Patents

Literature

275 results about "Induction welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Induction welding is a form of welding that uses electromagnetic induction to heat the workpiece. The welding apparatus contains an induction coil that is energised with a radio-frequency electric current. This generates a high-frequency electromagnetic field that acts on either an electrically conductive or a ferromagnetic workpiece. In an electrically conductive workpiece, the main heating effect is resistive heating, which is due to induced currents called eddy currents.

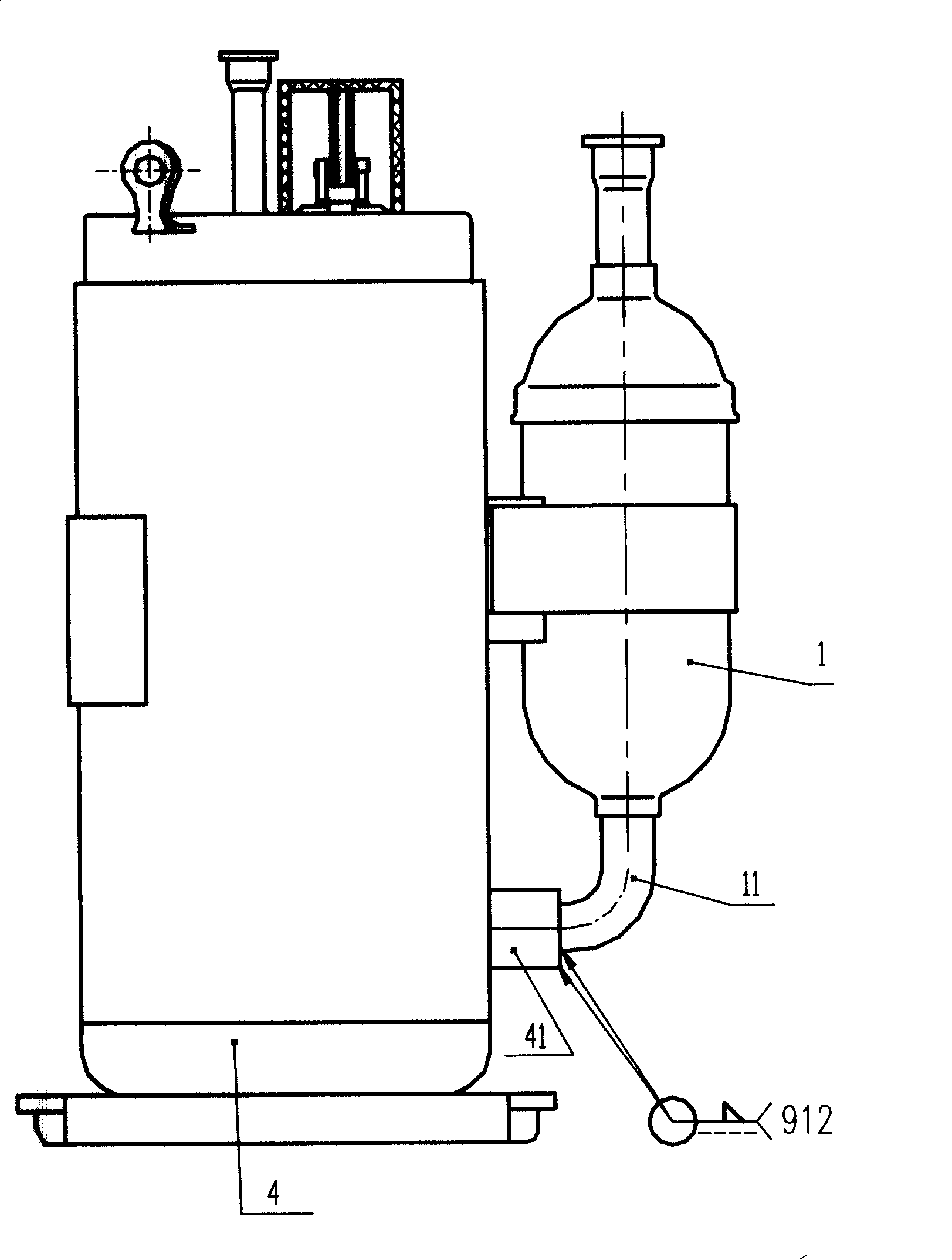

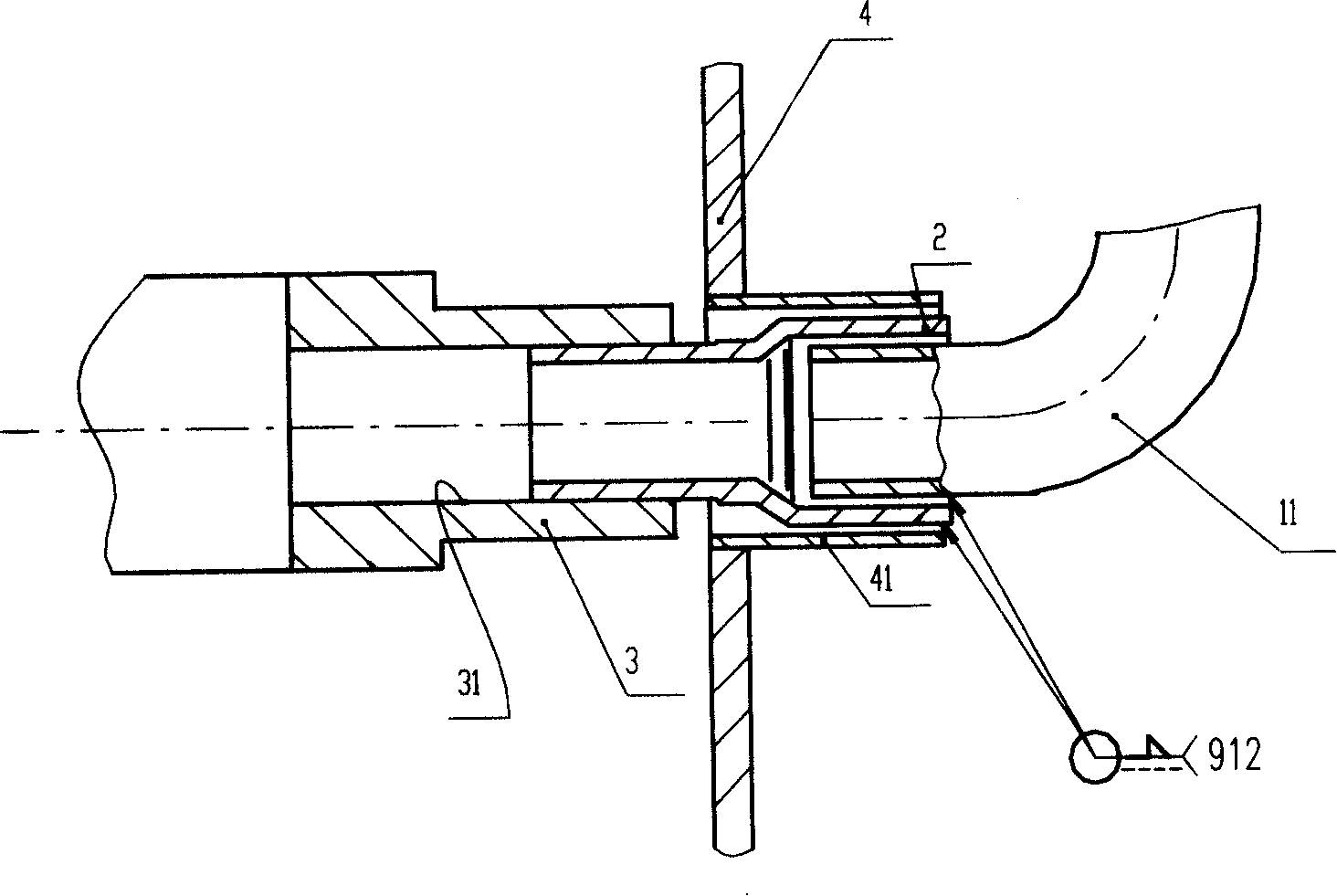

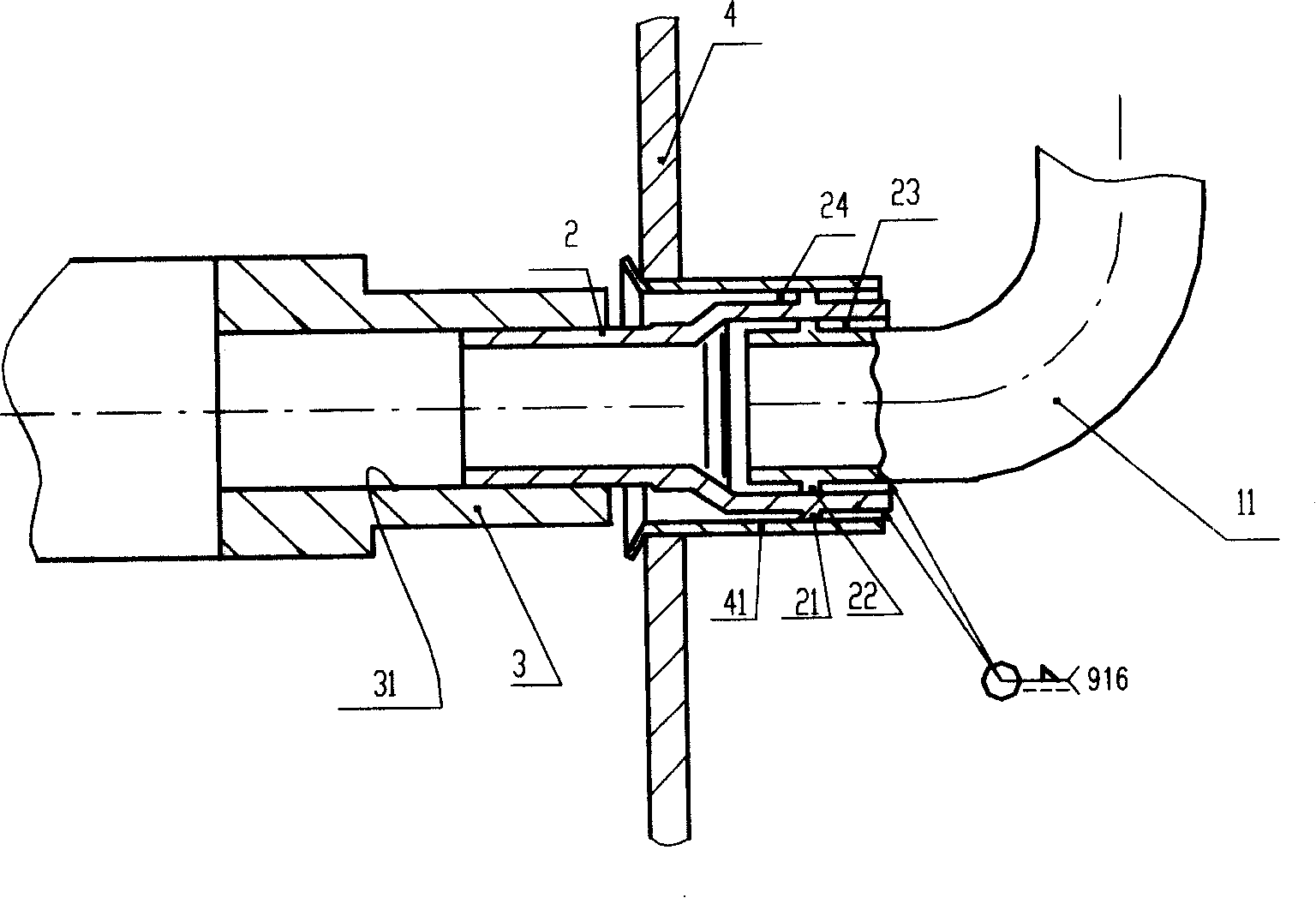

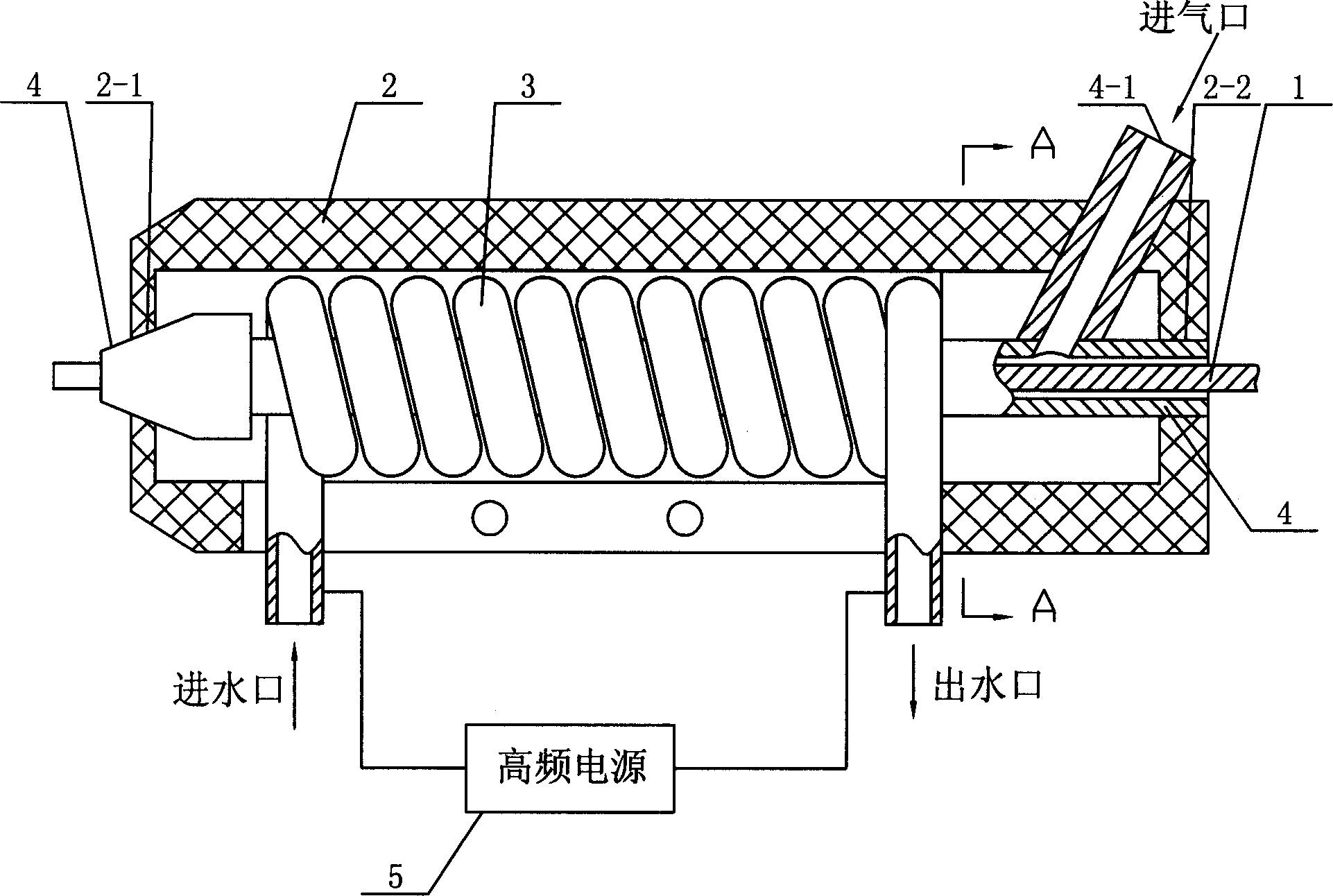

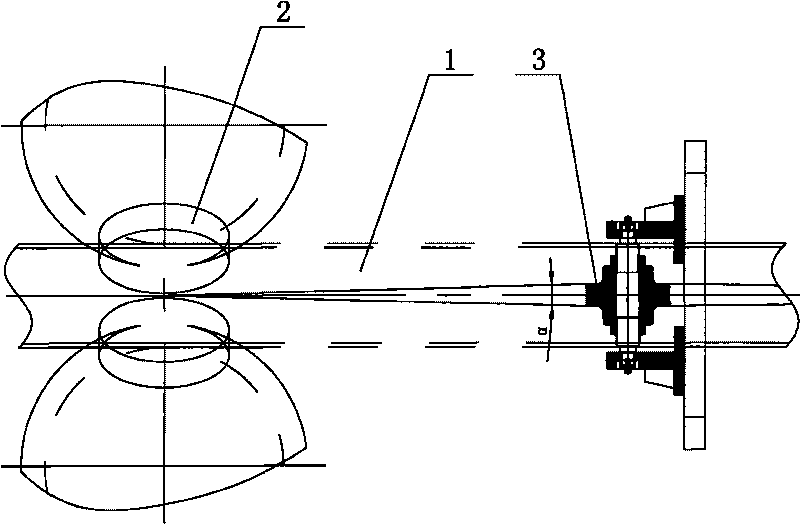

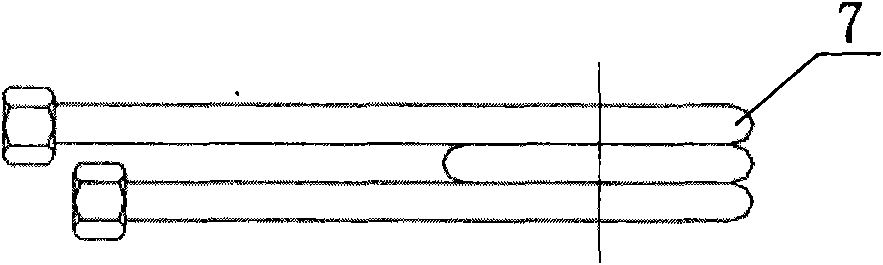

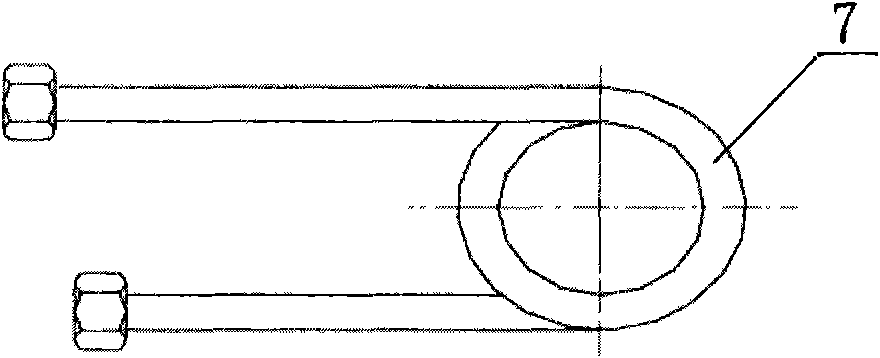

Totally-enclosed -type compressor suction duct connecting mechanism

ActiveCN101235812AReduce manufacturing costGood welding performancePositive displacement pump componentsHigh frequency current welding apparatusWeld seamInduction welding

