A kind of high-throw steel pipe self-compacting concrete and preparation process thereof

A technology of self-compacting concrete and high-throw steel pipe, applied in the field of concrete, can solve the problems of poor fluidity, internal structure porosity of concrete, increase of micro-cracks, uneven distribution of concrete, etc. The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

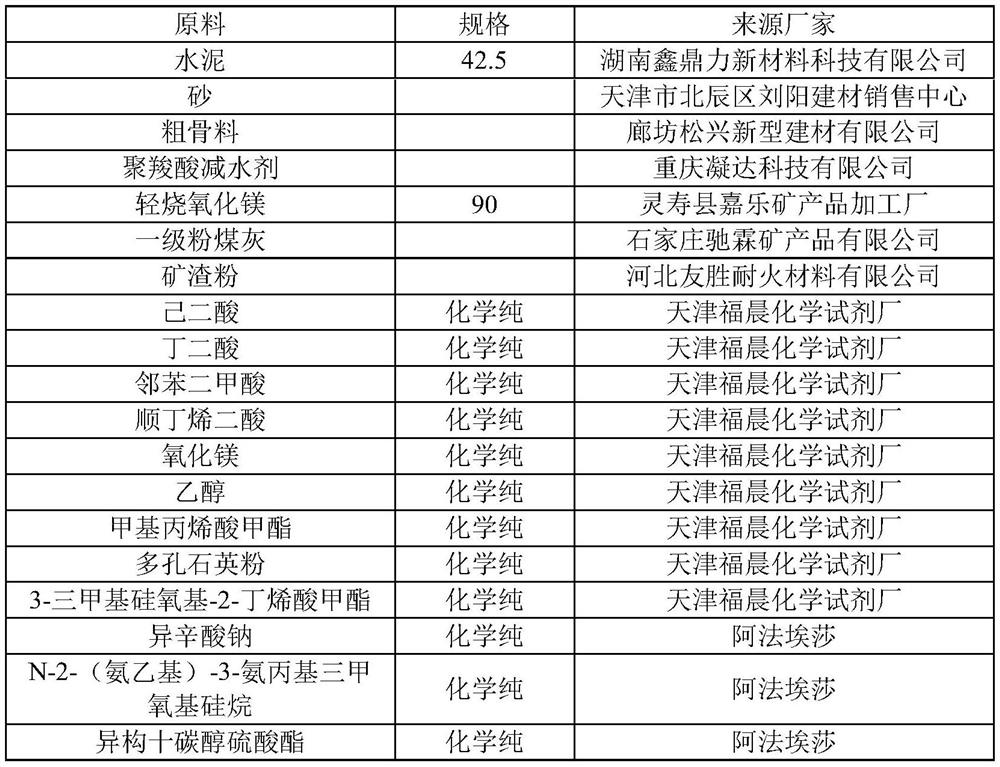

Image

Examples

preparation example Construction

[0045] Preferably, the preparation method of dibasic carboxylate magnesium polymer comprises the following steps:

[0046] 1) get an appropriate amount of dicarboxylic acid and place it in the reactor, add distilled water and stir to dissolve the dicarboxylic acid completely;

[0047] 2) in the flask in the step 1), add the magnesium oxide of an equimolar amount with the dicarboxylic acid, after continuing the stirring reaction, the solvent is evaporated to dryness, the gained reactant is cleaned with ethanol, and then dried under 150 ° C. have to.

[0048] Preferably, methyl methacrylate is grafted on the surface of the light-burned magnesium oxide. Further preferably, the light-burned magnesium oxide surface grafting methyl methacrylate comprises the following steps:

[0049] 1) Dry the light-burned magnesia powder at 120°C for 5h in an oven, and then irradiate it with electron beams, the irradiation time is 15-20min, and the irradiation dose is 30-50kGy;

[0050] 2) Dilu...

Embodiment 1

[0068] The high-throw steel pipe self-compacting concrete of the present embodiment is made from the following raw materials: coarse aggregate 750kg, fine aggregate 700kg, cement 350kg, fly ash 50kg, slag powder 90kg, water 150kg, water reducing agent 6kg, expansion agent 35kg, modifier 20kg.

[0069] Wherein, the modifier is N-2-(aminoethyl)-3-aminopropyltrimethoxysilane, and the expansion agent is the preparation technology of the high-throw steel pipe self-compacting concrete of the present embodiment of light-burned magnesia, and the preparation process comprises the following steps:

[0070] 1) mixing cement, fly ash and slag powder in a mixer for 15min at a rotating speed of 600rpm to obtain a mixture;

[0071] 2) adding water, water reducing agent, swelling agent and modifier into the mixture in step 1), stirring 2min at a rotating speed of 800rpm to obtain slurry A;

[0072] 3) adding the fine aggregate to the slurry A in step 2) and stirring at a speed of 400 rpm for...

Embodiment 2

[0075] The high-throw steel pipe self-compacting concrete of this embodiment is made of the following raw materials: coarse aggregate 780kg, fine aggregate 730kg, cement 380kg, fly ash 60kg, slag powder 100kg, water 155kg, water reducing agent 7kg, expansion agent 38kg, modifier 25kg.

[0076] Wherein, the modifier is N-2-(aminoethyl)-3-aminopropyltrimethoxysilane, and the expansion agent is the preparation technology of the high-throw steel pipe self-compacting concrete of the present embodiment of light-burned magnesia, and the preparation process comprises the following steps:

[0077] 1) mixing cement, fly ash and slag powder in a mixer for 20min at a rotating speed of 700rpm to obtain a mixture;

[0078] 2) adding water, water reducing agent, swelling agent and modifier into the mixture in step 1), stirring at a rotating speed of 900rpm for 4min to obtain slurry A;

[0079] 3) adding the fine aggregate to the slurry A in step 2) and stirring for 2 min at a rotating speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com