Patents

Literature

93results about How to "Fully settled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

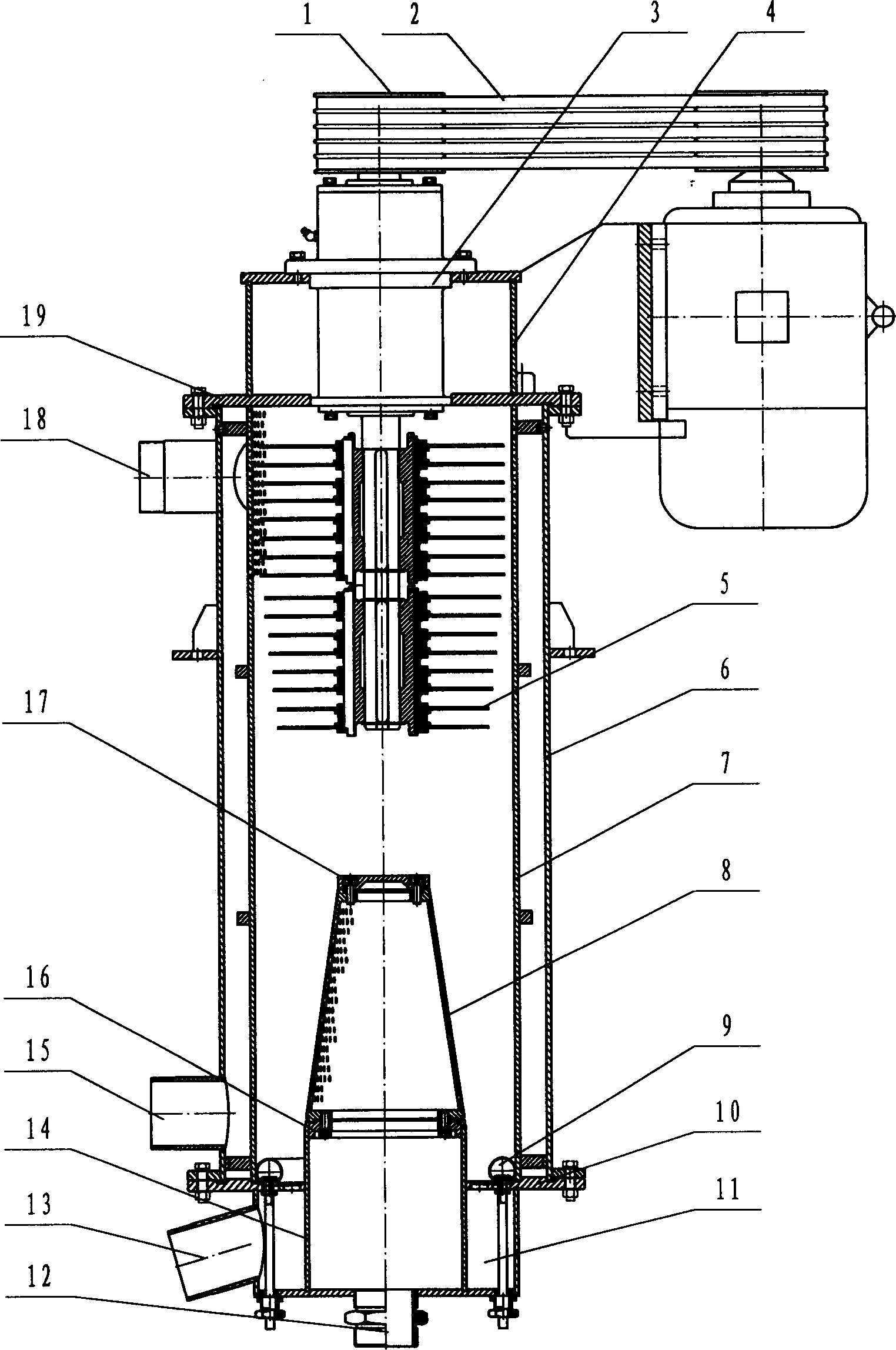

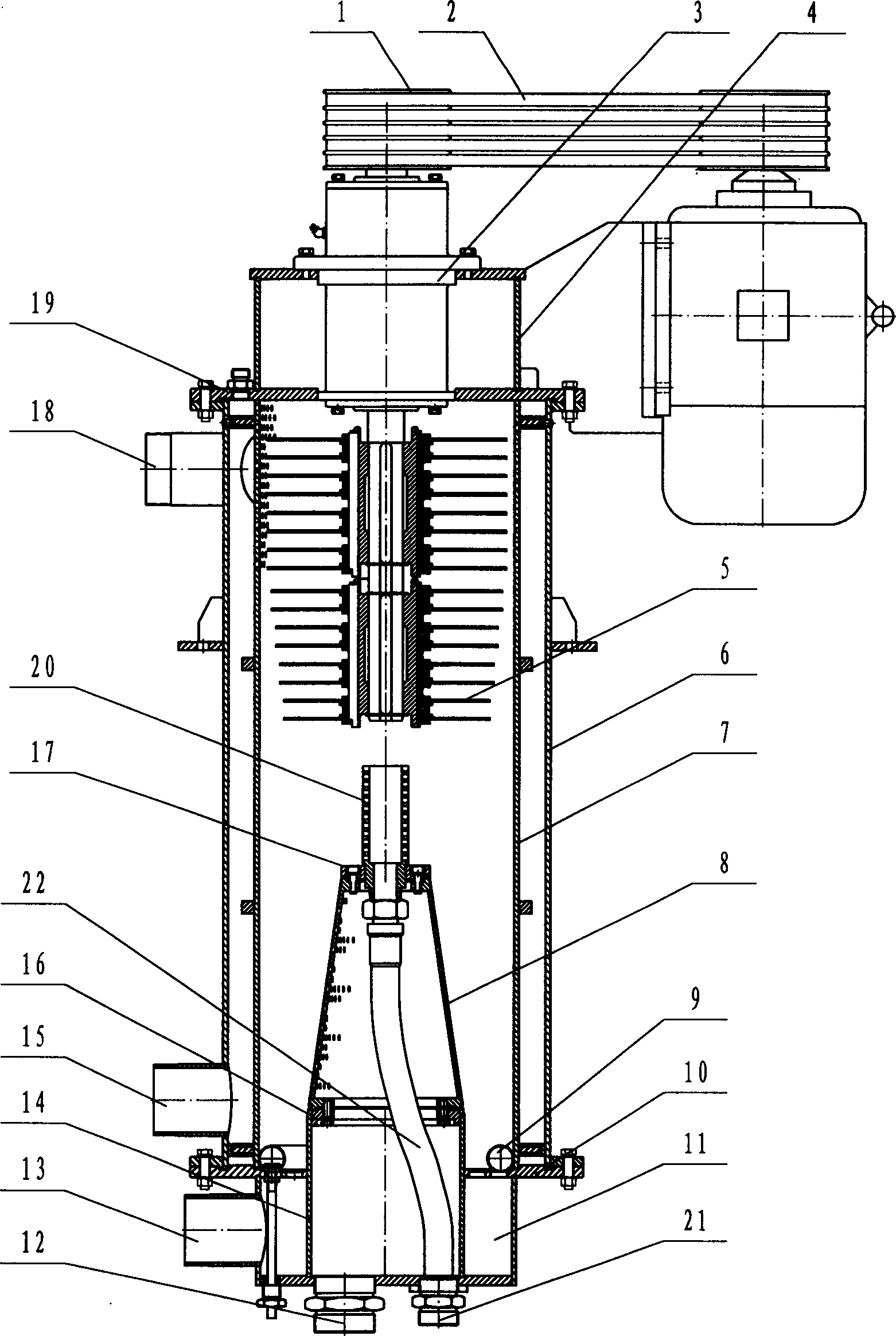

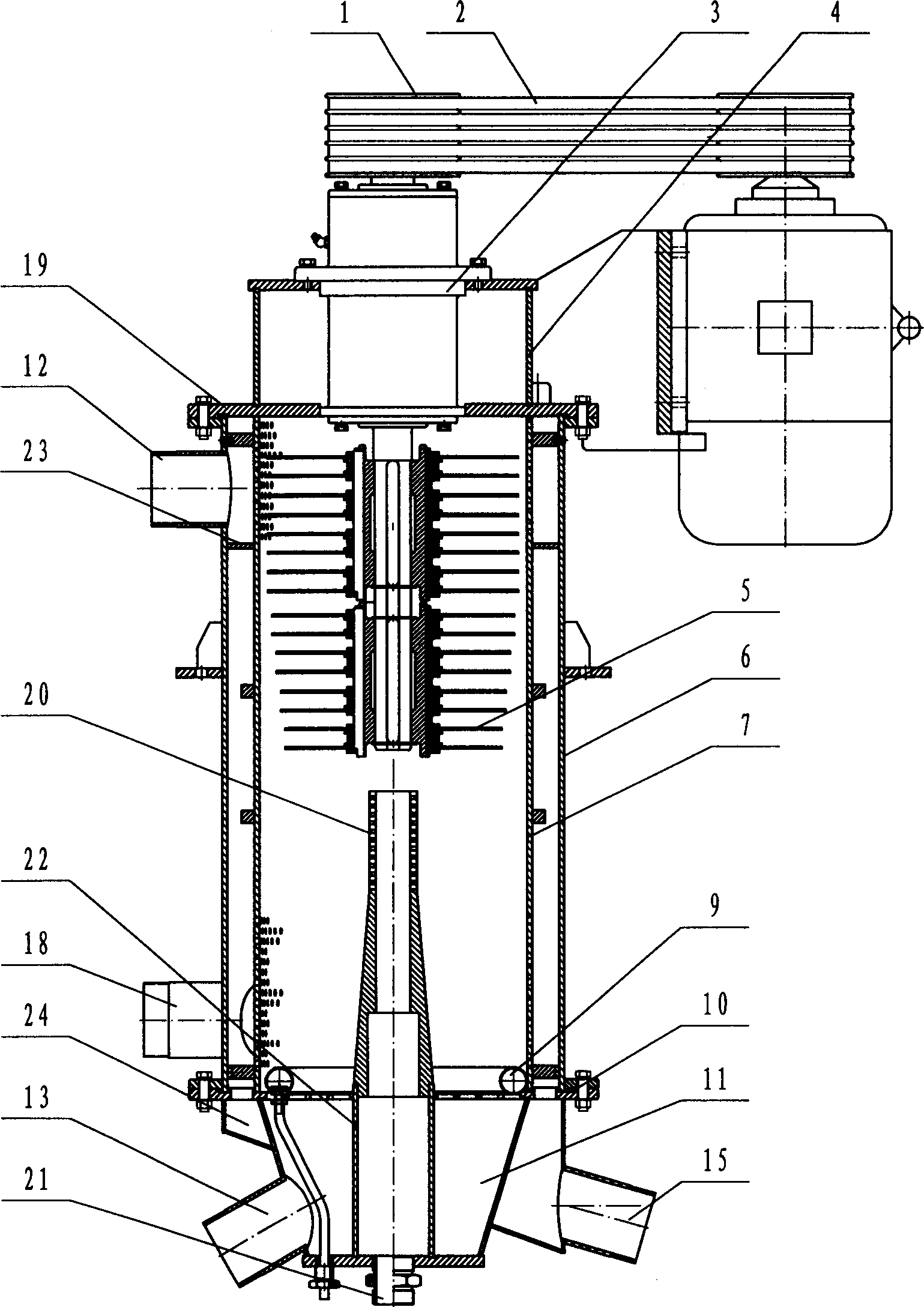

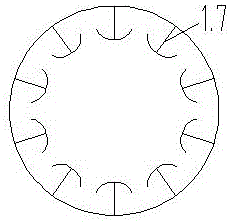

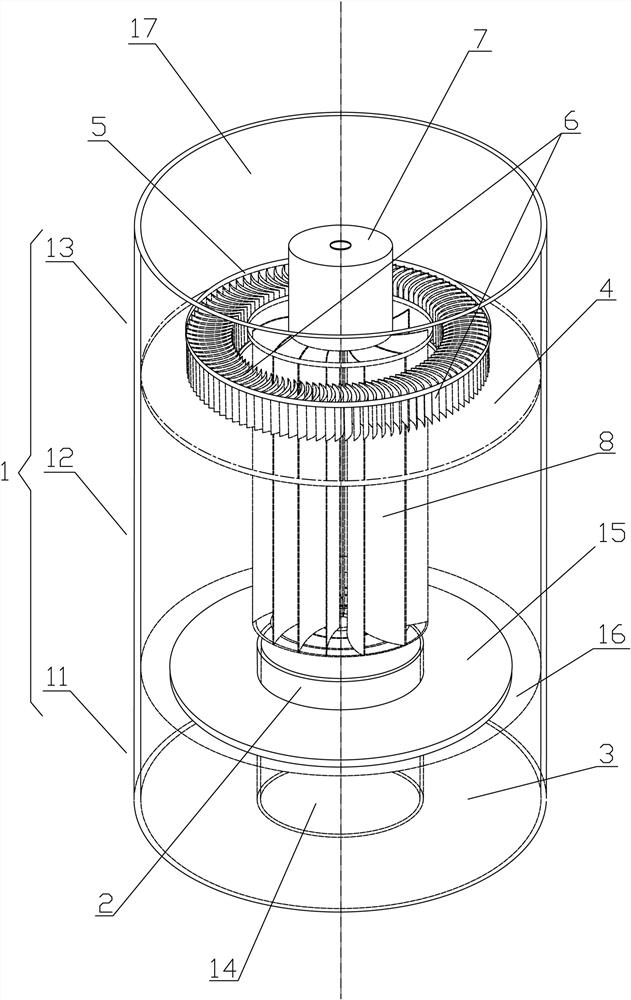

Settling centrifuger with internal rotor

InactiveCN1383926ADiffusion evenly distributedEasy to separateWater/sewage treatment by centrifugal separationCentrifugal force sediment separationSlurrySewage treatment

The present invention relates to the technology of centrifugal separation of mixed liquid. The centrifuge incldues transmission mechanism, pin wheel rotor with extending area covering at least partial centrifugal cavity space, slurry intake, casing and filtering cylinder assembly, aerator, slurry outlet filter and light phase skimming out device. The centrifugal cavity has several modes and several slurry and material discharge combinations. The material in slurry discharge filter is eliminated by centrifugal vortex and gravity. The present invention is used in solid-solid, liquid-liquid and solid-liquid-liquid separation, mass-transferring reaction and sewage treatment.

Owner:高根树

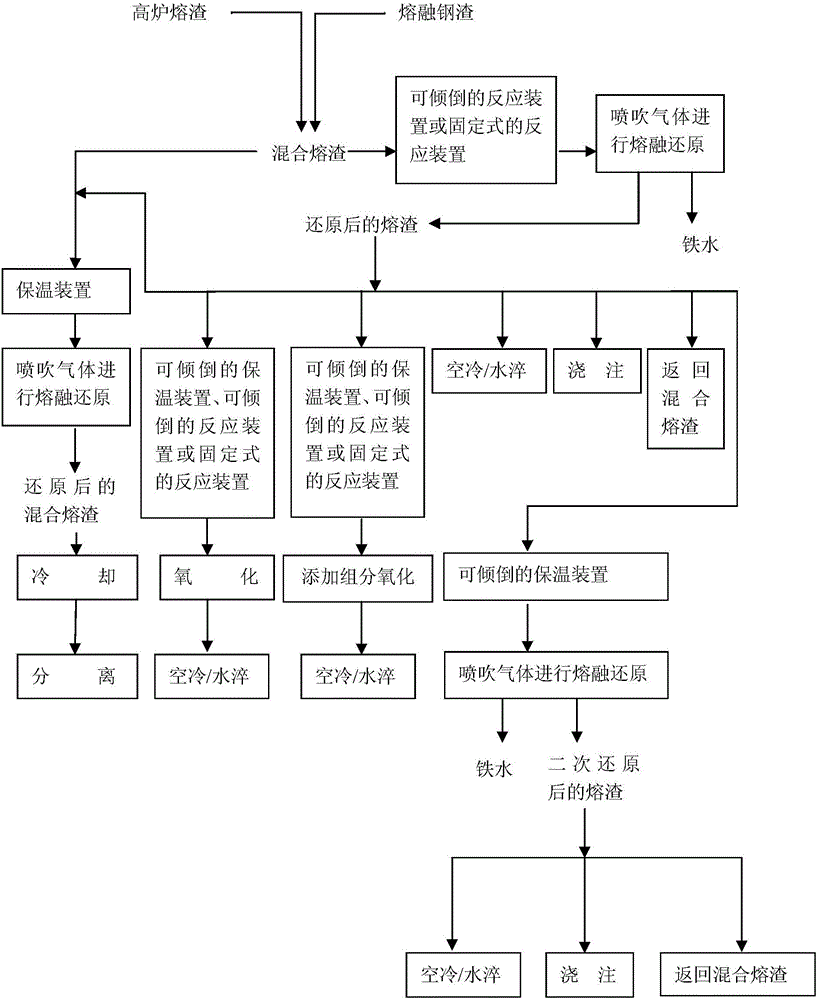

Method for mixed slag smelting reduction recycling and thermal refining

ActiveCN106048109ARealize smelting reduction ironmakingEasy to removeCement productionRecycling and recovery technologiesThermal energyEconomic benefits

The invention discloses a method for mixed slag smelting reduction recycling and thermal refining, and belongs to the field of non-blast furnace iron making and comprehensive utilization of resources. With the method, pig iron or steel and a phosphorus-rich phase are recycled from mixed slag, and slag thermal refining is carried out. The method comprises the following steps that (1) blast furnace slag and molten steel slag are mixed; (2) gas blowing is carried out to carry out smelting reduction; and (3) separation and recycling are carried out. According to the method, blast furnace slag and the molten steel slag are mixed, then, oxidizing gas is blown to carry out molten reduction iron making, the iron in the mixed slag is recycled, phosphorus-rich phase recycling and slag thermal refining are achieved, and the reduced slag can serve as slag cement or a cement regulator or an additive in cement production or cement clinker, or be used for producing high-value-added cement clinker. The method for mixed slag smelting reduction recycling and thermal refining is short in reaction time, high in metal recycling rate, low in production cost, high in material adaptability, high in handling capacity, friendly to the environment, high in economic benefit, and capable of effectively achieving the purpose of high-efficiency recycling of metallurgical resources and thermal energy, and is a new smelting reduction technology.

Owner:NORTHEASTERN UNIV

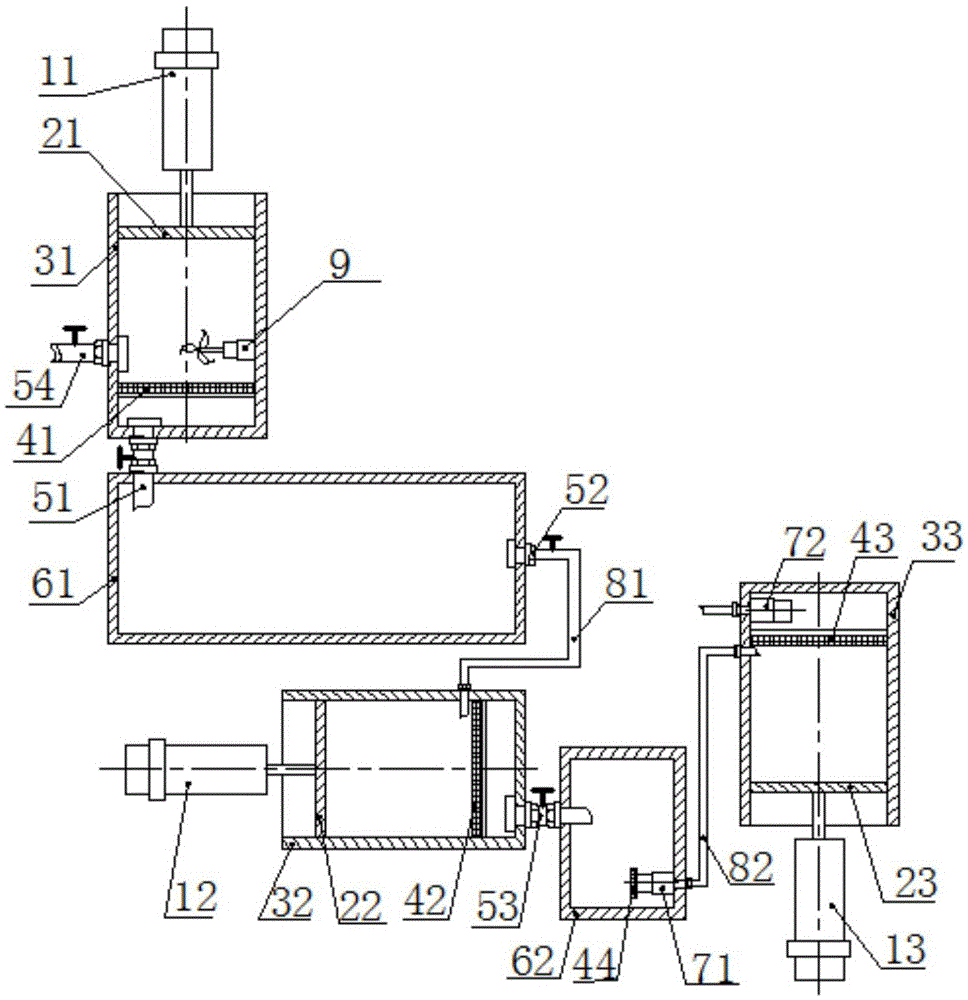

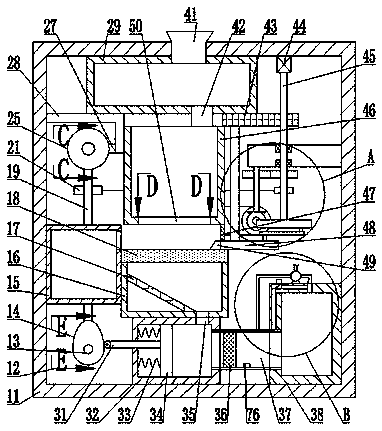

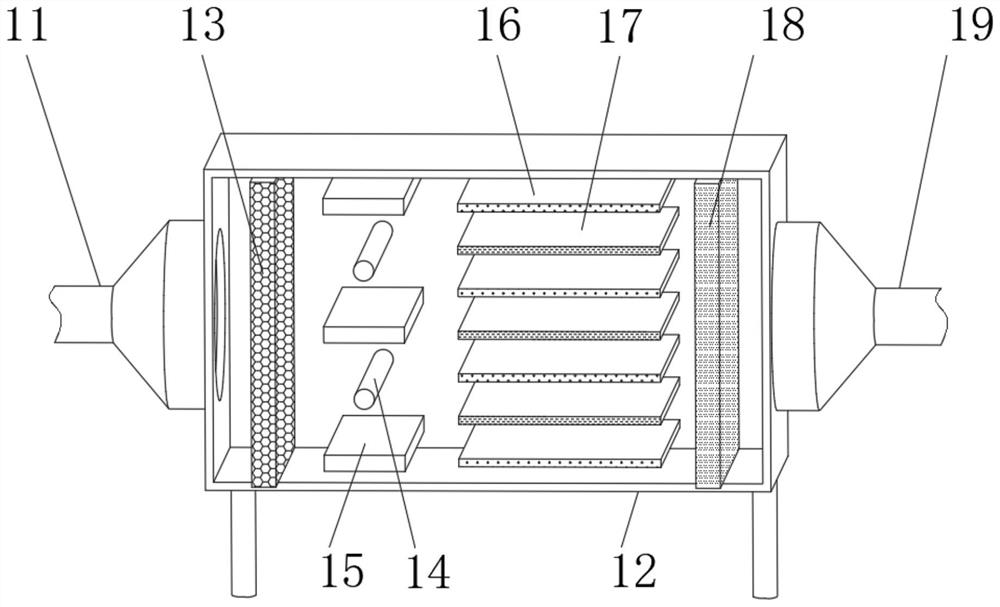

Magnetorheological fluid multi-stage treatment device and control method and component manufacturing method thereof

ActiveCN105457392AWell mixedSpeed up the reaction processMagnetic liquidsMembrane filtersMagnetorheological fluidEngineering

The invention discloses a magnetorheological fluid multi-stage treatment device and a control method and component manufacturing method thereof and belongs to the technical field of machine manufacturing. The magnetorheological fluid multi-stage treatment device comprises a preposition piston cylinder, a middle piston cylinder, a postposition piston cylinder, a preposition piston, a middle piston, a postposition piston, a preposition filtering box, a middle filtering box, a postposition filtering box, a preposition filtering mesh, a middle filtering mesh and a postposition filtering mesh. The preposition piston cylinder is connected with the preposition piston through a bolt, the preposition bolt is matched with an inner cavity of the preposition filtering box, the preposition filtering box is vertically arranged, and the axis is in the vertical direction; meanwhile, the invention further provides corresponding control method and a key component manufacturing method of the device. According to the magnetorheological fluid multi-stage treatment device and the control method and component manufacturing method thereof, a two-standing three-filtering mode is adopted to filter mixed liquid, the characteristic of the mixed liquid at each stage is fully utilized, and the purpose of fast and thoroughly separating magnetic substances and solvent is finally achieved.