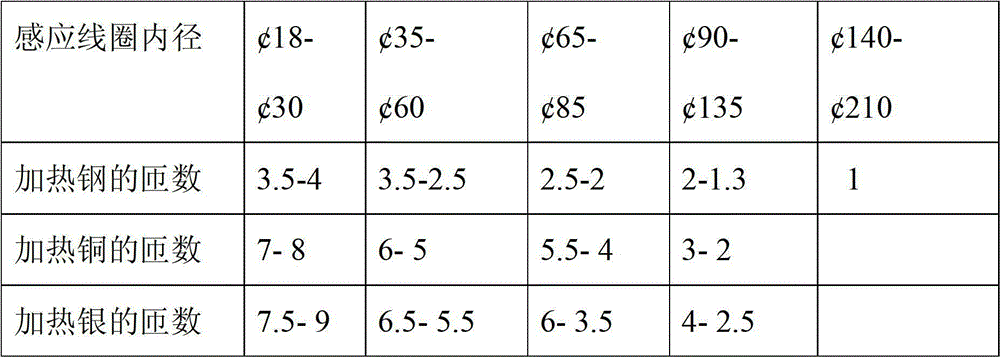

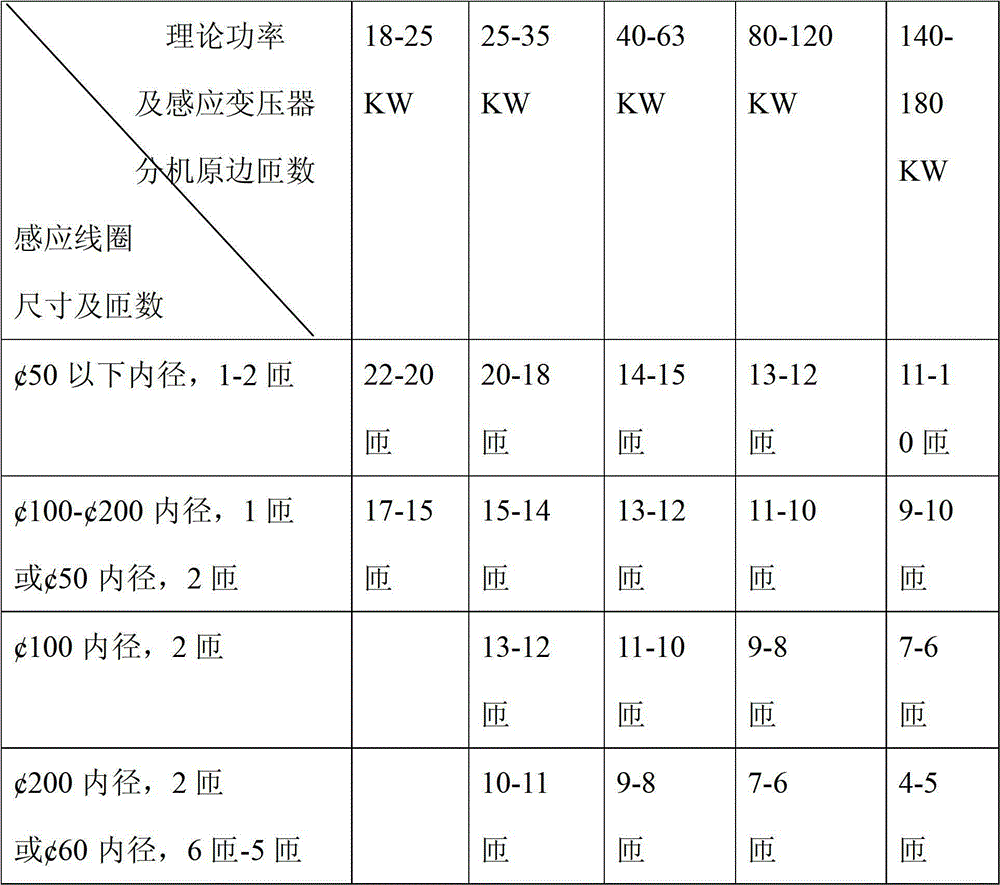

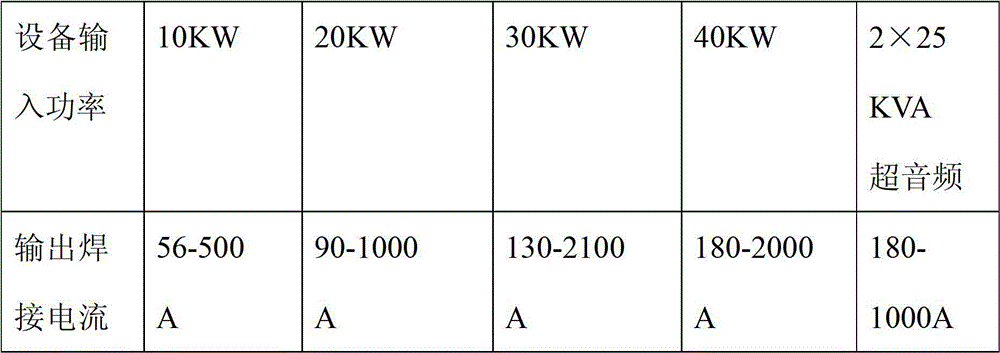

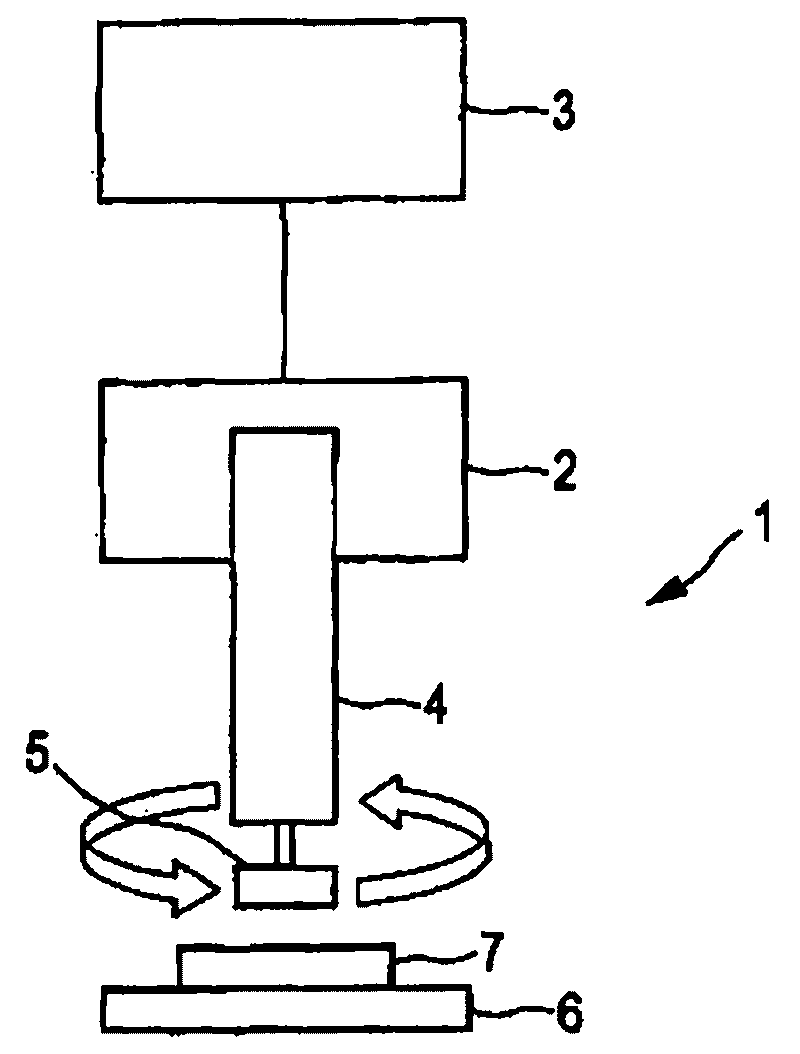

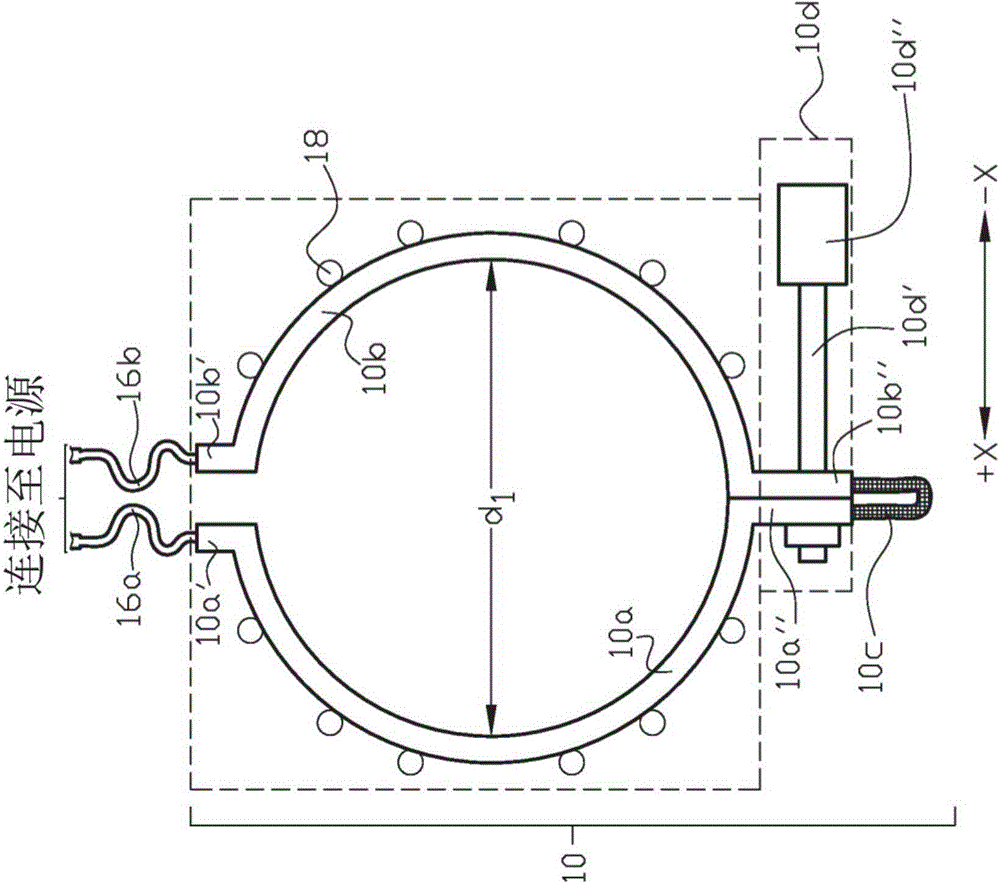

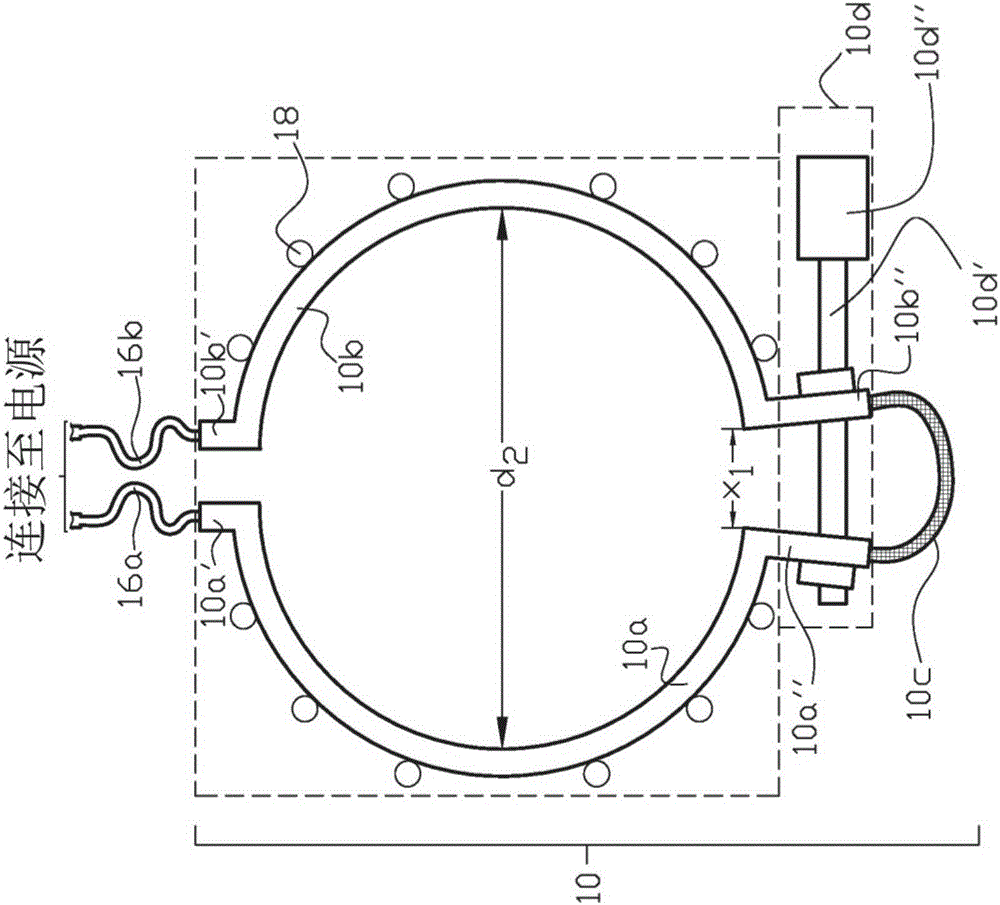

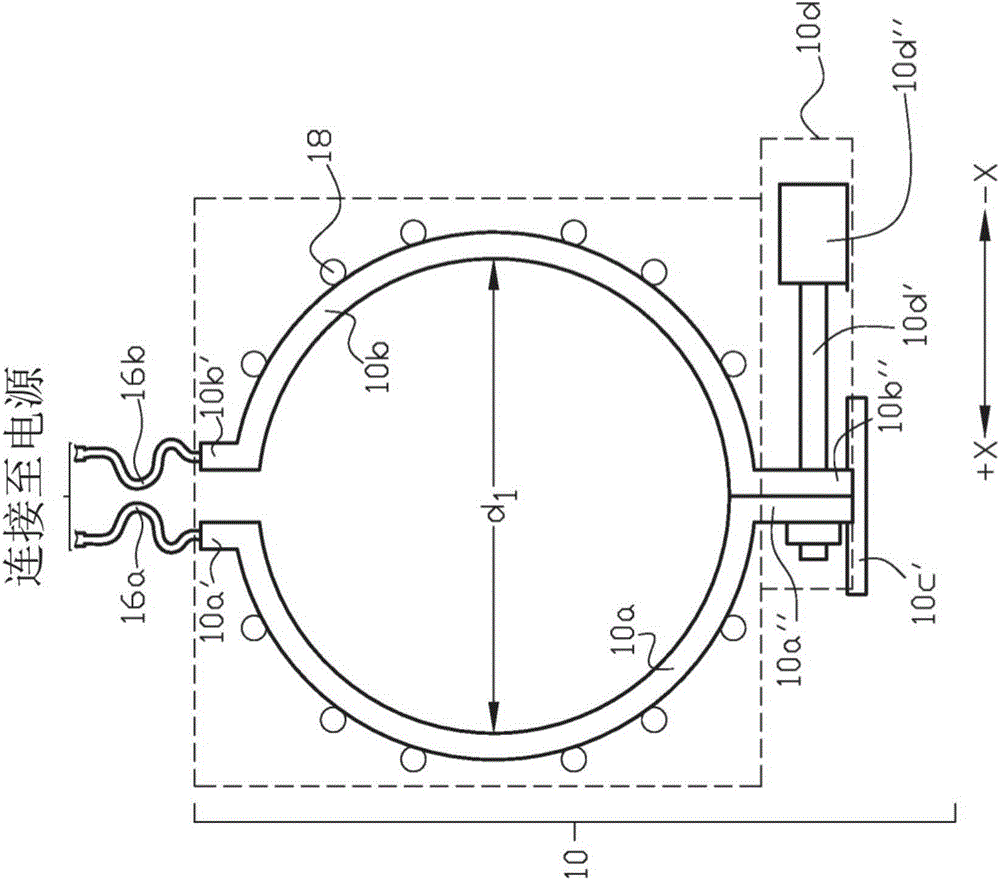

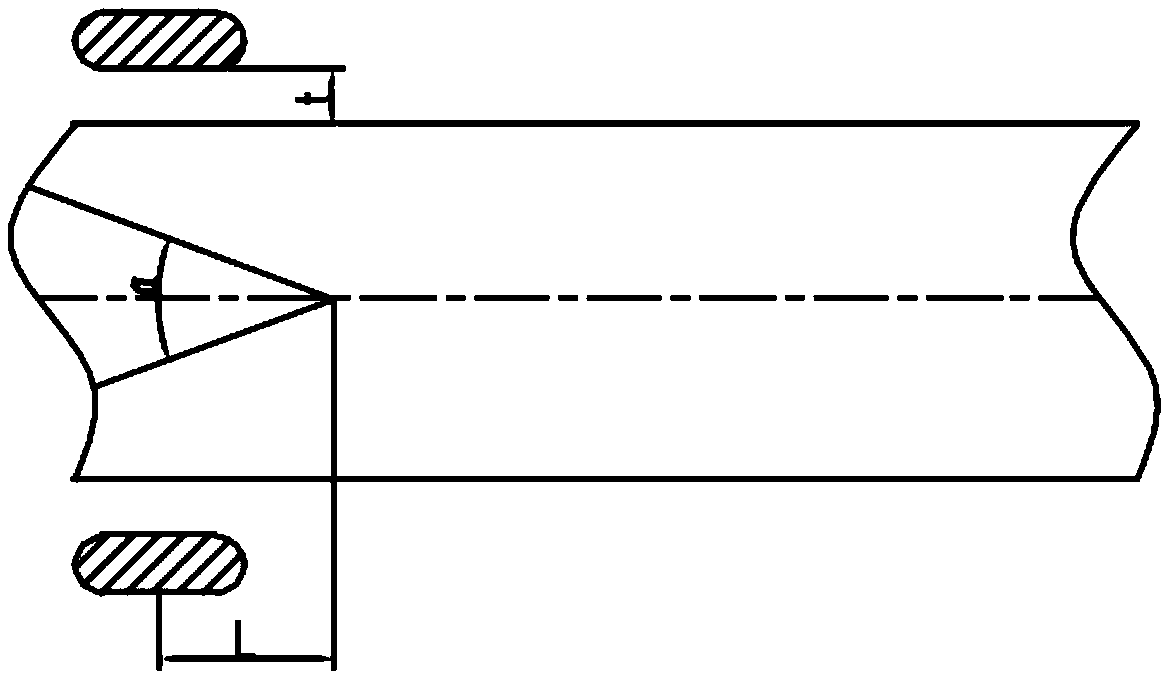

The invention relates to a connecting structure of a fully-closed compressor suction pipe, wherein gaps of welding seams are evenly distributed, which are guaranteed through a raised girdle is designed on a welding gap position of a connecting pipe, a cylinder inserting pipe and an L-shaped pipe which are arranged on a closed shell or is designed on the welding gap position between the connecting pipe and the cylinder inserting pipe. When a connecting mechanism of the fully-closed compressor suction pipe is welded, a solenoid whose two ends are an U shape in a same rotating direction is used, and a high frequency induction welding of an induction coil of a soft magnetic material is plugged between the U shapes which are arranged on the two sides. When welding, an U-shaped open of the U-shaped induction coil is aimed to the outer circle of the connecting pipe to achieve the circumferential weld of the three. The connecting mechanism of the fully-closed compressor suction pipe is capable of increasing the welding performance, achieving the automation or the semi-automation of welding, increasing the productivity effect, and saving produce cost.

Owner:XIAN QINGAN REFRIGERATION EQUIP CO LTD

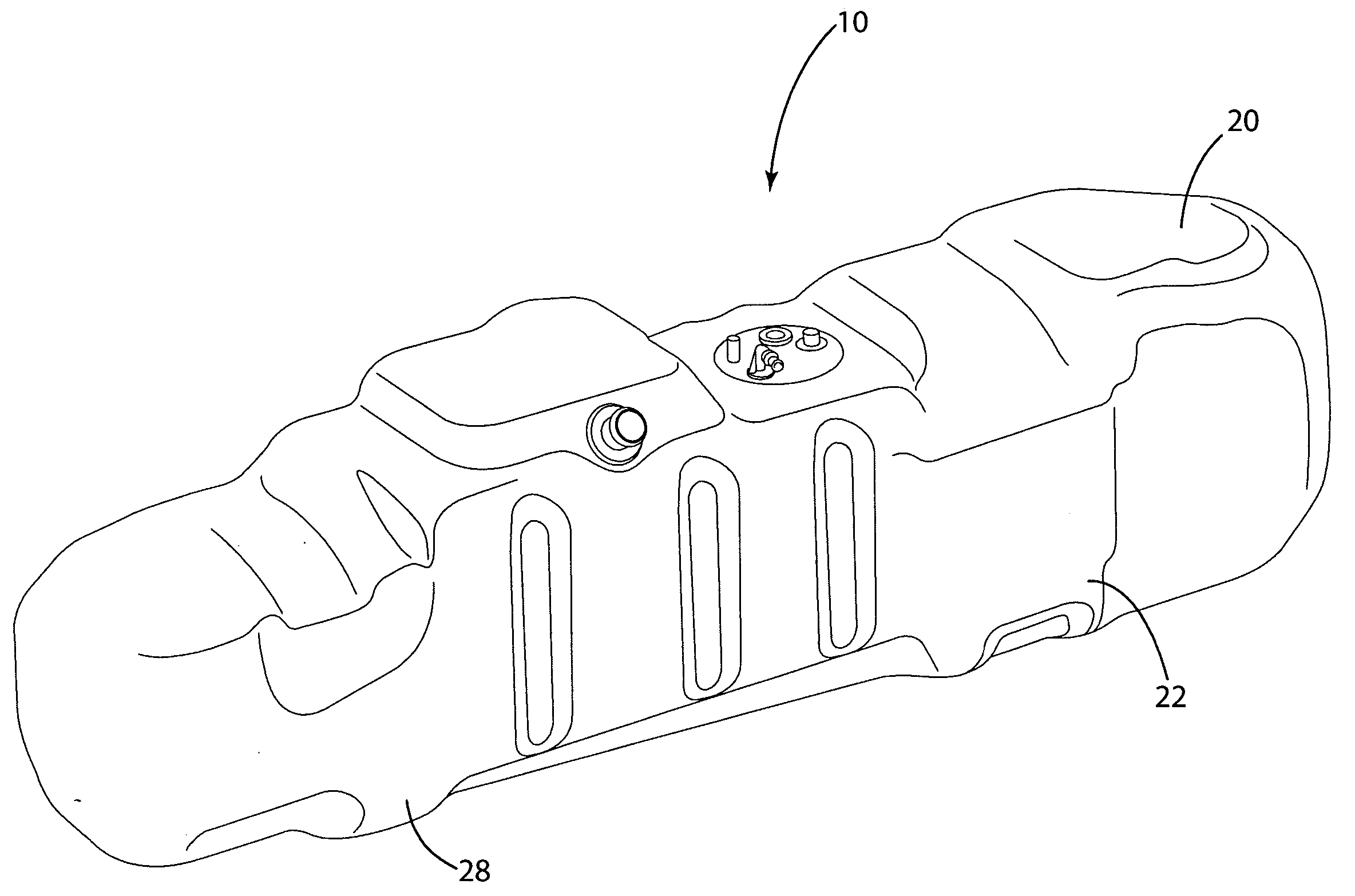

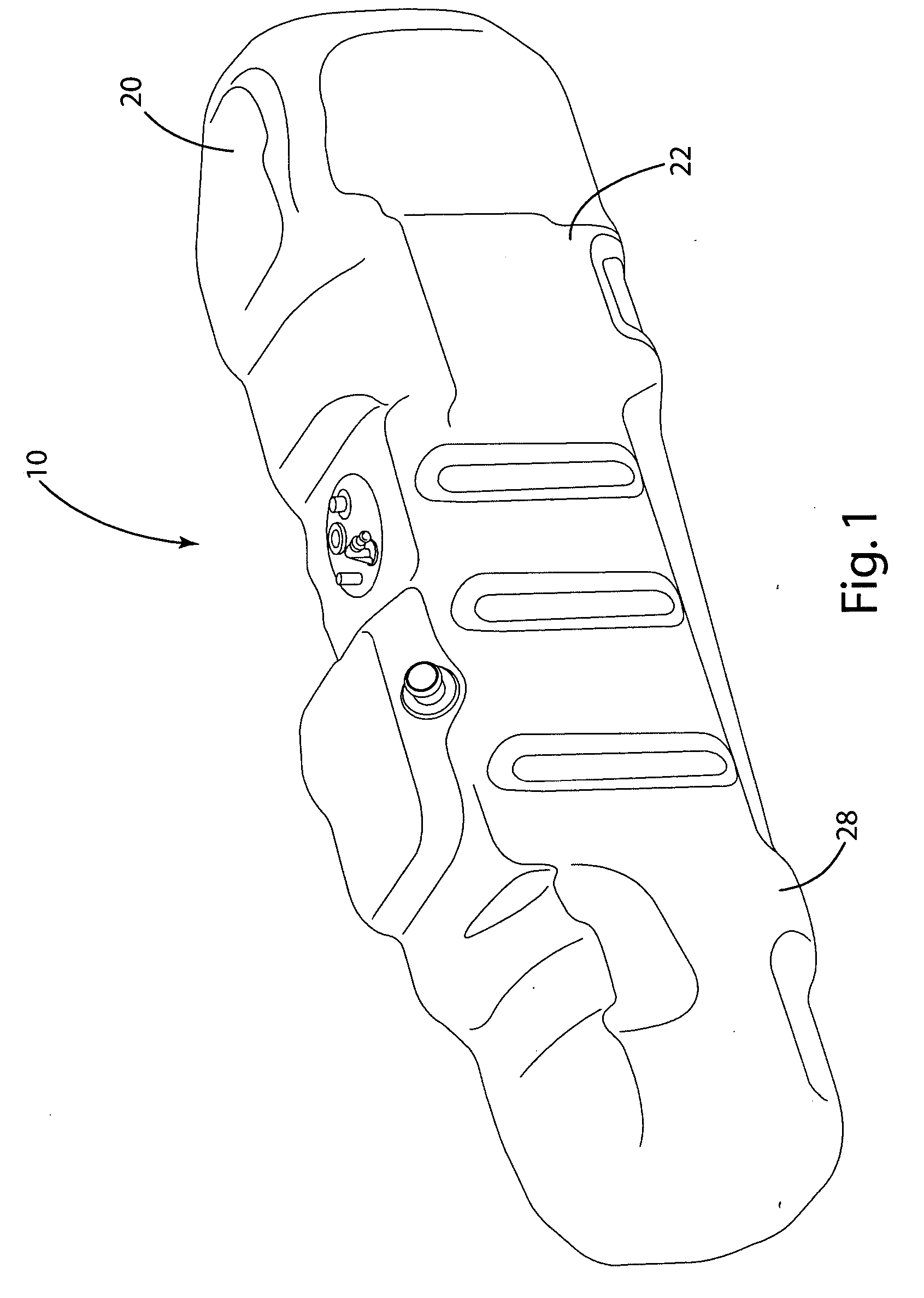

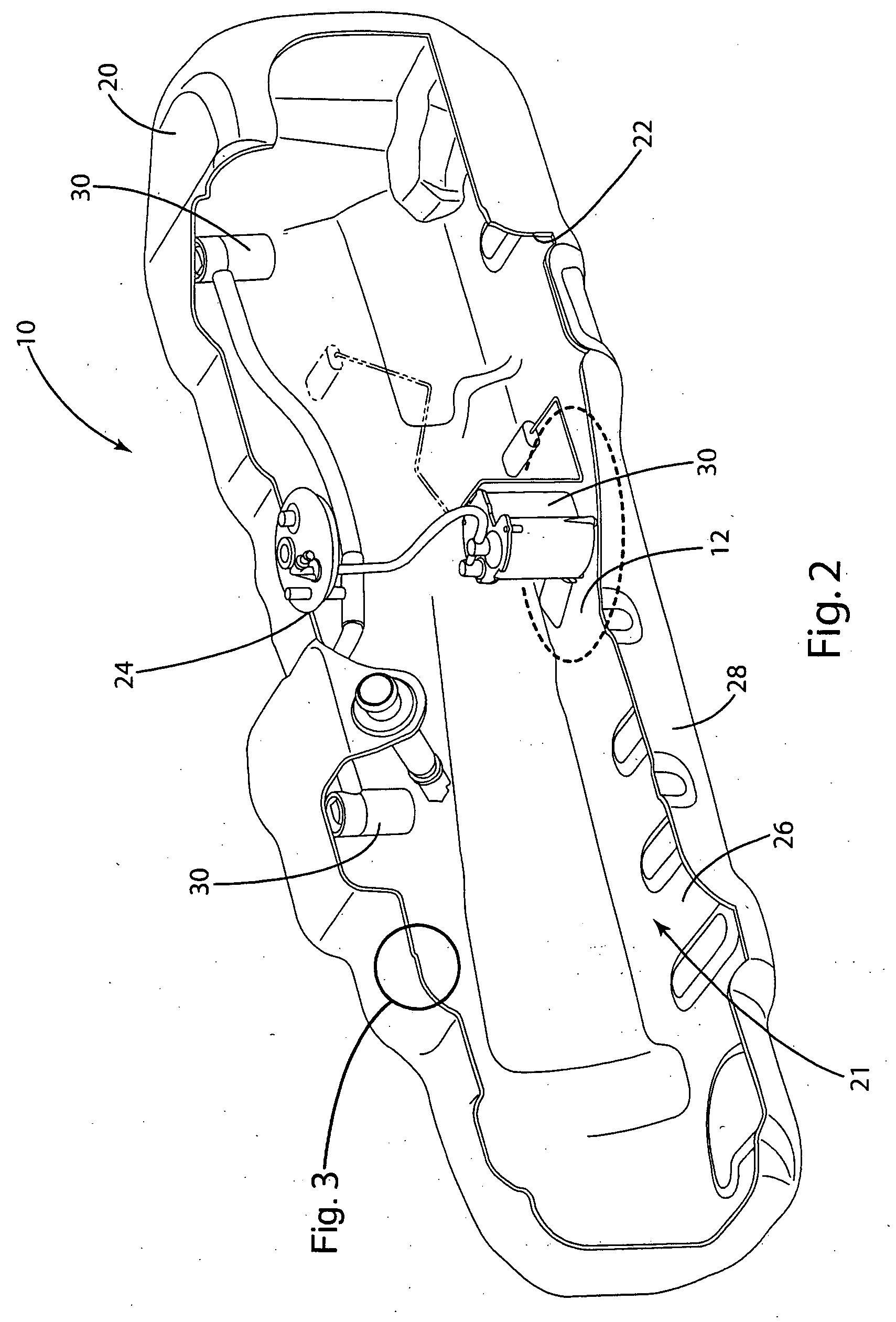

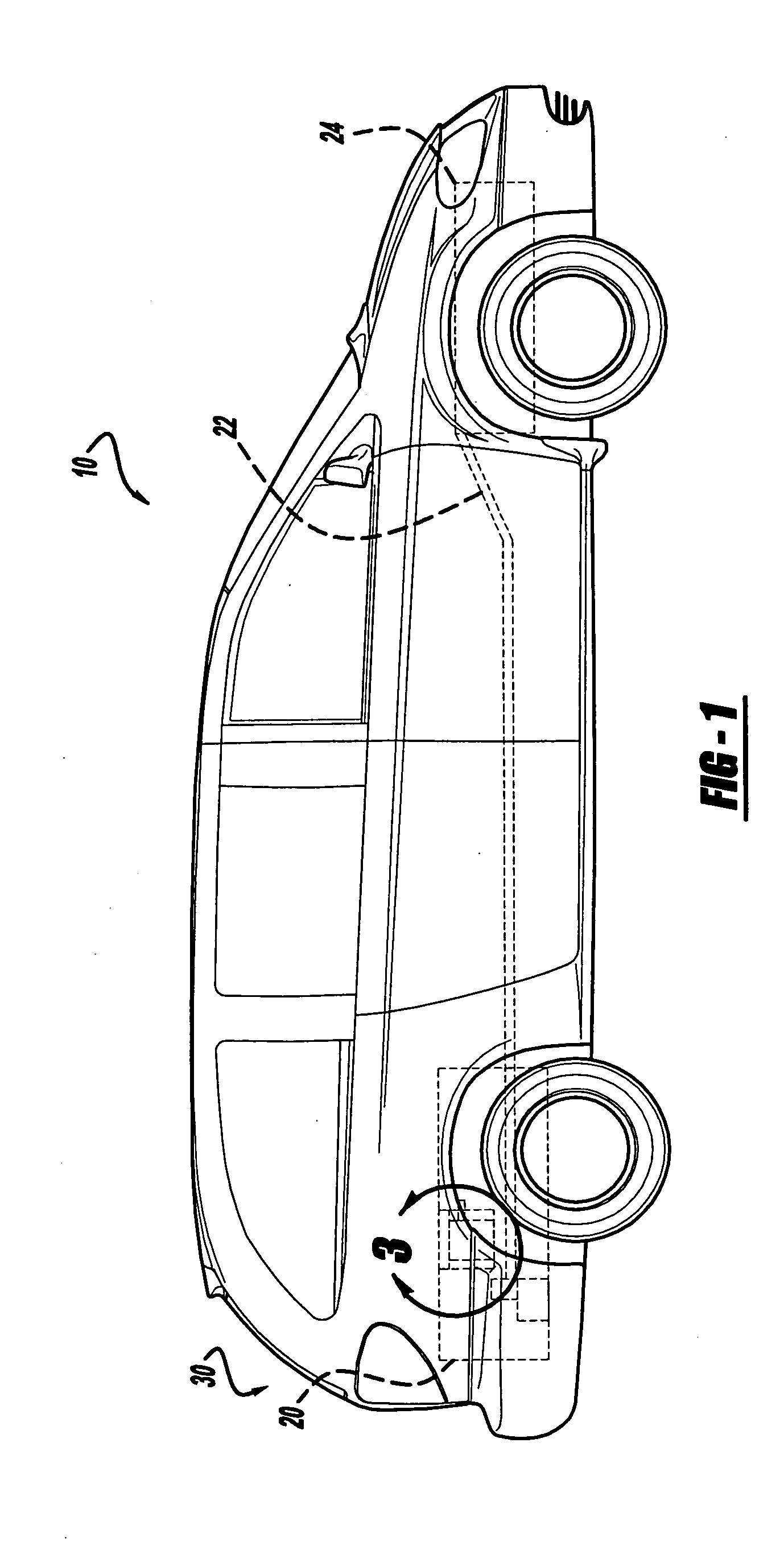

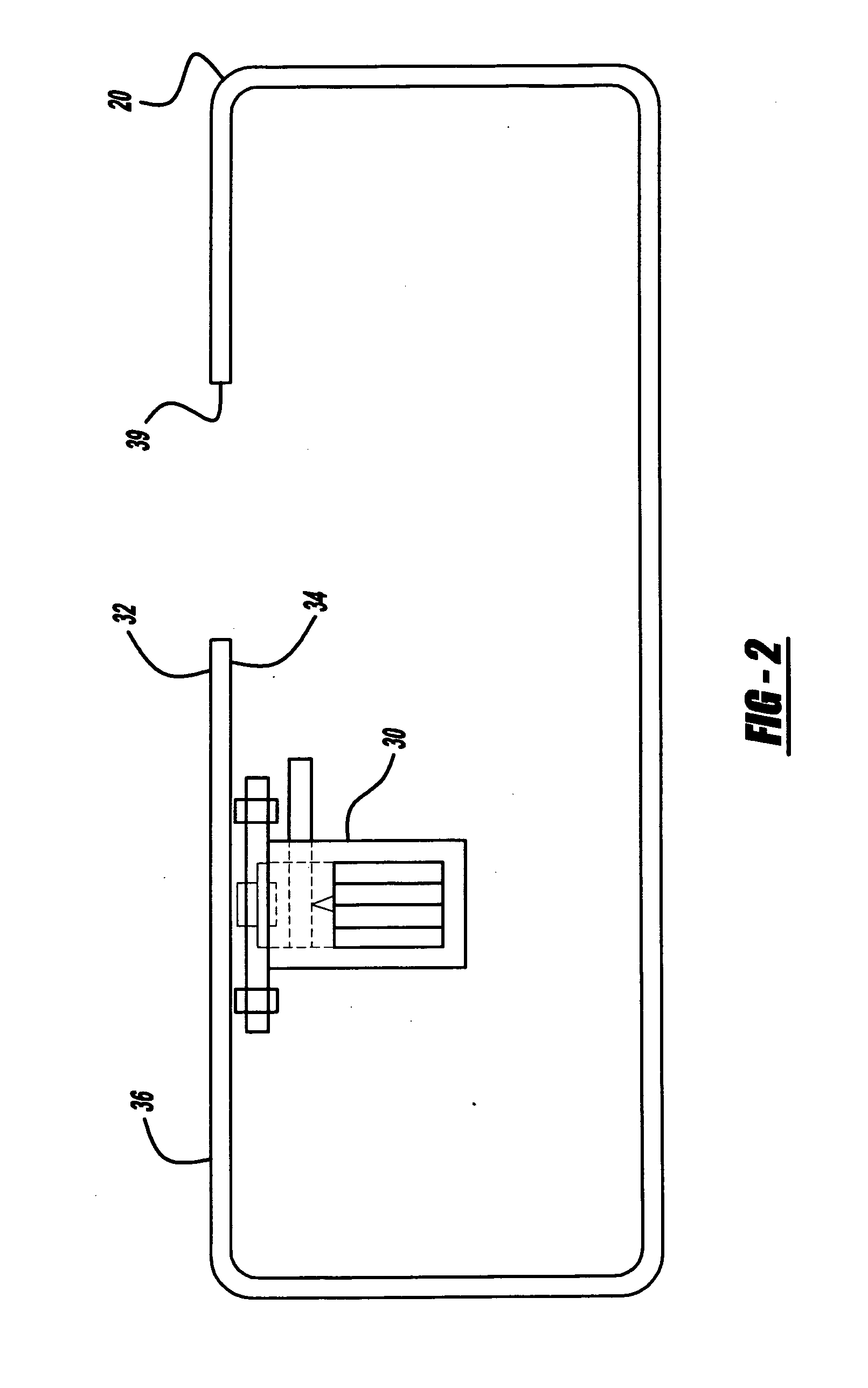

Fuel tank assembly and method of assembly

The present invention relates to a fuel tank assembly and method of securing a component in a fuel tank using induction welding. The method generally includes the steps of placing a component in contact with an inner surface of a fuel tank and inductively welding the component to the inner surface of the fuel tank. The fuel tank assembly generally includes a fuel tank having a wall having a cavity, an inner surface, an outer surface, and an access opening extending through the wall and communicating with the cavity and a component inductively welded to said inner surface.

