Patents

Literature

539results about "Unfolding thin materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

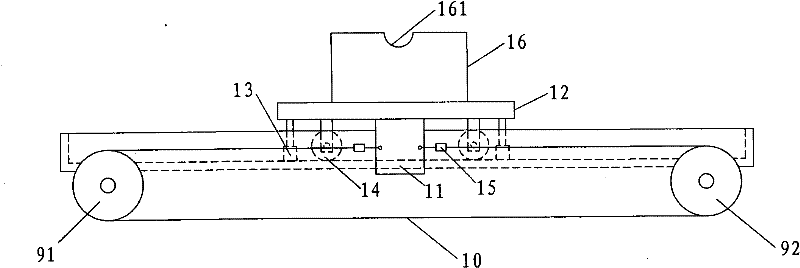

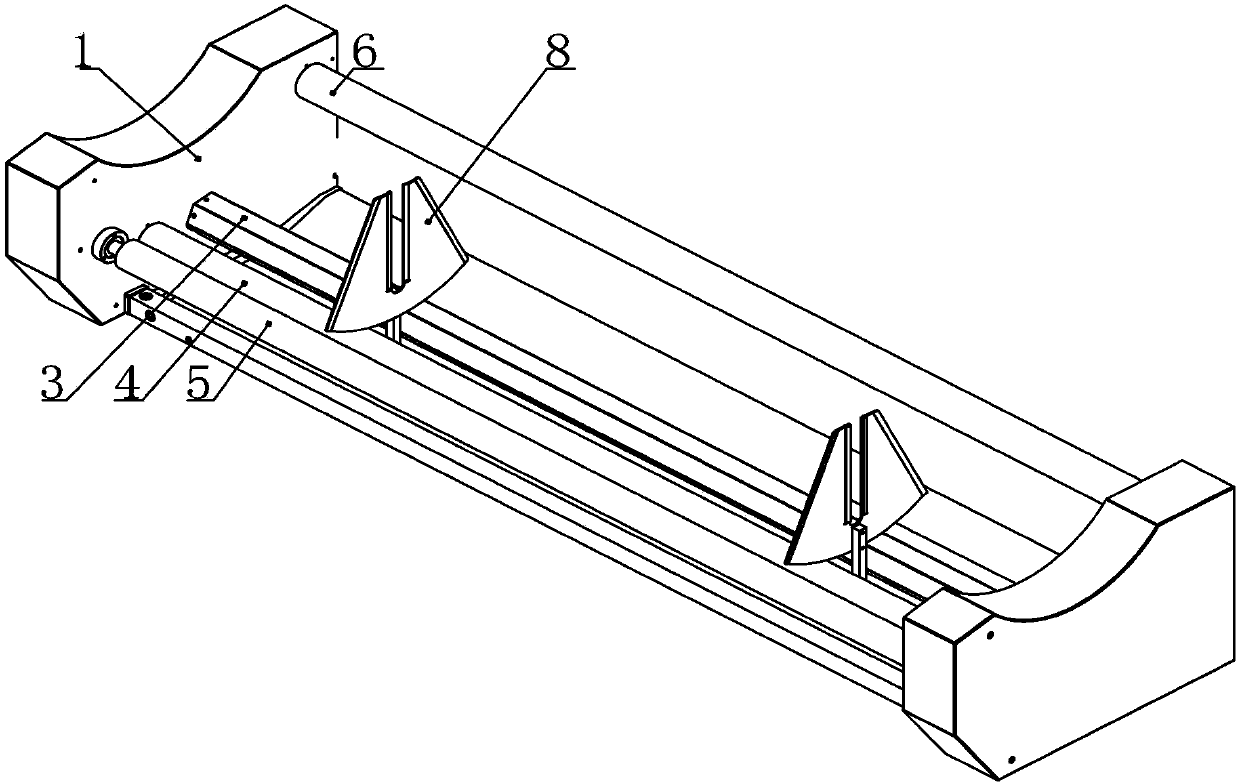

Cloth laying machine

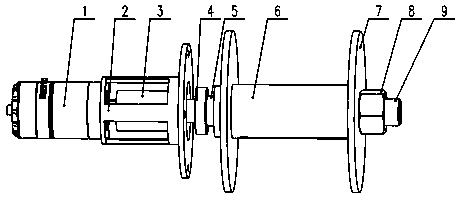

ActiveCN104444559ACreases are effectively flattenedFlat cutUnfolding thin materialsMotor driveDrive wheel

The invention discloses a cloth laying machine. The cloth laying machine comprises a machine frame, a cloth feeding device, a cloth spreading device and a cloth placing device, wherein the cloth feeding device, the cloth spreading device and the cloth placing device are arranged on the machine frame. The cloth spreading cloth comprises a movable cloth pressing roll, a cloth unwinding roll and two cloth spreading transmission mechanisms opposite in operating direction, wherein the movable cloth pressing roll and the cloth unwinding roll are arranged on the machine frame in parallel. The movable cloth pressing roll is located in the cloth path from the feeding device to the cloth unwinding roll. The cloth spreading transmission mechanisms are arranged on a platform of the machine frame and located in the cloth path from the movable cloth pressing roll to the cloth unwinding roll, and each comprise a driving wheel, a driven wheel, a second belt and a transmission motor driving the driving wheel to rotate. Through the structure, the cloth laying machine is high in cloth laying efficiency and good in cloth laying effect.

Owner:石狮市卓诚机械自动化设备有限责任公司

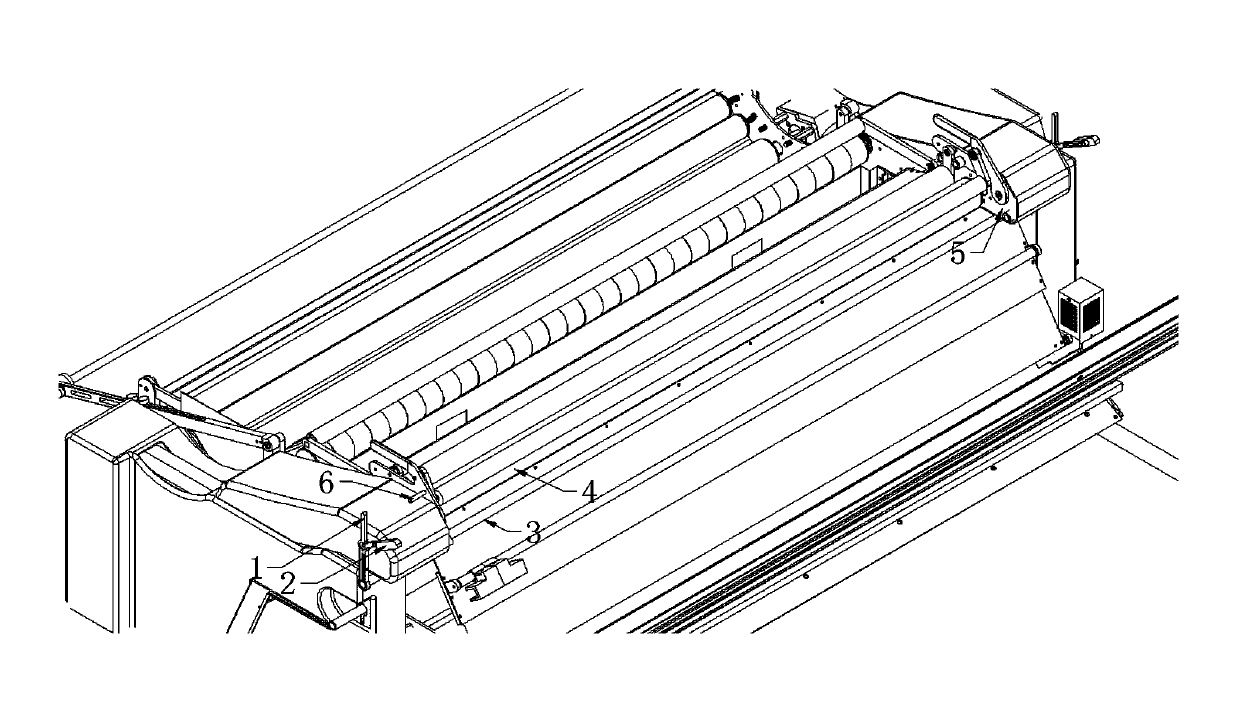

Full-automatic paper spreading machine

InactiveCN102431834ASimple structureGood effectUnfolding thin materialsProduction linePulp and paper industry

The invention provides a full-automatic paper spreading machine, which is used for automatically paper spreading of a paper spreading station in an automatic artificial board veneering production line and comprises a framework, a paper spreading moving rack, a driving device and a photoelectric detecting device. The driving device is arranged at the left end above the framework, the paper spreading moving rack is connected with a crossbeam arranged on the framework, and the photoelectric detecting device is arranged below the framework and fittingly used with the paper spreading machine. The full-automatic paper spreading machine is simple in structure, evident in effect, stable in working, safe and reliable.

Owner:SUZHOU XINXIELI MACHINE MFG

Cloth spreading machine

InactiveCN103144998ASimple structureEasy to operateFolding thin materialsUnfolding thin materialsEngineeringPulley

The invention discloses a cloth spreading machine which comprises a workbench, a moving frame, a feeding frame and a three-phase motor, wherein two parallel guide rails are arranged in an X axis direction of the workbench; pulleys forming straight sliding matching with the parallel guide rails are correspondingly arranged on the moving frame; cloth pressing plates are symmetrically arranged at the left end and the right end of the X axis direction of the workbench; rolling wheels are mounted at the two end parts of the cloth pressing plates; inclined rails forming vertical sliding matching with the rolling wheels on the cloth pressing plates in an Z axis direction are correspondingly arranged on the moving frame; the feeding frame is mounted on the moving frame; a cloth containing groove is formed in the upper end face of the feeding frame; and two parallel and clingy primary output rollers for supporting a cloth roll are mounted on the feeding frame. With the adoption of the structure, the cloth spreading machine is simple in structure and lower in cost, can spread and superpose cloth on the cloth roll, and is suitable for flattening and superposing cloth not rolled into a cloth roll.

Owner:叶茂顺

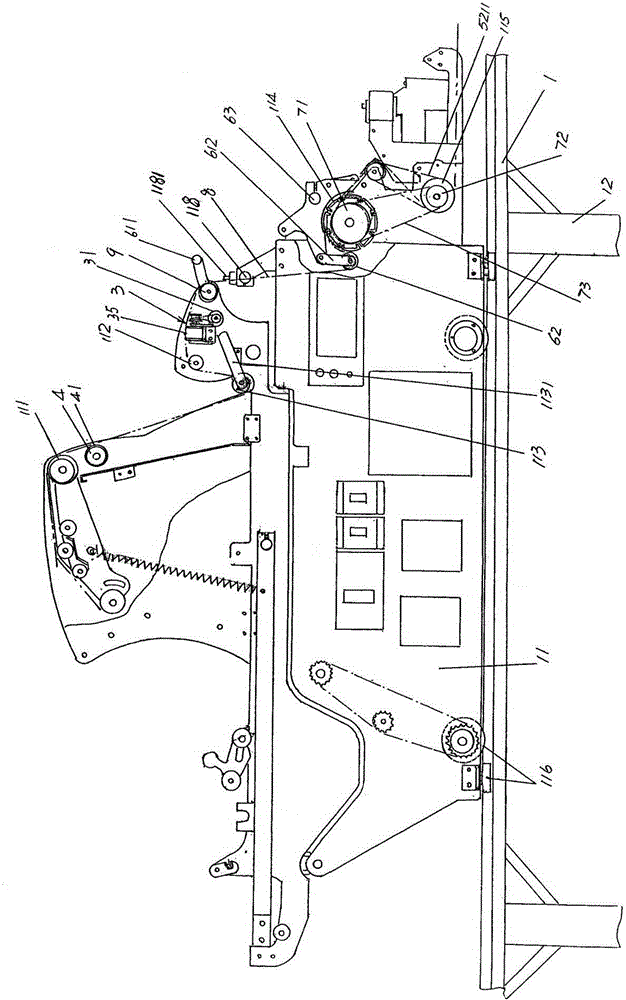

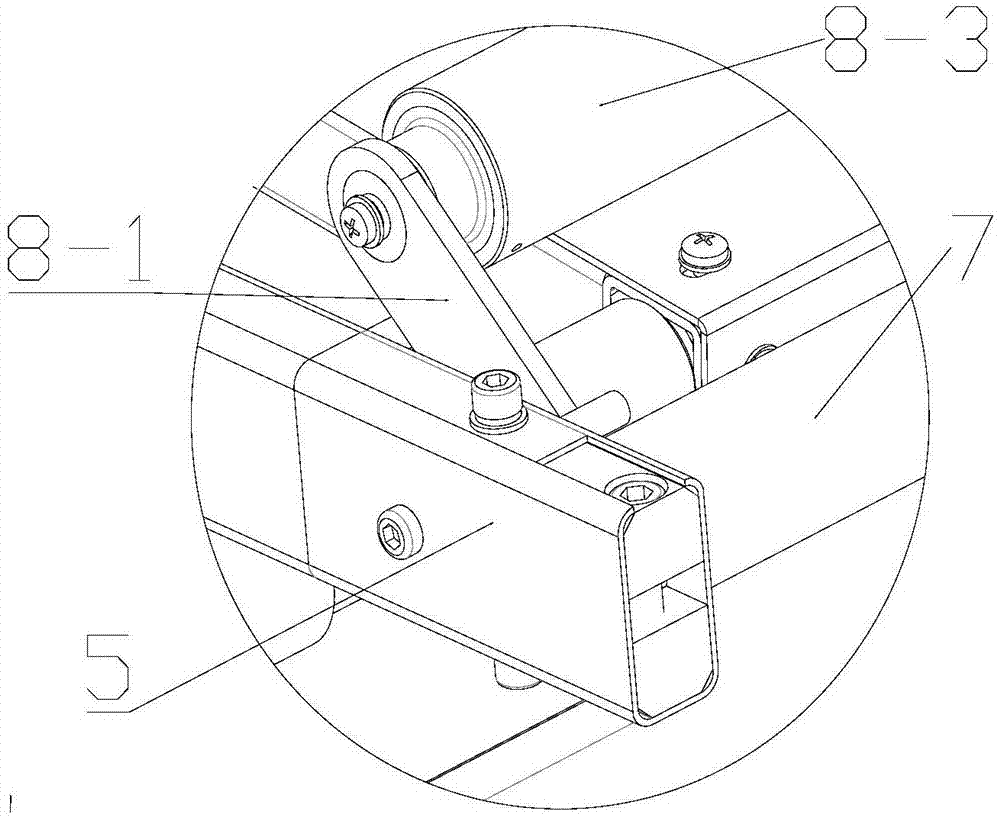

Cloth pressing device of spreading machine

ActiveCN103991750AMake sure to rabEnsure the effect of spreadingUnfolding thin materialsWebs handlingEngineeringMechanical engineering

The invention provides a cloth pressing device of a spreading machine and belongs to the technical field of garment processing machinery. The spreading machine comprises a spreading table, a cross beam, a pair of toothed belt edge stripping mechanisms and front and rear cloth spreading rollers, wherein a rack is arranged on the spreading table, upper and lower cloth guiding roller, a cloth guiding roller, a large cloth spreading roller and a lower cloth spreading roller are arranged on the rack. The cloth pressing device is characterized by comprising a large cloth spreading roller cloth pressing mechanism, wherein the large cloth spreading roller cloth pressing mechanism comprises a pair of cloth pressing roller carriers, a large cloth spreading roller front cloth pressing roller, a large cloth spreading roller upper cloth pressing roller and a large cloth spreading roller rear cloth pressing roller, the right end of one pair of cloth pressing roller carriers is pivoted on the rack, a handle is fixed in the middle of one pair of cloth pressing roller carriers, one opposite side of one end of one pair of cloth pressing roller carriers is connected with the upper end of a front pressing roller arm, one opposite side of the right end of one pair of cloth pressing roller carriers is connected with the upper end of a rear pressing roller arm, a large cloth spreading roller front cloth pressing roller is arranged at the lower end of the front pressing roller arm, the large cloth spreading roller upper cloth pressing roller is arranged between one pair of cloth pressing roller carriers, and the large cloth spreading roller rear cloth pressing roller is fixed at the lower end of the rear pressing roller arm. The cloth pressing device creates edge stripping conditions for a toothed belt edge stripping mechanism and ensures the cloth pulling and spreading effects.

Owner:SUZHOU BIYANGTE CLOTHING EQUIP CO LTD

Anti-fold cloth feeding device for cloth spreading machine

InactiveCN106006163ASimple structureEasy to operateUnfolding thin materialsWebs handlingElectrostatic coatingMechanical engineering

The invention relates to an anti-wrinkle cloth feeding device of a spreading machine. The front end of the device is provided with a cloth pressing roller parallel to the cloth discharging roller. The two ends of the cloth pressing roller are embedded in the slider through bearings. The sliding block is slidingly matched with the chute arranged on the end of the cross bar of the frame, and a spring is arranged between the sliding block and the end of the chute; the cloth outlet roller and / or pressing roller are hollow rollers, and the hollow roller There are several ventilation holes evenly arranged on the wall, one end of the hollow roller is provided with a plugging head, and the other end of the hollow roller is connected to the steam source through an air pump and a pipeline; an antistatic coating is provided on the surface of the press roller, and the corresponding cloth passes through The cloth guide roller is driven by the cloth feed roller to convey to the tension roller, and is sent out from between the cloth outlet roller and the cloth pressure roller. The cloth adjusting device of the cloth spreader has the characteristics of relatively simple structure, convenient operation, smooth output cloth, can eliminate static electricity on the cloth surface, and is safe and reliable to use.

Owner:SHAGNHAI YIN SCI&TECH CO LTD

Automatic cloth paving device

ActiveCN102190205AReduce manufacturing costSimple structureUnfolding thin materialsEngineeringProcess control

The invention discloses an automatic cloth paving device designed mainly for providing an automatic cloth paving device which has the advantages of simple structure and tension generation in a cloth paving process. The automatic cloth paving device comprises a control unit, a transmission unit and a cloth paving unit, wherein the control unit outputs a control instruction to the transmission unit according to a pre-set process control program; the control instruction input end of the transmission unit is connected with the control instruction output end of the control unit, and the transmission unit outputs linear power outwards according to the control instruction output by the control unit; the cloth paving unit is composed of a working board and a moving trolley capable of moving relative to the working board; and the moving trolley is connected with the linear power output end of the transmission unit directly or through a connecting piece.

Owner:JIHUA 3543 KNITTING CLOTHING

Horizontal type spreading device for spreading machine

ActiveCN104925580AImprove Rab QualityUnfolding thin materialsArticle deliveryMechanical engineeringEngineering

The invention discloses a horizontal spreading device for a spreading machine. The horizontal spreading device for the spreading machine is characterized by further comprising a control mechanism controlling the rotating speed of a first motor and the rotating speed of a second motor, and a cloth storage plate is arranged between an upper cloth conveying roller and a lower cloth conveying roller; a concave part is formed in the upper surface of the cloth storage plate, and a through hole is formed in the side, close to the lower cloth conveying roller, of the cloth storage plate; an optoelectronic switch is installed below the though hole, and a reflector which is matched with the optoelectronic switch is installed on the side, close to the upper cloth conveying roller, of the cloth storage plate; the rotating speed of the first motor and / or the second motor is dynamically adjusted by the control mechanism according to an output signal of the optoelectronic switch, so that the rotating speed of the upper cloth conveying roller is matched with the rotating speed of the lower cloth conveying roller, and a light path between the through hole and the reflector is not shaded by cloth, in the sliding state, on the cloth storage plate. According to the horizontal spreading device for the spreading machine, under the control of the control mechanism, the situation that cloth stays on the cloth storage plate due to the fact that the rotating speed of the upper cloth conveying roller is higher than that of the lower cloth conveying roller is avoided, the situation that cloth cannot be conveyed in time due to the fact that the rotating speed of the lower cloth conveying roller is higher than that of the upper cloth conveying roller is also avoided, and thus the spreading quality is improved.

Owner:伊士曼缝制机械(宁波)有限公司

Edge peeling and positioning device of spreading machine

ActiveCN104003231ABlock replyPrevent swimmingUnfolding thin materialsWebs handlingEngineeringContact effects

An edge peeling and positioning device of a spreading machine belongs to the field of clothing machines. The spreading machine comprises a spreading table, a machine frame is arranged on the spreading table and provided with an upper cloth guiding roller, a lower cloth guiding roller, a cloth pressing roller, a large cloth spreading roller and a lower cloth spreading roller. The edge peeling and positioning device comprises a beam and a pair of toothed belt type edge peeling mechanisms and is characterized by further comprising a front cloth expanding roller, a rear cloth expanding roller and a peeled and expanded cloth edge maintaining roller, wherein the front cloth expanding roller is supported on the machine frame and provided with front cloth expanding threads, the rear cloth expanding roller is provided with rear cloth expanding threads, and the peeled and expanded cloth edge maintaining roller is provided with flanges; the beam is fixedly provided with a pair of belt supporting unit seats, which extend into an edge peeling toothed belt cavity and are fixedly provided with belt supporting units, and the belt supporting units are arranged inside the edge peeling toothed belt cavity and are in contact with the inner side of the edge peeling toothed belt. The edge peeling and positioning device of the spreading machine enables the cloth edges of both sides in the length direction of cloth spread on the spreading table to maintain a trim state, prevents both sides the cloth from moving towards the middle, eliminates the deflection of the edge peeling toothed belt and improves the integral contact effects of the edge peeling toothed belt with the cloth edges.

Owner:SUZHOU BIYANGTE CLOTHING EQUIP CO LTD

Cloth pressing machine with ironing function

InactiveCN104609248AAvoid the problem of inaccurate cropping sizeQuality assuranceIroning machinesUnfolding thin materialsEngineeringUltimate tensile strength

A cloth pressing machine with the ironing function comprises a rack, a cloth guide roller, a cloth spreading table, a pair of shaft roller seat supports, a pair of pressing arms and a cloth pressing rod. The cloth guide roller and the cloth spreading table are arranged on the rack, and the shaft roller seat supports are arranged on the left side and the right side of the front end of the rack; the two ends of the cloth pressing rod are fixed to one ends of the pressing arms respectively; the other ends of the pressing arms are rotatably arranged on the shaft roller seat supports through arm pressing shaft sleeves; steam spraying holes are formed in the cloth pressing rod, and an annular bottom plate and heating elements are arranged in the cloth pressing rod; steam spraying holes corresponding to the cloth pressing rod are formed in the annular bottom plate; a water storage device is arranged on the annular bottom plate and the heating elements; and a water inlet of the water storage device is formed in the side edge of the rack through a water inlet pipe, and the water storage device is connected with the annular bottom plate through steam outlet pipes. According to the cloth pressing machine, cloth is smoother, and the problem that due to cloth telescopic deformation of cloth in the pulling process, the cutting size is inaccurate is solved; the quality is ensured, and meanwhile machining of a back working procedure is facilitated; and the labor intensity is reduced, and the production efficiency is improved.

Owner:TAIZHOU TIANSHENG GARMENT CO LTD

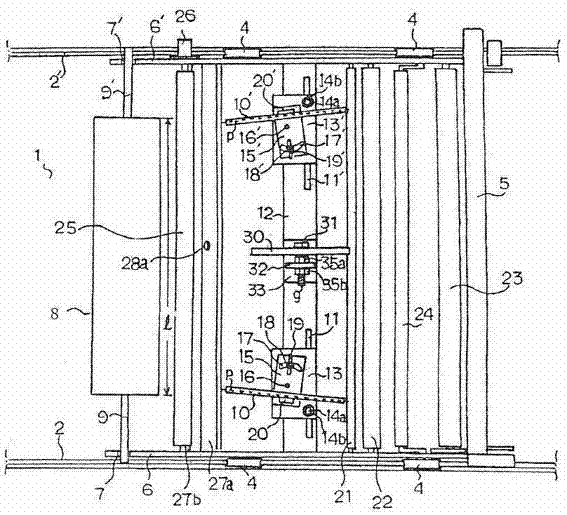

Double-spreading cloth pressing device for automatic cloth paving machines

InactiveCN102774690ASimple structureRealize double pull and press clothFolding thin materialsUnfolding thin materialsLinear motionEngineering

The invention discloses a double-spreading cloth pressing device for automatic cloth paving machines. The double-spreading cloth pressing device comprises a movable folder mechanism, a double-spreading mechanism and a fixed folder mechanism, wherein the movable folder mechanism comprises a handwheel, a locking screw, a pressure plate, a fixed plate, a clamping plate, a small bearing wheel, a large bearing wheel, a straight spool, a linear slide, a support bar, a movable folder holder, a cloth-pressing connecting rod, a spindle connecting plate, a stop lever, a cloth-pressing chopping block, a toothed belt and a locking block; the double-spreading mechanism comprises a raised pole, a side plate, an L-shaped connecting rod and a connection fixed plate; the fixed folder mechanism comprises a straight spool, a linear slide, a support bar, a cloth-pressing connecting rod, a spindle connecting plate, a stop lever, a cloth-pressing chopping block, a toothed belt, a locking block and a fixed folder holder; and the double-spreading mechanism carries out a reciprocating linear motion so as to realize cloth paving and drive the movable folder mechanism and the fixed folder mechanism to realize a cloth-pressing action. The cloth pressing device disclosed by the invention has the advantages that the device is simple in structure, an effect of tension-free folding-type multilayer cloth pressing is achieved, the device is convenient to turn over for taking out fabrics, and the like.