Owner:浙江永金生物科技有限公司

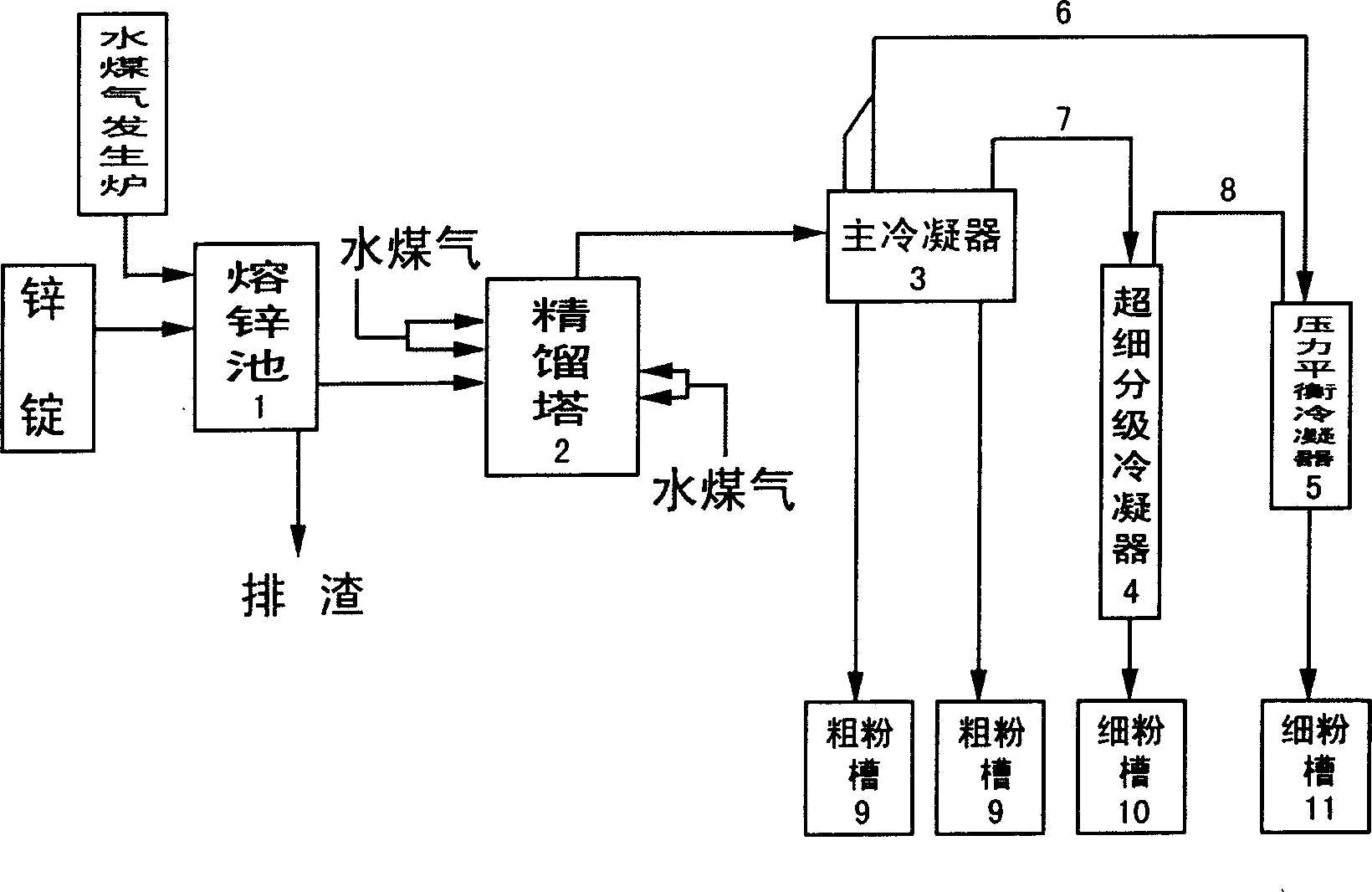

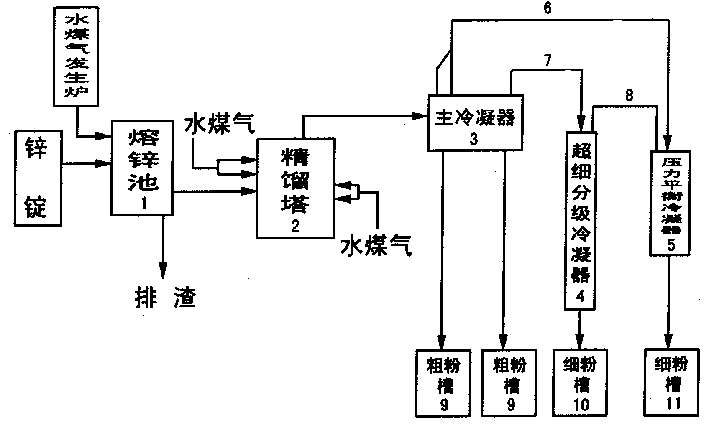

Method for producing zinc powder and its mfg. device

A process for preparing zinc powder includes smelting raw zinc, introducing to rectifying tower with high-temp towe trays, evaporating while rectifying for removing impurities, introducing Zn vapour to primary condenser, sudden condensing, outputting zinc powder from higher-temp end and then introducing to pressure-balanced condenser to obtain superfine zinc powder, outputting zinc powder from lower-temp end, superfine classifying to obtain superfine and ultrapure zinc powder, ball grinding in inertial gas, and squeezing to obtain flaky zinc powder. Its advantages are high uniformity, not oxidizing, and easy control.

Owner:上海笙创新材料有限公司 +1

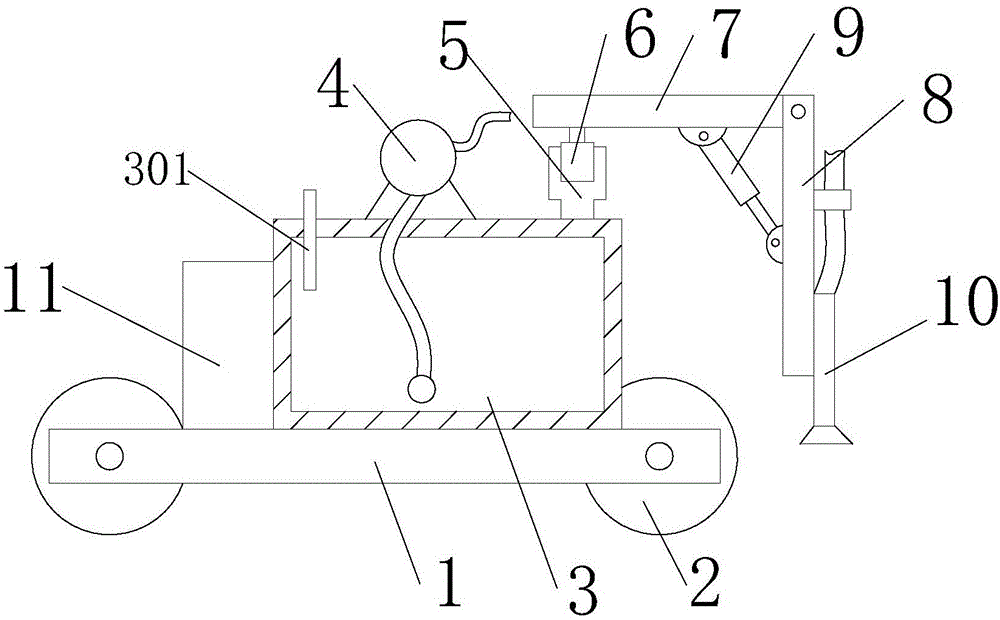

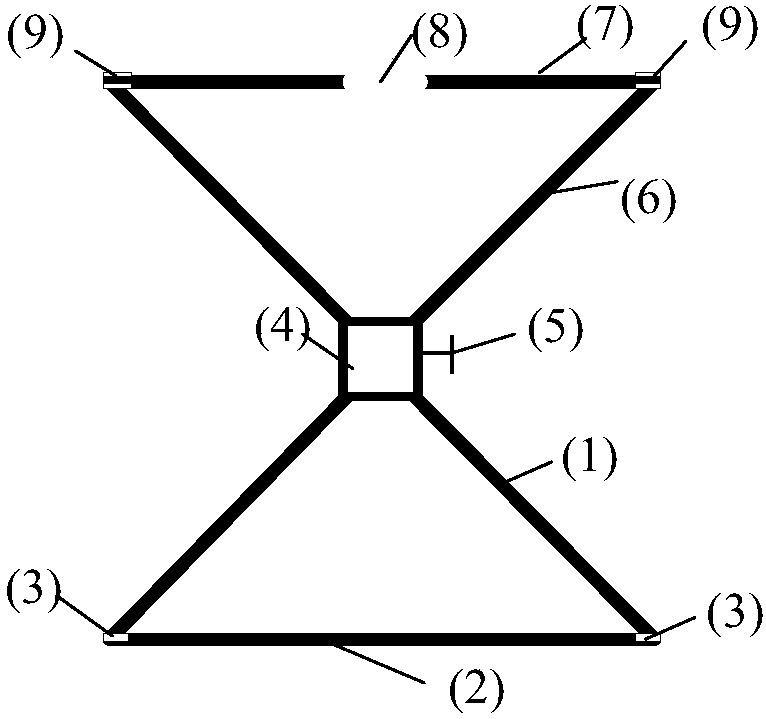

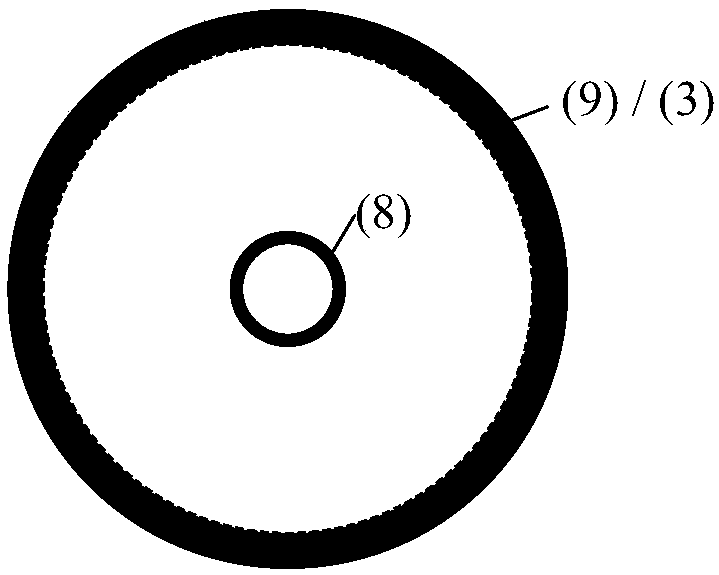

Expansion joint cutting equipment for bridge construction

InactiveCN108035228AFully settledImprove cutting efficiencyUsing liquid separation agentBridge erection/assemblyExpansion jointArchitectural engineering

Owner:程新锋

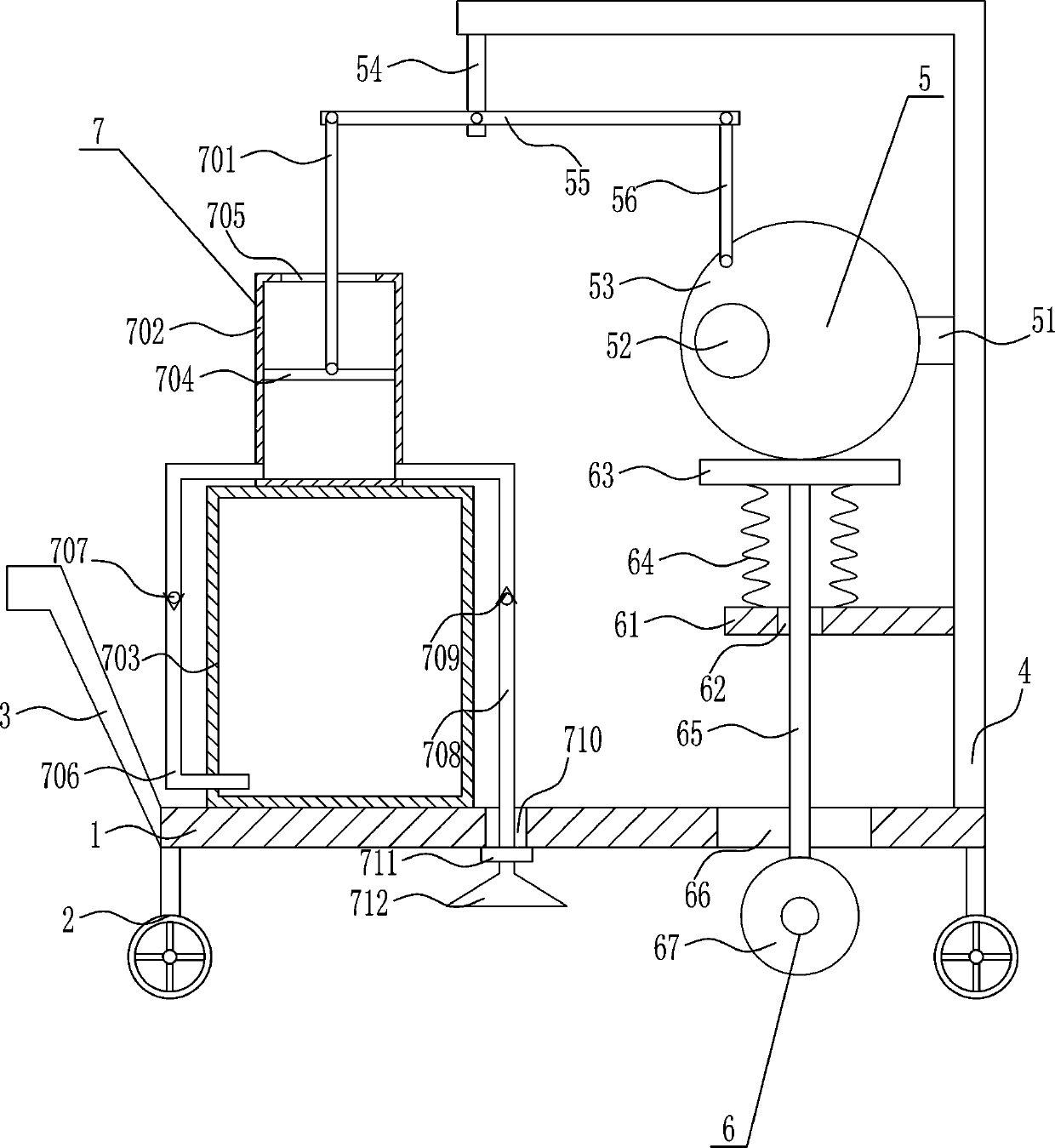

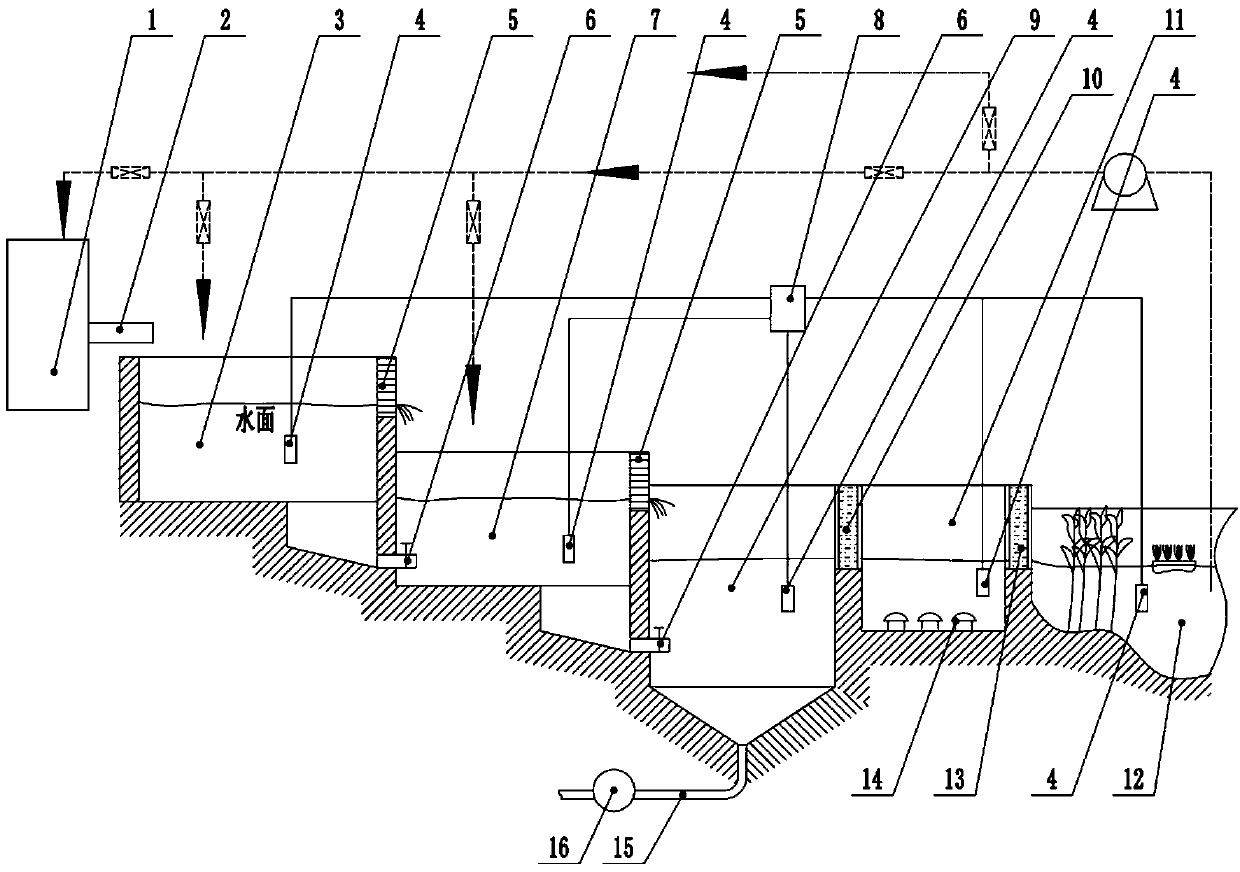

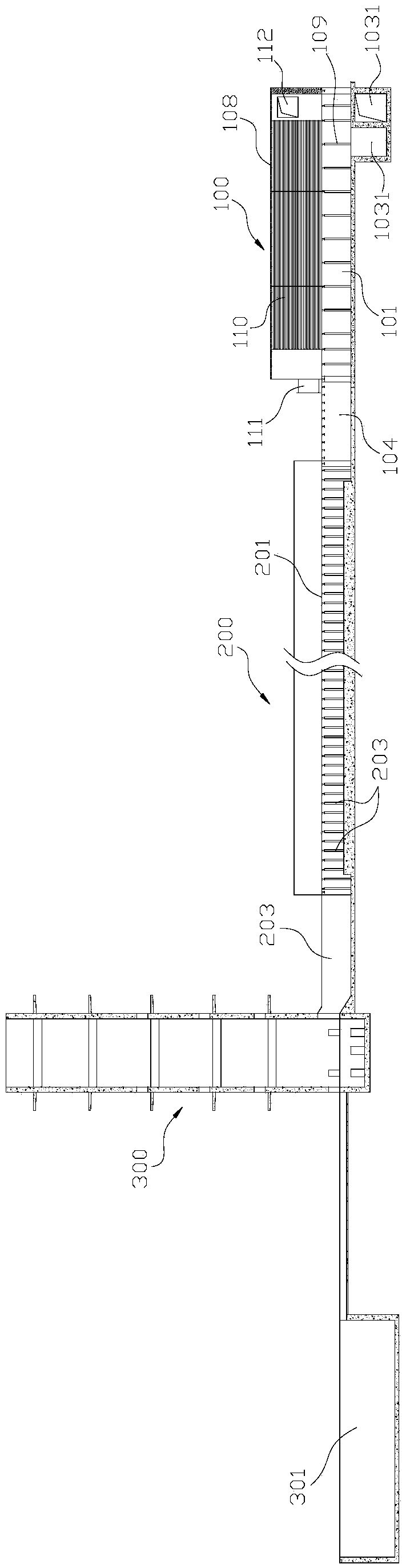

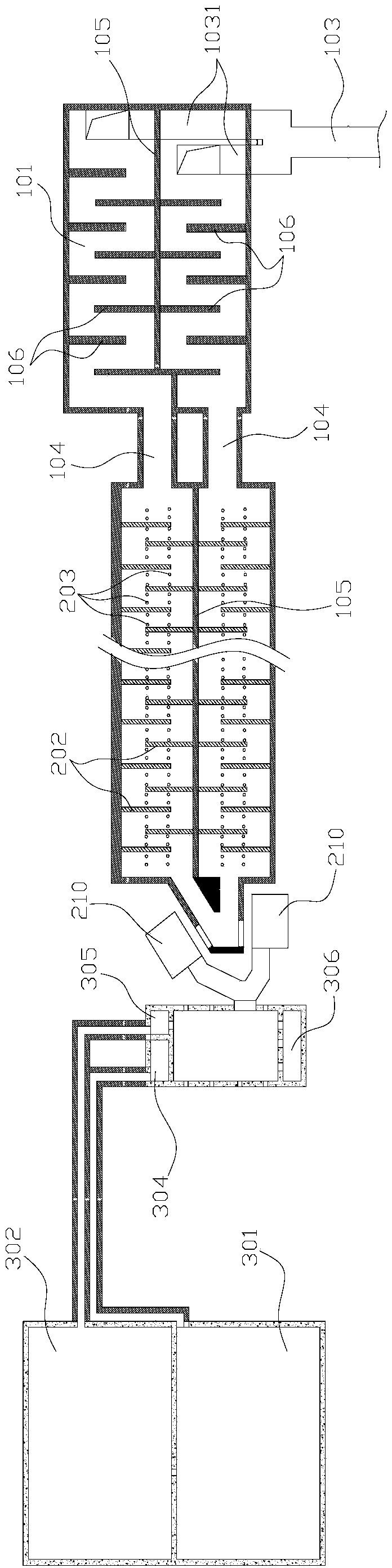

River wastewater treatment system and river wastewater treatment method

InactiveCN106746381AImprove performanceSignificant long-term running effectMultistage water/sewage treatmentRestoration methodWastewater

The invention discloses a river wastewater treatment system. A chemical settlement method, a biological restoration method and a physical adsorption method are combined, so that the wastewater treatment performance is reliable, the operation is stable, the maintenance cost is low and the long-term operation effect is significant. A mixing area is formed in a settlement area, a flocculating agent is fully mixed with wastewater firstly and then enters a gentle settlement area and the wastewater can be fully settled under the action of the flocculating agent; an impermeable layer is paved on the bottom surface of the gentle settlement area and can prevent settled pollutants from permeating an underlying channel along with water to cause underwater pollution and secondary pollution; a plant slow settlement area is arranged between the settlement area and a purification area, and sediments from the settlement area are further slowly settled and effectively prevented from entering the purification area under the action of plants; the purification area is provided with two stages of purification area, and a riverway of the purification area is set into an S form, so that the standing time of wastewater in the purification area is effectively prolonged and the full and effective purification effect can be achieved.

