Preparation method of bacteria cellulose/hyaluronic acid composite

A technology of bacterial cellulose and bacterial cellulose membrane, which is applied in the field of crosslinking, can solve the problem of not realizing the transformation of membrane matrix material nutrition control release skin layer damage repair function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

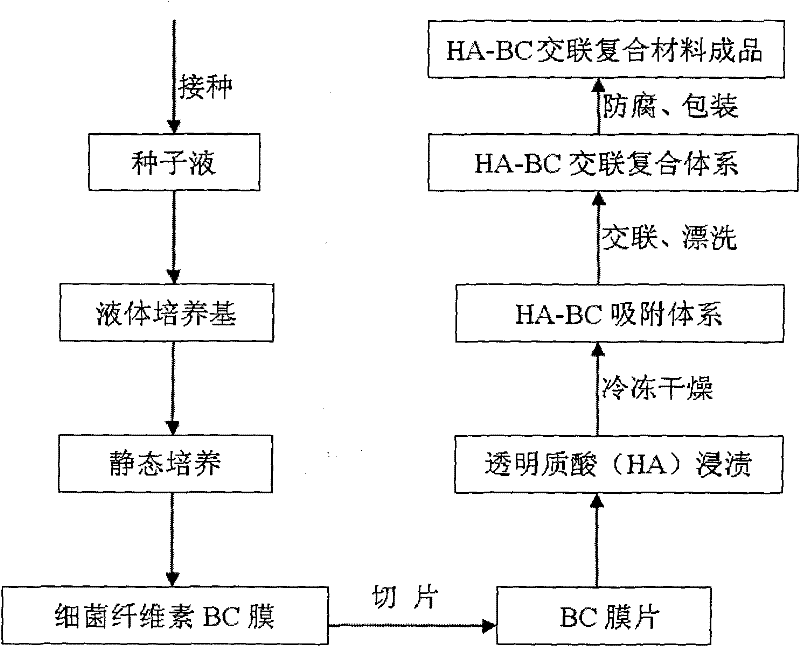

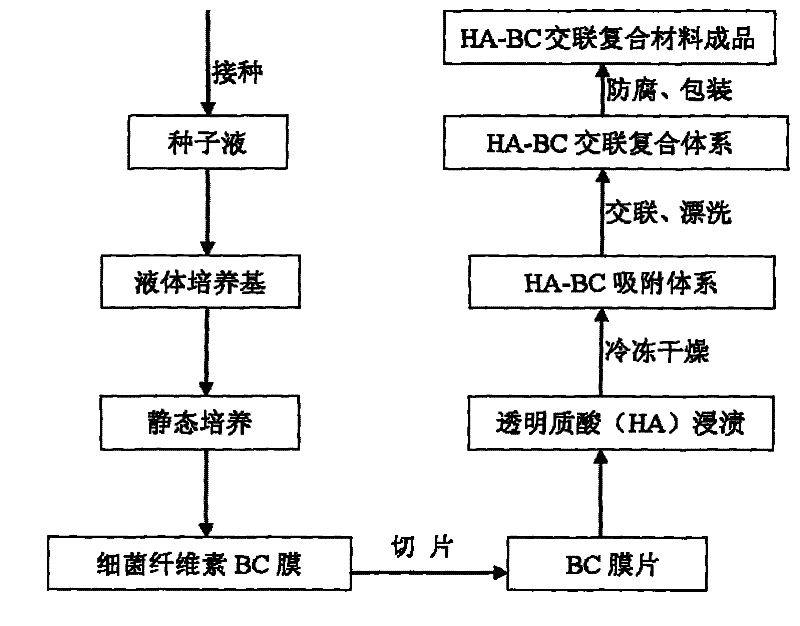

[0016] With reference to the drawings, the preparation method of the bacterial cellulose / hyaluronic acid composite material of the present invention includes the following steps:

[0017] In the first step, the activated Acetobacter xylinum strain is connected to the seed culture solution for shaking culture, the seed culture solution is connected to the fermentation culture solution, shaken, and then statically cultured at a culture temperature of 26-32°C. The amount of seed liquid is 1%-10%, and the bacterial cellulose membrane is prepared;

[0018] In the second step, the bacterial cellulose membrane prepared in the second step is rinsed with water and then placed in hot water. The temperature of the hot water is 80-90°C and the standing time is 3 hours. Then the bacterial cellulose membrane is taken out and placed Soak the membrane in an alkaline solution, then neutralize it with an acid buffer solution, soak the bacterial cellulose membrane in deionized water to neutral; the a...

Embodiment 1

[0025] Implementation Example 1: The preparation method of the bacterial cellulose / hyaluronic acid composite material of the present invention includes the following steps:

[0026] The first step is to take the activated Acetobacter xylinum strains and insert them into the seed culture solution, and culture at 29°C for 12 hours with shaking at a constant temperature of 120r·min. -1 . Add 5% of the inoculum to the fermentation broth, shake well, and incubate at a constant temperature of 29°C for one week to prepare a bacterial cellulose membrane.

[0027] The second step is the purification treatment of the product. The cellulose membrane prepared above is taken out and rinsed with tap water several times and then rinsed with deionized water; the rinsed membrane is placed in 80 ℃ water and treated for 3 hours; 1% sodium hydroxide Soak it in the solution, and place the soaking solution in a 40℃ water bath for 60 hours; neutralize the sodium hydroxide with an acetic acid-sodium aceta...

Embodiment 2

[0032] Implementation Example 2: The preparation method of the bacterial cellulose / hyaluronic acid composite material of the present invention includes the following steps: the first step is to take the activated Acetobacter xylinum strain into the seed culture solution, culture at 30°C with constant shaking for 8 hours, shake Bed speed 200r·min -1 . Add 3% of the inoculum to the fermentation broth, shake well, and incubate at a constant temperature of 30°C for one week to prepare a bacterial cellulose membrane.

[0033] The second step is the purification treatment of the product. The cellulose membrane prepared above is taken out and rinsed with tap water for several times and then rinsed with deionized water; the rinsed membrane is placed in 90℃ water and treated for 3 hours; 2% sodium carbonate solution Soak it and place the soaking solution in a water bath at 50°C for 48h; neutralize sodium hydroxide with a pH 4.5 acetic acid-sodium acetate buffer solution; soak the cellulos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com