Patents

Literature

138 results about "Trifluoroethene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trifluoroethene has an atmospheric lifetime of 250 years, with Global Warming Potentials of 8200, 9200, and 12,500 at 20, 100, and 500 years, respectively(3). Trifluoroethene is not expected to undergo hydrolysis in the environment due to the lack of functional groups that hydrolyze under environmental conditions(4).

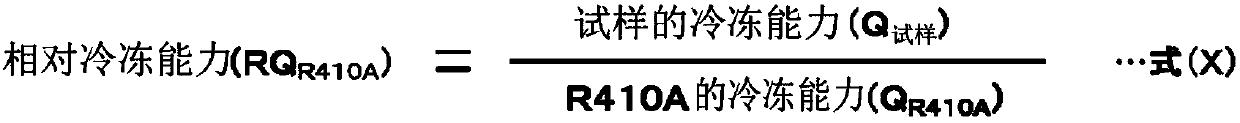

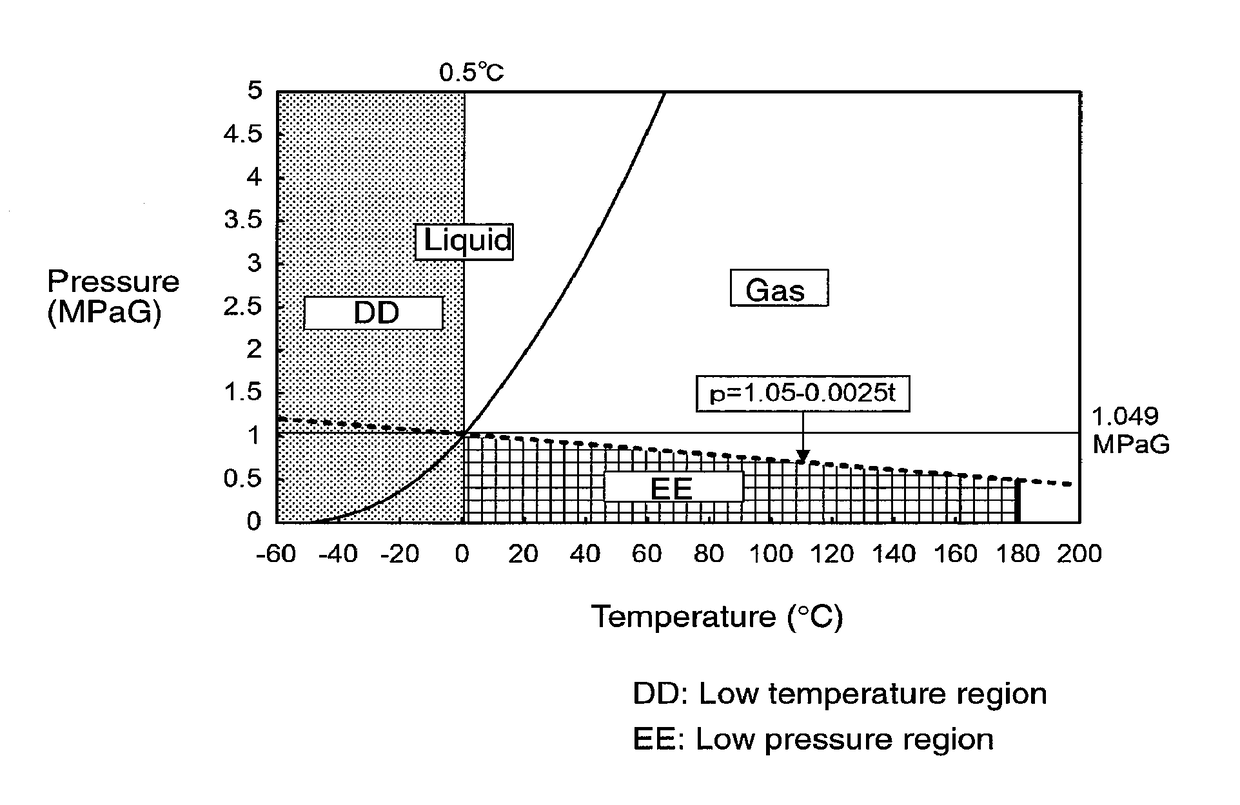

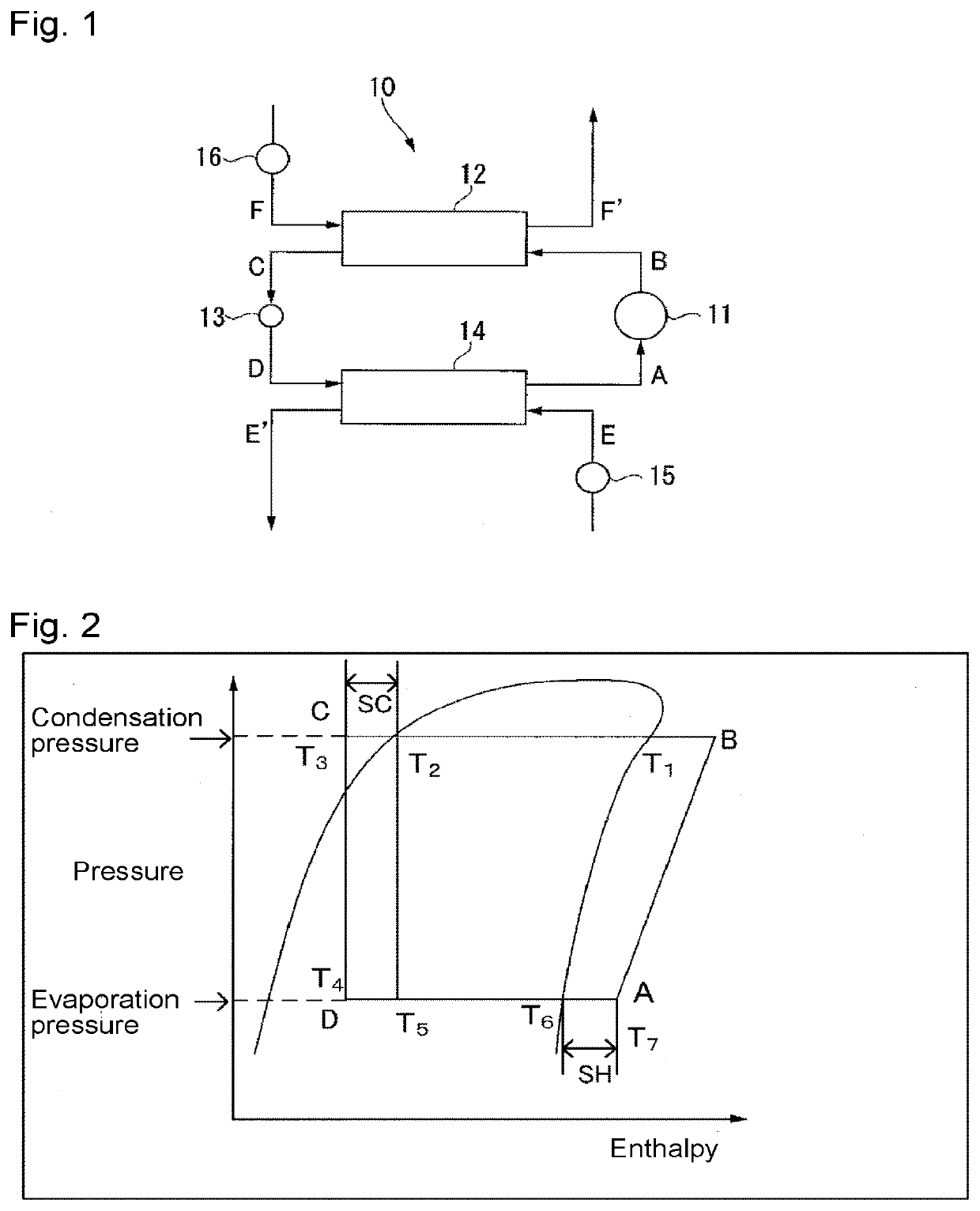

Working medium for heat cycles, composition for heat-cycle systems, and heat-cycle system

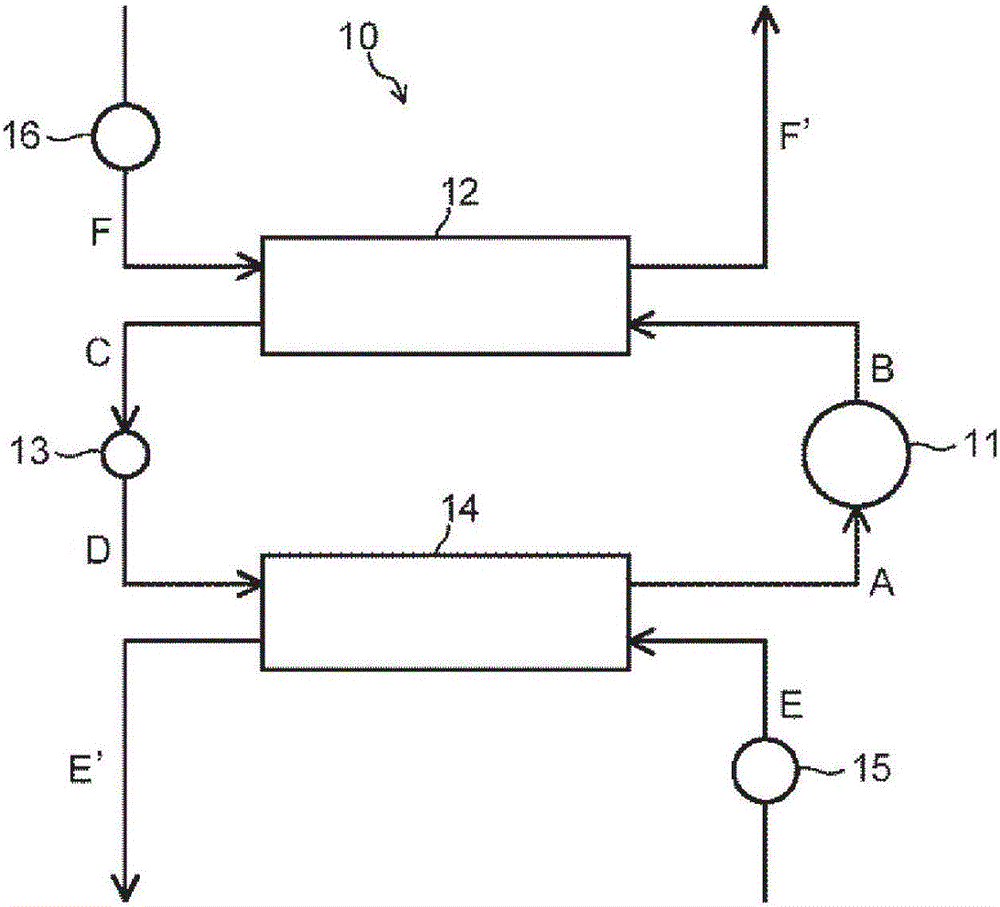

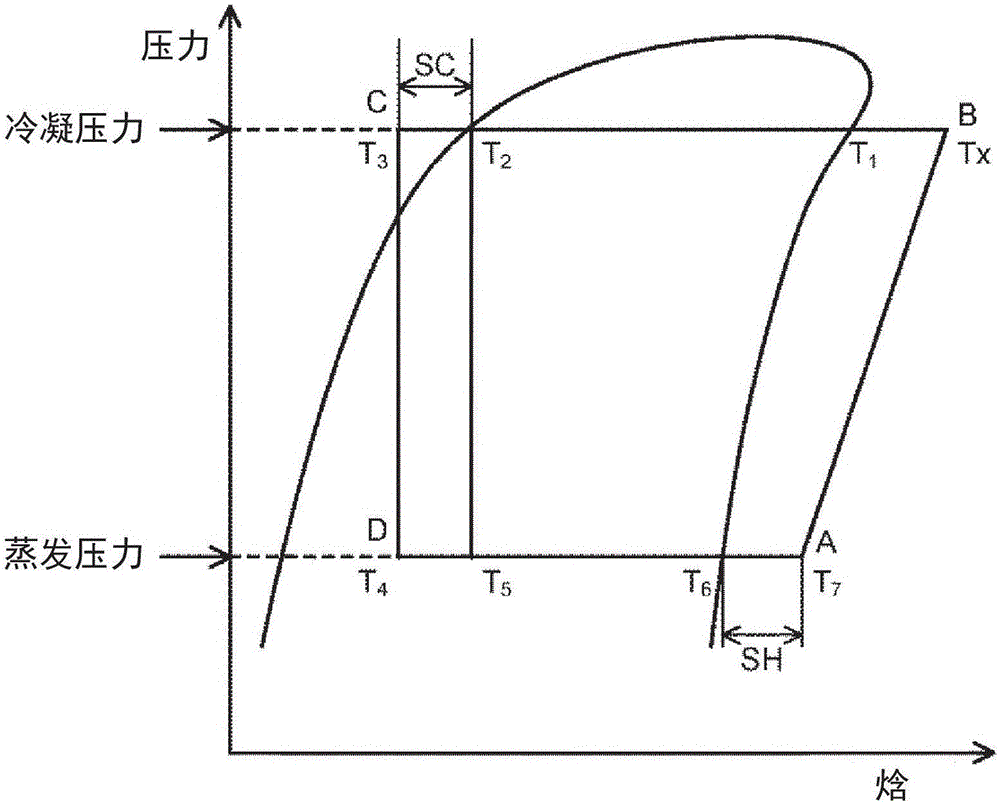

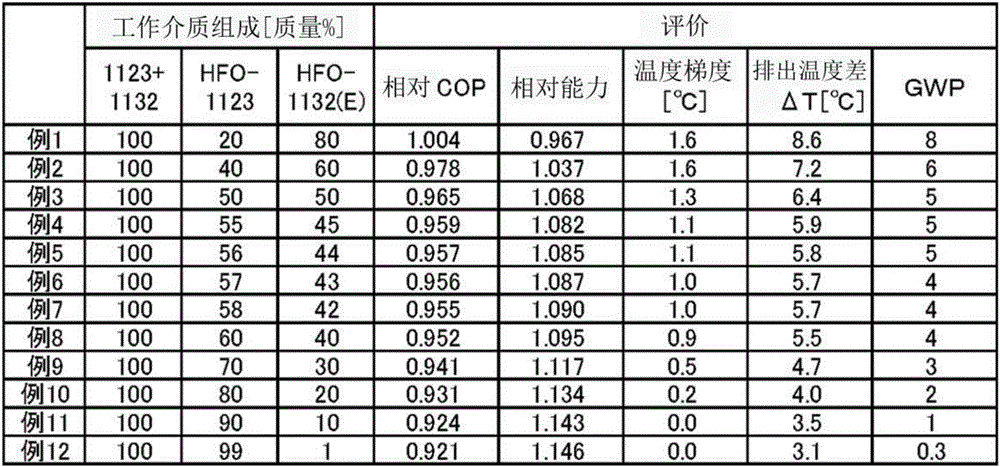

ActiveCN106133110AReduce temperature gradientLower discharge temperatureCompressorCompression machines with non-reversible cycleEngineeringRefrigeration

Provided are: a working medium for heat cycles which has a low impact on global warming, a low temperature gradient, and a sufficiently low discharge temperature, and which exhibits excellent cycle performance (i.e. refrigeration capacity and coefficient of performance); a composition for heat-cycle systems; and a heat-cycle system. The working medium for heat cycles includes trifluoroethylene and 1, 2-difluoroethylene. Also provided are: a composition for heat-cycle systems; and a heat-cycle system which uses the working medium and the composition. It is prefereable that, in the working medium for heat cycles, the ratio of the total amount of trifluoroethylene and 1, 2-difluoroethylene be at least 20 mass%, and equal to or less than 100 mass%.

