Patents

Literature

333results about How to "Lower discharge temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

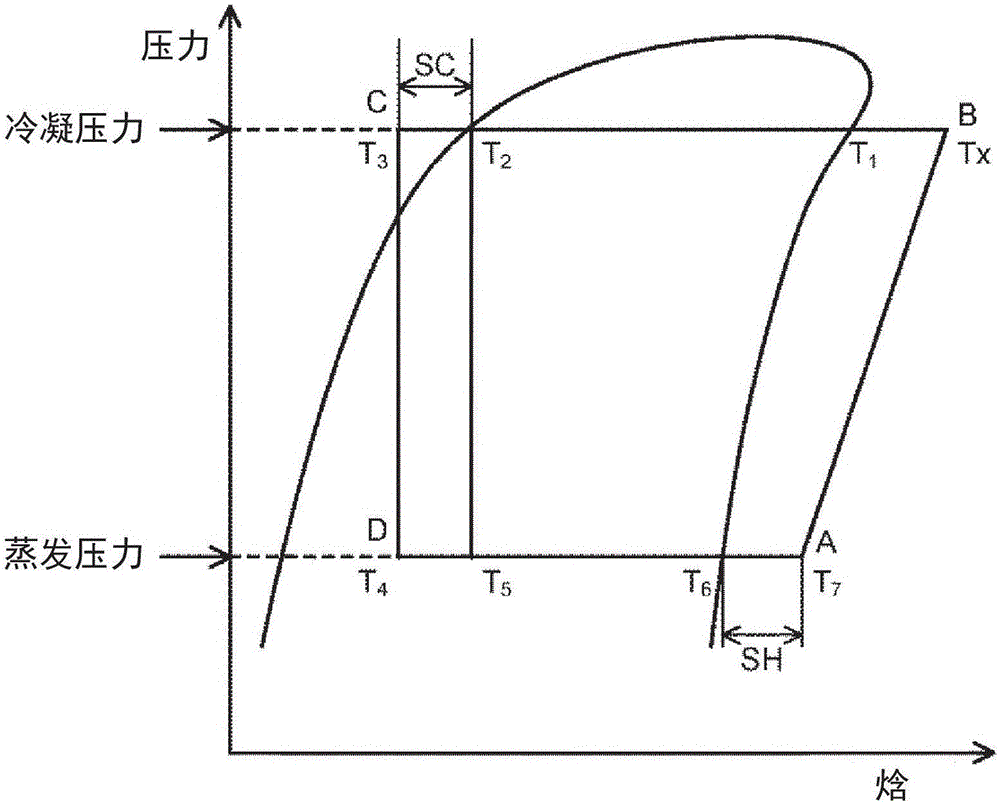

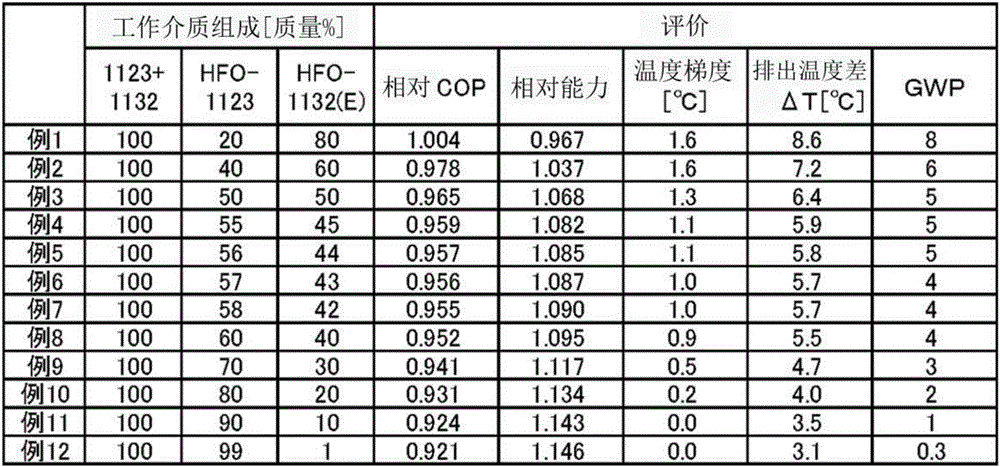

Working medium for heat cycles, composition for heat-cycle systems, and heat-cycle system

ActiveCN106133110AReduce temperature gradientLower discharge temperatureCompressorCompression machines with non-reversible cycleEngineeringRefrigeration

Provided are: a working medium for heat cycles which has a low impact on global warming, a low temperature gradient, and a sufficiently low discharge temperature, and which exhibits excellent cycle performance (i.e. refrigeration capacity and coefficient of performance); a composition for heat-cycle systems; and a heat-cycle system. The working medium for heat cycles includes trifluoroethylene and 1, 2-difluoroethylene. Also provided are: a composition for heat-cycle systems; and a heat-cycle system which uses the working medium and the composition. It is prefereable that, in the working medium for heat cycles, the ratio of the total amount of trifluoroethylene and 1, 2-difluoroethylene be at least 20 mass%, and equal to or less than 100 mass%.

Owner:AGC INC

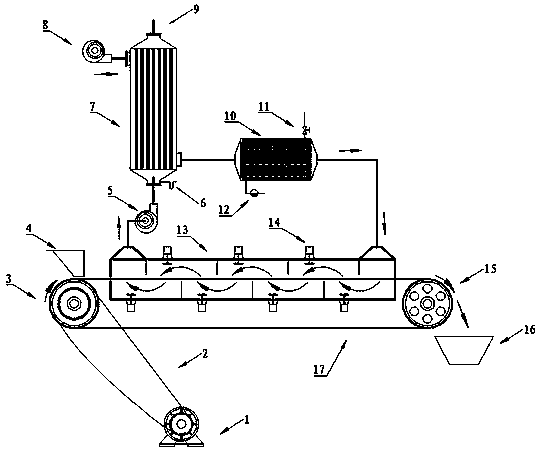

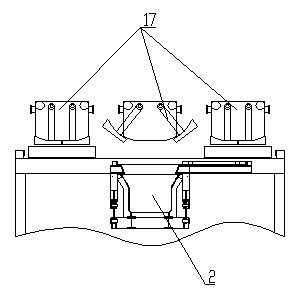

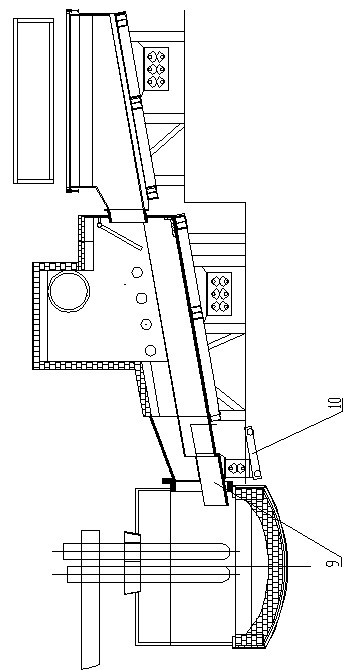

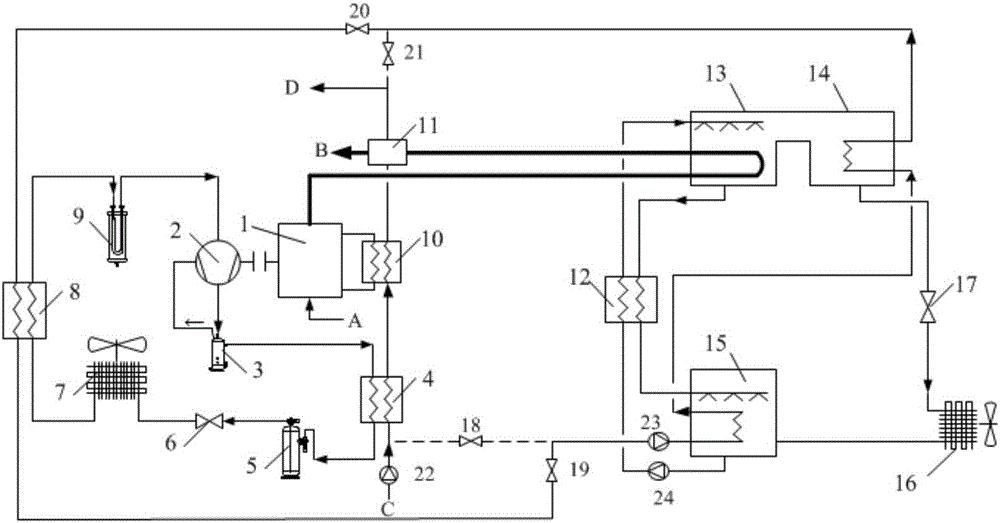

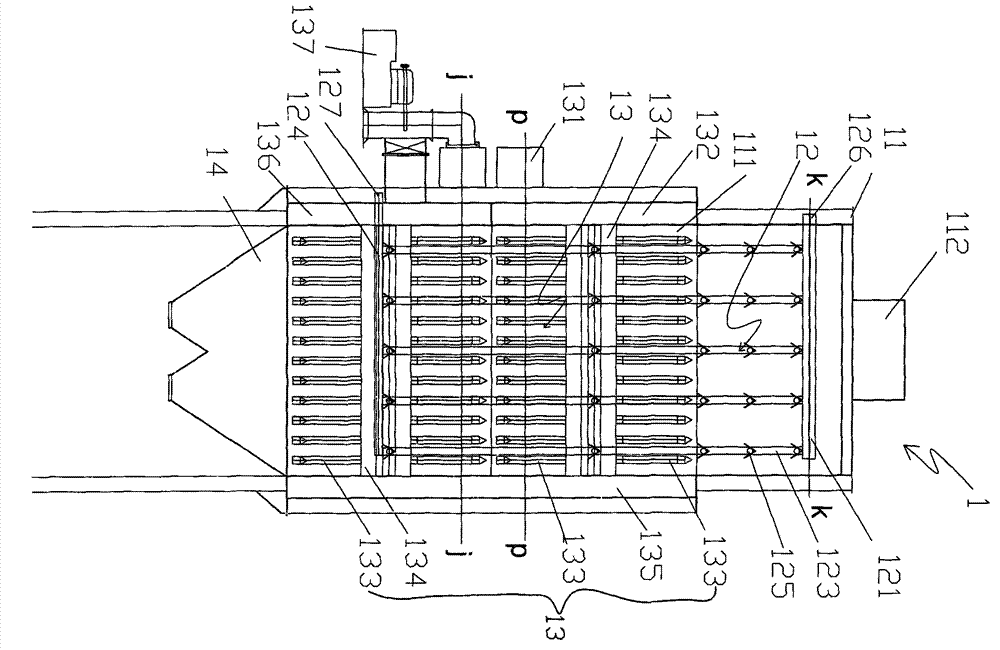

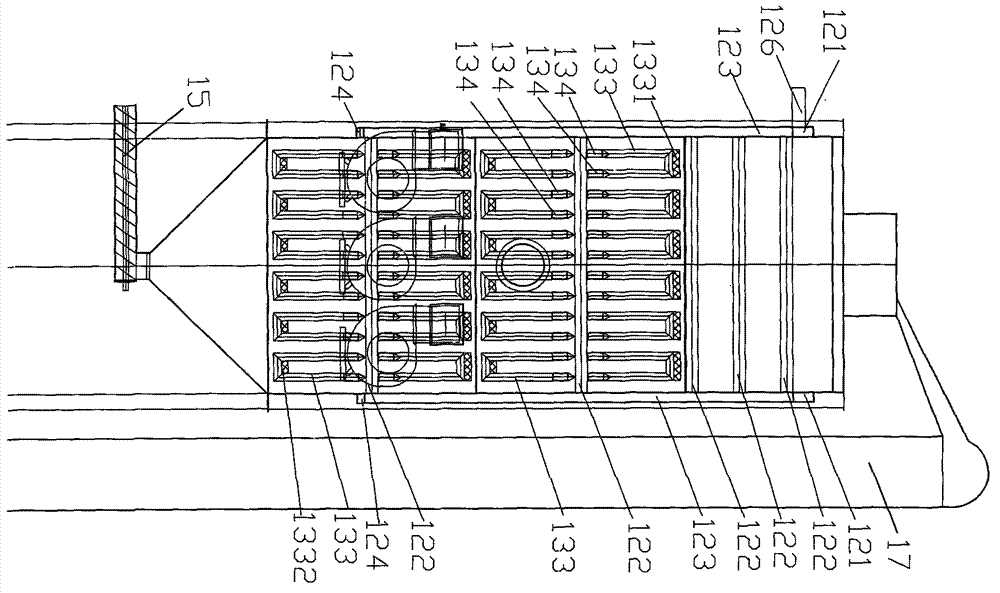

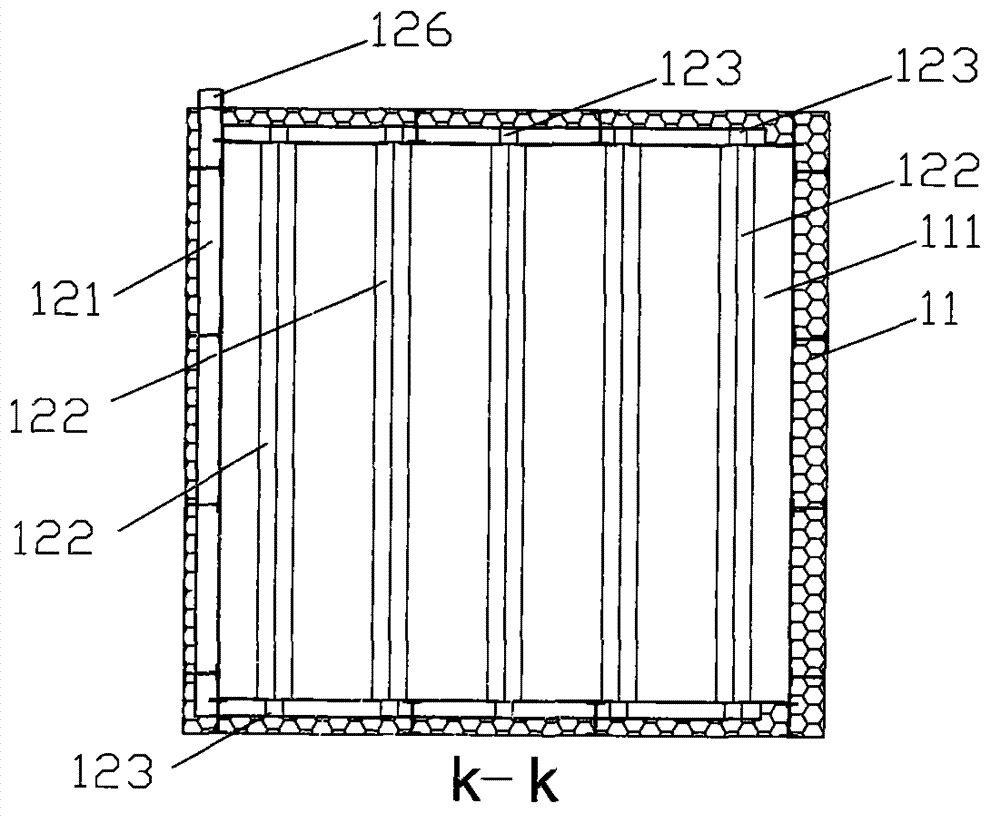

Penetrating type reverse-flow drying device

InactiveCN103471373AStrong penetrating powerLow running costDrying gas arrangementsDrying machines with progressive movementsTransport systemPulp and paper industry

The invention discloses a penetrating type reverse-flow drying device. The penetrating type reverse-flow drying device comprises a heat exchanger, an air heater, a driving drum, a driven drum, a sieve plate type conveying steel belt and a dryer body, wherein an air blower is connected with one side of the upper end of the heat exchanger, the air heater is connected with one side of the lower end of the heat exchanger, the driving drum is connected with a double-stage cycloidal-pin wheel speed reducer through a transmission chain, a material conveying system is formed by the driving drum and the driven drum through the sieve plate type conveying steel belt, a feeding hopper is arranged at one end of the material conveying system, a discharging hopper is arranged at the other end of the material conveying system, the sieve plate type conveying steel belt penetrates through the dryer body, the dryer body is of a sealed structure, a plurality of axial fans are reasonably distributed on the top face and the bottom face of the dryer body, one side of the dryer body is connected with an outlet of the air heater, the other side of the dryer body is connected with an suction fan, and an air outlet of the suction fan is connected with an inlet pipe arranged at the bottom of the heat exchanger. The penetrating type reverse-flow drying device is simple in structure and good in practicability, can achieve rapid and efficient drying of materials, is low in energy consumption and has broad prospects.