Owner:AUTOMOTIVE COMPONENTS HOLDINGS

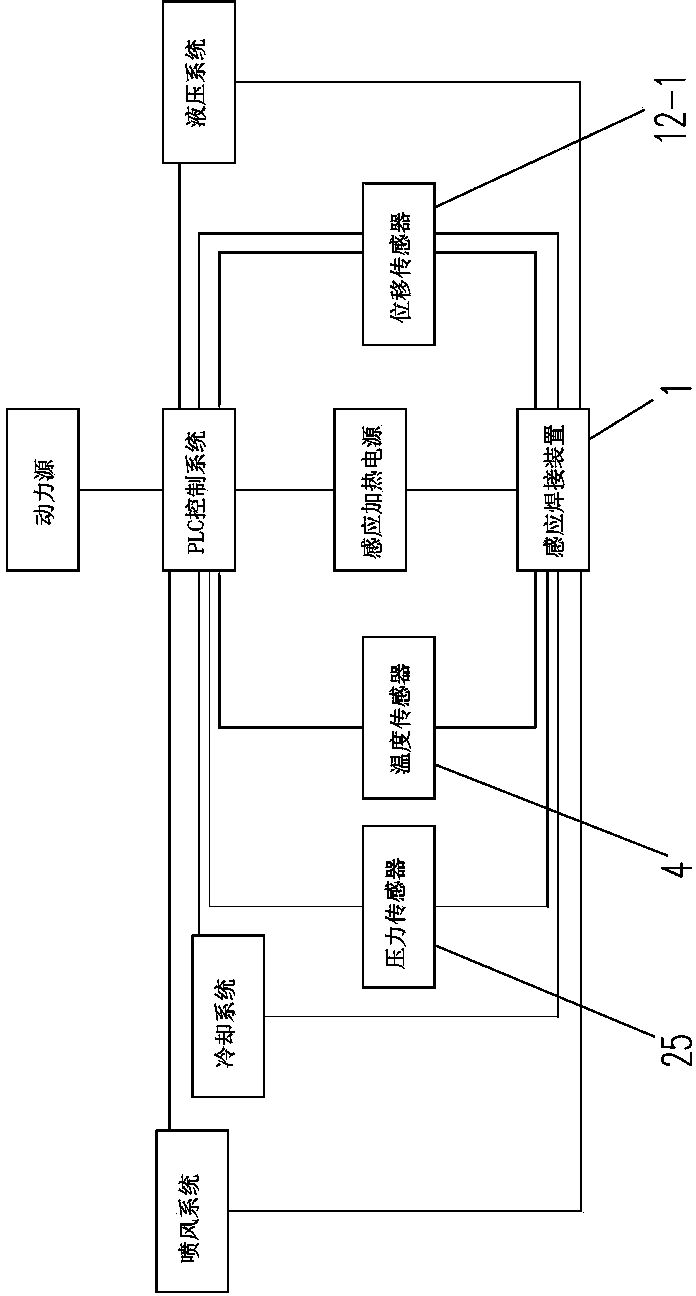

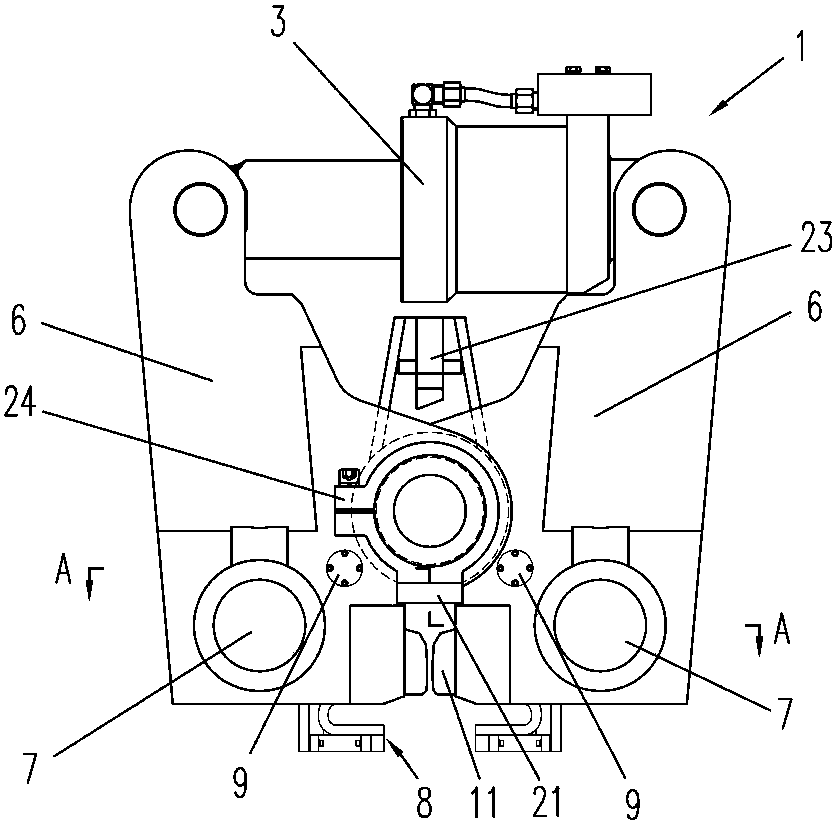

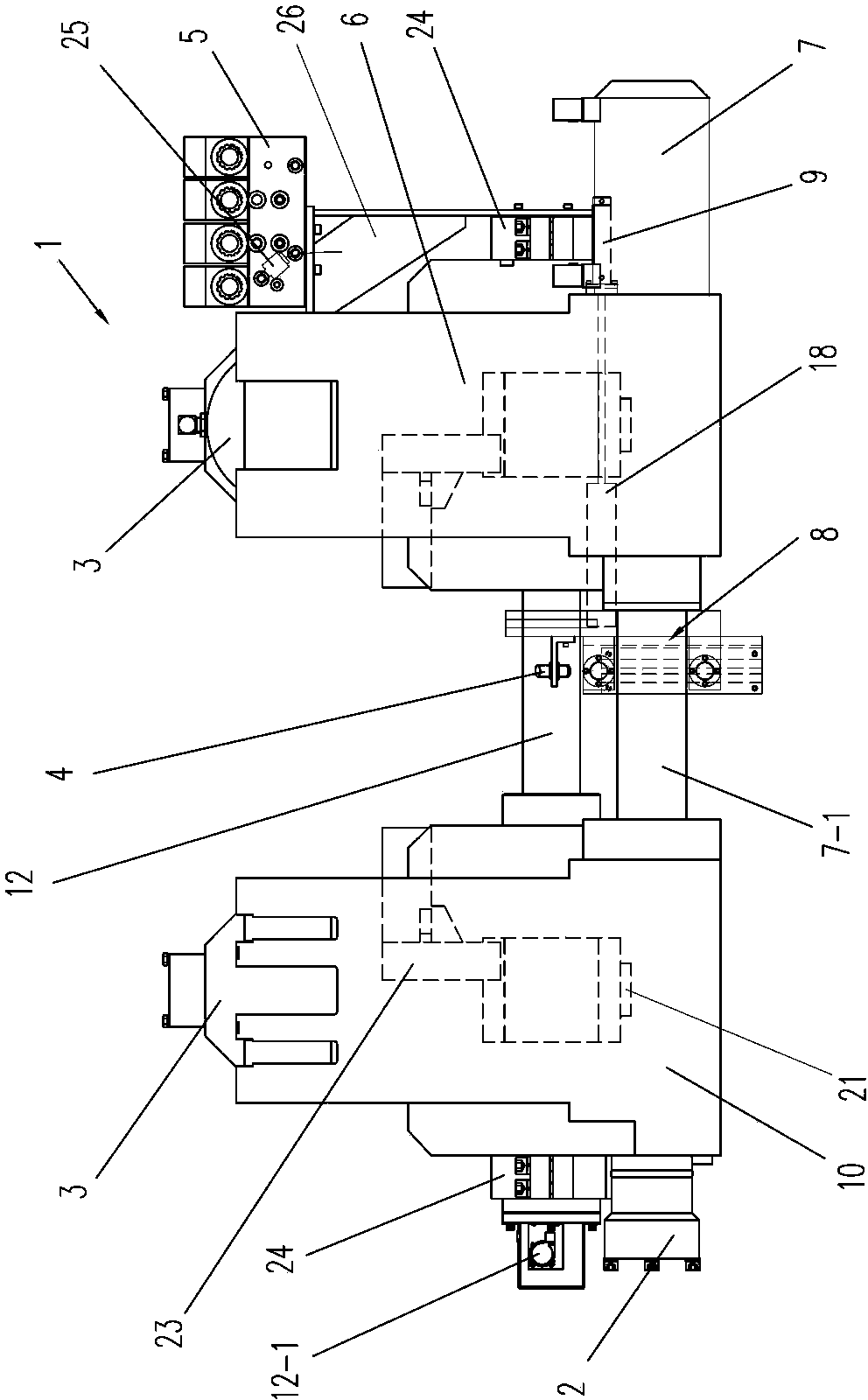

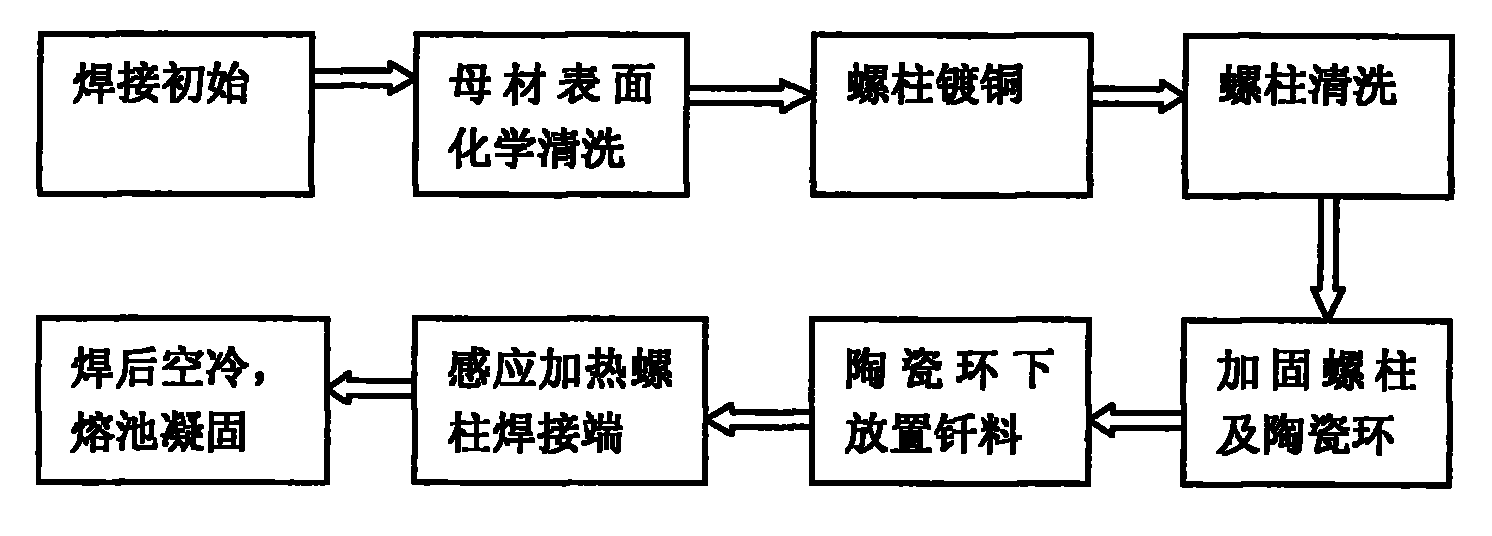

Steel rail induction butt welding and heat treatment method

ActiveCN103521935AImprove organizational efficiencyHigh degree of automationRailsWelding/cutting auxillary devicesButt weldingForceps

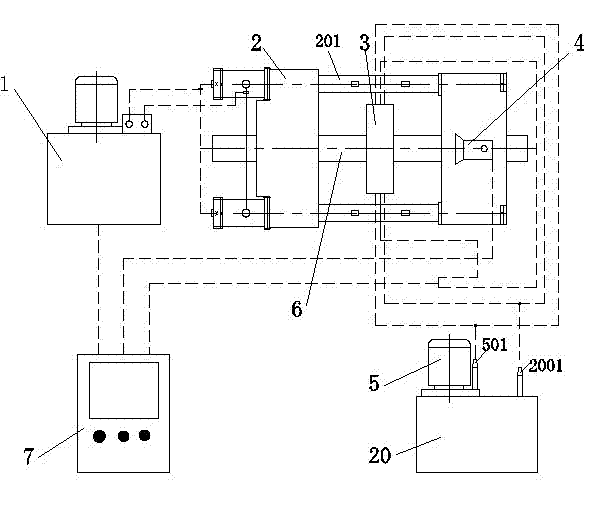

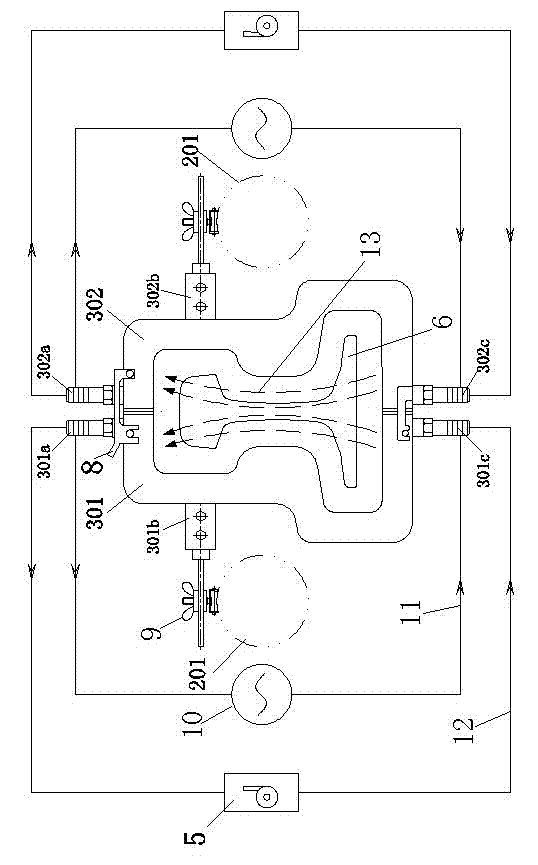

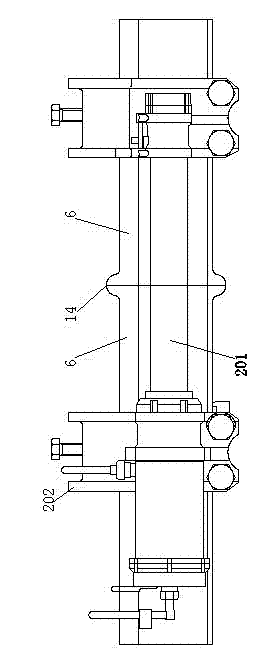

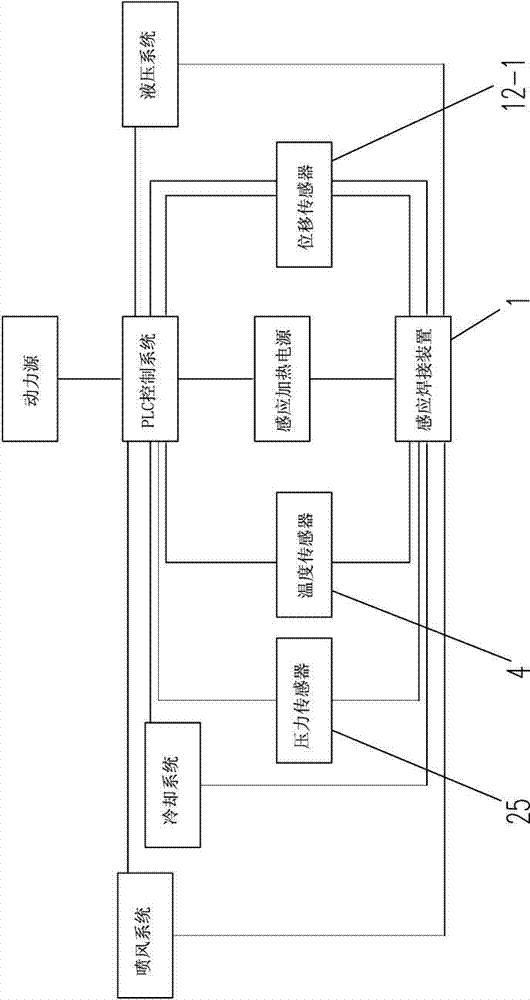

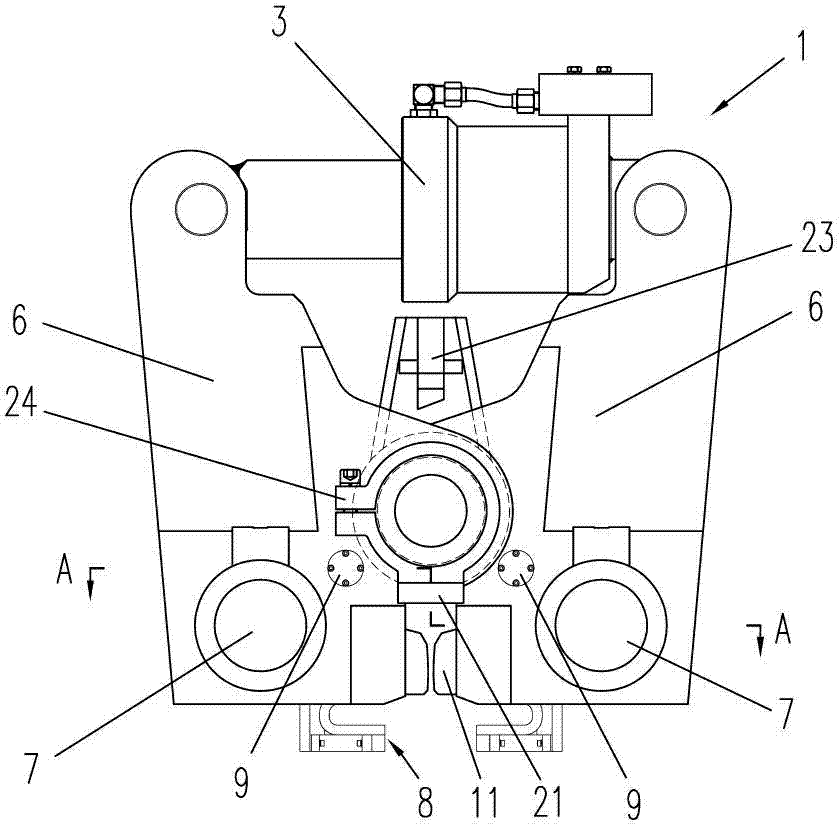

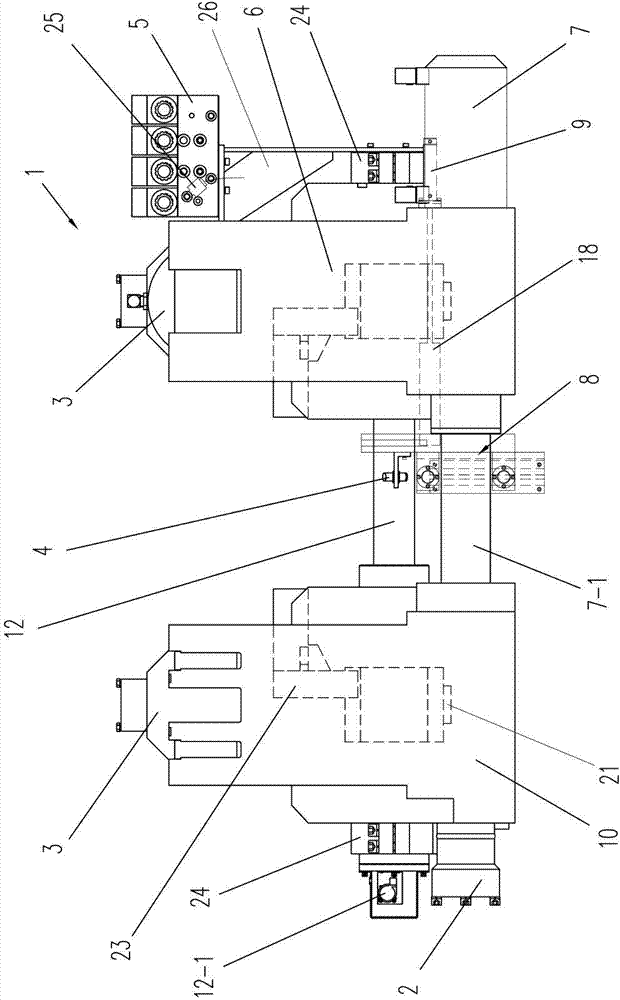

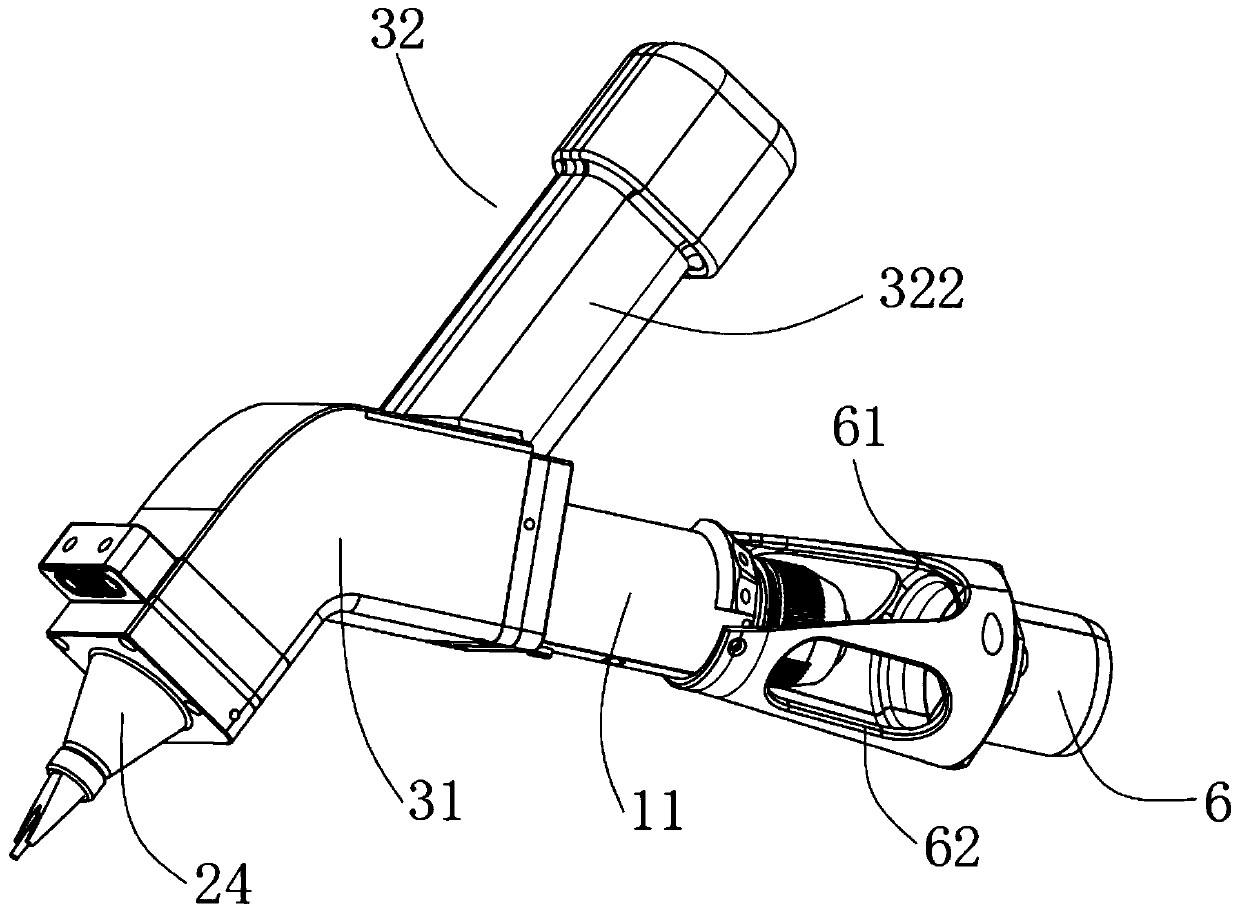

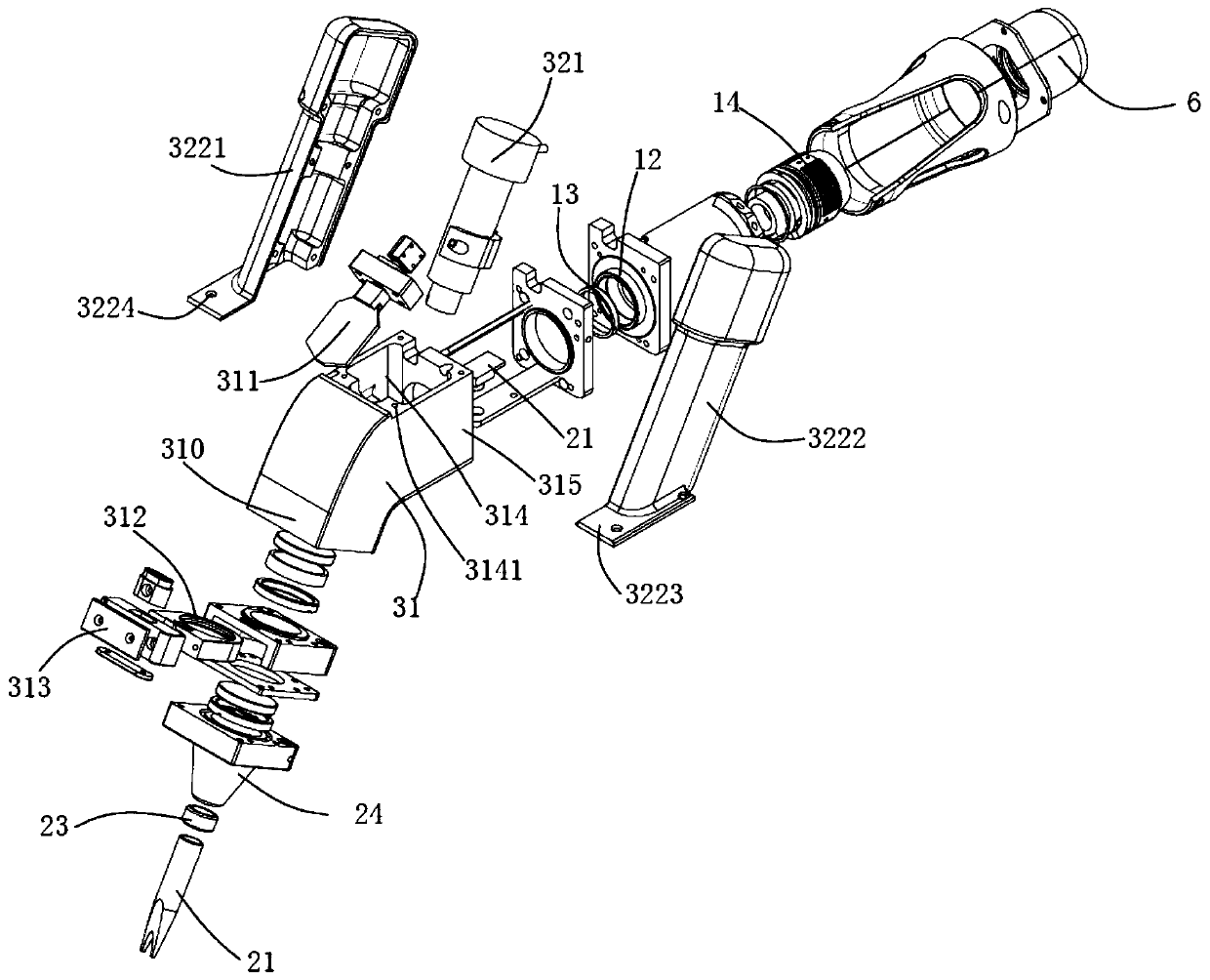

The invention discloses a steel rail induction butt welding and heat treatment method which includes the following steps: locating two steel rails through locating pieces which are installed on the lower portions of center shafts of an induction welding device in a connected mode, enabling jaws of two sets of clamp forceps to clamp the two steel rails respectively and carry out centring, enabling an opening-closing type induction heating coil to be moved to the joint of the two steel rails with the help of auxiliary oil cylinders and wrap the steel rails, enabling two sub-coils to be in contact with electrode structures, enabling a PLC to control the induction heating coil to heat the joint of the steel rails, when the temperature reaches the preset welding temperature of 1200 DEG C to 1430 DEG C, enabling upsetting oil cylinders to exert preset upsetting force to enable the end faces of the two steel rails to be tightly welded together, enabling a protrusion eliminating device to cut welding beading at the joint of the steel rails, enabling the induction heating coil to heat the weld joint of the steel rails again, after the temperature reaches the preset normalizing temperature of 830 DEG C to 950 DEG C, starting an air blasting system to cool the weld joint of the steel rails, and enabling the two sub-coils to be separated through the locating oil cylinders to enable the jaws of the two sets of clamp forceps to be opened to loosen the steel rails. The steel rail induction butt welding and heat treatment method is automatic in operation and high in efficiency.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

