Safety-increasing explosion-proof type variable-frequency adjustable-speed asynchronous motor for petroleum drilling winch

A technology for asynchronous motors and variable frequency speed regulation, which is applied in the direction of asynchronous induction motors, electric components, electrical components, etc., can solve problems such as prone to electric corrosion, poor ventilation and heat dissipation, and cannot satisfy users, so as to reduce the deflection of the shaft, Overcoming poor ventilation and heat dissipation effects, reasonable and reliable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

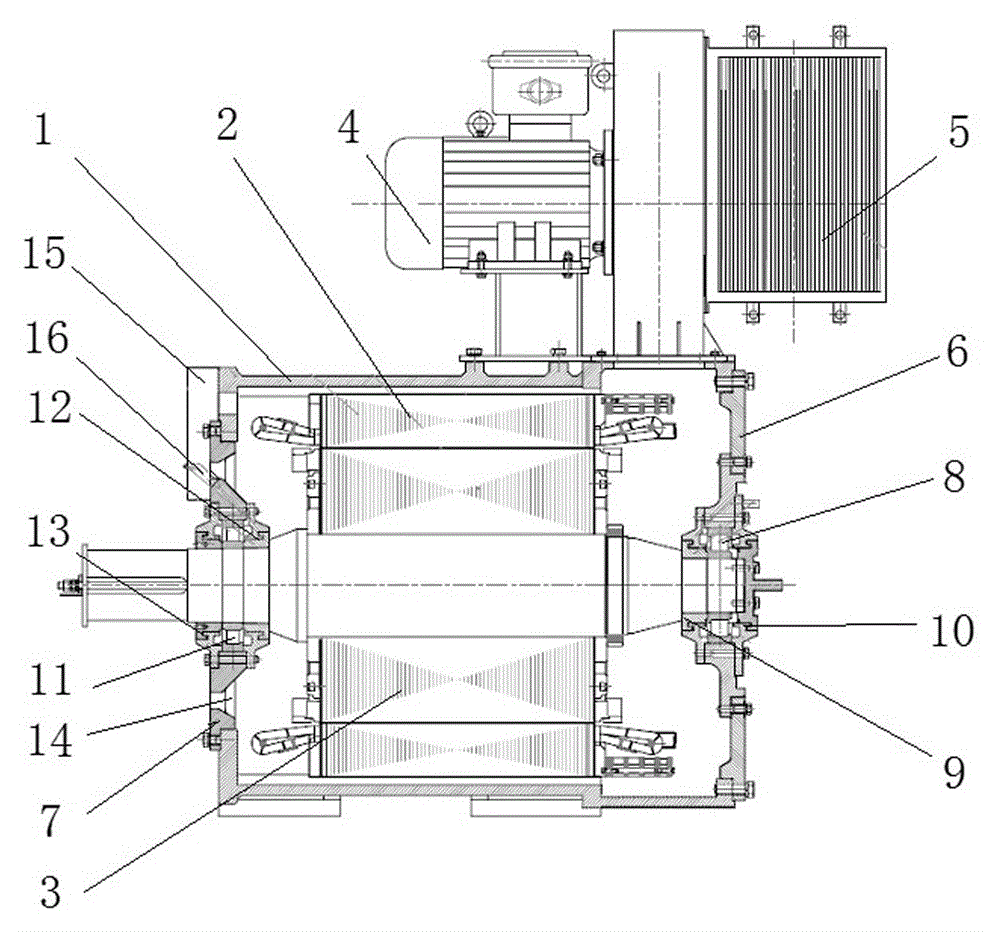

[0010] Safety-increased explosion-proof variable frequency speed-regulating asynchronous motor for oil drilling drawworks, including an all-steel horizontal frame 1, a stator 2 and a rotor 3 inside it, a fan 4 is arranged above the all-steel horizontal frame 1, and the front side of the fan 4 A rain shield 5 located above the air inlet is provided, reinforcing ribs are arranged inside the all-steel horizontal machine base 1, and both ends of the all-steel horizontal machine base 1 are provided with a concave insulating front end cover 6 and a rear end cover 7, The insulating front cover 6 is provided with NJ+HJ326ECM / C4VA301 bearing 8 and the front bearing cover 9 and front sealing ring 10 matched with NJ+HJ326ECM / C4VA301 bearing 8, and the rear end cover 7 is provided with NU236ECMA / C4 bearing 11 and NU236ECMA / C4 The rear bearing cap 12 and the rear sealing ring 13 matched with the bearing 11, between the front bearing cap 9 and the front sealing ring 10 and the NJ+HJ326ECM / C4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com