Production method for film generating in-plane uniaxial magnetic anisotropy in non-inducement magnetic field

A magnetic anisotropy, non-induction technology, applied in the direction of magnetic layer, ion implantation plating, coating, etc., can solve the problems such as difficulty in obtaining magnetic anisotropy field, optimization obstacles and limitations of soft magnetic thin film process conditions, etc. Achieve the effects of excellent soft magnetic properties, easy operation in the production process, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

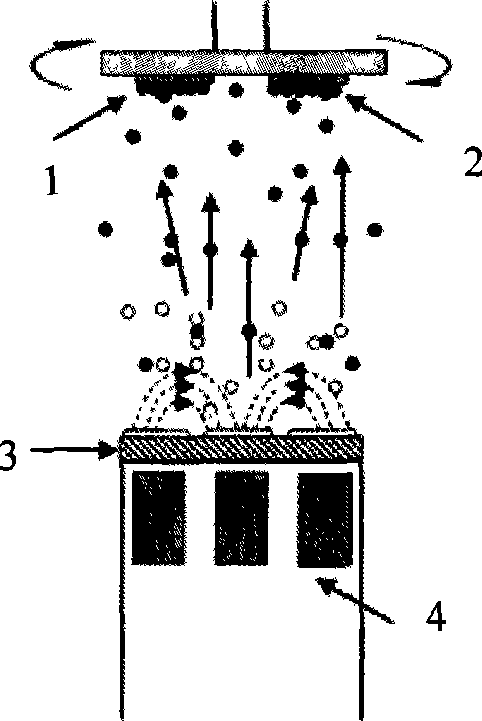

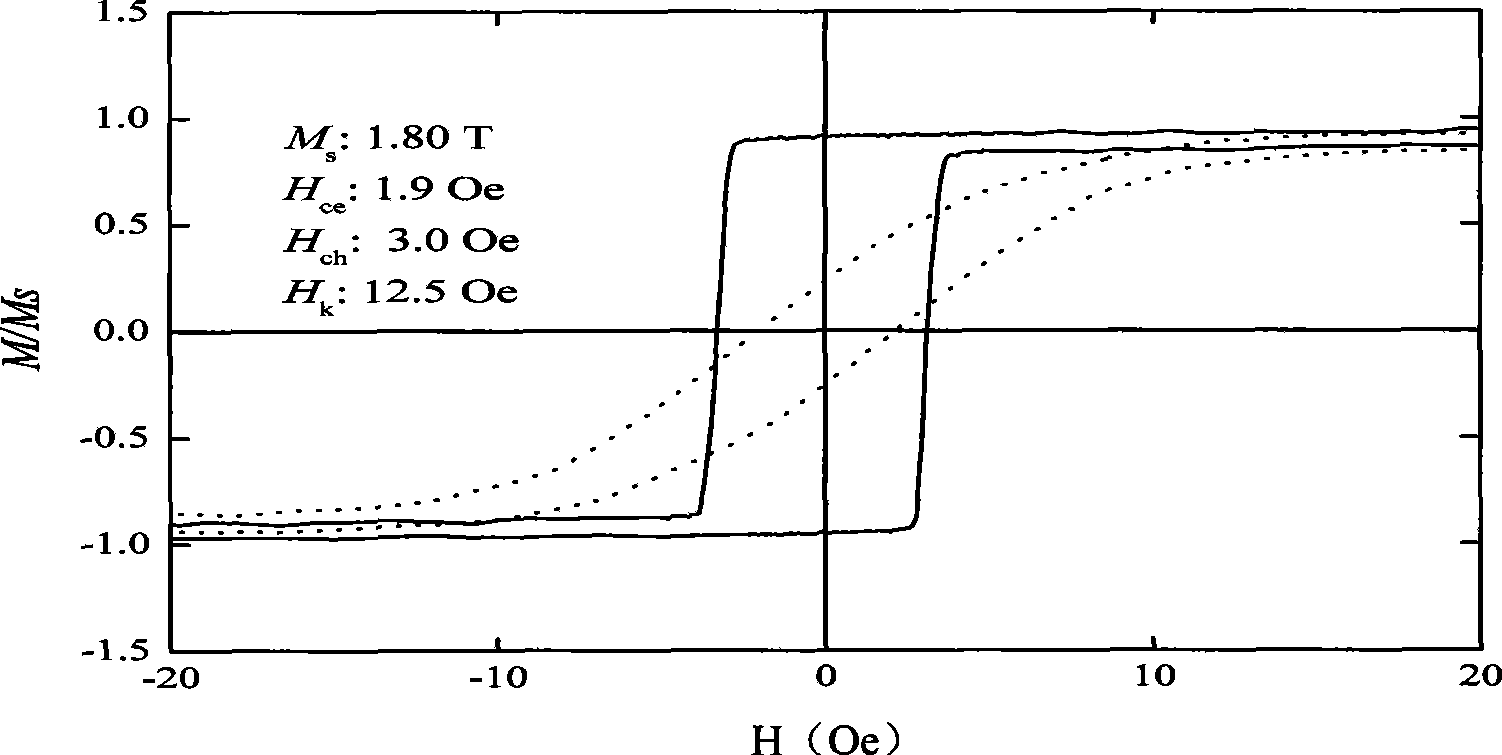

[0022] Example 1: Preparation of a Fe-Co-Cr-N nanocrystalline soft magnetic film with a thickness of 50 nm at room temperature

[0023] 1) Clean the glass substrate ultrasonically with alcohol, acetone, and distilled water, then soak it in chromic acid for 12 hours, then wash it with distilled water, and finally blow it dry with a nitrogen gun and put it in an oven for drying. Monocrystalline silicon wafers use NH 3 ·H 2 O and H 2 o 2 Prepared alkaline aqueous solution, HCl and H 2 o 2 The prepared acidic aqueous solution was ultrasonically cleaned, then rinsed with HF acid for 15 