Owner:AGC INC

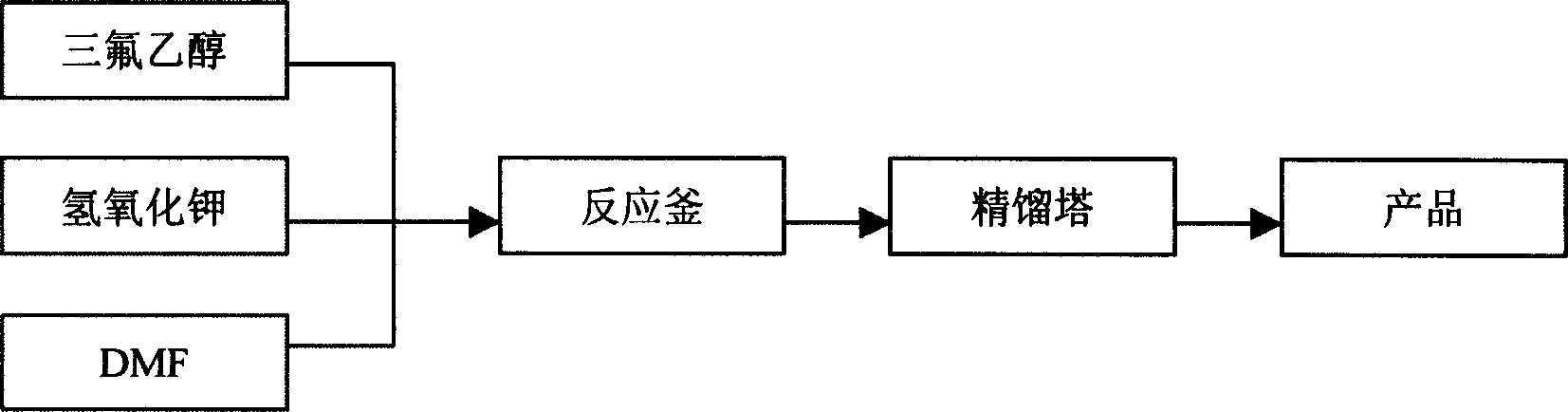

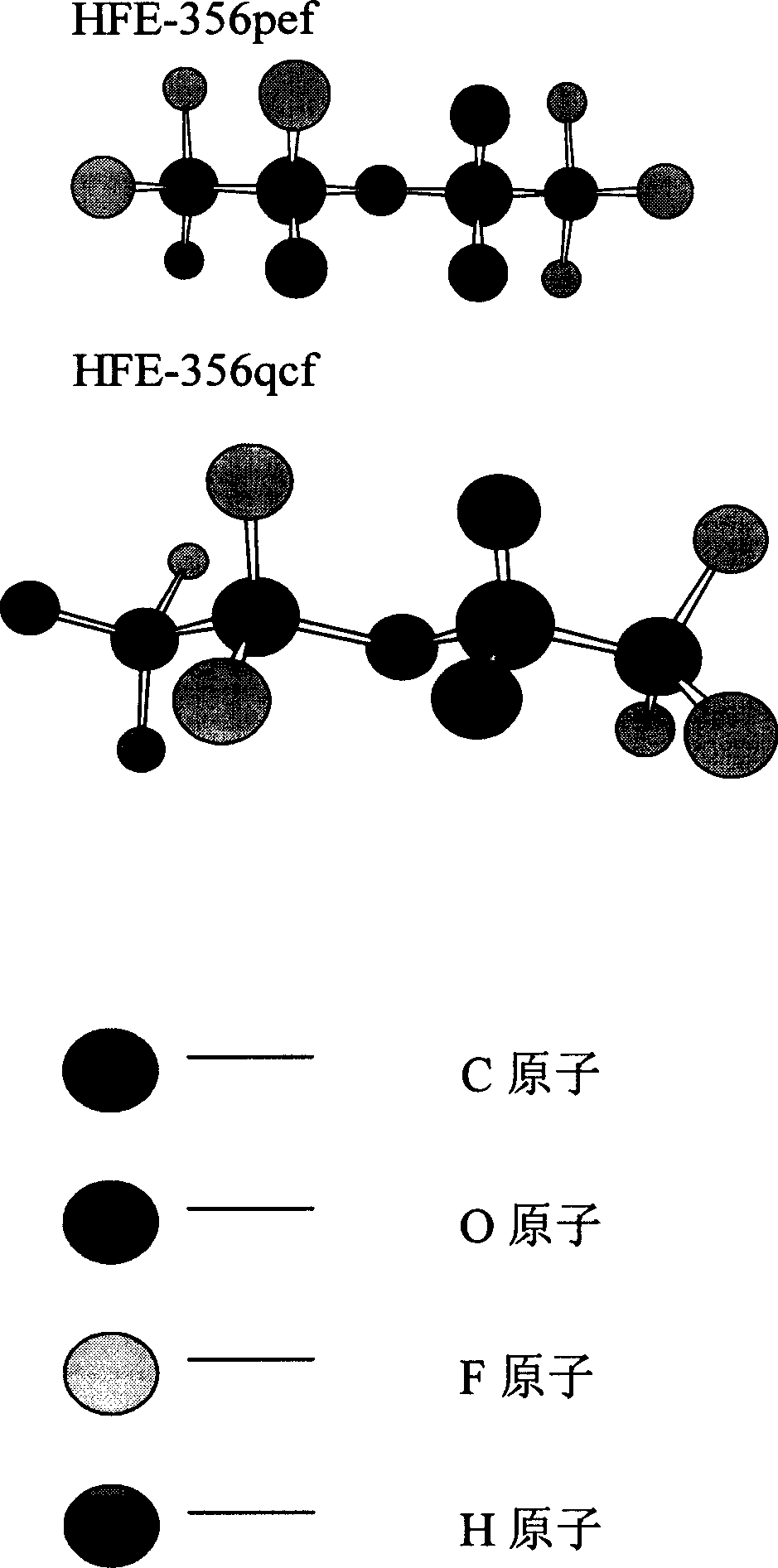

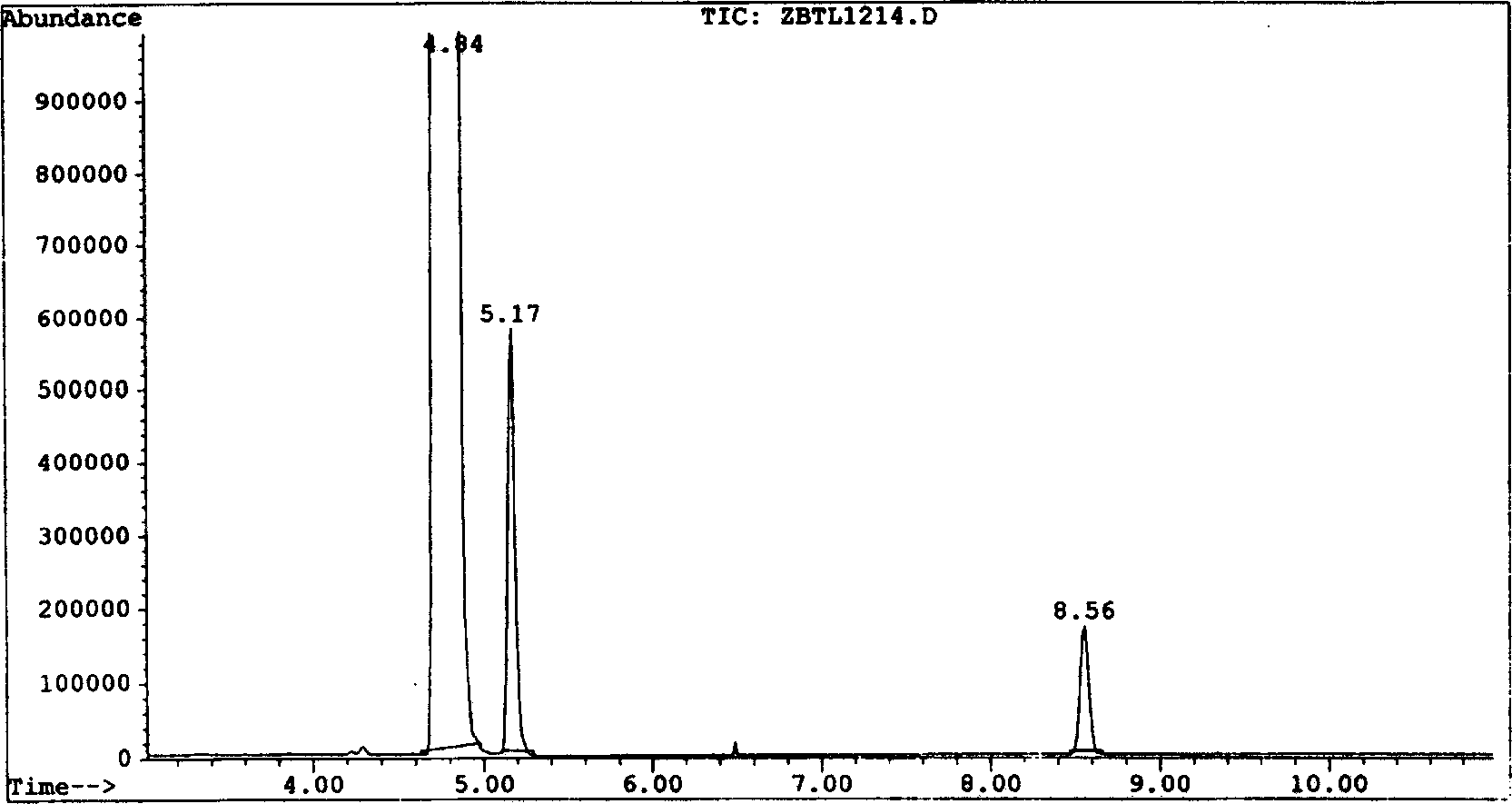

New hydrofluoro ether and its preparation method

InactiveCN1651378AHigh yieldEasy to separate and purifyEther preparationFoaming agentOrganic solvent

A process for preparing hydrofluoroether features the reaction between one of trifluoroethene, tetrafluoroethene, hexafluoro propene, etc and one of trifluoroethanol, trifluoropropanol, metanol, etc in organic solvent (DMF or DMSO). Its advantages are high output rate and easy purifying and separating.

Owner:大连振邦氟涂料股份有限公司

Working medium for heat cycle, composition for heat cycle system, and heat cycle system

ActiveCN107614652AFully playLow greenhouse potentialHeat-exchange elementsCompression machinesKryptonEngineering

This working medium for a heat cycle contains trifluoroethylene and a first component comprising at least one substance selected from carbon dioxide, fluoromethane, trifluoroiodomethane, methane, ethane, propane, helium, neon, argon, krypton, xenon, nitrogen, and ammonia.

Owner:ASAHI GLASS CO LTD

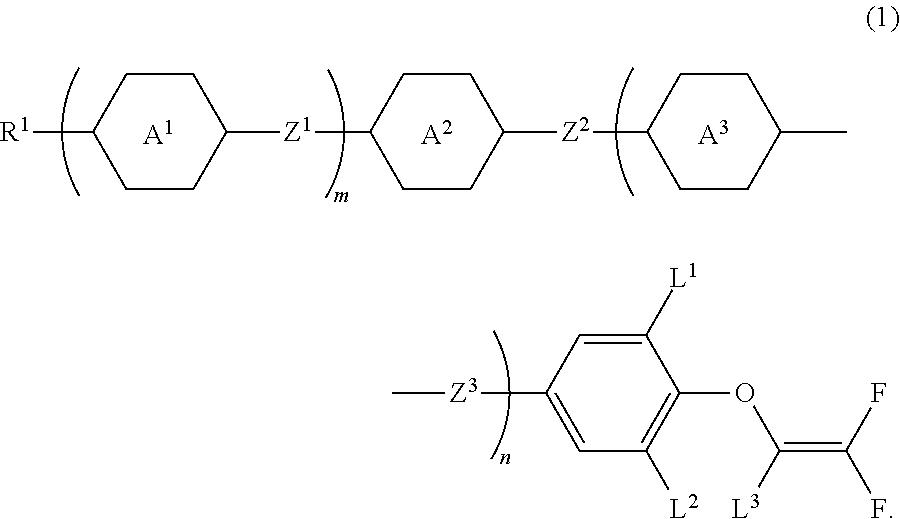

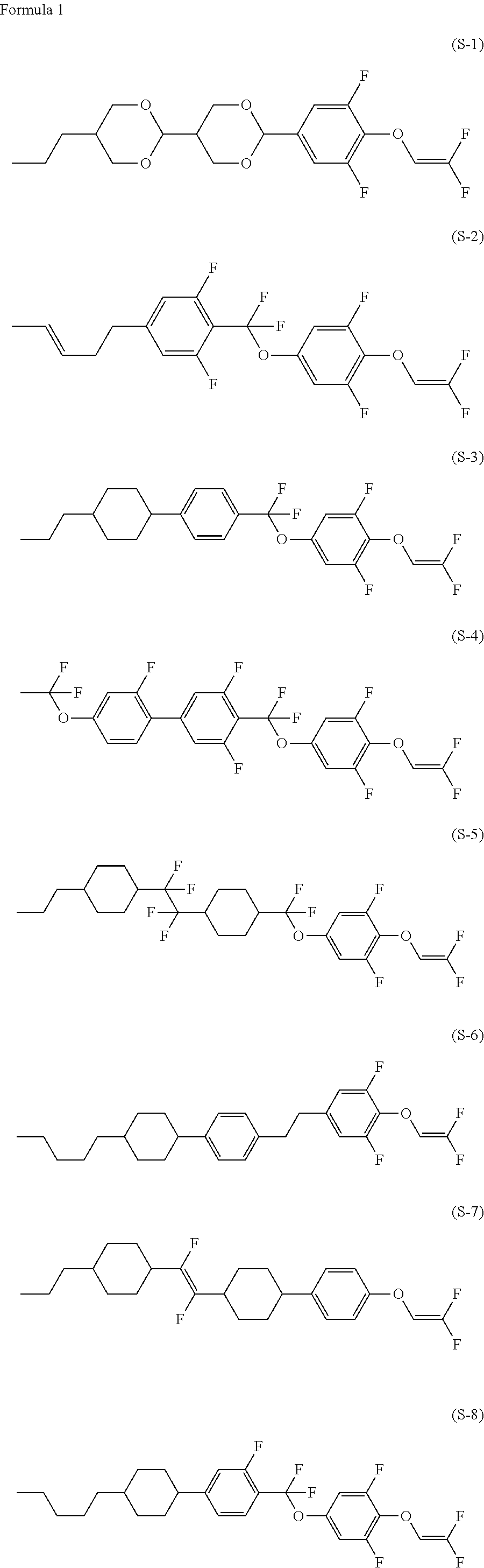

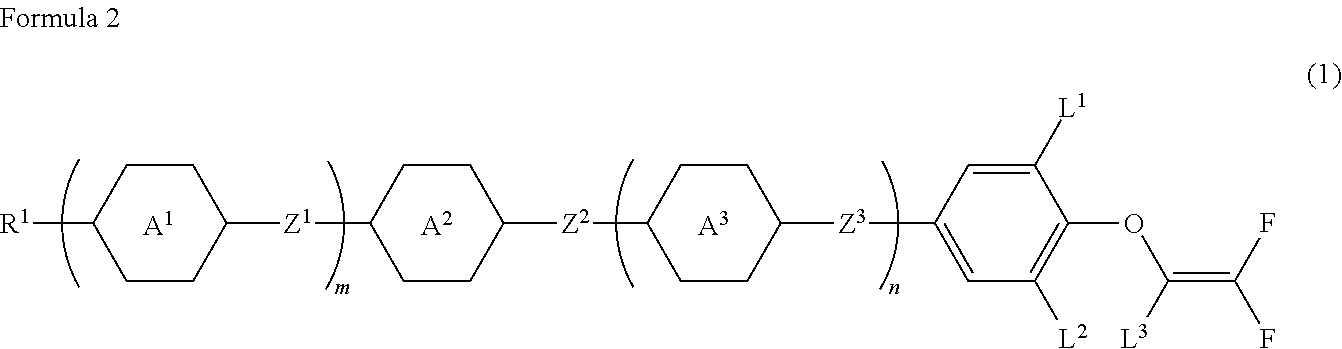

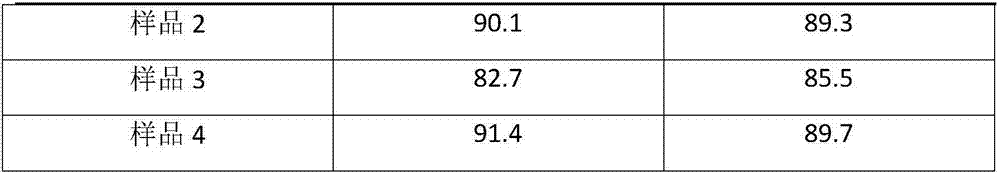

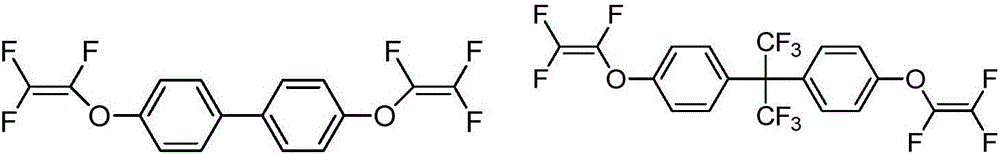

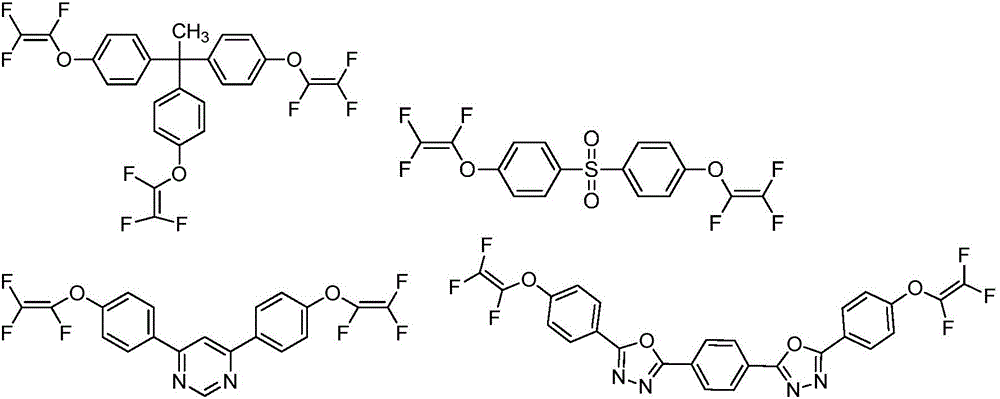

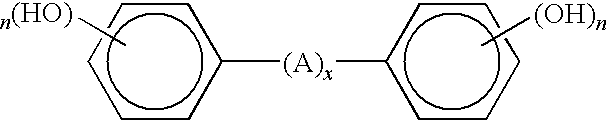

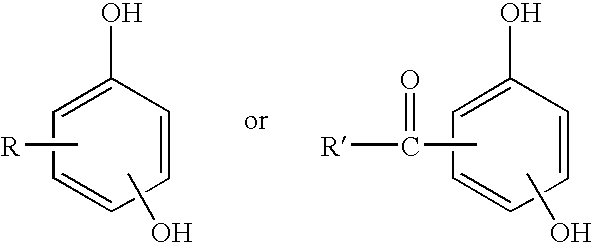

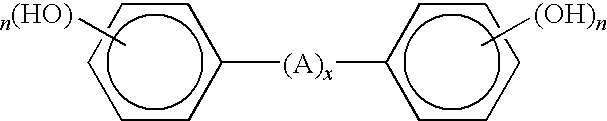

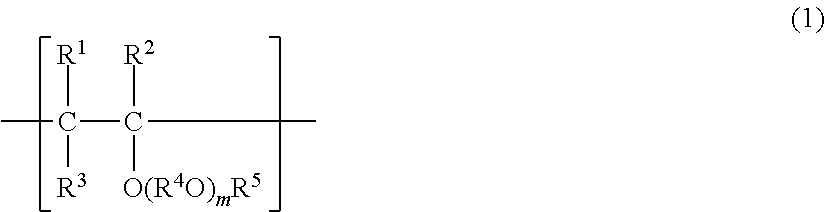

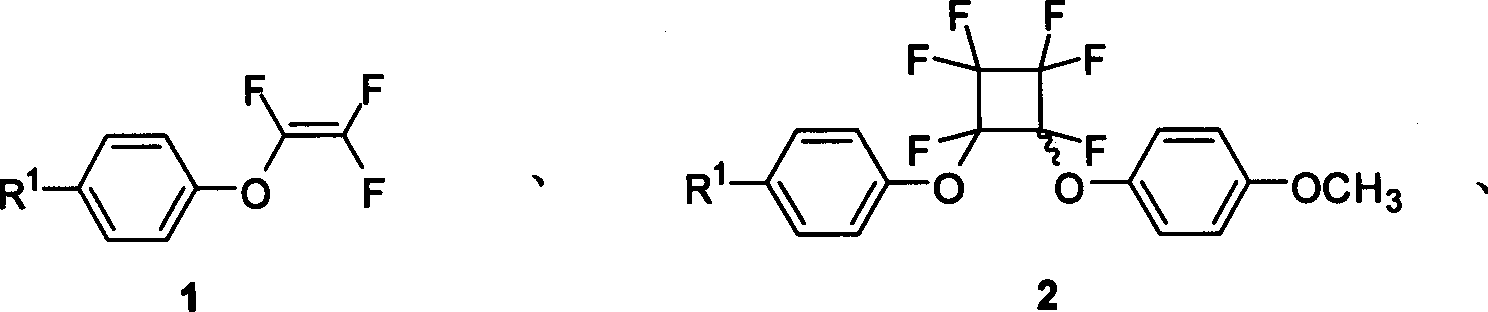

Compound having 2,2-difluorovinyloxy group or 1,2,2-trifluorovinyloxy group, liquid crystal composition and liquid crystal display device