Owner:BINZHOU UNIV

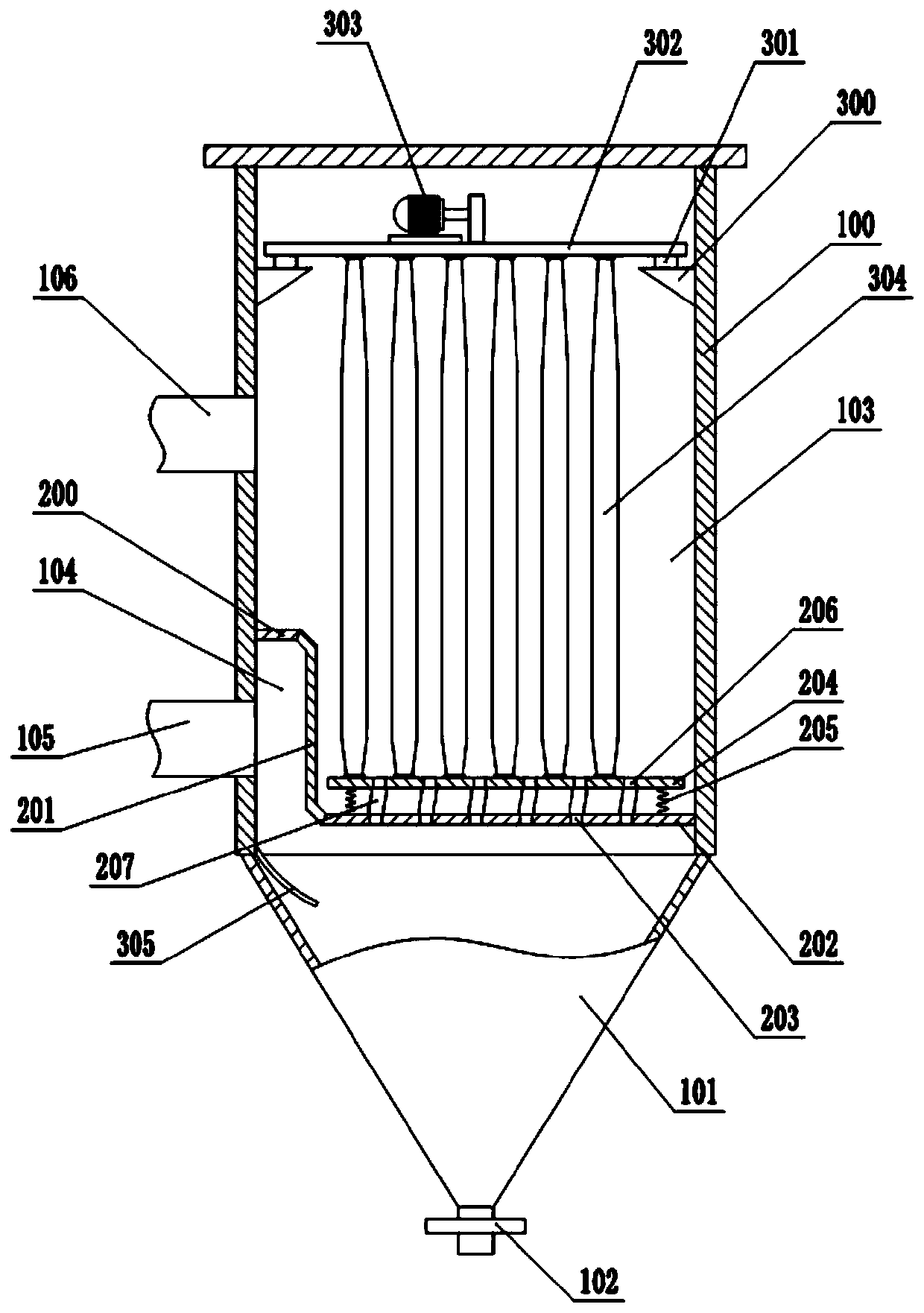

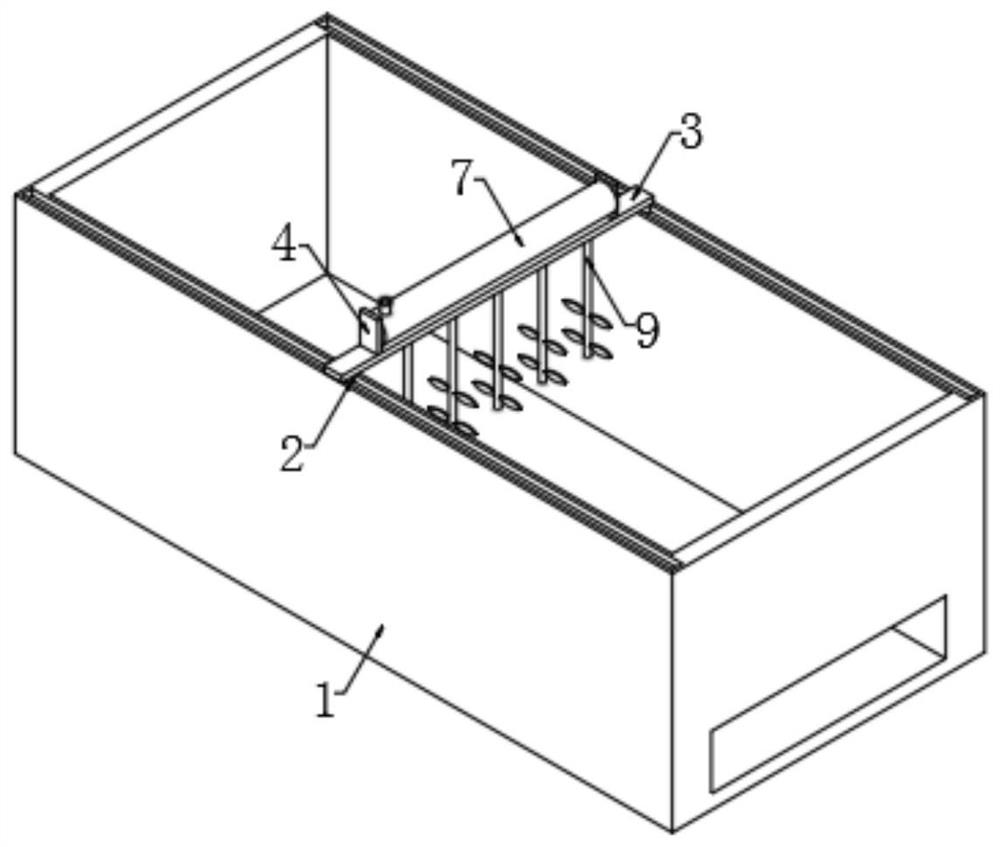

Sewage treatment device capable of automatically cleaning filter screen

InactiveCN111481992AReduce pollutionSettling fastSpecific water treatment objectivesTreatment involving filtrationSewageSewage treatment

The invention discloses a sewage treatment device capable of automatically cleaning a filter screen. The sewage treatment device comprises a machine body, wherein a working cavity is formed in the machine body; a precipitation assembly for precipitating large particles in the sewage is arranged in the working cavity; the precipitation assembly comprises an inverted L-shaped sliding plate which isconnected with the inner wall of the left side of the working cavity in a front-back sliding manner; rotating shafts extending front and back are rotationally connected to the inner walls of the frontand back sides of the working cavity; when the device works, the device works, particles in the sewage can be quickly settled through the settling assembly; sewage and sediment can be controlled to fall down through the switch assembly; the cleaning assembly can be used for cleaning sediments on the filter screen to prevent blockage, the purification assembly can be used for accelerating the removal of peculiar smell of treated sewage, the detection assembly can be used for detecting to enable qualified water to enter a collecting box, otherwise, the qualified water enters the water inlet boxagain, the treatment efficiency is improved, the treatment effect is enhanced, and the environmental pollution is reduced.

Owner:JINHUA XUANYA ENVIRONMENTAL PROTECTION TECH CO LTD

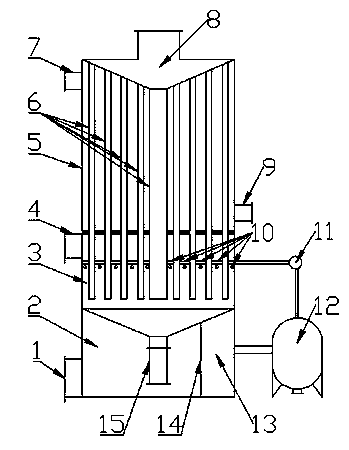

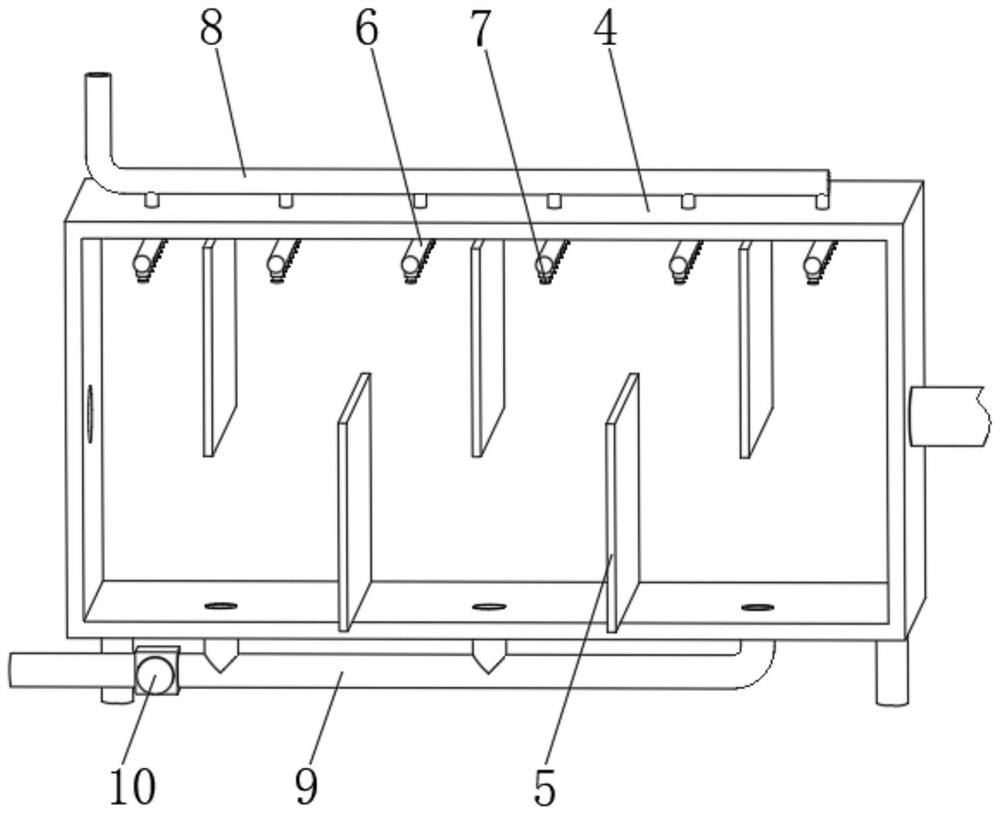

Flue gas waste heat recovery and dust removal device

InactiveCN103629956AFull absorption of waste heatFully settledUsing liquid separation agentStationary tubular conduit assembliesWater sourceFlue gas

The invention discloses a flue gas waste heat recovery and dust removal device. A plurality of heat exchange pipes are adopted to absorb the waste heat of the flue gas of a boiler, and then the cold flue gas enters the bottom of a dust removal chamber; a spray device in the dust removal chamber is used for removing the dust of the flue gas; after that, dust-free gas is discharged outside from an exhaust hole arranged at the upper part of the dust removal chamber; sewage is discharged into a sewage settling tank from a sewage outlet arranged at the bottom of the dust removal chamber; clear water enters a clear water chamber under the action of a filter device and then is further treated by a water purifier, so that part of water source is provided for the spray device. The flue gas waste heat recovery and dust removal device not only is capable of fully absorbing the waste heat of the flue gas, thus achieving the aim of saving energy, but also is capable of carrying out full sedimentation on the dust and acid gas in the flue gas, thus guaranteeing the discharged gas to be colorless, odorless and very environment-friendly; the sewage used for removing the dust is recycled after being further treated, so that the water resource is saved.

Owner:WUHAN UNIV OF SCI & TECH +1

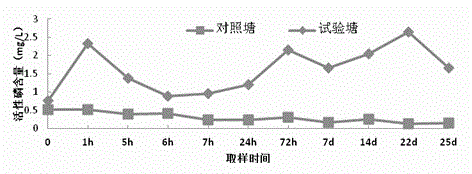

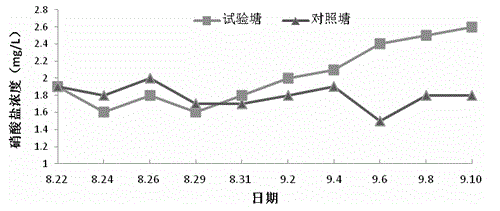

Efficiency-increasing breeding method for resourcefully treating bottom mud of intensive pond

ActiveCN104604773ARepair functionRepair function, restore oxidation stateClimate change adaptationPisciculture and aquariaOxygen enhancedGenetic stock

The invention relates to an efficiency-increasing breeding method for resourcefully treating bottom mud of an intensive pond, and belongs to the technical field of aquiculture. The method includes the steps of matching breeding species, resourcefully treating the bottom mud and using oxygen-increasing facilities. Omnivorous fish and filtering-feeding fish are bred in a mixed mode in proportion of 5:1 to 5:2, the bottom mud is resourcefully treated in the breeding period through a specific method, and finally the specific oxygen-increasing facilities are added; the three links act on one another, nutrients in the bottom mud are recycled, and therefore the aim of increasing efficiency during breeding is achieved; on one hand, original functions of the bottom mud are restored and the oxidization state is restored, and on the other hand, organics are oxidized and removed and the oxygen debt probability and the disease outbreak probability are lowered; the aim of increasing both production and income is achieved without throwing in more fish feed.

Owner:TONGWEI

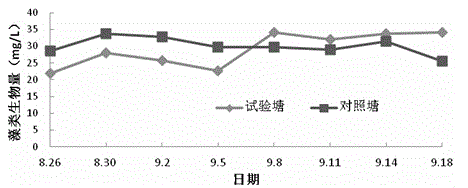

Apparatus for improving sulfur recovery ability of sulfur melting system

The invention discloses an apparatus for improving the sulfur recovery ability of a sulfur melting system, and relates to the technical field of recovery of sulfur in the sulfur melting system. The apparatus includes an oxidizing regeneration tank, an intermediate tank, elevated tanks and a sulfur melting kettle which are connected, the overflow opening of the sulfur melting kettle is connected to a semi removal tower through a transfer pump, a cooling pool, a cooling pool pump and a rich liquid tank are orderly connected between the overflow opening of the sulfur melting kettle and the transfer pump, the middle part of the intermediate tank is provided with a liquid outlet, and the outlet of a sulfur foam pump is connected with a liquid transferring tube connected with the rich liquid tube; and a sulfur foam outlet is connected with the sulfur foam pump through a first valve, the outlet of the sulfur foam pump is connected with the elevated tanks through second valves, the liquid outlet of the intermediate tank is connected with the inlet of the sulfur foam pump through a third valve, and the liquid transferring tube is provided with a fourth valve. Compared with apparatuses in the prior art, the apparatus disclosed in the invention allows sulfur foams to be fully settled, separated and concentrated, reduces the load of a sulfur recovery device, and increases the sulfur recovery rate; and a residual liquid generated in the sulfur melting kettle is cooled, settled, separated and recovered to the system, so the resistance of the semi removal is reduced.

Owner:广西鹿寨化肥有限责任公司

Utilization method of phosphate ores

InactiveCN105692575ALow viscosityDimensionally stableCalcium/strontium/barium sulfatesPhosphoric acidCalcium phosphorusTri calcium phosphate

The invention discloses a utilization method of phosphate ores. The utilization method comprises the following steps: crushing and finely grinding the phosphate ores to obtain phosphate ore powder; stirring the phosphate ore powder and hydrochloric acid to react at a room temperature for 0.5 hour to 6 hours; carrying out solid-liquid separation; carrying out fluorine removal, impurity removal, calcium-phosphorus separation (sedimentation, filtering, extracting, drying and the like) on a liquid solution; furthermore, treating a residual calcium chloride solution; finally, obtaining products including fertilizer-grade calcium hydrogen phosphate, feed-grade calcium hydrogen phosphate, phosphorus-nitrogen composite flame retardant, tricalcium phosphate, calcium sulfate whiskers and the like, and also obtaining a diluted hydrochloric acid solution; rectifying and concentrating the diluted hydrochloric acid solution and returning the solution back to a phosphate ore powder acidolysis procedure. According to the utilization method, the used hydrochloric acid can be circularly utilized, and the hydrochloric acid can be generated; the obtained hydrochloric acid is used for decomposing the phosphate ores again and the acidolysis cost is low; meanwhile, the phosphorus chemical products including the fertilizer-grade calcium hydrogen phosphate, the feed-grade calcium hydrogen phosphate, the phosphorus-nitrogen composite flame retardant, the tricalcium phosphate, the calcium sulfate whiskers and the like can also be obtained, so that the comprehensive utilization efficiency of the phosphate ores is high and the economic benefits are good.

Owner:GUIZHOU INST OF METALLURGY & CHEM ENG

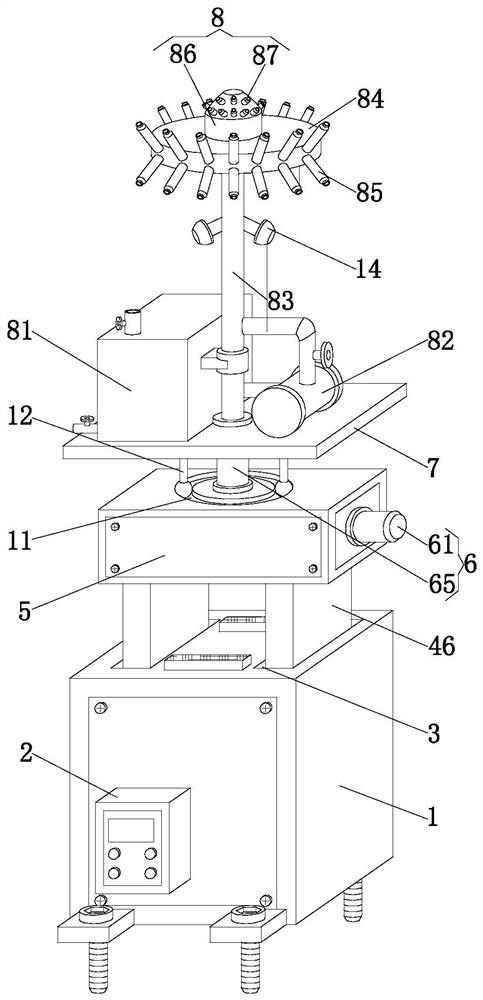

Constructional engineering environment monitoring device

PendingCN112452076AExpand the surveillance shooting areaImprove monitoring effectTelevision system detailsUsing liquid separation agentEnvironmental resource managementAtomizer nozzle

The invention relates to the field of constructional engineering, in particular to a constructional engineering environment monitoring device. The height of a moving box and the height of a monitoringcamera can be adjusted in a lifting mode, a monitoring shooting area of the monitoring camera is enlarged, the monitoring effect of the monitoring camera on a construction site is enhanced, the supporting plate can be driven to rotate circumferentially at a constant speed, and therefore dust flying all around can be evenly sprayed with water; flying dust can be uniformly wetted, so that water vapor is in effective contact with dust particles, the settling effect of the dust is enhanced, and the environment-friendly treatment operation of a construction engineering site is facilitated; auxiliary sliding supporting can be conducted on the lifting plate, the stability of the supporting plate in the lifting process is enhanced, the situation that the lifting plate shakes is avoided, high-pressure nozzles and atomizing nozzles are distributed along the center of a disc in a circumferential structure, dust particles flying around can be subjected to uniform water spraying treatment, and thepurpose of fully settling the dust is achieved.