Owner:东莞市胜源纸品有限公司

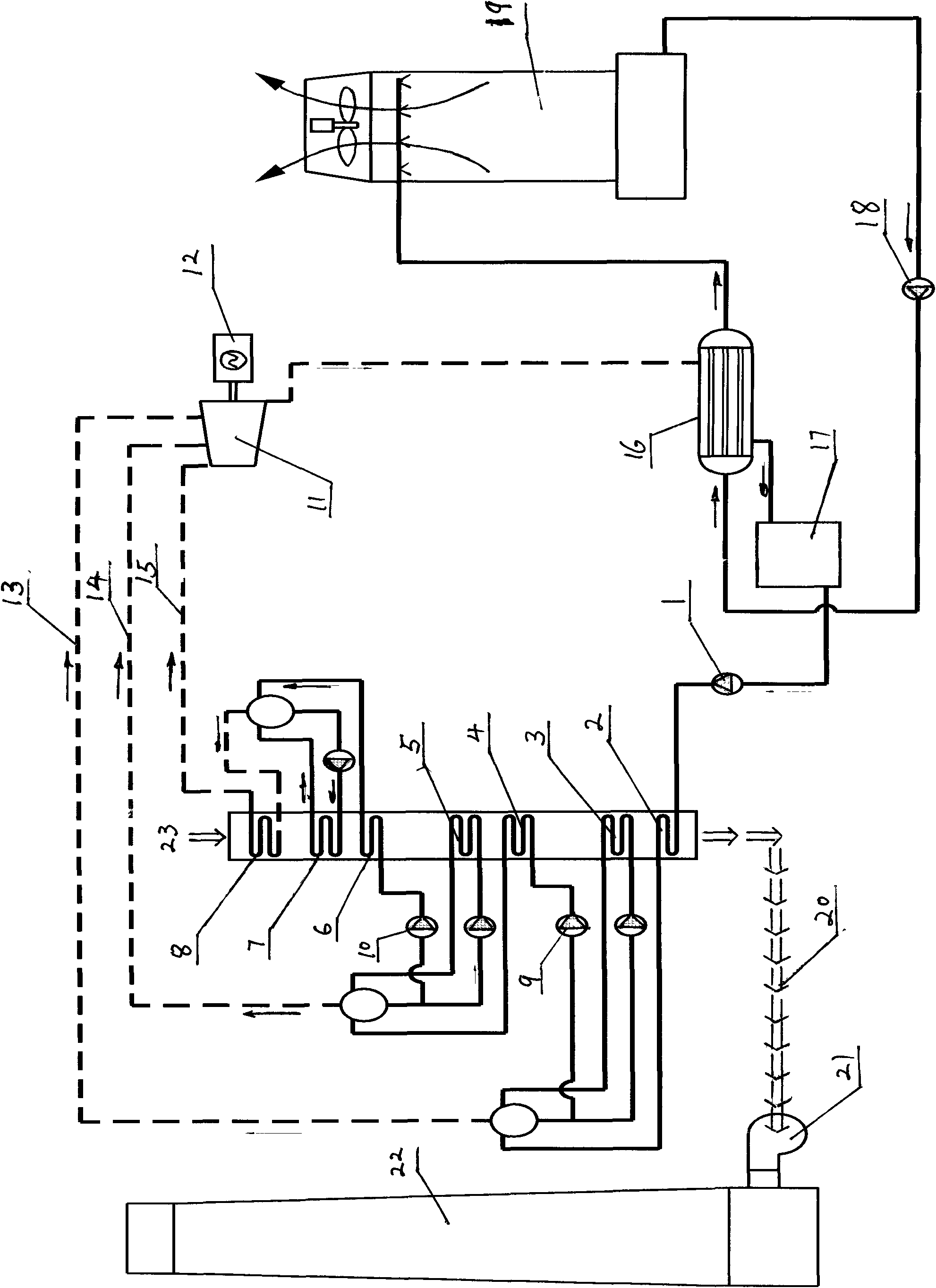

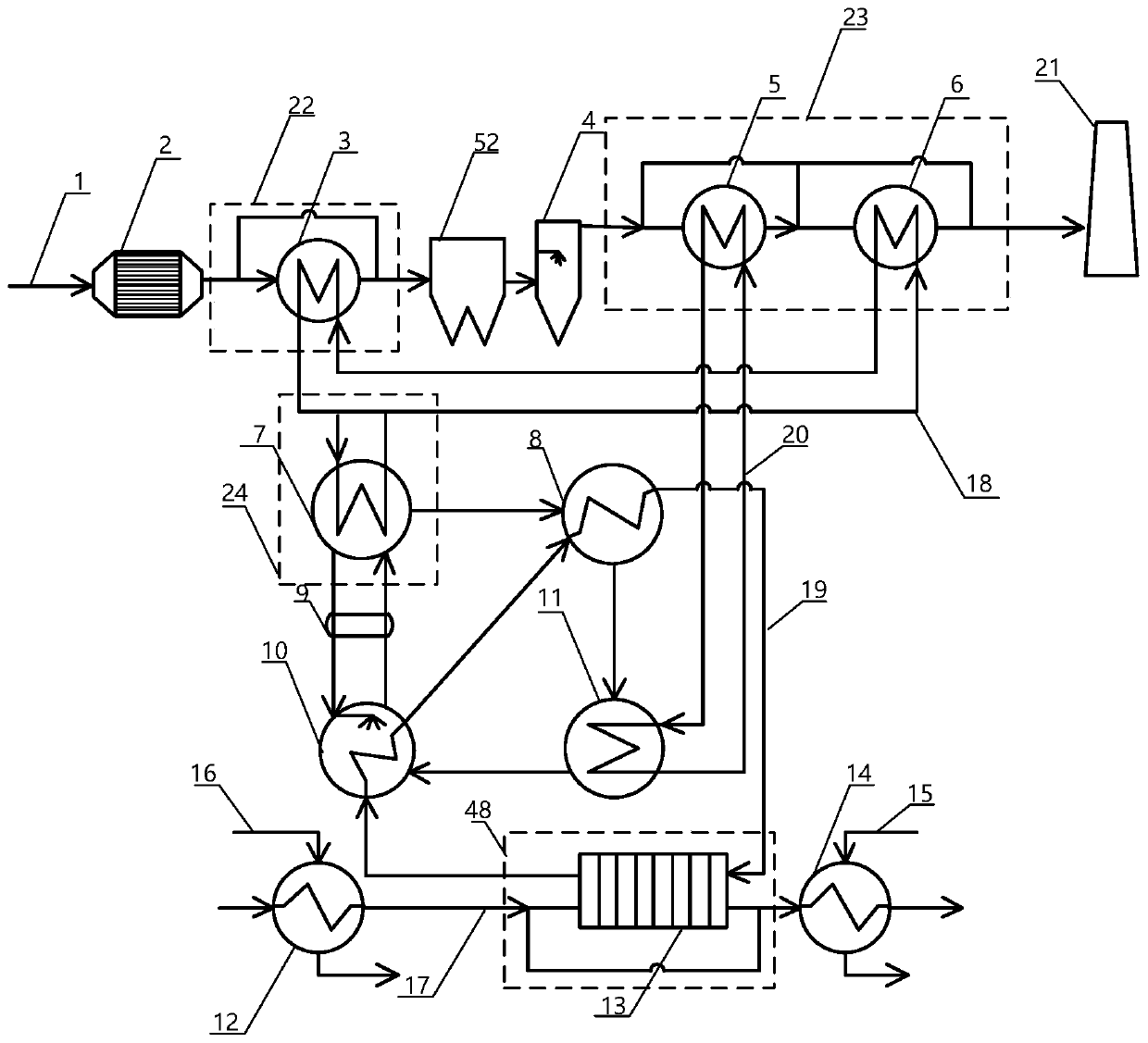

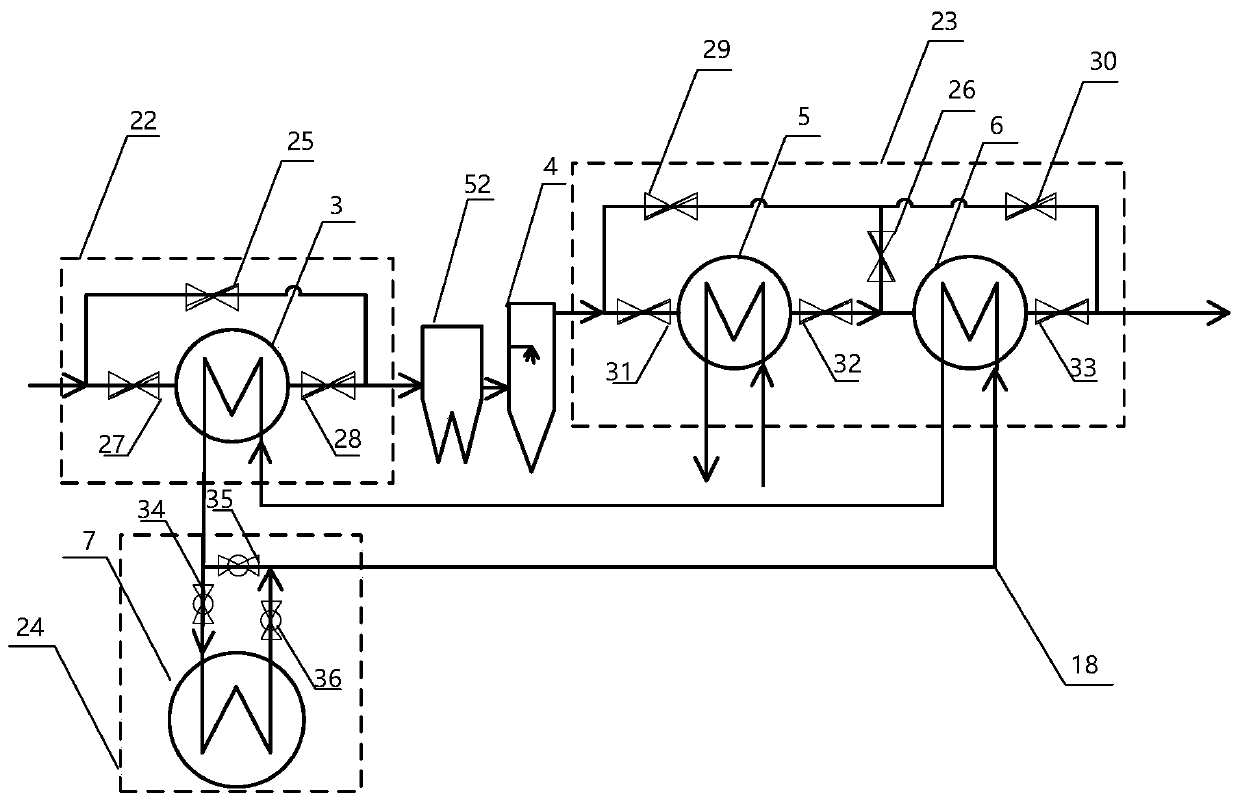

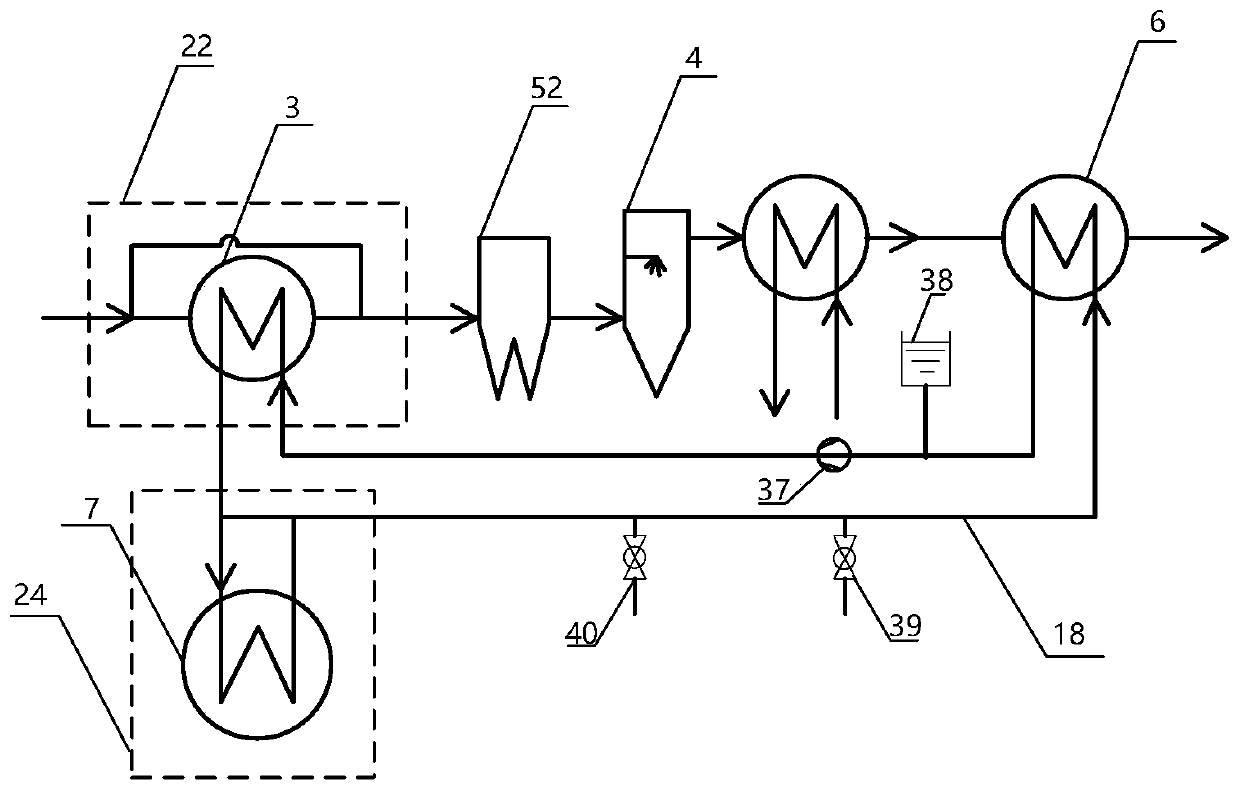

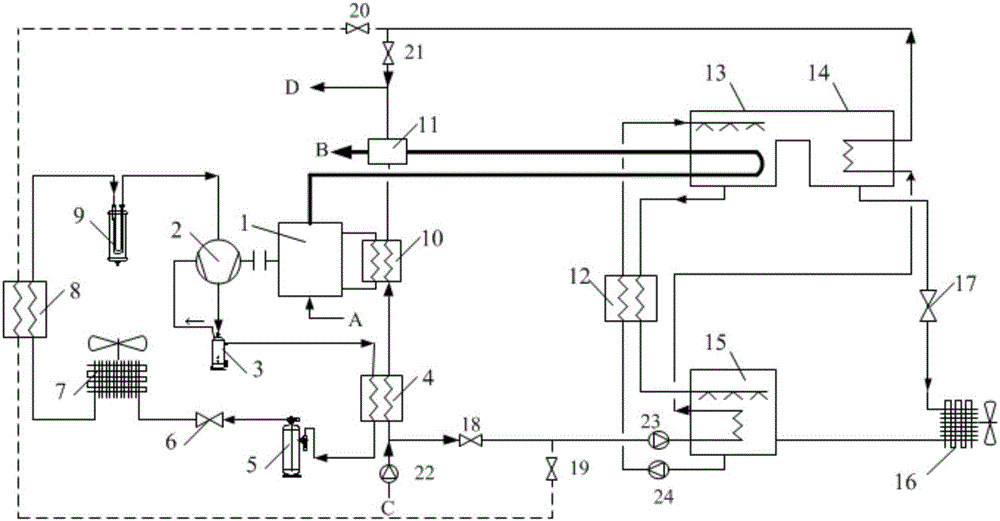

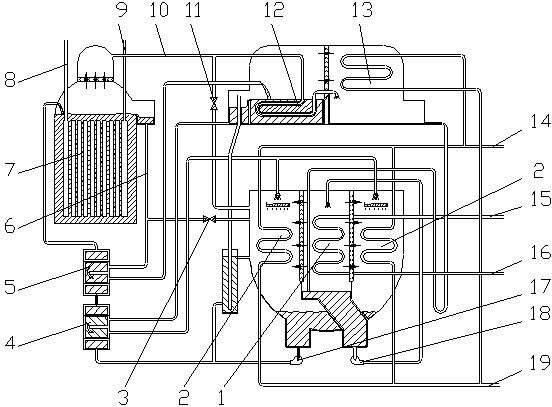

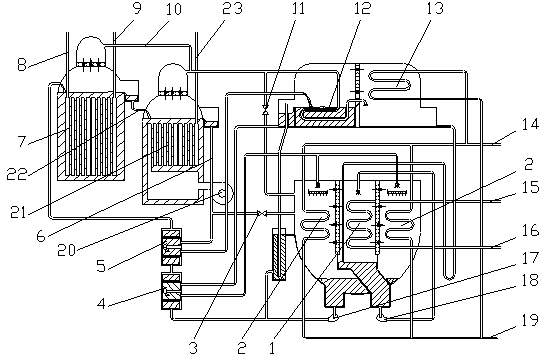

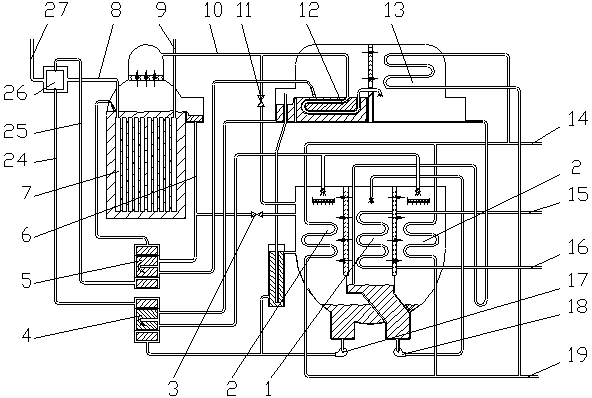

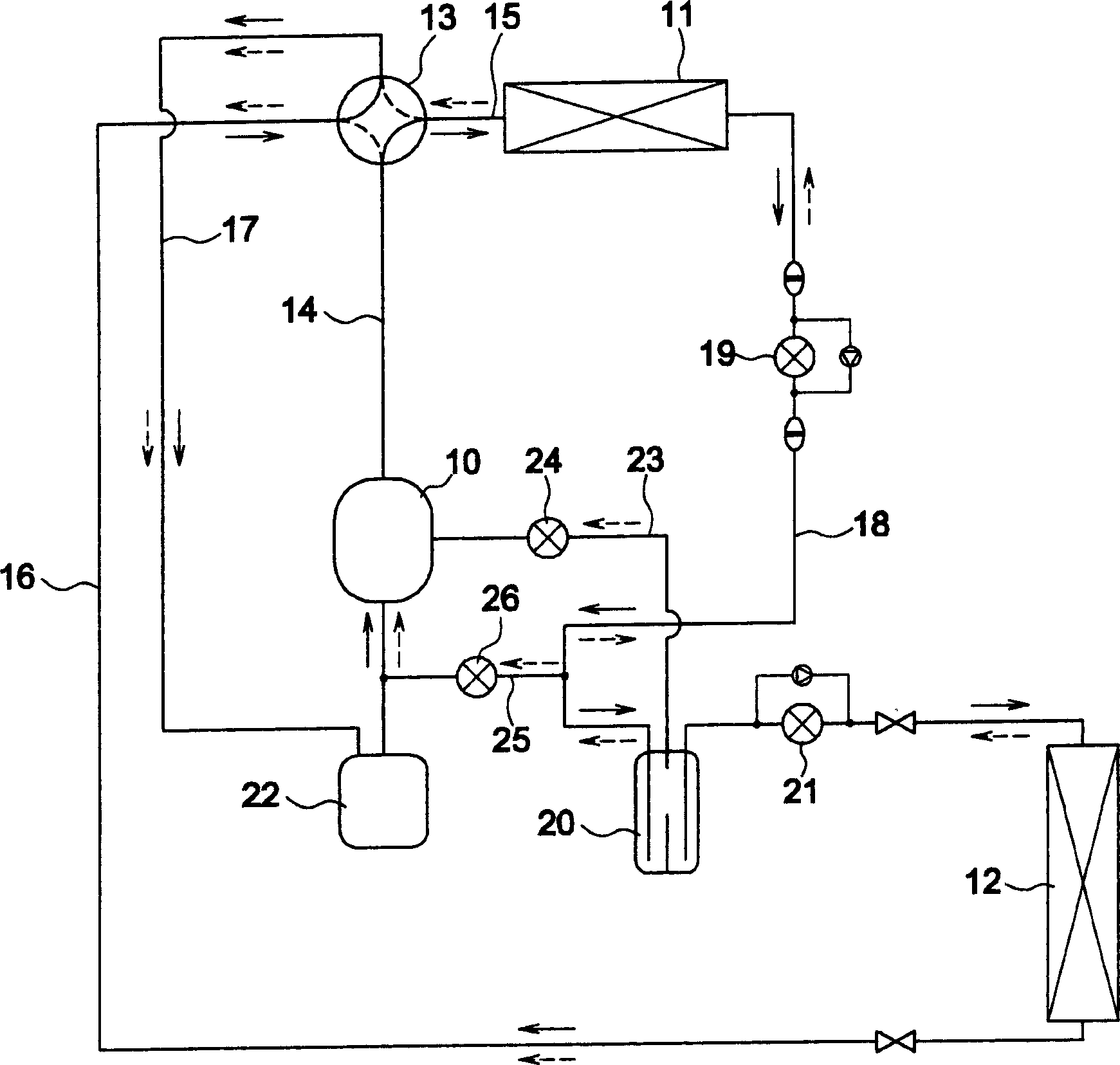

Multistage evaporation organic Rankine cycle waste heat recovery generation system and method thereof

InactiveCN101806232AImprove efficiencyLower discharge temperatureEnergy industrySteam engine plantsVapor–liquid separatorBooster pump

The invention relates to a multistage evaporation organic Rankine cycle waste heat recovery generation system and a process thereof. The multistage evaporation organic Rankine cycle waste heat recovery generation system is provided with an organic working medium waste heat boiler, a multistage organic turbine with an intermediate air supplementation port, a condenser, a water cooling tower, a draught fan and the like according to required generation capacity; the organic working medium waste heat boiler, the multistage organic turbine, the condenser, a liquid storage device, a vapor-liquid separator, various stages of working medium booster pumps, a cooling water circulating pump, the water cooling tower, a valve and other equipment and accessories are arranged and connected by pipelines; and the working medium charging quantity can be calculated according to the pipeline volume and R290, R245fa, n-pentane or n-hexane are metered and charged into a circulating pipeline. The invention can efficiently convert medium-low temperature waste gas waste heat into high-grade electric energy, improve the efficiency by 2-5 percent in comparison with single-stage evaporation organic Rankine cycle and remarkably improve the benefit of waste heat recovery.

Owner:KUNMING UNIV OF SCI & TECH +1

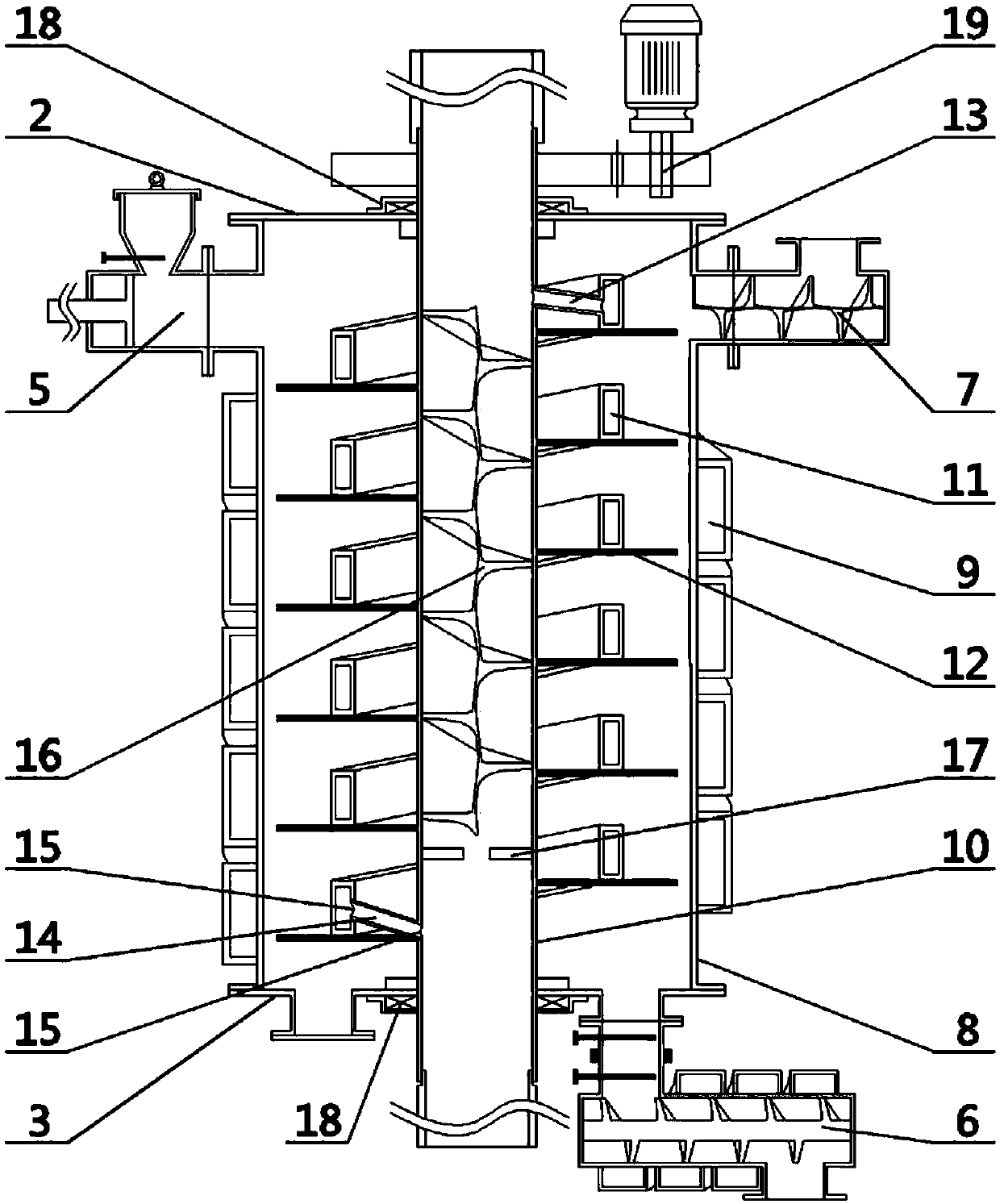

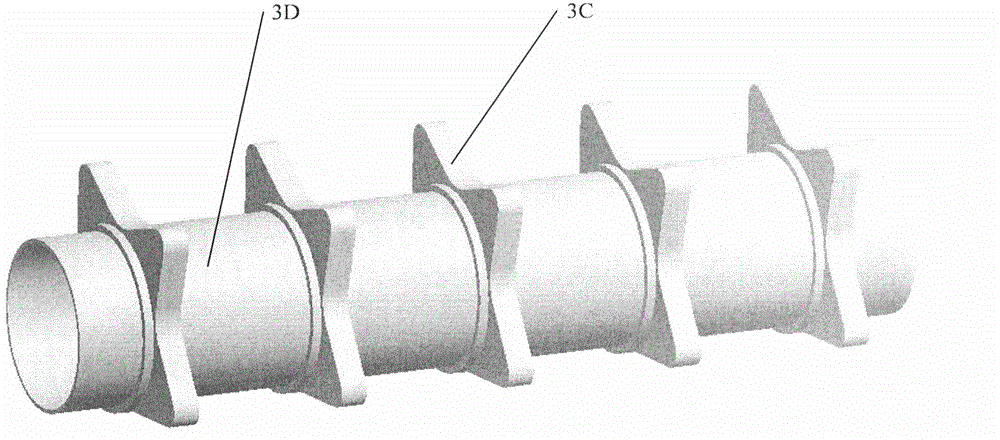

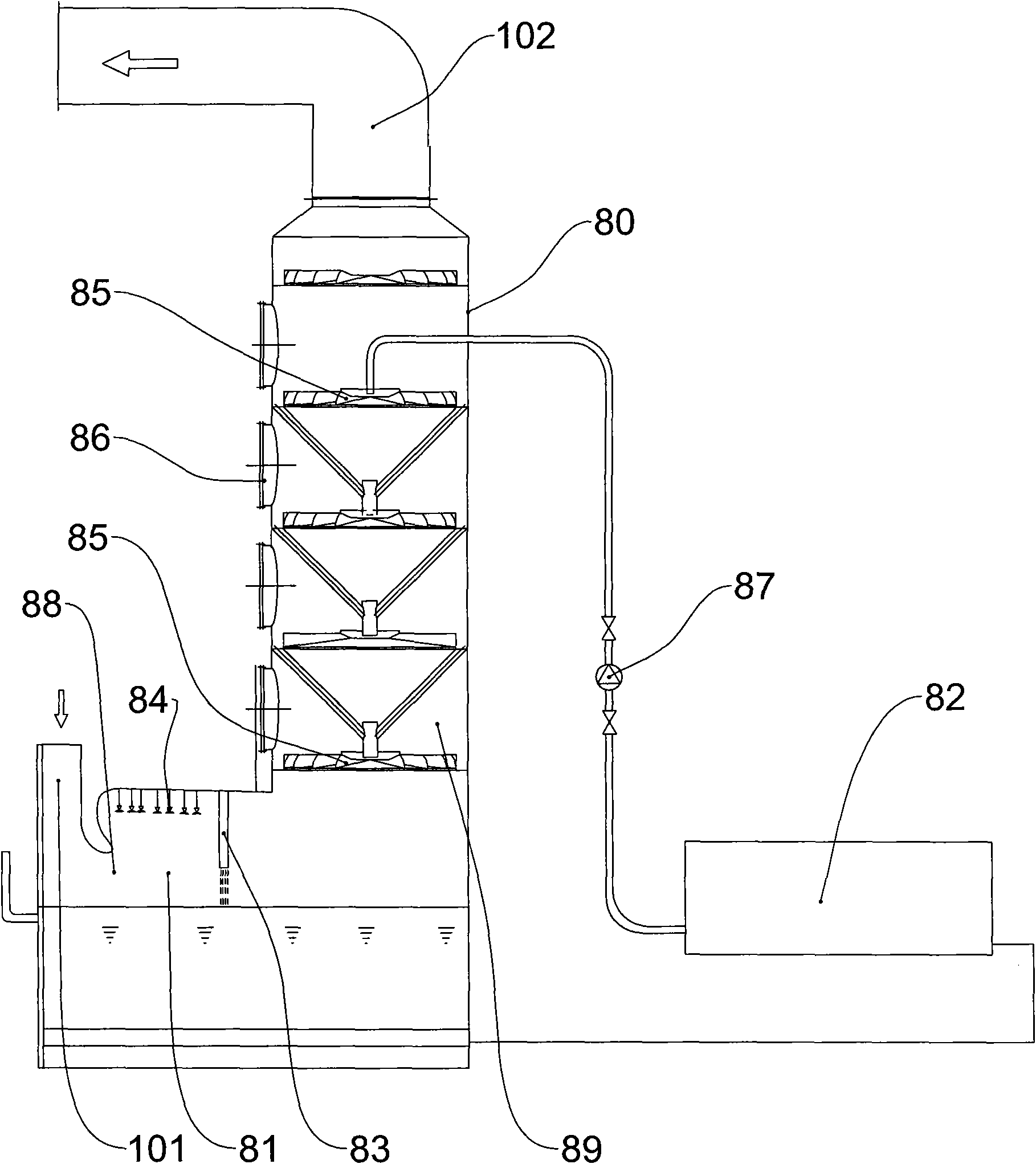

Vertical multidirectional heating organic solid waste pyrolysis device

ActiveCN107649491AExtended stayRelease fullyTransportation and packagingSolid waste disposalSlagEngineering

The invention discloses a vertical multidirectional heating organic solid waste pyrolysis device. Closed pyrolysis space is formed among an outer barrel body, an inner barrel body, an upper end coverand a lower end cover of the device. A spiral coiled pipe serving as an outer heating channel is coiled on the outer wall of an outer barrel of the device, and a feeding opening connected with a feeding device and a gas outlet connected with a pyrolysis gas guide-out device are formed in the outer side face of the upper portion of the outer barrel. A spiral pipe barrel is coiled on the periphery of a center barrel of the device, the spiral pipe barrel is fixed through blades on the outer side of the center barrel, the two ends of the spiral pipe barrel communicate with the center barrel, a spiral plate is arranged in the center barrel, and therefore a heating gas spiral channel is formed in the center barrel, and a flow limiting hole plate is arranged below the spiral plate. The center barrel is driven by a variable frequency motor, and the lower sealing cover is provided with a slag outlet connected with a slag outlet device. The vertical multidirectional heating organic solid waste pyrolysis device is provided with an inner heating heat source and an inner heating heat source, the inner heat source is divided into a center heat source and a middle heat source, and the pyrolysis device guarantees material anaerote continuity. By means of the spiral channel, the heating area and the heating gas retention time are greatly increased, heat can be fully released, and the productioncapacity can be improved.