ActiveUS20140034876A1Stable lightingSmall viscosityLiquid crystal compositionsOrganic chemistryCrystallographyDielectric anisotropy

To provide a liquid crystal compound having a high stability to light, a high clearing point, a low minimum temperature of a liquid crystal phase, a small viscosity, a suitable optical anisotropy, a large dielectric anisotropy, a suitable elastic constant and an excellent solubility in other liquid crystal compounds. The invention concerns a compound represented by formula (1), a liquid crystal composition containing the compound and a liquid crystal display device including the composition:

Owner:JNC CORP +1

Composite fiber and polymer based flexible composite film and preparation method thereof

ActiveCN103709565AStrong polarizationHigh dielectric constantInorganic material artificial filamentsCoatingsEpoxyFiber

The invention discloses a composite fiber and polymer based flexible composite film and a preparation method thereof. The composite fiber and polymer based flexible composite film comprises a composite fiber and a polymer matrix, wherein the volume percentage of the composite fiber is 1-30%; the composite fiber is composed of an oxide fiber and ceramic particles and / or metal particles embedded in the oxide fiber; the polymer matrix is at least one out of polyvinylidene fluoride, epoxy resin, polyvinylidene fluoride-trifluoroethene, polypropylene, polyethylene terephthalate and polyimide. According to the composite fiber and polymer based flexible composite film disclosed by the invention, the composite fiber and the polymer matrix are compounded, and since additional polarization is introduced into the composite fiber, the polymer based flexible composite film can get a higher dielectric constant under a condition of small adding dosage so as to meet the dielectric performance requirements of the composite material and maintain original related properties of the polymer film, such as mechanical flexibility, to the maximum extent at the same time.

Owner:TSINGHUA UNIV

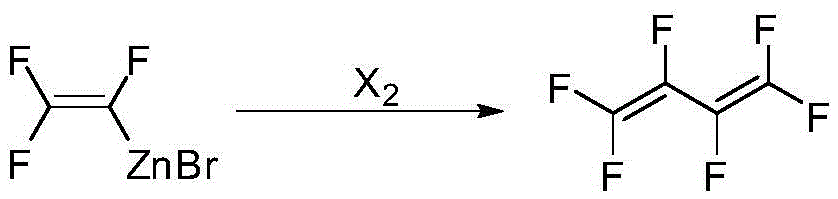

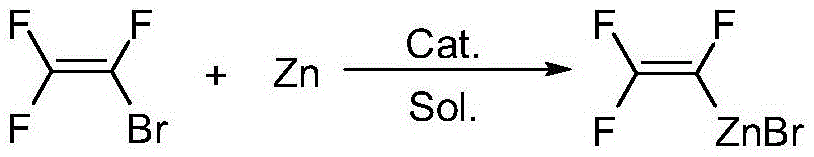

Method for synthesizing hexafluoro-1,3-butadiene

ActiveCN104844411ASave raw materialsConvenient sourceChemical recyclingHalogenated hydrocarbon preparationChemical synthesisHydrogen fluoride

The invention relates to a method for synthesizing hexafluoro-1,3-butadiene, and belongs to the field of organic chemistry synthesis. The method for synthesizing hexafluoro-1,3-butadiene comprises the following steps: removing hydrogen fluoride from tetrafluoro ethane (HFC-134a) under the action of a catalyst to generate trifluoroethylene; rapidly reacting trifluoroethylene with liquid bromine to generate 1,2-dibromo-1,1,2-trifluoroethane, and removing hydrogen bromide under alkaline conditions to obtain trifluorobromoethylene; and reacting trifluorobromoethylene with activated zinc powder and N,N-dimethyl formamide to generate trifluorovinylzinc, and carrying out a coupling reaction on trifluorovinylzinc under the action of Fe<3+> to generate hexafluoro-1,3-butadiene. A solvent can be recovered after above reactions. The method has the advantages of low price and convenient source of raw materials, good stability and long service of the catalyst, simple separation and purification of the above product, and easy industrial production.

Owner:泉州宇极新材料科技有限公司

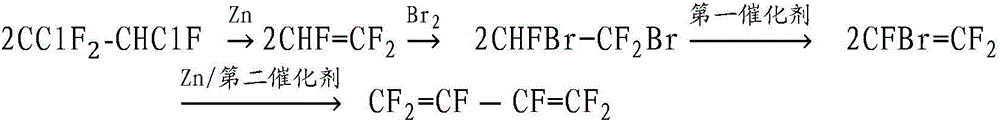

Method for preparing hexafluoro-1,3-butadiene

ActiveCN106495982AIncrease added valueRaw materials are cheap and easy to getPreparation by dehalogenationPreparation by hydrogen halide split-offGas phaseTwo step

The invention relates to a method for preparing hexafluoro-1,3-butadiene. The method comprises the following steps: performing reduction dechloridation on 1,2-dichloro-1,1,-2-halothane with zinc powder to obtain a CF2=CHF gas phase intermediate product, introducing into liquid bromine to carry out an addition reaction, and obtaining CBrF2CHBrF; evaporating CBrF2CHBrF in an evaporator to generate a gas, and using a reaction tube filled with a first catalyst to remove one molecule HBr and generate trifluorovinyl bromide; performing two steps of reactions on the trifluorovinyl bromide under the action of the zinc powder, the solvent and a second catalyst, thereby obtaining the hexafluoro-1,3-butadiene. The method has the advantages of being simple in process, high in yield, easy in raw material obtaining, easy in industrialization, green and environment-friendly.

Owner:湖北广钢气体电子材料有限公司

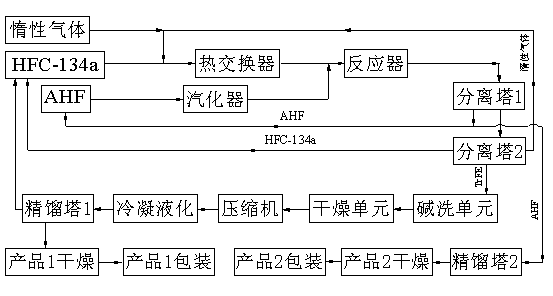

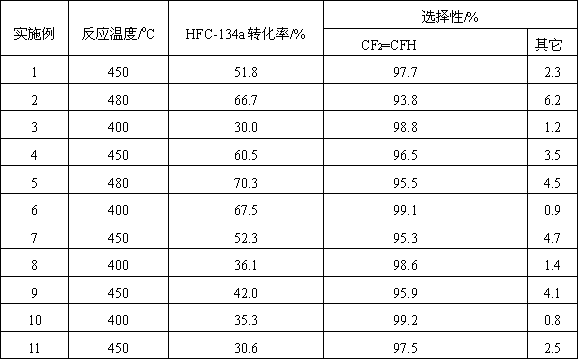

Method for co-production of trifluoroethylene and hydrogen fluoride

InactiveCN103288589ALow costImprove performancePreparation by hydrogen halide split-offPhysical/chemical process catalystsHydrogen fluoridePtru catalyst

The invention relates to a method for the co-production of trifluoroethylene and hydrogen fluoride, and is used for producing the trifluoroethylene in a hydrogen fluoride removing manner by taking 1,1,1,3-tetrafluoroethane as a main raw material as well as co-producing the hydrogen fluoride. The method comprises the following steps: mixing HFC-134a (1,1,1,2-tetrafluoroethane) and an inert gas at a molar ratio f 1:(1-20); performing a reaction of removing HF (Hydrogen Fluoride) from the HFC-134a in a fixed bed reactor through an acid catalyst under the conditions that the temperature ranges from 300 to 650 DEG C, the air speed ranges from 300 to 2000h<-1> and the pressure ranges from 0.1 to 0.8Mp; separating tail gas in a first separation tower; pretreating the catalyst and producing an anhydrous hydrogen fluoride product through the cyclic utilization of the separated hydrogen fluoride; realizing the cyclic utilization of the HFC-134a and the inert gas after separating the HFC-134a with a low boiling point, the inert gas and the trifluoroethylene in a second separation tower; performing alkaline cleaning, drying, compression and condensation liquefaction on the trifluoroethylene; then enabling the trifluoroethylene to enter a first rectifying tower; finally drying and packaging the trifluoroethylene treated in the first rectifying tower. The method is suitable for the production of the trifluoroethylene, and belongs to an atomic economic reaction. The two reaction products have important economic values; the conversion rate of the HFC-134a is high; the selectivity and yield of the trifluoroethylene as a main product are high.

Owner:TONGJI UNIV

Curable base-resistant fluoroelastomers

InactiveUS20080207861A1Good curing propertiesImprove adhesionFibre treatmentSpecial tyresPolymer scienceEnd-group

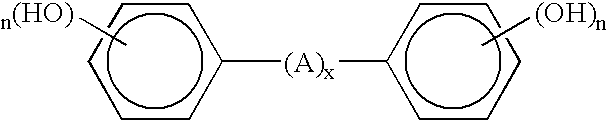

Compositions of fluoroelastomers containing copolymerized units of tetrafluoroethylene, propylene, a first cure site selected from the group consisting of i) trifluoroethylene, ii) 3,3,3-trifluoropropene-1, iii) 1,2,3,3,3-pentafluoropropylene, iv) 1,1,3,3,3-pentafluoropropylene, and v) 2,3,3,3-tetrafluoropropene, and a second cure site selected from the group consisting of i) copolymerized units of a brominated cure site monomer, ii) copolymerized units of an iodinated cure site monomer, iii) copolymerized units of a chlorinated cure site monomer, iv) brominated endgroups, v) iodinated endgroups and vi) a combination of any of i)-v) are readily curable with polyhydroxy curing systems. The resulting cured articles have a combination of excellent resistance to alkaline fluids, superior tensile properties and compression set resistance, and excellent adhesion to metal substrates. Optionally, the fluoroelastomers may be dual cured by both a polyhydroxy system and an organic peroxide system.

Owner:THE CHEMOURS CO FC LLC

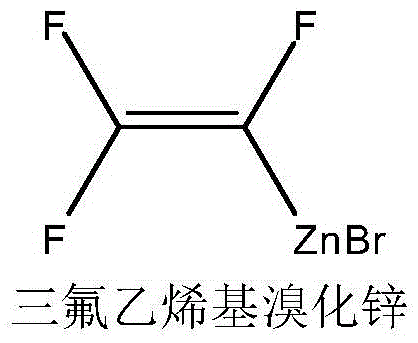

Preparation method of hexafluoro-1,3-butadiene

ActiveCN106673953AImprove responseHalogenated hydrocarbon preparationZinc organic compoundsHalogenChemistry

The invention discloses a preparation method of hexafluoro-1,3-butadiene. 1,1,2-trifluoroethenyl zinc bromide and a nonmetal oxidizing agent halogen are reacted in order to form hexafluoro-1,3-butadiene. The preparation method has the advantages of simple process, high reaction yield, low raw material cost, and small "three wastes (waste gas, waste water and industrial residue)"; hexafluoro-1,3-butadiene is suitable for preparing dry etching gas and the like.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +2

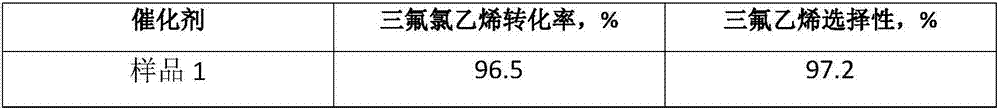

Catalyst, preparation method thereof and application thereof

ActiveCN106890662AActivity does not affectExtended service lifePreparation by hydrogen halide split-offPhysical/chemical process catalystsPlatinumGas phase

The invention discloses a catalyst, a preparation method thereof and application thereof. The catalyst takes a porous metal fluoride or an oxyfluoride as a carrier, noble metal palladium or platinum is taken as a main active component, part of elements are added to serve as a promoter, and the catalyst is prepared by adopting a steeping method. The manufactured catalyst is used for gas-phase reaction after filtration, drying, roasting and activation. When used for reaction for gas phase preparation of trifluoroethylene, the catalyst has the advantages of being high in activity and selectivity and long in service life.

Owner:泉州宇极新材料科技有限公司

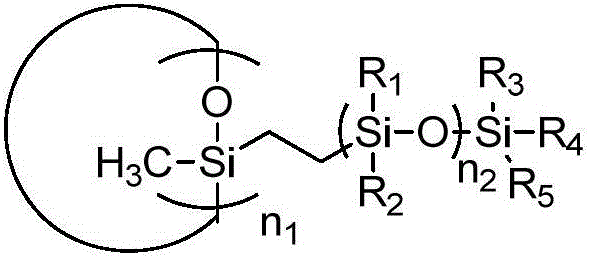

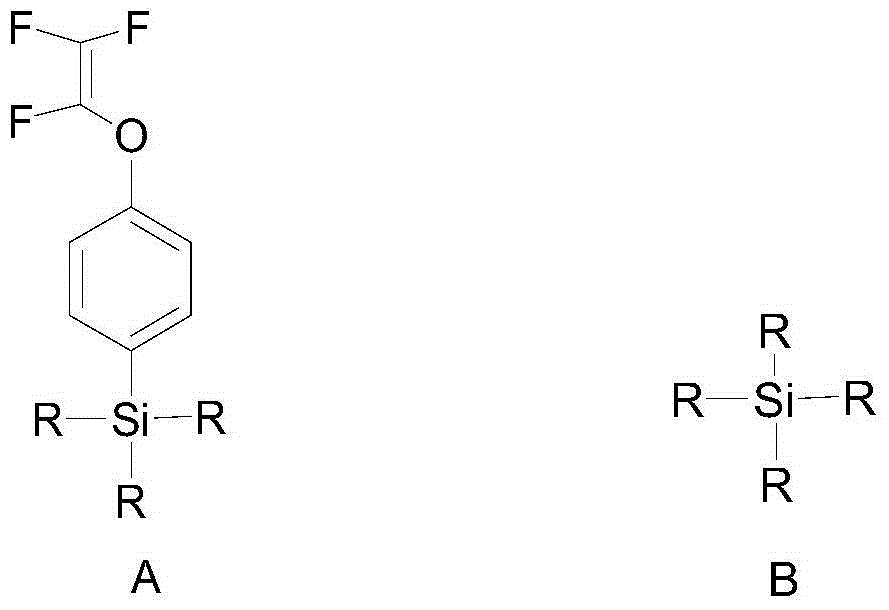

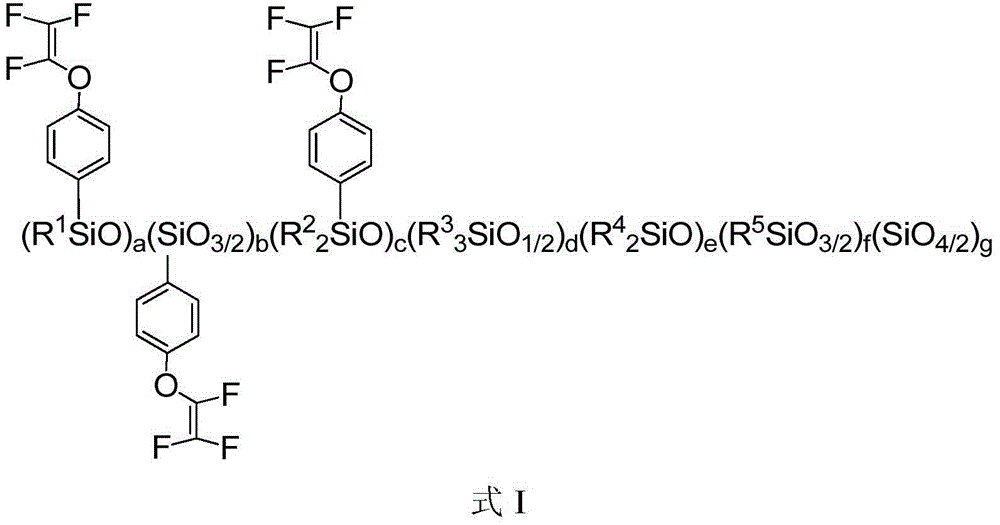

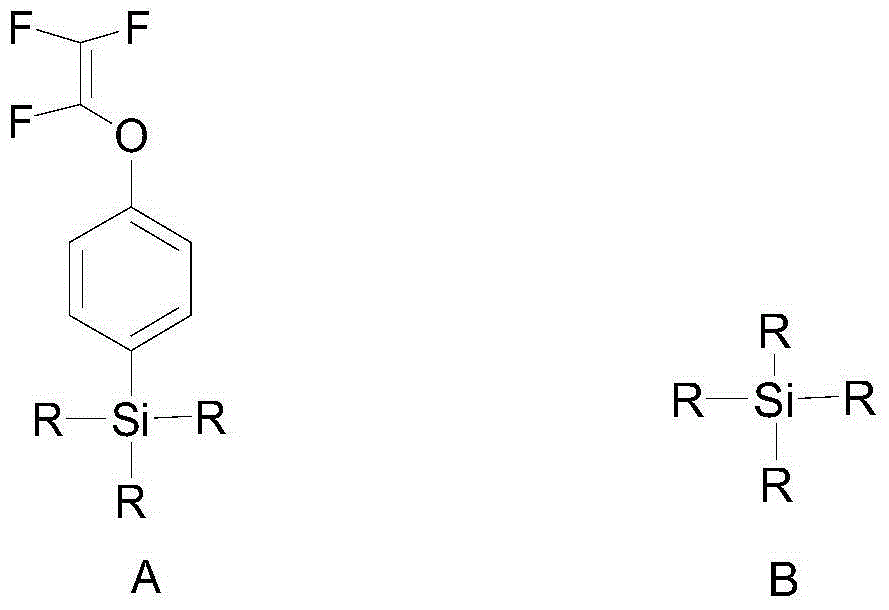

Preparation and application of trifluorovinyl-ether-containing cyclosiloxane capable of direct heat curing