Owner:徐州中交徐盐高铁客运枢纽有限公司

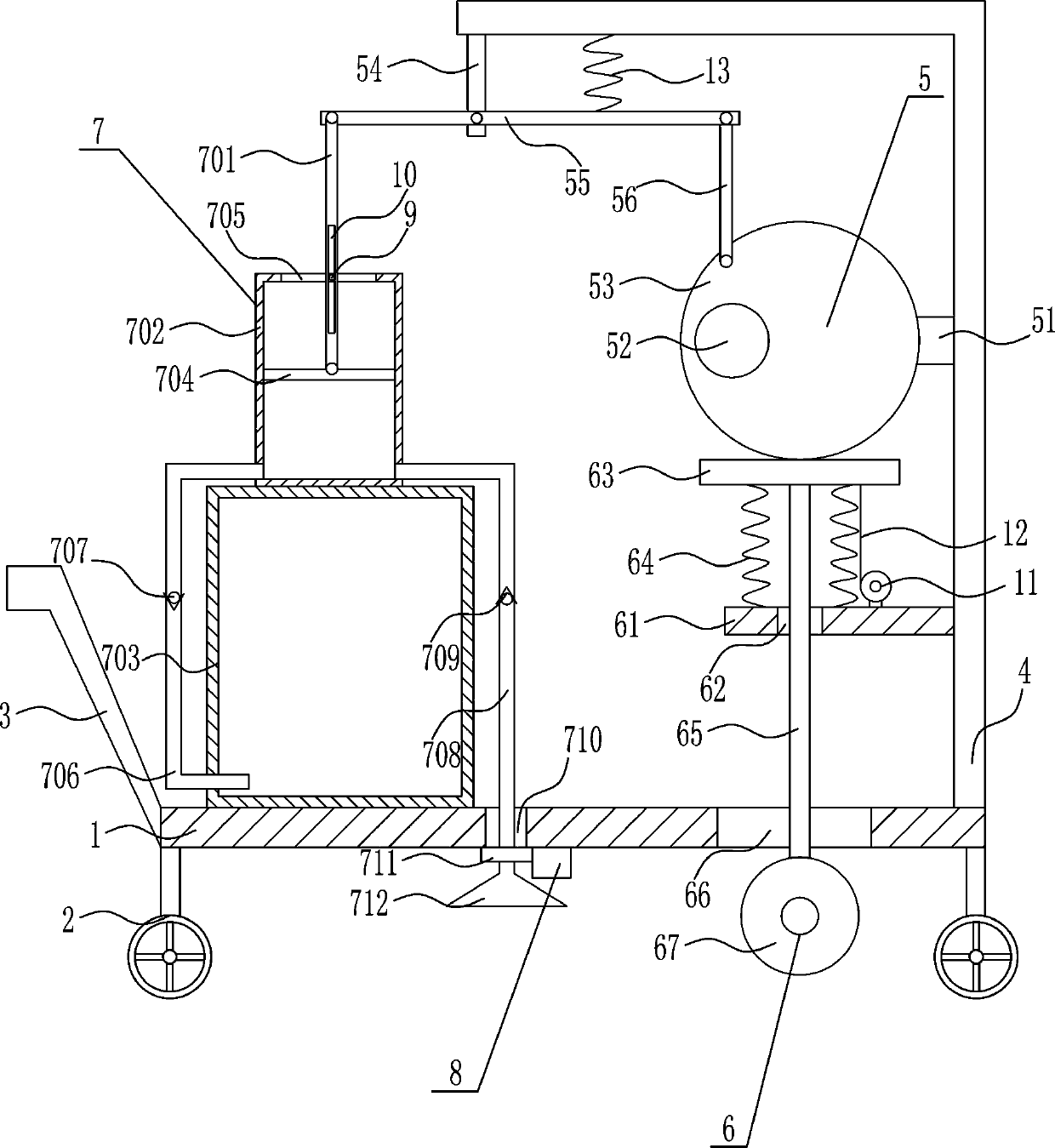

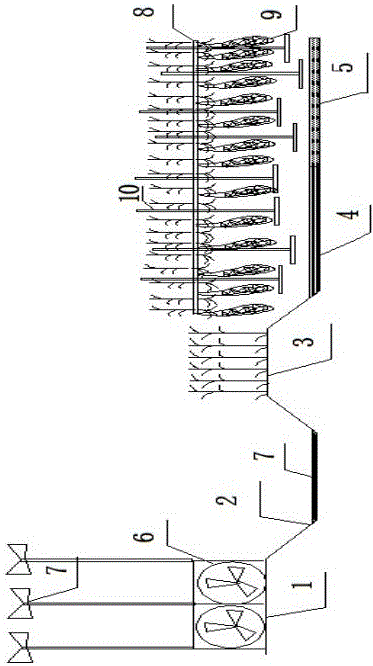

Seed screening and water separating device

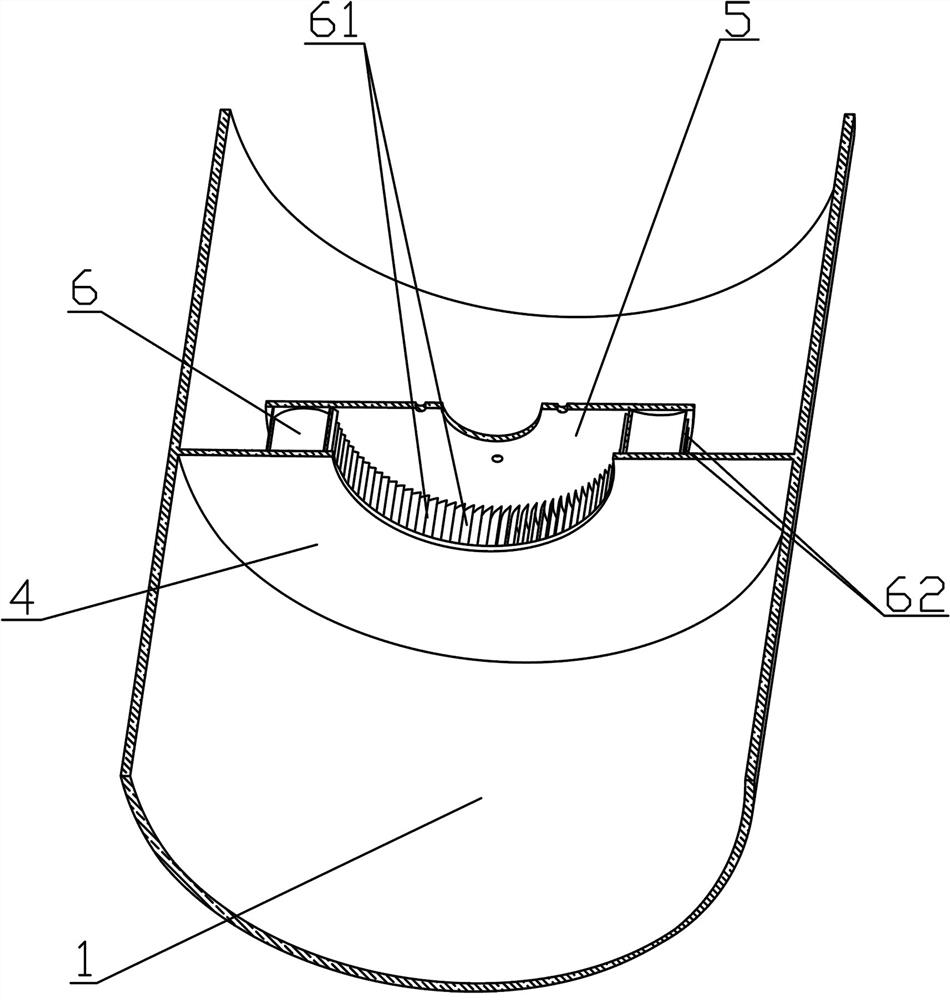

InactiveCN109013042AAgitation worksEffective settlementSeed and root treatmentCleaning using liquidsScreening effectSurface mounting

The invention relates to the technical field of seed water separation and screening and discloses a seed screening and water separating device. The device comprises a base, and top of the base is fixedly connected with two symmetric supporting frames. A supporting plate is fixedly connected between the top ends of the two supporting frames, and the front face of the supporting plate is fixedly connected with two symmetric fixed sleeves. A water inlet pipe is sleeved between the inner rings of the two fixed sleeves, and spray heads are mounted on the outer surface of the water inlet pipe at equal intervals. A fixed plate is fixedly connected between the opposite side faces of the two supporting frames. The bottom of the fixed plate is fixedly connected with a motor and two supports. An output shaft of the motor is fixedly connected with a first belt wheel through a rotary shaft, and a rotary rod is movably connected between the side faces of the two supports. The seed screening and water separating device solves the problems that an existing seed water separation device is not high in work efficiency, seed separation is not thorough, trouble is caused, and labor is wasted, and has the beneficial effects of being high in work efficiency and good in screening effect and saving trouble and labor.

Owner:合肥安农源生物工程技术有限公司

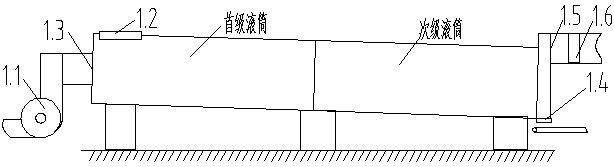

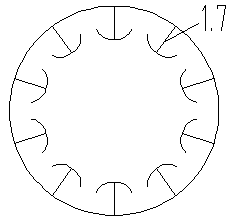

Environment-friendly suspended hot air furnace for coarse straw bran

InactiveCN109058974AEnvironmental protection is goodLow costDrying gas arrangementsSolid fuel combustionEnvironmental resistanceCombustion chamber

The invention belongs to the technical field of hot air furnaces, and discloses an environment-friendly suspended hot air furnace for coarse straw bran. The environment-friendly suspended hot air furnace comprises a bracket; a spiral auger, an air blower, a main combustion chamber, a secondary combustion chamber and a settling chamber are arranged on the bracket; a horizontal first air distribution plate is arranged in the main combustion chamber; the secondary combustion chamber is arranged on one side, far from the air blower, of the main combustion chamber; a first opening formed in the upper end of the first air distribution plate in the main combustion chamber; the settling chamber is formed in one side, far from the main combustion chamber, of the secondary combustion chamber; a hotair output pipeline is vertically fixedly connected to one side, opposite to a second opening, of the settling chamber; and igniters are arranged at the position where the main combustion chamber is positioned at the upper end of the first air distribution plate and the position where the secondary combustion chamber is positioned at a second air distribution plate. The environment-friendly suspended hot air furnace is simple in structure and high in environment-friendly performance, can be widely applied in the field of grain drying, and has obvious progressive significance.

Owner:ANHUI CHENYU MECHANICAL

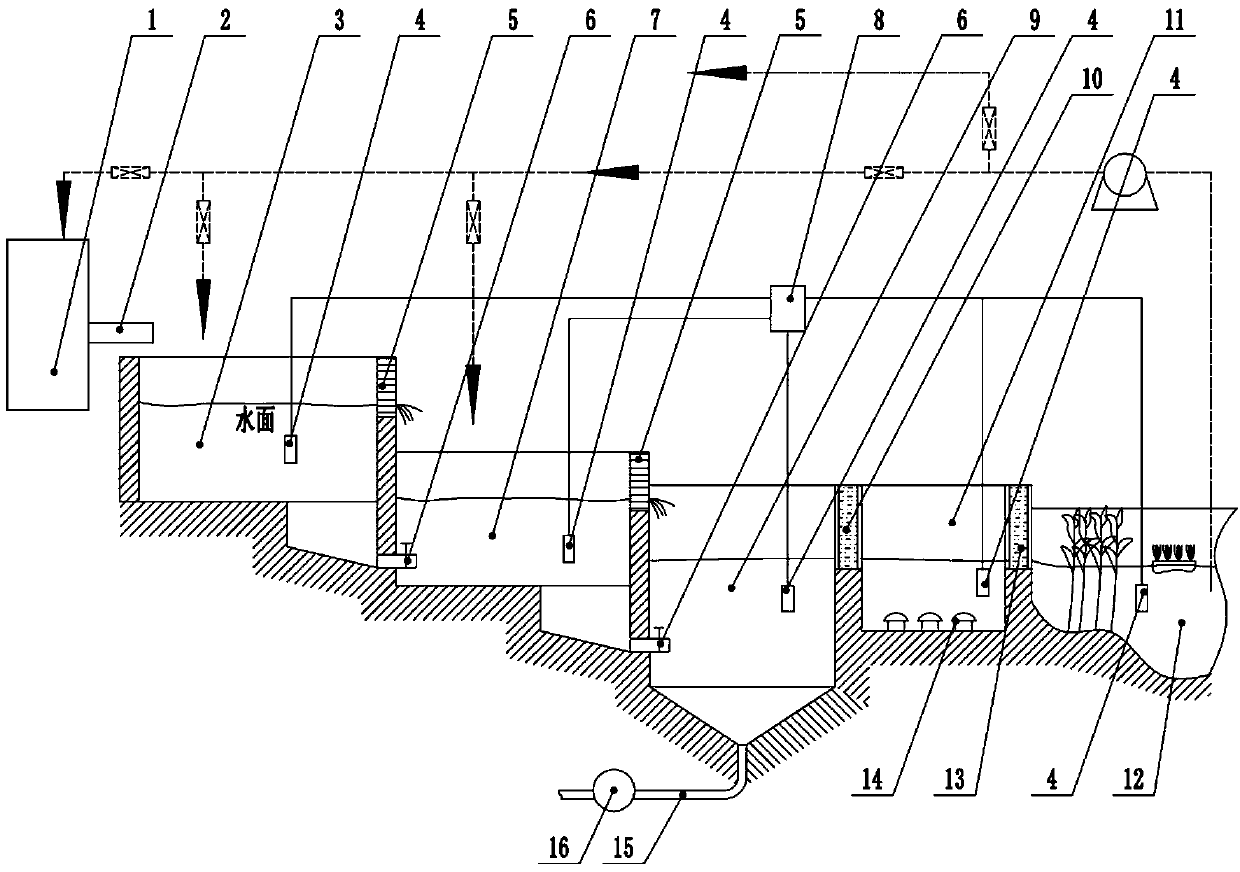

Culture tail water ditch circulating treatment system

PendingCN111115989AEasy to handlePlay the role of isolation protectionWater/sewage treatment by irradiationWater aerationSludgeSewage

The invention relates to a culture tail water ditch circulating treatment system. The circulating treatment system comprises a precipitation ditch, a sewage collection conical-bottom round pool, an aeration pool and an ecological pond; a draft tube is communicated with one side of the precipitation ditch, and the other side of the precipitation ditch is communicated with the upper part of one sideof the sewage collection conical-bottom round pool through a fence to form a tangential water inlet channel; the upper part of the other side of the sewage collection conical-bottom circular tank iscommunicated with the upper part of one side of the aeration tank through a primary filter dam; the upper part of the other side of the aeration tank is communicated with the ecological pond through asecondary filter dam; sludge pumping equipment is connected to the bottom of the sewage collection conical-bottom round pool through a sludge discharge pipe; an underwater ultraviolet lamp is arranged in the middle of the sewage collection conical-bottom round pool; the bottom of the water inlet end of the ditch section is horizontally arranged, the bottom of the water outlet end is sunken and inclines towards the water outlet end, and the left and right sides of the water outlet end incline towards the middle to form chutes; a standby blow-off pipe is arranged at the lower end of each chute;and one or more of a biological hairbrush, purified water fishes and an ecological base band is placed in the ditch section according to the characteristics of tail water. The system is good in tailwater purification effect and low in maintenance and operation cost.

Owner:广西壮族自治区水产引育种中心

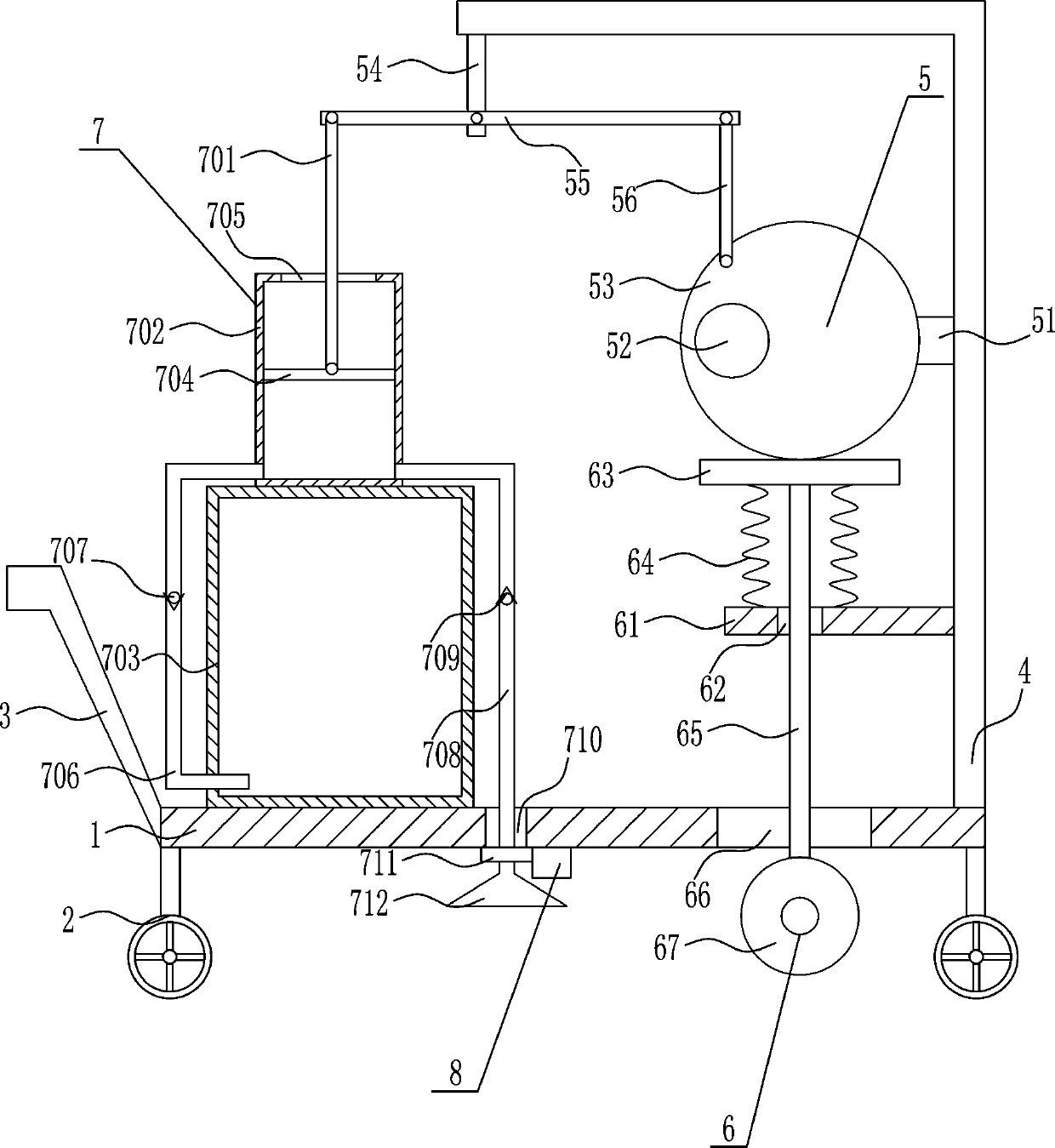

Indoor dust reduction equipment

InactiveCN105833635AImprove filtering effectMeet quality requirementsUsing liquid separation agentAir filtrationEngineering

The invention relates to an indoor dust suppression device, comprising a support base plate, wheels are provided on both sides of the support base plate, a water tank is provided on the upper end of the support base plate, a water inlet pipe is provided on the water tank, and a fixing frame is provided on the upper end of the water tank. A rotator is provided on the fixed frame, the rotator is connected to one end of the first connecting rod, the first connecting rod is connected to the second connecting rod, and the first connecting rod and the second connecting rod are connected to each other. An adjustment rod is provided, and a dust suppression nozzle is provided at the lower end of the second connecting rod, and the dust suppression nozzle is connected with the water pump through a water delivery pipe. When the present invention is in use, the water pump presses the water inside the water tank into the nozzle of the dust-reducing nozzle to realize sufficient settlement and filtration of dust in the air. At the same time, the position of the dust-reducing nozzle is adjusted on the adjusting rod, which effectively improves the effect of air filtration and satisfies the needs of people. Air quality requirements.

Owner:齐宽宽

Device and method for measuring stability of strong suspension pulp at normal temperature

ActiveCN107621429AHigh precisionOperating economyWeighing by removing componentSetting timeSedimentation

The invention relates to a device and a method for measuring the stability, belongs to the technical field of soil measurement, and particularly relates to a device and a method for measuring the stability of a strong suspension pulp at the normal temperature. The main principle is that a slurry container is divided into two cone parts, the volumes of the upper part and the lower part are the same, the normal sedimentation of the slurry is not affected, the upper part and the lower part of the container are connected through a union, and after the slurry stands for a set time, the union is slightly screwed, a valve is closed, the upper container and the lower container are communicated, the slurry in the upper-layer container and the slurry in the lower-layer container are respectively poured out from the top part and the bottom part, the weights of the slurries are weighed, and the settleability of the slurry is obtained through the mass difference of the slurry on the upper layer andthe slurry on the lower layer.

Owner:中煤科工生态环境科技有限公司

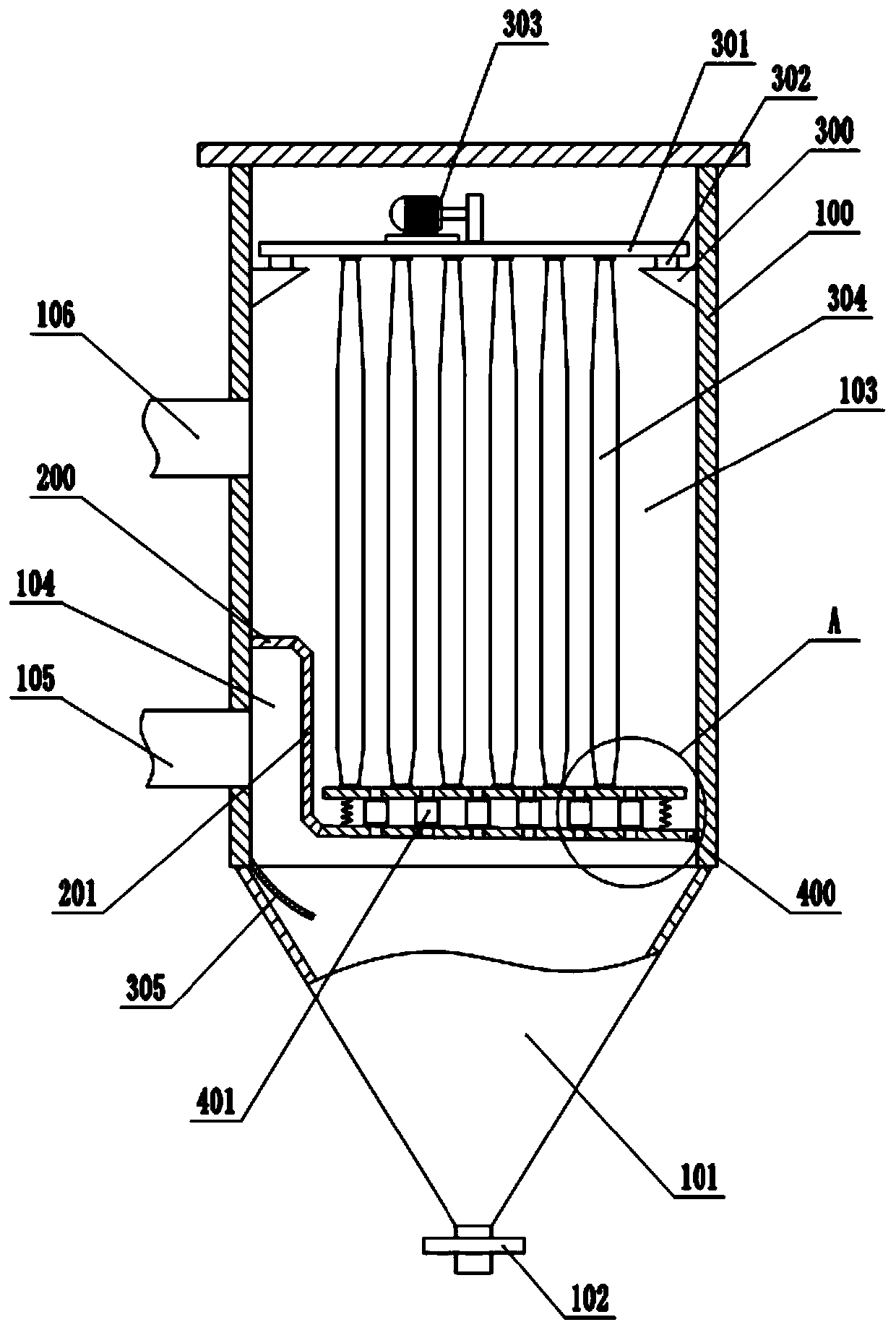

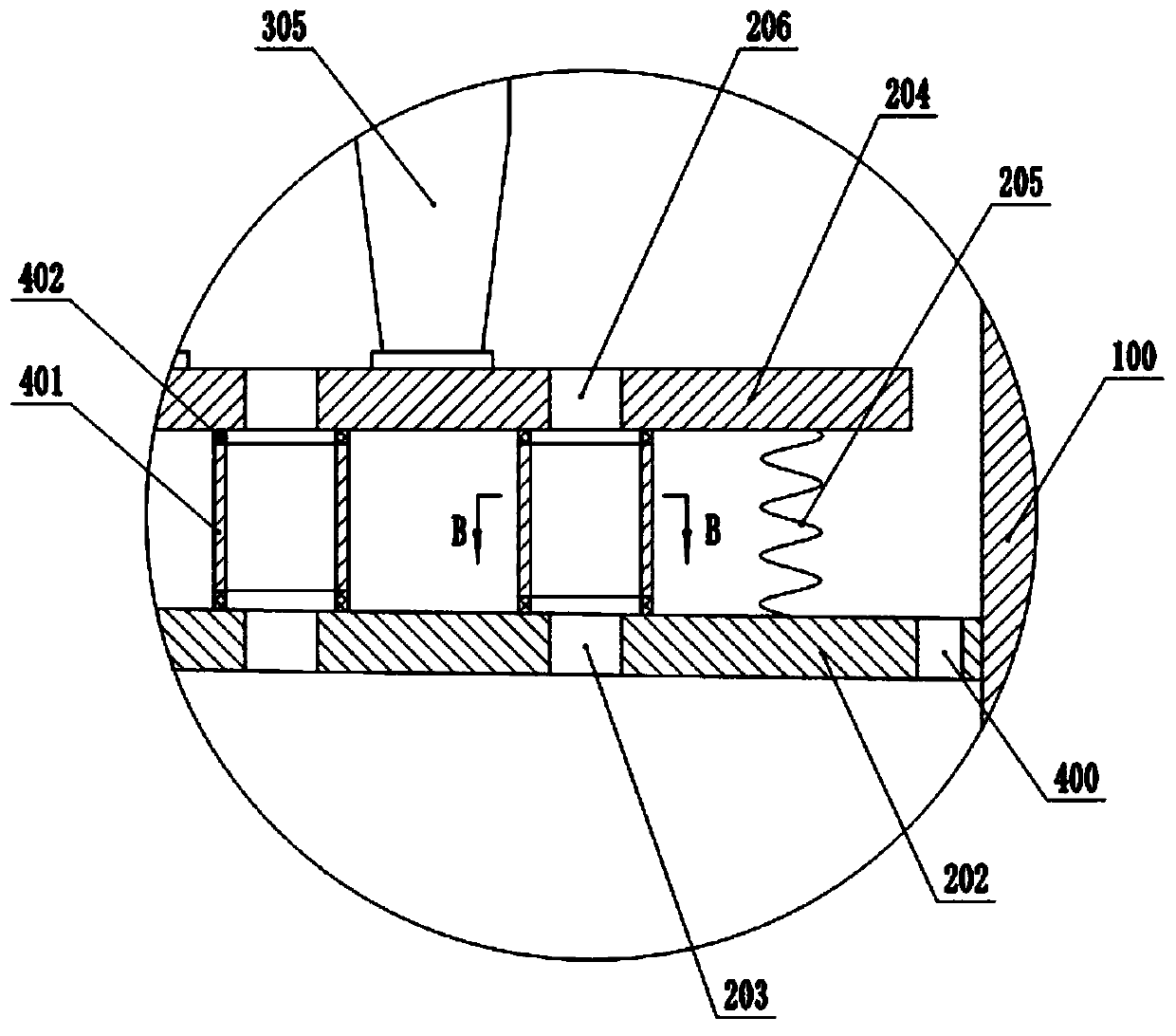

Dust remover for dumping furnace self-baking electrode volatile matter

ActiveCN110339640AExtended service lifeReduce pulling forceCombination devicesDispersed particle filtrationEngineeringElectrode

The invention relates to the technical field of waste-gas treatment equipment, and particularly discloses a dust remover for dumping furnace self-baking electrode volatile matter. The dust remover comprises a box body and an ash hopper; a partition plate is laterally fixed in the box body, the partition plate divides the box body into a purification chamber and a cleaning chamber, and the partition plate is provided with a plurality of through holes I; the box body is provided with a gas inlet communicating with the purification chamber and a gas outlet communicating with the cleaning chamber,a plurality of filter bags located above the partition plate is vertically arranged in the box body, and a vibrating unit vibrating the filter bags is arranged in the box body; and a buffer plate isarranged above the partition plate, the bottoms of the filter bags are fixed on the buffer plate, the baffle plate is connected with the partition plate through elastic parts, the buffer plate is provided with a plurality of through holes II, and each middle pipe communicates with one corresponding through holes I and one corresponding through holes II. The dust remover provided by the invention can solve the problem that connection positions of filter bags and a partition plate are broken because the connection positions are pulled during vibration in the prior art.

