Patents

Literature

76results about How to "Reduce core loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

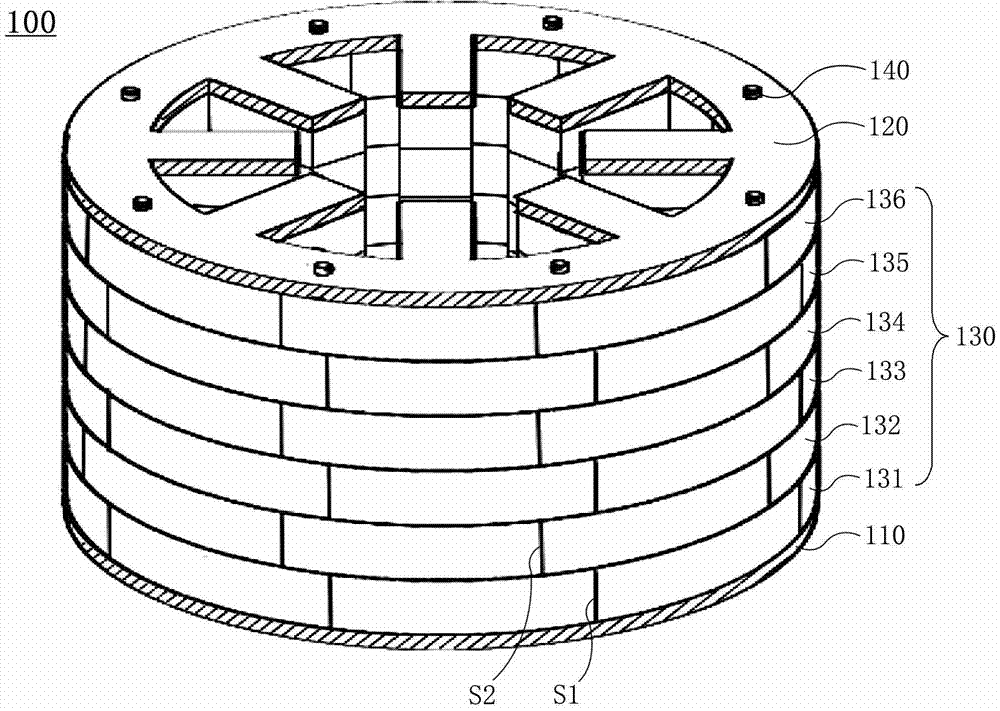

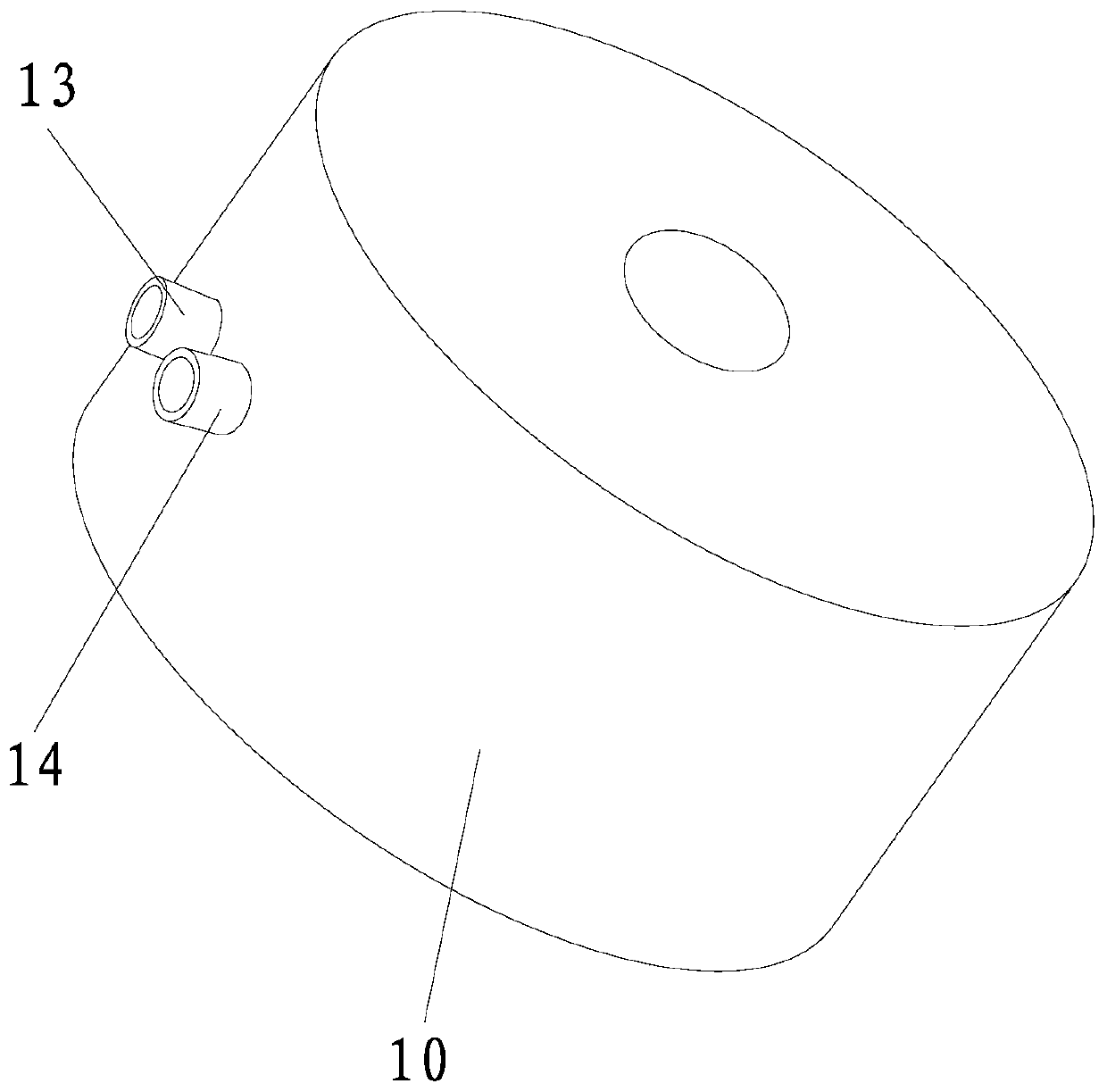

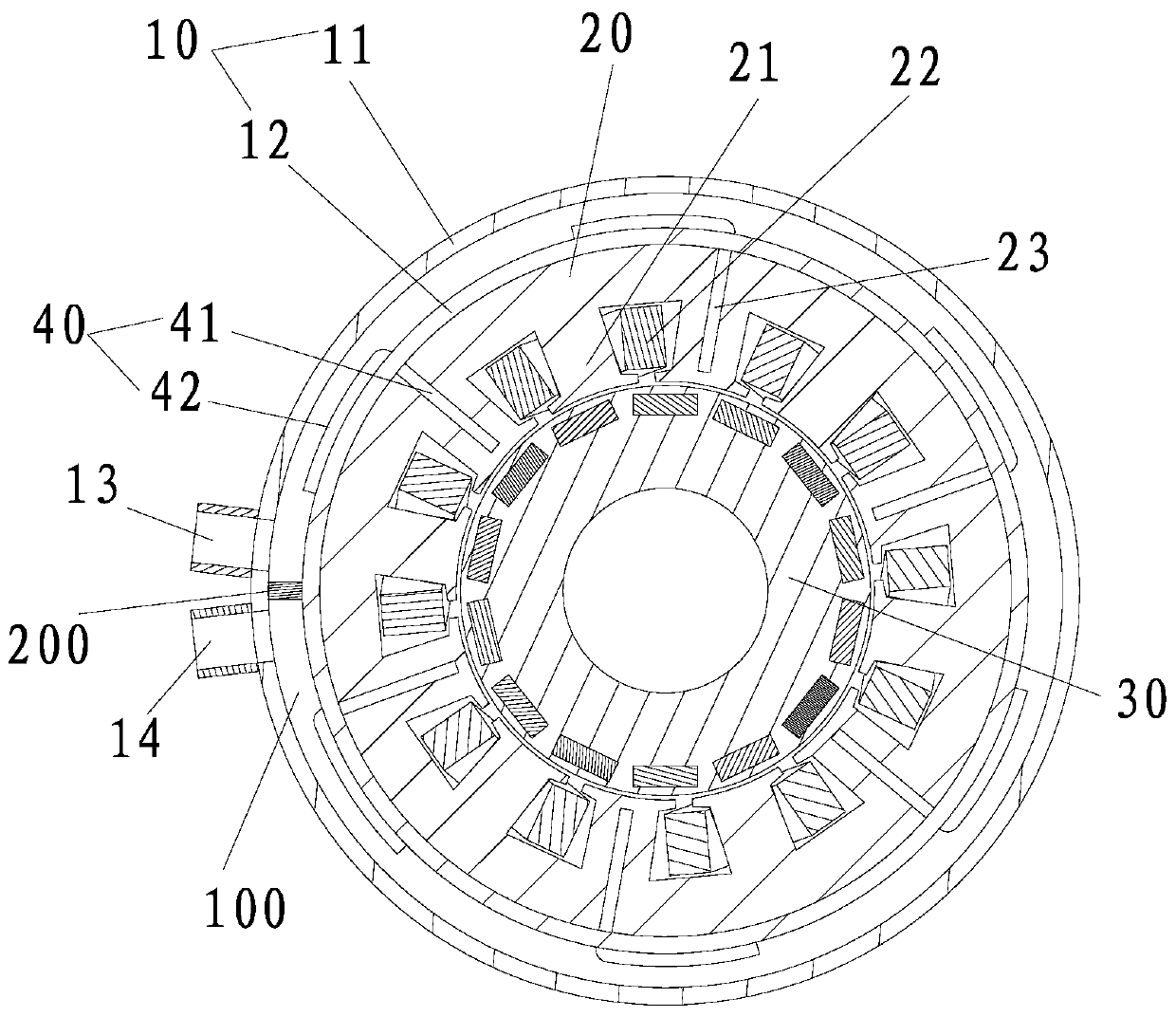

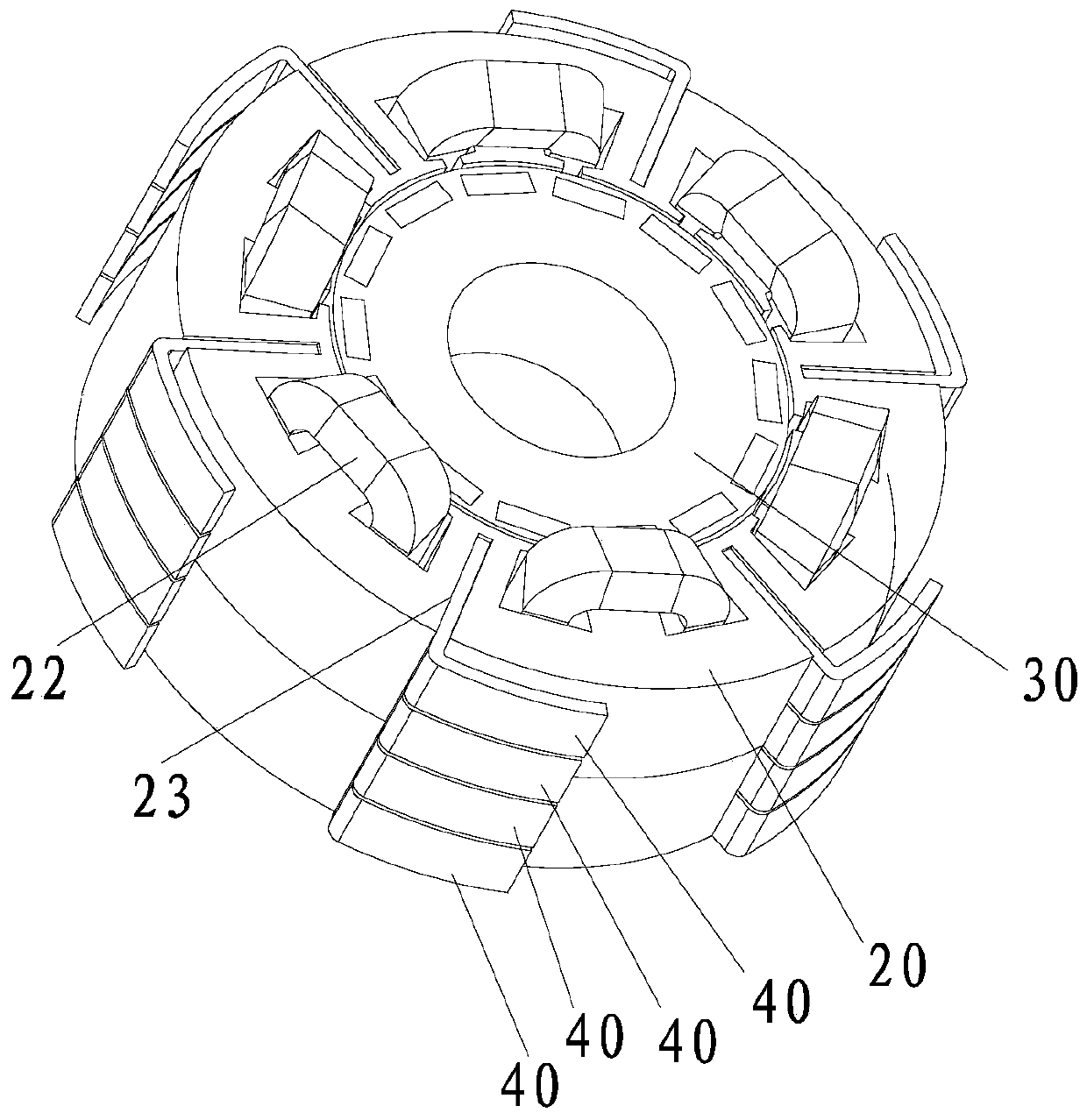

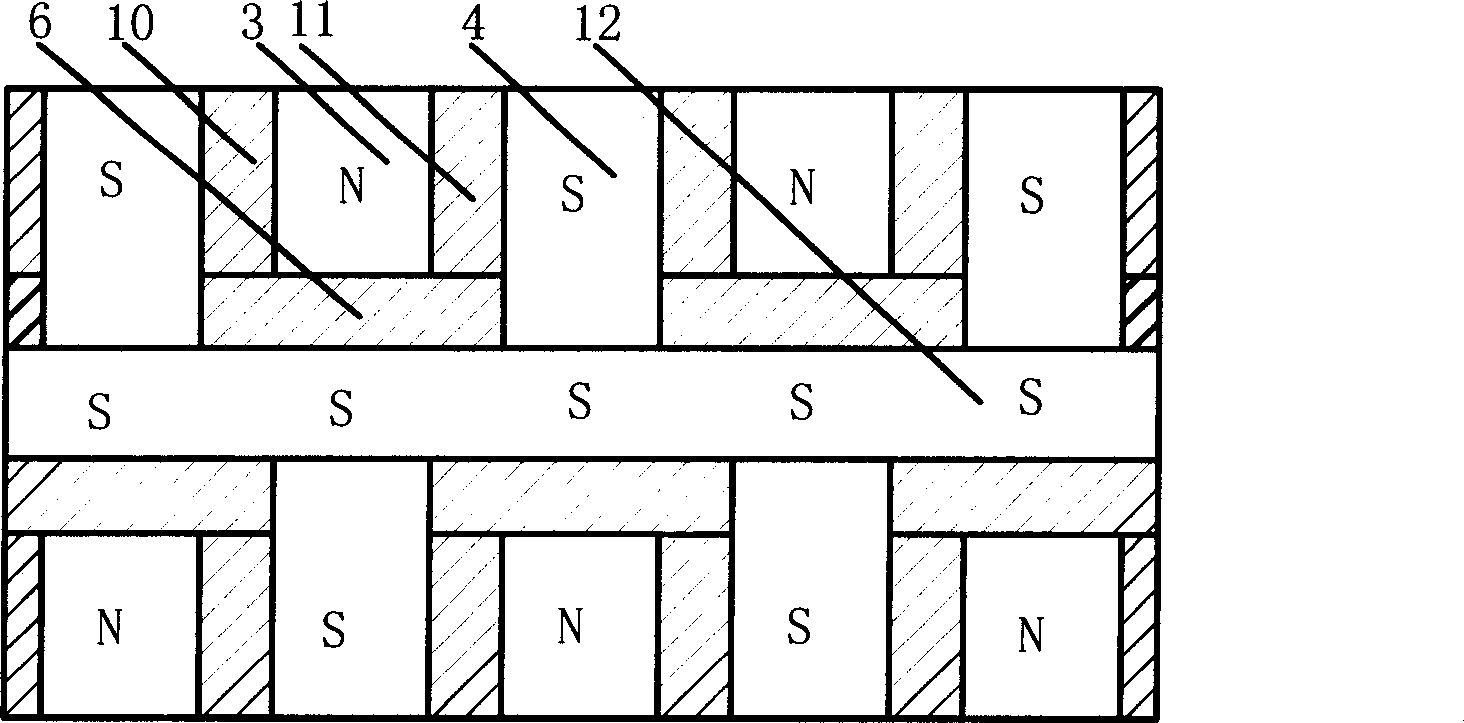

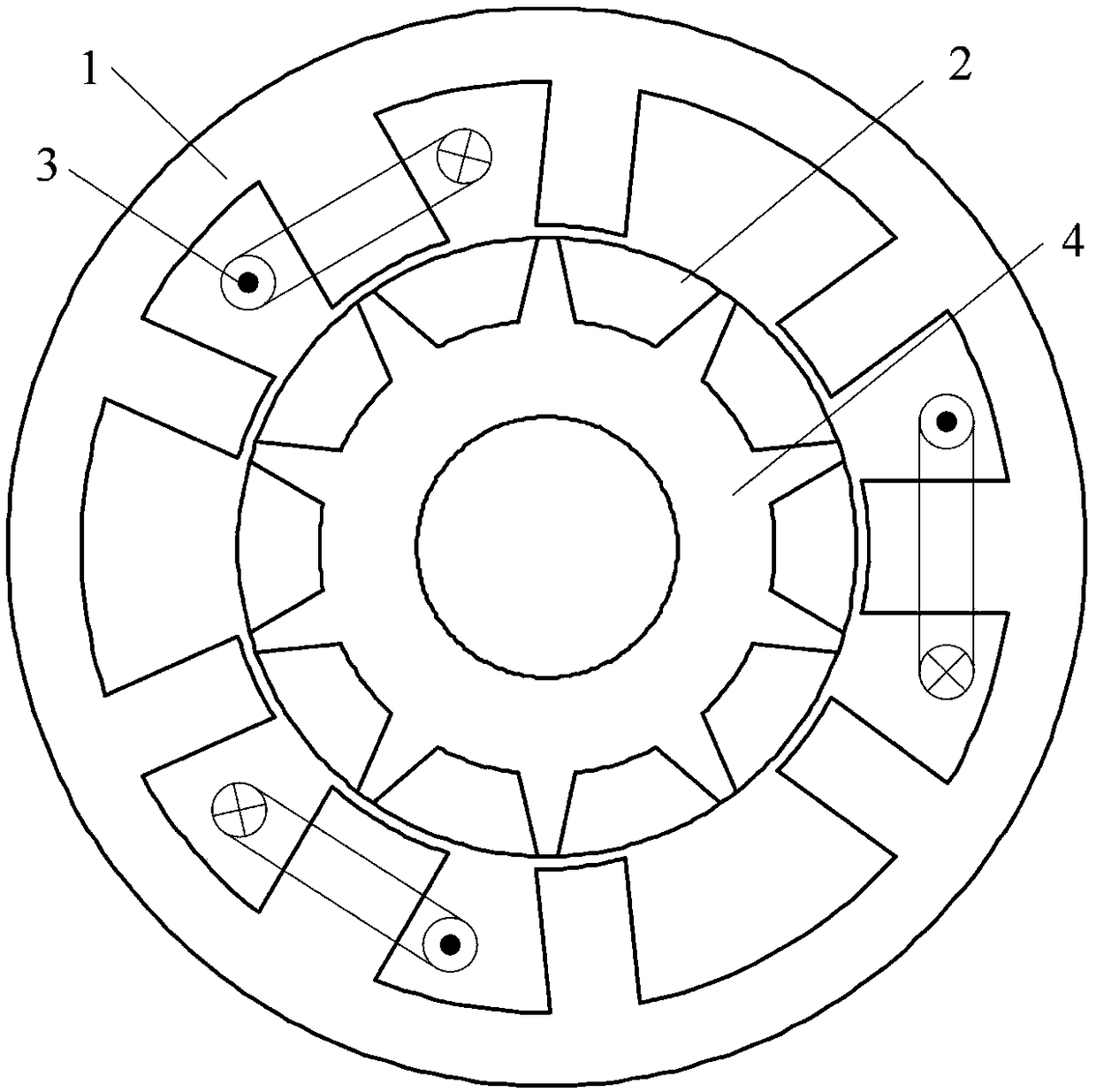

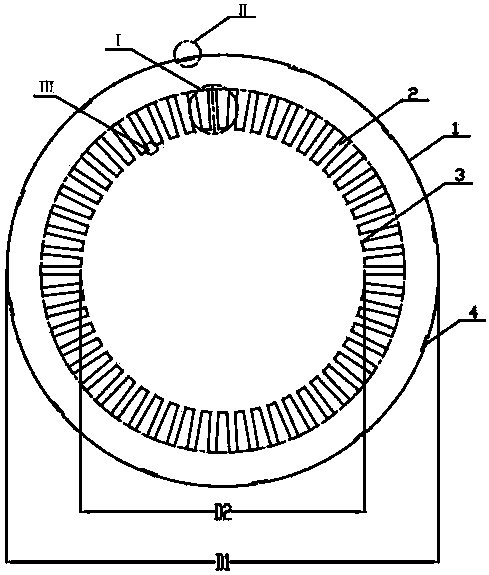

Double-stator magnetic field modulation permanent magnet motor

ActiveCN104883016AImprove power densityImprove power efficiencyMagnetic circuit rotating partsElectric machinesPower factorPermanent magnet motor

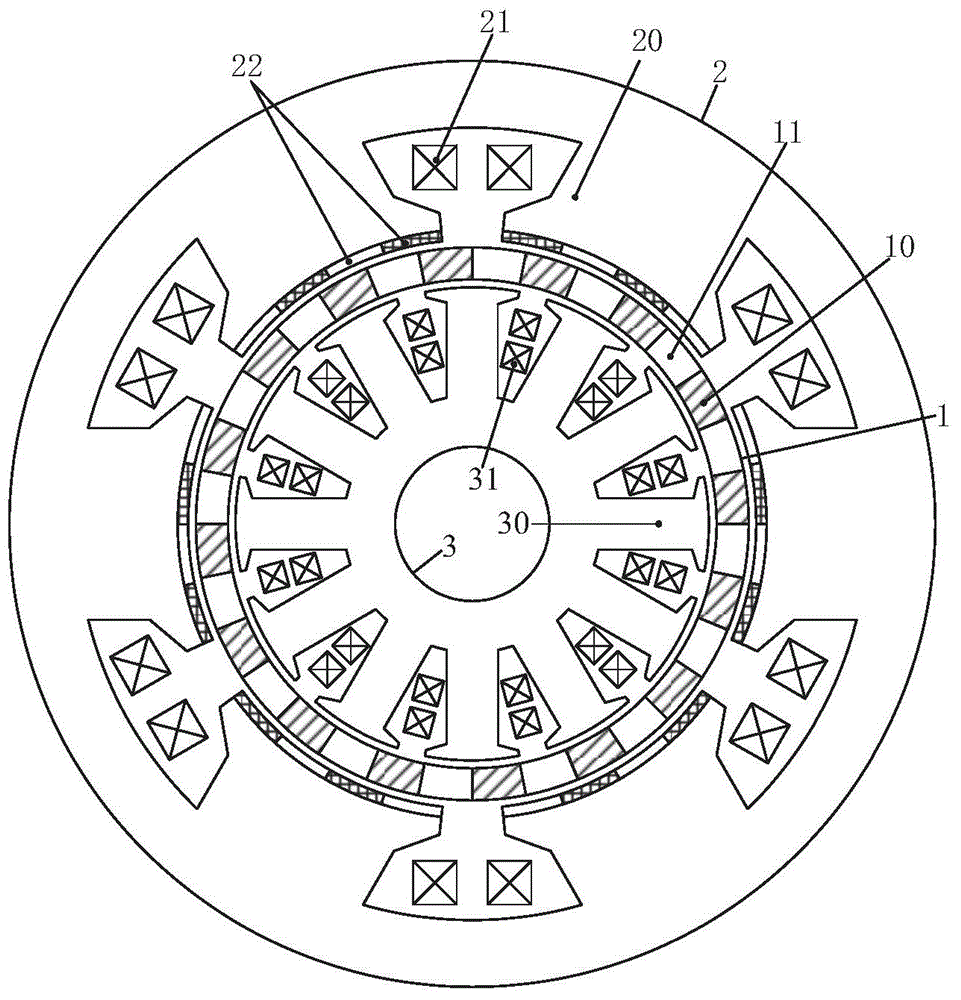

The invention discloses a double-stator magnetic field modulation permanent magnet motor comprising an inner stator, an outer stator, and a rotor. Air gaps are formed between the rotor and the inner and outer stators. The rotor is formed by magnetic conductors and non-magnetic conductors which are arranged alternately. The outer stator is formed by outer stator teeth, radial magnetizing permanent magnets, and an armature winding. The radial magnetizing permanent magnets adhere to the inner surfaces of the outer stator teeth. Adjacent permanent magnets on the same outer stator tooth have opposite magnetizing directions. The inner stator is just formed by inner stator teeth equipped with grooves along the circumferential direction and an armature winding in the grooves while not being provided with any permanent magnet. According to the double-stator magnetic field modulation permanent magnet motor, the two armature windings are used while the amount of the permanent magnets is not increased. Thus, an armature magnetic field is fully utilized and a power factor and the power density are increased. Compared with a product in the prior art, the double-stator magnetic field modulation permanent magnet motor is not provided with a rotor magnetic conductive yoke portion, decreased in rotor size and iron loss, and increased in the power density and efficiency, and can be used in power systems such as electric automobile, wind power generation or the like.

