Cloth paving machine

A cloth spreader and cloth technology, which is applied in the direction of spreading thin soft materials, sending objects, thin material processing, etc., can solve the problem of poor quality of cutting and cutting cloth, the operation of cloth spreading machine is easily disturbed by wind force, and the quality of cloth pressing is not good. To avoid problems such as good quality and achieve the effect of avoiding burrs and solving easy curling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below according to the drawings and embodiments.

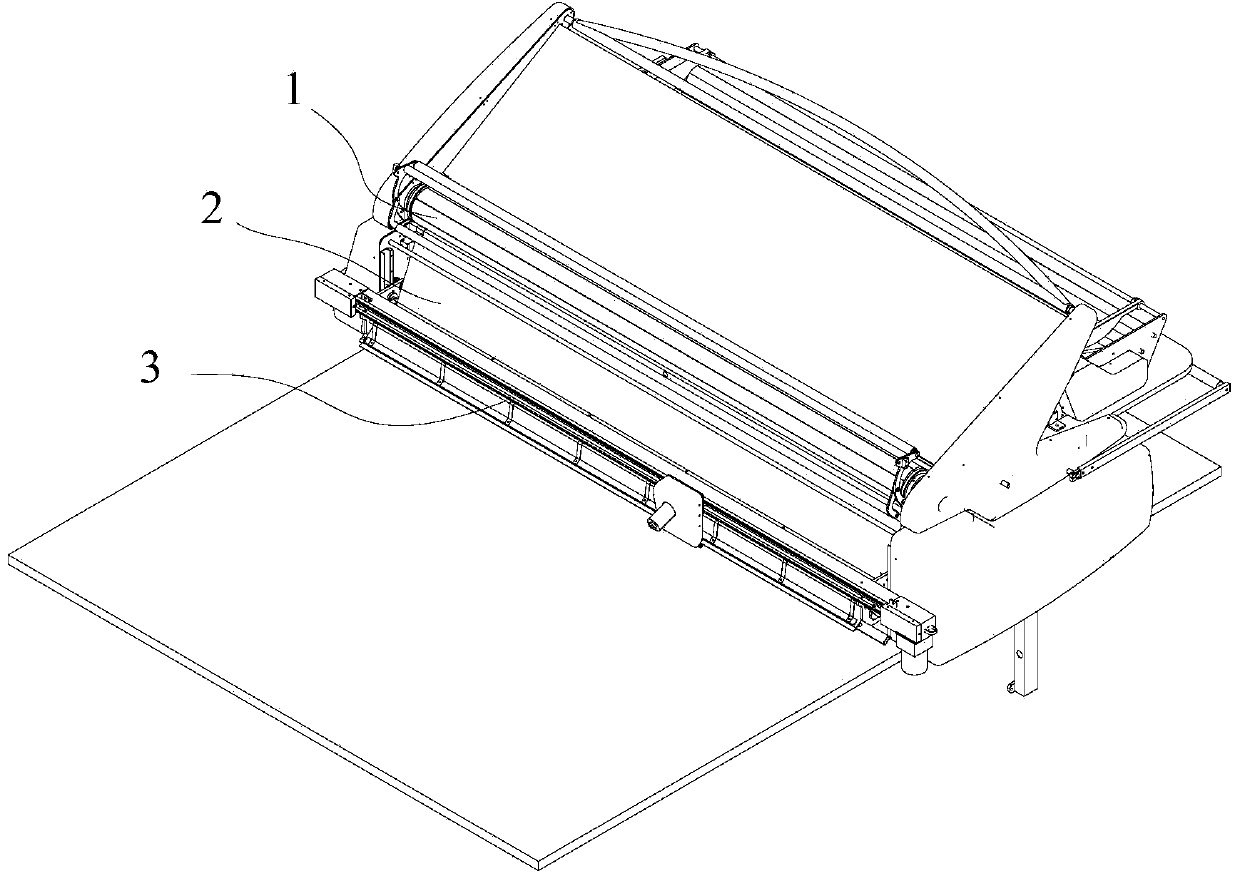

[0038] figure 1 For the three-dimensional structure diagram of the spreading machine in this implementation case, refer to figure 1 , In the present invention, the spreading machine includes a cloth pressing and conveying device 1 for the spreading machine, a windshielding device 2 for the spreading machine, and a cutting device 3 for the spreading machine.

