Patents

Literature

79results about How to "Fully compacted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetorheological fluid multi-stage treatment device and control method and component manufacturing method thereof

ActiveCN105457392AWell mixedSpeed up the reaction processMagnetic liquidsMembrane filtersMagnetorheological fluidEngineering

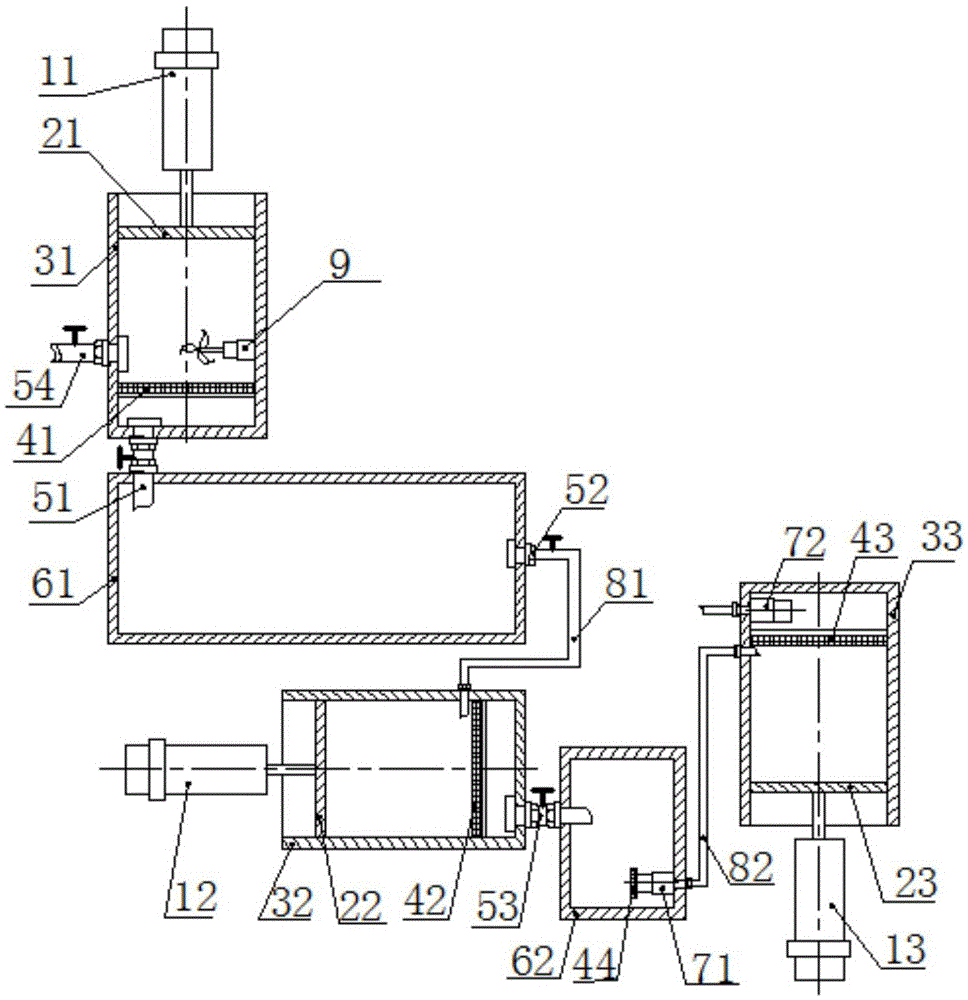

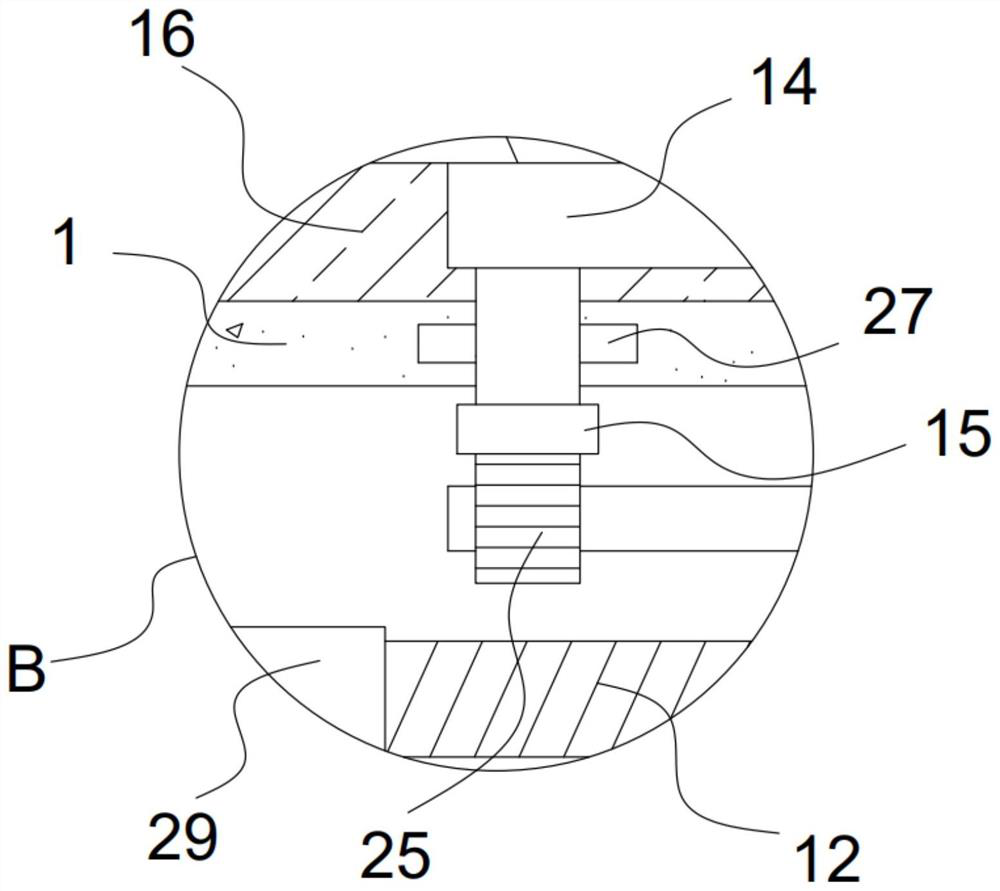

The invention discloses a magnetorheological fluid multi-stage treatment device and a control method and component manufacturing method thereof and belongs to the technical field of machine manufacturing. The magnetorheological fluid multi-stage treatment device comprises a preposition piston cylinder, a middle piston cylinder, a postposition piston cylinder, a preposition piston, a middle piston, a postposition piston, a preposition filtering box, a middle filtering box, a postposition filtering box, a preposition filtering mesh, a middle filtering mesh and a postposition filtering mesh. The preposition piston cylinder is connected with the preposition piston through a bolt, the preposition bolt is matched with an inner cavity of the preposition filtering box, the preposition filtering box is vertically arranged, and the axis is in the vertical direction; meanwhile, the invention further provides corresponding control method and a key component manufacturing method of the device. According to the magnetorheological fluid multi-stage treatment device and the control method and component manufacturing method thereof, a two-standing three-filtering mode is adopted to filter mixed liquid, the characteristic of the mixed liquid at each stage is fully utilized, and the purpose of fast and thoroughly separating magnetic substances and solvent is finally achieved.

Owner:浙江永金生物科技有限公司

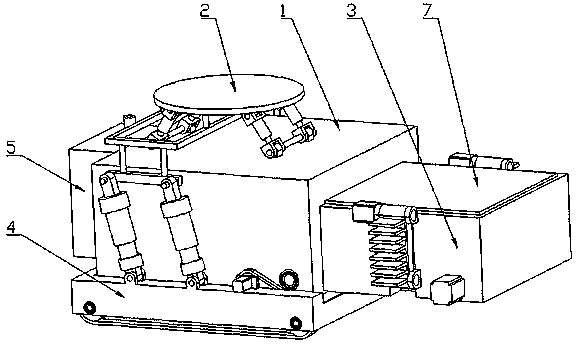

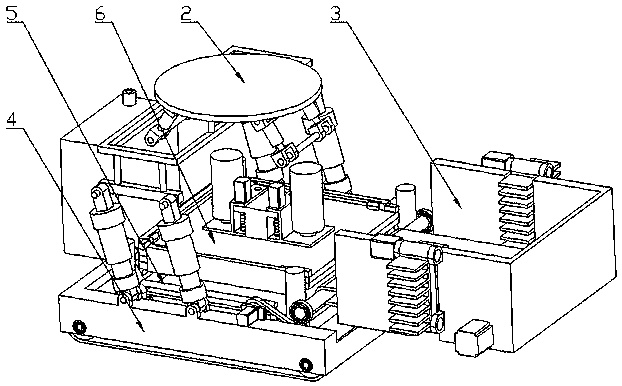

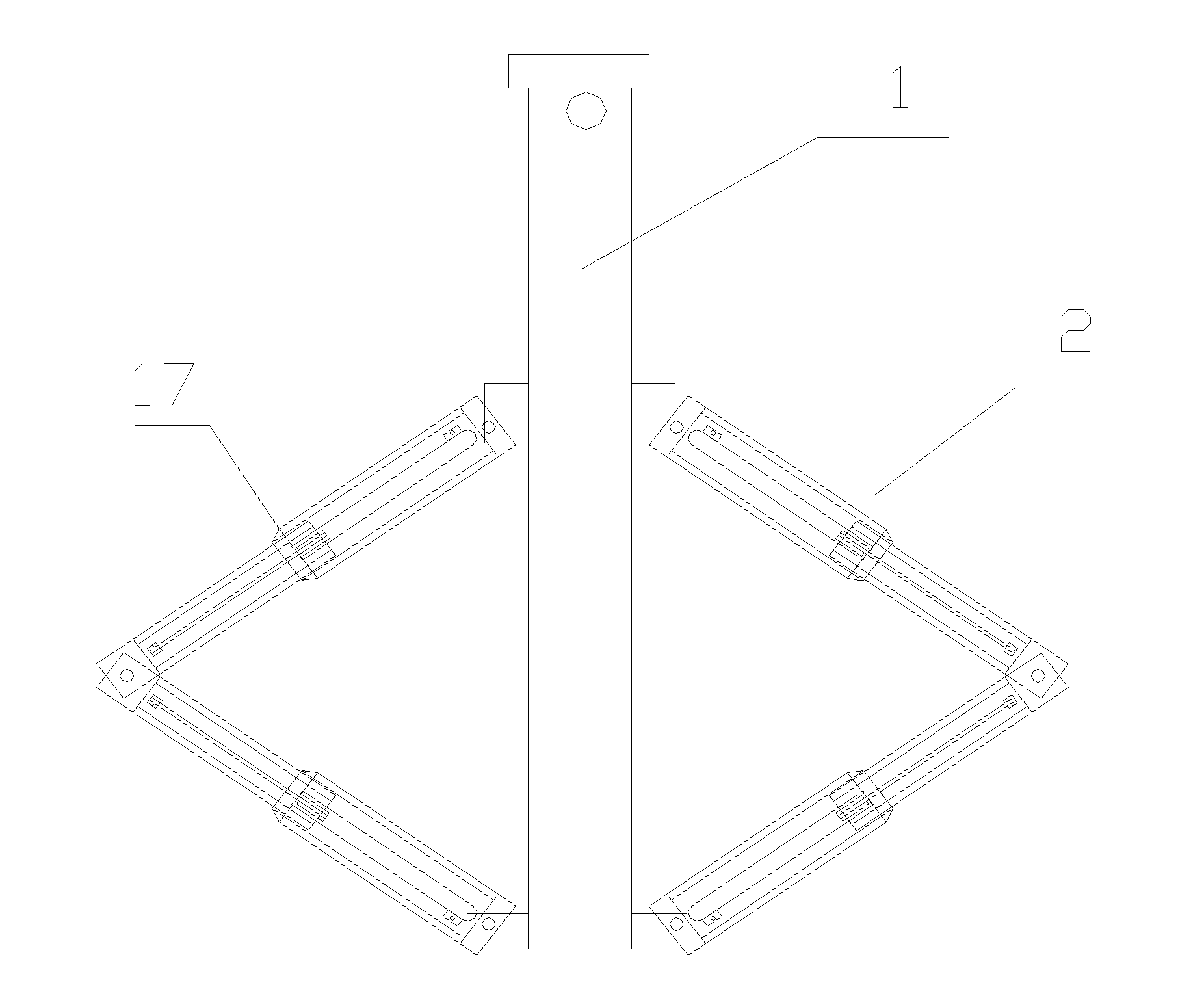

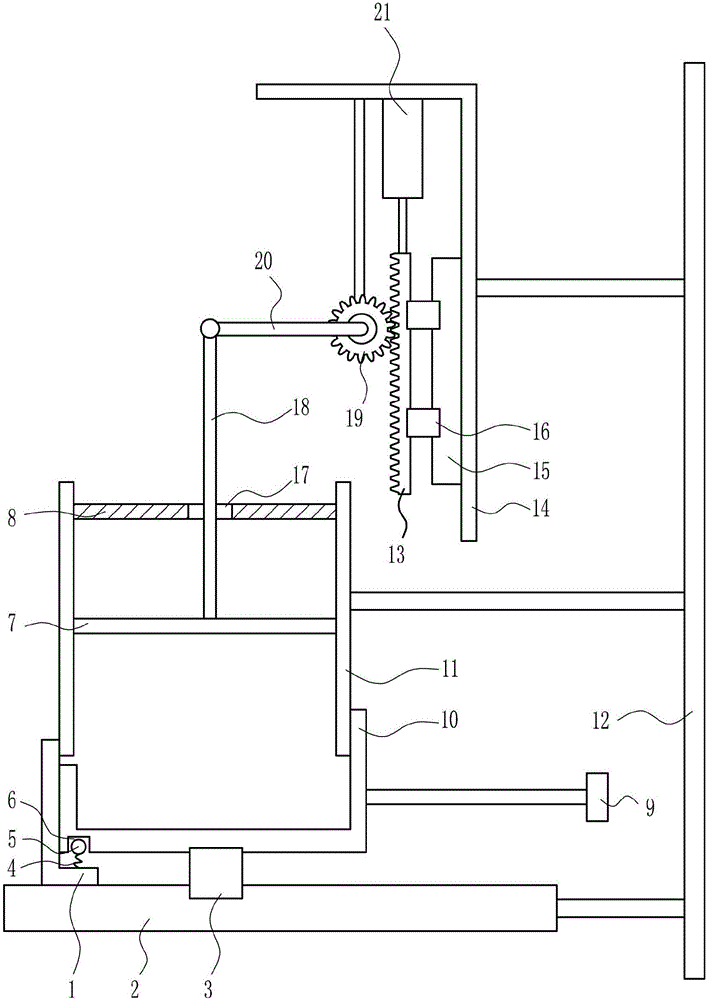

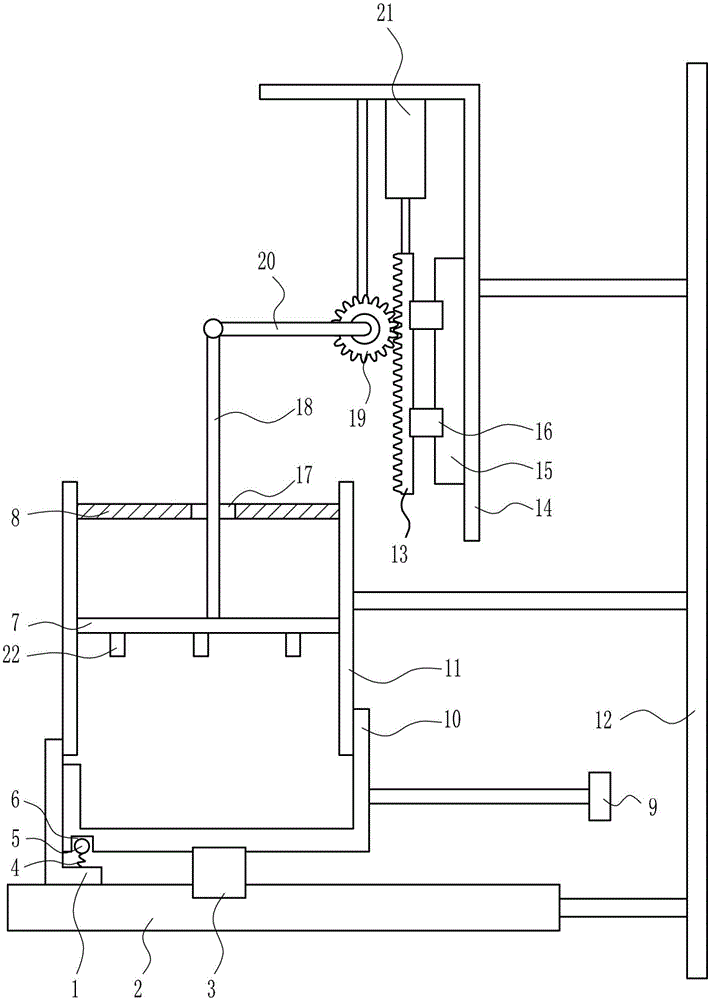

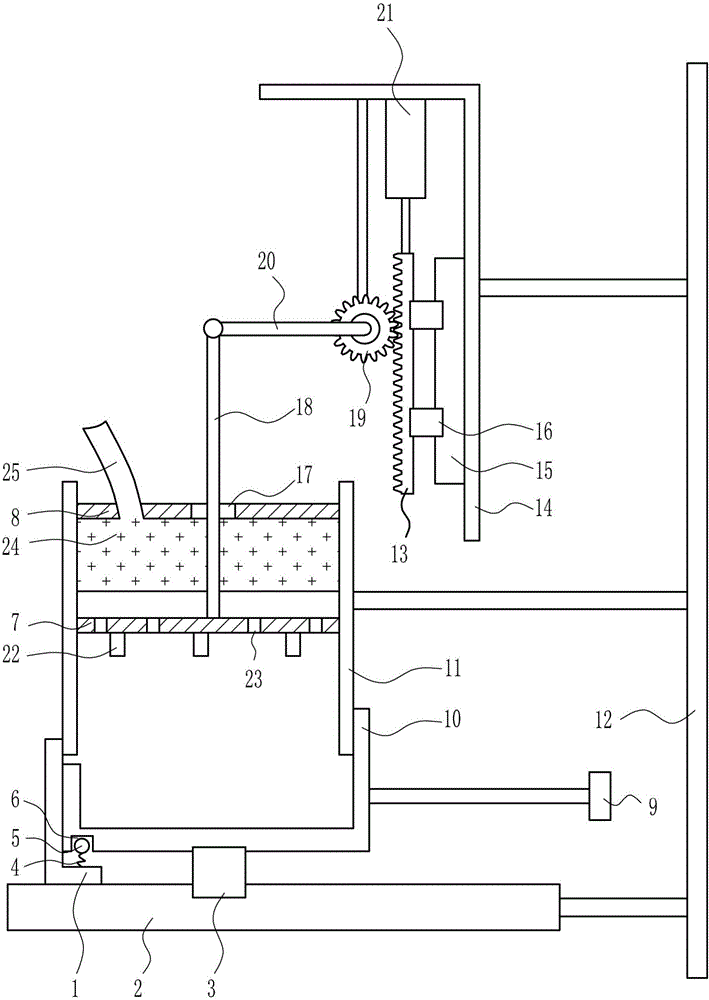

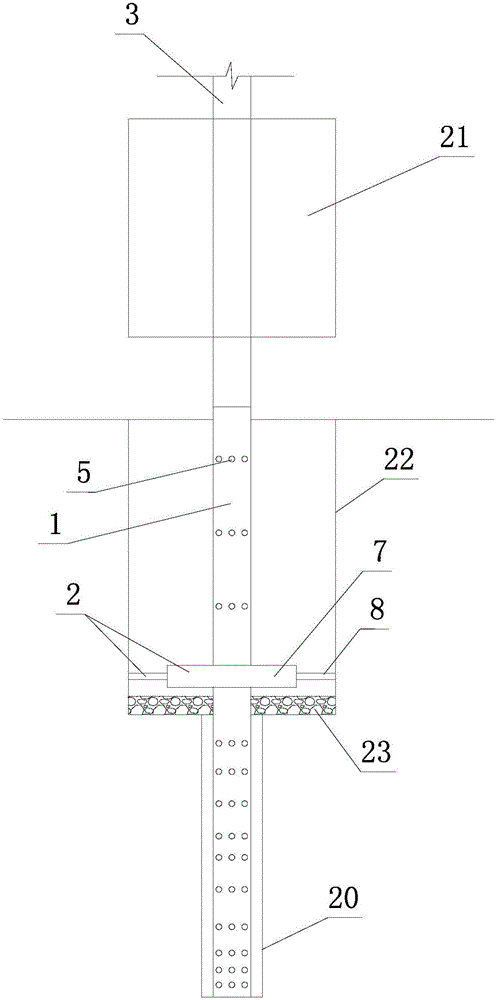

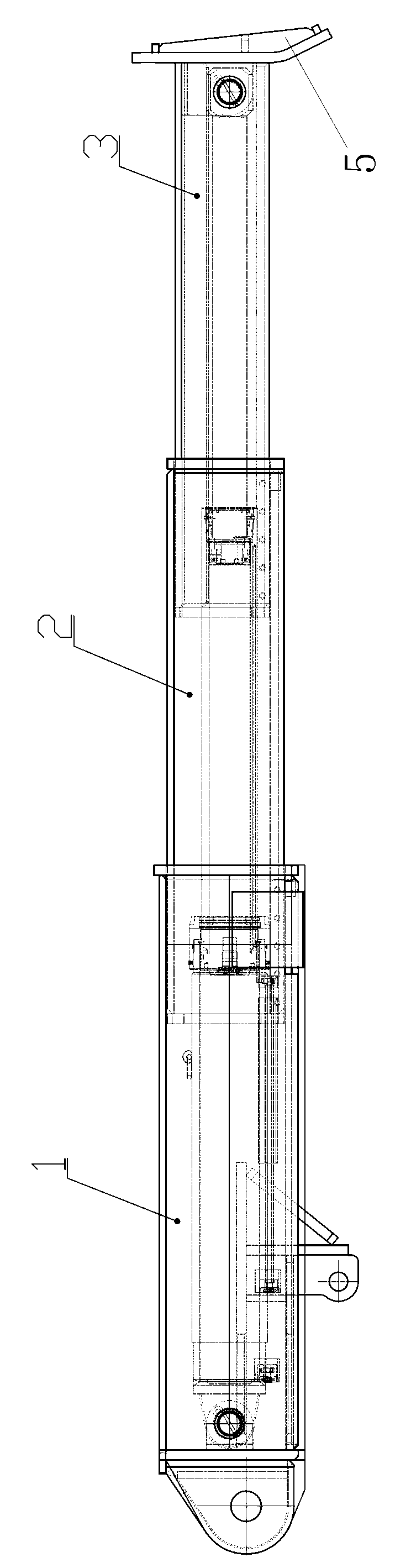

Sample production apparatus and sample production method of layered rock-soil body sample

InactiveCN105115794AThe test results are accurate and reliableChanges in DensityPreparing sample for investigationPhysicsFreeze thaw cycling