Owner:JIANGSU UNIV

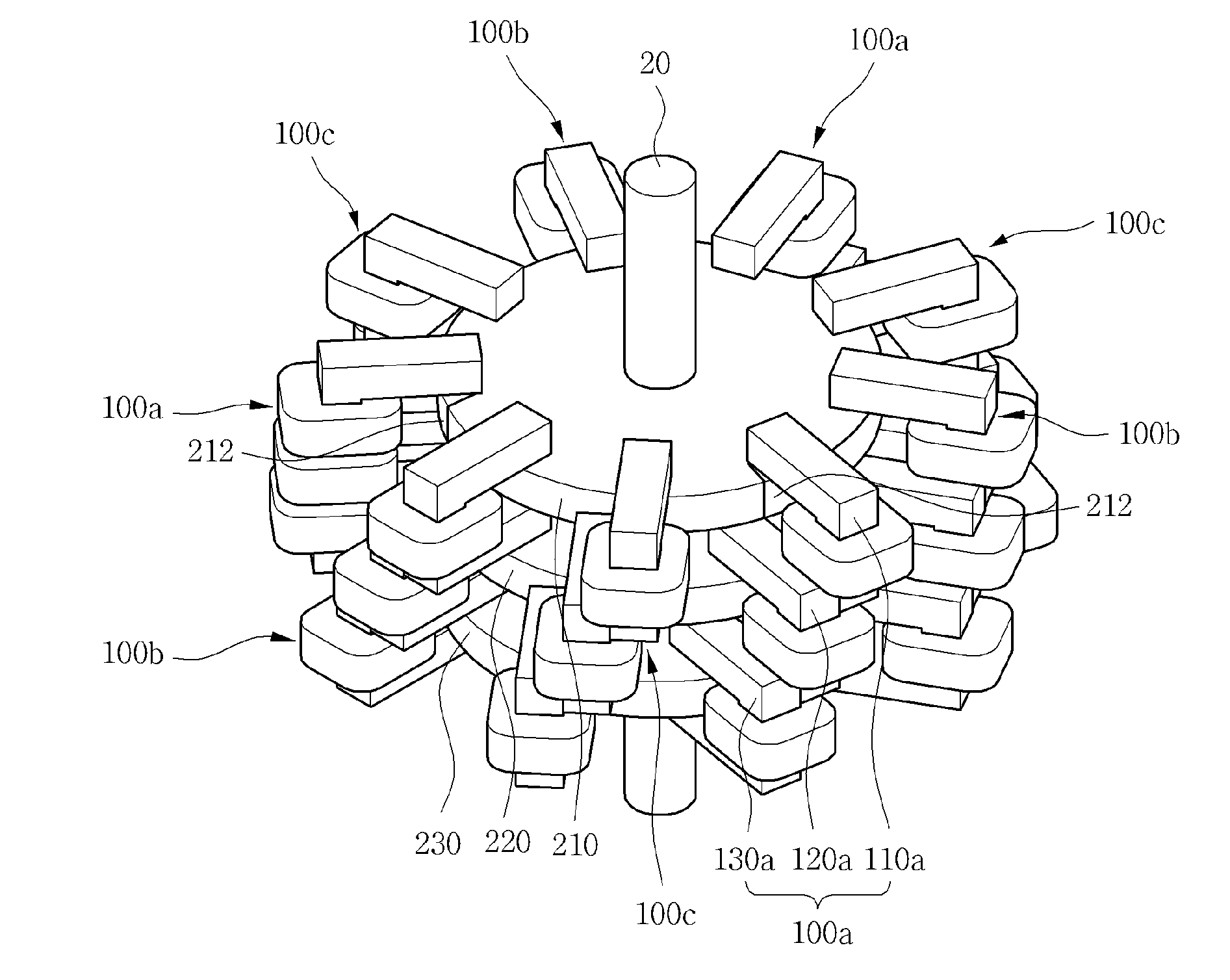

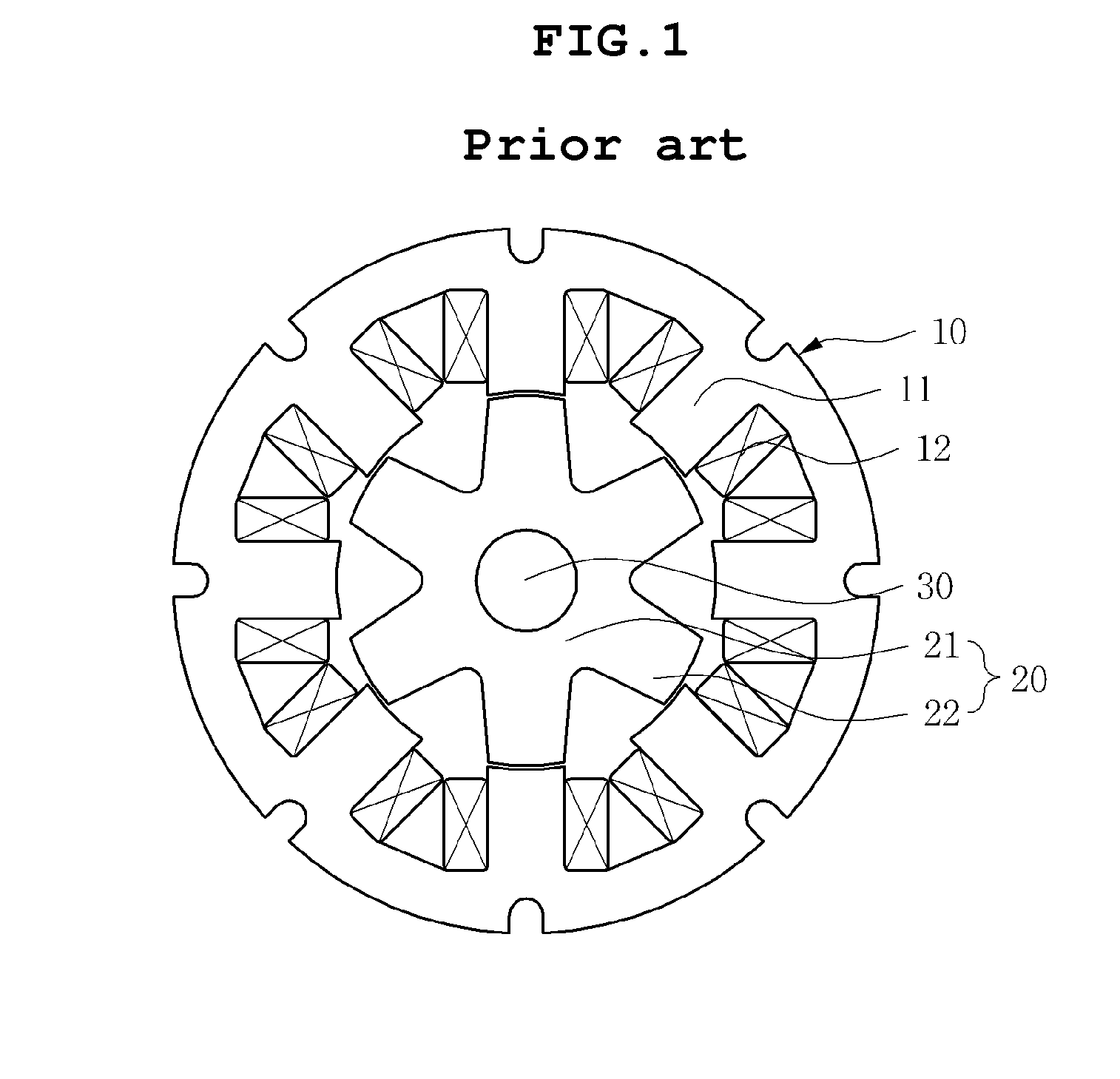

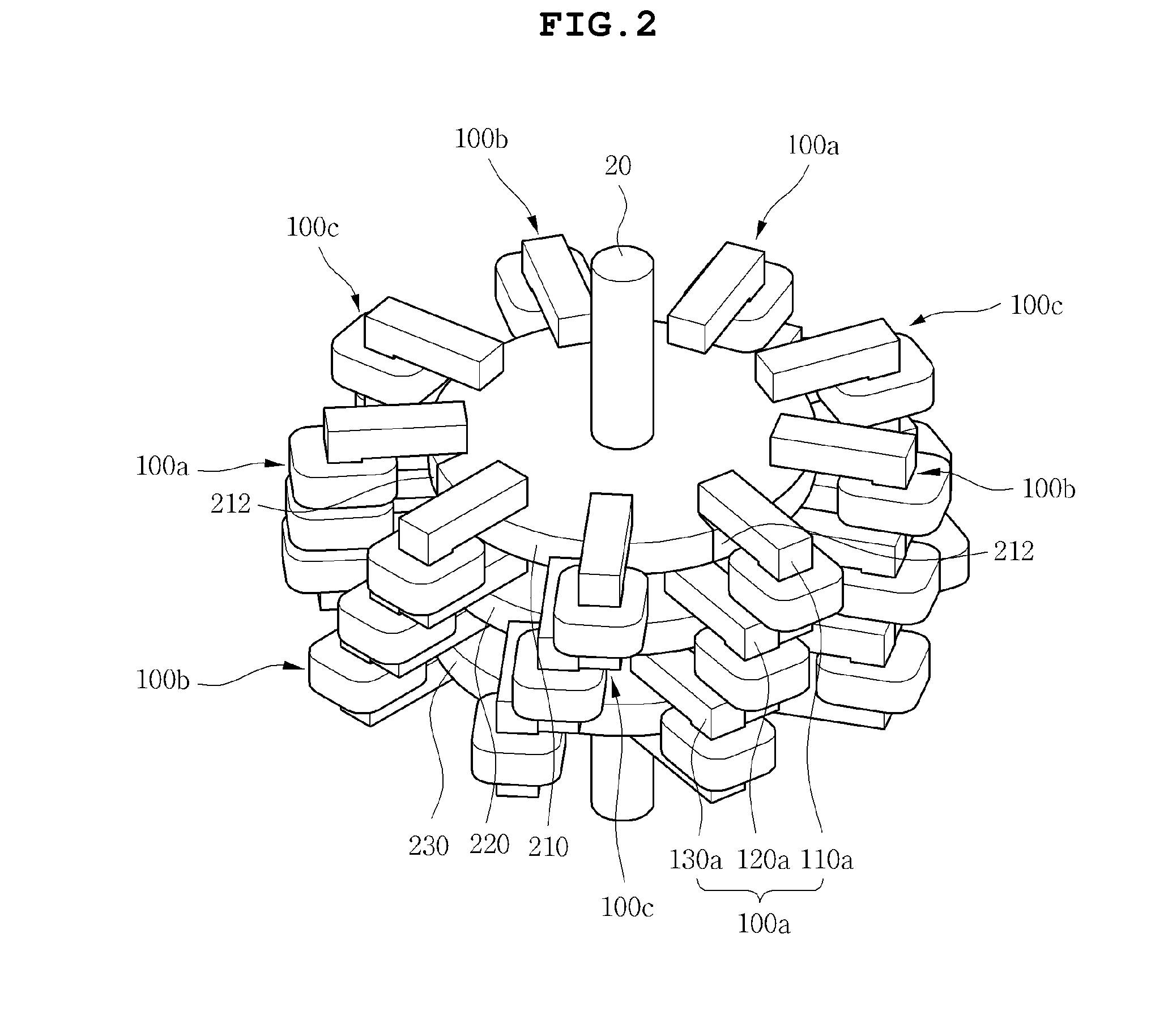

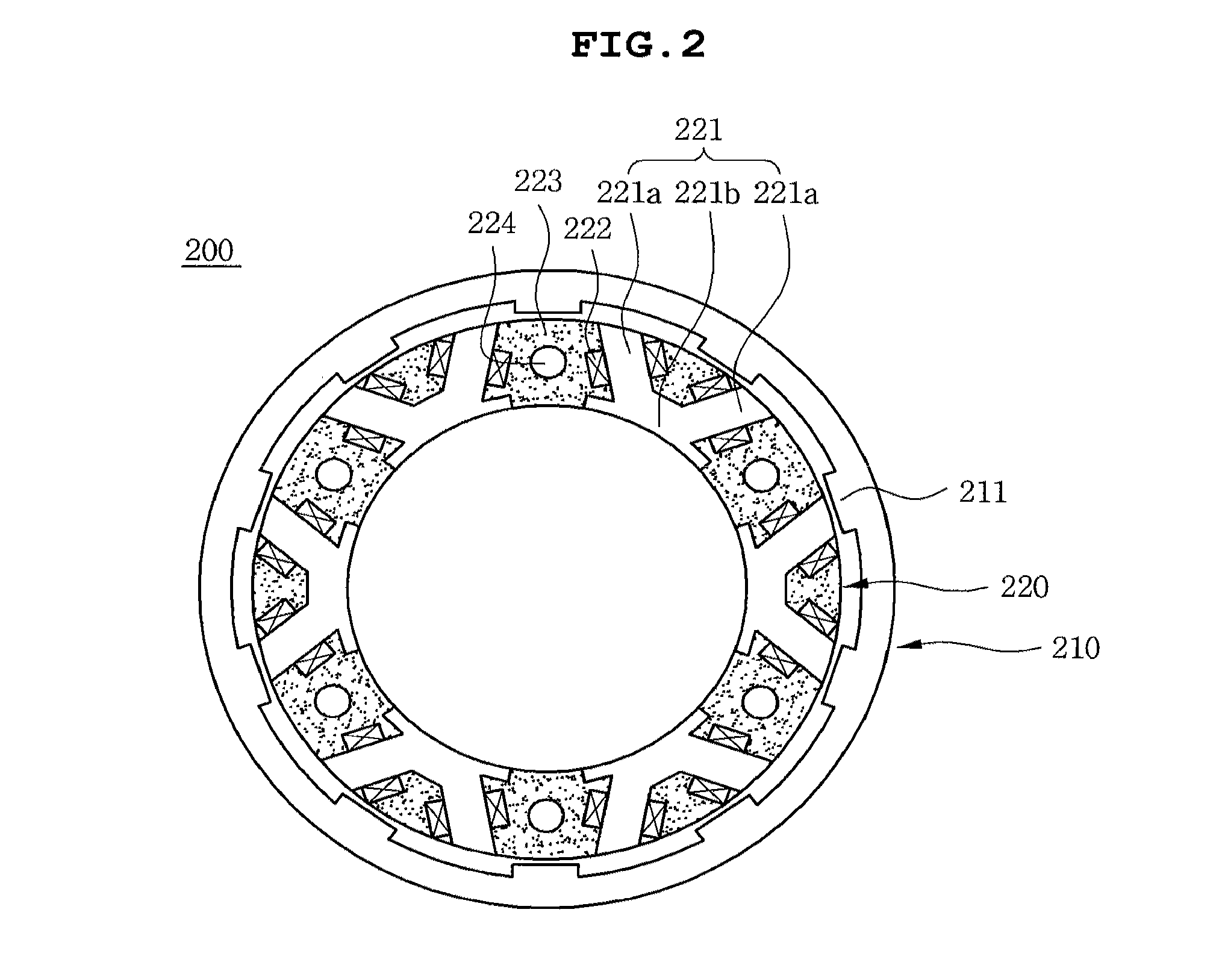

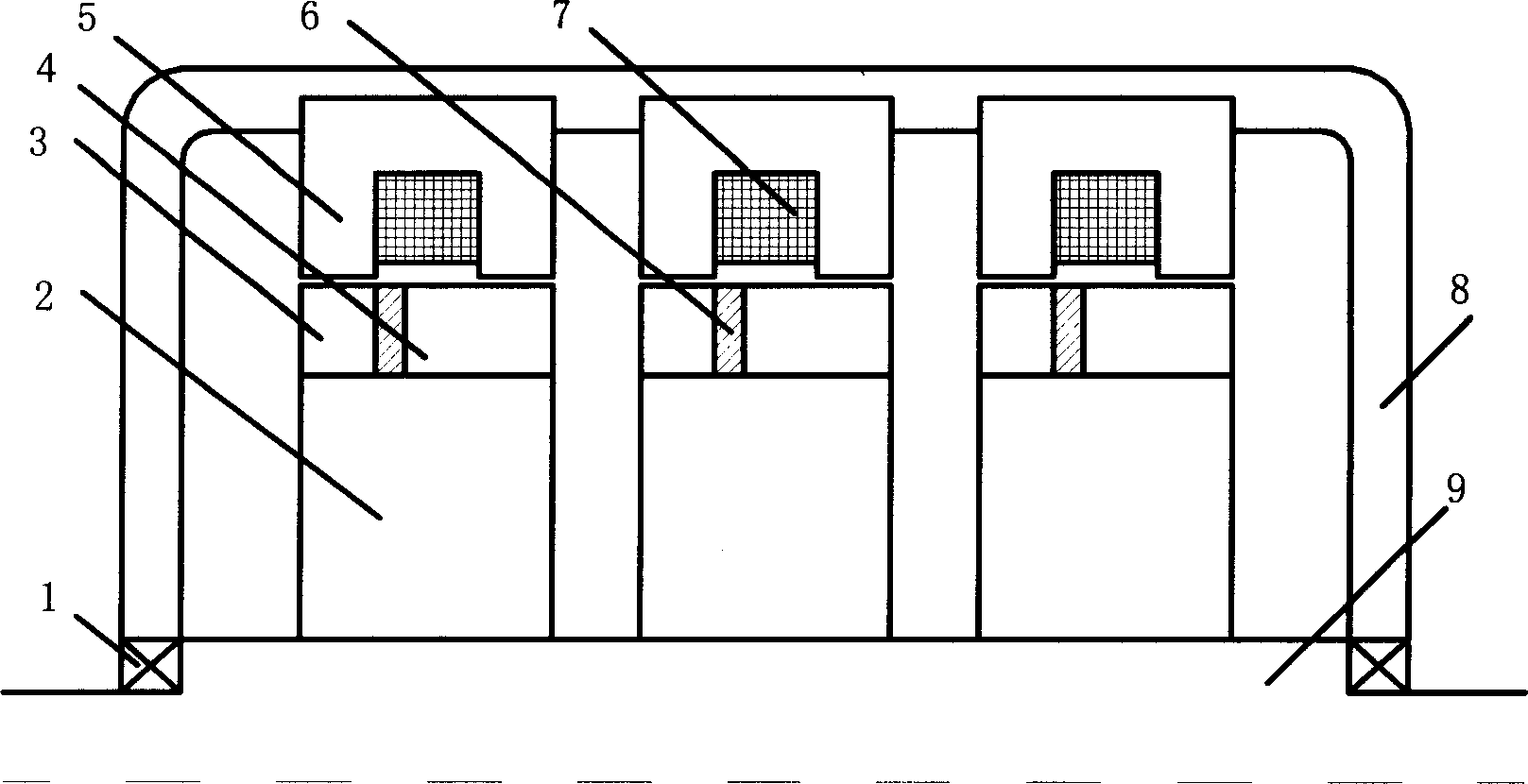

Traversal switched reluctance motor

InactiveUS20130026864A1Reduce core lossEasy to driveWindingsSynchronous motorsEngineeringMechanical engineering

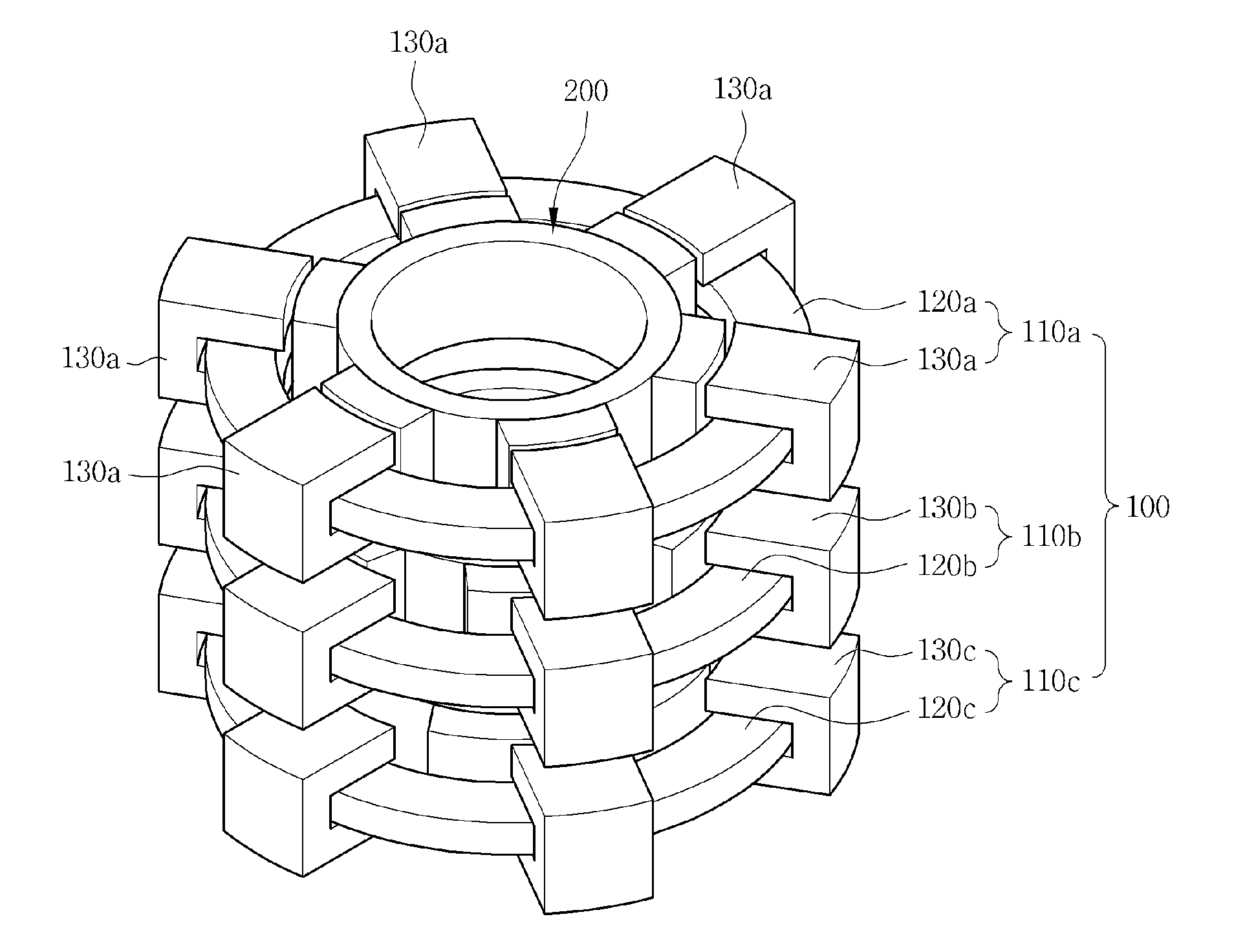

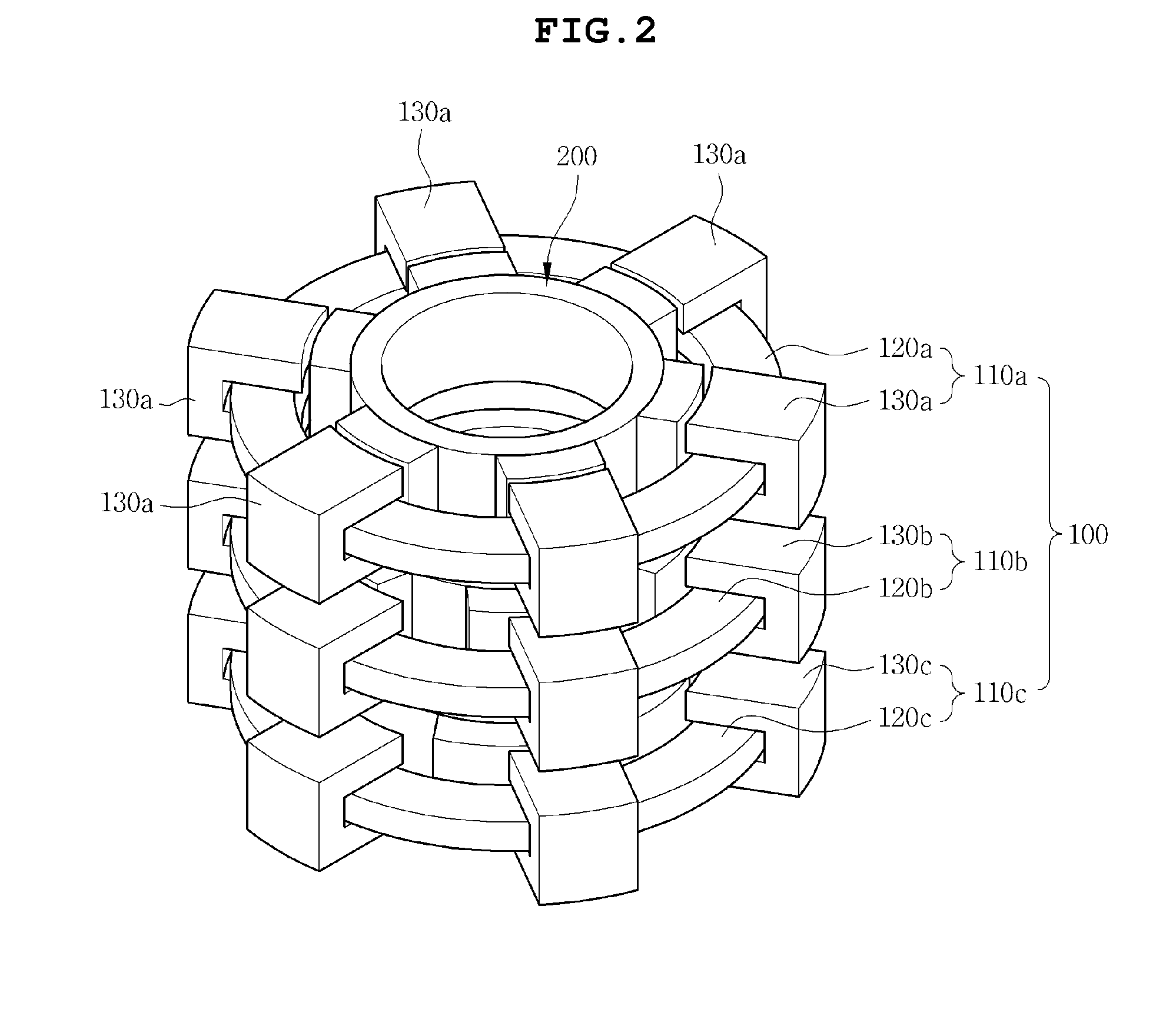

Disclosed herein is a transversal switched reluctance motor including: a rotor assembly formed by arranging a plurality of rotors including a rotor pole mounting part having a shaft coupled to an inner portion thereof and a plurality of rotor poles coupled to the rotor pole mounting part along an outer peripheral surface thereof in a direction of the shaft; and a stator assembly including a plurality of stators each including a coil enclosing an outer peripheral surface of the rotor assembly so that the rotor assembly is rotatably received in an inner portion thereof and a plurality of stator cores fitted with the coil from one side direction thereof along an outer peripheral surface thereof to thereby face the plurality of rotor poles, wherein the stator core has a C shaped cross section with respect to the direction of the shaft around which the rotor assembly rotates.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

