Phase-change heat exchanger and heat exchange method thereof

A phase change heat exchanger and heat method technology, which is applied in indirect heat exchangers, lighting and heating equipment, and greenhouse gas reduction, etc., can solve the problems of decreased heat transfer efficiency, scrapped heat exchangers, and high manufacturing and maintenance costs of heat pipes. , to achieve the effect of stable exhaust gas temperature and wall temperature, reducing flue gas emission temperature and avoiding corrosion phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

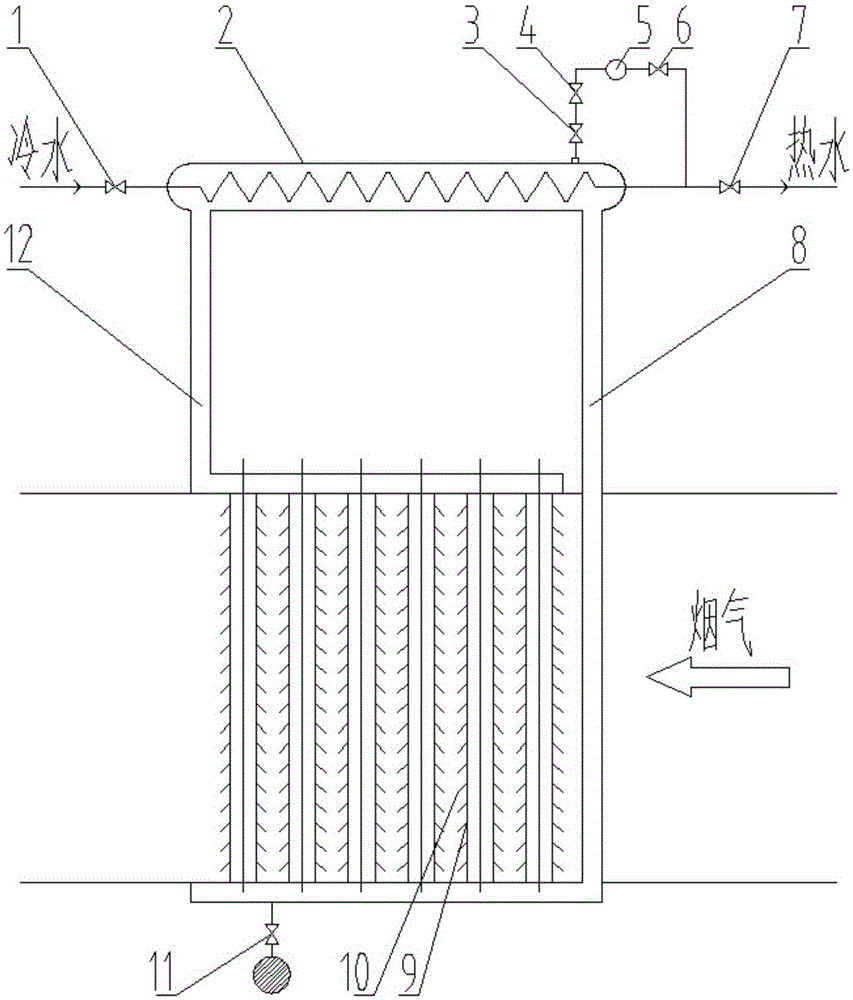

[0037] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

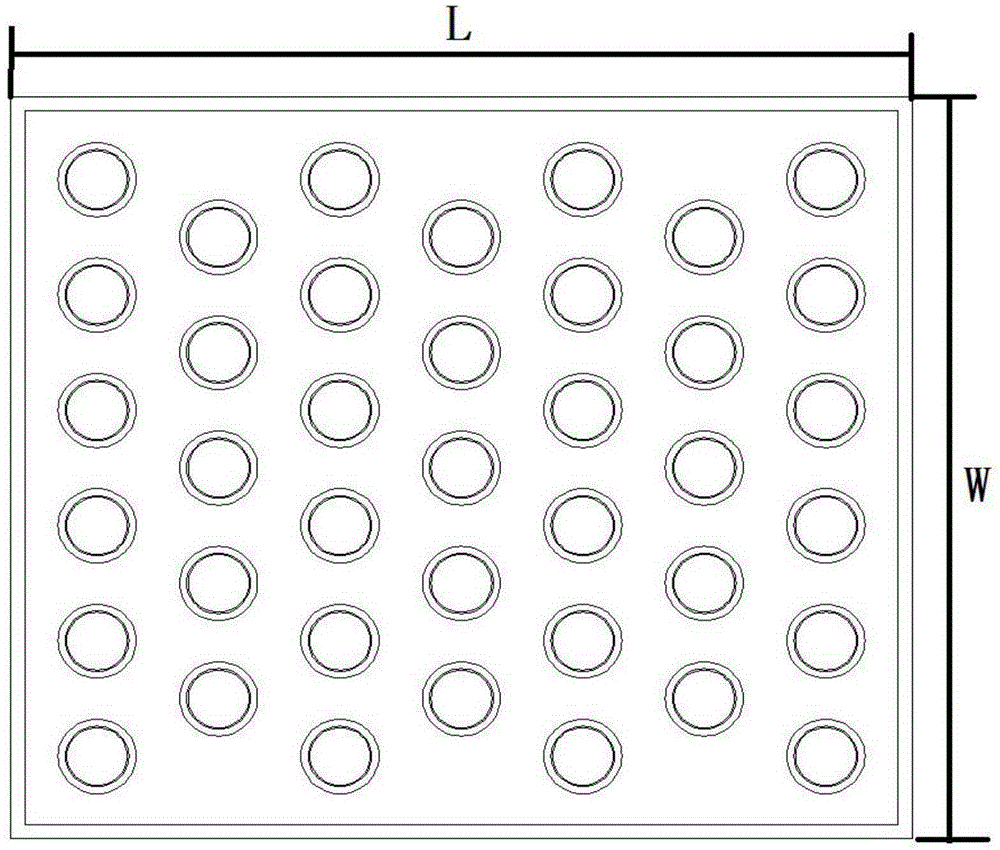

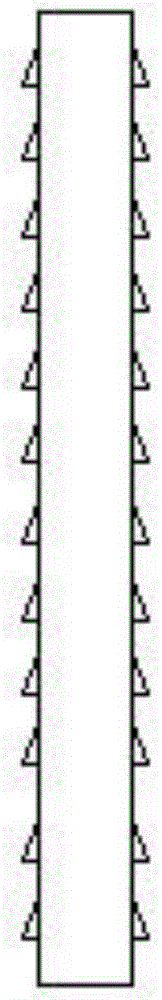

[0038] The heat transfer principle of the phase change heat exchanger provided by the present invention is similar to that of a heat pipe, and can be regarded as a large heat pipe. It is mainly composed of two parts: the evaporation chamber and the condensation chamber. A number of straight pipes are arranged in the evaporation chamber. The straight pipe is equipped with an intermediate cooling medium. The medium and low temperature flue gas flows through the area between the evaporation chamber and the straight pipe. The condensation chamber is equipped with a condensate pipe. 12. Multiple valves are set on the top of the condensation chamber. The specific structure of the phase change heat exchanger of the present invention is as follows:

[0039] Such as figure 1 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com