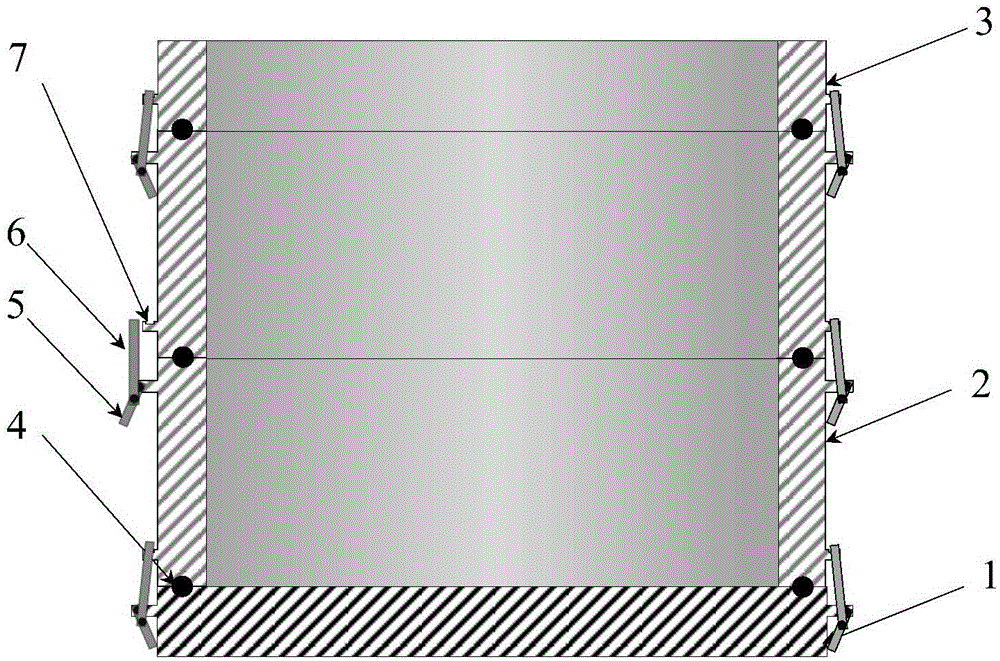

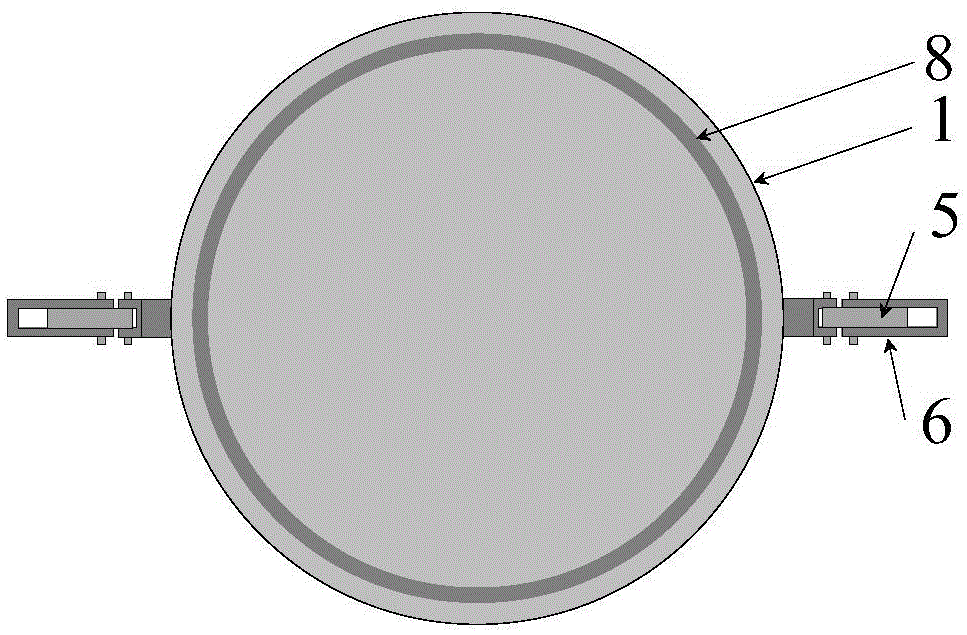

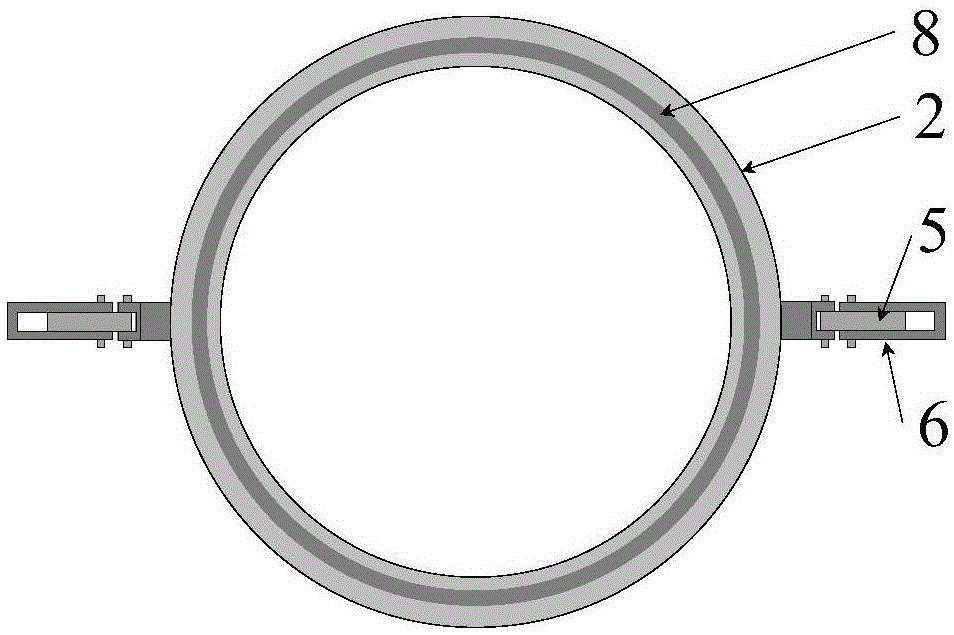

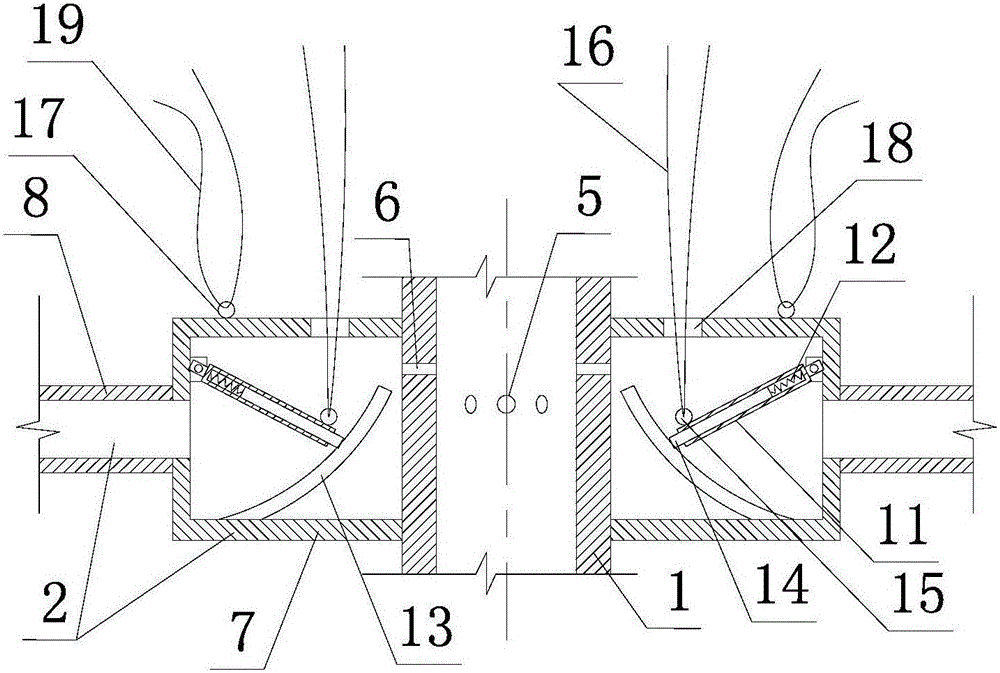

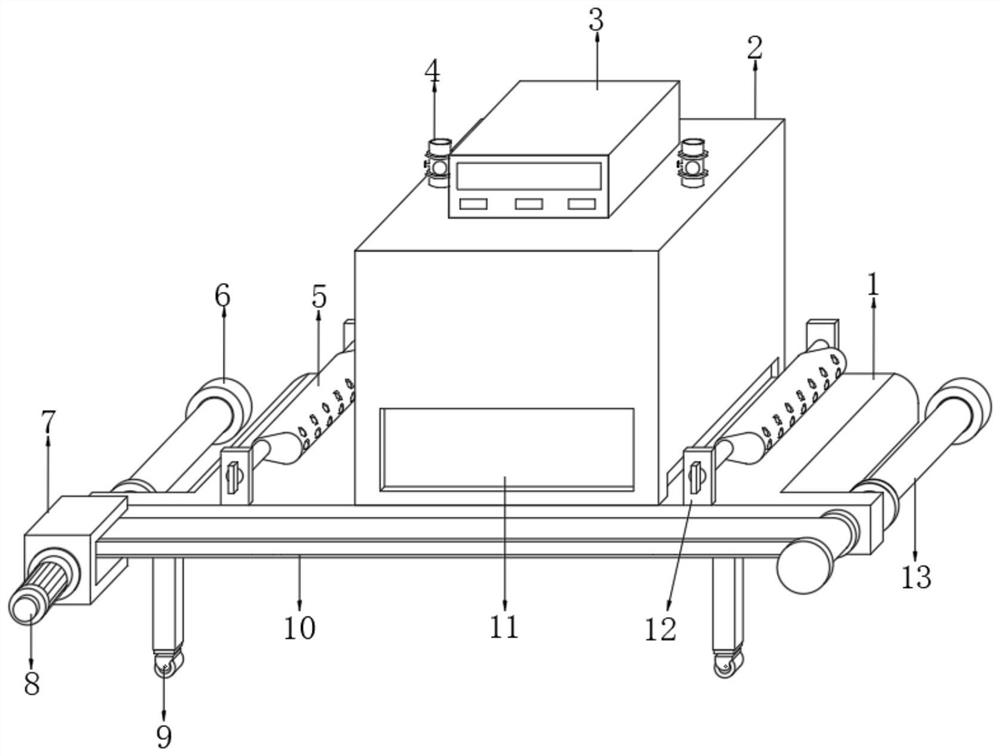

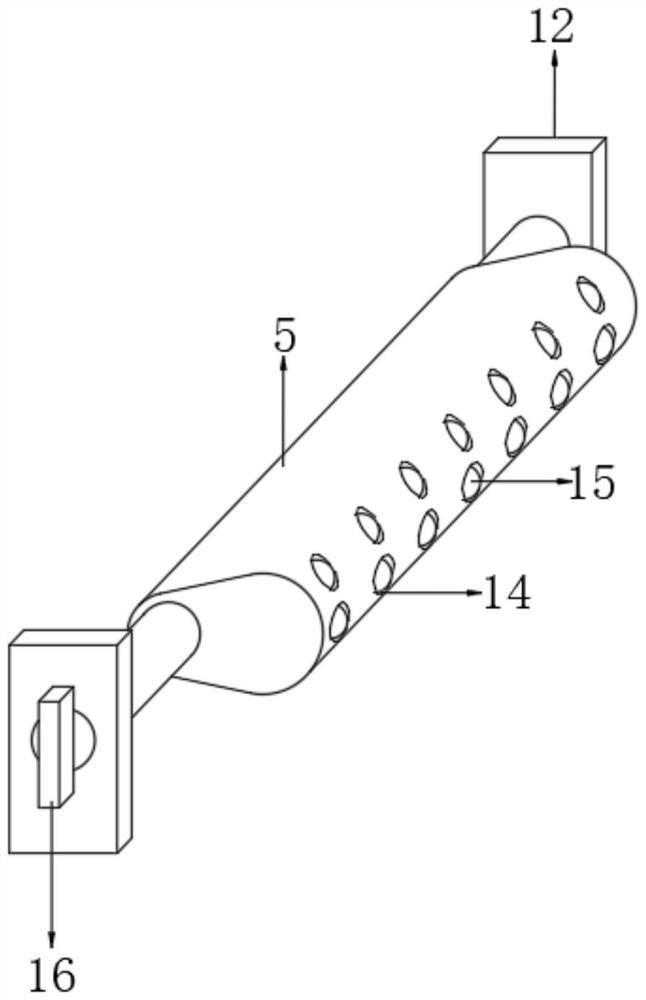

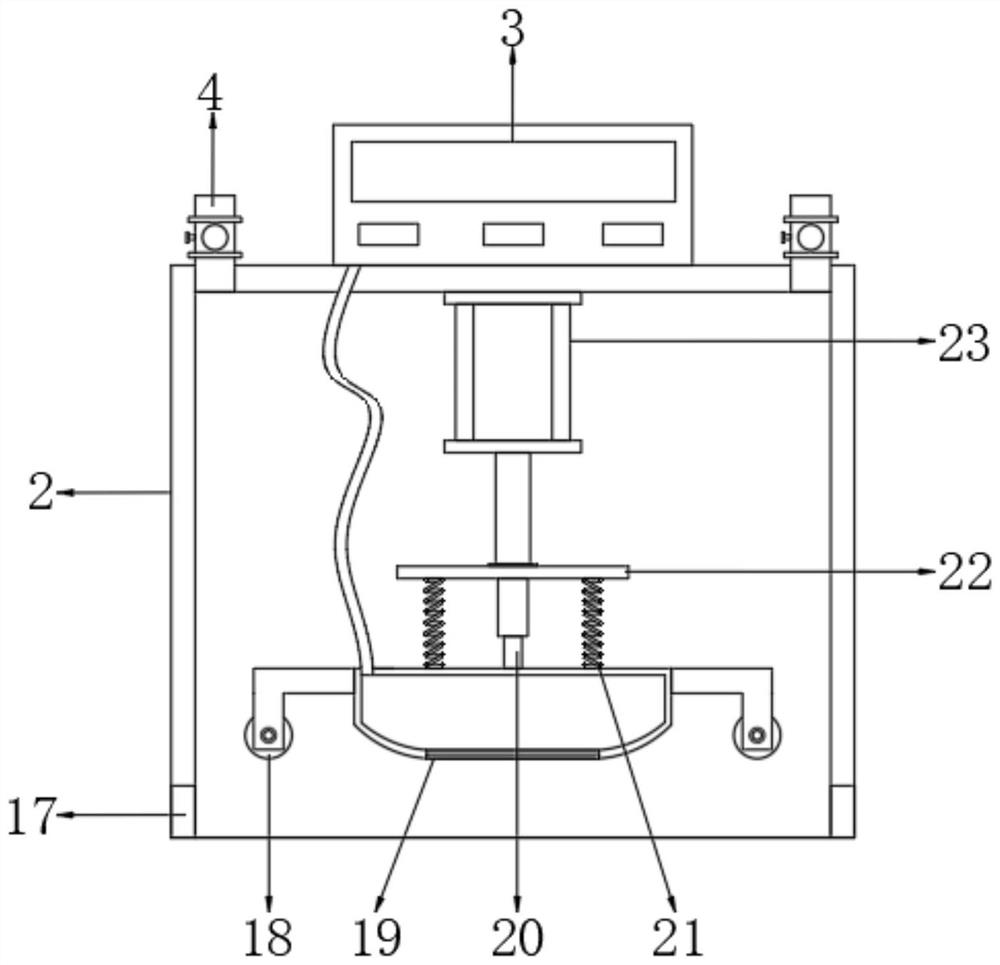

The present invention discloses a sample production apparatus and a sample production method of a layered rock-soil body sample. The sample production apparatus is characterized by comprising a first layer sample production device and a plurality of second layer sample production devices, wherein the first layer sample production device and the second layer sample production devices are movably connected, the first layer sample production device comprises a sample production base (1), universal cylinders (2) and an auxiliary cylinder (3), the sample production base (1), the universal cylinders (2) and the auxiliary cylinder (3) are sequentially and movably connected from bottom to top, the second layer sample production device comprises a sample production auxiliary top cover (9) and the two universal cylinders (2) arranged in an up-and-down manner, the sample production auxiliary top cover (9) and the two universal cylinders (2) are sequentially and movably connected from bottom to top, the connection surfaces of the movable connections are respectively provided with an annular concave groove (8), and O-shaped rubber gaskets (4) are arranged inside the annular concave grooves (8). According to the present invention, with the apparatus and the method, the densities of each layer of the rock-soil body sample can be accurately controlled, such that the accurate and reliable test result can be obtained when the unidirectional freeze thawing cycling test, the penetration test, the compression test and other tests of the layered rock-soil body sample are performed.