Owner:SHAGNHAI YIN SCI&TECH CO LTD

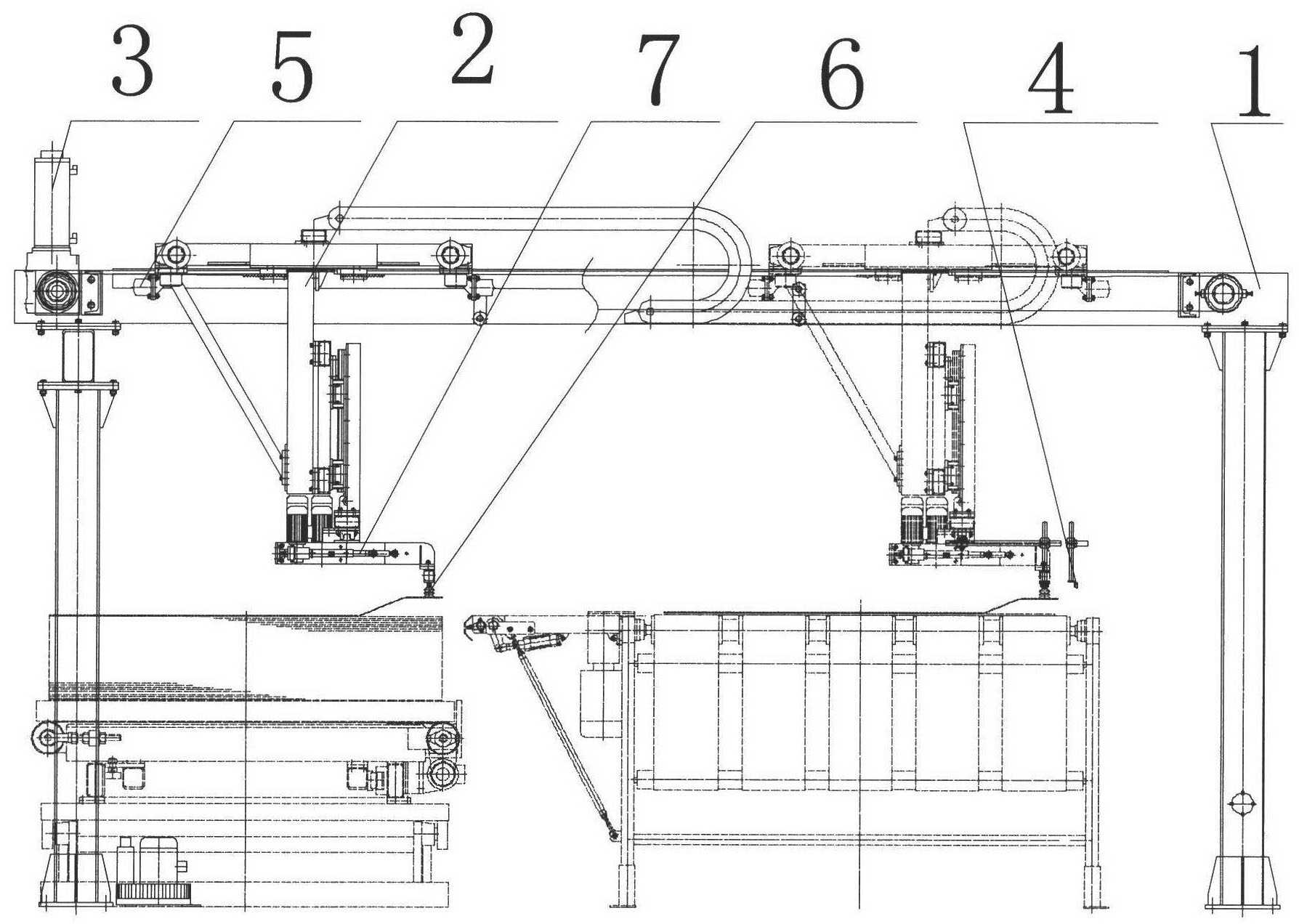

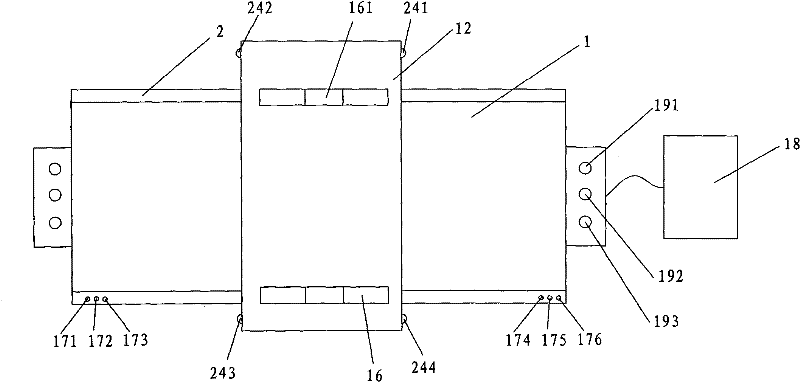

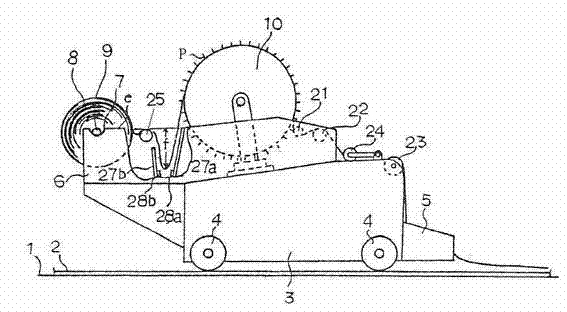

Cloth laying machine

InactiveCN102442578AEliminate generationDoor width automatic adjustmentUnfolding thin materialsPulp and paper industryDrive motor

The invention discloses a cloth laying machine, comprising a platform plate, tracks, a cloth laying machine body, a driving mechanism, a V-shaped guide plate, a fabric shaft, a guide device and a shearing device, wherein the tracks are arranged at the two sides of the platform plate; the cloth laying machine body travels on the tracks; the shearing device is arranged at the front of the body; the cloth laying machine body is provided with a dial frame which is provided with a dial; a cloth loosening roller is arranged between the guide plate and the fabric shaft; and a supporting fabric drooping device is arranged vertically below the middle fabric of the dial. A long screw also can be arranged between the tracks and is positioned at the edge side of the dial; the edge side of a mother plate is provided with a sliding nut which is screwed on the long screw; and one end of the long screw is provided with a driving motor for driving the long screw to rotate. The cloth laying machine can eliminate the problem caused by inferior-quality products due to serious drooping of the middle part of the fabric when the fabric is wide, thick and heavy, and the fabric width can be adjusted automatically when the cloth is laid.