The invention provides preparation and application of trifluorovinyl-ether-containing cyclosiloxane capable of direct heat curing, particularly cyclosiloxane disclosed as Formula I (the groups are defined in the specification) and a curing product prepared from the cyclosiloxane. The cyclosiloxane preparation method is simple and controllable in processing; the monomer can be subjected to direct heat curing, is used for preparing high-performance thermosetting resins with high heat resistance, high weather resistance and low water absorptivity, has excellent and stable dielectric properties from low frequency to high frequency, and is suitable to be used as an electronic component packaging material in electronic and electric industries and used as a high-temperature-resistant adhesive in the fields of aerospace, national defense and the like.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

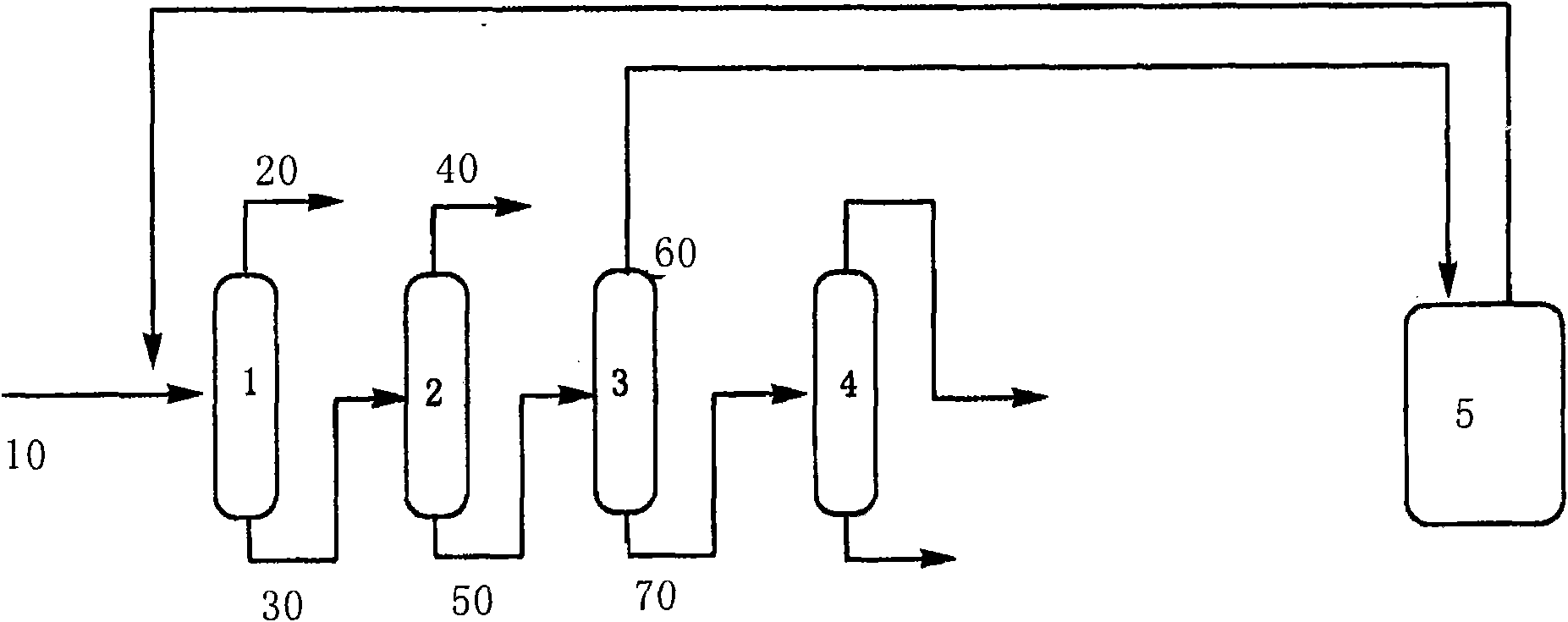

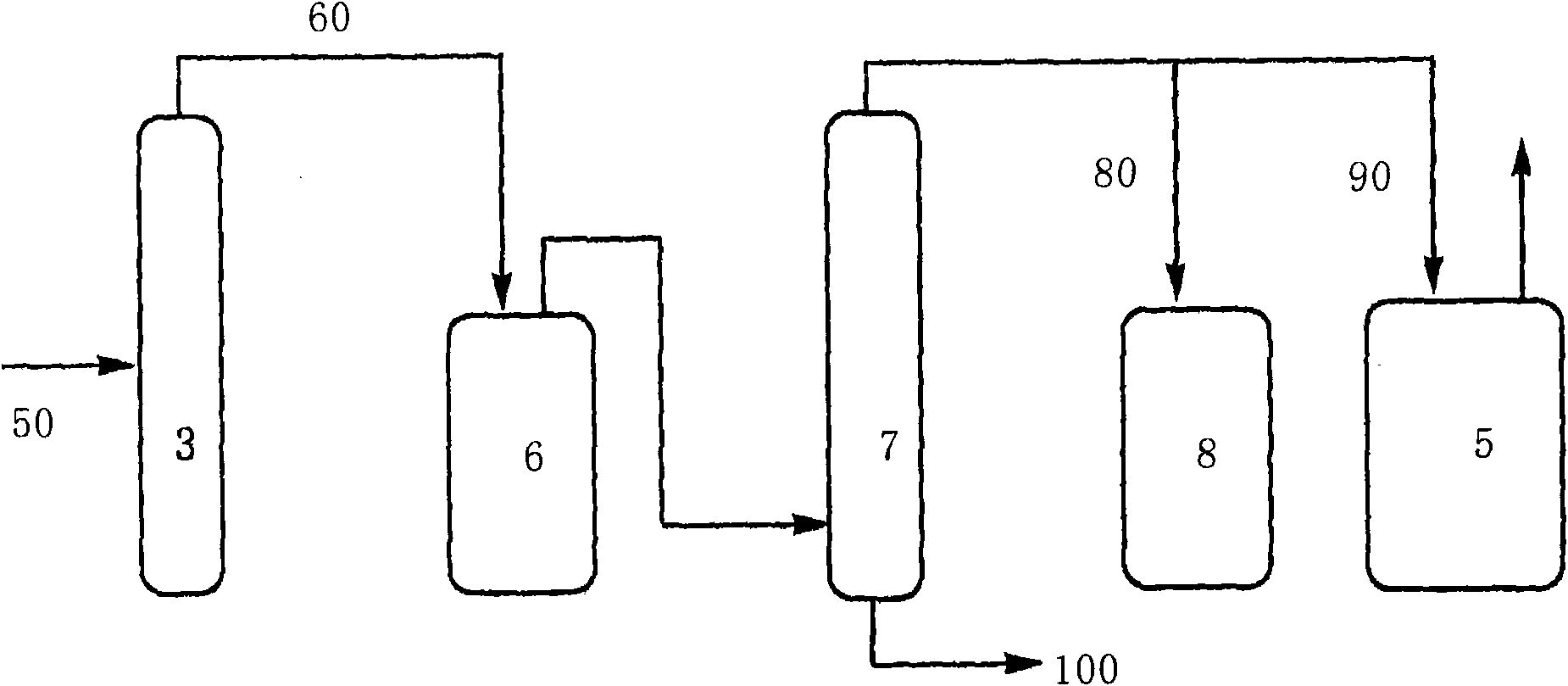

Trifluoroethylene recovery method and device thereof

Disclosed is a trifluoroethylene recovery method and the device thereof. The method comprises: (1) rectifying and separating step: including rectifying and recovering tetrafluoroethlene product from cracked gas, and loading the distillations containing trifluoroethene, part of tetrafluorethylene and other components into the tetrafluoroethlene recovering step; (2) tetrafluoroethlene recovering step: including rectifying and recovering the distillates containing trifluoroethene and tetrafluorethylene from the distillations containing trifluoroethene, part of tetrafluorethylene and other components; and (3) cycling step: including cycling the distillates containing trifluoroethene and tetrafluorethylene to the rectifying and separating step. The invention is characterized in that: the method further comprises a trifluoroethylene concentration monitoring step before applying the above cycling step; when the trifluoroethylene concentration reaches a predetermined value, the method also comprises a step for rectifying and separating the distillates containing trifluoroethene and tetrafluorethylene.

Owner:SHANGHAI 3F NEW MATERIAL TECH CO LTD +1

Curable base-resistant fluoroelastomers

InactiveUS20090306303A1Excellent set resistanceImprove tensile propertiesTetrafluoroethyleneVulcanization

Compositions of fluoroelastomers containing copolymerized units of tetrafluoroethylene, propylene, optionally vinylidene fluoride, and a cure site monomer selected from the group consisting of i) trifluoroethylene, ii) 3,3,3-trifluoropropene-1, iii) 1,2,3,3,3-pentafluoropropylene, iv) 1,1,3,3,3-pentafluoropropylene, and v) 2,3,3,3-tetrafluoropropene are readily curable with polyhydroxy curatives and at least one vulcanization accelerator of formula R1R2R3R4NBF4 wherein R1, R2, R3, R4 are the same or different C1-C12 alkyl groups.

Owner:EI DU PONT DE NEMOURS & CO

Preparation method and application of trifluoroethyleneoxyphenyl-containing silicone resin

The invention provides a preparation method and application of trifluoroethyleneoxyphenyl-containing silicone resin. In the process of preparing the organic silicone resin, a trifluoroethyleneoxyphenyl-containing alkoxy silane monomer and various alkoxy silane monomers are hydrolyzed to be subjected to copolymerization to obtain the novel high-temperature cured silicone resin with a high refractive index, good heat resistance and excellent dielectric properties. The silicone resin can be applied to the fields of microelectronic industry, electrical appliances and aerospace as a high-performance resin matrix or packaging material.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

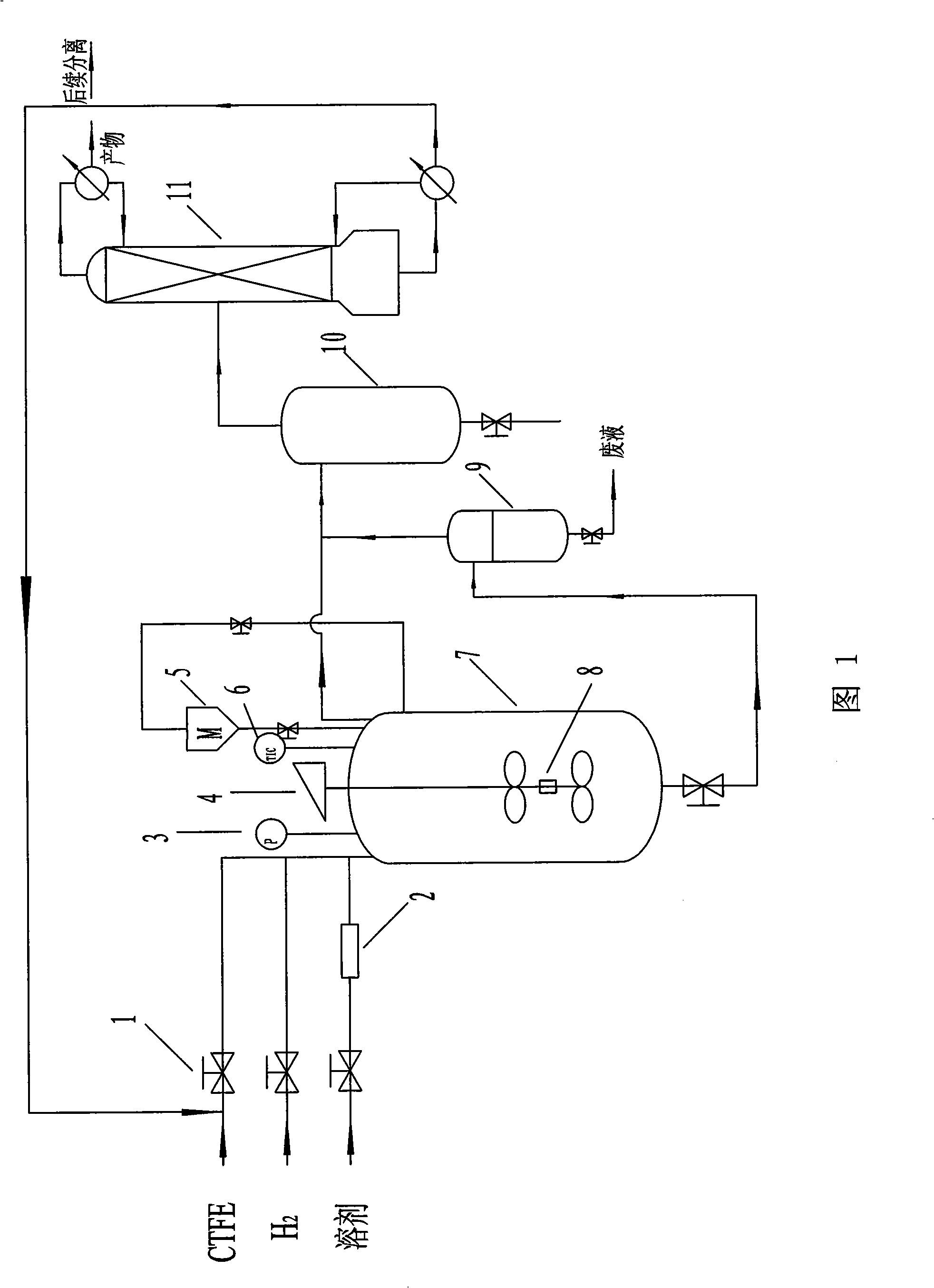

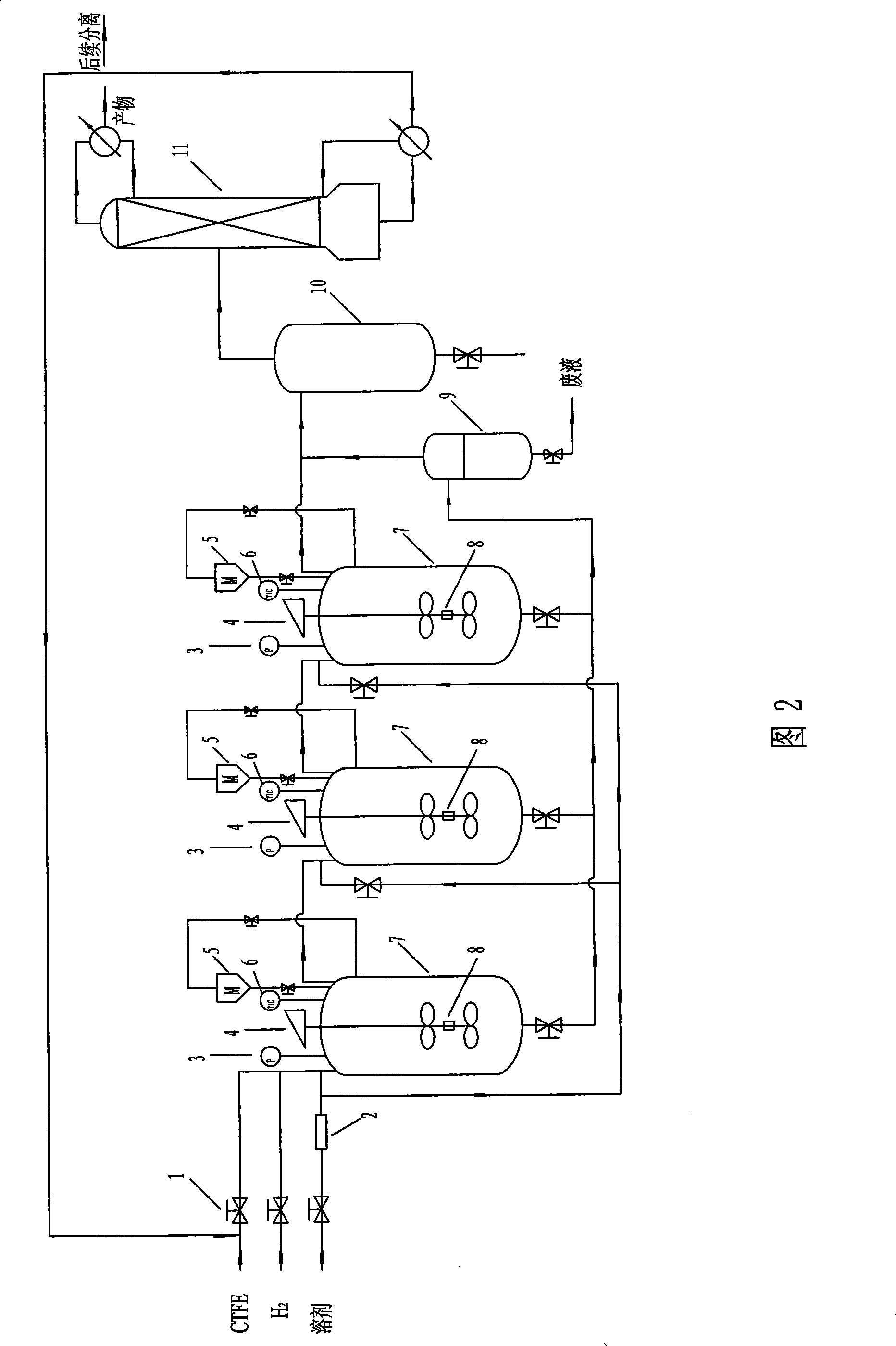

Process and special equipment for producing trifluoro ethylene with catalytic hydrogenolysis of chlorotrifluoroethylene