Owner:重庆市赛特刚玉有限公司

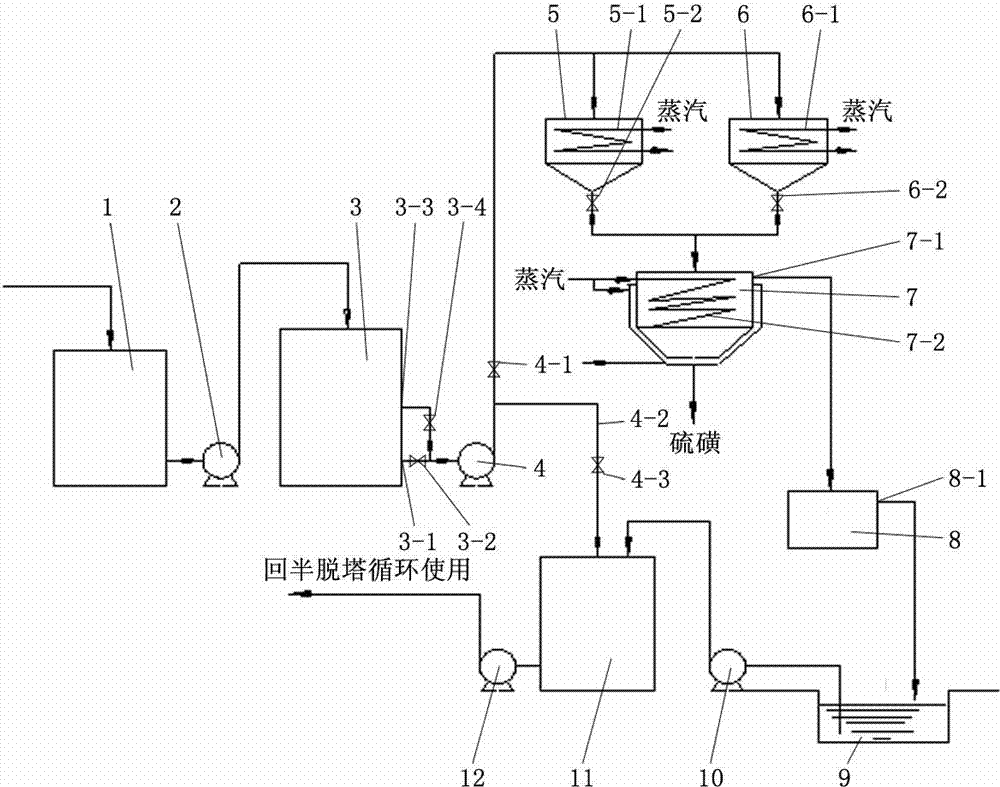

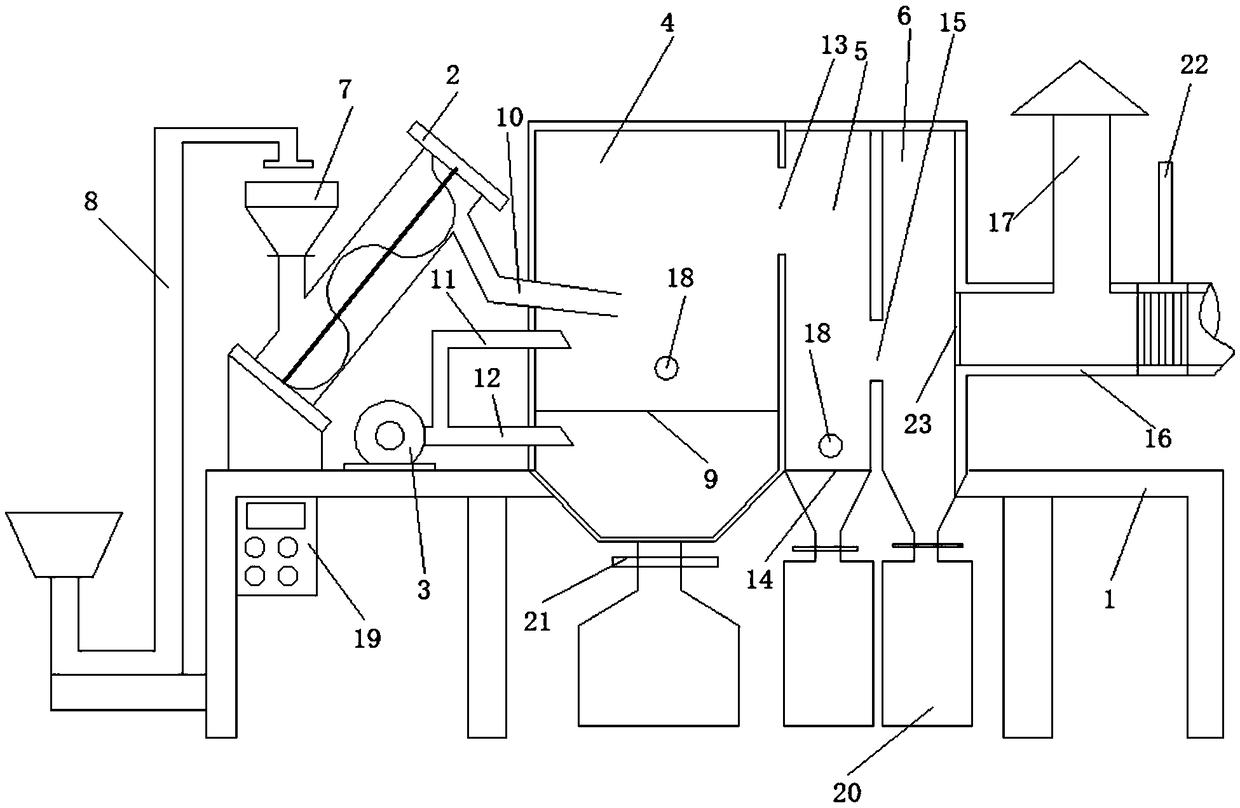

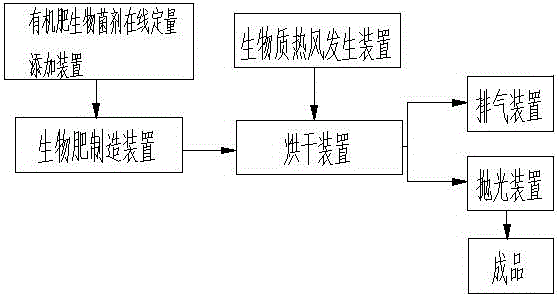

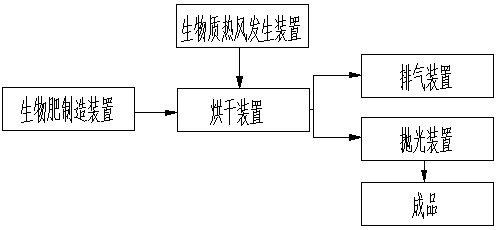

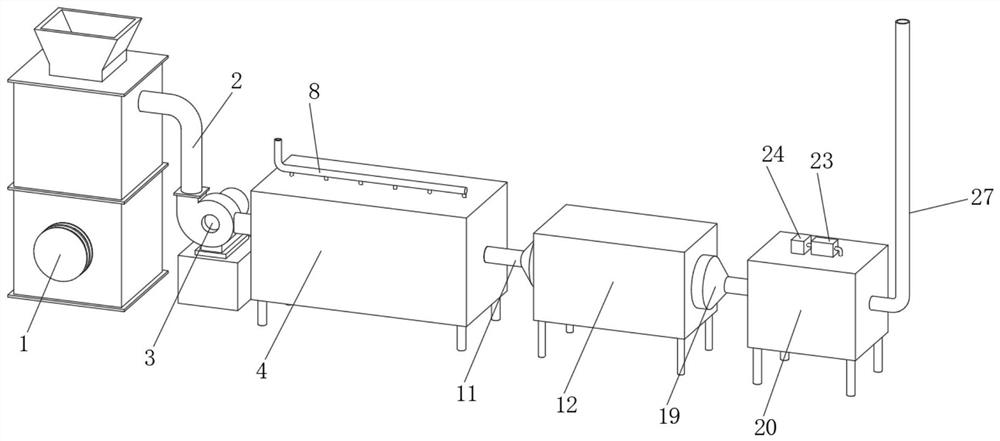

Novel organic bio-fertilizer production system

InactiveCN106083239ASmooth feedingAdd evenlyBio-organic fraction processingManure dryingPulp and paper industryBiomass

The invention discloses a novel organic bio-fertilizer production system. The novel organic bio-fertilizer production system comprises an organic fertilizer bio-inoculant online quantitative addition device, a bio-fertilizer preparation device, a biomass energy hot air generation device, a drying device, an exhaust device and a polishing device. The organic fertilizer bio-inoculant online quantitative addition device is connected with the bio-fertilizer preparation device through a conveying belt, the bio-fertilizer preparation device and the biomass energy hot air generation device are connected with a feeding port and an air inlet of the drying device respectively, and the tail end of the drying device is connected with the polishing device and the exhaust device. The novel organic bio-fertilizer production system aims at achieving the technical purposes of continuously producing organic bio-fertilizer, quantitatively adding bio-inoculant online and achieving higher environmental friendliness, energy saving performance and efficiency; according to the novel organic bio-fertilizer production system, biomass energy is utilized for producing bio-fertilizer, so that the production cost of an enterprise is lower, and higher environmental friendliness is achieved.

Owner:SICHUAN KAIERFENG AGRI TECH CO LTD

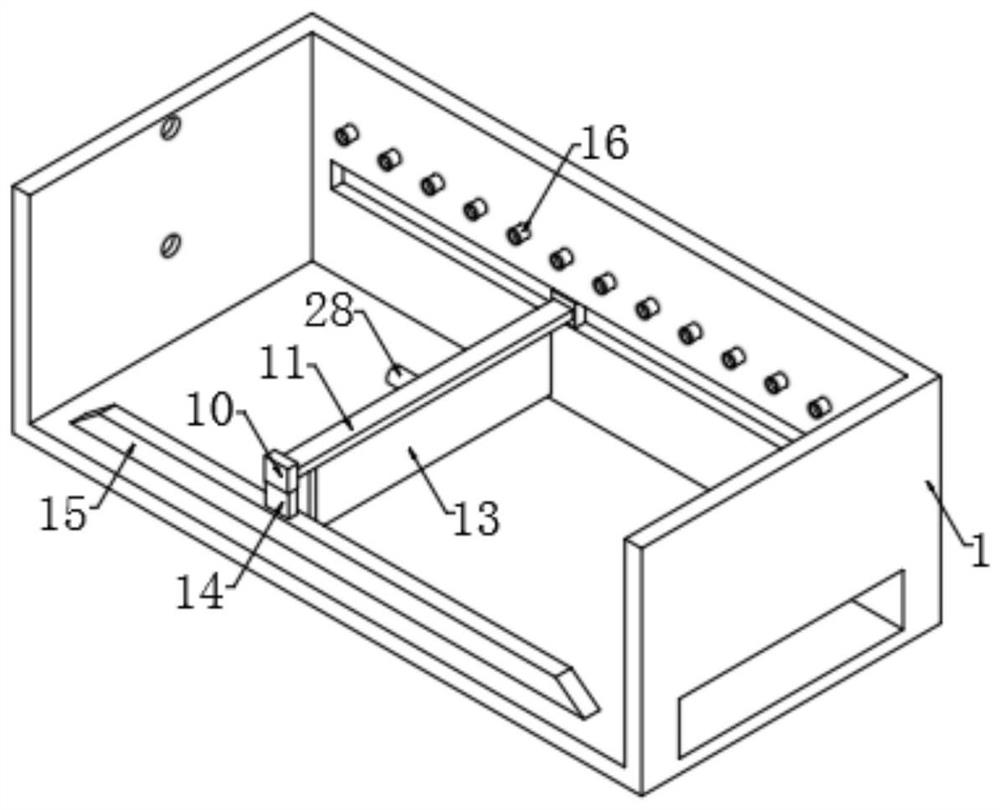

Nickel surface treatment wastewater treatment system and method

PendingCN113620398AImprove the settlement effectEasy to wipe cleanSludge treatment by de-watering/drying/thickeningRotary stirring mixersComposite materialStructural engineering

The invention discloses a nickel surface treatment wastewater treatment system and method. The system comprises a sedimentation tank, first sliding grooves are formed in the two sides of the top end of the sedimentation tank correspondingly, first sliding blocks are slidably connected in the two first sliding grooves correspondingly, the two first sliding blocks are slidably arranged on the two sides of the bottom end of a first sliding plate correspondingly, and supporting blocks are fixedly arranged on the two sides of the top end of the first sliding plate correspondingly, wherein one side of one supporting block is fixedly provided with a first supporting rod, and the two sides of the first supporting rod are each fixedly provided with a plurality of stirring rods. According to the nickel surface treatment wastewater treatment system and method, through the arrangement of the rotating cylinder and the stirring shaft, in the movement process of the first sliding plate, through the meshing effect of the second rack and the second gear, the rotating drum is driven to rotate under the transmission action of the first bevel gear and the second bevel gear, and the complexing breaking agent in the rotating drum is uniformly sprayed into the sedimentation tank through the liquid outlet, so that the complexing breaking agent is uniformly distributed in the wastewater in the sedimentation tank, and the complexing breaking agent and the wastewater can uniformly and fully react conveniently.