Owner:嘉兴川上服装设备有限公司

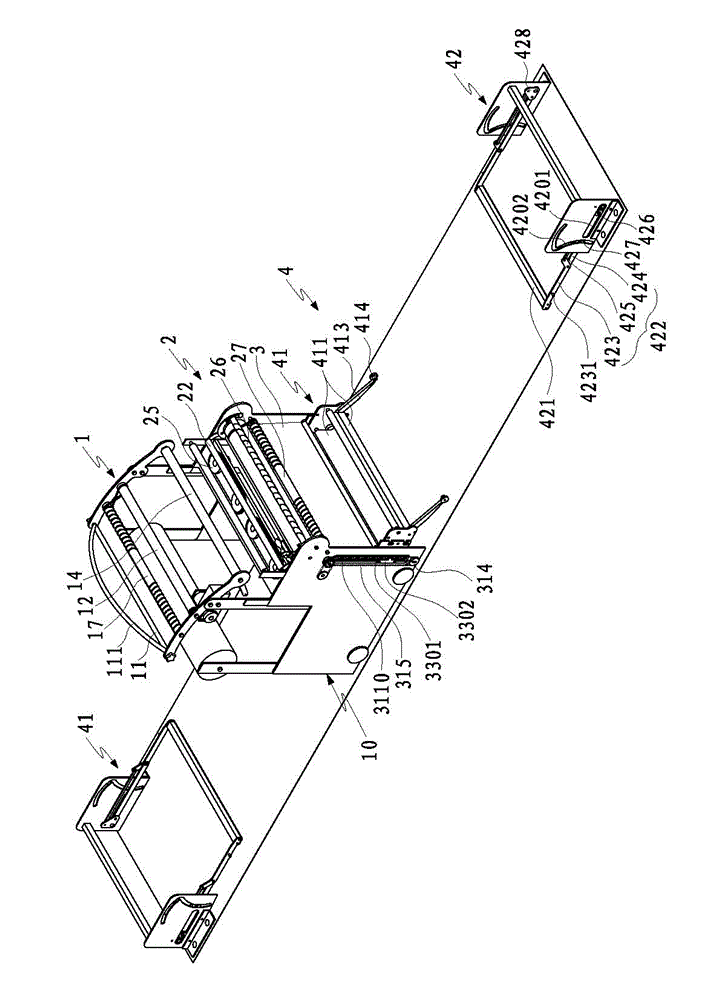

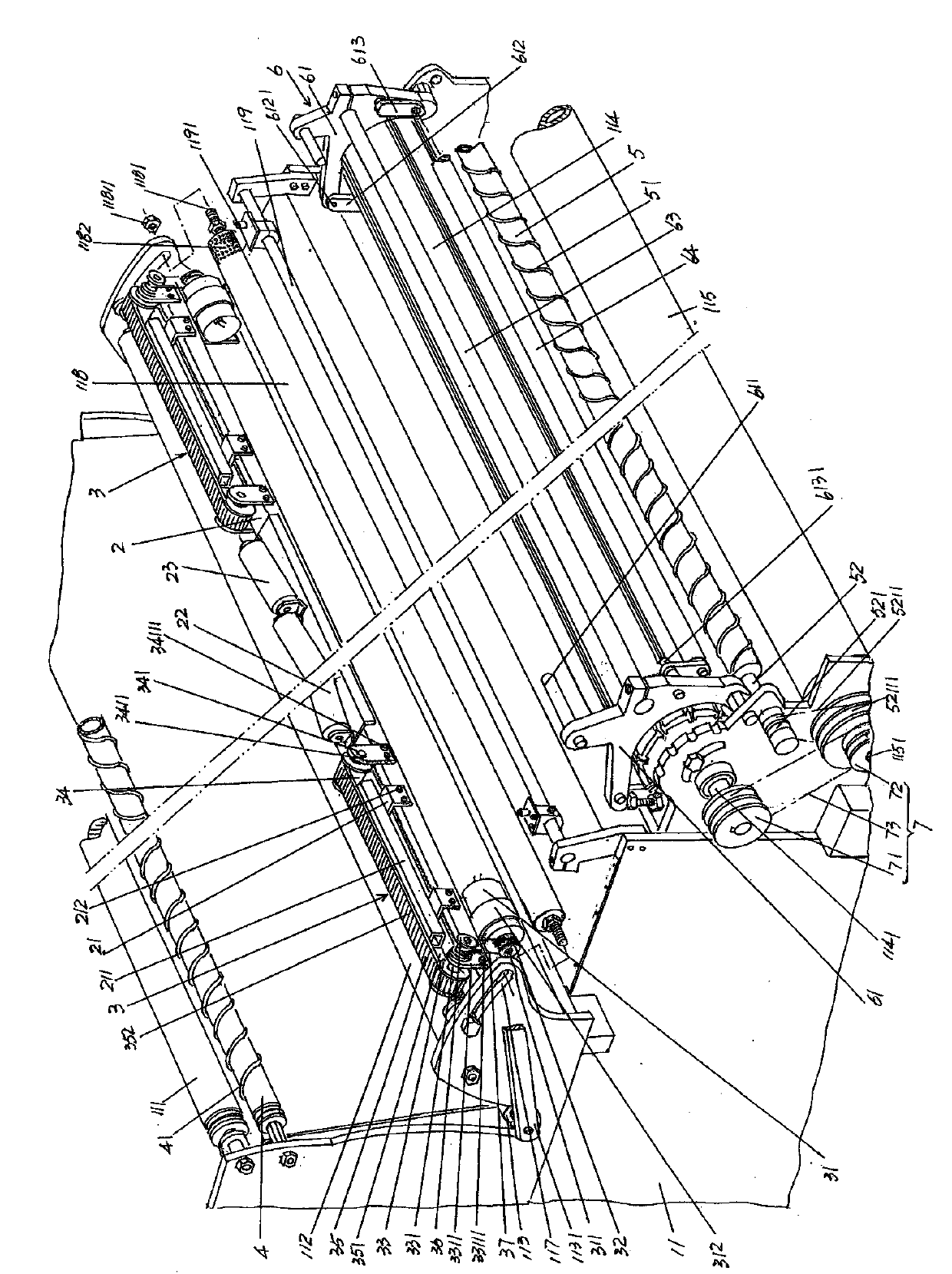

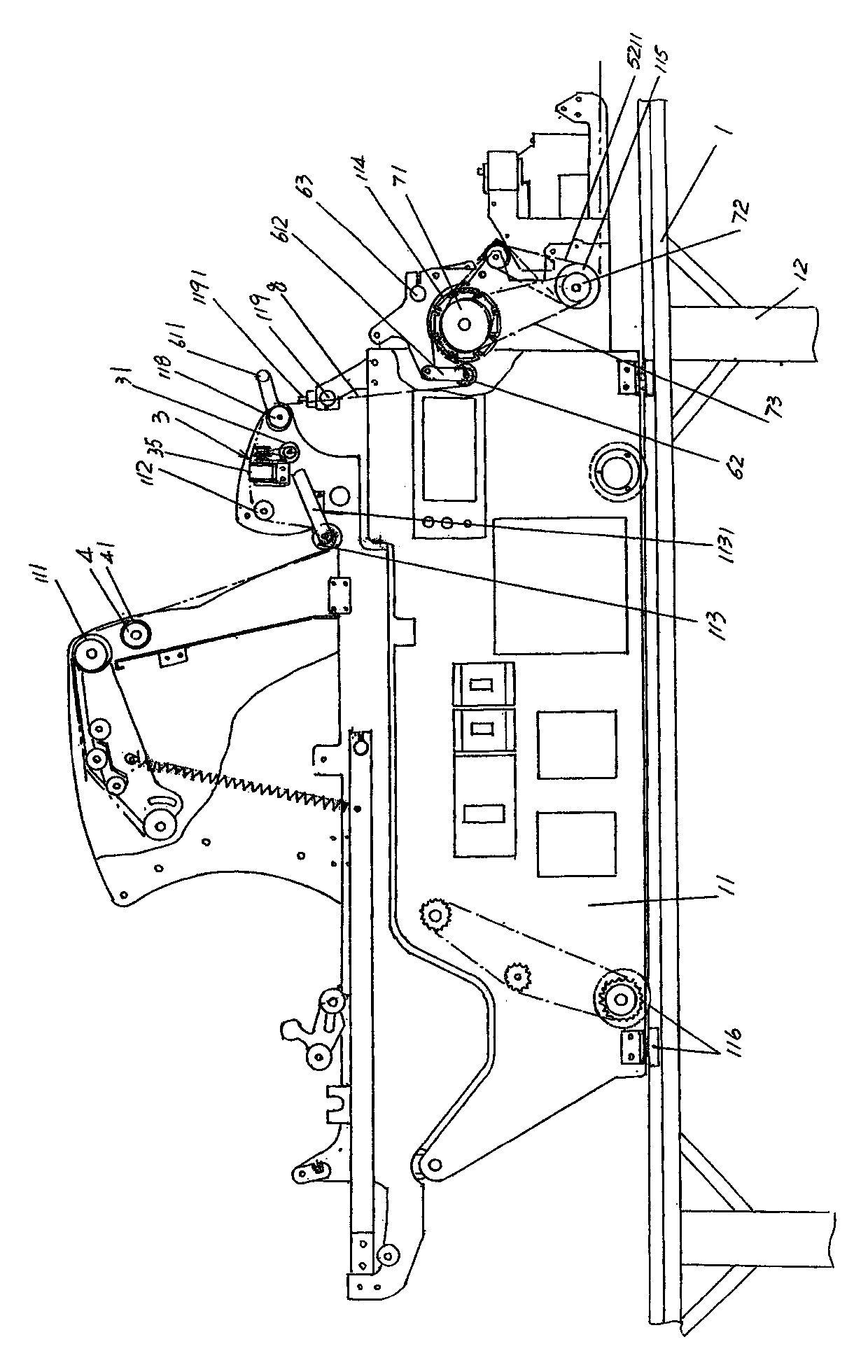

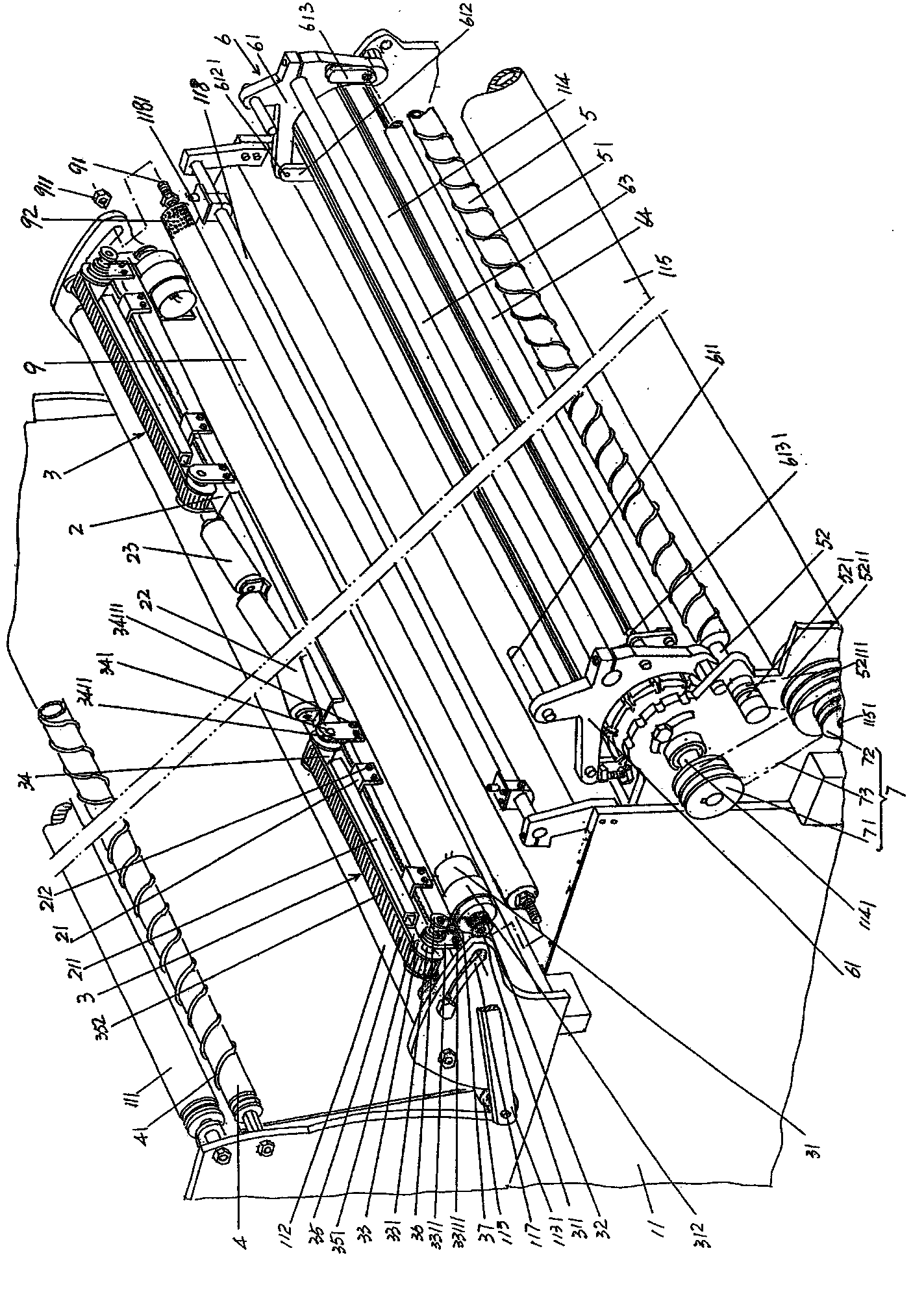

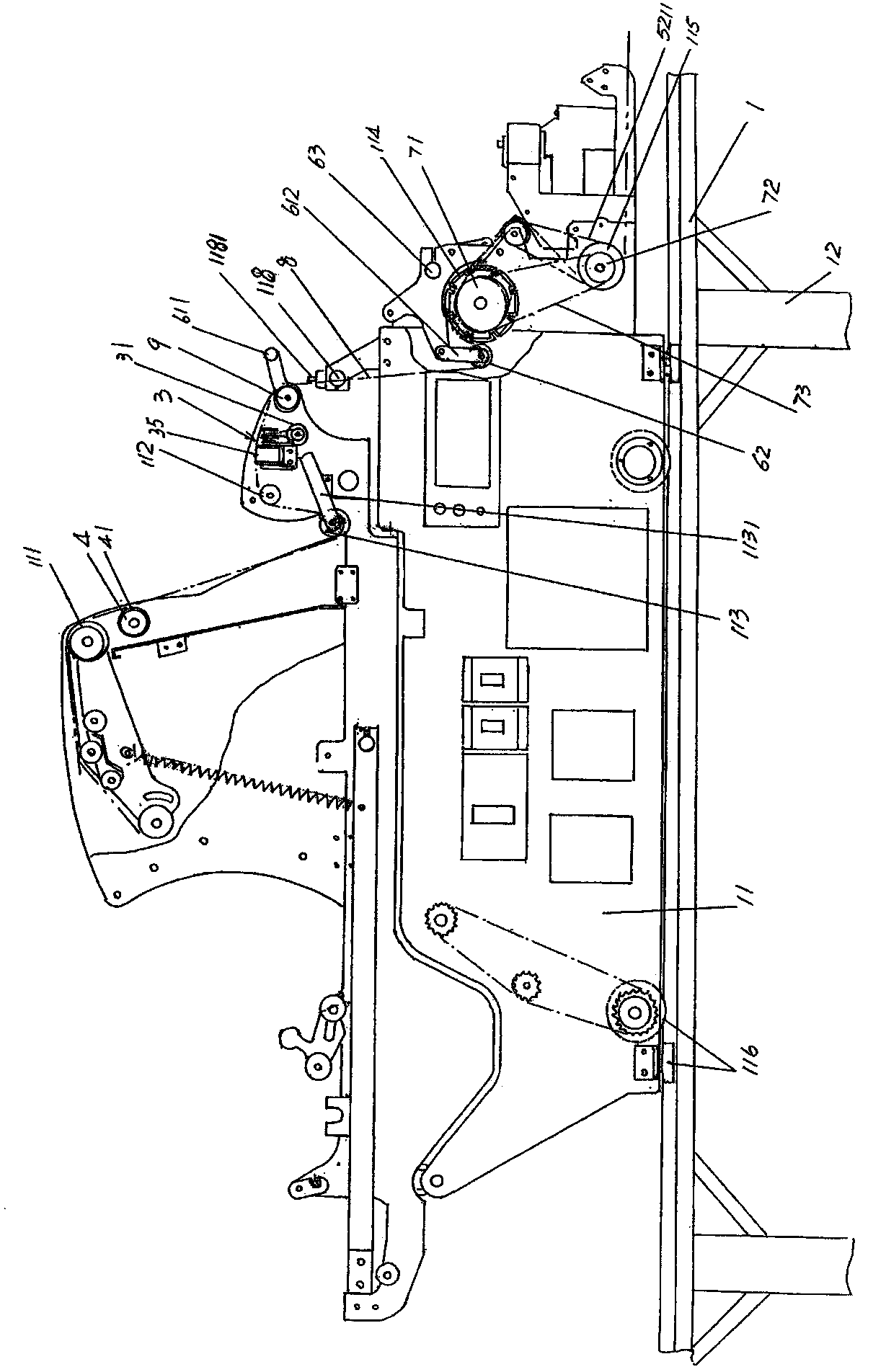

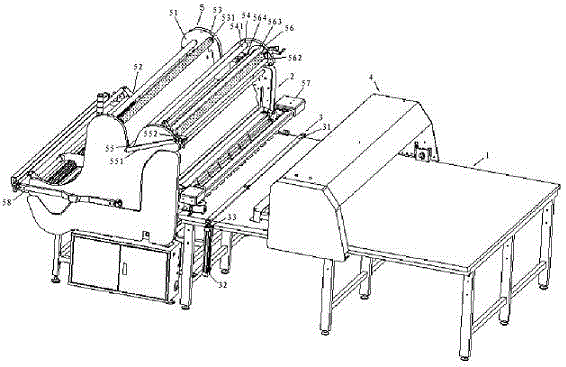

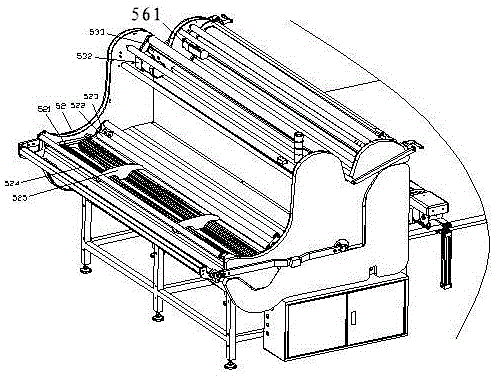

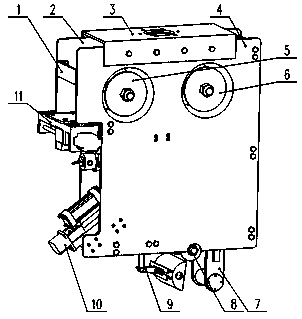

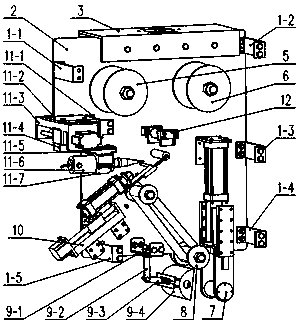

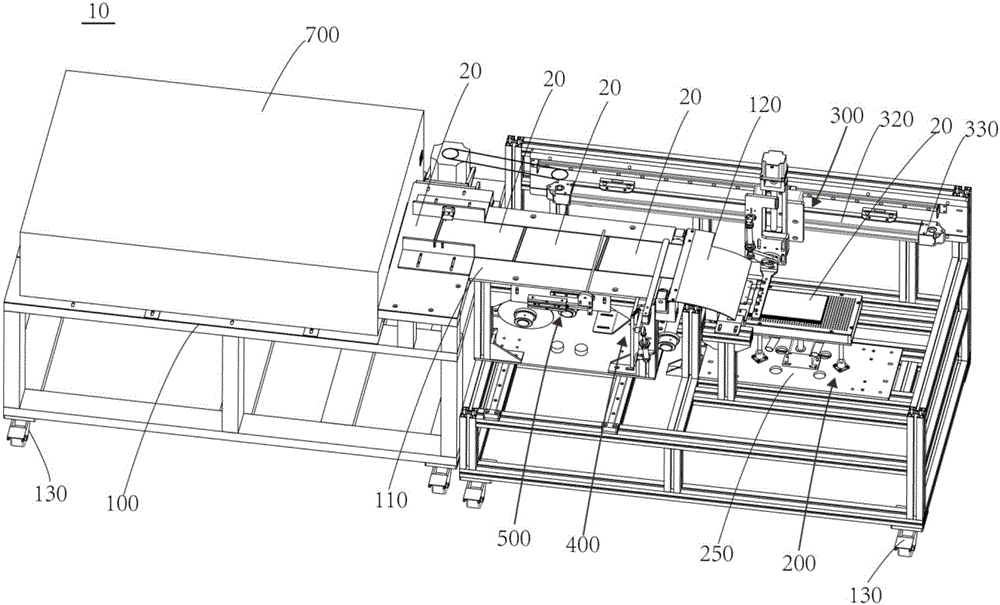

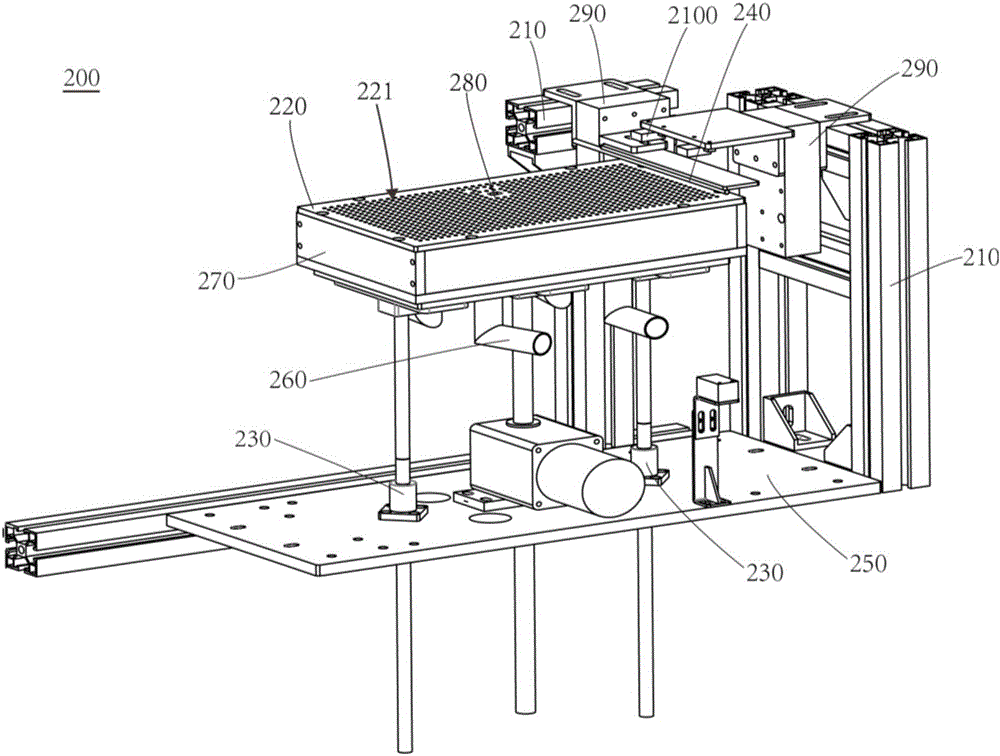

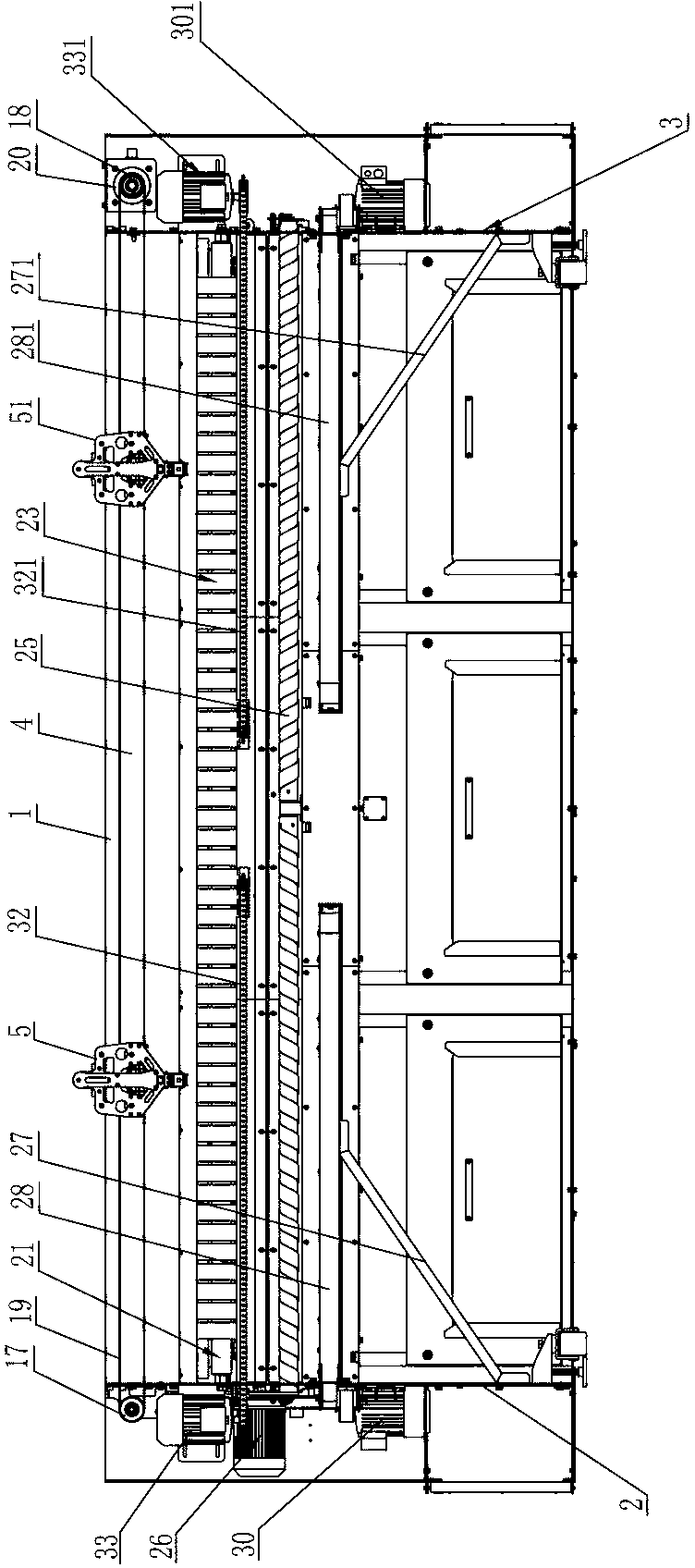

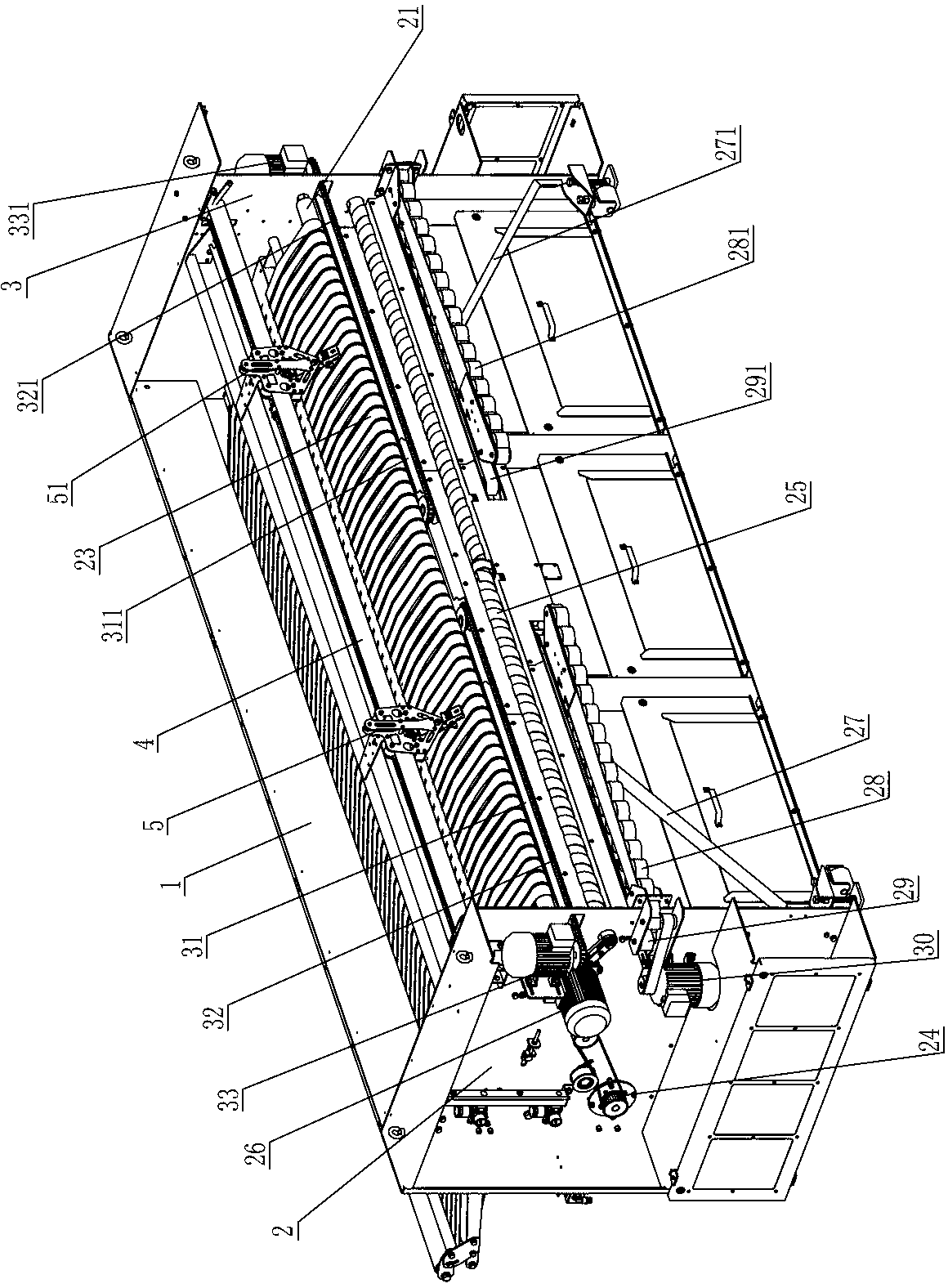

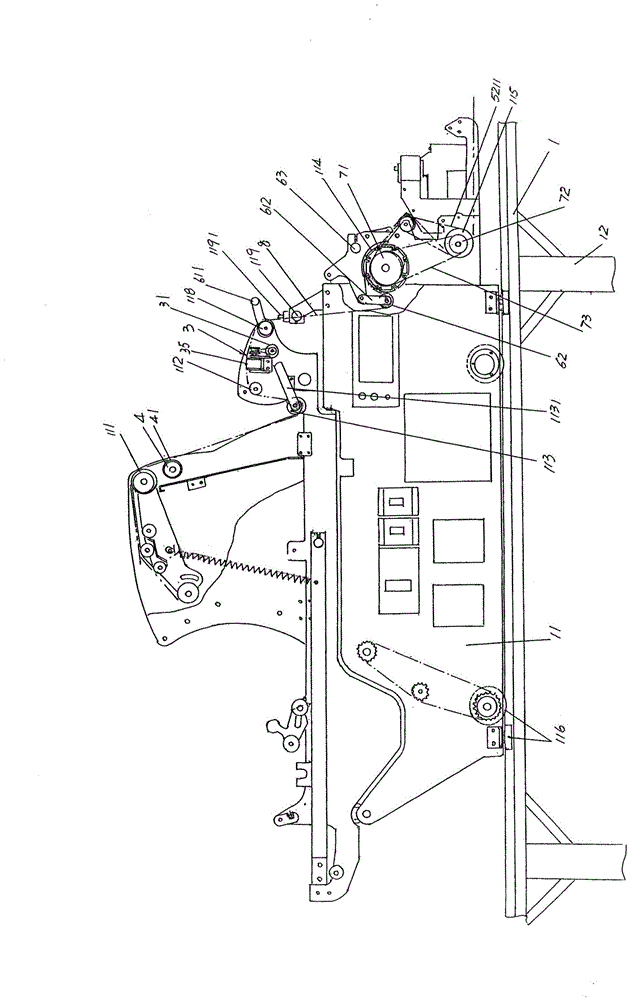

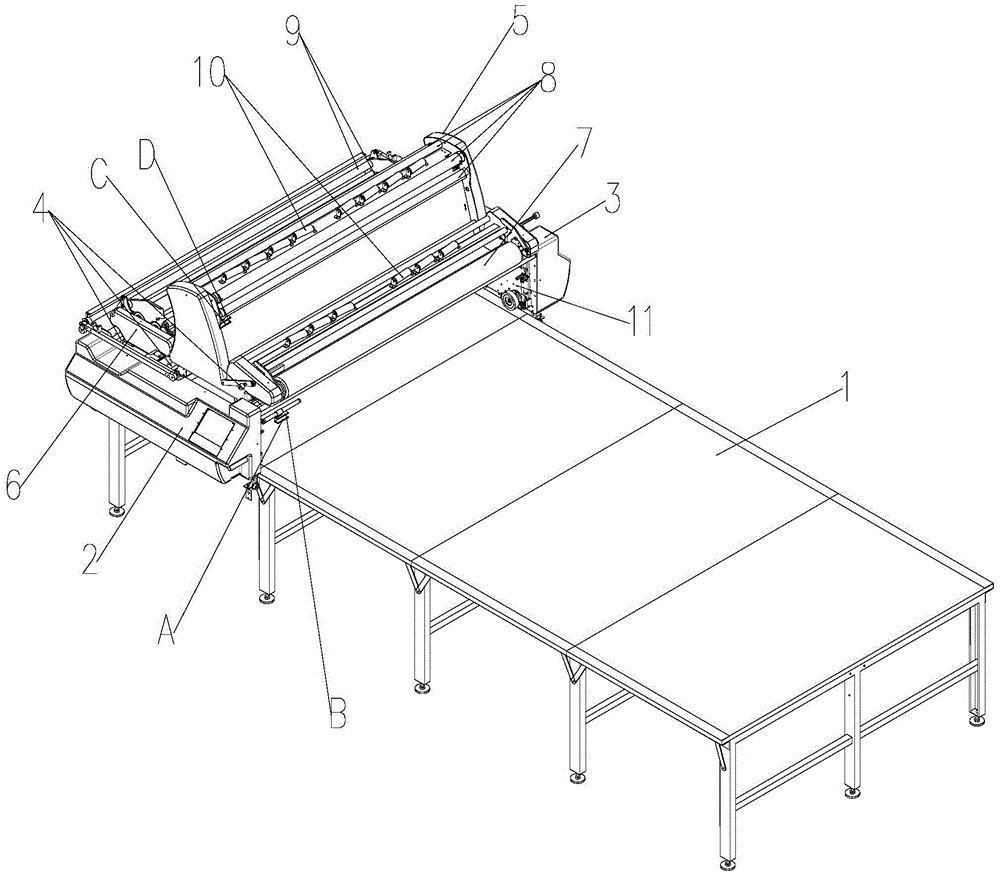

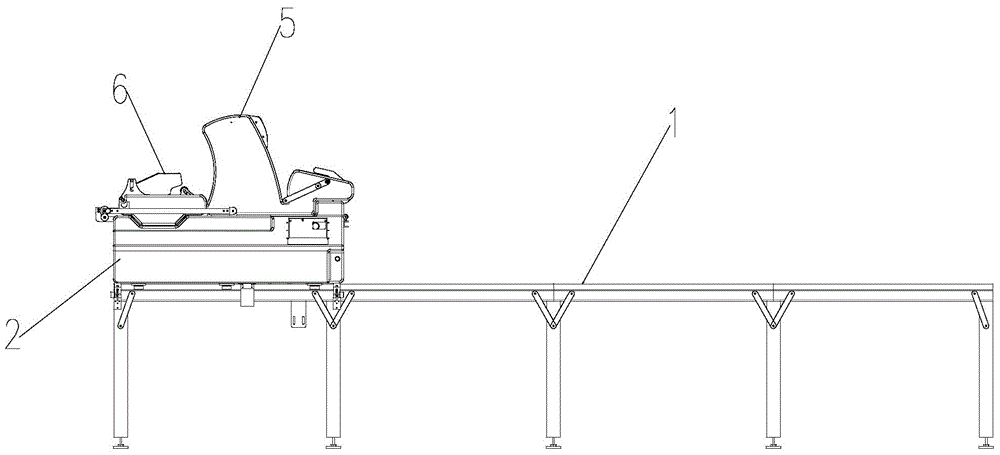

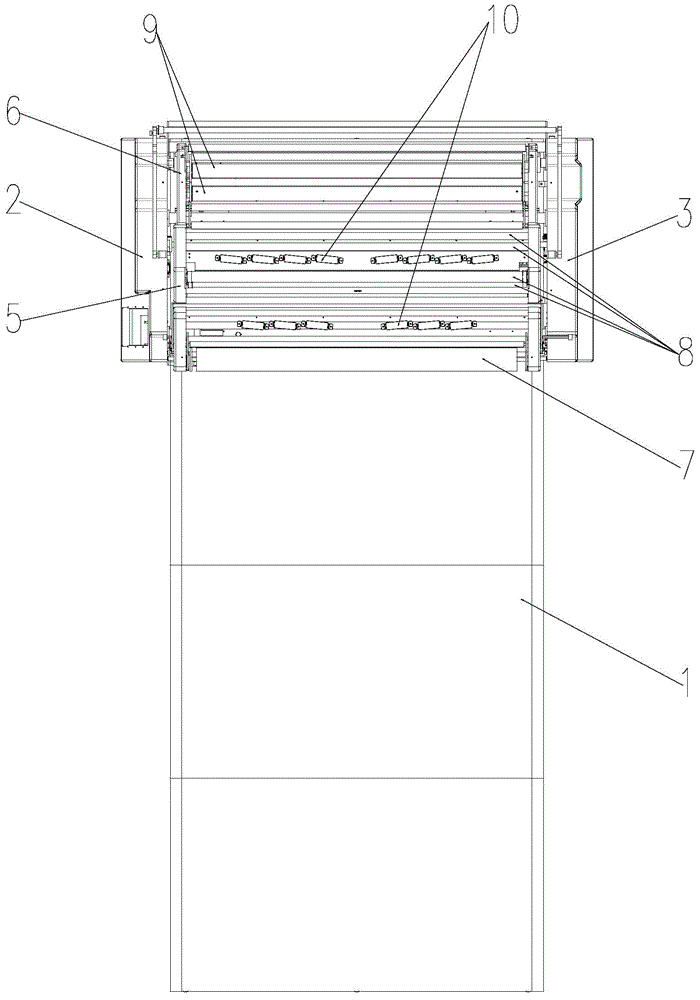

Cloth spreading machine with manipulator gripping mechanism

ActiveCN103342251BGuaranteed uptimeHigh precisionUnfolding thin materialsArticle deliveryManipulatorTextile

The invention provides a cloth spreading machine with a manipulator cloth clamping mechanism. The cloth spreading machine comprises a making bed, a main machine, a cloth pressing mechanism above the making bed, and the manipulator cloth clamping mechanism arranged on the making bed in a sliding mode. The main machine is provided with a cloth making mechanism, a cloth releasing mechanism is arranged on one side of the cloth making mechanism, a cloth spreading mechanism is arranged on the other side of the cloth making mechanism, a front-positioning cloth spreading mechanism is arranged in front of the cloth spreading mechanism, a cloth feeding mechanism is arranged in front of the front-positioning cloth spreading mechanism, and a cloth cutting device is arranged below the cloth feeding mechanism; cloth materials enter from the cloth releasing mechanism to the cloth cutting device through the cloth spreading mechanism, the front-positioning cloth spreading mechanism and the cloth feeding mechanism, and the manipulator cloth clamping mechanism arranged on the making bed in the sliding mode is matched with the cloth cutting device to cut off cloth materials with setting lengths. The cloth spreading machine has the advantages that the manipulator cloth clamping mechanism is adopted to carry out single-pulling cloth folding, positioning is accurate, precision is high, the cloth is tidily folded, neatness of the two ends of the cloth can be effectively controlled, accuracy of cloth cutting is improved, and working efficiency is high.

Owner:YYC IND CO LTD CHINA

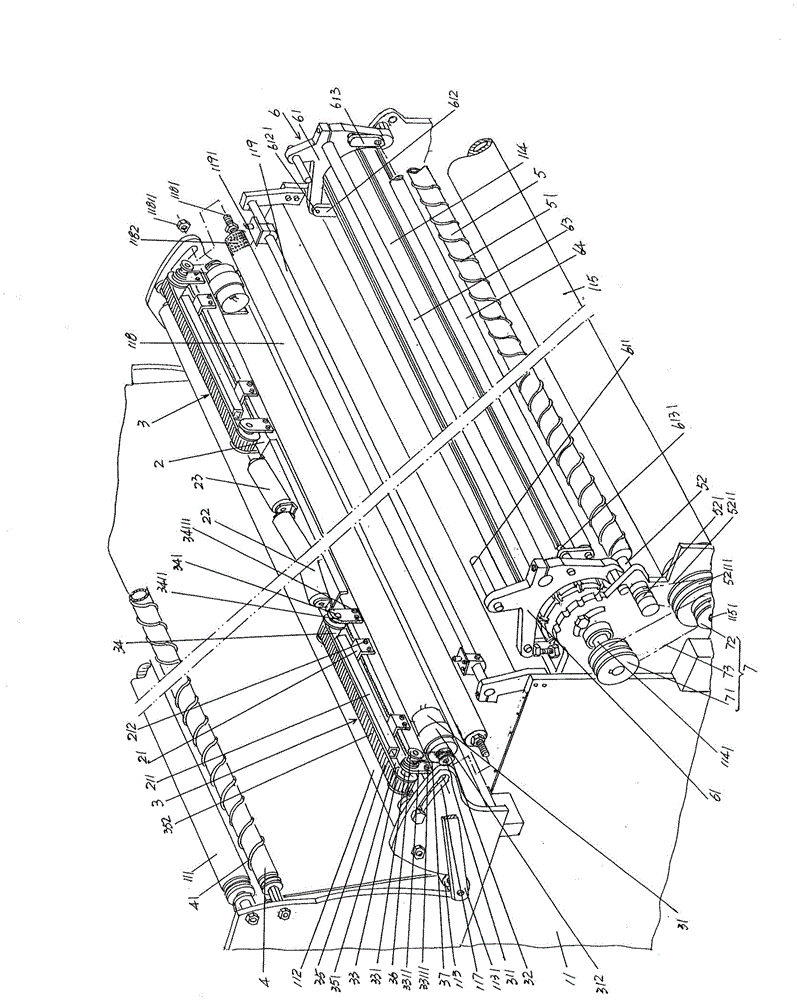

Automatic laying device for prestripping of composite material prepreg tape lining paper

ActiveCN111115333AImprove efficiencyQuality improvementUnfolding thin materialsArticle deliveryStructural engineeringSlip sheet

The invention discloses an automatic laying device for prestripping of composite material prepreg tape lining paper. The automatic laying device comprises an upper rack connected with a mechanical armflange, a left rack located at the left end of the upper rack, a right rack located at the right end of the upper rack, an ultrasound cutting mechanism, an infrared heating mechanism, a middle rack,a pressing roller mechanism, a transferring mechanism, a limiting mechanism, a winding mechanism, an unwinding mechanism and a stripping mechanism, wherein the left ends and the right ends of the ultrasound cutting mechanism, the infrared heating mechanism, the middle rack, the pressing roller mechanism, the transferring mechanism and the limiting mechanism are correspondingly connected with the left rack and the right rack; the winding mechanism and the unwinding mechanism are connected with the left rack; and the stripping mechanism is connected with the right rack. Therefore, according to the automatic laying device for prestripping of the composite material prepreg tape lining paper, functions of cutting, transferring, heating and laying composite materials can be realized, the automatic laying device for prestripping of the composite material prepreg tape lining paper has the characteristics of simple structure, high automation degree, high laying efficiency, low cost and the like, the problem of difficult control of the cutting depth of a traditional prepreg tape is effectively solved, and thus, the composite material laying process control is simple and reliable.

