Composite fiber and polymer based flexible composite film and preparation method thereof

A composite fiber and composite film technology, applied in the direction of fiber chemical characteristics, rayon manufacturing, coating, etc., can solve the problems of reduced mechanical flexibility of polymers, high dielectric loss of conductive components, and reduced breakdown field strength, etc., to achieve The effect of increased dielectric constant, excellent dielectric properties, mechanical properties, and improved dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1, preparation composite fiber

[0045] Weigh 2ml of tetrabutyl titanate and 4ml of acetylacetone into 4ml of ethanol dropwise in sequence, and stir until uniform and stable, then add 1g of barium titanate (BaTiO 3 ) particles (particle size 50nm) continue to stir until uniform and stable, then add 0.4g PVP (addition amount is 0.04g / ml sol, used to adjust the viscosity of the sol to a viscosity value suitable for spinning), and stir for 2 hours to form a stable sol, the sol was transferred to a syringe for electrospinning, the electrospinning was carried out under an electric field of 1.3kV / cm, and the electrospun fibers were collected by rollers and calcined at 500°C for 2h to obtain composite fibers (with a density of 5g / cm 3 ).

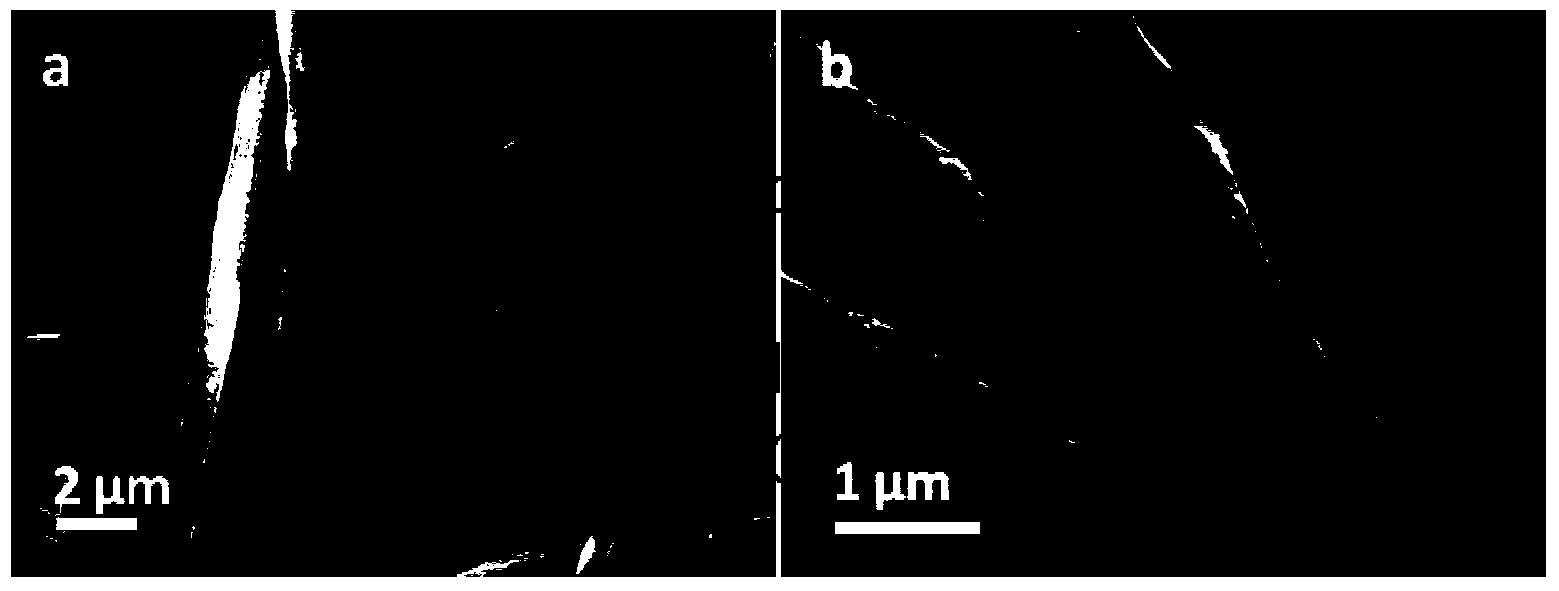

[0046] The scanning electron microscope picture of the composite fiber morphology that the present embodiment obtains is as follows figure 1 As shown, among them, figure 1 The scale bar in (a) is 2 μm, figure 1 The scale in (...