Owner:HOHAI UNIV

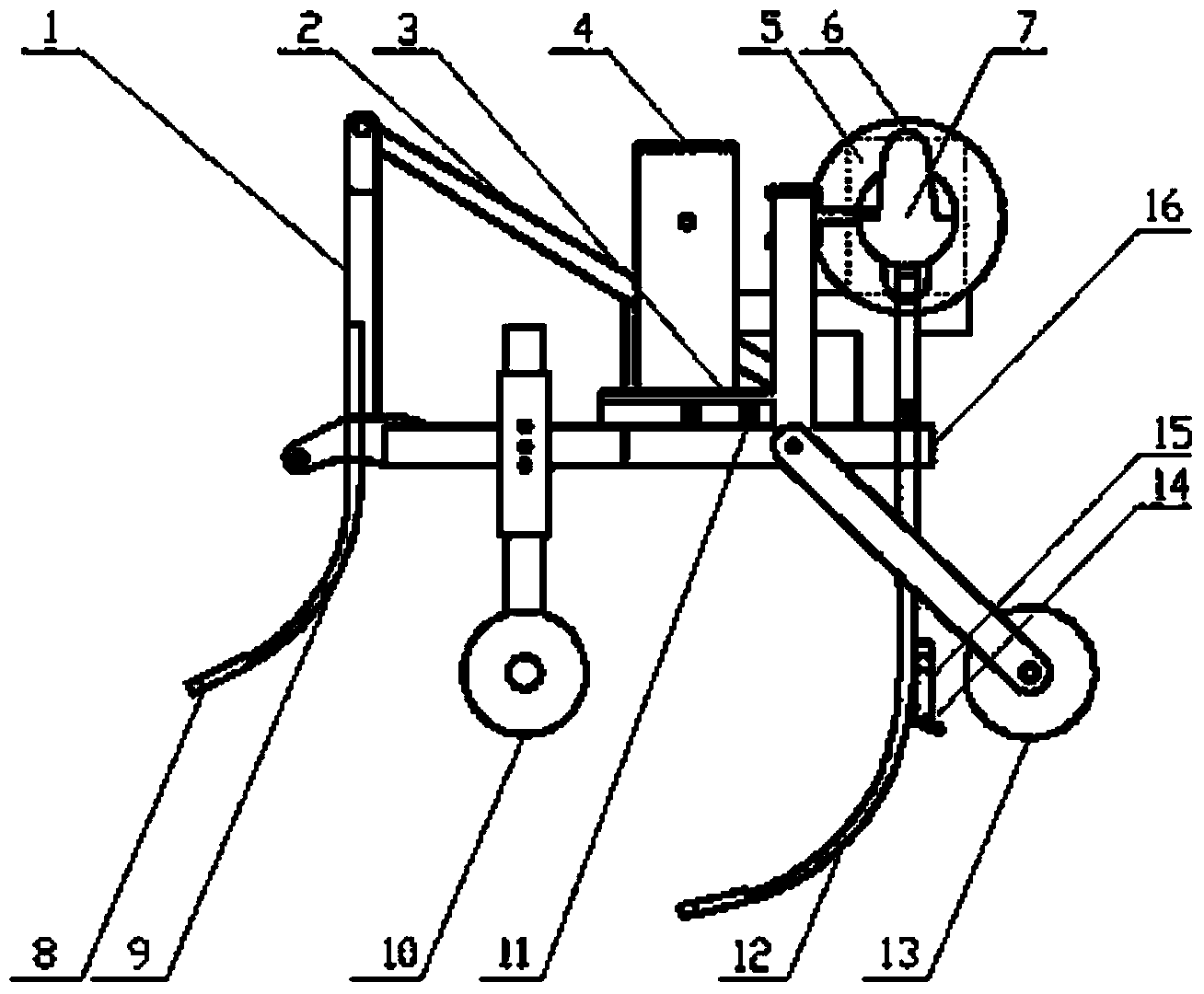

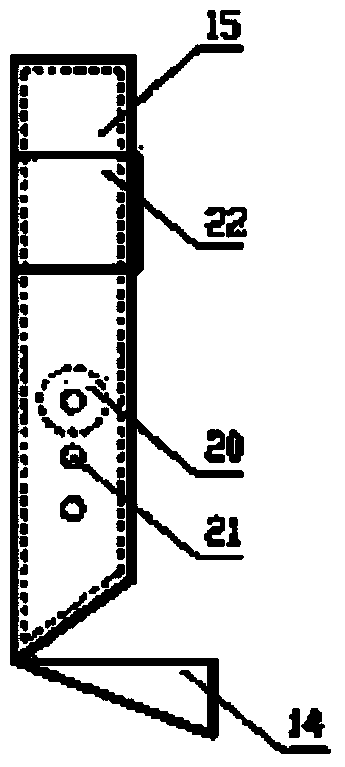

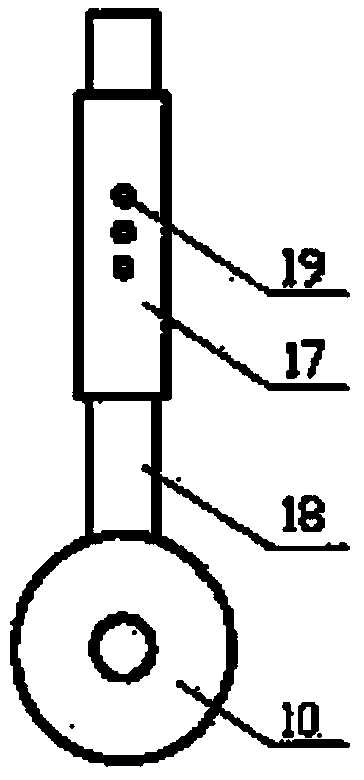

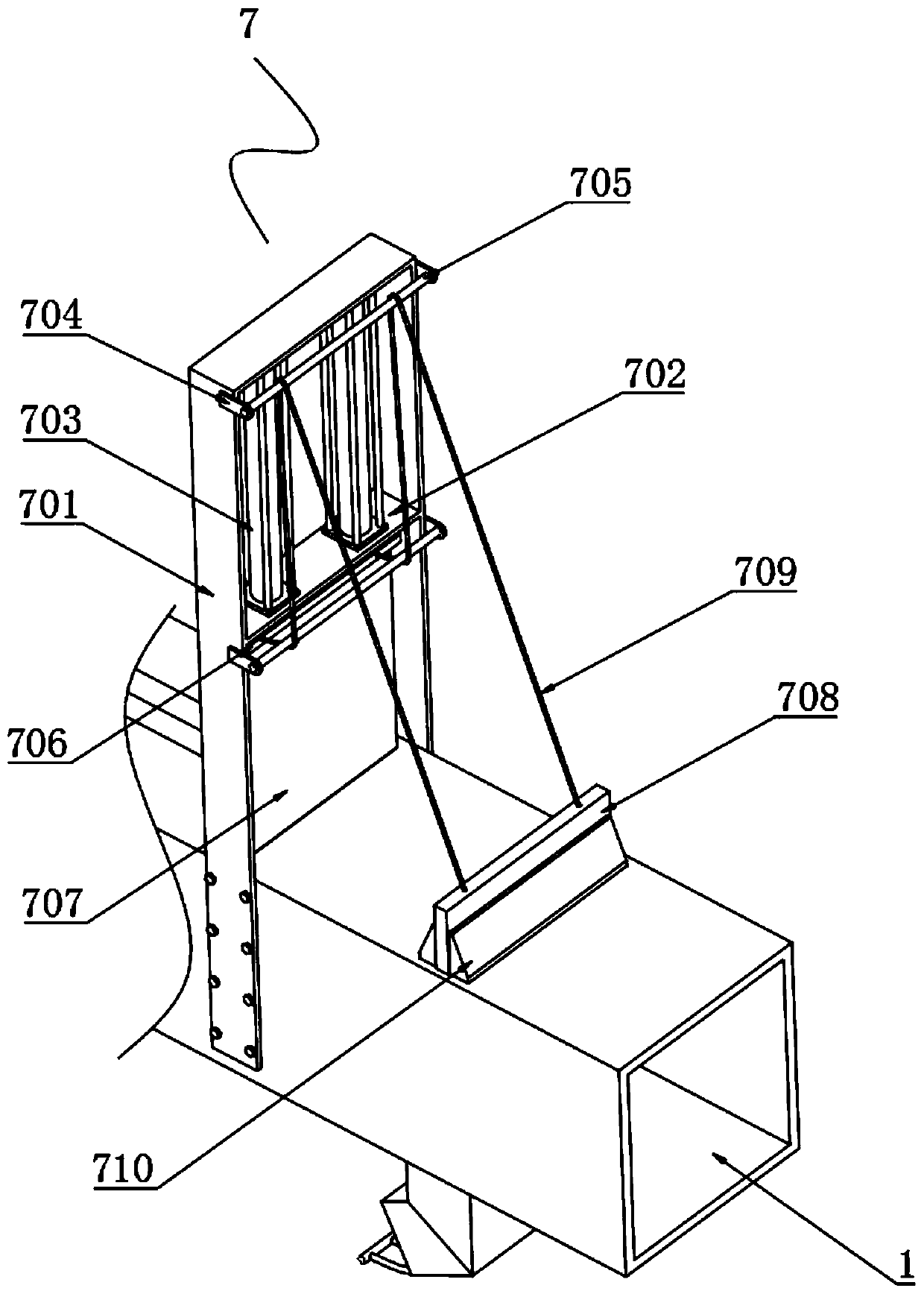

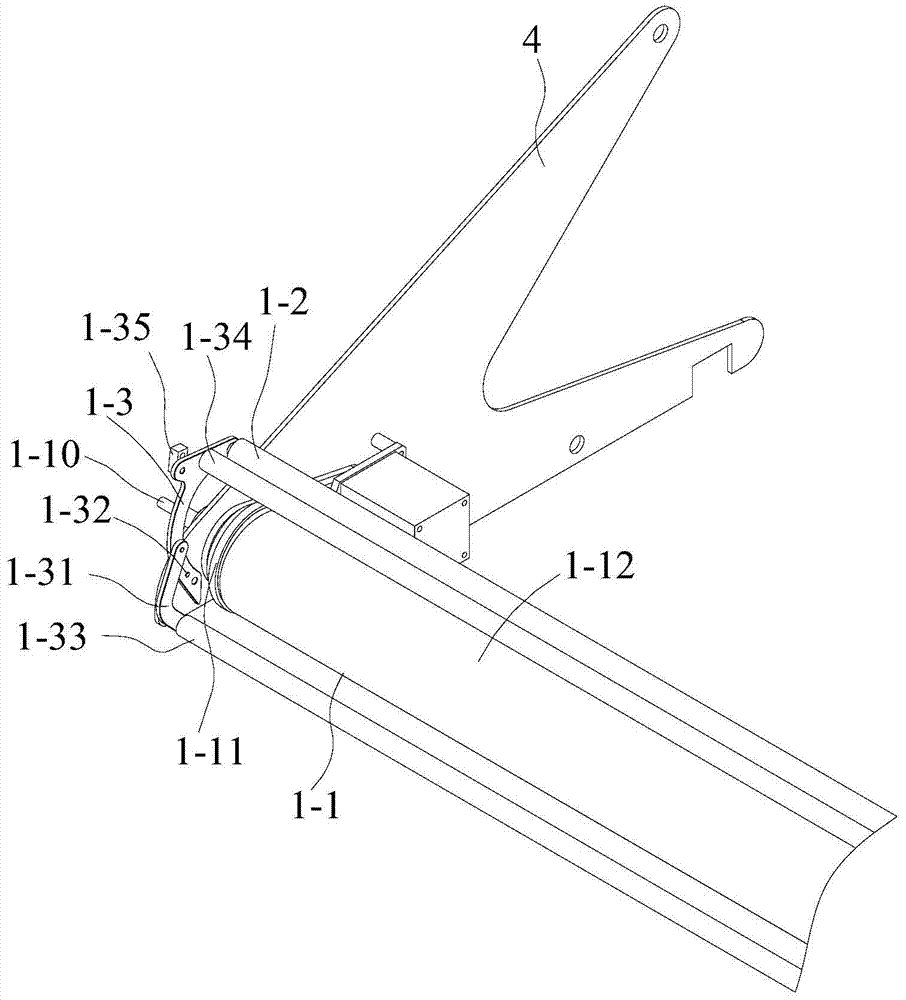

Alternate vibratory subsoiling and fertilizing all-in-one machine

InactiveCN103477741AAchieve loose but not overturned effectFully compactedSpadesPloughsAgricultural engineeringDepth limit

The invention discloses an alternate vibratory subsoiling and fertilizing all-in-one machine, which comprises a vibratory subsoiling device, a depth controller, a fertilizing device and a traction device, which are arranged on a rack; the traction device comprises a hanging support, the hanging support is arranged on the middle part of the front end part of the rack, a subsoiler of the vibratory subsoiling device comprises a half subsoiler, a full subsoiler and an alternate vibration generating device, the alternate vibration generating device comprises a plurality of groups of crank necks arranged on a rotating shaft at intervals, the back side of the full subsoiler is provided with a vertical fertilizer discharge pipe, the fertilizing device comprises a fertilizer box, a fertilizer outlet of the fertilizer box is connected with an inlet of the fertilizer discharge pipe through a hose, the depth controller is depth-adjustable depth-limiting wheels arranged on two sides of the rack, and two sides of the rack behind the depth-limiting wheels are provided with pressing wheels arranged at the hindmost part by virtue of a pull rod respectively. The all-in-one machine disclosed by the invention can be matched with a large / middle-sized tractor for use, dry land vibration subsoiling operation can be carried out, the production efficiency is high, the subsoiling effect is good, and the operation cost is low.

Owner:ANHUI AGRICULTURAL UNIVERSITY

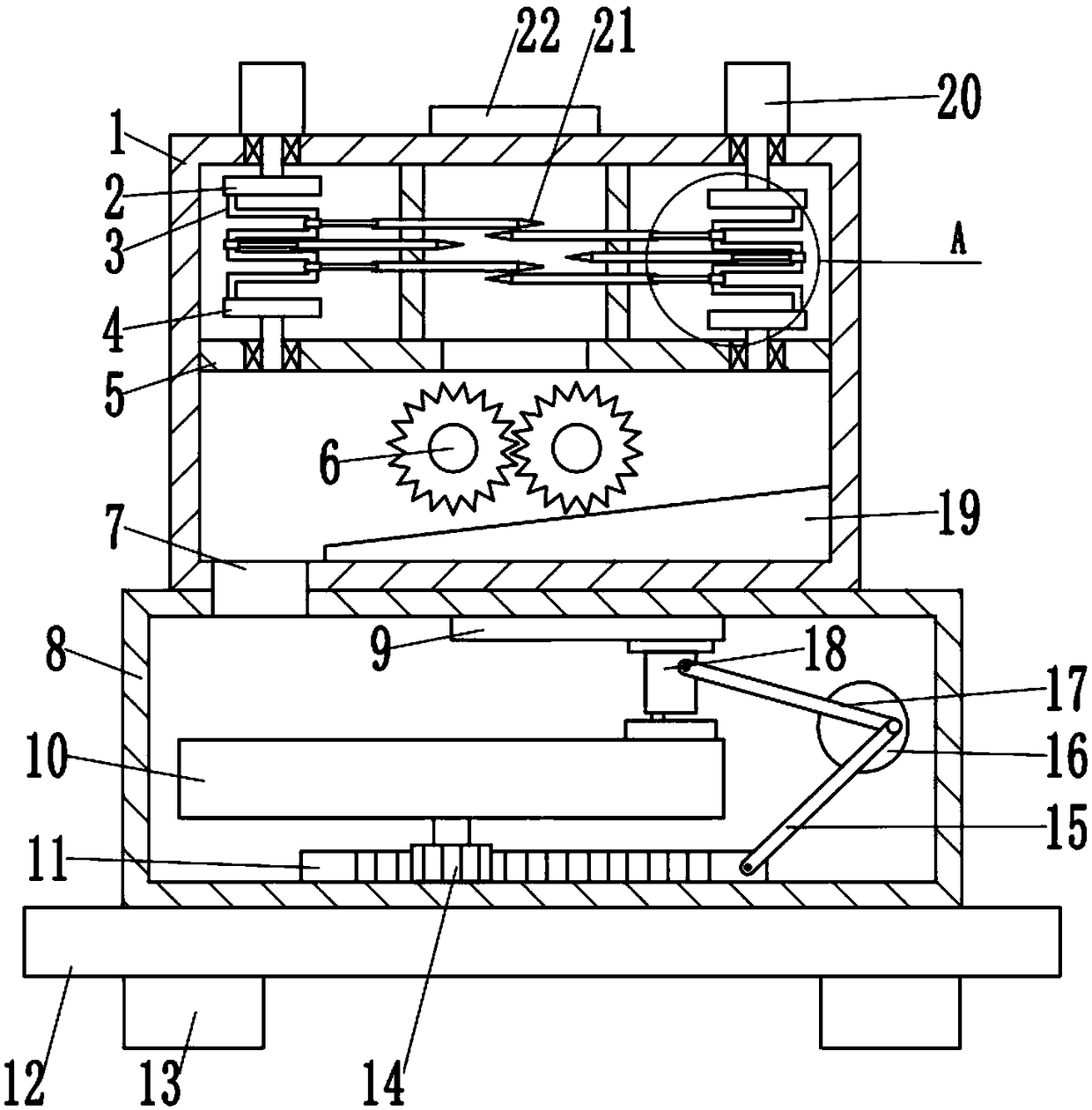

Agricultural corn straw recycling briquetting device

InactiveCN108055929AReduce wasteFully compactedCrop conditionersMowersAgricultural engineeringCorn stover

The invention discloses an agricultural corn straw recycling briquetting device. The device comprises a pulverizing case, a briquetting case, a briquetting box and a base; the pulverizing case is fixedly installed on the upper side of the briquetting case, the briquetting case is fixedly installed on the base, and the left side of the bottom of the pulverizing case is communicated with the interior of the briquetting case through a feeding port; a feeding inlet is formed in the top of the pulverizing case, a separation plate is fixedly installed in the pulverizing case, and the inside of the pulverizing case is separated into a primary pulverizing case and a fine-pulverizing case from top to bottom by the separation plate. According to the device, the pulverizing case and the briquetting case are arranged as an integrated structure, so that the amount of equipment is reduced, not only are operation of people facilitated and economic costs reduced, but also waste of straw is reduced totake the full advantage of straw resources, and meanwhile the straw are pulverized by arranging a plurality of cutter blades in a scattered mode, pulverizing shafts are arranged to perform pulverizingon the straw, so that the pulverizing effect is excellent.

Owner:王泽成

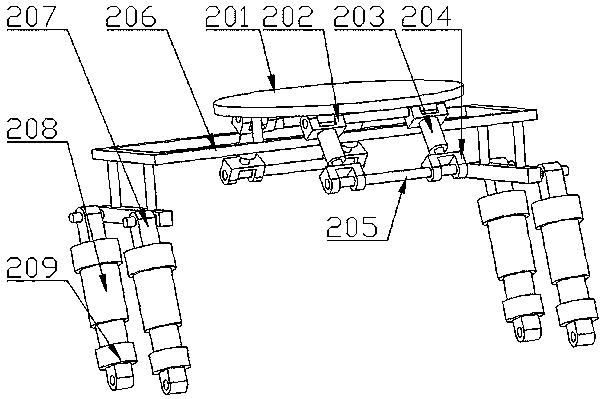

Floor tile laying robot for building construction

The invention discloses a floor tile laying robot for building construction. A main body of the floor tile laying robot is composed of a robot shell, a connecting part, a tile inlet part, a travelingpart, a cement part, a tile laying part and the like; the connecting part comprises a disc connecting part, a connecting frame and the like; the tile inlet part comprises a tile inlet shell, a tile transmission belt and the like; the traveling part comprises a traveling seat, a main transmission wheel, a traveling crawler and the like; and the cement part comprises a cement box, a cement frame andthe like; and the tile laying part comprises a tile pressing plate, a descending block and the like. During using, the robot travels to the place needing tile laying through the traveling part, thenthe posture of the robot is adjusted through the connecting part, floor tiles are conveyed to the tile laying part through the tile inlet part, the cement part smears cement on the ground well, and then the floor tiles are laid on the ground through the tile laying part.

Owner:泰安宝巨机械科技有限公司

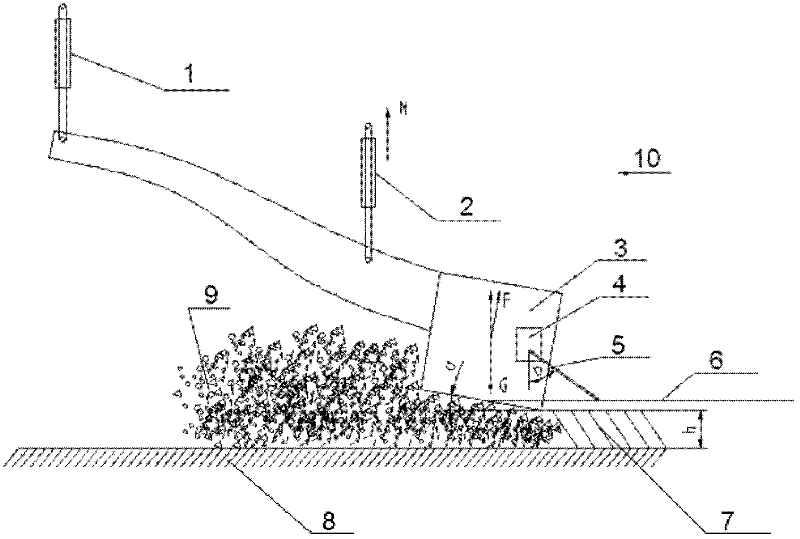

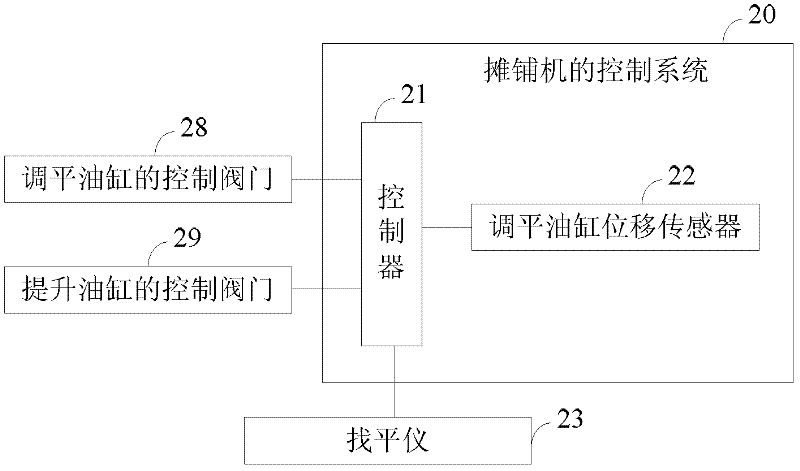

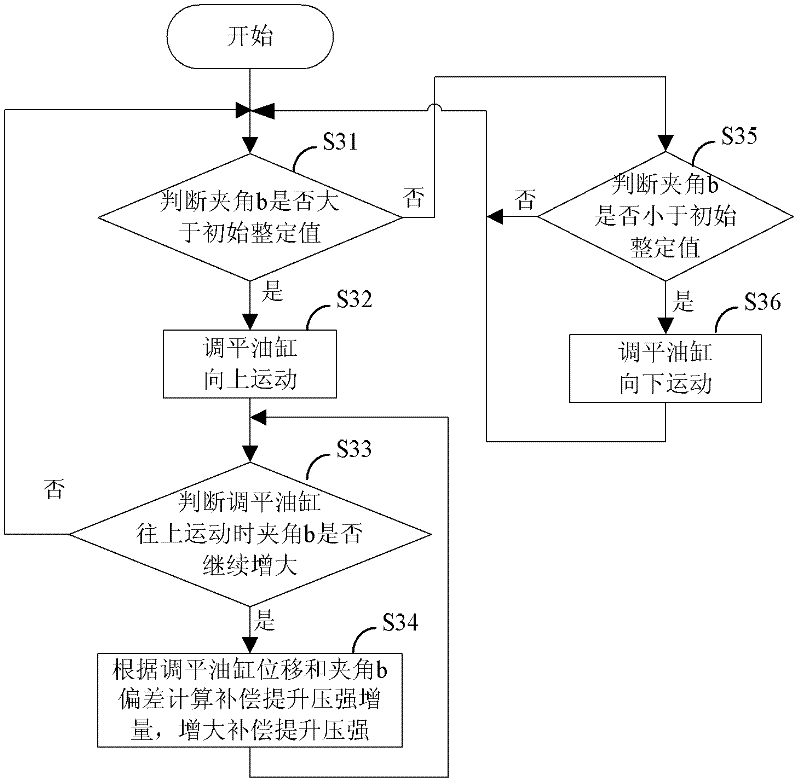

Paver as well as control method, device and system thereof

The invention provides a paver as well as a control method, device and system thereof which are used for solving the problems of insufficient compactness and flatness of the formed pavement under the condition that aggregates can not support a screed of the paver in the prior art. The method comprises: in the working process of the paver, when a leveling cylinder of the paver moves upwards, the included angle between a sensing arm of a leveling instrument of the paver and the vertical direction is increased and the compensated lift pressure increment of a lift cylinder is computed according to the difference between the current displacement of the leveling cylinder and the displacement of the leveling cylinder at the time of recent stabilization and the difference between the included angle and the predetermined setting value of the included angle; and the compensated lift pressure of the lift cylinder is increased according to the compensated lift pressure increment so as to control the lift cylinder of the paver to move upwards. By utilizing the technical scheme of the invention, the paver and the control method, device and system are beneficial to improvement of the compactness and flatness of the formed pavement.