InactiveCN101402548AImprove conversion rateHigh selectivityPreparation by dehalogenationHydrogenEconomic benefits

The invention discloses a process method for preparing trifluoroethene through the catalytic hydrogenolysis of chlorotrifluoroethylene. Trifluoroethene can be prepared through the hydrogenolysis of hydrogen and chlorotrifluoroethylene under the action of a catalyst in a solvent containing a hydrogen chloride acceptor, wherein the hydrogen chloride acceptor, the solvent, hydrogen and chlorotrifluoroethylene, after the initial feeding, pulse type continuous operation is adopted both for the feeding and discharging of the reaction. The hydrogenolysis is carried out in one or a plurality of reaction kettles connected in series. The invention also discloses a special device for the technical method. The technical method has the advantages that the technical method can realize continuous operation, has a higher conversion rate and selectivity,can be easily applied to the industrialized production; in addition, the dosage of the hydrogen chloride acceptor and the solvent needed by unit chlorotrifluoroethylene is reduced, thereby bringing about obvious economic benefits; and the pulse intermittent feeding and discharging of liquid generate no solid residue in the kettle, thereby facilitating the stability of the reaction kettle.

Owner:EAST CHINA UNIV OF SCI & TECH +1

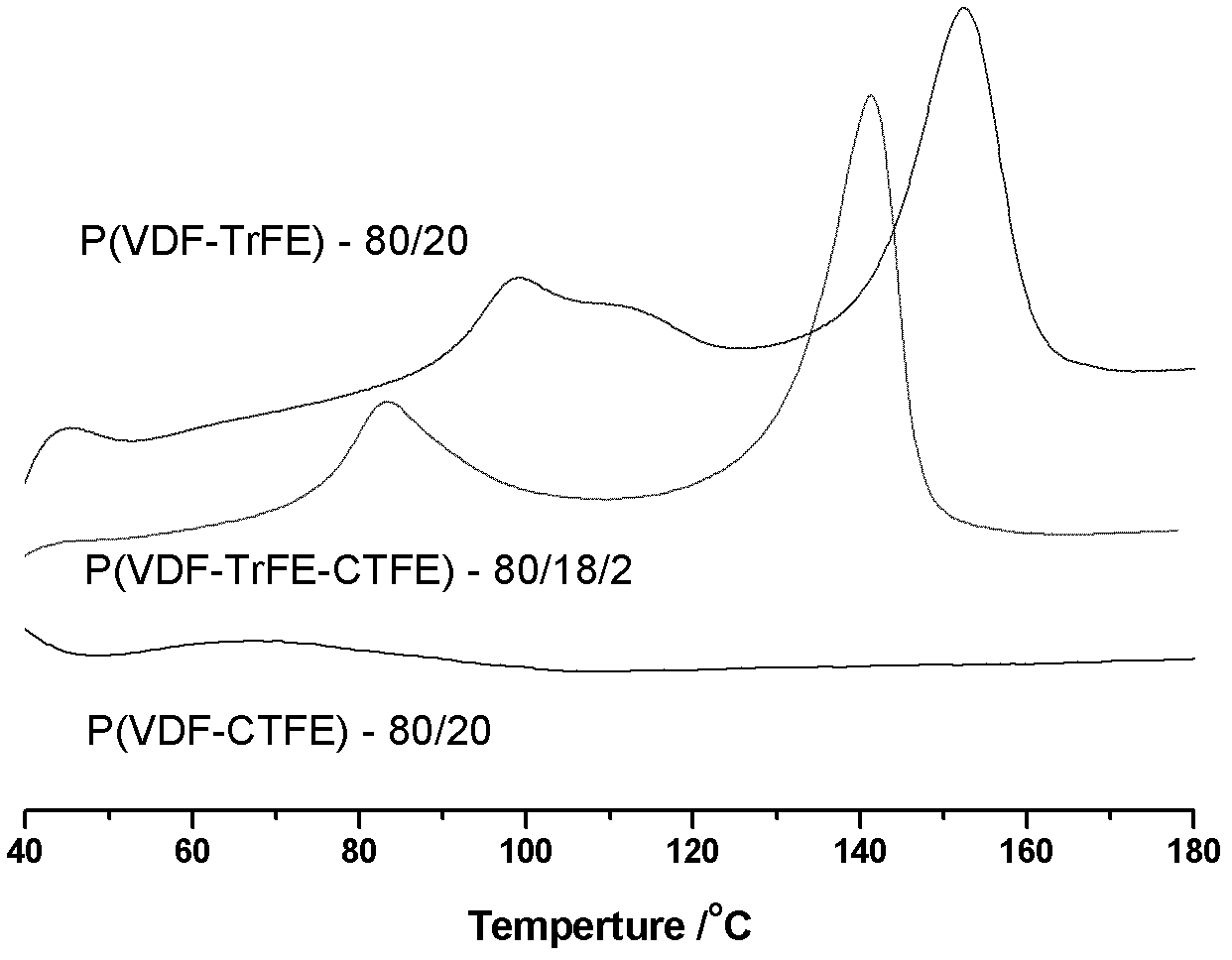

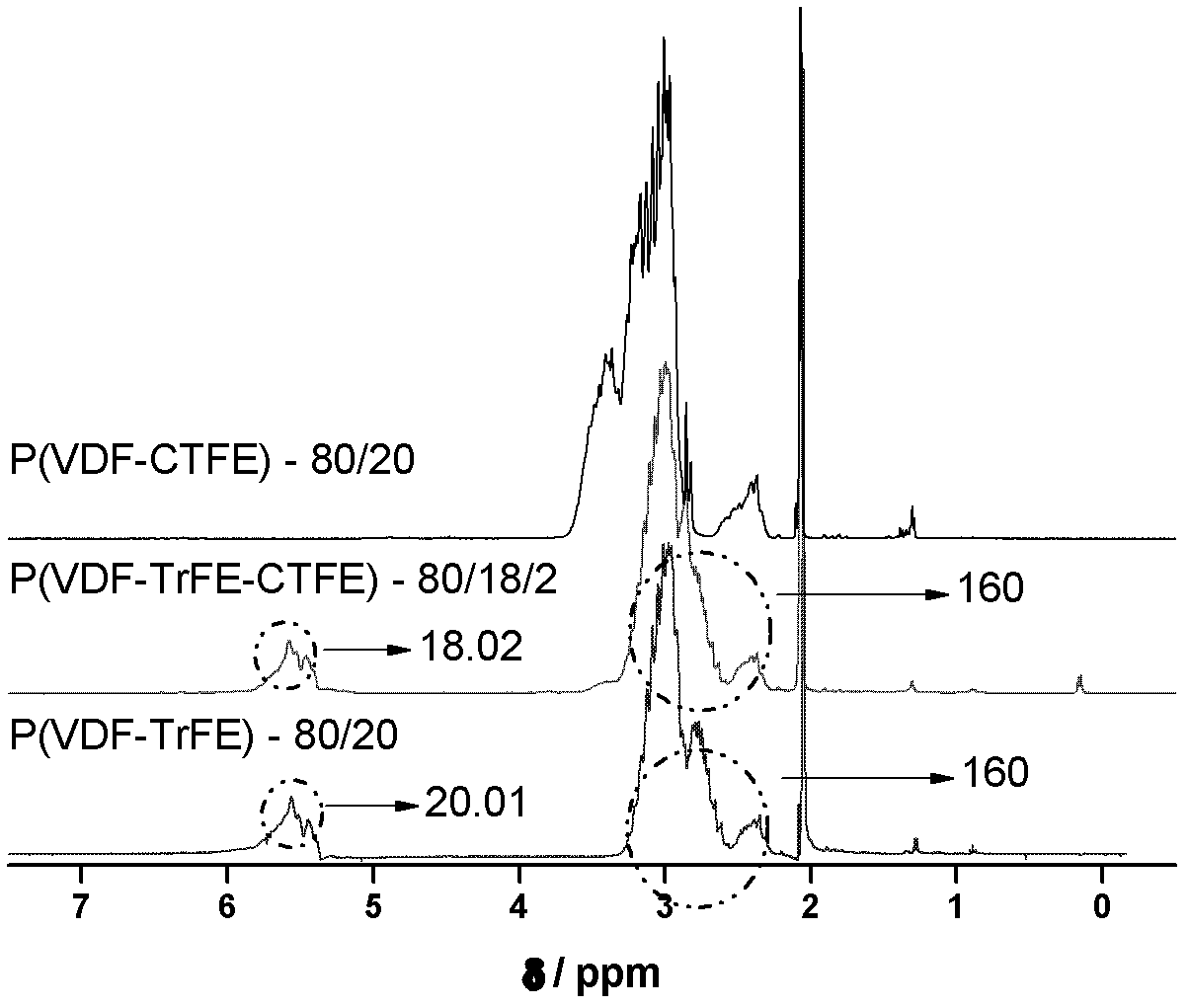

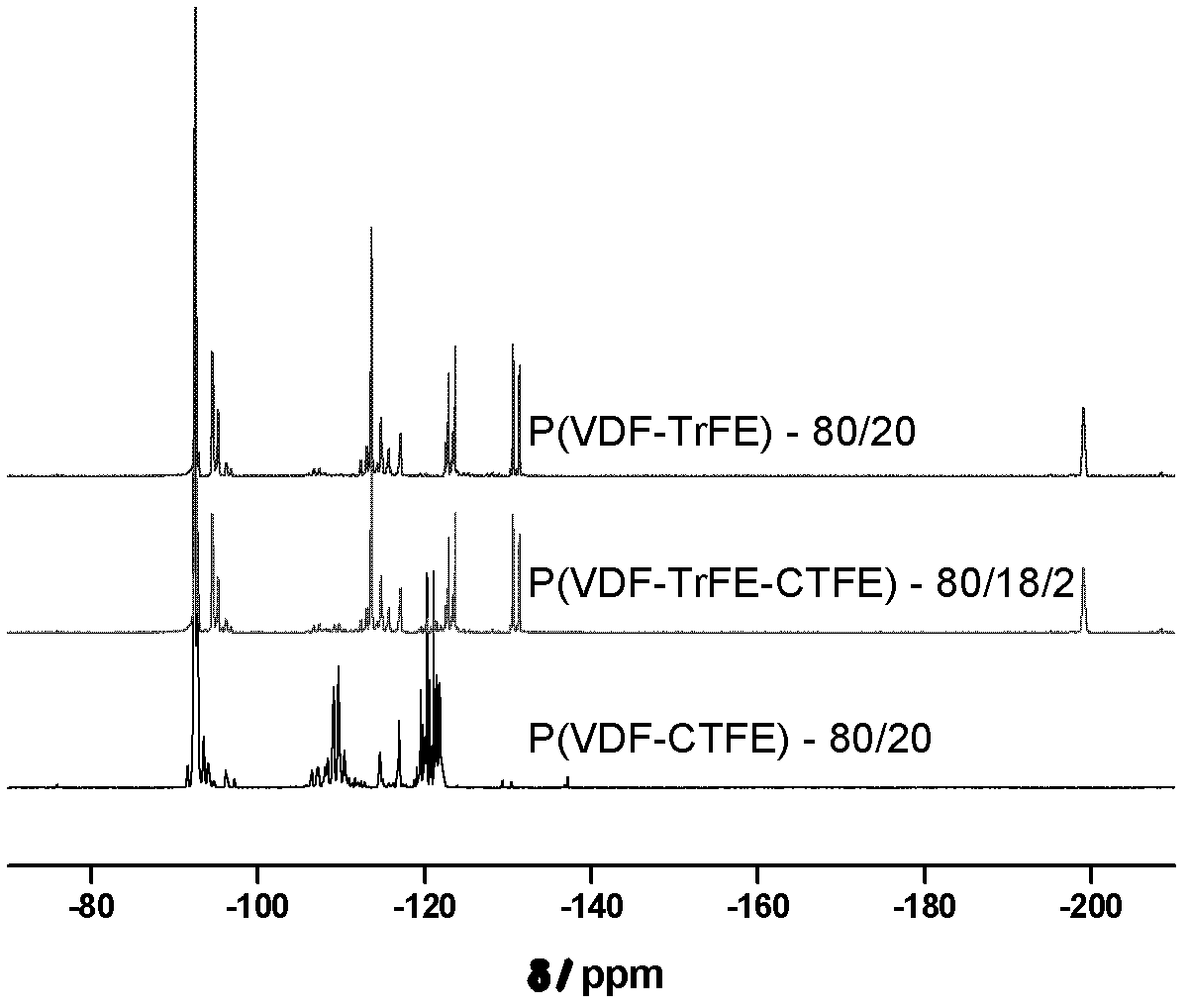

Method for preparing poly(vinylidene fluoride-trichloroethylene) or poly(vinylidene fluoride-chlorotrifluoroethylene-trichloroethylene)

The invention discloses a method for preparing poly(vinylidene fluoride-trichloroethylene) or poly(vinylidene fluoride-chlorotrifluoroethylene-trichloroethylene). The method comprises the following steps of: adding poly(vinylidene fluoride-chlorotrifluoroethylene) into a three-neck bottle, adding a solvent simultaneously, adding a reducing agent after the poly(vinylidene fluoride-chlorotrifluoroethylene) is fully dissolved, and continually stirring and reacting at the room temperature for 16-24 hours; and pouring an obtained solution into a beaker filled with hydrochloric acid of which the pH is 3, stirring for 1 hour, precipitating a polymer out, repeatedly washing the obtained polymer to whiteness with methanol, and performing vacuum drying under the condition that the temperature is not higher than 60 DEG C to constant weight to obtain a target product. In the method, poly(vinylidene fluoride-trichloroethylene) or poly(vinylidene fluoride-chlorotrifluoroethylene-trichloroethylene) is synthesized by taking poly(vinylidene fluoride-chlorotrifluoroethylene) as a raw material with a one-step process; the method is easy to operate and control; an adopted reaction system has the advantages of low cost and friendliness to human bodies and environment; and the reducing agent is easy to remove from a polymer.

