Patents

Literature

144results about How to "Precise and controllable thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

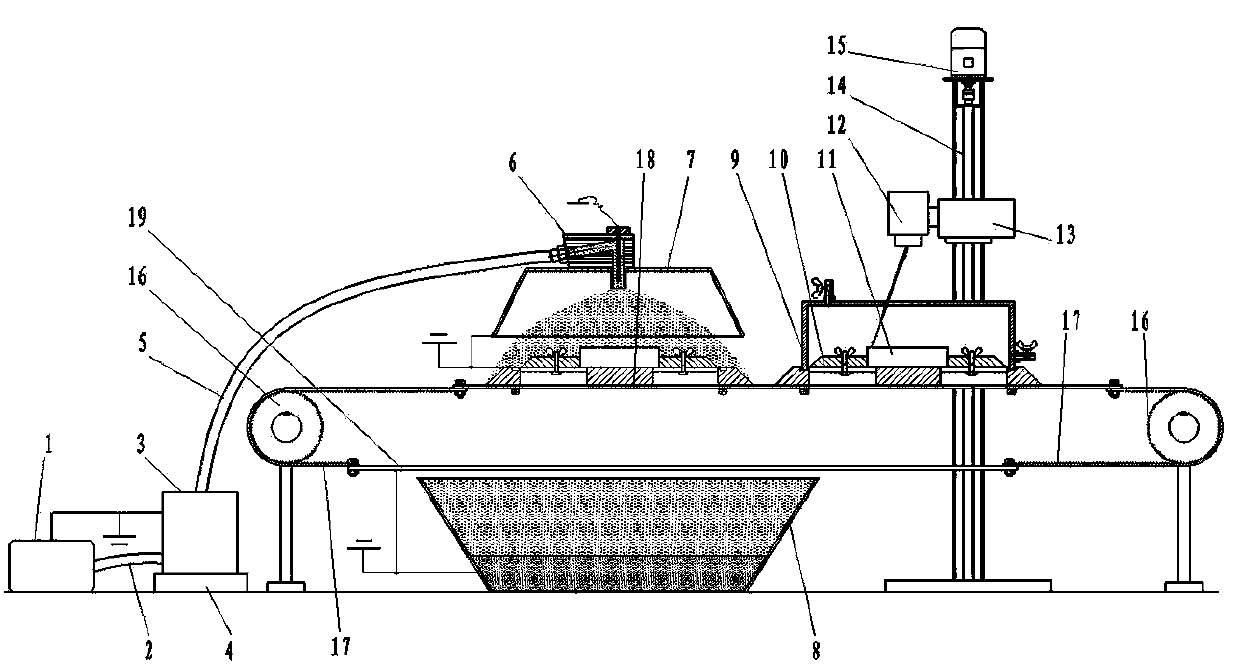

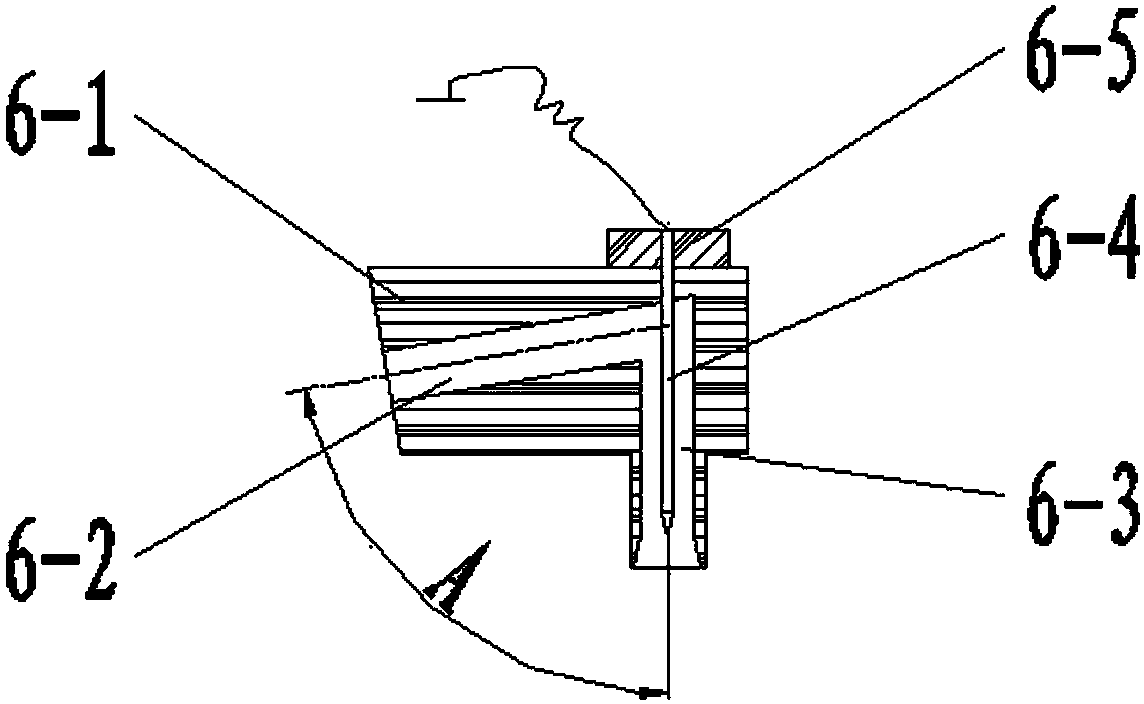

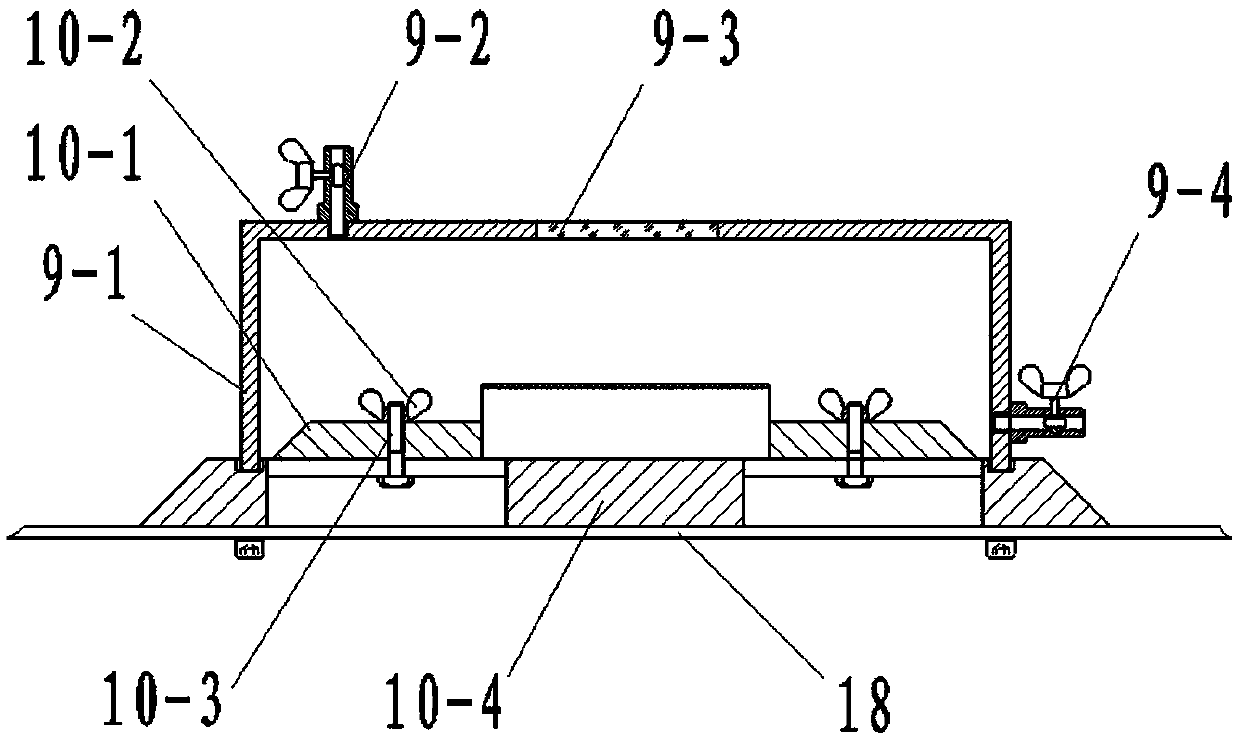

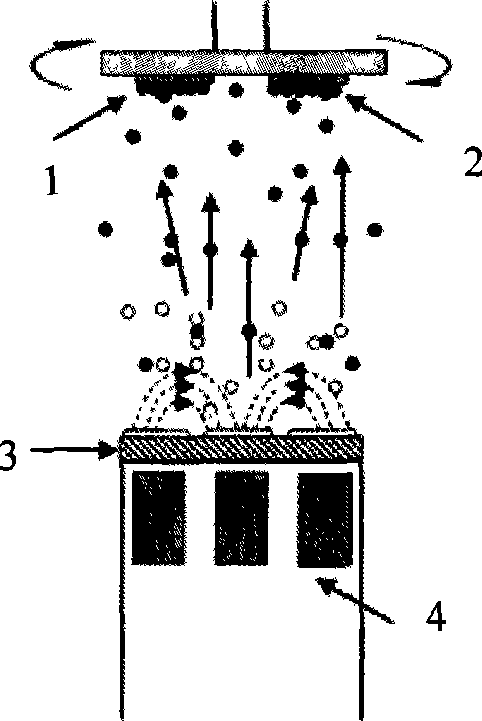

Quick laser cladding device and cladding method of flat metal parts

ActiveCN103741139AImprove surface qualityPrecise and controllable thicknessMetallic material coating processesGalvanometerRapid scan

The invention relates to a quick laser cladding device of flat metal parts. The quick laser cladding device comprises five modules, namely an electrostatic powder spraying device, a quick laser galvanometer scanning device, a gas protection module, a parts conveying module, and a parts fixing clamp. The quick laser cladding device has the advantages of low equipment building and operating costs, fast powder adding method, fast cladding speed, good cladding layer surface quality, accurate and controllable cladding layer thickness and the like. According to the quick laser cladding device, the system building and operating costs are reduced, the production efficiency is improved, and good cladding quality is also obtained. By adopting the method, the requirements of cladding the flat metal parts at low cost, large batch, high speed and high quality can be met.

Owner:苏州科弗曼机械有限公司

Making method for IV-VI semiconductor single crystal film and the heterogeneous structure

InactiveCN101106092AQuality improvementPrecise and controllable thicknessSemiconductor/solid-state device manufacturingFrom condensed vaporsBeam sourceUltra-high vacuum

The invention discloses a method to produce IV-VI semiconductor single-crystal thin film and the hetero-structure thereof. Under the condition of accurately controlled ultra-high vacuum, IV-VI atom and molecular beams vaporized from a beam source furnace encounter a clean single-crystal liner surface with good crystal surface orientation, and atom and molecular reaching the surface of the liner form high-quality single-crystal thin film after processes such as attachment, transition, and crystallization on the surface of liner. Through the accurate control of growth conditions, such as beam runoff and linear temperature, extended IV-VI compounds grow on the surface of linear by a molecular layer and a molecular layer. The method can grow IV-VI semiconductor hetero-structures, including quantum-well and super-lattice. The production cost is low, and the quality is high.

Owner:ZHEJIANG UNIV

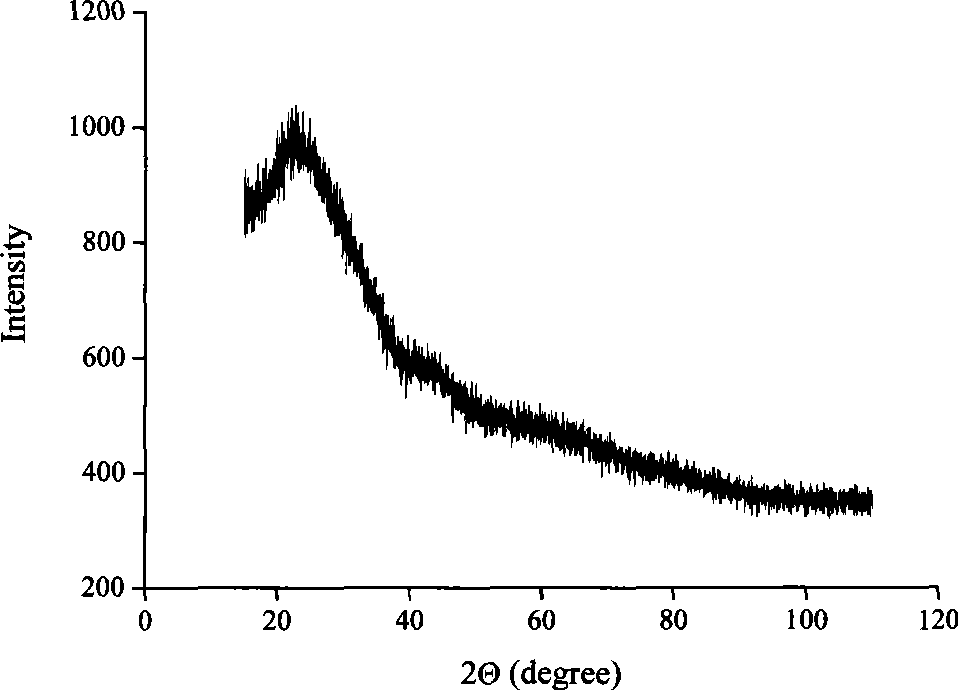

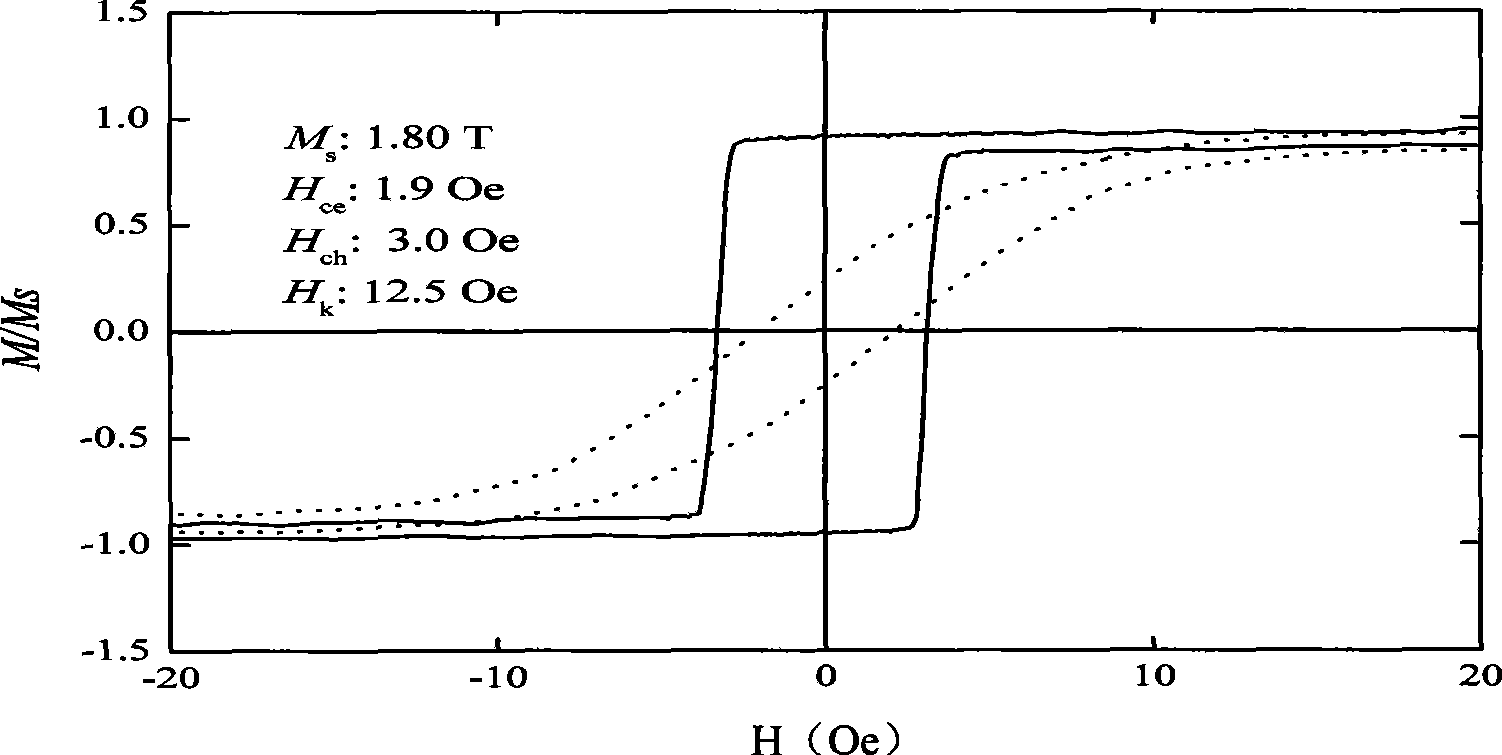

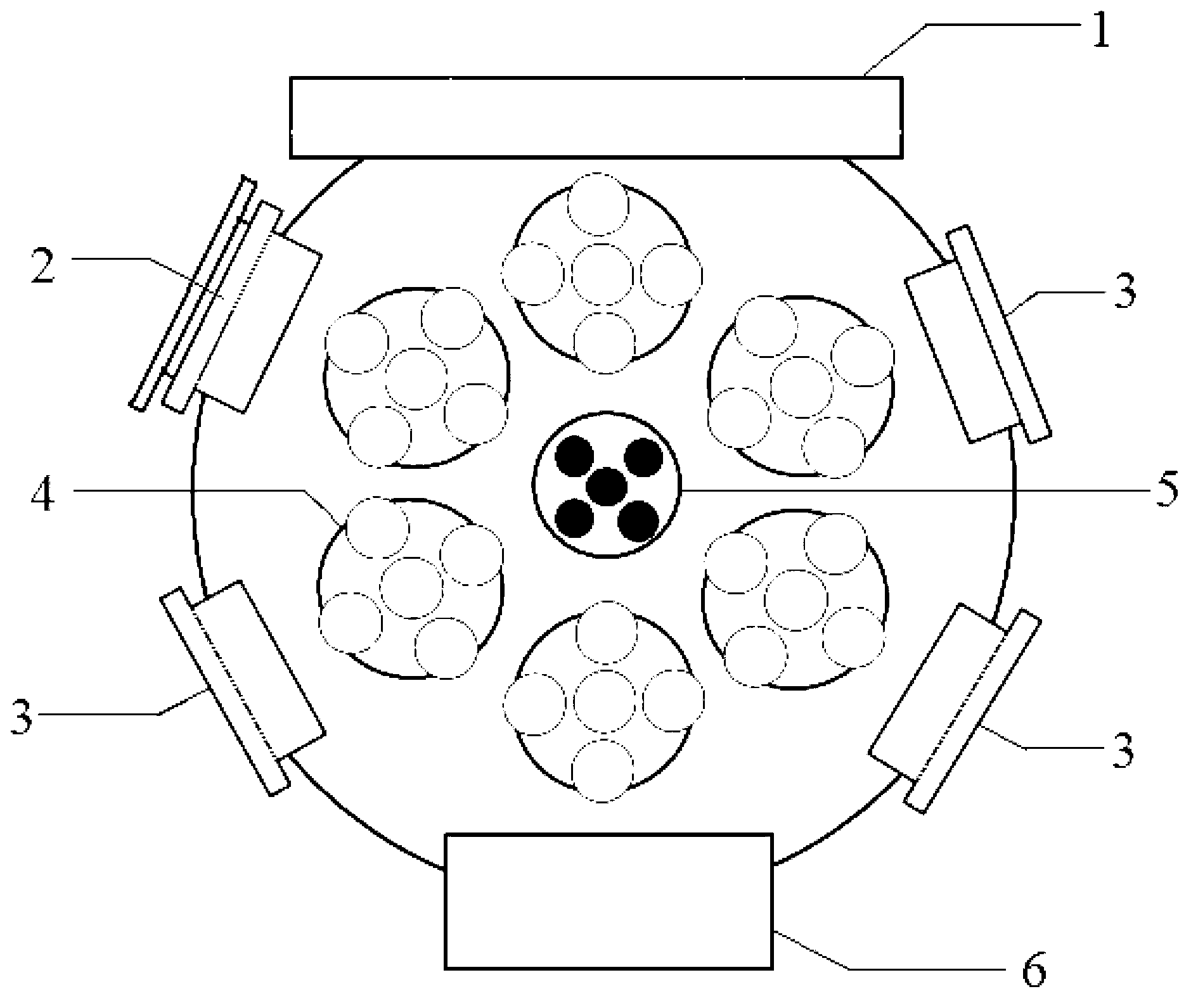

Production method for film generating in-plane uniaxial magnetic anisotropy in non-inducement magnetic field

InactiveCN101429646AExcellent soft magnetic propertiesUniform film formationVacuum evaporation coatingSputtering coatingSputter depositionMagnetic anisotropy

The invention provides a preparation method for an in-plane uniaxial magnetic anisotropic film generated in a non-induction magnetic field, and relates to a soft-magnetic film material. The invention provides the preparation method for the in-plane uniaxial magnetic anisotropic film generated in the non-induction magnetic field. The soft-magnetic film material comprises the following components according to the atomic percentage: 92 to 98 percent of magnetic alloy or magnetic metal and 2 to 8 percent of non-magnetic metal. The preparation method comprises the following steps: assembling a substrate into a sputtering chamber, and installing an iron target and a non-magnetic metal target, or a ferrocobalt target and a non-magnetic metal target; starting a vacuum system for air extraction till the background vacuity of the sputtering chamber is above 5x10<-4>Pa; heating up the substrate to reach a preset temperature of the substrate; and introducing reaction gas into the sputtering chamber to make the target surface build up luminance, carrying out presputtering firstly, then starting a substrate rotating button when the luminance is stable, opening a substrate baffle, and finally carrying out sputtering deposition to obtain the in-plane uniaxial magnetic anisotropic film generated in the non-induction magnetic field.