Owner:ZOOMLION HEAVY IND CO LTD

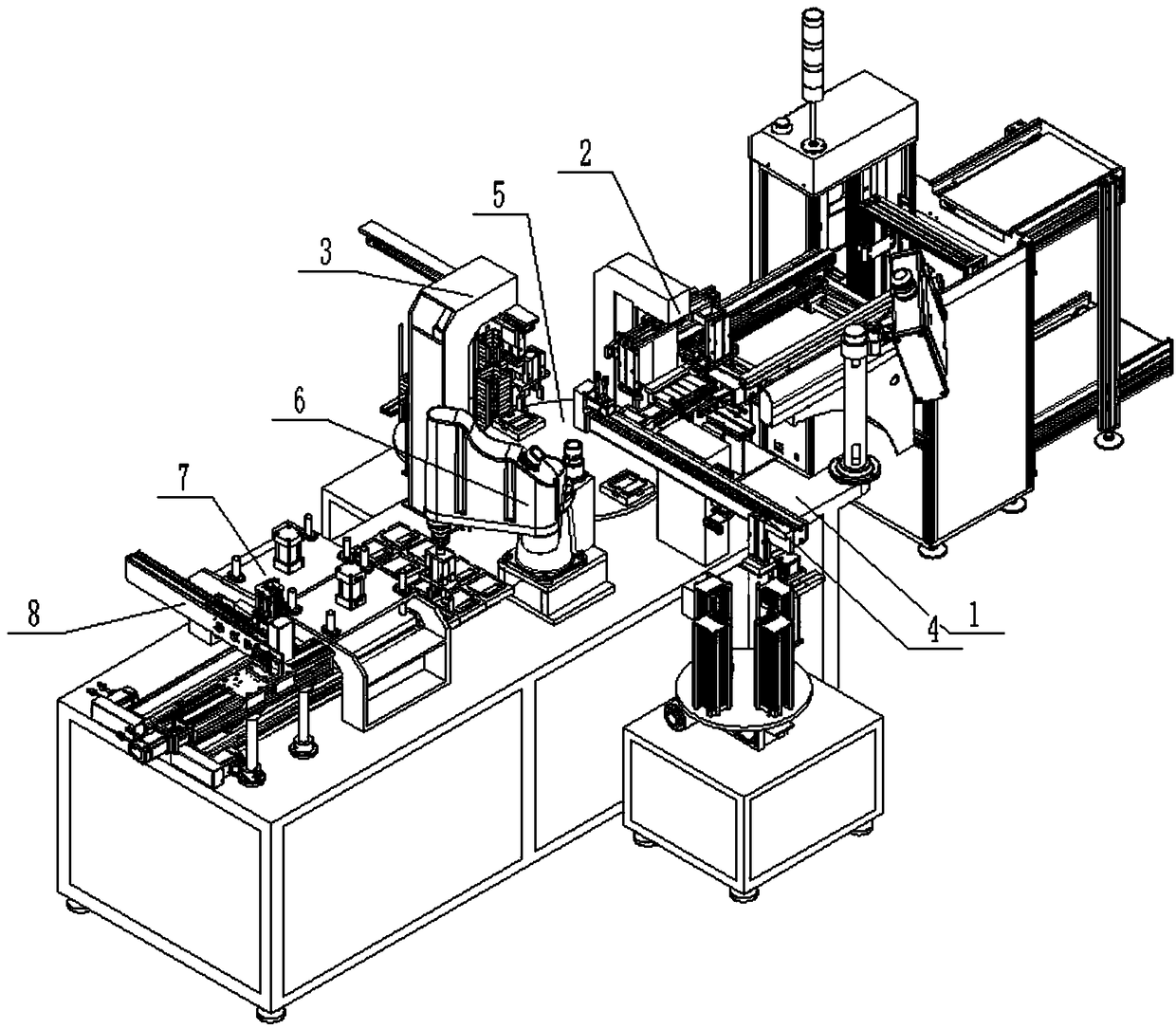

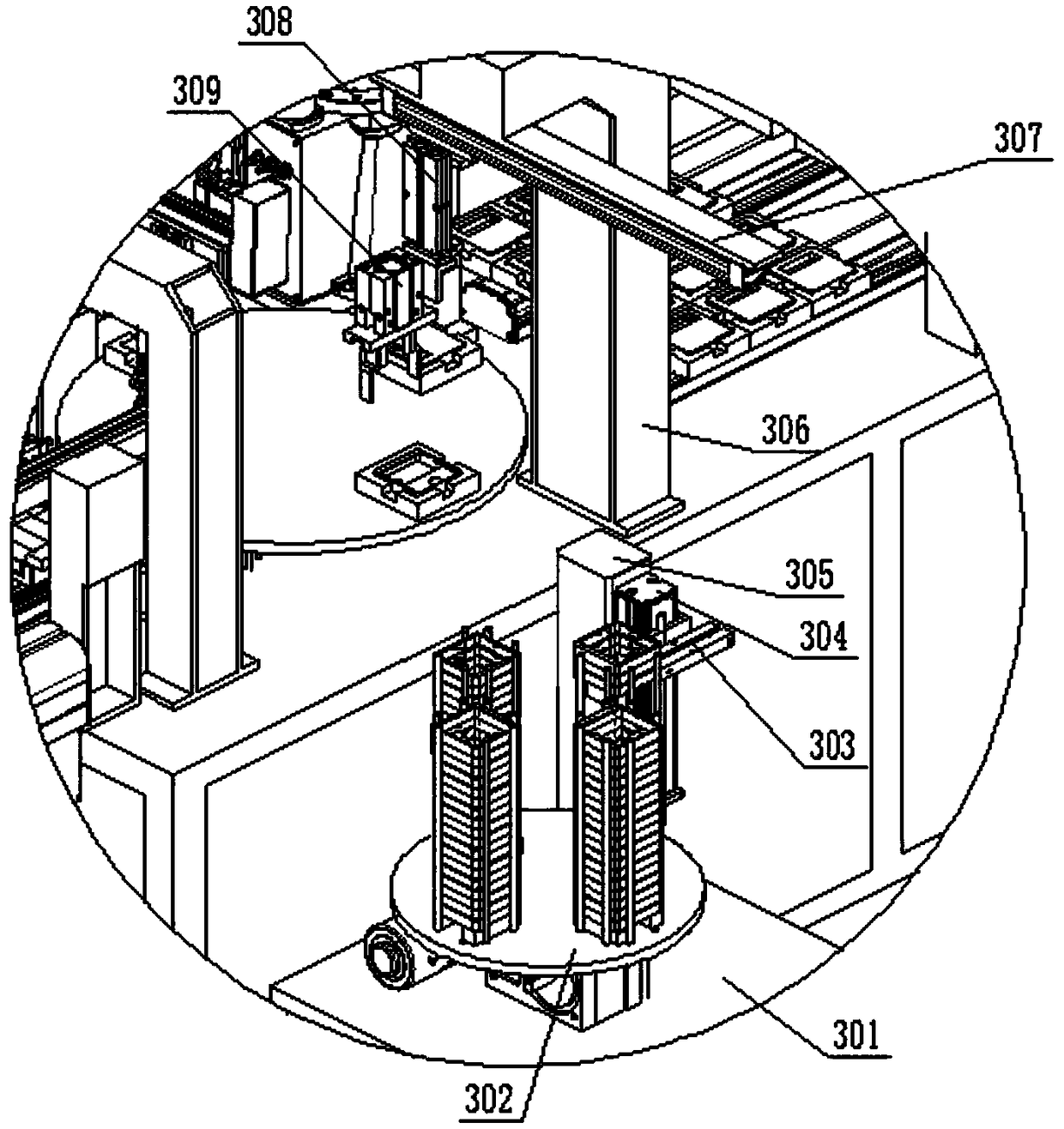

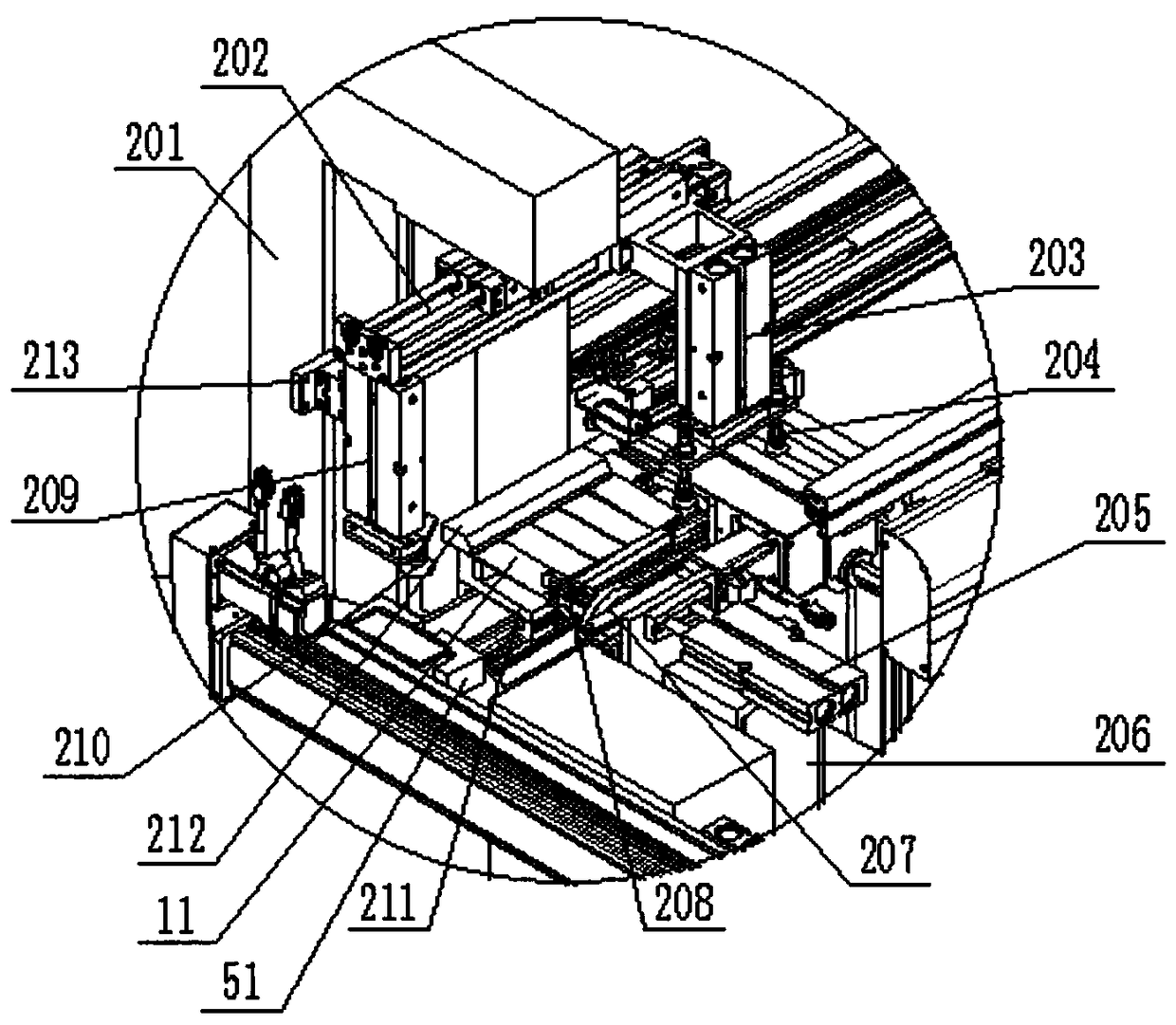

Faceplate assembly line

PendingCN108890291AIncrease productivityGuarantee product qualityAssembly machinesMetal working apparatusGrippersPrinted circuit board

Owner:山东红宝自动化有限公司

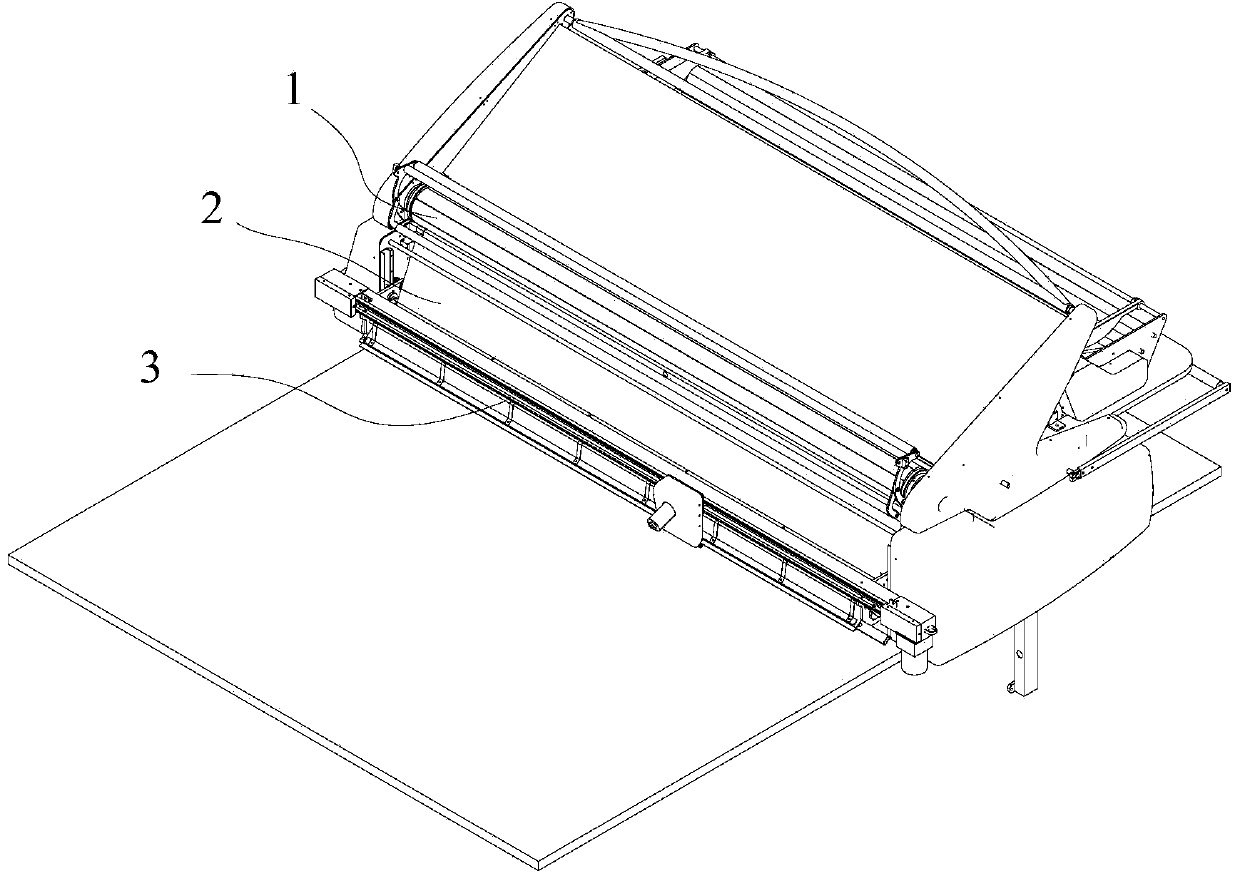

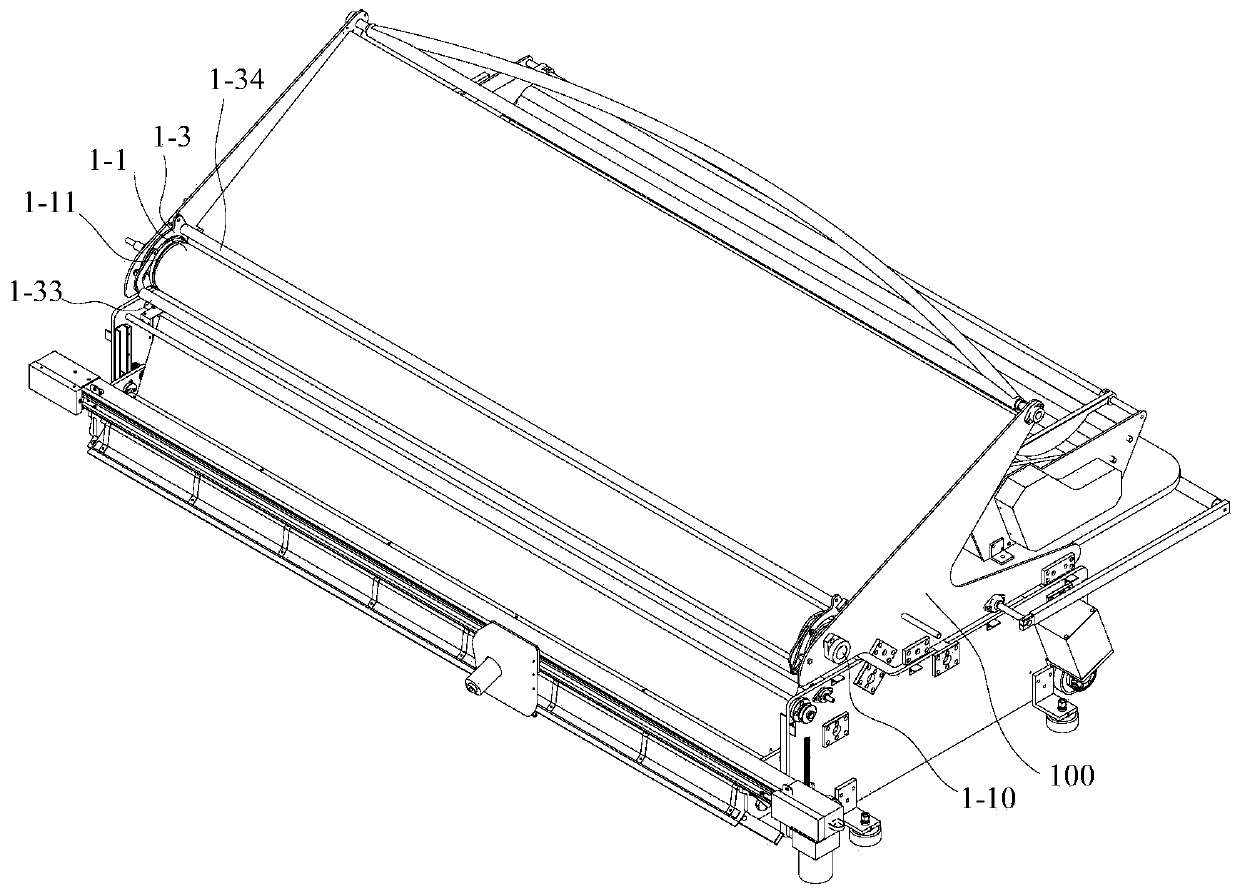

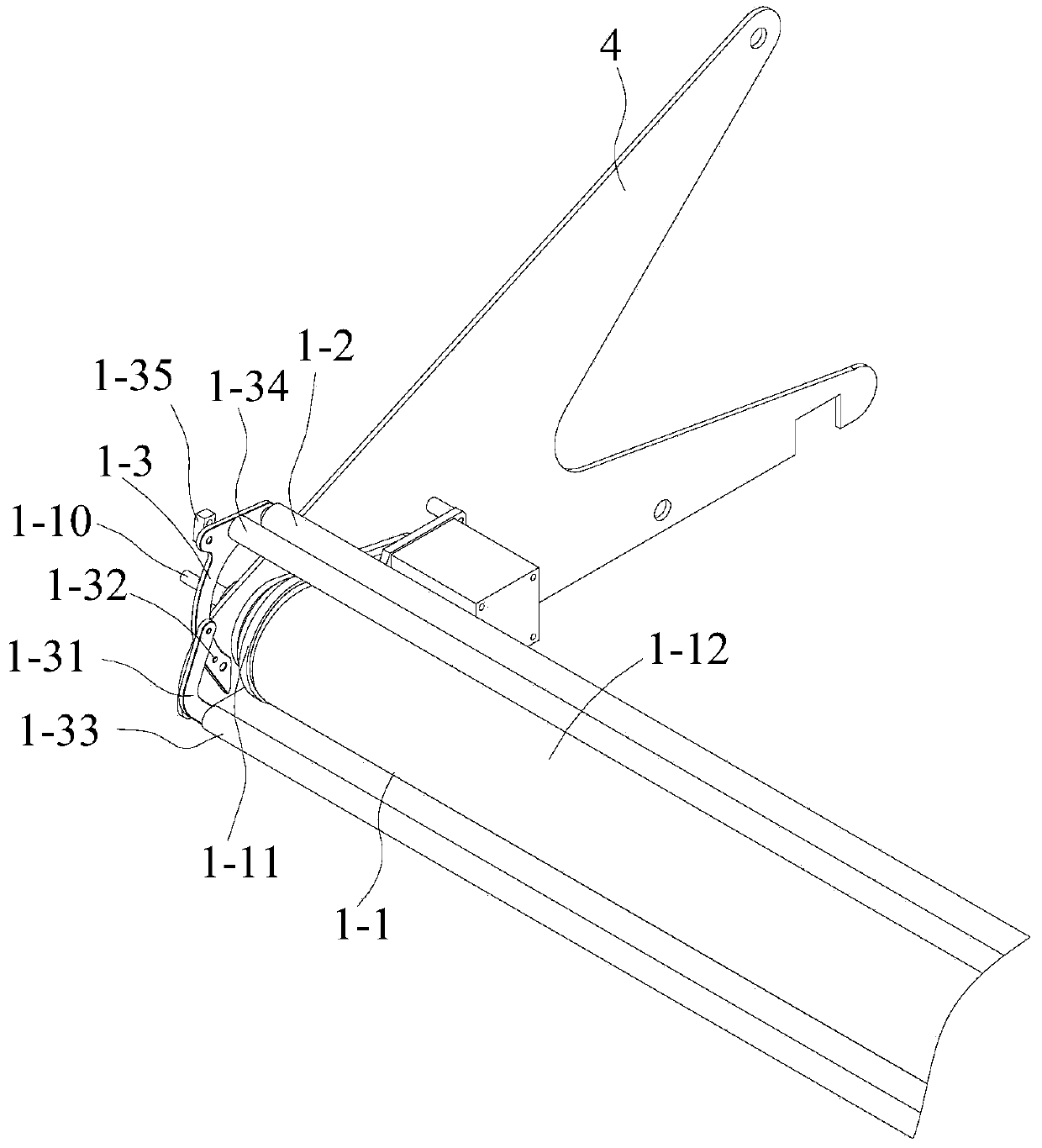

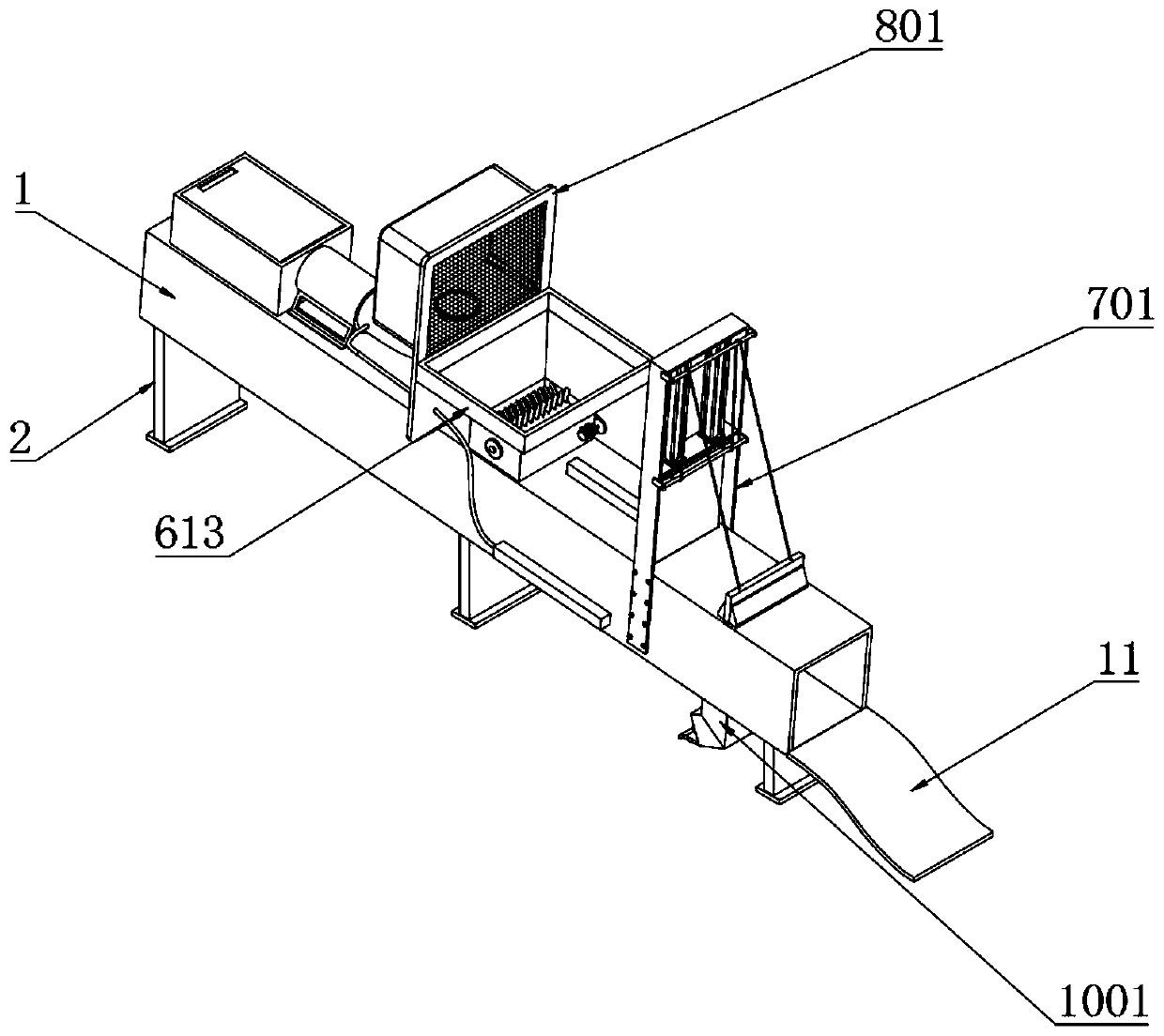

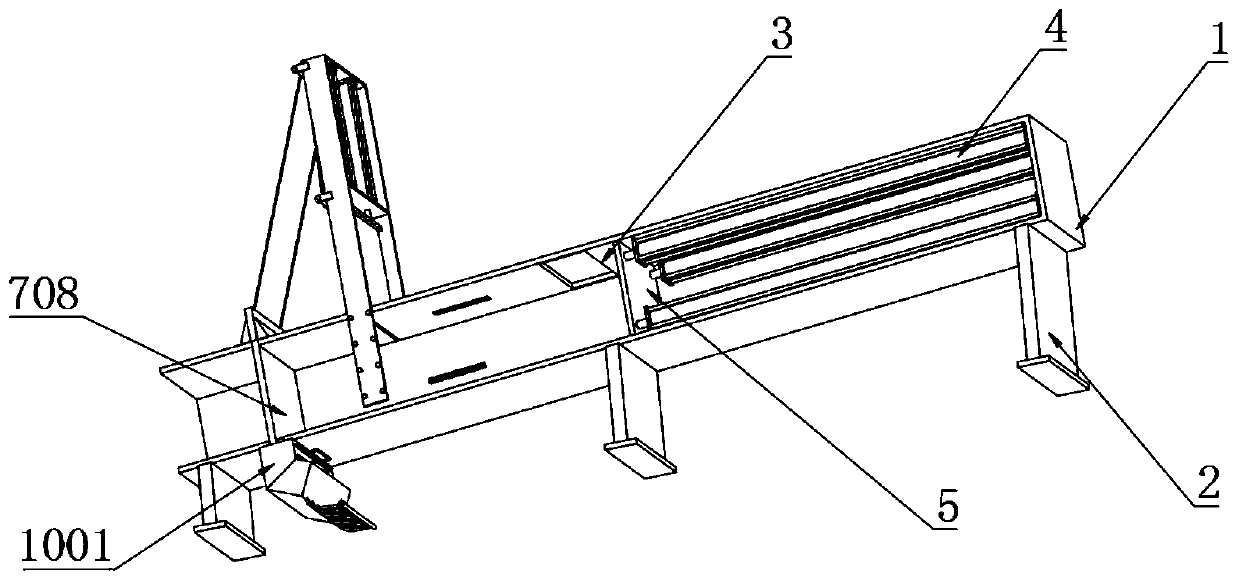

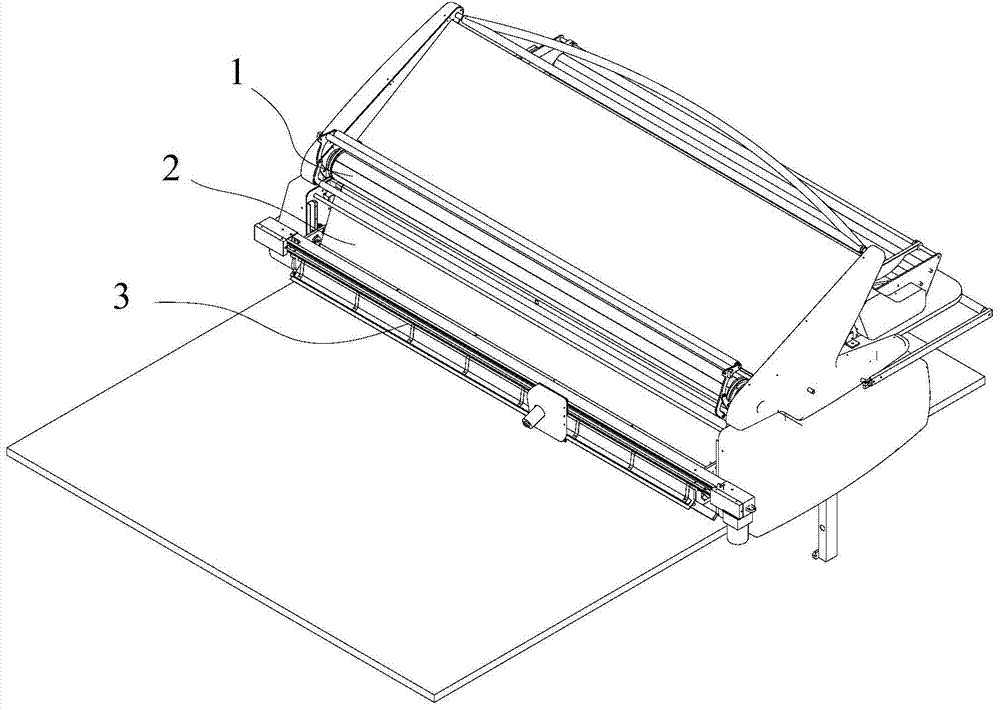

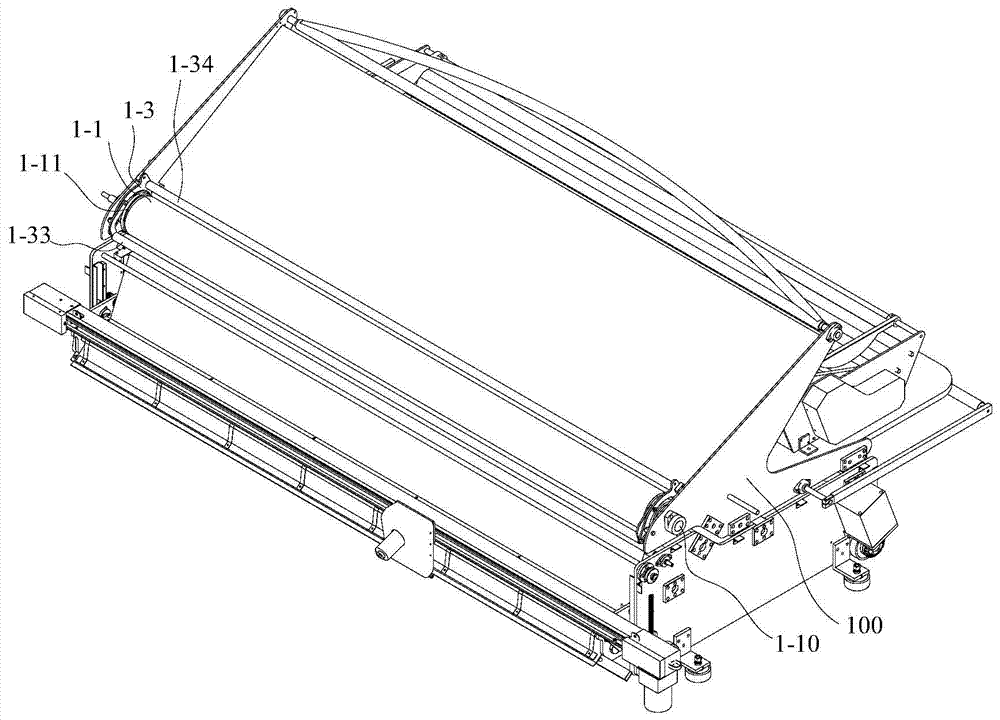

Cloth paving machine

ActiveCN104192632AFully compactedUniform tensionUnfolding thin materialsArticle deliveryAutomotive engineering