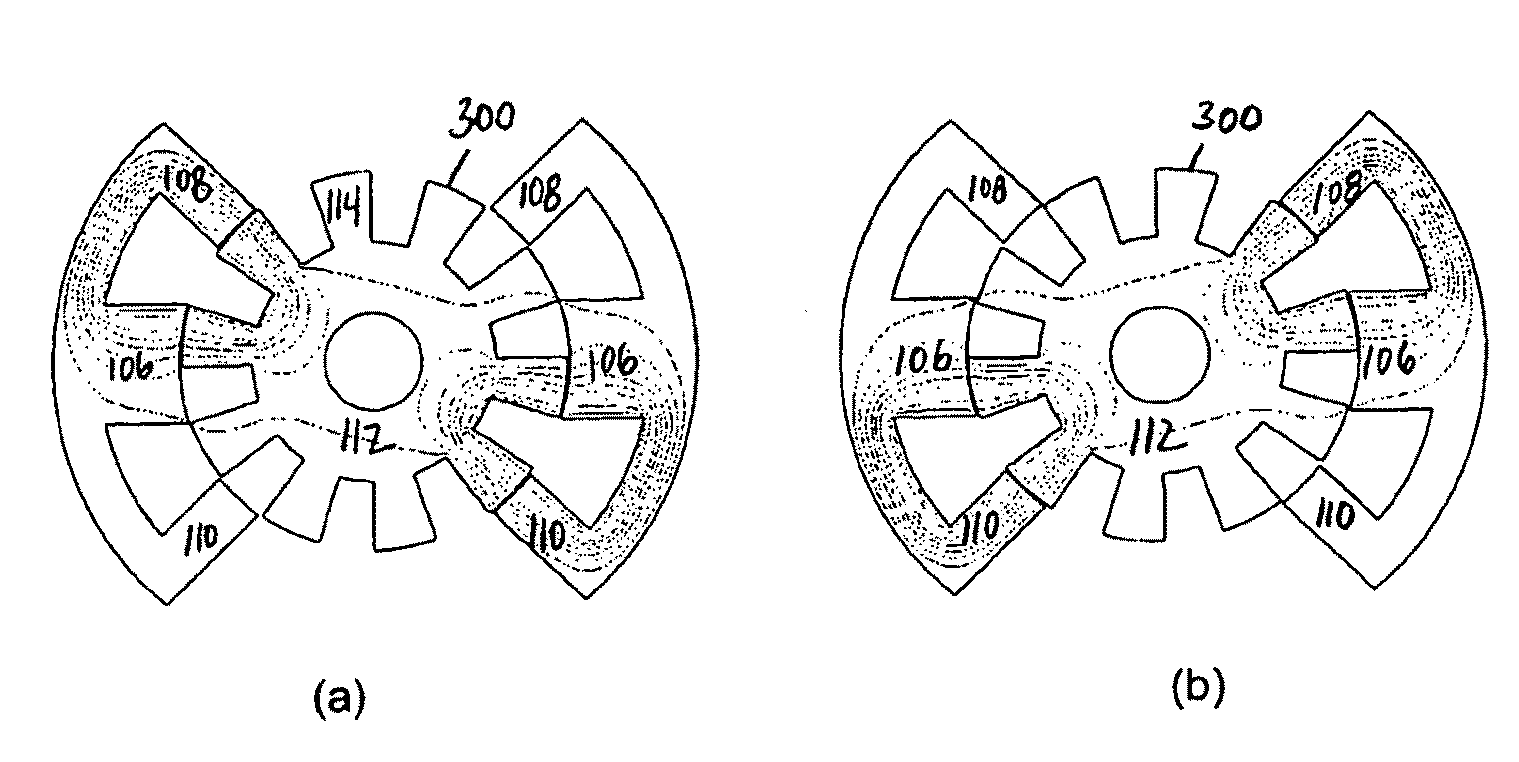

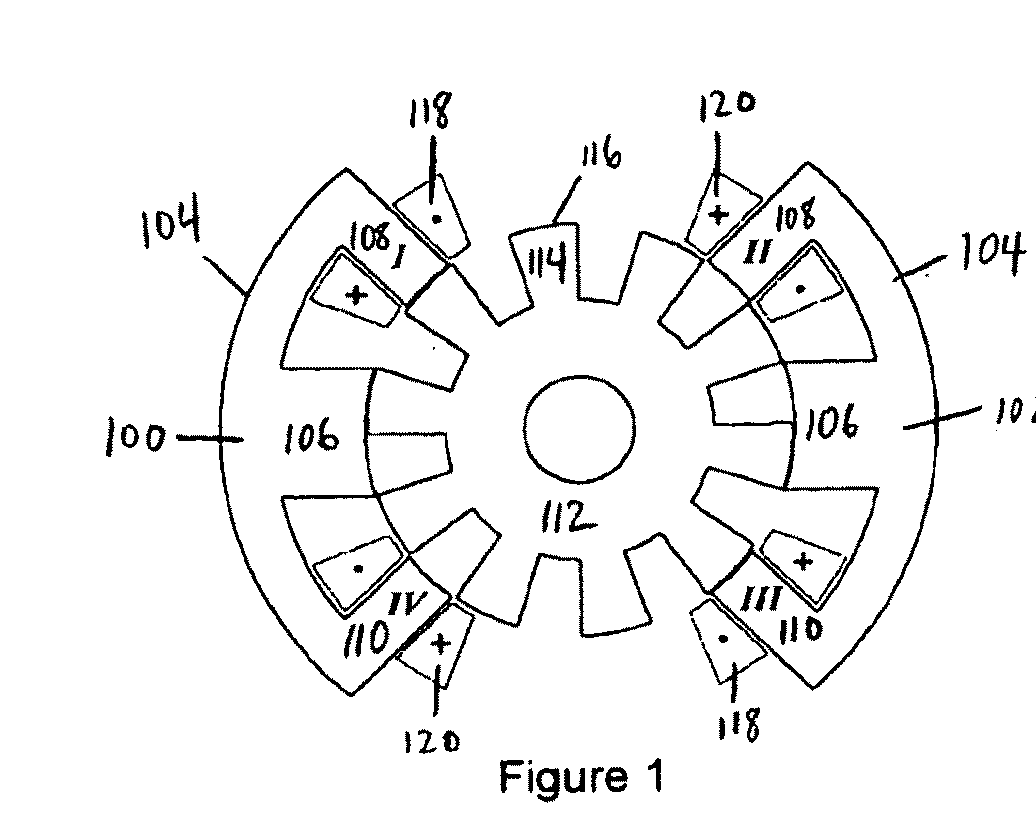

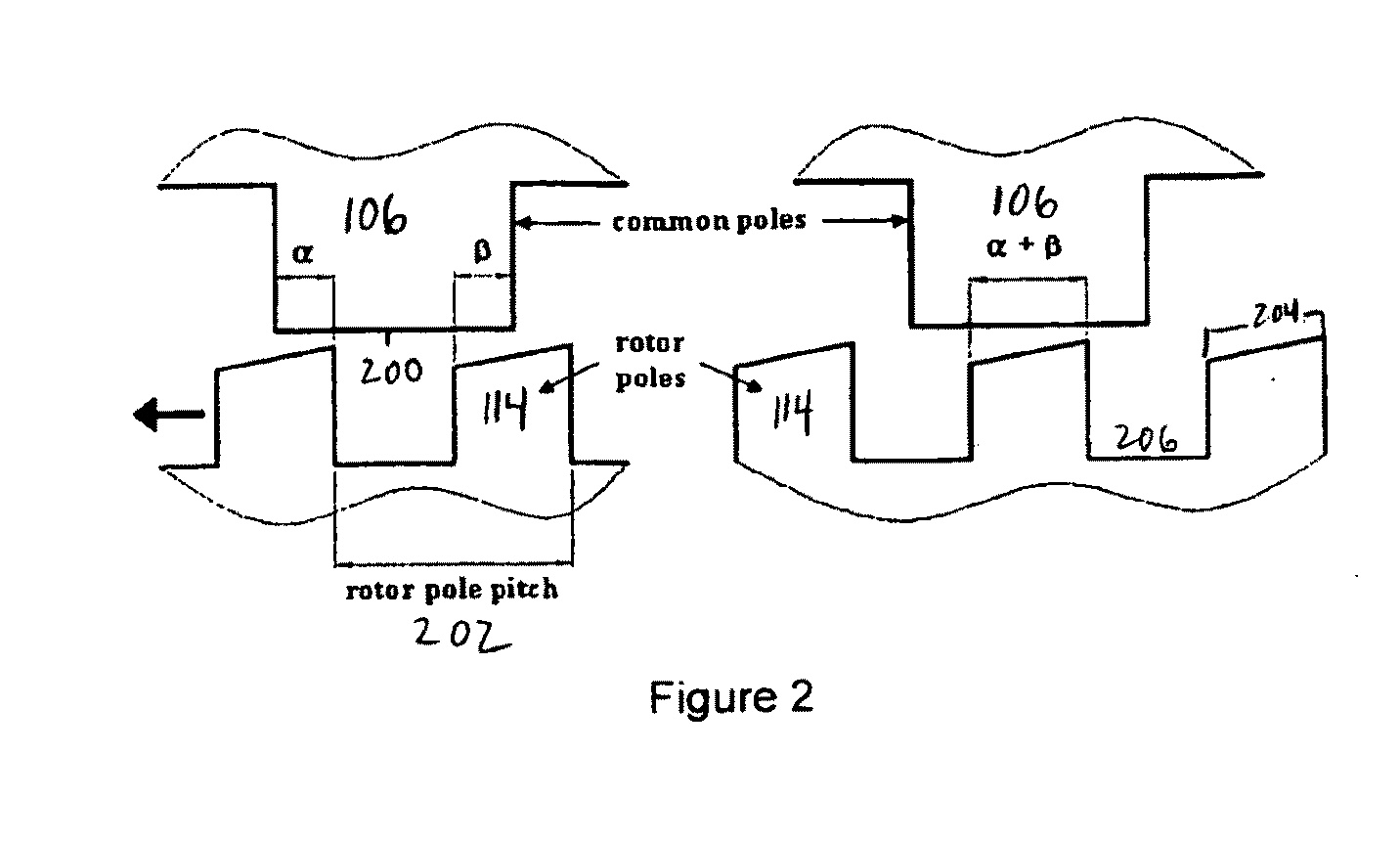

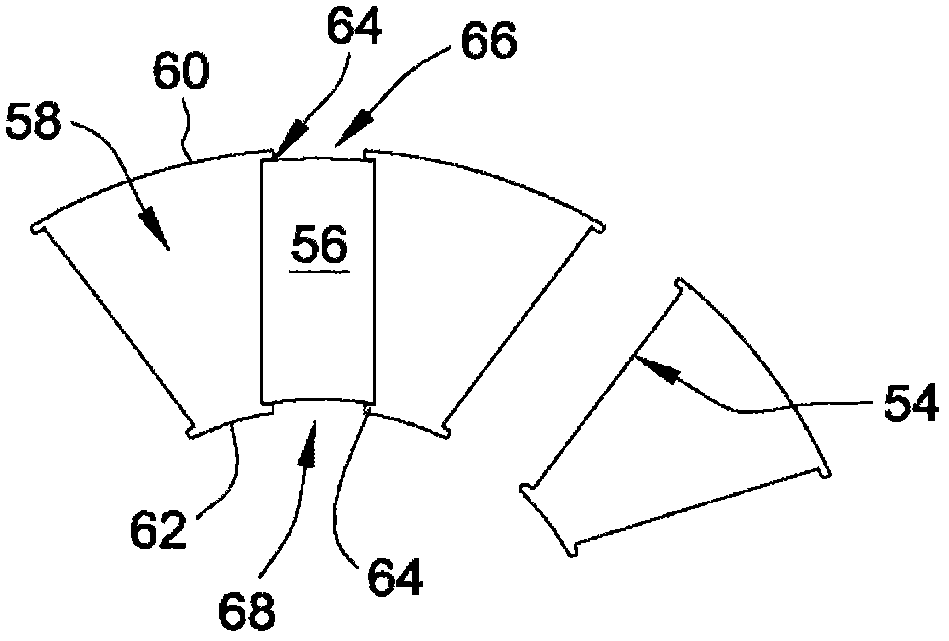

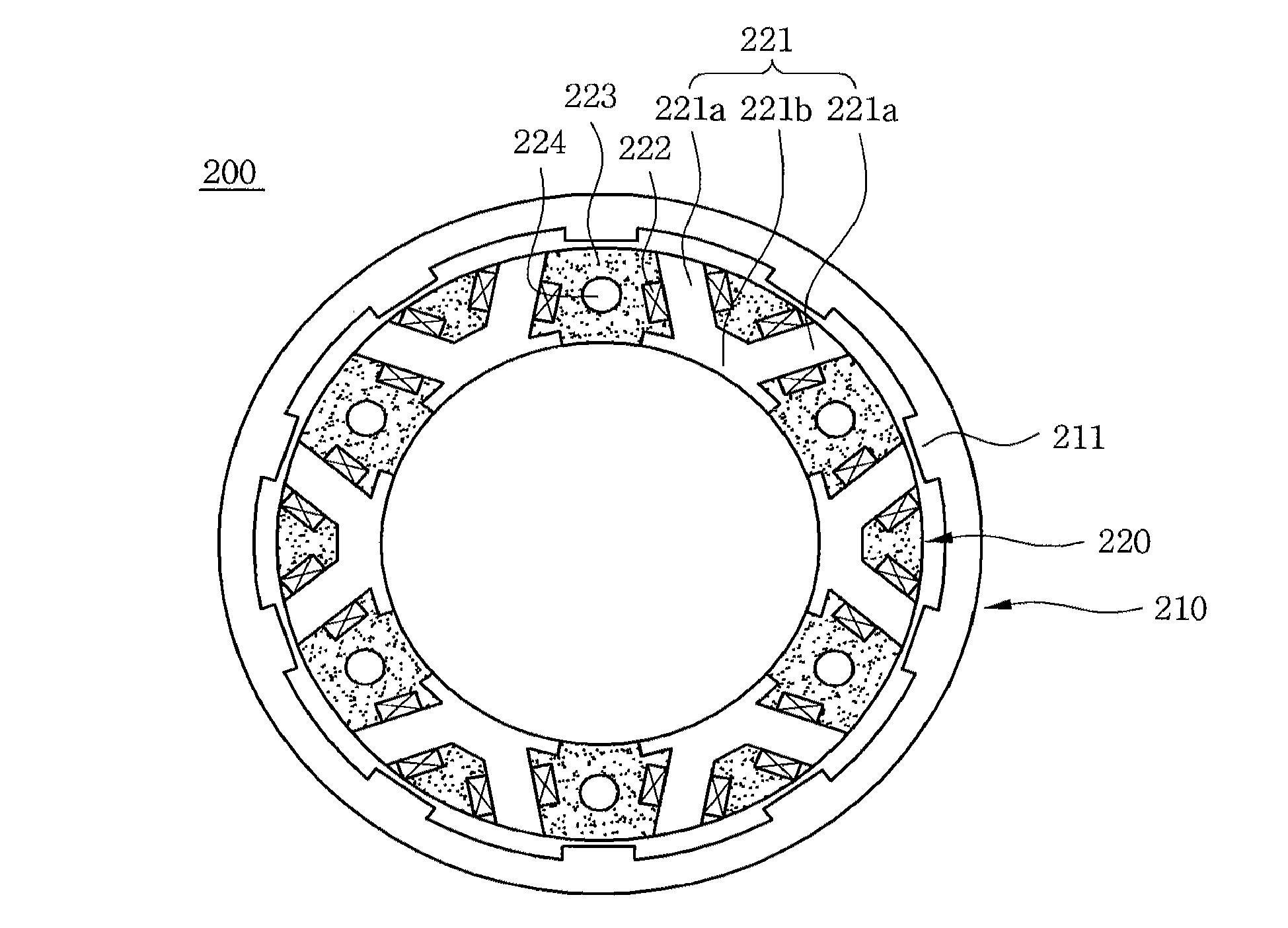

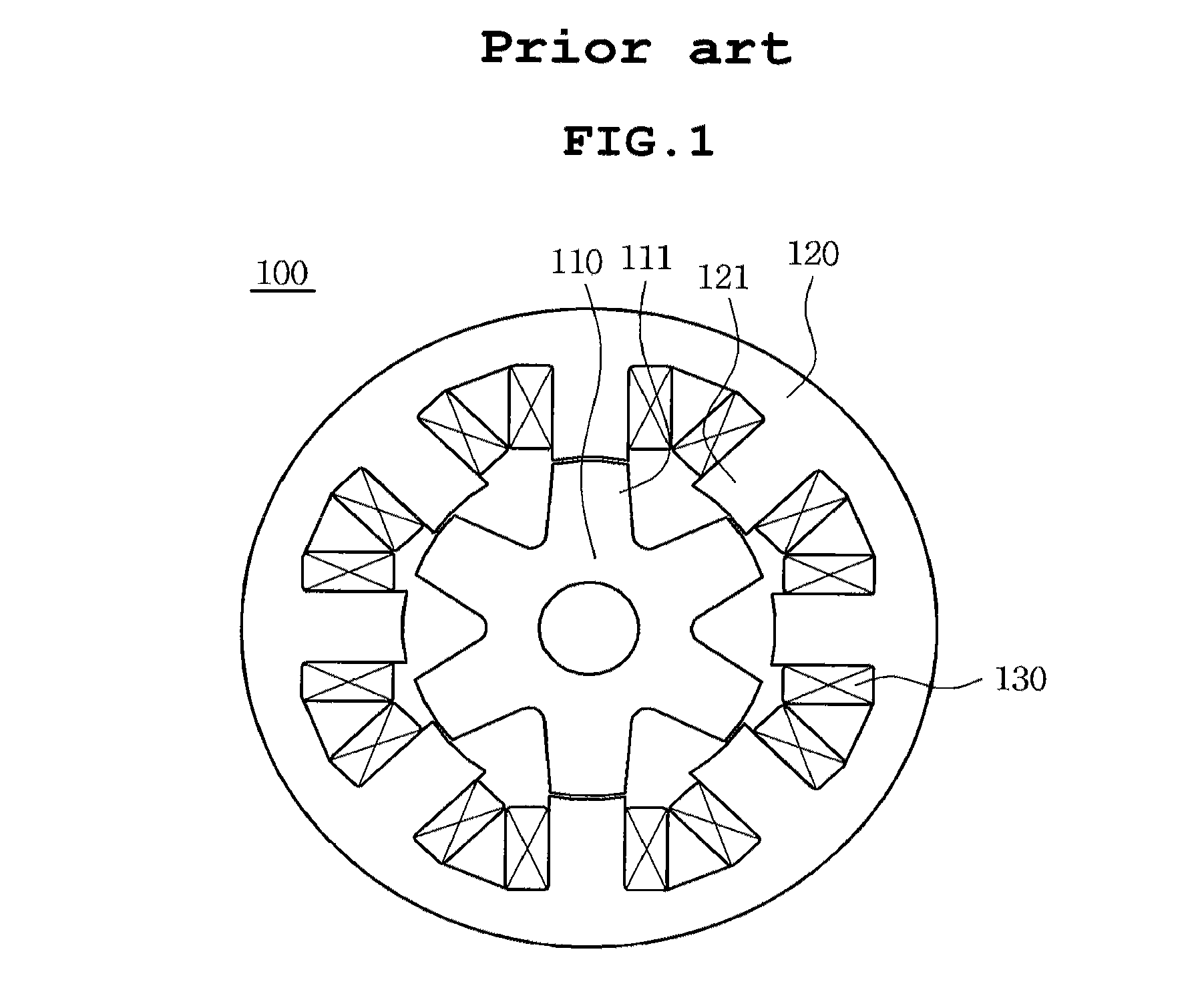

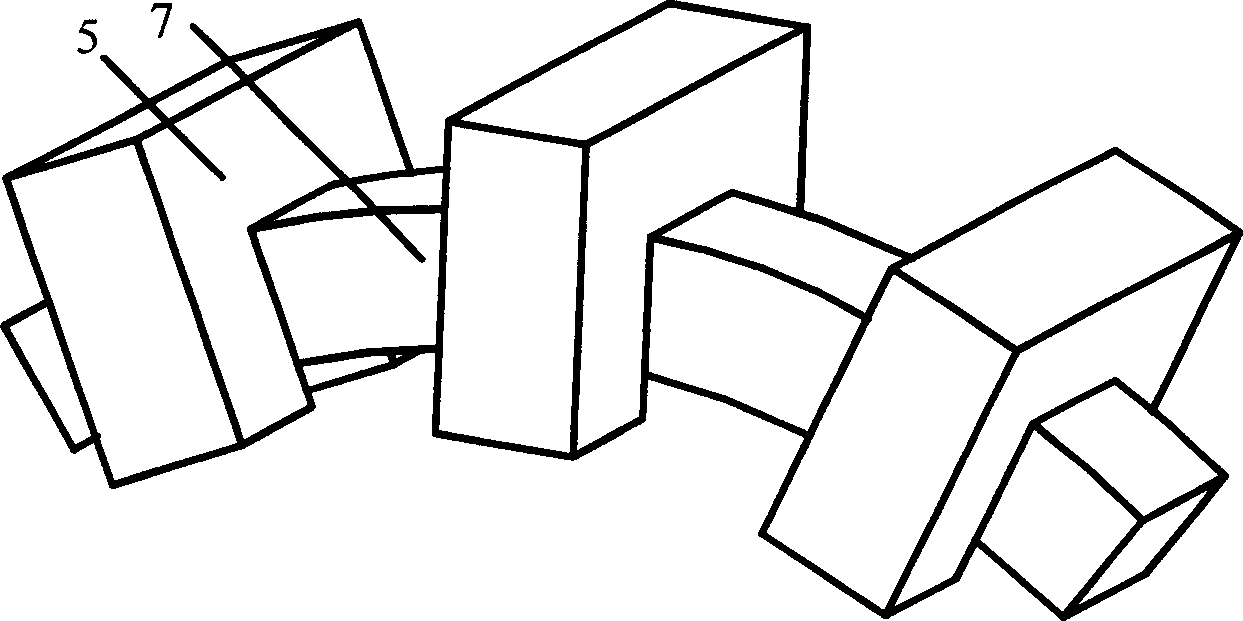

Switched Reluctance Machines with Minimum Stator Core

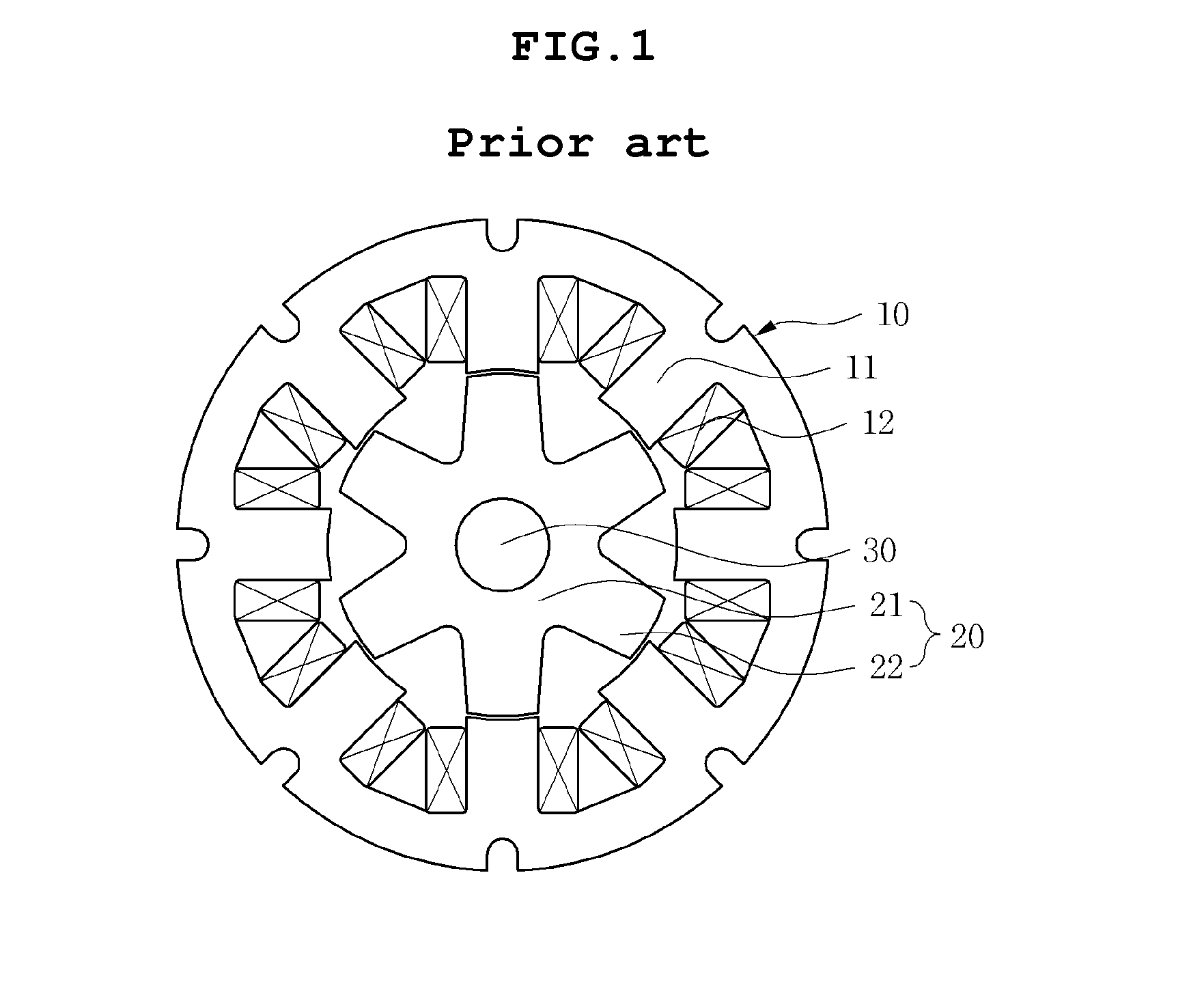

InactiveUS20100141061A1Minimized in sizeReduce path lengthSynchronous machinesMagnetic circuit stationary partsConductor CoilCost savings

A two-phase switched reluctance machine is provided using discontinuous core structures as the stator for low-cost, high-performance drives. This discontinuous stator core structure contains short flux paths and maximum overlap between the rotor poles and stator poles in the stator discontinuous core structures, regardless of the rotor position. Example configurations of such core structure include E-core, L-core and I-core configurations. Using less steel and magnet wire than in conventional SRM designs results in cost savings of stator material and winding material. Efficiency of this novel SRM is improved because of shorter flux paths resulting in reduction of core losses and decreased phase resistance resulting in reduction of copper losses. Two-phase simultaneous excitation of the novel SRM can reduce torque ripple during commutation as compared with existing two-phase SRMs.

Owner:VIRGINIA TECH INTPROP INC +1

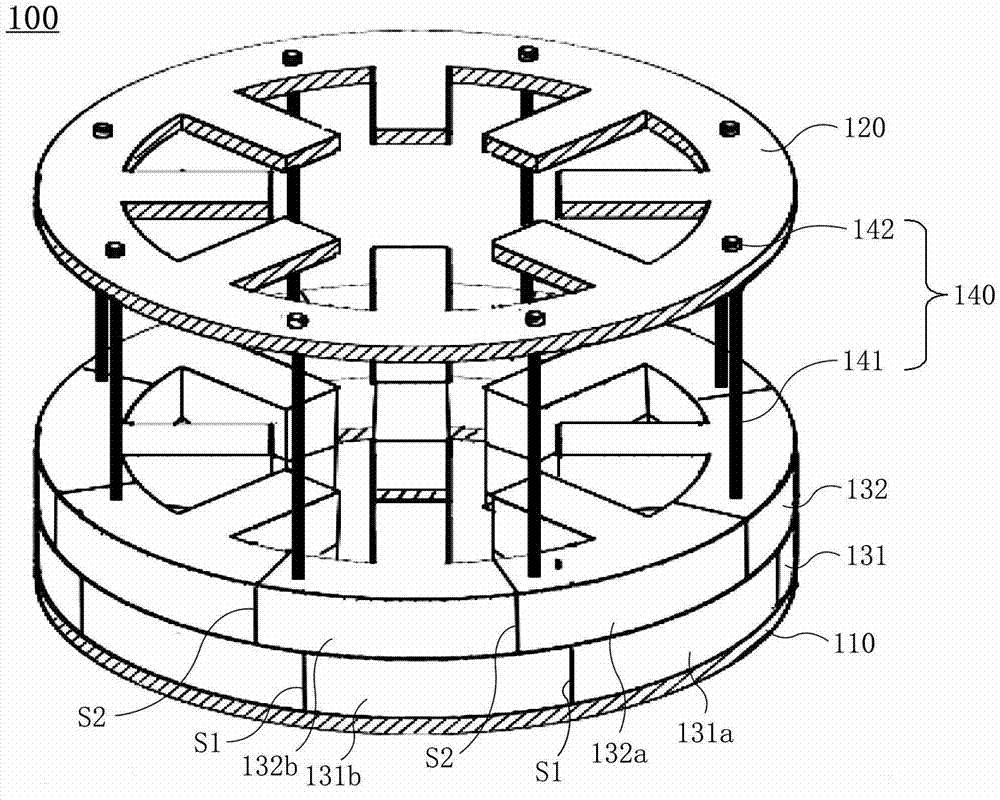

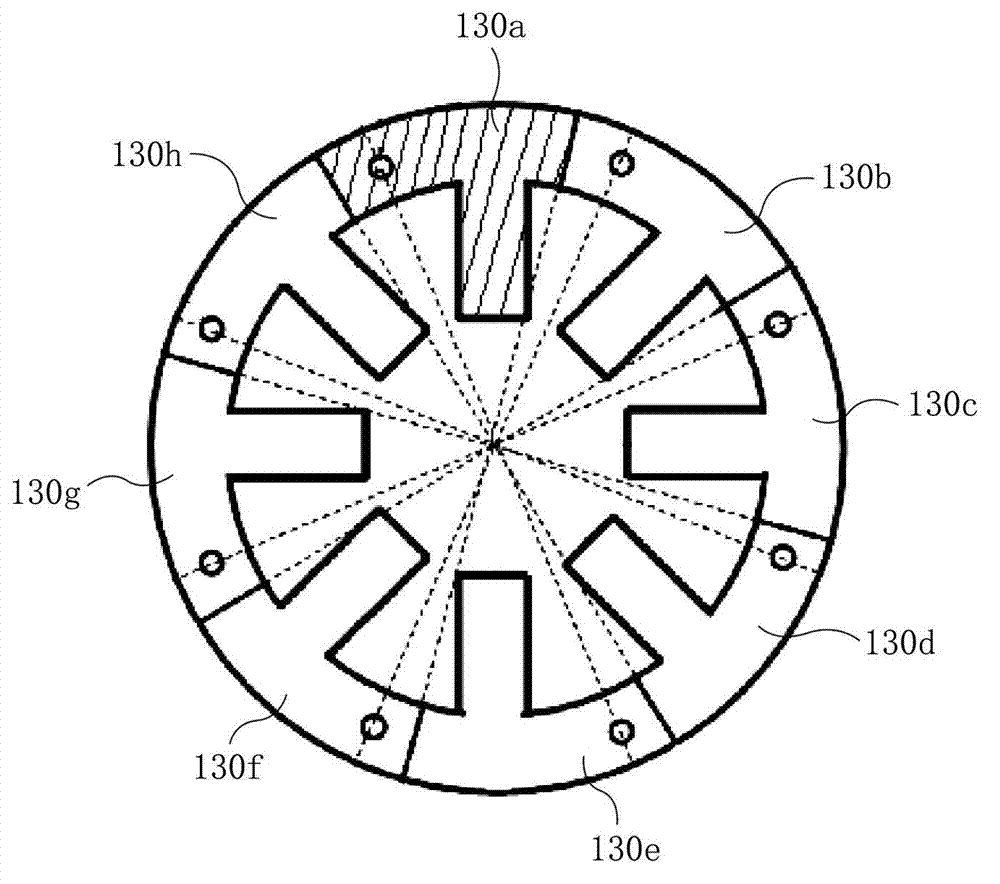

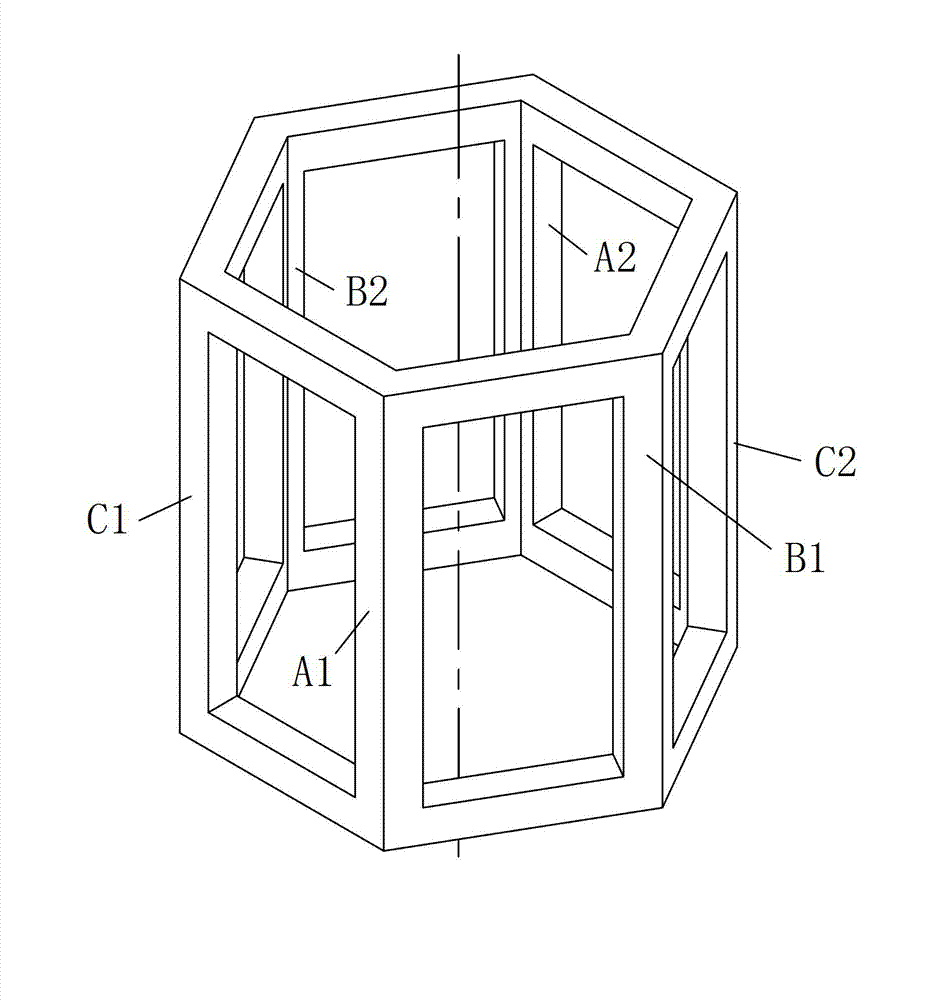

Stator core and manufacturing method thereof

InactiveCN102868241AGood soft magneticStable structureMagnetic circuit stationary partsManufacturing stator/rotor bodiesEngineeringStator