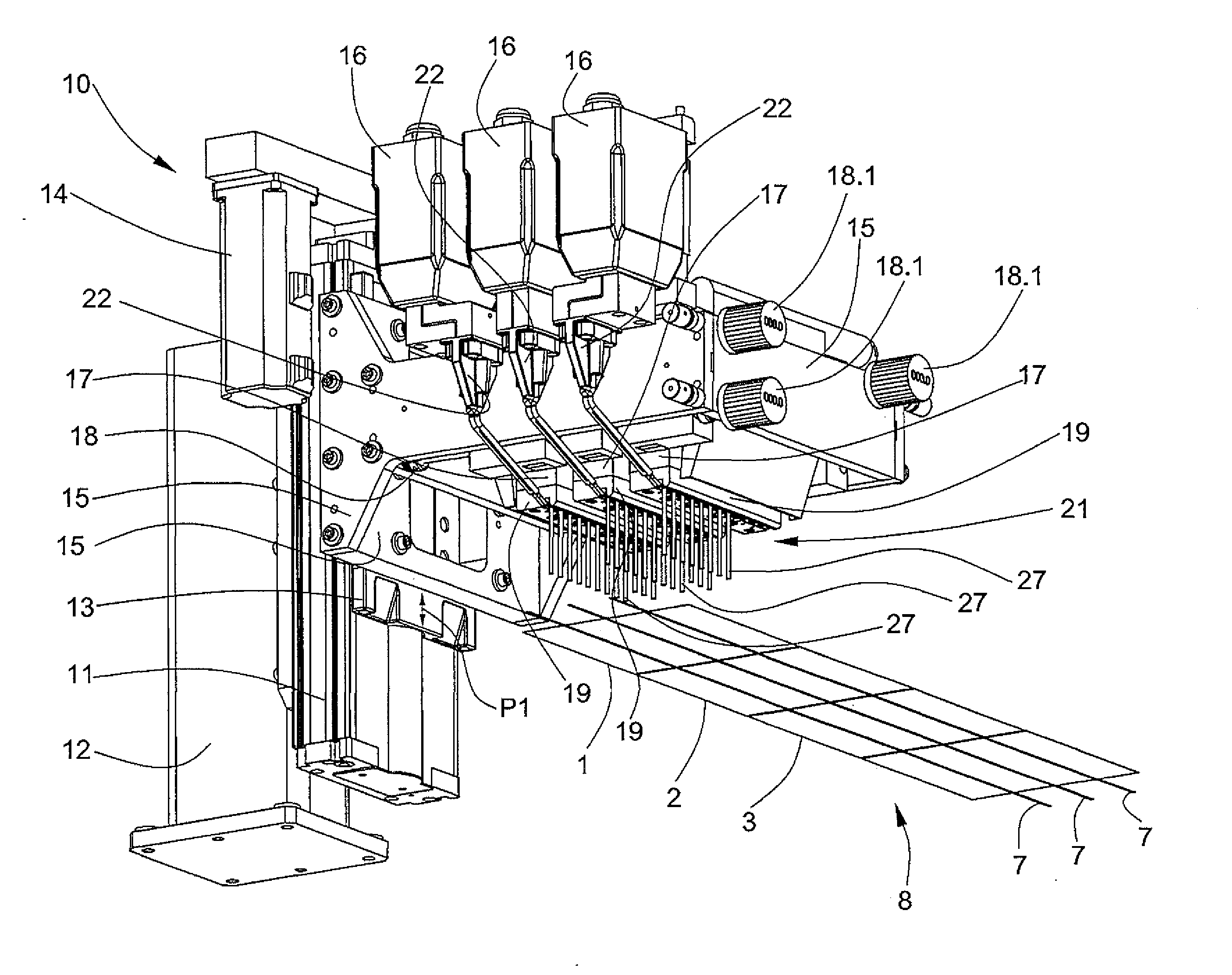

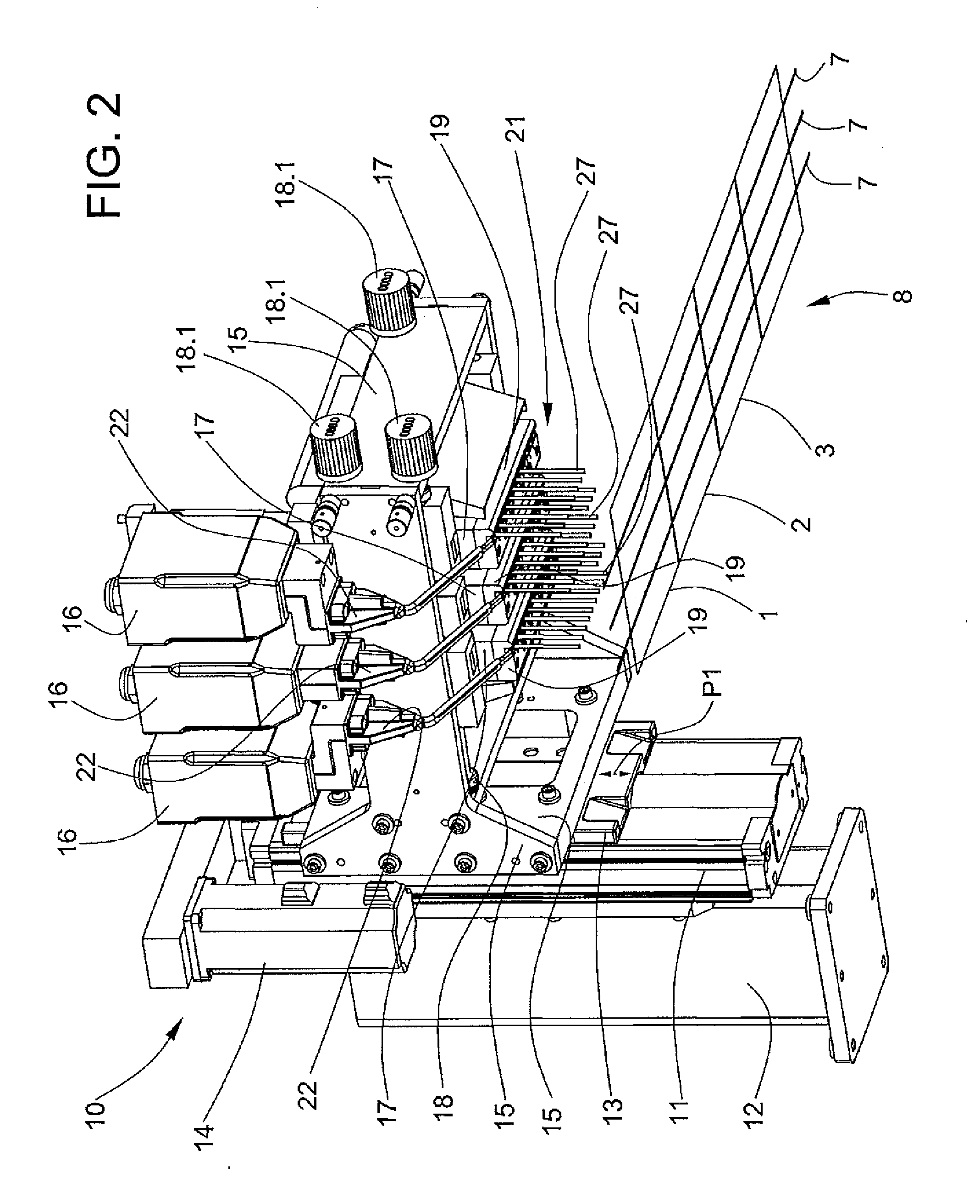

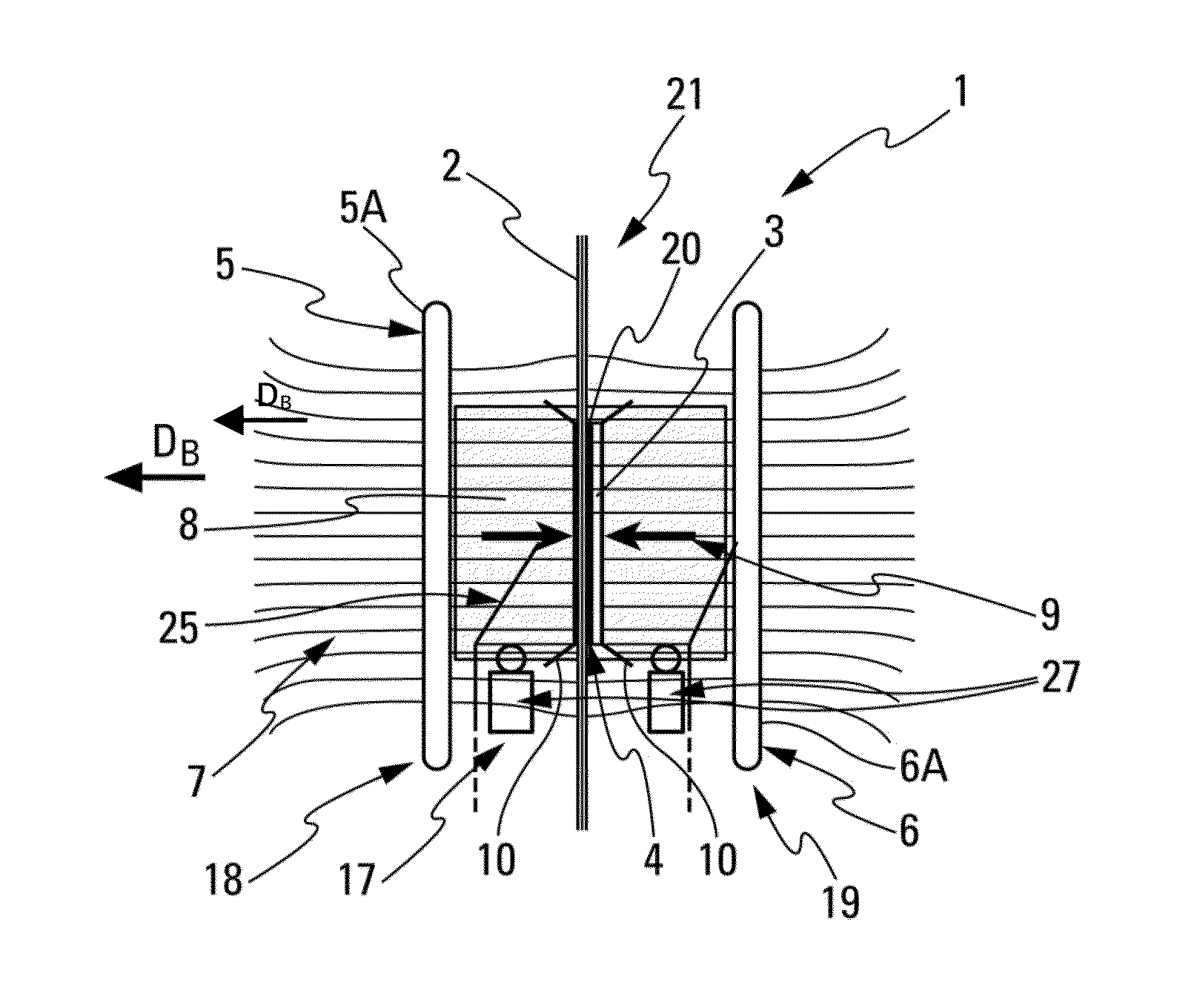

Inductive soldering device

InactiveUS20100038358A1Reduce the impactReduce impactHeating appliancesMetal working apparatusElectrical conductorMagnetic bead

A soldering apparatus for connecting solar cells includes an induction heat source to connect cell conducting tracks, provided with soldering medium, with electric conductors. The heat source has a high-frequency generator and an inductor loop in which the flow of a high-frequency current causes a high-frequency magnetic field to induce in the conducting track and in the electric conductor arranged along the conducting track eddy currents that generate the heat that is necessary for the soldering operation. The inductor loop includes a U-shaped loop element that has narrowings and widening in one arm that is positioned closer to the conductor. Ferrite beads and ferrite tubes at the widening concentrate the magnetic field to optimize the heat development in the soldering zone and thus also save energy.

Owner:KOMAX HOLDING

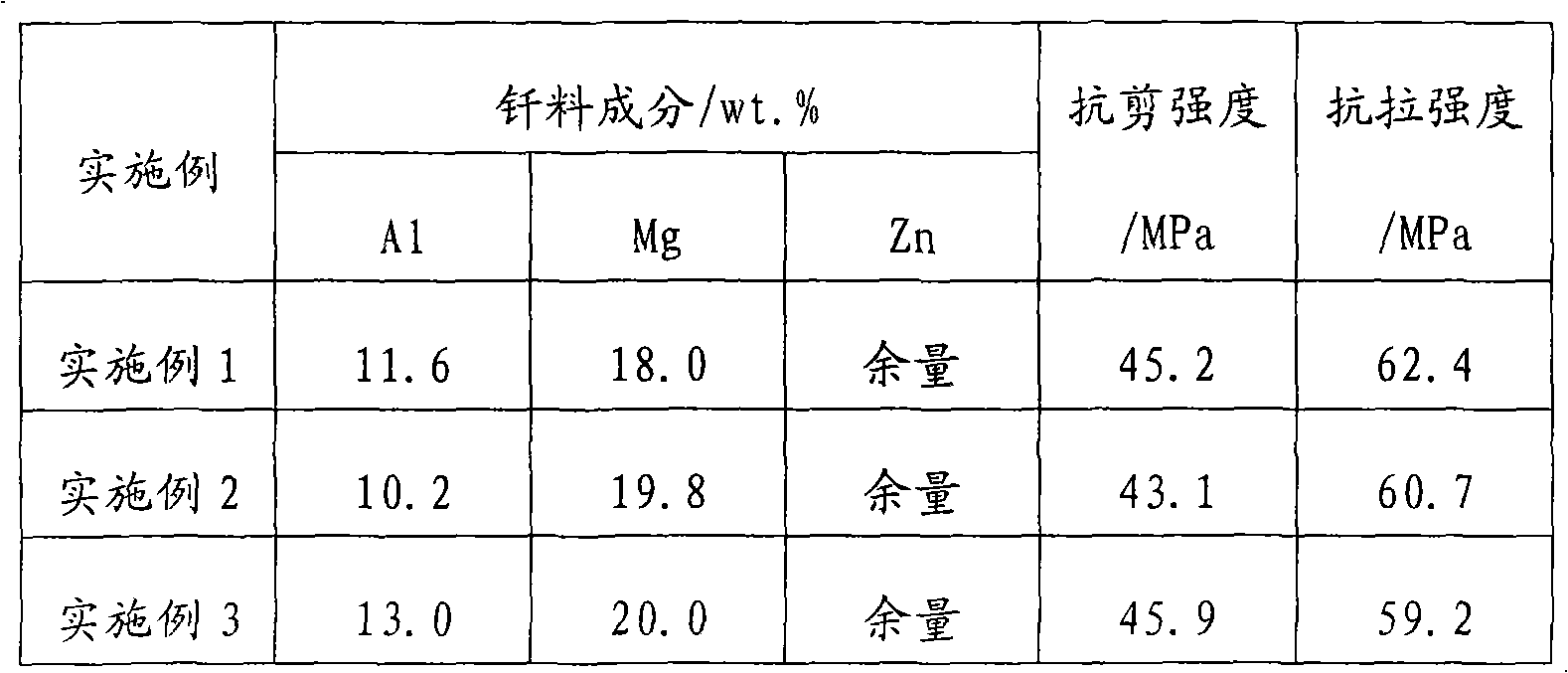

Zn-Mg-Al magnesium alloy solder

InactiveCN101653879AGood spreadabilityExcellent gap fillingWelding/cutting media/materialsSoldering mediaButt jointSoldering

The invention provides a Zn-Mg-Al magnesium alloy solder, belonging to the technical field of magnesium alloy welded joint. The components of the provided Zn-Mg-Al magnesium alloy solder contain 10% to 13% of Al, 18% to 20% of Mg and the remains are Zn. The melt temperature of the Zn-Mg-Al magnesium alloy solder is ranged from 379 DEG C to 488 DEG C and the soldering temperature is ranged from 500DEG C to 510 DEG C. The solder can be applied to the magnesium alloy solder with solidus temperature above 510 DEG C. The AZ31B magnesium can be soldered in the manner of high frequency induction welding. The slip resistance of the solder overlap joint is ranged from 43MPa to 45 MPa and the tensile strength of the butt joint is ranged from 59MPa to 62MPa.

Owner:BEIJING UNIV OF TECH

Single purpose high-frequency induction welding wire heating apparatus for hot wire TIG welding

InactiveCN1593829AFast heatingEliminate magnetic blowoutArc welding apparatusEngineeringInduction welding

The invention relates to a kind of device using high frequency induction to heat the welding thread when hot thread TIG welding. The circling wire coils the insulation conduit, and makes the magnetic induction axis of the circling wire and the axis of the insulation conduit superposited. Two ends of the inducting wire connect respectively to the two exporting ends. The two ends of the insulation conduit respectively pass through the two holes of the inter body. The welding thread passes through one end of the insulation conduit. And outer round surface of the welding thread connect to inter round surface. The invention can heat the welding thread with high frequency heating, eliminate magnetic blow phenomenon, speed up the heating, adjust the heating depth, and heat evenly, and control the heating temperature. It can be used for heating all kinds of metal welding thread, and has simple structure so as to be repaired easily.

Owner:HARBIN INST OF TECH

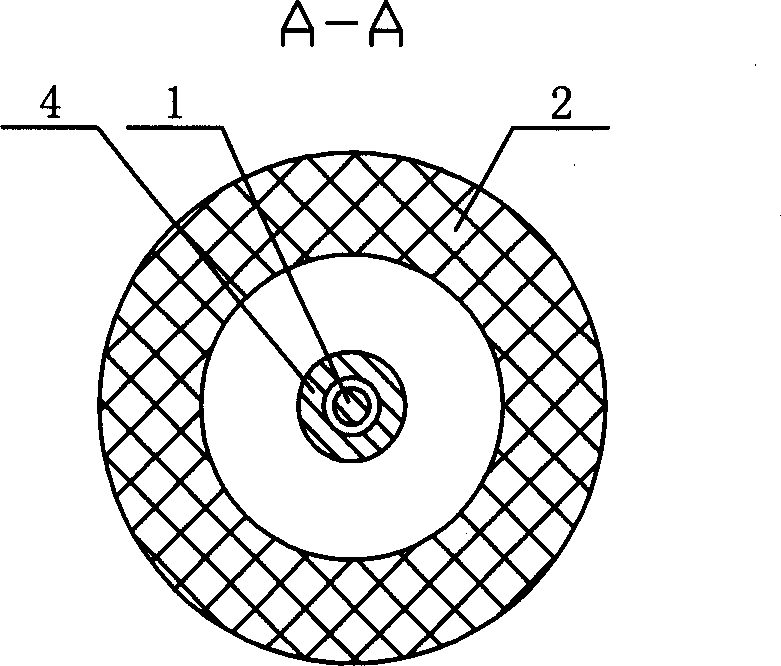

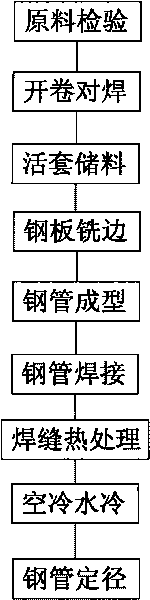

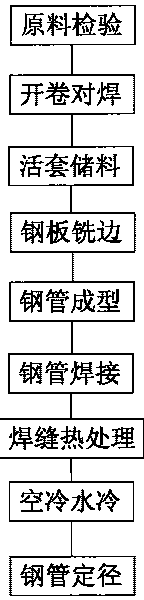

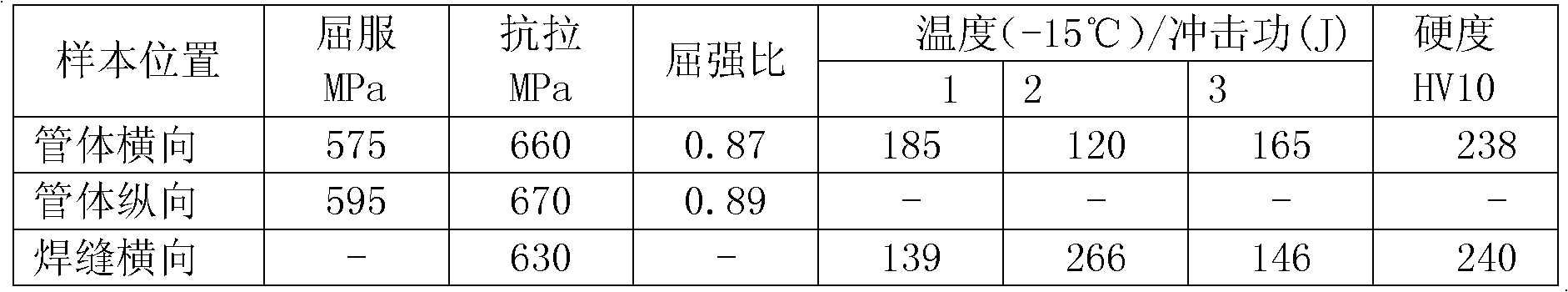

Manufacturing method of submerged pipeline steel pipe

InactiveCN101701315AGrain refinementImprove performance indicatorsFurnace typesHeat treatment furnacesOcean bottomManganese

The invention discloses a manufacturing method of a submerged pipeline steel pipe, which comprises the following technological processes of: raw material inspection, steel pipe welding and weld heat treatment, wherein the process of steel pipe welding adopts high frequency induction welding. The raw materials comprise the following chemical components: 0.04-0.08% of C, not more than 0.25% of Si, not more than 1.65% of Mn, not more than 0.020% of P which is less than or equal to, not more than 0.005% of S, not more than 0.15% of Nb+V+Ti, and not more than 0.41% of Ce. Because the technical scheme is adopted, the chemical components with low carbon content, low manganese content and microalloy are determined, and the maximum value of harmful elements and the content ratio of microalloy elements are controlled, thereby achieving the purposes of refining grains and improving the performance indexes of products; and the products have high strength, corrosion resistance and high pressure resistance.

Owner:CNOOC KINGLAND PIPELINE

Production method of brazed diamond wire saw

InactiveCN101596749AIncrease productivityReduce manufacturing costFine working devicesStone-like material working toolsDiamond wire sawInduction welding

The invention relates to a production method of a brazed diamond wire saw, comprising the following process steps: 1. a steel wire enters a vessel stored with paste solder; 2. the steel wire adhered with solder enters a first wire-drawing die to facilitate the steel wire passing through the first wire-drawing die to be evenly coated with a layer of solder; 3. the steel wire adhered with solder enters a sealed dust box which contains diamond powder with diameter being 20-30 mum, a blower device blows the diamond fine powder, and the steel wire adhered with solder is evenly coated with a layer of diamond powder after passing through the dust box; 4. the steel wire adhered with solder enters a second wire-drawing die and is evenly and tightly coated with a layer of diamond powder; 5. the steel wire adhered with solder enters the center of a coil of high frequency induction welding, the solder melts down instantly, and diamond and the wire are fixedly and metallurgically bonded; and 6. a roll-up wheel evenly winds the finished diamond wire by welding. The method of the invention has quick production speed, and the prepared brazed diamond wire saw has long service life.