The invention discloses a cloth paving machine which comprises a cloth paving machine cloth pressing and conveying device, a cloth paving machine wind shielding device and a cloth paving machine cutting device. The cloth paving machine cloth pressing and conveying device comprises a conveying roller and a pressing roller. The cloth paving machine wind shielding device comprises a wind shielding film, a wind shielding film first roller and a wind shielding film second roller. The cloth paving machine cutting device comprises an output roller, a cloth falling plate, a horizontal moving mechanism and a cutter assembly. The cloth paving machine has the advantages of being capable of comprehensively improving all the performance of the cloth paving machine.

Owner:HEFEI AORUI DIGITAL CONTROL SCI & TECH

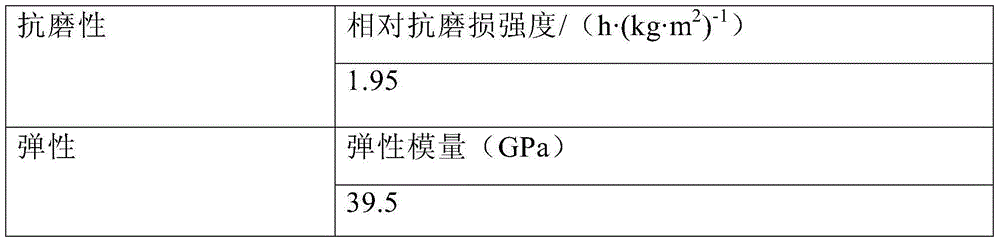

Road patching material with favorable elasticity and abrasion resistance and application thereof

The invention relates to a road patching material with favorable elasticity and abrasion resistance and application thereof. The road patching material comprises the following components in percentage by weight: 30-60% of tailing, 20-40% of cement, 5-30% of modified adhesive and 0.5-10% of rubber granule. The road patching material has the advantages of favorable abrasion resistance and favorable elasticity.

Owner:北京元泰达环保科技有限公司

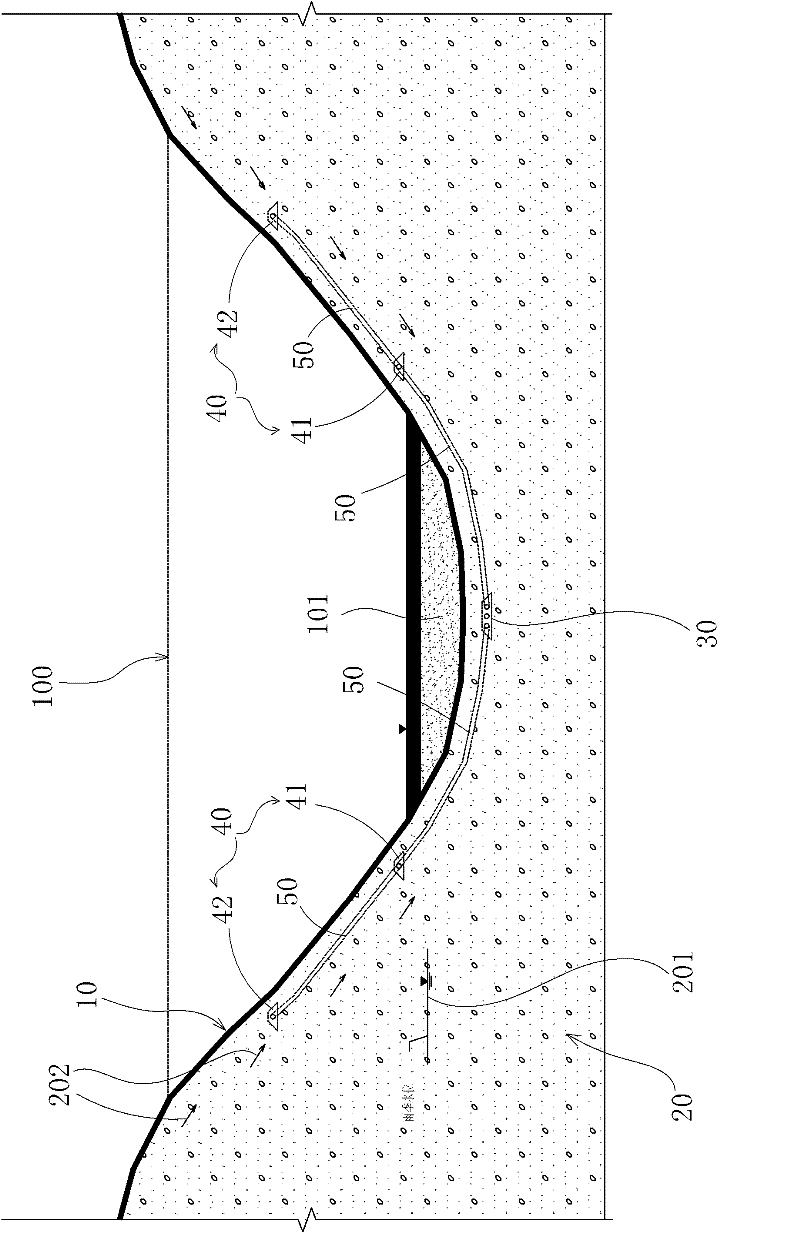

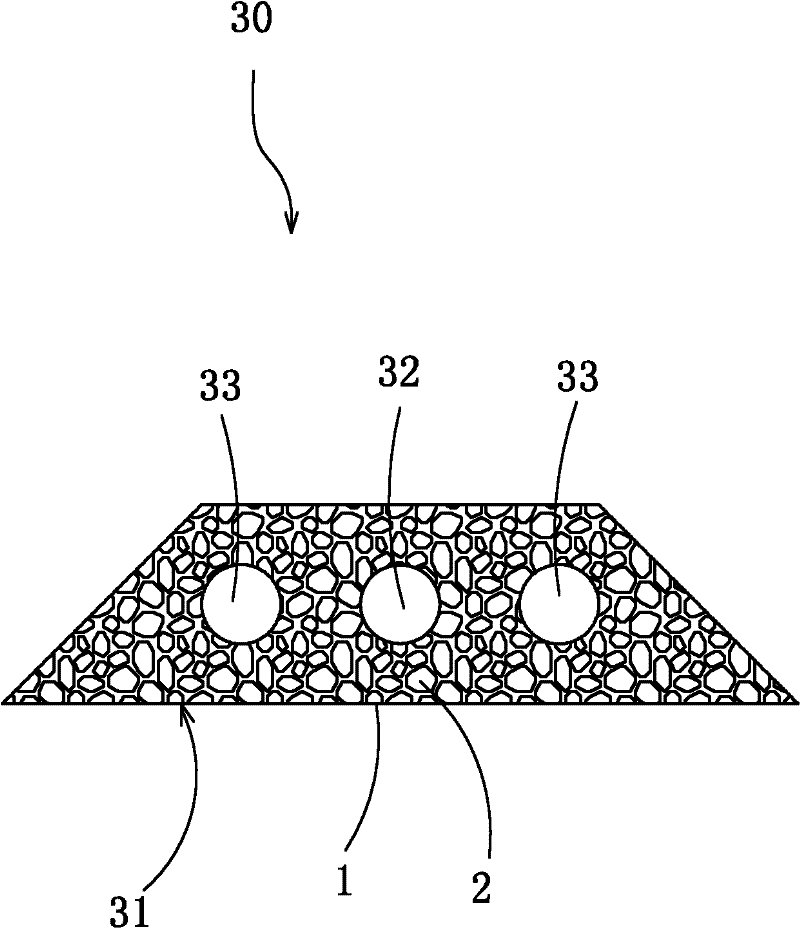

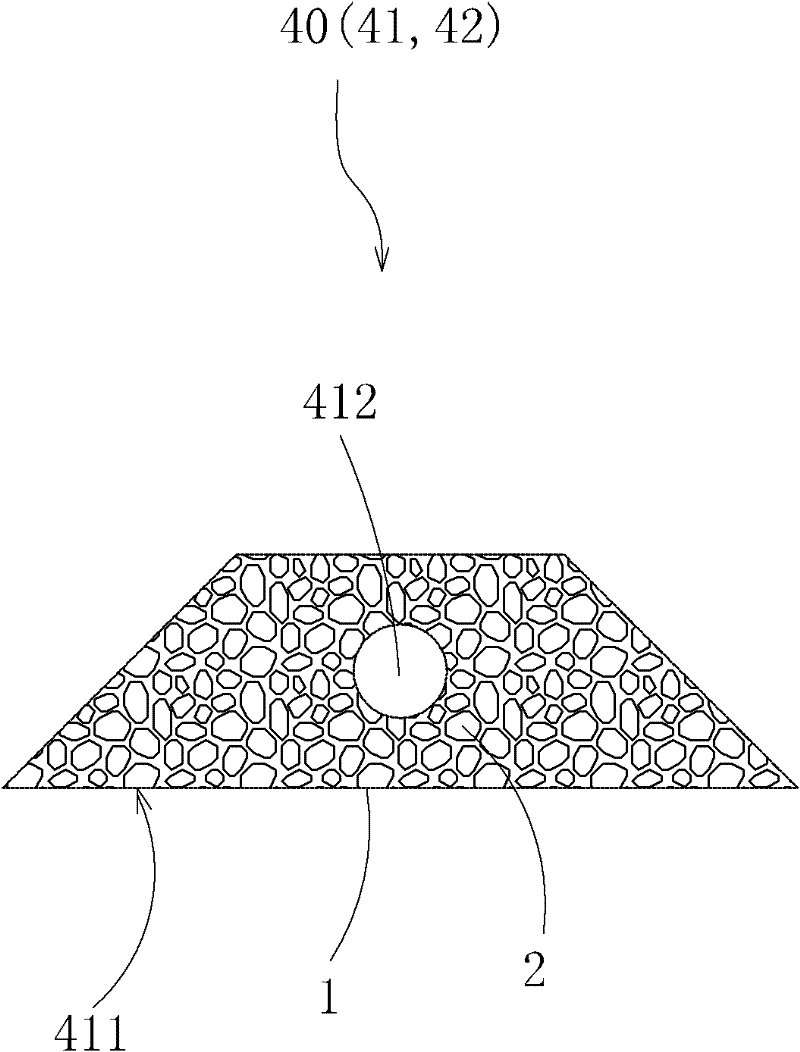

Underground water guiding and draining system under impermeable membrane of industrial waste residue storage yard

InactiveCN102182208AJacking uplift preventionAvoid bumpingSewerage structuresProtective foundationLeaking waterSolid wall

An underground water guiding and draining system under an impermeable membrane of an industrial waste residue storage yard is arranged in a mountain body (20) below a impermeable membrane (10) in a storage yard, and comprises a main guiding-leaking blind ditch (30), a branch guiding-leaking blind ditch (40) and a water guiding blind ditch (50), wherein the main guiding-leaking blind ditch is arranged at the lowest position of a valley, and the length of the main guiding-leaking blind ditch extends to the downstream of the storage yard along the tail end of the storage yard; the branch guiding-leaking blind ditch is arranged by surrounding the storage yard along the hillside surrounding the storage yard, a plurality of leaking water grooves for containing water leaking from the hillside are arranged on a guiding-leaking pipe in the branch guiding-leaking blind ditch, and a water outlet is arranged at one end of the branch guiding-leaking blind ditch positioned at the downstream of the storage yard; and the branch guiding-leaking blind ditch and the main guiding-leaking blind ditch are communicated with each other by a plurality of water guiding blind ditches or solid-wall HDPE (High-Density Polyethylene) water guiding pipes, which are arranged at intervals. The underground water guiding and draining system forms spider net shape under the impermeable membrane of the waste residue storage yard, so that underground water can be drained effectively, the support force on the impermeable membrane caused by underground water can be reduced, the upheaval and cracking of the impermeable membrane can be prevented, so that the completeness of the impermeable membrane can be kept, and the impermeable function of the impermeable membrane can be guaranteed.

Owner:中城建胜义(深圳)环境科技有限公司 +2

Barrier-free base construction method for urban roads

ActiveCN104652238AFully compactedTight compactionArtificial islandsUnderwater structuresRoad traffic controlSocial benefits

The invention discloses a barrier-free base construction method for urban roads. The construction process of the barrier-free base construction method comprises the following steps: preparation before construction, construction-parameter determination, spreading, rolling, treatment of an inspection well, joint treatment, maintenance and traffic control. The barrier-free base construction method disclosed by the invention has the advantages that the construction is convenient, and the construction effect is good; the same height of the inspection well and a road bed in spreading is ensured, so that no barrier exists on the road in spreading; simultaneously, the continuous supplying is adopted, so that the construction efficiency is greatly improved; the adopted technology is advanced, the safe and reliable effects can be achieved, and the economic benefit and the social benefit are obvious, so that the barrier-free base construction method is worthy of being promoted and applied.

Owner:无锡市市政设施建设工程有限公司

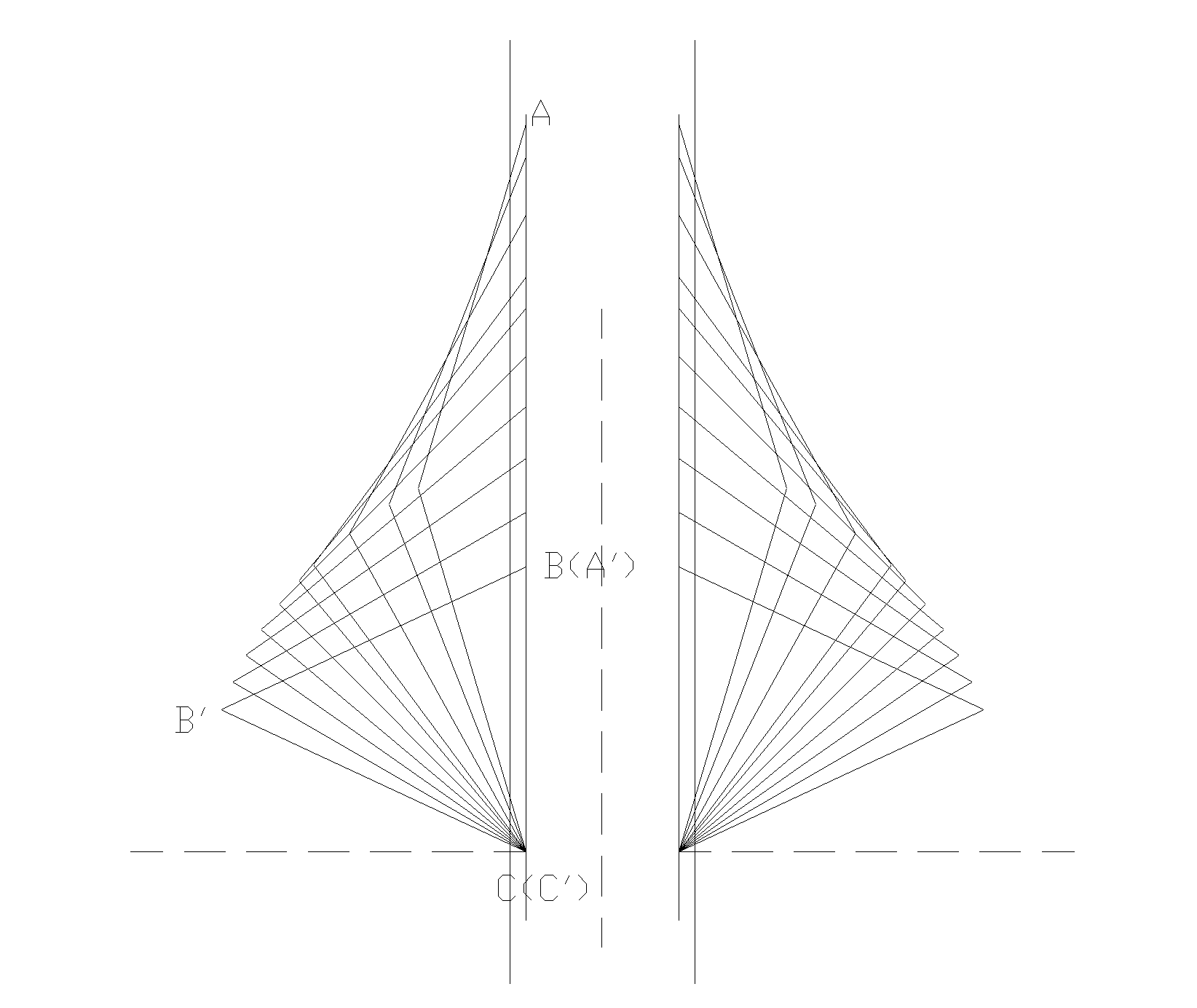

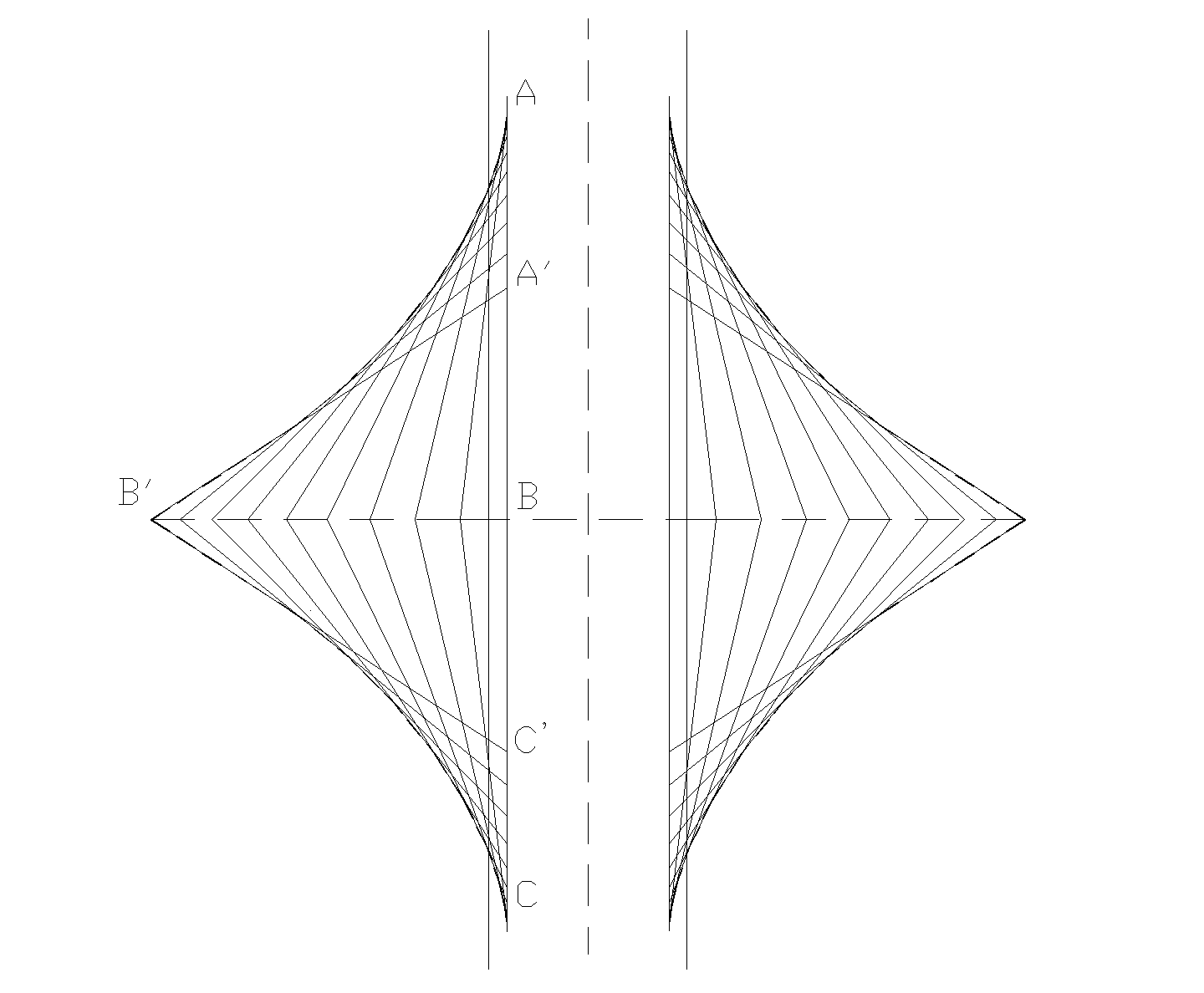

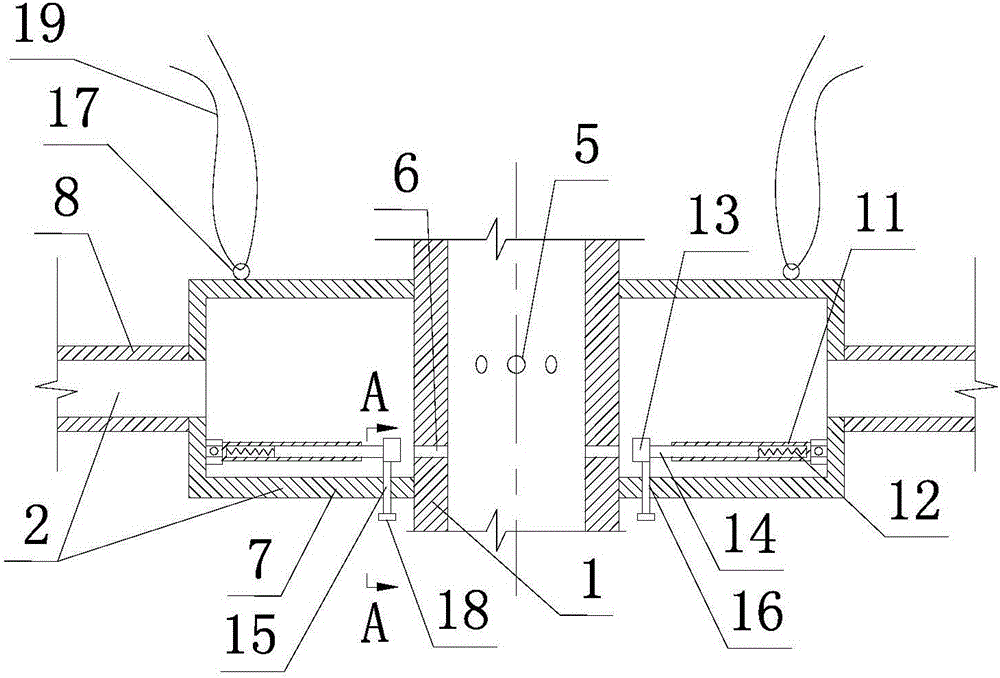

Extruding-expanding device and method for pile foundation

The invention relates extruding-expanding device and method for a pile foundation. The device comprises a supporting device and an extruding-expanding arm connected with the supporting device, wherein the extruding-expanding arm comprises a telescopic expanding arm. The extruding-expanding device and method for the pile foundation overcome the defects of a single-cylinder one-way extruding-expanding device and a double-cylinder two-way extruding-expanding device and prevent the soil mass from falling in an arm with a box-shaped section; the telescopic extruding-expanding arm always contacts the soil mass, and the soil mass is fully compacted; the horizontally-projected area of an extruded disk cavity is larger; and the bearing capacity of an extruding-expanding pile is larger.