Owner:XIAMEN UNIV

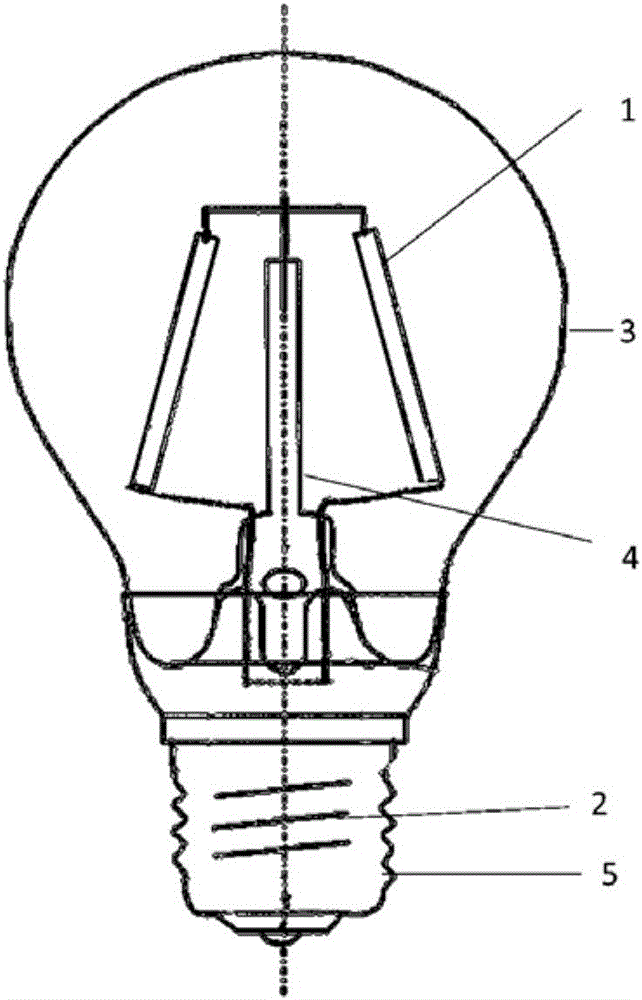

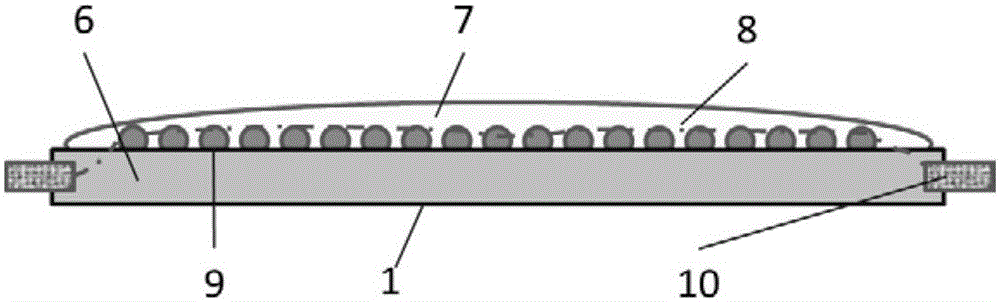

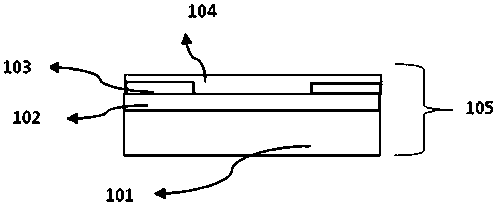

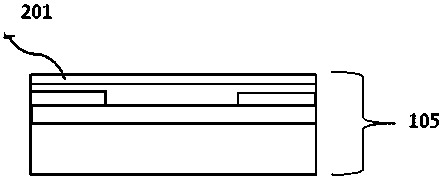

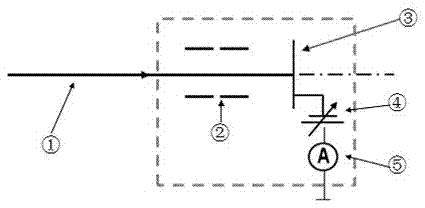

LED-chip shining-light-bar base plate material and LED bulb lamp

InactiveCN106190124AExtended service lifeImprove use reliabilityElectric circuit arrangementsChemical industryColor rendering indexOptical transmittance

The invention relates to an LED-chip shining-light-bar base plate material and an LED bulb lamp. The LED-chip shining-light-bar base plate material and the LED bulb lamp are characterized in that the LED bulb lamp is composed of shining strips (1), a driving power source (2), a glass bulb shell (3), a glass support core column (4) and an electric connector (5); the glass bulb shell (3) and the glass support core column (4) are subjected to vacuum sealing to a cavity to be filled with high thermal conduction gas, the glass support core column (4) and the shining strips (1) fixed on the glass support core column (4) are contained in the sealed cavity; the shining strips (1) are sequentially electrically connected with the driving power source (2) and the electric connector (5); the LED-chip shining strips (1) are composed of YAG, wherein Ce raw material powder and nitride red fluorescence powder are fired to achieve the effect that one face of the base plate material (6) comprises LED blue light chips (9), and the surfaces of the blue light chips (9) are coated with a fluorescent powder layer (7). According to the LED-chip shining-light-bar base plate material and the LED bulb lamp, low-cost preparing of the high-quality transparent fluorescence polycrystal base plate material is achieved with the novel environment-friendly aqueous tape-casting technology. The fluorescence polycrystal base plate material which is high in lighting efficiency, color rendering index and optical transmittance and the bulb lamp which is good in color-temperature consistency heat dissipation, high in reliability and long in service life are obtained.

Owner:张伯文

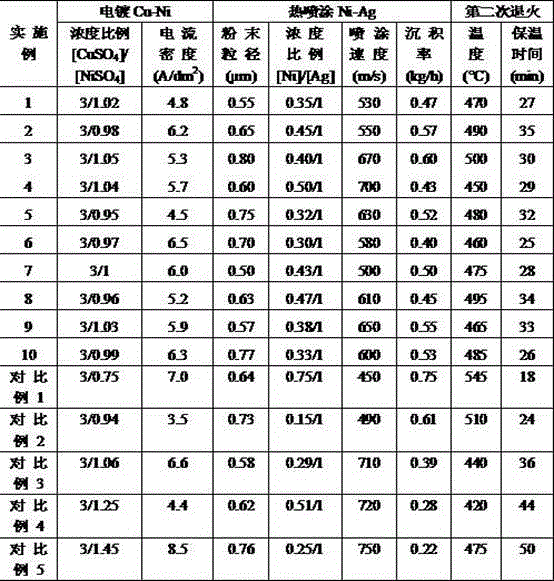

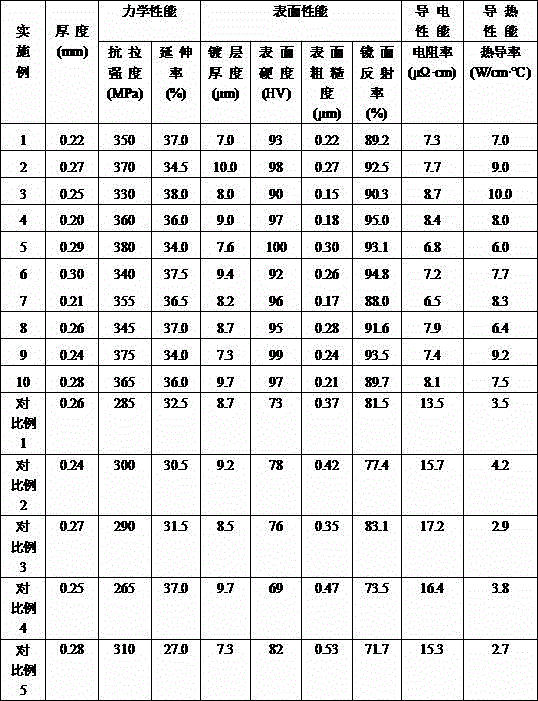

Production method for Cu-Ni/Ni-Ag double-composite coating extra-thin steel strip

InactiveCN104805484ALow costGuaranteed thicknessMolten spray coatingThermal sprayingRoom temperature

The invention discloses a production method for a Cu-Ni / Ni-Ag double-composite coating extra-thin steel strip. The production method comprises the following steps of performing primary cold rolling on an SPHC hot rolled coil subjected to acid pickling; after conventional degreasing is finished, performing primary annealing; performing secondary cold rolling; performing conventional degreasing and coiling; preparing a strip; uncoiling, striping and removing burrs; electroplating Cu-Ni; performing primary conventional washing and drying; performing thermal spraying on Ni-Ag; performing secondary conventional washing and drying; performing secondary annealing; naturally cooling to room temperature and then coiling. According to the product disclosed by the production method disclosed by the invention, the tensile strength is 330 to 380MPa, and the elongation is 34 to 38 percent; a layer of Cu-Ni / Ni-Ag double-composite coating with uniformity, compactness and high adhesive force is generated on the surface of the product; the surface hardness of the coating is 90 to 100HV, the roughness of the coating is 0.15 to 0.30 mu m, the mirror reflectivity is 88 to 95 percent, the resistivity is 6.5 to 8.7 mu omega cm, and the thermal conductivity is 6 to 10W / cm DEG C. The problems of high cost, great waste, serious pollution and low efficiency caused by a traditional process are solved.

Owner:武钢集团有限公司

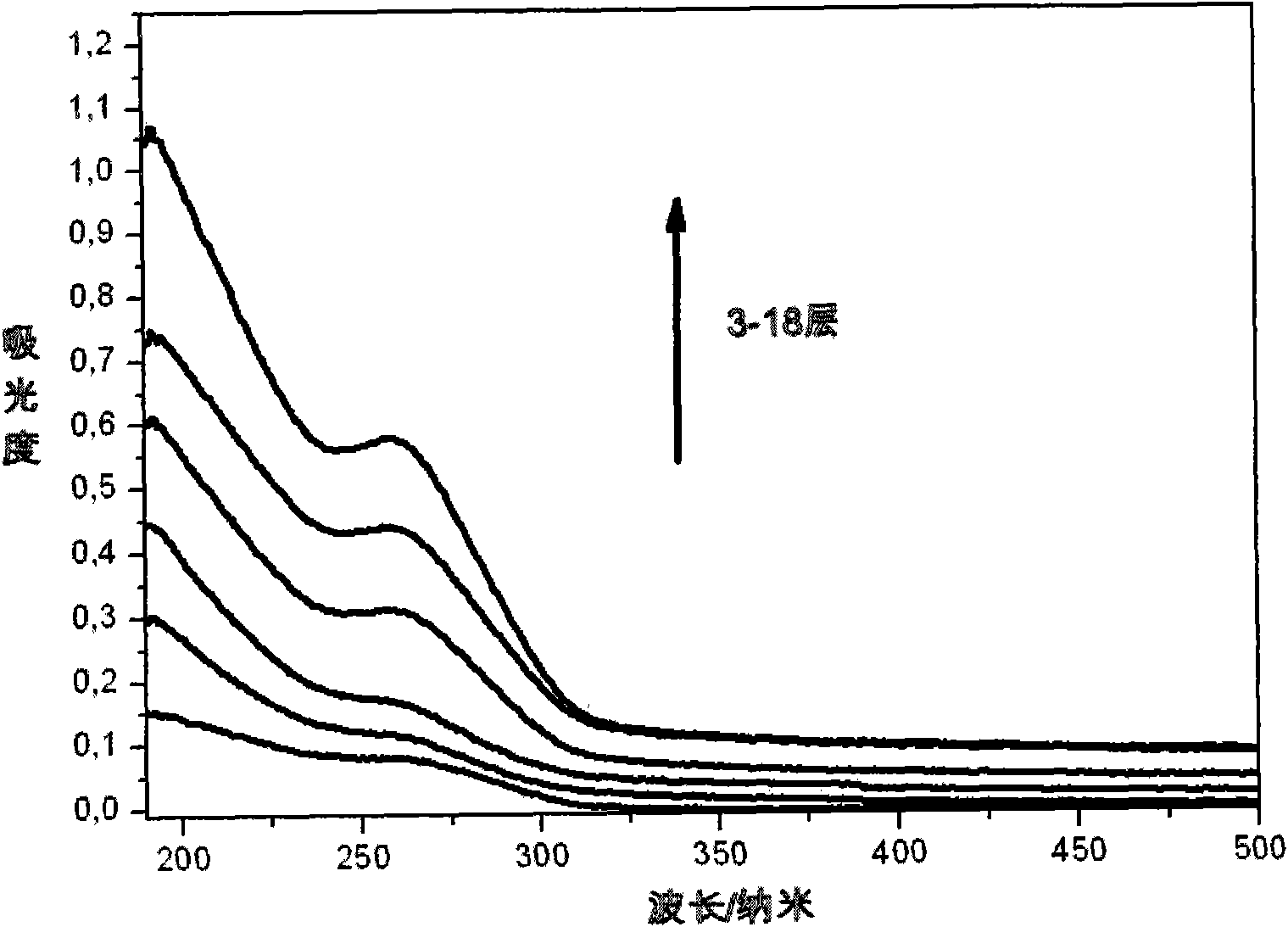

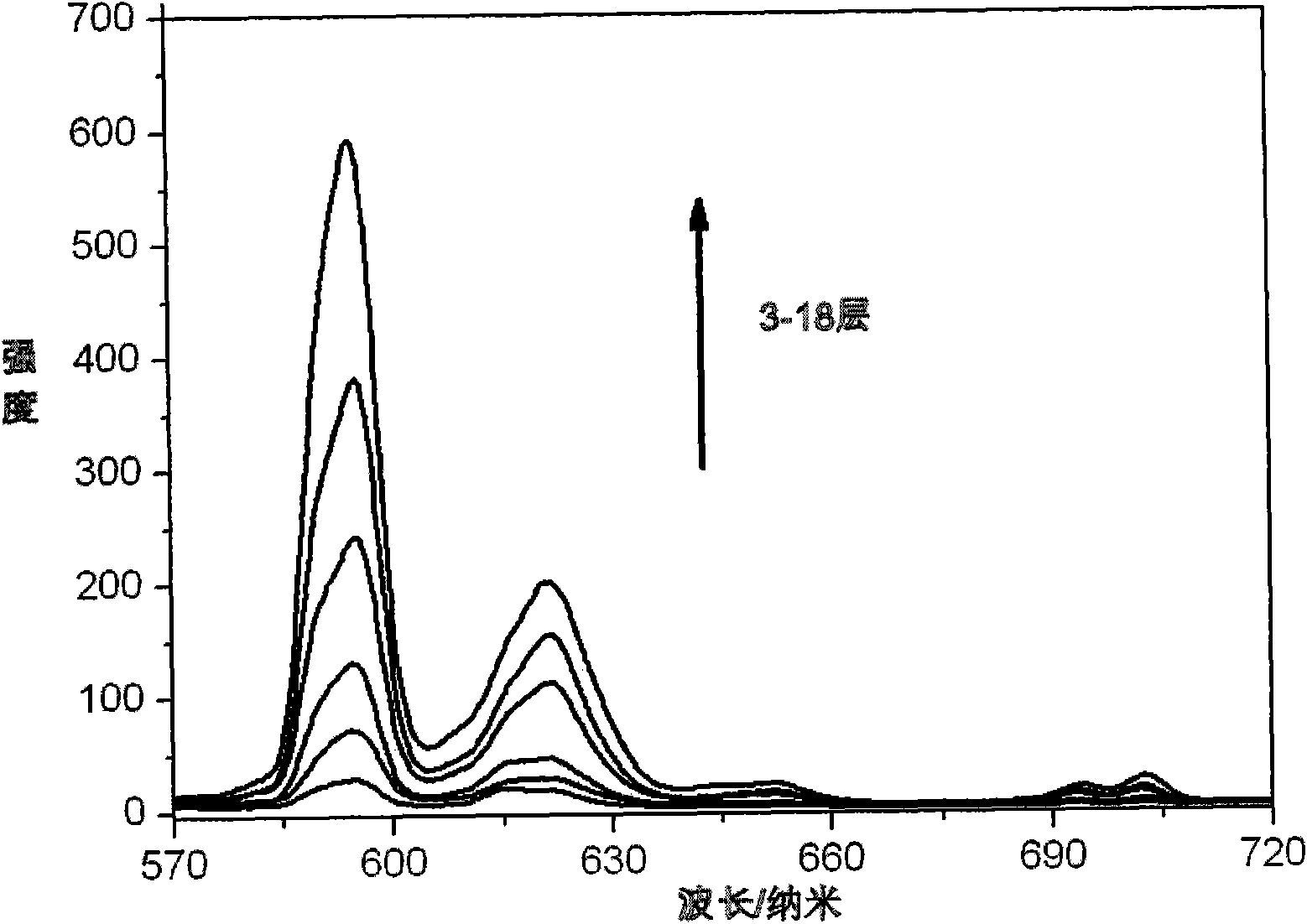

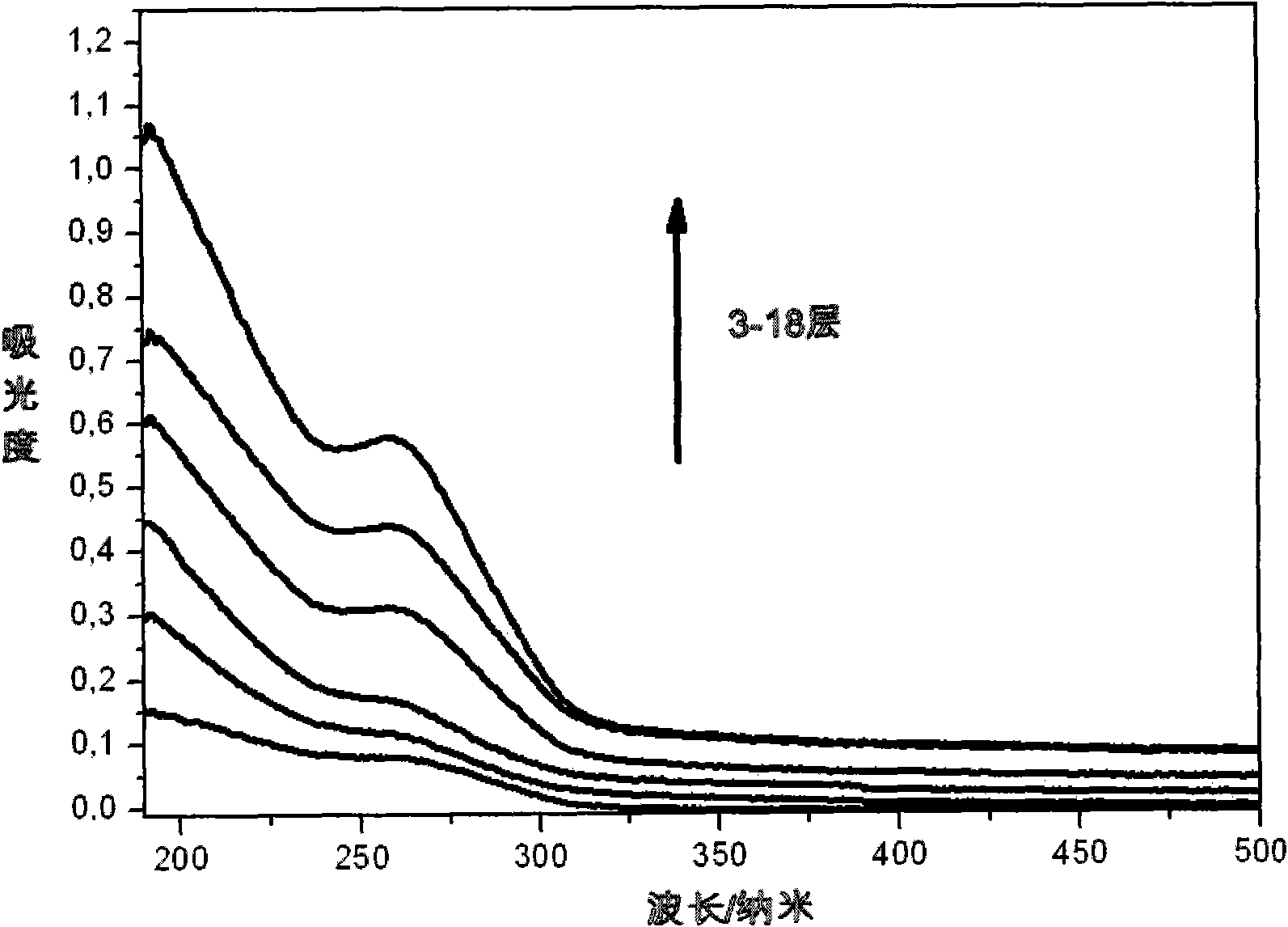

Composite luminescent film containing rare earth polyacid and brucite and preparation method thereof

The invention discloses a composite luminescent film containing rare earth polyacid and brucite and a preparation method thereof and belongs to the technical field of the preparation of inorganic composite luminescent films. The preparation method comprises the following steps of: preparing brucite colloidal solution stripped by using a formamide solvent; confecting rare earth polyacid-containingsolution; and performing a plurality of alternate assemblies in two types of solution by using a hydrophilically-treated substrate to obtain a composite multilayer luminescent film containing the rare earth polyacid and the brucite. In the preparation method, sequential assembly of rare earth polyacid-containing functional molecules and brucite nanosheets is realized for the first time, and the application field of a material containing the rare earth polyacid and the brucite is expanded. The thickness of the obtained film is accurately controllable in nanoscale. Simultaneously, the space limiting function of the brucite and coaction between a host and a guest are utilized, so that the immobilization of luminescent molecules containing the rare earth polyacid is realized, the controllableluminous intensity of the film is realized by changing assembly times, the thermal stability of the film is enhanced effectively, and fluorescent quenching caused by aggregation is reduced.

