Working medium for heat cycle, composition for heat cycle system, and heat cycle system

A technology of working medium and thermal cycle, applied in the field of thermal cycle system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

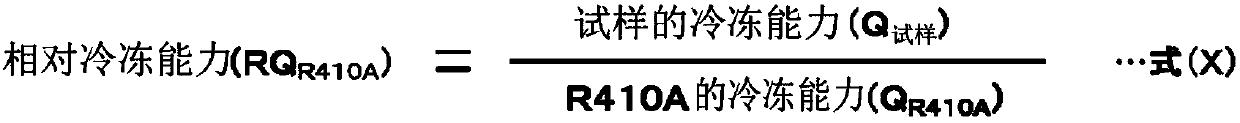

[0211] In Example 1, HFO-1123 and carbon dioxide (CO 2 ), fluoromethane (HFC-41), trifluoroiodomethane (CF 3 I) or propane (C 3 h 8 ) mixed with the ratio shown in Table 3 as the thermal cycle working medium (hereinafter also referred to as "working medium"), the greenhouse effect potential value (GWP), relative cycle performance (relative in R410A) and self-decomposability. The results are shown in Table 3 together with the composition of the working medium. In addition, in Table 3, No.1, No.9, No.10, No.15, No.16, No.21, No.22, and No.27 are comparative examples.

[0212] [table 3]

[0213]

Embodiment 2

[0215] In Example 2, HFO-1123 and carbon dioxide (CO 2 ), the working medium obtained by mixing HFC-32, HFO-1234yf or HFO-1234ze as the second component in the ratio shown in Table 4-6, and the greenhouse effect potential value (GWP) was measured, calculated and judged by the above method , relative cycle performance (relative to R410A) and self-decomposition. The results are shown in Tables 4-6 together with the composition of the working medium.

[0216] [Table 4]

[0217]

[0218] [table 5]

[0219]

[0220] [Table 6]

[0221]

Embodiment 3

[0223] In Example 3, HFO-1123, propane (C 3 h 8 ), the working medium obtained by mixing HFC-32, HFO-1234yf or HFO-1234ze as the second component in the ratio shown in Table 7-9, the greenhouse effect potential value (GWP) was measured, calculated and determined according to the above method , relative cycle performance (relative to R410A) and self-decomposition. The results are shown in Tables 7-9 together with the composition of the working medium.

[0224] [Table 7]

[0225]

[0226] [Table 8]

[0227]

[0228] [Table 9]

[0229]

[0230] It can be seen that the thermal cycle working medium containing HFO-1123 and the first component shown in Table 3 has no self-decomposition property, low greenhouse effect potential, and excellent cycle performance sufficient for practical use. In addition, it can be seen that the working media for thermal cycles containing HFO-1123, the first component and the second component shown in Tables 4 to 9 do not have self-decompos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com