Owner:青岛伊诺威能源化工新技术有限公司

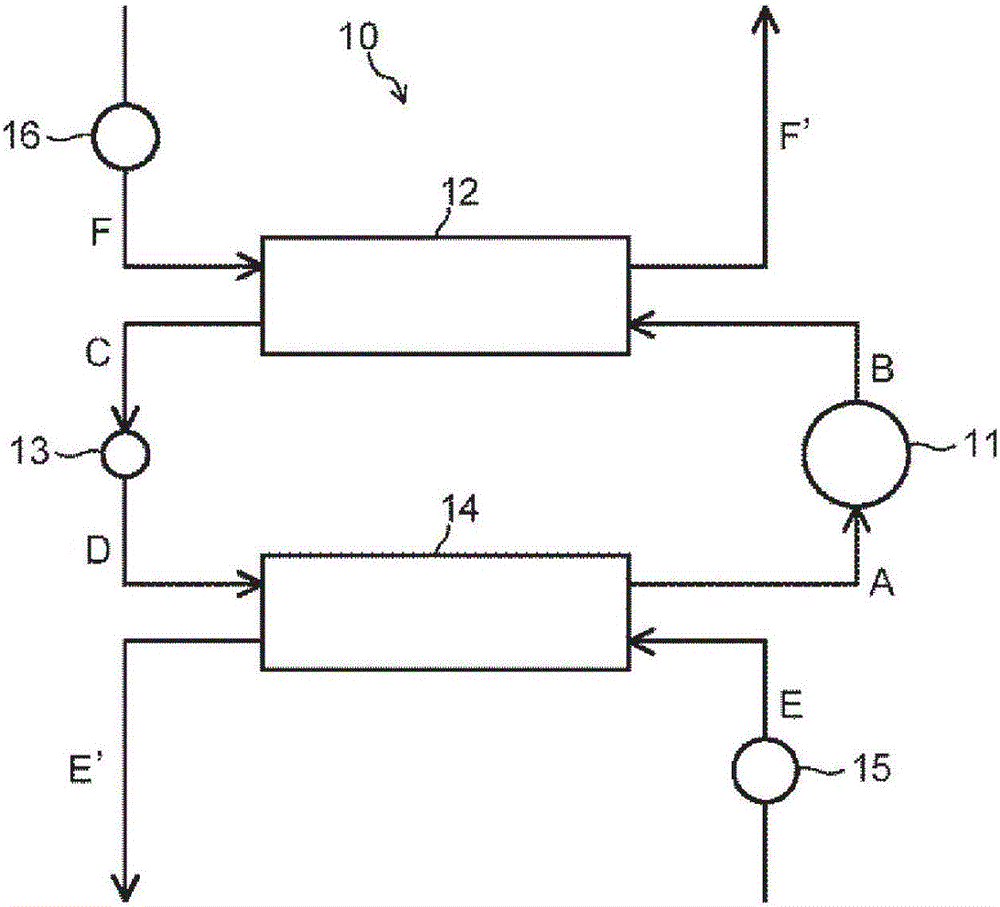

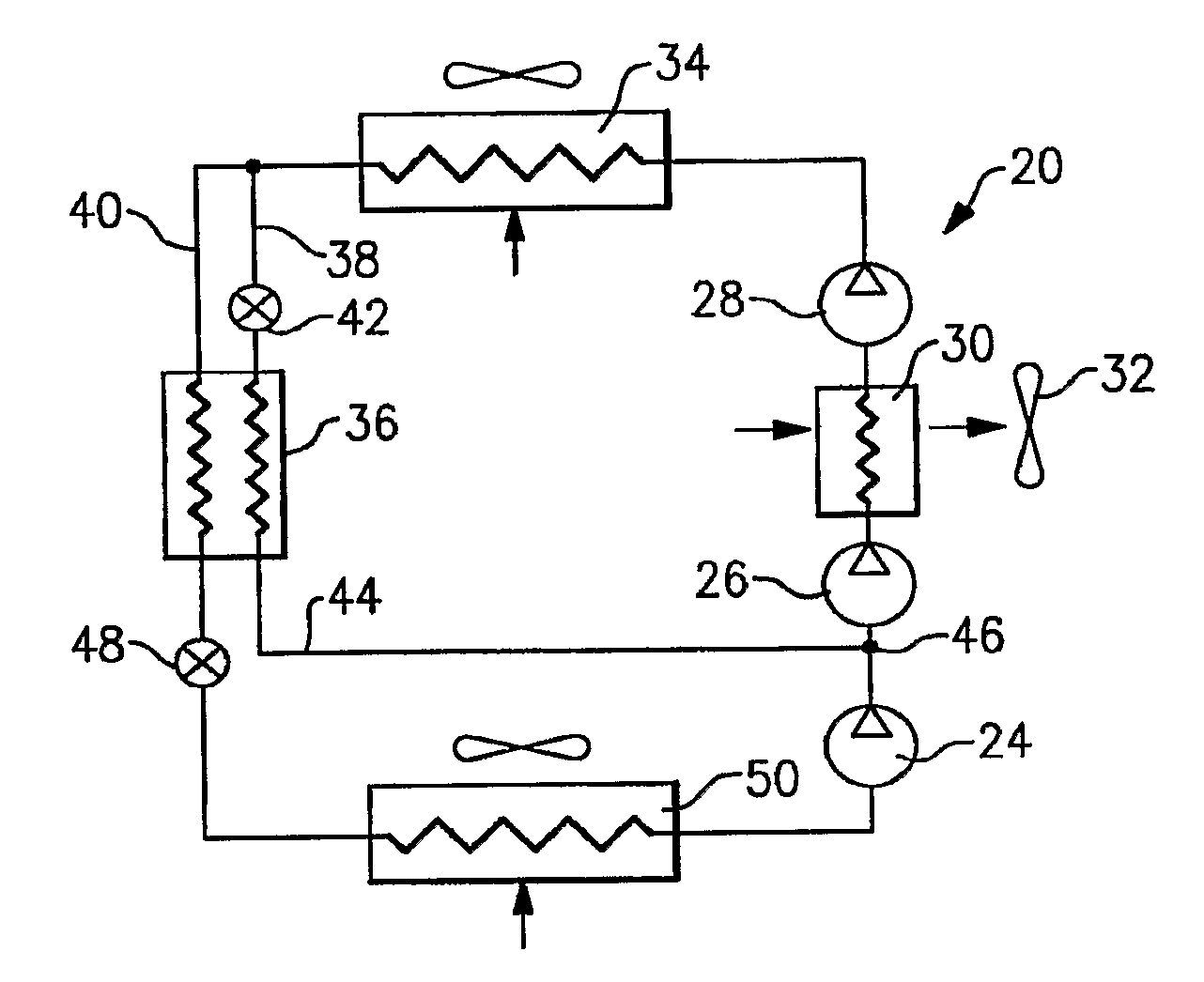

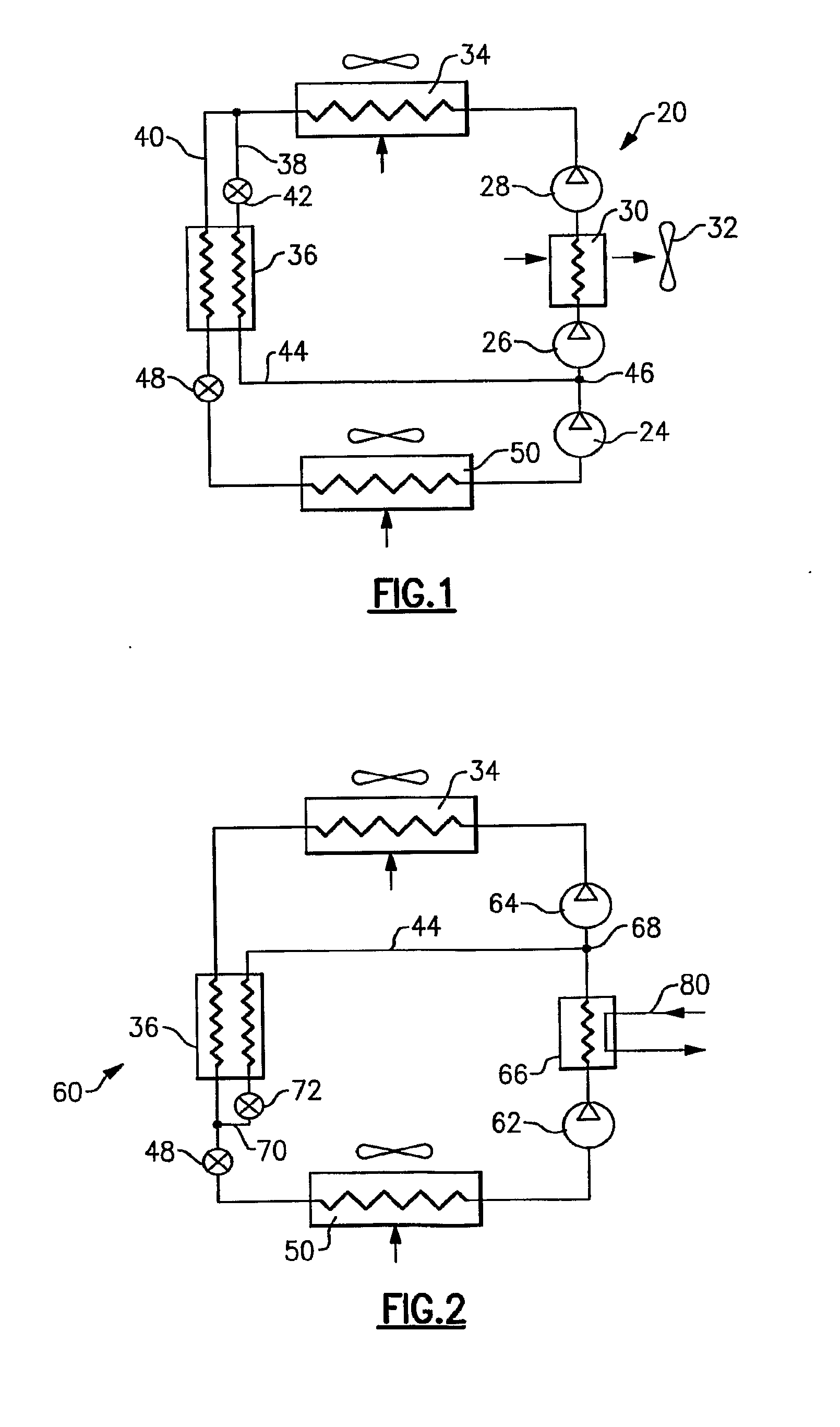

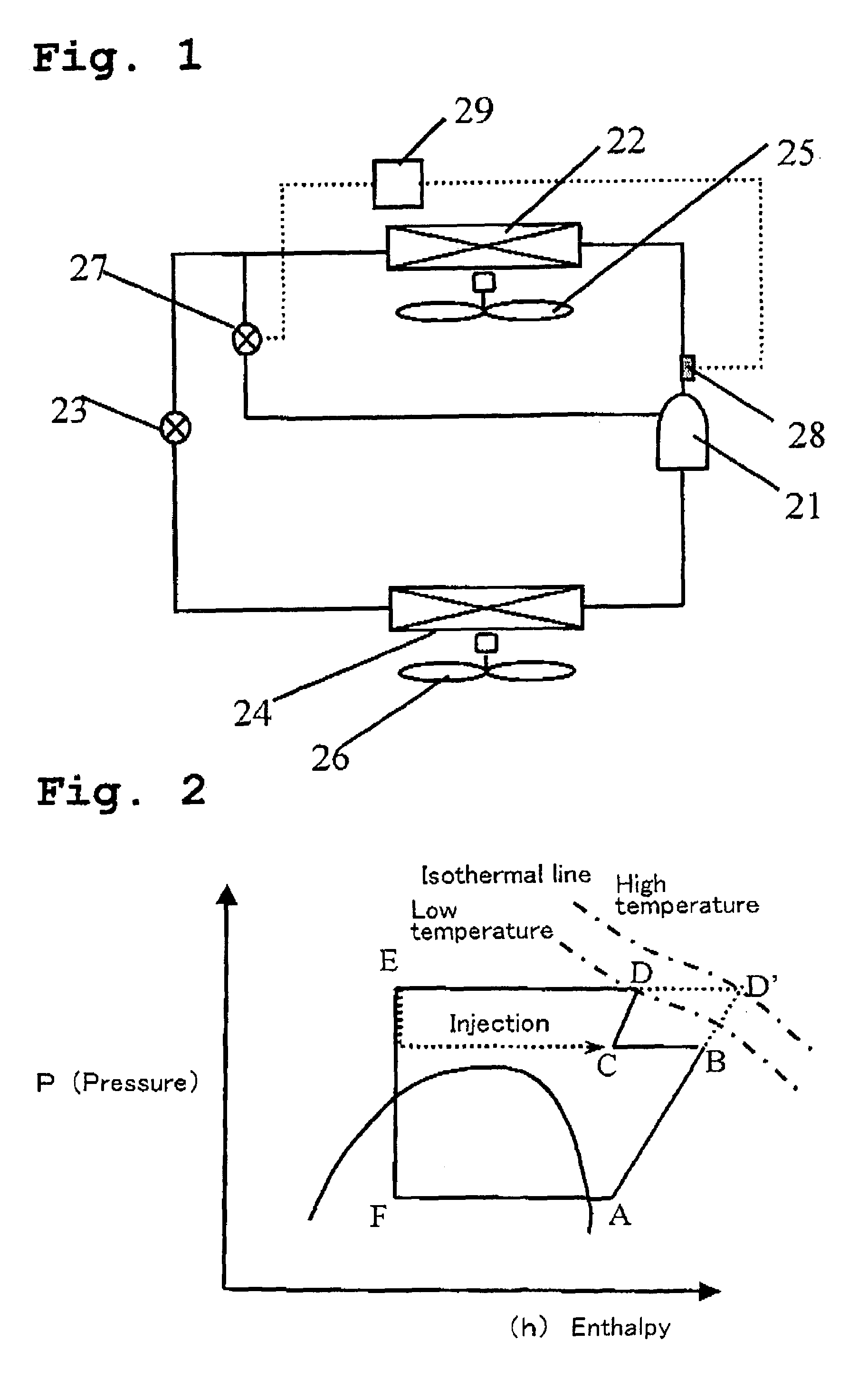

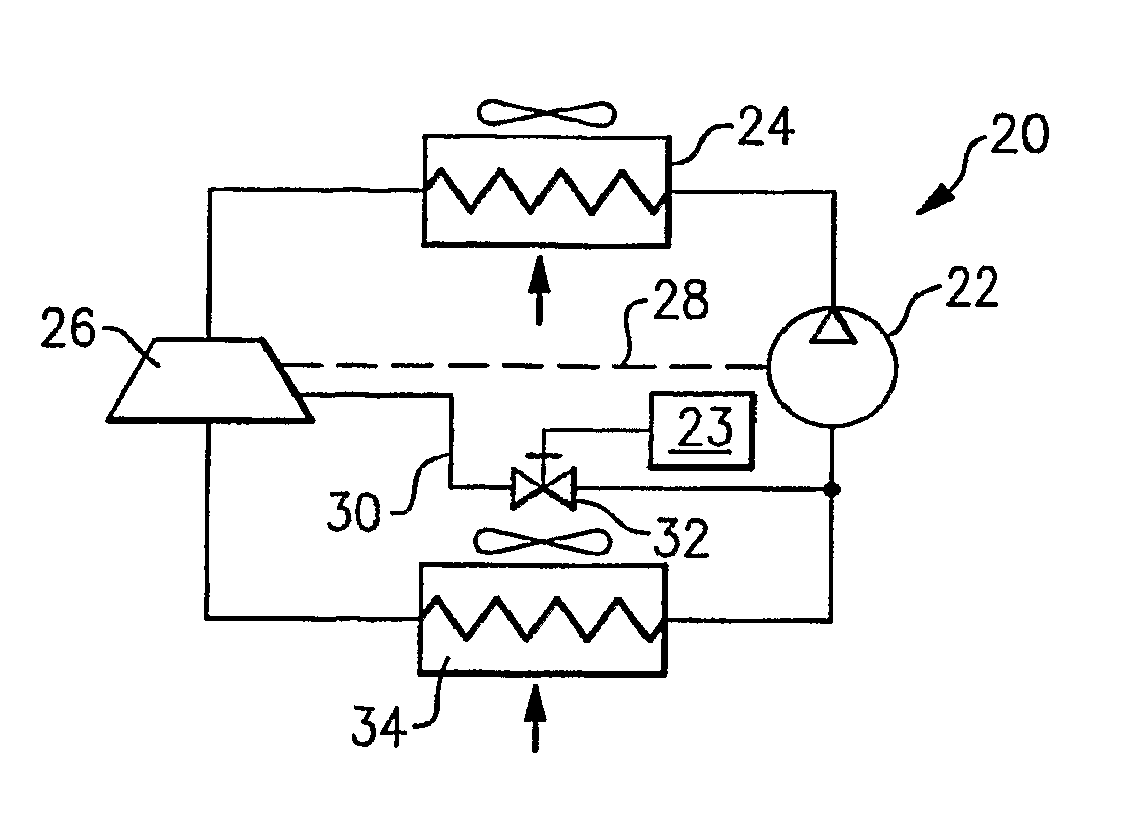

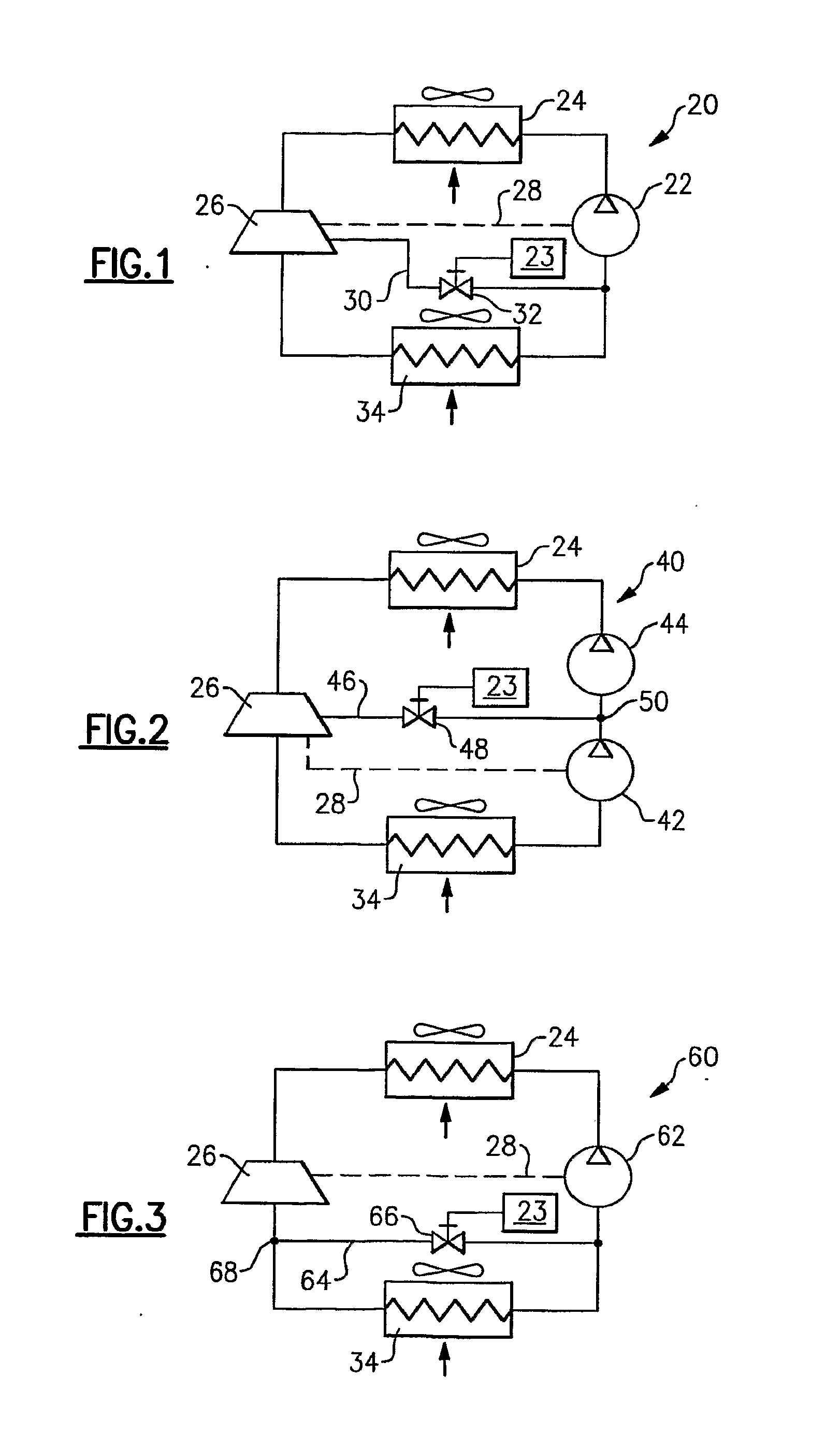

Refrigerant system with economizer, intercooler and multi-stage compressor

InactiveUS20100058781A1Large temperature differenceImprove performanceCompression machines with non-reversible cycleCompression machines with cascade operationEngineeringIntercooler

A refrigerant system is provided with a multi-stage compression system. An intercooler is positioned between at least two compression stages to cool a refrigerant, by heat transfer interaction with a secondary fluid, after it has been compressed in the lower compression stages to some intermediate pressure. The intercooler enhances refrigerant system performance, improves compressor reliability, and extends operational envelope. Further, at least one economizer circuit is incorporated into the refrigerant system that returns the economized refrigerant flow at the location between at least two compression stages.

Owner:CARRIER CORP

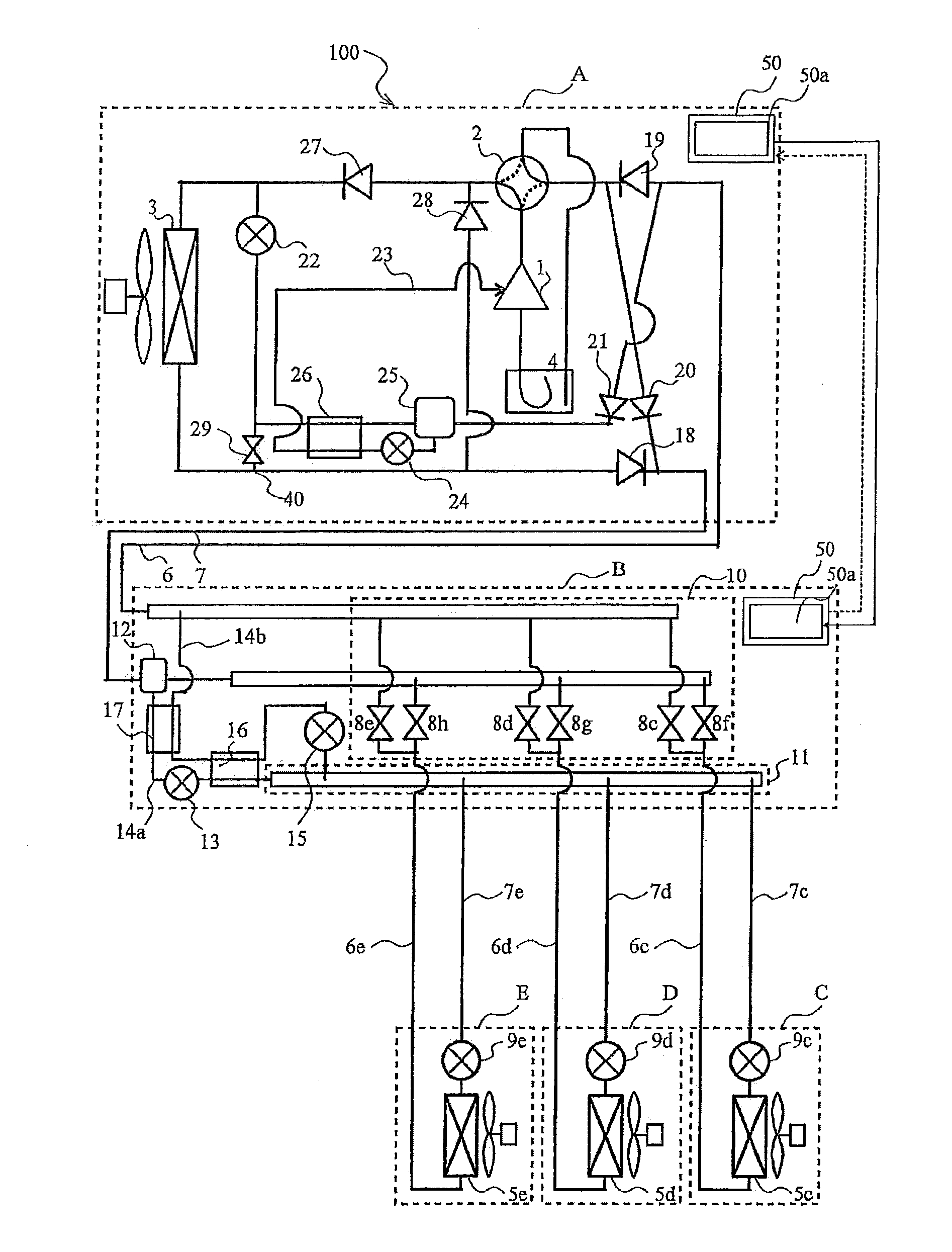

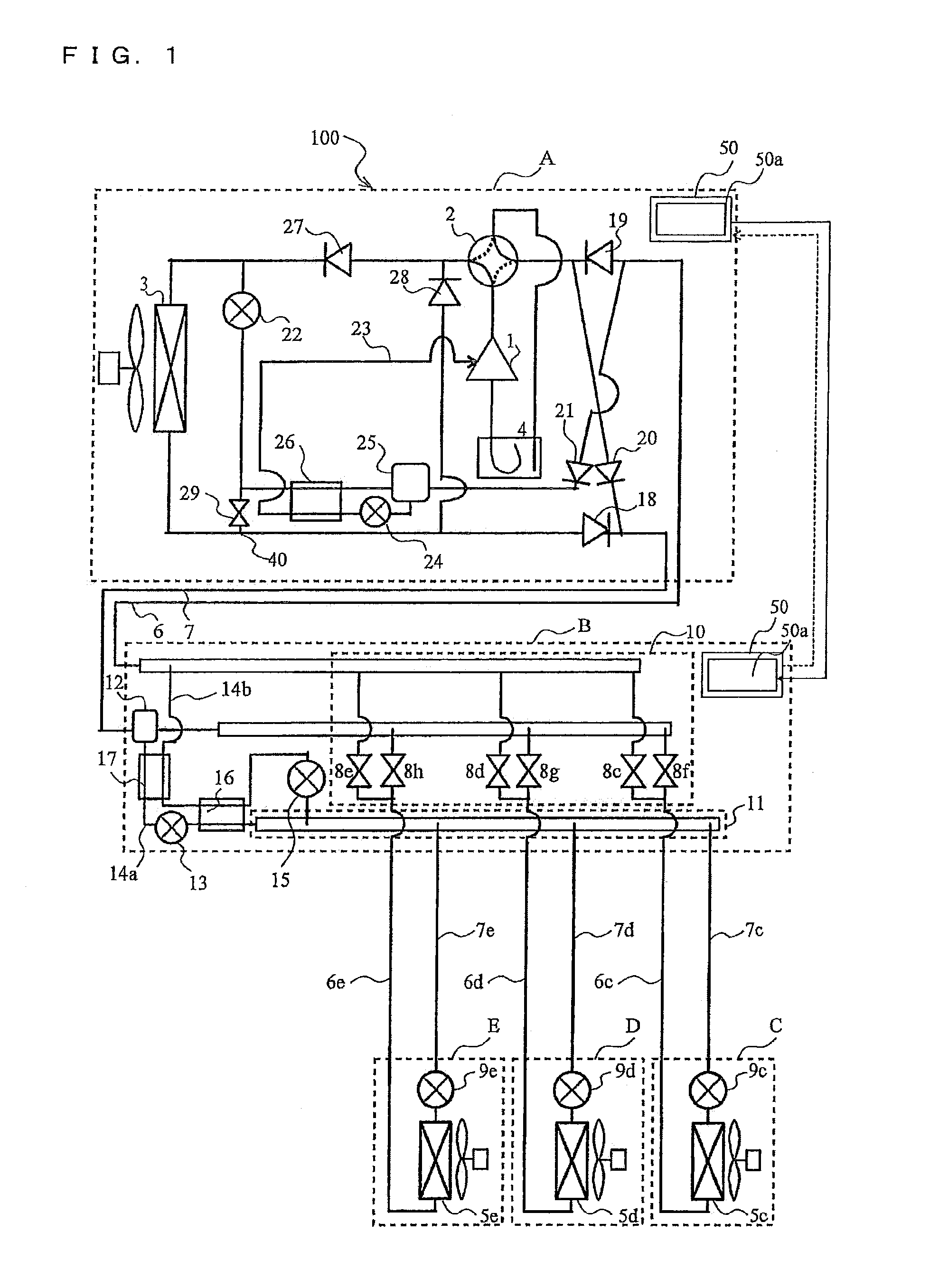

Air-conditioning apparatus

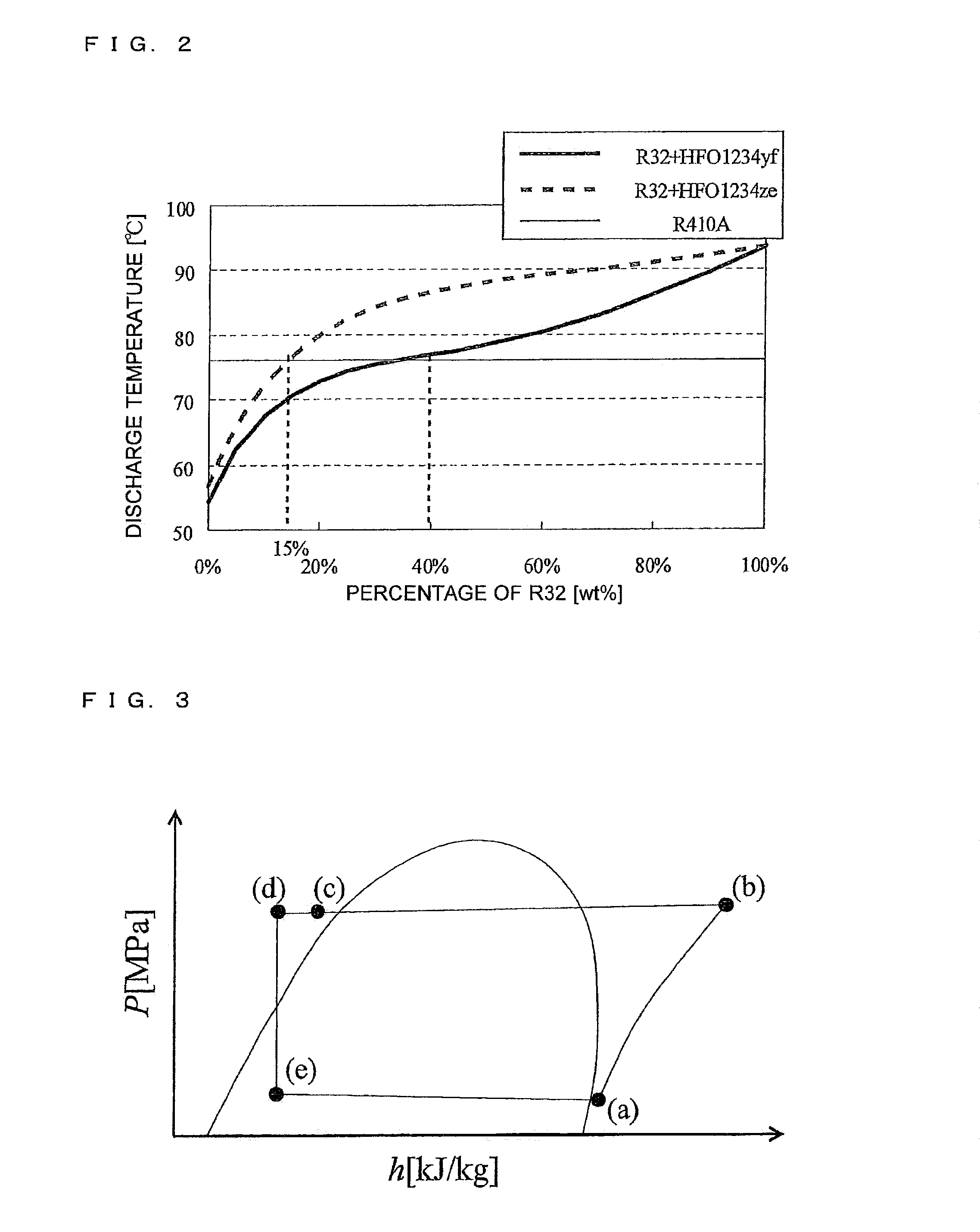

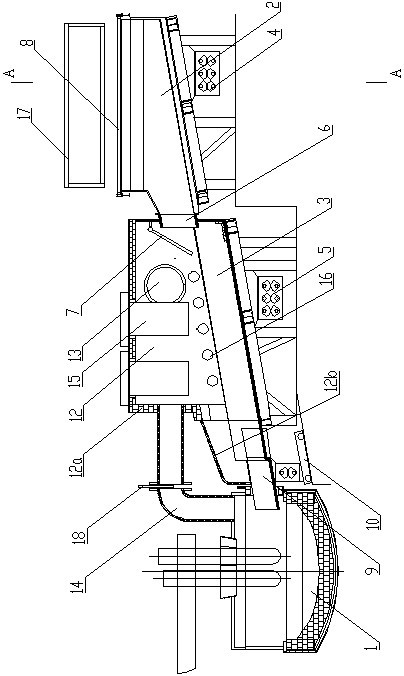

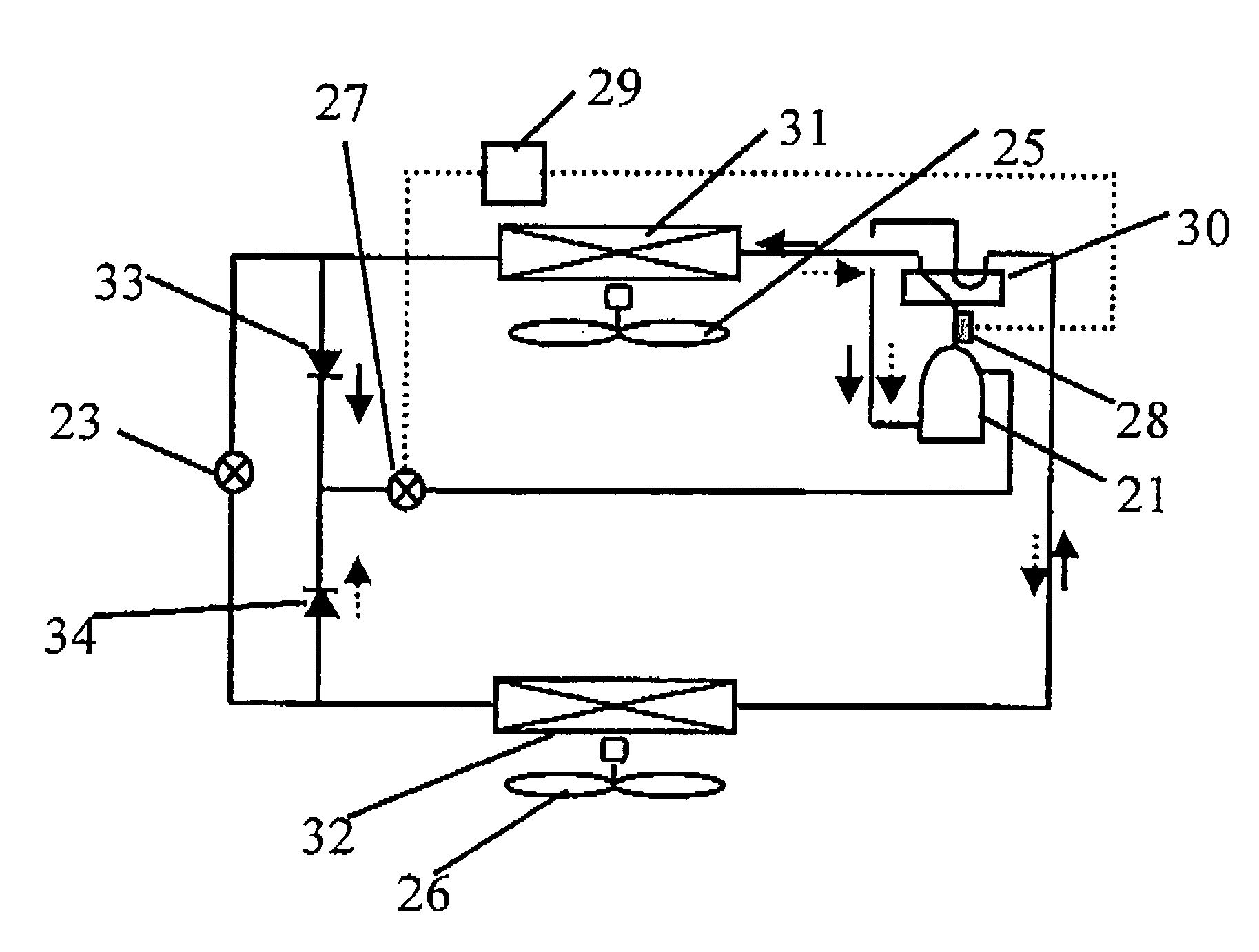

ActiveUS20130283843A1Lower the discharge temperatureStable operation of compressorCompression machines with reversible cycleRefrigeration componentsEngineeringAir conditioning

An air-conditioning apparatus uses R32, a refrigerant mixture containing R32 and HFO1234yf in which R32 has a mass percentage of 40% or higher, or a refrigerant mixture containing R32 and HFO1234ze in which R32 has a mass percentage of 15% or higher, as a heat-source refrigerant. The air-conditioning apparatus includes a low-pressure shell-structure compressor, a first flow switching valve, a heat-source-side heat exchanger, first flow control devices, and plural use-side heat exchangers connected by refrigerant pipes, forming a refrigeration cycle. The compressor includes a compression chamber within a sealed container including an opening extending between inside and outside of the sealed container. The air-conditioning apparatus can perform only a heating at the use-side heat exchangers, only a cooling at the use-side heat exchangers, and a mixed cooling and heating in a mixed fashion at the use-side heat exchangers.

