Working medium for heat cycles, composition for heat-cycle systems, and heat-cycle system

A technology of working medium and circulation system, applied in the field of thermal cycle system, can solve the problems of heat resistance, difficulty in obtaining energy efficiency thermal cycle system, etc., and achieve the effects of high durability, excellent energy efficiency, and low discharge temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0187] Hereinafter, the present invention will be described in detail through examples, but the present invention is not limited to the following examples. Examples 1 to 48 are examples, and Examples 50 to 55 are reference examples having different compositions from the working medium of the present invention. In addition, Example 49 is an example of R410A used as an evaluation standard in the working examples of Examples 1 to 48 and the reference examples of Examples 50 to 55, and is a comparative example.

[0188] The measurement and evaluation of the refrigeration cycle performance (refrigeration capacity Q and efficiency coefficient COP), temperature gradient and discharge temperature of the working medium are carried out in the following manner.

[0189]

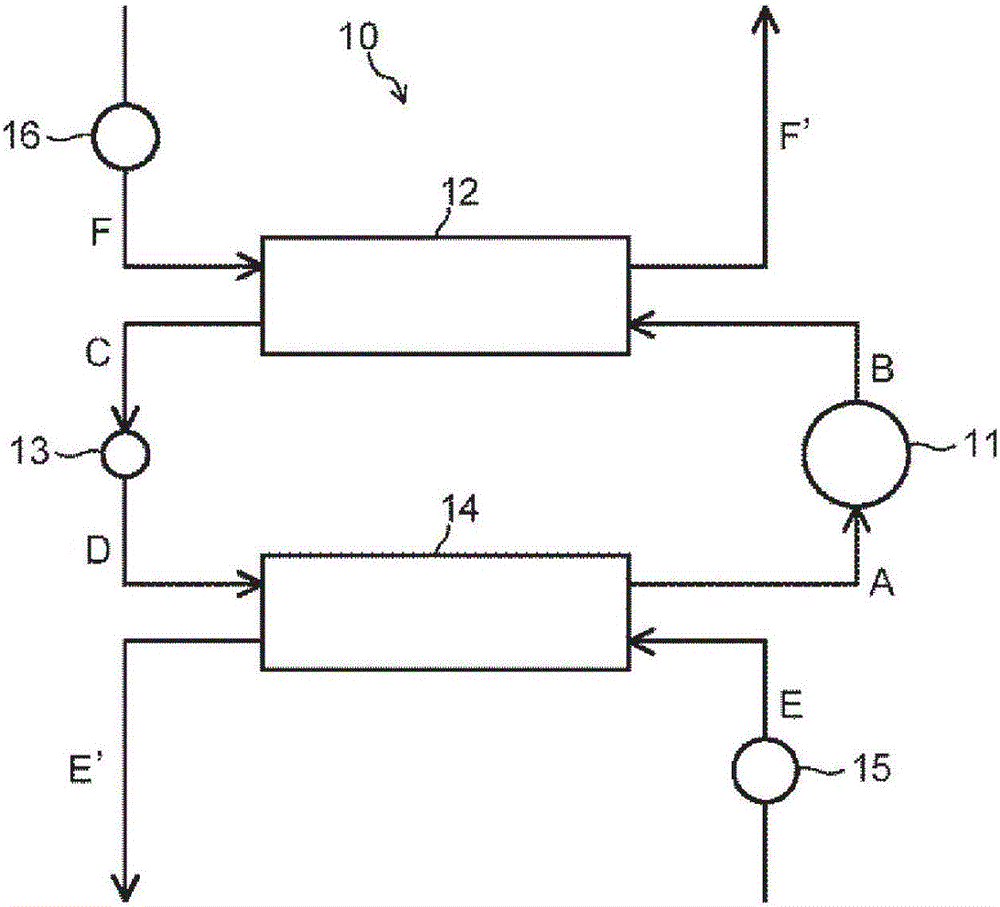

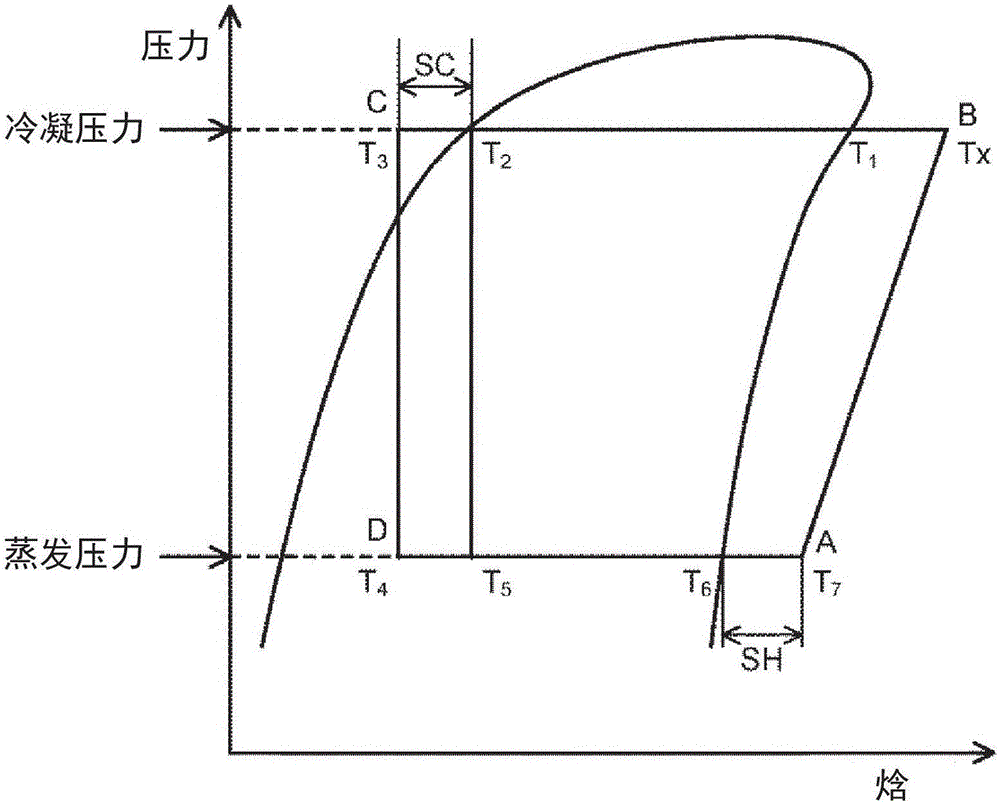

[0190] The determination of refrigeration cycle performance (refrigeration capacity and efficiency coefficient) and temperature gradient is carried out as follows: figure 1 The working medium is used in the shown ref...

example 1~12

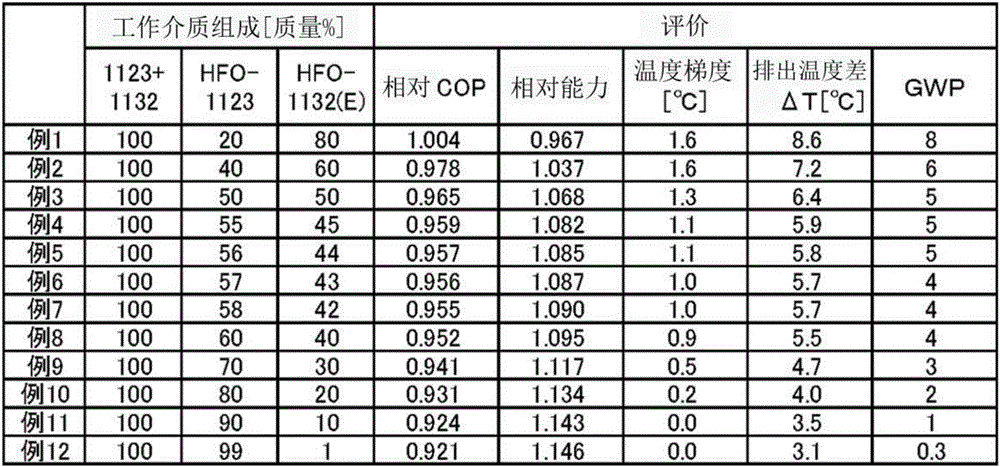

[0202] Among examples 1~12, preparation mixes the working medium of HFO-1123 and HFO-1132 with the ratio shown in table 2, according to above-mentioned method to the refrigerating cycle performance (freezing ability Q and coefficient of efficiency COP) of these working mediums, temperature gradient and The discharge temperature was measured and evaluated.