Owner:陕西德天励成新材料科技有限公司

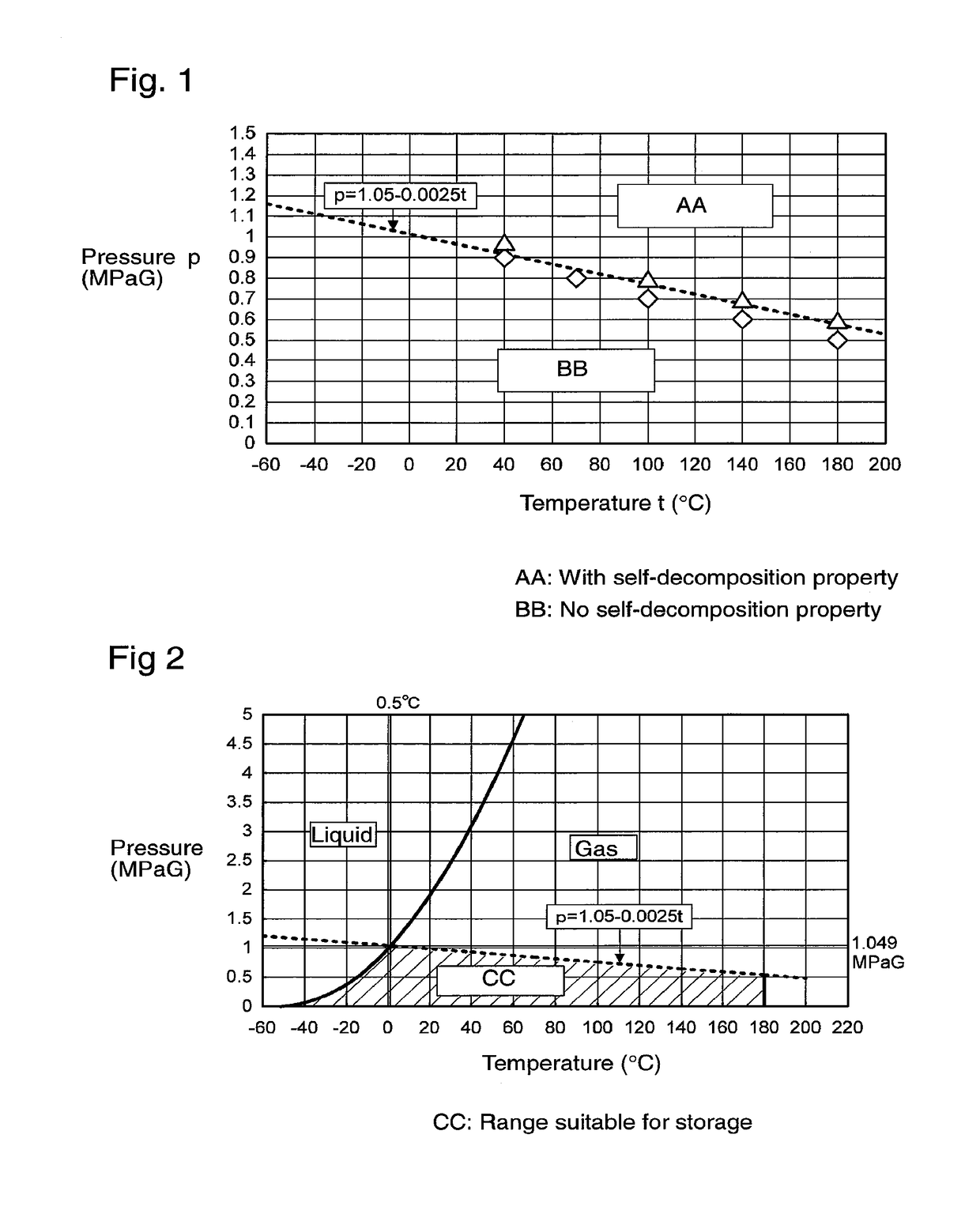

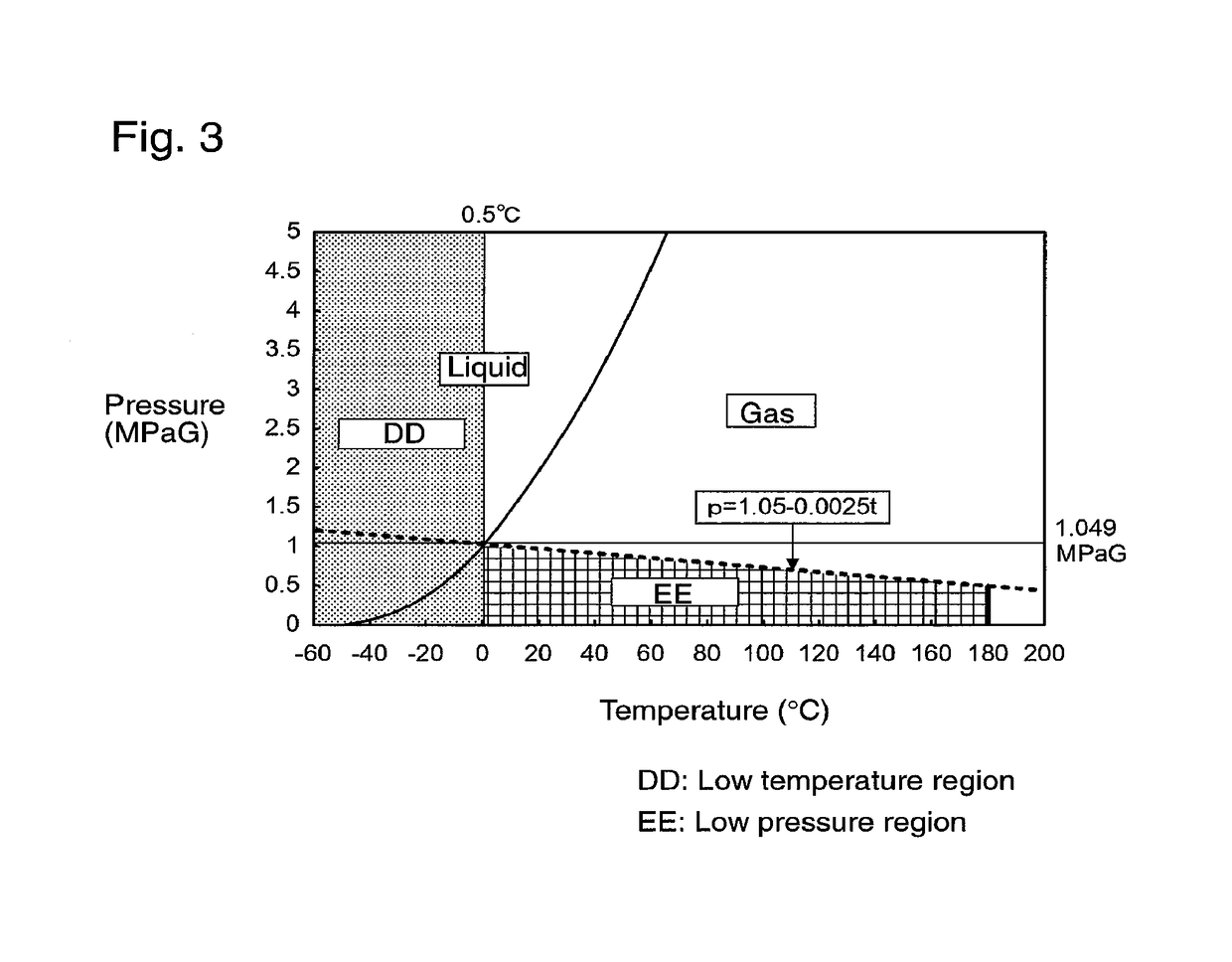

Method for producing working fluid

ActiveUS9969917B2Less influenceImprove cycle performanceHeat-exchange elementsWorking fluidDecomposition

Owner:ASAHI GLASS CO LTD

Compositions

ActiveUS11136482B2Reduce environmental impactImprove propertiesOther chemical processesNon-surface-active detergent compositionsVinyl fluorideEthylene

The invention provides a composition comprising 1,1-difluoroethene (R-1132a), difluoromethane (R-32), 2,3,3,3-tetra-fluoropropene (R-1234yf), optionally carbon dioxide (CO2, R-744), and, optionally, 1,1,2-trifluoroethene (R-1123).

Owner:MEXICHEM FLUOR S A DE CV

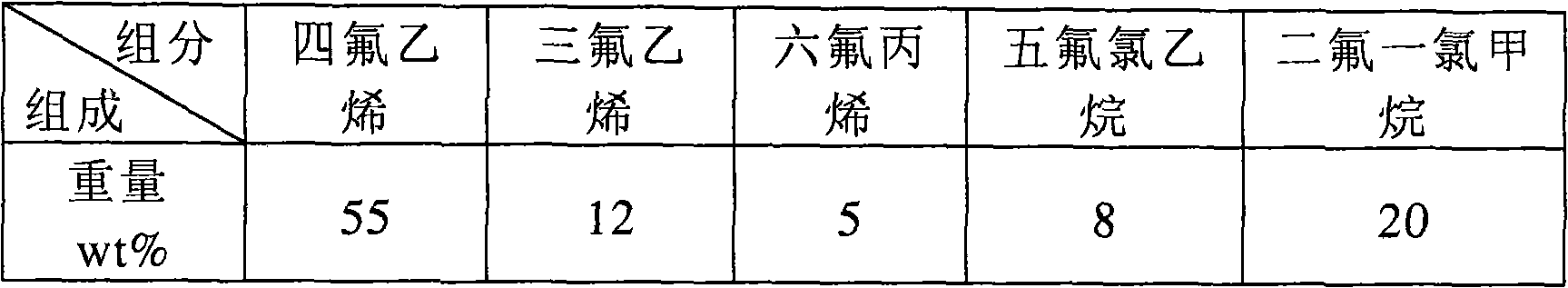

Resource utilization method of tail gas from trifluoroethylene production

InactiveCN102863313AHas the effect of energy saving and emission reductionSimple processPreparation by halogen additionEthyl acetatePlant growth

The invention discloses a resource utilization method of tail gas from trifluoroethylene production. According to the invention, addition reaction between the tail gas from the trifluoroethylene production and bromine is performed to generate dibromotrifluoroethane and dibromotrifluoro chloroethane. The preparation method has the following advantages: the technology is simple; reaction condition is mild; purification is easy; and the technology is suitable for large-scale production. The method provided by the invention has effects of energy conservation and emission reduction. The prepared dibromotrifluoroethane can be used to prepare a dry etching gas hexafluorobutadiene, novel gyroscope suspension fluorobromohydrocarbon oil, alpha, beta, beta-trifluorostyrene and an insecticide and acaricide 1,4-diaryl-2,3-difluoro-2-butene. The prepared dibromotrifluoro chloroethane can be used to prepare a plant growth regulator's intermediate ethyl bromodifluoroacetate and a chain transfer agent used as radical polymerization.

Owner:SINOCHEM LANTIAN +1

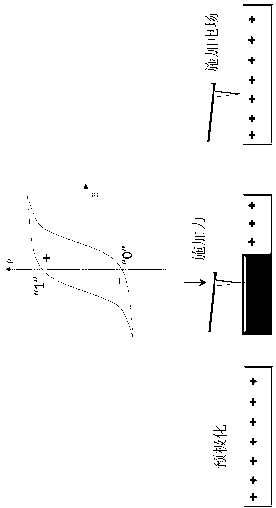

High-density ferroelectric data storage method realized by piezo response force microscope (PFM) probe

The invention relates to a high-density information storage method realized by a piezo response force microscope (PFM) probe. A film forming method that a copolymer solution of vinylidene fluoride and trifluoroethylene is spun on a conductive silicon substrate is adopted for preparing a sample, a PFM probe is applied to apply a force field on the surface of a film after being polarized to change a piezoelectric phase of the polarize film so as to record information, and the information can be erased under the polarization condition of an electric field. The high-density information storage method provided by the invention has a great application prospect in information storage, information can be conveniently stored, and the possibility is provided for achieving high-capacity high-density data storage in nano scale. Compared with the existing storage method, the high-density information storage method provided by the invention has the advantages that an implementation manner is simple, the cost is low and the application range is wide.

Owner:NANJING UNIV

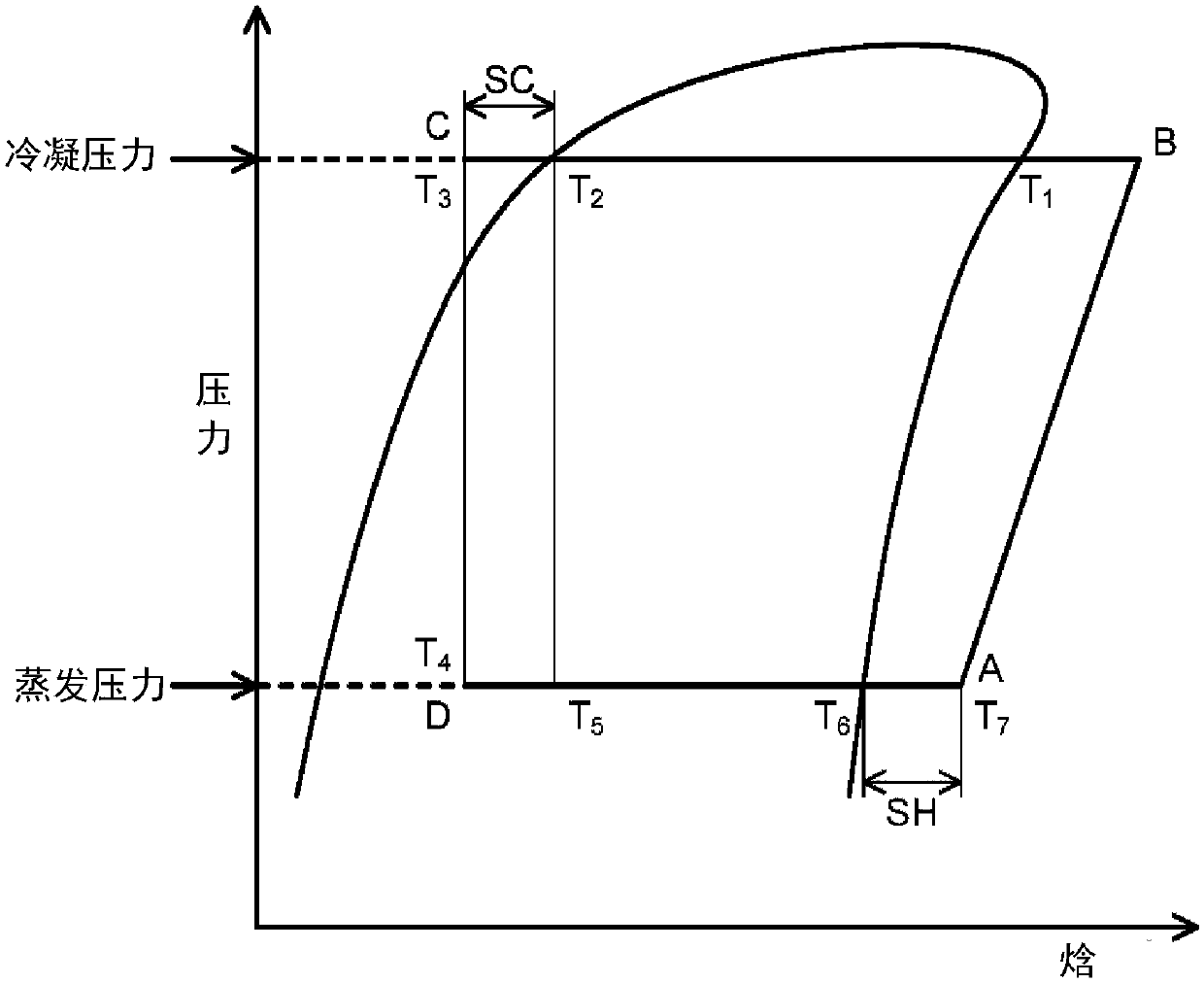

Composition for heat cycle system, and heat cycle system

InactiveUS20200040242A1Improve cycle performanceLow global warming potentialCompressorCompression machines with non-reversible cycleThermodynamicsProcess engineering

To provide a composition for a heat cycle system, which comprises a working fluid for heat cycle which has a low global warming potential and high stability, and which can replace R410A, and a heat cycle system employing the composition. A composition for a heat cycle system, which comprises a working fluid for heat cycle containing trifluoroethylene, and a stabilizer for preventing deterioration of the working fluid for heat cycle, such as an oxidation resistance-improving agent, a heat resistance-improving agent or a metal deactivator, and a heat cycle system employing the composition for a heat cycle system.

Owner:ASAHI GLASS CO LTD

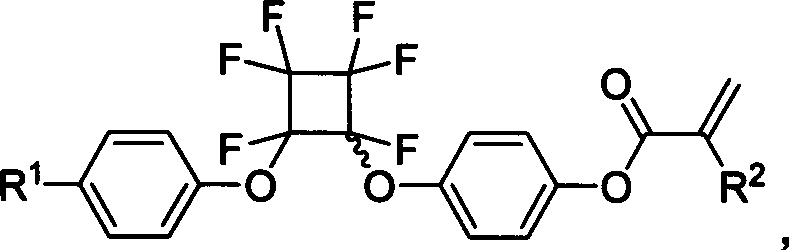

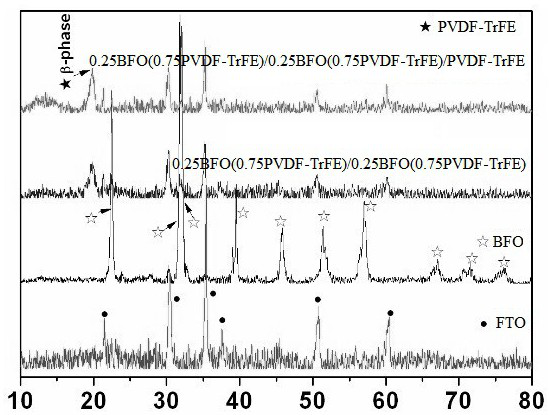

Functional acrylic esters monomers containing perfluorocyclobutane aryl-ether unit, preparation method and application

The invention provides a function acrylic ester monomer containing perfluor cyclobutyl aryl ether unit, a preparation method and the application thereof. The preparation method comprises a three-step reactions: firstly, thermal cyclization reaction is carried out between trifluoro vinyl aryl ether and trifluoro vinyl (4-methoxyphenyl) ether to produce perfluor cyclobutyl aryl ether, and then methyl is removed to obtain phenol containing perfluor cyclobutyl aryl ether unit, finally, by esterification, acrylic ester monomer containing perfluor cyclobutyl aryl ether unit is obtained. The monomer can be used for preparing polyacrylate polymer containing perfluor cyclobutyl aryl ether unit.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