Owner:MITSUBISHI ELECTRIC CORP

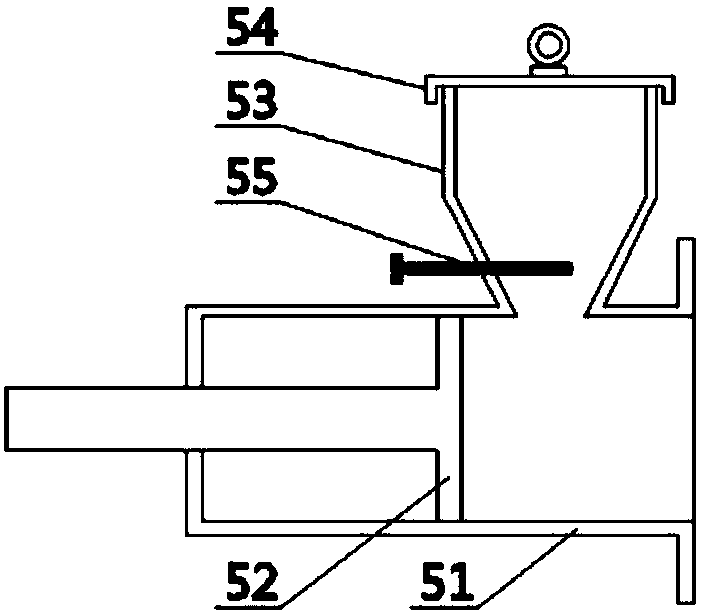

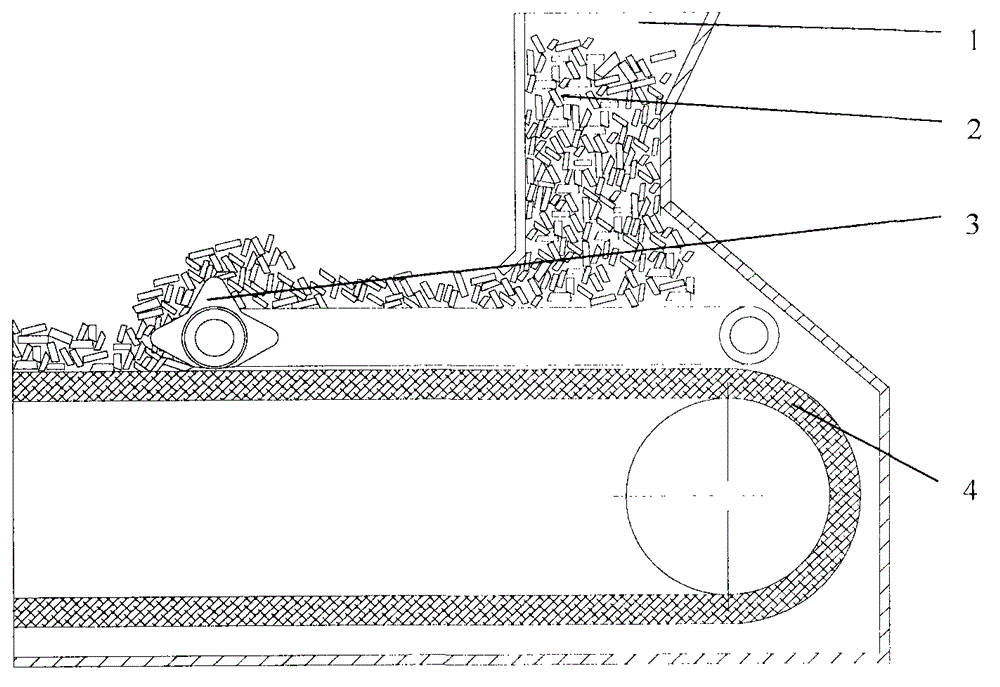

Differential motion airtight feeding electric furnace smelting device and feeding method thereof

ActiveCN102181601AShorten the lengthIncrease the feeding speedCharge manipulationElectric furnaceEngineeringHeat losses

The invention discloses a differential motion airtight feeding electric furnace smelting device and a feeding method thereof. The device comprises an electric furnace and a charging device, wherein the charging device comprises a cold receiving conveying trough and a heat conveying trough; the lower sides of the cold receiving conveying trough and the heat conveying trough are provided with an independently-controlled excitation device respectively; the outlet of the cold receiving conveying trough is provided with a conveying throat opening which is extended into the heat conveying trough; and the distance between the conveying throat opening and the bottom of the heat conveying trough is greater than or equal to the depth of the heat conveying trough. By the feeding method, shock excitation at different frequencies is applied to the two conveying troughs to realize the differential motion conveying of raw materials, so that a thicker material layer can be laid on the cold receiving conveying trough, and the material loading speed is increased; simultaneously, a shorter cold receiving conveying trough and a shorter material-conveying bottom elongated slot can be designed, so that the device and the method make project implementation convenient. In addition, due to the adoption of the throat opening and a sealed door structure, the possibility of material blocking and the air leakage rate are greatly reduced, and the device has low heat loss and a good dedusting effect, and is high-efficient, energy-saving and environment-friendly during smelting.

Owner:CISDI ENG CO LTD

Refrigerator

InactiveUS7024879B2Increase the compression ratioReliable dischargeCompressorCompression machines with non-reversible cycleEngineeringRefrigerant

Owner:PANASONIC CORP

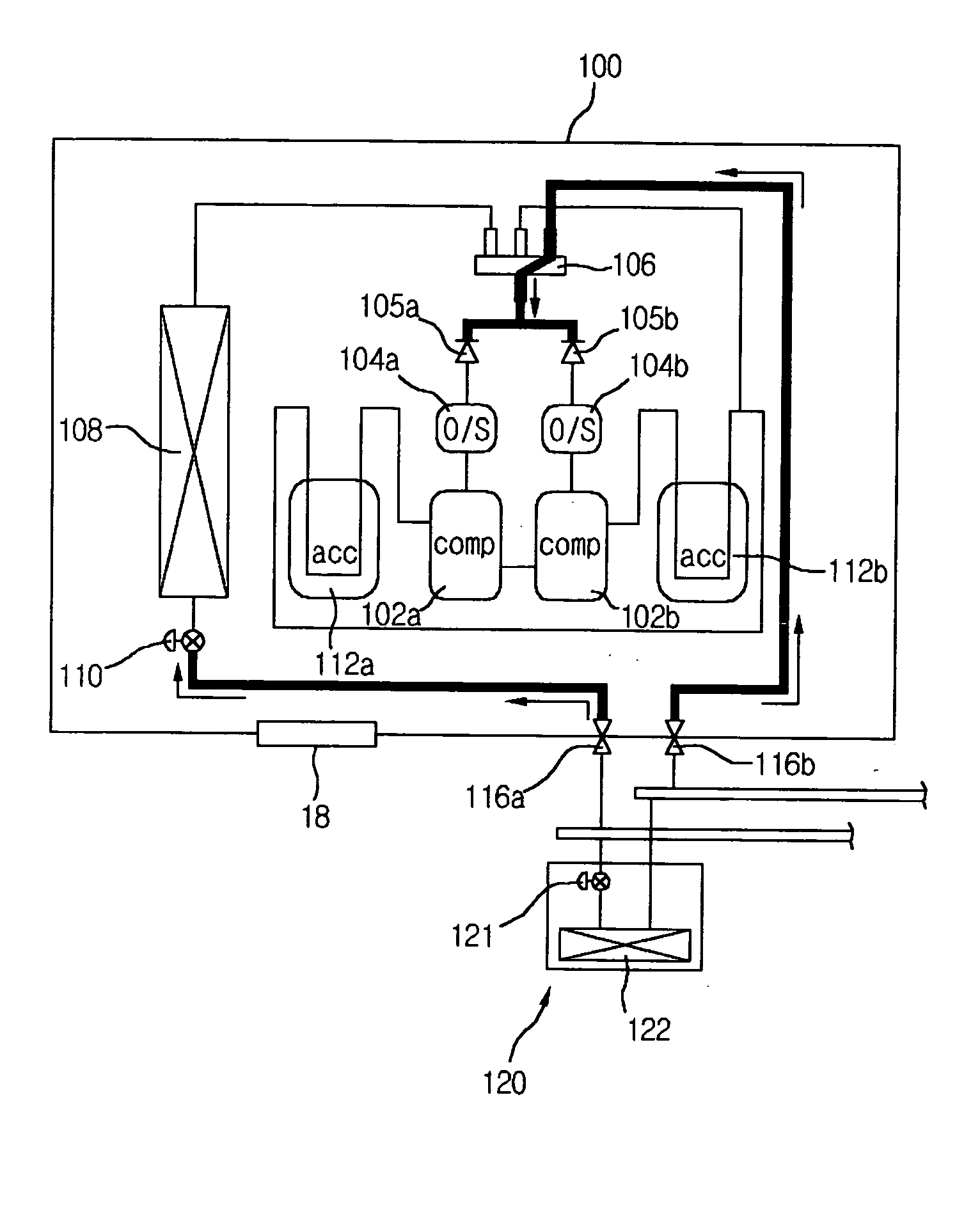

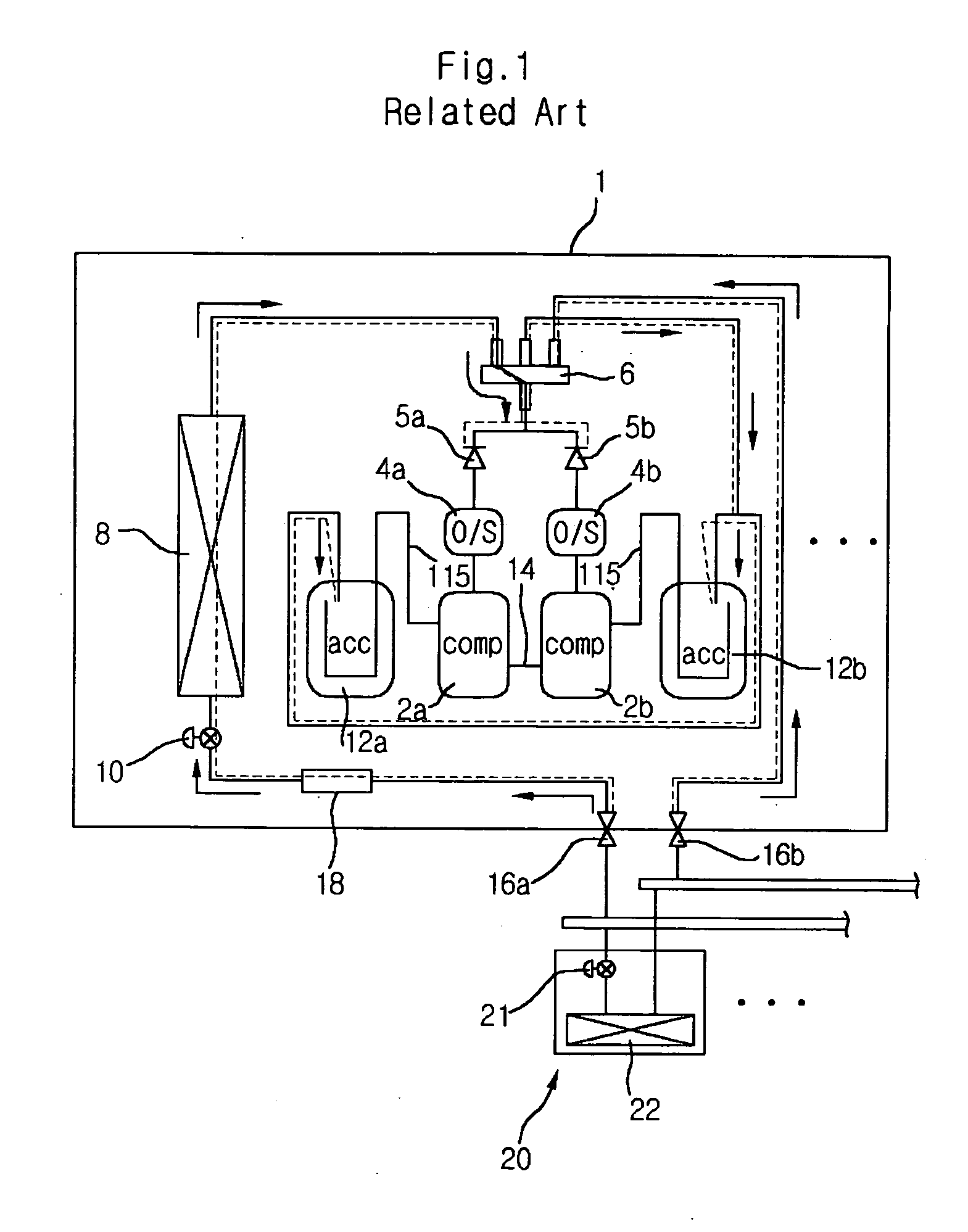

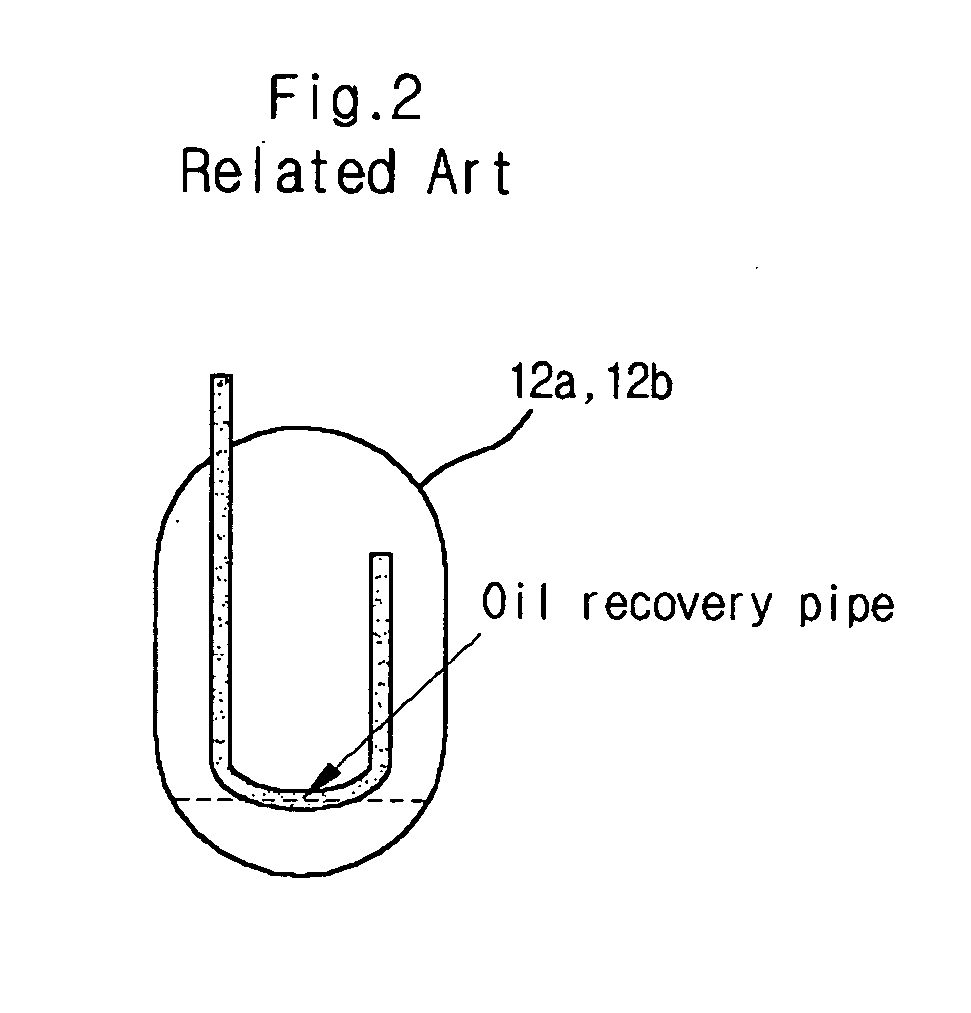

Apparatus for preventing liquid refrigerant accumulation of air conditioner and method thereof

ActiveUS20050081537A1Avoid accumulationLower discharge temperatureCompressorPositive displacement pump componentsFour-way valveEngineering

Disclosed is an apparatus and method for preventing liquid refrigerant accumulation in an accumulator of an outdoor unit of an air conditioner. The method includes the steps of: determining a state of a compressor; if the compressor is in standby mode or off state, turning on a four-way valve; determining whether the state of the compressor in standby mode or off state continues longer than a predetermined amount of time; and if the state of the compressor continues longer than the predetermined amount of time, closing an expansion valve. Particularly, high-pressure refrigerant flows in the closed expansion valve while low-pressure refrigerant flows in a check valve through the four-way valve. The apparatus includes a suction pipe connected to spray oil of the accumulator to the compressor; a liquid recovery pipe with one end being connected to the suction pipe and the other end being connected to the accumulator; and a liquid recovery valve for controlling opening / closing of the liquid recovery pipe, in which a compressor of the air conditioner in cooling or heating mode is operated and a liquid recovery valve for controlling a liquid recovery pipe connected to the compressor and an accumulator is opened to reduce oil in the accumulator. According to the present invention, when the compressor is off, it is possible to prevent liquid refrigerant accumulation by changing refrigerant flow line to the accumulator and the refrigerant at the lower end of the accumulator can be recovered.

Owner:LG ELECTRONICS INC

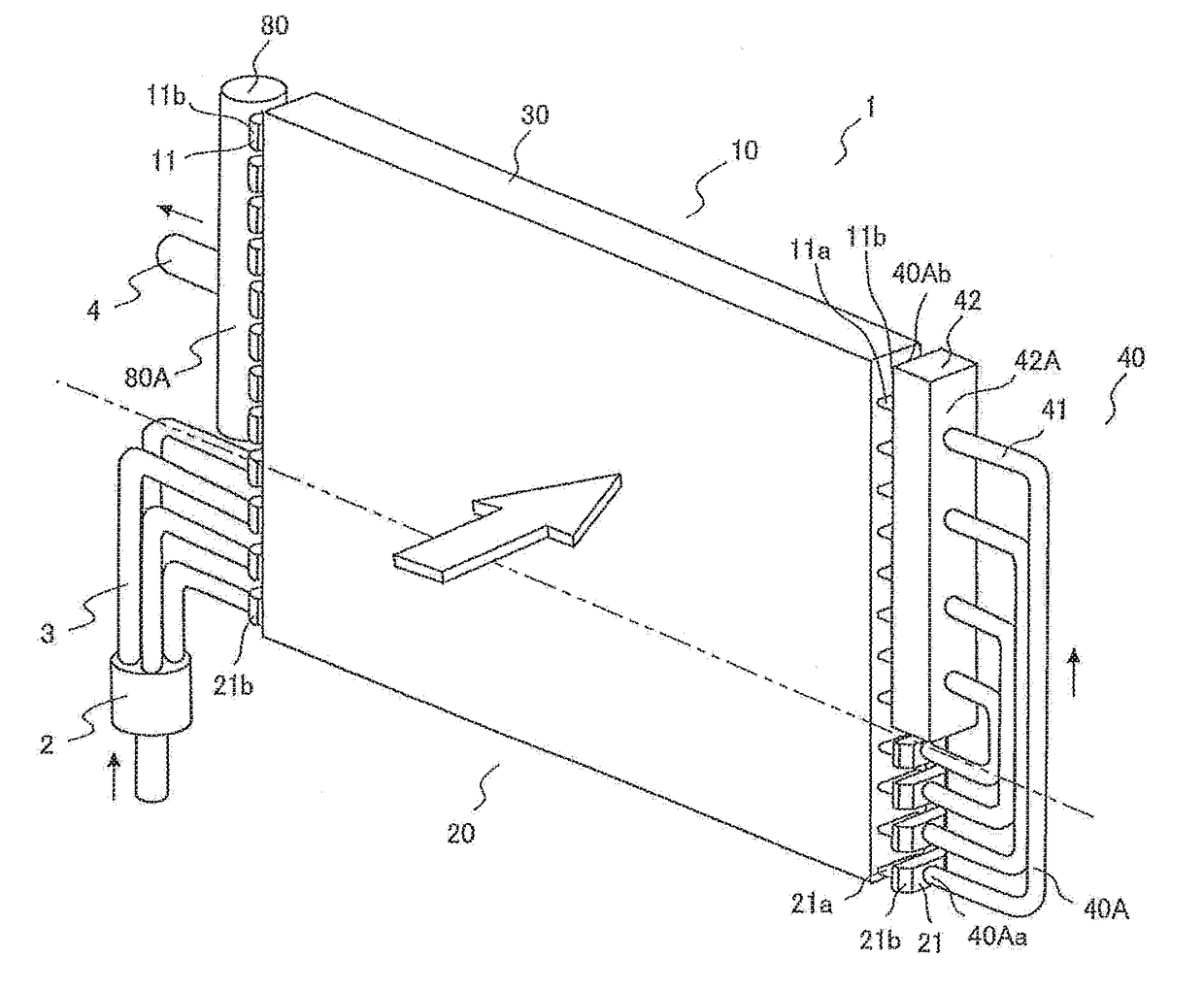

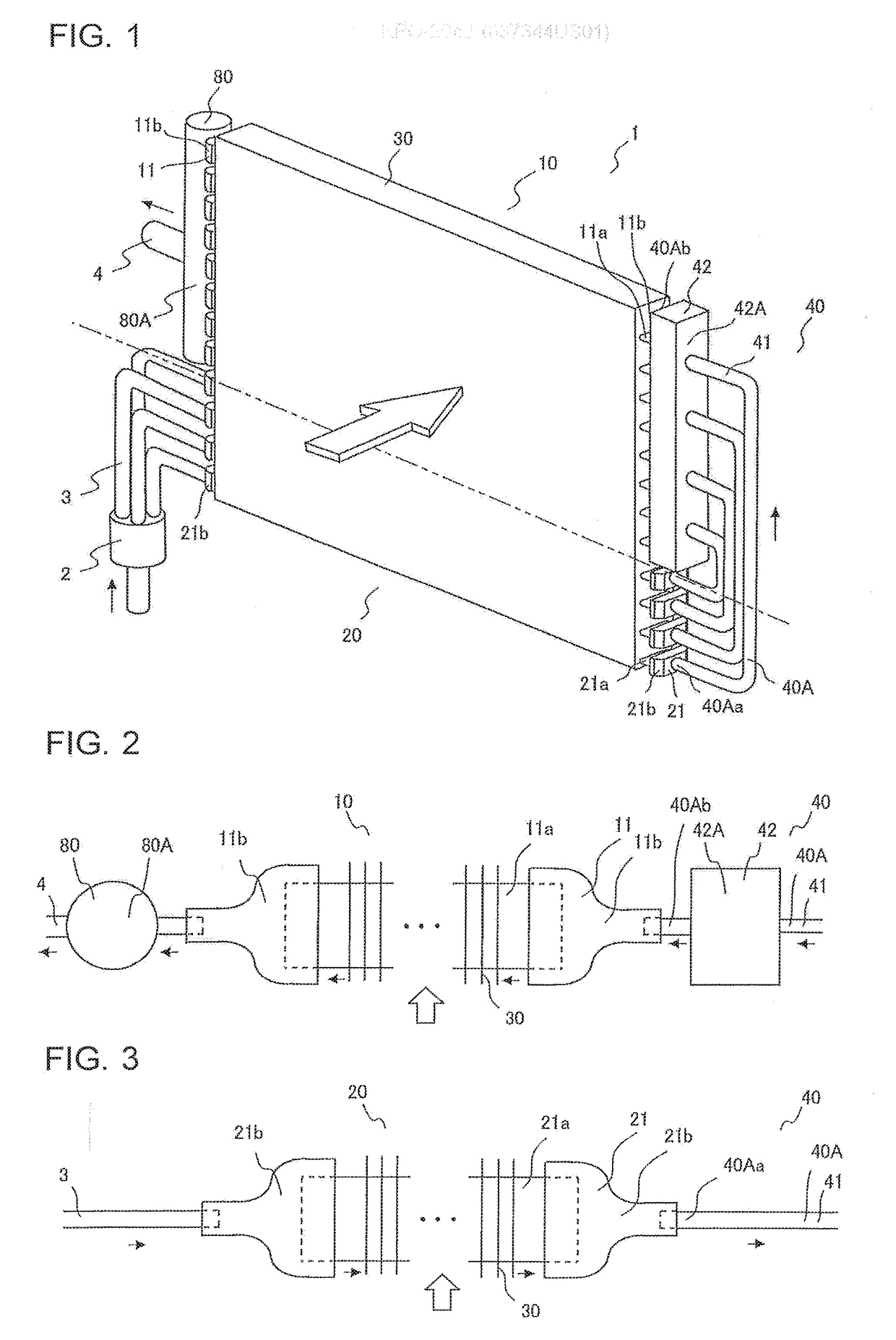

Heat exchanger and air-conditioning apparatus

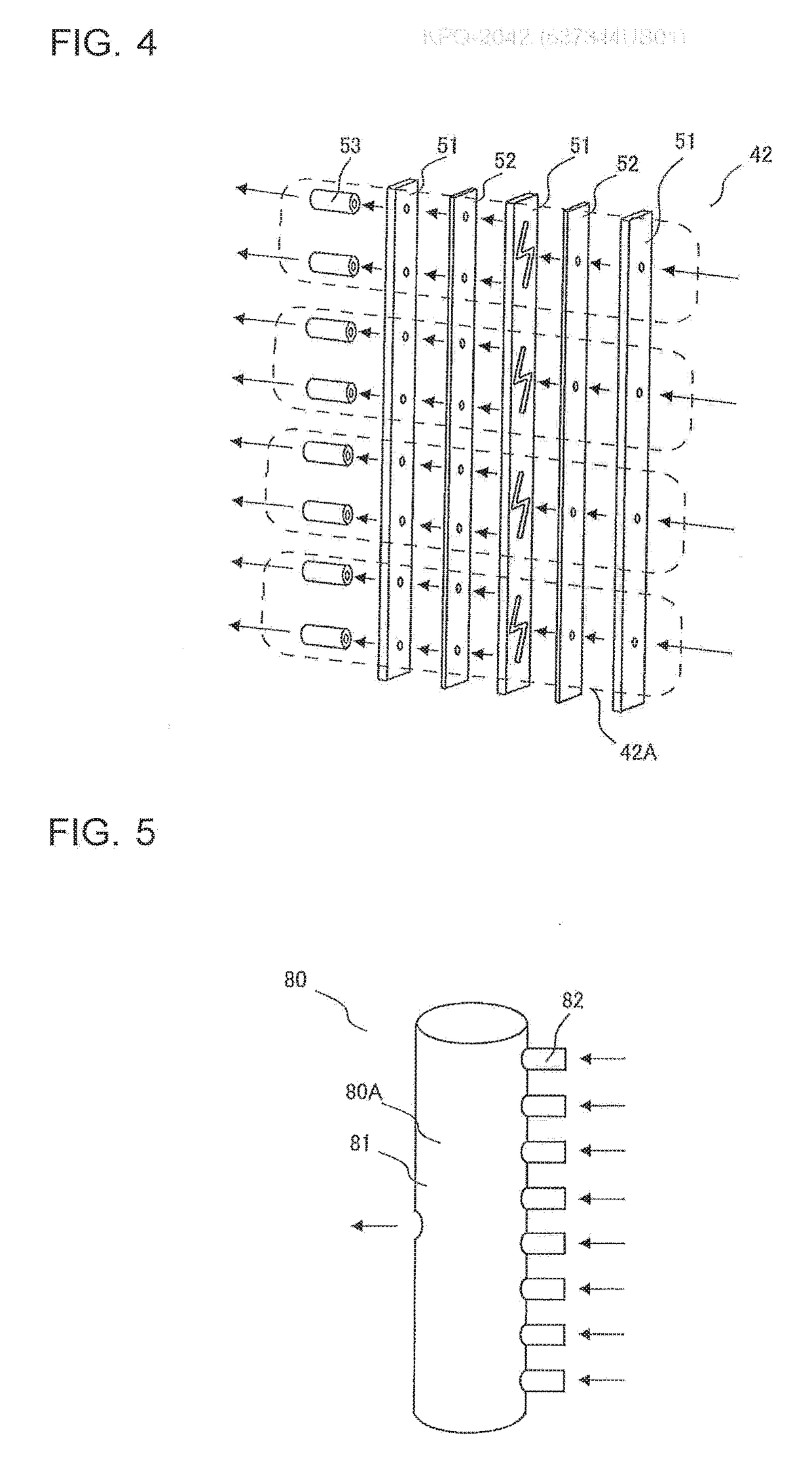

ActiveUS20170241684A1Effectively suppress the reduction in performance of the heat exchangerEasy to operateCompression machines with non-reversible cycleEvaporators/condensersEngineeringAir conditioning

A heat exchanger, in which refrigerant causing disproportionation is used, includes a main heat exchange unit including a plurality of first heat transfer pipes arranged side by side, a sub-heat exchange unit including a plurality of second heat transfer pipes arranged side by side, and a relay unit including a plurality of relay passages connecting the plurality of first heat transfer pipes and the plurality of second heat transfer pipes. Each of the plurality of relay passages has one inlet connected to a corresponding one of the plurality of second heat transfer pipes, and a plurality of outlets each connected to a corresponding one of the plurality of first heat transfer pipes. Each of the plurality of relay passages distributes the refrigerant flowing from the one inlet, without merging streams of the refrigerant together, and causes the refrigerant to flow out of the plurality of outlets.

