Reinforcement grouting material

A technology of grouting material and mass fraction, applied in the field of reinforcing grouting material, can solve the problems of fast flow loss, large bleeding of the slurry, poor fluidity, etc., and achieve the effects of poor stability, good self-tightness, and good self-flowing properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

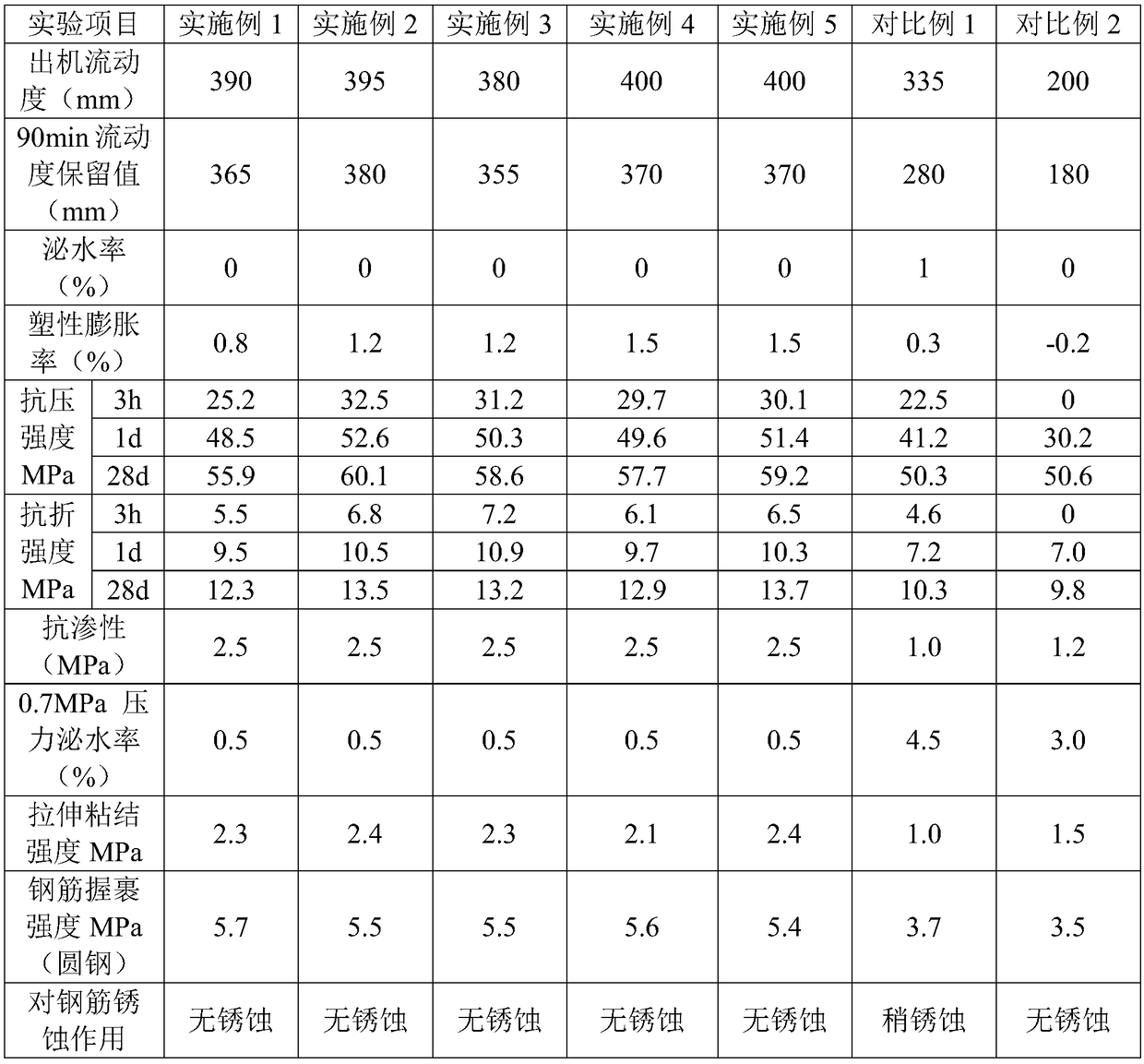

Examples

Embodiment 1

[0041] Add 500kg of low-alkalinity fast-hardening sulfoaluminate cement with a total alkalinity of less than 0.6%, 45kg of S140 superfine mineral powder, 43.5kg of silica fume with a particle size of 0.15 microns, and UEA-H retarding pumping concrete expansion agent. 50kg, 350kg of quartz sand with a fineness modulus of 2.5, 4.0kg of TOJ-10T high-water-reducing polyether-type polycarboxylate early-strength water-reducer with a water-reducing rate of 25%, 2..0kg of L-tartaric acid, 0.5cm basalt chopped fiber 2.5kg, E-325D type GPE polyether defoamer with a relative molecular weight of 3000-3600 1.0kg, lithium carbonate 2.0kg; mix and stir evenly to prepare tunnel and culvert reinforcement grouting material.

Embodiment 2

[0043] Sequentially add 600kg of low-alkalinity fast-hardening sulfoaluminate cement with a total alkalinity of less than 0.6%, 20kg of S140 ultra-fine mineral powder, 50kg of silica fume with a particle size of 0.1 micron, 62kg of UEA-H low-alkali antifreeze concrete expansion agent, fine 250kg of quartz sand with a degree modulus of 2.3, 6.0kg of TOJ-10T high-water-reducing polyether-type polycarboxylate early-strength superplasticizer with a water-reducing rate of 25%, 5.0kg of L-tartaric acid, and 0.5cm chopped basalt Fiber 2.5kg, G-20B type linear polysiloxane defoamer with a relative molecular weight of 5000-6000 2.5kg, lithium carbonate 2.0kg; mix and stir evenly to prepare tunnel and culvert reinforcement grouting material.

Embodiment 3

[0045] Add 590kg of low-alkalinity fast-hardening sulfoaluminate cement with a total alkalinity of less than 0.6%, 40kg of S140 ultrafine mineral powder, 20kg of silica fume with a particle size of 0.3 microns, and 80kg of UEA-H retarding pumping concrete expansion agent. , 252kg of quartz sand with a fineness modulus of 3.0, 6.0kg of TOJ-10A retarded polyether polycarboxylate early strength superplasticizer with a water reducing rate of 25%, 5.0kg of L-tartaric acid, 1.0cm chopped basalt Fiber 2.0kg, E325-D type GPE type polyether defoamer with a relative molecular weight of 3000-3600 3.0kg, lithium carbonate 2.0kg; mix and stir evenly to prepare tunnel and culvert reinforcement grouting material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com