Owner:SUZHOU PLATER ELECTRONICS CO LTD

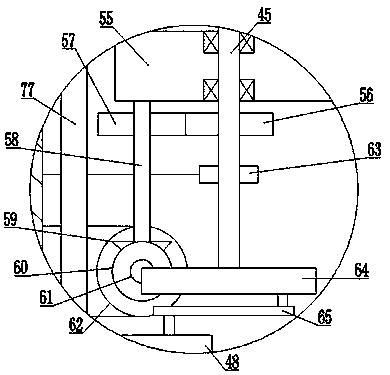

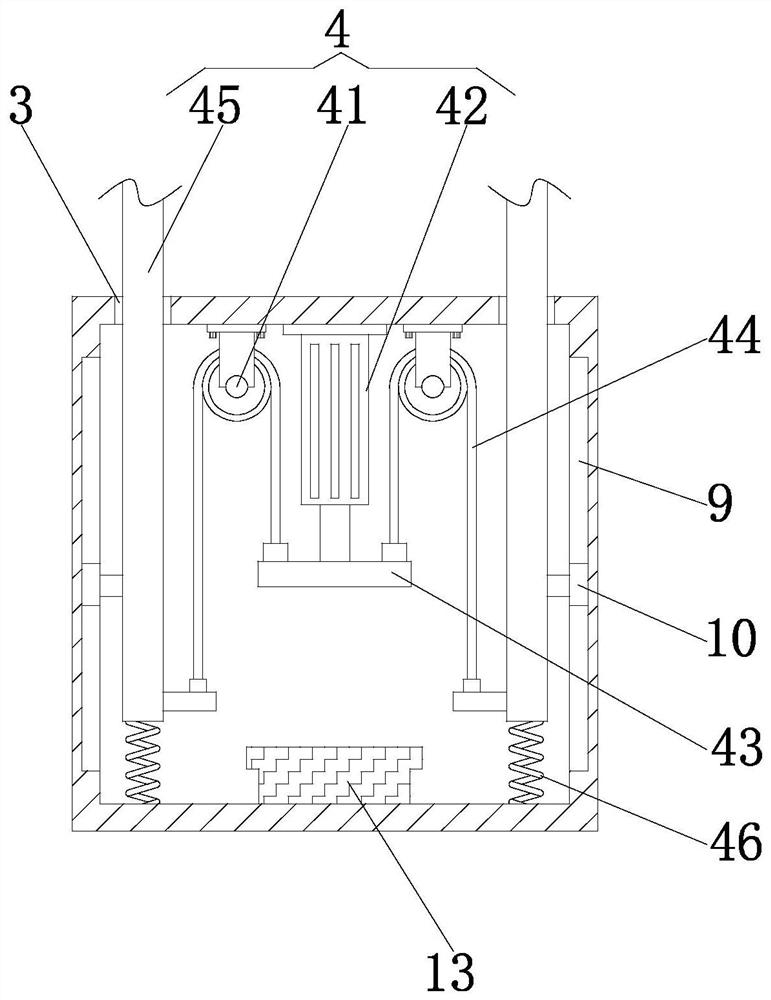

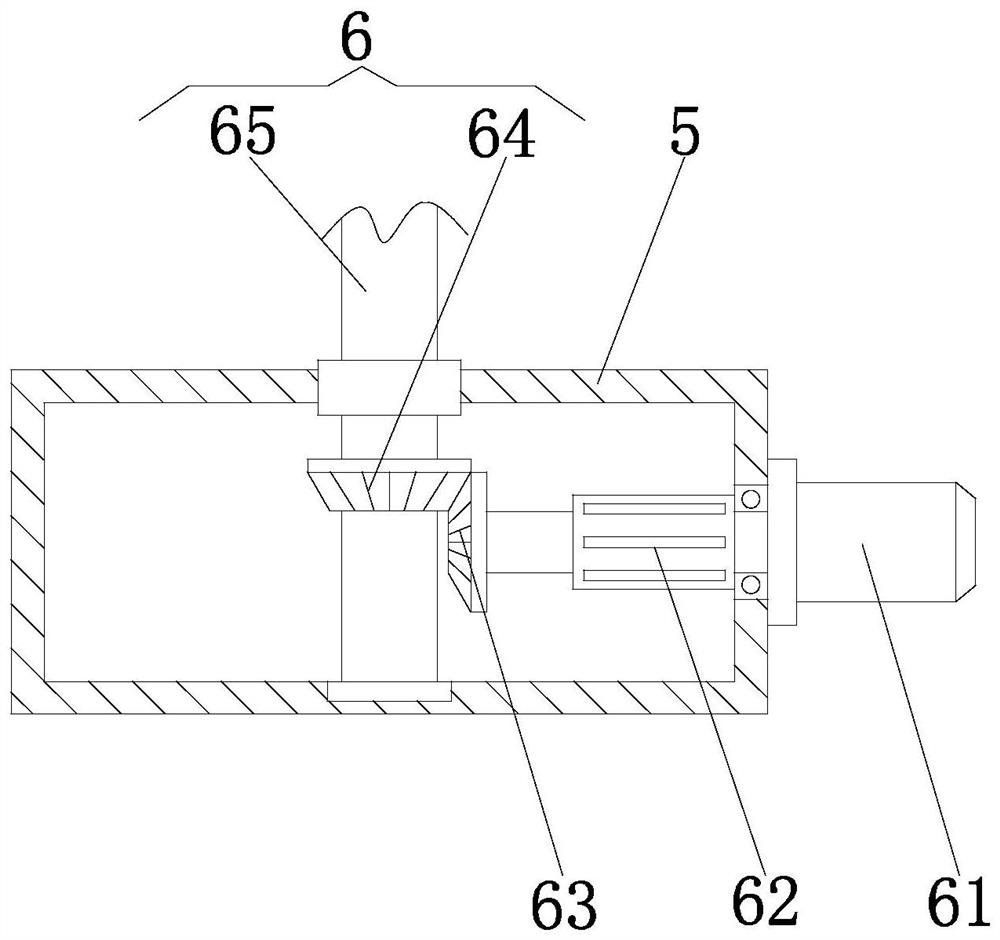

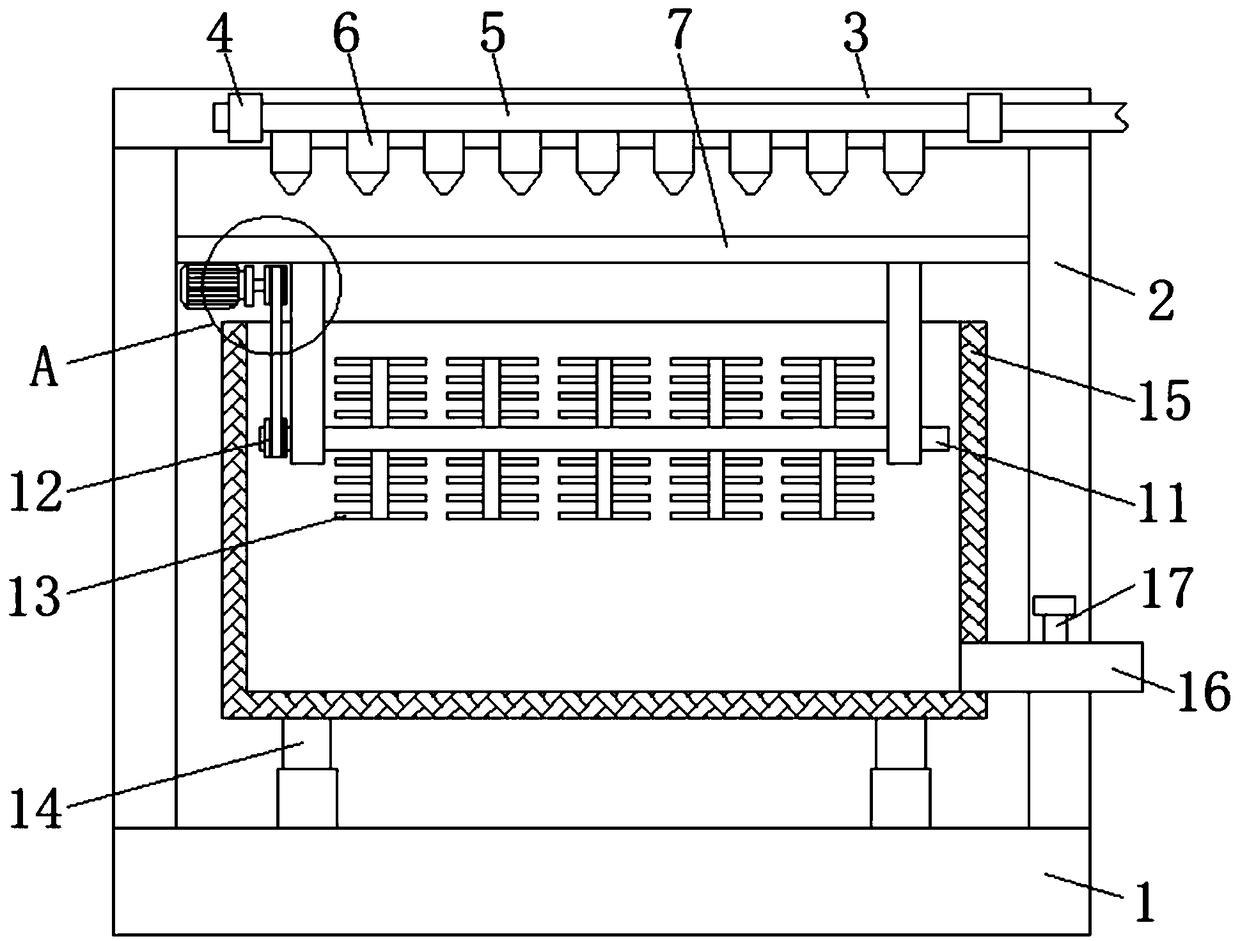

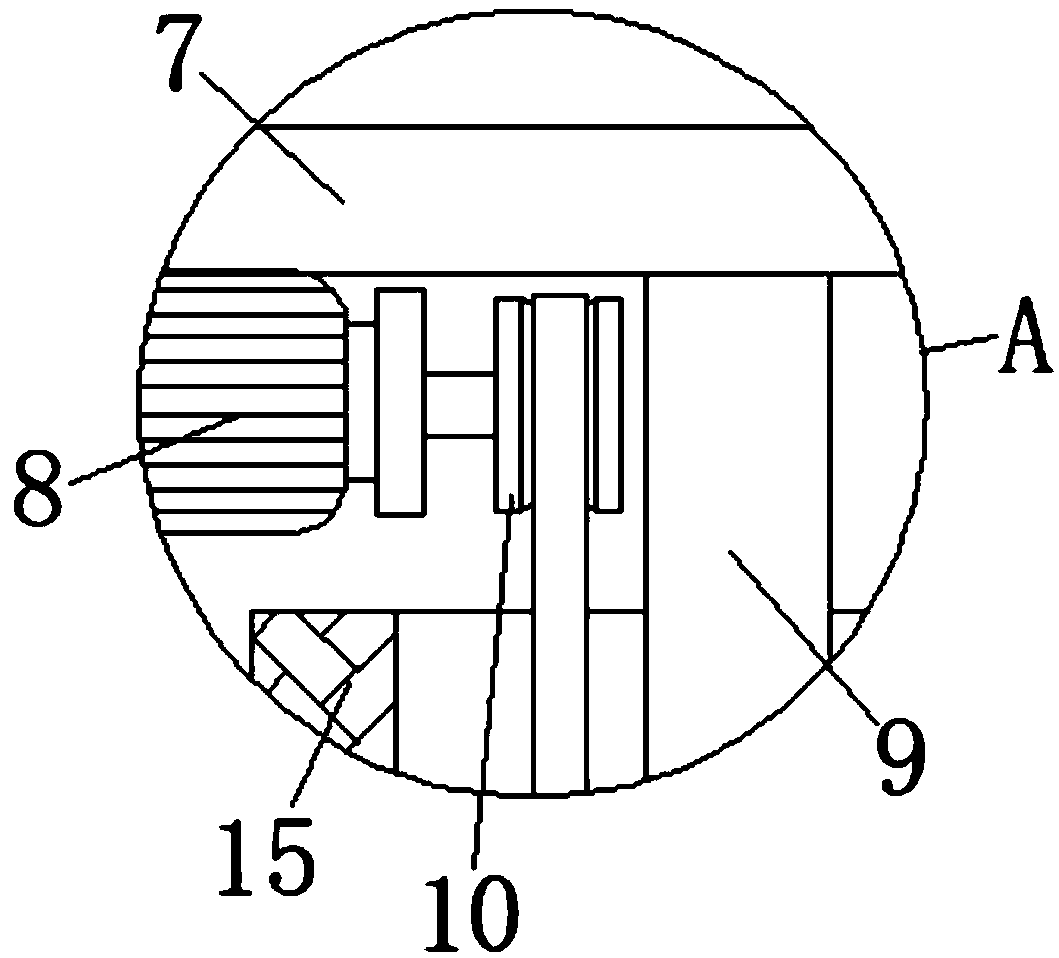

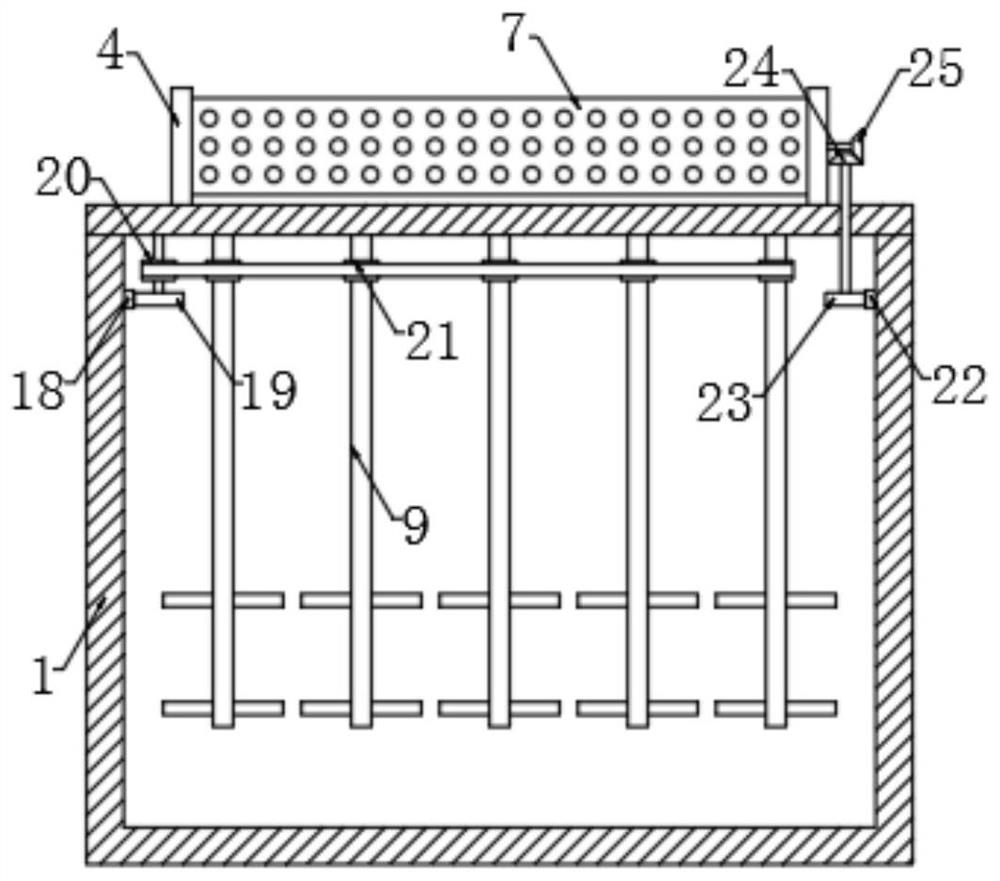

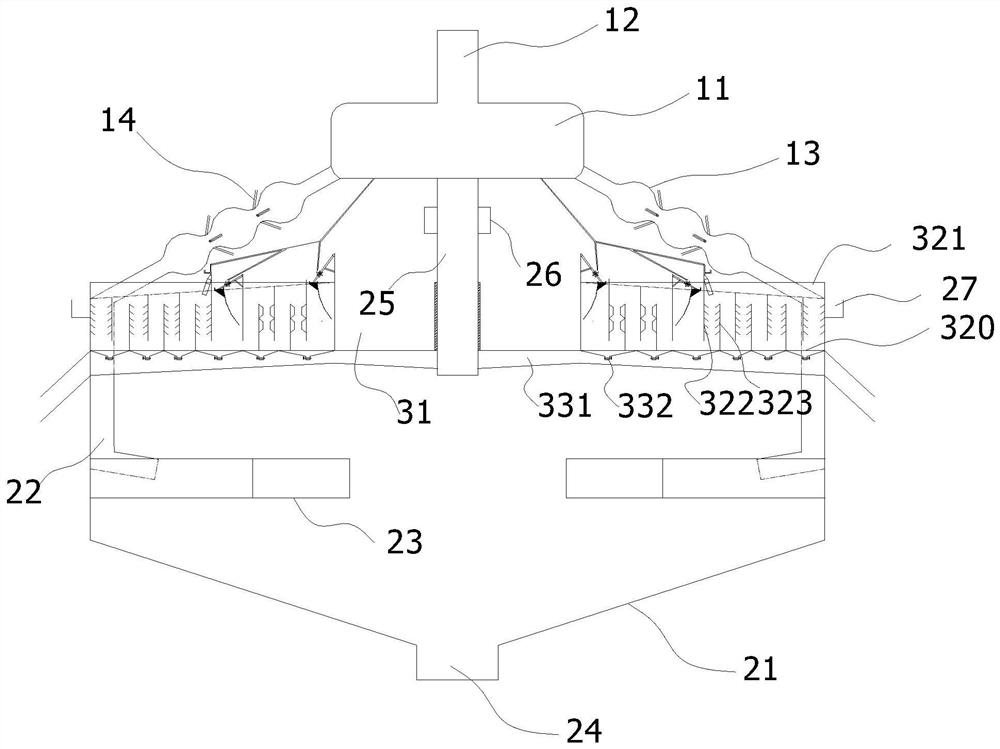

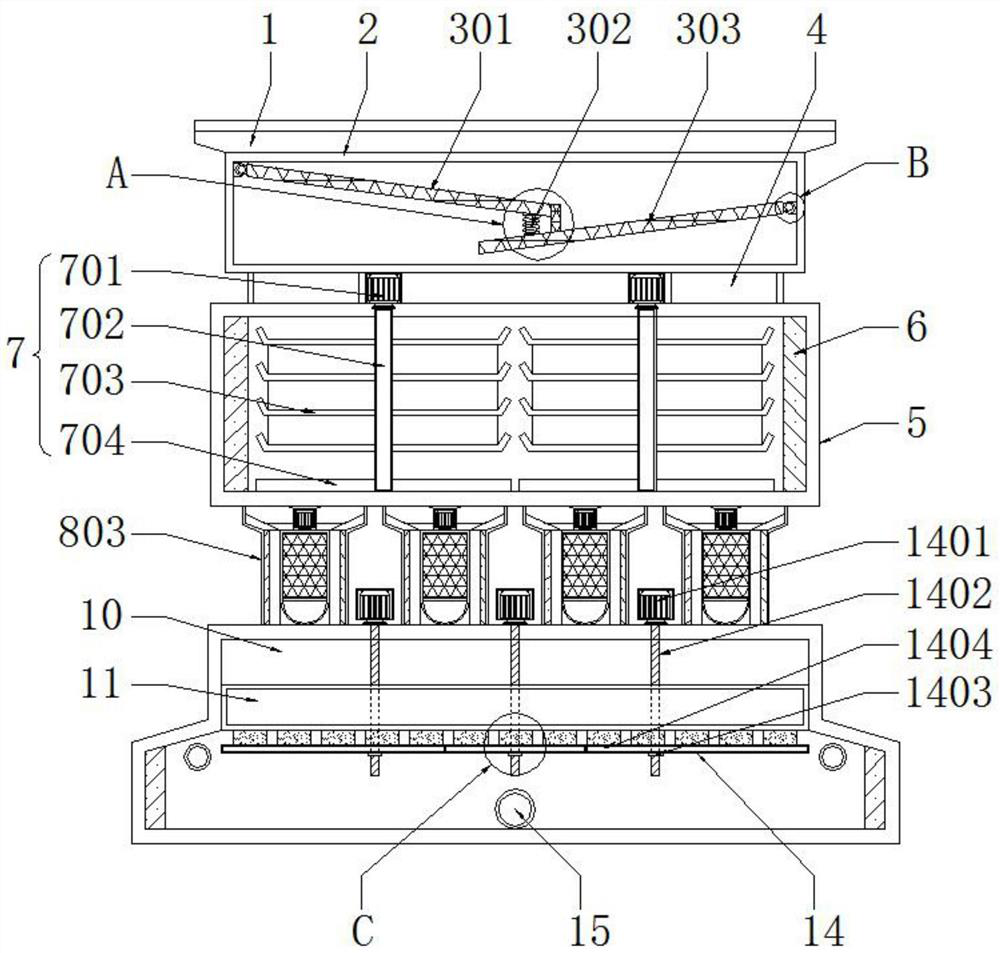

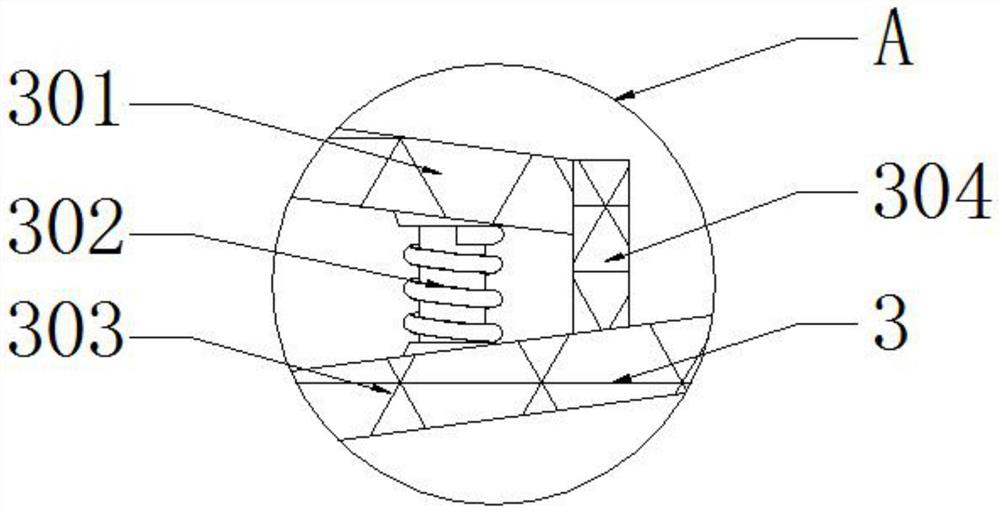

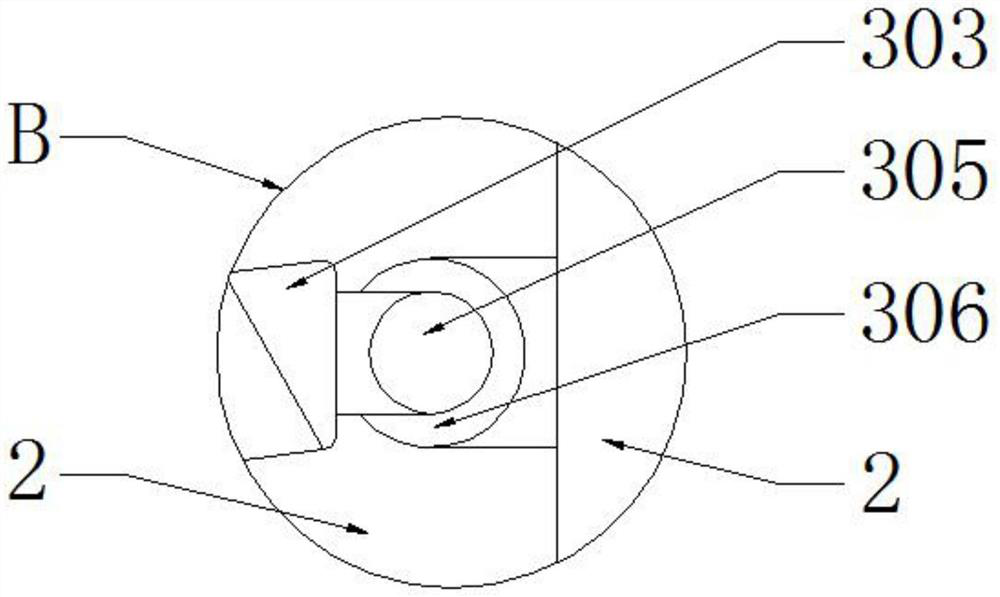

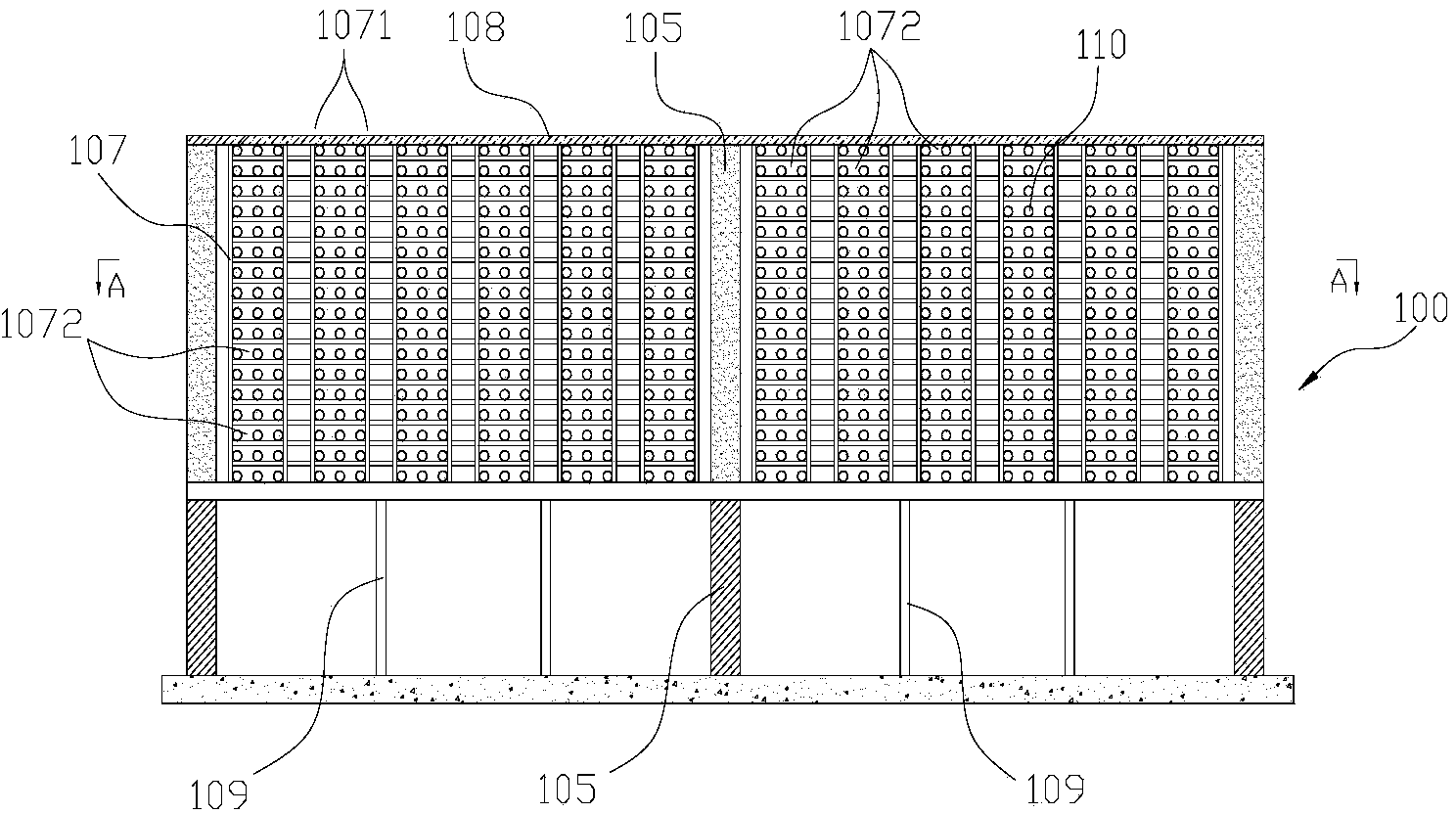

Multistage sedimentation rake-free concentration device capable of uniformly distributing materials

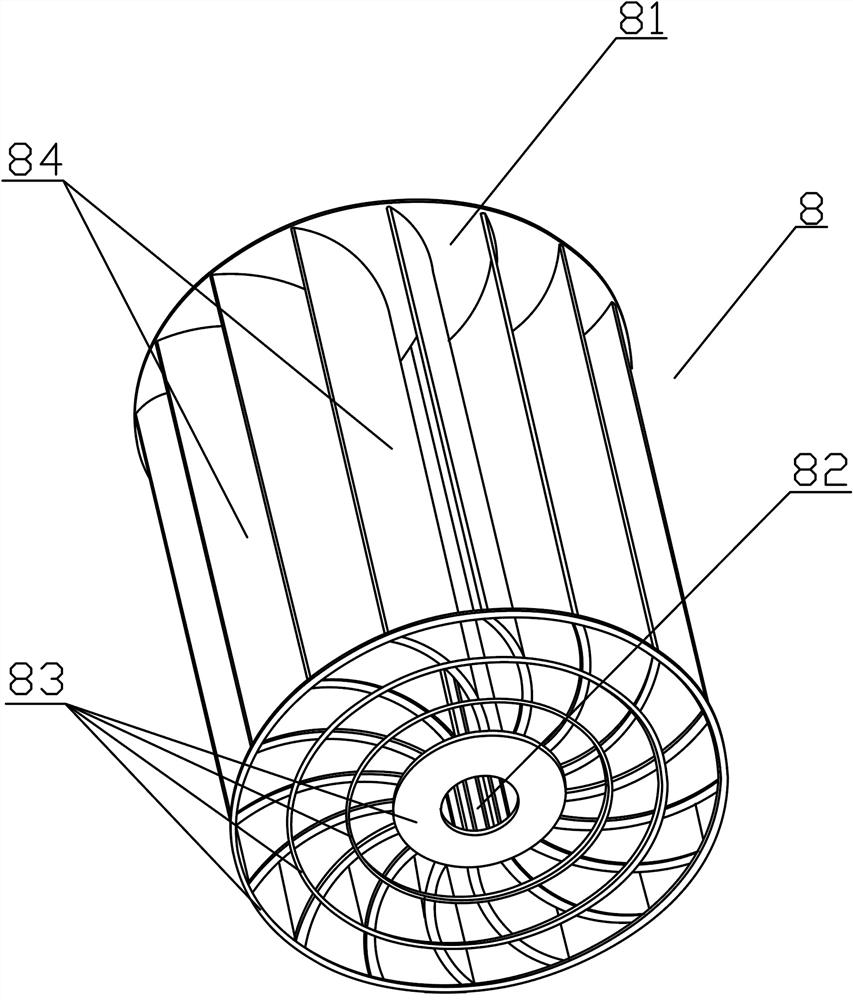

ActiveCN112221210ASmall footprintRealize self-flow without powerSludge treatment by de-watering/drying/thickeningSettling tanks feed/dischargeProcess engineeringMechanical engineering

The invention relates to the field of slime water treatment, in particular to a multi-stage sedimentation rake-free concentration device capable of uniformly distributing materials. The device comprises a feeding assembly, a flow guide assembly, a clean coal collecting assembly, the flow guide assembly comprises a central groove body, slime water and a chemical agent flow from the upper part of the central groove body to the inner side wall of the central groove body through the feeding assembly, and then flow to the middle of the central groove body through the flow guide assembly, bubbles after reaction carry fine coal slime to move upwards into the clean coal collecting assembly, the clean coal collecting assembly is located above an outlet of the flow guide assembly, and the clean coalcollecting assembly is sequentially provided with a central material collecting area, a bubble removing area and a flow guide settling area from middle to outside. The device has the advantages thatthe structure of a traditional multi-stage concentration tank is integrated, and the occupied area of the traditional multi-stage concentration tank is greatly reduced.

