Self-polishing antifouling paint and preparation method thereof

A technology of self-polishing and antifouling paint, which is applied in the direction of antifouling/underwater paint, paint containing biocide, coating, etc. It can solve the problems of not being able to meet environmental protection requirements and high content, and achieve improved hydrophobicity and controllable hydrolysis Sex, good hydrophobicity and lubricity, and the effect of increasing solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

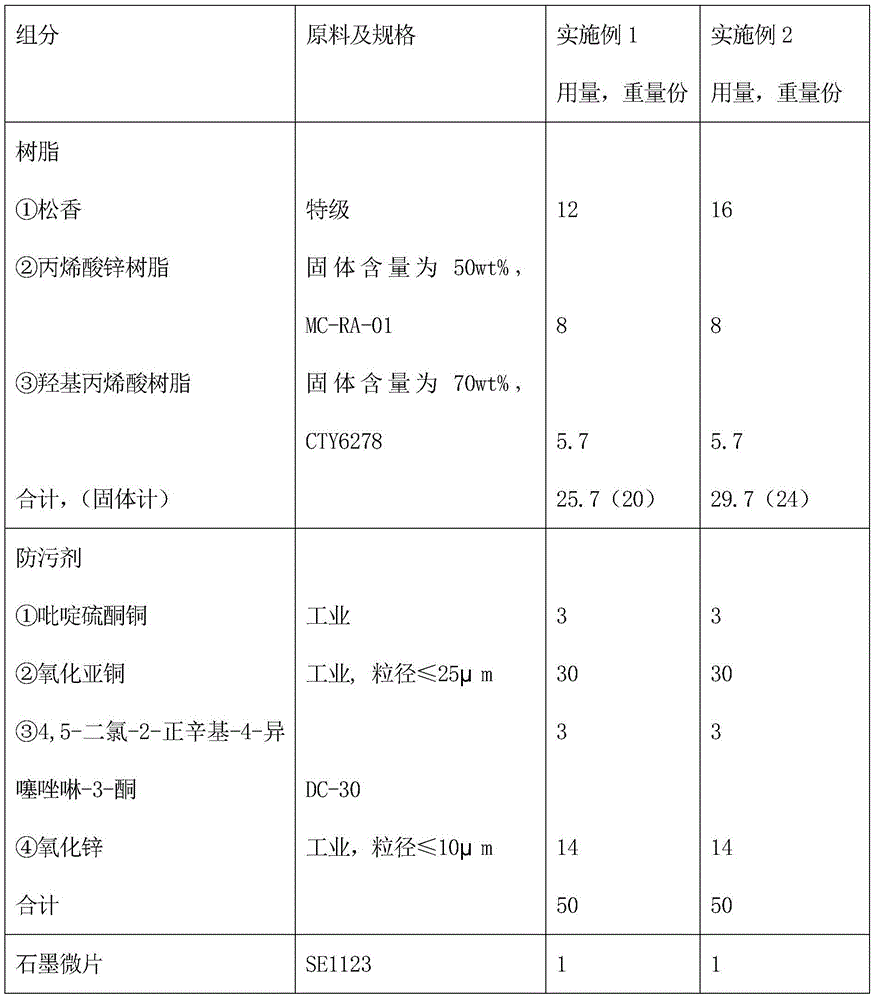

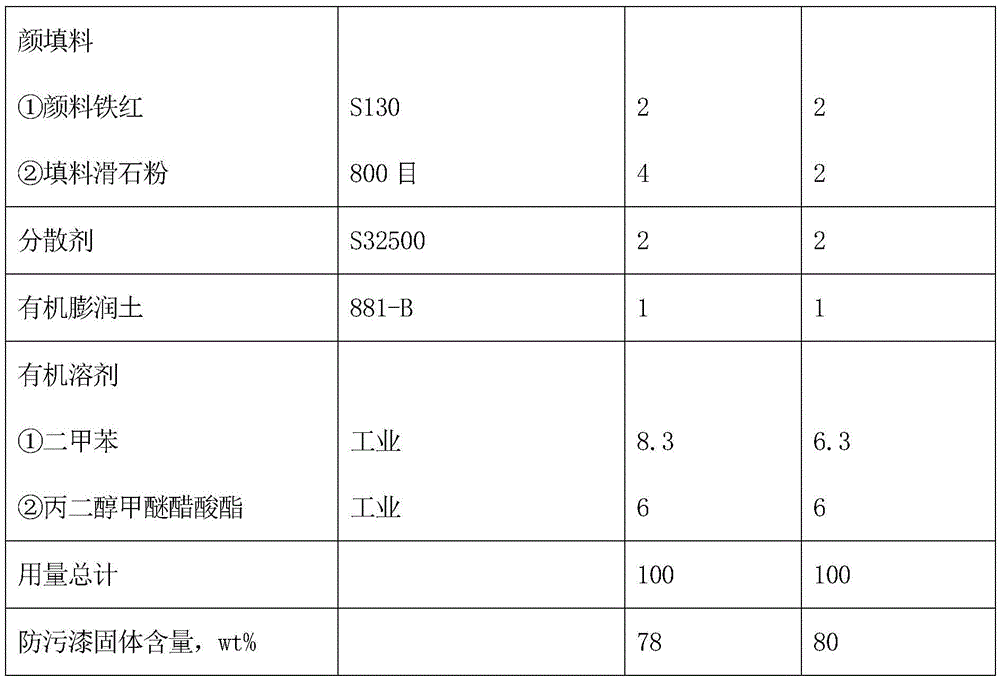

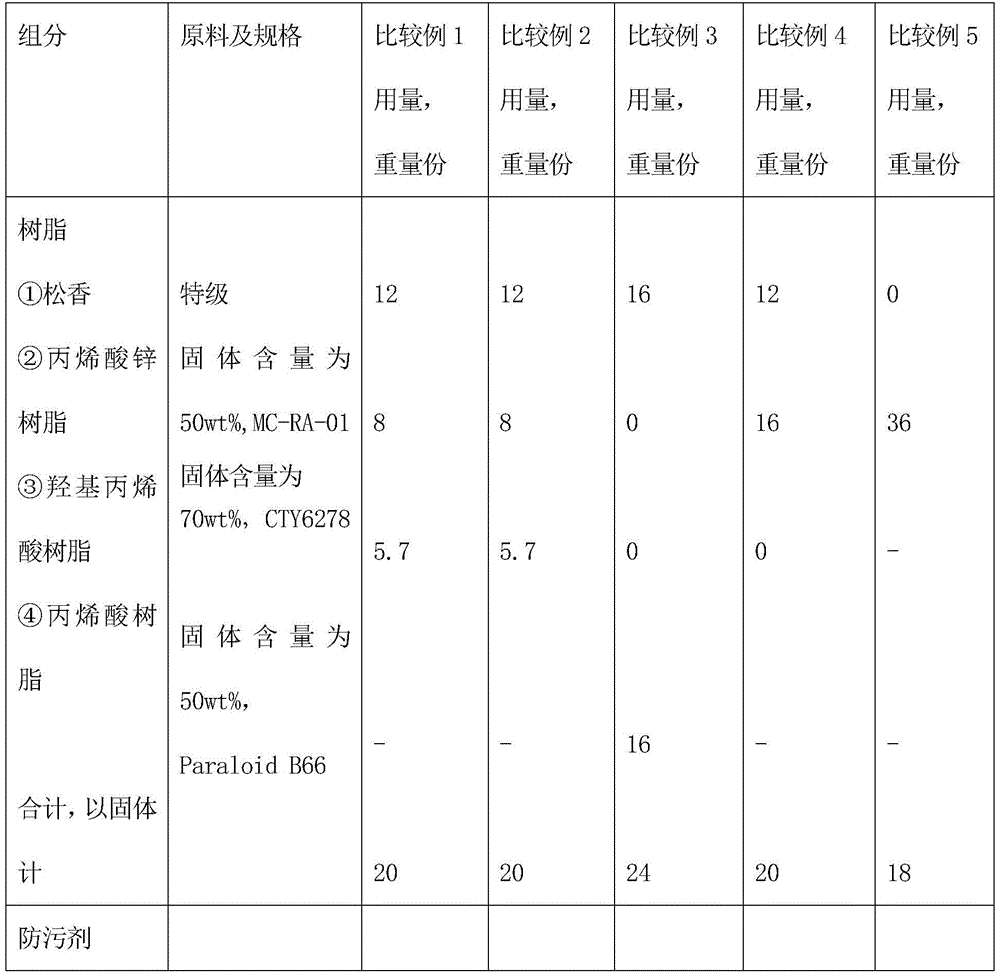

[0028] Embodiment 1 prepares self-polishing antifouling paint 1 and 2

[0029] In 100 parts by mass of the self-polishing antifouling paint of the present invention, there are 18 to 24 parts of resin in solids, 50 to 55 parts of antifouling agent, 0.5 to 1.5 parts of graphene microflakes, 3 to 6 parts of pigments and fillers, and 1 to 5 parts of dispersant. 2 parts, 1-2 parts of organic bentonite, and the balance is organic solvent;

[0030] The 18-24 parts of solid-based resin is composed of 4 parts of solid-based hydroxyl acrylic resin, 4-6 parts of solid-based zinc acrylate resin, and the balance is rosin, wherein the zinc content of solid-based zinc acrylate resin is 12-15wt %, the hydroxyl content of the hydroxy acrylic resin in solids is 4 to 5wt%;

[0031] The 50-55 parts of antifouling agent is composed of 3 parts of copper pyrithione, 3 parts of 4,5-dichloro-2-n-octyl-4-isothiazolin-3-one, 30-35 parts of cuprous oxide , the balance is composed of zinc oxide;

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com