Owner:WUHAN UNIV

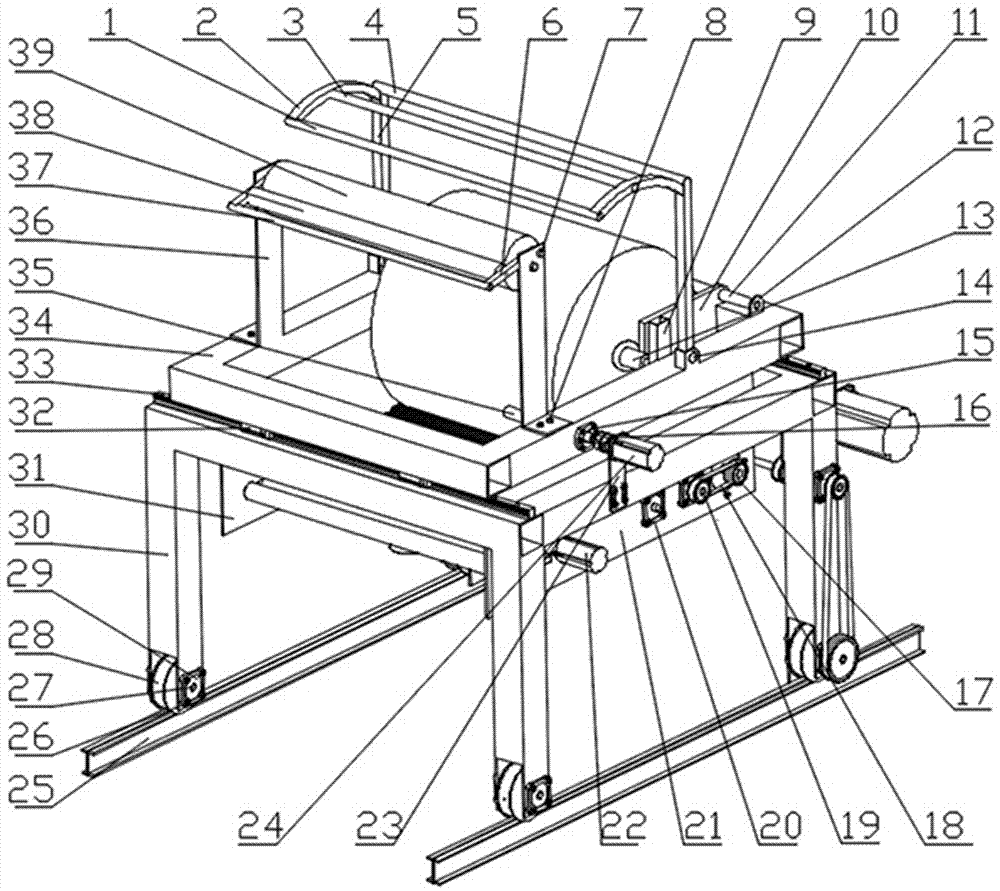

Cloth paving machine

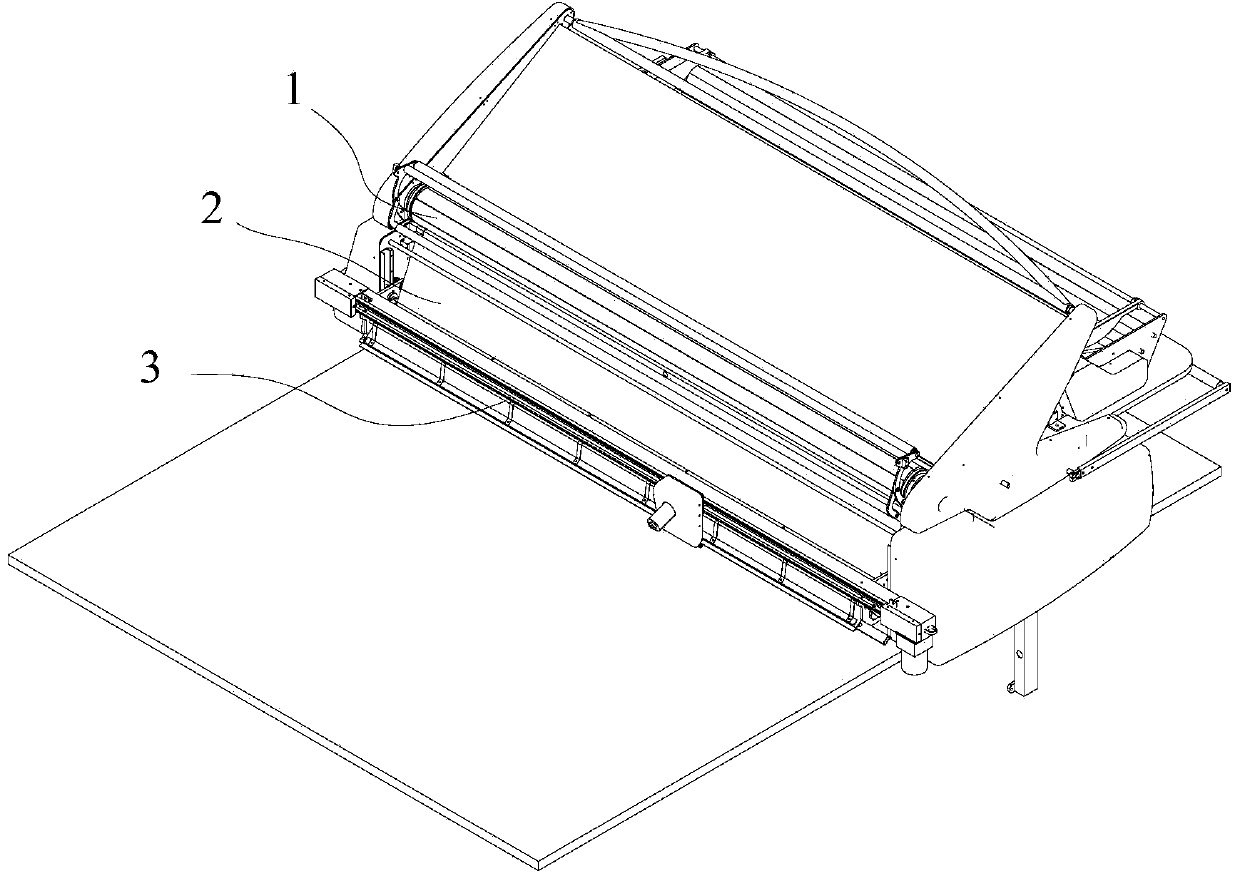

ActiveCN104192632AFully compactedUniform tensionUnfolding thin materialsArticle deliveryAutomotive engineering

The invention discloses a cloth paving machine which comprises a cloth paving machine cloth pressing and conveying device, a cloth paving machine wind shielding device and a cloth paving machine cutting device. The cloth paving machine cloth pressing and conveying device comprises a conveying roller and a pressing roller. The cloth paving machine wind shielding device comprises a wind shielding film, a wind shielding film first roller and a wind shielding film second roller. The cloth paving machine cutting device comprises an output roller, a cloth falling plate, a horizontal moving mechanism and a cutter assembly. The cloth paving machine has the advantages of being capable of comprehensively improving all the performance of the cloth paving machine.

Owner:HEFEI AORUI DIGITAL CONTROL SCI & TECH

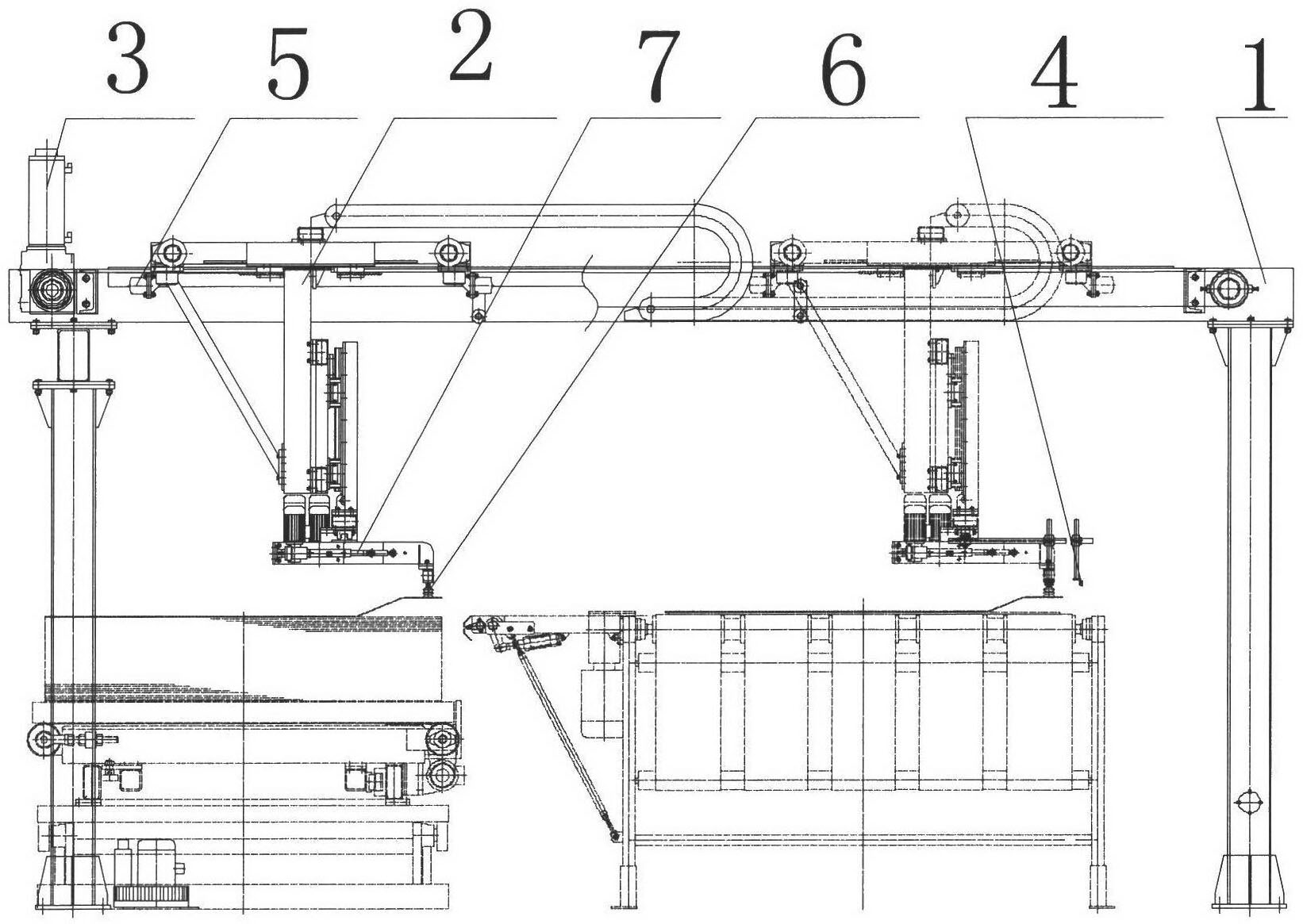

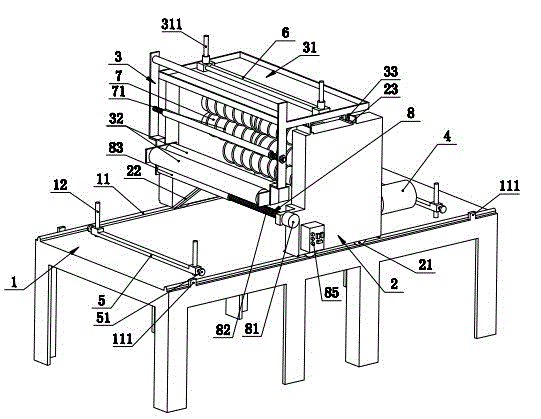

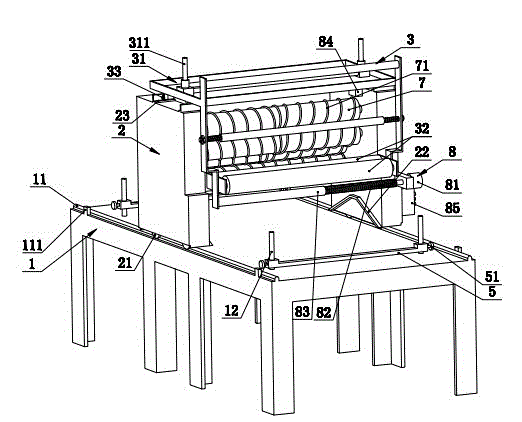

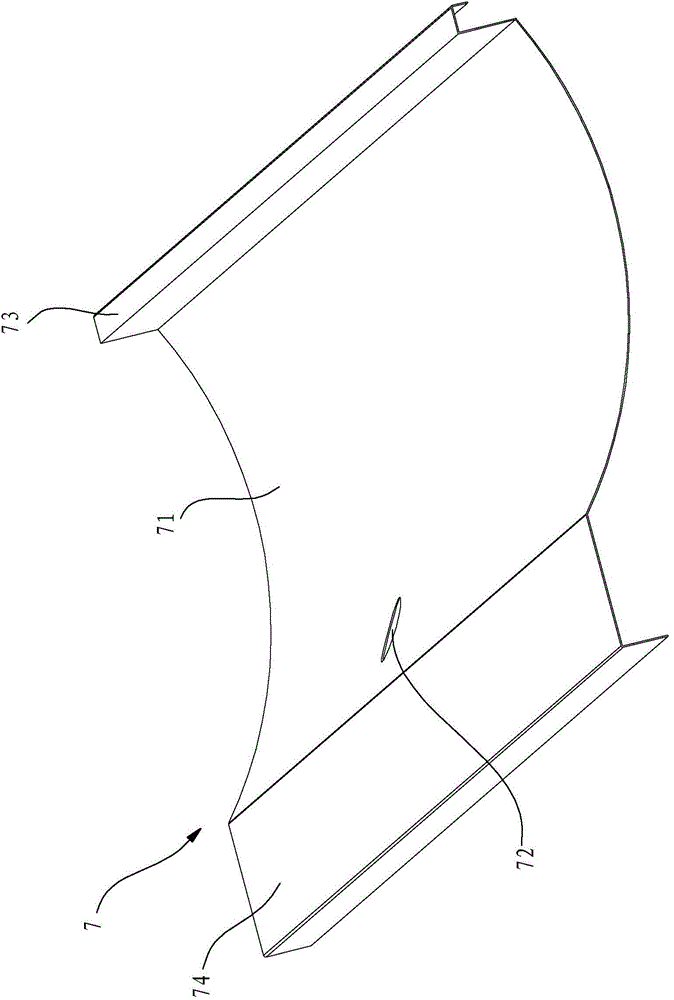

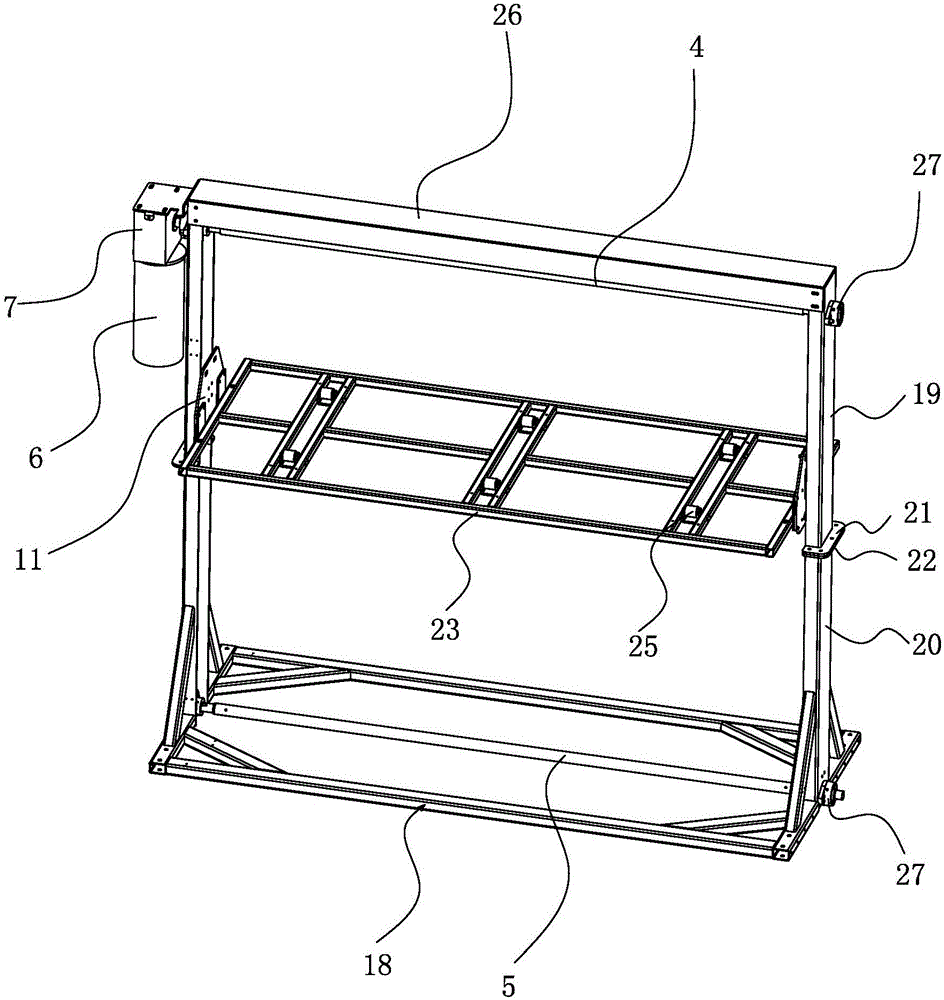

Linen undertaking and unfolding device in cloth sending machine

The invention discloses a linen undertaking and unfolding device in a cloth sending machine. The device comprises: a main frame, side brackets are arranged at both sides of the main frame, a track is arranged between the side brackets, two linen unfolding devices are arranged on the track, and driving devices for driving the linen unfolding devices are arranged on the two side brackets. Each of the linen unfolding devices adopts the following structure: a movable frame mounted with a pulley, a swinging cylinder is arranged on the movable rack, a swinging bracket is supported on the movable rack, a holding-on base plate is arranged on the swinging bracket, a holding-on arm and a holding-on air cylinder are arranged on the holding-on base plate. At least one linen undertaking device is arranged on the main rack and adopts the following structure: an undertaking rack is fixed on the main rack, a slide is arranged within the undertaking rack, a rod-less air cylinder is arranged on the slide, a sliding block is arranged on the rod-less air cylinder, a clamping base bracket is fixed with the sliding block, an elastic clip is arranged at the end part of the clamping base bracket, and a stripper plate for opening the elastic clip is arranged on the undertaking rack. The linen undertaking and unfolding device is simple in operation, and can greatly improving working efficiency.