Owner:BEIJING UNIV OF CHEM TECH

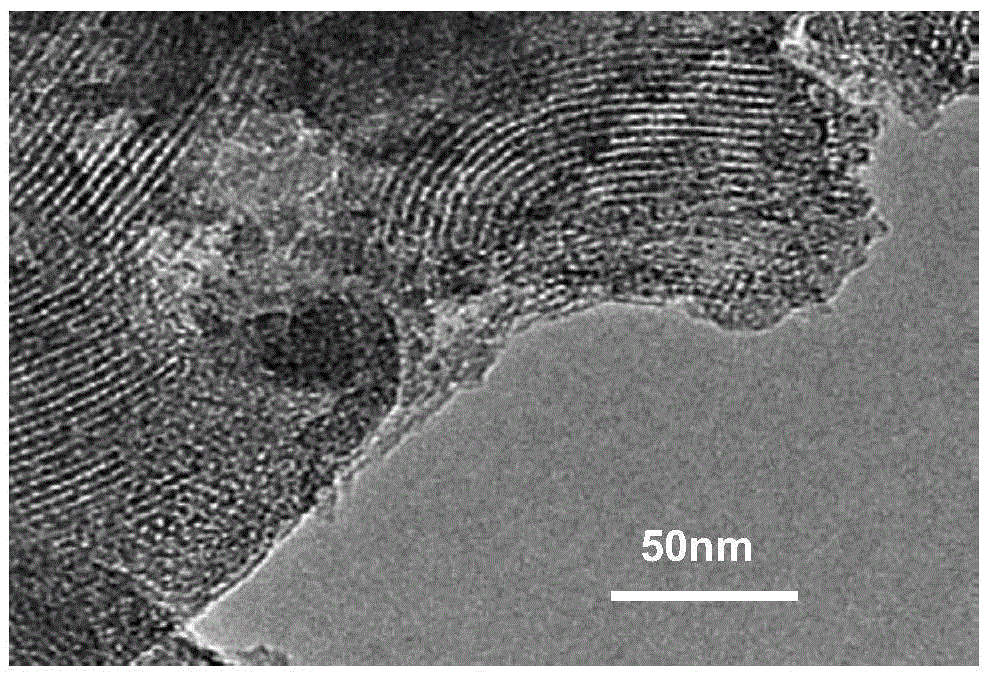

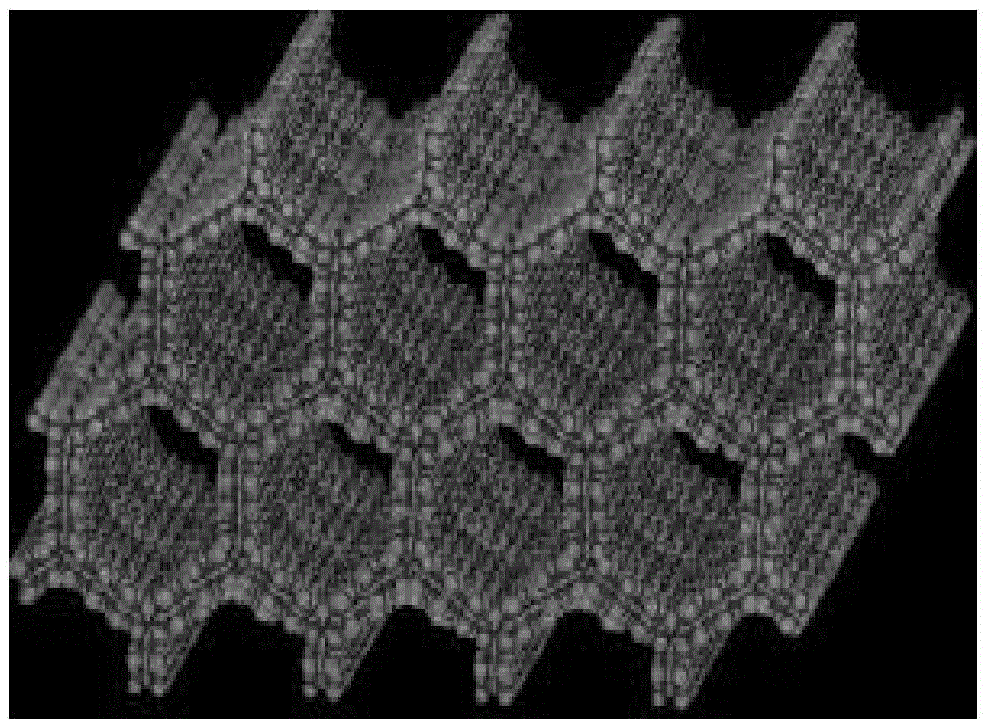

Method for preparing acetylene selective hydrogenation catalyst

ActiveCN105536851ASimple structureUniform film formationMolecular sieve catalystsCatalyst activation/preparationDispersityNano structuring

The invention discloses a method for preparing an acetylene selective hydrogenation catalyst. The method mainly overcomes the defects that in the prior art, Pd particle size distribution is wide, distribution uniformity is poor, and a metallic oxide serving as a substrate lacks a controllable nano structure. Firstly, a three-dimensional nano structure is provided through a mesoporous material, a metallic oxide is deposited on the structure, and a metallic oxide substrate with the three-dimensional nano structure same as the mesoporous material is obtained; then, by means of the atomic layer deposition, nano Pd metal particles are loaded and deposited on the surface of the metallic oxide substrate, and the loading amount of Pd and the metallic oxide can be adjusted according to different deposition period numbers. The catalyst prepared through the method is of the three-dimensional nano structure and large in specific surface area, the Pd metallic particles are high in dispersity, uniform in distribution, uniform in size and good in activity, selectivity and stability in the acetylene selective hydrogenation catalysis reaction. The method avoids the characteristics that metallic particle size distribution is wide and distribution is not uniform in the preparation process of an impregnation method and a chemical plating method.

Owner:XIAN MODERN CHEM RES INST

Stripable paint for laser impact treatment

This invention discloses a strippable coating for laser shock processing, which is composed of carbon powders 5-15 wt.%, bonding agent 50-70 wt.%, self-drying thinner 15-35 wt.% and additive 2-5 wt.%. The thickness of the coating layer is generally 60-150 mums. The strippable coating is manufactured by: (1) placing carbon powders in a reactor, and adding bonding agent, self-drying thinner and additive; and (2) stirring uniformly, and adjusting the pH value to 7.5 with 25% ammonia solution. The strippable coating can intimately adhere to the surface of metals, and cannot be stripped during continuous laser shock process, thus having a good shock effect.

Owner:JIANGSU UNIV

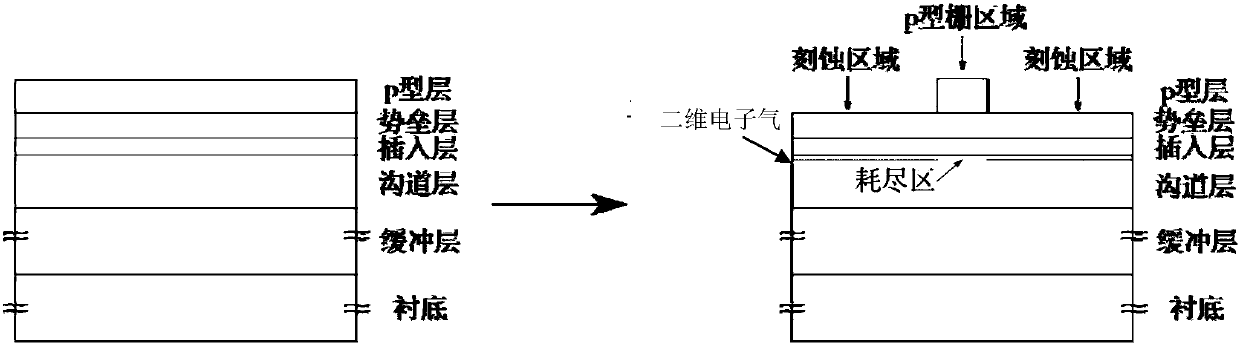

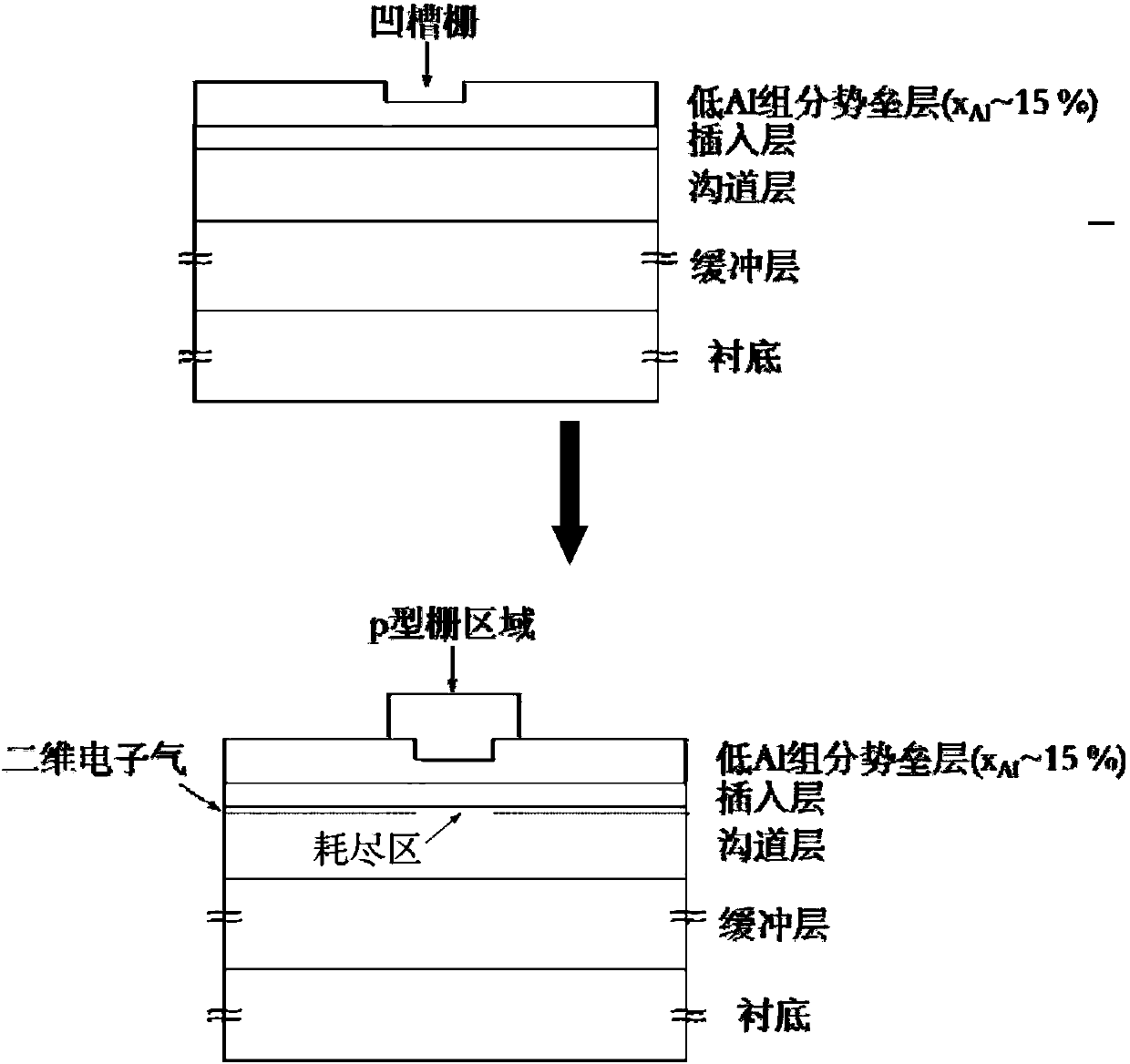

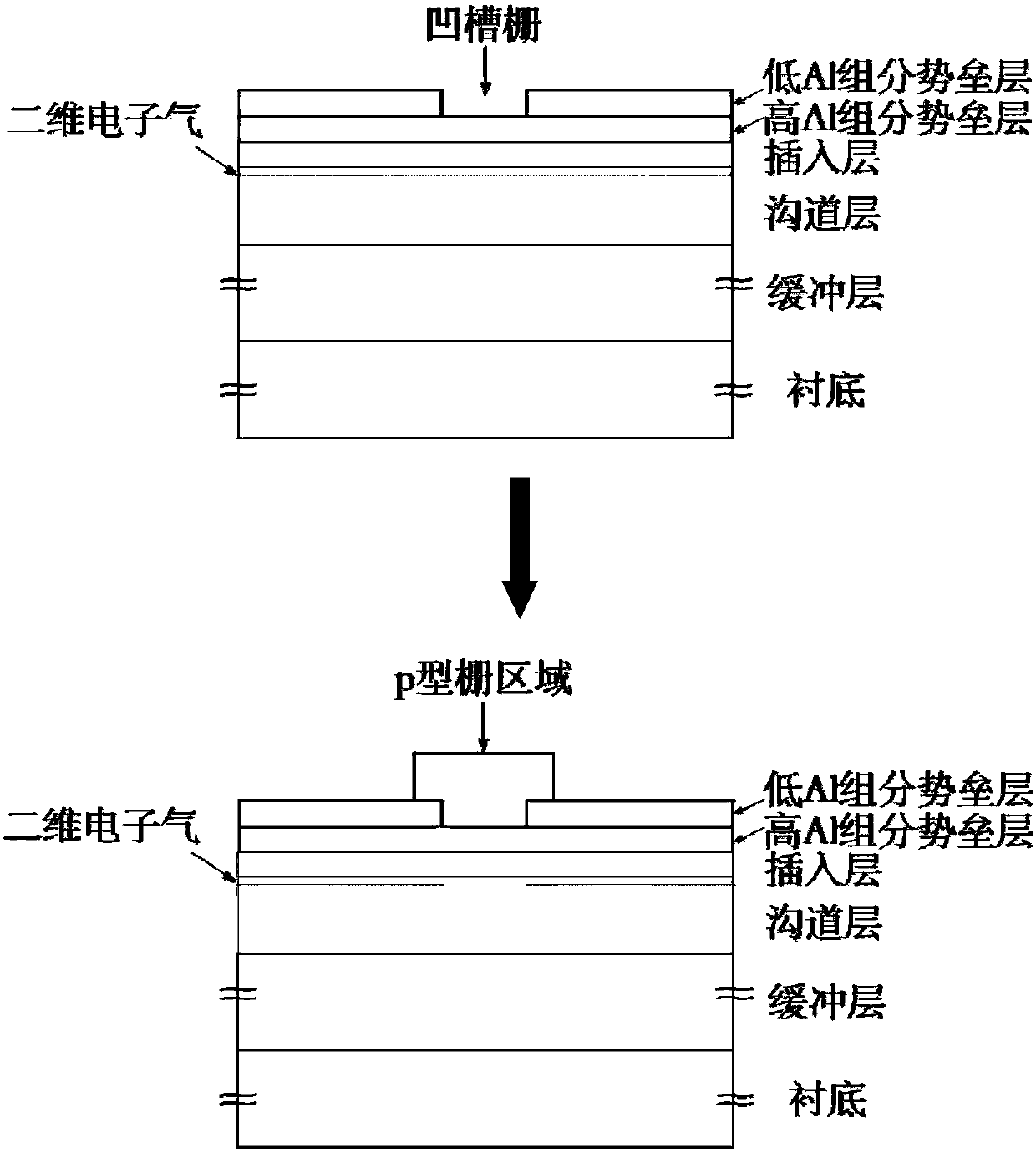

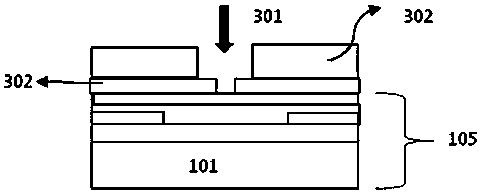

III-nitride enhanced HEMT based on composite barrier layer structure and manufacturing method of III-nitride enhanced HEMT

ActiveCN110034186ASuppress leakageSimplify the etch processSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringNitride

The invention discloses a III-nitride enhanced HEMT based on a composite barrier layer structure and a manufacturing method of the III-nitride enhanced HEMT. The HEMT comprises a first semiconductor,a second semiconductor, a third semiconductor serving as a p-type layer, a source electrode, a drain electrode, a grid electrode and the like, wherein the first semiconductor and the second semiconductor respectively serve as a channel layer and a barrier layer, a groove structure is formed in the area, corresponding to the grid electrode, of the barrier layer, the groove structure cooperates withthe third semiconductor and the grid electrode to form a p-type grid, and the second semiconductor comprises a first structure layer and a second structure layer which are sequentially arranged on the first semiconductor. Compared with a mode of determining an etching reagent, the first structure layer has higher etching resistance than the second structure layer. The HEMT structure can be more accurately regulated and controlled, meanwhile, the HEMT has the better device performance. For example, the forward gate leakage and gate threshold voltage swing amplitude are remarkably improved, thein-chip uniformity of threshold voltage of the device can be guaranteed, and meanwhile, the HEMT structure is easier to manufacture and suitable for large-scale production.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

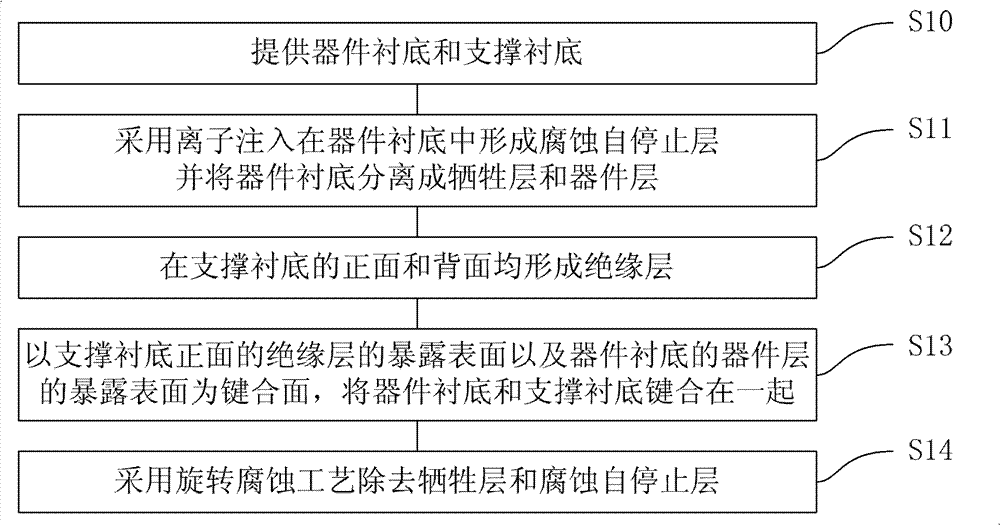

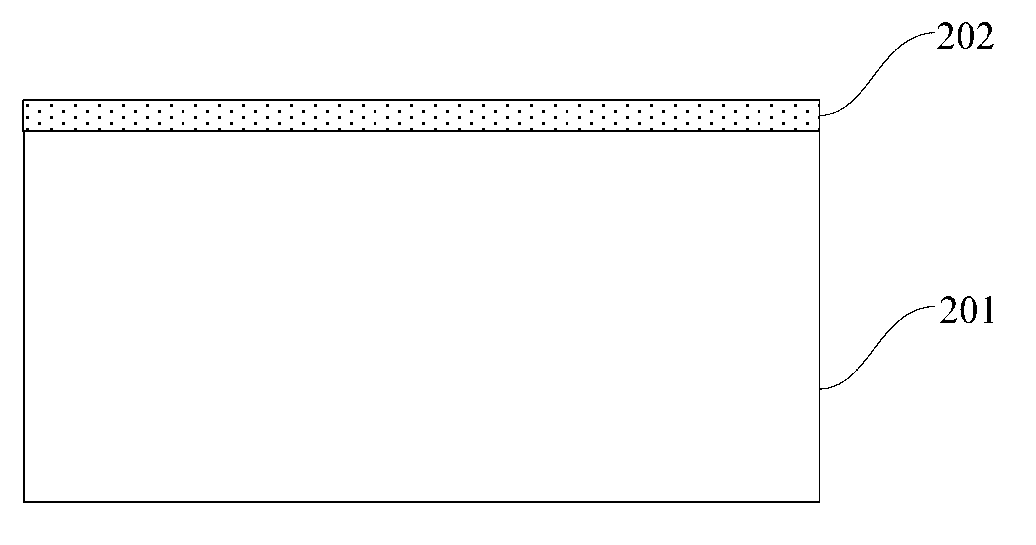

Method for preparing substrate with buried insulation layers by selective etching

InactiveCN102903607AAvoid damagePrecise and controllable thicknessSemiconductor/solid-state device manufacturingEtchingEngineering

The invention provides a method for preparing a substrate with buried insulation layers by selective etching. The method includes the steps: providing a device substrate and a support substrate; forming an etching self-stopping layer on the device substrate by ion implantation, and separating the device substrate into a sacrificial layer and a device layer; forming insulation layers on the front side and the back side of the support substrate; bonding the device substrate and the support substrate together by using the exposed surface of the insulation layer on the front side of the support substrate and the exposed surface of the device layer of the device substrate as bonding surfaces; and removing the sacrificial layer and the etching self-stopping layer by the whirl etching process so as to form the substrate composed of the device layer, the insulation layers and the support substrate and provided with the buried insulation layers.

