass ratio of 1:(6-10):(0.04-0.10):(0.2-0.4), and stirring; adding tetraethyl orthosilicate or methyl silicate, then adding ammonia water, stirring continuously, washing, filtering and drying; placing the obtained composite powder with a core-shell heterostructure into an annealing furnace, performing heat preservation for 1-3 h under the condition of 600-800 DEG C, performing furnace cooling and performing compression moulding; sintering for 1-10 h under the condition of 900-1350 DEG C, so that the iron-based soft magnetic composite magnetic powder core is obtained after furnace cooling. The prepared iron-based soft magnetic composite magnetic powder core has the characteristics that the insulating property is good, the iron loss is low, high magnetic strength is achieved, the heat stability is good and the service life is prolonged when the iron-based soft magnetic composite magnetic powder core is used at a higher environment temperature.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com