Method for producing zinc powder and its mfg. device

A manufacturing method and zinc powder technology are applied in the field of zinc powder manufacturing and its preparation device, and can solve the problems of environmental pollution, mixed thickness and fineness of zinc powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

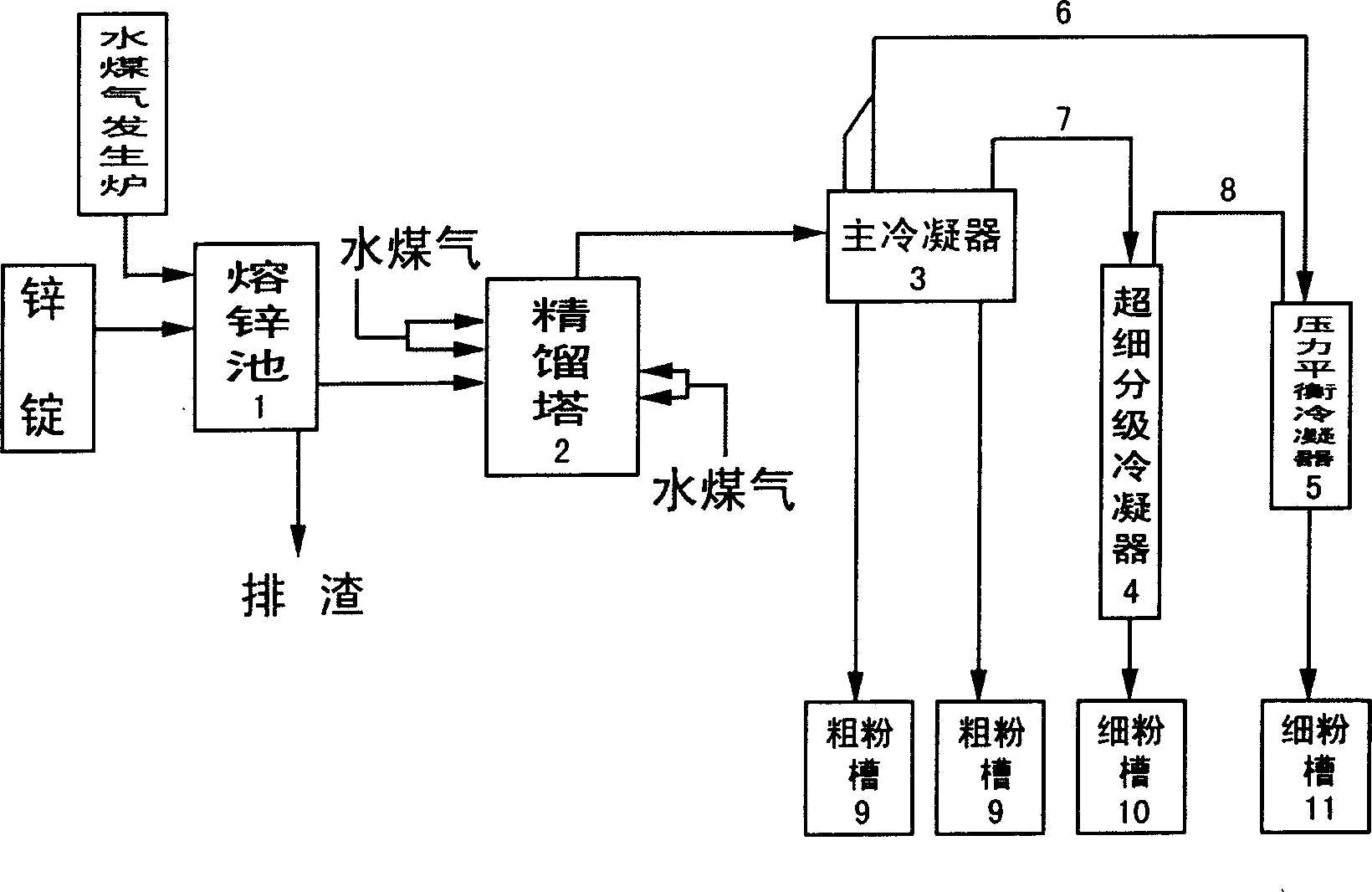

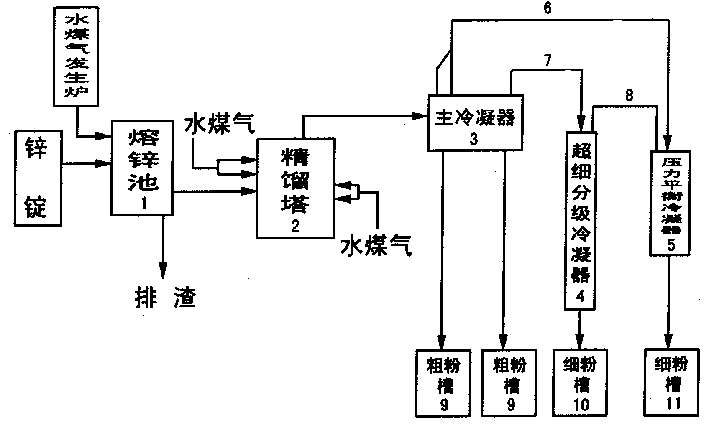

[0012] according to figure 1 As shown, the present invention is mainly composed of molten zinc pool 1, rectification tower 2, main condenser 3, super-fine condenser 4 and pressure balance condenser 5, coarse powder tank 9 and fine powder tanks 10 and 11; The lower part of the tank 1 is equipped with a slag discharge port. The rectification tower 2 is formed by staggered stacking of silicon carbide trays with holes on one side and a plate shape on the other. The zinc vapor enters the main condenser 3 from the upper outlet of the rectification tower 2 , The main condenser 3 is a cavity in the middle, the cavity and the outer wall is a cooling water interlayer, the main condenser 3 is provided with a zinc powder front outlet in front of the top of the main condenser 3, and a zinc powder transport is connected between the zinc powder front outlet and the pressure balance condenser 5 Tube 6, the main condenser 3 is provided with a zinc powder rear outlet behind the top of the main cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com