Owner:江苏中博钻石科技有限公司

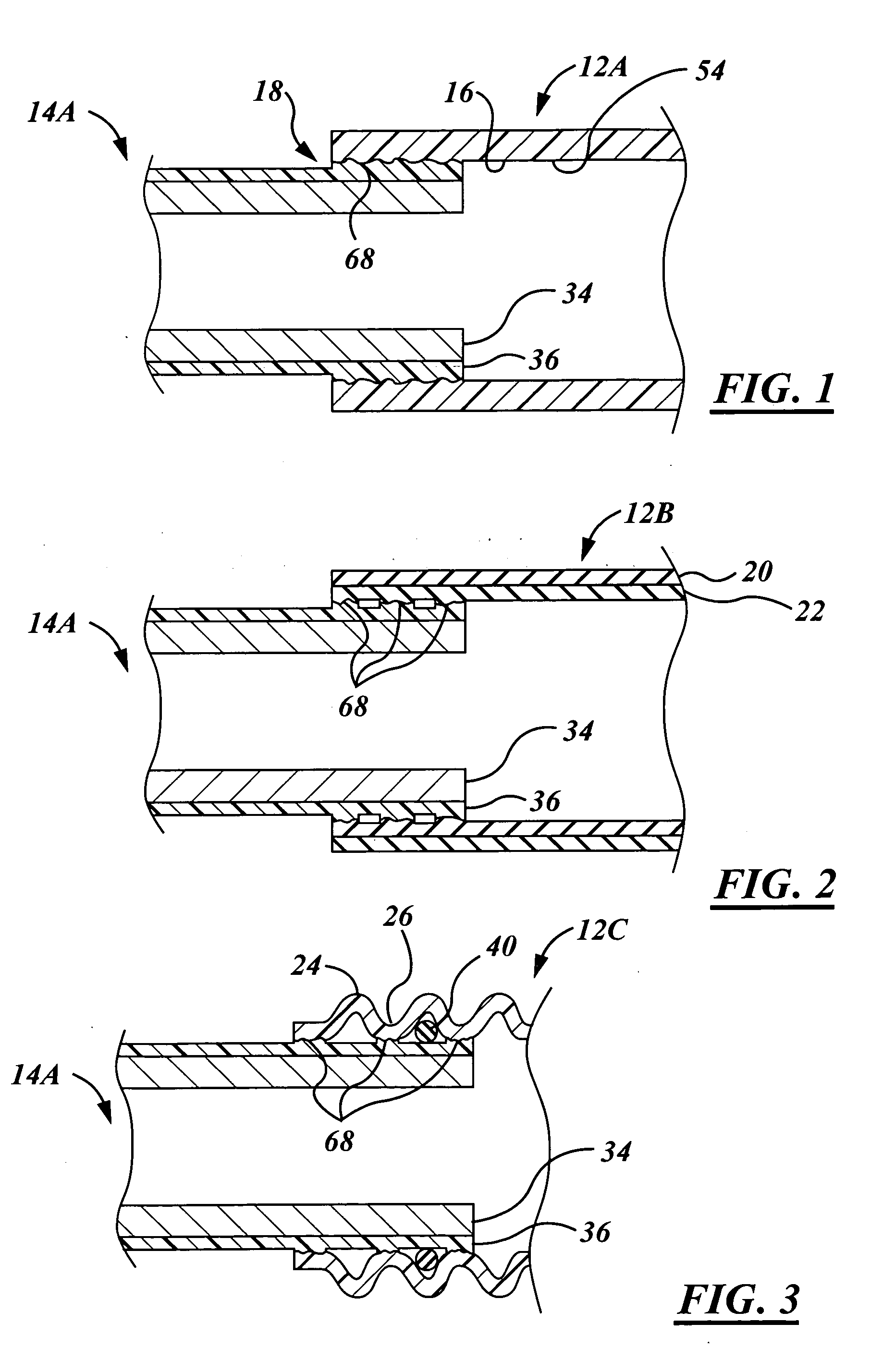

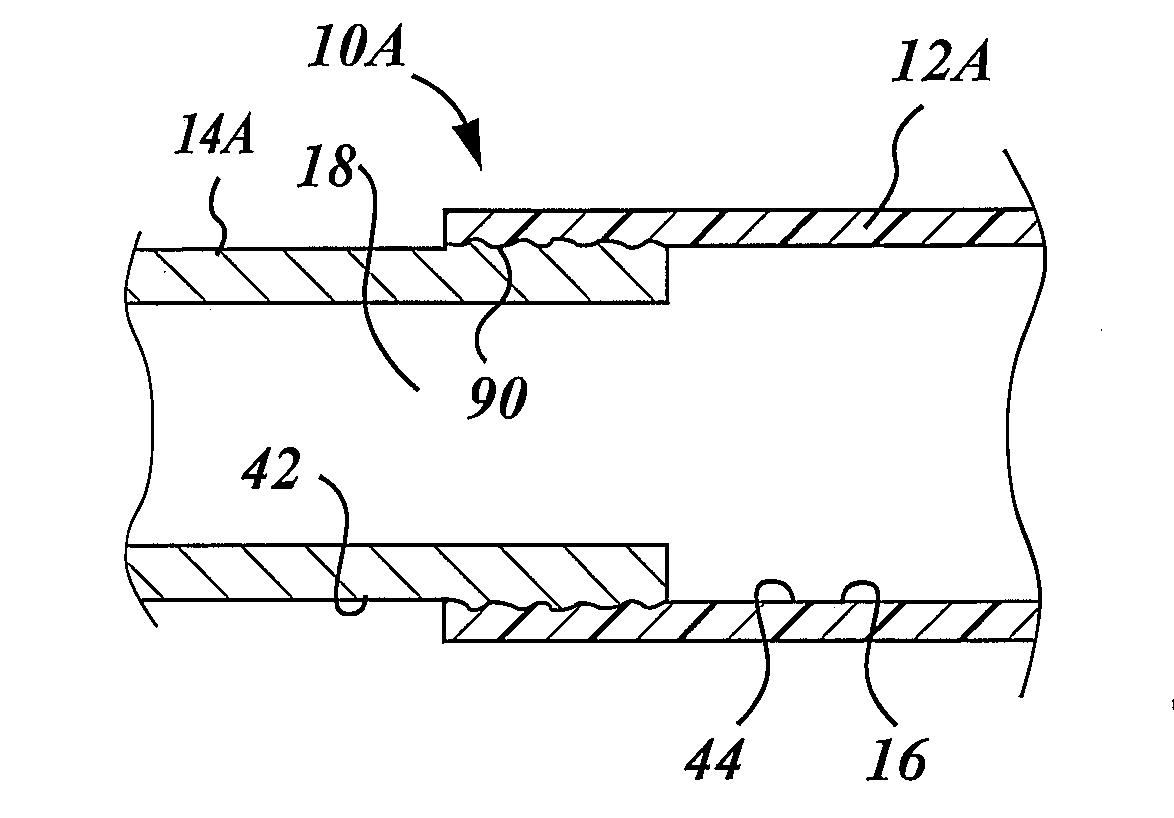

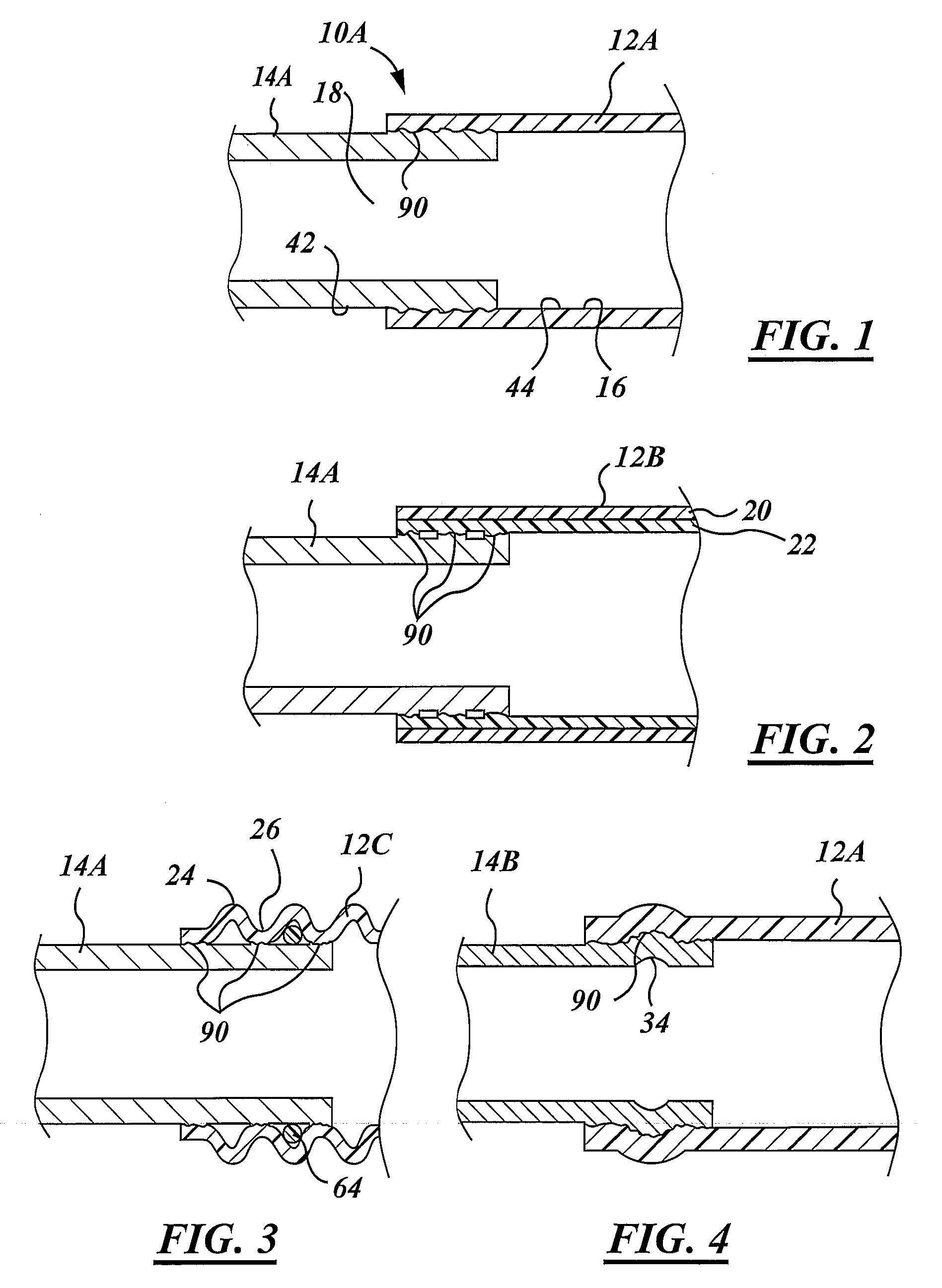

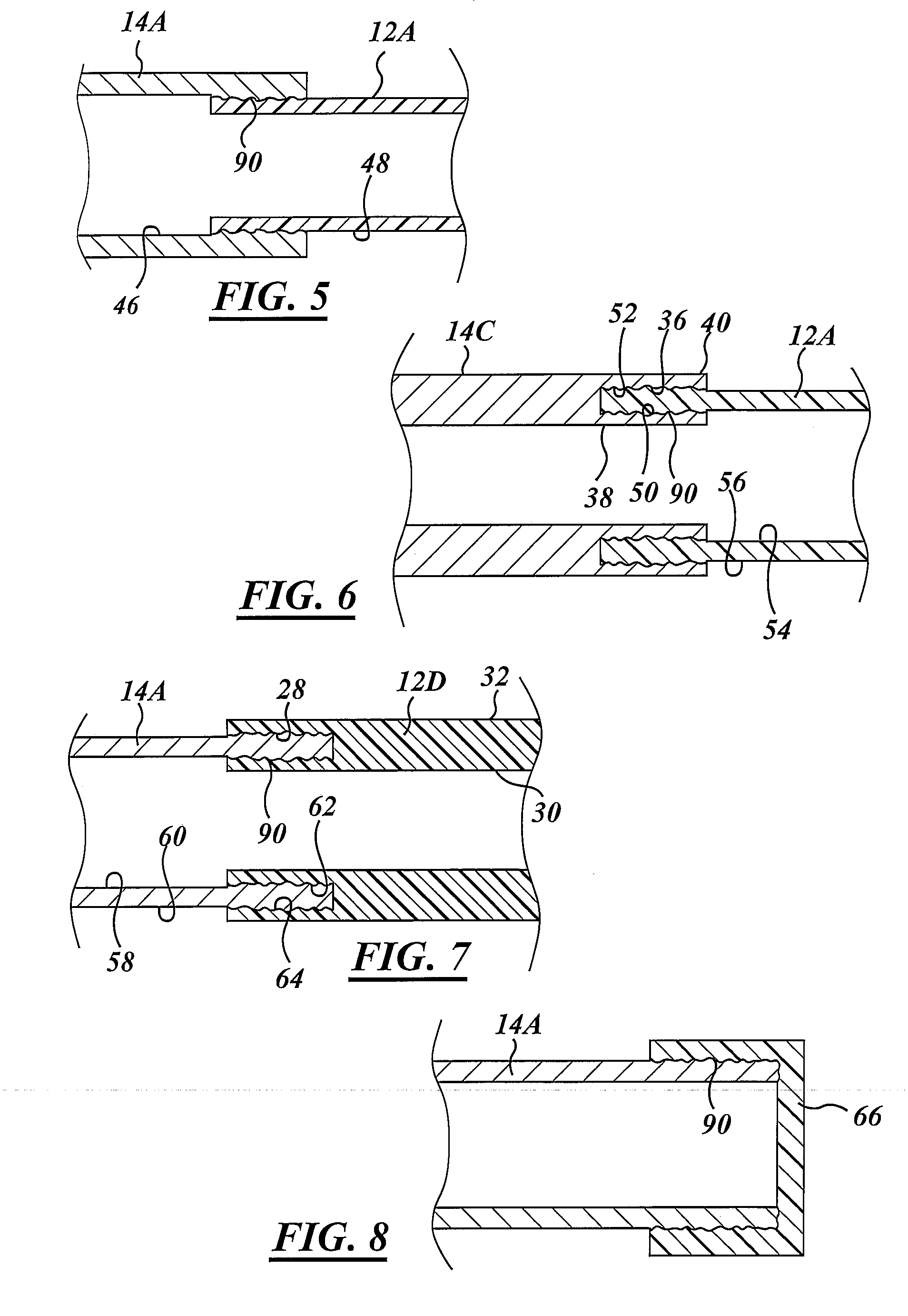

Method of coupling polymeric tubing to polymeric coated metal tubing

InactiveUS20070023129A1Shorten assembly timeLamination ancillary operationsFilament handlingEngineeringInduction welding

A method of coupling tubular bodies is provided, particularly for use in fluid handling systems requiring a fluid-tight, pressurized joint. One tubular body is made from a polymer. The other tubular body is formed as a laminate having a metallic layer and a polymeric layer (e.g., nylon coated aluminum tubing). The tubular bodies are positioned relative to one another (e.g., the laminated tubular body may be inserted within the polymeric tubular body when the polymeric layer of the laminated tubular body is outward of the metallic layer). The tubular bodies are then joined together by induction welding to cause heat transfer from the laminated tubular body's metallic layer to its polymeric layer thereby resulting in deformation of the polymeric layer and bonding of the polymeric layer to a surface of the polymeric tubular body, forming the joint.

Owner:DANA AUTOMOTIVE SYST GRP LLC

Induction welding method for aluminum water-cooling base plate and stainless joint

ActiveCN101642840ASolve Welding ProblemsFull shapeWelding/cutting media/materialsSoldering mediaIgbt power modulesInduction welding

The invention relates to an induction welding method for an aluminum water-cooling base plate and a stainless joint, which mainly comprises the following steps: processing the stainless joint and thewater-cooling base plate by sodium hydroxide and sulfuric acid solution and drying; bending a zinc-aluminum alloy flux-cored welding wire with a melting point of 420-480 DEG C into a circle and placing the zinc-aluminum alloy flux-cored welding wire to the root part of the stainless joint exposing out of the end surface of the water-cooling base plate and the chamfering position of a screw hole ofthe end surface of the water-cooling base plate; connecting an induction coil of the water-cooling base plate with one induction heating power supply and placing the water-cooling base plate into theinduction coil; connecting an induction coil of the stainless joint with the other high frequency induction heating power supply and placing the stainless joint into the induction coil. The temperature in the welding position of the water-cooling base plate rises to 450-480 DEG C and the temperature in the welding position of the stainless joint rises to 500-550 DEG C during welding. The invention more ideally solves the problem of welding two different material components of aluminum and stainless steel; welded brazing filler metal has full and even appearance and completely fills a seam andcan lead the welding position to be sealed permanently; and the stable working state of an IGBT power module is ensured.

Owner:CRRC DALIAN INST CO LTD

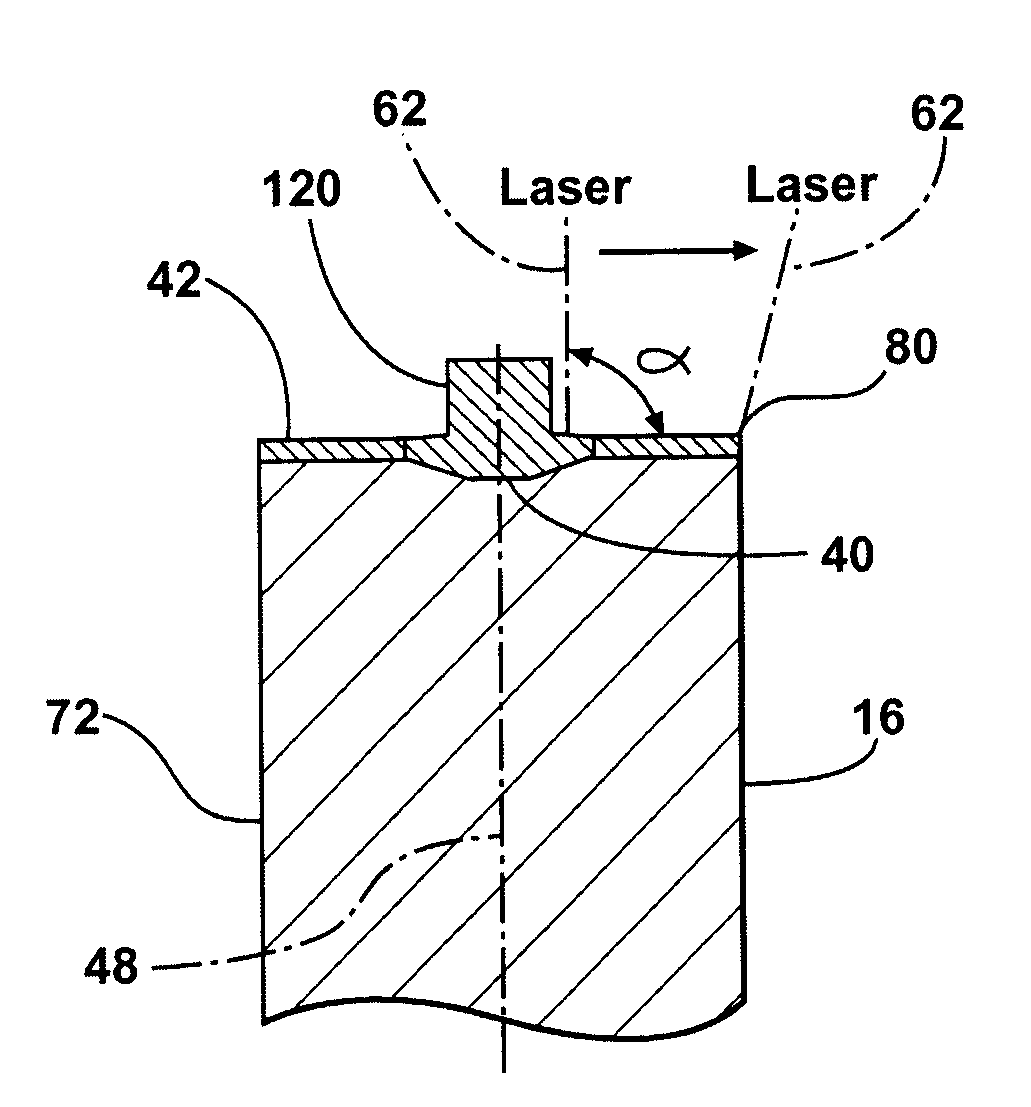

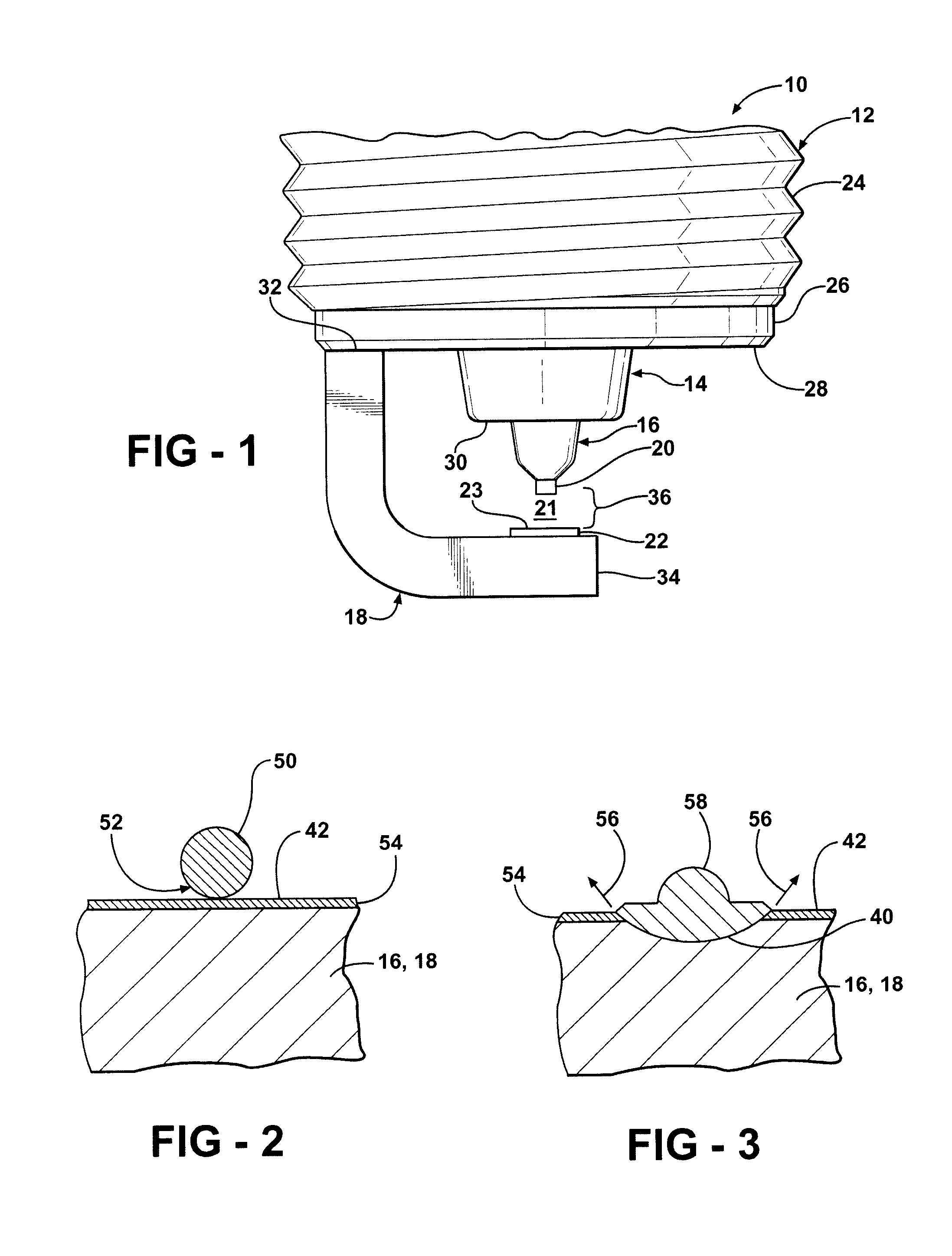

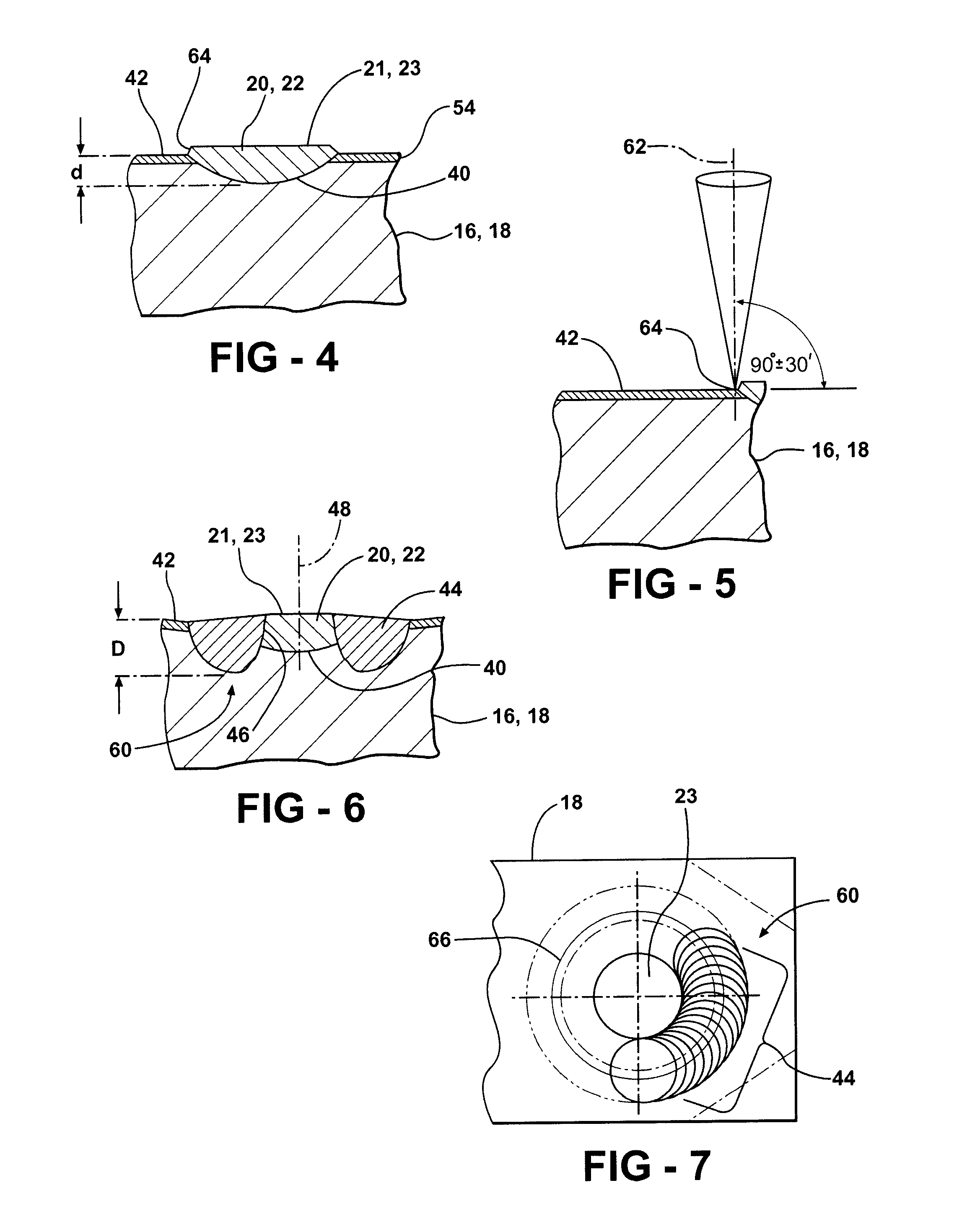

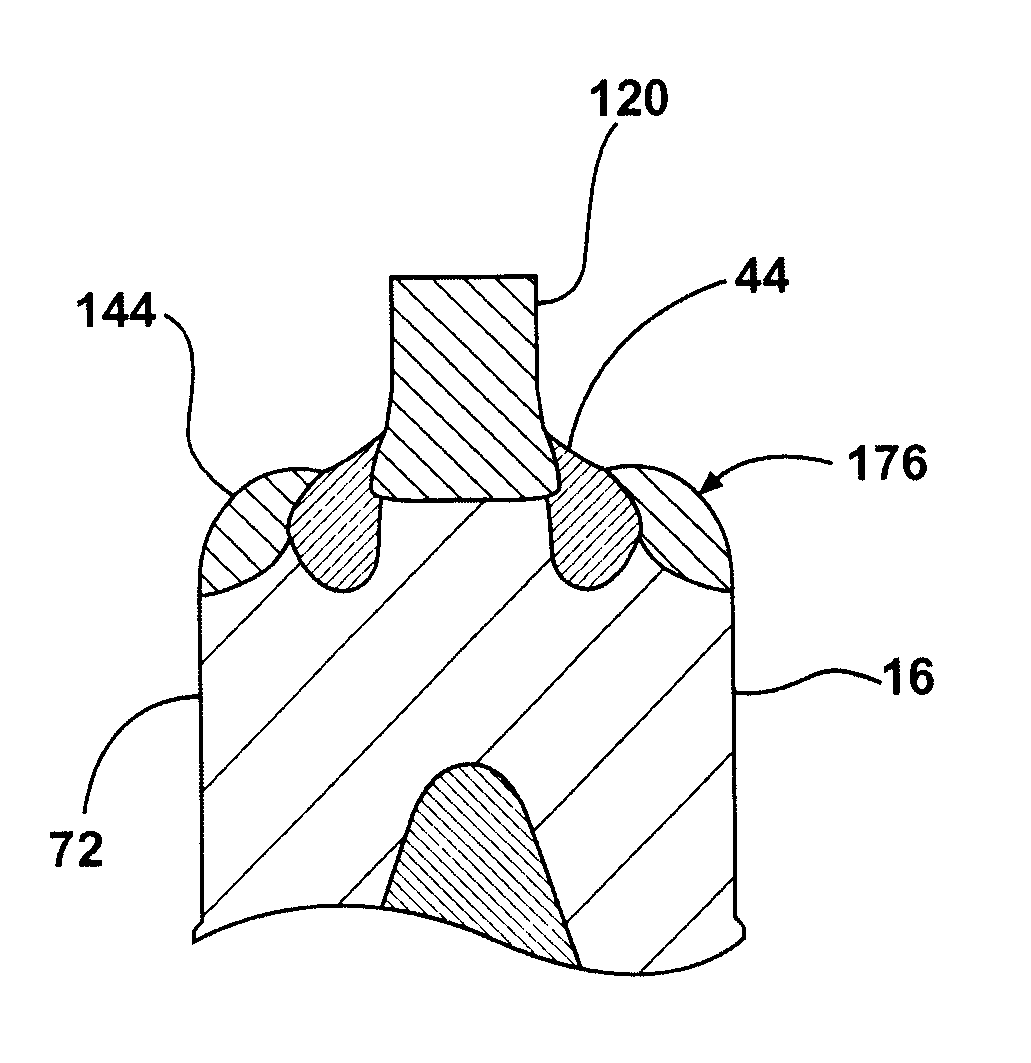

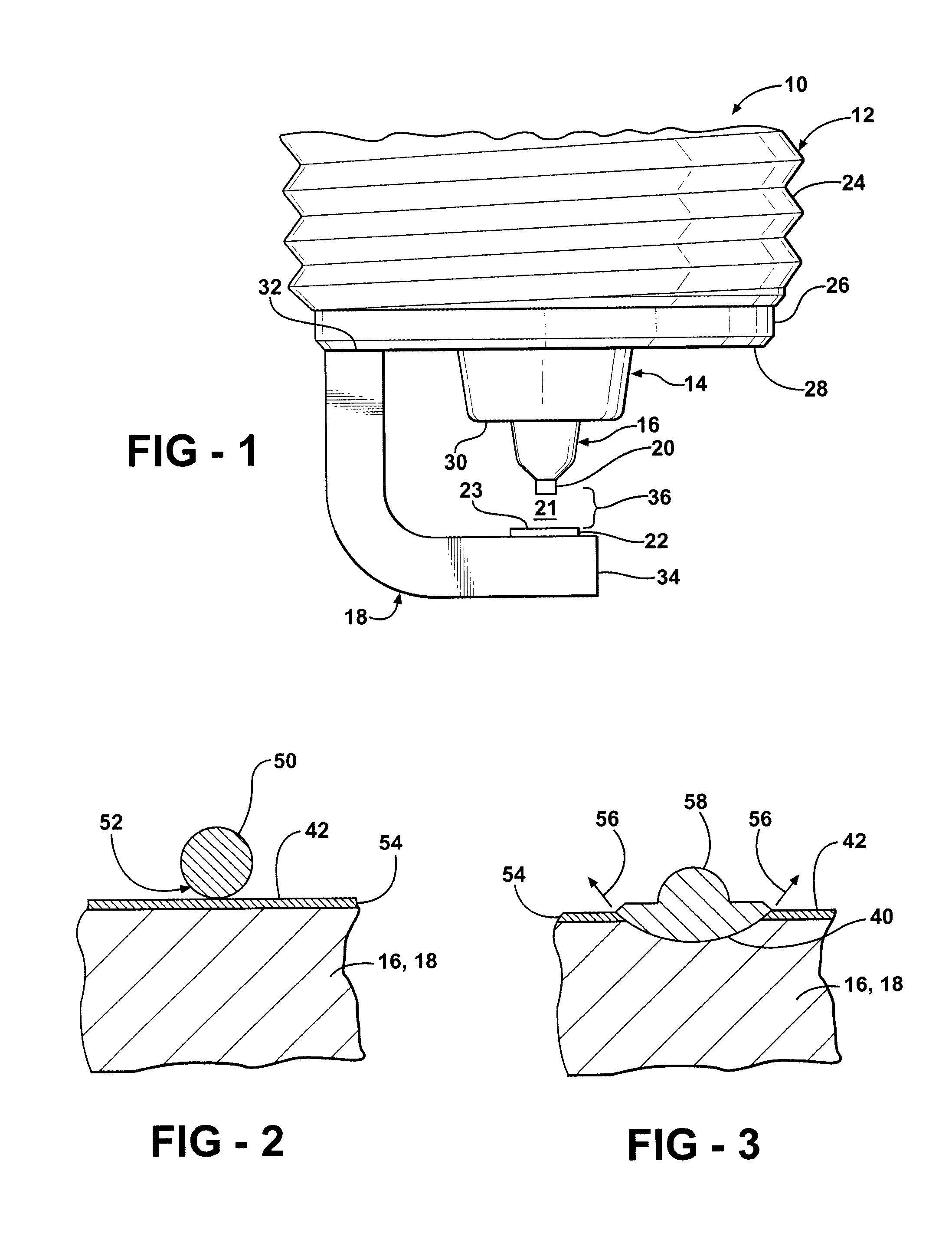

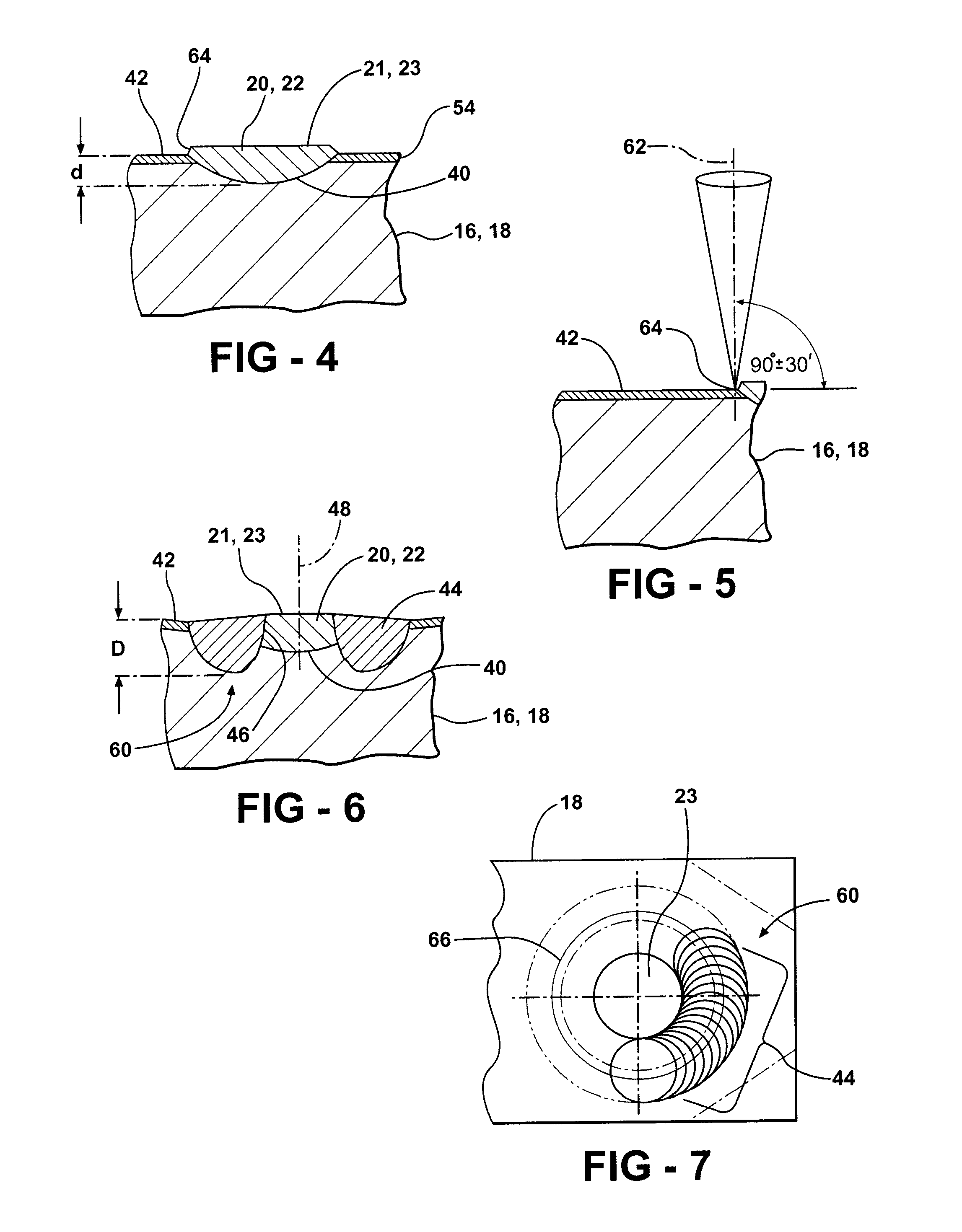

Ignition device having an induction welded and laser weld reinforced firing tip and method of construction

ActiveUS20080174222A1Spark gap detailsSparking plugs manufactureEngineeringInternal combustion engine

An ignition device for an internal combustion engine and method of construction therefore includes a housing with an insulator secured therein. A center electrode is mounted within the insulator. A ground electrode extends from the housing with a portion of the ground electrode defining a spark gap across from the center electrode. The center electrode has a firing tip, wherein a resistance weld joint initially bonds the firing tip to the center electrode and a continuous bead of overlapping first weld pools formed substantially from the material of the firing tip further bonds the firing tip to the electrode. A continuous bead of overlapping second weld pools formed radially outwardly from the first weld pools forms a rounded shoulder surface extending from the first weld pools to an outer surface of the center electrode.

