A method for comprehensively recovering various valuable metals in copper slag floating copper tailings

A valuable metal and copper tailing slag technology, applied in chemical instruments and methods, flotation, process efficiency improvement and other directions, can solve the problems of inability to utilize copper slag as a resource, single type of valuable metal, waste of resources, etc. Avoid excessive soot deposition, improve resource utilization, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

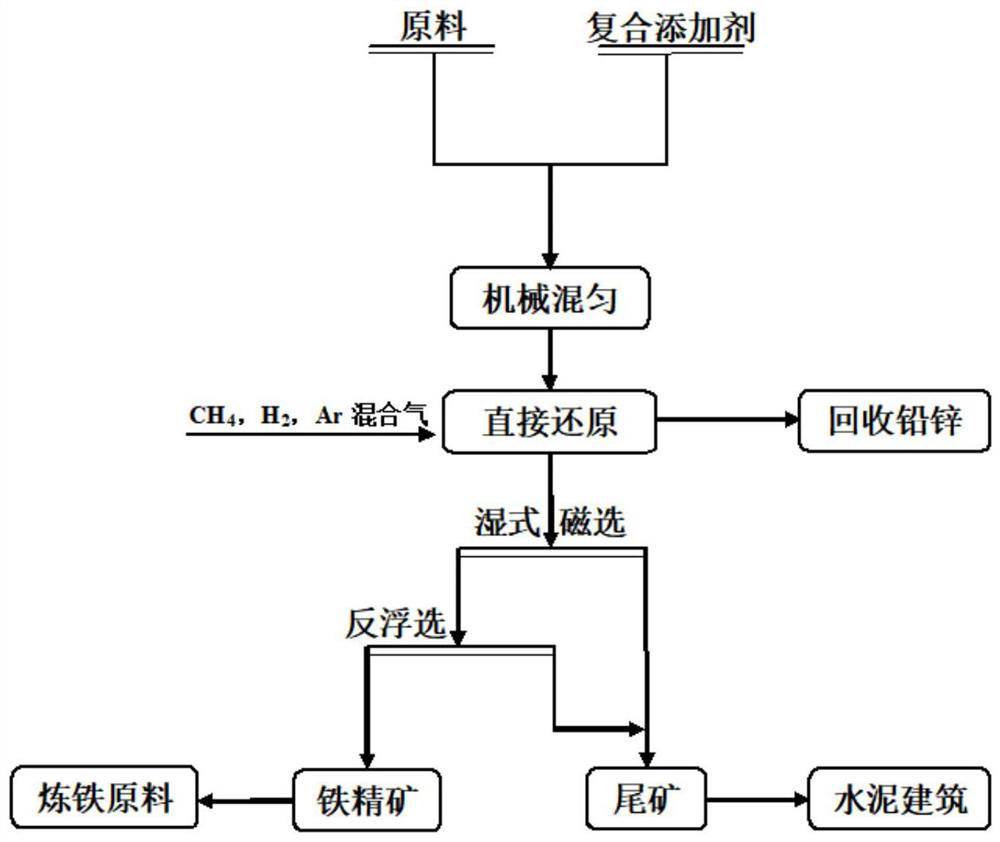

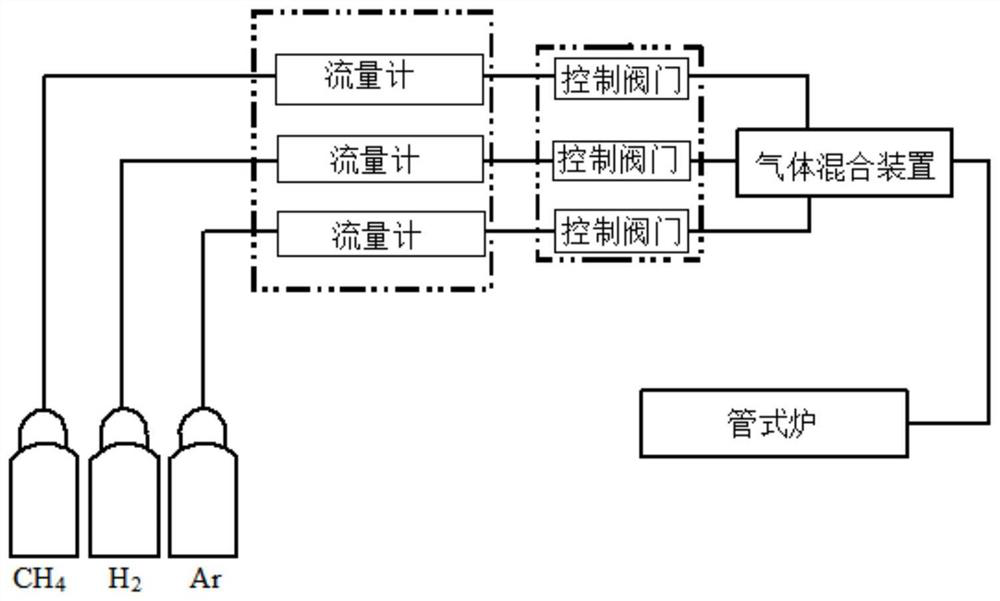

[0059] like figure 1 , 2 As shown, a method for comprehensively recovering multiple valuable metals in copper slag floating copper tailings according to the present embodiment includes the following steps:

[0060] Step 1. Direct restore

[0061] The composite additive of calcium oxide and sodium carbonate (CaO:Na 2 CO 3 =2) The ratio of 10% is mixed with the copper slag and put into the tube furnace, and the gas mixture of methane, hydrogen and argon is introduced to carry out reduction roasting, the roasting temperature is 700 ℃, and the roasting time is 120min. The constant volume fraction of dry argon is 50%, the concentrations of methane and hydrogen used are 5vol% and 45vol%, and the total flow rate of the mixed gas into the tube furnace is 800mL / min to remove zinc and lead in the slag. and other harmful impurities, and recover the zinc and lead, the obtained smoke dust has a lead and zinc grade of more than 30%, which can be used as raw materials for lead and zinc s...

Embodiment 2

[0067] like figure 1 , 2 As shown, a method for comprehensively recovering multiple valuable metals in copper slag floating copper tailings according to the present embodiment includes the following steps:

[0068] Step 1. Direct restore

[0069] The composite additive of calcium oxide and sodium carbonate (CaO:Na 2 CO 3 =1.5) The ratio of 15% is mixed with copper slag and put into a tube furnace, and the gas mixture of methane, hydrogen and argon is introduced to carry out reduction roasting, the roasting temperature is 800 ℃, and the roasting time is 100min. The constant volume fraction of dry argon is 50%, the concentrations of methane and hydrogen used are 10vol% and 40vol%, and the total flow rate of the mixed gas into the tube furnace is 800mL / min to remove zinc and lead in the slag. and other harmful impurities, and the zinc and lead are recovered, and the obtained smoke dust has a lead-zinc grade of more than 30%, which can be used as raw materials for lead-zinc sm...

Embodiment 3

[0075] like figure 1 , 2 As shown, a method for comprehensively recovering multiple valuable metals in copper slag floating copper tailings according to the present embodiment includes the following steps:

[0076] Step 1. Direct restore

[0077] The composite additive of calcium oxide and sodium carbonate (CaO:Na 2 CO 3 =2) The ratio of 15% is mixed with copper slag and put into the tube furnace, and the gas mixture of methane, hydrogen and argon is introduced to carry out reduction roasting, the roasting temperature is 900 ℃, and the roasting time is 90min. The constant volume fraction of dry argon is 50%, the concentrations of methane and hydrogen used are 15vol% and 35vol%, and the total flow rate of the mixed gas into the tube furnace is 700mL / min to remove zinc and lead in the slag. and other harmful impurities, and recover the zinc and lead, the obtained smoke dust has a lead and zinc grade of more than 30%, which can be used as raw materials for lead and zinc smelt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com