Owner:MITSUBISHI ELECTRIC CORP

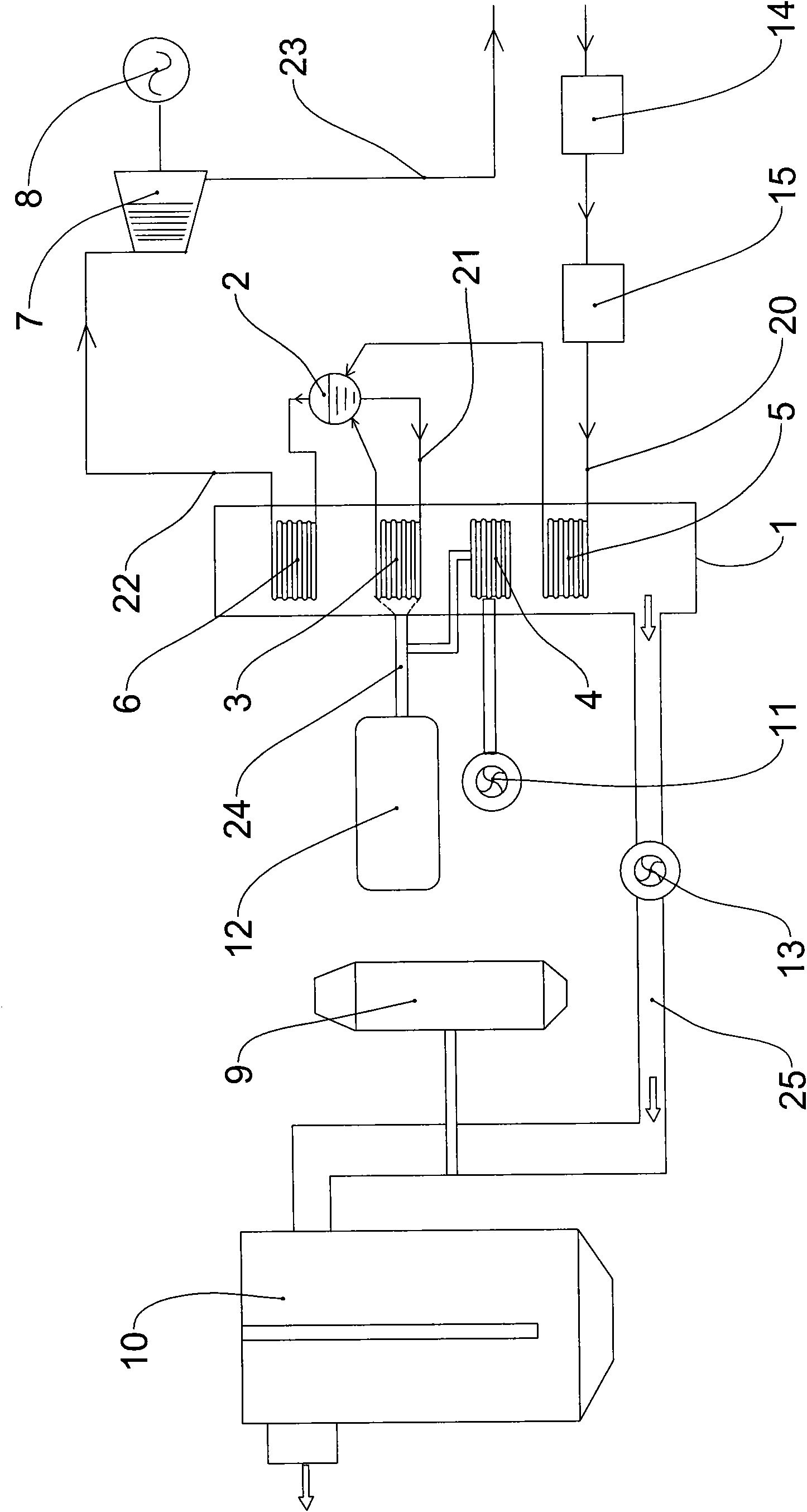

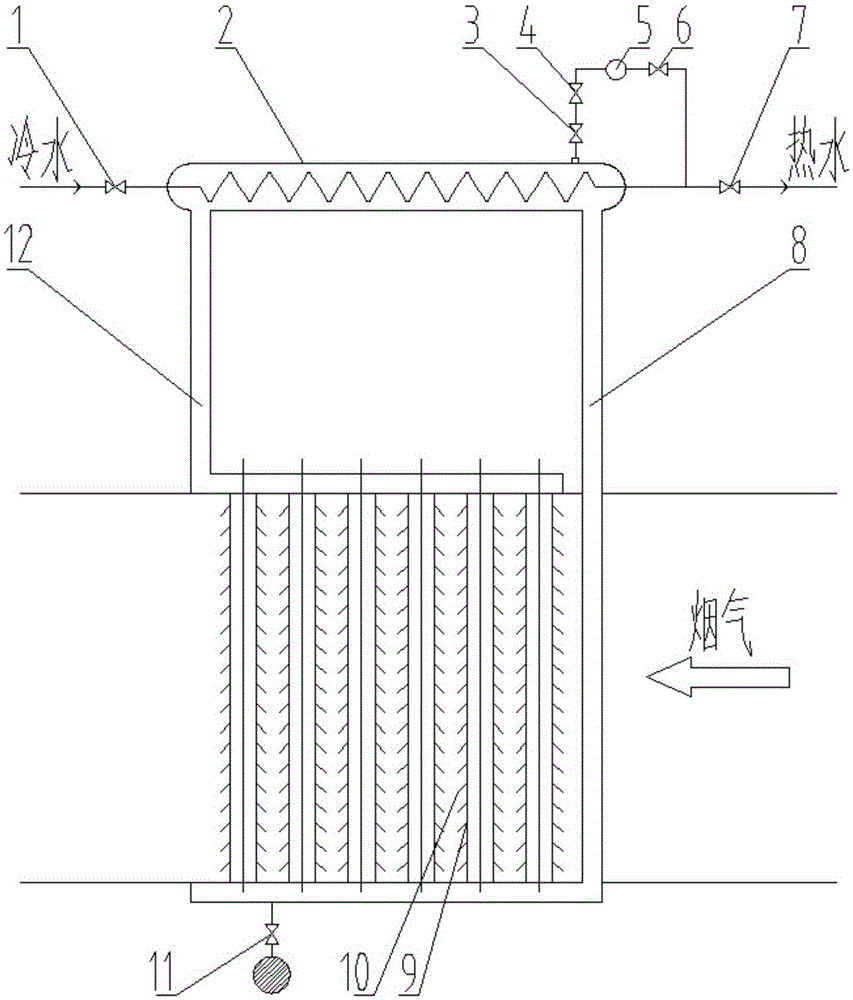

Deep recovery device for flue gas heat of power station boiler and method of deep recovery device

PendingCN109855109AImprove COPIncrease temperatureHeat pumpsEnergy efficient heating/coolingLithium bromideEvaporator

The invention discloses a deep recovery device for flue gas heat of a power station boiler and a method of the deep recovery device. The recovery device comprises an air preheater, a sensible heat exchanger, a desulfurization tower, a latent heat exchanger, a flue gas heater, a plate heat exchanger, a lithium bromide absorption heat pump generator, a lithium bromide absorption heat pump condenser,a lithium bromide absorption heat pump evaporator and a lithium bromide absorption heat pump absorber. Compared with an existing thermal power plant flue gas heat recovery system, by the adoption ofthe deep recovery device and the method, on the premise of satisfying the user load, by adopting the coupling use of the lithium bromide absorption heat pump and a low-pressure heater, sensible heat of flue gas after the air preheater in a thermal power plant can be recycled, and latent heat of vaporization of moisture in flue gas after the desulfurization tower can be also recycled, so that the coal consumption for power generation is reduced, meanwhile moisture carried by flue gas is reduced, colored smoke plume is eliminated, and the device and the method better respond to the policy requirements on energy saving and emission reduction in China.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Series connection and parallel connection switching type heat supplying method of compressing absorbing hybrid heat pump of gas engine

ActiveCN106595122AEfficient and clean utilizationReduce power consumptionClimate change adaptationFluid circulation arrangementEngineeringThermal water

The invention discloses a series connection and parallel connection switching type heat supplying method of a compressing absorbing hybrid heat pump of a gas engine. The method involves a parallel connection mode and a series connection mode; when the environmental temperature is high, a hybrid heat pump heat supplying system enters the parallel connection mode, and user returned water is divided into two parts; one part of the returned water is sequentially heated through a first condenser, a cylinder sleeve heat exchanger and a smoke heat exchanger through connecting pipes; another part of the user returned water sequentially flows through a first valve, a second water pump, an absorber, a second condenser and a fourth valve by the connecting pipes and then is mixed with previous hot water; when the environmental temperature is low, the hybrid heat pump heat supplying system enters the series connection mode, and the user returned water is sequentially heated through the first condenser, the cylinder sleeve heat exchanger and the smoke heat exchanger so as to produce water supplied to a user. With the adoption of the method, the heating capacity of the whole system can be greatly improved, and meanwhile, the smoke exhaust temperature can be reduced.

Owner:TIANJIN CHENGJIAN UNIV

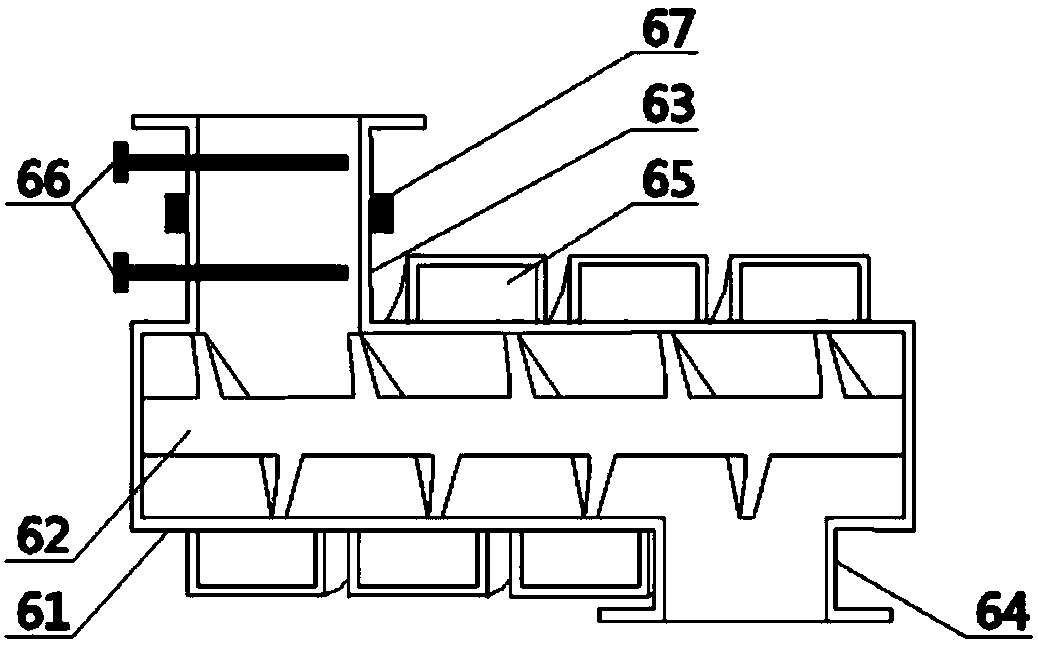

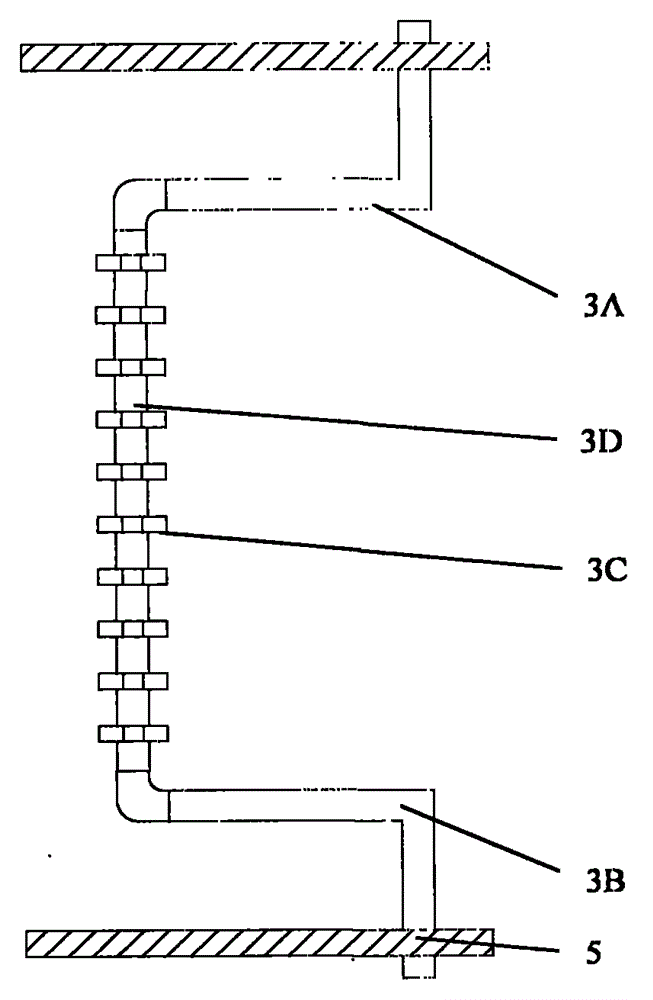

Cinder breaking device for biomass boiler

InactiveCN104344412ASolve the problem that coking cannot be cleanedSolve problems that cannot be dischargedLighting and heating apparatusSolid fuelEngineering

The invention discloses a cinder breaking device for a biomass boiler, belongs to the technical field of solid fuel burning, is applied to biomass boilers for burning of biomass granular fuel, and actively breaks and burns clinker. The device is installed in the hearth of the biomass boiler, and comprises a water inlet pipe, a water outlet pipe, cinder breaking teeth and a cooling water pipe, is horizontally placed in the hearth of the biomass boiler, and is perpendicular to a chain fire grate; the distance between the device and the fire grate is smaller than 5 mm; burning fuel and cinder move with the movement of the chain fire grate; the burnt coked cinder is broken through the cinder breaking device and then discharged. The cinder breaking device solves the problem that the cinder of biomass granular fuel is coked after being burnt, can greatly improve the efficiency and prolong the service life of the biomass boiler, and facilities promotion of the industrialization effect of straw biomass granular fuel, the coal is replaced with biomass granular fuel, and the cinder breaking device has good economic, social and environmental benefits.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

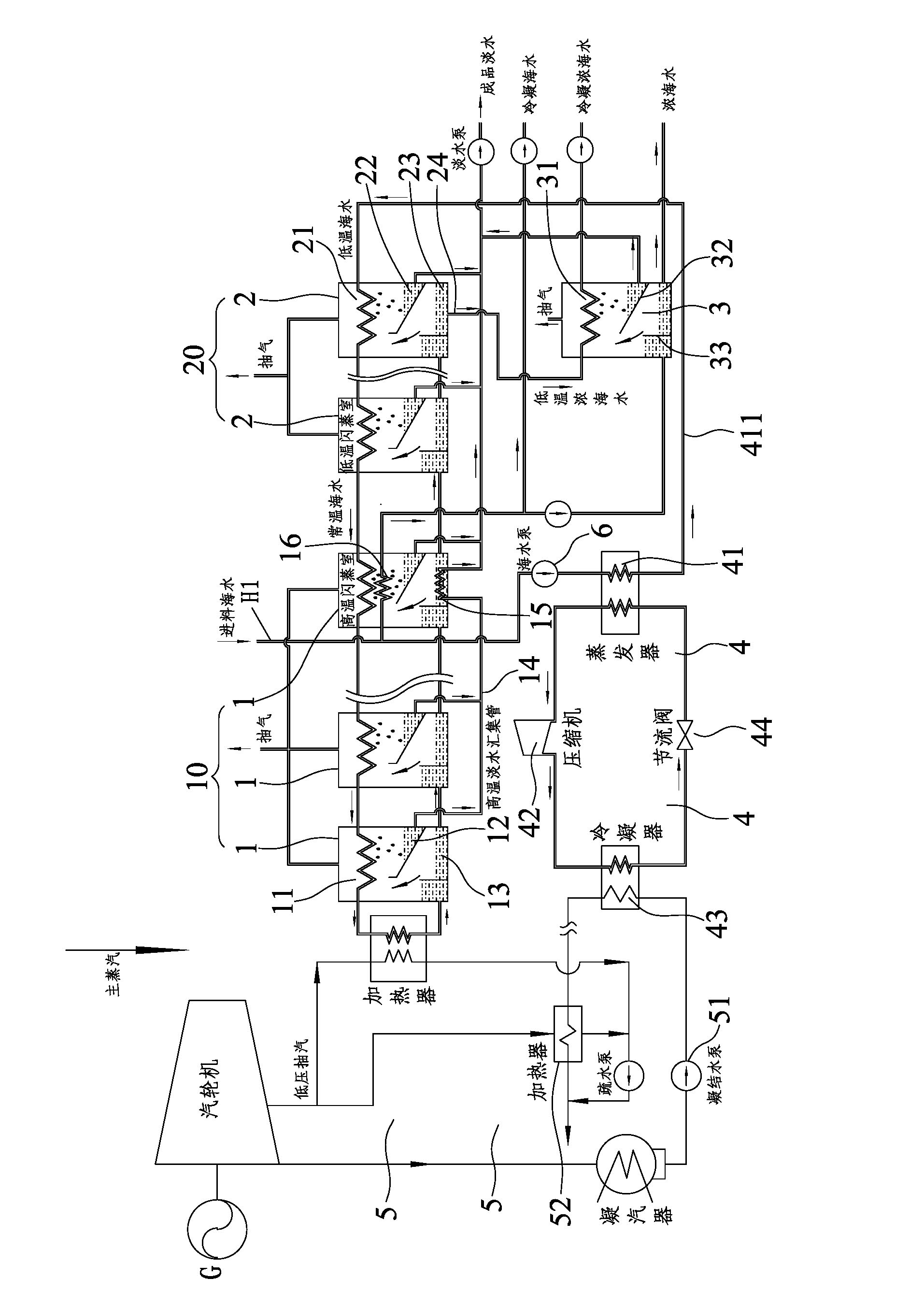

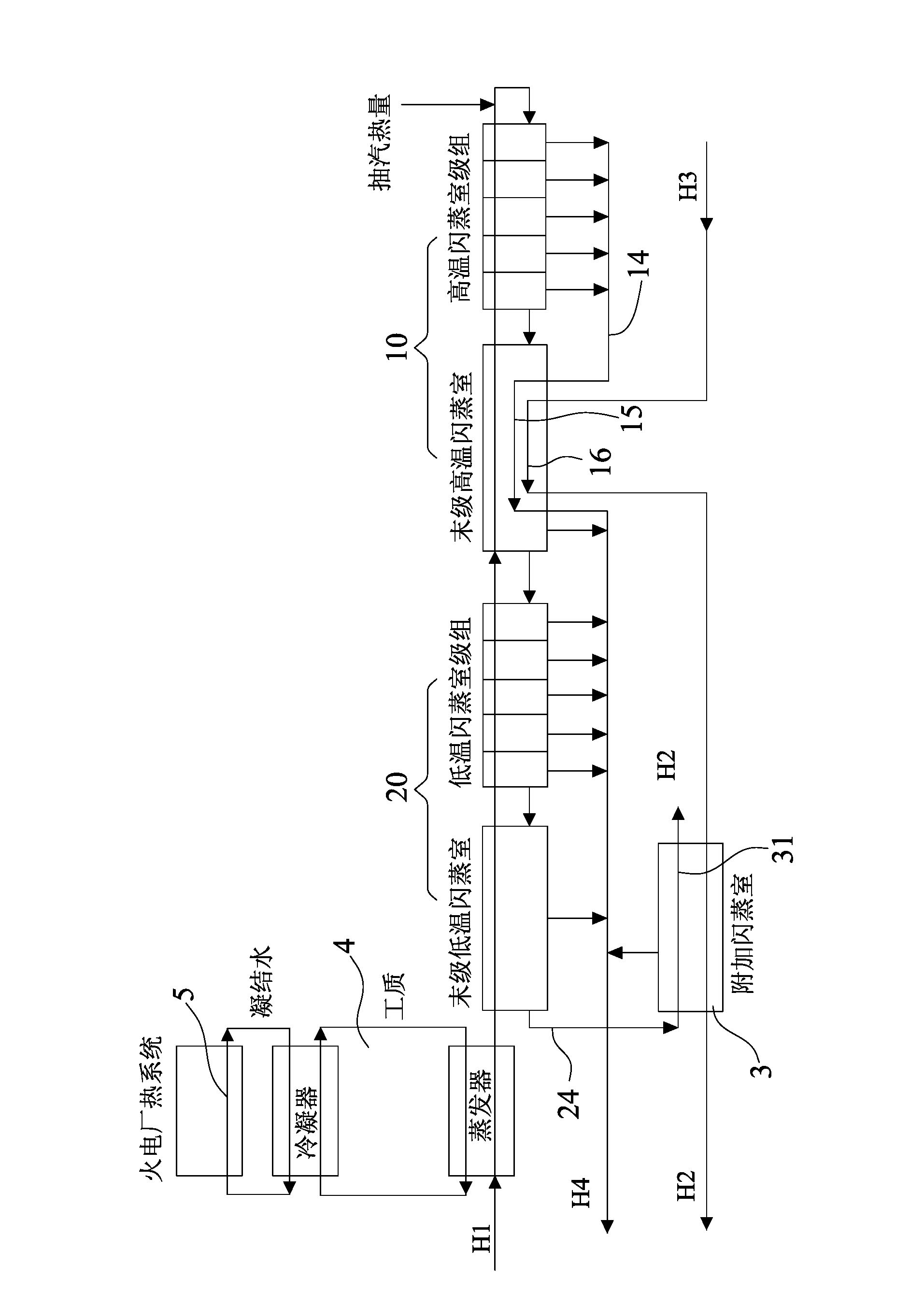

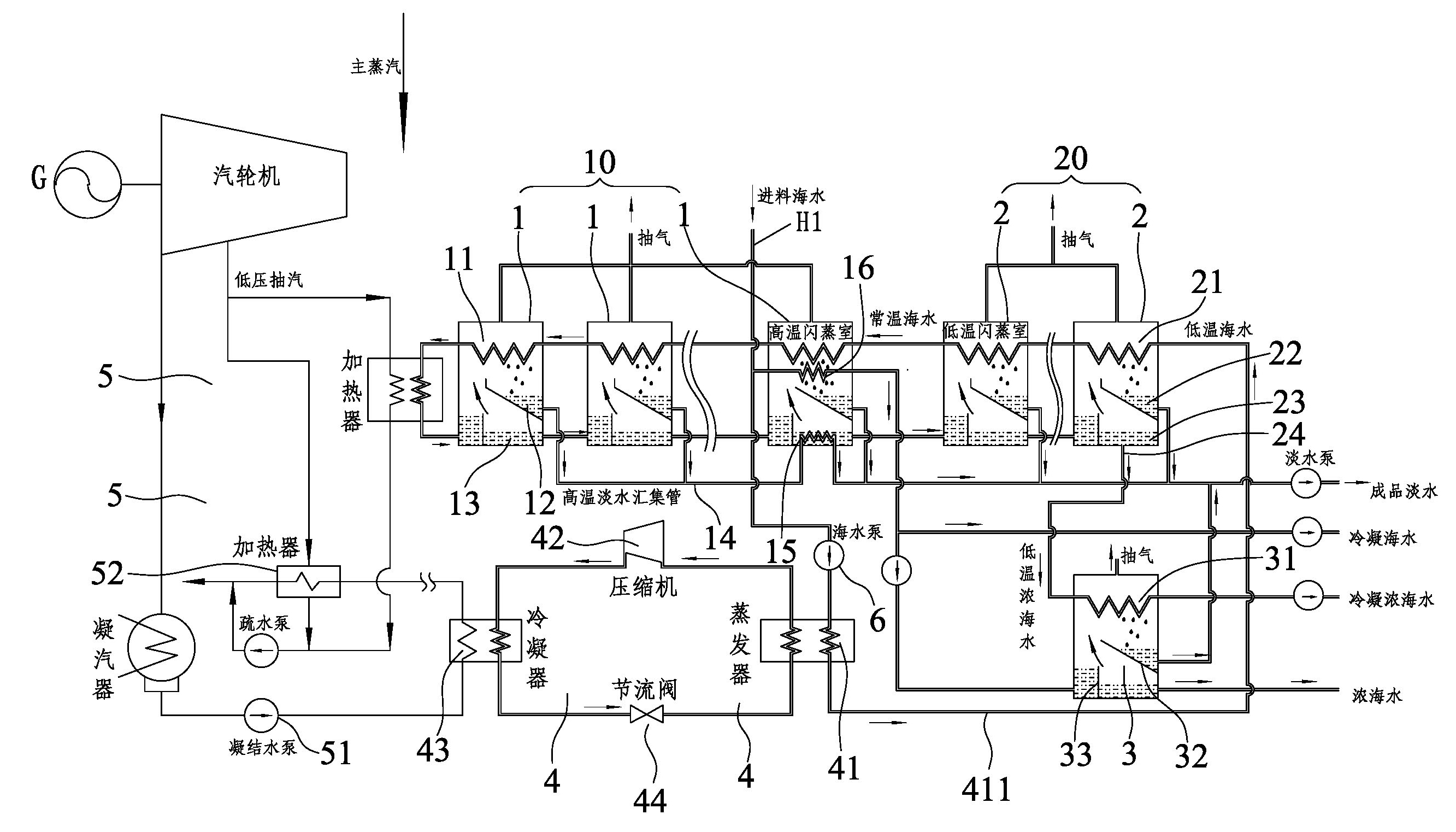

New multistage flash evaporation seawater desalting system of thermal power plant

InactiveCN102502902ALower discharge temperatureReduce cold source lossGeneral water supply conservationSeawater treatmentSeawaterEngineering

The invention discloses a new multistage flash-evaporation seawater desalting system of a thermal power plant. The seawater desalting system comprises high-temperature flash-evaporation chamber groups, low-temperature flash-evaporation chamber groups, an additional flash-evaporation chamber, a compression thermal pump system and a thermal power plant thermal system. According to the seawater desalting system, the low-temperature flash-evaporation chamber groups and the additional flash-evaporation chamber are increased, and the flash evaporation grade is increased, so the freshwater output isincreased; effective heat of high temperature products is recovered and utilized, so the freshwater output is further increased; and the thermal pump system sends pure heat to the thermal power plantthermal system, so the economic of the thermal power plant is improved. The seawater desalting system of the invention, which has the characteristics of much flash evaporation grade, large freshwateroutput, low freshwater cost, and improvement of the comprehensive utilization of the system energy, and is suitable for the low-cost large-scale production of the thermal power plant, can be widely applied to the seawater desalting field.