Owner:FEDERAL MOGUL WORLD WIDE LLC

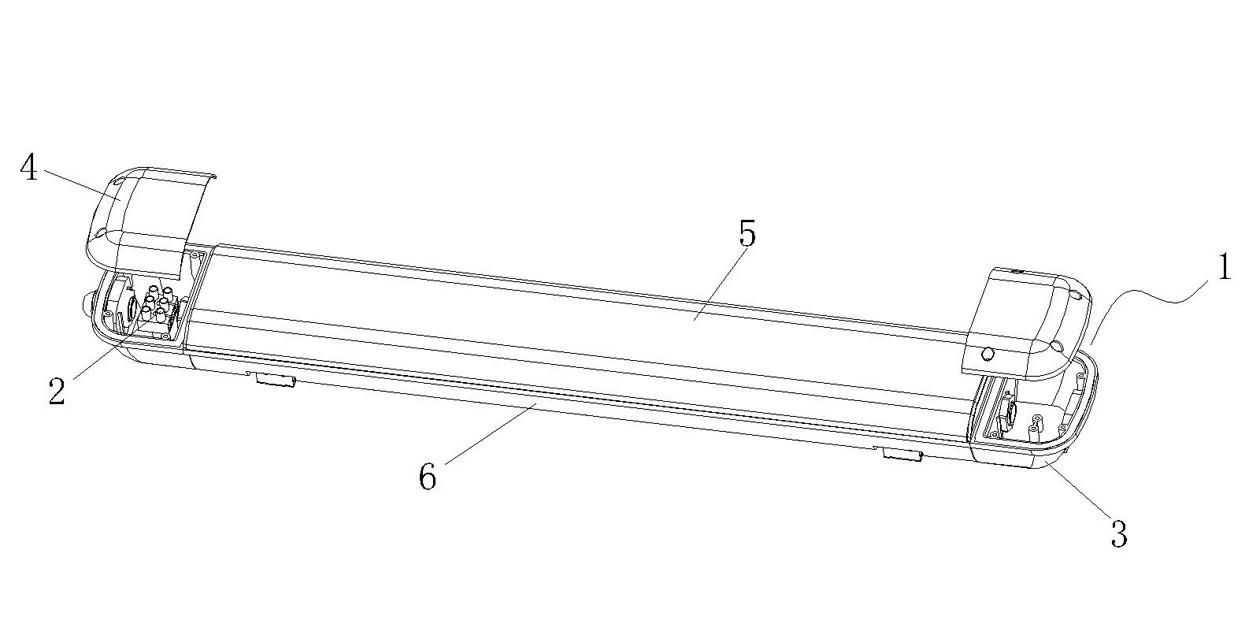

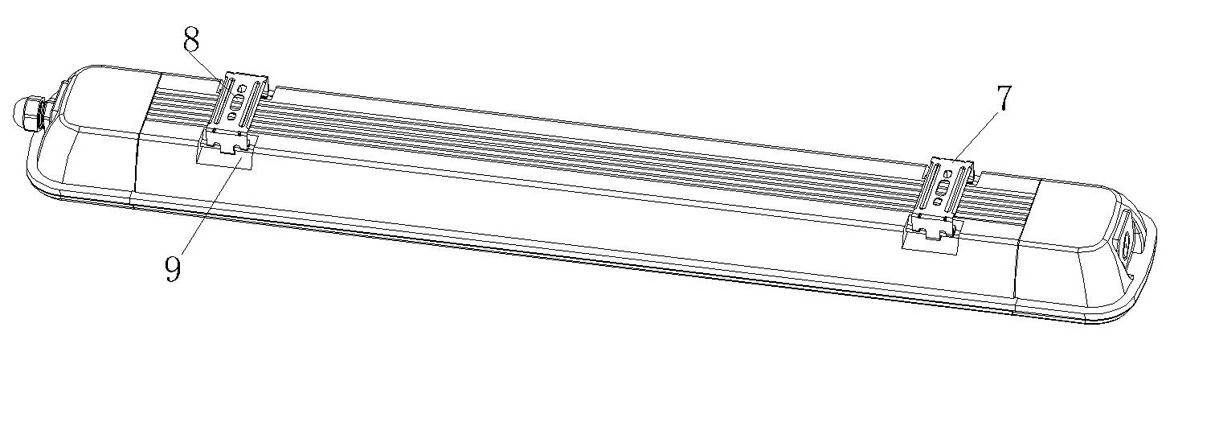

Novel tri-proof light and manufacturing method thereof

ActiveCN102252208AEasy to installImprove sealingProtective devices for lightingGas-tight/water-tight arrangementsButt jointEngineering

The invention discloses a novel tri-proof light. The novel tri-proof light comprises a light body; the two ends of the light body are provided with terminal boxes; the lamp body comprises an upper light body made of plastic and a lower lamp body made of plastic; the upper lamp body and the lower lamp body are integrated; and the back of lower lamp body is provided with a hanging plate which is provided with a hanging hole. The manufacturing method for the tri-proof light comprises the following steps of: forming the terminal box, and the upper and lower lamp bodies; and performing butt joint of the upper lamp body and the lower lamp body, sandwiching a steel wire between the upper lamp body and the lower lamp body, and welding by using a high-frequency induction welding machine to ensure that the steel wire emit heat and the upper lamp body and the lower lamp body are melted on the contact part of the steel wire and the upper lamp body and the lower lamp body are integrated through melting. The upper lamp body and the lower lamp body are integrated, and the sealing performance and the water proofness performance are obvious; and the terminal box is arranged independently so as to contribute to wire connection, and specifically, when the terminal box is detachably connected with the lamp body, the wire connection is facilitated. The back of the lamp body is provided with the hanging plate, and during installation, after a hanging hook is arranged on a wall surface, the hook is hooked into the hanging hole of the hanging plate.

Owner:NINGBO BEC LIGHTING

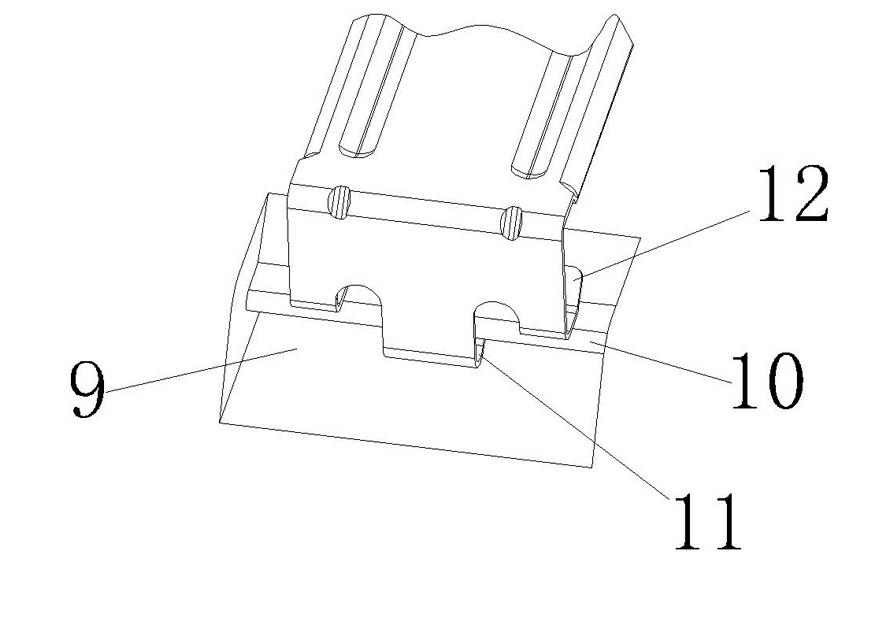

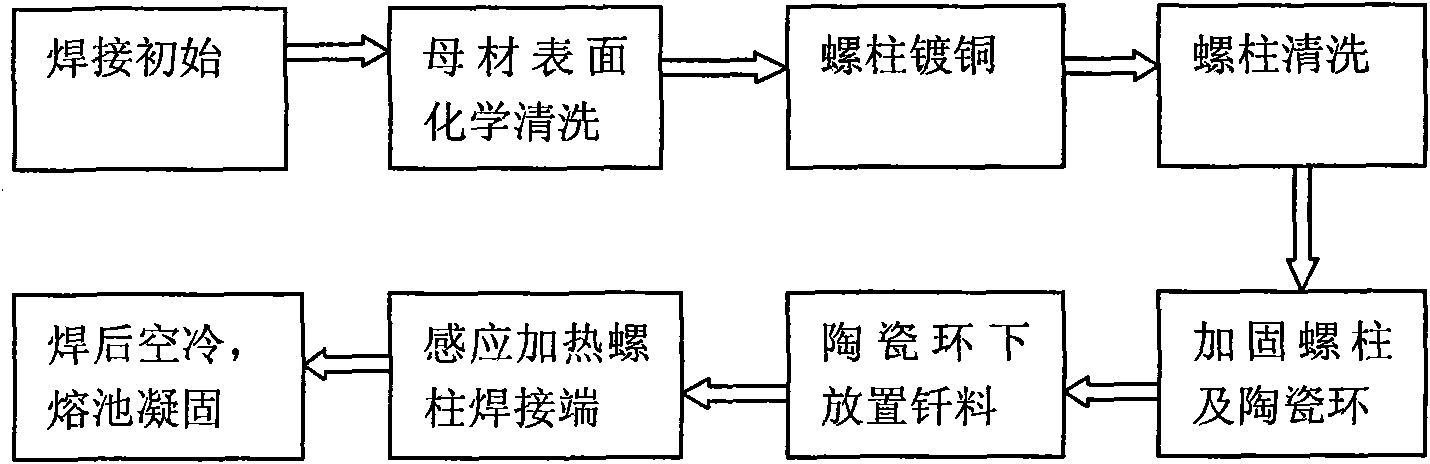

Method of pre-copper-plated induction welding-brazing of aluminum-steel stud bolt

ActiveCN102114561AImprove welding qualityEasy to operateSoldering apparatusWelding/soldering/cutting articlesFriction weldingCopper plating

The invention discloses a method of pre-copper-plated induction welding-brazing of an aluminum-steel stud bolt, which comprises the following steps: processing a steel stud bolt into a flat-bottom no-nut-cap type and conducting copper immersion plating to one end of the steel stud bolt; carrying out chemical cleaning to the surface of an aluminium base material and brazing filler metal; cleaning the surface of an aluminium base material and a brazing filler metal with alcohol, fast drying, and coating a layer of brazing protective agent on the surface of the base material; horizontally placing the aluminum base material, vertically placing the copper-plated end of the steel stud bolt on the aluminum base material, applying vertical downward pressure on the copper-plated end of the steel stud bolt, and filling enough cleaned brazing filler metal on the contact surface of the two; placing a ceramic ring matched with the stud bolt at the contact position of the copper-plated end of the steel stud bolt and the aluminum base material, and filling the brazing filler metal in the ceramic ring; and sheathing an induction heating coil at a welding end of the stud bolt, heating the induction heating coil and completing the welding. The invention can realize the welding of the small-diameter steel stud bolt and the aluminum base material, and has wide range of application to the thickness of plates.

Owner:NANJING UNIV OF SCI & TECH

Induction brazing welding method for metal part

The invention discloses an induction brazing welding method for a metal part. The method utilizes induction brazing welding equipment and then is implemented according to the following steps of: a step 1 of selecting the induction brazing welding equipment and determining related parameters; a step 2 of carrying out weldment surface processing, i.e. roughening the welding surface of a weldment, processing the metal-plated surface of the weldment, carrying out matched selection between the weldment and a soldering flux, a brazing filler metal, a welding temperature and a brazing clearance and selecting each process parameter of induction brazing; a step 3 of assembling and fixing the weldment; and a step 4 of implementing welding. According to the induction brazing welding method disclosed by the invention, the induction welding and the induction brazing welding of structures of different materials, pipe fittings, sheets, tube plates and the like are implemented, the sealing performance of a weld joint is improved, the intensity of the weld joint is reduced, the electrical conductivity is obviously improved, and the weld joint has a reliable quality.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

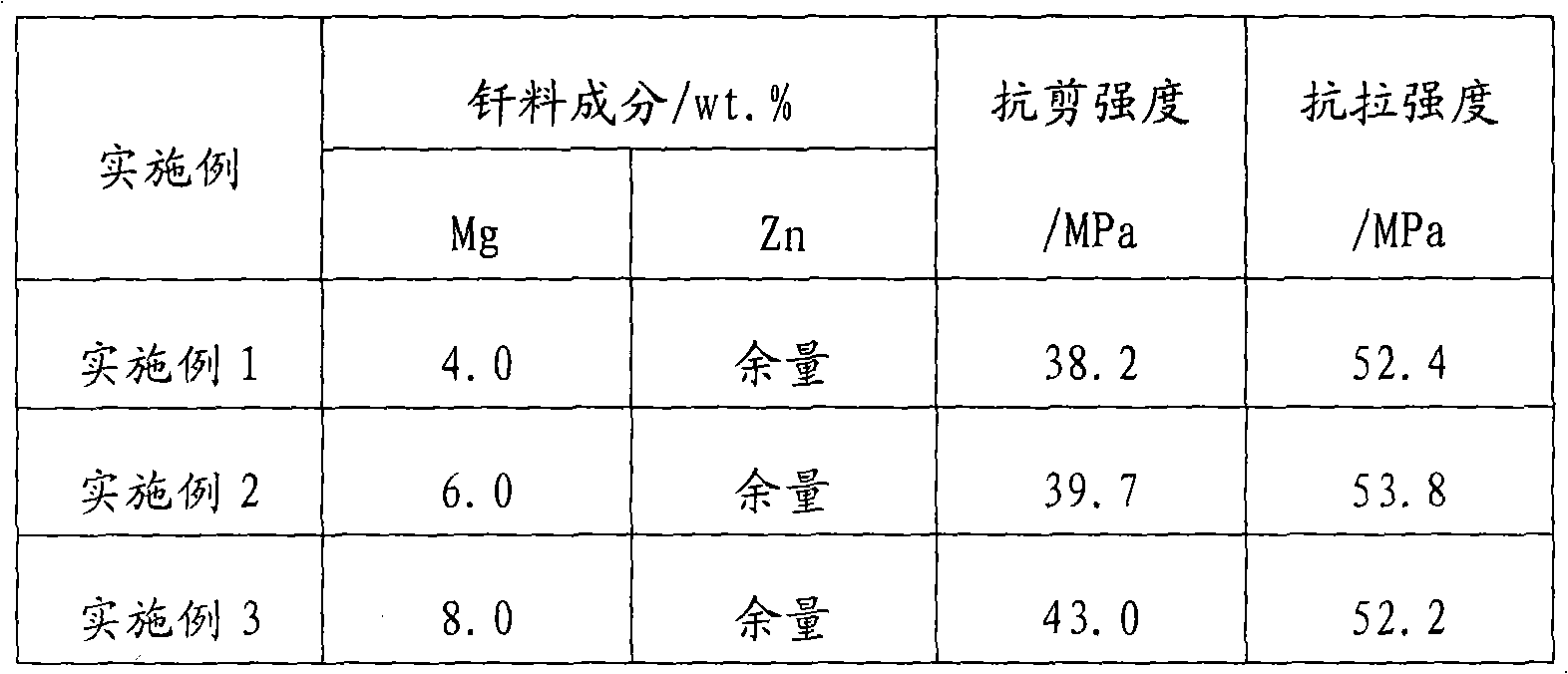

Zn-Mg magnesium alloy solder

InactiveCN101653878AGood spreadabilityExcellent gap fillingWelding/cutting media/materialsSoldering mediaButt jointSoldering

The invention provides a Zn-Mg magnesium alloy solder, belonging to the technical field of magnesium alloy welded joint. The components of the provided Zn-Mg magnesium alloy solder contain 4% to 8% ofMg and the remains are Zn. The melt temperature of the Zn-Mg magnesium alloy solder is ranged from 365 DEG C to 396 DEG C and the soldering temperature is ranged from 420 DEG C to 450 DEG C. The solder can be applied to the magnesium alloy solder with solidus temperature above 450 DEG C. The AZ31B magnesium can be soldered in the manner of high frequency induction welding. The slip resistance ofthe solder overlap joint is ranged from 38MPa to 43 MPa and the tensile strength of the butt joint is ranged from 52MPa to 53MPa.

Owner:BEIJING UNIV OF TECH

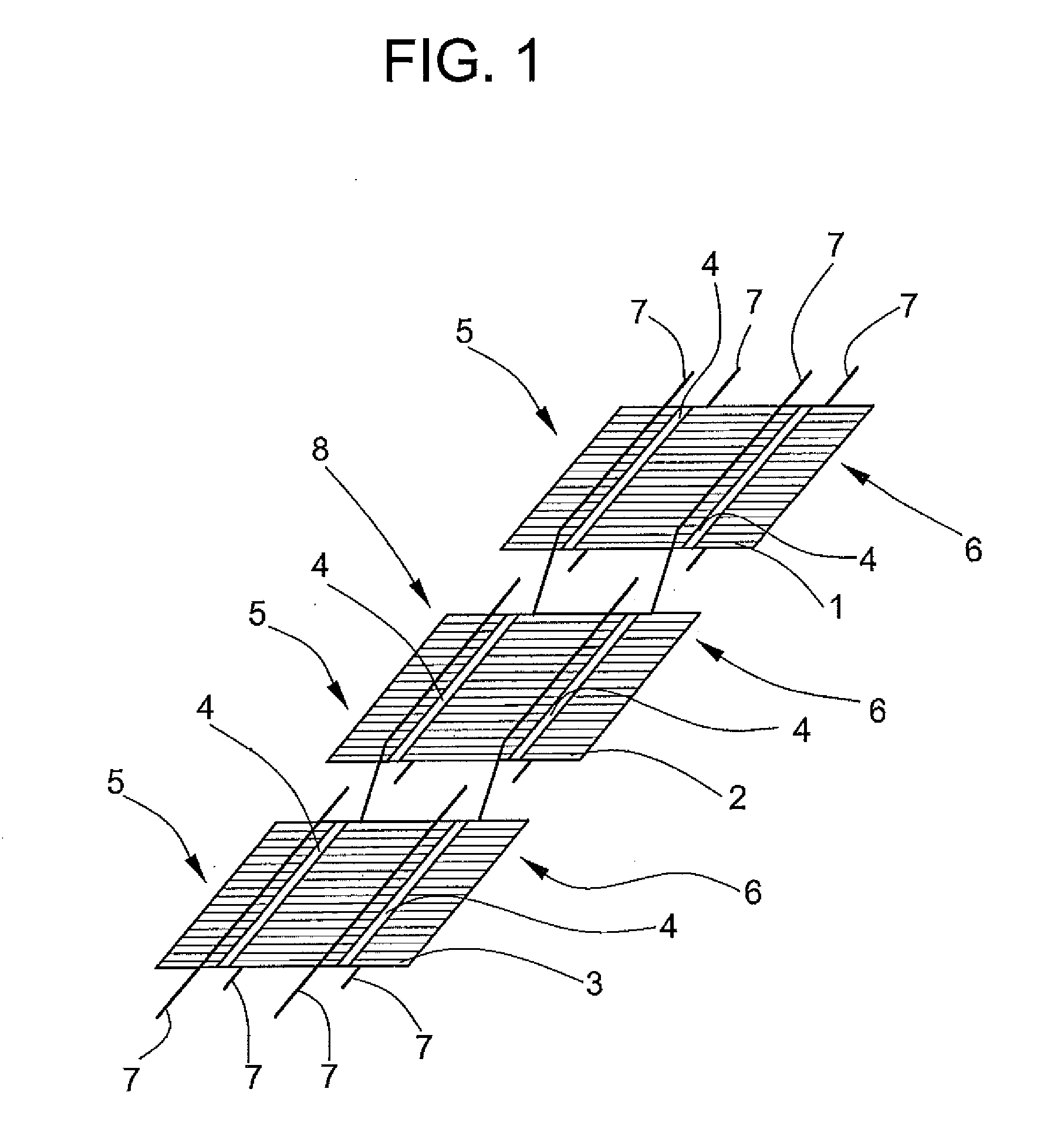

Method of joining a thermoplastic material to a fibre composite material

ActiveCN101730618AShorten the timeEasy to change joint positionSynthetic resin layered productsDomestic articlesConductive materialsFibrous composites

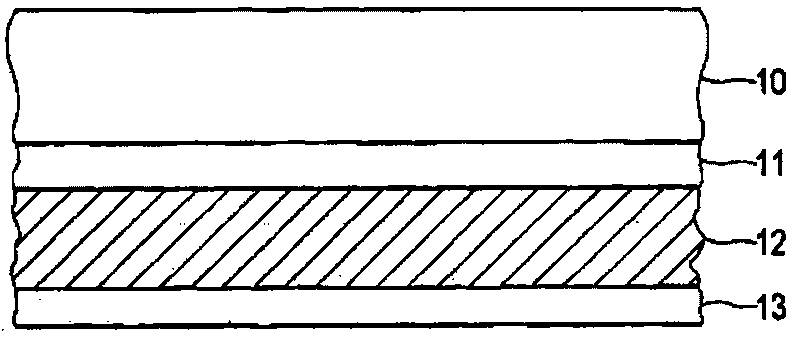

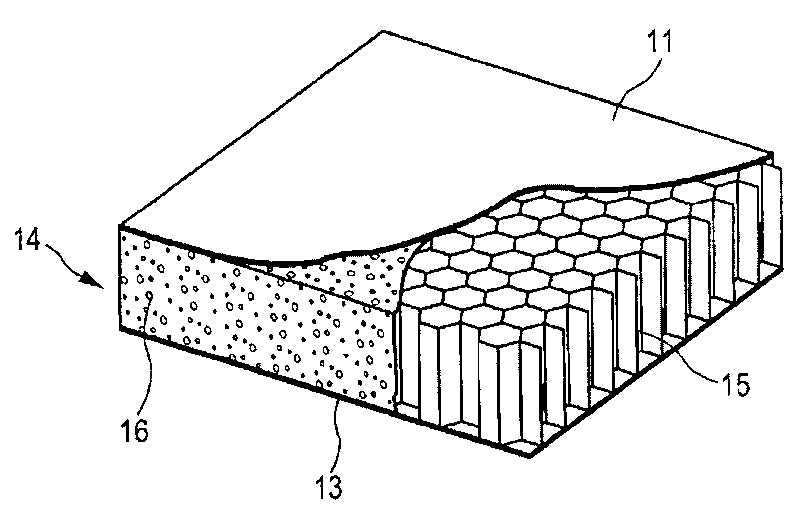

The invention relates to a method of joining a thermoplastic material (10) to a fibre composite material (11), the thermoplastic material (10) being welded to the fibre composite material (11), wherein the fibre composite material is a fibre- reinforced matrix material or comprises a fibre-reinforced matrix material and wherein the matrix material is a thermoset or comprises a thermoset. Preferably, the thermoplastic material (10) and the fibre composite material (11) are welded together by motion welding and / or by induction welding. In addition, it is preferred that, for the preferred induction welding, an electrically conductive material is arranged in a joint area between the thermoplastic material and the fibre composite material and induction heat is generated in the electrically conductive material which is sufficient to cause the thermoplastic material to start to melt and to heat the fibre composite material.

Owner:AIRBUSOPERATIONS有限公司

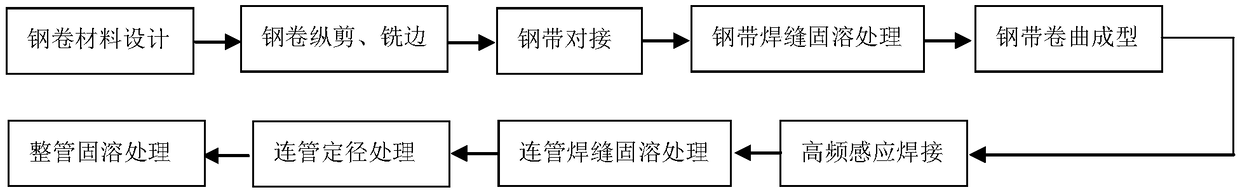

Austenitic stainless steel continuous pipe and manufacturing method thereof

The invention discloses an austenitic stainless steel continuous pipe and a manufacturing method of the austenitic stainless steel continuous pipe. The austenitic stainless steel continuous pipe comprises, by mass percent, 0.03% or below of C, 5-10% of Mn, 13-19% of Cr, 1.5-3.0% of Ni, 0.15-0.5% of N, 0.04% or below of P, 0.01% or below of S, and the balance Fe and unavoidable impurities. A plate for the continuous pipe is manufactured through the processes of refining, controlled rolling, acid pickling and the like; pipe manufacturing is conducted by the adoption of cage-roll forming and the high frequency induction welding (HFW) technology; the austenitic stainless steel continuous pipe is manufactured through follow-up heat treatment. The austenitic stainless steel continuous pipe is good in mechanical performance and corrosion resistance, applicable to environments where the austenitic stainless steel continuous pipe makes direct contact with CO2, and capable of being used under gas wells with high CO2 content in Sichuan province, Tarim and the like, and the corrosion resistance of the austenitic stainless steel continuous pipe is improved by over 3 times compared with a common low-carbon micro-alloyed steel continuous pipe.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Medium frequency induction welding method of rail

InactiveCN102773614ANo casting defectsNo flash welding gray spotsRailsWelding apparatusMedium frequencyInductor

The invention discloses a medium frequency induction welding method of a rail. The medium frequency induction welding method is characterized by comprising the following steps: 1. a rail to be welded is clamped by utilizing a gas pressure welding clamping machine; the end surface area to be welded of the rail to be welded is heated by a medium frequency inductor; in the heating process, an infrared thermometer is used for detecting whether the heating temperature of the end surface area to be welded reaches a welding upsetting initial temperature or not; and the medium frequency inductor is connected with a medium frequency power source and a water cooling system; and 2. the welding upsetting of the rail to be welded is realized. Through the medium frequency induction welding method disclosed by the invention, in a welding process, the welding upsetting temperature is accurately controlled; the interference of anthropic factors on the welding quality is eliminated to a maximum extent; the stability is high; foundry defects and flash welding ash spots are not generated; and when the welding quality is guaranteed, the automatic flow line production is conveniently realized and the welding production efficiency is favorably improved.