Embodiment 2

[0048] Embodiment 2, preparation composite fiber

[0049] Weigh 2ml of tetrabutyl titanate and 4ml of acetylacetone and add them dropwise into 4ml of ethanol in sequence, and stir until uniform and stable, then add 0.5g of barium titanate (BaTiO 3 ) particles (particle size 50nm) continue to stir until uniform and stable, then add 0.4g PVP (addition amount is 0.04g / ml sol) and stir for 2h to form a stable sol, transfer the sol to a syringe for electrospinning, electrospinning The filaments were carried out under an electric field of 1.3kV / cm, and the electrospun fibers were obtained by drum collection, and calcined at 450°C for 2 hours to obtain composite fibers.

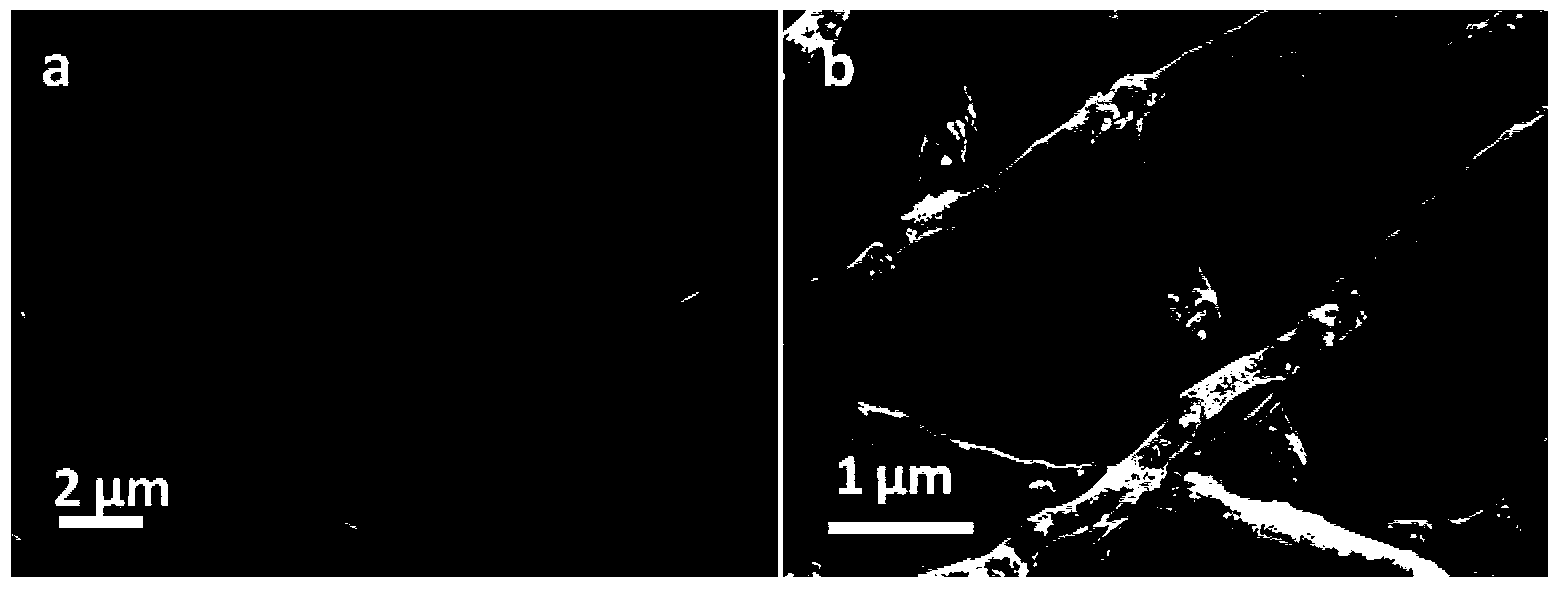

[0050] The scanning electron microscope picture of the composite fiber morphology that the present embodiment obtains is as follows figure 2 As shown, among them, figure 2 The scale bar in (a) is 2 μm, figure 2 The scale in (b) is 1 μm. It can be seen from the figure that the diameter of the composite fiber pr...