The invention provides a stator core and a manufacturing method thereof. The stator core comprises a lower end plate, an upper end plate, a plurality of laminated bodies and a plurality of connection members, wherein the laminated bodies are laminated between the lower end plate and the upper end plate; the connection members are penetrated through the laminated bodies and are connected with the lower end plate and the upper end plate; each laminated body comprises a plurality of laminated body units which are sequentially arranged in the circumferential direction and form a circumference; each laminated body unit comprises a yoke part and an inner tooth; the yoke part is an arc-shaped flat piece or plate; the inner tooth is a flat piece or plate and extends from the yoke part to the circle center of the yoke part; at least one of the yoke part and the inner tooth comprises a hole; adjacent laminated body units among the multiple laminated body units of each laminated body form joint seams; each connection member comprises a rod; the rod is penetrated through the hole of the laminated body unit; the lower end of the rod is fixed to the lower end plate, and the upper end of the rod is fixed to the upper end plate; the yoke parts of the multiple laminated bodies overlap along the direction of the rod; the inner teeth of the multiple laminated bodies overlap along the direction of the rod; and the multiple joint seams of the adjacent laminated bodies among the multiple laminated bodies do not overlap.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

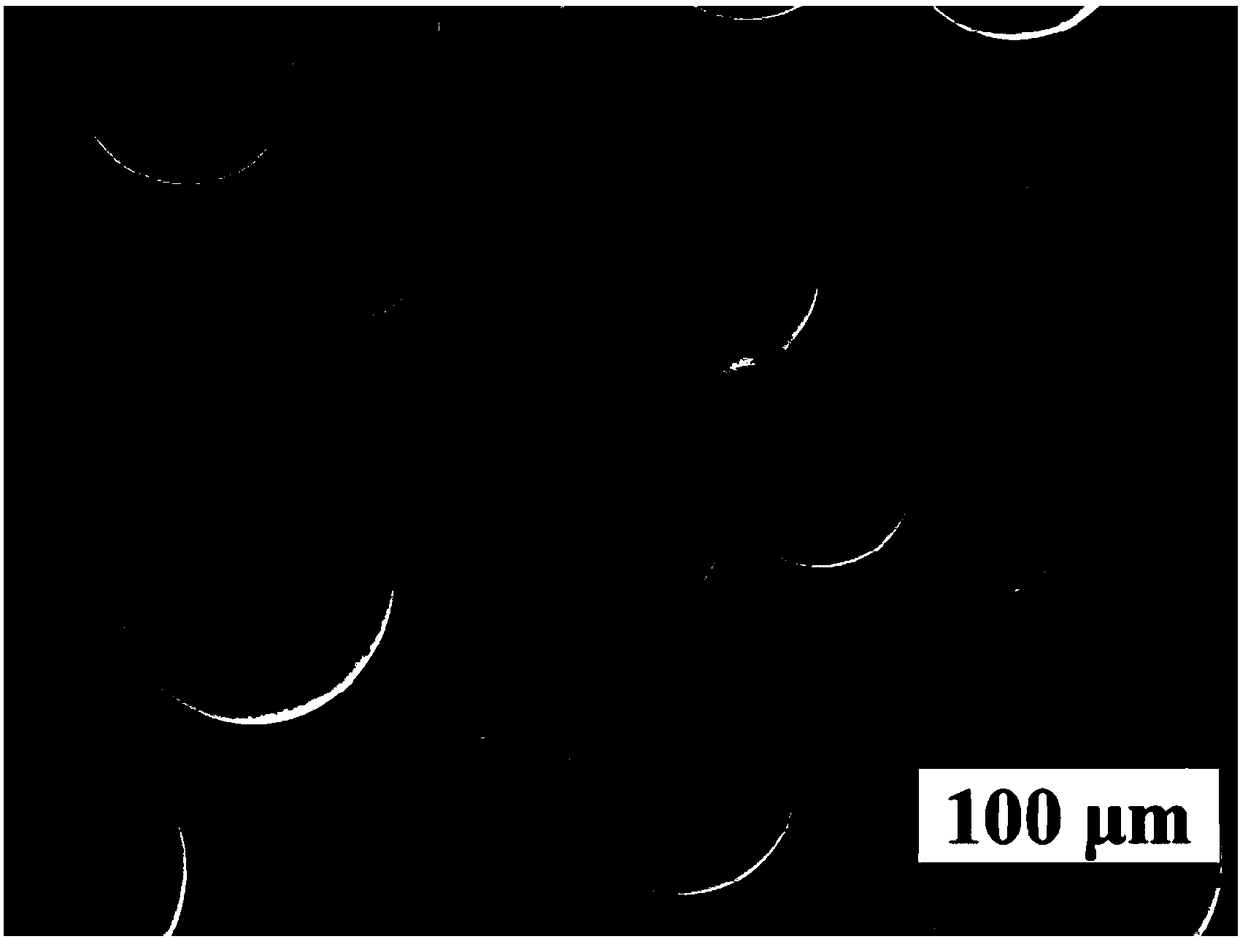

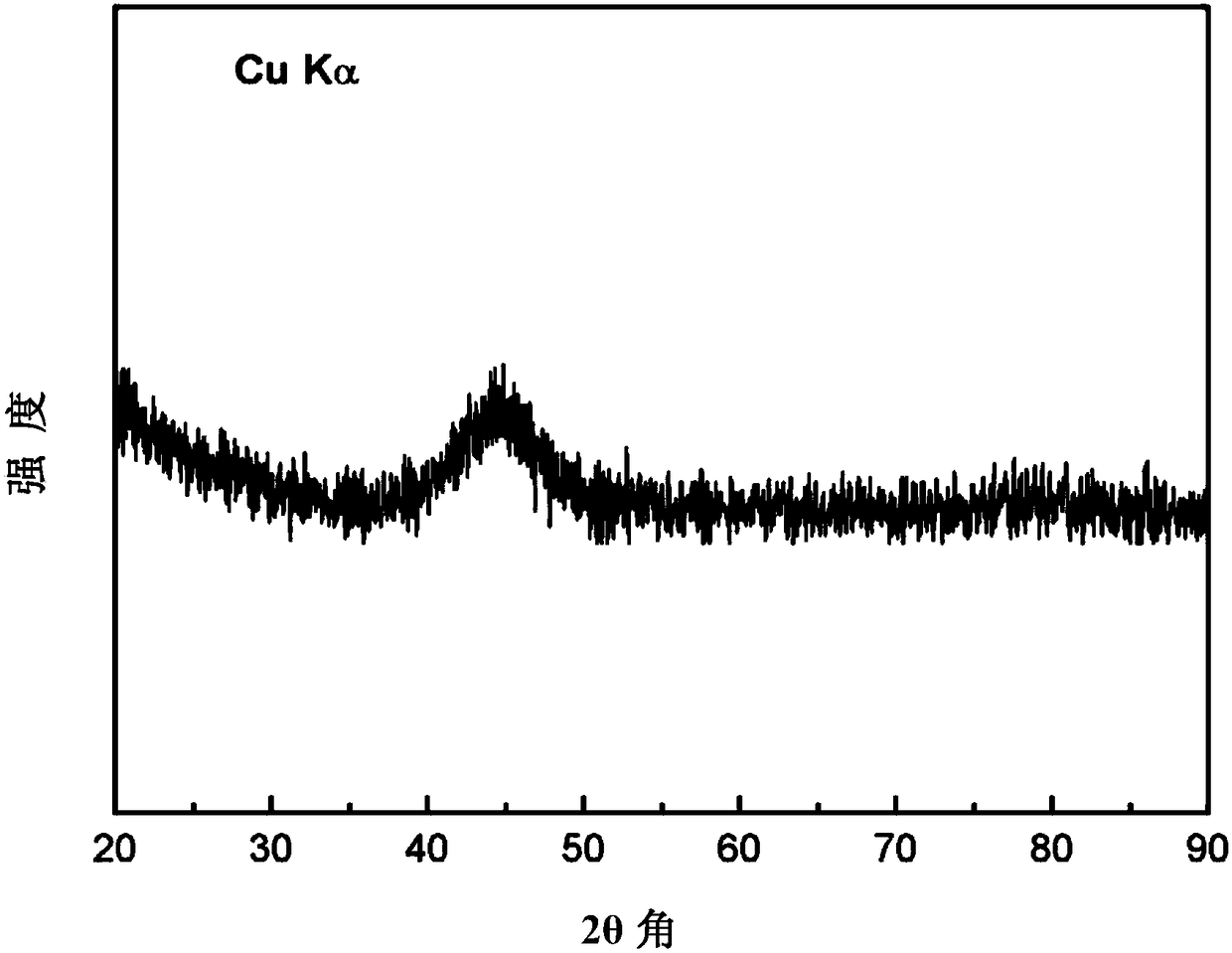

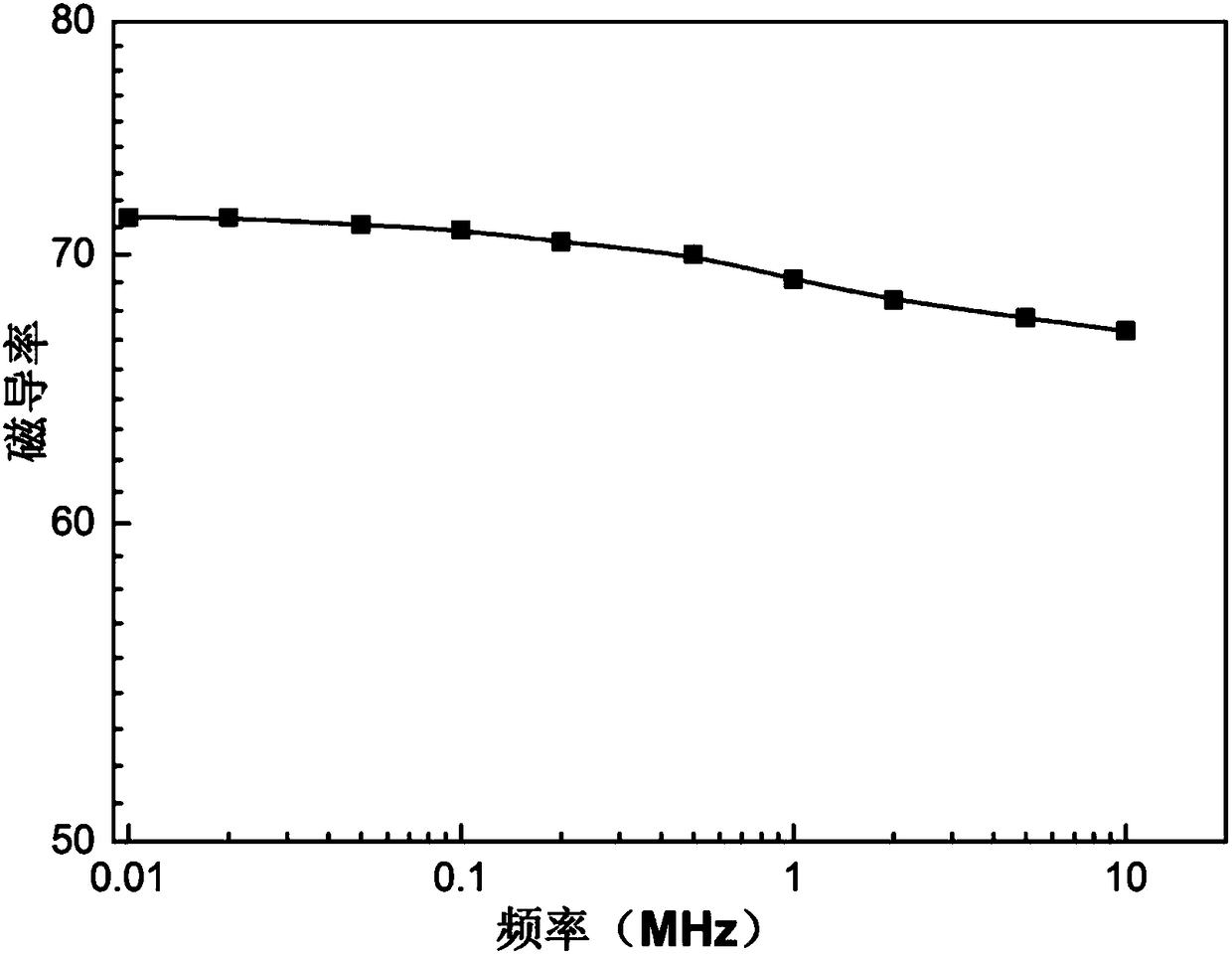

Spherical iron-based amorphous alloy powder and preparation method and application in preparation of amorphous magnetic powder core

The invention discloses a preparation method of a spherical iron-based amorphous alloy powder; the spherical iron-based amorphous alloy powder is prepared by a gas atomization method, and the iron-based amorphous alloy with large amorphous forming capacity is used as a raw material; the atomic percentage composition of the iron-based amorphous alloy with large amorphous forming capacity is Fe<100-a-b-c-d-e>SiBP<c>Nb<d>Cu<e>, wherein a is 7-10, b is 7-11, c is 3-6, d is 0-3, and e is 0-2. The invention provides a method for preparing the spherical iron-based amorphous alloy powder by thegas atomization method to obtain the spherical alloy powder with a regular appearance, uniform particle size and complete amorphous state. The amorphous magnetic powder core prepared by taking the spherical iron-based amorphous alloy powder as the raw material has the advantages of uniform structure, high strength, high density and constant magnetic conductivity.