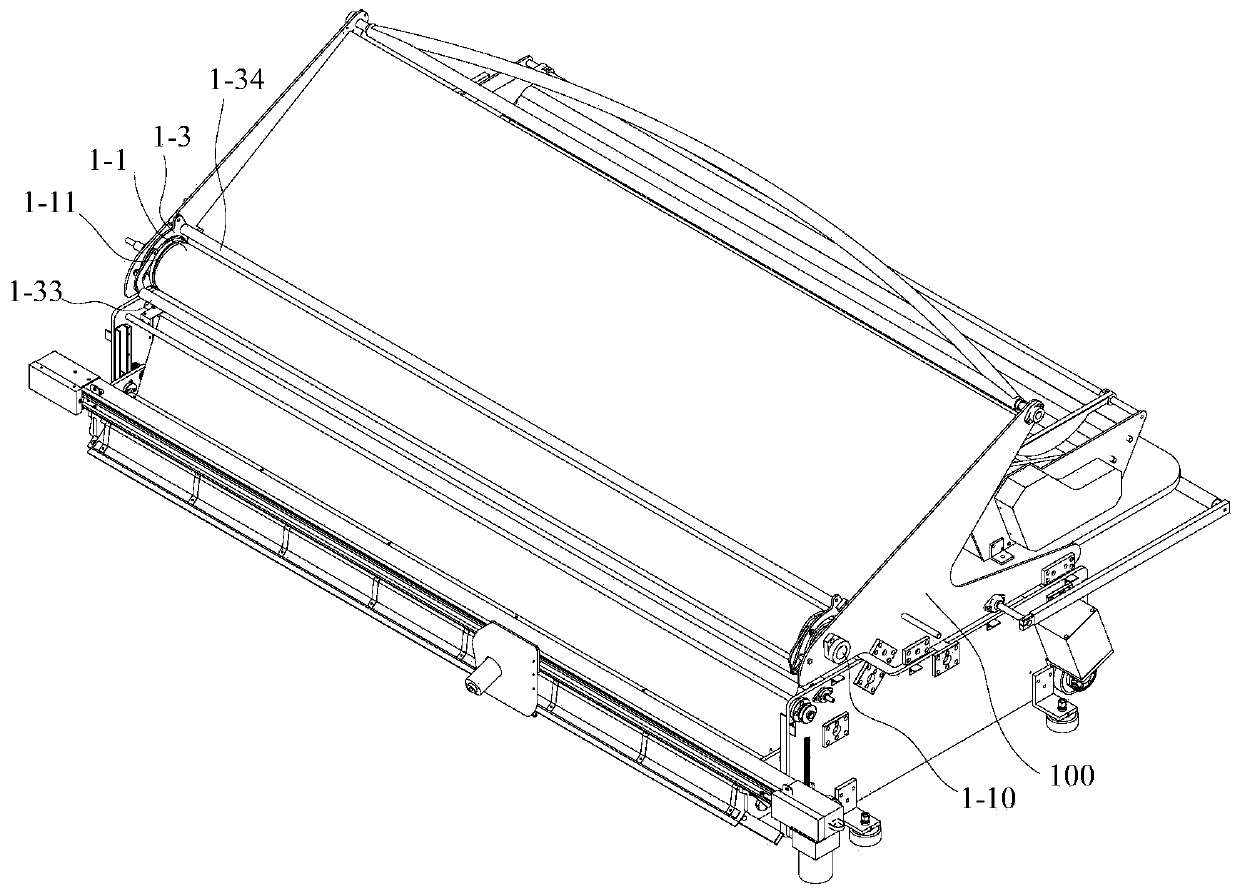

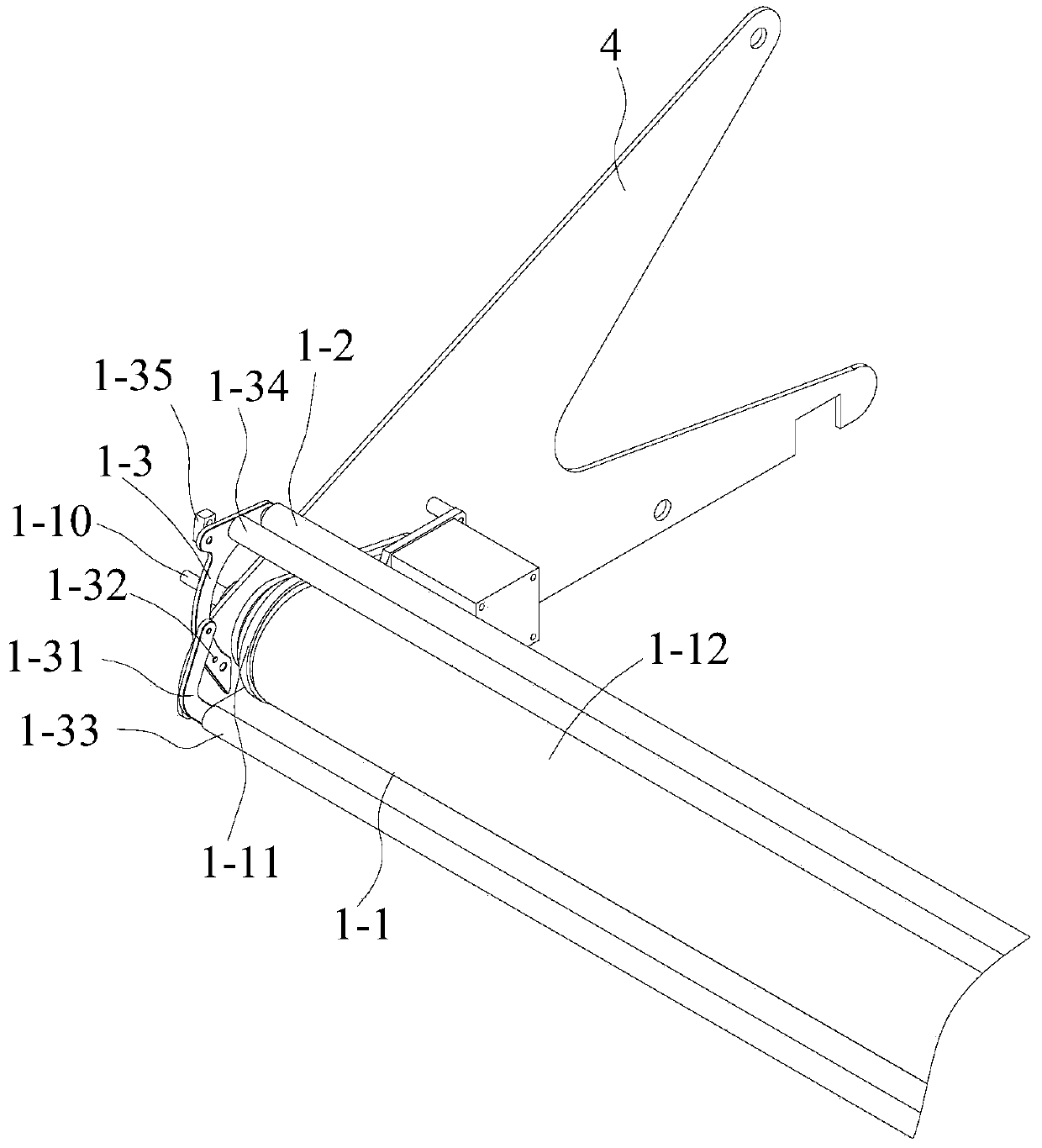

[0039] figure 2 It is a schematic diagram of the structure of the cloth pressing and conveying device of the spreading machine in this implementation case, image 3 For the partial expansion diagram of the cloth pressing and conveying device of the spreading machine in this implementation case, refer to figure 2 , image 3, for the paver cloth pressing and conveying device 1, it includes a conveying roller 1-1 and a pressing roller 1-2, and the rotating shafts 1-10 at both ends of the conveying roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com