Owner:JIANGSU SEA LION MASCH GRP CO LTD

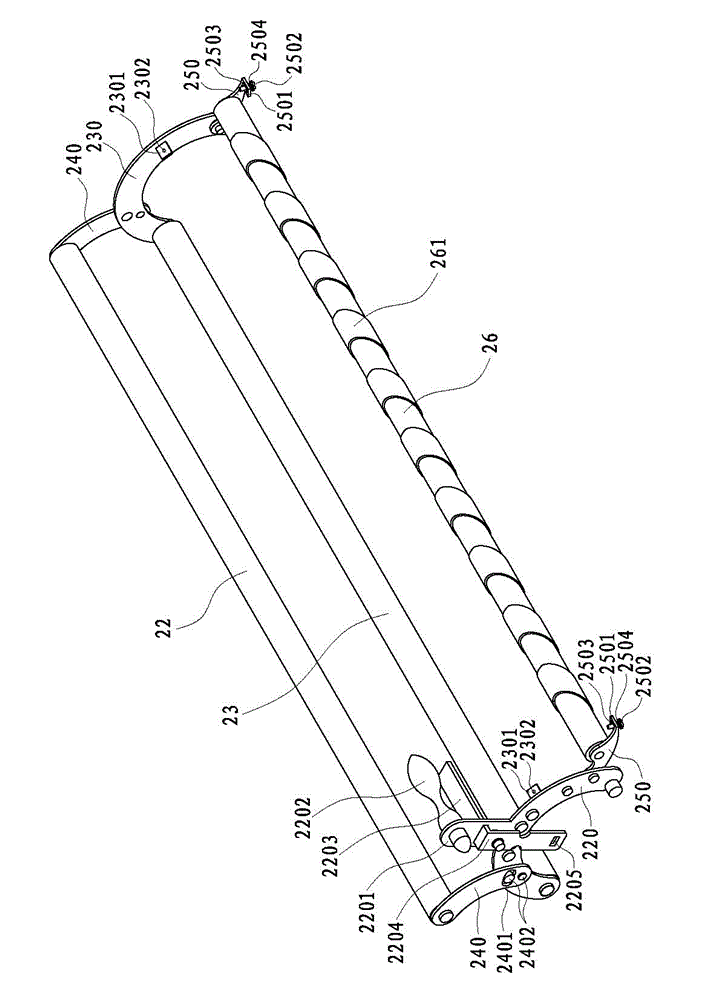

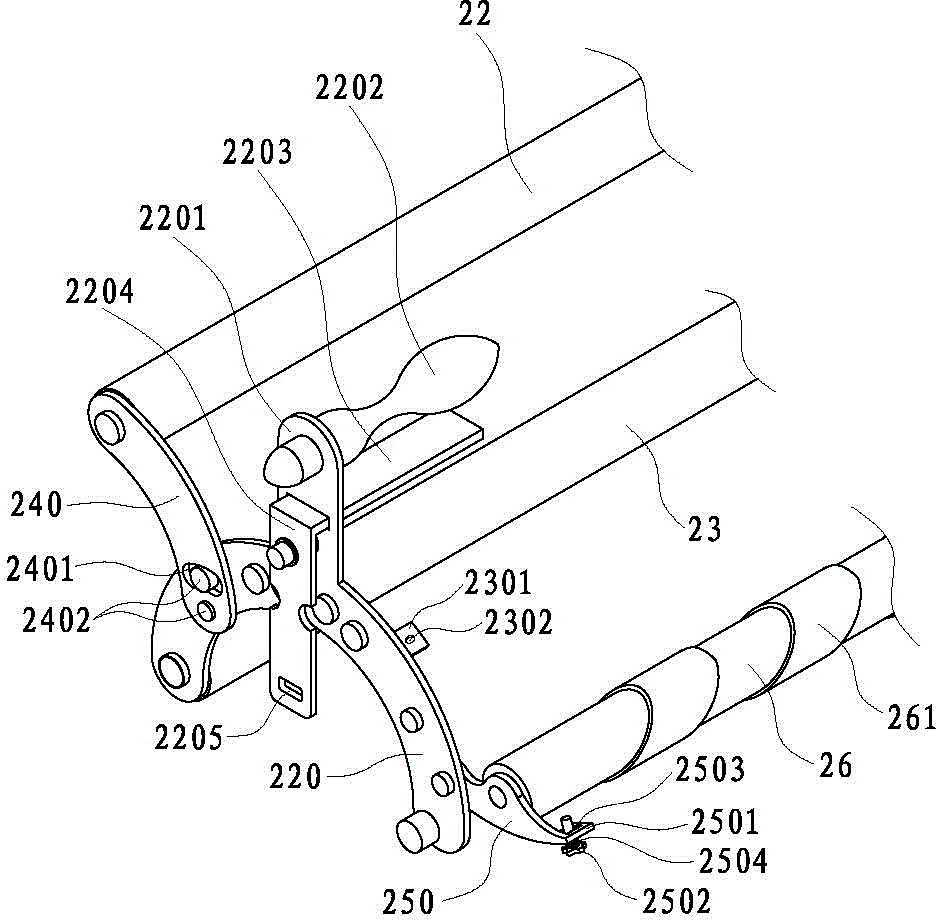

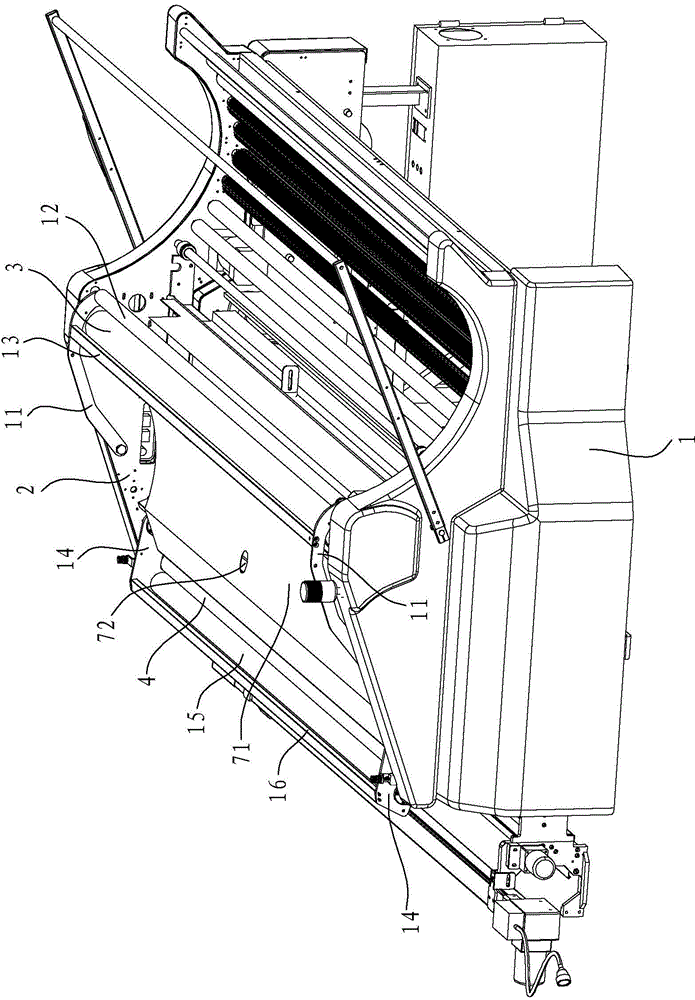

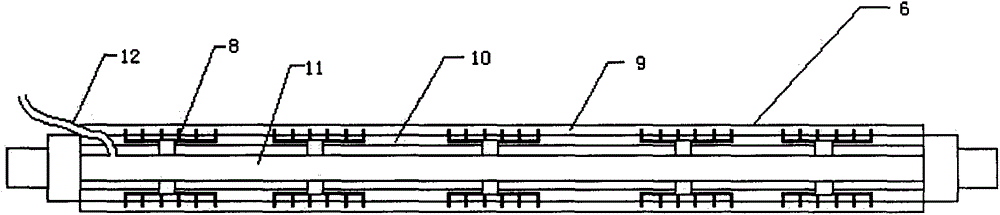

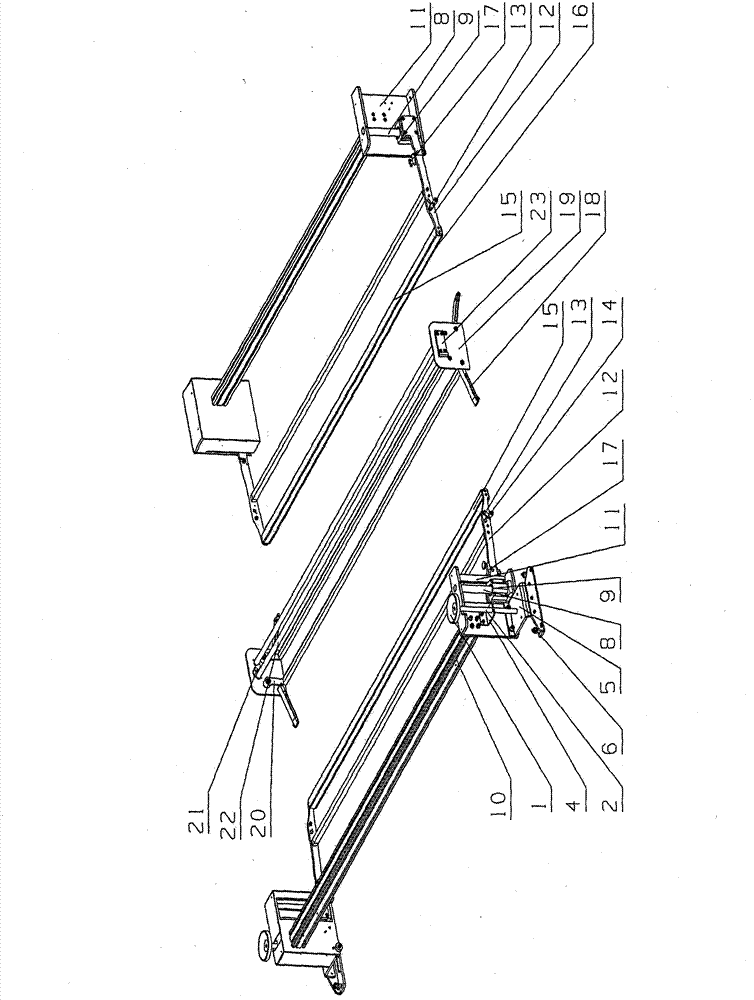

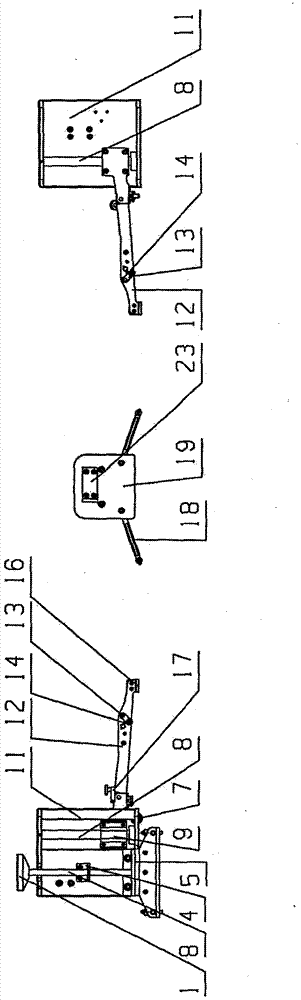

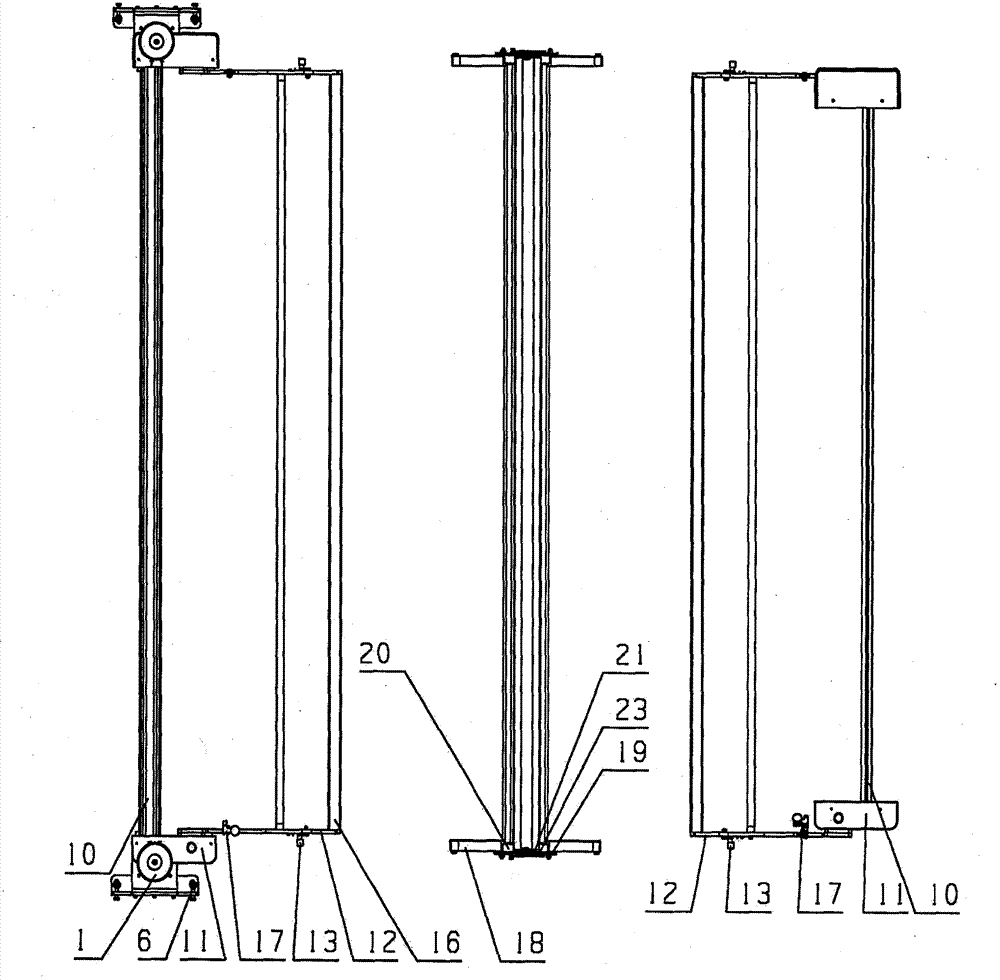

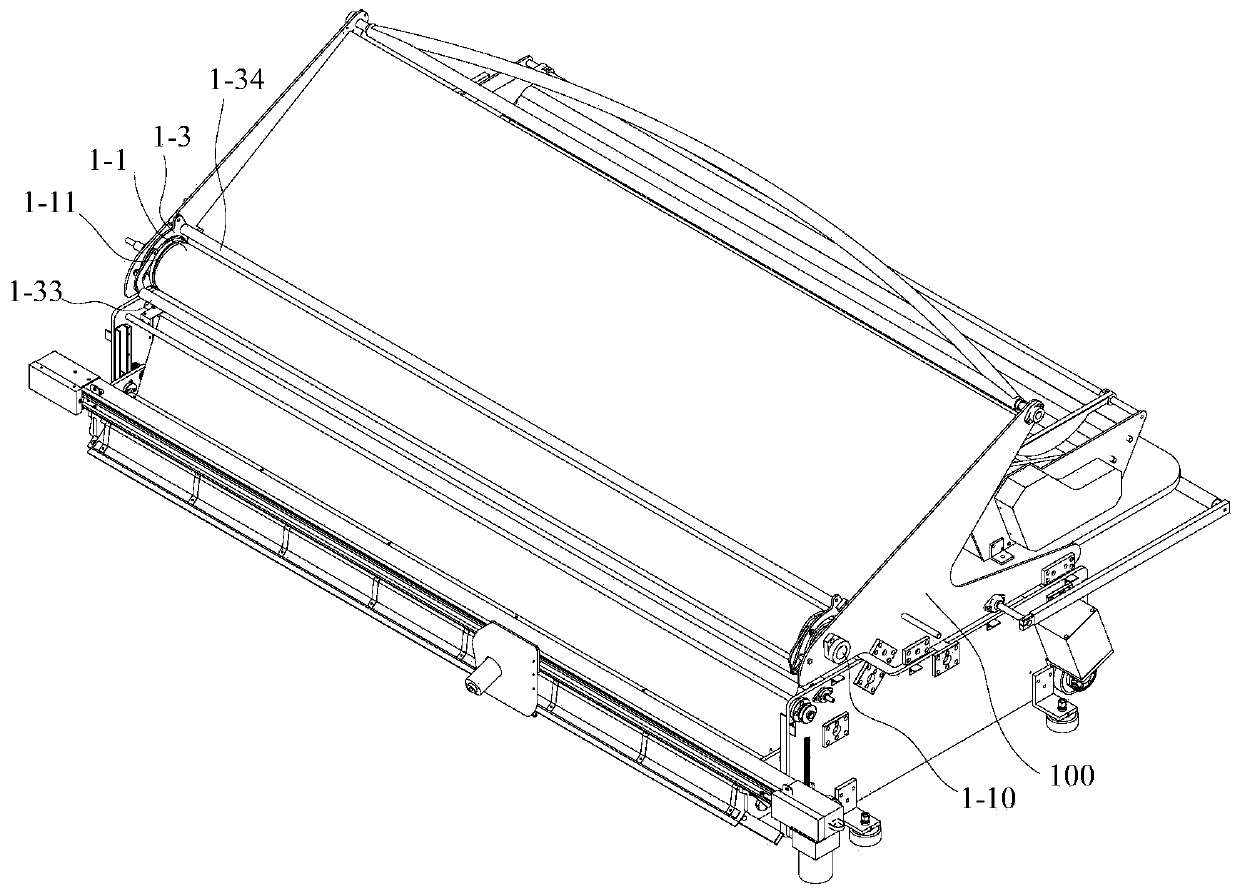

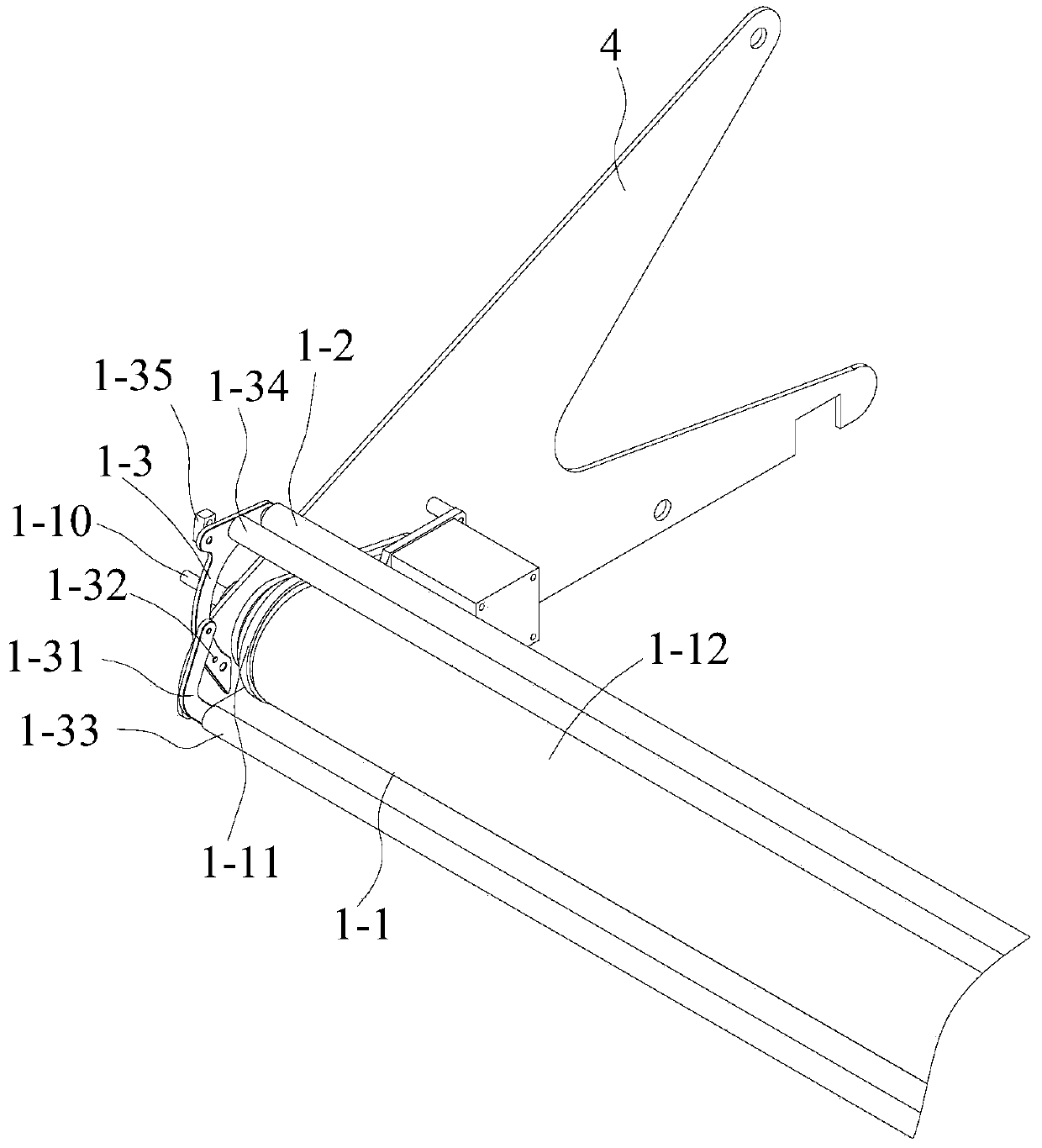

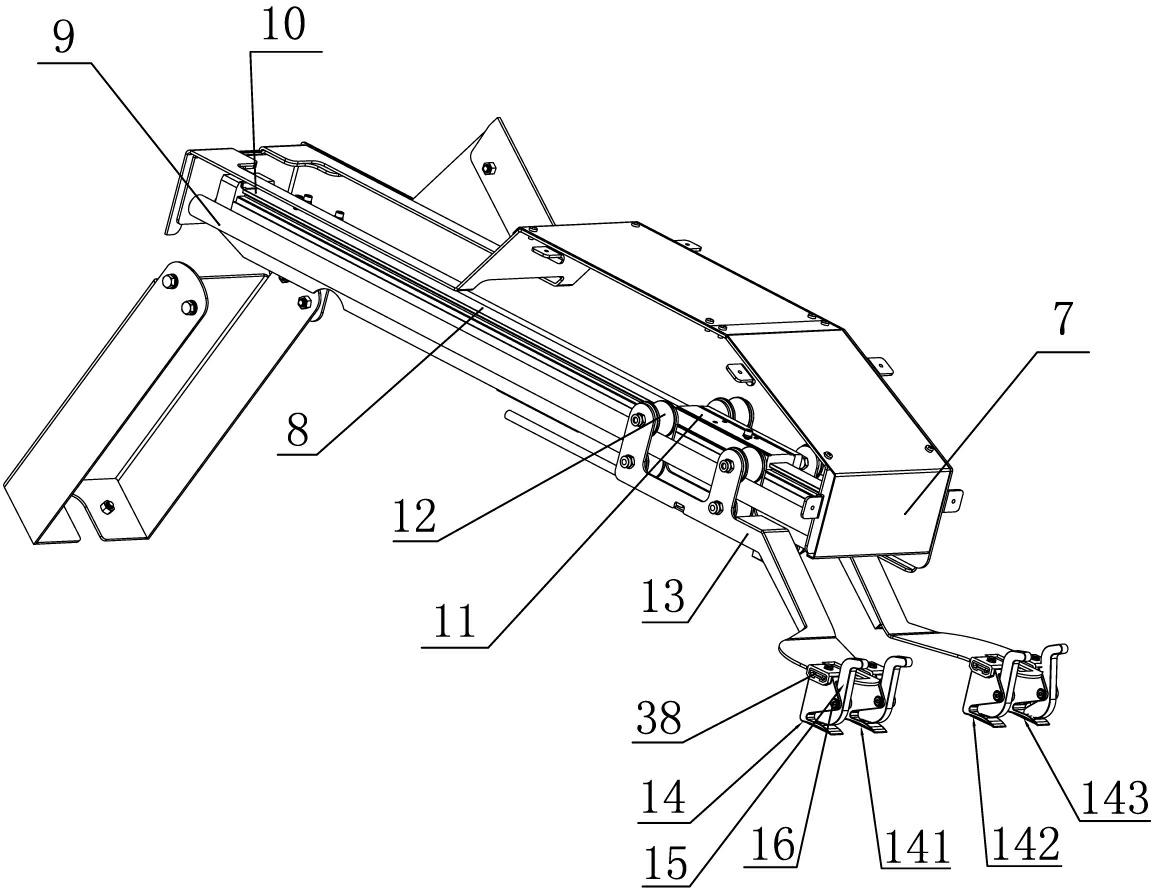

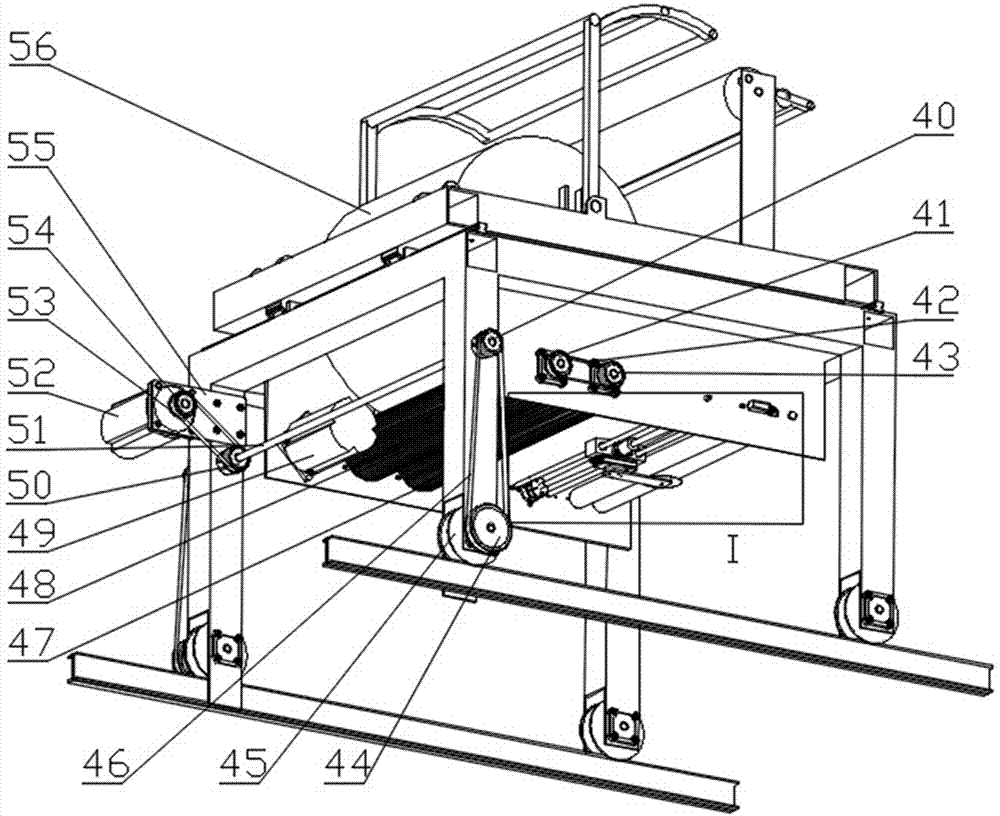

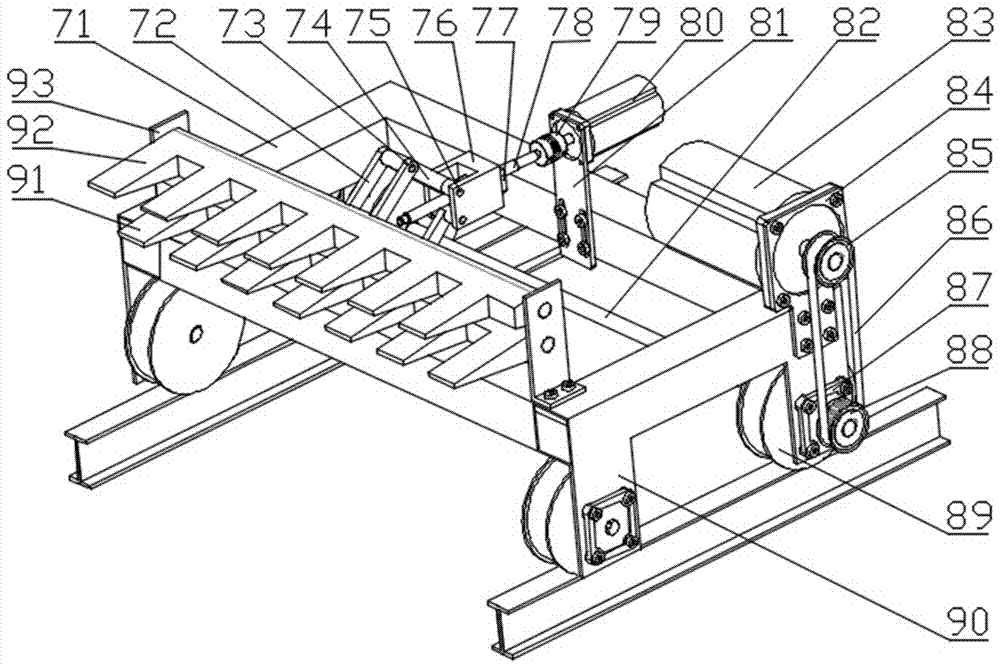

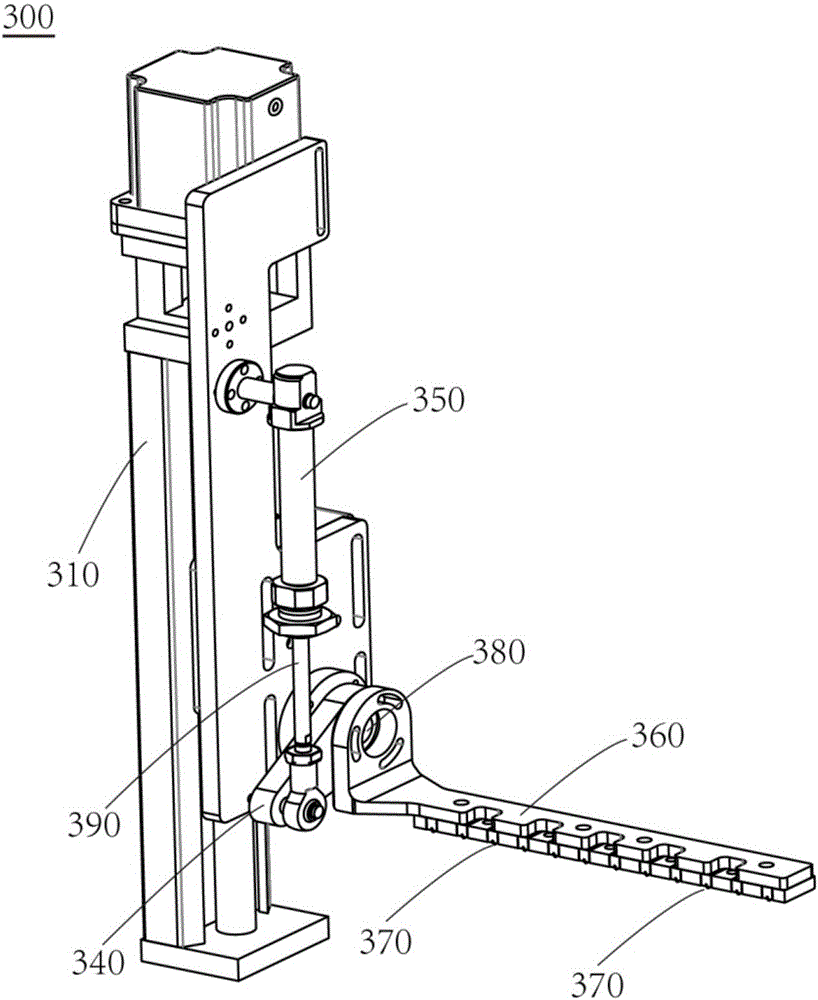

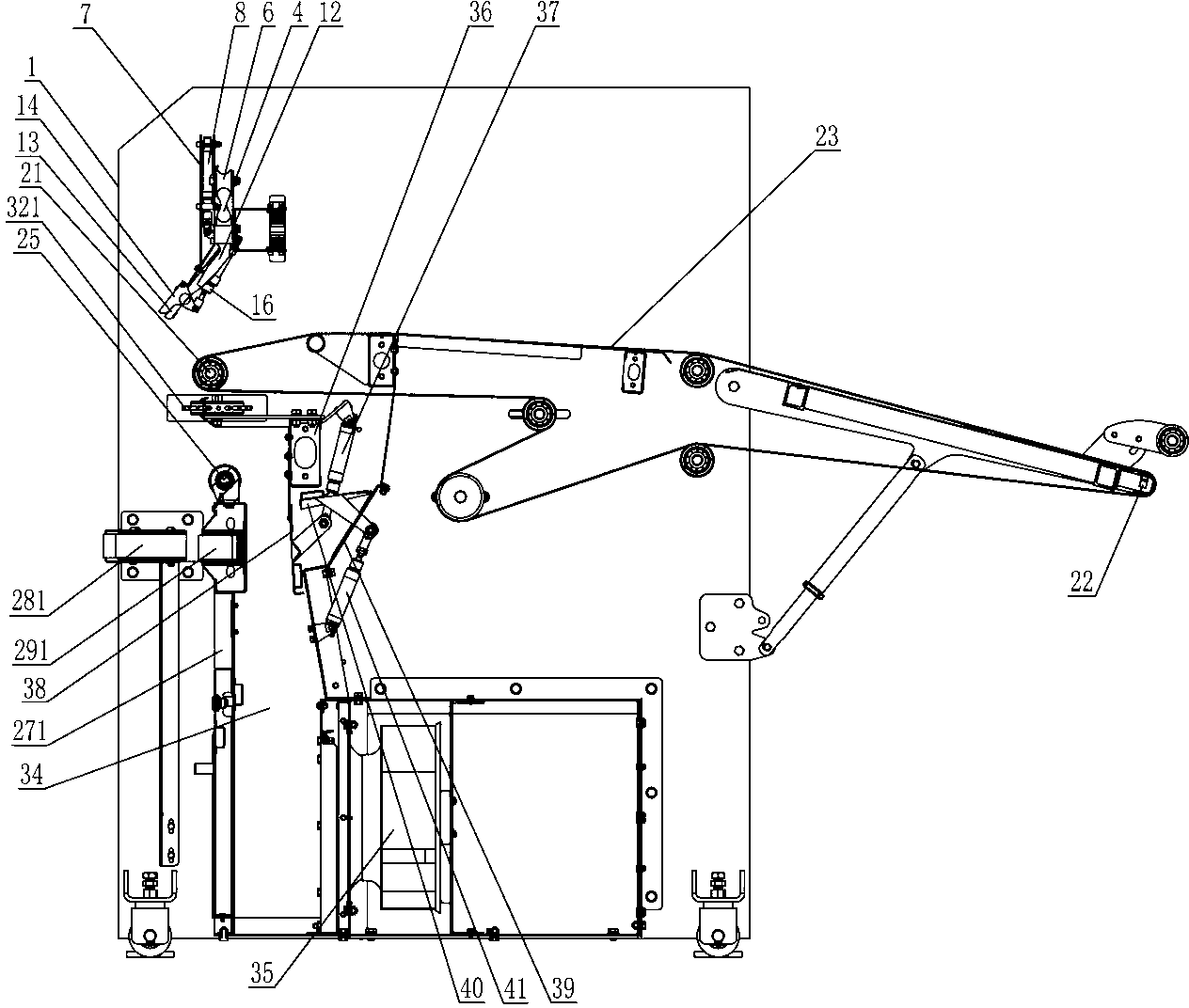

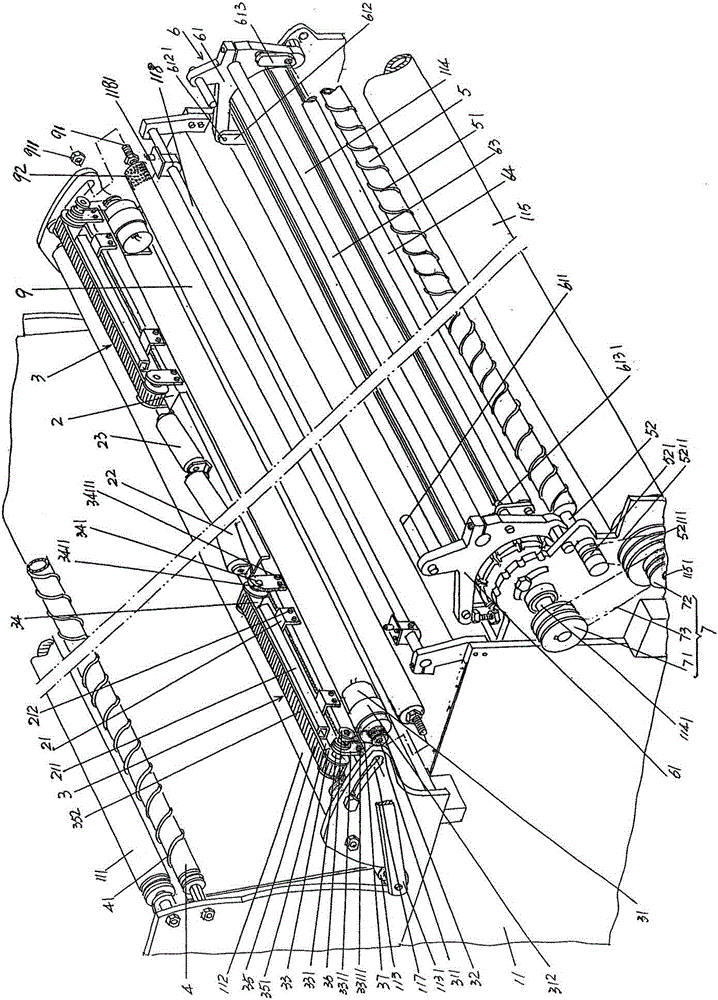

Automatic paving method and device of fiber cloth for wind power blade main beam molding