Owner:嘉兴长维新材料科技有限公司 +1

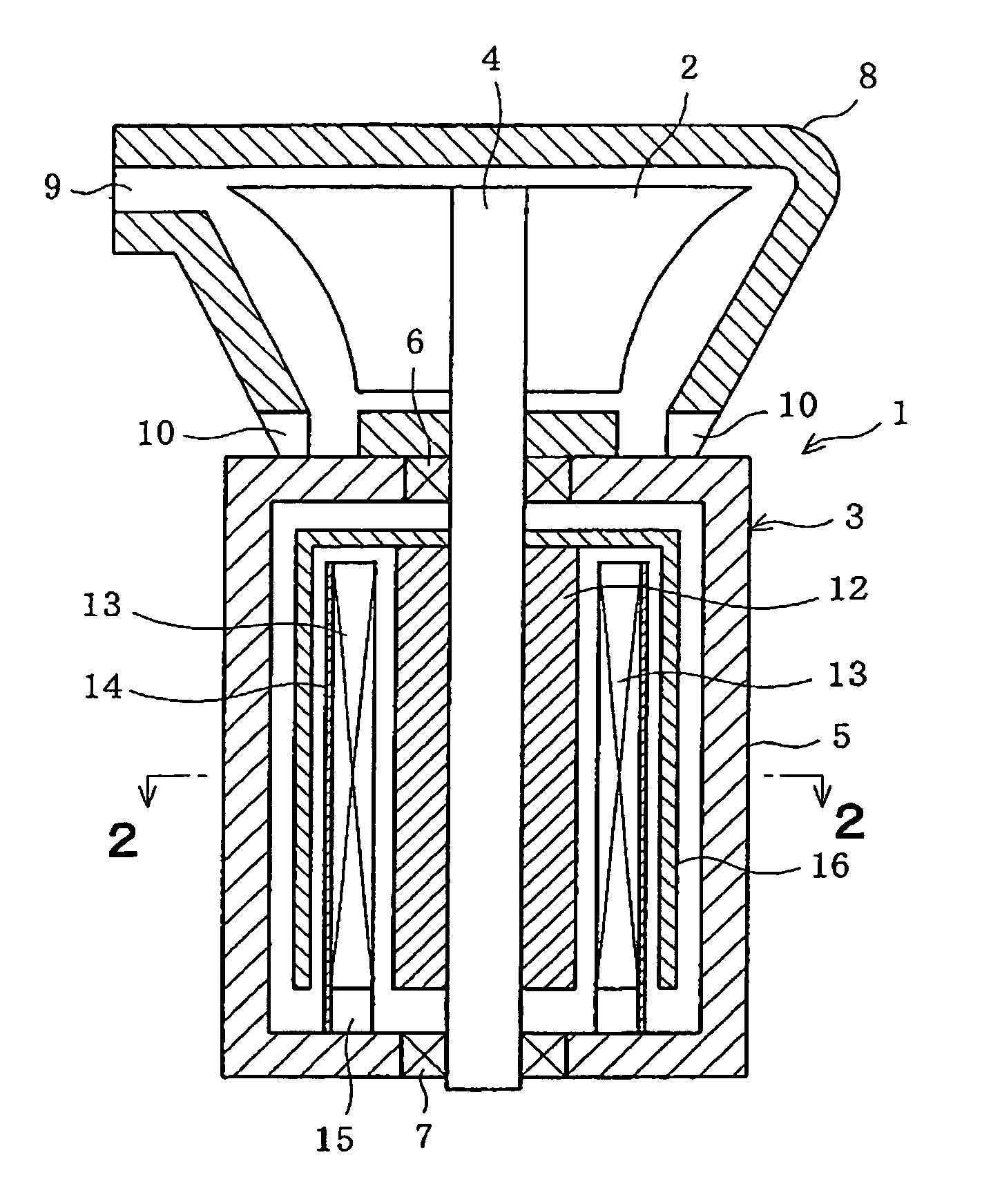

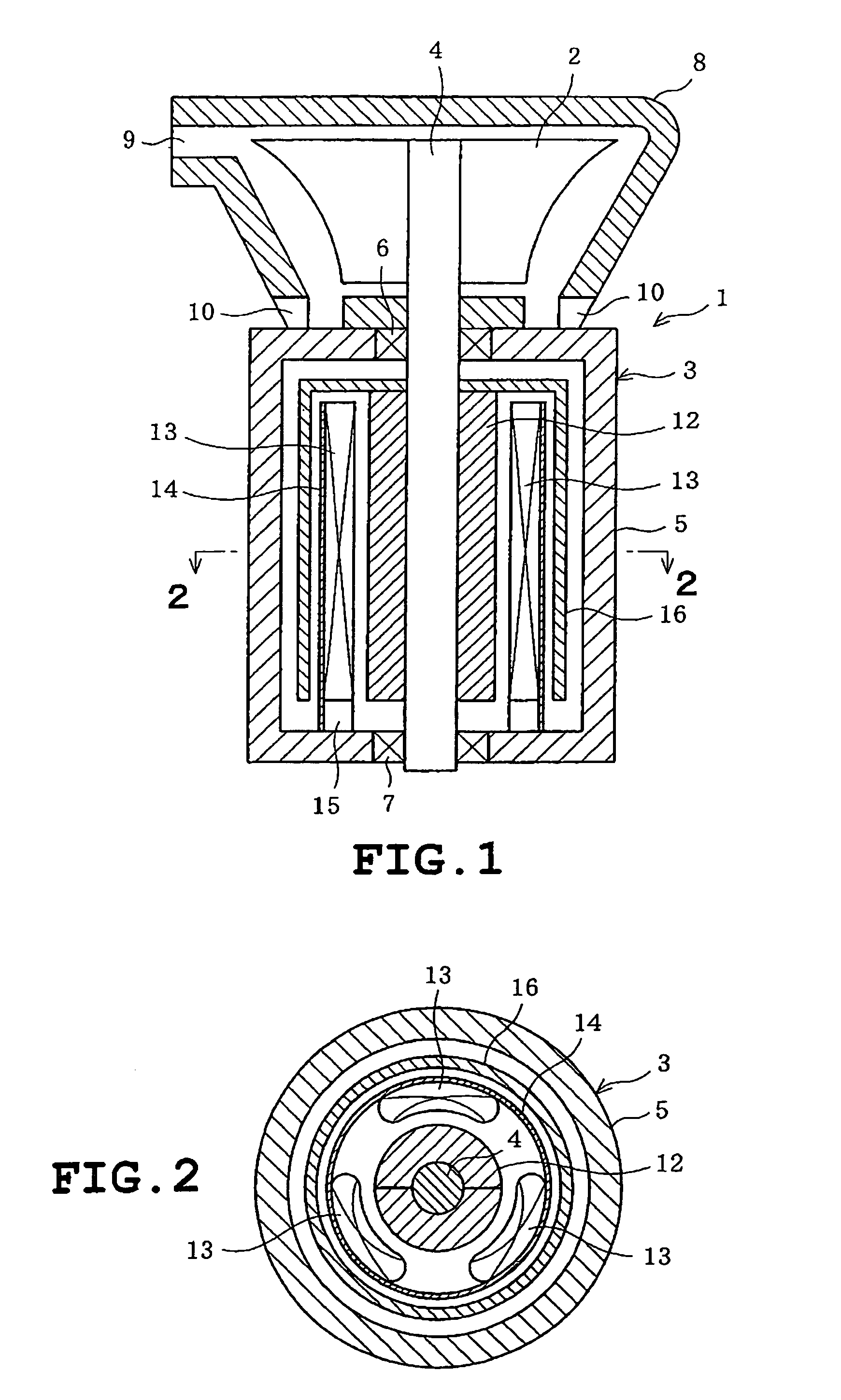

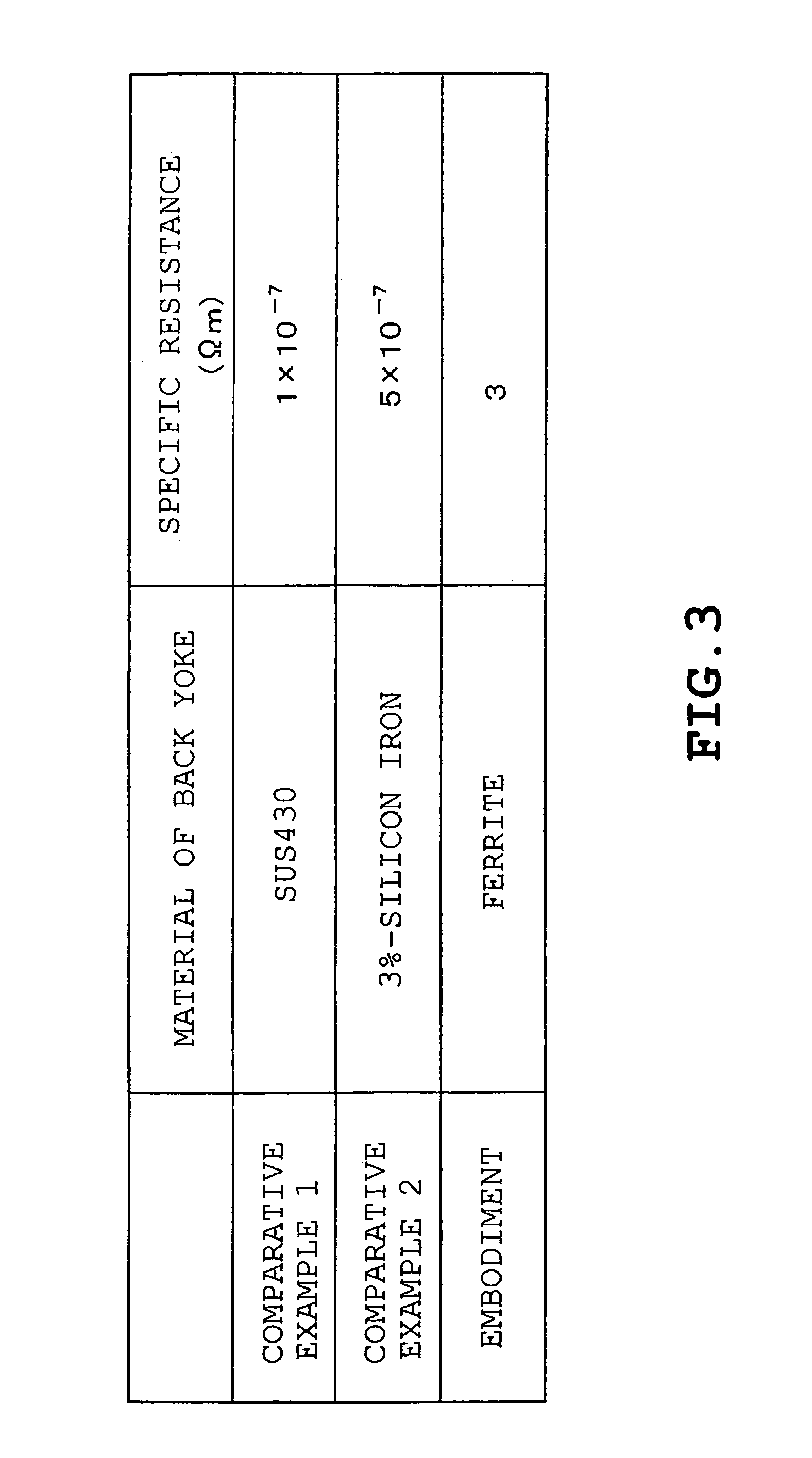

Power generating system

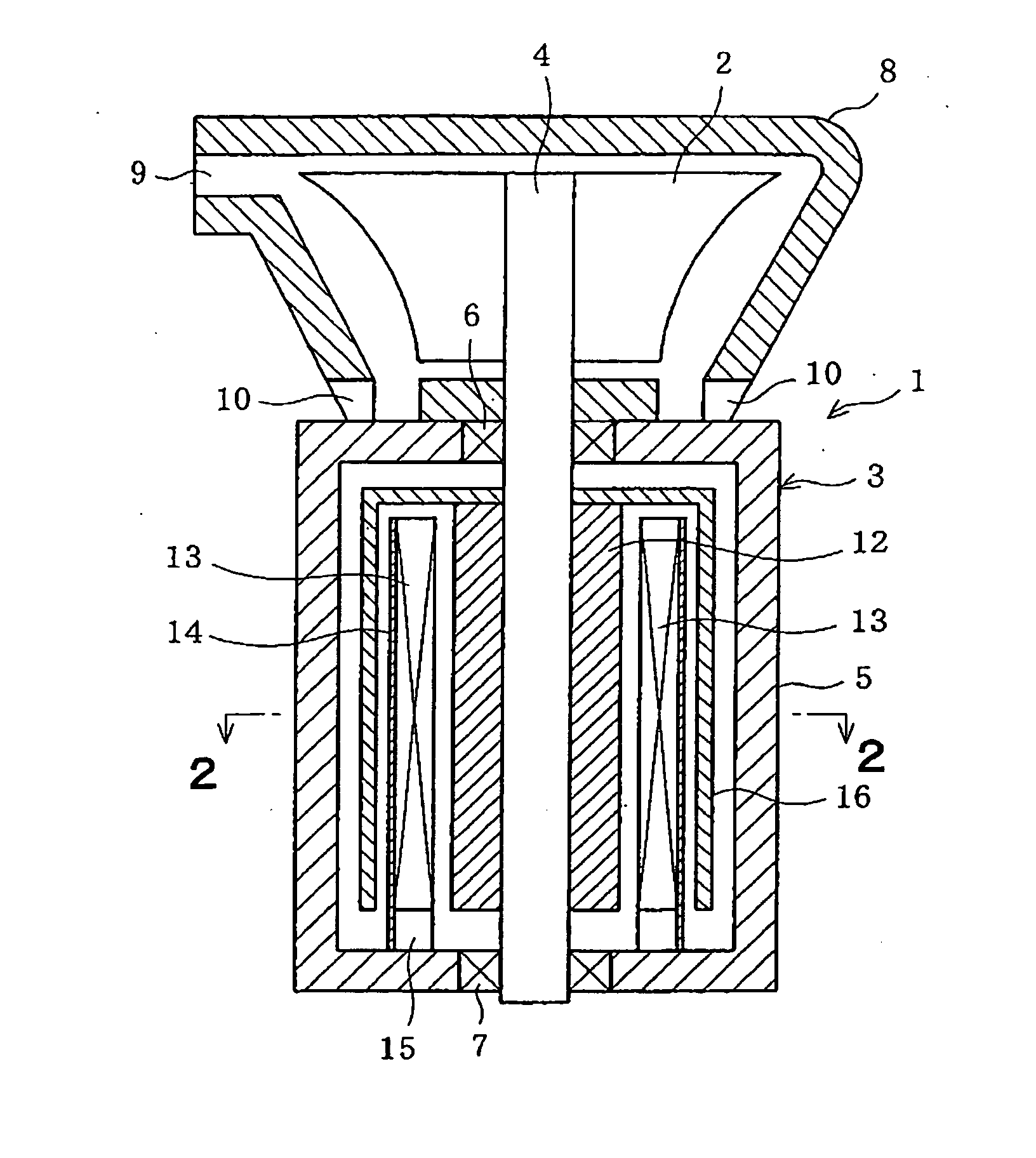

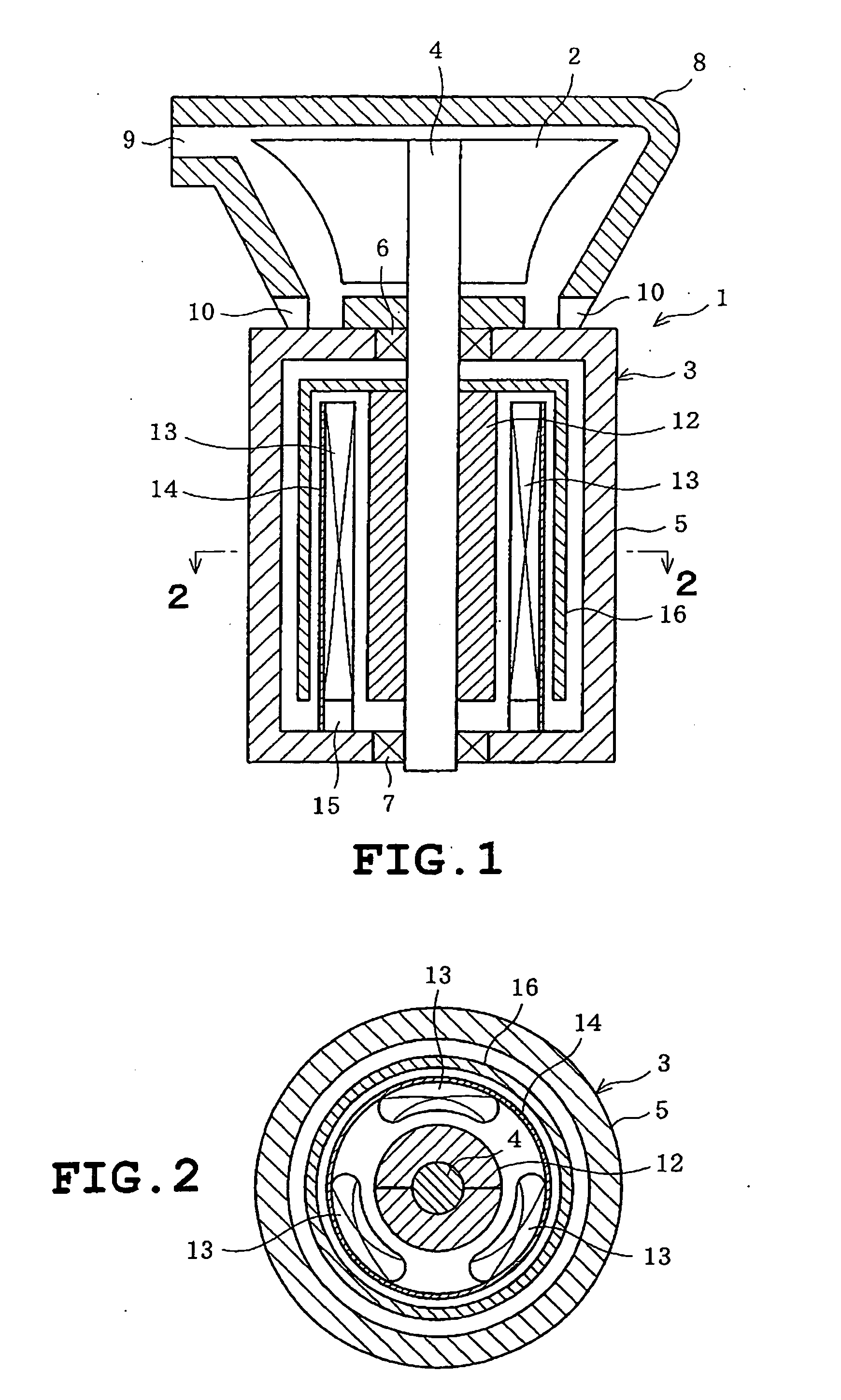

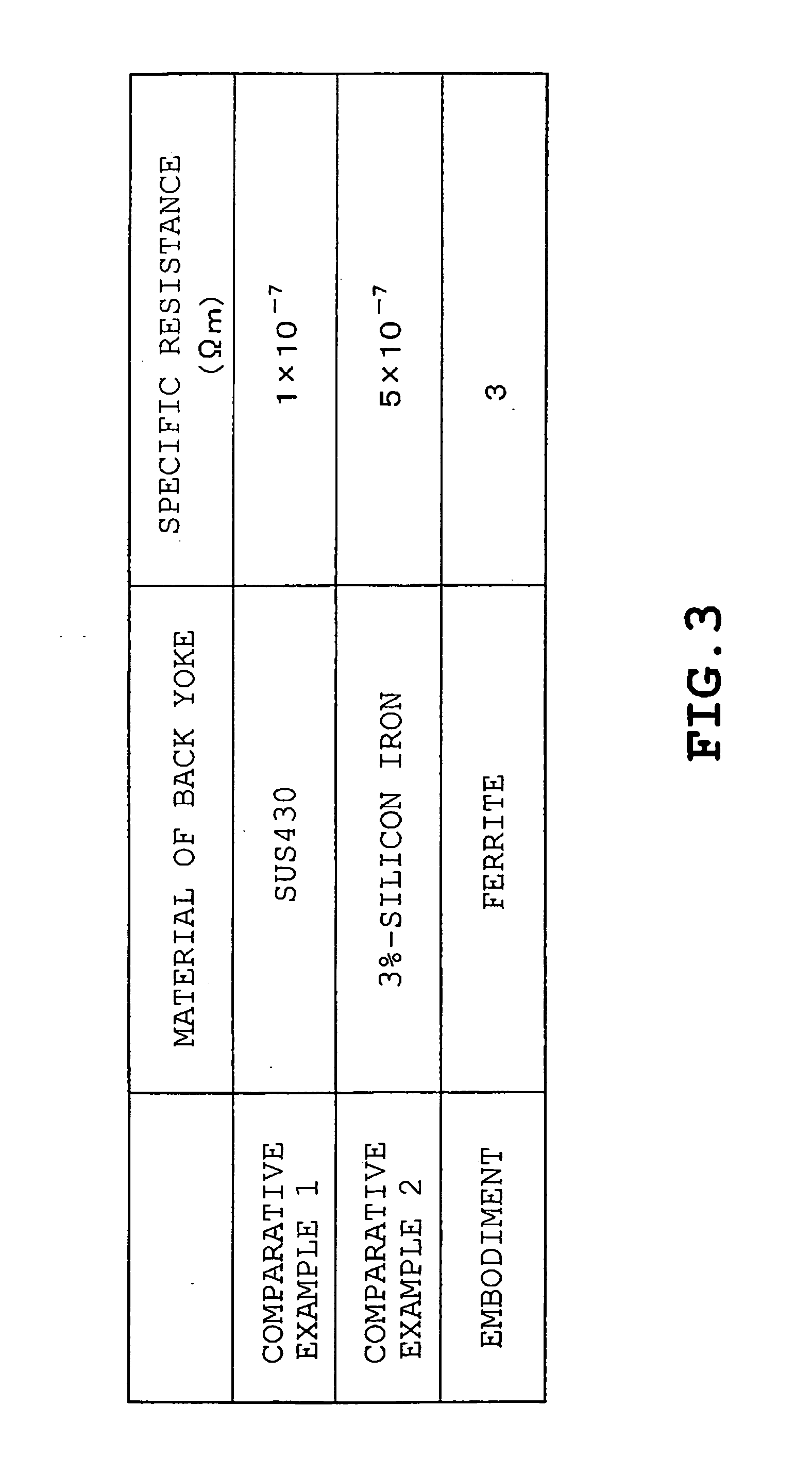

InactiveUS7531932B2Reduce core lossImprove power generation efficiencyMagnetic circuit rotating partsMechanical energy handlingPermanent magnet rotorTurbine

A small power generating system includes a turbine driven by a fluid, a small high-speed rotation power generator including a permanent magnet rotor having a permanent magnet and rotated together with the turbine and a plurality of stator coils each of which is comprised of a coreless coil, the rotor being rotated such that voltage is induced on the stator coils, whereby power is generated by the power generator, and a back yoke disposed at one of two opposed sides of the stator coils which is opposed to the other side thereof further confronting the permanent magnet of the rotor, the back yoke being made of a magnetic material with a predetermined electrical resistance.

Owner:KK TOSHIBA

Inhomogeneous nucleation insulation coating processing method of metal soft magnetic composite material

ActiveCN104028747APrecise thickness controlPrecise control of its chemical compositionInorganic material magnetismInsulation layerSpray coating

The invention discloses an inhomogeneous nucleation insulation coating processing method of a metal soft magnetic composite material. The method includes the following steps that (1) particle size distribution is conducted on metal magnetic powder after sieving is conducted; (2) insulation coating is conducted on the distributed metal powder through an inhomogeneous nucleation method, and then the metal powder is dried; (3) the dried magnetic powder and a binding agent are evenly fixed, a release agent is added to conduct dry pressing and forming, and the mixture is pressed to form blank samples; (4) heat preservation is conducted on the blank samples for half an hour to two hours in a protective atmosphere, and air cooling and spray coating are conducted to obtain the target product. The composite powder prepared through the inhomogeneous nucleation method is even and compact in coating and controllable in coating layer thickness, and has high oxidation resistance, high resistivity, high saturation magnetization intensity, the good magnetic property and the good mechanical property; the surface of the metal magnetic powder is evenly coated with an A12O3 insulation layer through the inhomogeneous nucleation method, so that the coating effect is superior to that of an existing method, the operability is high and volume production is facilitated.

Owner:ZHEJIANG UNIV

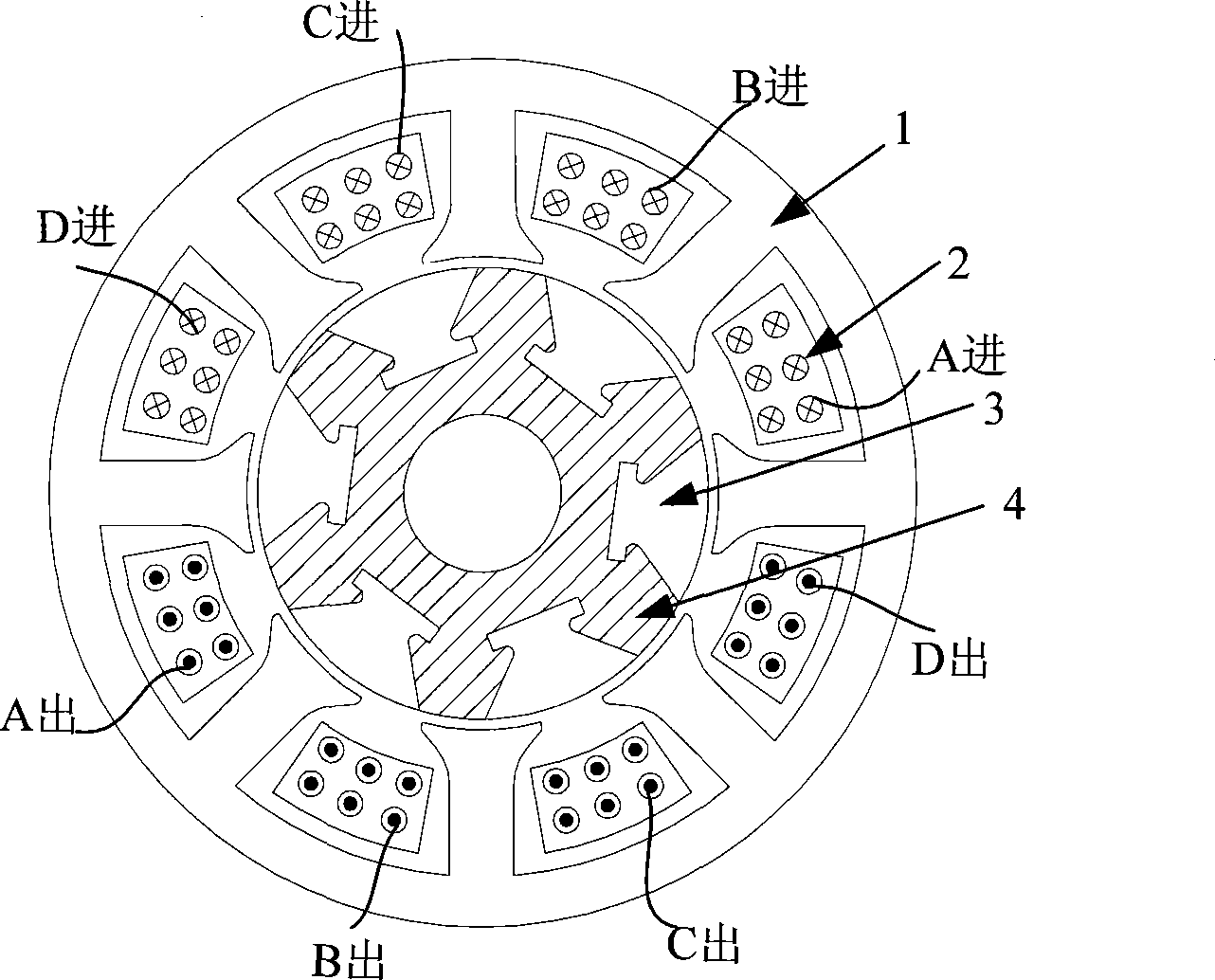

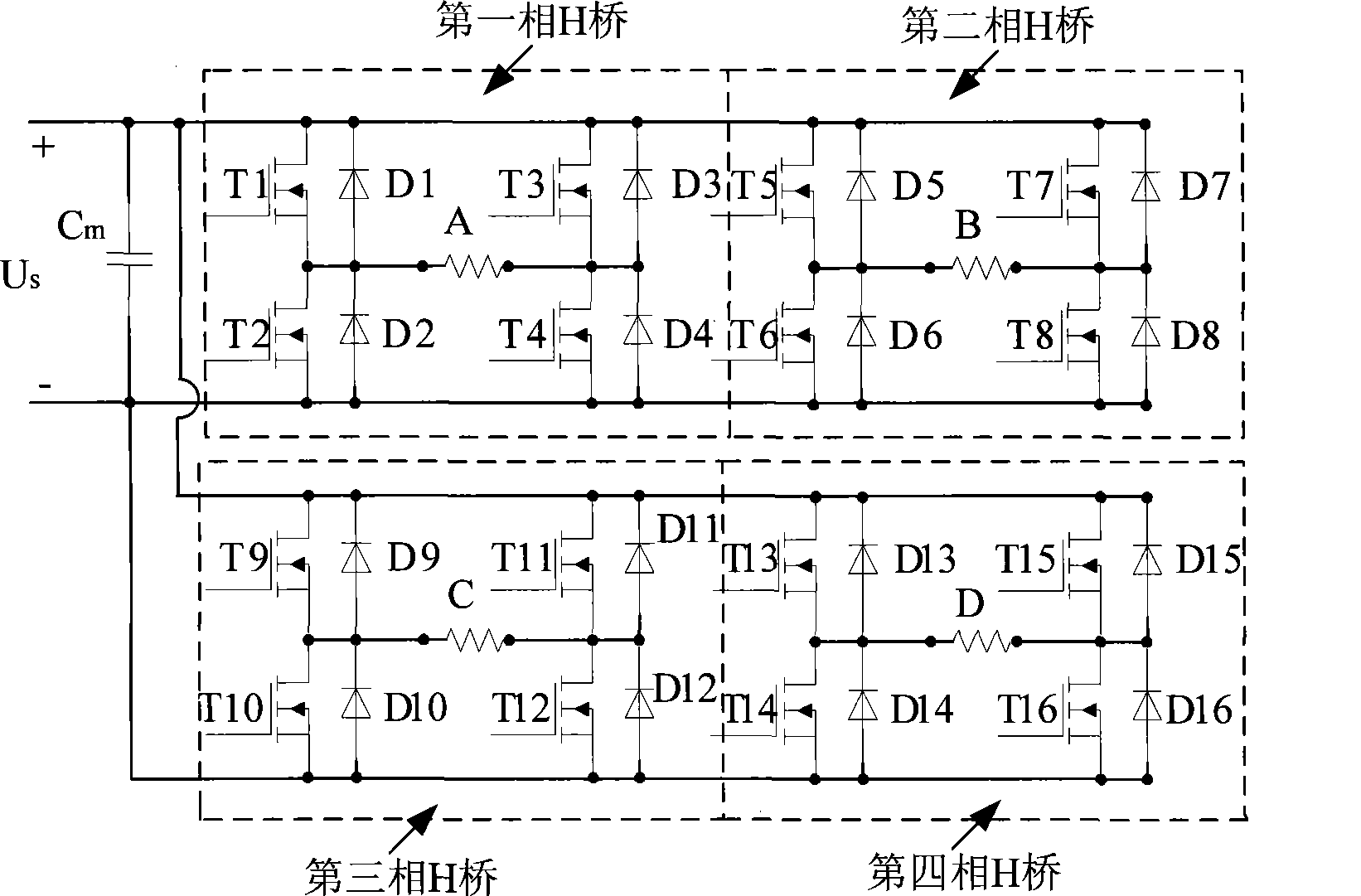

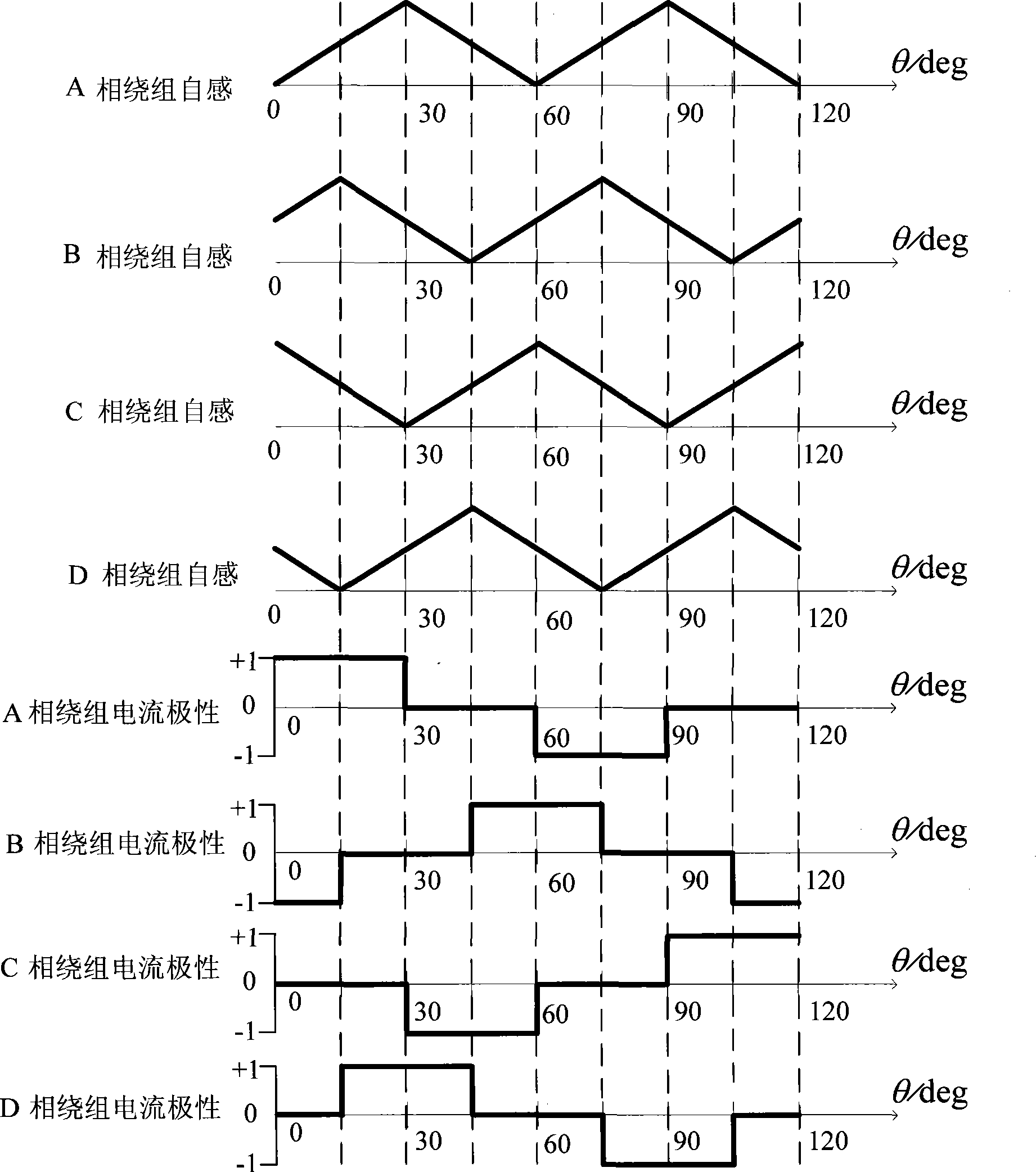

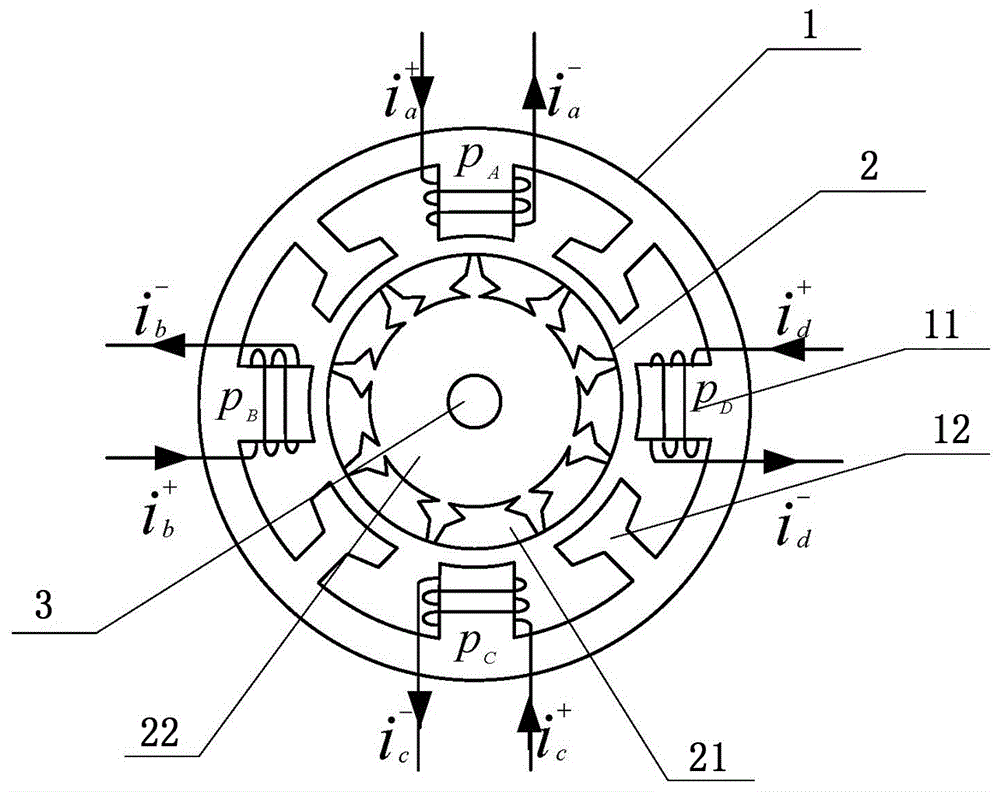

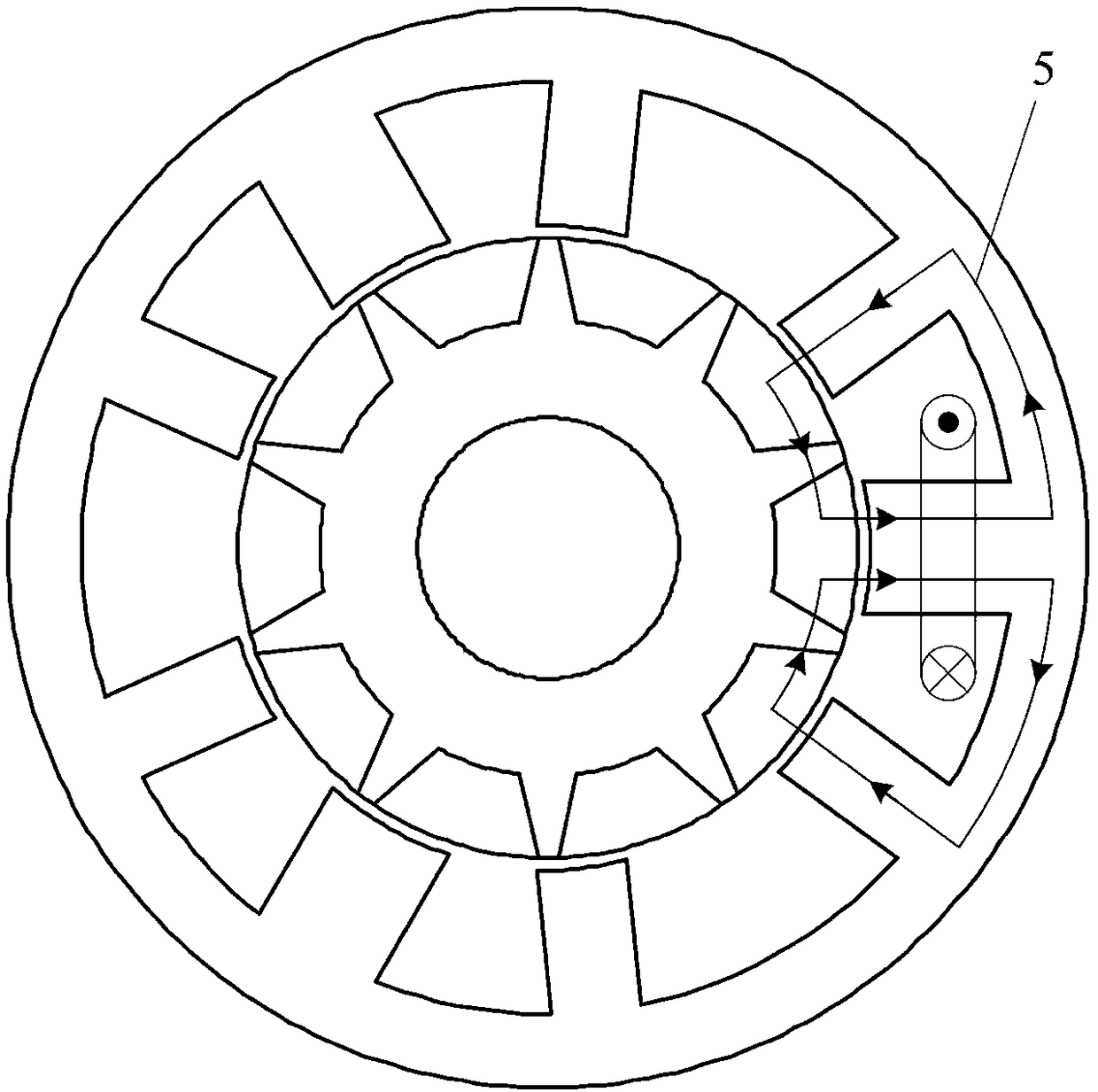

Switched reluctance motor with bipolar excitation 8/6 structure sectional rotor

InactiveCN101534026AReduce core lossSimple structureMagnetic circuit rotating partsSingle motor speed/torque controlWork periodPosition angle

The invention discloses a switched reluctance motor with a bipolar excitation 8 / 6 structure sectional rotor, which belongs to the field of switched reluctance motors. The switched reluctance motor comprises a radial stator, stator windings, sectional rotor iron core blocks and a nonmagnetic rotor sleeve, wherein six sectional rotor iron core blocks are embedded in the nonmagnetic rotor sleeve to form a cylindrical rotor; the radial stator has a structure with eight teeth and eight grooves; the stator windings in two opposite grooves form a solenoid, each solenoid is a phase winding respectively, the number of the phase windings is four, and each phase winding is connected through a bipolar excitation four-phase H bridge topological circuit and is electrified during the period when the self inductance of each phase winding rises so that one working period of the motor is a 120-degree rotor position angle. The switched reluctance motor has the advantages of small wind (oil) resistance at high speed, low loss of iron cores and simple structure, and an excitation topology of the motor adopts a modularized H bridge circuit to save the cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

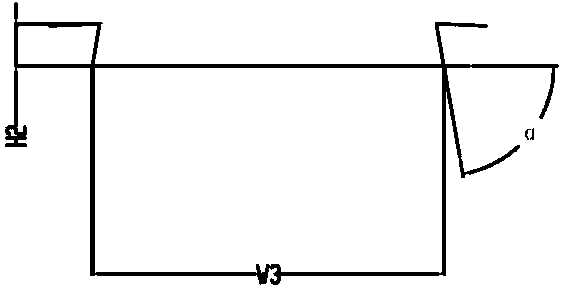

Transverse switched reluctance motor

InactiveUS20130015741A1Reduce core lossEasy to driveSynchronous motorsMagnetic circuitMagnetic fluxMechanical engineering

Disclosed herein is a transverse switched reluctance motor including: a rotor including a plurality of rotor disks each having a shaft fixedly coupled to an inner portion thereof, having a plurality of rotor poles fixedly coupled thereto along an outer peripheral surface thereof, and arranged in a direction of a shaft; and a stator assembly including a plurality of stators each facing the plurality of rotor poles, having coils wound therearound, and arranged in a circumferential direction of the plurality of rotor disks so that the plurality of rotor disks are rotatably received therein, wherein magnetic flux paths are formed so that magnetic fluxes move in the direction of the shaft by the plurality of stators and the plurality of rotor poles facing the plurality of stators to circulate the stators.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

High-bonding-strength insulated coating treatment method of metal soft magnetic composite material

The invention discloses a high-bonding-strength insulated coating treatment method of a metal soft magnetic composite material. The method comprises the following steps: (1) sieving metal magnetic powder, and performing particle size distribution; (2) performing insulated coating on the distributed metal magnetic powder by using a sol-gel method, and then drying the metal magnetic powder; (3) uniformly mixing the dried magnetic powder and an adhesive, adding a release agent, and performing dry pressing to obtain a magnetic ring; (4) performing heat preservation, air cooling and spraying on the magnetic ring in protective atmosphere to obtain a target product. The bonding strength of composite powder prepared by using the sol-gel method and magnetic powder particles is high, the powder is coated uniformly and densely, and a coating layer is controllable in thickness, good, oxidation resistance and high saturation magnetization intensity are achieved, excellent in magnetic property and mechanical property, high in bonding strength, and not prone to disengagement; the coating effect is superior to that of an existing method; the method is high in operability and facilitates batch production; the resistivity of soft magnetic metal particles is effectively improved, and the magnetic core loss of the soft magnetic composite material is greatly reduced.