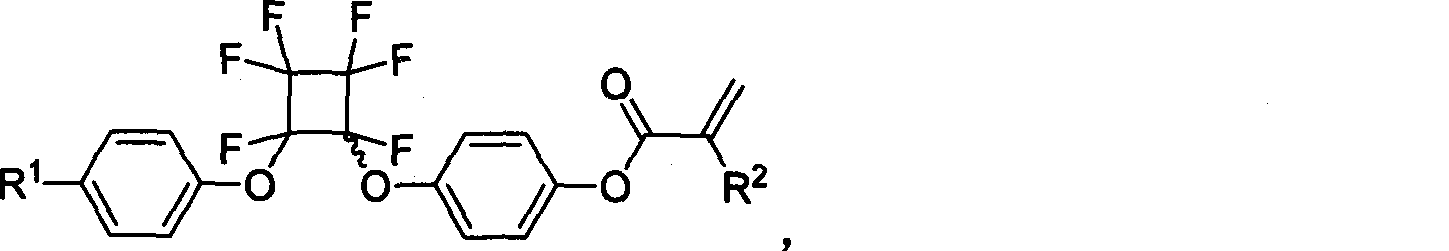

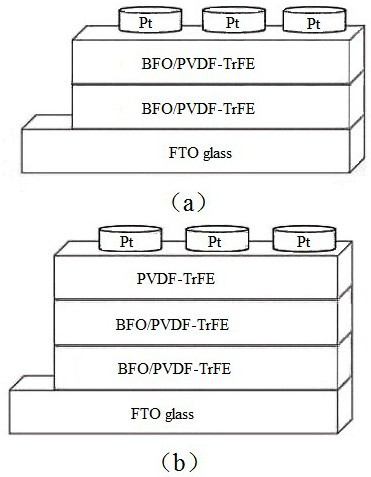

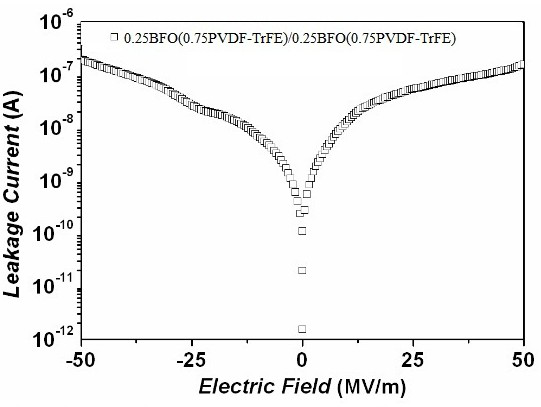

Bismuth ferrite/polyvinylidene fluoride-trifluoroethylene multilayer composite film and preparation method thereof

ActiveCN111662469ACompact structureSolve the disadvantage of large leakage currentSolid-state devicesSemiconductor/solid-state device manufacturingComposite filmProcess equipment

The invention belongs to the technical field of multiferroic films, and concretely relates to a bismuth ferrite / polyvinylidene fluoride-trifluoroethylene multilayer composite film. The multilayer composite film comprises a PVDF-TrFE thin film and at least one layer of BFO / PVDF-TrFE composite film, and the PVDF-TrFE film is attached to the uppermost BFO / PVDF-TrFE composite film. A preparation method of the multilayer composite film comprises the following steps: dissolving PVDF-TrFE powder to obtain a solution A, and adding BFO nanoscale powder into the solution A to obtain a mixed solution B;taking FTO conductive glass as a substrate, spin-coating the FTO conductive glass with the mixed solution B to prepare a BFO / PVDF-TrFE composite film, drying, and spin-coating the BFO / PVDF-TrFE composite film with the solution A to prepare a PVDF-TrFE film; and then annealing the wet film to obtain a cobalt ferrite / polyvinylidene fluoride-trifluoroethylene multilayer composite film, and finally plating a platinum point electrode on the cobalt ferrite / polyvinylidene fluoride-trifluoroethylene multilayer composite film. The bismuth ferrite / polyvinylidene fluoride-trifluoroethylene multilayer composite film disclosed by the invention not only has low leakage current, but also has relatively high remnant polarization intensity, and is low in process equipment cost, simple in process and high in controllability.

Owner:HUBEI UNIV

Method for producing a quartz glass tank for use in ultrasonic cleaning used for fabricating semiconductor and quartz glass tank obtainable from that method

InactiveUS20040023510A1Improve adhesionReduce flakingSemiconductor/solid-state device manufacturingCleaning using liquidsComposite materialMegasonic cleaning

An object of the present invention is to provide a quartz glass tank for use in ultrasonic cleaning that can be used for a long time without causing etching or layer peeling of the quartz glass and a method for producing the same. In order to achieve the objects above, the present invention provides a method for producing a quartz glass tank for ultrasonic cleaning used in fabricating semiconductors, wherein the entire surface thereof is coated with a fluoric resin coating having a film thickness in a range of from 10 mum to 5 mm. The fluoric resin is at least one kind selected from tetrafluoroethylene-perfluoroalkylvinylether resin, perfluoroethylene-propylene resin, ethylene-tetrafluoroethylene resin, ethylene-chlorotrifluoroethylene resin, vinyl fluoride resin, vinylidene fluoride resin and tetrafluoroethylene-perfluorodioxole resin. The method can further comprise that before coating with a fluoric resin a frosting process is applied to the surface of the quartz glass tank.

Owner:HERAEUS QUARZGLAS +1

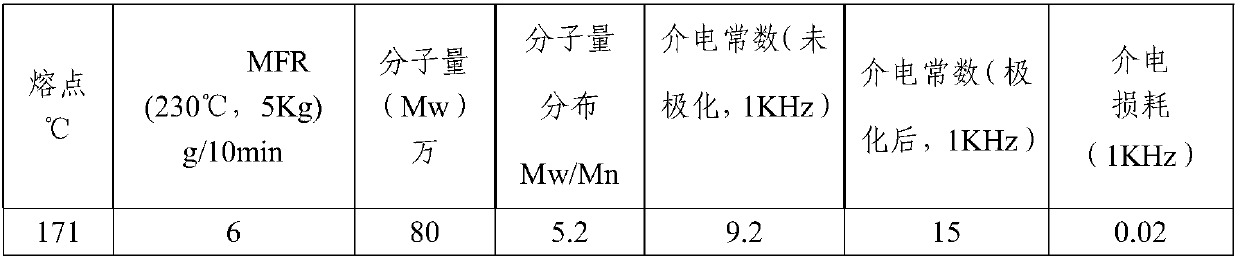

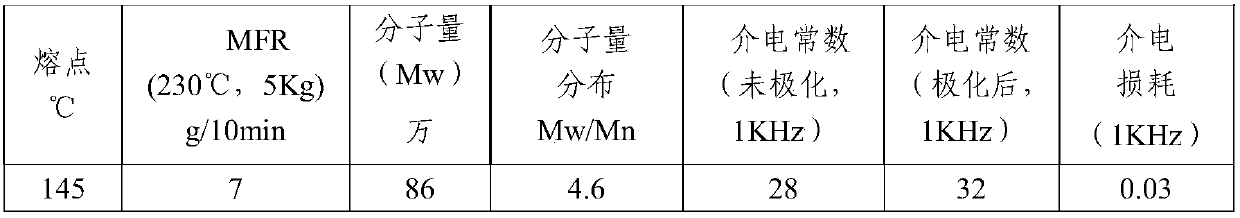

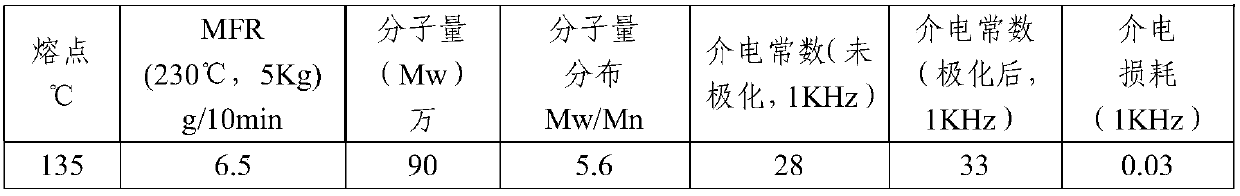

High-dielectric-constant polyvinylidene fluoride (PVDF) as well as preparation method and application thereof

ActiveCN109810212AReduce crystallinityExcellent electrical performancePolyvinylidene fluorideOrganic chemicals

The invention relates to the technical field of organic chemical materials and specifically relates to high-dielectric-constant polyvinylidene fluoride (PVDF) and a preparation method thereof. The preparation method comprises the following steps: carrying out a polymerization reaction on vinylidene fluoride, fluoroolefin or a vinylidene fluoride monomer in the presence of an initiator, a chain transfer agent and a pH (Potential of Hydrogen) regulator, wherein the fluoroolefin is one of trifluoroethylene, trifluorochloroethylene, difluorochloroethylene and tetrafluoroethylene; the initiator isorganic peroxide; and the organic peroxide is one of dicumyl peroxide, cumene hydroperoxide, di-tert-butyl peroxide, tert-butyl peroxybenzoate and tert-butyl hydroperoxide. Polyvinylidene fluoride resin prepared by the preparation method involved in the invention has the properties of low crystallization degree, highly-irregular chain segments, high beta-phase type polymers and the like; and a product of the preparation method has excellent electrical performance in electronic devices, energy storage containers and sensors.

Owner:CHENGUANG RES INST OF CHEM IND

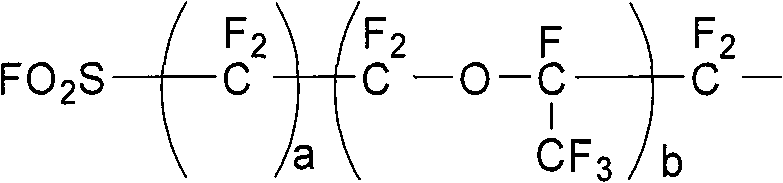

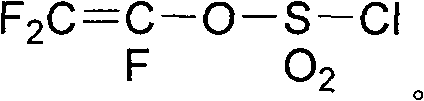

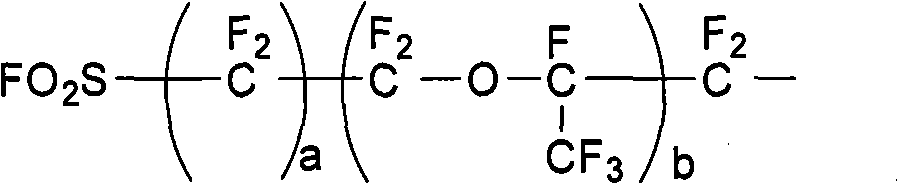

Method for preparing fluoro olefin

The invention discloses a method for preparing fluoro olefin, which comprises that: a perfluoro straight chain or branched chain acyl fluoride compound reacts with trifluoro vinyl ethyl sulfate in an organic solvent under the action of a catalyst so as to form a product having a general formula shown by the formula (I). The method avoids a pyrolysis route and uses no unconventional monomers, the used trifluoro vinyl ethyl sulfate can be prepared at a yield of above 95 percent, and a fluoro olefin monomer is prepared easily through an addition reaction, and a high-purity monomer can be obtained through rectification. CF2=CF-O-Rf (I).

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

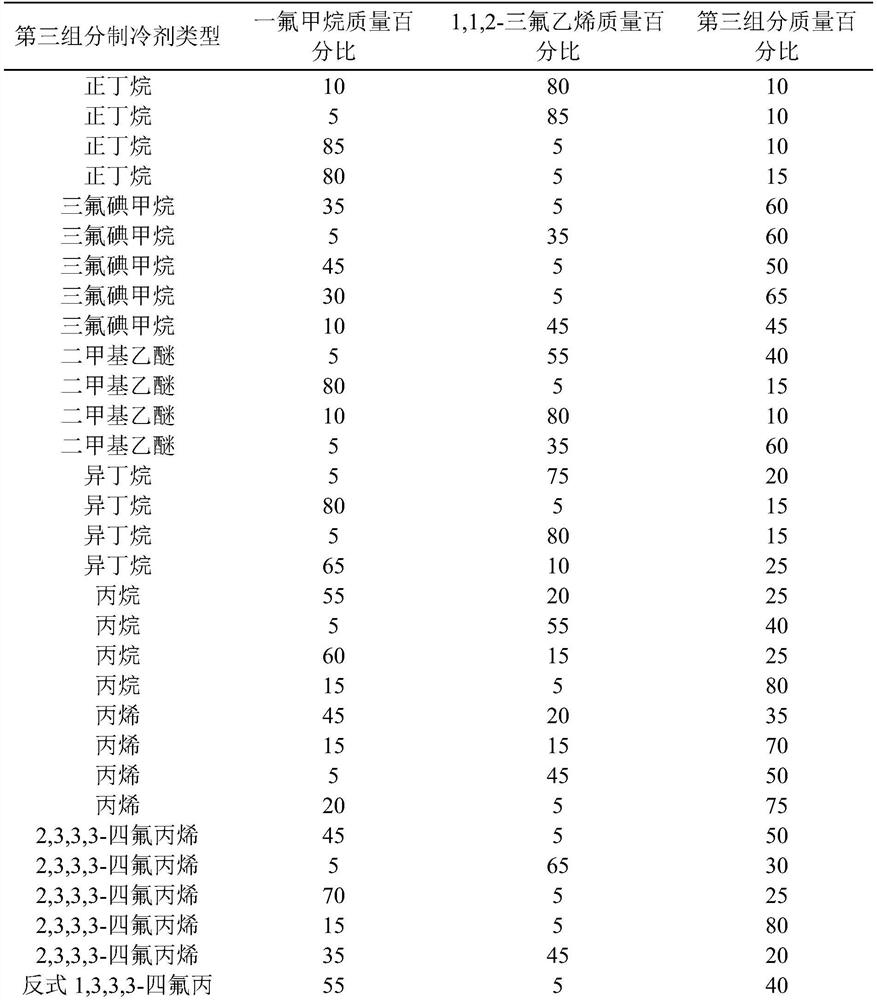

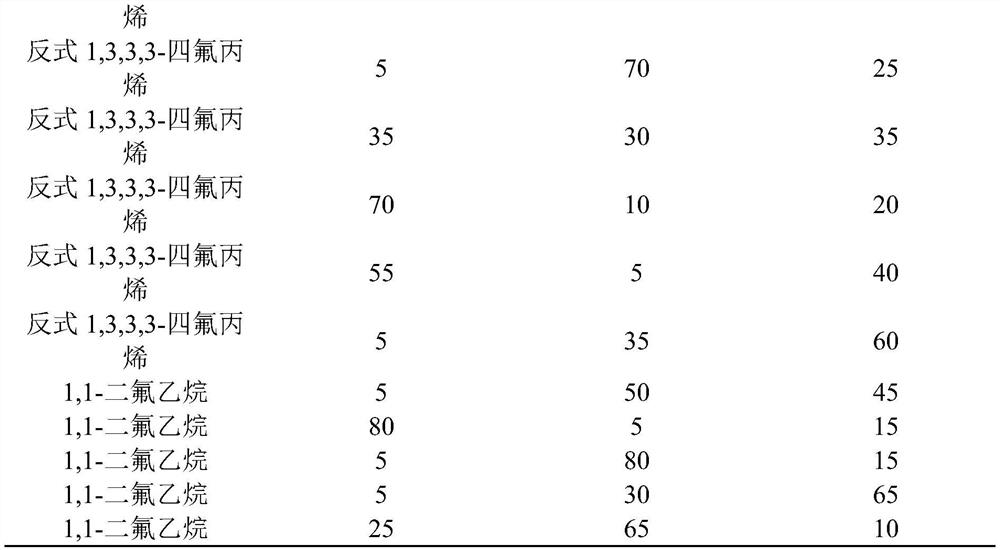

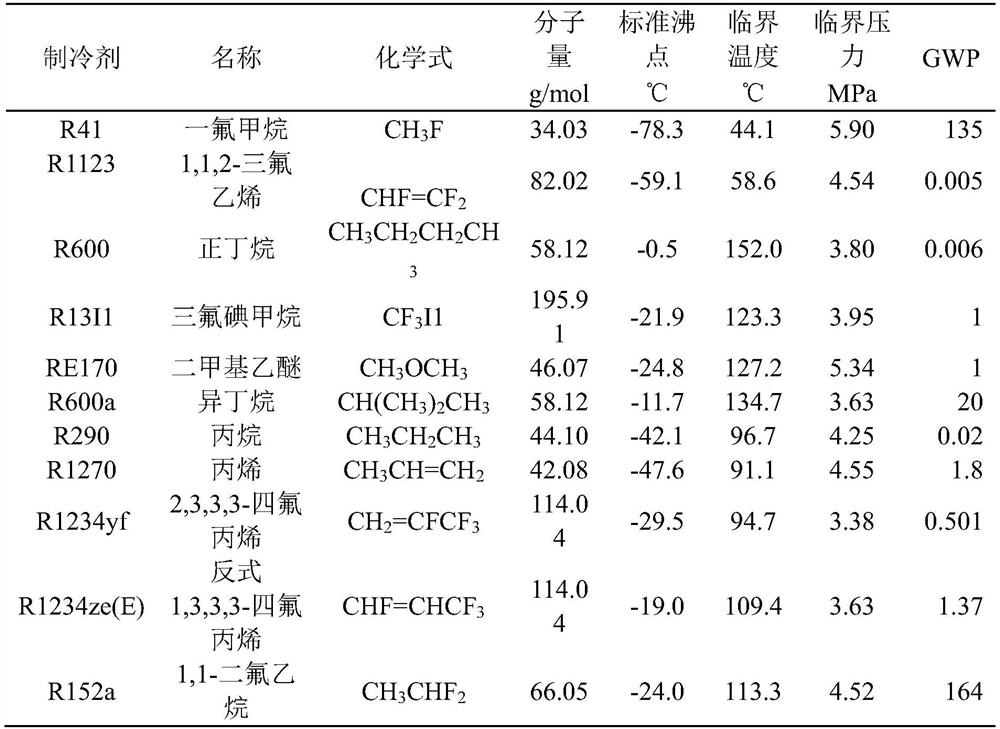

Environment-friendly energy-saving refrigerant composition as well as preparation method and application thereof

ActiveCN114045155AReduce irreversible lossImprove energy efficiencyChemical industryCompression machinesDifluoroethyneProcess engineering

The invention relates to the technical field of refrigeration, and discloses an environment-friendly energy-saving refrigerant composition as well as a preparation method and application thereof. The refrigerant composition comprises a first component, a second component and a third component, wherein the first component is monofluoromethane, the second component is 1,1,2-trifluoroethylene, and the third component is n-butane, trifluoroiodomethane, dimethyl ether, isobutane, propane, propylene, 2,3,3,3-tetrafluoropropene, trans-1,3,3,3-tetrafluoropropene or 1,1-difluoroethane. Based on the temperature slippage characteristic of the non-azeotropic refrigerant, the environment-friendly energy-saving refrigerant composition with low GWP and high system energy efficiency is provided by weighing the respective characteristics of different refrigerants; the refrigerant composition has good environmental performance, and the GWP of the refrigerant composition is lower than 140 while the GWP of most refrigerant compositions is lower than 100; and meanwhile, the refrigerant composition can remarkably improve the operation energy efficiency of refrigeration equipment, and the purpose of saving energy is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

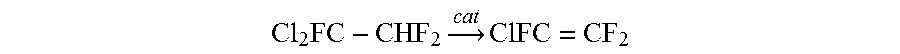

Process for producing chlorotrifluoroethylene

ActiveUS20160068455A1Preparation by dehalogenationPreparation by hydrogen halide split-offTrifluoroethaneMetal alloy

The present invention relates, at least in part, to a process for making chlorotrifluoroethylene (CFO-1113) from 1,2-dichloro-1,1,2-trifluoroethane (HCFC-123a). In certain aspects, the process includes dehydrochlorinating 1,2-dichloro-1,1,2-trifluoroethane (HCFC-123a) in the presence of a catalyst selected from the group consisting of (i) one or more metal halides; (ii) one or more halogenated metal oxides; (iii) one or more zero-valent metals or metal alloys; (iv) combinations thereof.