ActiveCN107472982AEnsure stable qualityReduce physical injuryUnfolding thin materialsArticle deliveryFiberCar driving

The invention provides automatic layer paving equipment of fiber cloth for a wind power blade main beam. The equipment comprises a main car and a cloth clamping positioning device. The main car comprises an upper frame, a lower frame, a cloth rack, a guide rubber roller mechanism, a cloth roll positioning mechanism, a cloth feeding mechanism, an upper frame left-right adjustment mechanism, a main car walking mechanism and a cloth cutting mechanism; the cloth clamping positioning device comprises a walking mechanism and a cloth clamping mechanism; the cloth clamping positioning device clamps cloth at one end; the main car drives a cloth roller to reach consistency with the advancement speed of the main car through a cloth feeding rubber roller I and a cloth feeding rubber roller II to guarantee constant tension of the fiber cloth in the paving process; the cloth paving length precision is guaranteed through transmission modes of servo motor driving and a synchronous belt; and the fiber cloth clamping stability is guaranteed through lead screw driven staggered-tooth clamping jaws in the cloth clamping positioning device. The equipment replaces manual fiber cloth paving work, is high in mechanical cloth paving efficiency, is simple in structure and liable to operate, and greatly reduces the cloth paving cost of wind power blades.

Owner:SHANDONG UNIV OF TECH

Automatic cut-part laying mechanism

ActiveCN106081676APrevent fallingNot easy to dropUnfolding thin materialsArticle separationFeed driveMechanical engineering

The invention discloses an automatic cut-part laying mechanism. The automatic cut-part laying mechanism comprises a machine, a feeding device, a reclaiming device and a flattening device. The machine is provided with a transmission plane, the feeding device is provided with a support, a feeding plate, a feeding driving part and a positioning blowpipe, the support is used for being connected to the machine, the feeding device part is used for being arranged on the machine and connected to the feeding plate so as to drive the feeding plate to move, the feeding plate is used for allowing multiple cut-parts to be placed in an overlapped mode, the feeding plate is provided with fixed air draft holes, and the positioning blowpipe is arranged on the support and located above the feeding plate; the reclaiming device is arranged on the machine and used for obtaining the cut-parts from the feeding plate and moving the cut-parts to the transmission plane; the flattening device is provided with a flattening rod and a flattening driving part, the flattening driving part is arranged on the machine and connected to the flattening rod, the flattening driving part is used for driving the flattening rod to move along the transmission plane, and the flattening rod can flatten the cut-parts. The automatic cut-part laying mechanism saves time and labor.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

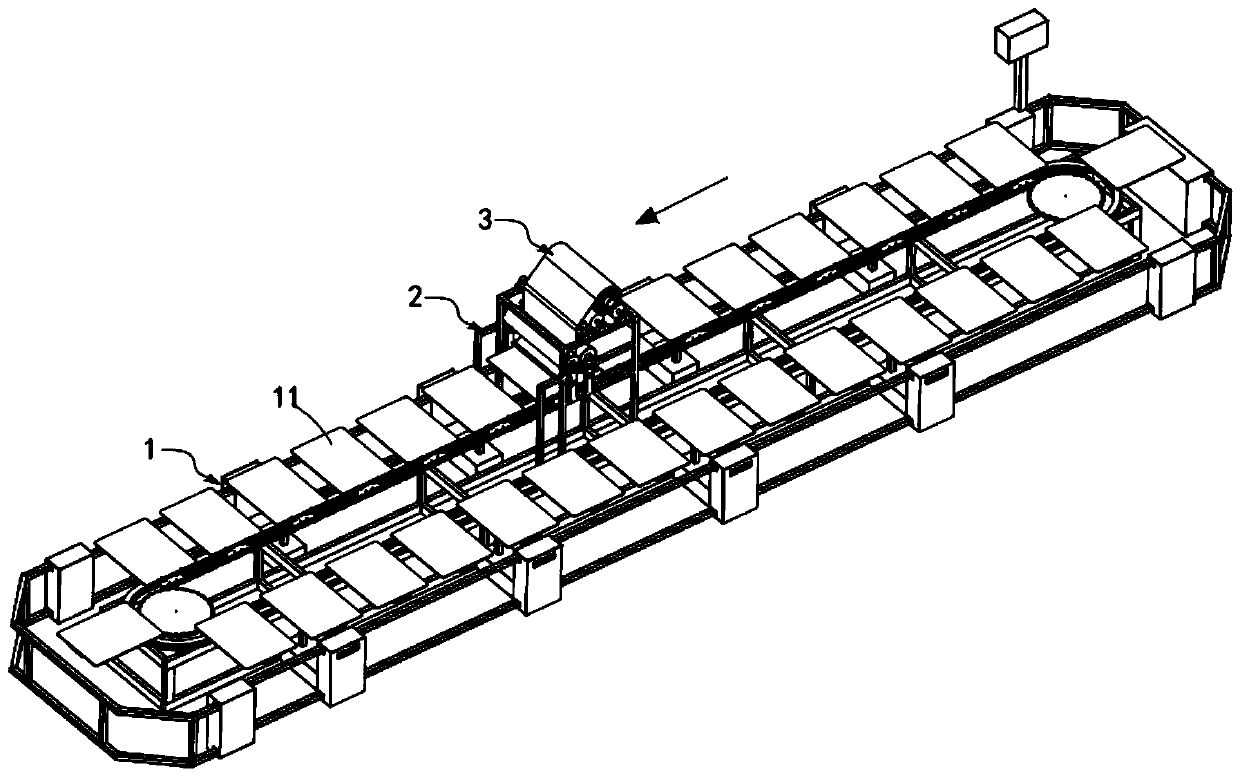

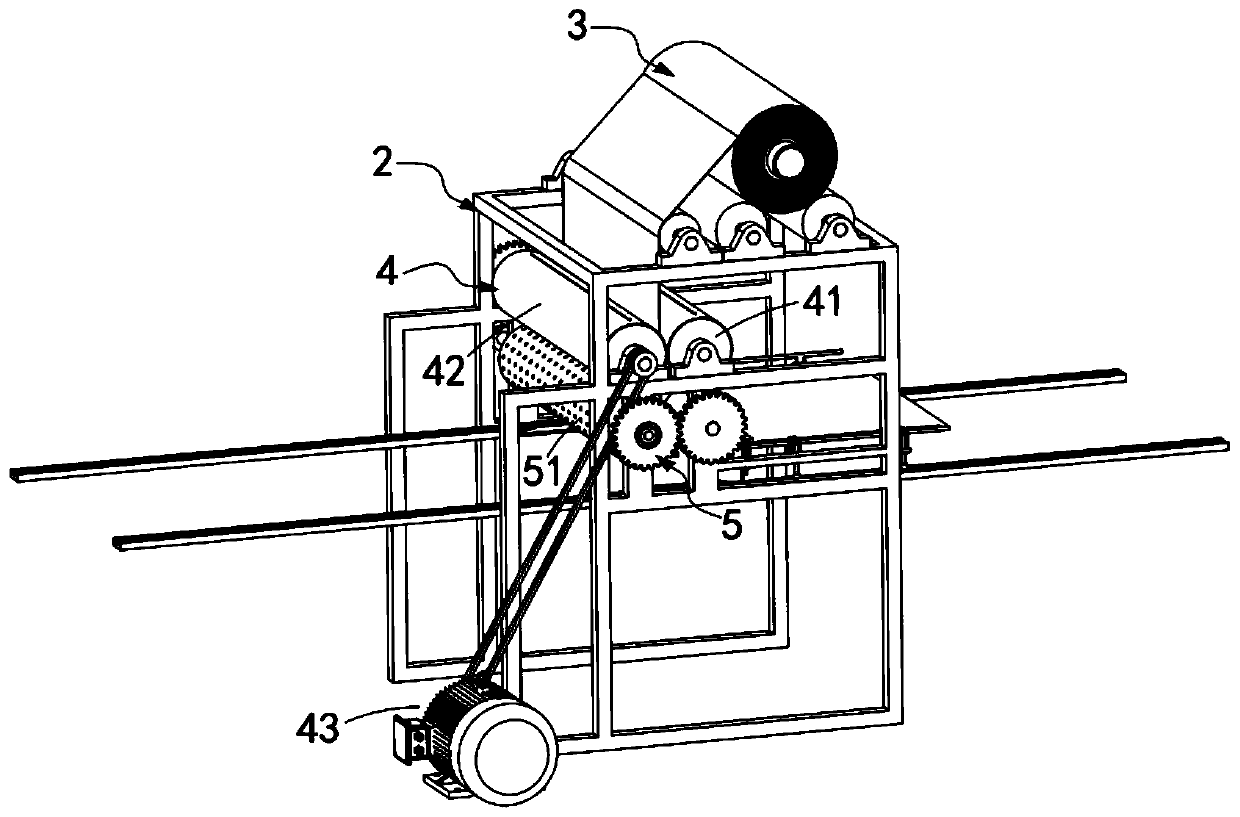

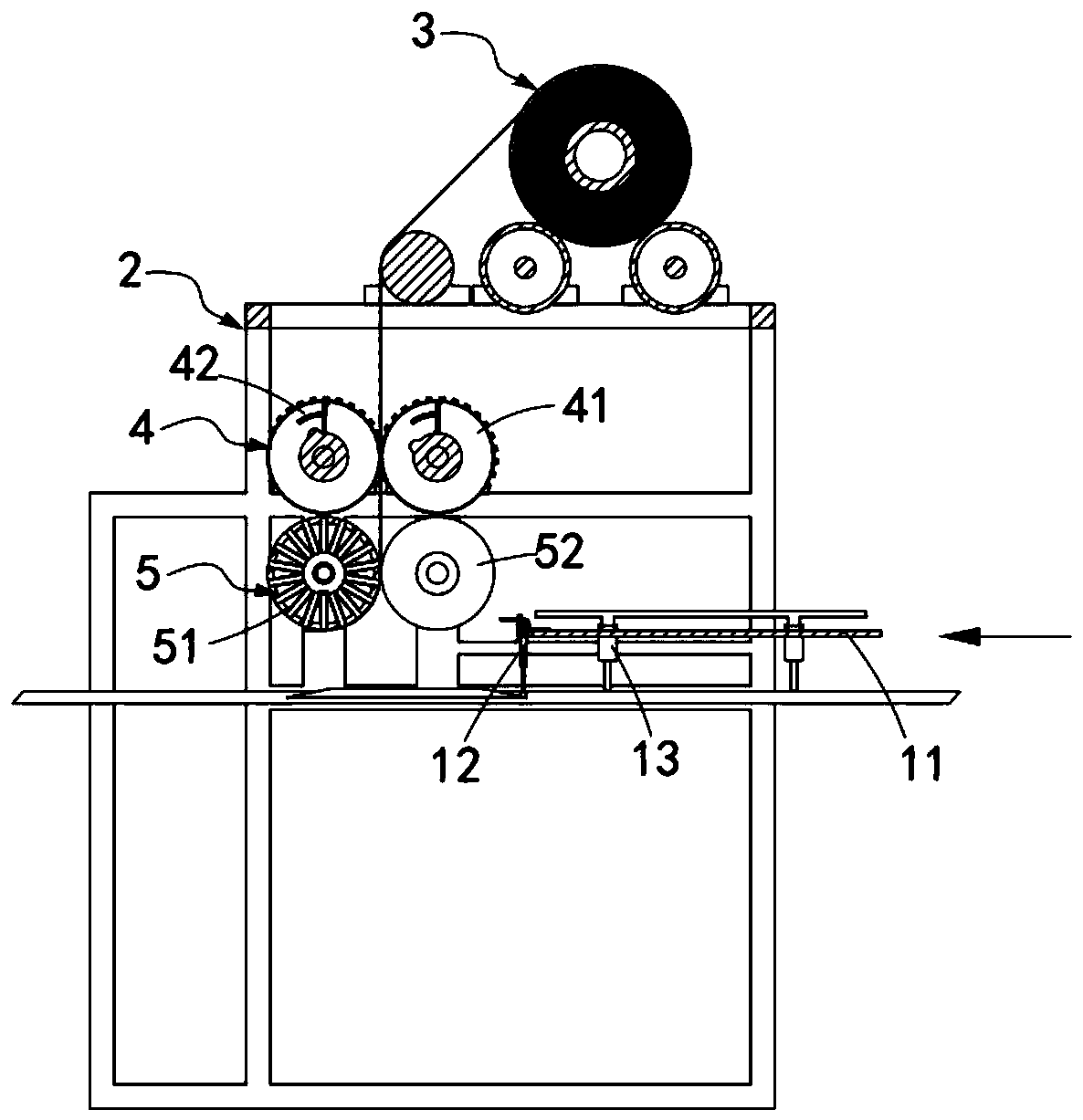

Textile fabric automatic discharging and spreading device

ActiveCN111232743ASolve the technical problem of automatic tiling onto the spreading tableImprove cutting effectSevering textilesUnfolding thin materialsStructural engineeringMechanical engineering

The invention relates to the technical field of garment fabric spreading machinery and specifically discloses a textile fabric automatic discharging and spreading device. The textile fabric automaticdischarging and spreading device comprises a conveying line, a rack, a cutting mechanism and an adsorption spreading mechanism. Fabric spreading boards are equidistantly conveyed on the conveying line. A textile fabric roll is erected on the rack. The cutting mechanism comprises a cutting roll assembly, a butting roll assembly and a driving assembly. The adsorption spreading mechanism comprises avacuum adsorption roll assembly and a clamping roll which are arranged in parallel. The textile fabric automatic discharging and spreading device automatically cuts the textile fabric roll through thecutting mechanism and spreads the cut textile fabric roll on the fabric spreading boards through the adsorption spreading mechanism. The technical problem of how to automatically spread the textile fabric roll onto the fabric spreading boards is solved. Meanwhile, the textile fabric automatic discharging and spreading device maintains the flatness of the textile fabric roll through the cutting roll assembly and the butting roll assembly in the cutting process and the spreading process.