Owner:ZHEJIANG UNIV

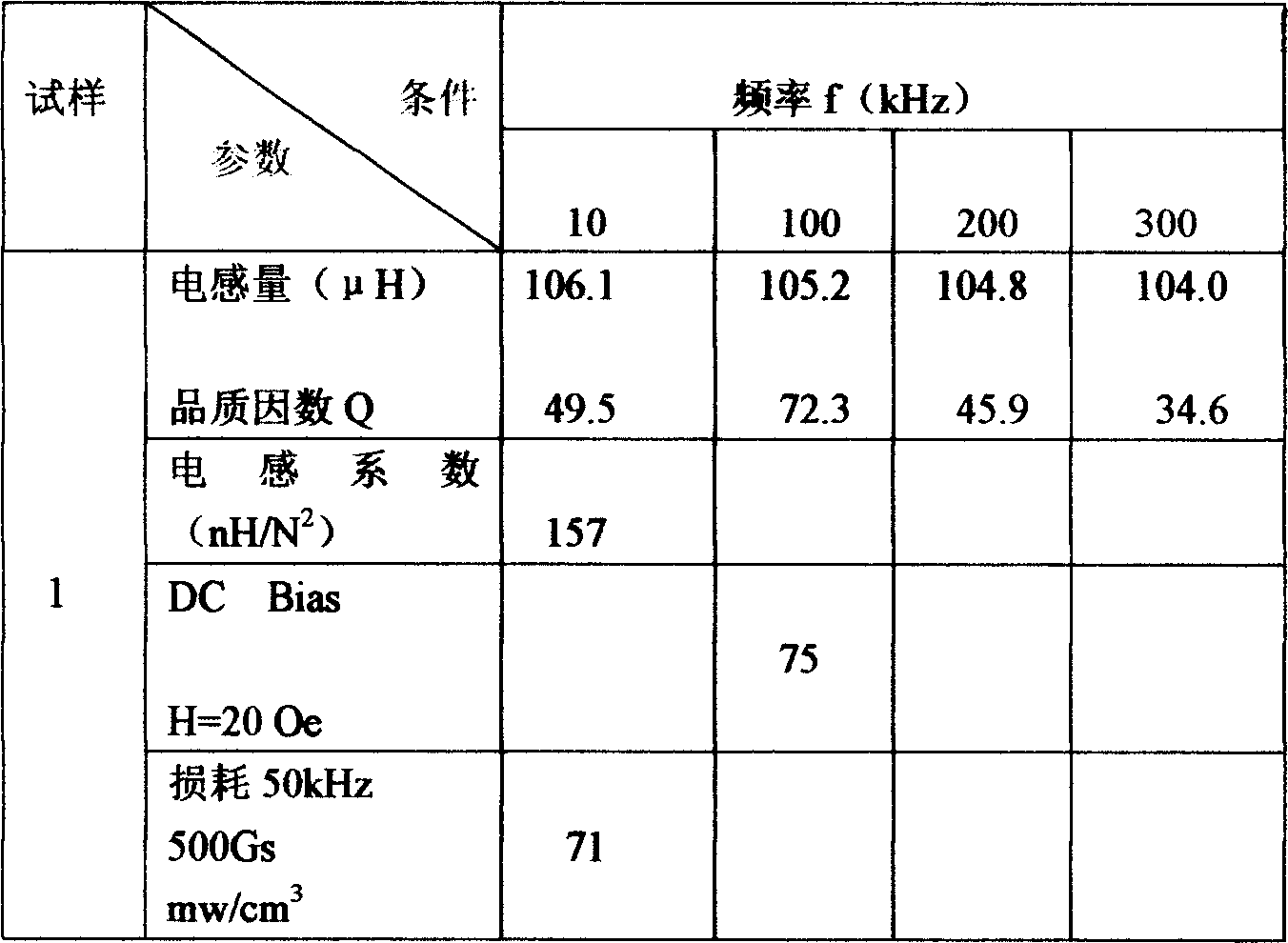

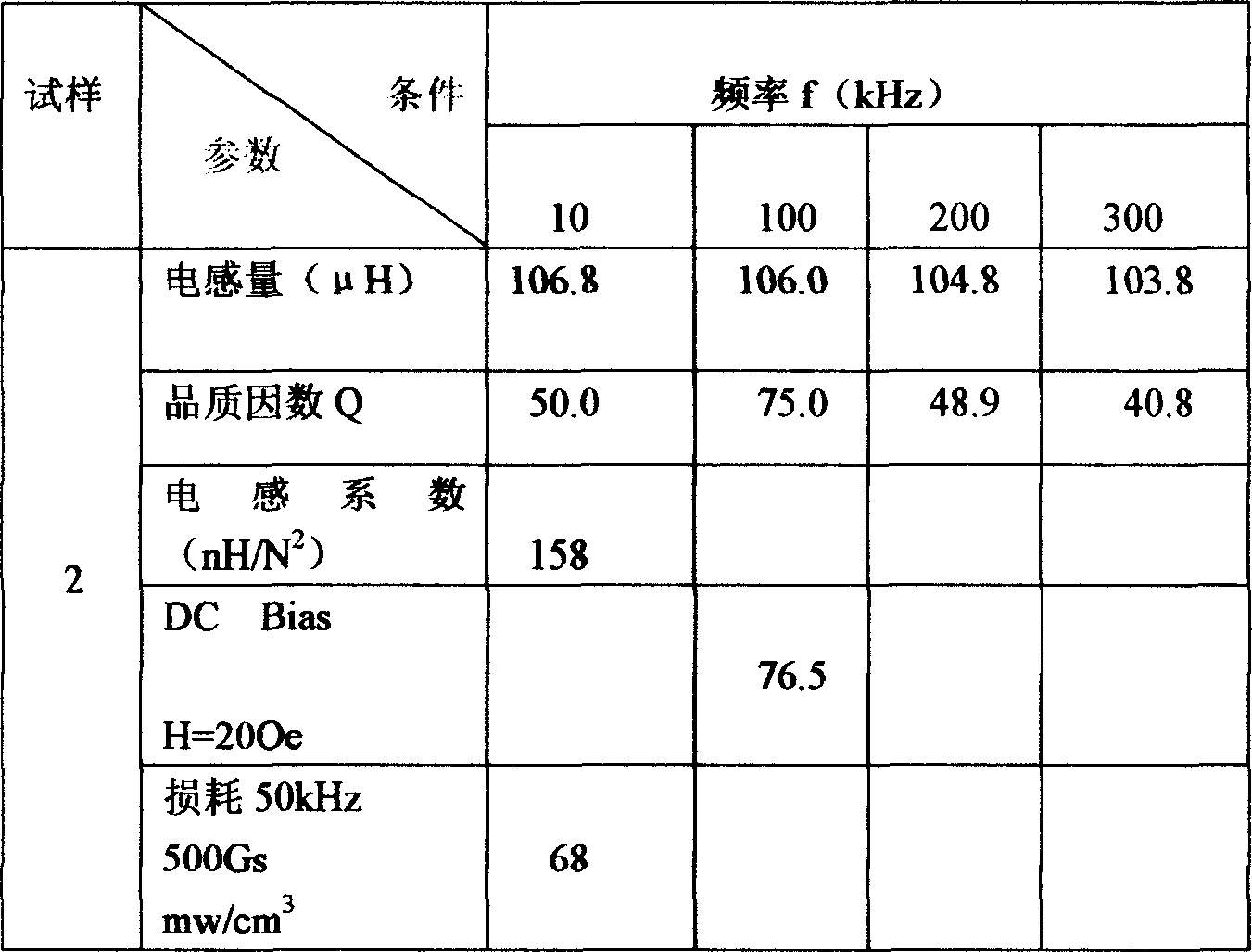

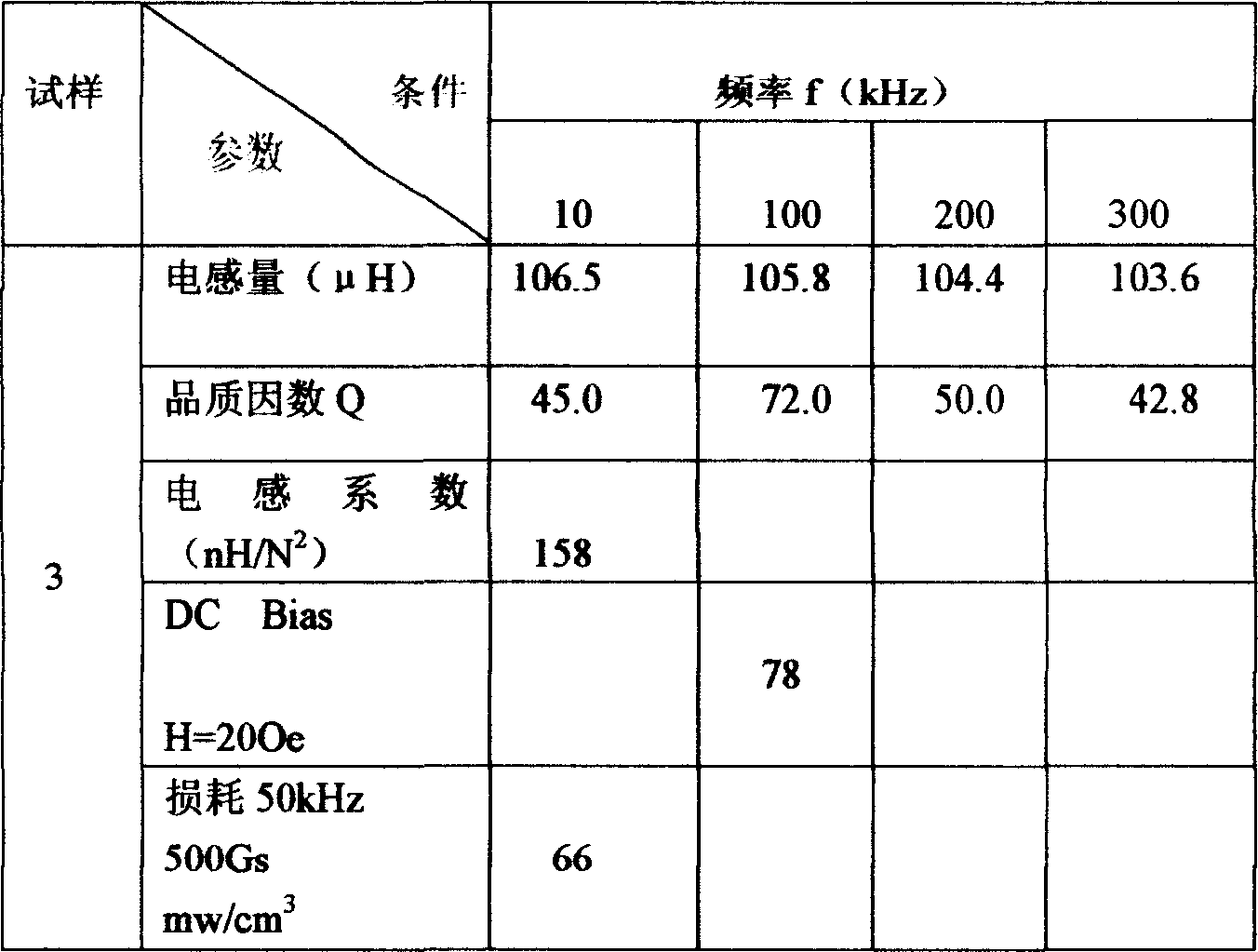

Method for manufacturing powder used for pressing and manufacturing Fe-Si-Al magnetic core

InactiveCN1967737AGood formabilityImprove the compaction effectInorganic material magnetismManganeseTitanium

The invention relates to a method for producing iron silicon aluminum magnetic powder, wherein it comprises that: using vacuum sensitive furnace to smelt, adding some manganese, titanium, to prepare the iron silicon aluminum alloy casting block; using mechanical method to break block into powder lower than 120 deals, removing stress and reducing. Since it adds manganese and titanium into alloy, the saturated magnetic density can reach 11000-11500Gs, the correct force is lower than 160A / m; and it uses mechanical breaking method to make the powder into polygons, to be molded in low pressure. The inventive magnetic powder has low magnetic consumption and better direct-current bias magnetic field (DC Bias). And via different diameters and formulas, it can produce the iron silicon aluminum magnetic powder whose effective magnetic conductivity is mue=60, mue=75, mue=90, and mue=125.

Owner:武汉欣达磁性材料有限公司

Preparing method of amorphous meal soft magnetic powder core

ActiveCN104952583AReduce coercive force and lossReduce core lossInorganic material magnetismPhosphoric acidMagnetic core

The invention discloses a preparing method of an amorphous meal soft magnetic powder core. The preparing method includes the steps of 1, embrittling an amorphous strip, and crushing the amorphous strip embrittled to obtain amorphous metal powder; 2, screening the amorphous metal powder, and performing particle size matching; 3, subjecting the matched amorphous metal powder to passivation; 4, subjecting the amorphous metal powder, passivated by phosphoric acid, to insulation coating; 5, adding binder, and granulating the amorphous metal powder coated; 6, subjecting the granulated amorphous metal powder to magnetic field orientation forming; 7, subjecting a magnetic core, subjected to orientation forming, to axial magnetic thermal treatment; and 8, cooling the magnetic core, subjected to axial magnetic thermal treatment, and performing spraying to obtain a product. The preparing method has the advantages that magnetic domain forms in the amorphous magnetic core, coercive force and loss are lowered, magnetic core loss is further reduced, magnetic conductivity is improved, soft magnetic property of the amorphous magnetic core is improved, and the cost is lowered.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

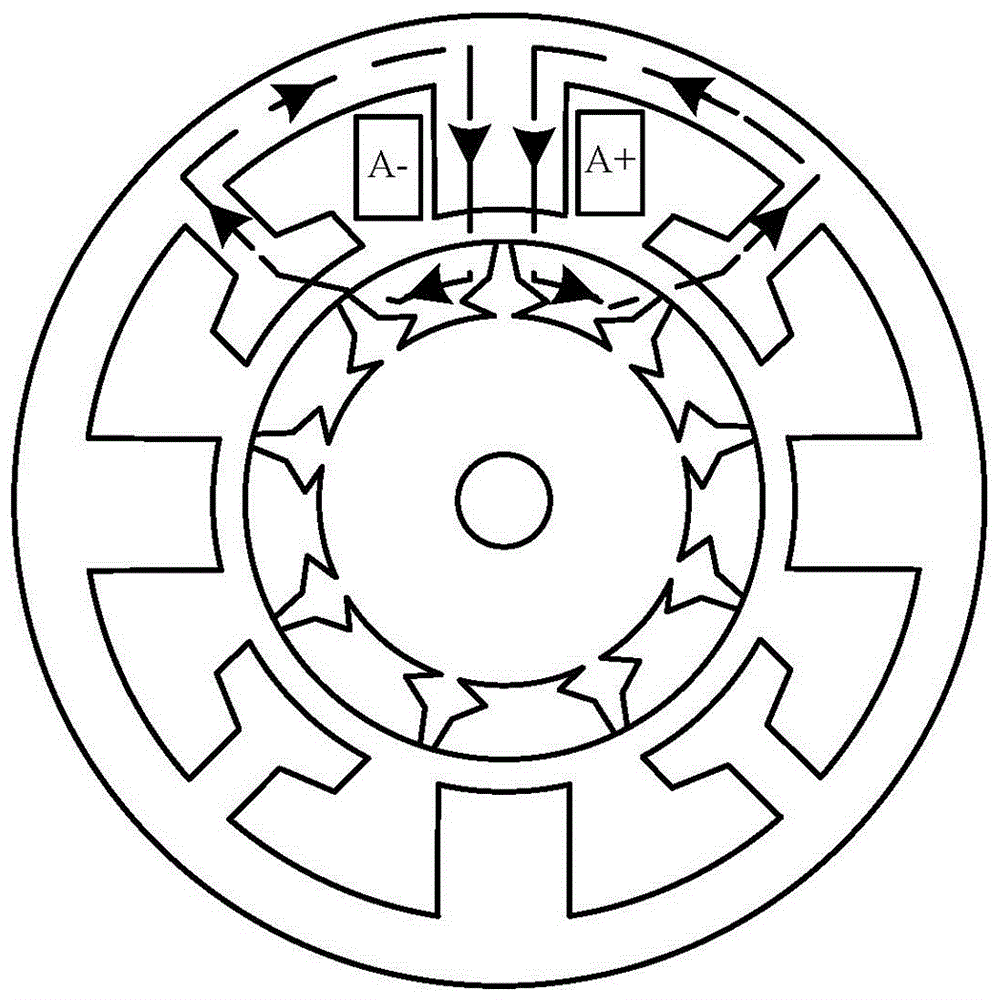

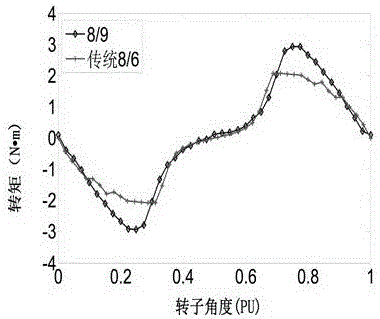

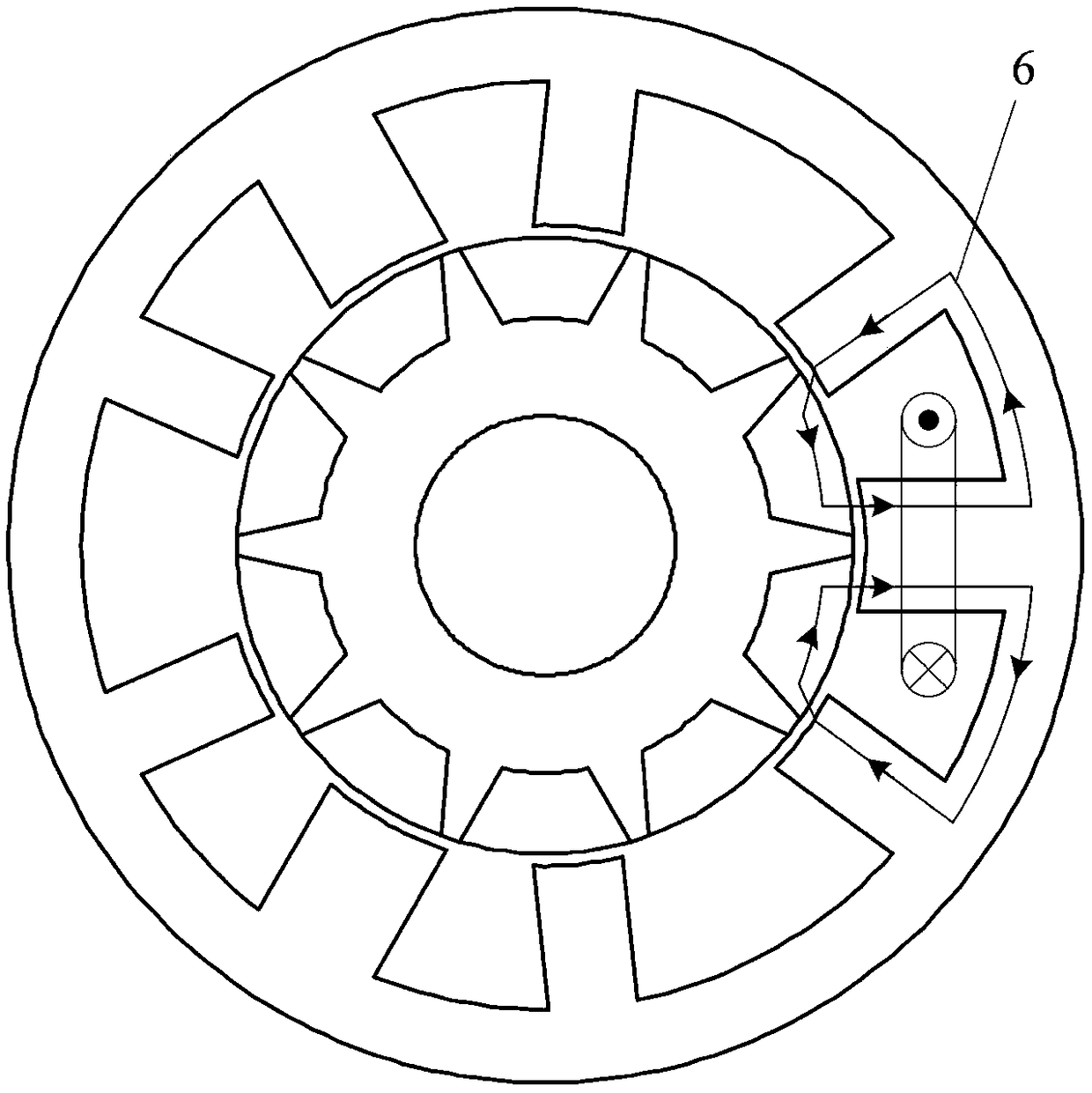

Switched reluctance motor with 8/9 structure

PendingCN106026434ALarge output torqueIncrease output torqueMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineFlux loop

The present invention relates to a switched reluctance motor with 8 / 9 structure. The switched reluctance motor provided by the invention is a block rotor equipped switched reluctance motor having a four-phase eight-pole stator and a nine-pole rotor. Fixedly arranged on the motor shell, the stator is provided with exciting poles and auxiliary poles alternately; the rotor comprises nine independent rotor poles and a non-conductive magnet. All the rotor poles are embedded in the non-conductive magnet evenly; each of the independent rotor poles forms an independent magnetic flux circuit with its adjacent exciting pole and auxiliary pole. The internal part of the rotor is provided with a motor shaft penetrating through the rotor center and driving the rotor to move. Because of the short flux path, there is no reversal of magnetic flux in the stator and rotor. In the process of motor rotating and phase changing, no negative torque will be generated. In addition, the motor adopts single-phase concentrated winding. The number of motor turns decreases; and required end winding is reduced so much that it can be neglected. Under the same input condition, the motor copper consumption is small, the core loss is small, the output torque is large, and therefore, the output efficiency of the motor is increased.

Owner:BRILLIANCE AUTO

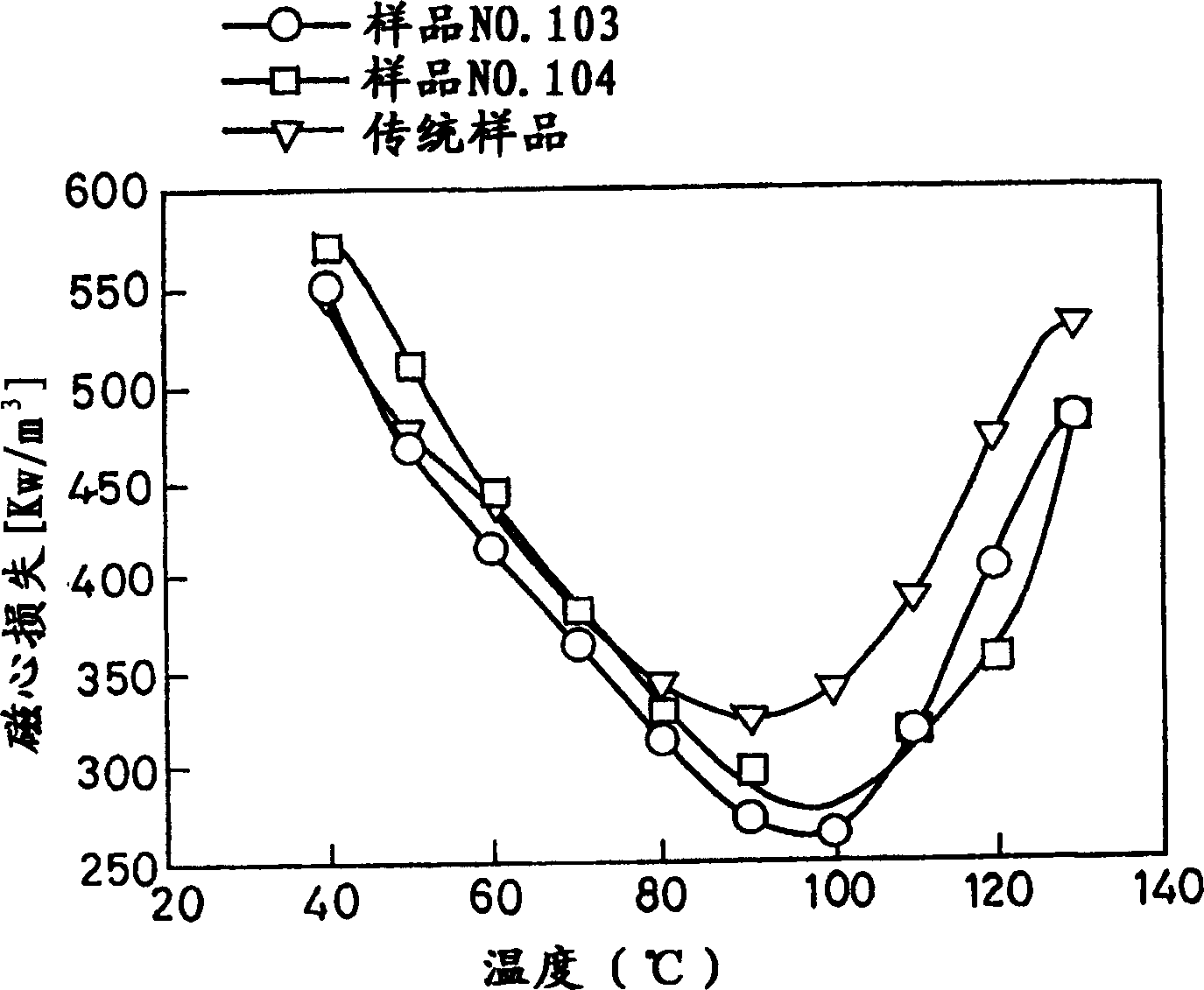

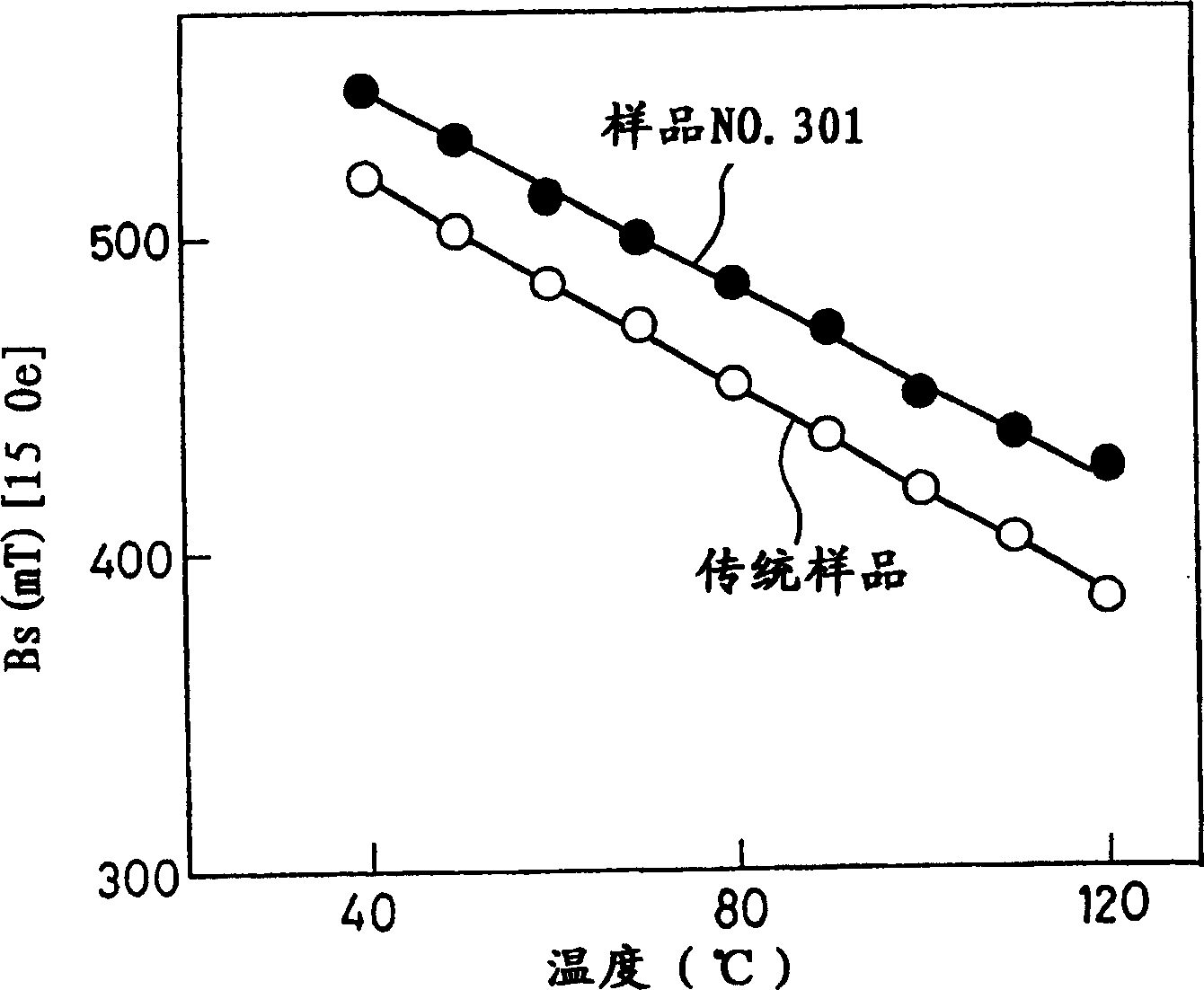

Ferrite, and transformer and method for driving it

InactiveCN1627455AReduce core lossInorganic material magnetismTransformers/inductances magnetic coresTransformerMiniaturization

The invention provides: a kind of Mn-Zn ferrite, at high temperature, the magnetic core loss in the ferrite is low, and Bs is high; a kind of transformer that can be miniaturized and suitable for use under high temperature; an effective drive method for the transformer. At the same time, a transformer that can be miniaturized and is suitable for use in a wide temperature range including high temperature is provided. Also provided are a high-efficiency transformer capable of miniaturization, in which a core loss in a ferrite core is low and a saturation magnetic flux density is high at a temperature at which the transformer is driven; and a high-efficiency driving method for the transformer. The transformer magnetic core is made of Mn-Zn ferrite whose composition is as stated in the specification.