Owner:HONEYWELL INT INC

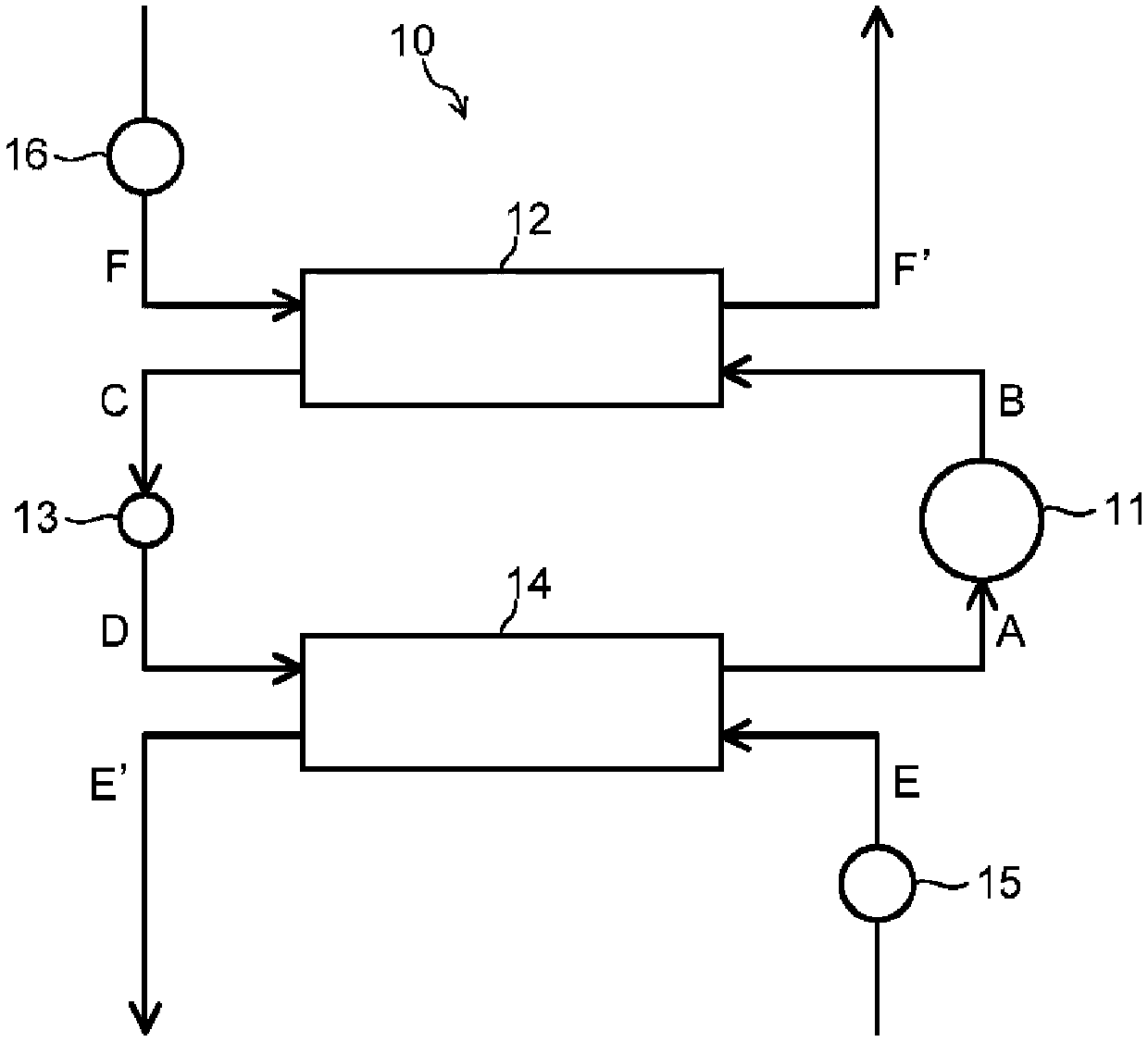

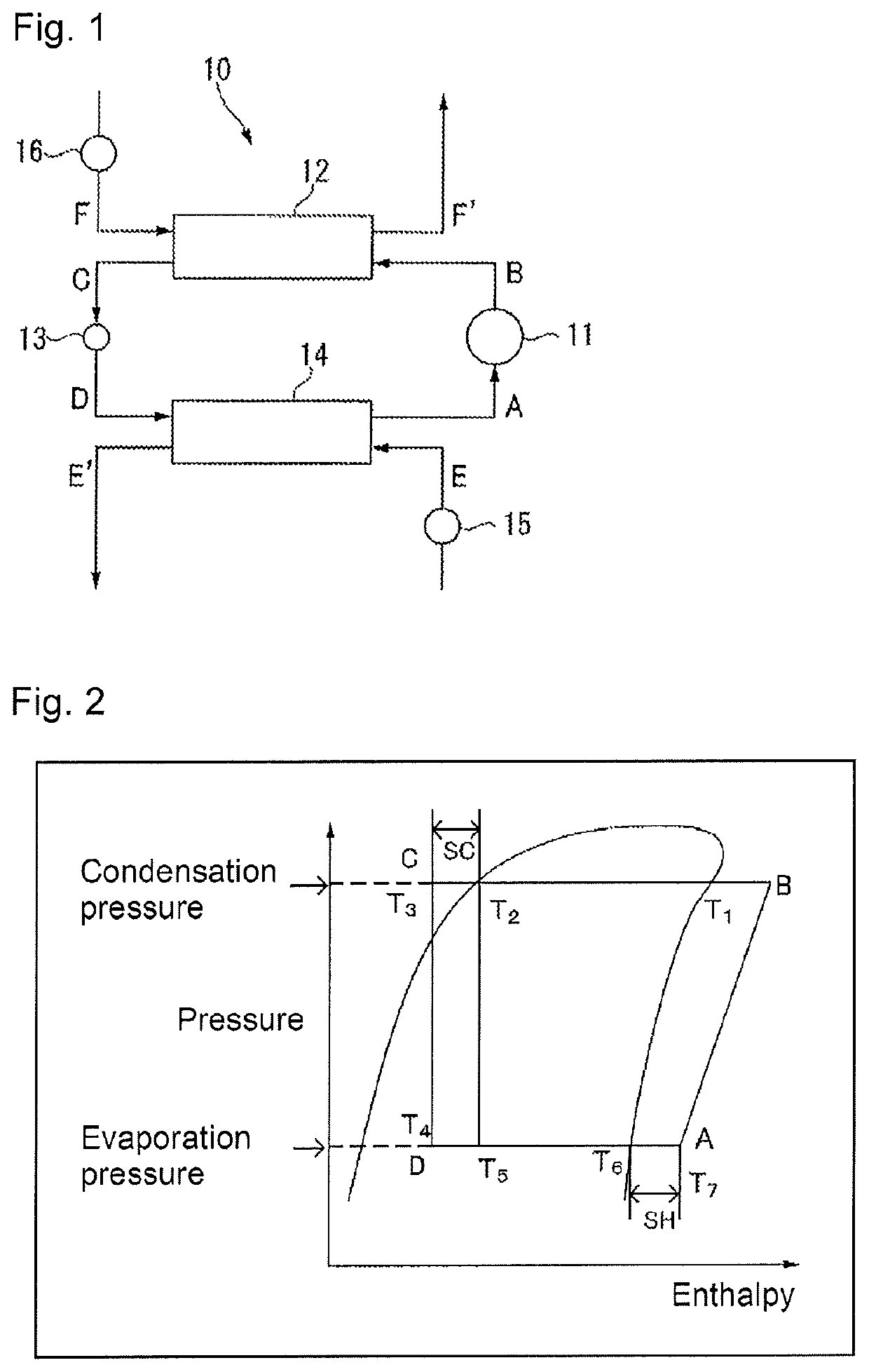

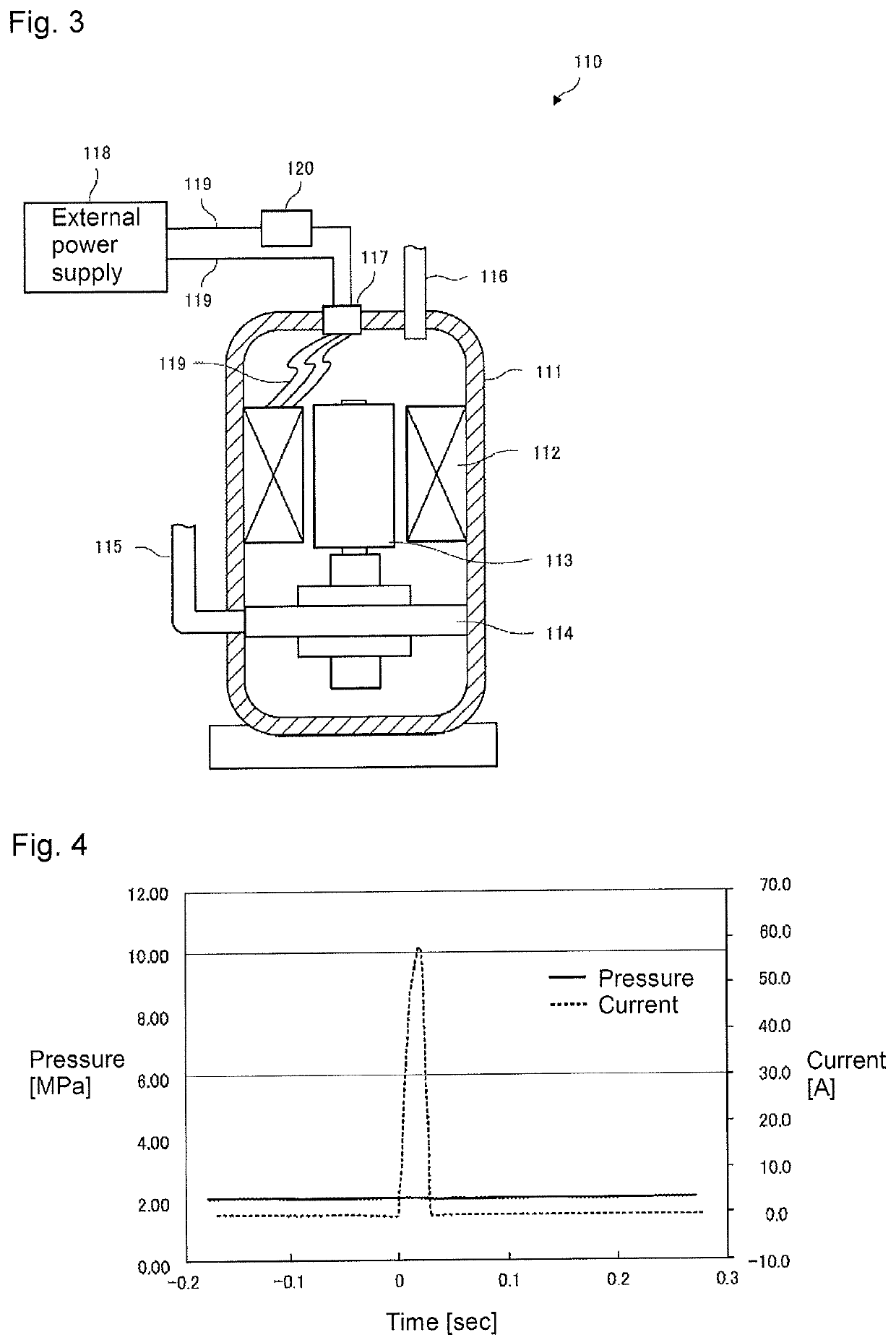

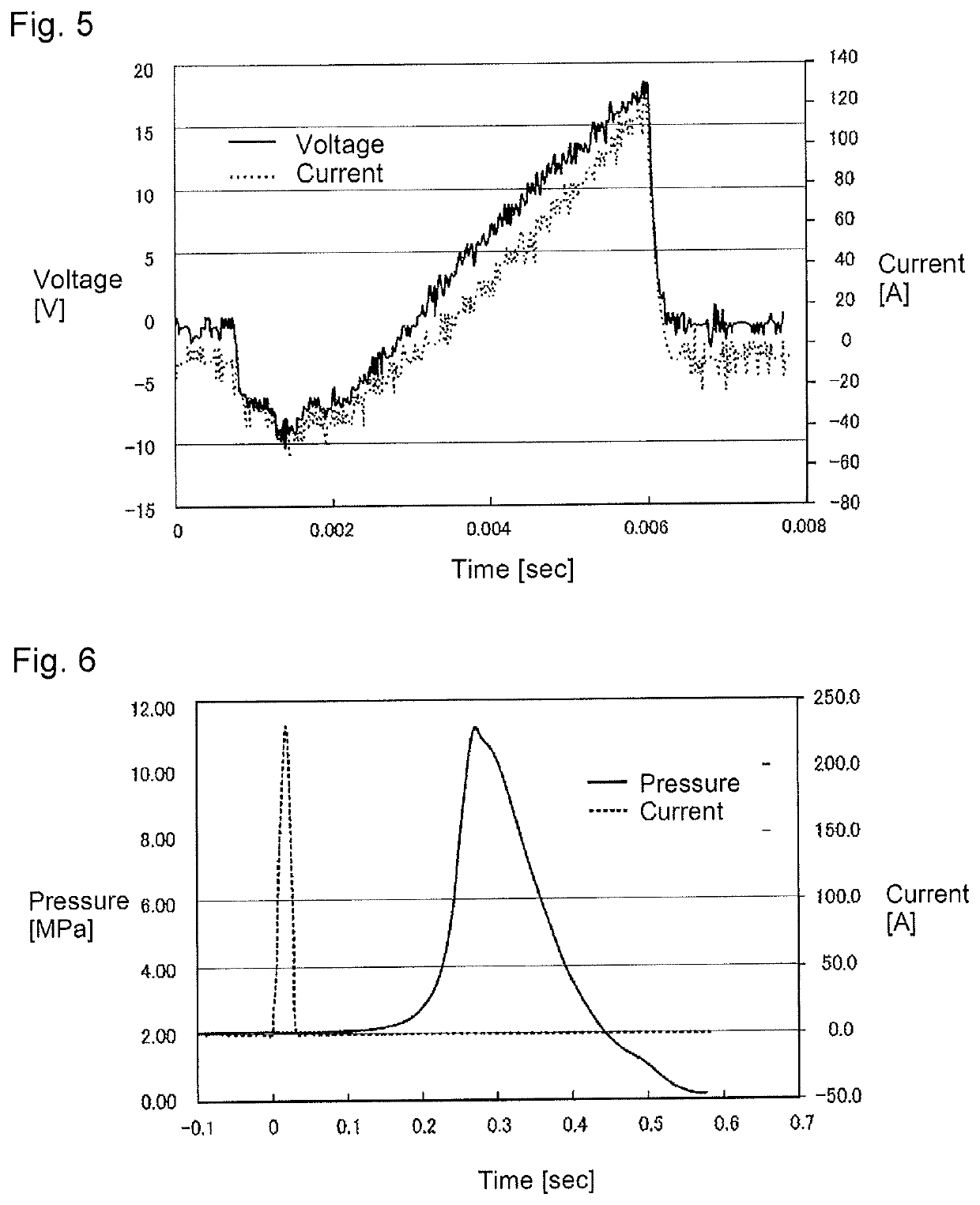

Heat cycle system

ActiveUS10830518B2Practical heat cycle performanceSuppressing influence over global warmingCompression machines with non-reversible cycleHeat-exchange elementsWorking fluidEngineering

A heat cycle system with high durability, which employs a working fluid for heat cycle containing trifluoroethylene having a low global warming potential. A heat cycle system, having a circulation path in which a working fluid for heat cycle containing trifluoroethylene is circulated from a compressor via a condenser, an expansion valve and an evaporator to the compressor, wherein the compressor has in its electrical circuit a current-limiting apparatus capable of limiting the current within 6 milliseconds after the heat cycle system enters into an abnormal operation state.

Owner:ASAHI GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com