Sub-frame post-cast joint with external permanent aluminum plate outer mold

A sub-frame and permanent technology, which is applied to post-cast joints and construction fields with permanent aluminum plates outside the sub-frame, and can solve problems such as cross-sections that cannot meet architectural requirements, sub-frame vertical discontinuity, and structural stress. , to achieve the effect of saving labor and construction period, less consumables and good self-flowing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In this embodiment, the installation process requirements of the concrete pouring formwork, the construction technical requirements of steel bar binding, the construction process requirements of concrete pouring, the welding process requirements, etc. will not be described in detail, and the emphasis will be on the external permanent aluminum plate external formwork involved in the secondary frame of the present invention. Implementation mode of pouring node construction.

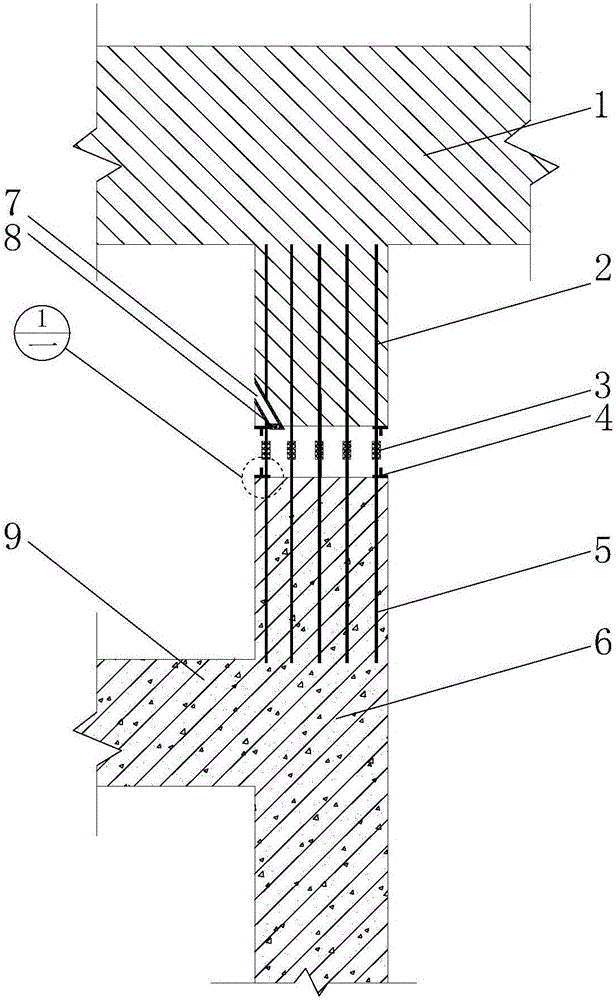

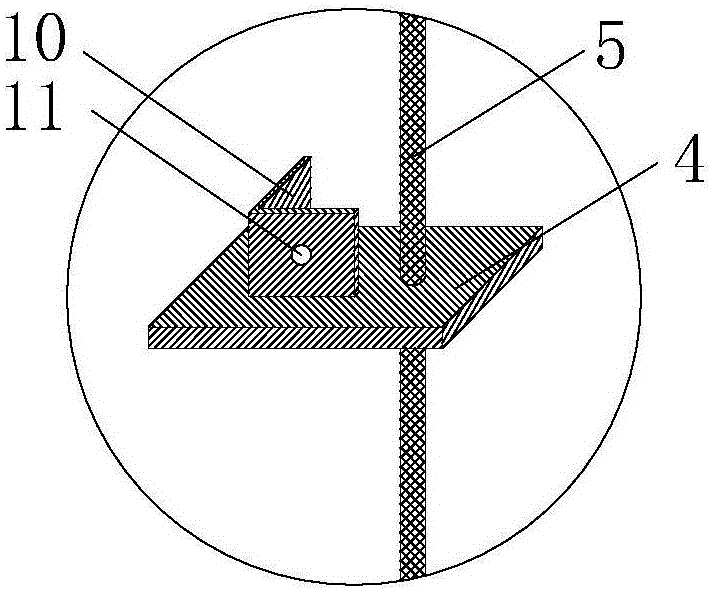

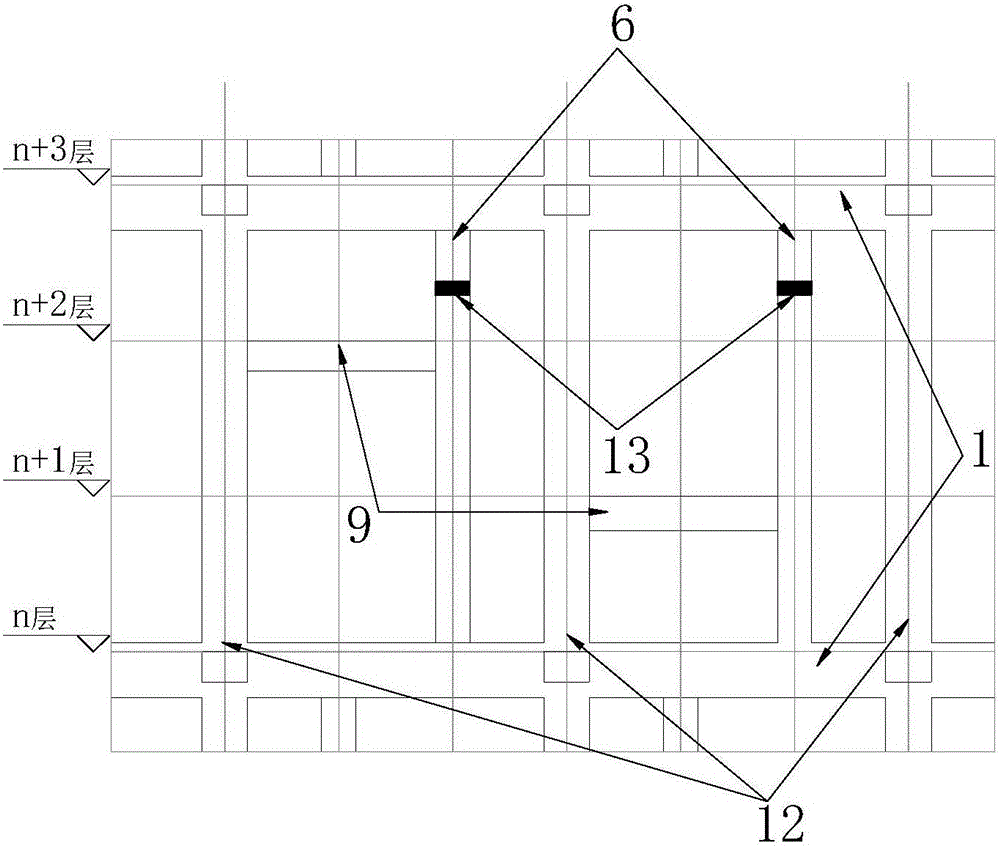

[0038] figure 1 It is a cross-sectional view of the structure before pouring of the post-cast node of the external permanent aluminum plate external mold of the secondary frame of the present invention, figure 2 yes figure 1 A zoom-in diagram of the middle node, image 3 is a schematic diagram of post-pouring node location distribution, Figure 4 It is a cross-sectional view of the structure of the temporary filler of the present invention after installation, Figure 5 It is a structural section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com