Owner:JIMEI UNIV

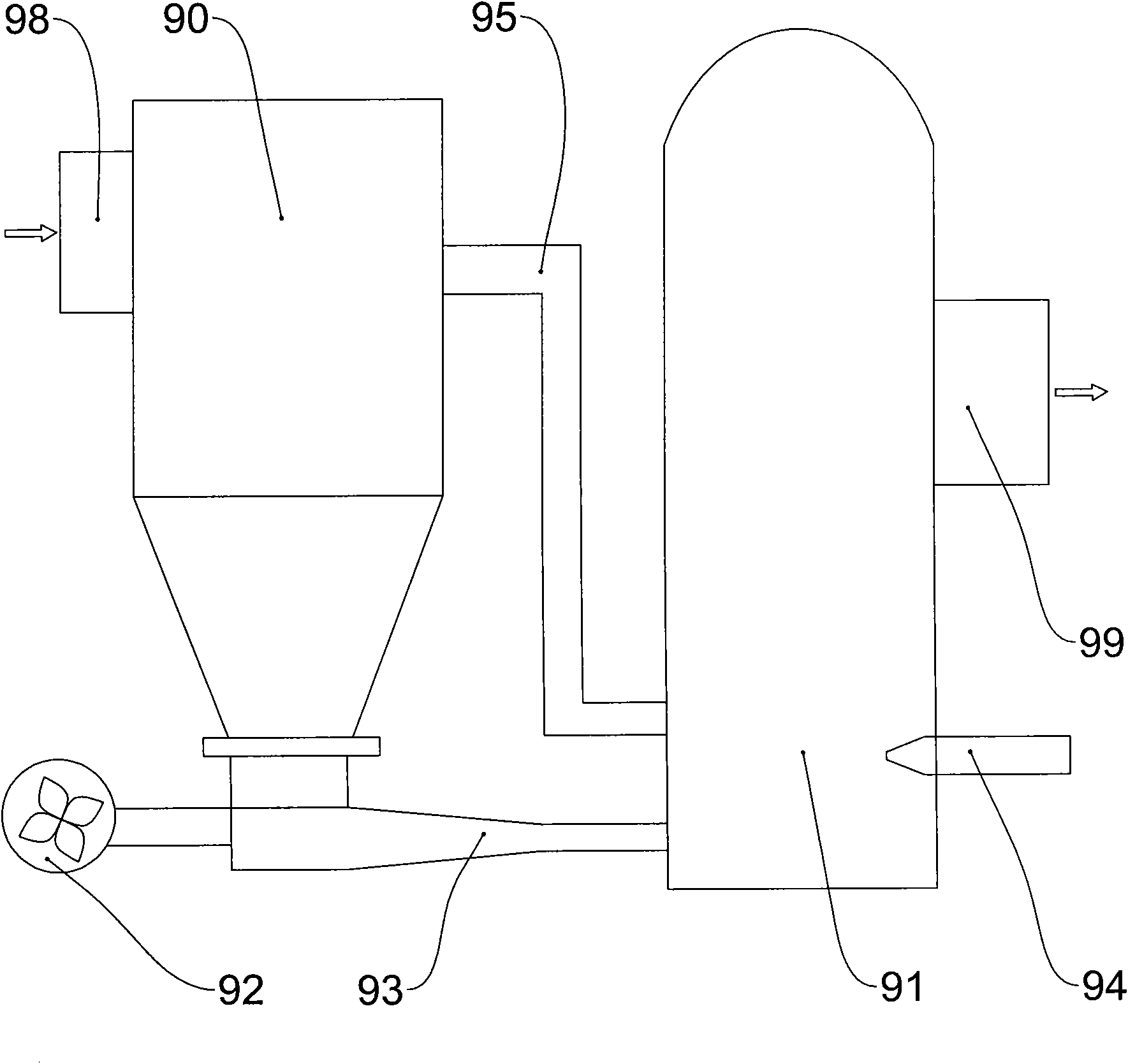

Thermal-cycle continuous pyrolysis-gasification comprehensive device for coal gangues

ActiveCN103205278ASignificant environmental benefitsGood economic valueIndirect and direct heating destructive distillationGas purification with selectively adsorptive solidsExhaust fumesProcess engineering

The invention provides a thermal-cycle continuous pyrolysis-gasification comprehensive device for coal gangues. The thermal-cycle continuous pyrolysis-gasification comprehensive device for coal gangues comprises a coal gangue pyrolysis-gasification furnace, a raw coke oven gas condensing device, a raw coke oven gas recycling and purifying device, a furnace coal gangue heat waste gas humidifying and dehydrating device and tail gas water-spraying purifier, wherein a raw coke oven gas guide-out device of the coal gangue pyrolysis-gasification furnace is communicated with the raw coke oven gas condensing device; and the raw coke oven gas condensing device is communicated with the raw coke oven gas recycling and purifying device. The purified raw coke oven gas is combusted; the combusted waste gas is fed to the furnace coal gangue heat waste gas humidifying and dehydrating device; and the dehydrated waste gas is exhausted through the tail gas water-spraying purifier. Besides, the combusted waste gas is fed to an active coke regenerator of the raw coke oven gas recycling and purifying device; and the waste gas regenerated by the active coke regenerator is fed to a waste gas heat exchange dehydrator or the tail gas water-spraying purifier. The thermal-cycle continuous pyrolysis-gasification comprehensive device for the coal gangues is prominent in environmental protection benefit by utilizing the pyrolysis-gasification of the coal gangues and not consuming extra energy resources, and is considerable in economic value.

Owner:SHANXI XINLI ENERGY TECH

Device for reclaiming and utilizing tail gas of automobile engine

InactiveCN1865676AReduce pollutionReduce heat pollutionAir-treating devicesInternal combustion piston enginesCold sideEngineering

The invention relates to a tail-gas recycle utilize device, with lower temperature of tail gas, saved energy, and environment protection. Wherein, it comprises an engine (7), a ventilate tube (8) of engine, a tail gas tube (9), a sound silencer (10), a heat exchanger (1), a water tank (2), a hot water pump (3), at least one heat emitter (4), and a relief valve (5); the hot side of heat exchanger (1) is connected to the ventilate tube (8) and the tail gas tube (9); the cold side of heat exchanger (1), said water tank (2), hot water pump (3) and the heat emitter (4) are serially connected by the hot water tube to form a cycle circuit; said relief valve (5) is on the hot water tube. The invention can be used in energy-saving technique of vehicle.

Owner:谢适发

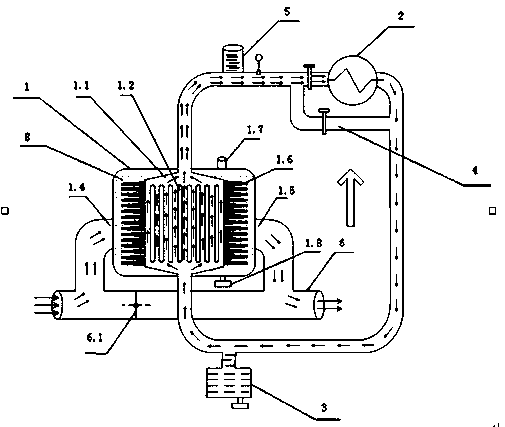

Smoke lithium bromide absorption refrigerating unit with smoke solution heat exchanger

ActiveCN103759462ALower discharge temperatureFully recycleClimate change adaptationEnergy efficient heating/coolingLithium bromideEvaporator

The invention relates to a smoke lithium bromide absorption refrigerating unit with a smoke solution heat exchanger. The smoke lithium bromide absorption refrigerating unit comprises a high pressure generator, an evaporator (1), an absorber (2), a low pressure generator (12), a condenser (13), a high-temperature heat exchanger (5), and a low-temperature heat exchanger (4). A waste heat smoke outlet tube (8) of the high pressure generator is provided with a smoke solution heat exchanger (26). A dilute solution outgoing tube of the low-temperature heat exchanger (4), as a smoke solution heat exchanger solution incoming tube (24), is connected to the smoke solution heat exchanger (26); a smoke solution heat exchanger solution outgoing tube (25) is connected to the high-temperature heat exchanger (5). Emission temperature of waste heat smoke from the smoke lithium bromide absorption refrigerating unit can be further lowered both in refrigerating and heating.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

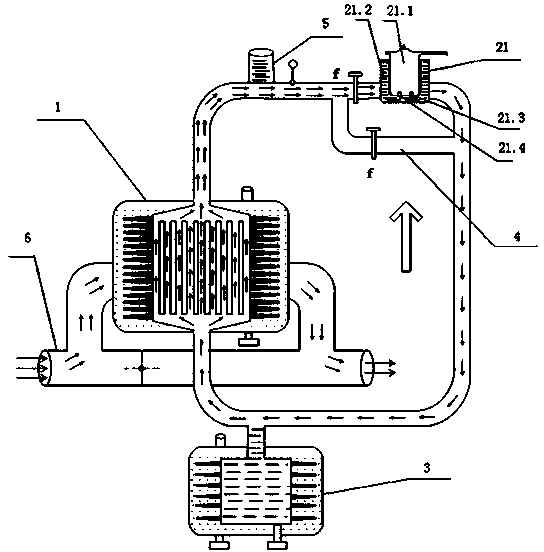

Automobile exhaust thermal energy storing and converting method and device

InactiveCN103485867AFunction increaseIncrease profitInternal combustion piston enginesExhaust apparatusThermal energyThermal energy storage

The invention relates to the technical field of automobile auxiliary equipment and discloses an automobile exhaust thermal energy storing and converting method and device. The device adopted by the method comprises an energy collecting heat exchanger, an energy heat exchanger and a thermal energy storage tank, wherein the upper end of the energy collecting heat exchanger connected between automobile exhaust pipes is communicated with the energy heat exchanger by a conduction oil pipeline; the energy heat exchanger is communicated with the energy collecting heat exchanger by the conduction oil pipeline, or the energy heat exchanger is communicated with the lower end of the energy collecting heat exchanger by the conduction oil pipeline through the thermal energy storage tank; the energy heat exchanger is connected with a by-pass oil conduit provided with a valve F in parallel. According to the automobile exhaust thermal energy storing and converting method and device, thermal energy can be stored and converted by using the automobile exhaust, the thermal energy is used for processing food, heating and generating electricity, the recycle of the thermal energy of the exhaust is improved, the fuel consumption and the greenhouse gas effect are reduced, thermoelectric power generation is realized by using a stored energy thermal conversion device, the method and the device can be used for the work of a large-scale electric appliance and illumination, and energy sources are saved.

Owner:李建营

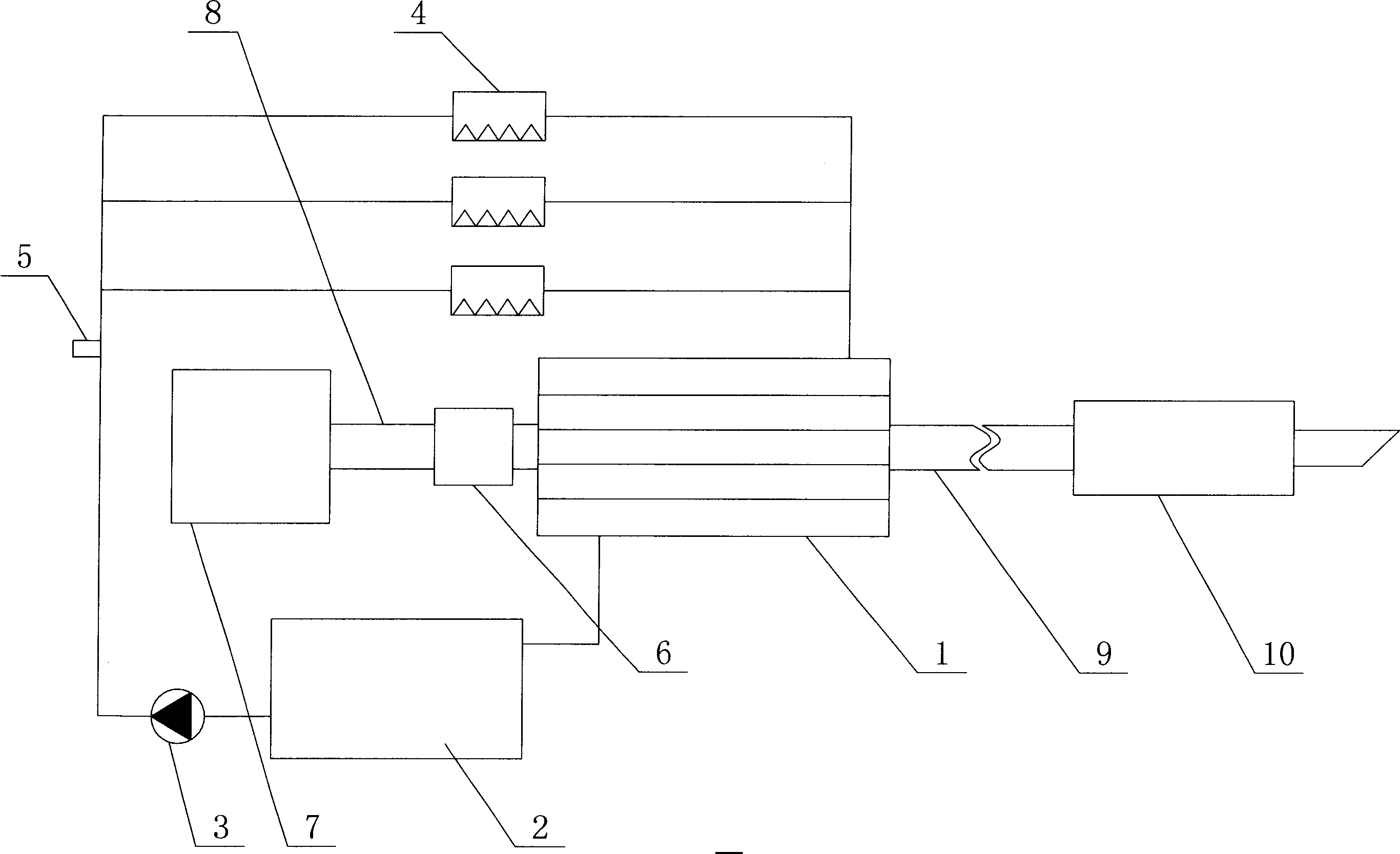

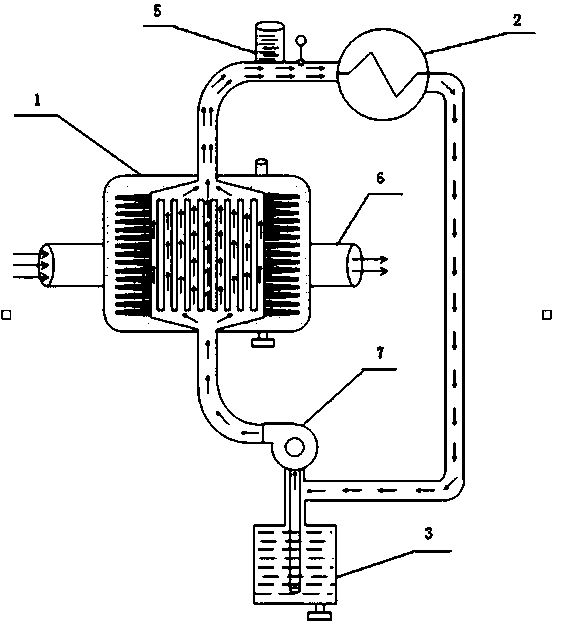

Integrated low-carbon micro-discharge energy-saving and emission-reduction boiler system

ActiveCN101986025AObvious superiorityLower discharge temperatureSteam generation plantsIndirect carbon-dioxide mitigationCombustionEngineering

The invention discloses an integrated low-carbon micro-discharge energy-saving and emission-reduction boiler system. The system comprises a boiler body (1), a steam drum (2), a heat exchanger (3), a preheater (4), an economizer (5), a superheater (6), a steam turbine (7), a generator (8), a secondary smoke combustion device (9), a desulfuration and dust collect unit (10), an air blower (11) and a smoke exhauster (13), wherein the steam drum (2) and the heat exchanger (3) constitute a hot-water heating circulation loop, the economizer (5) is connected with the steam drum (2), and the air blower (11) feeds air to the preheater (4); the steam drum (2) is connected with the superheater (6), and then connected with the steam turbine (7) by a superheated steam pipe (22); the steam turbine (7) is connected with a low-pressure steam pipe (23), and the generator (8) is linked with the steam turbine (7); and the outlet of a gas duct of the boiler body (1) is connected with a smoke pipe (25), and the smoke exhauster (13) is arranged on the smoke pipe (25), and sequentially feeds smoke into the secondary smoke combustion device (9) and the desulfuration and dust collect unit (10) so as to process and discharge the smoke.

Owner:慧生能源科技有限公司

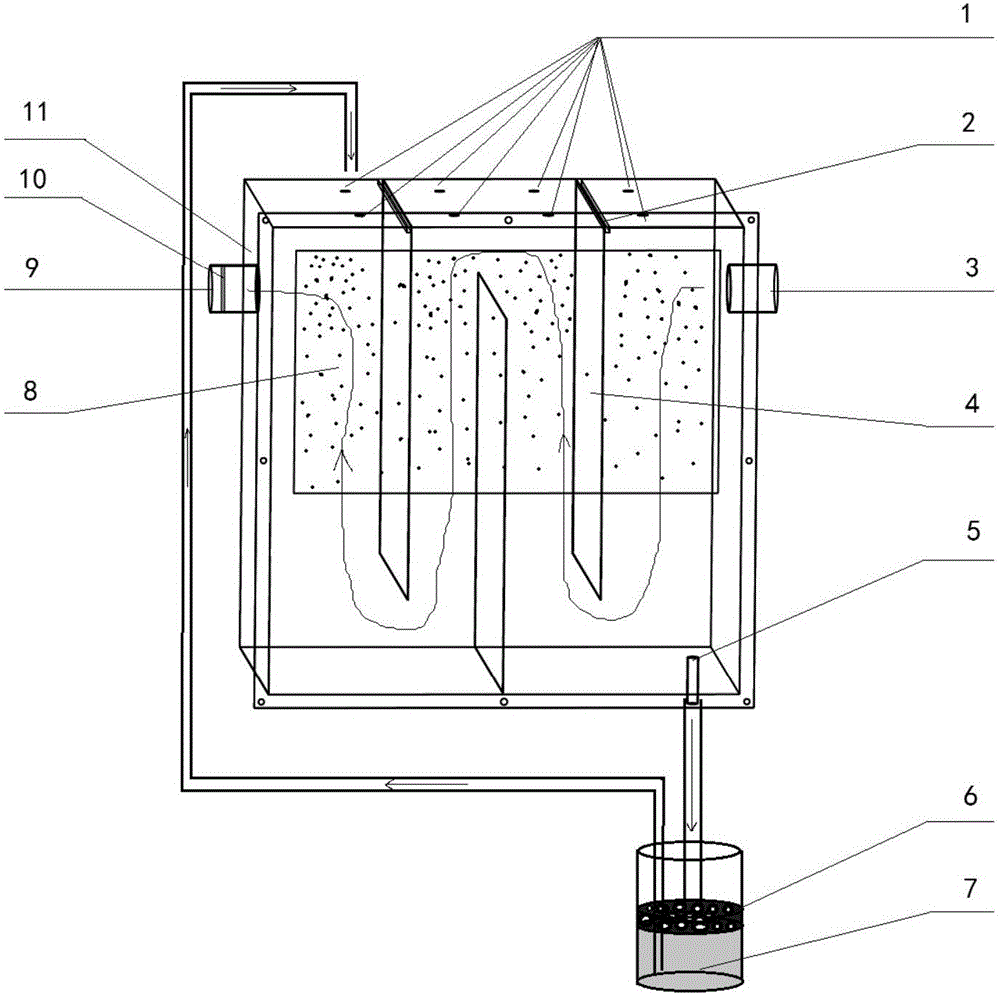

Device for harmless treatment of high-temperature tail gas in combustion process

InactiveCN105727658ALower discharge temperatureUsing liquid separation agentSeparation devicesExhaust gasWater circulation

The invention relates to a device for harmless treatment of high-temperature tail gas in a combustion process, and belongs to the technical field of waste gas treatment. It mainly includes a tail gas treatment device and a waste water treatment device. The tail gas treatment device includes a box body, several nozzles, 3 baffles and an observation window, and the waste water collection device mainly includes a waste water filtering device. When working, several nozzles generate fully atomized water mist to fill the entire box, and the 3 baffles are fixed by slots, mainly to change the trajectory of the exhaust gas, so that the exhaust gas and the water mist are fully mixed, and the fine solid particles in the exhaust gas are increased. absorption while lowering the temperature. The final waste water enters the waste water filtering device from the waste water outlet, and the filtered water is then used for spraying, so as to achieve the effect of water circulation and save water consumption. The tail gas treatment device is small in size, simple in structure, low in manufacturing cost, and easy to clean; it can fully absorb harmful particles in the tail gas, has high efficiency, and can fully reduce the discharge temperature of the tail gas to protect the environment.