Owner:沅江市凯祥纺织有限公司

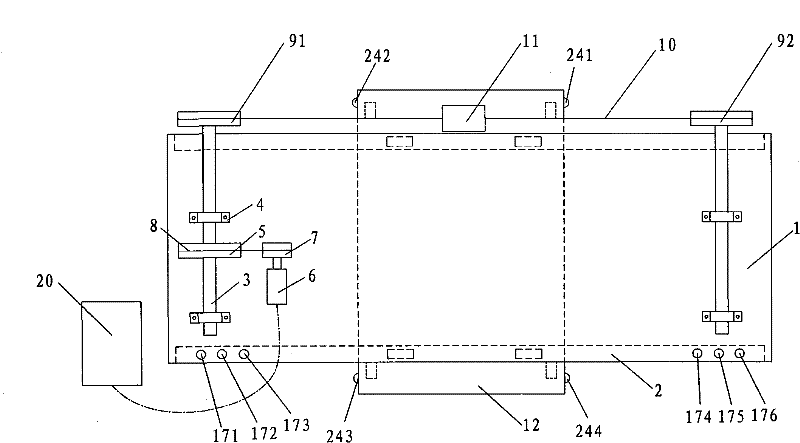

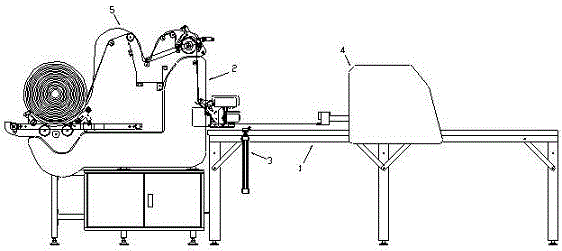

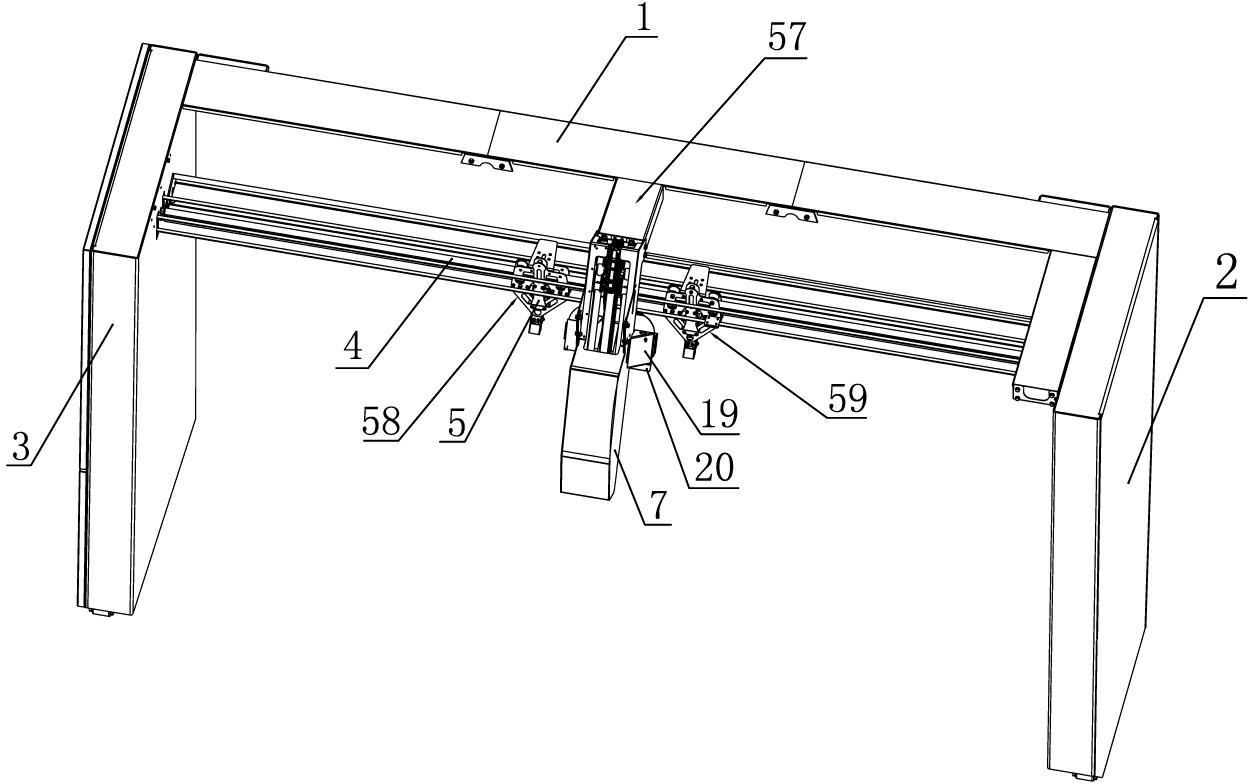

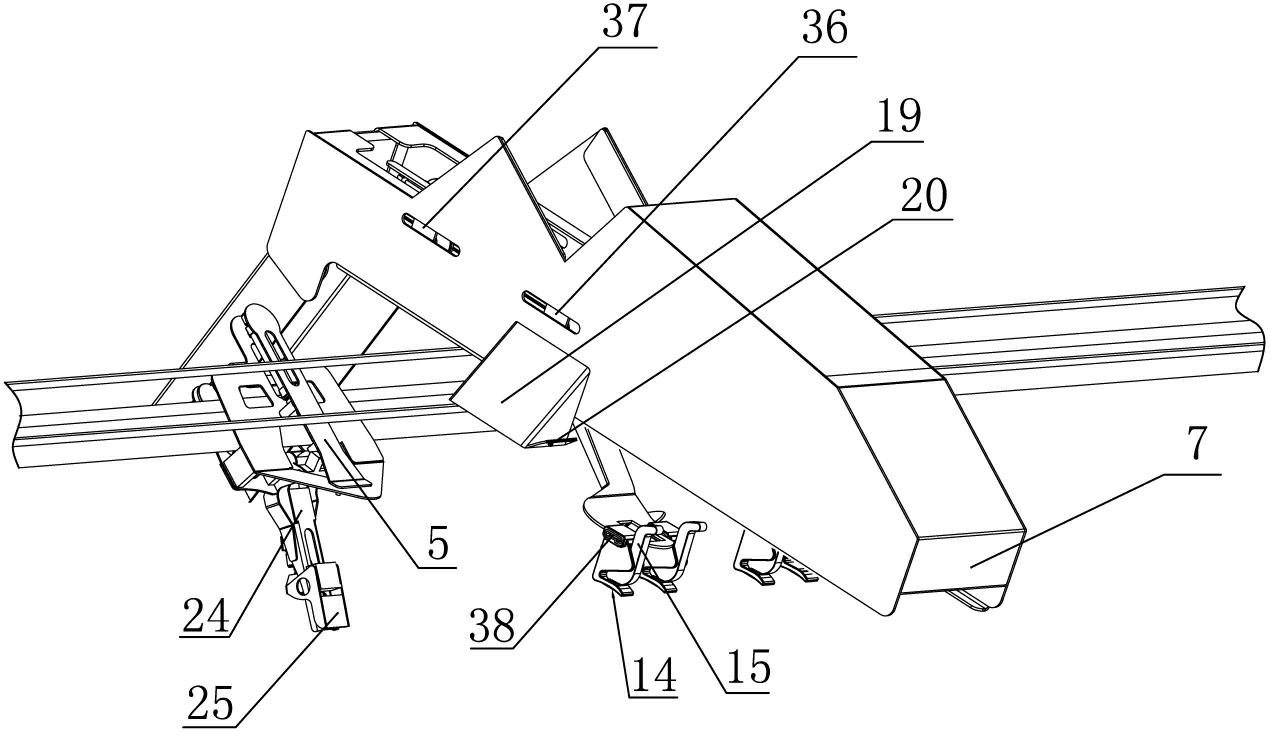

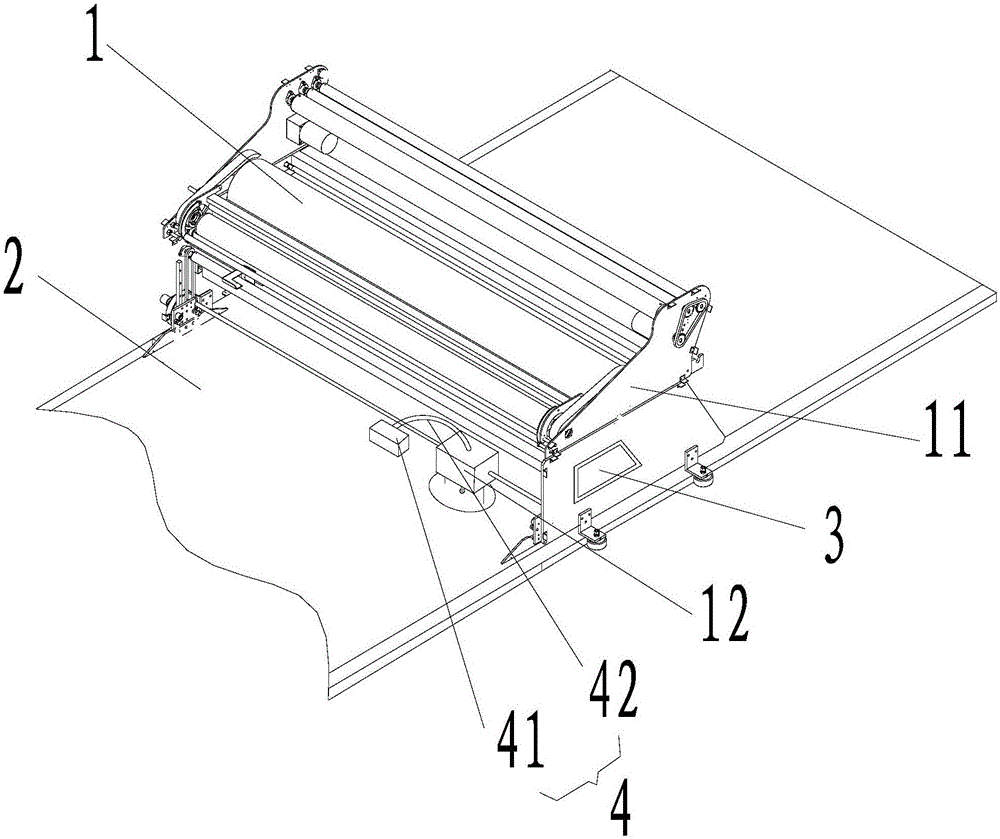

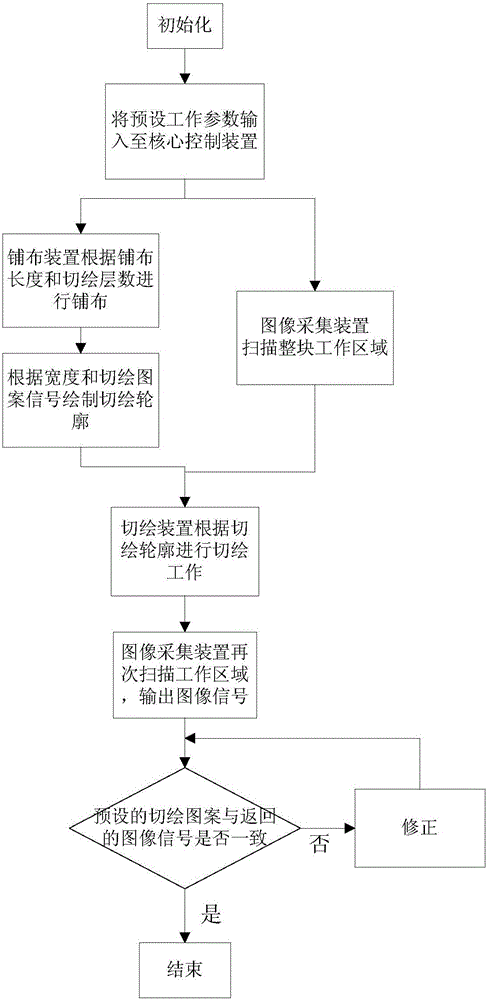

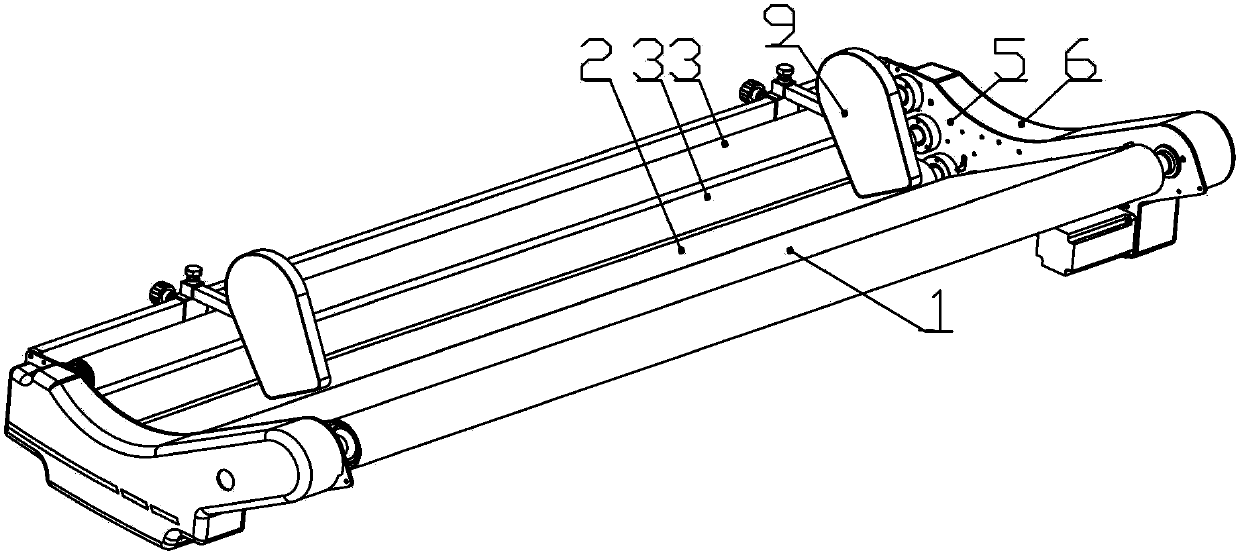

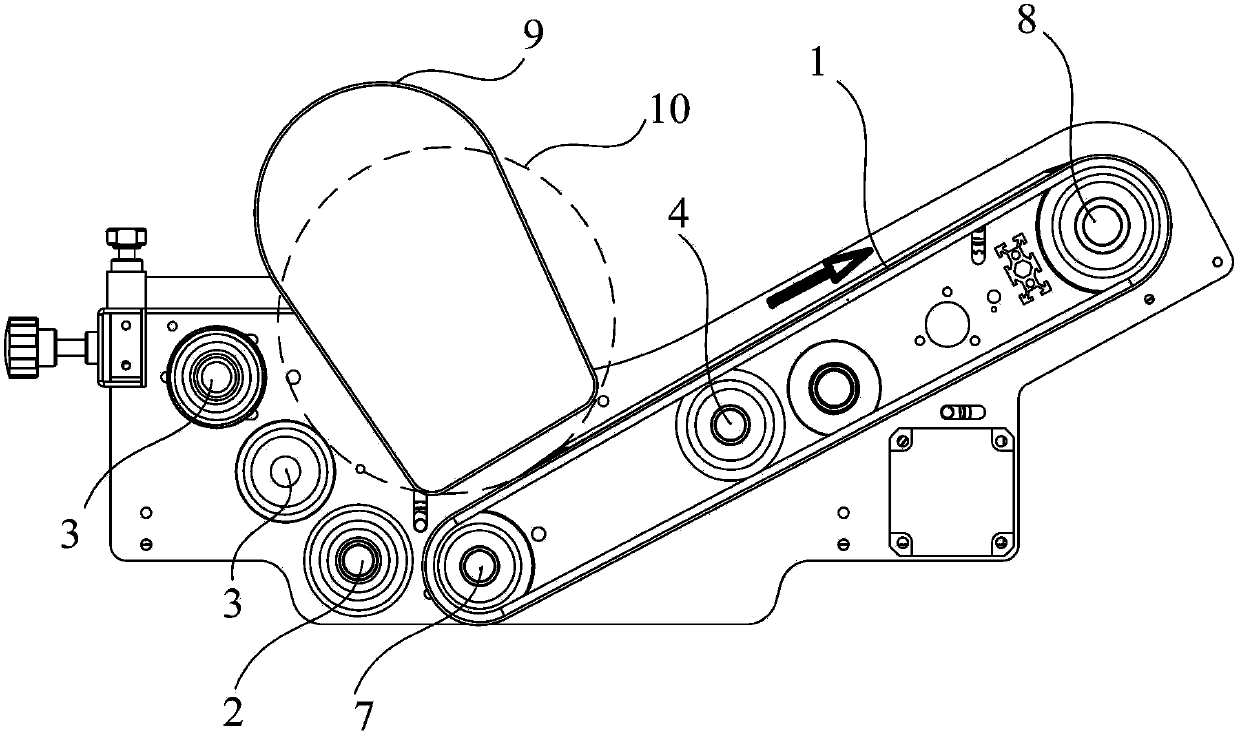

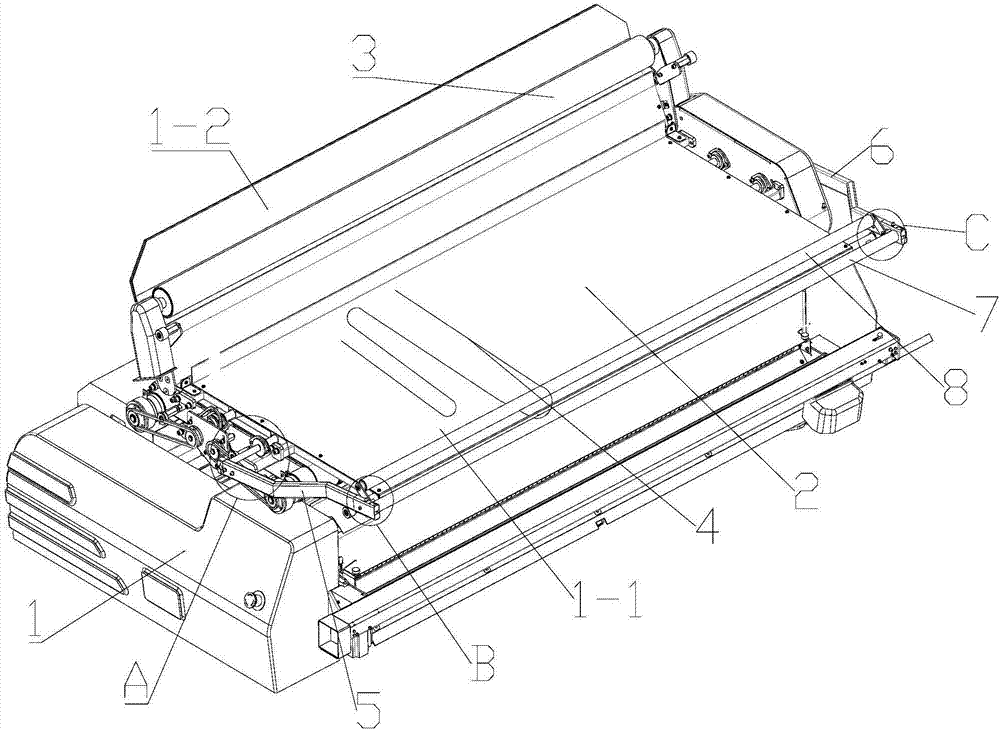

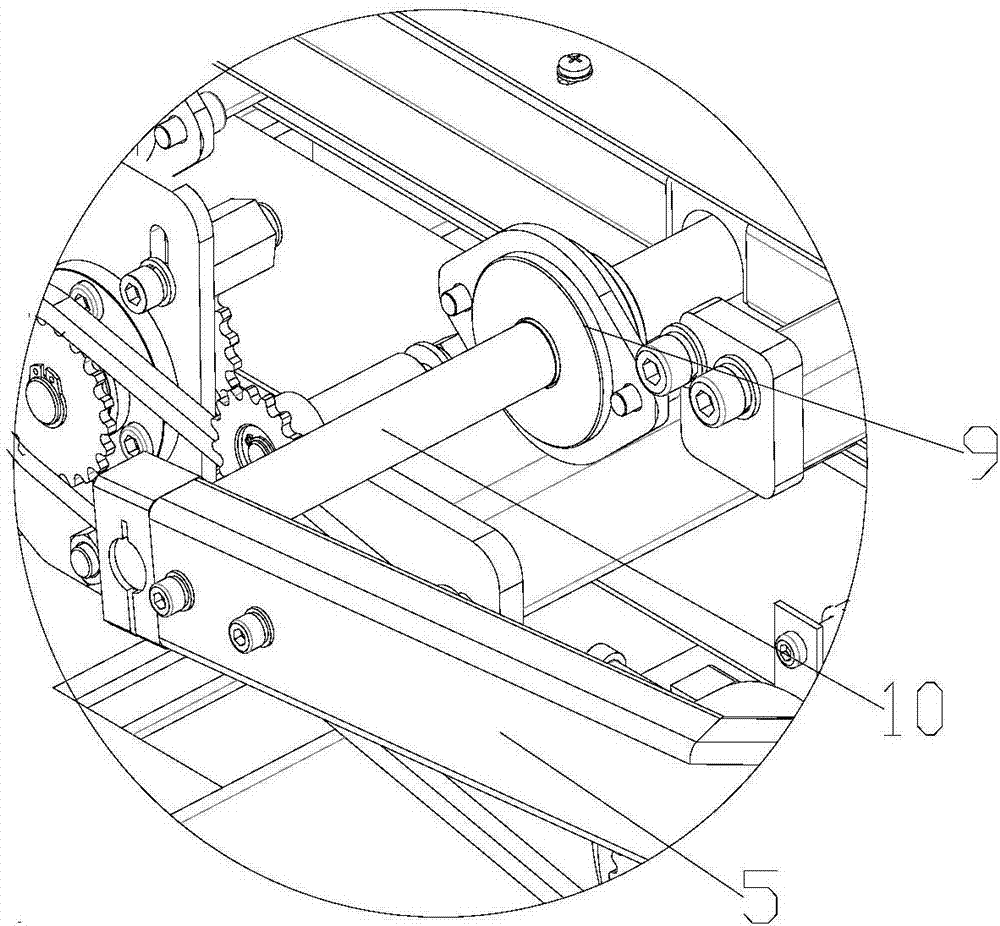

Cloth spreading and cutting plotter and control method thereof

ActiveCN105133280AImprove processing efficiencyHigh degree of automationSevering textilesUnfolding thin materialsMotor controlEngineering

The invention discloses a cloth spreading and cutting plotter and a control method thereof. The cloth spreading and cutting plotter includes a plotter body (1), a rectangular workbench (2), and a motor; the plotter body (1) is positioned on the rectangular workbench (2); a cloth spreading device (11) and a cutting and plotting device (12) are positioned on the plotter body (1), and the plotter body (1) is also provided with a core control device (3) and an image acquisition device (4);a control unit of the image acquisition device (4) and the cutting and plotting device (12), and a control unit of the motor are electrically connected to the core control device (3); the control unit of the motor controls the motor to drive the plotter body (1) to move, and the image acquisition device (4) is positioned on a tool bit of the cutting and plotting device (12). According to the invention, the cloth spreading and cutting plotter integrates a cloth spreading function with a cutting and plotting function, the processing efficiency of cloth is improved; and meanwhile, the cloth spreading and the cutting and plotting can be operated simultaneously; batch cutting and plotting can be performed according to a preset program; detection and revision functions of the image acquisition device can assure the accuracy of the cutting and plotting, and the degree of automation is greatly improved.

Owner:HEFEI AORUI DIGITAL CONTROL SCI & TECH

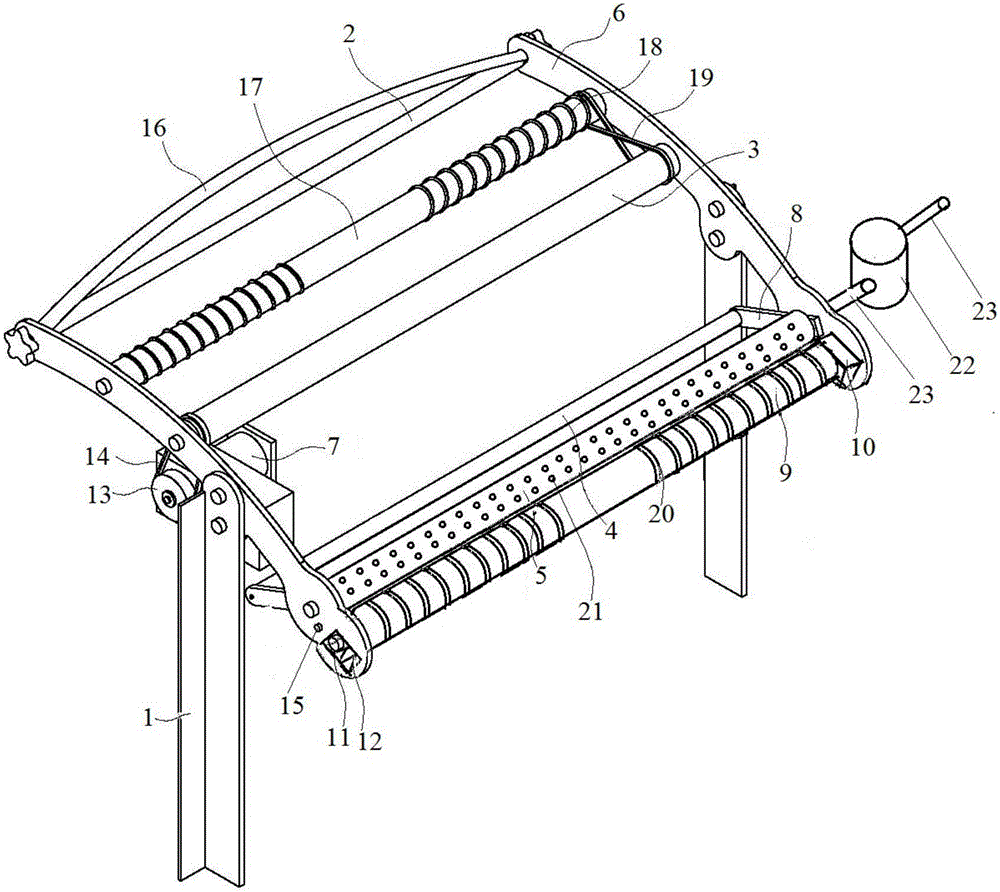

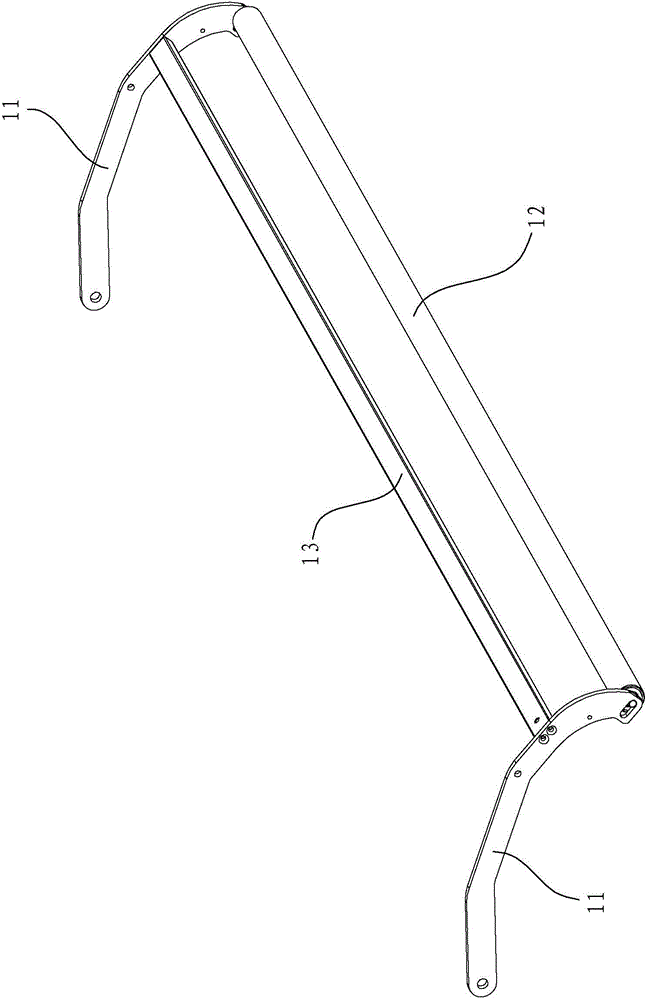

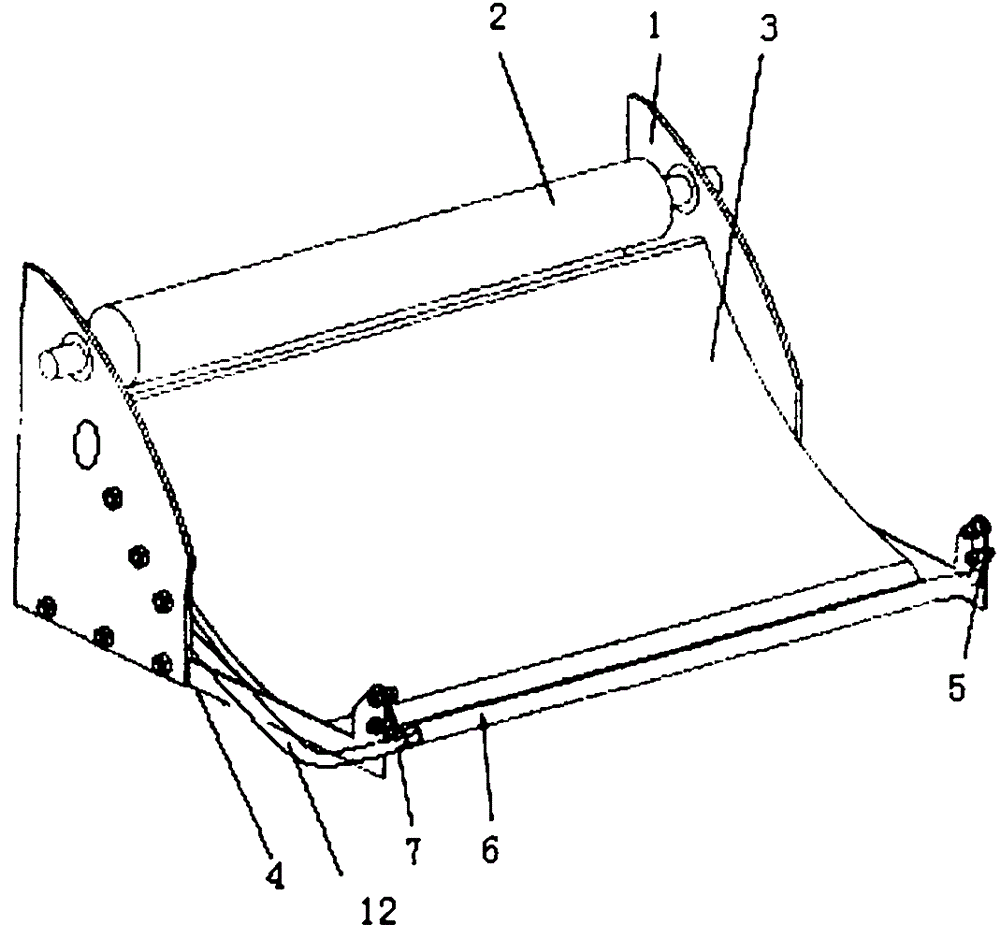

Cloth paving machine and cloth feeding cradle device thereof

ActiveCN103964240ASimple structureEasy to installUnfolding thin materialsWebs handlingEngineeringMechanical engineering

The invention provides a cloth paving machine and a cloth feeding cradle device thereof. The cloth feeding cradle device comprises two mounting plates, a support rod, a group of stop plate components fixedly connected with the support rod at intervals, and a support roller, a driving roller, a cloth feeding roller and a first limiting roller movably clamped between the two mounting plates. The cloth feeding cradle device is suitable for cloth pavement of large rolls of cloth, and not easy to deform even if the larger rolls of cloth are fed. Besides, without a conveying belt, the cloth feeding cradle device of the cloth paving machine is simpler in structure, convenient to mount and lower in cost as compared with an existing cloth feeding cradle device of the cloth paving machine.

Owner:长园和鹰科技(河南)有限公司

Automatic fabric feeding tightness adjusting device of fabric spreading machine

InactiveCN103466370AThe spreading effect is evenImprove adaptabilityUnfolding thin materialsWebs handlingControl systemStructural engineering

The invention discloses an automatic fabric feeding tightness adjusting device of a fabric spreading machine. The automatic fabric feeding tightness adjusting device comprises two swing rods and an adjusting rod. The two swing rods are vertically movably fixed to the upper portions of the outer sides of the front ends of left and right fixing plates of the fabric spreading machine, the adjusting rod is horizontally fixed to space between the lower ends of the two swing rods, is transversely arranged below the left and right fixing plates and is close to fabrics discharged from a fabric feeding roller, saddle weights are respectively arranged on the swing rods on the two sides of the fabric spreading machine, the adjusting rod can be finely repositioned by the saddle weights via the gravity, and a sensor which is connected with a control system and can sense the position of the adjusting rod is fixed onto a fabric handle on the left side of the fabric spreading machine and faces an exposed portion of the upper end of the left swing rod. The saddle weights are arranged at positions, which are fixed to the left and right fixing plates, of the swing rods and extend towards the oblique upper side of the front of the fabric spreading machine, The automatic fabric feeding tightness adjusting device has the advantages that a flat fabric spreading effect can be realized, the automatic fabric feeding tightness adjusting device is good in adaptability, can be added to common machines, is convenient to use and is practical.

