Magnetorheological fluid multi-stage treatment device and control method and component manufacturing method thereof

A magnetorheological fluid and processing device technology, applied in magnetic fluids, separation methods, chemical instruments and methods, etc., can solve the problems of magnetorheological fluid lack of recycling and processing devices, environmental pollution, energy waste, etc., and shorten the reaction time. , Improve the filtration efficiency and enhance the effect of the filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings of the description.

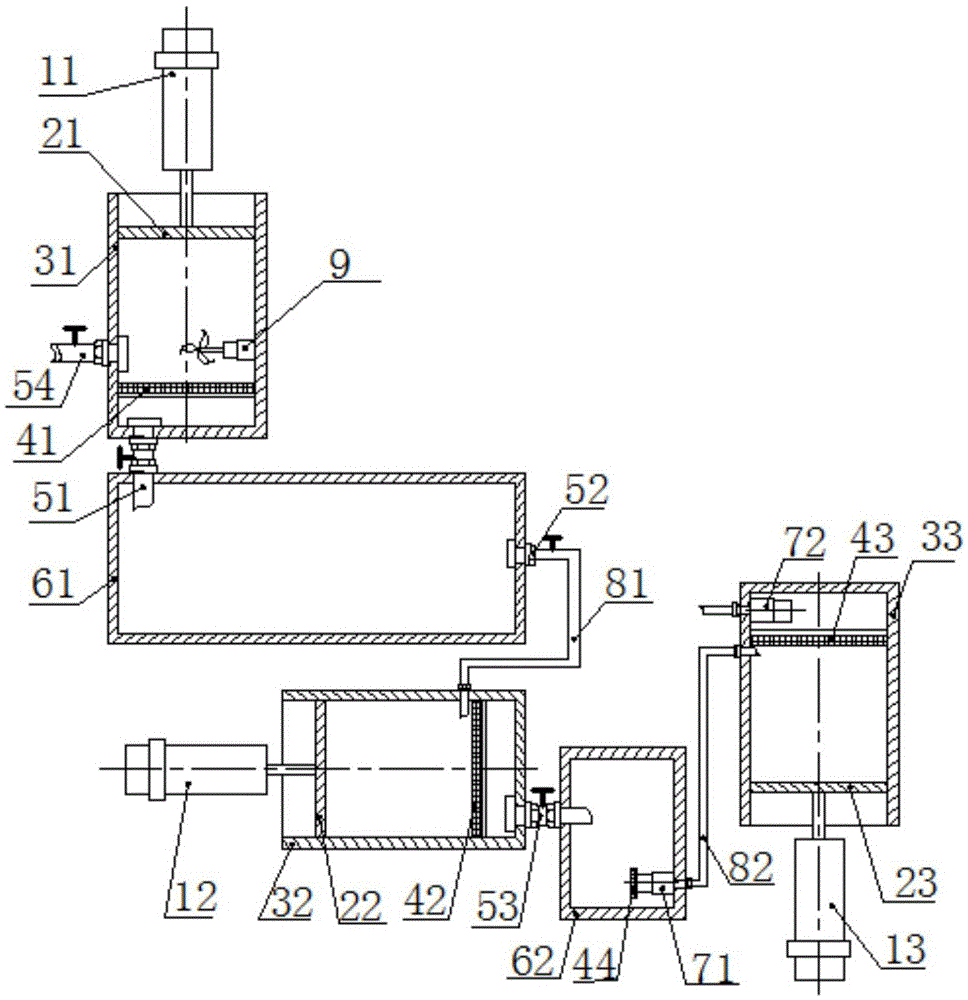

[0055] Such as figure 1 As shown, a magneto-rheological fluid multi-stage treatment device includes a front piston cylinder 11, a middle piston cylinder 12, a rear piston cylinder 13, a front piston 21, a middle piston 22, a rear piston 23, a front Filter box 31, middle filter box 32, rear filter box 33, pre-filter 41, middle filter 42, rear filter 43, pump port filter 44, front valve 51, middle valve 52, Rear valve 53, inlet valve 54, front liquid storage tank 61, rear liquid storage tank 62, submersible pump 71, outlet pump 72, front conduit 81, rear conduit 82, agitator 9,

[0056] The front piston cylinder 11 is connected to the front piston 21 through bolts, and the front piston 21 is matched with the inner cavity of the front filter box 31. The front filter box 31 is placed vertically, and its axis For the vertical direction, the pre-filter b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com