Integrated filter system

A filter system and filter unit technology, applied in the direction of filter separation, filter loop, gravity filter, etc., can solve the problems of narrow filter system requirements, low filter system precision, high installation and transportation costs, etc., and achieve pipeline layout design Unique and reasonable, save water and clean water, and occupy a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

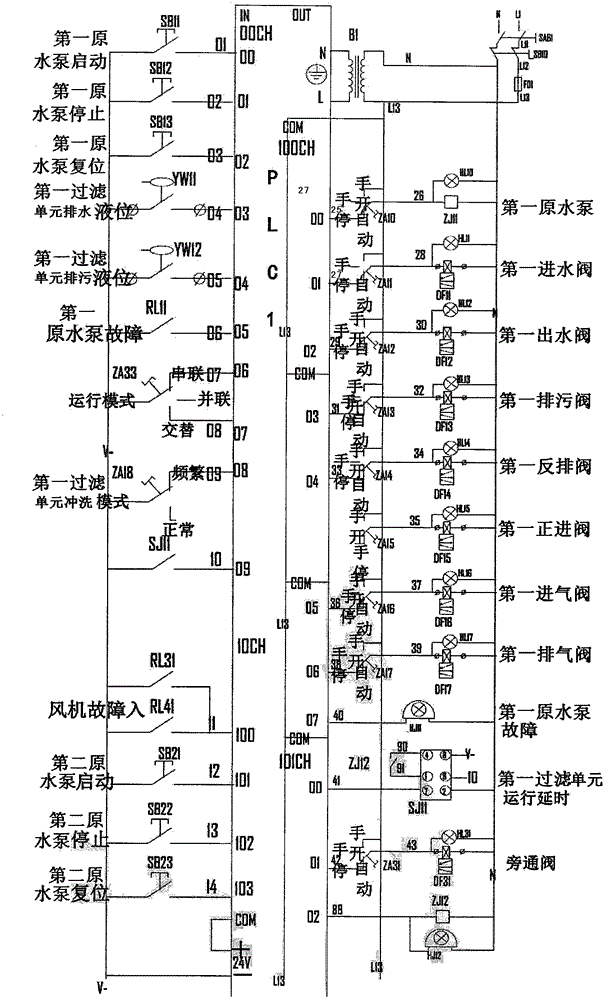

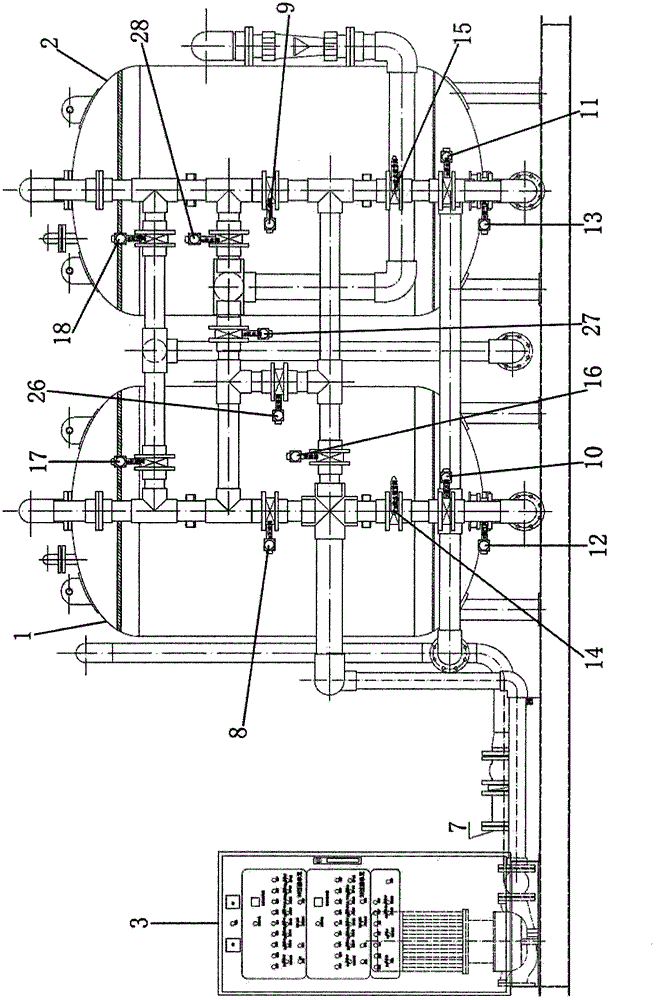

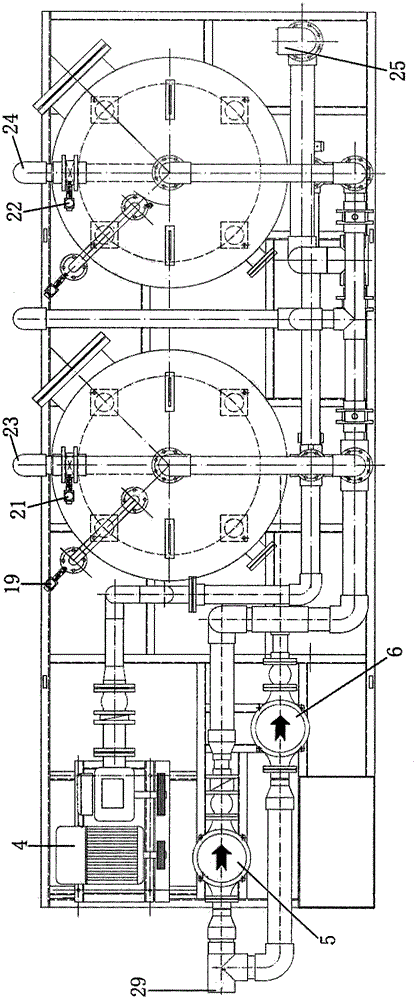

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0042] Such as figure 1 , figure 2 with image 3 As shown, an integrated filtration system includes a first filter unit 1, a second filter unit 2, a first raw water pump 5, a Roots blower 4 and an automatic control cabinet 3, wherein: the automatic control cabinet 3 and the first A raw water pump 5, the first filter unit 1 and the second filter unit 2 are air-connected; the Roots blower 4 is respectively connected to the bottom of the first filter unit 1 and the second filter unit 2 through pipelines; The first raw water pump 5 is connected to the bottoms of the first filter unit 1 and the second filter unit 2 through pipelines. The integrated filtration system also includes a second raw water pump 6, which is connected in parallel with the first raw water pump 1 through a pipeline, and the second raw water pump 6 is used as a backup pump. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com