Owner:TDK CORPARATION

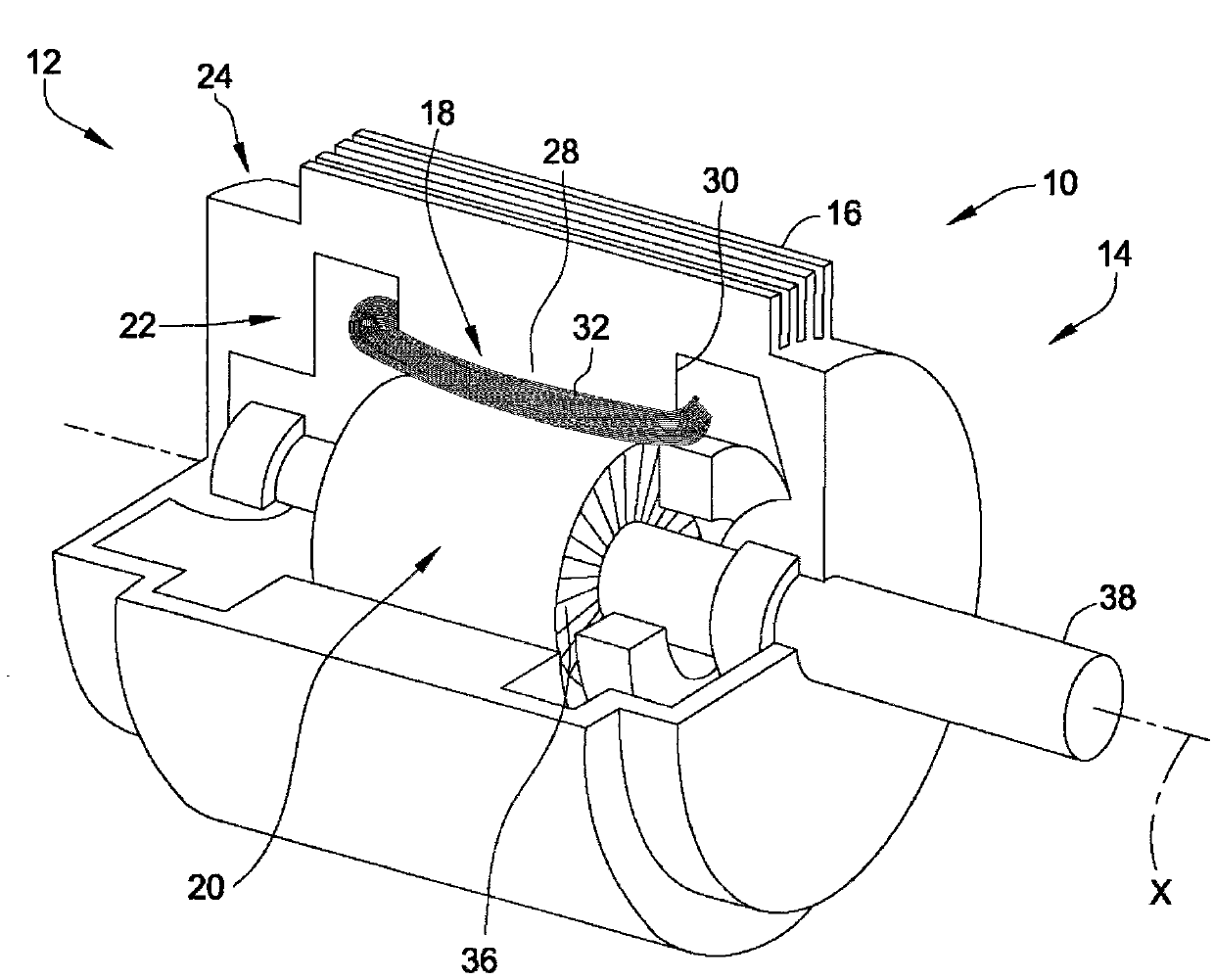

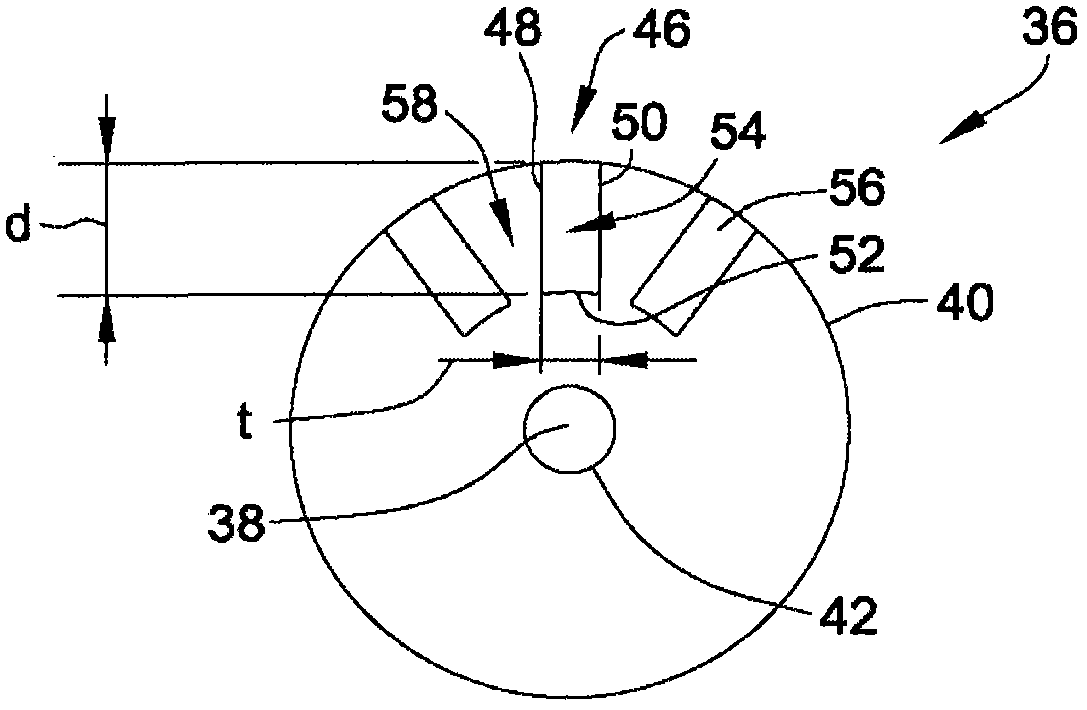

Permanent magnet rotor and method thereof

ActiveCN103795168AReduce flux densityReduced flux outputMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet rotorElectric machine

In one embodiment, an electric machine is provided. The electric machine includes a machine housing and a stator disposed at least partially within the housing. The stator comprises a plurality of teeth and an aluminum winding wound around at least one tooth of the plurality of teeth. The electric machine further includes a radially embedded permanent magnet rotor disposed at least partially within the housing; and the rotor comprises at least one radially embedded permanent magnet and configured to provide increased flux to reduce motor efficiency loss compared to a copper winding.

Owner:REGAL BELOIT AMERICA

Efficient flux barrier motor based on hybrid cooling technology

ActiveCN109787405AReduce usageRealize the cooling effectMagnetic circuit stationary partsCooling/ventillation arrangementEvaporationEngineering

The invention relates to an efficient flux barrier motor based on the hybrid cooling technology. The efficient flux barrier motor comprises an enclosure, and a stator assembly and a rotor assembly, which are arranged in the enclosure, wherein the enclosure comprises a motor inner shell and a motor outer shell, a cooling liquid passage is formed between the motor inner shell and the motor outer shell, the motor outer shell is provided with a liquid inlet and a liquid outlet, both of the liquid inlet and the liquid outlet communicate with the cooling liquid passage, the stator assembly comprisesa stator, stator teeth formed in the stator and a winding wound in the stator teeth, the efficient flux barrier motor further comprises a heat pipe installed in the stator assembly, the heat pipe hasan evaporation section and a condensation section, the efficient flux barrier motor further comprises a plurality of flux barrier grooves, the flux barrier grooves extend from an outer wall of the stator into the stator teeth, the plurality of flux barrier grooves are arranged along the circumferential direction of the stator, the heat pipe is a heat pipe made of a non-permeability magnetic material, the evaporation section is installed in the flux barrier grooves, and the condensation section is arranged in the cooling liquid passage. The efficient flux barrier motor provided by the invention has the advantages of fast heat dissipation rate and can improve the motor efficiency.

Owner:QUANZHOU INST OF EQUIP MFG

Power generating system

InactiveUS20070057593A1Reduce core lossReduce power generation efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetVoltage

A small power generating system includes a turbine driven by a fluid, a power generator including a permanent magnet rotor having a permanent magnet and rotated together with the turbine and a plurality of stator coils each of which is comprised of a coreless coil, the rotor being rotated such that voltage is induced on the stator coils, whereby power is generated by the power generator, and a back yoke disposed at one of two opposed sides of the stator coils which is opposed to the other side thereof further confronting the permanent magnet of the rotor, the back yoke being made of a magnetic material with a predetermined electrical resistance.

Owner:KK TOSHIBA

Method of preparing iron silicon aluminum magnetic powder core with magnetic-conductivity [Mu] of 26

InactiveCN101226806AImprove frequency characteristicsExcellent inductive performanceInorganic material magnetismInductances/transformers/magnets manufacturePowder mixtureSendust

The invention provides a process for preparing sendust cores with magnetic permeability of Mu=26, which comprises steps of a) taking proper sendust for disintegrating at high speed, b) adding passivant when roasting to a temperature of 30DEG C-80DEG C, adding silicone grease and insulating compound when roasting to a temperature of 200DEG C-400DEG C, then continuing roasting till being dried, c) granulating, namely adding binder of 1-12% in powder mixture prepared via step b), screening after grinding up to obtain grain size of 60-150 meshes, d) adding lubricating agent, e) press-forming, f) heat processing to obtain targeted products. The invent has the advantages that 1 production cost is largely reduced by employing sendust with low price, 2 the method of disintegrating at high speed is employed, which enables the powder after being press-formed has perfect frequency characteristic, inductance property and high quality factor, and 3) the prepared magnetic powder cores with magnetic permeability of 26 Mu has lower iron core loss and perfect direct current bias field performance.

Owner:祁峰

A high thermal stability insulation coating treatment method for metal soft magnetic composite materials

ActiveCN104028749BThickness is easy to controlImprove antioxidant capacityInorganic material magnetismAdhesiveHigh resistivity

The invention discloses a high-thermal-stability insulated coating treatment method of a metal soft magnetic composite material. The method comprises the following steps: (1) sieving metal magnetic powder, and performing particle size distribution; (2) performing insulated coating on the distributed metal magnetic powder by using a sol-gel method, and then drying the metal magnetic powder; (3) uniformly mixing the dried magnetic powder and an adhesive, adding a release agent, and performing dry pressing to obtain a magnetic ring; (4) performing heat preservation on the magnetic ring in protective atmosphere for 0.5-2 h, and then performing air cooling and spraying to obtain a target product. Composite powder prepared by using the sol-gel method is coated uniformly and densely, and a coating layer is controllable in thickness, and high thermal stability, high resistivity, high saturation magnetization intensity, an excellent magnetic property and an excellent mechanical property are achieved; the surface of the metal magnetic powder is uniformly coated with an Al2O3 insulated layer by using the sol-gel method, so that the coating effect is superior to that of an existing method; the method is high in operability and facilitates batch production; the magnetic core loss of the soft magnetic composite material is greatly reduced.

Owner:ZHEJIANG UNIV

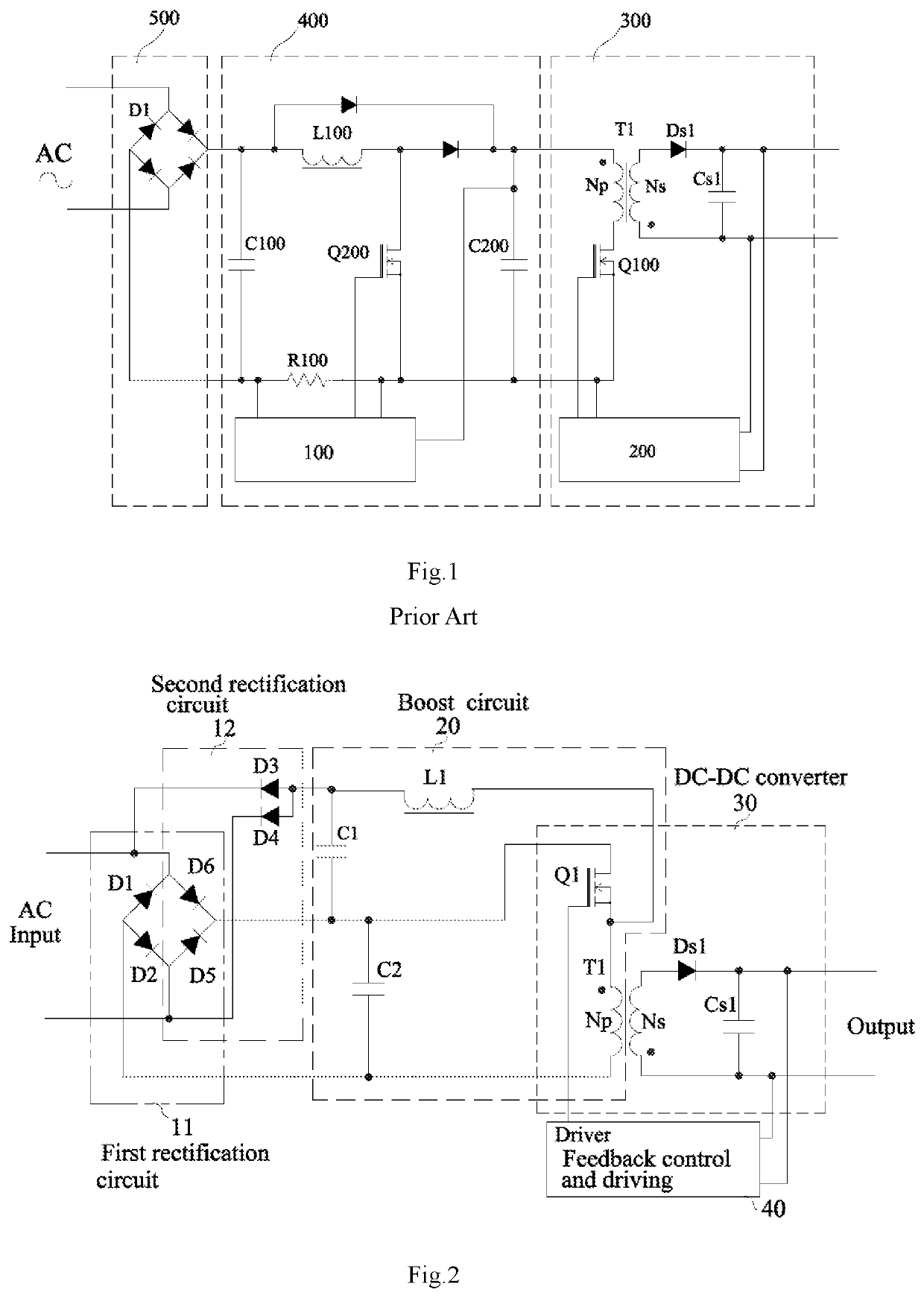

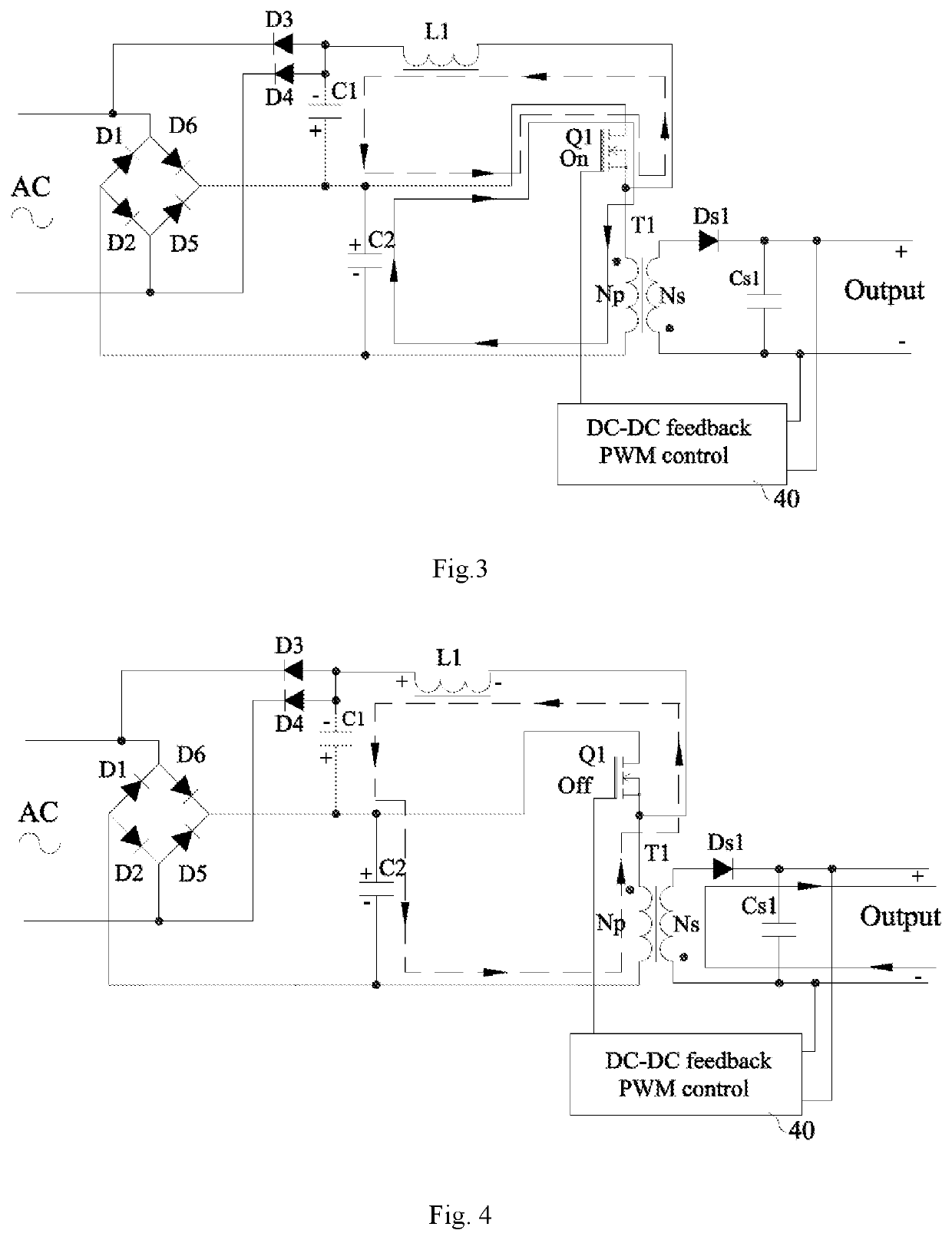

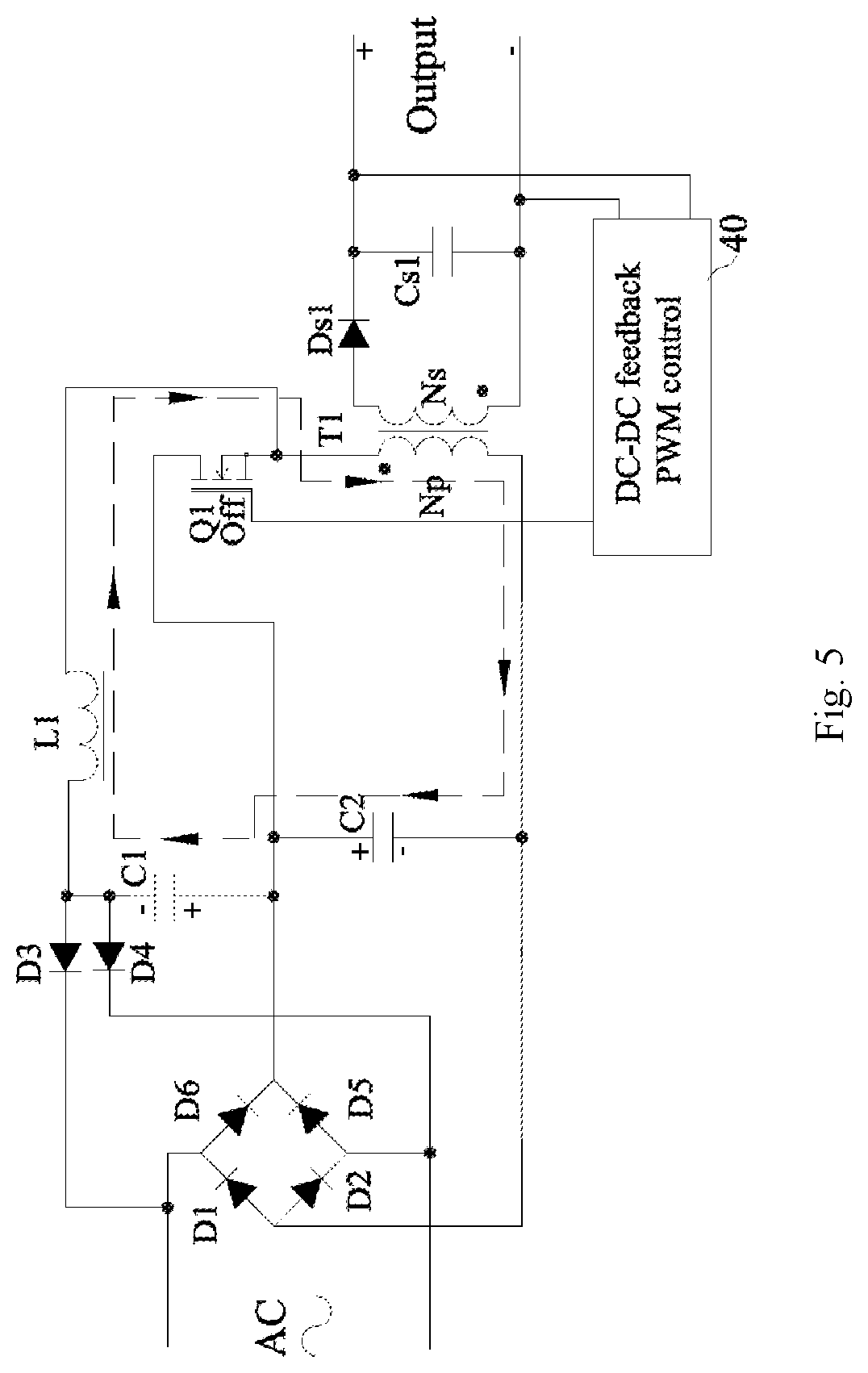

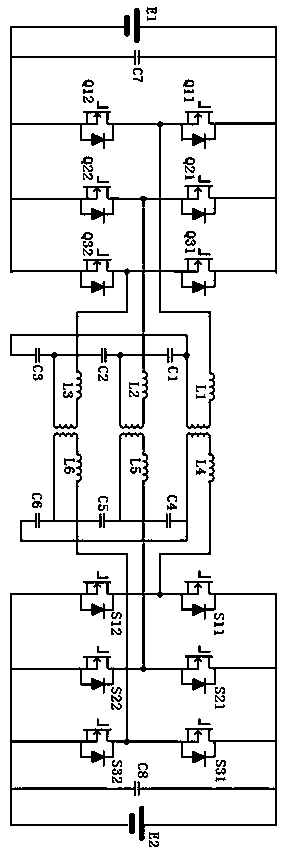

Switching-mode power supply circuit

ActiveUS20200328671A1Good performanceReduce cost and volumeEfficient power electronics conversionDc-dc conversionCapacitancePower circuits

A switching-mode power supply circuit includes a boost inductor, a boost capacitor, a storage capacitor, a transformer or DC-DC inductor, a first switching component, an output rectification component, a filter capacitor, a feedback and control circuit, first and second rectification circuits. When first switching component conducts, the boost inductor, boost capacitor and first switching component form a first boost loop, the boost inductor stores energy, and the storage capacitor, first switching component and transformer or DC-DC inductor form a first DC-DC loop. When first switching component cuts off, the boost inductor, boost capacitor, storage capacitor and transformer or DC-DC inductor form a second boost loop, and the transformer or DC-DC inductor, output rectification component and filter capacitor form a second DC-DC loop. The filter capacitor supplies energy to a load. The feedback and control circuit drives the first switching component to turn on / off according to a chopping wave having specific frequency and duty to control a voltage, current or power output to the load.