Owner:JIANGSU UNIV

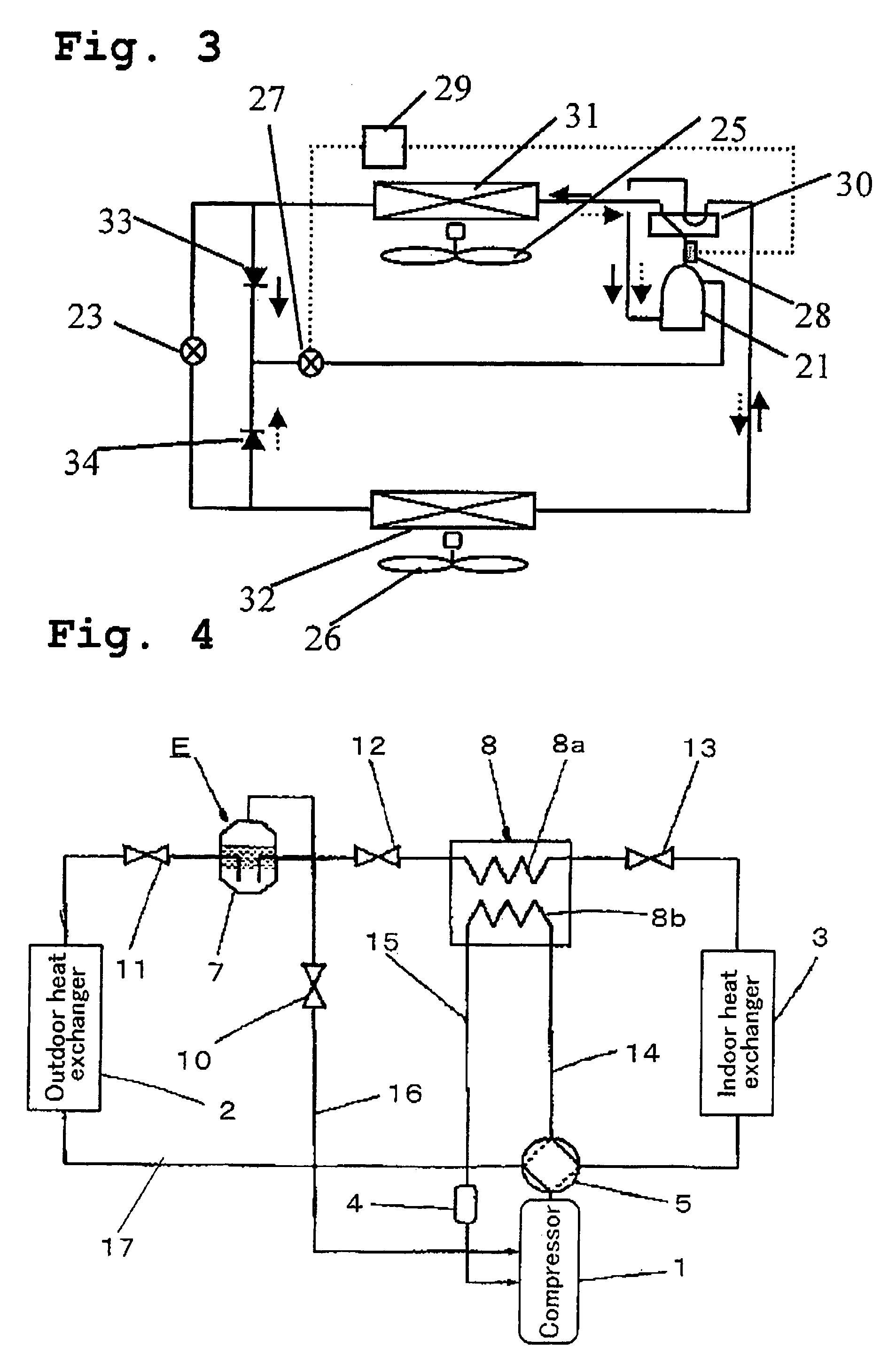

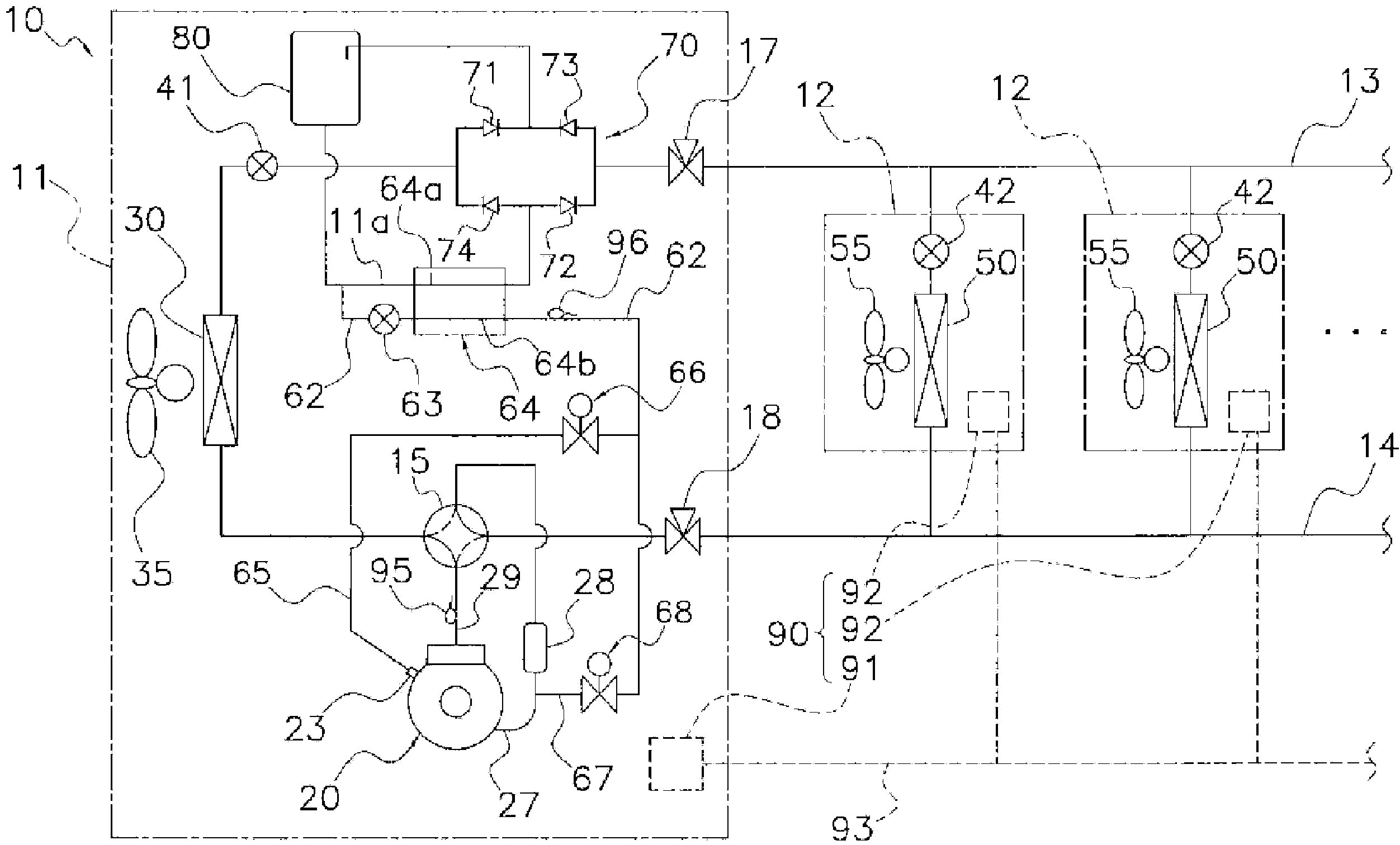

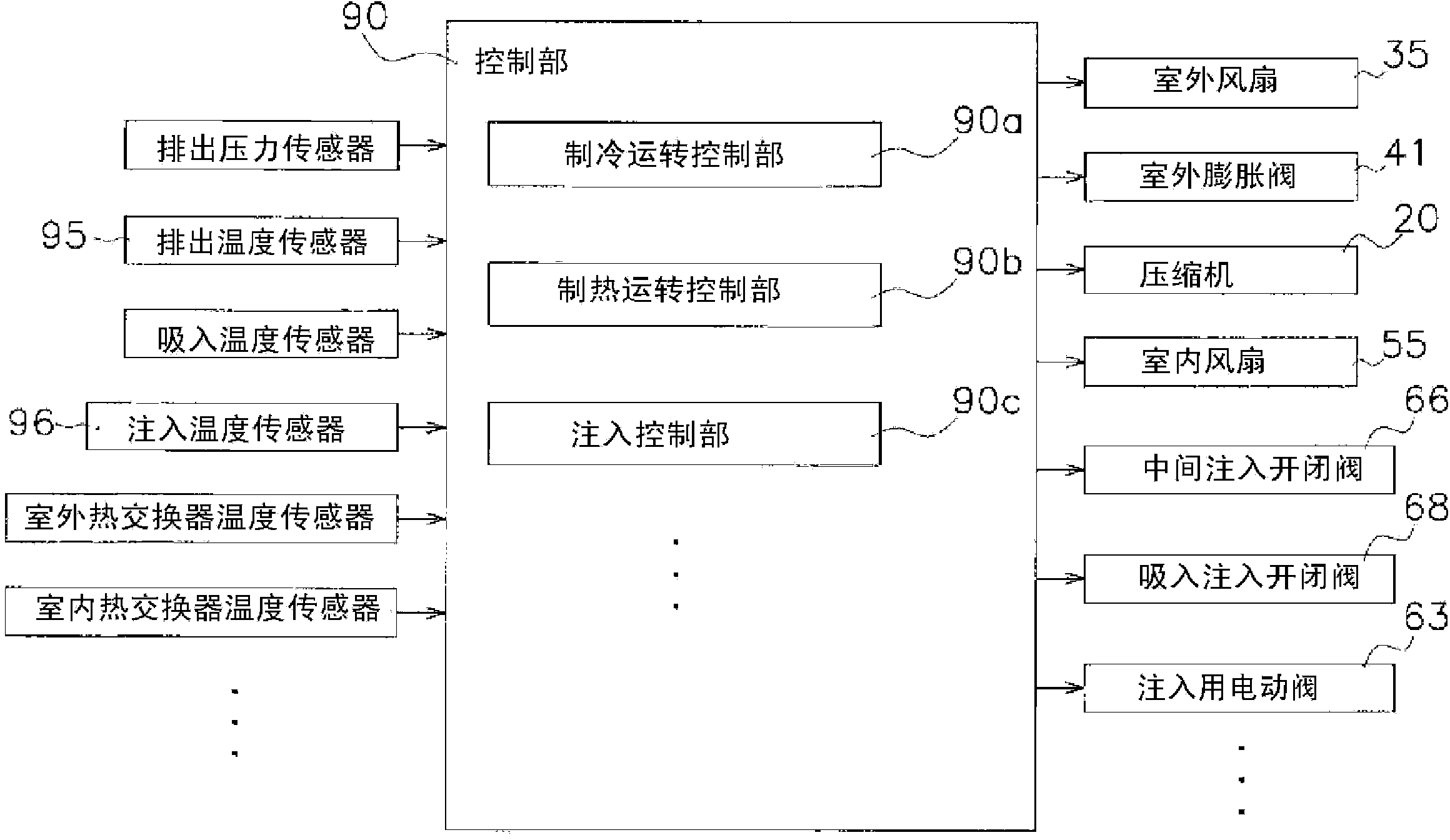

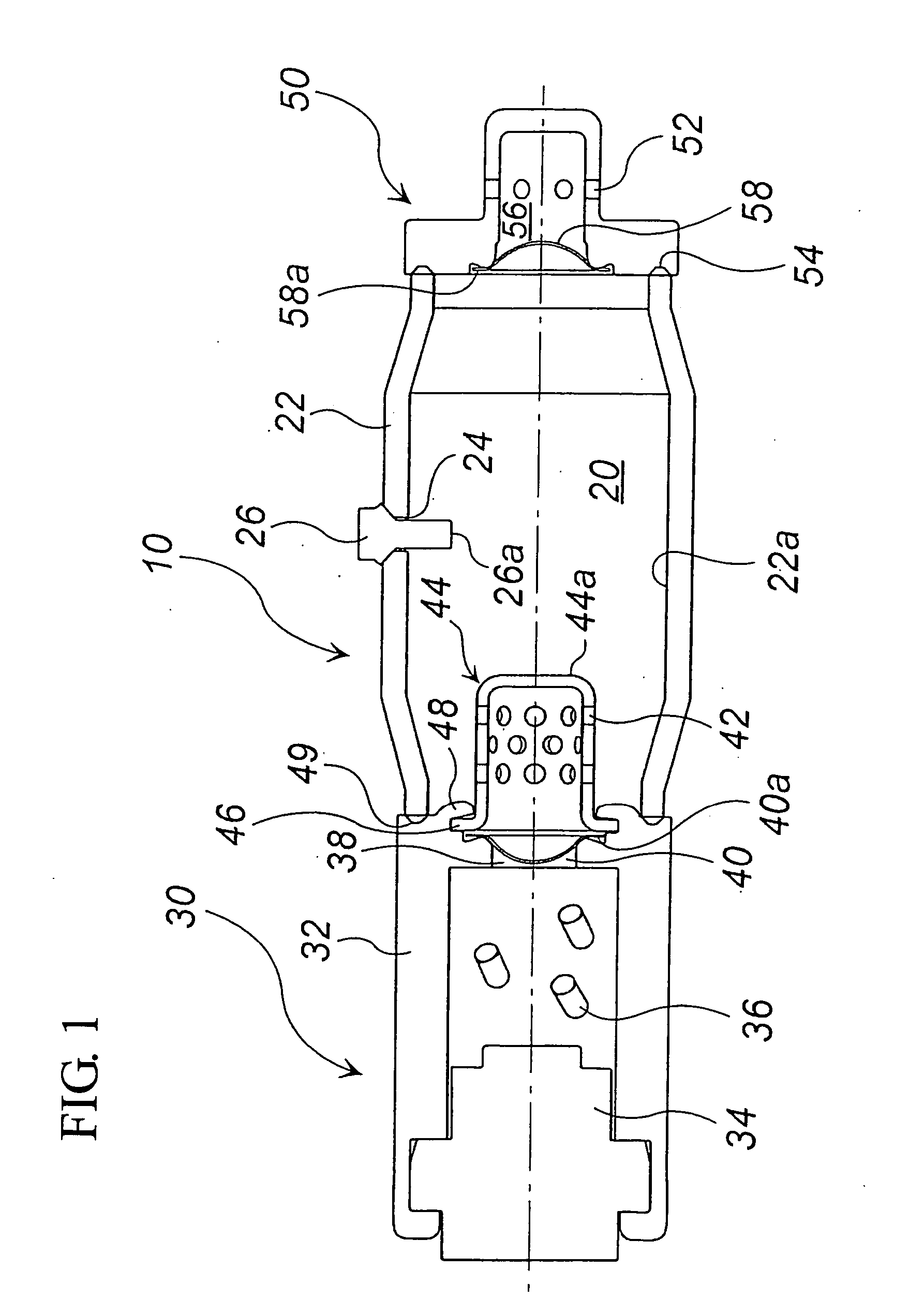

Freezer

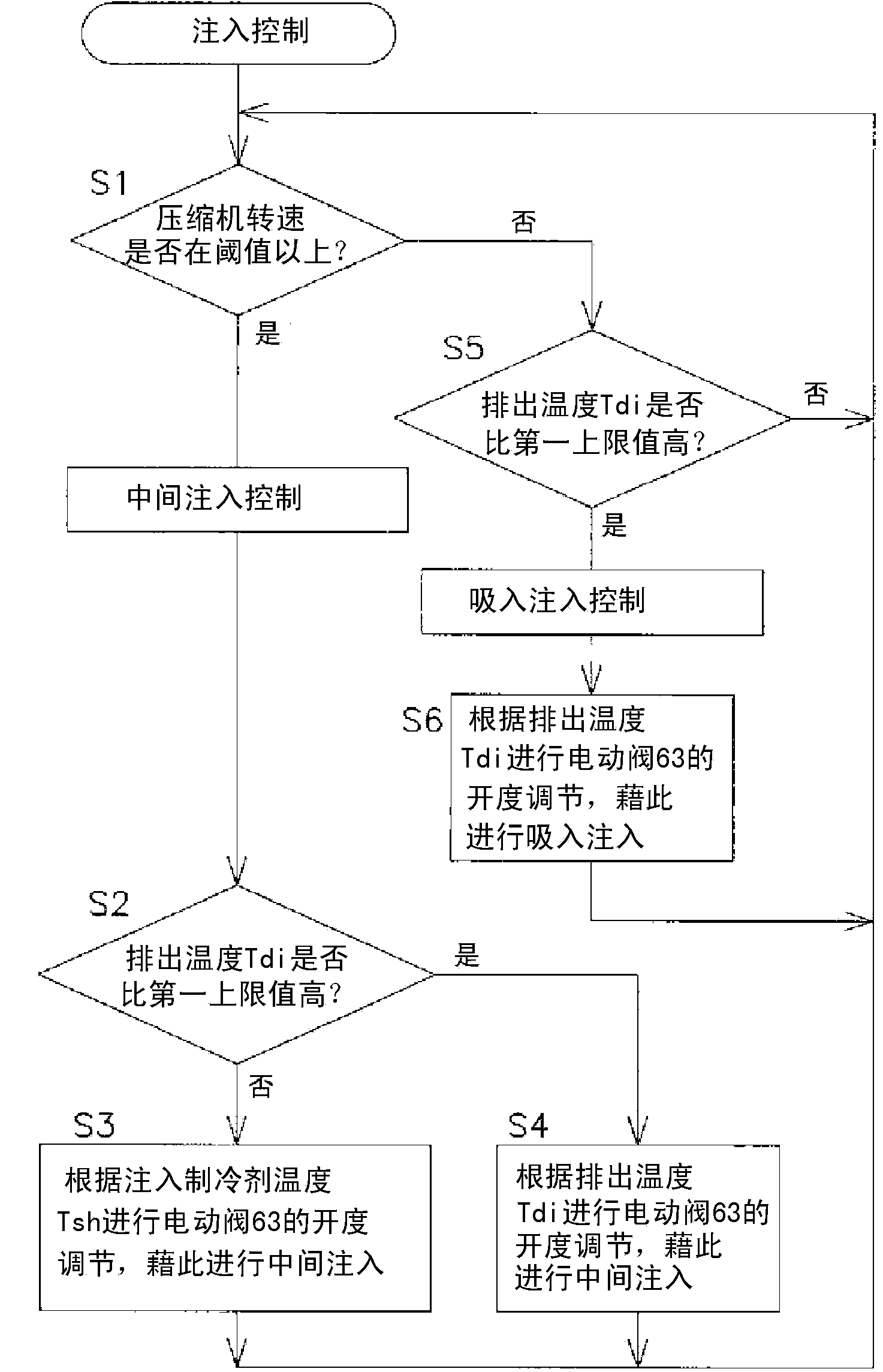

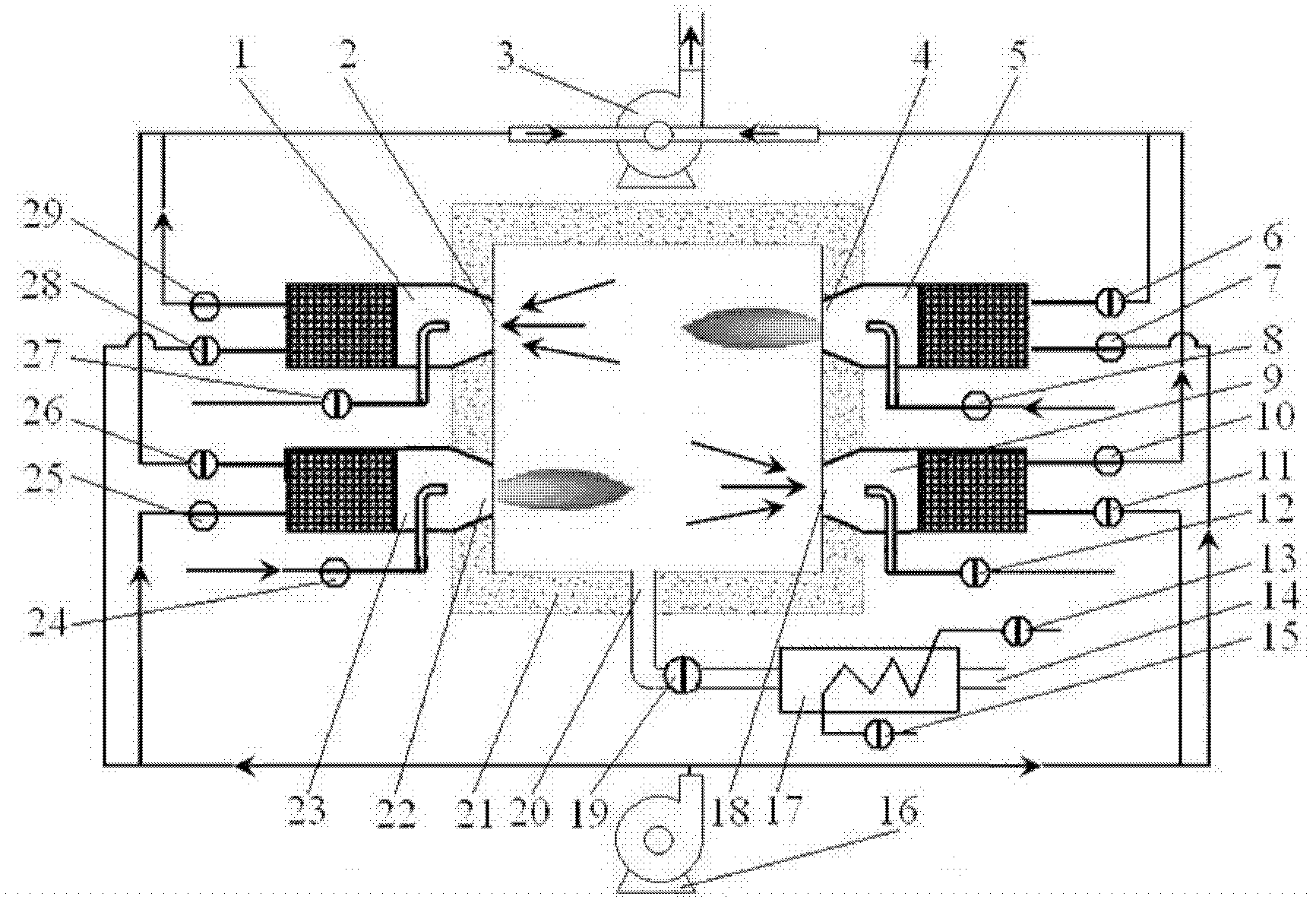

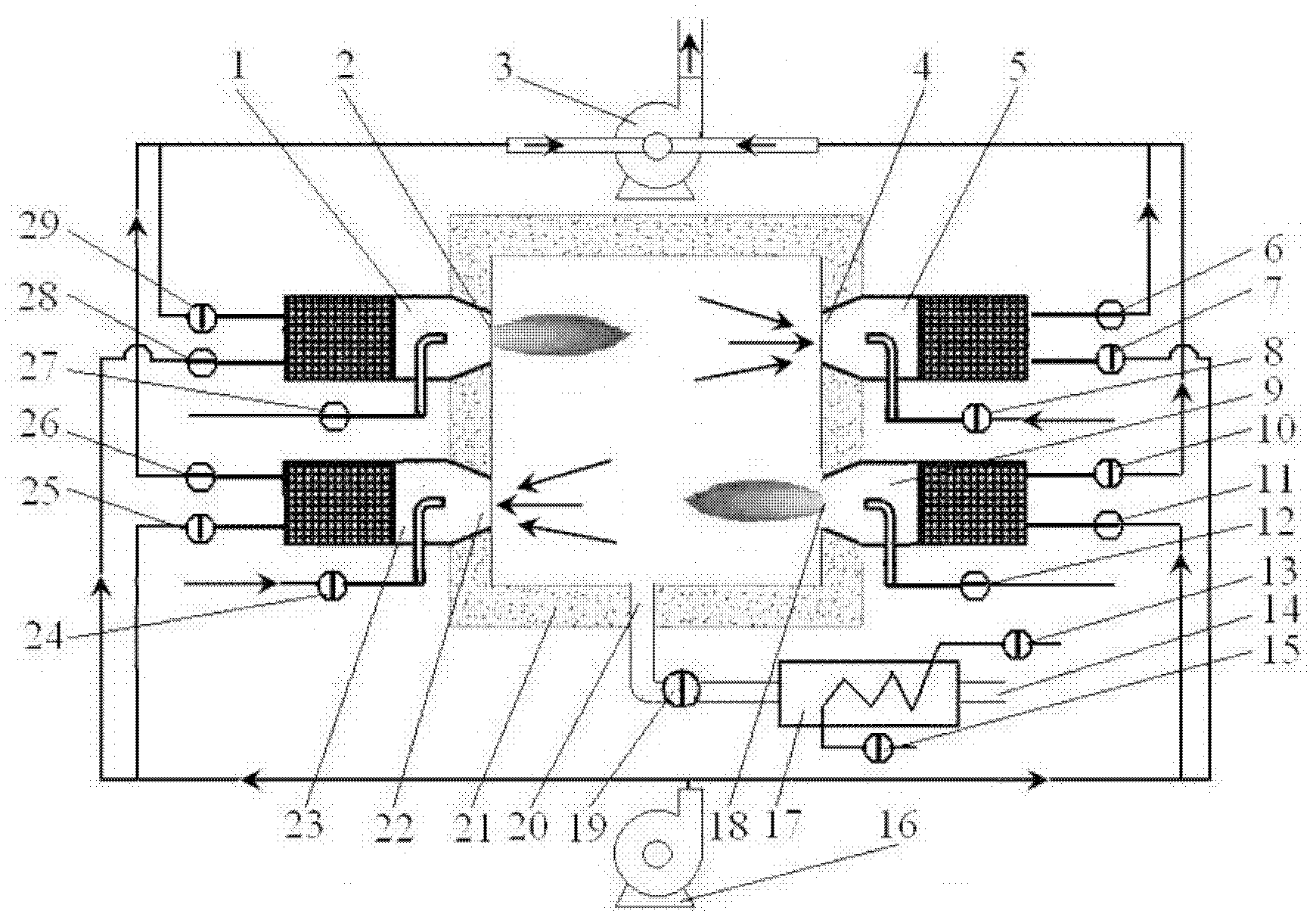

ActiveCN104321597ALower discharge temperatureGuaranteed operating efficiencyMechanical apparatusCompression machines with non-reversible cycleEngineeringAir conditioning

This freezer uses R32 and, even when the operation efficiency deteriorates due to an intermediate injection, enables injections for keeping down the discharge temperature. An air conditioning device (10) using an R32 refrigerant is provided with a compressor (20), an indoor heat exchanger (50), an outdoor expansion valve (41), an outdoor heat exchanger (30), an intermediate injection flow path (65), an intake injection flow path (67) and injection opening and closing valves (66, 68). The intermediate injection flow path (65) merges a part of the refrigerant flowing through a main refrigerant flow path (11a) with the intermediate-pressure refrigerant in the compressor (20). The intake injection flow path (67) guides a part of the refrigerant in the main refrigerant flow path (11a) to an intake flow path (27).

Owner:DAIKIN IND LTD

Energy-saving type shuttle type kiln

InactiveCN102564127AIncrease disturbanceUniform pressure distributionFurnace typesIncreasing energy efficiencyCombustorEngineering

The invention discloses an energy-saving type shuttle type kiln. The energy-saving type shuttle type kiln comprises a furnace body, at least one pair of heat-accumulating type combustors, a heat exchanger, corresponding valves, pipelines and a fan, wherein the combustors are arranged on the furnace body and are connected with the fan and a gas pipeline by the pipelines and the valves. When one of the combustors is in a combusting state, the other one is in a smoke-exhausting state, and the smoke stores heat in a heat-accumulating material in the combustors, and then is exhausted out of the system. When the preset time is up, the valves of the two combustors are switched, the combustor in the smoke-exhausting state is changed to be in the combusting state, and air absorbs the heat stored in the heat-accumulating material when passing through the combustor and carries the heat into a furnace so as to realize heat recovery. When a plurality of pairs of combustors are arranged, the working state of each combustor is opposite to that of the peripheral combustors so as to realize cross combustion. In the cooling process, heating and water supply are performed on the hot air by the heat exchanger on a spare flue, and the heat is absorbed by water so as to be utilized. The energy-saving type shuttle type kiln has the advantages that not only is the energy-saving effect obvious, but also the temperature distribution in the hearth is uniform, the temperature rising speed is high and the combustion temperature is high.

Owner:WUHAN ANHE ENERGY SAVING TECH

Nonflammable, nonozone depleting, refrigerant mixtures suitable for use in mineral oil

InactiveUS6863840B2Improve energy efficiencyReduce compressor discharge temperatureDistillation regulation/controlEnergy recuperation in distillationR-407cMineral oil

The present invention relates to refrigerants generally, and more specifically to nonflammable, nonozone depleting, mixtures of refrigerants that may be substituted for HCFC-22, R-407C, R-417A, R-502, R-500, CFC-12, R-404A, HFC-134a, and others, and is usable in mineral oil systems. Among the most preferred embodiments of the present invention are mixtures that are substitutes for these refrigerants, comprising about 1 to 85 weight percent R-125, and about 1 to 80 weight percent R-134a, and about 0 to 12 weight percent of R-1270, R-290 or a mixture thereof, and about 1 to 15 weight percent R-E170 and about 0 to 20 weight percent R-227ea, with the weight percentages of the components being weight percentages of the overall mixture.

Owner:GOBLE GEORGE H

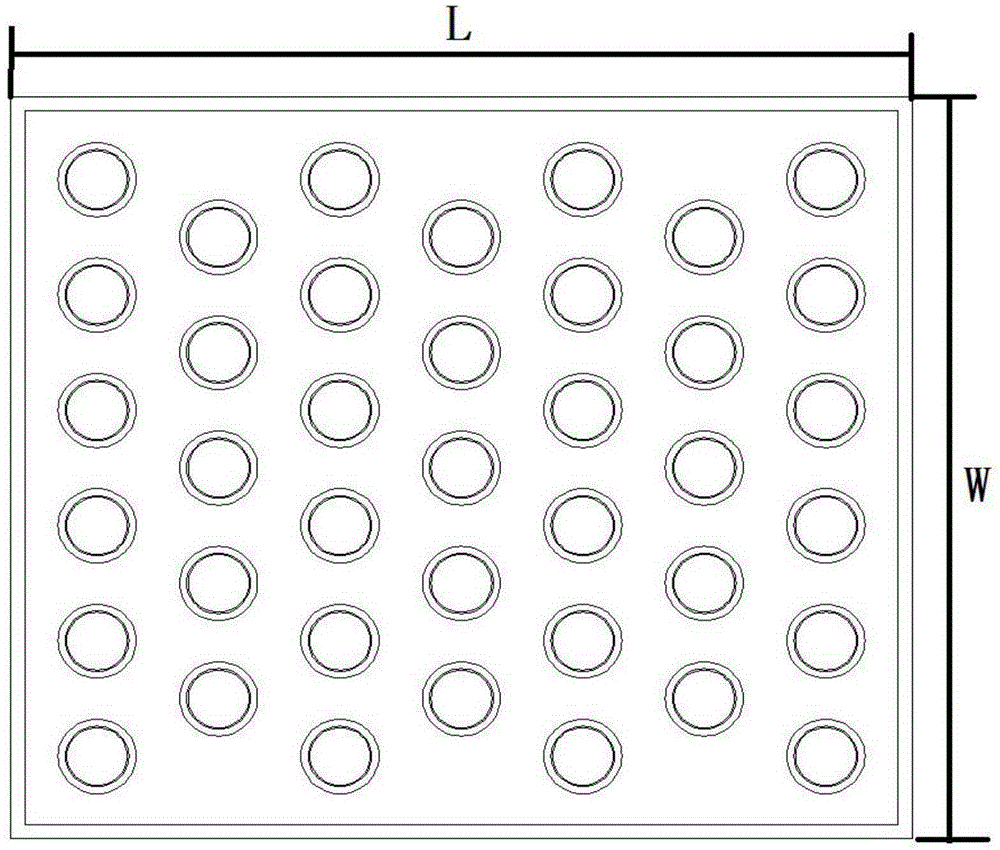

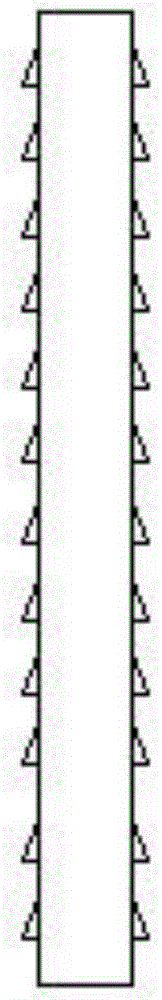

Phase-change heat exchanger and heat exchange method thereof

InactiveCN105277027ALower discharge temperatureTake advantage ofIndirect heat exchangersCombustion technology mitigationWater pipeDew point

The invention discloses a phase-change heat exchanger and a heat exchange method thereof. The heat exchanger is composed of a condensation chamber above and an evaporation chamber below. A steam package is arranged in the condensation chamber, and a valve bank is arranged on the top of the condensation chamber and connected with the steam package so that closed-loop control can be carried out over the lowest temperature of a heated metal wall face in a system; a plurality of straight tubes are distributed in the evaporation chamber, the top end of the evaporation chamber is communicated with one end of the steam package through a condensation water pipe, the bottom end of the evaporation chamber is communicated with the other end of the steam package through a steam raising pipe, and a loop is formed between the condensation chamber and the evaporation chamber. The heat exchanger is matched with an economizer in a power station boiler to recycle smoke waste heat and carry out circulating phase-change heat exchange. By means of the phase-change heat exchanger and the heat exchange method thereof, smoke exhaust temperature can be greatly lowered, and meanwhile smoke waste heat is fully used. Besides, the temperature of the heated metal wall face is further kept on a high temperature level, so that the heated metal wall face is far away from a dew point corrosion area of acid. Thus, the corrosion phenomenon is avoided, and use reliability of equipment is improved.

Owner:JILIN ELECTRIC POWER RES INST +1

Injection of refrigerant in system with expander

InactiveUS20100058783A1Effective expansionLower the discharge temperatureDomestic cooling apparatusCompression machines with non-reversible cycleEngineeringRefrigerant

A refrigerant system incorporates an expander. At least a portion of refrigerant bypasses an evaporator and is injected into the compression process to cool main refrigerant vapor flow and compressor elements. In disclosed embodiments, the injected refrigerant may be partially expanded in the expander and routed either into the compressor suction or to an intermediate point in the compression process. A valve may control the amount of the injected refrigerant to achieve desired operational characteristics for the refrigerant system.

Owner:CARRIER CORP

Gas generator

InactiveUS20060202455A1Reduce temperature changesMaintain internal pressurePedestrian/occupant safety arrangementGas generation devicesInternal pressureEngineering

The present invention provides a hybrid gas generator which is capable of keeping an air bag inflated by generating a lower-temperature gas so that the internal pressure of the air bag is maintained following inflation of the air bag. An opening serving as a gas outlet is formed in a cylindrical bottle 22 storing a pressurized medium, and the opening is sealed by a first sealing member 58 which is ruptured by an increase in the internal pressure of the bottle 22. The increase in the internal pressure of the bottle 22 is produced by activating heating means, and the temperature increase range of the pressurized medium before and after activation is not more than approximately 500° C.

Owner:DAICEL CHEM IND LTD

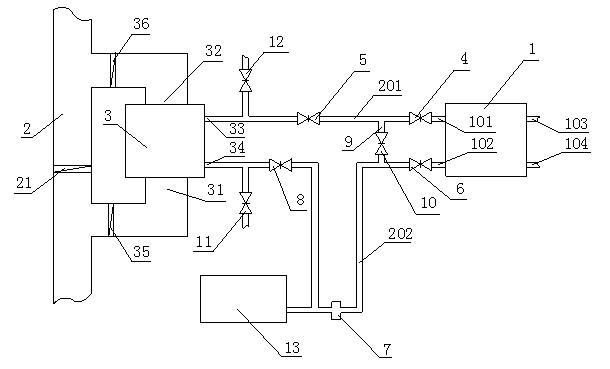

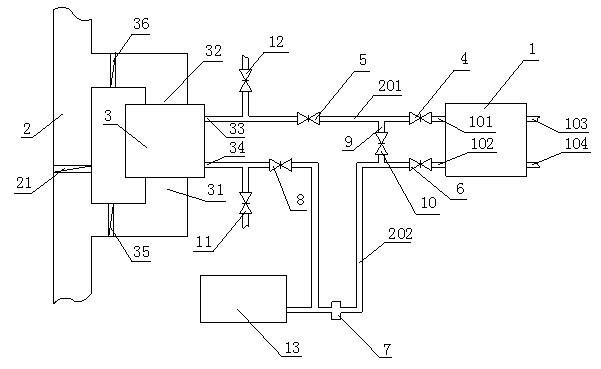

Air conditioning system

InactiveCN1637351AReduce the compression ratioLower discharge temperatureMechanical apparatusCompression machines with non-reversible cycleFour-way valveLiquid state

An air conditioning system with a compressor for compressing refrigerant, an outdoor heat exchanger for exchanging heat between the refrigerant and outdoor air, an indoor heat exchanger for exchanging heat between the refrigerant and indoor air, for converting Four-way valve for the direction of refrigerant flow, a refrigeration expansion device installed in the refrigerant pipe connecting the outdoor heat exchanger and the indoor heat exchanger, installed in the refrigerant pipe connecting the refrigeration expansion device and the indoor heat exchanger The vapor-liquid separator comprises: a liquid refrigerant supply pipe, which connects the vapor-liquid separator and the inlet of the compressor, and is used to supply the liquid refrigerant in the vapor-liquid separator to the inlet of the compressor; and the liquid refrigerant supply A valve for controlling the supply of liquid refrigerant through the liquid refrigerant supply pipe. The air conditioning system has improved heating performance, and in a heating mode under an extremely low outdoor temperature condition, reduces a compression ratio and a discharge temperature of a compressor, thereby improving reliability of the compressor.

