Road repair material and application thereof

A technology of road repair and repair material, which is applied in the field of repair of various airport runways, and can solve problems such as difficulty in simultaneously taking into account strength performance and crack resistance performance, cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

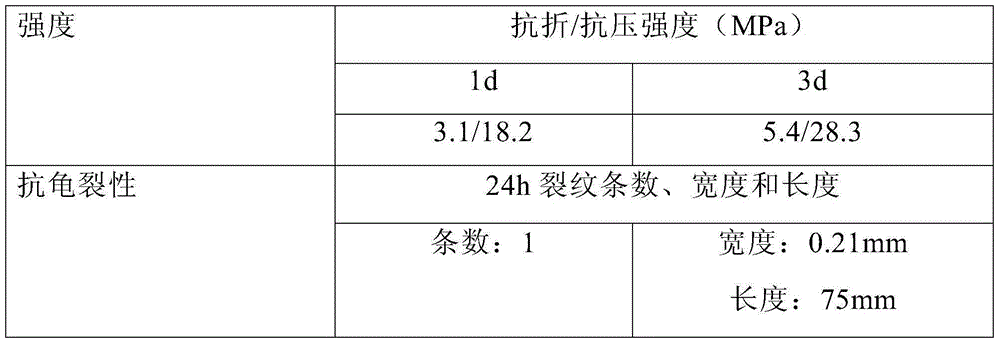

Embodiment 1

[0036] Contains tailings, cement, modified glue and polypropylene fiber, wherein based on the total weight of the road repair material, the content of tailings is 30-60%, the content of cement is 20-40%, and the content of modified glue is 5-30%, the content of polypropylene fiber is 5-20%.

[0037] The road repair material is prepared from tailings, cement, modified glue and polypropylene fiber. Based on the total weight of the road repair material, the content of tailings is 50%, the content of cement is 30%, and the content of modified glue is 10%. %, the content of polypropylene fiber is 10%. The tailings are rare earth tailings (obtained from Tangshan Iron and Steel Concentrator), and the cement is a mixture of Portland cement and sulphoaluminate cement (both obtained from Hebei Tangshan Yandong Cement Company) with a weight ratio of 1:1 , and added calcium chloride accounting for 1.5% of the total weight of cement. The modified glue is commercially available polyuretha...

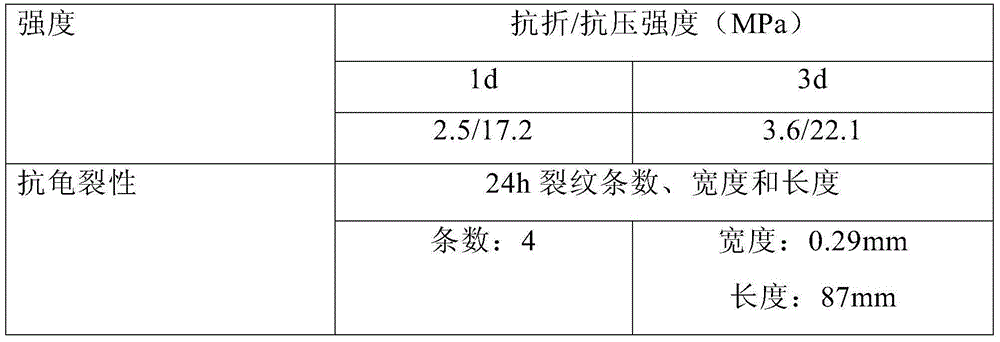

Embodiment 2

[0039] (1) Pretreatment of the road repair material obtained according to Example 1: the road repair material is mixed with a solvent in a weight ratio of 3:1 to obtain a pre-repair material, and the solvent is water and ethanol in a 4:1 weight ratio mixture;

[0040] (2) Clean up road cracks or potholes: Use mechanical or manual methods to clean up road cracks or potholes until the concrete stabilization layer is exposed; among them, small cracks and narrow potholes need to be cleaned manually, and the loose concrete structure at the edge of the cracks needs to be completely removed. Clean up debris and engineering waste until the concrete stabilization layer is seen, use a high-power blower to thoroughly remove dust and sundries in the repaired area, and paint emulsified asphalt with a solid content of 50% in the repaired area, and wait until it is completely demulsified Carry out the direct pouring of the following pre-repair materials;

[0041] (3) Repair road cracks or p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com