Blast furnace slag treatment method

A treatment method and technology of blast furnace slag, which is applied in the field of blast furnace slag treatment, can solve problems such as difficulty in obtaining high-grade slag and iron, and achieve the effects of simplifying the production process and reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

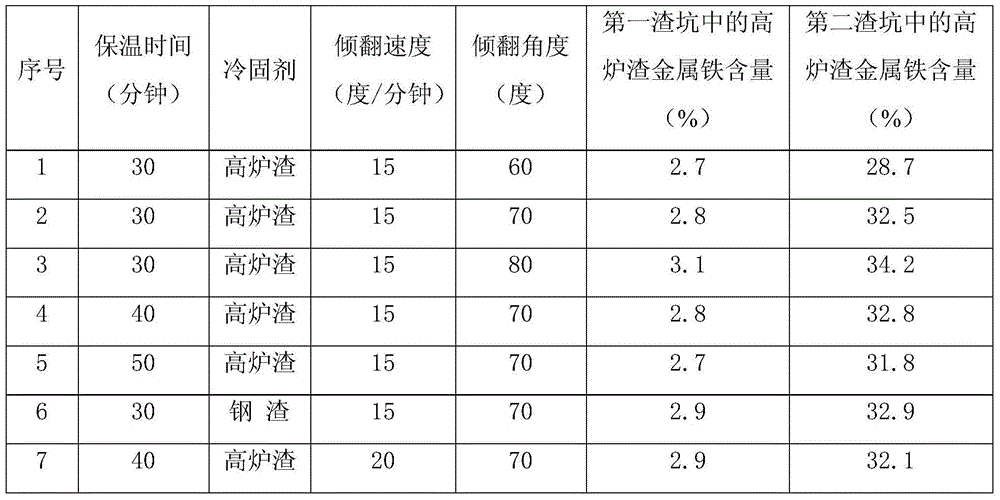

[0029] The blast furnace slag processing method, the steps are:

[0030] A. The blast furnace slag in the molten state is transported by slag tank truck. During the transportation, the blast furnace slag in the molten state is kept warm for 30 minutes to 50 minutes, so that the metallic iron in the blast furnace slag can be fully settled; the high temperature in the molten state The slag heat preservation method is as follows: after the blast furnace slag is loaded into the slag tank car, spray a cooling agent on the surface of the blast furnace slag, and make the cooling agent crust on the surface of the molten blast furnace slag in the slag tank to completely cover the surface of the molten blast furnace slag, thereby To heat preservation, the cooling agent is blast furnace slag or steel slag in natural state;

[0031] B. The blast furnace slag is transported to the slag dumping yard by the slag tank truck. After entering the predetermined station, it will dump the slag towa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com