Owner:李征 +2

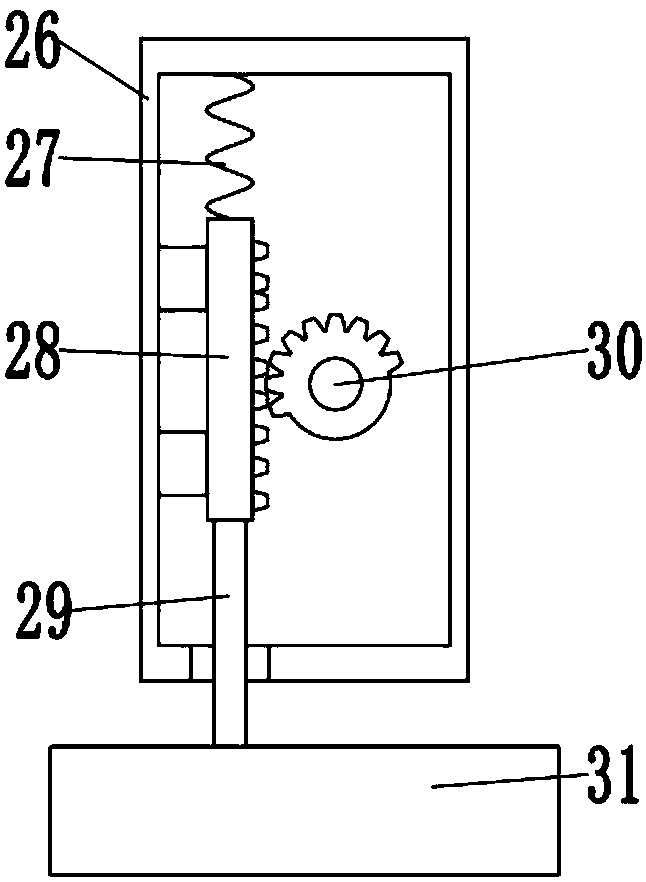

Carton compacting device for environmental protection

The invention relates to a carton compacting device, in particular to a carton compacting device for environmental protection. The carton compacting device for environmental protection aims to achieve the technical effects of being environmentally friendly, free of pollution, simple in structure and capable of achieving full compacting. The carton compacting device for environmental protection comprises a baffle, a first sliding rail, a first sliding block, a spring, a steel ball, a pressing plate, a guide plate, a pull rod, a moving frame, a compacting box, a right frame, a rack, a support, a second sliding rail and the like. The first sliding block is arranged on the first sliding rail. The baffle is arranged on the left side of the first sliding rail. The baffle is provided with the spring. The steel ball is connected with the upper side of the spring. The moving frame is connected to the first sliding block. The bottom of the left side of the moving frame is provided with a groove. The groove is matched with the steel ball. The carton compacting device for environmental protection achieves the effects of being environmentally friendly, free of pollution and simple in structure and conducting full compacting. The carton compacting device for environmental protection is light, handy, convenient to use and capable of compacting waste cartons to the greatest extent.

Owner:中山市美易达包装有限公司

Foundation reinforcement device and method

InactiveCN106120706AImprove bearing capacityFully compactedBulkheads/pilesSoil preservationStructural engineeringSlurry

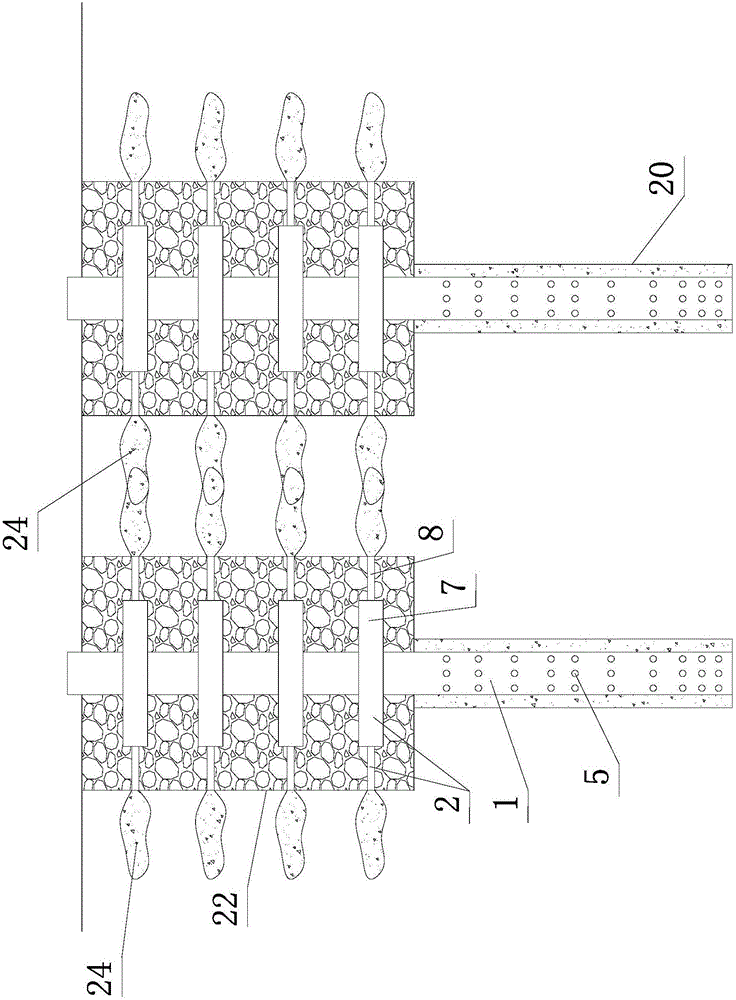

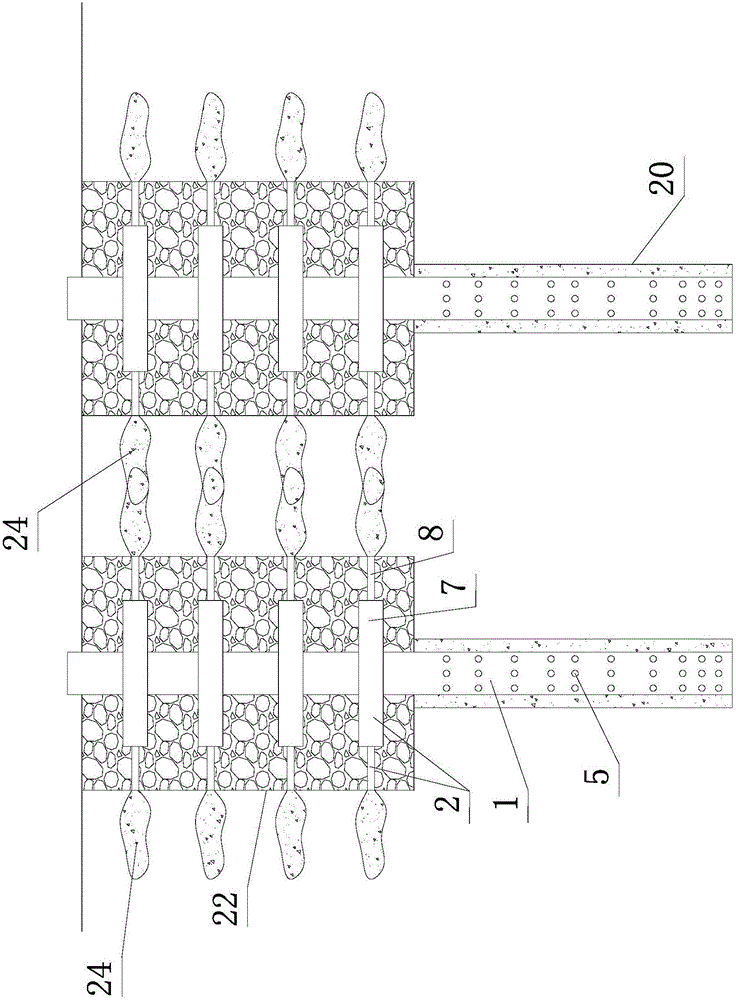

The invention discloses a foundation reinforcement device and method. The foundation reinforcement device comprises a floral pipe (1) and a plurality of grouting discs (2). The floral pipe (1) is provided with a plurality of circles of grouting holes (5) with different layer heights and is further provided with locating holes with different layer heights. Each grouting disc (2) comprises a hollow disc body (7) and a plurality of grouting conduits (8). All the grouting conduits (8) are located on the side walls of the hollow disc bodies (7) correspondingly. Each hollow disc body (7) is provided with a locating assembly used for achieving locating with the corresponding locating holes in the floral pipe (1). The key of the reinforcement method lies in that after layer-by-layer filler filling and tamping, the grouting discs (2) are put in, during final grouting, slurry liquid enters the grouting discs (2) through the floral pipe (1) and then enters a soil body around an enlarging hole (22) through the grouting conduits (8) to form nodular concrete (24), and nodular concrete (24) of different pile bodies achieve mutual crosslinking. Through the foundation reinforcement device and method, the areas between piles can be reinforced effectively.

Owner:浙大宁波理工学院资产经营有限公司

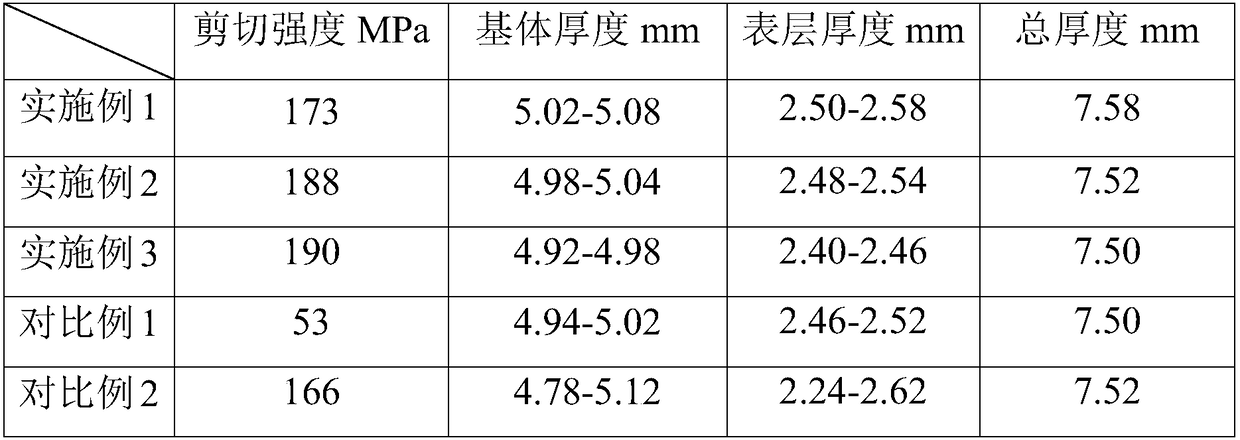

Preparation method for powder sintering material

ActiveCN108097973AHigh bonding strengthFully compactedTurbinesOther manufacturing equipments/toolsBLENDER/MIXERHigh pressure

The invention discloses a preparation method for a powder sintering material. The preparation method comprises the following steps that a matrix and a surface layer raw material are weighed accordingto the formulation requirement; the matrix and the surface layer raw material are added into a blender mixer to be fully mixed, anda matrix mixture and a surface layer mixture are obtained; a matrix green body is pressed and made, and then a surface layer green body is pressed and made; and the matrix green body and the surface layer green body are sequentially placed in a forming mould for beingpressing into a pressing blank, andthe pressing blank is placed into a sintering furnace for sintering to obtain the powder sintering material. According to the preparation method for the powder sintering material, the forming process is divided into pre-pressing forming and re-pressing forming, the matrix green body and the surface layer green body are pressed in the pre-forming mould by using low pre-pressure, during pre-pressing pressing, powder flows to make the surface of the green bodies become smooth, and the green bodies with the even thickness are obtained in a pressedmode; and then high pressure is used to pressing the green bodies into the pressing blank, and due to the fact that re-pressing pressure is greater than the pre-pressing pressure, during re-pressing, laminated materials can be fully compacted, and defects cannot be left inside the laminated material green bodies.

Owner:合肥波林新材料股份有限公司

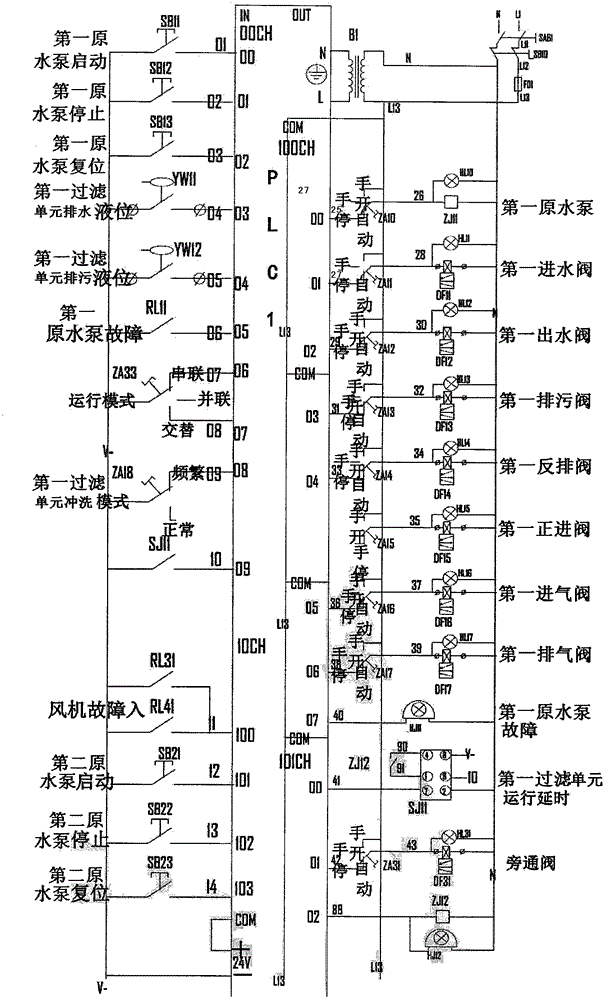

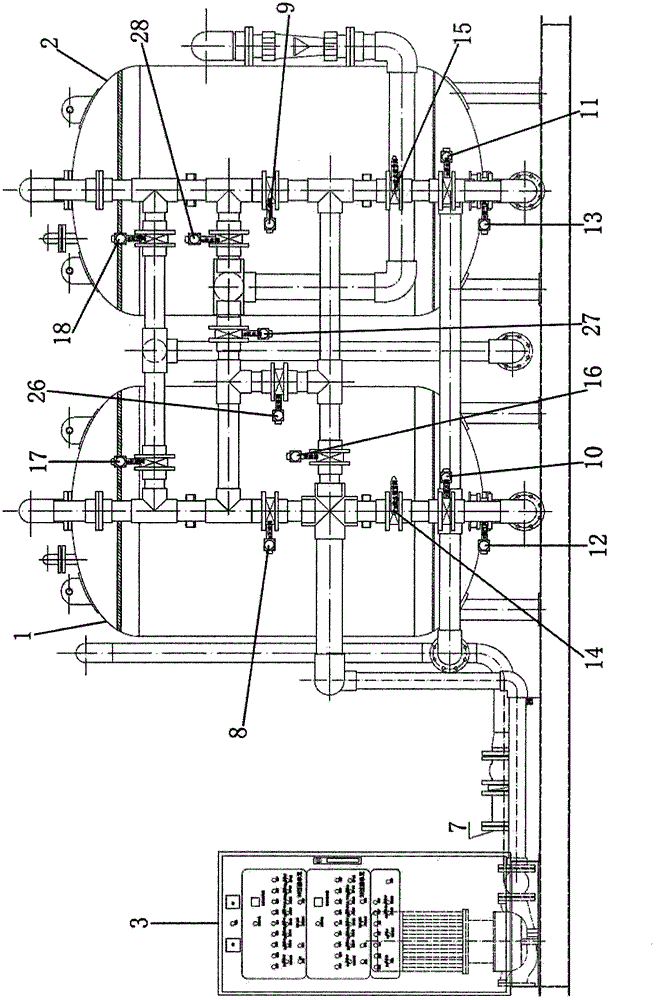

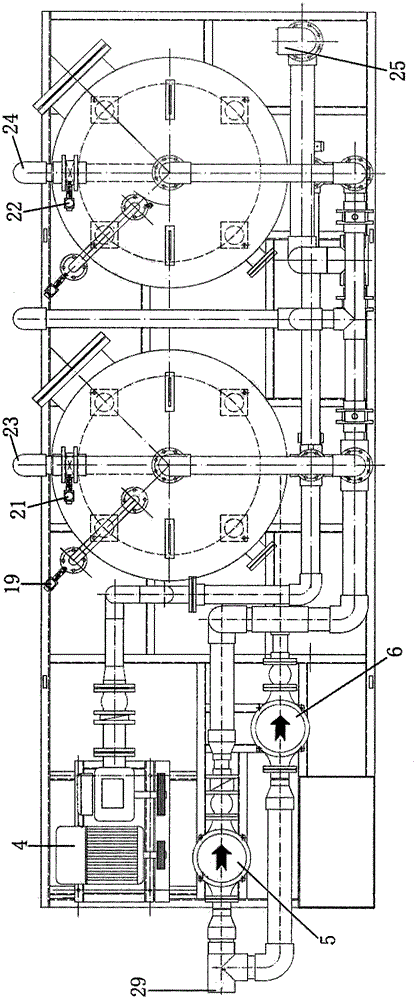

Integrated filter system

InactiveCN104857767AUnique and reasonable layout designEasy dischargeLoose filtering material filtersGravity filtersMicrocomputerAutomatic control

The invention relates to an integrated filter system. The integrated filter system comprises a first filter unit, a second filter unit, a first raw water pump, a Roots blower and an automatic control cabinet, wherein the automatic control cabinet is connected with the first raw water pump, the first filter unit and the second filter unit through gas circuits; the Roots blower is connected with the bottom of the first filter unit and that of the second filter unit through pipelines respectively; the first raw water pump is connected with the bottom of the first filter unit and that of the second filter unit through pipelines. The integrated filter system is automatically controlled by a PLC microcomputer, and is unattended during operation; moreover, the operation of the filter units is greatly changed, and the operation of the filter units is consistent with the water flow direction of backwashing; compared with the prior art, equipment does not need to produce water during backwashing, raw water is directly used for backwashing, and a backwashing water pump does not need to be prepared independently, so that the manpower is saved, and the energy consumption and water consumption are also reduced.

Owner:张国明

Compaction device preventing odor emission for solid waste treatment

ActiveCN110624668AEasy to useConsistent volumeSolid waste disposalDirt cleaningHydraulic cylinderEngineering

The invention discloses a compaction device preventing odor emission for solid waste treatment. The device comprises a compaction cylinder, wherein the compaction cylinder is mounted on the ground through a support frame, the end parts of hydraulic rods of four compaction hydraulic cylinders are in welded connection with a compaction plate, a hydraulic rod of a cutting hydraulic cylinder penetrates through a middle plate and is provided with a connecting plate, a cutting knife plate is clamped at the bottom of the connecting plate, the top end of a baffle is fixedly connected with a traction rope, and limiting stop blocks are welded at the positions, corresponding to the two sides of the baffle, of the top end of the compaction cylinder. According to the compaction device, cutting of a compacted waste solid material is completed through a cutting mechanism, so that the compacted discharged solid waste is consistent in size, stable and regular placement into a transport vehicle is facilitated, the stability of the solid waste in a transportation process is improved, and meanwhile, the baffle is driven by the traction rope to move up and down, the purpose of quick cutting and quick discharging after cutting is achieved, and the compacted solid waste is more easily taken out.