Owner:ANHUI UNIV OF SCI & TECH

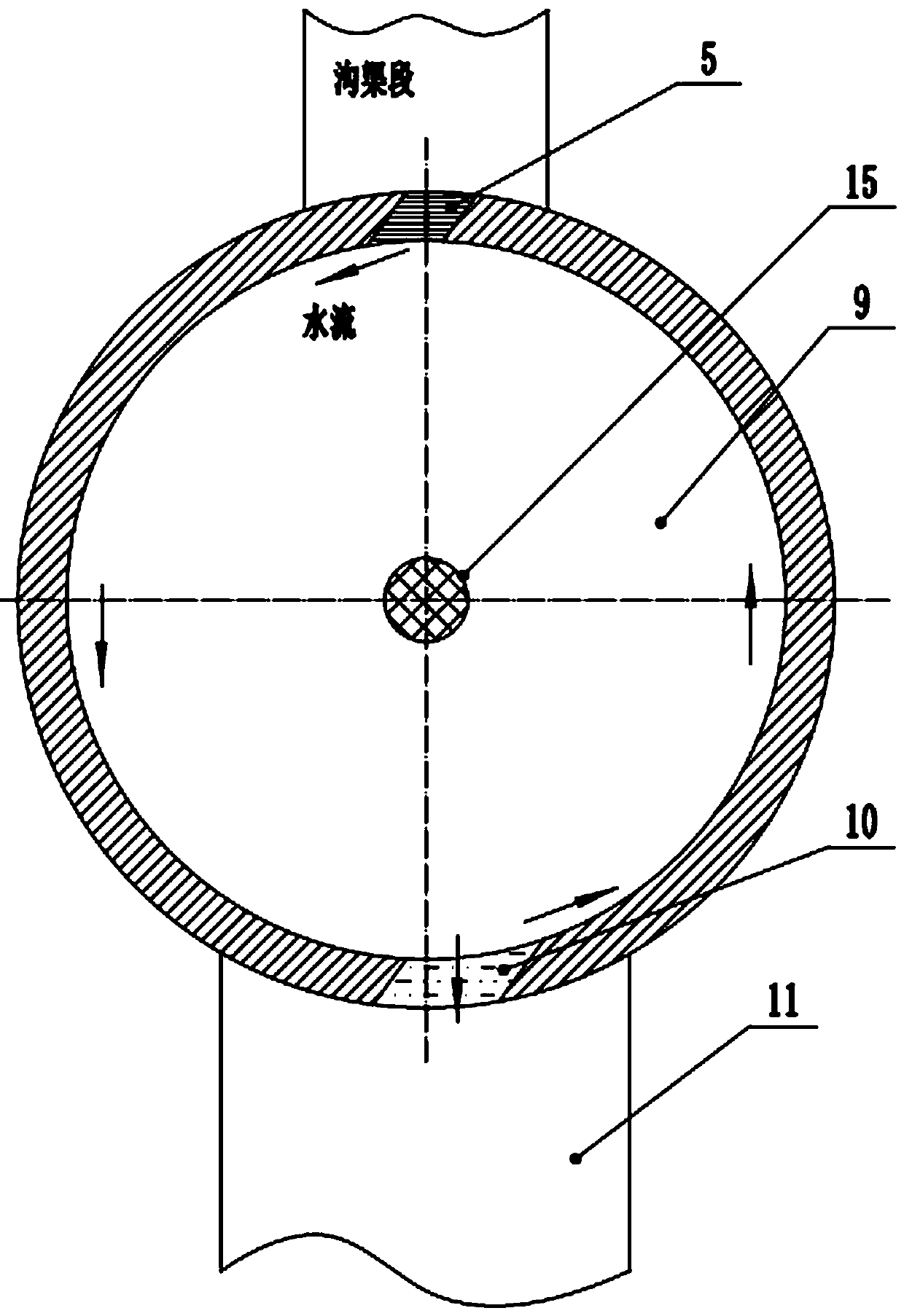

Internal and external cyclone reverse shunting-type air dedusting method and device

PendingCN113181715ASmall centrifugal accelerationSimple structureDispersed particle separationImpellerEngineering

The invention relates to the technical field of air dust removal, in particular to an internal and external cyclone reverse shunting-type air dedusting method and device, and solves the technical defects that existing cyclone centrifugal dust removal devices are complex in structure and large in size. According to the technical scheme, a shell is divided into an air inlet dust collection section, a cyclone reverse shunting section and an air exhaust section, the air inlet dust collection section comprises an air inlet barrel and a dust collection box, and the cyclone reverse shunting section comprises a packing ring, a flow deflector, a fixed plate, a driving shaft and a centrifugal impeller. The device has the beneficial effects that: the centrifugal impeller drives dust-containing air to move to form rotationally-rising inner cyclone, particle impurities in the dust-containing air radially settle under the action of centrifugal force and gravity to form external airflow, clean air rises to the upper end of the centrifugal impeller and enters the exhaust section through a radial air inlet channel and a radial air outlet channel, a small amount of clean air is shunted and returned under the action of the flow deflector and drives external airflow to rotate and descend to form outer cyclone, most of the impurities settle in the dust collection box, a small amount of the impurities converges into inner cyclone, and the device is good in dust removal effect, simple in structure and small in size.

Owner:张昌锐

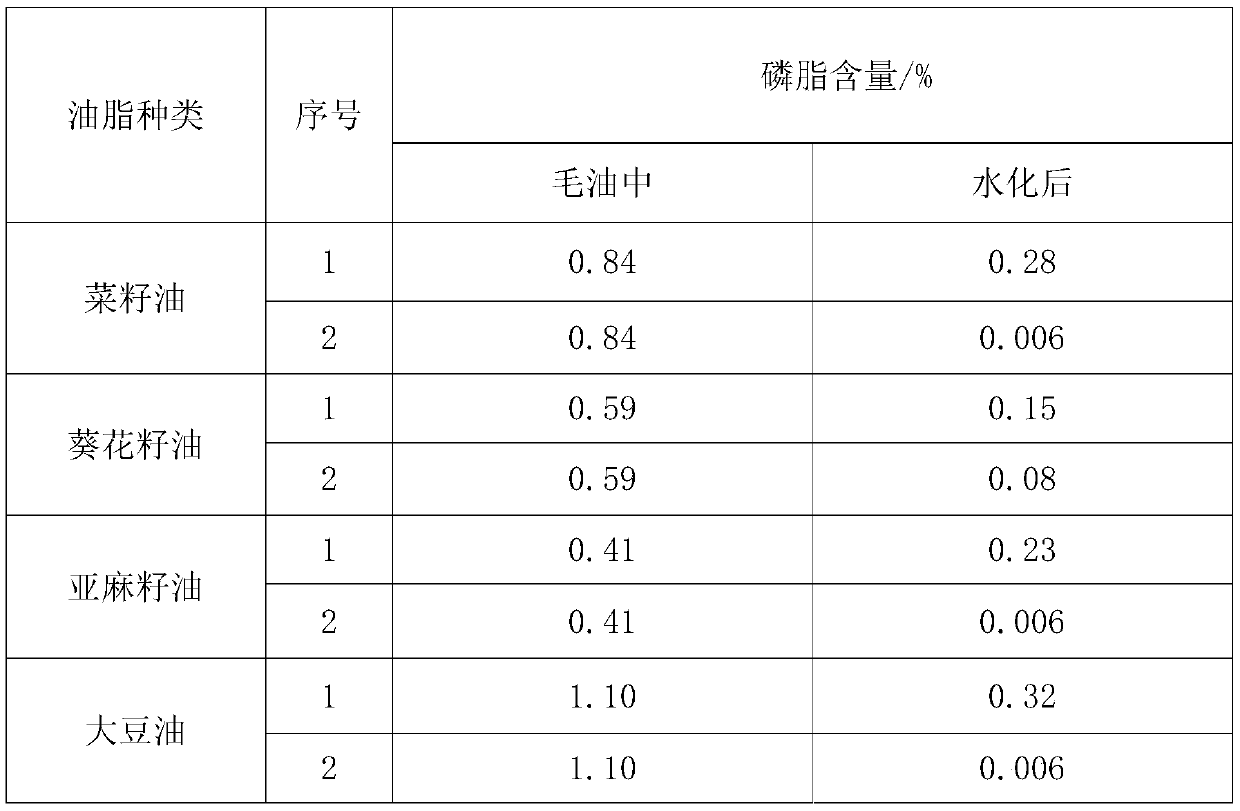

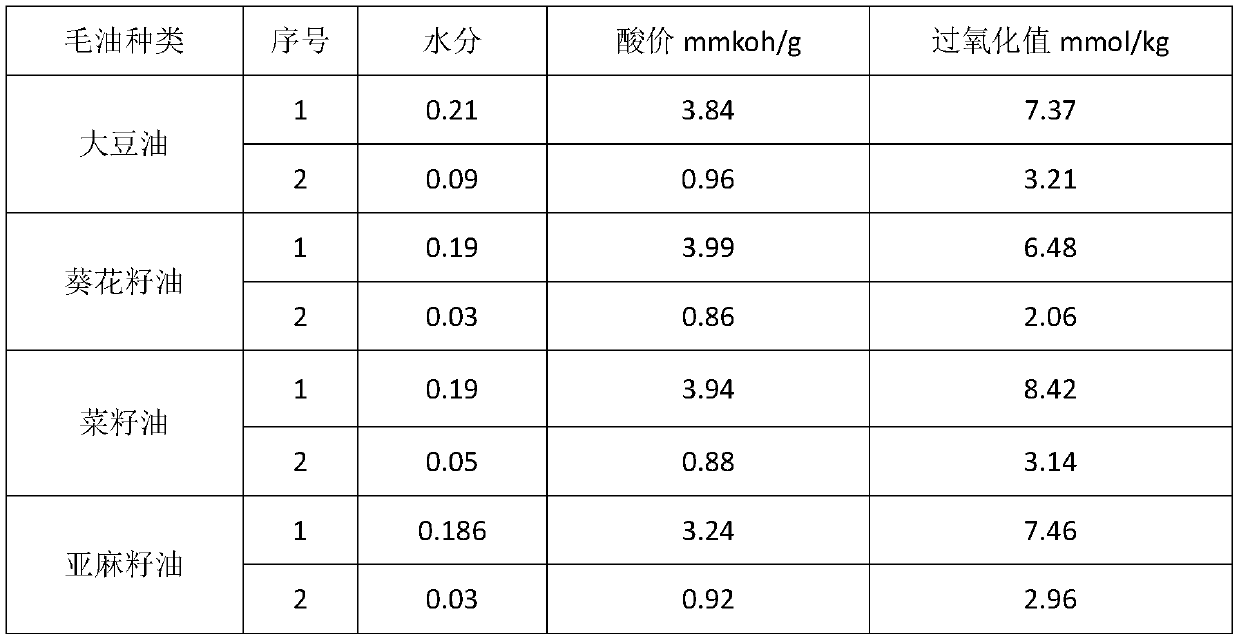

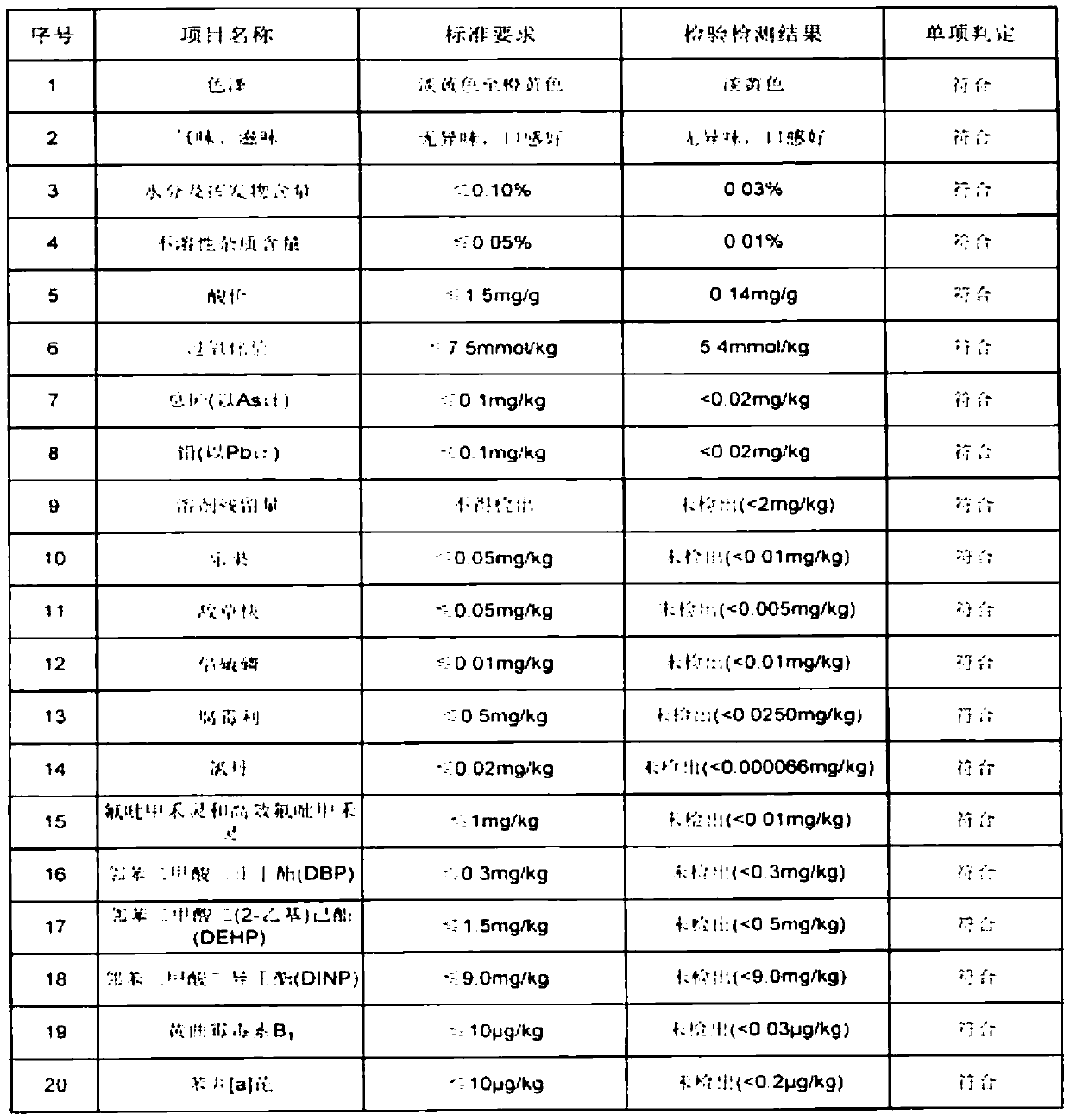

Low-temperature refining technology for plant oil through four-step method

PendingCN109880689AImprove qualityRemove completelyFatty-oils/fats refiningOil and greasePhospholipid

The invention discloses a low-temperature refining technology for plant oil through a four-step method. The low-temperature refining technology includes the following steps: (1) hydration, (2) depuration, (3) purification and (4) winterization. The refining technology is completed at the temperature lower than 100 DEG C, high-temperature oxidation, vitamin loss and formation of benzopyrene and trans-fatty acid are avoided, the grease quality is greatly improved, and meanwhile, energy consumption is reduced; the technological process is short, the production efficiency is high, equipment inputis less, and the equipment input is reduced by nearly 30% compared with a conventional technology; a gradient water-adding method is adopted in hydration, full absorption and settlement of phospholipids and part of proteins and colloids are ensured, alkali adding and washing are not needed, and thus the raw material cost is lowered; and in the purification technology, depurated grease is decoloredthrough activated carbon, so that the peroxide value content in the grease is decreased, in this way, it can be ensured that plant oil is bright in color, and the shelf life of the plant oil is prolonged more effectively.

Owner:内蒙古金格勒食品有限公司

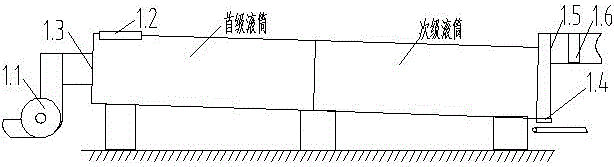

Organic biological fertilizer production system

InactiveCN107759265ASmooth circulationEasy to dryManure dryingDrying gas arrangementsCombustion chamberTechnical object

The invention discloses an organic biological fertilizer production system, which comprises a biological fertilizer production device, a biomass energy source hot air generation device, a drying device, an exhaust device and a polishing device, wherein the biological fertilizer production device and the biomass energy source hot air generation device are connected with a feed inlet and an air inlet of the drying device respectively; the tail end of the drying device is connected with the polishing device and the exhaust device; the biomass energy source hot air generation device comprises a biomass gas generation furnace, a filter and a combustion chamber which are sequentially connected; and a pipeline between the filter and the combustion chamber is connected with an air blower. The technical object of the invention is to provide the organic biological fertilizer production system which is more environment-friendly and energy-saving and higher in efficiency, and the organic biological fertilizer production system uses biomass energy sources to produce a biological fertilizer, so that the production cost of enterprises is lower and a better environmental protection effect is achieved.

Owner:SICHUAN KAIERFENG AGRI TECH CO LTD

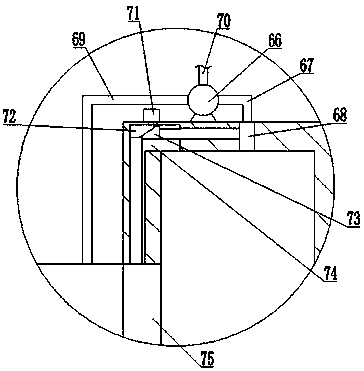

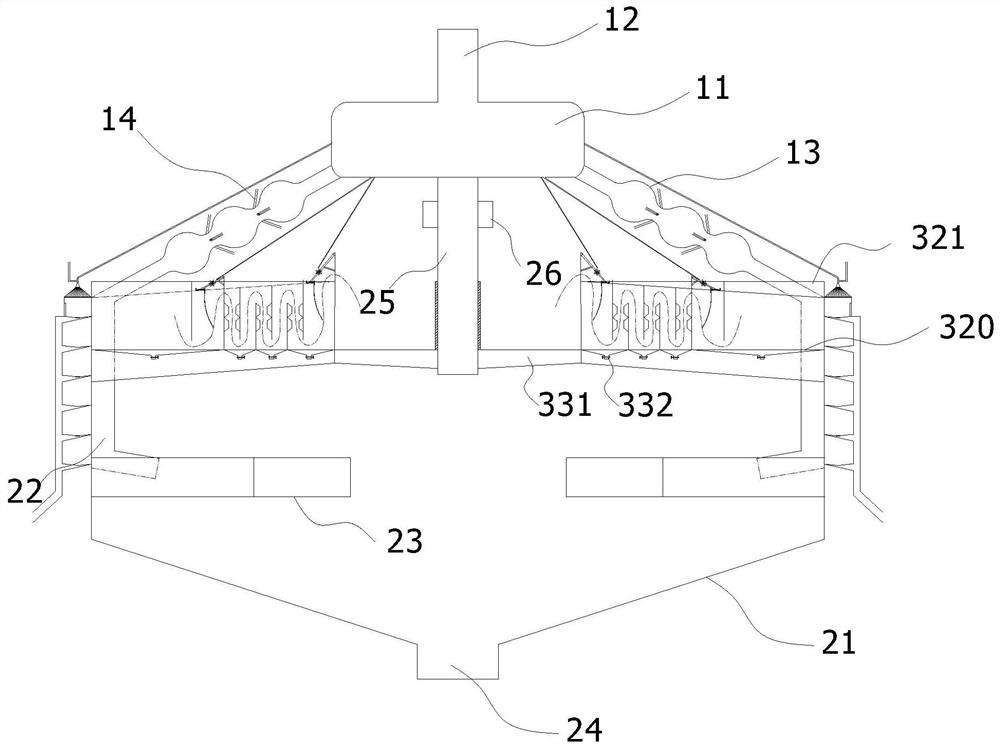

Compact rake-free concentrator

ActiveCN110935207ASmall footprintRealize self-flow without powerWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningThermodynamicsMechanical engineering

The invention relates to the field of slime water treatment, in particular to a compact rake-free concentrator. The compact rake-free concentrator comprises a feeding assembly, a diversion assembly and a clean coal collecting assembly. The diversion assembly further comprises a central tank body, coal slime water passes through the feeding assembly, flows with a medicament from the upper part of the central tank body to the middle part of the central tank body, and is diffused in all directions, after the reaction, residual mineralized bubbles and fine coal slime move upwards into the clean coal collecting assembly from the inner side wall of the central tank body, the clean coal collecting assembly is located above the outlet of the diversion assembly, the clean coal collecting assembly is sequentially provided with an edge feeding area and a defoaming area from outside to inside, the clean coal collecting assembly further comprises a diversion settling area arranged on the outer sidewall of the central tank body, and slime water defoamed by the defoaming area is output to the inlet of the diversion settling area from the middle of the central tank body through a first overflow discharge pipe. According to the compact rake-free concentrator, a traditional multi-section concentration tank is structurally integrated, and the occupied area of the traditional multi-section concentration tank is greatly reduced.