Owner:SHANGHAI TUITUO TECH CO LTD

Safety-increasing explosion-proof type variable-frequency adjustable-speed asynchronous motor for petroleum drilling winch

InactiveCN105141093AReduce support spacingEasy maintenanceAsynchronous induction motorsCooling/ventillation arrangementConstant powerWinch

The invention specifically provides a safety-increasing explosion-proof type variable-frequency adjustable-speed asynchronous motor for a petroleum drilling winch, and solves the problems of bad ventilation and heat radiation effects, high possibility of causing electric corrosion phenomenon, and impossibility of satisfying load requirements of high power and wide constant-power scopes of users in the existing electric motors. A draught fan is arranged above a full-steel-plate horizontal type engine base; a rain shielding device is arranged on the front side of the draught fan; an inward-concave type insulation front cover plate and a back cover plate are arranged at the two ends of the full-steel-plate horizontal type engine base; the insulation front end cover is provided with an NJ+HJ326ECM / C4 VA301 bearing, a front bearing cover and a front sealing ring; the back end cover is provided with an NU236 ECM / C4 bearing, a back bearing cover and a back sealing ring; a waist-shaped air outlet is formed in the back end cover; an air outlet housing is arranged in the waist-shaped air outlet; the material of a conducting bar of a rotor is pure copper T2; a conducting bar and an end bar of the rotor are in induction welding; the rotor punching material is 50WW470; and the stator punching material is cold rolling 50TW470.

Owner:CRRC YONGJI ELECTRIC CO LTD

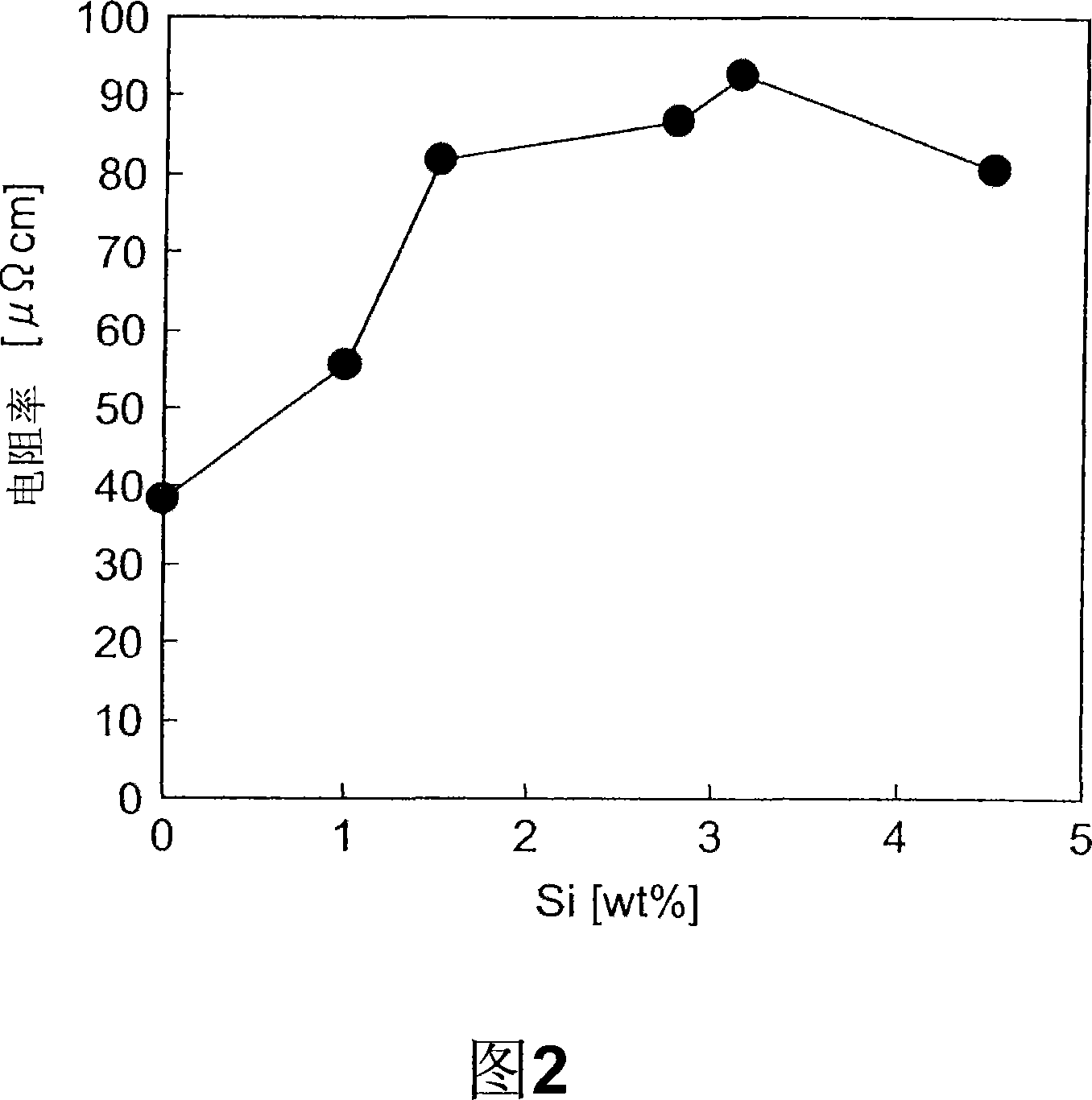

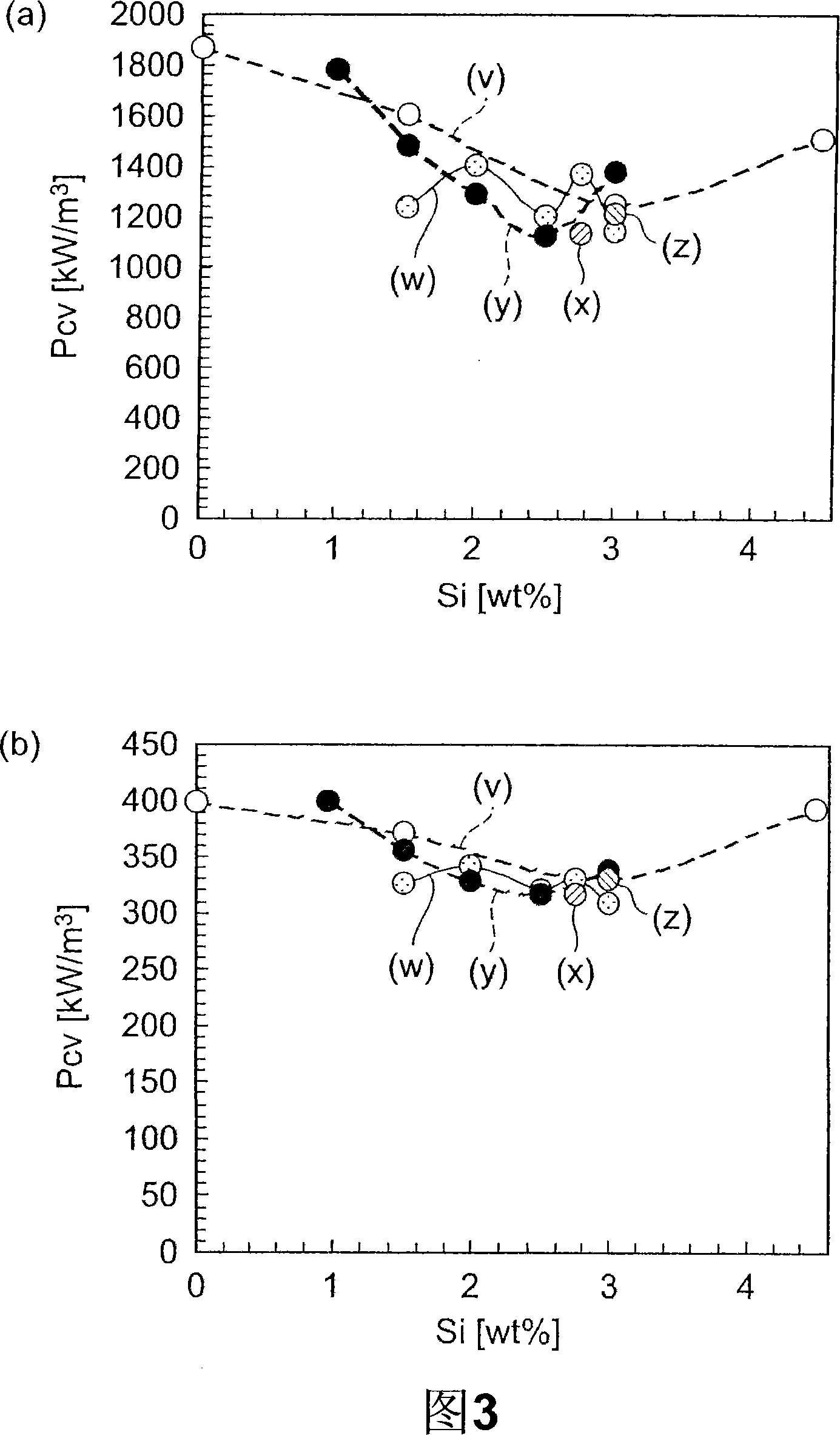

Soft magnetic alloy powder, compact, and inductance element

ActiveCN101202139AReduce core lossStrong magnetismInorganic material magnetismTransformers/inductances detailsMetallurgyMagnetic characteristic

A soft magnetic alloy powder containing Fe-Ni-based crystal particles is provided as one capable of adequately reducing core loss of a powder magnetic core and achieving satisfactory magnetic characteristics at an effective operating temperature of an element. The present invention provides a soft magnetic alloy powder containing Fe-Ni-based crystal particles containing 45 to 55 mass % Fe and 45 to 55 mass % Ni, relative to a total mass of Fe and Ni, and containing 1 to 12 mass % Co and 1.2 to 6.5 mass % Si, relative to a total mass of Fe, Ni, Co, and Si.

Owner:TDK CORPARATION

A kind of high insulation insulation coating treatment method of metal soft magnetic composite material

ActiveCN104028751BThickness is easy to controlImprove antioxidant capacityInorganic material magnetismAdhesiveHigh resistivity

The invention discloses a high-insulativity insulated coating treatment method of a metal soft magnetic composite material. The method comprises the following steps: (1) sieving metal magnetic powder, and performing particle size distribution; (2) performing insulated coating on the distributed metal magnetic powder by using a sol-gel method, and then drying the metal magnetic powder; (3) uniformly mixing the dried magnetic powder and an adhesive, adding a release agent, and performing dry pressing to obtain a magnetic ring; (4) performing heat preservation on the magnetic ring in protective atmosphere for 0.5-2 h, and then performing air cooling and spraying to obtain a target product. According to the high-insulativity insulated coating treatment method of the metal soft magnetic composite material, provided by the invention, a conventional insulated coating process has the universal defects of poor insulativity, non-uniformity in coating and the like. An insulated layer is uniform in coating, and high insulativity and high frequency stability are achieved by adopting the sol-gel method for coating. A MgO insulated layer has extremely high resistivity, the resistivity of the soft magnetic composite material can be greatly improved by coating the surface of magnetic powder with the MgO insulated layer, and the higher magnetic conductivity and lower magnetic core loss are achieved.

Owner:ZHEJIANG UNIV

Switched reluctance motor

InactiveUS20120306298A1High strengthReduce noiseMagnetic circuitSynchronous motorsConductor CoilMagnetic flux

Disclosed herein is a switched reluctance motor comprising: an outer rotor provided with a plurality of salient poles protruded at equidistance along an inner peripheral surface thereof; and a stator provided in the outer rotor, including a plurality of stator cores including a pair of stator salient poles protruded toward the salient pole of the outer rotor and a stator yoke connecting and supporting stator salient poles to each other, and having phase windings in which coils are wound around the stator salient poles, wherein a magnetic flux generated by applying a current to the phase winding flows through the pair of stator salient poles and the salient pole of the outer rotor.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Bidirectional resonant converter

InactiveCN110401352AReduce lossEliminate third harmonic currentEfficient power electronics conversionDc-dc conversionSoft switchingFull bridge

The invention discloses a bidirectional resonant converter. The bidirectional resonant converter comprises a first three-phase full-bridge circuit, a first resonance circuit, a second resonance circuit and a second three-phase full-bridge circuit which are connected in sequence. The output end of the first three-phase full-bridge circuit is connected with the input end of the first resonance circuit. The first resonance circuit and the second resonance circuit are connected through a transformer subunit between the first resonance circuit and the second resonance circuit. The transformer subunit comprises a primary winding and a secondary winding. The output end of the second resonance circuit is connected with the input end of the second three-phase full-bridge circuit. A resonance element is added to the secondary side of the transformer. The full-range soft switching characteristic during forward and reverse energy transmission can be achieved.

Owner:GUOCHUANG INNOVATION CENTER OF MOBILE ENERGY (JIANGSU) CO.,LTD.

Transverse magnetic field permanent-magnet synchronous motor with rotor magnetic pole three-sided wall type structure

InactiveCN1885687AIncrease air gap flux densityImprove performanceMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPhysicsSynchronous motor

The disclosed horizontal magnetic-field permanent magnet synchronous motor comprises: the U-shaped stator with number same as motor pole pair fixed on shell, a ring stator coiling on bottom of U-shaped slot, every phase of rotor with two magnetic pole rings included 180deg electric angle to form main magnetic pole. This invention applies three-wall gather-magnetic structure for rotor to reduce iron core loss and increase magnetic air gap density.

Owner:TSINGHUA UNIV

Iron core column with symmetric structure of three-phase magnetically controlled reactor

InactiveCN102903487AReduce lossReduce dosageTransformers/inductances magnetic coresTransformerHarmonic

The invention discloses an iron core column with a symmetric structure of a three-phase magnetically controlled reactor. The iron core column comprises a central shaft and three phase planes, wherein each phase plane is internally provided with two iron cores parallel to the central shaft, the two iron cores in the same phase plane are symmetrically arranged by taking the central shaft as a symmetry axis to form a phase, and the ends of any two adjacent iron cores in the same direction are all linked into a whole through magnetic yokes. By designing the structural style of the iron core column to be in cubical symmetry, and arranging the iron cores by taking the central shaft as the symmetry axis, compared with a conventional arrangement mode of the iron cores, on the premise of same capacity, the structure can reduce the using amount of iron core materials, inhibit the generation of own harmonic to the utmost extent, and reduce iron core loss and occupied area. The iron core column shortens the length of an equivalent alternating-current magnetic circuit, and can reduce magnetic resistance and iron core loss of the reactor, improve the non-load and load efficiency of the reactor, and be used in the field of transformer devices.

Owner:广州骏发电气有限公司 +1

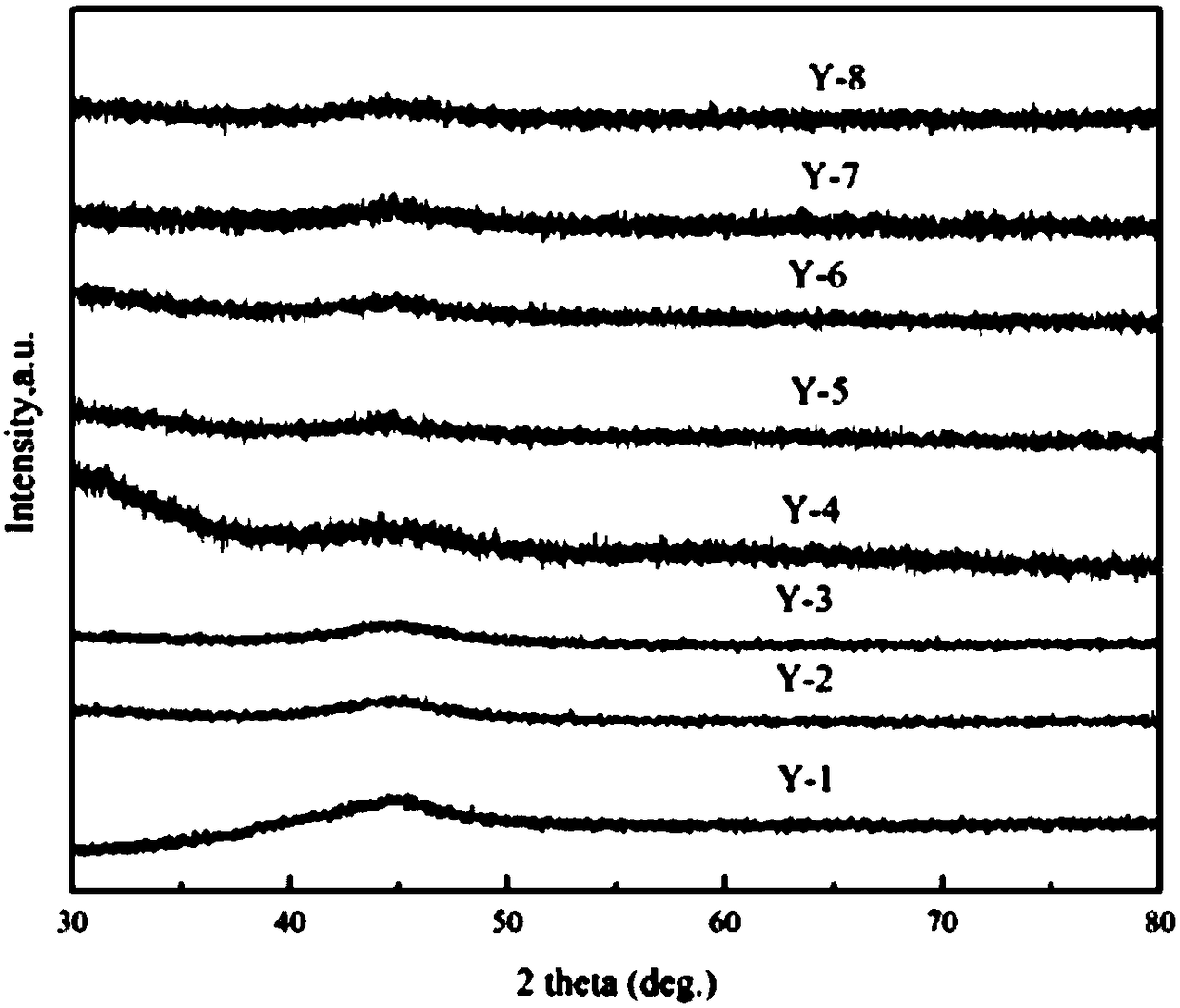

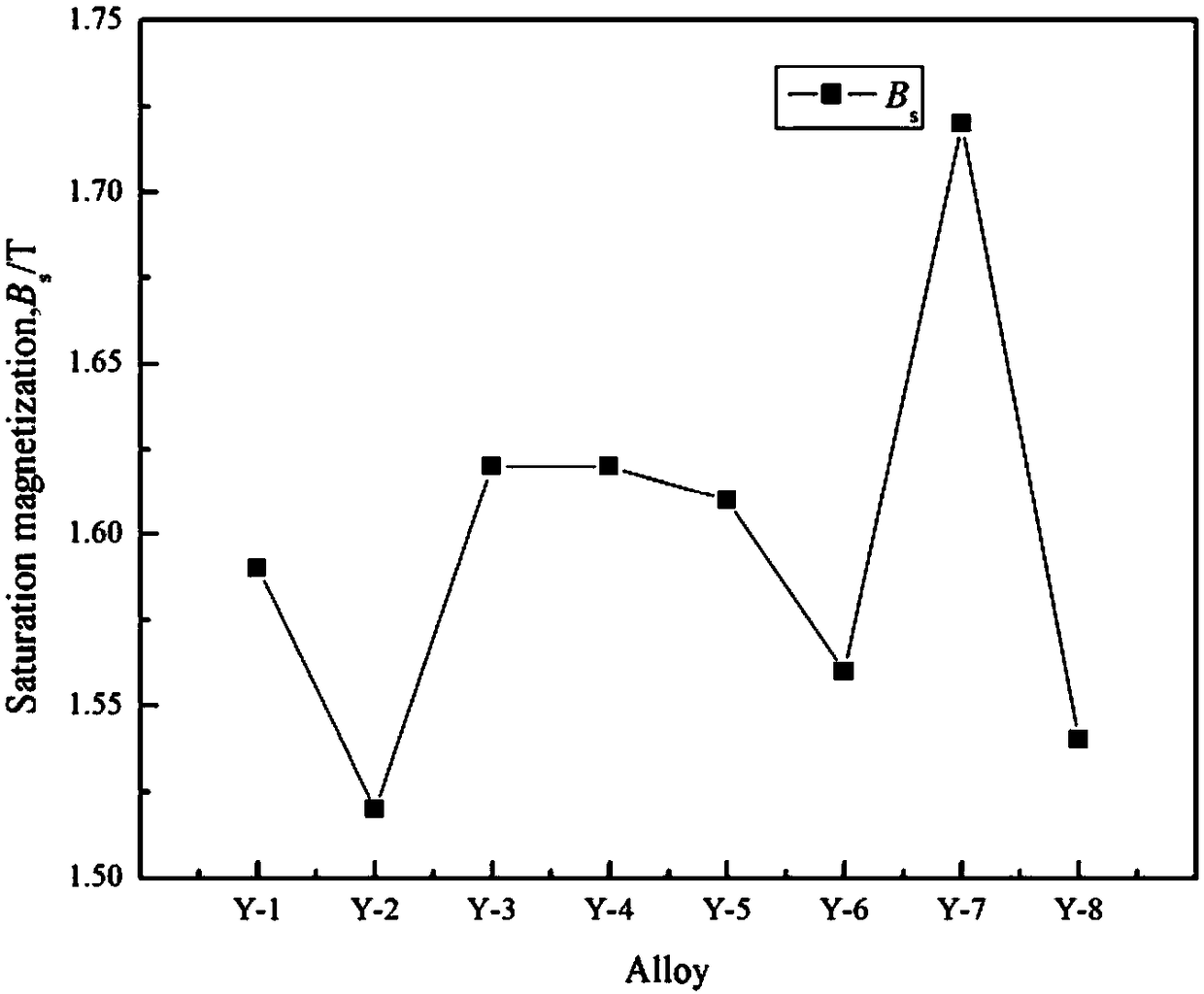

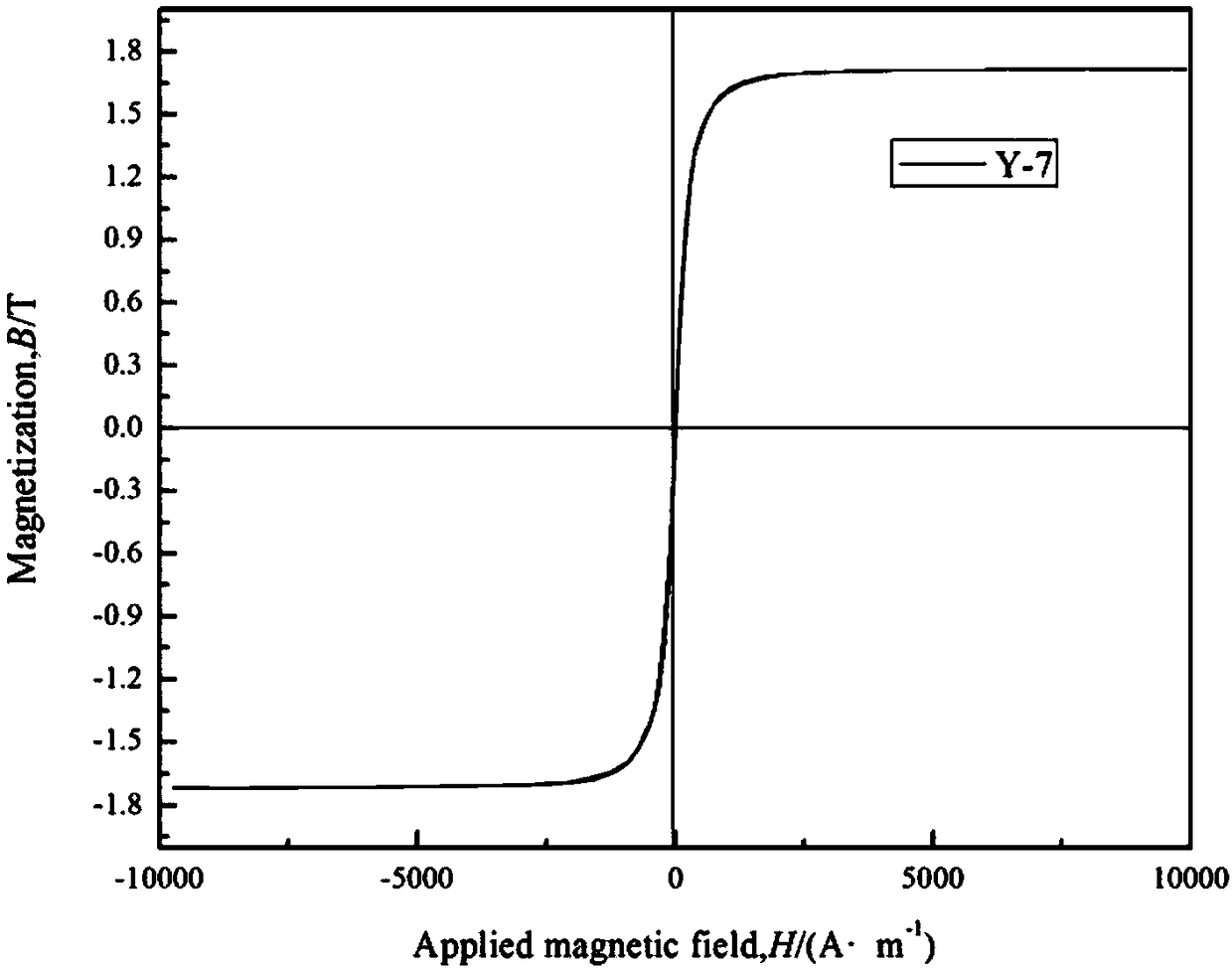

Multicomponent iron-based amorphous soft magnetic alloy

InactiveCN108597715AEnhanced Amorphous Formation AbilityHigh saturation magnetic inductionMagnetic materialsIron basedHigh frequency

The invention relates to a multicomponent iron-based amorphous soft magnetic alloy. An expression of the alloy is FeaSibBcPdNieCf, wherein a, b, c, d, e and f are atomic percentage contents of corresponding components respectively and meet the conditions that a is 77-82, b is 3-14, c is 8-14, d is 0-0.3, e is 0-2.2, f is 0-2, and the sum of a, b, c, d, e and f is equal to 100. The multicomponent iron-based amorphous soft magnetic alloy has high saturation magnetic induction density Bs, high effective magnetic permeability [mu]e, high frequency stability, low coercivity Hc and low core loss andis good in moldability, loose in preparation technological conditions and low in production cost.

Owner:ZHENGZHOU UNIV

A 9n/10n pole segment rotor switched reluctance motor

ActiveCN109149800AReduce windage lossReduce core lossMagnetic circuit rotating partsMagnetic circuit stationary partsPhysicsTorque ripple

The invention discloses a 9n / 10n pole segmented rotor switched reluctance motor. The motor stator teeth number is 9n, the rotor teeth number is 10n, the phase number is 3, and n is a natural number; The stator teeth comprise 3n wide teeth and 6n narrow teeth, one coil is wound on each wide tooth, and a wireless loop on the narrow tooth; The wide teeth are evenly distributed on the circumference ofthe wide teeth, and the difference is 120 DEG / n; 2 narrow teeth are arranged between the wide teeth and the wide teeth, each narrow tooth is 36 degrees / n different from its adjacent wide teeth, and the adjacent two narrow teeth are 48 degrees / n different from each other; The rotor is composed of 10n rotor iron cores and one non-magnetic permeable support frame, and the rotor iron core is fixed onthe non-magnetic permeable support frame; Each phase magnetic circuit is of short magnetic circuit structure, the loss of iron core is small, and the magnetic circuits between the phases are not coupled, and the windings are isolated from each other. The invention has the advantages of strong starting ability, small torque ripple, small wind resistance loss, small vibration noise, high reliability and fault tolerance.

Owner:南京埃克锐特机电科技有限公司

Stator punching sheet of high-voltage permanent-magnet synchronous motor, winding stator and motor

InactiveCN109638991AGuaranteed uptimeImprove performanceWindingsSynchronous machine detailsPunchingSynchronous motor

The invention discloses a stator punching sheet of a high-voltage permanent-magnet synchronous motor, a winding stator and the motor. A stator punching sheet body is in a round shape, 54 rectangular winding grooves are formed in the stator body and are uniformly distributed along a circumference, the widths W1 of the winding grooves are 13.7 millimeters, H1 of the winding grooves are 65 millimeters, a magnetic groove wedge slot is formed in a winding groove opening and is used for placing a magnetic groove wedge, 12 swallowtail positioning grooves are formed in an outer circle profile of the stator punching sheet body and are uniformly distributed along the circumference, the magnetic groove wedge slot is in a semi-circular shape, the radius R2 of the magnetic groove wedge slot is 1 millimeter, a fillet is arranged at a connection position of the magnetic groove wedge slot and the winding groove, the arc radius R3 is 0.2 millimeter, and the opening width W2 of the magnetic groove wedgeslot is 15.7 millimeters. The semi-circular magnetic groove wedge is employed, the air gap magnetic field distribution is improved, and the vibration and the noise of the motor are reduced; and an inner circle and an outer circle of the stator punching sheet and the winding groove are reasonable in design, the iron core loss of the motor is reduced, and the running performance of the motor is improved.

Owner:NANTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com