Owner:SAMSUNG ELECTRONICS CO LTD

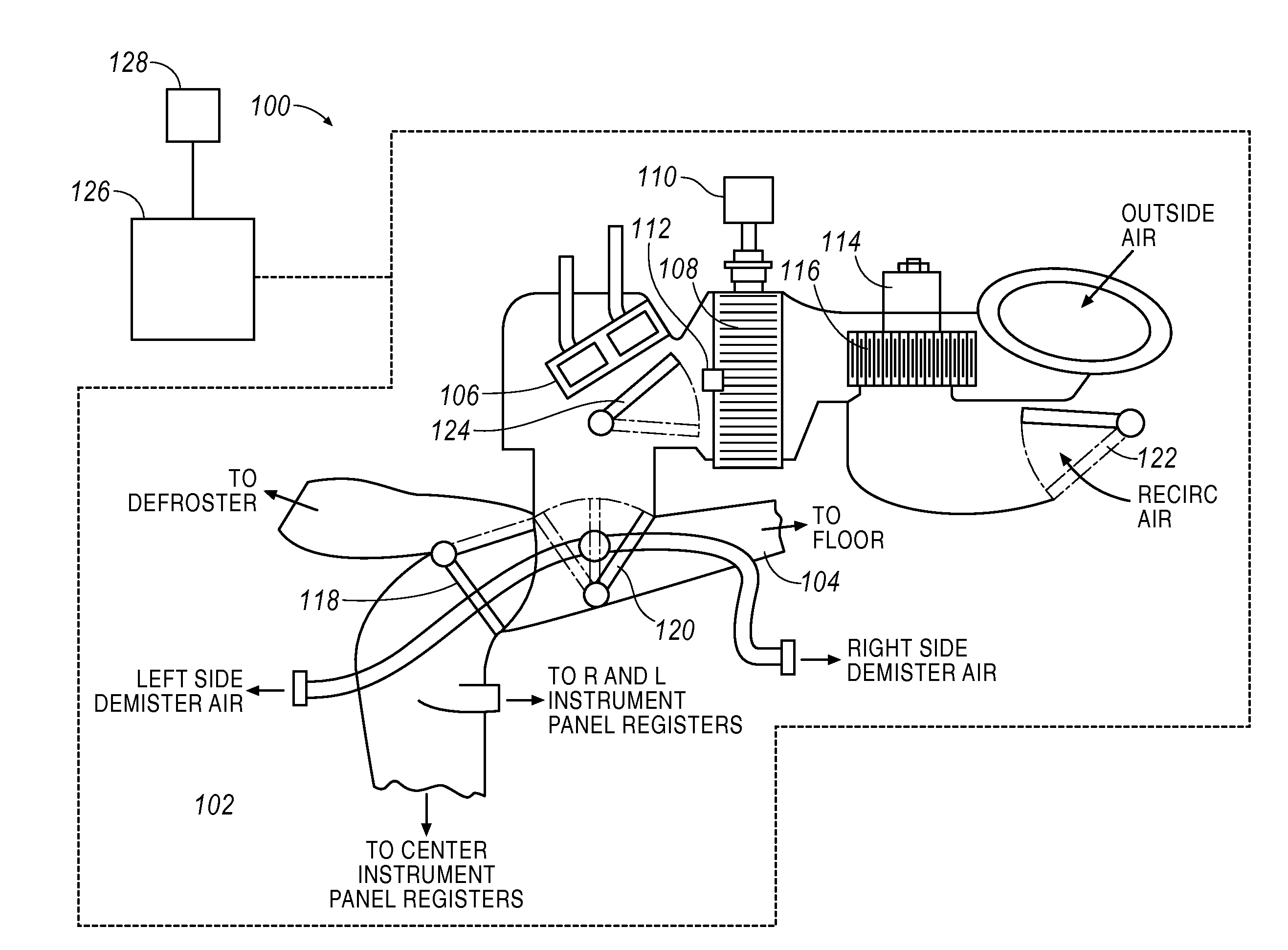

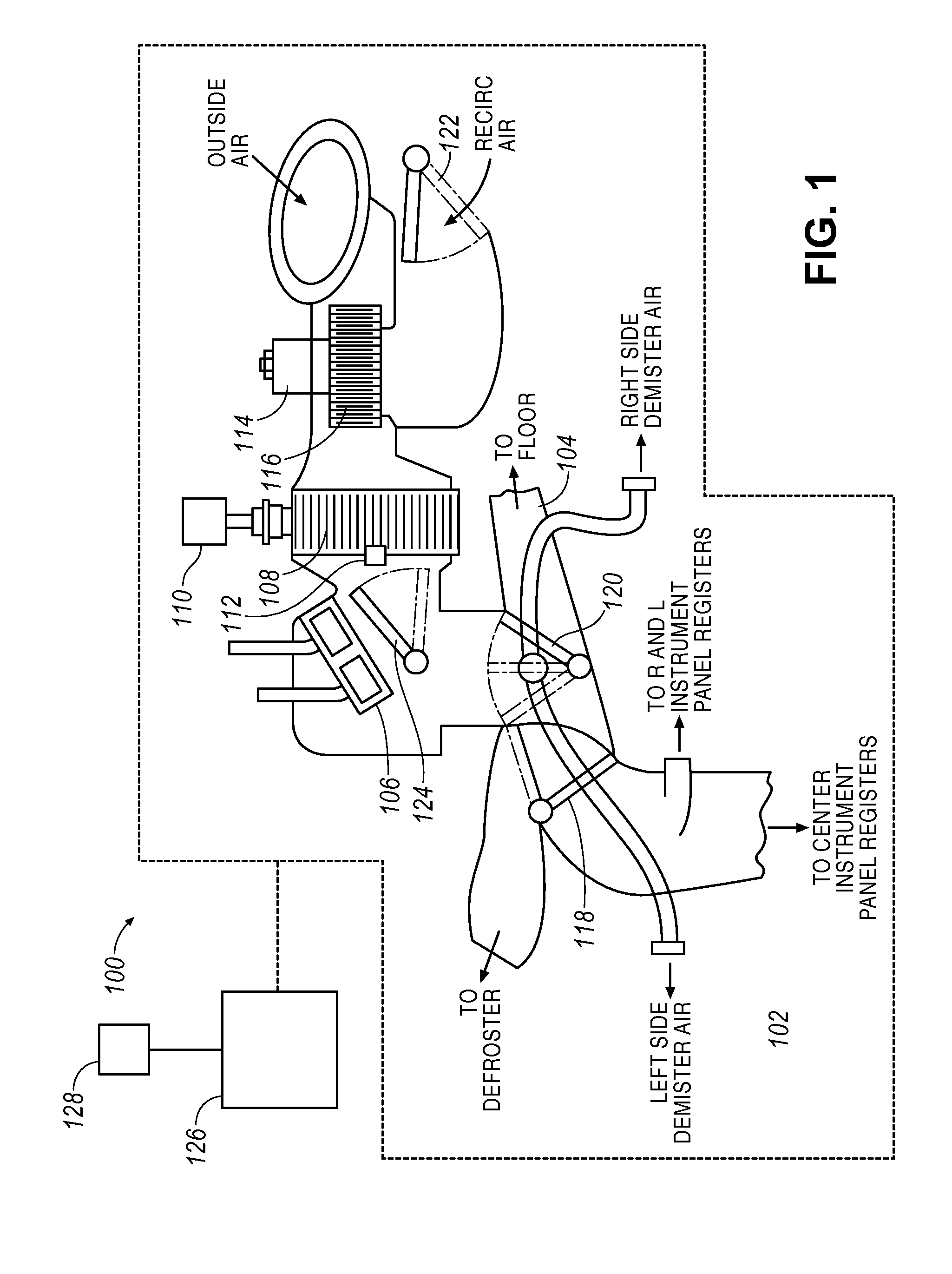

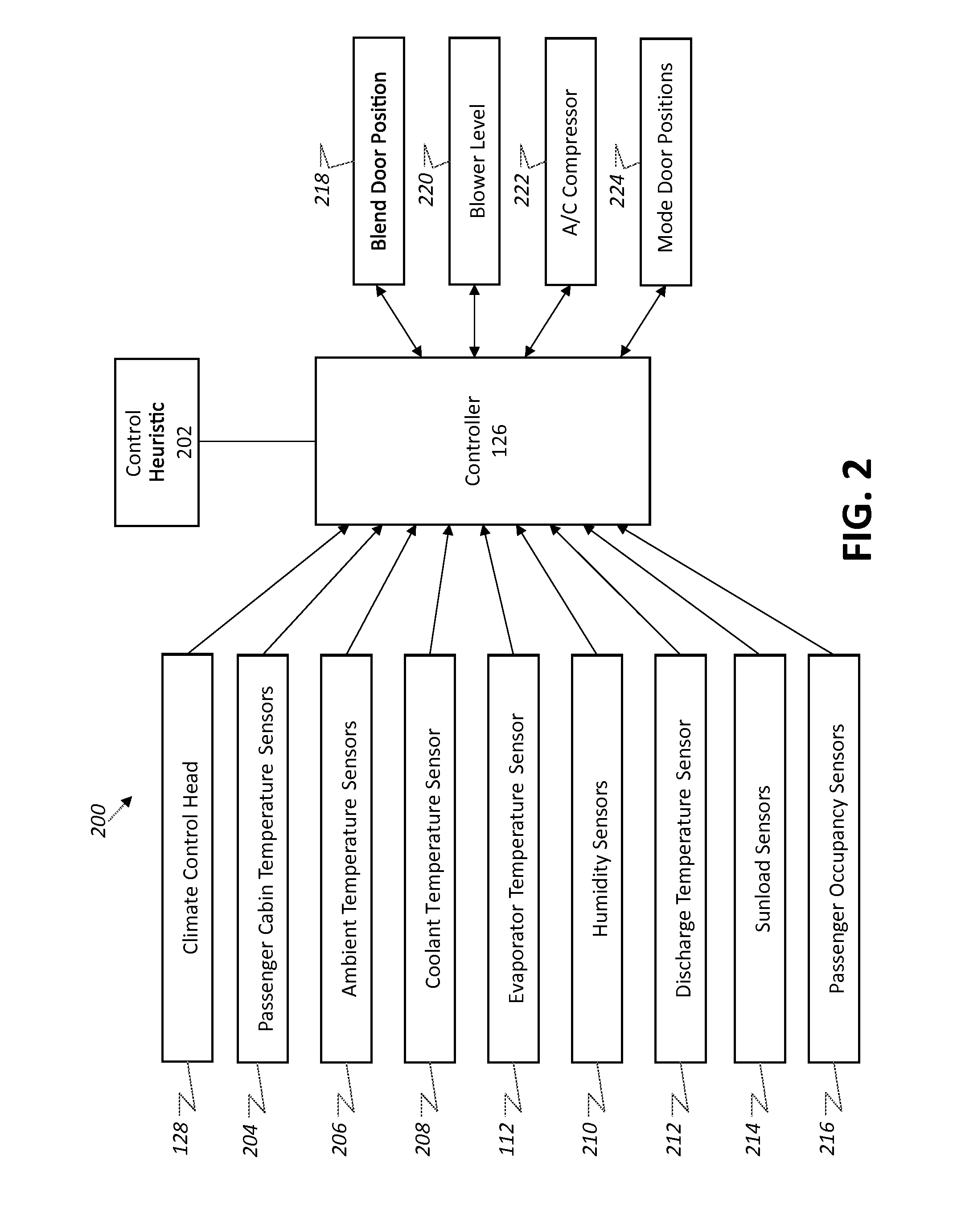

Coolest a/c discharge temperature for all operating conditions

ActiveUS20140216705A1Reduce the possibilityIncrease speedAir-treating devicesVehicle heating/cooling devicesControl systemEngineering

An automatic climate controller device may be configured to perform operations including identifying, by an automatic climate controller device, an operating zone of the climate control system according to at least two input factors; identifying a discharge temperature of the climate control system; determining, based on the operating zone and the discharge temperature, whether to perform at least one override action to override a climate control system setting to reduce the possibility of evaporator core icing; and adjusting an evaporator set point according to the at least one override action to reduce the discharge temperature. The input factors may include evaporator temperature and cabin relative humidity. The actions may include to increase blower speed and to increase use of recirculated air.

Owner:FORD GLOBAL TECH LLC

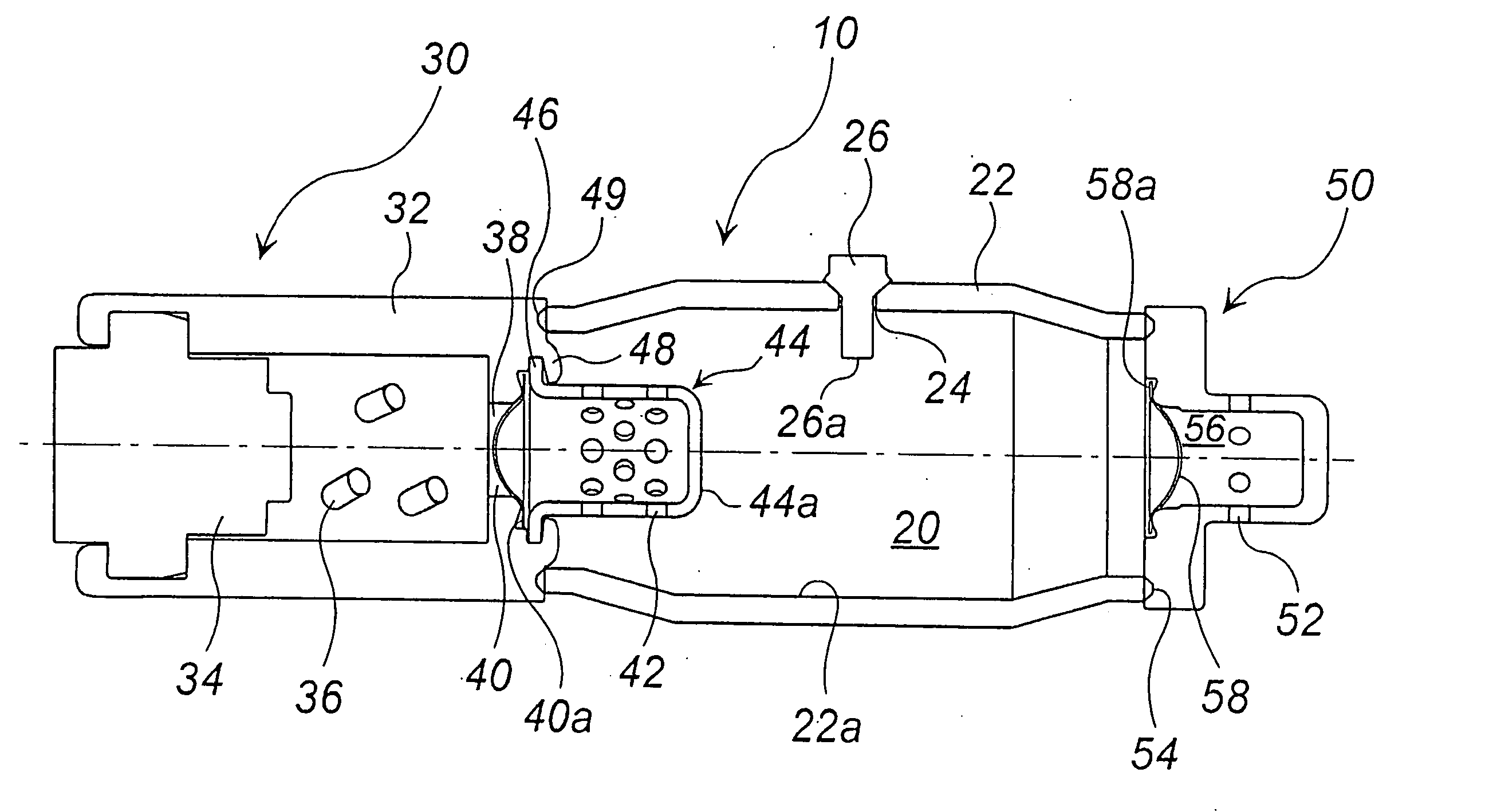

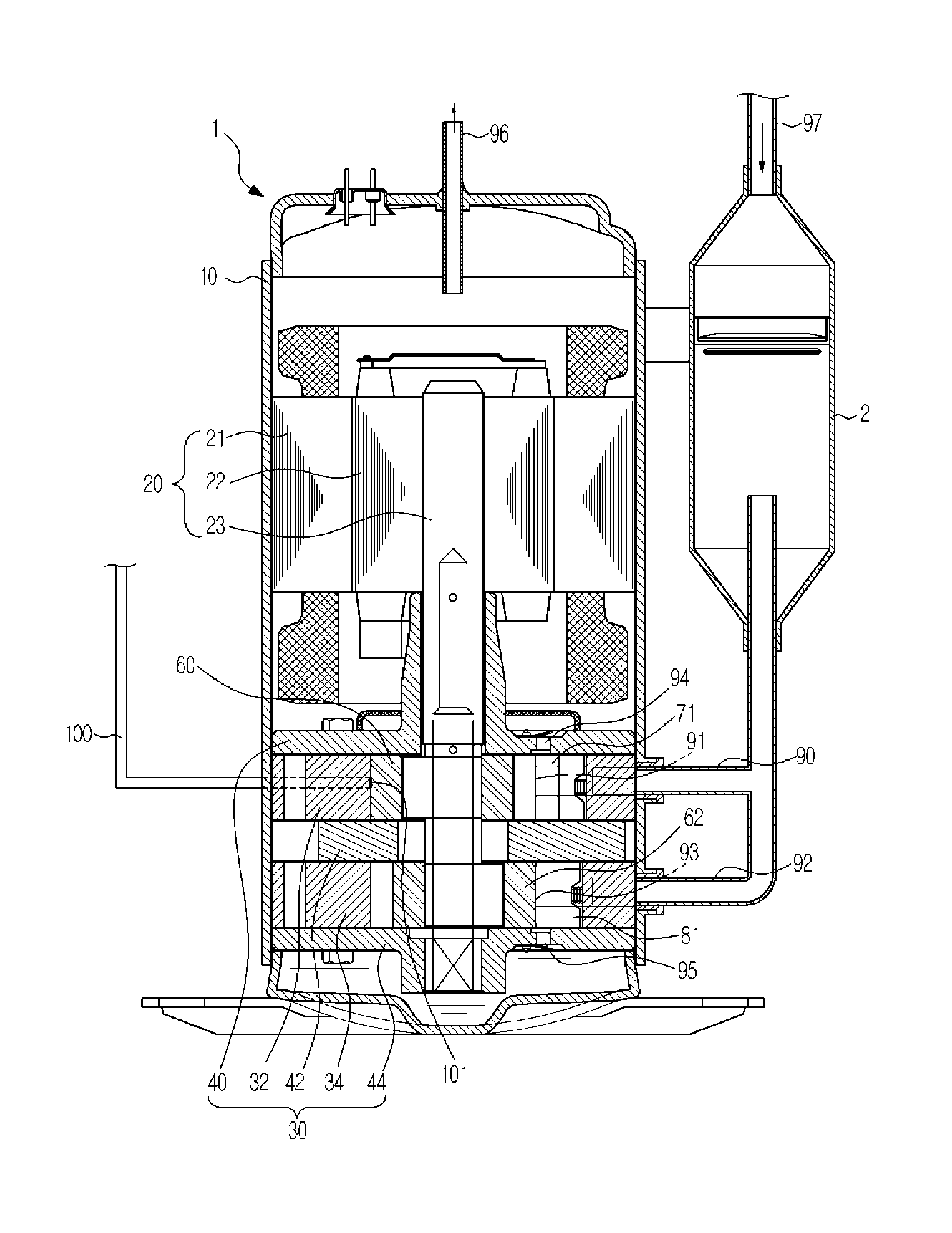

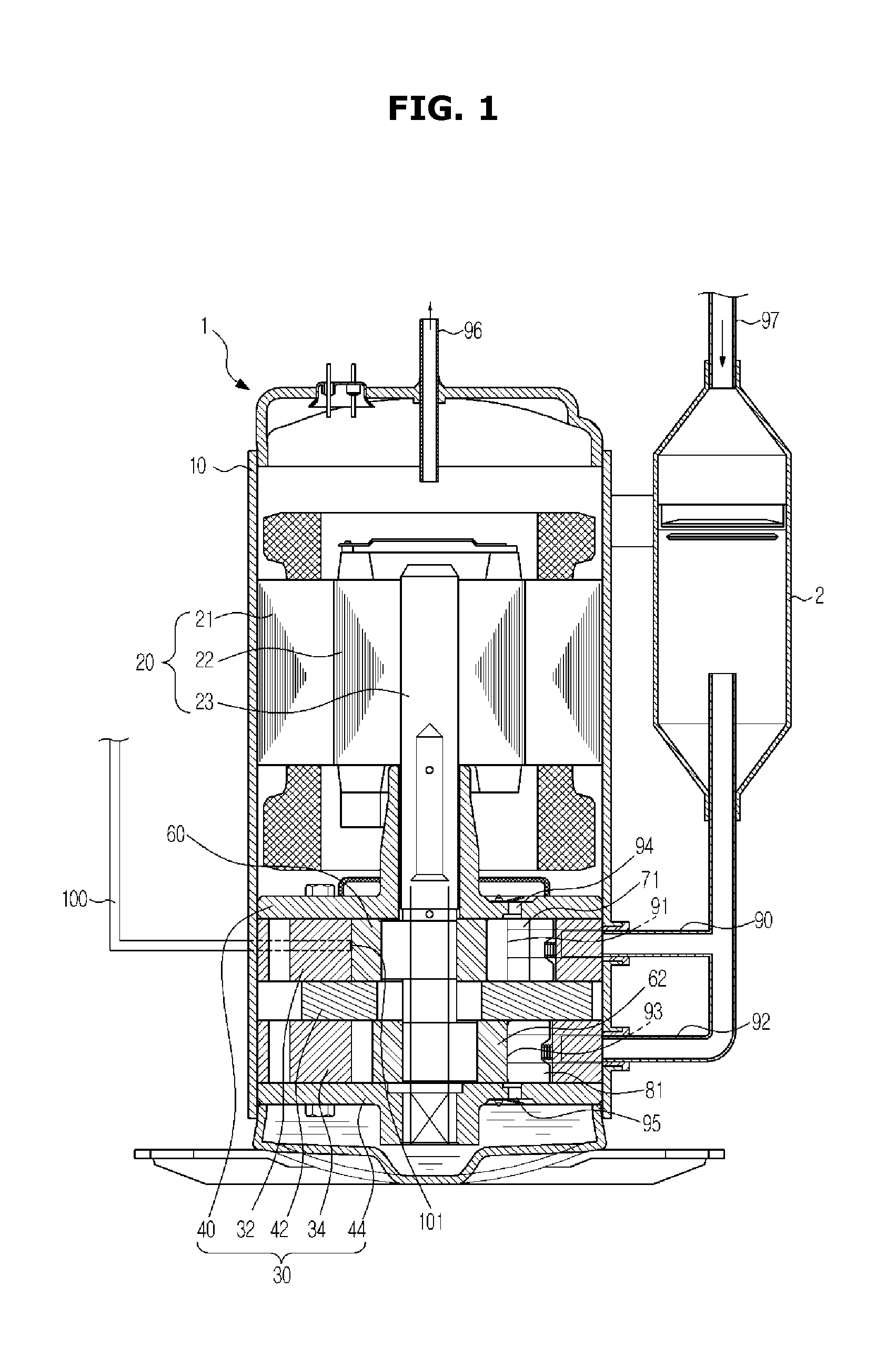

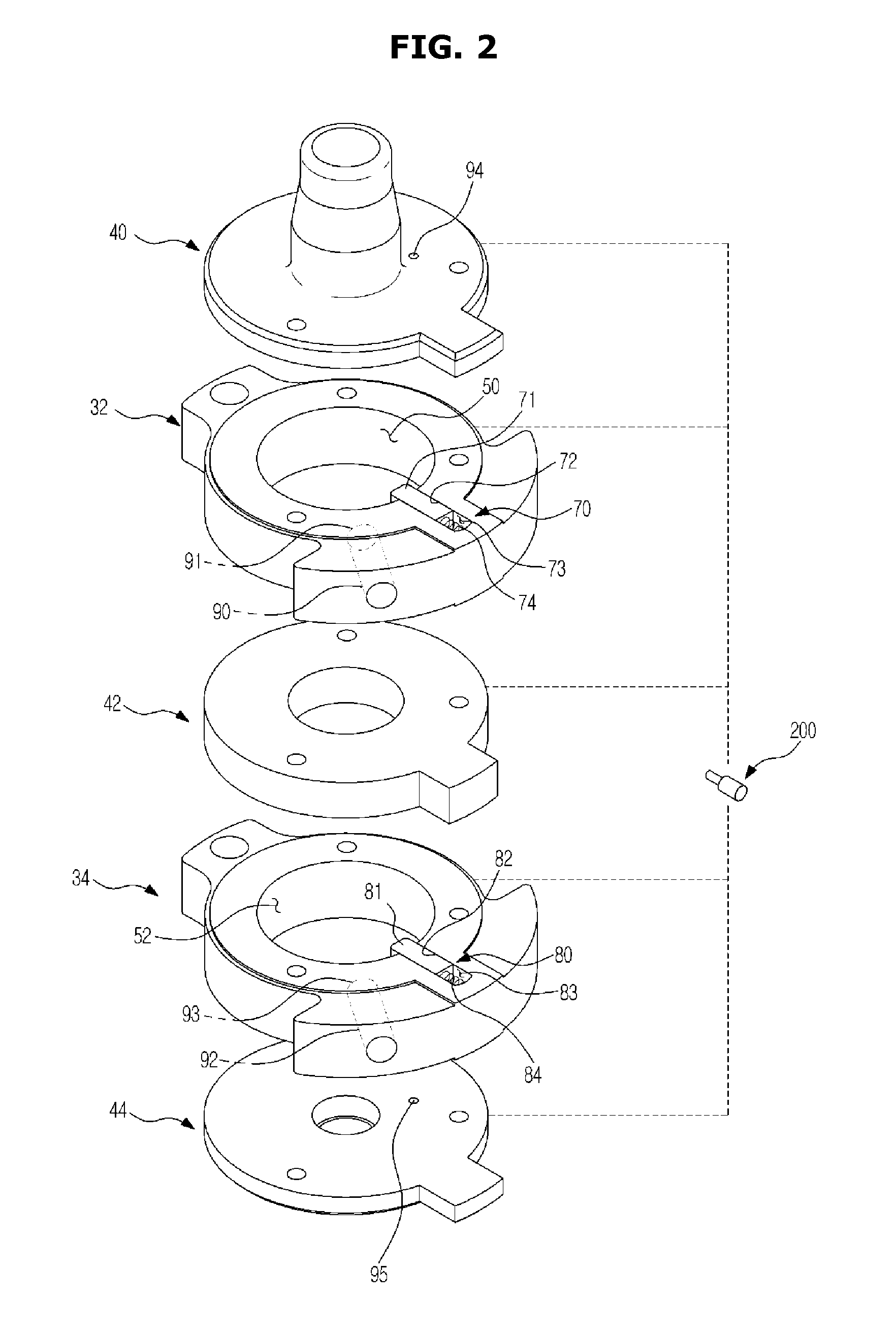

Compressor and air conditioner including the same

ActiveUS20150040608A1Simple structureImprove the heating effectRotary/oscillating piston combinations for elastic fluidsCompressorInterior spaceLine tubing

A compressor and an air conditioner including the same having an improved structure capable of decreasing a discharge temperature of the compressor. The compressor which compresses and discharges refrigerant includes a casing defining an external appearance thereof, at least one cylinder including an inner space, a rolling piston which eccentrically turns in the inner space, a vane which radially abuts the rolling piston and divides the inner space into a suction chamber and a compression chamber, and a vane chamber recessed outward of the inner space such that the vane advances and retreats, a plurality of plates disposed above and below the at least one cylinder so as to define the inner space, an injection line provided in one of the at least one cylinder and the plural plates, and a check valve installed on the injection line.

Owner:SAMSUNG ELECTRONICS CO LTD

Waste gas afterheat recovery system

InactiveCN102032804AExchangeReduce consumptionStationary conduit assembliesCombustion technology mitigationInlet valveRecuperator

The invention provides a waste gas afterheat recovery system which has high heat recovery utilization rate. The waste gas afterheat recovery system comprises a heat exchanger, a chimney and an afterheat recoverer, wherein an air inlet and an air outlet of the afterheat recoverer are communicated with the chimney; the heat exchanger comprises a first water inlet, a first water outlet, a second water inlet and a second water outlet, wherein the first water inlet is communicated with the first water outlet and the second water inlet is communicated with the second water outlet by respectively utilizing pipelines inside the heat exchanger; the first water inlet is communicated with the water outlet of the afterheat recoverer through a water inlet pipe; the water inlet pipe is sequentially provided with a water inlet valve and a first control valve; the first water outlet is communicated with the water inlet of the afterheat recoverer through a water outlet pipe; the water outlet pipe is sequentially provided with a water outlet valve, a water pump and a second control valve; the first water inlet is also communicated with the first water outlet through a water passing pipe arranged outside the heat exchanger; and the water passing pipe is provided with a third control valve. The waste gas afterheat recovery system can enhance the recovery utilization rate of heat contained in waste gases by utilizing the water as a medium.

Owner:CHERY AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com