Owner:INST OF SCI & TECH SHENYANG RAILWAYBUREAU +1

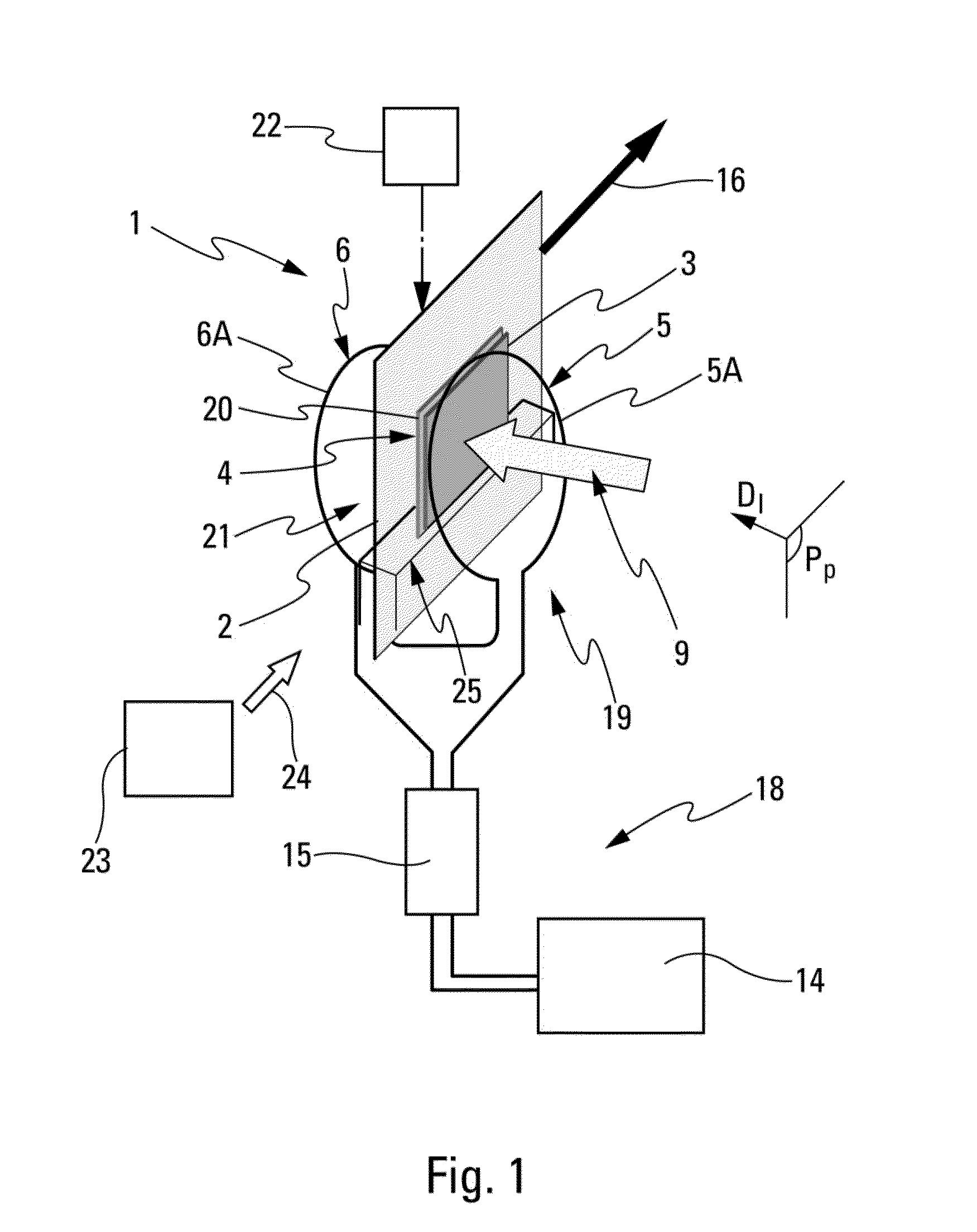

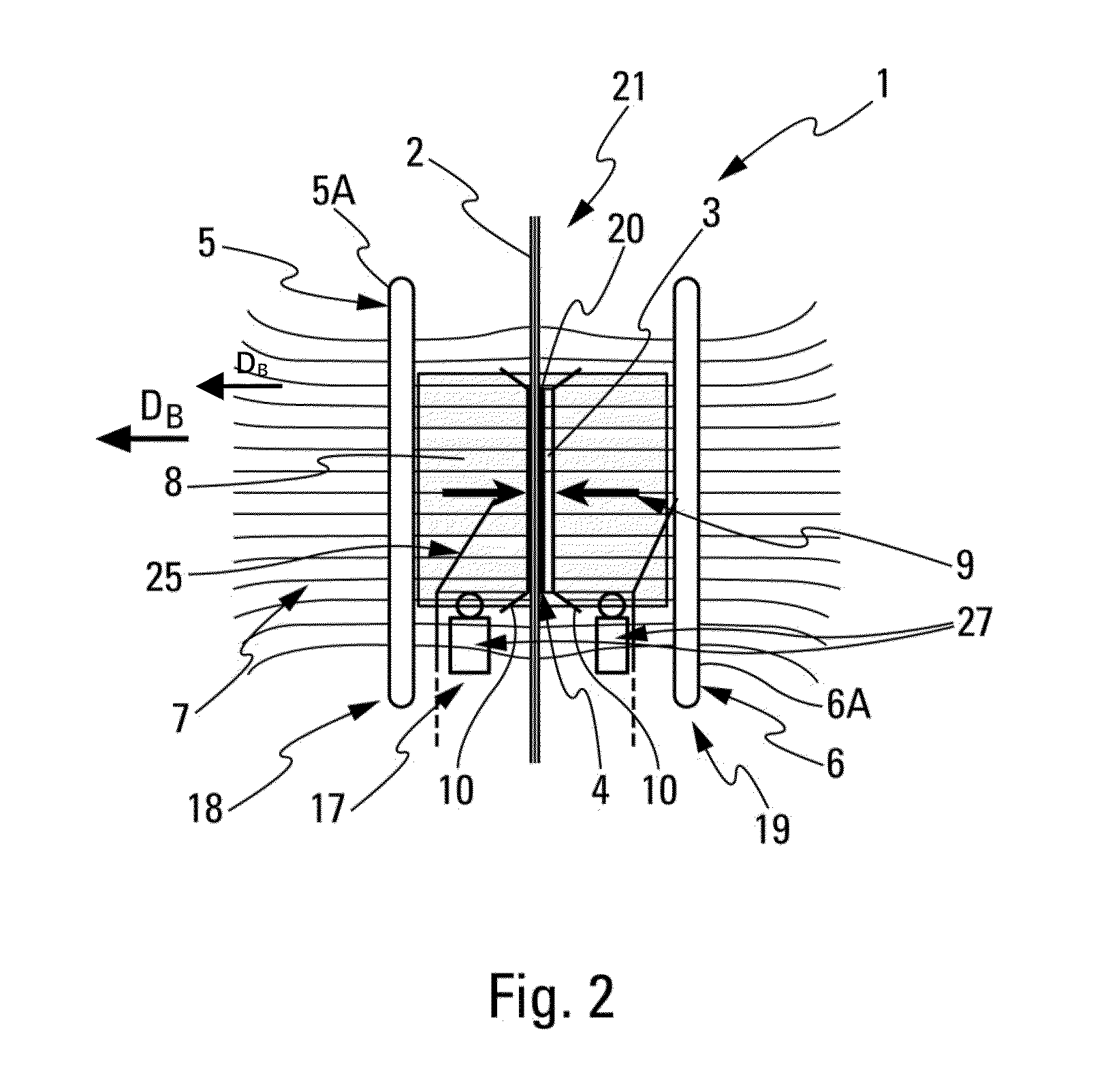

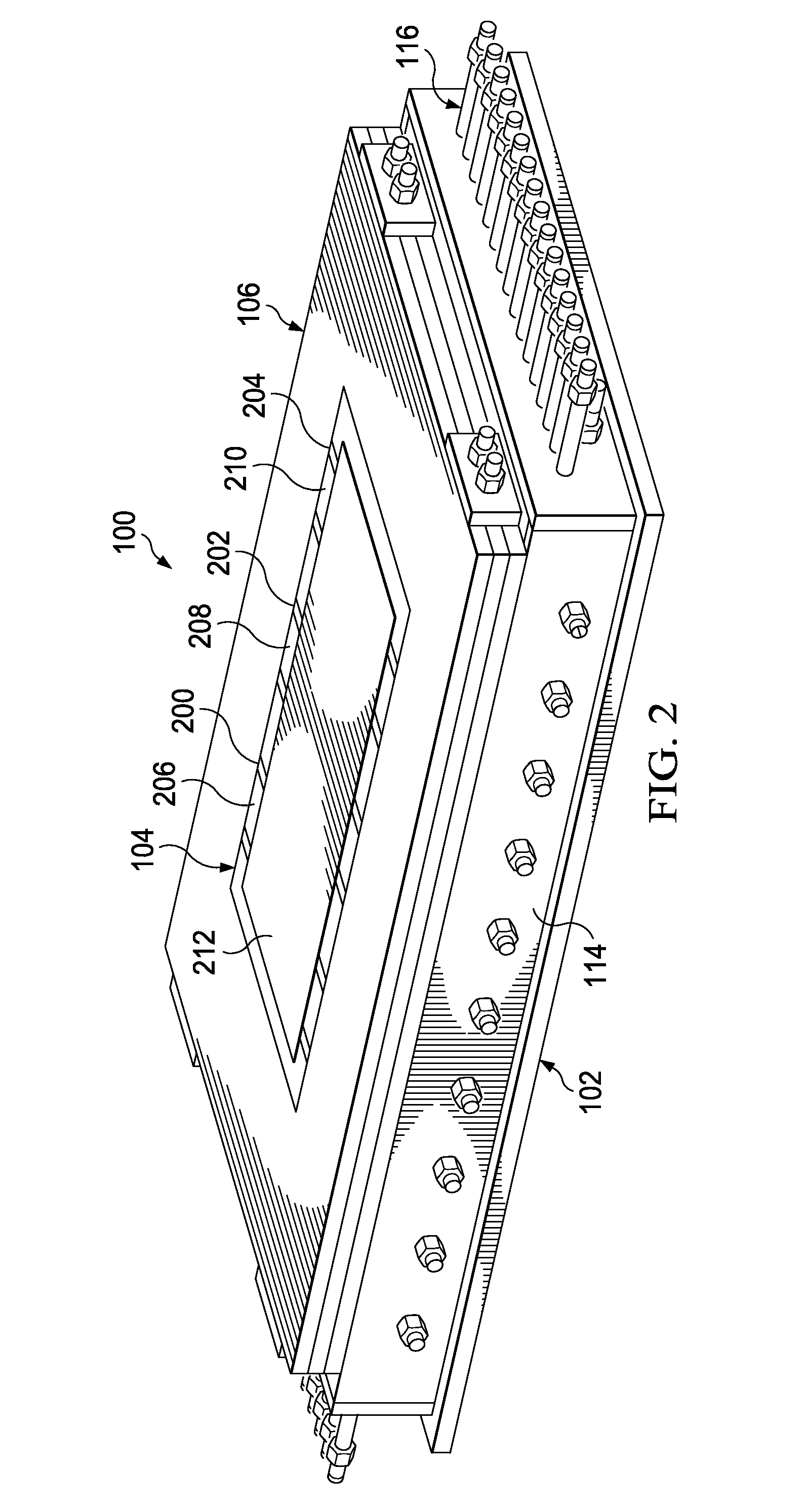

Induction welding process and device for parts made of composite materials

A device comprising at least one pressure generation unit and a heating unit, the heating unit comprising a two-sided inductor and being configured to generate a uniform alternating magnetic field in an assembly comprising two parts made of composite materials comprising carbon fibers embedded in a resin and a field absorber. The field absorber is configured to absorb the magnetic field and comprising a ferromagnetic material. The field absorber is arranged at the contact walls of the two parts, so as to heat them to at least a transformation temperature of the resin.

Owner:AIRBUS OPERATIONS (SAS)

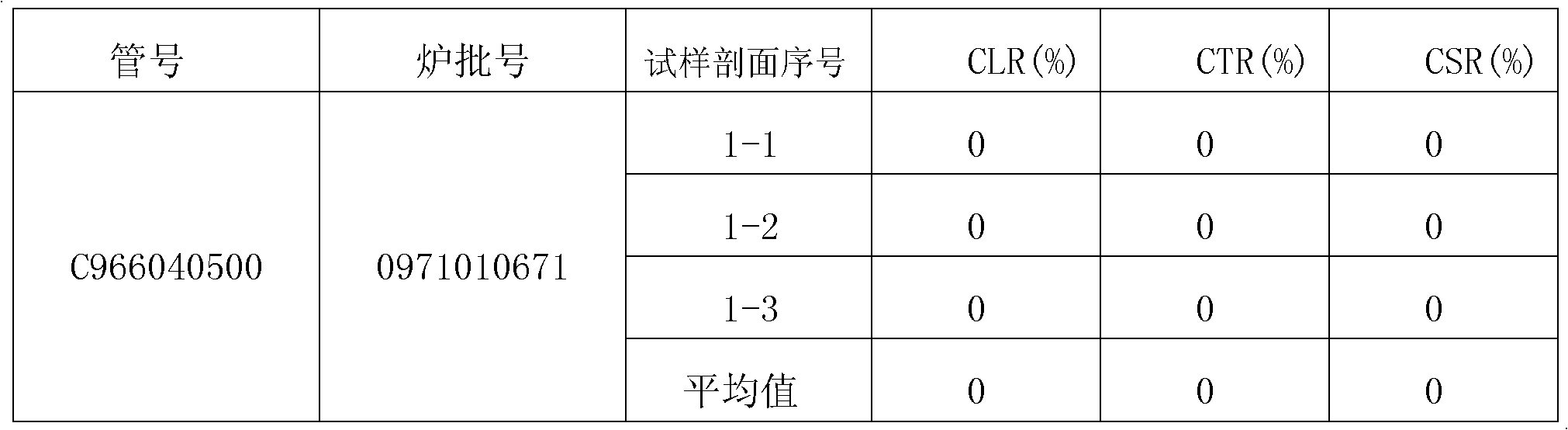

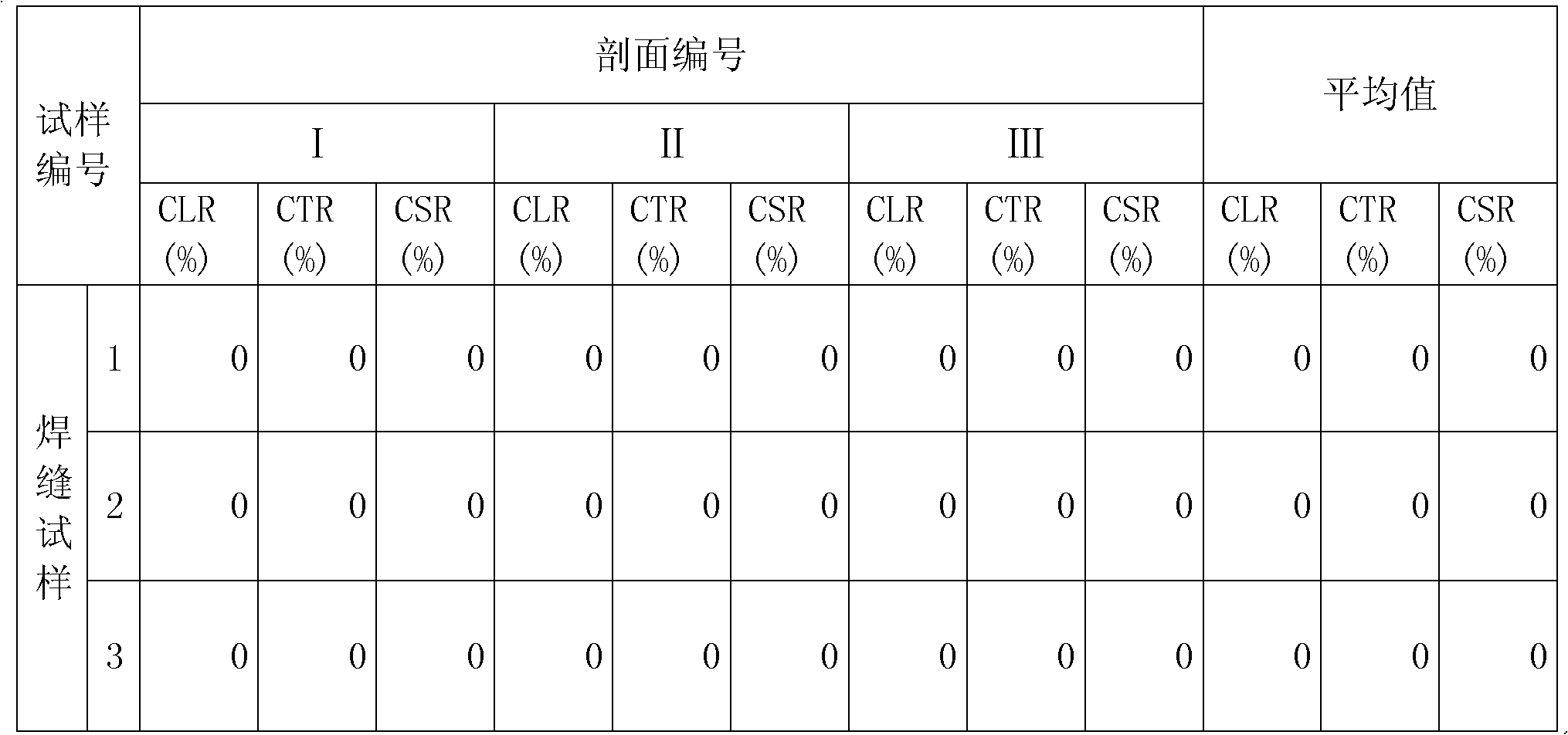

Method for manufacturing delivery steel pipe serving acid environment

InactiveCN102121081AGuaranteed corrosion resistanceFulfil requirementsHigh frequency current welding apparatusWelding/soldering/cutting articlesCrack resistanceIntermediate frequency

The invention discloses a method for manufacturing a delivery steel pipe serving an acid environment. The steel pipe comprises the following chemical components of raw materials in percentage by weight: less than or equal to 0.1 percent of C, less than or equal to 1.6 percent of Mn, less than or equal to 0.02 percent of P, less than or equal to 0.002 percent of S, less than or equal to 0.15 percent of Nb, V and Ti, less than or equal to 0.22 percent of Pcm, more than or equal to 1.5 percent of Ca / S and the balance of Fe. High frequency induction welding is adopted in welding of the steel pipe; the welding quality is improved in the welding process by increasing the welding extrusion quantity, controlling the open angle of seams and increasing welding protective gas; and on-line quenching and on-line tempering are performed in heat treatment of the seams by adopting six intermediate frequency heat treatment machines. By selection of raw material components and metallographic structures, completeness of a welding mechanism and improvement of the heat treatment process, the steel pipe has hydrogen induced cracking resistance and sulfide stress corrosion resistance and has high strength and high pressure resistance, the cost can be reduced, and the use of the steel pipe under the acid serving condition can be met.

Owner:CHINA NAT OFFSHORE OIL CORP +2

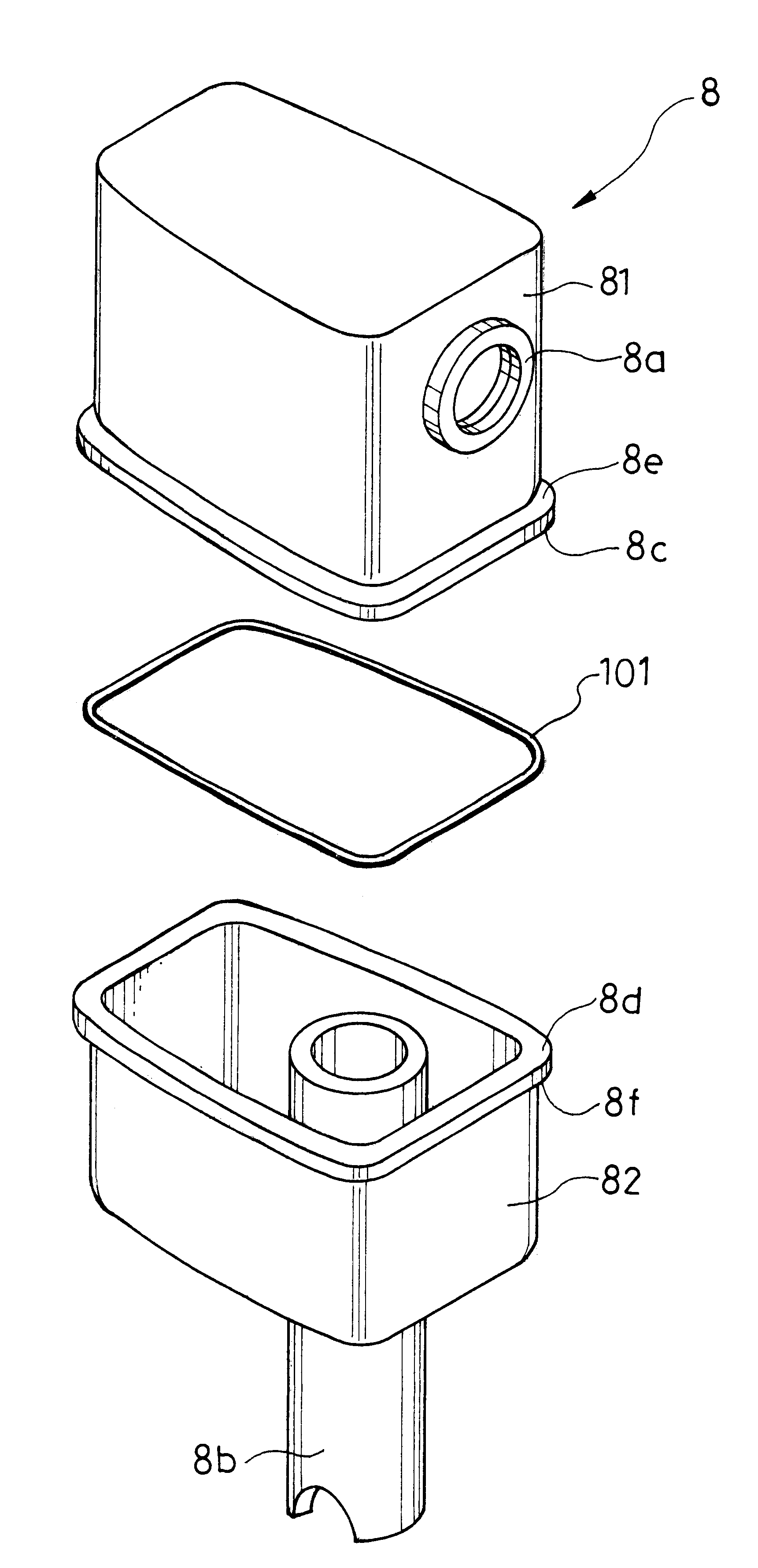

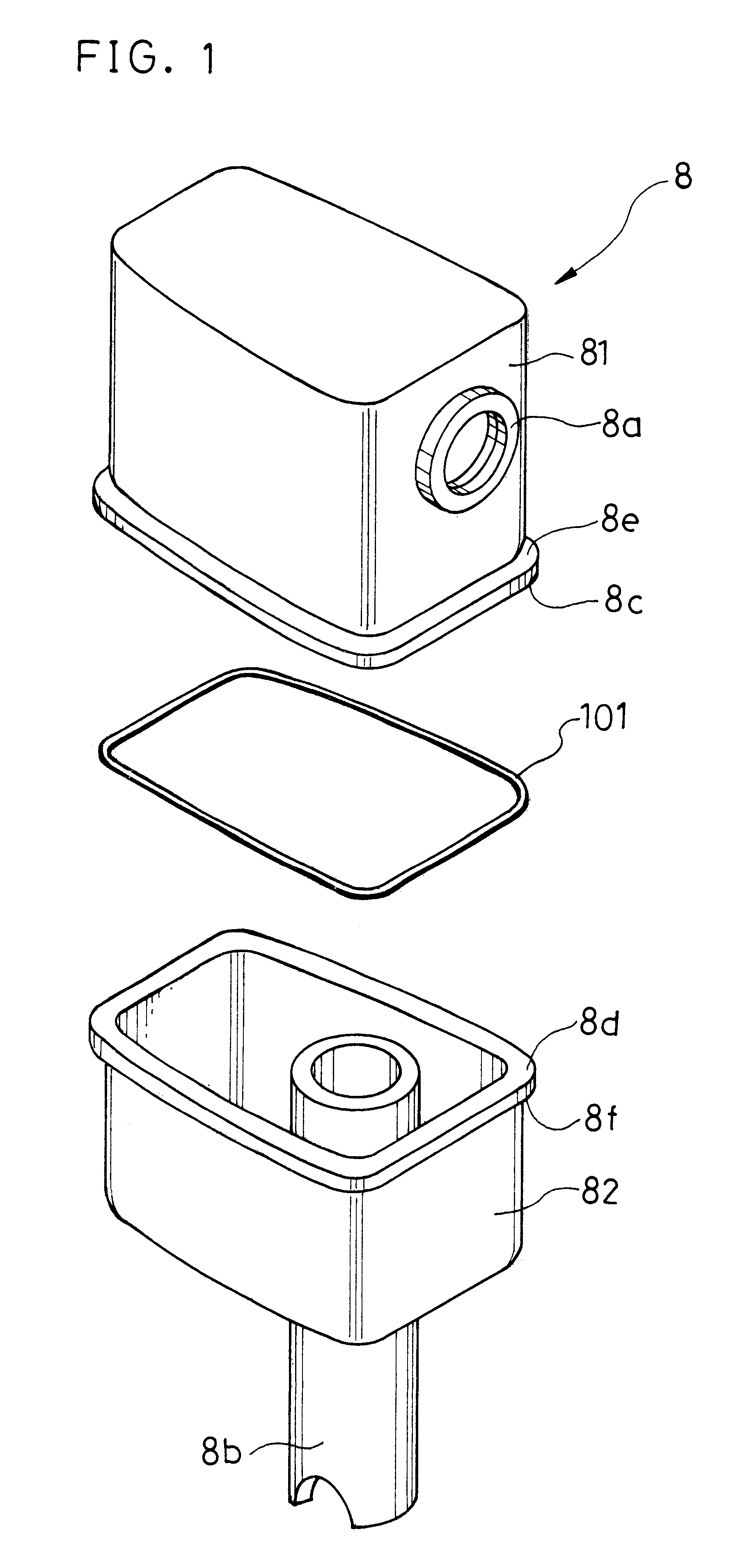

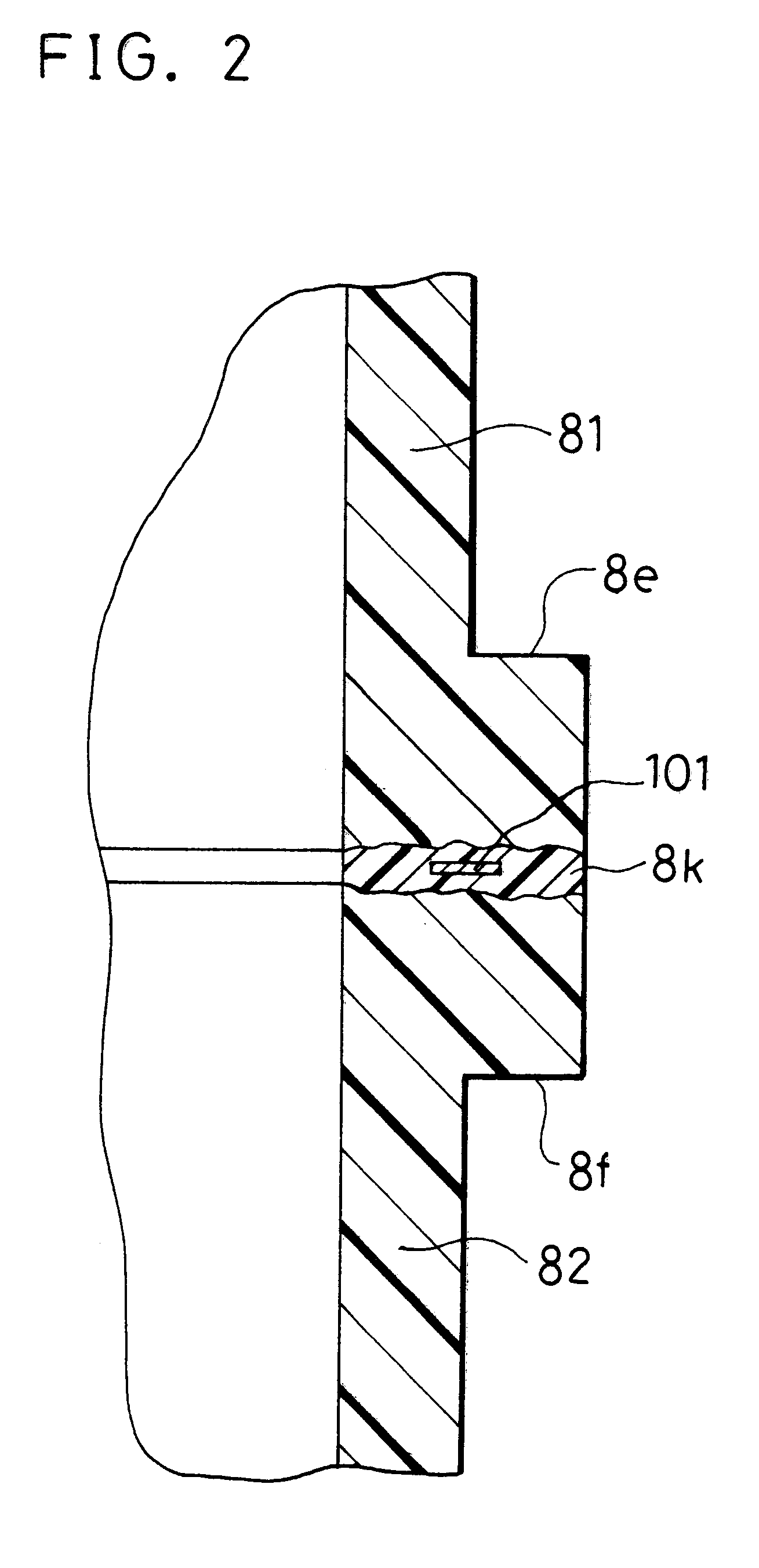

Suction muffler and hermetic compressor

InactiveUS6361290B1Uniform welding strengthImprove welding strengthPositive displacement pump componentsSheet joiningFriction weldingUltrasonic welding

The present invention provides a suction muffler comprising component portions formed by injection forming a thermoplastic synthetic resin and joined to each other by induction welding, and also provides a hermetic compressor including the suction muffler. The suction muffler having this configuration is superior to conventional suction mufflers having joint portions joined by ultrasonic welding and vibration welding in the uniformity of the welding strength at the whole joint portion thereof and in minimizing the occurrence of fins.