[0203] Table 2 shows the measurement and evaluation results of the refrigeration capacity (with respect to R410A) and the efficiency coefficient (with respect to R410A), the measurement results of the temperature gradient and the discharge temperature difference, and the calculation results of GWP.

[0204] [Table 2]

[0205]

[0206] From the results shown in Table 2, it can be seen that the working mediums of Examples 1 to 12 composed of HFO-1123 and HFO-1132(E) not only have good efficiency coefficient and refrigeration capacity relative to R410A, but also have a small temperature gradient. In addition, GWP is also a...

example 13~48

[0208] In Examples 13 to 20, working media in which HFO-1123, HFO-1132(E), and HFC-32 were mixed in the proportions shown in Table 3 were prepared. In addition, in Examples 21 to 28, working media in which HFO-1123, HFO-1132(E), and HFC-125 were mixed at the ratios shown in Table 4 were prepared. In Examples 29 to 34, working mediums in which HFO-1123, HFO-1132(E), HFC-32 and HFC-125 were mixed in the proportions shown in Table 5 were prepared. Further, the ratio of HFO-1132(E) prepared in Example 35 to Example 48 was 10% by mass, and HFO-1132(E), HFO-1123, HFC-32 and / or HFC-32 were mixed in the ratio shown in Table 6. 125 working medium. In addition, in Tables 3 to 6, as "1123+1132" [mass %], the ratio of the total amount of HFO-1123 and HFO-1132 (E) to the total amount of the working medium is expressed in mass % ((1123+1132) / working medium). The same applies to Table 2 and Table 8 described below.

[0209] With respect to the working medium thus obtained, the refrigera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com