Owner:SHANGHAI SIMGUI TECH +1

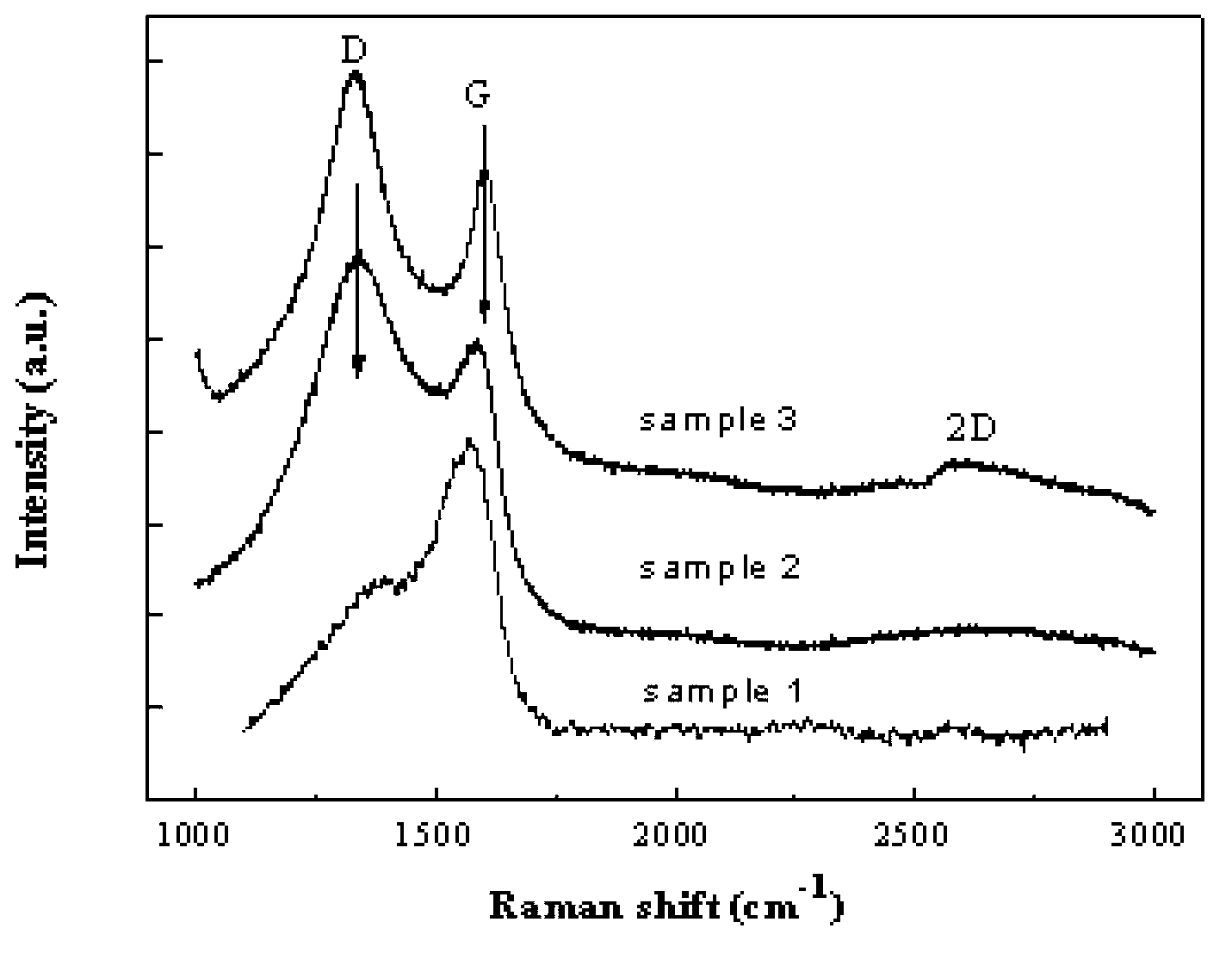

Method for preparing graphene or ultrathin carbon film by PVD (physical vapor deposition) technique

ActiveCN103266306AQuality improvementReduce formationChemical vapor deposition coatingCarbon filmElectric field

The invention provides a method for preparing a graphene or ultrathin carbon film by a PVD (physical vapor deposition) technique, which comprises the following steps: putting a substrate on a substrate rack in a deposition chamber, and carrying out glow cleaning on the substrate surface; introducing an acetylene-argon gas mixture into the gas mixture at 70-100 DEG C in an argon environment under the conditions of vacuum degree 0.5-1 Pa and the substrate voltage bias -200V; opening an anode layer ion source to ionize the gas mixture, wherein the voltage of the anode layer ion source is 300-500V in the ionization process, the acetylene is ionized to generate carbonous cations, and the cations bombards the substrate under the action of an electric field and deposits on the substrate; and after the deposition is finished, annealing under vacuum conditions for 1-2 hours, thereby preparing the graphene or ultrathin carbon film on the substrate surface after the annealing is finished. The method provided by the invention can satisfy the large-scale preparation of uniform-thickness graphene or ultrathin carbon films, and has important industrial application prospects.

Owner:YICHANG HOUHUANG VACUUM TECH

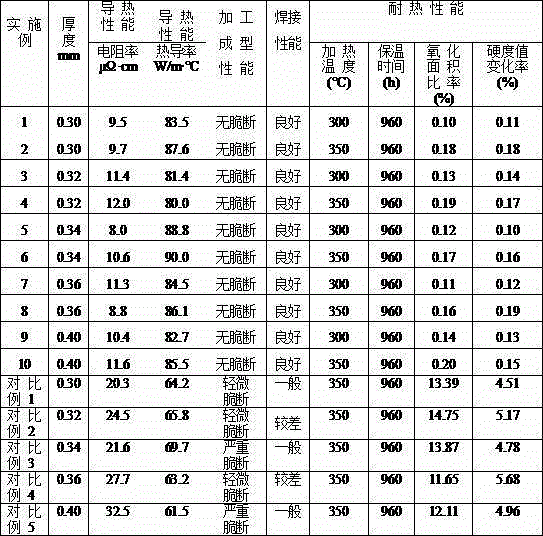

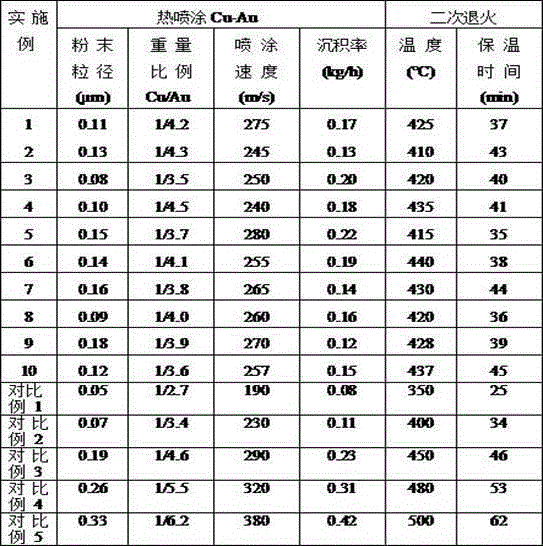

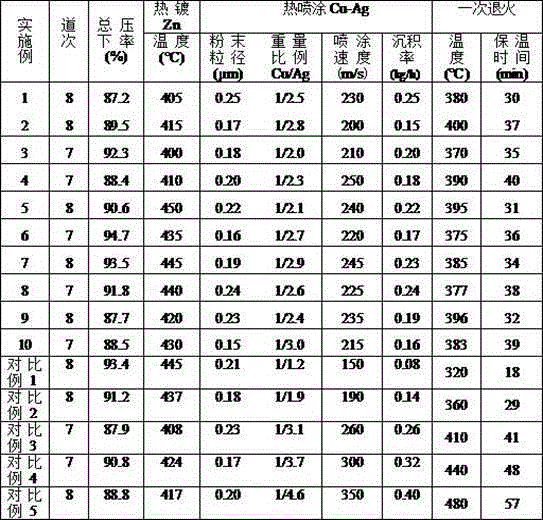

Production method of Zn/Cu-Ag/Cu-Au composite coating steel band for photoelectric material

ActiveCN105063620AReduce internal stressGuaranteed surface finishSuperimposed coating processLoss rateHydrogen

A production method of a Zn / Cu-Ag / Cu-Au composite coating steel band for a photoelectric material comprises the following steps: using a 08Al cold-rolled steel sheet as a raw material and carrying out cold rolling; after conventional degreasing, carrying out uncoiling, splitting and deburring; hot-dipping Zn; thermally spraying Cu-Ag; carrying out primary annealing at a pure nitrogen protective atmosphere; thermally spraying Cu-Au; carrying out secondary annealing at a pure nitrogen protective atmosphere; and air-cooling to a room temperature and coiling. The tensile strength is 250-300MPa, and the elongation percent is 42-48%. One Zn / Cu-Ag / Cu-Au composite coating is generated on the surface. After the Zn / Cu-Ag / Cu-Au composite coating steel band is placed under an indoor conventional atmospheric condition for 960 days, the gloss loss rate of the coating is not larger than 0.3%, and the surface corroded area is not larger than 0.3%. The product has excellent electricity and heat conductivity. After the Zn / Cu-Ag / Cu-Au composite coating steel band is kept at 300-350 DEG C for 960 days, the surface oxidized area is not larger than 0.2%, and the hardness variation rate is not larger than 0.2%. The product also has excellent welding and machining performance.

Owner:武汉钢铁有限公司

Method for improving charge accumulation in GaN HEMT (High Electron Mobility Transistor) surface electron beam direct writing

ActiveCN107910371AFlat surfaceImprove consistencySemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricAdhesive

The invention relates to a method for improving charge accumulation in GaN HEMT (High Electron Mobility Transistor) surface electron beam direct writing. The method is characterized by comprising theprocessing steps of (1) preparation of components; (2) preparation of nanometer thin layer metal germanium; (3) preparation of an electron beam direct writing gate; (4) first removing of the nanometerthin layer metal germanium; (5) etching of a gate dielectric, and evaporation and stripping of gate metal; and (6) second removing of the nanometer thin layer metal germanium. The advantages are that1, the metal germanium is adopted to serve as a bottom conductive layer, the consistency is good, the thickness can be accurately controlled, and an electron beam adhesive coated at the surface has good adhesion and is easy to be removed; 2, the metal germanium with the thickness being below 10nm can have very good conductive characteristics and has an excellent effect for improving charge accumulation of GaN HEMT surface electron beams.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

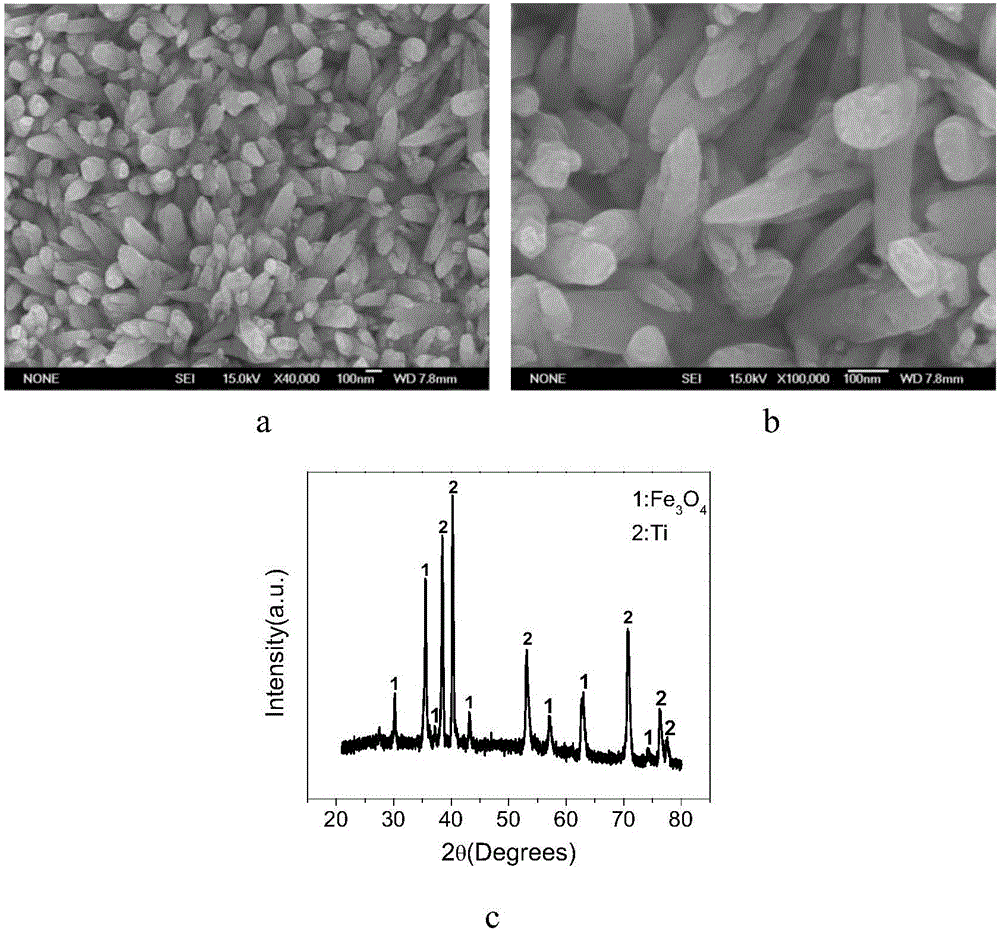

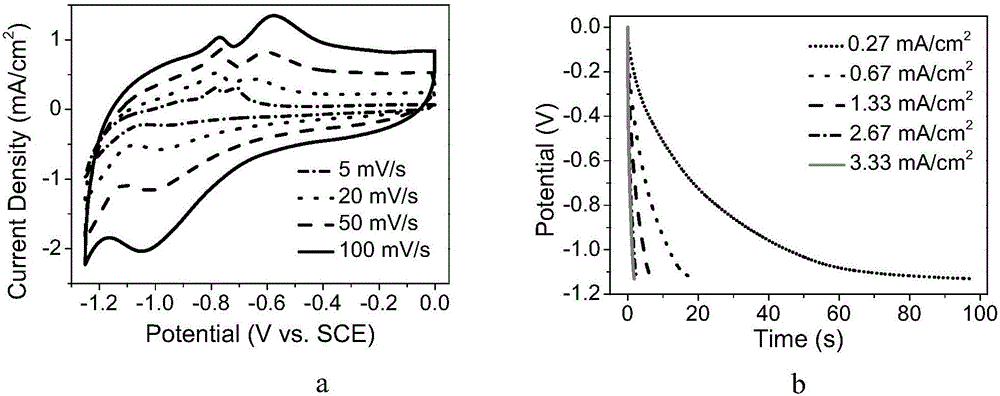

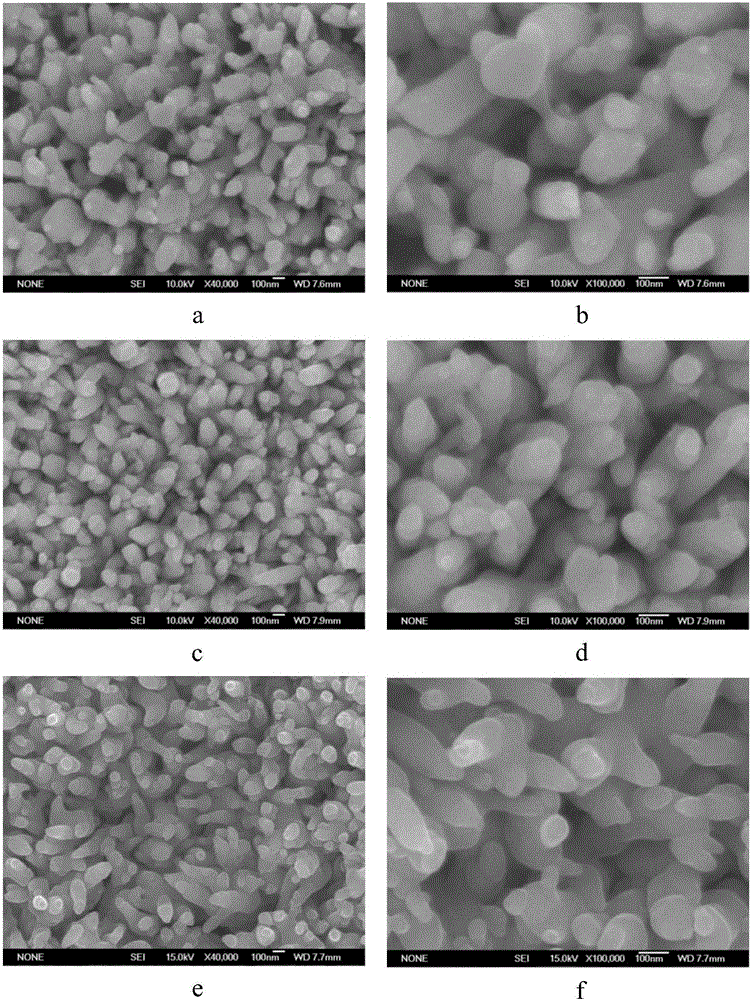

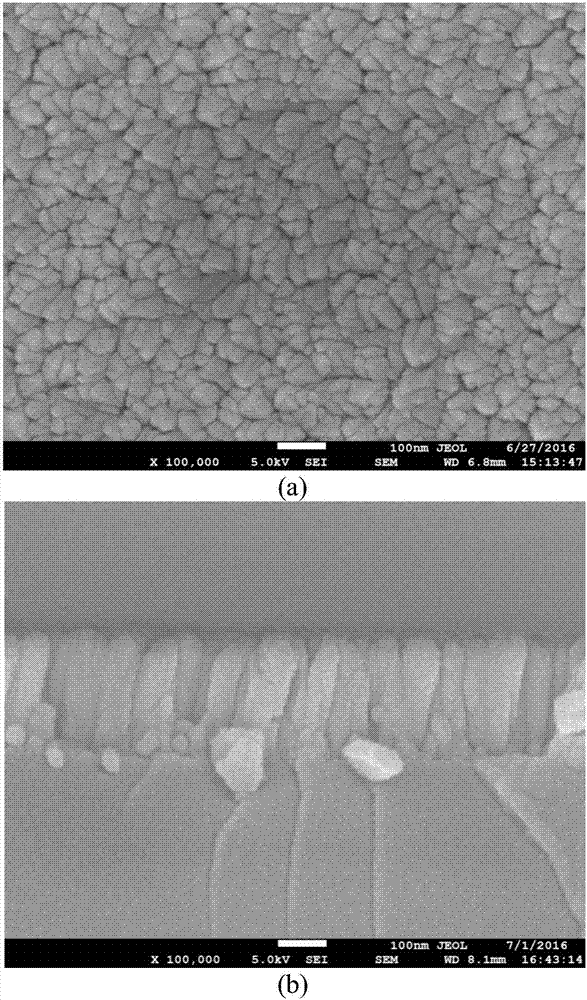

Ferroferric oxide@titanium dioxide nanorod array electrode on titanium substrate and preparation method of ferroferric oxide@titanium dioxide nanorod array electrode

ActiveCN106531989AImprove cycle performanceIncrease capacityMaterial nanotechnologyHybrid capacitor electrodesElectrolytic agentTitanium metal

The invention relates to a ferroferric oxide@titanium dioxide nanorod array electrode on a titanium substrate and a preparation method of the ferroferric oxide@titanium dioxide nanorod array electrode. The ferroferric oxide@titanium dioxide nanorod array electrode on the titanium substrate is characterized by comprising a titanium metal substrate and a ferroferric oxide@titanium dioxide composite nanorod array growing on the titanium metal substrate; the diameter of a single composite nanorod is 85-115nm and the composite nanorods are vertically, uniformly and densely distributed on the surface of the titanium metal substrate and are in an array form; and titanium dioxide coats the outer surface of ferroferric oxide. According to a titanium dioxide protection layer of the ferroferric oxide@titanium dioxide nanorod array electrode on the titanium substrate, the cycle performance of the electrode can be greatly improved, the side reaction of water electrolysis in an electrolyte is effectively suppressed, the capacity of the electrode is improved, the electrochemical properties are greatly improved, and particularly, the cycle performance is outstanding; and the ferroferric oxide@titanium dioxide nanorod array electrode can be used as a negative electrode material for a water-based hybrid super-capacitor (or other hybrid electrochemical energy storage devices).