Owner:山东环沃环保科技有限公司 +1

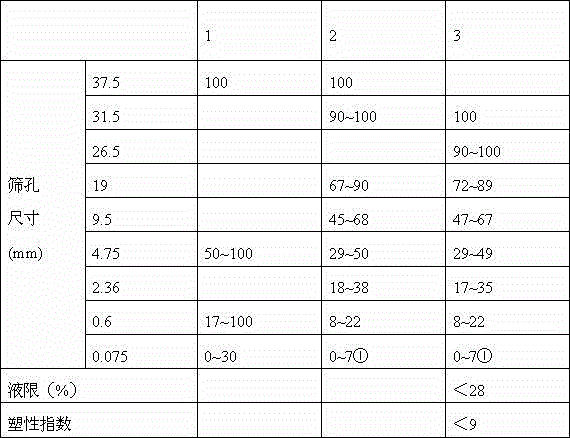

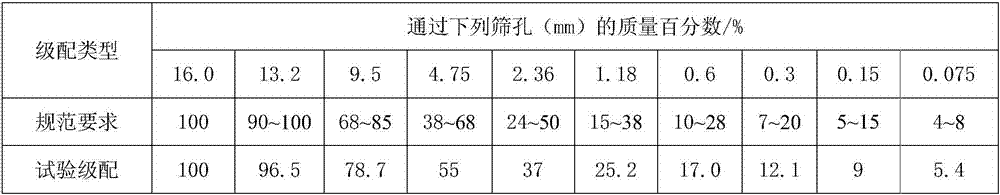

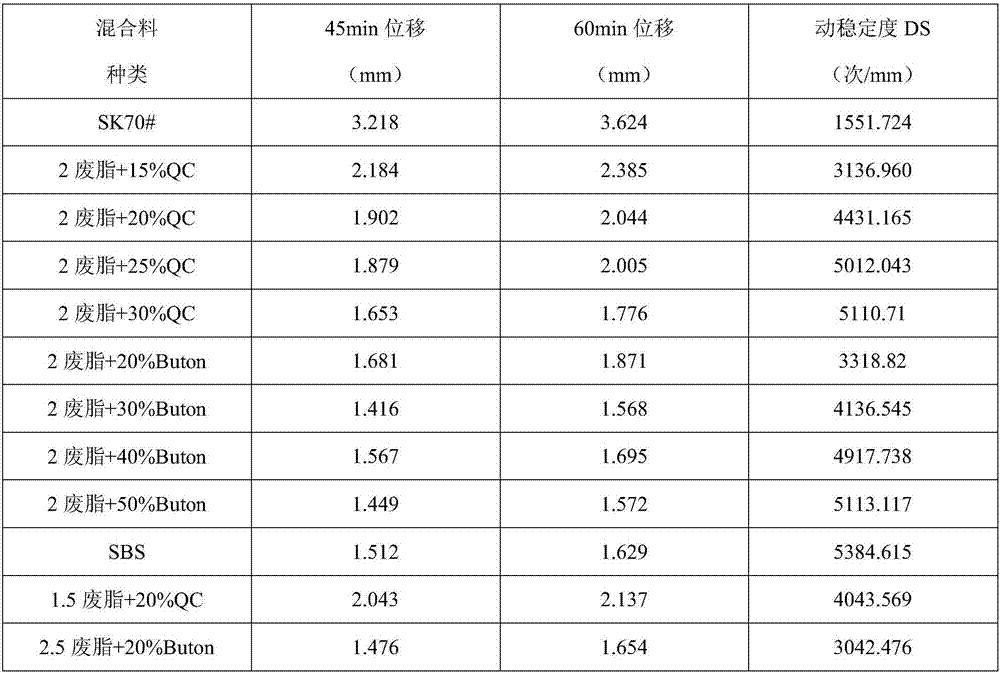

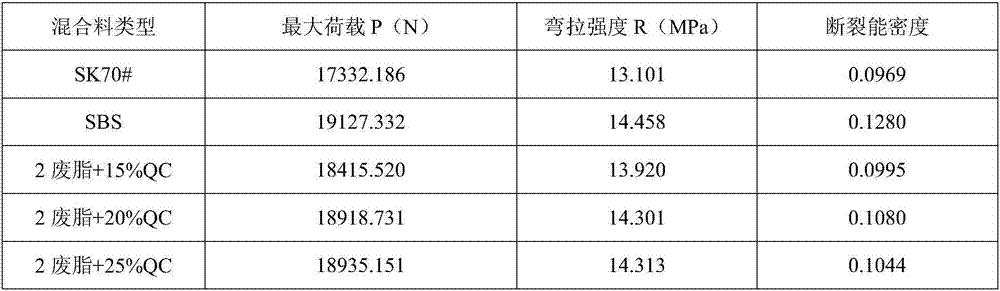

Waste grease premixed reinforced asphalt mixture and preparation method thereof

InactiveCN107500611AEasy constructionImprove workabilityClimate change adaptationGreenhouse gasHigh energy

The invention discloses a waste grease premixed reinforced asphalt mixture and a preparation method thereof. The preparation method comprises the following steps: step 1, adding 1.5 to 2.5 percent o waste grease into matrix asphalt, uniformly stirring, developing, and obtaining waste grease soft asphalt; step 2, premixing aggregates by using the waste grease soft asphalt prepared in step 1, and obtaining a premixed material; step 3, re-mixing the premixed material obtained in step 2 by using rock asphalt powder, and obtaining a remixed material; step 4, adding mineral powder into the remixed material obtained in step 3, and uniformly mixing, thus obtaining the waste grease premixed reinforced asphalt mixture. The waste grease premixed reinforced asphalt mixture can well use the waste grease and can solve the problems in the asphalt mixture pavement laying process such as high energy consumption, emission of a great amount of greenhouse gas and harmful gas and the like.

Owner:CHANGAN UNIV +1

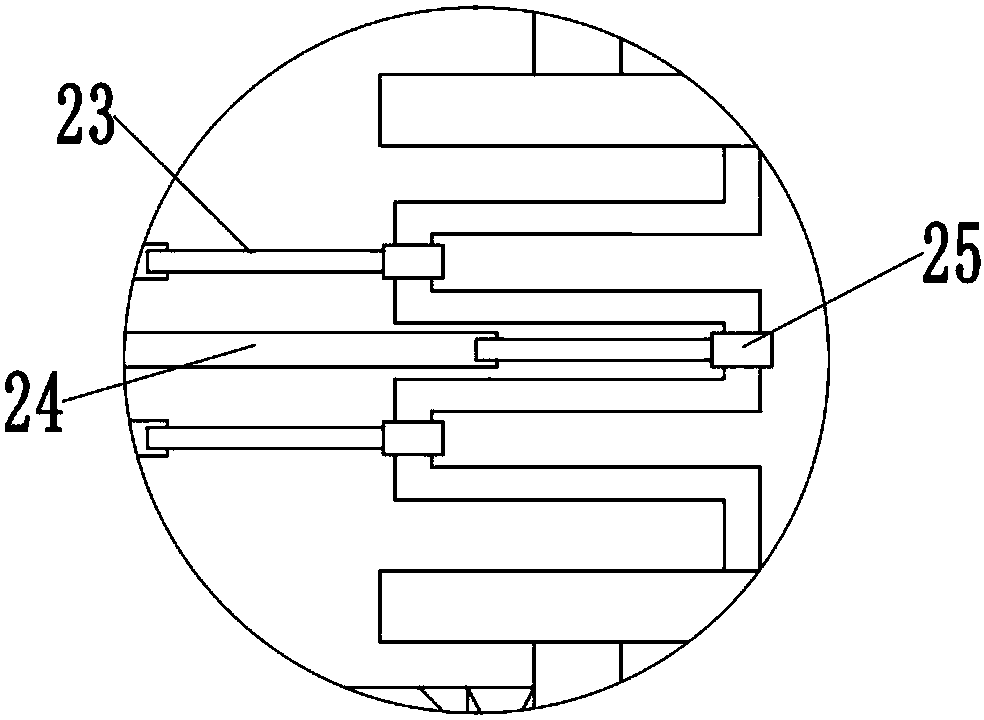

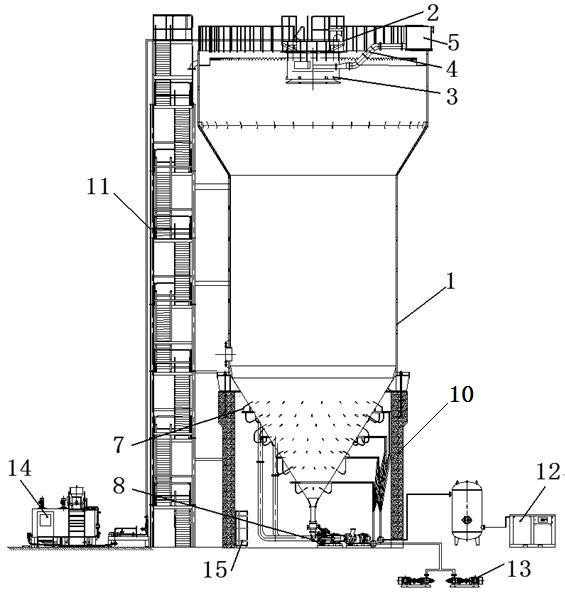

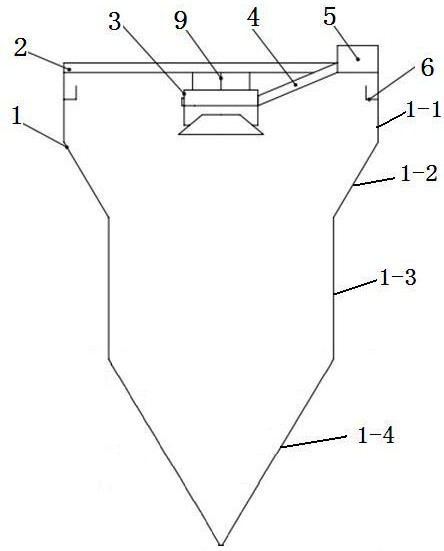

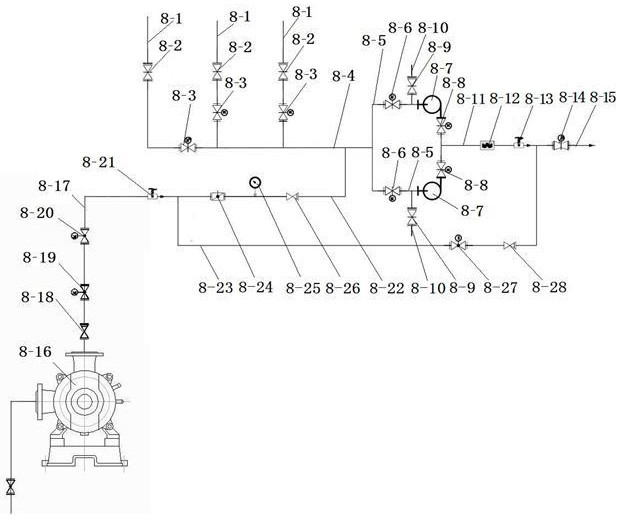

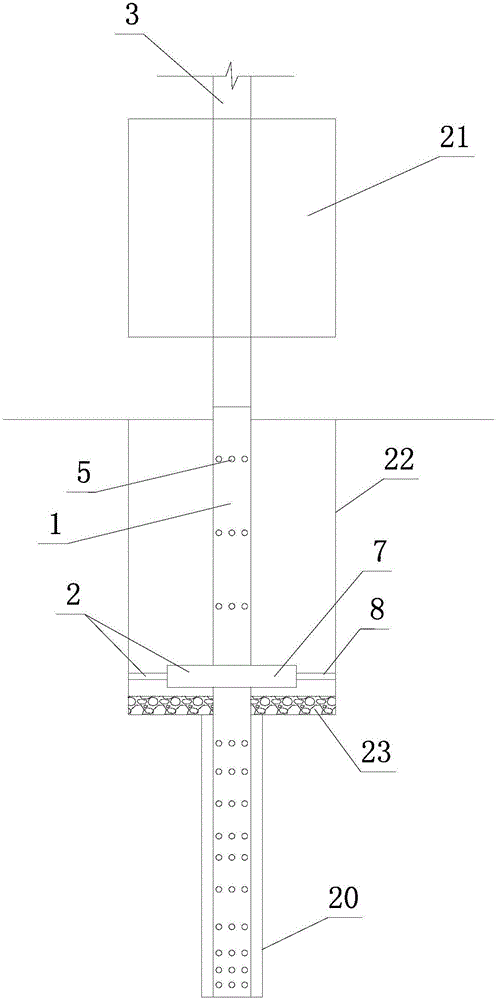

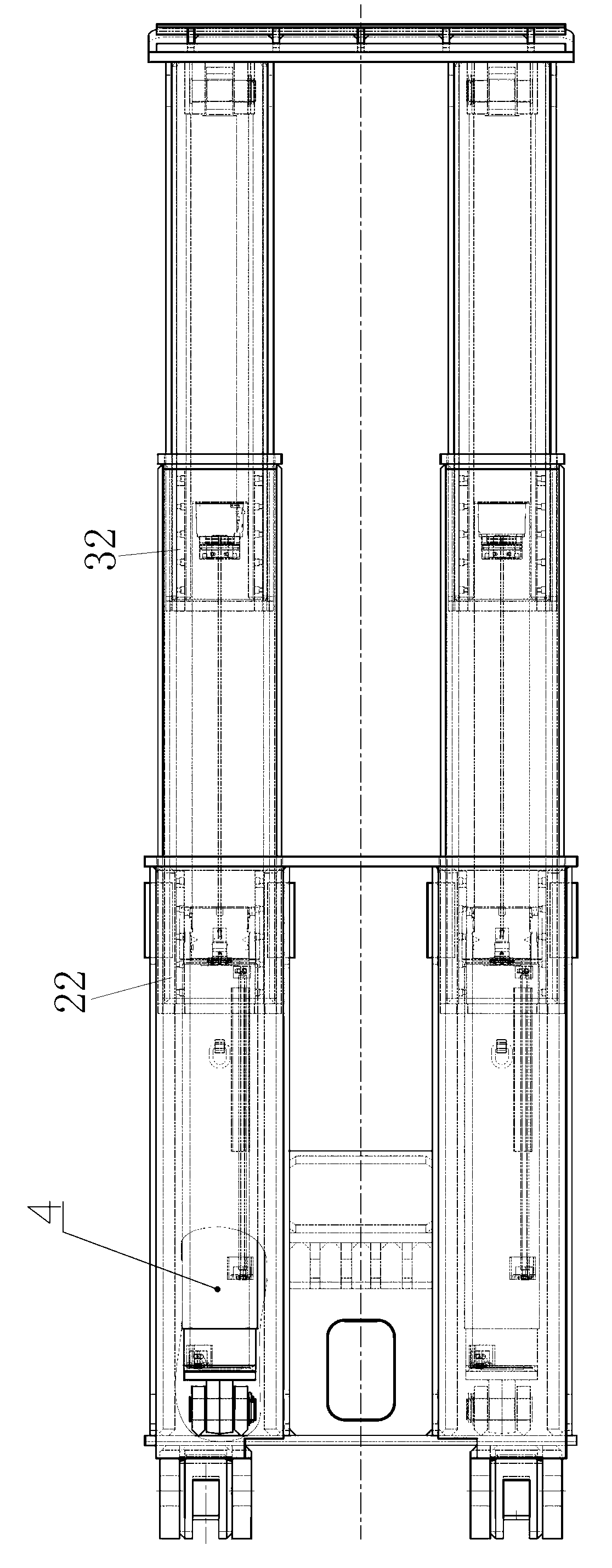

Fine-fraction high-concentration tailing filling and thickening device

ActiveCN113513363AImprove concentrationImprove the cycle efficiency of mining and chargingWaste water treatment from quariesWater/sewage treatment by centrifugal separationEngineeringSlurry

The invention discloses a fine-fraction high-concentration tailing filling and thickening device which comprises a tank body part, a wind-water slurry making system, an underflow conveying system, an electric control system, a flocculating agent preparing and adding system and the like. The wind-water slurry making system comprises an annular water pipe group and an annular gas pipe group; annular water pipes of all layers of the annular water pipe group and annular air pipes of all layers of the annular air pipe group are located at different height positions and distributed in an inverted cone shape, the annular water pipes and the annular air pipes of each layer are respectively connected with a plurality of high-pressure rubber water (air) spraying pipes, valves and external water (wind) slurry making nozzles; and the annular water pipes are connected with a water supply and drainage header pipe, and the annular air pipes are connected with an air supply and exhaust header pipe. By means of the fine-fraction high-concentration tailing filling and thickening device, the material storage capacity is large, the mining and filling circulation efficiency of a mine is improved, no power part exists, fault points are few, power consumption is low, and the operation cost is low; and long-time continuous steady-state slurry discharging is achieved, the stability of technological parameters and the working efficiency of filling operation are improved, the concentration capacity of the thickening device is improved, and the continuity of filling operation of the thickening device is guaranteed.

Owner:山金重工有限公司

Foundation treatment device and foundation treatment method

The invention discloses a foundation treatment device and a foundation treatment method. The device comprises a floral tube (1) and a plurality of grouting discs (2), wherein a plurality of circles of grouting holes (5) with different storey heights are formed in the floral tube (1); positioning holes with different storey heights are further formed in the floral tube (1); each grouting disc (2) comprises a hollow disc body (7) and a plurality of grouting ducts (8); all the grouting ducts (8) of each grouting disc (2) are positioned on the side wall of the corresponding disc body (7); each disc body (7) is provided with a positioning assembly which is used for positioning together with the corresponding positioning hole of the floral tube (1). The method is characterized in that after padding is filled layer by layer and is tamped, the grouting discs (2) are placed, during grouting finally, slurry enters the grouting discs (2) through the floral tube (1) and enters soil on the peripheries of expanding holes (22) from the grouting ducts (8) to form concrete nodes (24), and the concrete nodes (24) of different piles are cross-linked. By the device and the method, regions among piles can be reinforced effectively.

Owner:浙大宁波理工学院资产经营有限公司

Spreading machine

ActiveCN104192632BFully compactedUniform tensionUnfolding thin materialsArticle deliveryEngineeringAutomotive engineering

Owner:HEFEI AORUI DIGITAL CONTROL SCI & TECH

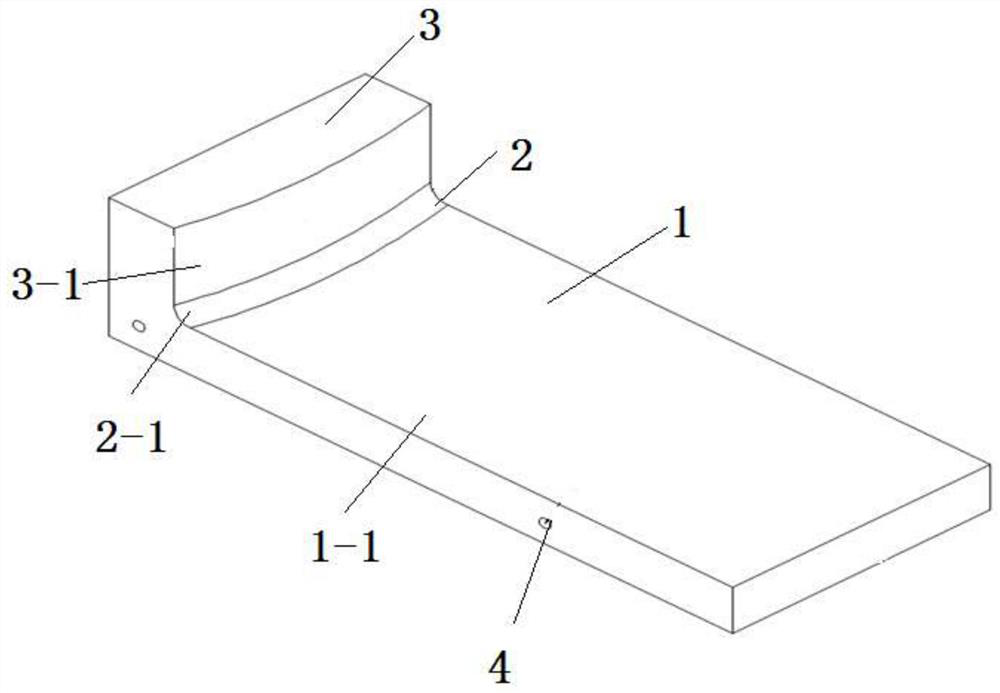

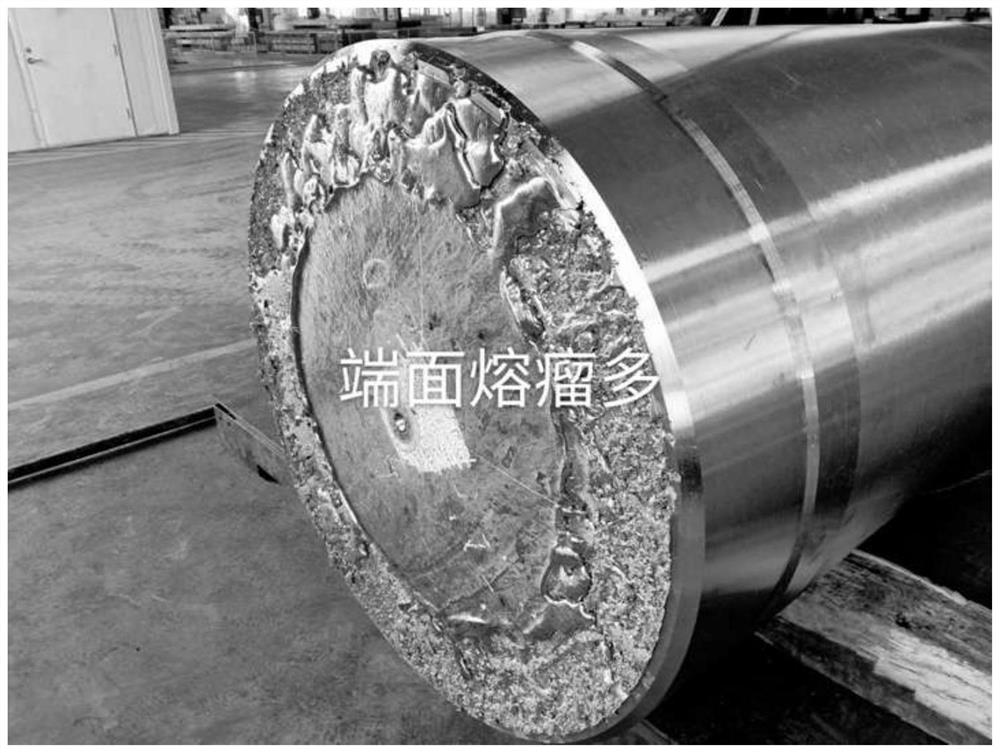

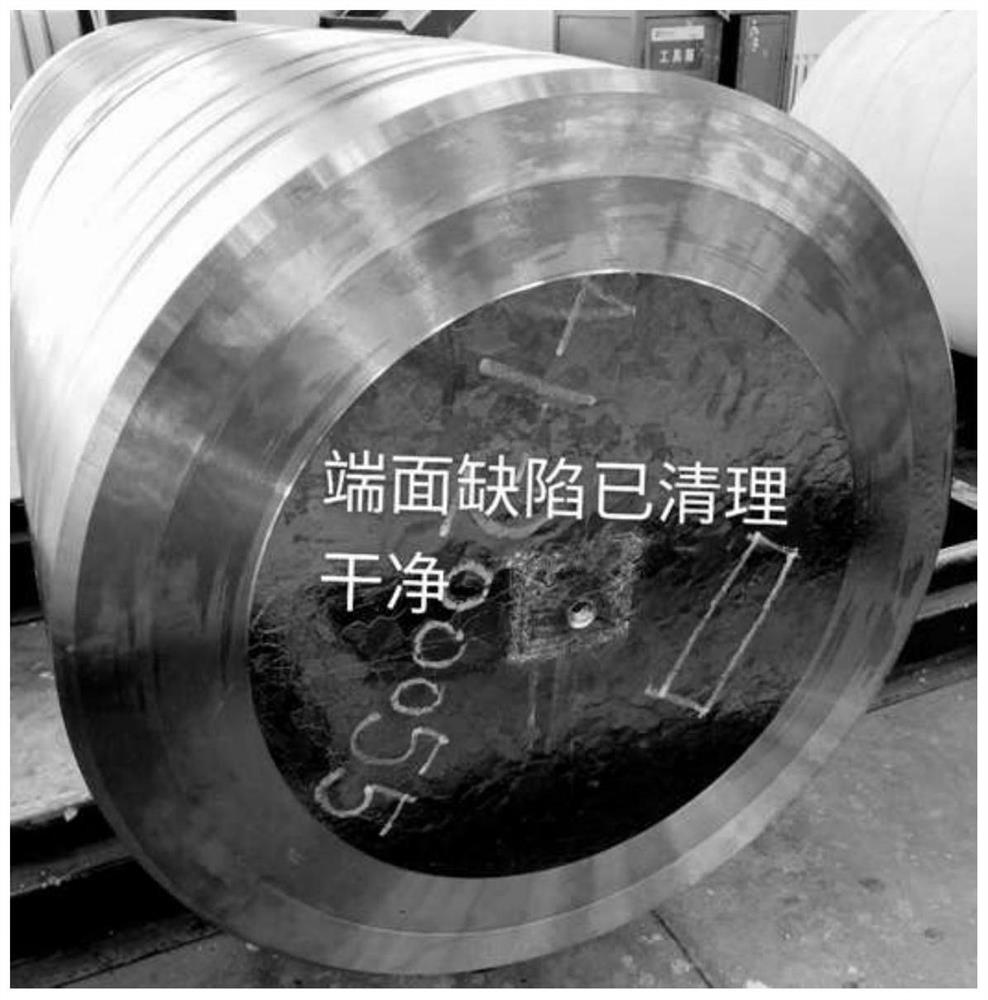

Forging mold for near-net-formed titanium strip plate blank and free forging machining method

PendingCN112077252AImprove yieldSolve the phenomenon of lack of meat at the corners of the head and tailForging/hammering/pressing machinesStructural engineeringTitanium

The invention discloses a forging mold for a near-net-formed titanium strip plate blank, comprising a bottom plate. A transition baffle plate and a vertical baffle plate are sequentially arranged at one end of the bottom plate from bottom to top; a first side wall surface of the transition baffle plate and a second side wall surface of the vertical baffle plate are located on the same side; the first side wall surface, the second side wall surface and the upper surface are all contact surfaces of the mold and the blank; the first side wall surface and the second side wall surface are both arcsurfaces; the upper surface of the first bottom plate is a rectangular plane; the first side wall surface is in smooth connection with the upper surface through transition of the second side wall surface; and a plurality of lifting holes are formed in the side wall surface of the bottom plate. The invention further discloses a free forging machining method for the near-net-formed titanium strip plate blank formed by applying the mold; and the method greatly improves the yield on the premise that it is guaranteed that the machining process is simple and the production efficiency is remarkably improved.