Owner:上工富怡智能制造(天津)有限公司

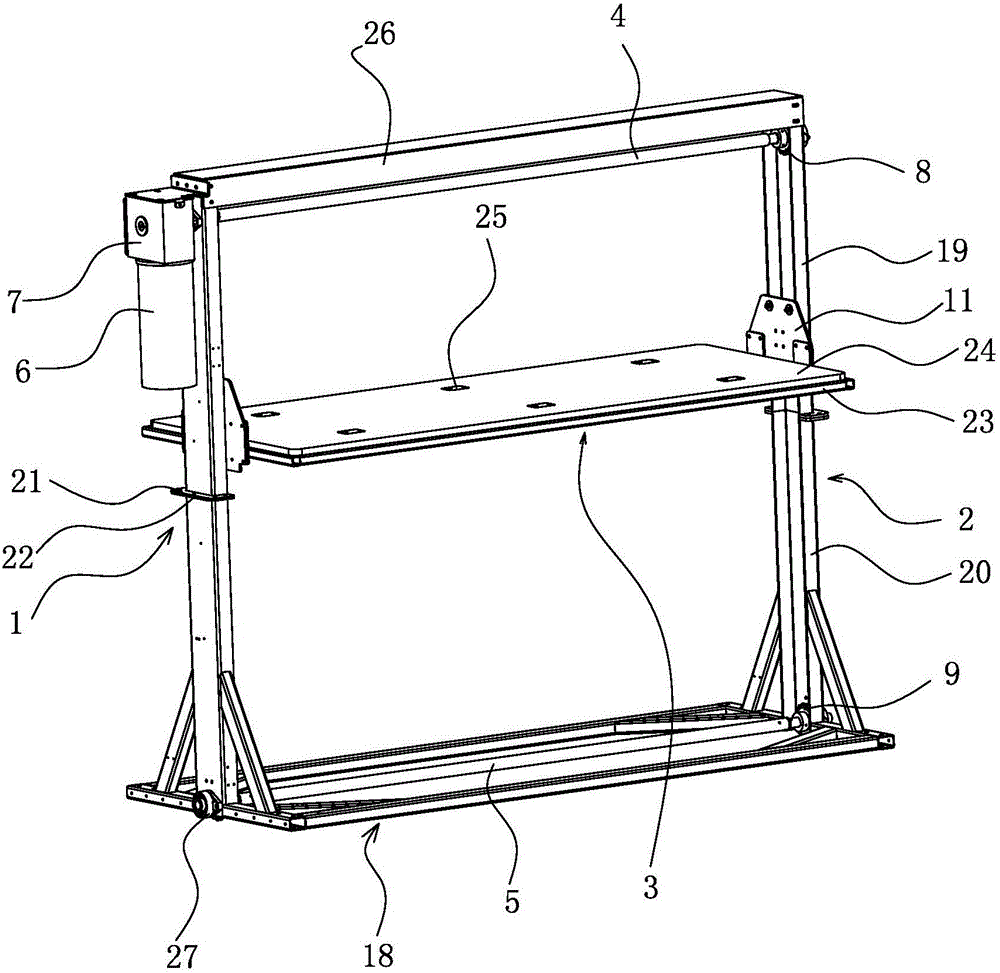

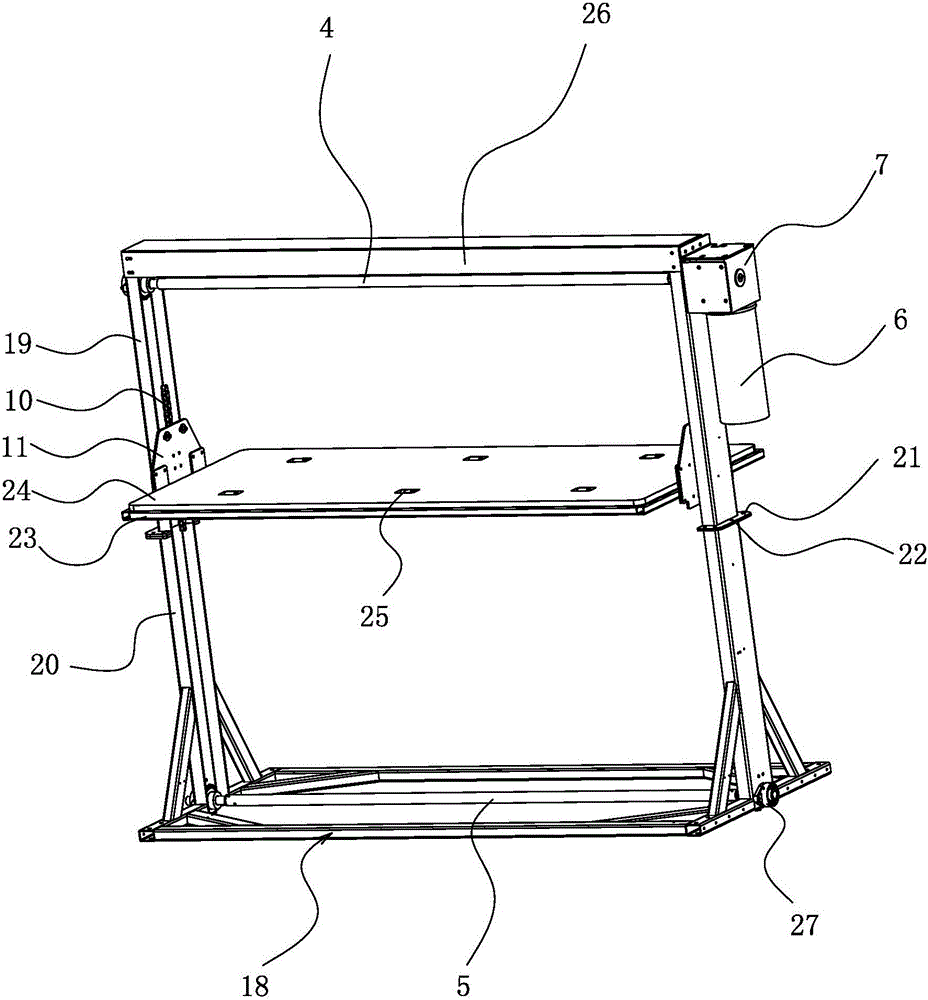

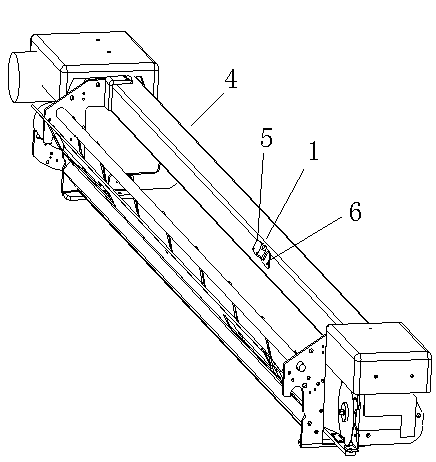

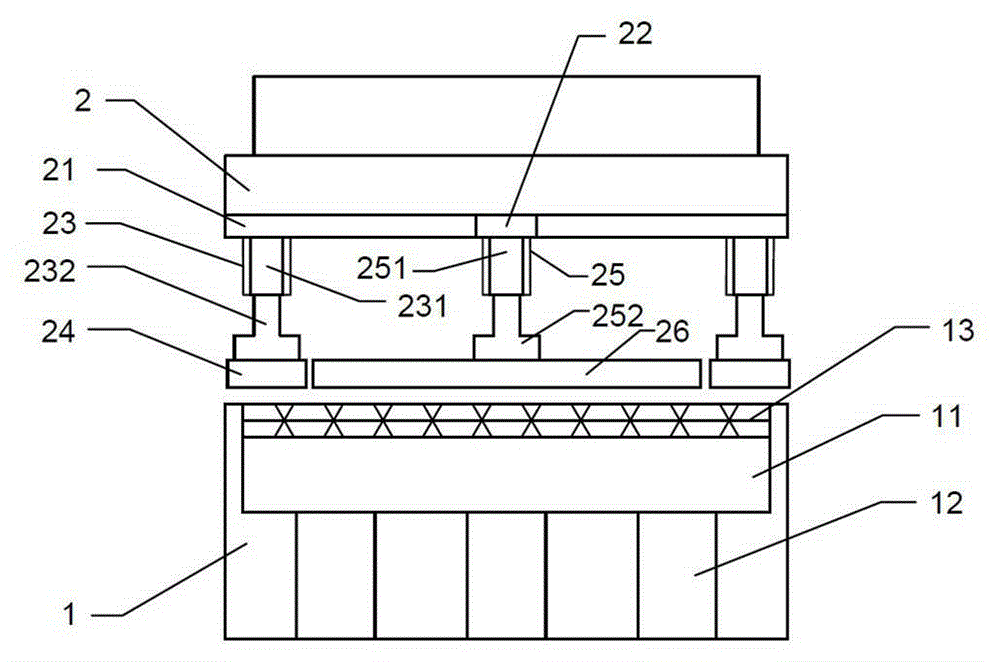

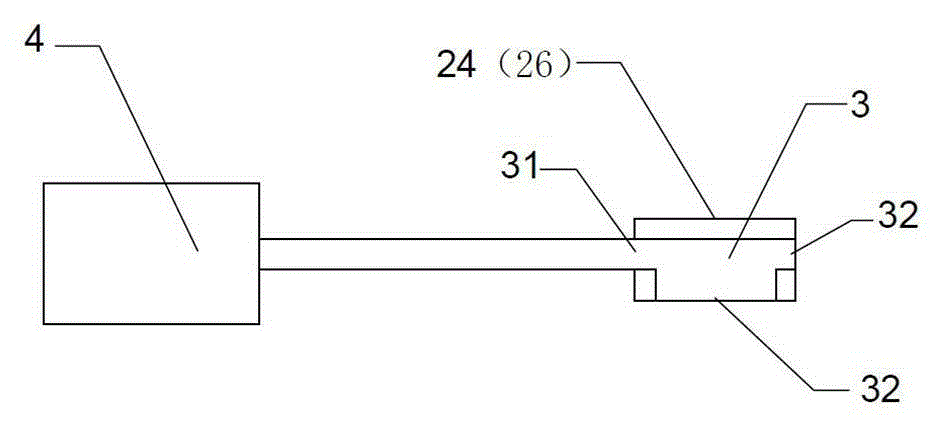

Cloth feeding lifting device for cloth paving machine

InactiveCN105936441AReduce labor intensityShorten the timeLifting framesUnfolding thin materialsIndustrial engineeringTextile

The invention belongs to the technical field of corollary equipment of a cloth paving machine, and particularly relates to a cloth feeding lifting device for a cloth paving machine. The cloth feeding lifting device comprises a left support and a right support, a lifting table is arranged between the left support and the right support, and the lifting table vertically moves in the height direction of the left support and the right support under the action of a drive device; and according to the cloth feeding lifting device, manual cloth feeding can be replaced, labor intensity of workers is reduced, time is saved, operation is convenient, and production benefits are improved.

Owner:BULLMER ELECTROMECHANICAL TECH

Automatic cloth spreading tightness adjusting device of cloth spreading machine

InactiveCN103058008AAdjust the tightness of the clothHigh precisionSevering textilesUnfolding thin materialsEngineeringMechanical engineering

The invention provides an automatic cloth spreading tightness adjusting device of a cloth spreading machine and realizes that tightness of cloth spread by the cloth spreading machine can be automatically adjusted and accuracy of cloth cutting can be increased. The automatic cloth spreading tightness adjusting device mainly comprises a tightness detecting device. The tightness detecting device detects cloth spreading tightness to transmit to a controller, the controller is connected with a servo motor connected with a cloth feed mechanism, and the control device receives cloth spreading tightness signals transmitted by the tightness detecting device and controls the servo motor to increase or decrease cloth feed speed. The automatic cloth tightness adjusting device of the cloth spreading machine has the advantages that cloth spreading tightness on the cloth spreading machine can be automatically stably adjusted, and accordingly, accuracy of cloth cutting is increased, and both labor and cloth are saved.

Owner:徐小林

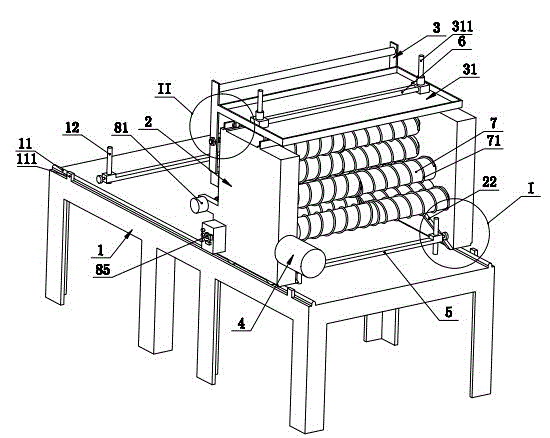

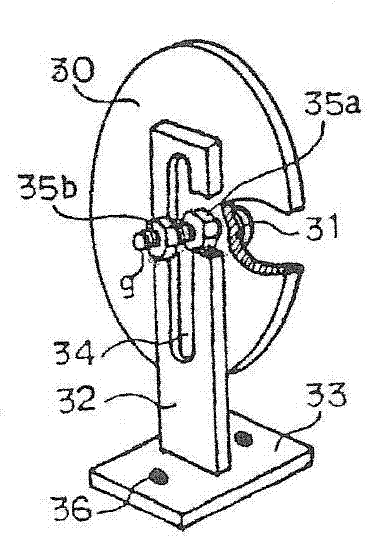

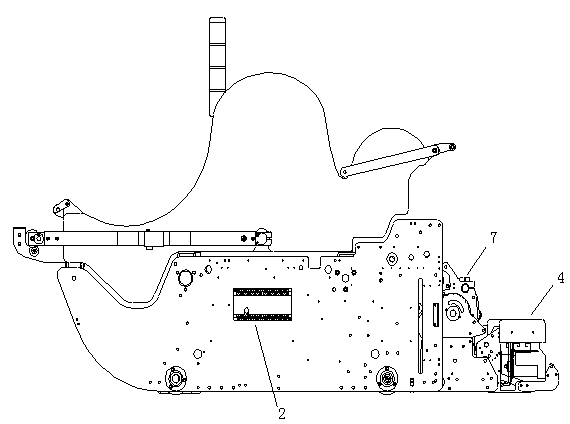

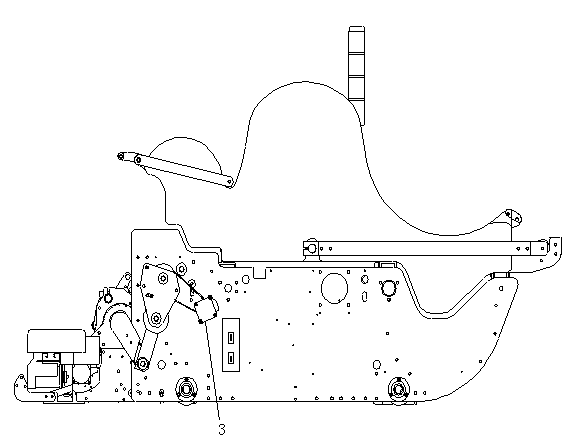

Single working station linen unfolding and conveying device

The invention discloses a single working station linen unfolding and conveying device. The single working station linen unfolding and conveying device comprises a rack, wherein a track is arranged between a left side panel and a right side panel above the front end of the rack; two unfolding mechanical hands for clamping linen are arranged on the track; the unfolding mechanical hands are driven by a motor to move on the track; a linen output platform is arranged on the rack below the track; a lifting forwarding roller which is driven by the motor is arranged at the front end of the rack below the linen output platform; unfolding flat belt brackets are respectively arranged on the left side and the right side of the front end of the rack below the lifting forwarding roller; unfolding flat belt mechanisms which are capable of pulling and correcting the linen are arranged on the unfolding flat belt brackets; a vacuum box with a top opening on the top part is arranged inside the rack behind the lifting forwarding roller and below the linen output platform; a transverse opening is formed in the upper part of the rear wall of the vacuum box; and a plurality of air sucking fans of which air sucking ports are communicated with the vacuum box are arranged on the rack. The single working station linen unfolding and conveying device has the advantages that the linen can be unfolded and conveyed automatically and the surface of the linen is constantly kept in high flatness.

Owner:JIANGSU SEA LION MASCH GRP CO LTD

Cloth pressing device of stretching machine

The invention provides a cloth pressing device of a spreading machine and belongs to the technical field of garment processing machinery. The spreading machine comprises a spreading table, a cross beam, a pair of toothed belt edge stripping mechanisms and front and rear cloth spreading rollers, wherein a rack is arranged on the spreading table, upper and lower cloth guiding roller, a cloth guiding roller, a large cloth spreading roller and a lower cloth spreading roller are arranged on the rack. The cloth pressing device is characterized by comprising a large cloth spreading roller cloth pressing mechanism, wherein the large cloth spreading roller cloth pressing mechanism comprises a pair of cloth pressing roller carriers, a large cloth spreading roller front cloth pressing roller, a large cloth spreading roller upper cloth pressing roller and a large cloth spreading roller rear cloth pressing roller, the right end of one pair of cloth pressing roller carriers is pivoted on the rack, a handle is fixed in the middle of one pair of cloth pressing roller carriers, one opposite side of one end of one pair of cloth pressing roller carriers is connected with the upper end of a front pressing roller arm, one opposite side of the right end of one pair of cloth pressing roller carriers is connected with the upper end of a rear pressing roller arm, a large cloth spreading roller front cloth pressing roller is arranged at the lower end of the front pressing roller arm, the large cloth spreading roller upper cloth pressing roller is arranged between one pair of cloth pressing roller carriers, and the large cloth spreading roller rear cloth pressing roller is fixed at the lower end of the rear pressing roller arm. The cloth pressing device creates edge stripping conditions for a toothed belt edge stripping mechanism and ensures the cloth pulling and spreading effects.

Owner:SUZHOU BIYANGTE CLOTHING EQUIP CO LTD

Cloth flattening device

ActiveCN105173873AAvoid creasesAvoid embossingUnfolding thin materialsEngineeringMechanical engineering

The invention discloses a cloth flattening device. The device comprises a cloth laying platform and an installation top base located above the cloth flattening device, the installation top base is provided with a first displacement track, a second displacement track, a first cloth flattening mechanism moving along the first displacement track and a second cloth flattening mechanism moving along the second displacement track, an air blowing mechanism is arranged on the first cloth flattening mechanism and the second cloth flattening mechanism, and the cloth laying platform is provided with an air drafting mechanism matched with the air blowing mechanism. The device is simple in structure, convenient to use and capable of stretching cloth in all dimensions including the length direction and the width direction of a cloth surface, cloth tension is released sufficiently, the air blowing mechanism and the air drafting mechanism are utilized for conducting ionic wind static-electricity-removal treatment on the cloth surface simultaneously, creases and impressions of the cloth surface are prevented, and the quite excellent cloth flattening effect is achieved.

Owner:盐城市怡泰制衣有限公司

Stripping and fixing device of stretching machine

ActiveCN104003231BBlock replyPrevent swimmingUnfolding thin materialsWebs handlingScrew threadContact effects

An edge peeling and positioning device of a spreading machine belongs to the field of clothing machines. The spreading machine comprises a spreading table, a machine frame is arranged on the spreading table and provided with an upper cloth guiding roller, a lower cloth guiding roller, a cloth pressing roller, a large cloth spreading roller and a lower cloth spreading roller. The edge peeling and positioning device comprises a beam and a pair of toothed belt type edge peeling mechanisms and is characterized by further comprising a front cloth expanding roller, a rear cloth expanding roller and a peeled and expanded cloth edge maintaining roller, wherein the front cloth expanding roller is supported on the machine frame and provided with front cloth expanding threads, the rear cloth expanding roller is provided with rear cloth expanding threads, and the peeled and expanded cloth edge maintaining roller is provided with flanges; the beam is fixedly provided with a pair of belt supporting unit seats, which extend into an edge peeling toothed belt cavity and are fixedly provided with belt supporting units, and the belt supporting units are arranged inside the edge peeling toothed belt cavity and are in contact with the inner side of the edge peeling toothed belt. The edge peeling and positioning device of the spreading machine enables the cloth edges of both sides in the length direction of cloth spread on the spreading table to maintain a trim state, prevents both sides the cloth from moving towards the middle, eliminates the deflection of the edge peeling toothed belt and improves the integral contact effects of the edge peeling toothed belt with the cloth edges.

Owner:SUZHOU BIYANGTE CLOTHING EQUIP CO LTD

Two-stage edge aligning system of full-automatic cloth laying machine

InactiveCN105314456AExcellent manual stacking effectUnfolding thin materialsSmall rangeAerospace engineering

The invention discloses a two-stage edge aligning system of a full-automatic cloth laying machine. The two-stage edge aligning system comprises a bedplate, left and right side plates arranged at two sides of the rear upper part of the bedplate, a plurality of crossbeams which are fixedly arranged between the two side plates, front and rear cradles which are installed on the crossbeams in a left and right-movable manner, cloth feeding rollers which are respectively installed on the front end and the rear end of the front cradle and a plurality of cloth unfolding rollers, wherein the left side of the front cradle is fixedly connected with two primary edge aligning sensors at the output side of the cloth unfolding roller, the left side plate is fixedly connected with two secondary edge aligning sensors at the output side of the cloth unfolding rollers, and the distance between the two secondary edge aligning sensors is smaller than the distance between the two primary edge aligning sensors. By adopting two-stage edge aligning system, the rear cradle is used for performing the rough edge aligning, the unevenly cloth edges are kept in a smaller range, then the front cradle is used for performing the fine aligning, so that the edges of the coiled cloth or blank cloth can be furthest aligned in the specially-unevenly circumstance.

Owner:上工富怡智能制造(天津)有限公司

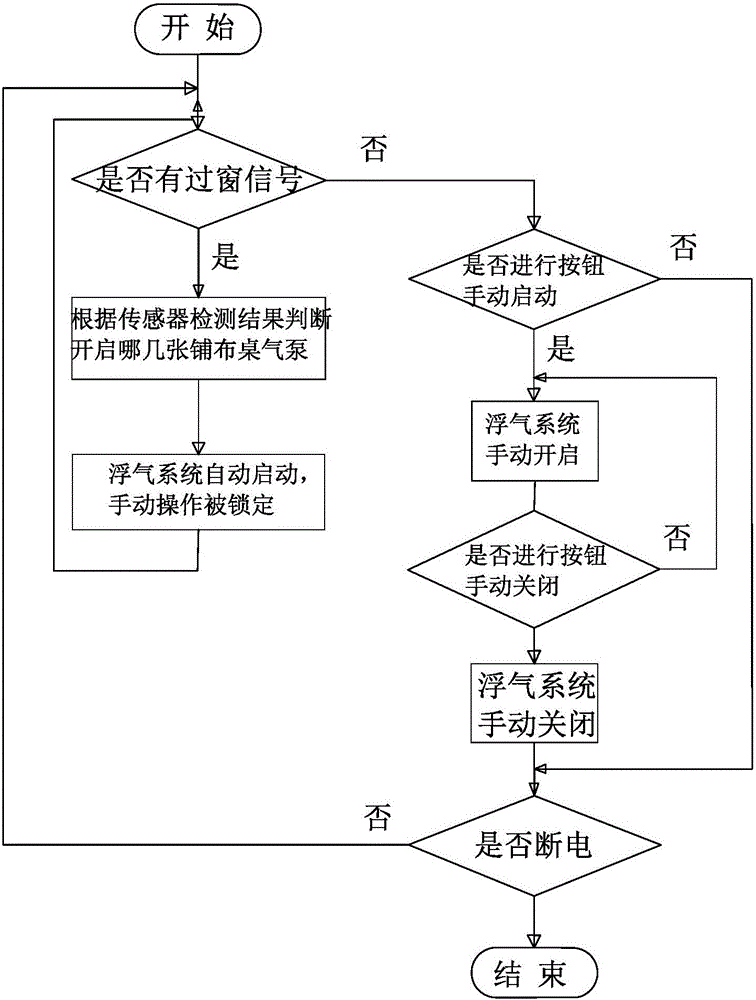

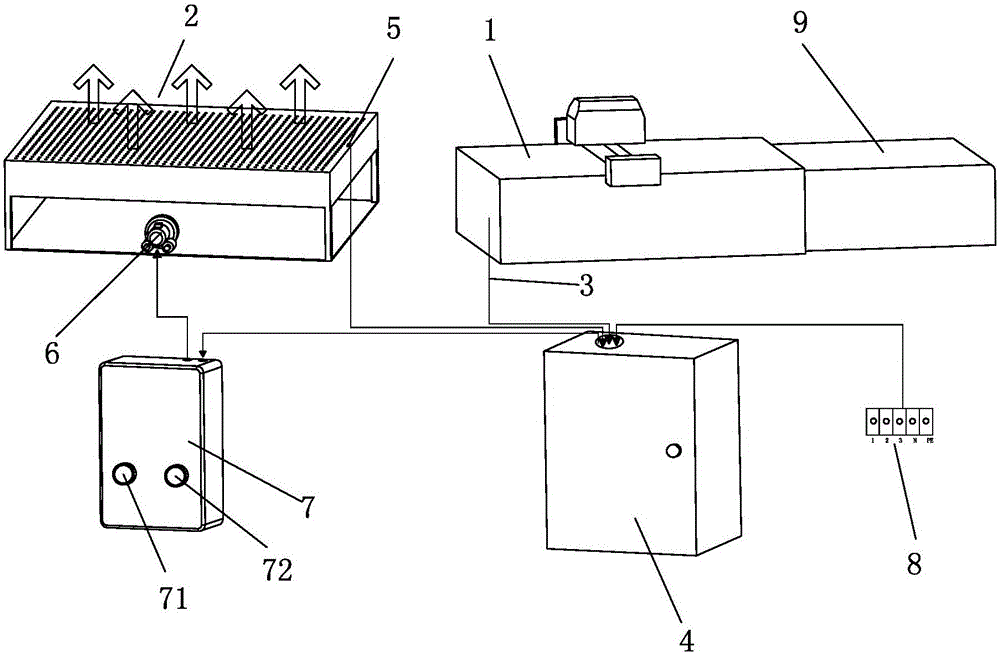

Synchronous air flotation system for cloth-paved tables

The invention belongs to the technical field of cloth-paved tables, and particularly relates to a synchronous air flotation system for cloth-paved tables. The synchronous air flotation system comprises a window-passing signal provided by a cutting bed and one or more cloth-paved tables arranged in parallel. A signal line of the window-passing signal is electrically connected with a control box, air pumps are arranged below the cloth-paved tables respectively and controlled by the control box in combination with the window-passing signal to be started or stopped, and the control box is electrically connected with a power supply. The synchronous air flotation system is low in cost and convenient to modify, reduces manual operation through automatic operation, saves energy, lowers the cost and accords with the novel industrial development status of energy conservation; the synchronous air flotation system is started through the window-passing signal provided by the cutting bed, so that the trouble of frequent manual operation is saved; segmented control is achieved through detection of photoelectric sensors, so that energy conservation and automatic operation are achieved.

Cloth spreading device and cloth spreading machine

InactiveCN107032175AReduce difficultyCause wrinklesUnfolding thin materialsWebs handlingEngineeringMechanical engineering

The invention relates to a spreading machine, in particular to a spreading device and a spreading machine with the same. The cloth spreading device includes: a walking frame, which is used for linear motion along the length direction of the cloth spreading table of the spreading machine, and includes a cloth input side and a cloth output side; a cloth feeding mechanism is arranged on the cloth output side of the walking frame, including Cloth feeding roller; cloth placing platform, set on the cloth feeding side of the walking frame, used to store the cloth; cloth throwing mechanism, hinged on the walking frame, used to feed the cloth with the hinged part of the walking frame as the pivot point. Turn over between the cloth side and the cloth outlet side, send the cloth placed on the cloth spreading table to the cloth feed roller, and cooperate with the cloth feed roller to clamp the cloth when the cloth feed roller conveys the cloth. In the whole operation process, because the operator only needs to turn the cloth throwing lever to complete the conveying of the cloth head, it is very convenient for the operator to operate, and at the same time, it can also avoid the wrinkling phenomenon caused by the artificial conveying when the cloth is laid. Improves the flatness of the fabric when laying.

Owner:SHAGNHAI YIN SCI&TECH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com