seconds, then washed with distilled water, and finally dried with a nitrogen gun and placed in an oven for drying. The cleaned glass and single crystal substrate were loaded into the sputtering chamber. Install iron-cobalt alloy target and chromium target at the same time.

[0024] 2) The sputtering chamber is pumped until the background vacuum is higher than 5×10 -4 Pa;

[0025] 3) Passing A...

Embodiment 2

[0026] Example 2: Preparation of a Fe-Co-Cr-N nanocrystalline soft magnetic film with a thickness of 150 nm at room temperature

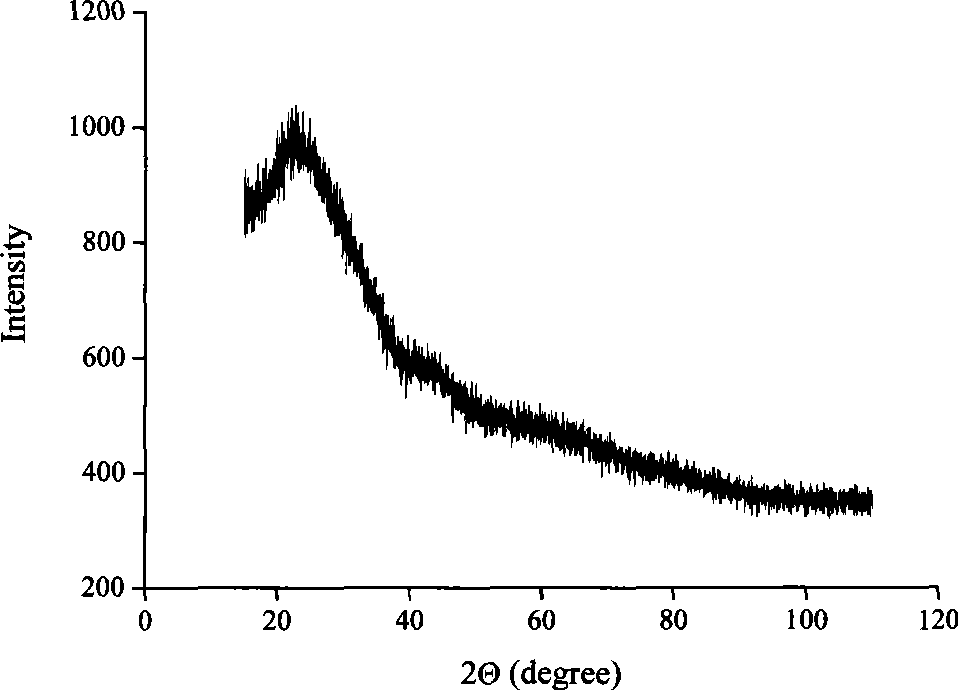

[0027] The same steps as in Example 1 were adopted. The sputtering deposition time is 10min. Different film thicknesses have obvious effects on the microstructure of the film, and the grain size and surface roughness also change accordingly.

Embodiment 3

[0028] Example 3: Preparation of a Fe-Co-Cr-N nanocrystalline soft magnetic film with a thickness of 300 nm at room temperature

[0029] The same steps as in Example 1 were adopted. The sputtering deposition time is 20min. Different film thicknesses have obvious effects on the microstructure of the film, and the grain size and roughness also change accordingly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com