Owner:新疆湘润新材料科技有限公司

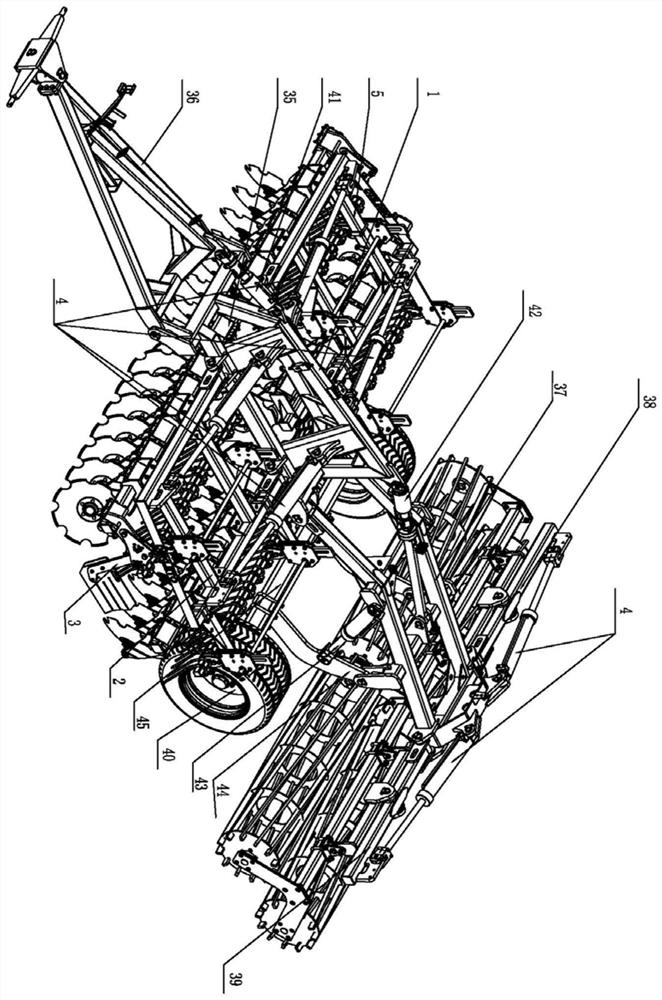

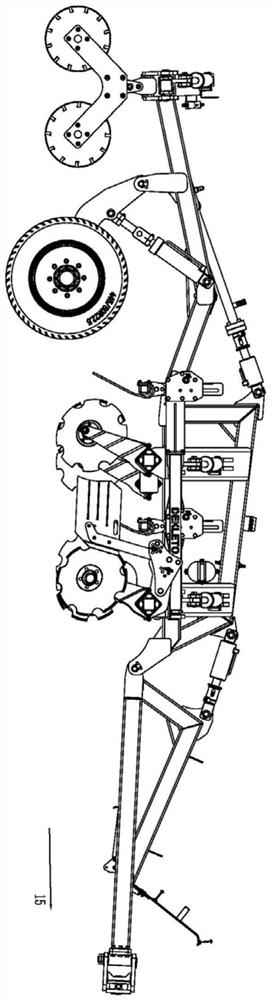

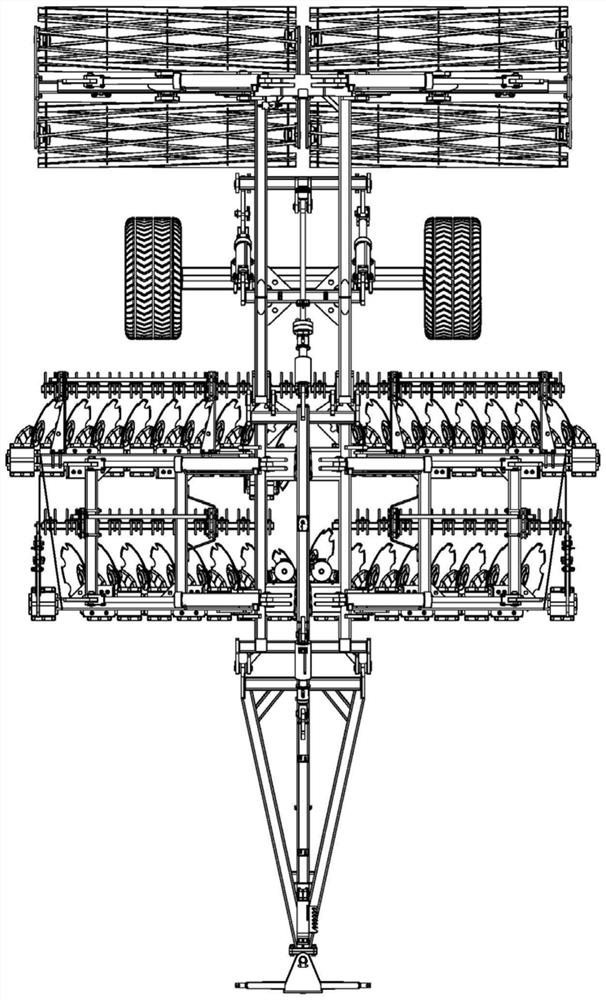

High-speed stubble cleaning harrow

The invention discloses a high-speed stubble cleaning harrow. The high-speed stubble cleaning harrow comprises a main harrow frame assembly, a middle harrow frame assembly, a left folding harrow frameassembly and a right folding harrow frame assembly, wherein the left folding harrow frame assembly and the right folding harrow frame assembly are connected to the left side and the right side of themain harrow frame assembly in a foldable mode, and the rear end of the main harrow frame assembly is movably connected with a rear adjusting tailstock assembly; a left folding press roller assembly and a right folding press roller assembly are connected to the left side and the right side of the rear portion of the rear adjusting tailstock assembly respectively, two walking wheels are connected to the lower end of the rear adjusting tailstock, the two walking wheels are connected through an axle, and the axle is connected with the rear adjusting tailstock through a connecting arm; and the harrow blades on the left-right harrow frame and the front-back harrow frame are symmetrically designed, lateral traction force is avoided, power is exerted more sufficiently, and oil consumption is reduced.

Owner:宜兴博登泰科工业装备有限公司

3D graphene and copper composite in-situ prepared with solid carbon source on surface of copper powder and preparing method

ActiveCN111069605APrevent fusion bondingImprove performanceTransportation and packagingMetal-working apparatusSolid carbonPolymethyl methacrylate

The invention discloses a 3D graphene and copper composite in-situ prepared with a solid carbon source on the surface of copper powder and a preparing method. Stainless steel balls, copper powder, magnesium oxide and polymethyl methacrylate serve as raw materials, ethyl alcohol serves as a ball milling medium, and a mixed solution is obtained through mixing; the ethyl alcohol is removed, screeningis carried out, and dry and evenly-dispersed copper, magnesium oxide and polymethyl methacrylate powder is obtained; the copper, magnesium oxide and polymethyl methacrylate powder is subjected to low-temperature reduction treatment and high-temperature reduction treatment respectively, and in-situ grown 3D graphene, copper and magnesium oxide mixed powder is obtained; magnesium oxide in the 3D graphene, copper and magnesium oxide mixed powder is removed through acid pickling with diluted hydrochloric acid, then washing is carried out with ethyl alcohol, drying is carried out, and in-situ-grown 3D graphene and copper composite powder is obtained; the 3D graphene and copper composite powder is subjected to vacuum hot pressing sintering formation, and the 3D graphene and copper composite isobtained. According to the 3D graphene and copper composite in-situ prepared with the solid carbon source on the surface of the copper powder and the preparing method, the preparing technology is simple, and the obtained composite is high in tensile strength and good in conductivity and has well application prospects.

Owner:XI AN JIAOTONG UNIV

Containing gangue filling and tamping mechanism for gangue filling hydraulic support

ActiveCN102926780APrevent leakageThe effect is positive and obviousMaterial fill-upMine roof supportsMagnificationEngineering

The invention discloses a containing gangue filling and tamping mechanism for a gangue filling hydraulic support. The mechanism comprises a swing beam, a floating telescopic beam, a telescopic jack, a telescopic beam and a bucket, wherein the bucket is arranged at the rear end of the telescopic beam; two ends of the telescopic jack are hinged between the front end of the swing beam and the rear end of the telescopic beam; the floating telescopic beam is a box with a front opening and a rear opening; a sliding pair is formed along the length direction between the swing beam and the floating telescopic beam; and a sliding pair is formed along the length direction between the swing beam and the telescopic beam. The gangue filling and tamping mechanism is designed to have a box containing structure, a jack is independently arranged in each branch of the swing beam and the telescopic beam, an enough space is provided to leak gangue to prevent coal ash, gangue and other impurities from leaking into the damping mechanism, the magnification ratio is increased, a filling range and the damping capacity are improved as much as possible, the gangue is fully damped and filled, and the sunk phenomenon after damping in the prior art is avoided.

Owner:CATERPILLAR ZHENGZHOU

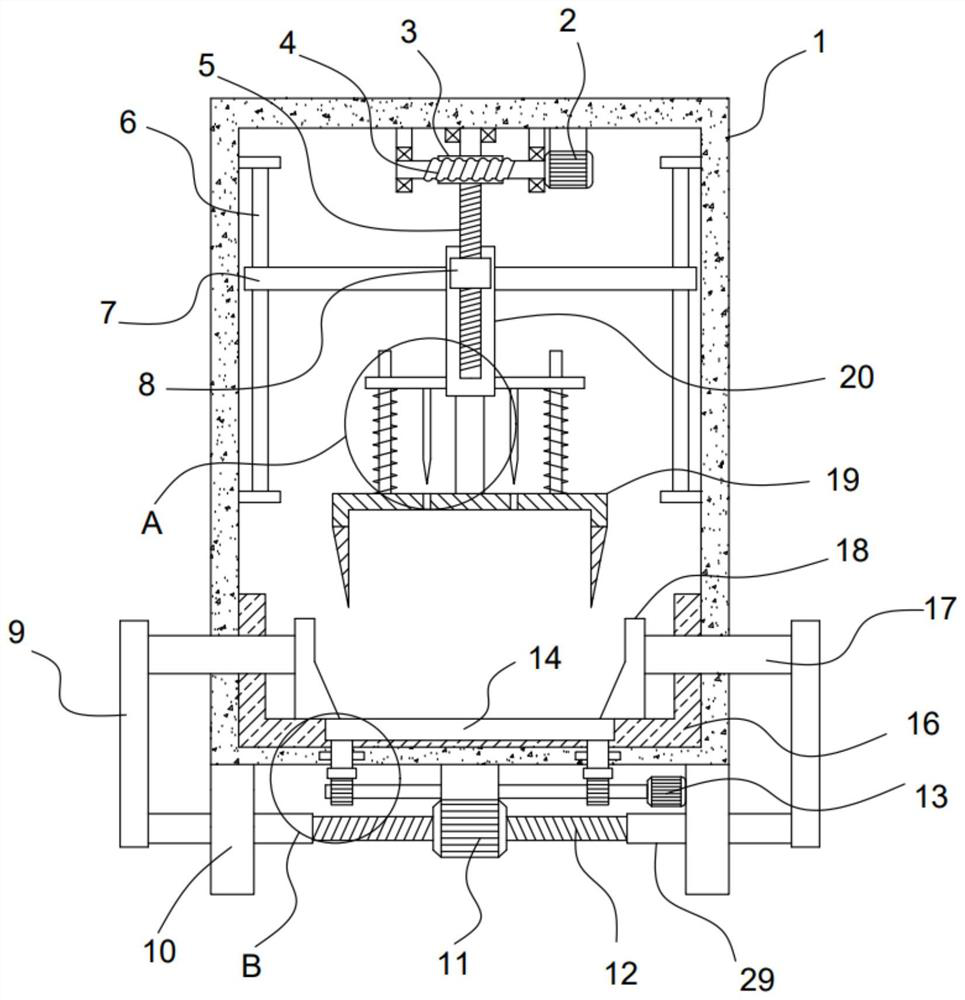

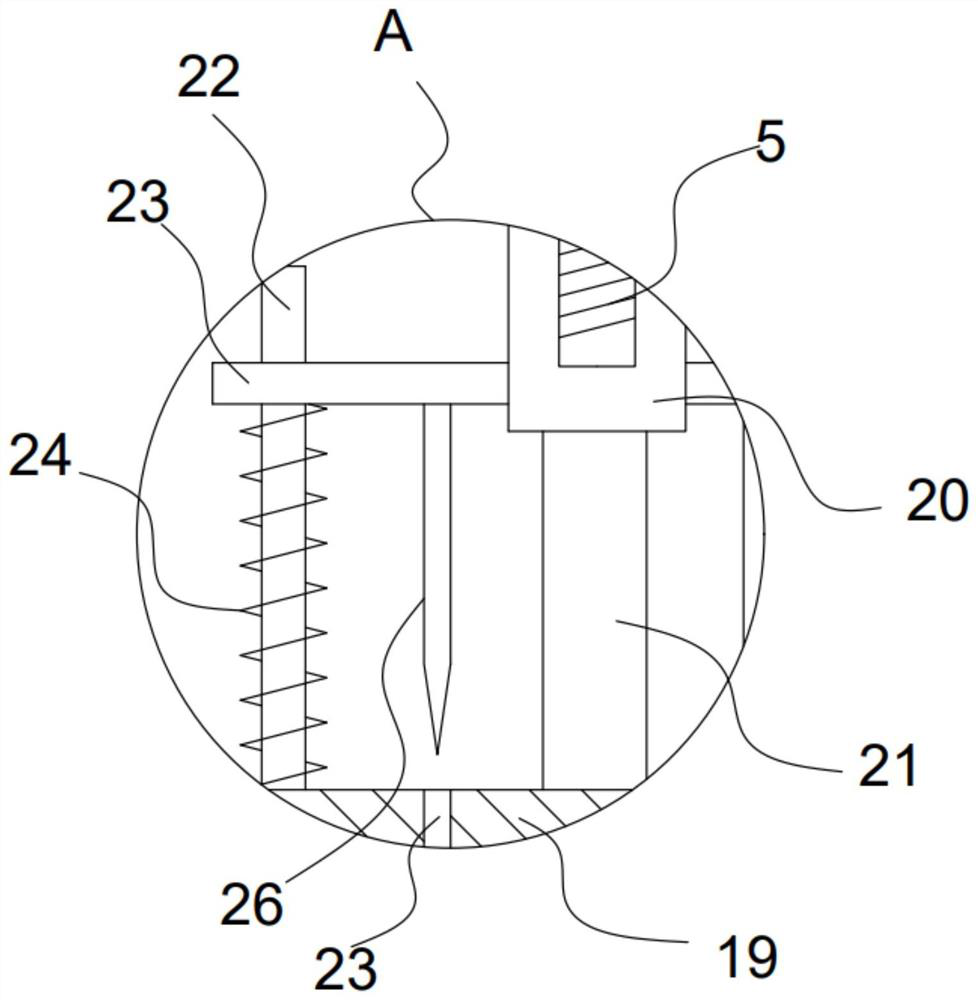

Manufacturing device for preparing construction materials from construction waste

InactiveCN112428611AImprove pressing qualityFully compactedMetal working apparatusPressesArchitectural engineeringRefuse Disposals

The invention discloses a manufacturing device for preparing construction materials from construction waste, and relates to the technical field of construction waste treatment. The manufacturing device for preparing the construction materials from the construction waste comprises a fixing frame, wherein wedge-shaped push plates located in a manufacturing groove are in transmission connection ontoa translation mechanism; the upper surface of a sliding supporting plate is flush with the inner bottom surface of the manufacturing groove; and a conveying mechanism used for driving the sliding supporting plate to horizontally move relative to the manufacturing groove is fixed onto a supporting plate. According to the manufacturing device for preparing the construction materials from the construction waste provided by the invention, vertical lifting of a pressing mechanism is achieved through an arranged vertical lifting mechanism, so that the pressing mechanism can move downwards and pressthe construction waste in a fine crushing state in the manufacturing groove into blocky materials; in the pressing process, the pressed blocky materials can be integrally cut and blocked through arranged separation blades, so that pressing and separating are achieved in one step; and the arranged translation mechanism can drive the wedge-shaped push plates to move oppositely to push the construction waste to be gathered towards the center of the sliding supporting plate, so that the construction waste is effectively guaranteed to be fully and tightly pressed into blocks, and the pressing quality of the construction waste is effectively improved.

Owner:郅新礼

Cloth ironing equipment for garment production

PendingCN112030443AEasy to limit processingEasy to operateTextile shapingWebs handlingElectric machineEngineering

The invention discloses cloth ironing equipment for garment production. The equipment comprises a supporting table, mounting grooves are formed at the two sides of the top of the supporting table correspondingly, fixing rods are arranged on the inner walls of one sides of the mounting grooves correspondingly, a mounting frame is fixedly connected to one end of the outer wall of one side of the supporting table, and a motor is fixedly connected to one side of the mounting frame. One end of one fixing rod is fixedly connected with a connecting shaft penetrating through the supporting table, a transmission assembly is arranged between the outer wall of the connecting shaft and the outer wall of an output shaft of the motor, an ironing box is fixedly connected to the middle of the top of the supporting table, and inlets and outlets are formed at the bottoms of the two sides of the ironing box. According to the equipment, limiting treatment can be conveniently conducted on cloth through a limiting barrel and a check ring, the bottom of an ironing piece makes contact with the cloth, the cloth is ironed through a steam generator and the ironing piece, operation is convenient, the cloth isfully pressed, and the problem that the cloth wrinkles again in the ironing process is avoided.

Owner:安徽绿岛制衣有限公司

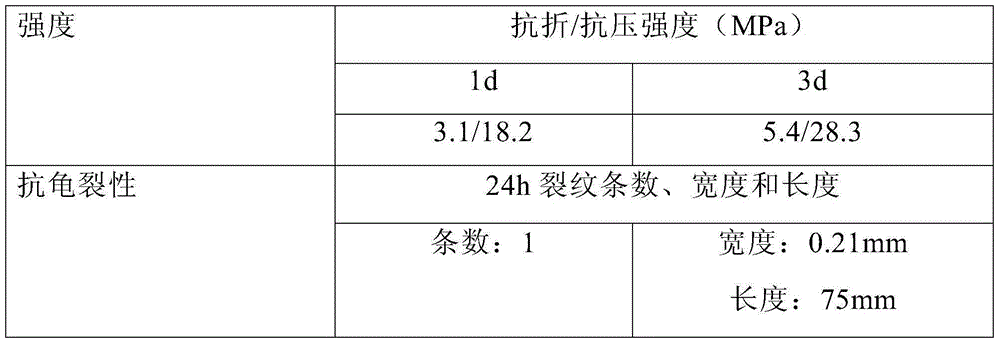

Road repair material and application thereof

The invention discloses a road repair material and an application thereof. The road repair material comprises the following components in terms of the total weight of the road repair material: 30 to 60% of tailings, 20 to 40% of cement, 5 to 30% of modified gum and 5 to 20% of polypropylene fiber. The road repair material provided by the invention has the advantages of high strength and good crack resistance.

Owner:韩先福 +2

Preparation method of high-density die-casting aluminum alloy

The invention discloses a method for preparing a high-density die-casting aluminum alloy, which relates to the technical field of aluminum alloy manufacturing. The method comprises the following steps: heating each component of the alloy, and then melting the aluminum; adding Si and Mn to the aluminum liquid Melt in sequence, then cool down to 650-660°C, completely press Mg into the alloy liquid; raise the temperature to 720-750°C, remove scum, then add the remaining alloy components into the alloy liquid in turn, keep warm for 20-30 minutes, Then carry out refining to remove scum; when just pouring, the volume of alloy liquid is 65-70% of the volume of the pressure chamber, and the casting temperature is 600-620°C; slow injection, the speed is 0.3-0.5m / s, and then Carry out high-speed injection filling with an injection speed of 1.5m / s; after the filling is completed, pressurize the die-casting and inject with a pressure of 280‑300MPa. The invention solves the problem of low compactness of existing die-casting aluminum.

Owner:LIUZHOU BAITIAN MACHINERY

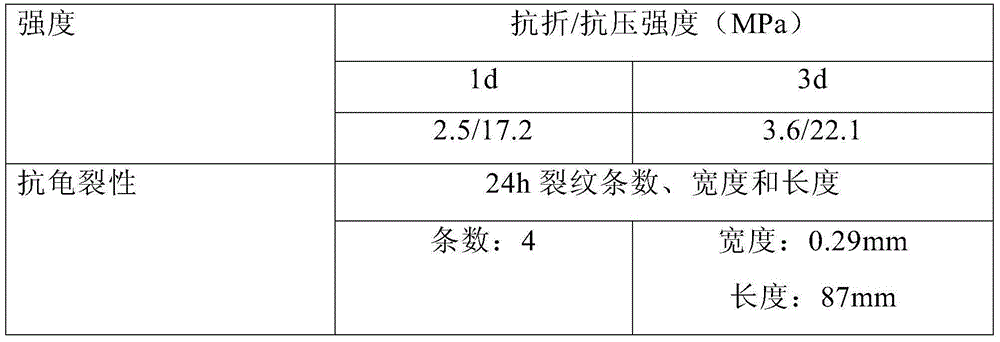

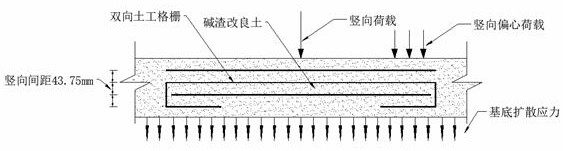

Road structure processing method based on reinforced alkaline residue improved soil

The invention relates to the technical field of road traffic construction, and discloses a road structure processing method based on reinforced alkaline residue improved soil, which comprises the following steps: taking a proper amount of alkaline residue, fly ash and cohesive soil, adding water for mixing by adopting the optimal water content of 23%, and then conducting sealing for 14 days to promote volcanic ash reaction; smearing engine oil in a road structure mold cylinder for lubrication, and packing the mixture into the alkaline residue improved soil in a multi-layer volume-controlled manner; after each layered volume is filled, laying a layer of reinforced material, laying 8-12 cm of alkaline residue improved soil for rolling compaction, and after compaction, sequentially packing the upper-layer mixture until a next-layer reinforcing layer is reached; and circulating and repeating the steps to form the reinforced road structure. Compared with the prior art, the reinforced alkaline residue improved soil is reasonably designed, geogrids and the alkaline residue improved soil are used as raw materials according to the optimal grid spacing, the base layer structure for the solid waste regeneration road is constructed, the design requirements of roads at or below a second level can be met, and resource utilization of alkaline residue solid waste is greatly promoted.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com