Owner:WUHAN UNIV OF TECH

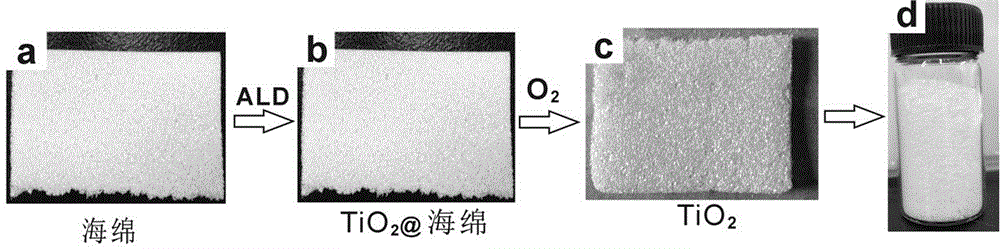

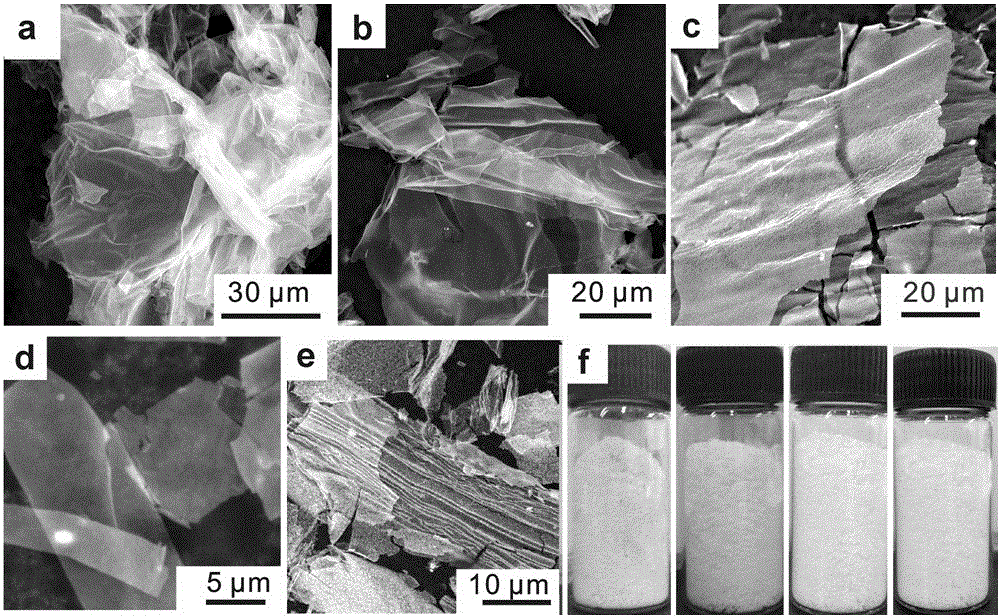

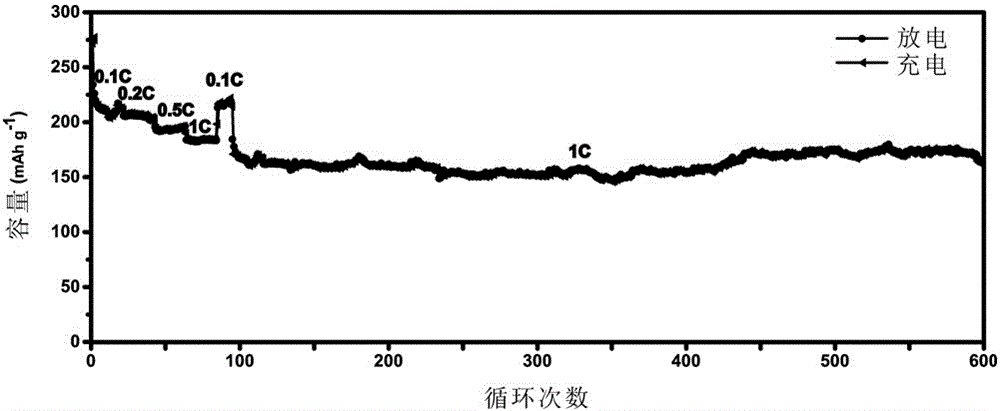

Two-dimensional nanometer thin film negative electrode material of lithium ion battery and preparation method of negative electrode material

InactiveCN106207147AUniform and dense thicknessGood flexibilityCell electrodesSecondary cellsLithium electrodeLithium battery

The invention belongs to the technical field of electrochemistry, and in particular relates to a two-dimensional nanometer thin film negative electrode material of a lithium ion battery and a preparation method of the negative electrode material. The problems of abrupt capacity attenuation and poor stability of a TiO2 negative electrode during large-current charge and discharge are solved by preparing a TiO2 two-dimensional nanometer structure. The preparation method comprises the following steps of growing a TiO2 nanometer thin film on a sponge by an atomic layer deposition method; and performing thermal treatment on the sponge coated with the TiO2 nanometer thin film to remove the sponge so as to obtain a TiO2 two-dimensional nanometer thin film after deposition frequency is reached, wherein the thin film is used for a negative electrode of the lithium ion battery. By simply changing the deposition frequency, the nanometer thin films with different thicknesses can be obtained. The preparation method has the advantages of simplicity in process, high repeatability and high yield. The negative electrode material of the lithium ion battery, prepared according to the method, has the advantages of structural stability and good cycle performance.

Owner:FUDAN UNIV

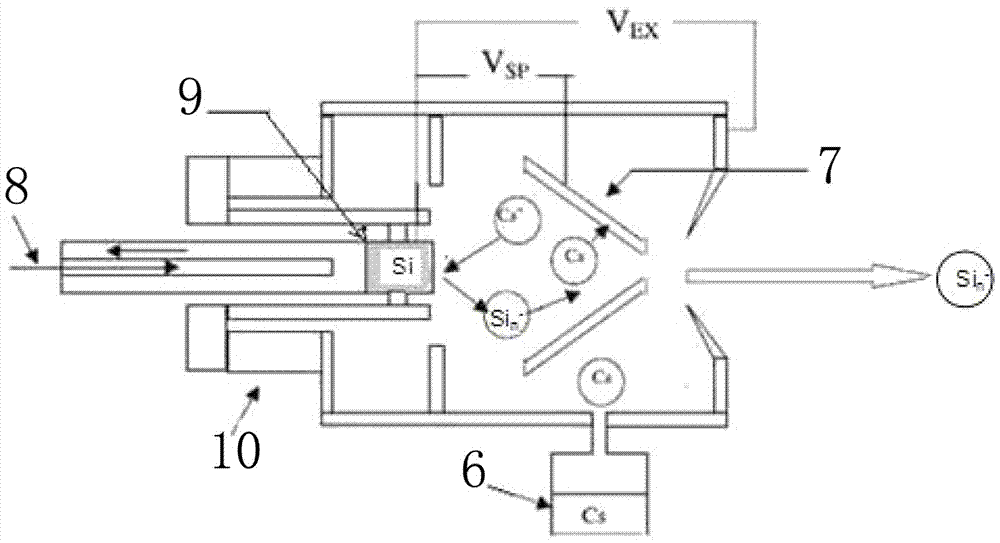

Preparation method of silene

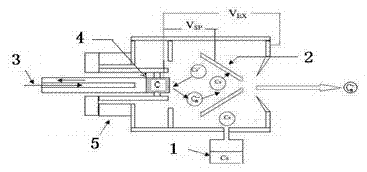

ActiveCN105439148APrecise and controllable thicknessImprove uniformitySilicon compoundsElectric fieldVoltage

The invention provides a method for preparing silene. The method specifically comprises: processing silicon blocks into a concave tapered silicon target; mounting the silicon target on a sputtering target of a cesium sputtering negative ion source; sputtering the silicon target by using cesium ions; leading out Si<2-> cluster negative ion beams generated by sputtering from extraction electrode extraction holes, wherein Si<2-> cluster negative ions are uniformly deposited on an Ag (111) substrate through scanning electric field after being accelerated by extraction electrode voltage; and putting a sample into a vacuum chamber, sputtering the surface of the sample by Ar<+> ions, and then carrying out annealing treatment on the sample in an ultrahigh vacuum to finish the preparation of silene. According to the preparation method provided by the invention, by using the advantages of low energy of a single atom of low-energy cluster negative ion beams, and an accurate and controllable dose, the silene can be prepared directly by virtue of a direct deposition method.

Owner:武汉纽飞格纳米科技有限公司

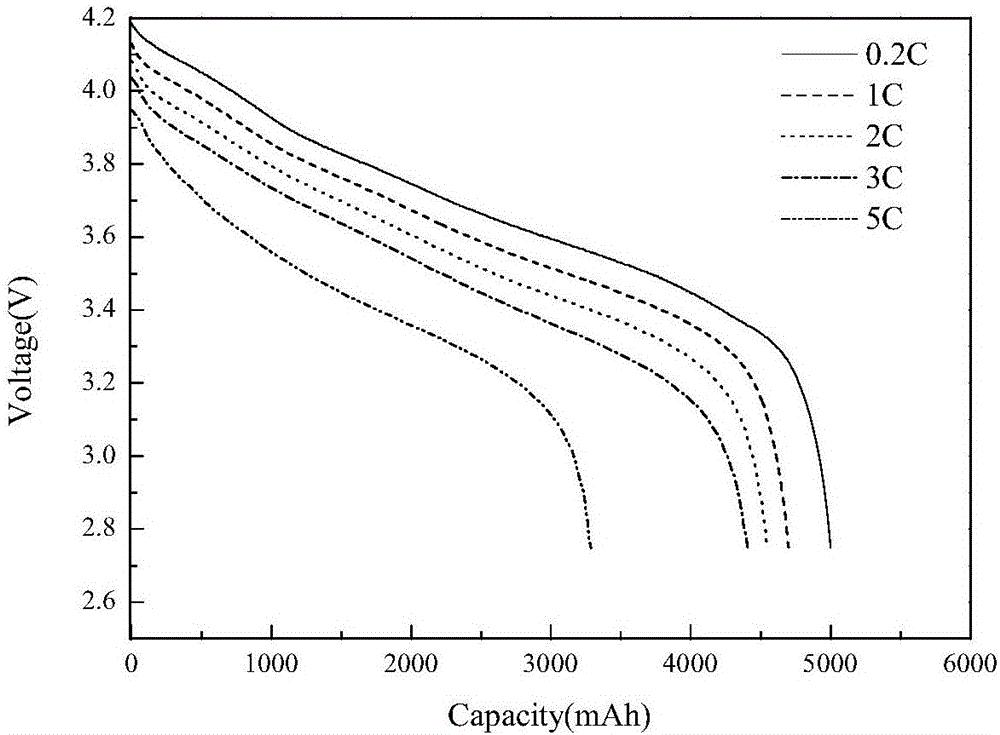

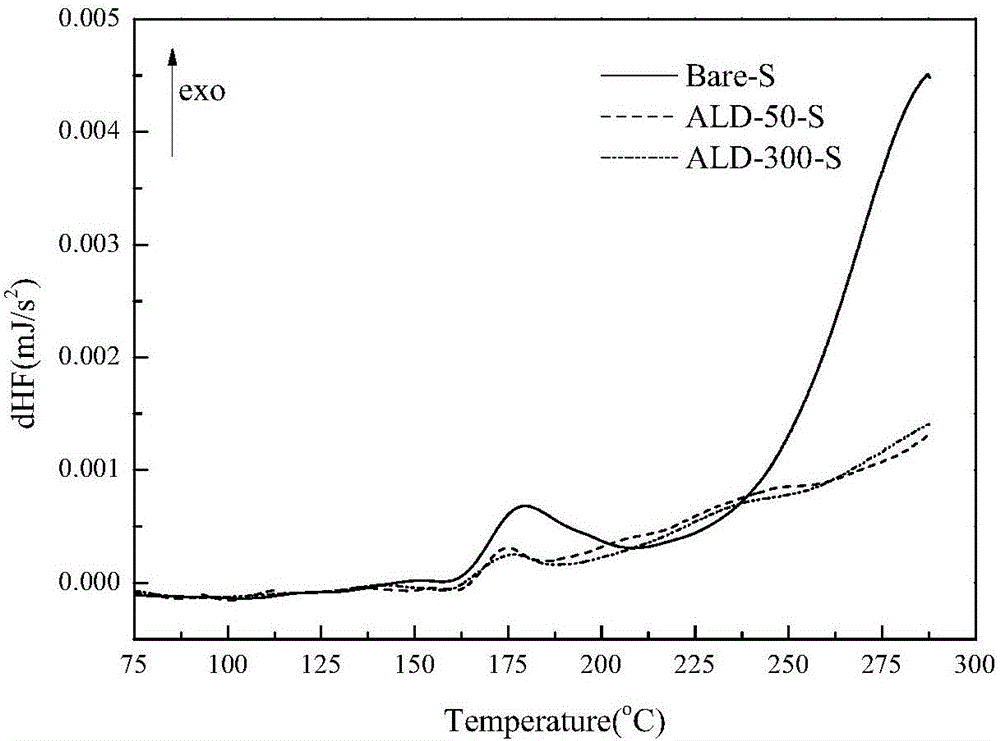

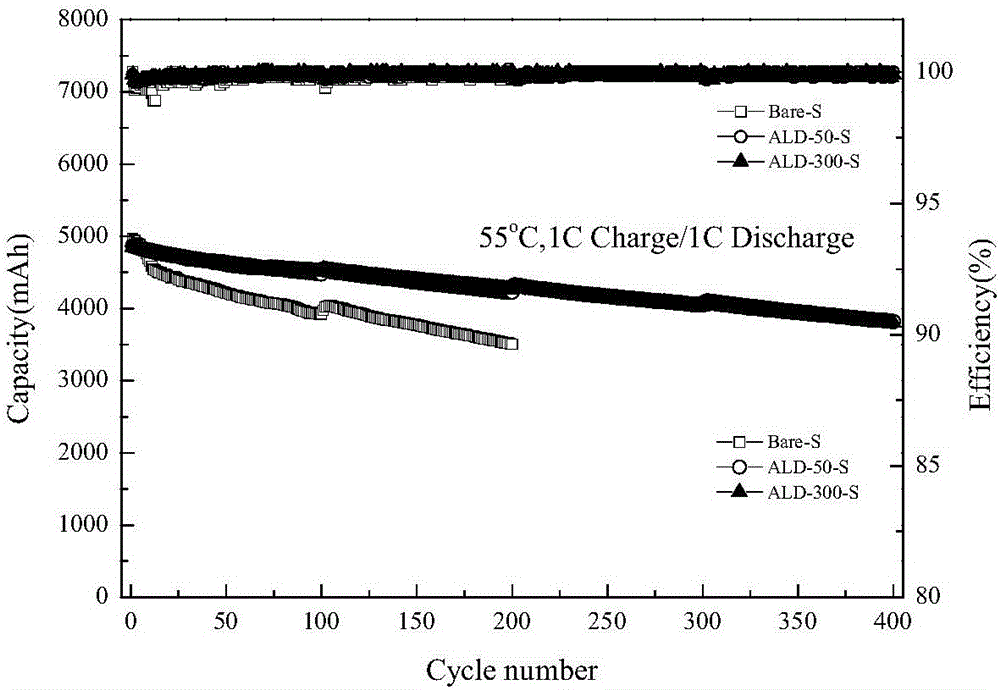

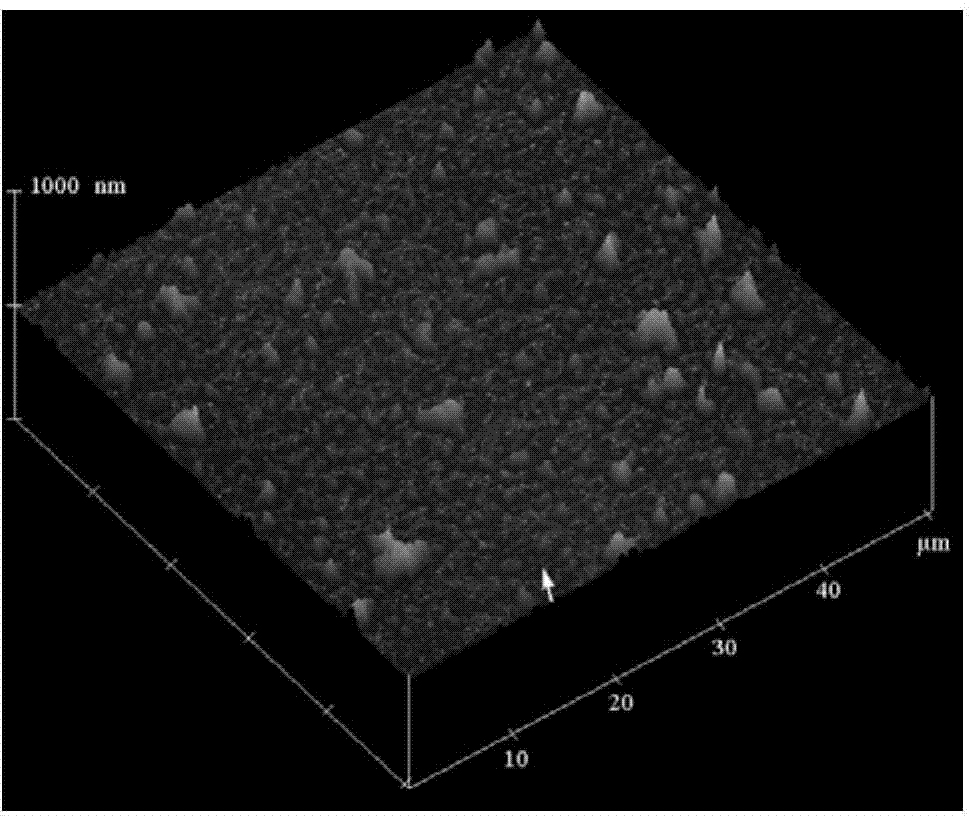

Atomic layer deposition modified lithium-ion battery and preparation method thereof

InactiveCN106384838AImprove high temperature stabilityImprove cycle stabilitySecondary cellsVapour deposition manufacturingPole pieceEngineering

The invention discloses an atomic layer deposition (ALD) modified lithium-ion battery and a preparation method thereof. According to the atomic layer deposition modified lithium-ion battery disclosed by the invention, a modification layer is formed on at least one surface of a positive electrode active material and a negative electrode active material; each modification layer is formed through adopting an atomic layer deposition process; or a modification layer is formed at least one surface of a positive electrode pole piece and a negative electrode pole piece, and each modification layer is formed through adopting the atomic layer deposition process.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