Owner:ANHUI UNIV OF SCI & TECH

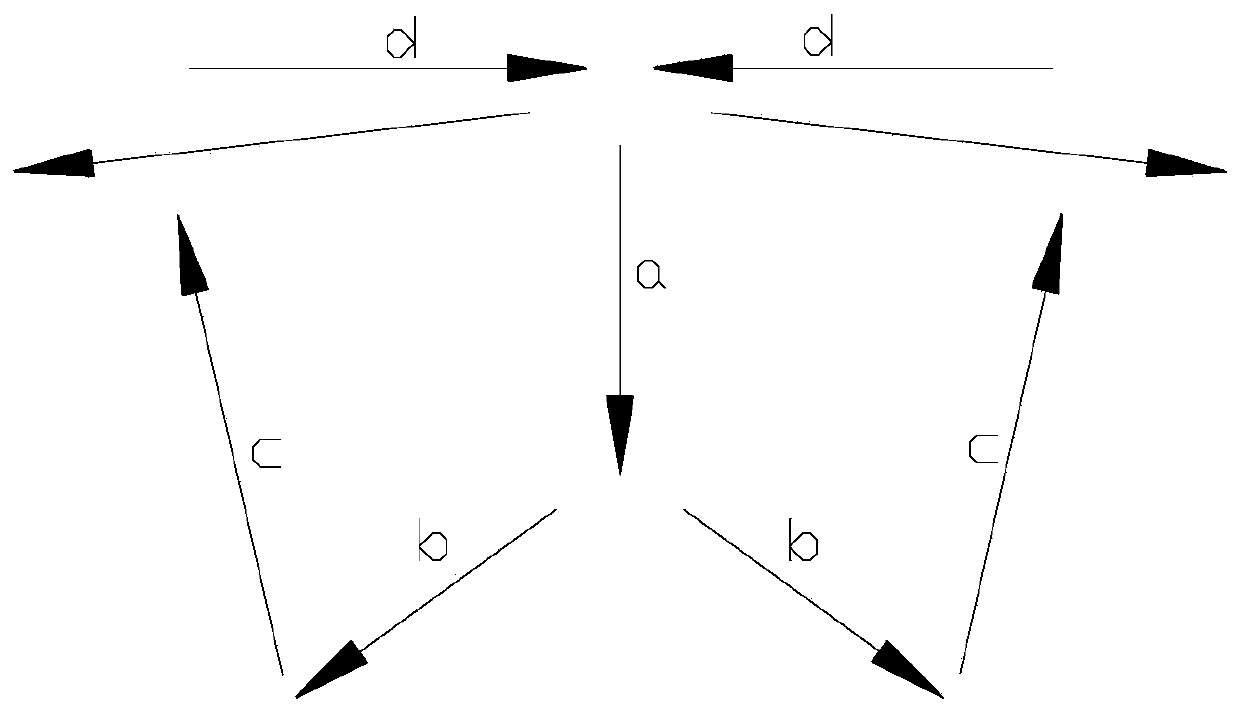

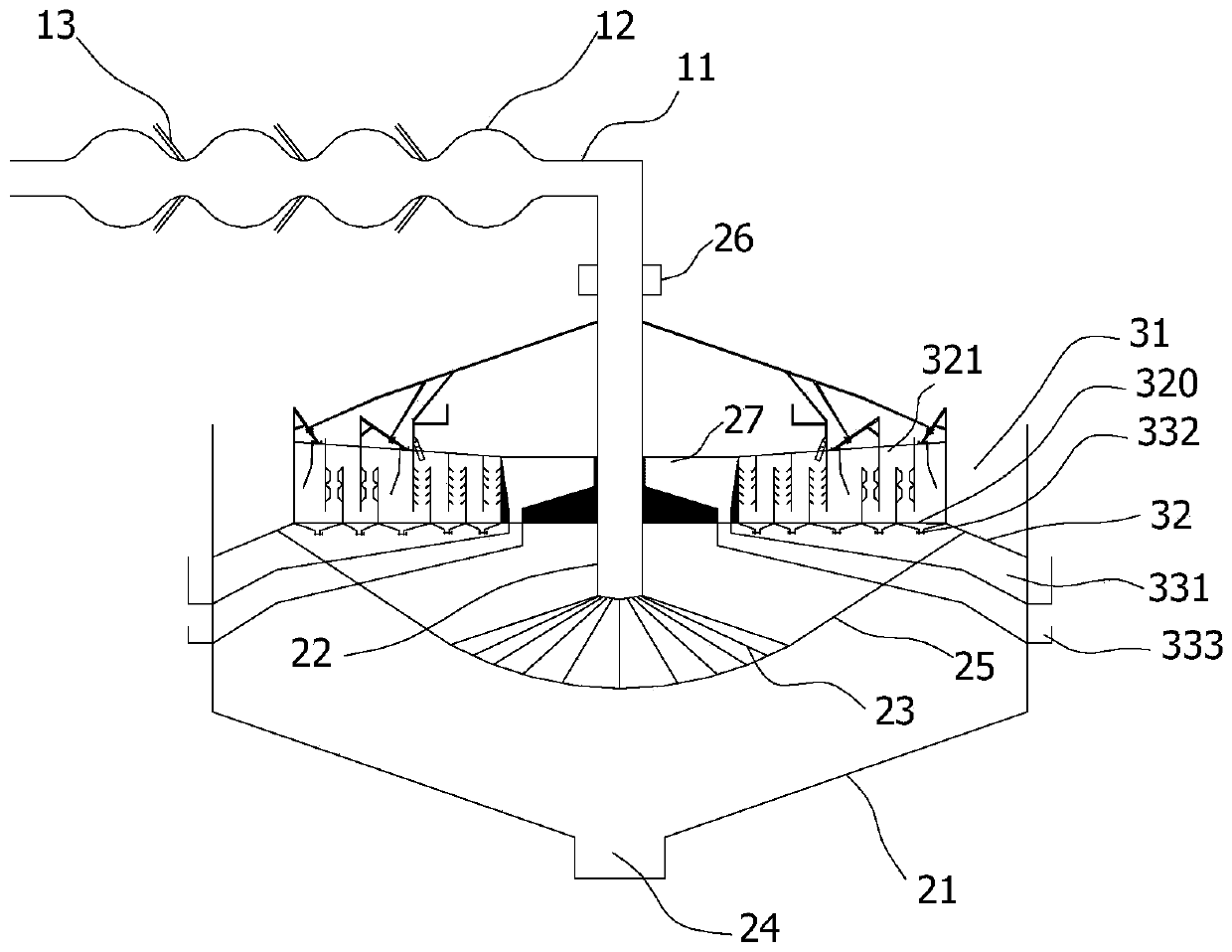

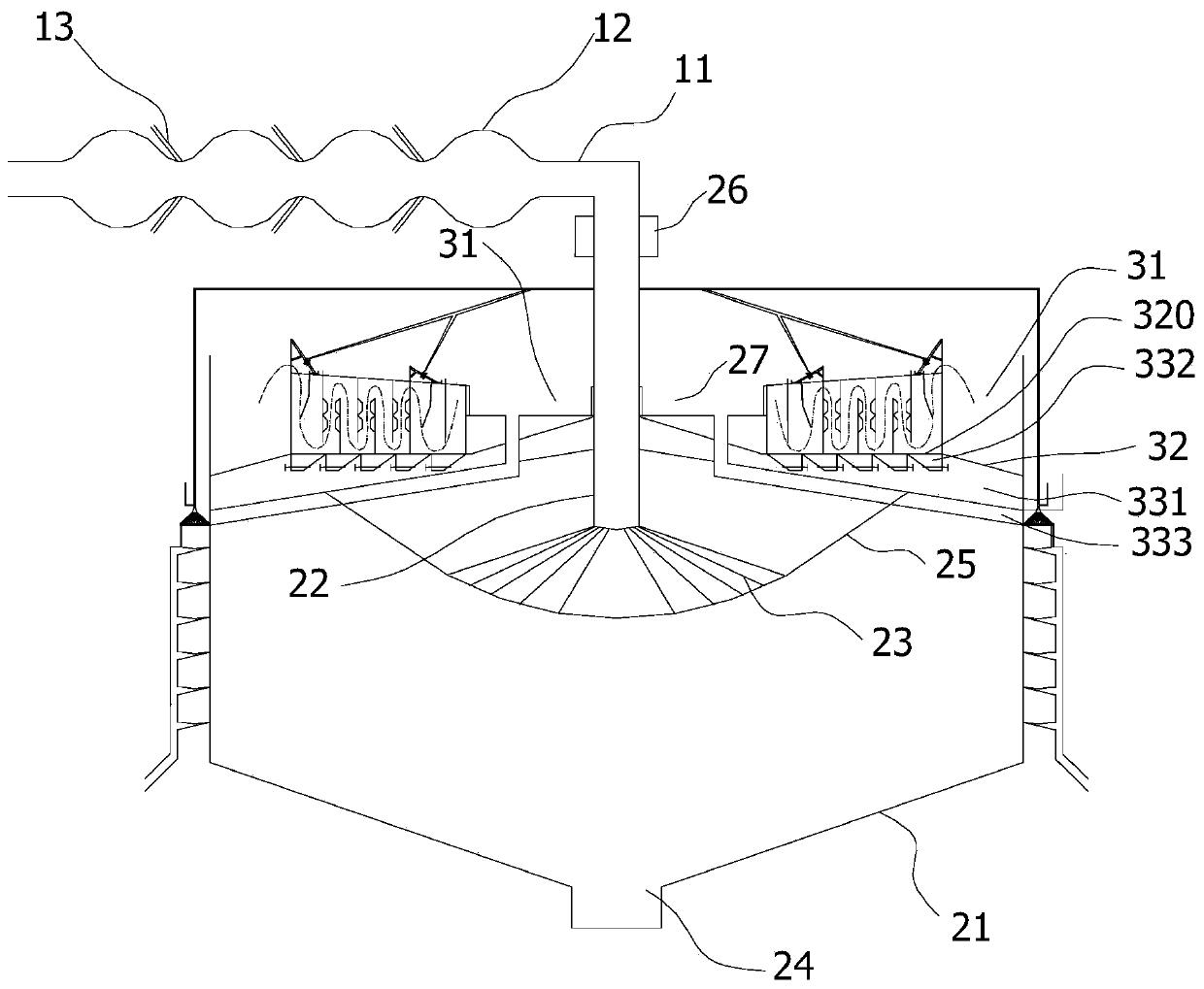

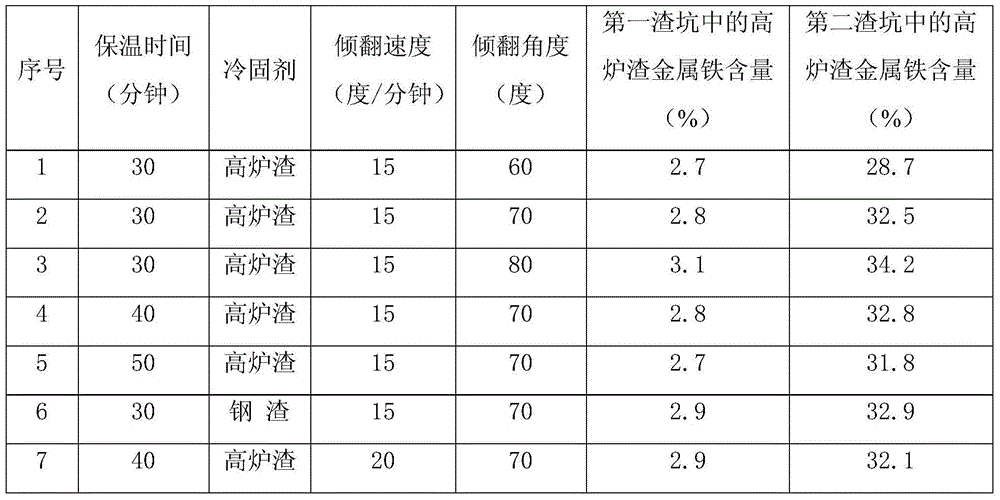

Blast furnace slag treatment method

ActiveCN104818357AHigh metallic iron contentFully settledRecycling and recovery technologiesSlagMetal

The invention relates to a blast furnace slag treatment method comprising the steps of A, loading and transporting molten blast furnace slag by using a slag pot car, and carrying out heat insulation treatment on the molten blast furnace slag in the transportation process to sufficiently settle metal iron in the blast furnace slag; B, transporting the blast furnace slag to a slag dumping field by using the slag pot car, dumping slag towards a first slag pit after entering a preset station, controlling the dumping angle of a slag ladle, and dumping part of the blast furnace slag into the first slag pit; C, dumping the residual blast furnace slag into a second slag pit; and D, respectively obtaining blast furnace slag from the first slag pit and the second slag pit after cooling the blast furnace slag. According to the blast furnace slag treatment method, the metal iron is enriched to the bottom of the slag pot car in advance through heat insulation treatment, and then, the blast furnace slag with relatively low metal iron content is dumped into the first slag pit and the blast furnace slag with relatively high metal iron content is dumped into the second slag pit in a in-batch slag dumping way to obtain two kinds of blast furnace slag, so that the subsequent treatment on the blast furnace slag can be conveniently realized.

Owner:攀枝花攀西蓝星化学清洗有限公司

Convenient-to-clean sedimentation treatment device for municipal sewage

PendingCN114506943AFully settledFully contactedWater/sewage treatment by centrifugal separationSpecific water treatment objectivesFlocculationWater filter

The invention discloses a convenient-to-clean sedimentation treatment device for municipal sewage, and relates to the technical field of municipal sewage treatment.The convenient-to-clean sedimentation treatment device comprises a water inlet hopper, a flow guide assembly and a centrifugal sedimentation assembly, a water filtering tank is fixed to the lower portion of the water inlet hopper, a filtering assembly is installed in the water filtering tank, and drainage pipes are fixed to the two sides of the lower portion of the water filtering tank; a water drainage pipe is arranged below the water inlet pipe, a flocculation mixing chamber is installed below the water drainage pipe, a first flocculant layer is arranged on the inner wall of the flocculation mixing chamber, a stirring assembly is installed in the flocculation mixing chamber, the flow guide assembly is fixed below the flocculation mixing chamber, and the flow guide assembly comprises a discharging hopper, a flow guide plate, an outer frame, a second flocculant layer and a water drainage flow channel. According to the sedimentation treatment device convenient to clean and used for municipal sewage, sewage can make full contact with a flocculating agent layer, so that the gravity sedimentation efficiency is improved, centrifugal sedimentation, flocculating sedimentation and gravity sedimentation can be combined, municipal sewage is fully settled, and therefore the good sedimentation treatment effect is achieved.

Owner:湖南旭晟环境科技有限公司

Kiln tail-gas energy-saving and emission-reducing processing equipment

ActiveCN103776269ARaise the furnace temperatureLower discharge temperatureCombustion processIndirect carbon-dioxide mitigationCold airCombustion

The invention discloses kiln tail-gas energy-saving and emission-reducing processing equipment, which comprises a heat-exchanging chamber and a smoke-gas channel, wherein the smoke-gas channel is communicated with the inner part of the heat-exchanging chamber, the heat exchange of combustion-supporting air and hot smoke gas is carried out in the heat-exchanging chamber, and the smoke gas after being subjected to heat exchange is then introduced into the smoke-gas channel for smoke-dust settlement. When the kiln tail-gas energy-saving and emission-reducing processing equipment works, the heat exchange of cold air and the hot smoke gas is carried out in the heat-exchanging chamber in the mode of convection, so that the heat-transferring efficiency is high, the temperature of the combustion-supporting air entering a kiln can be increased, and meanwhile, the discharging temperature of the hot smoke gas is decreased; when the smoke gas after being subjected to heat exchange is introduced into the smoke-gas channel, the advancing speed becomes lower, which is favorable to the sufficient settling of smoke dust. Practice indicates that the temperature of the combustion-supporting air after being subjected to heat exchange can be increased to 120 to 150 DEG C, and 70% smoke dust can be reduced in the smoke gas after a settling process, so that the kiln tail-gas energy-saving and emission-reducing processing equipment has remarkable energy-saving and emission-reducing effects and conforms to the requirement of environmental protection.

Owner:佛山市三水有为玻璃制品有限公司

Dust removal device for ore crusher

PendingCN112620292AFully settledSlow down circulationCombination devicesUsing liquid separation agentMining engineeringCrusher

The invention discloses a dust removal device for an ore crusher, and relates to the technical field of ore processing, in particular to a dust removal device for an ore crusher. The device comprises a crusher; the right side of the crusher is fixedly connected with a dust suction pipe; the bottom of the dust suction pipe is fixedly connected with a conveying fan; the right side of the conveying fan is fixedly connected with a settling chamber; a flow baffle is fixedly mounted in the settling chamber; and a water spraying pipe is fixedly mounted at the top of the settling chamber. According to the dust removal device for the ore crusher, the water spray pipe is arranged in the settling chamber, dust generated during crushing is sucked into the settling chamber through a dust suction pipe, water mist is sprayed out through an atomizing spray head at the top of the water spray pipe, and small water drops adsorb dust in dusty gas, so that the dust in the dusty gas settles along with the water drops, and the dust is prevented from polluting air.

Owner:福建省大田县山友机械有限公司

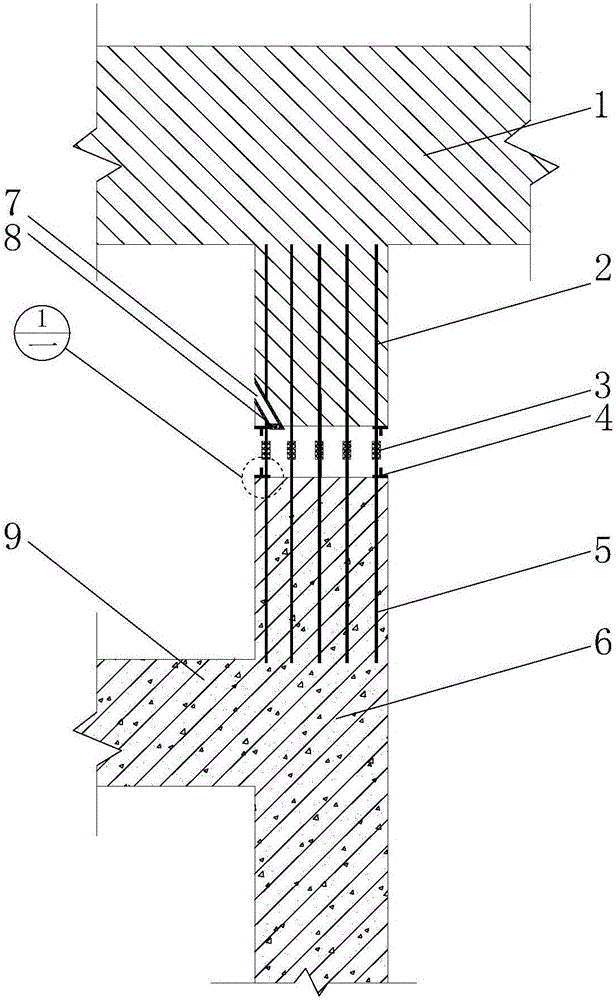

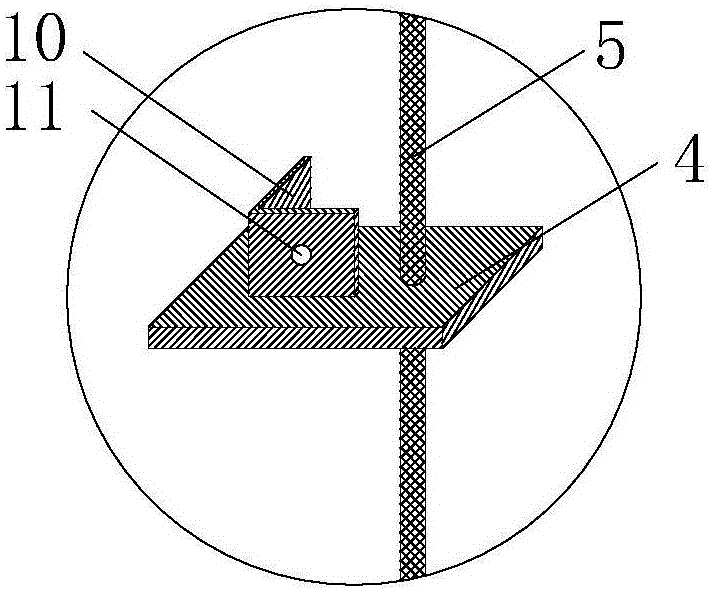

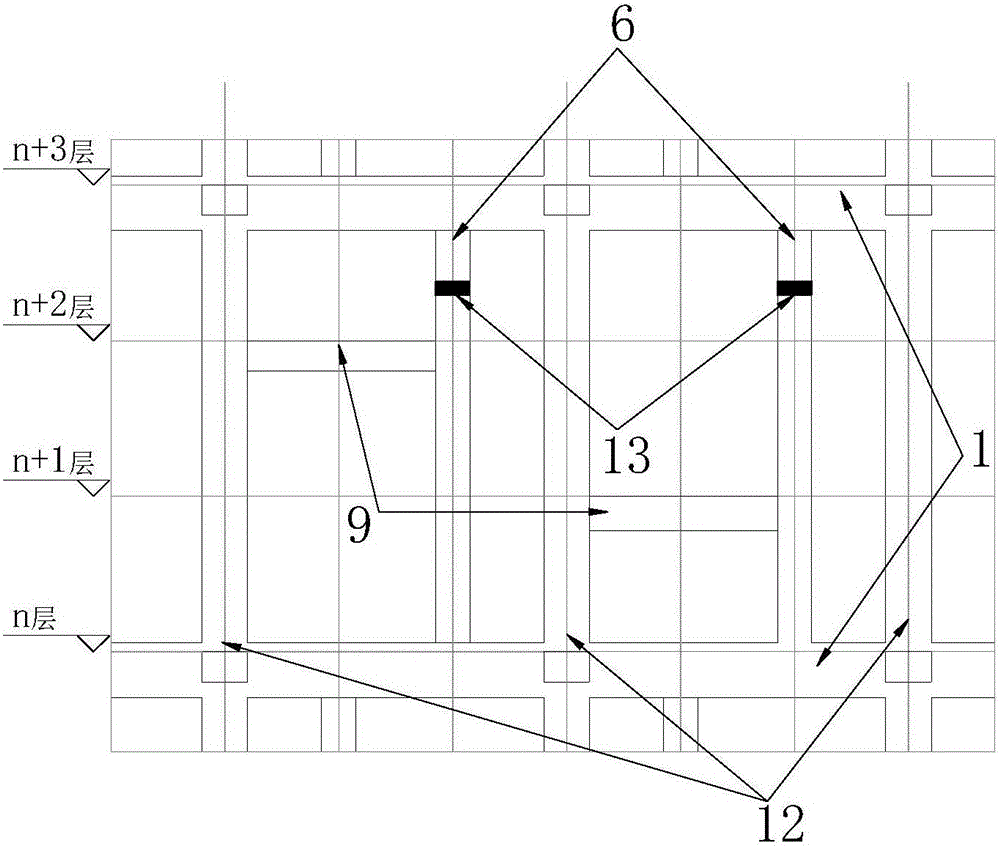

Sub-frame post-cast joint with external permanent aluminum plate outer mold

ActiveCN105951987AGood self-flowTightly boundForms/shuttering/falseworksBuilding reinforcementsRebar

The invention relates to a sub-frame post-cast joint with an external permanent aluminum plate outer mold. The sub-frame post-cast joint mainly comprises a sub-frame column, steel bar connection sleeves, aluminum plate connectors, an external aluminum plate, a prefabricated grouting material opening, a steel screen and connecting bolts. The post-cast joint is arranged on the sub-frame column to separate the sub-frame column into two parts. The aluminum plate connectors are welded to the upper reinforcing steel bars and the lower reinforcing steel bars of the sub-frame column, and the upper reinforcing steel bars and the lower reinforcing steel bars are connected through the steel bar connection sleeves. The prefabricated grouting material opening is welded in one upper reinforcing steel bar of the sub-frame column. The external aluminum plate is fixedly connected with the aluminum plate connectors through the connecting bolts and self-fixed in an enclosed manner through anchoring screws. Grouting material fills the space formed by the external aluminum plate and the steel screen in an enclosed manner. A leveling concrete layer is arranged outside the external aluminum plate. The sub-frame post-cast joint has the advantages that a main structure and a sub-structure are completely disconnected first to allow the main frame to subside sufficiently and allow a sub-frame to be unstressed, and structure safety is guaranteed. The invention further provides a construction method of the sub-frame post-cast joint.

Owner:浙江新曙光建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com