Embodiment 3

[0052] Embodiment 3, preparation flexible composite film

[0053] Take 0.2 g of the composite fiber prepared in Example 1 and place it in 50 ml of 0.01 mol / L dopamine aqueous solution, stir at 60° C. for 10 h, centrifuge, wash with ethanol and dry at 60° C. for 5 h. Measure 3.5ml of DMF solvent, add 0.018g of the above-mentioned composite fiber, ultrasonic 30min, then add 0.332g of PVDF (density 1.2g / cm 3 ), stirred for 5 hours to a uniform and stable state, then cast the mixture, and dried at 50°C for 2 hours to obtain a film.

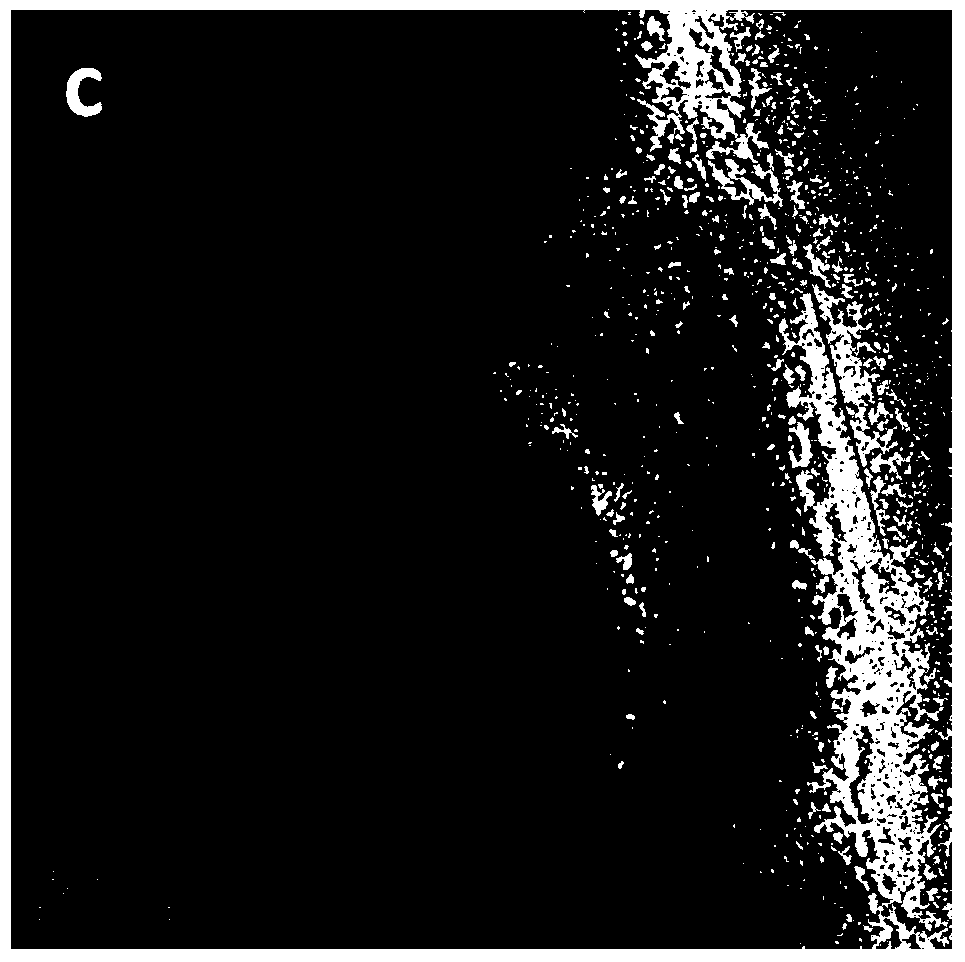

[0054] In this embodiment, the high-resolution electron microscope picture of the composite fiber coated with dopamine is as follows: image 3 As shown, it can be seen from the figure that the thickness of the coated dopamine film layer is 3nm.

[0055] The surface scanning electron microscope picture of the composite film prepared in this embodiment is as follows Figure 4 As shown, it can be seen from the figure that the thickness of the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com