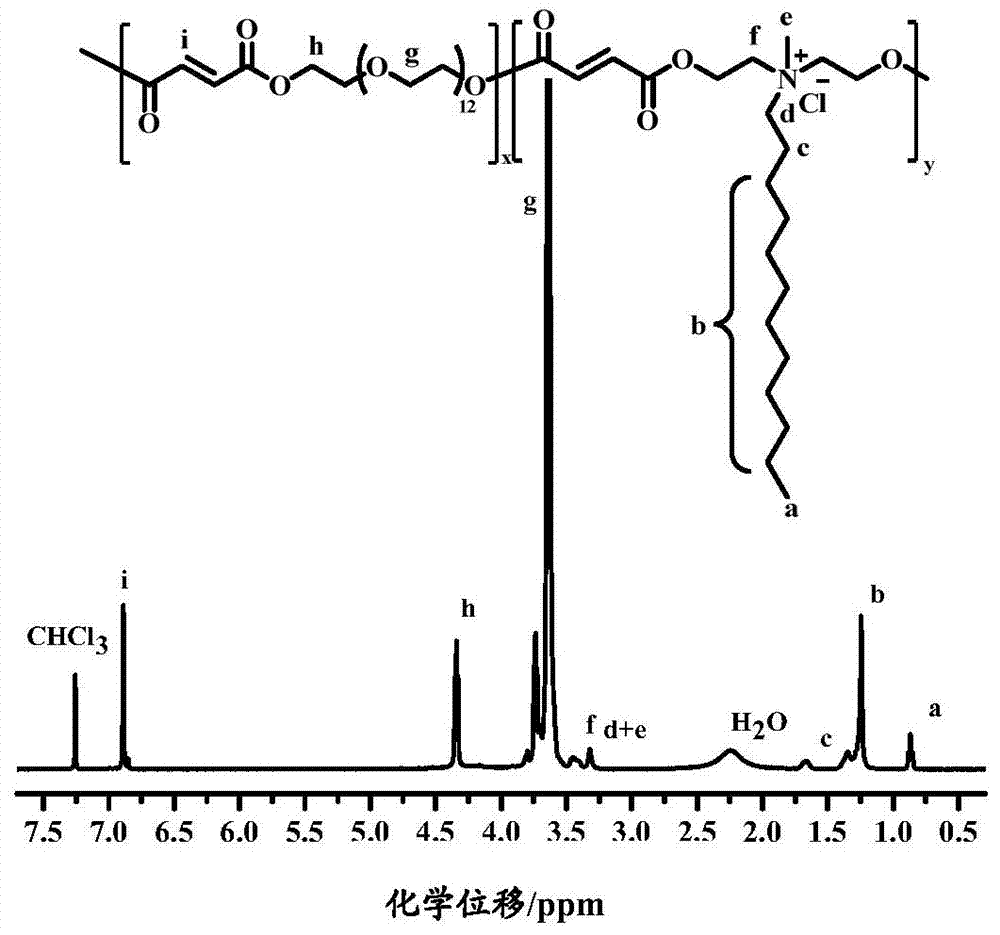

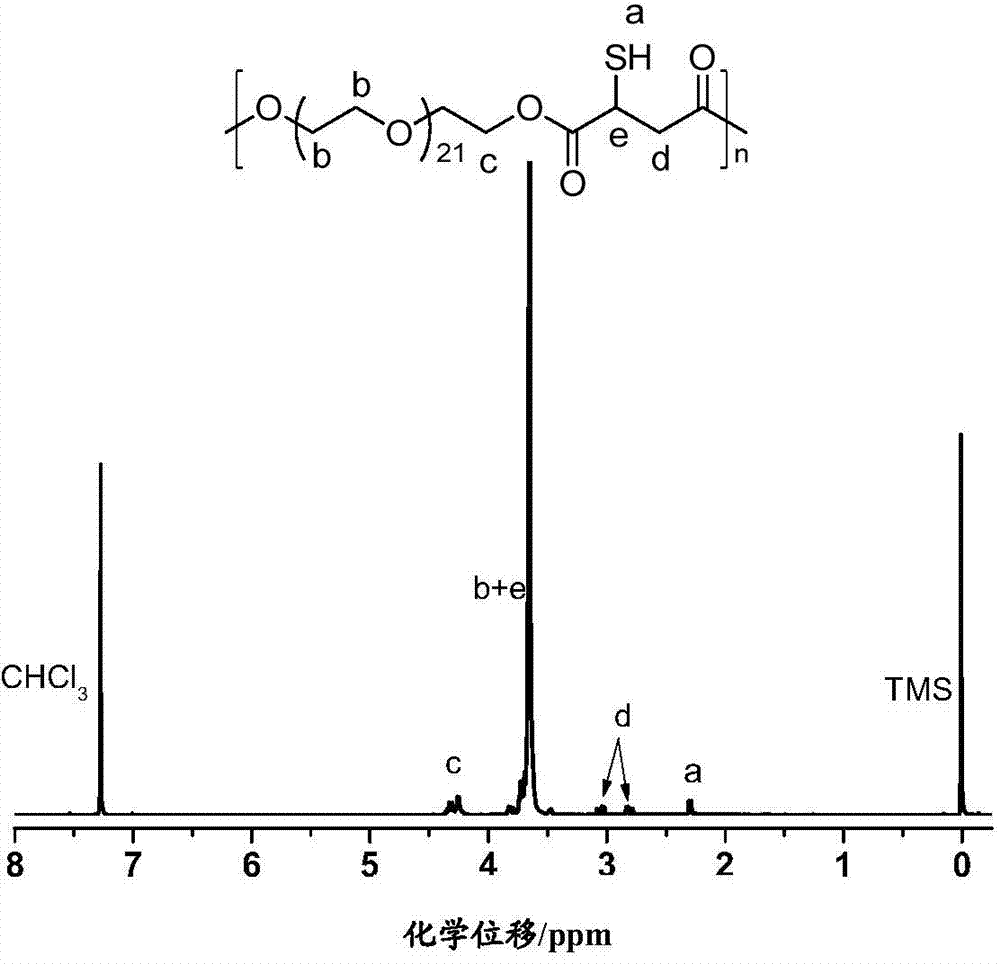

Making method of ultrathin antibiotic hydrogel film

InactiveCN103705965AGood biocompatibilityEasy to operateAbsorbent padsMetallic material coating processesPolymer scienceSilanes

The invention discloses a making method of an ultrathin antibiotic hydrogel film. The making method comprises the following steps: mixing a component A with a buffering solution to obtain a copolymer solution I, and mixing a component B with the buffering solution to obtain a copolymer solution II; sequentially immersing a substrate in a concentrated sulfuric acid / hydrogen peroxide mixed solution and a silane coupling agent solution; and taking out the substrate, sequentially immersing the substrate in the copolymer solution I and the copolymer solution II, and repeating the immersion in the copolymer solution I and the copolymer solution II several times to obtain the ultrathin antibiotic hydrogel film. The component A is a polymer with the main chain containing a plurality of double bonds, and the component B is a polymer with the main chain containing a plurality of mercapto groups. The making method has the advantages of no need of a catalyst, rapid implementation under a physiologic condition, and good biocompatibility and maneuverability; and the made hydrogel film has the advantages of stable structure in a saline solution, accurate and controllable thickness, and free regulation of the thickness of the film in nanometer and micrometer scales, and has a good antibiosis effect on Escherichia coli and Staphylococcus aureus.

Owner:ZHEJIANG UNIV

Preparation method of titanium alloy foil

ActiveCN102941228ALower requirementAvoid high resistance to deformationAuxillary arrangementsMetal rolling arrangementsSheet steelAcid washing

The invention provides a preparation method of a titanium alloy foil, comprising the following steps of: 1, carrying out surface oxidization treatment on a titanium alloy plate; 2, overlapping the titanium alloy plate which is subjected to the surface oxidization treatment between two sheets of steel plates; 3, laminating edges of the steel plates and carrying out electric arc welding on a press fit seam, reserving a ventilating opening at any one end and carrying out argon arc welding on the ventilating opening to obtain an overlapped and rolled bag; 4, heating the overlapped and rolled bag; 5, carrying out hot rolling by a four-roller rolling machine; and 6, removing the steel plates and carrying out acid washing and surface flattening treatment to obtain the titanium alloy foil with the thickness of 0.05-0.3 mm. The titanium alloy foil is prepared by using a covering, overlapping and rolling process so that the requirement on rolling equipment is greatly reduced; and a twenty-roller rolling machine which is complicated and expensive is not needed and the titanium alloy foil can be prepared by using a regular four-roller reversible hot rolling machine. The titanium alloy foil prepared by the preparation method disclosed by the invention has the advantages of controllable thickness precision and good surface quality, and is capable of realizing large-scale industrial production.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Preparation method of titanium alloy foil

ActiveCN102941228BLower requirementReduce processing stepsAuxillary arrangementsMetal rolling arrangementsAcid washingTitanium alloy

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

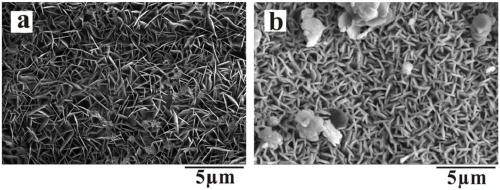

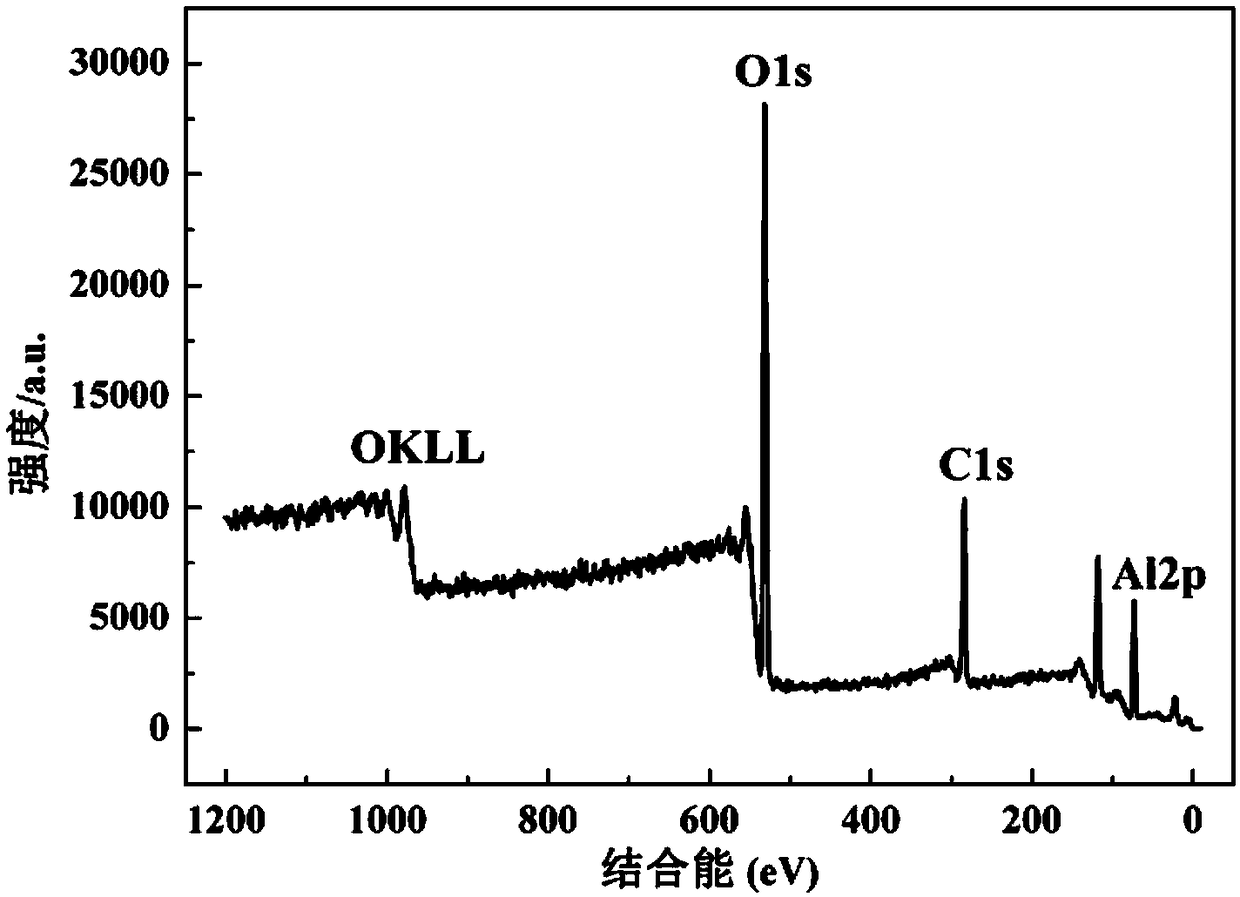

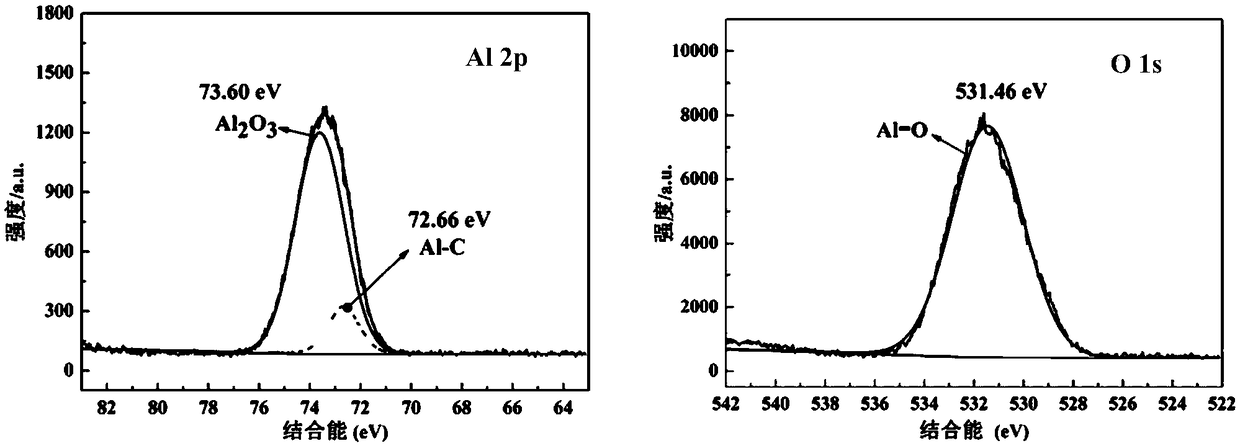

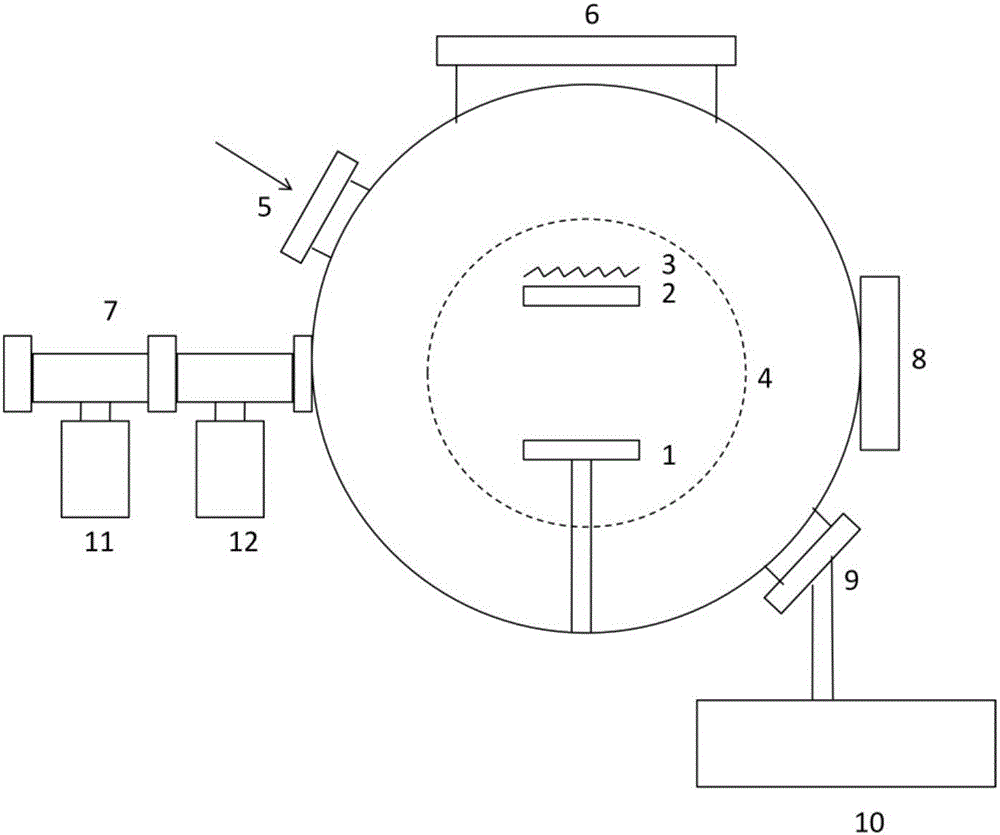

Preparation method of magnesium/magnesium alloy hydrotalcite-aluminum oxide composite coating

InactiveCN109023299AImprove bindingGood surface coverageLiquid/solution decomposition chemical coatingChemical vapor deposition coatingBiological activationAtomic layer deposition

The invention provides a preparation method of a magnesium / magnesium alloy hydrotalcite-aluminum oxide composite coating. The preparation method comprises the four steps including pretreatment of a magnesium alloy, preparation of a hydrotalcite coating, pretreatment of the hydrotalcite coating and atomic layer deposition of an aluminum oxide layer. The main chemical raw materials include aluminumnitrate, magnesium nitrate, sodium carbonate, sodium hydroxide, trimethyl aluminum and ultrapure water. The technical route is characterized in that a hydrothermal method is adopted to synthesize a carbonate hydrotalcite film on the surface of a magnesium / magnesium alloy matrix; and then the aluminum oxide coating is deposited on the surface of the hydrotalcite by using an atomic layer depositiontechnique after surface activation. The invention has the advantages that simple preparation and easy control are achieved, and the obtained composite coating has the compact structure, strong adhesion and good corrosion resistance; and the composite material prepared is suitable for the protection of magnesium alloy materials for engineering equipment.

Owner:SHANDONG UNIV OF SCI & TECH

Epitaxial growth method of yttrium iron garnet film

ActiveCN106048726AInsulationRoom temperature ferromagneticPolycrystalline material growthFrom chemically reactive gasesHigh energyRoom temperature

An epitaxial growth method of a yttrium iron garnet film comprises the following steps: vacuumizing a vacuum cavity with a treated yttrium iron garnet substrate to be 8.6+ / -1*10-6 Pa, and heating the yttrium iron garnet substrate to the constant temperature which is 736 DEG C; in a heating process, feeding ozone when heating to the temperature of 250 DEG C; after heating to the temperature of 736 DEG C, maintaining air pressure of the vacuum cavity, adjusting the mass fraction of the ozone to be 40%, meanwhile insulating for half a hour, and starting a reflective high-energy electron diffraction instrument (RHEED) to adjust so as to obtain diffraction spots of a substrate; maintaining real-time and in-situ monitoring of the RHEED in the whole process, and focusing laser onto a YIG target through a lens by using a KrF excimer laser of which the wavelength is 248 nm; after growth of the film is finished, maintaining the temperature of the substrate unchanged, annealing in situ for 15 minutes, then naturally cooling the film to the temperature about 250 DEG C, stopping protective gas and cooling to the room temperature. The obtained YIG film has uniform components, is controllable in thickness and good in process repeatability, and has high preparation efficiency.