Owner:PANASONIC APPLIANCES REFRIGERATION DEVICES SINGAPORE

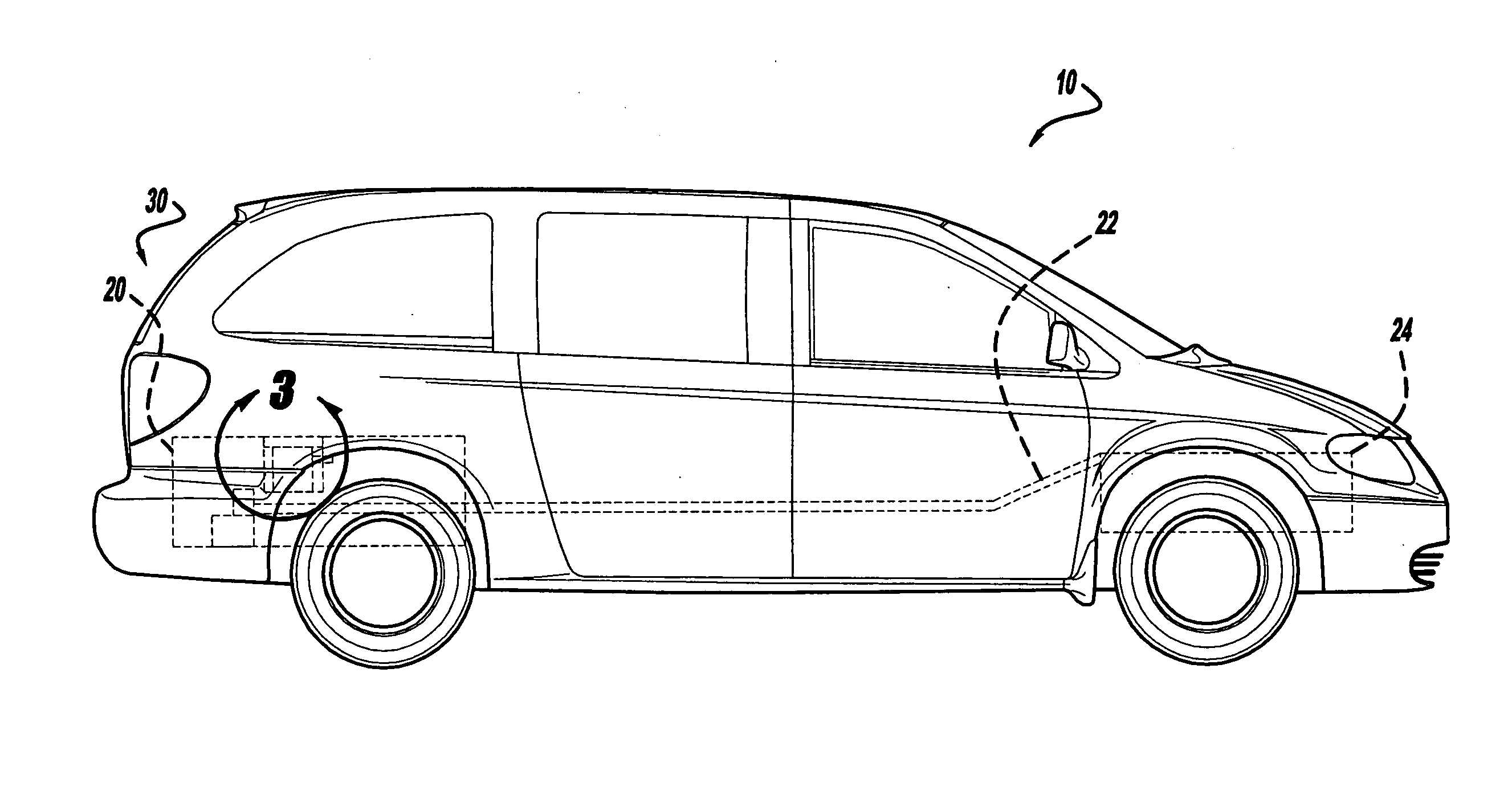

Method of welding a component inside a hollow vessel

A method of welding plastic components using an induction weldable plastic material to a wall of a hollow plastic vessel entails providing a metal disk to a first plastic component, providing the first plastic component with a weldable plastic material, inserting the plastic component through a hole in a wall of the hollow plastic vessel, the inserting being from an exterior of the vessel to an interior of the vessel, positioning the first plastic component against or proximate an interior wall of the hollow plastic vessel, orienting an electro-magnet about the exterior of the vessel, orienting an induction coil about the electro-magnet such that the induction coil encircles the electromagnet; energizing the electro-magnet so that the metal disk of the first plastic component is secured against the wall of the vessel, and energizing the induction coil so that the induction weldable plastic material welds to the vessel wall.

Owner:DENSO INTERNATIONAL AMERICA

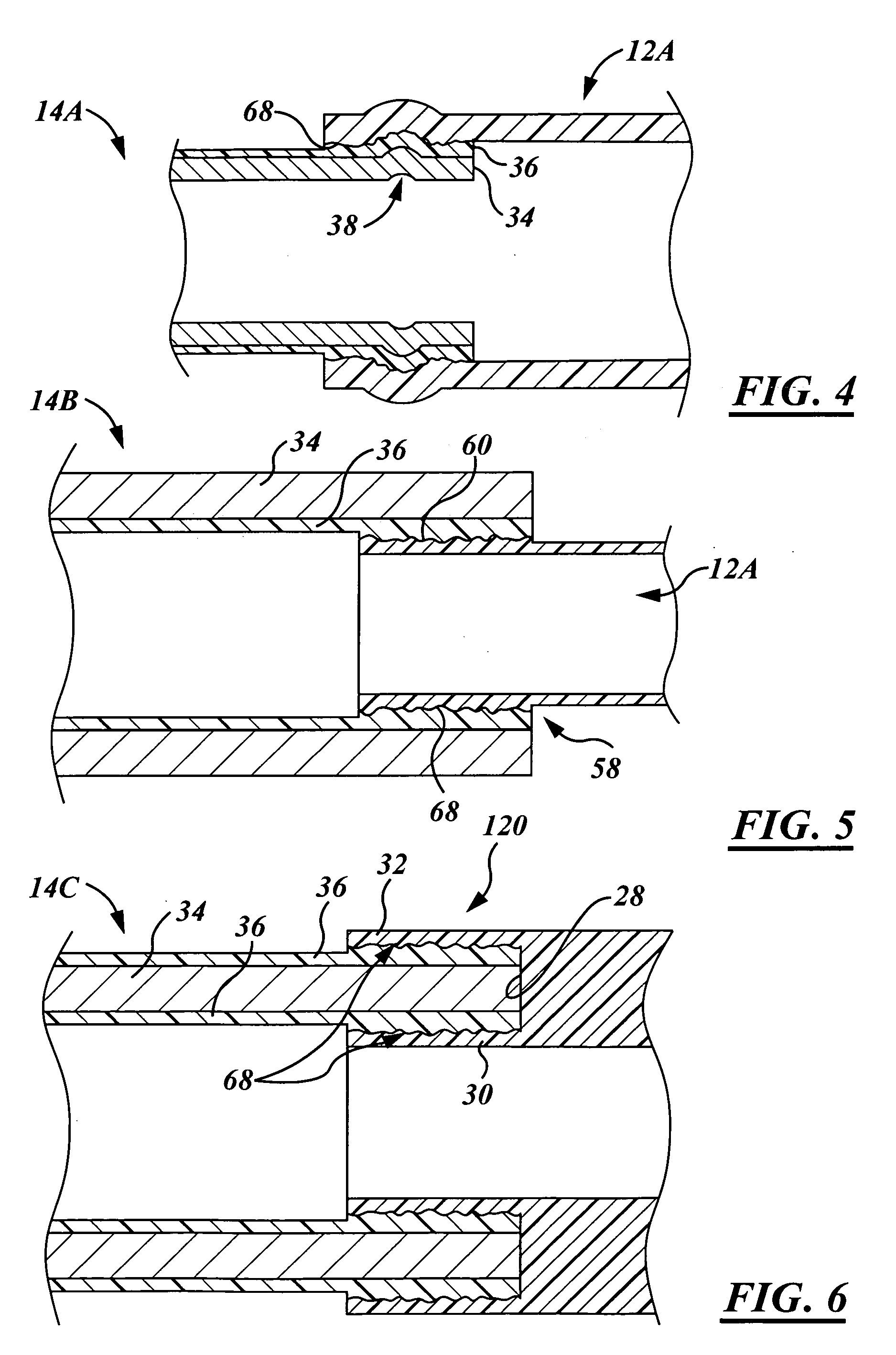

Method of coupling plastic components to metal tubing

InactiveUS20080028592A1Shorten assembly timePipe connection arrangementsMetal working apparatusInduction weldingBiomedical engineering

A method of coupling tubular bodies is provided, particularly for use in fluid handling systems requiring a fluid-tight, pressurized joint. One tubular body is made from a polymer. The other tubular body is formed as a bare metallic body (e.g., aluminum tubing). The tubular bodies are positioned relative to one another (e.g., the metallic tubular body may be inserted within the polymeric tubular body). The tubular bodies are then joined together by generating heat (e.g., through induction welding) to cause heat transfer from the metallic tubular body to the polymeric tubular body thereby resulting in deformation of the polymeric tubular body and bonding of the polymeric tubular body to the metallic tubular body.

Owner:DANA AUTOMOTIVE SYST GRP LLC

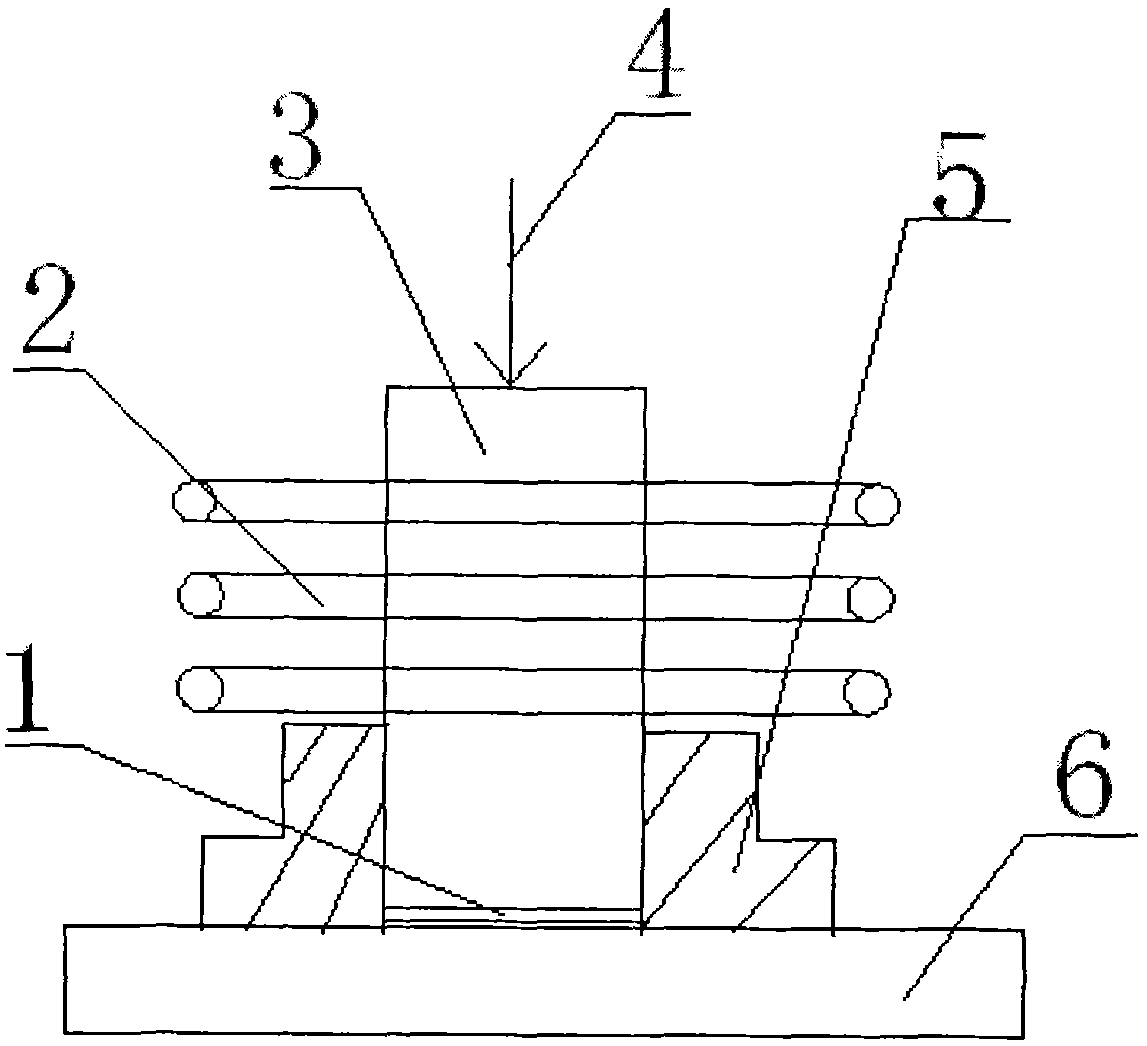

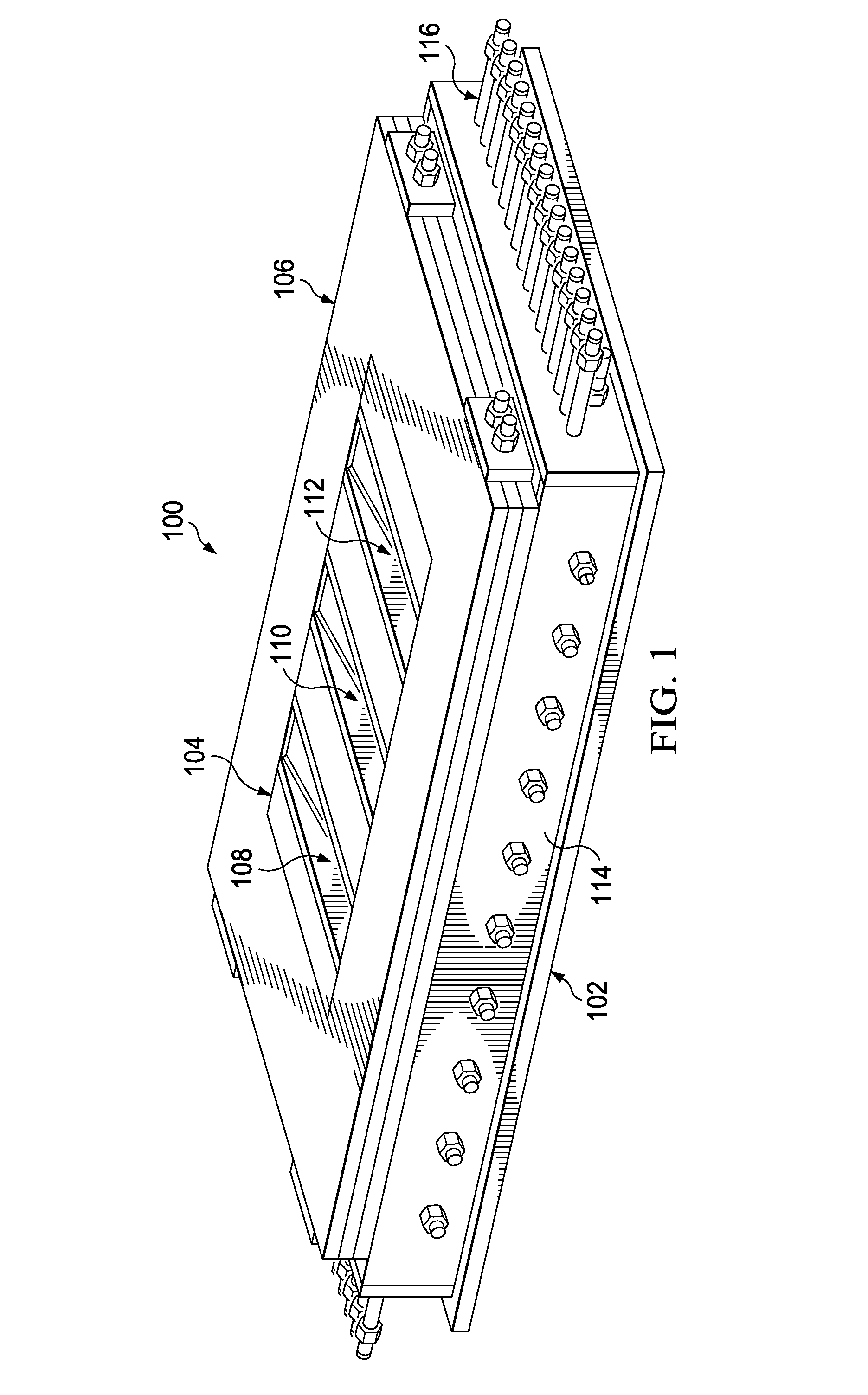

Steel rail induction butt welding and heat treatment device

ActiveCN103495800AFast welding speedImprove welding efficiencyRailsWelding/cutting auxillary devicesButt weldingControl system

A steel rail induction butt welding and heat treatment device comprises an induction welding device, a PLC control system, a hydraulic system, a cooling system, an induction heating power supply and an air spray system. The induction welding device comprises a first group of clip bodies, a second group of clip bodies, a central shaft, a clamping oil cylinder, an upsetting oil cylinder, a protrusion pushing device and a jaw. A left installation plate and a right installation plate are arranged between the first group of clip bodies and the second group of clip bodies, and corresponding locating oil cylinders are arranged on the left installation plate and the right installation plate. The induction welding device further comprises an opening and closing induction heating coil, an electrode structure is fixed on the left installation plate or the right installation plate, auxiliary oil cylinders are arranged on the second group of clip bodies, piston rods of the two auxiliary oil cylinders are respectively connected with nozzles, a locating part is arranged at the lower portion of the central shaft, and a displacement sensor and a temperature sensor are both electrically connected with the PLC control system. The steel rail induction butt welding and heat treatment device is automatic in operation and high in efficiency.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

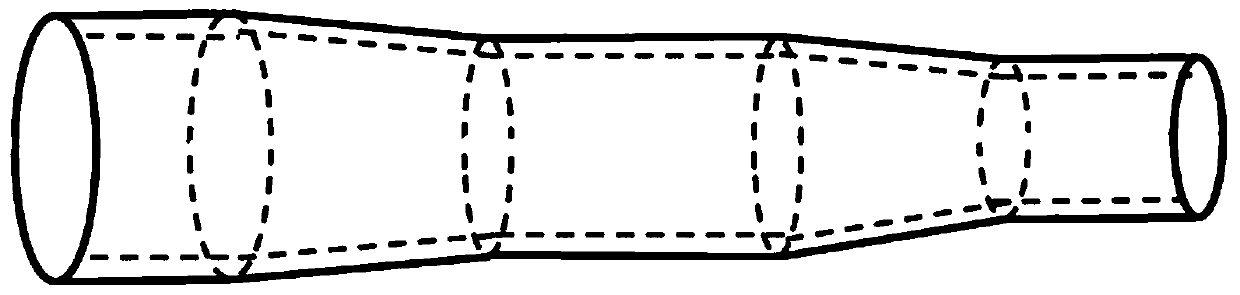

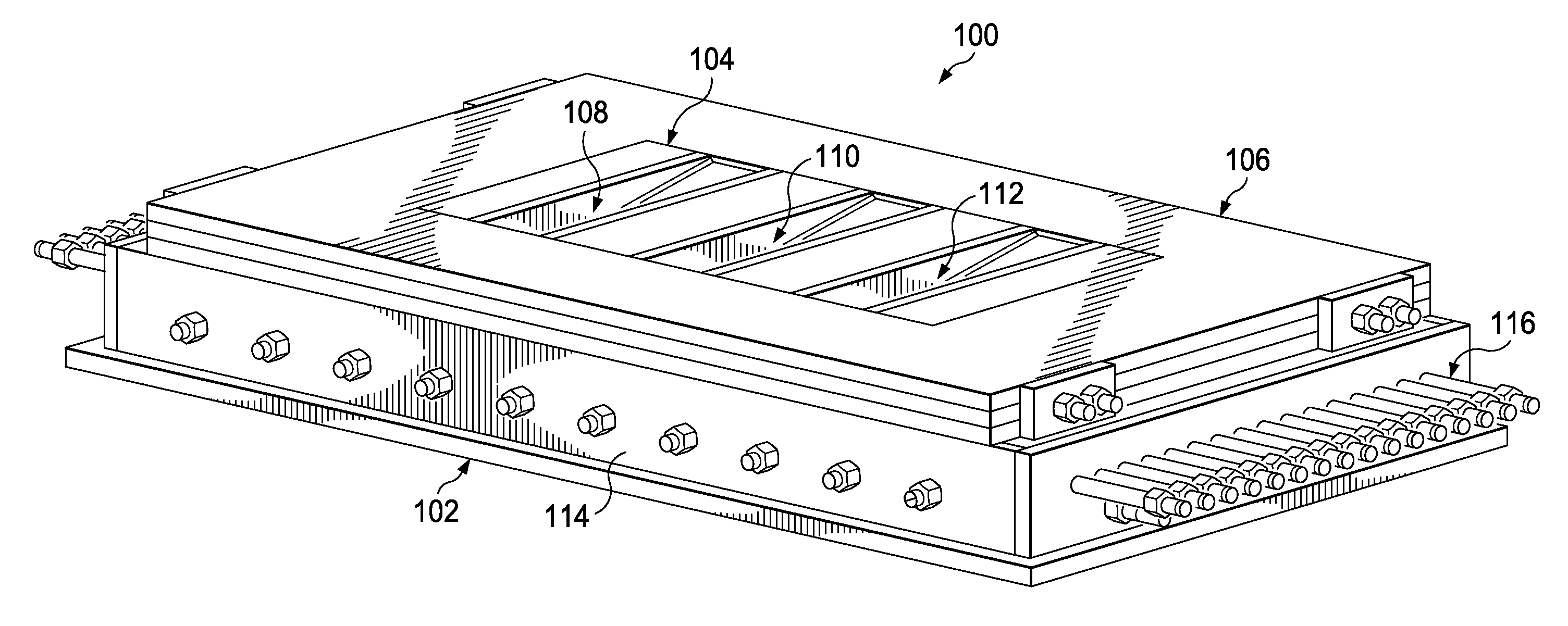

Induction coil with dynamically variable coil geometry

ActiveCN105229757ACoil arrangementsTransformers/inductances coils/windings/connectionsEngineeringInduction welding

A solenoidal induction coil with dynamically variable coil geometry is provided for inductively welding or heating continuous or discontinuous workpieces passing through the solenoidal induction coil in a process line. The coil geometry can change, for example, as the outer dimension of the workpiece passing through the solenoidal induction coil changes or as non-continuous workpieces pass through the solenoidal induction coil in an induction heating or welding process line.

Owner:THERMATOOL

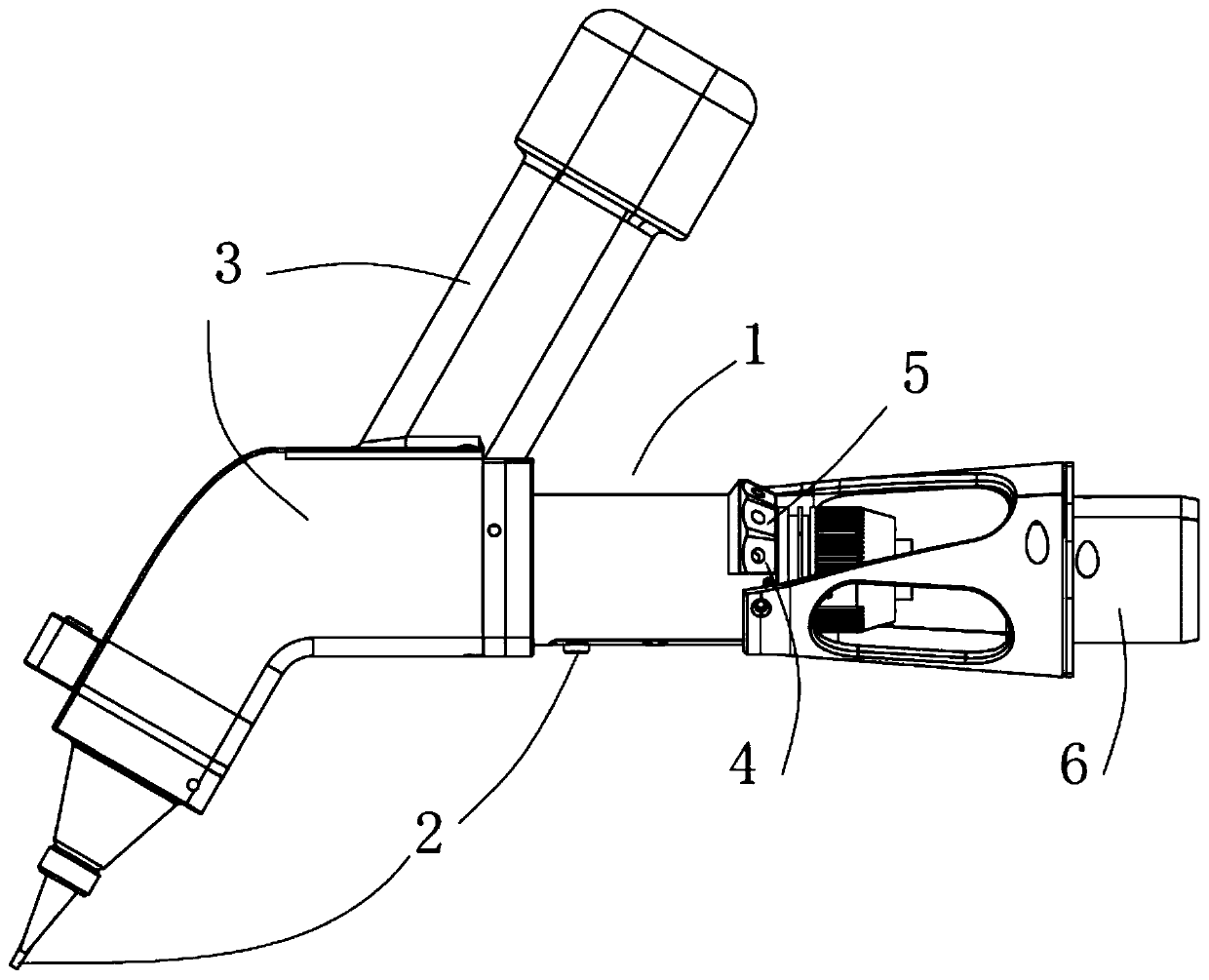

Light handheld laser swinging welding head

PendingCN110293316ASolve the non-adjustable weld seamAddress limitationsLaser beam welding apparatusHand heldEngineering

The invention discloses a light handheld laser swinging welding head. The light handheld laser swinging welding head comprises a collimating unit, a control unit and a light path unit, the collimatingunit is provided with a collimating connecting cylinder, the outer side wall of the circumference of the collimating connecting cylinder is a holding part, a laser incident end and a laser emergent end are oppositely arranged at the two ends of the collimating connecting cylinder, the control unit comprises a light contact switch and an induction welding nozzle, the light path unit comprises a light path main body and a swinging main body, the light path emergent end of the light path main body is bent downwards and is connected with a welding head body, the light path incident end of the light path main body is horizontally connected with the laser emergent end, and the swinging main body is arranged in a mode of extending upwards in the direction away from the outer end surface of the light path incident end. According to the light handheld laser swinging welding head, a swinging motor is arranged to control the angle of a reflecting lens in real time, and the laser light path is adjusted, so that the width of a weld joint is adjusted, the width of the weld joint is increased, then a product is not prone to weld penetration, and the welding efficiency and the welding quality areimproved.

Owner:广东昊胜智能设备有限公司

High-performance seamless continuous pipe and manufacturing method thereof

The invention discloses a high-performance seamless continuous pipe and a manufacturing method thereof. The method comprises the steps of preparing a continuous pipe dedicated board through processesof high-purity refining, continuous casting, thermal controlled rolling and controlled cooling, acid pickling and the like; preparing pipe blanks through rolled plate longitudinal shear, steel strip abut joint, cage-roll forming and high-frequency induction welding with protection gas; continuously producing equal-outer-diameter or variable-outer-diameter pipes through hot rolling reducing of thesame specification of pipe blanks; destressing the pipes to achieve the aims of reducing the pipe residual stress, improving the pipe toughness and reducing the pipe hardness, and obtaining the continuous pipe product with the good comprehensive property. The continuous pipe product meets the API standard need, through the hot rolling reducing technology, the pipe annular and longitudinal weldingjoint structure is obviously refined, and tends to be consistent with the base metal structure, physical seamlessness is achieved, the continuous pipe whole property can be effectively improved, the service life of the continuous pipe is prolonged, work safety of the continuous pipe is improved, the continuous pipe work technology advancing can be greatly pushed, and the market application prospect is wide.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Induction Welding System

A method and apparatus for performing induction welding. A number of protective layers are positioned between a susceptor layer and at least one of a plurality of workpieces at a weld location. An undesired current path is prevented from forming at the weld location during induction heating of the plurality of workpieces by the number of protective layers.

Owner:THE BOEING CO

Ignition device having an induction welded and laser weld reinforced firing tip and method of construction

An ignition device for an internal combustion engine and method of construction therefore includes a housing with an insulator secured therein. A center electrode is mounted within the insulator. A ground electrode extends from the housing with a portion of the ground electrode defining a spark gap across from the center electrode. The center electrode has a firing tip, wherein a resistance weld joint initially bonds the firing tip to the center electrode and a continuous bead of overlapping first weld pools formed substantially from the material of the firing tip further bonds the firing tip to the electrode. A continuous bead of overlapping second weld pools formed radially outwardly from the first weld pools forms a rounded shoulder surface extending from the first weld pools to an outer surface of the center electrode.

Owner:FEDERAL MOGUL WORLD WIDE LLC

High-alloy and corrosion-resistant continuous oil pipe formed by high frequency induction welding and manufacturing method thereof

InactiveCN108942097AGood resistance to uniform corrosionAccelerated corrosionFurnace typesHigh frequency current welding apparatusCoiled tubingHigh pressure

The invention belongs to the technical field of pipe materials for land and ocean oil and gas wells, and particularly relates to a high-alloy and corrosion-resistant continuous oil pipe formed by highfrequency induction welding. The continuous oil pipe is a ferrite and austenite duplex stainless steel continuous oil pipe, and the content of ferrite in a metallographic structure of the continuousoil pipe ranges from 35% to 55%. The continuous oil pipe is high in content of alloy elements, and can meet the application requirements of high-pressure, high-CO2 and H2S corrosion environments. Themanufactured continuous oil pipe is high in strength and long in fatigue life, and the flexible fatigue life of the continuous oil pipe can be 3-5 times that of a conventional CT90 continuous pipe.

Owner:JASON ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com