Owner:NANJING UNIV

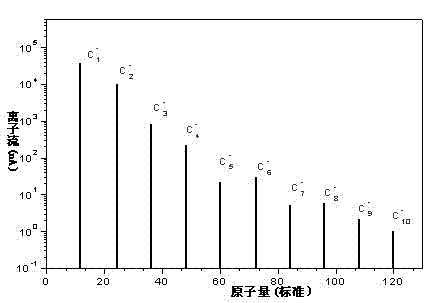

Method for preparing ultrathin carbon film by using carbon cluster ion beam

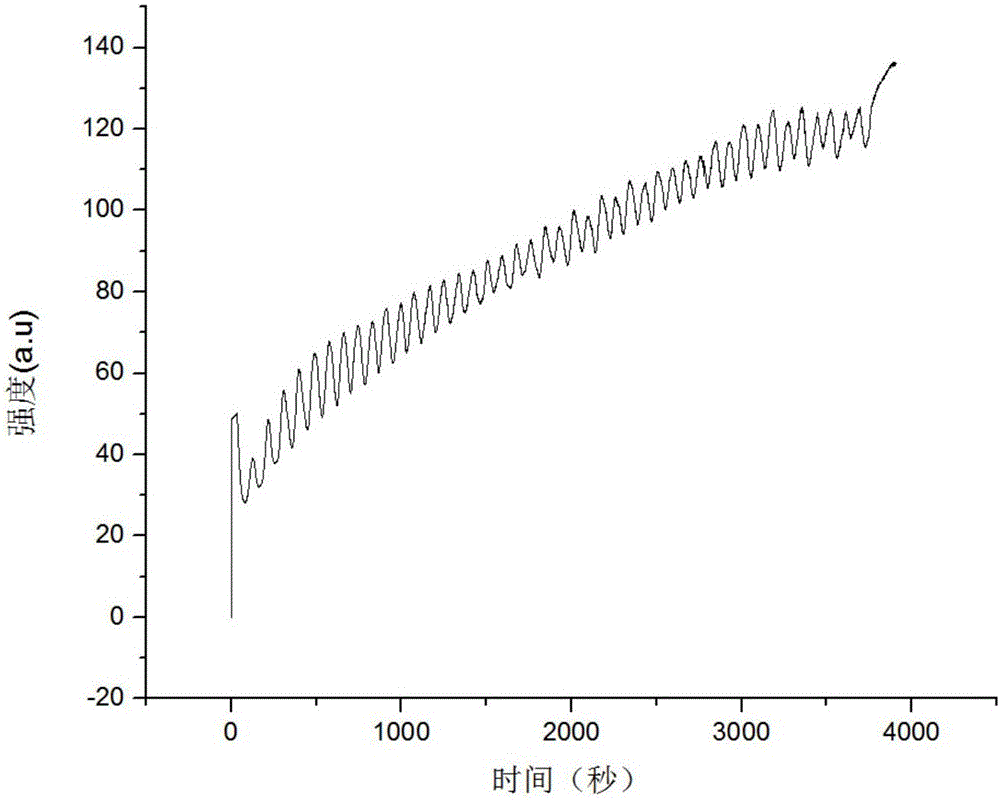

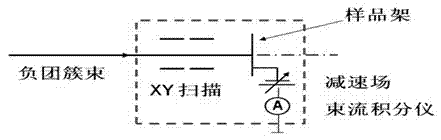

InactiveCN102373433APrecise and controllable dosagePrecise and controllable thicknessVacuum evaporation coatingSputtering coatingCarbon filmIon source

The invention provides a method for preparing an ultrathin carbon film. A small carbon cluster negative ion beam is produced by sputtering a graphite target with cesium ions, and the ultrathin carbon film is formed by scanning and depositing the small carbon cluster negative ion beam on the surface of a base material through a magnetic retarding field in proper vacuum conditions. The device mainly comprises an ion source, a scanner, a deposition target chamber and a vacuum system, wherein the ion source, the scanner and the deposition target chamber are successively connected and are in the vacuum system. The energy of the carbon cluster negative ion beam produced by the ion source is reduced from ten-odd of KeV to tens or hundreds of eV, and the ultrathin carbon film with uniform thickness is formed on the substrate through scanning. In the invention, the advantages of low energy and accurate and controllable dosage of the low-energy cluster negative ion beam are utilized, and the ultrathin carbon film is prepared by using the direct deposition method.

Owner:WUHAN UNIV

Titanium-antimony-tellurium phase-changing material depositing method and preparation method of phase-changing storage unit

ActiveCN103000807APrecise and controllable thicknessImprove compactnessElectrical apparatusHigh densityTitanium

The invention provides a titanium-antimony-tellurium phase-changing material depositing method and a preparation method of a phase-changing storage unit. The titanium-antimony-tellurium phase-changing material depositing method includes: depositing a Ti precursor which comprises one or more than one of (R1)4Ti, (R1R2N)4Ti, (R1O)4Ti, ((R1)3Si)4Ti and TiM4, wherein R1 and R2 are linear chains, branched chains or annular alkyls containing 1-10 carbons, and M is Cl, F or Br; depositing a Te precursor which comprises one or more than one of (R1)2Te, (R1R2N)2Te and ((R1)3Si)2Te, wherein R is selected from a linear chain, a branched chain or an annular alkyl or alkenyl containing 1-10 carbons; and depositing Sb precursors which comprise one or more than one of (R1)3Sb, (R1R2N)3Sb, (R1O)3Sb, ((R1)3Si)3Sb and SbM3, wherein R1 and R2 are linear chains, branched chains or annular alkyls containing 1-10 carbons, and M is Cl, F or Br. The TiSbTe phase-changing materials prepared by the titanium-antimony-tellurium phase-changing material depositing method have the advantages of being accurate and controllable in thickness, good in thin film compactness and strong in pore filling capability. Phase-changing thin films prepared by the titanium-antimony-tellurium phase-changing material depositing method can be applied to a storer, so that high-density storing can be achieved, and simultaneously low-energy-consumption devices can be obtained.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

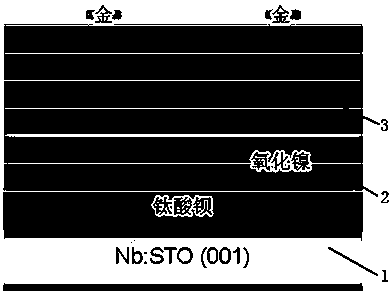

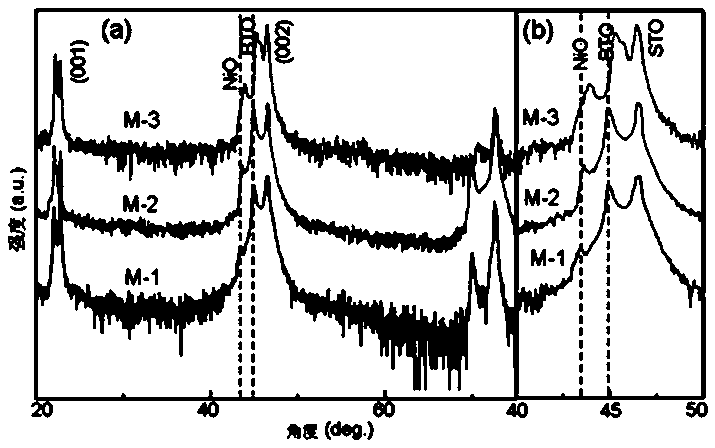

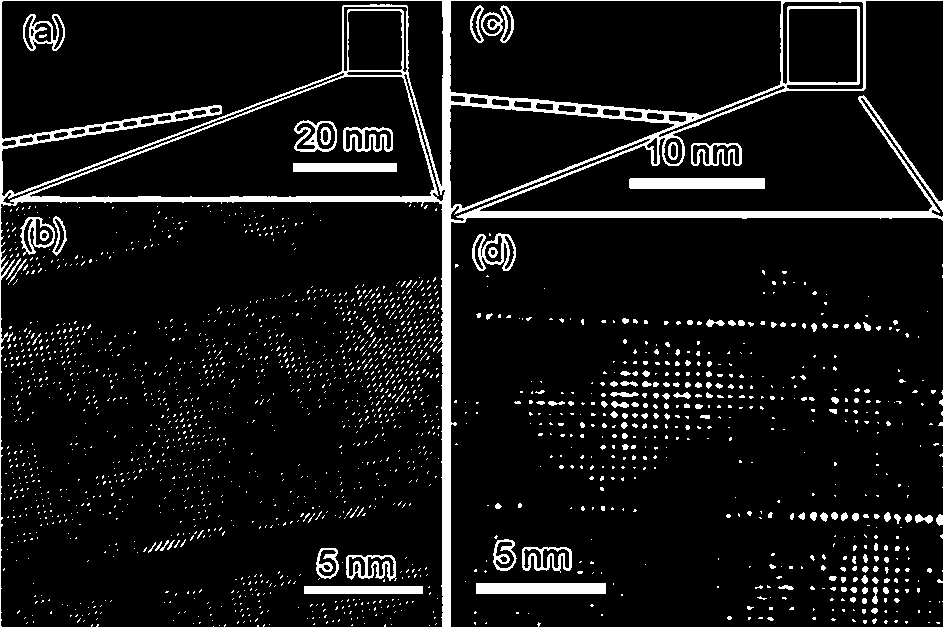

Nickel oxide and barium titanate nano composite ferroelectric film material and preparation method and application thereof

InactiveCN107604310APrecise and controllable thicknessUniform grain distributionVacuum evaporation coatingSputtering coatingComposite filmBarium titanate

The invention provides a nickel oxide and barium titanate nano composite ferroelectric film material and a preparation method and application thereof. A film has the (001) face crystal orientation andcomprises, by volume percentage, 10-30% of nickel oxide and 70-90% of barium titanate. The preparation method comprises the steps of preparing the barium titanate, the nickel oxide and a nickel oxideand barium titanate composite target material through a solid phase deposition method; and then adopting a pulsed laser deposition method, and preparing the nano layered nickel oxide and barium titanate nano composite ferroelectric film, the nano columnar nickel oxide and barium titanate nano composite ferroelectric film and the nano granulated nickel oxide and barium titanate nano composite ferroelectric film by controlling deposition parameters. The nickel oxide and barium titanate nano composite ferroelectric film material and the preparation method and application thereof are simple in process. The obtained nano composite film has the beneficial effects that the microstructure is continuous and adjustable; nanoscale crystalline grains are distributed uniformly; the film thickness canbe controlled precisely; and crystal orientation extends outwards. Ferroelectric performance of the composite film material is effectively improved; dielectric performance is enhanced; the obtained high-performance material can be applied to the fields of ferroelectric storage devices, supercapacitors, crystalline field effect tubes, acoustic surface wave devices and the like; and the applicationscope is wide.

Owner:HEBEI UNIVERSITY

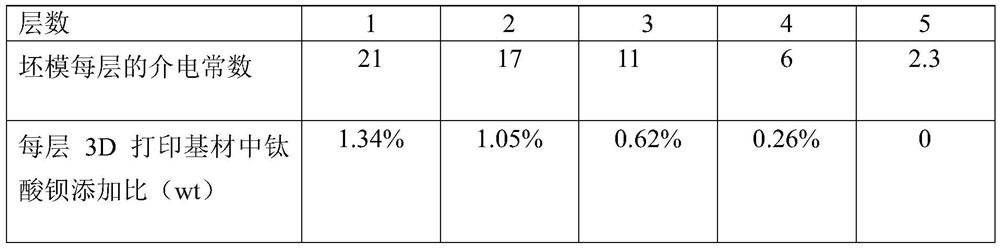

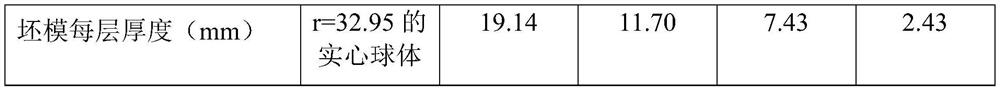

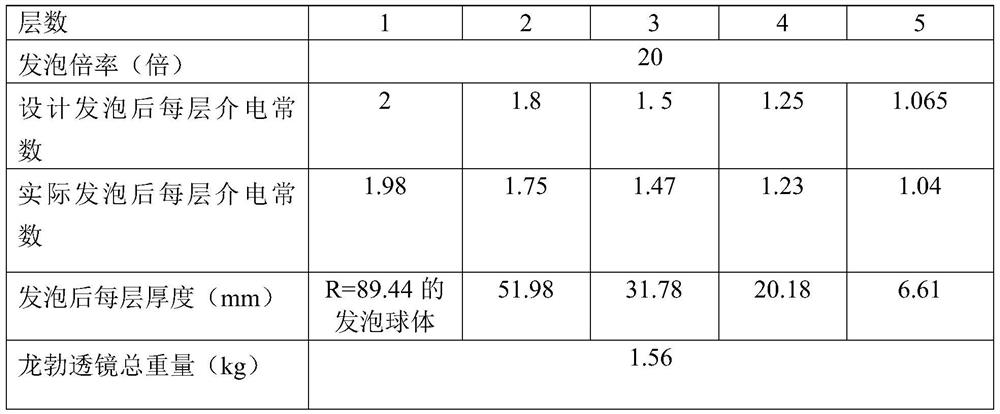

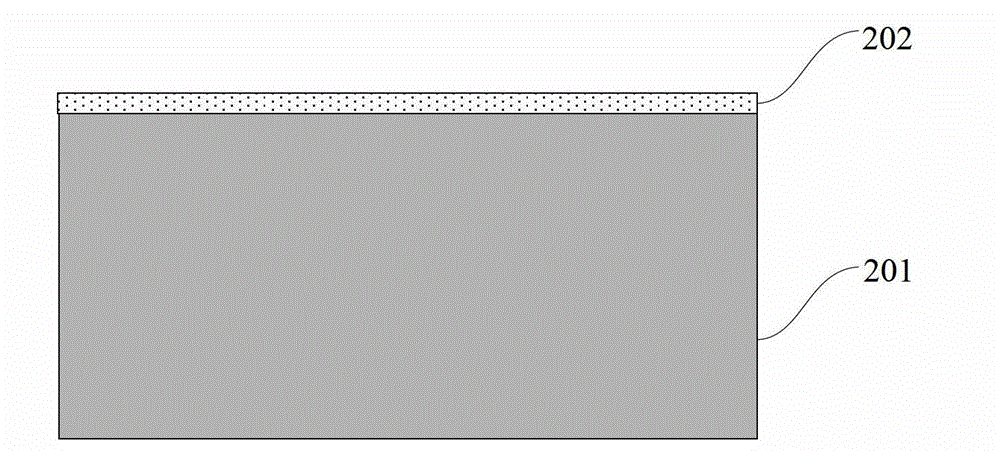

Foaming Luneberg lens and production process thereof

ActiveCN112736485ASimple methodEasy to operateAdditive manufacturing apparatusAntennasPolymer scienceComputer printing

The invention discloses a production process of a foaming Luneberg lens. The process is characterized by comprising the following steps: designing the foaming ratio of m layers of foaming Luneberg lenses to be obtained and a size and a dielectric constant of each layer, wherein the m is greater than or equal to 5 and less than or equal to 15; fully mixing a resin material and a dielectric regulator according to the mass ratio of a dielectric regulator, and then sequentially preparing m parts of 3D printing base materials; through a fused deposition modeling method, sequentially printing the m parts of 3D printing base materials into m layers of spherical structures through a 3D printer, and acquiring a spherical blank mold; and finally, impregnating the spherical blank mold with a supercritical fluid, and performing pressure relief foaming to obtain the foaming Luneberg lens. The dielectric modifier is used for adjusting the foamable resin material to serve as a 3D printing base material, a fused deposition modeling method is used for obtaining a Luneberg lens sphere blank mold, the supercritical fluid physical foaming is used for obtaining the foaming Luneberg lens, the method is simple and convenient to operate, and the dielectric constant of each layer of the printed foaming Luneberg lens is accurate and controllable.

Owner:SHINCELL NEW MATERIAL CO LTD

Method for preparing titanium-stibium-tellurium (Ti-Sb-Te) phase change material and method for preparing phase change storage unit

ActiveCN102978588APrecise and controllable thicknessGood film densityElectrical apparatusChemical vapor deposition coatingHigh density storageComposite material

The invention provides a method for preparing a titanium-stibium-tellurium (Ti-Sb-Te) phase change material and a method for preparing a phase change storage unit. The method for preparing the Ti-Sb-Te phase change material comprises the following steps: 1) introducing a precursor SbCl3 pulse of Sb to a substrate, washing away unabsorbed SbCl3, then introducing a precursor (R3Si)2Te pulse of Te and washing away the unabsorbed (R3Si)2Te and by-products of reaction; 2) introducing a TiCl4 pulse of Ti to the substrate, washing away the residual TiCl4, then introducing the precursor (R3Si)2Te pulse of Te and washing away the residual (R3Si)2Te and by-products of reaction; and 3) introducing a precursor SbCl3 pulse of Sb to the substrate, washing away the residual SbCl3, then introducing a (R3Si)3Sb of Sb and washing away the unabsorbed (R3Si)3Sb and by-products of reaction. The Ti-Sb-Te phase change material prepared by using the method has the characteristics of accurately controllable thickness, good film compactness and strong pore-filling capability. A phase change film prepared by using the method can realize high-density storage when applied to a memorizer, and meanwhile a low power-cost device can be obtained.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

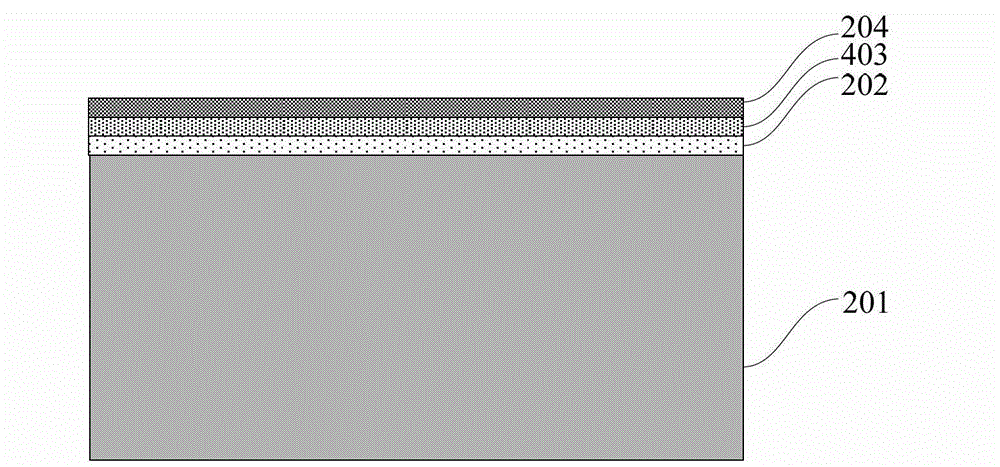

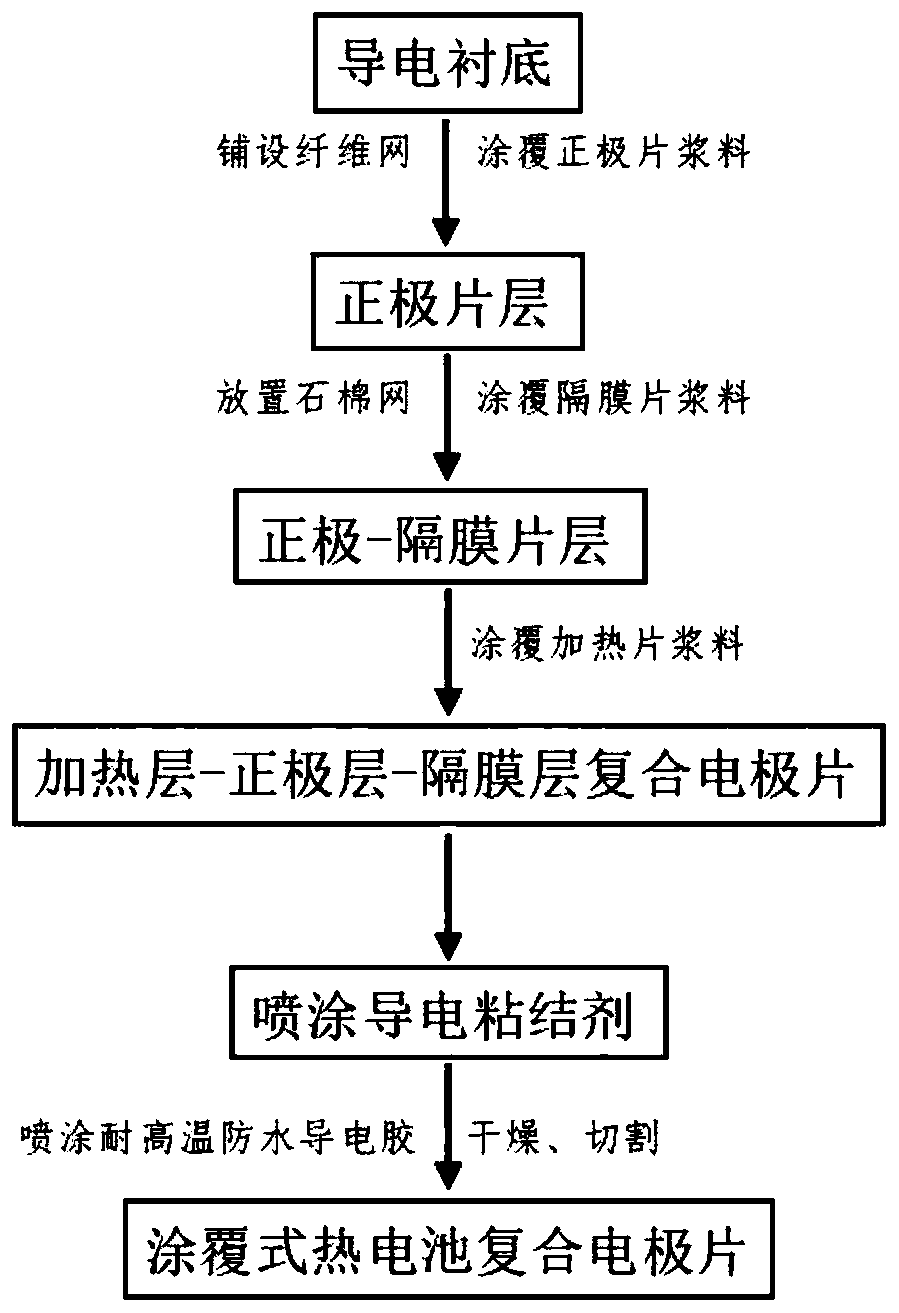

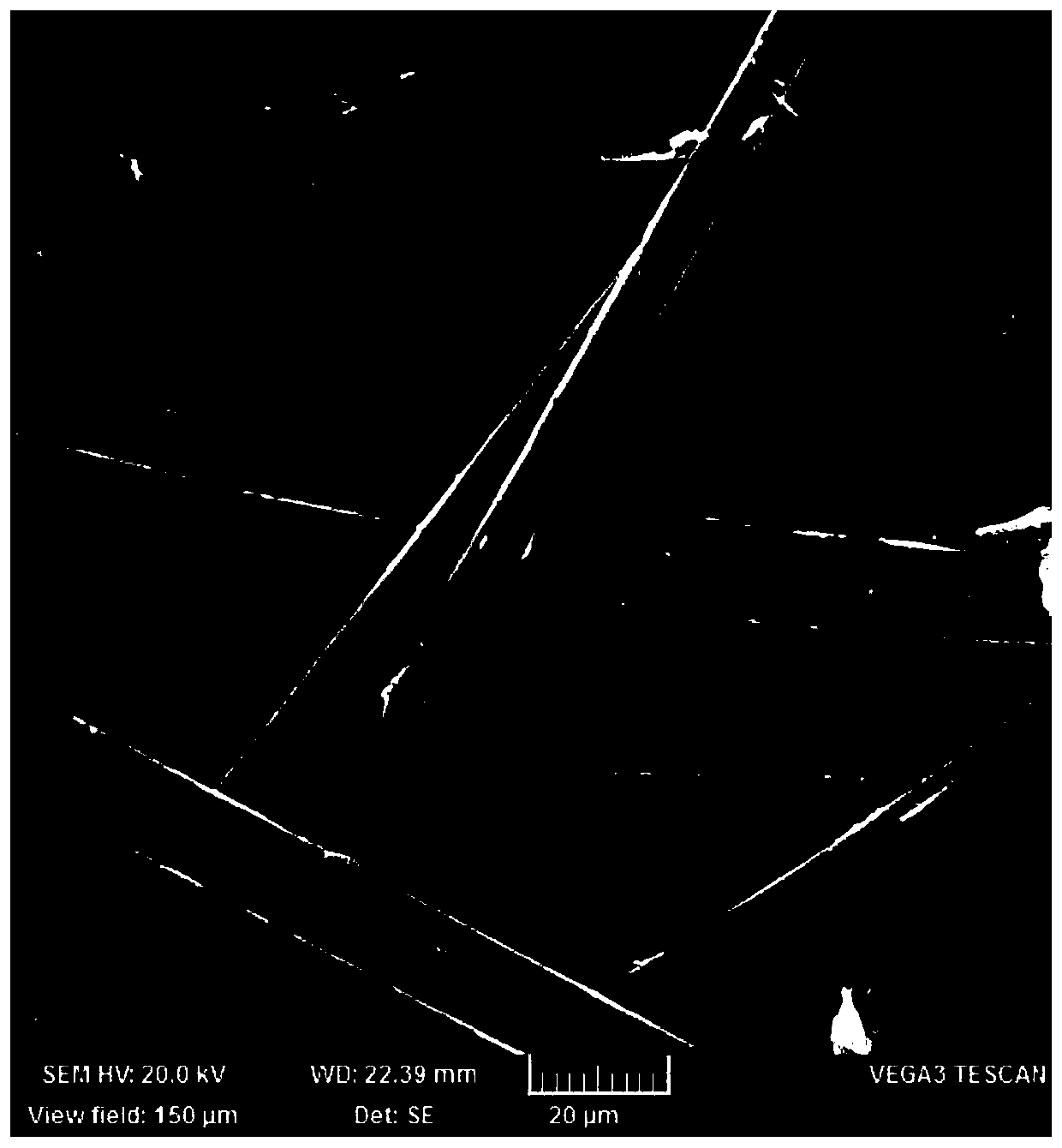

Preparation method of coated thermal battery composite electrode sheet

ActiveCN110112431APrecise and controllable thicknessSuitable for development needsPrimary cell manufactureElectrode manufacturing processesFiberComposite electrode

The invention discloses a preparation method of a coated thermal battery composite electrode sheet. The composite electrode sheet is composed of a heating layer, a positive electrode layer and a separator layer. For the preparation method, firstly, a layer of fiber mesh is laid on a conductive substrate, a positive electrode layer is then coated, after drying, an asbestos mesh is placed on a surface of the positive electrode layer; secondly, the separator layer is then coated on the positive electrode layer on which the asbestos mesh is placed, after the separator layer is dried, the heating layer is coated on the other side of the conductive substrate to obtain a composite sheet; and thirdly, high temperature resistant waterproof conductive adhesive is coated on both sides of the composite sheet, after drying, the composite positive electrode layer is obtained. The composite electrode sheet is advantaged in that thickness of the composite electrode sheet can be adjusted according to height of a scraper in the preparation process, so the thickness of the composite electrode sheet is precisely controlled, the composite electrode sheet is combined with a thermal battery negative electrode LiB sheet with controllable thickness to form an ultra-thin thermal battery cell, the obtained composite electrode sheet has a function of preventing moisture absorption and preventing a diaphragm from being melted and overflowing, and the preparation method has advantages of high chip rate and simple process and meets requirements of engineering use.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

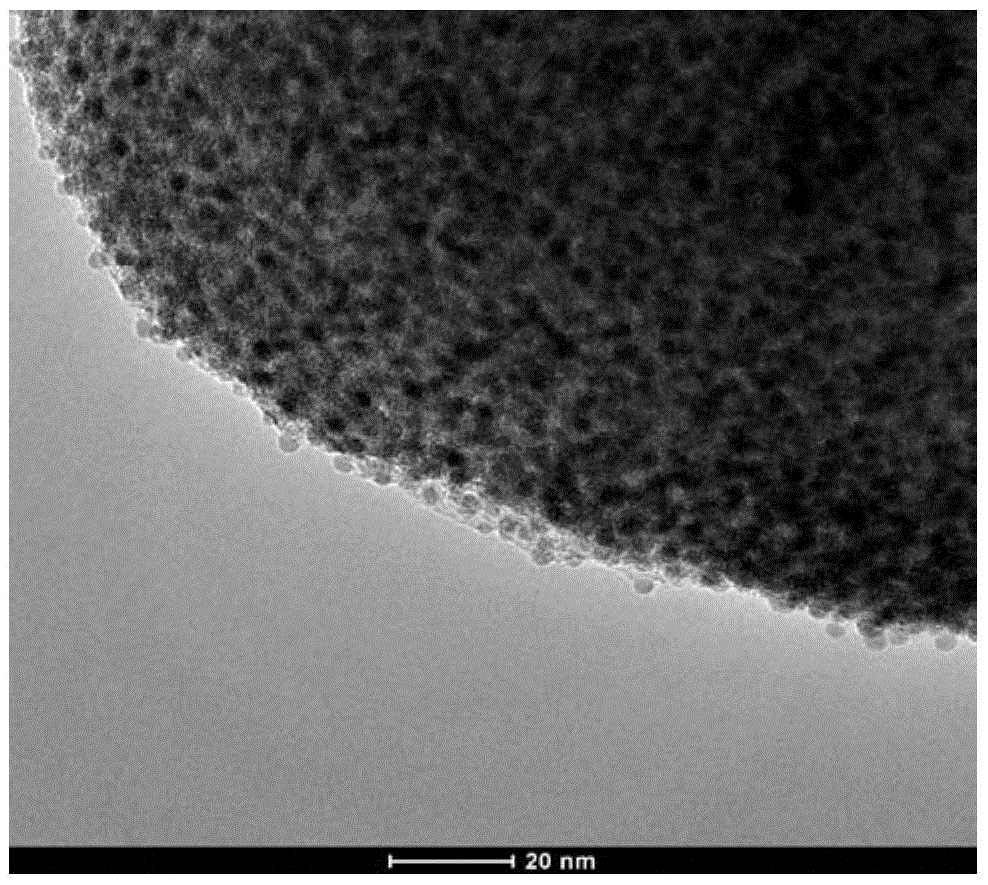

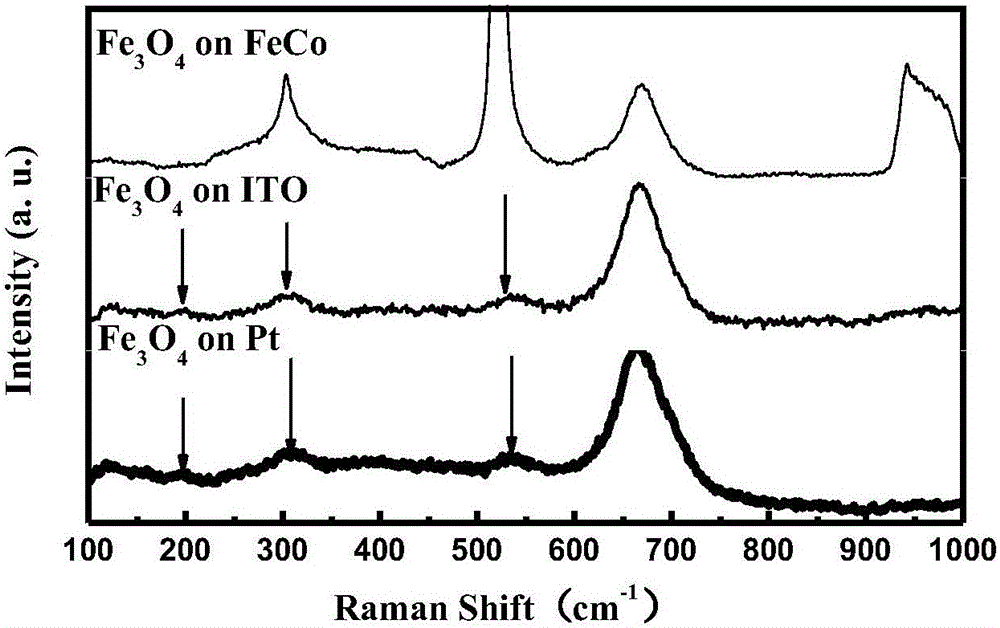

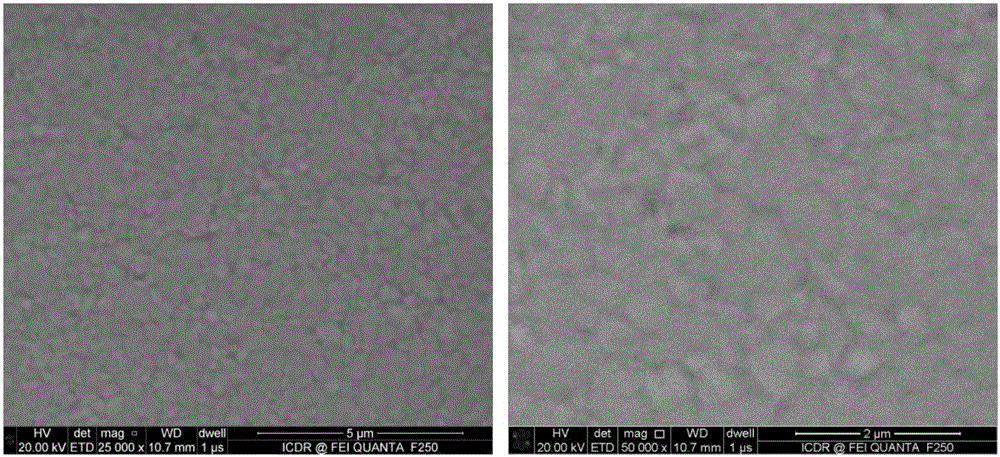

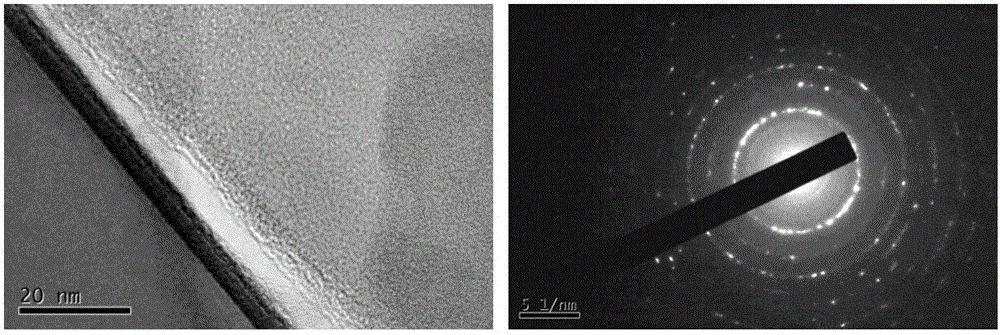

Method for in-situ preparationof oxide/metal ferromagnetic heterojunction through atomic layer deposition method

ActiveCN105925955AQuality improvementPrecise thickness controlChemical vapor deposition coatingHeterojunctionCoupling

The invention provides a method for in-situ preparation of an oxide / metal ferromagnetic heterojunction through an atomic layer deposition method. According to the method, the atomic layer deposition method is adopted, ferrocene serves as a Fe source, oxygen serves as an oxygen source, and ferroferric oxide is deposited on metal substrates; and by means of an atomic layer deposition system, ferrocene and oxygen are alternately introduced to a reaction cavity of the atomic layer deposition system, deposition of ferroferric oxide on different metal substrates is realized, and then the oxide / metal ferromagnetic heterojunction is established. The oxide / metal ferromagnetic heterojunction prepared through the method has the advantages that cost is low, the components and the thickness of a film can be precisely controlled, and three-dimensional uniform shape preserving is good and can serve as a key device for magnetoelectric coupling control.

Owner:XI AN JIAOTONG UNIV

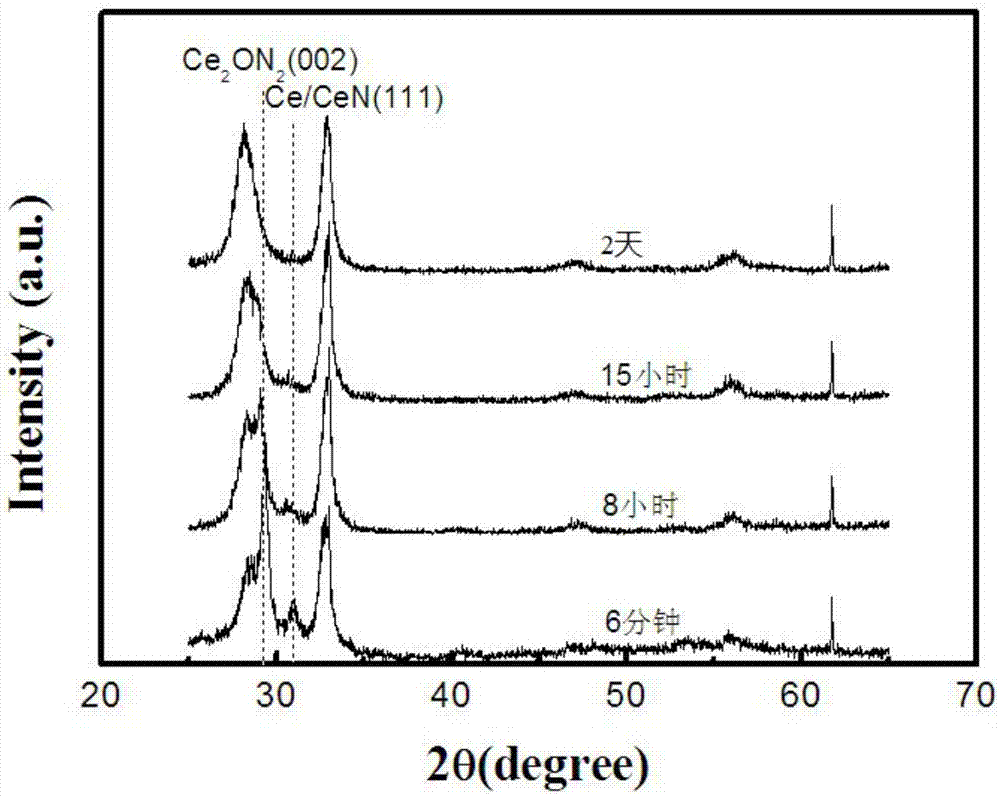

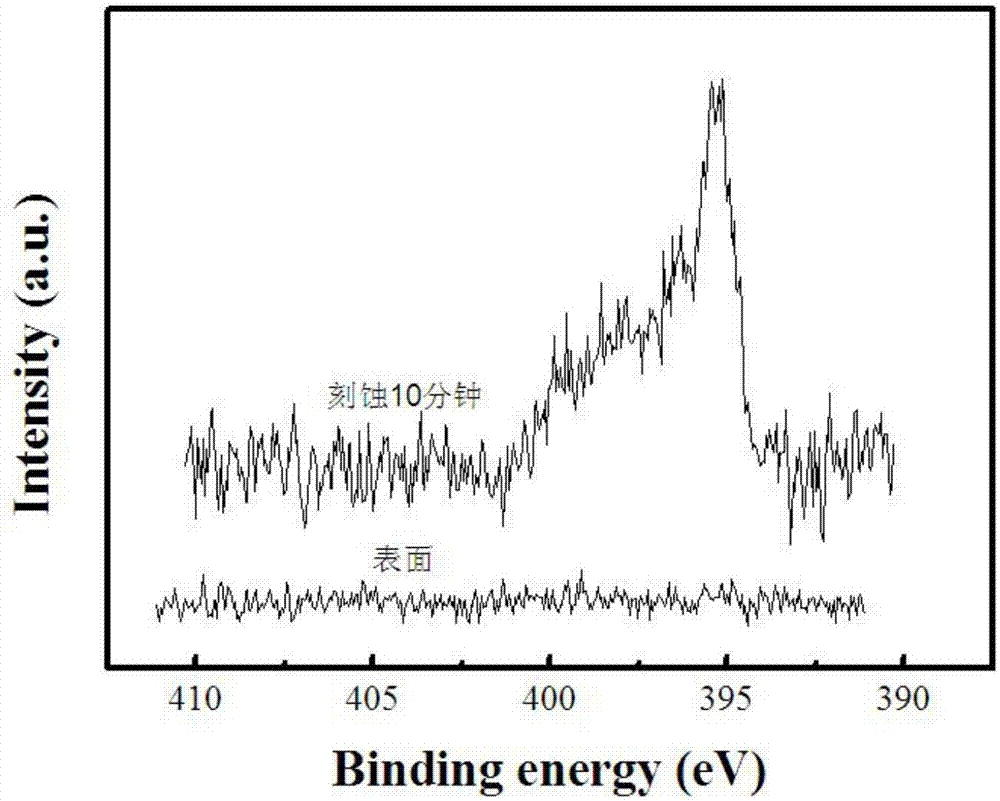

Preparation method of n ion-doped cerium dioxide film

ActiveCN107164728AIncrease the concentration of vacanciesSolve pollutionFinal product manufactureVacuum evaporation coatingSputteringFuel cells

The invention provides a preparation method of an N<3-> doped CeO2 film. The preparation method comprises the steps of carrying out magnetron sputtering in an Ar and N2 mixed atmosphere with metal Ce adopted as a target material, so as to obtain a CeN film; and oxidizing the obtained CeN film, so as to obtain the N<3-> doped CeO2 film. According to the preparation method, the N<3-> doped CeO2 solid oxide fuel battery electrolyte film is prepared through magnetron sputtering under the low temperature condition, the environmental pollution problem caused by the fact that high temperature and organic solvents need to be adopted when conventionally a chemical preparation method is adopted is solved, and compared with a traditional chemical method, the preparation method has the advantages that uniformity of the prepared material is good, thickness is accurate and controllable, the material and a substrate are firmly combined, and the material can be utilized to prepare nanocrystalline films.

Owner:CHANGCHUN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com